Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20541

FORM 10-K

x | | ANNUAL REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended October 31, 2008

o | | TRANSITION REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission file number: 000-32531

NOVA BIOSOURCE FUELS, INC.

(Exact name of registrant in its charter)

Nevada

(State or other jurisdiction

of incorporation or organization) | | 91-2028450

(I.R.S. Employer

Identification No.) |

| | |

109 North Post Oak Lane, Suite 422, Houston, Texas

(Address of principal executive offices) | | 77024

(Zip Code) |

(713) 869-6682

(Registrant’s Telephone Number, Including Area Code)

Securities registered under Section 12(b) of the Exchange Act:

Title of Each Class | | Name of Each Exchange On Which Registered |

Common Stock, $0.001 par value | | American Stock Exchange |

Securities registered under Section 12(g) of the Exchange Act:

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes o No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

Yes o No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definitions of large accelerated filer, accelerated filer and smaller reporting company in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer o | | Accelerated filer x |

Non-accelerated filer o (do not check if a smaller reporting company) | | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes o No x

As of April 30, 2008, the aggregate market value of the voting and non-voting common equity held by non-affiliates was approximately $93,388,000 based on the closing price as reported on the American Stock Exchange.

As of January 15, 2009, there were 110,047,996 shares of the registrant’s common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s definitive proxy statement for the 2009 annual meeting of stockholders are incorporated herein by reference in Part III.

Table of Contents

Nova Biosource Fuels, Inc. and Subsidiaries

Annual Report on Form 10-K for the Year Ended October 31, 2008

Table of Contents

i

Table of Contents

Basis of Presentation

In this Annual Report on Form 10-K, the terms “Nova,” “the Company,” “we,” “our” and “us” refer to Nova Biosource Fuels, Inc., a Nevada corporation, and its subsidiaries on a consolidated basis. The term “Nova Biosource Fuels” refers to Nova Biosource Fuels, Inc. on a stand alone basis only, and not its subsidiaries. The term “Nova Oil” refers to Nova Oil, Inc. prior to the share exchange with Biosource America, Inc. on March 31, 2006. Nova Oil, Inc. changed its name to Nova Biosource Fuels, Inc. on September 12, 2006.

Market and Industry Data and Forecasts

This document includes industry data and forecasts that the Company has prepared based, in part, upon information obtained from industry publications and surveys and internal company surveys. Third-party industry publications and surveys and forecasts generally state that the information contained therein has been obtained from sources believed to be reliable, but do not guarantee the accuracy and completeness of such information. In particular, we have based much of our discussion of the biodiesel industry, including government regulation relevant to the industry and forecasted growth in demand, on information published by the National Biodiesel Board, the national trade association for the U.S. biodiesel industry. Because the National Biodiesel Board is a trade organization for the U.S. biodiesel industry, it may present information in a manner that is more favorable to the industry than would be presented by an independent source. Forecasts are particularly likely to be inaccurate, especially over long periods of time.

The industry standard ASTM D6751 refers to the product specifications and quality standards published by the American Society of Testing and Materials, or ASTM, for biodiesel (B100) fuel blend stock for middle distillate fuels. It is used to control pure biodiesel (B100) quality prior to blending with conventional diesel type fuels. ASTM D6751 is mandated in the Energy Independence and Security Act of 2007. The U.S. Environmental Protection Agency also requires that all biodiesel intended for use as a fuel meet the ASTM D6751 standard.

Forward-Looking Statements

This report contains forward-looking statements. These forward-looking statements relate to our outlook or expectations for earnings, revenues, expenses, future financial or business performance, plans, goals, strategies, intent, beliefs or current expectations. Specifically, forward looking statements may include statements preceded by, followed by or that include the words: “believe,” “plan,” “intend,” “anticipate,” “target,” “estimate,” “expect,” “project,” “forecast” and the like, or future-tense or conditional constructions (“will,” “may,” “could,” “should,” etc.). Statements contemplating or making assumptions about actual or potential future sales, economic performance, financial condition, business prospects, feedstock costs, product sales prices, revenue, income, market size, refinery construction, testing, completion and production schedules, collaborations, and trends or operating results also constitute forward-looking statements.

Although these forward-looking statements reflect the good faith judgment of management based on currently available information, forward-looking statements involve a number of risks and uncertainties that may cause actual results to be materially different from those discussed in these forward-looking statements. Some of the factors, risks and uncertainties that could cause actual results to differ include general economic conditions, availability of financing on economic terms, cost and availability of feedstocks, engineering and construction delays, adverse weather conditions, wholesale and retail prices of petroleum-based diesel fuels, consumer acceptance of biodiesel derived from animal fats, competitive rate fluctuations, continued government mandates and incentives for the use of alternative fuels and audits or tax assessments of various federal, state or local taxing authorities, including the Internal Revenue Service, the risk factors listed under “Part I, Item 1A. Risk Factors” and other risks referenced from time to time in our SEC filings.

The forward looking statements are made pursuant to safe harbor provisions of the Private Securities Litigation Reform Act of 1995. You are urged not to place undue reliance on these forward-looking statements, which speak only as of the date of this report. We assume no obligation to update any forward-looking statements in order to reflect any event or circumstance that may arise after the date of this report, other than as may be required by applicable law or regulation. You are urged to carefully review and consider the various disclosures that we make in our reports filed with the SEC which attempt to advise interested parties of the risks and factors that may affect our business, financial condition, results of operations and cash flows. If one or more of these risks or uncertainties materialize, or if the underlying assumptions prove incorrect, our actual results may vary materially from those expected or projected.

1

Table of Contents

ITEM 1. BUSINESS

Overview

We are an energy company that refines and markets ASTM D6751 biodiesel and related co-products from a variety of feedstocks, such as animal-derived fats, vegetable-based oils and greases. Our strategy is to profitably use our patented, proprietary biodiesel technology and become the industry leader in the production of biodiesel. Biodiesel is a clean burning, biodegradable and renewable fuel made from a variety of feedstocks, such as animal-derived fats, oils and greases and vegetable-based oils. Biodiesel is typically blended with petroleum diesel to create a biodiesel blend that is nearly indistinguishable from, and in some respects superior to, 100% petroleum diesel.

We currently own three fully continuous flow biodiesel refineries. Our largest full scale refinery is located in Seneca, Illinois and has an annual biodiesel production capacity of 60,000,000 gallons per year. Our second full scale refinery is located in Clinton County, Iowa and has an annual biodiesel production capacity of 10,000,000 gallons per year. Our third is a smaller scale biodiesel refinery in Butte, Montana, which we use primarily for research, development and technology demonstration purposes.

We believe our technology allows us to process over 25 different animal-derived fats, oils and greases and vegetable-based oils with free fatty acid levels in excess of 20% to produce our two primary marketable products: ASTM D6751 quality biodiesel and technical grade glycerin. Our ability to process a wide range of feedstocks, including single feedstock or blends of feedstocks, such as animal-derived feedstocks with higher free fatty acid content, gives us a significant cost advantage because many of these feedstocks are residual by-products that have limited alternative uses. Many of our competitors are limited to a more narrow range of feedstocks and, in many instances, their feedstock options are limited to vegetable-based oils, and they have little or no ability to economically process meaningful amounts of lower cost animal-based feedstocks.

Our Seneca, Illinois refinery is designed to have production capacity of 60,000,000 gallons per year. It began start-up operations in March 2008. We have entered into feedstock supply and biodiesel sale agreements for the requirements of this refinery. The Clinton County, Iowa refinery is designed to have a production capacity of 10,000,000 gallons per year. It began start-up operations in May 2006, and we purchased the refinery in September 2007. It suffered a casualty in late September 2008, although repairs have been completed with re-start expected to commence in late January or early February 2009.

