QuickLinks -- Click here to rapidly navigate through this documentAs filed with the Securities and Exchange Commission on April 15, 2005

Registration No. 333-122749

Securities and Exchange Commission

Washington, D.C. 20549

Amendment No. 1

to

FORM S-1

REGISTRATION STATEMENT UNDER THE SECURITIES ACT OF 1933

COFFEYVILLE RESOURCES, INC.

(Exact Name of Registrant as Specified in Its Charter)

| Delaware | | 2911 | | 22-2269010 |

(State or Other Jurisdiction of

Incorporation or Organization) | | (Primary Standard Industrial

Classification Code Number) | | (I.R.S. Employer

Identification Number) |

10 East Cambridge Circle Drive

Kansas City, Kansas 66103

(913) 982-0500

(Address, Including Zip Code, and Telephone Number, Including Area Code, of Registrant's Principal Executive Offices)

Philip L. Rinaldi

Coffeyville Resources, Inc.

10 East Cambridge Circle Drive

Kansas City, Kansas 66103

(913) 982-0500

(Name, Address, Including Zip Code, and Telephone Number, Including Area Code, of Agent for Service)

With a copy to:

Bruce S. Mendelsohn

Akin, Gump, Strauss, Hauer & Feld, L.L.P.

Robert S. Strauss Building

1333 New Hampshire Avenue

Washington, D.C. 20036

Telephone: (202) 887-4000 | | Peter M. Labonski

Latham & Watkins LLP

885 Third Avenue

New York, NY 10022

Telephone: (212) 906-1200 |

Approximate date of commencement of proposed sale to the public: As soon as practicable on or after the effective date of this Registration Statement.

If any of the securities being registered on this form are to be offered on a delayed or continuous basis pursuant to Rule 415 under the Securities Act of 1933, check the following box. o

If this form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, please check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

If this form is a post-effective amendment filed pursuant to Rule 462(c) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

If this form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

If delivery of the prospectus is expected to be made pursuant to Rule 434, please check the following box. o

CALCULATION OF REGISTRATION FEE

|

Title of Shares to be Registered

| | Proposed Maximum Aggregate Offering Price(1)(2)

| | Amount of Registration Fee

|

|---|

|

| Common Stock, $0.01 par value | | $300,000,000 | | $35,310(3) |

|

- (1)

- Includes offering price of shares which the underwriters have the option to purchase solely to cover over-allotments, if any.

- (2)

- Estimated solely for the purpose of calculating the registration fee pursuant to Rule 457(o) of the Securities Act of 1933, as amended.

- (3)

- Previously paid.

The registrant hereby amends this registration statement on such date or dates as may be necessary to delay its effective date until the registrant shall file a further amendment which specifically states that this registration statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933, as amended, or until the registration statement shall become effective on such date as the Securities and Exchange Commission, acting pursuant to said Section 8(a), may determine.

SUBJECT TO COMPLETION, DATED APRIL 15, 2005.

The information in this prospectus is not complete and may be changed. We may not sell these securities until the registration statement filed with the Securities and Exchange Commission is effective. This prospectus is not an offer to sell these securities and it is not soliciting an offer to buy these securities in any state where the offer or sale is not permitted.

Shares

Coffeyville Resources, Inc.

Common Stock

Prior to this offering there has been no public market for our common stock. The initial public offering price of the common stock is expected to be between $ and $ per share. We intend to apply to list our common stock on the Nasdaq National Market under the symbol " ."

We are selling shares of common stock in this offering and the selling stockholders are selling shares of common stock in this offering. We will not receive any proceeds from the sale of shares by the selling stockholders.

The underwriters have an option to purchase a maximum of additional shares from the selling stockholders to cover over-allotments.

Investing in our common stock involves risks. See "Risk Factors" on page 11.

| | Price to

Public

| | Underwriting

Discounts and

Commissions

| | Proceeds to

Coffeyville Resources, Inc.

| | Proceeds to

the Selling

Stockholders

|

|---|

| Per Share | | $ | | $ | | $ | | $ |

| Total | | $ | | $ | | $ | | $ |

Delivery of the shares of common stock will be made on or about , 2005.

Neither the Securities and Exchange Commission nor any state securities commission has approved or disapproved of these securities or determined if this prospectus is truthful or complete. Any representation to the contrary is a criminal offense.

| Credit Suisse First Boston | | Jefferies & Company, Inc. |

The date of this prospectus is , 2005.

TABLE OF CONTENTS

| | Page

|

|---|

| PROSPECTUS SUMMARY | | 1 |

| RISK FACTORS | | 11 |

| CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS | | 25 |

| USE OF PROCEEDS | | 26 |

| DIVIDEND POLICY | | 26 |

| CAPITALIZATION | | 27 |

| DILUTION | | 28 |

| UNAUDITED PRO FORMA CONDENSED CONSOLIDATED STATEMENTS OF OPERATIONS | | 29 |

| SELECTED HISTORICAL CONSOLIDATED FINANCIAL DATA | | 32 |

| MANAGEMENT'S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS | | 36 |

| INDUSTRY OVERVIEW | | 62 |

|

|

|

| BUSINESS | | 75 |

| MANAGEMENT | | 102 |

| PRINCIPAL AND SELLING STOCKHOLDERS | | 108 |

RELATED PARTY TRANSACTIONS |

|

110 |

| DESCRIPTION OF OUR INDEBTEDNESS | | 113 |

| DESCRIPTION OF CAPITAL STOCK | | 118 |

| SHARES ELIGIBLE FOR FUTURE SALE | | 120 |

| UNDERWRITING | | 121 |

| NOTICE TO CANADIAN RESIDENTS | | 125 |

| LEGAL MATTERS | | 126 |

| EXPERTS | | 126 |

| WHERE YOU CAN FIND MORE INFORMATION | | 127 |

| GLOSSARY OF SELECTED TERMS | | 128 |

| INDEX TO CONSOLIDATED FINANCIAL STATEMENTS | | F-1 |

You should rely only on the information contained in this document or to which we have referred you. We have not authorized anyone to provide you with information that is different. This document may only be used where it is legal to sell these securities. The information in this document may only be accurate on the date of this document. We will amend or supplement this document as required by law.

Dealer Prospectus Delivery Obligation

Until , 2005, all dealers that effect transactions in these securities, whether or not participating in this offering, may be required to deliver a prospectus. This is in addition to the dealer's obligation to deliver a prospectus when acting as an underwriter and with respect to unsold allotments or subscriptions.

i

PROSPECTUS SUMMARY

This summary highlights information about Coffeyville Resources, Inc. and the offering contained elsewhere in this prospectus. You should carefully read the entire prospectus, including the "Risk Factors" and our consolidated financial statements and related notes included elsewhere in this prospectus before making an investment decision. In this prospectus, all references to "Coffeyville," "the Company," "we," "us," and "our" refer to Coffeyville Resources, Inc. and its consolidated subsidiaries, unless the context otherwise requires or where otherwise indicated. You should also see the "Glossary of Selected Terms" beginning on page 128 for definitions of some of the terms we use to describe our business and industry.

