HARMONY GOLD MINING COMPANY LIMITED

Technical Report Summary of the

Mineral Resources and Mineral Reserves

for

Mine Waste Solutions (MWS) and West Wits Operations

North West and Gauteng Provinces,

South Africa

Effective Date: June 30, 2024

Final Report Date: August 31, 2024

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

| | |

IMPORTANT NOTICE

This Technical Report Summary has been prepared for Harmony Gold Mining Company Limited in support of disclosure and filing requirements with the United States Securities and Exchange Commission’s (SEC) under Subpart 1300 of Regulation S-K 1300 and Section 229.601(b)(96) of Regulation S-K. The quality of information, estimates, and conclusions contained in this Technical Report Summary apply as of the effective date of this report. Subsequent events that may have occurred since that date may have resulted in material changes to such information, estimates and conclusions in this summary. |

Effective Date: June 30, 2024

ii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

QP Consent and Sign-off

I have read and understood the requirements of:

•the South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the "SAMREC Code, 2016 edition")

•the Harmony Guidelines on the Reporting of Exploration Results, Mineral Resources and Mineral Reserves

•Subpart 1300 (17 CFR 229.1300) of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (“Regulation S-K 1300”)

I am a Competent Person as defined by the SAMREC Code, 2016 edition and the Qualified Person (“QP”) under Regulation S-K 1300, having more than five years` experience that is relevant to the style of mineralization and type of deposit described in the Report, and to all activities for which I am accepting responsibility and have been appointed as QP for Mine Waste Solutions Mineral Resources and Mineral Reserves.

I am a Member of SAGC and my registration is as follow:

Mineral Resource

Bareng Joseph Selebogo

SAGC (South African Geomatics Council)

Nr MS 0151

Years’ Experience: 13

I have reviewed the tables and graphs included for the Mine Waste Solutions Mineral Resource and Mineral Reserve which will be used in the 2024 Harmony Gold Mineral Resource and Mineral Reserve Report to which this Consent Statement applies.

I acknowledge responsibility for all the sections of the TRS report and as the QP and author I relied on information provided by various subject experts.

At the effective date of the Report, to the best of my knowledge, information and belief, the Report contains all scientific and technical information that is required to be disclosed to make the Report not misleading.

/s/ Bareng Joseph Selebogo

___________________________________

Mr Bareng Joseph Selebogo

NHD Mineral Resource Management

SAGC (No. MS 0151), MSCC (No. 1900)

Ore Reserve Manager

Harmony Gold Mining Company Limited

Effective Date: June 30, 2024

iii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

List of Contents

Effective Date: June 30, 2024

iv

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Effective Date: June 30, 2024

v

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Effective Date: June 30, 2024

vi

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Effective Date: June 30, 2024

vii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Effective Date: June 30, 2024

viii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

List of Figures

Effective Date: June 30, 2024

ix

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

List of Tables

Effective Date: June 30, 2024

x

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Effective Date: June 30, 2024

xi

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Units of Measure and Abbreviations

| | | | | |

| Unit / Abbreviation | Description or Definition |

| °C | degrees Celsius |

| µm | Micrometers |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| AE | Abnormal expenditure |

| Ag | Silver |

| AGA | AngloGold Ashanti Limited |

| Au | Gold |

| AuBIS | Harmony electronic database |

| Ave. | Average |

| Bn | Billion |

| c. | Approximately |

| CCLAS | Comlabs Computerised Laboratory Automation System |

| CIL | Carbon in leach |

| CIP | Carbon-In-Pulp |

| CLR | Carbon Leader Reef |

| cm | Centimeter |

| cmg/t | Centimetre-grams per tonne |

| CODM | Chief Operating Decision-Maker |

| Company | Harmony Gold Mining Company Limited |

| COP | Code of Practice |

| COV | Coefficient of Variation |

| CRG | Central Rand Group |

| CRM | Certified Reference Material |

| Datamine™ | Datamine™ Studio RM modelling software |

| DMRE | Department of Mineral Resources and Energy |

| DTM | Digital Terrain Model |

| DWS | Department of Water and Sanitation |

| EIA | Environmental Impact Assessment |

| EMPR | Environmental Management Program |

| EMS | Environmental Management System |

| ESG | Environmental Social and Governance |

| ETF | Exchange traded funds |

| EW-SX | Electro-wining solvent extraction |

| FAAS | Flame Atomic Absorption Spectroscopy |

| FX | Foreign Exchange rate |

| g | Gram |

| g/t | Grams per tonne |

| g/t | Grams per metric tonne |

| GISTM | Global Industry Standard on Tailings Management |

| GPS | Global positioning system |

| Ha | Hectares |

| Harmony | Harmony Gold Mining Company Limited |

| HPE | Hydro-powered |

| Kg | Kilogram |

| km | Kilometer |

km2 | Square kilometer |

| Kusasalethu | Kusasalethu Gold Mine |

| kWh | Kilowatt-hour |

| LOM | Life of Mine |

Effective Date: June 30, 2024

xii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

| | | | | |

| Unit / Abbreviation | Description or Definition |

| Ltd | Limited |

| m | Meter |

| M | Million |

m3/hr | Cubic meters per hour |

| masl | Meters above sea level |

| MCC | Mining Charter Compliance |

| MCF | Mine Call Factor |

| Mine Waste Solutions | Mine Waste Solutions operation |

| Mintek | South Africa's national mineral research organization |

| Mlb | Million pounds |

| Moz | Million troy ounces |

| Mponeng | Mponeng Gold Mine |

| MPRDA | Mineral and Petroleum Resources Development Act, 28 of 2002 |

| Mt | Million tonnes |

| Mtpa | Million tonnes per annum |

| Mtpm | Million tonnes per month |

| MWS Operations | Mine Waste Solutions Operation on Free State / North West Province boundary |

| NEMA | National Environmental Management Act, 107 of 1998 |

| No. | Number |

| NPV | Net present value |

| OTC | Over the counter |

| oz | Troy ounce |

| PSD | Particle Size Distribution |

| Pty | Proprietary |

| QA/QC | Quality Assurance/Quality Control |

| QP | Qualified Person |

| ROM | Run-of-Mine |

| SACNASP | South African Council for Natural Scientific Professions |

| SAMREC | The South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves |

| Savuka | Savuka Gold Mine |

| SD | Standard Deviation |

| SEC | Securities and Exchange Commission |

| SGS | SGS South Africa (Pty) Limited |

| SLP | Social Labour Plan |

| t | Metric tonne |

t/m3 | Tonne per cubic meter |

| TauTona | TauTona Gold Mine |

| TRS | Technical Report Summary |

| TSF | Tailings Storage Facility |

| USD | United States Dollars |

| USD/oz | United States Dollar per troy ounce |

| VCR | Ventersdorp Contact Reef |

| VR | Vaal Reef |

| West Wits | Harmony's West Rand operations |

| WRD | Waste Rock Dump |

| WRG | West Rand Group |

| WUL(s) | Water Use License(s) |

| XRF | is X-ray fluorescence spectrometry |

| ZAR | South African Rand |

| ZAR/kg | South African Rand per kilogram |

Effective Date: June 30, 2024

xiii

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Glossary of Terms

| | | | | |

| Term | Definition |

| Cut-off grade | Cut-off grade is the grade (i.e. the concentration of metal or mineral in rock) that determines the destination of the material during mining. For purposes of establishing “prospects of economic extraction,” the cut-off grade is the grade that distinguishes material deemed to have no economic value (it will not be mined in underground mining or if mined in surface mining, its destination will be the waste dump) from material deemed to have economic value (its ultimate destination during mining will be a processing facility). Other terms used in similar fashion as cut-off grade include net smelter return, pay limit, and break-even stripping ratio. |

| Dilution | Unmineralized rock that is by necessity, removed along with ore during the mining process that effectively lowers the overall grade of the ore. |

| Head grade | The average grade of ore fed into the mill. |

| Economically viable | Economically viable, when used in the context of Mineral Reserve determination, means that the qualified person has determined, using a discounted cash flow analysis, or has otherwise analytically determined, that extraction of the Mineral Reserve is economically viable under reasonable investment and market assumptions. |

| Indicated Mineral Resource | Indicated Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of adequate geological evidence and sampling. The level of geological certainty associated with an Indicated Mineral Resource is sufficient to allow a qualified person to apply modifying factors in sufficient detail to support mine planning and evaluation of the economic viability of the deposit. Because an Indicated Mineral Resource has a lower level of confidence than the level of confidence of a Measured Mineral Resource, an Indicated Mineral Resource may only be converted to a probable Mineral Reserve. |

| Inferred Mineral Resource | Inferred Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. The level of geological uncertainty associated with an Inferred Mineral Resource is too high to apply relevant technical and economic factors likely to influence the prospects of economic extraction in a manner useful for evaluation of economic viability. Because an Inferred Mineral Resource has the lowest level of geological confidence of all Mineral Resources, which prevents the application of the modifying factors in a manner useful for evaluation of economic viability, an Inferred Mineral Resource may not be considered when assessing the economic viability of a mining project, and may not be converted to a Mineral Reserve. |

| Kriging | A method of interpolation based on Gaussian process governed by prior covariances. It uses a limited set of sampled data points to estimate the value of a variable over a continuous spatial field |

| Mine Call Factor | The ratio, expressed as a percentage, of the total quantity of recovered and unrecovered mineral product after processing with the amount estimated in the ore based on sampling. |

| Measured Mineral Resource | Measured Mineral Resource is that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of conclusive geological evidence and sampling. The level of geological certainty associated with a Measured Mineral Resource is sufficient to allow a qualified person to apply modifying factors, as defined in this section, in sufficient detail to support detailed mine planning and final evaluation of the economic viability of the deposit. Because a Measured Mineral Resource has a higher level of confidence than the level of confidence of either an Indicated Mineral Resource or an Inferred Mineral Resource, a Measured Mineral Resource may be converted to a Proven Mineral Reserve or to a Probable Mineral Reserve. |

| Mineral Reserve | Mineral Reserve is an estimate of tonnage and grade or quality of Indicated and Measured Mineral Resources that, in the opinion of the qualified person, can be the basis of an economically viable project. More specifically, it is the economically mineable part of a Measured or Indicated Mineral Resource, which includes diluting materials and allowances for losses that may occur when the material is mined or extracted. |

| Mineral Resource | Mineral Resource is a concentration or occurrence of material of economic interest in or on the Earth’s crust in such form, grade or quality, and quantity that there are reasonable prospects for economic extraction. A Mineral Resource is a reasonable estimate of mineralization, taking into account relevant factors such as cut-off grade, likely mining dimensions, location or continuity, that, with the assumed and justifiable technical and economic conditions, is likely to, in whole or in part, become economically extractable. It is not merely an inventory of all mineralization drilled or sampled. |

| Modifying Factors | Modifying factors are the factors that a qualified person must apply to Indicated and Measured Mineral Resources and then evaluate in order to establish the economic viability of Mineral Reserves. A qualified person must apply and evaluate modifying factors to convert Measured and Indicated Mineral Resources to Proven and Probable Mineral Reserves. These factors include but are not restricted to; mining; processing; metallurgical; infrastructure; economic; marketing; legal; environmental compliance; plans, negotiations, or agreements with local individuals or groups; and governmental factors. The number, type and specific characteristics of the modifying factors applied will necessarily be a function of and depend upon the mineral, mine, property, or project. |

Effective Date: June 30, 2024

xiv

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

| | | | | |

| Term | Definition |

| Pre-Feasibility Study | A pre-feasibility study (or preliminary feasibility study) is a comprehensive study of a range of options for the technical and economic viability of a mineral project that has advanced to a stage where a qualified person has determined (in the case of underground mining) a preferred mining method, or (in the case of surface mining) a pit configuration, and in all cases has determined an effective method of mineral processing and an effective plan to sell the product. (1) A pre-feasibility study includes a financial analysis based on reasonable assumptions, based on appropriate testing, about the modifying factors and the evaluation of any other relevant factors that are sufficient for a qualified person to determine if all or part of the Indicated and Measured Mineral Resources may be converted to Mineral Reserves at the time of reporting. The financial analysis must have the level of detail necessary to demonstrate, at the time of reporting, that extraction is economically viable. (2) A pre-feasibility study is less comprehensive and results in a lower confidence level than a feasibility study. A pre-feasibility study is more comprehensive and results in a higher confidence level than an initial assessment. |

|

|

| Probable Mineral Reserve | Probable Mineral Reserve is the economically mineable part of an Indicated and, in some cases, a Measured Mineral Resource. |

| Proven Mineral Reserve | Proven Mineral Reserve is the economically mineable part of a Measured Mineral Resource and can only result from conversion of a Measured Mineral Resource. |

| Qualified Person | A qualified person is: (1) A mineral industry professional with at least five years of relevant experience in the type of mineralization and type of deposit under consideration and in the specific type of activity that person is undertaking on behalf of the registrant; and (2) An eligible member or licensee in good standing of a recognized professional organization at the time the technical report is prepared. For an organization to be a recognized professional organization, it must: (i) Be either: (A) An organization recognized within the mining industry as a reputable professional association; or (B) A board authorized by U.S. federal, state or foreign statute to regulate professionals in the mining, geoscience or related field; (ii) Admit eligible members primarily on the basis of their academic qualifications and experience; (iii) Establish and require compliance with professional standards of competence and ethics; (iv) Require or encourage continuing professional development; (v) Have and apply disciplinary powers, including the power to suspend or expel a member regardless of where the member practices or resides; and (vi) Provide a public list of members in good standing. |

|

|

|

|

|

|

|

|

|

|

| Tailings | Finely ground rock of low residual value from which valuable minerals have been extracted is discarded and stored in a designed dam facility. |

| Tailings Freeboard | The vertical height between the beached tailings against the embankment crest and the crest itself. |

Effective Date: June 30, 2024

xv

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

1Executive Summary

Section 229.601(b)(96)(iii)(B) (1)

The QP of Harmony Gold Mining Company Limited (“Harmony” or the “Company”) has prepared this Technical Report Summary (“TRS”) to disclose the Mineral Resource and Mineral Reserve estimates for the Company’s Mine Waste Solutions (“Mine Waste Solutions”) operations. The TRS has been prepared in accordance with the U.S. Securities and Exchange Commission's (“SEC”), Regulation S-K 1300, with an effective date as at June 30, 2024. No material changes have occurred between the effective date and the date of signature of this TRS.

This TRS updates the TRS filed by Harmony on Mine Waste Solutions on October 31, 2022, named Exhibit 96.8 Technical Report Summary of the Mineral Resources and Mineral Reserves for Mine Waste Solutions (MWS) and West Wits Operations, North West and Gauteng Provinces, South Africa, which was effective on June 30, 2022. This TRS is prepared to satisfy the requirement of Item 1302(e)(6) of Regulation S-K. An economic assessment was included, using a detailed discounted cashflow analysis for the Mineral Reserves, excluding all scheduled Inferred Mineral Resource which is not reported under Mineral Reserve. This TRS is necessitated by the change of scheduled Mineral Resources (LOM plan), capital and operating costs as well as the change in Mineral Reserve price.

Property Description

Mine Waste Solutions is a surface operation in production stage which produces an estimated 95,000 ounces (“oz”) of gold per annum from the reclamation of gold from tailings storage facilities (“TSFs”) and waste rock dumps (“WRDs”). Mine Waste Solutions is divided into two distinct, geographically separated operations namely, the MWS operation (or “MWS”) and the West Wits operation.

The MWS operation is located near the Vaal River, on the Free State - North West Provincial border and processes reclaimed tailings from TSFs, which are fed via three ore streams operating as separate plants within the MWS gold plant. The MWS operation also has access to WRDs which are included in its Mineral Resource estimates. These WRD are not processed at the MWS processing plant because the plant is only equipped to process tailings material. Kopanang plant used to process these WRDs but has since been placed on care and maintenance. Only the Moab MOD is being processed at Noligwa plant and the rest of the WRD are not being processed currently.

The West Wits operation (“West Wits”) is situated in the West Rand region of the Gauteng Province. The West Wits operation is in production stage and processes reclaimed tailings from the Old North TSF and waste rock from the Savuka WRD. The Savuka plant processes the reclaimed Old North tailings only, while the Kusasalethu plant processes both the Old North tailings and the Savuka WRD. Mponeng plant processes the Mponeng WRD as a gap-filler for the reef.

Both the MWS operation and West Wits operation are broadly governed by Harmony’s underground mining operations and their respective mining rights and environmental permits. There is no requirement under the existing legislative framework to hold a mining right to process mine residue stockpiles which are linked to existing operations by road, rail and/or pipeline. All the TSFs and WRDs are within Harmony's surface rights.

Ownership

Mine Waste Solutions and its associated mineral rights are wholly owned by Harmony through its interest in Chemwes Proprietary Limited. Harmony acquired the assets as part of the transaction to take full ownership and control of AngloGold Ashanti's remaining South African business, as of October 1, 2020.

