The various steps taken by Exeter to ensure the integrity of analytical data are consistent with standard industry practice. The sampling procedures are appropriate for the style of mineralization and structural controls for the Caspiche Project. Cube’s examination of drill cores, particularly in regard to the recognition of mineralized intervals, verified the soundness of the core sampling procedure.

Exeter conducts comprehensive internal and external validation of its databases, both in hard copy and electronic format. Drill collars are professionally surveyed and independent audits are encouraged. All laboratory results are checked by a qualified geologist before loading into the database and again at regular intervals for long term trends.

Comprehensive external database audits have been conducted several times during the period October 2008 to September 2011. AMEC has audited the Exeter Caspiche mineral resource database on four occasions during January 2009, August 2009, January 2010 and August 2010. The AMEC database audits have included checking of collar, survey, lithology, stratigraphic unit, alteration, oxidation and assay data against original logging sheets and assay records. In addition to database auditing, AMEC has checked the location of drill holes in the field, and sampled and assayed select drill core intervals during their site visit in October 2008.

AMEC performed four audits of the Caspiche mineral resource database during the period October 2008 to August 2010 and found that it was adequately free of data entry errors and determined that it was acceptable for use in mineral resource estimation (Wakefield and Marinho, 2009a, 2009b, 2010, and Tolman and Perkins, 2010).

At the end of the 2010 drill season, Exeter performed an internal database audit on all hard copy and electronic data and determined that no significant data entry problems existed.

In August 2010, AMEC performed an audit of Caspiche drilling data received since the effective date of the previous mineral resource estimate for the Property. No significant errors were found in the mineral resource database in collar, survey, lithology, stratigraphic unit, alteration or oxidation in data entry from original logs. A selection of assay records in the database were checked against the original assay certificates and no errors were found.

Cube undertook an extensive verification of the drill holes database whilst in Exeter’s Copiapó office in Chile. Database verification included:

Exeter routinely uses a professional surveyor to determine the exact position of drill hole locations. Drill hole collar locations are surveyed using a Leica TC 600 total station unit with centimetre accuracy using the Instituto Geográfico Militar 26° to 36° transform.

Drill hole locations were verified during an October 2008 site visit to the property by AMEC who collected handheld GPS location readings for seven drill hole locations in the Caspiche Porphyry area to verify the accuracy of the drill hole coordinates in the mineral resource database. An additional three holes were surveyed by Cube in September 2011 with a hand held Garman 76Cx GPS unit. A comparison between Exeter surveyed drill hole locations and GPS location readings are shown in Table 12.1.

Significant differences were noted between the Exeter surveyed drill hole locations and GPS collar coordinates. Handheld GPS coordinates were collected using the PSAD56 datum, which is a general transform that can vary up to 50 m from the more precise Instituto Geográfico Militar 26° to 36° transform used by Exeter (Galaz, 2008). AMEC compared Exeter surveyed collar locations with drill pads on geo-referenced digital images, and found the collar locations to be acceptably accurate (Wakefield and Marinho, 2010).

AMEC, during their October 2008 site visit, selected six Exeter drill hole intervals for check assaying to confirm the presence of gold and copper in the Caspiche drill core (Wakefield and Marinho, 2009a). Mineralized intervals at various depths were selected from the three most relevant drill holes available at the time (CSD014, CSD015, and CSD016). Exeter split (sawn quarter-core), sampled, and bagged the core under AMEC supervision and AMEC submitted the samples to ACME Laboratories in Santiago, Chile, for assaying. ACME assayed gold by standard 30-g fire assay and atomic absorption finish (ACME code G6), and copper by four-acid total digestion and atomic absorption (ACME code 8TD).

Table 12.2 is a summary of the ACME check sampling of Caspiche drill core, and shows the assay results from the original Exeter half-core sampling and the AMEC quarter-core sampling. A single SRM submitted with the check samples reported good assay accuracy for gold and copper.

The assay results shown in Table 12.2 confirm the presence of gold and copper in Exeter Caspiche drill core. AMEC assay results also agree reasonably well with Exeter assay results.

Rio Tinto undertook a review of the Caspiche project in October 2008. As part of this review, Rio Tinto took six samples of drill core coarse reject material for metallurgical testwork. The samples were selected to be representative of a variety of alteration styles occurring at Caspiche. A comparison of drill hole intercept grades and metallurgical testwork head grades are presented in Table 12.3. In general, there is very good agreement between the metallurgical testwork head grades and the drill hole assay grades as recorded in the drill hole database.