We are also in the process of developing two additional biodiesel refineries for our own use. We are evaluating potential sites for these additional refineries, engineering and permitting process and have purchased and fabricated certain long-lead time process equipment, which are ready to be installed upon completion of site selection and preparation subject to obtaining sufficient debt and equity financing to support construction, start-up and working capital requirements. The equipment would be the primary equipment for additional capacity of 120,000,000 gallons per year.

Our initial focus was to design and build biodiesel refineries for third parties while we transitioned to our primary business plan of building and operating our own refineries. We have finished this initial phase of our business plan with the completion of the design, construction and startup of three full scale biodiesel refineries for third parties. The first refinery was the Clinton County refinery (which we purchased from the owner in September 2007). The second refinery was completed near DeForest, Wisconsin for Sanimax Energy, Inc. in October 2007 and has a production capacity of 20,000,000 gallons per year. The last such refinery was built in Greenville, Mississippi for Scott Petroleum Corporation and has a production capacity of 20,000,000 gallons per year. Biodiesel production was achieved at the refinery’s full rated capacity in February 2008. We had previously executed an agreement with Scott for the right to buy 50% of this facility’s production over an initial ten year period at approximately the production cost, excluding plant depreciation. We were required to pay a tolling fee and other costs to secure the right to purchase this production capacity. The agreement commenced in September 2008, and, as of October 31, 2008, we had paid approximately $3,390,000 in tolling fees and other costs and had purchased approximately 221,000 gallons of biodiesel related to this agreement. However, in October 2008, we disputed the calculation of the purchase price of the biodiesel and ultimately refused to take delivery of any additional product. As a result, Scott exercised their right to request a termination of the agreement, and we accepted the request, which relieved us of any further obligations related to the agreement.

The financial information set forth in Item 6 Selected Financial Data and Item 8 Financial Statements and Supplementary Data are incorporated by reference into this Item 1 Business.

2

Table of Contents

Biodiesel Industry Overview

Biodiesel is a clean burning, biodegradable and renewable, natural fuel composed of mono-alkyl esters of long chain fatty acids derived from vegetable oils, animal fats and recycled cooking oils. If produced from soybean oil, it may be referred to as soy methyl esters, or SME. If produced from animal fats, oils or greases, it may be referred to as fatty acid methyl esters, or FAME. Biodiesel is typically blended with petroleum diesel to create a biodiesel blend that is nearly indistinguishable from, and in some respects superior to, 100% petroleum diesel. In addition, 100% biodiesel fuel, or B100, can be used in all compression-ignition (diesel) engines without modifications, which some end users use in environmentally sensitive areas and for large fleets of diesel powered vehicles.

In Illinois, the principal market for our flagship refinery, the majority of the consumption will likely be a blend of 11% biodiesel and 89% petroleum diesel, or B11, due to state tax incentives, although a B5 blend of 5% biodiesel and 95% petroleum diesel is also common in the U.S. and is the most common blend in Europe and Australia. Currently, the key markets in the U.S. for biodiesel and biodiesel blends are diesel blending facilities and distributors, government fleets, mass transit vehicles, commercial fleets and marine fleets, as well as for general use in environmentally sensitive areas. One example of government fleet use is the Portland Water Bureau, which, since 2006, uses a B99 blend (99% biodiesel, 1% petroleum diesel) in its city-owned, diesel-powered vehicles and equipment from spring through fall and a B50 blend (50% biodiesel, 50% petroleum diesel) in the winter.

The biodiesel market has grown significantly over the past several years with most consumption concentrated in the federal, state and local government. According to the National Biodiesel Board, U.S. biodiesel production was approximately 15,000,000 gallons in 2002 and U.S. production has grown to an estimated 690,000,000 gallons in 2008. By comparison, the European biodiesel market is more mature than the U.S. market, having consumed approximately 1 billion gallons of biodiesel in 2005.

Drivers of the biodiesel market include:

· Beneficial government initiatives and incentives. Initiatives and incentives at the federal, state and local government levels enhance the economics and market demand for biodiesel production. These initiatives include tax credits as well as mandates for increased use of biodiesel and biodiesel blends.

· Environmental benefits. Biodiesel is biodegradable, nontoxic and essentially free of sulfur and aromatics. Additionally, biodiesel reduces tailpipe exhaust emissions, greenhouse gas emissions and sulfur dioxide emissions (acid rain) and minimizes black smoke and smog-causing particulate matter.

· Easy integration into existing infrastructure. As discussed above, biodiesel can be used in diesel engines with no modifications as B100 or mixed with petroleum diesel, such as the B11 and B5 blends. A blended biodiesel may enhance petroleum diesel because it has the ability to extend engine life and decrease operating expenses due to the increase in engine lubricity.

· Increased energy security. U.S. domestic oil production has continuously declined while demand has grown since the mid-1980s, increasing dramatically our nation’s import requirements. Use of biodiesel, which can be produced with a variety of feedstocks from both domestic and worldwide sources, can help reduce dependence on imported oil. Many of these feedstocks are normally unfit for human consumption.

3

Table of Contents

· Imbalance of supply and demand. We believe that the biodiesel industry lacks sufficient capacity for production of high quality B100 to meet current and anticipated demand for biodiesel. The United States consumes over 60 billion gallons per year of petrodiesel based on 2006 volumes reported by the Energy Information Administration for No. 1 and No. 2 diesel and fuel oils. Therefore, a mandated blend as low as B5 would require 3 billion gallons of biodiesel production per year. The National Biodiesel Board reports that only 690,000,000 gallons of biodiesel were produced in the United States in 2008 (see chart above), even though 176 biodiesel refineries were operational as of September 29, 2008 with a reported capacity of approximately 2.61 billion gallons per year.

Biodiesel Refining Process, Quality Standards and Feedstocks

Refining Process.

Biodiesel is produced through a process called transesterification, which was first conducted using vegetable oil in 1853. Transesterification involves reacting organically-derived fats, oils and greases with an alcohol, typically methanol, in the presence of a base catalyst, typically sodium or potassium hydroxide (common caustic potash), to form methyl esters, or biodiesel, and glycerin.

Traditional Process. The traditional process typically requires feedstock (frequently soybean oil) with a free fatty acid content of less than 2% because the presence of higher free fatty acid content during the transesterification process can produce soap, which can prevent the separation of the biodiesel from the glycerin resulting in yield losses and higher production costs.

For this reason, using high free fatty acid feedstocks in the traditional process requires a pretreatment step, consisting of either a steam stripping process to remove the free fatty acids or an acid esterification process to reduce the feedstock’s free fatty acids through a chemical reaction that uses acids, such as sulphuric or hydrochloric acid, which are later removed after transesterification using a water wash process.

The traditional process then incorporates a settling or centrifugation process or desiccant drying media to reduce the water content of the biodiesel, while the glycerin mixture undergoes a separate process to remove methanol and to produce a crude glycerin of less than 90% purity. While the normal feedstock to biodiesel input-output ratio is approximately 8 to 9 pounds of feedstock for every one gallon of biodiesel produced, the use of greater than 2% free fatty acid feedstocks in the traditional method reduces the amount of biodiesel yield considerably due to the increased need for the acid esterification or steam stripping processes and the subsequent acid neutralization and co-product removal process. The entire process typically takes approximately 40 hours per batch produced.

Innovation. Nova’s technology and continuous refining processes are fundamentally different from the traditional batch processes.

Quality Standards.

