| | Independent NI 43-101 Technical Report AN UPDATED LIFE OF MINE PLAN ("LOMP") FOR CAMPBELL PIT AND PRE-FEASIBILITY STUDY FOR NAN AND GAN DEPOSITS Maracás Menchen Project, Bahia, Brazil Prepared by GE21 Consultoria Mineral on behalf of: Largo Inc. |

| | Issue Date: December 16th, 2021 Effective Date: October 10th, 2021 Qualified Persons: Porfírio Cabaleiro Rodriguez - BSc (Min Eng), FAIG Guilherme Gomides Ferreira - BSc (Min Eng), MAIG Fabio Valério Câmara Xavier - BsC (Geo), MAIG Marlon Sarges Ferreira - BsC (Geo), MAIG |

Authors | Porfirio Cabaleiro Rodriguez | Mining Engineer | BSc (Mine Eng), FAIG |

| Guilherme Gomides Ferreira | Mining Engineer | BSc (Mine Eng), MAIG |

| Fábio Valério Câmara Xavier | Geologist | BSc (Geo), MAIG |

| Marlon Sarges Ferreira | Geologist | BSc (Geo), MAIG |

Effective date: | October 10th, 2021 | |

| | | |

Issue date: | December 16th, 2021 | |

| | | |

GE21 Project no: | GE21_210606 | |

| | | |

Version: | Final | |

| | | |

Work directory: | S:\Projetos\Largo\210606-ReservasLargo\23_Relatorio | |

| | | |

Print date: | December 17, 2021 | |

| | | |

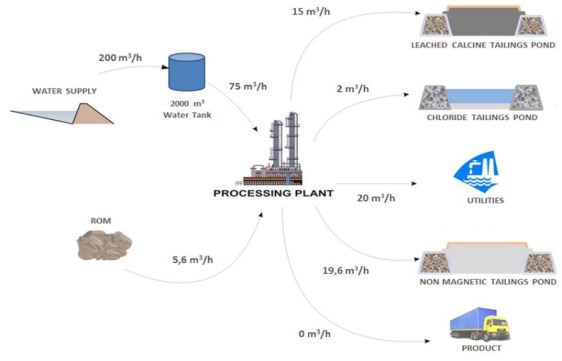

| | |

| | | |

Copies: | Largo Inc. | (1) | |

| | | | |

| GE21 Consultoria Mineral | (1) | |

Change Control

Version | Description | Authors | Date |

| | | |

| | | |

| | | |

Original document signed and sealed | Original document signed and sealed |

Porfírio Cabaleiro Rodriguez BSc (Mine Eng.), FAIG | Guilherme Gomides Ferreira BSc (Mine Eng.), MAIG |

Original document signed and sealed. | Original document signed and sealed |

Fabio Valério Câmara Xavier BSc (Geo.), MAIG | Marlon Sarges Ferreira BSc (Geo.), MAIG |

Date and Signature

This report, entitled "An Updated Life of Mine Plan ("LOMP") for Campbell Pit and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil", having an effective date of October 10th, 2021, was prepared and signed by the following authors.

Dated in Belo Horizonte, Brazil, on December 16th, 2021.

Original document signed and sealed

|

Porfírio Cabaleiro Rodriguez, BSc (Mine Eng.), FAIG |

Original document signed and sealed

|

Guilherme Gomides Ferreira, BSc (Mine Eng.), MAIG |

Original document signed and sealed.

|

Fabio Valério Câmara Xavier, BSc (Geo.), MAIG |

Original document signed and sealed

|

Marlon Sarges Ferreira, BSc (Geo), MAIG |

QP CERTIFICATE OF PORFÍRIO CABALEIRO RODRIGUEZ

a) I, Porfírio Cabaleiro Rodriguez, am a Mining Engineer and Director for GE21 Consultoria Mineral, located at Avenida Afonso Pena, 3130 - 13º andar, Belo Horizonte, MG, Brazil, CEP 30.130-910.

b) This certificate applies to the Technical Report entitled "An Updated Life of Mine Plan ("LOMP") for Gulçari A ("Campbell Pit") and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil" with an effective date of October 10th, 2021.

c) I hold the following academic qualifications: a B.A.Sc. in Mining Engineering from the Federal University of Minas Gerais, in Belo Horizonte, Brazil.

d) I am a professional Mining Engineer, with more than 43 years of experience in the mining industry. My relevant experience for the purpose of this Technical Report includes:

1986 to 2015 - Consultant, manager, and director with consulting engineering firms that specialize in technical studies and audits of mineral resource and reserves, mine planning, geometallurgy, pit optimization, and analysis of economic viability for many types of mineral deposits, including gold projects in their exploration and development phases, as well as producing gold mines.

2015 to present - Director of GE21 Consultoria Mineral, which provides advice, assistance, and audits for the entire mining cycle, from defining strategies, generating and selecting targets and investments, mineral exploration, project development, geological assessments, resource reserve estimation for JORC and NI 43-101 reports, conceptual technical and economic studies, and economic feasibility.

e) I am a fellow of the Australian Institute of Geoscientists (#3708).

f) I meet all the education, work experience, and professional registration requirements of a "Qualified Person" as defined in section 1.1 of National Instrument 43-101.

g) I have not inspected the property that is the subject of this Technical Report.

h) I responsable for Technical Report and supervised the production of all sections of the document and am solely responsible for sections 2, 3, 13, 17,18, 19, 20, 21, 22, 23, 24 and jointly responsible for sections through 1, 25, 26 and 27 of this Technical Report.

i) I am independent of the Issuer, Largo Inc.

j) Previously, I have worked on the An Updated Mine Plan, Mineral Reserve and Preliminary Economic Assessment of The Inferred Resources (PEA) for the property that is the subject of this Technical Report and served as a QP for the NI 43-101 report on that document.

k) I have read National Instrument 43-101 and the parts of the Technical Report for which I am responsible have been prepared in compliance with this Instrument, including the CIM Definition Standards on Mineral Resources and Mineral Reserves.

l) At the effective date of the Technical Report, and at the date it was filed, to the best of my knowledge, information, and belief, the parts of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Original document signed and sealed

Belo Horizonte, Brazil, on 16th December 2021.

QP CERTIFICATE OF GUILHERME GOMIDES FERREIRA

a) I, Guilherme Gomides Ferreira, am a Mining Engineer for GE21 Consultoria Mineral, located at Avenida Afonso Pena, 3130 − 12º andar, Belo Horizonte, MG, Brazil, CEP 30.130-910.

b) This certificate applies to the Technical Report entitled "An Updated Life of Mine Plan ("LOMP") for Campbell Pit and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil" with an effective date of October 10th, 2021.

c) I hold the following academic qualifications: a B.A.Sc. in Mining Engineering from the Federal University of Minas Gerais, in Belo Horizonte, Brazil.

d) I am a professional Mining Engineer, with more than 16 years of experience in the mining industry. My relevant experience for the purpose of this Technical Report includes:

- 2006 to 2017- Mining Engineer at mining companies, developing technical studies of Mineral Reserves, mine planning, pit optimization, and economic analysis as well a producing iron ore and gold mine.

- 2017 to present - Manager of GE21 Consultoria Mineral, which provides advice, assistance, and audits for the entire mining cycle, from defining strategies, generating and selecting targets and investments, mineral exploration, project development, geological assessments, resource reserve estimation for JORC and NI 43-101 reports, conceptual technical and economic studies, and economic feasibility.

e) I am a member of the Australian Institute of Geoscientists (#7586).

f) I meet all the education, work experience, and professional registration requirements of a "Qualified Person" as defined in Section 1.1 of National Instrument 43-101.

g) I inspected between 27th to 29th of April 2021 the property that is the subject of this Technical Report.

m) I am jointly responsible for Sections 15, 16 and I jointly responsible for Sections through 1, 12, 25 and 26 of this Technical Report.

h) of this Technical Report.

i) I am independent of the Issuer, Largo Inc.

j) I have read National Instrument 43-101 and the parts of the Technical Report for which I am responsible have been prepared in compliance with this Instrument, including the CIM Definition Standards on Mineral Resources and Mineral Reserves.

k) At the effective date of the Technical Report, and at the date it was filed, to the best of my knowledge, information, and belief, the parts of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Original document signed and sealed

Belo Horizonte, Brazil, on 16th December 2021.

QP CERTIFICATE OF FÁBIO VALÉRIO CÂMARA XAVIER

a) I, Fábio Valério Câmara Xavier, am a Geologist for GE21 Consultoria Mineral, located at Avenida Afonso Pena, 3130 − 12º andar, Belo Horizonte, MG, Brazil, CEP 30.130-910.

b) This certificate applies to the Technical Report entitled "An Updated Life of Mine Plan ("LOMP") for Gulçari A ("Campbell Pit") and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil" with an effective date of October 10th, 2021.

c) I hold the following academic qualifications: a B.Sc. (Geology) Universidade Federal do Rio Grande do Norte (UFRN).

d) I am a professional Geologist, with more than 18 years of experience in the mining industry. My relevant experience for the purpose of this Technical Report includes:

• I have 7 years of experience as a specialist geologist on geotechnologies applied to mineral exploration and 11 years as a Mineral Resource Estimatior. My experience includes open pit and underground mines and considerable experience dealing with various commodities, such as phosphate, iron ore, gold and copper ore, vanadium, in addition to rare earth elements, among others.

e) I am a member of the Australian Institute of Geoscientists (#5179).

f) I meet all the education, work experience, and professional registration requirements of a "Qualified Person" as defined in Section 1.1 of National Instrument 43-101.

g) I inspected between 27th to 29th of April 2021 the property that is the subject of this Technical Report.

h) I am jointly responsible for Sections 12 of this Technical Report.

i) I am independent of the Issuer, Largo Inc.

j) I have read National Instrument 43-101 and the parts of the Technical Report for which I am responsible have been prepared in compliance with this Instrument, including the CIM Definition Standards on Mineral Resources and Mineral Reserves.

k) At the effective date of the Technical Report, and at the date, it was filed, to the best of my knowledge, information, and belief, the parts of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Original document signed and sealed

Belo Horizonte, Brazil, on 16th December 2021.

QP CERTIFICATE OF MARLON SARGES FERREIRA

a) I, Marlon Sarges Ferreira, am a Geologist for GE21 Consultoria Mineral, located at Avenida Afonso Pena, 3130 − 12º andar, Belo Horizonte, MG, Brazil, CEP 30.130-910.

b) This certificate applies to the Technical Report entitled "An Updated Life of Mine Plan ("LOMP") for Gulçari A ("Campbell Pit") and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil" with an effective date of October 10th, 2021.

c) I hold the following academic qualifications: a B.A.Sc. in Geology from Universidade Federal do Pará, Brazil and a masters degree in Mineral Engineering from Universidade Federal de Ouro Preto, Brazil.

d) I am a professional geologist, with more than 15 years of experience in the mining industry. My relevant experience for the purpose of this Technical Report includes:

- 2006 to 2011 - Geologist at various consulting companies, developing technical studies of exploration, open pit design, projects and validation of mineral resources for mining negotiations;

- 2011 and 2015 - Geologist at a mining company responsible by long- term mineral resource supporting company strategies decisions and development of new business;

- 2015 to present - Geologist which provides advice, assistance, and audits for the entire mining cycle, from defining strategies, generating and selecting mineral targets, mineral exploration, geological assessments, resource reserve estimation for JORC and NI 43-101 reports in level of conceptual technical and economic studies, and economic feasibility.

e) I am a member of the Australian Institute of Geoscientists (#6914).

f) I meet all the education, work experience, and professional registration requirements of a "Qualified Person" as defined in Section 1.1 of National Instrument 43-101.

g) I am jointly responsible for Sections 5, 6, 7, 8, 9, 10, 11 and 14, and jointly responsible for Sections through 1 and 25 of this Technical Report.

h) I am independent of the Issuer, Largo Inc.

i) I have read National Instrument 43-101 and the parts of the Technical Report for which I am responsible have been prepared in compliance with this Instrument, including the CIM Definition Standards on Mineral Resources and Mineral Reserves.

j) At the effective date of the Technical Report, and at the date it was filed, to the best of my knowledge, information, and belief, the parts of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Original document signed and sealed

Belo Horizonte, Brazil, on 16th December 2021.

IMPORTANT NOTICE

This report was prepared as National Instrument 43-101 Technical Report for Largo Inc. (Largo or the Company) by GE21 Consultoria Mineral Ltda. (GE21) as part of a team of consultants contracted by Largo. The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in the report authors' services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Largo subject to terms and conditions of its individual contracts with the report authors and to the relevant securities legislation. The contracts between Largo and the authors allow Largo to file this report as a Technical Report with Canadian securities regulatory authorities, pursuant to National Instrument 43-101, Standards of Disclosure for Mineral Projects. Except for the purposes legislated under Canadian provincial and territorial securities laws, any other use of this report by any third party is at that party's sole risk. The responsibility for this disclosure remains with Largo. GE21 is under no obligation to update this Technical Report, except as may be agreed to between Largo and GE21 by contract from time to time. The user of this document should ensure that this is the most recent Technical Report for the property as it is not valid if a new Technical Report has been issued.

Currency is expressed in U.S. dollars and metric units are used, unless otherwise stated.

© 2021 GE21 Consultoria Mineral Ltda.

This document, as a collective work of content and the coordination, arrangement and any enhancement of said content, is protected by copyright held by GE21 Consultoria Mineral Ltda.

| 1 EXECUTIVE SUMMARY | 30 |

| | |

| 1.1 Qualified Persons, Experience, and Independence | 30 |

| | |

| 1.2 Introduction | 30 |

| | |

| 1.3 Reliance on Other Experts | 31 |

| | |

| 1.4 Property Description and Location | 31 |

| | |

| 1.5 Accessibility, Climate, Local Resources, Infrastructure, and Physiography | 31 |

| | |

| 1.6 History | 32 |

| | |

| 1.7 Geological Setting and Mineralization | 32 |

| | |

| 1.8 Deposit Types | 33 |

| | |

| 1.9 Exploration | 33 |

| | |

| 1.10 Drilling | 33 |

| | |

| 1.11 Sample Preparation, Analyses, and Security | 34 |

| | |

| 1.12 Data Verification | 34 |

| | |

| 1.13 Mineral Processing and Metallurgical Testing | 35 |

| | |

| 1.14 Mineral Resource Estimates | 35 |

| | |

| 1.15 Mineral Reserve Estimates | 38 |

| | |

| 1.16 Mining Methods | 41 |

| | |

| 1.17 Recovery Methods | 42 |

| | |

| 1.18 Project Infrastructure | 42 |

| | |

| 1.19 Market Studies and Contracts | 43 |

| | |

| 1.19.1 Demand | 43 |

| | |

| 1.19.2 Vanadium Prices | 44 |

| | |

| 1.19.3 Ilmenite Prices | 45 |

| | |

| 1.19.4 Titanium Pigment Prices | 46 |

| | |

| 1.19.5 Outlook | 47 |

| | |

| 1.19.6 Contracts | 47 |

| | |

| 1.19.7 Selling Prices adopted | 47 |

| | |

| 1.20 Capital and Operating Costs | 47 |

| | |

| 1.20.1 Sustaining Capital Cost | 50 |

| | |

| 1.21 Economic Analysis | 50 |

| | |

| 1.22 Interpretation and Conclusions | 50 |

| | |

| 2 INTRODUCTION | 52 |

| | |

| 2.1 Qualifications, Experience, and Independence | 52 |

| | |

| 2.2 Effective Date | 53 |

| 2.3 Units of Measurement | 53 |

| | |

| 3 RELIANCE ON OTHER EXPERTS | 54 |

| | |

| 4 PROPERTY DESCRIPTION AND LOCATION | 55 |

| | |

| 4.1 Location | 55 |

| | |

| 4.2 Mineral Title in Brazil | 56 |

| | |

| 4.3 Mining Legislation, Administration and Rights | 57 |

| | |

| 4.4 Mineral Exploration Licenses | 58 |

| | |

| 4.5 Mineral Concessions | 58 |

| | |

| 4.6 Annual Fees and Reporting Requirements | 58 |

| | |

| 4.7 Largo Mineral Tenure | 58 |

| | |

| 4.8 Environmental Liabilities and Permits | 63 |

| | |

| 5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY | 65 |

| | |

| 5.1 Access | 65 |

| | |

| 5.2 Infrastructure | 65 |

| | |

| 5.3 Climate | 65 |

| | |

| 5.4 Landscape | 66 |

| | |

| 5.5 Vegetation | 66 |

| | |

| 6 HISTORY | 67 |

| | |

| 6.1 Summary | 67 |

| | |

| 6.2 Exploration History | 68 |

| | |

| 6.3 Historical Drilling | 71 |

| | |

| 6.4 Historical Resource Estimates - Odebrecht, 1986 | 75 |

| | |

| 6.5 Historical Technical and Environmental Studies | 76 |

| | |

| 7 GEOLOGICAL SETTING AND MINERALIZATION | 78 |

| | |

| 7.1 Regional Geology | 78 |

| | |

| 7.2 Rio Jacaré Intrusion | 79 |

| | |

| 7.3 Property Geology | 81 |

| | |

| 7.4 Individual Deposits | 85 |

| | |

| 7.4.1 Gulçari A Deposit | 86 |

| | |

| 7.4.2 Gulçari A Norte (GAN) Deposit | 88 |

| | |

| 7.4.3 Novo Amparo Norte (NAN) Deposit | 90 |

| | |

| 7.4.4 São José (SJO) Deposit | 92 |

| | |

| 7.4.5 Novo Amparo (NAO) Deposit | 94 |

| | |

| 7.5 Mineralization | 94 |

| | |

| 7.6 Oxidation | 96 |

| | |

| 8 DEPOSIT TYPE | 98 |

| 8.1 Mineralization Styles | 98 |

| | |

| 8.2 Conceptual Models | 99 |

| | |

| 9 EXPLORATION | 102 |

| | |

| 9.1 2006 Exploration Program - Largo Inc. (Micon, 2007) | 102 |

| | |

| 9.2 Previous Geophysical Surveys | 103 |

| | |

| 9.3 Discussion of Present Geophysical Techniques | 103 |

| | |

| 9.4 Geophysical Survey Results | 104 |

| | |

| 9.5 2008 Exploration Program (RungePincockMinarco, 2012) | 104 |

| | |

| 9.6 2011-2012 Exploration Program (RungePincockMinarco, 2012) | 104 |

| | |

| 9.7 2012 Infill Drill Program (Micon, 2016) | 105 |

| | |

| 9.8 2015 Exploration Program (Micon, 2016) | 105 |

| | |

| 9.8.1 Davis Tube Tests | 105 |

| | |

| 9.9 2018-2019 Exploration Program | 106 |

| | |

| 9.10 2020 Exploration Program | 108 |

| | |

| 9.11 Topography Survey | 110 |

| | |

| 10 DRILLING | 112 |

| | |

| 10.1 Drilling by Previous Operators (Micon 2006 and 2007) | 112 |

| | |

| 10.2 2007 Largo Drill Program | 112 |

| | |

| 10.3 2008 Largo Drill Program | 117 |

| | |

| 10.4 2011-2012 Largo Drill Program (RungePincockMinarco, 2012) | 119 |

| | |

| 10.5 2012 Largo Infill Drill Program | 127 |

| | |

| 10.5.1 Logging (Micon, 2016.) | 130 |

| | |

| 10.6 2018 Largo Infill Drill Program (Campbell Pit) | 131 |

| | |

| 10.6.1 Logging | 133 |

| | |

| 10.7 2018 Largo Exploration Drill Program | 133 |

| | |

| 10.7.1 Logging | 137 |

| | |

| 10.8 2019 Largo Exploration Drill Program | 137 |

| | |

| 10.9 2020 Largo Drill Program | 147 |

| | |

| 11 SAMPLE PREPARATION, ANALYSES, AND SECURITY | 160 |

| | |

| 11.1 Sampling Method | 160 |

| | |

| 11.1.1 Previous Operators | 160 |

| | |

| 11.1.2 2006 and Early 2007 Re-logging | 161 |

| | |

| 11.1.3 2007 Exploration Drill Program | 161 |

| | |

| 11.1.4 2018 Largo Core Drill Program | 162 |

| | |

| 11.1.5 2019 Largo Core Drill Program | 163 |

| | |

| 11.1.6 2020 Largo Core Drilling Program | 163 |

| | |

| 11.2 Chemical Sample Preparation, Analyses and Security | 164 |

| 11.2.1 Pre-2006 Analytical Work | 164 |

| | |

| 11.2.2 Largo Analytical Work (2007, 2008 and 2011-2012) | 165 |

| | |

| 11.2.3 2015 Davis tube work | 165 |

| | |

| 11.2.4 2018-2019 Chemical Assay Preparation, Analyses and Security | 169 |

| | |

| 11.2.5 2020 Chemical Assay Preparation, Analyses and Security | 169 |

| | |

| 11.3 Density Determination | 170 |

| | |

| 11.3.1 Until 2015 | 170 |

| | |

| 11.3.2 2020 Determination Density (by Pycnometer) | 172 |

| | |

| 11.4 Largo QAQC program | 173 |

| | |

| 11.4.1 Pre-2006 program | 173 |

| | |

| 11.4.2 2006 program | 173 |

| | |

| 11.4.3 Early 2007 | 174 |

| | |

| 11.4.4 2007 Campaign | 176 |

| | |

| 11.4.5 Coffey Analysis | 183 |

| | |

| 11.4.6 Coffey Verification | 183 |

| | |

| 11.5.1 2021 GE21 QAQC Analysis | 185 |

| | |

| 11.5.2 Qualified Person's opinion | 197 |

| | |

| 12 DATA VERIFICATION | 198 |

| | |

| 12.1 Site visit | 198 |

| | |

| 12.1.1 Topographic survey | 198 |

| | |

| 12.1.2 Drilling | 198 |

| | |

| 12.1.3 Geological Map | 198 |

| | |

| 12.1.4 Core Shed | 199 |

| | |

| 12.1.5 Operating procedures | 201 |

| | |

| 12.1.6 Geological Description | 202 |

| | |

| 12.1.7 QAQC | 202 |

| | |

| 12.1.8 Density | 203 |

| | |

| 12.1.9 Internal Laboratory | 203 |

| | |

| 12.1.10 Drilling Database | 203 |

| | |

| 12.2 Data received for estimate | 203 |

| | |

| 12.2.1 Database | 204 |

| | |

| 12.3 Qualified Person's Opinion | 204 |

| | |

| 13 MINERAL PROCESSING AND METALLURGICAL TESTING | 205 |

| | |

| 13.1 Introduction | 205 |

| | |

| 13.2 Process Technical and Economical References | 205 |

| | |

| 13.3 Metallurgical Recovery of Vanadium and Titanium of Ore from Campbell Pit | 206 |

| | |

| 13.3.1 Sample Characterization - Campbell Pit | 207 |

| | |

| 13.3.2 Dry Magnetic Separation -Campbell Pit | 207 |

| 13.3.3 Wet Magnetic Separation -Campbell Pit | 208 |

| | |

| 13.3.4 Flotation -Campbell Pit | 210 |

| | |

| 13.3.5 Global Recovery of Titanium - Pit Campbell | 212 |

| | |

| 13.4 Metallurgical Recovery of Vanadium and Titanium of Ore from Gulçari A Norte (GAN) | 212 |

| | |

| 13.4.1 Sample Characterization - Gulçari A Norte (GAN) | 213 |

| | |

| 13.4.2 Dry Magnetic Separation Results - Gulçari A Norte (GAN) | 216 |

| | |

| 13.4.3 Wet Magnetic Separation - Gulçari A Norte (GAN) | 218 |

| | |

| 13.4.4 Calcination - Gulçari A Norte (GAN) | 219 |

| | |

| 13.4.5 Leaching and Chemical Treatment - Gulçari A Norte (GAN) | 221 |

| | |

| 13.4.6 Global Recovery of Vanadium - Gulçari A Norte (GAN) | 222 |

| | |

| 13.4.7 Recovery of Titanium - Gulçari A Norte (GAN) | 222 |

| | |

| 13.5 Metallurgical Recovery of Vanadium and Titanium of Ore from Novo Amparo Norte | 228 |

| | |

| 13.5.1 Sample Characterization - Novo Amparo Norte | 229 |

| | |

| 13.5.2 Dry Magnetic Separation Tests - Novo Amparo Norte | 232 |

| | |

| 13.5.3 Wet Magnetic Separation Assays - Novo Amparo Norte | 234 |

| | |

| 13.5.4 Calcination Tests - Novo Amparo Norte | 235 |

| | |

| 13.5.5 Leaching and Chemical Treatment - Novo Amparo Norte | 238 |

| | |

| 13.5.6 Global Recovery of Vanadium - Novo Amparo Norte | 239 |

| | |

| 13.5.7 Metallurgical Recovery of Vanadium and Titanium of Ore from Novo Amparo | 240 |