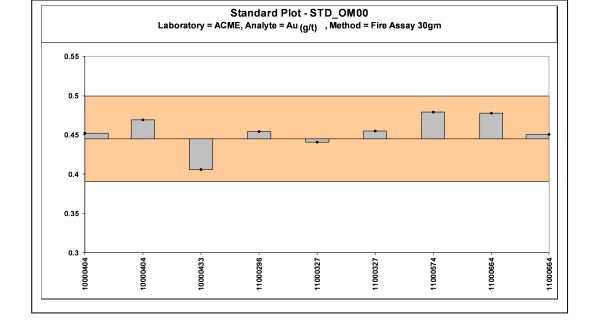

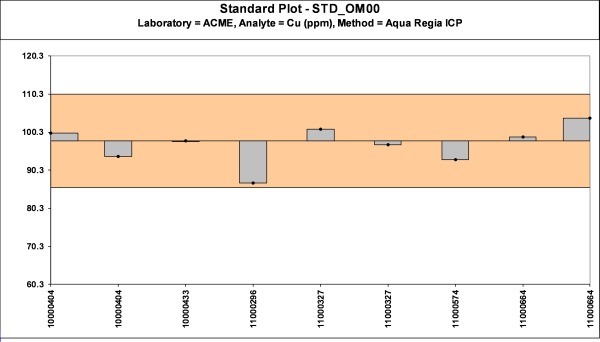

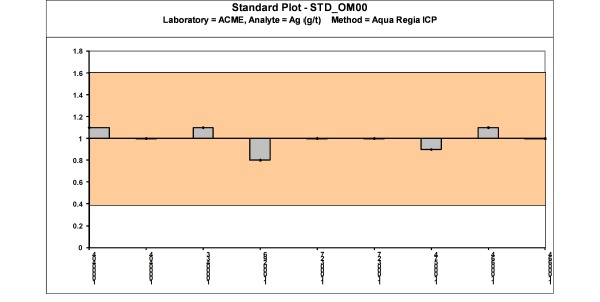

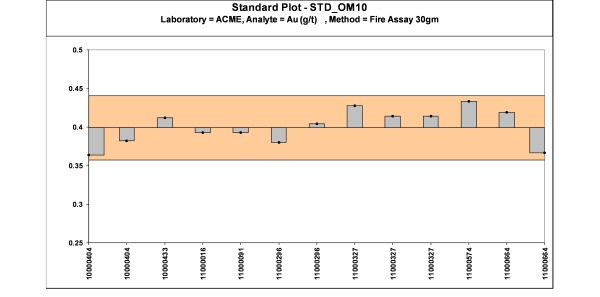

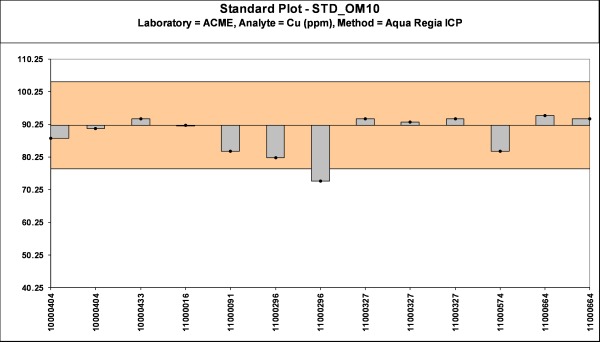

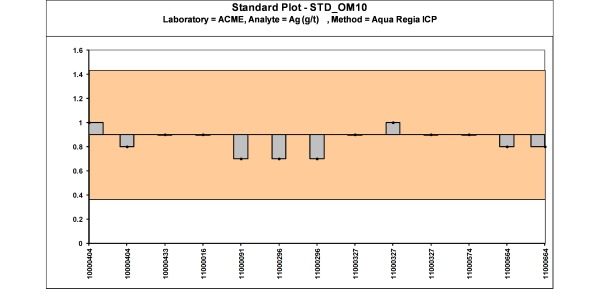

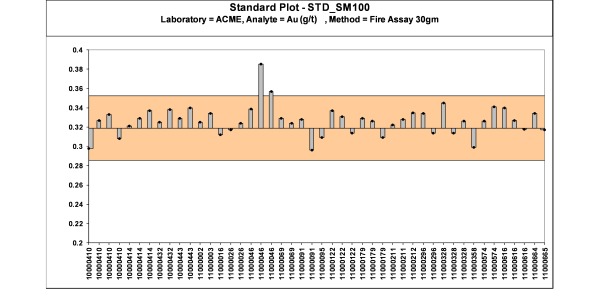

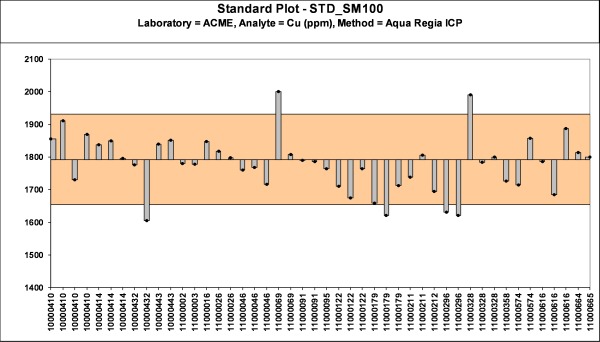

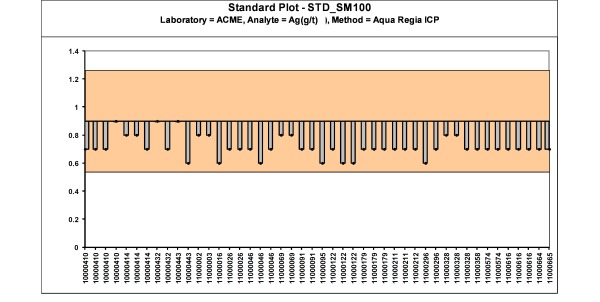

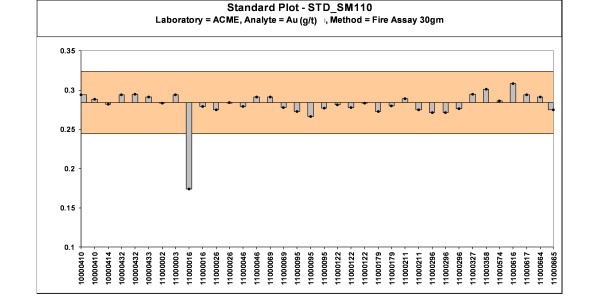

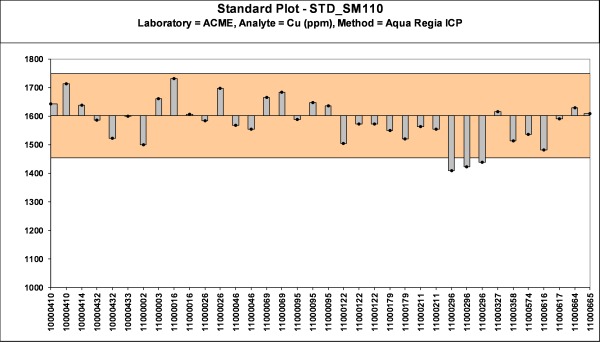

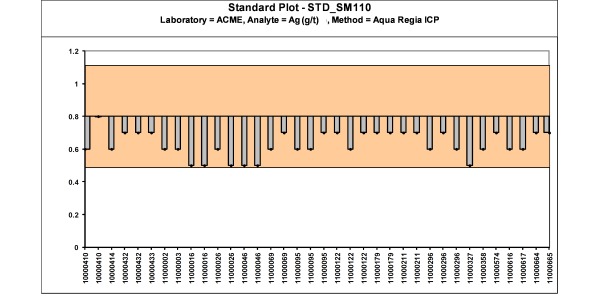

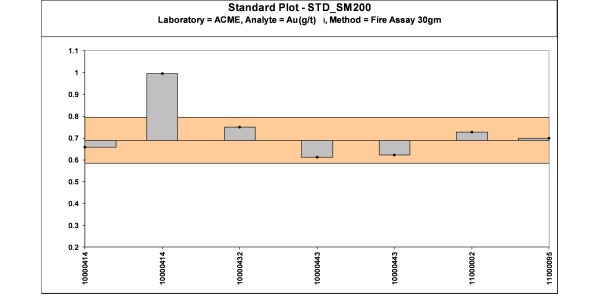

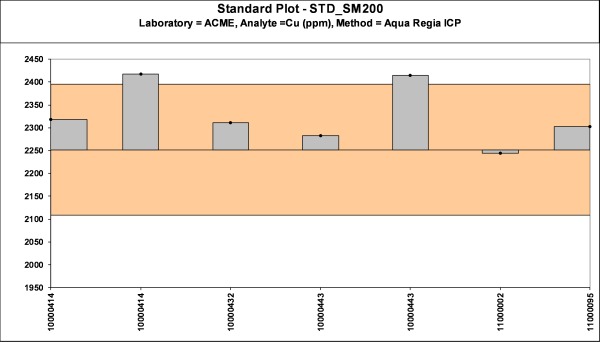

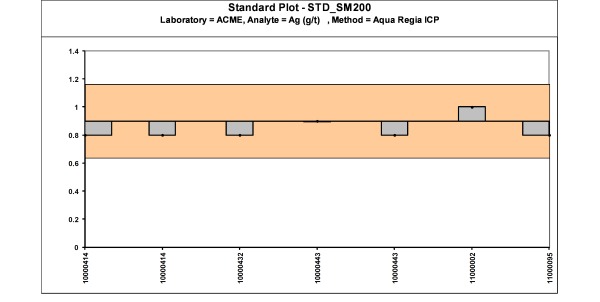

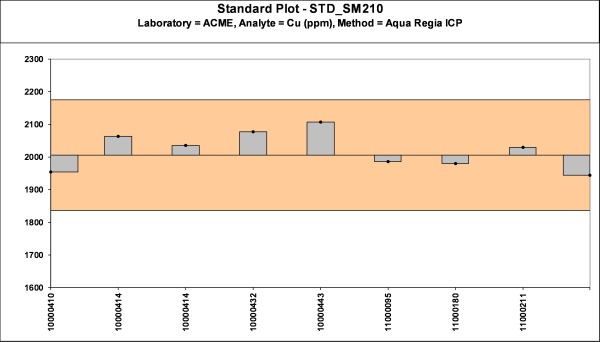

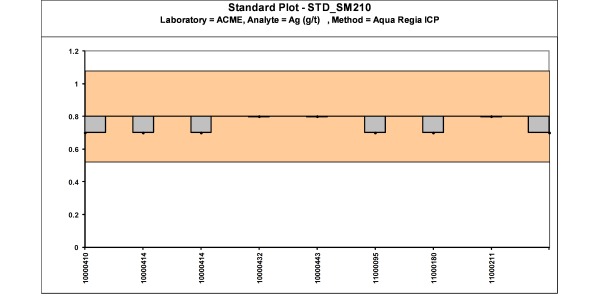

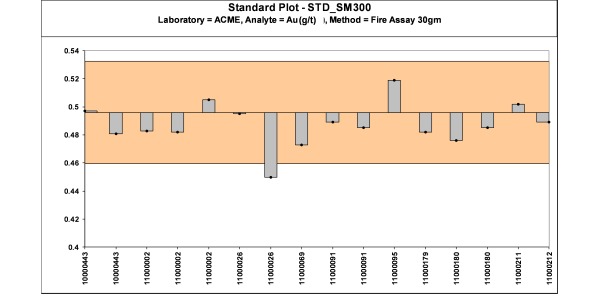

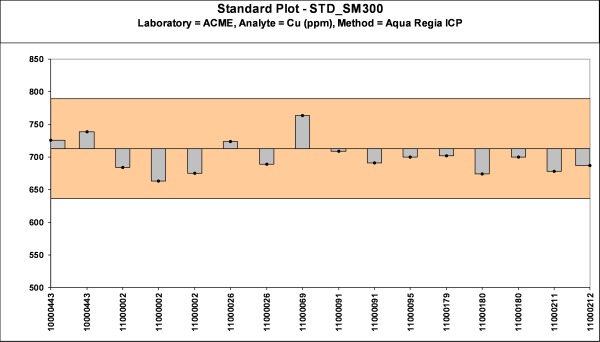

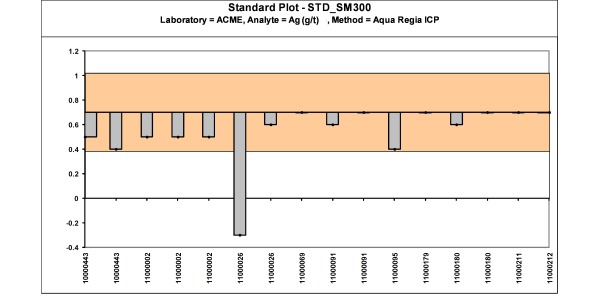

Geochemical Standard Reference Material (SRM’s) has been used by Exeter in all drilling programmes at Caspiche. During the period January 2008 to September 2011, SRM’s and blanks have been inserted at rates varying between 1 in 25 to 1 in 40 samples. The majority of SRM’s are provided by Geostats Pty. Ltd. (“Geostats”) of Australia. Exeter has also

produced and characterised some SRM’s based on representative Caspiche mineralized material. To date, a total of 928 gold SRM’s have been submitted from 28 different standards with recommended assay values varying from 0.24 to 2.14 Au ppm. In addition, a total of 169 copper SRM’s have been submitted from 7 different standards with recommended assay values varying from 90 to 2,252 Cu ppm

Cube undertook a review of all SRM results for the entire period between January 2007 to September 2011. During this period, the majority of gold and copper SRM's performed within the expected limits with 93 % and 92 % being within two standard deviations of the expected value respectively. Cube made selected random checks of the database for SRM values that were outside two standard deviations of the expected value and noted that in all cases Exeter had highlighted these for follow-up.

In general, blanks showed acceptable performance with only 11 values exceeding 0.03 Au ppm and only 1 value exceeding 0.09 Au ppm.

Cube is of the opinion that Exeter has implemented and continues to maintain a well managed and robust QA/QC program and there does not appear to be evidence of systematic error or material bias.

Exeter conducted selected confirmation drilling of Anglo drilling (two holes) and Newcrest drilling (four holes).

Exeter confirmation drilling of Anglo drilling revealed a slight high-bias, on average, in the Anglo gold assays, however the thickness of the intercepts are approximately equal. Anglo copper assays are, on average, unbiased when compared to Exeter confirmation drilling intercepts. Exeter confirmation drilling of Newcrest drilling showed that no significant bias exists, on average, in the Newcrest gold assays, and that the thicknesses of the intercepts are approximately equal. Newcrest copper and silver assays are, on average, unbiased when compared to Exeter confirmation drilling intercepts.

AMEC reviewed the results from all six twinned holes and concluded that the Exeter drilling confirms gold, copper, and silver grades (Newcrest only for silver) and thicknesses of both the Anglo and Newcrest drill intercepts. AMEC concluded that Anglo and Newcrest drill hole are acceptable for use in mineral resource estimation (Wakefield and Marinho, 2010). Cube briefly reviewed the twin data and concurs with the AMEC conclusion.

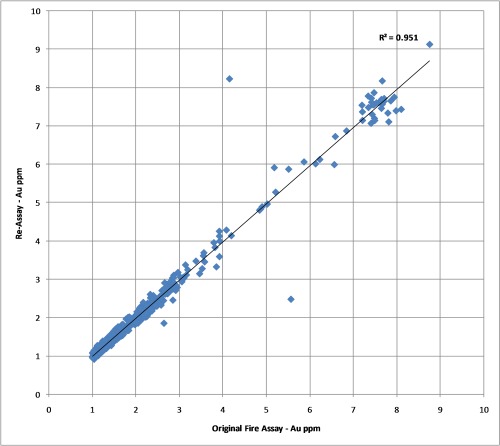

As part of the assaying procedure, samples that return significant gold values greater than 1-2 Au ppm, are routinely re-assayed with a second fire assay using the same method as the original assay. Figure 12.1 shows a scatter plot of the original assay versus the re-assay of all gold samples with an original grade of greater than 1 Au ppm, a total of 560 pairs, with one outlier removed. This comparison shows reasonable correlation indicating relatively low variability within the pulp sample. This re-assaying procedure also includes the geochemical standards.

Cube Consulting has undertaken reasonable endeavours to assess the veracity of drilling data for the Caspiche project. It can be concluded that all logging, sampling and data QA/QC procedures between January 2007 and September 2011 have been carried out to a high industry standard and record keeping and database management is excellent.

Cube believes that the current database provides an accurate and robust representation of the Caspiche project and is appropriate for use in mineral resource estimation.

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING |

This Item summarizes the metallurgical testwork undertaken and in progress. It discusses the nature and extent of the testing and analytical procedures and provides a summary of the relevant results. Additional information is provided where available on sample representivity on the different styles of mineralization and potential deleterious elements.

Prior to 2008, the only metallurgical testwork carried out on Caspiche mineralization was leaching testwork of a scouting nature on oxide samples. Exeter carried out bottle roll tests on reverse circulation (RC) drill chips from the discovery hole CSD 013 at SGS Santiago. Ten years earlier, Newcrest also carried out similar level scouting work on six intercepts at SGS Santiago. There were no records of any metallurgical work being carried out by Anglo. The test details of all these early metallurgical programmes were reported by Van Kerkvoort, Delendatti and Perkins, in the first Exeter NI 43-101 Technical Report, “Technical Report & Proposed Exploration for Caspiche Project, Region III, Chile” 26 April 2008, by Van Kerkvoort, G., Delendatti, G.L.A., and Perkins, J. (Section 27, References).

| 13.1.2 | Core Samples for Test Work |

The first Exeter test programme was carried out on RC chips because of the timing of CSD 013 at the very end of the first field drilling season prior to the Andean winter. It was decided that all future work would be carried out on drill core, and indeed from that time all drilling at the Caspiche Porphyry was with diamond core, with the exception of a minor amount of shallow RC precollars.

Following an examination of early assay statistics, Exeter geologists and metallurgists decided it would be prudent to make a preliminary split of coarse crushed (nominal 70 % passing 10 mm) half-drill core and store this material for future metallurgical test regimes. If future statistics indicated a nugget effect that would require finer crushing of all the half-core, this procedure would be reviewed.

In August 2008, Exeter selected drill-hole intervals from the Caspiche Porphyry oxide and sulphide mineralized intercepts for metallurgical test work. Six oxide and six sulphide intervals were selected and the stored coarse crushed material was appropriately assembled and sent to two laboratories.

| 13.1.3 | Preliminary Oxide Test Work |

Caspiche oxide mineralization appeared to lie as a relatively thick horizontal blanket with little to no copper content, averaging less than 0.01 %Cu or below the detection limit of the laboratory analyses. It was hoped that this material would be amenable to heap leaching as it was thought it would be very difficult to float any gold values into a concentrate.

McClelland Laboratories International (MLI) of Sparks, Nevada carried out bottle roll tests on each of the six oxide intercepts at the as received size and at a finer crush of 1.7 mm. The intercepts were then combined to form two composites classified as Andesite and Porphyry which provided sufficient material for a column leach test on both. Gold dissolutions of

Project No.: C-580 January, 2012 | Page 129 - 378 |  |

approximately 77 % and 84 % were achieved in 30 days of leaching with moderate reagent consumptions. Exeter considered these results to be encouraging for heap leaching the oxide blanket. The programme was reported in detail in the independent Amec NI 43-101 Technical Report, “Caspiche Property, Region III, Chile, NI 43-101 Technical Report, Prepared for Exeter Resource Corporation” dated 14 September 2009 by Wakefield, T. W., and Marinho, R.

There was little oxide mineralization encountered in the 2009 drill programme and a dedicated oxide drill campaign was planned for 2010 with the results described in 13.3 following.

| 13.1.4 | Preliminary Sulphide Test Work |

The first six sulphide intercepts were sent to G&T Metallurgical Laboratories in Kamloops, BC in August 2008. G&T and Exeter agreed that the preliminary testwork for Caspiche should examine a wide range of rock and alteration types for liberation and flotation characteristics, prior to compositing.

All six samples were subjected to detailed modal analyses and mineralogical investigation to identify probable primary and regrind sizes for a conventional porphyry copper circuit. Rougher flotation was examined using standard reagents and once performance was stabilized, concentrate samples were reground and three stages of cleaning carried out with the objective of producing a 25 %Cu concentrate grade. The variable presence of enargite (Cu3AsS4) was confirmed in all samples as a significant copper mineral.

Later, in July 2009, following the completion of the 2009 field programme, Exeter selected a further 14 sulphide intervals which were a mix of quarter core and coarse reject material, which in combination with the previous six, provided a broad and representative sample of the mineralization to depths greater than 1,000 m down hole. Characterization test work similar to the original six samples was completed at G&T in Kamloops, followed by a similar programme of flotation testing.

As might be anticipated, the results were variable. Final concentrate grades ranged from 18 %Cu to 35 %Cu with an average of 27 %Cu, and average recovery at this grade was 83 %Cu. Gold recoveries to rougher concentrates averaged 78 % but dropped sharply through the cleaner circuit to average 52 % in final concentrate. Enargite in final copper concentrates resulted in arsenic assays from 0.02 % to just under 10 % with an average of 1.6 %As. Arsenic is considered by most smelters to be a deleterious element in commercial copper concentrates, generally above levels of 0.01 %As. Antimony was also noted at levels close to levels where smelter penalties might be levied.

Centrifugal gravity testwork was also carried out on selected rougher tails to gauge potential for scavenging gold values. Even though the rougher tails gold values were very low, approximately 0.15 g/tAu, on some samples, there appeared to be some potential.

Flotation performance was interpreted to be more sensitive to changes in sulphur grade than the style of mineralization, and it was decided to form composites from retained material from the 20 intercepts based on sulphur content, and move to flowsheet and locked-cycle testing (LCT). The high and low sulphur samples (HS and LS) were further split into high and low arsenic (HA and LA) so that 4 composites in total were tested and designated, LSLA, LSHA, HSLA and HSHA.

Project No.: C-580 January, 2012 | Page 130 - 378 |  |

G&T carried out the detailed flotation programme on these composites in the first half of 2010 using slightly lower than normal dosage rates of conventional reagents. In the rougher flotation tests copper recovery averaged 90 % and gold recovery, 80 %. In general the results pointed toward a primary grind P80 of about 130 µm, a rougher pH of 8.5, a concentrate regrind P80 of about 20 – 25 µm, and an elevated cleaner pH of 11 – 11.5. Flotation conditions were varied but found to have a relatively small impact on performance.

The locked cycle tests confirmed that the high sulphur composites were more difficult to treat, with copper and gold recoveries averaging 85 % and 55 % respectively into a 24 %Cu concentrate. Arsenic grades were 0.6 % As and 2.2 % As for the low and high arsenic composites respectively. The low sulphur composites performed better with 87 % and 73 % gold being recovered into a 27 %Cu concentrate, with similar arsenic grades for the LA and HA samples.

G&T averaged the results of the four groups of LCTs but it is believed that this is not a good representation of the tests as the conditions between the tests were altered in an attempt to improve recovery and to some extent the concentrate grade.

The 8 LCT tests are summarized in Table 13.1. It can be seen that varying conditions did indeed change the results, particularly the copper concentrate grade, significantly in composites HSHA and LSLA. For all composites, high grade copper concentrates of at least 25 % Cu were achieved in all the tests except one.

Table 13.1: LCT Test Results at G&T

Test No | Composite | Copper | Gold | Arsenic |

| %Cu | %Cu Recv. | g/t Au | %Au Recv. | % |

| 47 | HS - HA | 30.0 | 82.0 | 68.7 | 52.1 | 3.3 |

| 51 | HS - HA | 16.5 | 88.6 | 43.3 | 59.2 | 1.7 |

| G&T Average | HS - HA | 20.2 | 84.9 | 50.9 | 57.9 | 2.3 |

| 29 | HS - LA | 27.3 | 83.3 | 30.5 | 47.2 | 0.4 |

| 39 | HS - LA | 28.3 | 84.4 | 32.0 | 56.4 | 0.7 |

| G&T Average | HS - LA | 27.8 | 84.6 | 31.6 | 52.0 | 0.6 |

| 13 | LS - HA | 33.5 | 86.1 | 79.4 | 69.9 | 3.2 |

| 37 | LS - HA | 24.7 | 87.5 | 57.0 | 71.2 | 2.6 |

| G&T Average | LS - HA | 27.9 | 86.7 | 65.9 | 72.4 | 2.9 |

| 20 | LS - LA | 25.1 | 88.6 | 64.8 | 72.6 | 0.6 |

| 38 | LS - LA | 30.4 | 90.4 | 73.4 | 75.5 | 0.6 |

| G&T Average | LS - LA | 26.8 | 89.1 | 67.2 | 72.7 | 0.6 |

Project No.: C-580 January, 2012 | Page 131 - 378 |  |

A number of gravity tests, using a laboratory scale Knelson concentrator and a super-panner, were carried out on all four composites. Negligible gold was recovered in all but one composite, HS – HA. In this composite, 10.4 % of the gold from flotation feed was recovered into a concentrate containing 33 g/t Au.

