ANNUAL REPORT ON FORM 10-K

Page | ||||

1 | ||||

1 | ||||

2 | ||||

2 | ||||

2 | ||||

2 | ||||

2 | ||||

2 | ||||

3 | ||||

3 | ||||

3 | ||||

3 | ||||

3 | ||||

5 | ||||

5 | ||||

6 | ||||

7 | ||||

7 | ||||

8 | ||||

9 | ||||

Management’s Discussion and Analysis of Financial Condition and Results of | 9 | |||

26 | ||||

26 | ||||

27 | ||||

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 55 | |||

55 | ||||

56 | ||||

56 | ||||

56 | ||||

Security Ownership of Certain Beneficial Owners and Management and | 56 | |||

Certain Relationships and Related Transactions, and Director Independence | 58 | |||

58 | ||||

58 | ||||

59 | ||||

60 | ||||

61 | ||||

Consent of Independent Registered Public Accounting Firm | 63 | |||

Certifications of Officers | 64 |

Donaldson Company, Inc. (“Donaldson” or the “Company”) was founded in 1915 and organized in its present corporate form under the laws of the State of Delaware in 1936.

The Company is a worldwide manufacturer of filtration systems and replacement parts. The Company’s product mix includes air and liquid filtersfiltration systems and exhaust and emission control products for mobile equipment; in-plant air cleaning systems; compressed air purification systems; air intake systems for industrial gas turbines and specialized filters for such diverse applications as computer disk drives and semi-conductor processing.products. Products are manufactured at more than 3540 plants around the world and through three of our joint ventures. The Company has two reporting segments engaged in the design, manufacture and sale of systems to filter air and liquid and other complementary products. The two segments aresegments: Engine Products and Industrial Products. Products in the Engine Products segment consist of air intakefiltration systems, exhaust and emissions systems, liquid filtration systems and replacement parts. The Engine Products segment sells to original equipment manufacturers (“OEM”OEMs”) in the construction, mining, agriculture, aerospace, defense, and transportationtruck markets and to independent distributors, OEM dealer networks, private label accounts and large equipment fleets. Products in the Industrial Products segment consist of dust, fume and mist collectors, compressed air purification systems, liquid filters and parts, static and pulse-cleanfiltration systems, air filter systems for gas turbines, and specialized air filtration systems for diverse applications including computer hard disk drives. The Industrial Products segment sells to various industrial end-users, OEMs of gas-fired turbines and OEMs and end-users requiring highly purifiedclean air.

The table below shows the percentage of total net sales contributed by the principal classes of similar products for each of the last three fiscal years:

| Year Ended July 31 | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||

| 2007 | 2006 | 2005 |

| Year Ended July 31 |

| ||||||||||||||||||||

| 2009 |

| 2008 |

| 2007 |

| |||||||||||||||||||

| Engine Products segment |

|

|

|

|

|

|

| ||||||||||||||||||

| Off-road Equipment Products (including defense products) | 18 | % | 18 | % | 18 | % | |||||||||||||||||||

| Truck Products | 9 | % | 11 | % | 11 | % | |||||||||||||||||||

| Aftermarket Products (including replacement part sales to our OEMs) | 30 | % | 29 | % | 29 | % | |||||||||||||||||||

Off-Road Equipment Products (including Aerospace and Defense products) |

| 20 | % |

| 20 | % |

| 18 | % | ||||||||||||||||

On-Road Products |

| 4 | % |

| 6 | % |

| 9 | % | ||||||||||||||||

Aftermarket Products (including replacement part sales to the Company’s OEM’s) |

| 30 | % |

| 29 | % |

| 30 | % | ||||||||||||||||

| Industrial Products segment |

|

|

|

|

|

|

| ||||||||||||||||||

| Industrial Filtration Solutions Products | 27 | % | 26 | % | 27 | % |

| 27 | % |

| 27 | % |

| 27 | % | ||||||||||

| Gas Turbine Systems Products | 8 | % | 8 | % | 7 | % |

| 11 | % |

| 10 | % |

| 8 | % | ||||||||||

| Special Applications Products | 8 | % | 8 | % | 8 | % |

| 8 | % |

| 8 | % |

| 8 | % | ||||||||||

Financial information about segment operations appears in Note J in the Notes to Consolidated Financial Statements on page 47.51.

The Company makes its annual reports on Form 10-K, quarterly reports on Form 10-Q and current reports on Form 8-K, and amendments to those reports, available free of charge through its website, at www.donaldson.com, as soon as reasonably practicable after it electronically files such material with (or furnishes such material to) the Securities and Exchange Commission. Also available on the Company’s website are corporate governance documents, including the Company’s code of business conduct and ethics, corporate governance guidelines, Audit Committee charter, Human Resources Committee charter, and Corporate Governance Committee charter. These documents are available in print, free of charge to any shareholder who requests them. The information contained on the Company’s website is not incorporated by reference into this Annual Report on Form 10-K and should not be considered to be part of this Form 10-K.

1

In general, the Company’s Engine Products and Industrial Products segments are not considered to be seasonal. However, a number of ourthe Company’s end markets are dependent on the construction, agricultural and agriculturalpower generation industries, which are generally stronger in the second half of ourthe Company’s fiscal year.

Principal methods of competition in both the Engine Products and Industrial Products segments are technology, price, geographic coverage, service and product performance. The Company competes in a number of highly competitive filtration markets in both the Engine Products and Industrial Products segments. The Company believes it is a market leader inwith many of its primary product lines. The Company believes within the Engine Products segment it is a market leader in its Off-Road Equipment and On-Road Products lines for OEMs and is a significant participant in the aftermarket for replacement filters. The Engine Products segment’s principal competitors include several large global competitors and regional competitors, especially in the Engine Aftermarket Products business. The Industrial Products segment’s principal competitors vary from country to country and include several large regional orand global competitors and a significant number of smallsmaller competitors who compete in a limitedspecific geographical region or in a limited number of product applications. The Company believes within the Engine Products segment it is a market leader in its Off-road Equipment and Truck Products lines for OEMs and is a significant participant in the aftermarket for replacement filters and hard parts. The Engine Products segment’s principal competitors vary from country to country and include several large regional or global competitors, and small regional competitors, especially in the Engine Aftermarket Products business.

The principal raw materials that we usethe Company uses are steel, filter media and filter media. We purchaseplastics. The Company purchases a variety of types of steel for various applications. During fiscal 2007 commoditysteel. Commodity prices were relatively stable after experiencing increases in fiscal 2006 primarily related tohigh during the costfirst half of steel.the year, but decreased during the second half such that the full year was comparable with Fiscal 2008. The Company experienced no significant or unusualsupply problems in the purchase of its raw materials or commodities.materials. The Company typically has more than one sourcemultiple sources of supply for the raw materials essential to its business. The Company is not required to carry significant amounts of raw material inventory to meet rapid delivery demands or secure supplier allotments. However, the Company does stock finished goods inventory at its regional distribution centers around the world in order to meet anticipated Customer demand.

The Company owns various patents and trademarks, which it considers in the aggregate to constitute a valuable asset, including patents and trademarks for products and filtration systems sold under the Ultra-Web®, PowerCore®, and Donaldson® trademarks. However, it does not regard the validity of any one patent or trademark as being of material importance.

There were no Customers that accounted for over 10 percent of net sales in Fiscal 2009. Sales to Caterpillar Inc. and its subsidiaries (“Caterpillar”) accounted for 10 percent of net sales in 2007Fiscal 2008 and 12 percent of net sales in both 2006 and 2005.Fiscal 2007. Caterpillar has been a customer of the Company for many years and it purchases many models and types of products for a variety of applications. Sales to the U.S. Government do not constitute a material portion of the Company’s business. There were no Customers over 10 percent of gross accounts receivable in 2007Fiscal 2009 or 2006.2008.

At August 31, 2007,2009, the backlog of orders expected to be delivered within 90 days was $328,939,000.$259,181,000. All of this backlog is expected to be shipped during Fiscal 2010. The 90-day backlog at August 31, 20062008, was $291,011,000.$415,078,000. Backlog is one of many indicators of business conditions in our market.the Company’s markets. However, it is not always indicative of future results for a number of reasons, including short lead times in our aftermarketthe Company’s replacement parts business and the timing of receipt of orders in many of our original equipmentthe Company’s Engine OEM and industrialIndustrial markets.

