UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-Q

|

| |

| x | Quarterly report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934. |

| | |

| | For the quarterly period ended April 30, 20122013 |

| | |

| | OR |

| | |

| o | Transition report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934. |

| | |

| | For the transition period from to . |

| | |

| | COMMISSION FILE NUMBER 000-51277 |

GRANITE FALLS ENERGY, LLC

(Exact name of registrant as specified in its charter)

|

| | | | |

| Minnesota | | 41-1997390 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

| | | |

| 15045 Highway 23 SE, Granite Falls, MN 56241-0216 |

| (Address of principal executive offices) |

| |

| (320) 564-3100 |

| (Registrant's telephone number, including area code) |

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

x Yes o No

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

x Yes o No

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act:

|

| |

Large Accelerated Filer o | Accelerated Filer o |

Non-Accelerated Filer x | Smaller Reporting Company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

o Yes x No

Indicate the number of shares outstanding of each of the issuer's classes of common stock, as of the latest practicable date: As of June 14, 20122013 there were 30,606 membership units outstanding.

INDEX

PART I FINANCIAL INFORMATION

Item 1. Financial Statements

GRANITE FALLS ENERGY, LLC

Condensed Balance Sheets

| | | ASSETS | | April 30, 2012 | | October 31, 2011 | | April 30, 2013 | | October 31, 2012 |

| | (Unaudited) | |

| | (Unaudited) | |

|

| Current Assets | |

| |

| |

| |

|

| Cash | | $ | 9,352,443 |

| | $ | 13,064,560 |

| | $ | 1,386,003 |

| | $ | 685,828 |

|

| Restricted cash | | 600,000 |

| | 1,503,000 |

| | 474,000 |

| | 494,000 |

|

| Accounts receivable | | 4,239,714 |

| | 3,777,547 |

| | 6,152,560 |

| | 7,356,534 |

|

| Inventory | | 5,047,702 |

| | 8,615,411 |

| | 12,790,395 |

| | 12,013,169 |

|

| Commodity derivative instruments | | — |

| | 404,050 |

| |

| Prepaid expenses and other current assets | | 255,101 |

| | 177,793 |

| | 262,314 |

| | 165,519 |

|

| Total current assets | | 19,494,960 |

| | 27,542,361 |

| | 21,065,272 |

| | 20,715,050 |

|

| |

| |

| |

| |

|

| Property, Plant and Equipment | |

| |

| |

| |

|

| Land and improvements | | 7,081,707 |

| | 3,627,973 |

| | 6,552,967 |

| | 7,095,172 |

|

| Railroad improvements | | 4,121,148 |

| | 4,121,148 |

| | 7,961,096 |

| | 4,121,148 |

|

| Process equipment and tanks | | 64,087,173 |

| | 63,592,688 |

| | 64,678,860 |

| | 64,678,860 |

|

| Administration building | | 279,734 |

| | 279,734 |

| | 279,734 |

| | 279,734 |

|

| Office equipment | | 154,072 |

| | 154,072 |

| | 244,160 |

| | 154,072 |

|

| Rolling stock | | 1,250,056 |

| | 642,908 |

| | 1,305,395 |

| | 1,305,395 |

|

| Construction in progress | | 409,030 |

| | 366,979 |

| | 1,636,310 |

| | 3,831,263 |

|

| | | 77,382,920 |

| | 72,785,502 |

| | 82,658,522 |

| | 81,465,644 |

|

| Less accumulated depreciation | | 38,986,619 |

| | 36,886,541 |

| | 43,365,199 |

| | 41,047,562 |

|

| Net property, plant and equipment | | 38,396,301 |

| | 35,898,961 |

| | 39,293,323 |

| | 40,418,082 |

|

| |

| |

| |

| |

|

| | | | | | | | | |

| Total Assets | | $ | 57,891,261 |

| | $ | 63,441,322 |

| | $ | 60,358,595 |

| | $ | 61,133,132 |

|

Notes to Unaudited Condensed Financial Statements are an integral part of this Statement.

GRANITE FALLS ENERGY, LLC

Condensed Balance Sheets

| | | LIABILITIES AND MEMBERS' EQUITY | | April 30, 2012 | | October 31, 2011 | | April 30, 2013 | | October 31, 2012 |

| | (Unaudited) | |

| | (Unaudited) | |

|

| Current Liabilities | |

| |

| |

| |

|

| Current portion of long-term debt | | $ | 112,525 |

| | $ | — |

| | $ | 116,953 |

| | $ | 114,718 |

|

| Accounts payable | | 1,359,760 |

| | 1,591,036 |

| | 1,432,609 |

| | 3,527,840 |

|

| Corn payable to FCE - related party | | 2,785,992 |

| | 2,516,923 |

| |

| Corn payable to FCE | | | 4,496,144 |

| | 1,995,997 |

|

| Commodity derivative instruments | | | 47,813 |

| | 45,563 |

|

| Accrued liabilities | | 338,682 |

| | 375,425 |

| | 602,592 |

| | 318,819 |

|

| Distribution payable | | — |

| | 9,196,800 |

| |

| Total current liabilities | | 4,596,959 |

| | 13,680,184 |

| | 6,696,111 |

| | 6,002,937 |

|

| |

| |

| |

| |

|

| Long-Term Debt, less current portion | | 440,830 |

| | — |

| | 553,789 |

| | 5,274,870 |

|

| |

| |

| |

| |

|

| Commitments and Contingencies | |

| |

| |

| |

|

| |

| |

| |

| |

|

| Members' Equity, 30,606 and 30,656 units authorized, issued and outstanding at April 30, 2012 and October 31, 2011, respectively | | 52,853,472 |

| | 49,761,138 |

| |

| Members' Equity, 30,606 units authorized, issued and outstanding | | | 53,108,695 |

| | 49,855,325 |

|

| |

| |

| |

| |

|

| Total Liabilities and Members’ Equity | | $ | 57,891,261 |

| | $ | 63,441,322 |

| | $ | 60,358,595 |

| | $ | 61,133,132 |

|

| | | | | | | | | |

| | | | | | | | | |

Notes to Unaudited Condensed Financial Statements are an integral part of this Statement.

GRANITE FALLS ENERGY, LLC

Condensed Statements of Operations

| |

| Three Months Ended | | Three Months Ended | | Six Months Ended | | Six Months Ended | Three Months Ended | | Three Months Ended | | Six Months Ended | | Six Months Ended |

| April 30, 2012 | | April 30, 2011 | | April 30, 2012 | | April 30, 2011 | April 30, 2013 | | April 30, 2012 | | April 30, 2013 | | April 30, 2012 |

| (Unaudited) | | (Unaudited) | | (Unaudited) | | (Unaudited) | (Unaudited) | | (Unaudited) | | (Unaudited) | | (Unaudited) |

| | | | | |

| |

| | | | |

|

| |

|

|

| Revenues | $ | 39,025,122 |

| | $ | 34,537,750 |

| | $ | 82,770,898 |

| | $ | 65,254,096 |

| $ | 48,020,602 |

| | $ | 39,025,122 |

| | $ | 95,137,724 |

| | $ | 82,770,898 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Cost of Goods Sold - primarily related party | 38,367,706 |

| | 30,833,215 |

| | 78,425,531 |

| | 58,015,828 |

| |

| Cost of Goods Sold | | 44,390,630 |

| | 38,367,706 |

| | 90,675,608 |

| | 78,425,531 |

|

|

| |

| |

| |

|

| |

| |

|

| |

|

|

| Gross Profit | 657,416 |

| | 3,704,535 |

| | 4,345,367 |

| | 7,238,268 |

| 3,629,972 |

| | 657,416 |

| | 4,462,116 |

| | 4,345,367 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Operating Expenses | 590,481 |

| | 458,806 |

| | 1,254,217 |

| | 1,016,927 |

| 582,965 |

| | 590,481 |

| | 1,145,660 |

| | 1,254,217 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Operating Income | 66,935 |

| | 3,245,729 |

| | 3,091,150 |

| | 6,221,341 |

| 3,047,007 |

| | 66,935 |

| | 3,316,456 |

| | 3,091,150 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Other Income (Expense) |

| |

| |

| |

|

| |

| |

| |

|

| Other income, net | 51,004 |

| | 6,890 |

| | 65,548 |

| | 7,340 |

| 23,078 |

| | 51,004 |

| | 24,225 |

| | 65,548 |

|

| Interest income | 4,052 |

| | 18,008 |

| | 15,281 |

| | 59,001 |

| 41 |

| | 4,052 |

| | 95 |

| | 15,281 |

|

| Interest expense | (5,525 | ) | | (517 | ) | | (13,225 | ) | | (5,976 | ) | (38,183 | ) | | (5,525 | ) | | (87,406 | ) | | (13,225 | ) |