Geology and Mineralization

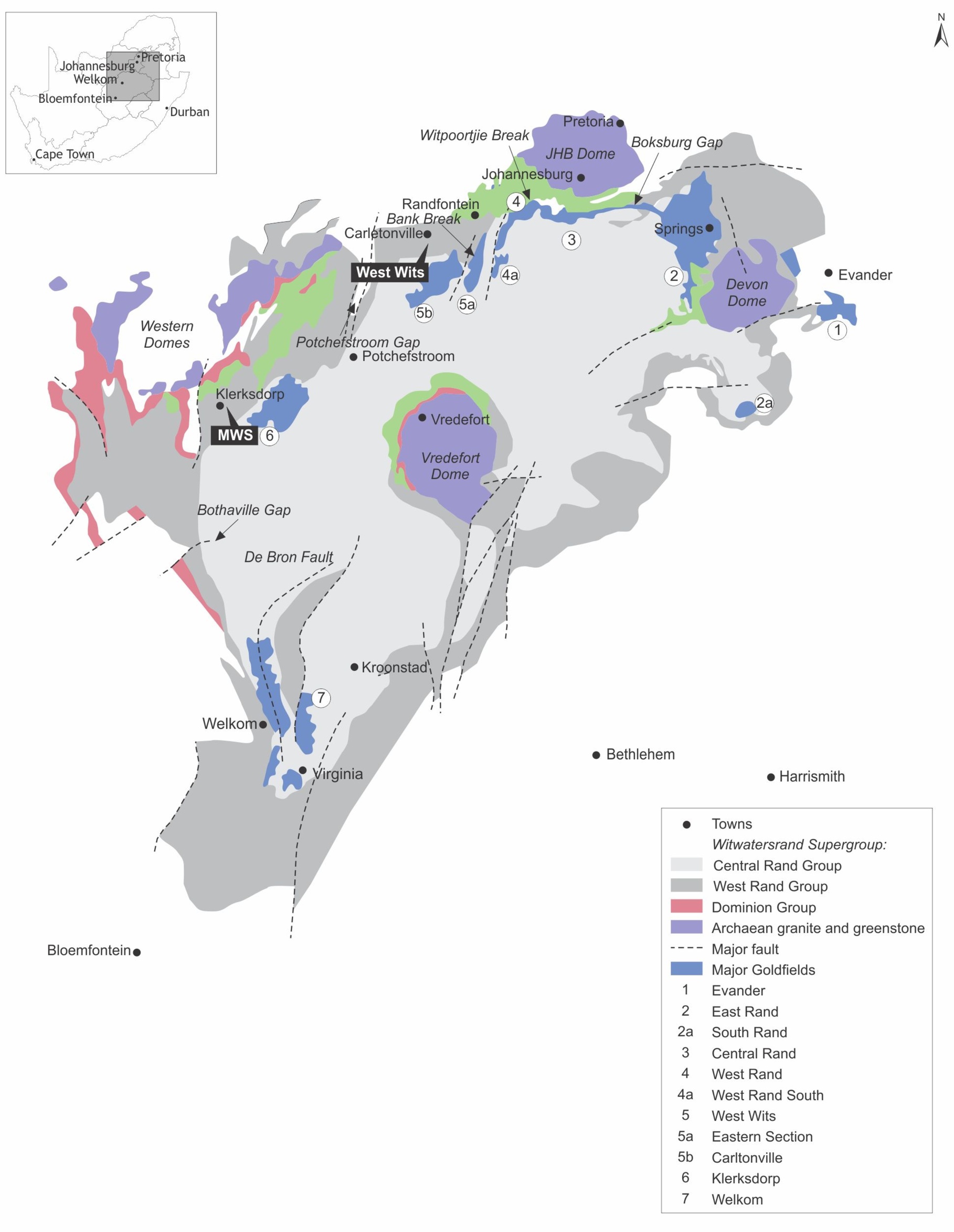

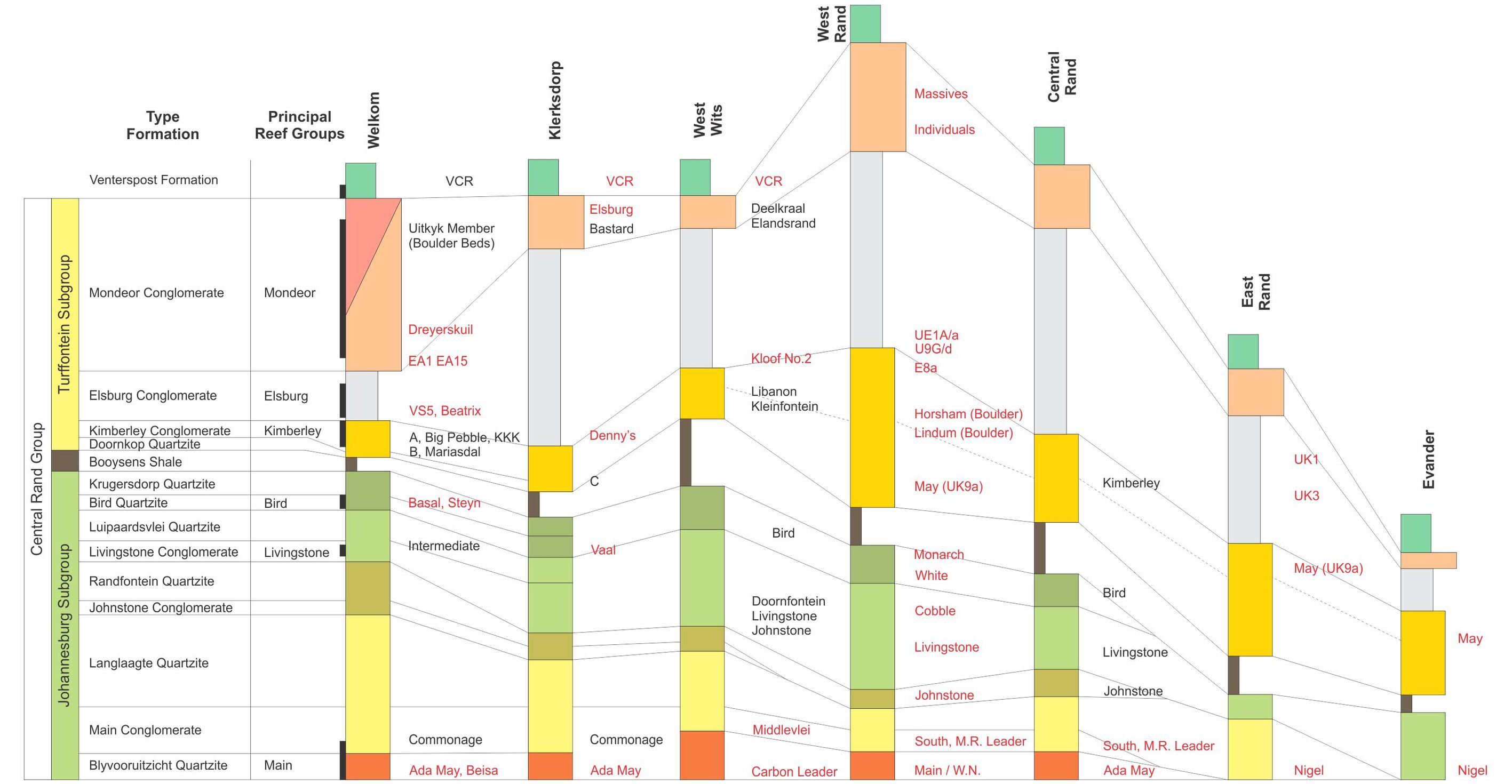

Material contained in the TSFs and WRDs predominantly originates from deep level gold mines, operated by Harmony and others, mostly located in Klerksdorp and Carletonville. The West Wits processed TSF material is generated from the original processing of the Ventersdorp Contact Reef ("VCR") and Carbon Leader Reef ("CLR") while the TSF's re-mined and processed in the MWS area are derived from the historical processing of the Vaal Reef ("VR"). The WRD were also generated from the waste development to mine the afore mentioned reefs respectively.

Effective Date: June 30, 2024

1

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

The Witwatersrand reefs occur within the Archaean Witwatersrand Basin which hosts the Witwatersrand Supergroup succession. The VCR horizon is located at the top of the Turffontein Subgroup of the Central Rand Group (“CRG”), capping the Witwatersrand Supergroup. The VR horizon is situated within the Krugersdorp Formation, in the Johannesburg Subgroup of the CRG. The CLR is situated near the base of the Johannesburg Subgroup.

The TSF material comprises previously treated residues of gold-bearing conglomeratic reefs processed by carbon-in-leach (“CIL”). They are man-made “deposits” and are not the result of natural sedimentary processes. The grade of the TSFs is determined by the grade of the ore source at the time that they were processed, and the processing efficiency.

The WRDs are unconsolidated and are comprised of untreated, low grade, gold-bearing material from underground workings. The WRDs are also man-made deposits, with no geological structure or continuity, and one in which the grade does not behave as a natural mineral deposit.

The most significant mineral in the TSFs and WRDs is quartz, which makes up more than 60% of the bulk mineral composition. The gold predominantly occurs in pyrite. Other minerals identified include uranium, iron oxide, titanium oxide and calcite from the VR, VCR and CLR conglomerates.

Current Status of Exploration, Development and Operation

Prior to 2011, grade estimations for the TSFs were based on residue grades obtained from the process plants, as well as various sampling projects in selected areas. Most of these TSFs have since been re-sampled by means of an extensive auger drilling exercise which commenced in 2011. The remaining active TSFs will be re-sampled once they go out of service and become dormant.

Mine Waste Solutions made a recent decision not to treat WRD material, and hence the Savuka plant was converted to a TSF-only processing facility by late 2021.

Mineral Resource Estimate

The current Mineral Resources for the TSFs were estimated using Datamine™ Studio RM modelling software (“Datamine™”), based on a validated Datamine™ Fusion database. The database contained auger drillhole sampling data obtained until June 2023. The QP created three dimensional (“3D”) digital terrain models (“DTM”) based on the TSF topographical survey results and gold values were estimated using the ordinary kriging interpolation method.

The Mineral Resources for the WRDs were also estimated using 3D DTMs to constrain the volumes. The gold grade was estimated by using the weighted average of the sample assays, as well as the gold grades obtained from reclaimed tonnes and from rock deposited on the stockpiles.

The Mineral Resources were originally prepared, classified and reported according to the South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves, 2016 edition (“SAMREC, 2016”). For the purposes of this TRS, the Mineral Resources have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K), similar to the SAMREC 2016 classification scheme.

The Mineral Resource estimates, as at June 30, 2024, exclusive of the reported Mineral Reserves, are summarized in Table 1-1 and Table 1-2 for the MWS and West Wits operations, respectively.

The QP compiling the Mineral Resource estimates is Mr BJ Selebogo, who is the Ore Reserve Manager and an employee of Harmony.

Effective Date: June 30, 2024

2

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 1-1: Summary of the MWS Operation Mineral Resources as at June 30, 2024 (exclusive of Mineral Reserves)

| | | | | | | | | | | | | | | | | | | | |

| METRIC | Grade | Metal Content |

| Mineral Resource Category | Source | Tonnes (Mt) | Gold (g/t) | U3O8 (kg/t) | Gold (kg) | U3O8 (t) |

| Measured | TSF | 52.334 | 0.20 | 0.067 | 10,513 | 3,507 |

| | | | | |

| | | | | |

| Indicated | TSF | 52.459 | 0.24 | 0.088 | 12,613 | 4,616 |

| WRD | 1.872 | 0.30 | — | 563 | — |

| | | | | |

| Total / Ave. Measured + Indicated | 106.665 | 0.22 | 0.078 | 23,689 | 8,123 |

| Inferred | TSF | 79.585 | 0.13 | 0.039 | 10,505 | 3,067 |

| WRD | 2.502 | 0.24 | — | 611 | — |

| Total / Ave Inferred | 82.087 | 0.14 | 0.037 | 11,116 | 3,067 |

| |

| IMPERIAL | Grade | Metal Content |

| Mineral Resource Category | Source | Tons (Mt) | Gold (oz/t) | U3O8 (lb/t) | Gold (Moz) | U3O8 (Mlbs) |

| Measured | TSF | 57.688 | 0.006 | 0.134 | 0.338 | 7.730 |

| | | | | |

| | | | | |

| Indicated | TSF | 57.826 | 0.007 | 0.176 | 0.406 | 10.177 |

| WRD | 2.064 | 0.009 | — | 0.018 | — |

| | | | | |

| Total / Ave. Measured + Indicated | 117.578 | 0.006 | 0.152 | 0.762 | 17.907 |

| Inferred | TSF | 87.727 | 0.004 | 0.077 | 0.338 | 6.762 |

| WRD | 2.758 | 0.007 | — | 0.020 | — |

| Total / Ave Inferred | 90.486 | 0.004 | 0.075 | 0.357 | 6.762 |

Notes:

1. The Mineral Resources were originally prepared, classified and reported according to SAMREC, 2016. For the purposes of this TRS, the Mineral Reserves have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). The QP responsible for the estimate is Mr BJ Selebogo, who is Ore Reserve Manager, and a Harmony employee.

2. The Mineral Resource tonnes are reported as in-situ tailings quantities deposited on TSF's with reasonable prospects for economic extraction.

3. A cut-off grade of 0.0g/t has been applied for the estimation of Mineral Resources. Mineral Resource tonnes are reported based on a recovery of 45.32%, an operating cost of R102/t and a gold price of USD1,878/oz.

4. Tonnes are reported as million tonnes rounded to three decimal places. Gold values are rounded to zero decimal places.

5. Uranium content is reported as part of the MWS Mineral Resource estimate as a bi product of Gold with no contribution to project economics.

6. Metal content does not include allowances for processing losses.

7. Mineral Resources are exclusive of Mineral Reserves. Mineral Resources are not Mineral Reserves and do not necessarily demonstrate economic viability, but have been assessed for prospects for economic extraction.

Table 1-2: Summary of the West Wits operation Mineral Resources as at June 30, 2024 (exclusive of Mineral Reserves)

| | | | | | | | | | | | | | | | | | | | |

| METRIC | Grade | Metal Content |

| Mineral Resource Category | Source | Tonnes (Mt) | Gold (g/t) | U3O8 (kg/t) | Gold (kg) | U3O8 (t) |

| | | | | | |

| | | | | |

| | | | | |

| Indicated | TSF | 25.736 | 0.32 | — | 8,321 | — |

| WRD | 0.152 | 0.37 | — | 56 | — |

| | | | | |

| Total / Ave. Measured + Indicated | 25.888 | 0.32 | — | 8,376 | — |

| | | | | | |

| | | | | |

| | | | | |

| |

| IMPERIAL | Grade | Metal Content |

| Mineral Resource Category | Source | Tons (Mt) | Gold (oz/t) | U3O8 (lb/t) | Gold (Moz) | U3O8 (Mlbs) |

| | | | | | |

| | | | | |

| | | | | |

| Indicated | TSF | 28.369 | 0.009 | — | 0.268 | — |

| WRD | 0.167 | 0.011 | — | 0.002 | — |

| | | | | |

| Total / Ave. Measured + Indicated | 28.537 | 0.009 | — | 0.269 | — |

| | | | | | |

| | | | | |

| | | | | |

Notes:

1. The Mineral Resources were originally prepared, classified and reported according to SAMREC, 2016. For the purposes of this TRS, the Mineral Reserves have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). The QP responsible for the estimate is Mr BJ Selebogo, who is Ore Reserve Manager, and a Harmony employee.

2. The Mineral Resource tonnes are reported as in-situ tailings quantities deposited on TSF's with reasonable prospects for economic extraction.

3. A cut-off grade of 0.0g/t has been applied for the estimation of Mineral Resources. Mineral Resource tonnes are reported based on a recovery of 42.5%, an operating cost of R98/t and a gold price of USD1,878/oz.

4. Tonnes are reported as million metric tonnes (“Mt”) rounded to three decimal places. Gold values are rounded to zero decimal places.

5. Metal content does not include allowances for processing losses.

6. Mineral Resources are exclusive of Mineral Reserves. Mineral Resources are not Mineral Reserves and do not necessarily demonstrate economic viability, but have been assessed for prospects for economic extraction.

7. The Mineral Resource estimate is for Harmony’s 100% interest.

Effective Date: June 30, 2024

3

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Mineral Reserve Estimate

The Mineral Reserves were originally prepared, classified and reported according to SAMREC, 2016. For the purposes of this TRS, the Mineral Reserves have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K).

Mineral Reserves are derived from the Mineral Resources, a detailed business plan and the operational planning processes. The planning team utilises and takes into consideration historical technical parameters achieved. In addition, Mineral Resource conversion to Mineral Reserves considers modifying factors, costs, gold price and recovery to calculate the cut-off grade.

The Mineral Reserves are reported at June 30, 2024, as delivered to the plant. The Mineral Reserves are declared as delivered to the plant for all TSFs, except for the recovered gold content. This gold content is calculated after factoring in the plant recovery as a modifying factor. The Mineral Reserve estimates for MWS and West Wits operations are provided in Table 1-3 and Table 1-4, respectively

The QP compiling the Mineral Resource estimates is Mr BJ Selebogo, who is the Ore Reserve Manager and an employee of Harmony.

Table 1-3: Summary of the MWS operation Mineral Reserves as at June 30, 2024

| | | | | | | | | | | | | | |

| METRIC |

| Mineral Reserve Category | Source | Tonnes (Mt) | Gold Grade (g/t Au) | Gold Content (kg) |

| Proved | TSF | 7.499 | 0.28 | 2,099 |

| | | |

| | | |

| Probable | TSF | 367.071 | 0.28 | 101,389 |

| | | |

| | | |

| Total / Ave (Proved + Probable) | 374.570 | 0.28 | 103,488 |

| IMPERIAL |

| Mineral Reserve Category | Source | Tons (Mt) | Gold Grade (oz/t) | Gold Content (Moz) |

| Proved | TSF | 8.266 | 0.008 | 0.067 |

| | | |

| | | |

| Probable | TSF | 404.626 | 0.008 | 3.260 |

| | | |

| | | |

| Total / Ave (Proved + Probable) | 412.892 | 0.008 | 3.327 |

Notes:

1. The Mineral Reserves were originally prepared, classified and reported according to SAMREC, 2016. For the purposes of this TRS, the Mineral Reserves have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). The QP responsible for the estimate is Mr BJ Selebogo, who is the Ore Reserve Manager, and a Harmony employee.

2. Tonnes, grade, and content are declared as tailings delivered to the mills.

3. Gold content is gold before applying PRF. Metallurgical recovery factors have not been applied to the reserve figures.

4. Mineral Reserves are reported using a cut-off grade of 0.22g/t at recovery of 45.32%, a gold price of USD1,772/oz and R102/t operating cost.

5. Recovered gold (kg) is based on a conversion factor of 32.1507oz/kg.

6. Rounding as required by reporting guidelines may result in apparent summation differences.

Table 1-4: Summary of the West Wits operation Mineral Reserves as at June 30, 2024

| | | | | | | | | | | | | | |

| METRIC |

| Mineral Reserve Category | Source | Tonnes (Mt) | Grade (g/t Au) | Content Au (kg) |

| | | | |

| | | |

| | | |

| Probable | TSF | 12.281 | 0.32 | 3,931 |

| | | |

| | | |

| Total / Ave (Proved + Probable) | 12.281 | 0.32 | 3,931 |

| IMPERIAL |

| Mineral Reserve Category | Source | Tons (Mt) | Gold Grade (oz/t) | Content (Moz Au) |

| | | | |

| | | |

| | | |

| Probable | TSF | 13.537 | 0.009 | 0.126 |

| | | |

| | | |

| Total / Ave (Proved + Probable) | 13.537 | 0.009 | 0.126 |

Notes:

1. The Mineral Reserves were originally prepared, classified and reported according to SAMREC, 2016. For the purposes of this TRS, the Mineral Reserves have been classified in accordance with § 229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). The QP responsible for the estimate is Mr BJ Selebogo, who is the Ore Reserve Manager, and a Harmony employee.

2. Tonnes, grade, and gold content are declared as tailings delivered to the mills.

3. Gold content is gold before applying PRF. Metallurgical recovery factors have not been applied to the reserve figures.

4. Mineral Reserves are reported using a cut-off grade of 0.22g/t at recovery of 42.5%, a gold price of USD1,772/oz and R98/t.

5. Recovered gold (kg) is based on a conversion factor of 32.1507oz/kg.

6. Rounding as required by reporting guidelines may result in apparent summation differences.

In my opinion as the QP, given that Mine Waste Solutions is an established operation, the modifying factors informing the Mineral Reserve estimates would at minimum, satisfy the confidence levels of a Pre-Feasibility Study.

Effective Date: June 30, 2024

4

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

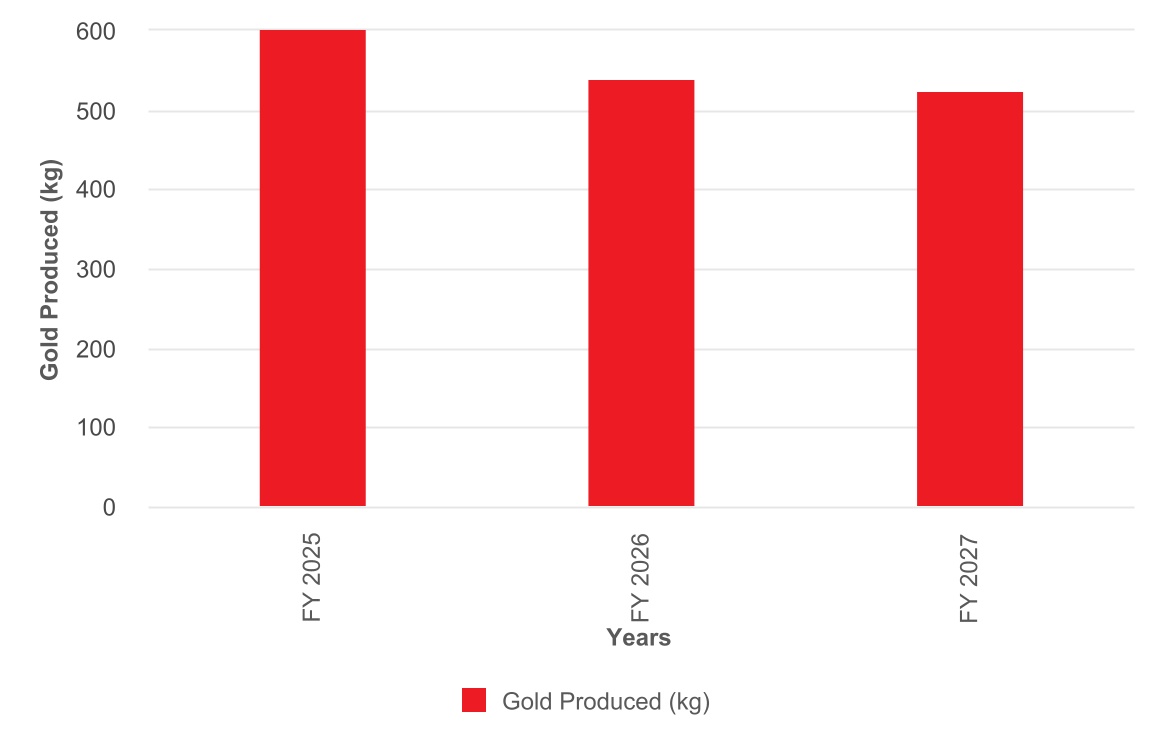

The economic analysis of the cash flows displays positive results and are deemed both technically and economically achievable. The discounted cashflow NPV for Mine Waste Solutions for the current business plan amounts to ZAR3,818 million. The first year two years is cash negative due to the Kareerand extension project capital, and from FY 2027 until end of life in FY 2039 the cashflow is cash positive.

Capital and Operating Cost Estimates

The capital cost estimates for the MWS and West Wits operations are determined at corporate level, using the business plan as a basis. The capital cost elements include equipment, infrastructure and operating capital. The capital costs are reported in ZAR terms and on a real basis. Project Capital to ensure ongoing TSF reclamation includes Kareerand Extension project for future TSF residue deposition, construction of Stream 4 planned to be in production from mid November 2024, this will increase processing capacity and bring gold forward, as well as Pumpstation construction for MWS 4 & 5 which will be operational from September 2024. Mispah TSF's planned production will start in July 2026.

