UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORMFORM 10-K

x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE | |

| SECURITIES EXCHANGE ACT OF 1934 | ||

| For the fiscal year ended December 31, 2014 | ||

For the fiscal year ended December 31, 2011

OR

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE | |

| SECURITIES EXCHANGE ACT OF 1934 | ||

For the transition period fromto | ||

For the transition period from to

Commission File No.: 000-51826

MERCER INTERNATIONAL INC.

(Exact name of Registrant as specified in its charter)

| Washington | 47-0956945 | |

(State or other jurisdiction | (IRS Employer Identification No.) | |

| of incorporation or organization ) |

|

Suite 1120, 700 West Pender Street, Vancouver,

Suite 1120, 700 West Pender Street, Vancouver, British Columbia, Canada | V6C 1G8 (Zip Code) | |

| (Address of Principal Executive Office) |

British Columbia, Canada, V6C 1G8

Address of Office

Registrant’s telephone number including area code:(604) 684-1099

Securities registered pursuant to Section 12(b) of the Act:

Title of each class | Name of each exchange on which registered | |

| Common Stock, par value $1.00 per share | NASDAQ Global Select Market |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrantRegistrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. ¨ Yes x No

Indicate by check mark if the registrantRegistrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Securities Act. ¨ Yes x No

Indicate by check mark whether the registrantRegistrant (1) has filed all reports required to be filed by Section 13 or 15(d) of theSecurities Exchange Act of 1934during the preceding 12 months (or for such shorter period that the registrantRegistrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether registrantRegistrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrantRegistrant was required to submit and post such files). Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’sRegistrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrantRegistrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a non-accelerated filer.smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer¨ | Accelerated filerx | Smaller reporting company ¨ | ||||||

(Do not check if a smaller reporting company) |

Indicate by check mark whether the registrantRegistrant is a shell company (as defined in Rule 12b-2 of the Act). ¨ Yes x No

The aggregate market value of the registrant’sRegistrant’s voting and non-voting common equity held by non-affiliates of the registrantRegistrant as of June 30, 2011,2014, the last business day of the registrant’sRegistrant’s most recently completed second fiscal quarter, based on the closing price of the voting stock on the NASDAQ Global Select Market on such date, was approximately $461,949,697.$674,869,524.

As of February 17, 2012,12, 2015, the registrantRegistrant had 55,779,20464,414,322 shares of common stock, $1.00 par value per share, outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Certain information that will be contained in the definitive proxy statement for the Registrant’s annual meeting to be held in 20122015 is incorporated by reference into Part III of this Form 10-K.

| 5 |

ITEM 1. | ||||||

| 5 | |||||

| 5 | ||||||

| 7 | ||||||

| 8 | ||||||

2

EXCHANGE RATES

Our3

CHANGE IN REPORTING CURRENCY

Effective October 1, 2013, we changed our reporting currency from the Euro to the U.S. dollar, as management is of the opinion that a U.S. dollar reporting currency enhances communication and understanding with our shareholders, analysts and other stakeholders and improves comparability of our financial information with our competitors and peer group companies. Consolidated financial statements issued prior to October 1, 2013 were prepared using the Euro as the reporting currency; however, subsequent to October 1, 2013, both current and historical financial information have been translated to U.S. dollars in accordance with the method described in Note 1, “The Company and Summary of Significant Accounting Policies – Foreign Operations and Currency Translation”, of the consolidated financial statements included in this annual report are in Euros, as a significant majority of our business transactions are originally denominated in Euros. We translate non-Euro denominated assets and liabilities at the rate of exchange on the balance sheet date. Revenues and expenses are translated at the average rate of exchange prevailing during the period.Form 10-K.

The following table sets out exchange rates, based on the noon buying rates in New York City for cable transfers in foreign currencies as certified for customs purposes by the Federal Reserve Bank of New York, (thereferred to as the “Noon Buying Rate”), for the conversion of U.S. dollars to Euros and Canadian dollars to U.S. dollars in effect at the end of the following periods, the average exchange rates during these periods (based on daily Noon Buying Rates) and the range of high and low exchange rates for these periods:

| Years Ended December 31, | Year Ended December 31, | |||||||||||||||||||||||||||||

| 2011 | 2010 | 2009 | 2008 | 2007 | 2014 | 2013 | 2012 | 2011 | 2010 | |||||||||||||||||||||

| (€/$) | ($/€) | |||||||||||||||||||||||||||||

End of period | 0.7708 | 0.7536 | 0.6977 | 0.7184 | 0.6848 | 1.2101 | 1.3779 | 1.3186 | 1.2973 | 1.3269 | ||||||||||||||||||||

High for period | 0.6723 | 0.6879 | 0.6623 | 0.6246 | 0.6729 | 1.2101 | 1.2774 | 1.2062 | 1.2926 | 1.1959 | ||||||||||||||||||||

Low for period | 0.7736 | 0.8362 | 0.7970 | 0.8035 | 0.7750 | 1.3927 | 1.3816 | 1.3463 | 1.4875 | 1.4536 | ||||||||||||||||||||

Average for period | 0.7186 | 0.7541 | 0.7176 | 0.6826 | 0.7304 | 1.3297 | 1.3281 | 1.2859 | 1.3931 | 1.3261 | ||||||||||||||||||||

| (C$/$) | ($/C$) | |||||||||||||||||||||||||||||

End of period | 1.0168 | 1.0009 | 1.0461 | 1.2240 | 0.9881 | 0.8620 | 0.9401 | 1.0042 | 0.9835 | 0.9991 | ||||||||||||||||||||

High for period | 0.9448 | 0.9960 | 1.0289 | 0.9717 | 0.9168 | 0.8588 | 0.9348 | 0.9600 | 0.9430 | 0.9280 | ||||||||||||||||||||

Low for period | 1.0605 | 1.0776 | 1.2995 | 1.2971 | 1.1852 | 0.9423 | 1.0164 | 1.0299 | 1.0584 | 1.0040 | ||||||||||||||||||||

Average for period | 0.9887 | 1.0298 | 1.1412 | 1.0660 | 1.0740 | 0.9060 | 0.9712 | 1.0007 | 1.0121 | 0.9714 | ||||||||||||||||||||

On February 10, 2012, the date of9, 2015, the most recent weekly publication of the daily Noon Buying Rate before the filing of this annual report on Form 10-K reported that the Noon Buying Rate as of February 6, 2015 for the conversion of U.S. dollars to Euros and Canadian dollars to U.S. dollars was €0.7583$1.1330 per U.S. dollarEuro and C$1.0016$0.7985 per U.S.Canadian dollar.

In addition, certain financial information relating to our Celgar mill included in this annual report on Form 10-K is stated in Canadian dollars while we report our financial results in Euros. The following table sets out exchange rates, based on the noon rate provided by the Bank of Canada (the “Daily Noon Rate”), for the conversion of Canadian dollars to Euros in effect at the end of the following periods, the average exchange rates during these periods (based on Daily Noon Rates) and the range of high and low exchange rates for these periods:

| Years Ended December 31, | ||||||||||||||||||||

| 2011 | 2010 | 2009 | 2008 | 2007 | ||||||||||||||||

| (C$/€) | ||||||||||||||||||||

End of period | 1.3193 | 1.3319 | 1.5000 | 1.7046 | 1.4428 | |||||||||||||||

High for period | 1.2847 | 1.2478 | 1.4936 | 1.4489 | 1.3448 | |||||||||||||||

Low for period | 1.4305 | 1.5067 | 1.6920 | 1.7316 | 1.5628 | |||||||||||||||

Average for period | 1.3761 | 1.3671 | 1.5851 | 1.5603 | 1.4690 | |||||||||||||||

On February 20, 2012, the Daily Noon Rate for the conversion of Canadian dollars to Euros was C$1.3148 per Euro.

| ITEM 1. | BUSINESS |

In this document, please note the following:

| • | references to “we”, “our”, “us”, the “Company” or “Mercer” mean Mercer International Inc. and its subsidiaries, unless the context clearly suggests otherwise, and references to “Mercer Inc.” mean Mercer International Inc. excluding its subsidiaries; |

| • | references to “ADMTs” mean air-dried metric tonnes; |

| • | references to “MW” mean megawatts and “MWh” mean megawatt hours; and |

| • | all references to “$” shall mean U.S. dollars, which is our reporting currency, unless otherwise stated; “€” refers to Euros; and “C$” refers to Canadian dollars. |

Due to “we”, “our”, “us”,rounding, numbers presented throughout this report may not add up precisely to totals we provide and percentages may not precisely reflect the “Company” or “Mercer” mean Mercer International Inc. and its subsidiaries, unless the context clearly suggests otherwise, and references to “Mercer Inc.” mean Mercer International Inc. excluding its subsidiaries;absolute figures.

references to “ADMTs” mean air-dried metric tonnes;

references to “MW” mean megawatts and “MWh” mean megawatt hours;

information is provided as of December 31, 2011, unless otherwise stated or the context clearly suggests otherwise;

all references to monetary amounts are to “Euros”, the lawful currency adopted by most members of the European Union, unless otherwise stated; and

“€” refers to Euros; “$” refers to U.S. dollars; and “C$” refers to Canadian dollars.

