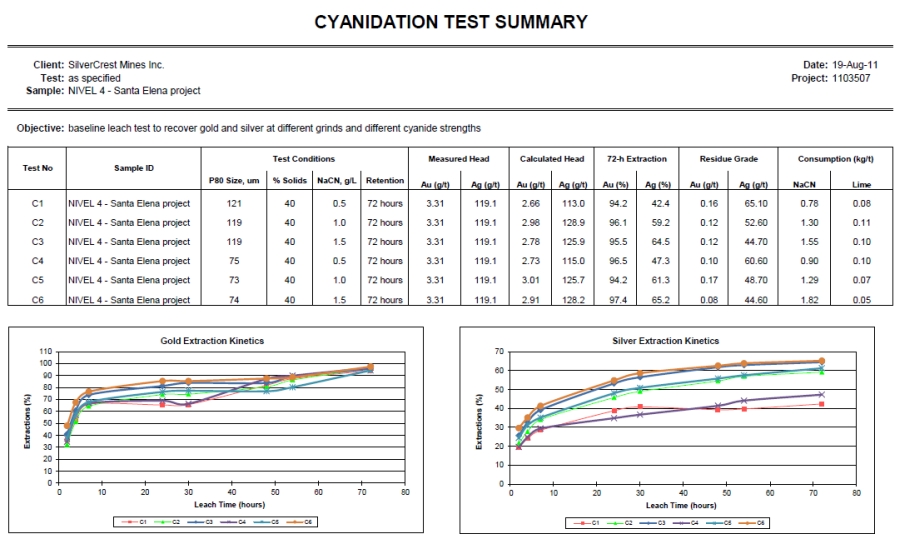

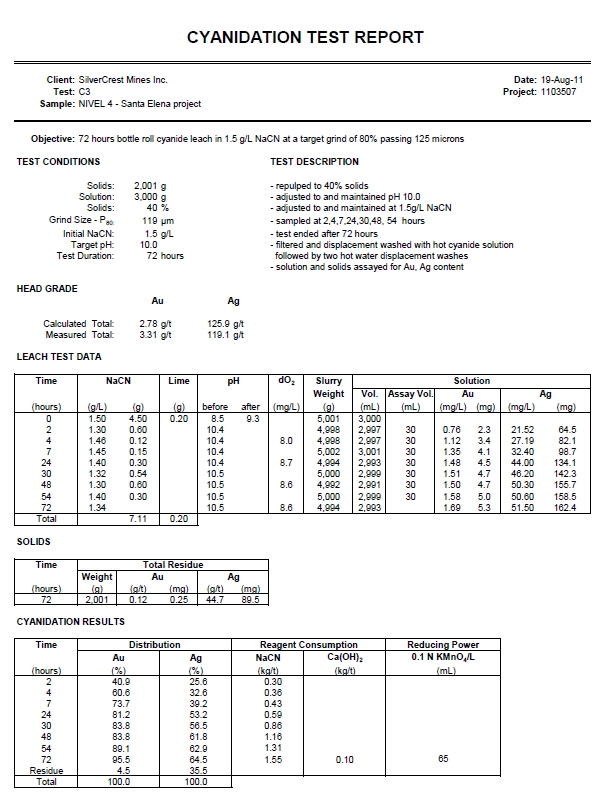

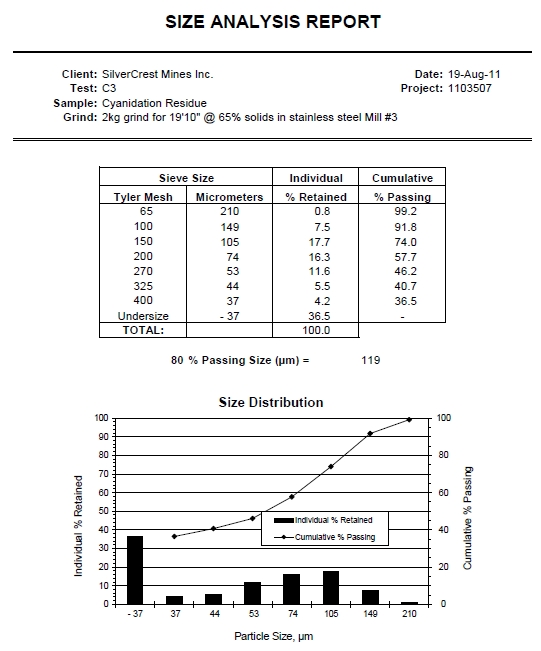

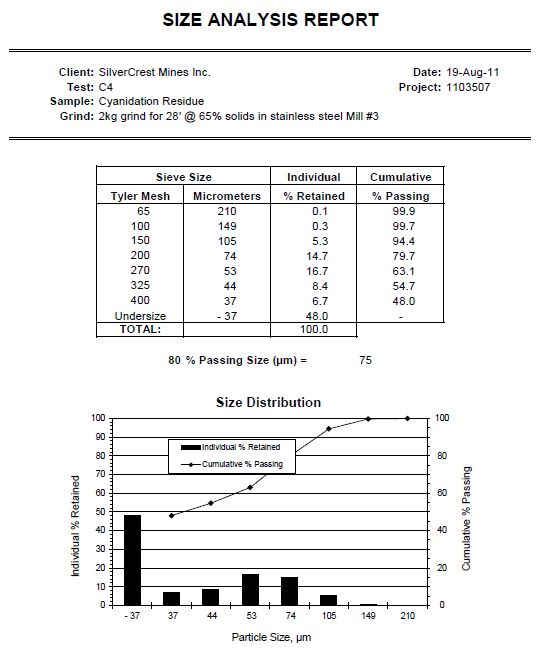

Client: SilverCrest Mines Inc. Date: 19-Aug-11

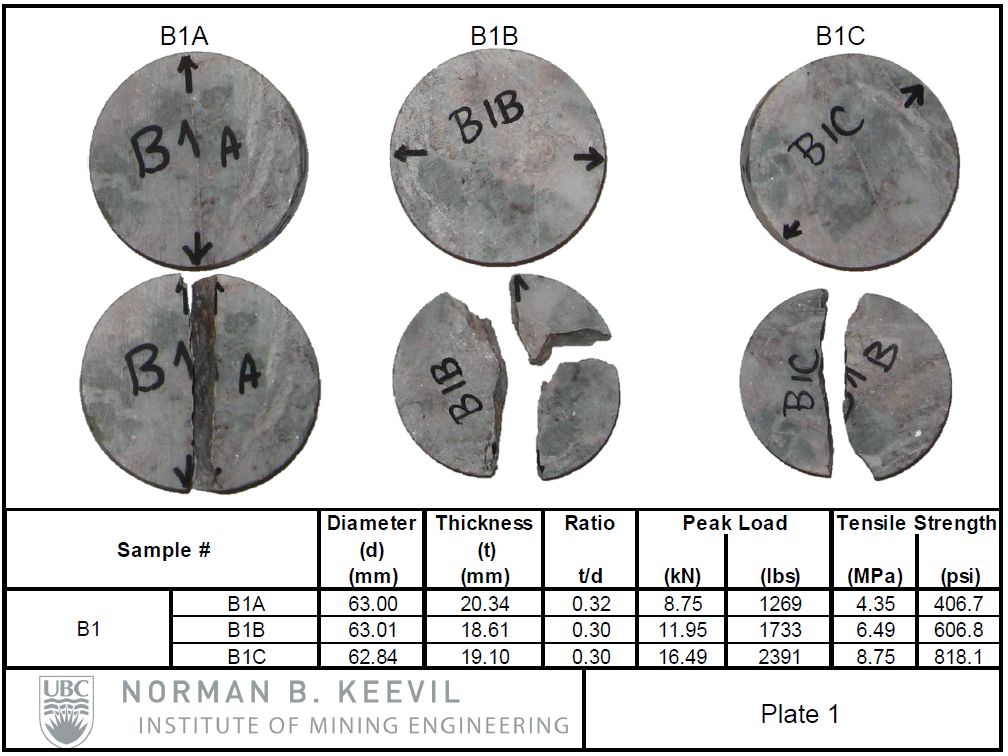

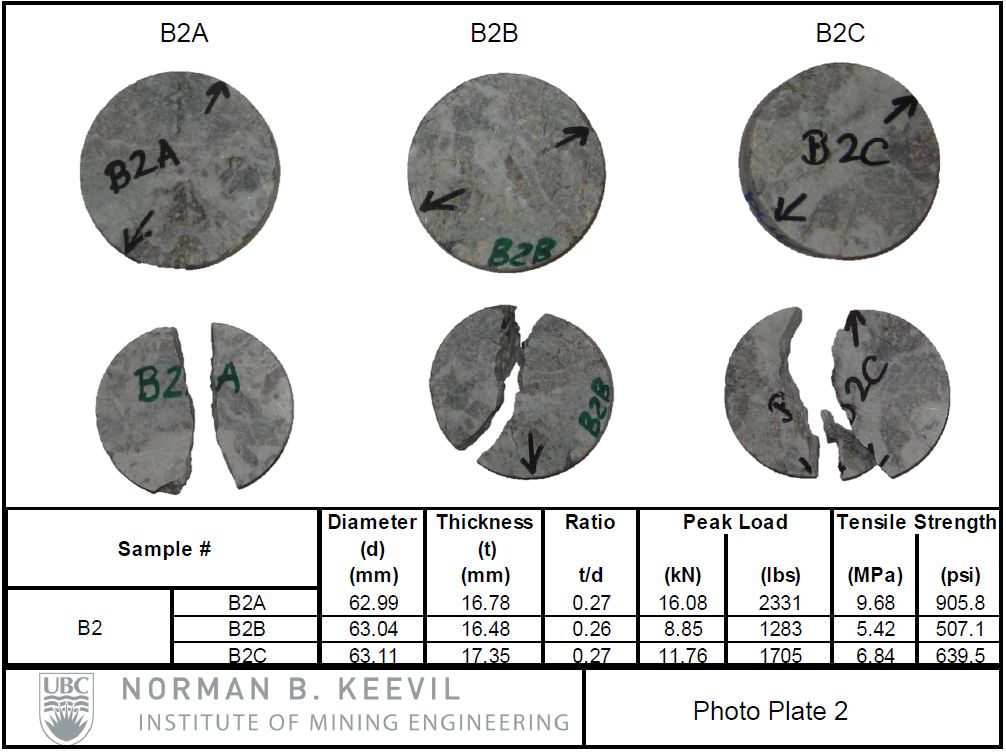

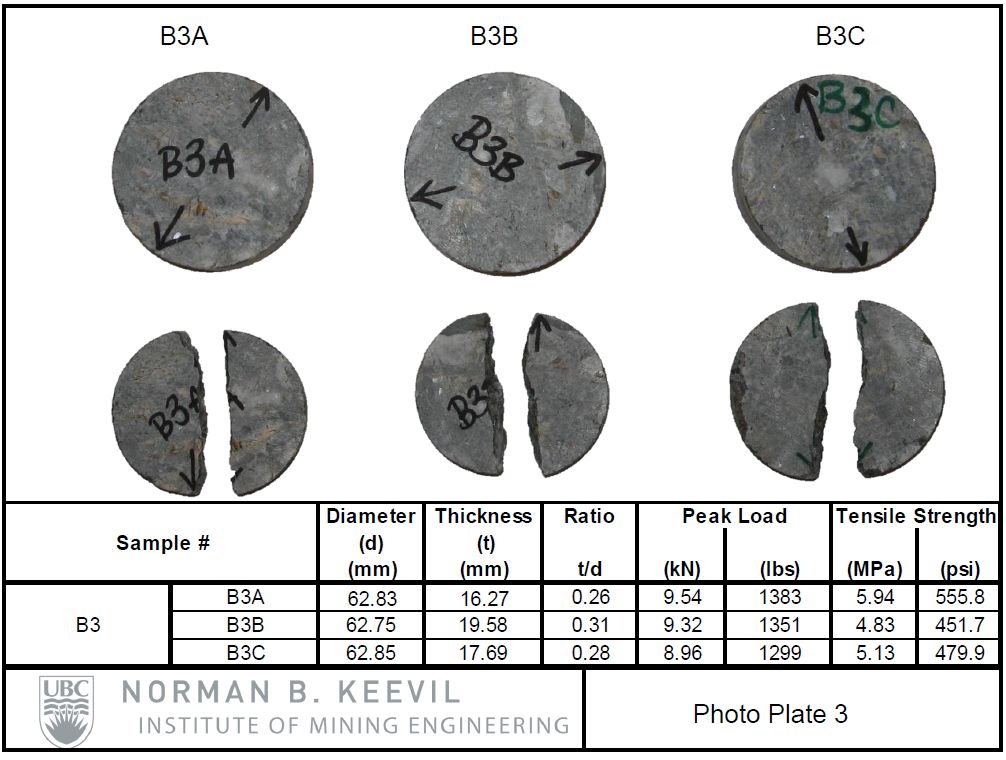

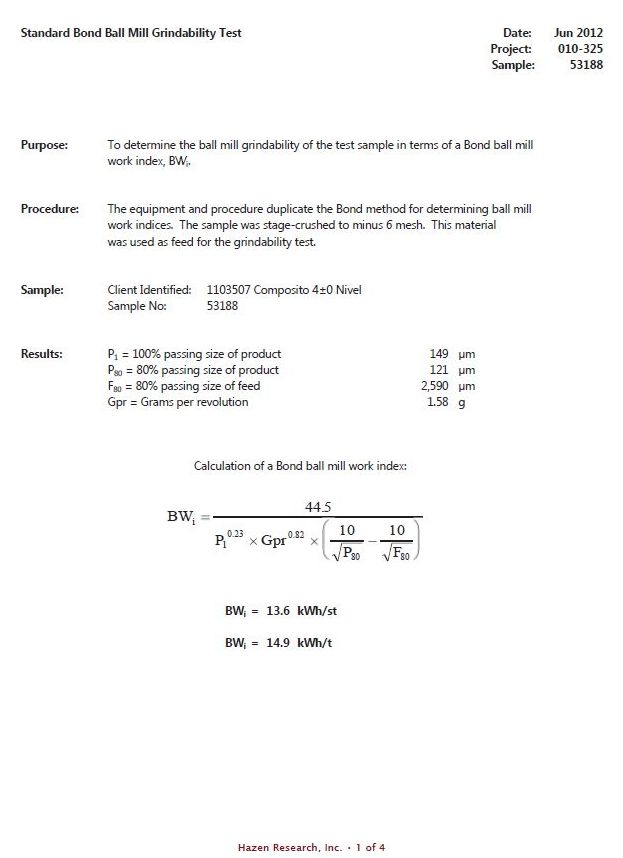

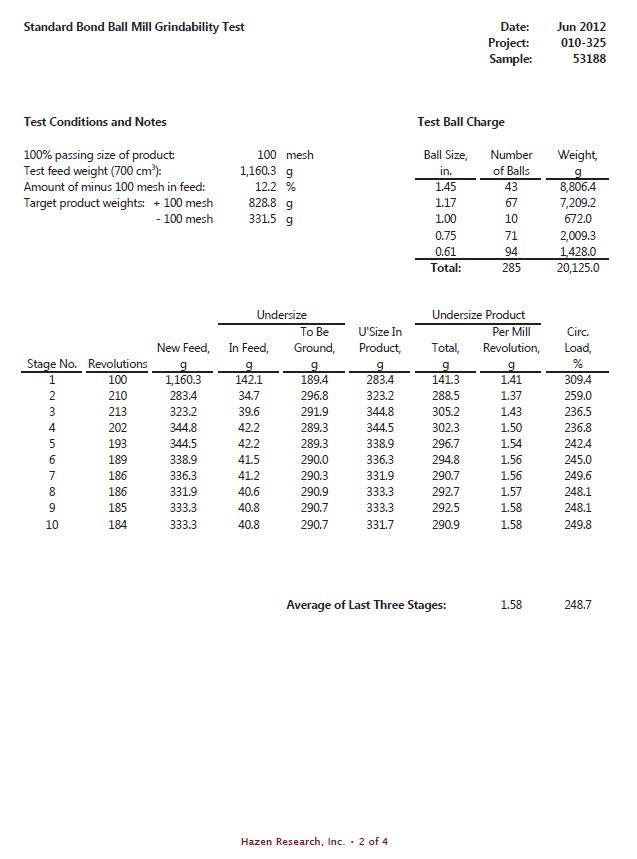

Test: C4 Project: 1103507

Sample: Cyanidation Residue

Grind: 2kg grind for 28' @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.1 99.9

100 149 0.3 99.7

150 105 5.3 94.4

200 74 14.7 79.7

270 53 16.7 63.1

325 44 8.4 54.7

400 37 6.7 48.0

Undersize - 37 48.0 -

TOTAL: 100.0

80 % Passing Size (μm) = 75

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

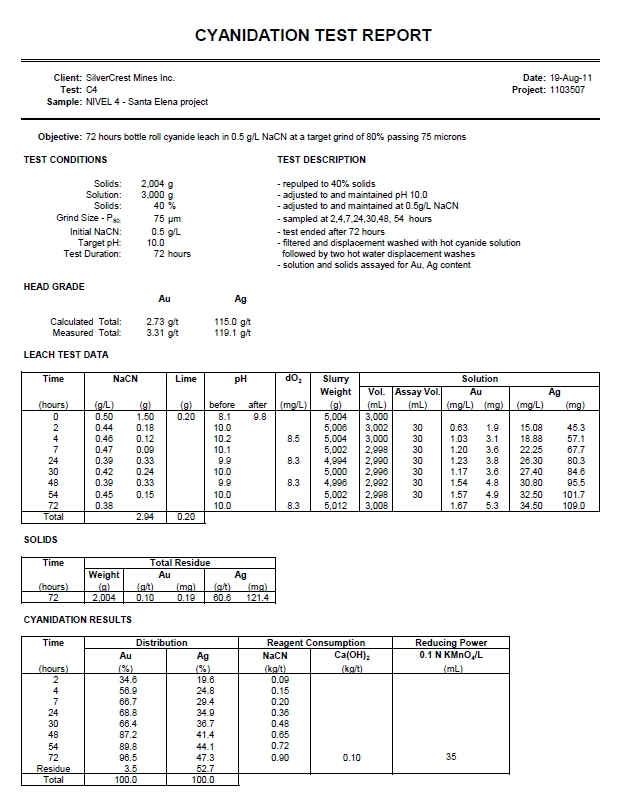

Client: SilverCrest Mines Inc. Date: 19-Aug-11

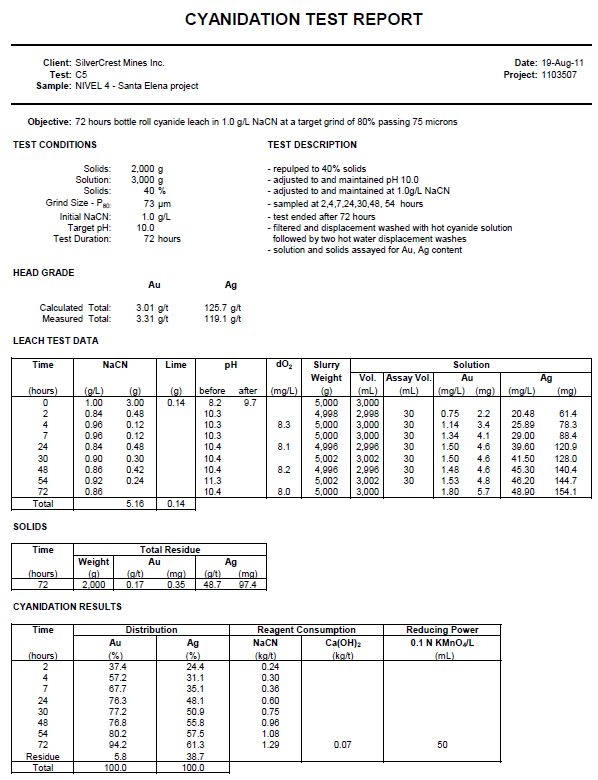

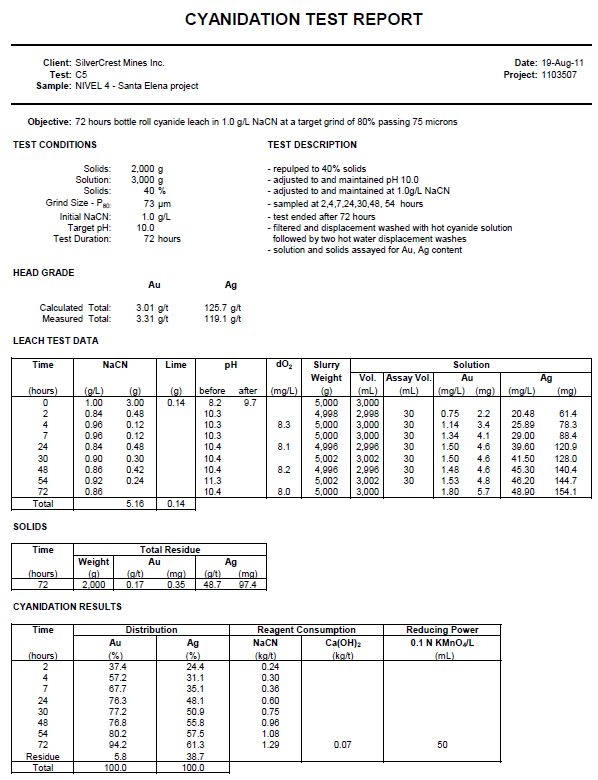

Test: C5 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: 72 hours bottle roll cyanide leach in 1.0 g/L NaCN at a target grind of 80% passing 75 microns

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,000 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 1.0g/L NaCN

Grind Size - P80: 73 μm - sampled at 2,4,7,24,30,48, 54 hours

Initial NaCN: 1.0 g/L - test ended after 72 hours

Target pH: 10.0 - filtered and displacement washed with hot cyanide solution

Test Duration: 72 hours followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 3.01 g/t 125.7 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.00 3.00 0.14 8.2 9.7 5,000 3,000

2 0.84 0.48 10.3 4,998 2,998 30 0.75 2.2 20.48 61.4

4 0.96 0.12 10.3 8.3 5,000 3,000 30 1.14 3.4 25.89 78.3

7 0.96 0.12 10.3 5,000 3,000 30 1.34 4.1 29.00 88.4

24 0.84 0.48 10.4 8.1 4,996 2,996 30 1.50 4.6 39.60 120.9

30 0.90 0.30 10.4 5,002 3,002 30 1.50 4.6 41.50 128.0

48 0.86 0.42 10.4 8.2 4,996 2,996 30 1.48 4.6 45.30 140.4

54 0.92 0.24 11.3 5,002 3,002 30 1.53 4.8 46.20 144.7

72 0.86 10.4 8.0 5,000 3,000 1.80 5.7 48.90 154.1

Total 5.16 0.14

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,000 0.17 0.35 48.7 97.4

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

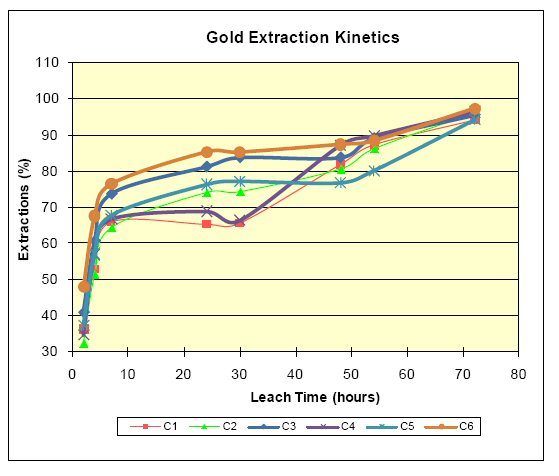

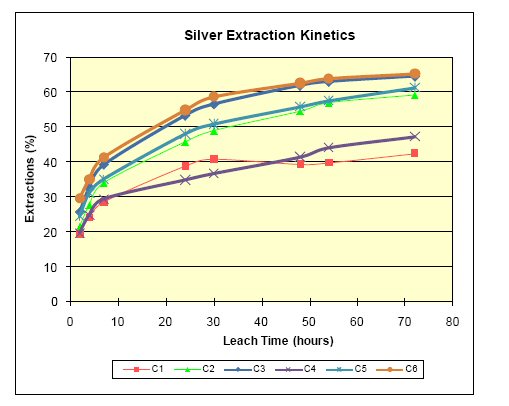

2 37.4 24.4 0.24

4 57.2 31.1 0.30

7 67.7 35.1 0.36

24 76.3 48.1 0.60

30 77.2 50.9 0.75

48 76.8 55.8 0.96

54 80.2 57.5

72 94.2 61.3 1.29 0.07

Residue 5.8 38.7

Total 100.0 100.0

1.08

50

CYANIDATION TEST REPORT

Solution

Ag

Total Residue

Distribution Reagent Consumption

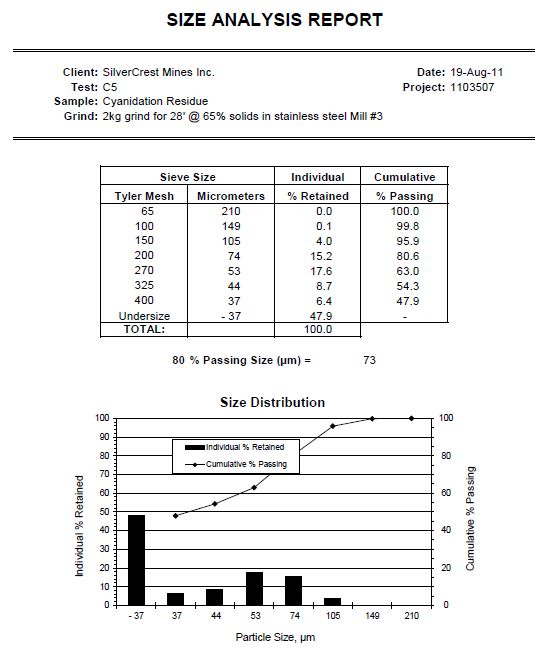

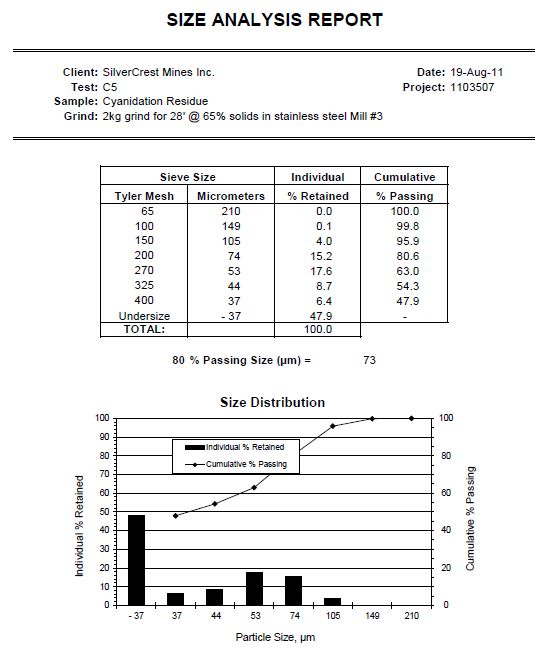

Client: SilverCrest Mines Inc. Date: 19-Aug-11

Test: C5 Project: 1103507

Sample: Cyanidation Residue

Grind: 2kg grind for 28' @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.0 100.0

100 149 0.1 99.8

150 105 4.0 95.9

200 74 15.2 80.6

270 53 17.6 63.0

325 44 8.7 54.3

400 37 6.4 47.9

Undersize - 37 47.9 -

TOTAL: 100.0

80 % Passing Size (μm) = 73

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

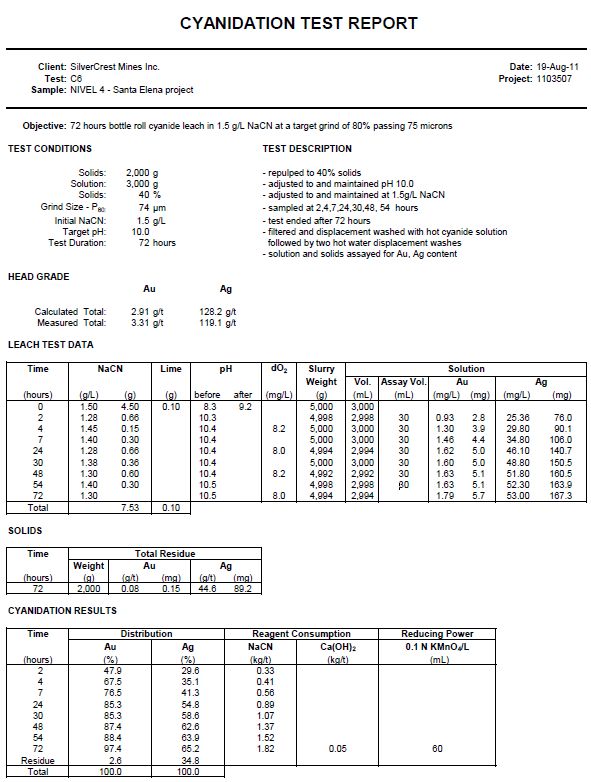

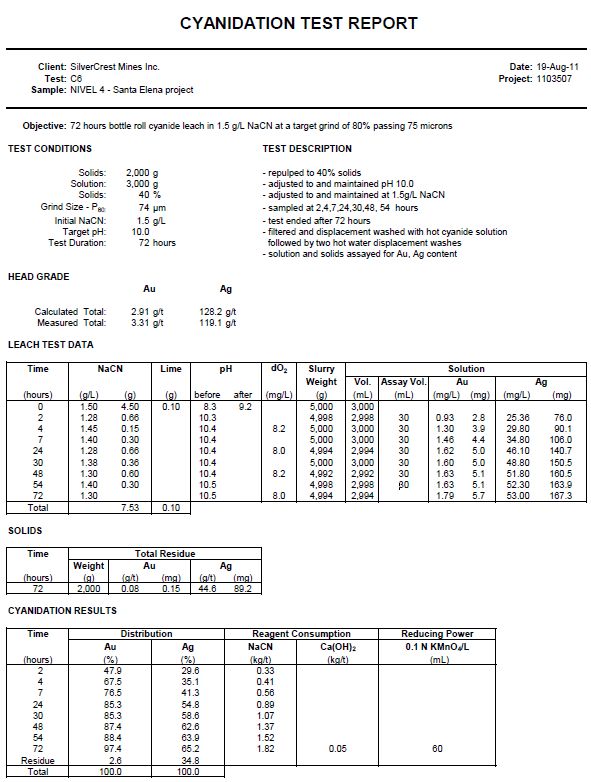

Client: SilverCrest Mines Inc. Date: 19-Aug-11

Test: C6 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: 72 hours bottle roll cyanide leach in 1.5 g/L NaCN at a target grind of 80% passing 75 microns

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,000 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 74 μm - sampled at 2,4,7,24,30,48, 54 hours

Initial NaCN: 1.5 g/L - test ended after 72 hours

Target pH: 10.0 - filtered and displacement washed with hot cyanide solution

Test Duration: 72 hours followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.91 g/t 128.2 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 4.50 0.10 8.3 9.2 5,000 3,000

