UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| x | Annual Report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 For the fiscal year ended December 31, 20122013 |

| |

| o | Transition Report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 For the transition period from _______to_______ |

Commission File Number 0-53713

OTTER TAIL CORPORATION

(Exact name of registrant as specified in its charter)

| | |

| MINNESOTA | | 27-0383995 |

| (State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

| | | |

| 215 SOUTH CASCADE STREET, BOX 496, FERGUS FALLS,MINNESOTA | | 56538-0496 |

(Address (Address of principal executive offices) | (Zip | (Zip Code) |

Registrant’s telephone number, including area code: 866-410-8780

Securities registered pursuant to Section 12(b) of the Act:

| | | | |

| Title of each class | | Name of each exchange on which registered |

| | COMMON SHARES, par value $5.00 per share | | The NASDAQ Stock Market LLC |

Securities registered pursuant to Section 12(g) of the Act:

CUMULATIVE PREFERRED SHARES, without par valueNone

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. (Yes x No o)

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or

Section 15(d) of the Act. (Yes oNo x))

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. (Yes x No o)

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). (Yes xNo o)

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| | | |

| Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one): |

| | Large Accelerated Filer x | | Accelerated Filer o |

| | Non-Accelerated Filer o | | Smaller Reporting Company o |

| | (Do not check if a smaller reporting company) | | |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). (Yeso No x)

The aggregate market value of common stock held by non-affiliates, computed by reference to the last sales price on June 29, 201228, 2013 was $777,976,655.972,636,461.

Indicate the number of shares outstanding of each of the registrant’s classes of common stock, as of the latest practicable date: 36,169,48836,340,637 Common Shares ($5 par value) as of February 15, 2013.14, 2014.

Documents Incorporated by Reference:

Proxy Statement for the 20132014 Annual Meeting-Portions incorporated by reference into Part III

OTTER TAIL CORPORATION

FORM 10-K TABLE OF CONTENTS

| | | Description | Page Numbers |

| | Description | Page |

| | | 2 | |

| | | | |

| | | 4 | |

| | | 2928 | |

| | | 35 | |

| | | 35 | |

| | | 36 | |

| | | 36 | |

| | | 36 | |

| | | | | |

| | | | |

| | | 37 | |

| | | 38 | |

| | | 38 | |

| | | 6165 | |

| | | | |

| | | | 6367 | |

| | | 6468 | |

| | | 6670 | |

| | | 6771 | |

| | | 6872 | |

| | | 6973 | |

| | | 7074 | |

| | | 7175 | |

| | | 120125 | |

| | | 121126 | |

| | | 121126 | |

| | | 121126 | |

| | | | |

| | | | |

| | | 122127 | |

| | | 122127 | |

| | | 123127 | |

| | | 123127 | |

| | | 123127 | |

| | | | |

| | | | |

| | | 124128 | |

| | | | |

| | | 132137 | |

The following abbreviations or acronyms are used in the text. References in this report to “the Company”, “we”, “us” and “our” are to Otter Tail Corporation, collectively.Corporation.

| | |

| ADP | | Advance Determination of Prudence |

| Aevenia | | Aevenia, Inc. |

| AFUDC | | Allowance for Funds Used During Construction |

| AQCS | | Air Quality Control System |

| ARO | | Accumulated Asset Retirement Obligation |

| ASC | | Accounting Standards Codification |

| ASC 980 | | ASC Topic 980 - Regulated Operations |

| ASM | | Ancillary Services Market |

| Aviva | | Aviva Sports, Inc. |

| BACT | | Best-Available Control Technology |

| BART | | Best-Available Retrofit Technology |

| Bemidji Project | | Bemidji-Grand Rapids 230 kV Project |

| Brookings Project | | Brookings-Southeast Twin Cities 345 kV Project |

| BTD | | BTD Manufacturing, Inc. |

| CAA | | Clean Air Act |

| CAIR | | Clean Air Interstate Rule |

| CapX2020 | | Capacity Expansion 2020 |

| Cascade | | Cascade Investment LLC |

| Cascade Note | | $50 million 8.89% Senior Unsecured Note due November 30, 2017 |

| CCMC | | Coyote Creek Mining Company, L.L.C. |

CCRA | Conservation Cost Recovery Adjustment |

CO2 | | Carbon Dioxide |

| CON | | Certificate of Need |

| CSAPR | | Cross-State Air Pollution Rule |

| CWIP | | Construction Work in Progress |

| DENR | | Department of Environment and Natural Resources |

DMIDMS | DMI Industries, Inc. |

DMS | DMS Health Technologies, Inc. |

ECRRECR | | Environmental Cost Recovery Rider |

| EEI | | Edison Electric Institute Index |

| EEP | | Energy Efficiency Plan |

| EPA | | Environmental Protection Agency |

| ERCOT | | Electric Reliability Council of Texas |

| ESSRP | | Executive Survivor and Supplemental Retirement Plan |

| Fargo Project | | Fargo-Monticello 345 kV Project |

| FASB | | Financial Accounting Standards Board |

| FERC | | Federal Energy Regulatory Commission |

| Foley | | Foley Company |

| GAAP | | Generally Accepted Accounting Principles |

| GHG | | Greenhouse Gas |

| IMD | | IMD, Inc. |

| IPH | | Idaho Pacific Holdings, Inc. |

| IRP | | Integrated Resource Plan |

| JPMS | | J.P. Morgan Securities |

| kV | | kiloVolt |

| kW | | kiloWatt |

| kwh | | kilowatt-hour |

| LSA | | Lignite Sales Agreement |

| MAPP | | Mid-Continent Area Power Pool |

| MATS | | Mercury and Air Toxics Standards |

| MDU | | MDU Resources Group, Inc. |

| MEI | | Moorhead Electric, Inc. |

| MISO | Midwest | Midcontinent Independent Transmission System Operator, Inc. |

| MISO Tariff | | MISO Open Access Transmission, Energy and Operating Reserve Markets Tariff |

| MNCIP | | Minnesota Conservation Improvement Program |

| MNDOC | | Minnesota Department of Commerce |

| Minnesota Office of Attorney General | |

| MNRRA | | Minnesota Renewable Resource Adjustment |

| MPCA | | Minnesota Pollution Control Agency |

| MPUC | | Minnesota Public Utilities Commission |

| MRO | | Midwest Reliability Organization |

| MVP | | Multi-Value Project |

| MW | | Megawatt |

| mwh | | Megawatt-hour |

| NAEMA | | North American Energy Marketers Association |

| NDDOH | | North Dakota Department of Health |

| NDPSC | | North Dakota Public Service Commission |

| NDRRA | | North Dakota Renewable Resource Cost Recovery Rider Adjustment |

| NICF | | Notice of InterestIntent to Construct Facilities |

| NPCA | | National Parks Conservation Association |

| NPDES | | National Pollutant Discharge Elimination System |

| Northern Pipe | | Northern Pipe Products, Inc. |

NOx | | Nitrogen Oxide |

| NSPS | | New Source Performance Standards |

| NYMEX | | New York Mercantile Exchange |

| OTESCO | | Otter Tail Energy Services Company |

| OTP | | Otter Tail Power Company |

PACEPCOR | Partnership in Assisting Community Expansion |

PCOR | Plains CO2Reduction Partnership |

PEM | | Power and Energy Market |

| PM2.5 | | Particulate Matter Less Than 2.5 Microns |

PSPSD | Polystyrene |

PSD | Prevention of Significant Deterioration |

| PTC | | Production Tax Credit |

| PVC | | Polyvinyl Chloride |

| RCRA | | Resource Conservation and Recovery Act |

| SCR | | Selective Catalytic Reduction |

| SDPUC | | South Dakota Public Utilities Commission |

| SEC | | Securities and Exchange Commission |

| SF6 | | Sulfur Hexaflouride |

ShoreMasterShrco | ShoreMaster, | Shrco, Inc. |

| SIP | | State Implementation Plan |

SO2 | | Sulfur Dioxide |

| T.O. Plastics | | T.O. Plastics, Inc. |

| Tariff | | Energy and Operating Reserve Markets Tariff |

| TCR | | Transmission Cost Recovery |

| Trinity | | Trinity Industries, Inc. |

VaRVaristar | Value at Risk |

Varistar | Varistar Corporation |

| VIC | | Voluntary Investigation and Cleanup |

| VIE | | Variable Interest Entity |

| Vinyltech | | Vinyltech Corporation |

| Wylie | | E.W. Wylie Corporation |

(a) General Development of Business

Otter Tail Power Company was incorporated in 1907 under the laws of the State of Minnesota. In 2001, the name was changed to “Otter Tail Corporation” to more accurately represent the broader scope of electric and nonelectric operations and the name Otter Tail Power Company (OTP) was retained for use by the electric utility. On July 1, 2009, Otter Tail Corporation completed a holding company reorganization whereby OTP, which had previously been operated as a division of Otter Tail Corporation, became a wholly owned subsidiary of the new parent holding company named Otter Tail Corporation (the Company). The new parent holding company was incorporated in June 2009 under the laws of the State of Minnesota in connection with the holding company reorganization. The Company’s executive offices are located at 215 South Cascade Street, P.O. Box 496, Fergus Falls, Minnesota 56538-0496 and 4334 18th Avenue SW, Suite 200, P.O. Box 9156, Fargo, North Dakota 58106-9156. The Company’s telephone number is (866) 410-8780.