| Total other income, net | 49,531 |

| | 24,381 |

| | 67,604 |

| | 60,365 |

| |

| Total other income (expense), net | | (15,064 | ) | | 49,531 |

| | (63,086 | ) | | 67,604 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Net Income | $ | 116,466 |

| | $ | 3,270,110 |

| | $ | 3,158,754 |

| | $ | 6,281,706 |

| $ | 3,031,943 |

| | $ | 116,466 |

| | $ | 3,253,370 |

| | $ | 3,158,754 |

|

|

| |

| |

| |

|

| |

| |

| |

|

| Weighted Average Units Outstanding - Basic and Diluted | 30,606 |

| | 30,656 |

| | 30,623 |

| | 30,656 |

| 30,606 |

| | 30,606 |

| | 30,606 |

| | 30,623 |

|

| | | | | |

| |

| | | | |

| |

|

| Net Income Per Unit - Basic and Diluted | $ | 3.81 |

| | $ | 106.67 |

| | $ | 103.15 |

| | $ | 204.91 |

| $ | 99.06 |

| | $ | 3.81 |

| | $ | 106.30 |

| | $ | 103.15 |

|

| | | | | |

| |

|

| |

| |

| |

|

| Distributions Per Unit | $ | — |

| | $ | — |

| | $ | 300.00 |

| | $ | 300.00 |

| |

| Distributions Per Unit - Basic and Diluted | | $ | — |

| | $ | — |

| | $ | — |

| | $ | 300.00 |

|

| | | | | | | | | | | | | | | |

Notes to Unaudited Condensed Financial Statements are an integral part of this Statement.

GRANITE FALLS ENERGY, LLC

Condensed Statements of Cash Flows

| |

| Six Months Ended | | Six Months Ended | Six Months Ended | | Six Months Ended |

| April 30, 2012 | | April 30, 2011 | April 30, 2013 | | April 30, 2012 |

| (Unaudited) | | (Unaudited) | (Unaudited) | | (Unaudited) |

| Cash Flows from Operating Activities |

| |

|

| |

|

| Net income | $ | 3,158,754 |

| | $ | 6,281,706 |

| $ | 3,253,370 |

| | $ | 3,158,754 |

|

| Adjustments to reconcile net income to net cash provided by operations: |

| |

|

| |

|

| Depreciation and amortization | 2,100,078 |

| | 1,912,414 |

| |

| Depreciation | | 2,317,637 |

| | 2,100,078 |

|

| Change in fair value of derivative instruments | 1,301,250 |

| | (2,243,876 | ) | (26,582 | ) | | 1,301,250 |

|

| Changes in assets and liabilities: |

| |

|

| |

|

| Restricted cash | 903,000 |

| | (44,031 | ) | 20,000 |

| | 903,000 |

|

| Derivative instruments | (897,200 | ) | | 1,776,066 |

| |

| Derivative Instruments | | 28,832 |

| | (897,200 | ) |

| Accounts receivable | (462,167 | ) | | 1,236,456 |

| 1,203,974 |

| | (462,167 | ) |

| Inventory | 3,567,709 |

| | (2,879,109 | ) | (777,226 | ) | | 3,567,709 |

|

| Prepaid expenses and other current assets | (77,308 | ) | | (81,745 | ) | (96,795 | ) | | (77,308 | ) |

| Accounts payable | 37,793 |

| | 344,177 |

| 404,916 |

| | 37,793 |

|

| Accrued liabilities | (103,163 | ) | | 83,272 |

| 283,773 |

| | (103,164 | ) |

| Net Cash Provided by Operating Activities | 9,528,746 |

| | 6,385,330 |

| 6,611,899 |

| | 9,528,745 |

|

|

| |

|

| |

|

| Cash Flows from Investing Activities |

| |

|

| |

|

| Proceeds from maturity of short-term investments | — |

| | 3,500,000 |

| |

| Proceeds from sale of land | | 540,000 |

| | — |

|

| Payments for capital expenditures | (135,680 | ) | | (107,423 | ) | (1,732,878 | ) | | (8,174 | ) |

| Payments for land acquisition | (3,453,734 | ) | | — |

| — |

| | (3,990,270 | ) |

| Payments for construction in process | (409,030 | ) | | (2,505,789 | ) | |

| Net Cash Provided by (Used in) Investing Activities | (3,998,444 | ) | | 886,788 |

| |

| Net Cash Used in Investing Activities | | (1,192,878 | ) | | (3,998,444 | ) |

|

| |

|

| |

|

| Cash Flows from Financing Activities |

| |

|

| |

|

| Payments on long-term debt | (45,619 | ) | | (30,490 | ) | |

| Payments on long-term debt, net | | (4,718,846 | ) | | (45,619 | ) |

| Member distributions paid | (9,196,800 | ) | | (9,196,800 | ) | — |

| | (9,196,800 | ) |

| Net Cash Used in Financing Activities | (9,242,419 | ) | | (9,227,290 | ) | (4,718,846 | ) | | (9,242,419 | ) |

|

| |

|

| |

|

| Net Decrease in Cash | (3,712,117 | ) | | (1,955,172 | ) | |

| Net Increase (Decrease) in Cash | | 700,175 |

| | (3,712,118 | ) |

|

| |

|

| |

|

| Cash - Beginning of Period | 13,064,560 |

| | 10,664,225 |

| 685,828 |

| | 13,064,560 |

|

|

| |

|

| |

|

| Cash - End of Period | $ | 9,352,443 |

| | $ | 8,709,053 |

| $ | 1,386,003 |

| | $ | 9,352,442 |

|

|

| |

|

| |

|

| Supplemental Cash Flow Information |

| |

|

| |

|

| Cash paid during the period for: |

| |

|

| |

|

| Interest expense | $ | 13,225 |

| | $ | 5,983 |

| $ | 87,406 |

| | $ | 13,225 |

|

|

| |

|

| |

|

| Supplemental Disclosure of Noncash Investing, Operating and Financing Activities |

| |

| |

|

| |

| |

| Supplemental Disclosure of Non-Cash Investing and Financing Activities | |

| |

|

| Transfer of construction in process to fixed assets | | $ | 2,194,953 |

| | $ | 366,979 |

|

| Capital expenditures financed with long-term debt | $ | 598,974 |

| | $ | — |

| $ | — |

| | $ | 598,974 |

|

|

| |

|

| |

|

| Transfer of construction in process to fixed assets | $ | 366,979 |

| | $ | 2,447,516 |

| |

Notes to Unaudited Condensed Financial Statements are an integral part of this Statement.

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 20122013

1. SUMMARY OF SIGNIFICANT ACCOUNTING POLICIES

Basis of Presentation

The accompanying condensed balance sheet as of October 31, 20112012 is derived from audited financial statements. The unaudited interim condensed financial statements of Granite Falls Energy, LLC (the “Company”) reflect all adjustments consisting only of normal recurring adjustments that are, in the opinion of management, necessary for a fair presentation of financial position and results of operations and cash flows. The results for the three and six month periods ended April 30, 20122013 are not necessarily indicative of the results that may be expected for a full fiscal year. Certain information and note disclosures normally included in annual financial statements prepared in accordance with accounting principles generally accepted in the United States of America (“GAAP”) are condensed or omitted pursuant to the rules and regulations of the Securities and Exchange Commission (“SEC”), although the Company believes that the disclosures made are adequate to make the information not misleading. These condensed financial statements should be read in conjunction with the Company's audited financial statements and notes thereto included in its annual report for the year ended October 31, 20112012 filed on Form 10-K with the SEC.

Nature of Business

Granite Falls Energy, LLC (“GFE” or the “Company”) is a Minnesota limited liability company currently producing fuel-grade ethanol, distillers grains, and crude corn oil near Granite Falls, Minnesota and sells these products, pursuant to marketing agreements, throughout the continental United States and on the international market. GFE's plant has an approximate annual production capacity of 60 million gallons. However, until recently the plant was only gallons, but is currently permitted to produce 49.9up to 70 million gallons of undenatured ethanol on a twelve month rolling sum basis. During the second quarter of fiscal 2011, the Company obtained an amendment to its environmental permits allowing the Company to produce up to 70 million gallons of undenatured ethanol on a twelve month rolling sum basis.