General

Mercer Inc. is a Washington corporation and our shares of common stock are quoted and listed for trading on the NASDAQ Global Market (MERC) and the Toronto Stock Exchange (MRI.U).

We operate in the pulp business and are among the largest publicly traded producerproducers of market northern bleached softwood kraft, or “NBSK”, pulp in the world. Mercer Inc. reorganized as a corporation under the laws of the State of Washington in 2006 from a Washington business trust. Its common stock is quoted and listed for trading on the NASDAQ Global Select Market (MERC) and the Toronto Stock Exchange (MRI.U).

We are the sole NBSK producer, and the only significant producer of pulp for resale, known as “market pulp”, in Germany, which is the largest pulp import market in Europe. We also generate and sell a significant amount of surplus “green” energy to regional utilities. Our operations are located in Eastern Germany and Western Canada. We currently employ approximately 1,039 people at our German operations, 439 people at our Celgar mill in Western Canada and 17 people at our office in Vancouver, British Columbia, Canada.1,430 people. We operate three NBSK pulp mills with a consolidated annual production capacity of approximately 1.5 million ADMTs:ADMTs of NBSK pulp and 305 MW of electrical generation:

| • | Rosenthal mill. Our wholly-owned subsidiary, Rosenthal, owns and operates the Rosenthal mill, a modern, efficient ISO 9001, 14001 and 50001 certified NBSK pulp mill that has an annual production capacity of approximately 360,000 ADMTs and 57 MW of electrical generation. The Rosenthal mill generated and exported 178,266 MWh of electricity during the year ended December 31, 2014, resulting in approximately $21.9 million in revenues. The Rosenthal mill is located in the town of Blankenstein, Germany, approximately 300 kilometers south of Berlin. |

| • | Stendal mill. Our subsidiary, Stendal owns and operates the Stendal mill, a state-of-the-art, single-line, ISO 9001 and 14001 certified NBSK pulp mill that has |

5

| • | Celgar mill. Our wholly-owned subsidiary, Celgar, owns and operates the Celgar mill, a modern, efficient ISO 9001 and 14001 certified NBSK pulp mill with an annual |

|

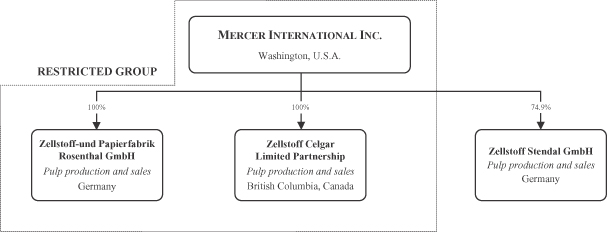

Organizational Chart

The following chart sets out our directly and indirectly owned principal operating subsidiaries, their jurisdictions of organization, their principal activities and their principal activities:annual pulp production and electrical generation capacity:

History and Development of Business

We acquired our initialIn 1994, we commenced pulp operations in 1994, with the acquisition of our Rosenthal mill. In late 1999, we completed a major capital project which, among other things, converted itthat mill to the production of kraft pulp from sulphite pulp, increased its annual production capacity reduced costs and improved efficiencies. The aggregate cost of this project was approximately €361.0$385.7 million, of which approximately €102.0$100.8 million was financed through government grants. Subsequent minor capital investments and efficiency improvements have reduced emissions and energy costs and increased the Rosenthal mill’s annual production capacity to approximately 345,000360,000 ADMTs. Our Rosenthal mill completed a capital project to also produce and sell tall oil in the fourth quarter of 2014.

In September 2004, we completed construction of the Stendal mill at an aggregate cost of approximately €1.0$1.1 billion. The Stendal mill is one of the largest NBSK pulp mills in Europe. The Stendal mill was financed through a combination of government grants totaling approximately €275.0$332.0 million, low-cost, long-term project debt which iswas largely severally guaranteed by the federal government and a state government in Germany, and equity contributions.

We initially had a 63.6% ownership interest in Stendal and, over time,Stendal. We subsequently increased our interest in Stendal through acquisitions and/or further investments to 70.6% in 2006, 74.9%.

We, in 2009 and 83.0% in 2013. In September 2014, we made an additional capital investment in Stendal and its noncontrolling shareholder are parties to a shareholders’ agreement dated August 26, 2002, as amended, to govern our respective interests in Stendal. The agreement contains terms and conditions customary for these typesacquired all of agreements, including restrictions on transfers of share capital andthe shareholder loans and substantially all of the shares of the minority shareholder in Stendal and other thanrights. As a result of such transactions, we now consolidate all of the economic interest in Stendal.

In December 2013, our Stendal mill completed a $49.3 million project, referred to affiliates, rightsas “Project Blue Mill”, which was designed to increase production and efficiency through debottlenecking initiatives including the installation of first refusal on sharean additional 46 MW steam turbine at our Stendal mill. The debottlenecking which, among other

6

things, required a new turbine in order to enhance and shareholder loan transfers, pre-emptive rightsefficiently utilize steam production was designed to increase the mill’s annual pulp production capacity by 30,000 ADMTs. The new turbine permits the mill to produce an additional 109,000 MWh annually of surplus renewable energy for sale at premium pricing and piggyback rights on dispositions of our interest. The shareholders are not obligated to fund any further equity capital contributions to the project. The shareholders’ agreement provides that Stendal’s managing directors are appointed by holders of a simple majority of its share capital. Further, shareholder decisions, other than those mandated by law or for the provision of financial assistance to a shareholder, are determined by a simple majority of Stendal’s share capital.is fully operational.

A significant portion of the capital investments at our German mills, including the construction of the Stendal mill, were financed through government grants. Since 1999,1998, our German mills have benefited from an aggregate €384.9approximately $468.6 million in government grants. These grants reduce the cost basis of the assets purchased when the grants are received and are not reported in our income.

In February 2005, we acquired the Celgar mill for $210.0 million of which $170.0 million was paid in cash and $40.0 million was paid in our shares, plus $16.0 million for the defined working capital of the mill. The Celgar mill was completely rebuilt in the early 1990s through a C$850.0 million modernization and expansion project, which transformed it into a modern and competitive producer.

In 2007,Since its acquisition, we completed a C$28.0 millionhave effected several capital project which improved efficienciesprojects and reliability and, with other measures, increasedinitiatives at the Celgar mill’smill to increase its annual pulp production capacity to 500,000 ADMTs. In September 2010, we completed520,000 ADMTs and its production of “green” energy. This includes a capital project, referred to as the “Celgar Energy Project”, to increasewhich was completed in September 2010 and increased the Celgar mill’s production of “green” energy and optimizeoptimized its power generation capacity, at an aggregate cost of approximately C$64.9$60.6 million, of which approximately C$48.0$44.6 million was financed by grants from the Canadian federal government. See “—Capital Expenditures”. We have also increased the Celgar mill’s overall annual pulp production capacity to approximately 520,000 ADMTs through increased efficiencies.

