NI 43-101 Technical Report

Veris Gold Corp. Jerritt Canyon Property

Elko County, Nevada

Effective Date: December 31, 2012

Filing Date: July 11, 2013

Prepared For:

Veris Gold Corp. (VG)

900 - 688 West Hastings Street

Vancouver, BC V6B 1P1 Canada

Endorsed by Qualified Professionals:

Primary Author

Todd Johnson P.E., Vice President Exploration, Veris Gold Corp.

Contributing Authors

Mark Odell, P.E., Consulting Mine Engineer, Practical Mining LLC

Karl Swanson, Mining Consultant, SME, MAusIMM

Michele White, Geologic Consultant, CPG#11252 AIPG

John Fox, P. Eng., Consulting Metallurgist

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | ii |

This page intentionally left blank.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | iii |

Table of Contents

| Table of Contents | iii |

| | | | | |

| List of Tables | vii |

| | | | | |

| List of Figures | ix |

| | | | | |

| 1 | Summary | 1-1 |

| | 1.1 | Mineral Resource estimate | 1-2 |

| | 1.2 | Mineral Reserves estimate | 1-3 |

| | 1.3 | Conclusions | 1-4 |

| | 1.4 | Recommendations | 1-5 |

| | | | | |

| 2 | Introduction | 2-1 |

| | 2.1 | Terms of reference and purpose of the report | 2-1 |

| | 2.2 | Qualifications of consultants and authors | 2-1 |

| | 2.3 | Price strategy | 2-2 |

| | 2.4 | Units of measure | 2-2 |

| | 2.5 | Coordinate system, projections, and topography maps | 2-3 |

| | 2.6 | Calendar | 2-3 |

| | | | | |

| 3 | Reliance on other experts | 3-1 |

| | | | | |

| 4 | Property description and location | 4-1 |

| | 4.1 | Property description | 4-1 |

| | 4.2 | Property location | 4-1 |

| | 4.3 | Status of mineral titles | 4-1 |

| | 4.4 | Location of mineralization | 4-5 |

| | | | | |

| 5 | Accessibility, climate, vegetation, physiography, local resources and infrastructure | 5-1 |

| | 5.1 | Access to the site | 5-1 |

| | 5.2 | Climate | 5-1 |

| | 5.3 | Vegetation | 5-1 |

| | 5.4 | Physiography | 5-1 |

| | 5.5 | Local resources and infrastructure | 5-1 |

| | | | | |

| 6 | History | 6-1 |

| | 6.1 | Mining history | 6-1 |

| | 6.2 | Production history | 6-1 |

| | 6.3 | Historical mineral resource and reserve estimates | 6-3 |

| | | | | |

| 7 | Geological setting and mineralization | 7-1 |

| | 7.1 | Regional geology | 7-1 |

| | 7.2 | Local geology | 7-4 |

| | | | | |

| 8 | Deposit types | 8-1 |

| | 8.1 | Mineralization | 8-1 |

| | | 8.1.1 | SSX-Steer Mine | 8-2 |

| | | 8.1.2 | Saval Mine and Saval 4 | 8-4 |

| | | 8.1.3 | Smith Mine | 8-4 |

| | | 8.1.4 | Murray Mine | 8-5 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | iv |

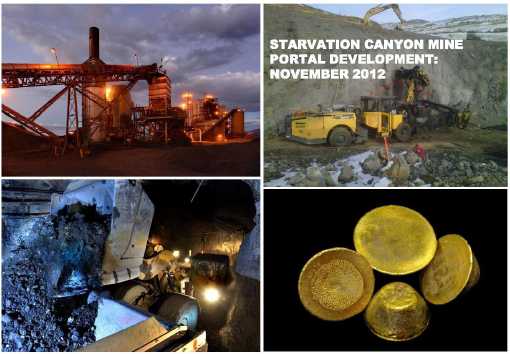

| | | 8.1.5 | Starvation Canyon | 8-6 |

| | | 8.1.6 | West Mahala | 8-6 |

| | | 8.1.7 | Wright Window | 8-6 |

| | | 8.1.8 | Pie Creek | 8-6 |

| | | 8.1.9 | Mill Creek | 8-7 |

| | | 8.1.10 | Road Canyon | 8-7 |

| | | 8.1.11 | Burns Basin | 8-7 |

| | | 8.1.12 | California Mountain | 8-7 |

| | | | | |

| 9 | Exploration | 9-1 |

| | | | | |

| 10 | Drilling and sampling methodology | 10-1 |

| | | | | |

| | 10.1 | Surface drilling | 10-3 |

| | 10.2 | Underground drilling | 10-4 |

| | 10.3 | Core and chips recovery | 10-18 |

| | 10.4 | Security procedures: core and pulps | 10-18 |

| | 10.5 | Logging drilled core and chips observations | 10-18 |

| | 10.6 | Sampling methodology: core and pulps | 10-18 |

| | | | | |

| 11 | Sample preparation, analyses, security, and QAQC | 11-1 |

| | | | | |

| | 11.1 | Jerritt Canyon laboratory sampling procedures | 11-1 |

| | | 11.1.1 | Sample preparation | 11-1 |

| | | 11.1.2 | Sampling analysis protocol | 11-1 |

| | | 11.1.3 | Sample security measures | 11-2 |

| | 11.2 | Commercial laboratory sample preparation, analysis protocol, and security | 11-2 |

| | 11.3 | Quality control measures | 11-3 |

| | | 11.3.1 | Current Jerritt Canyon and commercial laboratory QAQC procedures | 11-3 |

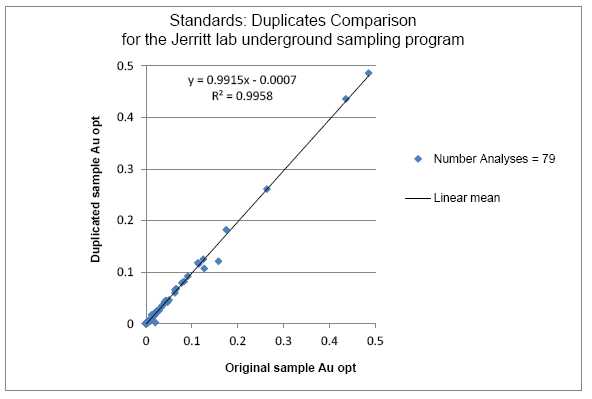

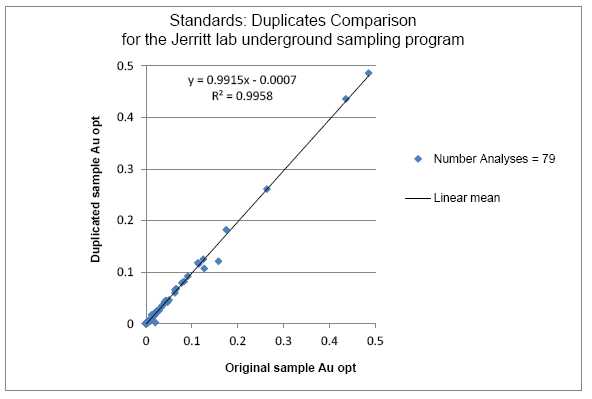

| | | 11.3.2 | Re-assays and duplicates performance | 11-5 |

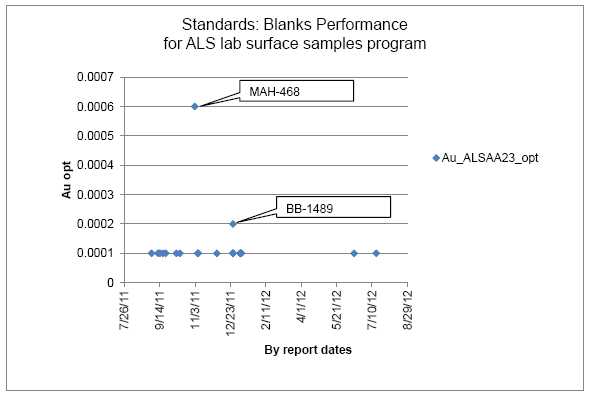

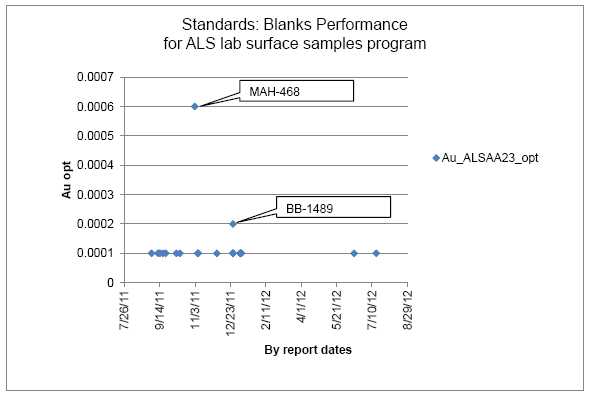

| | | 11.3.3 | Blank performance | 11-7 |

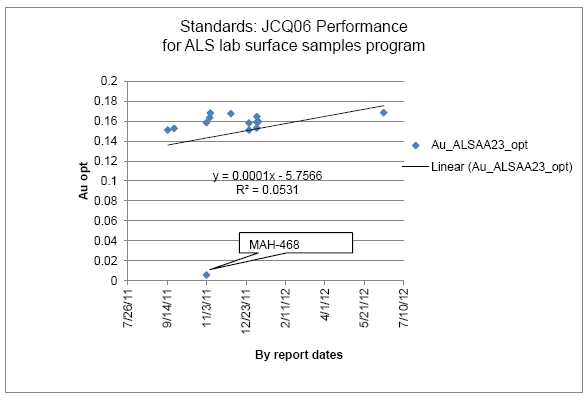

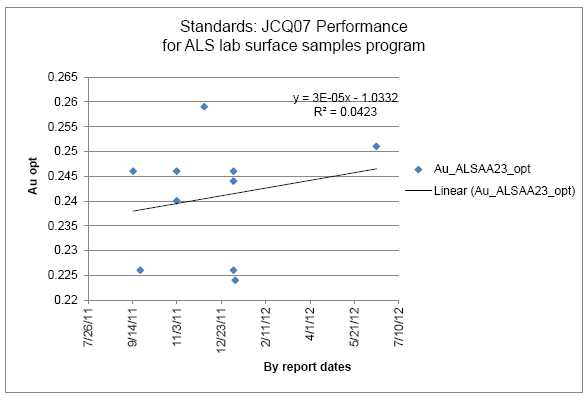

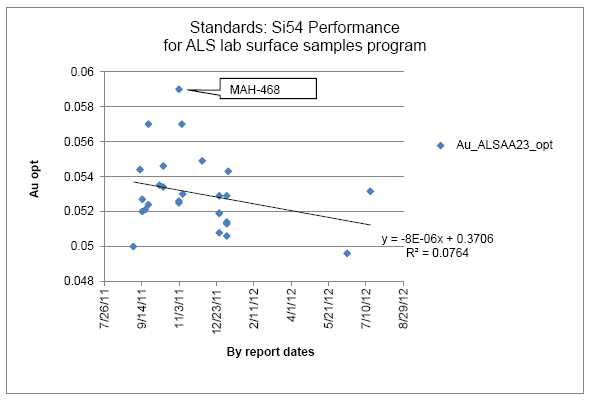

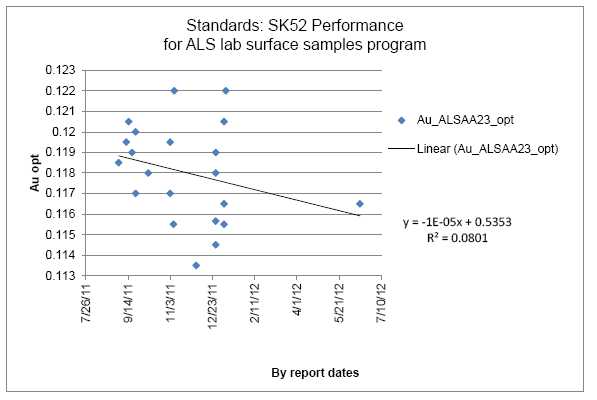

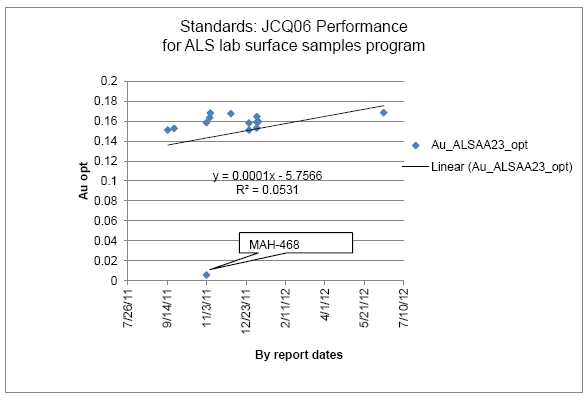

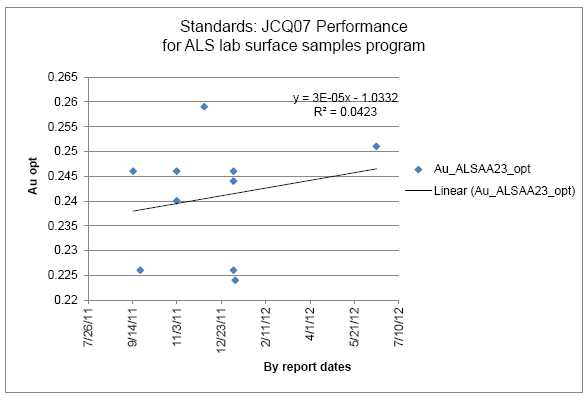

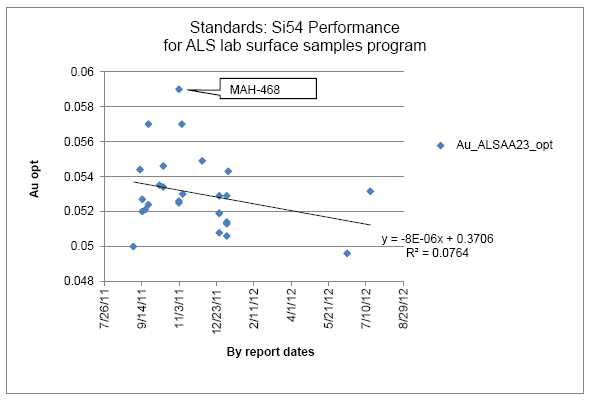

| | | 11.3.4 | Standards performance: surface core drilling | 11-9 |

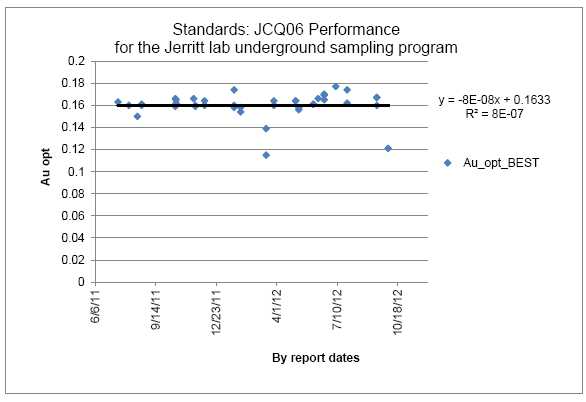

| | | 11.3.5 | Standards performance: underground Cubex drilling | 11-13 |

| | 11.4 | Opinion on the adequacy of the sampling methodolgy | 11-16 |

| | | | | |

| 12 | Data verification | 12-1 |

| | | | | |

| | 12.1 | Data vetting prior to August 2008 | 12-1 |

| | 12.2 | Data vetting performed after August 2008 to January 2010 | 12-2 |

| | 12.3 | Data vetting performed on 2011 drilling results | 12-4 |

| | 12.4 | Current data vetting June 18, 2011 to December 31, 2012 | 12-5 |

| | | 12.4.1 | Datasets submitted for evaluation | 12-6 |

| | | 12.4.2 | acQuire to ISIS comparison of assay data | 12-8 |

| | | 12.4.3 | Comparison of intervals versus sample numbers | 12-8 |

| | | 12.4.4 | Checks of format conversions: Au opt-Au ppb-Au ppm-Au best selection | 12-9 |

| | | 12.4.5 | Assay certificates compared to acQuire and ISIS Au values | 12-9 |

| | | 12.4.6 | Lithology checks: formation, rock type, and intervals | 12-10 |

| | 12.5 | Summary of database verification | 12-10 |

| | | | | |

| 13 | Mineral processing and metallurgical testing | 13-1 |

| | | | | |

| 14 | Mineral resource estimates | 14-1 |

| | | | | |

| | 14.1 | Introduction | 14-1 |

| | 14.2 | Drill hole database and compositing | 14-3 |

| | 14.3 | Geology and grade shell modeling | 14-8 |

| | 14.4 | Specific gravity and density | 14-16 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | v |

| | 14.5 | Statistics and variography | 14-17 |

| | | 15.4.1 | Grade capping | 14-23 |

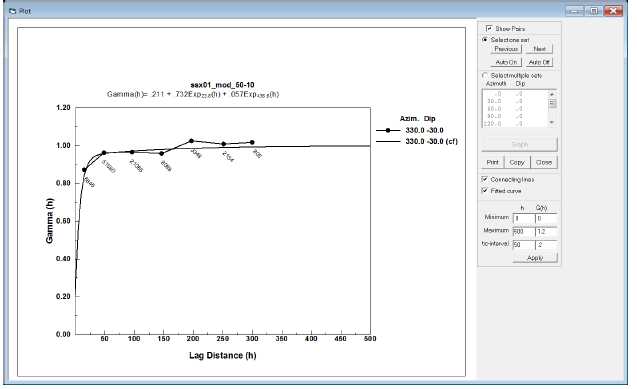

| | | 15.4.2 | Variography | 14-23 |

| | 14.6 | Block modeling | 14-35 |

| | 14.7 | Gold grade estimation and block calculations | 14-43 |

| | 14.8 | Mined depletion and sterilization | 14-47 |

| | 14.9 | Mineral resource classification | 14-54 |

| | 14.10 | Block model validation | 14-56 |

| | 14.11 | Mineral resource statement | 14-59 |

| | | 14.11.1 | Underground mineral resources | 14-59 |

| | | 14.11.2 | Open pit mineral resources | 14-62 |

| | 14.12 | Other resource constraints | 14-62 |

| | | | | |

| 15 | Mineral Reserve estimate | 15-1 |

| | | | | |

| | 15.1 | Underground mine reserves | 15-1 |

| | 15.2 | Open pit mine reserves | 15-7 |

| | | | | |

| 16 | Mining methods | 16-1 |

| | | | | |

| | 16.1 | Mining operations | 16-1 |

| | 16.2 | Mining production | 16-1 |

| | 16.3 | Underground mining methods | 16-3 |

| | | 16.3.1 | Mine development | 16-6 |

| | | 16.3.2 | Underground geotechnical considerations | 16-7 |

| | | 16.3.3 | Ventilation | 16-7 |

| | | 16.3.4 | Dewatering | 16-7 |

| | 16.4 | Open pit mining methods | 16-7 |

| | 16.5 | Ore control and sampling procedures (underground) | 16-8 |

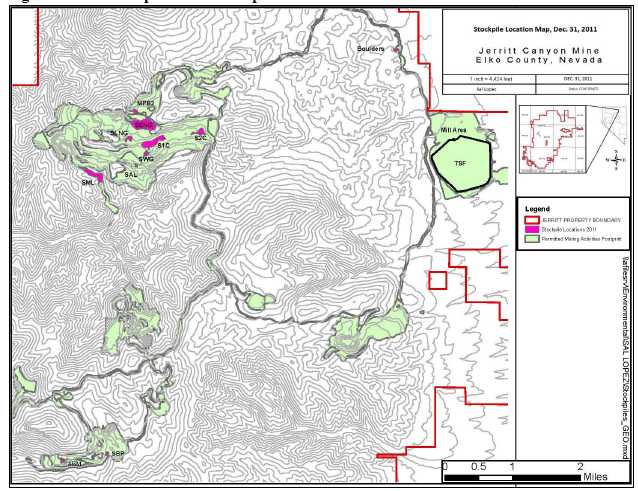

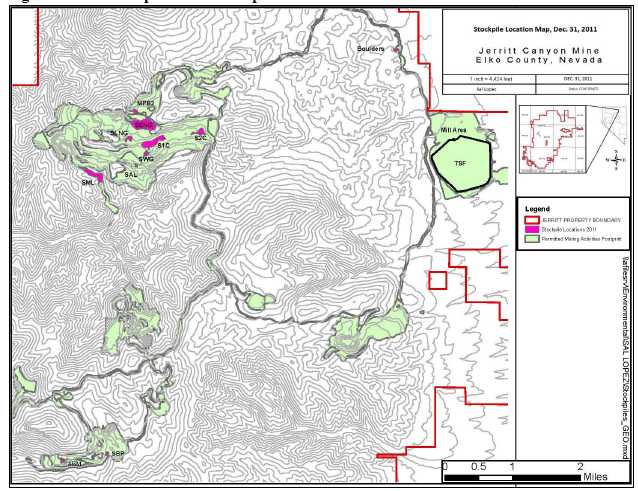

| | 16.6 | Jerritt Canyon Stockpiles | 16-8 |

| | | | | |

| 17 | Recovery methods | 17-1 |

| | | | | |

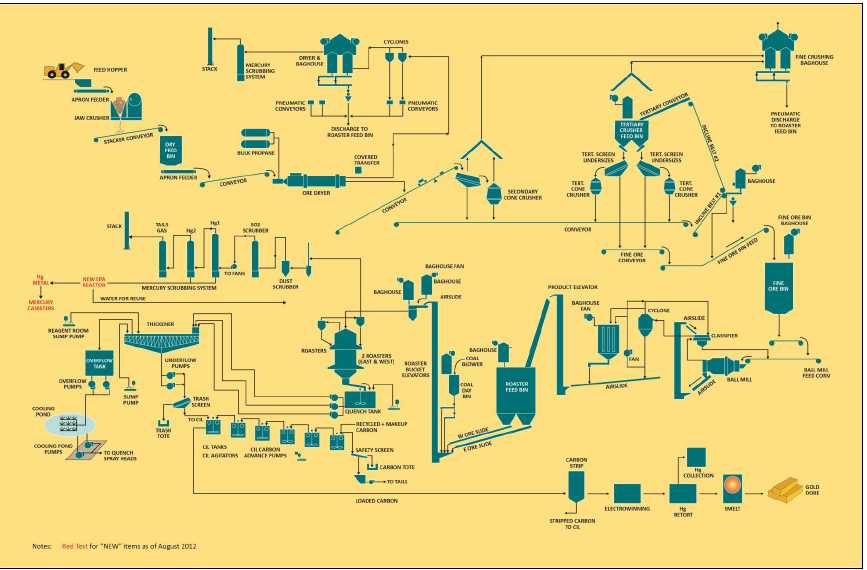

| | 17.1 | Processing facilities, operating parameters, and process flow sheet | 17-1 |

| | 17.2 | Recoverability | 17-4 |

| | 17.3 | Historic processing plant production and cost data | 17-5 |

| | | | | |

| 18 | Project infrastructure | 18-1 |

| | | | | |

| | 18.1 | Road access | 18-1 |

| | 18.2 | Water sources | 18-1 |

| | 18.3 | Power | 18-1 |

| | 18.4 | Sewage and waste disposal | 18-1 |

| | 18.5 | Ore stockpiles | 18-1 |

| | 18.6 | Tailings facilities | 18-1 |

| | | | | |

| 19 | Market studies and contracts | 19-1 |

| | | | | |

| | 19.1 | Market studies | 19-1 |

| | 19.2 | Contracts | 19-2 |

| | | | | |

| 20 | Environmental studies, permitting, and social or community impact | 20-1 |

| | | | | |

| | 20.1 | Environmental issues | 20-3 |

| | 20.2 | Environmental liabilities | 20-3 |

| | | 20.2.1 | Waste rock seepage | 20-4 |

| | | 20.2.2 | Tailings impoundment seepage control | 20-4 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | vi |

| | | 20.2.3 | Air emissions control technology | 20-5 |

| | | 20.2.4 | Reclamation bond cost | 20-5 |

| | 20.3 | Permits | 20-5 |

| 21 | Capital and operating costs | 21-1 |

| | 21.1 | Capital costs | 21-1 |

| | 21.2 | Operating costs | 21-1 |

| | 21.3 | Cutoff grades | 21-2 |

| 22 | Economic analysis | 22-1 |

| | 22.1 | LoM plan and economics | 22-1 |

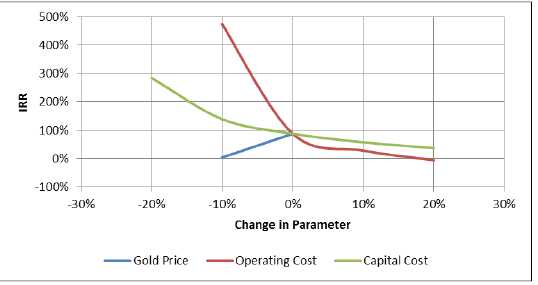

| | 22.2 | Project sensitivity | 22-3 |

| 23 | Adjacent properties | 23-1 |

| 24 | Other relevant data and information | 24-1 |

| 25 | Interpretations and conclusions | 25-1 |

| 26 | Recommendations | 26-1 |

| | 26.1 | Dewatering | 26-1 |

| | 26.2 | 2013 Geological program | 26-1 |

| 27 | References | 27-1 |

| 28 | Glossary | 28-1 |

| 29 | Date and signature page | 29-1 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | vii |

List of Tables

| Table 1.1.1: | Jerritt Canyon mineral resources including reserves – December 31, 2012 | 1-3 |

| Table 1.2.1: | Jerritt Canyon mineral reserves – December 31, 2012. | 1-4 |

| Table 2.4.1: | Units of measure. | 2-3 |

| Table 4.3.1: | Land and claim summary for Veris Gold USA’s Jerritt Canyon Project. | 4-2 |

| Table 6.2.1: | Historic open pit and underground mine production at the Jerritt Canyon before recovery losses | 6-2 |

| Table 6.3.1: | Historic measured and indicated mineral resources, including reserves. | 6-3 |

| Table 6.3.2: | Historic inferred mineral resources. | 6-3 |

| Table 6.3.3: | Historic proven and probable mineral reserves | 6-3 |

| Table 10.1: | Jerritt Canyon drilling (2000 through year end 2012). | 10-2 |

| Table 12.4: | Summary of datasets submitted for January 2013 audit. | 12-6 |

| Table 12.4: | Number of drill holes per dataset audited. | 12-7 |

| Table 12.4: | Number of records reviewed per dataset. | 12-7 |

| Table 13.1: | Starvation Canyon ore metallurgy testswork results. | 13-2 |

| Table 14.2.1: | Geology database formation codes. | 14-4 |

| Table 14.5.1: | Summary of statistics by open pit model | 14-17 |

| Table 14.5.2: | Summary of statistics by underground model. | 14-17 |

| Table 14.5.1.1: | Cap grade by open pit model | 14-23 |

| Table 14.5.1.2: | Cap grade by underground model. | 14-23 |

| Table 14.5.2.1: | Vulcan ordinary kriging input parameters by model. | 14-24 |

| Table 14.5.2.2: | Smith variogram parameters. | 14-24 |

| Table 14.5.2.3: | SSX variogram parameters. | 14-26 |

| Table 14.5.2.4: | Starvation variogram parameters | 14-28 |

| Table 14.5.2.5: | Burns Basin variogram parameters. | 14-30 |

| Table 14.5.2.6: | Saval variogram parameters | 14-32 |

| Table 14.6.1: | Burns Basin block model details. | 14-35 |

| Table 14.6.2: | Saval open pit block model details | 14-36 |

| Table 14.6.3: | Smith block model details. | 14-38 |

| Table 14.6.4: | SSX block model details. | 14-39 |

| Table 14.6.5: | Starvation model details. | 14-41 |

| Table 14.6.6: | Block model variables | 14-43 |

| Table 14.7.1: | Burns Basin grade shell search ellipsoid orientations. | 14-44 |

| Table 14.7.2.: | Estimation parameters by block model. | 14-45 |

| Table 14.10.1: | Block model and composite grade comparison by deposit | 14-58 |

| Table 14.11.1: | Jerritt Canyon mineral resources including reserves – December 31, 2012 | 14-59 |

| Table 15.1.1: | Jerritt Canyon mineral reserves – December 31, 2012. | 15-1 |

| Table 16.2.1: | Jerritt Canyon 2010-2012 production | 16-2 |

| Table 16.6.1: | Jerritt Canyon stockpile reserve summary. | 16-9 |

| Table 17.1.1: | Operating parameters for the Jerritt Canyon processing plant. | 17-1 |

| Table 17.2.1: | Jerritt Canyon 2008-2012 gold recovery by month | 17-4 |

| Table 17.3.1: | Jerritt Canyon historic process production and cost data. | 17-5 |

| Table 18.6.1: | Design criteria for the TSF-2 | 18-2 |

| Table 20.3.1: | Operating permits. | 20-6 |

| Table 21.1.1: | Jerritt Canyon Life of Mine (LoM) capital expenditures ($000’s). | 21-1 |

| Table 21.2.1: | Jerritt Canyon Life of Mine (LoM) operating costs (US $/Ore Ton) | 21-2 |

| Table 21.3.1: | Jerritt Canyon resource cut off grades at US $1,620/oz | 21-3 |

| Table 21.3.2: | Jerritt Canyon reserve cut off grades at US $1,490/oz | 21-4 |

| Table 22.1.1: | Life of Mine production schedule (ktpy). | 22-1 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | viii |

| Table 22.1.2: | Income statement 2013 to 2018 ($000’s). | 22-2 |

| Table 22.1.3: | Cash flow statement 2013 to 2019 ($000’s). | 22-2 |

| Table 22.1.4: | Key operating and financial statistics. | 22-3 |

| Table 26.2.1: | Proposed 2013 Jerritt Canyon drilling and geology program ($M). | 26-2 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | ix |

List of Figures

| Figure 4.3.1: General location map of the Jerritt Canyon Mine | 4-3 |

| Figure 4.3.2: General land map of the Jerritt Canyon property with model areas. | 4-4 |

| Figure 7.1.1: General geology map of the Jerritt Canyon District. | 7-3 |

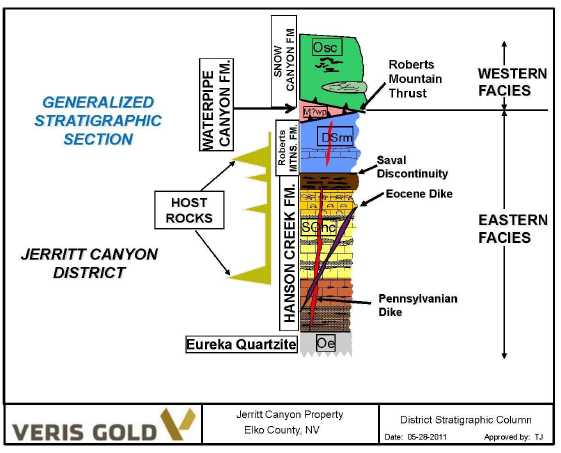

| Figure 7.1.2: General stratigraphic section of the Jerritt Canyon District. | 7-4 |

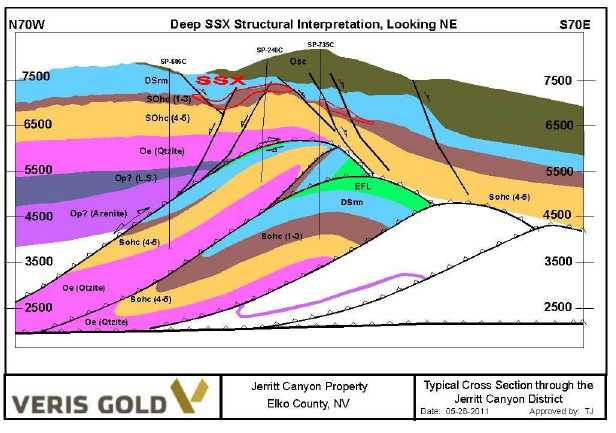

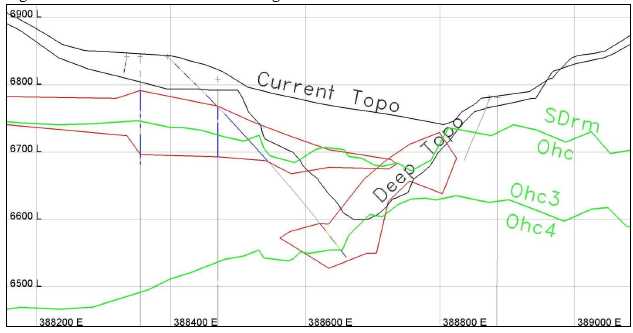

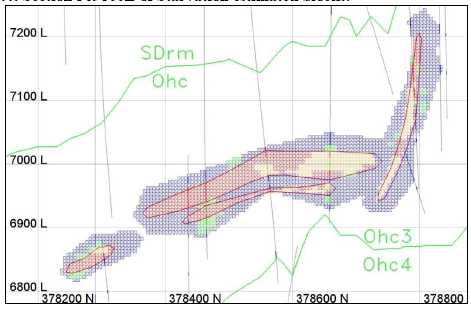

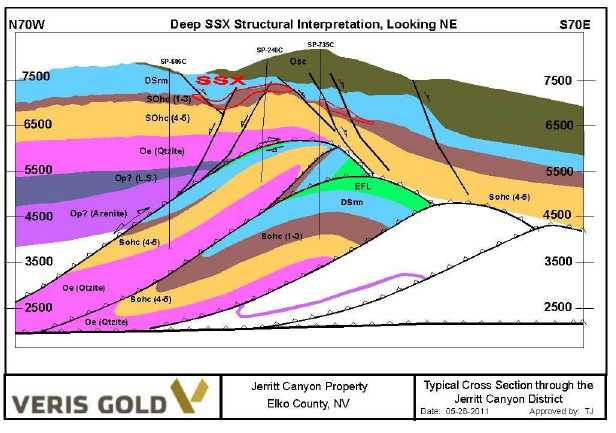

| Figure 8.1.1.1: Cross-section through the SSX deposit showing general geology. | 8-3 |