In the U.S., biodiesel quality is measured by ASTM Standard D6751, which specifies the required properties of B100 biodiesel for use as a blend component with petroleum diesel fuel oils. This standard specifies, among other qualities, maximum amounts of free glycerin, total glycerin, water and sediment content, monoglycerides, sulfated ash, total sulfur, copper corrosivity, carbon residue and, magnesium, calcium, sodium and phosphorous. The standard also specifies minimum flash point and cetane numbers. The ASTM recently revised the standard to include cold soak filtration specifications. The cold soak filtration test subjects the biodiesel to a soak period at cold temperatures, re-warms the fuel, and then filters the biodiesel through 0.7 micron filter. The test is a qualitative evaluation meant to replicate performance of the biodiesel in cold climates. Compliance with these standards requires a process that provides for complete transesterification and efficient and thorough separation and purification processes.

In October 2008, ASTM International, published the biodiesel blend specifications for general use. The new blend specifications included:

· ASTM D975-08a, Specification for Diesel Fuel Oils — used for on- and off-road diesel applications; revised to include requirements for up to 5 percent biodiesel.

4

Table of Contents

· ASTM D396-08b, Specification for Fuel Oils — used for home heating and boiler applications; revised to include requirements for up to 5 percent biodiesel.

· ASTM D7467-08, Specification for Diesel Fuel Oil, Biodiesel Blend (B6 to 20) — a completely new specification that covers finished fuel blends of between 6 (B6) and 20 (B20) percent biodiesel for on- and off-road diesel engine use.

The majority of Original Equipment Manufacturers (OEMs) viewed the adoption of the ASTM blended fuel specification as a key component for full, universal acceptance of B20. Several OEMs had requested this specification for years, and having it in place makes way for increased usage. Even before the recent revisions, hundreds of major fleets are using B20 biodiesel, including all branches of the U.S. military for administrative uses and more than 200 school districts. The blended fuel specification Biodiesel blends are available to the public at more than 1,250 retail filling stations nationwide.

Coupled with the ASTM quality requirements, the U.S. biodiesel industry’s BQ-9000 program ensures organizations have sound quality management systems in place. Nova’s Seneca refinery recently obtained its BQ-9000 Producer accreditation.

Biodiesel

The price of refined ASTM D6751 biodiesel is primarily related to the price of petroleum diesel. As a result, the profitability of biodiesel production is largely determined by the difference between the cost of feedstocks, which are agricultural commodities not correlated to the price of petroleum diesel, and the price for refined ASTM D6751 biodiesel, which typically sells at a premium to petroleum diesel due to governmental mandates and incentives for use of biodiesel, as well as environmental factors and other market drivers, although during winter months higher cloud point biodiesel typically sells at a greater discount to low cloud point biodiesel and may in some cases even sell at a slight discount to petroleum diesel. We believe that implementation of the cold soak filtration specification, increasing interest by customers to have low levels of mono-glycerides in biodiesel, and increased customer consumer use of and experience with Nova-quality, distilled biodiesel will help reduce the price disparity.

2008 B100 versus Diesel Price

Source: Jacobsen Commentary and Market News Bulletin January 2009

B100 Midwest vs Diesel

Weekly Average Wholesale Prices

Feedstocks

Biodiesel production costs are highly dependent on feedstock costs. Typically, the costs of fats, oils or greases used to make biodiesel are approximately 70% to 80% of the finished product cost. To produce biodiesel profitability, a biodiesel refiner must have a process that can efficiently convert low-cost feedstock into high quality B100. Suitable feedstocks for

5

Table of Contents

biodiesel production include vegetable oils, animal fats and recycled cooking oils and greases. According to U.S. Department of Agricultural statistics, in 2007, 23.2 billion pounds of vegetable oils, 6.9 billion pounds of edible and inedible tallow, pork and poultry fat and 2.6 billion pounds of yellow and other greases were produced in the U.S. These are the most commonly available feedstocks that are produced in the U.S. and economically available for biodiesel production. Therefore, we estimate that the total available feedstock supply in the U.S. is 32.7 billion pounds, although most of the edible feedstocks would be used for human and animal consumption and could not be used economically for biodiesel production.

Animal Fats. Animal fats used for biodiesel production include edible fats, such as tallow and choice white grease with a free fatty acid content of up to 0.8%, inedible fats with a free fatty acid content of up to 10%, and fish oil, poultry fats and other fats and lards with higher free fatty acid content. Our business plan is to focus on the use of as high an amount of inedible animal fats as possible in order to lower the average cost of our feedstocks and seek to avoid competition with feedstocks suitable for human consumption. Biodiesel produced from animal fats tends to have a higher cloud point than biodiesel produced from soybean oil or corn oil.

Vegetable Oils. Vegetable oils used for biodiesel production include soybean (the most commonly used biodiesel feedstock in the U.S.), palm, rapeseed or canola (the most commonly used biodiesel feedstock in Europe), corn, camelina, cottonseed, groundnut, sunflower, coconut, olive, castor, sesame and linseed oils. Soybean oil is the primary feedstock for over 95% of biodiesel produced by traditional processes in the U.S. Soybean oil can be obtained in various grades with a free fatty acid content of approximately 1% or less. Corn oil extracted from dried distiller’s grains, a byproduct of the ethanol production process, can have a free fatty acid content of between 1% to 10%.

Second Use Oils and Greases. Second use oils and greases used for biodiesel production include yellow grease with a free fatty acid content of up to 15% and brown grease with a free fatty acid content of greater than 15%, although these feedstocks tend to be in more limited supply than animal fats and vegetable oils. Recent changes to the biodiesel blenders excise tax credit have eliminated the disparity in government incentives between second use feedstocks and virgin feedstocks.

Feedstock Costs. The costs of the various feedstocks depend largely on whether the feedstock may be used in the food market. The graph below shows a higher price associated with a vegetable oil used in the food market vs other inedible fats and greases. Similar to several other commodities, animal fats and vegetable oil pricing experienced significant volatility over the last twelve months. Soybean oil (RBD) ranged in pricing from over $0.72/lb to $0.33/lb, versus a prior 15 year average price of approximately $0.22/lb. Similarly, inedible tallow ranged in pricing from over $0.50/lb to $0.11/lb versus a historical average price of approximately $0.16 per pound. We believe that there are a variety of market factors responsible for the volatility, which are unrelated to the production of biodiesel.

2008 Feedstock Prices

Source: Jacobsen Commentary and Market News Bulletin January 2009 and Energy Information Administration

SBO (RBD), BFT, CWG, SPF and YG

Weekly Average Wholesale Prices

6

Table of Contents

Government Incentives

In the interest of environmental protection and energy security, federal, state and local governments have enacted a variety of incentives and mandates to promote the production and use of biodiesel. These incentives and mandates generally have three approaches:

· To lower the effective cost of biodiesel in order to make it more price competitive with petroleum diesel, primarily through tax credits, rebates and deductions;

· To increase the use of biodiesel through mandates, such as requirements for use of a biodiesel blend for certain government fleets or requiring a certain percentage of sales to consist of a biodiesel blend; and

· To encourage investments in production and distribution capacity, as well as technology to promote end use of biodiesel, through tax credits, rebates and deductions, grants for construction or purchase of new equipment or government loan guarantees.