Our competitive strengths include the following:

| • |

|

Leading Market Position. |

| • | Stable Income Source from the Sale of Surplus Renewable |

| • | Modern and Globally Cost Competitive Mills. We believe the relative age, production capacity and electrical generation capacity of our mills provide us with certain manufacturing cost and other advantages over many of our competitors. We believe competitors’ older mills do not have the equipment or capacity to produce or sell surplus power or chemicals in a meaningful amount. In addition, since our mills are relatively new they benefit from lower maintenance capital requirements and higher efficiency relative to many of our competitors’ mills. |

7

| • | Strategic Locations Providing Cost and |

| • |

|

|

Proximity of Abundant Fiber Supply.Although fiber is cyclical in both price and supply, there is a significant amount of high-quality fiber within a close radius of each of our mills. This fiber supply, combined with our purchasing power and our |

| • | Experienced Management Team.Our directors and senior managers have extensive experience in the pulp and forestry industries. |

Our corporate strategy is to create shareholder value by focusing on the expansion ofexpand our asset and earnings base.base through organic growth and acquisitions, primarily in Europe and North America. We pursue organic growth through active management and targeted capital expenditures to generate a high return by increasing pulp, energy and chemical production, reducing costs and improving efficiency. We are also developing innovative new products based on other derivatives of the kraft pulping process. We seek to acquire interests in companies and assets in the pulp industry and related businesses where we can leverage our experience and expertise in adding value through a focused management approach. Key featureselements of our strategy include:

| • | Focus on Premium Grade NBSK Market Pulp.We |

| • |

|

8

December 2013, our |

| • |

|

|

| • | Achieving Operational Excellence. Operating our mills reliably and at a competitive cost is important for our financial performance. In addition to our capital expenditure program, we continuously strive to develop maintenance systems and procedures that will improve the throughput of our |

| • | Strategic Opportunities. We believe there will be continuing change and consolidation in the pulp and |

General

Pulp is used in the production of paper, tissues and paper-related products. Pulp is generally classified according to fiber type, the process used in its production and the degree to which it is bleached. Kraft pulp, a type of chemical pulp, is produced through a sulphate chemical process in which lignin, the component of wood which binds individual fibers, is dissolved in a chemical reaction. Chemically prepared pulp allows the wood’s fiber to retain its length and flexibility, resulting in stronger paper products. Kraft pulp can be bleached to increase its brightness. Kraft pulp is noted for its strength, brightness and absorption properties and is used to produce a variety of products, including lightweight publication grades of paper, tissues and other paper-related products.

There are two main types of bleached kraft pulp, being softwood kraft made from coniferous trees and hardwood kraft made from deciduous trees. Softwood species generally have long, flexible fibers which add strength to paper while fibers from species of hardwood contain shorter fibers which lend bulk and opacity. Generally, list prices for softwood pulp are higher than list prices for hardwood pulp.

We produce and sell NBSK pulp, which is a bleached kraft pulp manufactured using species of northern softwood and is considered a premium grade because of its strength. It generally obtains the highest price relative to other kraft pulps. Southern bleached softwood kraft pulp is kraft pulp manufactured using southern softwood species and does not possess the strength found in NBSK pulp. NBSK pulp is the sole pulp product of our mills.

The selling price of kraft pulp depends in part on the fiber used in the production process. There are two primary species of wood used as fiber: softwood and hardwood. Softwood species generally have long, flexible fibers which add strength to

9

Most paper while fibers from species of hardwood contain shorter fibers which lend bulk and opacity. Generally, prices for softwood pulp are higher than for hardwood pulp. Most usesusers of market kraft pulp including fine printing papers, coated and uncoated magazine papers and various tissue products, utilizeuse a mix of softwood and hardwood grades to optimize production and product qualities. In recent2014, market kraft pulp consumption was approximately 53% hardwood bleached kraft, 43% softwood bleached kraft and the remainder comprised of unbleached pulp. Over the last several years, production of hardwood pulp, based on fast growing plantation fiber primarily from Asia and South America, has increased much more rapidly than that of softwood grades that have longer growth cycles. Hardwood kraft generally has a cost advantage over softwood kraft as a result of lower fiber costs, higher wood yields and, for newer hardwood mills, economies of scale. As a result of thethis growth in supply and lower costs, kraft pulp customers have substituted some of the pulp content in their products to hardwood pulp.

Counteracting customers’ increased proportionate usage ofability to substitute lower priced hardwood pulp has beenfor NBSK pulp is the requirement for strength and formation characteristics in finished goods. Paper and tissue makers focus on larger paper machines with higher machine speeds and lower basis weights for publishingcertain papers which also require the strength characteristics of softwood pulp. WeAdditionally, where paper products are lightweight or specialized, like direct mail, magazine paper or premium tissue, or where strength or absorbency are important, softwood kraft forms a significant proportion of the fiber used. As a result, we believe that the ability of kraft pulp users to continue to further substitute hardwood for softwood pulp is limited by such requirements.

Kraft pulp can be made in different grades, with varying technical specifications, for different end uses. High-quality kraft pulp is valued for its reinforcing role in mechanical printing papers, while other grades of kraft pulp are used to produce lower priced grades of paper, including tissues and paper-related products.

Markets

We believe that over 125130.0 million ADMTs of kraftchemical pulp are converted annually into tissues, printing and writing papers, tissues, carton boards and other whitespecialty grades of paper and paperboard around the world. We also believe that approximatelyover one third of this pulp is sold on the open market as market pulp, while the remainder is produced for internal purposes by integrated paper and paperboard manufacturers.

Demand for kraft pulp is cyclical in nature and is generally related to global and regional levels of economic activity. In 2008, overallOverall global demand for all kraft pulp types, including softwood, was negatively impacted by the weak global economic conditions and global financial and credit turmoil the world began to experience in the second halflatter part of that year2008 and which continued intocontinuing through the first half of 2009. Significant producer shutdowns and curtailments, along with strong demand from China, resulted in an improved supply-demand balance and improved prices in the second half of 2009 through 2010. Although global pulp markets continued to strengthen in the first half of 2011, mainly driven by demand from Asia, economic uncertainty in Europe and credit tightening in China resulted in a decrease in demand and weaker pulp prices in the fourth quarter of 2011. In 2012, continued economic uncertainty in Europe, credit tightening in China and weak demand for paper in Europe resulted in some integrated producers curtailing their paper production and selling their pulp on the market, primarily in China. These factors negatively impacted demand and supply of pulp and resulted in generally weak pulp prices. In 2013, demand from China was stable throughout the year and supply was slightly under-balanced, which resulted in higher prices in 2013. In 2014, demand in both European and Chinese markets was stable, while supply was slightly under-balanced throughout the year which kept prices at relatively high levels.

10

Between 20002005 and 20102014, worldwide demand for softwoodchemical market pulp grew at an average rate of approximately 1.6% annually. Demand2% annually, with worldwide demand for bleached softwood kraft market pulp was negatively impacted by weakhaving grown at an average of approximately 1% per annum. The following chart illustrates the global economic conditions in 2009. However, the supply/demand balance for softwoodchemical market pulp improvedfor the periods indicated:

Two key macro-economic trends in 2010, primarily due to strongworldwide NBSK pulp demand in China,over the residual effects of the Chilean earthquake that affected millslast several years have been:

| • | a significant increase in demand from emerging markets, and in particular China, which has more than offset a decline in demand in the mature markets of Europe, North America and Japan; and |

| • | partly related to the foregoing, there has been a significant shift in demand by end use, as demand from tissue and specialty producers has increased markedly and offset the secular decline in |

Since 2005, demand for chemical softwood market pulp has grown in the emerging markets of Asia, Eastern Europe and Latin America. China in particular has experienced substantial growth and its demand forimports of softwood market pulp grew by approximately 15.9%11% per annum between 20002005 and 2010.2014. We believe the emerging markets now account for approximately 51% of total world demand. China now accounts for approximately 20%29% of global bleached softwood kraft market pulp demand, compared to only 5%13% in 2000.2005. Western Europe currently accounts for approximately 30%27% of global bleached softwood kraft market pulp demand.demand, compared to approximately 37% in 2005. The demand in the mature markets of Europe, North America and Japan in 2014 declined by approximately 2.8 million ADMTs from its peak in 2005.

11

The following chart sets forth industry-wide bleached softwood kraft delivery levels to China for the periods indicated:

Growth in NBSK pulp demand in China and other emerging markets has, to a large extent, been driven by increased demand from tissue producers, as a result of economic growth and rising income levels and living standards in such markets. These factors generally contribute to a greater demand for personal hygiene products in such regions. In China alone, tissue producers have publicly announced plans to add a total of 30 tissue paper machines at various sites during 2015 to increase their annual tissue capacity by approximately 1.2 million ADMTs. At this time there can be no assurance as to when and how much of such capacity expansion will be implemented.

