Exhibit 99.1

TECHNICAL REPORT and Preliminary Economic ASSESSMENT FOR combined mill and heap leach processing at THE NORTH BULLFROG PROJECT,

BULLFROG MINING DISTRICT,

NYE COUNTY, NEVADA

June 16, 2015

Amended and Restated

May 18, 2016

PREPARED FOR:

CORVUS GOLD INC.

by

QUALIFIED PERSONS:

Scott E. Wilson, C.P.G., SME Metal Mining Consultants, Inc. 9137 S. Ridgeline Blvd., Ste. 140 Highlands Ranch, CO 80129 720-348-1646 | Stephen Batman, Mining Eng., SME SBB Mining Solutions, LLC #232, 12650 W 64th Avenue, Unit E Arvada, CO 80004 720-353-0573 |

| | |

Herbert C. Osborne, Metallurgical Eng, SME H. C. Osborne and Associates 12885 Lanewood Street Commerce City, CO 80022 303-654-0431 | William J. Pennstrom, Jr., Metallurgical Eng., SME Pennstrom Consulting Inc. 2728 Southshire Rd., Highlands Ranch, CO 80126 303-683-9227 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 2 |

DATE AND SIGNATURE PAGE

Corvus Gold Inc.: Technical Report And Preliminary Economic Assessment For Combined Mill and Heap Leach Processing At The North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada.

The effective date of this report June 16, 2015.

Dated this 19th day of May, 2016

| (signed/sealed) Scott E. Wilson | | |

| Scott E. Wilson, C.P.G., | | |

| Geologist | | |

| | | |

| (signed) Stephen B. Batman | | |

| Stephen B. Batman, SME-RM | | |

| Mining Engineer | | |

| | | |

| (signed) Herbert Osborne | | |

| Herbert Osborne, SME-RM | | |

| Metallurgist | | |

| | | |

| (signed) William J. Pennstrom, Jr. | | |

| William J. Pennstrom, Jr., SME-RM | | |

| Metallurgist | | |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 3 |

AUTHOR’S CERTIFICATE

Scott E. Wilson

I, Scott E. Wilson, C.P.G, SME, of Highlands Ranch, Colorado, as an author of the technical report entitled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” with an effective date of June 16, 2015 as amended and restated on May 18, 2016 prepared for Corvus Gold, Inc. (the “Issuer”), do hereby certify:

| 1. | I am currently employed as President by Metal Mining Consultants Inc., 9137 S. Ridgeline Blvd., Suite 140, Highlands Ranch, Colorado 80129. |

| | 2. | I graduated with a Bachelor of Arts degree in Geology from the California State University, Sacramento in 1989. |

| | 3. | I am a Certified Professional Geologist and member of the American Institute of Professional Geologists (CPG #10965) and a Registered Member (#4025107) of the Society for Mining, Metallurgy and Exploration, Inc. |

| | 4. | I have been employed as either a geologist or an engineer continuously for a total of 27 years. My experience included resource estimation, mine planning, geological modeling, geostatistical evaluations, project development, and authorship of numerous technical reports and preliminary economic assessments of various projects throughout North America, South America and Europe. Of note I was responsible for the mineral resource estimation for Hemco Nicaragua from 2009 through 2012, which is a producing underground epithermal gold deposit. I have employed and mentored mining engineers and geologists continuously since 2003. |

| | 5. | I have read the definition of “Qualified Person” set out in National Instrument 43-101 (“NI 43-101) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for the purposes of NI 43-101. |

| | 6. | I made a personal inspection of the North Bullfrog Project on January 30th and 31st, 2012, on March 24, 2014 and on November 2nd and 3rd, 2015. |

| | 7. | I am responsible for Sections 1 through 12, Section 14, Section 20 and Sections 23 through 27 of the technical report titled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” as amended and restated on May 18, 2016 (the “Technical Report.”). |

| | 8. | I am independent of the issuer as independence is described in Section 1.5 of NI 43-101. |

| | 9. | Prior to being retained by Corvus Gold Inc. (the “issuer”), I have not had prior involvement with the property that is the subject of the Technical Report. |

| | 10. | That I have read NI 43-101 and Form 43-101F1, and that this Technical Report was prepared in compliance with NI 43-101. |

| | 11. | As of the effective date of this report, to the best of my knowledge, information and belief, the overall preparation of this report and specifically Sections 1 through 12, Section 14, Section 20 and Sections 23 through 27 of the Technical Report contains all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Dated: May 19, 2016

| (signed/sealed) Scott Wilson | |

| Scott E. Wilson, C.P.G. | |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 4 |