2 1.28 0.66 10.3 4,998 2,998 30 0.93 2.8 25.36 76.0

4 1.45 0.15 10.4 8.2 5,000 3,000 30 1.30 3.9 29.80 90.1

7 1.40 0.30 10.4 5,000 3,000 30 1.46 4.4 34.80 106.0

24 1.28 0.66 10.4 8.0 4,994 2,994 30 1.62 5.0 46.10 140.7

30 1.38 0.36 10.4 5,000 3,000 30 1.60 5.0 48.80 150.5

48 1.30 0.60 10.4 8.2 4,992 2,992 30 1.63 5.1 51.80 160.5

54 1.40 0.30 10.5 4,998 2,998 30 1.63 5.1 52.30 163.9

72 1.30 10.5 8.0 4,994 2,994 1.79 5.7 53.00 167.3

Total 7.53 0.10

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,000 0.08 0.15 44.6 89.2

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 47.9 29.6 0.33

4 67.5 35.1 0.41

7 76.5 41.3 0.56

24 85.3 54.8 0.89

30 85.3 58.6 1.07

48 87.4 62.6 1.37

54 88.4 63.9

72 97.4 65.2 1.82 0.05

Residue 2.6 34.8

Total 100.0 100.0

1.52

60

CYANIDATION TEST REPORT

Solution

Ag

Total Residue

Distribution Reagent Consumption

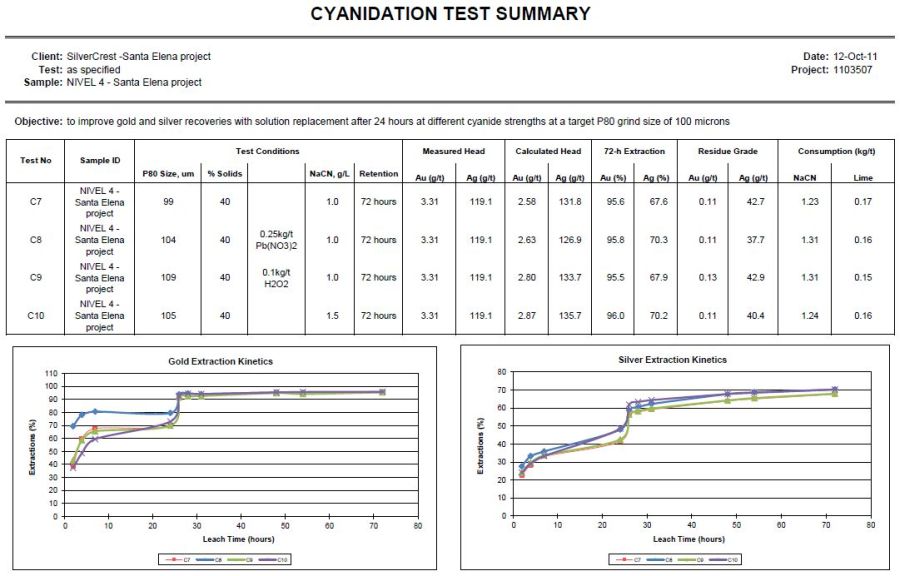

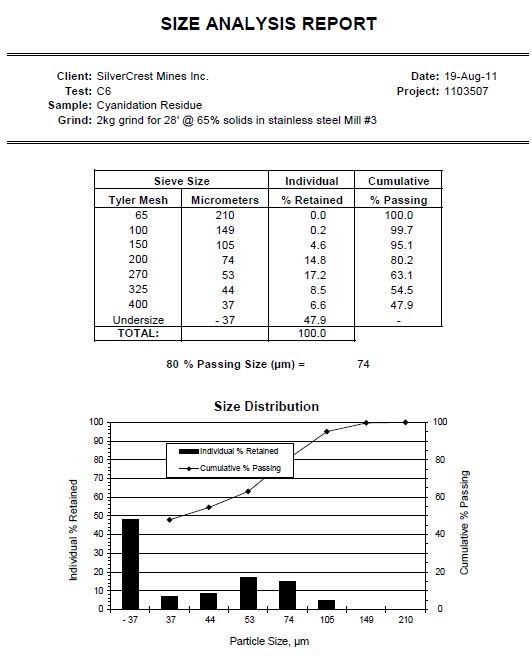

Client: SilverCrest Mines Inc. Date: 19-Aug-11

Test: C6 Project: 1103507

Sample: Cyanidation Residue

Grind: 2kg grind for 28' @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.0 100.0

100 149 0.2 99.7

150 105 4.6 95.1

200 74 14.8 80.2

270 53 17.2 63.1

325 44 8.5 54.5

400 37 6.6 47.9

Undersize - 37 47.9 -

TOTAL: 100.0

80 % Passing Size (μm) = 74

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

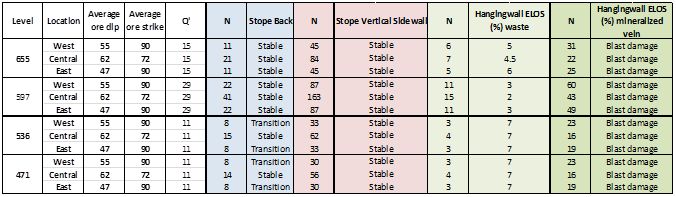

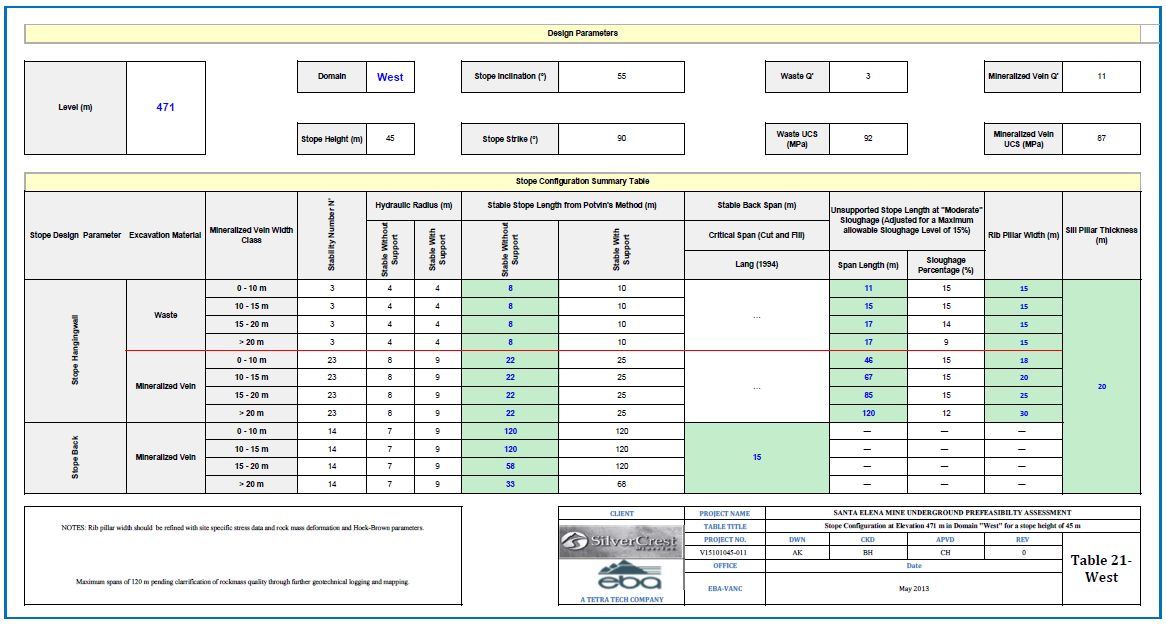

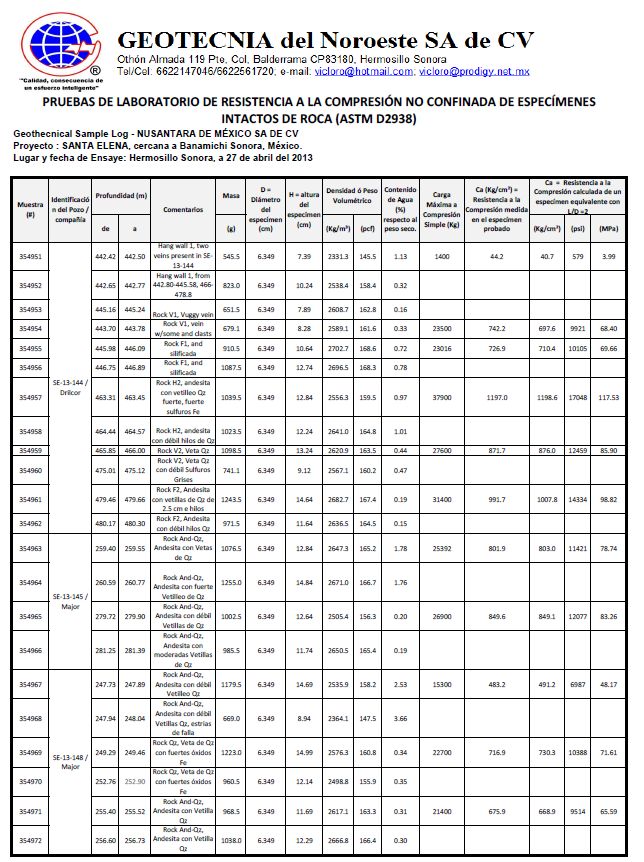

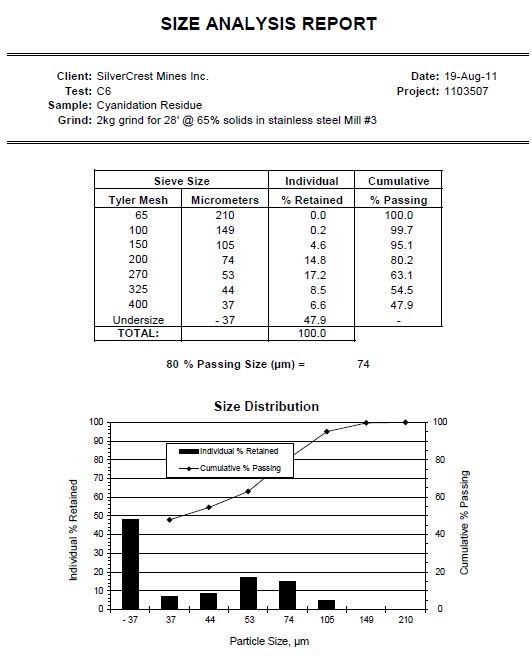

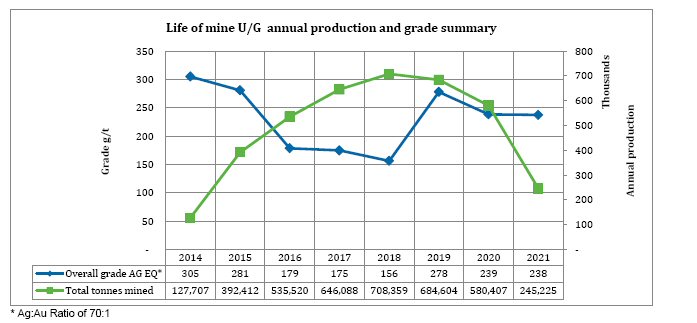

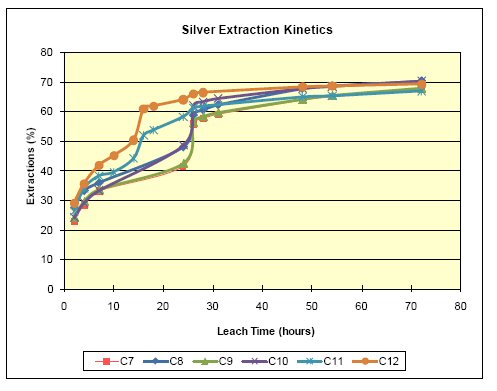

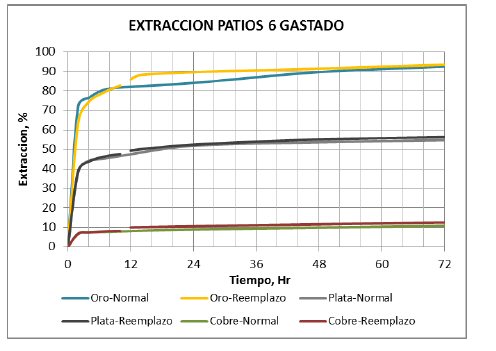

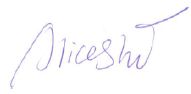

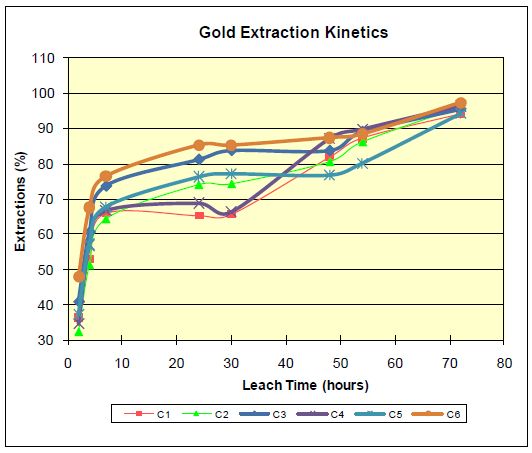

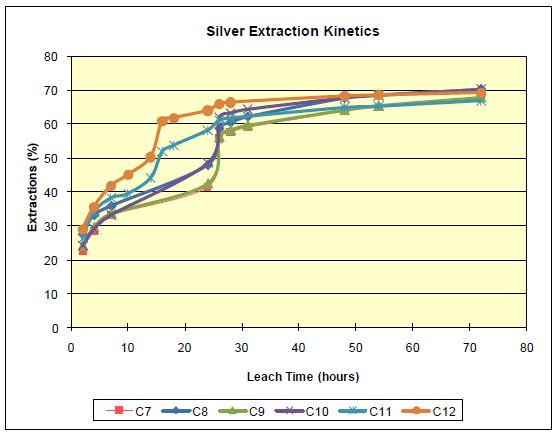

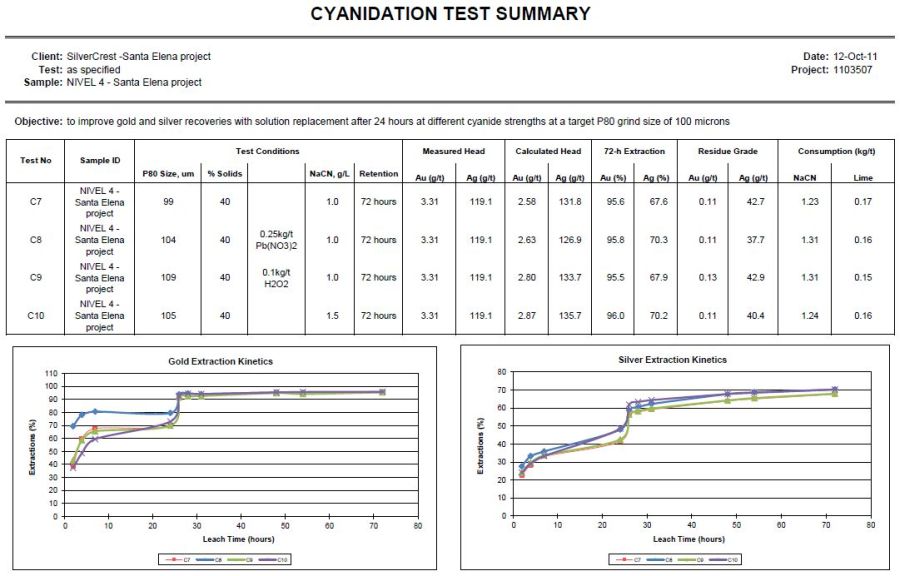

Client: SilverCrest -Santa Elena project Date: 12-Oct-11

Test: as specified Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: to improve gold and silver recoveries with solution replacement after 24 hours at different cyanide strengths at a target P80 grind size of 100 microns

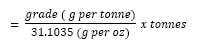

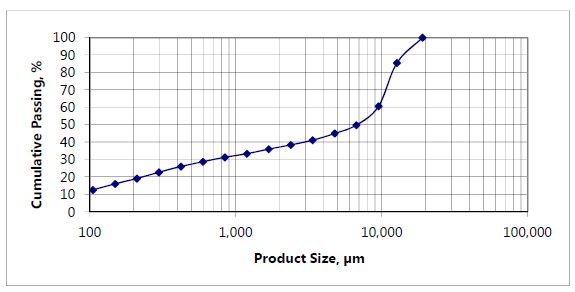

P80 Size, um % Solids NaCN, g/L Retention

Au (g/t) Ag (g/t) Au (g/t) Ag (g/t) Au (%) Ag (%) Au (g/t) Ag (g/t) NaCN Lime

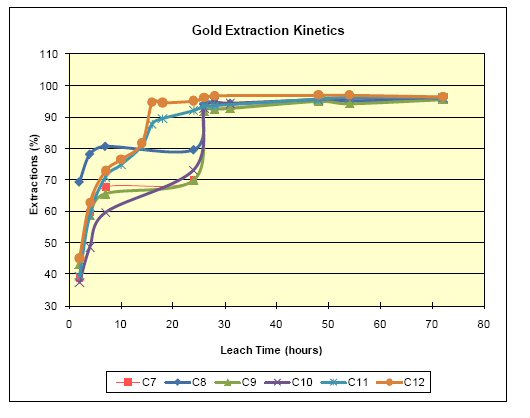

C7

NIVEL 4 -

Santa Elena

project

99 40 1.0 72 hours 3.31 119.1 2.58 131.8 95.6 67.6 0.11 42.7 1.23 0.17

C8

NIVEL 4 -

Santa Elena

project

104 40

0.25kg/t

Pb(NO3)2

1.0 72 hours 3.31 119.1 2.63 126.9 95.8 70.3 0.11 37.7 1.31 0.16

C9

NIVEL 4 -

Santa Elena

project

109 40

0.1kg/t

H2O2

1.0 72 hours 3.31 119.1 2.80 133.7 95.5 67.9 0.13 42.9 1.31 0.15

C10

NIVEL 4 -

Santa Elena

project

105 40 1.5 72 hours 3.31 119.1 2.87 135.7 96.0 70.2 0.11 40.4 1.24 0.16

CYANIDATION TEST SUMMARY

Consumption (kg/t)

Test No Sample ID

Measured Head Calculated Head 72-h Extraction Test Conditions Residue Grade

0

10

20

30

40

50

60

70

80

90

100

110

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Gold Extraction Kinetics

C7 C8 C9 C10

0

10

20

30

40

50

60

70

80

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Silver Extraction Kinetics

C7 C8 C9 C10

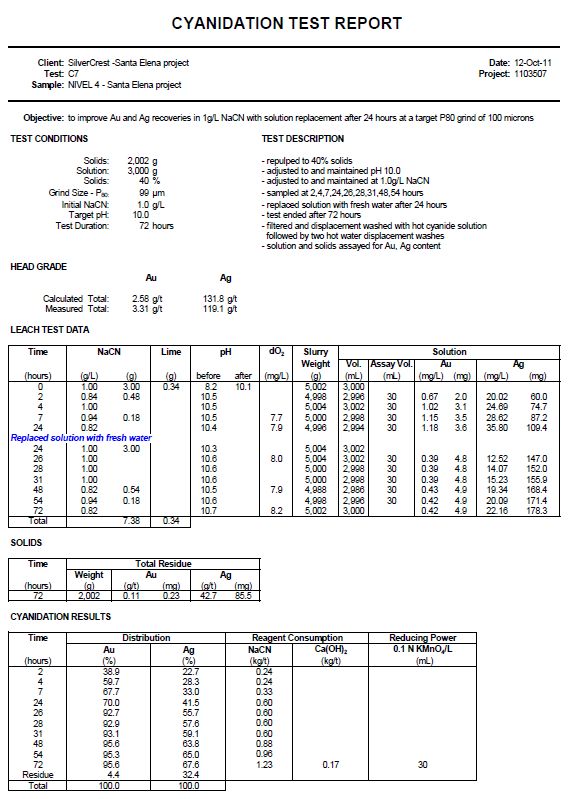

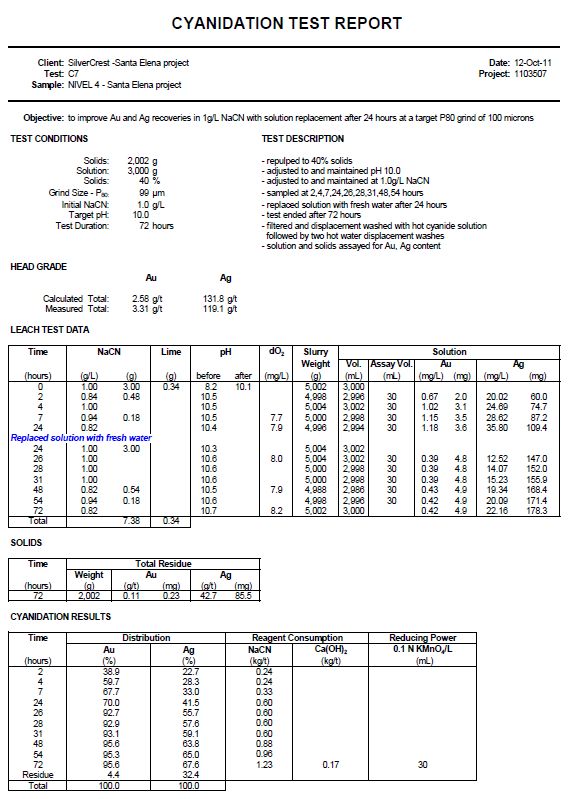

Client: SilverCrest -Santa Elena project Date: 12-Oct-11

Test: C7 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: to improve Au and Ag recoveries in 1g/L NaCN with solution replacement after 24 hours at a target P80 grind of 100 microns

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,002 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 1.0g/L NaCN

Grind Size - P80: 99 μm - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 1.0 g/L - replaced solution with fresh water after 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.58 g/t 131.8 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.00 3.00 0.34 8.2 10.1 5,002 3,000

2 0.84 0.48 10.5 4,998 2,996 30 0.67 2.0 20.02 60.0

4 1.00 10.5 5,004 3,002 30 1.02 3.1 24.69 74.7

7 0.94 0.18 10.5 7.7 5,000 2,998 30 1.15 3.5 28.62 87.2

24 0.82 10.4 7.9 4,996 2,994 30 1.18 3.6 35.80 109.4

Replaced solution with fresh water

24 1.00 3.00 10.3 5,004 3,002

26 1.00 10.6 8.0 5,004 3,002 30 0.39 4.8 12.52 147.0

28 1.00 10.6 5,000 2,998 30 0.39 4.8 14.07 152.0

31 1.00 10.6 5,000 2,998 30 0.39 4.8 15.23 155.9

48 0.82 0.54 10.5 7.9 4,988 2,986 30 0.43 4.9 19.34 168.4

54 0.94 0.18 10.6 4,998 2,996 30 0.42 4.9 20.09 171.4

72 0.82 10.7 8.2 5,002 3,000 0.42 4.9 22.16 178.3

Total 7.38 0.34

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,002 0.11 0.23 42.7 85.5

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 38.9 22.7 0.24

4 59.7 28.3 0.24

7 67.7 33.0 0.33

24 70.0 41.5 0.60

26 92.7 55.7 0.60

28 92.9 57.6

31 0.60

48 0.88

54 95.3 65.0

72 95.6 67.6 1.23 0.17

Residue 4.4 32.4

Total 100.0 100.0

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

30

0.96

Distribution Reagent Consumption

93.1

95.6

59.1

63.8

0.60

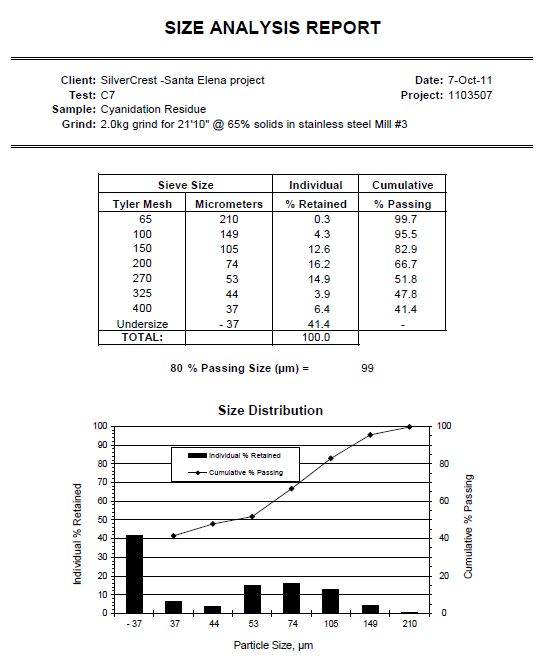

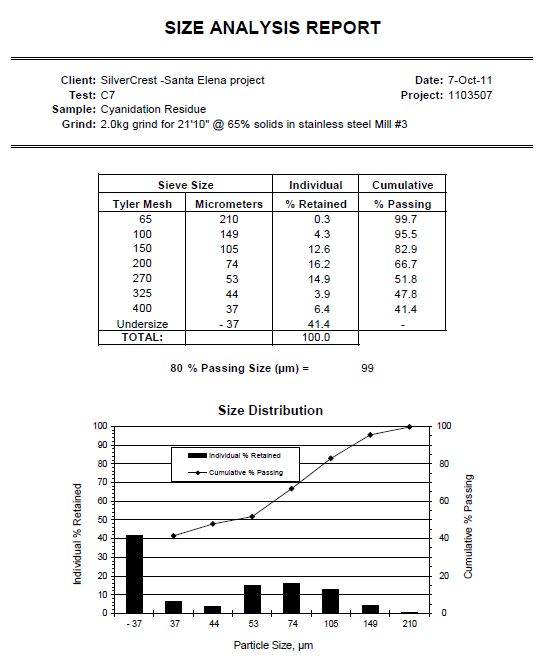

Client: SilverCrest -Santa Elena project Date: 7-Oct-11

Test: C7 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.3 99.7

100 149 4.3 95.5

150 105 12.6 82.9

200 74 16.2 66.7

270 53 14.9 51.8

325 44 3.9 47.8

400 37 6.4 41.4

Undersize - 37 41.4 -

TOTAL: 100.0

80 % Passing Size (μm) = 99

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

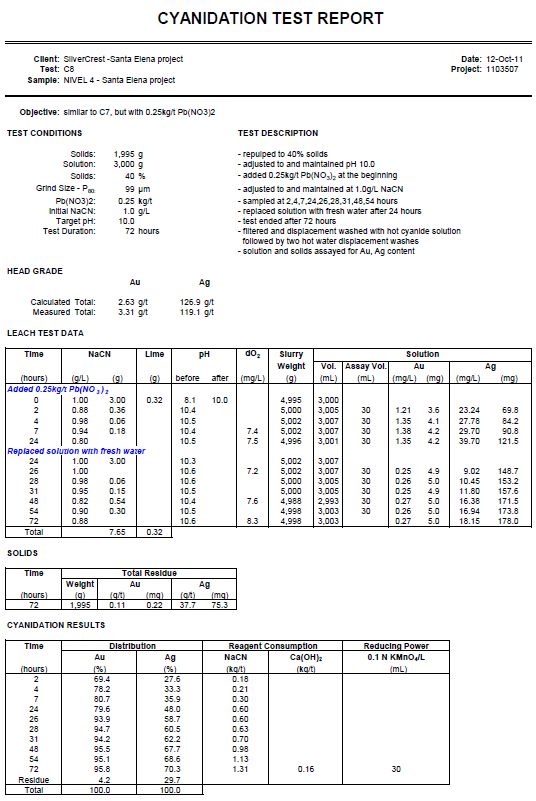

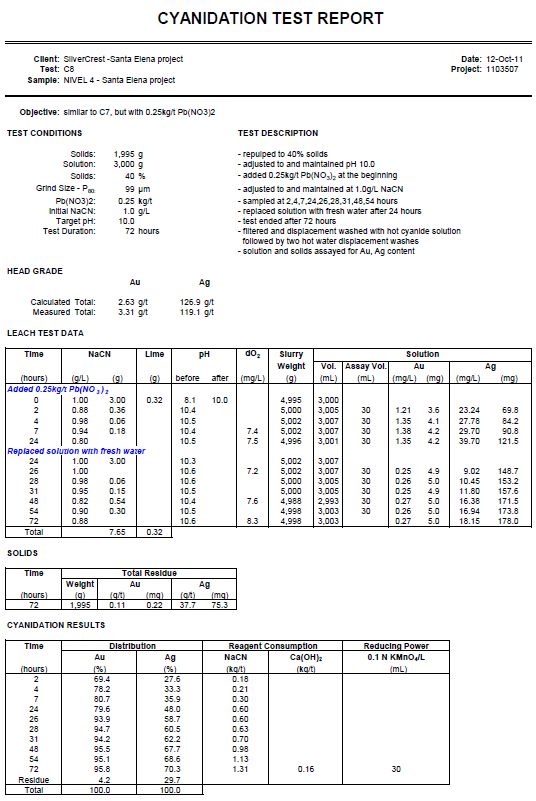

Client: SilverCrest -Santa Elena project Date: 12-Oct-11

Test: C8 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: similar to C7, but with 0.25kg/t Pb(NO3)2

TEST CONDITIONS TEST DESCRIPTION

Solids: 1,995 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - added 0.25kg/t Pb(NO3)2 at the beginning

Grind Size - P80: 99 μm - adjusted to and maintained at 1.0g/L NaCN

Pb(NO3)2: 0.25 kg/t - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 1.0 g/L - replaced solution with fresh water after 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.63 g/t 126.9 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