Also shown in Table 1-5 is the stay in business plant capital to ensure plans run at optimal performance. The capital cost estimates for MWS are presented in Table 1-5. West Wits does not have any capital requirements outside the plant, but has planned a capital of R85.9m to keep the plant running to make sure that the Mineral Reserve plan is realized.

The operating cost estimates for the MWS and West Wits operations are categorised into nine allocated cost categories. The capital costs are reported in ZAR terms and on a real basis. A summary of the MWS and West Wits operating cost estimate, per stream, are presented in Table 1-6 and Table 1-7, respectively. The Capex and Opex budgets are consistent with feasibility level.

Table 1-5: Summary of Mineral Reserve capital cost estimate for MWS operation major projects

| | | | | |

| Capital Cost Element (ZAR'000) | Total Reserve Plan (FY2025- FY2039) |

| Kareerand | 1,015,278 |

| Stream 4 Gold Plant Implementation | 58,311 |

| MWS 4 & 5 Pump Station | 36,153 |

| Mispah Pump Station | 507,321 |

| |

| West Pump Station | 2,500 |

| Other | 1,823,788 |

| Total | 3,443,351 |

Effective Date: June 30, 2024

5

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 1-6: Summary of operating cost estimates for MWS operation (MWS gold plant)

| | | | | |

| Operating Cost Element (ZAR'000) | Total Reserve Plan |

| Wages - Payroll 1 | 812,126 |

| Wages - Payroll 2 | 419,974 |

| Stores and materials | 1,286,560 |

| Electric Power and Water | 2,493,878 |

| Outside Contractors | 2,235,188 |

| Other | 1,227,661 |

| Total Direct Costs | 8,475,387 |

| Pumping Allocation | — |

| Refining Charges | 64,046 |

| Uranium Allocation | — |

| Hostel Cost | — |

| Backfill Cost | — |

| Plant Treatment Cost | 24,884,331 |

| Working Cost Transfer to Capital | — |

| Care and Maintenance | — |

| Mine Overheads Re-allocated | 1,822,038 |

| Total | 35,245,802 | |

Table 1-7: Summary of operating cost estimates for West Wits operation

| | | | | | |

| Operating Cost Element (ZAR'000) | Total Reserve Plan | |

| Wages - Payroll 1 | — | |

| Wages - Payroll 2 | — | |

| Stores and materials | 15,381 | |

| Electric Power and Water | 42,821 | |

| Outside Contractors | 53,061 | |

| Other | 6,585 | |

| Total Direct Costs | 117,848 | |

| Pumping Allocation | — | |

| Refining Charges | 2,831 | |

| Uranium Allocation | — | |

| Hostel Cost | — | |

| Backfill Cost | — | |

| Plant Treatment Cost | 923,082 | |

| Working Cost Transfer to Capital | — | |

| Care and Maintenance | — | |

| Mine Overheads Re-allocated | 70,934 | |

| Total | 1,114,695 | | |

Permitting Requirements

To successfully operate a mining or reclamation operation in South Africa, the State requires compliance with applicable environmental laws, regulations, permits and standards. Mine Waste Solutions and West Wits operations adhere to said compliance and regulatory standards and have, in addition, implemented an Environmental Management System in line with the ISO 14001. Mine Waste Solutions has all permits required to operate. The status of the permits held by the company are presented in Table 1-8. The permits expiring in 2024 are the ones that are renewed yearly and will be by the beginning of the year.

Effective Date: June 30, 2024

6

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 1-8: Status of environmental permits and licenses

| | | | | | | | | | | | | | | | | |

| Operation | Permit / License | Reference No. | Issued By | Date Granted | Validity |

| MWS | MWS: AEL License CHEMWES: Atmospheric Emission License | NWPG/CHEMWES/AEL. 4.1,4.2 & 4.17/October 2020 | DEDECT | 30-Sep-20 | 30-Sep-26 |

| MWS Plant: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4357 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| Harties 1 & 2: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4354 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| Kareerand: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4356 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| Sulphur Pay Dam: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4355 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| East Complex: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4353 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| West Complex: Certificate of Registration Inflammable Liquids and Substances (required by the by-laws) | 4358 | City Council of Matlosana Fire and Rescue | 29/11/2023 | 31/12/2024 |

| Water Use License: Bio-monitoring - 6 monthly reporting. Water balance quarterly | 27/2/2/C224/101/1 - 27087241 - 08/C24B/AACIG/8368 | DWS | 31/11/2018 | 10 years |

| Water Use License: Environmental Water report - Quarterly. Water incidents - as they occur | 08/C24B/AIACGI/11868 | DWS | 18/09/2023 | 20 years |

| Water Use Licence (Mispah): 6 Monthly monitoring reports must be submitted to the Provincial Head/CEO for the duration of the construction phase and yearly thereafter or until otherwise agreed in writing with the Provincial Head/CEO. | 08/C24B/CI/13793 | DWS | 20/10/2023 | 20-Oct-29 |

| Environmental authorisation for expansion of Kareerand tailings storage facilities, re-processing of the waste dumps and disposal of tailings in respect of various portions | NWP/EIA/176/2008 | DMRE | 21/11/2022 | N/A |

| NEMA Amendment Authorisation for the construction of pipelines | NW 30/5/1/2/3/2/1/378 EM | DMRE | 21/11/2021 | N/A |

Effective Date: June 30, 2024

7

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

| | | | | | | | | | | | | | | | | |

| Operation | Permit / License | Reference No. | Issued By | Date Granted | Validity |

| MWS | License to Construct a Dam with Safety Risk | 12/2/C241/37 | DWS | 18/06/2010 | N/A |

| Application to discharge Sewerage into Municipal system | 17/3/1/1 | City Council of Matlosana Fire and Rescue | 29/02/2002 | N/A |

| MWS: Certificate of Registration | COR-30 (Variation 30) | NNR | 14/04/2023 | N/A |

| License to Construct Harmony Solar PV Facility | NWP/EIA/75/2023: May be reviewed at intervals of not more than 5 years | DEDECT | 07/05/2024 | N/A |

| Environmental authorisation for the construction of a return water pipeline from Kareerand Tailings storage facility to Midway | NWP/EIA/32/2023: EA is valid for 5 Years- Activities must be concluded within 5 years from the date of issue. Awaiting WUL | DEDECT | 06/11/2023 | N/A |

| MWS: Environmental Authorisation for Mispah TSF Reclamation and associated pipelines in the Free State and North West Provinces | 14/12/16/3/3/1/2714 | DFFE | 07/09/2023 | N/A |

| WW | Environmental Authorisation | WR/16-17/AEL9/3 | Dr. Kenneth Kaunda District Municipality | 14-Dec-2023 | 31-Dec-2028 |

| Water Use Licence | 08/C23E/AFGJCEI/12157 | DWS | 27/09/2022 | 27/09/2031 |

| Environmental Authorisation | (GP) 30/5/1/2/3/2/1(01) EM | DMRE | 29-Mar-23 | N/A |

| (GP) 30/5/1/2/2(01) MR |

| In progress of updating |

| Waste Management Licence | Gaut 002/09-10/W0011 | GDARD | 27-Jul-15 | Expired |

| Golden Core Trade and Invest (Pty) LTD submitted renewal application. Awaiting approval. | DMRE |

Note: DEDET - Department of Economic Development, Environment, Conservation and Tourism, DWS - Department of Water and Sanitation, Department of Mineral Resources and Energy, GDARD - Gauteng Department of Agriculture and Rural Development, AGA - Anglogold Ashanti Limited.

Effective Date: June 30, 2024

8

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Conclusions

In the opinion of the QP, Mine Waste Solutions is a wholly owned asset of Harmony, which is comprised of the MWS and West Wits operations. The majority of the assets were previously owned by AngloGold Ashanti and have been operating for many years. The operations are accessible and have good regional infrastructure. Management has a good handle on aspects pertaining to legal and environmental matters with respect to operating within the South African law, as regulated by the MPRDA, and supporting legislation.

MWS and West Wits have a significant Mineral Resource base, comprising gold-bearing TSFs and WRDs. These man-made deposits have their own depositional and mineralization characteristics, and the exploration, modelling and estimation practices informing Mineral Resource estimates for these types of deposits is well established. The exploitation of these deposits either through reclamation by hydraulic monitoring guns or through loading operations is also well established, and Mine Waste Solutions has all the necessary infrastructure required to implement the mineral reserve plan.

Under the assumptions in this TRS, the MWS and West Wits operations show a positive cash flow over the Mineral Reserve plan which supports the Mineral Resource and Mineral Reserve estimates, and the Mineral Reserve plan is achievable under the set of assumptions and parameters used.

Mine Waste Solutions did not incur any fines or penalties for non-compliance during the year ended June 30, 2024 and no significant encumbrances exist.

Recommendations

The QP recommend that an aerial survey be carried out monthly, instead of a manual GPS survey, to provide a high degree of accuracy with respect to digital terrain model and monthly survey results.

In the case where deposition occurred after drilling, it is recommended that the model totals be updated with the deposited volumes, tonnage and gold grade.

Effective Date: June 30, 2024

9

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

2Introduction

Section 229.601(b)(96)(iii)(B) (2) (i-v)

This TRS on Mine Waste Solutions has been prepared for the registrant, Harmony. The TRS has been prepared in accordance with Regulation S-K 1300. It has been prepared to meet the requirements of Section 229.601(b)96 - Technical Report Summary. The purpose of this TRS is to provide open and transparent disclosure of all material, exploration activities, Mineral Resource and Mineral Reserve information to enable the investor to understand MWS and West Wits Surface Sources which form part of Harmony’s activities.

This TRS is prepared to satisfy the requirement of Item 1302(e)(6) of Regulation S-K. An economic assessment was included, using a detailed discounted cashflow analysis for the Mineral Reserves, excluding all scheduled Inferred Mineral Resources which are not reported under Mineral Reserve. This TRS is necessitated by the change of scheduled Mineral Resources (LOM plan), capital and operating costs as well as the change in Mineral Reserve price.

This TRS has been prepared from the following sources of information:

•Competent Persons Report dated June 30, 2024 prepared by Mr BJ Selebogo;

•BP2025 Harmony Corporate Mineral Reserves plan;

•Published Mineral Resource and Mineral Reserve statement as at June 30, 2024; and

•Various internal technical reports from various stakeholders.

This TRS was prepared by a QP employed on a full-time basis by the registrant. The QPs qualifications, areas of responsibility (Sections in the TRS report) and Professional Organization are presented in Table 2-1.

Table 2-1: QP qualification, section responsibilities and personal inspections

| | | | | | | | | | | | | | |

| Qualified Person | Professional Organization | Qualification | TRS Section Responsibility | Personal Insp. |

| Mr. BJ. Selebogo | SAGC | MSCC, HND (MRM) | All Sections | Full time |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

The QP states that this TRS updates the TRS filed by Harmony on Mine Waste Solutions on October 31, 2022, named Exhibit 96.8 Technical Report Summary of the Mineral Resources and Mineral Reserves for Mine Waste Solutions (MWS) and West Wits operations, North West and Gauteng Provinces, South Africa, which was effective on June 30, 2022. This updated TRS has an effective date as at June 30, 2024. No material changes have occurred between the effective date and the date of signature. This TRS is necessitated by the change of scheduled Mineral Resources (LOM plan), capital and operating costs as well as the change in Mineral Reserve price. An economic assessment was included, using a detailed discounted cashflow analysis for the Mineral Reserves, excluding all scheduled Inferred Mineral Resources which are not reported under Mineral Reserve.

Effective Date: June 30, 2024

10

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

3Property Description and Location

Section 229.601(b)(96)(iii)(B) (3) (i-vii)