AUTHOR’S CERTIFICATE

Stephen Batman

I, Stephen Batman, Mining Engineer, SME of Arvada, Colorado, as an author of the technical report entitled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” with an effective date of June 16, 2015 as amended and restated on May 18, 2016 prepared for Corvus Gold, Inc. (the “Issuer”), do hereby certify:

| | 1. | I am currently employed as Principle Mining Engineer by SBB Mining Solutions, LLC, #232, 12650 W 64th Avenue, Unit E, Arvada, Colorado 80004. |

| 2. | I graduated with a Bachelor of Science degree in Mining Engineering from the Colorado School of Mines, Golden, Colorado in 1985. |

| 3. | I am a Registered Member (#181580RM) of the Society for Mining, Metallurgy and Exploration, Inc. |

| 4. | I have been employed as either a miner or an engineer continuously for a total of 30 years. My experience included resource estimation, mine planning, pit optimizations and geostatistical evaluations of numerous technical reports and preliminary economic assessments of various projects throughout North America, South America and Africa. I have been involved in the evaluation and conceptual development of new and existing mining projects, managing studies to develop projects and managing due diligences for acquisitions. Prior to entering the consulting business, I was employed as a mining engineer twenty five of my thirty years at operating mines in Nevada, the US and Australia. I have prepared capital and operating budgets and developed mining and haulage studies. I have overseen and developed operational schedules and implemented mine plans to meet targets. I have been involved with mine supervision in several large pits, mining equipment purchases, and construction projects. I have employed and mentored mining engineers over the last ten years. |

| 5. | I have read the definition of “Qualified Person” set out in National Instrument 43-101 (“NI 43-101) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for the purposes of NI 43-101. |

| 6. | I made a personal inspection of the North Bullfrog Project on March 12,2015. |

| 7. | I am responsible for sections 15, 16, and relevant portions of 21 and 25 of the technical report titled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada, as amended and restated on May 18, 2016 (the “Technical Report.”). |

| 8. | I am independent of the issuer as independence is described in Section 1.5 of NI 43-101. |

| 9. | I have not had prior involvement with the property that is the subject of the Technical Report. |

| 10. | That I have read NI 43-101 and Form 43-101F1, and that this Technical Report was prepared in compliance with NI 43-101. |

| 11. | As of the effective date of this report, to the best of my knowledge, information and belief, the portions of the Technical Report for which I am responsible contains all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Dated: May 19, 2016

| (signed) Stephen B. Batman | |

| Stephen B. Batman, SME-RM | |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 5 |

AUTHOR’S CERTIFICATE

Herbert Osborne

I, Herbert Osborne, Metallurgist, SME, of Commerce City, Colorado, as an author of the technical report entitled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” with an effective date of June 16, 2015 as amended and restated on May 18, 2016 prepared for Corvus Gold, Inc. (the “Issuer”), do hereby certify that:

| 1. | I am a consulting metallurgical engineer at H.C. Osborne and Associates and reside at 12885 Lanewood Street, Commerce City, CO, USA 80022. |

| 2. | I am a graduate of the Colorado School of Mines with a degree in Metallurgical Engineering. |

| 3. | I am Registered Member No. 2430050 RM, in good standing, of the Society of Mining, Metallurgy and Exploration. |

| 4. | I have worked in the Mineral Processing Industry for a total of 53 years after attending the Colorado School of Mines. During this time, I have held positions as Mill Engineer, Mill Superintendent, Plant Superintendent, Mine Manager and Manager of Mines. I have been a practicing consulting engineer since 1983. |

| 5. | I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of education, past relevant work experience, and affiliation with a professional associations (as defined in NI 43-101), I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101. |

| 6. | I have not visited the North Bullfrog Property. |

| 7. | I am responsible for the preparation of Section 13 and 17, and the relevant portions of Sections 1, and 25, of the technical report titled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” as amended and restated on May 18, 2016 (the “Technical Report”). |

| 8. | I am independent of the issuer applying all of the tests in section 1.5 of NI 43-101. |

| 9. | I have not had prior involvement with the property that is the subject of the Technical Report. |

| 10. | I have read NI 43-101, and the portions of the Technical Report for which I am responsible have been prepared in compliance with NI 43-101. |

| 11. | As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the portions of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Dated May 19, 2016

| (signed) Herbert Osborne | |

| Herbert Osborne, SME-RM |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 6 |

AUTHOR’S CERTIFICATE

William J. Pennstrom, Jr.