The Company makes available free of charge at its internet website (www.ottertail.com) its annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, Forms 3, 4 and 5 filed on behalf of directors and executive officers and any amendments to these reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as soon as reasonably practicable after such material is electronically filed with or furnished to the Securities and Exchange Commission (SEC). Information on the Company’s website is not deemed to be incorporated by reference into this Annual Report on Form 10-K.

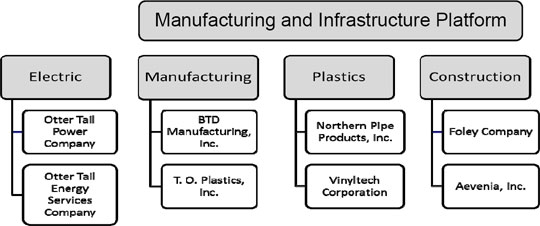

Otter Tail Corporation and its subsidiaries conduct business primarily in the United States. The Company had approximately 2,2862,336 full-time employees in its continuing operations at December 31, 2012.2013. The Company’s businesses have been classified in four segments to be consistent with its business strategy and the reporting and review process used by the Company’s chief operating decision maker. The four segments are Electric, Manufacturing, Plastics and Construction. We may refer to our Manufacturing, Plastics and Construction segments collectively as our manufacturing and infrastructure businesses.

In 2011 and 2012,Over the last three years, the Company sold several businesses in execution of itsan announced strategy of realigningto realign its business portfolio to reduce its risk profile and dedicate a greater portion of its resources toward electric utility operations. In 2011, the Company sold Idaho Pacific Holdings, Inc. (IPH), its Food Ingredient Processing business, and E.W. Wylie Corporation (Wylie), its trucking company, which was included in its former Wind Energy segment. In January 2012, the Company sold the assets of Aviva Sports, Inc. (Aviva), a recreational equipment manufacturer and a wholly owned subsidiary of ShoreMaster,Shrco, Inc. (ShoreMaster)(Shrco), the Company’s former waterfront equipment manufacturer. In February 2012, the Company sold DMS Health Technologies, Inc. (DMS), its former Health Services segment business. In November 2012, the Company completed the sale of the assets of DMI Industries,IMD, Inc. (DMI)(IMD), itsthe Company’s former wind tower manufacturer, of towers for wind turbines, and exited the wind tower manufacturing business. In December 2012,On February 8, 2013 the Company entered into negotiations to sellsold substantially all the assets of ShoreMaster and completed the sale on February 8, 2013. The Company’s business structure now consists of the following segments: Electric, Manufacturing, Construction and Plastics.Shrco.

All informationThe chart below indicates the companies included in this report, including comparative financial information, has been revised to reflect the continuing operationseach of the Company’s businessreporting segments.

| | ● | Electric includes the production, transmission, distribution and sale of electric energy in Minnesota, North Dakota and South Dakota by OTP. In addition, OTP is an active wholesale participant in the MidwestMidcontinent Independent Transmission System Operator, Inc. (MISO) markets. OTP’s operations have been the Company’s primary business since 1907. Additionally, Electric alsothe electric segment includes Otter Tail Energy Services Company (OTESCO), which providesprovided technical and engineering services.services through December 31, 2012. OTESCO ceased operations and did not record any operating revenues, expenses or net income in 2013. |

| | ● | Manufacturing consists of businesses in the following manufacturing activities: contract machining, metal parts stamping and fabrication, and production of material and handling trays and horticultural containers. These businesses have manufacturing facilities in Illinois and Minnesota, and sell products primarily in the United States. |

| | ● | Plastics consists of businesses producing polyvinyl chloride (PVC) pipe at plants in North Dakota and Arizona. The PVC pipe is sold primarily in the upper Midwest and Southwest regions of the United States. |

| ● | Construction consists of businesses involved in commercial and industrial electric contracting and construction of fiber optic, and electric distribution, systems, water, wastewater and HVAC systems primarily in the central United States. |

| ● | Plastics consists of businesses producing polyvinyl chloride (PVC) pipe in the upper Midwest and Southwest regions of the United States.

|

OTP is a wholly owned subsidiary of the Company. All of the Company’s manufacturing and infrastructure businesses are owned by its wholly owned subsidiary, Varistar Corporation (Varistar). The Company’s corporate operating costs include items such as corporate staff and overhead costs, the results of the Company’s captive insurance company and other items excluded from the measurement of operating segment performance. Corporate assets consist primarily of cash, prepaid expenses, investments and fixed assets. Corporate is not an operating segment. Rather, it is added to operating segment totals to reconcile to totals on the Company’s consolidated financial statements.

OTPThe Company has lowered its overall risk by investing in rate base growth opportunities in its Electric segment and OTESCO are wholly owned subsidiaries of the Company. All ofdivesting certain nonelectric operating companies that no longer fit the Company’s other businesses are owned byportfolio criteria. This strategy has provided a more predictable earnings stream, improved the Company’s credit quality and preserved its wholly owned subsidiary, Varistar Corporation (Varistar).

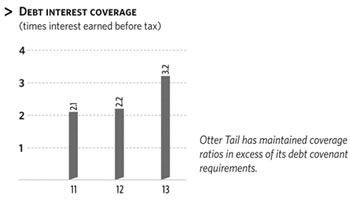

ability to fund the dividend. The Company’s current strategygoal is to deliver annual growth in earnings per share between four to seven percent over the next several years, using 2012 as the measurement year. The growth is expected to come from the substantial increase in the Company’s regulated utility rate base and from planned increased earnings from existing capacity already in place at the Company’s manufacturing and infrastructure businesses. The Company will continue to review its business portfolio to see where additional opportunities exist to improve its risk profile, improve credit metrics and generate additional sources of cash to support the growth opportunities in its electric utility. The Company has lowered its overall risk by investing in rate base growth opportunities in its Electric segment and divesting certain non-electric operating companies that no longer fit the Company’s portfolio criteria. This strategy is intended to create a more predictable earnings stream, improve the Company’s credit quality and preserve its ability to fund the dividend. The Company’s goal is to deliver annual growth in earnings per share between four to seven percent over the next several years. The growth is expected to come from the substantial increase in the Company’s regulated utility rate base and from planned increased earnings from existing capacity already in place at the Company’s manufacturing and infrastructure businesses. The Company will also evaluate opportunities to allocate capital to potential acquisitions in its Manufacturing segment. Over time, the Company expects the electric utility business will provide approximately 75% to 85% of its overall earnings. The Company expects its Manufacturingmanufacturing and Infrastructureinfrastructure businesses will provide 15% to 25% of its earnings, and will continue to be a fundamental part of its strategy. The actual mix of earnings from continuing operations in 2013 was 77% from the electric utility and 23% from the manufacturing and infrastructure businesses.

In evaluating its portfolio of operating companies, the Company looks for the following characteristics:

| | ● | a threshold level of net earnings and a return on invested capital in excess of the Company’s weighted average cost of capital, |

| | ● | a strategic differentiation from competitors and a sustainable cost advantage, |

| | ● | a stable or growing industry, |

| | ● | an ability to quickly adapt to changing economic cycles, and |

| | ● | a strong management team committed to operational excellence. |

For a discussion of the Company’s results of operations, see “Management’s“Management’s Discussion and Analysis of Financial Condition and Results of Operations,” on pages 38 through 6065 of this Annual Report on Form 10-K.

(b) Financial Information about Industry Segments

The Company is engaged in businesses classified into four segments: Electric, Manufacturing, ConstructionPlastics and Plastics.Construction. Financial information about the Company’s segments and geographic areas is included in note 2 of “Notes to Consolidated Financial Statements” on pages 8085 through 8387 of this Annual Report on Form 10-K.