Added 0.25kg/t Pb(NO3 ) 2

0 1.00 3.00 0.32 8.1 10.0 4,995 3,000

2 0.88 0.36 10.4 5,000 3,005 30 1.21 3.6 23.24 69.8

4 0.98 0.06 10.5 5,002 3,007 30 1.35 4.1 27.78 84.2

7 0.94 0.18 10.4 7.4 5,002 3,007 30 1.38 4.2 29.70 90.8

24 0.80 10.5 7.5 4,996 3,001 30 1.35 4.2 39.70 121.5

Replaced solution with fresh water

24 1.00 3.00 10.3 5,002 3,007

26 1.00 10.6 7.2 5,002 3,007 30 0.25 4.9 9.02 148.7

28 0.98 0.06 10.6 5,000 3,005 30 0.26 5.0 10.45 153.2

31 0.95 0.15 10.5 5,000 3,005 30 0.25 4.9 11.80 157.6

48 0.82 0.54 10.4 7.6 4,988 2,993 30 0.27 5.0 16.38 171.5

54 0.90 0.30 10.5 4,998 3,003 30 0.26 5.0 16.94 173.8

72 0.88 10.6 8.3 4,998 3,003 0.27 5.0 18.15 178.0

Total 7.65 0.32

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 1,995 0.11 0.22 37.7 75.3

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 69.4 27.6 0.18

4 78.2 33.3 0.21

7 80.7 35.9 0.30

24 79.6 48.0 0.60

26 93.9 58.7 0.60

28 94.7 60.5 0.63

31 0.70

48 0.98

54 95.1 68.6

72 95.8 70.3 1.31 0.16

Residue 4.2 29.7

Total 100.0 100.0

30

1.13

Distribution Reagent Consumption

94.2

95.5

62.2

67.7

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

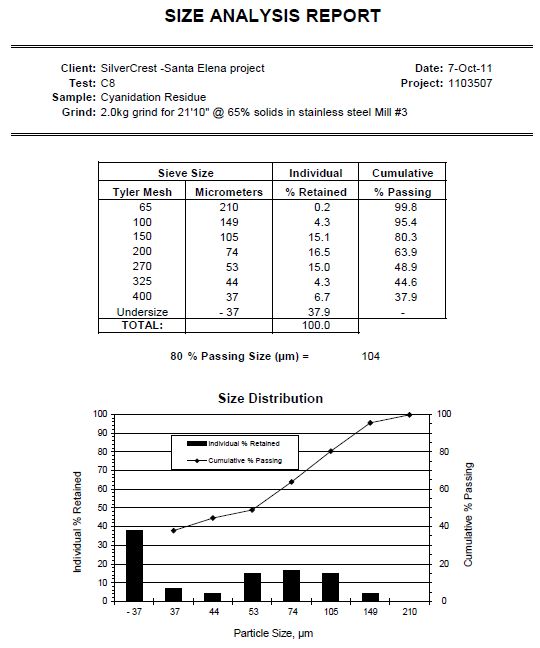

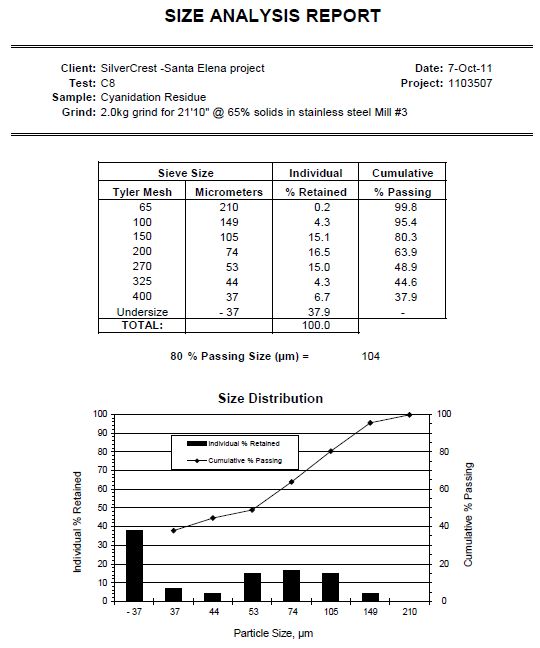

Client: SilverCrest -Santa Elena project Date: 7-Oct-11

Test: C8 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.2 99.8

100 149 4.3 95.4

150 105 15.1 80.3

200 74 16.5 63.9

270 53 15.0 48.9

325 44 4.3 44.6

400 37 6.7 37.9

Undersize - 37 37.9 -

TOTAL: 100.0

80 % Passing Size (μm) = 104

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

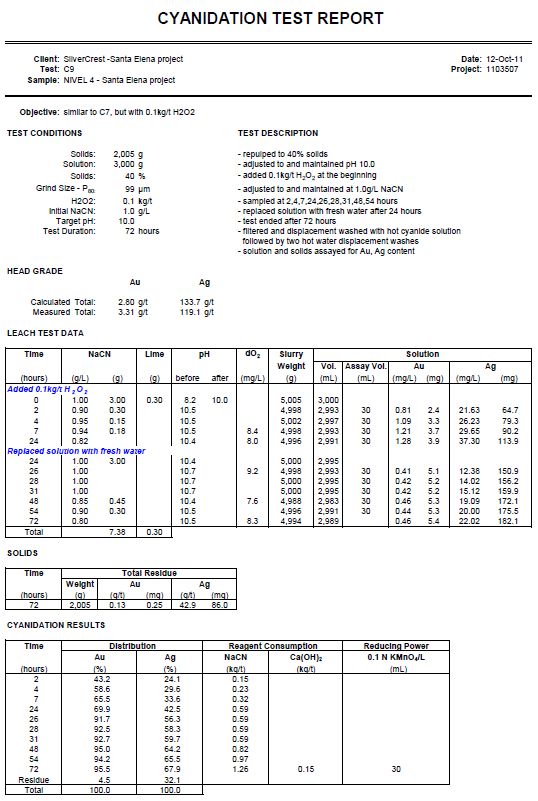

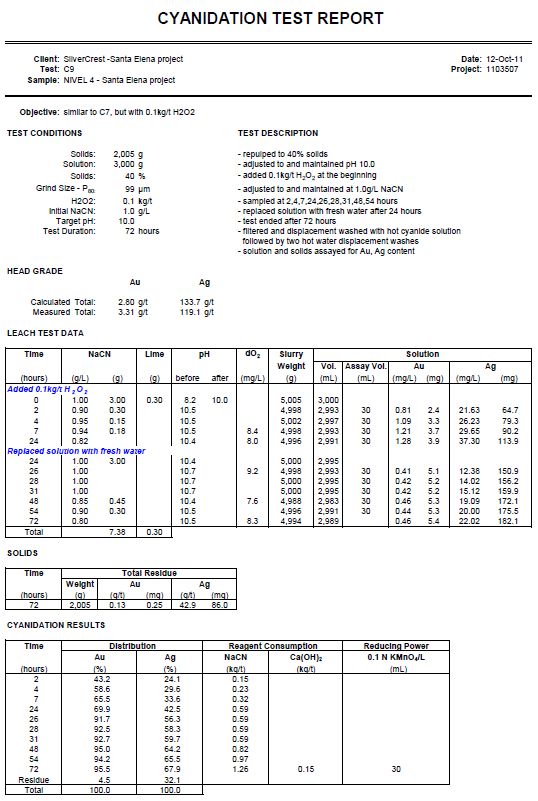

Client: SilverCrest -Santa Elena project Date: 12-Oct-11

Test: C9 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: similar to C7, but with 0.1kg/t H2O2

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,005 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - added 0.1kg/t H2O2 at the beginning

Grind Size - P80: 99 μm - adjusted to and maintained at 1.0g/L NaCN

H2O2: 0.1 kg/t - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 1.0 g/L - replaced solution with fresh water after 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.80 g/t 133.7 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

Added 0.1kg/t H 2O2

0 1.00 3.00 0.30 8.2 10.0 5,005 3,000

2 0.90 0.30 10.5 4,998 2,993 30 0.81 2.4 21.63 64.7

4 0.95 0.15 10.5 5,002 2,997 30 1.09 3.3 26.23 79.3

7 0.94 0.18 10.5 8.4 4,998 2,993 30 1.21 3.7 29.65 90.2

24 0.82 10.4 8.0 4,996 2,991 30 1.28 3.9 37.30 113.9

Replaced solution with fresh water

24 1.00 3.00 10.4 5,000 2,995

26 1.00 10.7 9.2 4,998 2,993 30 0.41 5.1 12.38 150.9

28 1.00 10.7 5,000 2,995 30 0.42 5.2 14.02 156.2

31 1.00 10.7 5,000 2,995 30 0.42 5.2 15.12 159.9

48 0.85 0.45 10.4 7.6 4,988 2,983 30 0.46 5.3 19.09 172.1

54 0.90 0.30 10.5 4,996 2,991 30 0.44 5.3 20.00 175.5

72 0.80 10.5 8.3 4,994 2,989 0.46 5.4 22.02 182.1

Total 7.38 0.30

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,005 0.13 0.25 42.9 86.0

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 43.2 24.1 0.15

4 58.6 29.6 0.23

7 65.5 33.6 0.32

24 69.9 42.5 0.59

26 91.7 56.3 0.59

28 92.5 58.3 0.59

31 0.59

48 0.82

54 94.2 65.5

72 95.5 67.9 1.26 0.15

Residue 4.5 32.1

Total 100.0 100.0

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

30

0.97

Distribution Reagent Consumption

92.7

95.0

59.7

64.2

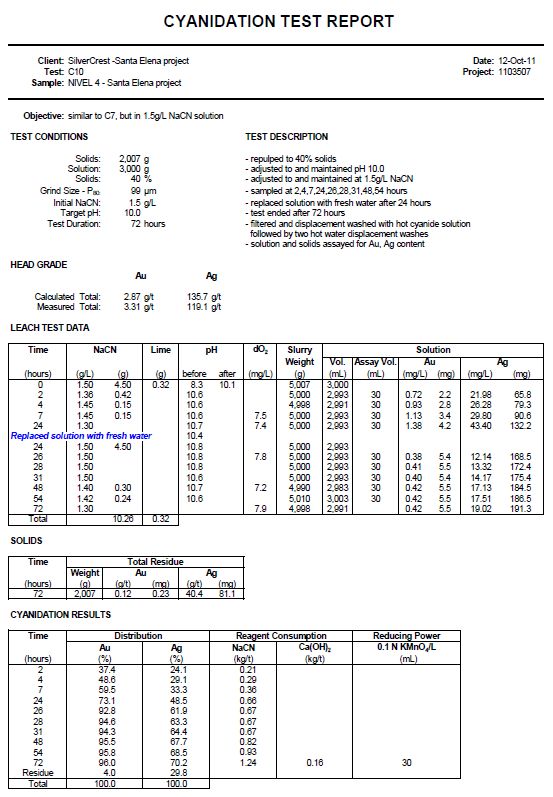

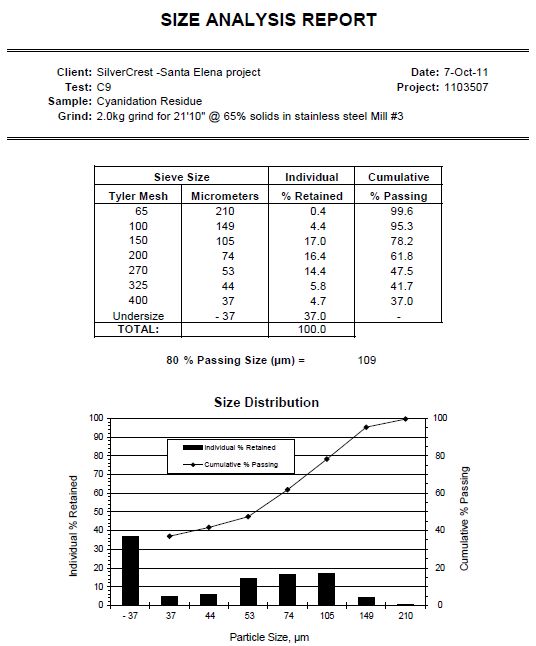

Client: SilverCrest -Santa Elena project Date: 7-Oct-11

Test: C9 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.4 99.6

100 149 4.4 95.3

150 105 17.0 78.2

200 74 16.4 61.8

270 53 14.4 47.5

325 44 5.8 41.7

400 37 4.7 37.0

Undersize - 37 37.0 -

TOTAL: 100.0

80 % Passing Size (μm) = 109

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

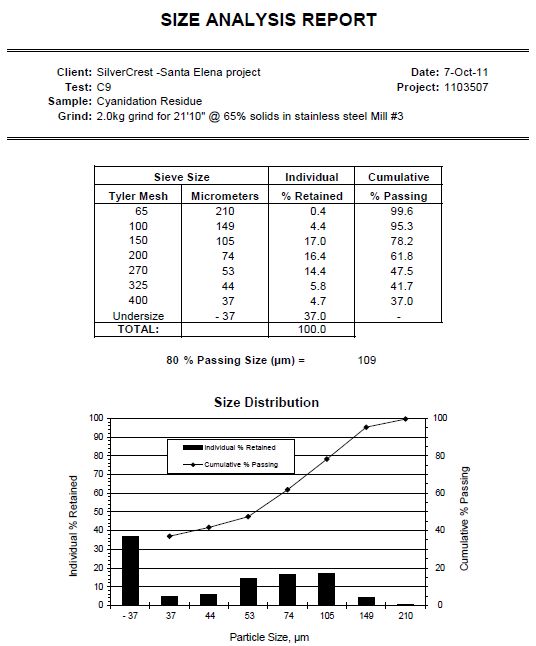

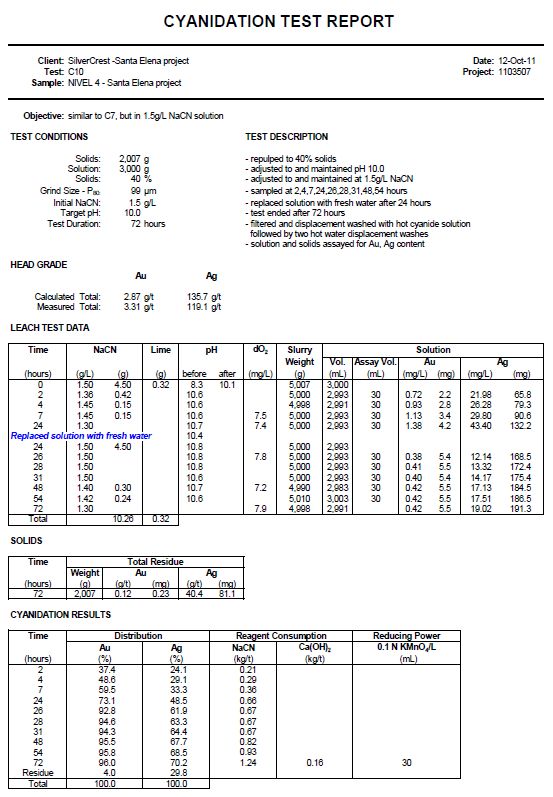

Client: SilverCrest -Santa Elena project Date: 12-Oct-11

Test: C10 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: similar to C7, but in 1.5g/L NaCN solution

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,007 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 99 μm - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 1.5 g/L - replaced solution with fresh water after 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.87 g/t 135.7 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 4.50 0.32 8.3 10.1 5,007 3,000

2 1.36 0.42 10.6 5,000 2,993 30 0.72 2.2 21.98 65.8

4 1.45 0.15 10.6 4,998 2,991 30 0.93 2.8 26.28 79.3

7 1.45 0.15 10.6 7.5 5,000 2,993 30 1.13 3.4 29.80 90.6

24 1.30 10.7 7.4 5,000 2,993 30 1.38 4.2 43.40 132.2

Replaced solution with fresh water 10.4

24 1.50 4.50 10.8 5,000 2,993

26 1.50 10.8 7.8 5,000 2,993 30 0.38 5.4 12.14 168.5

28 1.50 10.8 5,000 2,993 30 0.41 5.5 13.32 172.4

31 1.50 10.6 5,000 2,993 30 0.40 5.4 14.17 175.4

48 1.40 0.30 10.7 7.2 4,990 2,983 30 0.42 5.5 17.13 184.5

54 1.42 0.24 10.6 5,010 3,003 30 0.42 5.5 17.51 186.5

72 1.30 7.9 4,998 2,991 0.42 5.5 19.02 191.3

Total 10.26 0.32

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,007 0.12 0.23 40.4 81.1

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 37.4 24.1 0.21

4 48.6 29.1 0.29

7 59.5 33.3 0.36

24 73.1 48.5 0.66

26 92.8 61.9 0.67

28 94.6 63.3 0.67

31 0.67

48 0.82

54 95.8 68.5

72 96.0 70.2 1.24 0.16

Residue 4.0 29.8

Total 100.0 100.0

30

0.93

Distribution Reagent Consumption

94.3

95.5

64.4

67.7

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

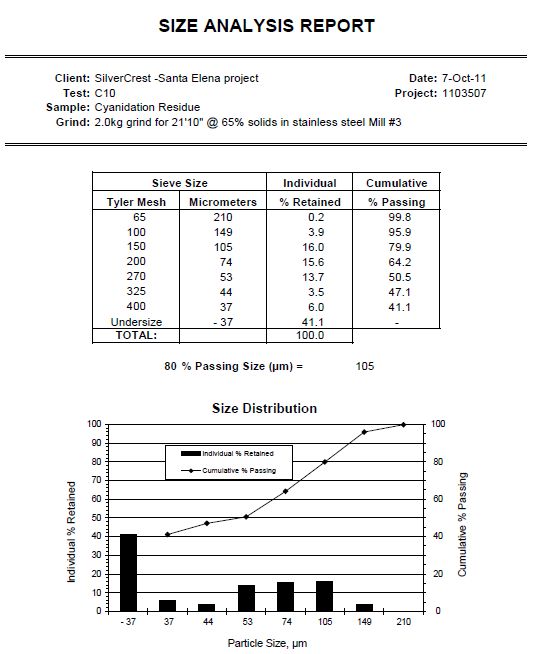

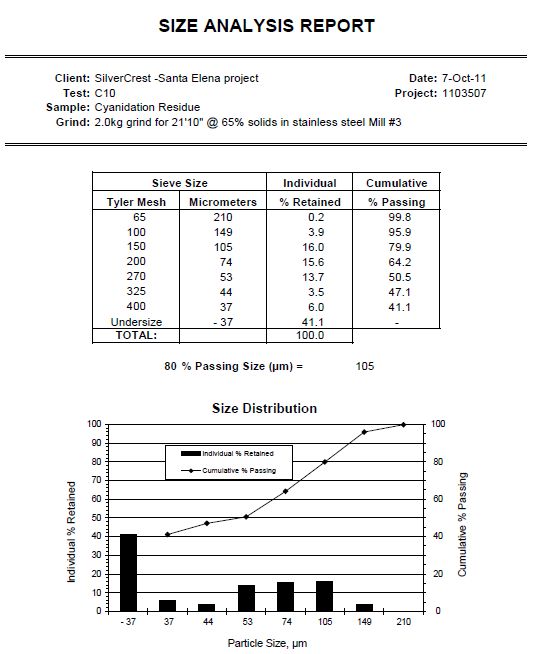

Client: SilverCrest -Santa Elena project Date: 7-Oct-11

Test: C10 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.2 99.8

100 149 3.9 95.9

150 105 16.0 79.9

200 74 15.6 64.2

270 53 13.7 50.5

325 44 3.5 47.1

400 37 6.0 41.1

Undersize - 37 41.1 -

TOTAL: 100.0

80 % Passing Size (μm) = 105

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

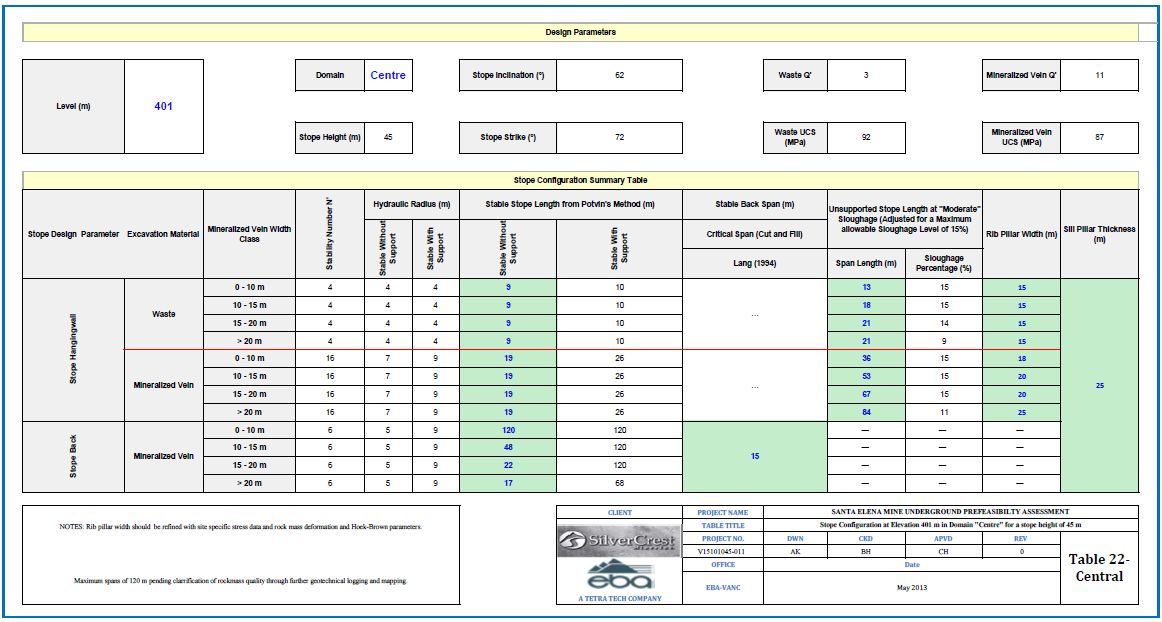

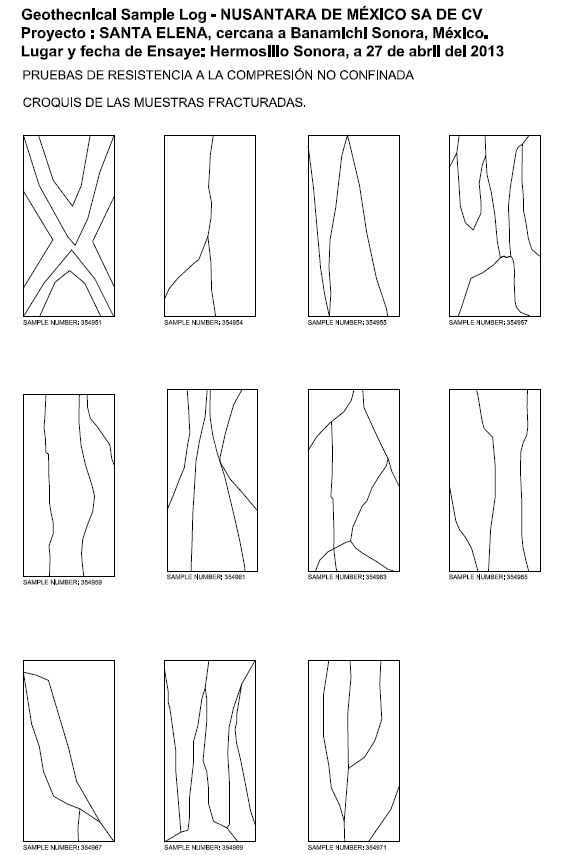

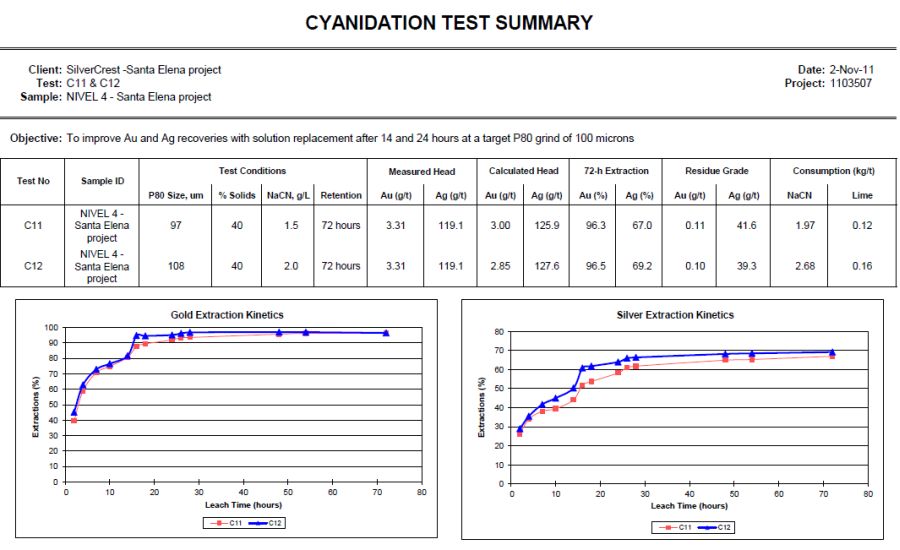

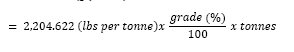

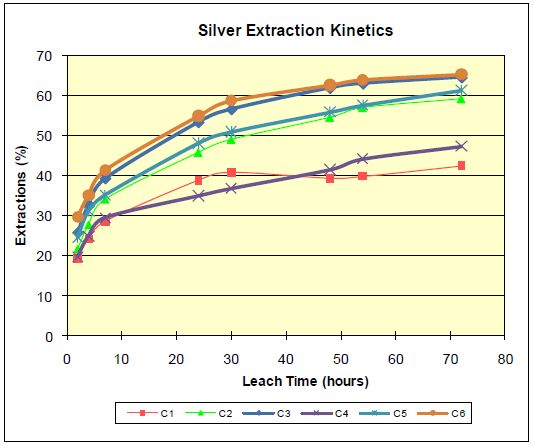

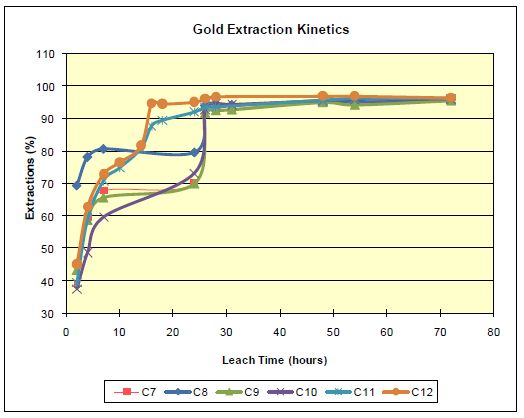

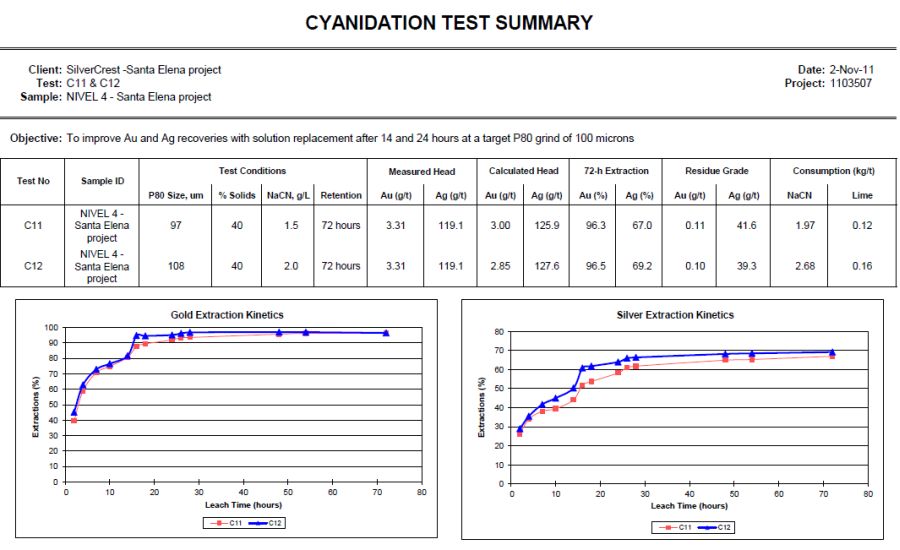

Client: SilverCrest -Santa Elena project Date: 2-Nov-11

Test: C11 & C12 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective: To improve Au and Ag recoveries with solution replacement after 14 and 24 hours at a target P80 grind of 100 microns

P80 Size, um % Solids NaCN, g/L Retention Au (g/t) Ag (g/t) Au (g/t) Ag (g/t) Au (%) Ag (%) Au (g/t) Ag (g/t) NaCN Lime

C11

NIVEL 4 -

Santa Elena

project

97 40 1.5 72 hours 3.31 119.1 3.00 125.9 96.3 67.0 0.11 41.6 1.97 0.12

C12

NIVEL 4 -

Santa Elena

project

108 40 2.0 72 hours 3.31 119.1 2.85 127.6 96.5 69.2 0.10 39.3 2.68 0.16

CYANIDATION TEST SUMMARY

Consumption (kg/t)

Test No Sample ID

Measured Head Calculated Head 72-Test Conditions h Extraction Residue Grade

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Gold Extraction Kinetics

C11 C12

0

10

20

30

40

50

60

70

80

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Silver Extraction Kinetics

C11 C12

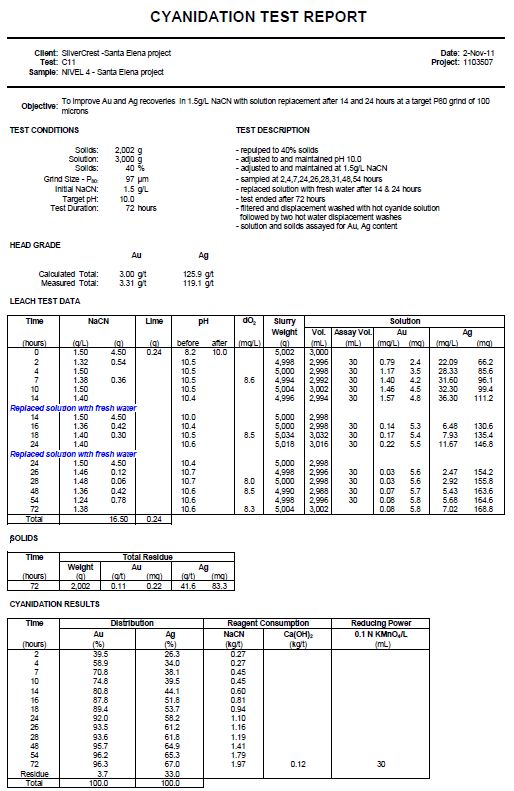

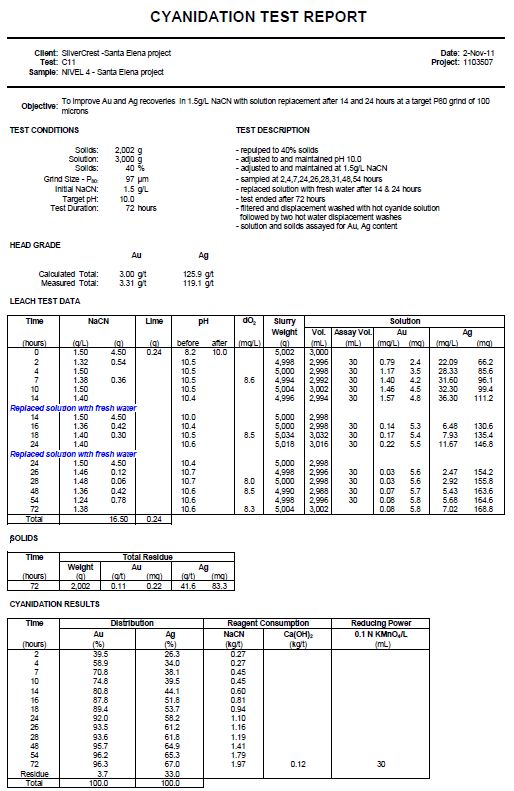

Client: SilverCrest -Santa Elena project Date: 2-Nov-11

Test: C11 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,002 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 97 μm - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 1.5 g/L - replaced solution with fresh water after 14 & 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 3.00 g/t 125.9 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 4.50 0.24 8.2 10.0 5,002 3,000

