| ý | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| TEXAS | 74-2088619 | |

(State or other jurisdiction of incorporation or organization) |

| |

| 78209 | |

| (Address of principal executive offices) | (Zip Code) | |

Title of each class | Name of each exchange on which registered | |

| Common Stock, $0.10 par value | ||

þ No ¨

Large accelerated filer | Accelerated filer | |||

Non-accelerated filer | (Do not check if a smaller reporting company) | Smaller reporting company | ||

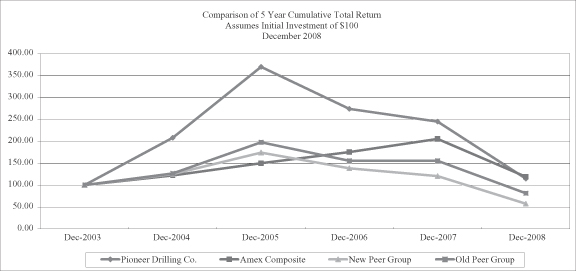

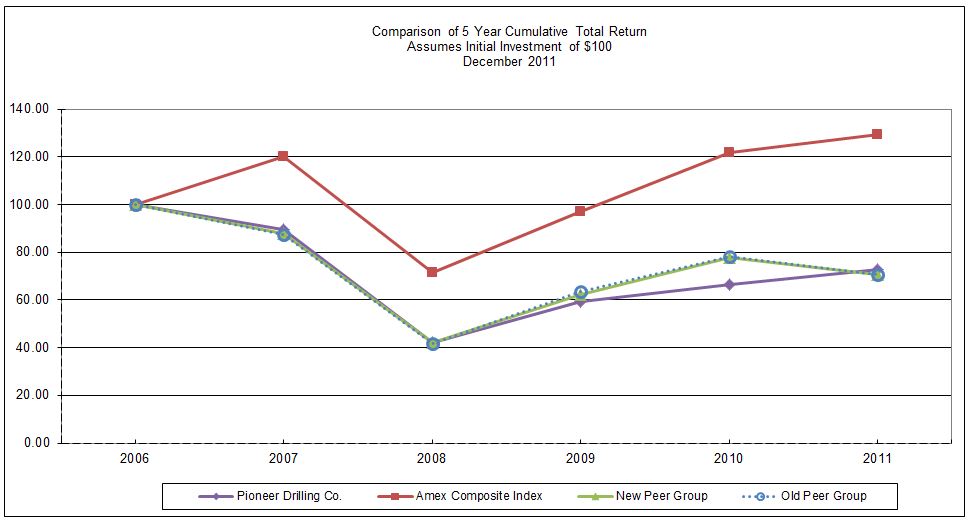

Item 1. Item 1A. Item 1B. Item 5. Item 6. Item 7. Item 7A. Item 8. Item 9. Item 9A. Item 10. Item 11. Item 12. Item 13. Item 14. Item 15. general economic and business conditions and industry trends; the continued the highly competitive nature of our business; our future financial performance, including availability, terms and deployment of capital; the continued availability of drilling rig, well service rig, wireline unit and coiled tubing unit components; changes in, or our failure or inability to comply with, governmental regulations, including those relating to the environment. Pioneer Drilling Company provides drilling services and production services to independent and major oil and gas exploration and production companies throughout much of the oil and gas producing regions of the United States and internationally in Colombia. Drilling Division Locations South Texas East Texas West Texas Utah Colombia Well Services. Existing and newly-drilled wells require a range of services to establish and maintain production over their useful lives. We use our premium well service rig fleet Oil (West Texas Intermediate) Natural Gas (Henry Hub) U.S. Land Rig Count U.S. Workover Rig Count U.S. land rig counts and U.S. well service rig counts. Since late 2009, increases primarily in oil prices have caused increases in exploration and production spending and the corresponding increases in drilling and well services activities are reflected by increases in the U.S. land rig counts and the U.S. well service rig counts in 2010 and 2011. to the short-term viability of a lease or field, but these projects are less sensitive to commodity price volatility as compared to capital expenditures for exploration. Discretionary operating expenditure work is evaluated according to a simple short-term payout criterion which is far less dependent on commodity price forecasts. routed from the mud pits to the mud pump and from the mud pump through a standpipe and the rotary hose to the drill stem. The drilling mud travels down the drill stem to the bit, up the annular space between the drill stem and the borehole and through the blowout preventer stack to the return flow line. It then travels to a shale shaker for removal of rock cuttings, and then back to the mud pits, which are usually steel tanks. The reserve pits, usually one or two fairly shallow excavations, are used for waste material and excess water around the location. These upgrades provide our customers with drilling rigs that have more varied capabilities for drilling in unconventional plays, and they improve our efficiency and safety. Top drives provide maximum torque and rotational control, improved well control and better hole conditioning. In horizontal drilling, operators can utilize top drives to reach formations that may not be accessible with conventional rotary drilling. An iron roughneck is a remotely operated pipe handling feature on the rig floor, which is used to help reduce the occurrence of repetitive motion injuries and decrease drill pipe tripping time. Walking systems increase efficiency by allowing multiple wells to be drilled on the same pad site and permitting the drilling rig to move between wells while drill pipe remains in the derrick, thus reducing move times and costs. Our walking system enables the drilling rig to move forward, backward, and side to side which affords the operator additional flexibility. An automated catwalk is a drill pipe handling feature used to raise drill pipe, drill collars, casing, and other necessary items to the drilling rig floor. Its function significantly reduces pick up and lay down time, thereby decreasing operator costs for handling casing. Average number of operating rigs for the period Average utilization rate Type of Contract Daywork Turnkey Footage Total number of wells We provide drilling services and production services to numerous major and independent oil and gas exploration and production companies that are active in the geographic areas in which we operate. The following table shows our three largest customers as a percentage of our total revenue for each of our last three fiscal years. Customer Chesapeake Operating, Inc. the type and condition of each of the competing drilling rigs; the mobility and efficiency of the rigs; the quality of service and experience of the rig crews; the safety records of the rigs; the offering of ancillary services; and the ability to provide drilling equipment adaptable to, and personnel familiar with, new technologies and drilling techniques. better withstand industry downturns; compete more effectively on the basis of price and technology; better retain skilled rig personnel; and build new rigs or acquire and refurbish existing rigs so as to be able to place rigs into service more quickly than us in periods of high drilling demand. blowouts; fires and explosions; loss of well control; collapse of the borehole; lost or stuck drill strings; and damage or loss from natural disasters. suspension of drilling operations; damage to, or destruction of, our property and equipment and that of others; personal injury and loss of life; damage to producing or potentially productive oil and gas formations through which we drill; and environmental damage. Our corporate office facilities are located at 1250 N.E. Loop 410, Suite 1000 San Antonio, Texas 78209 and are leased through December 2020with subject to special protective measures and which may expose us to additional operating costs and liabilities for accidental discharges of oil, natural gas, drilling fluids or contaminated water, or for noncompliance with other aspects of applicable laws. We are also subject to the requirements of the federal Occupational Safety and Health Act our revenues, cash flows and profitability; the fair market value of our drilling rig fleet and production service assets; our ability to maintain or increase our borrowing capacity; our ability to obtain additional capital to finance our business and make acquisitions, and the cost of that capital; and our ability to retain skilled rig personnel whom we would need in the event of an upturn in the demand for our services. Currently, there are growing expectations of a possible downturn in the global economic environment in 2012, which could lead to a decline in oil and natural gas prices that would adversely affect our business. the type and condition of each of the competing drilling, the mobility and efficiency of the rigs; the quality of service and experience of the rig crews; the safety records of the rigs; the offering of ancillary services; and the ability to provide drilling and production equipment adaptable to, and personnel familiar with, new technologies and drilling and production techniques. better withstand industry downturns; compete more effectively on the basis of price and technology; retain skilled rig personnel; and build new rigs or acquire and refurbish existing rigs so as to be able to place rigs into service more quickly than us in periods of high drilling demand. results of operations. Under a typical turnkey drilling contract, we agree to drill a well for our customer to a specified depth and under specified conditions for a fixed price. We provide technical expertise and engineering services, as well as most of the equipment and drilling supplies required to drill the well. We often subcontract for related services, such as the provision of casing crews, cementing and well In addition, since we are only paid by our customers after we have performed the terms of the drilling contract in full, our liquidity can be affected by the number of turnkey and footage contracts that we enter into. blowouts; cratering; fires and explosions; loss of well control; collapse of the borehole; damaged or lost drilling equipment; and damage or loss from natural disasters. suspension of operations; damage to, or destruction of, our property and equipment and that of others; personal injury and loss of life; damage to producing or potentially productive oil and gas formations