| | |

| 13.6 Recomendations | 245 |

| | |

| 13.7 Qualified Person's Opinion | 245 |

| | |

| 14 MINERAL RESOURCE ESTIMATION | 246 |

| | |

| 14.1 Introduction | 246 |

| | |

| 14.2 Database | 246 |

| | |

| 14.3 Geological Modelling | 248 |

| | |

| 14.4 Composite Regularization | 253 |

| | |

| 14.5 Exploratory Data Analysis (EDA) | 254 |

| | |

| 14.6 Density | 265 |

| | |

| 14.7 Variographic Analysis | 267 |

| | |

| 14.8 Block Model | 270 |

| | |

| 14.9 Grade Interpolation | 271 |

| | |

| 14.10 Estimate Validation | 273 |

| | |

| 14.11 Mineral Resource Statement | 283 |

| | |

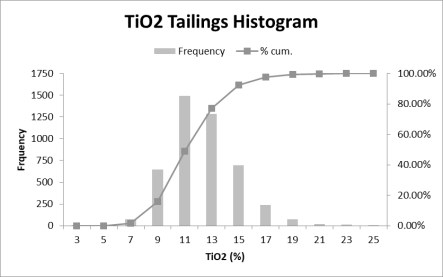

| 14.11.1 TiO2 Resource in Non-Magnetic Tailings | 286 |

| | |

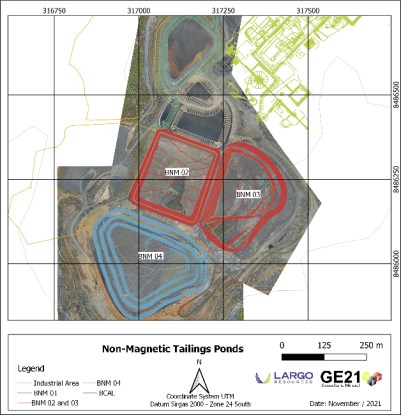

| 14.11.2 Non-Magnetic Ponds Resource Estimate | 289 |

| | |

| 14.12 Qualified Person's Opinion | 290 |

| 15 MINERAL RESERVE ESTIMATES | 291 |

| | |

| 15.1 Summary | 291 |

| | |

| 15.2 Disclosure | 293 |

| | |

| 15.3 Pit Optimization | 293 |

| | |

| 15.3.1 Campbell Pit | 295 |

| | |

| 15.3.2 GAN Deposit | 296 |

| | |

| 15.3.3 NAN Deposit | 298 |

| | |

| 15.4 Ultimate Pit Design | 299 |

| | |

| 15.4.1 Campbell-GAN Pit | 299 |

| | |

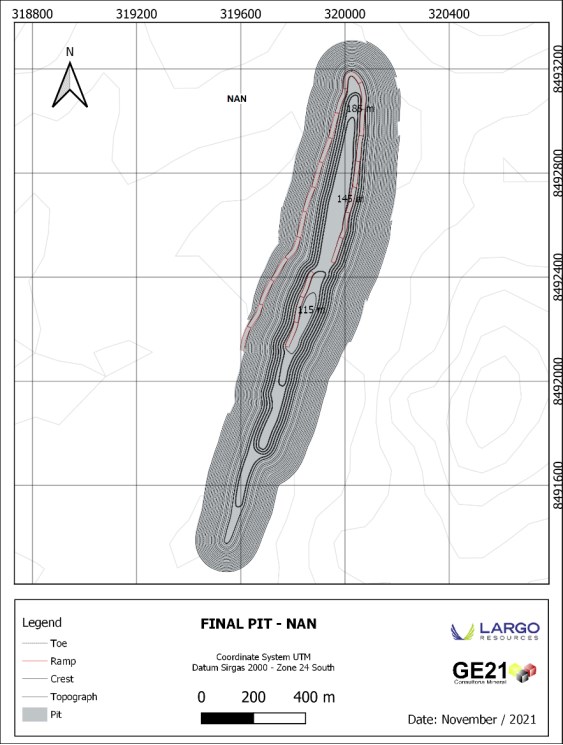

| 15.4.2 NAN Pit | 302 |

| | |

| 15.5 TiO2 Reserves in Non-Magnetic Tailings | 304 |

| | |

| 15.5.1 Reconciliation data and topographic surveying of ponds | 304 |

| | |

| 15.5.2 Non-Magnetic Ponds Reserves Estimate | 307 |

| | |

| 15.5.3 Optimization risks assessment | 308 |

| | |

| 15.6 Qualified Person's Opinion | 308 |

| | |

| 16 MINING METHODS | 310 |

| | |

| 16.1 Geotechnical Studies | 310 |

| | |

| 16.1.1 Introduction | 310 |

| | |

| 16.1.2 Local Conditions | 310 |

| | |

| 16.1.3 Geotechnical Analysis | 312 |

| | |

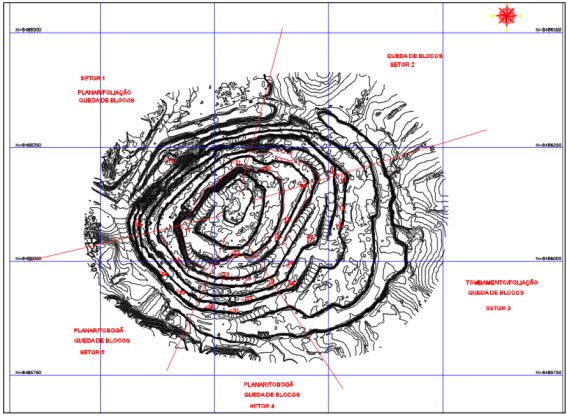

| 16.1.4 Disruption mechanisms | 317 |

| | |

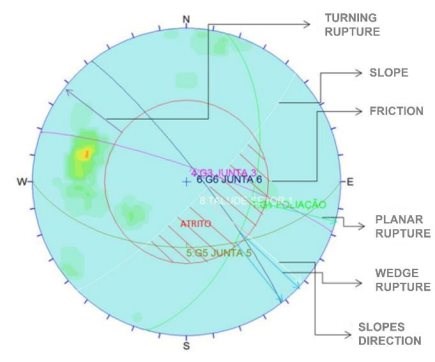

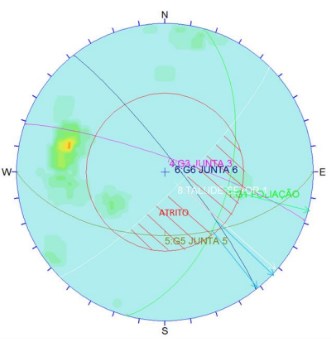

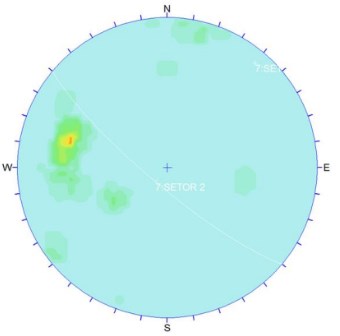

| 16.1.5 Kinematic Analysis | 317 |

| | |

| 16.1.6 Recommended geometry for slopes | 325 |

| | |

| 16.1.7 Final Considerations and Recommendations | 326 |

| | |

| 16.2 Mine Schedule | 327 |

| | |

| 16.2.1 Mining Scheduling Production | 327 |

| | |

| 16.2.2 Non-Magnetic Tailings Reclamation | 339 |

| | |

| 16.3 Waste Disposal | 340 |

| | |

| 16.4 Mining Fleet Sizing | 344 |

| | |

| 17 RECOVERY METHODS | 347 |

| | |

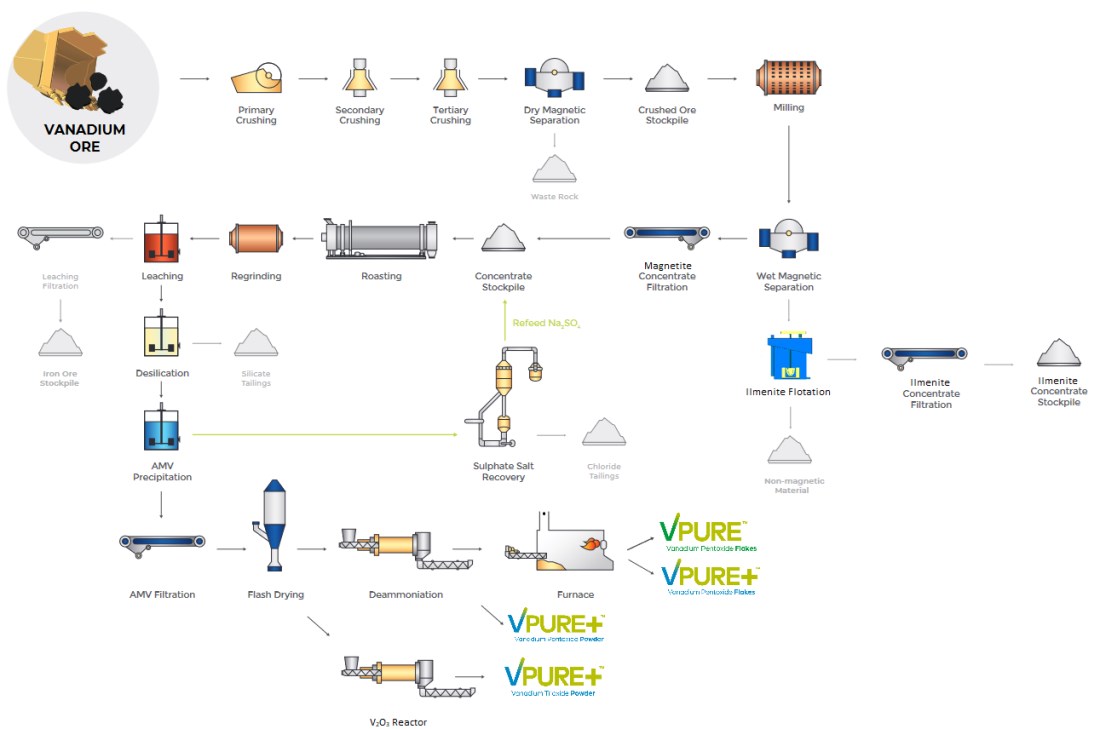

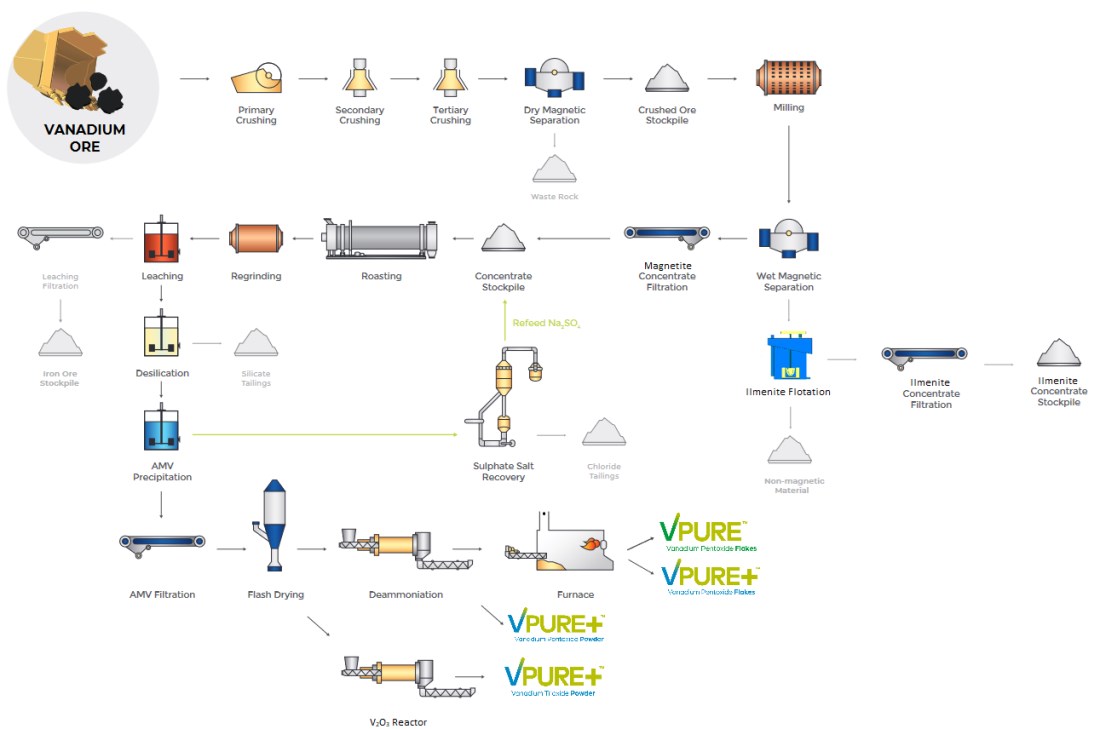

| 17.1 Process Description | 347 |

| | |

| 17.2 Crushing | 350 |

| | |

| 17.3 Dry Magnetic Separation | 350 |

| | |

| 17.4 Milling | 350 |

| | |

| 17.5 Magnetite Concentrate Filtering | 350 |

| | |

| 17.6 Ilmenite Flotation | 351 |

| | |

| 17.7 Ilmenite Concentrate Filtering | 351 |

| 17.8 Roasting (Kiln) | 351 |

| | |

| 17.9 Leaching | 351 |

| | |

| 17.10 Precipitation | 352 |

| | |

| 17.11 Evaporation | 352 |

| | |

| 17.12 AMV Drying | 353 |

| | |

| 17.13 Ammonia Removal | 353 |

| | |

| 17.14 Melting | 353 |

| | |

| 17.15 V2O5 Screening | 353 |

| | |

| 17.16 V2O3 Reactor | 353 |

| | |

| 17.17 Titanium Pigment Processes | 354 |

| | |

| 17.17.1 Ore storage | 354 |

| | |

| 17.17.2 Drying and milling | 354 |

| | |

| 17.17.3 Digestion and black liquor filtration | 354 |

| | |

| 17.17.4 FeSO4 crystallization | 354 |

| | |

| 17.17.5 Hydrolysis | 355 |

| | |

| 17.17.6 Calcination | 355 |

| | |

| 17.17.7 Surface treatment | 355 |

| | |

| 17.17.8 Micronization and Shipment | 355 |

| | |

| 17.17.9 Acid regeneration | 355 |

| | |

| 18 PROJECT INFRASTRUCTURE | 356 |

| | |

| 18.1 Water pumping System | 356 |

| | |

| 18.2 Process Water | 356 |

| | |

| 18.3 Water Treatment | 356 |

| | |

| 18.4 Sewage Treatment | 357 |

| | |

| 18.5 Fuel and Lubricant Storage and Distribution | 357 |

| | |

| 18.6 Compressed Air | 357 |

| | |

| 18.6.1 Air Emissions and Air Quality Monitoring | 357 |

| | |

| 18.7 Heating | 358 |

| | |

| 18.8 Power Supply | 358 |

| | |

| 18.9 Buildings | 360 |

| | |

| 18.10 Assay Laboratory | 363 |

| | |

| 18.11 Miscellaneous Buildings | 363 |

| | |

| 18.12 Explosives Magazine | 363 |

| | |

| 18.13 Communications | 363 |

| | |

| 18.14 Roads | 363 |

| | |

| 18.15 Tailings Facility | 364 |

| | |

| 18.15.1 Tailings Disposal Ponds | 364 |

| 18.16 Waste Management | 366 |

| | |

| 18.17 Future Developments | 368 |

| | |

| 18.17.1 Ilmenite Concentration Plant ("Ilmenite Plant") | 368 |

| | |

| 18.17.2 Expansion Phase 4 - 15,900 t/year of V2O5 | 371 |

| | |

| 18.17.3 TiO2 Pigment and Ammonium Sulfate Plants | 373 |

| | |

| 18.17.4 Other Future Infrastructure | 374 |

| | |

| 19 MARKET STUDY AND CONTRACTS | 376 |

| | |

| 19.1 Information Sources | 376 |

| | |

| 19.2 The Market for Vanadium | 377 |

| | |

| 19.2.1 Demand | 378 |

| | |

| 19.2.2 International Trade | 379 |

| | |

| 19.2.3 Vanadium Prices | 379 |

| | |

| 19.2.4 Ilmenite Prices | 380 |

| | |

| 19.2.5 Titanium Pigment Prices | 381 |

| | |

| 19.3 Outlook | 382 |

| | |

| 19.4 Contracts | 382 |

| | |

| 19.5 Selling Prices adopted | 383 |

| | |

| 20 ENVIRONMENTAL STUDIES, PERMITING AND SOCIAL OR COMMUNITY IMPACT | 384 |

| | |

| 20.1 Regulatory Framework Overview | 384 |

| | |

| 20.2 Environmental Permitting Status | 386 |

| | |

| 20.3 Environmental Baseline Conditions | 386 |

| | |

| 20.3.1 Climate and Physiography | 387 |

| | |

| 20.3.2 Water Resources | 387 |

| | |

| 20.3.3 Flora Characterization | 388 |

| | |

| 20.3.4 Fauna Characterization | 392 |

| | |

| 20.3.5 Aquatic Biota | 394 |

| | |

| 20.4 Social and Economic Baseline | 396 |

| | |

| 20.4.1 Populations Dynamics | 397 |

| | |

| 20.4.2 Employment Structure and Unemployment Rate | 397 |

| | |

| 20.4.3 Economic Aspects | 398 |

| | |

| 20.4.4 Land Use and Occupation | 399 |

| | |

| 20.4.5 Villages around the Project | 399 |

| | |

| 20.4.6 Historical and Cultural Heritage | 404 |

| | |

| 20.4.7 Living Standards | 405 |

| | |

| 20.4.8 Education | 406 |

| | |

| 20.4.9 Health | 406 |

| | |

| 20.4.10 Housing Conditions and Infrastructure | 407 |

| | |

| 20.4.11 Leisure, Tourism and Culture | 408 |

| 20.4.12 Public Safety | 408 |

| | |

| 20.4.13 Property Disputes and Rural Settling | 409 |

| | |

| 20.4.14 Water Supply | 409 |

| | |

| 20.5 Environmental Impact Assessment, Mitigation and Compensation | 409 |

| | |

| 20.5.1 Physical Environment | 410 |

| | |

| 20.5.2 Biotic Environment | 420 |

| | |

| 20.5.3 Environmental Mitigation | 421 |

| | |

| 20.6 Social and Economic Environment | 422 |

| | |

| 20.6.1 Job and Income Generation | 422 |

| | |

| 20.6.2 Boosting the Local and Regional Economy | 423 |

| | |

| 20.6.3 Improvement of Access and Roads | 423 |

| | |

| 20.6.4 Pressure on the Water Supply System | 424 |

| | |

| 20.7 Geotechnics And Hydrology | 424 |

| | |

| 20.7.1 Hydrological Studies | 424 |

| | |

| 20.7.2 Geological/Geotechnical Characterization of the Overall Project Area | 428 |

| | |

| 20.8 Current Activities and Plans | 434 |

| | |

| 20.8.1 Project Organization and Sustainability Team | 434 |

| | |

| 20.8.2 Equator Principles Audit Review | 435 |

| | |

| 20.8.3 Socio-Environmental Action Plan and Environmental Management System | 435 |

| | |

| 21 CAPITAL AND OPERATING COSTS | 440 |

| | |

| 21.1 Mining Costs | 441 |

| | |

| 21.2 Processing Plant and Infrastructure | 441 |

| | |

| 21.2.1 Phase 1: Ilmenite Plant 150 Kt/year Concentrate + Titanium Pigment Plant 30 kt/year Concentrate - Construction (2022-2023); | 442 |

| | |

| 21.2.2 Phase 2: Titanium Pigment Processing Plant + Vanadium Trioxide Plant Expansions (2024-2025); | 444 |

| | |

| 21.2.3 Phase 3: Titanium Pigment Processing + Ilmenite Concentration Plant Expansions (2026-2028) | 446 |

| | |

| 21.2.4 Phase 4: Vanadium Expansion Second Kiln (2029-2032). | 447 |

| | |

| 21.3 Sustaining Capital Cost | 448 |

| | |

| 21.4 CAPEX Summary | 448 |

| | |

| 21.5 Operating Cost Estimate | 450 |

| | |

| 21.5.1 Mining Cost Contracted | 450 |

| | |

| 21.5.1 Processing Cost | 451 |

| | |

| 21.5.2 General and Administration | 452 |

| | |

| 22 ECONOMICAL ANALYSIS | 453 |

| | |

| 22.1 Taxes | 453 |

| | |

| 22.2 Royalties | 453 |

| | |

| 22.3 Depreciation | 454 |

| 22.4 Discounted Cash Flow | 454 |

| | |

| 22.5 Internal Rate Return and Payback Analysis | 458 |

| | |

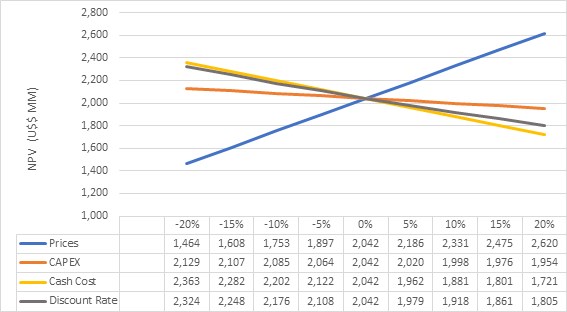

| 22.6 Sensitivity Analysis | 458 |

| | |

| 23 ADJACENT PROPERTIES | 460 |

| | |

| 24 OTHER RELEVANT DATA INFORMATION | 461 |

| | |

| 25 INTERPRETATION AND CONCLUSIONS | 462 |

| | |

| 25.1 Mineral Exploration and Geology | 462 |

| | |

| 25.2 Security and QA/QC | 462 |

| | |

| 25.3 Geological Model | 462 |

| | |

| 25.4 Grade estimation | 463 |

| | |

| 25.5 Mineral Resource Estimate | 463 |

| | |

| 25.6 Mining | 463 |

| | |

| 25.7 Processing | 465 |

| | |

| 25.8 Economic Analysis | 466 |

| | |

| 26 RECOMMENDATIONS | 467 |

| | |

| 26.1 Mineral Resources | 467 |

| | |

| 26.2 Mining | 467 |

| | |

| 26.3 Metalurgical Testing and Processing | 467 |

| | |

| 26.4 Capital and Operating and Costs | 468 |

| | |

| 26.5 Environment | 468 |

| | |

| 26.6 Estimates Costs | 468 |

| | |

| 27 REFERENCES | 469 |

| Table 1-1 Total Mineral Deposit Resource Statement | 37 |

| Table 1-2: Near Mine Target Mineral Resource (2012) | 38 |

| Table 1-3: TiO2 Resources in Non-Magnetic Tailings | 38 |

| Table 1-4: Maracás Menchen Project - Mineral Reserves Estimate | 40 |

| Table 1-5 Maracás Menchen Project - Non-Magnetic Mineral Reserves in Ponds | 41 |

| Table 1-6: World Mine Production of Vanadium | 43 |

| Table 1-7: Roskill Price Trend (US$/lb V2O5) | 45 |

| Table 1-8: Selling Price | 47 |

| Table 1-9: CAPEX summary | 49 |

| Table 2-1 Qualified Persons | 53 |

| Table 4-1: Largo Mineral Tenure | 60 |

| Table 4-2: Largo Enviromental Permits | 64 |

| Table 6-1: Mineral Exploration areas | 67 |

| Table 6-2: Historic Production Statistic for the Maracás Menchen Mine | 68 |

| Table 6-3: Summary of Total Drill Holes and Meters Drilled. | 70 |

| Table 6-4: Summary of Diamond drilling, Maracás Property. | 72 |

| Table 6-5: Historical Diamond Drilling Gulçari A deposit (1981 - 1987) | 72 |

| Table 6-6: Summary of Historical Drilling by Target | 74 |

| Table 6-7: Historical "Reserve" Estimate (1986) - Campbell | 75 |

| Table 6-8: Historical Reserve Estimate (2017 GE21) - Campbell | 76 |

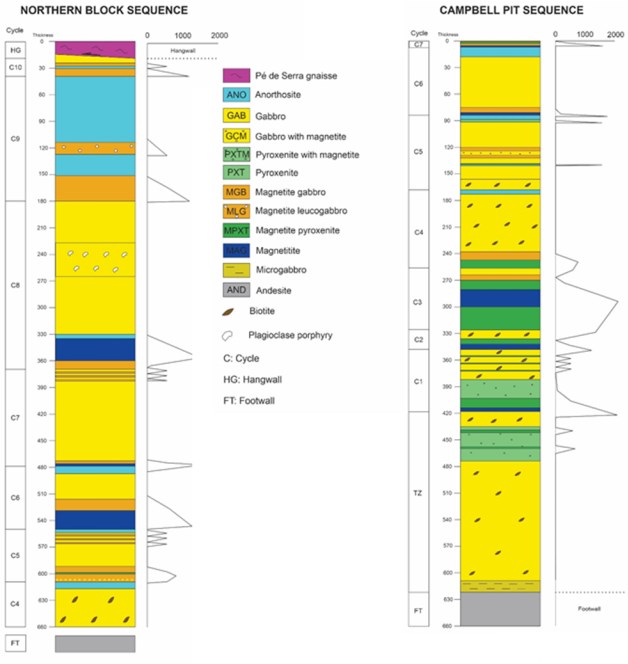

| Table 7-1: Description of cyclic units of Rio Jacaré Intrusion | 81 |

| Table 7-2: Recovery Reduction Factors for Oxidized material, Campbell | 97 |

| Table 10-1: Summary of Diamond drilling, Maracás Property | 112 |

| Table 10-2: Largo 2007 Maracás Drill Program | 112 |

| Table 10-3: 2007 Novo Amparo drilling campaign | 114 |

| Table 10-4: Drill Hole Summary for the 2007 Campbell Drill Program | 114 |

| Table 10-5: 2007 Campbell Drill Results | 115 |

| Table 10-6: 2008 Drill Program Summary | 118 |

| Table 10-7: 2008 Drill Program Information | 118 |

| Table 10-8: 2008 Drill Program Summary of Significant Results | 119 |

| Table 10-9: Largo 2011 - 2012 Drill Program | 120 |

| Table 10-10: Campbell Zone Drilling | 120 |

| Table 10-11: Gulçari A Norte Zone Drilling | 121 |

| Table 10-12: Gulçari B Zone Drilling | 121 |

| Table 10-13: Gulçari B Sul Zone Drilling | 121 |

| Table 10-14: São José Zone Drilling | 121 |

| Table 10-15: Novo Amparo Zone Drilling | 122 |

| Table 10-16: Novo Amparo Nort Zone Drilling | 122 |

| Table 10-17: 2011-2012 Drill Program Summary of Significant Drill Results | 124 |

| Table 10-18: Total Maracás Drilling to 2012 | 126 |

| Table 10-19: 2007 Late Drill Results | 127 |

| Table 10-20: Largo 2012 Infill Drill Program | 128 |

| Table 10-21: 2012 Infill Drill Program Summary of Significant Results | 130 |

| Table 10-22: Summary 2018 Largo Infill Drill Program | 131 |

| Table 10-23: 2018 Largo Infill Drill Assay Results | 132 |

| Table 10-24: 2018 Largo Exploration Drill Program summary | 134 |

| Table 10-25: 2018 NAN Drill Program | 134 |

| Table 10-26: 2018 NAN Largo Drill Assay | 136 |

| Table 10-27: South Block Drill Campaign: Braga and Jacaré targets, 2018 | 136 |

| Table 10-28: 2019 Drilling Summary | 137 |

| Table 10-29: 2019 NAN Drill Program | 137 |

| Table 10-30: Significant Drill Intercepts from the 2019 NAN Drill Program | 140 |

| Table 10-31: Campbell Pit 2019 Drill Program | 140 |

| Table 10-32: 2019 Campbell Pit Drill Assay of significant results | 141 |

| Table 10-33: GAN - 2019 Drill Program | 142 |

| Table 10-34: 2019 GAN Drill Assay of significant results | 143 |

| Table 10-35: GAS - 2019 Drilling Program | 144 |

| Table 10-36: NAO - 2019 Drill Program | 144 |

| Table 10-37: SJO 2019 Drill Program | 145 |

| Table 10-38: Magmatic Cycle Revision: Relogged Geological Description, 2019 | 146 |

| Table 10-39: 2019 Drilling Summary | 147 |

| Table 10-40: 2020 Campbell Pit Drilling Program | 147 |

| Table 10-41: Campbell Drill Assay of Significant Results | 148 |

| Table 10-42: 2020 GAN Drilling Program | 149 |

| Table 10-43: 2020 GAN Significant Drill Assay Results | 152 |

| Table 10-44: 2020 NAN Drilling Program | 153 |

| Table 10-45: 2020 NAN Drill Assay of Significant Result | 155 |

| Table 10-46: São José Drill Program | 157 |

| Table 10-47: 2020 Novo Amparo Drill Program | 158 |

| Table 11-1:Density Summary (until 2015) | 171 |

| Table 11-2:Average Specific Gravity for the Campbell deposit, Largo Data 2016 | 172 |

| Table 11-3:Average Specific Gravity from 2016 to 2019, Largo Database | 172 |

| Table 11-4:Average Specific Gravity for deposits, 2020 Pycnomter Data | 173 |

| Table 11-5: Internal Standard Detection Limits | 183 |

| Table 11-6:Standards and Blank QA/QC Summary Results | 183 |

| Table 11-7:QA/QC Program Summary | 184 |

| Table 11-8- Main Certified Reference Mateial used by Largo | 185 |

| Table 13-1: Summary of Results - TiO2 Recovery - Campbell Pit | 206 |

| Table 13-2: Lithologies of Samples - Campbell Pit | 207 |

| Table 13-3: Chemical Analysis of Samples - Campbell Pit | 207 |

| Table 13-4: Summary of Results - Dry Magnetic Separation - Campbell Pit | 208 |

| Table 13-5: Top and Bottom Zones - Dry Magnetic Separation Recoveries - Campbell Pit | 208 |

| Table 13-6: Proportions - Blend B and C - Campbell Pit | 209 |

| Table 13-7: Chemical Analysis - Blend B and C - Campbell Pit | 209 |

| Table 13-8: Summary of Results - Wet Magnetic Separation - Blend B and C - Campbell Pit | 209 |

| Table 13-9: Chemical Analysis - Wet Non-Magnetic Blend B and C - Campbell Pit | 210 |

| Table 13-10: Desliming Results - Wet Non-Magnetic Blend B and C - Campbell Pit | 210 |

| Table 13-11: Flotation Results - Blend B and C - Campbell Pit | 211 |

| Table 13-12: Summary of Results - Global Recovery of TiO2 - Campbell Pit | 212 |

| Table 13-13: Summary of V2O5 Recoveries - Gulçari A Norte (GAN) | 213 |

| Table 13-14: Summary of TiO2 Recoveries - Gulçari A Norte (GAN) | 213 |

| Table 13-15: Chemical Analysis of Lithologies (GAN) | 213 |

| Table 13-16: Chemical Analysis of Samples (GAN) | 214 |

| Table 13-17: Mineralogical Distribution of Samples (GAN) (-150+20 µm) | 215 |

| Table 13-18: Vanadium Distribution by Mineral (GAN) (-150+20 µm) | 215 |

| Table 13-19: Titanium Distribution by Mineral (GAN) (-150+20 µm) | 215 |

| Table 13-20: Liberation - Magnetite and Ilmenite (GAN) | 216 |

| Table 13-21: Dry Magnetic Separation Results - Low Intensity | 217 |

| Table 13-22: Dry Magnetic Product - Wi and Specific Weight | 218 |

| Table 13-23: Chemical Analysis - Wet Magnetic Separation Feed | 218 |

| Table 13-24: Summary of Results - Wet Magnetic Separation | 219 |

| Table 13-25: Chemical Analysis - Calcination Feed | 220 |

| Table 13-26: Calcination Results | 221 |

| Table 13-27: Leaching and Chemical Treatment | 222 |

| Table 13-28: Summary - V2O5 Recoveries | 222 |

| Table 13-29: Chemical Analysis - Desliming Feed | 223 |

| Table 13-30: Chemical Analysis - Desliming | 223 |

| Table 13-31: Flotation Results | 224 |

| Table 13-32: Summary of Results - Collect 3 - Flotation | 225 |

| Table 13-33: Summary of Results - Flotation VMSA Lab | 226 |

| Table 13-34: Summary of Results - Dry Magnetic Separation - Titanium Recoveries | 227 |

| Table 13-35: Summary of Results - Wet Magnetic Separation - Titanium Recoveries | 228 |

| Table 13-36: Summary of Results - Titanium Recoveries by Area/Process | 228 |

| Table 13-37: Summary of V2O5 Recoveries - Novo Amparo Norte (NAN) | 229 |

| Table 13-38: Summary of TiO2 Recoveries - Novo Amparo Norte (NAN) | 229 |

| Table 13-39: Particle Size Distribution and Chemical - Samples M3, M4 and M5 | 230 |

| Table 13-40: Mineralogical Analysis - Sample HBPC (M3 and M4) | 231 |

| Table 13-41: Liberation Analysis - Sample HBPC (M3 and M4) | 231 |

| Table 13-42: Work Index and Abrasiveness Index | 231 |

| Table 13-43: Dry Magnetic Separation by Set Up - Mass Recovery, Magnetic Recovery and Enrichment | 233 |

| Table 13-44: Dry Magnetic Separation - Summary of Results | 234 |

| Table 13-45: Wet Magnetic Separation - Summary of Results | 235 |

| Table 13-46: Calcination - Summary of Results | 237 |

| Table 13-47: Global Recovery per Sample | 239 |

| Table 13-48: Average Global Recovery - Resources | 240 |

| Table 13-49: Particle Size Distribution and Chemical Analysis | 241 |

| Table 13-50: Cycloning of Non-magnetic | 242 |

| Table 13-51: Flotation Test Results - Accumulated Grades and Recoveries | 243 |

| Table 13-52: Flotation Test Results - Collect 2 - Average Results Summary | 244 |

| Table 13-53: Flotation Test Results - By Fraction - Average Results Summary | 244 |

| Table 13-54: TiO2 Recovery by Area, by Sample and Reserve - Average Summary | 244 |

| Table 14-1: Drilling Campbell Pit Summary | 247 |

| Table 14-2: Drilling GAN Summary | 247 |

| Table 14-3: Drilling NAN Summary | 247 |

| Table 14-4: Campbell Pit, NAN and GAN Typology | 249 |

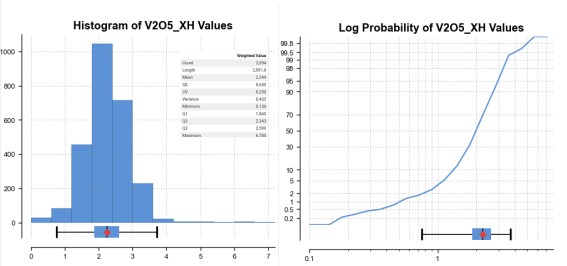

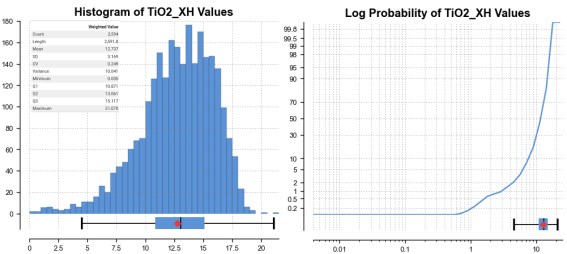

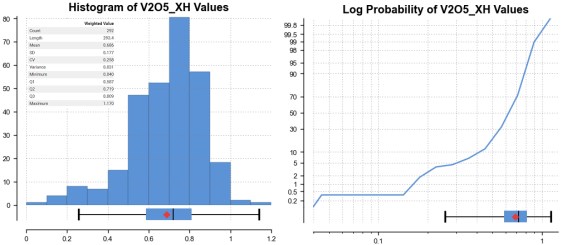

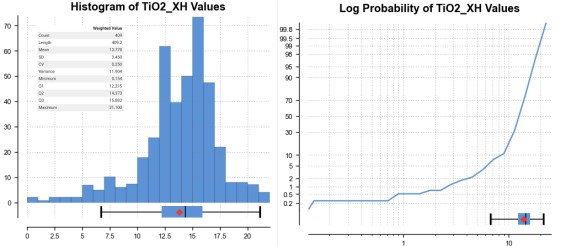

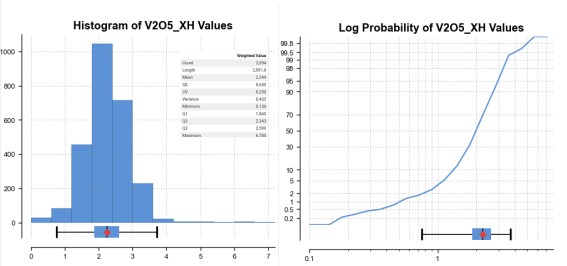

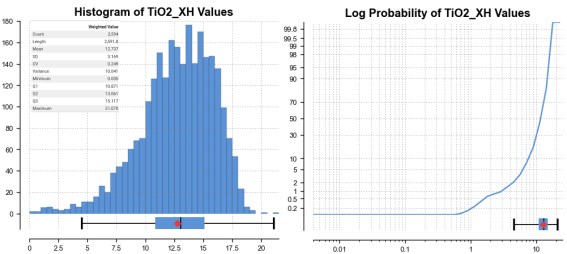

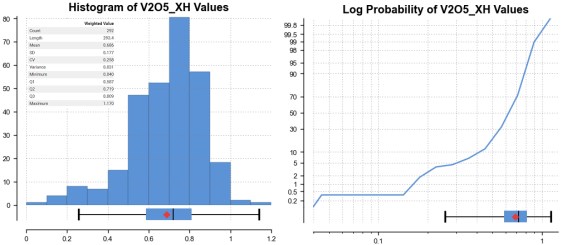

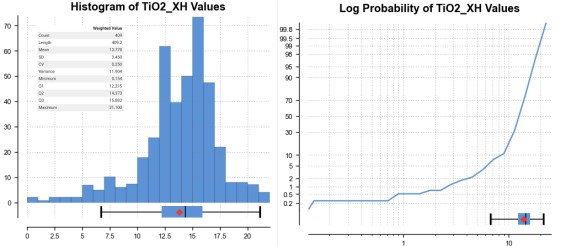

| Table 14-5: Campbell Pit Descriptive statistic. "XH" suffix means content in head grades and "XC" means content in the Davis Tube magnetic concentrates | 257 |

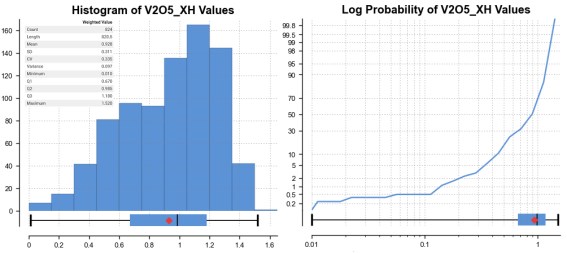

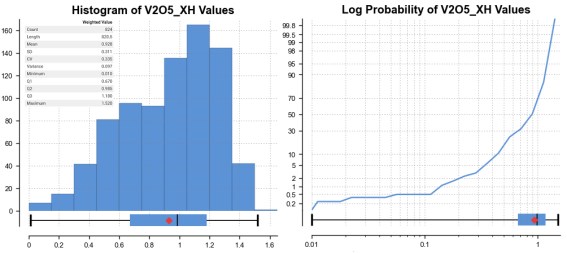

| Table 14-6: GAN Deposit Descriptive statistic. "XH" suffix means content in head grades and "XC" means content in the Davis Tube magnetic concentrates | 260 |