During 2007,Fiscal 2009, the Company spent $36,458,000$40,643,000 on research and development activities relatingactivities. Research and development expenses include basic scientific research and the application of scientific advances to the development of new and improved products or improvements of existing products or manufacturing processes.and their uses. The Company spent $33,887,000$43,757,000 in 2006Fiscal 2008 and $32,234,000$36,458,000 in 2005Fiscal 2007 on research and development activities. Substantially all commercial research and development is performed in-house.

2

The Company does not anticipate any material effect on its capital expenditures, earnings or competitive position during fiscal 2008Fiscal 2010 due to compliance with government regulations regulating the discharge of materials into the environment or otherwise relating to the protection of the environment.

The Company employed over 12,00010,600 persons in worldwide operations as of August 31, 2007.2009.

Financial information about geographic areas appears in Note J of the Notes to Consolidated Financial Statements on page 47.51.

Item 1A. RISK FACTORSRisk Factors

There are inherent risks and uncertainties associated with our global operations that involve the design, manufacturing and sale of products for highly demanding Customer applications throughout the world. TheThese risks and uncertainties associated with our business could adversely affect our operating performance and financial condition. The following discussion, along with discussions elsewhere in this report, outlines the risks and uncertainties that we believe are the most material to our business. However, these are notIn light of the onlycurrent global economic slowdown, we want to further highlight the risks and uncertainties associated with: world economic factors; the reduction in sales volume and orders due to decreased global demand and Customers aggressively working to reduce their levels of inventory; increased governmental laws and regulations, including the unprecedented financial actions being undertaken by governments around the world; a significant tightening of credit availability; and potential global health outbreaks. We undertake no obligation to publicly update or uncertainties that could affect our business. Therefore, the following is not intended to be a complete discussion of all potential risks or uncertainties.revise any forward-looking statements.

Operating internationally carries risks which could negatively effectaffect our financial performance.

We have sales and manufacturing operations throughout the world, with the heaviest concentrations in North America, Europe and Asia. Our stability, growth and profitability are subject to a number of risks of doing business internationally that could harm our business, including:

• | political and military events, | |

• | legal and regulatory requirements, including import, export and defense regulations, | |

• | tariffs and trade barriers, | |

• | potential difficulties in staffing and managing local operations, | |

• | credit risk of local Customers and distributors, | |

• | difficulties in protecting intellectual property, | |

• | local economic, political and social conditions, specifically in China and Thailand where we have significant investments, | |

• | potential global health outbreaks. |

Maintaining a competitive advantage requires continuing investment with uncertain returns.

We operate in highly competitive markets and have numerous competitors who may already be well established in those markets. We experience price pressures from these competitors in certain product lines and geographic markets. We expect our competitors to continue improving the design and performance of their products and to introduce new products that arecould be competitive in both price and performance. We believe that we have certain technological advantages over our competitors, but maintaining these advantages requires us to continually invest in research and development, sales and marketing and Customer service and support. There is no guarantee that we will be successful in maintaining these advantages. We are currently makingmake investments in emissions technology developmentnew technologies that address increased performance and potential new emission systems products to meet the changing regulatory requirements worldwide.around the globe. There is no guarantee that we will be successful in completing development or achieving sales of these products or that the margins on such products will be acceptable. Our financial performance may be negatively impacted if a competitor’s successful product innovation reaches the market before ours or gains broader market acceptance.

A number Several of our major OEM Customers also manufacture component products for their own use.filtration systems. Although these OEM Customers rely on us and other suppliers for othersome of their component products,

3

filtration systems, they sometimes choose to manufacture additional component productsfiltration systems for their own use. There is also a risk that a Customer could acquire one or more of our competitors.

We may be adversely impacted by changes in technology that could reduce or eliminate the demand for our products. We are at risk with respect to:These risks include:

• | breakthroughs in technology which provide a viable alternative to diesel | |

• | reduced demand for disk drive products if |

We participate in highly competitive markets with pricing pressure. If we are not able to compete effectively our margins and results of operations could be adversely affected.

The businesses and product lines in which we participate are very competitive and we risk losing business based on a wide range of factors, including technology, price, delivery, service, product performance and Customer satisfaction.service. Large Customers continue to seek productivity gains and lower prices from their suppliers. We may lose business or negatively impact our margins if we are unable to deliver the best value to our Customers through our technology and innovation and our product cost reduction and lean improvement efforts in manufacturing and throughout the Company.Customers.

Demand for our products relies on economic and industrial conditions worldwide.

Demand for certain of our products tends to be cyclical and respondsrespond to varying levels of construction, agricultural, mining and industrial activity in the United States and in other industrialized nations.

Sales to Caterpillar Inc. and its subsidiaries accounted for slightly less than 10 percent of our net sales in the most recent yearFiscal 2009 and greater than 10 percent of our net sales in the previous three fiscal years.Fiscal 2008. An adverse change in Caterpillar’s financial performance or a material reduction in our sales to itCaterpillar could negatively impact our operating results.

Changes in our product mix impacts our financial performance.

We sell products in various product lines that have varying profit margins. Our financial performance can be impacted positively or negatively depending on the mix of products we sell during a given period as compared to a previous period.

Unavailable or higher cost materials could result in our Customers being dissatisfied.

We obtain raw material, including a significant amount of various gradessteel, filter media and types of steel,plastics, and certain manufacturedother components from third-party suppliers and tend to carry limited raw material inventories. Even a briefAn unanticipated delay in delivery or increases in prices by our suppliers could result in the inability to satisfydeliver on-time and meet the expectations of our Customers on delivery and pricing.Customers. This could negatively affect our financial performance. An increase in commodity prices during a recession or an otherwise challenging business and economic environment could result in lower operating margins.

Difficulties with the Company’s information technology systems could adversely affect the Company’s results.

The Company has many information technology systems that are important to the operation of its businesses. The Company could encounter difficulties in developing new systems or maintaining and upgrading existing systems. Such difficulties could lead to significant expenses due to disruption in business operations and could adversely affect the Company’s results.

Unfavorable fluctuations in foreign currency exchange rates could negatively impact our results of operations and financial position.

We have operations in many countries. Each of our subsidiaries reports its results of operations and financial position in its relevant foreign currency, which is then translated into United StatesU.S. dollars. TheThis translated financial information is included in our consolidated financial statements. The strengthening of the United StatesU.S. dollar in comparison to the foreign currencies of our subsidiaries could have a negative impact on our results of operations orand financial position.

Acquisitions may not necessarily have a positivean impact on our results.

We have made and continue to pursue acquisitions of complementary product lines, technologies and businesses.acquisitions. We cannot guarantee that these acquisitions will have a positive impact on our results. These acquisitions could negatively impact our profitability due to operating and integration inefficiencies, the incurrence of debt, contingent liabilities and amortization expenses related to intangible assets. There are also a number of other risks involved in acquisitions. For example, weWe could lose key existing or

4

potential Customers, have difficulties in assimilating the acquired operations, assume unanticipated legal liabilities or lose key employees of the acquired company.employees.

Compliance with environmental laws and regulations can be costly.

We are subject to many environmental laws and regulations in the jurisdictions in which we operate. We routinely incur product development capital and operating costs in order to comply with these laws and regulations. We may be adversely impacted by new or changing environmental laws and regulations that affect both our operations and our ability to develop and sell products that meet our Customers’ product and performance requirements.

Item 1B. UNRESOLVED STAFF COMMENTSUnresolved Staff Comments

None.

The Company’s principal office and research facilities are located in Bloomington, Minnesota, a suburb of Minneapolis, Minnesota. The principal European administrative and engineering offices are located in Leuven, Belgium. The Company also has extensive operations in the Asia-Pacific region.

The Company’s principal plant activities are carried out in the United States and internationally. Following is a summary of the principal plants and other materially important physical properties owned or leased by the Company.