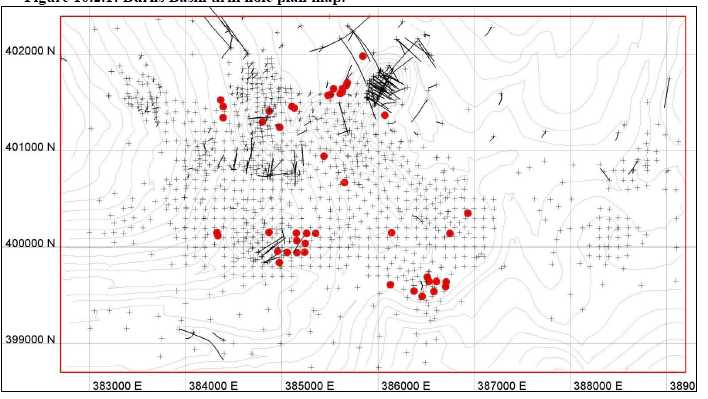

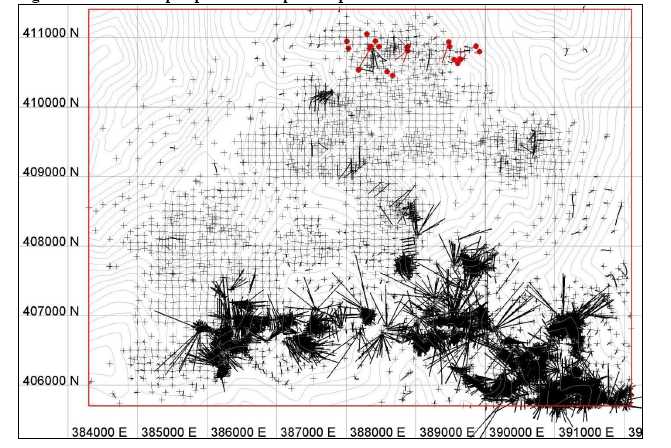

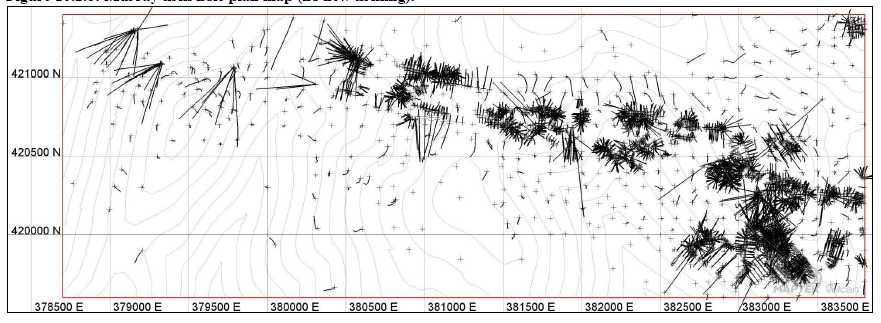

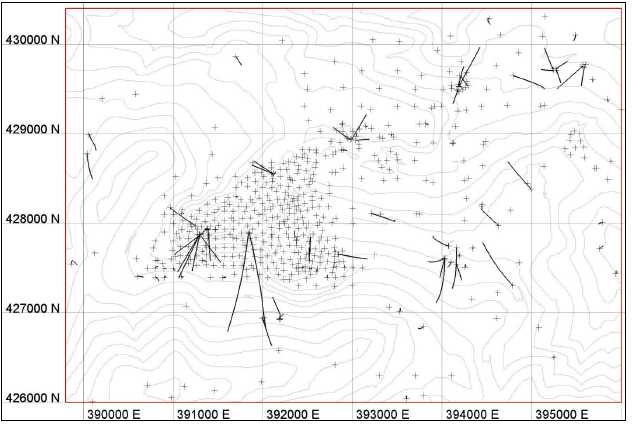

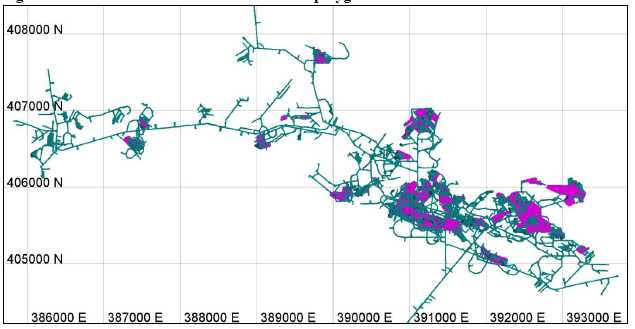

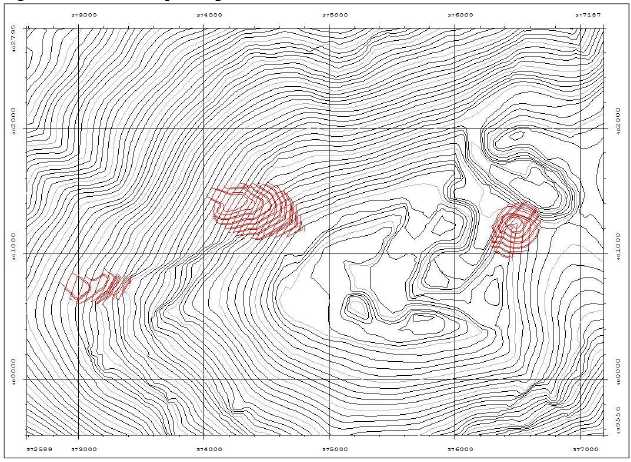

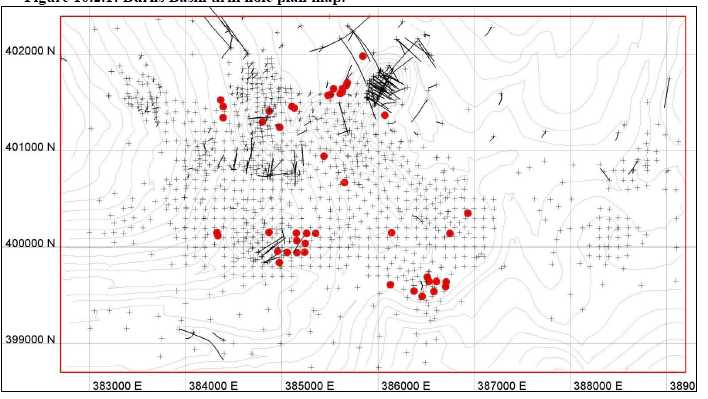

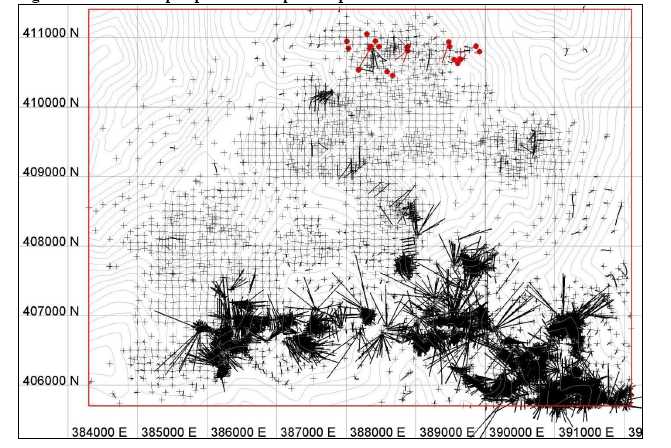

| Figure 10.2.1: Burns Basin drill hole plan map. | 10-6 |

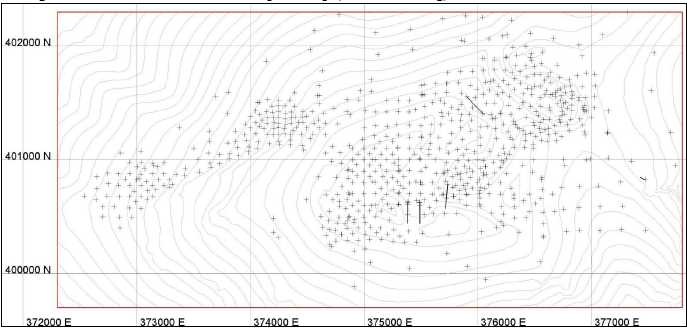

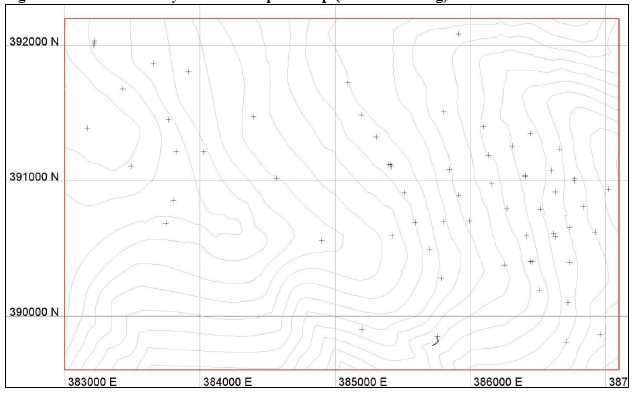

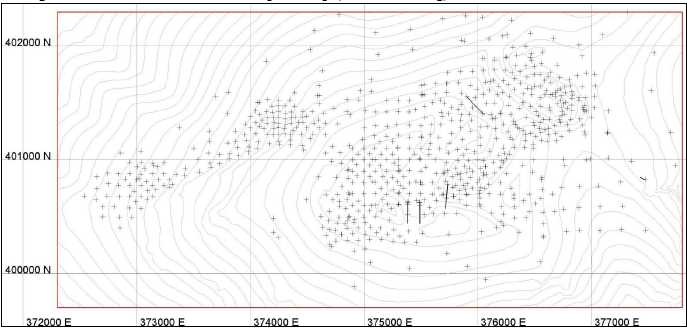

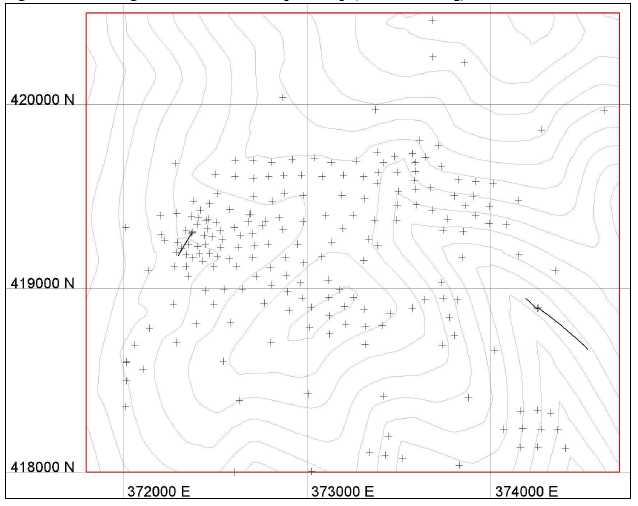

| Figure 10.2.2: Mill Creek drill hole plan map (no new drilling) | 10-7 |

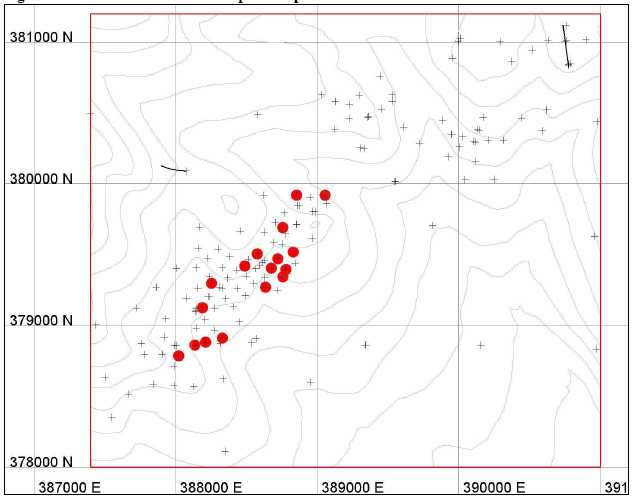

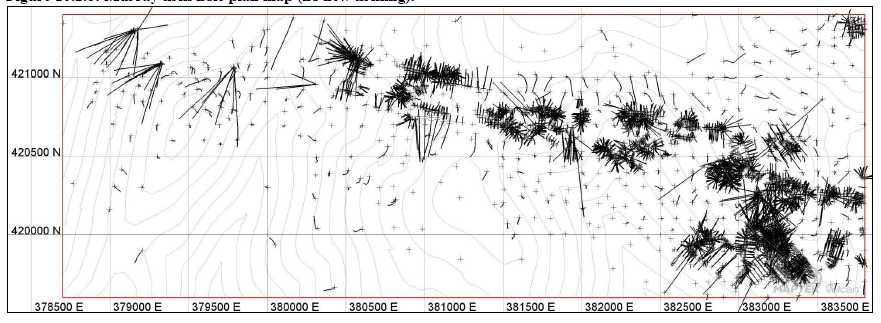

| Figure 10.2.3: Pie Creek drill hole plan map | 10-8 |

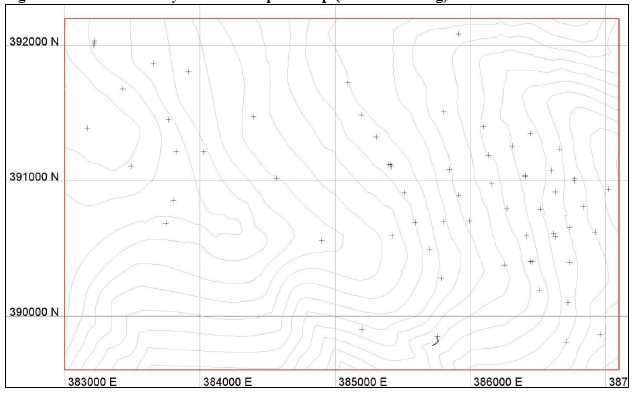

| Figure 10.2.4: Road Canyon drill hole plan map (no new drilling) | 10-9 |

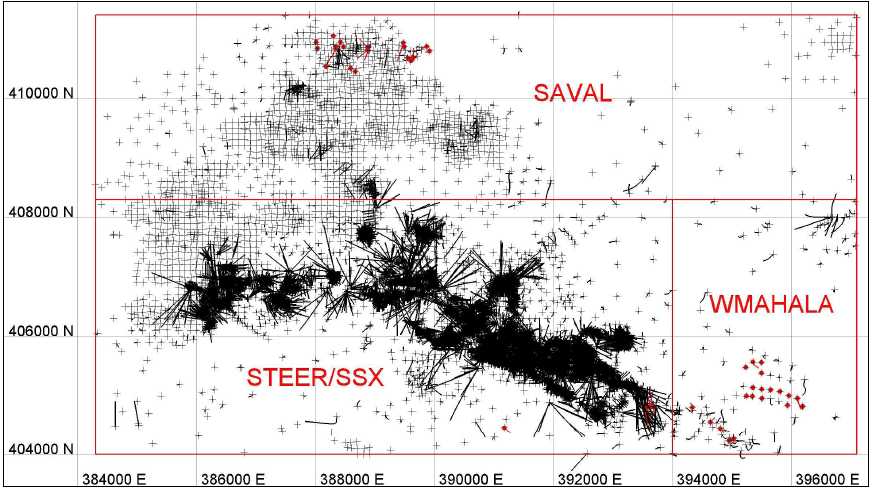

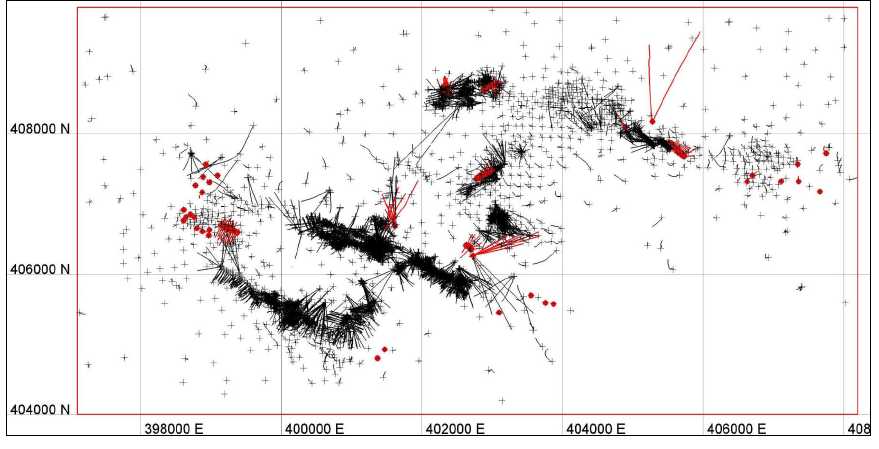

| Figure 10.2.5: Saval open pit drill hole plan map | 10-10 |

| Figure 10.2.6: Wright Window drill hole plan map (no new drilling) | 10-11 |

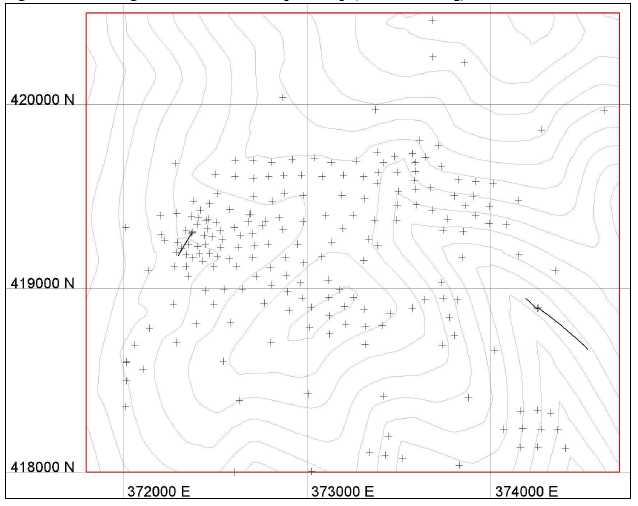

| Figure 10.2.7: California Mountain drill hole plan map (no new drilling). | 10-12 |

| Figure 10.2.8: Murray drill hole plan map (no new drilling). | 10-13 |

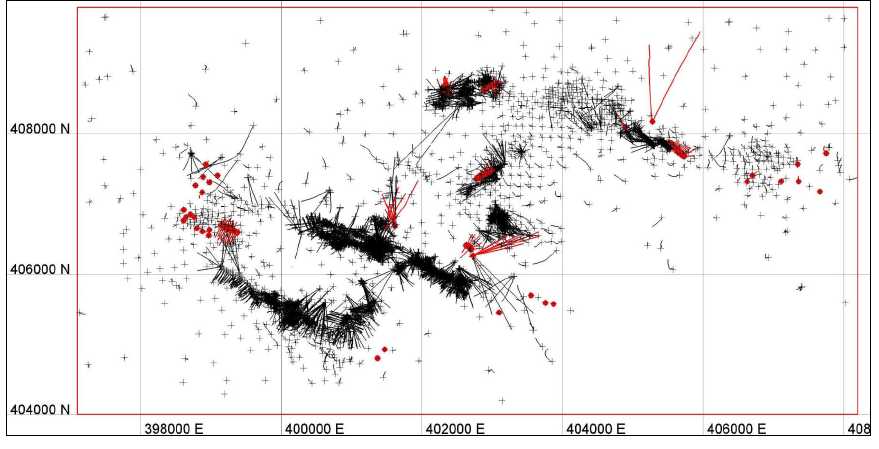

| Figure 10.2.9: Smith drill hole plan map. | 10-14 |

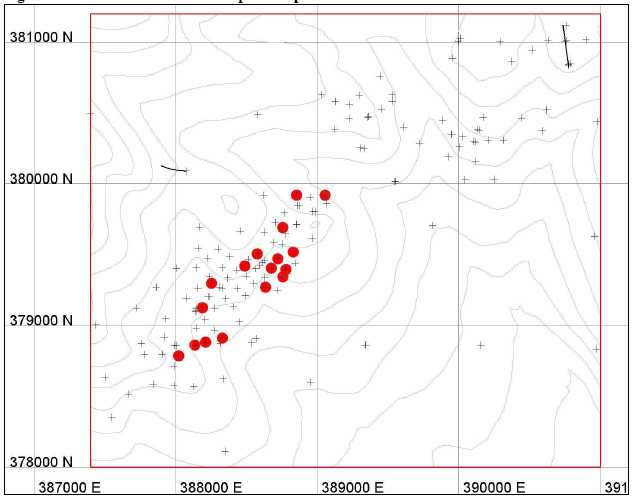

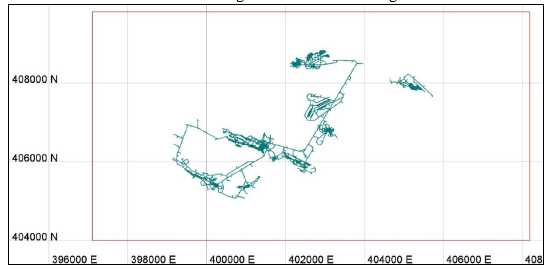

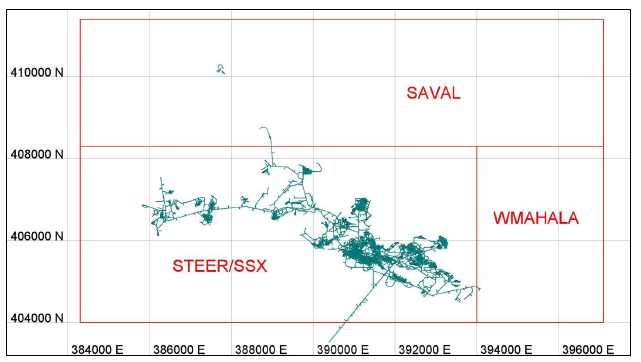

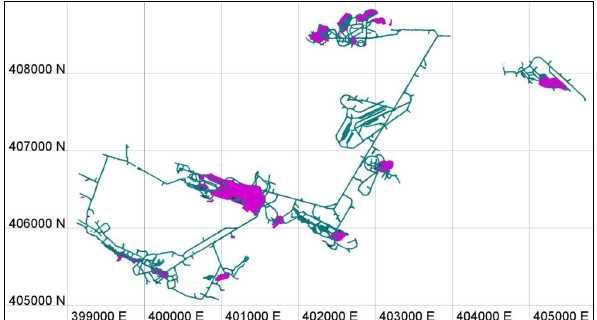

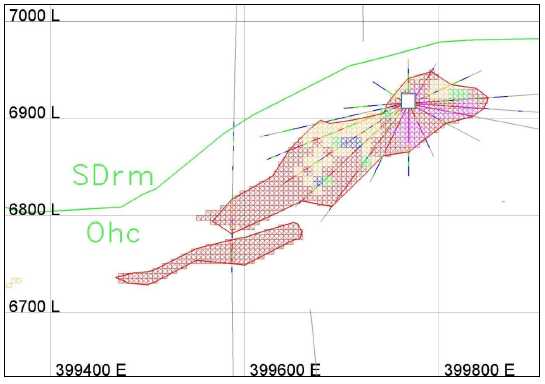

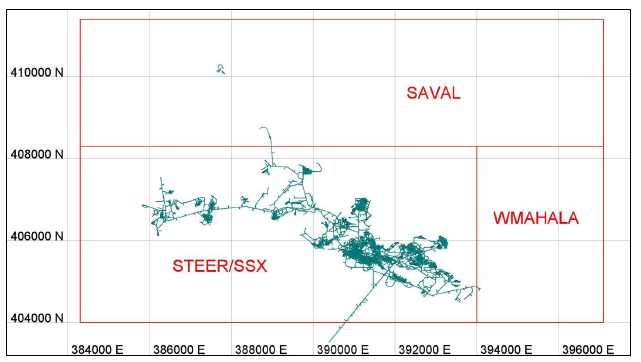

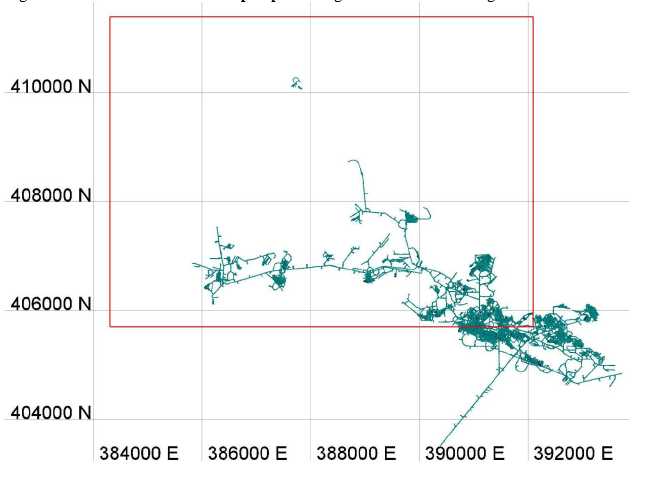

| Figure 10.2.10: SSX drill hole plan map. | 10-15 |

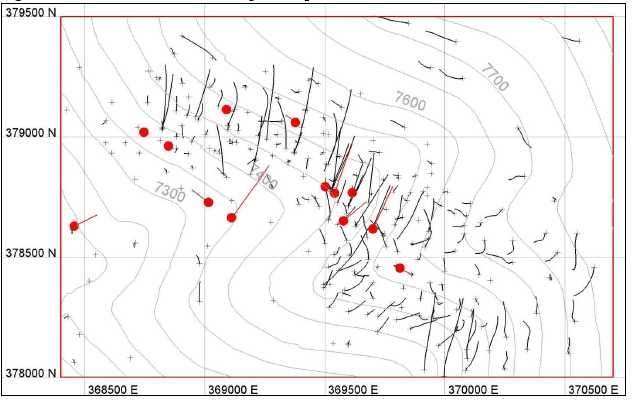

| Figure 10.2.11: Starvation drill hole plan map. | 10-16 |

| Figure 10.2.12: Winters Creek drill hole plan map (no new drilling). | 10-17 |

| Figure 11.3.2.1: Jerritt lab duplicate results from June 18, 2011- December 31, 2012. | 11-6 |

| Figure 11.3.3.1: ALS lab blanks results from June 18, 2011 – December 31, 2012 | 11-7 |

| Figure 11.3.3.2: Jerritt lab blank results from June 18, 2011 – December 31, 2012. | 11-8 |

| Figure 11.3.4.1: ALS lab JCQ06 standard results from June 18, 2011 – December 31, 2012. | 11-9 |

| Figure 11.3.4.2: ALS lab JCQ07 standard results from June 18, 2011 - December 2012 | 11-10 |

| Figure 11.3.4.3: ALS lab Si54 standard results from June 18, 2011 - December 31, 2012. | 11-11 |

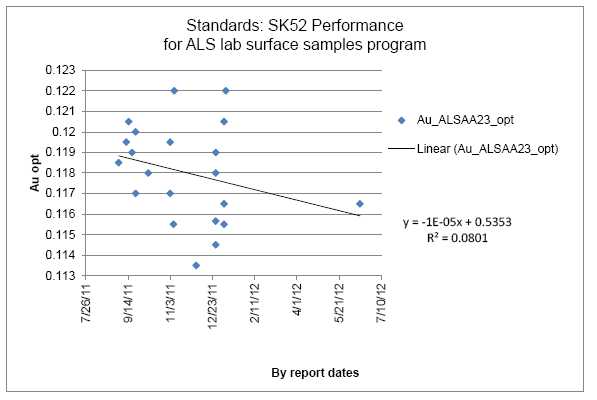

| Figure 11.3.4.4: ALS lab SK52 standard results from June 18, 2011 - December 31, 2012. | 11-12 |

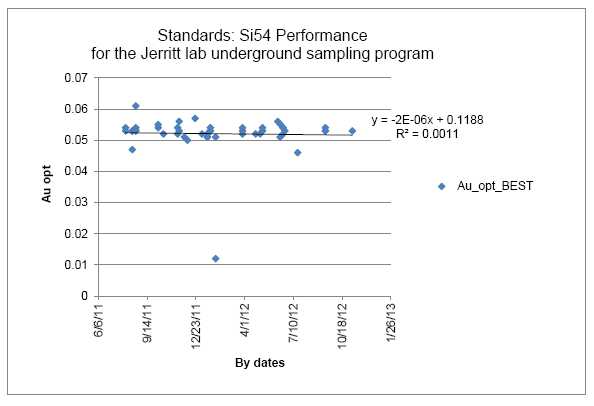

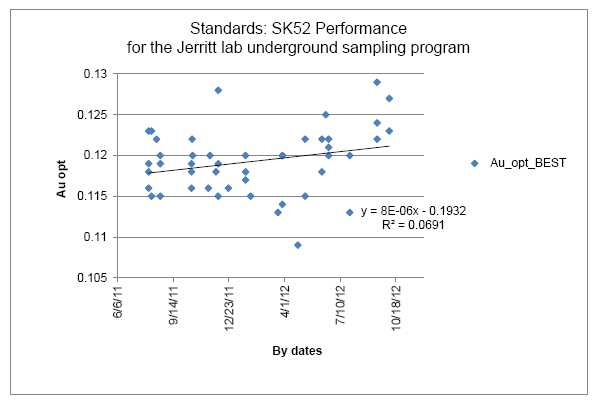

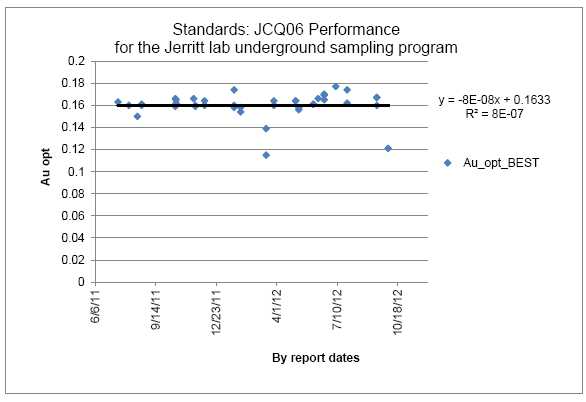

| Figure 11.3.5.1: Jerritt lab JCQ06 standard results from June 18, 2011 - December 31, 2012. | 11-13 |

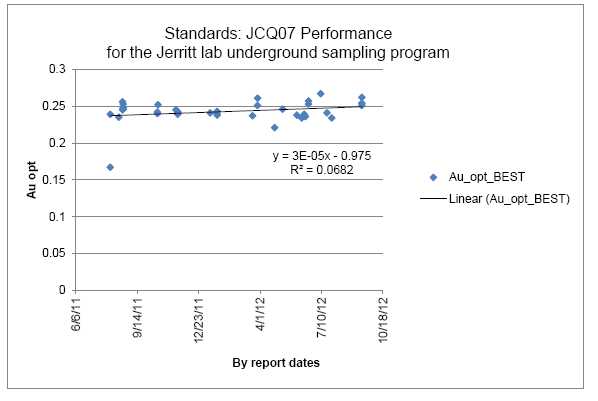

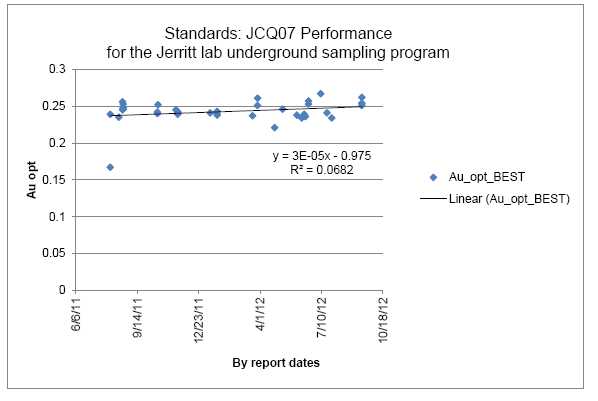

| Figure 11.3.5.2: Jerritt lab JCQ07 standard results from June 18, 2011 - December 31, 2012. | 11-14 |

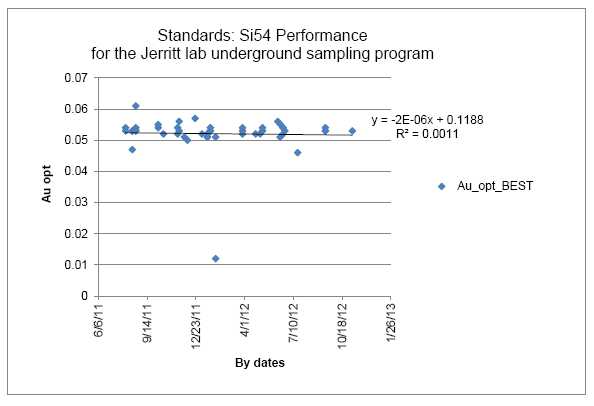

| Figure 11.3.5.3: Jerritt lab Si54 standard results from June 18, 2011 - December 31, 2012 | 11-15 |

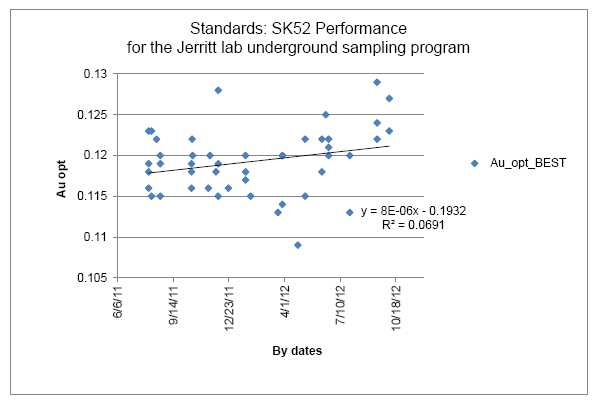

| Figure 11.3.5.4: Jerritt lab SK52 standard results from June 18, 2011 - December 31, 2012. | 11-16 |