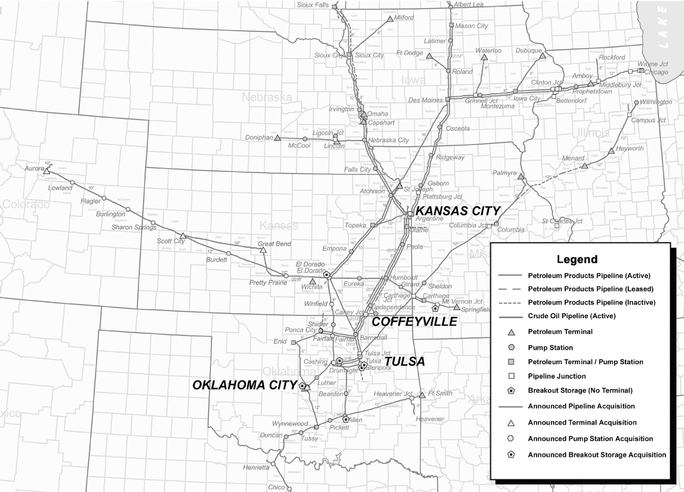

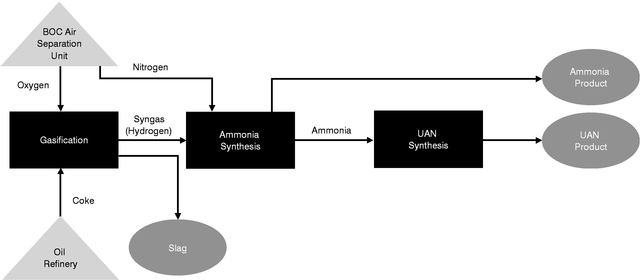

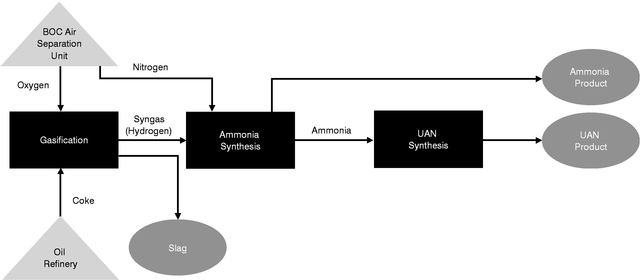

Our Company

We are one of the largest independent high complexity petroleum refiners and marketers in the mid-continental U.S. and the lowest cost producer and marketer of upgraded nitrogen fertilizer products in North America. Our operations are organized into two business segments: petroleum and nitrogen fertilizer. Our petroleum business includes a complex cracking/coking oil refinery in Coffeyville, Kansas, a crude oil gathering system throughout Kansas and Northern Oklahoma, and storage and terminalling facilities for asphalt and refined fuels in Phillipsburg, Kansas. Our refinery operates in close proximity to our primary customer base and benefits from favorable crude oil supply and product distribution logistics. Our nitrogen fertilizer business in Coffeyville, Kansas, includes a petroleum coke gasification plant that produces high purity hydrogen that is converted to ammonia at our ammonia plant and upgraded to urea ammonium nitrate (UAN) at our UAN plant. Our position as the only commercial nitrogen fertilizer plant in North America utilizing a coke gasification process to produce nitrogen fertilizers provides us with a significant competitive advantage due to high prevailing and volatile natural gas prices. On a pro forma basis, we generated revenue of $1.3 billion and $1.7 billion during the fiscal years ended December 31, 2003 and 2004, respectively, an increase of 31%. On a pro forma basis for the same periods, net income was $17.9 million and $59.8 million, respectively, an increase of 234% and our earnings before net interest, taxes, depreciation and amortization (EBITDA), was $32.5 million and $116.5 million, respectively, an increase of 258%.

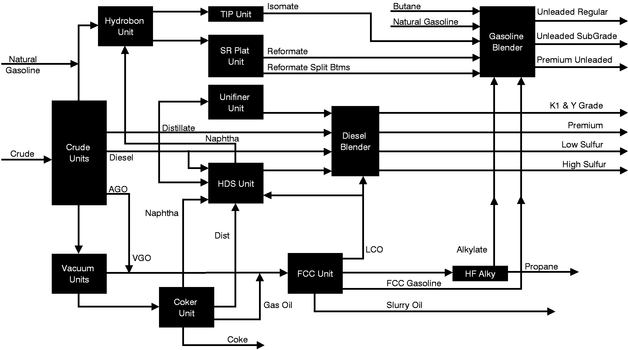

Petroleum Business

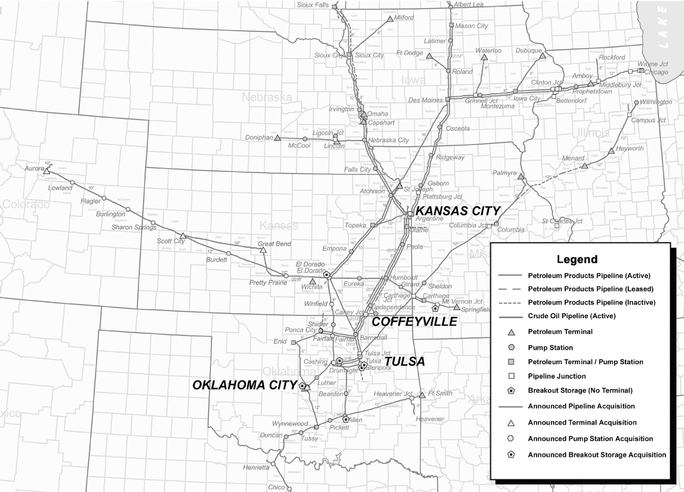

We produce at a throughput of 100,000 barrels per day (bpd), which accounts for approximately 15% of the production of the seven fuels refineries located in the mid-continental U.S. Our cracking/coking refinery has a modified Solomon complexity of approximately 8.8 and Nelson complexity of approximately 9.7, making ours one of the more complex refineries in our region. This complexity allows us to process heavier, less expensive, crude oil compared to competitors with less complex facilities, and still produce a high percentage of high-value, clean transportation fuels such as gasoline and diesel.

We primarily target customers in the Midwestern states where regional demand for petroleum products has exceeded regional refining production. As a result of our geographic location, we do not incur the high cost of transporting refined products to customers in the Midwest compared to refiners located outside the Midwest. Consequently, we estimate our region's refining margins have exceeded Gulf Coast refining margins by approximately $1.93 per barrel on average for the last four years.

Nitrogen Fertilizer Business

We operate the only commercial nitrogen fertilizer plant in North America utilizing a coke gasification process to generate hydrogen feedstock that is converted to ammonia and UAN. By using petroleum coke rather than natural gas as a raw material, we currently have a significant cost advantage over North American natural gas based fertilizer producers. In addition, we benefit

1

economically from high prevailing natural gas prices because fertilizer prices tend to rise with natural gas prices.

We obtain approximately 80% of the petroleum coke we use at our nitrogen fertilizer plant from our adjacent refinery. The use of coke as a raw material in our fertilizer plant also provides a superior value to our refinery's coke, which would otherwise be sold at significantly lower economic value, as is the current practice in the industry. Coke is also readily available in the open market. Our plant produces approximately 370,000 tons per annum of ammonia. We upgrade approximately two-thirds of our ammonia into approximately 638,000 tons per annum of high value UAN (5.6% of U.S. demand), bringing our salable product to approximately 755,000 tons per annum. Due to our close proximity to our nitrogen fertilizer customers and favorable access to transportation logistics, we believe we also enjoy a freight advantage over U.S. Gulf Coast ammonia importers of approximately $65 per ton and over U.S. Gulf Coast UAN importers of approximately $37 per ton. Such cost differentials represent a significant portion of the market price of these commodities.

Market Trends

We have identified several key factors we believe lead to a favorable outlook for the refining and nitrogen fertilizer industries for the next several years.

For the refining industry, these factors include:

- •

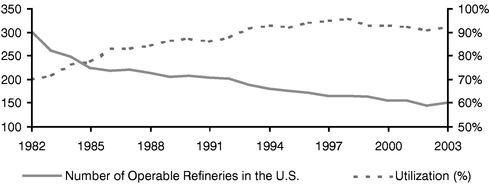

- Continued strong demand as well as supply restrictions experienced since the 1990s are expected to continue as the demand for refined products continues to exceed increases in refining capacity.

- •

- Continued excess availability of lower cost sour and heavy sour crude oil is expected to provide a cost advantage to complex refiners with the ability to process these crude oils.

- •

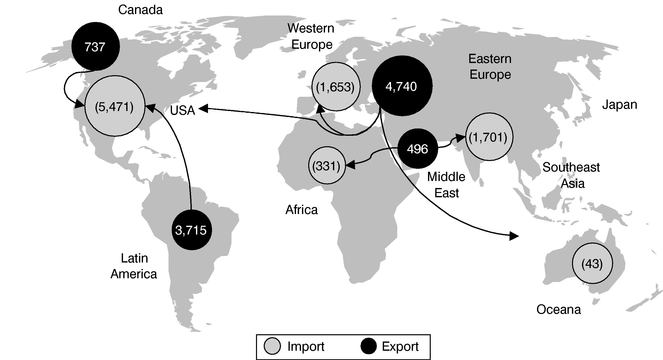

- Increasing reliance on imports to satisfy demand for refined products and lower ability to meet region-specific refined products specifications will favor regional refiners with transportation cost advantages.

- •

- More products based on new and evolving fuel specifications, such as ultra-low sulfur content, will require refiners to blend and process these boutique fuels and exert pressure on product availability.

- •

- High capital costs, excess capacity, and environmental regulatory requirements have severely limited the construction of new refineries in the U.S. over the past thirty years.

For the nitrogen fertilizer industry, these factors include:

- •

- Persistently high natural gas prices, a deficit in natural gas supply and increased demand for natural gas in North America are expected to result in reduced production of natural gas based nitrogen fertilizer products in the U.S. and will help maintain high nitrogen fertilizer prices in the central Midwestern U.S., or the U.S. farm belt, the largest market for nitrogen fertilizer products in the U.S.

- •

- The combined impact of a growing world population, improving diets, and low grain inventories will drive grain prices and productions worldwide and consequently drive high nitrogen and nitrogen based fertilizer prices.