Accounting Estimates

Management uses estimates and assumptions in preparing these condensed financial statements in accordance with generally accepted accounting principles in the United States of America. Those estimates and assumptions affect the reported amounts of assets and liabilities, the disclosure of contingent assets and liabilities, and the reported revenues and expenses. The Company uses estimates and assumptions in accounting for the following significant matters, among others: economic lives of property, plant, and equipment, valuation of commodity derivatives and inventory, and the assumptions used in the impairment analysis of long-lived assets. Actual results may differ from previously estimated amounts, and such differences may be material to our condensed financial statements. The Company periodically reviews estimates and assumptions, and the effects of revisions are reflected in the period in which the revision is made.

Revenue Recognition

The Company generally sells ethanol and related products pursuant to marketing agreements. Revenues from the production of ethanol and the related products are recorded when the customer has taken title and assumed the risks and rewards of ownership, prices are fixed or determinable and collectability is reasonably assured. Ethanol and related products are generally shipped free on board (FOB) shipping point. The Company believes there are no ethanol sales, during any given month, which should be considered contingent and recorded as deferred revenue.

In accordance with the Company's agreements for the marketing and sale of ethanol and related products, marketing fees and commissions due to the marketers are deducted from the gross sales price as earned. These fees and commissions are recorded net of revenues, as they do not provide an identifiable benefit that is sufficiently separable from the sale of ethanol and related products. Shipping costs incurredpaid by the Company to the marketer in the sale of ethanol are not specifically identifiable and, as a result, are recorded based on the net selling price reported to the Company from the marketer. Shipping costs incurred by the Company in the sale of distillers grains and corn oil are included in cost of goods sold.

Derivative Instruments

From time to time the Company enters into derivative transactions to hedge its exposures to commodity price fluctuations. The Company is required to record these derivatives in the balance sheetsheets at fair value.

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 20122013

In order for a derivative to qualify as a hedge, specific criteria must be met and appropriate documentation maintained. Gains and losses from derivatives that do not qualify as hedges, or are undesignated, must be recognized immediately in earnings. If the derivative does qualify as a hedge, depending on the nature of the hedge, changes in the fair value of the derivative will be either offset against the change in fair value of the hedged assets, liabilities, or firm commitments through earnings or recognized in other comprehensive income until the hedged item is recognized in earnings. Changes in the fair value of undesignated derivatives are recorded in cost of goods sold.earnings.

Additionally, the Company is required to evaluate its contracts to determine whether the contracts are derivatives. Certain contracts that literally meet the definition of a derivative may be exempted as “normal purchases or normal sales”. Normal purchases and normal sales are contracts that provide for the purchase or sale of something other than a financial instrument or derivative instrument that will be delivered in quantities expected to be used or sold over a reasonable period in the normal course of business. Contracts that meet the requirements of normal purchases or sales are documented as normal and exempted from accounting and reporting requirements, and therefore, are not marked to market in our condensed financial statements.

In order to reduce the risks caused by market fluctuations, the Company occasionally hedges its anticipated corn, natural gas, and denaturant purchases and ethanol sales by entering into options and futures contracts. These contracts are used with the intention to fix the purchase price of anticipated requirements for corn in the Company's ethanol production activities and the related sales price of ethanol. The fair value of these contracts is based on quoted prices in active exchange-traded or over-the-counter market conditions. Although the Company believes its commodity derivative positions are economic hedges, none have been formally designated as a hedge for accounting purposes and derivative positions are recorded on the balance sheet at their fair market value, with changes in fair value recognized in current period earnings or losses. The Company does not enter into financial instruments for trading or speculative purposes.

The Company has adopted authoritative guidance related to “Derivatives and Hedging,” and has included the required enhanced quantitative and qualitative disclosure about objectives and strategies for using derivatives, quantitative disclosures about fair value amounts of gains and losses from derivative instruments, and disclosures about credit-risk-related contingent features in derivative agreements. See further discussion in Note 4.

2. RISKS AND UNCERTAINTIES

The Company has certain risks and uncertainties that it experiences during volatile market conditions. These volatilities can have a severe impact on operations. The Company's revenues are derived from the sale and distribution of ethanol, distillers grains, and corn oil to customers primarily located in the U.S.United States. Corn for the production process is supplied to our plant primarily from local agricultural producers and from purchases on the open market. Ethanol sales typically average 80-85%75-85% of total revenues and corn costs typically average 70-80%75-85% of cost of goods sold.

The Company's operating and financial performance is largely driven by the prices at which they sell ethanol and the net expense of corn. The price of ethanol is influenced by factors such as supply and demand, the weather, government policies and programs, and unleaded gasoline prices and the petroleum markets as a whole. Excess ethanol supply in the market, in particular, puts downward pressure on the price of ethanol. Our largest cost of production is corn. The cost of corn is generally impacted by factors such as supply and demand, the weather, government policies and programs, and our risk management program used to protect against the price volatility of these commodities.

3. INVENTORY

Inventories consist of the following:

| | | | | | | | | April 30, 2013 | | October 31, 2012 |

| | April 30, 2012 | | October 31, 2011 | (Unaudited) | | |

| Raw materials | $ | 1,790,385 |

| | $ | 5,323,615 |

| $ | 8,817,361 |

| | $ | 8,977,820 |

|

| Spare parts | 648,555 |

| | 584,011 |

| 671,881 |

| | 682,896 |

|

| Work in process | 1,101,054 |

| | 1,150,239 |

| 1,174,317 |

| | 1,183,188 |

|

| Finished goods | 1,507,708 |

| | 1,557,546 |

| 2,126,836 |

| | 1,169,265 |

|

| Totals | $ | 5,047,702 |

| | $ | 8,615,411 |

| $ | 12,790,395 |

| | $ | 12,013,169 |

|

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 2013

The Company performs a lower of cost or market analysis on inventory to determine if the market values of certain inventories are less

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 2012

than their carrying value, which is attributable primarily to decreases in market prices of corn and ethanol. Based on the lower of cost or market analysis, the Company did not record a lower of cost or market changeadjustment on certain inventories for the quarterthree or six month periods ended April 30, 2012 or 2011.2013 and 2012.

4. DERIVATIVE INSTRUMENTS

As of April 30, 2013, the total notional amount of the Company's outstanding corn derivative instruments was approximately 1,185,000 bushels that were entered into to hedge forecasted corn purchases through July 2013. There may be offsetting positions that are shown on a net basis that could lower the notional amount of positions outstanding as disclosed above.

The following tables provide details regarding the Company's derivative instruments at April 30, 2013, none of which are designated as hedging instruments:

|

| | | | | | | | | |

| | Balance Sheet location | | Assets | | Liabilities |

| | | | | | |

| Corn contracts | Commodity Derivative instruments | | $ | — |

| | $ | (47,813 | ) |

| | | | | | |

| Totals | | | $ | — |

| | $ | (47,813 | ) |

In addition, as of April 30, 2013 the Company maintained $474,000 of restricted cash related to margin requirements for the Company's commodity derivative instrument positions.

As of October 31, 2012, the Company did not have anytotal notional amount of the Company's outstanding corn derivative instruments.instruments was approximately 1,235,000 bushels that were entered into to hedge forecasted corn purchases through March 2013. There may be offsetting positions that are shown on a net basis that could lower the notional amount of positions outstanding as disclosed above.

The following tables provide details regarding the Company's derivative instruments at October 31, 2011,2012, none of which are designated as hedging instruments:

| | | | Balance Sheet location | | Assets | | Liabilities | Balance Sheet location | | Assets | | Liabilities |

| | | | | | | | | | | |

| Corn contracts | Commodity Derivative instruments | | $ | 404,050 |

| | $ | — |

| Commodity Derivative instruments | | $ | — |

| | | $ | (45,563 | ) | |

| | | | | | | | | | | |

| Totals | | | $ | 404,050 |

| | $ | — |

| | | $ | — |

| | | $ | (45,563 | ) | |

In addition, as of October 31, 20112012 the Company maintained $903,000$494,000 of restricted cash related to margin requirements for the Company's commodity derivative instrument positions.