2 1.32 0.54 10.5 4,998 2,996 30 0.79 2.4 22.09 66.2

4 1.50 10.5 5,000 2,998 30 1.17 3.5 28.33 85.6

7 1.38 0.36 10.5 8.6 4,994 2,992 30 1.40 4.2 31.60 96.1

10 1.50 10.5 5,004 3,002 30 1.46 4.5 32.30 99.4

14 1.40 10.4 4,996 2,994 30 1.57 4.8 36.30 111.2

Replaced solution with fresh water

14 1.50 4.50 10.0 5,000 2,998

16 1.36 0.42 10.4 5,000 2,998 30 0.14 5.3 6.48 130.6

18 1.40 0.30 10.5 8.5 5,034 3,032 30 0.17 5.4 7.93 135.4

24 1.40 10.6 5,018 3,016 30 0.22 5.5 11.67 146.8

Replaced solution with fresh water

24 1.50 4.50 10.4 5,000 2,998

26 1.46 0.12 10.7 4,998 2,996 30 0.03 5.6 2.47 154.2

28 1.48 0.06 10.7 8.0 5,000 2,998 30 0.03 5.6 2.92 155.8

48 1.36 0.42 10.6 8.5 4,990 2,988 30 0.07 5.7 5.43 163.6

54 1.24 0.78 10.6 4,998 2,996 30 0.08 5.8 5.68 164.6

72 1.38 10.6 8.3 5,004 3,002 0.08 5.8 7.02 168.8

Total 16.50 0.24

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,002 0.11 0.22 41.6 83.3

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 39.5 26.3 0.27

4 58.9 34.0 0.27

7 70.8 38.1 0.45

10 74.8 39.5 0.45

14 80.8 44.1 0.60

16 87.8 51.8 0.81

18 89.4 53.7

24 92.0 58.2

26 1.16

28 1.19

48 1.41

54 96.2 65.3

72 96.3 67.0 1.97 0.12

Residue 3.7 33.0

Total 100.0 100.0

61.8

64.9

0.94

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

To improve Au and Ag recoveries in 1.5g/L NaCN with solution replacement after 14 and 24 hours at a target P80 grind of 100

microns

30

1.79

Distribution Reagent Consumption

93.6

1.10

93.5 61.2

95.7

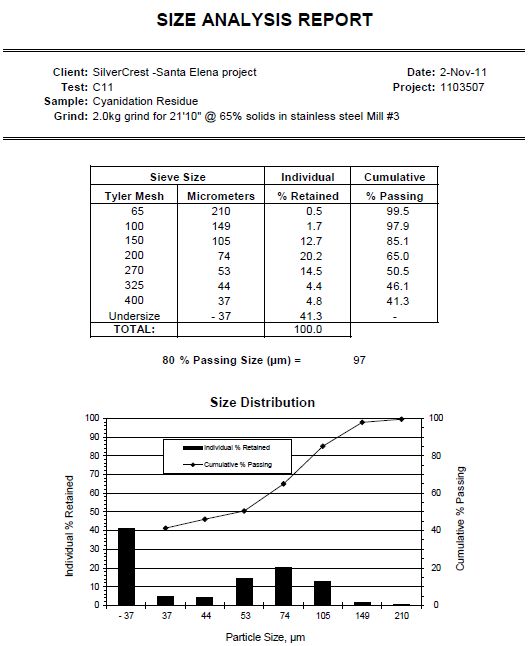

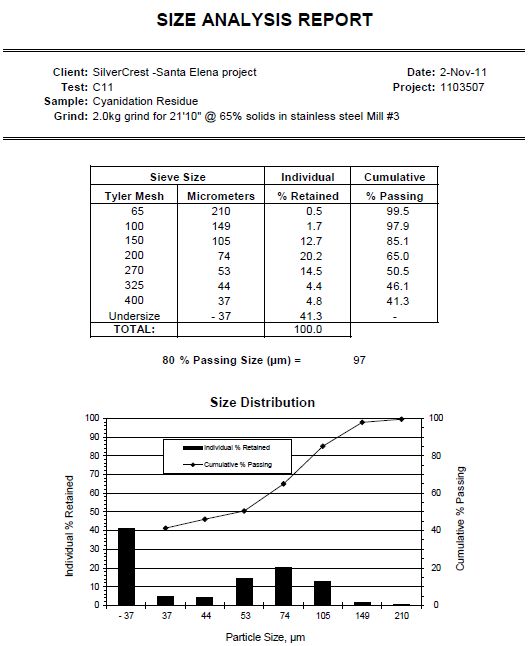

Client: SilverCrest -Santa Elena project Date: 2-Nov-11

Test: C11 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.5 99.5

100 149 1.7 97.9

150 105 12.7 85.1

200 74 20.2 65.0

270 53 14.5 50.5

325 44 4.4 46.1

400 37 4.8 41.3

Undersize - 37 41.3 -

TOTAL: 100.0

80 % Passing Size (μm) = 97

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

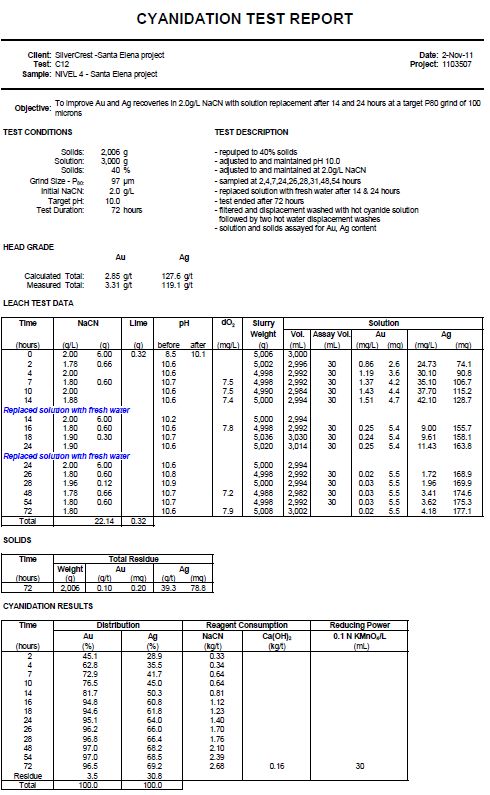

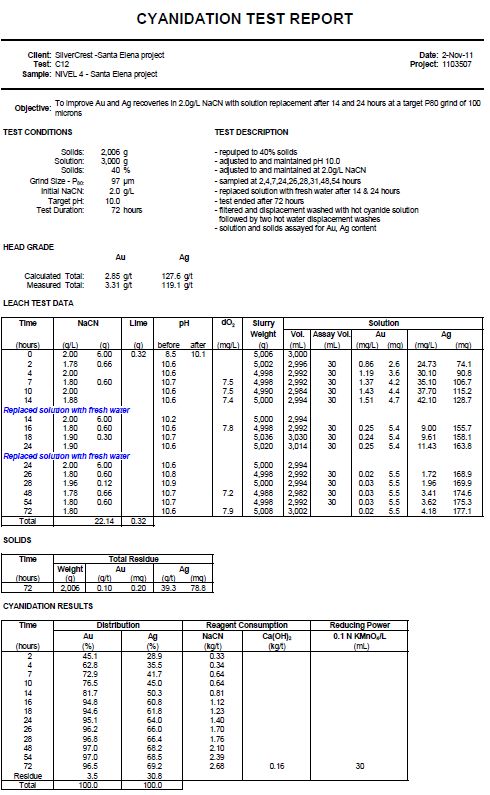

Client: SilverCrest -Santa Elena project Date: 2-Nov-11

Test: C12 Project: 1103507

Sample: NIVEL 4 - Santa Elena project

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,006 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 2.0g/L NaCN

Grind Size - P80: 97 μm - sampled at 2,4,7,24,26,28,31,48,54 hours

Initial NaCN: 2.0 g/L - replaced solution with fresh water after 14 & 24 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 2.85 g/t 127.6 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 2.00 6.00 0.32 8.5 10.1 5,006 3,000

2 1.78 0.66 10.6 5,002 2,996 30 0.86 2.6 24.73 74.1

4 2.00 10.6 4,998 2,992 30 1.19 3.6 30.10 90.8

7 1.80 0.60 10.7 7.5 4,998 2,992 30 1.37 4.2 35.10 106.7

10 2.00 10.6 7.5 4,990 2,984 30 1.43 4.4 37.70 115.2

14 1.88 10.6 7.4 5,000 2,994 30 1.51 4.7 42.10 128.7

Replaced solution with fresh water

14 2.00 6.00 10.2 5,000 2,994

16 1.80 0.60 10.6 7.8 4,998 2,992 30 0.25 5.4 9.00 155.7

18 1.90 0.30 10.7 5,036 3,030 30 0.24 5.4 9.61 158.1

24 1.90 10.6 5,020 3,014 30 0.25 5.4 11.43 163.8

Replaced solution with fresh water

24 2.00 6.00 10.6 5,000 2,994

26 1.80 0.60 10.8 4,998 2,992 30 0.02 5.5 1.72 168.9

28 1.96 0.12 10.9 5,000 2,994 30 0.03 5.5 1.96 169.9

48 1.78 0.66 10.7 7.2 4,988 2,982 30 0.03 5.5 3.41 174.6

54 1.80 0.60 10.7 4,998 2,992 30 0.03 5.5 3.62 175.3

72 1.80 10.6 7.9 5,008 3,002 0.02 5.5 4.18 177.1

Total 22.14 0.32

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,006 0.10 0.20 39.3 78.8

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 45.1 28.9 0.33

4 62.8 35.5 0.34

7 72.9 41.7 0.64

10 76.5 45.0 0.64

14 81.7 50.3 0.81

16 94.8 60.8 1.12

18 94.6 61.8 1.23

24 95.1 64.0 1.40

26 1.70

28 1.76

48 2.10

54 97.0 68.5

72 96.5 69.2 2.68 0.16

Residue 3.5 30.8

Total 100.0 100.0

30

2.39

Distribution Reagent Consumption

96.8

97.0

66.4

68.2

96.2 66.0

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

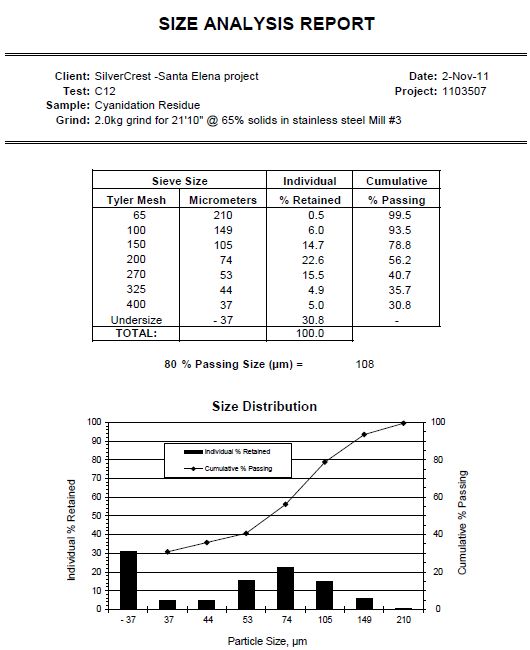

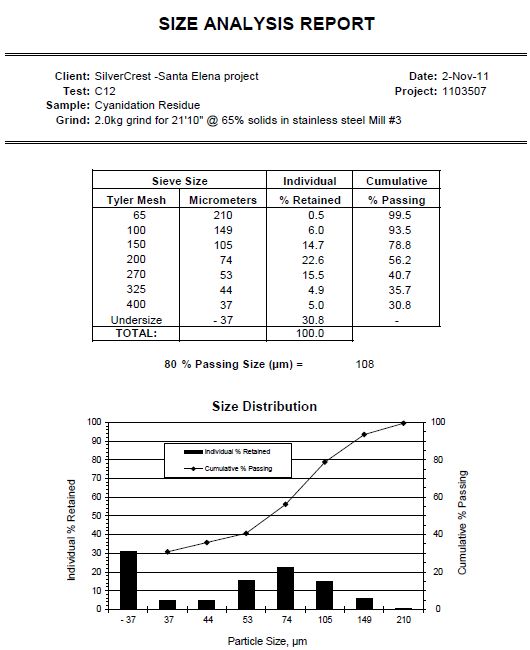

Client: SilverCrest -Santa Elena project Date: 2-Nov-11

Test: C12 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'10" @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.5 99.5

100 149 6.0 93.5

150 105 14.7 78.8

200 74 22.6 56.2

270 53 15.5 40.7

325 44 4.9 35.7

400 37 5.0 30.8

Undersize - 37 30.8 -

TOTAL: 100.0

80 % Passing Size (μm) = 108

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

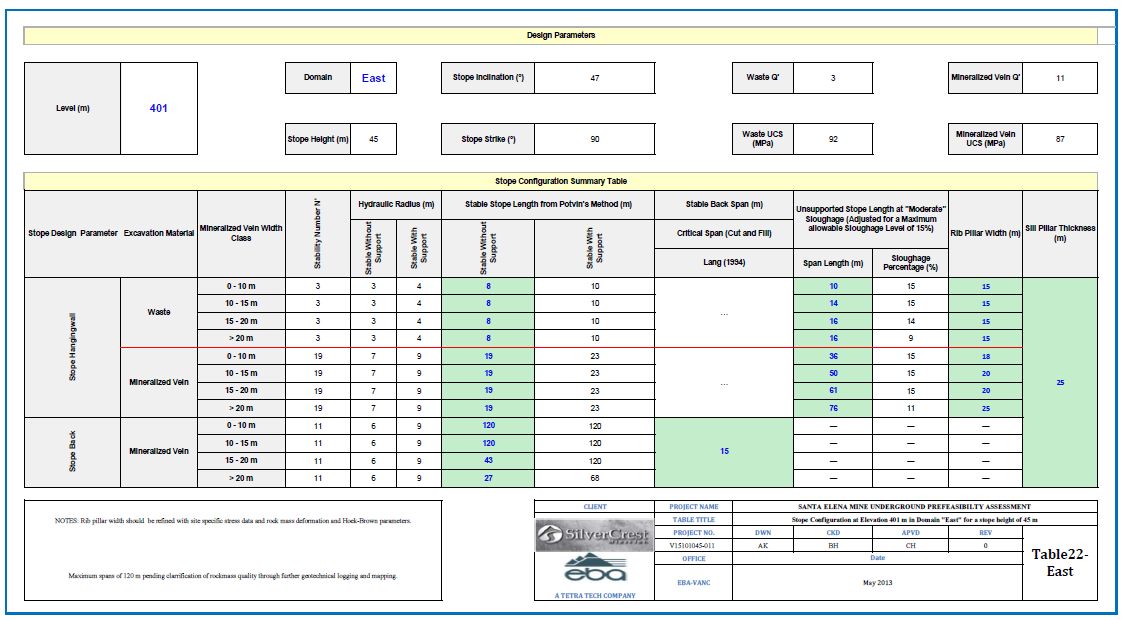

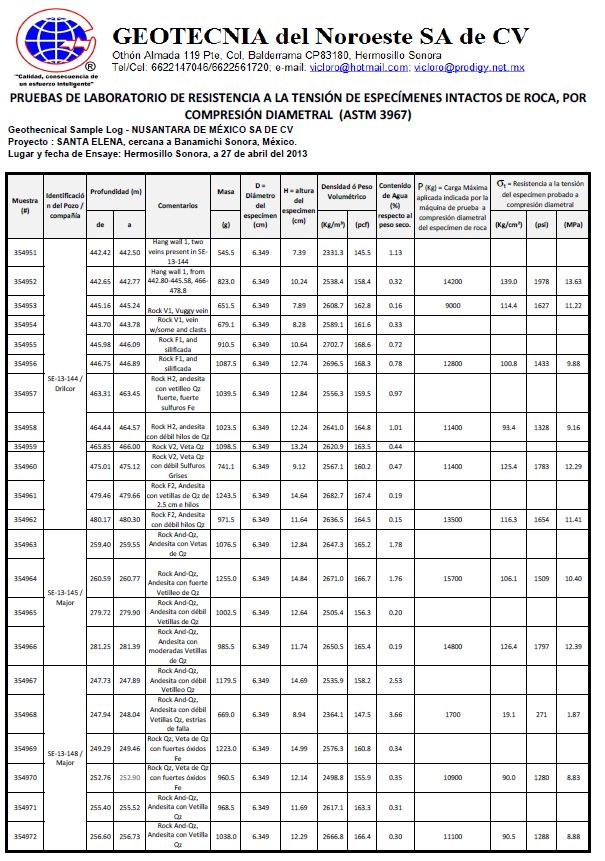

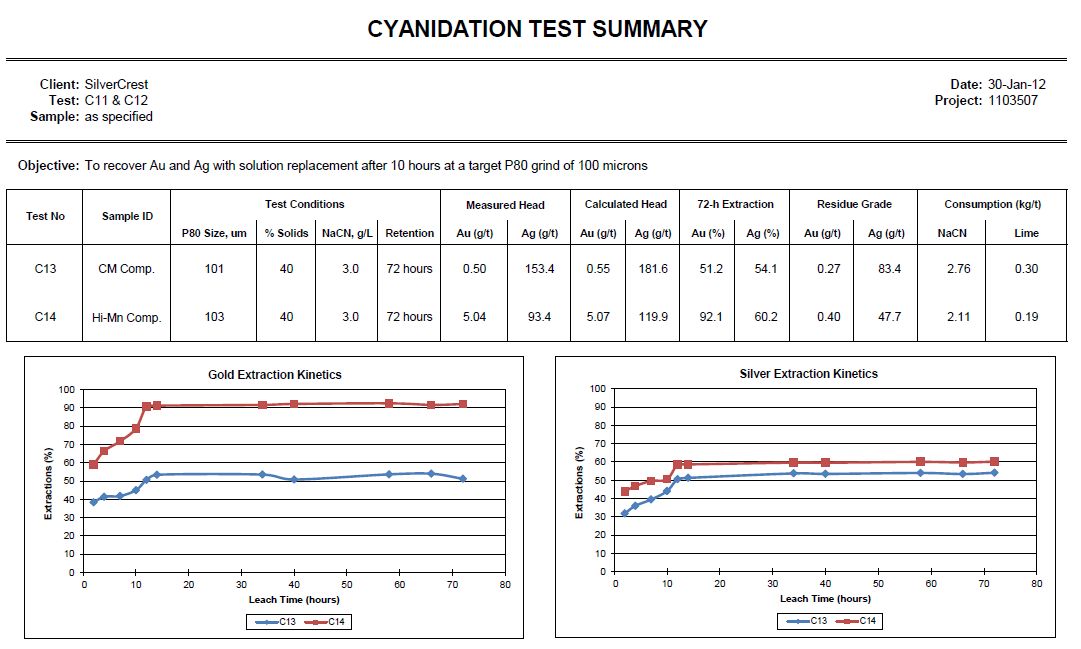

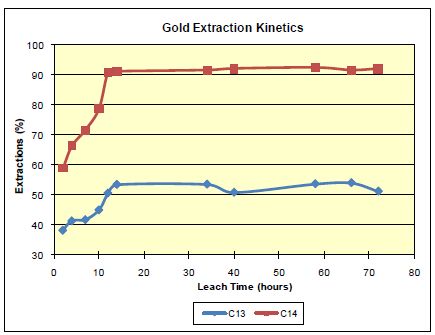

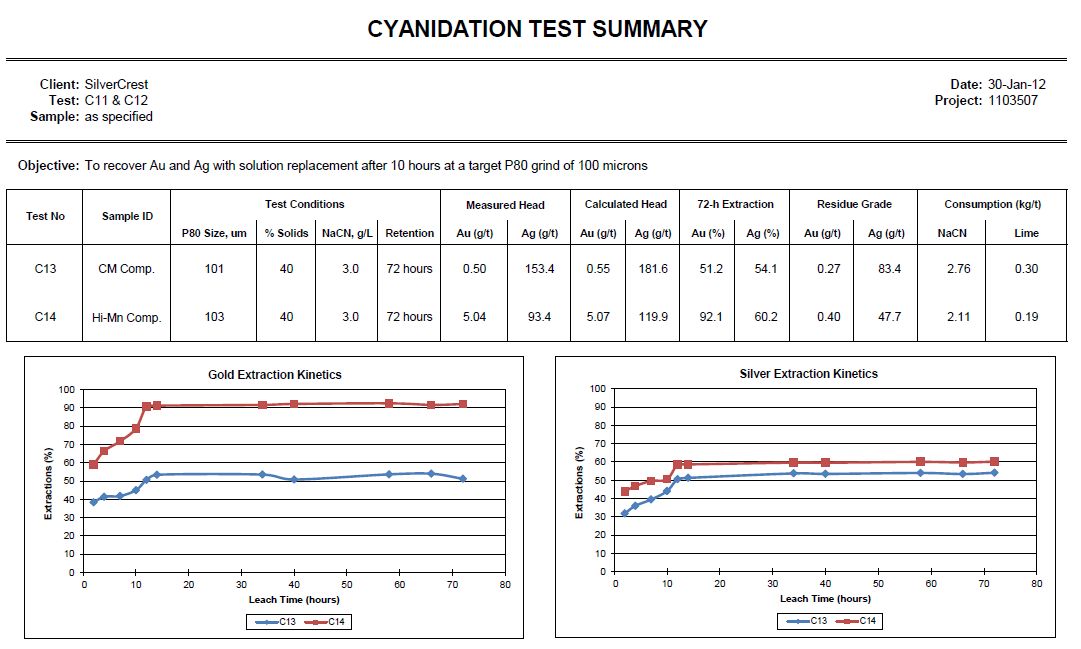

Client: SilverCrest Date: 30-Jan-12

Test: C11 & C12 Project: 1103507

Sample: as specified

Objective: To recover Au and Ag with solution replacement after 10 hours at a target P80 grind of 100 microns

P80 Size, um % Solids NaCN, g/L Retention Au (g/t) Ag (g/t) Au (g/t) Ag (g/t) Au (%) Ag (%) Au (g/t) Ag (g/t) NaCN Lime

C13 CM Comp. 101 40 3.0 72 hours 0.50 153.4 0.55 181.6 51.2 54.1 0.27 83.4 2.76 0.30

C14 Hi-Mn Comp. 103 40 3.0 72 hours 5.04 93.4 5.07 119.9 92.1 60.2 0.40 47.7 2.11 0.19

CYANIDATION TEST SUMMARY

Test No Sample ID

Test Conditions Measured Head Calculated Head 72-h Extraction Residue Grade Consumption (kg/t)

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Gold Extraction Kinetics

C13 C14

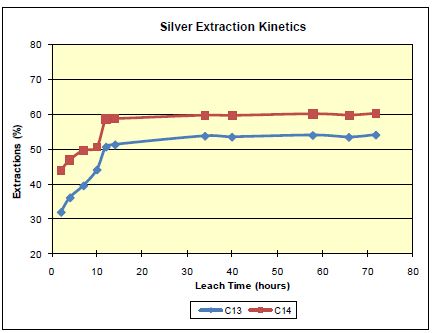

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Silver Extraction Kinetics

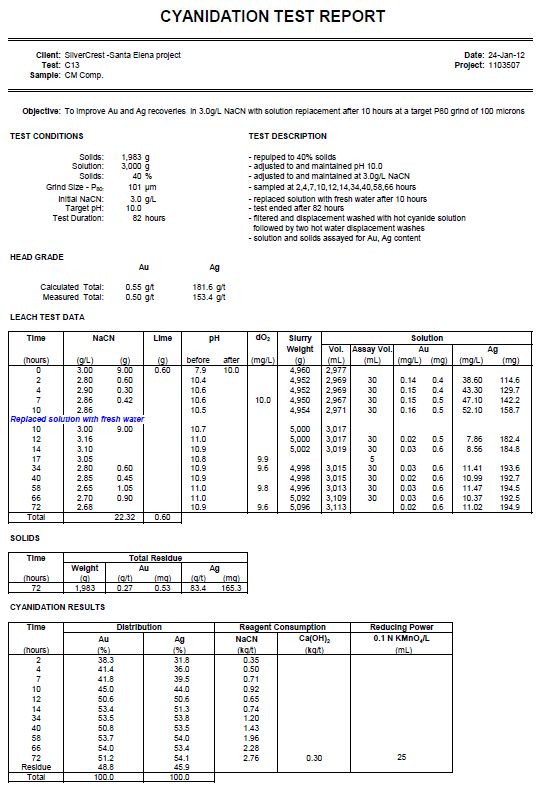

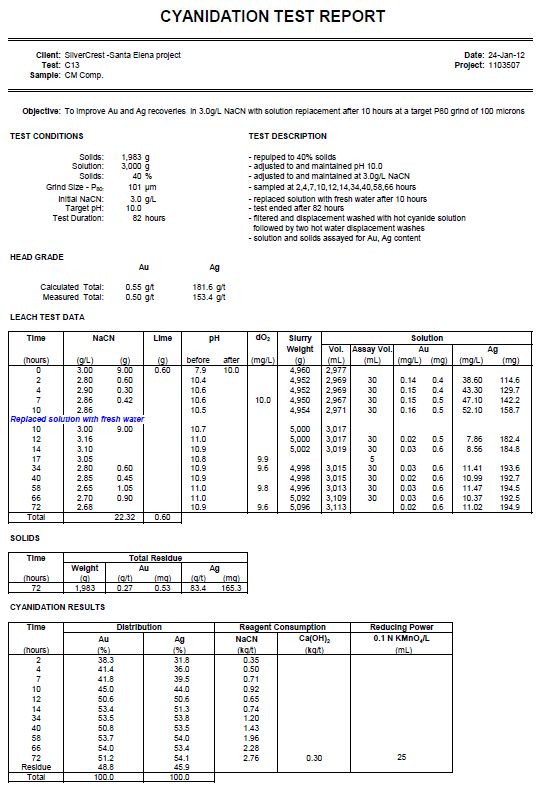

Client: SilverCrest -Santa Elena project Date: 24-Jan-12

Test: C13 Project: 1103507

Sample: CM Comp.

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 1,983 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 3.0g/L NaCN

Grind Size - P80: 101 μm - sampled at 2,4,7,10,12,14,34,40,58,66 hours

Initial NaCN: 3.0 g/L - replaced solution with fresh water after 10 hours

Target pH: 10.0 - test ended after 82 hours

Test Duration: 82 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 0.55 g/t 181.6 g/t

Measured Total: 0.50 g/t 153.4 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 3.00 9.00 0.60 7.9 10.0 4,960 2,977

2 2.80 0.60 10.4 4,952 2,969 30 0.14 0.4 38.60 114.6

4 2.90 0.30 10.6 4,952 2,969 30 0.15 0.4 43.30 129.7

7 2.86 0.42 10.6 10.0 4,950 2,967 30 0.15 0.5 47.10 142.2

10 2.86 10.5 4,954 2,971 30 0.16 0.5 52.10 158.7

Replaced solution with fresh water

10 3.00 9.00 10.7 5,000 3,017

12 3.16 11.0 5,000 3,017 30 0.02 0.5 7.86 182.4

14 3.10 10.9 5,002 3,019 30 0.03 0.6 8.56 184.8

17 3.05 10.8 9.9 5

34 2.80 0.60 10.9 9.6 4,998 3,015 30 0.03 0.6 11.41 193.6

40 2.85 0.45 10.9 4,998 3,015 30 0.02 0.6 10.99 192.7

58 2.65 1.05 11.0 9.8 4,996 3,013 30 0.03 0.6 11.47 194.5

66 2.70 0.90 11.0 5,092 3,109 30 0.03 0.6 10.37 192.5

72 2.68 10.9 9.6 5,096 3,113 0.02 0.6 11.02 194.9

Total 22.32 0.60

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 1,983 0.27 0.53 83.4 165.3

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 38.3 31.8 0.35

4 41.4 36.0 0.50

7 41.8 39.5 0.71

10 45.0 44.0 0.92

12 50.6 50.6 0.65

14 53.4 51.3 0.74

34 53.5 53.8

40 50.8 53.5

58 1.96

66 2.28

72 51.2 54.1 2.76 0.30

Residue 48.8 45.9

Total 100.0 100.0

53.7 54.0

53.4

1.20

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

To improve Au and Ag recoveries in 3.0g/L NaCN with solution replacement after 10 hours at a target P80 grind of 100 microns

25

Distribution Reagent Consumption

54.0

1.43

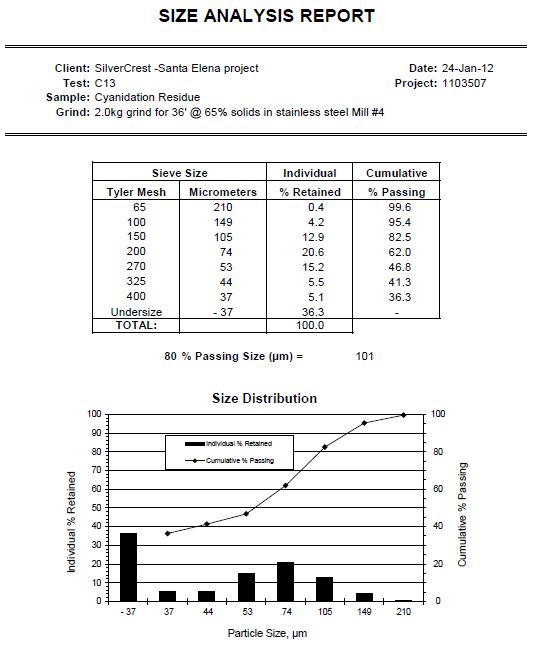

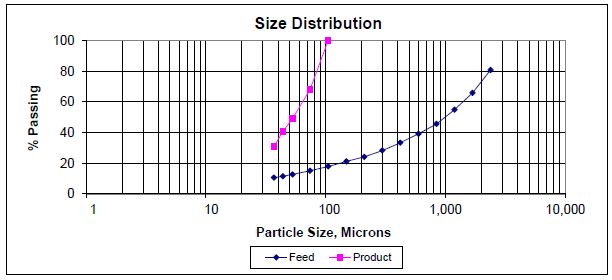

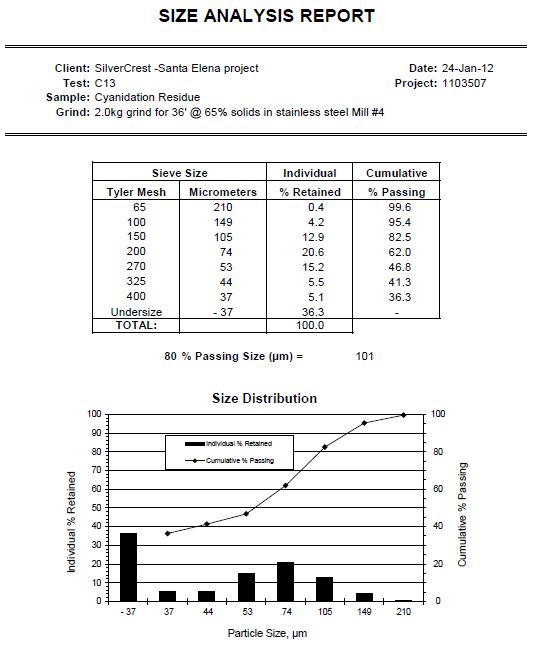

Client: SilverCrest -Santa Elena project Date: 24-Jan-12

Test: C13 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 36' @ 65% solids in stainless steel Mill #4

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.4 99.6

100 149 4.2 95.4

150 105 12.9 82.5

200 74 20.6 62.0

270 53 15.2 46.8

325 44 5.5 41.3

400 37 5.1 36.3

Undersize - 37 36.3 -

TOTAL: 100.0

80 % Passing Size (μm) = 101

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

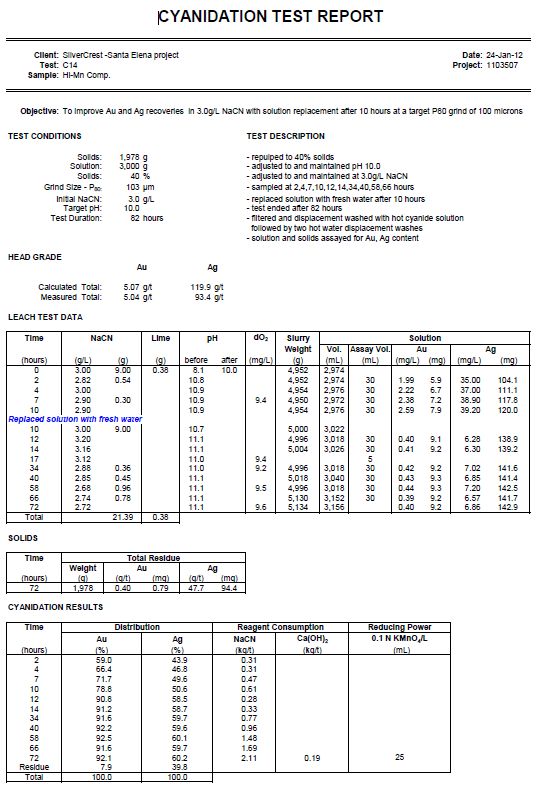

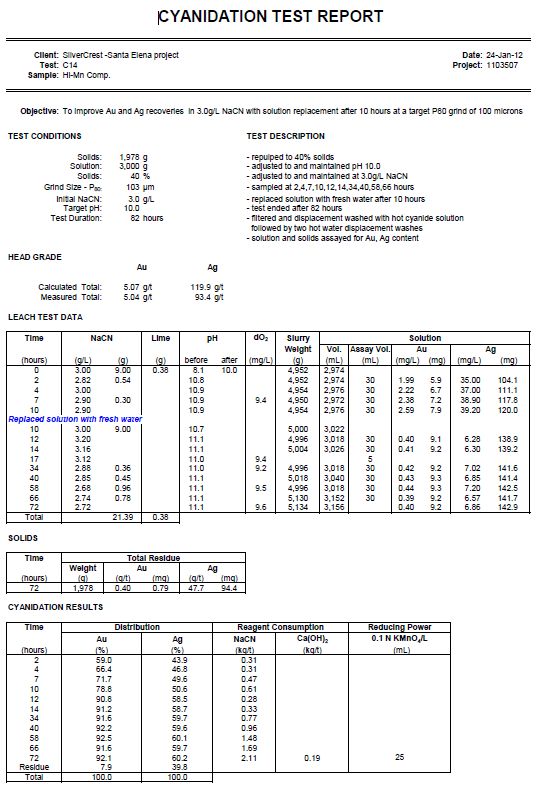

Client: SilverCrest -Santa Elena project Date: 24-Jan-12

Test: C14 Project: 1103507

Sample: Hi-Mn Comp.