Tax Incentives. The primary federal government incentive intended to lower the effective cost of biodiesel is the biodiesel blenders excise tax credit, which is available to registered blenders of biodiesel and petroleum diesel. As an independent biodiesel producer, we do not currently have blending operations and, accordingly, are not a direct recipient of the tax credit, but only receive the benefits of the tax credit indirectly through improved pricing of biodiesel. The tax credit is currently set to expire on December 31, 2009. Due to recent Congressional action signed into law in October 2008, all biodiesel fuel, regardless of feedstock source, now qualifies for the $1.00 per gallon biodiesel incentive as of January 1, 2009. Under the past legislation, biodiesel produced from second use, or non-virgin, feedstocks, such as yellow grease collected from restaurants, was only eligible for a $0.50 per gallon tax incentive. Additionally, the new legislation closes the so-called “splash and dash” loophole, which allowed foreign-produced biodiesel to be sent to the U.S., splash blended to claim the tax incentive, and then shipped to a third country for final use. In December 2007, the Energy Independence and Security Act of 2007 established a renewable fuels standard for biodiesel use in the United States of one billion gallons by 2012.

In addition to the federal biodiesel blenders tax credit, various states, such as Arkansas, Illinois, Iowa, Idaho, Kansas, Kentucky, Maryland, Montana, North Dakota, Oklahoma, Rhode Island, South Carolina, South Dakota and Washington, also provide for tax credits, rebates, deductions or reduced state, excise or other taxes for the blending or sale of biodiesel within their states.

Use Mandates. A number of federal and state regulations mandate the use of biodiesel blends. The Energy Independence and Security Act of 2007 requires a 36 billion gallons per year renewable fuels standard (RFS) by 2022, to be administered by the U.S. Environmental Protection Agency. The new RFS begins in 2008 and requires 9 billion gallons of biofuels to be used in 2008 and 11 billion gallons in the following year. The RFS contains three sub-levels:

· 21 billion gallons of the overall 36 billion gallons mandate are to be “advanced biofuels” (defined as cellulosic ethanol, ethanol derived from sugar or starch, biogas, biomass-based diesel, butanol or other alcohols and other fuel derived from cellulosic biomass) by 2022;

· 16 billion gallons of that amount, under the same timeframe, are to come from cellulosic biofuel; and

· 1 billion gallons by 2012 are required to be from biomass-based diesel.

In addition to the federal government, a number of states have mandated state-owned vehicles to reduce petroleum diesel usage through the use of biodiesel blends. For example:

· Illinois has required all state- or city-owned diesel-powered vehicles to use a biodiesel blend containing at least 2% biodiesel (B2);

· Minnesota is targeting a 10% and 25% reduction in petroleum diesel use by 2010 and 2015, respectively, through the purchase of vehicles that use B20 to B100 blends; and

· New Mexico has mandated all cabinet-level agencies, public schools and institutions of higher learning to obtain 15% of their transportation fuel requirements from renewable fuels, including biodiesel, by 2010.

7

Table of Contents

Capital Investment Incentives. Federal and state governments have also passed laws encouraging capital investments to support production, distribution and use of biodiesel and other renewable fuels. For example, through 2010, fueling stations are eligible for a 30% federal tax credit for the cost of installing clean-fuel refueling equipment, including any B20 or greater biodiesel blend. In Louisiana, property and equipment used in the manufacture, production or extraction of biodiesel, as well as biodiesel used as fuel by a registered manufacturer are exempt from state sales and use taxes. Louisiana has also established an income tax credit equal to 20% of the cost of constructing an alternative fuel refueling station, as well as 20% of the cost of converting a vehicle to run on alternative fuels, or of the incremental cost to purchase a new alternative fuel vehicle.

Our Competitive Strengths

We believe that our patented, proprietary technology, clearly defined growth plan and experienced management team will combine to provide us with the following competitive strengths:

· Patented, proprietary technology consistently produces high quality biodiesel with minimal waste in a continuous process. Our patented, proprietary technology produces biodiesel that consistently exceeds current ASTM D6751 specifications. In addition, our process does not generate significant amounts of toxic or hazardous byproducts that are often found in alternative processes. The principal byproduct generated in our production process is technical grade glycerin with additional byproducts consisting of crude glycerin, a biodiesel “bottoms,” which can be used as a burner fuel, and a “sweetwater” product, which can be used as fertilizer for crop irrigation. Each of the co-products can be sold to reduce our net biodiesel processing costs. Based upon our experiences to date, the minimal environmental impact of our facilities has resulted in faster facility permitting.

· True multi-feedstock technology gives us the ability to use lower-cost feedstock. Our production process is able to use over 25 different feedstocks with free fatty acid levels in excess of 20%, thereby allowing us to use the lowest cost feedstock available at any given time in any given market. Our process can use at any one time a single feedstock, a blend of feedstocks or multiple feedstocks without modification to the process equipment. Because feedstock represents 70 to 80% of biodiesel production costs, the ability to use a variety of potentially cheaper sources, animal fats in particular, dramatically increases our potential profitability and ability to grow.

· Clearly defined growth plan based on proven technology. Based on data from the small scale refinery in Butte, Montana, from two years of operation and production from the full scale, 10,000,000 gallons per year Clinton County, Iowa refinery, from nearly two years of operation and production from the 20,000,000 gallons per year Sanimax refinery in DeForest, Wisconsin, from nearly a year of operation and production from the 20,000,000 gallons per year Scott refinery in Greenville, Mississippi, and, most importantly, from the start-up and operation of our 60,000,000 gallons per year flagship refinery in Seneca, Illinois, our technology has been shown to be operationally viable, which has laid the framework for future expansion.

· Our decision to construct future refineries using three parallel 20,000,000 gallons per year “trains” producing side-by-side has been very effective. By standardizing and modularizing the production units, we dramatically reduced construction and design risk and compressed construction schedules as evidenced by our completion of the Seneca refinery from ground breaking to mechanical completion in nine months. We intend to employ this same strategy for future potential sites, which we believe will not require significant reengineering or changes in construction methods.

· Strategic relationships with high quality equipment, feedstock and distribution partners. We have positioned ourselves to take advantage of the rapidly growing biodiesel market through agreements with business partners throughout the production process. We have entered into feedstock supply and biodiesel fuel sale agreements with affiliates of Kaluzny Brothers, Inc. (Lipid Logistics, LLC) and Gavilon, LLC as well as strategic relationships with equipment vendors, construction subcontractors, instrumentation and controls equipment providers, rail and transport companies and a variety of consumable product suppliers for methanol and other chemical commodities.

· Experienced management team. Our management team has extensive operating and finance experience in the energy industry. Our Chairman and CEO, Kenneth T. Hern, served as President of Texaco Saudi, Vice Chairman and Managing Director of Texaco Nigeria and President of Texaco Brazil. Our Chief Financial Officer, Jay Fillman, was a founder and vice president of Illinois River Energy, LLC, a 50,000,000 gallons per year ethanol refinery located in Rochelle, Illinois. He was responsible for all financial aspects of the

8

Table of Contents

development, capital raising, construction and initial operation of the refinery. Our operations executives and senior managers have extensive experience in petrochemical facility construction and refinery operations and have successfully overseen the construction of four full-scale biodiesel refineries in the last two years months. Our Chief Operating Officer, Dick Talley, has led Nova’s research and development, process development, design, construction and startup teams for the past eight years and has overseen similar projects throughout the U.S. during his career. Our Vice President of Marketing, Rusty Sammons, most recently worked for ExxonMobil Refining & Supply, where he supervised planning and controls of refinery system turnarounds and large refinery maintenance projects at ExxonMobil’s largest U.S. refinery.