Americas |

| |

Auburn, Alabama (E) | Kadan, Czech Republic (I) | |

Riverbank, California (I)* | Klasterec, Czech Republic | |

Valencia, California (E)* | Domjean, France (E) | |

Dixon, Illinois | Paris, France (E) | |

Frankfort, Indiana | Dulmen, Germany (E) | |

Cresco, Iowa | Flensburg, Germany (I) | |

Grinnell, Iowa (E) | Haan, Germany (I) | |

Nicholasville, Kentucky | Ostiglia, Italy | |

Bloomington, Minnesota | Barcelona, Spain (I) | |

Chillicothe, Missouri (E) | Hull, United Kingdom | |

St. Charles, Missouri* (E)

|

| Leicester, United Kingdom (I) |

Philadelphia, Pennsylvania (I) | Cape Town, South Africa | |

Greeneville, Tennessee | Johannesburg, South Africa* | |

Baldwin, Wisconsin | ||

Stevens Point, Wisconsin | Australia | |

Sao Paulo, Brazil (E)* | Wyong, Australia | |

Athens, Canada (I) | ||

Aguascalientes, Mexico | Asia | |

Monterrey, Mexico | Hong Kong, China* | |

Wuxi, China | ||

Joint Venture Facilities | New Delhi, India | |

Most, Czech Republic (E) | Gunma, Japan | |

Champaign, Illinois (E) | Rayong, Thailand (I) | |

Jakarta, Indonesia | ||

Dammam, Saudi Arabia (I) | Third-Party Logistics Providers | |

Alsip, Illinois | ||

Distribution Centers | Plainfield, Indiana (I) | |

Brugge, Belgium | New Hampton, Iowa | |

Rensselaer, Indiana | Waterloo, Iowa (E) | |

Aguascalientes, Mexico | Greeneville, Tennessee (I) | |

Johannesburg, South Africa | Singapore |

The Company’s properties are utilized for both the Engine and Industrial ProductProducts segments except as indicated with an (E) for Engine or (I) for Industrial. The Company also leases certain of its facilities, primarily under long-term leases. The facilities denoted facilitieswith an asterisk (*) are leased facilities. In Wuxi, China, a portion of the operations are conducted in leased facilities. The Company’sCompany uses third-party logistics providers for some of its product distribution and neither leases nor owns the facilities. The Company considers its properties are considered to be suitable for their present purposes, well-maintained and in good operating condition.

5

Item 3. LEGAL PROCEEDINGSLegal Proceedings

In accordance with SFAS No. 5, “Accounting for Contingencies,” (SFAS No. 5), the Company records provisions with respect to identified claims or lawsuits when it is probable that a liability has been incurred and the amount of the loss can be reasonably estimated. Claims and lawsuits are reviewed quarterly and provisions are taken or adjusted to reflect the status of a particular matter. The Company isbelieves the recorded reserves in its consolidated financial statements are adequate in light of the probable and estimable outcomes. Any recorded liabilities were not currently subject to any pending litigation other than litigation which arises out of and is incidentalmaterial to the conductCompany’s financial position, results of the Company’s business. All such matters are subject to many uncertaintiesoperation and outcomes that are not predictable with assurance. Theliquidity and the Company does not considerbelieve that any of such proceedings that arethe currently pending to be likely to result in a material adverse effect on the Company’s consolidatedidentified claims or litigation will materially affect its financial position, or results of operation.operation and liquidity.

Item 4. SUBMISSION OF MATTERS TO A VOTE OF SECURITY HOLDERSSubmission of Matters to a Vote of Security Holders

No matters were submitted to a vote of security holders of the Company during the quarter ended July 31, 2007.2009.

Executive Officers of the Registrant

Current information regarding executive officers is presented below. All terms of office are for one year. There are no arrangements or understandings between individual officers and any other person pursuant to which the officer was selected as an executive officer.

|

|

|

|

|

|

| |||||||

| Name | Age | Positions and Offices Held | First Year Elected or Appointed as an Executive Officer |

|

| Age |

| Positions and Offices Held |

| First Year Elected or | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Tod E. Carpenter | Tod E. Carpenter |

| 50 |

| Vice President, Europe and Middle East |

| 2008 | ||||||

|

|

|

|

| |||||||||

| William M. Cook | 54 | Chairman, President and Chief Executive Officer | 1994 | William M. Cook |

| 56 |

| Chairman, President and Chief Executive Officer |

| 1994 | |||

|

|

|

|

|

| ||||||||

| Sandra N. Joppa | 42 | Vice President, Human Resources, Communications and Facilities | 2005 | Sandra N. Joppa |

| 44 |

| Vice President, Human Resources |

| 2005 | |||

|

|

|

|

|

| ||||||||

| Norman C. Linnell | 48 | Vice President, General Counsel and Secretary | 1996 | Norman C. Linnell |

| 50 |

| Vice President, General Counsel and Secretary |

| 1996 | |||

|

|

|

|

|

| ||||||||

| Charles J. McMurray | 53 | Senior Vice President, Industrial Products and South Africa | 2003 | Charles J. McMurray |

| 55 |

| Senior Vice President, Industrial Products |

| 2003 | |||

|

|

|

|

|

| ||||||||

| Mary Lynne Perushek | 49 | Vice President and Chief Information Officer | 2006 | Mary Lynne Perushek |

| 51 |

| Vice President and Chief Information Officer |

| 2006 | |||

|

|

|

|

|

| ||||||||

| Lowell F. Schwab | 59 | Senior Vice President, Engine Systems and Parts | 1994 | Lowell F. Schwab |

| 61 |

| Senior Vice President, Global Operations |

| 1994 | |||

|

|

|

|

|

| ||||||||

| David W. Timm | 54 | Vice President, Asia-Pacific | 2007 | David W. Timm |

| 56 |

| Vice President, Asia-Pacific |

| 2007 | |||

| William I. Vann | 62 | Vice President, NAFTA Operations and Mexico | 2004 | ||||||||||

|

|

|

|

|

| ||||||||

| Thomas R. VerHage | 54 | Vice President and Chief Financial Officer | 2004 | Thomas R. VerHage |

| 56 |

| Vice President and Chief Financial Officer |

| 2004 | |||

|

|

|

|

|

| ||||||||

| Jay L. Ward | 43 | Vice President, Europe and Middle East | 2006 | Jay L. Ward |

| 45 |

| Senior Vice President, Engine Products |

| 2006 | |||

|

|

|

|

|

| ||||||||

| Debra L. Wilfong | 52 | Vice President and Chief Technology Officer | 2007 | Debra L. Wilfong |

| 54 |

| Vice President and Chief Technology Officer |

| 2007 | |||

Mr. Carpenter joined the Company in 1996 and has held various positions, including Gas Turbine Systems General Manager from 2002 to 2004; General Manager, Industrial Filtration Systems (IFS) Sales from 2004 to 2006; General Manager, IFS Americas in 2006; and Vice President, Global IFS from 2006 to 2008. Mr. Carpenter was appointed Vice President, Europe and Middle East in August 2008.

Mr. Cook joined Donaldsonthe Company Inc. in 1980 and has held various positions, including CFO and Senior Vice President, International from 2001 to 2004 and President and CEO from 2004 to 2005. Mr. Cook was appointed Chairman, President and CEO in July 2005.

Ms. Joppa was appointed Vice President, Human Resources and Communications in November 2005 and added responsibility for Facilities in May 2007.2005. Prior to that time Ms. Joppa held various positions at General Mills, a consumer food products company, from 1989 to 2005, including service as Director of Human Resources for several different operating divisions from 1999 to 2005.

Mr. Linnell joined Donaldsonthe Company Inc. in 1996 as General Counsel and Secretary and was appointed Vice President, General Counsel and Secretary in 2000.

6

Mr. McMurray joined Donaldsonthe Company Inc. in 1980 and has held various positions, including Director, Global Information Technology from 2001 to 2003; Vice President, Human Resources & Communication, Information Technology and Logistics from 2004 to 2005; and Vice President, Information Technology, Europe, South Africa and Mexico from 2005 to 2006. Mr. McMurray became Senior Vice President, Industrial Products, Technology, and South Africa in September 2006 and transferred responsibility for Information Technology upon the hiring of Ms. Perushek in November 2006.

Ms. Perushek was appointed Vice President and Chief Information Officer in November 2006. Prior to that time, Ms. Perushek was Vice President of Global Information Technology at H.B. Fuller Company, a worldwide manufacturer of adhesive products, from 2005 to 2006 and Chief Information Officer for Young America Corporation, a marketing company, from 1999 to 2004.