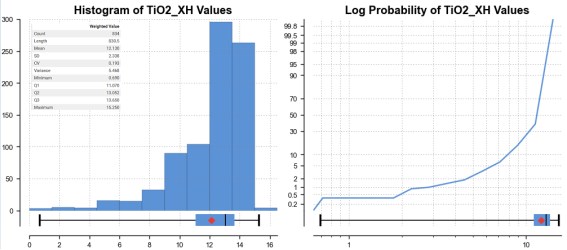

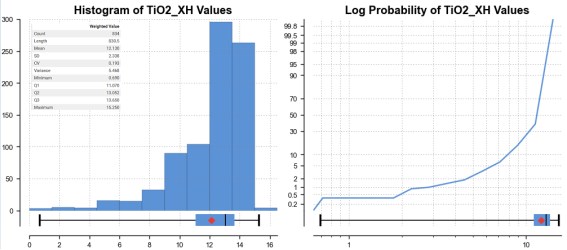

| Table 14-7: NAN deposit Descriptive statistic. "XH" suffix means content in head grades and "XC" means content in the Davis Tube magnetic concentrates | 264 |

| Table 14-8: Average Specific Gravity for the Campbell deposit, Largo Database. 2012-2019 | 266 |

| Table 14-9: Average Specific Gravity by pycnometer for deposits, 2020 Largo Data 2020 | 266 |

| Table 14-10: Average Specific Gravity assigned in Mineral Resource Estimates in 2021 | 267 |

| Table 14-11: Campbell Pit Deposit Variographic Parameters | 267 |

| Table 14-12: GAN Deposit Variographic Parameters | 268 |

| Table 14-13: NAN area Varigraphic Parameters | 270 |

| Table 14-14: Campbell Pit Block Model Summary | 270 |

| Table 14-15: GAN Block Model Summary (block corner) | 271 |

| Table 14-16: NAN Block Model Summary (block corner) | 271 |

| Table 14-17: Attributes Summary | 271 |

| Table 14-18: Campbell Pit Kriging Plan | 272 |

| Table 14-19: GAN Deposit Kriking Plan | 273 |

| Table 14-20: NAN Deposit Kriging Plan | 273 |

| Table 14-21: Campbell Pit Mineral Resource Statement. (Ordinary Kriging Method) | 285 |

| Table 14-22: GAN Mineral Resource Statement. (Ordinary Kriging Method) | 285 |

| Table 14-23: NAN Mineral Resource Statement. (Ordinary Kriging Method) | 286 |

| Table 14-24: 2013 Satellite Deposits Mineral Resource (2012) | 286 |

| Table 14-25: TiO2 Resource in Non-Magnetic Tailings | 290 |

| Table 15-1: Maracás Menchen Project - Mineral Reserves Estimate | 292 |

| Table 15-2: Maracás Menchen Project - Non-Magnetic Mineral Reserves in Ponds | 293 |

| Table 15-3: Pit Optimization Parameters for Campbell Pit | 295 |

| Table 15-4: Nested Pits Results for Campbell | 296 |

| Table 15-5: Pit Optimization Parameters for GAN | 296 |

| Table 15-6: Nested Pits Results for GAN | 297 |

| Table 15-7: Pit Optimization Parameters for NAN | 298 |

| Table 15-8: Nested Pits Results for NAN | 299 |

| Table 15-9: Mine Design Parameters for Campbell Pit and GAN | 299 |

| Table 15-10: Maracás Menchen Project - Campbell Pit Reserves | 301 |

| Table 15-11: Maracás Menchen Project - GAN Mine Design Statement | 302 |

| Table 15-12: Mine Design Parameters for NAN | 302 |

| Table 15-13: Maracás Menchen Project - NAN Reserves | 304 |

| Table 15-14: TiO2 Reserves in Non-Magnetic Tailings (Effective Date - October,20, 2021) | 307 |

| Table 16-1: Massif Classes - Bieniawski Geomechanical Classification, 1989 | 313 |

| Table 16-2: Test results of the gabbro gazed (source MFL) | 314 |

| Table 16-3: Pyroxenite - pegmatite - isotropic gabbro test results (Source MFL) | 314 |

| Table 16-4: Campbell Pit Sectors | 316 |

| Table 16-5: Geotechnical Angles Adopted in Campbell's pit | 326 |

| Table 16-6: Geotechnical Angles Adopted for GAN and NAN | 326 |

| Table 16-7: Maracás Menchen Project - Mining Schedule | 328 |

| Table 16-8: Non-Magnetic Volume in Ponds by topography | 339 |

| Table 16-9: Non-Magnetic Tailings Reclaimation Plan | 340 |

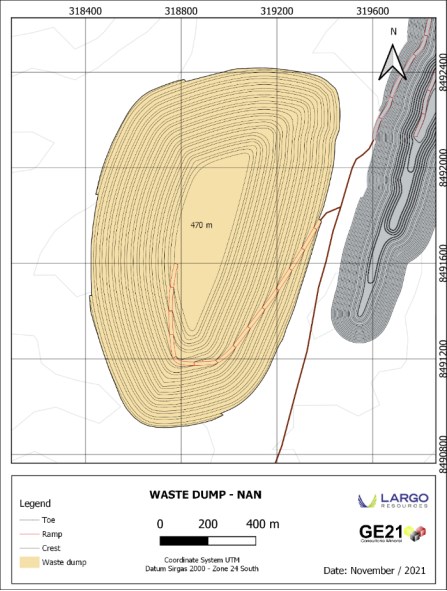

| Table 16-10: Waste dumps design parameters | 340 |

| Table 16-11: Waste dumps volume and areas | 341 |

| Table 16-12: Mining Fleet Contract | 344 |

| Table 16-13: Yearly Required Mining Flee | 346 |

| Table 17-1: Summary of Key Process Design Criteria | 348 |

| Table 18-1: List of Equipment | 359 |

| Table 18-2: Ilmenite Concentration Plant Utilities | 370 |

| Table 19-1: World Mins Production and Reserves | 378 |

| Table 19-2: World Crude Steel Production (Million tonnes) | 379 |

| Table 19-3: Roskill Price Trend (US$/lb V2O5) | 380 |

| Table 19-4: Selling Price | 383 |

| Table 20-1: Vulnerable Species | 391 |

| Table 20-2: Rare Species | 391 |

| Table 20-3: Test work results - ABA-M - Waste Rock- Campbell | 411 |

| Table 20-4: Test work results - ABA-M- Waste Rock- Campbell | 412 |

| Table 20-5: Neutralization Potential Ratio (NPR) Screening Criteria (after Price et al, 1997) | 412 |

| Table 20-6: Test work Results - ABA-M -Magnetite Rocks- Campbell | 413 |

| Table 20-7: Test work Results - ABA-M -Magnetite Rocks- Campbell | 414 |

| Table 20-8: Maracás Vanadium Plant Atmospheric Emissions | 418 |

| Table 20-9: Maximum Long-Term Plant Emission Concentrations | 418 |

| Table 20-10: Mitigation Measures - Operations Phase | 422 |

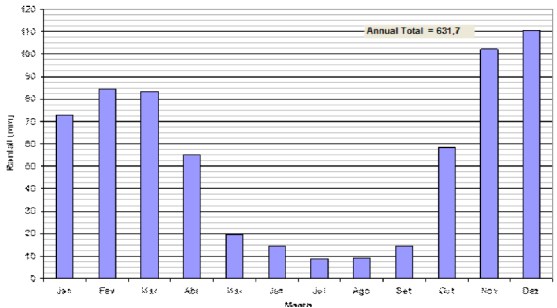

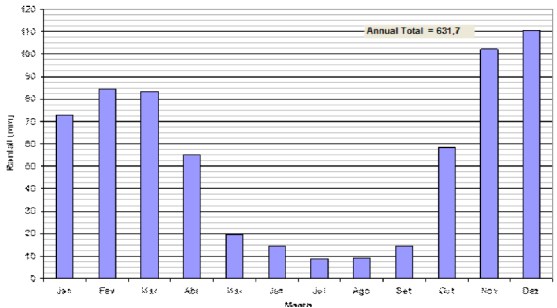

| Table 20-11: Rainfall Rates (mm) | 426 |

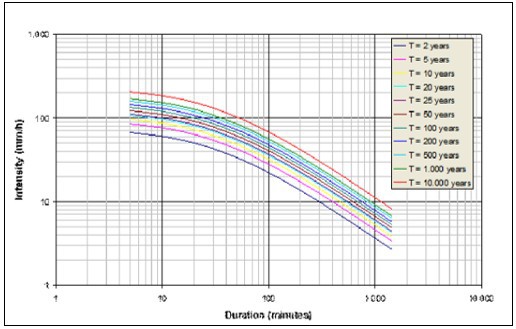

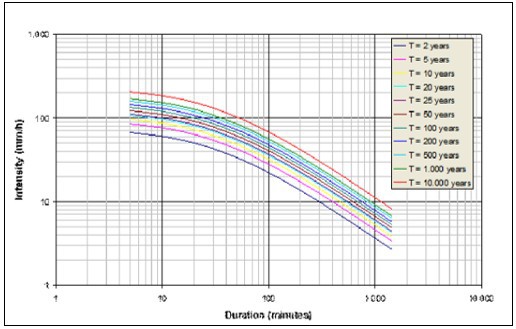

| Table 20-12: Design Flow Volumes for the Hydraulic Structures | 427 |

| Table 20-13: Characterization of Soils and Outcrops in the Project Area | 428 |

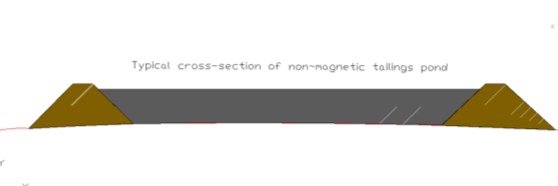

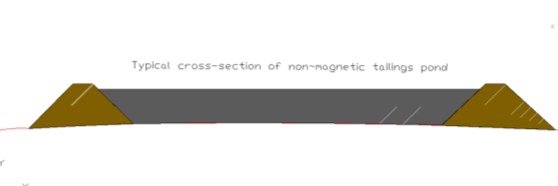

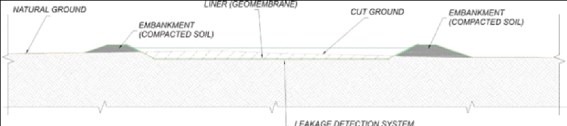

| Table 20-14: Summary of Key Non-Magnetic Tailings Pond 3 Design Aspects | 428 |

| Table 20-15: Schedule of Non-Magnetic Tailing Pond Construction and Usage | 429 |

| Table 20-16: Main Geometric Characteristics of the Leached Calcine Tailings Stack | 432 |

| Table 20-17: Main Geometric Characteristics of the Chloride Control Purge Pond | 432 |

| Table 20-18: Main Characteristics of the Ridges | 434 |

| Table 20-19: Action Plan - Environmental Programs | 436 |

| Table 21-1: Process Plant Capex - Ilmenite Plant - Maracás - 150 Kt/year concentrate | 443 |

| Table 21-2: Process Plant Capex - TiO2 Pigment - 30 Kt/year | 444 |

| Table 21-3: Process Plant Capex - V2O3 Plant - 7 kt/year | 445 |

| Table 21-4: Process Plant Capex - TiO2 Pigment - 60 kt/year | 445 |

| Table 21-5:Process Plant Capex - TiO2 Pigment - 120 kt/year | 446 |

| Table 21-6: Process Plant Capex - Ilmenite Plant - 425 kt/year concentrate | 447 |

| Table 21-7: Process Plant Capex - V2O5 Expansion Second Kiln | 448 |

| Table 21-8: CAPEX summary | 449 |

| Table 21-9: Contract Loading & Haulage Costs | 450 |

| Table 21-10: Operating Costs - Mining | 451 |

| Table 21-11: Operating Costs - Vanadium Processing | 451 |

| Table 21-12: Operating Costs - Ilmenite Processing | 452 |

| Table 21-13: Operating Costs - Titanium Pigment Chemical Plant | 452 |

| Table 21-14: General and Administration Costs | 452 |

| Table 22-1: Royalties and CFEM | 454 |

| Table 22-2: Product Selling Prices | 455 |

| Table 22-3: Main Economic Parameters | 455 |

| Table 22-4: Base Case Life of Mine Annual Cash Flow | 456 |

| Table 22-5: PROJECT CASH FLOW (US$ x 1000) - Without Leverage | 457 |

| Table 22-6: Economical Analysis Summary | 458 |

| Table 22-7: Marginal Results for IRR and PayBack | 458 |

| Table 25-1: Maracás Menchen Project - Total Mineral Reserves Estimate. | 464 |

| Table 25-2: Maracás Menchen Project - Non-Magnetic Mineral Reserves in Ponds. | 464 |

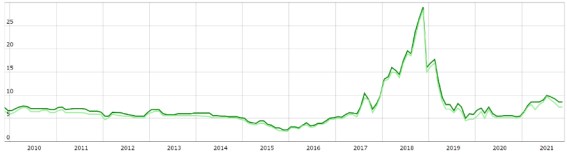

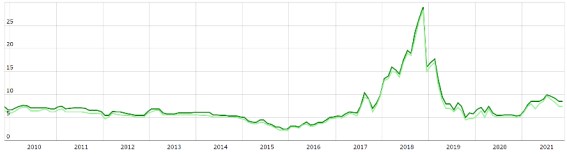

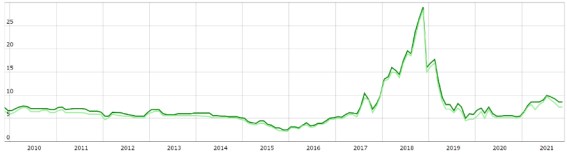

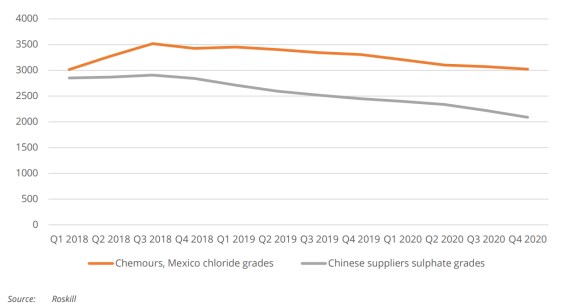

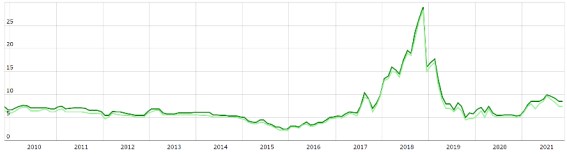

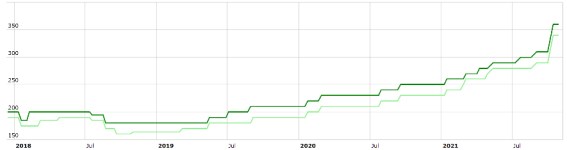

| Figure 1.1: Vanadium Pentoxide Price Trend (US$/lb V2O5) | 45 |

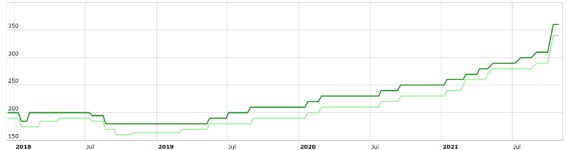

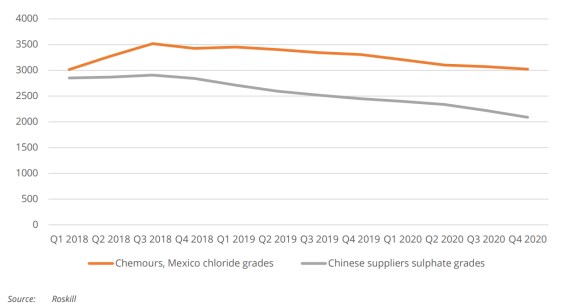

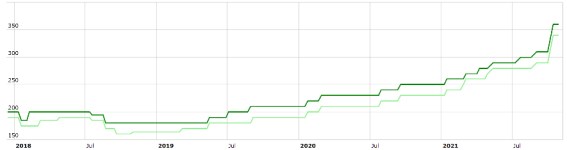

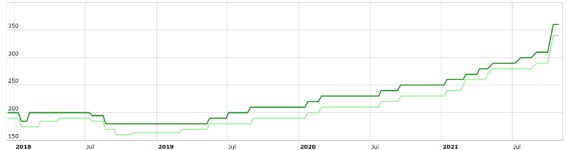

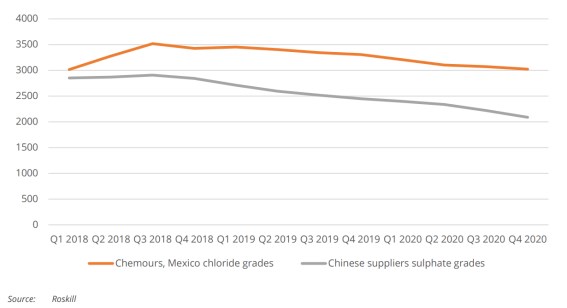

| Figure 1.2: Ilmenite Price Trend (US$/t) | 46 |

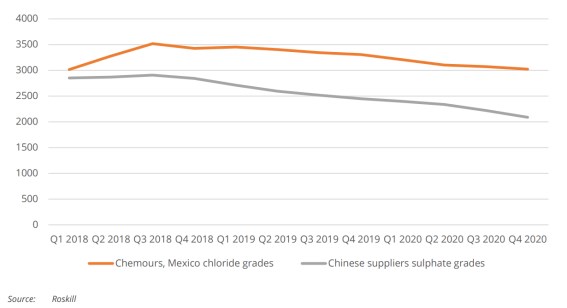

| Figure 1.3: Benchmark imported TiO2 pigment prices (US$/t, CIF Brazilian port) | 46 |

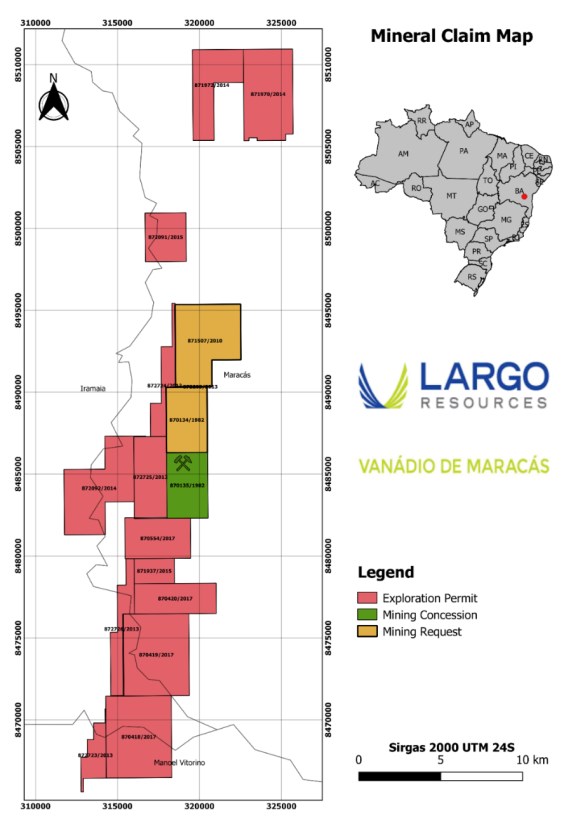

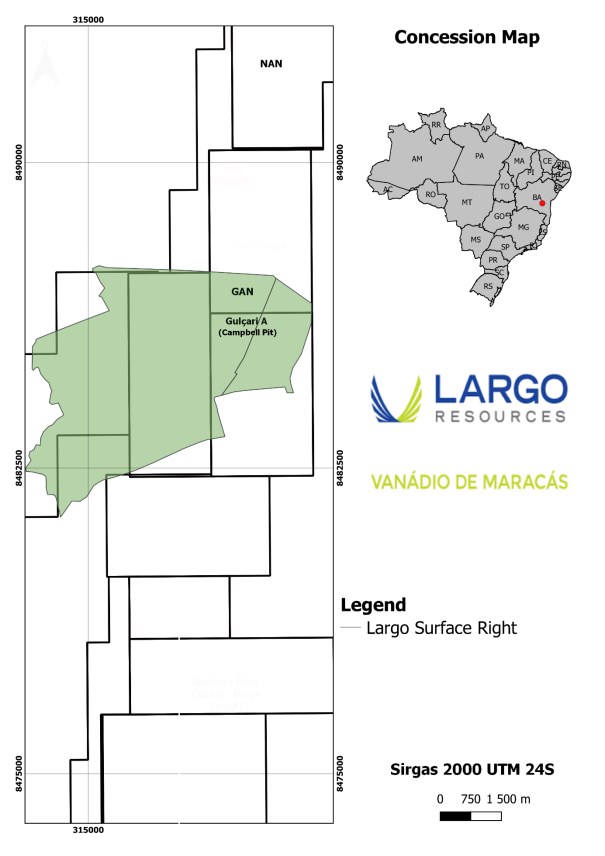

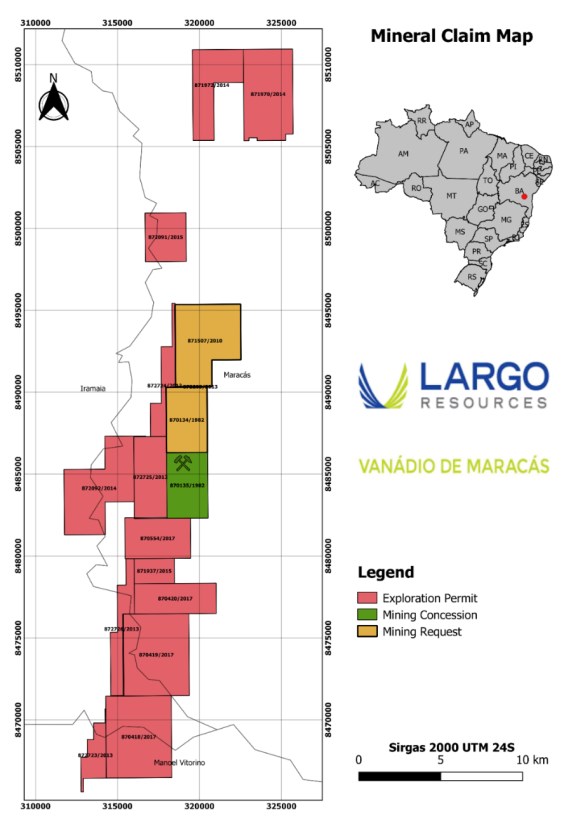

| Figure 4.1 Maracás Menchen Mine Location Map | 56 |

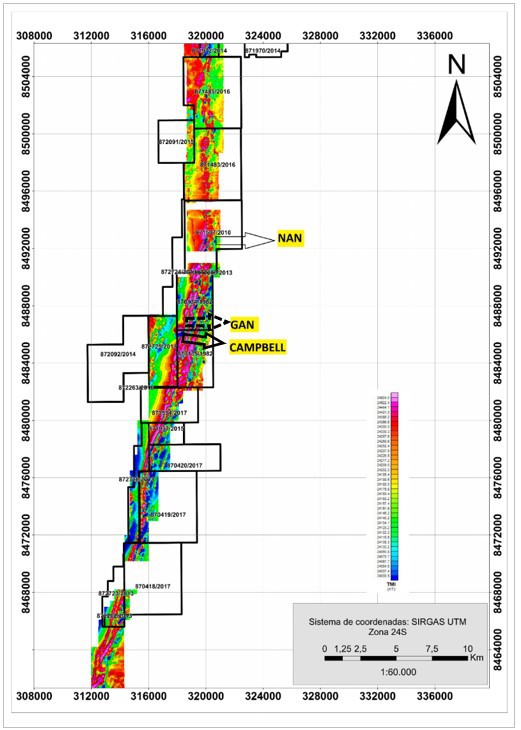

| Figure 4.2: Largo Mineral Tenure Location Map | 59 |

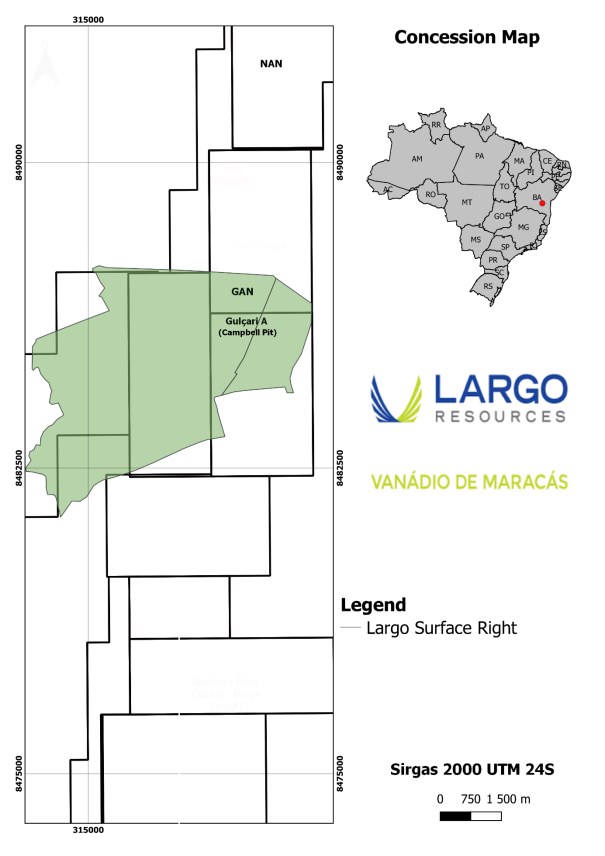

| Figure 4.3: Property area related to Mineral Rights | 62 |

| Figure 5.1: Maracás Menchen Mine with Campbell Hill in Background | 66 |

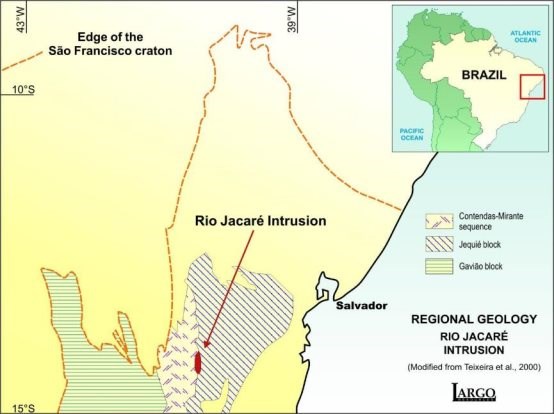

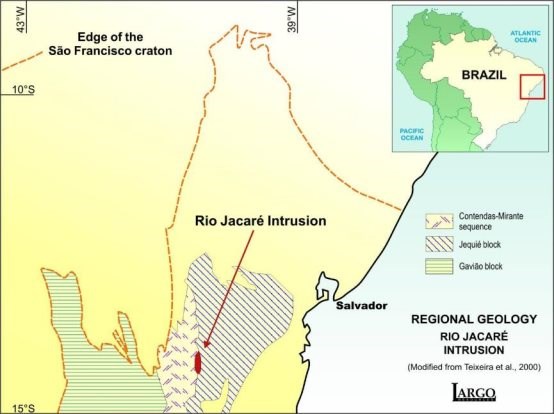

| Figure 7.1: Maracás Area Simplified Regional Geology Map | 79 |

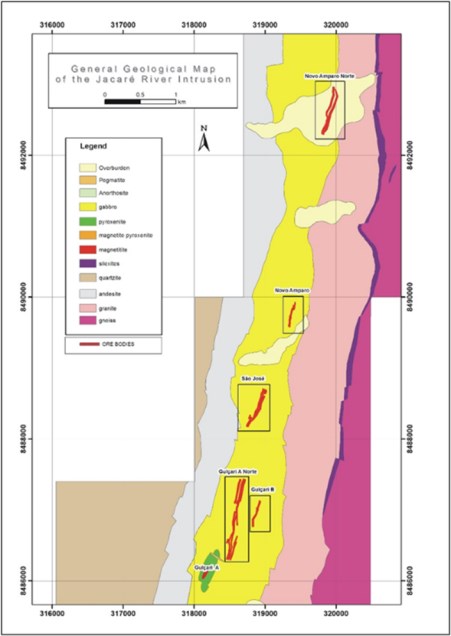

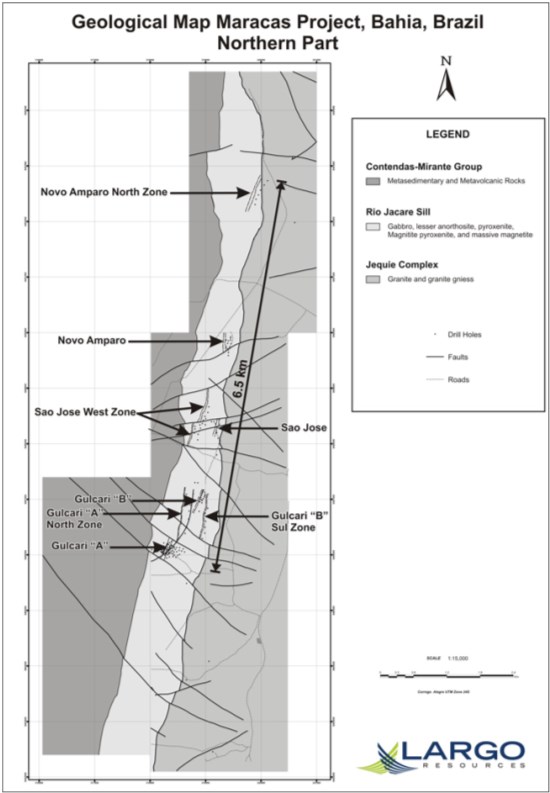

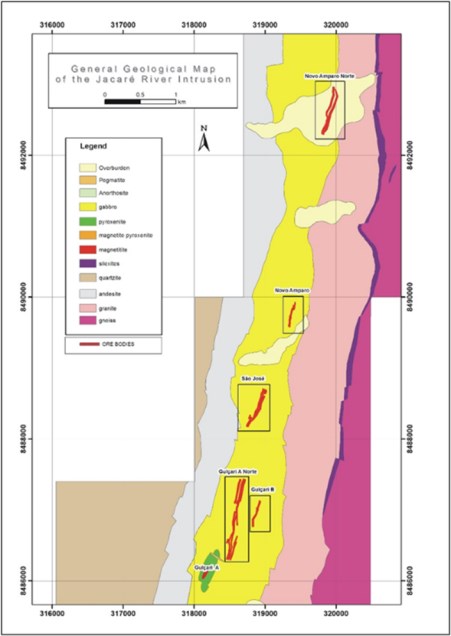

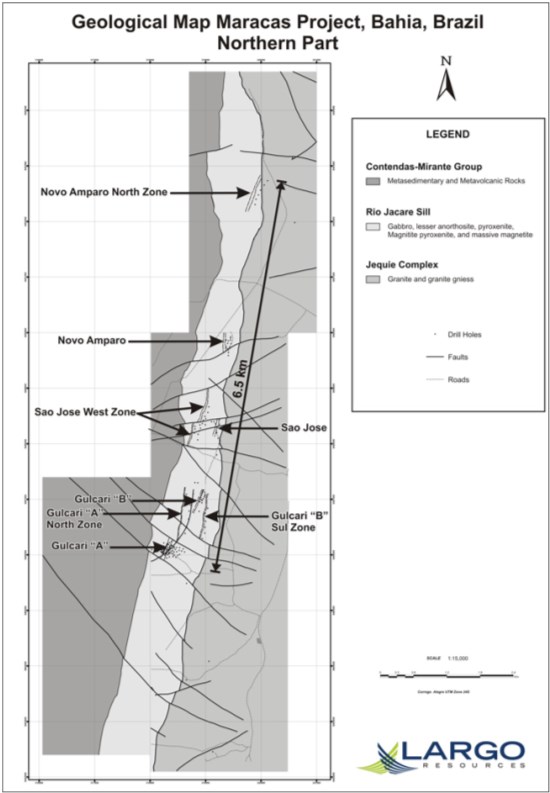

| Figure 7.2: Geological Geology Map of the Rio Jacaré mafic-ultramafic Intrusion in the general vicinity of the Maracás Menchen Mine showing the Gulcari A Deposit (Campbell Pit) and the other Near Mine Targets | 80 |

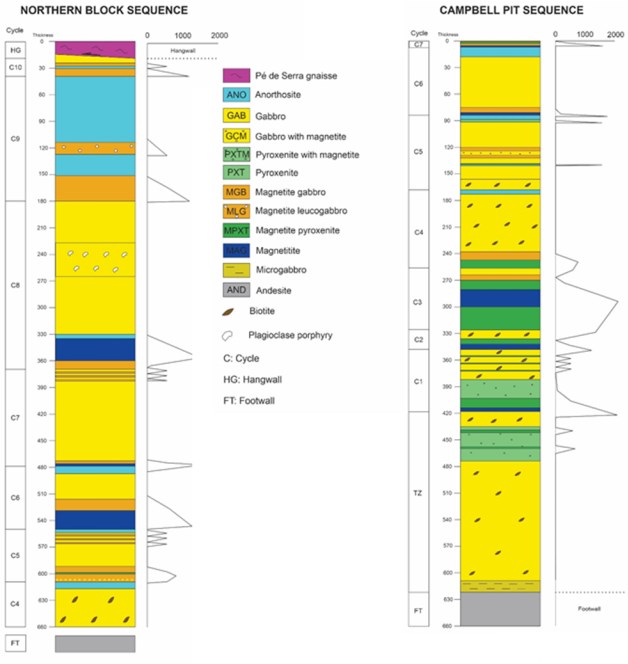

| Figure 7.3: Stratigraphic sequence of the magmatic pulses proposal according to last work of Largo | 84 |

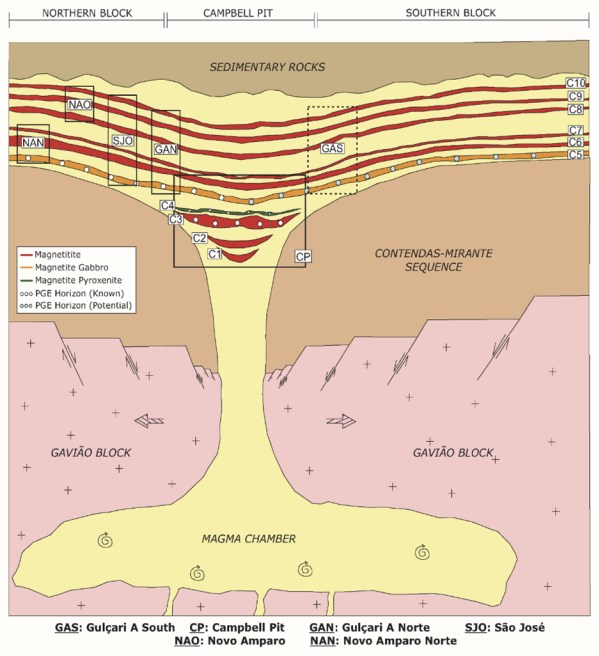

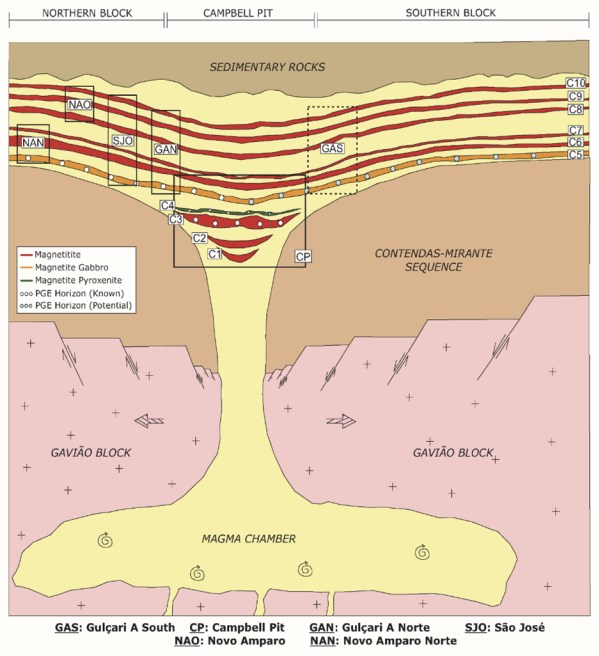

| Figure 7.4: Schematic longitudinal section through the Rio Jacaré intrusion, illustrating the continuity of various cyclic units. Note that units are not drawn to scale | 85 |

| Figure 7.5: Schematic map of the location of the various deposits relative to cyclic units | 86 |

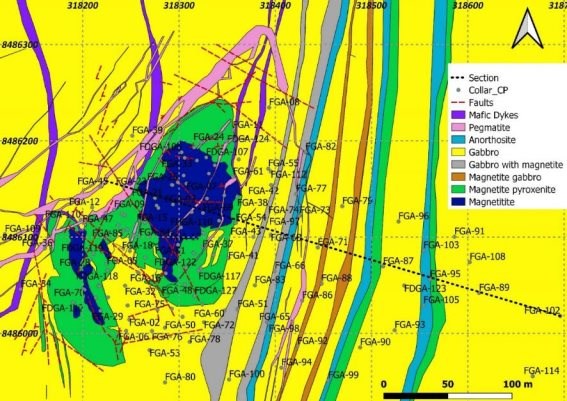

| Figure 7.6: Geological Map of the Campbell deposit | 87 |

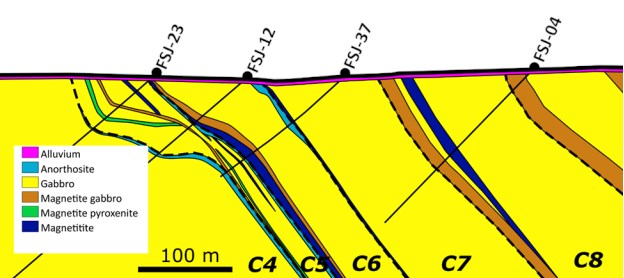

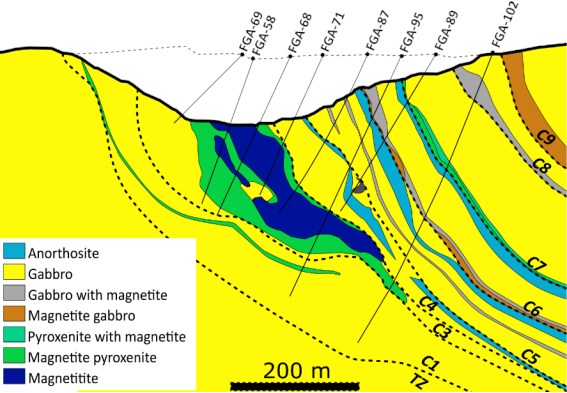

| Figure 7.7: Cross-section (NW-SE) through the Campbell deposit, showing various lithologies and their subdivision into cyclic units from TZ to C9. Note that magnetite mineralization is contained predominantly within the C3 unit in magnetite pyroxenite and magnetitite. Topography represents the pit in September 2020, however original topography is also indicated | 88 |