In view of lower gold recoveries in the high sulphur composites, in mid-2010 Exeter commissioned SGS Lakefield laboratories to carry out an independent test programme on residual sample of the two high sulphur composites. Despite different reagent suites and operators, very similar results were obtained.

The results from these two programmes were reported in more detail in the September 2009 Technical Report by AMEC and the September 2010 Technical Report by Tolman and Perkins.

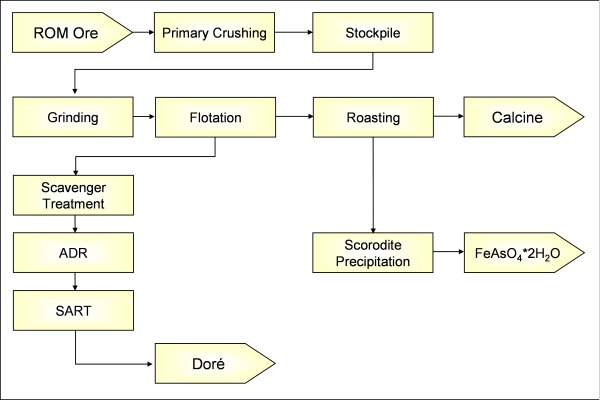

| 13.1.5 | Concentrate Treatment |

Exeter realized that Caspiche copper concentrates would almost certainly require further treatment to remove arsenic from final concentrates in order for them to be marketable. A large number of alternative treatment routes for arsenic removal either existed or were being developed. However, with the low copper grades encountered at Caspiche, it would be impractical to obtain sufficient concentrate from normal drill core samples to test more than one or two.

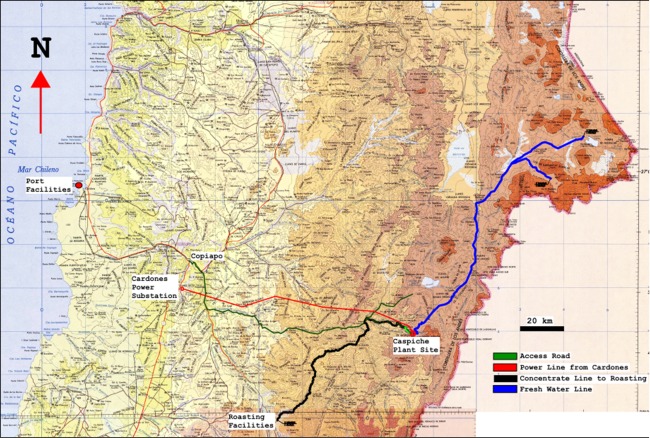

In 2009, SNC Lavalin Australia (SNC) was retained to review the appropriate technologies and select those most suited to Caspiche considering the concentrate characteristics and the physical location of the project. The basis was a hypothetical Caspiche concentrate based on flotation test results and hypothetical high and low altitude locations for treatment facilities. Reductive roasting was selected to remove arsenic and antimony and produce a saleable calcine product suited to existing custom copper smelters. Pressure oxidation was recommended as an alternative to allow cathode copper and doré gold to be produced directly; thereby bypassing the need to market concentrates. Testwork programmes were developed to confirm these two approaches.

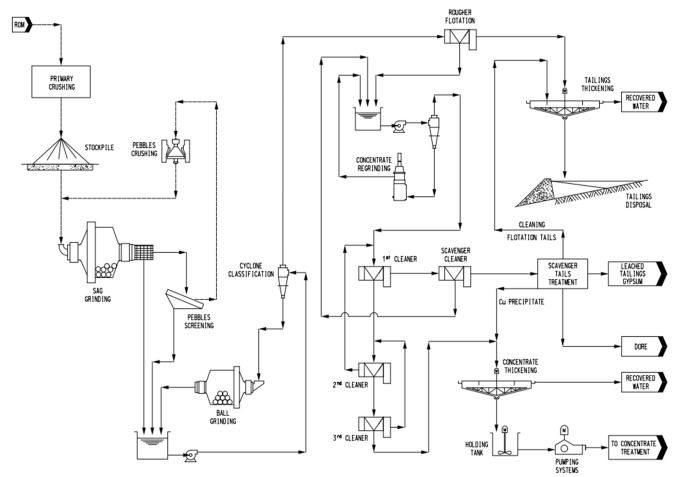

| 13.2 | Sulphide Mineralization |

Metallurgical testwork on mineralized sulphide material has continued and a number of programmes are ongoing as of the effective date of this report (see section 13.5).

| 13.2.1 | November 2010 Pilot Plant |

Initially, Exeter geologists and metallurgists selected and sent 91 intercepts and used 84 of these intercepts for the pilot plant blend that was considered representative of the sulphide mineralization. The selections included all rock and alteration types and extended from 200 m to over 1300 m down hole. In total, 8620 metres of mineralization was represented and the calculated head assay of the combined mass was 0.25 %Cu, 0.53 g/tAu, 2.05 %S and 0.03 %As. This assay approximates that of the overall reserves and in Exeter’s opinon confirmed the representivity of the pilot plant sample.

This material all existed as coarse -9.5 mm crushed core with a total weight of over 11 tonnes and was sent to SGS Lakefield in Canada. The prime objective of the pilot plant programme was to produce sufficient copper concentrate for roasting and pressure oxidation

Project No.: C-580 January, 2012 | Page 132 - 378 |  |

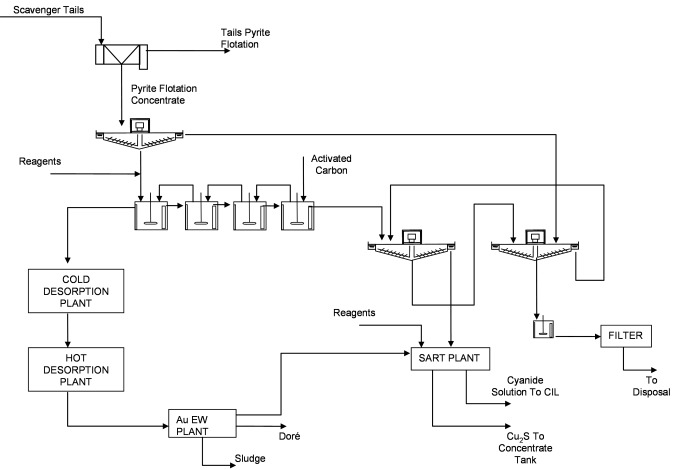

testwork, estimated at around 60 to 70 kg. In addition large quantities of other flotation products were collected, especially cleaner-scavenger tails which potentially represented a significant loss of gold from circuit. Cleaner scavenger tails samples were cyanide leached to test for gold recovery. A secondary but important objective was to test the flowsheet as developed. A third, equally important objective was to obtain plant design parameters on key process streams, for example rougher and cleaner tailings as well as the final concentrate.

Prior to the start of pilot plant operation, samples were split out for various physical tests and pre-pilot flotation testing. The physical tests included Bond Ball Mill Work Index, SMC® (SMC Testing Laboratories pty ltd) testing and gravity recoverable gold testing. The pre-pilot flotation testwork included the same progression as previous test work; from batch rougher tests to batch cleaner tests to locked cycle tests, and was carried out to confirm grind targets and reagent conditions. In addition batch pyrite flotation was tested on the first cleaner scavenger tails of two of the cleaner tests as well as on the same product from the final cycle of the locked cycle test.

The pilot plant campaigns began on 9th November 2010 and lasted for just over two weeks. The plant was assembled to mirror the flowsheet tested with flotation residence times being approximately twice those indicated in laboratory test work. Target primary grind size was 120 µm to 130 µm and rougher concentrate regrind target was 20 µm to 30 µm. The reagents used were potassium ethyl xanthate (PEX), potassium amyl xanthate (PAX), Aerofloat 208 (A208), Methyl Isobutyl Carbinol (MIBC) as a frother, carboxy methyl cellulose (CMC 7LT) as a depressant and hydrated lime for pH control.

The assembled plant was only run on day shift, and time was taken to assess early results and make decisions on any changes to operating conditions, as well as to occasionally test possible variations on flotation conditions in the laboratory. Five campaigns were run at about 100 kg/hour for a single shift followed by an extended sixth run for approximately 60 hours. The campaigns were observed in part by Exeter and Aker Solutions (now Jacobs) metallurgists.

Pilot plant flotation performance was reasonably steady for a manually controlled plant and cleaner recycle flows appeared to stabilize approximately 1 to 2 hours after start up, confirmed by hourly control samples. Grinding targets were difficult to achieve and the closed circuit screen size had to be progressively increased until the 5th campaign. All rougher tails and cleaner-scavenger tails flows were collected in 200 litre drums without overflow, and allowed to settle. During the second campaign, a pyrite circuit was operated on cleaner-scavenger tails using PAX as a stronger collector to produce a separate pyrite concentrate and final tail.

Solid-liquid separation tests and rheology tests were carried out on rougher tails, cleaner-scavenger tails and 3rd cleaner concentrate (final concentrate). The rheology tests were carried out on the thickened material. Filtration tests were also carried out on the 3rd cleaner concentrate. Detailed sizings and mineralogy of cleaner products was carried out.

Samples of cleaner-scavenger tails and the pyrite concentrate from the second campaign were tested for gold dissolution in cyanide leaching tests. Selected solutions from these tests were subject to sulphidization, acidification, recycling and thickening (SART) of precipitate test work. Subsequently samples of the same products from locked cycle flotation tests were similarly tested to check on variability of response.

Project No.: C-580 January, 2012 | Page 133 - 378 |  |

A very large volume of data and test results were generated by the pilot plant programme described above. The principal results below were extracted from the SGS report, Project 12403-003, Final Report dated 28 February 2011. A selection of head assay values are illustrated in Table 13.2. indicating that the material tested closely matched the material selected.

Table 13.2: Sample Assays

| Sample | Cu % | Au g/t | S % | As % |

| Exeter – Calculated head assay | 0.23 | 0.54 | 1.79 | 0.03 |

| SGS – Actual head assay split | 0.25 | 0.53 | 2.1 | 0.03 |

| SGS – PP feed average assay | 0.25 | 0.55 | 2.03 | n/a |

| SGS – LCT calculated head assay | 0.20 | 0.44 | 1.85 | n/a |

Duplicate SMC tests were carried out to provide Julius Kruttschnitt Mineral Research Centre (JKMRC) Drop Weight Index (DWI) values, and other JKMRC mill design parameters, as well as solids SG.

The results which are summarized in Table 13.3 indicated that the samples straddled the average of more than 11000 test results on over 600 deposits in the JKMRC database.

Table 13.3: Physical Tests

| Sample | DWI | A | b | Abrasion parameter ta | SG | Ab | T10 |

| | kWh/m3 | | | | | Value | Rank | Value | Rank |

| 1 | 6.29 | 81.6 | 0.51 | 0.41 | 2.62 | 41.6 | mod hard | 32.6 | medium |

| 2 | 5.21 | 69.8 | 0.72 | 0.50 | 2.62 | 50.3 | medium | 35.8 | mod soft |

The Bond Ball Mill work index (BWi) of a head sample at a passing screen size of 106 µm was 12.8 kWh/tonne. The operating work index of the primary grinding mill during the pilot plant extended run was 12.2 kWh/tonne when producing a P80 of around 120 µm, which is in reasonable agreement.

| 13.2.1.2 | Flotation Summary |

Table 13.4 below summarizes the locked cycle tests and the average pilot plant results:

Project No.: C-580 January, 2012 | Page 134 - 378 |  |

Table 13.4: Selected Pilot Plant Flotation Results

| | Product | Mass Wt% | Assay (Adj.) | Distribution, % |

| Cu % | Au g/t | S % | Cu | Au | S |

AVG PP-06A to PP-06D | PP Feed | 100.0 | 0.25 | 0.55 | 2.03 | 100.0 | 100.0 | 100.0 |

| Rougher Conc | 8.7 | 2.48 | 4.68 | 16.6 | 87.4 | 74.7 | 71.1 |

| Rougher Tail | 91.3 | 0.034 | 0.15 | 0.64 | 12.6 | 25.3 | 28.9 |

| 1st Cleaner Scav Tail | 7.9 | 0.34 | 1.55 | 15.0 | 10.8 | 22.5 | 58.3 |

| 3rd Cleaner Conc | 0.8 | 23.5 | 35.4 | 32.2 | 76.6 | 52.2 | 12.8 |

| LCT | Head (calc) | 100.0 | 0.20 | 0.44 | 1.85 | 100.0 | 100.0 | 100.0 |

| Rougher Conc | 8.3 | 2.08 | 4.04 | 15.1 | 86.5 | 76.0 | 67.7 |

| Rougher Tail | 91.7 | 0.029 | 0.12 | 0.65 | 13.5 | 24.0 | 32.3 |

| 1st Cleaner Scav Tail | 7.5 | 0.15 | 1.13 | 12.9 | 5.6 | 19.3 | 52.6 |

| 3rd Cleaner Conc | 0.8 | 20.9 | 32.3 | 35.9 | 81.0 | 56.7 | 15.0 |

The pilot plant was not intended to simulate or predict full scale plant recoveries; however LCTs are often used for this purpose. The results were in reasonable agreement although the LCT sample appeared to have a lower grade. The best pilot plant run was the 4th which produced a final concentrate of 31 %Cu at 75 % copper recovery and 59 % gold recovery. As in previous test work, losses of gold and copper to first cleaner-scavenger tails were considerable as can be seen in the table above.

Of note were the mass pulls to rougher concentrate that were necessary to achieve these recoveries, and the resultant high weights reporting to cleaner tails together with substantial copper and gold values. To a large extent this was considered normal and a function of the low copper head grade and significant quantities of pyrite present.

Table 13.5 details assays that were carried out on the concentrate and cleaner-scavenger tailings for downstream testwork. Mineralogical analyses indicated that 55 % of the copper was present as chalcopyrite and 30 % as enargite in both products. In this concentrate the arsenic and antimony contents would be considered deleterious by most custom smelters. Mercury is also elevated and could at a level considered deleterious by some smelters.

Table 13.5: Detailed Product Assays

| Product Stream | Cu % | Au g/t | Ag g/t | S % | As % | Cl g/t | F % | Hg g/t | Sb % | SiO2% |

3rd Cleaner Conc | 22.3 | 31 | 73 | 33.5 | 2.27 | 150 | 0.017 | 48 | 0.41 | 9.2 |

| Cleaner-Scav tails | 0.24 | 1.2 | 3.7 | 14.2 | 0.07 | 85 | 0.16 | 1.9 | 0.00 | 46.0 |

Project No.: C-580 January, 2012 | Page 135 - 378 |  |

| 13.2.1.3 | Product Characteristics |

All three principal products settled well with non-ionic flocculant Magnafloc 333 with clear supernatants. There was quite a large variation in results and the best results for good percentage underflow solids are summarized in Table 13.6:

Table 13.6: Settling Test Results

| Product Stream | Mag 333 | Feed | Underflow | Unit Area | Critical Solids |

| g/t | % solids (wt) | % solids (wt) | m2/t/day | Density % wt |

| Rougher Tailings | 25 | 10 | 57 | 0.048 | 66 |

3rd Cleaner Conc | 10 | 16 | 76 | 0.021 | nd |

| Cleaner-Scav tails | 46 | 5 | 45 | 0.103 | 50 |

For rougher tailings, unit areas were in the range of 0.048 to 0.071 m2/t/d for a flocculant dosage of 25 - 45 g/t.