(c) Narrative Description of Business

ELECTRIC

General

Electric consists of two businesses:includes OTP and, OTESCO.through December 31, 2012, the operations of OTESCO, which were not materially significant in 2012 and 2011. OTP, headquartered in Fergus Falls, Minnesota, provides electricity to more than 129,000130,000 customers in a service area with outer boundaries that encompass a total expanse of 70,000 square miles of western Minnesota, eastern North Dakota, and northeastern South Dakota. OTESCO, headquartered in Fergus Falls, Minnesota, providesprovided technical and engineering services primarily in North Dakota and Minnesota. The Company derived 41%42%, 41% and 48%41% of its consolidated operating revenues and 64%, 74% and 88% of its consolidated operating income from the Electric segment for each of the three years ended December 31, 2013, 2012 2011 and 2010,2011, respectively.

The breakdown of retail electric revenues by state is as follows:

| State | | 2012 | | | 2011 | | | 2013 | | | 2012 | |

| Minnesota | | | 48.9 | % | | | 48.8 | % | | | 48.2 | % | | | 48.9 | % |

| North Dakota | | | 42.0 | | | | 42.2 | | | | 42.8 | | | | 42.0 | |

| South Dakota | | | 9.1 | | | | 9.0 | | | | 9.0 | | | | 9.1 | |

| Total | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % |

The territory served by OTP is predominantly agricultural. The aggregate population of OTP’s retail electric service area is approximately 230,000. In this service area of 422 communities and adjacent rural areas and farms, approximately 125,646 people live in communities having a population of more than 1,000, according to the 2010 census. The only communities served which have a population in excess of 10,000 are Jamestown, North Dakota (15,427); Bemidji, Minnesota (13,431); and Fergus Falls, Minnesota (13,138). As of December 31, 2012,2013, OTP served 129,786130,188 customers. Although there are relatively few large customers, sales to commercial and industrial customers are significant.

The following table provides a breakdown of electric revenues by customer category. All other sources include gross wholesale sales from utility generation, net revenue from energy trading activity and sales to municipalities.

| Customer Category | | 2012 | | | 2011 | | | 2013 | | | 2012 | |

| Commercial | | | 36.0 | % | | | 36.2 | % | | | 36.9 | % | | | 36.0 | % |

| Residential | | | 32.6 | | | | 32.9 | | | | 33.3 | | | | 32.6 | |

| Industrial | | | 25.0 | | | | 23.8 | | | | 23.2 | | | | 25.0 | |

| All Other Sources | | | 6.4 | | | | 7.1 | | | | 6.6 | | | | 6.4 | |

| Total | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % |

Wholesale electric energy kilowatt-hour (kwh) sales were 11.8%12.5% of total kwh sales for 20122013 and 12.9%11.8% for 2011.2012. Wholesale electric energy kwh sales decreasedincreased by 10.8%13.9% between the years while revenue per kwh sold decreasedincreased by 14.5%18.8%. Activity in the short-term energy market is subject to change based on a number of factors and it is difficult to predict the quantity of wholesale power sales or prices for wholesale power in the future.

Capacity and Demand

As of December 31, 20122013 OTP’s owned net-plant dependable kilowatt (kW) capacity was:

| | | |

| Baseload Plants | | | |

| Big Stone Plant | | 256,600256,700 | kW |

| Coyote Station | | | 149,100149,000 | |

| Hoot Lake Plant | | | 141,600148,900 | |

| Total Baseload Net Plant | | 547,300554,600 | kW |

| Combustion Turbine and Small Diesel Units | | 108,000104,900 | kW |

| Hydroelectric Facilities | | 2,8002,600 | kW |

| Owned Wind Facilities (rated at nameplate) | | | | |

| Luverne Wind Farm (33 turbines) | | 49,500 | kW |

| Ashtabula Wind Center (32 turbines) | | | 48,000 | |

| Langdon Wind Center (27 turbines) | | | 40,500 | |

| Total Owned Wind Facilities | | 138,000 | kW |

The baseload net plant capacity for Big Stone Plant and Coyote Station constitutes OTP’s ownership percentages of 53.9% and 35%, respectively. OTP owns 100% of the Hoot Lake Plant. During 2012,2013, OTP generated about 68.3%70.8% of its retail kwh sales and purchased the balance.

In addition to the owned facilities described above OTP had the following purchased power agreements in place on December 31, 2012:

2013:

| |

| Purchased Wind Power Agreements (rated at nameplate and greater than 2,000 kW) | |

| Ashtabula Wind III | | 62,400 | kW |

| Edgeley | | | 21,000 | kW |

| Langdon | | | 19,500 | |

| Total Purchased Wind | | 40,500102,900 | kW |

| | | | |

| Other Purchased Power Agreements (in excess of 1 year and 500 kW) | | | | |

Wisconsin Electric Power CompanyGreat River Energy1

| | 50,000100,000 | kW |

Great River Energy2

| | | 50,000 | |

Total Purchased Power | | 100,000 | kW |

1Expires Through May 2013. 2Increases to 100,000 kW from June 2013 through May 2017.2021.

| | | |

OTP has a direct control load management system which provides some flexibility to OTP to effect reductions of peak load. OTP also offers rates to customers which encourage off-peak usage.

OTP’s capacity requirement is based on MISO Module E requirements. OTP is required to have sufficient PlanningZonal Resource Credits to meet its monthly weather normalized forecast demand, plus a reserve obligation. The MISO Resource Adequacy Construct changed significantly for the 2013/2014 MISO Planning Year effective June 1, 2013. OTP met its MISO obligation for all months in 2012. The MISO Resource Adequacy Construct is significantly changed for the 2013/2014 MISO Planning Year. These changes will be effective beginning June 1, 2013. OTP generating capacity combined with additional capacity under purchased power agreements (as described above) and load management control capabilities is expected to meet 20132014 system demand and MISO reserve requirements.

Fuel Supply

Coal is the principal fuel burned at the Big Stone, Coyote and Hoot Lake generating plants. Coyote Station, a mine-mouth facility, burns North Dakota lignite coal. Hoot Lake Plant and Big Stone plantsPlant burn western subbituminous coal.

The following table shows the sources of energy used to generate OTP’s net output of electricity for 20122013 and 2011:

2012:

| | |

| | | 2012 | | | 2011 | | | 2013 | | | 2012 | |

| Sources | | Net Kilowatt

Hours

Generated

(Thousands) | | | % of Total

Kilowatt

Hours

Generated | | | Net Kilowatt

Hours

Generated

(Thousands) | | | % of Total

Kilowatt

Hours

Generated | | | Net Kilowatt

Hours

Generated

(Thousands) | | | % of Total

Kilowatt

Hours

Generated | | | Net Kilowatt

Hours

Generated

(Thousands) | | | | % of Total

Kilowatt

Hours

Generated | |

| Subbituminous Coal | | | 2,094,293 | | | | 61.2 | % | | | 2,125,170 | | | | 56.7 | % | | | 2,322,608 | | | | 62.4 | % | | | 2,094,293 | | | | 61.2 | % |

| Lignite Coal | | | 782,358 | | | | 22.9 | | | | 1,062,153 | | | | 28.3 | | | | 881,973 | | | | 23.7 | | | | 782,358 | | | | 22.9 | |

| Wind and Hydro | | | 490,387 | | | | 14.3 | | | | 527,913 | | | | 14.1 | | | | 471,176 | | | | 12.7 | | | | 490,387 | | | | 14.3 | |

| Natural Gas and Oil | | | 55,637 | | | | 1.6 | | | | 33,367 | | | | 0.9 | | | | 43,165 | | | | 1.2 | | | | 55,637 | | | | 1.6 | |

| Total | | | 3,422,675 | | | | 100.0 | % | | | 3,748,603 | | | | 100.0 | % | | | 3,718,922 | | | | 100.0 | % | | | 3,422,675 | | | | 100.0 | % |

OTP has the following primary coal supply agreements:

| | | |

| Plant | Coal Supplier | Type of Coal | Expiration Date |

| Big Stone Plant | Peabody COALSALES, LLC | Wyoming subbituminous | December 31, 2016 |

| Big Stone Plant | Westmoreland Resources, Inc. | Montana subbituminous | December 31, 2014 |

| Coyote Station | Dakota Westmoreland Corporation | North Dakota lignite | May 4, 2016 |

| Coyote Station | Coyote Creek Mining Company, L.L.C. | North Dakota lignite | December 31, 2040 |

| Hoot Lake Plant | Cloud Peak Energy Resources LLC | Montana subbituminous | December 31, 20142015 |

OTP has about 42%58% of its coal needs for Big Stone under contract through December 2016.