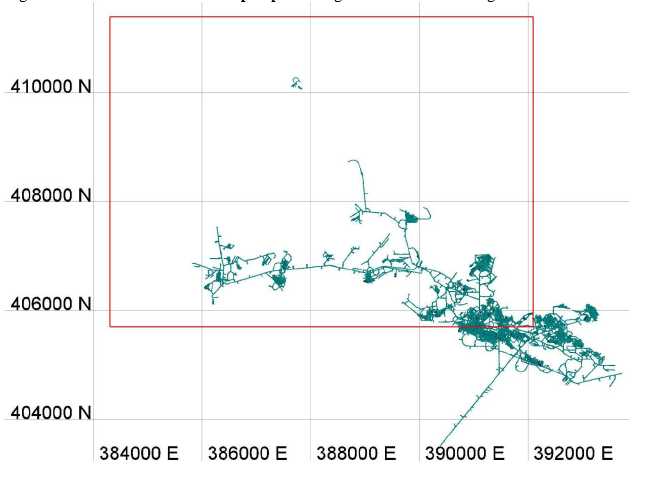

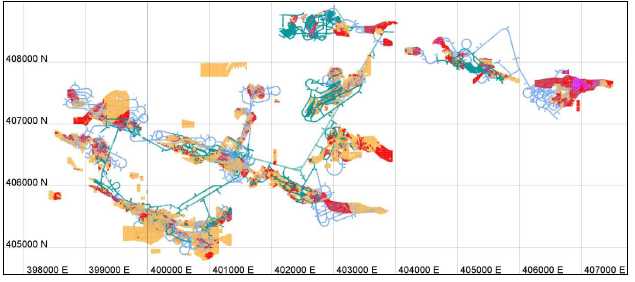

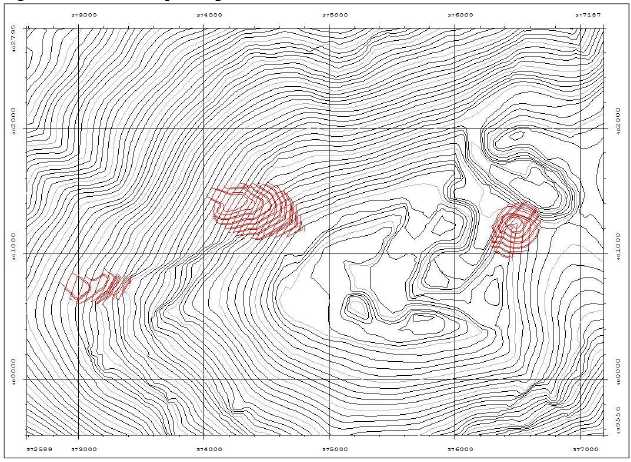

| Figure 14.1.1: Updated open pit model locations. | 14-2 |

| Figure 14.1.2: Updated underground model locations. | 14-3 |

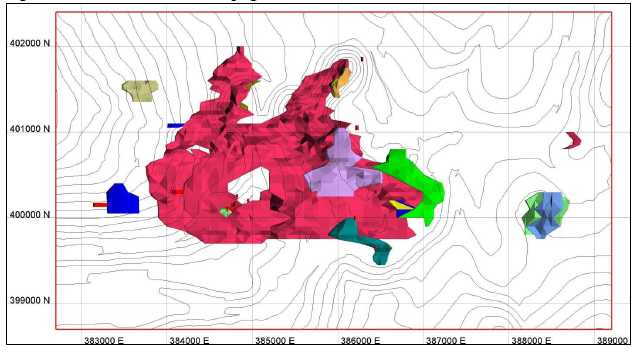

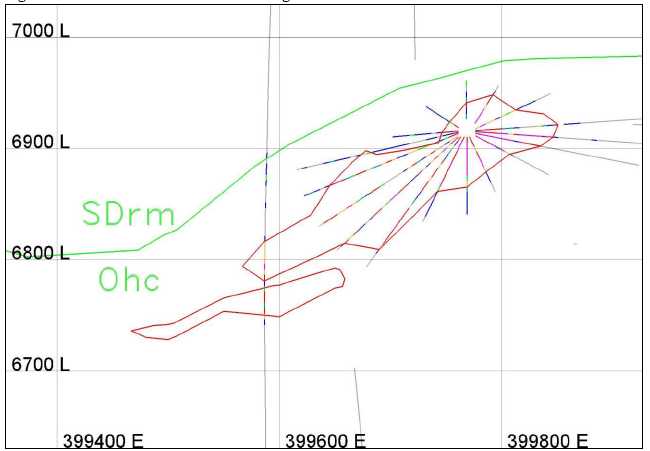

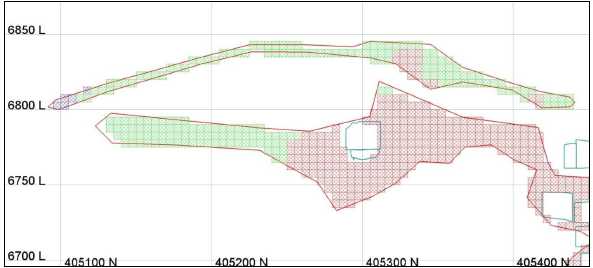

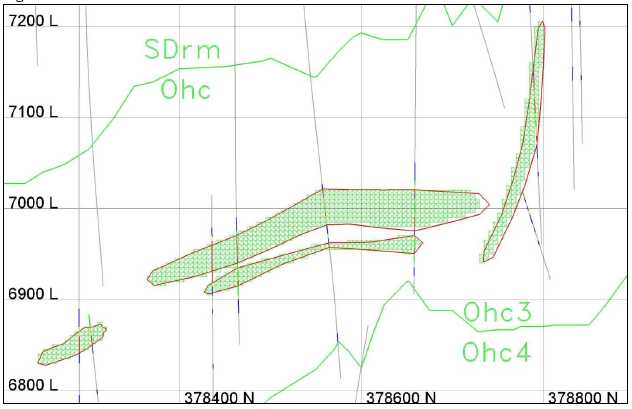

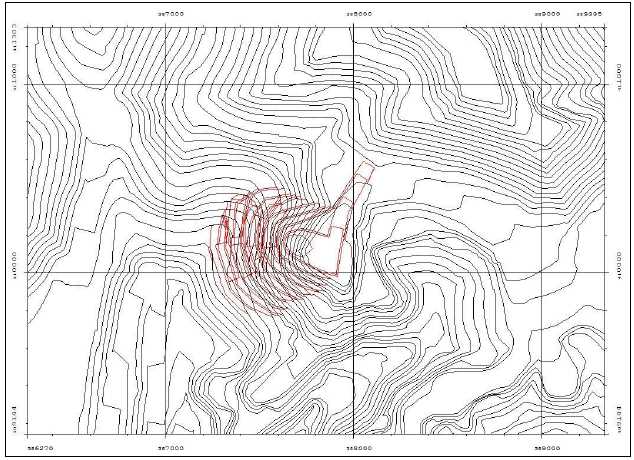

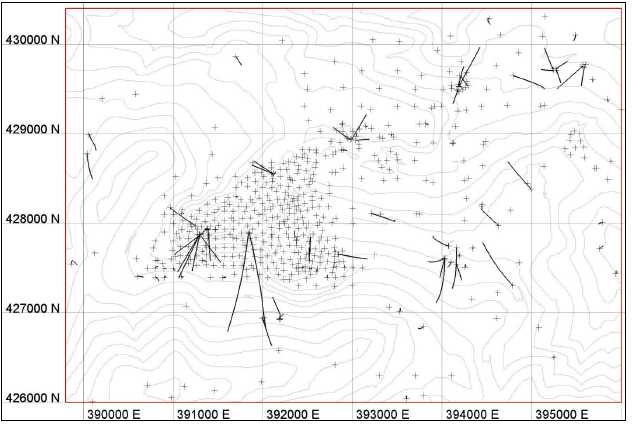

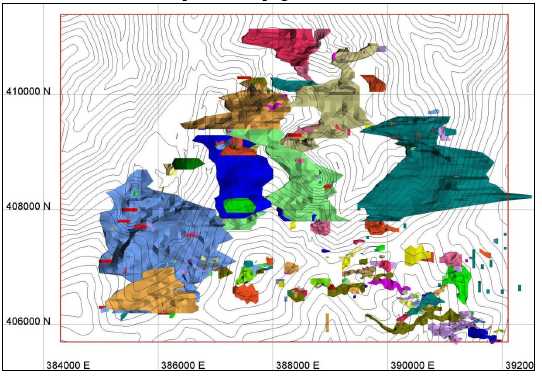

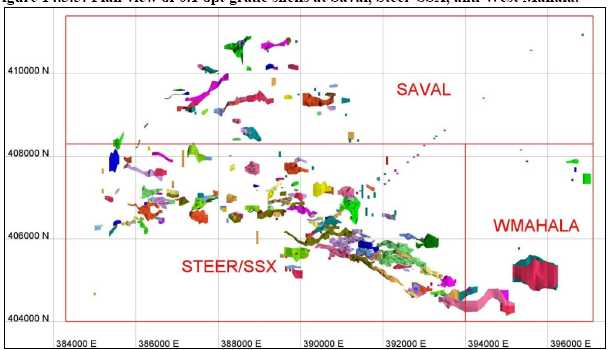

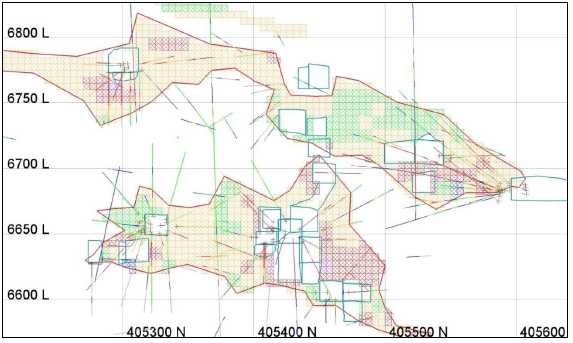

| Figure 14.3.1: Plan view of 0.01 opt grade shells at Burns Basin. | 14-9 |

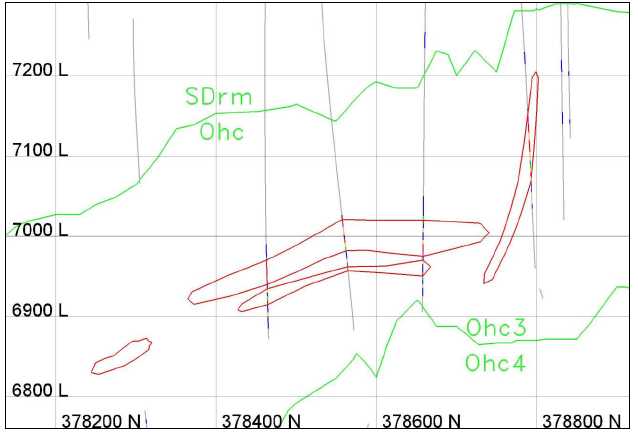

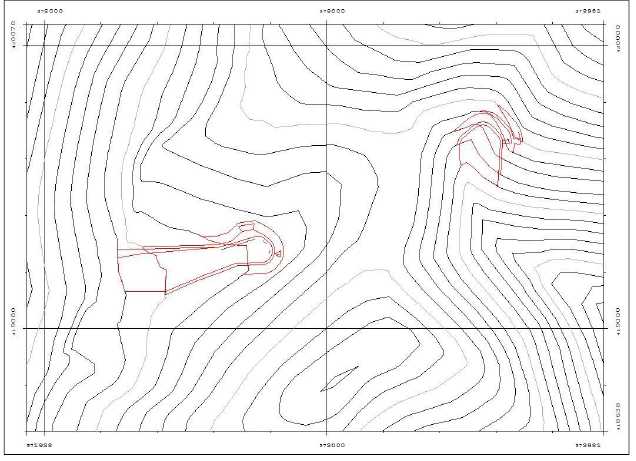

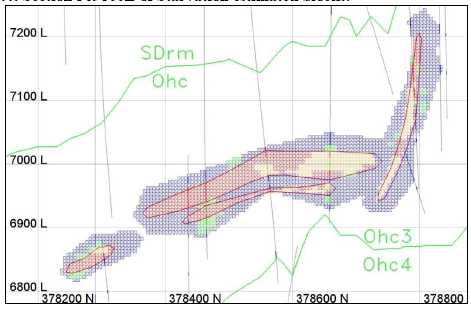

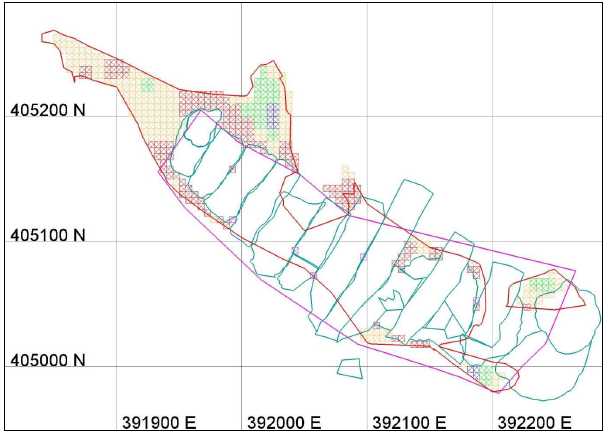

| Figure 14.3.2: Plan view of 0.01 opt and 0.1 opt grade shells at Saval | 14-10 |

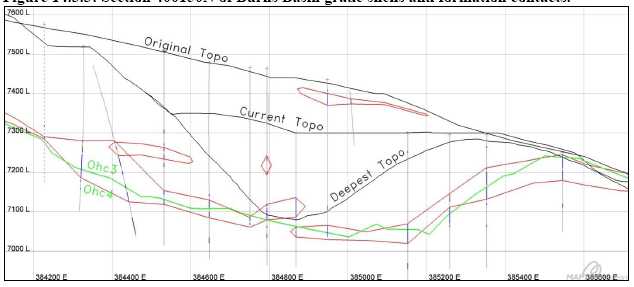

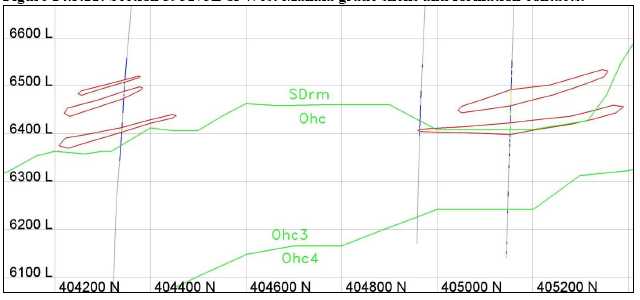

| Figure 14.3.3: Section 400150N of Burns Basin grade shells and formation contacts. | 14-11 |

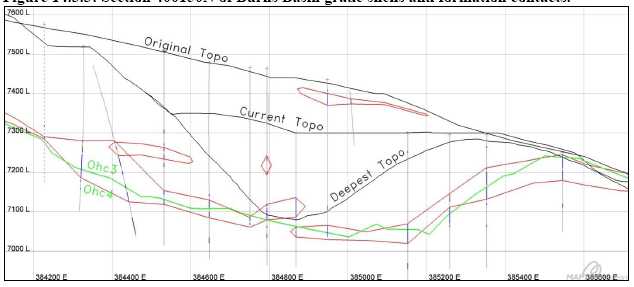

| Figure 14.3.4: Section 41085N of Saval grade shells and formation contacts. | 14-11 |

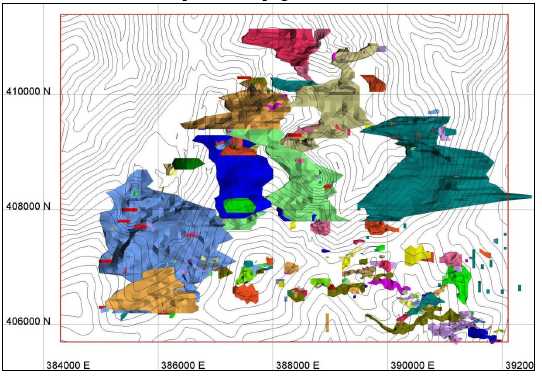

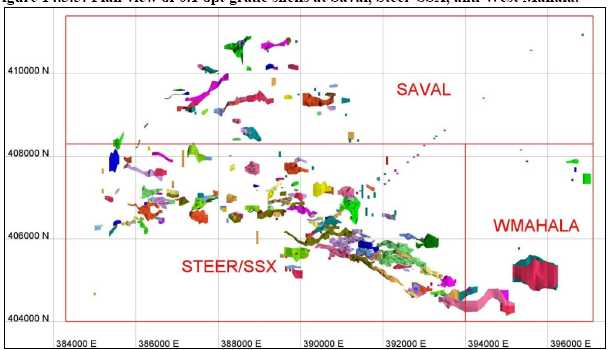

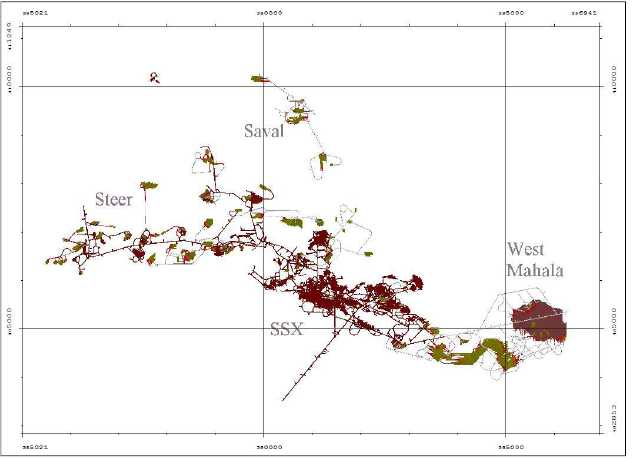

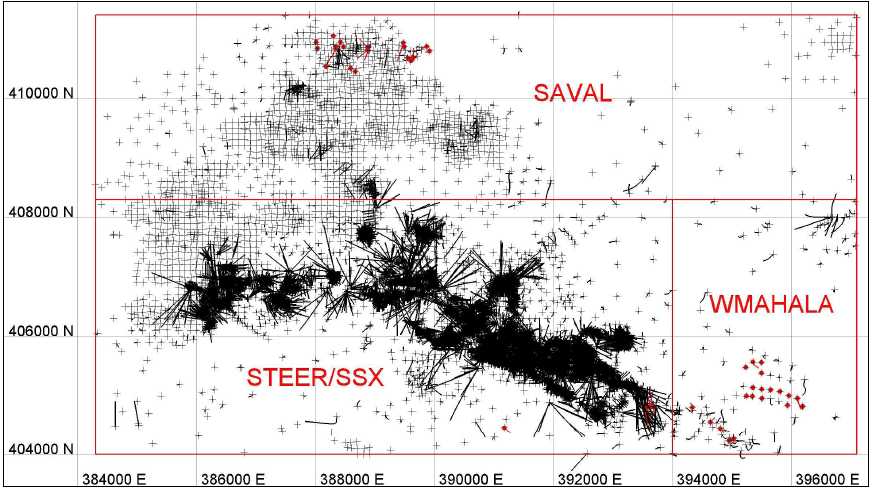

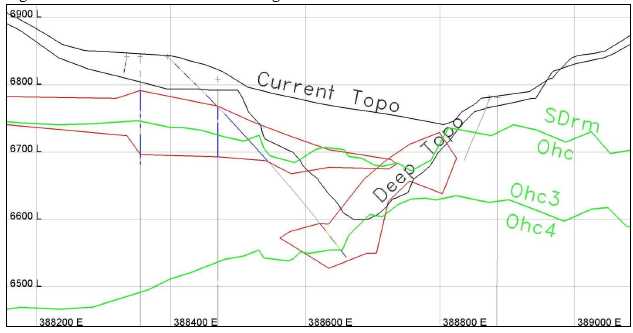

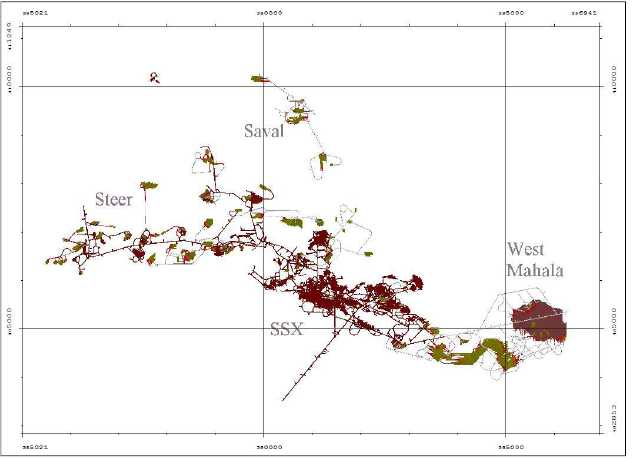

| Figure 14.3.5: Plan view of 0.1 opt grade shells at Saval, Steer-SSX, and West Mahala. | 14-12 |

| Figure 14.3.6: Plan view of 0.1 opt grade shells at Smith. | 14-12 |

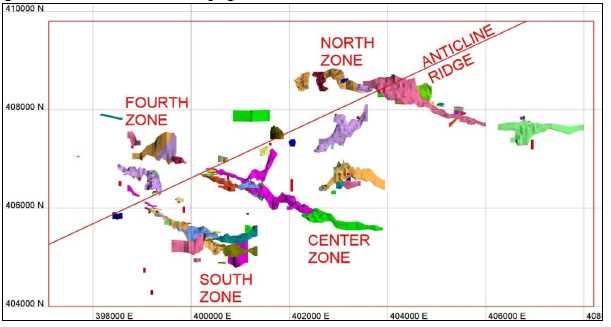

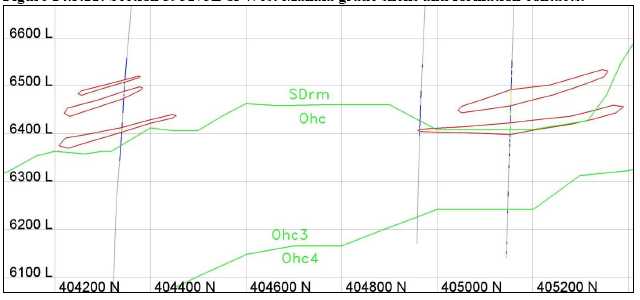

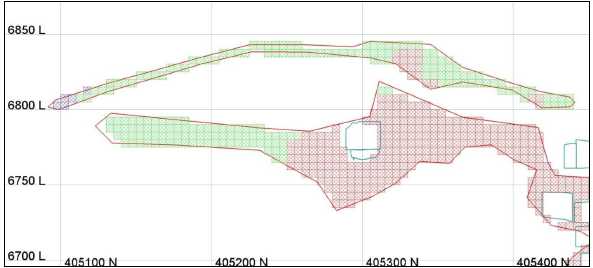

| Figure 14.3.7: Plan view of 0.1 opt grade shells at Starvation. | 14-13 |

| Figure 14.3.8: Section 406975N of Smith grade shells and formation contacts. | 14-13 |

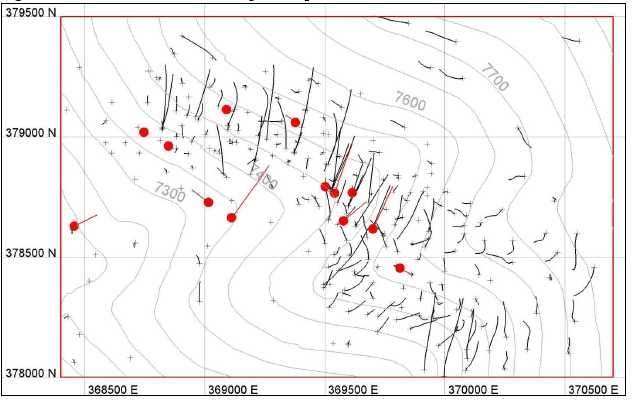

| Figure 14.3.9: Section 369800E of Starvation grade shells and formation contacts. | 14-14 |

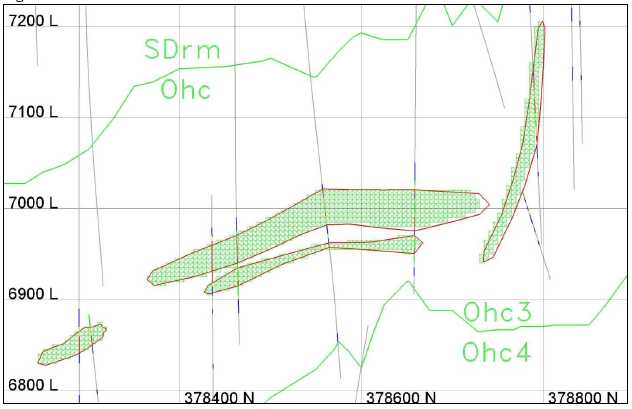

| Figure 14.3.10: Section 393600E of Steer-SSX grade shells and formation contacts | 14-14 |

| Figure 14.3.11: Section 395175E of West Mahala grade shells and formation contacts | 14-15 |

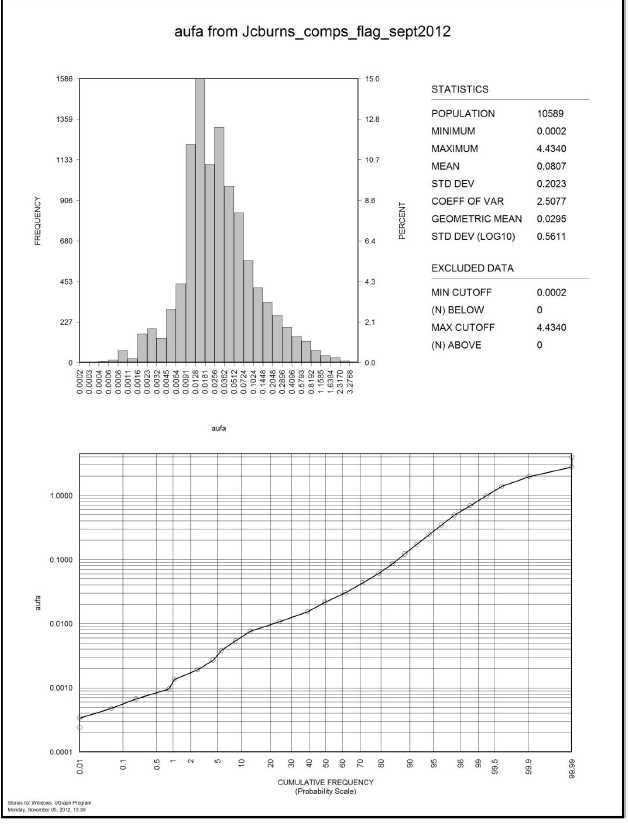

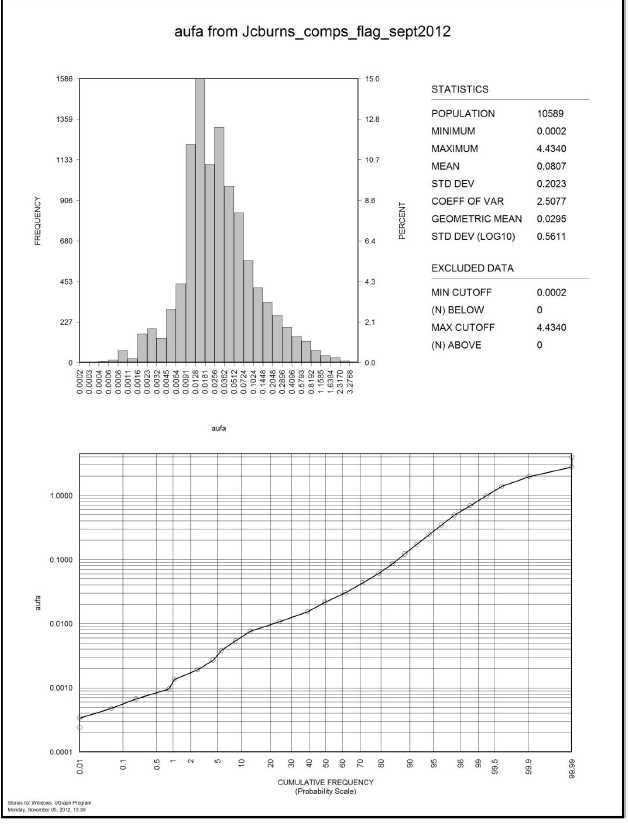

| Figure 14.5.1: Burns Basin gold histogram and cumulative frequency plot | 14-18 |

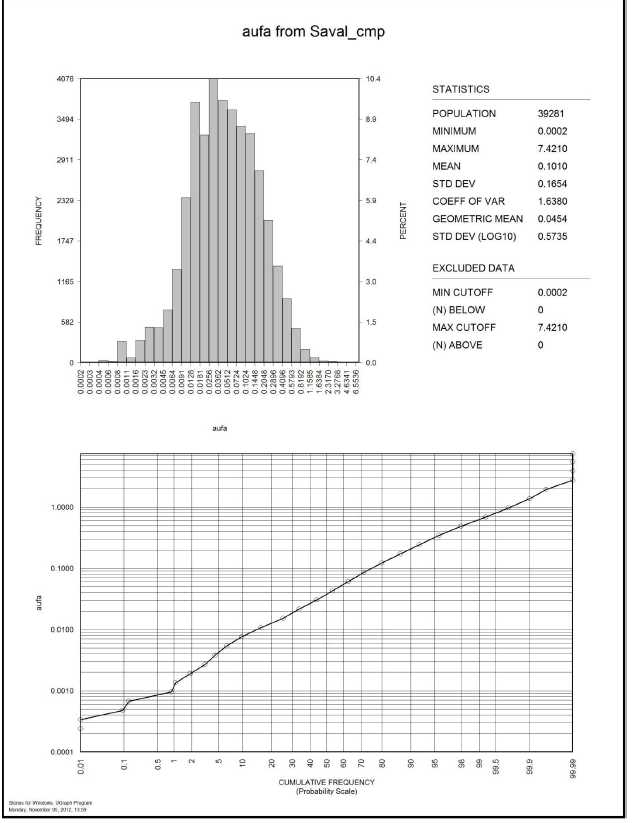

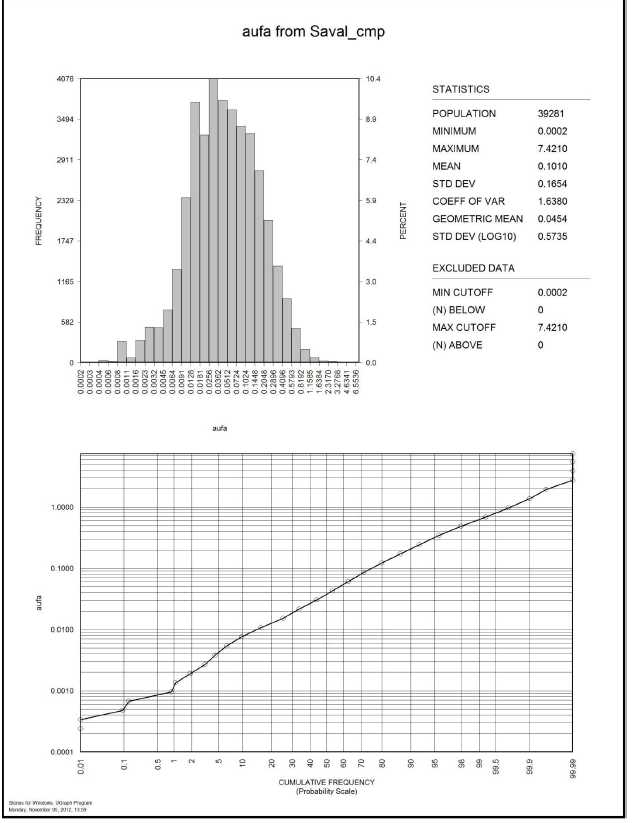

| Figure 14.5.2: Saval gold histogram and cumulative frequency plot. | 14-19 |

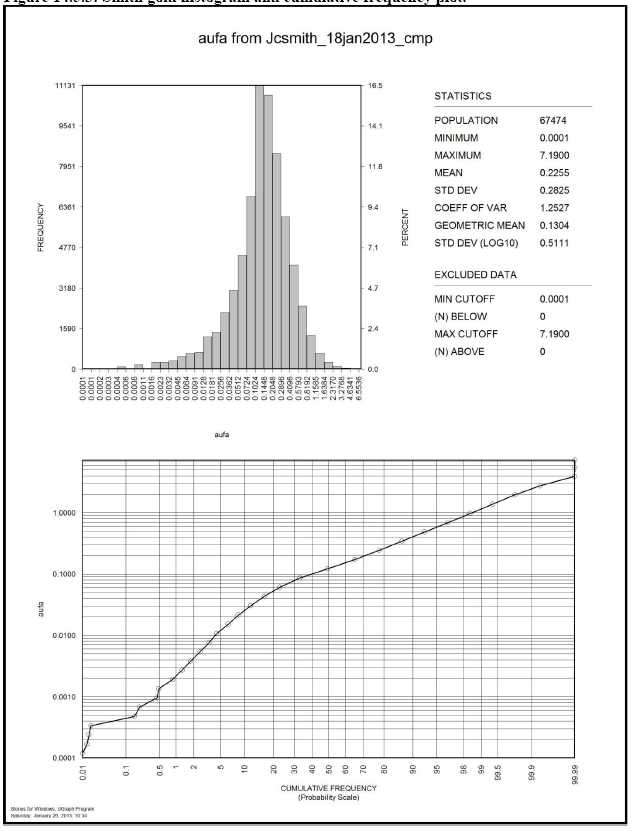

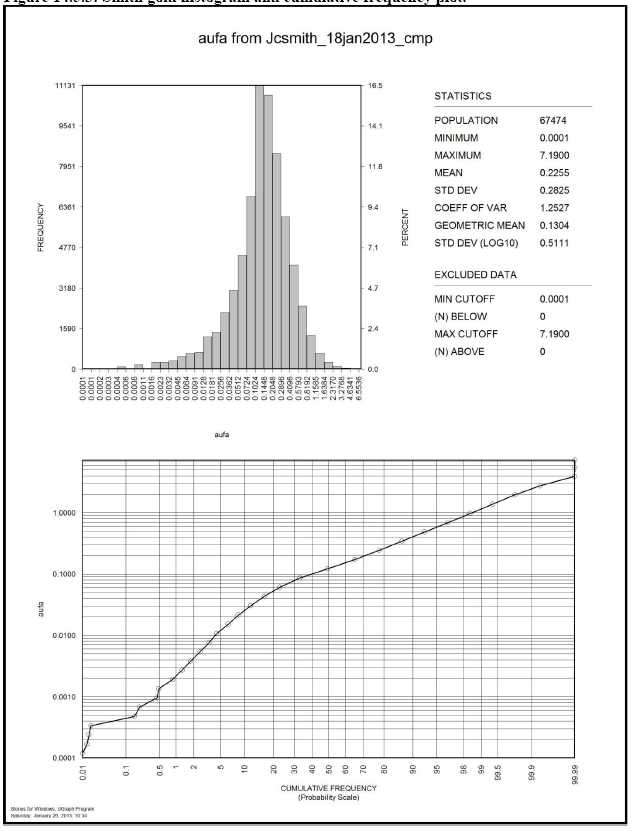

| Figure 14.5.3: Smith gold histogram and cumulative frequency plot | 14-20 |

| Figure 14.5.4: SSX gold histogram and cumulative frequency plot | 14-21 |

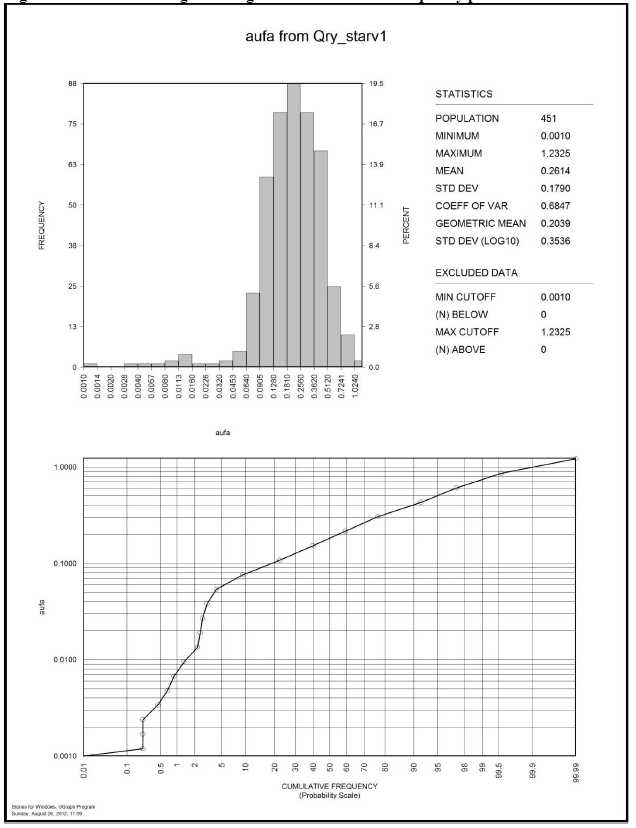

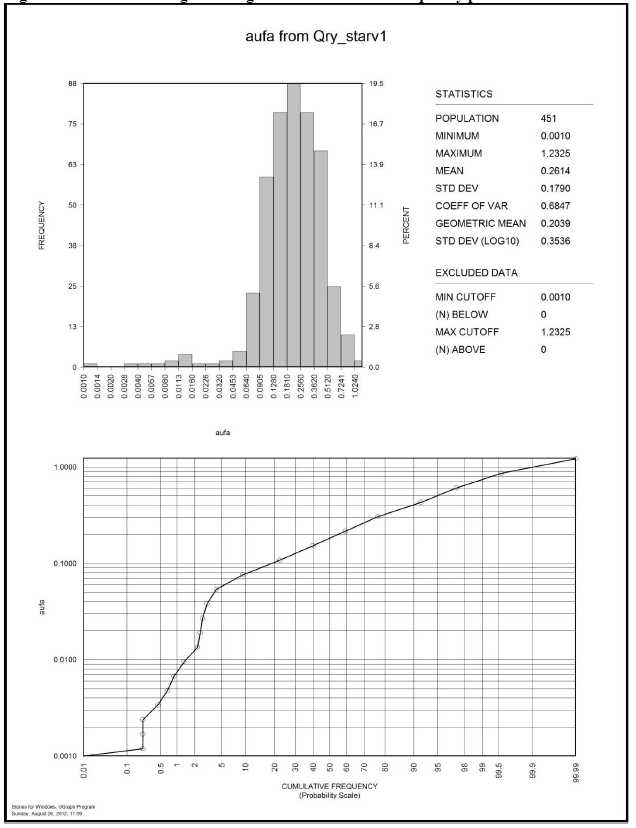

| Figure 14.5.5: Starvation gold histogram and cumulative frequency plot. | 14-22 |