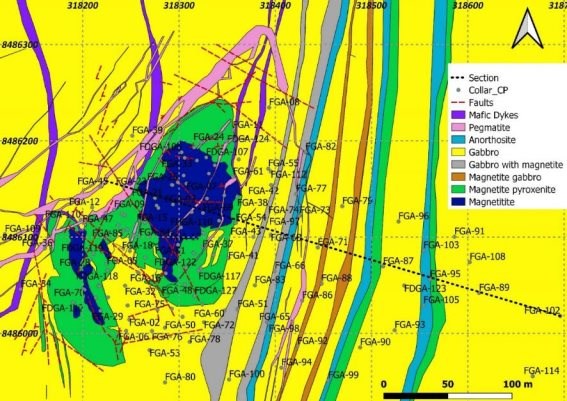

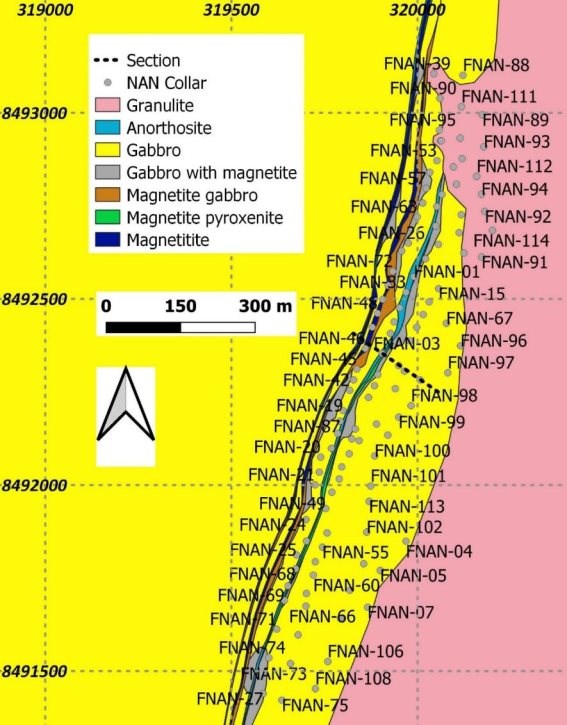

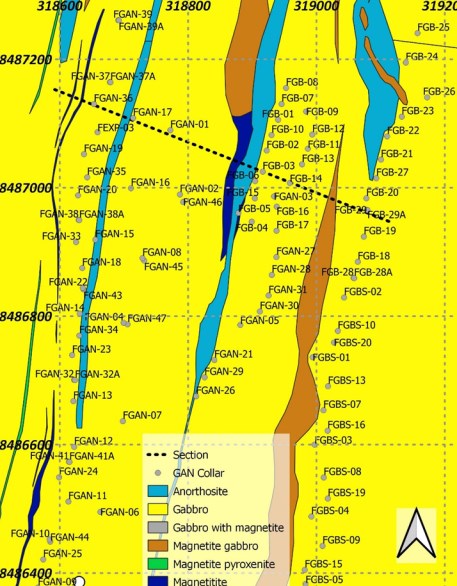

| Figure 7.8: Geological Map of the GAN Deposit | 89 |

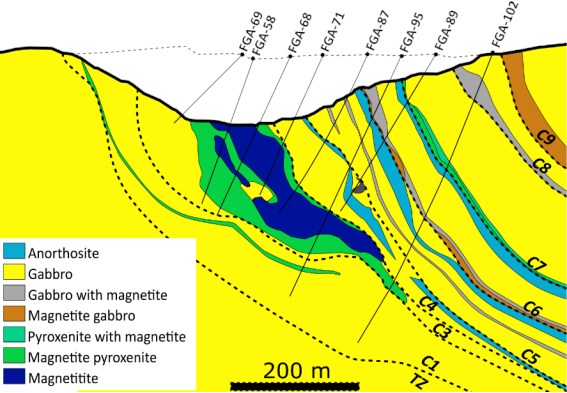

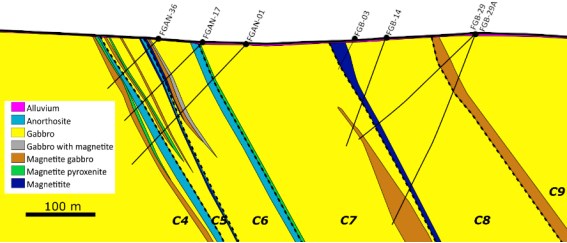

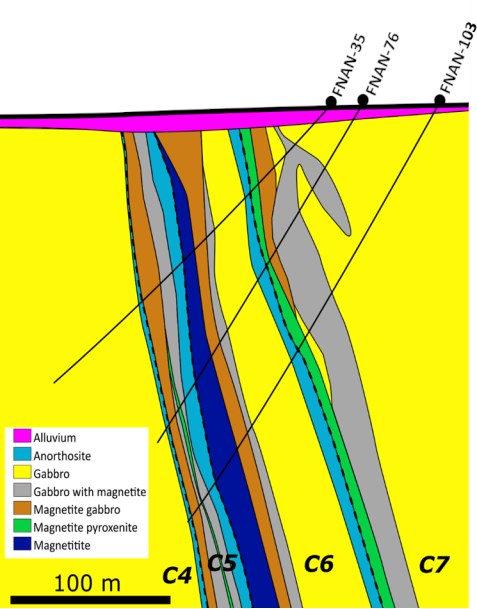

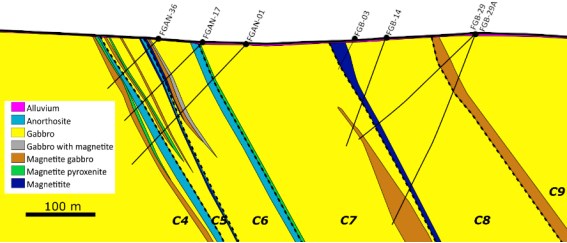

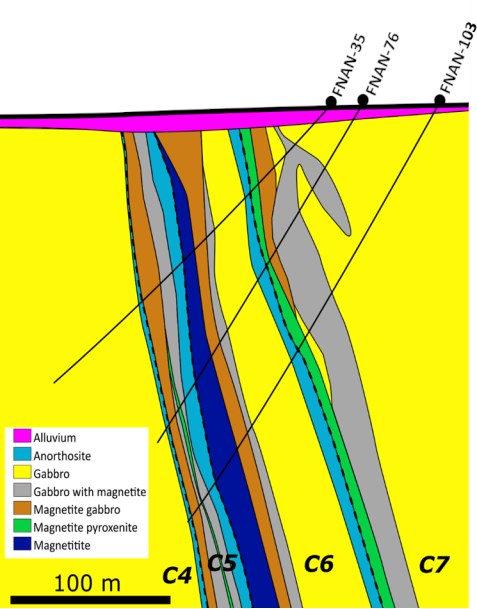

| Figure 7.9: Cross-section (NW-SE) through the GAN deposit, showing various lithologies and their subdivision into cyclic units from C4 to C9 | 90 |

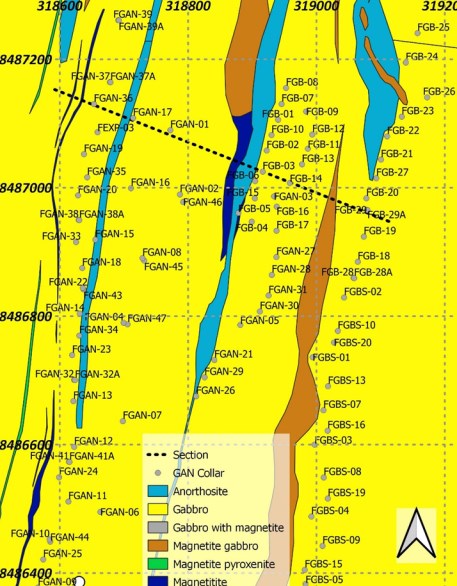

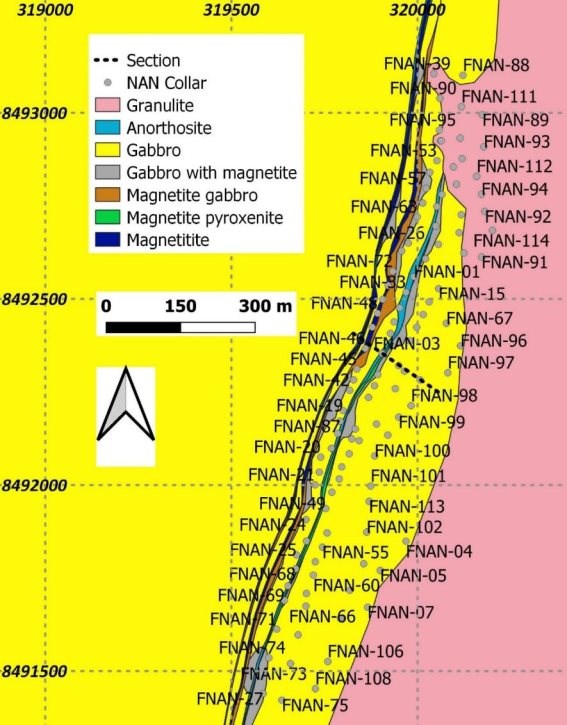

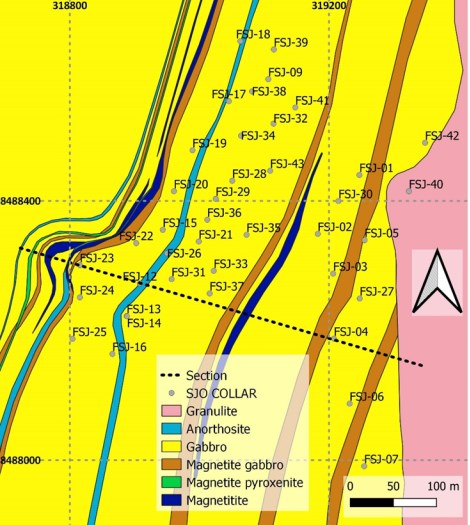

| Figure 7.10: Geological Map of the NAN deposit | 91 |

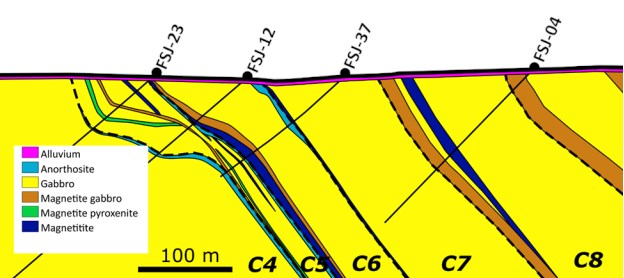

| Figure 7.11: NW-SE cross-section (looking towards 020°) through the NAN deposit | 92 |

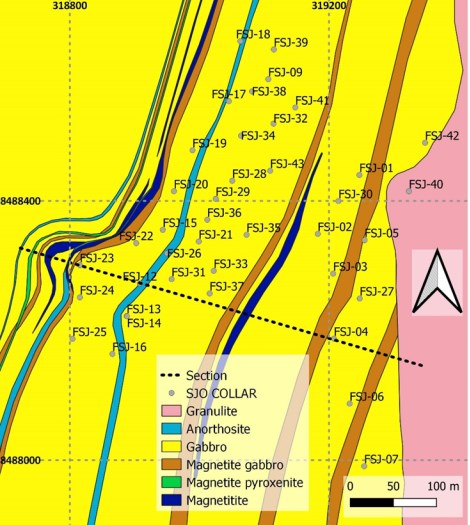

| Figure 7.12: Shows the integrated map of São José Deposit | 93 |

| Figure 7.13: Shows a representative cross-section of the São José deposit | 94 |

| Figure 7.14: Recovery Reduction Factors for Oxidized material, Campbell | 96 |

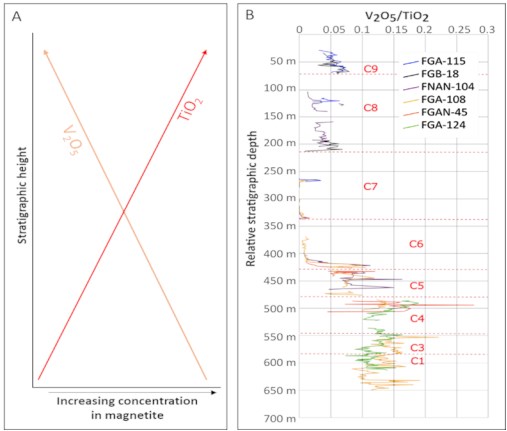

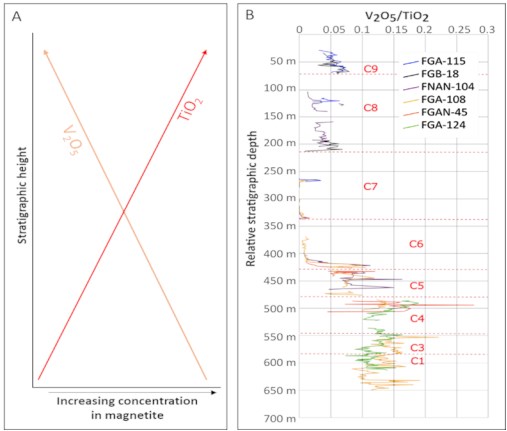

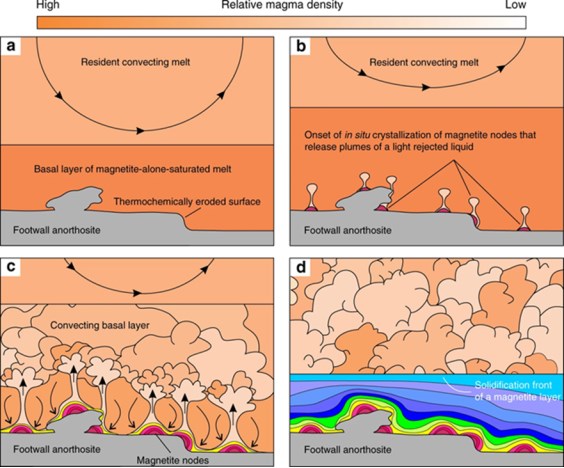

| Figure 8.1: Illustration of the general increase in TiO2 and decrease in V2O5 in magnetite with increased stratigraphic height in the upper portions of layered mafic complexes. B: V2O5/TiO2 ratios through the Rio Jacare Intrusion. Note that lower layers (C1-C4) have higher V2O5/TiO2, and that a large change occurs through the C5 and C6 units | 99 |

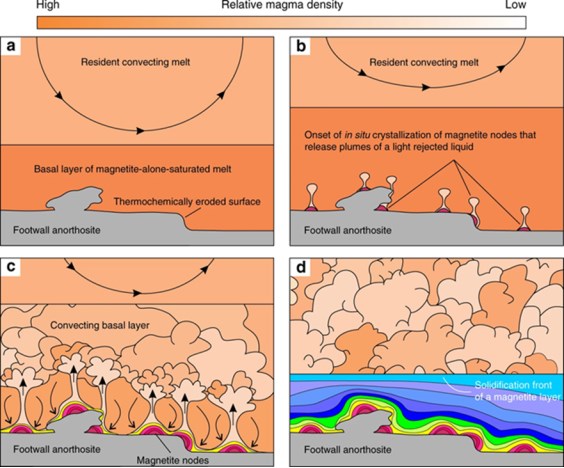

| Figure 8.2: Illustration of in-situ magnetite crystallization and growth of a magnetitite layer on the base of a magma chamber. From Kruger & Latypov, 2020 | 101 |

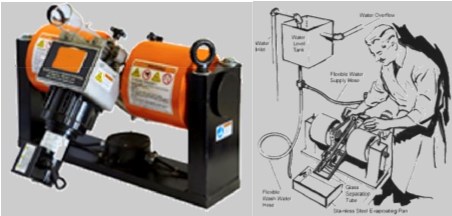

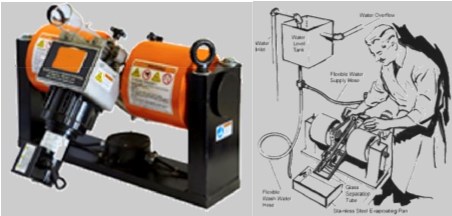

| Figure 9.1: Davis Tube Test Apparatus | 106 |

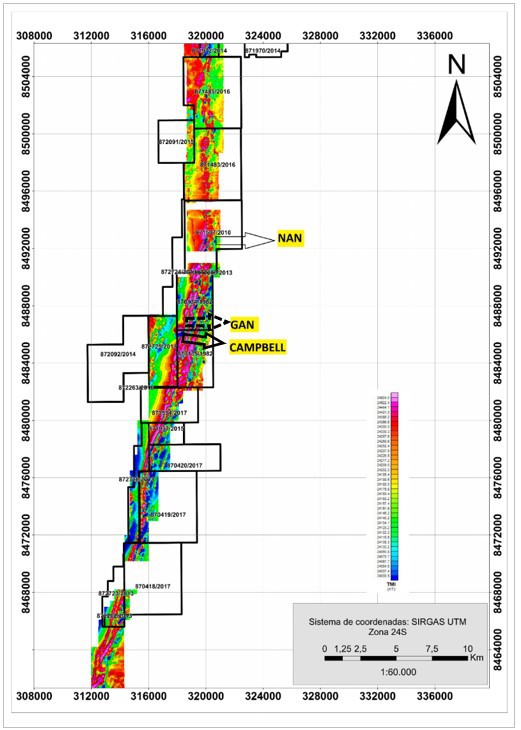

| Figure 9.2: Largo Ground Magnetometer Survey and Key Deposits | 107 |

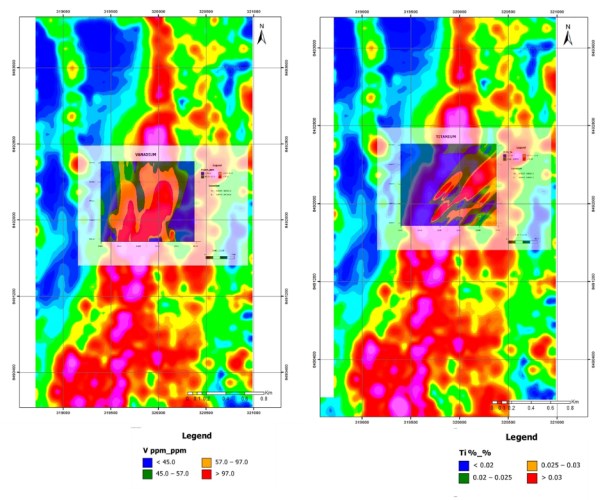

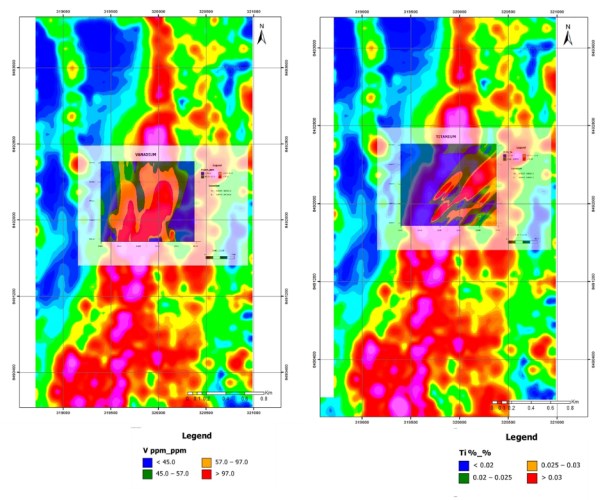

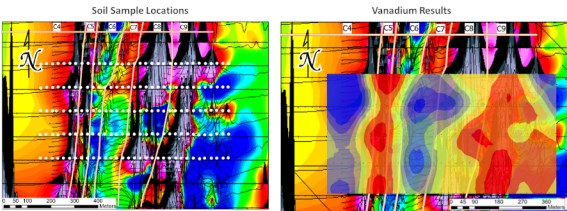

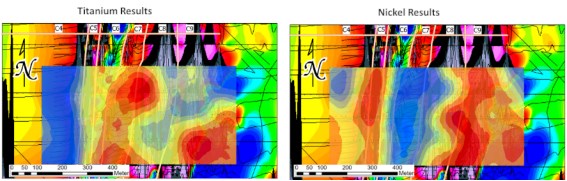

| Figure 9.3: Geochemical maps of Vanadium and Titanium generated from the 2020 NAN campaign | 109 |

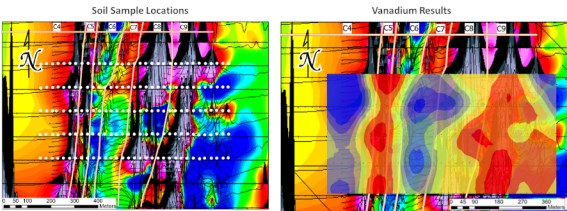

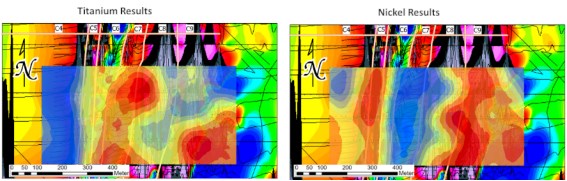

| Figure 9.4: Geochemical maps of Vanadium, Titanium and Nickel generated from the 2020 GAN campaign | 110 |

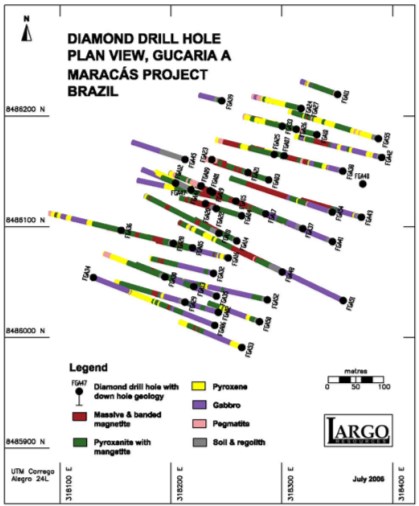

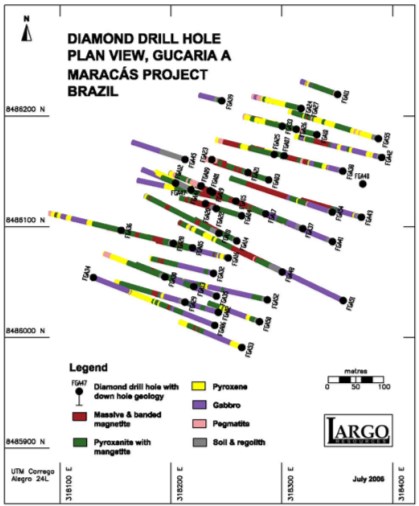

| Figure 10.1: Gulçari A Deposit Drill-Hole Plan Maracás Vanadium Project | 113 |

| Figure 10.2: Zone Location Map (October 17, 2011) | 123 |

| Figure 10.3: Campbell 2018 Drill Program Grid | 131 |

| Figure 10.4: 2018 NAN Exploration Drill Program Grid | 135 |

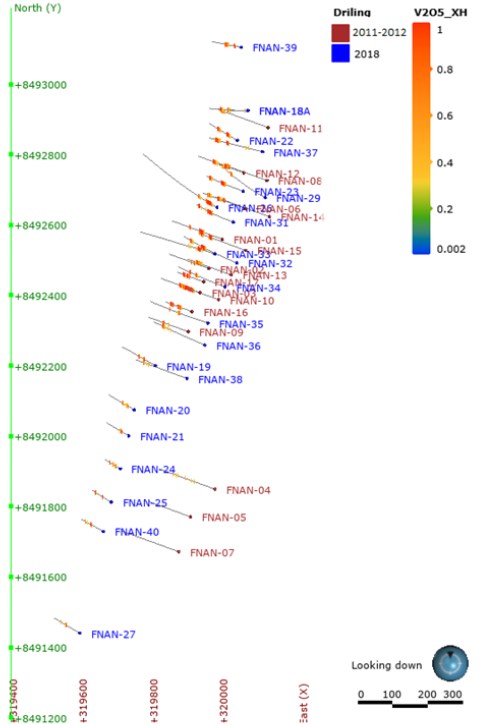

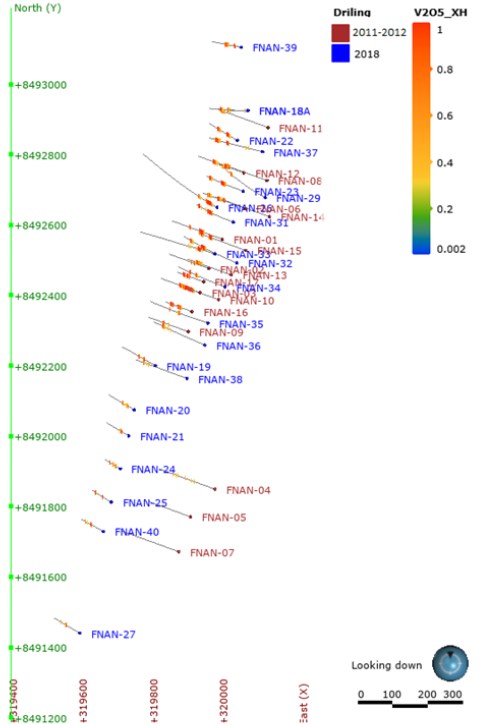

| Figure 10.5: NAN 2019 Driling Campaign Grid in green | 139 |

| Figure 10.6: Campbell Pit 2019 Driling Campaign Grid in green | 141 |

| Figure 10.7: GAN Pit 2019 Driling Campaign Grid in green | 142 |

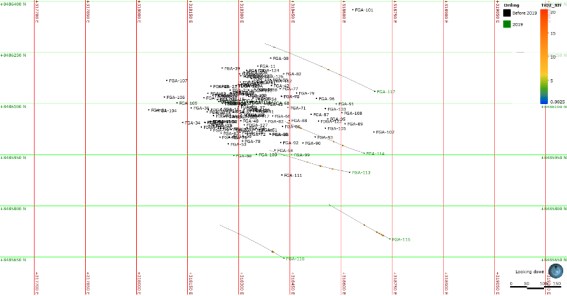

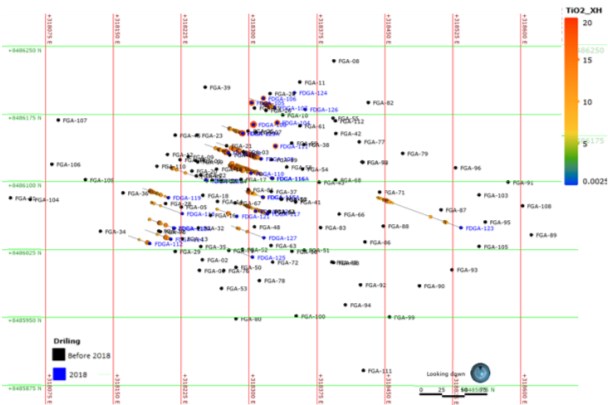

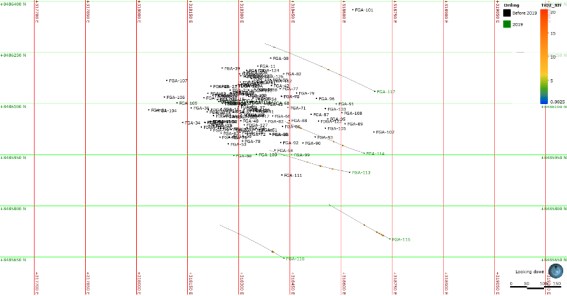

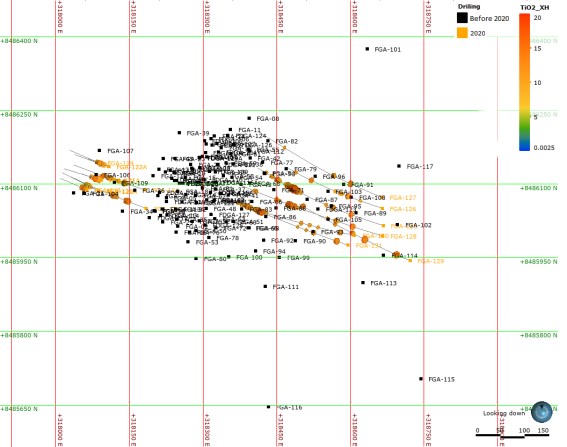

| Figure 10.8: Campbell Pit 2020 Drilling Campaign in red | 148 |

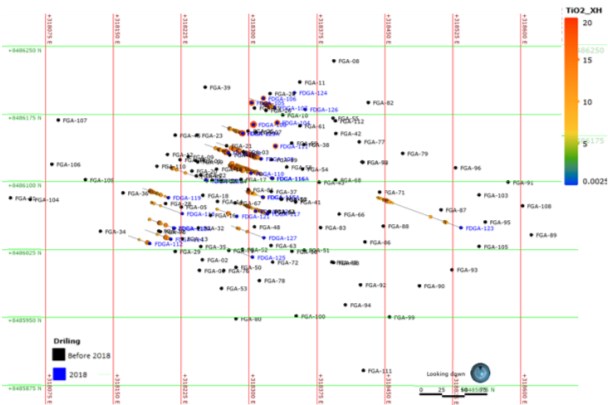

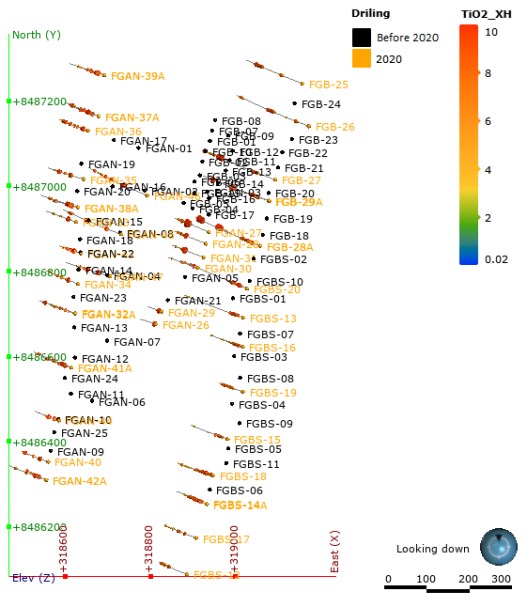

| Figure 10.9: GAN 2020 Driling Campaign in orange | 151 |

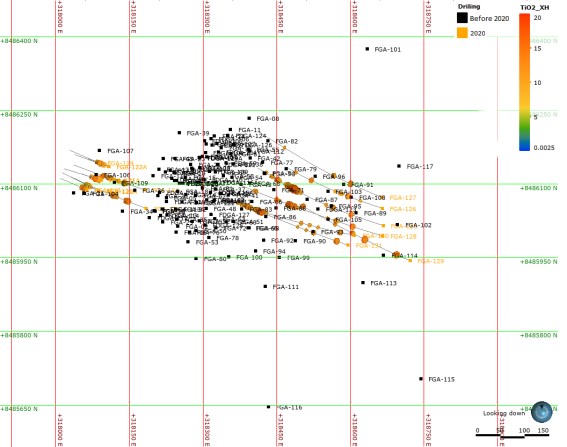

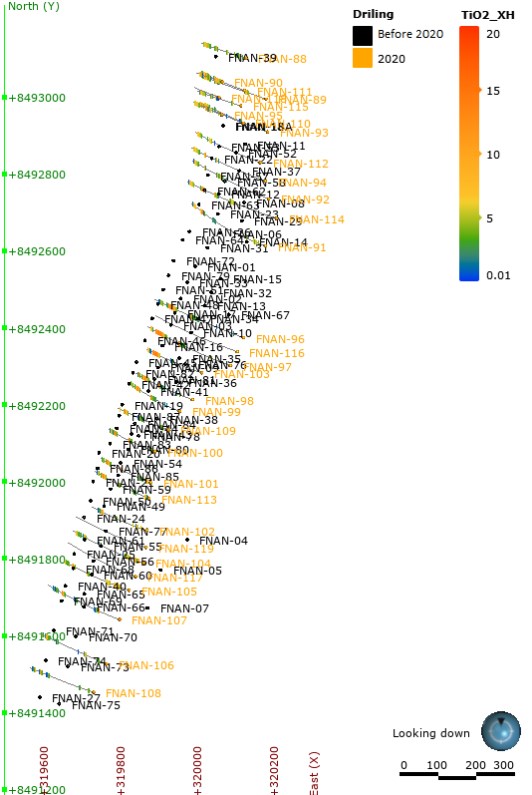

| Figure 10.10: 2020 NAN Drilling Program | 154 |

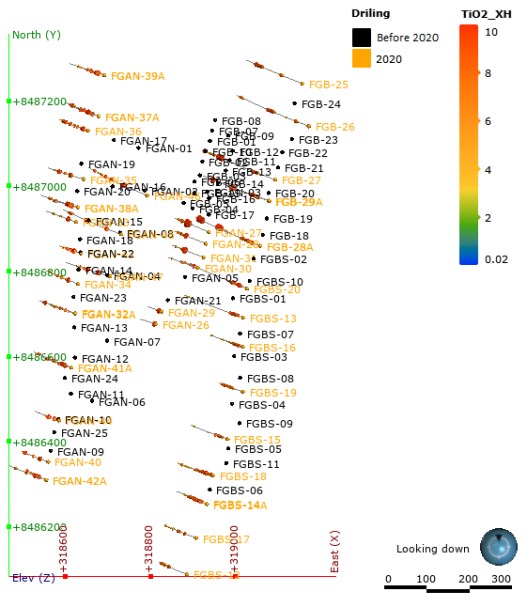

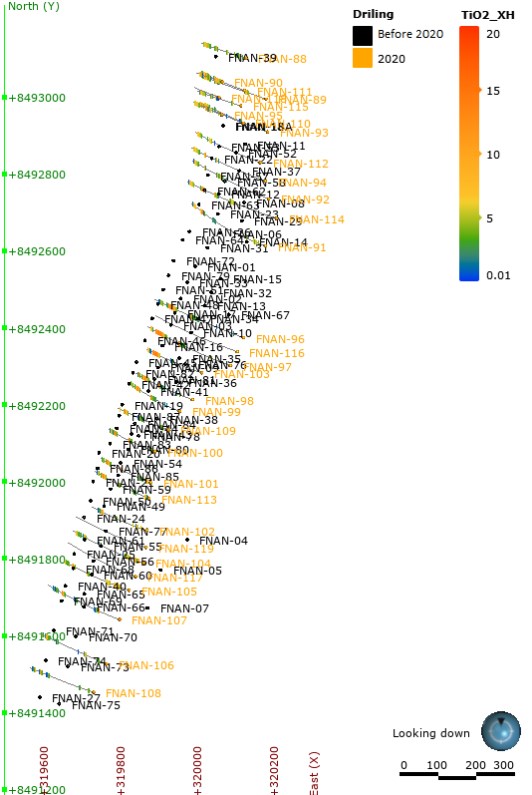

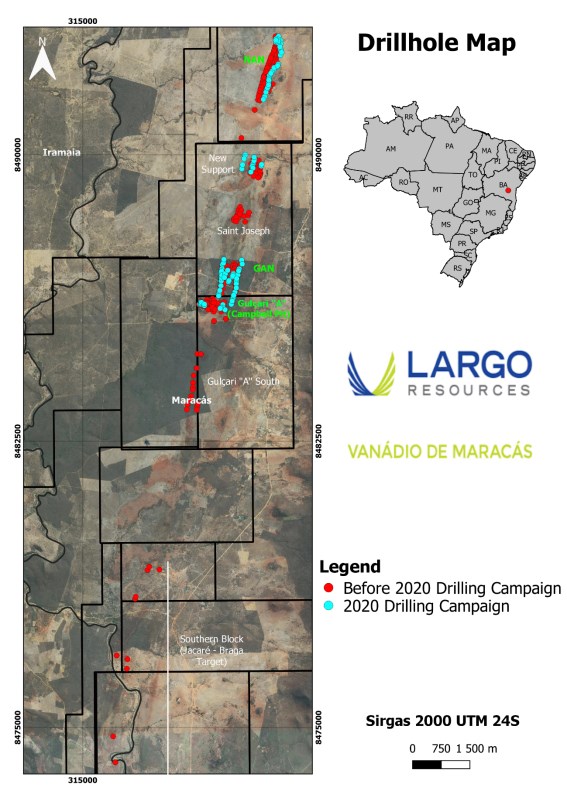

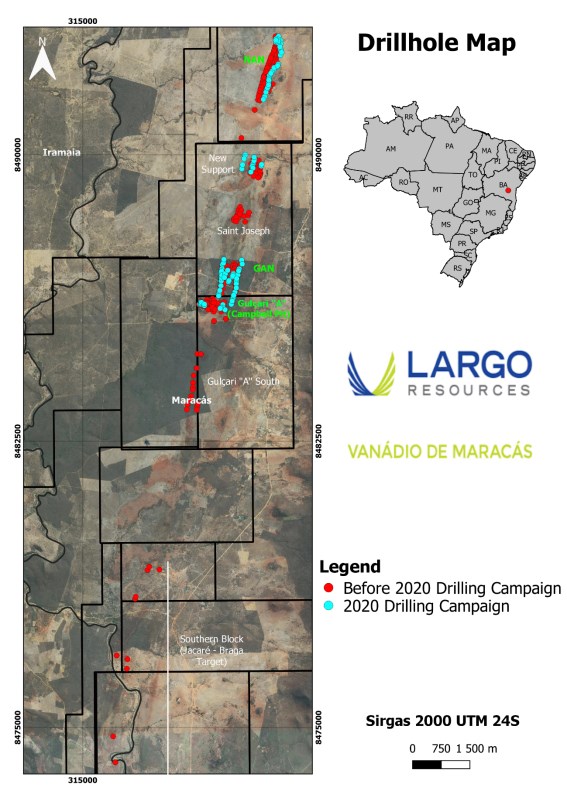

| Figure 10.11: 2020 Drillng Campaign Map of Menchen Maracás Project | 159 |

| Figure 11.1:Largo core cutting facility for the 2018-2019 Exploration Program | 162 |