Mr. Schwab joined Donaldsonthe Company Inc. in 1977 and has held various positions, including Senior Vice President, Operations from 1994 to 2004 and was promoted to Senior Vice President, Engine Systems and PartsProducts from 2004 to 2008. Mr. Schwab was appointed Senior Vice President, Global Operations, in 2004.August 2008.

Mr. Timm joined Donaldsonthe Company Inc. in 1983 and has held various positions, including General Manager, Disk Drive from 1995 to 2004; General Manager, Disk Drive and New Business Development from 2004 to 2005;2005 and General Manager, Gas Turbine Systems Products from 2005 to 2006. Mr. Timm was appointed Vice President, Asia-Pacific in March 2007.December 2006.

Mr. Vann joined Donaldson Company, Inc. in 1967 and has held various positions, including General ManagerTable of Industrial Air Filtration from 2000 to 2004; Vice President, NAFTA Operations in 2005; and Vice President, NAFTA Operations and Mexico since 2006.Contents

Mr. VerHage was appointed Vice President and Chief Financial Officer in March 2004. Prior to that time, Mr. VerHage was a partner for Deloitte & Touche, LLP, an international accounting firm, from 2002 to 2004.

Mr. Ward joined Donaldsonthe Company Inc. in 1998 and has held various positions, including Director, Operations from 2001 to 2003; Director, Product and Business Development, Industrial Filtration SolutionsIFS Group from 2003 to 2004; and Managing Director, Europe from 2004 to 2006. Mr. Ward was appointed2006; and Vice President, Europe and Middle East from 2006 to 2008. Mr. Ward was appointed Senior Vice President, Engine Products in December 2006.August 2008.

Ms. Wilfong was appointed Vice President and Chief Technology Officer in May 2007. Prior to that time, Ms. Wilfong held various director positions in research and development at 3M Company, an international consumer products company, from 2000 to 2007, most recently as Director, Research and Development for the 3M Automotive Division from 2006 to 2007.

Effective August 3, 2007, Mr Geert Henk Touw retired as Senior Vice President, Asia-Pacific.

Item 5. Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities

The common shares of the Company are traded on the New York Stock Exchange under the symbol DCI. The amount and frequency of all cash dividends declared on the Company’s common stock for 2007Fiscal 2009 and 20062008 appear in Note LN of the Notes to Consolidated Financial Statements on page 51.55. As of September 21, 2007,23, 2009, there were 1,8362,109 shareholders of record of common stock.

The low and high sales prices for the Company’s common stock for each full quarterly period during 2007Fiscal 2009 and 20062008 were as follows:

First Quarter | Second Quarter | Third Quarter | Fourth Quarter | |||||

Fiscal 2008 | $ | $ | $ | $ | ||||

Fiscal 2009 | $28.04 — 49.00 | $23.40 — 36.29 | $21.82 — 34.37 | $31.00 — 38.93 |

7

The following table sets forth information in connection with purchases made by, or on behalf of, the Company or any affiliated purchaser of the Company, of shares of the Company’s common stock during the quarterly period ended July 31, 2007.2009.

| Period | Total Number of Shares Purchased(1) | Average Price Paid per Share | Total Number of Shares Purchased as Part of Publicly Announced Plans or Programs | Maximum Number of Shares that May Yet Be Purchased Under the Plans or Programs | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| May 1-May 31, 2007 | — | — | — | 4,402,200 | ||||||||||||||

| June 1-June 30, 2007 | 204,400 | $ | 35.15 | 204,400 | 4,197,800 | |||||||||||||

| July 1-July 31, 2007 | 219,989 | $ | 35.59 | 219,800 | 3,978,000 | |||||||||||||

| Total | 424,389 | $ | 35.38 | 424,200 | 3,978,000 | |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Period |

| Total Number of |

| Average Price |

| Total Number of |

| Maximum Number |

| |||||

May 1-May 31, 2009 |

|

| — |

|

| — |

|

| — |

|

| 930,210 |

| |

June 1-June 30, 2009 |

|

| 18,972 |

| $ | 36.12 |

|

| — |

|

| 930,210 |

| |

July 1-July 31, 2009 |

|

| — |

|

| — |

|

| — |

|

| 930,210 |

| |

Total |

|

| 18,972 |

| $ | 36.12 |

|

| — |

|

| 930,210 |

| |

(1) | On March 31, 2006, the Company announced that the Board of Directors authorized the repurchase of up to 8.0 million shares of common stock. This repurchase authorization, which is effective until terminated by the Board of Directors, replaced the existing authority that was authorized on January 17, 2003. There were no repurchases of common stock made outside of the Company’s current repurchase authorization during the quarter ended July 31, | |

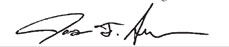

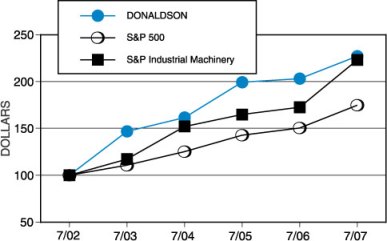

The graphsgraph below comparecompares the cumulative total stockholder return on the Company’s Common Stock for the last five fiscal years with the cumulative total return of the Standard & Poor’s 500 Stock Index and the Standard & Poor’s Index of Industrial Machinery Companies. The graph and table assume the investment of $100 in each of Donaldson’sthe Company’s Common Stock and the specified indexes at the beginning of the applicable period, and assume the reinvestment of all dividends.

COMPARISON OF 5 YEAR CUMULATIVE TOTAL RETURN

Among Donaldson Company, Inc., The S&P 500 Index

And The S&P Industrial Machinery Index

| Year ended July 31, | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2007 | 2006 | 2005 | 2004 | 2003 | 2002 | ||||||||||||||||||||||

| Donaldson Company, Inc. | $ | 227.06 | $ | 203.15 | $ | 199.28 | $ | 161.65 | $ | 146.84 | $ | 100.00 | |||||||||||||||

| S&P 500 | 174.78 | 150.50 | 142.81 | 125.22 | 110.64 | 100.00 | |||||||||||||||||||||

| S&P Industrial Machinery | 223.02 | 172.58 | 164.80 | 152.07 | 117.32 | 100.00 | |||||||||||||||||||||

8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Year ended July 31, |

| ||||||||||||||||

|

| 2009 |

| 2008 |

| 2007 |

| 2006 |

| 2005 |

| 2004 |

| ||||||

Donaldson Company, Inc. |

| $ | 150.18 |

| $ | 175.88 |

| $ | 140.46 |

| $ | 125.67 |

| $ | 123.27 |

| $ | 100.00 |

|

S&P 500 |

|

| 99.33 |

|

| 124.10 |

|

| 139.58 |

|

| 120.19 |

|

| 114.05 |

|

| 100.00 |

|

S&P Industrial Machinery |

|

| 102.93 |

|

| 133.98 |

|

| 146.65 |

|

| 113.48 |

|

| 108.37 |

|

| 100.00 |

|

Item 6. SELECTED FINANCIAL DATASelected Financial Data

The following table sets fourth selected financial data for each of the fiscal years in the five-year period ended July 31, 20072009 (in millions, except per share data):

| Year ended July 31, | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2007 | 2006 | 2005 | 2004 | 2003 | |||||||||||||||||||

| Net Sales | $ | 1,918.8 | $ | 1,694.3 | $ | 1,595.7 | $ | 1,415.0 | $ | 1,218.3 | |||||||||||||

| Income from continuing operations | 150.7 | 132.3 | 110.6 | 106.3 | 95.3 | ||||||||||||||||||

| Diluted earnings per share | 1.83 | 1.55 | 1.27 | 1.18 | 1.05 | ||||||||||||||||||

| Total assets | 1,319.0 | 1,124.1 | 1,111.8 | 1,001.6 | 882.0 | ||||||||||||||||||

| Long-term obligations | 129.0 | 100.5 | 103.3 | 70.9 | 105.2 | ||||||||||||||||||

| Cash dividends declared per share | 0.370 | 0.410 | 0.180 | 0.213 | 0.180 | ||||||||||||||||||

| Cash dividends paid per share | 0.360 | 0.320 | 0.235 | 0.205 | 0.175 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Year ended July 31, |