The following tables provide details regarding the gains and (losses) from Company's derivative instruments in statements of operations, none of which are designated as hedging instruments:

|

| | | | | | | | | | | | |

| | | Statement of Operations location | | Three Months Ended April 30, |

| | | | 2012 | | 2011 |

| | | | | | | |

| Ethanol contracts | | Revenue | | — | | | (10,546 | ) |

| Corn contracts | | Cost of Goods Sold | | (30,682 | ) | | 1,369,782 | |

| Natural gas contracts | | Cost of Goods Sold | | — | | | 14,985 | |

| | | | | | | |

| Total gain (loss) | | | | $ | (30,682 | ) | | $ | 1,374,221 | |

|

| | | | | | | | | | | | |

| | | Statement of Operations location | | Three Months Ended April 30, |

| | | | 2013 | | | 2012 | |

| | | | | | | |

| Corn contracts | | Cost of Goods Sold | | $ | (248,955 | ) | | $ | (30,682 | ) |

| | | | | | | |

| Total Gain (Loss) | | | | $ | (248,955 | ) | | $ | (30,682 | ) |

| | | | | | | |

|

| | | | | | | | | | | | |

| | | Statement of Operations location | | Six Months Ended April 30, |

| | | | 2012 | | 2011 |

| | | | | | | |

| Ethanol contracts | | Revenue | | — | | | (10,546 | ) |

| Corn contracts | | Cost of Goods Sold | | (1,301,250 | ) | | 2,245,607 | |

| Natural gas contracts | | Cost of Goods Sold | | — | | | 8,815 | |

| | | | | | | |

| Total gain (loss) | | | | $ | (1,301,250 | ) | | $ | 2,243,876 | |

5. REVOLVING LINE OF CREDIT

The Company has a Loan Agreement with a bank. Under the Loan Agreement, the Company has a revolving line of credit with a maximum of $6,000,000 available through March 2013 and is secured by substantially all of the Company's assets. The interest rate on the revolving line of credit is at 0.25 percentage points above the prime rate as reported by the Wall Street Journal, with a minimum rate of 4.0%. The interest rate on the revolving line of credit at April 30, 2012 was 4.0%, the minimum rate under the terms of the agreement. At April 30, 2012, the Company had no outstanding balance on this line of credit. The Company is required

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 20122013

to maintain

|

| | | | | | | | | | | | |

| | | Statement of Operations location | | Six Months Ended April 30, |

| | | | 2013 | | | 2012 | |

| | | | | | | |

| Corn contracts | | Cost of Goods Sold | | $ | 26,582 | | | $ | (1,301,250 | ) |

| | | | | | | |

| Total Gain (Loss) | | | | $ | 26,582 | | | $ | (1,301,250 | ) |

| | | | | | | |

5. REVOLVING LINE OF CREDIT AND LONG-TERM DEBT

The Company has two credit facilities with a savings account balance withlender. The first is a seasonal revolving operating loan facility in the Bank totaling 10%amount of $6,000,000. The second is a revolving term loan facility in the maximumamount of $8,000,000. However, the amount available for borrowing under this facility reduces by $1,000,000 every six months, beginning September 1, 2013, with final payment due March 1, 2017.

The interest rates for both facilities are based on the line of credit to serve as collateralbank's "One Month LIBOR Index Rate," plus 265 and 290 basis points on this line of credit. At boththe seasonal and revolving term commitments, respectively. Both facilities are available through March 2017. The outstanding balance on the revolving term loan on April 30, 20122013 and October 31, 2011, this amount totaled $600,0002012 was $229,912 and is included in restricted cash.$4,891,952, respectively, and the interest rates were 3.10% and 3.12% as of those dates, respectively. The Company currently has no outstanding balance on the seasonal revolving operating loan facility.

The credit facilities require the Company to comply with certain financial covenants. As of April 30, 2013 and October 31, 2012, the Company was in compliance with these financial covenants and expects to be in compliance through fiscal 2013. The credit facilities are secured by substantially all assets of the Company.

At April 30, 2013, the Company also hashad letters of credit totaling $386,928$337,928 with the bank as part of a credit requirement of Northern Natural Gas. These letters of credit reduce the amount available under the seasonal revolving line of creditoperating loan to approximately $5,613,000.

6. LONG-TERM DEBT$5,662,000.

Long-term debt consists of the following:

| | | | April 30, 2012 | | October 31, 2011 | April 30, 2013 | | October 31, 2012 |

| Capital One Equipment Leasing/Finance: | | | | | | |

| Shuttlewagon Railcar Mover (5 year term at 3.875%) | $ | 553,355 |

| | $ | — |

| $ | 440,830 |

| | $ | 497,636 |

|

| | | | | |

| Revolving Term Loan | | 229,912 | | | 4,891,952 | |

| Total Debt | | 670,742 | | | 5,389,588 | |

| Less: Current Maturities | (112,525 | ) | | — |

| (116,953 | ) | | (114,718 | ) |

| | | | | | | |

| Total Long-Term Debt | $ | 440,830 |

| | $ | — |

| $ | 553,789 |

| | $ | 5,274,870 |

|

The estimated maturities of long-term debt at April 30, 2013 are as follows:

|

| | | | |

| May 1, 2013 to April 30, 2014 | | $ | 116,953 |

|

| May 1, 2014 to April 30, 2015 | 351,468 | |

| May 1, 2015 to April 30, 2016 | 126,340 | |

| May 1, 2016 to April 30, 2017 | 75,981 | |

| Total debt |

| $ | 670,742 |

|

7.6. LEASES

The Company has a lease agreement with Trinity Industries Leasing Company (“Trinity”) for 75 hopper cars to assist with the transport of distiller's grains by rail through November 2015.April 2018. The Company will pay Trinity $620$620 per month plus $0.03$0.03 per mile traveled in excess of 36,000 miles per year. Rent expense for these leases was approximately $137,355$139,000 and $137,640$137,000 for the three month

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 2013

periods ended April 30, 20122013 and 2011,2012, respectively. Rent expense for these leases was approximately $278,000 and $272,000 for the six month periods ended April 30, 2013 and 2012, and 2011, respectively, was approximately $272,000 and $278,000.respectively.

At April 30, 2012, theThe Company hadhas lease agreements with three leasing companies for 177 rail car leases for the transportation of the Company's ethanol with various maturity dates through October 2017. The rail car lease payments are due monthly in the aggregate amount of approximately $107,000.$107,000. Rent expense for these leases was approximately $317,835$364,000 and $275,606$318,000 for the three month periods ended April 30, 20122013 and 2011,2012, respectively. Rent expense for these leases was approximately $709,000 and $636,000 for the six month periods ended April 30, 2013 and 2012, and 2011, respectively, was approximately $636,000 and $540,000.respectively.

8.7. MEMBERS' EQUITY

The Company has one class of membership units. The units have no par value and have identical rights, obligations and privileges. Income and losses are allocated to all members based upon their respective percentage of units held. As of April 30, 20122013 and October 31, 2011,2012, the Company had 30,606 and 30,656 respectively, membership units issued and outstanding.

In October 2011, the Board of Governors declared a cash distribution of $300 per unit or $9,196,800 for unit holders of record as of October 27, 2011. The distribution was paid on December 15, 2011.

In December 2011, the Board of Governors exercised its discretion to redeem 50 membership units totaling $66,250 from an investor due to a unique restriction on transfers situation.

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 2012

9.8. FAIR VALUE

The Company did not have any financial assets orfollowing table provides information on those derivative liabilities measured at fair value on a recurring basis at April 30, 2012.2013:

|

| | | | | | | | | | | | | | | | | | | | |

| |

Carrying Amount in Balance Sheet April 30, 2013 |

Fair Value April 30, 2013 | Fair Value Measurement Using |

Quoted Prices in Active Markets (Level 1) | Significant Other Observable Inputs (Level 2) |

Significant unobservable inputs (Level 3) |

| Financial Liabilities: | | | | | |

| Commodity derivative instruments | $ | (47,813 | ) | | $ | (47,813 | ) | | $ | (47,813 | ) | | $ | — |

| | $ | — |

| |

The following table provides information on those assetsderivative liabilities measured at fair value on a recurring basis at October 31, 2011:

2012:

| | | |

Carrying Amount in Balance Sheet October 31, 2011 |

Fair Value October 31, 2011 | Fair Value Measurement Using |

Carrying Amount in Balance Sheet October 31, 2012 |

Fair Value October 31, 2012 | Fair Value Measurement Using |

Quoted Prices in Active Markets (Level 1) | Significant Other Observable Inputs (Level 2) |

Significant unobservable inputs (Level 3) | Quoted Prices in Active Markets (Level 1) | Significant Other Observable Inputs (Level 2) |

Significant unobservable inputs (Level 3) |

| Financial Assets: | | |

| Financial Liabilities: | | |

| Commodity derivative instruments | $ | 404,050 |

| $ | 404,050 |

| $ | 404,050 |

| $ | — |

| $ | — |

| $ | (45,563 | ) | $ | (45,563 | ) | $ | (45,563 | ) | $ | — |

| $ | — |

|

The Company determines the fair value of thecommodity derivative instruments are based on quotedby obtaining fair value measurements from an independent pricing service. The fair value measurements consider observable data that may include dealer quotes and live trading levels from the Chicago Board of Trade market prices in an active market.and New York Mercantile Exchange.