· In-house development expertise. Our staff engineers began developing our biodiesel technology in 2000 when Charlie Vignieri, the founder of Kenosha Beef International, sponsored the research and development effort to discover a commercially viable process to produce quality biodiesel in a continuous process from high free fatty acid feedstocks, such as animal tallow. This engineering team further developed and demonstrated the process through the construction and operation of the small scale refinery in Butte, Montana. They continue to develop and refine the process. In the process of continually optimizing our proprietary technology and scaling up our production capacity, we have developed significant in-house engineering competence. The Nova technology and in-house engineering and project delivery teams have built and commissioned four refineries in the last two years, bringing the total production capacity of biodiesel refineries using Nova’s process technology to 110,000,000 gallons per year.

Nova Process Technology.

Our biodiesel production technology differs from the traditional biodiesel production process in several important respects. Our technology allows for consistent high quality production of ASTM D6751 standard biodiesel and technical grade glycerin that is 97% pure, the use of lower cost feedstocks, continuous processing and energy recovery, and reduced processing time and reduced environmental discharges. The Nova process incorporates two components: a seamless conversion of high free fatty acid feedstocks, which is incorporated into the Sanimax, Scott and Seneca refineries, and a distillation-based purification and refining process, which is incorporated into all Nova-built biodiesel refineries, including Clinton County. In lieu of the acid esterification or steam stripping pretreatment, the Nova process incorporates a patented, heterogeneous catalytic conversion process that seamlessly and simultaneously reacts free fatty acids and pure triglycerides. After transesterification, we employ a continuous separation process to separate the biodiesel from the glycerin.

The biodiesel then undergoes a purification and refining process to remove excess moisture, glycerin, glycerides and other impurities without using a water wash or dry wash system, while the glycerin is similarly purified and refined to remove methanol, excess moisture and other impurities. A methanol recovery step then purifies the excess methanol for reuse in the transesterification process. The biodiesel purification and refining step also produces a heavy oil, which may be used to supply a portion of the energy needs of the plant as both the biodiesel and glycerin purification and refining processes employ a waste heat recovery system for use in other parts of the process. The entire Nova biodiesel refining process takes approximately twelve hours to complete, compared to forty hours using the traditional process.

Nova Biodiesel Quality.

The Nova process results in consistent high quality production of ASTM D6751 standard biodiesel by replacing the traditional water wash system with a distillation system. In testing our small scale refinery in Butte and in commercial operations at all refineries, we have consistently produced biodiesel that exceeds ASTM D6751 specifications. We believe our consistent biodiesel quality will have a positive effect in marketing our biodiesel as our product gains wider recognition and distribution and as the ASTM D6751 standard is strengthened. As a result of our process, our Seneca refinery obtained BQ-9000 certification in January 2009 from the National Biodiesel Accreditation Commission, an independent committee of the National Biodiesel Board, for our quality assurance program. The BQ-9000 Quality Assurance Program for the Biodiesel Industry seeks to promote the commercial success and public acceptance of biodiesel by helping to assure that biodiesel fuel is produced to and maintained at the ASTM D6751 standard on a consistent basis. We believe that our Clinton County refinery will also obtain BQ-9000 certification in due course.

Nova Cost Advantage.

As discussed above, feedstock cost is the primary driver for profitable biodiesel production. Feedstock markets makes up 70% to 80% of the production cost. The ability to use lower cost feedstocks, i.e., feedstocks with high free fatty acid content typically animal-based, without a loss of yield, gives us a competitive advantage over biodiesel refiners that use the traditional process.

9

Table of Contents

The production of technical grade glycerin (refined and 97% pure) also provides an additional pricing advantage when compared to the traditional process that can only produce and sell a crude, or splitter’s grade, glycerin, which is typically only 80% to 90% pure. Recently, the market prices for crude glycerin have ranged from $0.03 to $0.08 per pound while the market prices for technical grade glycerin have ranged from $0.18 to $0.25 per pound. These higher selling prices for this portion of the production enables us to potentially reduce our net biodiesel production costs. Our cost advantage is also enhanced by the waste heat recovery process incorporated into the Nova production system.

Environmental Factors

The Nova process is a completely closed loop system, allowing for the recovery and treatment of vapors and condensable products to provide for odor control and limits on emissions to comply with air quality standards and permit limits. By eliminating the “water wash” step used in traditional processes, the Nova process substantially reduces the amount of waste water and the related water disposal challenges. For example, for a 20,000,000 gallons per year refinery, the traditional process would generate approximately 8,000,000 gallons of waste water. In contrast, the Nova process generates only approximately 140,000 gallons of waste water: a 98.25% reduction in waste water discharge.

Business Strategy

Operation of Biodiesel Refineries.

We have designed our biodiesel refineries, after the first refinery in Clinton County, Iowa, to have a nameplate capacity of 20, 40 or 60,000,000 gallons per year through the construction of either one, two or three 20,000,000 gallons per year “trains” designed to operate in parallel. We believe this design permits us to standardize the engineering of the various vessels, tanks, piping, valves, pumps and motors that comprise a refinery in order to facilitate procurement of the raw materials, equipment and supplies and to provide for modular construction off-site. This approach significantly reduces the construction time of our refineries, and enables standardization of our operating procedures, equipment and spare parts inventories, and permits production from any one train to continue independently of the operational status of an adjacent train.

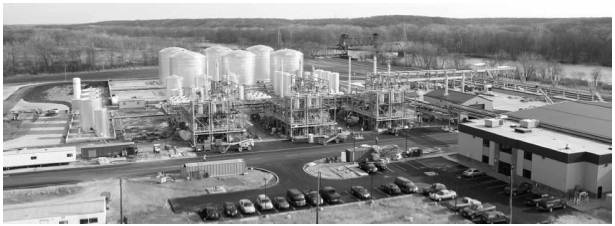

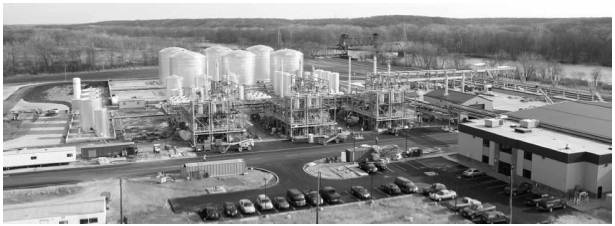

Nova’s Flagship, BQ-9000 Certified 60,000,000 Gallons Per Year Biodiesel Refinery in Seneca, Illinois

In June 2006, we purchased 54 acres of land in the Shipyard Industrial Park of Seneca, Illinois for a purchase price of $3,650,000 and began construction of 60,000,000 gallons per year biodiesel refinery on the property in April of 2007. The Seneca Shipyard Industrial Park, located southwest of Chicago, Illinois, has ready truck, barge and rail access and we have entered into a Redevelopment Agreement with the Village of Seneca with respect to a tax incentive financing district that will provide a $7,000,000 property tax abatement for the construction of infrastructure improvements and related matters. The refinery began start-up operations in March 2008 and was certified as substantially complete in September 2008.

10

Table of Contents

Nova’s 10,000,000 Gallons Per Year Biodiesel Refinery in Clinton, Iowa

In September 2007, we acquired the Clinton County facility and as a result now own and operate this 10,000,000 gallons per year biodiesel refinery. Nova designed and built this biodiesel refinery for its former owners who used soybean oil as the principal feedstock.

As soon as practicable after our refineries are operating profitably with sufficient capital, our objective is to build additional biodiesel refineries in the twelve to eighteen month period thereafter that will have an additional 120,000,000 to 140,000,000 gallons of annual biodiesel production capacity. We currently own certain long-lead time process equipment for such capacity, which are ready to be installed upon completion of site selection, permitting and final plant layout and design efforts. Upon completion of such biodiesel refineries, we will have 190,000,000 to 210,000,000 gallons of annual biodiesel production capacity. Until our two refineries are operating profitably with sufficient capital, however, implementation of our long-term business strategy will consist mostly of planning and financing activities only.

