UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 20062007

or

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number 001-12019

QUAKER CHEMICAL CORPORATION

(Exact name of Registrant as specified in its charter)

| A Pennsylvania Corporation | No. 23-0993790 | |

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification No.) |

One Quaker Park, 901 Hector Street, Conshohocken, Pennsylvania | 19428 | |

| (Address of principal executive offices) | (Zip Code) |

Registrant’s telephone number, including area code: (610) 832-4000

Securities registered pursuant to Section 12(b) of the Act:

Title of each class | Name of each Exchange on which registered | |

| Common Stock, $1.00 par value | New York Stock Exchange | |

| Stock Purchase Rights | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the Registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a non-accelerated filer.smaller reporting company. See definitionthe definitions of “large accelerated filer,” “accelerated filerfiler” and large accelerated filer”“smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer ¨ | Accelerated filer x | |||

Non-accelerated filer ¨ (Do not check if smaller reporting company) | ||||

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No x

State aggregate market value of common stock held by non-affiliates of the Registrant. (The aggregate market value is computed by reference to the last reported sale on the New York Stock Exchange on June 30, 2006)29, 2007): $184,494,293.$238,506,650

Indicate the number of shares outstanding of each of the Registrant’s classes of common stock as of the latest practicable date: 10,020,58810,227,877 shares of Common Stock, $1.00 Par Value, as of February 28, 2007.29, 2008.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Registrant’s definitive Proxy Statement relating to the Annual Meeting of Shareholders to be held on May 9, 20077, 2008 are incorporated by reference into Part III.

PART I

As used in this Report, the terms “Quaker,” the “Company,” “we” and “our” refer to Quaker Chemical Corporation, its subsidiaries, and associated companies, unless the context otherwise requires.

| Item 1. | Business. |

General Description

Quaker develops, produces, and markets a broad range of formulated chemical specialty products for various heavy industrial and manufacturing applications and, in addition, offers and markets chemical management services (“CMS”). Quaker’s principal products and services include: (i) rolling lubricants (used by manufacturers of steel in the hot and cold rolling of steel and by manufacturers of aluminum in the hot rolling of aluminum); (ii) corrosion preventives (used by steel and metalworking customers to protect metal during manufacture, storage, and shipment); (iii) metal finishing compounds (used to prepare metal surfaces for special treatments such as galvanizing and tin plating and to prepare metal for further processing); (iv) machining and grinding compounds (used by metalworking customers in cutting, shaping, and grinding metal parts which require special treatment to enable them to tolerate the manufacturing process, achieve closer tolerance, and improve tool life); (v) forming compounds (used to facilitate the drawing and extrusion of metal products); (vi) hydraulic fluids (used by steel, metalworking, and other customers to operate hydraulically activated equipment); (vii) technology for the removal of hydrogen sulfide in various industrial applications; (viii) chemical milling maskants for the aerospace industry and temporary and permanent coatings for metal and concrete products; (ix) construction products, such as flexible sealants and protective coatings, for various applications; and (x) programs to provide chemical management services. Individual product lines representing more than 10% of consolidated revenues for any of the past three years are as follows:

| 2006 | 2005 | 2004 | 2007 | 2006 | 2005 | |||||||||||||

Rolling lubricants | 21.0 | % | 21.3 | % | 22.3 | % | 19.8 | % | 21.0 | % | 21.3 | % | ||||||

Machining and grinding compounds | 16.6 | % | 16.4 | % | 15.0 | % | 17.6 | % | 16.6 | % | 16.4 | % | ||||||

Chemical management services | 10.3 | % | 11.7 | % | 13.6 | % | 12.2 | % | 10.3 | % | 11.7 | % | ||||||

Hydraulic fluids | 10.8 | % | 10.4 | % | 10.1 | % | 10.7 | % | 10.8 | % | 10.4 | % | ||||||

Corrosion preventives | 10.6 | % | 9.5 | % | 9.8 | % | 10.3 | % | 10.6 | % | 9.5 | % | ||||||

A substantial portion of Quaker’s sales worldwide are made directly through its own employees and its CMS programs with the balance being handled through value-added resellers and agents. Quaker employees visit the plants of customers regularly and, through training and experience, identify production needs which can be resolved or alleviated either by adapting Quaker’s existing products or by applying new formulations developed in Quaker’s laboratories. Quaker makes little use of advertising but relies heavily upon its reputation in the markets which it serves. Generally, separate manufacturing facilities of a single customer are served by different personnel. As part of the Company’s chemical management services, certain third-party product sales to customers are managed by the Company. Where the Company acts as a principal, revenues are recognized on a gross reporting basis at the selling price negotiated with the customers. Where the Company acts as an agent, such revenue is recorded using net reporting as service revenues, at the amount of the administrative fee earned by the Company for ordering the goods. Third partyThird-party products transferred under arrangements resulting in net reporting totaled $52.7 million, $62.8 million and $38.8 million for 2007, 2006 and $35.2 million for 2006, 2005, and 2004, respectively. The Company recognizes revenue in accordance with the terms of the underlying agreements, when title and risk of loss have been transferred, collectibility is reasonably assured, and pricing is fixed or determinable. This generally occurs for product sales when products are shipped to customers or, for consignment arrangements, upon usage by the customer and when services are performed. License fees and royalties are recognized in accordance with agreed-upon terms, when performance obligations are satisfied, the amount is fixed or determinable, and collectibility is reasonably assured, and are included in other income.

Competition

The chemical specialty industry comprises a number of companies of similar size as well as companies larger and smaller than Quaker. Quaker cannot readily determine its precise position in every industry it serves. Based on information available to Quaker, however, it is estimated that Quaker holds a leading and significant global position (among a group in excess of 25 other suppliers) in the market for process fluids to produce sheet steel. It is also believed that Quaker holds significant global positions in the markets for process fluids in portions of the automotive and industrial markets. Many competitors are in fewer and more specialized product classifications or provide different levels of technical services in terms of specific formulations for individual customers. Competition in the industry is based primarily on the ability to provide products that meet the needs of the customer and render technical services and laboratory assistance to customers and, to a lesser extent, on price.

Major Customers and Markets

In 2006,2007, Quaker’s five largest customers (each composed of multiple subsidiaries or divisions with semi-autonomous purchasing authority) accounted for approximately 23%29% of its consolidated net sales with the largest customer (General Motors)(Arcelor-Mittal Group) accounting for approximately 6%10% of consolidated net sales. A significant portion of Quaker’s revenues are realized from the sale of process fluids and services to manufacturers of steel, automobiles, appliances, and durable goods, and, therefore, Quaker is subject to the same business cycles as those experienced by these manufacturers and their customers. Furthermore, steel customers typically have limited manufacturing locations as compared to metalworking customers and generally use higher volumes of products at a single location. Accordingly, the loss or closure of a steel mill of a significantor other major customer site can have a material adverse effect on Quaker’s business.

Raw Materials

Quaker uses over 1,000 raw materials, including mineral oils and derivatives, animal fats and derivatives, vegetable oils and derivatives, ethylene derivatives, solvents, surface active agents, chlorinated paraffinic compounds, and a wide variety of other organic and inorganic compounds. In 2006, only2007, three raw material groups (mineral oiloils and derivatives, animal fats and derivatives, and vegetable oils and derivatives) each accounted for as much as 10% of the total cost of Quaker’s raw material purchases. The price of mineral oil can be affected by the price of crude oil and refining capacity. In addition, animal fat and vegetable oil prices have increased due to increased biodiesel consumption. Accordingly, significant fluctuations in the price of crude oil can have a material effect upon the Company’s business. Many of the raw materials used by Quaker are “commodity” chemicals, and, therefore, Quaker’s earnings can be affected by market changes in raw material prices. Quaker has multiple sources of supply for most materials, and management believes that the failure of any single supplier would not have a material adverse effect upon its business. Reference is made to the disclosure contained in Item 7A of this Report.