This has also led to an overall shift in demand for NBSK pulp, as demand from tissue producers has increased, while demand from printing and writing end uses has decreased. Between 2003 and 2013, NBSK pulp demand for tissue production increased by approximately 168%, an approximate 10% compound annual growth rate. From 2003 to 2013, a period very affected by “digital substitution” of traditional paper grades, total NBSK demand grew by 14%.

12

The following chart compares NBSK pulp demand by end use in each of 2003 and 2013 (the latest year for which figures are currently available).

We believe 2014 NBSK demand by end use was generally consistent with the trend in the chart above.

A measure of demand for kraft pulp is the ratio obtained by dividing the worldwide demand of kraft pulp by the worldwide capacity for the production of kraft pulp, or the “demand/capacity ratio”. An increase in this ratio generally occurs when there is an increase in global and regional levels of economic activity. An increase in this ratio also generally indicates greater demand as consumption increases, which often results in rising kraft pulp prices and a reduction of inventories by producers and buyers. As prices continue to rise, producers continue to run at higher operating rates. However, an adverse change in global and regional levels of economic activity generally negatively affects demand for kraft pulp, often leading buyers to reduce their purchases and relyingrely on existing pulp inventories. As a result, producers run at lower operating rates by taking downtime to limit the build-up of their own inventories. The demand/capacity ratio for softwood kraft pulp was approximately 92%93%, 94% and 94% in 2011, approximately 93% in 20102014, 2013 and approximately 91% in 2009.2012, respectively.

A significant factor affecting our market is the amount of closures of old, high-cost capacity. InOver the four-year period from 2006 to 2009, we estimate approximately 5.3 million tonnes of predominantly NBSK capacity waslast several years, mills in North America, Finland and Sweden were permanently or indefinitely closed. Such closures have been partially offset by approximately 1.9 million tonnesAlthough some capacity was restarted in late 2009 and 2010. The2010 in response to very high NBSK pulp prices, we believe the overall net effect reduced NBSK pulp supply and positively impacted markets. Between 2011 and 2014, we believe approximately 800,000 ADMTs of thesepulp capacity was idled or shut down through mill closures or curtailments. Further, in efforts to improve environmental and restartssafety standards, China has publicly stated that it will be reducing existing pulp and paper capacity in the near term by closing “old” mills, targeting a removal of 4.9 million ADMTs by the end of 2014. At this time, there can be no certainty as to the actual amount and timing of any such closures.

By the end of 2014, the global supply of bleached hardwood kraft pulp increased by approximately 1.6 million ADMTs, primarily from South America. This increase in bleached hardwood kraft pulp is largely targeted at the growing demand for pulp in developing markets, particularly in China, by producers of tissues, specialty papers and packaging. If such additional bleached hardwood kraft pulp supply is not absorbed by such demand growth, as a result of generally lower prices for bleached hardwood kraft pulp, this supply increase could

13

put downward pressure on NBSK pulp prices. However, we believe customers’ ability to further substitute NBSK pulp for lower priced bleached hardwood kraft pulp is limited by the strength characteristic of NBSK pulp which is required by large modern paper machines to run lower basis-weight paper products efficiently. As pulp prices are highly cyclical, there can be no assurances that prices will not decline in the future.

In 2013, one new NBSK mill was started up in Russia, which resulted in an estimated 3.4 million tonnesincremental increase of capacity removed from the market. Weapproximately 490,000 ADMTs in annual production capacity. Currently, we are aware of only one plannedseveral publicly announced modernization and expansion projects for NBSK plantmills in Europe that may be implemented over the next three years, ranging from small expansions of existing mills to potential “greenfield” mills. We currently believe a few of these projects will be implemented while others are currently subject to various conditions including financing and further development. We believe that, because of fiber constraints, any significant expansion worldwideof NBSK capacity in the next few years.region would require the closure of older mills. At this time, we cannot predict which of the publicly announced expansion projects will be completed or how much additional NBSK production capacity may come online.

In addition, certain integrated pulp and paper producers have the ability to discontinue paper production by idling their paper machines and selling their NBSK pulp production on the market, if market conditions, prices and trends warrant such actions. We believe that the absence of other plant expansions is due in part to fiber supply constraints and high capital costs.

NBSK Pulp Pricing

Pulp prices are highly cyclical. In general, kraft pulp is a globally traded commodity. Pricing and demand are influenced by the balance between supply and demand, as affected by global macroeconomic conditions, changes in consumption and capacity, the level of customer and producer inventories and fluctuations in exchange rates. As Northern Europe has historically been the world’s largest market and NBSK is the premium grade, the European NBSK market price is generally used as a benchmark price by the industry.

The average European list prices for NBSK pulp since 2005 have fluctuated between a low of approximately $575 per ADMT in 2009 and a high of $1,030 per ADMT in 2011.

The following chart sets out the changes in list prices for NBSK pulp in Europe, as stated in U.S. dollars, Canadian dollars and Euros for the periods indicated:

14

In 2006, pulp prices increased steadily from approximately $600 per ADMT in Europe to $870 per ADMT at the end of 2007. These price increases resulted from increased demand and the closure of several pulp mills, particularly in North America, which reduced NBSK capacity. In the second half of 2008, list prices for NBSK pulp decreased markedly due to weak global economic conditions. As a result, list prices for NBSK pulp in Europe decreased from $900 per ADMT in mid-2008 to $635 per ADMT at the end of the year. Such pulp price weakness continued into early 2009, though commencing in mid-2009, pulp markets began to strengthen which led to improved prices. Strong demand from China, capacity closures and historically low global inventories for bleached softwood kraft pulp helped support upward price momentum. During the second half of 2009, several price increases raised European list prices by a total of $170 per ADMT to $800 per ADMT by year end. Such price increases were partially offset by the continued weakening of the U.S. dollar versus the Euro and Canadian dollar during the period. In 2010, several increases lifted prices to record levels in the middle of the year and at the end of 2010 list prices were near historic highs of $950, $960 and $840 per ADMT in Europe, North America and China, respectively.

In 2011, pulp prices remained strong in the first half of the year, reaching record levels of $1,030 per ADMT in Europe and $1,035 and $920 per ADMT in North America and China, respectively. However, uncertainty concerning the economic situation in Europe, along with credit tightening in China in the last part of the year, caused pulp prices to drop sharply to $825 per ADMT in Europe and $890 and $670 per ADMT in North America and China, respectively, by the end of the year. Economic uncertainty in Europe and China continued to dampen demand and NBSK pulp prices, which remained generally weak in 2012. In 2012, year-end list prices were approximately $810, $870 and $655 per ADMT in Europe, North America and China, respectively.

In 2013, demand from China was stable throughout the year and supply was slightly under-balanced, which resulted in higher year-end list prices of $905 per ADMT in Europe and $990 and $750 per ADMT in North America and China, respectively. In 2014, demand in both Europe and China was stable, while supply was slightly under-balanced throughout the year which kept prices relatively high. At the end of 2014, list prices in Europe were approximately $935 per ADMT, while list prices in North America and China were approximately $1,020 and $700 per ADMT, respectively.

A producer’s net sales realizations are list prices, net of customer discounts, commissions and other selling concessions. While there are differences between NBSK list prices in Europe, North America and Asia, European prices are generally regarded as the global benchmark and pricing in other regions tends to follow European trends. The nature of the pricing structure in Asia is different in that, while quoted list prices tend to be lower than Europe, customer discounts and rebates are much lower, resulting in net sales realizations that are generally similar to other markets.

The majority of market NBSK pulp is produced and sold by Canadian and Northern European producers, while the price of NBSK pulp is generally quoted in U.S. dollars. As a result, NBSK pricing is often affected by fluctuations in the currency exchange rates for the U.S. dollar versus the Canadian dollar, the Euro and local currencies. NBSK pulp price increases during 2006, 2007 and the first half of 2008 were in large part offset by the negative impact on our operating costs of a weakening of the U.S. dollar. Similarly, the strengthening of the U.S. dollar against the Canadian dollar and the Euro towards the end of 2008 helped partially offset pulp price decreases caused by the deterioration in global economic conditions. The overall strengthening of the U.S. dollar against the Euro in 2010, and in particular in the first half of 2010, improved the operating margins of our German mills. Although the U.S. dollar weakened against the Euro for most of 2011, it strengthened at the end of 2011. Overall, the U.S. dollar was 8% stronger against the Euro in 2012 compared to 2011. In 2013, the U.S. dollar was 3% weaker against the Euro, compared to 2012, which reduced the operating margins of our German mills. However, by the end of 2014, the U.S. dollar was 12% and 8% stronger against the Euro and the Canadian dollar, respectively, compared to 2013, which increased the operating margins of our three mills.