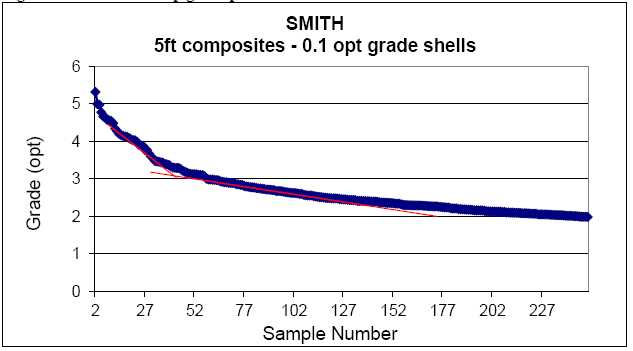

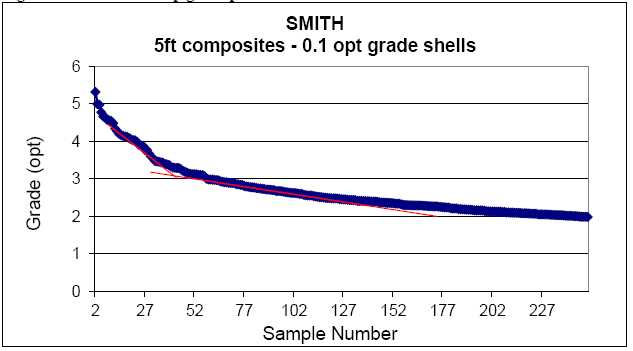

| Figure 14.5.1.1: Smith cap grade plot. | 14-23 |

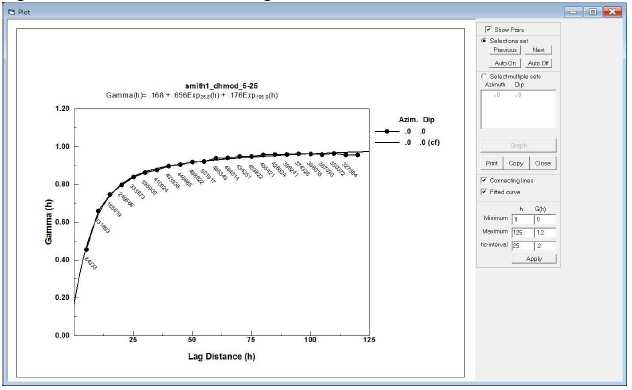

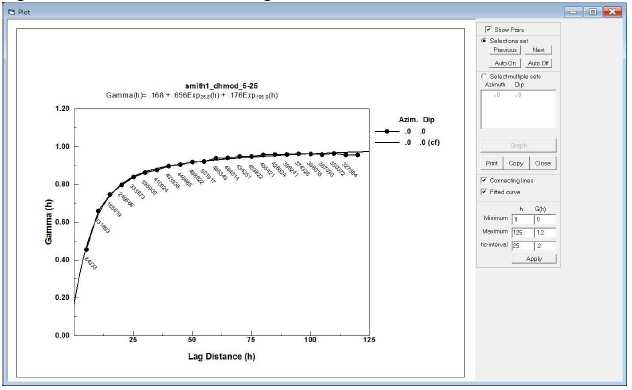

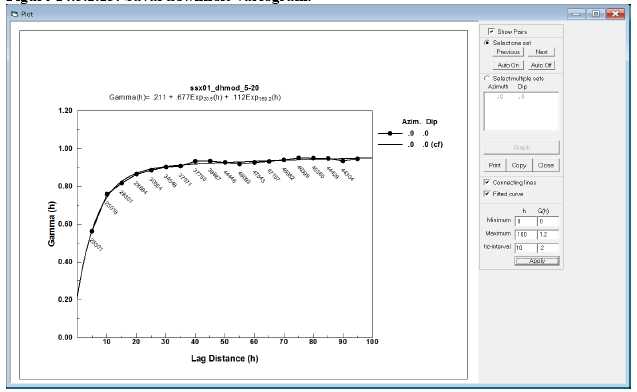

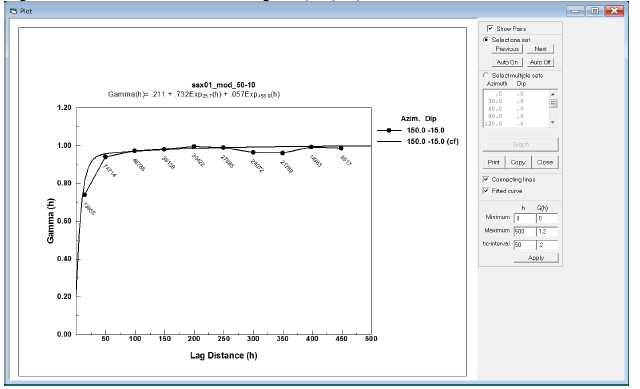

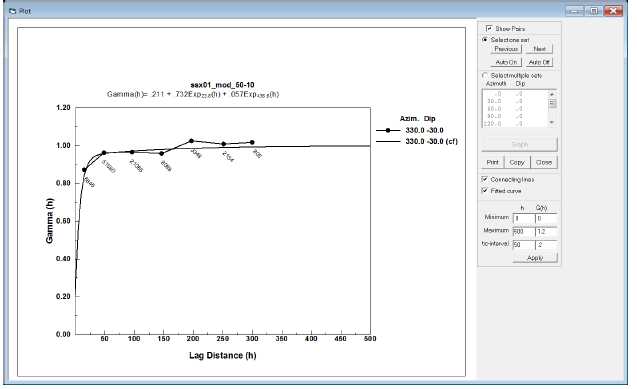

| Figure 14.5.2.1: Smith downhole variogram. | 14-25 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | x |

| Figure 14.5.2.2: Smith modeled variogram (120,-15). | 14-25 |

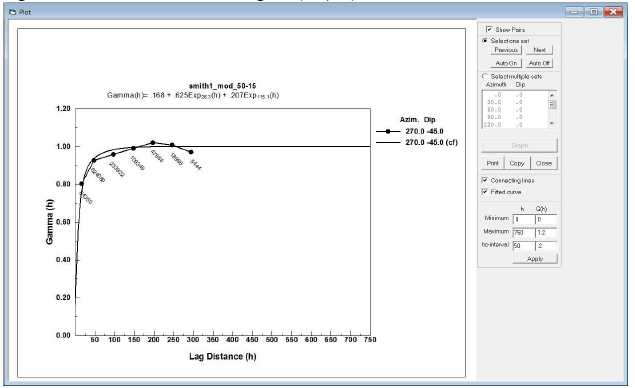

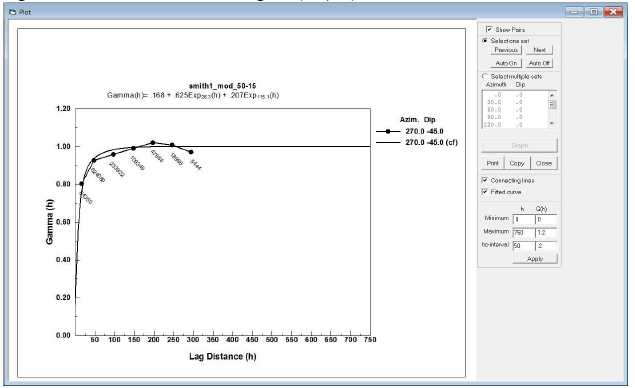

| Figure 14.5.2.3: Smith modeled variogram (270,-45). | 14-26 |

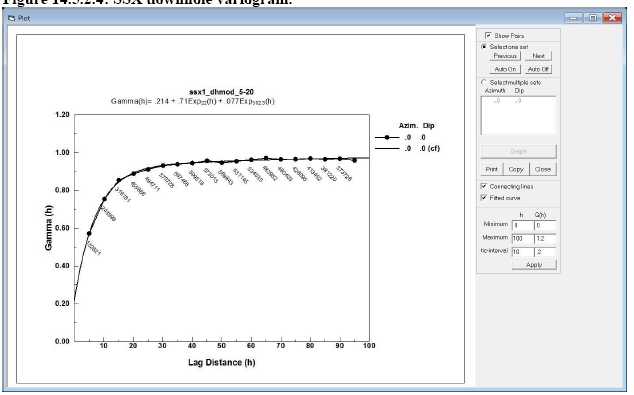

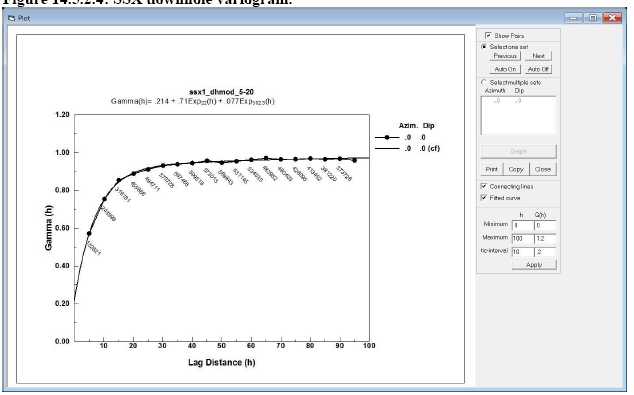

| Figure 14.5.2.4: SSX downhole variogram. | 14-27 |

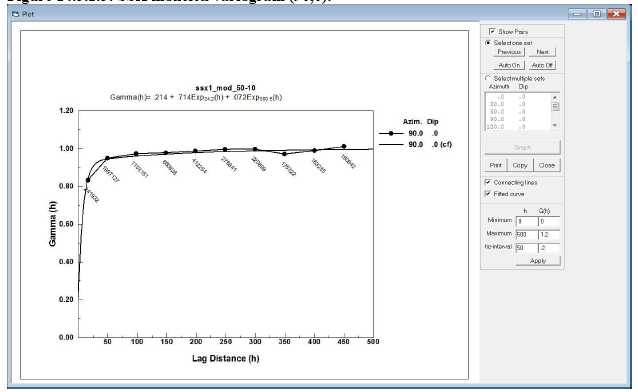

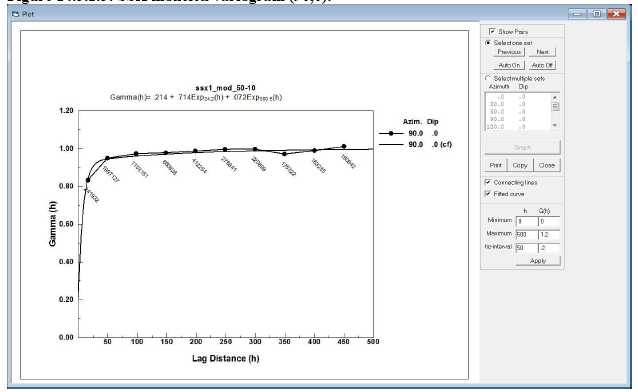

| Figure 14.5.2.5: SSX modeled variogram (90,0). | 14-27 |

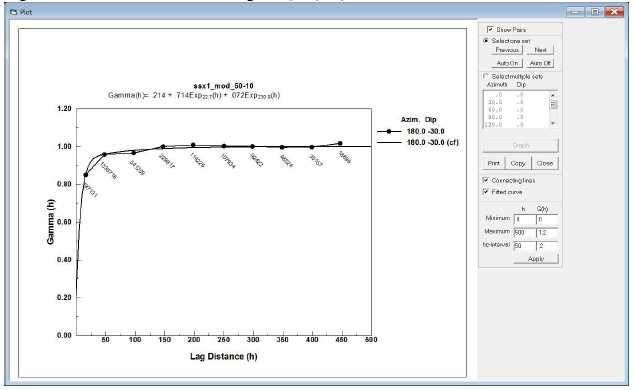

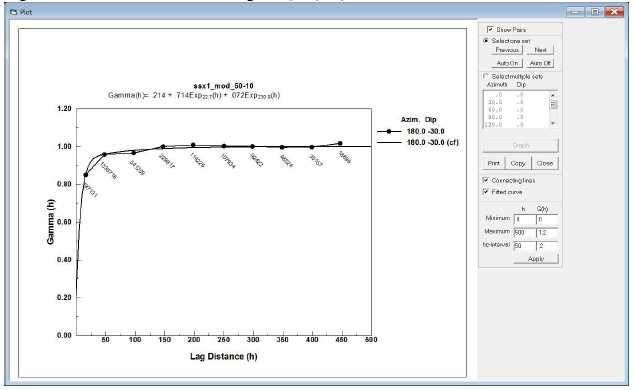

| Figure 14.5.2.6: SSX modeled variogram (180,-30). | 14-28 |

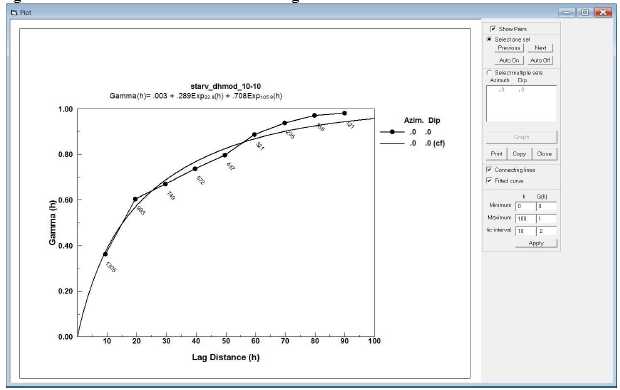

| Figure 14.5.2.7: Starvation downhole variogram. | 14-29 |

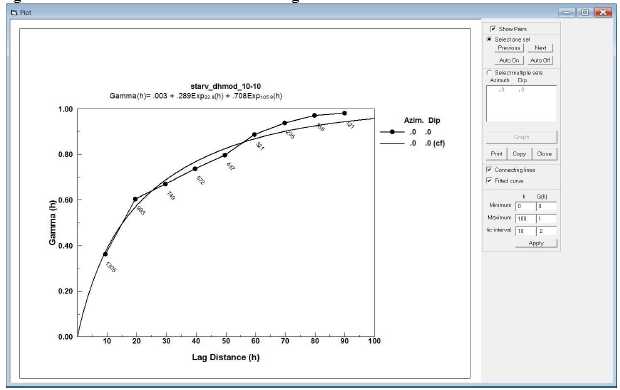

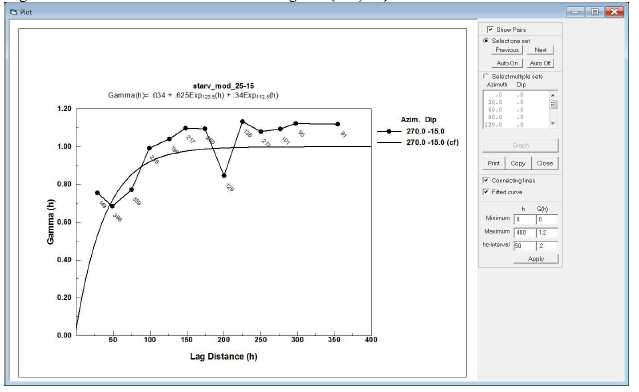

| Figure 14.5.2.8: Starvation modeled variogram (270,-15). | 14-29 |

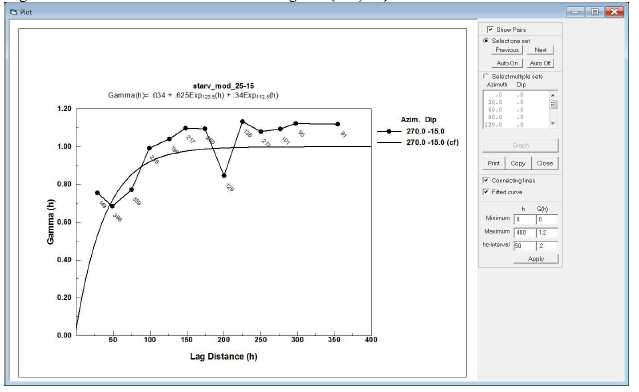

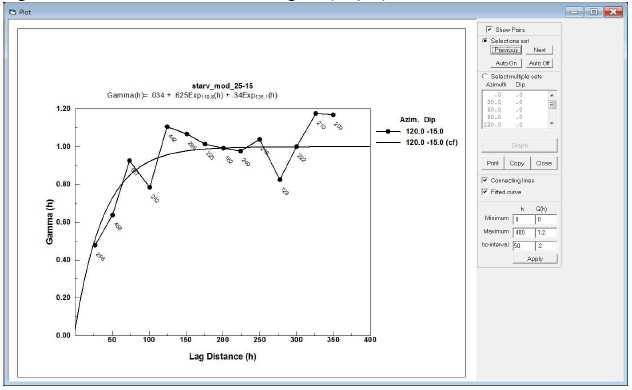

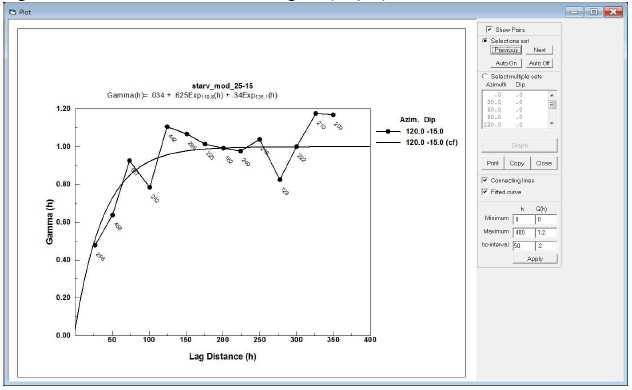

| Figure 14.5.2.9: Starvation modeled variogram (120,-15). | 14-30 |

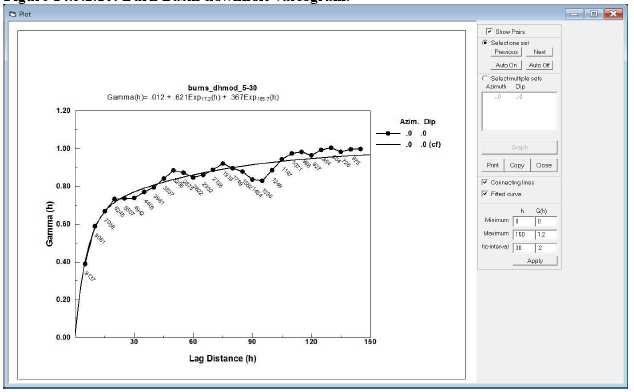

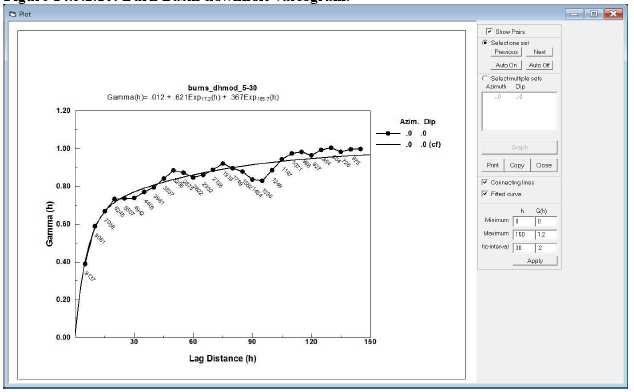

| Figure 14.5.2.10: Burn Basin downhole variogram. | 14-31 |

| Figure 14.5.2.11: Burns Basin modeled variogram (150,0). | 14-31 |

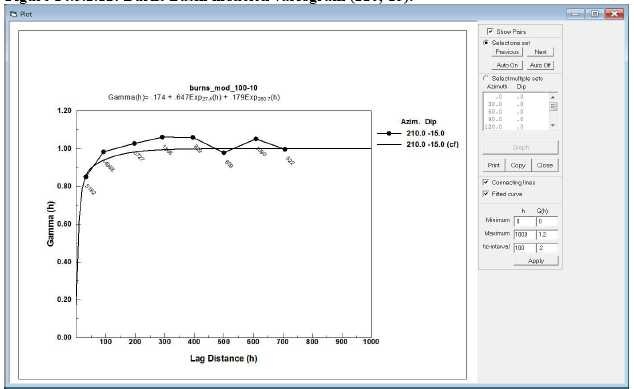

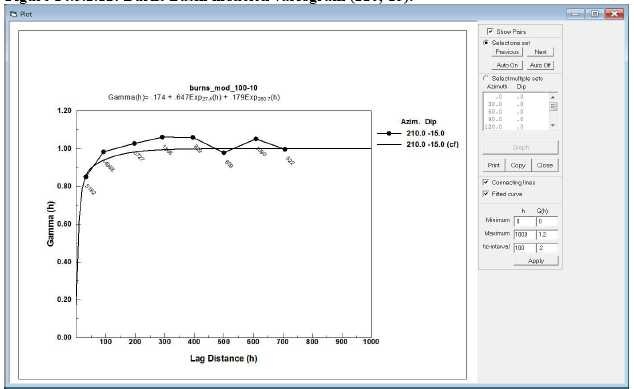

| Figure 14.5.2.12: Burns Basin modeled variogram (210,-15). | 14-32 |

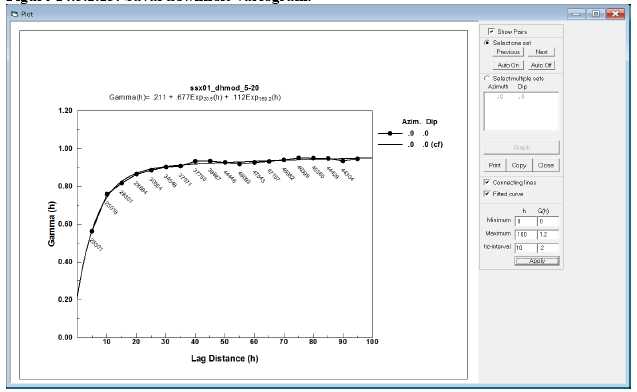

| Figure 14.5.2.13: Saval downhole variogram. | 14-33 |

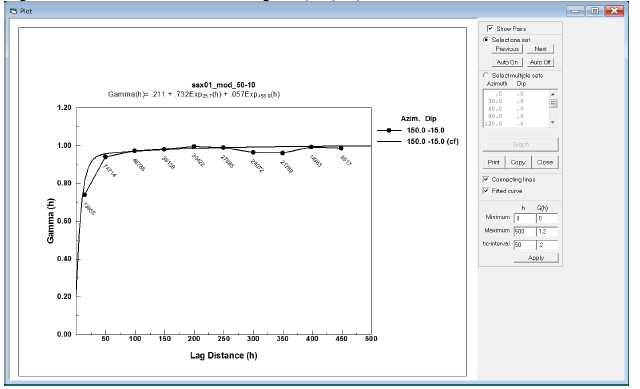

| Figure 14.5.2.14: Saval modeled variogram (150,-15) | 14-33 |

| Figure 14.5.2.15: Saval modeled variogram (330,-30) | 14-34 |

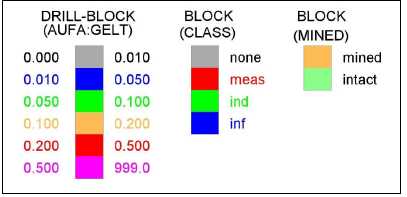

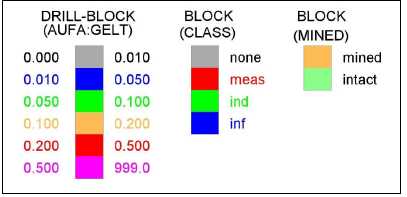

| Figure 14.7.1: Jerritt Canyon color legends | 14-45 |

| Figure 14.7.2: Section 406975N of Smith estimated blocks | 14-46 |

| Figure 14.7.3: Section 400150N of Burns Basin estimated blocks | 14-46 |

| Figure 14.7.4: Section 369800E of Starvation estimated blocks. | 14-47 |

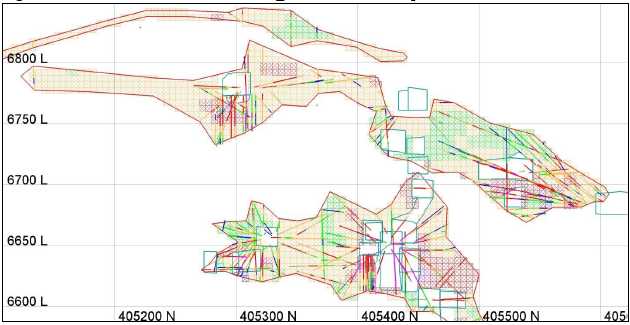

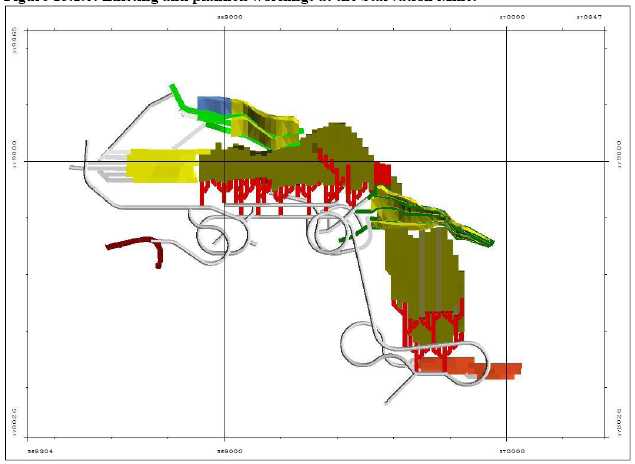

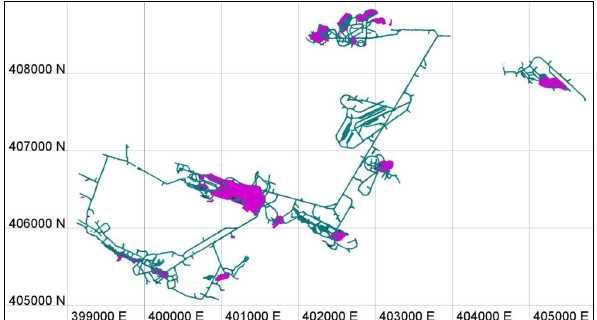

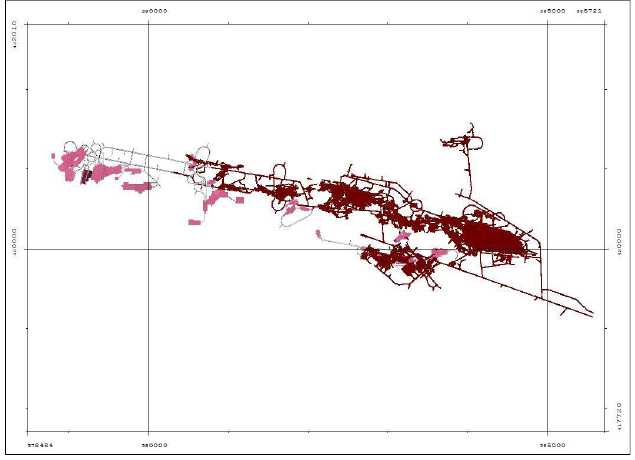

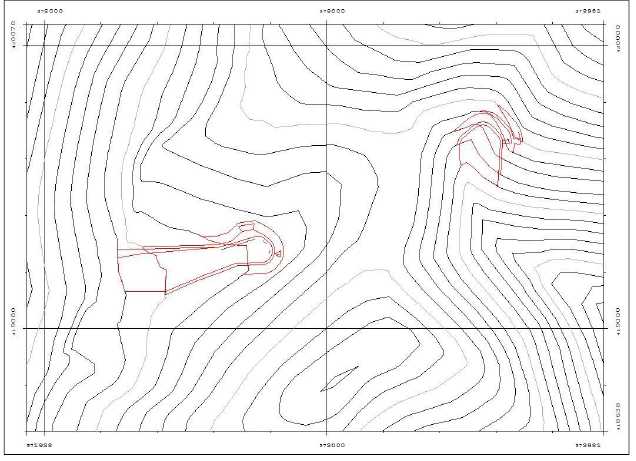

| Figure 14.8.1: Plan view of Smith underground asbuilt workings | 14-47 |

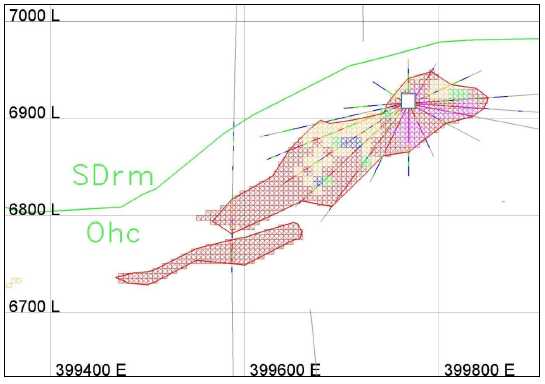

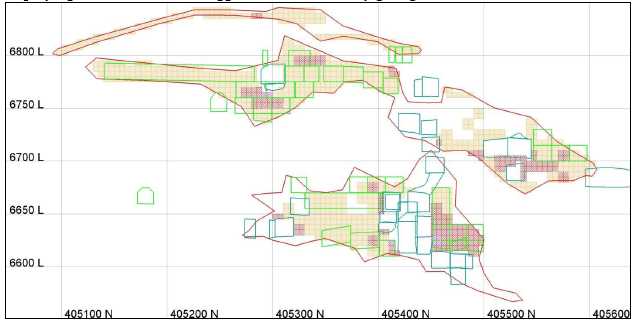

| Figure 14.8.2: Plan view of SSX underground asbuilt workings | 14-47 |

| Figure 14.8.3: Plan view of Saval open-pit underground asbuilt workings. | 14-48 |

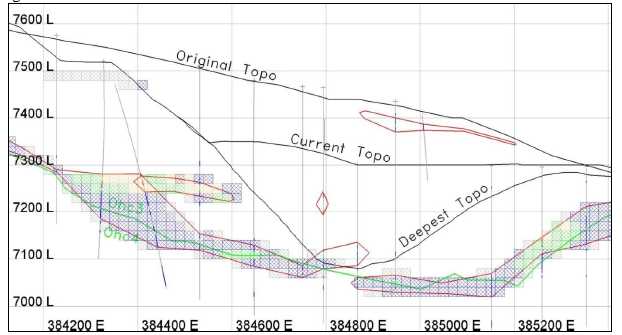

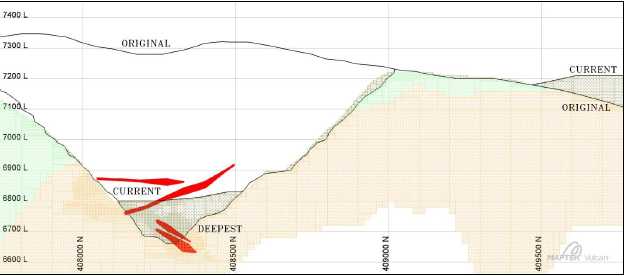

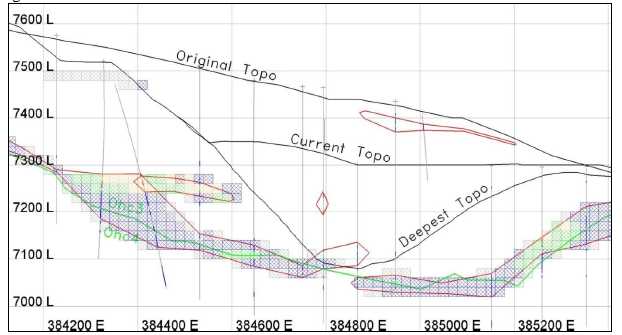

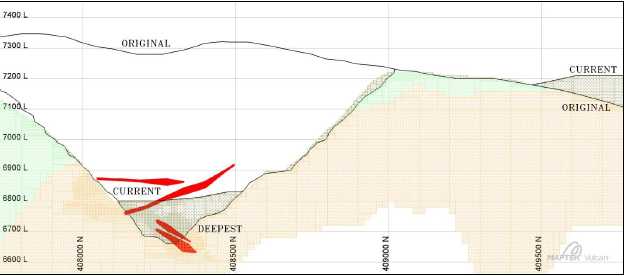

| Figure 14.8.4: Section view of Smith depleted blocks at 400,150E | 14-49 |

| Figure 14.8.5: Plan view of existing pit at Burns Basin. | 14-50 |

| Figure 14.8.6: Plan view of existing pit at Saval. | 14-51 |

| Figure 14.8.7: Plan view of existing pit at Smith. | 14-51 |

| Figure 14.8.8: Section view of the Smith Dash pit at 404650E. | 14-52 |

| Figure 14.8.9: Plan view of Smith sterilization polygons. | 14-53 |

| Figure 14.8.10: Plan view of SSX sterilization polygons. | 14-53 |

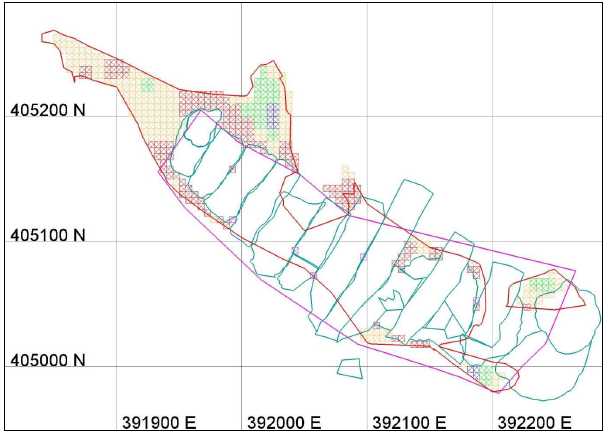

| Figure 14.8.11: Plan view of SSX sterilization detail at the 7370 elevation. | 14-54 |

| Figure 14.9.1: Section 400150E of Smith classified blocks | 14-55 |

| Figure 14.9.2: Section 369800E of Starvation classified blocks | 14-56 |

| Figure 14.10.1: Section view of Smith au_ok blocks and composites at 400150E | 14-57 |

| Figure 14.10.2: Section view of SSX au_ok blocks with composites at 391400E. | 14-57 |

| Figure 14.10.3: Section view of Starvation au_ok blocks with composites at 369800E | 14-58 |

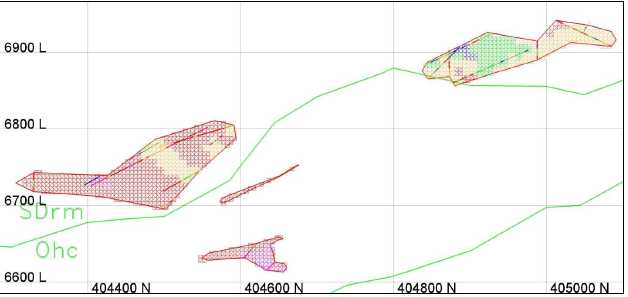

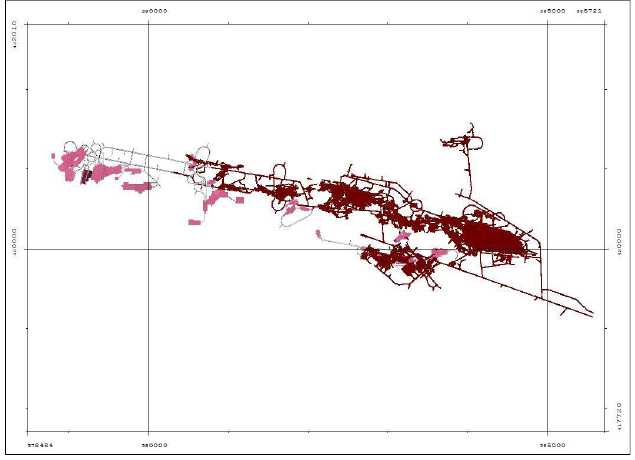

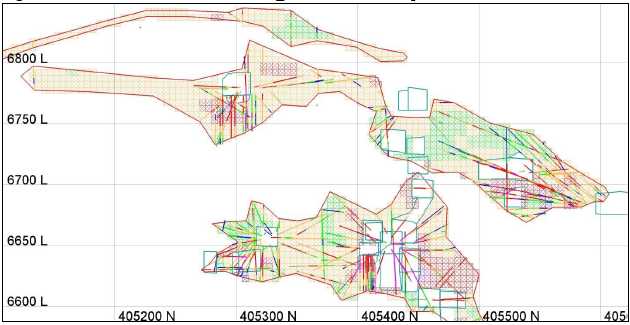

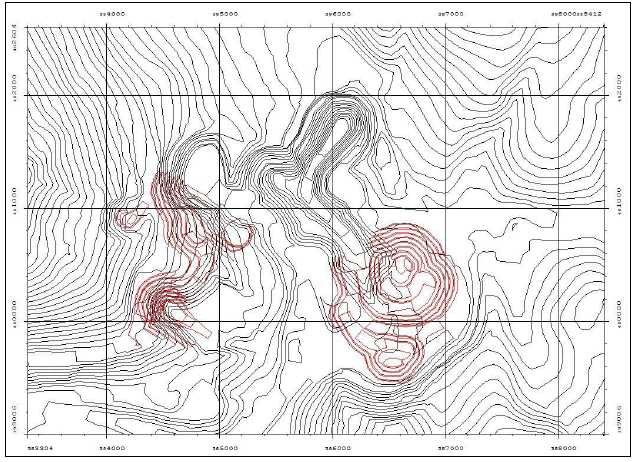

| Figure 14.11.1: Plan view of Smith underground resources, which include reserves displaying “des” and “reso” flagged blocks colored by gold grade. | 14-60 |

| Figure 14.11.2: Section 400,150E Smith underground resources, which include reserves displaying “des” and “reso” flagged blocks colored by gold grade. | 14-61 |

| Figure 14.11.3: Plan view of SSX-Steer underground resources, which include reserves displaying “des” and “reso” flagged blocks colored by gold grade. | 14-61 |

| Figure 14.11.4: Section 393,600E SSX-Steer underground resources, which include reserves displaying “des” and “reso” flagged blocks by gold grade. | 14-62 |

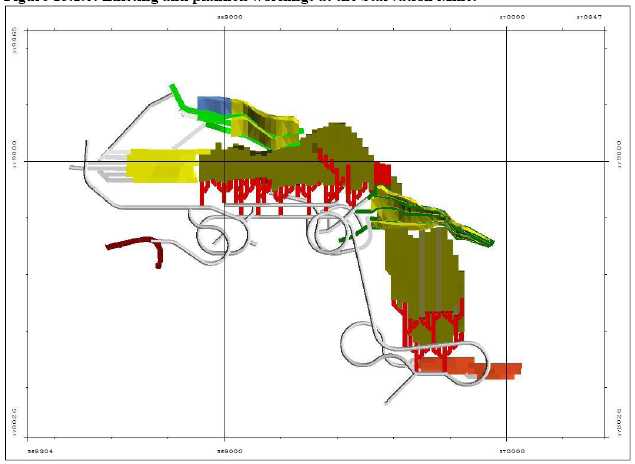

| Figure 15.1.1: Existing and planned workings at the Smith Mine | 15-2 |

| Figure 15.1.2: Section 400,150E Smith Mine underground reserves showing the reserve blocks by gold grade with the design solids. | 15-3 |

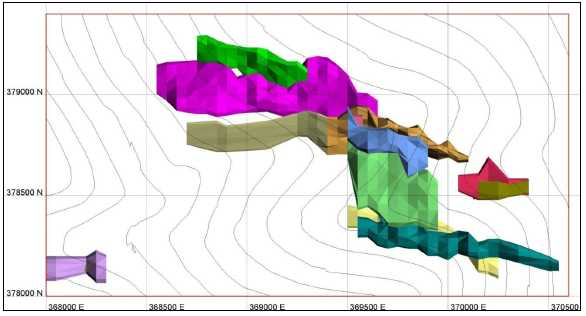

| Figure 15.1.3: Existing and planned working in the SSX complex including Saval UG and West Mahala | 15-4 |