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 1,978 g - repulped to 40% solids

Solution: 3,000 g - adjusted to and maintained pH 10.0

Solids: 40 % - adjusted to and maintained at 3.0g/L NaCN

Grind Size - P80: 103 μm - sampled at 2,4,7,10,12,14,34,40,58,66 hours

Initial NaCN: 3.0 g/L - replaced solution with fresh water after 10 hours

Target pH: 10.0 - test ended after 82 hours

Test Duration: 82 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 5.07 g/t 119.9 g/t

Measured Total: 5.04 g/t 93.4 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 3.00 9.00 0.38 8.1 10.0 4,952 2,974

2 2.82 0.54 10.8 4,952 2,974 30 1.99 5.9 35.00 104.1

4 3.00 10.9 4,954 2,976 30 2.22 6.7 37.00 111.1

7 2.90 0.30 10.9 9.4 4,950 2,972 30 2.38 7.2 38.90 117.8

10 2.90 10.9 4,954 2,976 30 2.59 7.9 39.20 120.0

Replaced solution with fresh water

10 3.00 9.00 10.7 5,000 3,022

12 3.20 11.1 4,996 3,018 30 0.40 9.1 6.28 138.9

14 3.16 11.1 5,004 3,026 30 0.41 9.2 6.30 139.2

17 3.12 11.0 9.4 5

34 2.88 0.36 11.0 9.2 4,996 3,018 30 0.42 9.2 7.02 141.6

40 2.85 0.45 11.1 5,018 3,040 30 0.43 9.3 6.85 141.4

58 2.68 0.96 11.1 9.5 4,996 3,018 30 0.44 9.3 7.20 142.5

66 2.74 0.78 11.1 5,130 3,152 30 0.39 9.2 6.57 141.7

72 2.72 11.1 9.6 5,134 3,156 0.40 9.2 6.86 142.9

Total 21.39 0.38

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 1,978 0.40 0.79 47.7 94.4

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 59.0 43.9 0.31

4 66.4 46.8 0.31

7 71.7 49.6 0.47

10 78.8 50.6 0.61

12 90.8 58.5 0.28

14 91.2 58.7 0.33

34 91.6 59.7

40 92.2 59.6

58 1.48

66 1.69

72 92.1 60.2 2.11 0.19

Residue 7.9 39.8

Total 100.0 100.0

CYANIDATION TEST REPORT

To improve Au and Ag recoveries in 3.0g/L NaCN with solution replacement after 10 hours at a target P80 grind of 100 microns

Solution

Ag

Total Residue

Distribution Reagent Consumption

25

0.77

0.96

92.5 60.1

91.6 59.7

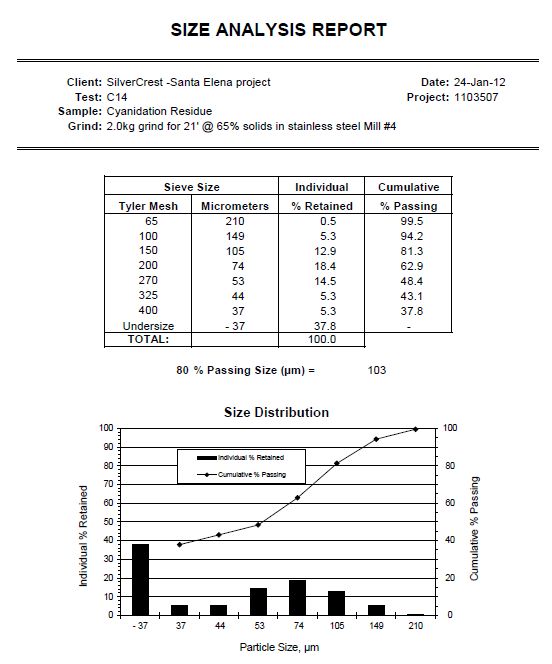

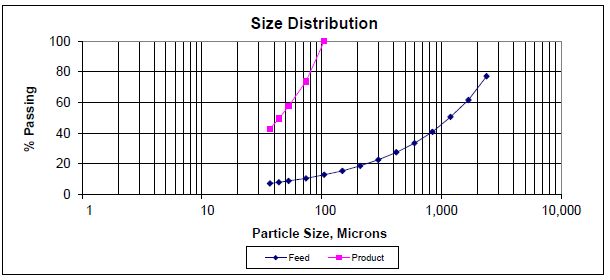

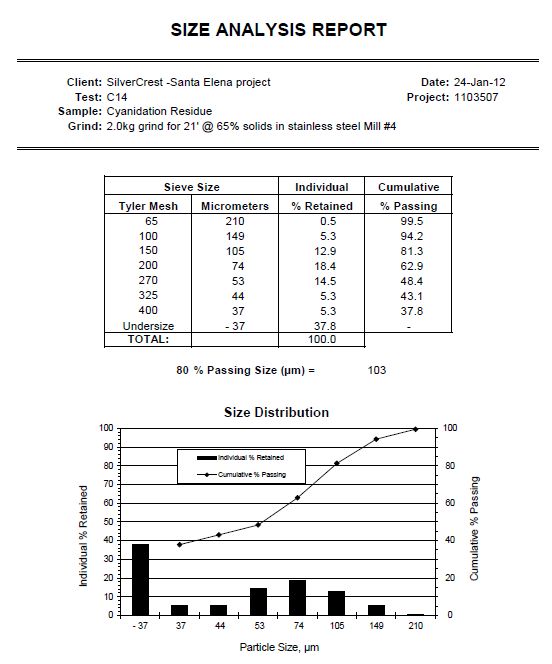

Client: SilverCrest -Santa Elena project Date: 24-Jan-12

Test: C14 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21' @ 65% solids in stainless steel Mill #4

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.5 99.5

100 149 5.3 94.2

150 105 12.9 81.3

200 74 18.4 62.9

270 53 14.5 48.4

325 44 5.3 43.1

400 37 5.3 37.8

Undersize - 37 37.8 -

TOTAL: 100.0

80 % Passing Size (μm) = 103

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

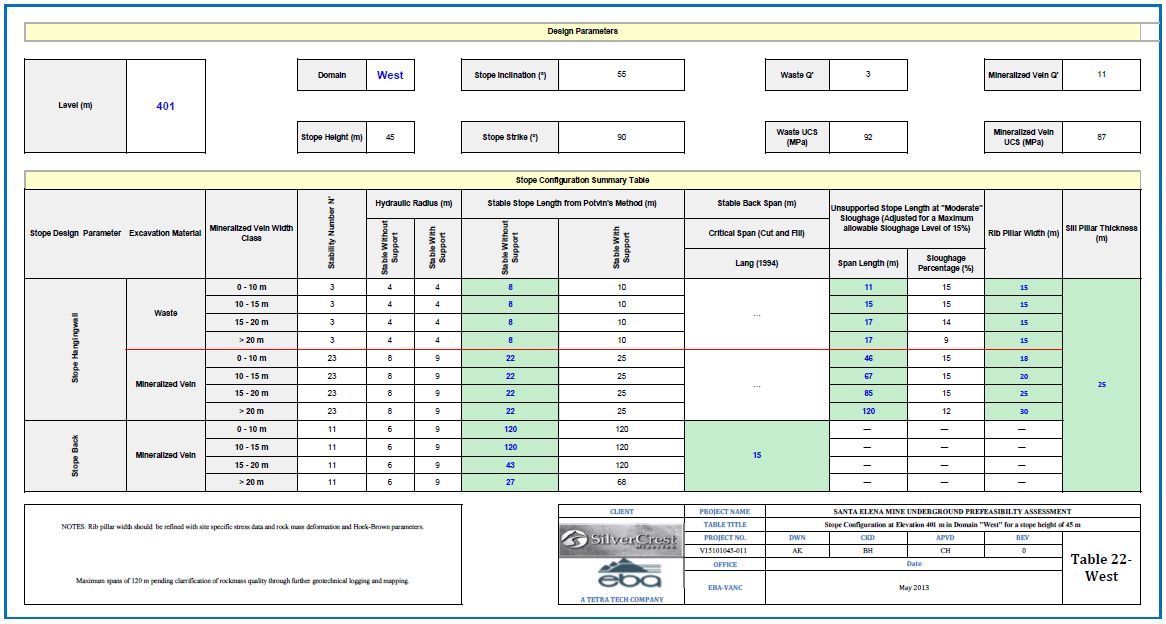

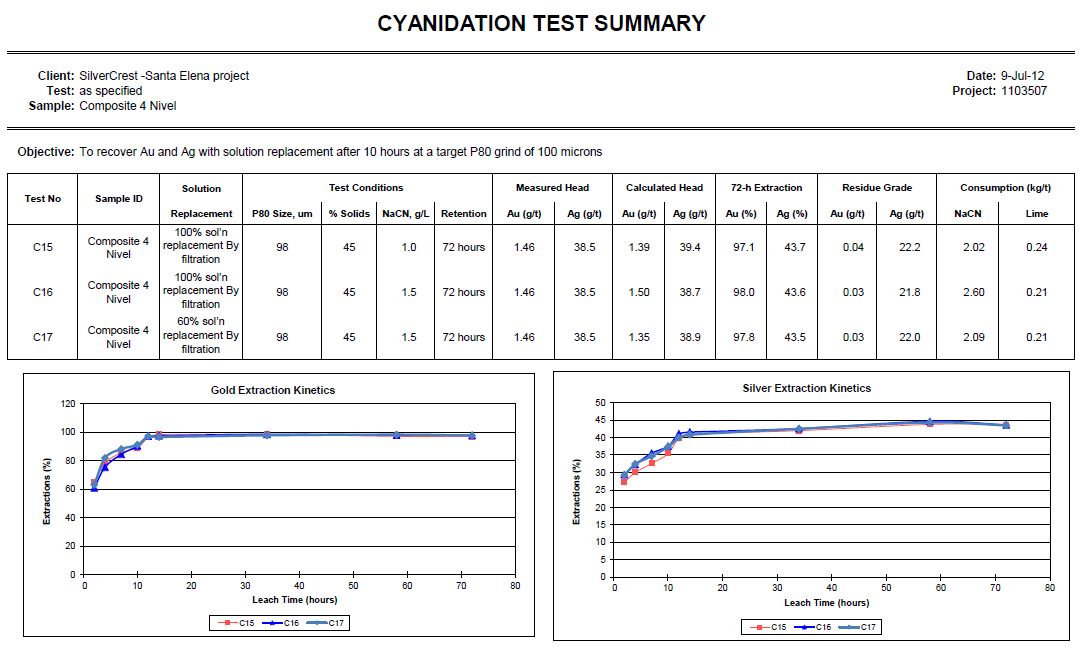

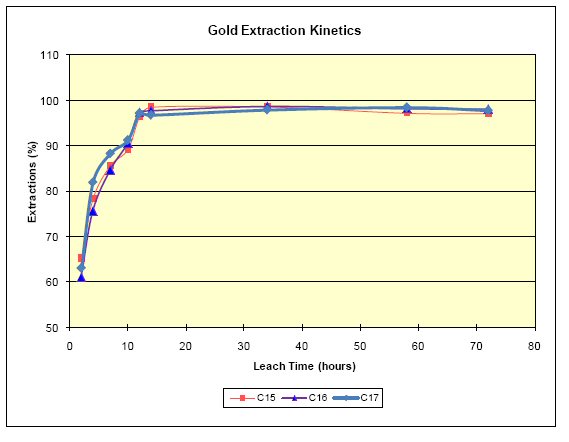

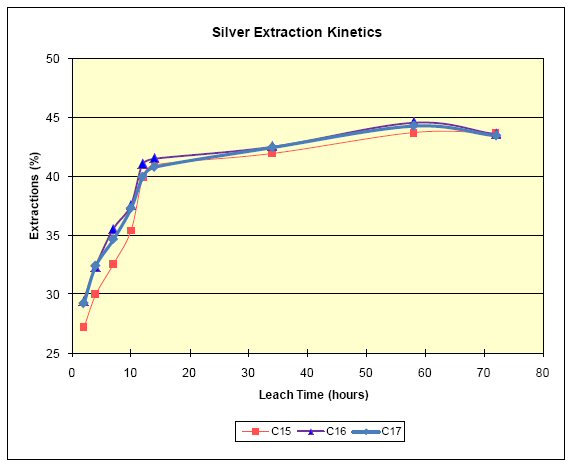

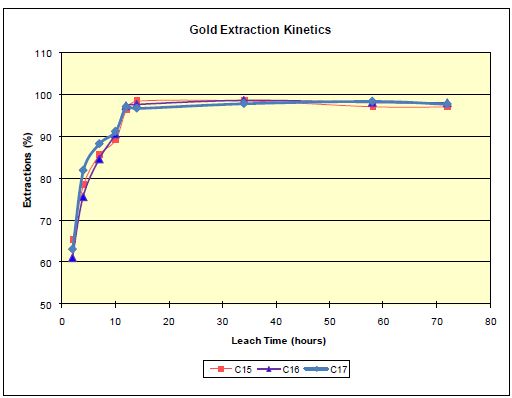

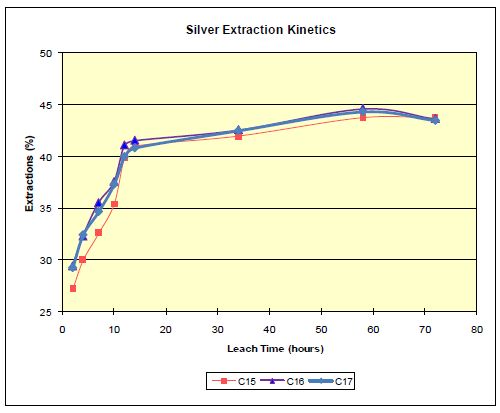

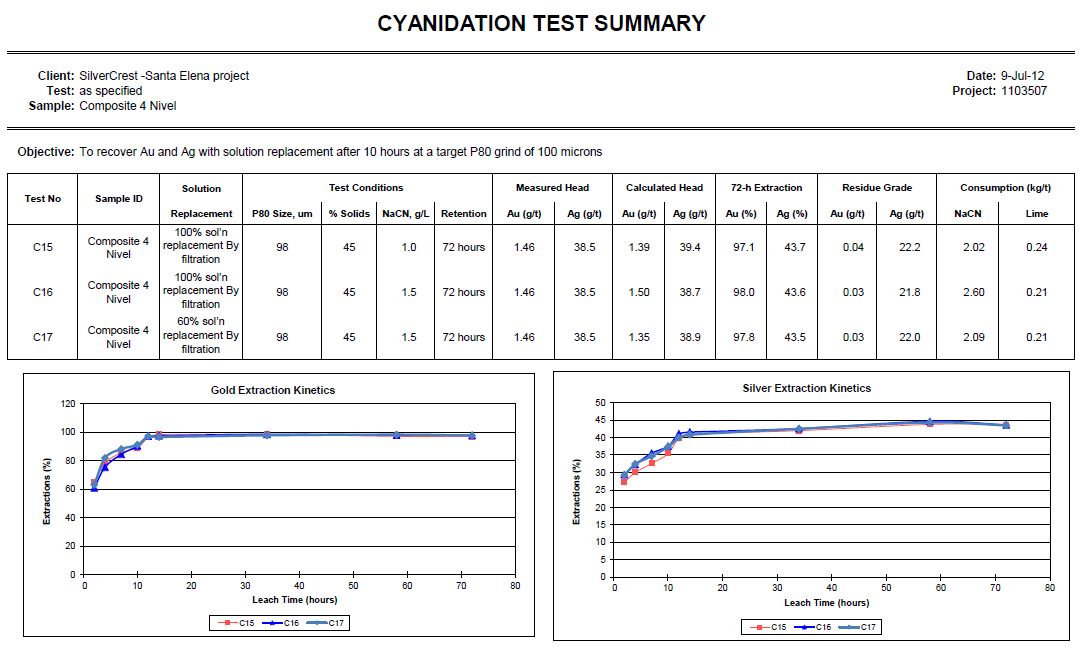

Client: SilverCrest -Santa Elena project Date: 9-Jul-12

Test: as specified Project: 1103507

Sample: Composite 4 Nivel

Objective: To recover Au and Ag with solution replacement after 10 hours at a target P80 grind of 100 microns

Solution

Replacement P80 Size, um % Solids NaCN, g/L Retention Au (g/t) Ag (g/t) Au (g/t) Ag (g/t) Au (%) Ag (%) Au (g/t) Ag (g/t) NaCN Lime

C15

Composite 4

Nivel

100% sol’n

replacement By

filtration

98 45 1.0 72 hours 1.46 38.5 1.39 39.4 97.1 43.7 0.04 22.2 2.02 0.24

C16

Composite 4

Nivel

100% sol’n

replacement By

filtration

98 45 1.5 72 hours 1.46 38.5 1.50 38.7 98.0 43.6 0.03 21.8 2.60 0.21

C17

Composite 4

Nivel

60% sol’n

replacement By

filtration

98 45 1.5 72 hours 1.46 38.5 1.35 38.9 97.8 43.5 0.03 22.0 2.09 0.21

CYANIDATION TEST SUMMARY

Consumption (kg/t)

Test No Sample ID

Test Conditions Measured Head Calculated Head 72-h Extraction Residue Grade

0

20

40

60

80

100

120

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Gold Extraction Kinetics

C15 C16 C17

0

5

10

15

20

25

30

35

40

45

50

0 10 20 30 40 50 60 70 80

Extractions (%)

Leach Time (hours)

Silver Extraction Kinetics

C15 C16 C17

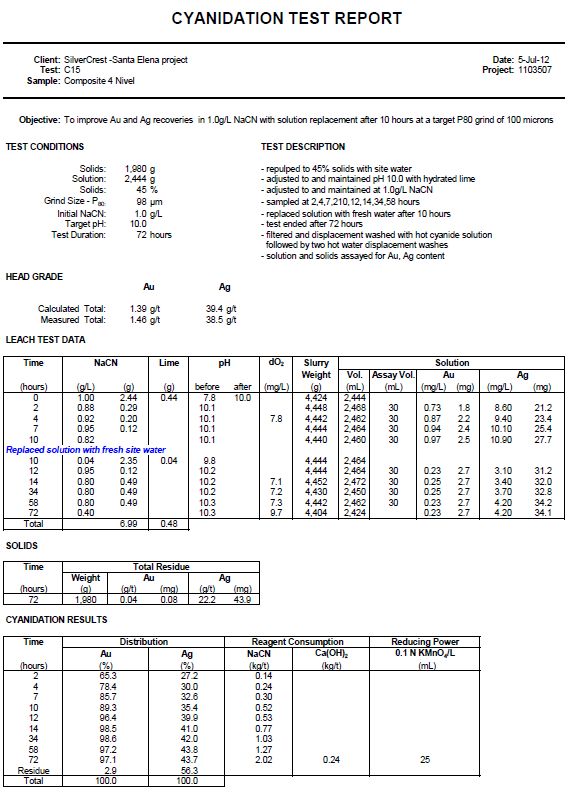

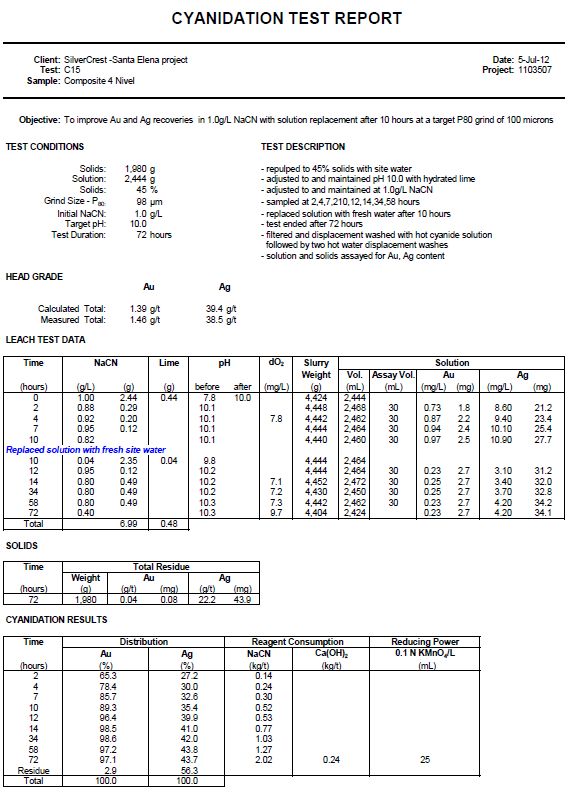

Client: SilverCrest -Santa Elena project Date: 5-Jul-12

Test: C15 Project: 1103507

Sample: Composite 4 Nivel

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 1,980 g - repulped to 45% solids with site water

Solution: 2,444 g - adjusted to and maintained pH 10.0 with hydrated lime

Solids: 45 % - adjusted to and maintained at 1.0g/L NaCN

Grind Size - P80: 98 μm - sampled at 2,4,7,210,12,14,34,58 hours

Initial NaCN: 1.0 g/L - replaced solution with fresh water after 10 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 1.39 g/t 39.4 g/t

Measured Total: 1.46 g/t 38.5 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.00 2.44 0.44 7.8 10.0 4,424 2,444

2 0.88 0.29 10.1 4,448 2,468 30 0.73 1.8 8.60 21.2

4 0.92 0.20 10.1 7.8 4,442 2,462 30 0.87 2.2 9.40 23.4

7 0.95 0.12 10.1 4,444 2,464 30 0.94 2.4 10.10 25.4

10 0.82 10.1 4,440 2,460 30 0.97 2.5 10.90 27.7

Replaced solution with fresh site water

10 0.04 2.35 0.04 9.8 4,444 2,464

12 0.95 0.12 10.2 4,444 2,464 30 0.23 2.7 3.10 31.2

14 0.80 0.49 10.2 7.1 4,452 2,472 30 0.25 2.7 3.40 32.0

34 0.80 0.49 10.2 7.2 4,430 2,450 30 0.25 2.7 3.70 32.8

58 0.80 0.49 10.3 7.3 4,442 2,462 30 0.23 2.7 4.20 34.2

72 0.40 10.3 9.7 4,404 2,424 0.23 2.7 4.20 34.1

Total 6.99 0.48

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 1,980 0.04 0.08 22.2 43.9

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 65.3 27.2 0.14

4 78.4 30.0 0.24

7 85.7 32.6 0.30

10 89.3 35.4 0.52

12 96.4 39.9 0.53

14 98.5 41.0 0.77

34 98.6 42.0 1.03

58 1.27

72 97.1 43.7 2.02 0.24

Residue 2.9 56.3

Total 100.0 100.0

25

Distribution Reagent Consumption

97.2 43.8

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

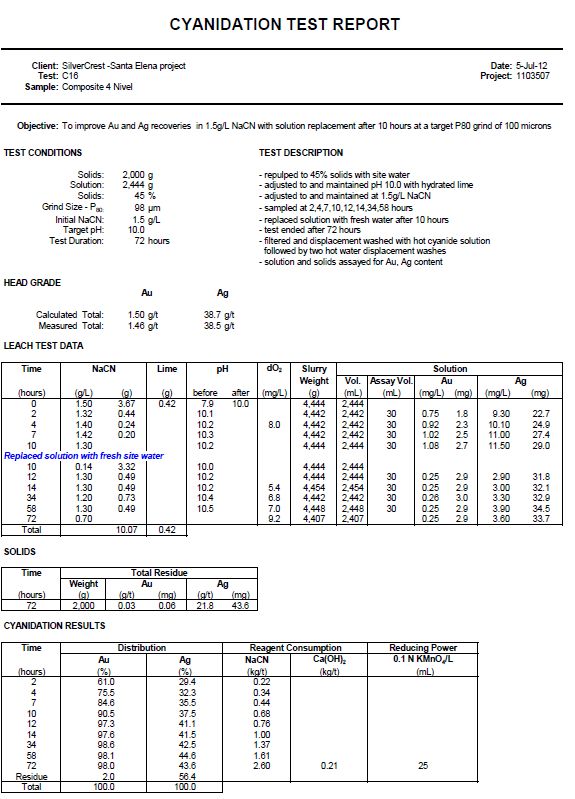

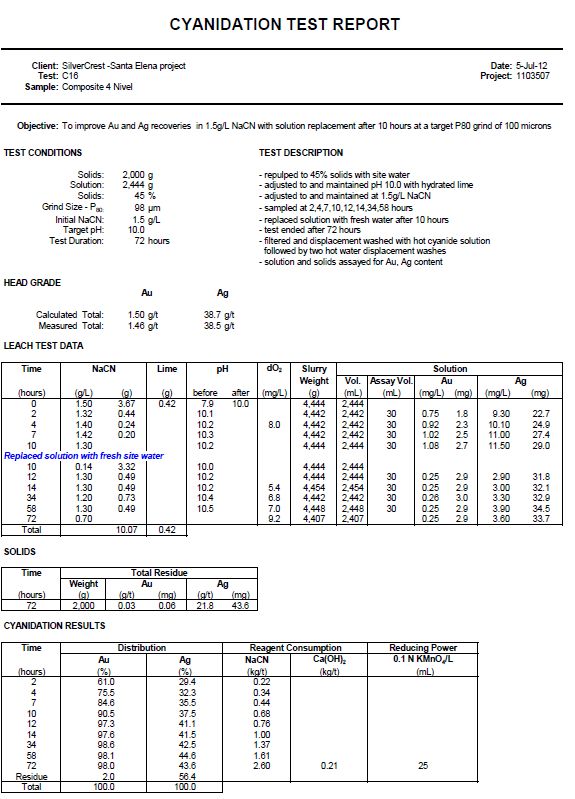

Client: SilverCrest -Santa Elena project Date: 5-Jul-12

Test: C16 Project: 1103507

Sample: Composite 4 Nivel

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,000 g - repulped to 45% solids with site water

Solution: 2,444 g - adjusted to and maintained pH 10.0 with hydrated lime

Solids: 45 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 98 μm - sampled at 2,4,7,10,12,14,34,58 hours

Initial NaCN: 1.5 g/L - replaced solution with fresh water after 10 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 1.50 g/t 38.7 g/t

Measured Total: 1.46 g/t 38.5 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 3.67 0.42 7.9 10.0 4,444 2,444

2 1.32 0.44 10.1 4,442 2,442 30 0.75 1.8 9.30 22.7

4 1.40 0.24 10.2 8.0 4,442 2,442 30 0.92 2.3 10.10 24.9

7 1.42 0.20 10.3 4,442 2,442 30 1.02 2.5 11.00 27.4

10 1.30 10.2 4,444 2,444 30 1.08 2.7 11.50 29.0

Replaced solution with fresh site water

10 0.14 3.32 10.0 4,444 2,444

12 1.30 0.49 10.2 4,444 2,444 30 0.25 2.9 2.90 31.8

14 1.30 0.49 10.2 5.4 4,454 2,454 30 0.25 2.9 3.00 32.1

34 1.20 0.73 10.4 6.8 4,442 2,442 30 0.26 3.0 3.30 32.9

58 1.30 0.49 10.5 7.0 4,448 2,448 30 0.25 2.9 3.90 34.5

72 0.70 9.2 4,407 2,407 0.25 2.9 3.60 33.7

Total 10.07 0.42

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,000 0.03 0.06 21.8 43.6

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 61.0 29.4 0.22

4 75.5 32.3 0.34

7 84.6 35.5 0.44

10 90.5 37.5 0.68

12 97.3 41.1 0.76

14 97.6 41.5 1.00

34 98.6 42.5 1.37

58 1.61

72 98.0 43.6 2.60 0.21

Residue 2.0 56.4

Total 100.0 100.0

98.1 44.6

25

CYANIDATION TEST REPORT

To improve Au and Ag recoveries in 1.5g/L NaCN with solution replacement after 10 hours at a target P80 grind of 100 microns

Solution

Ag

Total Residue

Distribution Reagent Consumption

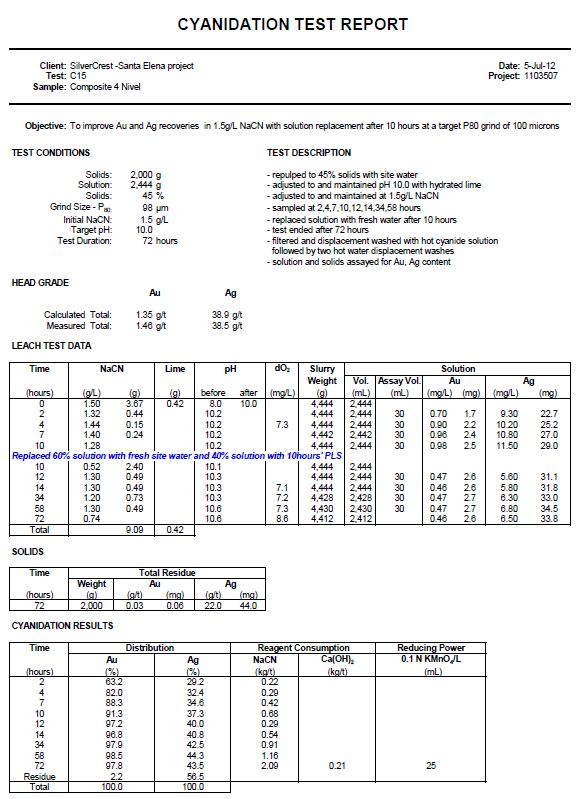

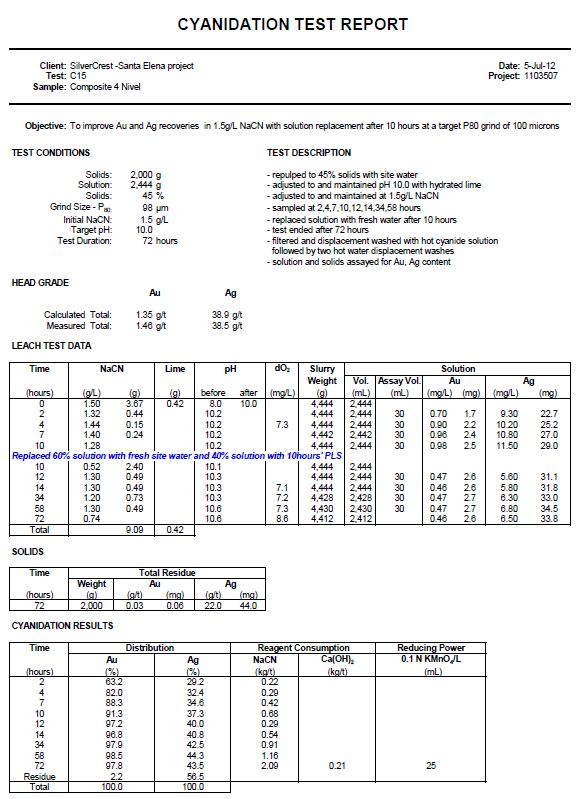

Client: SilverCrest -Santa Elena project Date: 5-Jul-12

Test: C15 Project: 1103507

Sample: Composite 4 Nivel

Objective:

TEST CONDITIONS TEST DESCRIPTION

Solids: 2,000 g - repulped to 45% solids with site water

Solution: 2,444 g - adjusted to and maintained pH 10.0 with hydrated lime

Solids: 45 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 98 μm - sampled at 2,4,7,10,12,14,34,58 hours

Initial NaCN: 1.5 g/L - replaced solution with fresh water after 10 hours

Target pH: 10.0 - test ended after 72 hours

Test Duration: 72 hours - filtered and displacement washed with hot cyanide solution

followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 1.35 g/t 38.9 g/t

Measured Total: 1.46 g/t 38.5 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 3.67 0.42 8.0 10.0 4,444 2,444