2

Competitive Strengths

Strong Oil Refining Industry Fundamentals

Throughout the U.S., expected annual increases in demand continue to exceed expected increases in refining capacity. As a consequence, there has been a shortage of refined products as evidenced by inventories of refined products, especially gasoline, below their historical averages. These nationwide trends are more pronounced in our marketing region and have benefited us economically.

Strong Nitrogen Fertilizer Industry Fundamentals

We expect the current high nitrogen fertilizer prices to prevail in North America for the foreseeable future due to strong demand from the farming industry and rising grain prices, as well as strong natural gas prices, a deficit in North American ammonia and UAN production and a shortage of fertilizer transportation infrastructure into the mid-continent market where nitrogen fertilizer is primarily consumed.

Regional Focus and Strategic Location

We are located in close proximity to our customers and we benefit from favorable crude oil supply and product distribution logistics, including access to pipelines and railroads in our petroleum and nitrogen fertilizer businesses, respectively. As a result, we believe that our low transportation costs enable us to capture higher margins than similar refineries outside the Midwest.

Efficient, Modern Asset Base

Since 1994, approximately $188 million has been invested to modernize our oil refinery to make it one of the more advanced in our region and to meet environmental regulations. Similarly, between 1999 and 2002, approximately $370 million was invested in our nitrogen fertilizer plant. Our nitrogen fertilizer plant's gasification process uses less than 1% of the natural gas used by natural gas based nitrogen fertilizer plants and emits significantly less pollutants during normal operations compared to other nitrogen fertilizer facilities.

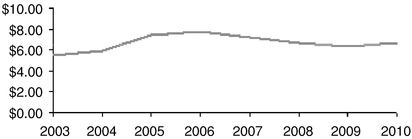

Low Input and Operational Costs

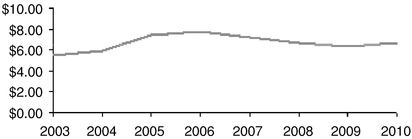

Our refinery is capable of processing heavy sour crude oil, which has become an increasing share of global crude oil production and which tends to be less expensive than lighter, sweeter crudes and contributes to higher margins. In addition, we estimate that our fertilizer plant retains its competitive advantage at natural gas prices in the range of $1.50 to $2.50 per million Btu and above, depending on variations in the UAN premium and logistics costs. This price level is generally low by historical industry standards and our cost advantage is more pronounced at current natural gas prices, which have generally fluctuated between $5.00 and $8.00 per million Btu since the end of 2003.

Experienced Management Team

We have a highly experienced management team, averaging over 23 years of industry experience. Under the leadership of our chief executive officer, Philip L. Rinaldi, we have made significant operational improvements, which have reduced operating costs and increased stockholder value.

Our Business Strategy

We have executed several key strategic initiatives that we believe have significantly enhanced our competitive position and improved our financial and operational performance. Our goal is to continue to be a premier independent refiner and marketer of high-value, clean transportation fuels and

3

producer of ammonia and UAN. We believe that this offering will strengthen our ability to execute the following strategic objectives:

- •

- Continue to take advantage of favorable supply and demand dynamics in the Midwest.

- •

- Selectively invest in high-return projects that enhance our operating efficiency and expand our capacity while rigorously controlling costs.

- •

- Increase our sales and supply capabilities of boutique fuels, UAN, and other high-value products, while finding cheaper sources of raw materials.

- •

- Continue to focus on being a reliable, low-cost supplier to our existing and new customers.

- •

- Continue to devote significant time and resources toward improving the reliability, safety and environmental performance of our operations.

Our History

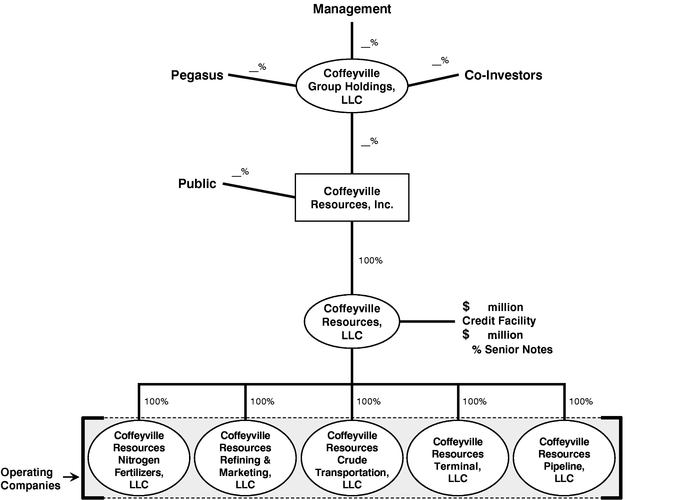

Prior to March 3, 2004, our assets were operated as a small component of Farmland Industries, Inc. (Farmland), an agricultural cooperative. Farmland filed for bankruptcy protection on May 31, 2002. Coffeyville Resources, LLC, a subsidiary of Coffeyville Group Holdings, LLC, won the bankruptcy court auction for Farmland's petroleum business and a nitrogen fertilizer plant and completed the purchase of these assets on March 3, 2004. Throughout this prospectus we refer to this purchase as the Acquisition.

Other Transactions

Prior to the completion of this offering:

- •

- We intend to complete a reorganization pursuant to which the five direct subsidiaries of Coffeyville Group Holdings, LLC will merge with and into us, in exchange for which we will issue 74,852,941 shares of our common stock to Coffeyville Group Holdings, LLC. Coffeyville Group Holding, LLC will then distribute shares of our common stock to certain of its members.

- •

- We intend to liquidate our joint venture with The Leiber Group, Inc., which may include, to the extent required by the terms of the joint venture, a distribution of cash by Coffeyville Resources, LLC to the joint venture which will then distribute the cash to The Leiber Group, Inc. to fully redeem its interest in the joint venture.

- •

- Coffeyville Resources, LLC intends to enter into a new $ million senior secured credit facility, including one or more term loan facilities aggregating $ million and a $ million revolving loan facility.

- •

- Coffeyville Resources, LLC intends to offer $ million aggregate principal amount of % senior notes.

- •

- Coffeyville Resources, LLC intends to repay its existing senior secured credit facility.

- •

- We intend to pay a $ million dividend to Coffeyville Group Holdings, LLC.

Our reorganization and the liquidation of our joint venture with The Leiber Group, Inc. will be completed prior to the offering. The repayment of our existing senior secured credit facility, the entry by Coffeyville Resources LLC into a new senior secured credit facility, the offering by Coffeyville Resources, LLC of the % senior notes, and the payment of a dividend to Coffeyville Group Holdings, LLC are not conditions to the completion of this offering and are referred to in this prospectus as the "related transactions." See "Use of Proceeds," "Related Party Transactions," and "Description of Our Indebtedness."

4

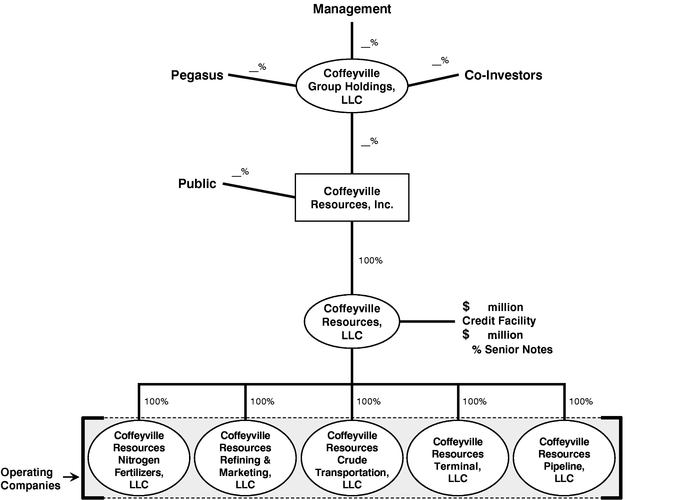

Post-Offering Organizational Structure

The following chart illustrates our organizational and capital structure upon completion of this offering and the related transactions:

5

The Offering

| Issuer | | Coffeyville Resources, Inc. |

Common stock offered by us |

|

shares. |

Common stock offered by the selling stockholders |

|

shares ( shares if the underwriters' over-allotment option is fully exercised). |

Common stock outstanding after the offering |

|

shares. |

Use of proceeds |

|

We estimate that the net proceeds to us in this offering, after deducting underwriters' discounts and commissions of $ million, will be $ million. We plan to use the proceeds from the related transactions (1) to repay existing debt under our senior secured credit facility and (2) to pay a dividend to Coffeyville Group Holdings, LLC. We intend to use the net proceeds from this offering and any remaining net proceeds from the related transactions for general corporate purposes including maintaining available cash. We will not receive any proceeds from the sale of shares by the selling stockholders, including any proceeds from the purchase by the underwriters of up to shares from the selling stockholders to cover over-allotments. See "Use of Proceeds." |

Proposed Nasdaq National Market symbol |

|

" ." |

Risk Factors |

|

See "Risk Factors" beginning on page 11 of this prospectus for a discussion of factors that you should carefully consider before deciding to invest in shares of our common stock. |

Prior to the completion of this offering (i) Coffeyville Resources, LLC intends to enter into a new $ million senior secured credit facility and issue $ million aggregate principal amount of % senior notes and (ii) we intend to repay our existing senior secured credit facility and to pay a $ million dividend to Coffeyville Group Holdings, LLC. None of the repayment of our existing senior secured credit facility, the entry into a new senior secured credit facility, the payment of a dividend to Coffeyville Group Holdings, LLC or the offering of senior notes is a condition to the completion of this offering.