| |||||||||||||

|

| 2009 |

| 2008 |

| 2007 |

| 2006 |

| 2005 |

| |||||

Net sales |

| $ | 1,868.6 |

| $ | 2,232.5 |

| $ | 1,918.8 |

| $ | 1,694.3 |

| $ | 1,595.7 |

|

Income from continuing operations |

|

| 131.9 |

|

| 172.0 |

|

| 150.7 |

|

| 132.3 |

|

| 110.6 |

|

Diluted earnings per share |

|

| 1.67 |

|

| 2.12 |

|

| 1.83 |

|

| 1.55 |

|

| 1.27 |

|

Total assets |

|

| 1,334.0 |

|

| 1,548.6 |

|

| 1,319.0 |

|

| 1,124.1 |

|

| 1,111.8 |

|

Long-term obligations |

|

| 253.7 |

|

| 176.5 |

|

| 129.0 |

|

| 100.5 |

|

| 103.3 |

|

Cash dividends declared per share |

|

| 0.460 |

|

| 0.430 |

|

| 0.370 |

|

| 0.410 |

|

| 0.180 |

|

Cash dividends paid per share |

|

| 0.455 |

|

| 0.420 |

|

| 0.360 |

|

| 0.320 |

|

| 0.235 |

|

Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operation

Results of Operation

The following discussion of the Company’s financial condition and results of operations should be read in conjunction with the Consolidated Financial Statements and Notes thereto and other financial information included elsewhere in this report.

Executive Table of Contents

Overview

The Company manufactures and distributes filtration systems and replacement parts. The Company’s core strengths are leading filtration technology, strong Customer relationships and global presence. The Company operates through two reporting segments, Engine Products and Industrial Products, and has a product mix including air and liquid filters and exhaust and emission control products. As a worldwide business, the Company’s results of operations are affected by conditions in the global industrial and economic factors. Theenvironment. Under normal economic conditions, the Company’s diversity between its original equipment and replacement parts Customers, its diesel engine and industrial end markets, and its North American and international end markets has helped to limit the impact of weakness in any one of these factors and marketsproduct line, market or geography on the consolidated results of the Company. The continued strong demand in most ofHowever, the global recession had a dramatic negative impact on the Company’s end markets combined with strong international growthresults in both our Engine ProductFiscal 2009 as nearly every product group and Industrial Product segments drove record earnings in fiscal 2007.geographic area was impacted.

The Company reported record sales in 2007Fiscal 2009 of $1.919 billion, up 13.3$1,868.6 million, down 16.3 percent from $1.694 billion$2,233.5 million in the prior year. The Company’s results were positivelynegatively impacted by foreign currency translation for the year.translation. The impact of foreign currency translation during the year increaseddecreased sales by $47.2$76.8 million. Excluding the current year impact of foreign currency translation, worldwide sales increased 10.5decreased 12.9 percent during the year.

Although net sales excluding foreign currency translation is not a measure of financial performance under GAAP, the Company believes it is useful in understanding its financial results and provides a comparable measure for understanding the operating results of the Company’s foreign entitiesCompany between different fiscal periods excluding the impact of foreign currency translation. FollowingThe following is a reconciliation to the most comparable GAAP financial measure of this non-GAAP financial measure (in millions):

| July 31, 2007 | July 31, 2006 |

|

|

|

|

|

|

| |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| July 31, |

| July 31, |

| |||||||||||||

| Net sales, excluding foreign currency translation | $ | 1,871.6 | $ | 1,719.6 |

| $ | 1,945.4 |

| $ | 2,110.0 |

| ||||||

| Current year foreign currency translation impact | 47.2 | (25.3 | ) | ||||||||||||||

Foreign currency translation impact |

|

| (76.8 | ) |

| 122.5 | |||||||||||

| Net sales | $ | 1,918.8 | $ | 1,694.3 |

| $ | 1,868.6 | $ | 2,232.5 | ||||||||

Gross margin of 31.5 percent was down from the gross margin of 32.9 percent in the prior year. A number of factors combined to lower the gross margin for the year, including higher than expected global distribution costs due to increased Customer demand, some lower margin Gas Turbine System and Industrial Filtration Solutions sales as well as some process inefficiencies. Gross margin was

9

negatively impacted by higher than expected distribution costs associated with implementing the investments made to increase the Company’s distribution capacity and capabilities.

Although not as large as the impact on net sales, the Company’s net earnings were also positivelynegatively impacted by foreign currency translation for the year.translation. The impact of foreign currency translation during the year increaseddecreased net earnings by $5.1$3.8 million. Excluding the current year impact of foreign currency translation, net earnings increased 10.1 percent during the year.decreased 21.1 percent.

Although net earnings excluding foreign currency translation is not a measure of financial performance under GAAP, the Company believes it is useful in understanding its financial results and provides a comparable measure for understanding the operating results of the Company’s foreign entitiesCompany between different fiscal periods excluding the impact of foreign currency translation. FollowingThe following is a reconciliation to the most comparable GAAP financial measure of this non-GAAP financial measure (in millions):

| July 31, 2007 | July 31, 2006 |

|

|

|

|

|

|

| |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| July 31, |

| July 31, |

| |||||||||||||

| Net earnings, excluding foreign currency translation | $ | 145.6 | $ | 133.1 |

| $ | 135.7 |

| $ | 159.1 |

| ||||||

| Current year foreign currency translation impact, net of tax | 5.1 | (0.8 | ) | ||||||||||||||

Foreign currency translation impact, net of tax |

|

| (3.8 | ) |

| 12.9 | |||||||||||

| Net earnings | $ | 150.7 | $ | 132.3 |

| $ | 131.9 | $ | 172.0 | ||||||||

The Company reported record diluted earnings per share of $1.83, an 18.1$1.67, a 21.2 percent increasedecrease from $1.55$2.12 in the prior year.

Included in the results are pre-tax restructuring charges of $17.8 million resulting primarily from workforce reductions of 2,800 since the beginning of the year. Gross margin and operating expenses include $10.1 million and $7.7 million of restructuring expenses, respectively. The Company also realized $43.0 million in cost savings from restructuring actions completed throughout the year.

The effective tax rate for Fiscal 2009 was 18.3 percent compared to 27.2 percent in Fiscal 2008. This decrease is attributable to a number of discrete tax items, partially offset by increased expense from the repatriation of foreign earnings. Absent these items, the underlying tax rate for the Fiscal 2009 has decreased

from Fiscal 2008 by 1.2 points to 30.4 percent. The reinstatement of the U.S. Research and Experimentation credit, changes in current year unrecognized tax benefits, reduced statutory tax rates and the mix of earnings between foreign jurisdictions all contributed to the reduction in the underlying rate.

The Company continued to improve an already strong liquidity position which allowed for continued investment in business and debt reduction while increasing cash reserves and maintaining its dividend. While Fiscal 2009 was significantly impacted by the global recession, there are signs that some of the Company’s end markets have begun to stabilize. While the Company’s future visibility remains limited and it’s too early to call a recovery, the Company believes that the worst of the global economic downturn is behind it in many of its early and mid-cycle end markets, including the heavy truck, construction, special applications and replacement parts markets. This view is factored into the Fiscal 2010 outlook discussed below.