Patents and Trademarks

Quaker has a limited number of patents and patent applications, including patents issued, applied for, or acquired in the United States and in various foreign countries, some of which may prove to be material to its business. Principal reliance is placed upon Quaker’s proprietary formulae and the application of its skills and experience to meet customer needs. Quaker’s products are identified by trademarks that are registered throughout its marketing area.

Research and Development—Laboratories

Quaker’s research and development laboratories are directed primarily toward applied research and development since the nature of Quaker’s business requires continual modification and improvement of formulations to provide chemical specialties to satisfy customer requirements. Research and development costs are expensed as incurred. Research and development expenses during 2006, 2005 and 2004 were $13.0 million, $14.2 million and $13.8 million, respectively.

Quaker maintains quality control

laboratory facilities in each of its manufacturing locations. In addition, Quaker maintains in Conshohocken, Pennsylvania, Placentia, California and Uithoorn, The Netherlands, laboratory facilities that are devoted primarily to applied research and development.

Research and development costs are expensed as incurred. Research and development expenses during 2007, 2006 and 2005 were $14.6 million, $13.0 million and $14.2 million, respectively.

Most of Quaker’s subsidiaries and associated companies also have laboratory facilities. Although not as complete as the Conshohocken or Uithoorn laboratories, these facilities are generally sufficient for the requirements of the customers being served. If problems are encountered which cannot be resolved by local laboratories, such problems may be referred to the laboratory staff in Conshohocken or Uithoorn.

Regulatory Matters

In order to facilitate compliance with applicable Federal, state, and local statutes and regulations relating to occupational health and safety and protection of the environment, the Company has an ongoing program of site assessment for the purpose of identifying capital expenditures or other actions that may be necessary to comply with such requirements. The program includes periodic inspections of each facility by Quaker and/or independent experts, as well as ongoing inspections and training by on-site personnel. Such inspections are addressed to operational matters, record keeping, reporting requirements, and capital improvements. In 2006,2007, capital expenditures directed solely or primarily to regulatory compliance amounted to approximately $0.8$0.9 million compared to $0.8 million and $0.7 million in 2006 and $1.1 million in 2005, and 2004, respectively. In 2007,2008, the Company expects to incur approximately $1.2$2.6 million for capital expenditures directed primarily to regulatory compliance. Incorporated by reference is the information regarding AC Products, Inc. contained in Note 1820 of Notes to Consolidated Financial Statements included in Item 8 of this Report.

Number of Employees

On December 31, 2006,2007, Quaker’s consolidated companies had 1,2871,335 full-time employees of whom 540560 were employed by the parent company and its U.S. subsidiaries and 747775 were employed by its non-U.S. subsidiaries. Associated companies of Quaker (in which it owns 50% or less) employed 159163 people on December 31, 2006.2007.

Product Classification

The Company’s reportable segments are as follows:

(1) Metalworking process chemicals—industrial process fluids for various heavy industrial and manufacturing applications.

(2) Coatings—temporary and permanent coatings for metal and concrete products and chemical milling maskants.

(3) Other chemical products—other various chemical products.

Incorporated by reference is the segment information contained in Note 1315 of Notes to Consolidated Financial Statements included in Item 8 of this Report.

Non-U.S. Activities

Since significant revenues and earnings are generated by non-U.S. operations, Quaker’s financial results are affected by currency fluctuations, particularly between the U.S. dollar, the E.U. euro, the Brazilian real, and the Chinese renminbi and the impact of those currency fluctuations on the underlying economies. Incorporated by reference is the foreign exchange risk information contained in Item 7A of this Report and the geographic information in Note 1315 of Notes to Consolidated Financial Statements included in Item 8 of this Report.

Quaker on the Internet

Financial results, news and other information about Quaker can be accessed from the Company’s Web site at http://www.quakerchem.com. This site includes important information on products and services, financial reports, news releases, and career opportunities. The Company’s periodic and current reports on Forms 10-K, 10-Q and 8-K, including exhibits and supplemental schedules filed therewith, and amendments to those reports, filed with the Securities and Exchange Commission (“SEC”) are available on the Company’s Web site, free of charge, as soon as reasonably practicable after they are electronically filed with or furnished to the SEC. Information that can be accessed through the Company’s Web site is not incorporated by reference in this Report and accordingly you should not consider that information part of this Report.

Factors that May Affect Our Future Results

(Cautionary Statements under the Private Securities Litigation Reform Act of 1995)

Certain information included in this Report and other materials filed or to be filed by Quaker with the SEC (as well as information included in oral statements or other written statements made or to be made by us) contain or may contain forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. These statements can be identified by the fact that they do not relate strictly to historical or current facts. We have based these forward-looking statements on our current expectations about future events. These forward-looking statements include statements with respect to our beliefs, plans, objectives, goals, expectations, anticipations, intentions, financial condition, results of operations, future performance, and business, including:

statements relating to our business strategy;

our current and future results and plans; and

statements that include the words “may,” “could,” “should,” “would,” “believe,“believe,” “expect,” “anticipate,” “estimate,” “intend,” “plan” or similar expressions.

Such statements include information relating to current and future business activities, operational matters, capital spending, and financing sources. From time to time, oral or written forward-looking statements are also included in Quaker’s periodic reports on Forms 10-Q and 8-K, press releases, and other materials released to the public.

Any or all of the forward-looking statements in this Report, in Quaker’s Annual Report to Shareholders for 2006,2007, and in any other public statements we make may turn out to be wrong. This can occur as a result of inaccurate assumptions or as a consequence of known or unknown risks and uncertainties. Many factors discussed in this Report will be important in determining our future performance. Consequently, actual results may differ materially from those that might be anticipated from our forward-looking statements.

We undertake no obligation to publicly update any forward-looking statements, whether as a result of new information, future events or otherwise. However, any further disclosures made on related subjects in Quaker’s subsequent reports on Forms 10-K, 10-Q and 8-K should be consulted. These forward-looking statements are subject to risks, uncertainties and assumptions about us and our operations that are subject to change based on various important factors, some of which are beyond our control. A major risk is that the Company’s demand is largely derived from the demand for its customers’ products, which subjects the Company to uncertainties related to downturns in a customer’s business and unanticipated customer production shutdowns. Other major risks and uncertainties include, but are not limited to, significant increases in raw material costs, worldwide economic and political conditions, foreign currency fluctuations, and terrorist attacks such as those that occurred on September 11, 2001, each of which is discussed in greater detail in Item 1A of this Report. Furthermore, the Company is subject to the same business cycles as those experienced by steel, automobile, aircraft, appliance,

and durable goods manufacturers. These risks, uncertainties, and possible inaccurate assumptions relevant to our business could cause our actual results to differ materially from expected and historical results. Other factors

beyond those discussed in this Report could also adversely affect us. Therefore, we caution you not to place undue reliance on our forward-looking statements. This discussion is provided as permitted by the Private Securities Litigation Reform Act of 1995.

| Item 1A. | Risk Factors |

Changes to the industries and markets that Quaker serves could have a material adverse effect on the Company’s liquidity, financial position, and results of operations.

The chemical specialty industry comprises a number of companies of similar size as well as companies larger and smaller than Quaker. It is estimated that Quaker holds a leading global position in the markets for process fluids to produce sheet steel and in portions of the automotive and industrial markets. The industry is highly competitive, and a number of companies with significant financial resources and/or customer relationships compete with us to provide similar products and services. Our competitors may be positioned to offer more favorable pricing and service terms, resulting in reduced profitability and loss of market share for us. Historically, competition in the industry has been based primarily on the ability to provide products that meet the needs of the customer and render technical services and laboratory assistance to the customer and, to a lesser extent, on price. Success factors critical to the Company’s business include successfully differentiating the Company’s offering from its competition, operating efficiently and profitably as a globally integrated whole, and increasing market share and customer penetration through internally developed business programs and strategic acquisitions.