I, William J. Pennstrom, Jr., Metallurgist, SME, of Highlands Ranch, Colorado, as an author of the technical report entitled “Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” with an effective date of June 16, 2015 as amended and restated on May 18, 2016 prepared for Corvus Gold, Inc. (the “Issuer”), do hereby certify that:

| 1. | I am a consulting metallurgical engineer and President of Pennstrom Consulting, Inc., 2728 Southshire Rd., Highlands Ranch, CO 80126, USA. |

| 2. | I am a graduate of the University of Missouri Rolla (currently known as Missouri S&T) with a BS degree in Metallurgical Engineering. I am also a graduate of Webster University in St. Louis, MO, with a MA degree in Business Management. |

| 3. | I am a Registered Member in good standing of the Society of Mining, Metallurgy and Exploration (#2503900RM). I am also a Qualified Professional Member of the Mining and Metallurgical Society of America. |

| 4. | I have worked in the Mineral Processing Industry for a total of 32 years since before, during, and after my attending the University of Missouri. I have been an independent process/metallurgical consultant for the last twelve (12) years for the mining industry. |

| 5. | I have read the definition of "qualified person" set out in National Instrument 43-101 (NI 43-101) and certify that by reason of education, experience, independence and affiliation with a professional association (as defined in NI 43-101), I meet the requirements of a Qualified Person as defined in NI 43-101. |

| 6. | I have visited the North Bullfrog Project site on January 30th and 31st, 2012 and on March 12, 2015. |

| 7. | I am responsible for the preparation of Sections 18, 19 and 22, portions of Section 21, and relevant portions of Sections 1 and 25 of the technical report titled "Technical Report and Preliminary Economic Assessment for Combined Mill and Heap Leach Processing at the North Bullfrog Project, Bullfrog Mining District, Nye County, Nevada” as amended and restated on May 18, 2016 (the “Technical Report” |

| 8. | I am independent of the issuer as independence is described in section 1.5 of NI 43-101. |

| 9. | I have not previously had any prior involvement with the property that is the subject of the Technical Report. |

| 10. | I have read National Instrument 43-101 and Form 43-101F1, and the Technical Report has been prepared in compliance with that instrument and form. |

| 11. | As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the portions of the Technical Report for which I am responsible contains all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Dated May 19, 2016

| (signed) William J. Pennstrom, Jr. | |

| William J. Pennstrom, Jr., SME-RM | |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 7 |

TABLEOF CONTENTS

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 8 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 9 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 10 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 11 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 12 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 13 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 14 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 15 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 16 |

LIST OF TABLES

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 17 |

| Table 13-6 North Bullfrog Project Summary of Mcclelland Bulk Sample Column Leach Test Results | 137 |

| Table 13-7 North Bullfrog Project Summary Metallurgical Results, Grind Size Optimization Bottle Roll Tests, Bulk Mayflower Samples | 138 |

| Table 13-8 Summary Metallurgical Results, Bottle Roll Tests, North Bullfrog Drill Core Composites, Mayflower (MF) | 139 |

| Table 13-9 Summary Metallurgical Results, Bottle Roll Tests, North Bullfrog Drill Core Composites, Savage Valley (SV). | 140 |

| Table 13-10 Summary Metallurgical Results, Gold Recovery from Column Percolation Leach Tests, Mayflower Drill Core Composites (kg-Kilograms, mt – Metric Tonnes). | 141 |

| Table 13-11 Summary Metallurgical Results, Silver Recovery from Column Percolation Leach Tests, Mayflower Drill Core Composites (kg-Kilograms, mt – Metric Tonnes) | 142 |

| Table 13-12 Summary Metallurgical Results, Gold Recovery from Column Percolation Leach Tests, Savage Valley Drill Core Composites (kg-Kilograms; mt-Metric Tonnes). | 142 |