For scavenger cleaner tails, unit areas were in the range of 0.103 – 0.144 m2/t/d for a flocculant dosage of 36 – 56 g/t.

Rheology tests were carried out using a concentric cylinder rotational viscometer (CCRV) to determine critical solids density (CSD) of the three products. The CSD of rougher tailings was 66 % wt of solids at 98 Pa unsheared yield stress. The sample appeared thixotropic on shearing with a solids content of up to 68.7 %. The Cleaner Scavenger tails CSD was 50 % wt corresponding to an unsheared yield stress of 55 Pa. Both samples displayed primarily Bingham Plastic behaviour.

Final concentrate was fast settling when shear was applied and a vane viscometer had to be used. At 83.1 and 81.7 % solids, peak yield stresses of 122 and 60 Pa were measured respectively. Such fast settling behaviour will need to be examined in more detail for pumping calculations.

Pressure filtration testing of the final concentrate was not possible due to settling in the feed chamber of the feed diaphragm pump. Alternative pump units to suit the chamber were not available; however Exeter metallurgists believe such issues are not considered likely to affect commercially available production units.

Vacuum filtration testing was straightforward and SGS predictions were as shown in Table 13.7.

Project No.: C-580 January, 2012 | Page 136 - 378 |  |

Table 13.7: Vacuum Filtration Test Results

| Filter Test Predictions | Feed Solids | Cake Thickness | Cake Moisture | Vacuum Filter Cycle Times (Minutes) | Dry Output |

| % wt | mm | % wt | Form | Dry | kg/m2/hr |

| Belt Filter | 75 | 15 | 9 | 0.12 | 0.86 | 2062 |

| 75 | 30 | 9 | 0.47 | 1.73 | 1842 |

| Disc or Drum Filter | 75 | 10 | 11.8 | 0.05 | 0.09 | 7770 |

| 75 | 18 | 10.9 | 0.17 | 0.28 | 4317 |

| 75 | 30 | 10.1 | 0.47 | 0.78 | 2590 |

The results for the specific throughput for the belt filter at a lower moisture content of 8 % were about 950 kg/m2/h – this would be an acceptable parameter for the design criteria. However, a pressure filter is likely to produce a better result than a belt filter and should be tested at the earliest opportunity with one of the commercial suppliers. The use of a drum filter is not recommended due to the higher product moisture.

A rougher tailings sample from the pilot plant campaign has been treated for almost 40 weeks in a humidity cell at SGS Lakefield. The leach solutions appear relatively stable and at the time of writing no parameters are outside Chilean environmental limits.

The SGS pilot plant run provided the opportunity to gather representative kilogram-quantity samples of cleaner-scavenger tails and test further processing of them in efforts to reduce losses of copper and gold, as well as potential silver, that had occurred in all flotation test work to date.

In view of the high mass pulls to rougher flotation concentrate, it was decided to follow up selective earlier laboratory tests and try to separate a pyrite concentrate from the cleaner-scavenger tails containing gold values. This was done during the second pilot plant campaign throughout an operational shift and the results are shown in Table 13.8:

Table 13.8: Pilot Plant Pyrite Flotation Results

| Product | Weight % | Assay | Distribution % |

| Cu % | Au g/t | S % | Cu | Au | S |

| Pyrite Feed (Cl Sc Tails) | 100.0 | 0.13 | 0.76 | 8.23 | 100.0 | 100.0 | 100.0 |

| Pyrite Concentrate | 33.4 | 0.32 | 1.92 | 21.7 | 82.7 | 83.8 | 88.0 |

| Pyrite Tails | 66.6 | 0.03 | 0.19 | 1.49 | 17.3 | 16.2 | 12.0 |

It should be pointed out that the actual operational mass pull during this pyrite flotation test was quite high at 12.3 % as opposed to more normal mass pull targets of 7 % to 8 %. A sample of pilot plant cleaner-scavenger tailings and pyrite concentrate as well as two samples of cleaner scavenger tails from locked cycle tests were pre-aerated for 24 hours and then leached for 48 hours in 0.1 % NaCN solution at 40 % solids as the optimum conditions. No carbon additions were trialed in these tests. The results of the leach tests are summarized in Table 13.9.

Project No.: C-580 January, 2012 | Page 137 - 378 |  |

Table 13.9: Flotation Product Cyanide Leaching Results of Flotation Plant Products

| Sample Leached | 48 hour % extraction | NaCN | Calculated Head |

| Au | Ag | Cu | Kg/t | Au g/t | Ag g/t | Cu % |

| PP Cleaner Scavenger Tails | 67.6 | 39.1 | 46.5 | 3.99 | 1.25 | 4.1 | 0.26 |

| PP Pyrite Concentrate | 67.3 | 32.2 | 46.9 | 4.48 | 1.56 | 4.6 | 0.30 |

| LCT Cl Sc Tails - HSHA | 60.5 | 48.0 | 49.2 | 1.77 | 1.19 | 2.9 | 0.12 |

| LCT Cl Sc Tails - HSLA | 60.2 | 50.7 | 47.9 | 1.33 | 1.11 | 1.8 | 0.08 |

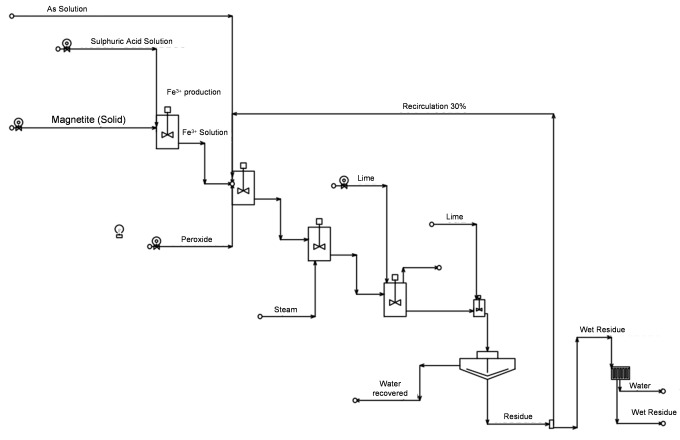

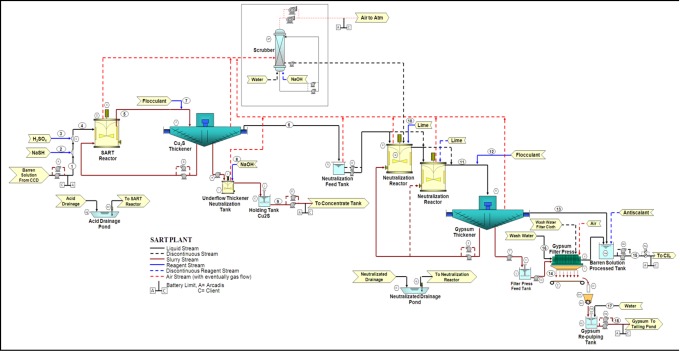

SART tests for cyanide recovery were carried out on three of the solutions from these tests. The optimum conditions were found to be pH 4 using 110 % of the stoichiometric requirement of sodium hydrogen sulphide (NaSH). Sulphuric acid additions ranged from 1.3 g/L to 1.8 g/L and re-neutralization hydrated lime additions ranged from 0.94 g/L to 1.4 g/L. The results are summarized in Table 13.10.

Table 13.10: SART Cyanide and Copper Recovery Results

| SART Sample | Sodium Cyanide | Copper |

| Added kg/t | Recovered kg/t | Recovered % | Feed mg/t | Tails mg/t | Recovered % |

| PP Cleaner Scavenger Tails | 4.74 | 3.5 | 74 | 851 | 0.4 | 100 |

| LCT Cl Sc Tails - HSHA | 3.03 | 2.6 | 86 | 363 | 8.0 | 98 |

| LCT Cl Sc Tails - HSLA | 2.64 | 2.1 | 80 | 244 | 0.4 | 100 |

The copper recoveries were almost quantitative as expected however the cyanide recoveries ranged from 74 % to 86 %, most probably as a result of cyanide present as thiocyanate, SCN-, which cannot be regenerated in the SART circuit and is instead mostly precipitated into the copper product.

| 13.2.3 | Pressure Oxidation of Caspiche Concentrate |

SGS were selected to carry out a batch bench-scale pressure oxidation (POX) testwork programme on a portion of the pilot plant final concentrate.

The POX tests were carried out in 2 litre Parr titanium autoclaves and examined the effects of temperature, residence time and grind size. Copper extraction was greater than 99 % for the conditions tested which included temperatures from 210 oC to 225 oC and 60 to 120 minutes residence time. As expected, reaction kinetics were faster at the higher temperature of 225 degrees and with a reground concentrate P80 of 32 µm complete oxidation occurred within 60 minutes. The arsenic content of final solutions was low, with 200 mg/L average depending on the conditions used in each individual test while virtually all antimony remained in the residue. The final solutions contained from 20 to 23 g/L Cu and 40 to 50 g/L H2SO4. Weight loss of solids was between 49-60 %. The POX residues were washed and selected samples were bottle-roll leached at 25 % solids in 1 g/L sodium cyanide solution for 24 to 48 hours. Gold dissolutions were high and ranged from 95 % to 99 % with an average cyanide consumption of 1.4 kg/t. Generally leaching was complete after 24 hours. Lime consumptions ranged from 5 to 70 kg/t with the lower figure obtained using a “hot cure” stage on the autoclave discharge to break down basic sulphates. Silver recoveries were low

Project No.: C-580 January, 2012 | Page 138 - 378 |  |

and ranged from 7 % to 29 %. It is possible that these could be improved by a post POX treatment route and should be investigated in future pilot plant work.

All leach tests resulted in calculated gold head assays lower than the assay head. SGS speculated that some gold could be in the POX pregnant solution as a result of chloride or fluoride but it did not show up in assays and was not investigated further.

A comparison leach was carried out on the un-oxidized flotation concentrate. This showed 14 % gold dissolution after 48 hours with 19 kg/t cyanide consumption.

| 13.2.4 | Reductive Roasting of Caspiche Concentrate |

Two roasting technology suppliers were contracted to carry out small scale roasting testwork on Caspiche pilot plant final concentrate. The objective was to reduce arsenic contained in the concentrate to 0.2 % As or less while maintaining sulphur content in the roaster product (“calcine”) as high as possible. Outotec carried out testwork in Germany and Sweden and Technip carried out testwork at Hazen Research in Denver, Colorado.

| 13.2.4.1 | Outotec Roasting Testwork |

Outotec carried out testwork in a standard Boliden rotary kiln and in a 50 mm fluid bed reactor using SO2 gas as the fluidizing medium. The resulting calcine values from both tests are held to reflect those for full scale operation.

The calcine indicated very good fluidizing properties when fluidized with nitrogen at up to 700 oC, however agglomeration was observed at 650 oC when fluidized with SO2. Outotec found the agglomerates to be soft and anticipated that this would not be an issue with a full scale roaster operating with double the gas velocities and with an inert sand fluidizing medium.

A summary of the fluidized bed calcine results is given in Table 13.11, copied from the Outotec report.

Table 13.11: Elemental Analysis of Calcine Test Products

| Test | Temp (oC) | Cu (%) | Fe (%) | S (%) | Zn (%) | As (%) | Sb (%) | SiO2 (%) | Al2O3 (%) |

| 113/10* | | 23.6 | 25.9 | 32.8 | 0.75 | 2.40 | 0.53 | 9.2 | 1.8 |

| 1 | 600 | 22.8 | 31.4 | 27.9 | 0.63 | 0.19 | 0.25 | 12.7 | 2.4 |

| 2 | 650 | 24.1 | 31.1 | 27.3 | 0.73 | 0.14 | 0.18 | 12.0 | 2.2 |

| 3 | 700 | 24.9 | 30.9 | 27.2 | 0.75 | 0.16 | 0.13 | 11.8 | 2.2 |

| 4 | 725 | 26.0 | 30.8 | 25.5 | 0.81 | 0.19 | 0.16 | 11.4 | 2.2 |

| 5 | 600 | 23.5 | 30.9 | 27.6 | 0.68 | 0.33 | 0.24 | 12.2 | 2.4 |

| 6 | 650 | 24.1 | 31.3 | 25.5 | 0.69 | 0.11 | 0.16 | 12.7 | 2.2 |

| 7 | 700 | 25.0 | 31.0 | 25.6 | 0.74 | 0.18 | 0.15 | 11.7 | 2.2 |

| 8 | 725 | 25.4 | 31.0 | 24.1 | 0.75 | 0.26 | 0.16 | 11.5 | 2.5 |

The programme indicated an optimum temperature in the 650 oC to 700 oC range for reducing arsenic and antimony while maintaining sulphur values. Calcine residues of much less than 0.20 %As were achieved and almost 70 % of the antimony was removed. Outotec considered the concentrate to be very good for full scale fluidized roasting and recommended further pilot scale work to optimize conditions.

Project No.: C-580 January, 2012 | Page 139 - 378 |  |

| 13.2.4.2 | Technip Roasting Testwork |

The testwork was carried out at Hazen Research’s facilities in Denver under the supervision of Technip personnel. Hazen carried out the work in a 107 mm inside diameter stainless steel fluidized bed reactor within a heating chamber. The inert fluidizing medium was sand. The off gases and solids were treated in a cyclone for solids recovery to underflow and the cyclone overflow passed to a baghouse. Final off gases were scrubbed by NaOH in a packed column. The column was fluidized with nitrogen into which a calculated amount of oxygen was metred. Process gases were sampled and analysed.

Six runs of approximately 2 hours duration at steady state were carried out under different process conditions. Technip found that temperatures of 725 oC to be best for arsenic removal and achieved calcines of 0.2 %As at these levels as indicated in Table 13.12, copied from the Hazen Research report. Sulphur assays in the calcine were 26 % to 27 %S.

The baghouse product (arsenic concentrate) assayed from 3 %As to almost 7 %As.