10.9. COMMITMENTS AND CONTINGENCIES

Corn Storage and Grain Handling Agreement and Purchase Commitments

The Company has a corn storage and grain handling agreement with Farmers Cooperative Elevator Company (FCE), a member. Under the current agreement, the Company agrees to purchase all of the corn needed for the operation of the plant from FCE. The price of the corn purchased will be the bid price the member establishes for the plant plus a set fee per bushel. At April 30, 2012,2013, the Company had 1,000,000basis contracts for forward corn purchase commitments with FCE for 2,375,000 bushels of forward purchased basis only corn with FCE.for deliveries from May 2013 through June 2013. At October 31, 2011,April 30, 2013, the Company also had 460,000885,000 bushels of stored corn totaling $2,862,550approximately $6,511,000 with FCE.

Ethanol Contracts

At April 30, 2012, the Company had forward ethanol sales contracts totaling approximately 7.6 million gallons for various delivery periods from May 2012 to June 2012. The prices on these contracts have a basis level established by the Oil Price Information Service (“OPIS”) Chicago ethanol market, the Platts Chicago market, and the Platts New York Harbor market between -$0.09 and -$0.18.

Distillers Grains Contracts

At April 30, 2012, the Company had forward distillers grains sales contracts totaling approximately 50,000 tons for various delivery periods from May 2012 to September 2012 at an average price of approximately $190 per ton.

Natural Gas Contracts

At April 30, 2012, the Company had forward contracts to purchase approximately 170,000 British thermal units (MMBTU) of natural gas during the months of May 2012 through January 2013 at an average price of approximately $4.10 per MMBTU.

Corn Oil Contracts

At April 30, 2012, the Company had forward corn oil sales contracts totaling approximately 13.3M pounds for various delivery periods from May 2012 to September 2012 at an average price of approximately $0.44 per pound.

Rail Infrastructure Improvement Project

The CompanyFCE that is currentlyincluded in the process of a rail infrastructure improvement project. As of April 30, 2012 the Company has acquired approximately $3,500,000 of land that will be used for this project. The Company has contracts with various contractors totaling approximately $3.8 million to construct the project, of which approximately $410,000 has been completed as of April 30, 2012. The project is expected to be completed in late 2012.inventory.

GRANITE FALLS ENERGY, LLC

Notes to UNAUDITED Condensed Financial Statements

April 30, 20122013

Ethanol Contracts

At April 30, 2013, the Company had forward contracts to sell approximately $13,212,000 of ethanol for deliveries from May 2013 through June 2013 which approximates 50% of its anticipated ethanol sales during that period.

Distillers Grains Contracts

At April 30, 2013, the Company had forward contracts to sell approximately $600,000 of distillers grains for delivery in May through June 2013 which approximates 10% of its anticipated distillers grain sales during that period.

11.10. LEGAL PROCEEDINGS

From time to time in the ordinary course of business, the Company may be named as a defendant in legal proceedings related to various issues, including without limitation, workers' compensation claims, tort claims, or contractual disputes. We are not currently a party to any material pending legal proceedings and we are not currently aware of any such proceedings contemplated by governmental authorities.

Item 2. Management's Discussion and Analysis of Financial Condition and Results of Operations

We prepared the following discussion and analysis to help you better understand our financial condition, changes in our financial condition, and results of operations for the three and six month periods ended April 30, 20122013, compared to the same period of the prior fiscal year. This discussion should be read in conjunction with the condensed financial statements and notes and the information contained in the Company's Annual Report on Form 10-K for the fiscal year ended October 31, 2011.2012.

Disclosure Regarding Forward-Looking Statements

This report contains historical information, as well as forward-looking statements. These forward-looking statements include any statements that involve known and unknown risks and relate to future events and our expectations regarding future performance or conditions. Words such as “may,” “will,” “should,” “expect,” “plan,” “anticipate,” “believe,” “estimate,” “future,” “intend,” “could,” “hope,” “predict,” “target,” “potential,” or “continue” or the negative of these terms or other similar expressions are intended to identify forward-looking statements, but are not the exclusive means of identifying such statements. These forward-looking statements, and others we make from time to time, are subject to a number of risks and uncertainties. Many factors could cause actual results to differ materially from those projected in forward-looking statements. While it is impossible to identify all such factors, factors that could cause actual results to differ materially from those estimated by us include, but are not limited to:

Changes in the availability and price of corn and natural gas;

Demand for corn exceeding supply; and corresponding corn price increases;

Changes in our business strategy, capital improvements or development plans;

Our ability to profitably operate the ethanol plant and maintain a positive spread between the selling price of our products and our raw materials costs;

Results of our hedging transactions and other risk management strategies;

Decreases in the market prices of ethanol and distillers grains;

Ethanol supply exceeding demand; and corresponding ethanol price reductions;

Changes in the environmental regulations that apply to our plant operations and changes in our ability to comply with such regulations;

Changes in plant production capacity or technical difficulties in operating the plant;

Changes in general economic conditions or the occurrence of certain events causing an economic impact in the agriculture, oil or automobile industries;

Lack of transport, storage and blending infrastructure preventing ethanol from reaching high demand markets;

Changes in federal and/or state laws (includingor regulations, including the elimination or modification of anythe federal and/or state ethanol tax incentives);renewable fuels standard;

Changes and advances in ethanol production technology;

Effects of mergers, consolidations or contractions in the ethanol industry;

Competition from alternative fuel additives;

The development of infrastructure related to the sale and distribution of ethanol;

Our inelastic demand for corn, as it is the only available feedstock for our plant;

Our ability to retain key employees and maintain labor relations;

Changes to our current water intake system, or our ability to cost-effectively construct a modified water intake system, if necessary;system;

The imposition of tariffs or other duties on ethanol imported into Europe; and

Volatile commodity and financial markets.

The cautionary statements referred to in this section also should be considered in connection with any subsequent written or oral forward-looking statements that may be issued by us or persons acting on our behalf. We do not undertake any duty to update forward-looking statements after the date they are made or to conform forward-looking statements to actual results or to changes in circumstances or expectations. Furthermore, we cannot guarantee future results, events, levels of activity, performance, or achievements. We caution you not to put undue reliance on any forward-looking statements, which speak only as of the date of this report. You should read this report and the documents that we reference in this report and have filed as exhibits, completely and with the understanding that our actual future results may be materially different from what we currently expect. We qualify all of our forward-looking statements by these cautionary statements.

Overview

Granite Falls Energy, LLC (“Granite Falls Energy” or the “Company”) is a Minnesota Limited Liability Company formed on December 29, 2000.

We are currently producing fuel-grade ethanol, distillers grains and crude corn oil for sale. Our plant has an approximate annual production capacity of 60 million gallons of denatured ethanol, but is currently permitted to produce up to 70 million

gallons of undenatured ethanol on a twelve month rolling sum basis. We intend to continue working toward increasing production to take advantage of the underutilized capacity ofadditional production allowed pursuant to our plantpermit as long as we believe it is profitable to do so.

Our operating results are largely driven by the prices at which we sell our ethanol, distillers grains, and corn oil as well as the other costs related to production. The price of ethanol has historically fluctuated with the price of petroleum-based products such as unleaded gasoline, heating oil and crude oil. The price of distillers grains has historically been influenced by the price of corn as a substitute livestock feed. We expect these price relationships to continue for the foreseeable future, although recent volatility in the commodities markets makes historical price relationships less reliable. Our largest costs of production are corn, natural gas, depreciation and manufacturing chemicals. Our cost of corn is largely impacted by geopolitical supply and demand factors and the outcome of our risk management strategies. Prices for natural gas, manufacturing chemicals and denaturant are tied directly to the overall energy sector, crude oil and unleaded gasoline.

On April 23, 2012, Steve Christensen was appointed as Chief Executive Officer of the Company. The date of Mr. Christensen's appointment coincides with the resignation of Wayne Gordon, who served as our interim Chief Executive Officer from February 10, 2012 through the date of his resignation. Mr. Gordon's appointment coincided with the departure of our previous Chief Executive Officer.

As of the date of this report, we have 3637 full time employees. Ten of these employees are involved primarily in management and administration. The remaining employees are involved primarily in plant operations. We do not currently anticipate any significant change in the number of employees at our plant.