| Table 13-13 Summary Metallurgical Results, Silver Recovery from Column Percolation Leach Tests, Savage Valley Drill Core Composites (kg-Kilograms; mt-Metric Tonnes) | 143 |

| Table 13-14 Summary Metallurgical Results, Bottle Roll Tests, North Bullfrog Drill Composites, Sierra Blanca | 143 |

| Table 13-15 Summary Metallurgical Results, Bottle Roll Tests, North Bullfrog Drill Core Composites, Jolly Jane | 146 |

| Table 13-16 Summary Metallurgical Results, Gold Recovery from Column Percolation Leach Tests, Jolly Jane Drill Core Composites (82 to 92% -19mm). | 147 |

| Table 13-17 Summary Metallurgical Results, Silver Recovery from Column Percolation Leach Tests, Jolly Jane Drill Core Composites (82 to 92% -19mm) | 147 |

| Table 13-18 Summary Metallurgical Results, Gold Recovery from Column Percolation Leach Tests, Sierra Blanca Drill Core Composites (86 to 94% -19mm) | 148 |

| Table 13-19 Summary Metallurgical Results, Silver Recovery from Column Percolation Leach Tests, Sierra Blanca Drill Core Composites (86 to 94% -19mm) | 148 |

| Table 13-20 Summary Metallurgical Results, Bottle Roll Tests, Yellow Jacket Drill Core Composites, 80%-75 µm Feed Size | 149 |

| Table 13-21 Summary of Bottle Roll Tests, YellowJacket YJ PQ Drill Core Composites. | 152 |

| Table 13-22 Summary Metallurgical Results, Gold Recovery from Column Percolation Leach Tests, YellowJacket YJ PQ Drill Core Composites (80% -6.3mm and 80% -19mm) | 153 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 18 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 19 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 20 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 21 |

LIST OF FIGURES

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 22 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 23 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 24 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 25 |

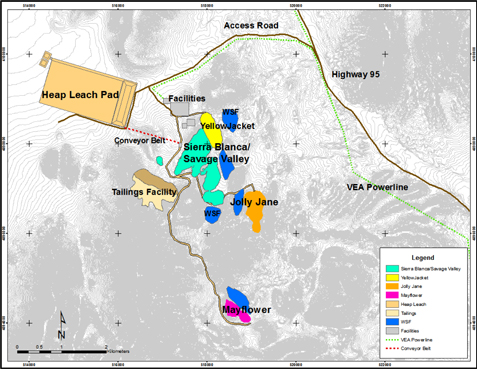

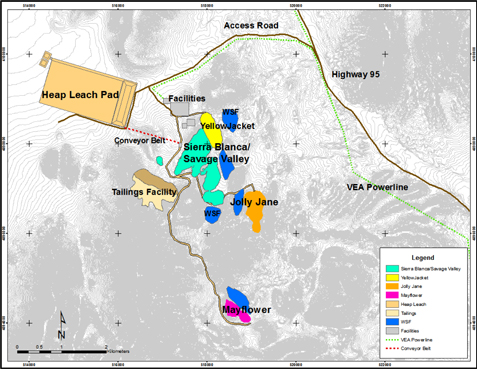

| Figure 18-1 Conceptual Configuration of the North Bullfrog Surface Mines and Associated Overburden Storage, Mill, Tailings and Leach Pad Facilities. | 221 |