Unless we specifically state otherwise, the information in this prospectus does not take into account the sale of up to shares of common stock, which the underwriters have the option to purchase from the selling stockholders to cover over-allotments.

Coffeyville Resources, Inc., was incorporated in Delaware in January 2005. Our principal executive offices are located at 10 East Cambridge Circle Drive, Kansas City, Kansas 66103, and our telephone number is (913) 982-0500. Our website address is www.coffeyvillegroup.com. Information contained on our website is not a part of this prospectus.

Pegasus Partners II, L.P., which is referred to in this prospectus as Pegasus, was the principal investor in the transaction that created Coffeyville Group Holdings, LLC. Pegasus Capital Advisors, L.P. is the manager of Pegasus. See "Related Party Transactions."

6

Summary Consolidated Financial Information

The summary consolidated financial information presented below under the caption Statement of Operations Data for the years ended December 31, 2002 and 2003, for the 62 day period ended March 2, 2004, and for the 304 day period ended December 31, 2004, and the summary consolidated financial information presented below under the caption Balance Sheet Data as of December 31, 2003 and 2004, have been derived from our consolidated financial statements included elsewhere in this prospectus, which consolidated financial statements have been audited by KPMG LLP, independent registered public accounting firm.

The summary unaudited pro forma condensed consolidated statement of operations data, other financial data and key operating statistics set forth below, give pro forma effect to the acquisition of the assets of the former Petroleum Division and one facility within the eight-plant Nitrogen Fertilizer Manufacturing and Marketing Division of Farmland Industries, Inc. (Farmland) (which we refer to collectively as the Predecessor) and to reflect the refinancing of our senior secured credit facility on May 10, 2004 and the distribution of $ to The Leiber Group, Inc. in connection with the liquidation of a joint venture, in the manner described under "Unaudited Pro Forma Condensed Consolidated Statements of Operations" as if each had occurred as of January 1, 2004. In addition, the summary unaudited pro forma condensed consolidated statement of operations data, other financial data and key operating statistics set forth below give pro forma effect to (i) the repayment of our existing senior secured credit facility, (ii) the entry into a new senior secured credit facility by Coffeyville Resources, LLC, (iii) the issuance of $ million in aggregate principal amount of % senior notes by Coffeyville Resources, LLC, and (iv) the payment of a $ million dividend to Coffeyville Group Holdings, LLC, in the manner described under "Unaudited Pro Forma Condensed Consolidated Statements of Operations" as if each had occurred on January 1, 2004. We refer to our acquisition of the Predecessor as the Acquisition. The summary unaudited pro forma information has been adjusted to include estimated general corporate expenses that would have been incurred if the Predecessor had operated as a stand-alone entity. The summary unaudited pro forma information does not purport to represent what our results of operations would have been if the Acquisition had occurred as of the date indicated or what these results will be for future periods.

Prior to March 3, 2004, our assets were operated as a component of Farmland. Farmland filed for bankruptcy protection under Chapter 11 of the U.S. Bankruptcy Code on May 31, 2002. On March 3, 2004, Coffeyville Resources, LLC completed the purchase of these assets from Farmland in a sales process under Chapter 11 of the U.S. Bankruptcy Code. See note 1 to our consolidated financial statements included elsewhere in this prospectus. As a result of certain adjustments made in connection with the Acquisition, a new basis of accounting was established on the date of the Acquisition and the results of operations for the 304 days ended December 31, 2004 are not comparable to prior periods.

During the Predecessor periods, Farmland allocated certain general corporate expenses and interest expense to the Predecessor. The allocation of these costs is not necessarily indicative of the costs that would have been incurred if the Predecessor had operated as a stand-alone entity. Further, the historical results are not necessarily indicative of the results to be expected in future periods.

We calculate earnings per share for the Successor on a pro forma basis, based on an assumed number of shares outstanding at the time of the initial public offering with respect to the existing shares. All information in this prospectus assumes that prior to this offering, the five direct subsidiaries of Coffeyville Group Holdings, LLC will merge with and into us, in exchange for which we will issue 74,852,941 shares of our common stock to Coffeyville Group Holdings, LLC. No effect has been given to any incremental shares that might be issued in this offering.

We have omitted per share data for the Predecessor because, under Farmland's cooperative structure, earnings of the Predecessor were distributed as patronage dividends to members and

7

associate members based on the level of business conducted with the Predecessor as opposed to a common shareholder's proportionate share of underlying equity in the Predecessor.

The Predecessor was not a separate legal entity, and its operating results were included with the operating results of Farmland and its subsidiaries in filing consolidated federal and state income tax returns. As a cooperative, Farmland was subject to income taxes on all income not distributed to patrons as qualifying patronage refunds and Farmland did not allocate income taxes to its divisions. As a result, the Predecessor periods do not reflect any provision for income taxes.

The historical data presented below has been derived from financial statements that have been prepared using U.S. generally accepted accounting principles and the pro forma data presented below has been derived from the "Unaudited Pro Forma Condensed Consolidated Statements of Operations" included elsewhere in this prospectus. This data should be read in conjunction with the financial statements and related notes and "Management's Discussion and Analysis of Financial Condition and Results of Operations" included elsewhere in this prospectus.

| |

| |

| |

| |

| |

| | Pro Forma to

Give Effect to

the Related

Transactions

|

|---|

| | Predecessor

| |

| |

|

|---|

| | Successor

| | Pro Forma

|

|---|

| | Year Ended

December 31,

| |

|

|---|

| | 62 Days

Ended

March 2,

2004

| | 304 Days

Ended

December 31,

2004

| | Year

Ended

December 31,

2004

| | Year

Ended

December 31,

2004

|

|---|

| | 2002

| | 2003

|

|---|

| |

| |

| |

| |

| | (unaudited)

| | (unaudited)

|

|---|

| | (in millions, except as otherwise indicated)

|

|---|

| Statement of Operations Data: | | | | | | | | | | | | | | | | | | |

| Net sales | | $ | 887.5 | | $ | 1,262.2 | | $ | 261.1 | | $ | 1,479.9 | | $ | 1,741.0 | | $ | |

| Gross profit (loss) | | | (58.5 | ) | | 63.9 | | | 15.9 | | | 116.5 | | | 132.5 | | | |

| Selling, general and administrative expenses | | | 16.3 | | | 23.6 | | | 4.7 | | | 16.5 | | | 19.5 | | | |

| Impairment, and other charges(1) | | | 375.1 | | | 10.9 | | | — | | | — | | | — | | | |

| | |

| |

| |

| |

| |

| |

|

| Operating income (loss) | | $ | (449.9 | ) | $ | 29.4 | | $ | 11.2 | | $ | 100.0 | | $ | 113.0 | | $ | |

| Other (income) expense(2) | | | 4.1 | | | 0.2 | | | — | | | 6.4 | | | (0.8 | ) | | |

| Interest expense | | | 11.7 | | | 1.3 | | | — | | | 10.1 | | | 13.4 | | | |

| | |

| |

| |

| |

| |

| |

|

| Income (loss) before taxes | | $ | (465.7 | ) | $ | 27.9 | | $ | 11.2 | | $ | 83.5 | | $ | 100.4 | | $ | |

| Income tax provision | | | — | | | — | | | — | | | 33.8 | | | 40.6 | | | |

| | |

| |

| |

| |

| |

| |

|

| Net income (loss) | | $ | (465.7 | ) | $ | 27.9 | | $ | 11.2 | | $ | 49.7 | | $ | 59.8 | | $ | |