Table 13.12: Summary for Partial Roast of Caspiche Flotation Concentrate

| Measurement | Fluid-bed Roast Test |

| 1 | 2 | 3 | 4 | 5 | 6 |

| Average Temperatures, °C | | | | | | |

| Bed zone (3) | 625 | 650 | 625 | 675 | 725 | 725 |

| Freeboard | 430 | 435 | 415 | 430 | 450 | 530 |

| Cyclone outlet | 290 | 300 | 285 | 300 | 315 | 350 |

| Average Rates, g/min | | | | | | |

| Concentrate | 27.2 | 26.8 | 25.2 | 26.6 | 26.2 | 120.6 |

| Cyclone | 21.6 | 20.4 | 21.8 | 21.0 | 20.6 | 85.2 |

| Baghouse | na | 0.64 | 0.63 | 0.73 | 0.51 | 3.8 |

Gas Flows, sft3*/min | | | | | | |

Fluidizing N2 | 2.93 | 2.93 | 2.93 | 2.93 | 2.93 | 1.03 |

Feed transport N2 | 0.45 | 0.45 | 0.45 | 0.45 | 0.45 | 0.48 |

Purge N2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

Oxidant, sLmin O2 | 1.9 | 1.9 | 2.4 | 2.4 | 2.4 | 9.3* |

| Total Sulfur Assay, wt% | | | | | | |

| Concentrate feed | 33.7 | 33.7 | 33.7 | 33.7 | 33.7 | 33.7 |

| Final test cyclone | 27.9 | 27.5 | 27.4 | 25.9 | 26.1 | 27.2 |

| Final test baghouse | na | 25.2 | 24.3 | 23.2 | 23.5 | 22.1 |

| Arsenic Assay, wt% | | | | | | |

| Concentrate feed | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 |

| Final test cyclone | 0.83 | 0.678 | 0.599 | 0.318 | 0.191 | 0.206 |

| Final test baghouse | na | 2.45 | 2.93 | 3.15 | 3.08 | 6.87 |

na = not availabe

* standard cubic feet per minute.56 sft3/min air added as oxidant with the N2 equivalent O2 (sL/min) from air hown.

For the prefeasibility study the parameters set were: Feed grades 0.231 %Cu and 0.562 g/tAu; recovery 83 %Cu and 60 %Au; concentrate grade 25 %Cu and 44 %Au; crushing P95 at 2”, grinding P80 at 130 µm, regrind P80 at 30m.

Project No.: C-580 January, 2012 | Page 140 - 378 |  |

There was very little additional oxide mineralization encountered in the 2009 drill programme, so a specific drilling programme was completed in the 2009 – 2010 field season to obtain appropriate oxide samples.

Following the encouraging results of the initial column leaching tests referred to in 13.1.3 a comprehensive column leach programme was implemented. The objective was to examine leaching characteristics at a range of oxide crush sizes in order to be able to select the most appropriate size or project possible run-of-mine (ROM) recoveries by heap leaching. Seven large diameter PQ core (85 mm diameter) and HQ core (63 mm diameter) drill holes were completed to characterize the oxide zone, with several of them “twinning” RC holes by earlier explorers. The oxide mineralization encountered in these PQ holes was considered by Exeter geologists to be broadly representative of the oxide resource in terms of depth and area.

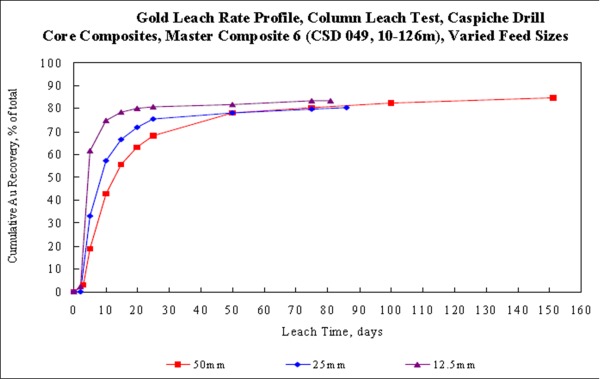

The mineralization intersected in these holes was split into 11 composites based on rock type, depth or location and ranged in length from 22 metres to 116 metres of continuous sample. The intention was to column test each composite at nominal P80 sizes of 50 mm, 25 mm and 12.5 mm, as well as completing bottle roll and physical (crushing, abrasion) testwork.

The programme was carried out at MLI in 2010 in 10’ high columns with diameters up to 12” selected to suit the top size of material. The weight requirements for the larger columns meant that only 8 of the 11 composites were able to be tested at all 3 sizes. One of these 8, Composite 8, was a transition sample, included to evaluate what might happen if leaching of oxide was extended into the transition zone. Composite 1 was a sample of mineralized transported material from 0 to 22 m depth and there was only sufficient to be tested at 12.5 mm. Composite 3 (86 m to 146 m) and Composite 11 (120 m to 150 m) were tested at P80 of 25 mm and 12.5 mm.

The whole PQ core was hand-crushed at MLI in order that the largest size range would be as coarse as possible. The average size distribution of the 8 composites tested at the coarser size turned out to be approximately 65 % passing (P65) 50 mm rather than the nominal 80% passing size. This coarser than nominal size should be considered when reviewing results. Head grades of all the oxide composites ranged from 0.39 to 0.67 g/t Au and 50 to 230 ppm Cu. The transition composite contained 0.07 %Cu and 0.83 % sulphide sulphur.

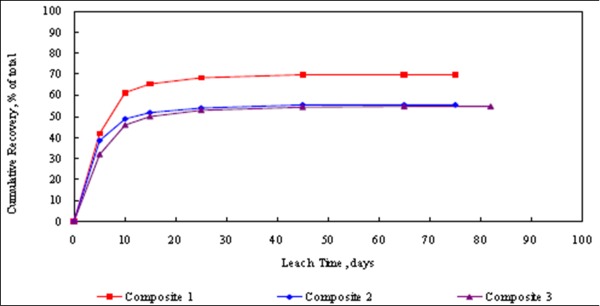

The seven oxide composites that were tested at all three feed sizes gave average gold recoveries of 79.3 %, 80.4 % and 81.7 % for 50 mm, 25 mm and 12.5 mm respectively. Gold recovery rates for the -50 mm feeds were substantially slower than for the finer feeds, however gold recovery was expected to approach those obtained from the finer feeds with a longer leaching cycle. Composite 11 (120 m to 130 m) gave the lowest gold recoveries of the oxide samples at just over 70 % for the 25 mm material. An example of a kinetic curve for gold dissolution from the test programme is given in the Figure 13.1.

Project No.: C-580 January, 2012 | Page 141 - 378 |  |

Figure 13.1: Gold Leach Rate Profile

Gold recoveries obtained from Composite 8 at -50 mm, -25 mm and -12.5 mm were 54.2 %, 68.8 % and 68.9 % respectively, and the leach kinetics were slower than for the oxide samples. As expected with the higher copper content, cyanide consumptions were significantly higher. The results suggest that transition material could be treated by heap leaching if required, however it is probable that copper might need to be removed and cyanide recovered in a SART facility, also that gold recoveries will be much lower. Due to the copper in solution, transition material should not be leached or mixed with oxide material.

Bottle roll test results at P80 -1.7 mm feed sizes were reasonably predictive of column test gold recoveries, and were effectively used for estimation of column test lime requirements. This suggests that in production, such tests might be able to be used for performance prediction if carried out on blast hole cuttings.

Cyanide consumptions for the oxide composites were high, but should be significantly lower in commercial production. This is based on comparative testwork data base results and actual production results of similar operations. Lime requirements were moderate, and pH control during leaching generally was not difficult. Load/permeability tests on the column residues indicated that the oxide ore material would display adequate permeability under expected heap stack height compressive loadings.

Sufficient material was left from two composites to carry out additional column leaches at 25 mm using lower cyanide concentrations, namely addition rates of 1.00, 0.50 and 0.25 kg/t NaCN. The results of this optimization programme are summarized in Table 13.13.

Project No.: C-580 January, 2012 | Page 142 - 378 |  |

Table 13.13: Results of Optimization Programme

Composite Number (P80 of 25 mm, 80 day leach) | Gold Recovery % at | NaCN Consumption, kg/t |

| NaCN Addition Strength g/L | NaCN Addition Strength g/L |

| 1.00 | 1.00 | 0.50 | 0.25 | 1.00 | 1.00 | 0.50 | 0.25 |

| 6 (CSD049; 10 m to 126 m) | 80.3 | 84.2 | 83.0 | 80.4 | 1.71 | 1.67 | 1.10 | 0.72 |

| 9 (CSD054; 24 m to 128 m) | 81.4 | 79.4 | 76.8 | 77.3 | 1.38 | 1.38 | 1.13 | 0.88 |

The programme indicated the expected downward trend in cyanide consumption together with a small reduction in gold recovery with the weaker solutions. Once again, even at the lower cyanide additions, consumptions in a full scale heap are expected to be considerably lower.

The results from this programme were considered to confirm comprehensively the technical application of heap leaching for oxide ore by both MLI and Exeter and, together with the crushing and abrasion results, provided sufficient information to carry out a detailed study into this treatment route by Aker Solutions.

Aker endorsed the Exeter programme results and during the preliminary engineering trade-off phase of the PFS determined that a 5 year oxide operation on -50 mm material would be close to optimal. In reviewing the crushing design, the conventional use of a gyratory crusher in the circuit for such a short operational life was considered sub-optimal as the crusher would be too small for the later sulphide operation. Aker’s conceptual design called for screening ahead of jaw crushing followed by open-circuit secondary crushing. Both Aker and a crusher manufacturer called for a large sample to be sized in order to develop reasonable crushing plant design parameters.

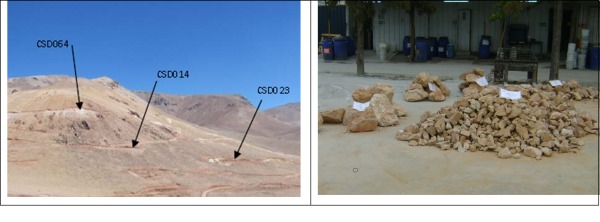

In January 2011, two truckloads of mineralized oxide material was excavated from 3 trenches located next to drill holes 14, 23 and 64 and were sent to SGS Santiago for sizing. This data was used to estimate screening requirements ahead of the jaw crusher and assist in dimensioning the crusher. The samples were selected and composited to reflect actual Caspiche oxide ore composition as much as practically possible given the limited outcrop and depth penetration. All waste or “transported” material was carefully excluded from the samples.

Project No.: C-580 January, 2012 | Page 143 - 378 |  |

Figure 13.2: Oxide Material

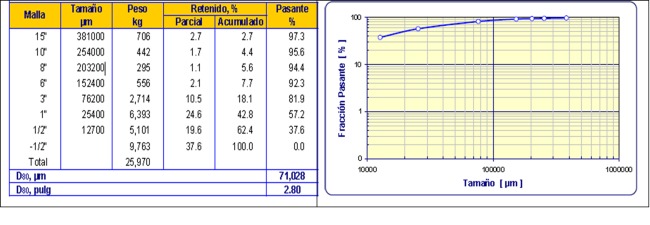

The results obtained from SGS are reproduced in Figure 13.3 and indicate ROM feed sizing (F80) from the test pit locations of 2.8” or 71 mm.

Figure 13.3: Results Obtained From SGS

MLI are also completing humidity cell testwork on column residues to check the propensity for acid rock drainage (ARD) on heap leach materials.

For the prefeasibility study the parameters set were: Feed grade average 0.404 g/tAu; recovery 78 %; crushing P95 at 2”.

Project No.: C-580 January, 2012 | Page 144 - 378 |  |

| 13.4 | MacNeill Zone Testwork |

The MacNeill Zone is an area of late stage intermediate sulphidation mineralization to the west-south-west of the main porphyry zone on the lower flange of a barren diatreme. It is characterized by low copper assays normally less than 0.10 %Cu and in general average to above average gold assays. Before it was recognized as a separate system, one intercept from the 20 original intercepts sent to G&T was from MacNeill. This intercept, CSD 036,

196 m – 262 m, assayed 0.03 %Cu and 0.94 g/t Au and was not amenable to flotation, recovering only 47 % of the copper and 34 % of the gold into a concentrate assaying 0.71 %Cu.

Accordingly it was decided to check the preliminary response of this zone to heap leaching by carrying bottle roll and column leach tests at MLI in Reno.

| 13.4.1.1 | Preliminary MacNeill Testwork |

Initially 6 samples from drill holes CSD 044 and CSD 042, considered typical of MacNeill mineralization, were sent to MLI and represented progressively deeper intervals in the zone. Gold assays varied from 0.36 g/t Au to 1.33 g/t Au and copper from 0.04 %Cu to 0.11 %Cu. In spite of the variations in gold head grade depths, bottle roll gold recoveries in % terms from all six samples were similar at similar stages of the leach, and averaged just under 60 % with a range of 54 % to 65 %. Cyanide consumptions averaged 0.5 kg/t NaCN on all but the 0.11 %Cu sample which consumed 1.2 kg/t NaCN. Leach kinetics appeared to be quite rapid.

| 13.4.1.2 | MacNeill Amenability Testwork |

It was decided to follow up this work at MLI with 13 coarse crushed (9.5 mm) intercepts from the 2009-2010 drilling campaign which were proportioned to make 7 composites, 3 destined for column tests and 4 destined for bottle roll and flotation tests. The 3 composites for column testing represented shallow, deep and “transitional” material - where MacNeill overprints conventional Caspiche mineralization (“McTrans”). The four for flotation testing represented MacNeill and McTrans split into high sulphur (HS) and low sulphur (LS) composites.

The results of cyanide leaching all 7 composites at different sizes are summarized in Table 13.14:

Project No.: C-580 January, 2012 | Page 145 - 378 |  |

Table 13.14: MacNeill & McTrans Gold Leach Recoveries

| Composite | Gold Recovery % | NaCN consumption kg/t |

| 9.5 mm | 1.7 mm | 75 µm | 9.5 mm | 1.7 mm | 75 µm |

| MacNeill Shallow | 69.7 | 69.0 | 80.6 | 1.29 | 0.68 | 0.59 |

| MacNeill Deep | 55.3 | 64.0 | 79.1 | 1.05 | 0.39 | 0.29 |

| McTrans | 54.7 | 63.1 | 71.4 | 1.27 | 1.00 | 1.05 |

| MacNeill HS | n/a | 65.0 | 73.6 | n/a | 0.45 | 0.47 |

| MacNeill LS | n/a | 67.2 | 75.9 | n/a | 0.75 | 0.67 |

| McTrans HS | n/a | 60.7 | 67.9 | n/a | 1.05 | 1.28 |

| McTrans LS | n/a | 68.8 | 83.6 | n/a | 1.22 | 0.52 |

The three 9.5 mm results represent agglomerated column tests where the gold leached very quickly to the final recovery levels of between 55 % and 70 %.