through which we drill; and environmental damage. Go-Coil to complement our existing production services offerings. unanticipated costs and assumption of liabilities and exposure to unforeseen liabilities of acquired businesses, including environmental liabilities; difficulties in integrating the operations and assets of the acquired business and the acquired personnel; limitations on our ability to properly assess and maintain an effective internal control environment over an acquired business in order to comply with applicable periodic reporting requirements; potential losses of key employees and customers of the acquired businesses; risks of entering markets in which we have limited prior experience; and increases in our expenses and working capital requirements. balance of impairing our ability to make investments and obtain additional financing for working capital, capital expenditures, acquisitions or other general corporate purposes; limiting our ability to use operating cash flow in other areas of our business because we must dedicate a substantial portion of these funds to make principal and interest payments on our indebtedness; making us more vulnerable to a downturn in our business, our industry or the economy in general as a substantial portion of our operating cash flow could be required to make principal and interest payments on our indebtedness, making it more difficult to react to changes in our business, limiting our flexibility in planning for, or reacting to, changes in our business and the industry in which we operate; putting us at a competitive disadvantage to competitors that have less debt; and increasing our vulnerability to rising interest rates. refinancing or restructuring our debt; selling assets; reducing or delaying acquisitions or capital investments, such as refurbishments of our rigs and related equipment; or seeking to raise additional capital. limitations on the incurrence of additional indebtedness; restrictions on investments, capital expenditures, mergers or consolidations, asset dispositions, acquisitions, transactions with affiliates and other transactions without the lenders’ consent; and limitation on dividends and distributions. Revolving Credit Facility and our Senior Notes. risks of war, terrorism, civil unrest and kidnapping of employees; expropriation, confiscation or nationalization of our assets; renegotiation or nullification of contracts; foreign taxation; the inability to repatriate earnings or capital due to laws limiting the right and ability of foreign subsidiaries to pay dividends and remit earnings to affiliated companies; changing political conditions and changing laws and policies affecting trade and investment; concentration of customers; the overlap of different tax structures; the burden of complying with multiple and potentially conflicting laws; the risks associated with the assertion of foreign sovereignty over areas in which our operations are conducted; difficulty in collecting international accounts receivable; and potentially longer payment cycles. environmental quality; pollution control; remediation of contamination; preservation of natural resources; transportation, and worker safety. cash flows. provisions regulating the ability of our shareholders to nominate candidates for election as directors or to bring matters for action at annual meetings of our shareholders; limitations on the ability of our shareholders to call a special meeting and act by written consent; provisions dividing our board of directors into three classes elected for staggered terms; and the authorization given to our board of directors to issue and set the terms of preferred stock. Fiscal Year Ended December 31, 2008: First Quarter Second Quarter Third Quarter Fourth Quarter Nine Months Ended December 31, 2007: First Quarter Second Quarter Third Quarter Fiscal Year Ended March 31, 2007: First Quarter Second Quarter Third Quarter Fourth Quarter NYSE Amex: 2011 Plan category Equity compensation plans approved by security holders Equity compensation plans not approved by security holders Total performance graph. Statement of Operations Data: Revenues (Loss) income from operations (Loss) income before income taxes Net (loss) earnings applicable to common stockholders (Loss) earnings per common share-basic (Loss) earnings per common share-diluted Other Financial Data: Net cash provided by operating activities Net cash used in investing activities Net cash provided by financing activities Capital expenditures Balance Sheet Data: Working capital Property and equipment, net Long-term debt and capital lease obligations, excluding current installments Shareholders’ equity Total assets The statement of operations data and other financial data for the The statement of operations data and other financial data for the year ended December 31, 2008 reflect the impact of a goodwill impairment charge of $118.6 million and an intangible asset impairment charge of $52.8 million. Drilling Division Locations South Texas East Texas West Texas Utah Colombia Well Services. Existing and newly-drilled wells require a range of services to establish and maintain production over their useful lives. We use our premium well service rig fleet Oil (West Texas Intermediate) Natural Gas (Henry Hub) U.S. Land Rig Count U.S. Workover Rig Count production companies. Exploration and production spending is generally categorized as either a capital expenditure or next 12 months. Drilling Services Division: Routine rigs Discretionary New-builds and acquisitions Total Drilling Services Division Production Services Division: Routine Discretionary New-builds and acquisitions Total Production Services Division costs on as necessary, from borrowings under our Revolving Credit Facility. 2010 Cash and cash equivalents Receivables, net Unbilled receivables Deferred income taxes Inventory Prepaid expenses and other current Current assets Accounts payable Current portion of long-term debt Prepaid drilling contracts Accrued expenses—payroll and related employee costs Accrued expenses—insurance premiums and deductibles Accrued expenses—other Current liabilities Working capital Colombian operations. payroll payments. Senior secured credit facility Subordinated notes payable Other Less current portion Other Contractual Obligations Contractual Obligations Long-term debt Interest on long term debt Purchase commitments Operating leases Restricted cash obligation Other Total through maturity. equipment. The total estimated cost for the Revolving Credit Facility. At unsecured basis by our existing domestic subsidiaries, except for Pioneer Services Holdings, LLC and Go-Coil, LLC, and by certain of our future domestic subsidiaries. The subsidiaries that generally operate our non-U.S. business concentrated in Colombia do not guarantee our Senior Notes. The non-guarantor subsidiaries do not have any payment obligations under the Senior Notes, the guarantees or the Indenture. In the event of a bankruptcy, liquidation or reorganization of any non-guarantor subsidiary, such non-guarantor subsidiary will pay the holders of its debt and other liabilities, including its trade creditors, before it will be able to distribute any of its assets to us. In the future, any non-U.S. subsidiaries, immaterial subsidiaries and subsidiaries that we designate as unrestricted subsidiaries under the Indenture will not guarantee the Senior Notes. —Our Drilling Services Division earns revenues by drilling oil and gas wells for our customers under daywork, turnkey or footage contracts, which usually provide for the drilling of a single well. We recognize revenues on daywork contracts for the days completed based on the dayrate each contract specifies. We recognize revenues from our turnkey and footage contracts on the percentage-of-completion method based on our estimate of the number of days to complete each contract. Individual contracts are usually completed in less than 60 days. The risks to us under a turnkey contract and, to a lesser extent, under footage contracts, are substantially greater than on a contract drilled on a daywork basis. Under a turnkey contract, we assume most of the risks associated with drilling operations that are generally assumed by the operator in a daywork contract, including the risks of blowout, loss of hole, stuck drill pipe, machinery breakdowns and abnormal drilling conditions, as well as risks associated with subcontractors’ services, supplies, cost escalations and personnel operations. We evaluate for potential impairment of long-lived assets and intangible assets subject to amortization when indicators of impairment