Pro forma earnings per share,

basic and diluted | | | | | | | | | | | $ | 0.67 | | $ | | | $ | |

Pro forma weighted average shares,

basic and diluted |

|

|

|

|

|

|

|

|

|

|

|

74.7 |

|

|

|

|

|

|

Other Financial Data: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Depreciation and amortization | | $ | 30.8 | | $ | 3.3 | | $ | 0.4 | | $ | 2.4 | | $ | 2.7 | | $ | |

| EBITDA(3) | | | (423.2 | ) | | 32.5 | | | 11.6 | | | 96.0 | | | 116.5 | | | |

| Adjusted EBITDA(4) | | | (47.8 | ) | | 42.1 | | | 11.6 | | | 103.2 | | | 116.5 | | | |

| Capital expenditures for property, plant and equipment | | | 272.4 | | | 0.8 | | | — | | | 14.2 | | | 14.2 | | | |

Petroleum Business |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Production (barrels per day) | | | 84,343 | | | 95,701 | | | 106,645 | | | 102,046 | | | 102,825 | | | |

| Crude oil throughput (barrels per day) | | | 74,446 | | | 85,501 | | | 92,596 | | | 90,418 | | | 90,787 | | | |

Nitrogen Fertilizer Business |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Production Volume: | | | | | | | | | | | | | | | | | | |

| | Ammonia (tons in thousands) | | | 265.1 | | | 335.7 | | | 56.4 | | | 252.8 | | | 309.2 | | | |

| | UAN (tons in thousands) | | | 434.6 | | | 510.6 | | | 93.4 | | | 439.2 | | | 532.7 | | | |

8

| | Predecessor

| | Successor

|

|---|

| | December 31,

2003

| | December 31,

2004

|

|---|

| | (in millions, except as otherwise indicated)

|

|---|

| Balance Sheet Data: | | | | | | |

| Cash, cash equivalents and short-term investments | | $ | — | | $ | 52.7 |

| Working capital(5) | | | 150.5 | | | 106.6 |

| Total assets | | | 199.0 | | | 229.2 |

| Liabilities subject to compromise | | | 105.2 | | | — |

| Total debt, including current portion | | | — | | | 148.9 |

| Divisional/members equity | | | 58.2 | | | 14.1 |

- (1)

- Includes the following:

- •

- During the year ended December 31, 2002, we recorded a $375.1 million asset impairment related to the write-down of the refinery and nitrogen fertilizer plant to fair market value.

- •

- During the year ended December 31, 2003, we recorded an additional charge of $9.6 million related to the asset impairment of the refinery and nitrogen fertilizer plant based on the expected sales price of the assets in the Acquisition. In addition, we recorded a charge of $1.3 million for the rejection of existing contracts.

- (2)

- During the 304 days ended December 31, 2004, we recognized a loss of $7.2 million on early extinguishment of debt.

- (3)

- EBITDA represents earnings before net interest, taxes, depreciation and amortization. Management believes that EBITDA is a useful adjunct to net income and other measurements under GAAP because it is a meaningful measure for evaluating our performance in a given period compared to prior periods and compared to other companies in our industry, as interest, taxes, depreciation and amortization can vary significantly across periods and between companies due in part to differences in accounting policies, tax strategies, levels of indebtedness, capital purchasing practices and interest rates. EBITDA also assists management in evaluating operating performance. EBITDA, with adjustments specified in our credit agreement, is also the basis for calculating our financial debt covenants under our existing credit facility. Accordingly, management believes that EBITDA is an accepted indicator of our ability to incur and service debt obligations. EBITDA has distinct limitations as compared to GAAP information, such as net income, income from continuing operations or operating income. By excluding interest and income taxes for example, it may not be apparent that both represent a reduction in cash available to us. Likewise, depreciation and amortization, while non-cash items, represent generally the decreases in value of assets that produce revenue for us. EBITDA should not be substituted as an alternative to net income or income from operations, which are measures of performance in accordance with accounting principles generally accepted in the United States of America (GAAP). We believe EBITDA assists the investing community in evaluating our performance. Our computation of EBITDA for this purpose may not be comparable to other similarly titled measures computed for other purposes or by other companies because all companies do not calculate EBITDA in the same fashion. The following is a reconciliation of EBITDA to net income:

| | Predecessor

| |

| |

|

|---|

| | Successor

| | Pro Forma

|

|---|

| | Year Ended December 31,

| |

|

|---|

| | 62 Days

Ended

March 2,

2004

| | 304 Days

Ended

December 31,

2004

| | Year

Ended

December 31,

2004

|

|---|

| | 2002

| | 2003

|

|---|

| |

| |

| |

| |

| | (unaudited)

|

|---|

| | (in millions)

|

|---|

| EBITDA | | $ | (423.2 | ) | $ | 32.5 | | $ | 11.6 | | $ | 96.0 | | $ | 116.5 |

| Less: | | | | | | | | | | | | | | | |

| | Income tax (benefit) provision for taxes | | | — | | | — | | | — | | | 33.8 | | | 40.6 |

| | Interest expense | | | 11.7 | | | 1.3 | | | — | | | 10.1 | | | 13.4 |

| | Depreciation and amortization | | | 30.8 | | | 3.3 | | | 0.4 | | | 2.4 | | | 2.7 |

| | |

| |

| |

| |

| |

|

| Net income (loss) | | $ | (465.7 | ) | $ | 27.9 | | $ | 11.2 | | $ | 49.7 | | $ | 59.8 |

- (4)

- For the periods presented, Adjusted EBITDA represents EBITDA plus or minus the items described below. We believe additional adjustments to EBITDA for these special charges provides a meaningful comparison of period-to-period results. We present Adjusted EBITDA as a further supplemental measure of our performance and ability to service debt. We prepare Adjusted EBITDA by adjusting EBITDA to eliminate the impact of a number of items we do not consider indicative of our ongoing operating performance. As an analytical tool, Adjusted EBITDA is subject to all of the limitations applicable to EBITDA. In addition, in evaluating Adjusted EBITDA, you should be aware that in the future we may incur expenses similar to the

9

adjustments in this presentation. Our presentation of Adjusted EBITDA should not be construed as an inference that our future results will be unaffected by unusual items.

| | Predecessor

| |

| |

|

|---|

| | Successor

| | Pro Forma

|

|---|

| | Year Ended December 31,

| |

|

|---|

| | 62 Days

Ended

March 2,

2004

| | 304 Days

Ended

December 31,

2004

| | Year

Ended

December 31,

2004

|

|---|

| | 2002

| | 2003

|

|---|

| |

| |

| |

| |

| | (unaudited)

|

|---|

| | (in millions)

|

|---|

| Adjusted EBITDA | | $ | (47.8 | ) | $ | 42.1 | | $ | 11.6 | | $ | 103.2 | | $ | 116.5 |

| Less: | | | | | | | | | | | | | | | |

| | Impairment of property, plant and equipment(a) | | | 375.1 | | | 9.6 | | | — | | | — | | | — |

| | Fertilizer lease payments(b) | | | 0.3 | | | — | | | — | | | — | | | — |

| | Loss on extinguishment of debt(c) | | | — | | | — | | | — | | | 7.2 | | | — |

| | |

| |

| |

| |

| |

|

| EBITDA | | $ | (423.2 | ) | $ | 32.5 | | $ | 11.6 | | $ | 96.0 | | $ | 116.5 |

- (a)

- During the year ended December 31, 2002, we recorded a $375.1 million asset impairment related to the write-down of our refinery and nitrogen fertilizer plant to fair market value. During the year ended December 31, 2003, we recorded an additional charge of $9.6 million related to the asset impairment of our refinery and nitrogen fertilizer plant based on the expected sales price of the assets in the Acquisition.

- (b)

- Reflects the impact of an operating lease structure utilized by Farmland to finance the nitrogen fertilizer plant. The cost of this plant under the operating lease was $263.0 million and the rental payments were $0.3 million for the period ended December 31, 2002. In February 2002, Farmland refinanced the operating lease into a secured loan structure, which effectively terminated the lease and all of Farmland's obligations under the lease.

- (c)

- Represents the write-off of $7.2 million of deferred financing costs in connection with the refinancing of our senior secured credit facility on May 10, 2004.

- (5)

- Excludes liabilities subject to compromise due to the Predecessor's bankruptcy of $105.2 million as of December 31, 2003 in calculating the Predecessor's working capital.

10

RISK FACTORS

You should carefully consider each of the following risks and all of the information set forth in this prospectus before deciding to invest in our common stock. If any of the following risks and uncertainties develops into actual events, our business, financial condition or results of operations could be materially adversely affected. In that case, the price of our common stock could decline and you could lose part or all of your investment.

Risks Related to Our Petroleum Business

Volatile margins in the refining industry may cause volatility or a decline in our future results of operations and decrease our cash flow.