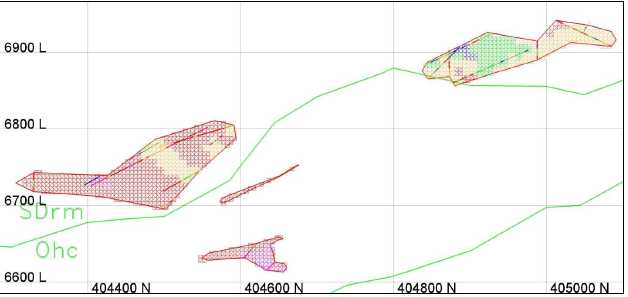

| Figure 15.1.4: Section 393,600E SSX-Steer Mine underground reserves showing the reserve blocks by gold grade with the design solids (green) and asbuilts (light blue) | 15-5 |

| Figure 15.1.5: Existing and planned workings at the Murray Mine | 15-6 |

| Figure 15.1.6: Existing and planned workings at the Starvation Mine | 15-7 |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | xi |

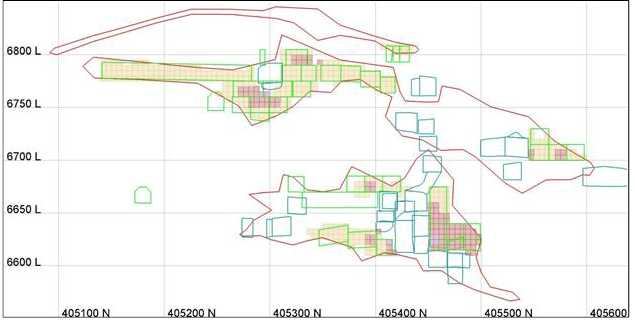

| Figure 15.2.1: Ultimate pit design for Saval mineral reserve area | 15-8 |

| Figure 15.2.2: Ultimate pit design for Mill Creek mineral reserve area | 15-9 |

| Figure 15.2.3: Ultimate pit design for Wright Window mineral reserve area | 15-10 |

| Figure 15.2.4: Ultimate pit design for Burns Basin mineral reserve area. | 15-11 |

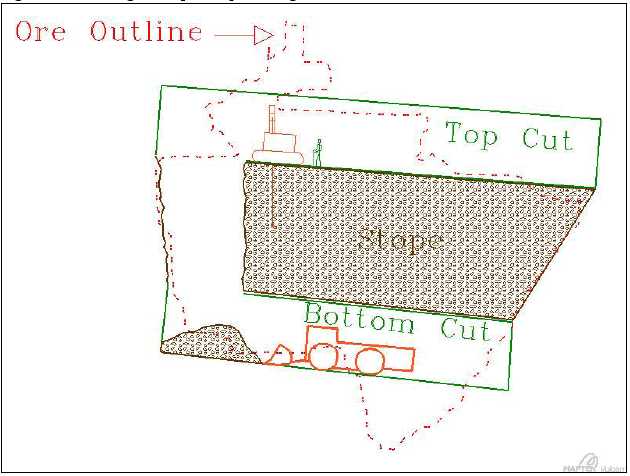

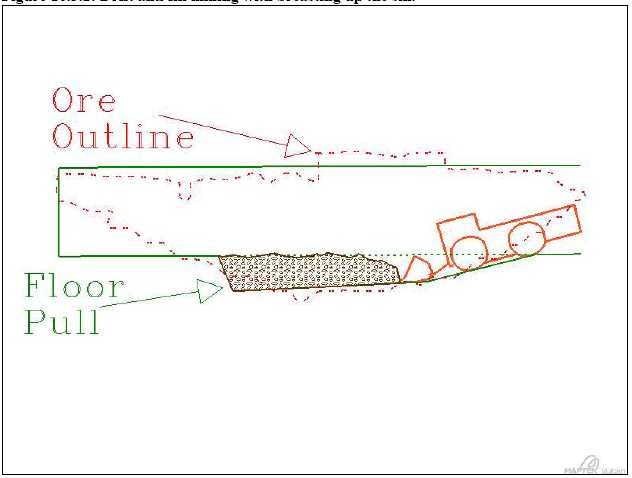

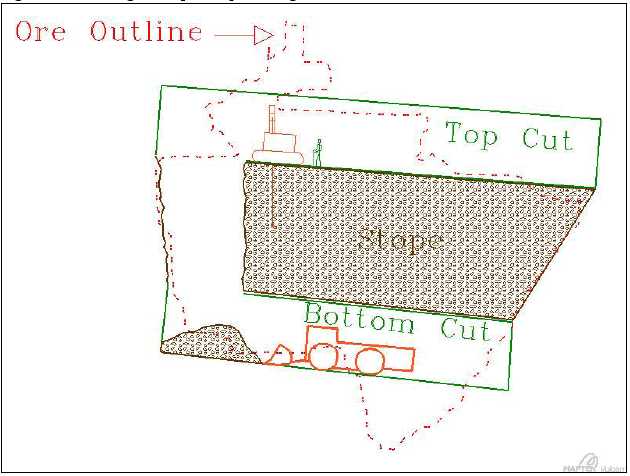

| Figure 16.3.1: Long-hole open stope mining. | 16-5 |

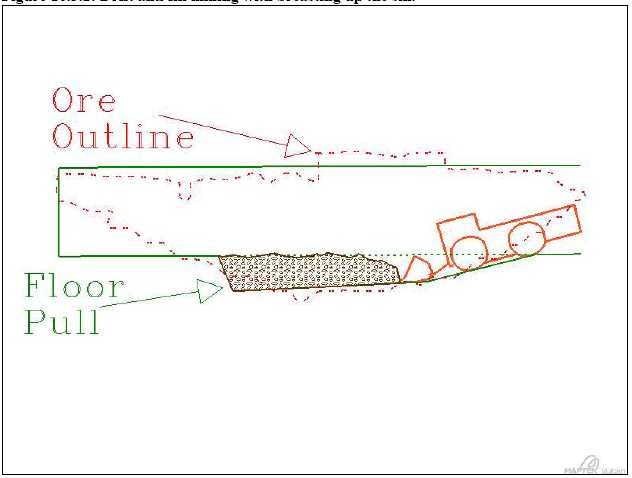

| Figure 16.3.2: Drift and fill mining with breasting up the sill. | 16-6 |

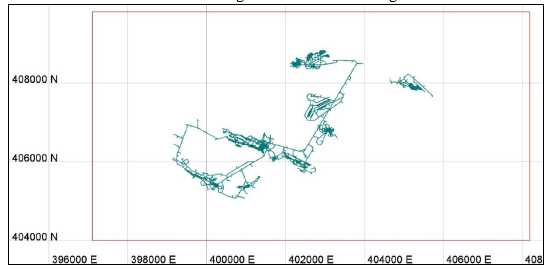

| Figure 16.6.1: Stockpile location map. | 16-9 |

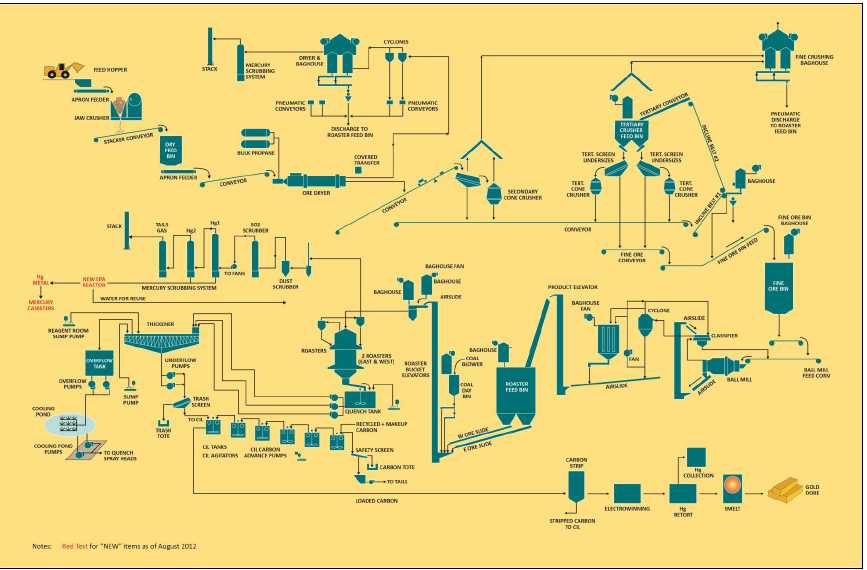

| Figure 17.1.1: Simplified ore processing flow sheet for the Jerritt Canyon Mine. | 17-2 |

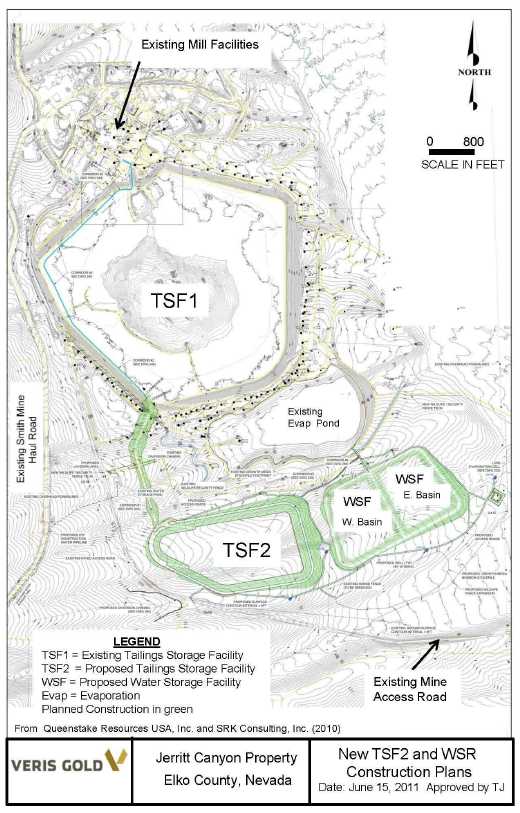

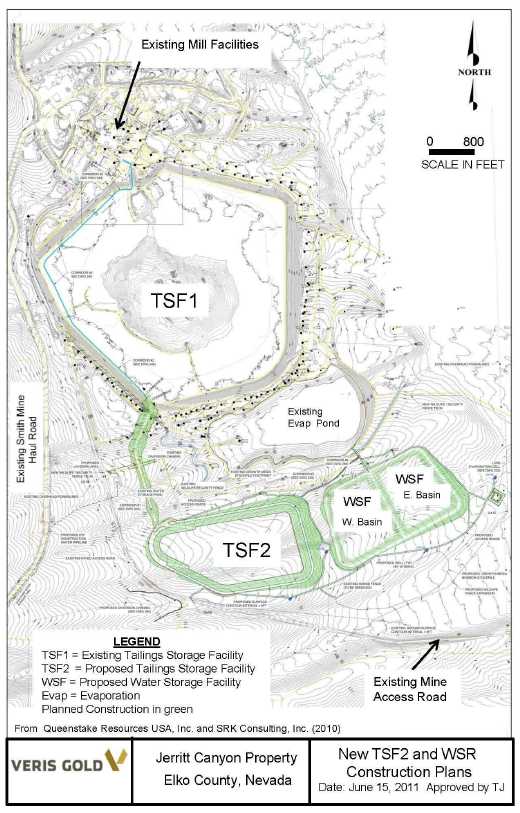

| Figure 18.6.1: Construction plan for the TSF-2 and WSF | 18-3 |

| Figure 18.6.2: Aerial view looking north: TSF-2 completed December 7, 2012 | 18-4 |

| Figure 18.6.3: Aerial view looking east: TSF-2 completed December 7, 2012. | 18-4 |

| Figure 18.6.4: Aerial view looking west: TSF-2 completed December 7, 2012. | 18-5 |

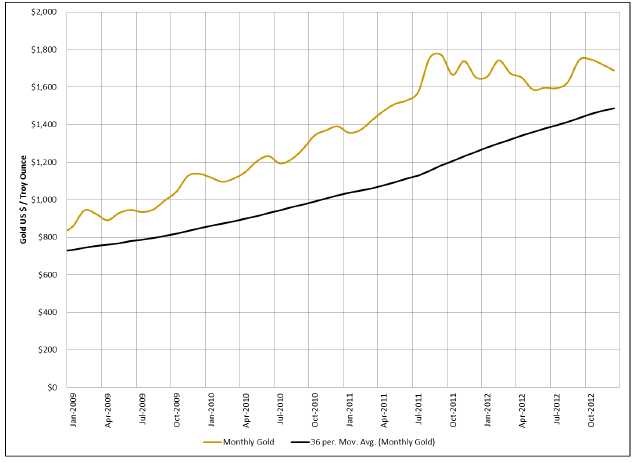

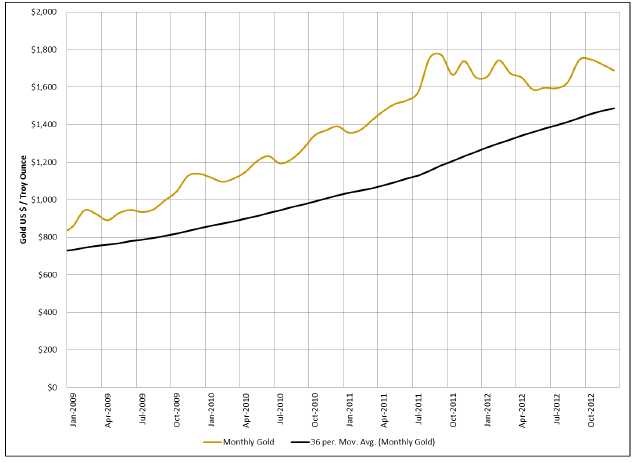

| Figure 19.1.1: Monthly gold price 2009 – 2012 | 19-1 |

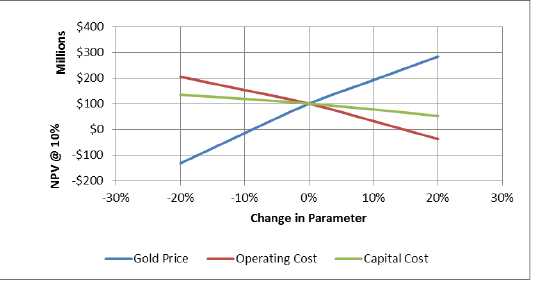

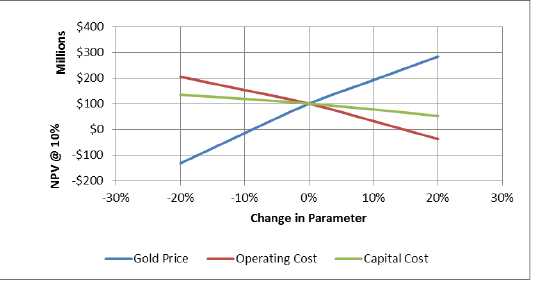

| Figure 22.2.1: NPV sensitivity. | 22-4 |

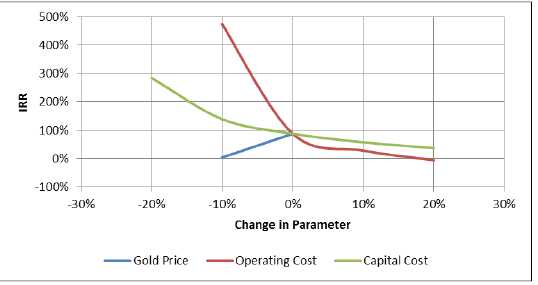

| Figure 22.2.2: IRR sensitivity. | 22-4 |

List of Appendices

| Appendix A – Certificate of Authors and Consent Forms |

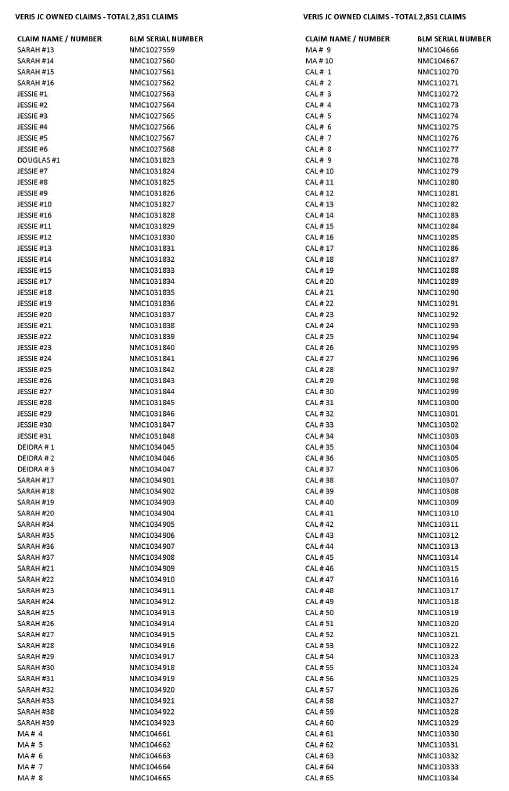

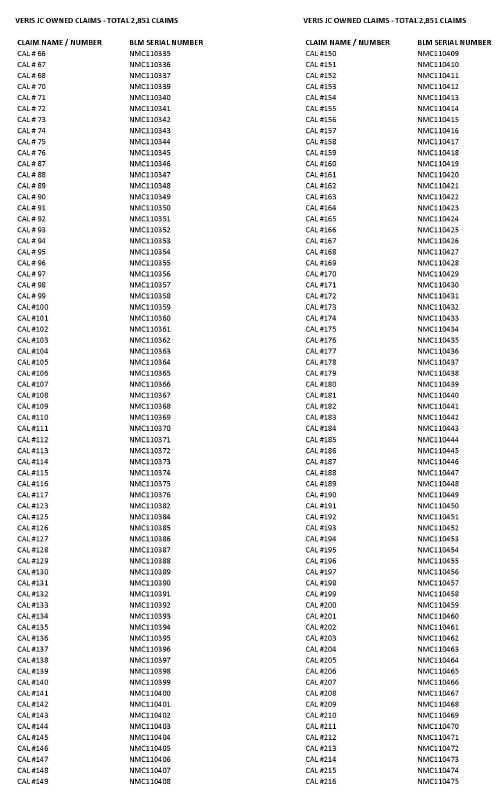

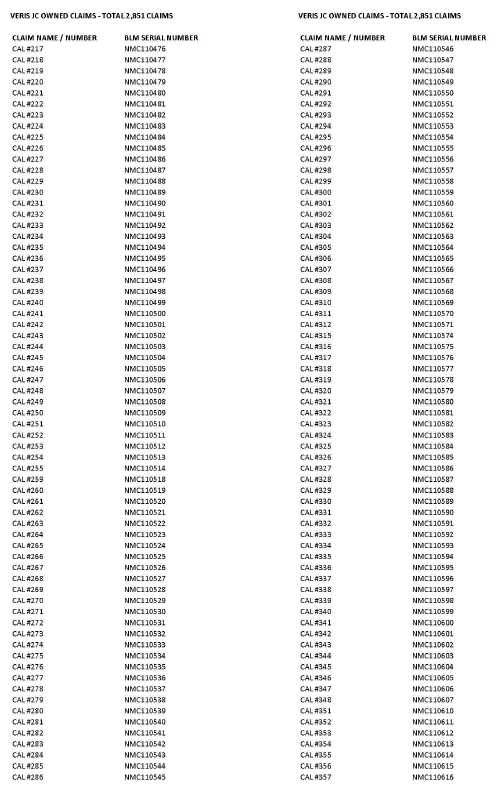

| Appendix B – Claim List |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 1-1 |

1 Summary

Veris Gold Corp. (VG, Veris, or the Company) engaged Mark Odell of Practical Mining LLC to assist in the preparation of a Canadian National Instrument 43-101 (NI 43-101) compliant Technical Report update on its 100% owned Jerritt Canyon operating gold mine property north of Elko, Nevada.

Veris ownership of the Jerritt Canyon property began on June 20, 2007, when Queenstake Resources Ltd. merged with YGC Resources Ltd. to form Yukon Nevada Gold Corp (YNG). As part of this merger the latter company (YNG) acquired the wholly-owned subsidiary of Queenstake Resources USA, Inc. (Queenstake), which owns and operates the Jerritt Canyon Mine in northern Nevada. As of October 5, 2012, YNG changed its name to Veris Gold Corp. In January of 2013, Queenstake Resources USA, Inc. changed their name to Veris Gold USA, Inc. (VUSA).

In summary, the Jerritt Canyon Mine is owned and operated by VUSA, a wholly owned subsidiary of Veris. This report is prepared for Veris and reflects the most recent resource and reserves based on data produced through December 31, 2012. The effective date of this report is December 31, 2012. The filing date is July 11, 2013.

The following personnel contributed to the preparation of the report:

| | • | Todd Johnson, Veris Gold Corp., Vice President of Exploration, P.E., Primary Author: Sections 1-10, 18, 20, and 23-29; |

| | | |

| | • | Mark Odell, Practical Mining LLC, P.E., Consulting Mine Engineer: Sections 15, 16, 19, 21 & 22 and the Starvation, Murray, Saval, and Winters Creek underground resources in Section 14.11.1 and Section 14.11.2; |

| | | |

| | • | Karl Swanson, Consulting Mine Engineer, SME, AusIMM: Resources: Section 14.1 – 14.10 and the SSX and Smith Underground Resources in Section 14.11. |

| | | |

| | • | Michele White, C.P.G., All One River Exploration Data Analysis: Sections 4, 11, and 12; and |

| | | |

| | • | John Fox, P.Eng, Laurion Consulting Inc., Consulting Metallurgist: Sections 13 and 17. |

These people are referred throughout this report as “author” with Todd Johnson, Vice President of Exploration for Veris Gold Corp., being the Primary Author.

Jerritt Canyon contains over 22 separately exploited Carlin-Type sediment-hosted deposits that have either been mined from open pit and/or underground methods and, since 1981, processed at the property or are intact and never previously mined and part of the December 31, 2012 Mineral Resources and/or Reserves. The Jerritt Canyon processing plant since July 1981 has produced over 8.0 million ounces of gold primarily from ores originating from the Jerritt Canyon property.

Certain of Newmont’s ores and stockpiles have been processed at the Jerritt Canyon processing plant.

Newmont USA Limited’s (Newmont) original Carlin Deposit discovered in the early 1960’s lies approximately 34 miles (55 km) southwest of the operating SSX-Steer underground mine at Jerritt Canyon.

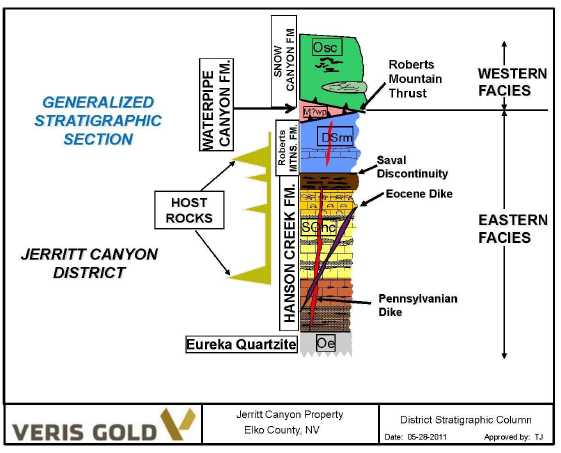

The Jerritt Canyon Carlin-Type deposits occur in a north-northeast trending mineralized belt called the Independence trend. The primary host rock for the Jerritt Canyon Carlin-Type deposits is the Silurian and Ordovician Hanson Creek Formation with much less mineralization hosted in the overlying Devonian and Silurian Roberts Mountain Formation. Dike rocks locally contain ore grade gold mineralization but are volumetrically insignificant relative to the sedimentary rock hosted ore materials.

The Jerritt Canyon sulfide ores are double refractory in nature because the gold mineralization is both included in solid solution within sulfide minerals (arsenic-rich pyrite), and is also locally associated as free grains with organic carbon in the host rock. The permitted and operating on-site Jerritt Canyon processing facility contains crushing and grinding circuits, two parallel, two-stage oxygen fluid-bed Dorr Oliver roasters (commissioned in 1989), a cyanidation circuit, and a refinery. The processing plant has a maximum capacity of 1.5 million tons per year. The roaster helps oxidize the refractory ores for subsequent cyanidation and has a currently permitted capacity of 250 tons per hour (6,000 tons per day) which is the engineering design capacity.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 1-2 |

Underground mining production in 2012 at the property was from the Smith and SSX-Steer mines. Underground mining methods use both long-hole stoping and modified drift and fill. Split set rock bolts and welded wire mesh provide the primary means of ground support with supplementary resin anchor rebar bolts, cable bolts and/or shotcrete where necessary.

Mining at Smith in 2012 was done by contract miner Small Mine Development LLC (SMD) whereas mining at SSX-Steer was performed by both VUSA staff and separate SMD crews. Exploration and development (resource conversion) drilling was active at Smith and SSX-Steer in 2012 using one contract diamond drill. Development drift and stope drilling and minor exploration using RC Cubex drills were also active at both operating mines in 2012. Initial underground development work (portal excavation and drift development) at Starvation Canyon started in November 2012 and continued through the end of the year and mining production at Starvation Canyon, operated by SMD, commenced in early April 2013.

The December 31, 2012 Mineral Resources and Reserves from 6 underground areas (Smith mine, SSX-Steer mine, Saval, Murray, Starvation Canyon and Winters Creek) and 6 open pits (Burns Basin, Mill Creek, Pie Creek, Road Canyon, Saval, and Wright Window) have been updated in this Technical Report based on additional drilling completed in 2012 and/or based on recent remodeling work. Reserve additions included in this Technical Report relative to the previous report are located at the Smith, SSX-Steer and Starvation underground mines and at the Burns Basin open pit. The Smith and SSX-Steer underground mines comprise the majority of the mineral reserves in the district.

1.1 Mineral Resource estimate

The December 31, 2012 Mineral Resources at Jerritt Canyon are contained within 6 open pits including Burns Basin, Mill Creek, Pie Creek, Road Canyon, Saval, and Wright Window, and 6 underground areas including Murray, Smith, SSX (including West Mahala) , Saval, Starvation Canyon, and Winter’s Creek (Table 1.1.1) . The recently revised underground mineral resource estimates are based on extensive underground and surface drilling data, a strict 0.10 opt grade shell digitized by hand on 50 foot cross-sections, and using geology constrained kriging estimation methods. Block modeling techniques incorporate 5x5x5 ft. block sizes within the digitized grade shells.

Measured Resources as of December 31, 2012 total 4511 ktons averaging 0.198 opt Au containing 891.7 koz. Indicated Resources as of December 31, 2012 total 7,932 ktons averaging 0.171 opt Au containing 1,359.4 koz. Combined Measured and Indicated Resources as of December 31, 2012 total 12,443 ktons at 0.181 opt Au, containing 2,251.1 koz. There is an additional Inferred Resource of 3,845 tons at 0.170 opt Au, containing 653.2 koz. Table 1.1.1 lists the resources by area. Resources were determined using a US$1,620/oz two-year average trailing gold price.

For this Technical Report, new drilling information for the open pit resources has been included for the Saval and Burns Basin open pits. Also for this Technical Report, new drilling information for underground resources has been included for Starvation, Smith and SSX underground mines.

One of the independent contributory authors conducted a January 2013 database audit of assay results from drilled material sampled between June 18, 2011 and December 31, 2012 for underground drilling, and between July 18, 2011 and December 21, 2011 for surface drilling. There was very little surface drilling in 2012. This database audit reviewed between 5 to 25 percent of the actual records and concluded excellent correlation between certified sampling results and the database as discussed in Section 12.2.1. The results of this audit commend the 2013 database for use in the new resource and reserve estimates listed below.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 1-3 |

Table 1.1.1: Jerritt Canyon mineral resources including reserves –December 31, 2012.

| | Measured | Indicated | Measured + Indicated | | Inferred |

| Area | kt | opt | koz | kt | opt | koz | kt | opt | koz | | kt | opt | koz |

| Open Pit | | | | | | | | | | | | | |

| Burns Basin | 46 | 0.106 | 4.9 | 430 | 0.096 | 41.4 | 476 | 0.097 | 46.3 | | 5 | 0.061 | 0.3 |

| Mill Creek | 3 | 0.089 | 0.3 | 299 | 0.094 | 28.0 | 302 | 0.094 | 28.3 | | 4 | 0.153 | 0.6 |

| Saval | 51 | 0.148 | 7.6 | 315 | 0.085 | 26.7 | 367 | 0.093 | 34.3 | | 10 | 0.083 | 0.8 |

| Wright Window | 5 | 0.174 | 0.9 | 115 | 0.090 | 10.3 | 120 | 0.094 | 11.2 | | 5 | 0.088 | 0.4 |

| Pie Creek | - | - | - | 225 | 0.086 | 19.2 | 225 | 0.086 | 19.2 | | 5 | 0.089 | 0.5 |

| Road Canyon | - | - | - | 17 | 0.070 | 1.2 | 17 | 0.070 | 1.2 | | 187 | 0.081 | 15.2 |

| Stockpiles | 37 | 0.124 | 4.6 | 254 | 0.049 | 12.4 | 291 | 0.059 | 17.1 | | - | - | - |

| Open Pit Resource | 144 | 0.128 | 18.3 | 1,654 | 0.084 | 139.3 | 1,798 | 0.088 | 157.6 | | 216 | 0.082 | 17.8 |

| | | | | | | | | | | | | | |

| Underground | | | | | | | | | | | | | |

| Smith | 2,980 | 0.200 | 597.3 | 2,214 | 0.204 | 452.1 | 5,193 | 0.202 | 1,049.4 | | 977 | 0.179 | 174.6 |

| SSX Including | | | | | | | | | | | | | |

| West Mahala | 1,205 | 0.201 | 242.6 | 2,438 | 0.198 | 481.7 | 3,643 | 0.199 | 724.3 | | 2,508 | 0.173 | 433.6 |

| Saval | 17 | 0.276 | 4.6 | 160 | 0.247 | 39.6 | 177 | 0.250 | 44.2 | | 51 | 0.238 | 12.2 |

| Murray | 142 | 0.163 | 23.1 | 404 | 0.165 | 66.8 | 545 | 0.165 | 89.9 | | 61 | 0.162 | 10.0 |

| Starvation | 24 | 0.238 | 5.8 | 946 | 0.176 | 166.8 | 970 | 0.178 | 172.6 | | 21 | 0.170 | 3.6 |

| Winters Creek | - | - | - | 117 | 0.112 | 13.1 | 117 | 0.112 | 13.1 | | 10 | 0.145 | 1.5 |

| Underground | | | | | | | | | | | | | |

| Resource | 4,367 | 0.200 | 873.4 | 6,278 | 0.194 | 1,220.1 | 10,645 | 0.197 | 2,093.5 | | 3,629 | 0.175 | 635.4 |

| Resource Total | 4,511 | 0.198 | 891.7 | 7,932 | 0.171 | 1,359.4 | 12,443 | 0.181 | 2,251.1 | | 3,845 | 0.170 | 653.2 |

Notes:

| | (1) | Mineral Resources that are not mineral reserves do not have demonstrated economic viability; |

| | (2) | Open Pit Mineral Resources are contained within Lerch Grossman pit shells constructed at $1,620/oz. gold price and meet the minimum cutoff grade; |

| | (3) | Open Pit Mineral Resources include 5% mining losses and 5% dilution; |

| | (4) | Underground Mineral Resources are constrained to 0.10 opt grade shells and occur outside existing asbuilts workings and sterilized areas, and are deemed by the Qualified Person to be potentially economic; and |

| | (5) | Underground Mineral Resources include 5% mining losses and 5-10% dilution. |

1.2 Mineral Reserves estimate

Mineral Reserves as of December 31, 2012 are listed below in Table 1.2.1. The following parameters were used to determine Mineral Reserves for each area:

- A three-year average trailing gold price of $1,490 per ounce

- Grade dependent gold recoveries varying from 75% to 90%

- $0.40 per ounce refining charges

- Open pit cut off grades vary from a low of 0.043 to 0.046 opt

- Underground cut off grades vary from 0.106 to 0.116 opt.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 1-4 |

Table 1.2.1: Jerritt Canyon mineral reserves– December 31, 2012.

| | Proven | Probable | Proven + Probable |

| | | | | | | | | | |

| Area | kt | opt | koz | kt | opt | koz | kt | opt | koz |

| Open Pit | | | | | | | | | |

| Burns Basin | 32 | 0.100 | 3.2 | 391 | 0.101 | 39.6 | 423 | 0.101 | 42.8 |

| Mill Creek | 3 | 0.089 | 0.3 | 194 | 0.090 | 17.4 | 197 | 0.090 | 17.7 |

| Saval | 51 | 0.155 | 7.9 | 32 | 0.089 | 2.9 | 83 | 0.129 | 10.8 |

| Wright Window | 5 | 0.174 | 0.9 | 109 | 0.093 | 10.1 | 114 | 0.096 | 11.0 |

| Stockpiles | 37 | 0.124 | 4.6 | 167 | 0.053 | 8.9 | 204 | 0.066 | 13.5 |

| Open Pit Reserve | 128 | 0.131 | 17.0 | 892 | 0.088 | 78.9 | 1,021 | 0.094 | 95.7 |

| | | | | | | | | | |

| Underground | | | | | | | | | |

| Smith | 1,750 | 0.162 | 283.5 | 1,262 | 0.168 | 211.8 | 3,012 | 0.164 | 495.3 |

| SSX Including West | | | | | | | | | |

| Mahala | 566 | 0.172 | 97.5 | 1,056 | 0.159 | 167.4 | 1,621 | 0.163 | 272.0 |

| Saval | 18 | 0.239 | 4.3 | 150 | 0.203 | 30.4 | 168 | 0.207 | 34.8 |

| Murray | 142 | 0.163 | 23.1 | 354 | 0.166 | 58.6 | 495 | 0.165 | 81.7 |

| Starvation | 24 | 0.238 | 5.8 | 946 | 0.176 | 166.8 | 970 | 0.178 | 172.6 |

| Underground Reserve | 2,499 | 0.166 | 414.3 | 3,766 | 0.169 | 635.0 | 6,266 | 0.167 | 1,049.3 |

| Reserve Total | 2,628 | 0.164 | 431.1 | 4,659 | 0.153 | 713.9 | 7,287 | 0.157 | 1,145.0 |

The reserves listed above are a subset of the resources listed in Table 1.1.1.Dewatering of some of the Smith, West Mahala and Murray reserve areas that lie below the water table will be required. The operating and capital costs at these mines contain provisions for construction and operation of the dewatering systems. The processing plant requires 700 gpm of makeup water which is derived from seepage wells surrounding the existing tailings storage facility (TSF-1) and from fresh water supply wells. With the replacement of TSF-1, the source of seepage water will gradually diminish and ultimately will no longer be available. Mine dewatering operations will replace the TSF-1 seepage over time. A water treatment plant and rapid infiltration basin (RIB) will be required to dispose of dewatering in excess of the 700 gpm process water requirement.

From January 1, 2012 to December 31, 2012 Jerritt Canyon processed 978 ktons of ore containing 127.7 kozs from Smith, SSX and stockpile sources (Hofer, W. 2013). During the year all ores processed at Jerritt Canyon were from onsite sources and no ore from offsite was processed.

Reserve additions net of depletion total 84 koz relative to the previous NI 43-101 report. The gains are concentrated at the Starvation and Smith underground mines with lesser additions at Burns Basin open pit. Stockpile reserves decreased by 44 koz due to depletion and reclassification based on a trenching sampling program conducted in 2012. Reserves at the SSX-Steer underground (including West Mahala) and Murray underground decreased slightly.

1.3 Conclusions

The six year Life of Mine Reserves Plan will produce robust financial results. Achieving sustained ore mining and processing rates of 1.5 million tons per year is critical to the success of the Jerritt Canyon mine operation. In 2013 ore will be sourced from the Smith and SSX underground mines, two new underground mines at Starvation Canyon and Saval, and low grade ore stockpiles.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 1-5 |

1.4 Recommendations

Additional ore sources need to be developed at the Saval Underground and Burns Basin Pit during the next two years to enhance production and replace the stockpile ores as they are depleted. Reopening of the Murray underground mine and adding to open pit reserves will be required to maintain processing rates at the desired level over the 6 year reserve life.

Resource conversion near the existing and planned underground workings should remain a drilling priority. Conversion of resources near the planned open pits could also significantly add to the project life and economics.

Dewatering will be necessary to recover 234 koz of the current reserves located in the Smith, SSX and Murray mines. Engineering and permitting of the dewatering facilities must be a high priority to ensure these reserves are available when needed.

Mining operations can implement more economical mining plans including raising the cutoff grade and including inferred resources in the LOM plan. The processing of third party toll milling ores to increase and maximize the mill capacity would also help lower the operating cost per ton and increase revenue but cannot be included in the present Cash flow Analysis due to NI 43-101 rules that limit this work to reserve materials sourced from the Jerritt Canyon property.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 2-1 |

2 Introduction

Veris Gold Corp. (VG) engaged Mark Odell, P.E., Consulting Engineer, of Practical Mining LLC; Michele White, C.P.G., Geologic Consultant and Exploration and Mining Data Analyst; Karl Swanson, SME, Mine Engineer Consultant; and John Fox, P.Eng, Consulting Metallurgist, to assist in the preparation of a Canadian National Instrument 43-101 (NI 43-101) compliant Technical Report update on its 100% owned Jerritt Canyon operating gold mine property north of Elko, Nevada.