The contract with Dakota Westmoreland Corporation expires on May 4, 2016. In October 2012, the Coyote Station owners, including OTP, entered into a lignite sales agreement (LSA) with Coyote Creek Mining Company, L.L.C. (CCMC), a subsidiary of The North American Coal Corporation, for the purchase of coal to meet the coal supply requirements of Coyote Station for the period beginning in May 2016 and ending in December 2040. The price per ton to be paid by the Coyote Station owners under the LSA will reflect the cost of production, along with an agreed profit and capital charge. The LSA provides for the Coyote Station owners to purchase the membership interests in CCMC in the event of certain early termination events and also at the end of the term of the LSA.

OTP has about 78%84% of its anticipated coal needs for Hoot Lake Plant secured under contract through December 2014.2015.

It is OTP’s practice to maintain a minimum 30-day inventory (at full output) of coal at the Big Stone Plant and a 20-day inventory at the Coyote Station and Hoot Lake Plant.

Railroad transportation services to the Big Stone Plant and Hoot Lake Plant are provided under a common carrier rate by the BNSF Railway. The common carrier rate is subject to a mileage-based methodology to assess a fuel surcharge. The basis for the fuel surcharge is the U.S. average price of retail on-highway diesel fuel. No coal transportation agreement is needed for the Coyote Station due to its location next to a coal mine.

The average cost of fuel consumed (including handling charges to the plant sites) per million British Thermal Units for each of the three years 2013, 2012, and 2011 was $2.055, $2.108, and 2010 was $2.108, $1.922, and $1.813, respectively.

General Regulation

OTP is subject to regulation of rates and other matters in each of the three states in which it operates and by the federal government for certain interstate operations.

A breakdown of electric rate regulation by each jurisdiction is as follows:

| | | 2012 | | | 2011 | | | 2013 | | | 2012 | |

| Rates | Regulation | | % of

Electric

Revenues | | | % of kwh

Sales | | | % of

Electric

Revenues | | | % of kwh

Sales | | Regulation | | % of

Electric

Revenues | | | % of kwh

Sales | | | % of

Electric

Revenues | | | % of kwh

Sales | |

| MN Retail Sales | MN Public Utilities Commission | | | 45.2 | % | | | 43.4 | % | | | 45.1 | % | | | 42.2 | % | MN Public Utilities Commission | | | 43.8 | % | | | 42.5 | % | | | 45.2 | % | | | 43.4 | % |

| ND Retail Sales | ND Public Service Commission | | | 38.8 | | | | 36.4 | | | | 39.1 | | | | 36.5 | | ND Public Service Commission | | | 39.0 | | | | 36.8 | | | | 38.8 | | | | 36.4 | |

| SD Retail Sales | SD Public Utilities Commission | | | 8.4 | | | | 8.5 | | | | 8.3 | | | | 8.4 | | SD Public Utilities Commission | | | 8.2 | | | | 8.2 | | | | 8.4 | | | | 8.5 | |

| Transmission & Wholesale | Federal Energy Regulatory Commission | | | 7.6 | | | | 11.7 | | | | 7.5 | | | | 12.9 | | Federal Energy Regulatory Commission | | | 9.0 | | | | 12.5 | | | | 7.6 | | | | 11.7 | |

| Total | | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % | | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % | | | 100.0 | % |

OTP operates under approved retail electric tariffs in all three states it serves. OTP has an obligation to serve any customer requesting service within its assigned service territory. The pattern of electric usage can vary dramatically during a 24-hour period and from season to season. OTP’s tariffs are designed to coverrecover the costs of providing electric service. To the extent that peak usage can be reduced or shifted to periods of lower usage, the cost to serve all customers is reduced. In order to shift usage from peak times, OTP has approved tariffs in all three states for residential demand control, general service time of use and time of day, real-time pricing, and controlled and interruptible service. Each of these specialized rates is designed to improve efficient use of OTP resources, while giving customers more control over their electric bill. OTP also has approved tariffs in its three service territories which allow qualifying customers to release and sell energy back to OTP when wholesale energy prices make such transactions desirable.

With a few minor exceptions, OTP’s electric retail rate schedules provide for adjustments in rates based on the cost of fuel delivered to OTP���sOTP’s generating plants, as well as for adjustments based on the cost of electric energy purchased by OTP. OTP also credits certain margins from wholesale sales to the fuel and purchased power adjustment. The adjustments for fuel and purchased power costs are presently based on a two month moving average in Minnesota and by the Federal Energy Regulatory Commission (FERC), a three month moving average in South Dakota and a four month moving average in North Dakota. These adjustments are applied to the next billing period after becoming applicable. These adjustments also include an over or under recovery mechanism, which is calculated on an annual basis in Minnesota and on a monthly basis in North Dakota and South Dakota.

The following summarizes the material regulations of each jurisdiction applicable to OTP’s electric operations, as well as any specific electric rate proceedings during the last three years with the Minnesota Public Utilities Commission (MPUC), the North Dakota Public Service Commission (NDPSC), the South Dakota Public Utilities Commission (SDPUC) and the FERC. The Company’s manufacturing and infrastructure businesses are not subject to direct regulation by any of these agencies.

Minnesota

Under the Minnesota Public Utilities Act, OTP is subject to the jurisdiction of the MPUC with respect to rates, issuance of securities, depreciation rates, public utility services, construction of major utility facilities, establishment of exclusive assigned service areas, contracts and arrangements with subsidiaries and other affiliated interests, and other matters. The MPUC has the authority to assess the need for large energy facilities and to issue or deny certificates of need, after public hearings, within one year of an application to construct such a facility.

Pursuant to the Minnesota Power Plant Siting Act, the MPUC has authority to select or designate sites in Minnesota for new electric power generating plants (50,000 kW or more) and routes for transmission lines (100 kilovolt (kV) or more) in an orderly manner compatible with environmental preservation and the efficient use of resources, and to certify such sites and routes as to environmental compatibility after an environmental impact study has been conducted by the Minnesota Department of Commerce (MNDOC) and the Office of Administrative Hearings has conducted contested case hearings.

The Minnesota Division of Energy Resources, part of the MNDOC, is responsible for investigating all matters subject to the jurisdiction of the MNDOC or the MPUC, and for the enforcement of MPUC orders. Among other things, the MNDOC is authorized to collect and analyze data on energy including the consumption of energy, develop recommendations as to energy policies for the governor and the legislature of Minnesota and evaluate policies governing the establishment of rates and prices for energy as related to energy conservation. The MNDOC also has the power, in the event of energy shortage or for a long-term basis, to prepare and adopt regulations to conserve and allocate energy.

2010 General Rate Case Filing—OTP filed a general rate case on April 2, 2010 requesting an 8.01% base rate increase as well as a 3.8% interim rate increase. On May 27, 2010, the MPUC issued an order accepting the filing, suspending rates, and approving the interim rate increase, as requested, to be effective with customer usage on and after June 1, 2010. The MPUC held a hearing to decide on the issues in the rate case on March 25, 2011 and issued a written order on April 25, 2011. The MPUC authorized a revenue increase of approximately $5.0 million, or 3.76% in base rate revenues, excluding the effect of moving recovery of wind investments to base rates. The MPUC’s written order included: (1) recovery of Big Stone II costs over five years, (2) moving recovery of wind farm assets from rider recovery to base rate recovery, (3) transfer of a portion of Minnesota Conservation Improvement Program (MNCIP) costs from rider recovery to base rate recovery, (4) transfer of the investment in two transmission lines from rider recovery to base rate recovery, and (5) changing the mechanism for providing customers with a credit for margins earned on asset-based wholesale sales of electricity from a credit to base rates to a credit to the Minnesota Fuel Clause Adjustment. Final rates went into effect October 1, 2011. The overall increase to customers was approximately 1.6% compared to the authorized interim rate increase of 3.8%, which resulted in an interim rate refund to Minnesota retail electric customers of approximately $3.9 million in the fourth quarter of 2011. Pursuant to the order, OTP’s allowed rate of return on rate base increased from 8.33% to 8.61% and its allowed rate of return on equity increased from 10.43% to 10.74%. OTP’s authorized rates of return are based on a capital structure of 48.28% long term debt and 51.72% common equity.

Conservation Improvement Programs—Under Minnesota law, every regulated public utility that furnishes electric service must make annual investments and expenditures in energy conservation improvements, or make a contribution to the state’s energy and conservation account, in an amount equal to at least 1.5% of its gross operating revenues from service provided in Minnesota. The Next Generation Energy Act of 2007, passed by the Minnesota legislature in May 2007, transitions from a conservation spending goal to a conservation energy savings goal.