Our petroleum business' financial results are primarily affected by the relationship, or margin, between refined product prices and the prices for crude oil and other feedstocks. Future volatility in refining industry margins may cause volatility or a decline in our results of operations, since the margin between refined product prices and feedstock prices may decrease below the amount needed for us to generate net cash flow sufficient for our needs. Although an increase or decrease in the price for crude oil generally results in a similar increase or decrease in prices for refined products, there is normally a time lag in the realization of the similar increase or decrease in prices for refined products. The effect of changes in crude oil prices on our results of operations therefore depends in part on how quickly and how fully refined product prices adjust to reflect these changes. A substantial or prolonged increase in crude oil prices without a corresponding increase in refined product prices, a substantial or prolonged decrease in refined product prices without a corresponding decrease in crude oil prices, or a substantial or prolonged decrease in demand for refined products could have a significant negative impact on our earnings, results of operations and cash flows.

If we are required to obtain our crude oil supply without the benefit of our credit intermediation agreement, our exposure to the risks associated with volatile crude prices may increase and our liquidity may be reduced.

We currently obtain the majority of our crude oil supply through a crude oil credit intermediation agreement with BP Oil Supply Company, which minimizes the amount of in transit inventory and mitigates crude pricing risks by ensuring pricing takes place extremely close to the time when the crude is refined and the yielded products are sold. In the event this agreement is terminated or is not renewed prior to expiration we may be unable to obtain similar services from another party at the same or better terms as our existing agreement. Our current credit intermediation agreement expires on December 31, 2005. We cannot assure you that we will be able to renegotiate a new credit intermediation agreement on similar terms, or at all. Further, if we were required to obtain our crude oil supply without the benefit of an intermediation agreement, our exposure to crude pricing risks may increase, even despite any hedging activity in which we may engage, and our liquidity would be negatively impacted due to the increased inventory and the negative impact of market volatility.

Disruption of our ability to obtain an adequate supply of crude oil could reduce our liquidity and increase our costs.

Our refinery requires approximately 80,000 bpd of crude oil in addition to the light sweet crude oil we gather locally in Kansas and Northern Oklahoma. We obtain a significant amount of our non-gathered crude oil, approximately 40% to 60% in any given month, from Latin America and South America. If these supplies become unavailable to us, we may be required to seek supplies from the Middle East, West Africa and the North Sea. We are subject to the political, geographic, and economic risks attendant to doing business with suppliers located in those regions. In the event that one or more of our traditional suppliers becomes unavailable to us, we may be unable to obtain an adequate supply of crude oil, or we may only able to obtain our crude oil supply at unfavorable prices. As a result, we

11

may experience a reduction in our liquidity and our results of operations could be materially adversely affected.

Our profitability is linked to the light/heavy crude oil price spread, which increased significantly in 2004. A decrease in the spread would negatively impact our profitability.

Our profitability is linked to the price spread between light and heavy crude oil. We prefer to refine heavier sour crude oils because they have historically provided wider refining margins than light sweet crude. Accordingly, any tightening of the light/heavy spread will reduce our profitability. During 2004 relatively high demand for lighter sweet crude due to increasing demand for more highly refined fuels resulted in an attractive light/heavy crude oil price spread. However, crude oil prices may not remain at current levels and the light/heavy spread may decline, which could result in a decline in profitability or operating losses, particularly if there is a worldwide softening of product demand that lessens the need for marginal sweet crude refining.

Our refinery faces operating hazards and interruptions, including unscheduled maintenance or downtime. The limits on insurance coverage could expose us to potentially significant liability costs to the extent such hazards or interruptions are not fully covered.

Our operations are subject to significant operating hazards and interruptions. If our refinery experiences a major accident or fire, is damaged by severe weather or other natural disaster, or is otherwise forced to curtail its operations or shut down, we could incur significant losses which would have an adverse impact on our financial results. In addition, a major accident, fire or other event could damage our refinery or the environment or result in injuries or loss of life. If our refinery experiences a major accident or fire or other event or an interruption in supply or operations, our business could be materially adversely affected if the damage or liability exceeds the amounts of business interruption, property, terrorism and other insurance that we maintain against these risks. We maintain insurance capped at $300 million. In the event of a business interruption we would not be entitled to recover our loses until such interruption exceeds 45 days in the aggregate. We are fully exposed to losses in excess of this cap and that occur in the 45 days of our deductible period.

Our refinery consists of many processing units, a number of which have been in operation for a long time. One or more of the units may require unscheduled down time for unanticipated maintenance or repairs that is more frequent than our scheduled turnaround every one to five years for each unit, or our planned turnarounds may last longer than anticipated. Scheduled and unscheduled maintenance could reduce our revenues during the period of time that our units are not operating.

If our access to the pipelines on which we rely for the supply of our feedstock and the distribution of our products is interrupted, our inventory and costs may increase and we may be unable to efficiently distribute our products.

If one of the pipelines on which we rely for one supply of our crude oil becomes inoperative, we would be required to obtain crude oil for our refinery through an alternative pipeline or from additional tank trucks, which could increase our costs and result in lower production levels and profitability. Similarly, if a major refined fuels pipeline becomes inoperative, we would be required to keep refined fuels in inventory or supplied to our customers through an alternative pipeline or by additional tank trucks from the refinery, which could increase our costs and result in a decline in profitability.

Our petroleum business' financial results are seasonal and generally lower in the first and fourth quarters of the year, which may cause volatility in the price of our common stock.

Demand for gasoline products is generally higher during the summer months than during the winter months due to seasonal increases in highway traffic and road construction work. As a result, our

12

results of operations for the first and fourth calendar quarters are generally lower than for those for the second and third quarters, which may cause volatility in the price of our common stock. Further, reduced agricultural work during the winter months somewhat depresses demand for diesel in the winter months. In addition to the overall seasonality of our business, unseasonably cool weather in the summer months and/or unseasonably warm weather in the winter months in the markets in which we sell our petroleum products could have the effect of reducing demand for gasoline and diesel which could result in lower prices and reduce operating margins.

We face significant competition, both within and outside of our industry. Competitors who produce their own supply of feedstocks, have extensive retail outlets, make alternative fuels or have greater financial resources than we do may have a competitive advantage over us.

The refining industry is highly competitive with respect to both feedstock supply and refined product markets. If we are unable to compete effectively with our competitors within and outside of our industry, we may be unable to sustain our current level of profitability. We compete with numerous other companies for available supplies of crude oil and other feedstocks and for outlets for our refined products. We are not engaged in the petroleum exploration and production business and therefore do not produce any of our crude oil feedstocks. We do not have a retail business and therefore are dependent upon others for outlets for our refined products. We do not have any long-term arrangements for much of our output. Many of our competitors in the U.S. as a whole, and one of our regional competitors, obtain a significant portion of their feedstocks from company-owned production and have extensive retail outlets. Competitors that have their own production or extensive retail outlets with brand-name recognition are at times able to offset losses from refining operations with profits from producing or retailing operations, and may be better positioned to withstand periods of depressed refining margins or feedstock shortages. A number of our competitors also have materially greater financial and other resources than us. These competitors have a greater ability to bear the economic risks inherent in all phases of the refining industry. In addition, we compete with other industries that provide alternative means to satisfy the energy and fuel requirements of our industrial, commercial and individual consumers.

Governmental regulations and policies affect the prices and demand for our petroleum products and will require us to make substantial capital expenditures in the future.

We expect to make significant capital expenditures over the next several years in order to comply with federal and local environmental regulations. The United States Environmental Protection Agency (EPA) has promulgated regulations under the federal Clean Air Act that establish stringent low sulfur content specifications for our petroleum products, including the Tier II gasoline standards, as well as regulations with respect to on- and off- road diesel fuel, which are designed to reduce air emissions from the use of these products. In addition, in May 2004 the EPA finalized regulations to reduce sulfur in off-road diesel fuel by 2010. Depending on our compliance strategy for the off-road diesel rules, we estimate our capital expenditures required to comply with the on- and off-road diesel standards will range between $75 to $85 million over the next two years. Based on our preliminary estimates, we believe that compliance with the Tier II gasoline standards will require us to spend approximately $35 million between 2008 and 2010. See "Business—Environmental Matters—Fuel Regulations."

There have been numerous recently promulgated National Emission Standards for Hazardous Air Pollutants (NESHAP or MACT). Some or all of these MACT standards may require us to install controls or changes to our operations in order to comply. These new requirements, other requirements of the federal Clean Air Act, or other presently existing or future environmental laws and regulations could cause us to expend substantial amounts to permit our refinery to produce products that meet applicable requirements and could have an adverse impact on our operations, financial condition or cash flows for any given period.