In June 2007, Queenstake Resources Ltd. merged with YGC Resources Ltd. through a plan of arrangement to create Yukon-Nevada Gold Corp. which subsequently changed its name to Veris Gold Corp on October 5, 2012. Queenstake Resources USA, Inc. changed its name to Veris Gold USA, Inc. in January of 2013. As a result, the Jerritt Canyon Mine is owned and operated by Veris Gold USA, Inc. (VUSA), which is a wholly owned subsidiary of Veris Gold Corp.

This report reflects the most recent resources and reserves based on data produced through December 31, 2012. The effective date of this report is December 31, 2012. All underground and open pit resources and reserves in this report have been modeled in Vulcan software version 8.1.3 and 8.2 (Vulcan).

Veris is considered to be a “producing issuer” for the 2012 year, based on the definition included in the NI 43-101 guidelines. Throughout this document there are “forward-looking” statements with regards to targeted future mill production for 2013, expectations for restarting mines, and for growing the resources at the property.

2.1 Terms of reference and purpose of the report

This report is intended to provide Veris with an updated resource and reserve review and technical report for the Jerritt Canyon property that follows existing regulations in Canada. The report meets the requirements for Canadian National Instrument 43-101 and conforms to Form 43-101F1 for technical reports. The technical report confirms details provided in the Veris Gold Corp’s press release dated June 17, 2013.

Resource and Reserve definitions are as set forth in the back of this Technical Report in accordance with Companion Policy 43-101 CP, “Canadian Institute of Mining, Metallurgy and Petroleum – Definitions Adopted by CIM Council, November 27, 2010.” This report has an effective date of December 31, 2012. The following description and summary of the Jerritt Canyon property is based mostly on the previous

Technical Report (the “Jerritt Canyon Report”) of Mark Odell, P.E., Michele White, CPG, Karl Swanson, SME, MAusIMM and John Fox., P. Eng with a filing date of April 27, 2012. The Jerritt Canyon Report is available atwww.sedar.com. An additional reference for this current Technical Report is: NI 43-101 Technical Report Update by Johnson et al. (2011; 2012) entitled “NI 43-101 Technical Report Update, Yukon-Nevada Gold Corp., Jerritt Canyon property, Elko County, Nevada, USA” dated on June 28, 2011, as amended on January 6, 2012.

2.2 Qualifications of consultants and authors

The report has been prepared based on a technical and economic evaluation by four independent consultants, along with Todd Johnson, a Veris Gold Corp. employee and the primary author. All five persons are occasionally referenced throughout the current report as authors of the Technical Report. The five authors were sourced from various areas of the western United States and British Columbia, Canada. The five authors are specialists in the fields of geology, geological engineering, exploration and mining data management, mineral resource and mineral reserve estimation and classification, metallurgy, and mine engineering including open pit and underground mining.

None of the four consultants employed in the preparation of this report have any beneficial interest in VUSA or Veris or in their assets. The four consultants will be paid a fee for this work in accordance with normal professional consulting practice. Mr. Johnson is currently paid a salary as a Veris employee and has received Company stock options in the recent past.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 2-2 |

The individuals who have provided input to the current Technical Report Update are cited as “contributing author” or “primary author” and are listed below. These authors have extensive experience in the mining industry and are members in good standing of appropriate professional institutions. The four consultants are all contributing authors. Mr. Odell was the Underground Mining Manager for Queenstake Resources from July 2003 to June 2005, and again as Mine Superintendent and Chief Engineer from March 2000 to July 2003 for Anglogold as an employee. Mr. Odell visited the property on several occasions in 2009, through 2013 as a Consulting Mine Engineer. Mr. Odell last visited the mine site on December 18, 2012. Ms. White consulted at the Jerritt Canyon Mine site from August 2009 to May 2010, and retained direct hire at the mine from May 2010 to March 2011. Ms. White last visited the mine site January 22-24, 2013. Mr. Swanson visited the property on several occasions in 2010, 2011, and 2012 as a Consulting Engineer and was last at the property on March 20, 2013. Mr. Fox is a former director of Veris and last visited the property on September 1-6, 2012.

Mr. Todd Johnson is the qualified person (QP) for this report and is cited as the Primary Author.Mr. Johnson has visited the property on several occasions in late 2008 to 2013 and last visited the mine site on May 1, 2013.

The key project personnel contributing to this report are listed below. The Certificate and Consent forms are provided in Appendix A.

Table 2.2.1: Key project personnel.

| Company | Name | Title | Discipline |

| Veris Gold Corp. | Todd Johnson | Vice President of Exploration | Geology, Resources |

| Practical Mining, LLC | Mark Odell | Consulting Mine Engineer | Mining, Reserves |

| Independent Consultant | Karl Swanson | Consulting Mine Engineer | Resources, Geology |

| | | Geologic Consultant and | |

| All One River, LLC | Michele White | Exploration and Mining Data | Data Validation, Geology, |

| | | Analyst | Land Status |

| Laurion Consulting Inc. | John Fox | Consulting Metallurgist | Mineral Processing |

2.3 Price strategy

The reserves were determined using a gold price of $1,490 per troy ounce (US) which is the 36-month trailing average price over the three years from January 2010 to December 2012. The revised underground and open pit resources were estimated using a gold price of US$1,620 per troy ounce.

2.4 Units of measure

The units of measure used in this report are shown below. System International (SI) units of measure are used throughout this report unless otherwise noted. A glossary of geological and mining related terms is provided in Section 28.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 2-3 |

Table 2.4.1: Units of measure.

| UNITS OF MEASURE |

| Linear Measure |

| 1 inch = 2.54 cm |

| 1 foot = 0.3048 m |

| 1 yard = 0.9144 m |

| 1 mile = 1.6 km |

| Area Measure |

| 1 acre = 0.4047 ha |

| 1 square mile = 640 acres = 259 ha |

| Weight |

| 1 short ton (st) = 2,000 lbs = 0.9071 tonne (t) |

| 1 lb = 0.454 kg = 14.5833 troy oz |

| Assay Values |

| 1 oz per short ton = 34.2857 g/t |

| 1 troy oz = 31.1035 g |

| 1 part per billion = 0.0000292 oz/ton |

| 1 part per million = 0.0292 oz/ton = 1g/t |

2.5 Coordinate system, projections, and topography maps

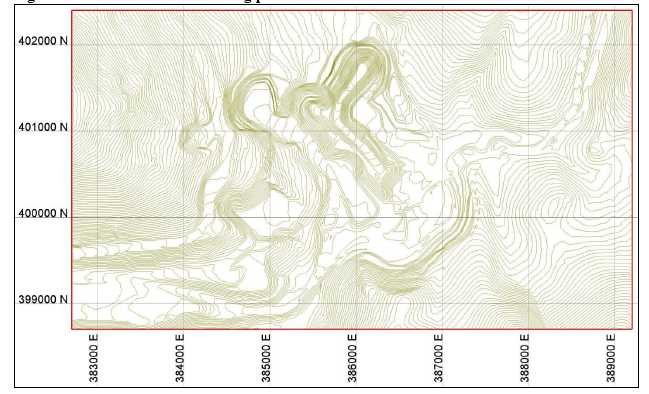

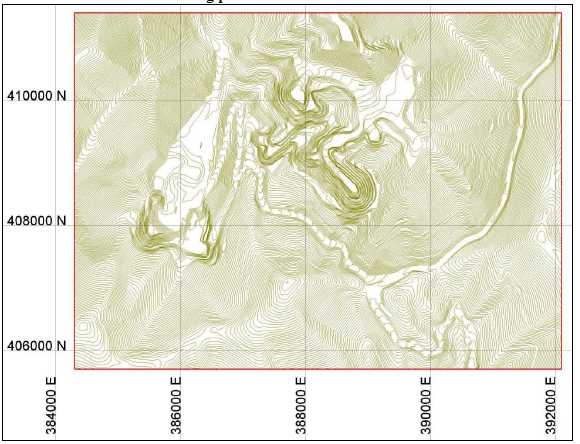

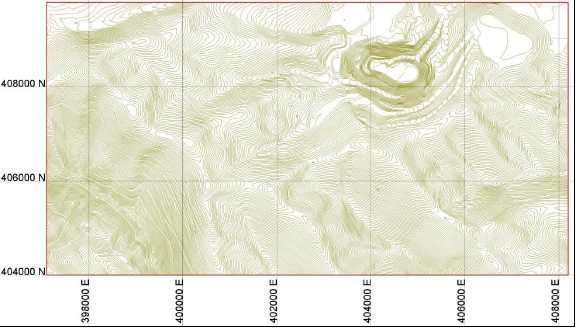

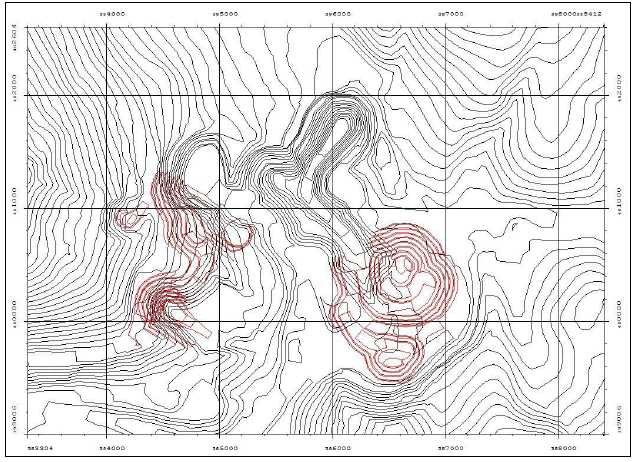

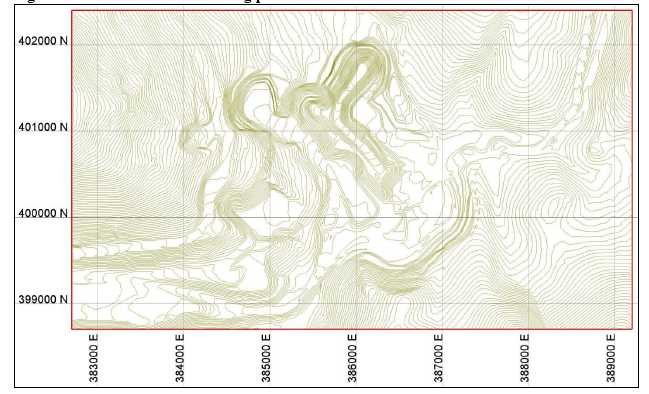

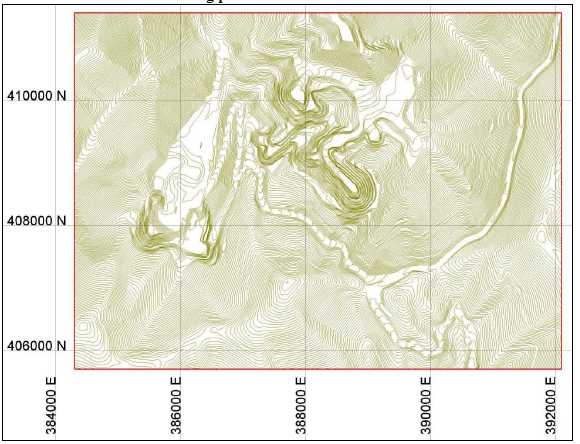

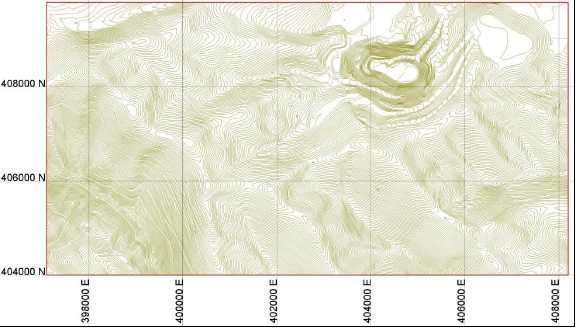

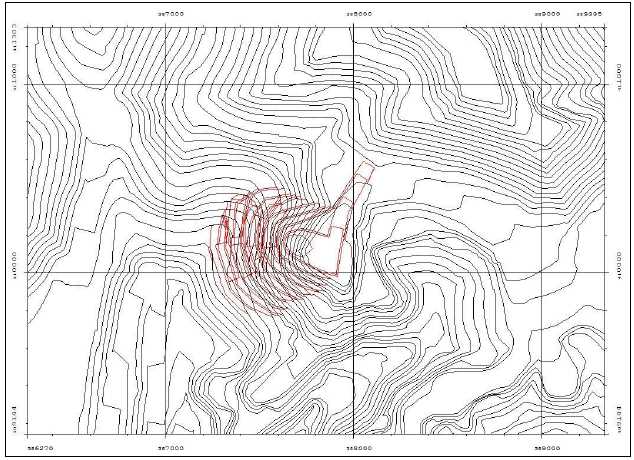

All of the drill hole data stored in the acQuire drill hole database are projected in Jerritt Grid. All plan map figures and cross-sections presented in this report are also presented in Jerritt Grid. Jerritt Grid is projected in foot units and equivalent to the NAD1927 State Plane, Nevada East, FIPS_2701 system with a difference of 2,000,000 feet subtracted from the northing grid values in order to limit the number of numeric characters to adhere to mining software constraints.

All plan maps in this report have grid north (in Jerritt Grid) oriented straight up. The major grid intervals are labeled with the appropriate values in feet and can be used to determine the scale of the drawing figure

Aerial topography mapping of the property was conducted in July 2004 on 5 foot contour line intervals and was utilized as the base map for most of the current models after close disturbance inspection and local modification. Recent aerial Lidar mapping of the property on 5 foot contour line spacing was conducted by Aero-graphics Geospatial Services from August 29 to September 2, 2011 on square tiles 1,800 ft. by 1,800 ft. in size. Finer 0.5 foot Lidar contour line interval definition in the mill and tailings areas were collected at this same time.

2.6 Calendar

Veris uses a fiscal year calendar that begins on January 1 and ends on December 31.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 3-1 |

3 Reliance on other experts

The authors’ opinions contained herein are based on information provided to us by Veris Gold USA and Veris Gold Corp. throughout the course of our investigations. The sources of information include data and reports supplied by Veris, Jerritt Canyon and VUSA personnel, as well as documents cited in Section 27 hereof.

In addition, discussions were held with the following personnel and experts from Veris regarding their field of expertise with the property:

- John Barta, Environmental Manager, Veris Gold USA, Inc. (Sections 18 and 20);

- William Hofer, Chief Mine Geologist, Veris Gold USA, Inc. (Sections 10, 16.6, and 26.2);

- Joel Casburn, Land Manager, Veris Gold USA, Inc. (Section 4); and

- Shaun Heinrichs, Chief Financial Officer (CFO) for Veris Gold Corp. who provided various financial data and operating statistics.

Sources of information are documented within the text and/or in the references (Section 27). The primary author believes the information from these individuals as true based on their work at the Jerritt Canyon Mine from 2009 through 2012. Reliance on the opinions and reports of the staff personnel is based on their better working knowledge of their specific disciplines than the primary author. The primary author asked detailed questions of each of these individuals to help verify and clearly state contributions included in this report:

- The Environmental contributions relied extensively on input from discussion with John Barta.

- The metallurgical content (2011 gold recoveries in the mill) was highly dependent on discussions with Noel Avenido (former Jerritt Metallurgist) and John Fox.

- The technical status for the claims and land holding is highly reliant on discussions with VG Land Manager, Joel Casburn and a 2012 Title Opinion by Richard K. Thompson.

- The extent of reliance for the stockpile discussion and Au reconciliation is based on discussions with William Hofer. Mr. Hofer also contributed the drilling methodology presented in Section 10.

- The construction update for the new tailings storage facility and water storage reservoir was provided by Kevin Kossel.

- Costs for 2012 were provided by Shaun Heinrichs.

The contributions listed above are considered to be accurate by the author.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 4-1 |

4 Property description and location

4.1 Property description

The Jerritt Canyon property is located primarily on private land controlled by VUSA, and public land administered mostly by the United States Forest Service (USFS) and some by the United States Bureau of Land Management (BLM). The land position covers over 119 square miles. The Jerritt Canyon Mine has been an operating gold property since 1981 with two currently active underground mines: SSX-Steer and Smith, which have been in production since the end of 2011. Mining at Smith has been conducted by a contract mining service since early 2010. Mining at the SSX-Steer mine has been conducted by Veris staff since the fourth quarter of 2011. The mines produce feed for a process plant located at the site, which includes 2 roasters and a carbon-in-leach (CIL) circuit. The project also consists of three non-operating underground mining areas (Murray, MCE, and West Generator); rock disposal areas (RDAs); related haul roads, maintenance facilities, ancillary structures; and a gold processing circuit, including mill facilities, heap leaching facilities (inactive), tailings facilities, and support facilities. Exploration and drilling is ongoing at the property to add additional resources and reserves.

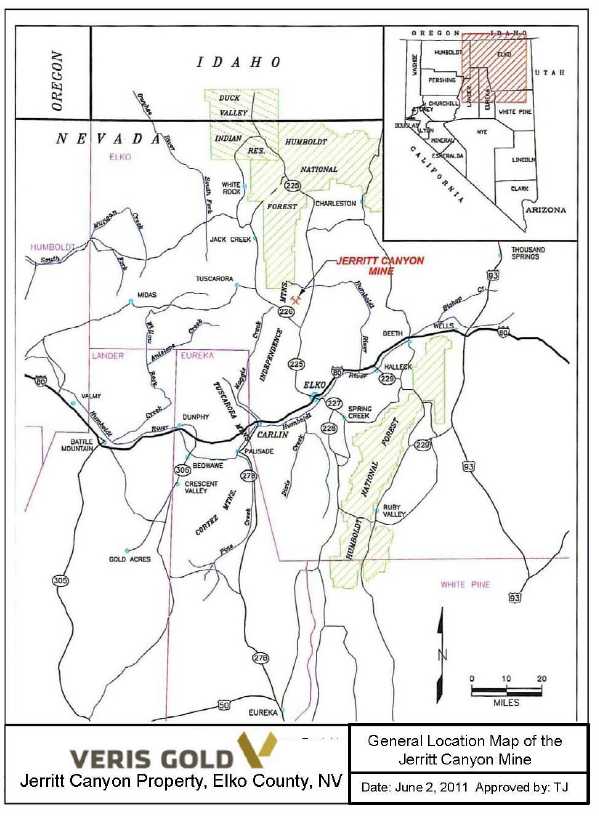

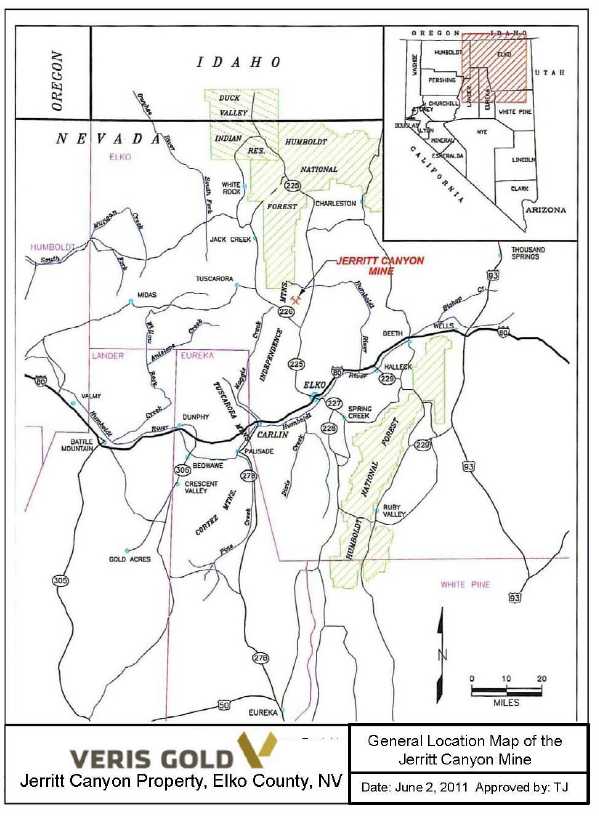

4.2 Property location

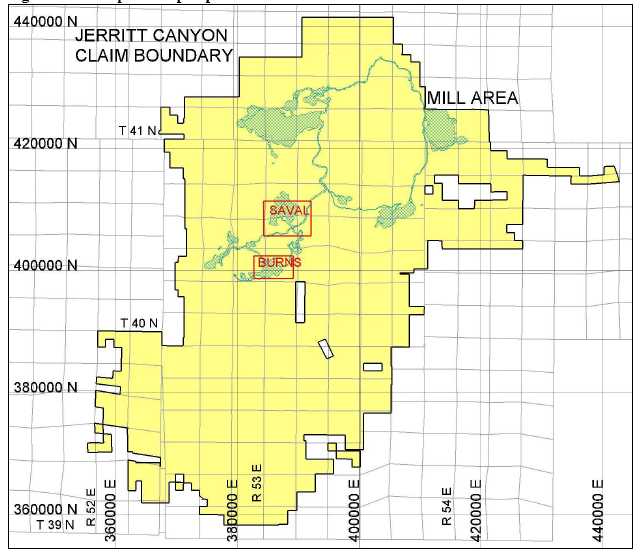

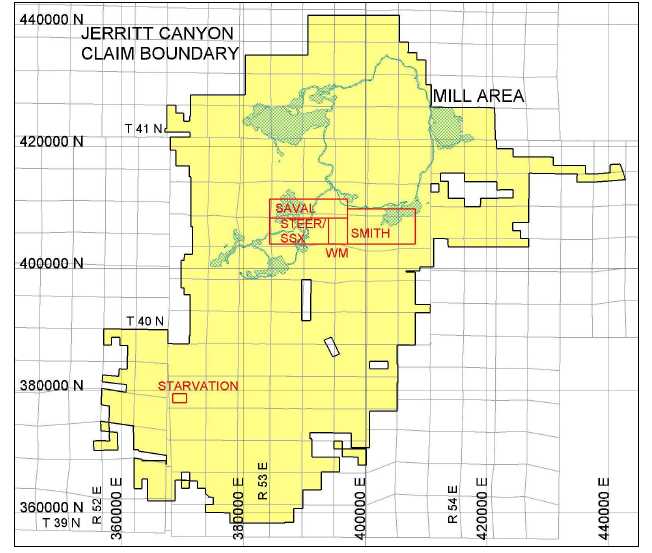

Jerritt Canyon Mine is located in Elko County, Nevada, approximately 50 miles north of Elko in the Independence Mountains at Latitude 41º 23’ North, Longitude 116º West. The property is accessed by paved State Highway 225 going north of Elko for about 45 miles to the paved mine access road. The property lies in ten townships within T39N to T41N and R52E to R54E relative to the Mount Diablo Base Line and Meridian (MDB&M). Figure 4.3.1 is a property location map. The property boundaries are located in the field with wooden stakes and were likely originally measured by tape and compass either from section corners or adjacent claims. All property boundaries have since been located with modern surveying equipment and/or GPS (Trimble 5800 RTK GPS Rover utilizing a Trimble base receiver for reference corrections) with a horizontal accuracy of ±0.5 cm and a vertical accuracy of ±1 cm.

4.3 Status of mineral titles

The property is 100% owned and operated by VUSA, which acquired the mine from the previous owner, a joint venture between Anglo Gold (70%) and Meridian Gold (30%), at the end of June 2003. VUSA is a wholly owned subsidiary of Veris. Claim details were discussed with the VUSA Land Manager as of April 19, 2013.

The operations are located on a combination of public and private lands, with the mines and mining related surface facilities being primarily located on mining claims in United States Forest Service (USFS) land within the Humboldt-Toiyabe National Forest. The process facilities, office, shop, and tailings are located on private land owned by Veris. Additional claims in the southern part of the land package are mostly located on private land with some located on land administered by the United States Bureau of Land Management (BLM). Claim-related fees are annually paid to the BLM and Elko County.