Figure 13.4: Cumulative Recovery

The high cyanide consumptions in the column tests are believed to be a function of leaching for 80 days and would be expected to be substantially less at 20 to 30 days. Generally cyanide consumptions are higher on McTrans than on MacNeill material and reflect the amount of copper present. Copper extractions ranged from 12.5 % to 25 %. No percolation problems or slumping was observed in the column tests.

While flotation was carried out on the appropriate composites, they did not respond particularl well at normal sizes and when recovery did improve at a 45 µm, concentrate copper grades were still low.

For the prefeasibility study the parameters set were: Feed grade average 0.508 g/tAu; recovery 40 %; crushing P95 at 2”.

Project No.: C-580 January, 2012 | Page 146 - 378 |  |

| 13.5 | Ongoing Test Programmes |

As of the effective date of this report, testwork is continuing on several programmes at both SGS Lakefield and MLI in Reno. While the work has not been formally finalized and no reports are available, in some cases final test data has been available and has been used by Aker and Exeter.

| 13.5.1 | Sulphide Mineralization |

| ● | 12403-008 Flotation Optimization |

This programme uses left-over pilot plant feed material to optimize flotation conditions and improve copper and gold flotation recoveries. It is a conventional programme looking at a wider range of physical and reagent conditions recommended by metallurgical experts in this field of low grade copper porphyry flowsheet development.

Within the scope are trials of magnetic separation, flash flotation and gravity recovery of gold from both feed and pilot plant tails.

| ● | 12403-005 Variability Assessment |

This programme has used lower than average copper grade drill core intercepts from the pilot plant shipment of 91 intercepts. Conditions close to the optimum identified in 12403-008 are being used to review the response of each sample to standard conditions but may be adjusted based on detailed mineralogy being carried out. This means that the programme necessarily has to lag behind the optimization programme. Weights of intercepts available for testwork are limited and it may not be possible to go to LCT tests.

| ● | 12403-006 HPGR and Physical Characteristics |

This programme uses whole HQ core from an abandoned drill hole, CSD039 (Composites 1, 2 and 3) and a metallurgical hole Mett03 (Composites A to H) drilled for the purpose down through the main zone of mineralization. The samples numbering is progressive with depth to reflect both key type changes in mineralization and to provide sufficient weight for a comparative comminution programme. Comminution results were largely completed some time ago and have been provided to Aker (Table 13.15) for use in preliminary HPGR evaluation; however the design criteria for the three cases under study have not used this data. Together with the pilot plant data and comparative work indices carried out by both G&T and SGS, Exeter consider the comminution characteristics have been adequately defined for pre-feasibility purposes in terms of representivity and variability in the deposit. Additional results of a confirmatory nature would be required for feasibility study purposes.

Project No.: C-580 January, 2012 | Page 147 - 378 |  |

Table 13.15: Physical Test Results 12403-006

Sample Name | Relative Density | SMC A x b | SPI Index (min) | Abrasion Index (g) | UCS Mpa | HPGR kWh/t | Bond Ball Wi kWh/t |

| Comp 1 | 2.66 | 76.5 | 50.1 | 0.36 | 73 | 1.8 | 9.9 |

| Comp 2 | 2.60 | 76.7 | 37.3 | 0.34 | 69 | 1.7 | 10.4 |

| Comp 3 | 2.49 | 97.1 | 32.0 | 0.10 | 16 | 1.7 | 9.9 |

| Comp A | 2.52 | 73.8 | 43.2 | 0.20 | 13 | 1.9 | 11.5 |

| Comp B | 2.50 | 85.8 | 39.9 | 0.26 | 27 | 1.7 | 9.2 |

| Comp C | 2.53 | 69.7 | 46.9 | 0.33 | 32 | 1.8 | 10.4 |

| Comp D | 2.57 | 57.0 | 49.6 | 0.40 | 53 | 1.8 | 11.5 |

| Comp E | 2.49 | 43.9 | 58.4 | 0.34 | 75 | 1.8 | 11.4 |

| Comp F | 2.55 | 51.8 | 62.1 | 0.36 | 59 | 1.9 | 11.1 |

| Comp G | 2.59 | 50.2 | 47.4 | 0.28 | 26 | 1.7 | 9.6 |

| Comp H | 2.53 | 44.3 | 69.2 | 0.39 | 76 | 1.9 | 12.5 |

When the PFS started, the density of the ore was unknown, however, for design purposes, 2.7 t/m3 was assumed as a typical for a porphyry copper ore in Chile. It has no impact in the crushing and conveying sizing because those systems were calculated with a bulk density (1.6 t/m3), and the effect on slurries are less than 1 % of volumetric flow rates, i.e. the pumps and pipes sizes for the project do not change.

Most of the data was as expected and suggested an increase in hardness with depth with the exceptions of Composites 3 and G. The UCS results appeared to be lower than expected and the detailed report suggested most have failed on fracture planes.

Locked cycle HPGR tests have been completed and the Bond Mill work index after HPGR will be compared with the conventional BWi and alternative SAG mill and HPGR circuits compared. In addition, flotation responses will be compared between conventionally milled and HPGR milled materials after mineralogical examinations are completed.

| ● | 12403-009 MacNeill HPGR and Flotation |

Two metallurgical HQ drill holes were drilled into the main MacNeill Zone and into McTrans material late in the 2010 drilling season. SGS have been supplied with part of this material to check the HPGR and physical characteristics of these two ore types and in general conduct a similar programme to 12403-006. Work has started on the various grinding parameters.

| 13.5.2 | Oxide Mineralization |

There is currently no testwork on oxide mineralization other than humidity cell leaching for environmental purposes. In the coming 2011/12 drill season, a second campaign of PQ holes is planned to provide samples for a comprehensive breakage and sizing assessment, together with further confirmatory column testwork. A proposal to set up a large column test programme on ROM ore was not accepted because of the difficulty of establishing the representivity of any near surface or accessible material.

Project No.: C-580 January, 2012 | Page 148 - 378 |  |

| 13.5.3 | MacNeill and Low Copper Mineralization |

MLI are carrying out a programme of column testing of MacNeill mineralization at sizes coarser than the 9.5 mm previously tested. This programme is expected to be reported in the near future.

Other low-copper gold mineralization exists in the main Caspiche hypogene zone with copper grades potentially too low to anticipate a reasonable flotation response given the results of the current testwork to date. Preliminary samples of typical material from these areas have been identified and sent to MLI in order to assess the possible amenability of this material to heap leaching.

Project No.: C-580 January, 2012 | Page 149 - 378 |  |

| 14.0 | MINERAL RESOURCE ESTIMATION |

The following discussion regarding mineral resource estimation was modified from an internal report prepared for Exeter by AMEC (Marinho, 2011).

The additional drilling, recommended in previous studies, improved the geological knowledge of the central and north-west areas of the deposit.

The Caspiche mineral resource estimate was updated by Daniel Silva under the supervision of Mr. Rodrigo Marinho, P.Geo (APEGBC), CPG (AIPG), AMEC Principal Geologist. The mineral resource estimates were prepared under the Canadian Institute of Mining Metallurgy and Petroleum (CIM) Definition Standards (2005) and CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (2003).

The Caspiche mineral resource estimate was reviewed and verified by Mr Ted Coupland, MAusIMM(CP), Director and Principal Geostatistician of Cube Consulting Pty Ltd ("Cube"). Cube is an independent Australian firm specializing in mining and mineral resource consulting services.

Exeter provided AMEC with a drilling database on the Caspiche property updated to 19 April, 2011. AMEC imported the collar, survey, lithology, alteration, and assay data into GEMS® (version 6.2.4), a commercial mining software program. GEMS® validation routines were used to check for overlapping intervals, missing intervals, and consistent drill hole lengths between tables, no errors were reported.

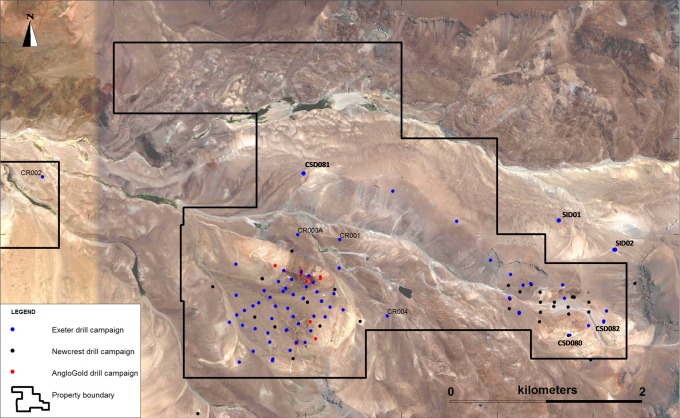

The actual database totals 69,293.85 m of drilling in 140 drill holes. Table 14.1 is a summary of the drill holes that were used for the current mineral resource estimate. The database includes 6,620 m of 6 additional drill holes completed by Exeter since the last update of the resource estimate (30 December, 2010).

Table 14.1: Summary of Drill Data used for the Caspiche Mineral Resource Estimate

| Campaign | No. Holes | Min. Length (m) | Max. Length (m) | Avg. Length (m) | Total(m) |

| AngloGold | 18 | 32 | 200 | 84.33 | 1,518 |

| Newcrest | 35 | 92 | 332 | 208.88 | 7,311 |

| Exeter | 87 | 73 | 1,497.10 | 694.99 | 60,464.85 |

| Total | 140 | 32 | 1,497.10 | 494.96 | 69,293.85 |

AMEC used an updated topographic surface file for the mineral resource estimates. The topographic model was based on 0.5 m resolution digital elevation model (DEM) modelling from high definition stereo satellite photos. Then, isolated portions of the topographic surface were adjusted using surveyed drill hole collar elevations to create a final topographic surface for use in mineral resource estimation.

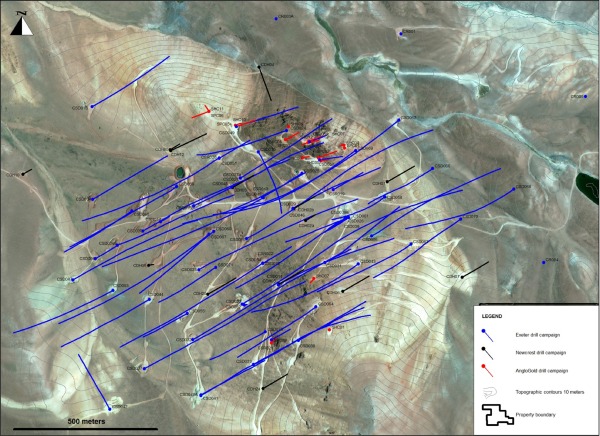

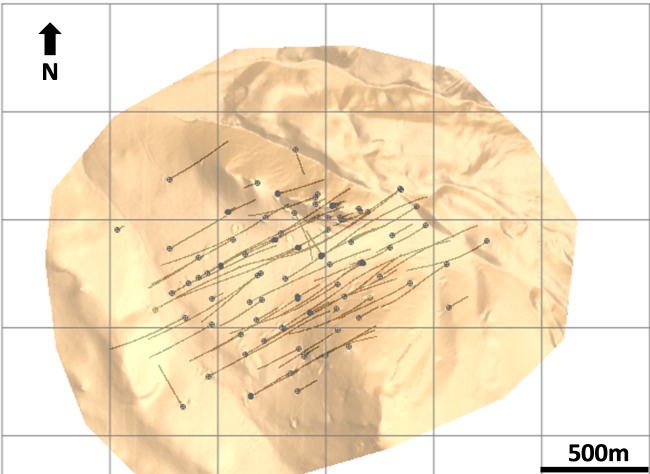

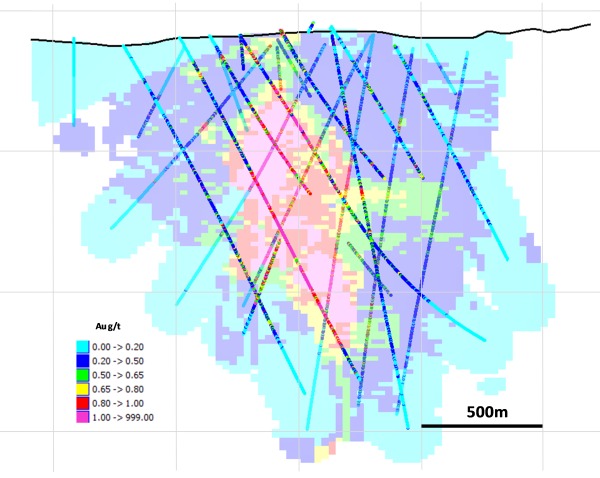

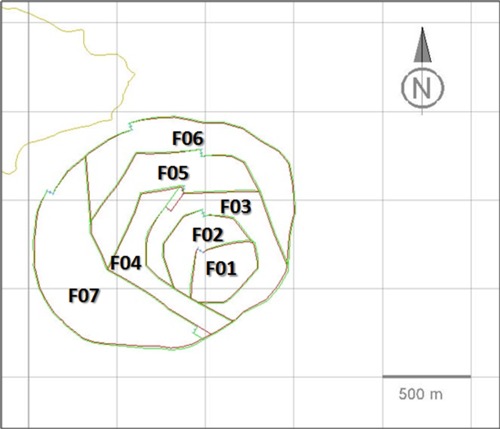

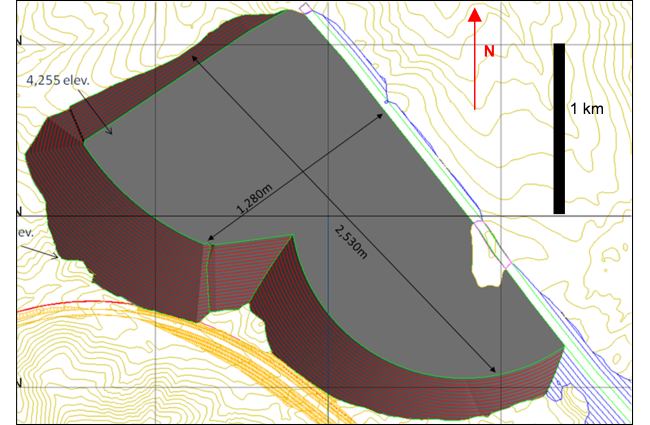

Figure 14.1 shows detailed topography and drill hole locations over the Caspiche Porphyry project.