15

The global supply and demand balance for NBSK pulp is a key determinant in pulp pricing. Generally, we and other producers consider global NBSK pulp supply and demand to be evenly balanced when world inventory levels are at about 30 days’ supply.

The following chart sets forth changes in FOEX PIX Pulp index prices for NBSK pulp and global bleached softwood kraft inventory levels between 2005 and 2014:

Seasonality

We are exposed to fluctuations in quarterly sales volumes and expenses due to seasonal factors. These factors are common in the NBSK pulp industry. We generally have weaker pulp demand in Europe during the summer holiday months and in China in the period relating to its lunar new year. We typically have a seasonal build-up in raw material inventories in the early winter months as our mills build up their fiber supply for the winter when there is reduced availability.

Competition

Pulp markets are large and highly competitive. Producers ranging from small independent manufacturers to large integrated companies produce pulp worldwide. Our pulp and customer services compete with similar products manufactured and distributed by others. While many factors influence our competitive position, particularly in weak economic times, a key factor is price. Other factors include service, quality and convenience of location. Some of our competitors are larger than we are in certain markets and have substantially greater financial resources. These resources may afford those competitors more purchasing power, increased financial flexibility, more capital resources for expansion and improvement and enable them to compete more effectively. Our key NBSK pulp competitors are principally located in Northern Europe and Canada.

NBSK Pulp Pricing

Pulp prices are highly cyclical. Global economic conditions, changes in production capacity, inventory levels, and currency exchange rates are the primary factors affecting NBSK pulp list prices. The average annual European list prices for NBSK pulp since 2000 have ranged from a low of approximately $447 per ADMT to a high of $1,030 per ADMT.16

Starting in 2006, pulp prices increased steadily from approximately $600 per ADMT in Europe to $870 per ADMT at the end of 2007. These price increases resulted from the closure of several pulp mills, particularly in North America, which reduced NBSK capacity by approximately 1.3 million ADMTs and better demand.

In the second half of 2008, list prices for NBSK pulp decreased markedly due to weak global economic conditions. As a result, list prices for NBSK pulp in Europe decreased from $900 per ADMT in mid-2008 to $635 per ADMT at the end of the year. Such price weakness continued into early 2009 as list prices in Europe fell to approximately $575 per ADMT. Commencing in mid-2009, pulp markets began to strengthen which led to improved prices. Strong demand from China, capacity closures and historically low global inventories for bleached softwood kraft pulp helped support upward price momentum. During the second half of 2009, several price increases raised European list prices by a total of $170 per ADMT to $800 per ADMT by year end. Such price increases were partially offset by the continued weakening of the U.S. dollar versus the Euro and Canadian dollar during the period. In December 2009, list prices for pulp were approximately $800 per ADMT in Europe, $830 per ADMT in North America and $700 per ADMT in China. In 2010, several increases lifted prices to record levels in the middle of the year and at the end of 2010 list prices were near historic highs of $950, $960 and $840 per ADMT in Europe, North America and China, respectively. Although pulp prices remained strong in 2011, reaching record levels of $1,030 per ADMT in Europe and $1,035 and $920 per ADMT in North America and China, respectively, uncertainty concerning the economic situation in Europe, along with credit tightening in China, caused pulp prices to drop to $825 per ADMT in Europe and $890 and $670 per ADMT in North America and China, respectively, by the end of the year. As pulp prices are highly cyclical, there can be no assurance that prices will not decline in the future.

A producer’s net sales realizations are list prices, net of customer discounts, commissions and other selling concessions. While there are differences between NBSK list prices in Europe, North America and Asia, European prices are generally regarded as the global benchmark and pricing in other regions tends to follow European trends. The nature of the pricing structure in Asia is different in that, while quoted list prices tend to be lower than Europe, customer discounts and commissions tend to be lower resulting in net sales realizations that are generally similar to other markets.

The majority of market NBSK pulp is produced and sold by Canadian and Scandinavian producers, while the price of NBSK pulp is generally quoted in U.S. dollars. As a result, NBSK pricing is affected by fluctuations in the currency exchange rates for the U.S. dollar versus the Canadian dollar, the Euro and local currencies. NBSK pulp price increases during 2006, 2007 and the first half of 2008 were in large part offset by the weakening of the U.S. dollar. Similarly, the strengthening of the U.S. dollar against the Canadian dollar and the Euro towards the end of 2008 helped partially offset pulp price decreases caused by the deterioration in global economic conditions. The overall strengthening of the U.S. dollar against the Euro in 2010, and in particular in the first half of 2010, improved the operating margins of our German mills. Although the U.S. dollar weakened against the Euro for most of 2011, it began to strengthen again at the end of the year.

The following chart sets out the changes in list prices for NBSK pulp in Europe, as stated in U.S. dollars, Canadian dollars and Euros for the periods indicated.

Source: Pulp & Paper Week and Bloomberg

The Manufacturing Process

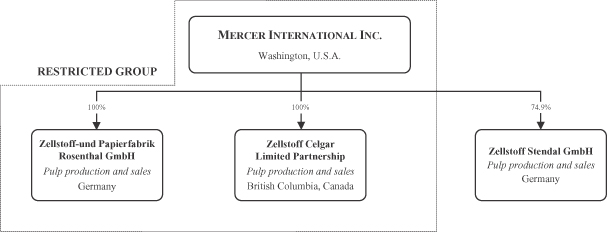

The following diagram provides a simplified description of the kraft pulp manufacturing process at our pulp mills:

In order to transform wood chips into kraft pulp, wood chips undergo a multi-step process involving the following principal stages: chip screening, digesting, pulp washing, screening, bleaching and drying.

In the initial processing stage, wood chips are screened to remove oversized chips and sawdust and are conveyed to a pressurized digester where they are heated and cooked with chemicals. This occurs in a continuous process at the Celgar and Rosenthal mills and in a batch process at the Stendal mill. This process softens and eventually dissolves the phenolic material called lignin that binds the fibers to each other in the wood.

Cooked pulp flows out of the digester and is washed and screened to remove most of the residual spent chemicals and partially cooked wood chips. The pulp then undergoes a series of bleaching stages where the brightness of the pulp is gradually increased. Finally, the bleached pulp is sent to the pulp machine where it is dried to achieve a dryness level of more thanapproximately 90%. The pulp is then ready to be baled for shipment to customers.

A significant feature of kraft pulping technology is the recovery system, whereby chemicals used in the cooking process are captured and extracted for re-use, which reduces chemical costs and improves environmental performance. During the cooking stage, dissolved organic wood materials and used chemicals, collectively known as black liquor, are extracted from the digester. After undergoing an evaporation process, black liquor is burned in a recovery boiler. The chemical compounds of the black liquor are collected from the recovery boiler and are reconstituted into cooking chemicals used in the digesting stage through additional processing in the recausticizing plant.

17

The heat produced by the recovery boiler is used to generate high-pressure steam. Additional steam is generated by a power boiler through the combustion of biomass consisting of bark and other wood residuals from sawmills and our woodrooms and residue generated by the effluent treatment system. Additionally, during times of upset, we may use natural gas to generate steam. The high pressure steam produced by the recovery and power boilers is used to power a turbine generator to generate electricity, as well aslow pressure steam coming off the turbine is then used to provide heat for the digesting and pulp drying processes.

We, along with other pulp producers both individually and through industry associations, are conducting research and development focused on developing innovative new products that are based on derivatives of the kraft pulping process. Currently these derivatives are focused in two broad categories:

| • | the further refinement of materials contained in black liquor, the extractive chemical and lignin containing compounds that are a result of the kraft pulping process; and |

| • | the further refinement of cellulose materials that are currently the basis of NBSK kraft pulp. |

We are engaged with several research partners to participate in and develop new innovative products. To date, one of the most well-developed of these projects is a cellulose derivative generally referred to in the industry as “cellulose filaments”. Cellulose filaments are the result of a new process that unbinds the individual filaments that make up a cellulose fiber. In northern softwoods, there are approximately 1,000 filaments making up a single fiber. The filaments resulting from this patented process are long, ribbon-like structures that have unique strength characteristics similar to other chemical derivatives, such as aramids. We believe that this material may have commercial potential in many applications, including strength enhancers, solution stabilizers and specialty solutions for numerous other industries.