Following is financial information for the Company’s Engine Products and Industrial Products segments. Corporate and Unallocated includes corporate expenses determined to be non-allocable to the segments and interest income and expense, non-operating income and expense and expenses not allocated to the business segments in the same period. During the first quarter of 2006, the Company adjusted its basis of measurement for earnings before income taxes such that certain expenses, such as amortization of intangibles, which were previously considered to be Corporate and Unallocated, are now included in the Engine and Industrial Products segment results. The impact of the change in the basis of measurement resulted in approximately $16.0 million of Corporate and Unallocated expenses being charged to the Engine and Industrial Products segments’ aggregate earnings before income taxes in fiscal 2006 as compared to fiscal 2005. This change resulted in approximately $8.0 million of additional expense to each of the Engine and Industrial Products segments during fiscal 2006 when compared to 2005. This adjustment to the basis of measurement of segment earnings did not change the business components included in each of the Company’s reportable segments.expense. See further discussion of segment information in Note J of the Company’s Notes to Consolidated Financial Statements.

| Engine Products | Industrial Products | Corporate & Unallocated | Total Company |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine |

| Industrial |

| Corporate & |

| Total |

| ||||||||||||||||||||||||

|

| (thousands of dollars) |

| |||||||||||||||||||||||||||||

2009 |

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

Net sales |

| $ | 1,001,961 |

| $ | 866,668 |

| $ | — |

| $ | 1,868,629 |

| |||||||||||||||||||

Earnings before income taxes |

| 83,797 |

| 89,526 |

| (11,898 | ) |

| 161,425 |

| ||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

2008 |

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

Net sales |

| $ | 1,229,171 |

| $ | 1,003,350 |

| $ | — |

| $ | 2,232,521 |

| |||||||||||||||||||

Earnings before income taxes |

| 158,931 |

| 102,420 |

| (25,188 | ) |

| 236,163 |

| ||||||||||||||||||||||

| (thousands of dollars) |

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

| 2007 |

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||

| Net sales | $ | 1,084,262 | $ | 834,566 | $ | — | $ | 1,918,828 |

| $ | 1,084,262 |

| $ | 834,566 |

| $ | — |

| $ | 1,918,828 |

| |||||||||||

| Earnings before income taxes | 140,762 | 80,321 | (16,222 | ) | 204,861 |

| 140,762 |

| 80,321 |

| (16,222 | ) |

| 204,861 |

| |||||||||||||||||

| 2006 | ||||||||||||||||||||||||||||||||

| Net sales | $ | 991,554 | $ | 702,773 | $ | — | $ | 1,694,327 | ||||||||||||||||||||||||

| Earnings before income taxes | 135,994 | 65,550 | (12,377 | ) | 189,167 | |||||||||||||||||||||||||||

| 2005 | ||||||||||||||||||||||||||||||||

| Net sales | $ | 923,840 | $ | 671,893 | $ | — | $ | 1,595,733 | ||||||||||||||||||||||||

| Earnings before income taxes | 125,454 | 53,709 | (24,430 | ) | 154,733 | |||||||||||||||||||||||||||

During fiscal 2007,Fiscal 2009, the Company’s Engine Products segment net sales decreased from the prior year as a percent of total net sales at 56.5to 53.6 percent compared to 58.555.1 percent in the prior year. For the Company’s Industrial Products segment, net sales as a percent of total net sales increased to 43.546.4 percent from 41.544.9 percent in the prior year.

Factors within the Company’s reporting segments that contributed to the Company’s results for fiscal 2007Fiscal 2009 included strong business conditions withina significant impact from the Company’s distributors and OEM customers aggressively working down their inventory levels. In the Engine Products segment, the Company experienced weak business conditions in most end markets and regions. Spending in the construction and mining end-markets in the United States, Europe and Asia

10

was down, resulting in a decrease in off-road equipment related sales. This decrease was partially offset by weaker Truckan increase in Aerospace and Defense sales and the benefit of the acquisition of Western Filter Corporation in October 2008. On-road Products sales decreased in the United States, Europe and Asia due to a drop in demand for new trucks, which lowered new truck build rates. Aftermarket sales also decreased due to decreases in equipment utilization in most off-road end markets and decreased freight activity which impacted on-road markets, partially offset by increases in retrofit emissions sales in the United States, Mexico and Canada. Specifically, strength in new construction and mining equipment spurred Off-road Equipment Products sales worldwide. Additionally, equipment utilization rates remained strong driving Aftermarket Products sales growth.States. In the Industrial Products segment, demand increaseswas also weak in Europe and Asia drove sales growth in the Company’sall markets across all regions. Demand for Industrial Filtration Solutions Products.Products was down as a result of the decline in general industrial activity. Also contributing to the decrease in Industrial Filtration Solutions Products sales was the sale of the air dryer business in Maryville, Tennessee, in October 2008, partially offset by the benefit from the acquisition of LMC West, Inc. in February of 2008. Worldwide sales in Gas Turbine Products weakened late in the year and full year sales were higher thanslightly lower as compared to the prior year primarily dueyear. Gas Turbine Products sales are typically large systems and, as a result, the Company’s shipments and revenues fluctuate from quarter to high demand for power generation capacity as well as strength in the oil and gas industry internationally.quarter. Sales of Special Applications Products were strong with continued strongweak due to decreased demand for membrane products.semiconductor fabrications and industrial uses for PTFE membranes and a sudden contraction of the disk drive market that resulted in decreased demand for the Company’s hard disk drive filters.

Following are net sales by product within both the Engine Products segment and Industrial Products segment:segments:

| 2007 | 2006 | 2005 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (thousands of dollars) | |||||||||||||||

| Engine Products segment: | |||||||||||||||

| Off-road Products | $ | 352,065 | $ | 308,175 | $ | 286,230 | |||||||||

| Truck Products | 166,370 | 184,303 | 175,048 | ||||||||||||

| Aftermarket Products* | 565,827 | 499,076 | 462,562 | ||||||||||||

| Total Engine Products segment | 1,084,262 | 991,554 | 923,840 | ||||||||||||

| Industrial Products segment: | |||||||||||||||

| Industrial Filtration Solutions Products | 515,022 | 440,230 | 424,727 | ||||||||||||

| Gas Turbine Products | 158,025 | 121,194 | 112,872 | ||||||||||||

| Special Applications Products | 161,519 | 141,349 | 134,294 | ||||||||||||

| Total Industrial Products segment | 834,566 | 702,773 | 671,893 | ||||||||||||

| Total Company | $ | 1,918,828 | $ | 1,694,327 | $ | 1,595,733 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| 2009 |

| 2008 |

| 2007 |

| |||

|

| (thousands of dollars) |

| |||||||

Engine Products segment: |

|

|

|

|

|

|

|

|

|

|

Off-Road Products* |

| $ | 362,785 |

| $ | 448,681 |

| $ | 352,065 |

|

On-Road Products |

|

| 71,958 |

|

| 123,146 |

|

| 166,370 |

|

Aftermarket Products** |

|

| 567,218 |

|

| 657,344 |

|

| 565,827 |

|

Total Engine Products segment |

|

| 1,001,961 |

|

| 1,229,171 |

|

| 1,084,262 |

|

Industrial Products segment: |

|

|

|

|

|

|

|

|

|

|

Industrial Filtration Solutions Products |

|

| 503,611 |

|

| 600,526 |

|

| 515,022 |

|

Gas Turbine Products |

|

| 206,760 |

|

| 213,138 |

|

| 158,025 |

|

Special Applications Products |

|

| 156,297 |

|

| 189,686 |

|

| 161,519 |

|

Total Industrial Products segment |

| 866,668 | 1,003,350 | 834,566 | ||||||

Total Company |

| $ | 1,868,629 | $ | 2,232,521 | $ | 1,918,828 | |||

* | Includes Aerospace and Defense products. | |

** | Includes replacement part sales to | |

Outlook

While it appears that conditions may have stabilized at many of the Company’s Customers and in many of its end markets, the Company continues to have limited visibility into the future. Consequently, the Company remains cautious in the near-term about forecasting a return to growth.

• | The Company is planning its total Fiscal 2010 sales to be between $1.65 and $1.75 billion, or approximately the pace of the past two quarters. For the full year Fiscal 2010 versus Fiscal 2009, sales are projected to be down 6 to 12 percent. Foreign currency translation is expected to provide a small benefit based on the Company’s planned rates for the Euro of US$1.39 and 98 Yen to the US Dollar for Fiscal 2010. | |

• | The Company did not complete all of its planned restructuring actions by the end of the fourth quarter of Fiscal 2009 and anticipates there could be additional restructuring charges of up to $17 million in Fiscal 2010. Including these costs, the full year Fiscal 2010 operating margin is still expected to be between 9.5 to 10.5 percent. | |

• | The Company expects its full year Fiscal 2010 tax rate to be between 30 and 32 percent. The Company does not anticipate significant discrete tax benefits as occurred in Fiscal 2009. | |

• | The Company expects that cash generated by operating activities will exceed $150 million in Fiscal 2010. Capital spending in Fiscal 2010 is planned at $30.0 million to $40.0 million. The Company will continue to use its cash flow for dividends, potential acquisitions, capital projects and maintenance of its strong liquidity position. |

OutlookEngine Products– The Company expects five to seven percent sales growth in fiscal 2008 for sales in its Engine Products segment. Due to the continued impact of the EPA diesel emissions standards, the Company expects its United States, Mexico and Canada Truck Productsfull year sales to decrease $303 to $40 million in8 percent, inclusive of the first three quartersimpact of 2008 before growth returns in the fourth quarter. Productionforeign currency translation.