Obtaining Commitments for the Sale of Biodiesel. Because biodiesel can be substituted for petroleum-based diesel or blended with petroleum-based diesel, the market for biodiesel is substantially the same as that of petroleum-based diesel. Both pure biodiesel and the blended product can be sold as a commodity through standard diesel distribution channels or it can be sold directly to large fleet buyers seeking to reduce emissions or dependence on foreign sources of oil. For example, large transportation companies using heavy trucks represent an opportunity for immediate biodiesel sales due to increased government regulations on emissions, established distribution channels and the lack of U.S. biodiesel production.

Also, the U.S. armed forces are currently the nation’s single largest consumer of diesel fuel. We believe there is an opportunity to provide fuel to the military’s existing vehicles, as well as future opportunities because it is expected that new government regulations will require that a high percentage of the Department of Defense’s new vehicles be able to use alternative fuels. The United States Post Office, as well as other government agencies, such as the National Parks Service, are expected in the future to be large consumers of biodiesel blends in their vehicles. In addition, the States of Minnesota and Texas have both passed legislation to increase the use of biodiesel in government vehicles.

We have entered into agreements with Gavilon, LLC to sell and market all of our biodiesel production from our Seneca refinery. We are currently engaged in discussions with various distribution channels and large fleet buyers with respect to selling biodiesel production from our Clinton County refinery and our future refineries.

Securing Feedstock Supply. Because feedstock represents approximately 70% to 80% of biodiesel’s production cost, it is imperative that we are able to acquire raw materials at a reasonable cost in order to be competitive in the marketplace. We have a feedstock supply agreement with Lipid Logistics, LLC for 100% of the Seneca refinery’s requirements. We are currently engaged in negotiations with other large food processing and rendering companies in an effort to obtain commitments for the supply of lower cost feedstock, which we believe would consist largely of feedstocks that are not normally fit for human consumption.

Logistics. The supply of feedstock and the distribution of biodiesel production will require management of a multi-faceted logistical system. Ideal prospective sites for biodiesel refineries include ready truck, rail and barge access near feedstock sources, such as rendering operations, and biodiesel consumption facilities, such as blending facilities or large fleet refueling stations. Biodiesel can be transported by pipeline and locating a refinery near existing refined products pipelines can also facilitate access to distant markets.

11

Table of Contents

We have entered into agreements with Lipid Logistics, LLC to manage the logistics and supply of feedstock and with Gavilon to manage the logistics for the offtake of biodiesel for the Seneca refinery. We have also entered into railcar leases for 125 insulated tank cars to ship biodiesel from the refineries. The leases are for 60 months beginning upon delivery and will be treated as operating leases for accounting purposes. The average rent for each car is approximately $680 per month. The railcars are used as necessary for the logistics requirements for our Clinton County refinery and our Seneca refinery.

Business Partners. In addition to building refineries for our own account, we intend to seek out business partners who are strategically situated to help us with respect to the engineering, construction and operation of biodiesel refineries for our mutual benefit. An example of such a strategic partner might be a supplier of feedstock or consumables or a distributor of diesel fuel who can also provide a portion of the equity or debt financing necessary to obtain project financing for the joint venture’s engineering and construction of a biodiesel refinery, as well as any working capital financing requirements.

Earlier Focus. Since the formation of our engineering and construction subsidiary, Biosource America, Inc., we initially focused on the completion of the construction of three biodiesel refineries for third parties in Clinton County, Iowa, DeForest, Wisconsin and Greenville, Mississippi while validating the technology on a commercial scale and planning for the financing and construction of biodiesel refineries for our own account. We purchased the Clinton County refinery in September 2007. All refineries are now fully operational.

International Expansion. Our long term business strategy includes expanding into international markets. In Europe, concerns over bovine spongiform encephalopathy, or Mad Cow Disease, have led to restrictions on the use of animal tallow in animal feed, resulting in a marked decline in the market prices for tallow. Brazil has long been a world leader in the development and production of alternative fuels, such as ethanol, and there appears to be significant government interest in building a biodiesel infrastructure as well. Accordingly, we are actively seeking business partners for the construction of biodiesel refineries in the U.K., South America and Europe. Further, the Nova process allows for the use of high free fatty acid palm oils that are currently a waste product for palm oil producers in Southeast Asia and Latin America. When coupled with government incentives for the construction of biodiesel refineries in developing countries, we believe there are excellent opportunities for expansion into foreign markets. We intend to continue to evaluate several other international markets and opportunities.

Long-term Strategy and Public Policy. As a nation, the United States has been reluctant to utilize its vast potential resources for the development of domestic sources of oil and gas, in part due to well-considered environmental concerns. Nonetheless, the United States is quickly depleting its petroleum resources to economically satisfy its energy needs, resulting in greater dependence on foreign sources of energy and increasing export of U.S. currency, sometimes known as petrodollars. Looking beyond the domestic energy situation, global oil and gas resources are being consumed at a rate greater than new oil and gas resources are being discovered and developed. For every two barrels being consumed worldwide, one replacement barrel is being developed. To put this in perspective, over 40,000 gallons of oil are being consumed every second and the probability of maintaining this massive demand over the long term is minimal at best.

We, as a company, are committed to earning a healthy return for our shareholders, providing a safe, friendly place to work for our employees and being a good neighbor and citizen. To do this, we will seek to produce large volumes of high quality biodiesel in an ecologically friendly manner.

We will press for school districts and major cities to adopt the use of B100 biodiesel to promote the health and safety of our children and to raise the quality of air in our urban areas. We will press for the use of this clean, biodegradable, nontoxic fuel in diesel powered boats in inland waterways and on ocean liners. And, to the extent available in sufficient quantities on economically viable terms, we will also seek to obtain feedstock not normally fit for human consumption in order to reduce the competition between food and fuel for our agricultural resources. Finally, as our refineries come online, we intend to invest in research to process feedstocks that have a minimal impact on human and animal food sources, such as algae and jatropha, which we hope will help meet the energy demands of future generations who will no longer have easy access to crude oil.

Competition

The National Biodiesel Board reports that, as of September 2008, there were approximately 176 commercial biodiesel refineries in the U.S. with an annual production capacity of approximately 2.61 billion gallons per year. In addition, the National Biodiesel Board reports that, as of September 2008, there were 39 commercial biodiesel refineries under construction and one existing commercial biodiesel refinery undergoing expansion in the U.S. The total additional anticipated annual production capacity of these plants under construction or expansion is approximately 850 million gallons per year.

12

Table of Contents

The biodiesel production market is very dynamic as there are a number of new entrants that may have greater access to capital or low cost feedstock. For example, large international agricultural companies, such as Archer Daniels Midland Corporation, or ADM, and Bunge Limited have begun to build or sponsor biodiesel refineries to take advantage of their access to agricultural feedstock. ADM is already the largest ethanol producer in the United States and has publicly stated an intention to build biodiesel refineries in the United States to complement its ethanol production and to take advantage of its vertically integrated agricultural supply chain. ADM estimates that, as of August 11, 2007, it had 1,600,000 metric tons of biodiesel production capacity worldwide. In addition, major energy companies have expressed an interest in investing in renewable energy projects, including biodiesel. Chevron Corporation, for example, reports that it has spent over $1.5 billion on renewable energy projects since 2000.

While the market for biodiesel may not be constrained by demand given the large volume of consumption of diesel in the United States and worldwide, we may face significant competition for feedstock and capital from these large, vertically integrated competitors, in addition to the other independent entrants into the market.

