Exhibit 99.4

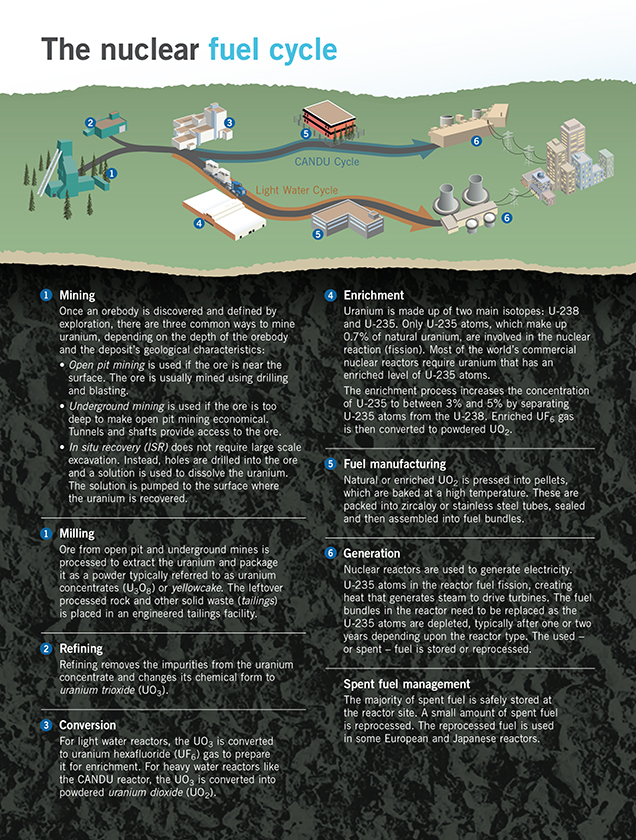

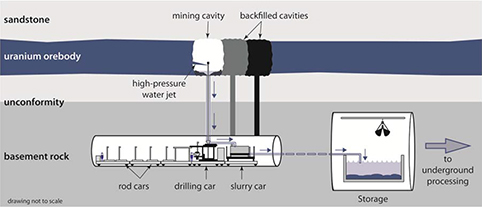

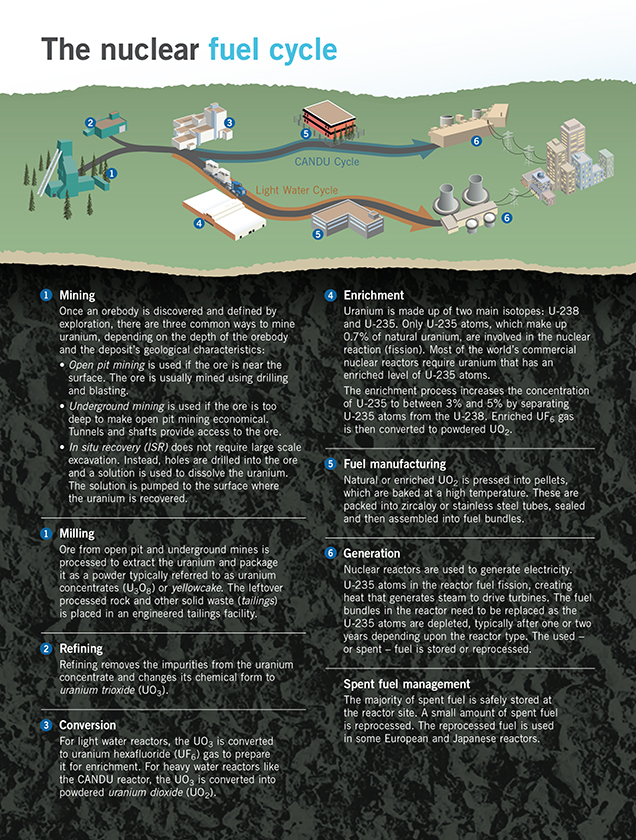

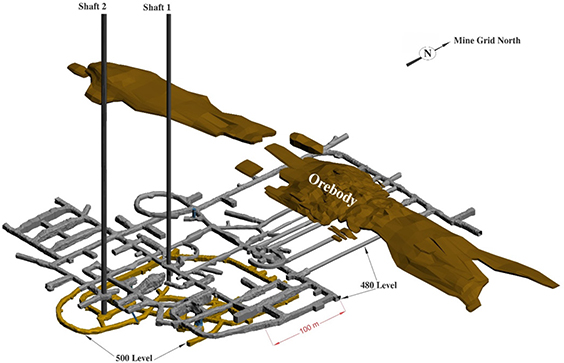

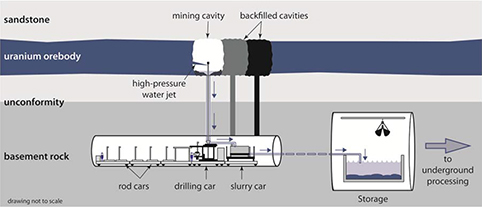

The nuclear fuel cycle l Mining Once an orebody is discovered and defined by exploration, there are three common ways to mine uranium, depending on the depth of the orebody and the deposit’s geological characteristics: Open pit mining is used if the ore is near the surface. The ore is usually mined using drilling and I’l.r.lllrJ. Underground mining is used if the ore is too deep to make open pit mining economical. Tunnels and shafts provide access to the ore. In situ recovery (ISR) does not require large scale excavation. Instead, holes are drilled into the ore and a solution is used to dissolve the uranium. The solution is pumped to the surface where the uranium is recovered. 1 Milling 2 Ore from open pit and underground mines is processed to extract the uranium and package it as a powder typically referred to as uranium concentrates (U3O8) or yellowcake. The leftover processed rock and other solid waste (tailings) is placed in an engineered tailings facility. 3 Refining 4 Refining removes the impurities from the uranium concentrate and changes its chemical form to uranium trioxide (UO3). 5 Conversion 6 For light water reactors, the UO3 is converted to uranium hexafluoride (UF6) gas to prepare it for enrichment. For heavy water reactors like the CANDU reactor, the UO3 is converted into powdered uranium dioxide (UO2). Enrichment Uranium is made up of two main isotopes: U-238 and U-235. Only U-235 atoms, which make up 0.7% of natural uranium, are involved in the nuclear reaction (fission). Most of the world’s commercial nuclear reactors require uranium that has an enriched level of U-235 atoms. The enrichment process increases the concentration of U-235 to between 3% and 5% by separating U-235 atoms from the U-238. Enriched UF6 gas is then converted to powdered UO2. Fuel manufacturing Natural or enriched UO2 is pressed into pellets, which are baked at a high temperature. These are packed into zircaloy or stainless steel tubes, sealed and then assembled into fuel bundles. 6 Generation Nuclear reactors are used to generate electricity. U-235 atoms in the reactor fuel fission, creating heat that generates steam to drive turbines. The fuel bundles in the reactor need to be replaced as the U-235 atoms are depleted, typically after one or two years depending upon the reactor type. The used—or spent—fuel is stored or reprocessed. Spent fuel management The majority of spent fuel is safely stored at the reactor site. A small amount of spent fuel is reprocessed. The reprocessed fuel is used in some European and Japanese reactors.

Message from the Chair

Dear Shareholder,

Cameco’s resilience as a company was clearly evident in 2013, as market conditions continued to challenge our industry. Although we saw uranium prices continue to decline and uncertainty persist, I am proud of the response from across the organization that resulted in strong operational and financial results.

Your board of directors is responsible for overseeing management to ensure the company stays on track to achieve its strategy and deliver value to you, the shareholder. We are committed to continual improvement, and this year achieved that goal on a number of fronts. We enhanced our risk oversight process by initiating quarterly presentations by management to allow a fuller understanding of the major enterprise risks and management’s mitigation strategies. Similarly, we enhanced our focus on financial performance and strategic growth and direction, with a quarterly review of strategic matters.

On that subject, at the end of 2013, the decision was made to move away from our plan to increase production to a fixed target by 2018. The board spent a significant amount of time working with Cameco’s management team on this decision. We are confident this move ensures the near-term challenges are addressed, while also positioning the company to benefit from the long-term growth we see for the industry. We believe the change is in line with our focus on providing value, and will serve the company and the shareholders well.

Another key responsibility for the board is to ensure strong board leadership and effective succession planning at the board level. We have added significant financial expertise over the last few years with a view to enhancing focus on financial performance and, this year, have enhanced our project value

analysis expertise with the addition of a new board member. Catherine Gignac will stand for election at our Annual Meeting of Shareholders in May. Ms. Gignac has more than 30 years of experience as a mining equity research analyst and geologist. Her extensive knowledge of finance and mineral resource estimation will be of great benefit to Cameco.

Of course, the other change to the board in 2013 was a change in leadership as Victor Zaleschuk stepped down from the position of chair after 10 years of service. Under his leadership, the company successfully met and dealt with multiple challenges in this very difficult market. I am pleased to say that Mr. Zaleschuk will continue to lend his wisdom as a director, and I have appreciated his guidance as I assumed my new position as chair of the board last May.

As we enter 2014, I am confident in our strategic plan and the team we have in place to carry it out. That includes our excellent senior management team and our talented employees, whom I sincerely thank for all their hard work over the past year. I believe we are uniquely positioned to face any challenges the year ahead may bring, and capitalize on opportunities as they arise.

Neil McMillan

Chair of the board

March 10, 2014

Cameco Board of DirectorsOur directors as at December 31, 2013 are listed below. More information is available in our proxy circular.

Ian Bruce

Former co-chairman of the board of Peters & Co. Limited

Daniel Camus

Former group CFO and head of strategy and international activities of Electricité de France SA

John Clappison

Former managing partner of the Greater Toronto Area office of PricewaterhouseCoopers LLP

Joe Colvin

Past president of the American Nuclear Society, and president emeritus of the Nuclear Energy Institute

James Curtiss

Principal of Curtiss Law

Donald Deranger

Advisor to the Athabasca Basin Development Corporation and non-executive chair of the board of Points Athabasca Contracting Limited Partnership

Catherine Gignac

Principal of Catherine Gignac & Associates

Tim Gitzel

President and CEO of Cameco

James Gowans

Executive vice president and COO of Barrick Gold Corp.