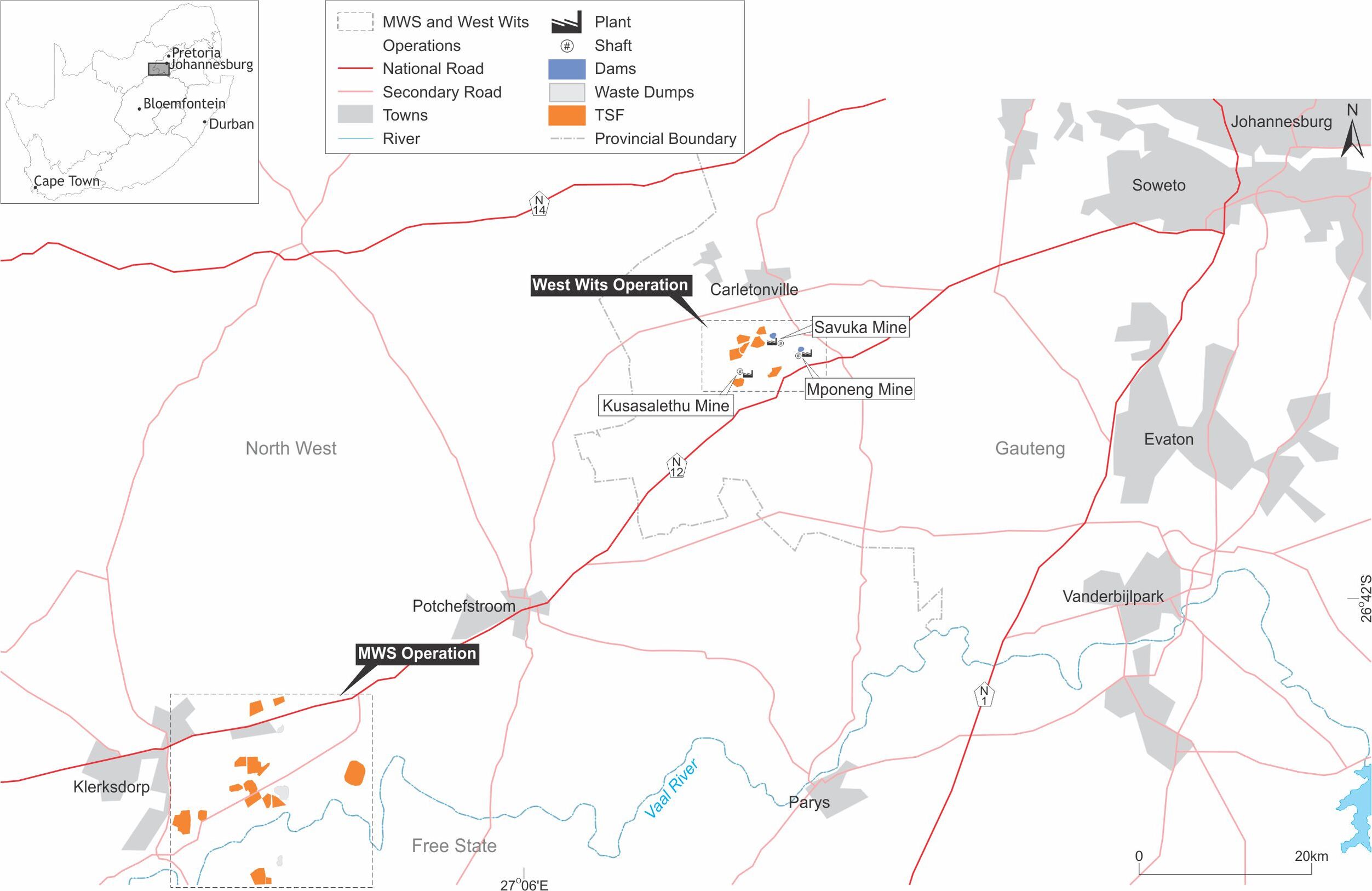

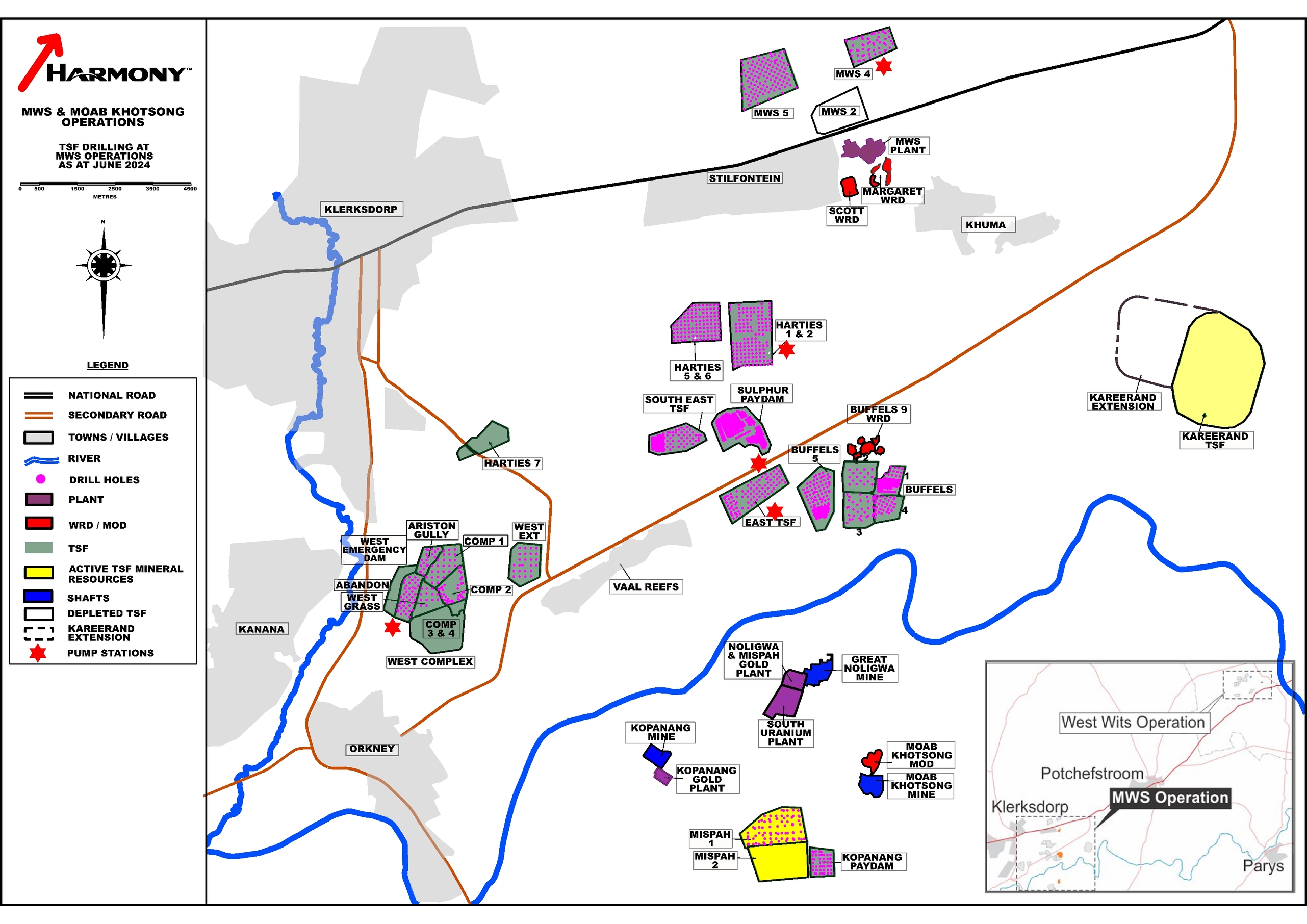

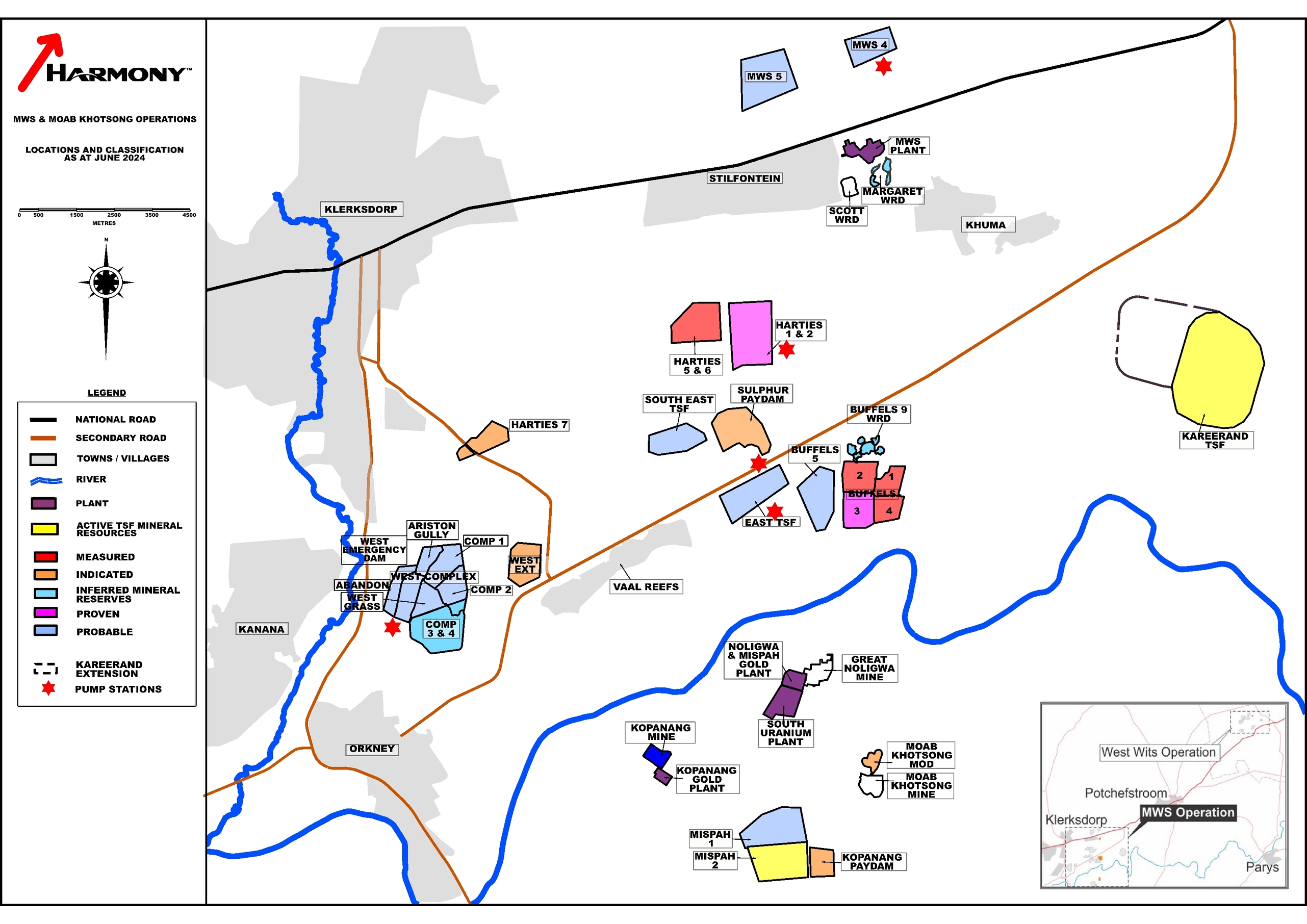

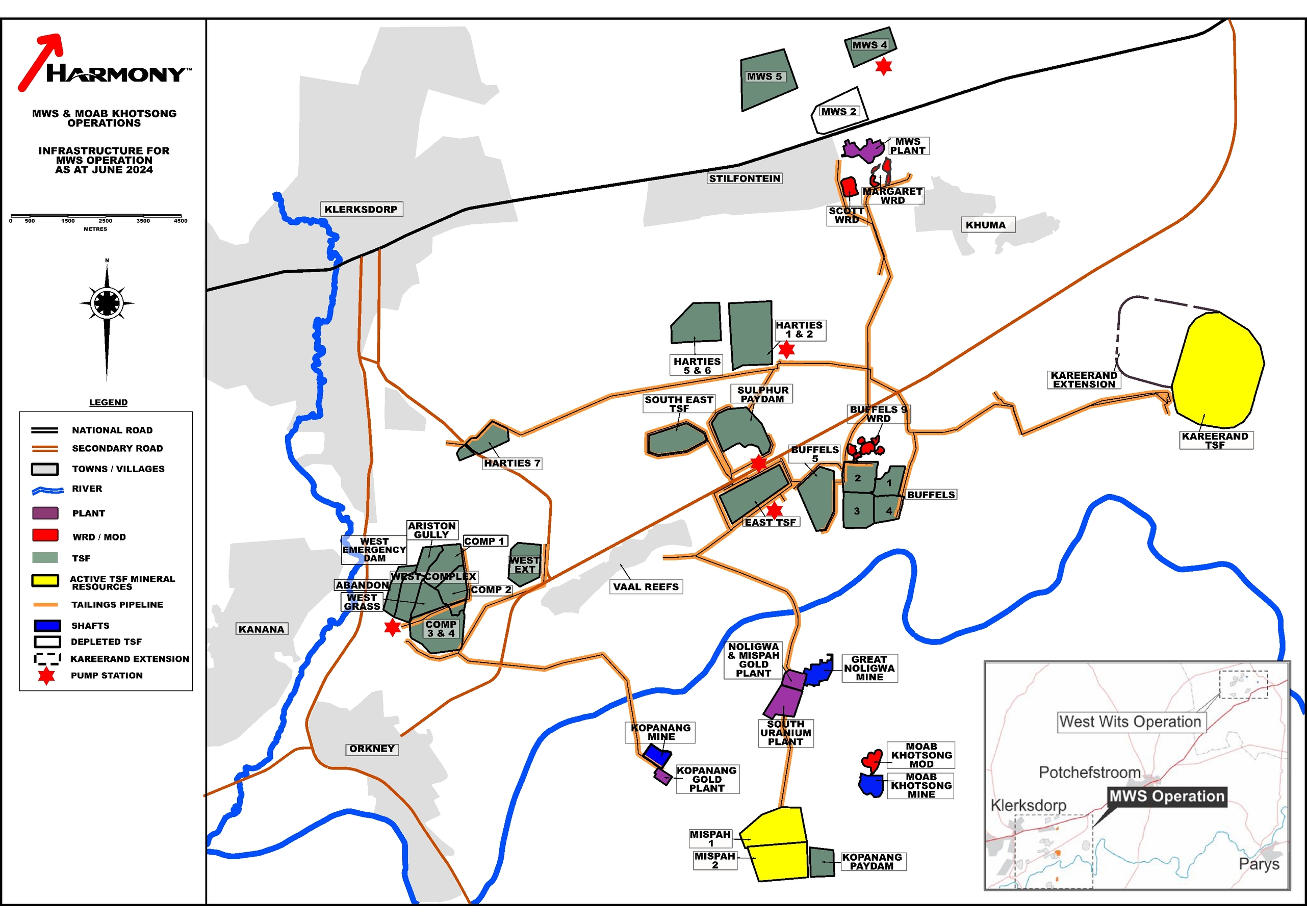

Mine Waste Solutions is comprised of two distinct, geographically separated, operations namely the MWS operation located on the Free State - North West provincial boundary, and the West Wits operation situated in the West Rand region of the Gauteng Province (Figure 3-1). Each operation will be discussed separately due to their geographical locations.

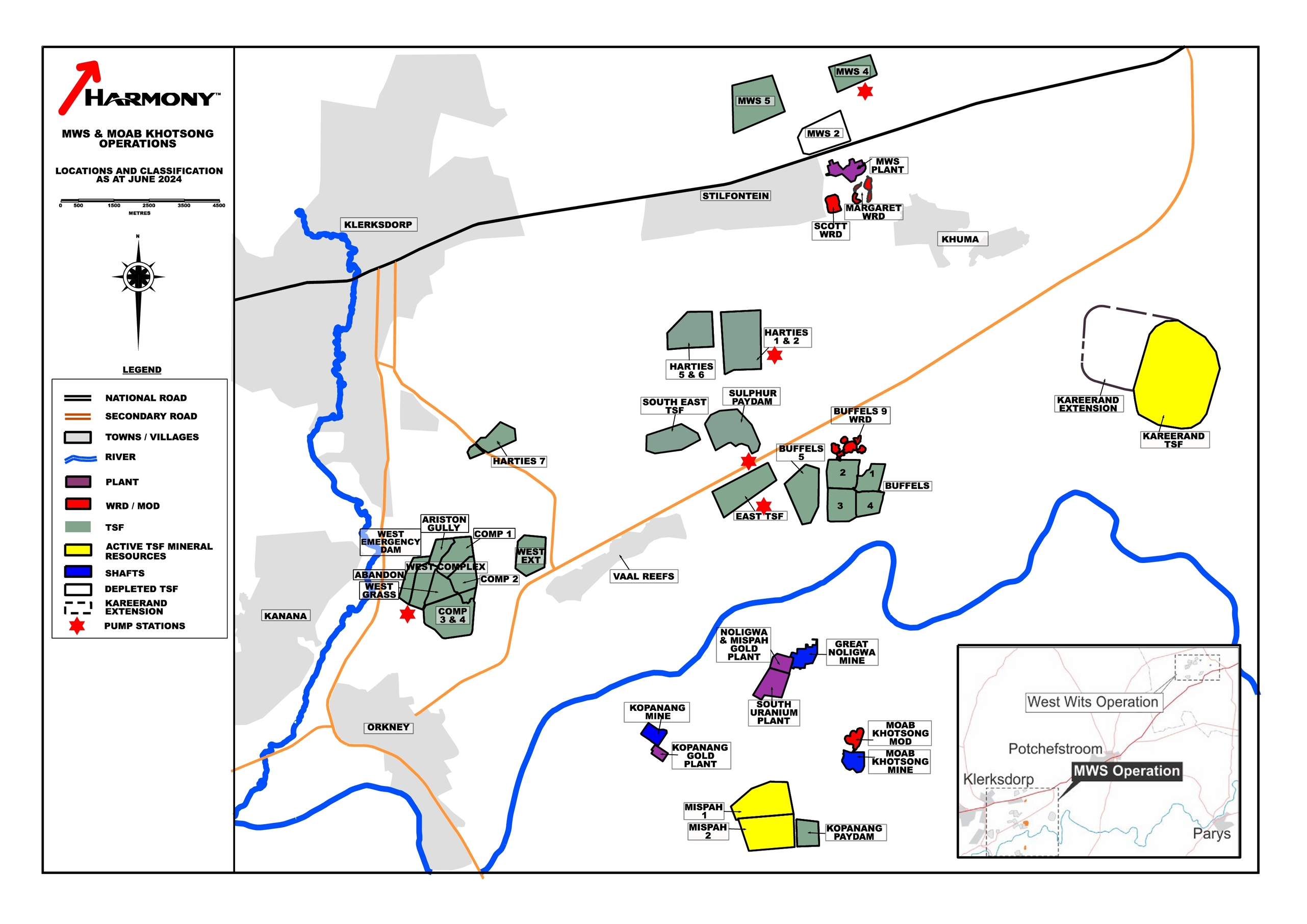

3.1MWS Operation

3.1.1Description and Location

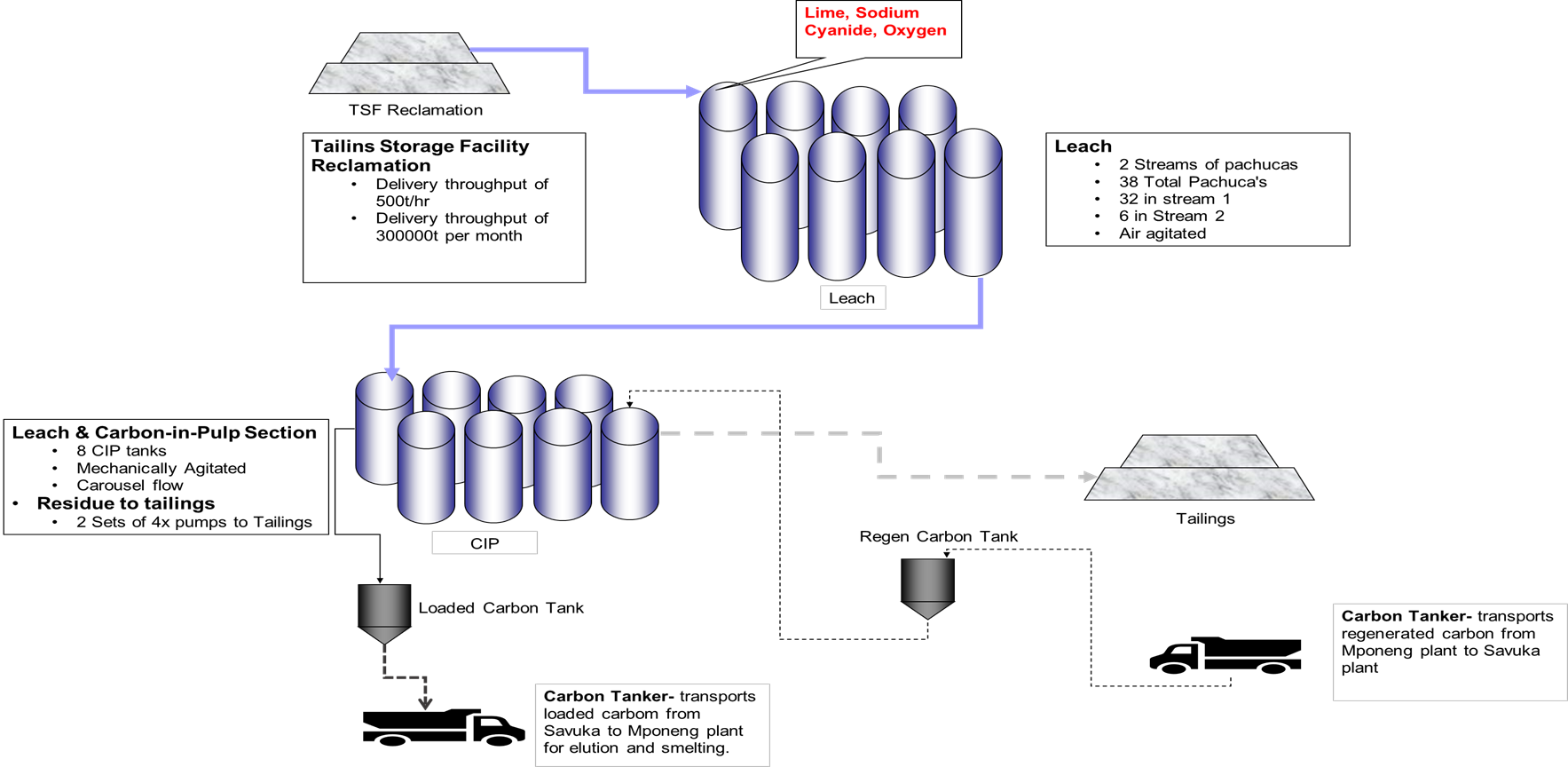

MWS is located in the Vaal River area, and straddles the Free State, North West provincial border of South Africa, close to the town of Klerksdorp. The MWS gold plant (26° 50’8.66”S; 26° 47’41.83”E) is situated close to the town of Stilfontein, while the TSFs and WRD for this operation are scattered over an area that stretches approximately 13.5km north to south and 14.0km east to west (Figure 3-1).

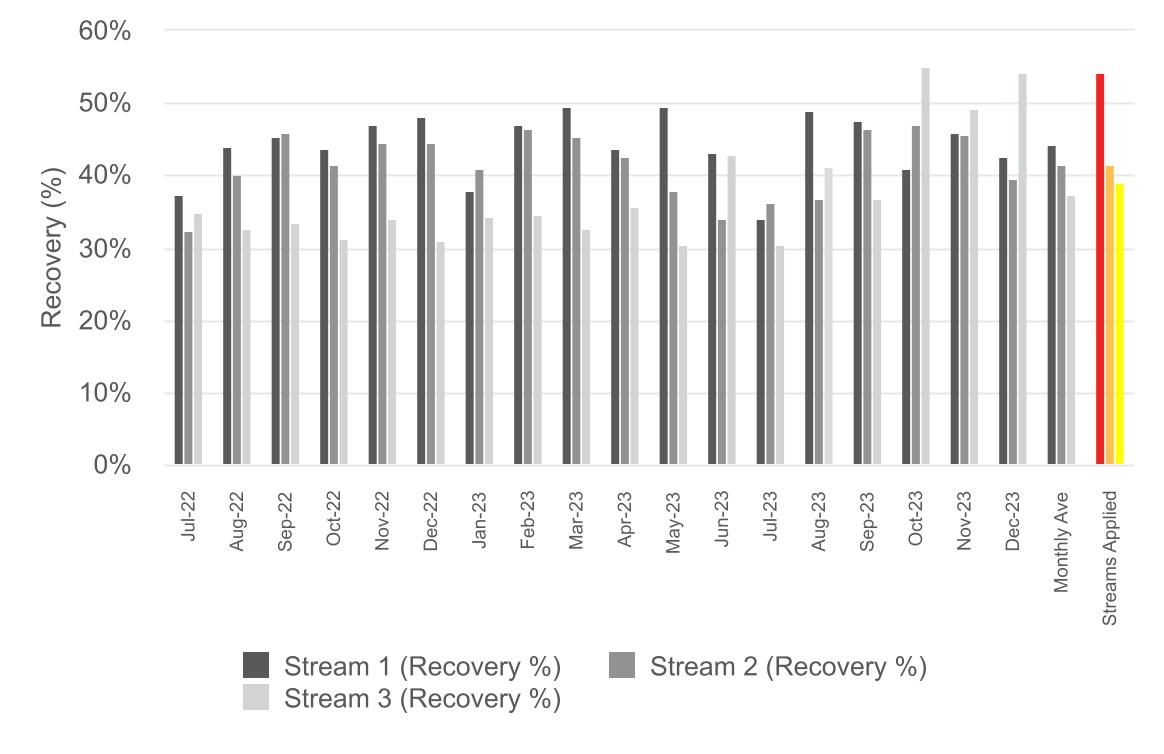

The MWS operation reprocesses tailings from 14 TSFs which are currently being fed to three separate streams and the fourth stream will be added later within the MWS gold plant (Table 3-1). The location of the surface deposits is indicated on Figure 3-2.

Table 3-1: MWS Surface Deposits and Processing Route

| | | | | | | | | | | | | | |

| Operation | Type | Surface Deposit ID | Processing Plant | Processing Stream |

| MWS | TSF | Abandon | MWS Gold Plant | Stream 1 & Stream 4 from West Sources |

| TSF | Ariston Gully |

| TSF | West Grass Dam |

| TSF | South East Extension |

| TSF | Sulphur Paydam |

| TSF | West Compartment 1 |

| TSF | West Compartment 2 |

| TSF | East Tailings | Stream 2 |

| TSF | Buffels 5 |

| TSF | Buffels 3 |

| TSF | Mispah 1 |

| TSF | Harties 1 | Stream 3 |

| TSF | Harties 2 |

| TSF | MWS 4 |

| TSF | MWS 5 |

| TSF | West Compartment 3 | In Mineral Resource - Not planned for in Life of Mine |

| TSF | West Compartment 4 |

| TSF | West Extension |

| TSF | Harties 5 |

| TSF | Harties 6 |

| TSF | Buffels 1 |

| TSF | Kopanang Paydam |

| WRD | Moab |

| WRD | Buffels 9 |

| WRD | Margaret |

3.1.2Mineral Tenure

The MWS operation’s license to operate is covered by the Environmental Authorization under the National Environmental Management Act No. 107 of 1998. In terms of the current legislation, the MPRDA, a mining right is not required to reclaim TSFs. No mineral title license is required to claim ownership of the TSFs and WRDs and surface rights automatically provides a legal claim to ownership. No mineral title license is required to claim ownership of the TSFs and WRDs and surface rights automatically provides a legal claim to ownership. The location of the various residue deposits is indicated in Figure 3-2.

Following the acquisition of MWS operation, all relevant permits and licenses were acquired by Harmony, including the approved EMP, the financial provision for rehabilitation liabilities for the MWS operation mining rights, as well as the historic surface rights permits for MWS operation. All of these permits are still valid.

Effective Date: June 30, 2024

11

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Figure 3-1: Location of MWS and West Wits

Effective Date: June 30, 2024

12

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Figure 3-2: Mineral tenure and location of MWS operation

Effective Date: June 30, 2024

13

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

3.1.3Property Permitting Requirements

MWS has all the permits required to operate and to realize the current Mineral Reserve plan reflected in the Mineral Reserve estimate and has access to all the properties it requires to conduct its current mining activities (Table 3-2).