The MNDOC may require a utility to make investments and expenditures in energy conservation improvements whenever it finds that the improvement will result in energy savings at a total cost to the utility less than the cost to the utility to produce or purchase an equivalent amount of a new supply of energy. Such MNDOC orders can be appealed to the MPUC. Investments made pursuant to such orders generally are recoverable costs in rate cases, even though ownership of the improvement may belong to the property owner rather than the utility. OTP recovers conservation related costs not included in base rates under the MNCIP through the use of an annual recovery mechanism approved by the MPUC.

A written order was issued by the MPUC onOn January 11, 2012 approvingthe MPUC approved the recovery of $3.5 million infor 2010 MNCIP financial incentives. Beginning in January 2012, OTP’s MNCIP Conservation Cost Recovery Adjustment (CCRA) increased from 3.0% to 3.8% for all Minnesota retail electric customers.

OTP recognized $2.2 million in MNCIP financial incentives in 2011 relating to 2011 program results. On March 30, 2012 OTP recognized an additional $0.4 million of incentive related to 2011 and submitted its annual 2011 financial incentive filing request for $2.6 million and recognized an additional $0.4 million of incentive related to 2011 in 2012.million. In December 2012, the MPUC approved the recovery of $2.6 million in financial incentives for 2011 and also ordered a change in the MNCIP cost recovery methodology used by OTP from a percentage of a customer’s bill to an amount per kwh consumed. The written order was issued on December 10, 2012. On January 1, 2013 OTP’s MNCIP surcharge decreased from 3.8% of athe customer’s bill to $0.00142 per kwh, which equates to approximately 1.9% of a customer’s bill. The per-kwh cost allocation method is the principle method approved by the MPUC for other electric utilities in Minnesota. OTP recognized $2.6 million of MNCIP financial incentives in 2012 and an additional $0.1 million in 2013 relating to 2012 program results.

OTP had a regulatory asset of $6.1 On October 10, 2013 the MPUC approved OTP’s 2012 financial incentive request for $2.7 million as well as its request for allowable costs and financial incentives eligible for recovery through the MNCIP rider that had not been billedan updated surcharge rate to Minnesota customers as of December 31, 2012.be implemented on November 1, 2013.

Integrated Resource Plan (IRP)—Minnesota law requires utilities to submit to the MPUC for approval a 15-year advance IRP. A resource plan is a set of resource options a utility could use to meet the service needs of its customers over a forecast period, including an explanation of the utility’s supply and demand circumstances, and the extent to which each resource option would be used to meet those service needs. The MPUC’s findings of fact and conclusions regarding resource plans shall be considered prima facie evidence, subject to rebuttal, in Certificate of Need (CON) hearings, rate reviews and other proceedings. Typically, the filings are submitted every two years.

On June 25, 2010 OTP filed its 2011-2025 IRP withIn the MPUC. The MNDOC requested and was granted an extension of the initial comment period to March 1, 2011. Presentations ofMPUC order approving the 2011-2025 IRP were madein February 2012, OTP was required to bothsubmit a base-load diversification study specifically focused on evaluating retirement and repower options for the NDPSC and SDPUC. Approximately 60% of the 2011-2025 IRP is comprised of improvements at existing resources and wholesale energy purchases similar to existing levels. The remaining 40% of the plan is comprised of the following components: 64% natural gas simple cycle combustion turbines, 21% conservation and demand response, and 15% wind generation. Capacity additions proposed in the 2011-2025 IRP are as follows:

Resource | Proposed |

Natural gas | 213 MW |

Demand Response/Conservation | 70 MW |

Wind | 50 MW |

On December 20, 2011 and February 9, 2012, respectively, the MPUC approved and issued a writtenHoot Lake Plant. In an order approving OTP’s 2011-2025 IRP, subject to the following conditions, among others:

| ● | Preparation and submission of a base-load diversification study specifically focused on evaluating retirement and repower options for Hoot Lake Plant to be filed no later than November 8, 2012. This study should evaluate the costs and OTP’s plans related to the Environmental Protection Agency’s (EPA) rules and how they might impact OTP operations. It also should include implications to transmission system reliability of any changes to Hoot Lake Plant. |

| ● | Future OTP IRPs should include carbon dioxide (CO2) costs at the mid-point of the commission-approved range in the base case and also should include market costs for sulfur dioxide (SO2) allowances. Future OTP IRPs should use the most current MISO long-term wind capacity credit or an average of its historical wind capacity credits.

|

| ● | OTP should increase its wind additions to 100 megawatts (MW) from the 50 MW of additional wind included in its five-year preferred plan, assuming the prices are reasonable. |

For resource planning purposes,dated March 25, 2013 the MPUC approved OTP’s 1.2% energy savings target and encouraged OTP to expand its demand-response and energy-efficiency portfolio. OTP’s next IRP filing is due no later than December 1, 2013.

In a January 31, 2013 hearing, the MPUC approved OTP’s recommendationrecommendations that Hoot Lake Plant add pollution-control equipment at a cost of approximately $10.0 million to comply with EPAU.S. Environmental Protection Agency’s (EPA) mercury and air toxics standards by 2015 and discontinue burning coal in 2020.

On December 2, 2013 OTP filed its 2014-2028 IRP with the MPUC. Copies of the 2014-2028 IRP were provided to both the NDPSC and SDPUC. Approximately 65% of the resource options called for by the 2014-2028 IRP are comprised of existing resources and wholesale energy purchases similar to existing levels. The remaining 35% is comprised of the following components: 65% natural gas simple cycle combustion turbines and 35% conservation and demand response. Capacity additions proposed in the 2014-2028 IRP are as follows:

| |

| Resource | Proposed Megawatts |

| Natural gas | 194 |

| Demand Response/Conservation | 106 |

OTP expects a MPUC order on its 2014-2028 IRP filing during the second quarter of 2014.

Renewable Energy Standards, Conservation, Renewable Resource Riders—The Minnesota legislature has enacted a statute thatlaw favors conservation over the addition of new resources. In addition, itMinnesota law requires the use of renewable resources where new supplies are needed, unless the utility proves that a renewable energy facility is not in the public interest. An existing environmental externality law requires the MPUC, to the extent practicable, to quantify the environmental costs associated with each method of electricity generation, and to use such monetized values in evaluating generation resources. The MPUC must disallow any nonrenewable rate base additions (whether within or outside of the state) or any related rate recovery, and may not approve any nonrenewable energy facility in an integrated resource plan, unless the utility proves that a renewable energy facility is not in the public interest. The state has prioritized the acceptability of new generation with wind and solar ranked first and coal and nuclear ranked fifth, the lowest ranking. The MPUC’s current estimate of the range of costs of future CO2 regulation to be used in modeling analyses for resource plans is $9 to $34/ton of CO2 commencing in 2012.2017. The MPUC is required to annually update these estimates.

Minnesota has a renewable energy standard which requires OTP to generate or procure sufficient renewable generation such that the following percentages of total retail electric sales to Minnesota customers come from qualifying renewable sources: 12% by 2012; 17% by 2016; 20% by 2020 and 25% by 2025. In addition, a new standard established by the 2013 legislature requires 1.5% of total electric sales to be supplied by solar energy by the year 2020. OTP is currently evaluating the new legislation and potential options for meeting that standard. Under certain circumstances and after consideration of costs and reliability issues, the MPUC may modify or delay implementation of the standards. OTP has acquired renewable resources and expects to acquire additional renewable resources in order to maintain compliance with the Minnesota renewable energy standard. OTP’s compliance with the Minnesota renewable energy standard will be measured through the Midwest Renewable Energy Tracking System.

Under the Next Generation Energy Act of 2007, an automatic adjustment mechanism was established to allow Minnesota electric utilities to recover investments and costs incurred to satisfy the requirements of the renewable energy standard. The MPUC is authorized to approve a rate schedule rider to enable utilities to recover the costs of qualifying renewable energy projects that supply renewable energy to Minnesota customers. Cost recovery for qualifying renewable energy projects can be authorized outside of a rate case proceeding, provided that such renewable projects have received previous MPUC approval. Renewable resource costs eligible for recovery may include return on investment, depreciation, operation and maintenance costs, taxes, renewable energy delivery costs and other related expenses.

The costs for three major wind farms previously approved by the MPUC issued an order on January 12, 2010 finding OTP’s Luverne Wind Farm project eligible for cost recovery through theOTP’s Minnesota Renewable Resource Adjustment (MNRRA). The 2010 annual MNRRA cost recovery filing was made on December 31, 2009 with a requested effective date of April 1, 2010. The MPUC approved OTP’s petition for a 2010 MNRRA in the third quarter of 2010 with implementation effective September 1, 2010. The 2010 MNRRA was in place from September 1, 2010 through September 30, 2011 with a recovery of $17.0 million.