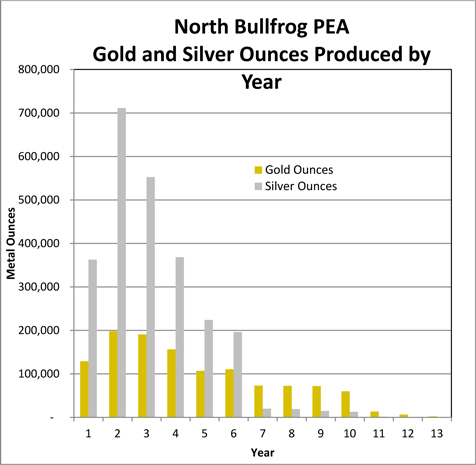

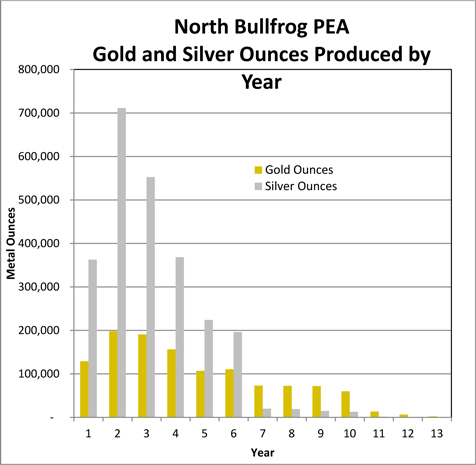

| Figure 22-1 Estimated Gold and Silver Production by Year for North Bullfrog Project (45% Measured and Indicated Resource; 55%% Inferred Resource). | 233 |

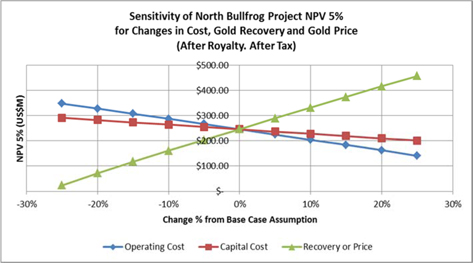

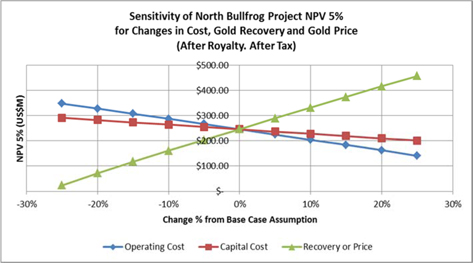

| Figure 22-2 Sensitivity of Estimated NPV @ 5% (after-Royalty and after-Tax) for Changes in Cost, Gold Recovery or Gold Price as a Percent of the Base Case at a Gold Price of $1,200 per Ounce, Gold:Silver Price Ratio of 73.7, 78%% Gold Recovery and Cost as Defined in Table 22-3 | 237 |

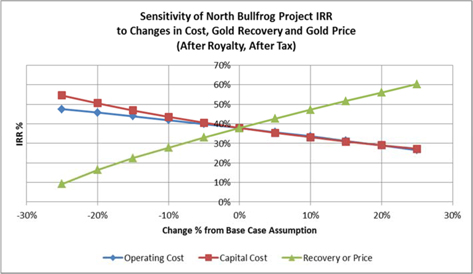

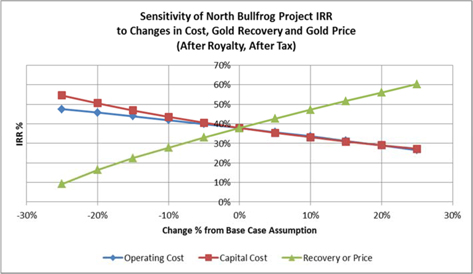

| Figure 22-3 Sensitivity of Estimated IRR (after-Royalty and after-Tax) for Changes in Cost, Gold Recovery or Gold Price as a Percent of the Base Case at a Gold Price of $1,200 per Ounce, Gold:Silver Price Ratio 0f 73.7, 78% Gold Recovery and Cost as Defined in Table 22-3. | 237 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 26 |

Metal Mining Consultants Inc. PEA Highlights: North Bullfrog Project. ("MMC"), SBB Mining Solutions LLC (“SBBM”), H. C. Osborne and Associates (“HCO”), and Pennstrom Consulting, Inc.(“PCI”) have been requested by Corvus Gold Inc. ("Corvus") to complete a Preliminary Economic Assessment (“PEA”) and associated National Instrument 43-101 (“NI 43-101”) Technical Report for the North Bullfrog Project (the "NBP" or the “Project”) located in Nevada.

The PEA has been prepared according to Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) Standards and in accordance with NI 43-101.