Nancy Hopkins

Partner with the law firm McDougall Gauley LLP

Anne McLellan

Former Deputy Prime Minister of Canada, currently counsel in Bennett Jones LLP

Neil McMillan

President and CEO of Claude Resources Inc.

Victor Zaleschuk

Former president and CEO of Nexen Inc.

Message from the CEO

Dear Shareholder,

2013 marked another challenging year for the nuclear industry. Overall, the big picture remained much the same: market uncertainty continued, as did the downward pressure on uranium prices. Despite the persistence of these market conditions, Cameco still achieved strong results, including record production, record revenue, and record annual average realized uranium price.

However, Cameco is not immune to negative market forces, which have continued for longer than expected. Those effects are more keenly felt the longer they persist. The advantage for Cameco is that we have the resources and the ability to dig deep, be innovative, weather the uncertainty, and come out the other side successful. In 2013, we took steps to do just that. We decided to pursue more aggressive cost controls and pull back on, and ultimately eliminate, our production growth target. We believe this course of action will allow us the flexibility necessary to provide the best value to our shareholders, and to benefit most when clarity returns to the market.

Cameco’s senior management team and I are very aware of the challenge this decision poses to our shareholders. A simple strategy to grow supply to 36 million pounds by 2018 provided a clear line of sight to what you could expect from Cameco. But we’ve always said that our plan to increase would not be “at any cost.” We would not sacrifice value in order to meet our target if the market didn’t call for it and, at this time, the market just is not signalling the need for the higher production level. Our primary goal is to provide value, which won’t necessarily come from adding volume, but from adding the right volume at the right time; and for now, the right time is uncertain.

What you can expect is that we will continue to pursue profitable growth through a relentless focus on capital discipline and operational excellence. Our biggest sources of production, and those that deliver the most value, will continue to be our priority. We plan to ramp up Cigar Lake and to expand the McArthur River/Key Lake operation, and to maintain our Inkai production at 5.2 million pounds per year. Any development or expansion of our remaining projects will be dependent upon how market conditions evolve.

Of course, over the long term, we remain very positive about the outlook for our industry, and particularly for Cameco. 2013 marked Cameco’s 25th anniversary, which is a long time in the life of a company. Over the past quarter-century, we’ve seen a lot—volatility in politics and global economics, uranium prices ranging from $10 to $140, and shifting supply- demand fundamentals. During those ups and downs, we have managed to grow into one of the world’s leading uranium producers and build a track record of operational and financial success.

Today, we’re doing what we have always done— putting our experience, knowledge and drive to work to position the company for continued success. That means watching the market closely, delivering strong production safely and responsibly, and always looking for ways to add value and be ever more efficient. I’m pleased with the progress we made in these areas in 2013, and proud of the team we have here at Cameco. I am confident that we will continue to deliver on our goals in 2014.

Tim Gitzel

President and CEO

March 10, 2014

Senior Management TeamYou can read more about our senior executive team on our website, at cameco.com

Tim Gitzel

President and Chief Executive Officer

Grant Isaac

Senior Vice-President and Chief Financial Officer

Gary Chad

Senior Vice-President, Chief Legal Officer and Corporate Secretary

Ken Seitz

Senior Vice-President and Chief Commercial Officer

Robert Steane

Senior Vice-President and Chief Operating Officer

Alice Wong

Senior Vice-President and Chief Corporate Officer

Management’s discussion and analysis

February 10, 2014

| | |

| 4 | | ABOUT CAMECO |

| |

| 7 | | 2013 HIGHLIGHTS |

| |

| 10 | | THE NUCLEAR ENERGY INDUSTRY TODAY |

| |

| 13 | | THE LONG-TERM VIEW |

| |

| 15 | | OUR STRATEGY |

| |

| 19 | | RESPONSIBILITY |

| |

| 25 | | FINANCIAL RESULTS |

| |

| 53 | | OUR OPERATIONS AND PROJECTS |

| |

| 83 | | MINERAL RESERVES AND RESOURCES |

| |

| 89 | | ADDITIONAL INFORMATION |

| |

| 92 | | 2013 CONSOLIDATED FINANCIAL STATEMENTS |

This management’s discussion and analysis (MD&A) includes information that will help you understand management’s perspective of our audited consolidated financial statements (financial statements) and notes for the year ended December 31, 2013. The information is based on what we knew as of February 7, 2014.

We encourage you to read our financial statements and notes as you review this MD&A. You can find more information about Cameco, including our financial statements and our most recent annual information form, on our website at cameco.com, on SEDAR at sedar.com or on EDGAR at sec.gov. You should also read our annual information form before making an investment decision about our securities.

The financial information in this MD&A and in our financial statements and notes are prepared according to International Financial Reporting Standards (IFRS), unless otherwise indicated.

Unless we have specified otherwise, all dollar amounts are in Canadian dollars.

Throughout this document, the terms we, us, our, the Company and Cameco mean Cameco Corporation and its subsidiaries, including NUKEM Energy GmbH (NUKEM), unless otherwise indicated.

Caution about forward-looking information

Our MD&A includes statements and information about our expectations for the future. When we discuss our strategy, plans, future financial and operating performance, or other things that have not yet taken place, we are making statements considered to beforward-looking information orforward-looking statements under Canadian and United States securities laws. We refer to them in this MD&A asforward-looking information.

Key things to understand about the forward-looking information in this MD&A:

| | • | | It typically includes words and phrases about the future, such as: anticipate, believe, estimate, expect, plan, will, intend, goal, target, forecast, project, strategy and outlook (see examples below). |

| | • | | It represents our current views, and can change significantly. |

| | • | | It is based on a number ofmaterial assumptions, including those we have listed on page 3, which may prove to be incorrect. |

| | • | | Actual results and events may be significantly different from what we currently expect, due to the risks associated with our business. We list a number of thesematerial risks on pages 2 and 3. We recommend you also review our annual information form, which includes a discussion of othermaterial risks that could cause actual results to differ significantly from our current expectations. |

| | • | | Forward-looking information is designed to help you understand management’s current views of our near and longer term prospects, and it may not be appropriate for other purposes. We will not necessarily update this information unless we are required to by securities laws. |

Examples of forward-looking information in this MD&A

| | • | | our expectations about 2014 and future global uranium supply, consumption, demand, contracting volumes, number of operable reactors and nuclear generating capacity, including the discussion under the headingsKey market facts, The nuclear energy industry today and The long-term view |

| | • | | the discussion under the headingOur strategy , including our expectation that market challenges will continue for the near to medium term |

| | • | | our expectations for uranium deliveries in the first quarter and for the balance of 2014 |

| | • | | the discussion of our expectations relating to our tax dispute with Canada Revenue Agency (CRA) including our estimate of the amount and timing of expected cash taxes and transfer pricing penalties payable to CRA |

| | • | | future tax payments and rates |

| | • | | our consolidated outlook for the year and the outlook for our uranium, fuel services and NUKEM segments for 2014 |

| | • | | our expectation that existing cash balances and operating cash flows will meet our anticipated 2014 capital requirements without the need for any significant additional funding |

| | • | | our expectations for 2014, 2015 and 2016 capital expenditures |

| | • | | our expectation that in 2014 we will continue to comply with all the covenants in our unsecured revolving credit facility |

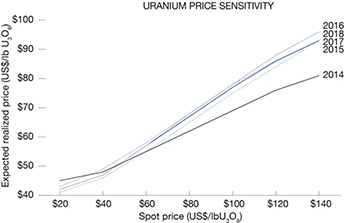

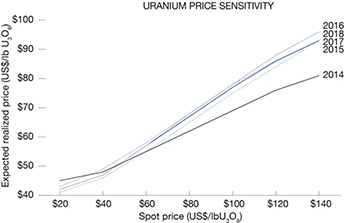

| | • | | our uranium price sensitivity analysis |

| | • | | our future plans and expectations for each of our uranium operating properties, development project and projects under evaluation, and fuel services operating sites |

| | • | | our expectation that we will begin mining in the first quarter of 2014 at Cigar Lake with AREVA’s McClean Lake mill processing the first ore at the end of the second quarter of 2014 |

| | • | | our mineral reserve and resource estimates |

Material risks

| | • | | actual sales volumes or market prices for any of our products or services are lower than we expect for any reason, including changes in market prices or loss of market share to a competitor |

| | • | | we are adversely affected by changes in foreign currency exchange rates, interest rates or tax rates |

| | • | | our production costs are higher than planned, or necessary supplies are not available, or not available on commercially reasonable terms |

| | • | | our estimates of production, purchases, costs, decommissioning or reclamation expenses, or our tax expense estimates, prove to be inaccurate |

| | • | | we are unable to enforce our legal rights under our existing agreements, permits or licences |

| | • | | we are subject to litigation or arbitration that has an adverse outcome, including lack of success in our dispute with CRA |

| | • | | there are defects in, or challenges to, title to our properties |

| | • | | our mineral reserve and resource estimates are not reliable, or we face unexpected or challenging geological, hydrological or mining conditions |

| | • | | we are affected by environmental, safety and regulatory risks, including increased regulatory burdens or delays |

| | • | | we cannot obtain or maintain necessary permits or approvals from government authorities |

| | • | | we are affected by political risks in a developing country where we operate |