Project No.: C-580 January, 2012 | Page 150 - 378 |  |

Figure 14.1: Caspiche and Drill Hole Locations – Caspiche Porphyry Project (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 151 - 378 |  |

| 14.3 | Lithological Model and Definition of Domains |

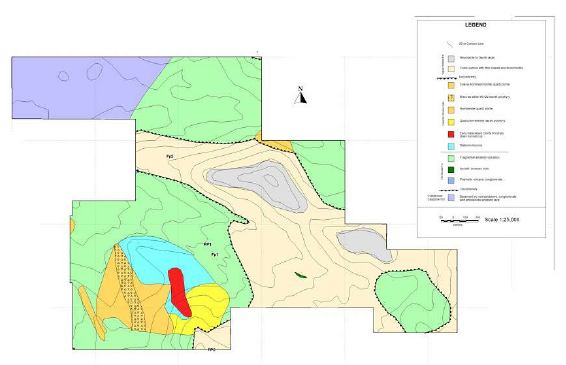

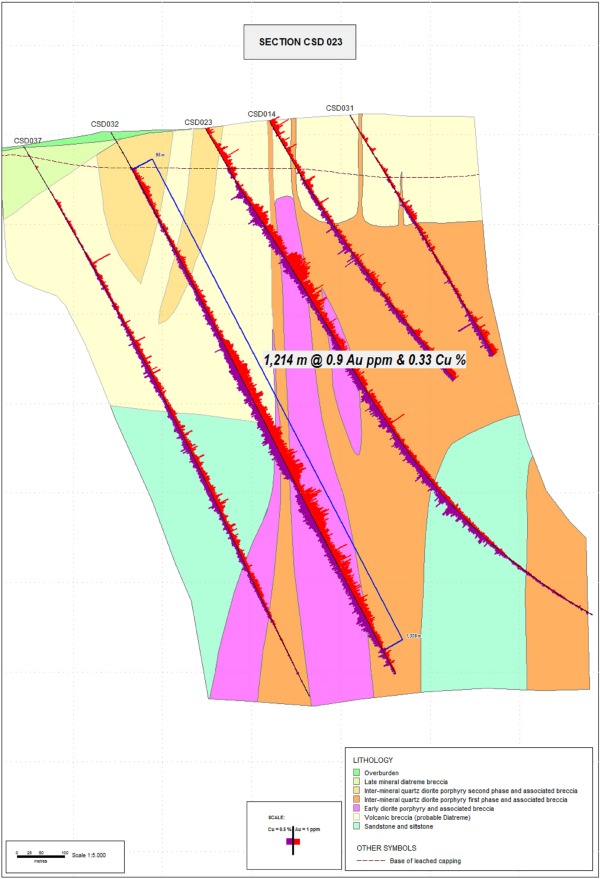

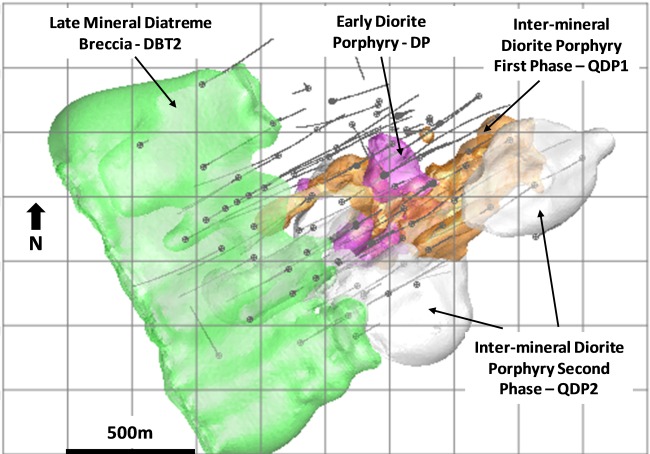

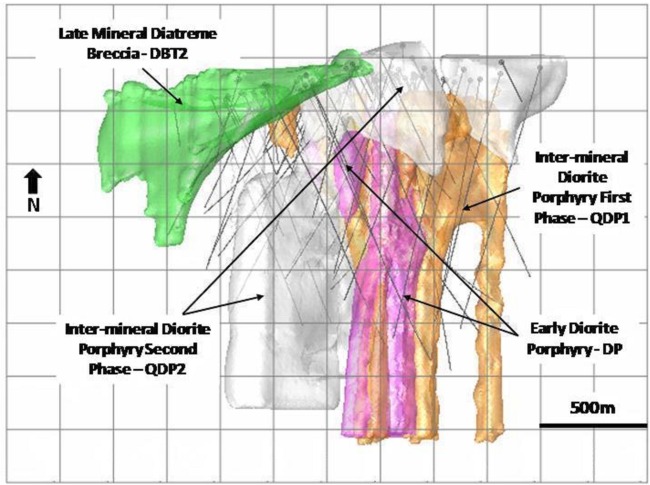

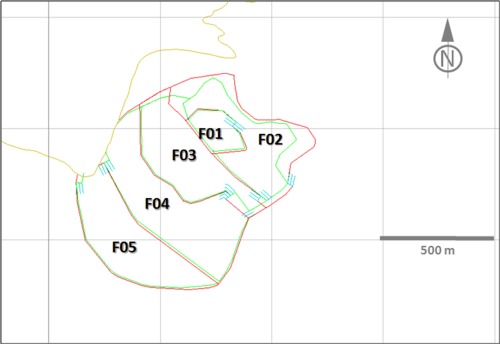

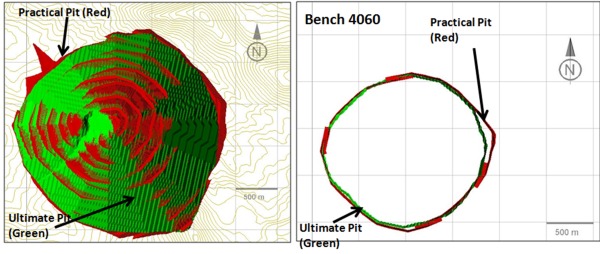

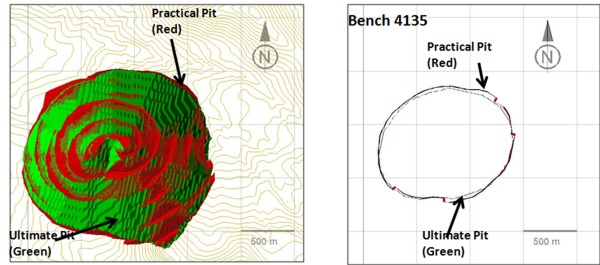

Exeter provided triangulated solid models representing the Caspiche lithological and alteration units. Examples of the lithological and alteration wireframes provided to AMEC are shown in Figure 14.2 to Figure 14.4.

AMEC reviewed interpreted shapes on vertical sections and level plans for the main lithological units; diorite Porphyry (DP), quartz-diorite Porphyry 1 (QDP1), quartz-diorite Porphyry 2 (QDP2), basement (CFB), volcanic breccias (VOLCBX), diatreme breccias (DTB) and MacNeill Zone (MAC).

Table 14.2 summarizes the lithological units used for the modelling.

An alteration model, consisting of potassic and argillic units and a calcite-potassic zone at the bottom of the system was also constructed.

Table 14.2: Lithological Unit Description

| Domain | Description |

| DP | Diorite Porphyry (main host rock for mineralization) |

| DTB | Diatreme breccia |

| QDP2 | Quartz-diorite Porphyry (late and lower grade) |

| QDP1 | Quartz-diorite Porphyry |

| VOLCBX | Volcanic breccias |

| CFB | Earliest cretaceous host rock (Basement) |

| OB | Overburden |

| MAC | MacNeill |

Exeter provided AMEC with an updated limit of oxidation boundary for this model update. The limit of oxidation was constructed from logging information; mainly sulphide descriptions. AMEC checked the oxide and sulphide solids against the drill holes database coding and found it to be acceptable.

The lithological solids provide the main support for the estimation domains. AMEC compared summary statistics and contact plots for combinations of lithology, alteration and weathering models. Final estimation domains for gold and silver were based on lithological and alteration codes without weathering zones. Copper estimation domains included weathering zones.

Gold grades are clearly higher in the DP but there are no clear lithological controls for gold mineralization. AMEC has interpreted the DP intrusion to be the source of mineralizing solutions carrying mainly gold and silver. The mineralizing solutions were disseminated through the other lithological units during the mineralization event.

Project No.: C-580 January, 2012 | Page 152 - 378 |  |

Figure 14.2: Caspiche Lithological Model - Plan (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 153 - 378 |  |

Figure 14.3: Caspiche Lithological Model – Looking North (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 154 - 378 |  |

Figure 14.4: Caspiche Lithological and Alteration Model – Looking North (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 155 - 378 |  |

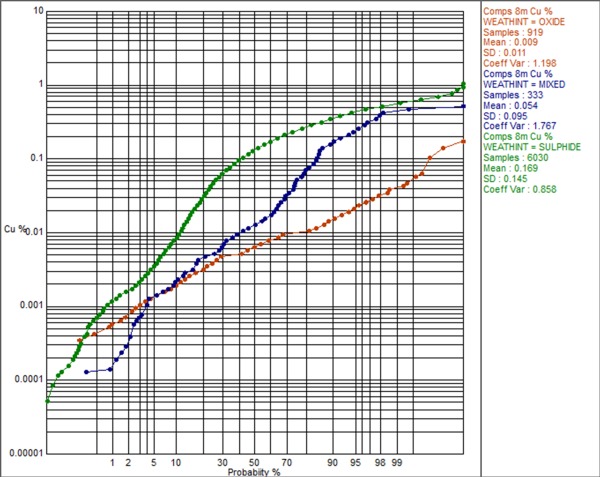

Copper mineralization is not controlled by lithological units, but is controlled by the oxidation boundary. The contact plots for copper show a transitional contact from the oxide to the sulphide zone and for grade estimation purposes AMEC created a transitional or mixed zone by projecting the oxide bottom surface 15 m above and below. Samples from oxide and sulphide zones are shared during grade estimation only for the transitional zone blocks.

The nominal sample length for assays is 2 m, and only six samples exceed 8 m in length. AMEC regularized the drilling data by compositing the drill-hole data into 8 m lengths within the lithological, alteration and weathering solids.

AMEC back-tagged the 8 m composites using the lithology solid shapes. The composites were also back-tagged with the oxide, mixed, sulphide and alteration solids.

| 14.5 | Exploratory Data Analysis |

Prior to estimation, AMEC constructed contact profiles to analyze the gold, copper and silver composite grade behaviour at the lithological boundaries. The aim of this analysis was to characterize the boundary conditions between the main lithological units and to determine the appropriate combinations of composite data for grade estimation.

Hard, firm, and soft contacts are important for the grade estimation plan. Soft contacts permit sample sharing from two adjacent lithological units during grade estimation. Hard contacts do not permit sample sharing. Firm contacts allow sample sharing across contacts for a certain distance only.

AMEC found firm contacts for the following domain contacts: DP / CFB, DP / VOLCBX, QDP1 / CFB and QDP1 / VOLCBX. The remaining domain boundaries were considered as hard. For the firm boundary domains, AMEC created halos where samples are shared. AMEC expanded the interpretations of DP and QDP1 units horizontally by 60 m and 30 m, respectively, to represent these halos. The estimation domain codes for the expanded DP and QDP1 units were denoted DPEX and QDP1EX respectively. During grade estimation, blocks within this halo shared samples from the DP and QDP1 domains. Additional estimation domains were defined based on potassic-calcic alteration (KCA). The KCA domain was expanded horizontally by 30 m (KCAEX) to allow sample sharing. A summary of grade estimation domains and sample sharing strategies for gold/silver and copper are shown in Table 14.3 and 14.4, respectively.

Project No.: C-580 January, 2012 | Page 156 - 378 |  |

Table 14.3: Estimation Domains and Data Combinations – Gold and Silver

| Domain | Sample Sharing |

| OB | Overburden Samples Only |

| CFB+VOLCBX | Shared Samples CFB+VOLCBX |

| KCA | Potassic-Calcic Alteration Samples Only |

| KCAEX | Samples within 30 m Halo Zone Outside KCA |

| DP | DP Samples Only |

| DPEX | Samples within 60 m Halo Zone Outside DP |

| QDP1 | QDP1 Samples Only |

| QDP1EX | Samples within 30 m Halo Zone Outside QDP1 |

| QDP2 | QDP2 Samples Only |

| DTB | DTB Samples Only |

| MAC | MAC Samples Only |

Table 14.4: Estimation Domains and Data Combinations – Copper

| Domain | Sample Sharing |

| Oxide | Oxide Samples Only |

| Mixed | Shared samples Between Oxide and Sulphide ±30 m |

| Sulphide | Sulphide Samples Only |

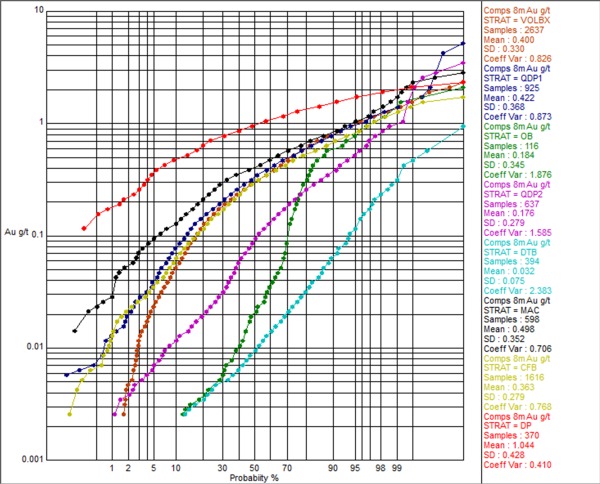

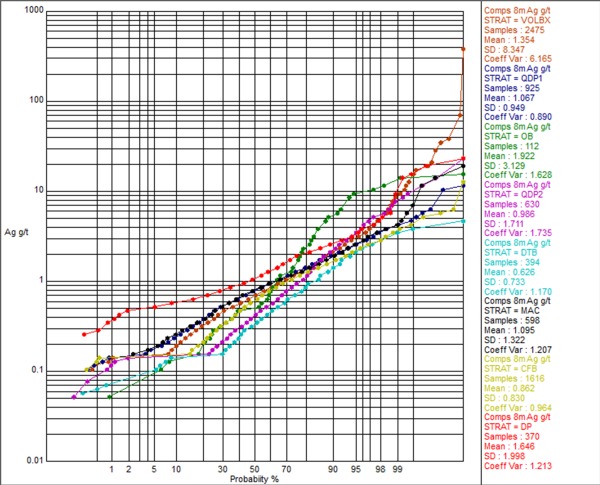

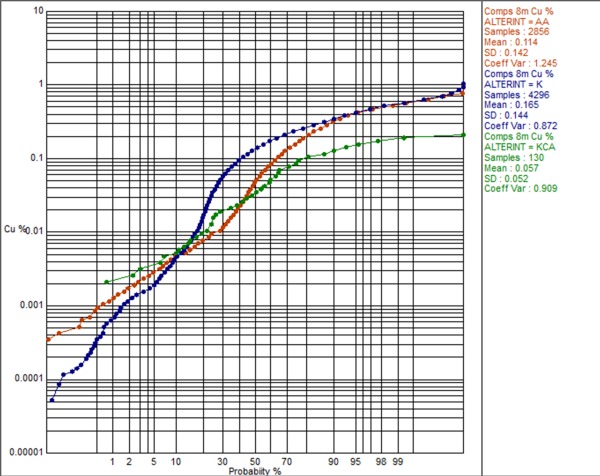

Exploratory data analysis comprised basic statistical evaluation for 8 m composites for gold, copper, silver, arsenic, iron, molybdenum, sulphur, cobalt and zinc. However, the main elements of interest are gold, copper and silver.