13

In March 2004, we entered into a Consent Decree with EPA and KDHE to address certain allegations of Clean Air Act violations by Farmland at the oil refinery in order to reduce environmental risks and liabilities going forward, including sulfur dioxide emissions. Pursuant to the Consent Decree, in the short-term, we will increase sulfur dioxide—reducing catalyst additives to the fluid catalytic cracking unit at the facility to reduce emissions of sulfur dioxide. We will install controls to minimize sulfur dioxide emissions in the long-term. In addition, we will undertake an investigation to verify the facility's compliance with the Benzene Waste Oil NESHAP. Depending upon the results of that investigation, we may need to install additional controls on the facility's wastewater treatment system. In addition, pursuant to the Consent Decree, we assumed certain cleanup obligations at the refinery. There are other permitting, monitoring, recordkeeping and reporting requirements associated with the Consent Decree. The overall costs of complying with the Consent Decree over the next six years are expected to be approximately $20 to $30 million.

Changes in our credit profile may affect our relationship with our suppliers, which could have a material adverse effect on our liquidity.

Changes in our credit profile may affect the way crude oil suppliers view our ability to make payments and induce them to shorten the payment terms of their invoices. Given the large dollar amounts and volume of our feedstock purchases, a change in payment terms may have a material adverse effect on our liquidity and our ability to make payments to our suppliers.

We have additional capital needs for which our internally generated cash flows and other sources of liquidity may not be adequate.

If we cannot generate cash flow or otherwise secure sufficient liquidity to support our short term and long term capital requirements, we may be unable to comply with certain environmental standards or pursue our business strategies, in which case our operations may not perform as well as we currently expect. We have substantial short term and long term capital needs, including for capital expenditures we will make to comply with Tier II gasoline standards, on-road diesel regulations, off-road diesel regulations and the Consent Decree. Most of these expenditures will occur during the next two years. Our short-term working capital needs are primarily crude oil purchase requirements, which fluctuate with the pricing and sourcing of crude oil. We also have significant long-term needs for cash. We currently estimate that mandatory capital and turnaround expenditures, excluding the non-recurring capital expenditures required to comply with Tier II gasoline standards, on-road diesel regulations, off-road diesel regulations and the Consent Decree described above, to be between $14.3 million and $27.2 million per year over the next five years.

Risks Related to Our Nitrogen Fertilizer Business

Our nitrogen fertilizer plant has high fixed costs. If natural gas prices fall below a certain level, our nitrogen fertilizer business may not generate sufficient revenue to operate profitably or cover its costs.

Our nitrogen fertilizer plant has high fixed costs. As a result, downtime or low productivity due to reduced demand, weather interruptions, equipment failures, low prevailing prices for our products or other causes can result in significant operating losses. Unlike our competitors, whose primary costs are related to the purchase of natural gas and whose fixed costs are minimal, we have high fixed costs not dependent on the price of natural gas. A decline in natural gas prices has the effect of reducing the base price for our products without a corresponding reduction in our costs. Any decline in the price of our fertilizer products for whatever reason would have a negative impact on our profitability and results of operations.

14

Our nitrogen fertilizer business is cyclical, which exposes us to potentially significant fluctuations in our financial condition and results of operations, which could result in volatility in the price of our common stock.

A significant portion of our nitrogen fertilizer product sales consists of sales of agricultural commodity products, exposing us to fluctuations in supply and demand in the agricultural industry. These fluctuations historically have had and could in the future have significant effects on prices across all of our nitrogen fertilizer products and, in turn, our nitrogen fertilizer business' results of operations and financial condition, which could result in significant volatility in the price of our common stock. The prices of nitrogen fertilizer products depend on a number of factors which are largely outside of our control, including general economic conditions, cyclical trends in end-user markets, supply and demand imbalances, and weather conditions, which have a greater relevance because of the seasonal nature of fertilizer application. Changes in supply result from capacity additions or reductions and from changes in inventory levels. Demand for fertilizer products is dependent, in part, on demand for crop nutrients by the global agricultural industry. Periods of high demand, high capacity utilization, and increasing operating margins have tended to result in new plant investment and increased production until supply exceeds demand, followed by periods of declining prices and declining capacity utilization until the cycle is repeated.

Adverse weather conditions during peak fertilizer application periods may have a negative effect upon our results of operations and financial condition, as our agricultural customers are geographically concentrated.

Sales of our fertilizer products to agricultural customers are concentrated in the Great Plains and Midwest states and are seasonal in nature. For example, our nitrogen fertilizer business generates greater net sales and operating income in the spring. Accordingly, an adverse weather pattern affecting agriculture in these regions or during this season could have a negative effect on fertilizer demand, which could, in turn, result in a decline in our net sales, lower margins and otherwise negatively affect our financial condition and results of operations. Our quarterly results may vary significantly from one year to the next due primarily to weather-related shifts in planting schedules and purchase patterns, as well as the relationship between natural gas and nitrogen fertilizer product prices.

If China begins to export urea on a large scale, the global market for fertilizer could be destabilized, which could negatively affect our margins, financial condition, and results of operations.

Given the rapid expansion of Chinese urea production and the possibility that other nitrogen based fertilizers may meet an increasing share of Chinese domestic demand, China may begin to export large volumes of urea, thereby putting downward pressure on the price of urea and UAN globally. Because we convert a significant portion of our ammonia production to UAN, and because UAN currently generates higher margins than ammonia, lower UAN prices could negatively affect our results of operations, margins and financial condition.

Our margins and results of operations may be adversely affected by the supply and price levels of petroleum coke and other essential raw materials.

Petroleum coke is a key raw material used in the manufacture of our nitrogen fertilizer products. Increases in the price of petroleum coke could result in a decrease in our profit margins or results of operations. Our profitability is directly affected by the price and availability of petroleum coke obtained from our oil refinery and purchased from third parties. If we are unable to obtain the majority of the coke we need from our adjacent oil refinery we will be required to purchase coke on the open market, which would subject us to fluctuations in the price of petroleum coke on the open market. We have no way of predicting to what extent petroleum coke prices will rise in the future. In addition, the air separation plant that provides oxygen, nitrogen, and compressed dry air to our nitrogen fertilizer plant's gasifier has experienced numerous short term (one to five minute) interruptions in our gasifier operations. If we cannot maintain a reliable supply of raw materials for our operations, we may be

15

unable to produce our products at current levels and our reputation, customer relationships and results of operations may be harmed.

We cannot assure you that we will be able to maintain an adequate supply of petroleum coke and other essential raw materials or that this supply will not be delayed or interrupted, resulting in production delays or in cost increases if alternative sources of supply prove to be more expensive or difficult to obtain. If our cost of raw materials were to increase, or if we were to experience an extended interruption in the supply of raw materials, including petroleum coke, to our production facilities, we could lose sale opportunities, damage our relationships with or lose customers, suffer lower margins, and experience other negative effects to our business, results of operations and financial condition. In addition, if natural gas prices in the U.S. were to decline to a level that prompts those U.S. producers who have permanently or temporarily closed production facilities to resume fertilizer production, this would likely contribute to a global supply/demand imbalance that could negatively affect our margins, results of operations and financial condition.

Ammonia can be very volatile. If we are held liable for accidents involving ammonia that cause severe damage to property and/or injury to the environment and human health, our financial condition and the price of our common stock could decline.

We manufacture, process, store, handle, distribute and transport ammonia, which is very volatile. Accidents, releases or mishandling involving ammonia could cause severe damage or injury to property, the environment and human health, as well as a possible disruption of supplies and markets. Such an event could result in civil lawsuits and regulatory enforcement proceedings, both of which could lead to significant liabilities. Any damage to persons, equipment or property or other disruption of our ability to produce or distribute our products could result in a significant decrease in operating revenues and significant additional cost to replace or repair and insure our assets, which could negatively affect our operating results and financial condition. In addition, we may incur significant losses or costs relating to the operation of railcars used for the purpose of carrying various products, including ammonia. Due to the dangerous and potentially destructive nature of the cargo, in particular ammonia, on board the railcars, a railcar accident may result in uncontrolled or catastrophic circumstances, including fires, explosions, accidents and severe pollution. Such circumstances may result in severe damage and/or injury to property, the environment and human health. Litigation from any such event may result in our being named as a defendant in lawsuits asserting claims for large amounts of damages. In the event of pollution, we may be strictly liable. If we are strictly liable, we could be held responsible even if we are not at fault and we complied with the laws and regulations in effect at the time, which could have a material adverse effect on our financial condition and the price of our common stock.