| Figure 11.2:Largo Core Shed in the 2018-2019 Mineral Exploration | 163 |

| Figure 11.3:Largo's First Davis Tube Device During Implementation on Site | 167 |

| Figure 11.4:Two Davis Tube devices at SGS Geosol in Belo Horizonte | 167 |

| Figure 11.5:Largo Staff During Site Visit at SGS (24th August 2015) | 168 |

| Figure 11.6:Density Determination by Archimedes Principle (until 2015) | 170 |

| Figure 11.7:Gulçari A Core Duplicate Sampling | 175 |

| Figure 11.8:Gulçari A Core Duplicate Sampling With Hole FGA-41 Removed | 176 |

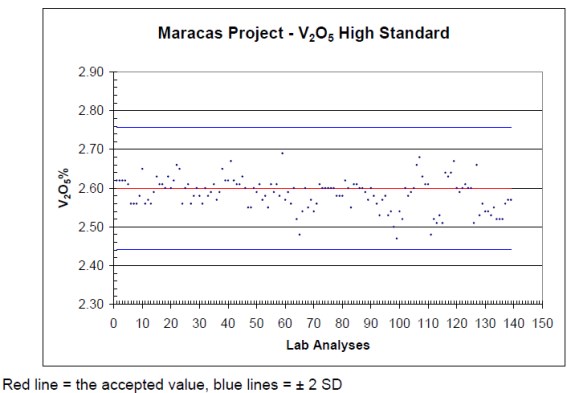

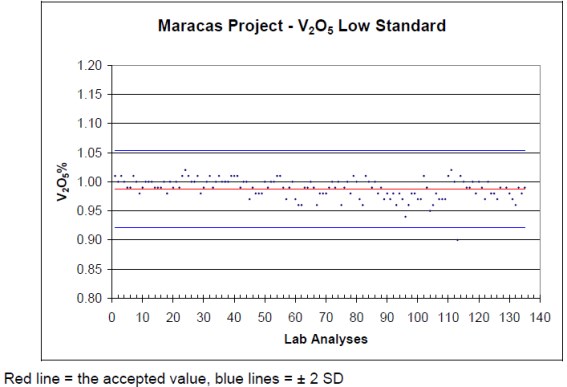

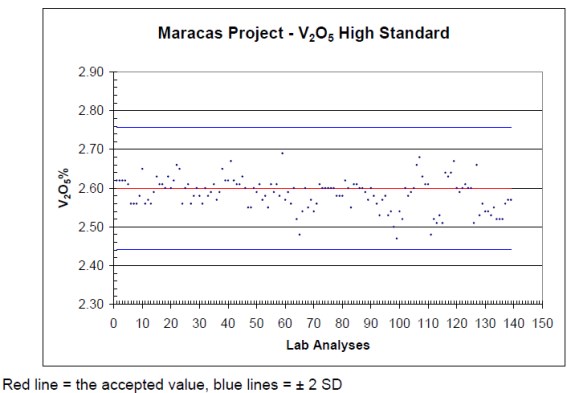

| Figure 11.9:Exploration High Standard V2O5 Assay Results | 177 |

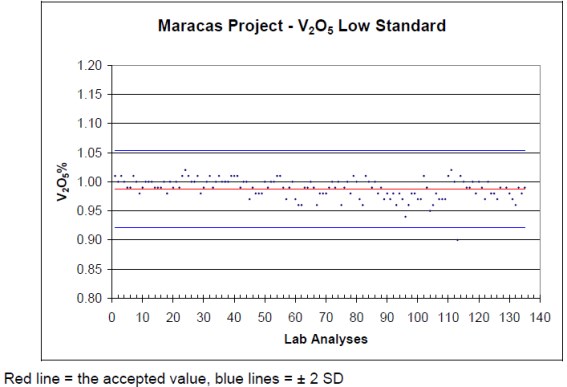

| Figure 11.10:2007 Exploration High Standard V2O5 Assay Results | 178 |

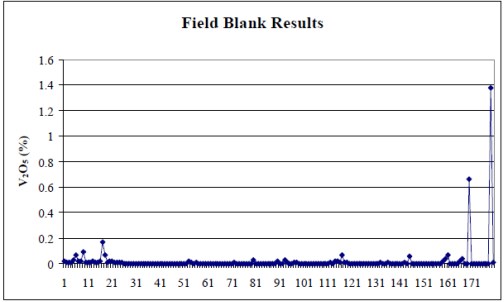

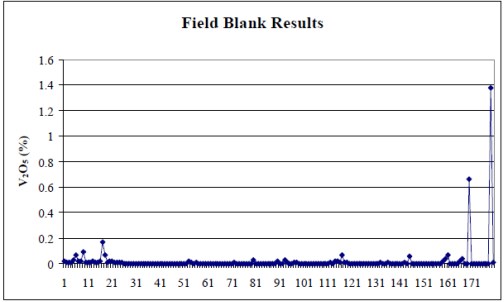

| Figure 11.11:2007 Exploration Field Blank Assay Results | 179 |

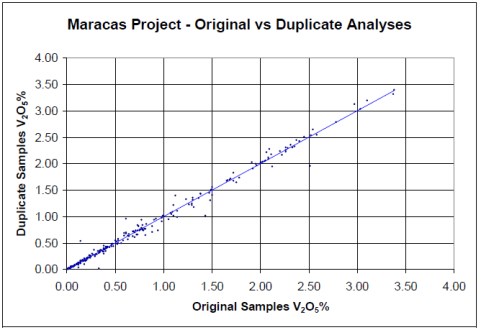

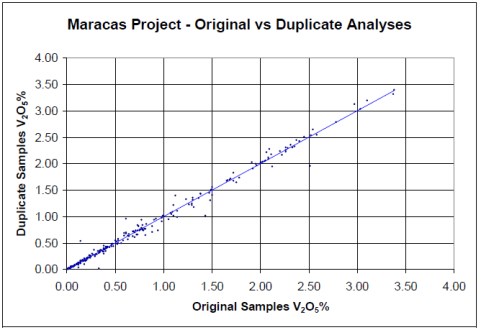

| Figure 11.12: Maracás Project - Original vs Duplicate Analyses | 180 |

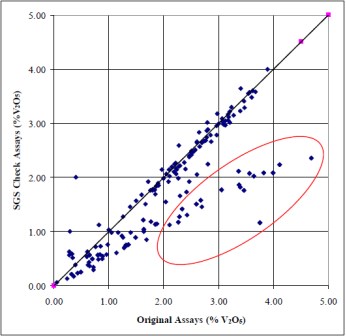

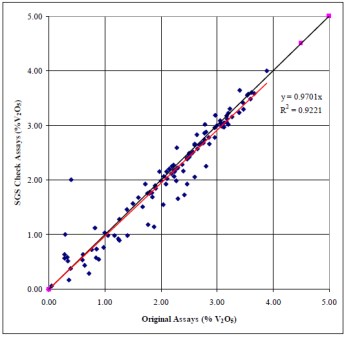

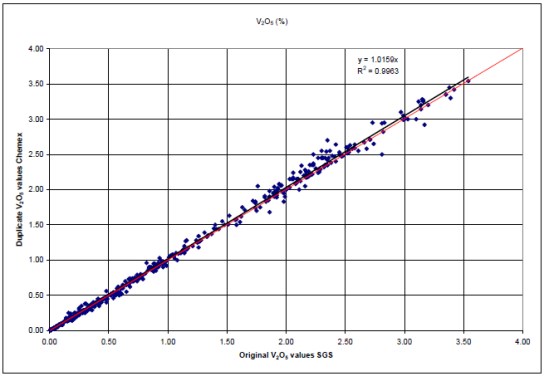

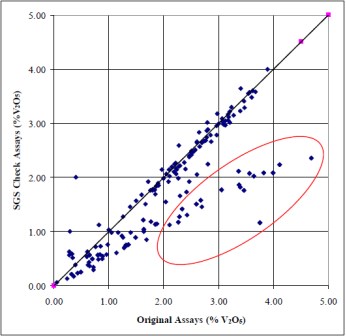

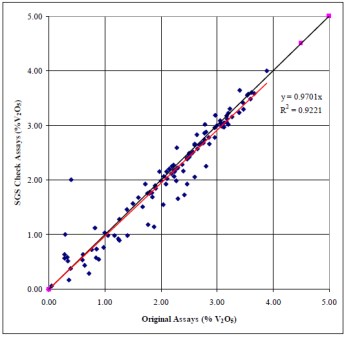

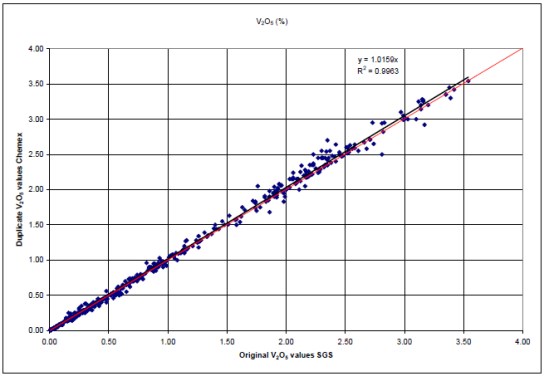

| Figure 11.13:Secondary Laboratory Check Assays - V2O5 | 181 |

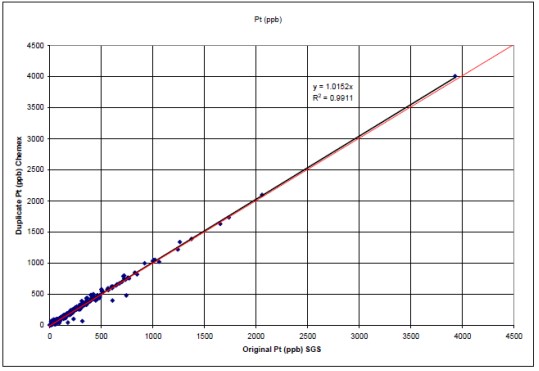

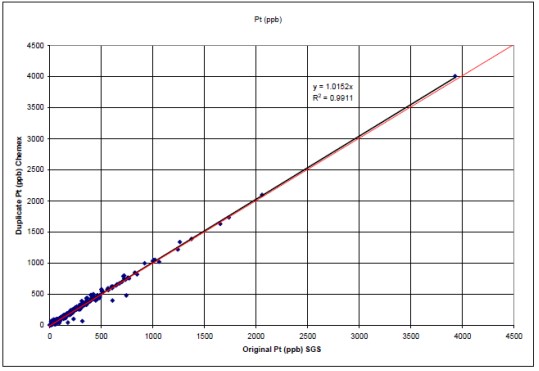

| Figure 11.14:Secondary Laboratory Check Assays - Pt | 182 |

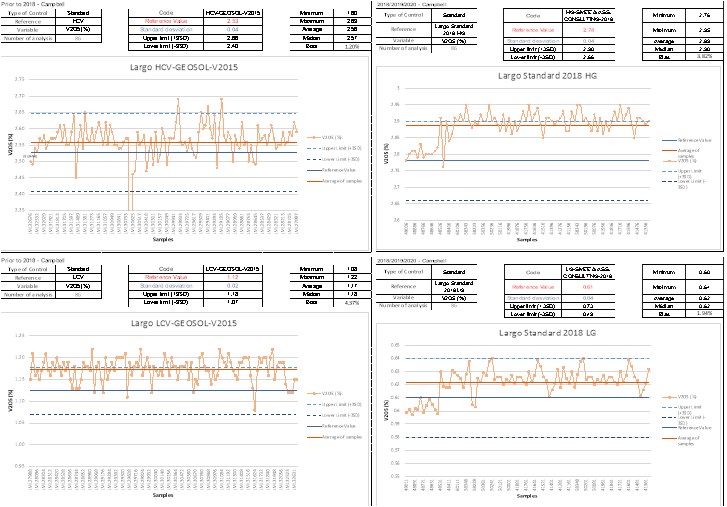

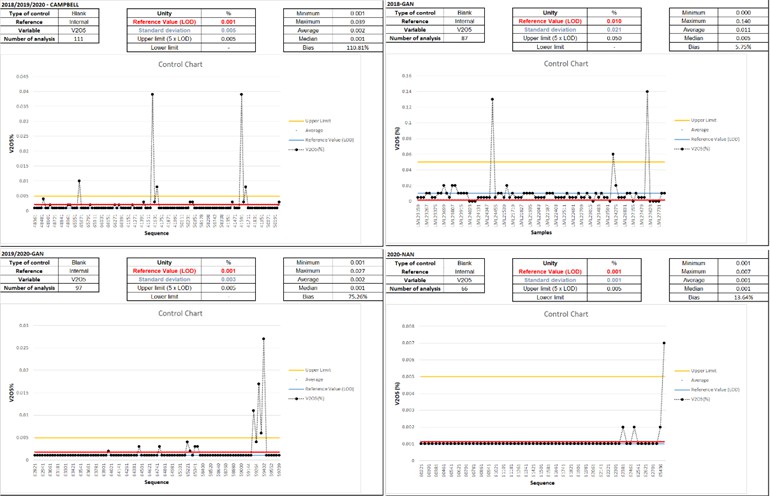

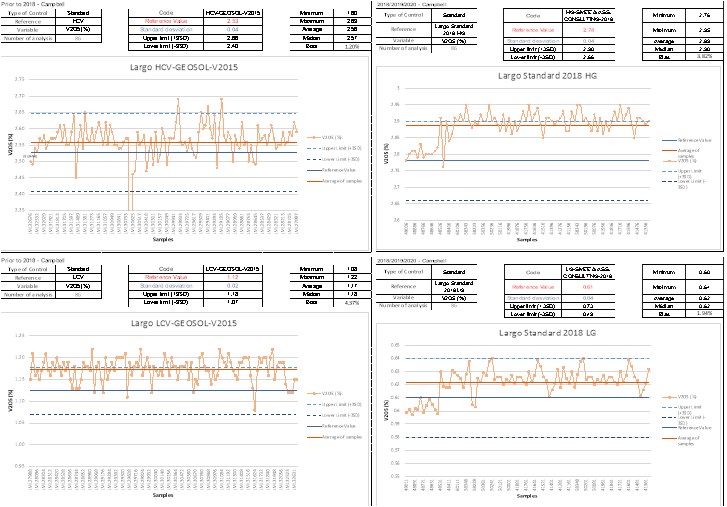

| Figure 11.15:Standard Campbell Graphic | 187 |

| Figure 11.16:Campbell Pit Standard Chart | 189 |

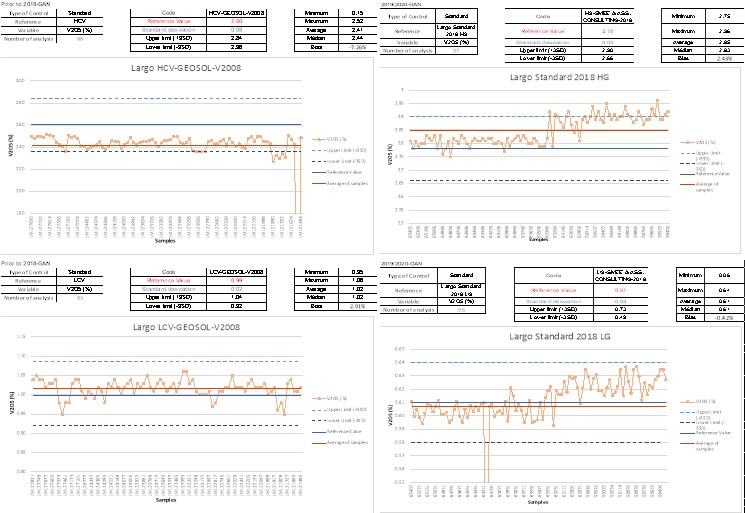

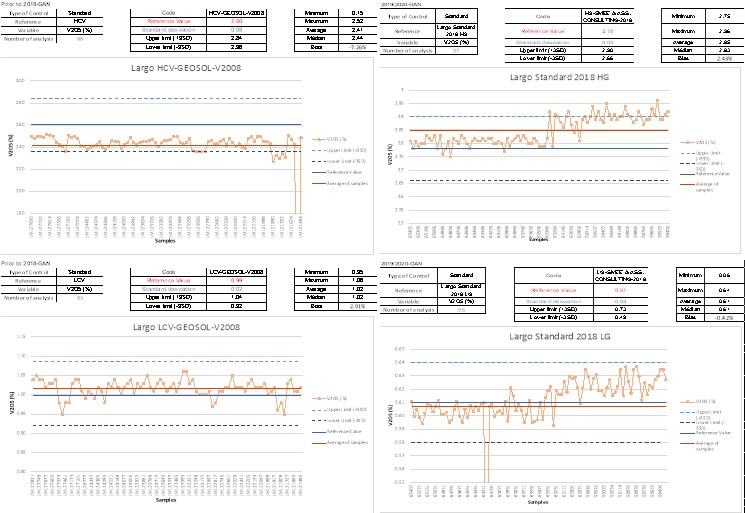

| Figure 11.17:Standard GAN Chart | 191 |

| Figure 11.18:NAN Standard Chart | 193 |

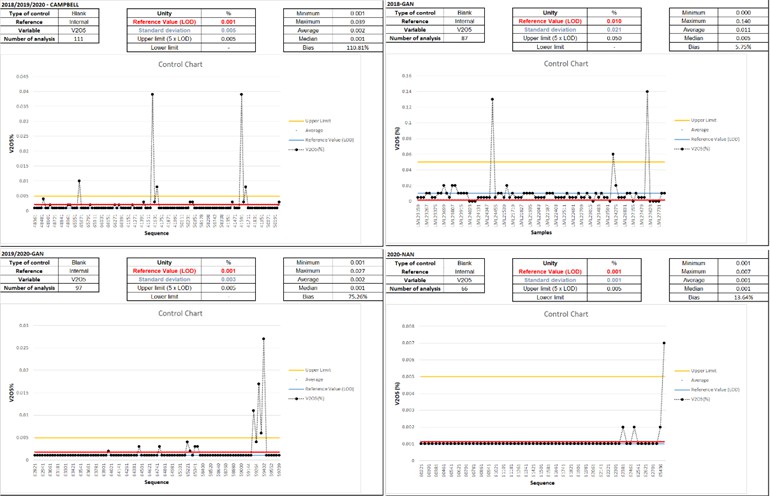

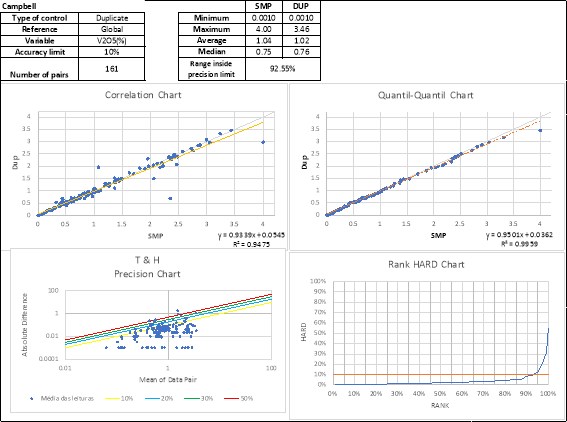

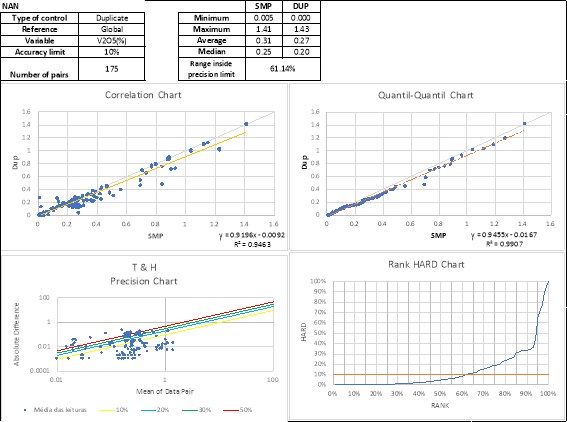

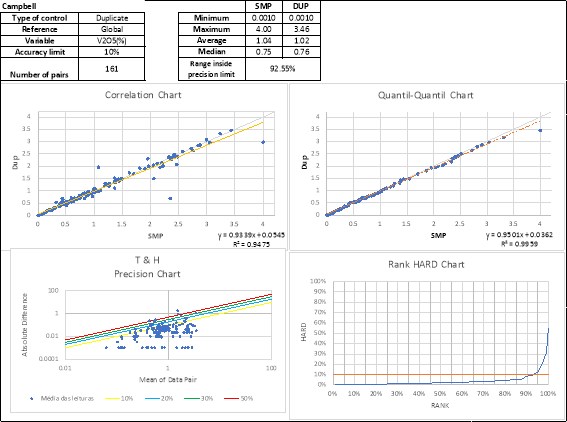

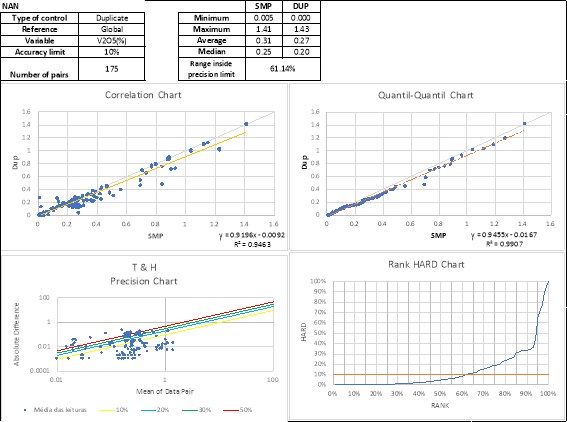

| Figure 11.19:Duplicates Campbell Chart | 194 |

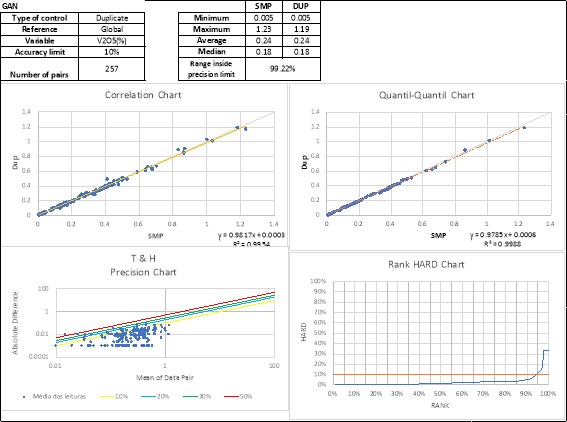

| Figure 11.20:Duplicates GAN Chart | 195 |

| Figure 11.21:Duplicates NAN Chart | 196 |

| Figure 12.1: Core shed infrastructure | 199 |

| Figure 12.2: Pulverized rejects box | 200 |

| Figure 12.3: Core boxes without covering | 201 |

| Figure 13.1: Crushed NAN ore (-12.5mm) and Dry Magnetic Separation Process in Drum Magnetic Separator (Low Intensity) | 232 |

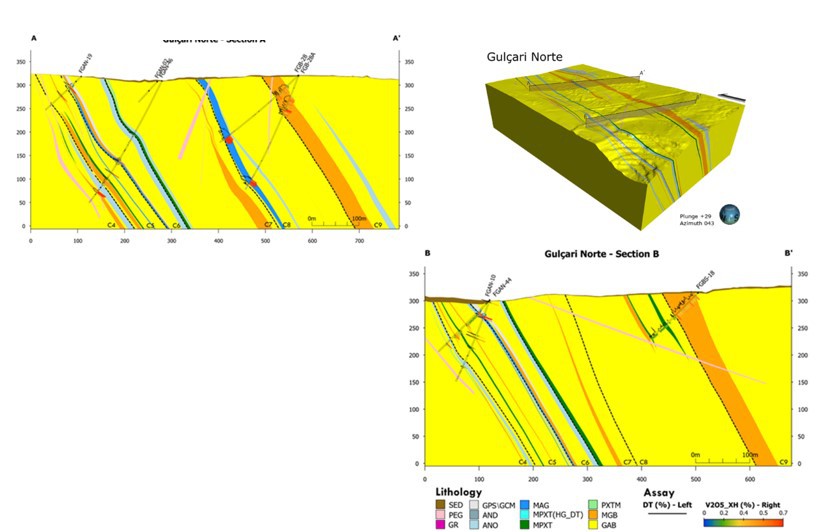

| Figure 14.1: Campbell Pit section A-Aˈ and B-Bˈ with sediments (SED), pegmatite (PEG), granite (GR), granite with magnetite (GCM), anorthosite (ANO), magnetite (MAG), magnetic magnetite-pyroxenite (MPXT - HG_DT)), pyroxenite (PXT), gabbro magnetite (MGB) and gabbro | 250 |

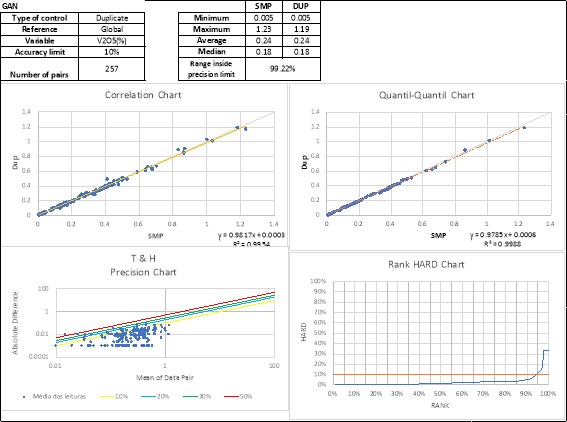

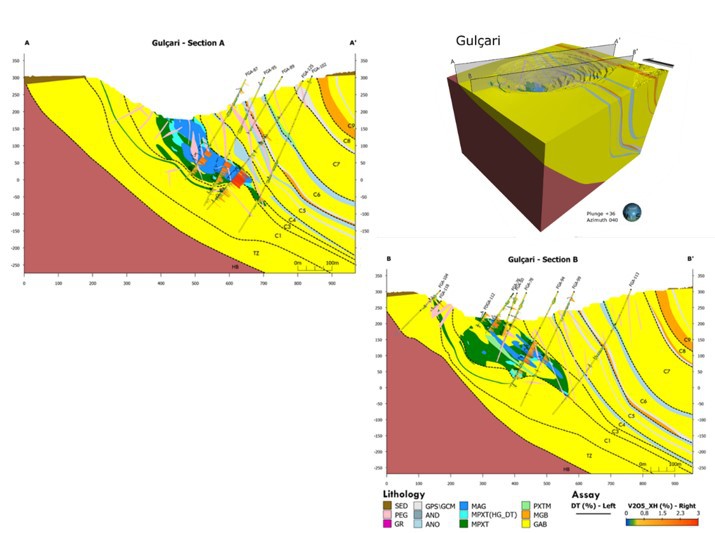

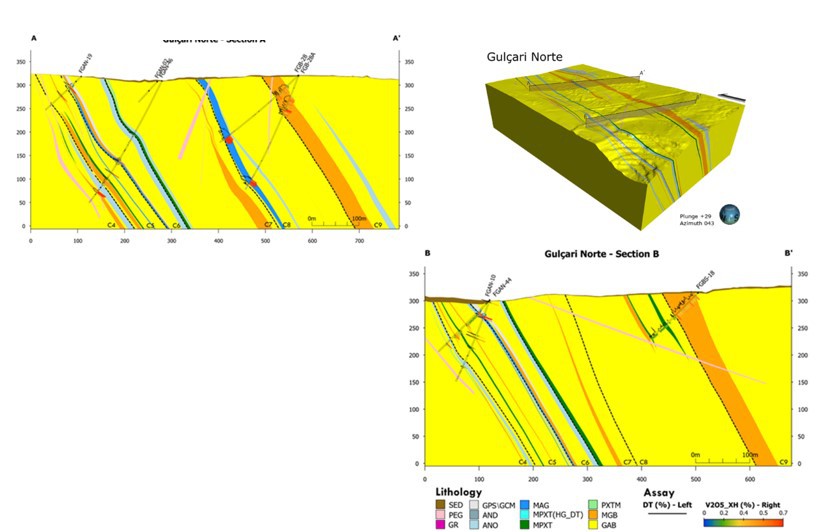

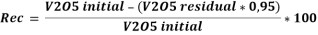

| Figure 14.2: GAN deposit section A-Aˈ and B-Bˈ with sediments (SED), pegmatite (PEG), granite (GR), granite with magnetite (GCM), anorthosite (ANO), magnetite (MAG), magnetic magnetite-pyroxenite (MPXT - HG_DT)), pyroxenite (PXT), gabbro magnetite (MGB) and gabbro (GAB). Diagram block without overburden | 251 |