2 CAMECO CORPORATION

| | • | | we are affected by terrorism, sabotage, blockades, civil unrest, social or political activism, accident or a deterioration in political support for, or demand for, nuclear energy |

| | • | | we are impacted by changes in the regulation or public perception of the safety of nuclear power plants, which adversely affect the construction of new plants, the relicensing of existing plants and the demand for uranium |

| | • | | there are changes to government regulations or policies that adversely affect us, including tax and trade laws and policies |

| | • | | our uranium and conversion suppliers fail to fulfil delivery commitments |

| | • | | our Cigar Lake mining or production plans are delayed or do not succeed, including as a result of any difficulties with the jet boring mining method or freezing the deposit to meet production targets, any difficulties with the McClean Lake mill modifications or commissioning or milling of Cigar Lake ore, or our inability to acquire any of the required jet boring equipment |

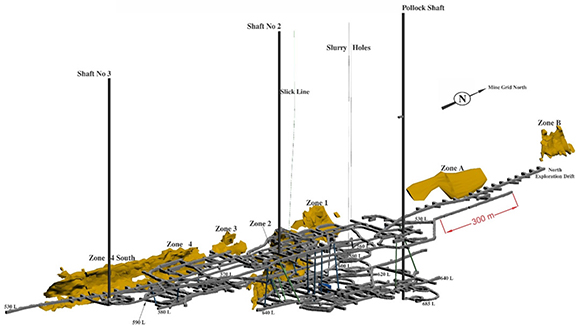

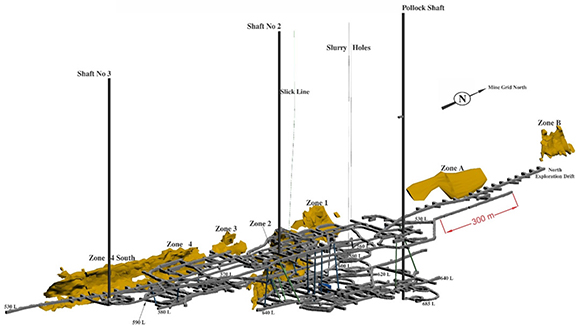

| | • | | our McArthur River development, mining or production plans are delayed or do not succeed for any reason |

| | • | | we are affected by natural phenomena, including inclement weather, fire, flood and earthquakes |

| | • | | our operations are disrupted due to problems with our own or our customers’ facilities, the unavailability of reagents, equipment, operating parts and supplies critical to production, equipment failure, lack of tailings capacity, labour shortages, labour relations issues (including an inability to renew agreements with unionized employees at McArthur River and Key Lake), strikes or lockouts, underground floods, cave- ins, ground movements, tailings dam failures, transportation disruptions or accidents, or other development and operating risks |

Material assumptions

| | • | | our expectations regarding sales and purchase volumes and prices for uranium, fuel services and electricity |

| | • | | our expectations regarding the demand for uranium, the construction of new nuclear power plants and the relicensing of existing nuclear power plants not being more adversely affected than expected by changes in regulation or in the public perception of the safety of nuclear power plants |

| | • | | our expected production level and production costs |

| | • | | the assumptions regarding market conditions upon which we have based our capital expenditures expectations |

| | • | | our expectations regarding spot prices and realized prices for uranium, and other factors discussed on page 41,Price sensitivity analysis: uranium |

| | • | | our expectations regarding tax rates and payments, foreign currency exchange rates and interest rates |

| | • | | our expectations about the outcome of the dispute with CRA |

| | • | | our decommissioning and reclamation expenses |

| | • | | our mineral reserve and resource estimates, and the assumptions upon which they are based, are reliable |

| | • | | the geological, hydrological and other conditions at our mines |

| | • | | our Cigar Lake mining and production plans succeed, including the additional jet boring system is acquired on schedule, the jet boring mining method works as anticipated, and the deposit freezes as planned |

| | • | | mill modifications and commissioning of the McClean Lake mill are completed as planned and the mill is able to process Cigar Lake ore as expected |

| | • | | our McArthur River development, mining and production plans succeed |

| | • | | our ability to continue to supply our products and services in the expected quantities and at the expected times |

| | • | | our ability to comply with current and future environmental, safety and other regulatory requirements, and to obtain and maintain required regulatory approvals |

| | • | | our operations are not significantly disrupted as a result of political instability, nationalization, terrorism, sabotage, blockades, civil unrest, breakdown, natural disasters, governmental or political actions, litigation or arbitration proceedings, the unavailability of reagents, equipment, operating parts and supplies critical to production, labour shortages, labour relations issues (including an inability to renew agreements with unionized employees at McArthur River and Key Lake), strikes or lockouts, underground floods, cave-ins, ground movements, tailings dam failure, lack of tailings capacity, transportation disruptions or accidents or other development or operating risks |

2013 ANNUAL REPORT 3

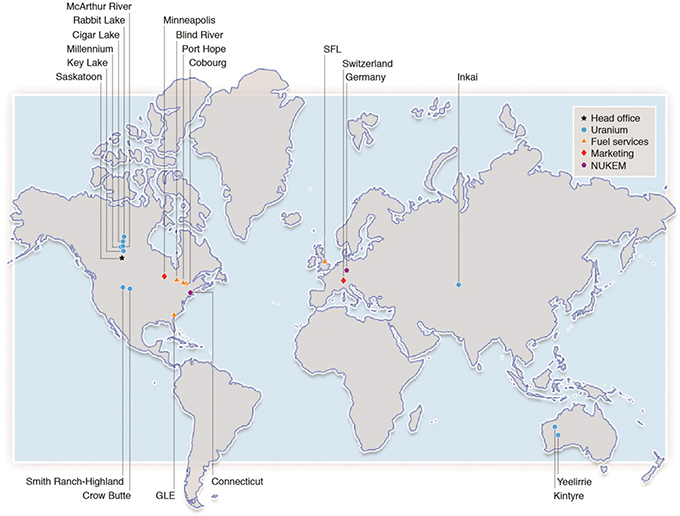

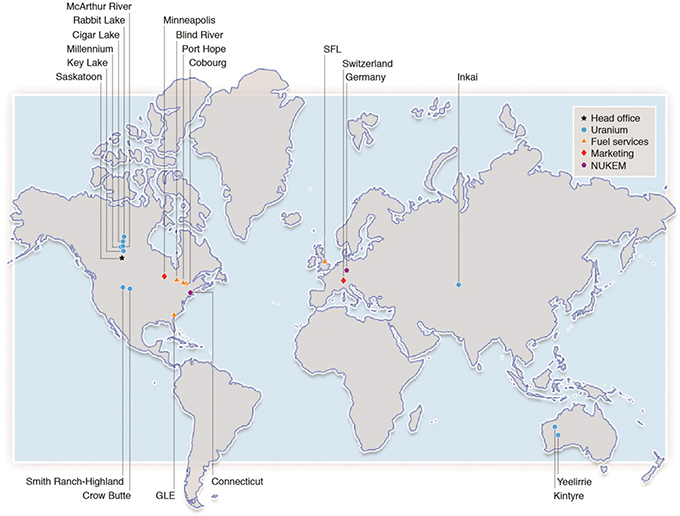

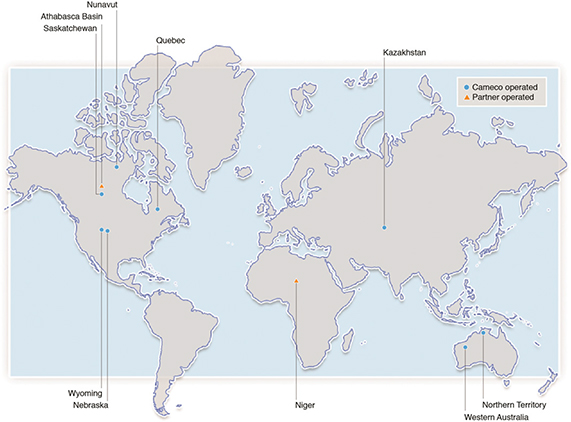

About Cameco

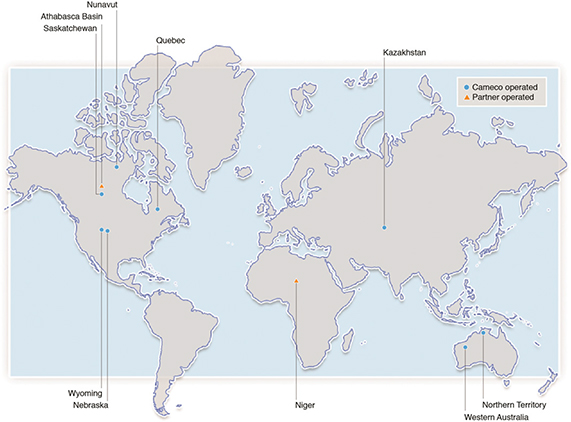

Our head office is in Saskatoon, Saskatchewan. We are one of the world’s largest uranium producers, with uranium assets on three continents. Nuclear energy plants around the world use our uranium products to generate one of the cleanest sources of electricity available today. Our operations and investments span the nuclear fuel cycle, from exploration to fuel manufacturing.

Strengths

We are a pure-play nuclear investment with a proven track record and the strengths to take advantage of the world’s rising demand for safe, clean and reliable energy.

With our extraordinary assets, contract portfolio, employee expertise, comprehensive industry knowledge and financial strength, we are confident in our ability to continue to grow and increase shareholder value.

Business segments

URANIUM

We are one of the world’s largest uranium producers, and in 2013 accounted for about 15% of the world’s production. We have controlling ownership of the world’s largest high-grade reserves, with ore grades up to 100 times the world average, and low-cost operations.