Using box plots AMEC observed similar gold means for the basement (CFB) and volcanic breccia units (VOLCBX). The diorite Porphyry (DP) has the highest gold mean and more constrained distribution of grades. All units, excepting OB and DTB, have low coefficient of variation values, confirming the low variability of gold composite grades in the main mineralized units.

Arsenic grades broadly correlate with intensity of argillic alteration which is strongest higher in the system. Although isolated “pods” of higher grade arsenic can locally occur at depth in the central portions of the system.

The DP unit is preferentially mineralized, i.e. it has a higher mean. AMEC notes that the weathering profile, associated with alteration types, is markedly the preferable control for copper mineralization.

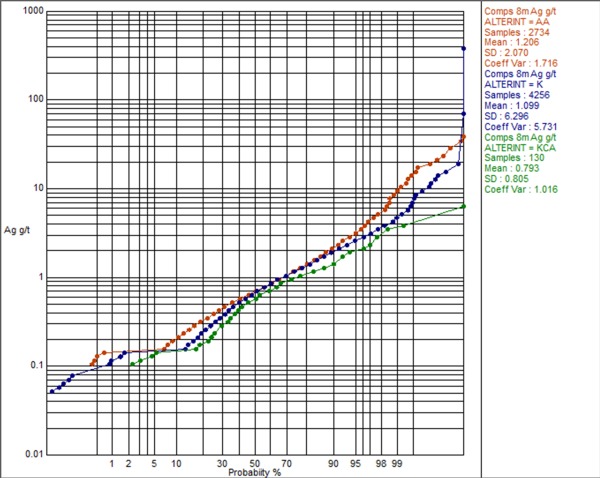

Silver grade distributions are consistent for most lithological units. The oxide portion of the VOLCBX has a higher average silver grade than the overall mean and also higher than the mixed and sulphide zones of the QDP1.

Molybdenum (Mo) grades are higher in VOLCBX, MacNeill and basement rock. This element is likely to be of magmatic provenance and like other gold rich porphyry deposits

Project No.: C-580 January, 2012 | Page 157 - 378 |  |

the distribution of molybdenum in a “halo” around the central intrusions is interpreted to be a function of temperature controlling mineral precipitation, but more detailed mineralogical studies are required to understand the controls for molybdenum mineralization. For this reason AMEC has not reported Mo grades or considered its participation in the economics of the project.

In general, the summary statistics show low variability of gold and copper grades in the main units, diorite Porphyry, basement, VOLCBX, and quartz-diorite porphyries. The homogeneous distribution is also indicated by the low CV values. This homogeneity can also be observed in the cumulative frequency distributions.

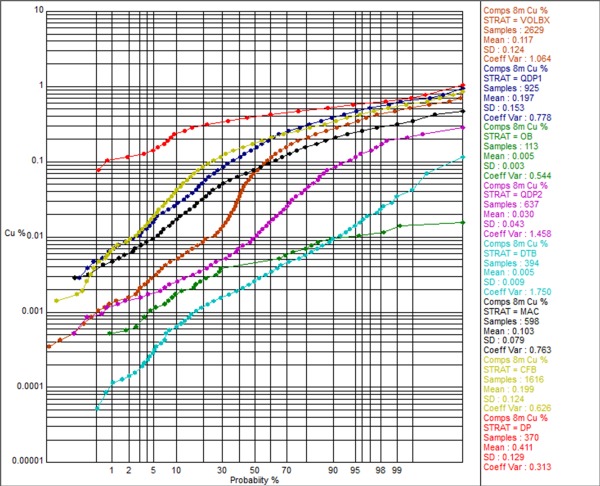

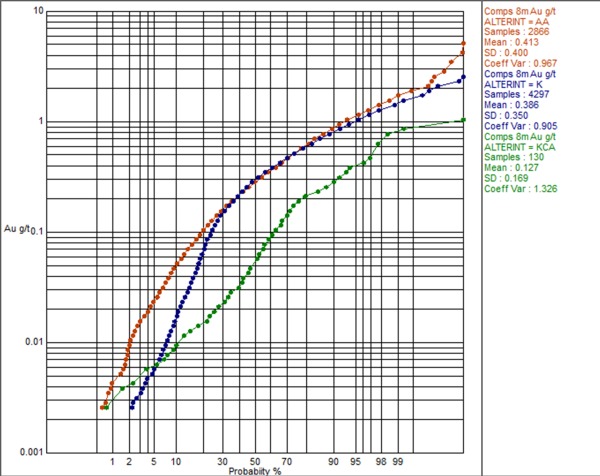

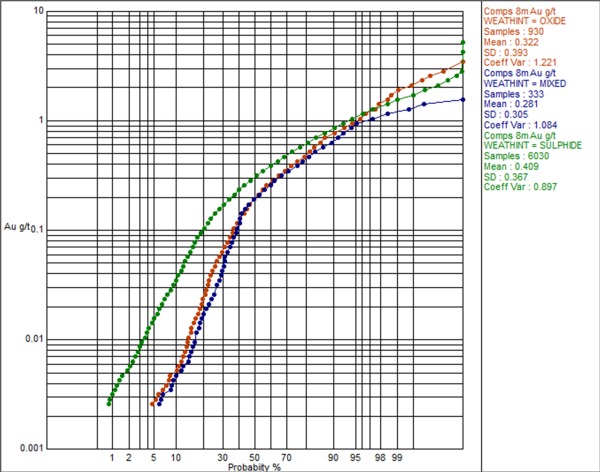

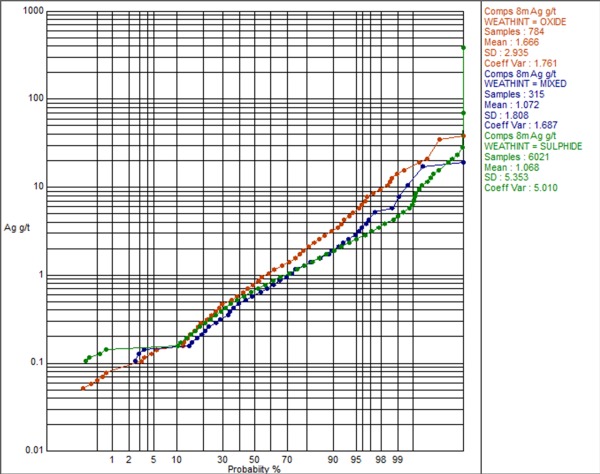

Figure 14.5 to Figure 14.13 show gold, silver and copper log-probability plots for 8 m downhole composites for the Caspiche Porphyry project classified by stratigraphy, alteration and weathering.

Figure 14.5: Caspiche 8 m Composites by Stratigraphy – Log-Prob Plot – g/t Au (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 158 - 378 |  |

Figure 14.6: Caspiche 8 m Composites by Stratigraphy – Log-Prob Plot – g/t Ag (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 159 - 378 |  |

Figure 14.7: Caspiche 8 m Composites by Stratigraphy – Log-Prob Plot - Cu % (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 160 - 378 |  |

Figure 14.8: Caspiche 8 m Composites by Alteration – Log-Prob Plot – g/t Au (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 161 - 378 |  |

Figure 14.9: Caspiche 8 m Composites by Alteration – Log-Prob Plot – g/t Ag (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 162 - 378 |  |

Figure 14.10: Caspiche 8 m Composites by Alteration – Log-Prob Plot - Cu % (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 163 - 378 |  |

Figure 14.11: Caspiche 8 m Composites by Weathering – Log-Prob Plot – g/t Au (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 164 - 378 |  |

Figure 14.12: Caspiche 8 m Composites by Weathering – Log-Prob Plot – g/t Ag (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 165 - 378 |  |

Figure 14.13: Caspiche 8 m Composites by Weathering – Log-Prob Plot - Cu % (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 166 - 378 |  |

Table 14.5 to Table 14.7 summarize basic statistics by estimation domain as determined by AMEC in Section 14.5.1 for gold, silver and copper respectively.

Table 14.5: Caspiche 8 m Composites by Estimation Domain – Summary Statistics - Au ppm

| Domain | No | Minimum | Maximum | Average | Standard | Coefficient |

| Sample | Au ppm | Au ppm | Au ppm | Deviation | of Variation |

| OB | 116 | 0.003 | 2.208 | 0.184 | 0.345 | 1.876 |

| CFB+VOLCBX | 3399 | 0.003 | 2.404 | 0.332 | 0.272 | 0.821 |

| KCA | 130 | 0.003 | 1.047 | 0.127 | 0.169 | 1.326 |

| KCAEX | 66 | 0.019 | 1.379 | 0.313 | 0.303 | 0.969 |

| DP | 356 | 0.177 | 2.263 | 1.075 | 0.407 | 0.379 |

| DPEX | 443 | 0.134 | 1.727 | 0.695 | 0.307 | 0.442 |

| QDP1 | 839 | 0.027 | 5.194 | 0.452 | 0.37 | 0.818 |

| QDP1EX | 354 | 0.023 | 2.165 | 0.524 | 0.401 | 0.764 |

| QDP2 | 598 | 0.003 | 3.4 | 0.184 | 0.286 | 1.552 |

| DTB | 394 | 0.003 | 0.938 | 0.032 | 0.075 | 2.383 |

| MAC | 598 | 0.014 | 2.748 | 0.498 | 0.352 | 0.706 |

Table 14.6: Caspiche 8 m Composites by Estimation Domain – Summary Statistics – Ag ppm

| Domain | No | Minimum | Maximum | Average | Standard | Coefficient |

| Sample | Ag ppm | Ag ppm | Ag ppm | Deviation | of Variation |

| OB | 112 | 0.05 | 15.68 | 1.922 | 3.129 | 1.628 |

| CFB+VOLCBX | 3237 | 0.1 | 399.153 | 1.177 | 7.304 | 6.204 |

| KCA | 130 | 0.1 | 6.204 | 0.793 | 0.805 | 1.016 |

| KCAEX | 66 | 0.15 | 5.076 | 0.929 | 0.842 | 0.907 |

| DP | 356 | 0.249 | 22.373 | 1.667 | 2.032 | 1.219 |

| DPEX | 443 | 0.150 | 6.575 | 1.142 | 0.829 | 0.726 |

| QDP1 | 839 | 0.141 | 11.258 | 1.089 | 0.961 | 0.882 |

| QDP1EX | 354 | 0.1 | 18.903 | 1.018 | 1.453 | 1.427 |

| QDP2 | 591 | 0.05 | 22.138 | 1.036 | 1.755 | 1.694 |

| DTB | 394 | 0.059 | 4.693 | 0.626 | 0.733 | 1.17 |

| MAC | 598 | 0.15 | 19.729 | 1.095 | 1.322 | 1.207 |

Project No.: C-580 January, 2012 | Page 167 - 378 |  |

Table 14.7: Caspiche 8 m Composites by Estimation Domain – Summary Statistics – Cu %

| Domain | No | Minimum | Maximum | Average | Standard | Coefficient |

| Sample | Cu % | Cu % | Cu % | Deviation | of Variation |

| Oxide | 919 | 0.000 | 0.173 | 0.009 | 0.011 | 1.198 |

| Mixed | 333 | 0.000 | 0.508 | 0.054 | 0.095 | 1.767 |

| Sulphide | 6030 | 0.000 | 1.066 | 0.169 | 0.145 | 0.858 |

AMEC used Sage2001 software to construct down-the-hole and directional correlograms for the estimation domains for gold, copper, silver, molybdenum, sulphur and arsenic. The nugget value was determined from the down-the-hole correlograms. Directional correlogram models were fitted using two spherical structures. Typically, the nugget value is low. The first structure ranges of gold along the mineralization plunge are long, reaching 480 m in the QDP1 intrusion. In most of intrusive domains, the variances of both the first and second structures are similar.

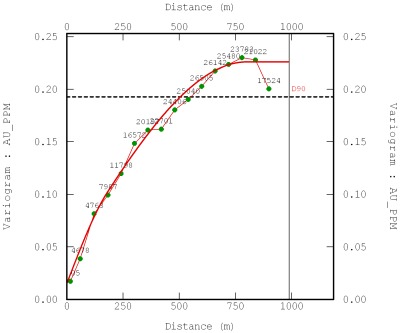

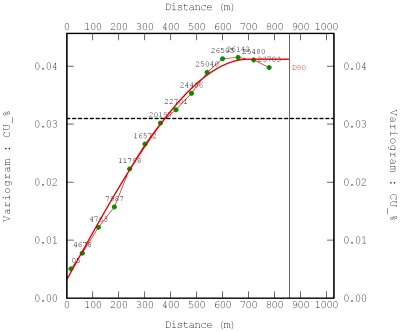

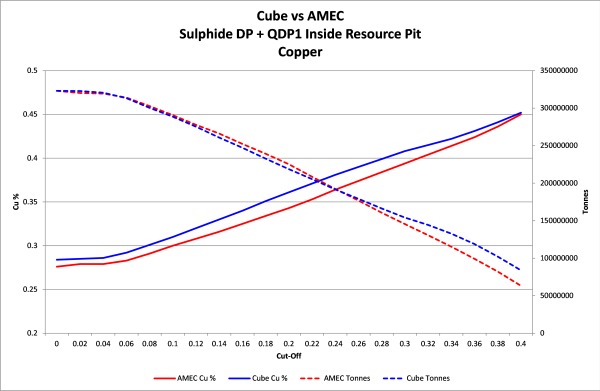

Cube undertook selected variography of the Caspiche Porphyry as part of an independent review of the AMEC 2011 resource estimate. Cube's findings were similar to that of AMEC, in particular, the presence of a low relative nugget value with long and very well structured variogram ranges in a vertical plunge direction for gold and copper. Silver appeared somewhat more variable, manifested by a higher relative nugget and less well developed variogram ranges. Cube combined the DP and QDP1 intrusive units for the purposes of variography. Figure 14.14 and Figure 14.15 show variogram models with maximum ranges of 750 m and 700 m in the vertical plunge direction for gold and copper respectively.

Figure 14.14: Caspiche Variogram Model – DP+QDP1 – Vertical Plunge - Gold (Source: Cube Consulting, 2011)

Project No.: C-580 January, 2012 | Page 168 - 378 |  |

Figure 14.15: Caspiche Variogram Model – DP+QDP1 – Vertical Plunge - Copper (Source: Cube Consulting, 2011)

| 14.7 | Restriction of Extreme High Grade Values |

AMEC evaluated probability plots to define grade outliers for gold, silver, copper, molybdenum, arsenic, sulphur, iron, cobalt and zinc by estimation domains.