are specifically, significant adverse changes in industry trends include significant declines in revenue rates, utilization rates, oil and natural gas market prices and industry rig counts for drilling rigs and Goodwill results from business acquisitions and represents the excess of acquisition costs over the fair value of the net assets acquired. flows that We provide deferred taxes for the basis differences in our property and equipment between financial reporting and tax reporting purposes and other costs such as compensation, tax depreciation exceeds our financial reporting depreciation, resulting in our providing deferred taxes on this depreciation difference. After 5 years, financial reporting depreciation exceeds tax depreciation, and the deferred tax liability begins to reverse. We consider the recognition of revenues and costs on turnkey and footage contracts to be critical accounting estimates. On these types of contracts, we are required to estimate the number of days needed for us to complete the contract and our total cost to complete the contract. Our actual costs could substantially exceed our estimated costs if we encounter problems such as lost circulation, stuck drill pipe or an underground blowout on contracts still in progress subsequent to the release of the financial statements. We receive payment under turnkey and footage contracts when we deliver to our customer a well completed to the depth specified in the contract, unless the customer authorizes us to drill to a more shallow depth. Since 1995, we have completed all our turnkey or footage contracts. Although our initial cost estimates for turnkey and footage contracts do not include cost estimates for risks such as stuck drill pipe or loss of circulation, we believe that our experienced management team, our knowledge of geologic formations in our areas of operations, the condition of our drilling equipment and our experienced crews have previously enabled us to make reasonable cost estimates and complete contracts according to our drilling plan. While we do bear the risk of loss for cost overruns and other events that are not specifically provided for in our initial cost estimates, our pricing of turnkey and footage contracts takes such risks into consideration. We are more likely to encounter losses on turnkey and footage contracts in periods in which revenue rates are lower for all types of contracts. During periods of reduced demand for drilling rigs, our overall profitability on turnkey and footage contracts has historically exceeded our profitability on daywork contracts. When we encounter, during the course of our drilling operations, conditions unforeseen in the preparation of our original cost estimate, we increase our cost estimate to complete the contract. If we anticipate a loss on a contract in progress at the end of a reporting period due to a change in our cost estimate, we accrue the entire amount of the estimated loss, including all costs that are included in our revised estimated cost to complete that contract, in our consolidated statement of operations for that reporting period. during 2011. for our Production Services Division. 2011 a drilling rig, 2010 future periods. actual achievement levels at the end of the pre-determined performance periods. Drilling Services Division: Revenues Operating costs Drilling Services Division margin Average number of drilling rigs Utilization rate Revenue days Average revenues per day Average operating costs per day Drilling Services Division margin per day Production Services Division: Revenues Operating costs Production Services Division margin Combined: Revenues Operating costs Combined margin EBITDA 2010 Reconciliation of combined margin and Combined margin Selling, general and administrative Bad debt expense Other income (expense) EBITDA Depreciation and amortization Impairment of goodwill Impairment of intangible assets Interest income (expense), net Income tax expense Net (loss) earnings contracts we are able to obtain. As demand for drilling rigs decreases, daywork rates move down and we may switch to performing more turnkey drilling contracts to maintain higher utilization rates and improve our Drilling Services Division’s margins. Turnkey drilling contracts also result in higher average revenues per day and higher average operating costs per day when compared to daywork drilling contracts. We completed 11 turnkey drilling contracts during 2010, as compared to 14 turnkey drilling contracts completed during 2009. The shift to fewer turnkey drilling contracts is due to the increase in the demand for drilling services in 2010. The following table provides percentages of our drilling revenues by drilling contract type for the years ended December 31, 2010 and 2009: 2009. costs. new wireline units. Contract drilling revenues: Daywork contracts Turnkey contracts Footage contracts Total contract drilling revenues Contract drilling costs: Daywork contracts Turnkey contracts Footage contracts Total contract drilling costs Drilling margin: Daywork contracts Turnkey contracts Footage contracts Total drilling margin Revenue days by type of contract: Daywork contracts Turnkey contracts Footage contracts Total revenue days EBITDA Contract drilling revenue per revenue day Contract drilling costs per revenue day Drilling margin per revenue day Rig utilization rates Average number of rigs during the period Reconciliation of drilling margin and EBITDA to net earnings: Drilling margin General and administrative expense Bad debt expense Other income EBITDA Income tax expense Interest income (expense), net Depreciation and amortization Net earnings January 2011. in In risk. 2011 21, 2012 Shareholders Go-Coil. 21, 2012 ASSETS Current assets: Cash and cash equivalents Receivables, net of allowance for doubtful accounts Unbilled receivables Deferred income taxes Inventory Prepaid expenses and other current assets Total current assets Property and equipment, at cost Less accumulated depreciation and amortization Net property and equipment Deferred income taxes Intangible assets, net of amortization Other long-term assets Total assets LIABILITIES AND SHAREHOLDERS’ EQUITY Current liabilities: Accounts payable Current portion of long-term debt Prepaid drilling contracts Accrued expenses: Payroll and related employee costs Insurance premiums and deductibles Other Total current liabilities Long-term debt, less current portion Other long-term liabilities Deferred income taxes Total liabilities Commitments and contingencies Shareholders’ equity: Preferred stock, 10,000,000 shares authorized; none issued and outstanding Common stock $.10 par value; 100,000,000 shares authorized; 49,997,578 shares and 49,650,978 shares issued and outstanding at December 31, 2008 and December 31, 2007, respectively Additional paid-in capital Accumulated earnings Accumulated other comprehensive loss Total shareholders’ equity Total liabilities and shareholders’ equity Revenues: Drilling services Production services Total revenue Costs and expenses: Drilling services Production services Depreciation and amortization Selling, general and administrative Bad debt expense Impairment of goodwill Impairment of intangible assets Total operating costs and expenses (Loss) income from operations Other (expense) income: Interest expense Interest income Other Total other (expense) income (Loss) income before income taxes Income tax expense Net (loss) earnings (Loss) earnings per common share—Basic (Loss) earnings per common share—Diluted Weighted average number of shares outstanding—Basic Weighted average number of shares outstanding—Diluted Balance as of March 31, 2006 Comprehensive income: Net earnings Total comprehensive income Issuance of common stock for: Exercise of options and related income tax benefits of $24 Stock-based compensation expense Balance as of March 31, 2007 Comprehensive income: Net earnings Total comprehensive income Issuance of common stock for: Exercise of options and related income tax benefits of $54 Stock-based compensation expense Balance as of December 31, 2007 Comprehensive loss: Net loss Unrealized loss on securities Total comprehensive loss Exercise of options and related income tax benefits of $244 Issuance of restricted stock Stock-based compensation expense Balance as of December 31, 2008 Cash flows from operating activities: Net (loss) earnings Adjustments to reconcile net (loss) earnings to net cash provided by operating activities: Depreciation and amortization Allowance for doubtful accounts (Gain) loss on dispositions of property and equipment Stock-based compensation expense Impairment