The business environment in which the Company operates remains challenging. The Company is subject to the same business cycles as those experienced by steel, automobile, aircraft, appliance, and durable goods manufacturers. A major risk is that the Company’s demand is largely derived from the demand for its customers’ products, which subjects the Company to uncertainties related to downturns in our customers’ business and unanticipated customer production shutdowns or curtailments. Customer production within the steel and automotive industries has been recently slowing especially in the U.S., South American and European markets. This is further impacted by the loss of market share of certain of the Company’s automotive customers in these markets. In addition, consolidation in the steel industry is concentrating sales among certain of the Company’s key customers. The Company has limited ability to adjust its cost level contemporaneously with changes in sales and gross margins. Thus, a significant downturn in sales or gross margins due to weak end-user markets, loss of a significant customer, and/or rising raw material costs could have a material adverse effect on the Company’s liquidity, financial position, and results of operations.

Our business depends on attracting and retaining qualified management personnel.

The unanticipated departure of any key member of our management team could have an adverse effect on our business. Given the relative size of the Company and the breadth of its global operations, there are a limited number of qualified management personnel to assume the responsibilities of management level employees should there be management turnover. In addition, because of the specialized and technical nature of our business, our future performance is dependent on the continued service of, and our ability to attract and retain qualified management, commercial and technical personnel. Competition for such personnel is intense, and we may be unable to continue to attract or retain such personnel.

Inability to obtain sufficient price increases or contract concessions to offset increases in the costs of raw material could have a material adverse effect on the Company’s liquidity, financial position, and results of operations. Price increases implemented could result in the loss of sales.

Quaker uses over 1,000 raw materials, including mineral oils and derivatives, animal fats and derivatives, vegetable oils and derivatives, ethylene derivatives, solvents, surface active agents, chlorinated paraffinic compounds, and a wide variety of other organic and inorganic compounds. In 2006,2007, three raw material groups (mineral oil

(mineral oils and derivatives, animal fats and derivatives, and vegetable oils and derivatives) each accounted for

as much as 10% of the total cost of Quaker’s raw material purchases. The price of mineral oil can be affected by the price of crude oil and refining capacity. In addition, many of the raw materials used by Quaker are “commodity” chemicals. Accordingly, Quaker’s earnings can be affected by market changes in raw material prices.

Over the past three years, Quaker has experienced significant increases in its raw material costs, particularly crude-oilcrude oil derivatives. For example, the price of crude oil averaged $66$72 per barrel in 2007 versus $66 in 2006 versusand $57 in 2005 and $42 in 2004.2005. In addition, refining capacity has also been constrained by various factors, which further contributed to higher raw material costs and negatively impacted margins. Animal fat and vegetable oil prices have increased due to increased biodiesel consumption. In response, the Company has aggressively pursued price increases to offset the increased raw material costs. Although the Company has been successful in recovering a substantial amount of the raw material cost increases, it has experienced competitive as well as contractual constraints limiting pricing actions. In addition, as a result of the Company’s pricing actions, customers may become more likely to consider competitor’scompetitors’ products, some of which may be available at a lower cost. Significant loss of customers could result in a material adverse effect on the Company’s results of operations.

Bankruptcy of a significant customer could have a material adverse effect on our liquidity, financial position, and results of operations.

During 2006,2007, our five largest customers (each composed of multiple subsidiaries or divisions with semi-autonomous purchasing authority) together accounted for approximately 23%29% of our consolidated net sales with the largest customer (General Motors)(Arcelor-Mittal Group) accounting for approximately 6%10% of consolidated net sales.

A significant portion of Quaker’s revenues is derived from sales to customers in the U.S. steel industry,and automotive industries, where a number of bankruptcies occurred during recent years. In addition, certain large industrial customersyears and companies have also experienced financial difficulty.difficulties. As part of the bankruptcy process, the Company’s pre-petition receivables may not be realized, customer manufacturing sites may be closed or contracts voided. The bankruptcy of a major customer could have a material adverse effect on the Company’s liquidity, financial position, and results of operations. Steel customers typically have limited manufacturing locations as compared to metalworking customers and generally use higher volumes of products at a single location. The loss or closure of a steel mill or other major customer site of a significant customer could have a material adverse effect on Quaker’s business.

Failure to comply with any material provisions of our credit facility could have a material adverse effect on our liquidity, financial position, and results of operations.

The Company maintains a $100.0$125.0 million unsecured credit facility (the “Credit Facility”) with a group of lenders, which can be increased to $125.0$175.0 million at the Company’s requestoption if lenders agree to increase their commitments and the Company satisfies certain conditions. The Credit Facility, which matures on September 30, 2010,in 2012, provides the availability of revolving credit borrowings. In general, the borrowings under the Credit Facility bear interest at either a base rate or LIBOR rate plus a margin based on the Company’s consolidated leverage ratio.

The Credit Facility contains limitations on capital expenditures, investments, acquisitions and liens, as well as default provisions customary for facilities of its type. While these covenants and restrictions are not currently considered to be overly restrictive, they could become more difficult to comply with as our business or financial conditions change. In addition, deterioration in the Company’s results of operations or financial position could significantly increase borrowing costs.

Quaker is exposed to market rate risk for changes in interest rates, due to the variable interest rate applied to the Company’s borrowings under its credit facilities. Accordingly, if interest rates rise significantly, the cost of debt to Quaker will increase, perhaps significantly, depending on the extent of Quaker’s borrowings under the Credit Facility. At December 31, 2006,2007, the Company had $79.2$73.8 million outstanding under its credit facilities. The

Company has entered into interest rate swaps in order to fix a portion of its variable rate debt and mitigate the

risks associated with higher interest rates. The combined notional value of the swaps was $25.0$35.0 million at December 31, 2006.2007. In February 2007, the Company completed a refinancing of its existing industrial development bonds to fix the interest rate of an additional $5.0 million of debt.

Failure to generate taxable income could have a material adverse effect on our financial position and results of operations.

At the end of 2006,2007, the Company had net U.S. deferred tax assets totaling $15.5$16.8 million, excluding deferred tax assets relating to additional minimum pension liabilities. In addition, the Company has $5.1$4.9 million in operating loss carryforwards primarily related to certain of its foreign operations. The Company records valuation allowances when necessary to reduce its deferred tax assets to the amount that is more likely than not to be realized. The Company considers future taxable income and ongoing prudent and feasible tax planning strategies in assessing the need for a valuation allowance. However, in the event the Company were to determine that it would not be able to realize all or part of its net deferred tax assets in the future, an adjustment to the deferred tax asset would be a non-cash charge to income in the period such determination was made, which could have a material adverse effect on the Company’s financial statements. The Company continues to closely monitor this situation as it relates to its net deferred tax assets and the assessment of valuation allowances. The Company is implementing actions that could positively impact taxable income.

Environmental laws and regulations and pending legal proceedings may materially and adversely affect the Company’s liquidity, financial position, and results of operations.

The Company is a party to proceedings, cases, and requests for information from, and negotiations with, various claimants and Federal and state agencies relating to various matters, including environmental matters. An adverse result in any such matters may materially and adversely affect the Company’s liquidity, financial position, and results of operations. Incorporated herein by reference is the information concerning pending asbestos-related litigation against an inactive subsidiary and amounts accrued associated with certain environmental investigatory and non-capital remediation costs in Note 1820 of Notes to Consolidated Financial Statements which appears in Item 8 of this Report.

AbilityWe might not be able to rapidly develop, manufacture and gain market acceptance of new and enhanced products required to maintain or expand our business.

We believe that our continued success depends on our ability to continuously develop and manufacture new products and product enhancements on a timely and cost-effective basis, in response to customers’ demands for higher performance process chemicals, coatings and other chemical products. Our competitors may develop new products or enhancements to their products that offer performance, features and lower prices that may render our products less competitive or obsolete and, as a consequence, we may lose business and/or significant market share. The development and commercialization of new products requires significant expenditures over an extended period of time, and some products that we seek to develop may never become profitable. In addition, we may not be able to develop and introduce products incorporating new technologies in a timely manner that will satisfy our customers’ future needs or achieve market acceptance.

The scope of our international operations subjects the Company to risks, including risks from changes in trade regulations, currency fluctuations, and political and economic instability.