Results of Operations for the Three Months Ended April 30, 20122013 and 20112012

The following table shows the results of our operations and the approximate percentage of revenues, costs of goods sold, operating expenses and other items to total revenues in our unaudited statements of operations for the three months ended April 30, 20122013 and 20112012:

| | | | 2012 | | 2011 | 2013 | | 2012 |

| Income Statement Data | Amount | | % | | Amount | | % | Amount | | % | | Amount | | % |

| Revenue | $ | 39,025,122 |

| | 100.0 | % | | $ | 34,537,750 |

| | 100.0 | % | $ | 48,020,602 |

| | 100.0 | % | | $ | 39,025,122 |

| | 100.0 | % |

| Cost of Goods Sold | 38,367,706 |

| | 98.3 | % | | 30,833,215 |

| | 89.3 | % | 44,390,630 |

| | 92.4 | % | | 38,367,706 |

| | 98.3 | % |

| Gross Profit | 657,416 |

| | 1.7 | % | | 3,704,535 |

| | 10.7 | % | 3,629,972 |

| | 7.6 | % | | 657,416 |

| | 1.7 | % |

| Operating Expenses | 590,481 |

| | 1.5 | % | | 458,806 |

| | 1.3 | % | 582,965 |

| | 1.2 | % | | 590,481 |

| | 1.5 | % |

| Operating Income | 66,935 |

| | 0.2 | % | | 3,245,729 |

| | 9.4 | % | 3,047,007 |

| | 6.4 | % | | 66,935 |

| | 0.2 | % |

| Other Income, net | 49,531 |

| | 0.1 | % | | 24,381 |

| | 0.1 | % | |

| Other Income (Expense), net | | (15,064 | ) | | — | % | | 49,531 |

| | 0.1 | % |

| Net Income | $ | 116,466 |

| | 0.3 | % | | $ | 3,270,110 |

| | 9.5 | % | $ | 3,031,943 |

| | 6.4 | % | | $ | 116,466 |

| | 0.3 | % |

Revenues

Our revenues from operations come from three primary sources: sales of fuel ethanol, sales of distillers grains and sales of corn oil. Our results of operations will continue to be affected by volatility in the commodity markets. In the event that we experience a prolonged period of negative operating margins, our liquidity may be negatively impacted.

The following table shows the sources of our revenue for the three months ended April 30, 2013:

|

| | | | | | | |

| Revenue Sources | Amount | | Percentage of Total Revenues |

| | | | |

| Ethanol sales | $ | 37,209,376 |

| | 77.5 |

| % |

| Distillers grains sales | 9,546,923 |

| | 19.9 |

| % |

| Corn oil sales | 1,264,303 |

| | 2.6 |

| % |

| Total Revenues | $ | 48,020,602 |

| | 100.0 |

| % |

The following table shows the sources of our revenue for the three months ended April 30, 2012:

| | | Revenue Sources | Amount | | Percentage of Total Revenues | Amount | | Percentage of Total Revenues |

| | | | | | | |

| Ethanol sales | $ | 31,250,124 |

| | 80.1 |

| % | $ | 31,250,125 |

| | 80.1 |

| % |

| Distillers grains sales | 6,860,000 |

| | 17.6 |

| % | 6,860,000 |

| | 17.6 |

| % |

| Corn oil sales | 914,997 |

| | 2.3 |

| % | 914,997 |

| | 2.3 |

| % |

| Total Revenues | $ | 39,025,122 |

| | 100.0 |

| % | $ | 39,025,122 |

| | 100.0 |

| % |

The following table shows the sources of our revenue forIn the three monthsmonth period ended April 30, 20112013:, ethanol sales comprised

|

| | | | | | | |

| Revenue Sources | Amount | | Percentage of Total Revenues |

| | | | |

| Ethanol sales | $ | 28,093,094 |

| | 81.3 |

| % |

| Distillers grains sales | 5,558,477 |

| | 16.1 |

| % |

| Corn oil sales | 896,724 |

| | 2.6 |

| % |

| Ethanol derivative activity (losses) | (10,546 | ) | | — |

| % |

| Total Revenues | $ | 34,537,750 |

| | 100.0 |

| % |

In77.5% of our revenues and distillers grains sales comprised 19.9% percent of our revenues, while corn oil sales comprised 2.6% of our revenues. For the three month period ended April 30, 2012, ethanol sales comprised 80.1% of our revenues andrevenue, distillers grains sales comprised 17.6% percent of our revenues, while corn oil sales comprised 2.3% of our revenues. For the three month period ended April 30, 2011, ethanol sales comprised 81.3% of our revenue, without including ethanol derivatives, and distillers grains sales comprised 16.1% of our revenue, while corn oil sales comprised 2.62.3% of our revenues.

The average ethanol sales price we received for the three month period ended April 30, 20122013 was approximately 10.7% lower12.7% higher than our average ethanol sales price for the comparable 20112012 period. Management attributes the decreaseincrease in our average ethanol sales price to sustained market oversupply resulting from anticipation ofdecreased ethanol inventories and a decrease in ethanol production in the expiration ofindustry compared to the Federal Volumetric Ethanol Excise Tax Credit (“VEETC”)prior year. Downward pressure on December 31, 2011. In an effort to capture asethanol prices throughout much of the VEETC as possible, blenders maximized the amount of ethanol they could blend at the end of calendar 2011. As a result of that timing, demand slowedyear 2012, combined with increased corn prices particularly during the beginninglast half of calendar 2012, resultinghave caused some ethanol plants to suspend or reduce production, leading to the decrease in increased ethanol inventories which have pressuredand production. As ethanol prices downward. Recent geopolitical events in the Middle Eastincrease, some plants that have caused significant uncertainty about the global supply of crude oil and other petroleum based products.suspended or reduced production may resume or increase production, which may once again pressure ethanol prices downward. Management anticipates that the price of ethanol will continue to be volatile during the remainder of our 20122013 fiscal year as a result of these factors.year. Our volume of ethanol sold during the three month period ended April 30, 20122013 was approximately 24.6%5.7% higher than the volume sold for the comparable 2011 period. This2012 period as we have continued to increase in ethanol sales is largely due to the de-bottlenecking improvements made to our facility in the last year.production efficiencies.

Distillers grains representrepresented a larger portion of our revenues during the three months ended April 30, 20122013 compared to the same period of 20112012 as a result of the higher prices and greater quantities of distillers grains produced and sold during our first fiscal quarter of 2012the three months ended April 30, 2013 compared to the same period of 2011.2012. The price we received for our dried distillers grains in the three month period ended April 30, 20122013 was approximately 4.6%34.0% higher than the price we received during the three months ended April 30, 20112012. This price increase, combined with the decrease in ethanol prices discussed above, resulted in distillers grains sales comprising a larger percentage of our total revenues during the three months ended April 30, 2012 relative to the same period during the prior year. Management believes these higher distillers grains prices are a result of the high price of other feed products available to livestock producers. We anticipate that the market price of our dried distillers grains will continue to be volatile as a result of changes in the price of corn and competing animal feed substitutes such as soybean meal. Volatility in distillers grains supplies related to changes in ethanol production is another factor that may impact the sales price of our distillers grains. Additionally, our quantity of distillers grains sold increased approximately 3.9% in the three month period ended April 30, 2013 compared to the three months ended April 30, 2012. This increase in quantity sold was largely a result of increased production during the three months ended April 30, 2013 as compared to the three months ended April 30, 2012. The price and quantity increases resulted in distillers grains sales comprising a larger percentage of our total revenues during the three months ended April 30, 2013 relative to the same period during the prior year, despite increases in the price and quantity sold of ethanol discussed above.

Corn oil represented a slightly smallergreater portion of our revenues during the three months ended April 30, 20122013 than it did for the same period of 2011.2012. Corn oil sales accounted for approximately 2.32.6% of our revenues during our quarter ended April 30, 20122013 compared to 2.62.3% for our quarter ended April 30, 20112012. The price we received for our corn oil decreased by approximately 16.2%9.4% during the three months ended April 30, 20122013 compared to the same period of 2011.2012. However, offsetting this price decrease, our total volume of corn oil sold increased by 21.8%52.5% as a result higher production rates at our facility.facility and increased extraction efficiencies. Management attributes the decrease in corn oil prices to additional corn oil entering the market. However, increased use of corn oil by biodiesel producers and animal feeders have continued to support demand.

We occasionally engage in hedging activities with respect to our ethanol sales. We recognize the gains or losses that result from the changes in the value of these derivative instruments in revenues as the changes occur. As ethanol prices fluctuate, the value of our derivative instruments are impacted, which affects our financial performance. We anticipate continued volatility in our revenues due to the timing of the changes in value of the derivative instruments relative to the price and volume of the ethanol being hedged. We did not recognize any gains or losses for the three month period ended April 30, 2012 related to our ethanol derivative instruments, as compared to an approximate $11,000 combined realized and unrealized loss for the three months ended April 30, 2011 related to our ethanol derivative instruments, which decreased our revenues.