We are part of an industry association that has made considerable progress in developing a particular manufacturing process. We, along with other member companies, including certain other NBSK producers, have license rights to further develop and market existing intellectual property registered under patent to our industry association. Further, such association, in conjunction with one of its member companies, is constructing a pilot production facility and we have access to its product for development purposes. While there remains much research and development to be done, we are encouraged enough to continue to expend resources to develop this technology, both individually and in joint development arrangements with third parties. We estimate expenditures totaling approximately $3.0 million over the three-year period from 2014 to 2016.

Such research and development is still at an early stage and there has been no commercialization of the research to date. We currently estimate it may take between three and five years before we can determine if product applications can be commercialized. However, there can be no assurance that such research and development will ever result in commercialization or the production or sales of any products by us at a profit or at all.

We manufacture and sell NBSK pulp produced from wood chips and pulp logs.logs at our three mills.

18

The following table sets out our pulp production capacity and actual production by mill for the periods indicated:

| Annual Production Capacity(1) | Year Ended December 31, | |||||||||||||||

| 2014 | 2013 | 2012 | ||||||||||||||

| Pulp Production by Mill: | (ADMTs) | |||||||||||||||

Rosenthal | 360,000 | 360,463 | 361,724 | 337,959 | ||||||||||||

Celgar | 520,000 | 453,104 | 447,935 | 490,018 | ||||||||||||

Stendal | 660,000 | 671,444 | 634,816 | 640,298 | ||||||||||||

|

|

|

|

|

|

|

| |||||||||

Total pulp production | 1,540,000 | 1,485,011 | 1,444,475 | 1,468,275 | ||||||||||||

|

|

|

|

|

|

|

| |||||||||

| (1) | Capacity is the rated capacity of the plants for the year ended December 31, 2014. |

Rosenthal Mill.The Rosenthal mill is situated on a 230 acre site in the town of Blankenstein in the state of Thüringia, approximately 300 kilometers south of Berlin. The Saale river flows through the site of the mill. In late 1999, we completed a major capital project which converted the Rosenthal mill to the production of kraft pulp. It is a single line mill with a current annual production capacity of approximately 360,000 ADMTs of kraft pulp. The mill is self-sufficient in steam and electrical power. Some excess electrical power which is constantly generated is sold to the regional power grid. The facilities at the mill include:

| • | an approximately 425,000 square feet fiber storage area; |

| • | debarking and chipping facilities for pulp logs; |

| • | an approximately 700,000 square feet roundwood yard; |

| • | a fiber line, which includes a Kamyr continuous digester and bleaching facilities; |

| • | a pulp machine, which includes a dryer, a cutter and a baling line; |

| • | an approximately 60,000 square feet finished goods storage area; |

| • | a chemical recovery line, which includes a recovery boiler, evaporation plant, recausticizing plant and lime kiln; |

| • | a fresh water plant; |

| • | a wastewater treatment plant; and |

| • | a power station with a turbine capable of producing 57 MW of electric power from steam produced by the recovery boiler and a power boiler. |

The kraft pulp produced at the Rosenthal mill is a long-fibered softwood pulp produced by a sulphate cooking process and manufactured primarily from wood chips and pulp logs. A number of factors beyond economic supply and demand have an impact on the market for chemical pulp, including requirements for pulp bleached without any chlorine compounds or without the use of chlorine gas. The Rosenthal mill has the capability of producing both “totally chlorine free” and “elemental chlorine free” pulp. Totally chlorine free pulp is bleached to a high brightness using oxygen, ozone and hydrogen peroxide as bleaching agents, whereas elemental chlorine free pulp is produced by substituting chlorine dioxide for chlorine gas in the bleaching process. This substitution virtually eliminates complex chloro-organic compounds from mill effluent.

Kraft pulp is valued for its reinforcing role in mechanical printing papers and is sought after by producers of paper for the publishing industry, primarily for magazines and advertising materials. Kraft pulp is also an important ingredient for tissue manufacturing, and tissue demand tends to increase with living standards in developing countries. Kraft pulp produced for reinforcement fibers is considered the highest grade of kraft

19

pulp and generally obtains the highest price. The Rosenthal mill produces pulp for reinforcement fibers to the specifications of certain of our customers. We believe that a number of our customers consider us their supplier of choice.

Stendal Mill. The Stendal mill is situated on a 200 acre site owned by Stendal that is part of a larger 1,250 acre industrial park near the town of Stendal in the state ofSaxony-Anhalt, approximately 300 kilometers north of the Rosenthal mill and 130 kilometers west of Berlin. The mill is adjacent to the Elbe river and has access to harbor facilities for water transportation. The mill is a single line mill with a current annual design production capacity of approximately 660,000 ADMTs of kraft pulp. The Stendal mill is self-sufficient in steam and electrical power. Some excess electrical power which is constantly being generated is sold to the regional power grid. The facilities at the mill include:

| • | an approximately 920,000 square feet fiber storage area; |

| • | debarking and chipping facilities for pulp logs; |

| • | a fiber line, which includes ten SuperBatch™ digesters and bleaching facilities; |

| • | a pulp machine, which includes a dryer, a cutter and a baling line; |

| • | an approximately 108,000 square feet finished goods storage area; |

| • | a chemical recovery line, which includes a recovery boiler, evaporation plant, recausticizing plant and lime kiln; |

| • | a fresh water plant; |

| • | a wastewater treatment plant; and |

| • | a power station with two turbines capable of producing 148 MW of electrical power since the completion of Project Blue Mill in December 2013. |

The kraft pulp produced at the Stendal mill is of a slightly different grade than the pulp produced at the Rosenthal mill as the mix of softwood fiber used is slightly different. This results in a complementary product more suitable for different end uses. The Stendal mill is capable of producing both totally chlorine free and elemental chlorine free pulp.

Celgar Mill. The Celgar mill is situated on a 400 acre site near the city of Castlegar, British Columbia. The mill is located on the south bank of the Columbia River, approximately 600 kilometers east of the port city of Vancouver, British Columbia, and approximately 32 kilometers north of theCanada-U.S. border. The city of Seattle, Washington is approximately 650 kilometers southwest of Castlegar. The Celgar mill is a single line mill with a current annual production capacity of approximately 520,000 ADMTs of kraft pulp. Internal power generating capacity resulting from the completion of the Celgar Energy Project in 2010 enables the Celgar mill to be self-sufficient in electrical power and to sell surplus electricity. The facilities at the Celgar mill include:

| • | chip storage facilities with a capacity of 250,000 cubic meters of chips; |

| • | a woodroom containing debarking and chipping equipment for pulp logs; |

| • | a fiber line, which includes a dual vessel hydraulic digester, two stage oxygen delignification and a four stage bleach plant; |

| • | two pulp machines, which each include a dryer, a cutter and a baling line; |

| • | a chemical recovery line, which includes a recovery boiler, evaporation plant, recausticizing area and wastewater treatment system; and |

| • | two turbines and generators capable of producing approximately 48 MW and 52 MW, respectively, of electric power from steam produced by the recovery boiler and a power boiler. |

20

The Celgar mill produces high-quality kraft pulp that is made from a unique blend of slow growing/long-fiber Western Canadian tree species. It is used in the manufacture of high-quality paper and tissue products. We believe the Celgar mill’s pulp is known for its excellent product characteristics, including tensile strength, wet strength and brightness. The Celgar mill is a long-established supplier to paper and tissue producers in Asia.

Generation and Sales of “Green” Energy and Chemicals at our Mills

Climate change concerns have caused a proliferation of renewable or “green” energy legislation, incentives and commercialization in both Europe and, increasingly, in North America. This has generated an increase in demand and legislated requirements for “carbon neutral” sources of energy supply. Our pulp mills are large scale bio-refineries that, produce bothin addition to pulp, andalso produce surplus “carbon neutral” or “green” energy. As part of the pulp production process our mills generate “green” energy using carbon-neutral biofuelsbio-fuels such as black liquor and wood waste. Through the incineration of biofuelsbio-fuels in the recovery and power boilers, our mills produce sufficient steam to cover all of our steam requirements and allowsallow us to produce surplus energyelectricity which we sell to third party utilities. As a result, we have benefited from “green” energy legislation, incentives and commercialization that have developed over the last few years in Europe and Canada. In addition, in recent years we have applied considerable resources to increasing our capacity to produce and sell chemicals, primarily tall oil for use in numerous applications including bio-fuels.