2 1.32 0.44 10.2 4,444 2,444 30 0.70 1.7 9.30 22.7

4 1.44 0.15 10.2 7.3 4,444 2,444 30 0.90 2.2 10.20 25.2

7 1.40 0.24 10.2 4,442 2,442 30 0.96 2.4 10.80 27.0

10 1.28 10.2 4,444 2,444 30 0.98 2.5 11.50 29.0

Replaced 60% solution with fresh site water and 40% solution with 10hours' PLS

10 0.52 2.40 10.1 4,444 2,444

12 1.30 0.49 10.3 4,444 2,444 30 0.47 2.6 5.60 31.1

14 1.30 0.49 10.3 7.1 4,444 2,444 30 0.46 2.6 5.80 31.8

34 1.20 0.73 10.3 7.2 4,428 2,428 30 0.47 2.7 6.30 33.0

58 1.30 0.49 10.6 7.3 4,430 2,430 30 0.47 2.7 6.80 34.5

72 0.74 10.6 8.6 4,412 2,412 0.46 2.6 6.50 33.8

Total 9.09 0.42

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

72 2,000 0.03 0.06 22.0 44.0

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 63.2 29.2 0.22

4 82.0 32.4 0.29

7 88.3 34.6 0.42

10 91.3 37.3 0.68

12 97.2 40.0 0.29

14 96.8 40.8 0.54

34 97.9 42.5 0.91

58 1.16

72 97.8 43.5 2.09 0.21

Residue 2.2 56.5

Total 100.0 100.0

98.5 44.3

25

CYANIDATION TEST REPORT

To improve Au and Ag recoveries in 1.5g/L NaCN with solution replacement after 10 hours at a target P80 grind of 100 microns

Solution

Ag

Total Residue

Distribution Reagent Consumption

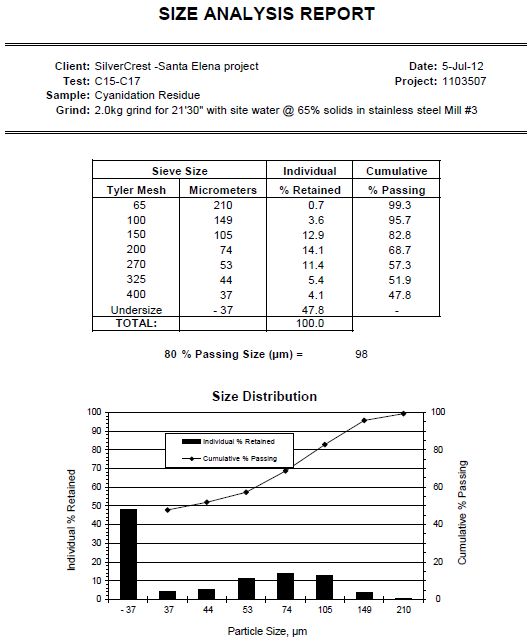

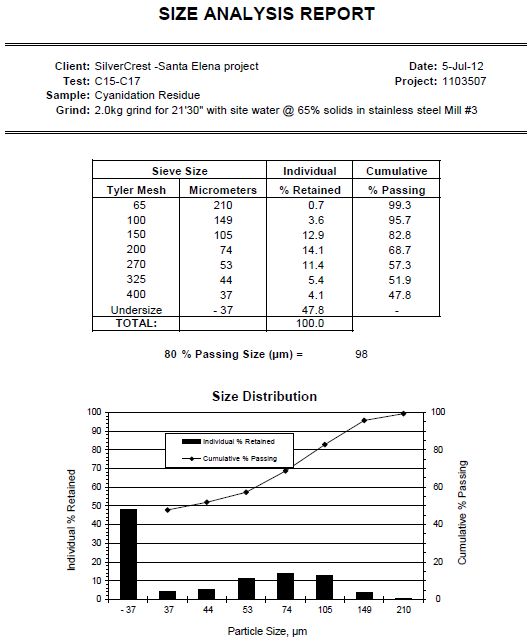

Client: SilverCrest -Santa Elena project Date: 5-Jul-12

Test: C15-C17 Project: 1103507

Sample: Cyanidation Residue

Grind: 2.0kg grind for 21'30" with site water @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.7 99.3

100 149 3.6 95.7

150 105 12.9 82.8

200 74 14.1 68.7

270 53 11.4 57.3

325 44 5.4 51.9

400 37 4.1 47.8

Undersize - 37 47.8 -

TOTAL: 100.0

80 % Passing Size (μm) = 98

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

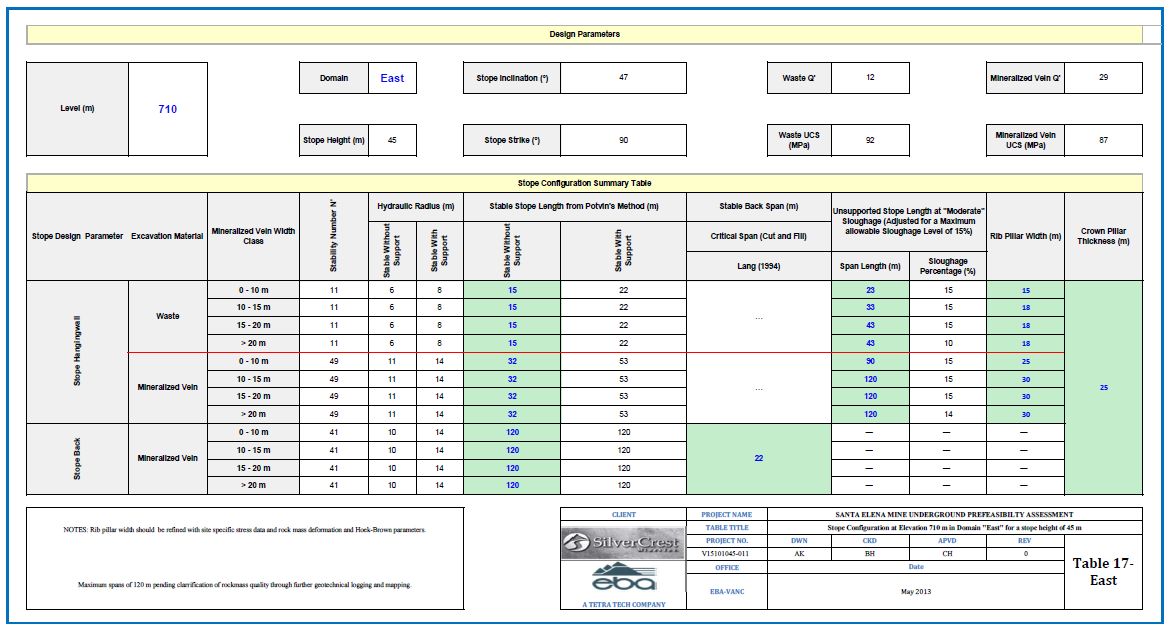

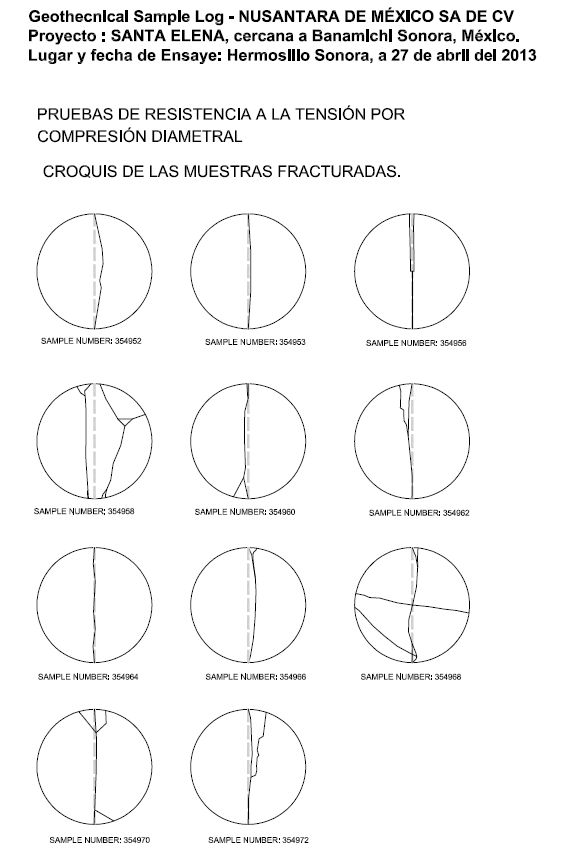

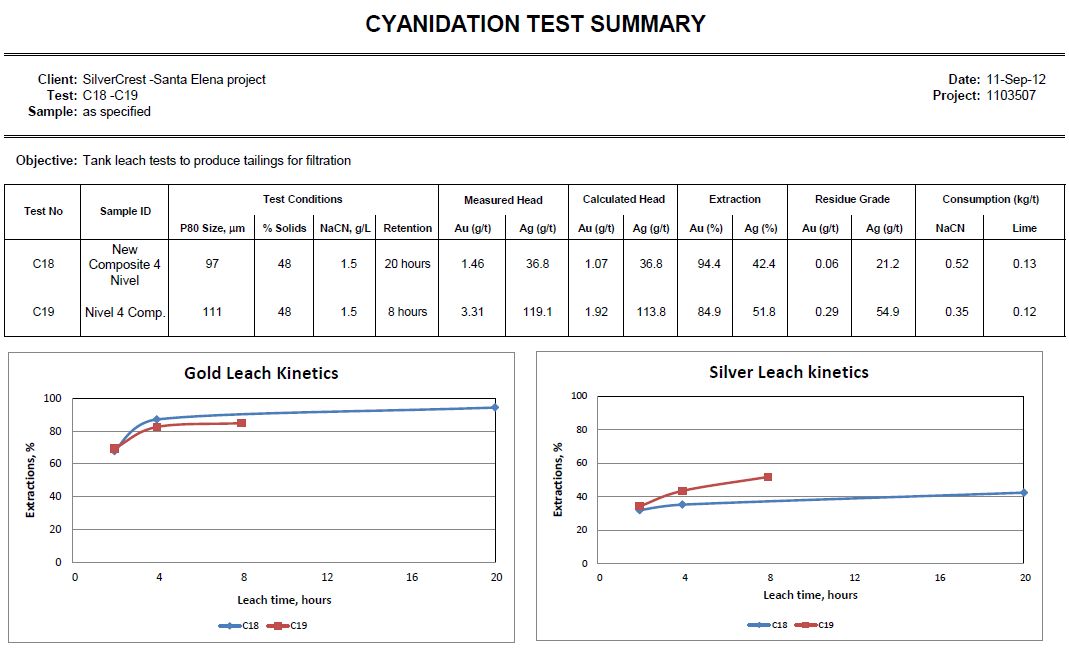

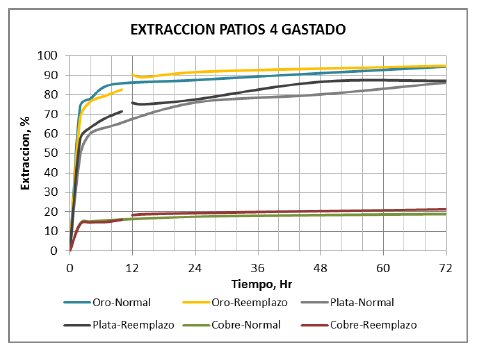

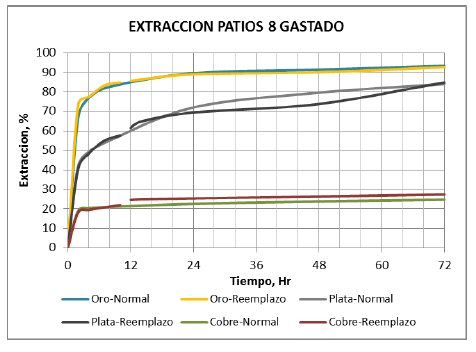

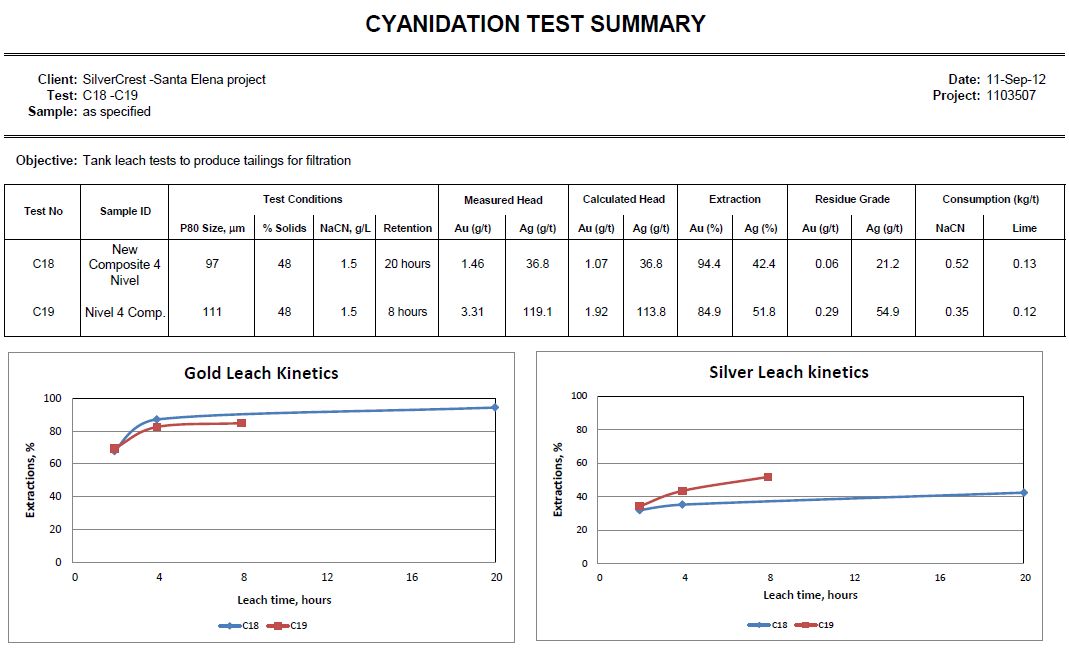

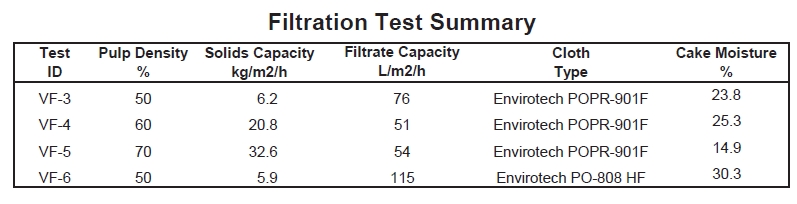

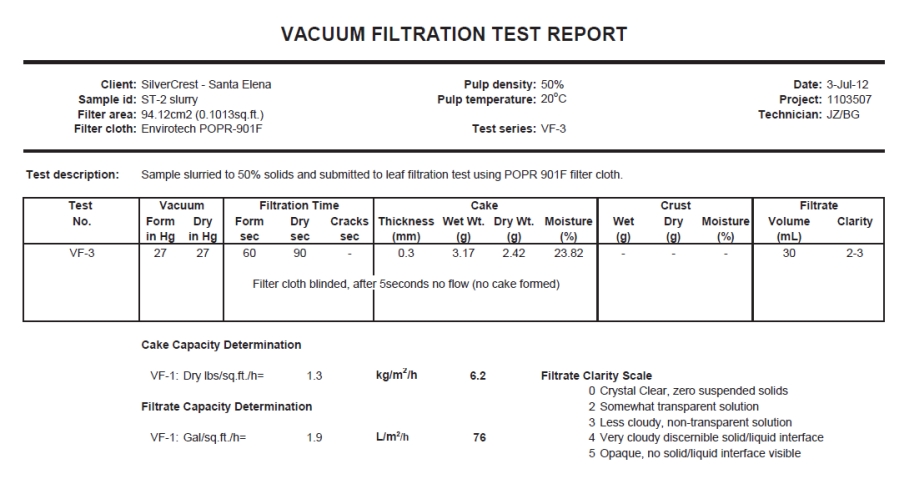

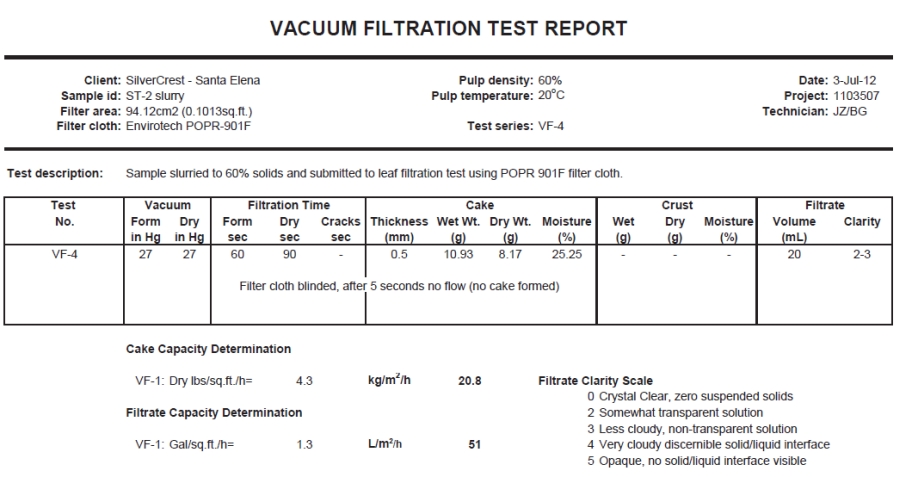

Client: SilverCrest -Santa Elena project Date: 11-Sep-12

Test: C18 -C19 Project: 1103507

Sample: as specified

Objective: Tank leach tests to produce tailings for filtration

P80 Size, mm % Solids NaCN, g/L Retention Au (g/t) Ag (g/t) Au (g/t) Ag (g/t) Au (%) Ag (%) Au (g/t) Ag (g/t) NaCN Lime

C18

New

Composite 4

Nivel

97 48 1.5 20 hours 1.46 36.8 1.07 36.8 94.4 42.4 0.06 21.2 0.52 0.13

C19 Nivel 4 Comp. 111 48 1.5 8 hours 3.31 119.1 1.92 113.8 84.9 51.8 0.29 54.9 0.35 0.12

CYANIDATION TEST SUMMARY

Consumption (kg/t)

Test No Sample ID

Measured Head Calculated Head Test Conditions Extraction Residue Grade

0

20

40

60

80

100

0 4 8 12 16 20

Extractions, %

Leach time, hours

Gold Leach Kinetics

C18 C19

0

20

40

60

80

100

0 4 8 12 16 20

Extractions, %

Leach time, hours

Silver Leach kinetics

C18 C19

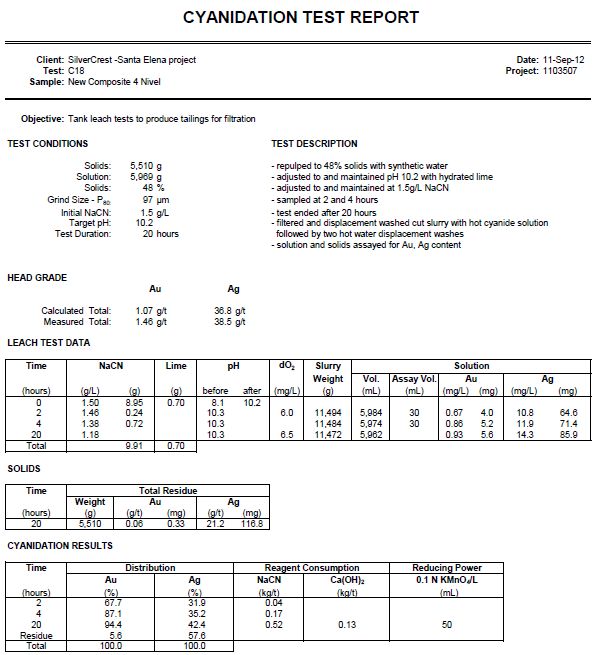

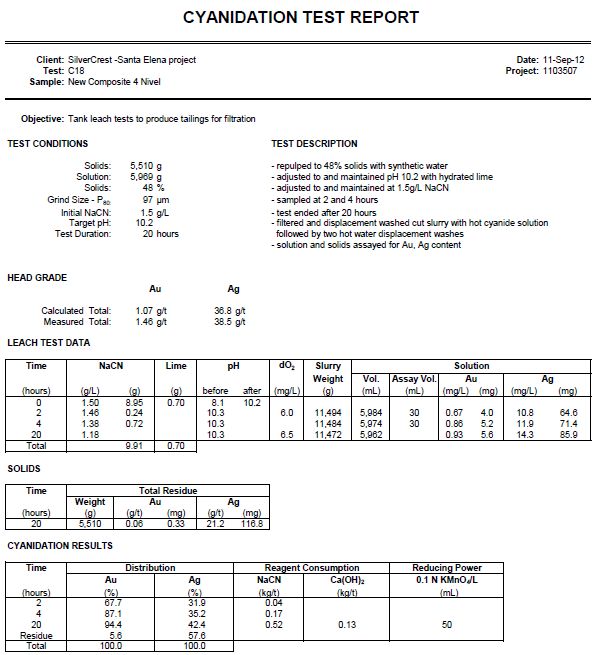

Client: SilverCrest -Santa Elena project Date: 11-Sep-12

Test: C18 Project: 1103507

Sample: New Composite 4 Nivel

Objective: Tank leach tests to produce tailings for filtration

TEST CONDITIONS TEST DESCRIPTION

Solids: 5,510 g - repulped to 48% solids with synthetic water

Solution: 5,969 g - adjusted to and maintained pH 10.2 with hydrated lime

Solids: 48 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 97 μm - sampled at 2 and 4 hours

Initial NaCN: 1.5 g/L - test ended after 20 hours

Target pH: 10.2 - filtered and displacement washed cut slurry with hot cyanide solution

Test Duration: 20 hours followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 1.07 g/t 36.8 g/t

Measured Total: 1.46 g/t 38.5 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 8.95 0.70 8.1 10.2

2 1.46 0.24 10.3 6.0 11,494 5,984 30 0.67 4.0 10.8 64.6

4 1.38 0.72 10.3 11,484 5,974 30 0.86 5.2 11.9 71.4

20 1.18 10.3 6.5 11,472 5,962 0.93 5.6 14.3 85.9

Total 9.91 0.70

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

20 5,510 0.06 0.33 21.2 116.8

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 67.7 31.9 0.04

4 87.1 35.2 0.17

20 94.4 42.4 0.52 0.13

Residue 5.6 57.6

Total 100.0 100.0

50

Distribution Reagent Consumption

CYANIDATION TEST REPORT

Total Residue

Solution

Ag

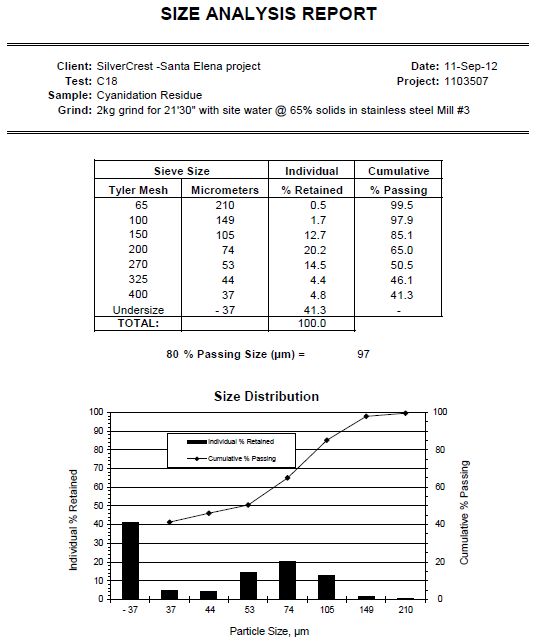

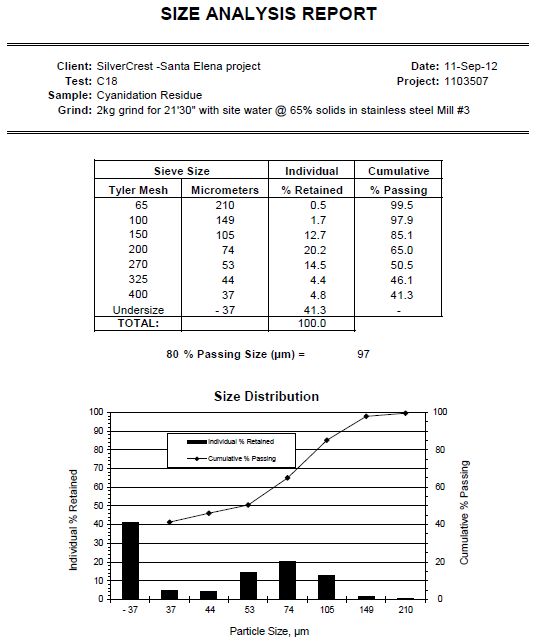

Client: SilverCrest -Santa Elena project Date: 11-Sep-12

Test: C18 Project: 1103507

Sample: Cyanidation Residue

Grind: 2kg grind for 21'30" with site water @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.5 99.5

100 149 1.7 97.9

150 105 12.7 85.1

200 74 20.2 65.0

270 53 14.5 50.5

325 44 4.4 46.1

400 37 4.8 41.3

Undersize - 37 41.3 -

TOTAL: 100.0

80 % Passing Size (μm) = 97

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

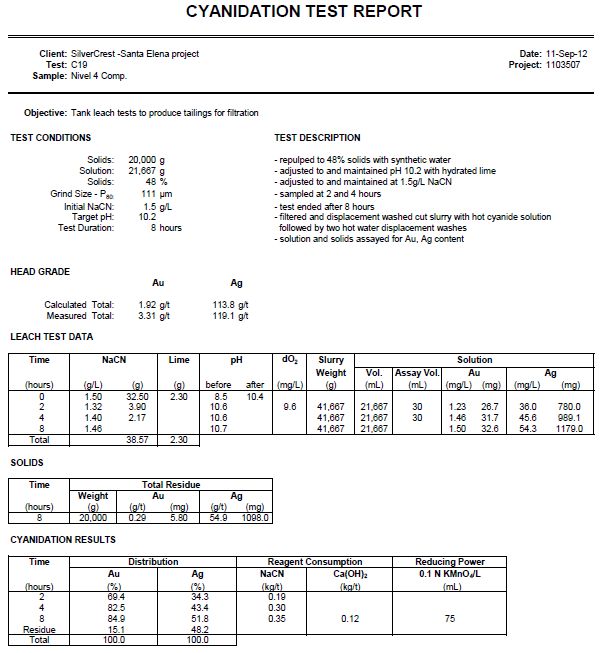

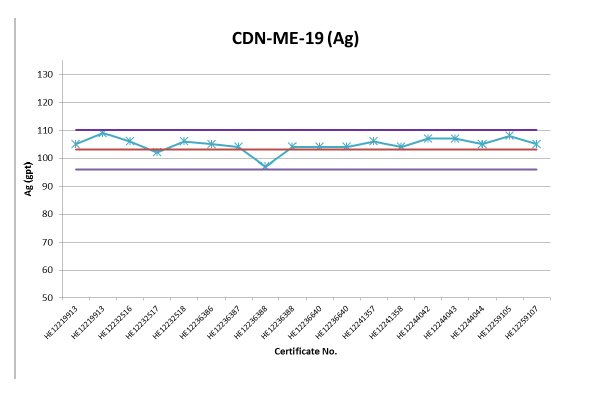

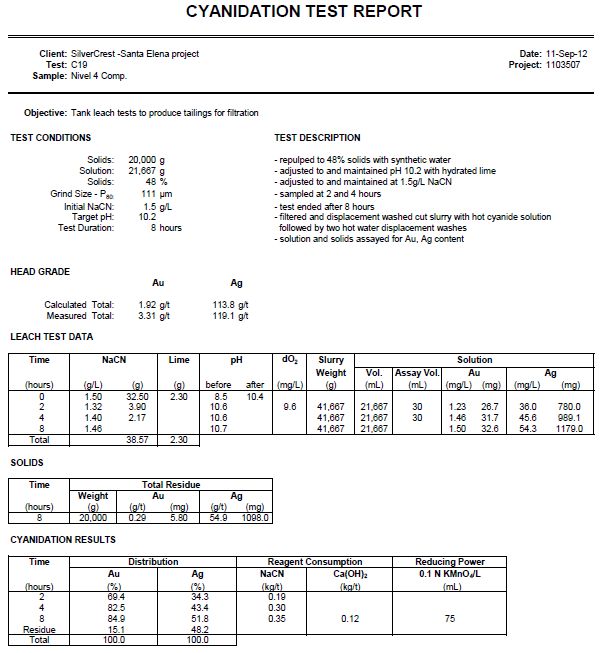

Client: SilverCrest -Santa Elena project Date: 11-Sep-12

Test: C19 Project: 1103507

Sample: Nivel 4 Comp.