Since significant revenues and earnings are generated by non-U.S. operations, Quaker’s financial results are affected by currency fluctuations, particularly between the U.S. dollar, the E.U. euro, the Brazilian real, and the Chinese renminbi and the impact of those currency fluctuations on the underlying economies. During the past three years, sales by non-U.S. subsidiaries accounted for approximately 53%55% to 56%58% of the annual consolidated net sales. All of these operations use the local currency as their functional currency. The Company generally does not use financial instruments that expose it to significant risk involving foreign currency transactions; however,

the size of non-U.S. activities has a significant impact on reported operating results and attendant net assets. Therefore, as exchange rates vary, Quaker’s results can be materially affected. Incorporated by reference is the foreign exchange risk information contained in Item 7A of this Report and the geographic information in Note 1315 of Notes to Consolidated Financial Statements included in Item 8 of this Report.

Additional risks associated with the Company’s international operations include but are not limited to the following:

Changes in economic conditions from country to country,

Changes in a country’s political condition,

Trade protection measures,

Licensing and other legal requirements,

Local tax issues,

Longer payment cycles in certain foreign markets,

Restrictions on the repatriation of our assets, including cash,

Significant foreign and United States taxes on repatriated cash,

The difficulties of staffing and managing dispersed international operations,

Less protective foreign intellectual property laws, and

Legal systems which may be less developed and predictable than those in the United States.

Terrorist attacks, or other acts of violence or war may affect the markets in which we operate and our profitability.

Terrorist attacks may negatively affect our operations. There can be no assurance that there will not be further terrorist attacks against the United StatesU.S. or United StatesU.S. businesses. Terrorist attacks or armed conflicts may directly impact our physical facilities or those of our suppliers or customers. Additional terrorist attacks may disrupt the global insurance and reinsurance industries with the result that we may not be able to obtain insurance at historical terms and levels for all of our facilities. Furthermore, additional attacks may make travel and the transportation of our supplies and products more difficult and more expensive and ultimately affect the sales of our products. The consequences of terrorist attacks or armed conflicts are unpredictable, and we may not be able to foresee events that could have an adverse effect on our business.

| Item 1B. | Unresolved Staff Comments. |

None.

| Item 2. | Properties. |

Quaker’s corporate headquarters and a laboratory facility are located in Conshohocken, Pennsylvania. Quaker’s other principal facilities are located in Detroit, Michigan; Middletown, Ohio; Placentia, California; Santa Fe Springs, California; Uithoorn, The Netherlands; Santa Perpetua de Mogoda, Spain; Rio de Janeiro, Brazil; Tradate, Italy; and Qingpu, China, which commenced operations in January 2007. All of the properties except Placentia, California and Santa Fe Springs, California are used by the metalworking process chemicals segment. The Placentia, California and Santa Fe Springs, California properties are used by the coatings segment. With the exception of the Conshohocken, Placentia, Santa Fe Springs and Tradate sites, which are leased, all of these principal facilities are owned by Quaker and as of December 31, 20062007 were mortgage free. Quaker also leases sales, laboratory, manufacturing, and warehouse facilities in other locations.

Quaker’s aforementioned principal facilities (excluding Conshohocken) consist of various manufacturing, administrative, warehouse, and laboratory buildings. Substantially all of the buildings (including Conshohocken) are of fire-resistant construction and are equipped with sprinkler systems. All facilities are primarily of masonry and/or steel construction and are adequate and suitable for Quaker’s present operations. The Company has a program to identify needed capital improvements that are implemented as management considers necessary or desirable. Most locations have various numbers of raw material storage tanks ranging from 7 to 66 at each location with a capacity ranging from 1,000 to 82,000 gallons and processing or manufacturing vessels ranging in capacity from 15 to 16,000 gallons.

In January 2001, the Company contributed its Conshohocken, Pennsylvania property and buildings (the “Site”) into a real estate joint venture (the “Venture”) in exchange for a 50% interest in the Venture. The Venture did not assume any debt or other obligations of the Company and the Company did not guarantee nor was it obligated to pay any principal, interest or penalties on any of the Venture’s indebtedness. The Venture renovated certain of the existing buildings at the Site, as well as built new office space. In December 2000, the Company entered into an agreement with the Venture to lease approximately 38% of the Site’s available office space for a 15-year period commencing February 2002, with multiple renewal options. The Company believes the terms of this lease were no less favorable than the terms it would have obtained from an unaffiliated third party. In February 2005, the Venture sold its real estate assets to an unrelated third party, which resulted in $4.2 million of proceeds to the Company after payment of the Venture’s obligations.

In 2005, the Company completed the sale of its Villeneuve, France site. Quaker had ceased manufacturing operations at this facility in March 2002. Production was consolidated into its facilities in Uithoorn, The Netherlands and Santa Perpetua de Mogoda, Spain. In November 2006, the Company’s former Chinese joint venture partner purchased the Wuxi joint venture’s manufacturing facility, withand production scheduled to bewas transferred to the Company’s Qingpu, China facility during 2007.

Each of Quaker’s 50% or less owned non-U.S. associated companies owns or leases a plant and/or sales facilities in various locations.

| Item 3. | Legal Proceedings. |

The Company is a party to proceedings, cases, and requests for information from, and negotiations with, various claimants and Federal and state agencies relating to various matters, including environmental matters. Incorporated herein by reference is the information concerning pending asbestos-related litigation against an inactive subsidiary and amounts accrued associated with certain environmental investigatory and non-capital remediation costs in Note 1820 of Notes to Consolidated Financial Statements, which appears in Item 8 of this Report. The Company is a party to other litigation which management currently believes will not have a material adverse effect on the Company’s results of operations, cash flow, or financial condition.

| Item 4. | Submission of Matters to a Vote of Security Holders. |

No matters were submitted to a vote of security holders during the last quarter of the period covered by this Report.

| Item 4(a). | Executive Officers of the Registrant. |

Set forth below are the executive officers of the Company. Each of the executive officers, with the exception of Mr. Hill, is elected annually to a one-year term. Mr. Hill is considered an executive officer in his capacity as principal accounting officer for purposes of this item.

Name, Age, and Present Position with the Company | Business Experience During Past Five Years and Period Served as an Officer | |

Ronald J. Naples, Chairman of the Board and

| Mr. Naples has served in his current position since 1997. | |

Vice President, Chief Financial Officer and Treasurer | Mr. | |

Michael F. Barry, Senior Vice President and Managing Director—North America | Mr. Barry assumed his current position in January 2006. He was Senior Vice President and Global Industry Leader—Metalworking and Coatings from July 2005 through December 2005. He was Vice President and Global Industry Leader—Industrial Metalworking and Coatings from January 2004 through June 2005 and Vice President and Chief Financial Officer from 1998 to August 2004. | |

D. Jeffry Benoliel, Vice President, Secretary and General Counsel | Mr. Benoliel has served in his current position since 2001. | |

Vice President and Managing Director—South America | Mr. Bregolato has served in his current position since 1993. | |

Mark A.

| ||

Senior Vice President—Global Strategy and Marketing | Mr. Harris assumed his current position in January 2006. He was Senior Vice President and Global Industry Leader—Steel from July 2005 through December 2005. He was Vice President and Global Industry Leader—Steel from January 2001 through June 2005. | |

George H. Hill, 33 Global Controller | Mr. Hill assumed his current position on April 17, 2007. He was Assistant Global Controller from May 2004 until he assumed his current position and Manager, Financial Reporting from October 2002 to May 2004. | |

Jan F. Nieman, Vice President and Managing Director—Asia/Pacific | Mr. Nieman was elected Vice President in February 2005, and has held the position of Managing Director, Asia/Pacific since August 2003. He was | |

Wilbert Platzer, Vice President and Managing Director—Europe | Mr. Platzer assumed his current position in January 2006. He was Vice | |

PART II

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters, and Issuer Purchases of Equity Securities. |