Prior to our acquisition of the nitrogen fertilizer plant and continuing into our ownership, the facility experienced an equipment failure that resulted in air releases of ammonia into the environment. We replaced the equipment in August 2004 and the new equipment also experienced difficulties and was subsequently replaced by a redesigned exchanger with upgraded metallurgy, which was operated without additional ammonia emissions. We have reported the excess emissions of ammonia to EPA and KDHE as part of an air permitting audit of the facility. The results of an air permitting compliance audit may reveal the need for additional controls which could require us to make significant capital expenditures. We cannot assure you that additional equipment or repairs will not be required or that government enforcement or third-party claims will not result from the excess ammonia emissions and ongoing operational difficulties continuing to be experienced at the fertilizer plant.

Governmental regulations and policies affect the prices and demand for our fertilizer products and changes in government regulations could require us to make substantial capital expenditures in the future.

We manufacture, process, store, handle, distribute and transport fertilizer products, including ammonia, that are subject to federal, state and local laws and regulations. Presently existing or future

16

environmental laws and regulations could cause us to expend substantial amounts to install controls or make operational changes to comply with changes in environmental requirements. In addition, future environmental laws and regulations, or new interpretations of existing laws or regulations, could limit our ability to market and sell our products to end users. We cannot assure you that any such future environmental laws or governmental regulations will not have a significant impact on the results of our operations.

The results of an air permitting compliance audit may reveal the need for additional controls which could require us to make significant capital expenditures.

When we acquired the fertilizer plant, we agreed to undertake a voluntary federal and state air permitting compliance audit. EPA and KDHE agreed not to seek civil penalties if we disclosed and corrected any discovered noncompliance in accordance with their policies. The audit has been completed and we are in the process of correcting noncompliance that was discovered. No penalties are expected to be imposed for the violations that were self-disclosed and corrected, but we have not reached a final resolution with the agencies. We cannot be certain that additional controls will not have to be installed in order to return the fertilizer plant to compliance. We also cannot be certain that each and every instance of noncompliance has been detected by the audit or will be covered by the agencies' audit policies so that no penalties would be imposed or liability would result from the audit.

Our nitrogen fertilizer operations are dependent on a few third-party suppliers. Failure by key third-party suppliers of elemental oxygen, nitrogen and electricity to perform in accordance with their contractual obligations may have a negative effect upon our results of operations and financial condition.

Our operations depend in large part on the performance of third-party suppliers, including The BOC Group, for the supply of oxygen and nitrogen, and the City of Coffeyville for the supply of electricity. Should either of those two suppliers fail to perform in accordance with the existing contractual arrangements, our gasification operation would be forced to a halt. We may be unable to obtain alternate sources of supply of elemental oxygen, nitrogen or electricity on similar terms or at all. Any shutdown of our operations would have a negative effect upon our results of operations and financial condition.

Risks Related to Our Entire Business

Our operations involve environmental risks that may require us to make substantial capital expenditures to remain in compliance or to remediate current or future contamination that could otherwise give rise to material liabilities.

Our results of operations may be affected by increased costs resulting from compliance with the extensive federal, state and local environmental laws to which our facilities are subject and from contamination of our facilities as a result of accidental spills, discharges or other releases of petroleum or hazardous substances.

Our operations are subject to a variety of federal, state and local environmental laws and regulations relating to the protection of the environment, including those governing the emission or discharge of pollutants into the environment, product specifications and the generation, treatment, storage, transportation and disposal, or remediation of solid and hazardous waste and materials. Environmental laws and regulations that affect the operations, processes and margins for our refined products are extensive and have become progressively more stringent. Violations of these laws and regulations or permit conditions can result in substantial penalties, injunctive orders compelling installation of additional controls, civil and criminal sanctions, permit revocations and/or facility shutdowns. Additional legislation or regulatory requirements or administrative policies could be imposed with respect to our products or activities. Compliance with more stringent laws or regulations or changes in compliance policies and guidance of the regulatory agencies could increase our costs,

17

which may adversely affect our financial position and results of operations and could require us to make substantial expenditures.

Our business is inherently subject to accidental spills, discharges or other releases of petroleum or hazardous substances into the environment. Past or future spills related to any of our operations, including our refinery, pipelines, product terminals, fertilizer plant or transportation of products or hazardous substances from those facilities, may give rise to liability (including strict liability, or liability without fault, and potential cleanup responsibility) to governmental entities or private parties under federal, state or local environmental laws, as well as under common law. For example, we could be held strictly liable under the Comprehensive Environmental Responsibility, Compensation and Liability Act (CERCLA) for past or future spills without regard to fault or whether our actions were in compliance with the law at the time of the spill. This may involve contamination associated with facilities we currently own or operate, facilities we used to own or operate, certain facilities Farmland used to own or operate and facilities to which we transported or arranged for the transportation of wastes or by-products for use, treatment, storage, or disposal. Accidental discharges could occur in the future, future action may be taken in connection with past discharges, governmental agencies may assess penalties against us in connection with past or future contamination or compel us to clean-up or reimburse another party for cleanup, and third parties may assert claims against us for damages allegedly arising out of any past or future contamination. The potential penalties and clean-up costs for past or future releases or spills, the failure of some prior owners of our facilities to complete their clean-up obligations, liability to third parties for damage to their property or exposure to hazardous substances, or the need to address newly discovered information or conditions that may require a response could be significant and the payment of these amounts could have a material adverse effect on our business, financial condition and results of operations.

We are subject to current liability for the investigation and clean-up of environmental contamination at two of our facilities and may be potentially liable for currently unknown or future contamination at each of the properties we own or operate and at contiguous, adjacent and off-site locations where we may have, or certain contiguous adjacent and off-site locations where Farmland may have, disposed of or arranged for the disposal of hazardous substances. We cannot assure you that we will not become involved in litigation or any other proceedings or that, if we were to be held responsible for damages or required to reimburse costs in any future litigation or other proceedings, such damages or costs would be covered by insurance or would not be material. For example, there is extensive contamination present at the refinery (which includes portions of the fertilizer plant), and the Phillipsburg terminal (which operated as a refinery until 1991). We have assumed Farmland Industries, Inc.'s responsibilities under certain Resource Conservation and Recovery Act (RCRA) corrective action orders related to contamination at or that originated from the refinery (which includes portions of the fertilizer plant) and the Phillipsburg terminal. If significant unforeseen liabilities arise in the areas where we have assumed liability for the corrective action, such liability could have a material adverse effect on our results of operations and financial condition and that may not be covered by insurance.

In addition, we may face liability for alleged personal injury or property damage due to exposure to chemicals or other hazardous substances located at or released from our facilities. We may also face liability for personal injury, property damage, natural resource damage or for clean-up costs for the alleged migration of contamination or other hazardous substances from our facilities to adjacent and other nearby properties. See "Business—Environmental Matters."

We may face future liability for disposal of hazardous wastes off-site. CERCLA may impose strict liability on generators of hazardous waste that is disposed of off-site when the off-site disposal area requires remediation. Although we have not been identified as a potentially responsible party under CERCLA for off site disposal of our hazardous wastes, we cannot assure you that we will not become involved in litigation or any other proceedings or that, if we were to be held responsible for damages or

18

required to reimburse costs in any future litigation or other proceedings relating to off-site disposal of our hazardous wastes, such damages or costs would be covered by insurance or would not be material.

We have a limited operating history as a stand-alone company and previous financial statements may not be indicative of our future performance.

Coffeyville Group Holdings, LLC was formed in March 2004 specifically for an investor group led by Pegasus for the Acquisition. Our limited historical financial performance as a stand-alone company makes it difficult for you to evaluate our business and results of operations to date and to assess our future prospects and viability. Further, our brief operating history has resulted in period over period revenue and profitability growth rates that may not be indicative of our future results of operations. As a result, our results of operations may be lower than we currently expect and the price of our common stock may be volatile.

The requirements of being a public company, including compliance with the reporting requirements of the Exchange Act and the requirements of the Sarbanes-Oxley Act, may strain our resources, increase our costs and distract management, and we may be unable to comply with these requirements in a timely or cost-effective manner.

As a public company, we will be subject to the reporting requirements of the Securities Exchange Act of 1934, or the Exchange Act, and the corporate governance standards of the Sarbanes-Oxley Act of 2002, or the Sarbanes-Oxley Act. These requirements may place a strain on our management, systems and resources. The Exchange Act will require that we file annual, quarterly and current reports with respect to our business and financial condition. The Sarbanes-Oxley Act will require that we maintain effective disclosure controls and procedures and internal controls for financial reporting. Due to our limited operating history as a stand-alone company, our disclosure controls and procedures and internal controls may not meet all of the standards applicable to public companies. In order to maintain and improve the effectiveness of our disclosure controls and procedures and internal control over financial reporting, significant resources and management oversight will be required. This may divert management's attention from other business concerns, which could have a material adverse effect on our business, financial condition, results of operations and the price of our common stock.