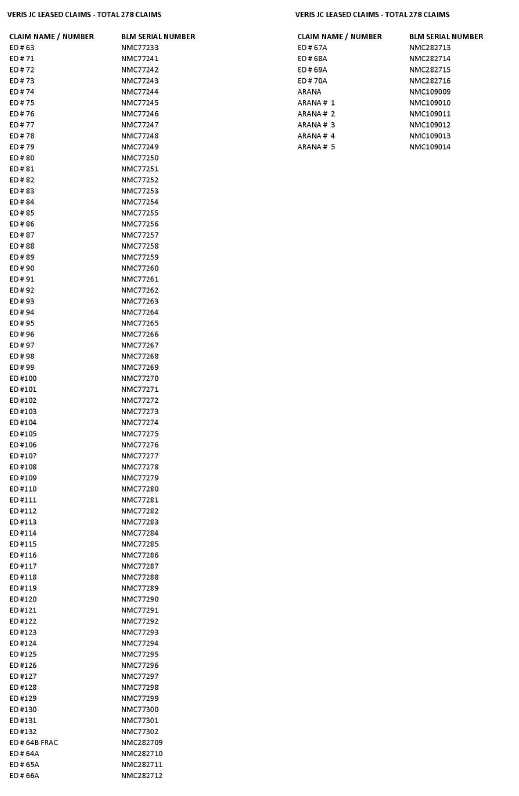

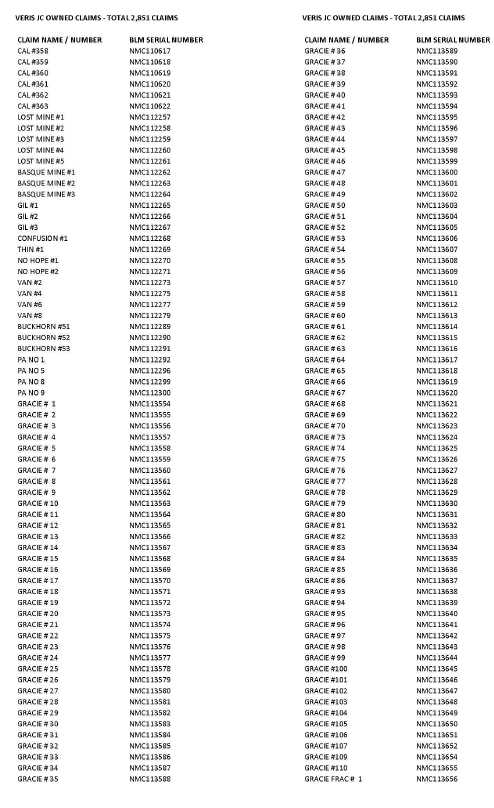

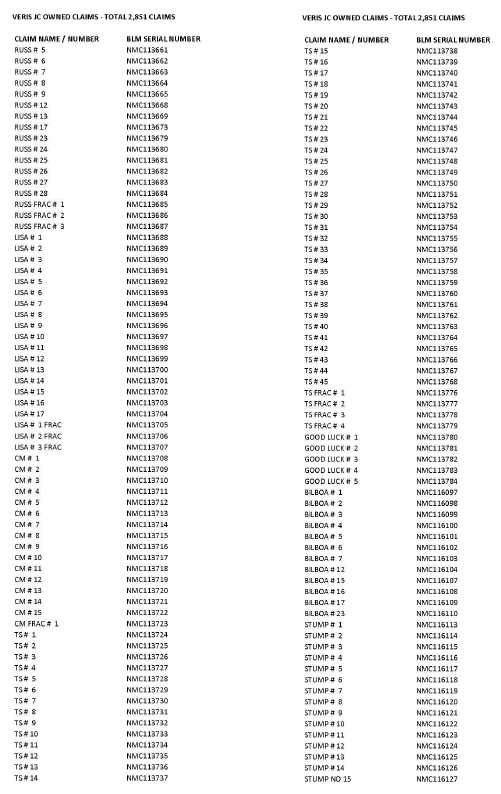

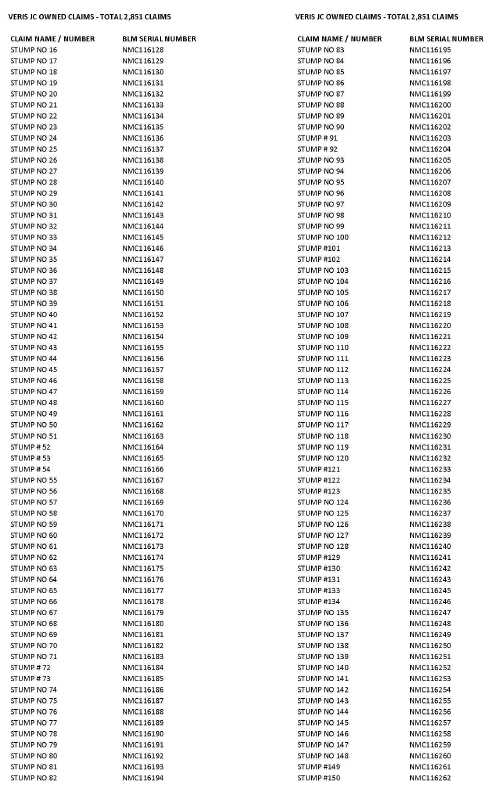

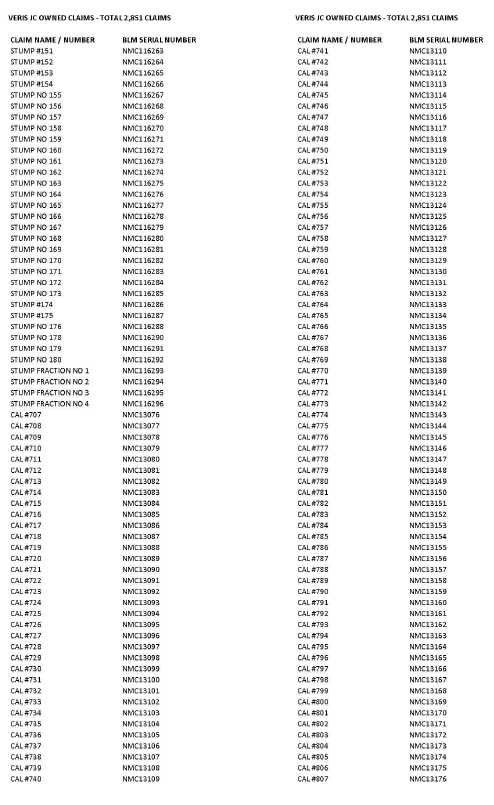

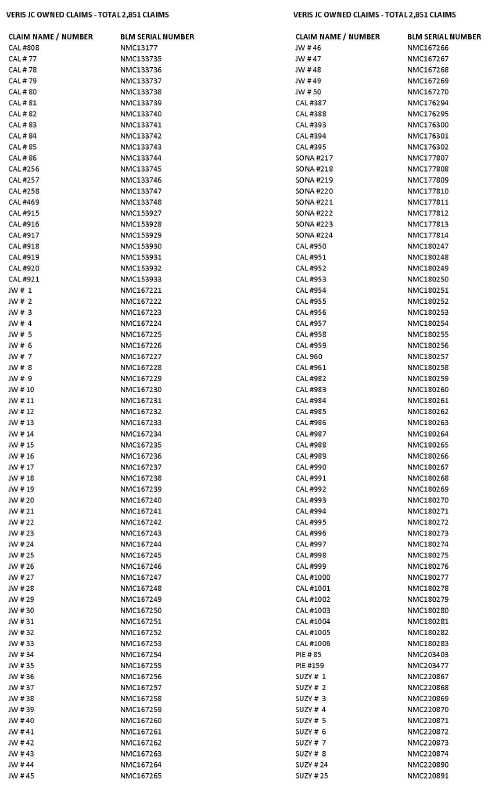

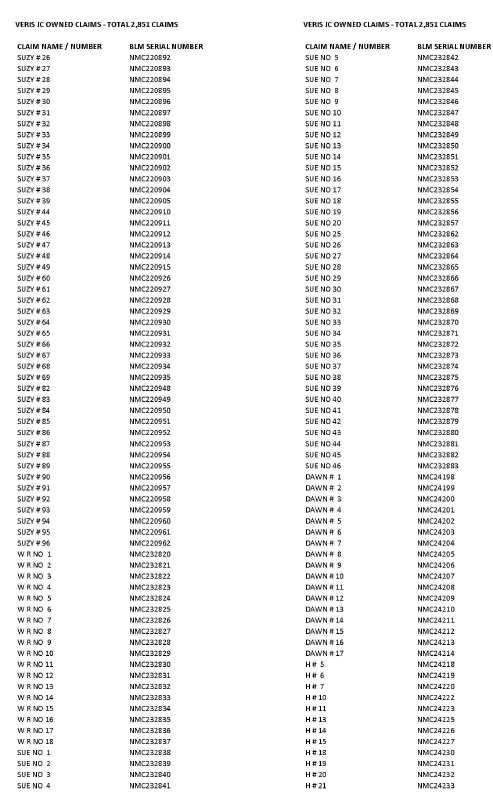

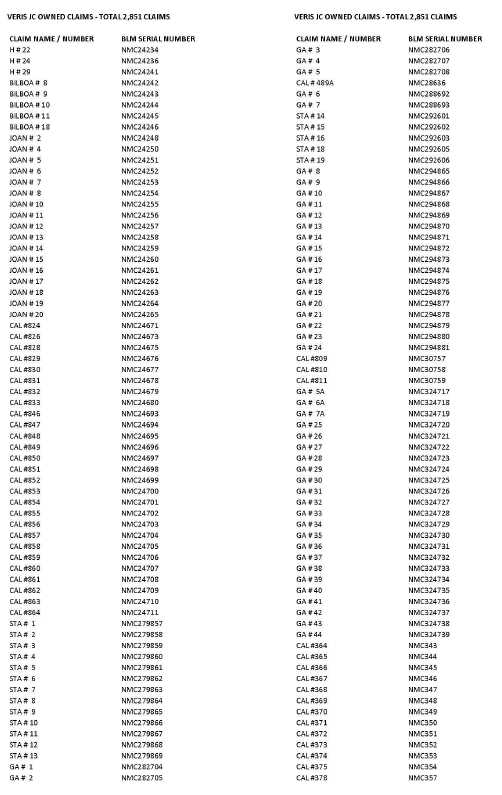

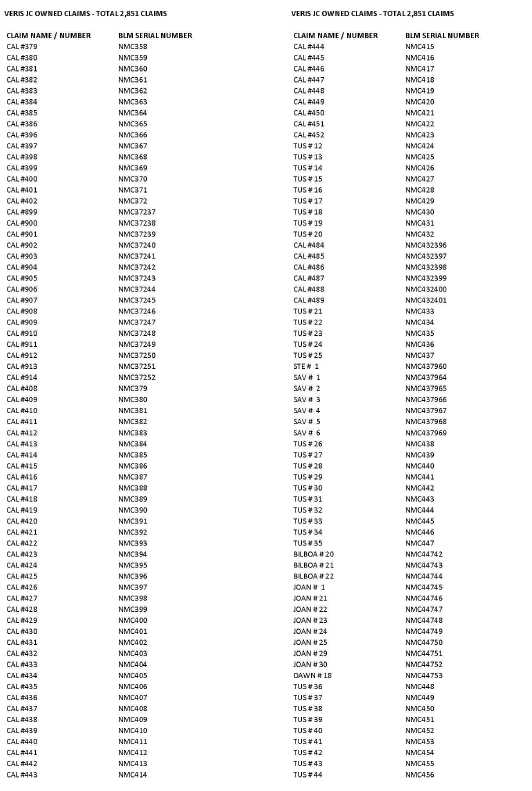

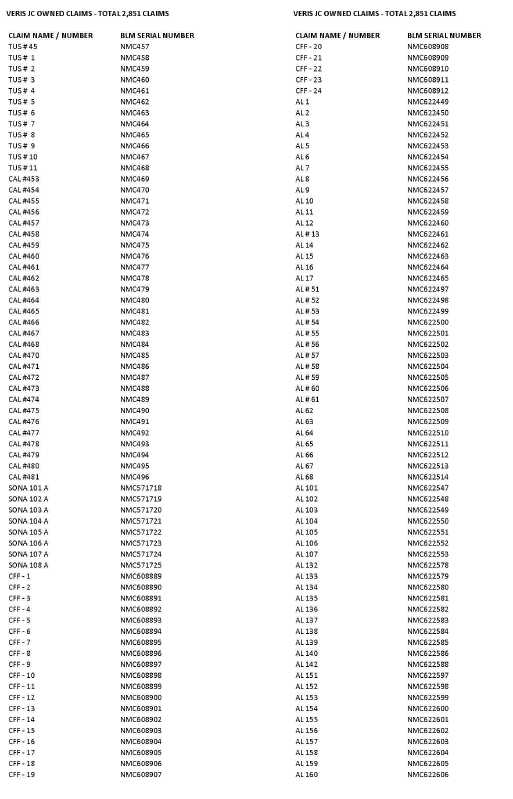

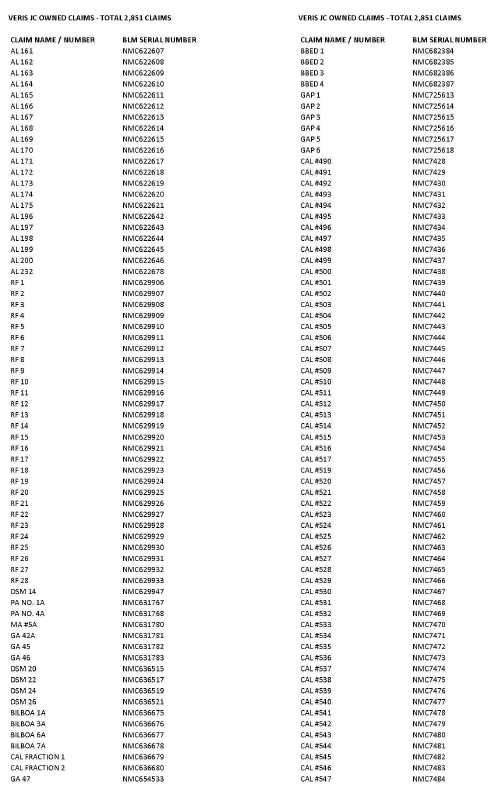

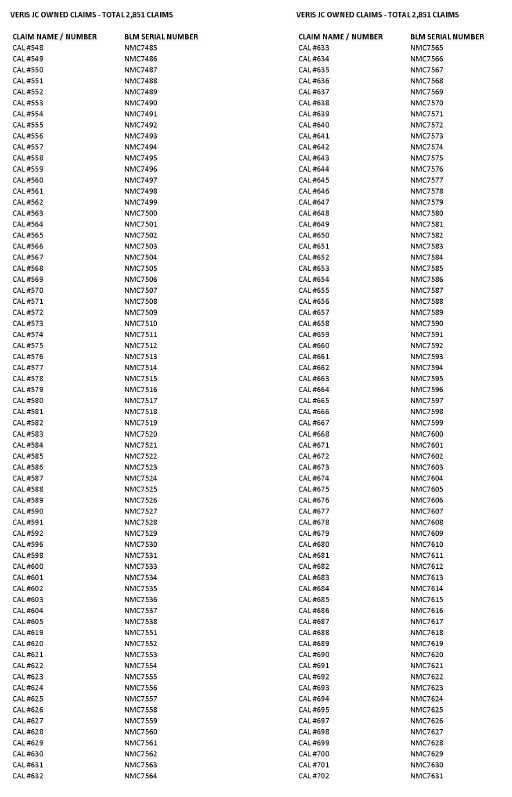

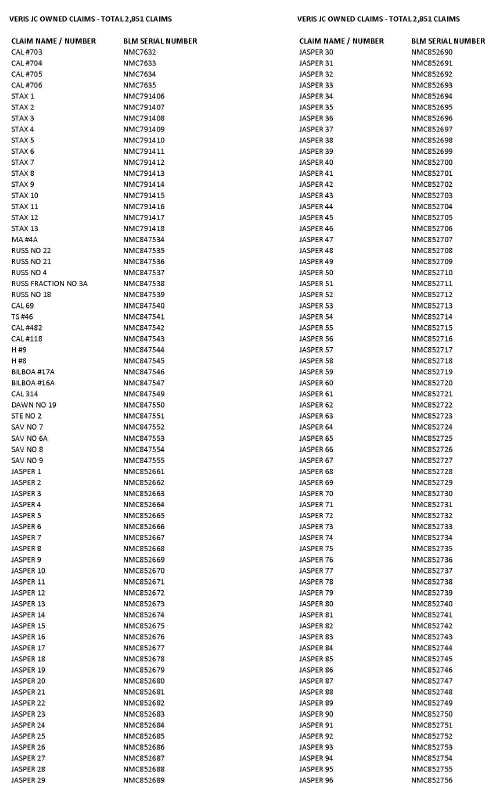

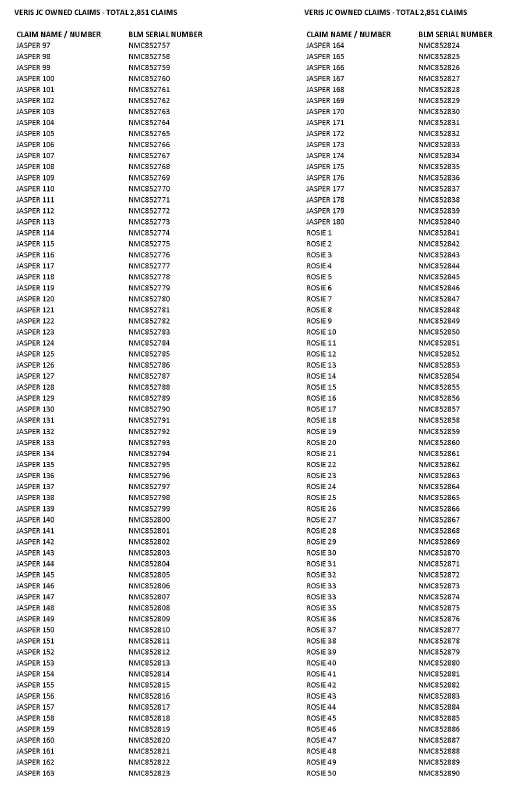

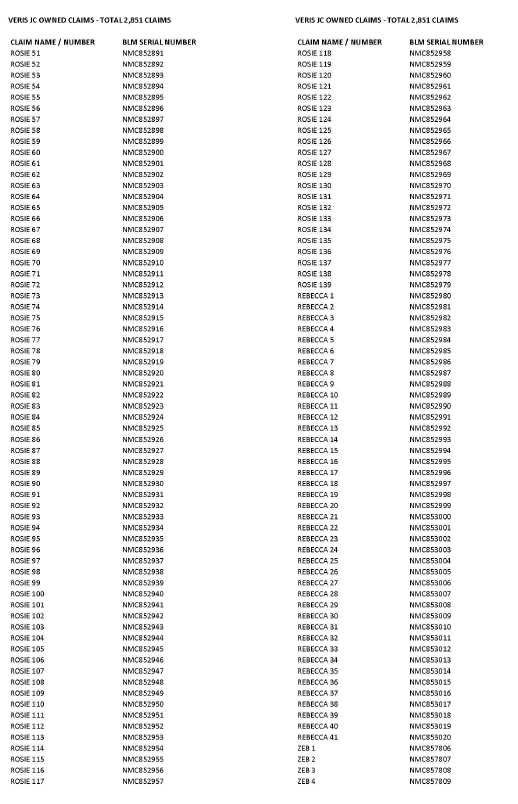

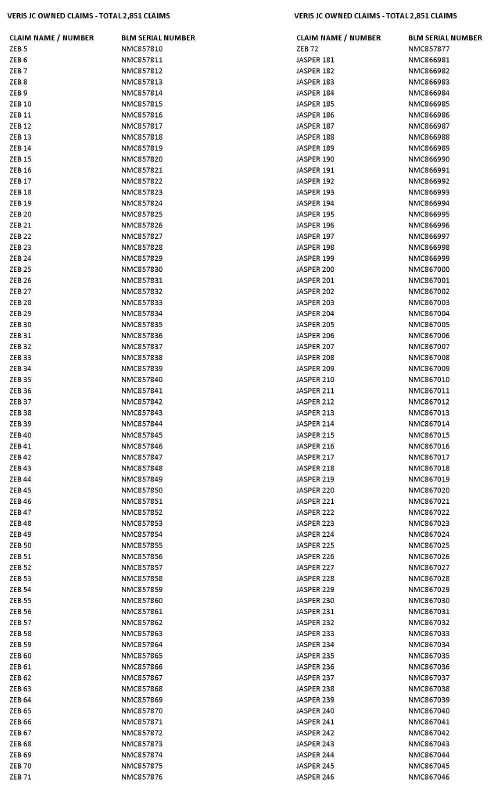

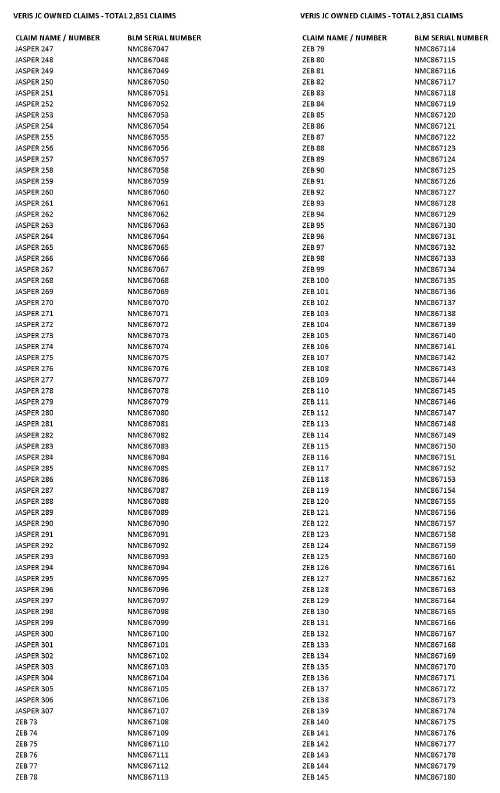

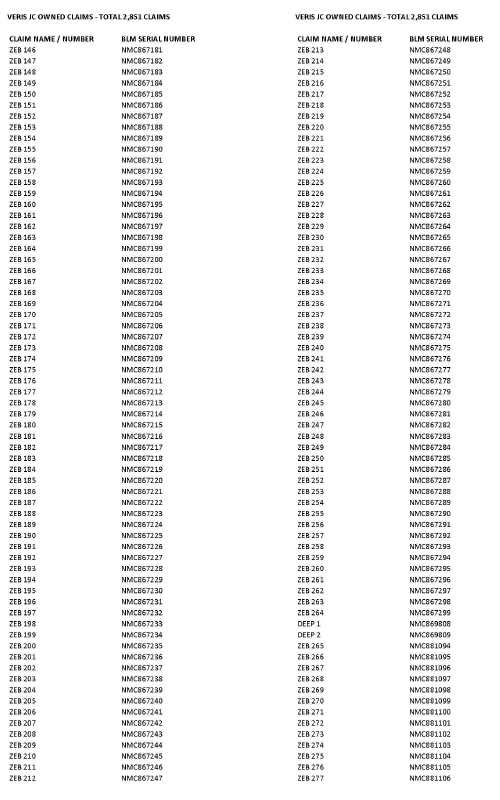

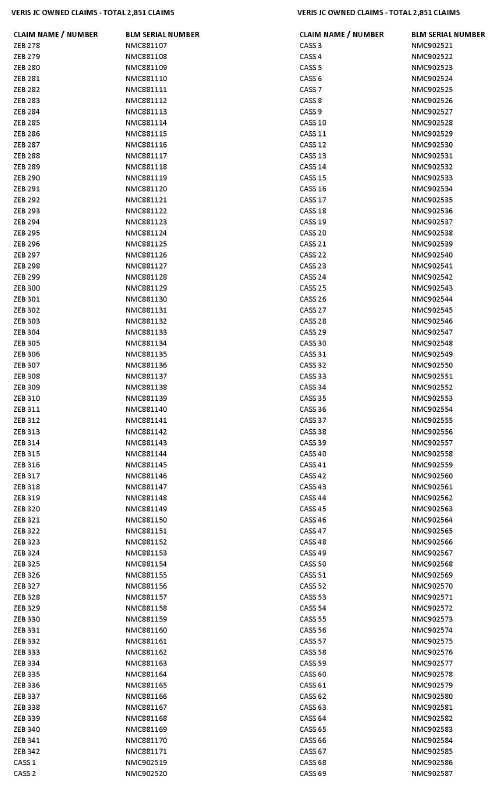

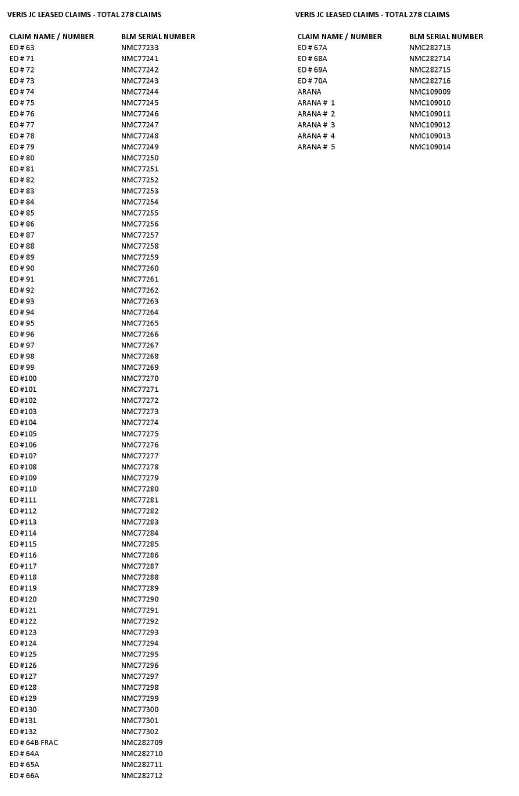

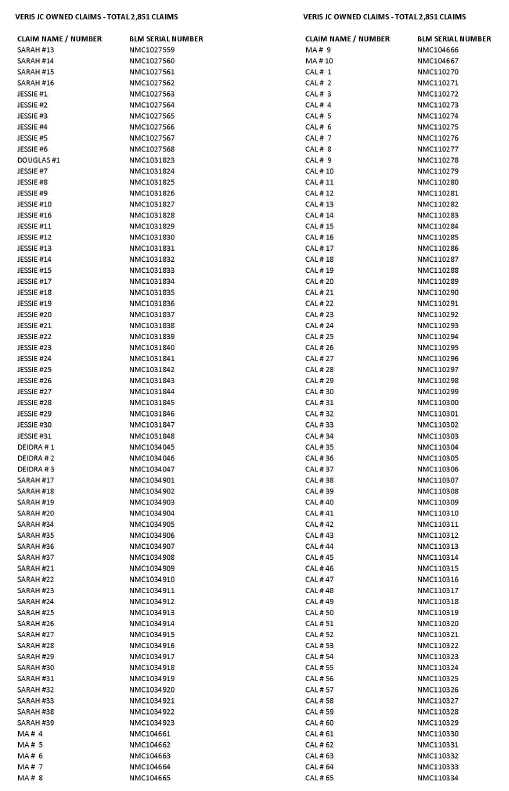

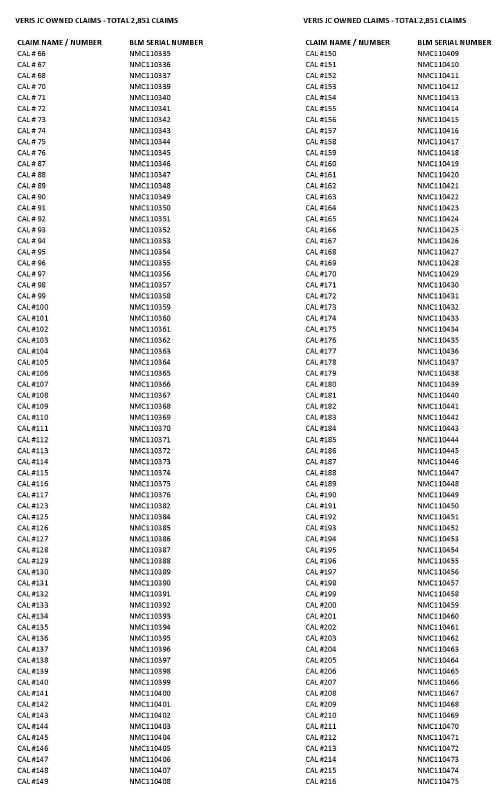

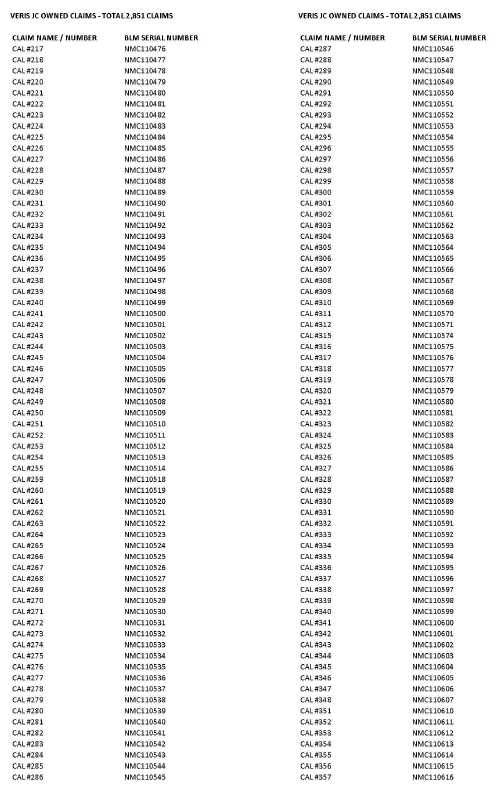

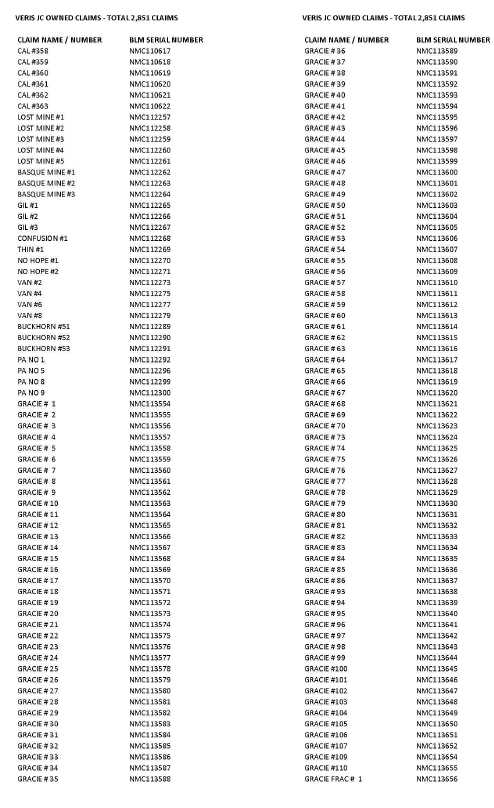

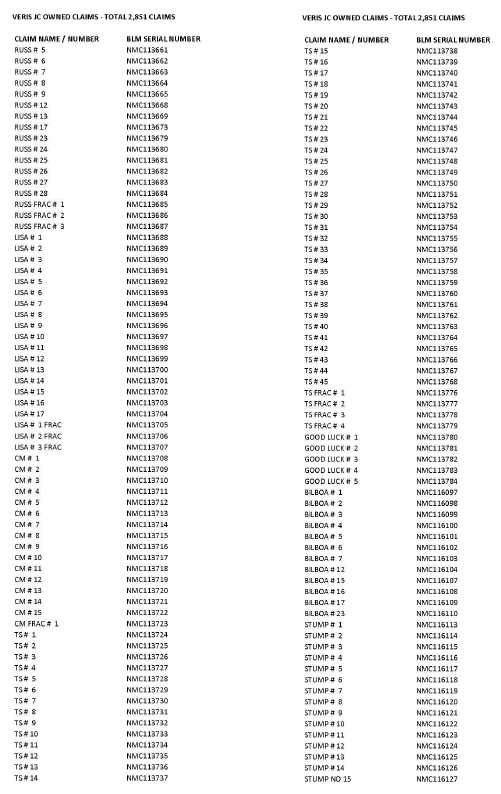

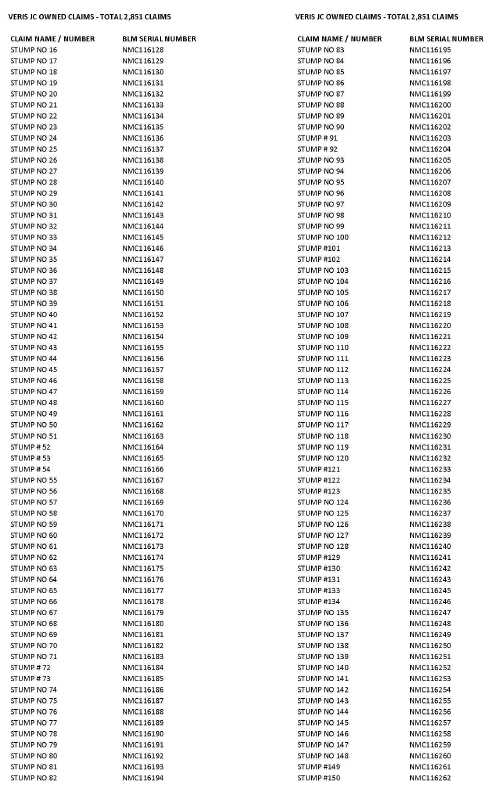

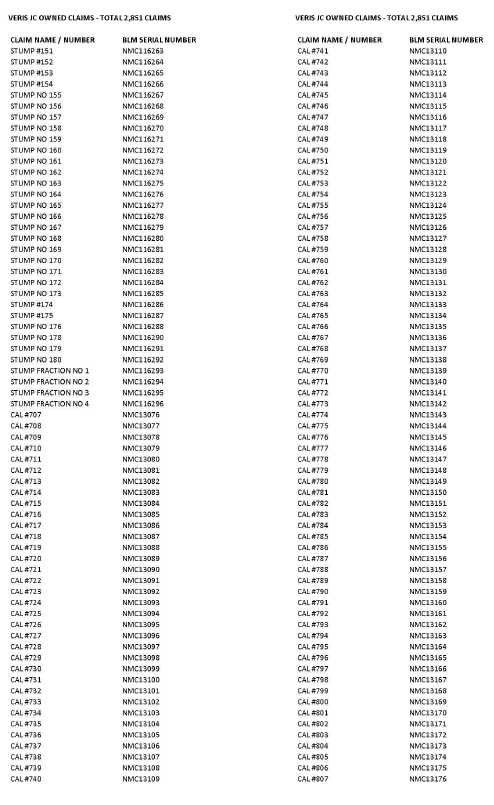

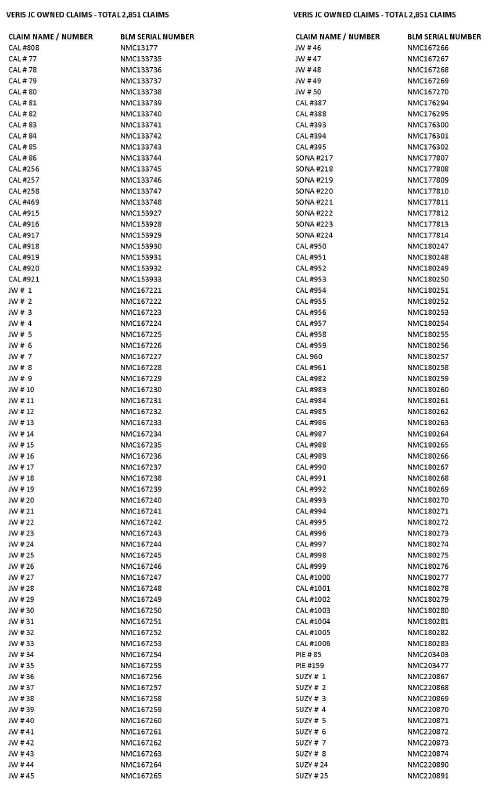

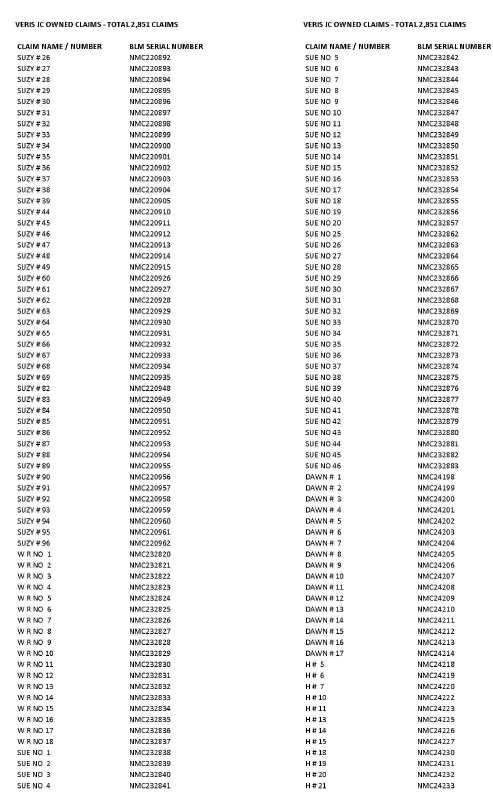

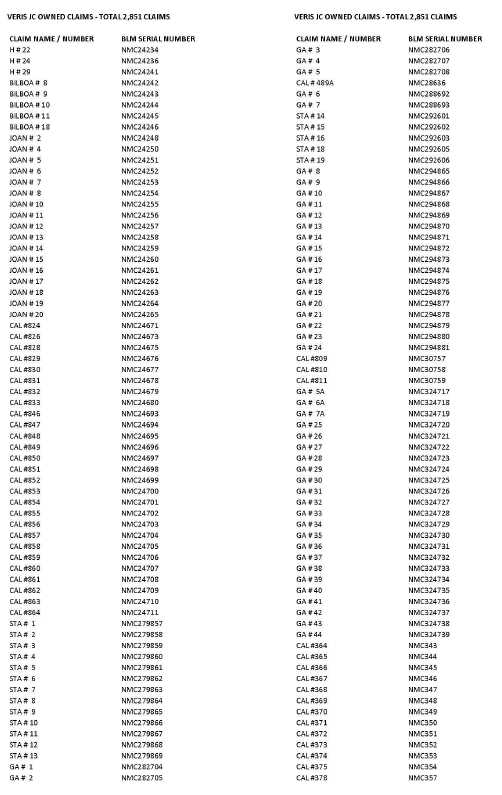

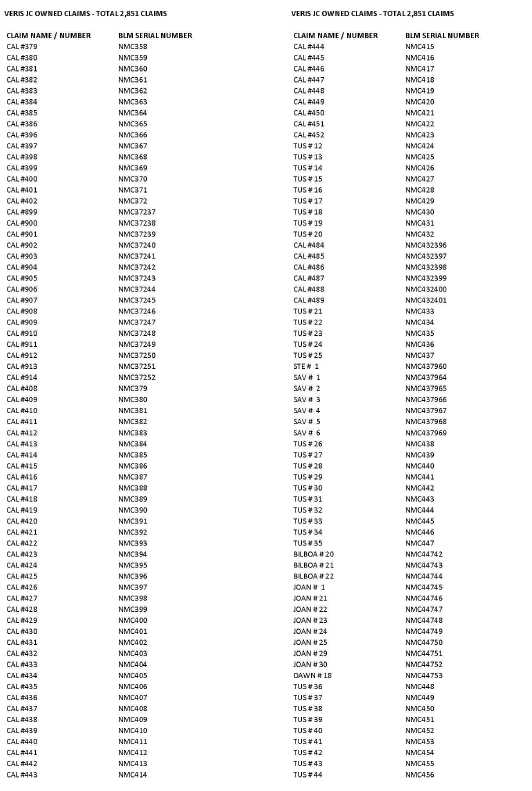

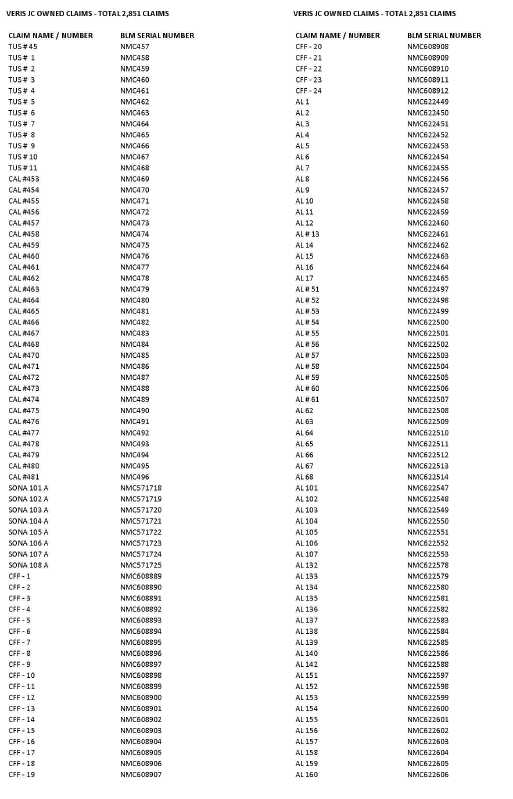

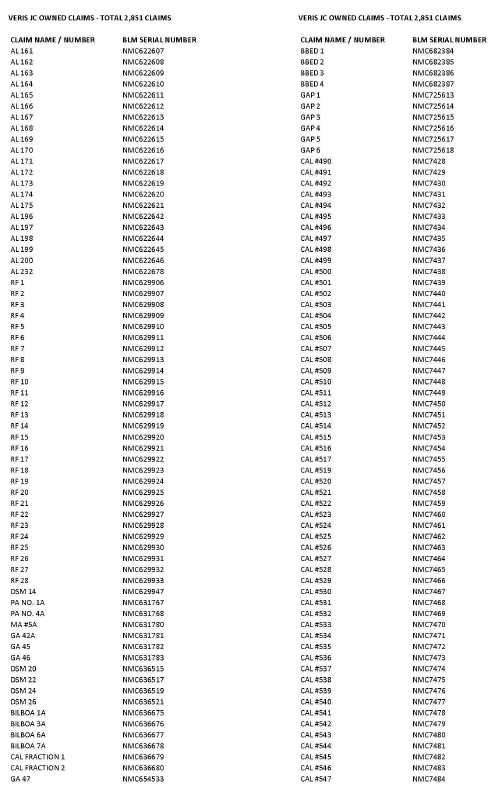

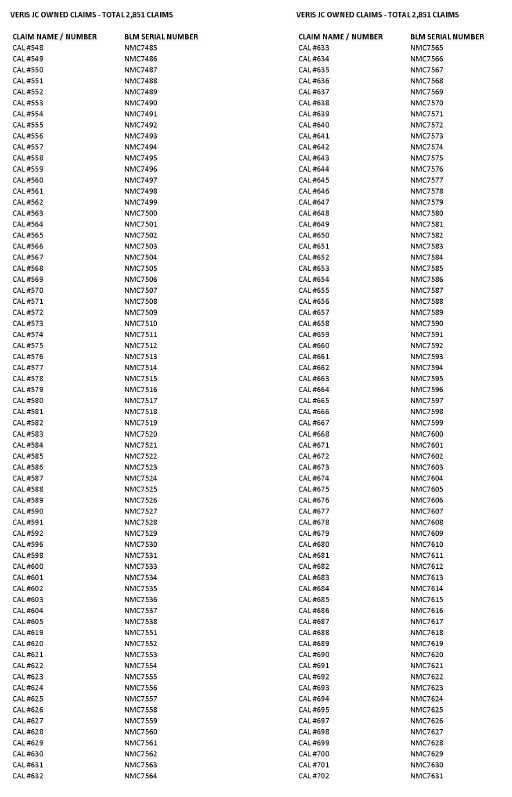

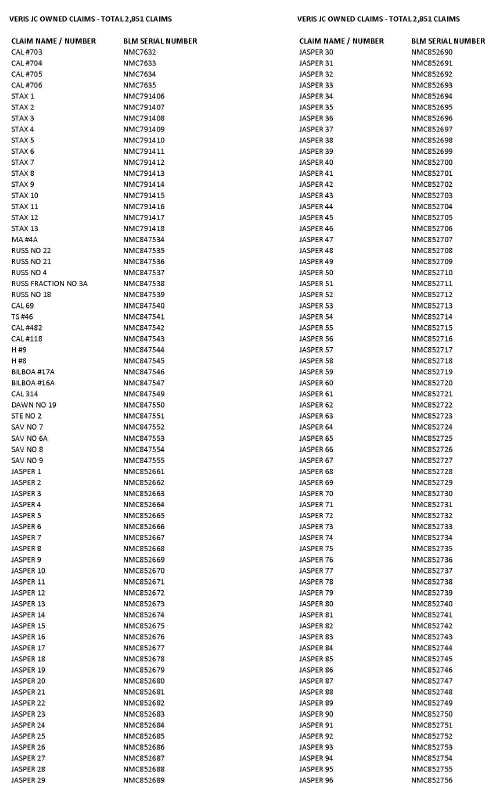

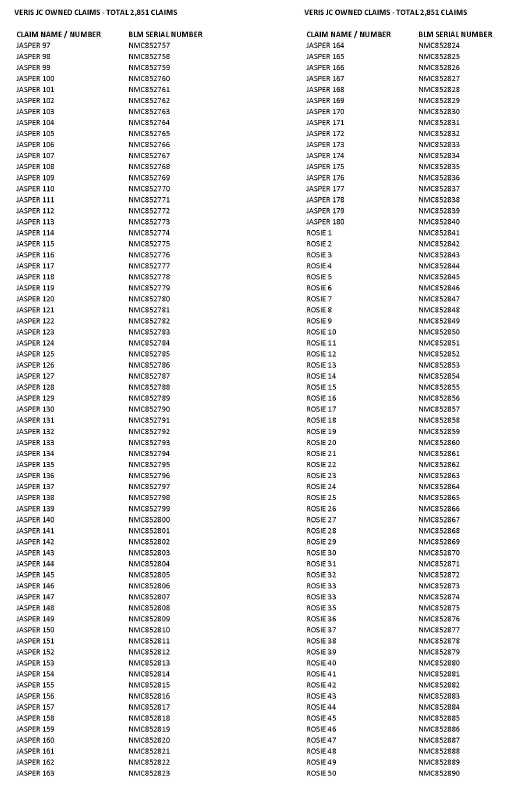

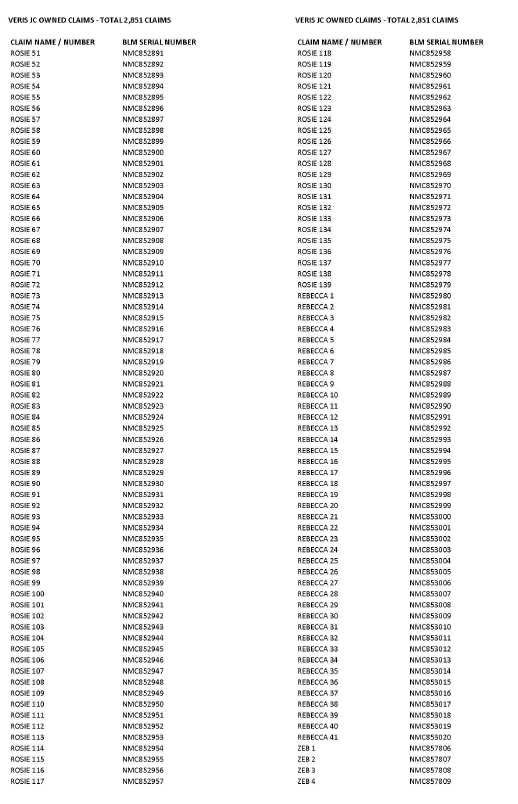

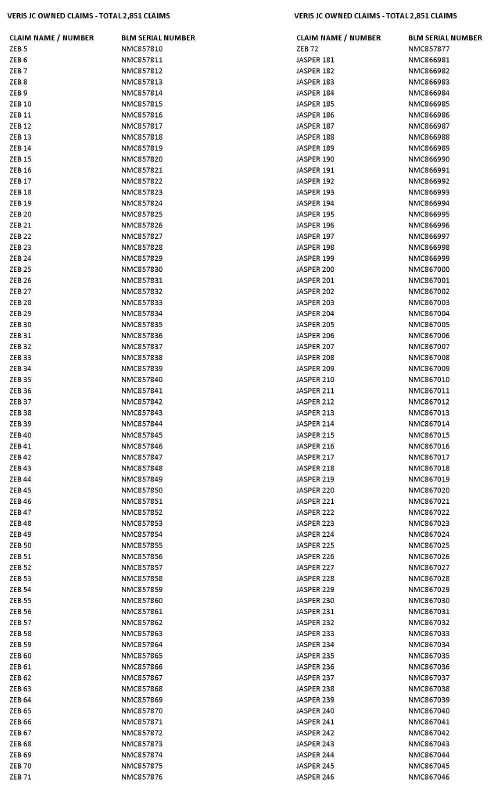

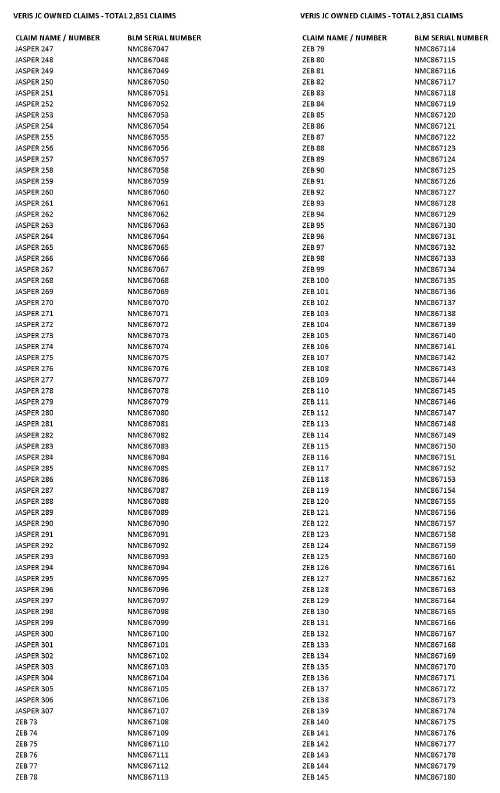

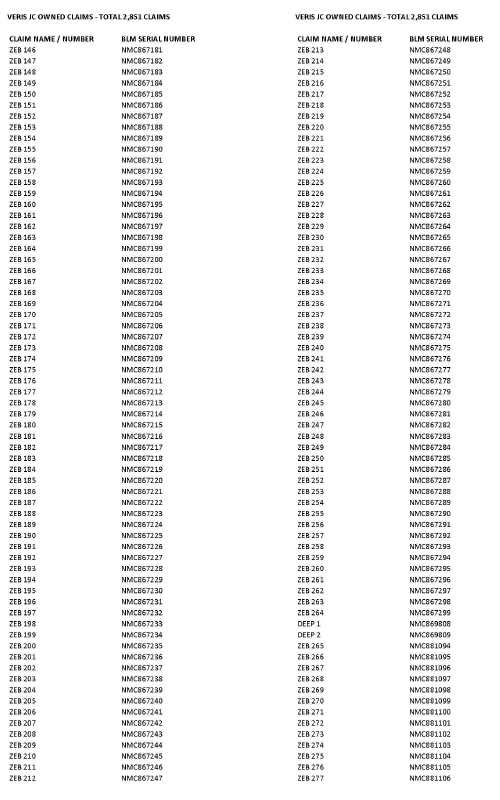

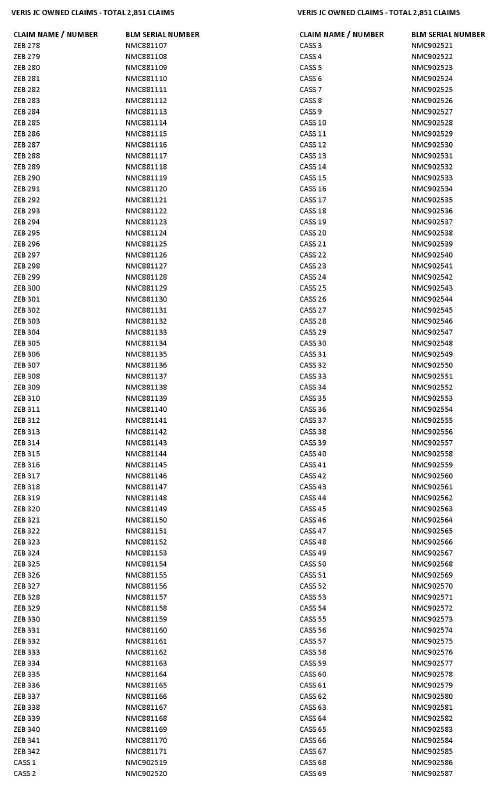

As of December 31, 2012, Veris owns 2,851 claims, 1,011 acres of patented claims, and 12,433 acres of fee land; in addition, Veris leases 278 claims and 11,271 acres of fee land with mineral rights (in the table below and as listed in Appendix B). A generalized land status map depicting the 2012 coverage is shown in Figure . All Jerritt Canyon property claims expire on September 1, 2013 but are always renewed every year by filing the necessary paperwork and claim fees with the BLM and the County. Estimated costs to maintain the 2,851 Veris-owned claims are $400,400 ($140 per claim), whereas the 278 leased claims are $38,920 (also at $140 per claim). Contributing author, Michele White, has reviewed the lease agreements and Jerritt claim map and finds them to be current and in good order. Additionally, a recent Title Opinion by Richard K. Thompson, November 15, 2012, supports a cohesive land package in compliance with Federal and State provisions for claim status with no issues.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 4-2 |

Table 4.3.1: Land and claim summary for Veris Gold USA’s Jerritt Canyon Project.

| Land Status | No. Claims | Acres |

| Owned Claims | 2,851 | |

| Leased Claims | 278 | |

| Total Claims | 3,129 | |

| Fee Land Owned | | 12,433 |

| Patented Claims Owned | | 1,011 |

| Fee Land Leased | | 11,271 |

| Total Acres | | 24,715 |

Veris controls more than 119 square miles of ground encompassing the mine area and surrounding acreage. The bulk of this is in the form of contiguous unpatented mining claims which are held in force by production from the mining activities. No production royalties are paid for gold deriving from these claims.