The Company’s common stock is listed on the New York Stock Exchange (“NYSE”) under the trading symbol KWR. The following table sets forth, for the calendar quarters during the past two most recent fiscal years, the range of high and low sales prices for the common stock as reported on the NYSE composite tape (amounts rounded to the nearest penny), and the quarterly dividends declared and paid:

| Price Range | Dividends Declared | Dividends Paid | Price Range | Dividends Declared | Dividends Paid | |||||||||||||||||||||||||||||||||||||||||||

| 2006 | 2005 | 2007 | 2006 | |||||||||||||||||||||||||||||||||||||||||||||

| High | Low | High | Low | 2006 | 2005 | 2006 | 2005 | High | Low | High | Low | 2007 | 2006 | 2007 | 2006 | |||||||||||||||||||||||||||||||||

First quarter | $ | 21.75 | $ | 18.90 | $ | 25.07 | $ | 20.03 | $ | 0.215 | $ | 0.215 | $ | 0.215 | $ | 0.215 | $ | 24.18 | $ | 21.01 | $ | 21.75 | $ | 18.90 | $ | 0.215 | $ | 0.215 | $ | 0.215 | $ | 0.215 | ||||||||||||||||

Second quarter | 21.94 | 16.70 | 22.00 | 17.30 | 0.215 | 0.215 | 0.215 | 0.215 | 24.74 | 22.10 | 21.94 | 16.70 | 0.215 | 0.215 | 0.215 | 0.215 | ||||||||||||||||||||||||||||||||

Third quarter | 20.29 | 18.04 | 19.11 | 16.57 | 0.215 | 0.215 | 0.215 | 0.215 | 25.00 | 19.25 | 20.29 | 18.04 | 0.215 | 0.215 | 0.215 | 0.215 | ||||||||||||||||||||||||||||||||

Fourth quarter | 22.49 | 18.25 | 19.34 | 15.80 | 0.215 | 0.215 | 0.215 | 0.215 | 24.40 | 19.67 | 22.49 | 18.25 | 0.215 | 0.215 | 0.215 | 0.215 | ||||||||||||||||||||||||||||||||

As of January 17, 2007,2008, there were 918930 shareholders of record of the Company’s common stock, its only outstanding class of equity securities.

Every holder of Quaker common stock is entitled to one vote or ten votes for each share held of record on any record date depending on how long each share has been held. As of January 17, 2007, 9,948,0532008, 10,147,319 shares of Quaker common stock were issued and outstanding. Based on the information available to the Company on January 17, 2007,2008, the holders of 1,054,2981,040,064 shares of Quaker common stock would have been entitled to cast ten votes for each share, or approximately 54%53% of the total votes that would have been entitled to be cast as of that record date and the holders of 8,893,7559,107,255 shares of Quaker common stock would have been entitled to cast one vote for each share, or approximately 46%47% of the total votes that would have been entitled to be cast as of that date. The number of shares that are indicated as entitled to one vote includes those shares presumed to be entitled to only one vote. Because the holders of these shares may rebut this presumption, the total number of votes entitled to be cast as of January 17, 20072008 could be more than 19,436,735.19,507,895.

Reference is made to the information in Item 12 of this Report under the caption “Equity Compensation Plans,” which is incorporated herein by this reference.

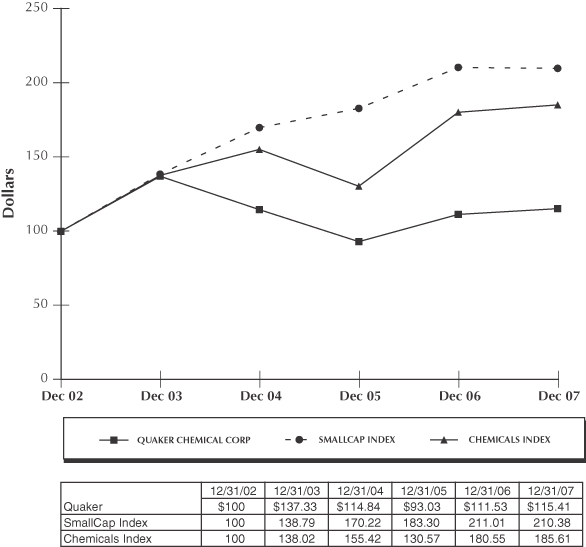

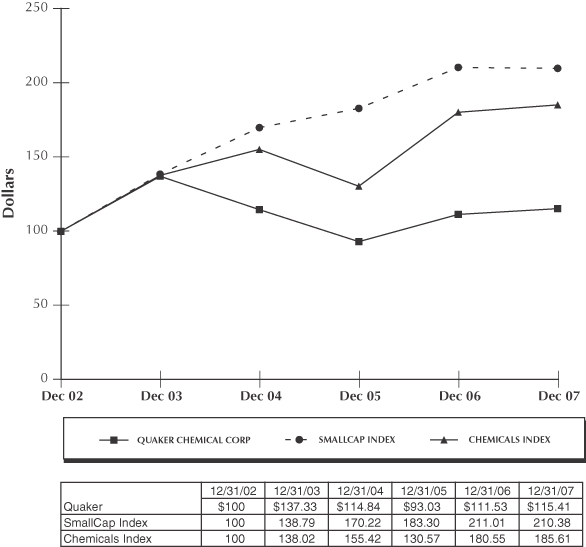

The following graph compares the cumulative total return (assuming reinvestment of dividends) from December 31, 20012002 to December 31, 20062007 for (i) Quaker’s common stock, (ii) the S&P SmallCap 600 Stock Index (the “SmallCap Index”) and (iii) the S&P Chemicals (Specialty) Index-SmallCap (the “Chemicals Index”). The graph assumes the investment of $100 on December 31, 20012002 in each of Quaker’s common stock, the stocks comprising the SmallCap Index, and the stocks comprising the Chemicals Index.

COMPARISON OF CUMULATIVE FIVE FIVE–YEAR TOTAL RETURN

| Item 6. | Selected Financial Data. |

The following table sets forth selected financial information for the Company and its consolidated subsidiaries:

| 2006 | 2005(1) | 2004 | 2003 | 2002 | |||||||||||

| (In thousands, except per share amounts) | |||||||||||||||

Summary of Operations: | |||||||||||||||

Net sales | $ | 460,451 | $ | 424,033 | $ | 400,695 | $ | 340,192 | $ | 274,521 | |||||

Income before taxes, equity income and minority interest | 18,440 | 6,615 | 17,457 | 24,118 | 24,318 | ||||||||||

Net income | 11,667 | 1,688 | 8,974 | 14,833 | 14,297 | ||||||||||

Per share: | |||||||||||||||

Net income-basic | $ | 1.19 | $ | 0.17 | $ | 0.93 | $ | 1.58 | $ | 1.56 | |||||

Net income-diluted | $ | 1.18 | $ | 0.17 | $ | 0.90 | $ | 1.52 | $ | 1.51 | |||||

Dividends declared | 0.86 | 0.86 | 0.86 | 0.84 | 0.84 | ||||||||||

Dividends paid | 0.86 | 0.86 | 0.855 | 0.84 | 0.835 | ||||||||||

Financial Position: | |||||||||||||||

Working capital | $ | 96,062 | $ | 79,105 | $ | 45,569 | $ | 37,137 | $ | 37,529 | |||||

Total assets | 357,382 | 331,995 | 324,893 | 289,467 | 213,858 | ||||||||||

Long-term debt | 85,237 | 67,410 | 14,848 | 15,827 | 16,590 | ||||||||||

Shareholders’ equity | 110,831 | 105,907 | 122,587 | 112,352 | 88,055 | ||||||||||

| 2007(1) | 2006 | 2005(2) | 2004 | 2003 | |||||||||||

| (In thousands, except per share amounts) | |||||||||||||||

Summary of Operations: | |||||||||||||||

Net sales | $ | 545,597 | $ | 460,451 | $ | 424,033 | $ | 400,695 | $ | 340,192 | |||||

Income before taxes, equity income and minority interest | 22,735 | 18,440 | 6,615 | 17,457 | 24,118 | ||||||||||