Objective: Tank leach tests to produce tailings for filtration

TEST CONDITIONS TEST DESCRIPTION

Solids: 20,000 g - repulped to 48% solids with synthetic water

Solution: 21,667 g - adjusted to and maintained pH 10.2 with hydrated lime

Solids: 48 % - adjusted to and maintained at 1.5g/L NaCN

Grind Size - P80: 111 μm - sampled at 2 and 4 hours

Initial NaCN: 1.5 g/L - test ended after 8 hours

Target pH: 10.2 - filtered and displacement washed cut slurry with hot cyanide solution

Test Duration: 8 hours followed by two hot water displacement washes

- solution and solids assayed for Au, Ag content

HEAD GRADE

Au Ag

Calculated Total: 1.92 g/t 113.8 g/t

Measured Total: 3.31 g/t 119.1 g/t

LEACH TEST DATA

Time NaCN Lime pH dO2 Slurry

Weight Vol. Assay Vol. Au

(hours) (g/L) (g) (g) before after (mg/L) (g) (mL) (mL) (mg/L) (mg) (mg/L) (mg)

0 1.50 32.50 2.30 8.5 10.4

2 1.32 3.90 10.6 9.6 41,667 21,667 30 1.23 26.7 36.0 780.0

4 1.40 2.17 10.6 41,667 21,667 30 1.46 31.7 45.6 989.1

8 1.46 10.7 41,667 21,667 1.50 32.6 54.3 1179.0

Total 38.57 2.30

SOLIDS

Time

Weight Au Ag

(hours) (g) (g/t) (mg) (g/t) (mg)

8 20,000 0.29 5.80 54.9 1098.0

CYANIDATION RESULTS

Time Reducing Power

Au Ag NaCN Ca(OH)2 0.1 N KMnO4/L

(hours) (%) (%) (kg/t) (kg/t) (mL)

2 69.4 34.3 0.19

4 82.5 43.4 0.30

8 84.9 51.8 0.35 0.12

Residue 15.1 48.2

Total 100.0 100.0

75

CYANIDATION TEST REPORT

Solution

Ag

Total Residue

Distribution Reagent Consumption

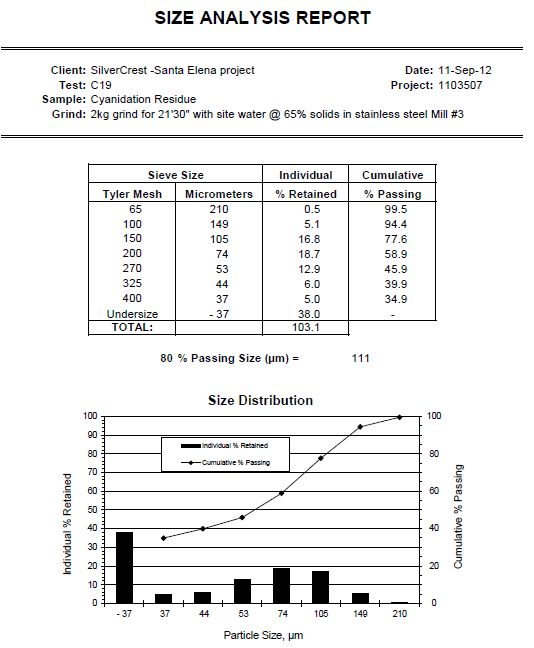

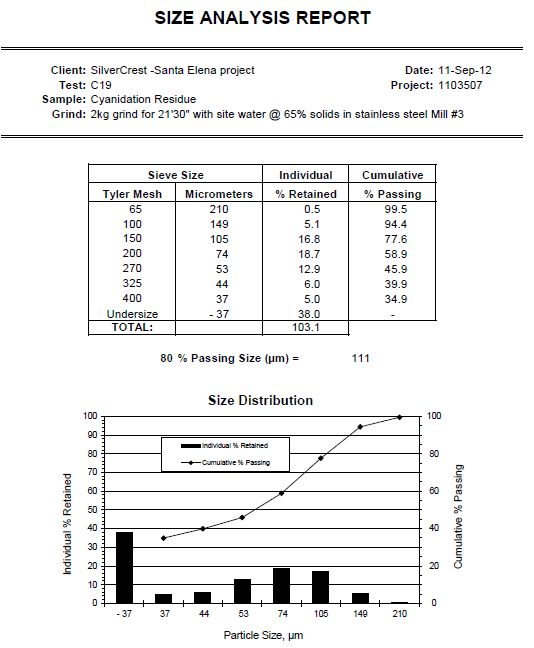

Client: SilverCrest -Santa Elena project Date: 11-Sep-12

Test: C19 Project: 1103507

Sample: Cyanidation Residue

Grind: 2kg grind for 21'30" with site water @ 65% solids in stainless steel Mill #3

Sieve Size Individual Cumulative

Tyler Mesh Micrometers % Retained % Passing

65 210 0.5 99.5

100 149 5.1 94.4

150 105 16.8 77.6

200 74 18.7 58.9

270 53 12.9 45.9

325 44 6.0 39.9

400 37 5.0 34.9

Undersize - 37 38.0 -

TOTAL: 103.1

80 % Passing Size (μm) = 111

SIZE ANALYSIS REPORT

0

20

40

60

80

100

0

10

20

30

40

50

60

70

80

90

100

- 37 37 44 53 74 105 149 210

Cumulative % Passing

Individual % Retained

Particle Size, μm

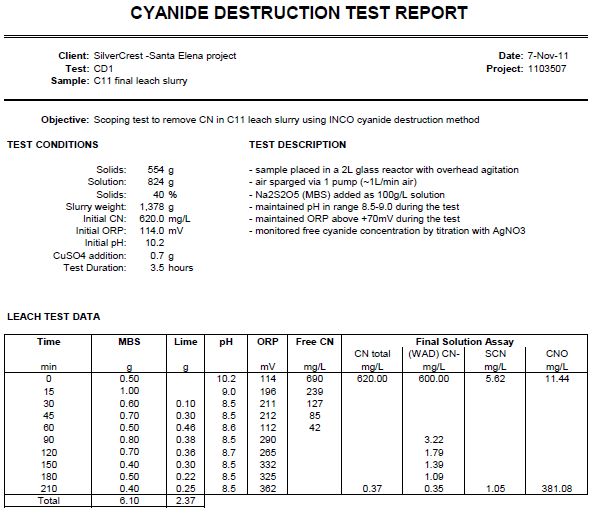

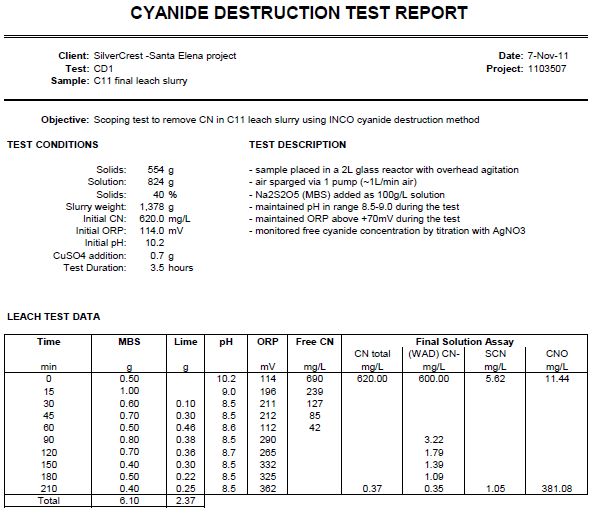

Client: SilverCrest -Santa Elena project Date: 7-Nov-11

Test: CD1 Project: 1103507

Sample: C11 final leach slurry

Objective: Scoping test to remove CN in C11 leach slurry using INCO cyanide destruction method

TEST CONDITIONS TEST DESCRIPTION

Solids: 554 g - sample placed in a 2L glass reactor with overhead agitation

Solution: 824 g - air sparged via 1 pump (~1L/min air)

Solids: 40 % - Na2S2O5 (MBS) added as 100g/L solution

Slurry weight: 1,378 g - maintained pH in range 8.5-9.0 during the test

Initial CN: 620.0 mg/L - maintained ORP above +70mV during the test

Initial ORP: 114.0 mV - monitored free cyanide concentration by titration with AgNO3

Initial pH: 10.2

CuSO4 addition: 0.7 g

Test Duration: 3.5 hours

LEACH TEST DATA

Time MBS Lime pH ORP Free CN

CN total (WAD) CN- SCN CNO

min g mV mg/L mg/L mg/L mg/L mg/L

0 10.2 114 690 620.00 600.00 5.62 11.44

15 9.0 196 239

30 0.10 8.5 211 127

45 0.30 8.5 212 85

60 0.46 8.6 112 42

90 0.38 8.5 290 3.22

120 0.36 8.7 265 1.79

150 0.30 8.5 332 1.39

180 0.22 8.5 325 1.09

210 0.25 8.5 362 0.37 0.35 1.05 381.08

Total 2.37

CYANIDE DESTRUCTION TEST REPORT

0.70

Final Solution Assay

g

1.00

0.60

6.10

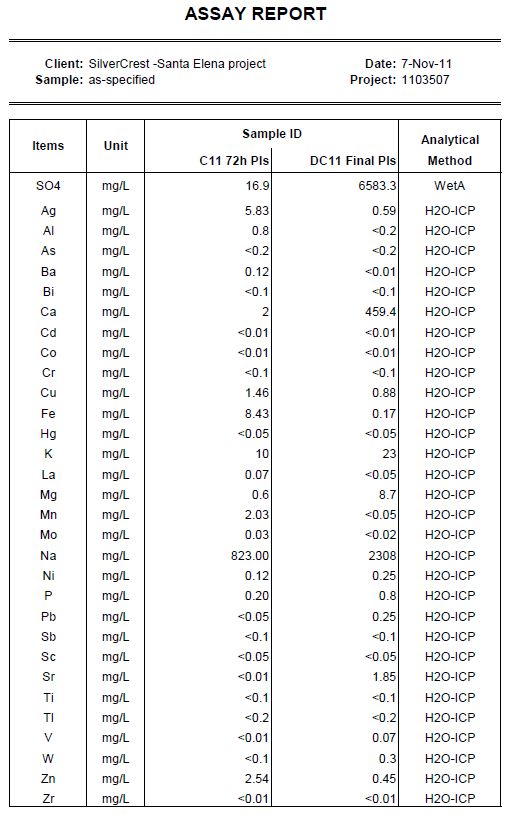

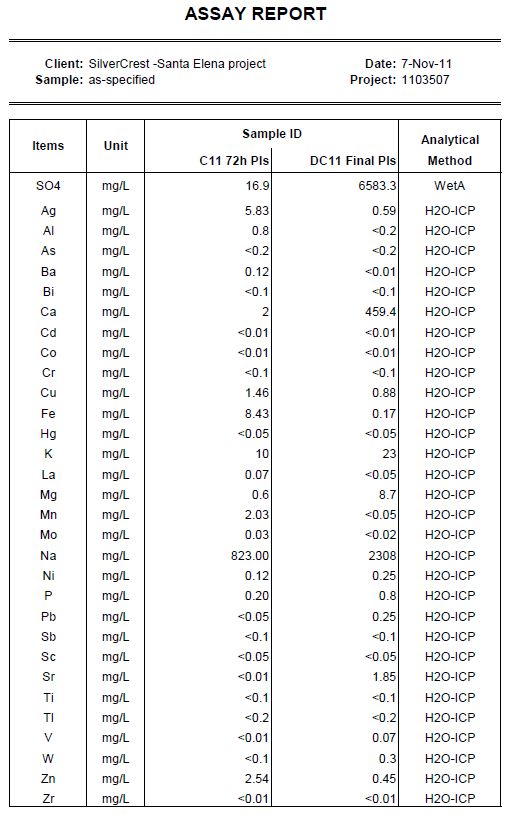

Assay report

Client: SilverCrest -Santa Elena project Date: 7-Nov-11

Sample: as-specified Project: 1103507

Analytical

C11 72h Pls DC11 Final Pls Method

SO4 mg/L 16.9 6583.3 WetA

Ag mg/L 5.83 0.59 H2O-ICP

Al mg/L 0.8 <0.2 H2O-ICP

As mg/L <0.2 <0.2 H2O-ICP

Ba mg/L 0.12 <0.01 H2O-ICP

Bi mg/L <0.1 <0.1 H2O-ICP

Ca mg/L 2 459.4 H2O-ICP

Cd mg/L <0.01 <0.01 H2O-ICP

Co mg/L <0.01 <0.01 H2O-ICP

Cr mg/L <0.1 <0.1 H2O-ICP

Cu mg/L 1.46 0.88 H2O-ICP

Fe mg/L 8.43 0.17 H2O-ICP

Hg mg/L <0.05 <0.05 H2O-ICP

K mg/L 10 23 H2O-ICP

La mg/L 0.07 <0.05 H2O-ICP

Mg mg/L 0.6 8.7 H2O-ICP

Mn mg/L 2.03 <0.05 H2O-ICP

Mo mg/L 0.03 <0.02 H2O-ICP

Na mg/L 823.00 2308 H2O-ICP

Ni mg/L 0.12 0.25 H2O-ICP

P mg/L 0.20 0.8 H2O-ICP

Pb mg/L <0.05 0.25 H2O-ICP

Sb mg/L <0.1 <0.1 H2O-ICP

Sc mg/L <0.05 <0.05 H2O-ICP

Sr mg/L <0.01 1.85 H2O-ICP

Ti mg/L <0.1 <0.1 H2O-ICP

Tl mg/L <0.2 <0.2 H2O-ICP

V mg/L <0.01 0.07 H2O-ICP

W mg/L <0.1 0.3 H2O-ICP

Zn mg/L 2.54 0.45 H2O-ICP

Zr mg/L <0.01 <0.01 H2O-ICP

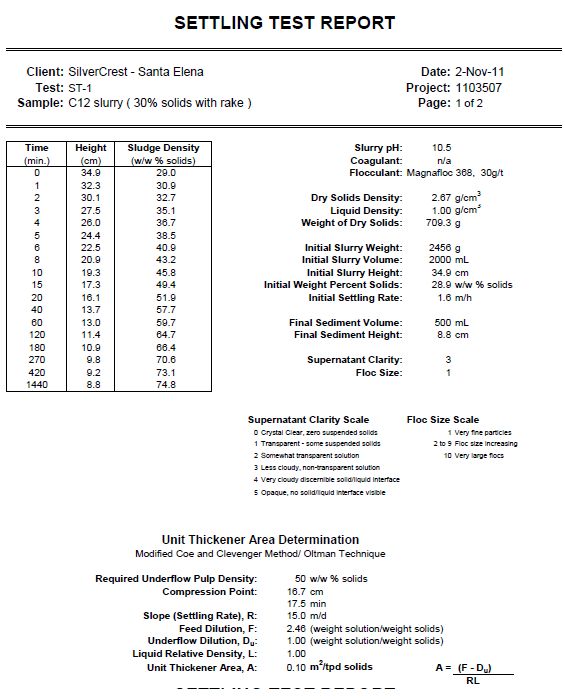

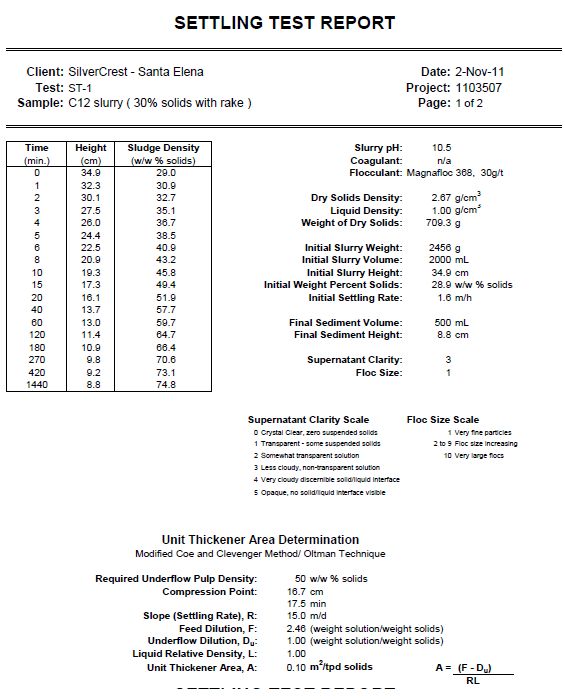

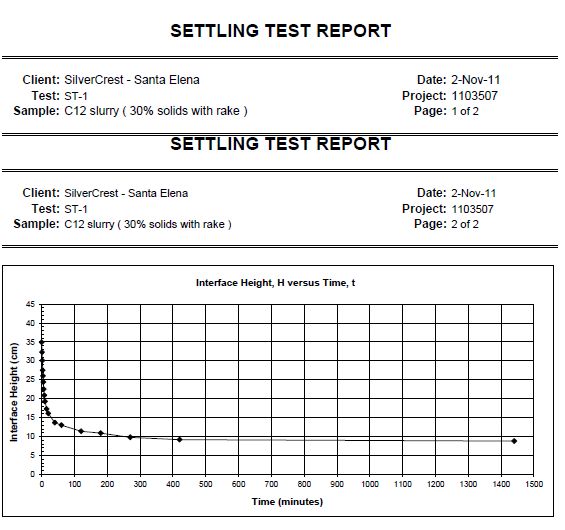

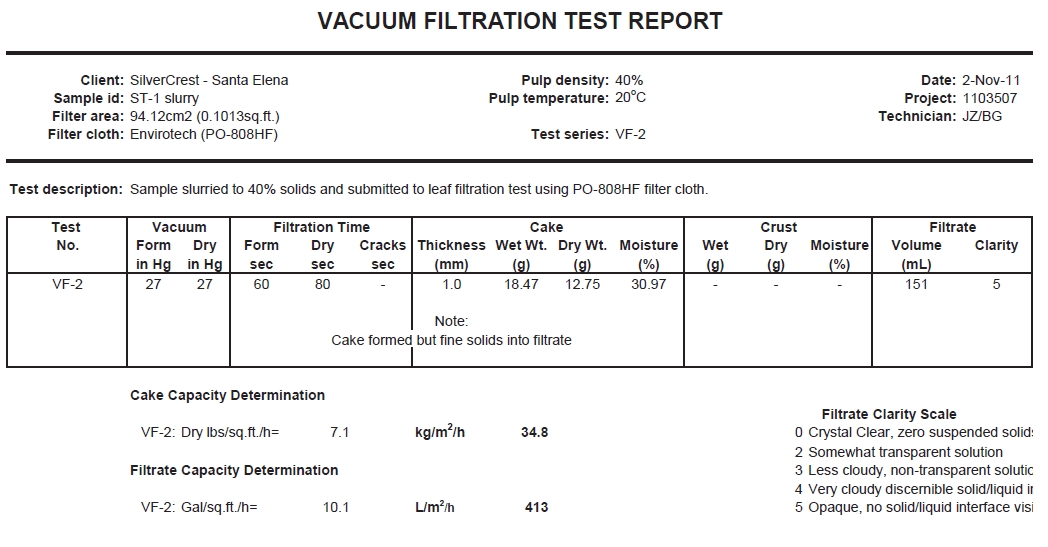

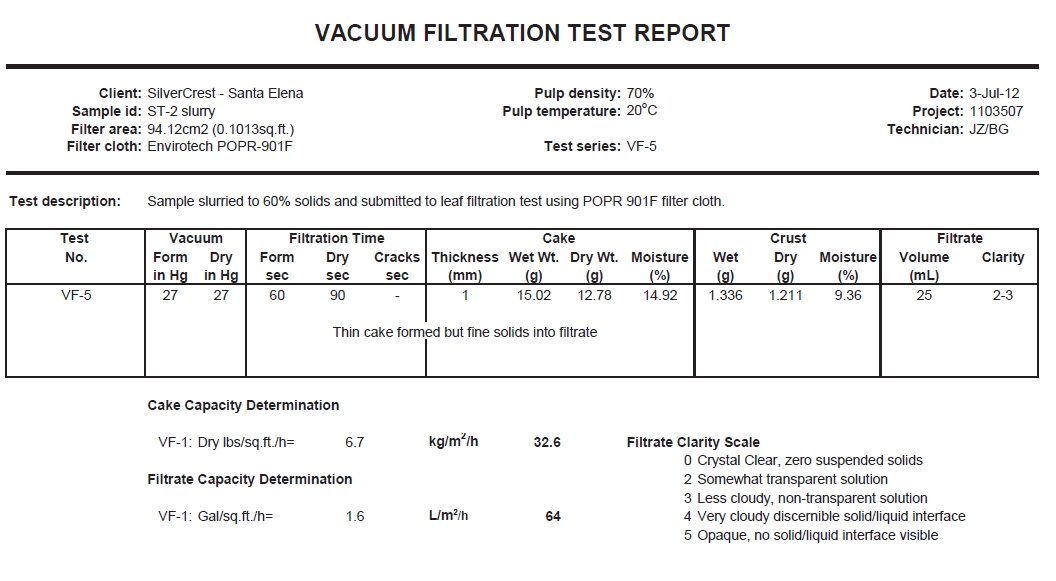

Client: Date: 2-Nov-11

Test: ST-1 Project: 1103507

Sample: C12 slurry ( 30% solids with rake ) Page: 1 of 2

Time Height Sludge Density Slurry pH: 10.5

(min.) (cm) (w/w % solids) Coagulant: n/a

0 34.9 29.0 Flocculant:

1 32.3 30.9

2 30.1 32.7 Dry Solids Density: 2.67 g/cm3

3 27.5 35.1 Liquid Density: 1.00 g/cm3

4 26.0 36.7 Weight of Dry Solids: 709.3 g

5 24.4 38.5

6 22.5 40.9 Initial Slurry Weight: 2456 g

8 20.9 43.2 Initial Slurry Volume: 2000 mL

10 19.3 45.8 Initial Slurry Height: 34.9 cm

15 17.3 49.4 Initial Weight Percent Solids: 28.9 w/w % solids

20 16.1 51.9 Initial Settling Rate: 1.6 m/h

40 13.7 57.7

60 13.0 59.7 Final Sediment Volume: 500 mL

120 11.4 64.7 Final Sediment Height: 8.8 cm

180 10.9 66.4

270 9.8 70.6 Supernatant Clarity: 3

420 9.2 73.1 Floc Size: 1

1440 8.8 74.8

Supernatant Clarity Scale Floc Size Scale

0 Crystal Clear, zero suspended solids 1 Very fine particles

1 Transparent - some suspended solids 2 to 9 Floc size increasing

2 Somewhat transparent solution 10 Very large flocs

3 Less cloudy, non-transparent solution

4 Very cloudy discernible solid/liquid interface

5 Opaque, no solid/liquid interface visible

Unit Thickener Area Determination

Modified Coe and Clevenger Method/ Oltman Technique

Required Underflow Pulp Density: 50 w/w % solids

Compression Point: 16.7 cm

17.5 min

Slope (Settling Rate), R: 15.0 m/d

Feed Dilution, F: 2.46 (weight solution/weight solids)

Underflow Dilution, Du: 1.00 (weight solution/weight solids)

Liquid Relative Density, L: 1.00

Unit Thickener Area, A: 0.10 m2/tpd solids A = (F - Du)

RL

SETTLING TEST REPORT

Magnafloc 368, 30g/t

SilverCrest - Santa Elena

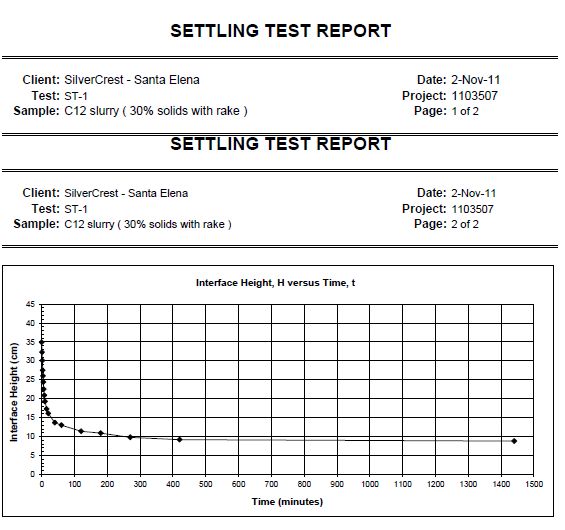

Client: Date: 2-Nov-11

Test: ST-1 Project: 1103507

Sample: C12 slurry ( 30% solids with rake ) Page: 1 of 2

SETTLING TEST REPORT

SilverCrest - Santa Elena

Client: SilverCrest - Santa Elena Date: 2-Nov-11

Test: ST-1 Project: 1103507

Sample: C12 slurry ( 30% solids with rake ) Page: 2 of 2

SETTLING TEST REPORT

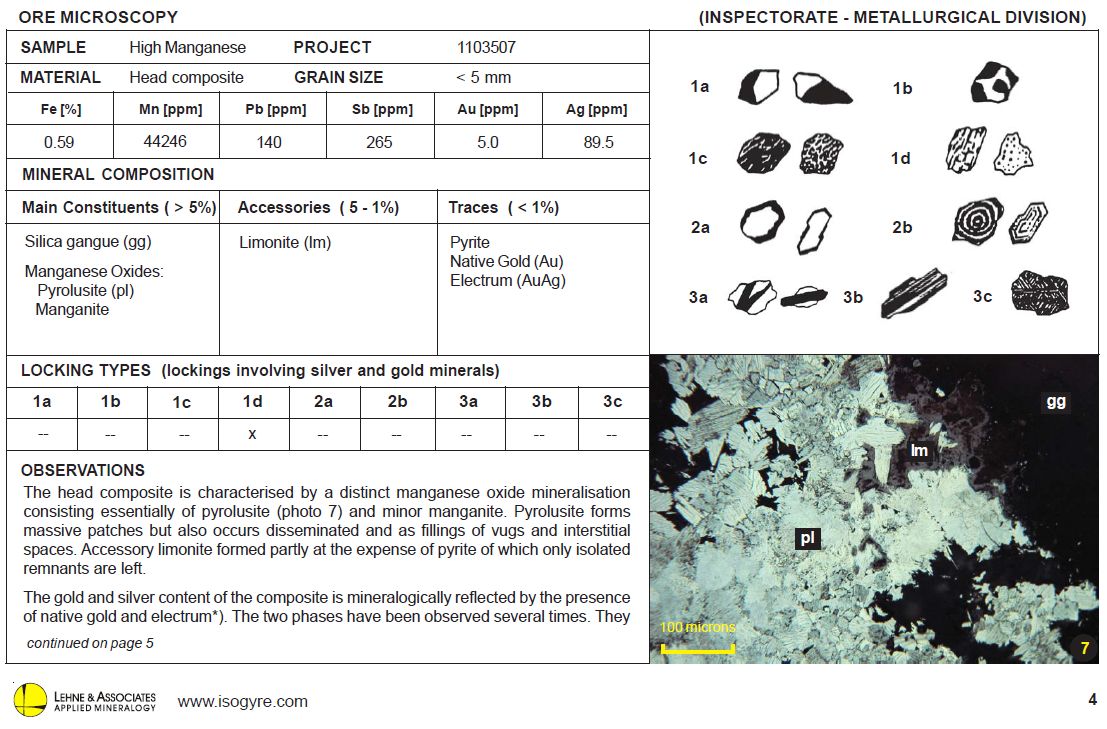

0

5

10

15

20

25

30

35

40

45

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

Interface Height (cm)

Time (minutes)

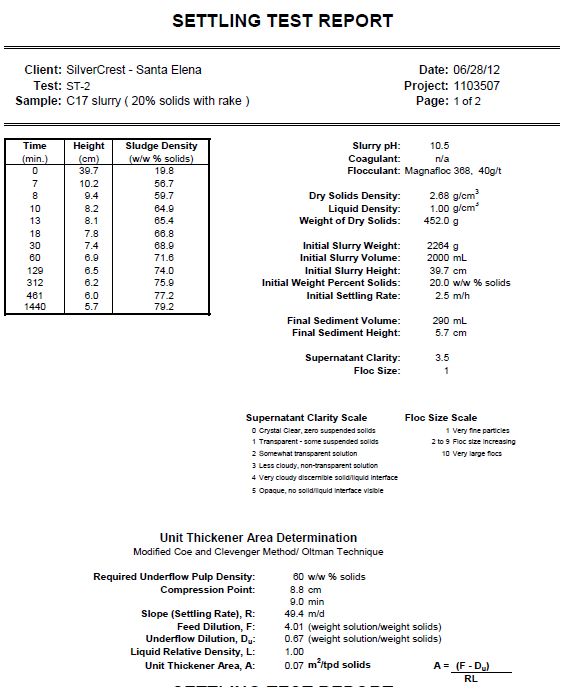

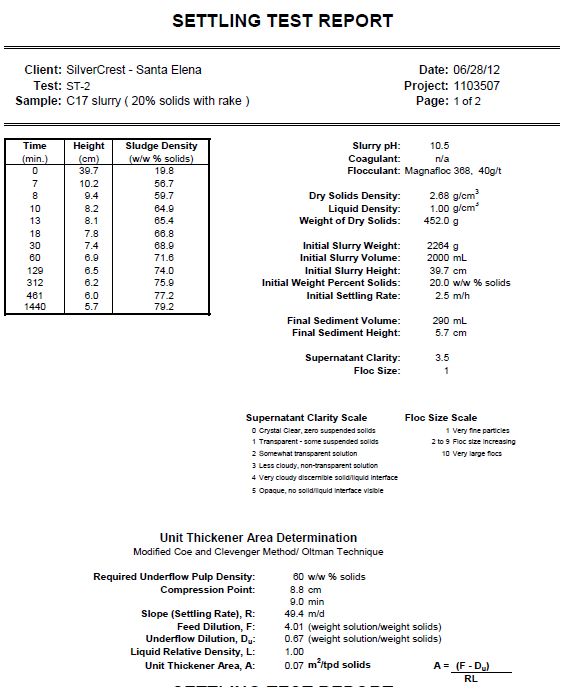

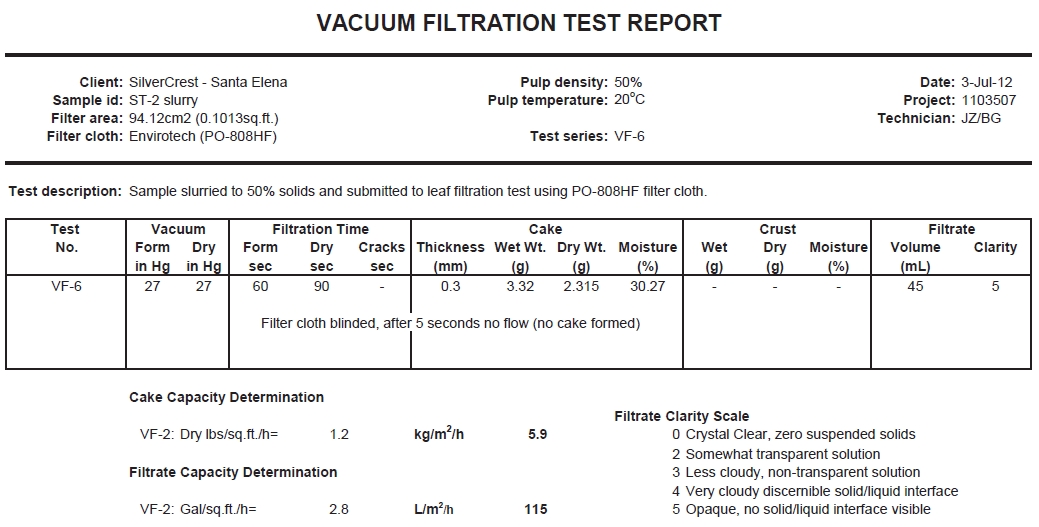

Client: Date: 06/28/12

Test: ST-2 Project: 1103507

Sample: C17 slurry ( 20% solids with rake ) Page: 1 of 2

Time Height Sludge Density Slurry pH: 10.5

(min.) (cm) (w/w % solids) Coagulant: n/a

0 39.7 19.8 Flocculant:

7 10.2 56.7

8 9.4 59.7 Dry Solids Density: 2.68 g/cm3

10 8.2 64.9 Liquid Density: 1.00 g/cm3

13 8.1 65.4 Weight of Dry Solids: 452.0 g

18 7.8 66.8

30 7.4 68.9 Initial Slurry Weight: 2264 g

60 6.9 71.6 Initial Slurry Volume: 2000 mL

129 6.5 74.0 Initial Slurry Height: 39.7 cm

312 6.2 75.9 Initial Weight Percent Solids: 20.0 w/w % solids

461 6.0 77.2 Initial Settling Rate: 2.5 m/h

1440 5.7 79.2

Final Sediment Volume: 290 mL

Final Sediment Height: 5.7 cm

Supernatant Clarity: 3.5

Floc Size: 1

Supernatant Clarity Scale Floc Size Scale

0 Crystal Clear, zero suspended solids 1 Very fine particles

1 Transparent - some suspended solids 2 to 9 Floc size increasing

2 Somewhat transparent solution 10 Very large flocs

3 Less cloudy, non-transparent solution

4 Very cloudy discernible solid/liquid interface

5 Opaque, no solid/liquid interface visible

Unit Thickener Area Determination

Modified Coe and Clevenger Method/ Oltman Technique

Required Underflow Pulp Density: 60 w/w % solids

Compression Point: 8.8 cm

9.0 min

Slope (Settling Rate), R: 49.4 m/d

Feed Dilution, F: 4.01 (weight solution/weight solids)

Underflow Dilution, Du: 0.67 (weight solution/weight solids)

Liquid Relative Density, L: 1.00

Unit Thickener Area, A: 0.07 m2/tpd solids A = (F - Du)