Product

| | • | | uranium concentrates (U3O8) |

Mineral reserves and resources

Mineral reserves

| | • | | approximately 443 million pounds proven and probable |

Mineral resources

| | • | | approximately 391 million pounds measured and indicated and 289 million pounds inferred |

Global exploration

| | • | | focused on four continents |

| | • | | approximately 2.0 million hectares of land |

Operating properties

| | • | | McArthur River and Key Lake, Saskatchewan |

| | • | | Rabbit Lake, Saskatchewan |

| | • | | Smith Ranch-Highland, Wyoming |

Development project

| | • | | Cigar Lake, Saskatchewan |

Projects under evaluation

| | • | | Inkai blocks 1 and 2 production increase, Kazakhstan |

| | • | | Inkai block 3, Kazakhstan |

| | • | | Millennium, Saskatchewan |

FUEL SERVICES

We are an integrated uranium fuel supplier, offering refining, conversion and fuel manufacturing services.

Products

| | • | | uranium hexafluoride (UF6) |

(control about 25% of world conversion capacity)

| | • | | fuel bundles, reactor components and monitoring equipment used by CANDU reactors |

Operations

| | • | | Blind River refinery, Ontario |

(refines uranium concentrates to UO3)

| | • | | Port Hope conversion facility, Ontario |

(converts UO3 to UF6 or UO2)

| | • | | Cameco Fuel Manufacturing Inc., Ontario |

(manufactures fuel bundles and reactor components)

| | • | | a toll conversion agreement with Springfields Fuels Ltd. (SFL), Lancashire, United Kingdom (UK) (to convert UO3 to UF6—expires in 2016) |

NUKEM

Our ownership of NUKEM GmbH (NUKEM) provides us with access to one of the world’s leading traders of uranium and uranium-related products. We acquired NUKEM in January 2013.

Activity

| | • | | physical trading of uranium concentrates, conversion and enrichment services through back-to-back purchase and sales transactions |

| | • | | recovery of natural and enriched non-standard uranium from western facilities and other sources |

4 CAMECO CORPORATION

Other fuel cycle investments

ENRICHMENT

We continue to explore innovative areas like laser enrichment technology to broaden our fuel cycle participation and help us serve our customers more effectively. Uranium enrichment is the second largest value component, after uranium, in a typical light water reactor fuel bundle. Having operational control of both uranium production and enrichment facilities would offer operational synergies that could significantly enhance profit margins.

The enrichment market has the same customer base as the uranium market, and most of the world’s commercial nuclear reactors need enriched uranium.

Investment

| | • | | we have a 24% interest in GE-Hitachi Global Laser Enrichment (GLE) in North Carolina, with General Electric (51%) and Hitachi Ltd. (25%). GLE is testing a third-generation technology that, if successful, will use lasers to commercially enrich uranium. |

GLOBAL PRESENCE

2013 ANNUAL REPORT 5

KEY MARKET FACTS

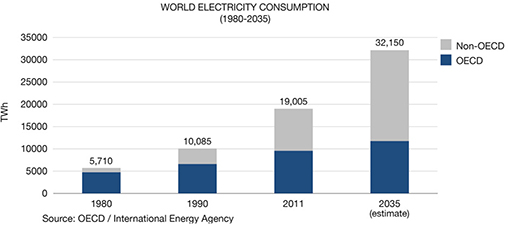

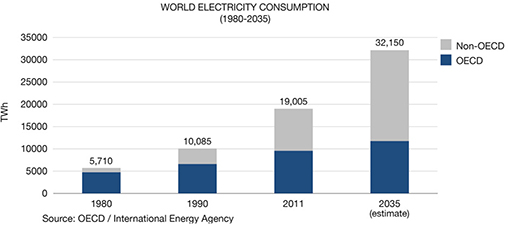

The 2013 World Energy Outlook predicts that, by 2035, electricity consumption will have grown by about 70% from current levels, driven mainly by growth in the developing world as it seeks to diversify sources of energy and provide security of supply.

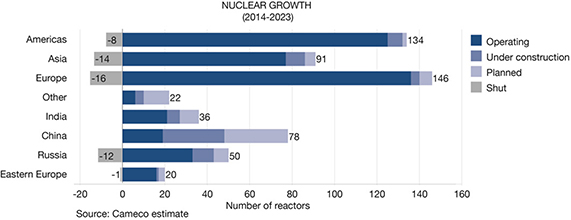

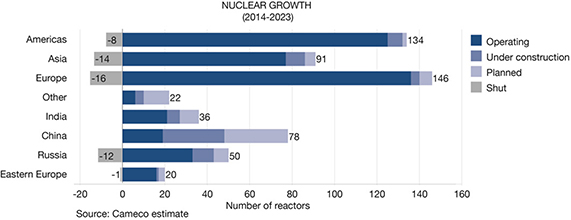

| | • | | At the start of 2014, there were 433 operable commercial nuclear power reactors in 31 countries, and by 2023, we expect that to grow to 526 reactors. |

| | • | | At the start of 2014, there were 70 reactors under construction in 15 countries, and dozens more planned to begin operation by 2023. |

| | • | | Most of this new build is being driven by rapidly developing countries such as China and India, which have severe energy deficits and want clean sources of electricity to improve their environment and sustain economic growth. |

| | • | | In emerging nuclear countries, construction has begun in the United Arab Emirates (UAE) and Belarus, and planning for first reactors is underway in Turkey, Vietnam, Bangladesh, Poland, Jordan and Saudi Arabia. |

| | • | | Over the next decade, we expect demand for uranium to grow by an average of 4% per year. To meet global demand, we expect about two-thirds of uranium supply will come from mines that are currently in operation, about 15% from finite sources of secondary supply (mainly government inventories and limited recycling), and about 20% will have to come from new sources of supply. |

| | • | | With uranium assets on three continents, including high-grade reserves and low-cost mining operations in Canada, and investments that span the nuclear fuel cycle from exploration to fuel manufacturing, we believe we are ideally positioned to benefit from the world’s growing need for clean, reliable energy. |

6 CAMECO CORPORATION

2013 highlights

The long-term outlook for growth in the nuclear industry remains very strong. Over 70 reactors are under construction at the beginning of 2014, and average annual uranium demand is expected to increase by about 4% over the next decade. However, challenges remain in the near to medium term, and have persisted for longer than anticipated due to the lingering effects of the events in Japan in 2011 and global economic slowdown. In this environment, our previous supply target of 36 million pounds by 2018 is no longer appropriate, and thus, we have eliminated that target. We expect this will allow us greater flexibility to respond to market conditions and deliver the best value until more certainty returns to the market environment.

In spite of the challenging market environment, we demonstrated our strengths again in 2013, exceeding our production target, delivering on our financial guidance and achieving a number of performance records. In particular, with the addition of NUKEM in 2013, our sales were about 42 million pounds, representing about 25% of 2013 reactor consumption.

Strong financial performance

Our financial results remained strong in 2013:

| • | | record annual revenue of $2.4 billion |

| • | | annual gross profit of $607 million |

| • | | record annual revenue of $1.6 billion from our uranium segment |

| • | | record annual average realized price of $49.81 per pound ($48.35 US per pound) in our uranium segment |

Net earnings attributable to our equity holders (net earnings) in 2013 were $318 million compared to $253 million in 2012. This $65 million increase in net earnings was the result of:

| • | | the impact of a one-time $168 million write-down of our investment in the Kintyre deposit in 2012 |

| • | | higher earnings in our fuel services segment as a result of an increase in sales volumes and realized prices |

| • | | lower exploration expenditures |

| • | | higher tax recoveries due to a decline in pre-tax earnings in Canada |

partially offset by:

| • | | lower earnings from our electricity business due to lower generation, a lower average realized price and higher costs |

| • | | a $70 million write-down of our Talvivaara asset, due to their weakened financial position and pending corporate restructuring |

| • | | higher losses on foreign exchange derivatives, due to the weakening of the Canadian dollar |

| | | | | | | | | | | | |

HIGHLIGHTS DECEMBER 31 ($ MILLIONS EXCEPT WHERE INDICATED) | | 2013 | | | 2012 | | | CHANGE | |

Revenue | | | 2,439 | | | | 1,891 | | | | 29 | % |

Gross profit | | | 607 | | | | 540 | | | | 12 | % |

Net earnings attributable to equity holders | | | 318 | | | | 253 | | | | 26 | % |

$ per common share (diluted) | | | 0.81 | | | | 0.64 | | | | 27 | % |

Adjusted net earnings (non-IFRS, see page 27) | | | 445 | | | | 434 | | | | 3 | % |

$ per common share (adjusted and diluted) | | | 1.12 | | | | 1.10 | | | | 2 | % |

Cash provided by operations (after working capital changes) | | | 530 | | | | 579 | | | | (8 | )% |

2013 ANNUAL REPORT 7

Solid progress in our uranium segment this year

In our uranium segment, we achieved record annual production and, in the fourth quarter, record quarterly production, as well as a number of successes at our mining operations and development project. Key highlights:

| • | | record annual production of 23.6 million pounds—2% higher than the guidance we provided in our 2013 third quarter MD&A |

| • | | record quarterly production of 7.5 million pounds in the fourth quarter—15% higher than in 2012 |

| • | | realized benefits of production flexibility provisions in our McArthur River/Key Lake licences, exceeding our annual production target by 4% and setting a new record for annual production from a uranium operation, anywhere in the world, with 20.1 million pounds (100% basis) in 2013 |

| • | | began commissioning the jet boring system at Cigar Lake, jetting a test cavity in waste rock followed by our first cavity in ore |

| • | | in the US, our North Butte satellite operation began production |

| • | | the Canadian Nuclear Safety Commission (CNSC) granted an eight-year operating licence for Cigar Lake, and 10-year operating licences for McArthur River, Key Lake and Rabbit Lake |

| • | | Inkai received government approval of an amendment to the resource use contract to increase production from blocks 1 and 2 to 5.2 million pounds (3.0 million pounds our share) |

| • | | we announced the signing of a collaboration agreement that will strengthen and formalize the relationship between us, AREVA Resources Canada Inc. (AREVA) and the English River First Nation, building on past co-operation and sharing of benefits from our operations |

| • | | the government of Saskatchewan announced changes to the provincial royalty system to encourage continued investment in Saskatchewan |

| • | | we delivered our first shipments of Canadian uranium to China under the Canada-China Nuclear Co-operation Agreement (NCA) |

| • | | the Canadian government announced the signing of the final agreement required to implement the Canada- India NCA, which, once brought into force, will allow us to export Canadian-origin uranium to India |

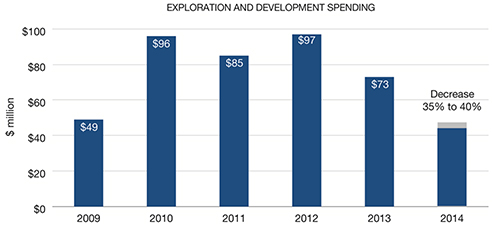

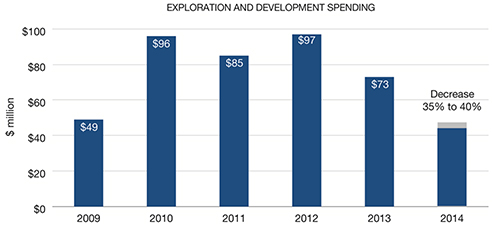

We also continued to advance our exploration activities, spending $9 million on seven brownfield exploration projects, $7 million on our projects under evaluation in Australia, and $13 million for resource definition at Inkai and at our US operations. We spent about $44 million on regional exploration programs, mostly in Saskatchewan, followed by Australia and the United States.