Net income | 15,471 | 11,667 | 1,688 | 8,974 | 14,833 | ||||||||||

Per share: | |||||||||||||||

Net income-basic | $ | 1.55 | $ | 1.19 | $ | 0.17 | $ | 0.93 | $ | 1.58 | |||||

Net income-diluted | 1.53 | $ | 1.18 | 0.17 | 0.90 | 1.52 | |||||||||

Dividends declared | 0.86 | 0.86 | 0.86 | 0.86 | 0.84 | ||||||||||

Dividends paid | 0.86 | 0.86 | 0.86 | 0.855 | 0.84 | ||||||||||

Financial Position: | |||||||||||||||

Working capital | $ | 107,150 | $ | 96,062 | $ | 79,105 | $ | 45,569 | $ | 37,137 | |||||

Total assets | 399,049 | 357,382 | 331,995 | 324,893 | 289,467 | ||||||||||

Long-term debt | 78,487 | 85,237 | 67,410 | 14,848 | 15,827 | ||||||||||

Shareholders’ equity | 130,393 | 110,831 | 105,907 | 122,587 | 112,352 | ||||||||||

Following amounts in thousands

| (1) | The results of operation for 2007 include a pre-tax environmental charge of $3,300 for the settlement of the ACP litigation and ongoing remediation activities at the site; a pre-tax charge of $701 related to a discontinued strategic initiative; a pre-tax charge of $487 related to certain customer bankruptcies; a non-cash out-of-period tax benefit adjustment of $993 primarily related to deferred tax accounting for the Company’s foreign pension plans; a tax refund of $665 relating to the Company’s increased investment in China; and a $391 tax charge related to the revaluation of deferred tax assets as a result of a tax law change. |

| (2) | The results of operation for 2005 include a net pre-tax charge for restructuring and related activities of $10,320, proceeds from the sale of real estate by the Company’s real estate joint venture of $4,187, and a $1,000 tax charge associated with the repatriation of accumulated earnings of its foreign subsidiaries. |

| Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations. |

Executive Summary

Quaker Chemical Corporation is a worldwide developer, producer, and marketer of chemical specialty products and a provider of chemical management services (“CMS”) for various heavy industrial and manufacturing applications around the globe with significant sales to the steel and automotive industries. The improved 2006 results largely reflect the continued execution of the Company’s actions taken throughout 2005 in response to its challenging business environment.

The revenue growth in 20062007 was primarily due to higher volumes, particularly in China and Europe, and increased selling prices, as well asprices. CMS revenues were also higher volume in China.due to the renewal and restructuring of several of the Company’s contracts throughout the year. Higher selling prices, combined with improved CMS profitability, helped offset higher raw material and third-party finished product costs, resulting in significantly higher gross margin dollars but with only a slight improvementdecrease in gross margin as a percentage of sales as compared to 2005.2006. Raw material costs primarily crude oil derivatives, continued to increase during 2006be higher as compared to the prior year mitigating pricing actions intendedand continued to improve gross margins as a percentage of sales. While oil prices have recently declined from a peak early insteadily rise throughout the third quarter of 2006, to date, the oil price reductions have not yet resulted in any significant reduction in raw material prices. Selling,year. Factors impacting higher selling, general and administrative expensescosts in 2007 include continued expansion into Asia/Pacific, higher commissions related to higher sales, higher incentive compensation as a result of higher earnings, higher legal and environmental costs, foreign exchange rate translation, as well as inflationary increases.

The full year 2007 results included some unusual items as well. A $3.3 million environmental charge was taken related to the settlement of environmental litigation involving AC Products, Inc. (“ACP”), a wholly owned subsidiary of Quaker, as well as additional costs for 2006 increased $4.6the estimated future remediation costs. A $0.7 million comparedcharge related to 2005. Cost savings from restructuring efforts completed in 2005 enabled increased spending in higher growth areas, higher variable compensation and higher professional fees.

Earnings per diluted share of $1.18 represent a considerable improvement over the $0.17 for 2005. The principal factors impacting 2006 earnings included a 9% growth in revenues and improved performance from CMS. The Company’s 2005 earnings included a $10.3 million pre-tax charge for restructuring and related activitiesdiscontinued strategic initiative and a $1.0$0.5 million charge related to certain customer bankruptcies were also taken. The effective tax charge attributable to the repatriationrate includes a $0.7 million refund of accumulated earnings of its foreign subsidiaries, which were offsettaxes in part by $4.2 million of pre-tax income from the sale of property by the Company’s real estate joint venture and lower minority interest primarilyChina as a result of the Company’s first quarter 2005 acquisitionincreased investment and a non-cash out-of-period tax benefit adjustment of $1.0 million related to certain deferred tax items, as well as a $0.4 million charge related to the revaluation of deferred tax assets due to a tax law change.

The net result was a considerable improvement in earnings per diluted share of $1.53 for 2007, compared to $1.18 for 2006. Notwithstanding the Company’s improved performance, the continued strength of the remaining 40% interest in its Brazilian affiliate. The Company’s 2005 restructuring efforts are positively impacting the bottom line as resources have been shiftedbusiness environment is subject to higher growth areas like China, CMSlimited visibility due to continued raw material price volatility and coatings. However, any improvementsan uncertain global economic environment. With crude oil near $100 per barrel and animal fats and vegetable oils impacted by increased biodiesel consumption, raw material prices continue to be a challenge. Any improvement in gross margin as a percentage of sales will depend in part upon a sustained period of stable or declining raw material costs. While demand is generally expected to remain stable, volume in certain markets was limited by customer end-market issues, including reduced vehicle sales experienced by some automotive customers and reduced steel demand, particularly in the U.S. With the settlement of the ACP environmental litigation, legal and environmental costs are expected to decline in the future. The Company remainswill remain focused on pursingpursuing revenue opportunities, managing its raw material and other costs, and pursuing pricing initiatives. Most recently, in the fourth quarter of 2006 the Company acquired the remaining minority interest in its China affiliate.

Notwithstanding the improved performance, the business environment in which the Company operates remains challenging. While demand in China is expected to continue to remain strong, volume in other markets was limited by customer end-market issues, including higher inventory levels in the U.S. steel industry and reduced vehicle sales experienced by some automotive customers, with indications that these conditions would continue for the foreseeable future. Raw material and third party product costs continue to remain higher as compared to the prior year. In certain instances, the Company faces competitive or contractual constraints limiting pricing actions to recover these higher costs.

Critical Accounting Policies and Estimates

Quaker’s discussion and analysis of its financial condition and results of operations are based upon Quaker’s consolidated financial statements, which have been prepared in accordance with accounting principles generally accepted in the United States. The preparation of these financial statements requires Quaker to make estimates and judgments that affect the reported amounts of assets, liabilities, revenues and expenses, and related disclosure of contingent assets and liabilities. On an ongoing basis, Quaker evaluates its estimates, including those related to customer sales incentives, product returns, bad debts, inventories, property, plant, and equipment, investments, goodwill, intangible assets, income taxes, financing operations, restructuring, incentive compensation plans (including equity-based compensation), pensions and other postretirement benefits, and contingencies and litigation. Quaker bases its estimates on historical experience and on various other assumptions that are believed to be reasonable under the

circumstances, the results of which form the basis for making judgments about the carrying values of assets and liabilities that are not readily apparent from other sources. Actual results may differ from these estimates under different assumptions or conditions.