Some property is leased from landowners in the region, and a royalty is paid on production from these lands. The royalty for mined material in 2012 varied by location and was as much as 6 percent of net smelter return (NSR), the total cost of which is dependent upon the gold sale price and the refining results.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 4-3 |

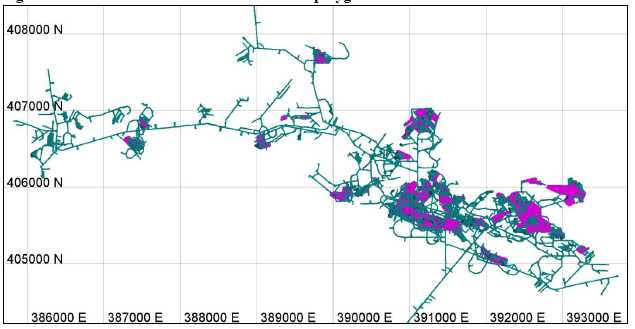

Figure 4.3.1: General location map of the Jerritt Canyon Mine.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 4-4 |

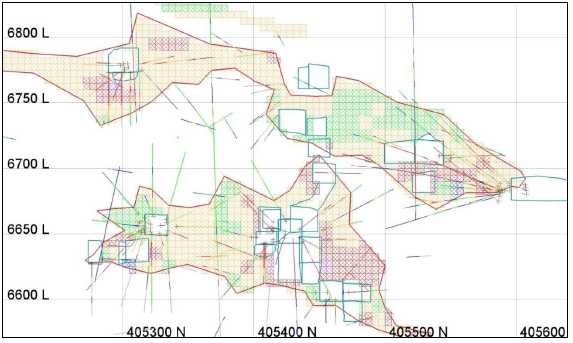

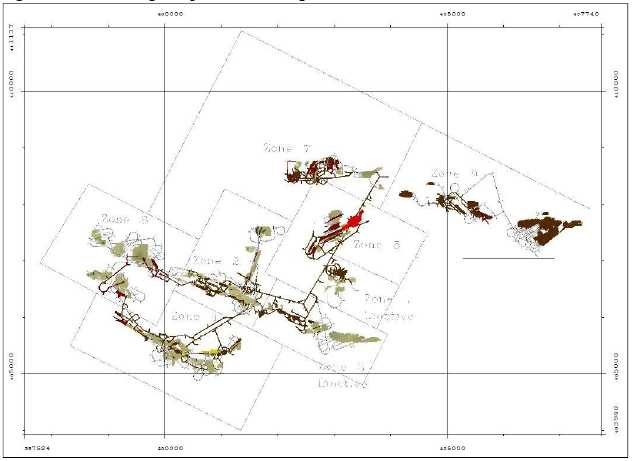

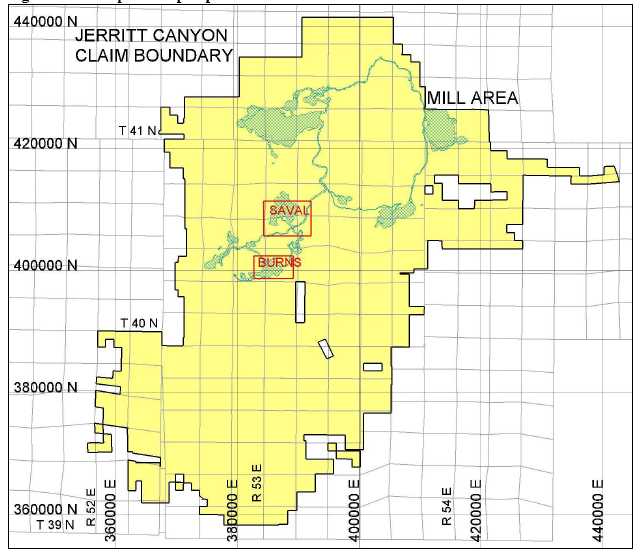

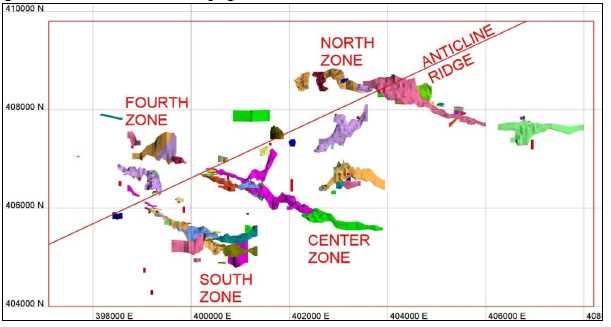

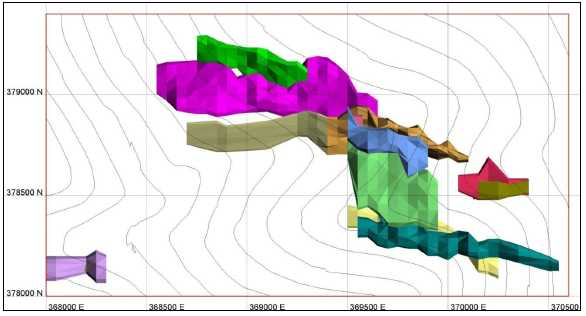

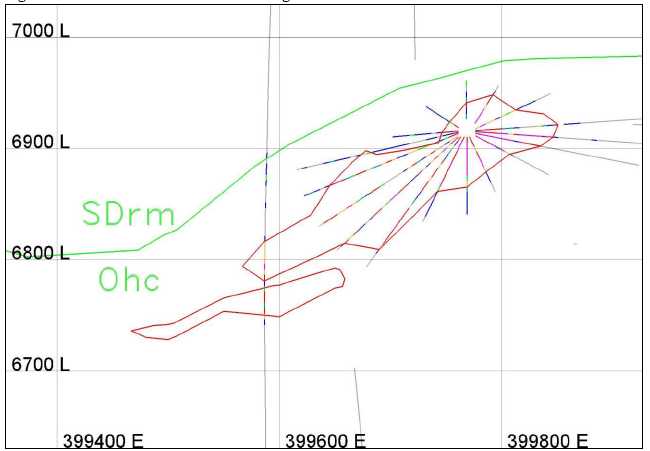

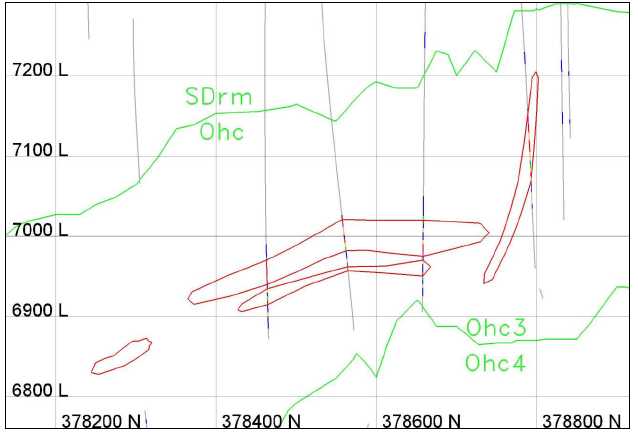

Figure 4.3.2: General land map of the Jerritt Canyon property with model areas.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 4-5 |

4.4 Location of mineralization

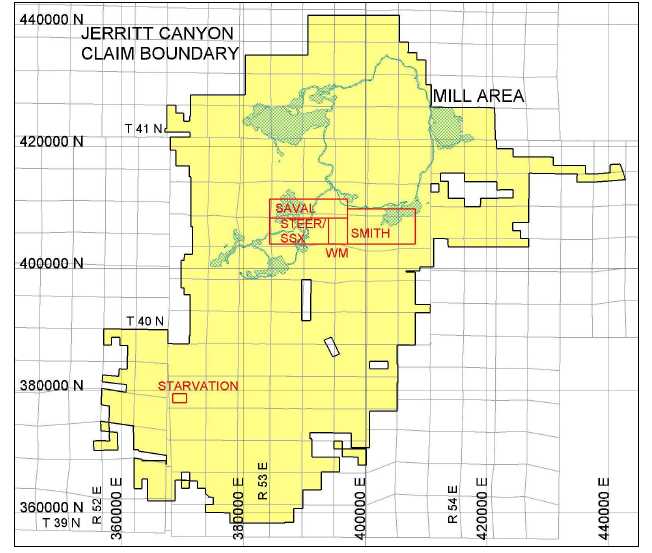

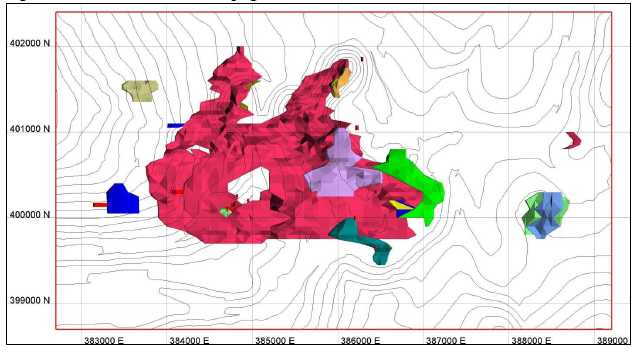

The resource and reserve areas and mine facilities are located within Veris owned or leased claims and fee land. Figure is a plan map showing the location of the property and claim boundary along with the model areas which contain the resources and/or reserves. The blue lettered areas are open pit models and the red numbered areas are the underground models.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 5-1 |

| 5 | Accessibility, climate, vegetation,physiography, local resources andinfrastructure |

5.1 Access to the site

The Jerritt Canyon Mine is located in Elko County, Nevada, approximately 50 miles north of Elko. Access to the property is by State Road 225 to the mine access road. The roads are paved and in excellent condition all the way to the main gate where the administrative offices, process plant, warehouse, and tailings impoundment are located. The mines are accessed by haul roads on VUSA controlled land.

5.2 Climate

The climate is temperate with winter temperatures between 0º and 40º Fahrenheit and summer temperatures between 35º and 90º. Average annual precipitation at the tailings impoundment is estimated at 14 inches per year with an estimated annual average evaporation of 43 inches. A significant amount of the total precipitation falls as snow and increases with elevation to the mining areas. Mine operations are only rarely halted by weather conditions, although ore haulage from the mines may be slowed. The mill, warehouse, shop, and administrative facilities are at a lower elevation and therefore are less exposed to weather extremes. Snowfall is generally common from the months of December to May.

5.3 Vegetation

The vegetation is typical of the Basin and Range province with sagebrush vegetation dominant at the lower elevations. Small stands of aspen and isolated fir trees grow in canyons and drainages.

5.4 Physiography

Jerritt Canyon Mine is located in the Independence Mountain Range in the Basin and Range province of northern Nevada. The topography ranges from about 6,400 feet at the administrative facilities and mill site to about 8,000 feet at the highest point of the haul road to the mines.

5.5 Local resources and infrastructure

Elko, Nevada with a population of 18,300 is the closest city to the mine. The city is on Interstate 80 and is serviced by daily commercial flights to Salt Lake City, Utah. Elko is a center for the mining operations in northern Nevada and services necessary for the mine are readily available there. The local population, along with the proximity of the other nearby cities (e.g. Salt Lake City in Utah and Battle Mountain, Winnemucca, Fernley, Fallon, Reno in Nevada) is large enough to supply most of the workers and supplies for all of the mines in the area.

Power to the mine site is purchased from Nevada Energy through a 125kV, 3-phase transmission line. Cost of electrical power is approximately US$0.066/kWh.

A new natural gas pipeline has recently been installed to the south of the property by another company. Veris is examining opportunities to use natural gas to help power some of the mine facilities.

There are sufficient supplies of water at the site to allow the processing facility and other mine facilities to efficiently operate. Approximately 700 gallons per minute (gpm) of water is required to operate the mill with two primary water sources: (1) a “dirty” water source consisting of the tailings storage facility 1 (TSF-1) seepage collection system that has contributions from 90 small diameter water wells around the TSF-1, four seepage collection trenches, and three embankment blanket drains that collectively produce 1,000 gpm; and (2) a cleaner water source from two deep water wells that are each capable of producing 500 gpm. A third deep water well exists at the property but is currently not operating. Once the TSF-1 is decommissioned and reclaimed, the additional necessary water sources for the mine facilities will come from the deep well sources and/or underground mine dewatering. All waters used at the Jerritt Canyon Mine are from permitted and certificated water rights held by Veris and regulated by the Nevada Division of Water Resources.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 5-2 |

There is sufficient room to place additional wastes on the property from future mining operations based on the existing claims owned by Veris. In addition, there is sufficient space to place the planned Tailings Storage Facility 2 (TSF-2) and Water Storage Reservoir (WSR) to the south of the existing tailings storage facility and existing evaporation pond (see Figure 18.6.1) .

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 6-1 |

6 History

6.1 Mining history

Prospectors explored for antimony in the 1910’s.Thirty to forty tons of stibnite as antimony ore were reportedly mined and shipped from the Burns Basin mine in the Jerritt Canyon district between 1918 and 1945. In the early 1970’s there was a renewed interest in antimony exploration when its price reached historic highs of $40 per pound. Around 1971, FMC began exploring for antimony in the Independence Mountains. In 1972, FMC, later known as Meridian Gold, discovered a disseminated gold deposit in the Jerritt Canyon area. In 1976, a joint venture was formed with Freeport Minerals Company to explore and develop the area, and mining commenced at Jerritt Canyon in 1981.

Open pit mining was conducted at the site from startup in 1981 until 1999. The first underground operation at Jerritt Canyon started up in 1993 at West Generator. Subsequently, five different underground mines have been operated at Jerritt Canyon over the years. West Generator Murray and MCE are now closed. Underground mining at the SSX-Steer complex started in 1997, was temporarily stopped in August 2008, and was restarted in October 2011. Underground mining at Smith started in 1999, was temporarily stopped in August 2008, and reopened in February 2010. The MCE underground mine was shut down in 2004, whereas the Murray underground mine was shut down in 2006. The new Steer mine portal, now a part of the SSX complex, was constructed in 2004.

6.2 Production history

Historic Jerritt Canyon open pit and underground mining production is shown in Table 6.2.1. Open pit mining was conducted at the site from startup in 1981 until 1999. The first underground operation at Jerritt Canyon started up in 1993 at West Generator. Subsequently Underground Mining was initiated at Murray, SSX, MCE and Smith. Currently only the Smith and SSX mines are operating.

On August 8, 2008, VG management decided to shut down mining operations due to increasing costs associated with the mine plan, required infrastructure expenditures that remained to be completed, and environmental concerns that remained to be addressed. The plan to continue toll milling after the shutdown of the mines was halted to complete repair work at the process mill. As a result, the workforce at Jerritt Canyon was reduced to maintenance levels while the Company undertook discussions with the Nevada Department of Environmental Protection (NDEP) to obtain permission to restart the facility and sought additional financing to fund the recommencement of operations. In order to obtain authorization to restart, the NDEP required detailed plans on how the aforementioned concerns would be addressed. On October 20, 2009, with these detailed plans in place and approved by the NDEP, and many already completed, Queenstake was able to restart operations under a Consent Decree order issued by the Attorney General of the State of Nevada, representing the NDEP. To address the environmental concerns, Queenstake (now VUSA) completed the installation of a calomel emission system on July 20, 2009 which is used to control mercury emissions. Queenstake also carried out significant overhauls and upgrades of many key components of the roaster, leach circuit, thickener, and other sections of the mill. New technical staff was hired in 2009 with directives to design a new mine plan. Underground mining at Smith recommenced in late January 2010 using contract miner Small Mine Development (SMD). Underground mining at SSX-Steer Complex recommenced in early October using Queenstake staff. Ore materials from Jerritt Canyon that currently feed the processing facility include underground ore from the

Smith Mine and stockpile materials that are either called remote or mill. The “remote” stockpiles are located in piles away from the processing facility and require hauling to the process plant while the “mill” stockpiles are located near the processing facilities.

Since its inception from July 1, 1981 to year-end 2012, the Jerritt Canyon Mill has produced 7.97 million ounces of gold. Annual production has historically averaged between 125,000 and 350,000 ounces of gold, at historical cash costs ranging from $240 to $554 per ounce. Veris internal reports indicate the total 2012 and 2011 mill production from Jerritt Canyon ores (including Jerritt Canyon stockpile and Newmont ores at 978,262 and 599,555 dry tons containing 105,627 and 73,823 ounces, respectively.)

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 6-2 |

Veris records indicate the 2010 and 2008 mill production from Jerritt Canyon ore (including Jerritt sourced stockpiles) at 628,418 and 224,618 tons with 89,238 and 32,131 ounces of recovered gold attributed to the operation respectively. Cash operating costs were high in 2008 due to mill shut downs in the early part of the year and the mine shut down on August 8, 2008.

Table 6.2.1: Historic open pit and underground mine production at the Jerritt Canyon before recovery losses.

Open Pit Deposit

Name | Years in Operation

| Mined Tons

(short) | Gold Grade

(oz/st) | Ounces(2)

(contained) |

| Marlboro Canyon | 1981-1990 | 5,798,600 | 0.241 | 1,400,045 |

| Alchem | 1991-1994 | 1,657,600 | 0.098 | 162,621 |

| L. North Gen. Hill | 1980-1993 | 1,226,000 | 0.192 | 235,461 |

| U. North Gen. Hill | 1980-1993 | 7,636,300 | 0.170 | 1,298,308 |

| West Generator | 1986-1993 | 3,979,000 | 0.155 | 616,647 |

| Burns Basin | 1988-1998 | 2,441,800 | 0.169 | 412,328 |

| Mill Creek | 1992-1994 | 895,700 | 0.121 | 108,270 |

| Pattani Springs | 1988-1990 | 387,000 | 0.108 | 41,896 |

| California Mtn. | 1993-1994 | 410,300 | 0.162 | 66,341 |

| Dash | 1996-1999 | 1,906,100 | 0.221 | 420,789 |

| Winter’s Creek | 1992-1995 | 1,243,700 | 0.126 | 156,317 |

| Steer Canyon | 1994-1997 | 477,300 | 0.132 | 63,004 |

| Saval Canyon | 1994-1997 | 1,741,900 | 0.126 | 218,682 |

| Subtotal | 1980-1999 | 29,801,300 | 0.175 | 5,200,709 |

| | | | | |

Underground Mine

Production | Years in Operation

| Mined Tons

(short) | Gold Grade

(oz/st) | Ounces(2)

(contained) |

| SSX | 1997-2008; 2011; 2012 | 4,715,693 | 0.281 | 1,327,025 |

| Steer | 2004-2006 | 68,174 | 0.233 | 15,879 |

| MCE (formerly Papillion) | 1997-2004 | 258,295 | 0.369 | 95,359 |

| Murray | 1997-2006 | 3,780,795 | 0.330 | 1,248,777 |

| Smith | 1999-2008; Jan. 2010-YE2012 | 2,024,882 | 0.239 | 483,737 |

| West Generator | 1993-1997 | 460,100 | 0.235 | 108,108 |

| Saval | 2004-2006 | 3,500 | 0.495 | 1,730 |

| Subtotal | 1993-YE2012 | 11,311,439 | 0.290 | 3,280,615 |

| | | | | |

| Grand Total | 1980-YE2012 | 41,112,739 | 0.206 | 8,481,324 |

| (1) | Abbreviations: st = short ton; L. = Lower; U = Upper; Mtn. = Mountain; YE = Year-End; |

| (2) | Contained ounces do not include metallurgical recovery; |

| (3) | Gold production from open pit mining at Jerritt Canyon started in July of 1981 at the Marlboro Canyon and North Generator Hill pits; |

| (4) | The last major open pit mine production was from Dash which was mined from 1996 to 1999; |

| (5) | Steer is included in with SSX starting in 2006; |

| (6) | Steer and Saval underground mining time period not discriminated; |

| (7) | Underground test mining began in September 1991 at the Phase 1 Test Project in the high-wall of the West Generator open pit; |

| (8) | The wet mill closed down in February 1997; the fluid-bed roaster started in 3rdquarter of 1989; |

| (9) | Production records above do not show later mining of various low grade stockpile ores; |

| (10) | Data compiled from internal Mine records and Jones (2005). |

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 6-3 |

6.3 Historical mineral resource and reserve estimates

The measured and indicated mineral resources, including reserves, at Jerritt Canyon during VUSA’s ownership, as documented in NI 43-101 filings are given below.

Table 6.3.1: Historic measured and indicated mineral resources, including reserves.

| | Measured | Indicated | Measured + Indicated |

| Year | | | koz | | | koz | | | koz |

| (Year-End) | kt | opt | Au | kt | opt | Au | kt | opt | Au |

| 2003 | 2,219.3 | 0.306 | 679.7 | 7,277.6 | 0.222 | 1,615.7 | 9,496.9 | 0.242 | 2,295.3 |

| 2004 | 2,263.0 | 0.287 | 650.1 | 7,724.8 | 0.228 | 1,759.5 | 9,987.8 | 0.241 | 2,409.6 |

| 2005 | 3,094.6 | 0.281 | 869.7 | 5,717.4 | 0.212 | 1,209.4 | 8,812.0 | 0.236 | 2,079.1 |

| 2006 | 2,573.9 | 0.272 | 700.1 | 5,629.3 | 0.214 | 1,207.1 | 8,203.2 | 0.232 | 1,907.2 |

| 2007 | 2,626.0 | 0.269 | 706.1 | 5,570.9 | 0.225 | 1,255.0 | 8,196.9 | 0.239 | 1,961.1 |

| 2010 | 4,549.9 | 0.236 | 1,073.1 | 6,459.5 | 0.204 | 1,316.8 | 11,009.4 | 0.217 | 2,389.9 |

| 2011 | 4,906.8 | 0.210 | 1,030.7 | 7,382.7 | 0.175 | 1,288.5 | 12,289.5 | 0.189 | 2,319.2 |

Notes: data relates to historic measured and indicated resources during VUSA’s ownership since 2003 and is from historically published NI 43-101 reports: Odell et al. (2012); Johnson et al. (2011; 2012); Pincock Allen and Holt (2004; 2005) and SRK Consulting (2006; 2007; 2008).

Historic inferred resources are listed below.

Table 6.3.2: Historic inferred mineral resources.

| | Inferred |

| Year | | | koz |

| (Year-End) | kt | opt | Au |

| 2003 | 5,415.4 | 0.191 | 1,034.0 |

| 2004 | 4,058.7 | 0.219 | 888.4 |

| 2005 | 2,646.5 | 0.229 | 605.6 |

| 2006 | 2,414.8 | 0.226 | 545.2 |

| 2007 | 2,319.7 | 0.224 | 520.4 |

| 2010 | 3,872.6 | 0.194 | 751.3 |

| 2011 | 4,115.7 | 0.182 | 748.4 |

Notes: Data relates to historic inferred reserves during VUSA’s ownership since 2003 and is from historically published NI 43-101 reports: Odell et al. (2012); Johnson et al. (2011; 2012); Pincock Allen and Holt (2004; 2005) and SRK Consulting (2006; 2007; 2008).

The historic proven and probable reserves at Jerritt Canyon during VUSA’s ownership, as documented in NI 43-101 filings are given below.

Table 6.3.3: Historic proven and probable mineral reserves.

| | Proven | Probable | Proven + Probable |

| Year (Year- | | | koz | | | koz | | | koz |

| End) | kt | opt | Au | kt | opt | Au | kt | opt | Au |

| 2003 | 932.8 | 0.299 | 279.0 | 2,132.4 | 0.254 | 541.1 | 3,065.3 | 0.268 | 820.1 |

| 2004 | 760.5 | 0.271 | 206.3 | 2,750.1 | 0.243 | 669.1 | 3,510.6 | 0.249 | 875.4 |

| 2005 | 1,211.3 | 0.257 | 311.7 | 2,511.7 | 0.225 | 566.2 | 3,723.0 | 0.236 | 877.9 |

| 2006 | 636.1 | 0.273 | 173.8 | 1,348.8 | 0.231 | 312.0 | 1,984.9 | 0.245 | 485.7 |

| 2007 | 653.4 | 0.229 | 149.9 | 2,501.8 | 0.227 | 567.4 | 3,155.2 | 0.227 | 717.3 |

| 2010 | 1,406.1 | 0.193 | 270.9 | 2,959.7 | 0.151 | 446.0 | 4,365.8 | 0.164 | 717.0 |

| 2011 | 1,980.2 | 0.189 | 374.8 | 4,076.7 | 0.168 | 686.0 | 6,056.9 | 0.175 | 1,060.8 |

Notes: Data relates to historic proven and probable reserves during VUSA’s ownership since 2003 and is from historically published NI 43-101 reports: Odell et al. (2012); Johnson et al. (2011; 2012); Pincock Allen and Holt (2004; 2005) and SRK Consulting (2006; 2007; 2008).

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 6-4 |

The aforementioned resources and reserves since 2003 have been prepared by Qualified Persons employed by Pincock, Allen and Holt, SRK Consulting, Practical Mining LLC, and Veris and are therefore viewed by the primary author of this report, Todd Johnson (QP), as being reliable and relevant. It is apparent that the historical proven and probable reserves documented every year in the NI 43-101 reports since 2003 range from 1,984.9 to 6,056.9 kt. It is also recognized that the measured and indicated resources documented every year in the NI 43-101 reports since 2003 range from 8,196.9 to 12,289.5 kt.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 7-1 |

7 Geological setting and mineralization

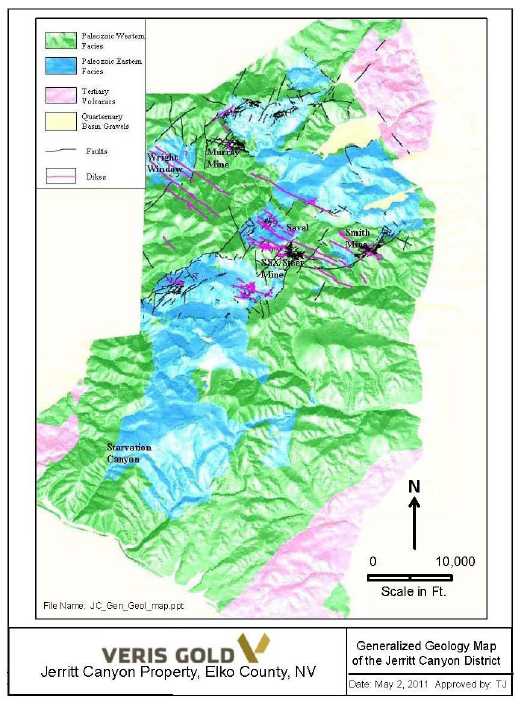

7.1 Regional geology

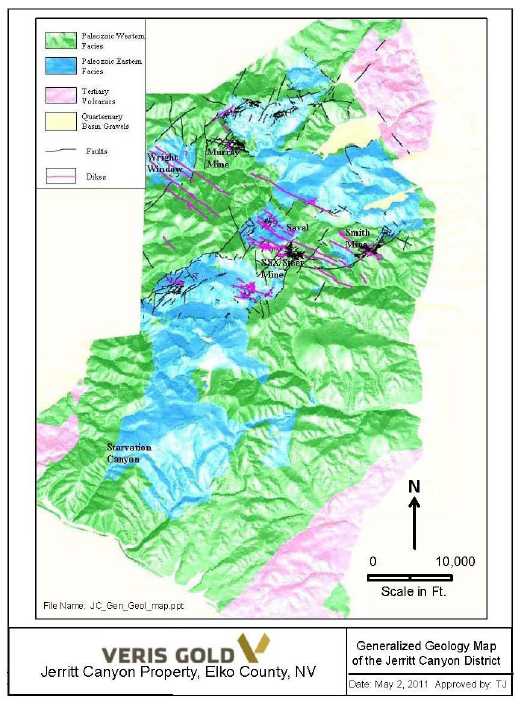

The Jerritt Canyon mining district is located in the Independence Mountain Range in northern Nevada. The range is part of the Basin and Range province of Nevada and is a horst block consisting primarily of Paleozoic sedimentary rocks with lesser Tertiary volcanic rocks and intrusive dikes. A district geologic map is shown in Figure 7.1.1 and a stratigraphic column is shown in Figure 7.1.2. Much of this data was previously presented in other published reports (Jones, 2005; McMillan, 2005; Daly et al., 1991) and is still considered to be relevant.

Contributing author of this report, Michele White, has reviewed the geological information in the drill hole databases and finds the geological determinations in the logs to be adequate for use in geological modeling of the resource areas and also deems them adequate for use in the present resource and reserve work.

There are four distinct Paleozoic sedimentary assemblages in the district characterized by their position relative to the Roberts Mountains thrust, a Devonian to Mississippian structure formed during the Antler orogeny:

The western facies, or upper plate of the thrust, consists of the Cambrian to Ordovician Valmy Group and forms about 70% of the exposed rock. In the Jerritt Canyon district, the Valmy Group consists of the Snow Canyon formation, a chert, argillite, greenstone, and carbonaceous siltstone sequence, and the McAfee Quartzite, a sequence of massive quartzite and shale;

The eastern facies, or lower plate of the thrust, consists of a sequence of Ordovician to Devonian shallow water sedimentary rocks that are exposed in tectonic and erosional windows through the upper plate. The gold mineralization in the district is contained with the eastern facies rocks. The Pogonip Group rock is exposed in the west-central part of the district and is composed of fossiliferous limestone with calcareous shale and dolomite interbeds. The Eureka Quartzite is a massive quartzite with minor interbeds of siltstone. The Hanson Creek Formation is one of two principal ore hosts in the district. It is divided into five units, with the contacts between the units being the favorable sites of gold mineralization. The Hanson Creek consists of interbedded silty limestone, calcareous siltstone, dolomite, chert, and carbonaceous limestone. The Roberts Mountains Formation is the second ore host and consists of calcareous, carbonaceous siltstone and thinly bedded, silty limestone. The Waterpipe Canyon formation is thought to have been deposited in a synkinematic foreland basin that formed during the Antler orogeny; it consists of carbonaceous shale with interbedded greywacke, chert pebble conglomerate, bedded chert, sandstone, and siltstone;

The Schoonover sequence occurs north of the district and consists of basaltic and andesitic greenstone, chert, tuff, volcaniclastics, and siliciclastic and limestone turbidites of Devonian to Permian age; and

The Antler overlap sequence is restricted to the north end of the range and consists of conglomerates, argillite, siltstone and limestone.

The Paleozoic sequences are cross-cut by Pennsylvanian basalt dikes, Eocene basalt-quartz monzonite dikes, and Miocene basalt dikes. The Pennsylvanian and Eocene basaltic dikes are altered and mineralized in most of the mines.

The structural fabric in the district consists of two dominant fault trends, west-northwest trending and north-northeast-trending.

| Veris Gold Corp. | |

| NI 43-101 Technical Report Jerritt Canyon Property, Nevada | 7-2 |

The geological chronology of regional structural event important to deformation and mineralization of rocks in the Jerritt Canyon district is complex with several regional deformation events being evident in the mines. The Devonian to Mississippian Antler orogeny, resulting from west to east compression, is represented in the upper plate Snow Canyon Formation with north-south folds in both the hanging wall and footwall of the thrust. The Permian to Triassic Sonoma orogeny emplaced the Golconda allochthon over parts of the Roberts Mountains allochthon to the north of the district. The northwest to southeast compression associated with this deformation is rarely seen in the district. The Jurassic to Cretaceous Nevadan orogeny resulted in east-west folds that are often associated with mineralization.

| Veris Gold Corp. | |