Updates on our other segments and investments

In our fuel services segment, production was 5% higher than in 2012 when we reduced production in response to weak market conditions for UF6. We also signed new three-year collective agreements with unionized employees at our Port Hope conversion facility.

In our electricity segment, Bruce Power Limited Partnership (BPLP) generated 24.8 terawatt hours (TWh) of electricity, at a capacity factor of 87%. Our share of earnings before taxes was $109 million, a 31% decrease compared to 2012.

On January 31, 2014, we announced the sale of our 31.6% limited partnership interest in BPLP and related entities to BPC Generation Infrastructure Trust, one of the limited partners in BPLP, for $450 million. The effective date for the sale is December 31, 2013. Under the agreements governing BPLP, the limited partners have rights of first offer upon a sale by us. Closing of the transaction is subject to completion or waiver of the right of first offer process by the other limited partners and receipt of certain regulatory approvals.

Our investment in GLE continues to progress. GLE is continuing its testing activities and engineering design work for a commercial facility. On November 27, 2013, the US Department of Energy (DOE) announced that it will negotiate with GLE for the sale of its depleted uranium hexafluoride inventory held at their Paducah, Kentucky and Portsmouth, Ohio sites. If negotiations are successful, we expect that definitive agreements would follow.

We completed our acquisition of NUKEM Energy GmbH in January 2013. NUKEM is one of the world’s leading traders and brokers of nuclear fuel products and services.

8 CAMECO CORPORATION

| | | | | | | | | | | | | | |

HIGHLIGHTS | | 2013 | | | 2012 | | | CHANGE | |

Uranium | | Production volume (million lbs) | | | 23.6 | | | | 21.9 | | | | 8 | % |

| | Sales volume (million lbs) | | | 32.8 | | | | 32.9 | | | | — | |

| | Average realized price ($US/lb) | | | 48.35 | | | | 47.72 | | | | 1 | % |

| | ($Cdn/lb) | | | 49.81 | | | | 47.72 | | | | 4 | % |

| | Revenue ($ millions) | | | 1,633 | | | | 1,571 | | | | 4 | % |

| | Gross profit ($ millions) | | | 550 | | | | 514 | | | | 7 | % |

Fuel services | | Production volume (million kgU) | | | 14.9 | | | | 14.2 | | | | 5 | % |

| | Sales volume (million kgU) | | | 17.6 | | | | 16.4 | | | | 7 | % |

| | Average realized price ($Cdn/kgU) | | | 18.12 | | | | 17.75 | | | | 2 | % |

| | Revenue ($ millions) | | | 319 | | | | 291 | | | | 10 | % |

| | Gross profit ($ millions) | | | 52 | | | | 41 | | | | 27 | % |

NUKEM | | Sales volume U3O8 (million lbs) | | | 8.9 | | | | — | | | | — | |

| | Average realized price ($Cdn/lb) | | | 42.26 | | | | — | | | | — | |

| | Revenue ($ millions) | | | 465 | | | | — | | | | — | |

| | Gross profit (loss) ($ millions) | | | 20 | | | | — | | | | — | |

Electricity | | Output (100%) (TWh) | | | 24.8 | | | | 26.8 | | | | (7 | )% |

| | Average realized price ($Cdn/MWh) | | | 54 | | | | 55 | | | | (2 | )% |

| | Revenue (100%) | | | 1,370 | | | | 1,487 | | | | (8 | )% |

| | Our share of earnings before taxes ($ millions) | | | 109 | | | | 157 | | | | (31 | )% |

SHARES AND STOCK OPTIONS OUTSTANDING

At February 6, 2014, we had:

| • | | 395,627,632 common shares and one Class B share outstanding |

| • | | 9,628,635 stock options outstanding, with exercise prices ranging from $15.79 to $54.38 |

DIVIDEND POLICY

Our board of directors has established a policy of paying a quarterly dividend of $0.10 ($0.40 per year) per common share. This policy will be reviewed from time to time based on our cash flow, earnings, financial position, strategy and other relevant factors.

2013 ANNUAL REPORT 9

The nuclear energy industry today

The long-term outlook for the uranium industry continues to be very positive, despite the uncertainty that exists today. Against the backdrop of the world’s growing need for safe, clean, reliable and large-scale sources of energy, nuclear energy continues to play a significant role in the global energy mix. The challenge for the industry is the pathway and timing of the transition from today’s stagnant, over-supplied short-term market to the promise of nuclear growth and positive uranium market conditions in the long term.

Market conditions deteriorated in 2013, and we believe the uncertainty could continue depending on how events unfold. In particular, the slower than expected pace of Japanese reactor restarts, unexpected reactor shutdowns in the United States and temporary shutdowns in South Korea led to demand erosion. Compounding the issue, the supply side performed well: primary supply remained stable while secondary supply increased modestly, primarily due to enricher underfeeding. The impact of these conditions was the extension of the post-Fukushima inventory overhang and further downward price pressure.

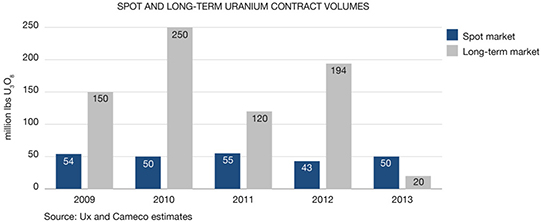

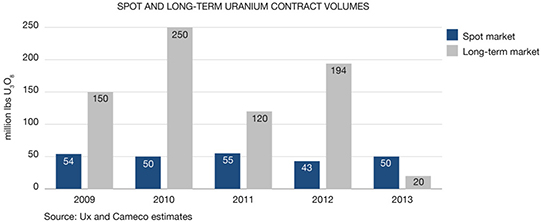

This market dynamic also led to a reduction in market contracting activity. Utilities are well covered under long-term contracts for the time being and are not under pressure to buy. Similarly, existing suppliers appear reluctant to enter into meaningful contract volumes at current prices. The result was very low levels of long-term contracting in 2013—around 10% of current annual reactor consumption estimates, highlighting a cordial stalemate between buyers and sellers. How this stalemate is resolved between buyers and sellers will be a key factor influencing the pace of market recovery.

Looking beyond the current market challenges, there were several positive indications for the long term in 2013. In Japan, more clarity was gained around the process for reactor restarts: the Nuclear Regulatory Authority (NRA) implemented measures that improved regulatory stability; restart applications were submitted by seven utilities covering 16 reactors; and, there was observable confidence from Japanese utilities who are spending billions of dollars on plant upgrades in anticipation of a positive restart environment.

In other regions, China’s remarkable nuclear growth program remains on track. Three more reactors were brought online, and construction began on four more in 2013. The UK also garnered positive attention as a result of a government-backed revenue arrangement with Electricité de France, designed to support new build there. Overall, the anticipated increase in nuclear plants from 433 (representing 394 gigawatts) today to 526 (representing 514 gigawatts) by 2023 illustrates a promising growth picture.

And it is clear that this growth will require new sources of uranium supply at a time when secondary supplies are diminishing and current market conditions have resulted in deferrals and cancellations of several uranium projects. Current prices are insufficient to incent new production. The end of the Russian Highly Enriched Uranium (HEU) commercial agreement in 2013, removing 24 million pounds of annual supply from the market, highlights the need for increasing reliance on primary uranium supply in the future. The timing of this required supply may well be muted in the near term due to the extension of the over-supply situation, but it remains clear new supply will be required this decade. The development and execution of new uranium supply projects, as well as continued performance of existing supply, will also play a significant role in determining the timing and pace of market recovery.