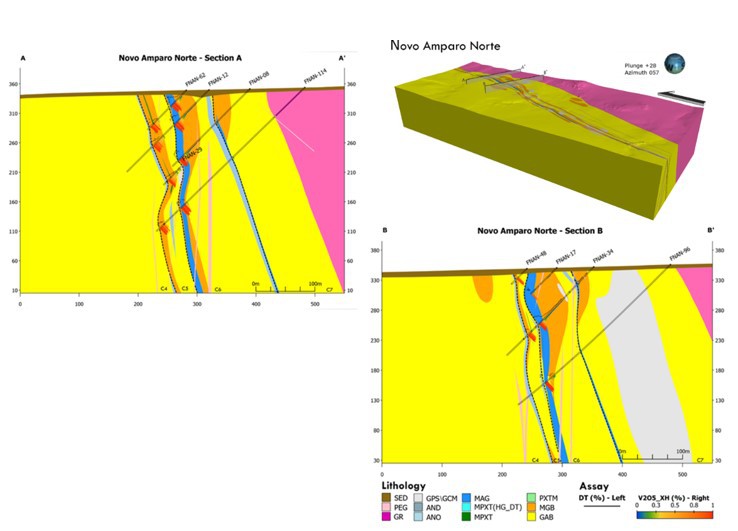

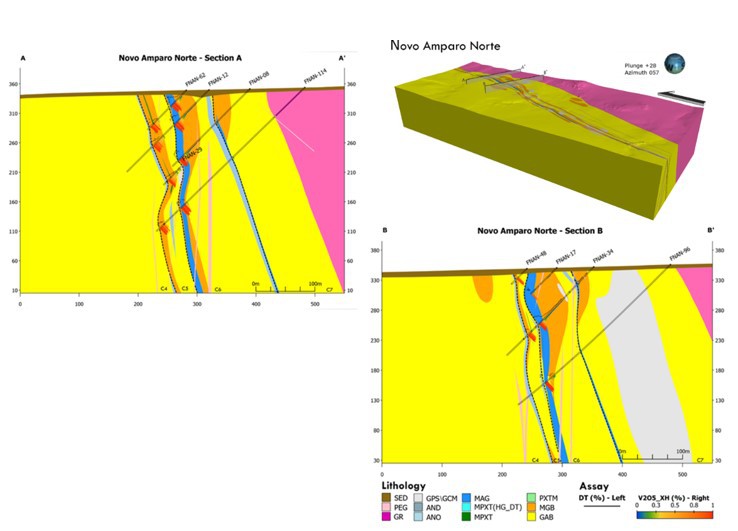

| Figure 14.3: NAN deposit section A-Aˈ and B-Bˈ with sediments (SED), pegmatite (PEG), granite (GR), granite with magnetite (GCM), anorthosite (ANO), magnetite (MAG), magnetic magnetite-pyroxenite (MPXT - HG_DT)), pyroxenite (PXT), gabbro magnetite (MGB) and gabbro (GAB). Diagram block without overburden | 252 |

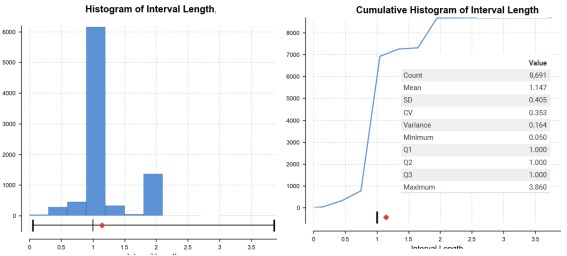

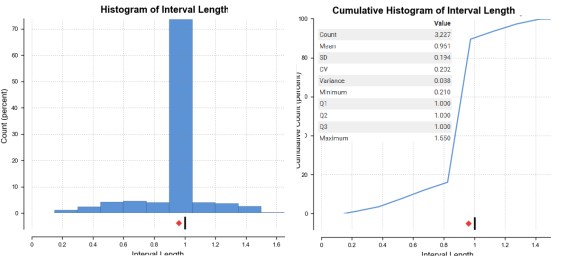

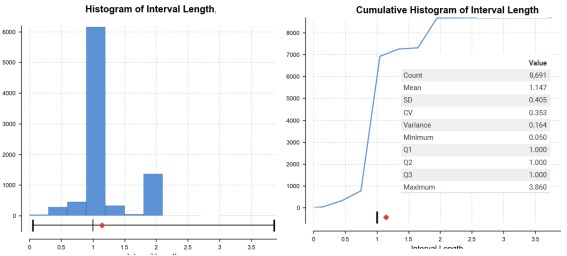

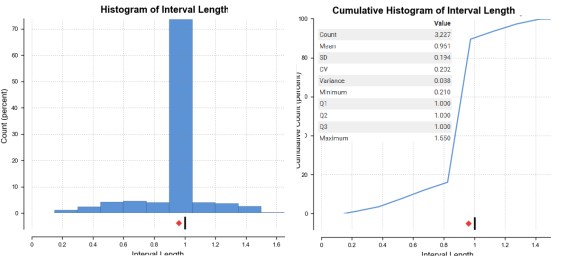

| Figure 14.4: Histogram and Cumilative Curve of Campbell Pit sample lenght | 253 |

| Figure 14.5: Histogram and Cumulative Curve of GAN deposit sample lenght | 253 |

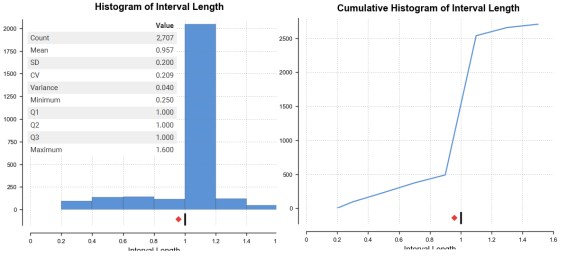

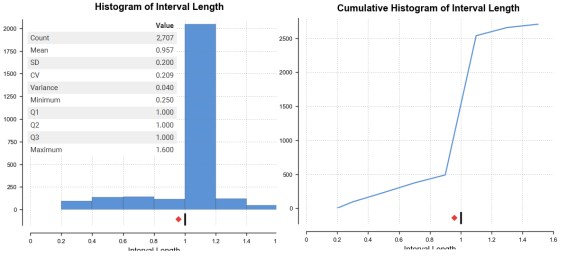

| Figure 14.6 : Histogram and Cumulative Curve of NAN deposit sample lenght | 254 |

| Figure 14.7- Campbell Pit V2O5 Histogram and Probability curve- MAG/Cycle 4 | 255 |

| Figure 14.8- Campbell Pit TiO2 Histogram and Probability curve- MAG/Cycle 4 | 255 |