Our surplus energy and chemical sales provide our mills with a new stable revenue source unrelated to pulp prices. Since our energy and chemical production are by-products of our pulp production process, there are minimal incremental costs and our surplus energy and chemical sales are highly profitable. We believe that this revenue source from power sales gives our mills a competitive advantage over other older mills which do not have the equipment or capacity to produce and/or sell surplus power and/or chemicals in a meaningful amount.

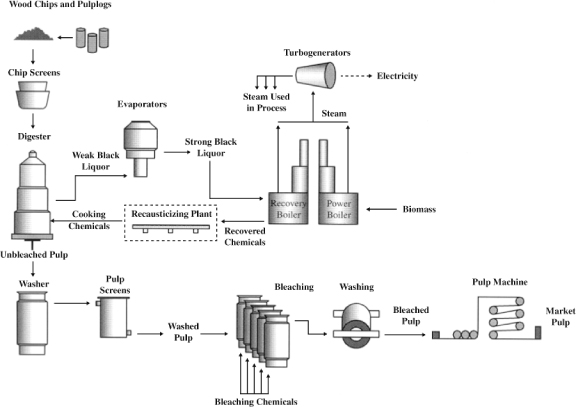

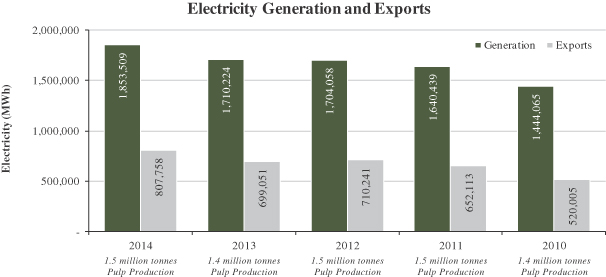

In 20112014 and 2010, we2013, our mills sold 652,113807,758 MWh and 520,005699,051 MWh of surplus energy,electricity, respectively, and recorded revenues of €58.0$88.8 million and €44.2$79.4 million, respectively, from such energy sales. Since our energy production is a by-productIn 2014 and 2013, revenues from the sale of our pulp production process, there are minimal incremental costschemicals were $12.7 million and our surplus energy sales are highly profitable. $12.8 million, respectively.

The following table sets out our electricity generation and surplus energyelectricity sales for the last three years:five years ended December 31, 2014:

21

The following chart sets forth our consolidated revenues from electricity and chemical sales for the five years ended December 31, 2014:

German Mills

Since January 2009, ourOur Rosenthal and Stendal mills have participatedparticipate in a program established pursuant to the Renewable Energy Act. The Renewable EnergySuch Act, in existence since 2000, requires that public electric utilities give priority to electricity produced from renewable energy resourcessources by independent power producers and pay a fixed tariff for a period of 20 years. Previously, this legislation was only applicable to installations with a capacity of 20MW or less, effectively excluding our Rosenthal and Stendal mills. Subsequent amendments to the Renewable Energy Act have removed this restriction. Under the program, our German mills now sell their surplus energy to the local electricity grid at the rates stipulated by the Renewable Energy Act for biomass energy.

Since 2005, our German mills have also benefited from the sale of emission allowances under the European Union Carbon Emissions Trading Scheme, referred to as “EU���EU ETS”. However, our eligibility for special tariffs under the Renewable Energy Act has reduced the amount of emissions allowances granted to our German mills under the EU ETS.

In January 2012,2014, our Rosenthal and Stendal mills sold approximately 178,266 MWh and 509,773 MWh of electricity, respectively, for proceeds of $21.9 million and $56.8 million, respectively.

In December 2013, we announcedcompleted Project Blue Mill which is designed to increasepermits the Stendal mill’smill to produce an annual pulp production byincremental 30,000 ADMTs of pulp and initially produce an additional 109,000 MWMWh of surplus renewable energy. Project Blue Millelectricity and is eligiblefully operational. Sales of such incremental surplus electricity generated approximately $9.7 million in revenues for €12.0 million of non-refundable government grants and theStendal in 2014.

In 2014, our Stendal mill has securedgenerated $11.9 million from the sale of tall oil, a new €17.0 million five-year amortizing secured term debt facility,by-product of which 80% will be government guaranteed. The balance of Project Blue Mill will be funded through operating cash flow ofour production process. In 2014, our Rosenthal mill completed a capital project to also produce and sell tall oil. We estimate that, based on current pricing, the Stendalproject should permit the Rosenthal mill and up to an aggregate of €6.5generate approximately $3.5 million in pro rata shareholder loansannual revenues from Mercer Inc. and its noncontrolling shareholder.tall oil sales.

Celgar Mill

In September 2010, we completed the Celgar Energy Project at the Celgar mill to increase and optimize the mill’s production of “green” energy and optimize its power generation capacity.energy. The project included the installation of a 48 MW condensing turbine,

22

which brought the mill’s installed generating capacity up to 100 MW, and upgrades to the mill’s bark boiler and steam consuming facilities. The Celgar mill has an Electricity Purchase Agreement with B.C.British Columbia Hydro and Power Authority, referred to as “B.C. Hydro”, for the sale of power generated from such project. Under the Electricity Purchase Agreement, the Celgar mill agreed to supply a minimum of approximately 238,000 MWh of surplus electrical energy annually to the utility over a ten-year term.

We financed the Celgar Energy Project largelyprincipally with funding from the GTP. In early October 2009, we received notification from Natural Resources Canada, or “NRCan”, of the Celgar mill’s original allocation of approximately C$57.7$44.6 million in credits under the GTP. In November 2009, we entered into a non-repayable contribution agreement, referred to as the “Contribution Agreement”, with NRCan whereby NRCan provided us with approximately C$40.0 million in grants (of our allocated C$57.7 million) towards certain costs associated with the Celgar Energy Project. Subsequently, NRCan provided an additional C$8.0 million pursuant to the terms of the Contribution Agreement. In 2011, NRCan agreed to allocate approximately C$1.6 million under its Transformative Technologies Program and we entered into additional contribution agreements bringing the total received from NRCan to C$56.1 million.Canadian governmental grants.

In 2011,2014, we produced and sold roughly 140,069approximately 119,719 MWh of surplus renewable electricity at our Celgar mill which generated approximately C$14.5$10.1 million in annual revenues.

Our major costs of production are fiber, labor, fiber, energy and chemicals. Fiber, comprised of wood chips and pulp logs, is our most significant operating expense. Given the significance of fiber to our total operating expenses and our limited ability to control its costs, compared with our other operating costs, volatility in fiber costs can materially affect our margins and results of operations.

Labor

Our labor costs tend to be generally steady, with small overall increases due to inflation in wages and health care costs. Over the last three years, we have been able to generally offset such increases by increasing our efficiencies and production and streamlining operations.

Fiber

Our mills are situated in regions which generally provide a relatively stable supply of fiber. The fiber consumed by our mills consists of wood chips produced by sawmills as a by-product of the sawmilling process and pulp logs. Wood chips are small pieces of wood used to make pulp and are either wood residuals from the sawmilling process or logs or pulp logs chipped especially for this purpose. Pulp logs consist of lower quality logs not used in the production of lumber. Wood chips and pulp logs are cyclical in both price and supply.

Generally, the cost of wood chips and pulp logs areis primarily affected by the supply and demand for lumber. Additionally, regional factors such as harvesting levels and weather conditions can also have a material effect on the supply, demand and price for fiber.

In Germany, since 2006, the price and supply of wood chips has been affected by increasing demand from alternative or renewable energy producers and government initiatives for carbon neutral energy. Declining energy prices, and weakeningweaker economies or warm winters such as in 2014 temper the first half of 2009 tempered the increased demand for wood chips that resultedresulting from initiatives by European governments to promote the use of wood as a carbon neutral energy. Over the long-term, we expect this non-traditional demand for fiber to continue to increase.