Table 3-2: MWS property and land ownership

| | | | | | | | | | | | | | |

| Surface Deposit ID | Farm Name & No. | Portion No. | Owner | Title Deed No. |

| MWS 4 | Stilfontein 408 IP | 15 | Chemwes Pty Ltd | T18439/2005 |

| Stilfontein 408 IP | 49 | Chemwes Pty Ltd | T18439/2005 |

| MWS 5 | Stilfontein 408 IP | 15 | Chemwes Pty Ltd | T18439/2005 |

| Stilfontein 408 IP | 48 | Chemwes Pty Ltd | T18439/2005 |

| Margaret WRD | Stilfontein 534 IP | 0 | Omv Pty Ltd | T35140/2021 |

| Harties 1&2 | Zandpan 423 IP | 0 | Driade cc | T2888/1992 |

| Zandpan 423 IP | 4 | Republic of South Africa | T75460/2012 |

| Mapaiskraal 441 IP | 1 | African Rainbow Minerals Ltd | T121387/2000 |

| Harties 5&6 | Zandpan 423 IP | 3 | Temotuo rehabilitation co | T25046/2001 |

| Zandpan 423 IP | 4 | Republic of South Africa | T75460/2012 |

| South East TSF | Modderfontein 440 IP | 4 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| Vaalkop 439 IP | 3 | Harmony Moab Khotsong Operations Pty Ltd | T100817/2022 |

| Sulphur Paydam | Modderfontein 440 IP | 4 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| East TSF | Modderfontein 440 IP | 4 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| Buffels 1 - 4 | Buffelsfontein 443 IP | 9 | Chemwes Pty Ltd | T76488/2013 |

| Buffels 5 | Mapaiskraal 441 IP | 0 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| Mapaiskraal 441 IP | 2 | Rocha Maria Ines Da | T37394/1990 |

| Buffels 9 WRD | Hartebeestfontein 422 IP | 8 | Buffelsfontein Gold Mines Ltd | T95911/1996 |

| Hartebeestfontein 422 IP | 41 | Buffelsfontein Gold Mines Ltd | T95911/1996 |

| Buffelsfontein 443 IP | 9 | Chemwes Pty Ltd | T76488/2013 |

| Kareerand | Megadam 574 IP | 0 | Chemwes Pty Ltd | T80960/2010 |

| Kareerand Extension | Wildebeestpan 442 IP | Re | Wildebeestpan (Portion 9 & 10) Communal Property Association | T76828/2005 |

| West Extension | Nooitgedacht 434 IP | 200 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| Witkop 438 IP | 2 | Harmony Moab Khotsong Operations Pty Ltd | T100817/2022 |

| West complex | Nooitgedacht 434 IP | 200 | Harmony Moab Khotsong Operations Pty Ltd | T85432/2022 |

| Witkop 438 IP | 1 | Harmony Moab Khotsong Operations Pty Ltd | T100817/2022 |

| 2 | Harmony Moab Khotsong Operations Pty Ltd | T100817/2022 |

| 4 | Harmony Moab Khotsong Operations Pty Ltd | T34454/2023 |

| Harties 7 TSF | Klerksdorp 424 IP | 1 | City of Matlosana | G201/1906 |

| Ellaton TSF | Strathmore 436 IP | 5 | City of Matlosana | T58081/1981 |

| Moab WRD | Anglo 593 | 0 | Harmony Moab Khotsong Operations Pty Ltd | T8152/2018 |

| Hoekplaats 598 | 0 | Harmony Moab Khotsong Operations Pty Ltd | T8152/2018 |

| Mispah 274 | 0 | Harmony Moab Khotsong Operations Pty Ltd | T8152/2018 |

| Mispah TSF | Mispah 274 | 0 | Harmony Moab Khotsong Operations Pty Ltd | T8152/2018 |

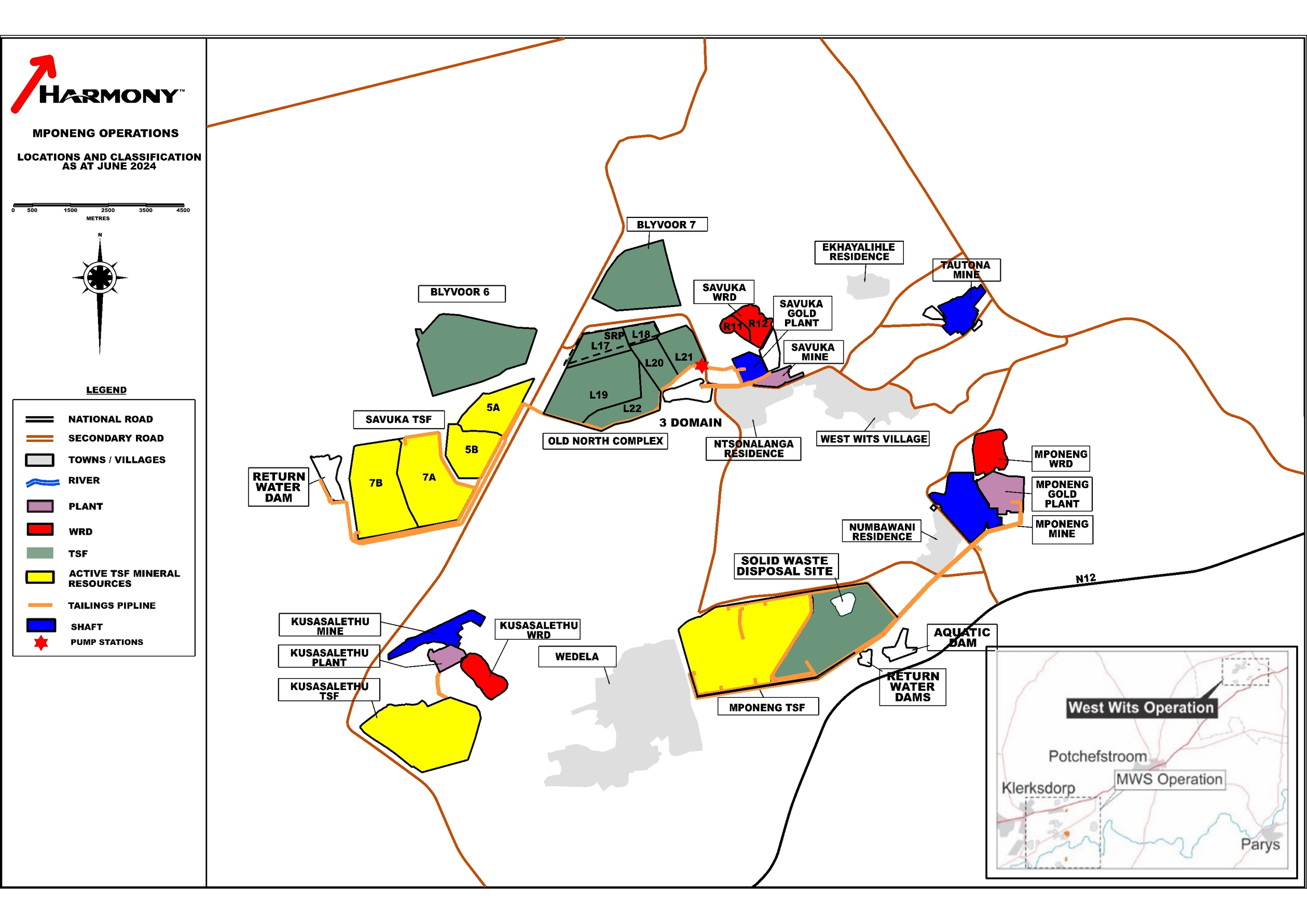

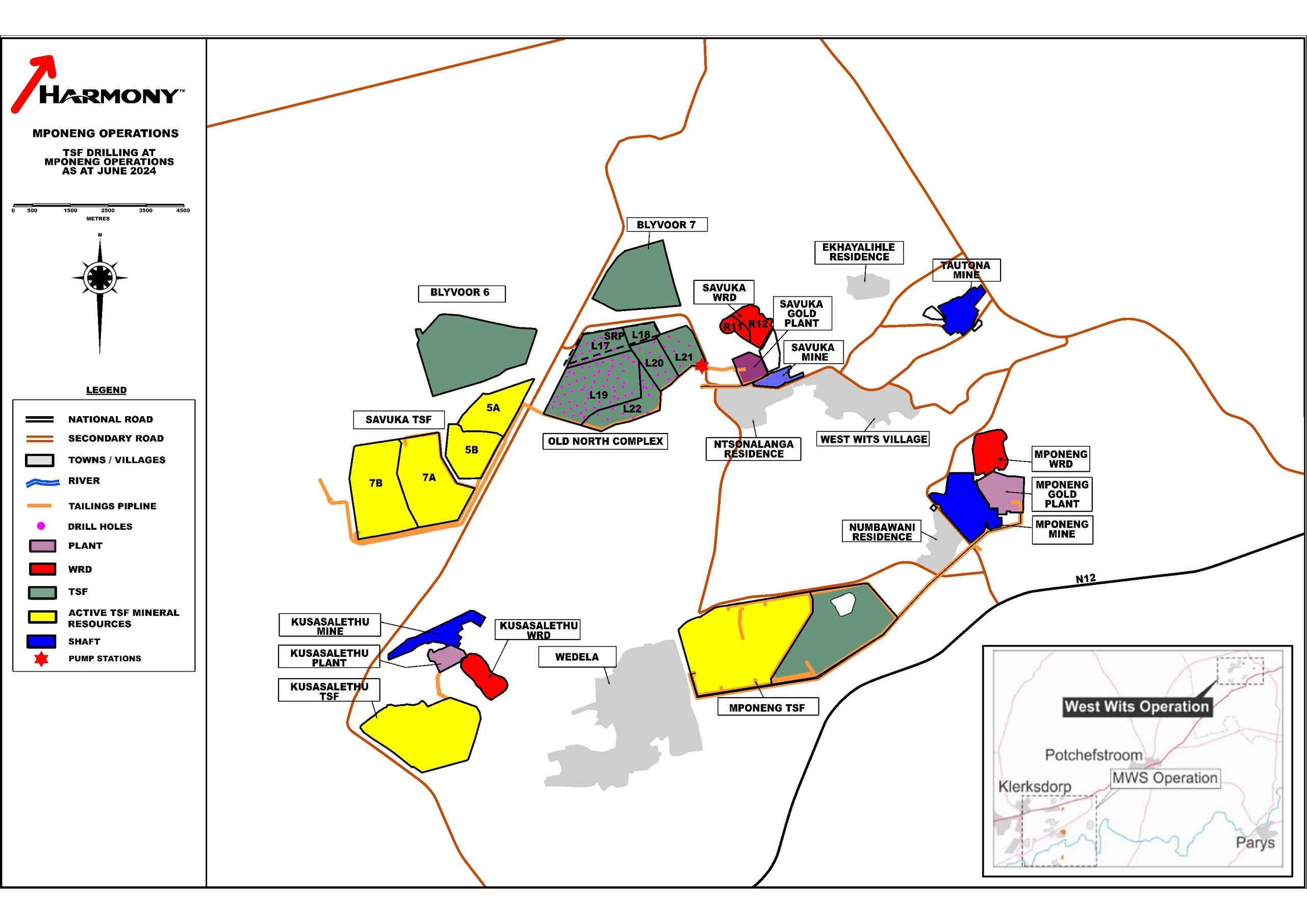

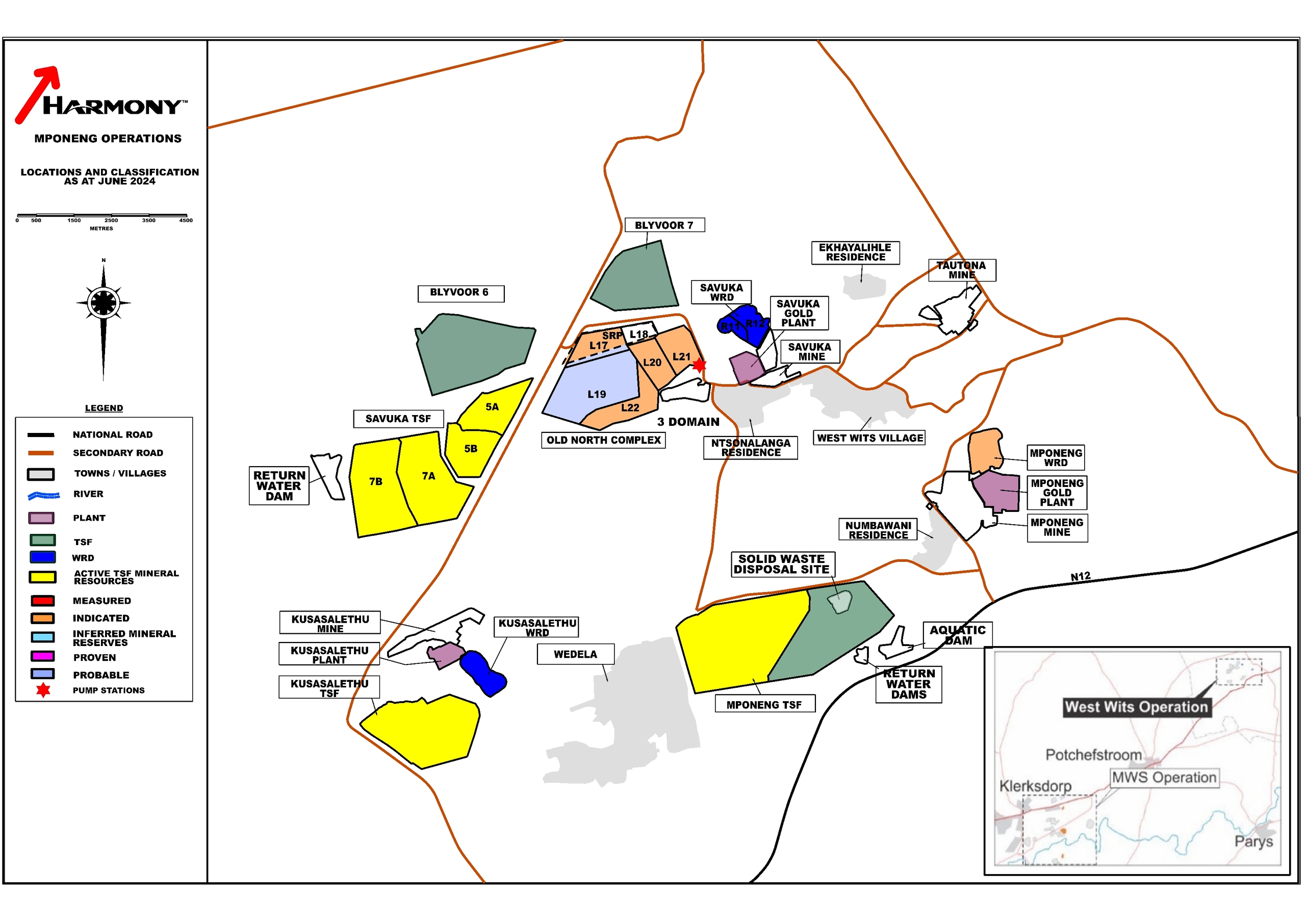

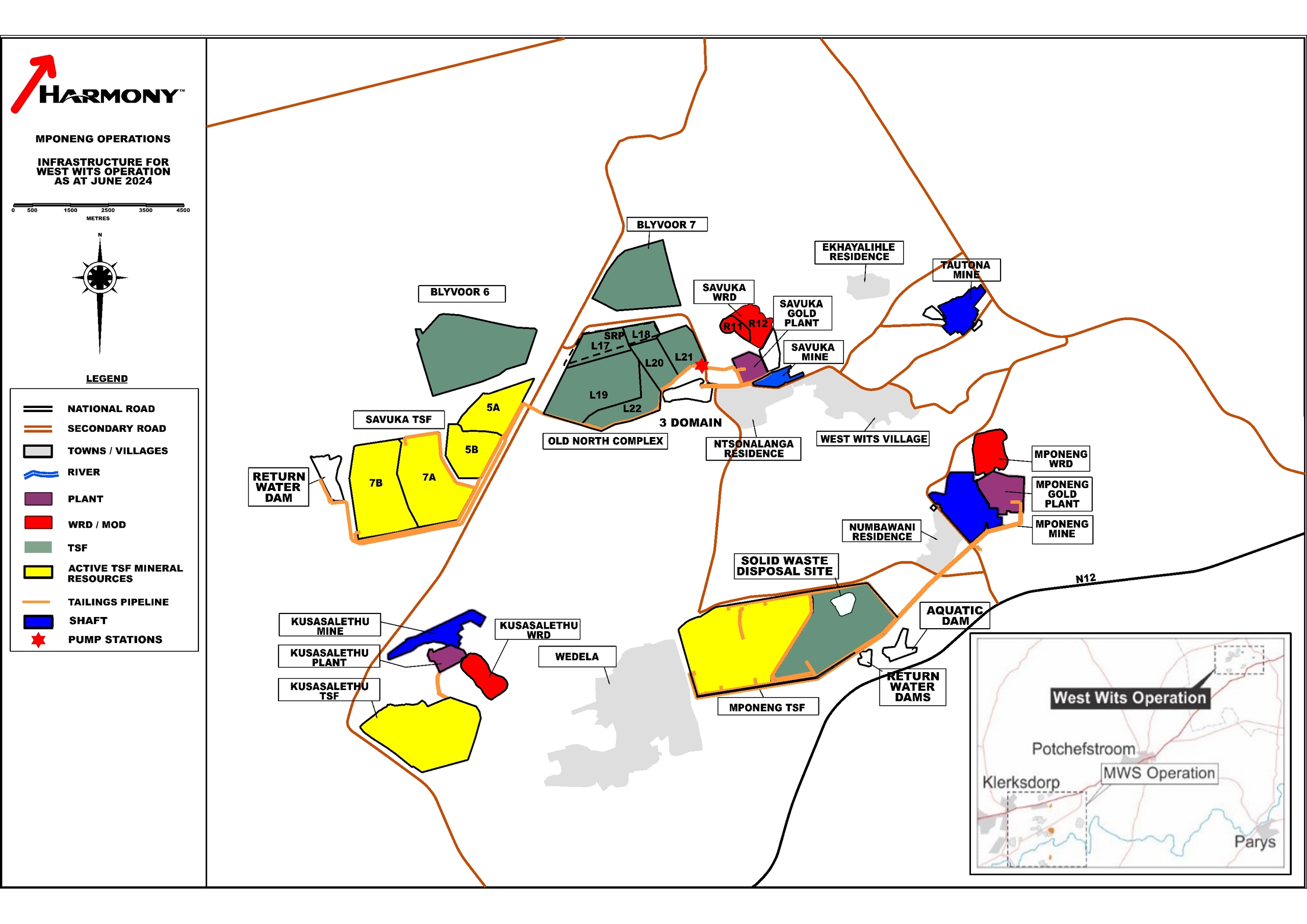

3.2West Wits Operation

3.2.1Description and Location

The West Wits operation is situated in the West Rand region of the Gauteng Province (Figure 3-1). The West Wits operation is situated approximately 75km west of Johannesburg. The site is approximately 7km south of Carletonville. West Wits operation occupies an area 4,176ha in extent and is close to the boundary between Gauteng and North West Province (Figure 3-1).