• | In its On-Road Products businesses, the Company believes that global build rates for heavy- and medium-duty trucks are stabilizing at the current levels. | |

• | The Company is forecasting slightly lower sales for its Aerospace and Defense Products as the level of Customer demand for defense products is decreasing. | |

• | The Company expects activity in the global construction and mining end markets to remain at their current levels during the first half of Fiscal 2010, and anticipates Customer demand in the farm equipment market outside of North America to continue its current decline. | |

• | The Company’s Aftermarket sales are expected to improve slightly from their current levels as utilization rates for both heavy trucks and off-road equipment are stabilizing. The Company expects |

to benefit from the increasing amount of equipment in the field with PowerCore® technology as well as its other proprietary filtration systems. |

Industrial Products– The Company expects non-residential and public construction marketsforecasts full year Fiscal 2010 sales to benefit from continued infrastructure investment indecrease 11 to 16 percent, inclusive of the United States. Productionimpact of new agriculture equipment by Customers is expected to remain strong globally. Aftermarket Products sales are expected to grow with continued strong equipment utilization in the field, and the increasing amount of equipment with the Company’s PowerCore™ filtration systems.foreign currency translation.

• | Industrial Filtration Solutions sales are projected to decrease 10 to 15 percent for the year due to difficult comparable sales in the first half of Fiscal 2010. The Company expects general manufacturing activity to remain near its current level. | |

• | The Company expects full year sales of its Gas Turbine Products to decrease 21 to 26 percent due the slowdown in demand for large power generation projects. | |

• | Special Applications Products’ sales are projected to be flat to down 5 percent, as conditions appear to have stabilized in the hard disk drive market but may continue to weaken in the short-term in the Company’s membrane products’ industrial end-markets. |

The Company expects eight to ten percent sales growth in fiscal 2008 for its Industrial Products segment. Industrial Filtration Solutions Products sales are expected to grow 10 percent due to continued strong global manufacturing investment and production utilization conditions. The Company expects full-year gas turbine sales growth in the high-single digits over last year’s 30 percent growth, with continued strength in the international power generation and oil and gas market segments. Special Applications Products sales are expected to grow in the mid-single digit percent.

Fiscal 20072009 Compared to Fiscal 20062008

Engine Products SegmentThe Engine Products segment sells to OEMs in the construction, mining, agriculture, aerospace, defense, and transportationtruck markets and to independent distributors, OEM dealer networks, private label accounts and large equipment fleets. Products include air intakefiltration systems, exhaust and emissions systems, liquid filtration systems and replacement filters.

Sales for the Engine Products segment were $1.084 billion, an increase$1,002.0 million, a decrease of 9.318.5 percent from $991.6$1,229.2 million in the prior year, reflecting increases in the worldwide Off-roadyear. International Engine Products sales decreased 24.3 percent and Aftermarket Products businesses partially offset by decreased Truck Products sales in the United States.

11

TableStates decreased 12.4 percent from the prior year. The impact of Contents

Within theforeign currency decreased sales by $38.9 million, or 3.2 percent. Earnings before income taxes as a percentage of Engine Products segment worldwide sales of Off-road8.4 percent decreased from 12.9 percent in the prior year. The Engine Products segment has been negatively impacted by lower absorption of fixed manufacturing costs due to the drop in sales volumes and increased costs related to restructuring, offset by cost savings as a result of workforce reductions already completed, improved distribution efficiencies as compared to the prior year and the impact of cost control measures including reductions in incentive compensation.

Worldwide sales of Off-Road Products were $352.1$362.8 million, an increasea decrease of 14.219.1 percent from $308.2$448.7 million in the prior year. Sales in the United States showed an increase of 7.6 percentdecreased 7.2 percent. Global mining activity started declining due to decreased commodity prices in the second quarter of Fiscal 2009, and remained weak throughout the remainder of the year. Spending in U.S. residential and non-residential construction markets was down more than 27 percent and 5 percent, respectively, over prior year, resulting in a decrease in the sales of the Company’s products into those markets. Domestic Aerospace and Defense sales benefited from the recent acquisition of Western Filter Corporation, which resulted in $15.4 million of incremental sales over the prior year, and continued improvements in new construction and agricultural equipment demand.strong demand for filters for military equipment. Internationally, sales of Off-roadOff-Road Products were up 21.9down 31.3 percent from the prior year, with sales increasingdecreasing in both Europe and Asia by 24.332.5 percent and 16.929.5 percent, respectively, reflecting strengthrespectively. Sales in the newEuropean construction and mining equipment demand internationally.end market decreased due to a decline in construction activity related to the economic downturn. Sales to the European agricultural end market also decreased. In Asia, sales have declined significantly in Japan in the construction end markets.

Worldwide sales of TruckOn-Road Products were $166.4$72.0 million, a decrease of 9.741.6 percent from $184.3$123.1 million in the prior year. TruckOn-Road Products sales in the United States decreased 14.943.2 percent from the prior year, primarily as a result of the new EPA emissions standards which resulteda 29 percent decrease in lower newClass 8 truck build rates, at our Customers.40 percent decrease in medium duty truck build rates by the Company’s Customers and a reduction in high value product mix over the prior year. International TruckOn-Road Products sales increased 5.3decreased 39.6 percent from the prior year. Strongyear, driven by decreased sales in Europe resulted in an increaseand Asia of 9.951.0 percent from strongerand 32.5 percent, respectively, reflecting the current economic downturn for freight activity and new truck build rates due to economic growth and increased market share.rates.

Worldwide Engine Aftermarket Products sales of $565.8$567.2 million increased 13.4decreased 13.7 percent from $499.1$657.3 million in the prior year. Sales in the United States increased 6.8decreased 9.5 percent over the prior year, while internationaldriven

by inventory adjustments at the Company’s Customers and decreases in utilization rates in the mining, construction and transportation industries, partially offset by increases in retrofit emission sales increased 21.3of $5.2 million. International sales decreased 17.4 percent withfrom the prior year, primarily driven by sales increasingdecreases in Europe and Asia and Mexico by 28.2 percent, 13.7of 26.1 percent and 29.98.0 percent, respectively. Equipment utilization remained high in all regions driving demand for replacement filters. Geographic expansion also contributedrespectively, due to the increases internationally.weak economic conditions.

Industrial Products SegmentThe Industrial Products segment sells to various industrial end-users, OEMs of gas-fired turbines, and OEMs and end-users requiring highly purified air. Products include dust, fume and mist collectors, compressed air purification systems, liquid filters and parts, static and pulse-clean air filter systems, PTFE membrane and laminates, and specialized air filtration systems for diverse applications including computer hard disk drives and PTFE membrane and laminates.drives.

Sales for the Industrial Products segment were $834.6$866.7 million, an increasea decrease of 18.813.6 percent from $702.8$1,003.4 million in the prior year resultingyear. International Industrial Products sales decreased 14.2 percent and sales in the United States decreased 12.3 percent from strongerthe prior year. The impact of foreign currency decreased sales by $37.9 million, or 3.8 percent. Despite the 13.6 percent decrease in sales, earnings before income taxes as a percentage of all products across all regions.

Within the Industrial Products segment worldwidesales of 10.3 percent increased from 10.2 percent in the prior year. The improvement in earnings as a percent of sales over the prior year was driven by better execution on large project shipments, cost savings from restructuring actions and the impact of cost control measures including reductions in incentive compensation expense. These were slightly offset by lower absorption of fixed costs and restructuring costs.

Worldwide sales of Industrial Filtration Solutions Products of $515.0$503.6 million increased 17.0decreased 16.1 percent from $440.2$600.5 million in the prior year. Sales in the United States and Europe Asia, South Africa and Mexico increased 7.2 percent, 24.9 percent, 18.8 percent, 27.7decreased 18.3 percent and 25.521.0 percent, respectively. Demand has been strong worldwide but specificallySales in Asia remained relatively flat as compared to the prior year. The decline in Europe wherewas due to reduced demand for industrial dust collectors and compressed air purification systems which fell with the downturn in general manufacturing investment conditions have been good.activity during the year. Domestic sales decreased from the prior year as a result of this same decline in general industrial activity. The results in the year were also influenced by the sale of the air dryer business in Maryville, Tennessee, on October 31, 2008 and the acquisition of LMC West, Inc. (LMC West) in February of Fiscal 2008. The sale of the air dryer business in Maryville, Tennessee, decreased sales $7.6 million over last year. The acquisition of LMC West contributed to $7.0 million of sales during the twelve months of Fiscal 2009 and $4.7 million during the latter six months of Fiscal 2008.