10 CAMECO CORPORATION

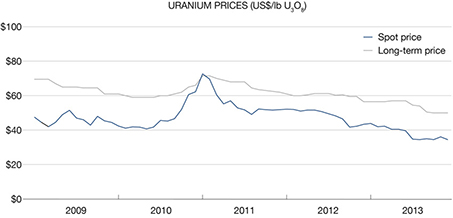

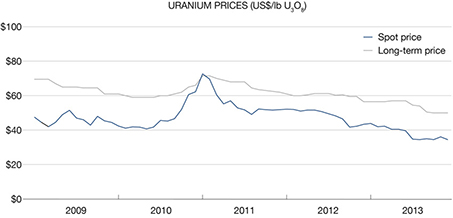

Industry prices

In 2013, the spot price declined from $44 (US) per pound to a low of about $34 (US) per pound. Utilities continue to be well covered under existing contracts. Given the current uncertainties in the market, we expect utilities and other market participants will continue to be opportunistic in their buying. We expect contracting over the next 12 months to remain somewhat discretionary.

| | | | | | | | | | | | |

| | | 2013 | | | 2012 | | | CHANGE | |

Uranium($US/lb U3O8)1 | | | | | | | | | | | | |

Average spot market price | | | 38.17 | | | | 48.40 | | | | (21 | )% |

Average long-term price | | | 54.13 | | | | 60.13 | | | | (10 | )% |

Fuel services($US/kgU as UF6)1 | | | | | | | | | | | | |

Average spot market price | | | | | | | | | | | | |

North America | | | 9.60 | | | | 7.99 | | | | 20 | % |

Europe | | | 10.07 | | | | 8.56 | | | | 18 | % |

Average long-term price | | | | | | | | | | | | |

North America | | | 16.50 | | | | 16.75 | | | | (1 | )% |

Europe | | | 17.17 | | | | 17.25 | | | | — | |

Note: the industry does not publish UO2 prices. | | | | | | | | | | | | |

Electricity($/MWh) | | | | | | | | | | | | |

Average Ontario electricity spot price | | | 25 | | | | 23 | | | | 9 | % |

| 1 | Average of prices reported by TradeTech and Ux Consulting (Ux) |

2013 ANNUAL REPORT 11

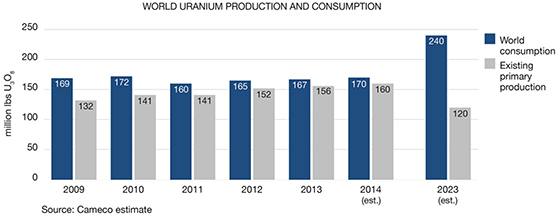

World consumption and production

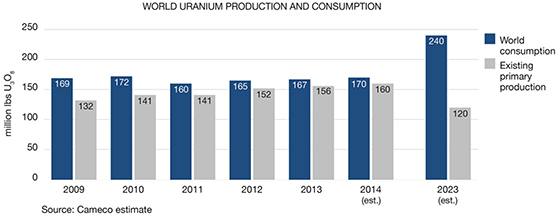

We estimate global uranium consumption in 2013 was about 167 million pounds and production was 156 million pounds.

We expect global uranium consumption to increase to about 170 million pounds in 2014, and global production to be approximately 160 million pounds. Secondary supplies should continue to bridge the gap.

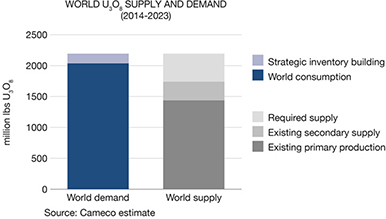

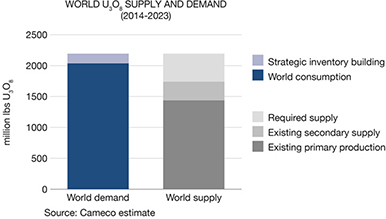

By 2023, we expect world uranium consumption to be about 240 million pounds per year, representing average annual growth of about 4%. These consumption estimates exclude strategic inventory building that we expect will occur in growth regions.

We expect existing primary production to decrease over the next decade, falling to 120 million pounds by 2023 and highlighting the need for new primary supply.

We expect world consumption for conversion services to increase similar to uranium consumption.

Contract volumes

The Ux estimate for global spot market sales in 2013 is about 50 million pounds, similar to previous years. Utilities and traders were responsible for the majority of the purchases, taking advantage of the lower spot prices to make opportunistic purchases.

At the start of 2013, we estimated long-term contracting volumes for the year to be between 75 million and 100 million pounds, although they ended the year at about 20 million pounds, a historical low. Neither buyers nor suppliers are under significant pressure to contract, and suppliers are likely hesitant to lock in meaningful volumes at current price levels. Long-term contracting volumes in 2014 will depend on market conditions.

12 CAMECO CORPORATION

The long-term view

We remain confident in the long-term fundamentals of the nuclear industry, despite the near- to medium-term challenges. Our industry is driven by demand for energy, which continues to grow as a result of continued increases in world population and industrial development. The 2013 World Energy Outlook predicts that, by 2035, electricity consumption will have grown by about 70% from current levels. Most of this energy will be used by developing (non-OECD) countries as their populations and standards of living increase.

New reactor outlook

Within this context, most countries are pursuing a diversified approach to energy growth, with an emphasis on energy security and clean energy. Nuclear power can generate baseload electricity with no toxic air pollutants, carbon dioxide (CO2) or other greenhouse gas emissions. It has the capacity to produce enough electricity on a global scale to meet the world’s growing needs, and while it is not the only solution, it is an affordable and sustainable source of safe, clean and reliable energy. As a result, we expect nuclear energy to remain an important part of the energy mix.

In 2013, four reactors were connected to the grid (three in China and one in India), offset by the closures of four reactors in the United States. Construction commenced on 11 units during the year: four in the United States, four in China and one each in the UAE, South Korea and Belarus. Power uprates added about 645 megawatts of capacity to existing units.

Today, there are 433 operable reactors with a total generating capacity of 394 gigawatts. Over the next 10 years, we expect the number of reactors to grow to 526, with the startup of 144 units, offset by 51 closures. That represents generating capacity of about 514 gigawatts by 2023, which translates to an average annual growth of 3%.

2013 ANNUAL REPORT 13

Of this growth, approximately 70 reactors with 75 gigawatts of generating capacity are under construction today. This is a significant rate of growth in new reactor construction. At the end of 2013, China continued to lead the growth with 29 reactors under construction. India, Russia, South Korea and the United States are also progressing in the expansion of their nuclear fleets. Of the 70 reactors under construction today, if startups occur as planned, 50 of those units (53 gigawatts) will be online over the next three years.

In the UK, the government is maintaining its commitment to nuclear energy as a source of emissions-free energy. Critical milestones have been reached, allowing potential vendors to move forward with new build plans. In addition, several previously non-nuclear countries are moving ahead with their reactor construction programs or considering adding nuclear to their energy programs in the future. Construction work continues on two of four planned units in the UAE that will supply 5.6 gigawatts of nuclear capacity by 2020. Turkey is also moving forward with plans to build eight new reactors at two different sites. Belarus, Saudi Arabia, Vietnam,Bangladesh, Poland and Jordan are also moving forward with plans to proceed with nuclear power development.

DEMAND FOR URANIUM IS GROWING

Not surprisingly, as the number of reactors grows, so too does the demand for uranium. Over the next decade, we expect world demand to grow at an average annual growth rate of about 4%, totaling approximately 2.2 billion pounds from 2014—2023. As a result of that growth, by 2023, we expect annual world consumption to be approximately 240 million pounds, plus about 20 million pounds per year for strategic inventory building, totaling 260 million pounds of world demand.

SUPPLY UNCERTAINTY

While demand is expected to increase over the next decade, many producers have announced delays and cancellations to their projects, which could have an effect on the longer term outlook for the uranium industry. Complicating the supply outlook further is the possibility of some projects, primarily driven by sovereign interests, moving forward in the near term despite market conditions.

We estimate roughly two-thirds of global uranium supply over the next 10 years to come from existing primary production—mines that are currently in commercial operation—and about 15% to come from existing secondary supply sources. However, most secondary sources are finite and will not meet long-term needs. One of the largest sources of secondary supply is uranium derived from the Russian HEU commercial agreement, which came to an end in 2013, removing about 24 million pounds per year from the market. This volume is more than our current total annual production.

The result is that we estimate about 20% of supply will need to come from new sources at a time when new projects are being delayed or cancelled because of current market conditions. The situation is exacerbated by barriers to entry and lead times for new uranium production being as long as 10 years or more, depending on the deposit type and location. As conditions continue to evolve, it is important to keep an eye on supply.

14 CAMECO CORPORATION

Our strategy

Our strategy remains focused on taking advantage of the long-term growth we see coming in our industry, while maintaining the ability to respond to market conditions as they evolve. As a result of the longer-than-anticipated market uncertainty, we are adjusting our plans in line with this focus.

Market challenges have persisted since early 2011, and we expect they will continue for the near to medium term, depending on:

| • | | the pace of Japanese reactor restarts |

| • | | how long it takes for excess supply to clear the market |

| • | | when long-term contracting resumes in meaningful quantities |

| • | | the development and execution of new uranium supply projects |

| • | | continued performance of existing supply |

In this environment, a fixed production target is no longer appropriate; although we still have an extensive portfolio of assets from which we can increase our production capacity, we have decided the prudent action is to eliminate our previous 2018 supply target of 36 million pounds. This will allow us increased flexibility in order to deliver the best value through this period of uncertainty, while at the same time retaining the ability to benefit when more certainty returns to the market environment, as we expect it will. Today, our strategy is to profitably produce at a pace aligned with market signals to increase long-term shareholder value.

We plan to:

| • | | carry out all of our business with a focus on safety, people and the environment |

| • | | ensure continued reliable, low-cost production from our flagship operation, McArthur River/Key Lake and seek to expand that production |

| • | | ensure continued reliable, low-cost production at Inkai |

| • | | successfully bring on and ramp up production at Cigar Lake |

| • | | manage the rest of our production facilities and potential sources of supply in a manner that retains the flexibility to respond to market signals and take advantage of value adding opportunities within our own portfolio and the uranium market |

| • | | manage and allocate capital in a way that balances growing the long-term value of the business and returns to shareholders, while maintaining a strong balance sheet and our investment grade rating |

Capital allocation

Delivering returns to our long-term shareholders is a top priority. We continually evaluate our investment options to ensure we allocate our capital in a way that we believe will:

| • | | create the greatest long-term value for our shareholders |

| • | | allow us to maintain our investment grade rating |

| • | | ensure we execute on our dividend policy |

We start by determining how much cash we have to invest (investable capital), which is based on our expected cash flow from operations minus expenses we consider to be a higher priority, such as dividends and financing costs, and could include others. This investable capital can be reinvested in the company or returned to shareholders.