of goodwill and intangibles assets Deferred income taxes Change in other assets Change in non-current liabilities Changes in current assets and liabilities: Receivables Inventory Prepaid expenses & other current assets Accounts payable Income tax payable Prepaid drilling contracts Accrued expenses Net cash provided by operating activities Cash flows from investing activities: Acquisition of production services business of WEDGE Acquisition of production services business of Competition Acquisition of other production services businesses Purchases of property and equipment Purchase of auction rate securities, net Proceeds from sale of property and equipment Proceeds from insurance recoveries Net cash used in investing activities Cash flows from financing activities: Payments of debt Proceeds from issuance of debt Debt issuance costs Proceeds from exercise of options Excess tax benefit of stock option exercises Net cash provided by financing activities Net decrease in cash and cash equivalents Beginning cash and cash equivalents Ending cash and cash equivalents Supplementary disclosure: Interest paid Income tax paid Drilling Division Locations South Texas East Texas West Texas Utah Colombia performed. We plan to add another The accompanying consolidated financial statements have been prepared in accordance with accounting principles generally accepted in the United States of America. In preparing the accompanying consolidated financial statements, we make various estimates and assumptions that affect the amounts of assets and liabilities we report as of the dates of the balance sheets and income and expenses we report for the periods shown in the income statements and statements of cash flows. Our actual results could differ significantly from those estimates. Material estimates that are particularly susceptible to significant changes in the near term relate to our recognition of revenues and costs for turnkey contracts, our estimate of the allowance for doubtful accounts, our estimate of the liability relating to the self-insurance portion of our health and workers’ compensation insurance, our estimate of asset impairments, our estimate of deferred taxes, our estimate of compensation related accruals and our determination of depreciation and amortization expense. 2012. complete the contract. Contract costs include labor, materials, supplies, repairs and maintenance, operating overhead allocations and allocations of depreciation and amortization expense. operating costs. recognized. As of monthly basis. Balances more than Balance at beginning of year Increase in allowance charged to expense Accounts charged against the allowance, net of recoveries Balance at end of year consolidated balance sheet. 2010 Depreciation and amortization expense using prior useful lives Impact of change in estimated useful lives Depreciation and amortization expense, as reported Diluted (loss) earnings per common share using prior useful lives Impact of change in estimated useful lives Diluted (loss) earnings per common share, as reported Goodwill balance at January 1, 2008 Goodwill relating to acquisitions Impairment Goodwill balance at December 31, 2008 2011 Cost: Customer Relationships Non-compete Trade marks Accumulated amortization: Customer Relationships Non-compete Trade marks Impairment: Customer Relationships capital using the average cost method. Net (loss) income Other comprehensive loss—unrealized loss on securities Comprehensive (loss) income thousands): substance, multiple awards. 3, Cash acquired Other current assets Property and equipment Intangibles and other assets Goodwill Total assets acquired Current liabilities Long-term debt Other long term liabilities Total liabilities assumed Net assets acquired Total revenues Net (loss) earnings (Loss) earnings per common share Basic Diluted Senior secured credit facility Subordinated notes payable Other Less current portion of representations and warranties, covenant defaults, cross-defaults to certain other material indebtedness in excess of specified amounts, certain events of bankruptcy and insolvency, judgment defaults in excess of specified amounts, failure of any guaranty or security document supporting the credit agreement and change of control. notes issued in the exchange offer. Years Ended December 31, 2009 2010 2011 2012 2013 Thereafter Domestic Foreign (Loss) income before income tax Current tax: Federal State Foreign Deferred taxes: Federal State Foreign Income tax expense Expected tax (benefit) expense State income taxes Incentive stock options Goodwill impairment Tax benefits in foreign jurisdictions Domestic production activities deduction Tax-exempt interest income Non deductible items for tax purposes Uncertain tax positions Other, net Results of operations Stockholders’ equity Deferred tax assets: Auction rate preferred securities Intangibles Employee benefits and insurance claims accruals Accounts receivable reserve Employee stock based compensation Accrued expenses not deductible for tax purposes Accrued revenue not income for book purposes Foreign net operating loss carryforward Valuation allowance Total deferred tax assets Deferred tax liabilities: Property and equipment Total deferred tax liabilities Net deferred tax liabilities 2011 losses can be carried forward indefinitely. 2011 Basic Net (loss) earnings Weighted average shares (Loss) earnings per share Diluted Net (loss) earnings Effect of dilutive securities Net (loss) earnings available to common shareholders after assumed conversion Weighted average shares: Outstanding Options (Loss) earnings per share antidilutive. We have stock based award plans that are administered by the Compensation Committee of our Board of Directors, which selects persons eligible to receive awards and determines the number of stock options, restricted stock, or restricted stock units subject to each award and the terms, conditions and other provisions of the awards. awards are exercised. Expected volatility Weighted-average risk-free interest rates Weighted-average expected life in years Weighted-average grant-date fair value Outstanding stock options as of March 31, 2007 Granted Exercised Canceled Forfeited Outstanding stock options as of December 31, 2007 Granted Exercised Canceled Forfeited Outstanding stock options as of December 31, 2008 Stock options exercisable as of December 31, 2008 2011 Nonvested stock options as of March 31, 2007 Granted Vested Forfeited Nonvested stock options as of December 31, 2007 Granted Vested Forfeited Nonvested stock options as of December 31, 2008 2009 Nonvested restricted stock as of December 31, 2007 Granted Vested Forfeited Nonvested restricted stock as of December 31, 2008 2011 Division— Drilling Division Locations South Texas East Texas West Texas Utah Colombia Identifiable assets Revenues Operating costs Segment margin Depreciation and amortization Capital expenditures Segment margin Depreciation and amortization Selling, general and administrative Bad debt (expense) recovery Impairment of goodwill Impairment of intangible assets Loss from operations Identifiable assets Revenues Year Ended December 31, 2008 (1) (2) Revenues Income (loss) from operations Income tax (expense) benefit Net earnings (loss) Earnings (loss) per share: Basic Diluted (3) Nine Months Ended December 31, 2007 Revenues Income from operations Income tax expense Net earnings Earnings per share: Basic Diluted (3) forms and (2) accumulated and communicated to our management, including our Chief Executive Officer and Chief Financial Officer, as appropriate to allow timely decisions regarding required disclosure. 53. 