Intellectual Property

Our main competitive strength derives from the expertise, know-how, production process and refinery technology developed by the engineers we currently employ. We intend to continue research and development into improvements in the Nova process and into the use of alternative feedstocks for the production of biodiesel, such as jatropha and algae. We estimate that since inception on December 1, 2005 we have spent less than $50,000 on research and development. We do not expect our research and development expenses to be borne by potential customers as the price of our biodiesel will be determined primarily by commodity prices at the time of sale.

We protect the intellectual property comprising the Nova process technology through a combination of patents, patent applications, common law copyrights and trade secrets. The first of our patents does not expire until 2023. All of our technical employees enter into confidentiality and invention assignment agreements and, in some cases, non-competition agreements. We also require contractors, vendors, construction customers and others to enter into confidentiality agreements of varying duration prior to being given access to our proprietary information regarding our technology. There can be no assurance, however, that such measures will be adequate to protect our technology.

Employees

As of October 31, 2008, we had approximately 90 full-time equivalent employees. We believe our relations with our employees are good.

Company History

Nova Biosource Fuels, Inc. was originally incorporated under the name Nova Oil, Inc. on February 25, 2000 under the laws of the State of Nevada and was organized primarily for the purpose of acquiring, either alone or with others, interests in developed producing oil and gas leases, with the objective of establishing steady cash flows from operations. As of October 19, 2005, Nova Oil completed the sale of all of its oil and gas well interests. As a result, Nova Oil became a “shell company,” as the term is defined under the Securities Exchange Act of 1934, as amended, because it ceased conventional oil and gas exploration and production operations and shifted its primary activity to seeking merger or acquisition candidates with whom it could either merge or acquire.

Our engineering and construction subsidiary, Biosource America, Inc., was incorporated in Texas on December 1, 2005, which is the date that we use as our date of inception for accounting purposes. On February 10, 2006, Biosource America completed the acquisition of substantially all of the assets of Biosource Fuels, LLC (an independent and non-affiliated company), which had been in the business of engineering, construction and licensing of processes and technologies for the refining of biodiesel and related co-products from animal-derived fats, oils and greases and vegetable-based oils.

On March 31, 2006, Nova Oil completed a share exchange and issued 40,000,000 shares of its common stock in exchange for all of the shares of common stock of Biosource America. As a result of the share exchange, Biosource America became a wholly-owned subsidiary of Nova Oil. A change of control of Nova Oil occurred because the former Biosource America shareholders acquired approximately 86% of the issued and outstanding shares of Nova Oil’s common stock. At that point, Nova Oil ceased being a “shell company” and became an energy company with long-term plans to refine and market standard biodiesel. An additional 23,462,523 shares of common stock were issued on April 24, 2006 as a result of a three for two forward stock split.

13

Table of Contents

For accounting purposes, this transaction was treated as an acquisition of Nova Oil by Biosource America coincident with a recapitalization of Biosource America. The historical financial statements and other information prior to March 31, 2006, unless expressly stated otherwise, are those of Biosource America. In connection with the share exchange, Nova Oil changed its fiscal year end from December 31 to October 31 to conform to the fiscal year end of Biosource America. On September 12, 2006, Nova Oil changed its name to Nova Biosource Fuels, Inc.

Originally, our common stock was quoted on the Over-The-Counter Bulletin Board System under the symbol “NVBF.” On May 9, 2007, the American Stock Exchange approved our listing application to trade our common stock on that exchange. Our common stock started trading on the American Stock Exchange under the symbol “NBF” on May 14, 2007.

In July 2008, we relocated our principal administrative offices from Houston, Texas to Butte, Montana and consolidated our accounting functions. Our Chief Executive Officer and other senior executive officers maintain an executive office in Houston, Texas. Our Chief Financial Officer relocated to our flagship biodiesel refinery in Seneca, Illinois to improve efficiency and reduce administrative costs. The corporate accounting offices were also consolidated in Butte, Montana.

Available Information

Our website address is www.novabiosource.com. We make available, free of charge through the Investor Relations portion of the website, annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the 1934 Act as soon as reasonably practicable after we electronically file such material with, or furnish it to, the SEC. Reports of beneficial ownership filed pursuant to Section 16(a) of the 1934 Act are also available on our website. Information contained on our website is not part of this report.

14

Table of Contents

ITEM 1A. RISK FACTORS

The following summarizes the material risks of purchasing or owning our securities. Additional unknown risks may also impair our financial performance and business operations. Our business, financial condition and/or results of operation may be materially adversely affected by the nature and impact of these risks. In such case, the market value of our securities could be detrimentally affected, and investors may lose part or all of the value of their investment. You should carefully consider the risks and uncertainties described below before purchasing our securities.

Risks Related To Our Business

We are engaged in a business focused on designing, building and operating biodiesel refineries, as well as producing biodiesel fuel through proprietary process technologies. The business is inherently risky and we face numerous and varied risks, both known and unknown. Despite the knowledge and experience of management, careful evaluation and strategic planning, we may not be able to overcome the risks associated with our business, which may prevent us from achieving our goals.

We are in an early stage with limited operating history and may never attain profitability.

We are currently in an early stage of our current business plan. We have limited operating history with respect to the construction and operation of biodiesel refineries for our own use. Our limited operating history makes it difficult for potential investors to evaluate our business. Therefore, our proposed operations are subject to all of the risks inherent in the initial expenses, challenges, complications and delays frequently encountered in connection with the formation of any new business, as well as those risks that are specific to the biodiesel industry in general. Investors should evaluate an investment in our company in light of the problems and uncertainties frequently encountered by companies attempting to develop markets for new products, services and technologies. Despite best efforts, we may never overcome these obstacles to achieve financial success.

Our business is speculative and dependent upon the implementation of our business plan, as well as our ability to enter into agreements with third parties for necessary financing, the provision of necessary feedstock sources, engineering, procurement and construction services and the sale and distribution of our biodiesel fuel on terms that will be commercially viable for us. There can be no assurance that our efforts will be successful or result in revenue or profit. There is no assurance that we will earn significant revenues or that our investors will not lose their entire investment.

We may be unable to obtain the additional capital required to implement our business plan.

We currently do not have sufficient cash reserves to meet all of our anticipated expenditure obligations for operating and capital purposes for the remainder of fiscal year 2009. As a result, we are in the process of seeking additional capital, particularly with respect to procuring working capital sufficient for operation of our Seneca refinery at full capacity, modifications and operations of our Clinton County refinery and corporate overhead. The revenues generated from designing and building biodiesel refineries for third parties were insufficient to cover the anticipated final costs of construction, and the proceeds from our most recently completed private placements of securities are not sufficient to fund operations as currently contemplated. We must secure additional financing of approximately $20,000,000 to fund additional working capital requirements as the Seneca refinery reaches full production, to cover general and administrative expenses, and to pay operating expenses that are expected to be incurred before the refining operations at Seneca become profitable. The additional capital may be provided by common or preferred equity or equity-linked securities, debt, tolling arrangements with industry participants, project financing, joint venture projects, a strategic business combination, particularly with a strategic partner with access to low-cost feedstocks such as corn oil extracted from dried distillers grains, or a combination of these. We will require additional capital to continue to expand our business beyond the initial phase. Limitations on the anti-dilution adjustments of our outstanding convertible notes implemented to comply with the American Stock Exchange listing rules, and related covenants, significantly constrain the amount of equity capital we can raise until such time as we can obtain stockholder approval to remove such anti-dilution adjustment limitations. There is no assurance that we will be able to obtain the capital required in a timely fashion, on favorable terms or at all. If we are unable to obtain required additional financing, we may be forced to restrain our growth plans or cut back existing operations.