| Figure 14.9- GAN V2O5 Histogram and Probability curve- MAG/Cycle 8 | 256 |

| Figure 14.10-GAN TiO2 Histogram and Probability curve - MAG/Cycle 8 | 256 |

| Figure 14.11- NAN V2O5 Histogram and Probability curve - MAG/Cycle 6 | 256 |

| Figure 14.12- NAN TiO2 Histogram and Probability curve - MAG/Cycle 6 | 257 |

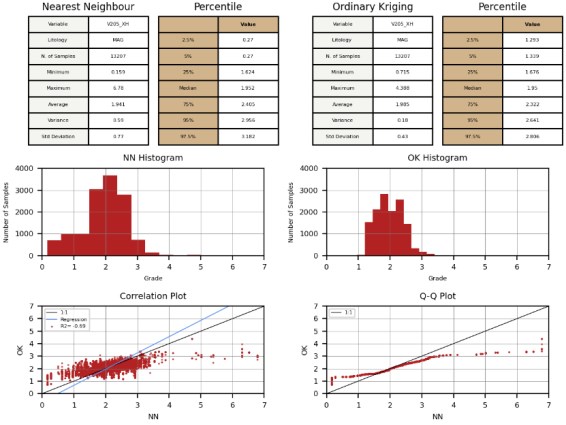

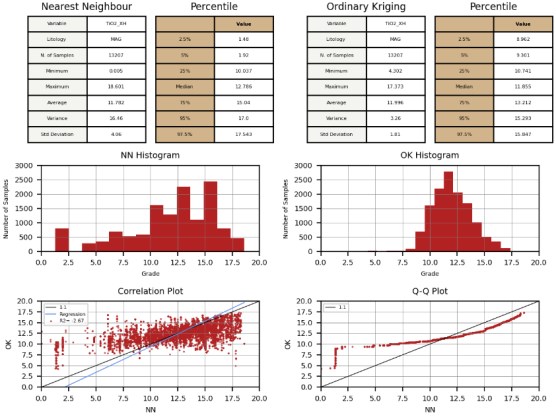

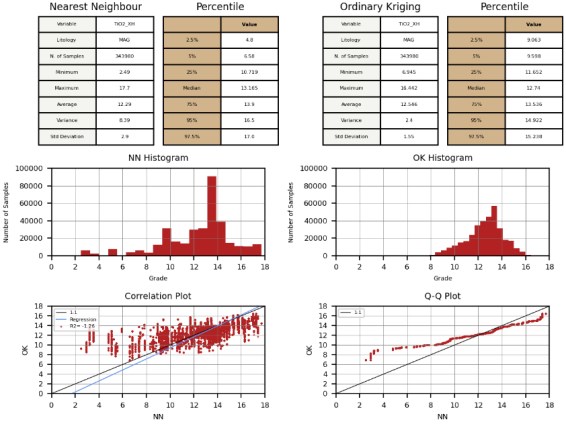

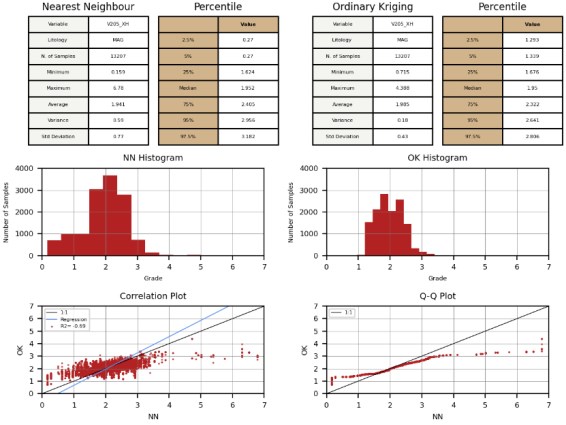

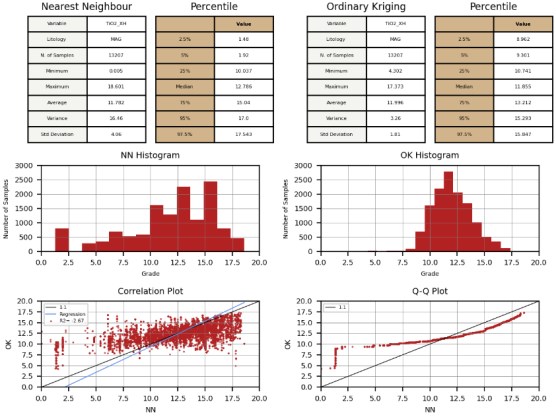

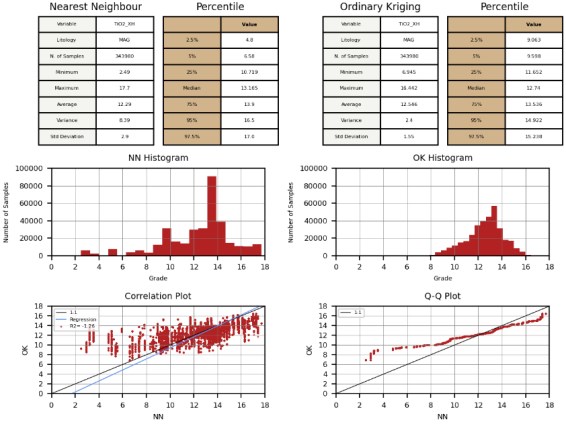

| Figure 14.13: Campbell Pit NN Checks Graphs (%V2O5_XH in MAG) | 274 |

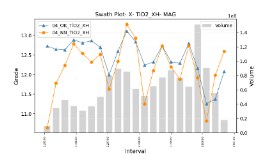

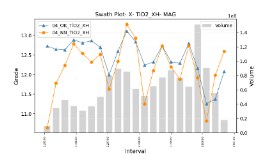

| Figure 14.14: Campbell Pit Checks Graphs (%TiO2_XH in MAG) | 275 |

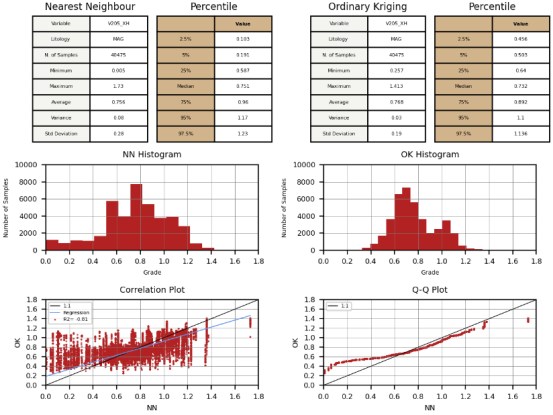

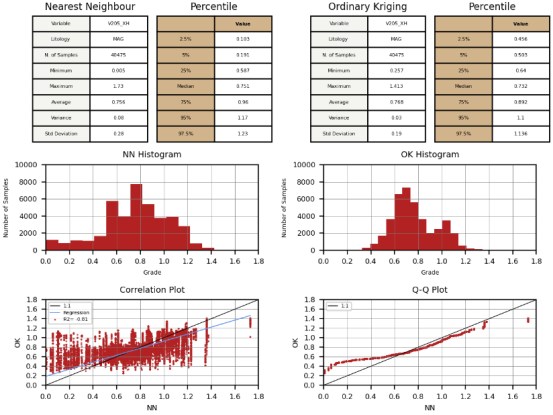

| Figure 14.15: GAN deposit Checks Graphs (%V2O5_XH in MAG) | 276 |

| Figure 14.16: GAN deposit Checks Graphs (%TiO2_XH in MAG) | 277 |

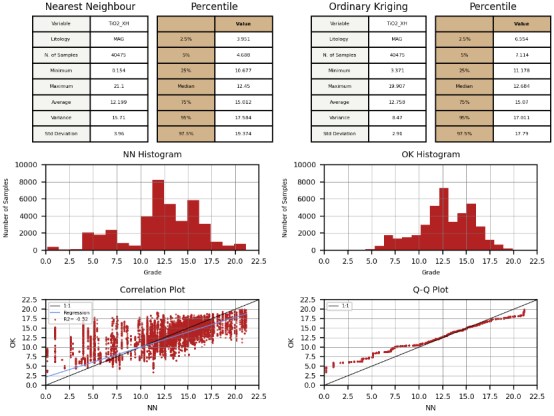

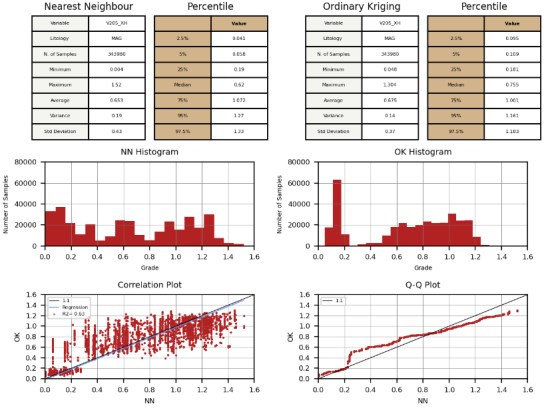

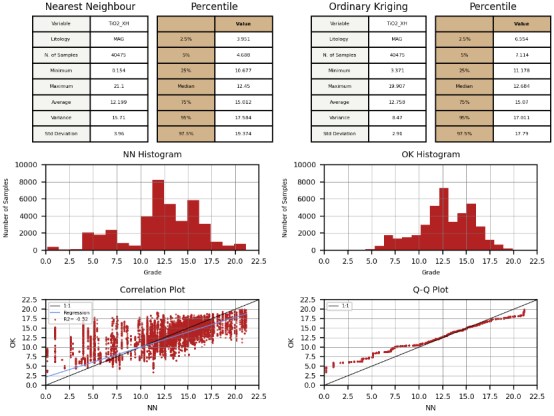

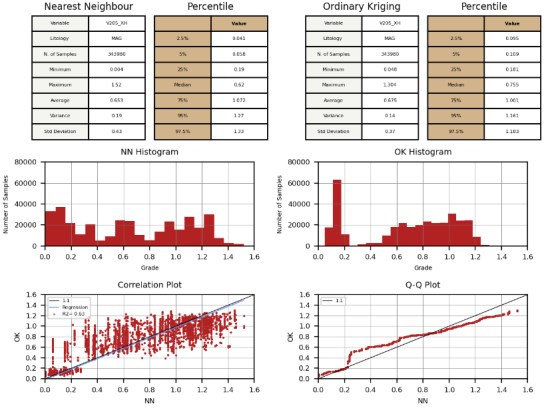

| Figure 14.17: NAN deposit Checks Graphs (%V2O5_XH in MAG) | 278 |

| Figure 14.18: NAN deposit Checks Graphs (%TiO2_XH in MAG) | 279 |

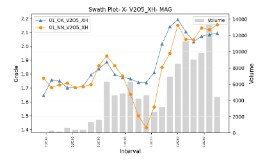

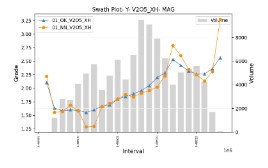

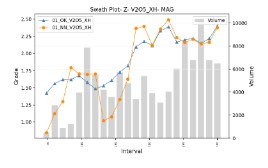

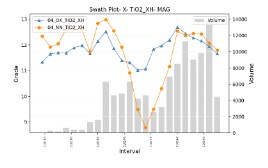

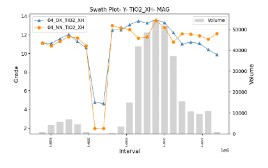

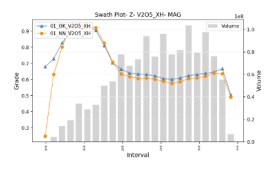

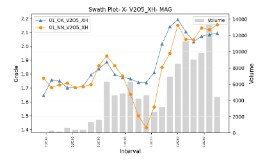

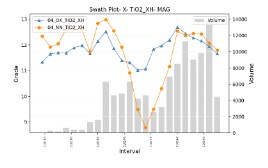

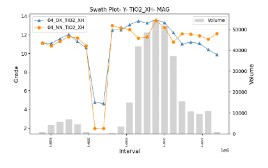

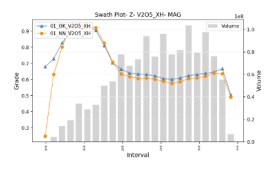

| Figure 14.19: Campbell Pit Swath Plots (%V2O5_H in MAG) | 280 |

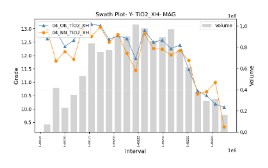

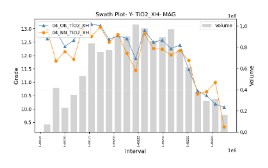

| Figure 14.20: Campbell Pit Swath Plots (%TiO2_XH in MAG) | 281 |

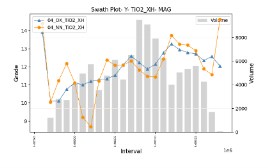

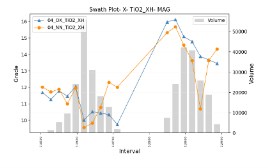

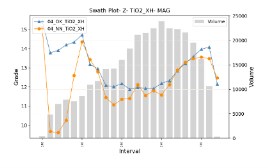

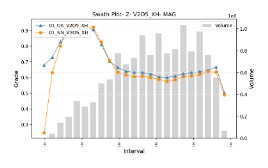

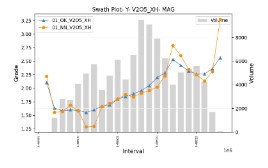

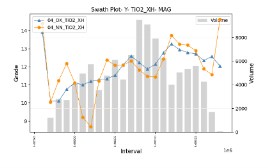

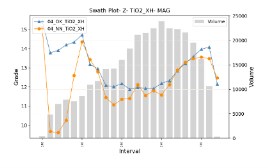

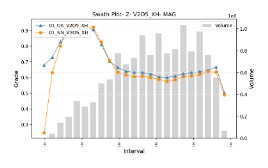

| Figure 14.21: GAN deposit Swath Plots (%V2O5_H in MAG) | 281 |

| Figure 14.22: GAN deposit Swath Plots (%TiO2_XH in MAG) | 282 |

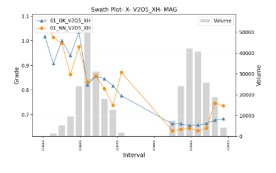

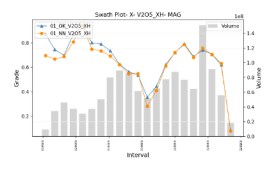

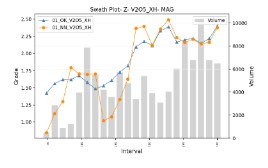

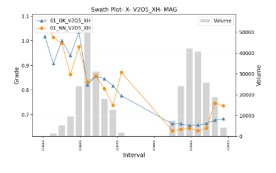

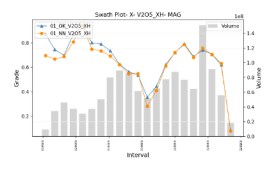

| Figure 14.23: NAN deposit Swath Plots (%V2O5_H in MAG) | 282 |

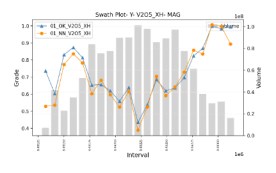

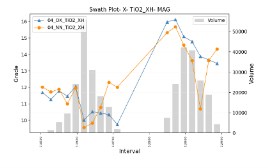

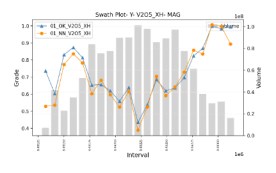

| Figure 14.24: NAN deposit Swat Plots (%TiO2_XH in MAG) | 283 |

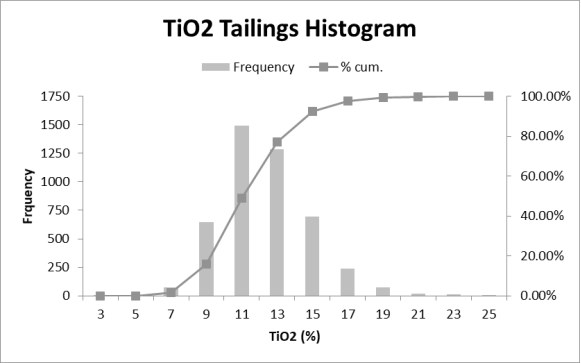

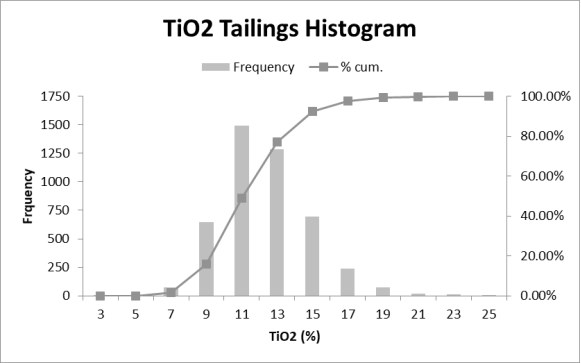

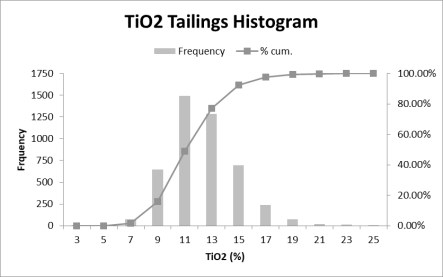

| Figure 14.25: TiO2 Tailings Histogram | 287 |

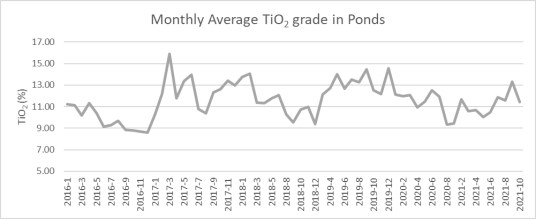

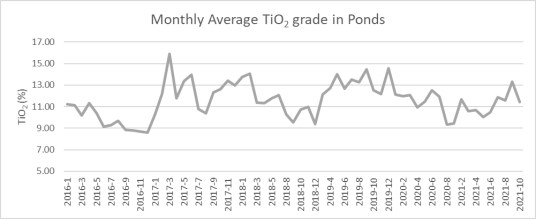

| Figure 14.26: Monthly Average TiO2 Grade in Ponds | 288 |

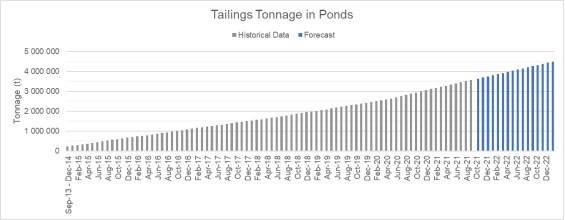

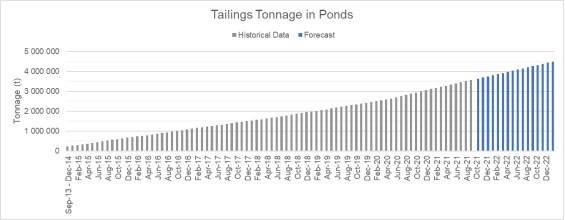

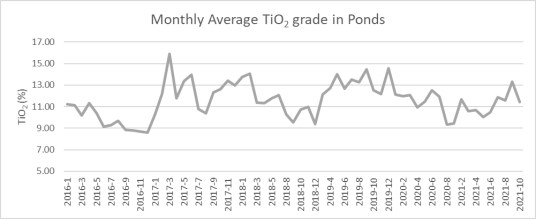

| Figure 14.27: Monthly Average TiO2 Grade in Ponds | 288 |

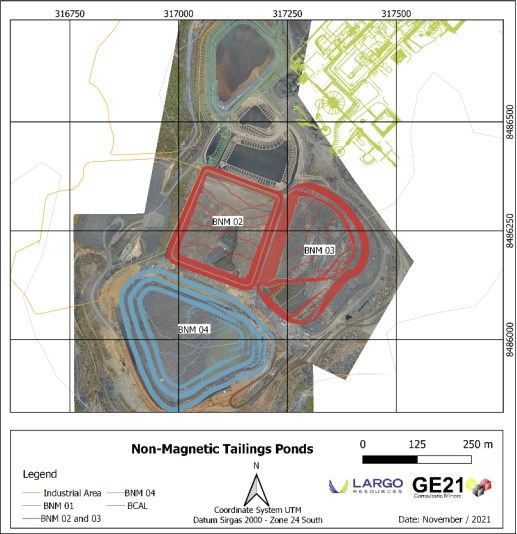

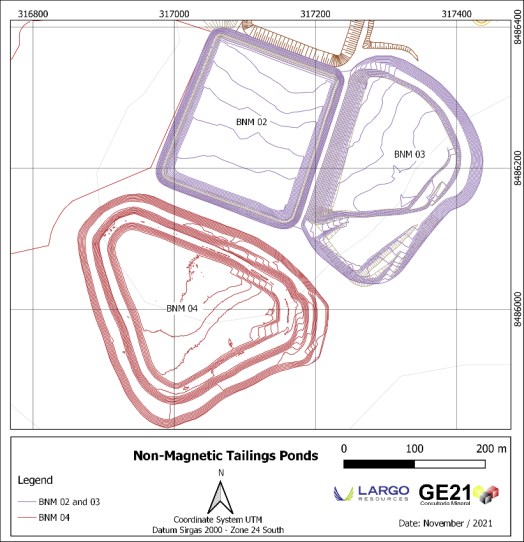

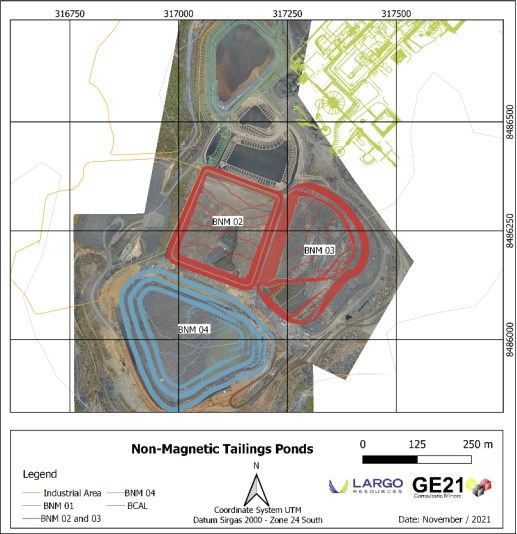

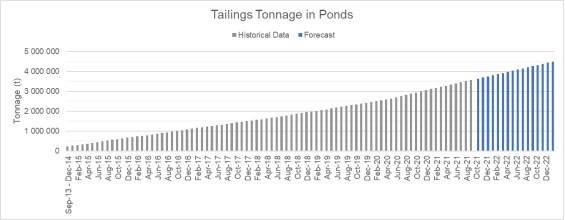

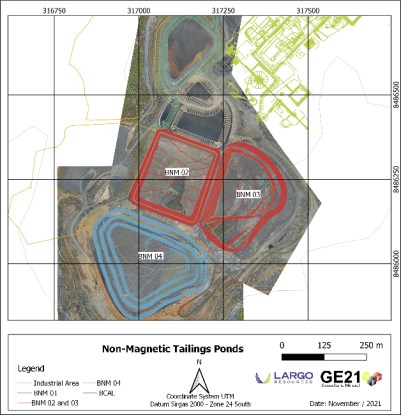

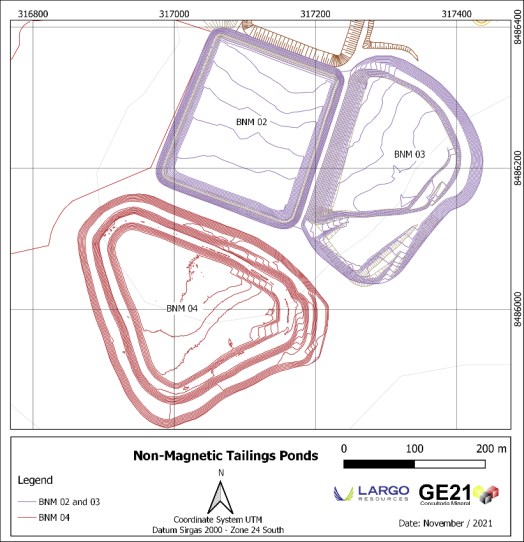

| Figure 14.28: Non-magnetic Tailings Ponds | 289 |

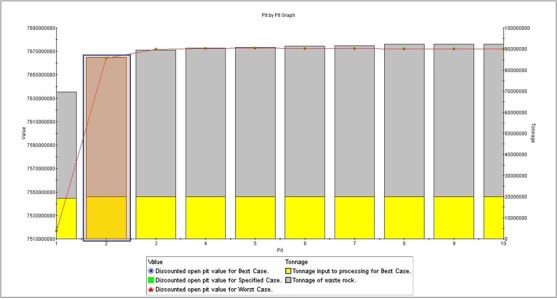

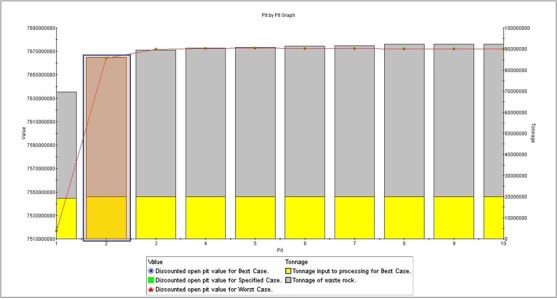

| Figure 15.1: Campbell - Pit Optimization Results Graph | 295 |

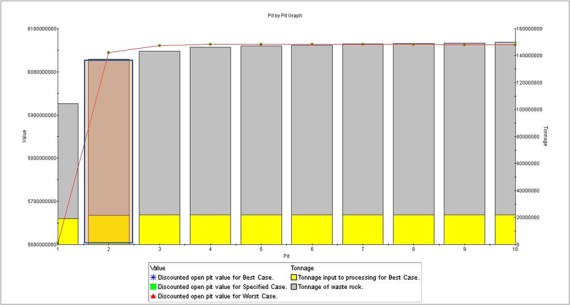

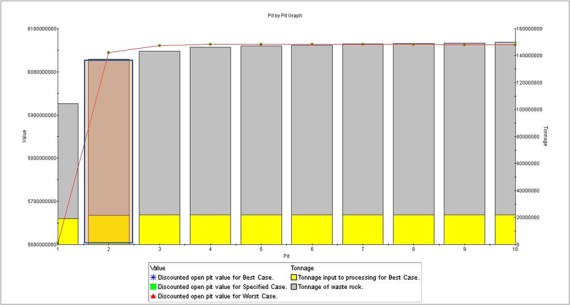

| Figure 15.2: GAN - Pit Optimization Results Graph | 297 |

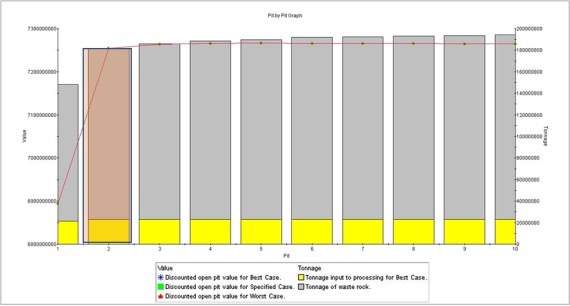

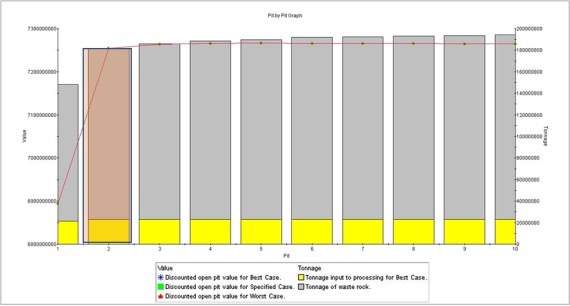

| Figure 15.3: NAN - Pit Optimization Results Graph | 298 |

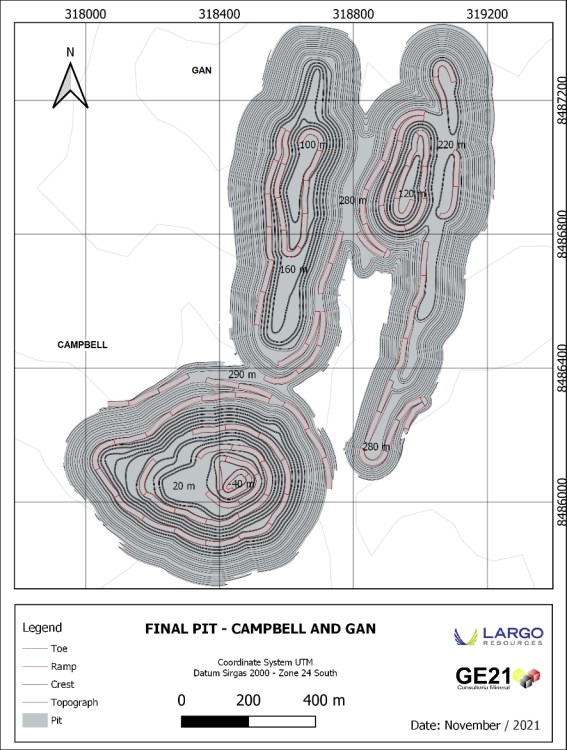

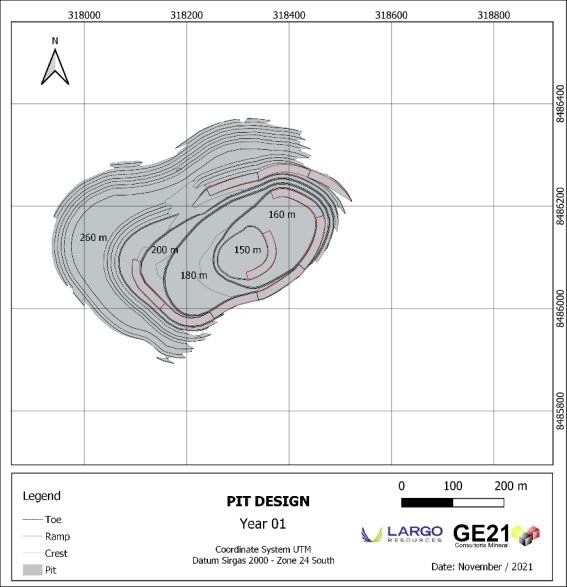

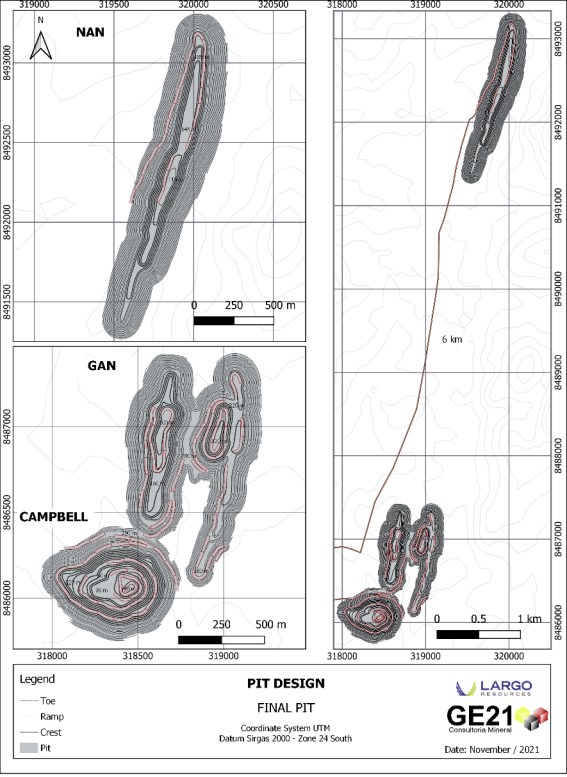

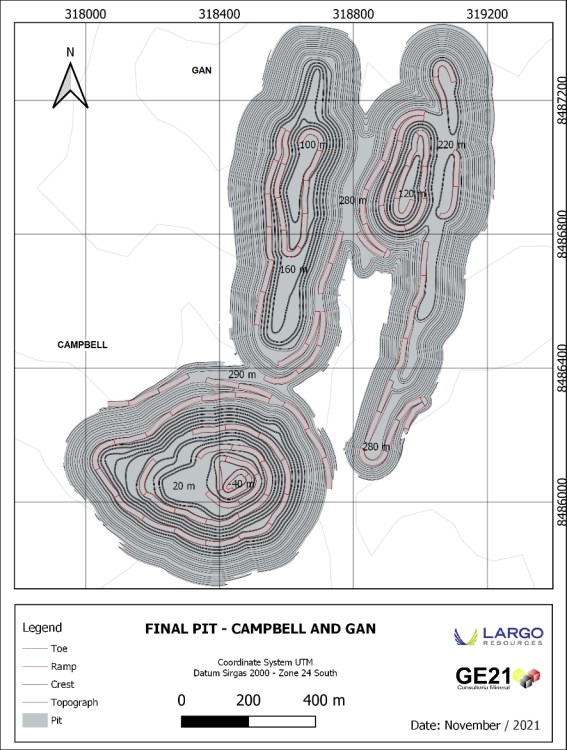

| Figure 15.4: Campbell Pit and GAN - Final Pit Design | 300 |

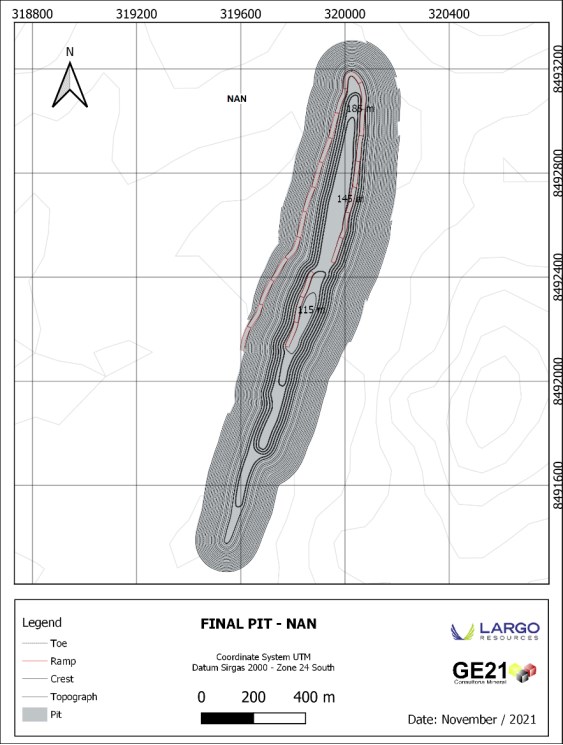

| Figure 15.5: NAN - Final Pit Design | 303 |

| Figure 15.6: TiO2 Tailings Histogram | 305 |

| Figure 15.7: Monthly Average TiO2 Grade in Ponds | 305 |

| Figure 15.8: Monthly Average TiO2 Grade in Ponds | 306 |

| Figure 15.9: Non-magnetic Tailings Ponds | 307 |

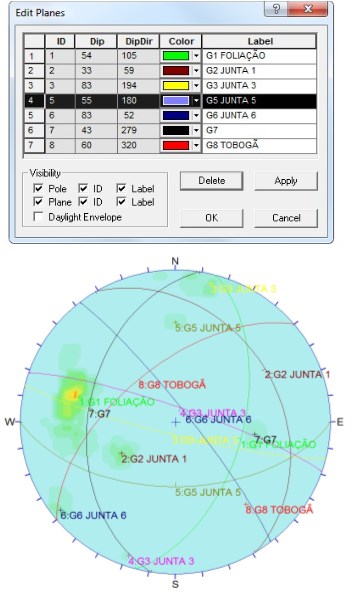

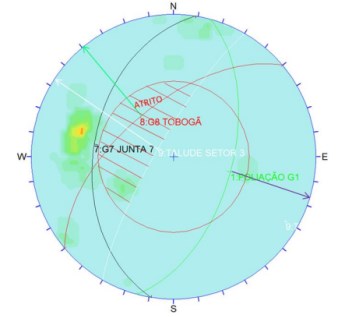

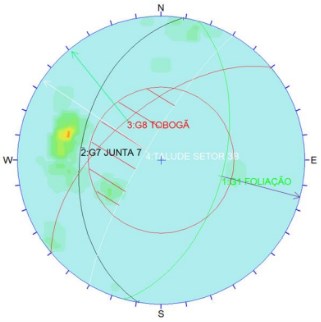

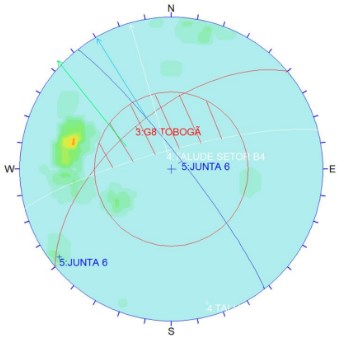

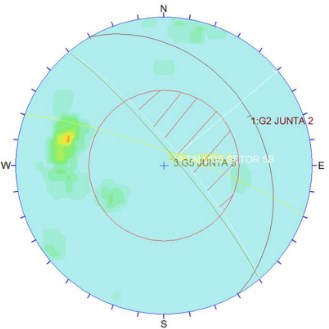

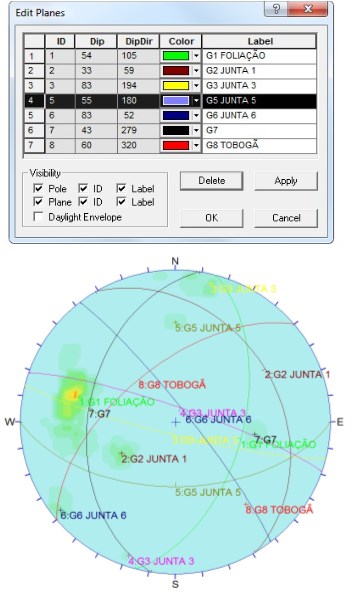

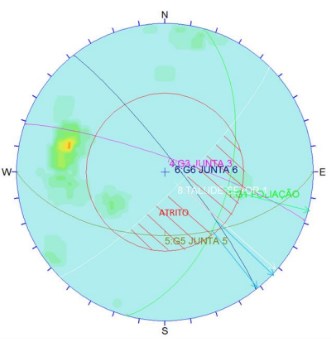

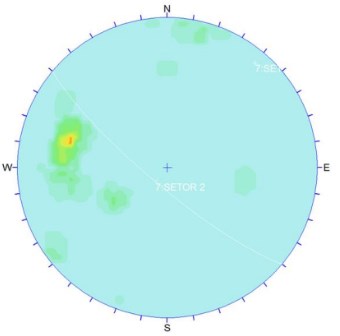

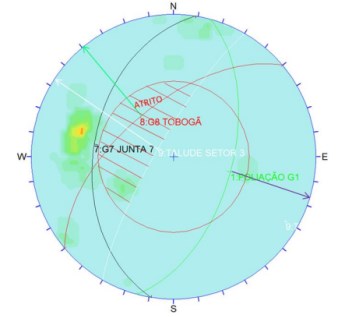

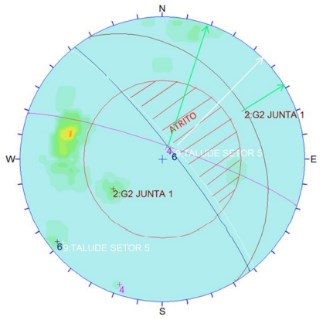

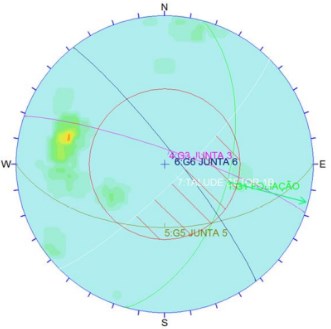

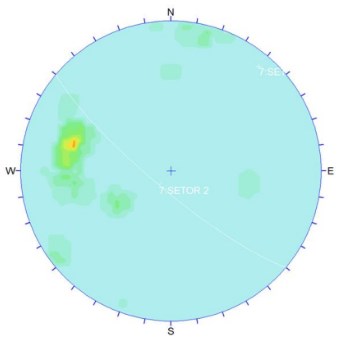

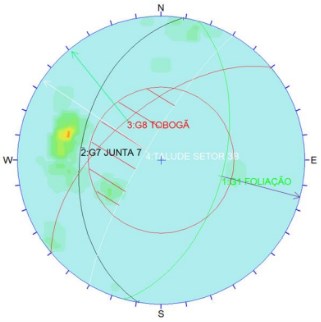

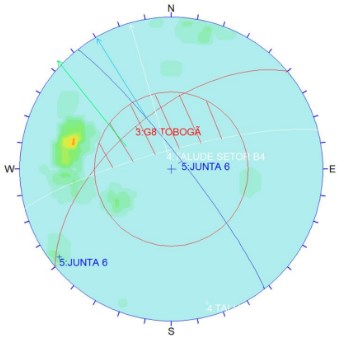

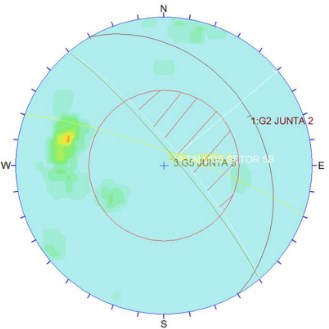

| Figure 16.1: Stereo system of the main structures in the pit | 312 |

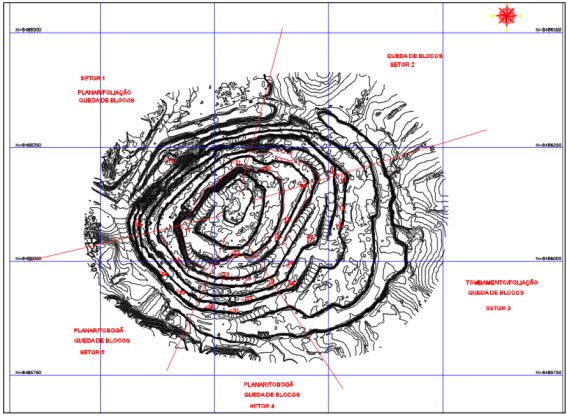

| Figure 16.2: Campbell pit sectors | 317 |

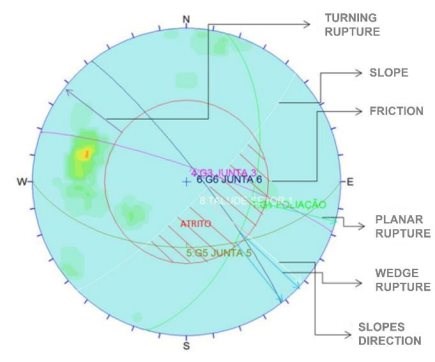

| Figure 16.3: Key design of elements considered in Kinematic Analysis | 318 |

| Figure 16.4: Pit sector A1 showing wedge ruptures and planar rupture | 319 |

| Figure 16.5: Pit sector A1 showing wedge ruptures and planar rupture | 319 |

| Figure 16.6: A3 sector of the pit showing planar and tipping ruptures | 320 |

| Figure 16.7: A4 sector of the pit showing planar and wedge breaks | 321 |

| Figure 16.8: Sector A5 of the pit showing planar ruptures blocked by friction and a dip greater than that of the slope | 321 |

| Figure 16.9: Sector B1 of the pit showing planar and wedge ruptures near the limit of the friction cone | 322 |

| Figure 16.10: B2 sector of the pit without ruptures by foundation structures | 323 |

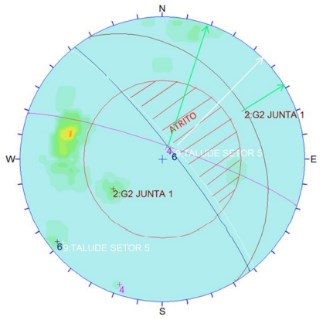

| Figure 16.11: Sector B3 of the pit, ruptures may occur due to tipping along the foliation and plan along the joint 8 (Tobogã) | 323 |

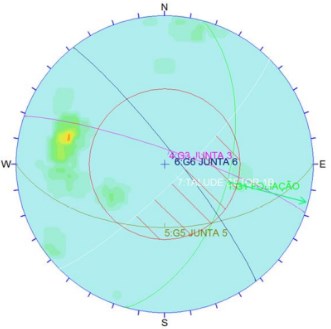

| Figure 16.12: Sector B4 of the pit, wedge ruptures may occur, planar rupture in joint 8 | 324 |

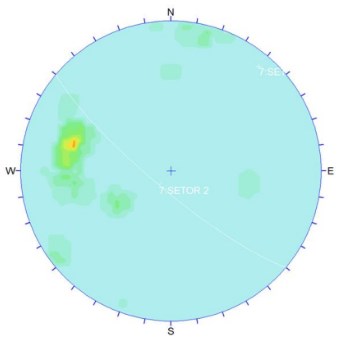

| Figure 16.13: Sector B5 of the pit indicating that the ruptures were blocked | 325 |