Reinvestment

Before investable capital is reinvested in sustaining, capacity replacement or growth, each investment must demonstrate that it can meet the required risk-adjusted return criteria, and we must identify at the corporate level the expected impact on cash flow, earnings and the balance sheet. All project risks must be identified, including the risks of not investing. Allocation of capital only occurs once an investment has cleared these hurdles.

This may result in some opportunities being held back in favour of higher return investments, and should allow us to generate the best return on investment decisions when we are faced with multiple prospects, while also controlling our costs. If there are not enough good growth prospects internally or externally, this may also result in residual investable capital, which we would then consider returning directly to shareholders.

2013 ANNUAL REPORT 15

Return

If we determine the best use of cash is to return it to shareholders, we can do that through a share repurchase or dividend—either a one-time special dividend or a dividend growth policy. When deciding between these options, we consider a number of factors, including generation of excess cash, our growth prospects, growth prospects for the industry, and the nature of the excess cash.

Share buyback: If we were generating excess cash while there were little or no growth prospects for the Company or the industry, then a share buyback might make sense. However, our current view is that the long-term fundamentals for Cameco and the industry remain strong.

Dividend: We view our dividend as a priority. Therefore, any change to our dividend policy must be carefully considered with a view to long-term sustainability. Currently, the conditions in the uranium market do not provide us with the level of certainty we require to implement changes in our dividend policy.

Marketing Strategy

As with our corporate strategy and our approach to capital allocation, the purpose of our marketing strategy is to deliver value and secure a solid base of earnings and cash flow, by maintaining a balanced contract portfolio that optimizes our realized price.

We sell uranium and fuel services directly to nuclear utilities around the world, as uranium concentrates, UO2, UF6, conversion services or fuel fabrication. Uranium is not traded in meaningful quantities on a commodity exchange. Utilities buy the majority of their uranium and fuel services products under long-term contracts with suppliers, and meet the rest of their needs on the spot market.

We have an extensive portfolio of long-term sales contracts which reflects the long-term, trusting relationships we have with our customers.

In addition, we are active in the spot market, buying and selling uranium where it is beneficial for us. With our purchase of NUKEM, we have enhanced our ability to participate in this regard as they are one of the world’s leading traders of uranium and uranium-related products. We undertake activity in the spot market prudently, looking at the spot price and other business factors to decide whether it is appropriate to purchase or sell into the spot market. This activity gives us insight into the underlying market fundamentals and is a source of profit.

OPTIMIZING REALIZED PRICE

We try to maximize our realized price by signing contracts with terms between five and 10 years (on average) that include mechanisms to protect us when market prices decline, and allow us to benefit when market prices go up.

Because we deliver large volumes of uranium every year, our net earnings and operating cash flows are affected by changes in the uranium price. Market prices are influenced by the fundamentals of supply and demand, geopolitical events, disruptions in planned supply and other market factors.

40% FIXED-PRICE CONTRACTS, 60% MARKET-RELATED CONTRACTS

We target a ratio of 40% fixed-price contracts and 60% market-related contracts. This is a balanced and flexible approach that allows us to adapt to market conditions, reduce the volatility of our future earnings and cash flow, and deliver the best value to shareholders over the long term. It is also consistent with the contracting strategy of our customers.

Over time, this strategy has allowed us to add increasingly favourable contracts to our portfolio that will enable us to participate in increases in market prices in the future.

Fixed Price Contracts:are typically based on the industry long-term price indicator at the time the contract is accepted and escalated over the term of the contract.

16 CAMECO CORPORATION

Market-Related Contracts:are different from fixed-price contracts in that they may be based on either the spot price or the long-term price, and that price is as quoted at the time of delivery rather than at the time the contract is accepted. These contracts also often include floor prices and some include ceiling prices, both of which are also escalated over the term of the contract.

Fuel Services Contracts:the majority of our fuel services contracts are at a fixed price per kgU, escalated over the term of the contract, and reflect the market at the time the contract is accepted.

CONTRACT PORTFOLIO STATUS

Currently, we are heavily committed under long-term uranium contracts through 2017, so we are being selective when considering new commitments. We have commitments to sell approximately 230 million pounds of U3O8 with 45 customers worldwide, and commitments to sell approximately 80 million kilograms as UF6 conversion with 41 customers worldwide.

Customers—U3O8:

| • | | 36% of volume to Americas (US, Canada, Latin America) |

| • | | 23% of volume to Europe |

| • | | five largest customers account for 50% of commitments |

Customers—UF6 conversion:

| • | | 40% of volume to Americas (US, Canada, Latin America) |

| • | | 35% of volume to Europe |

| • | | five largest customers account for 54% of commitments |

Managing our contract commitments and costs

We deliver more uranium than we produce every year. To meet our delivery commitments, we use uranium obtained:

| • | | from our existing production |

| • | | through purchases under long-term agreements and in the spot market |

| • | | from our existing inventory |

Over the past three years, we have maintained sales in excess of 32 million pounds annually. Previously, we planned to maintain our sales volumes year-over-year using a combination of sources, including production increases and normal course purchases, even once the Russian HEU commercial agreement came to an end. However, given the longer-than-expected period of market uncertainty, we have changed our plans in our continued pursuit to add value. Rather than maintaining sales at a fixed level, we will allow sales volume to vary depending on:

| • | | the level of sales commitments in our long-term contract portfolio (the annual average sales commitments over the next five years is 30 million pounds, with commitment levels through 2016 higher than in 2017 and 2018) |

| • | | our production volumes, including from the rampup of Cigar Lake and from planned increases at McArthur River/Key Lake |

| • | | purchases under existing and/or new arrangements |

| • | | discretionary use of inventories |

PRODUCTION

To help us operate efficiently and cost-effectively, we manage operating costs and improve plant reliability by prudently investing in production infrastructure, new technology and business process improvements. Like all mining companies, our uranium segment is affected by the rising cost of inputs such as labour and fuel. In 2013, labour, production supplies and contracted services made up 92% of the production costs at our uranium mines. Labour (37%) was the largest component. Production supplies (28%) included fuels, reagents and other items.

2013 ANNUAL REPORT 17

Contracted services (27%) included mining and maintenance contractors, air charters, security and ground freight.

In 2014 and over the next few years, we will complete a number of capital projects at our various production facilities, including Cigar Lake. Upon completion, we will begin to depreciate the assets. This will increase the non-cash portion of our production costs and is expected to increase our unit cost of sales.

In addition, starting this year, we expect to begin to recognize the profits or losses related to Cigar Lake’s operating activities. All expenditures incurred prior to that time are expected to be capitalized as development costs. Depending on the actual timing of the rampup to the full production rate, we expect that the cash cost of material produced from Cigar Lake will initially be higher, which is also expected to increase our unit cost of sales.

Operating costs in our fuel services segment are mainly fixed. In 2013, labour accounted for about 54% of the total. The largest variable operating cost is for energy (natural gas and electricity), followed by zirconium and anhydrous hydrogen fluoride.

PURCHASES AND INVENTORY

Our costs are also affected by the purchases of uranium and conversion services we make under long-term contracts and on the spot market.

Previously, our most significant long-term purchase contract was the Russian HEU commercial agreement, which ended in 2013. With that source of supply no longer available, and until Cigar Lake ramps up to full production, to meet our delivery commitments, we will make use of our inventories and we may purchase material where it is beneficial to do so. We expect our purchases will result in profitable sales; however, the cost of purchased material may be higher than our other sources of supply, depending on market conditions.

To determine our cost of sales, we calculate the average of all our sources of supply including opening inventory, production and purchases. Therefore, to the extent the cost of our purchases are higher than the cost of our other sources of supply, we would expect our unit cost of sales to increase.

OUTLOOK

The impact of these increased unit costs on our financial results is expected to be temporary. As greater certainty returns to the uranium market, based on our view that the market will transition from being supply-driven to being demand-driven, we expect uranium prices will rise to reflect the cost of bringing on new production to meet growing demand.

We expect rising market prices for uranium will have a positive impact on our average realized price. In addition, as Cigar Lake reaches full production and the expansion at McArthur River/Key Lake is complete, our production will increase, which we expect will create more stability in the unit cost of sales for our uranium segment.

18 CAMECO CORPORATION

Responsibility

Safety, environmental protection and supportive communities are high priorities during all stages of our activities, from exploration and development to operations, decommissioning and reclamation. We strive to be a leader in these areas through a strong safety culture, a focus on the environment, an engaged workforce, and informed and supportive communities. As a result, we are committed to the following principles:

| • | | preventing injury, ill health and pollution |

| • | | complying with and moving beyond legal and other requirements |

| • | | keeping risks at levels as low as reasonably achievable |

| • | | ensuring quality of processes, products and services |

Focus on long-term sustainability

Companies are under growing scrutiny for the way they conduct their business, and there has been a significant increase in stakeholder expectations for environmentally and socially responsible business practices.

Rather than viewing sustainable development as an ‘add-on’ to traditional business activity, we see it as integral to the way we do business, and have made it a strategic priority, integrating it into our objectives and compensation policies.

You can find out more in our 2012 Sustainable Development report and 2013 data update on our website (cameco.com), or in our upcoming 2014 Sustainable Development report, which will be available in June.

We are committed to continual improvement in all aspects of our performance to ensure our operations continue to be safe, clean and reliable.