Future construction and operation of biodiesel refineries, capital expenditures to build and operate our refineries, hiring qualified management and key employees, complying with licensing, registration and other requirements, maintaining compliance with applicable laws, production and marketing activities, administrative requirements, such as salaries, insurance expenses and general overhead expenses, legal compliance costs and accounting expenses will all require a substantial amount of additional capital and cash flow.

15

Table of Contents

We will be required to pursue sources of additional capital through various means, including joint venture projects, tolling arrangements, which may include a profit sharing component, debt financing, equity financing or other means. There is no assurance that we will be successful in locating a suitable financing or strategic business combination transaction in a timely fashion or at all. In addition, there is no assurance that we will be successful in obtaining the capital we require by any other means. Future financings through equity investments are likely, and these are likely to be dilutive to the existing shareholders as we issue additional shares of common stock to investors in future financing transactions and as these financings trigger anti-dilution adjustments in existing equity-linked securities. Also, the terms of securities we issue in future capital transactions may be more favorable for our new investors. Newly issued securities may include preferences, superior voting rights, the issuance of warrants or other derivative securities, and the issuances of incentive awards under employee equity incentive plans, which may have additional dilutive effects. Further, we may incur substantial costs in pursuing future capital or financing, including investment banking fees, legal fees, accounting fees, securities law compliance fees, printing and distribution expenses and other costs. We may also be required to recognize non-cash expenses in connection with certain securities we may issue, such as convertible notes and warrants, which may adversely affect our financial results.

Our ability to obtain needed financing may be impaired by such factors as the capital markets, both generally and specifically in the biodiesel industry, the fact that we are a new enterprise without a proven operating history, the location of our biodiesel refineries in the United States instead of Europe or other regions where biodiesel is more widely accepted, and the price of biodiesel and oil on the commodities market. Furthermore, if petroleum or biodiesel prices on the commodities markets decrease, then our revenues will likely decrease and decreased revenues may increase our requirements for capital. Some of the contractual arrangements governing our operations may require us to maintain minimum capital, and we may lose our contract rights if we do not have the required minimum capital. If the amount of capital we are able to raise from financing activities, together with our revenues from operations, are not sufficient to satisfy our capital needs, even to the extent that we reduce our operations accordingly, we may be required to cease operations.

Unanticipated problems or delays in operating biodiesel refineries to the proper specifications may harm our business and viability.

Our current operating cash flow depends on our ability to timely and economically operate our Seneca biodiesel refinery. Refinery operations require significant amounts of capital to procure feedstock before account receivables are paid for finished biodiesel. If our biodiesel refining operations are disrupted or the economic integrity of these projects is threatened for unexpected reasons, our business may experience a substantial setback. Prolonged problems may threaten the commercial viability of our refineries. Moreover, the occurrence of significant unforeseen conditions or events in connection with these refineries may require us to reexamine the thoroughness of our due diligence and planning processes. Any change to our business model or management’s evaluation of the viability of these projects may adversely affect our business.

Our construction costs for additional biodiesel refineries may also increase to a level that would make a new facility too expensive to complete or unprofitable to operate. Contractors, engineering firms, construction firms and equipment suppliers also receive requests and orders from other companies and, therefore, we may not be able to secure their services or products on a timely basis or on acceptable financial terms. We may suffer significant delays or cost overruns as a result of a variety of factors, such as increases in the prices of raw materials, shortages of workers or materials, transportation constraints, adverse weather, equipment failures, fires, damage to or destruction of property and equipment, environmental damage, unforeseen difficulties or labor issues, any of which could prevent us from commencing operations as expected at our facilities.

Our results of operations, financial condition and business outlook will be highly dependent on commodity prices, which are subject to significant volatility and uncertainty, and the availability of supplies, so our results could fluctuate substantially.

Our results are substantially dependent on many different commodity prices, especially prices for biodiesel, petroleum diesel, feedstock and materials used in the construction of our refineries. From 2006 to the fall of 2008, prices for all varieties of feedstock increased to record levels, which were approximately twice the level from when construction began on our refineries. The price of petroleum diesel and biodiesel increased at approximately a similar pace. Since the fall of 2008, the global economic downturn has resulted in significant declines in prices for petroleum diesel and biodiesel. During periods when feedstock and diesel prices are rising, in the absence of any commodity price risk mitigation strategies, the sale of finished biodiesel would generally result in higher margins due to the time difference between when feedstocks are procured and paid for and when the resulting biodiesel is delivered and paid for. Conversely, during periods when feedstock and diesel prices are declining, in the absence of any commodity price risk mitigation strategies, the sale of finished biodiesel

16

Table of Contents

would generally result in lower or negative margins due to the same time differences. This effect becomes especially pronounced in periods of extreme and rapid commodity price changes. We currently do not have sufficient working capital to purchase commodity forwards, futures, options or puts to fully implement a robust commodity price risk mitigation strategy.

Further, the market efficiency for animal-derived fats, oils and greases has been limited when compared to the market efficiency for vegetable-based oils, resulting in increased price volatility. As a result of the volatility of the prices for these items, our results may fluctuate substantially, and we may experience periods of declining prices for our products and increasing costs for our raw materials, which could result in operating losses. Although we may attempt to offset a portion of the effects of fluctuations in prices by entering into forward contracts to supply biodiesel or purchase feedstock or other items or by engaging in transactions involving exchange-traded futures contracts, the amount and duration of these hedging and other risk mitigation activities may vary substantially over time and these activities also involve substantial risks.

Biodiesel fuel is a commodity whose price is determined based on the price of petroleum diesel, world demand, supply and other factors, all of which are beyond our control. Prices for biodiesel fuel in the regions in which we sell have fluctuated widely in recent years. We expect that prices will continue to fluctuate in the future. Price fluctuations will have a significant impact upon our revenue, the return on our investment in biodiesel refineries and on our general financial condition. Price fluctuations for biodiesel fuel, regionally and globally, may also affect the investment market, and our ability to raise additional capital. Future decreases in the prices of biodiesel or petroleum diesel fuel may have a material adverse effect on our financial condition and future results of operations.

The price of feedstock is influenced by market demand, weather conditions, animal processing and rendering plant decisions, the level of feedstock use as feed for livestock, factors affecting crop yields, farmer planting decisions, foreign demand for feedstock and general economic, market and regulatory factors. These factors include government policies and subsidies with respect to agriculture and international trade, and global and local demand and supply. The significance and relative effect of these factors on the price of feedstock is difficult to predict. The prices for most commonly available biodiesel feedstocks were at or near record high levels until the fall of 2008 and then fell dramatically. Any event that tends to negatively affect the supply of feedstock, such as increased demand, adverse weather or crop disease, could increase feedstock prices and potentially harm our business. In addition, we may also have difficulty, from time to time, in physically sourcing feedstock on economical terms due to supply shortages or quality control issues of feedstock providers. For example, some animal rendering operations produce feedstock with unacceptable levels of polyethylene, which must be rejected before the feedstock enters the refinery. Such a shortage or quality control issues could require us to suspend operations until sufficient feedstock of acceptable quality is available at economical terms, which would have a material adverse effect on our business, results of operations and financial position. The price we pay for feedstock at a refinery could increase if an additional multi-feedstock biodiesel production facility is built in the same general vicinity or if alternative uses are found for lower cost feedstocks.

We are a holding company, and there are significant limitations on our ability to receive distributions from our subsidiaries.