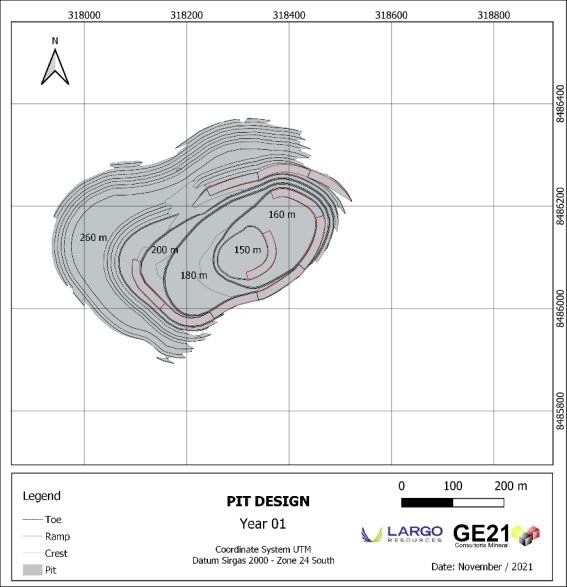

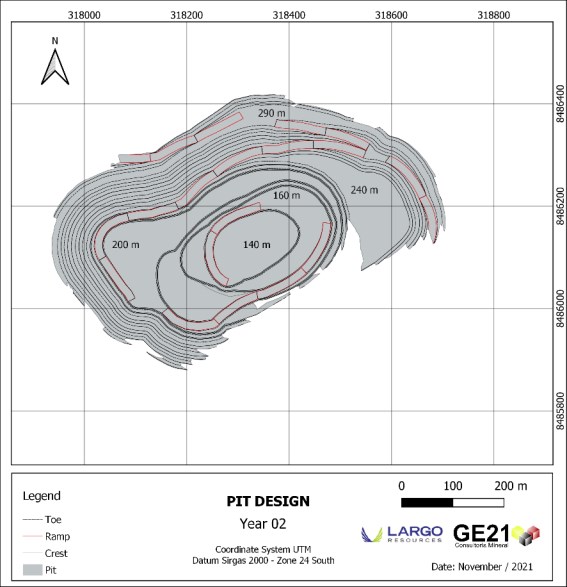

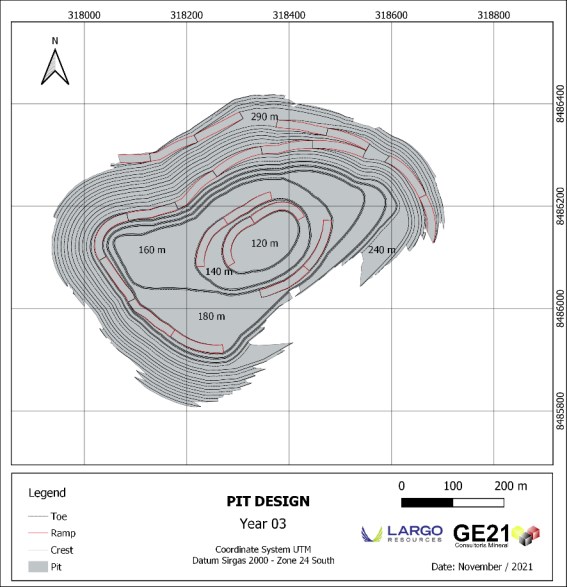

| Figure 16.14: Campbell-Year 01 | 329 |

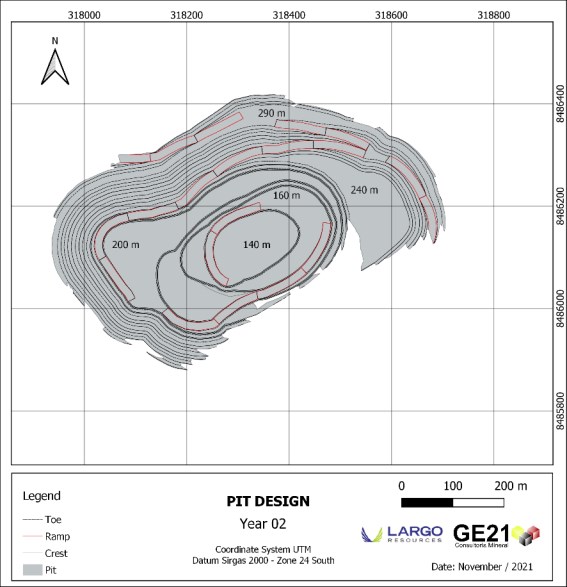

| Figure 16.15: Campbell-Year 02 | 330 |

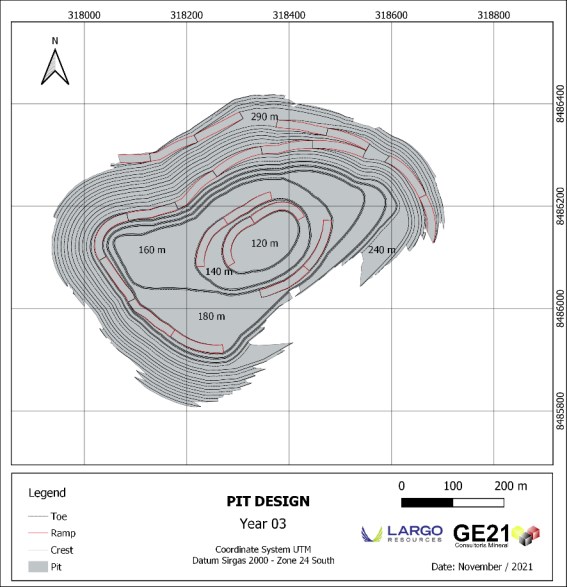

| Figure 16.16: Campbell-Year 03 | 331 |

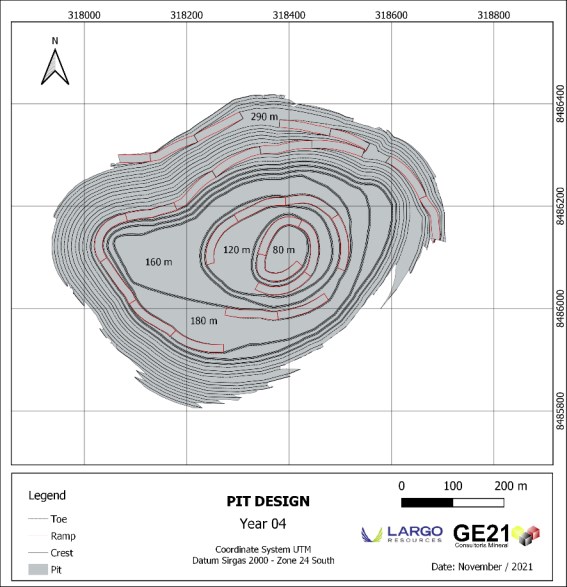

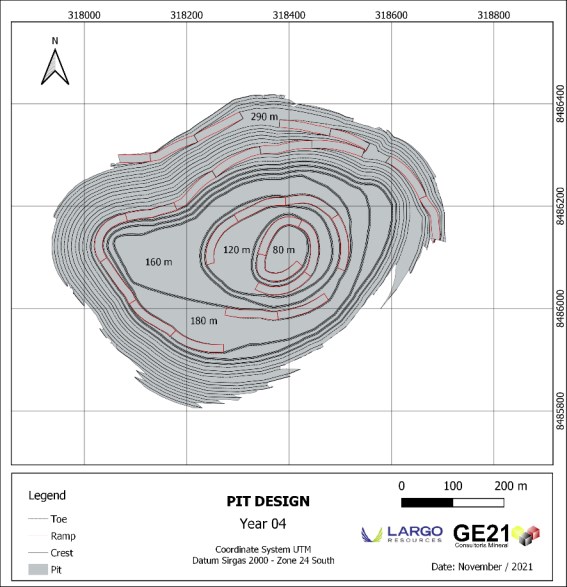

| Figure 16.17: Campbell-Year 04 | 332 |

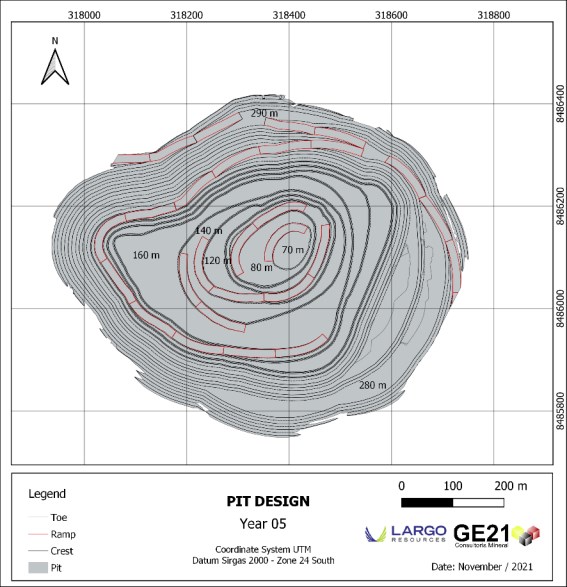

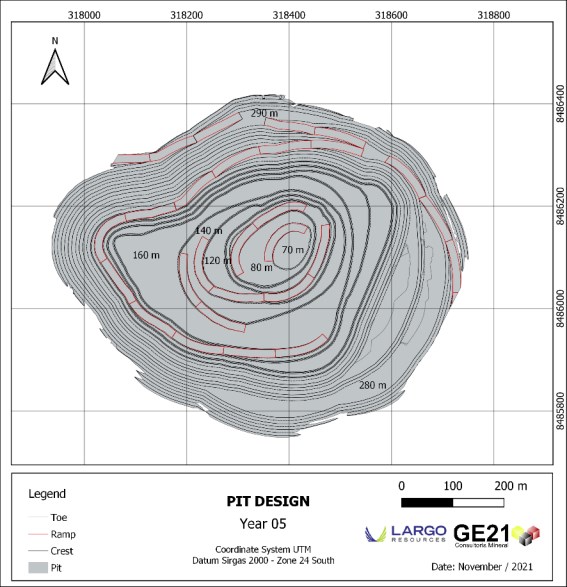

| Figure 16.18: Campbell-Year 05 | 333 |

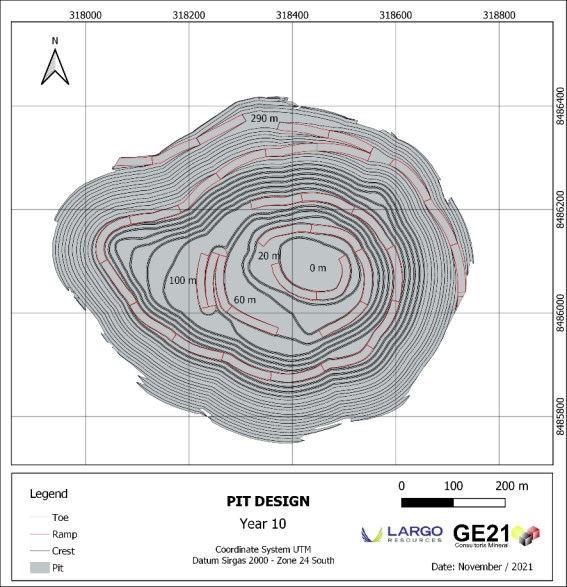

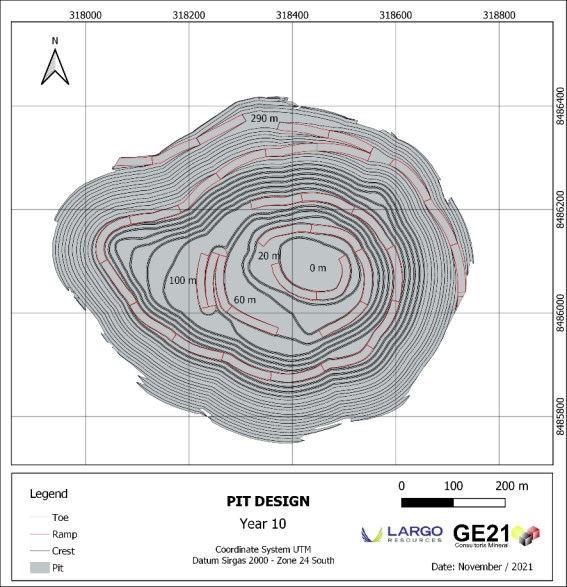

| Figure 16.19: Campbell-Year 10 | 334 |

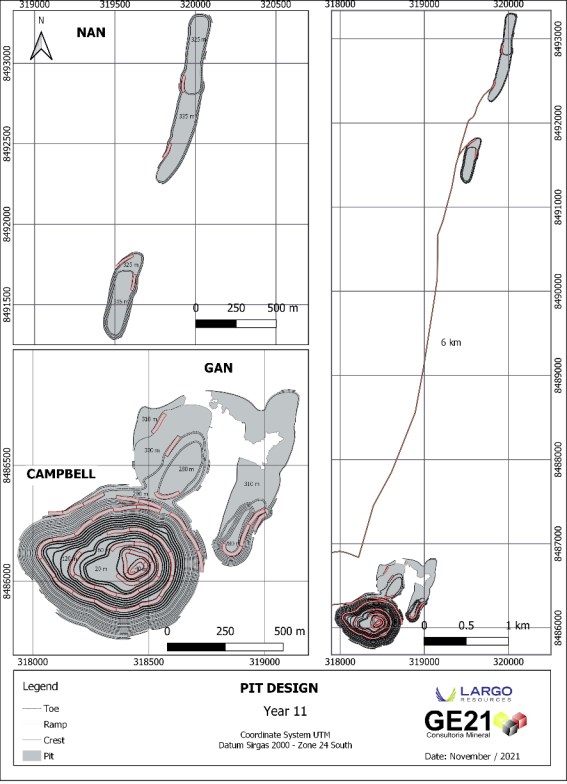

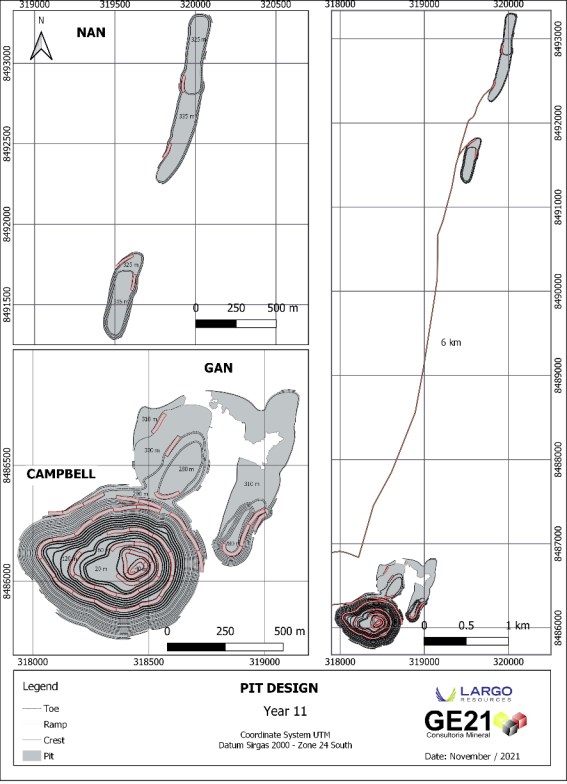

| Figure 16.20: Campbell, GAN and NAN - Year 11 | 335 |

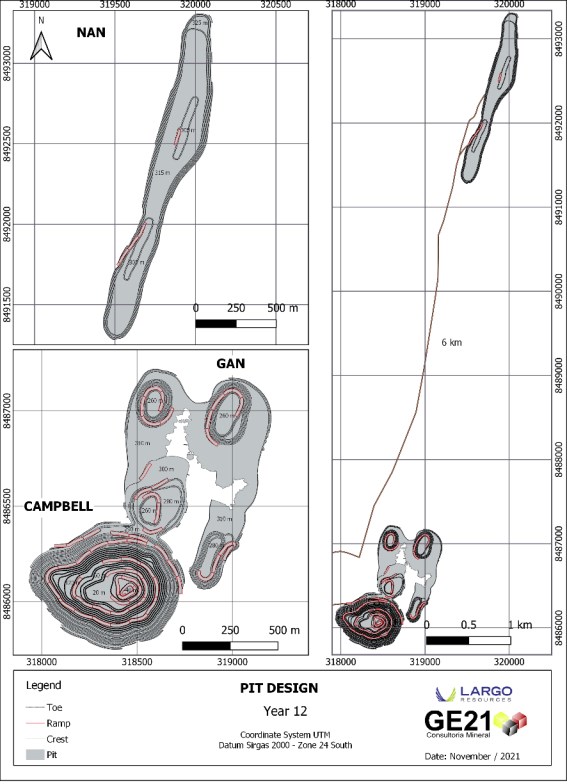

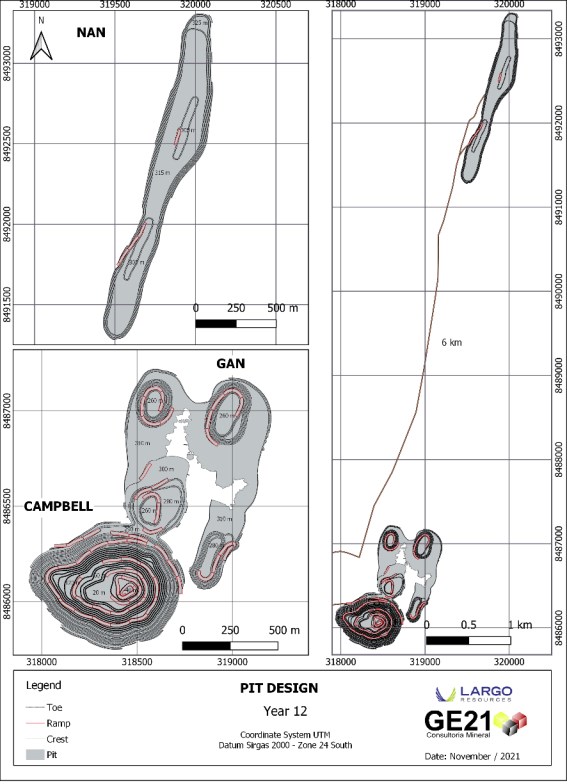

| Figure 16.21: GAN and NAN - Year 12 | 336 |

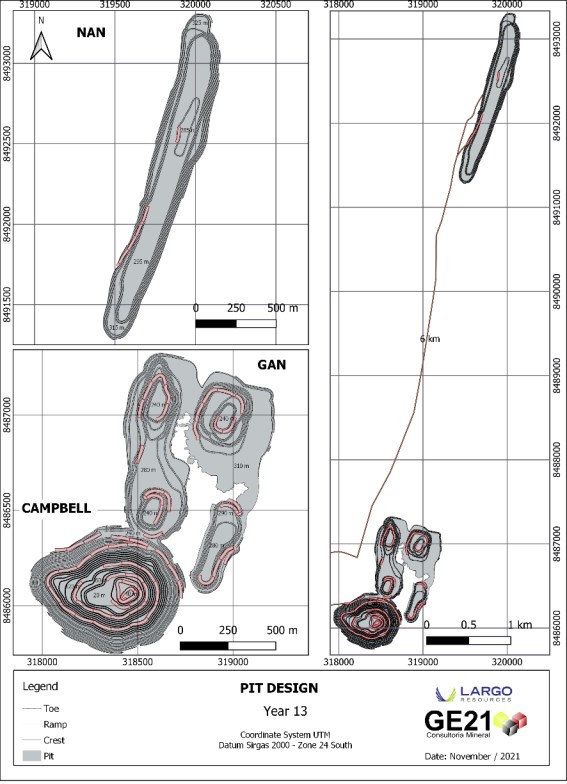

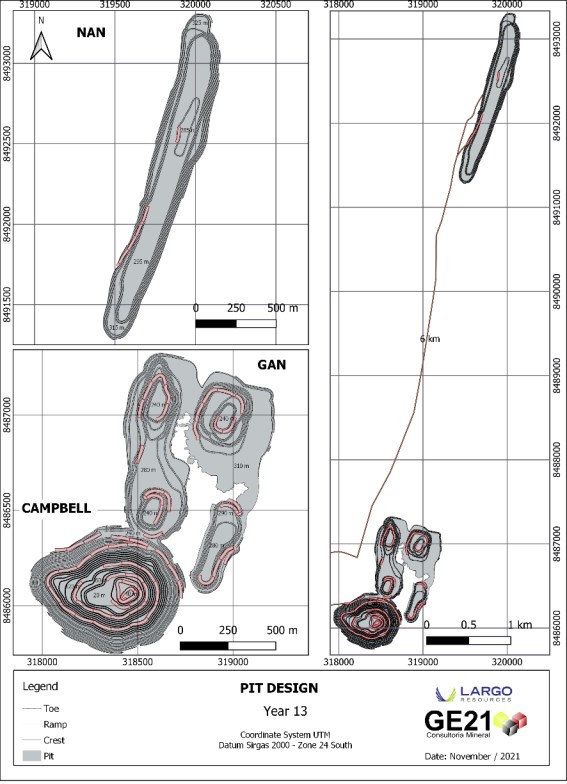

| Figure 16.22: GAN and NAN - Year 13 | 337 |

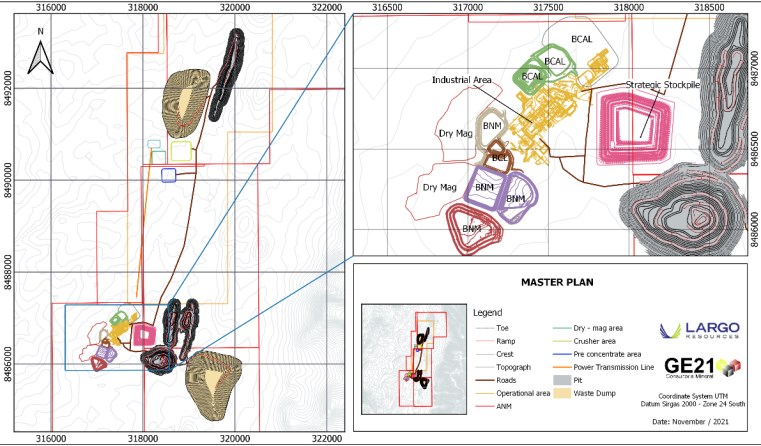

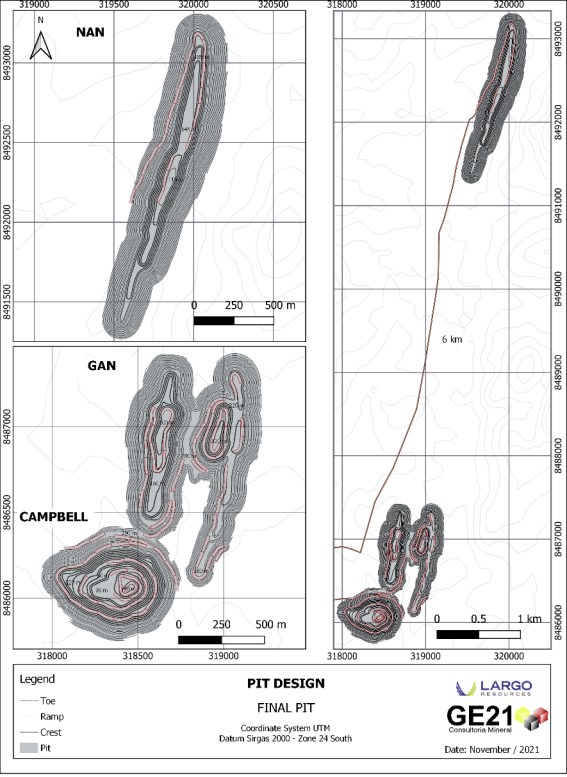

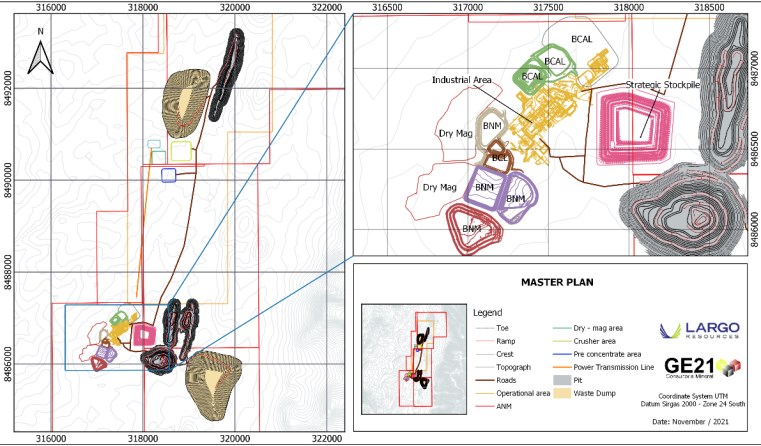

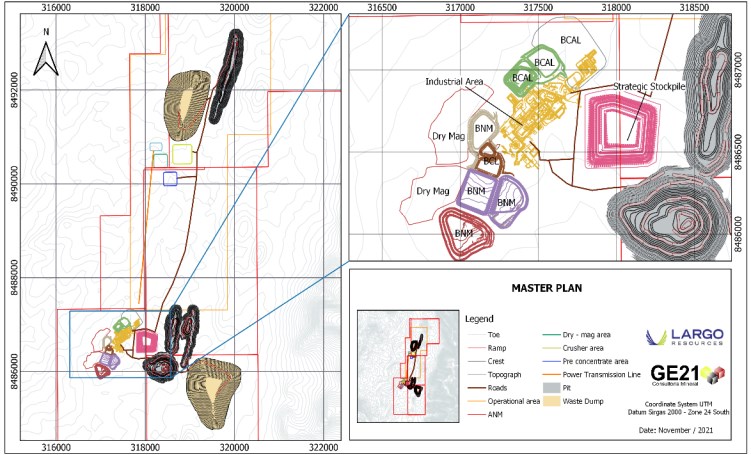

| Figure 16.23: Maracás Menchen Project - Final Pit Design | 338 |

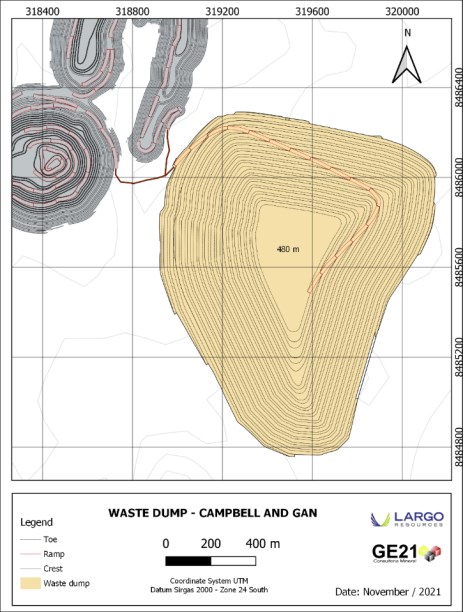

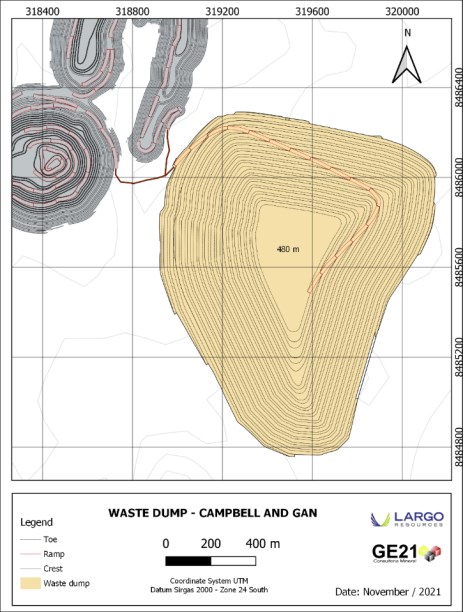

| Figure 16.24: Campbell/GAN Waste Dump | 341 |

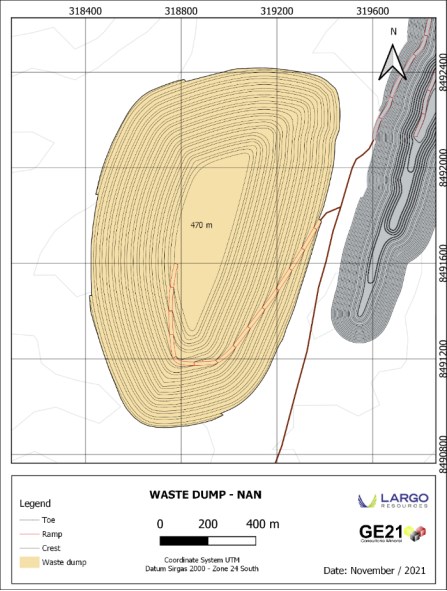

| Figure 16.25: NAN Waste Dump | 342 |

| Figure 16.26: Maracás Menchen Project - Final Pit Design | 343 |

| Figure 16.27: Minax Mining Equipments | 345 |

| Figure 17.1 Conceptual Process Flow Sheet - Vanadium Pentoxide | 349 |

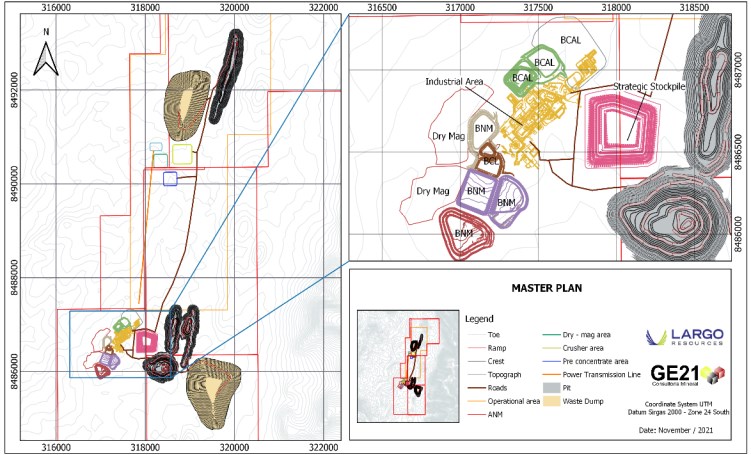

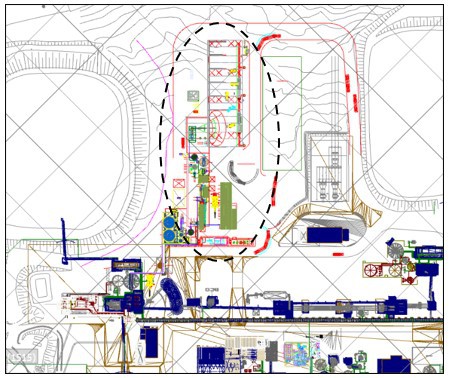

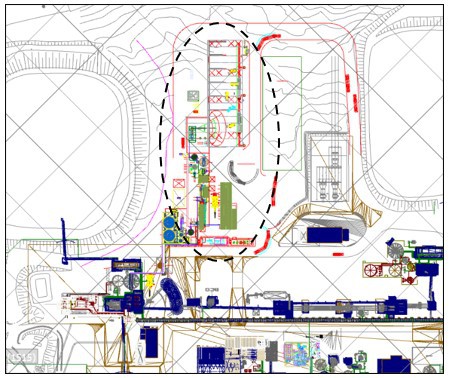

| Figure 18.1: General Layout - Plant Facility and Office Buildings | 361 |

| Figure 18.2: Plant Site Layout | 362 |

| Figure 18.3: Non-magnectic Talling Ponds | 366 |

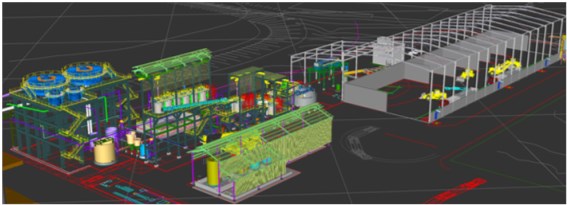

| Figure 18.4: General arrangement of ilmenite plant Phase 1 | 369 |

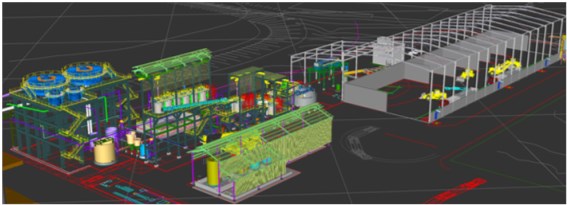

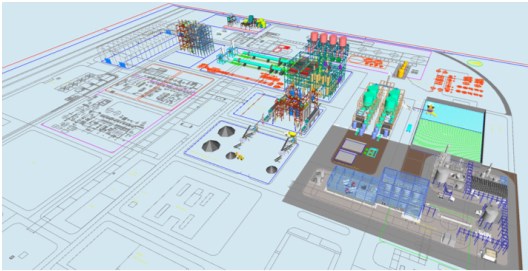

| Figure 18.5: 3D model of ilmenite plant Phase 1 | 369 |

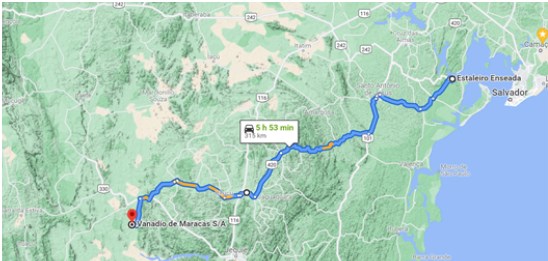

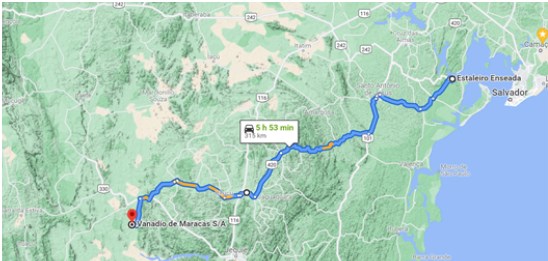

| Figure 18.6: Road to Enseada | 371 |

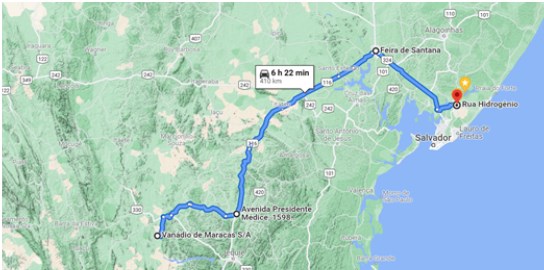

| Figure 18.7: Road to Camaçari | 371 |

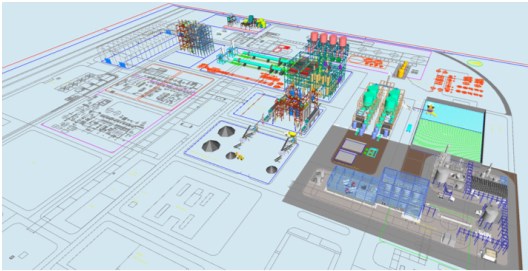

| Figure 18.8: Preliminary 3D model of Largo's Camaçari plant | 373 |

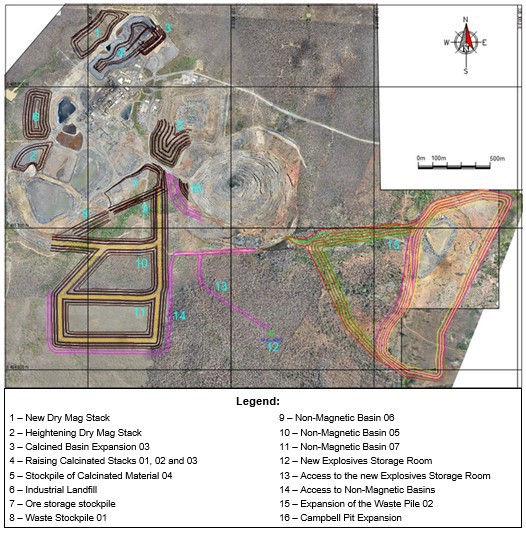

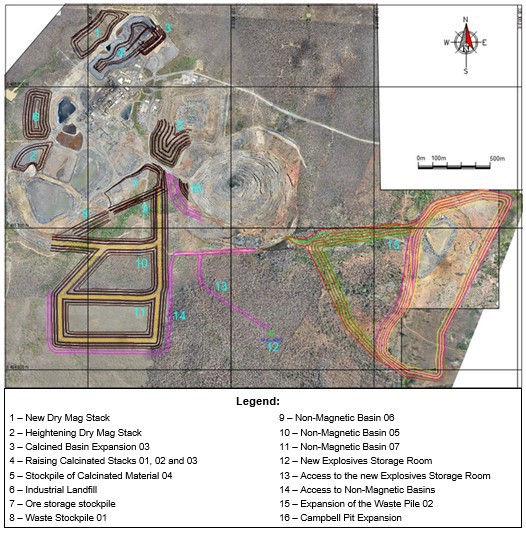

| Figure 18.9: Planned Infrastructure of Maracás Complex | 374 |

| Figure 19.1: Vanadium Pentoxide Price Trend (US$/lb V2O5) | 380 |

| Figure 19.2: Ilmenite Price Trend (US$/t) | 381 |

| Figure 19.3: Benchmark imported TiO2 pigment prices (US$/t, CIF Brazilian port) | 381 |

| Figure 20.1: Jacaré River (Dry period) | 388 |

| Figure 20.2: Pedras` Dam reservoir at Porto Alegre | 396 |

| Figure 20.3: Average Monthly Rainfall for the Pluviometric Station at Fazenda Alagadiço (ANA Code - 01340019) | 425 |

| Figure 20.4: Intensity, Duration and Frequency Curves | 426 |

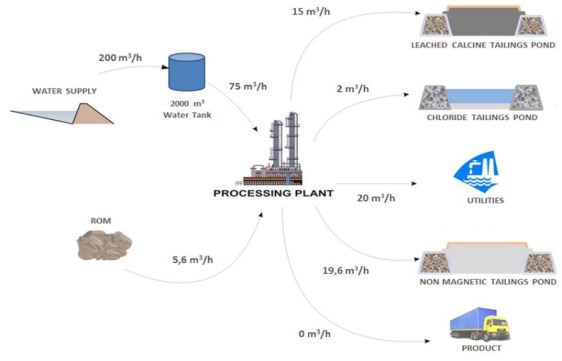

| Figure 20.5: Flow Chart of the Water Balance for the Project | 427 |

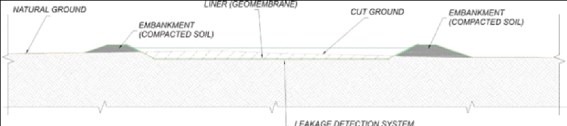

| Figure 20.6: Typical Cross-Section of the Non-Magnetic Tailings Pond | 429 |

| Figure 20.7: Layout of Non-Magnetic Tailings Ponds | 430 |

| Figure 20.8: Typical Cross-Section of the Leached Calcine Tailings Stack | 431 |

| Figure 20.9 Typical Cross-Section of the Chloride Control Purge Pond | 432 |

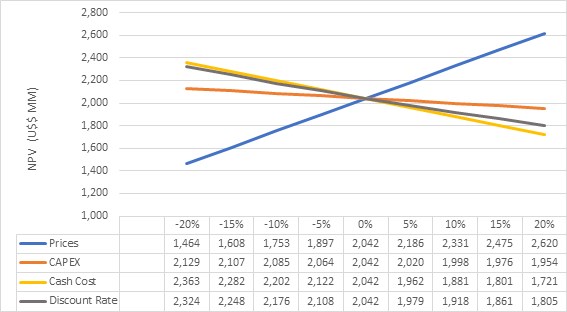

| Figure 22.1: Sensitivity analysis | 459 |

UNITS, SYMBOLS AND ABBREVIATIONS

% | Percent |

°C | Degrees Celsius |

µm | Micron |

2D | Two Dimensional |

3D | Three Dimensional |

AIG | Australian Institute og Geoscientists |

Al2O3 | Alumina |

AMF | Fauna Management Authorization |

AMV | Ammonium meta vanadate |

ANM | Agência Nacional de Mineração |

ANO | Anorthosite |

ASV | Vegetation Suppression Authorization |

BA | Bahia |

Bsc | Bachelor of science |

CaO | Calcium Oxide |

CAPEX | Capital Expenditure |

CBPM | Companhia Baiana de Pesquisa Mineral |

CIM | Canadian Institute of Mining |

CONAMA | Concelho Nacional do Meio Ambiente |

CRM | Certified Reference Material |

CSA | CSA Global |

CSLL | Social Contribution on Net Income |

DCF | Discounted Cash Flow |

DFS | Definitive Feasibility Study |

DGI | DGI Geoscience |

DNPM | Departamento Nacional de Produção Mineral |

DTRP | Hazardours Waste Transport Declaration |

DXF | Drawing Interchange Format |

EAP | Economico Agropastoril e Industrial S. A |

ECM | Engenharia e Consultoria Mineral S.A. |

EDA | Exploratory data analysis |

EIA | Environmental Impact Assessment |

FAIG | Fellow of the Australian Institute of Geoscientists |

Fe | Iron |

Fe2O3 | Iron Oxide |

FeSO4 | Ferrous sulfate |

FOS | Safety Factor |

ft | Feet |

G | Gauss |

G&A | General and administrative |

g/l | grams per liter |

g/t | Grams per Tonne |

GAN | Gulçari A Norte |

GE21 | GE21 Consultoria Mineral |

Geo | Geologist |

GFE | Gesellschaft fur Electrometallurgical |

GIS | Geographic Information System |

GPa | Giga Pascal |

GPS | Global Positioning System |

GR | Grafite |

h | Hour |

HPGR | High Pressure Grinding Rolls |

HSLA | High Srenght low alloy |

ICMS | Tax on Circulation of Goods and Services for Interstate and Intercity Transportation and Communication |

II | Import Tax |

IK | Indicator Kriging |

INCRA | National Land Reform Agency |

IPI | Tax on Manufactured Products |

IRPJ | Income tax |

IRR | Internal rate of return |

ISO | International Organization for Standardization |

ISSQN | Tax upon services of any kind |

K2O | Potassium oxide |

Kg or kg | Kilogram |

l | Liter |

L.A | Alteration License |

l/s | Liter per second |

LI | Installation License |

LIDAR | Light Detection and Ranging |

LO | Operational License |

LOM | Life of Mine |

LP | Preliminary License |

Ltda | Limited |

m³/h | Cubic meter per hour |

Ma | Million Years |

MAG | Magnetite |

MAIG | Member of the Australian Institute of Geoscientists |

MAX | Maximum |

MG | Minas Gerais |

MGB | Magnetite Gabbro |

MgO | Magnesium Oxide |

min | Minute |

MIN | Minimum |

ml | Millilitre |

mm | Millimeter |

MMA | Ministry of Environment |

MME | Ministry of Mines and Energy |

MnO | Manganese oxide |

MP | Provisional Measures |

QA/QC | Quality Assurance/Quality Control |

R$ or BRL | Brazilian Real |

ROM | Run-of-Mine |

SIRGAS | Sistema de Referencia Geocentric para Las Américas |

WRD | Waste rock dump |

OPEX | Operational Expenditure |

1 EXECUTIVE SUMMARY

1.1 Qualified Persons, Experience, and Independence

GE21 is an independent mineral consulting firm based in Brazil formed by a team of professionals accredited by the Australian Institute of Geoscientists ("AIG") as Qualified Persons ("QP") for declaration of Mineral Resources and Mineral Reserves in accordance with National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101").

The independent QP responsible for this report's content on issues related to mining, processing, mineral reserve and resource estimates and economic analysis is Porfírio Cabaleiro Rodriguez (FAIG, B.Sc.), a Principal Mining Engineer and Managing Director of GE21 Consultoria Mineral, who has at least 43 years of experience in all aspects of assessment of mining projects, from early exploration through to bankable feasibility studies.

The independent QP responsible for this report's content on issues related to Geology and Mineral Resources is Marlon Sarges Ferreira (MAIG, B.Sc.), a Geologist, who has at least 15 years of experience in the mineral industry.

The independent QP responsible for this report's content on issues related to Data Verification is Fábio Valério Câmara Xavier (MAIG, B.Sc.), a Geologist, who has at least 18 years of experience in mineral Industry.

The independent QP responsible for this report's content on issues related to Mineral Reserves estimation is Guilherme Gomides Ferreira (MAIG, B.Sc.), a Mining Engineer and Manager Engineer of GE21 Consultoria Mineral, who has at least 16 years of experience in mining projects.

1.2 Introduction

This technical report is "An updated Life of Mine Plan ("LOMP") for Campbell Pit and Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") Deposits, Maracás Menchen Project, Bahia, Brazil". Largo has undertaken a comprehensive optimization study for the Maracás Menchen Mine, with the objective of improving forecast vanadium production efficacy and extending mine life. Latest engineering works indicated that modest grades of titanium can be recovered from the Gulçari A deposit (Campbell Pit) and relatively higher grades of titanium can be recovered from the GAN and NAN deposits with the addition of specific process streams to current Largo circuit. Of this form titanium dioxide was classified as Resource and Reserve Mineral.

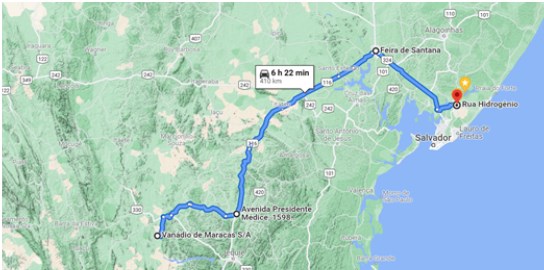

GE21 Consultoria Mineral was hired by Largo to update the Life of Mine Plan ("LOMP") for Campbell Pit and provide a Pre-Feasibility Study for Novo Amparo Norte ("NAN") and Gulçari A Norte ("GAN") deposits. The Maracás Menchen Project is located within the greater municipality of Maracás in eastern Bahia State, Brazil. Maracás lies about 250 km southwest of the City of Salvador, the capital of Bahia.

Largo's mining rights consist of eighteen (18) concessions, including 15 mineral exploration licenses and 3 exploitation licenses (one granted and two pending), totaling almost 18,000 ha.

1.3 Reliance on Other Experts

On issues related to ownership and mineral concession rights, the authors rely on legal opinions given to Largo by Stocche Forbes, namely that the Largo holds all of the necessary surface and access right required for the Project through its Brazilian subsidiary, and that its mineral concession rights are in good standing with the Agência Nacional de Mineração ("ANM"), the Brazilian federal agency that regulates and oversees mining. GE21's QP Marlon Sarges Ferreira verified on ANM's online platform that status of each of the eighteen Mineral Concessions is in accordance with the information in this Report.

On issues related to environmental permitting and studies, taxation and royalties, the authors rely on the information provided by Largo.

1.4 Property Description and Location

The Project is located in the greater municipality of Maracás in Bahia State in eastern Brazil. Maracás is approximately 250 km southwest of Bahia's capital city, Salvador. The City of Maracás has a population of approximately 20,393 inhabitants (IBGE 2020 Census) engaged primarily in the agriculture and livestock industries and a skilled labor force for mining activities.

Mineral exploration and mining licenses are independent from land ownership. To the extent that Largo requires additional surface or access rights for the Project, it must negotiate directly with the owner or lessee of the relevant portion of land.

1.5 Accessibility, Climate, Local Resources, Infrastructure, and Physiography

The town of Maracás is accessible by a paved secondary highway from the main Brazilian coastal highway through Bahia State. It is approximately 405 road kilometers from Salvador (population: 2.9 million (2020)). The Project is accessed by 29 km paved secondary highway, west from Maracás, followed by 20 km gravel road that leads to a ranch gate. The Project is located on the ranch and a 2.5-km sand and gravel trail leads to the Campbell Pit.

The local climate has two distinct seasons, one is typically hot and humid and the other during the winter is dry. The climate does not create any problem for exploration with diamond drilling or other geological/geochemical work. Tropical weathering can create specific issues for geochemistry and mapping. Exploration can be carried out at any time without facing difficulties.

Domestic power and telephone service are available both at the Property and in the town of Maracás, which is linked to the power grid. Maracás has a population of approximately 20,000. The water supply is available from a number of rivers and creeks which drain into the general area.

The Maracás Property is located in the region between the coast and the high plateau in an area of moderate to low-lying relief. At the Project itself site, the maximum relief is about 30 m. The surrounding terrain is a typical ranch/farm with low trees and shrubs and consists of a number of relatively flat plateaus adjacent to a series of creeks and ponds.

The local land is primarily used for agriculture with ranching and grazing being the primary activity on the land at the Maracás Project where both mining and exploration activities are permitted.

1.6 History

Exploration of the Rio Jacaré mafic to ultramafic intrusion by CBPM started in 1980 during a regional geological survey. This work led to the discovery of the vanadium-rich titaniferous magnetite occurrence on what is now part of the Maracás Property. In 1981, CBPM conducted an exploration program which included geological mapping, ground geophysical surveys (magnetic and VLF electromagnetic surveys), test pitting and trenching, and diamond drilling of two holes totaling 147 m. In 1983, CBPM continued work and focused on the Campbell deposit when it completed an additional 12 holes totaling 985 m.

Over the past 40 years, the Maracás Menchen Mine (the "Project") has undergone several additional phases of exploration and economic evaluation, including geophysical surveys, prospecting, trenching, diamond drilling programs, geological studies, resource estimates, petrographic studies, metallurgical studies, mining studies and economic analyses. These studies have advanced the Project to its present status of mine and to the development of exploration campaigns in target areas along the Rio Jacaré Intrusion.

The Project began mining operations in 2013, on the Gulçari A Deposit, now known as the Campbell Pit, with first V2O5 production commencing in August of 2014. It is the only vanadium mine in Latin America.

In 2018, the Company started an expansion process in the production plant to reach the capacity of 12 thousand tons per year. In July 2019, the Project achieved a monthly production record of 1,042 tons of vanadium pentoxide (V205). Also, in 2019, research and test projects were undertaken to recover titanium (pilot phase) and V2O3 conversion.

1.7 Geological Setting and Mineralization

The Rio Jacaré Intrusion, which hosts the Project's vanadium mineralization, is located in the south-central part of Bahia state in northeastern Brazil. It lies within the Archean São Francisco craton, which in this area is composed of the Contendas-Mirante Complex and the Gavião and Jequié blocks. The intrusion is located on the eastern edge of the Contendas-Mirante supracrustal sequence, which forms a large anticlinorium trending approximately north-south.

The Rio Jacaré mafic-ultramafic Intrusion is composed mainly of gabbro. It is a linear sheet-like structure that strikes almost north-south, with a length of approximately 70 km, an average width of 1.2 km, and a dip of 70° E.

Along the strike of the Rio Jacaré Intrusion within the property, several discrete deposits or areas containing vanadium-rich titanomagnetite bodies have been defined, namely the Gulçari A (Campbell Pit) deposit, the Gulçari A North (GAN) deposit, Gulçari B deposit (currently part of GAN), the São Jose deposit (SJO), the Novo Amparo (NAO) deposit and the Novo Amparo North (NAN) deposit. Each of these deposits are located at various stratigraphic heights within the Rio Jacaré Intrusion, and thus occur within different cyclic units.

Within all deposits, mineralized bodies consist of magnetitite layers or magnetite pyroxenite layers formed as cyclic magmatic units associated with the surrounding gabbro. Typically, magnetite-enriched units have sharp magmatic contacts with units below and gradational contacts with the units above.

Elements of interest at the Project are vanadium and titanium. Vanadium is hosted within titaniferous magnetite, which is the major oxide phase found within the deposit. Ilmenite forms a second oxide phase which is commonly present, and which hosts titanium mineralization.

1.8 Deposit Types