The recovery of MNRRA costs was were moved to base rates as of October 1, 2011 under the MPUC’s April 25, 2011 general rate case order with the exception of the remaining balance of the MNRRA regulatory asset. OTP had a regulatory asset of $0.9 million for amounts eligible for recovery through the MNRRA rider that had not been billed to Minnesota customers as of December 31, 2012. A request for an updated rate to be effective October 1, 2012 was initially filed on June 28, 2012, followed by a revised filing on July 25, 2012. The filing, which is still under review included aBecause the request to extend the period of the new rate for 18 months which would reduce the current balance of unrecovered costs to zero. However, it is now estimated the remaining unrecovered costs will be collected by the end of May 2013, so OTP is planning to makewas still under review, a supplemental filing to requestwas submitted on February 15, 2013, requesting that the current rate be retained until a majority of the remaining balance iscosts were recovered and that the MNRRA thenrate be suspended.set to zero effective May 1, 2013. The MPUC approved the February 15, 2013 request on April 4, 2013 and authorized that any unrecovered balance be retained as a regulatory asset to be recovered in OTP’s next general rate case. Effective May 1, 2013 the resource adjustment on OTP’s Minnesota customers’ bills no longer includes MNRRA costs.

Transmission Cost Recovery (TCR) Rider—In addition to the MNRRA rider, the Minnesota Public Utilities Act provides a similar mechanism for automatic adjustment outside of a general rate proceeding to recover the costs of new transmission facilities that have been previously approved by the MPUC in a CON proceeding, certified by the MPUC as a Minnesota priority transmission project, made to transmit the electricity generated from renewable generation sources ultimately used to provide service to the utility’s retail customers, or exempt from the requirement to obtain a Minnesota CON. The MPUC may also authorize cost recovery via such TCR riders for charges incurred by a utility under a federally approved tariff that accrue from other transmission owners’ regionally planned transmission projects that have been determined by the MISO to benefit the utility or integrated transmission system. The 2013 legislature passed legislation that also authorizes TCR riders to recover the costs of new transmission facilities approved by the regulatory commission of the state in which the new transmission facilities are to be constructed to the extent approval is required by the laws of that state and determined by the MISO to benefit the utility or integrated transmission system. Such TCR riders allow a return on investment at the level approved in a utility’s last general rate case. Additionally, following approval of the rate schedule, the MPUC may approve annual rate adjustments filed pursuant to the rate schedule. OTP’s initial request for approval of a TCR rider was granted by the MPUC on January 7, 2010, and became effective February 1, 2010.

OTP requested recovery of its transmission investments being recovered through its Minnesota TCR rider rate as part of its general rate case filed on April 2, 2010. In its April 25, 2011 general rate case order, the MPUC approved the transfer of transmission costs currentlythen being recovered through OTP’s Minnesota TCR rider to recovery in base rates. Final rates went into effect on October 1, 2011. OTP will continuecontinues to utilize the TCR rider cost recovery mechanism untilto recover the remaining balance of the current transmission projects has been collected as well asand to recover costs associated with approved regional projects. new transmission projects determined eligible for TCR rider recovery by the MPUC.

OTP filed a request for an update to its Minnesota TCR rider on October 5, 2010. The update to OTP’s Minnesota TCR rider, approved by the MPUC on March 26, 2012, went into effect April 1, 2012.

In this TCR rider update, the MNPUCMPUC addressed how to handle utility investments in transmission facilities that qualify for regional cost allocation under the MISO tariff.Open Access Transmission, Energy and Operating Reserve Markets Tariff (MISO Tariff). MISO regional cost allocation allows OTP to recover some of the costs of its transmission investment from the other MISO utilities. On March 26, 2012 the MPUC approved the update to OTP’s Minnesota TCR rider along with an all-in method for MISO regional cost allocations in which OTP’s retail customers would be responsible for the entire investment OTP made with an offsetting credit for revenues received from other MISO utilities under the MISO tariff.Tariff for projects included in the TCR. OTP’s updated Minnesota TCR rider went into effect April 1, 2012.

On May 24, 2012 OTP filed a petition with the MPUC to seek a determination of eligibility for the inclusion of 12twelve additional transmission related projects in subsequent Minnesota TCR rider filings. On August 22, 2012February 20, 2013 the MNDOC filed comments and on August 24, 2012 the Minnesota OfficeMPUC approved three of the Attorney General (MNOAG) filed comments. OTP filed reply comments on September 25, 2012 and supplemental comments on January 8, 2013 describing an agreement reached between OTP, the MNDOC and the MNOAG, to find eligible 3 of the 12 projects. MPUC approval of that agreement is pending. If approval is obtained to include additional projects in the rider, investment in the approved projects will be included in the next annual Minnesota TCR rider rate update filings, andas eligible for recovery of the investment will begin through the TCR rider. OTP filed its annual update to the TCR rider rates if subsequently approved byon February 7, 2013 to include the MPUC. Updatedthree new projects as well as updated costs associated with existing projects withinprojects. On January 30, 2014 the MPUC approved OTP’s 2013 TCR rider update but disallowed TCR rider recovery of capitalized internal labor costs and costs in excess of CON estimates. These costs will be removed from OTP’s Minnesota TCR rider effective as of the date of the MPUC’s order. OTP will also be includedallowed to seek recovery of these costs in a future rate case.

Big Stone Air Quality Control System (AQCS)—Minnesota law authorizes a public utility to petition the MPUC for an Advance Determination of Prudence (ADP) for a project undertaken to comply with federal or state air quality standards of states in which the utility’s electric generation facilities are located if the project has an expected jurisdictional cost to Minnesota ratepayers of at least $10 million. On January 14, 2011 OTP filed a petition asking the MPUC for ADP for costs associated with the design, construction and operation of the Best-Available Retrofit Technology (BART) compliant air quality control system at Big Stone Plant attributable to serving OTP’s Minnesota customers. The MPUC granted OTP’s petition for ADP for the AQCS in a written order issued on January 23, 2012. OTP’s share of the costs for the Big Stone Plant AQCS is expected to be $218 million.

On May 24, 2013 legislation was enacted in Minnesota which allowed OTP to file for an emission-reduction rider for recovery of the revenue requirements of the AQCS. The legislation authorizes the rider to allow a current return on investment (including Construction Work in Progress (CWIP)) at the level approved in OTP’s most recent general rate case, unless a different return is determined by the MPUC to be in the nextpublic interest. On July 31, 2013 OTP filed for a Minnesota Environmental Cost Recovery (ECR) rider with the MPUC for recovery of its Minnesota jurisdictional share of the revenue requirements of its investment in the AQCS under construction at Big Stone Plant. The ECR rider recoverable revenue requirements include a current return on the project’s CWIP balance. The MPUC granted approval of OTP’s Minnesota ECR rider on December 18, 2013 with an effective date of January 1, 2014. The rate will be updated in an annual rider rate update filing. OTP had a regulatory liability of $0.5 million as of December 31, 2012 for amounts billed to Minnesota customers thatfiling with the MPUC until the costs are subject to refund through the Minnesota TCR rider.rolled into base rates at an undetermined future date.

Big Stone II Project—OTP and a coalition of six other electric providers filed an application for a CON for the Minnesota portion of the Big Stone II transmission line project on October 3, 2005 and filed an application for a Route Permit for the Minnesota portion of the Big Stone II transmission line project with the MPUC on December 9, 2005. On January 15, 2009 the MPUC approved a motion to grant the CON and Route Permit for the Minnesota portion of the Big Stone II transmission line.line project.

The MPUC granted the CON subject to a number of additional conditions, including but not limited to: (1) fulfilling various requirements relating to renewable energy goals, energy efficiency, community-based energy development projects and emissions reduction; (2) that the generation plant be built as a “carbon capture retrofit ready” facility; (3) that the applicants report to the MPUC on the feasibility of building the plant using ultra-supercritical technology; and (4) that the applicants achieve specific limits on construction costs at $3,000/kW and CO2 costs at $26/ton.

The CON and Route Permit, required by state law, would have allowed the Big Stone II utilities to construct and upgrade 112 miles of electric transmission lines in western Minnesota for delivery of power from the Big Stone site and from numerous other planned generation projects, most of which are wind energy.