In April 2008, the Russian government raised tariffs on the export of sawmill and pulp wood to 25% from the 20%. A further increase to 80% was initially scheduled for January 1, 2009 but was officially deferred twice and Russia’s export tariff remained unchanged at 25% in 2011. In earlyAugust 2012, Russia agreed to enterentered the World Trade Organization, or “WTO”. It is currently expected that Russia will formally enter, and, due to inclusion in the WTO, in June 2012 and will lowerRussia has lowered its export tariffs for certain softwood species to between 13% and 15%, which we believe will havehas had a positive impact on the European fiber supply.

During the past few years, certain customers have endeavored to purchase pulp that is produced using fiber that meets certain recognized wood certification requirements from forest certification agencies like FSC, PEFC, SFI-CSA. If the fiber we purchase does not meet certain wood certifications required by customers, it may make it more difficult or prevent us from selling our pulp to such customers. The chain of custody wood certification process is a voluntary process which allows a company to demonstrate that they use forest resources in accordance with strict principles and standards in the areas of sustainable forest management practices and environmental management. In an effort to procure wood only from sustainably managed sources, we employ an FSC Chain of Custody protocol which requires tracking of fiber origins and preparing risk based assessments regarding the region and operator. In the areas where we operate, we are actively engaged in the further development of certification processes. Although wood certification requirements continue to evolve and are not

23

consistent from jurisdiction to jurisdiction, we currently do not expect certification requirements to have a material adverse impact on our fiber procurement and pulp sales.

Offsetting some of the increases in demand for wood fiber have been initiatives in which we and other producers are participating to increase harvest levels in Germany, particularly from small private forest owners. We believe that Germany has the highest availability of softwood forests in Europe suitable for harvesting and manufacturing. We believe private ownership of such forests is approximately 50%. Many of these forest ownership stakes are very small and have been harvested at rates much lower than their rate of growth. In early 2009, forest owners began to reduce their harvesting rates in response to slowing economies and weaker demand for pulp logs, forest owners reduced their harvesting rates slightly. While prices for pulp logs in Germany remained relatively low in the first half of 2009, further reductions in harvesting rates ledleading to an undersupply which resulted in increased fiber prices laterduring that year. Fiber prices continued to increase through most of 2010 and 2011, driven by a weak lumber market, lower levels of harvesting in central Germany combined withand increased demand for wood from the energy sector for heating and other bio-energy purposes. In 2012, fiber prices in Germany decreased by approximately 17% (in U.S. dollar terms), mainly due to reduced demand for fiber from the European particle board industry and other regional residual fiber users and the start of a recovery in lumber markets. In 2013, fiber prices in Germany increased by approximately 13%, mainly due to strong demand from the European board producers and sawmills, along with the increased demand for pellets due to an unusually cold winter. In addition to increased demand, high snow levels and summer floods in some areas in which we operate led to lower fiber supply levels during much of 2013. In 2014, our per unit fiber costs in Germany decreased by 6% due to sawmills running at high rates, a stronger supply of logs and lower demand from pellet producers and board manufacturers.

We believe we are the largest consumer of wood chips and pulp logs in Germany and often provide the best long-term economic outlet for the sale of wood chips in Eastern Germany. We coordinate the wood procurement activities for our German mills to reduce overall personnel and administrative costs, provide greater purchasing power and coordinate buying and trading activities. This coordination and integration of fiber flows also allows us to optimize transportation costs, and the species and fiber mix for both mills.

In 2011,2014, the Rosenthal mill consumed approximately 1.8 million cubic meters of fiber. Approximately 70%69% of such consumption was in the form of sawmill wood chips and approximately 30%31% was in the form of pulp logs. The wood chips for the Rosenthal mill are sourced from approximately 3126 sawmills located primarily in the states of Bavaria, Baden-Württemberg and Thüringia and are within a 300 kilometer radius of the Rosenthal mill.

Within this radius, the Rosenthal mill is the largest consumer of wood chips. Given its location and size, the Rosenthal mill is often the best economic outlet for the sale of wood chips in the area. Approximately 73%71% of the fiber consumed by the Rosenthal mill is spruce and the remainder is pine. While fiber costs and supply are subject to cyclical changes largely in the sawmill industry, we expect that we will be able to continue to obtain an adequate supply of fiber on reasonably satisfactory terms for the Rosenthal mill due to its location and our long-term relationships with suppliers. We have not historically experienced any significant fiber supply interruptions at the Rosenthal mill.

Wood chips for the Rosenthal mill are normally sourced from sawmills under one year or quarterly supplyone-year contracts with fixed volumes, which providequarterly adjustments for price adjustments.market pricing. Substantially all of our chip supply is sourced from suppliers with which we have a long-standing relationship. We generally enter into annual contracts with such suppliers. Pulp logs are sourced from the state forest agencies in Thüringia, Saxony and Bavaria on a contract basis and partly from private holders and traders on the same basis as wood chips. Like the wood chip supply arrangements, these contracts tend to be of less thanfor one-year terms with quarterly adjustments for market pricing. We organize the harvestingtransportation of pulp logs sourced from the state agencies in Thüringia, Saxony and Bavaria after discussions with the agencies regarding the quantities of pulp logs that we require.

In 2011,2014, the Stendal mill consumed approximately 3.23.4 million cubic meters of fiber. Approximately 25%30% of such fiber was in the form of sawmill wood chips and approximately 75%70% in the form of pulp logs. The core wood supply region for the Stendal mill includes most of the Northern part of Germany within an approximate 300 kilometer radius of the mill. We also purchase wood chips from Southwestern and Southern

24

Germany. The fiber base in the wood supply area for the Stendal mill consisted of approximately 68%55% pine, and 32%44% spruce and 1% other species in 2011.2014. The Stendal mill has sufficient chipping capacity to fully operate solely using pulp logs, if required. We source pulp logs partly from private forest holders, municipal forest owners and partly from state forest agencies in Thüringia,Saxony-Anhalt, Mecklenburg-Western Pomerania, Saxony, Lower Saxony, North Rhine-Westphalia, Hesse and Brandenburg.Brandenburg, Bavaria, Schleswig-Holstein, Rhineland Palatinate and the City of Berlin. The volumes are distributed at optimal costs between the mills. In addition, in 2013 and 2014, the Stendal mill also imported fiber from Poland and the Baltic Sea region.

In 2011,2014, the Celgar mill consumed approximately 2.62.4 million cubic meters of fiber. Approximately 61%78% of such fiber was in the form of sawmill wood chips and the remaining 39%22% came from pulp logs processed through its woodroom or chipped by a third party. The source of fiber at the mill is characterized by a mixture of species (whitewoods(pine, douglas fir, hemlock, cedar and cedar)spruce) and the mill sources fiber from a number of Canadian and U.S. suppliers.

As a result of the cyclical decline in sawmill chip availabilitysupply resulting from lower lumber production in British Columbia commencing in 2008, the Celgar mill has increased its U.S. purchases of fiber, diversified its suppliers and, where possible, increased chip production through third party field chipping contracts and existing sawmill suppliers. Additionally, in the early part ofIn 2009, the Celgar mill completed a project to upgradeupgraded its woodroom which, along with subsequent improvements during the year, increased its capacity to be able to process up to 50%40% of the mill’s fiber needs compared to only approximately 10% previously.needs. The woodroom upgrades also increased the mill’s ability to process smallsmaller diameter logs and facilitate an efficient flow of fiber. This has increased the overall volume of fiber being processed and helped mitigate increases in the price of fiber. A recovery in U.S. housing starts which commenced in the latter part of 2012 and continued in 2013 and 2014 resulted in increased sawmill activity. This increased the supply of wood chips for the Celgar mill and reduced its need for pulp logs, which are generally a higher cost for the mill than wood chips.

The Celgar mill has access to over 35approximately 29 different suppliers from Canada and the U.S., representing approximately 75%78% of its total annual fiber requirements. The Celgar mill’s woodroom and third party chippers supplied the remaining 25%22% of the mill’s fiber requirements in 2011.2014. Chips are purchased in Canada and the U.S. in accordance with chip purchase agreements. Generally, pricing is reviewed and adjusted periodically to reflect market prices. SeveralOne of the longer-term contracts areis a so-called “evergreen” agreements,agreement, where the contract remains in effect until one of the parties elects to terminate. Termination requires a minimum of two, and in some cases, five years’ writtenterminate after providing the stipulated notice. Certain non-evergreen long-term agreements provideAll other contracts are generally for renewal negotiations prior to expiry.one year with quarterly adjustments or on three-month terms.