51. Schedules Description Restated Articles of Incorporation of Pioneer Drilling Amended and Restated Bylaws of Pioneer Drilling Company (Form 8-K dated December 15, 2008 (File No. 1-8182, Exhibit 3.1)). Form of Certificate representing Common Stock of Pioneer Drilling Company (Form S-8 filed November 18, 2003 (Reg. No. 333-110569, Exhibit 4.3)). Pioneer Drilling Company 2007 Incentive Plan Form of Long-Term Incentive Cash Award Agreement (Form 10-Q dated August 5, 2010 (File No. 1-8182, Exhibit 10.2)). Pioneer Drilling Company Amended and Restated Key Executive Severance Plan dated December 10, 2007 (Form 10-Q for the quarter ended March 31, 2008 (File No. 1-8182, Exhibit 10.4)). Pioneer Drilling Company’s 1995 Stock Plan and form of Stock Option Agreement (Form 10-K for the year ended March 31, 2001 (File No. 1-8182, Exhibit 10.5)). Pioneer Drilling Company’s 1999 Stock Plan and form of Stock Option Agreement (Form 10-K for the year ended March 31, 2001 (File No. 1-8182, Exhibit 10.7)). Pioneer Drilling Company 2003 Stock Plan (Form S-8 filed November 18, 2003 (File No. 333-110569, Exhibit 4.4)). Pioneer Drilling Company Amended and Restated 2007 Incentive Plan (Form 10-Q for the quarter ended September 30, 2011 (File No. 1-8182, Exhibit 10.1)). Pioneer Drilling Company Form of Indemnification Agreement (Form 8-K dated August 8, 2007 (File No. 1-8182, Exhibit 10.1)). Pioneer Drilling Company Employee Relocation Policy Executive Employment Letter, effective March 1, 2008, from Pioneer Drilling Company to Joseph B. Eustace (Form 8-K dated March 5, 2008 (File No. 1-8182, Exhibit 10.1)). Confidentiality and Non-Competition Agreement, dated February 29, 2008, by and between Pioneer Drilling Company, Pioneer Production Services, Inc. and Joe Eustace (Form 8-K dated March 5, 2008 (File No. 1-8182, Exhibit 10.2)). Employment Letter, Subsidiaries of Pioneer Drilling Company. Certification by Wm. Stacy Locke, President and Chief Executive Officer, pursuant to Rule 13a-14(a) or Rule 15d-14(a) under the Securities Exchange Act of 1934. Certification by Lorne E. Phillips, Executive Vice President and Chief Financial Officer, pursuant to Rule 13a-14(a) or Rule 15d-14(a) under the Securities Exchange Act of 1934. Certification by Wm. Stacy Locke, President and Chief Executive Officer, pursuant to Section 906 of the Sarbanes-Oxley Act of 2002 (Subsections (a) and (b) of Section 1350, Chapter 63 of Title 18, United States Code). Certification by Lorne E. Phillips, Executive Vice President and Chief Financial Officer, pursuant to Section 906 of the Sarbanes-Oxley Act of 2002 (Subsections (a) and (b) of Section 1350, Chapter 63 of Title 18, United States Code). Incorporated by reference to the filing indicated. Management contract or compensatory plan or arrangement. PIONEER DRILLING COMPANY Title Executive Vice President and Chief Financial Officer Director Director Director Description Restated Articles of Incorporation of Pioneer Drilling Amended and Restated Bylaws of Pioneer Drilling Company (Form 8-K dated December 15, 2008 (File No. 1-8182, Exhibit 3.1)). Form of Certificate representing Common Stock of Pioneer Drilling Company (Form S-8 filed November 18, 2003 (Reg. No. 333-110569, Exhibit 4.3)). Pioneer Drilling Company 2007 Incentive Plan Form of Long-Term Incentive Cash Award Agreement (Form 10-Q dated August 5, 2010 (File No. 1-8182, Exhibit 10.2)). Pioneer Drilling Company Amended and Restated Key Executive Severance Plan dated December 10, 2007 (Form 10-Q for the quarter ended March 31, 2008 (File No. 1-8182, Exhibit 10.4)). Pioneer Drilling Company’s 1995 Stock Plan and form of Stock Option Agreement (Form 10-K for the year ended March 31, 2001 (File No. 1-8182, Exhibit 10.5)). Pioneer Drilling Company’s 1999 Stock Plan and form of Stock Option Agreement (Form 10-K for the year ended March 31, 2001 (File No. 1-8182, Exhibit 10.7)). Pioneer Drilling Company 2003 Stock Plan (Form S-8 filed November 18, 2003 (File No. 333-110569, Exhibit 4.4)). Pioneer Drilling Company Amended and Restated 2007 Incentive Plan (Form 10-Q for the quarter ended September 30, 2011 (File No. 1-8182, Exhibit 10.1)). Pioneer Drilling Company Form of Indemnification Agreement (Form 8-K dated August 8, 2007 (File No. 1-8182, Exhibit 10.1)). Pioneer Drilling Company Employee Relocation Policy Executive Officers – Package A (Form 8-K dated August 8, 2007 (File No. 1-8182, Exhibit 10.3)). Employment Letter, effective March 1, 2008, from Pioneer Drilling Company to Joseph B. Eustace (Form 8-K dated March 5, 2008 (File No. 1-8182, Exhibit 10.1)). Confidentiality and Non-Competition Agreement, dated February 29, 2008, by and between Pioneer Drilling Company, Pioneer Production Services, Inc. and Joe Eustace (Form 8-K dated March 5, 2008 (File No. 1-8182, Exhibit 10.2)). Employment Letter, Subsidiaries of Pioneer Drilling Company. Certification by Wm. Stacy Locke, President and Chief Executive Officer, pursuant to Rule 13a-14(a) or Rule 15d-14(a) under the Securities Exchange Act of 1934. Certification by Lorne E. Phillips, Executive Vice President and Chief Financial Officer, pursuant to Rule 13a-14(a) or Rule 15d-14(a) under the Securities Exchange Act of 1934. Certification by Wm. Stacy Locke, President and Chief Executive Officer, pursuant to Section 906 of the Sarbanes-Oxley Act of 2002 (Subsections (a) and (b) of Section 1350, Chapter 63 of Title 18, United States Code). Certification by Lorne E. Phillips, Executive Vice President and Chief Financial Officer, pursuant to Section 906 of the Sarbanes-Oxley Act of 2002 (Subsections (a) and (b) of Section 1350, Chapter 63 of Title 18, United States Code). Incorporated by reference to the filing indicated. Management contract or compensatory plan or arrangement. Page Page Item 2. Item 3. 27Item 2.27Item 3.28Item 4.28 535586Item 9B. 86Item 9B.88 88888888 88 89thatcontained in this Annual Report on Form 10-K, contains, including those that express a belief, expectation or intention, as well as those that are not statements of historical fact, are forward-looking statements. ThoseSuch forward-looking statements appear in Item 1—“Business” and Item 3—“Legal Proceedings” in Part I of this report; in Item 5—“Market for Registrant’s Common Equity, Related Shareholder Matters and Issuer Purchases of Equity Securities,” Item 7—“Management’s Discussion and Analysis of Financial Condition and Results of Operations,” Item 7A—“Quantitative and Qualitative Disclosures About Market Risk” and in the Notes to Consolidated Financial Statements we have included in Item 8 of Part II of this report; and elsewhere in this report. These forward-looking statements speak only as of the date of this report. We disclaim any obligation to update these statements, and we caution you not to rely on them unduly. We have based these forward-looking statements on our current expectations and assumptions about future events. While our management considers these expectations and assumptions to be reasonable, they are inherently subject to significant business, economic, competitive, regulatory and other risks, contingencies and uncertainties, most of which are difficult to predict and many of which are beyond our control. These risks, contingencies and uncertainties relate to, among other matters, the following:risks associated with the current global crisislevels and itsvolatility of oil and gas prices;strength of thedemand for drilling services or production services in the geographic areas where we operate;levels and volatility of oil and gas prices;decisions about onshore exploration and development projects to be made by oil and gas companies;workoverwell service rigs, wireline units and wirelinecoiled tubing units within the industry;the continued availability of drilling rig, workover rig and wireline unit components;our future financial performance, including availability, terms and deployment of capital;the continued availability of qualified personnel; and These factors are not necessarily allthe important factors that could affect us. Unpredictable or unknown factors we have not discussed in this report could also have material adverse effects on actual results of matters that are the subject of our forward-looking statements. We do not intend to update our description of important factors each time a potential important factor arises, except as required by applicable securities laws and regulations. We advise our security holders that they should (1) be aware that importantunpredictable or unknown factors not referred to above could affect the accuracy of our forward-looking statements and (2) use caution and common sense when considering our forward-looking statements. Also, please read the risk factors set forth in Item 1A—“Risk Factors.”Item 1. Business In December 2007, our Board of Directors approved a change in our fiscal year end from March 31st to December 31st. The fiscal year end change was effective December 31, 2007 and resulted in a nine month reporting period from April 1, 2007 to December 31, 2007. Fiscal years beginning with the year ended December 31, 2008, will represent twelve month reporting periods. We implemented the fiscal year end change to align our United States reporting period with the required Colombian statutory reporting period as well as the reporting periods of peer companies in the industry.GeneralOur companyPioneer Drilling Company was incorporated under the laws of the State of Texas in 1979 as the successor to a business that had been operating since 1968. Over the years, our business has grown through acquisitions and through organic growth. Since September 1999, we have