Quaker believes the following critical accounting policies describe the more significant judgments and estimates used in the preparation of its consolidated financial statements:

1. Accounts receivable and inventory reserves and exposures—Quaker establishes allowances for doubtful accounts for estimated losses resulting from the inability of its customers to make required payments. If the financial condition of Quaker’s customers were to deteriorate, resulting in an impairment of their ability to make payments, additional allowances may be required. As part of its terms of trade, Quaker may custom manufacture products for certain large customers and/or may ship product on a consignment basis. Further, a significant portion of Quaker’s revenues is derived from sales to customers in the U.S. steel industry,and automotive industries, where a number of bankruptcies have occurred during recent years. In recent years certain large industrial customersand companies have also experienced financial difficulty.difficulties. When a bankruptcy occurs, Quaker must judge the amount of proceeds, if any, that may ultimately be received through the bankruptcy or liquidation process. These matters may increase the Company’s exposure should a bankruptcy occur, and may require writedownwrite down or disposal of certain inventory due to its estimated obsolescence or limited marketability. Reserves for customers filing for bankruptcy protection are generally established at 75-100% of the amount outstanding at the filing date, dependent on the Company’s evaluation of likely proceeds from the bankruptcy process. Large and/or financially distressed customers are generally reserved for on a specific review basis while a general reserve is established for other customers based on historical experience. The Company’s consolidated allowance for doubtful accounts was $3.2$3.1 million and $4.1$3.2 million at December 31, 20062007 and 2005,2006, respectively. Further, the Company recorded provisions for doubtful accounts of $0.0 million, $0.0 million and $1.2 million in 2007, 2006 and $0.5 million in 2006, 2005 and 2004 respectively. An increase of 10% to the recorded provisions would have decreased the Company’s pre-tax earnings by $0.0 million, $0.0 million and $0.12 million in 2007, 2006 and $0.05 million in 2006, 2005, and 2004, respectively.

2. Environmental and litigation reserves—Accruals for environmental and litigation matters are recorded when it is probable that a liability has been incurred and the amount of the liability can be reasonably estimated. Accrued liabilities are exclusive of claims against third parties and are not discounted. Environmental costs and remediation costs are capitalized if the costs extend the life, increase the capacity or improve the safety or efficiency of the property from the date acquired or constructed, and/or mitigate or prevent contamination in the future. Estimates for accruals for environmental matters are based on a variety of potential technical solutions, governmental regulations and other factors, and are subject to a large range of potential costs for remediation and other actions. A considerable amount of judgment is required in determining the most likely estimate within the range, and the factors determining this judgment may vary over time. Similarly, reserves for litigation and similar matters are based on a range of potential outcomes and require considerable judgment in determining the most probable outcome. If no amount within the range is considered more probable than any other amount, the Company accrues the lowest amount in the range in accordance with generally accepted accounting principles. An inactive subsidiary of the Company is involved in asbestos litigation. If the Company ever concludes that it is probable it will be liable for any of the obligations of such subsidiary, then it will record the associated liabilities if they can be reasonably estimated. The Company will reassess this situation periodically in accordance with SFAS No. 5, “Accounting for Contingencies.” See Note 1820 of Notes to Consolidated Financial Statements which appears in Item 8 of this Report.

3. Realizability of equity investments—Quaker holds equity investments in various foreign companies, whereby it has the ability to influence, but not control, the operations of the entity and its future results. Quaker records an investment impairment charge when it believes an investment has experienced a decline in value that is other than temporary. Future adverse changes in market conditions, poor operating results of underlying investments, or devaluation of foreign currencies could result in losses or an inability to recover the carrying value of the investments that may not be reflected in an investment’s current carrying value.

These factors may result in an impairment charge in the future. The carrying amount of the Company’s equity investments at December 31, 20062007 was $7.0$7.3 million and was comprised of three investments totaling $3.6$3.9 million, $2.3$2.4 million and $1.1$1.0 million, respectively.

4. Tax exposures, valuation allowances and valuation allowances—uncertain tax positions—Quaker records expenses and liabilities for taxes based on estimates of amounts that will be ultimately determined to be deductible in tax returns filed in various jurisdictions. The filed tax returns are subject to audit, often several years subsequent to the date of the financial statements. Disputes or disagreements may arise during audits over the timing or validity of certain items or deductions, which may not be resolved for extended periods of time. Quaker establishes reservesadopted the provisions of FASB Interpretation No. 48, “Accounting for potentialUncertainty in Income Taxes, an interpretation of FASB Statement No. 109” (“FIN 48”) on January 1, 2007. FIN 48 applies to all income tax audit and other exposures as transactions occur and reviews these reservespositions taken on previously filed tax returns or expected to be taken on a regular basis; however, actual exposuresfuture tax return. FIN 48 prescribes a benefit recognition model with a two-step approach, a more-likely-than-not recognition criterion, and audit adjustments may vary from these estimates.a measurement attribute that measures the position as the largest amount of tax benefit that is greater than 50% likely of being realized upon effective settlement. FIN 48 also requires that the amount of interest expense and income to be recognized related to uncertain tax positions be computed by applying the applicable statutory rate of interest to the difference between the tax position recognized in accordance with FIN 48, including timing differences, and the amount previously taken or expected to be taken in a tax return. Quaker also records valuation allowances when necessary to reduce its deferred tax assets to the amount that is more likely than not to be realized. While Quaker has considered future taxable income and ongoing prudent and feasible tax planning strategies in assessing the need for the valuation allowance, in the event Quaker were to determine that it would be able to realize its deferred tax assets in the future in excess of its net recorded amount, an adjustment to the deferred tax asset would increase income in the period such determination was made. Likewise, should Quaker determine that it would not be able to realize all or part of its net deferred tax assets in the future, an adjustment to the deferred tax asset would be charged to income in the period such determination was made which could have a material adverse impact on the Company’s financial statements. U.S. income taxes have not been provided on the undistributed earnings of non-U.S. subsidiaries since it is the Company’s intention to continue to reinvest these earnings in those subsidiaries for working capital needs and growth initiatives. U.S. and foreign income taxes that would be payable if such earnings were distributed may be lower than the amount computed at the U.S. statutory rate due to the availability of foreign tax credits.

5. Restructuring liabilities—Restructuring charges may consist of charges for employee severance, rationalization of manufacturing facilities and other items. In 2001, Quaker recorded restructuring and other exit costs, including involuntary termination of certain employees, in accordance with the Financial Accounting Standards Board’s (“FASB”) Emerging Issues Task Force (“EITF”) Issue No. 94-3, “Liability Recognition for Certain Employee Termination Benefits and Other Costs to Exit an Activity (including Certain Costs Incurred in a Restructuring).” Certain of these items, particularly those involving impairment charges for assets to be sold or closed, require significant estimates and assumptions in terms of estimated sale proceeds, date of sale, transaction costs and other matters, and these estimates can change based on market conditions and other factors. In July 2002, the FASB issued SFAS No. 146, “Accounting for Costs Associated with Exit or Disposal Activities,” which nullified EITF Issue No. 94-3. TheActivities” and the Company adopted the provisions of SFAS No. 146 effective for exit or disposal activities initiated after December 31, 2002. The principal difference between SFAS No. 146 and EITF 94-3 relates to its requirements for recognition of a liability for a cost associated with an exit or disposal activity. SFAS No. 146 requires that a liability for a cost associated with an exit or disposal activity be recognized when the liability is incurred. Under EITF 94-3, a liability for exit costs is recognized at the date of an entity’s commitment to an exit plan.

6. Goodwill and other intangible assets—Goodwill and other intangible assets are evaluated in accordance with SFAS No. 142, “Goodwill and Other Intangible Assets.” Intangible assets, which do not have indefinite lives, are recorded at fair value and amortized over a straight-line basis over the life of the intangible asset based on third partythird-party valuations of the assets. Goodwill and intangible assets, which have indefinite lives, are no longernot amortized and are required to be assessed at least annually for impairment. The Company compares the assets’ fair value to their carrying value primarily based on future discounted cash flows in order to determine if an impairment charge is warranted. The estimates of future cash flows involve considerable management judgment and are based upon assumptions about expected future operating performance. Assumptions used in these forecasts are consistent with internal planning. The actual cash flows could differ from management’s estimates due to changes in business conditions, operating performance, and economic conditions. The Company completed its annual impairment assessment as of the end of the third quarter 2006,2007, and no impairment charge was warranted. The Company’s consolidated goodwill and indefinite-lived intangible assets at December 31, 2007 and 2006 were $44.4 million and 2005 were $39.3 million, and $36.0 million, respectively. The

Company’s assumption of weighted average cost of capital and estimated future net operating profit after tax (NOPAT) are particularly important in determining whether an impairment charge has been incurred. The Company currently uses a weighted average cost of capital of 12% and, at September 30, 2006,2007, this assumption would have had to increase by more than 2.54.2 percentage points before any of the Company’s reporting units would fail step one of the SFAS No. 142 impairment

analysis. Further, at September 30, 2006,2007, the Company’s estimate of future NOPAT would have had to decrease by more than 17%26% before any of the Company’s reporting units would be considered potentially impaired.