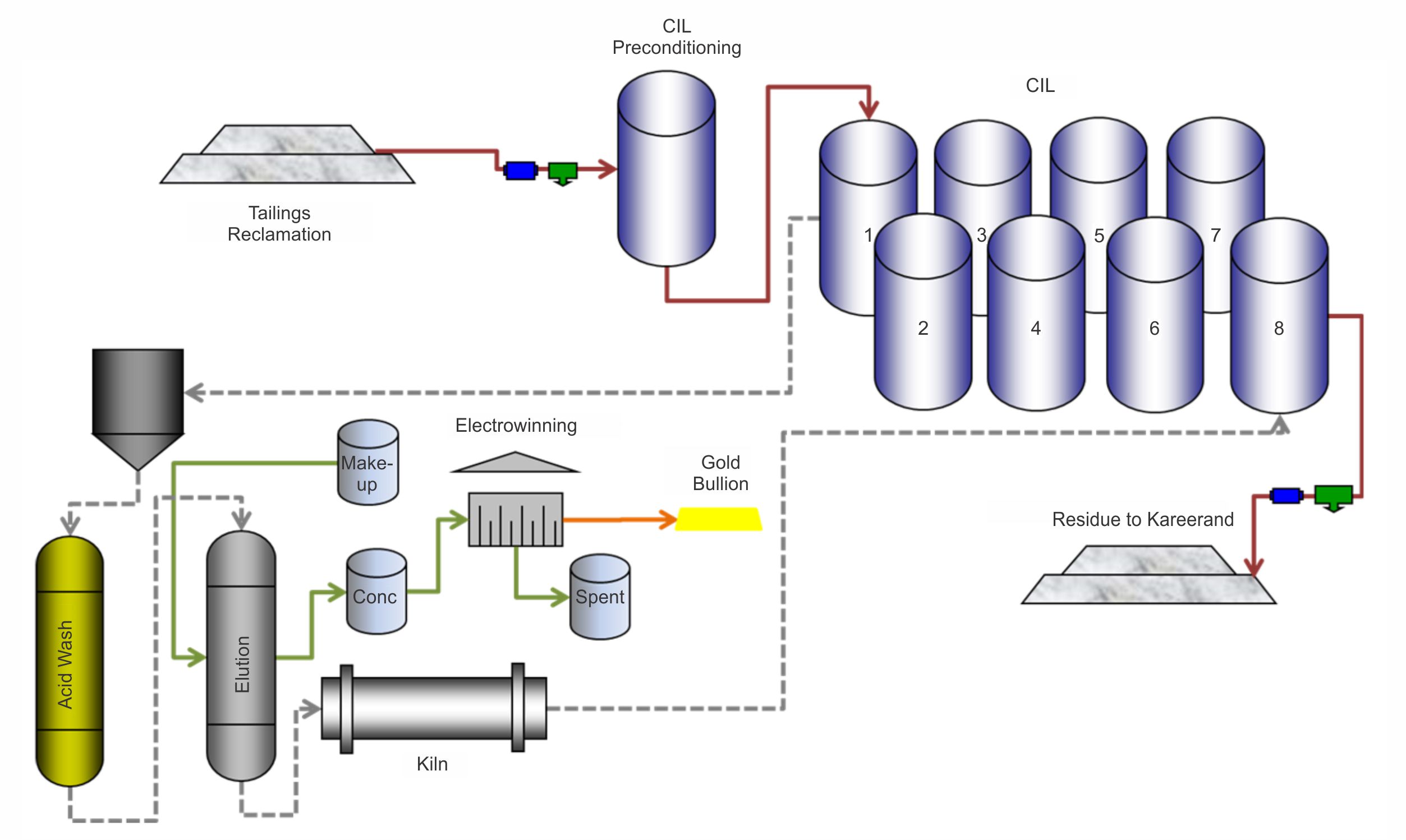

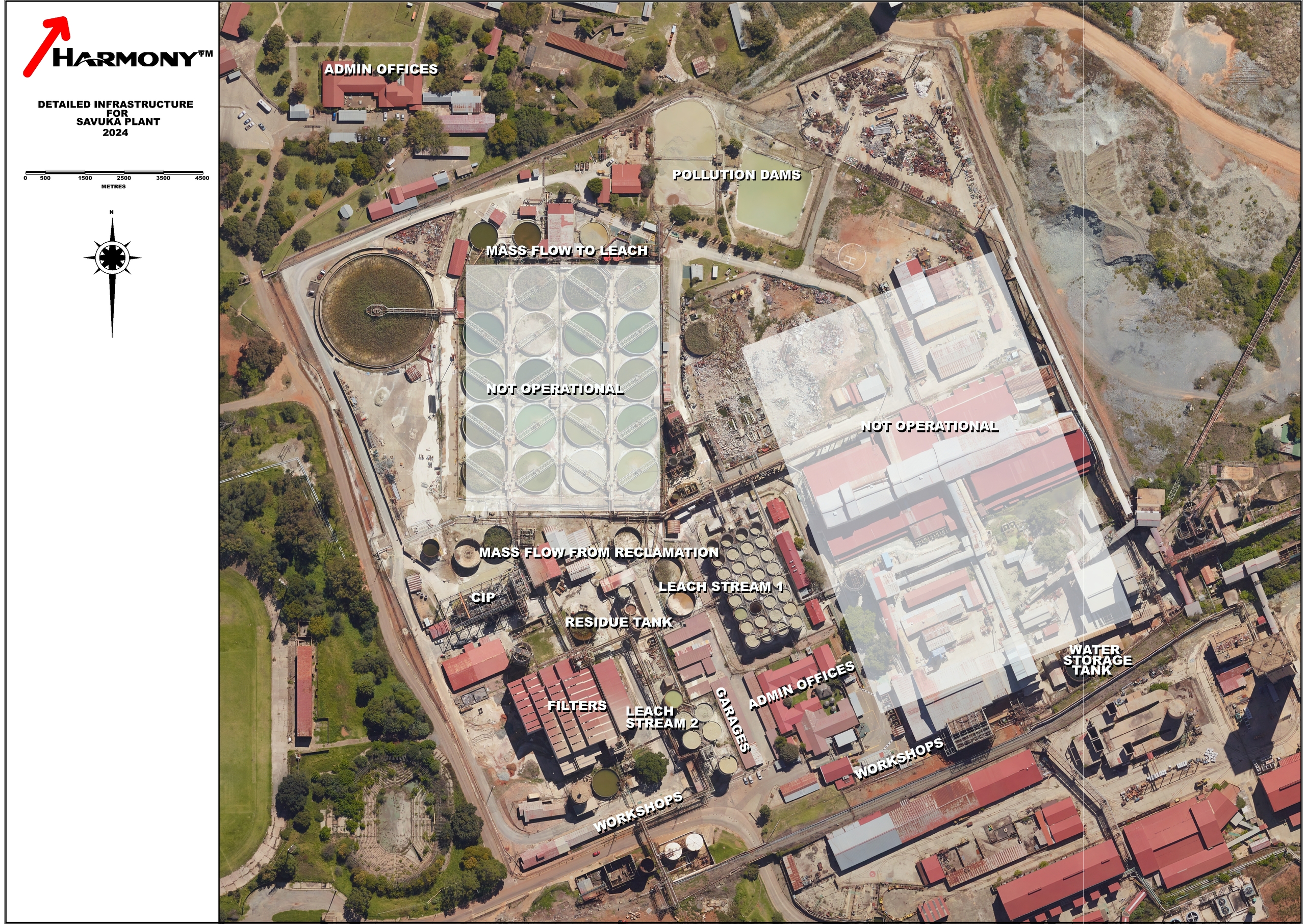

The West Wits operation processes reclaimed tailings from the Old North TSF and waste rock from the Savuka WRD and Mponeng WRD. The Savuka plant (26° 25’20.31”S and 27° 24’11.30”E) (Figure 3-3), processes the reclaimed Old North tailings only, while the Kusasalethu plant processes both the Old North tailings and the Savuka WRD. Mponeng plant processes the Mponeng WRD as a gap-filler for the reef.

Effective Date: June 30, 2024

14

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Figure 3-3: Mineral tenure and location of West Wits operation

The feed sources for West Wits are presented in Table 3-3.

Effective Date: June 30, 2024

15

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 3-3: West Wits surface deposits and processing route

| | | | | | | | | | | |

| Operation | Type | Surface Deposit ID | Processing Plant |

| West Wits | TSF | Old North TSF L 19 | Savuka Plant and Kusasalethu Plant |

| WRD | Mponeng Low Grade | In Mineral Resource - Planned in the 1st year of Mponeng Gold Plant |

| TSF | Old North TSF L17, L20, L21, L22 | In Mineral Resource - not currently being treated. |

3.2.2Mineral Tenure

South African Mining Law is regulated by the MPRDA which is the predominant piece of legislation dealing with acquisitions or rights to conduct reconnaissance, prospecting and mining. There are several other pieces of legislation which deal with such ancillary issues such as royalties (the Mineral and Petroleum Resources Royalty Act, 2008), title registration (the Mining Titles Registration Act, 1967), and health and safety (the Mine Health and Safety Act, 1996).

The following mining rights make up the full Mponeng mining right area of approximately 6,673ha:

•GP30/5/1/2/2(01) MR valid from February 14, 2006 to February 13, 2036; and

•GP30/5/1/2/2(248) MR (for sand) valid from October 16, 2012 to October 15, 2022.- in the process of being consolidated into a single mining right (GP30/5/1/2/2/01) and is currently pending at the DMRE.

The mining rights 01MR and 248MR were ceded from AngloGold Ashanti Limited ("AngloGold Ashanti" or “AGA”) to Golden Core Trade and Investment (Pty) Ltd ("Golden Core"), a wholly-owned subsidiary of Harmony on September 30, 2020 and were successfully registered in the Mining Titles Office on June 14, 2021 as part of AngloGold Ashanti’s sale of their last remaining South African assets to Harmony, including its West Wits operations ("Transaction").

A section 102 Application in terms of the MPRDA was submitted previously by AngloGold Ashanti in March 2017 to consolidate its West Wits mining rights into a single mining right (GP30/5/1/2/2(01) MR). The AngloGold Ashanti Application was approved by the Department of Minerals and Energy ("DMRE") in August 2020, but was, however, not implemented due to a change in circumstances as a result of the transaction, and has subsequently been withdrawn by AngloGold Ashanti. A renewal application for GP30/5/1/2/2(248) MR (for sand) was submitted timeously. However, the DMRE requested Golden core to withdraw the renewal so they could process the S102 Consolidation application. A conditional withdrawal was subsequently submitted for the renewal application. On February 15, 2022, Golden Core submitted an application in terms of section 102 of the MPRDA, substantively similar to the AngloGold Ashanti Application, to consolidate the mining rights and mining right areas into a single mining right (GP30/5/1/2/2(01) MR) ("Golden Core Application"). The Golden Core Application is currently pending at the DMRE. By operation of law, submission of these applications to the DMRE automatically extended the validity of MR248 in the interim until DMRE approves or rejects the application.

The mineral rights are summarized in Table 3-4. The location of the residue deposits is presented in Figure 3-3.

Table 3-4: Summary of mining rights for West Wits

| | | | | | | | | | | | | | | | | |

| Operation | License Type | Reference No. | Effective Date | Expiry Date | Area (ha) |

| Mponeng Mine | Mining Right | GP30/5/1/2/2(01) MR | 14-Feb-2006 | 13-Feb-2036 | 6,477 |

| Magnum Farm | Mining Right | GP30/5/1/2/2(248) MR (for sand) | 16-Oct-2012 | 15-Oct-2022 (application still pending at the DMRE) | 196 |

| Total | 6,673 |

There is no material litigation (including violations or fines) against Golden Core which threatens its mineral rights, tenure, or operations.

Effective Date: June 30, 2024

16

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

3.2.3Property Permitting Requirements

West Wits, operating as Golden Core, has all the permits required to operate and to realize the current LOM plan reflected in the Mineral Reserve estimate and has access to all the properties it requires to conduct its current mining activities (Table 3-5).

Following the acquisition of West Wits surface operations, all relevant permits and licenses were transferred to Golden Core including the approved EMP, the financial provision for rehabilitation liabilities for the West Wits operation mining rights, as well as the historic surface rights permits for West Wits operation. All of these permits are still valid.

Table 3-5: West Wits property and land ownership

| | | | | | | | | | | | | | |

| Surface Deposit ID | Farm Name & No. | Portion No. | Owner | Title Deed No. |

| Mponeng TSF | Elandsfontein 115 IQ | 23 | Golden Core Trade and Investment | T66629/2022 |

| New North TSF 7B | Doornfontein 118 IQ | 25 | Golden Core Trade and Investment | T66629/2022 |

| New North TSF 7A | Doornfontein 118 IQ | 25 | Golden Core Trade and Investment | T66629/2022 |

| Blyvooruitzicht 116 IQ | 93 | Golden Core Trade and Investment | T66629/2022 |

| New North TSF 5B | Blyvooruitzicht 116 IQ | 16 | Golden Core Trade and Investment | T66629/2022 |

| Blyvooruitzicht 116 IQ | 17 | Golden Core Trade and Investment | T66629/2022 |

| Blyvooruitzicht 116 IQ | 93 | Golden Core Trade and Investment | T66629/2022 |

| Doornfontein 118 IQ | 25 | Golden Core Trade and Investment | T66629/2022 |

| New North TSF 5A | Blyvooruitzicht 116 IQ | 16 | Golden Core Trade and Investment | T66629/2022 |

| Blyvooruitzicht 116 IQ | 93 | Golden Core Trade and Investment | T66629/2022 |

| Old North TSF | Blyvooruitzicht 116 IQ | 1 | Blyvooruitzicht Gold Mining Co Ltd | T14831/1986 |

| Blyvooruitzicht 116 IQ | 70 | Blyvooruitzicht Gold Mining Co Ltd | T11479/1966 |

| Blyvooruitzicht 116 IQ | 93 | Golden Core Trade and Investment | T66629/2022 |

| Savuka WRD | Blyvooruitzicht 116 IQ | 3 | Golden Core Trade and Investment | T66629/2022 |

| Mponeng WRD | Elandsfontein 115 IQ | 5 | Golden Core Trade and Investment | T66629/2022 |

Effective Date: June 30, 2024

17

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

4Accessibility, Climate, Local Resources, Infrastructure and Physiography

Section 229.601(b)(96)(iii)(B) (4) (i-iv)

4.1MWS Operation

4.1.1Accessibility

The MWS operation is accessible from Johannesburg via the N12 national road and R502 regional road in Klerksdorp, North West. A large network of either tarred roads or well-maintained gravel roads exist between the tailing dams, waste rock dumps and the MWS plant that are scattered in the area (Figure 3-1).

4.1.2Physiology and Climate

The area where the MWS operation is situated is at an elevation ranging between 1,270m above mean sea level (“amsl”) and 1,340 amsl. A natural rocky ridge (Black Reef rocks) constitutes the northern boundary of the operational area, with man-made structures such as headgears and TSFs altering the topography of the landscape.

The region’s climate is characterized as sub-tropical dry savanna, with a mean annual evaporation at ~1,300mm which far exceeds mean annual rainfall of ~600mm.

Temperature patterns are characterized by seasonal and daily variations, where summers are hot and winters are mild to cold. The seasonal fluctuations in mean temperatures vary between 2°C and 22°C in the winter months (May – August) and vary between 13°C and 29°C in the summer months (September – April). The month of June is generally the coldest month with lowest recorded temperatures of an estimated 2°C while the maximum recorded temperature of 29°C generally occurs in February.

4.1.3Local Resources and Infrastructure

Infrastructure in the region is well established supporting the numerous operational gold mines in the area. The regional infrastructure includes national and provincial paved road networks, power transmission and distribution networks, water supply networks and communication infrastructure. Harmony has enough reliable suppliers of consumables on its database and the company also has a healthy workforce to sustain the operation.

4.2West Wits Operation

4.2.1Accessibility

The West Wits Surface operations near Carletonville are accessible via the N12 national road and R500 regional road from Johannesburg.

4.2.2Physiology and Climate

The area where the West Wits operation is situated is approximately at an elevation of 1,700m above sea level. A prominent rocky ridge known as the Gatsrand extends across the West Wits operation from east to west forming a watershed. Other man-made structures such as headgears, TSFs and WRDs altering the topography of the landscape.

The West Wits operation falls within the Highveld climatic zone, which is characterized by warm temperatures, dry winters and summer rainfall (with all conditions being erratic and extremely variable). The mean annual evaporation is recorded at ~596mm with the highest precipitation occurring in January (194.7mm) and the lowest occurring in July (2.3mm).

The summer months are warm and mostly clear, and winters are cold and dry. The month of July is generally the coldest month with lowest recorded temperatures of an estimated 2°C while the maximum recorded temperature of 27°C generally occurs in February. The seasonal fluctuations in mean temperatures between the warmest and the coldest months vary between 12°C and 15°C.

4.2.3Local Resources and Infrastructure

Infrastructure in the region is well established supporting the numerous operational gold mines in the area. The regional infrastructure includes national and provincial paved road networks, power transmission and distribution networks, water supply networks and communication infrastructure. Harmony has enough reliable suppliers of consumables on its database and the company also has a healthy workforce to sustain the operation.

Effective Date: June 30, 2024

18

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

5History

Section 229.601(b)(96)(iii)(B) (5) (i-ii)

5.1Historical Ownership and Development

5.1.1MWS Operation

The MWS gold plant commenced production in 1952 and was the original gold processing plant for the Stilfontein gold mine. Following the rise in the uranium price in the 1970s, the operation investigated uranium recovery from the Stilfontein Gold Mine’s gold tailings dams and commissioned the uranium plant in mid-1979. The plant operated until 1989, processing 29.4Mt of tailings and recovering 4.56t of U3O8. In 2003, the plant was converted into a gold tailings treatment operation and no further uranium was produced at that stage.

In 2007, First Uranium (Pty) Ltd (South Africa) ("First Uranium") acquired the MWS operations with the purpose of treating the tailings dams for both gold and uranium. The second and third processing plants were commissioned between 2007 and 2012. The Stream 4 will start in November 2024.

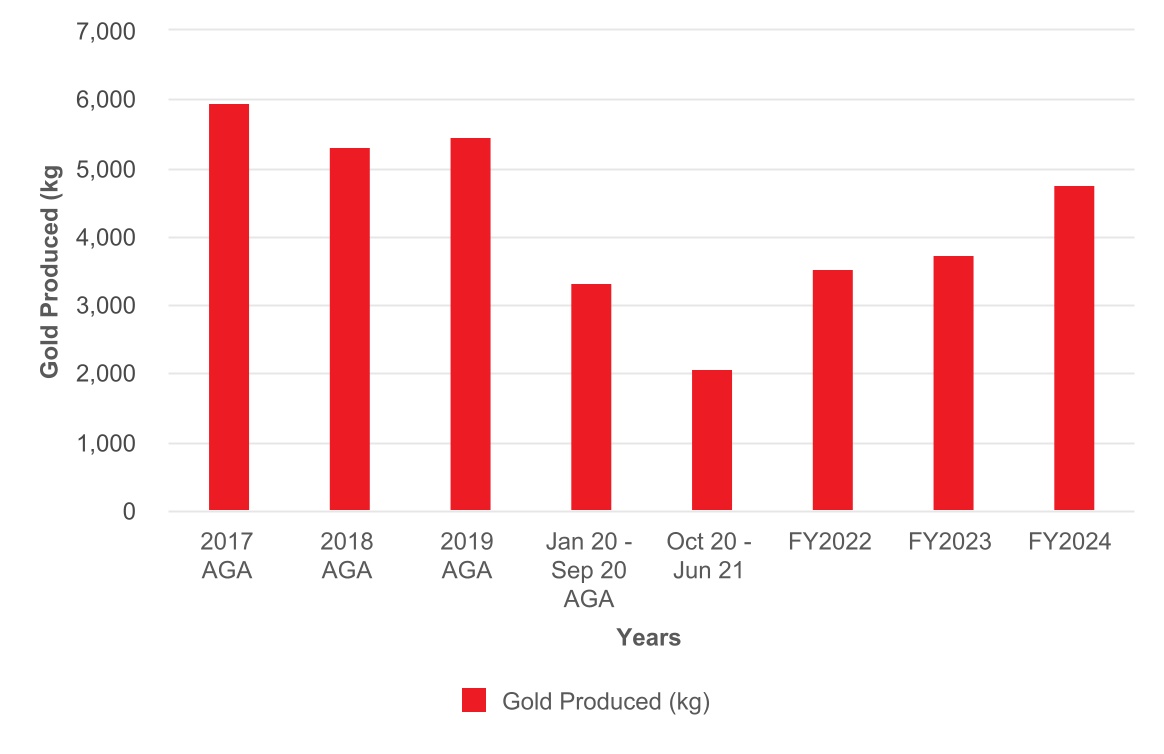

On July 20, 2012, the MWS operations were acquired by AngloGold Ashanti from First Uranium. The MWS uranium plant and flotation plants were commissioned in 2014 and were further reconfigured into a more efficient operation during 2016, as part of an optimisation drive. In 2017, the uranium and flotation plants were discontinued resulting in MWS plants producing only gold.

On October 1, 2020 Harmony acquired all of AngloGold Ashanti’s surface operations, including the MWS operations.

5.1.2West Wits Operation

The Savuka plant was commissioned in 1961 and originally designed to treat ore from Savuka mine and TauTona mine. In 2015, upon the change in strategy to treat the ore from Savuka and TauTona at Mponeng plant, the plant was converted into a tailings and WRD treatment facility. The Savuka plant treats tailings material from Old North TSF and Mponeng plant waste rock from the Mponeng WRD. On October 1, 2020, Harmony acquired all of AngloGold Ashanti’s South African business, including the surface assets which constitute the West Wits operation.

Kusasalethu plant was commissioned in 1980 as conventional filter plant. In 1998 Carousel pump cell CIP plant was introduced with off-site elutions. In 2012 the milling circuit was re-configured from open circuit primary milling to closed circuit primary milling and re-grind mill was de-commissioned. In 2014 an elution facility was constructed on site. Its treatment capacity is 120,000 tpm at 65 tph and 85% mill availability with

Recovery Efficiency of 95%. In July 2021 the plant was converted to a waste rock treatment facility. The plant has been converted into a small scale TSF re-treatment operation.

5.2Historical Exploration

Prior to 2011, grade estimations for the Vaal River TSFs were based on residue grades obtained from the process plants, as well as various sampling projects in selected areas. Post AGA ownership, the Vaal River TSFs including MWS TSFs, and West Wits TSFs were drilled on a regular grid spacing and sampled every 1.5m from the top of the TSF till red soil intersection using auger drilling. The same method of drilling continued post Harmony ownership in 2021. The exploration drilling carried out since 2011 has been used in the estimation of the Mineral Resources and, as such, is discussed in Section 11.