significantly expanded our drilling rig fleet by adding 42 rigs through acquisitions and by adding 27 rigs through the construction of rigs from new and used components. OnIn March 1, 2008, we significantly expanded our service offerings when we acquiredwith the acquisition of two production services businesses, of WEDGE Group Incorporated (“WEDGE”) for $314.7 million and Prairie Investors d/b/a Competition Wireline (“Competition”) for $30.0 million which provide well services, wireline services and fishing and rental services. We fundedhave continued to invest in the WEDGE acquisition primarily with $311.5 milliongrowth of borrowings underall our $400 million senior secured revolving credit facility. As of February 23, 2009, the senior secured revolving credit facility has an outstanding balance of $257.5 million, all of which maturesservice offerings through acquisitions and organic growth. On December 31, 2011, we acquired Go-Coil, LLC ("Go-Coil"), a coiled tubing service company based in February 2013.Maurice, Louisiana, to complement our existing production services offerings. Drilling services and production services are fundamental to establishing and maintaining the flow of oil and natural gas throughout the productive life atof a well site and enable us to meet multiple needs of our customers.11,10, Segment Information, of the Notes to Consolidated Financial Statements, included in Part II Item 8,Financial Statements and Supplementary Data,of this Annual Report on Form 10-K.•Drilling Services Division—Our Drilling Services Division provides contract land drilling services with its fleet of 70 drilling rigs in the following locations: Rig Count 1715 22518 North TexasDakota 9 64North Dakota6Oklahoma 5 5823, 2009, 3610, 2012, 55 drilling rigs are operating 29under drilling contracts, 44 of which are under term contracts. We have nine drilling rigs that are idle, and five drilling rigs locatedthree of which are under contract to begin working in our Oklahoma drilling division have been placed in storage or “cold stacked” due to lowdemand for drilling rigs in this region.the first quarter of 2012. We are actively marketing all our idle drilling rigs and we are earning revenue on two of these rigs through early termination fees on their drilling contracts with terms expiring in March 2009 and May 2009. We are constructing a 1500 horsepower drilling rig that we expect to be completed and available for operation in the in our North Dakota drilling division under a contract with a three year term beginning March 2009. rigs.•Production Services Division—Our Production Services Division provides a broad range of well services to oil and gas drilling and producing companies, including workover services, wireline services, and fishing and rental services. Our production services operations are managed regionally and are concentrated in the major United States onshore oil and gas producing regions in the Gulf Coast, Mid-Continent, and Rocky Mountain states. We provide our services to a diverse group of oil and gas companies. The primary productions services we offer are the following: of 74 workover rigs in seven division locations to provide these required services, including maintenance of existing wells, workover of existing wells, completion of newly-drilled wells, and plugging and abandonment of wells at the end of their useful lives. We haveacquired 15 well service rigs during 2011 and two additional well service rigs in early 2012, resulting in a premium workovertotal of 91 well service rigs in 12 locations as of February 10, 2012. Our well service rig fleet consistingconsists of sixty-nineeighty-one 550 horseposewerhorsepower rigs, fournine 600 horsepower rigs, and one 400 horsepower rig. The average age of this fleet is 1.4 years as of December 31, 2008. As of February 23, 2009, 62 workoverAll our well service rigs are currently operating and 12 workoveror are being actively marketed, with January2012 utilization of approximately 86%. We plan to add another 13 well service rigs are idle with no crews assigned.59 truck mounted wireline units in 15 division locations to provide these important logging and perforating services. We provide both open and cased-hole logging services, including the latest pulsed-neutron technology. In addition, we provide services which allow oil and gas exploration and production companies to evaluate the integrity of wellbore casing, recover pipe, or install bridge plugs. Our truck mountedWe acquired 21 wireline units have an average ageduring 2011 and four additional wireline units in early 2012, resulting in a total of 3.7 years109 wireline units in 24 locations as of December 31, 2008.February 10, 2012. We plan to add another 18 wireline units to our fleet during 2012.are often required tofrequently rent unique equipment such as power swivels, foam aircirculating units, blow-out preventers, air drilling equipment, pumps, tanks, pipe, tubing, and fishing tools. We have approximately $15 million worthprovide rental services out offour locations in Texas and Oklahoma. As of December 31, 2011 our fishing and rental tools that we provide outhave a gross book value of four locations in Texas and Oklahoma.$15.1 million.In recent months, there has been substantial volatility and a decline in oil and natural gas prices due to the deteriorating global economic environment. In addition, there has been substantial uncertainty in the capital markets and access to financing is uncertain. These conditions have adversely affected our business environment.Our customers have curtailed their drilling programs and reduced their production activities, which has resulted in a decrease in demand for drilling and production services and a reduction in day rates and utilization. In addition, certain of our customers could experience an inability to pay suppliers in the event they are unable to access the capital markets to fund their business operations. For three years before the end ofOilFrom late 2008 and into late 2009, there was substantial volatility and a decline in oil and natural gas prices declined significantly atdue to the end of 2008downturn in the global economic environment. In response, our customers curtailed their drilling programs and reduced their production activities, particularly in recent monthsnatural gas producing regions, which resulted in a deteriorating global economic environment,decrease in demand and revenue rates for certain of our drilling rigs and production services equipment. Additionally, there was uncertainty in the capital markets and access to financing was limited. These conditions adversely affected our business environment.have announced cuts inmodestly increased their exploration budgetsand production spending for 2009. We expect these reductions in oil2010 and gas exploration budgets to result in a reduction in ourindustry rig utilization and revenue rates improved, particularly in 2009. In addition,oil-producing regions and in certain shale regions. Increased natural gas production in the U.S. shale regions continues to depress natural gas prices, but oil prices continued to increase during 2011, resulting in continued increases in exploration and production spending during 2011, as compared to 2010. As a result, we may experience a shiftexperienced continued increases in industry rig utilization and revenue rates during 2011, as compared to more turnkey2010. We expect continued modest increases in exploration and footage drilling contracts from daywork drilling contracts. production spending for 2012, which we expect will result in modest increases in industry equipment utilization and revenue rates in 2012, as compared to 2011. However, if oil prices remain steady but natural gas prices further decline to historically low levels for the remainder of 2012, then industry equipment utilization and revenue rates could decrease.1A—“Risk1A – “Risk Factors” in Part I of this Annual Report on Form 10-K.6, 200910, 2012, the spot price for West Texas Intermediate crude oil was $40.17,$98.67, the spot price for Henry Hub natural gas was $4.67$2.51 and the Baker Hughes U.S. land rig count was 1,330,1,932, a 21% decrease14%increase from 1,6771,696 on February 8, 2008.4, 2011. The average weekly spot prices of West Texas Intermediate crude oil and Henry Hub natural gas, the average weekly domestic land rig count per the Baker Hughes land rig count, and the average monthly domestic workoverwell service rig count for the year ended December 31, 2008, the nine months ended December 31, 2007 and each of the previouslast five years ended March 31 were: Year Ended