7. Postretirement benefits—The Company provides certain pension and other postretirement benefits to employees and retirees. Independent actuaries, in accordance with accounting principles generally accepted in the United States, perform the required valuations to determine benefit expense and, if necessary, non-cash charges to equity for additional minimum pension liabilities. Critical assumptions used in the actuarial valuation include the weighted average discount rate, rates of increase in compensation levels, and expected long-term rates of return on assets. If different assumptions were used, additional pension expense or charges to equity might be required. For 2006, the Company incurred such a non-cash charge to equity of $9.3 million, in connection with the adoption of SFAS No. 158, “Employers’ Accounting for Defined Benefit and Other Postretirement Plans.” The Company’s pension plan year-end is November 30, which serves as the measurement date. The following table highlights the potential impact on the Company’s pre-tax earnings due to changes in assumptions with respect to the Company’s pension plans, based on assets and liabilities at December 31, 2006:2007:

| 1/2 Percentage Point Increase | 1/2 Percentage Point Decrease | 1/2 Percentage Point Increase | 1/2 Percentage Point Decrease | |||||||||||||||||||||||||||||||||||||||

| Foreign | Domestic | Total | Foreign | Domestic | Total | Foreign | Domestic | Total | Foreign | Domestic | Total | |||||||||||||||||||||||||||||||

| (Dollars in millions) | (Dollars in millions) | |||||||||||||||||||||||||||||||||||||||||

Discount rate | $ | (0.6 | ) | $ | (0.1 | ) | $ | (0.7 | ) | $ | 0.4 | $ | 0.1 | $ | 0.5 | $ | (0.5 | ) | $ | (0.1 | ) | $ | (0.6 | ) | $ | 0.5 | $ | 0.1 | $ | 0.6 | ||||||||||||

Expected rate of return on plan assets | $ | (0.2 | ) | $ | (0.2 | ) | $ | (0.4 | ) | $ | 0.2 | $ | 0.2 | $ | 0.4 | $ | (0.2 | ) | $ | (0.2 | ) | $ | (0.4 | ) | $ | 0.2 | $ | 0.2 | $ | 0.4 | ||||||||||||

Recently Issued Accounting Standards

In June 2006, the FASB issued FASB Interpretation No. 48, “Accounting for Uncertainty in Income Taxes, an interpretation of FASB Statement No. 109” (“FIN 48”). FIN 48 clarifies the accounting for uncertainty in income taxes by prescribing the recognition threshold a tax position is required to meet before being recognized in the financial statements. It also provides guidance on derecognition, classification, interest and penalties, accounting in interim periods, disclosure, and transition. FIN 48 is effective for fiscal years beginning after December 15, 2006. The cumulative effects, if any, of applying FIN 48 will be recorded as an adjustment to retained earnings as of the beginning of the period of adoption. The Company is currently evaluating the effect that the adoption of FIN 48 will have on its consolidated results of operations and financial condition and is not yet in a position to determine such effects.

In September 2006, the FASB issued FASB Staff Position (“FSP”) AUG AIR-1 “Accounting for Planned Major Maintenance Activities” (FSP AUG AIR-1). FSP AUG AIR-1 amends the guidance on the accounting for planned major maintenance activities; specifically, it precludes the use of the previously acceptable “accrue in advance” method. FSP AUG AIR-1 is effective for fiscal years beginning after December 15, 2006. The adoption of FSP AUG AIR-1 did not have a material effect on our consolidated financial position or results of operations.

In September 2006, the SEC staff issued Staff Accounting Bulletin (“SAB”) 108 “Considering the Effects of Prior Year Misstatements when Quantifying Misstatements in Current Year Financial Statements” (SAB 108). SAB 108 requires that public companies utilize a “dual-approach” to assessing the quantitative effects of financial misstatements. This dual approach includes both an income statement focused assessment and a balance sheet focused assessment. The guidance in SAB 108 must be applied to annual financial statements for fiscal years ending after November 15, 2006. The adoption of SAB 108 did not have a material effect on our consolidated financial position or results of operations.

In September 2006, the FASB issued SFAS No. 157, “Fair Value Measurements” (SFAS No. 157). SFAS No. 157 establishes a common definition for fair value to be applied to USU.S. GAAP guidance requiring use of fair

value, establishes a framework for measuring fair value, and expands disclosure about such fair value measurements. SFAS No. 157 is effective for fiscal years beginning after November 15, 2007. The Company is currently assessing the impact of SFAS No. 157this standard on its consolidated financial positionstatements.

In February 2007, the FASB issued SFAS No. 159, “The Fair Value Option for Financial Assets and resultsFinancial Liabilities Including an Amendment of operations.FASB No. 115” (SFAS No. 159). SFAS No. 159 permits entities to choose to measure many financial instruments and certain other items at fair value that are not currently required to be measured at fair value. This statement also establishes presentation and disclosure requirements designed to facilitate comparison between entities that choose different measurement attributes for similar types of assets and liabilities. SFAS No. 159 is effective for fiscal years beginning after November 15, 2007. The application of SFAS No. 159 is elective and the Company has chosen not to measure any additional financial instruments or any other items at fair value. The Company is currently assessing the impact of this standard on its consolidated financial statements.

In September 2007, EITF Issue 06-11 “Accounting for Income Tax Benefits of Dividends on Share-Based Payment Awards” (EITF 06-11) was issued. EITF 06-11 should be applied prospectively to the income tax benefits that result from dividends on equity-classified employee share-based payment awards that are declared in fiscal years beginning after December 15, 2007, and interim periods within those years. The Company is currently assessing the impact of this standard on its consolidated financial statements.

In December 2007, the FASB issued SFAS No. 141 (revised 2007), “Business Combinations (FAS 141(R))” and SFAS No. 160, “Noncontrolling Interests in Consolidated Financial Statements, as amendment of ARB No. 51 (FAS 160).” FAS 141(R) will significantly change how business acquisitions are accounted for and will impact financial statements both on the acquisition date and in subsequent periods. Some of the changes, such as the accounting for contingent consideration, will introduce more volatility into earnings. FAS 160 will change

the accounting and reporting for minority interests, which will be recharacterized as noncontrolling interests and classified as a component of equity. FAS 141(R) will be applied prospectively. FAS 160 requires retroactive adoption of the presentation and disclosure requirements for existing minority interests. All other requirements of FAS 160 shall be applied prospectively. FAS 141(R) and FAS 160 are effective for fiscal years beginning on or after December 15, 2008. The Company is currently assessing the impact of these standards on its financial statements.

Liquidity and Capital Resources

Quaker’s cash and cash equivalents remainedincreased to $20.2 million at December 31, 2007 from $16.1 million at December 31, 2006 and 2005. Operating and financing activities provided $8.22006. The $4.1 million and $4.2 million, respectively, which were offset by $13.5increase resulted primarily from $27.5 million of netcash provided by operating activities, offset in part by, $9.4 million of cash used in investing activities and $15.9 million of cash used in financing activities. The $27.5 million of cash provided by operating activities is the highest level the Company has achieved in recent history.

Net cash flows provided by operating activities were $27.5 million in 2007, compared to $8.2 million in 2006 versus $11.62006. The increased cash flow was largely due to lower working capital requirements in 2007 compared to 2006. Despite an $85.1 million sales increase, higher raw material costs, and increased business from our CMS channel, all of which typically require incremental investments in 2005. Theworking capital, the Company has made significant progress around the globe in limiting the pace of such increased investment. In addition, the Company’s higher net income, was more than offset byhigher depreciation, and the change in working capital accounts, increased net pension plan contributions and higher2006 completion of all restructuring payments in 2006, as a result of the actions takenactivities were also significant factors in the fourth quarter of 2005. The change in working capital accounts was largely driven by higher incentive compensation accruals in 2006 on higher earnings and the timing of accounts payable in the U.S. and Europe in the prior year.increased cash flow from operating activities.