The reader should note that drilling cannot be carried out on WRDs due to their composition of unconsolidated rock. Therefore, historical exploration is not available. These deposits are sampled by Harmony for the purposes of Mineral Resource estimation, as discussed in Section 11.

5.3Previous Mineral Resource and Mineral Reserve Estimates

The previous Mineral Resource estimate for Mine Waste Solutions and West Wits were declared as at June 2023 according to SAMREC Code, 2016. The previous Mineral Resource estimates, summarized in Table 5-1 and Table 5-2 for MWS and West Wits respectively, are exclusive of Mineral Reserves and have been superseded by the current estimate prepared by the QP in Section 11 of this TRS.

Effective Date: June 30, 2024

19

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 5-1: Summary of the previous MWS Mineral Resources as at June 30, 2023 (exclusive of Mineral Reserves)

| | | | | | | | | | | | | | | | | | | | |

| METRIC | Grade | Metal Content |

| Mineral Resource Category | Source | Tonnes (Mt) | Gold (g/t) | U3O8 (kg/t) | Gold (kg) | U3O8 (t) |

| Measured | TSF | 54.061 | 0.20 | 0.061 | 10,902 | 3,272 |

| WRD | — | — | — | — | — |

| Sub Total / Ave Measured | 54.061 | 0.20 | 0.061 | 10,902 | 3,272 |

| Indicated | TSF | 52.912 | 0.24 | 0.096 | 12,840 | 5,076 |

| WRD | 2.060 | 0.30 | — | 619 | — |

| Sub Total / Ave Indicated | 54.972 | 0.24 | — | 13,459 | 5,076 |

| Total / Ave. Measured + Indicated | 109.033 | 0.22 | 0.078 | 24,360 | 8,348 |

| Inferred | TSF | 77.701 | 0.13 | 0.039 | 9,984 | 3,031 |

| WRD | 2.502 | 0.24 | — | 611 | — |

| Total / Ave Inferred | 80.203 | 0.13 | 0.038 | 10,594 | 3,031 |

| |

| IMPERIAL | Grade | Metal Content |

| Mineral Resource Category | Source | Tons (Mt) | Gold (oz/t) | U3O8 (lb/t) | Gold (Moz) | U3O8 (Mlbs) |

| Measured | TSF | 59.592 | 0.006 | 0.133 | 0.351 | 7.946 |

| WRD | — | — | — | — | — |

| Sub Total / Ave Measured | 59.592 | 0.006 | 0.133 | 0.351 | 7.946 |

| Indicated | TSF | 58.326 | 0.007 | 0.190 | 0.414 | 11.102 |

| WRD | 2.270 | 0.009 | — | 0.020 | — |

| Sub Total / Ave Indicated | 60.596 | 0.007 | 0.190 | 0.434 | 11.102 |

| Total / Ave. Measured + Indicated | 120.188 | 0.007 | 0.323 | 0.785 | 19.048 |

| Inferred | TSF | 85.651 | 0.004 | 0.078 | 0.321 | 6.683 |

| WRD | 2.758 | 0.007 | — | 0.020 | — |

| Total / Ave Inferred | 88.409 | 0.004 | 0.076 | 0.341 | 6.683 |

Effective Date: June 30, 2024

20

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 5-2: Summary of the previous West Wits Mineral Resources as at June 30, 2023 (exclusive of Mineral Reserves)

| | | | | | | | | | | | | | | | | | | | |

| METRIC | Grade | Metal Content |

| Mineral Resource Category | Source | Tonnes (Mt) | Gold (g/t) | U3O8 (kg/t) | Gold (kg) | U3O8 (t) |

| Measured | TSF | — | — | — | — | — |

| WRD | — | — | — | — | — |

| Sub Total / Ave Measured | — | — | — | — | — |

| Indicated | TSF | 25.427 | 0.32 | — | 8,259 | — |

| WRD | 0.272 | 0.37 | — | 100 | — |

| Sub Total Indicated | 25.699 | 0.33 | — | 8,359 | — |

| Total / Ave. Measured + Indicated | 25.699 | 0.33 | — | 8,359 | — |

| Inferred | TSF | — | — | — | — | — |

| WRD | — | — | — | — | — |

| Total / Ave Inferred | — | — | — | — | — |

| |

| IMPERIAL | Grade | Metal Content |

| Mineral Resource Category | Source | Tons (Mt) | Gold (oz/t) | U3O8 (lb/t) | Gold (Moz) | U3O8 (Mlbs) |

| Measured | TSF | — | — | — | — | — |

| WRD | — | — | — | — | — |

| Sub Total / Ave Measured | — | — | — | — | — |

| Indicated | TSF | 28.028 | 0.009 | — | 0.266 | — |

| WRD | 0.300 | 0.011 | — | 0.003 | — |

| Sub Total Indicated | 28.328 | 0.009 | — | 0.269 | — |

| Total / Ave. Measured + Indicated | 28.328 | 0.009 | — | 0.269 | — |

| Inferred | TSF | — | — | — | — | — |

| WRD | — | — | — | — | — |

| Total / Ave Inferred | — | — | — | — | — |

The previous Mineral Reserve estimate for Mine Waste Solutions and West Wits as at June 30, 2023, were estimated in accordance with the SAMREC Code, 2016. Modifying factors were applied to the Mineral Resource estimates to arrive at the Mineral Reserve estimates. The previous Mineral Reserve estimates are summarized in Table 5-3 and Table 5-4 for MWS and West Wits, respectively, and has been superseded by the current estimate prepared by Harmony as detailed in Section 12 of this TRS.

Effective Date: June 30, 2024

21

Technical Report Summary for

Mine Waste Solutions, North West, South Africa

Table 5-3: Summary of the previous MWS Mineral Reserves as at June 30, 2023

| | | | | | | | | | | | | | |

| METRIC |

| Mineral Reserve Category | Source | Tonnes (Mt) | Gold Grade (g/t Au) | Gold Content (kg) |

| Proved | TSF | 14.215 | 0.27 | 3,823 |

| WRD | — | — | — |

| Sub Total / Ave Proven | 14.215 | 0.27 | 3,823 |

| Probable | TSF | 381.126 | 0.28 | 105,832 |

| WRD | — | — | — |

| Sub Total / Ave Probable | 381.126 | 0.28 | 105,832 |

| Total / Ave (Proved + Probable) | 395.341 | 0.28 | 109,655 |

| IMPERIAL |

| Mineral Reserve Category | Source | Tons (Mt) | Gold Grade (oz/t) | Gold Content (Moz) |

| Proved | TSF | 15.670 | 0.008 | 0.123 |

| WRD | — | — | — |

| Sub Total / Ave Proven | 15.670 | 0.008 | 0.123 |

| Probable | TSF | 420.119 | 0.008 | 3.403 |

| WRD | — | — | — |

| Sub Total / Ave Probable | 420.119 | 0.008 | 3.403 |

| Total / Ave (Proved + Probable) | 435.789 | 0.008 | 3.525 |

Table 5-4: Summary of the previous West Wits Mineral Reserves as at June 30, 2023

| | | | | | | | | | | | | | |

| METRIC |

| Mineral Reserve Category | Source | Tonnes (Mt) | Grade (g/t Au) | Content Au (kg) |