December 31,

2008 Nine Months

Ended

December 31,

2007 Years Ended March 31, 2007 2006 2005 2004 $ 99.86 $ 77.42 $ 64.96 $ 59.94 $ 45.04 $ 31.47 $ 8.81 $ 6.82 $ 6.53 $ 9.10 $ 5.99 $ 5.27 1,792 1,684 1,589 1,329 1,110 964 2,514 2,394 2,376 2,271 2,087 1,996 Increased expenditures for exploration and production activities generally lead to increased demand for our drilling services and production services. Over the past several years, rising Year ended December 31, 2011 2010 2009 2008 2007 Oil (West Texas Intermediate) $ 94.94 $ 79.39 $ 61.81 $ 99.86 $ 72.71 Natural Gas (Henry Hub) $ 3.95 $ 4.35 $ 3.85 $ 8.81 $ 6.90 U.S. Land Rig Count 1,829 1,493 1,035 1,792 1,670 U.S. Well Service Rig Count 2,075 1,854 1,735 2,514 2,388 and thefrom 2004 to late 2008 resulted in corresponding increase in onshore oil and natural gas exploration and production spending led to expanded drilling and well service activity as reflected by the increases in the U.S. land rig counts and U.S. workoverwell service rig counts, overwhile declines in prices from late 2008 to late 2009 led to decreases in the previous five years.an operating expenditure. Activities designed to add hydrocarbon reserves are classified as capital expenditures, while those associated with maintaining or accelerating production are categorized as operating expenditures.even a short periodlong periods of time, capital expenditure projects are routinely deferred until prices return to an acceptable level.Our business is influenced substantially by both operating and capital expenditures by exploration and production companies. operatesoperate in active drilling markets in the United States.States and Colombia. Our long-term strategy is to maintain and leverage our position as a leading land drilling and production services company, continue to expand our relationships with existing customers, expand our customer base in the areas in which we currently operate and evolve into a premier multi-service,further enhance our geographic diversification through selective international oilfield services provider.expansion. The key elements of this long-term strategy include:•Expand our Operations into International Markets—In early 2007, we announced our intention to expand internationally and began negotiating drilling contracts Colombia. We currently have five drilling rigs located in Colombia.•Pursue Opportunities into Other Oilfield Services—We strive to mitigate the cyclical risk in oilfield services by complementing our drilling services with certain production services. Effective March 1, 2008, we acquired the production services businesses of WEDGE and Competition which provide well services, wireline services and fishing and rental services. We now have a fleet of 74 workover rigs, 59 wireline units and approximately $15 million of fishing and rental tools equipment that operate out of facilities in Texas, Kansas, North Dakota, Colorado, Utah, Montana, Louisiana and Oklahoma. We expanded our Production Services Division with the acquisitions of Paltec, Inc. (Paltec) in August 2008 and Pettus Well Service (Pettus) in October 2008, both operating in Texas.•Continue Growth with Select Capital Deployment—We intend to continue growing our business by making selective acquisitions, continuing new-build programs and / or upgrading our existing assets. Our capital investment decisions are determined by strategic fit and an analysis of the projected return on capital employed on each of those alternatives. We are currently constructing one 1500 horsepower drilling rig that we expect to be completed and available for operation in our North Dakota drilling division under a contract with a three year term beginning March 2009. In addition, we will take delivery of two new wireline units in 2009.With the recent declineMost Attractive Domestic Markets. Shale plays and non-shale oil or liquid rich environments are increasingly important to domestic hydrocarbon production and not all drilling rigs are capable of successfully drilling in these unconventional opportunities. We are currently operating in unconventional areas in the Bakken, Marcellus and Eagle Ford shales and Permian and Uintah Basins, and we intend to add ten new-build drilling rigs that will be operating in the shale plays in 2012. We also intend to continue adding capacity to our wireline, coiled tubing, and well servicing product offerings, which are well positioned to capitalize on increased shale development.natural gas prices dueproduction. We are continuously evaluating additional international expansion opportunities and intend to target international markets that share the deteriorating global economic environmentfavorable characteristics of our Colombian operations and which would allow us to deploy sufficient assets in order to realize economies of scale.expected reductions ininvestment must be consistent with our rig utilization and revenue rates in 2009, our near-term strategy is to maintain a strong balance sheet and ample liquidity. Management has initiated certain cost reduction measures including workforce and wage rate reductionsstrategic objectives. We currently have term contracts for ten new-build AC drilling rigs that are fit for purpose for domestic shale plays, five of which we estimate will reduce operating expenses during the downturnbegin working in the industry cycle. Budgeted capital expenditures for 2009 represent routine capital expenditures necessaryfirst half of 2012, with the remaining five to keepbegin operating by the end of 2012. On December 31, 2011, we acquired the coiled tubing service company, Go-Coil, to complement our equipmentexisting production services offerings. We have also significantly increased our other production services fleets with the addition of 21 wireline units and 15 well service rigs in safe2011. We expect to add another 18 wireline units, 13 well service rigs and efficient working order and limited discretionary capital expendituresthree coiled tubing units by the end of new equipment or upgrades of existing equipment. In addition, our marketing initiatives are focused on identifying regional opportunities and evaluating more turnkey drilling contract opportunities. We believe this near-term strategy will position us to take advantage of business opportunities and continue our long-term growth strategy.2012.Thethe swivel assembly sustains the weight of the drill stem, permits its rotation and affords a rotating pressure seal and passageway for circulating drilling fluid into the top of the drill string. The swivel also has a large handle that fits inside the hook assembly at the bottom of the traveling block. Drilling fluid enters the drill stem through a hose, called the rotary hose, attached to the side of the swivel. The kelly is a triangular, square or hexagonal piece of pipe, usually 40 feet long, that transmits torque from the rotary table to the drill stem and permits its vertical movement as it is lowered into the hole. The bottom end of the kelly fits inside a corresponding triangular, square or hexagonal opening in a device called the kelly bushing. The kelly bushing, in turn, fits into a part of the rotary table called the master bushing. As the master bushing rotates, the kelly bushing also rotates, turning the kelly, which rotates the drill pipe and thus the drill bit. Drilling fluid is pumped through the kelly on its way to the bottom. The rotary table, equipped with its master bushing and kelly bushing, supplies the necessary torque to turn the drill stem. The drill pipe and drill collars are both steel tubes through which drilling fluid can be pumped. Drill pipe, sometimes called drill string, comes in 30-foot sections, or joints, with threaded sections on each end. Drill collars are heavier than drill pipe and both are also threaded on the ends. Collars are used on the bottom of the drill stem to apply weight to the drilling bit. At the end of the drill stem is the bit, which chews up the formation rock and dislodges it so that drilling fluid can circulate the fragmented material back up to the surface where the circulating system filters it out of the fluid.1036 rigs (with three additional spare top drives available for installation), iron roughnecks in 3749 rigs walking(with six additional spare iron roughnecks available for installation), walking/skidding systems in one rig (with three other systems available for installation)16 rigs and automatic catwalks in twoeight rigs.Our drilling rig fleet consists of 70 rigs. Not included in our 70 drilling rig count is a 1500 horsepower rig that we expect to be completed and available for operation in our North Dakota drilling division under a contract with a three year term beginning March 2009. We own all the rigs in our fleet. With the recent decline in demand for drilling services, as of February 23, 2009, we have 36 drilling rigs operating, 29 drilling rigs are idle and five drilling rigs located in our Oklahoma division have been placed in storage or “cold stacked” due to low demand for drilling rigs in this region. We are actively marketing all our idle drilling rigs and we are earning revenues on two of these rigs through early termination fees on these drilling contracts with terms expiring in March 2009 and May 2009. Year