Worldwide sales of Gas Turbine Products were $158.0$206.8 million, an increasea decrease of 30.43.0 percent from $121.2$213.1 million in the prior yearyear. Gas Turbine Products sales are typically large systems and, as a result, the Company’s shipments and revenues fluctuate from quarter to quarter. Incoming orders declined 58 percent in Fiscal 2009 versus Fiscal 2008, a reflection of the reduced demand for power generation remained strong internationally where thereprojects globally. This trend is a deficit of power generation capacity. High levels of activityexpected to continue in the oil and gas industry generated increased demand for small turbines and replacement filters.Fiscal 2010.

Worldwide sales of Special Applications Products were $161.5$156.3 million, a 14.317.6 percent increasedecrease from $141.3$189.7 million in the prior year. SalesDomestic Special Application Products sales decreased 10.0 percent. International sales of Special Application Products decreased 18.7 percent over the prior year. The primary decreases internationally were in the United States, Europe and Asia, increased 30.3which decreased 25.5 and 17.3 percent, 17.1 percent,respectively, due to a significant reduction in demand for hard disk drive filters, semiconductor filtration systems and 11.4 percent from the prior year duePTFE membrane filtration products. The reduction in demand is primarily to strengtha result of a worldwide contraction in the end markets served by our membrane product line.for computers, data storage devices and other electronic products that began in the second quarter of Fiscal 2009.

Consolidated ResultsThe Company reported record net earnings for 2007Fiscal 2009 of $150.7$131.9 million compared to $132.3$172.0 million in 2006, an increaseFiscal 2008, a decrease of 13.923.3 percent. Diluted net earnings per share was a record $1.83, up 18.1$1.67, down 21.2 percent from $1.55$2.12 in the prior year. The Company’s operating income of $211.1$170.0 million increaseddecreased from prior year operating income of $192.8$245.8 million by 9.530.9 percent. Operating income in

The table below shows the Engine Products segment as a percentpercentage of total operating income decreasedcontributed by each segment for each of the last three fiscal years. Corporate and Unallocated includes corporate expenses determined to 62.9 percent from 67.7 percent inbe non-allocable to the prior year. Operatingsegments and interest income in the Industrial Products segment as a percent of total operating income of 37.8 percent increased from the prior year of 33.6 percent.and expense:

|

|

|

|

|

|

|

|

|

|

|

|

| 2009 |

|

| 2008 |

|

| 2007 |

|

|

Engine Products |

| 44.5 | % |

| 61.1 | % |

| 62.9 | % |

|

Industrial Products |

| 51.8 | % |

| 42.1 | % |

| 37.8 | % |

|

Corporate and Unallocated |

| 3.7 | % |

| (3.2 | %) |

| (0.7 | %) |

|

Total Company |

| 100 | % |

| 100 | % |

| 100 | % |

|

International operating income, prior to corporate expense allocations, totaled 77.777.9 percent of consolidated operating income in 2007Fiscal 2009 as compared to 77.289.4 percent in 2006. Of the 2007 international operating income, prior to corporate expense allocations, Europe contributed 44.8 percent while Asia contributed 49.7 percent.Fiscal 2008. Total international operating income increased 10.2decreased 39.8 percent from the prior year. This increasedecrease is attributable to strong salesrestructuring charges internationally exceeding domestic restructuring costs, weaker foreign currencies and overall weak business conditions abroad. The table below shows the percentage of Special Applications Products and Gas Turbine Systems Products.total operating income contributed by each major geographic region for each of the last three fiscal years:

|

|

|

|

|

|

|

|

|

|

|

|

| 2009 |

|

| 2008 |

|

| 2007 |

|

|

United States |

| 22.1 | % |

| 10.6 | % |

| 22.3 | % |

|

Europe |

| 23.3 | % |

| 43.3 | % |

| 34.8 | % |

|

Asia |

| 43.5 | % |

| 37.9 | % |

| 38.6 | % |

|

Other |

| 11.1 | % | 8.2 | % |

| 4.3 | % |

| |

Total Company |

| 100 | % |

| 100 | % |

| 100 | % |

|

Gross margin for 2007Fiscal 2009 was 31.531.6 percent, a decrease from 32.932.5 percent in the prior year. A number of factors combined to lower theThe Company had $10.1 million in restructuring costs which reduced gross margin forin the year, including higher than expected global

12

Tableyear. In addition, lower absorption of Contents

distributionfixed costs due to increased Customer demand, some lower margin Gas Turbine System Products and Industrial Filtration Solutions Products sales as well as some process inefficiencies. Gross margin wasthe drop in production volumes, net of savings from completed restructuring related activities, negatively impacted gross margin by higher than expectedapproximately $23 million. Partially offsetting these factors were the positive impacts of improved product mix, improved distribution costs associated with implementingefficiencies and better execution on large project shipments. During Fiscal 2008, the investments madeCompany began using a new warehouse management system at its main U.S. distribution center. The company encountered start-up problems during the transition to increase the Company’s distribution capacity and capabilities. Plant rationalization and start-up costs for new facilities were $5.3systems which, although now resolved, resulted in $7.6 million in 2007, downunanticipated charges in Fiscal 2008 that did not recur in Fiscal 2009. The Company also incurred a charge of approximately $5.0 million to pretax income related to the use of the Last-In, First-Out (LIFO) accounting method for its U.S. inventories, which charges increasing commodity costs to income immediately. As commodity costs were relatively flat in Fiscal 2009, the Company did not experience a similar impact from $5.4 million in the prior year.rising commodity prices.

Operating expenses for 2007Fiscal 2009 were $393.8$419.8 million or 20.522.5 percent of sales, up from $363.8as compared to $480.1 million or 21.5 percent in the prior year. While operatingOperating expenses were up in total dollars, the amount as a percent of sales was downincreased due to a gainsales volume declines and $7.7 million in operating leverage with revenue increasesrestructuring cost during the year, offset by $19.4 million in benefits from restructuring actions taken and continued cost containment efforts.$19.5 million of lower incentive compensation expense as compared to the prior year. The Company’s expense reduction programs remain in effect.

Interest expense of $14.6$17.0 million increased $4.7$0.4 million from $9.9$16.6 million in the prior year as a result of investments in working capital, the Aerospace Filtration Systems, Inc. acquisition in March, and continued capital investments.higher debt levels. Net other income totaled $8.3$8.5 million in 2007 compared to $6.3Fiscal 2009 up from $6.9 million in the prior year. Components of other income for 2007Fiscal 2009 were as follows: interest income of $1.1$1.6 million, earnings from non-consolidated joint ventures of $5.9$2.3 million, royalty income of $6.1 million, charitable donations of $0.4$0.6 million, foreign exchange gainslosses of $0.2$0.4 million and other miscellaneous income and expense items resulting in incomeexpenses of $1.5$0.5 million.

The effective income tax rate for fiscal 2007Fiscal 2009 was 26.4 percent.18.3 percent compared to 27.2 percent in Fiscal 2008. The decrease in effective income tax rate for fiscal 2006 was 30.1 percent. In the fourth quarter of fiscal 2006, the Company recognized a $3.6 million tax charge for the additional $80.0 million foreign earnings repatriation plan approved pursuant to the American Jobs Creation Act of 2004. The favorable comparison for 2007 is primarily due to the settlements of long-standing court cases and examinations in various jurisdictions for tax charge mentioned above plusyears 2003 through 2006, the reassessment of the corresponding unrecognized tax benefits for the subsequent open years and a favorable resolution of a foreign tax matter. Partially offsetting these effects, the Company’s Fiscal 2009 tax rate was unfavorably impacted by an additional $3.1 millionincreased expense from the repatriation of discreteforeign earnings. Absent these items, in 2007 comparedthe underlying tax rate for the Fiscal