| Proved | TSF | — | — | — |

| WRD | — | — | — |

| Sub Total / Ave Proven | — | — | — |

| Probable | TSF | 17.357 | 0.32 | 5,485 |

| WRD | — | — | — |

| Sub Total / Ave Probable | 17.357 | 0.32 | 5,485 |

| Total / Ave (Proved + Probable) | 17.357 | 0.32 | 5,485 |

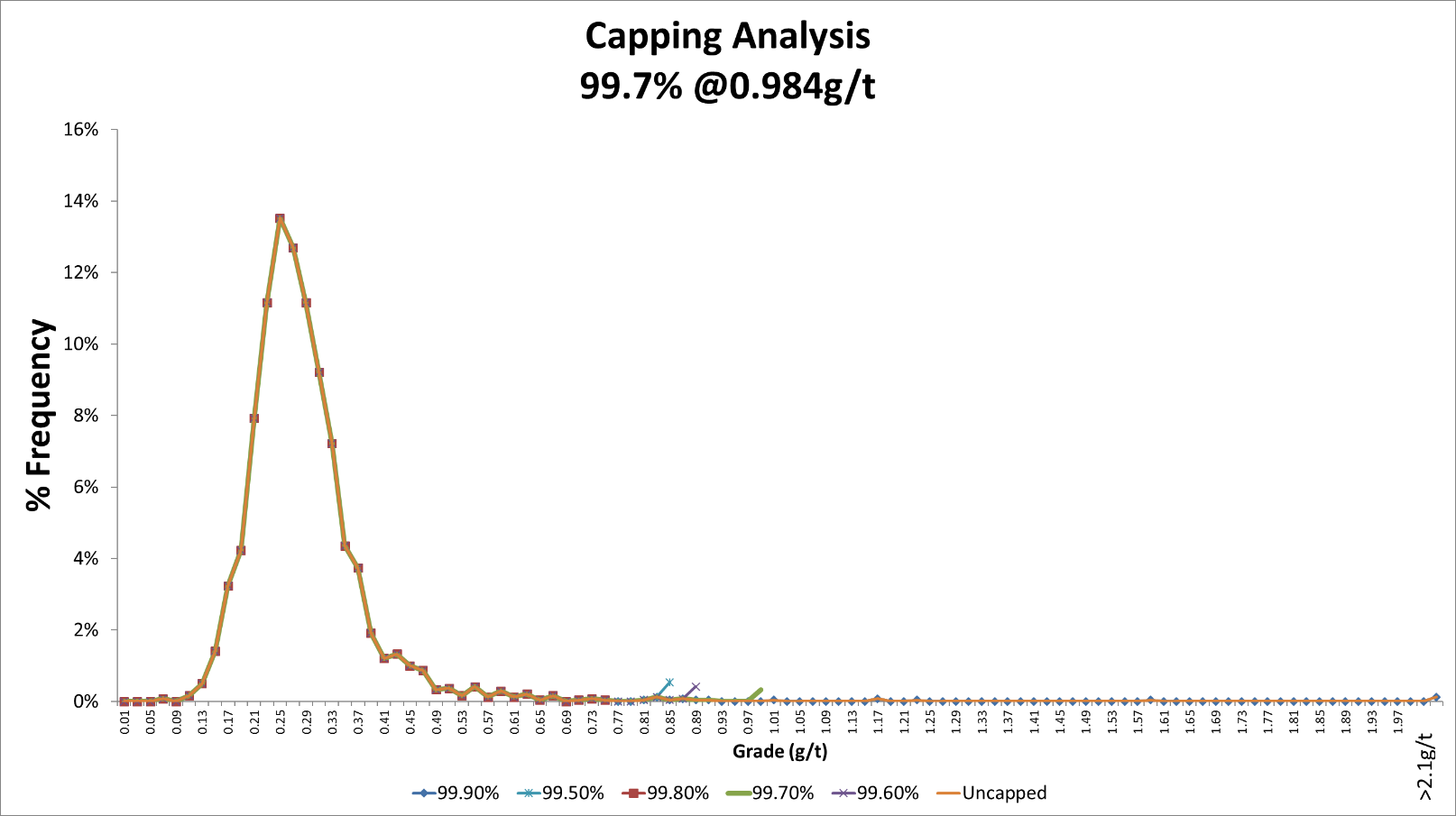

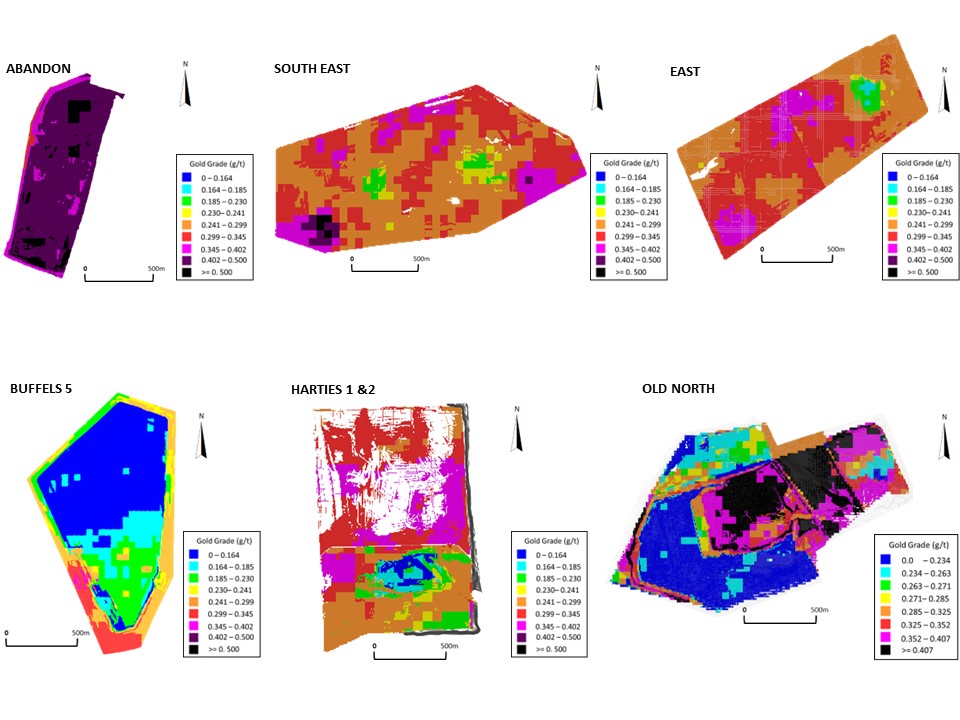

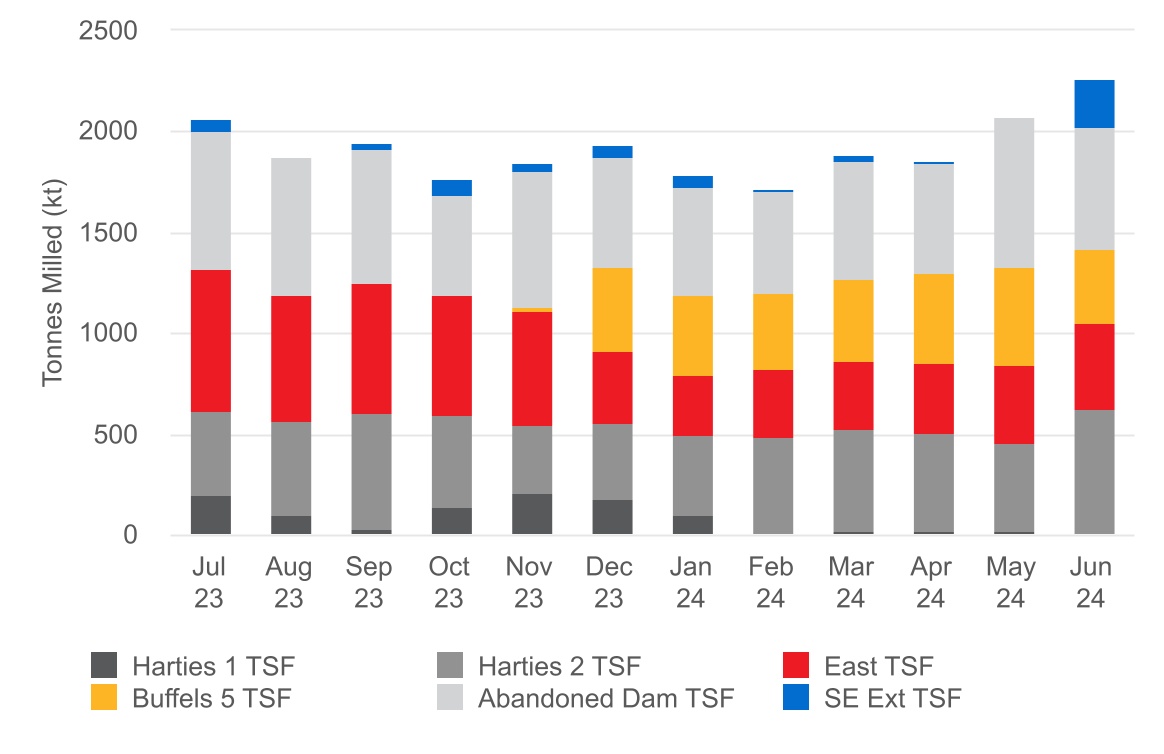

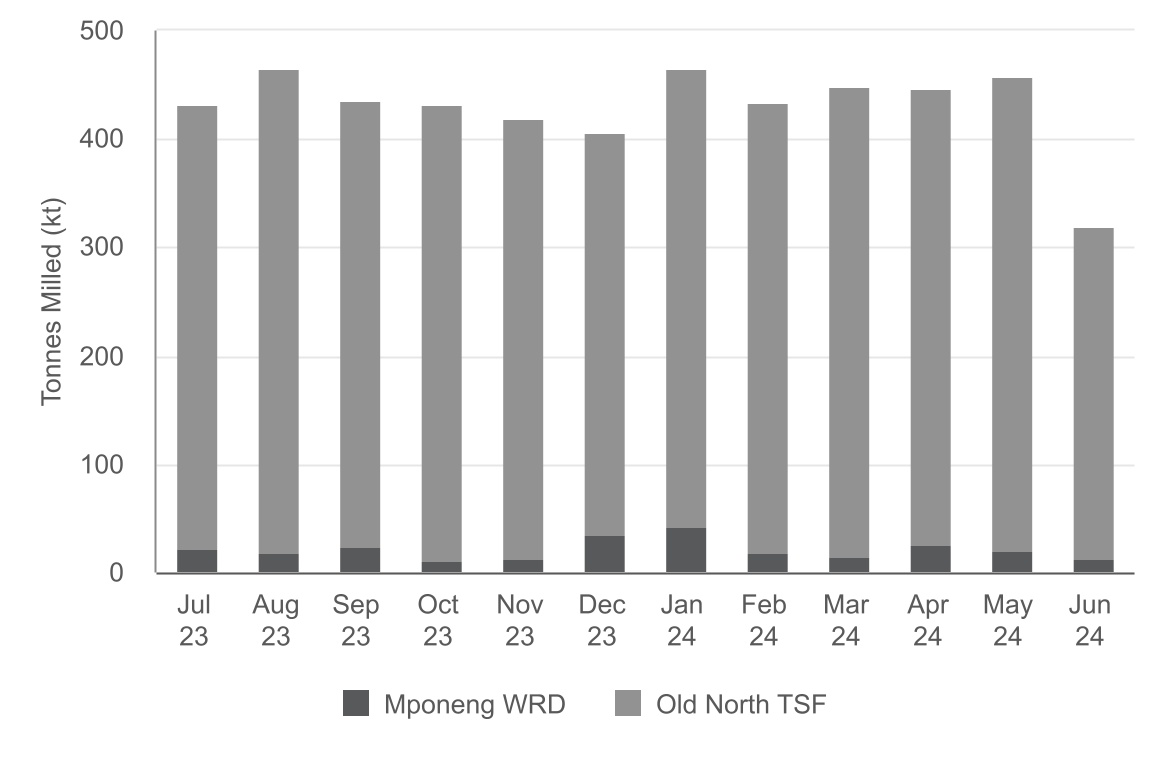

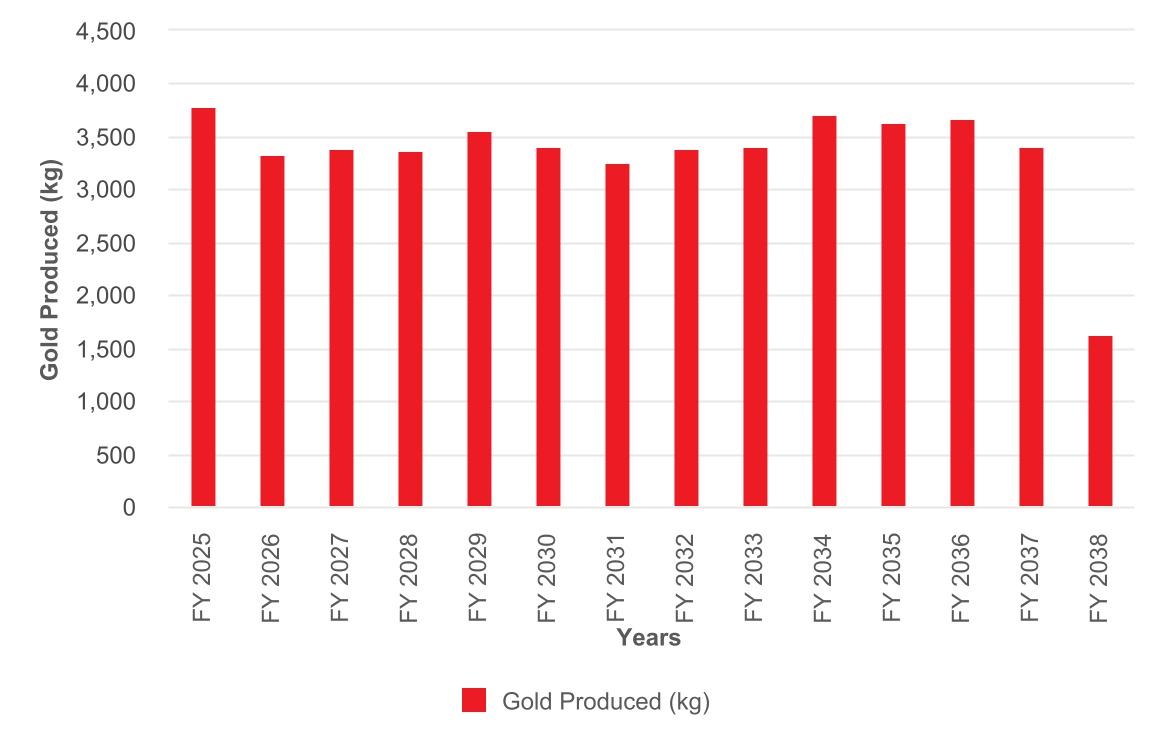

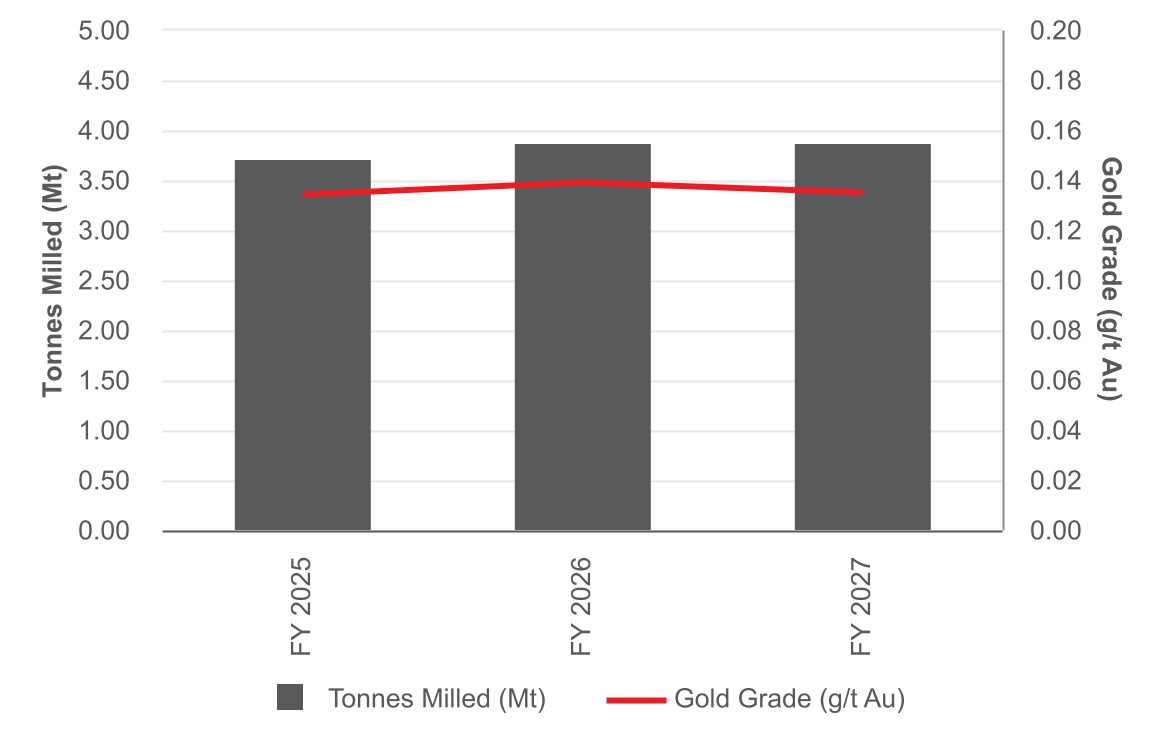

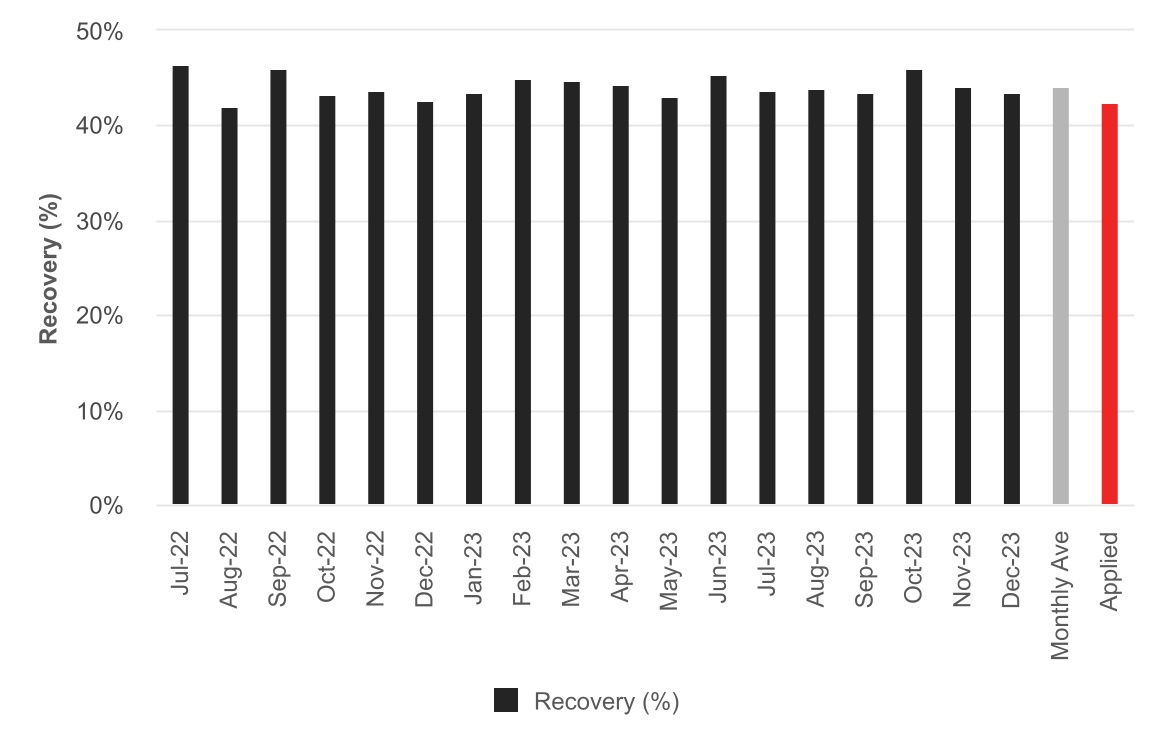

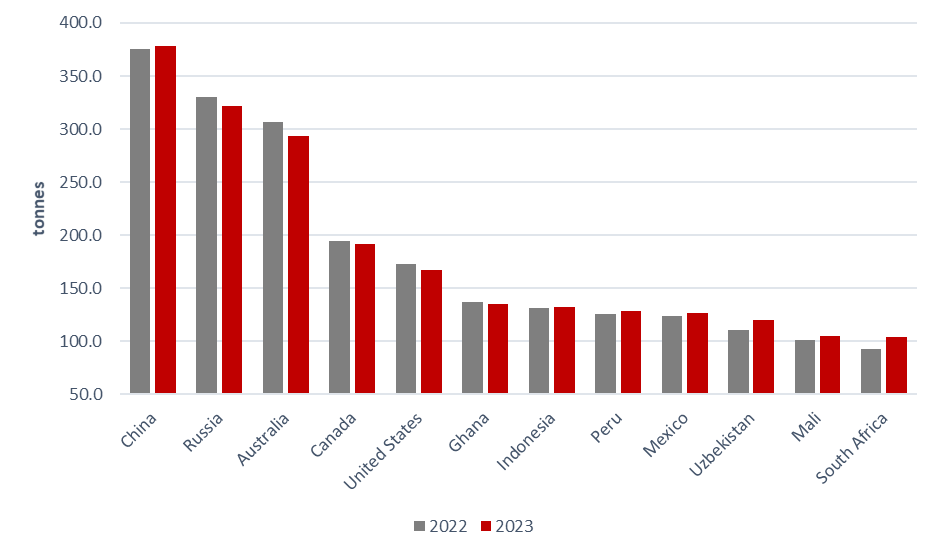

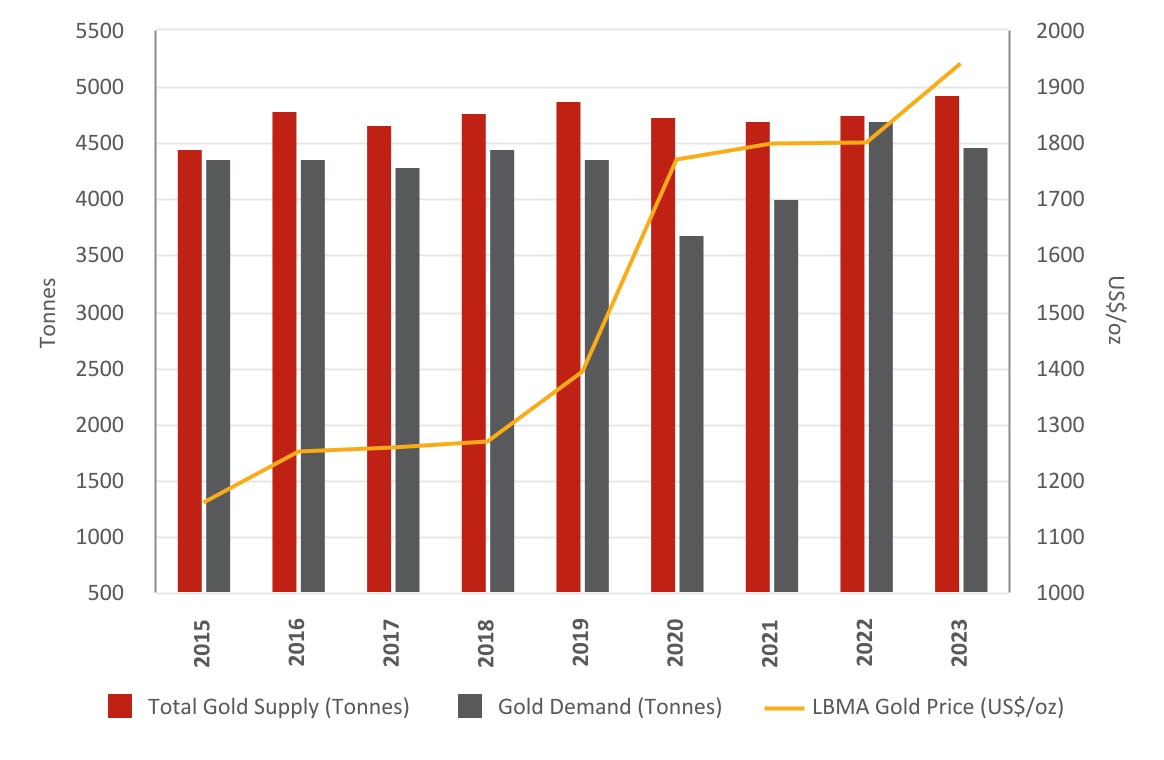

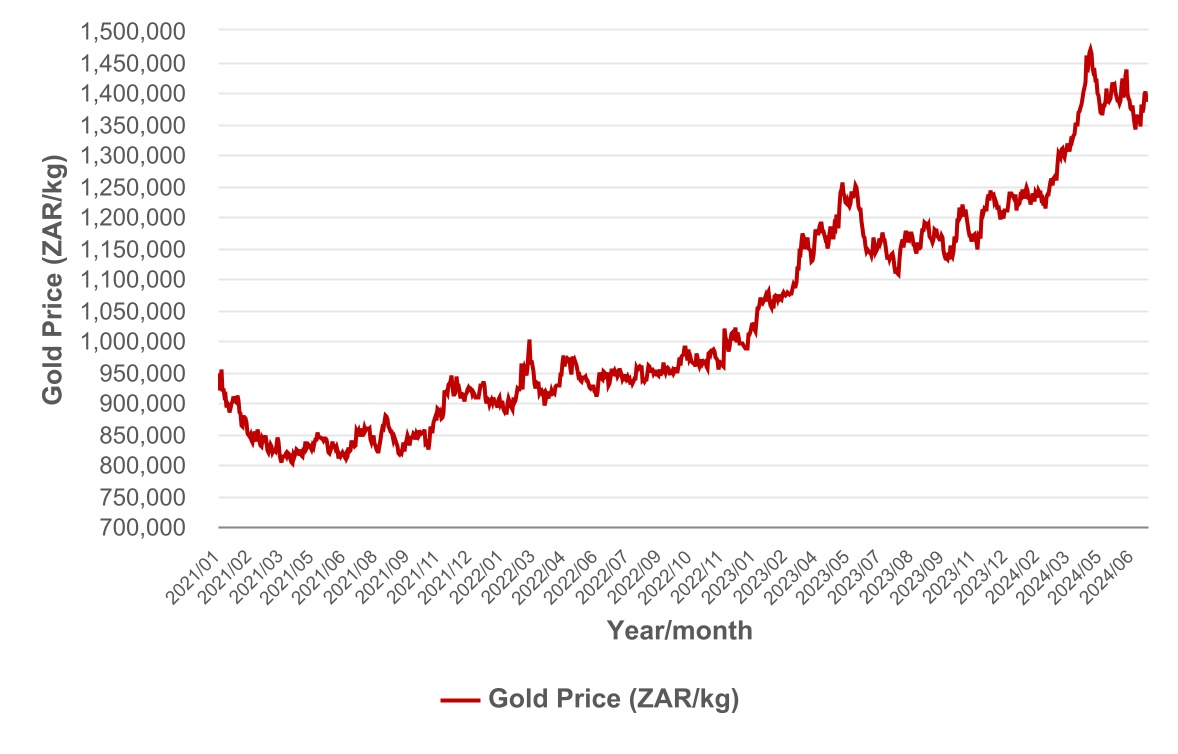

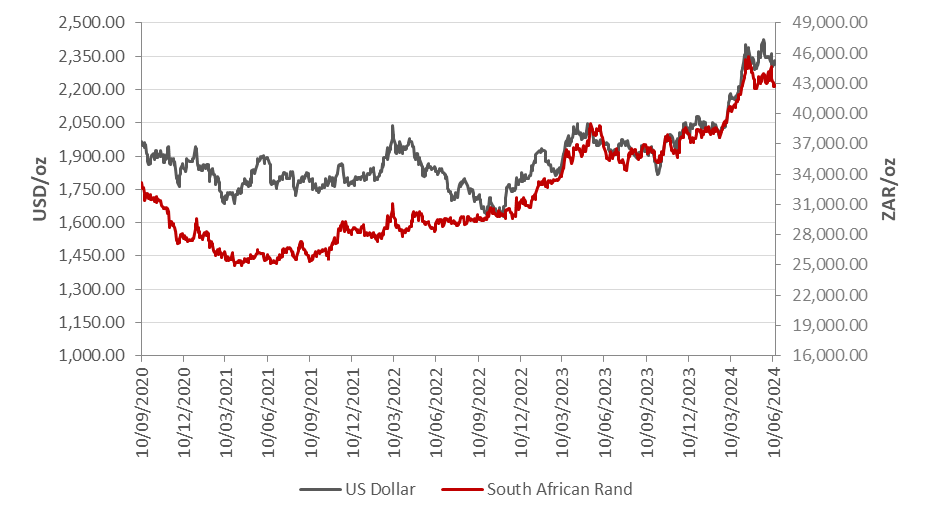

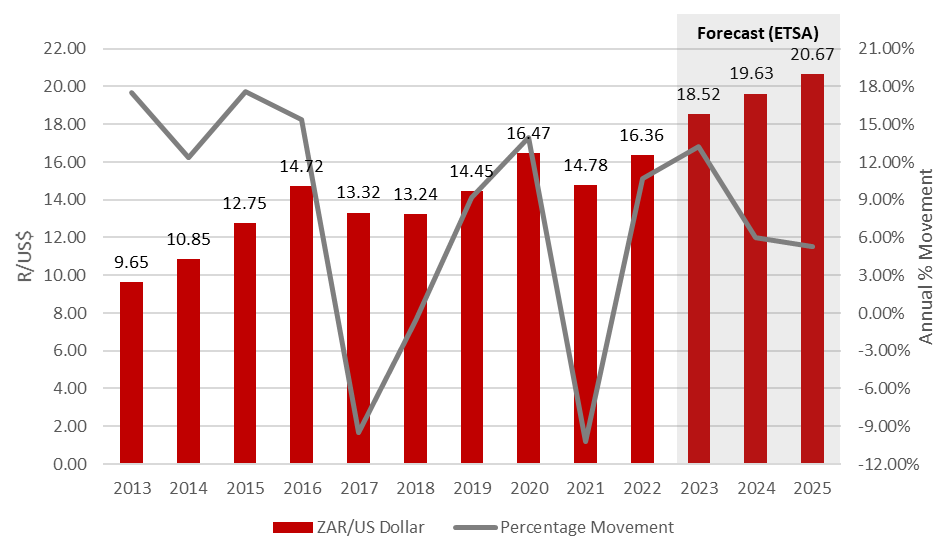

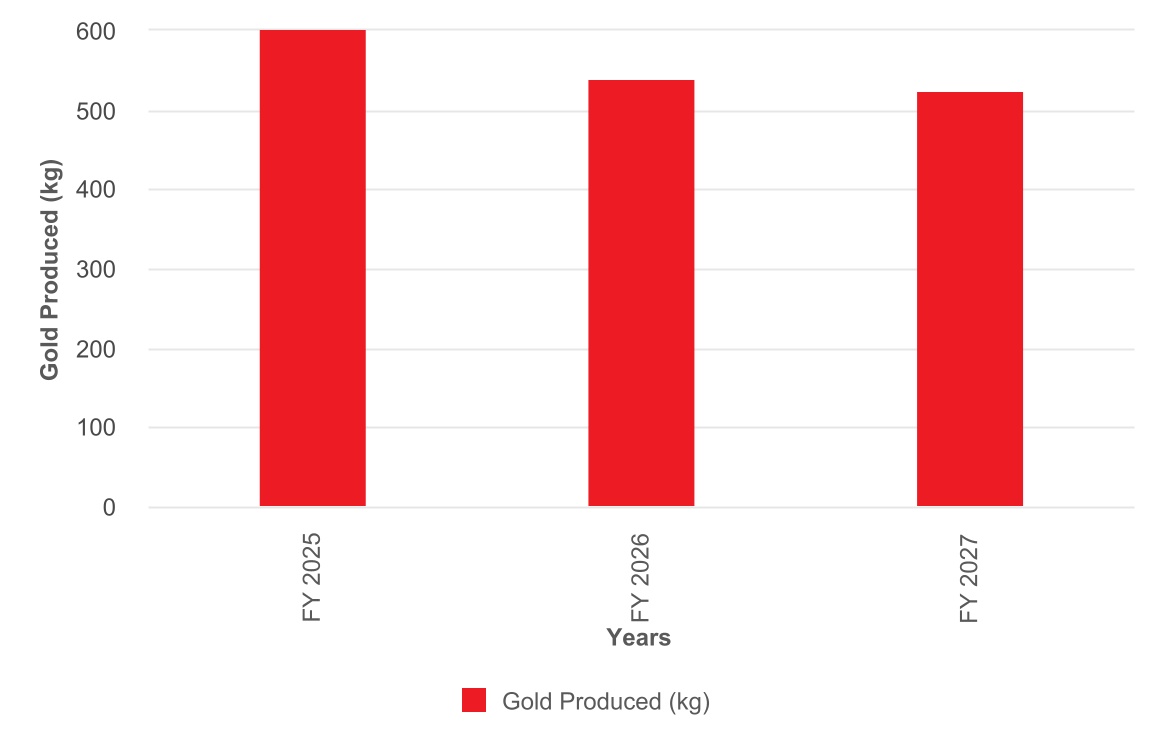

| IMPERIAL |