Following OTP’s September 11, 2009 withdrawal from the Big Stone II project and the remaining Big Stone II participants’ November 2, 2009 cancellation of the project, the suitability of the route permits and easements obtained by OTP as a MISO transmission owner for other interconnection customers backfilling through the MISO interconnection process into the Big Stone area continuescontinued to be evaluated.

On December 14, 2009 OTP filed a request with the MPUC for deferred regulatory accounting treatment for the costs incurred related to the cancelled Big Stone II plant. OTP requested recovery of the Minnesota portion of its Big Stone II development costs over a five-year period as part of its general rate case filed in Minnesota on April 2, 2010. In a written order issued on April 25, 2011, the MPUC authorized recovery of the Minnesota portion of Big Stone II generation development costs from Minnesota ratepayers over a 60-month recovery period which began on October 1, 2011. The amount of Big Stone II generation costs incurred by OTP that were deemed recoverable from Minnesota ratepayers as part of rates established in that proceeding was $3.2 million (which excludesexcluded $3.2 million of transmission-related project transmission-related costs). As of December 31, 2012, OTP had a regulatory asset of $2.1

Approximately $0.4 million of Big Stone II generation costs to be recovered.

On December 30, 2010 OTP filed a request for an extension of the total Minnesota Route Permit for the Big Stone transmission facilities. The request asked to extend the deadline for filing a CON for these transmission facilities until March 17, 2013. The April 25, 2011 MPUC order instructed OTP to transfer the $3.2 million Minnesotajurisdictional share of Big Stone II transmission costs were transferred to Construction Workthe Big Stone South - Brookings Multi-Value Project (MVP) in Progress (CWIP) andthe first quarter of 2013. The remaining costs, along with accumulated AFUDC, were transferred from CWIP to create a tracker account through which any over or under recoveries could be accumulated for refund or recovery determination in future rate cases as a regulatory liability or asset. If determined eligible for recovery under the FERC-approved MISO regional transmission tariff, the Minnesota portion of Big Stone II transmission costs and accumulated Allowance for Funds Used During Construction (AFUDC) will receive rate base treatment andUnrecovered Project Costs – Minnesota regulatory asset account in May 2013, based on recovery through the FERC-approved MISO regional transmission rates. Any amounts over or under collected through MISO rates will be reflectedgranted in the tracker account.

Big Stone Air Quality Control System (AQCS) Request for Advance DeterminationApril 25, 2011 order. The recoverable amount of Prudence (ADP)—Minnesota law authorizes a public utilityapproximately $3.5 million is expected to petition the MPUC forbe recovered over an ADP for a project undertaken to comply with federal or state air quality standards of statesanticipated 89-month recovery period which began in which the utility’s electric generation facilities are located, if the project has an expected jurisdictional cost to Minnesota ratepayers of at least $10 million. ADPs can help lower the cost of financing by providing additional regulatory certainty, which ultimately reduces customer costs. On January 14, 2011 OTP filed a petition asking the MPUC for an ADP for the design, construction and operation of the Best-Available Retrofit Technology (BART) compliant air quality control system at Big Stone Plant attributable to serving OTP’s Minnesota customers, and on December 20, 2011 the MPUC granted OTP’s petition. The MPUC’s written order was issued on January 23, 2012.May 2013.

Capacity Expansion 2020 (CapX2020)—CapX2020 is a joint initiative of eleven investor-owned, cooperative, and municipal utilities in Minnesota and the surrounding region to upgrade and expand the electric transmission grid to ensure continued reliable and affordable service. The CapX2020 companies identified four major transmission projects for the region: (1) the Fargo–Monticello 345 kV Project (the Fargo Project), (2) the Brookings–Southeast Twin Cities 345 kV Project (the Brookings Project), (3) the Bemidji – Grand Rapids 230 kV Project (the Bemidji Project), and (4) the Twin Cities–LaCrosse 345 kV Project. OTP is an investor in the Fargo Project, the Brookings Project and the Bemidji Project. Recovery of OTP’s CapX2020 transmission investments will be through the MISO Tariff (the Brookings Project as an MVP) and Minnesota, North Dakota and South Dakota TCR Riders.

The Fargo Project—All major permits have been received from state regulatory bodies and project agreements have been signed for the construction of the Fargo Project. The Monticello to St. Cloud portion of the Fargo Project was placed into service on December 21, 2011. Construction is underway for the remaining portions of the project with completion scheduled for the firstsecond quarter of 2015. OTP’s share of the costs for the St. Cloud to Fargo portion of the Fargo Project is expected to be $84.2$84.4 million.

The Brookings Project—All major permits have been received from state regulatory bodies and project agreements have been signed for the construction of the Brookings Project. The MISO granted unconditional approval of the Brookings Project as a Multi-Value Project (MVP)an MVP under the MISO Open Access Transmission, Energy and Operating Reserves Market Tariff (Tariff) in December 2011. This project willis anticipated to be placedcompleted in service in segments with the earliest segment being placed in service in the summer of 2013 and the last segment placed in service during the first quarter of 2015. OTP’s share of the costs for the Brookings Project is expected to be $26.0$26.5 million.

The Bemidji Project—The Bemidji-Grand Rapids transmission line was fully energized and put in service on September 17, 2012.

Recovery of OTP’s CapX2020 transmission investments will be through the MISO Tariff and the Minnesota, North Dakota and South Dakota TCR riders.

Capital Structure Petition—Minnesota law requires an annual filing of a capital structure petition with the MPUC. In this filing the MPUC reviews and approves the capital structure for OTP. Once the petition is approved, OTP may issue securities without further petition or approval, provided the issuance is consistent with the purposes and amounts set forth in the approved capital structure petition. The MPUC approved OTP’s current capital structure petition on June 20, 2013, which is in effect until the MPUC issues a new capital structure order for 2013.2014. OTP is required to file its 20132014 capital structure petition by May 14, 2013.2014.

North Dakota

OTP is subject to the jurisdiction of the NDPSC with respect to rates, services, certain issuances of securities, construction of major utility facilities and other matters. The NDPSC periodically performs audits of gas and electric utilities over which it has rate setting jurisdiction to determine the reasonableness of overall rate levels. In the past, these audits have occasionally resulted in settlement agreements adjusting rate levels for OTP.

The North Dakota Energy Conversion and Transmission Facility Siting Act grants the NDPSC the authority to approve sites in North Dakota for large electric generating facilities and high voltage transmission lines. This Act is similar to the Minnesota Power Plant Siting Act described above and applies to proposed newwind energy electric power generating plants exceeding 60,000500 kW of electricity, non-wind energy electric power generating plants exceeding 50,000 kW and proposed new transmission lines with a design in excess of 115 kV. OTP is required to submit a ten-year plan to the NDPSC annually.

The NDPSC reserves the right to review the issuance of stocks, bonds, notes and other evidence of indebtedness of a public utility. However, the issuance by a public utility of securities registered with the SEC is expressly exempted from review by the NDPSC under North Dakota state law.

General Rate CaseRates—On November 3, 2008 OTP filed aOTP’s most recent general rate case in North Dakota requesting an overall revenue increase of approximately $6.1 million, or 5.1%, and an interim rate increase of approximately 4.1%, or $4.8 million annualized, that went into effect on January 2, 2009. In an order issued by the NDPSC on November 25, 2009, OTP was granted an increase in North Dakota retail electric rates of $3.6 million, or approximately 3.0%, which went into effect in December 2009. The NDPSC order authorizing an interim rate increase required OTP to refund North Dakota customers the difference between final and interim rates, with interest. OTP established a refund reserve for revenues collected under interim rates that exceeded the final rate increase. The refund reserve balance of $0.9 million as of December 31, 2009 was refunded to North Dakota customers in January 2010. OTP deferred recognition of $0.5 million in rate case-related filing and administrative costs that are subject to amortization and recovery over a three year period beginning in January 2010. As requiredgranted by the NDPSC in an order in the OTP 2008 rate case, OTP submitted a filing for a request to remove the recovery of the costs associated with economic development in base rates in North Dakota. OTP proposedissued on November 25, 2009 and the NDPSC approved an Economic Development Cost Removal Rider, under which all North Dakota customers will receive a credit of $0.00025 per kwh. The monthly credit was effective with bills rendered on and after January 1, 2011.December 2009.

Renewable Resource Cost Recovery RiderAdjustment— On May 21, 2008 the NDPSC approved OTP’s request forOTP has a North Dakota Renewable Resource Cost Recovery Rider Adjustment (NDRRA) to enablewhich enables OTP to recover the North Dakota share of its investments in renewable energy facilities it owns in North Dakota. This rider allows OTP to recover costs associated with new renewable energy projects as they are completed. OTP included investment costs and expenses related to its 32 wind turbines at the Ashtabula Wind Energy Center that became commercially operational in November 2008 in its 2009 annual request to the NDPSC to increase the amount of the NDRRA. An NDRRA of $0.0051 per kwh was approved by the NDPSC on January 14, 2009 and went into effect beginning with billing statements sent on February 1, 2009. Terms of the approved settlement provide for the recovery of accrued costs and returns on investments in renewable energy facilities under the NDRRA over a period of 48 months beginning in January 2010.