RL

SETTLING TEST REPORT

SETTLING TEST REPORT

Magnafloc 368, 40g/t

SilverCrest - Santa Elena

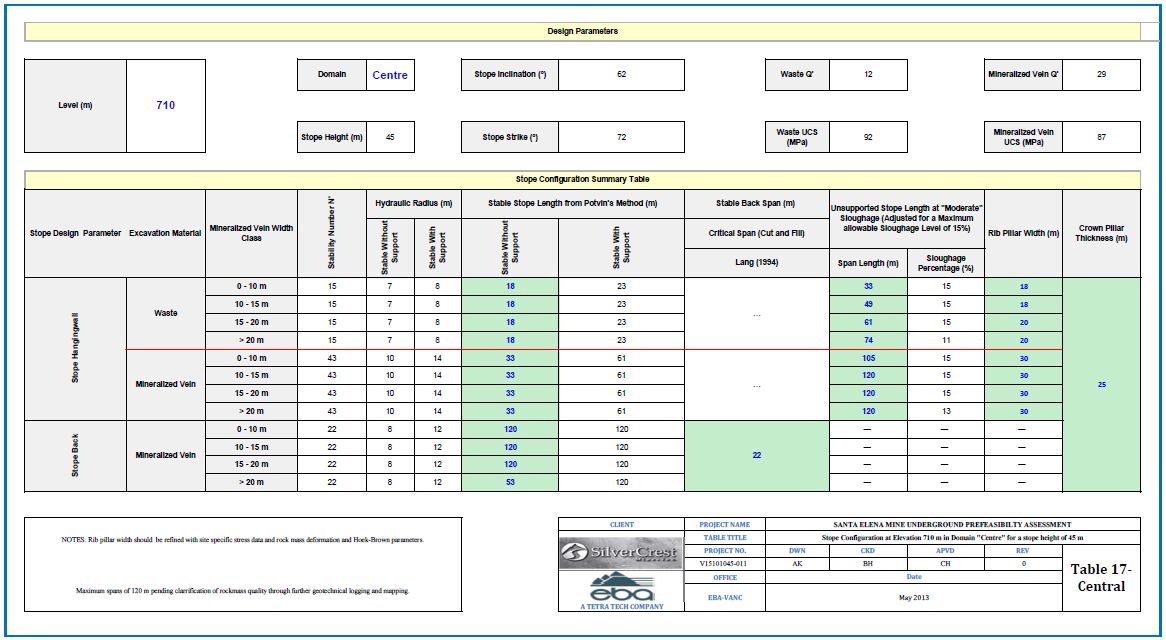

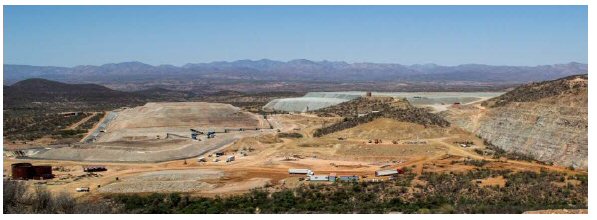

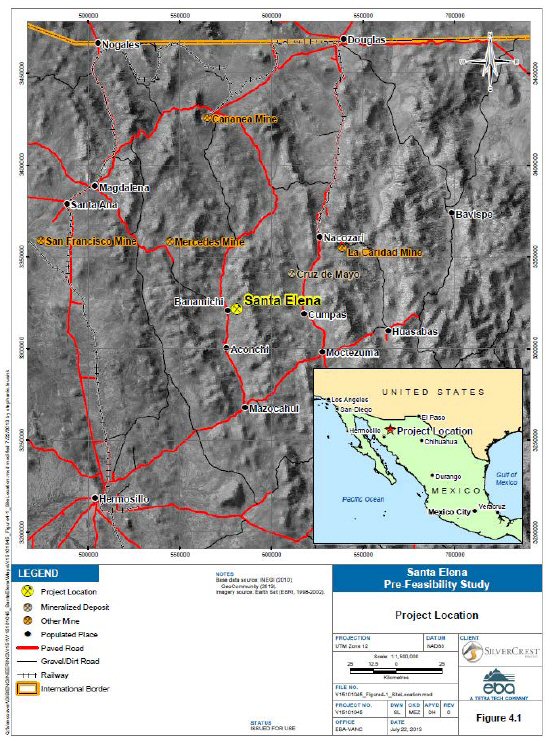

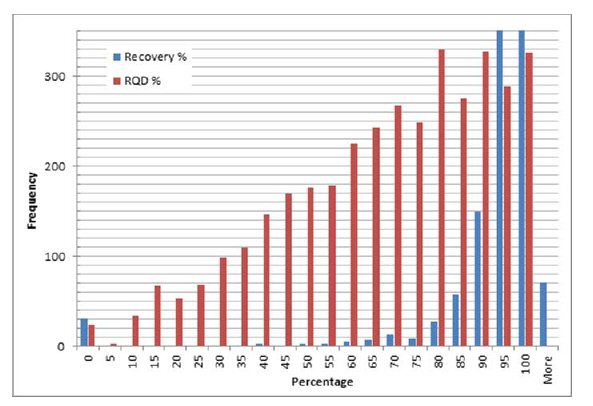

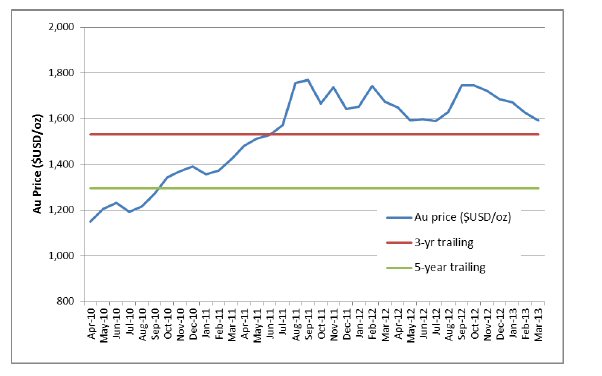

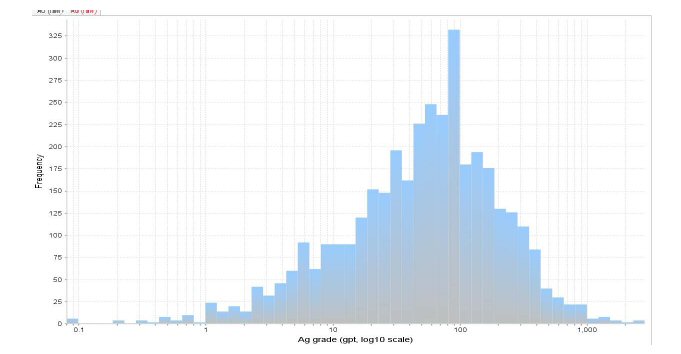

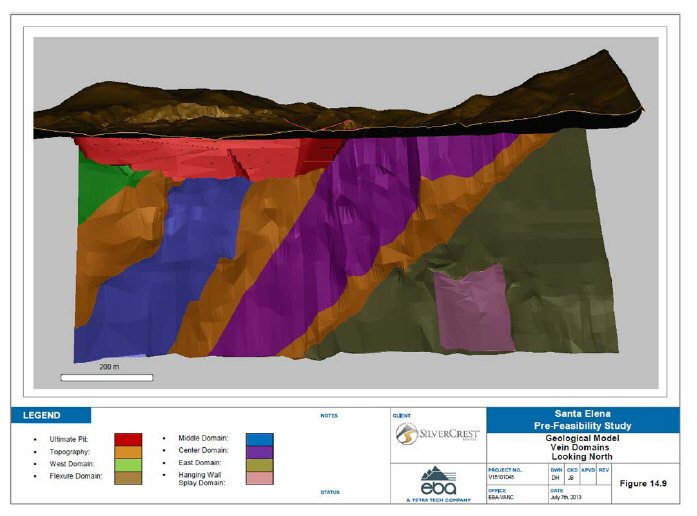

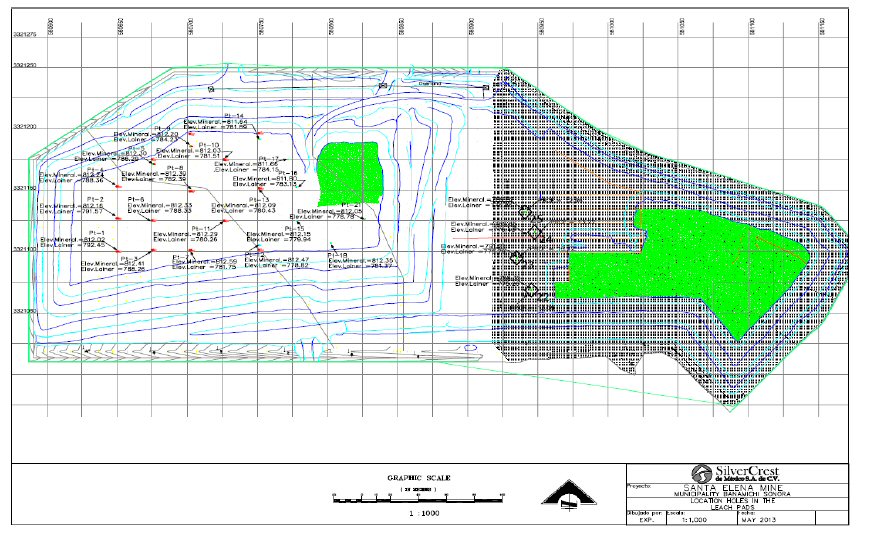

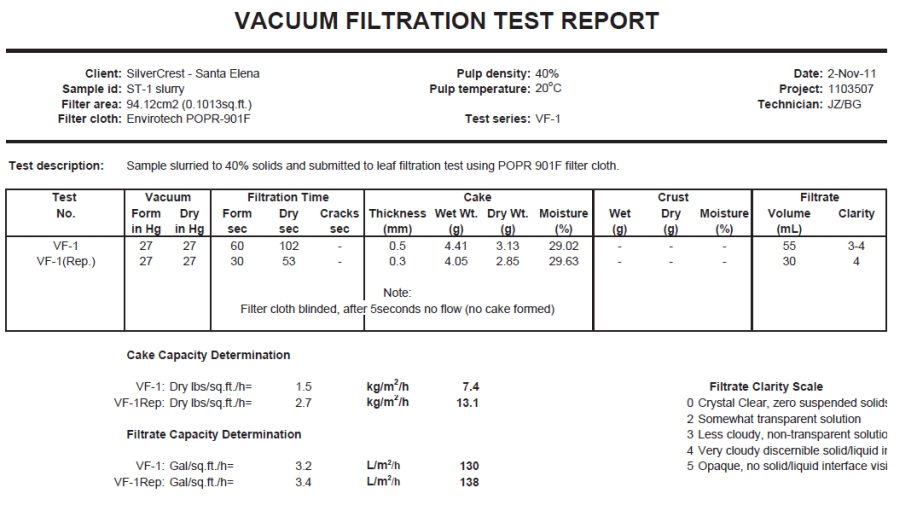

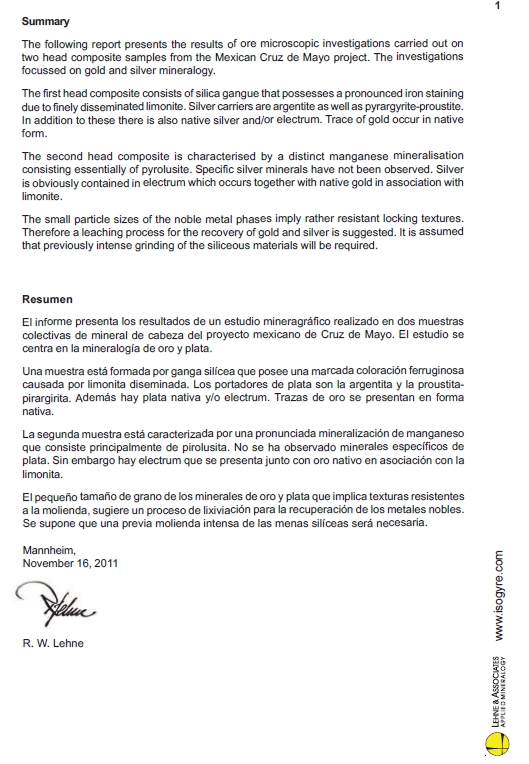

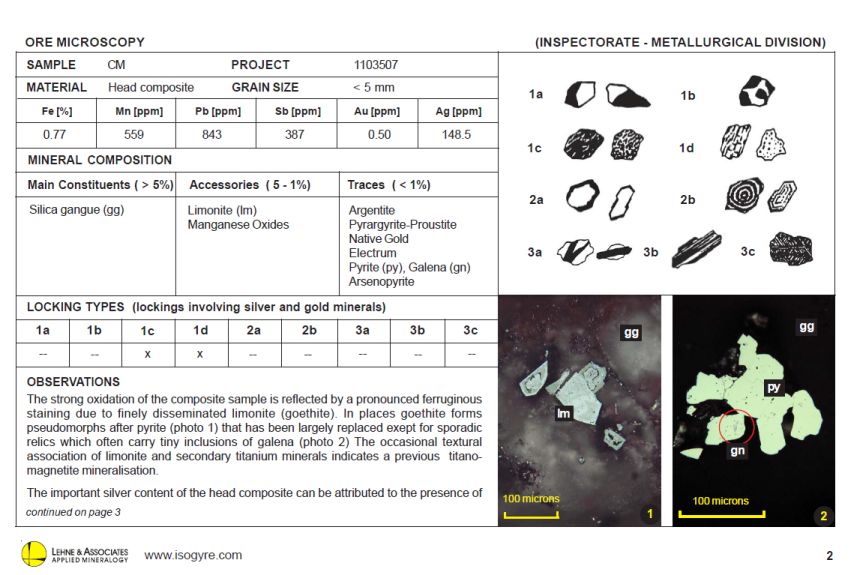

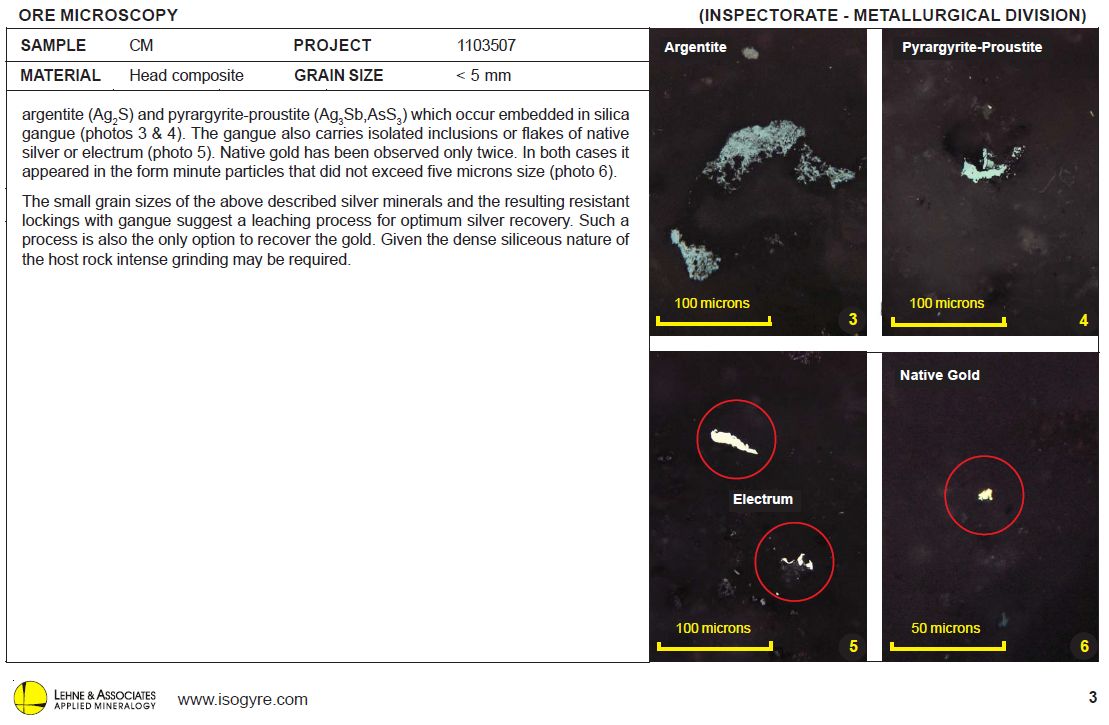

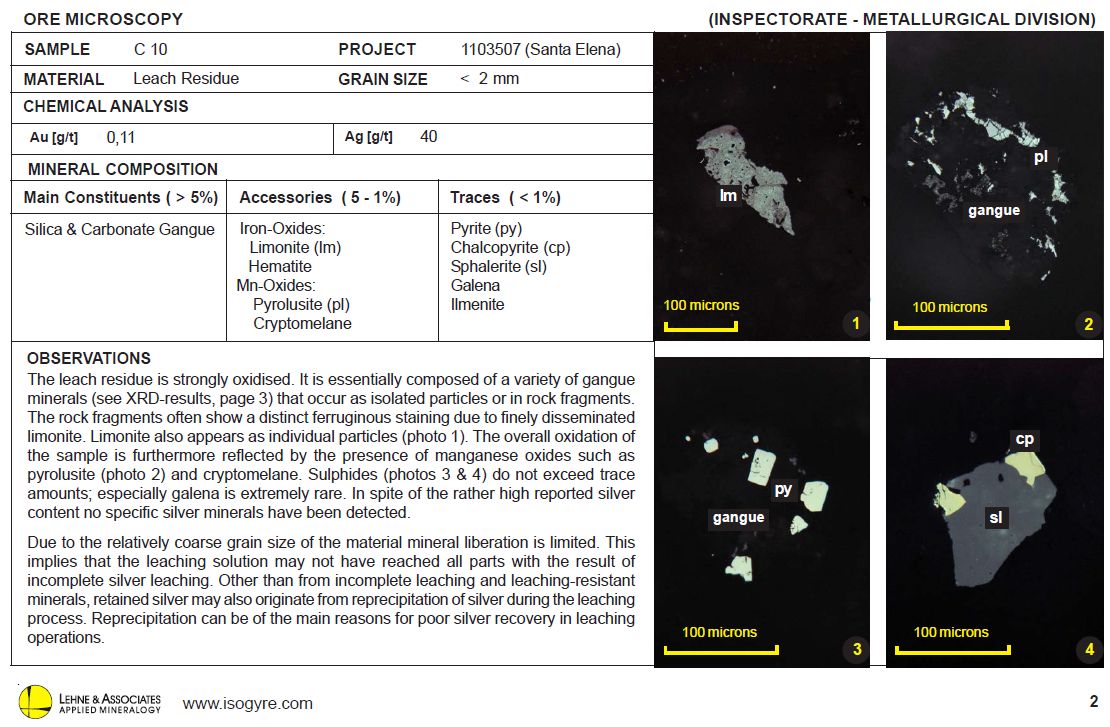

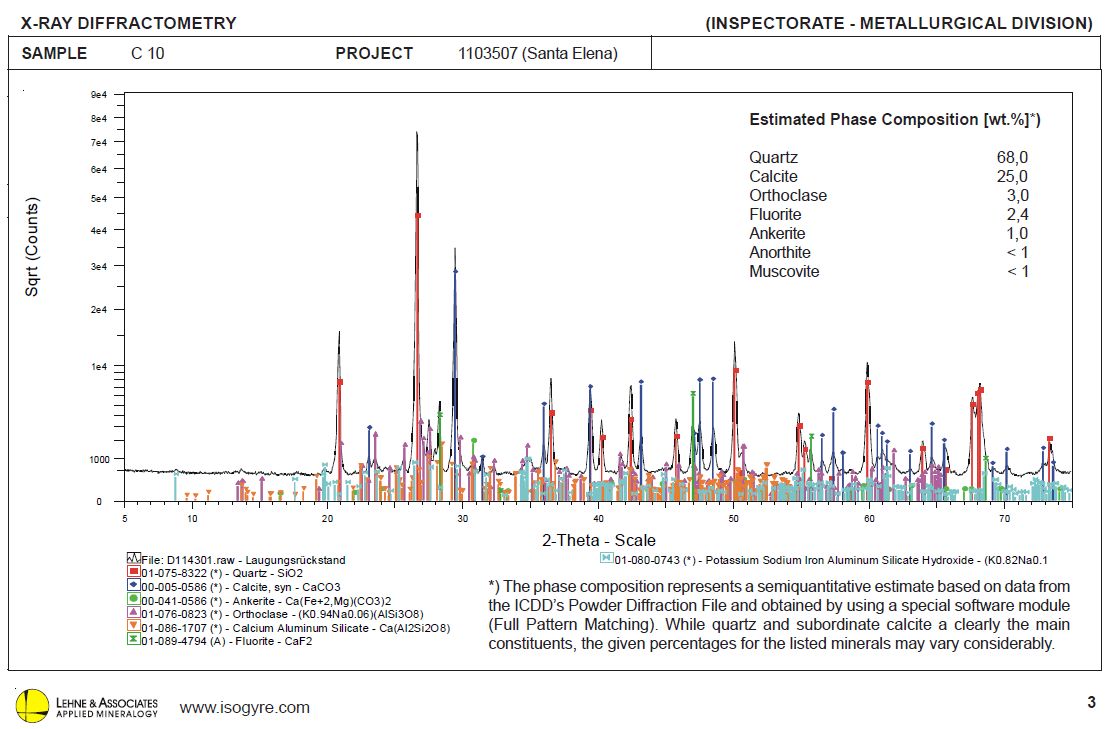

The following report presents the results of mineralogical investigations carried out on a silver-bearing leach residue from the Santa Elena Mine, Sonora, Mexico. The investigations comprised ore microscopy, X-ray diffractometry and microanalysis focussing on silver mineralogy and its potential deportment in a leaching process.

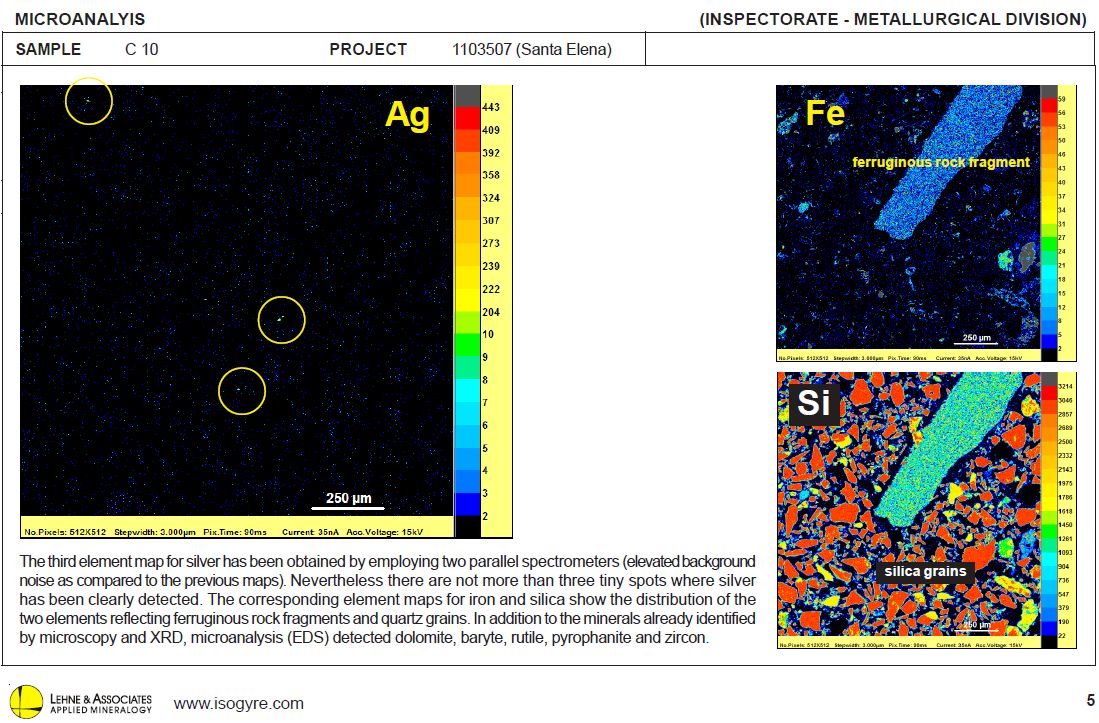

The leach residue consists mainly of silica and carbonate gangue (quartz and calcite). It carries rock fragments that show a distinct iron staining due to finely disseminated limonite. The general oxidation of the material is also reflected by the presence of manganese oxides. Sulphides do not exceed trace amounts. Specific silver minerals have not been detected.

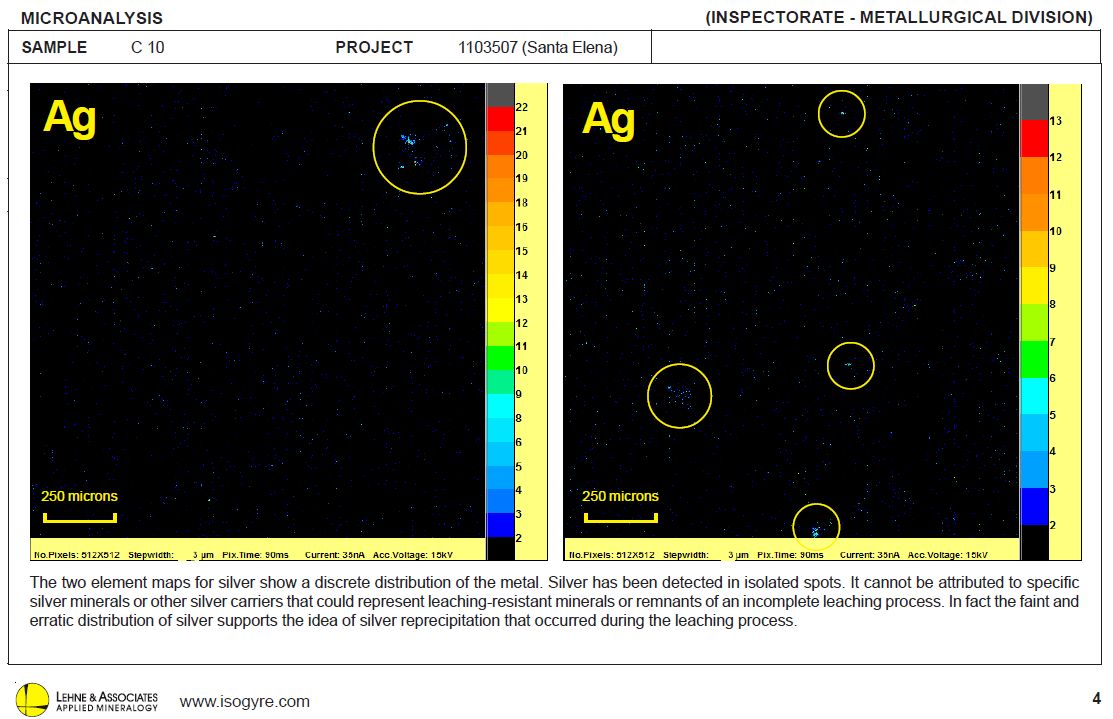

Microanalysis proved a faint and erratic distribution of silver that could not be attributed to specific silver minerals or other silver carriers. It is assumed that the silver retained in the sample originates from reprecipitation of silver during the leaching process. Reprecipitation can be of the main reasons for poor silver recovery in leaching operations.

El informe presenta los resultados de investigaciones mineralgicas realizadas en una muestra de residuo de lixiviacin argentfera de la mina de Santa Elena, Estado de Sonora, Mexico. Las investigaciones comprendieron mineragrafa, difractometra de rayos X y micronanlisis, enfocando la mineraloga y el comportamiento de plata.

El residuo est mayormente compuesto por cuarzo y calcita. Adems lleva fragmentos de roca que muestran una marcada coloracin ferruginosa causada por limonita diseminada. La oxidacin generalizada del material se manifiesta tambin en la presencia de xidos de manganeso. Los sulfuros no sobrepasan cantidades trazas. No se ha detectado minerales especficos de plata.

A travs de microanlisis se comprob una dbil y errtica distribucin de plata que no aparece con minerales especficos de plata u otros portadores de plata. Se supone que la plata retenida en la muestra resulta de una reprecipitacin de plata durante el proceso de lixiviacin. Reprecipitacin puede ser una de las causas principales para mermas de plata en operaciones de lixiviacin.

R.W. Lehne

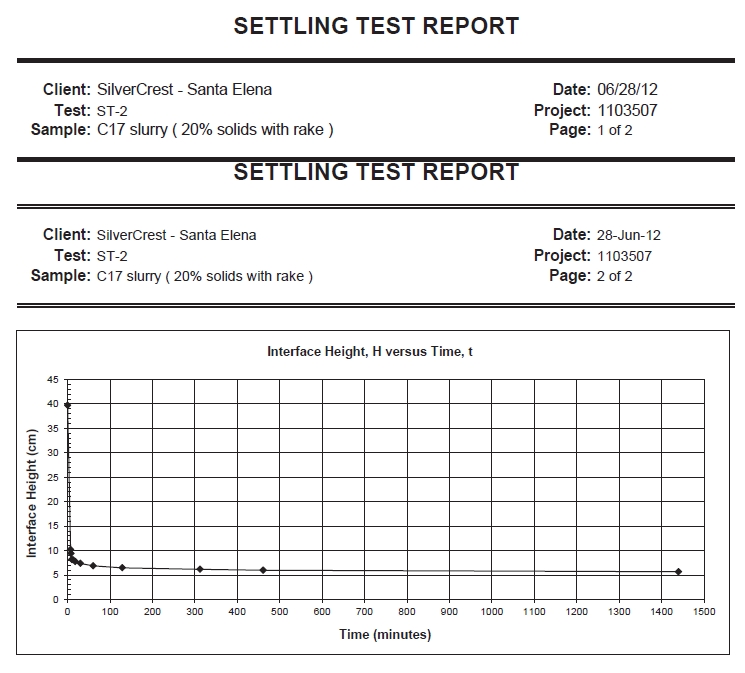

Client: SilverCrest - Santa Elena Date: 06/28/12 Test: ST-2

Client: SilverCrest - Santa Elena Date: 06/28/12 Test: ST-2

ORE MICROSCOPY (INSPECTORATE - METALLURGICAL DIVISION)

ORE MICROSCOPY (INSPECTORATE - METALLURGICAL DIVISION)

(1)

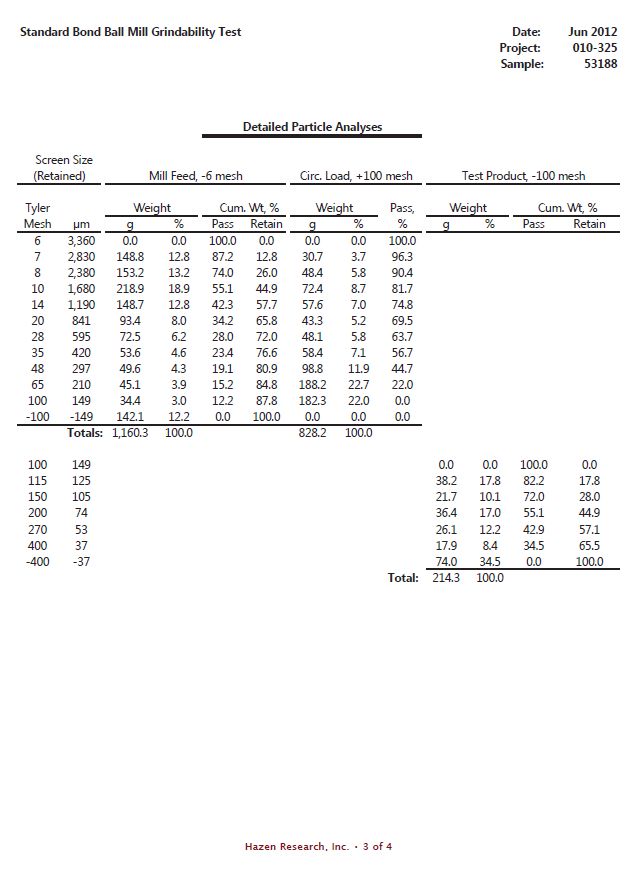

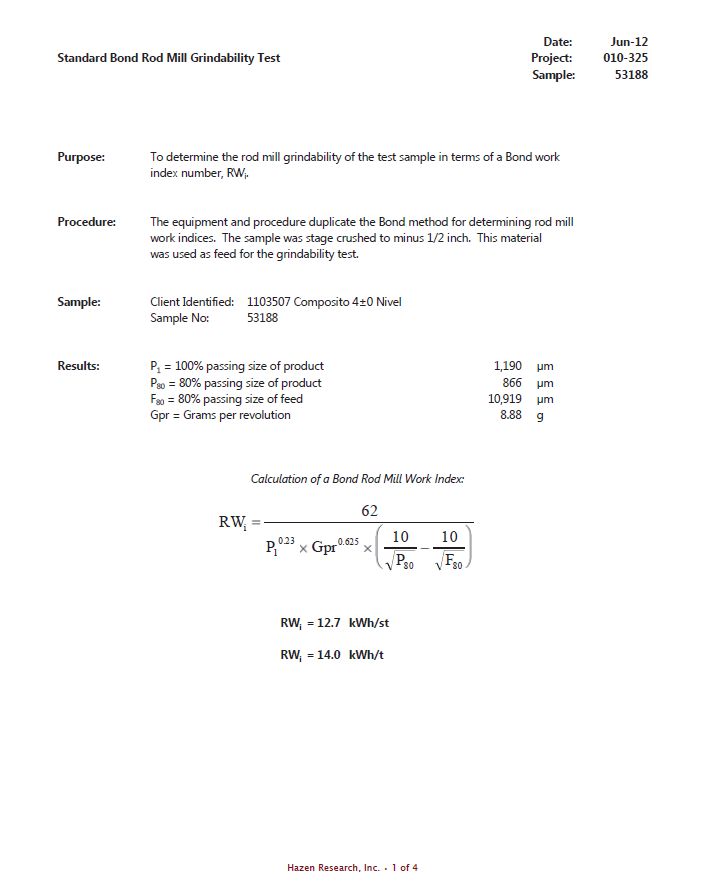

(1)