Safety

We have a long history of safety at our operations and across the organization as a result of a strong safety culture based around the following principles:

| • | | safety is our first priority |

| • | | we are all accountable for safety |

| • | | safety is part of everything we do |

| • | | safety leadership is critical to us |

| • | | we are a learning organization |

Over the past several years, we have focused on enhancing our safety culture, and our results in 2013 clearly show that we are achieving success. Many of our sites celebrated key safety milestones, including the Blind River Refinery (seven years without a lost-time injury (LTI)), Cameco Fuel Manufacturing Inc. (two years without an LTI), and the Port Hope conversion facility (one year without an LTI).

McArthur River, Key Lake, Rabbit Lake and Cigar Lake also delivered strong safety performance, with injury rates trending downward at each site. This is particularly noteworthy since all four facilities have seen increased levels of construction activity over the past several years.

A clean environment

We are committed to operating our business with the highest level of respect and care for the local and global environment. We strive to be a leader in environmental practices not only by complying with legal requirements, but by preventing pollution, conserving biodiversity, being properly prepared to respond to emergency situations, and by managing the environmental aspects of our business responsibly overall.

We continually refine our performance objectives and revisit the indicators we use to measure our progress, with the goal of continually improving.

Reducing our impact

We establish and implement risk-informed targets to reduce our potential effect on air, water and land, optimize our energy consumption, and manage waste. To ensure an effective approach to environmental performance, all of our operating sites have environmental management systems that are registered to the ISO-14001 standard.

| • | | Water: We have employed water treatment technologies that have improved the quality of the treated water released from our Saskatchewan uranium mining and milling operations. For example, we have dramatically reduced molybdenum, uranium and selenium in effluent at these operations. We continue to look at how we can improve these treatment circuits and increase the efficiency of our water use to achieve even better results at all of our operations. |

2013 ANNUAL REPORT 19

| • | | Waste: We continue to work on projects to reduce waste, improve the reclamation process and manage waste rock more effectively. For example, at our Rabbit Lake operation, we completed reclamation of the B-Zone waste rock pile, which was a significant undertaking over the past several years. |

| • | | Air: We continue to revitalize our facilities to extend the lifespan of our operating sites. Although our emissions have always met all regulatory requirements, we have further improved air emissions by replacing some existing facilities. For example, replacement and upgrades to the sulphuric acid plants at Key Lake and Rabbit Lake have significantly reduced emissions of sulphur dioxide at those sites. Work to replace the calciner at Key Lake is also underway, which is expected to reduce emissions to air from the drying and packaging of the mill’s final product. |

People

Our success over the past 25 years is largely a result of the knowledgeable, innovative, hard-working people that have been a part of the Cameco team. Going forward, it is important that we continue to have an engaged, qualified and diverse organization, capable of leading and implementing our strategies. Our challenge is to retain our current workforce and compete for the limited number of qualified people available. Our long-term people strategy includes identifying critical workforce segments and planning our workforce to meet this challenge.

Our approach is working. We were recognized in a number of ways for our employee programs in 2013: the Financial Post named us one of the Top 10 Best Companies to Work for in Canada for the fourth year in a row; Mediacorp named us one of Canada’s Top 100 Employers and also one of Canada’s Best Diversity Employers, both for the fourth year in a row; we were named one of Canada’s Top Employers for Young People by Mediacorp for the second year; and we were named a Top Employer for Canadians Over 40 by Mediacorp. You can find out more about our awards on cameco.com.

Supportive communities

To maintain public support for our operations, we need the respect and support of communities, indigenous people, governments and regulators affected by our operations.

We work with communities who are affected by our activities to tell them what we are doing and to receive feedback and further input to build and sustain trust. For example, in Saskatchewan, we participate in the Athabasca Working Group and Northern Saskatchewan Environmental Quality Committee. In Ontario, we liaise with our communities by regularly holding educational and environment-focused activities. Public opinion research shows that we have strong local support in these communities.

We build and sustain the trust of local communities by being a leader in corporate social responsibility (CSR). This was recognized by the Canadian Council of Aboriginal Business (CCAB) through its Progressive Aboriginal Relations program (PAR) when we were awarded our fourth consecutive Gold Level certification. Also in 2013, we were the proud recipient of the Prospector and Developer’s Association of Canada (PDAC) award in Environmental and Social Responsibility based on our long-term commitment to corporate social responsibility.

Through our CSR initiatives, we also educate, engage, employ and invest in the people in the regions where we operate.

For example, in northern Saskatchewan in 2013:

| • | | just under 50% of the employees at our northern mines were local residents (747) and were paid more than $74 million in wages |

| • | | more than $450 million was paid to northern businesses, which provided 67% of services to our northern minesites. This is the second straight year we have surpassed the $450 million mark in our northern service spend. |

| • | | we made more than 70 community visits in northern Saskatchewan to discuss potential projects at our northern operations, and to provide career information to high school students and community members |

20 CAMECO CORPORATION

| • | | we donated more than $1.1 million to northern and aboriginal initiatives for youth, health and wellness, education and literacy, and culture and recreation |

| • | | we supported high school and post-secondary students through scholarship, apprenticeship and summer student programs, work placements, and the Athabasca Education Awards |

In an effort to formalize our relationship with local communities and guide future co-operation and the sharing of benefits from our operations, we have now negotiated two collaboration agreements with northern Saskatchewan communities. In a joint effort with AREVA, in 2013, we signed a collaboration agreement with the English River First Nation. This agreement, similar to the one we signed with the northern village of Pinehouse and the Kineepik Metis Local in 2012, sets out specific commitments by the mining companies with respect to workforce development, business development, community engagement, environmental stewardship and community investment. These agreements confirm the support of the First Nation people for our existing projects and operations, subject to our continued work to protect the health and safety of people and the environment.

Our operations are closely regulated to give the public comfort that we are operating in a safe and environmentally responsible way. Regulators approve the construction, startup, continued operation and any significant changes to our operations. Our operations are also subject to laws and regulations related to safety and the environment, including the management of hazardous wastes and materials.

Our objectives are consistent with those of our regulators—to keep people safe, protect the environment and engage with local communities. We pursue these goals through transparent and respectful efforts with all of our regulators. We work to maintain their trust and that of stakeholders by continually striving to protect people and the environment.

2013 ANNUAL REPORT 21

Measuring our results

Our ability to build competitive advantage and deliver value is a function of our people, processes, assets and reputation.

We use four categories to define what we are committed to deliver, how we will measure our results, and how we determine compensation:

| • | | outstanding financial performance |

| • | | a safe, healthy and rewarding workplace |

We introduced these measures of success to proactively address the financial, social and environmental aspects of our business. We believe that each is integral to our overall success and that, together, they will ensure our long-term sustainability.

| | |

| OUTSTANDING FINANCIAL PERFORMANCE |

| |

2013 OBJECTIVES | | RESULTS |

| Earnings Measures | | Exceeded |

| |

• Achieve targeted adjusted net earnings and cash flow from operations (before working capital changes). | | • Adjusted net earnings1 were $445 million, 11% higher than our target. • Cash flow from operations (before working capital changes)1 was $669 million, 11% higher than our target. |

| |

| Capital Management | | Partially achieved |

| |

• Execute capital projects within scope, on time and on budget. | | • Our cost performance indicator for 2013 was 0.87 (over budget), above the threshold; however, below the target of 1.0, due to cost overruns and necessary scope additions at Cigar Lake. |

| |

| | • Our schedule performance indicator was below our threshold for 2013, resulting in a zero rating. |

| |

| Cigar Lake | | Not achieved |

| |

• Achieve production at Cigar Lake in 2013. | | • In 2013, we made strong progress toward production, including jetting in waste, assembling a second jet boring system underground, and commissioning most of the other mine systems. We were also successful in obtaining the required construction and operating licence. However, production of the first packaged pounds was delayed as a result of additional work to ensure the safe, efficient operation of the mine and mill. In December, we began jet boring in ore, and have since completed the first cavity in ore. |

| 1 | We use adjusted net earnings and cash flow from operations (before working capital changes) as a more meaningful way to compare our financial performance from period to period. These measures do not have a standardized meaning or a consistent basis of calculation under IFRS (non-IFRS measure), and they should not be considered in isolation or as a substitute for financial information prepared in accordance with IFRS. Other companies may calculate these measures differently. Adjusted net earnings (non-IFRS measure) is our net earnings attributable to equity holders, adjusted to better reflect the underlying financial performance for the reporting period. This measure reflects the matching of the net benefits of our hedging program with the inflows of foreign currencies in the applicable reporting period and adjusted for impairment charges, inventory write-downs, losses on exploration interests and income taxes on adjustments. Cash flow from operations (before working capital changes) of $669 million is cash provided by operations of $530 million with the changes in non-cash working capital of $139 million added back. Changes in non-cash working capital includes changes in accounts receivable, inventories, supplies and prepaid expenses, accounts payable and accrued liabilities, and certain other operating items, as further detailed in note 24 to our audited 2013 financial statements. |

22 CAMECO CORPORATION

| | |

| SAFE, HEALTHY AND REWARDING WORKPLACE |

| |

2013 OBJECTIVES | | RESULTS |

| |

• Strive for no lost-time injuries (LTI) at all Cameco-operated sites and, at a minimum, maintain a long-term downward trend in combined employee and contractor injury frequency and severity, and radiation doses. | | Exceeded • Overall safety performance was strong in 20131. Injury rates trended downward across the company and were better than expected. Average radiation doses remained low and stable. In the past two years, we have met our targets for safety performance. |

| |

• Attract and retain the employees needed to support operations and growth. | | Achieved • We were listed as both a Top 100 Employer (for the fourth year in a row) and one of the Financial Post’s 10 Best Companies to Work For, in addition to receiving awards for being among Saskatchewan’s Top 10 Employers, Canada’s Best Diversity Employers, Top Employer for Canadians Over 40, and a Top Employer for Young People. |

| |

| | • Our 2013 turnover rate of 8.3% (excluding the impact of restructuring) was lower than our target of 9%. |

| |

| | • The expected turnover rate for new hires within the first year of employment was slightly higher than expected at 12.7%. |