In a proceeding that was combined with OTP’s general rate case, the NDPSC reviewed whether to move the costs of the projects being recovered through the NDRRA into base rate cost recovery and whether to make changes to the rider. A settlement of the general rate case and the NDRRA reduced the NDRRA to $0.00369 for the period from December 1, 2009 until the effective date for the next annual NDRRA filing, requested to be April 1, 2010. Because the 2008 annual NDRRA filing was combined with the general rate case proceedings (concluded in November 2009), the 2009 annual filing to establish the 2010 NDRRA (which includes cost recovery for OTP’s investment in its Luverne Wind Farm project) was delayed until December 31, 2009, with a requested effective date of April 1, 2010. Approval for implementation of an updated NDRRA was received in the third quarter of 2010 with implementation effective September 1, 2010.

The 2010 NDRRA was in place for the period offrom September 1, 2010 through March 31, 2012 with a recovery of $15.6 million. On December 29, 2011 OTP submitted its annualMarch 21, 2012 the NDPSC approved an update to the renewable rider with anOTP’s NDRRA effective April 1, 2012 effective date, which was approved by the NDPSC on March 21, 2012. The 2011updated NDRRA has an expected recovery of $10.1recovered $9.9 million over the period April 1, 2012 through March 31, 2013. On December 28, 2012 OTP has a regulatory asset of $1.6 million for amounts eligible for recovery throughsubmitted its annual update to the NDRRA rider that havewith a proposed effective date of April 1, 2013. The update resulted in a rate reduction, so the NDPSC did not been billedissue an order suspending the rate change. Consequently, pursuant to North Dakota customers as ofstatute, OTP was allowed to implement updated rates effective April 1, 2013 and, on July 10, 2013, the NDPSC approved the rate implemented on April 1, 2013. OTP submitted its annual update to the NDRRA on December 31, 2012.2013 with a proposed April 1, 2014 effective date.

Transmission Cost Recovery Rider— North Dakota law provides a mechanism for automatic adjustment outside of a general rate proceeding to recover jurisdictional capital and operating costs incurred by a public utility for new or modified electric transmission facilities. On April 29, 2011 OTP filed a request for an initial North Dakota TCR rider with the NDPSC, on April 29, 2011, which was approved by the NDPSC on April 25, 2012 to go into effectand effective May 1, 2012. On August 31, 2012 OTP filed its annual update to the North Dakota TCR rider rate to reflect updated cost information associated with projects currently in the rider, as well as proposing to include costs associated with ten additional projects for recovery within the rider, whichrider. The NDPSC approved the NDPSC approvedannual update on December 12, 2012 to go into effectwith an effective date of January 1, 2013. On August 30, 2013 OTP hasfiled its annual update to its North Dakota TCR rider rate, which was approved on December 30, 2013 and became effective January 1, 2014.

Environmental Cost Recovery Rider—On May 9, 2012 the NDPSC approved OTP’s application for an ADP related to the Big Stone Plant AQCS. On February 8, 2013, OTP filed a request with the NDPSC for an ECR rider to recover OTP’s North Dakota jurisdictional share of carrying costs associated with its investment in the Big Stone Plant AQCS. On December 18, 2013 the NDPSC approved OTP’s North Dakota ECR rider based on revenue requirements through the 2013 calendar year and thereafter, with rates effective for bills rendered on and after January 1, 2014. OTP recorded a regulatory asset of $0.1$2.3 million for amounts eligible for recovery through the North Dakota TCRECR rider that havehad not been billed to North Dakota customers as of December 31, 2012.2013. The rate will be updated at least annually in a filing with the NDPSC until the project costs are rolled into base rates at an undetermined future date.

Big Stone II Project—A filing in North Dakota for an ADP of Big Stone II was made by OTP in November 2006. On August 27, 2008, the NDPSC determined that OTP’s participation in Big Stone II was prudent in a range of 121.8 to 130 MW. On January 20, 2010, OTP filed a request with the NDPSC for a determination that continuing with the Big Stone II project would not have been prudent. North Dakota’s ADP statute allows a utility to recover costs, and a reasonable return on the costs pending recovery, for a project previously deemed prudent and for which the NDPSC later makes a determination that continuing with the project was no longer prudent.

On December 14, 2009 OTP filed a request with the NDPSC for deferred regulatory accounting treatment for its costs incurred related to the cancelled Big Stone II project. In an order issued June 25, 2010, the NDPSC authorized recovery of Big Stone II development costs from North Dakota ratepayers, pursuant to a final settlement agreement filed June 23, 2010, between the NDPSC advocacy staff, OTP and the North Dakota Large Industrial Energy Group, which had intervened.as interveners. The terms of the settlement agreement indicate that OTP’s discontinuation of participation in the project was prudent and OTP should be authorized to recover the portion of costs it incurred related to the Big Stone II generation project. The total amount of Big Stone II generation costs incurred by OTP (which excludesexcluded $2.6 million of project transmission-related costs) was determined to be $10.1 million, of which $4.1 million represents North Dakota’s jurisdictional share. The North Dakota portion of Big Stone II generation costs is being recovered over a 36 month36-month period which began on August 1, 2010. As of December 31, 2012, OTP had a regulatory asset of $0.9 million of Big Stone II generation costs to be recovered.

The North Dakota’sDakota jurisdictional share of Big Stone II costs incurred by OTP related to transmission iswas $1.1 million. OTPApproximately $0.3 million of the total North Dakota jurisdictional share of Big Stone II transmission costs were transferred to the Big Stone South - Brookings MVP during the first quarter of 2013. On July 30, 2013 the NDPSC approved OTP’s request to continue the Big Stone II cost recovery rates for an additional eight months through March 31, 2014 to recover the remaining North Dakota share of Big Stone II transmissiontransmission-related costs to CWIP, with such costs subject toplus accrued AFUDC continuing from September 2009. If construction of all or a portion of the transmission facilities commences within three years of the NDPSC order approving the settlement agreement, the North Dakota portion of Big Stone II transmission costs and accumulated AFUDC shall be included in the rate base investment for these future transmission facilities. If construction is not commenced on any of the transmission facilities within three years of the NDPSC order approving the settlement agreement, OTP may petition the NDPSC to either continue accounting for these costs as CWIP or to commence recovery of such costs.

Big Stone Plant AQCS Request for ADP—An application for an ADP filed by OTP with the NDPSC on May 20, 2011 was approved on May 9, 2012.totaling $1.0 million.

CapX2020 Request for Advance Determination of Prudence—On October 5, 2009 OTP filed an application for an ADP with the NDPSC for its proposed participation in three of the four Group 1 projects: the Fargo Project, the Brookings Project and the Bemidji Project. An administrative law judge conducted an evidentiary hearing on the application in May 2010. On October 6, 2010 the NDPSC adopted an order approving a settlement between OTP and intervener NDPSC advocacy staff, and issued an ADP to OTP for participation in the three Group 1 projects. The order is subject to a number of terms and conditions in addition to the settlement agreement, including the provision of additional information on the eventual resolution of cost allocation issues relevant to the Brookings Project and its associated impact on North Dakota. On April 29, 2011, OTP filed its compliance filing with the NDPSC, seeking a determination of continued prudence for OTP’s investment in the Brookings Project. The NDPSC approved the request for an ADP for the Brookings Project on November 10, 2011 conditioned on the MISO MVP cost allocation remaining materially unchanged. The MISO granted unconditional approval of the Brookings Project as an MVP under the MISO Tariff in December 2011.

CapX2020 - Fargo Project—All major permits have been received from state regulatory bodies and project agreements have been signed for the construction of the Fargo Project. Completion of all phases of the Fargo Project is scheduled for the first quarter of 2015. OTP’s share of the costs of the Fargo Project is expected to be $84.2 million.

South Dakota

Under the South Dakota Public Utilities Act, OTP is subject to the jurisdiction of the SDPUC with respect to rates, public utility services, construction of major utility facilities, establishment of assigned service areas and other matters. Under the South Dakota Energy Facility Permit Act, the SDPUC has the authority to approve sites in South Dakota for large energy conversion facilities (100,000 kW or more) and transmission lines with a design of 115 kV or more.