Ended

December 31, Nine

Months

Ended

December 31, Years ended March 31, 2008 2007 2007 2006 2005 2004 67.4 66.7 60.8 52.3 40.1 27.3 89 % 89 % 95 % 95 % 96 % 88 % Year ended December 31, 2011 2010 2009 2008 2007 Average number of operating rigs for the period 69.3 71.0 70.7 67.4 66.1 Average utilization rate 73 % 59 % 41 % 89 % 89 % 6, 2009,10, 2012, we ownedown a fleet of 8054 trucks and related transportation equipment that we use to transport our drilling rigs to and from drilling sites. By owning our own trucks, we reduce the overall cost of rig moves and reduce downtime between rig moves.and footage contracts that expose us to greater risk of loss without commensurate increases inbut which offer higher potential contract profitability.We obtain our contracts for drilling oil and gas wells either through competitive bidding or through direct negotiations with customers. Our drilling contracts generally provide for compensation on either a daywork, turnkey or footage basis. The contract terms we offer generally depend on the complexity and risk of operations, the on-site drilling conditions, the type of equipment used and the anticipated duration of the work to be performed. Generally, our contracts provide for the drilling of a single well and typically permit the customer to terminate on short notice. However, we have entered into more longer-term drilling contracts during periods of high rig demand. In addition, we generally construct new drilling rigs once we have entered into longer-term drilling contracts for such rigs. As of February 6, 2009, we had 27 contracts with terms of six months to three years in duration, of which 18 will expire by August 6, 2009, six have a remaining term of six to 12 months, one has a remaining term of 12 to 18 months and two have a remaining term in excess of 18 months. Year

Ended

December 31,

2008 Nine

Months

Ended

December 31,

2007 Year

Ended

March 31,

2007 828 606 742 10 5 2 71 66 60 909 677 804 Year ended December 31, Types of Contracts 2011 2010 2009 Daywork 655 453 323 Turnkey 17 11 14 Footage — — 1 Total number of wells 672 464 338 We provide rig-basedOur well services rig fleet provides a range of well services, including maintenance of existing wells, workover of existing wells, completion of newly-drilled wells, and plugging and abandonment of wells at the end of their useful lives.workoverwell service rigs are also used to convert former producing wells to injection wells through which water or carbon dioxide is then pumped into the formation for enhanced oil recovery operations. Workovers also include major subsurface repairs such as repair or replacement of well casing, recovery or replacement of tubing and removal of foreign objects from the well bore. These extensive workover operations are normally performed by a workoverwell service rig with additional specialized auxiliary equipment, which may include rotary drilling equipment, mud pumps, mud tanks and fishing tools, depending upon the particular type of workover operation. All of our well servicingservice rigs are designed to perform complex workover operations. A workover may require a few days to several weeks and generally requires additional auxiliary equipment. The demand for workover services is sensitive to oil and gas producers’ intermediate and long-term expectations for oil and gas prices.servicingservice rigs to minimize the use of higher cost drilling rigs in the completion process. The completion process typically requires a few days to several weeks, depending on the nature and type of the completion, and generally requires additional auxiliary equipment. Accordingly, completion services require less well-to-well mobilization of equipment and generally provide higher operating margins than regular maintenance work. The demand for completion services is directly related to drilling activity levels, which are sensitive to changes in oil and gas prices.servicingservice rigs are also used in the process of permanently closing oil and gas wells no longer capable of producing in economic quantities. Many well operators bid this work on a “turnkey” basis, requiring the service company to perform the entire job, including the sale or disposal of equipment salvaged from the well as part of the compensation received, and complying with state regulatory requirements. Plugging and abandonment work can provide favorable operating margins and is less sensitive to oil and gas pricing than drilling and workover activity since well operators must plug a well in accordance with state regulations when it is no longer productive. We perform plugging and abandonment work throughout our core areas of operation in conjunction with equipment provided by other service companies.December 31, 2008,February 10, 2012, our fleet of well service rigs totaled 7491 rigs. These rigs are located mostly in Texas, serving the Gulf Coast and ArkLaTex regions, though we also have five rigs in Louisiana and four11 rigs in North Dakota. We estimate that approximately 20% of our rigs are located in predominantly oil regions while 80% of our rigs are located in predominantly natural gas regions. Our fleet is one ofamong the youngestnewest in the industry, consisting primarily of premium, 550 HPhorsepower rigs capable of working at depths of 20,000 feet.59109 wireline trucks.units, as of February 10, 2012. We provide these services in Texas, Kansas, Colorado, Utah, Montana, North Dakota, Louisiana, Oklahoma, Wyoming and North Dakota.Mississippi. Wireline services typically utilize a single truck equipped with a spool of wireline that is used to lower and raise a variety of specialized tools in and out of the wellbore. These tools can be used to measure pressures and temperatures as well as the condition of the casing and the cement that holds the casing in place. Other applications for wireline tools include placing equipment in or retrieving equipment from the wellbore, or perforating the casing and cutting off pipe that is stuck in the well so that the free section can be recovered. Electric wireline contains a conduit that allows signals to be transmitted to or from tools located in the well. Wireline trucks are often used in place of a well servicingservice rig when there is no requirement to remove tubulars from the well in order to make repairs. Wireline trucks, like well servicingservice rigs, are utilized throughout the life of a well.servicingservice rigs are equipped with a complement of tools to complete routine operations under normal conditions for most projects in the geographic area where they are employed. When downhole problems develop with drilling or servicing operations, or conditions require non-routine equipment, our customers will usually rely on a provider of rental and fishing tools to augment equipment that is provided with a typical drilling or well servicingservice rig package. The important rental tools that we offer include air drilling equipment, foam units, power swivels, and blowout preventers.wirelinecoiled tubing units are mobile, during periods of heavy snow, ice or rain, we may not be able to move our equipment between locations.Customers