Our results of operations for our 2012 fiscal year will continue to be affected by volatility in the commodity markets. If plant operating margins are negative for an extended period of time, management anticipates that this could negatively impact our liquidity. Management believes the industry will need to continue to grow demand and further develop an ethanol distribution

system to facilitate additional blending of ethanol and gasoline to offset the increased supply brought to the marketplace by additional production. In April 2012, the U.S. Environmental Protection Agency ("EPA") approved the first applications for registering ethanol for use in making a blend of fifteen percent ethanol, known as E15. Since that time, we have applied with the EPA to register ethanol for use in making E15, although our application remains pending as of the date of this report. We are optimistic that over time, as E15 is brought to market and gains market acceptance, demand for ethanol will increase. However, we do not anticipate that the EPA's acceptance of applications for registering ethanol for use in making E15 will impact ethanol demand or pricing in the near term.

Cost of SalesGoods Sold

Our costs of goods sold as a percentage of revenues were 98.3%92.4% for the three month period ended April 30, 20122013 compared to 89.3%98.3% for the same period of 2011.2012. Our two largest costs of production are corn (83.8%(83.7% of cost of goods sold for our three months ended April 30, 20122013) and natural gas (3.8%(4.0% of cost of goods sold for our three months ended April 30, 20122013). Our total cost of goods sold increased to approximately $38,368,000$44,390,630 for the three months ended April 30, 20122013 from approximately $30,833,000$38,367,706 in the three months ended April 30, 20112012. The main driver of our increased cost of goods sold was the increased volume of corn we processed due to our higher ethanol production. The volume of corn we processed was up 17.8%3.3% for the three months ended April 30, 20122013 as compared to the same period for our 20112012 fiscal year. Additionally, our per bushel corn costs increased by approximately 1.9%11.8% for the three

months ended April 30, 20122013 as compared to the same period for our 20112012 fiscal year. Tight corn supply following last growing season's drought has continued to place upward pressure on corn prices. Although the 2012 drought did not impact corn production in Minnesota to the same extent as other corn producing states, as a local consumer of corn we must nevertheless be cost competitive when sourcing corn in order to procure sufficient quantities for ethanol production. Management anticipates that corn prices will remain high throughoutfor the restduration of our 20122013 fiscal year, especially if extreme weather interferes with the 2012 growing season.year. The USDA's World Agricultural Supply and Demand Estimates published on May 10, 2012,2013 projects record domestic corn production of 14.814.14 billion bushels for the 2013 growing season, which would be a significant increase over the estimate of 10.78 billion bushels produced during the 2012 growing season. Management expects that this level of production, if realized, would put downward pressure onHowever, corn prices.planting in several Midwestern states has been behind historical pace due to wet conditions.

For the three month period ended April 30, 20122013, we experienced a decreasean increase of approximately 15.2%21.1% in our overall natural gas costs compared to the same period of 2011. Falling natural gas prices have decreased our natural gas costs, even though our natural gas consumption has risen2012 as a result of increases in natural gas prices and our 19.7% increase in ethanol production during the quarter ended April 30, 2012 asquantity of natural gas consumed. Natural gas prices continue to remain low compared to the same period in 2011.historic averages. We expect the market price for natural gas to remain steady in the near term as we continue to enjoy an abundant supply of domestic natural gas, due in part to the continued commissioning of new, highly productive natural gas wells.

We occasionally engage in hedging activities with respect to corn, natural gas or denaturant.corn. We recognize the gains or losses that result from the changes in the value of our derivative instruments in cost of goods sold as the changes occur. As corn natural gas and denaturant prices fluctuate, the value of our derivative instruments are impacted, which affects our financial performance. We anticipate continued volatility in our cost of goods sold due to the timing of the changes in value of the derivative instruments relative to the cost and use of the commodity being hedged.

We experienced an approximate $31,000$249,000 combined realized and unrealized loss for the three month period ended April 30, 20122013 related to our corn and natural gas derivative instruments, which increased our cost of goods sold. By comparison, we experienced an approximate $1,374,000$31,000 combined realized and unrealized gainloss for the three months ended April 30, 20112012 related to our corn and natural gas derivative instruments, which decreasedincreased our cost of goods sold. We recognize the gains or losses that result from the changes in the value of our derivative instruments from corn and natural gas in cost of goods sold as the changes occur. As corn and natural gas prices fluctuate, the value of our derivative instruments are impacted, which affects our financial performance.

Operating Expense

Our operating expenses as a percentage of revenues were relatively steadydecreased to 1.2% for the three month period ended April 30, 20122013 when compared tofrom 1.5% for the same period ended April 30, 20112012. The increase in ourOur total operating expenses for the three months ended April 30, 20122013 as compared to the same period for our 20112012 fiscal year is due primarily to an increase in rail car fees.decreased slightly. We continue to focus on increasing our operating efficiency and we strive to lower our operating expenses.

Operating Income

Our income from operations for the three months ended April 30, 20122013 was 0.2% of our revenuesapproximately $3,047,000, compared to income from operations of approximately 9.4% of our revenues for the three months ended April 30, 2011. For the three months ended April 30, 2012, we reported operating income of $66,935 and for the three months ended April 30, 2011, we had operating income of $3,245,729. This decrease in our operating income is primarily due to decreased ethanol sales prices.

Other Income and Expense

We had other income$67,000 for the three months ended April 30, 2012 of $. This increase in our operating income is primarily due to more favorable operating margins.

Other Income (Expense), Net

49,531 compared toOur other income of $24,381(expense), net for the three months ended April 30, 20112013.

Our other income and was an expense includes other income, net of $51,004 for the three months ended April 30, 2012, asapproximately $15,000, compared to $6,890 for the same period the prior year. Our other income net increased primarily due to income related to land rent for the property on which our loop track will be constructed and other miscellaneous income during the quarter ended April 30, 2012.

Also included in other income and expense is our interest income and expense. Interest expenseof approximately $50,000 for the three months ended April 30, 2012, was less than one tenth of one percent of our revenue and totaled approximately $5,525, compared to approximately $517 of interest expense for the three months ended April 30, 2011. The interest expense incurred during the three months ended April 30, 2012 is attributable to a 5 year, 3.875% note we took to purchase a Shuttlewagon Railcar Mover in December 2011 and the one percent fee on our letters of credit. The interest expense incurred during the three months ended January 31, 2011 is attributable to our low interest loan obtained through a local Economic Development Authority ("EDA") and the one percent fee on our letters of credit. On August 26, 2011, the board of governors decided to repay the EDA loan in the amount of approximately $187,000.

Our interest income was lower for the three months ended April 30, 2012 when compared to the three months ended April 30, 2011. This reduction in interest incomechange is primarily a result of us having less cash on handincreased interest expense during the quarter ended April 30, 20122013 as compared to the same period the prior year.year, attributable to borrowings on our United FCS credit facilities.

Results of Operations for the Six Months Ended April 30, 20122013 and 20112012

The following table shows the results of our operations and the percentage of revenues, cost of goods sold, operating expenses and other items to total revenues in our statement of operations for the six months ended April 30, 20122013 and 20112012:

| | | | 2012 | | 2011 | 2013 | | 2012 |

| Income Statement Data | Amount | | % | | Amount | | % | Amount | | % | | Amount | | % |

| Revenue | $ | 82,770,898 |

| | 100.0 | % | | $ | 65,254,096 |

| | 100.0 | % | $ | 95,137,724 |

| | 100.0 | % | | $ | 82,770,898 |

| | 100.0 | % |

| Cost of Goods Sold | 78,425,531 |

| | 94.8 | % | | 58,015,828 |

| | 88.9 | % | 90,675,608 |

| | 95.3 | % | | 78,425,531 |

| | 94.8 | % |

| Gross Profit | 4,345,367 |

| | 5.2 | % | | 7,238,268 |

| | 11.1 | % | 4,462,116 |

| | 4.7 | % | | 4,345,367 |

| | 5.2 | % |

| Operating Expenses | 1,254,217 |

| | 1.5 | % | | 1,016,927 |

| | 1.6 | % | 1,145,660 |

| | 1.2 | % | | 1,254,217 |

| | 1.5 | % |

| Operating Income | 3,091,150 |

| | 3.7 | % | | 6,221,341 |

| | 9.5 | % | 3,316,456 |

| | 3.5 | % | | 3,091,150 |

| | 3.7 | % |

| Other Income | 67,604 |

| | 0.1 | % | | 60,365 |

| | 0.1 | % | |

| Other Income (Expense), net | | (63,086 | ) | | (0.1 | )% | | 67,604 |

| | 0.1 | % |

| Net Income | $ | 3,158,754 |

| | 3.8 | % | | 6,281,706 |

| | 9.6 | % | $ | 3,253,370 |

| | 3.4 | % | | 3,158,754 |

| | 3.8 | % |

Revenues

The following table shows the sources of our revenue for the six months ended April 30, 20122013:

| | | Revenue Sources | Amount | | Percentage of Total Revenues | Amount | | Percentage of Total Revenues |

| | | | | | | |

| Ethanol sales | $ | 67,447,635 |

| | 81.5 | % | $ | 72,495,495 |

| | 76.2 | % |

| Distillers grains sales | 13,562,618 |

| | 16.4 | % | 20,251,604 |

| | 21.3 | % |

| Corn oil sales | 1,760,645 |

| | 2.1 | % | 2,390,625 |

| | 2.5 | % |

| Total Revenues | $ | 82,770,898 |

| | 100.0 | % | $ | 95,137,724 |

| | 100.0 | % |

The following table shows the sources of our revenue for the six months ended April 30, 20112012:

| | | Revenue Sources | Amount | | Percentage of Total Revenues | Amount | | Percentage of Total Revenues |

| | | | | | | |

| Ethanol sales | $ | 53,797,102 |

| | 82.4 | % | $ | 67,447,635 |

| | 81.5 | % |

| Distillers grains sales | 9,837,670 |

| | 15.1 | % | 13,562,618 |

| | 16.4 | % |

| Corn oil sales | 1,629,870 |

| | 2.5 | % | 1,760,645 |

| | 2.1 | % |

| Ethanol derivative activity gains (losses) | (10,546 | ) | | — | % | |

| Total Revenues | $ | 65,254,096 |

| | 100.0 |

| $ | 82,770,898 |

| | 100.0 |

|

Our total revenues were higher for the six monthmonths period ended April 30, 20122013 compared to the same period of 20112012. This increase in revenue is a result of a significant increase in our quantity ofWith respect to ethanol, sold during the first six months of our 2012 fiscal year compared to the same period of 2011. Wewe sold approximately 24.9%4.5% more gallons of ethanol during the six monthmonths period ended April 30, 2013 than we did in the same period of 2012. Additionally, the price we received for our ethanol was approximately 2.8% higher for the six months ended April 30, 2013 compared to the same period of 20112012. However, the price we received for our ethanol was only approximately 0.4% higher for the six month period ended April 30, 2012 compared to the same period of 2011. Our increase in our quantity of ethanol sold is largely due to the de-bottlenecking improvements made to our facility in the last year.

The average price we received for our distillers grains was approximately 13.7%35.1% higher for the first six months of our 20122013 fiscal year compared to the same period of 20112012. We also sold approximately 21.2%10.5% more tons of distillers grains during the first six months of our 20122013 fiscal year compared to the same period of 20112012 due to our increased ethanol production..

We sold approximately 12.6%51.2% more pounds of corn oil during the first six months of our 20122013 fiscal year compared to the same period of 20112012. However, offsetting our increase in corn oil sales, our average price per pound of corn oil decreased by approximately 4.1%10.2% for the first six months of our 20122013 fiscal year compared to the same period of 20112012.

Cost of Goods Sold

Our costs of goods sold were significantly higher for the first six months of our 20122013 fiscal year compared to the same period of our 20112012 fiscal year. Additionally, our costs of good sold as a percentage of our revenues were higher for the first six months of our 20122013 fiscal year compared to the same period of our 20112012 fiscal year. Our average cost per bushel of corn was approximately 11.6%11.9% higher during the first six months of our 20122013 fiscal year compared to the same period of 20112012. Additionally, we ground approximately 20.8%6.3% more corn during the first six months of our 20122013 fiscal year compared to the same period of 20112012 due to our increased production.

Our natural gas costs decreasedincreased during the first six months of our 20122013 fiscal year compared to the same period of 20112012. Our total cost of natural gas was approximately 5.8% lower8.2% higher during the first six months of our 20122013 fiscal year compared to the same period of 20112012. Our natural gas consumption during the first six months of our 2012 fiscal year was approximately 13.5% higher compared to the first six months of our 2011 fiscal year. Management attributes this increase in our natural gas consumption to increases in our ethanol production and quantity of distillers grains sold.

We experienced an approximate $1,301,000 combined realized and unrealized loss for the six month period ended April 30, 2012 related to our corn and natural gas derivative instruments, which increased our cost of goods sold. By comparison, we experienced an approximately $2,254,000$27,000 combined realized and unrealized gain for the six months ended April 30, 20112013 related to our corn natural gas , and denaturant derivative instruments, which decreased our cost of goods sold. By comparison, we experienced an approximately $1,301,000 combined realized and unrealized loss for the six months ended April 30, 2012 related to our corn derivative instruments, which increased our cost of goods sold. We recognize the gains or losses that result from the changes in the value of our derivative instruments from corn, natural gas, and denaturant in cost of goods sold as the changes occur. As corn natural gas, and denaturant prices fluctuate, the value of our derivative instruments are impacted, which affects our financial performance.

Operating Expenses

Our total operating expenses and our operating expenses as a percentage of revenues were relatively steady fordecreased in the six monthmonths period ended April 30, 20122013 when compared to the same period ended April 30, 20112012. The increasedecrease in our operating expenses for the six months ended April 30, 20122013 as compared to the same period for our 20112012 fiscal year is due primarily to an increasea decrease in personnel expenses following the accrual of our former Chief Executive Officer's bonus and vacation during the six months ended April 30, 2012 in connection with his departure from the Company, as well as a decrease in professional service expense in the six months ended April 30, 2013 compared to the six months ended April 30, 2012, when we conducted studies related to our rail car fees. We continue to focus on increasing our operating efficiencyinfrastructure and we strive to lower our operating expenses.water intake.

Other Income and Expense(Expense), Net

We had other expense, net for the six months ended April 30, 2013 of $63,086 compared to other income, net of $67,604 for the six months ended April 30, 2012 of $67,604 compared to $60,365 for. This change resulted primarily from increased interest expense during the six months ended April 30, 2011. Our other income, net increased primarily as a result of income related to land rent and other miscellaneous income.

Our interest income was lower for the six month2013 period ended April 30, 2012as compared to the same period of 2011 as a result of having less cashthe prior year, attributable to borrowings on hand during the 2012 period. Our interest expense was greater for the first six months of our 2012 fiscal year compared to the same period of 2011 due to the note we took to purchase a Shuttlewagon Railcar Mover in December 2011.United FCS credit facilities.

Changes in Financial Condition for the Six Months Ended April 30, 20122013

The following table highlights the changes in our financial condition for the six months endedat April 30, 20122013 from our previous fiscal year endedand October 31, 20112012:

| | | | April 30, 2012 | October 31, 2011 | April 30, 2013 | October 31, 2012 |

| Current Assets | $ | 19,494,960 |

| $ | 27,542,361 |

| $ | 21,065,272 |

| $ | 20,715,050 |

|

| Current Liabilities | $ | 4,596,959 |

| $ | 13,680,184 |

| $ | 6,696,111 |

| $ | 6,002,937 |

|

| Long-Term Debt | $ | 440,830 |

| $ | — |

| $ | 553,789 |

| $ | 5,274,870 |

|

| Members' Equity | $ | 52,853,472 |

| $ | 49,761,138 |

| $ | 53,108,695 |

| $ | 49,855,325 |

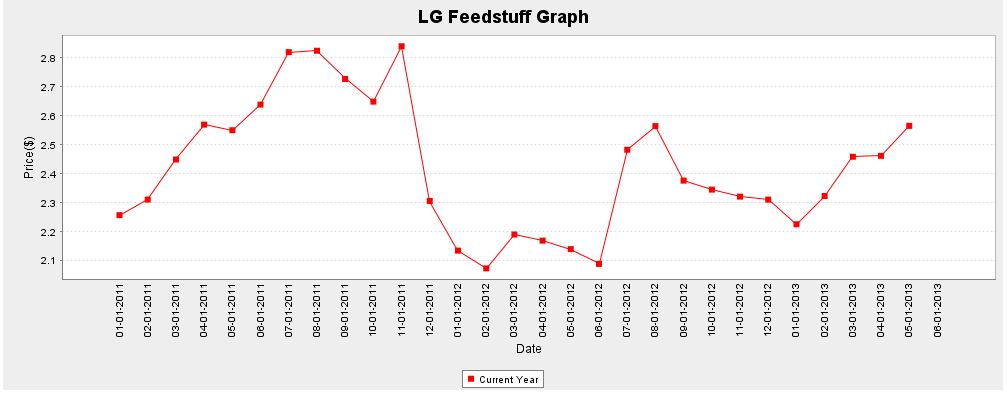

|