Summary results of the PEA are listed in Table 1-1. The PEA is preliminary in nature, and there is no certainty that the results set forth in the PEA will be realized. The mineral resource estimate included in this report includes inferred mineral resources which are too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves. A summary of projected financial performance is listed in Table 1-2.

| Table 1-1 PEA Highlights: North Bullfrog Project |

| Note: The reader is cautioned that Mineral Resources are not Mineral Reserves, and as such, do not have demonstrated economic viability. |

| Project Element | Mill | Heap Leach |

| Mineral Resource (Measured and Indicated) |

| M&I Resource (M tonnes) | 5.67 | 23.15 |

| M&I Resource (gram Au/tonne) | 2.22 | 0.30 |

| M&I Resource (gram Ag/tonne) | 16.67 | 0.46 |

| M&I Silver : Gold ratio | 7.5:1 | 1.5:1 |

| Strip Ratio (waste/resource) | 2.0:1 | 0.4:1 |

| Mineral Resource (Inferred) |

| Inferred Resource (M tonnes) | 1.48 | 176.4 |

| Inferred Resource (grams Au/tonne) | 0.83 | 0.19 |

| Inferred Resource (grams Ag/tonne) | 4.26 | 0.67 |

| Inferred Silver : Gold ratio | 5.1:1 | 3.5:1 |

| Production |

| Mine Life (years) | 6 | 10 |

| tonnes / day (nominal) | 3,000 | 43,000 |

| Gold Recovery (%) | 87% | 74% |

| Silver Recovery (%) | 74% | 6% |

| Total koz. Recovered (Au)(1) | 379.9 | 811.8 |

| Total koz. Recovered (Ag)(1) | 2,280.9 | 203.9 |

| Total koz. Recovered (Au eq.)(1)(2) | 410.8 | 814.5 |

| Project Financials |

| Estimated Capital (US $) | 258.7M |

| Capital / Recovered Au eq oz (US $/oz) | 206 |

| Estimated Total Cash Cost / Recovered Au Eq Oz. (US $) | 635 |

| Cash Cost / Recovered Au eq oz(1)(2) (US $/oz) | 620 |

| Net Present Value (NPV), 5% (US $)(3) | 246M |

Undiscounted Total Cash Flow (US $)(3) Rate of Return (DCF/ROR)(3) | 338M 37.9% |

| Payback Period (years)(3) | 2.2 |

(1) Includes Inferred Ounces (2) Au Price = $1,200/oz; Ag Price = $16.28/oz (3) After Tax and Royalty |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 27 |

Table 1-2 Projected North Bullfrog Project Economic Performance (US $).

| Item | Base Case |

| Gold Price Per Ounce | $1,200 |

| Silver Price Per Ounce | $16.28 |

| Pre-Tax Economics | |

| Net Cash Flow (US $Millions) | 479 |

| NPV @ 5% Discount Rate (US $Millions) | 365 |

| NPV @ 7.5% Discount Rate (US $Millions) | 320 |

| NPV @ 10% Discount Rate (US $Millions) | 281 |

| Internal Rate of Return | 53% |

| Operating Costs Per Ounce of Gold Produced (life of mine) | $635 |

| Total Costs Per Ounce of Gold Produced (includes all capital) | $841 |

| Post-Tax Economics | |

| Net Cash Flow (US $Millions) | 338 |

| NPV @ 5% Discount Rate (US $Millions) | 246 |

| NPV @ 7.5% Discount Rate (US $Millions) | 210 |

| NPV @ 10% Discount Rate (US $Millions) | 178 |

| Internal Rate of Return | 38% |

| Operating Costs Per Ounce of Gold Produced (life of mine) | $635 |

| Total Costs Per Ounce of Gold Produced (includes all capital) | $841 |

Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. This report presents the results of the PEA based on all available technical data and information as of June 16, 2015.

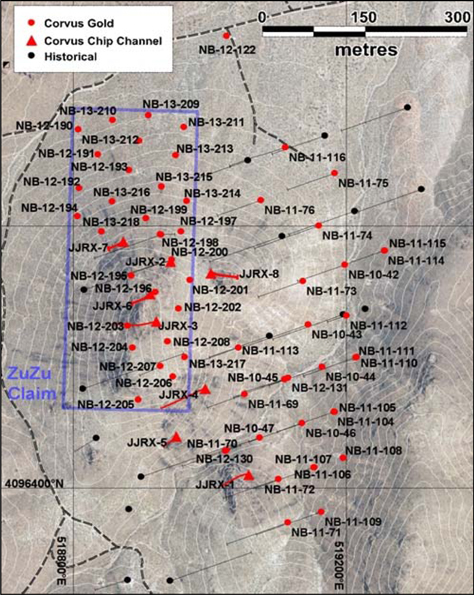

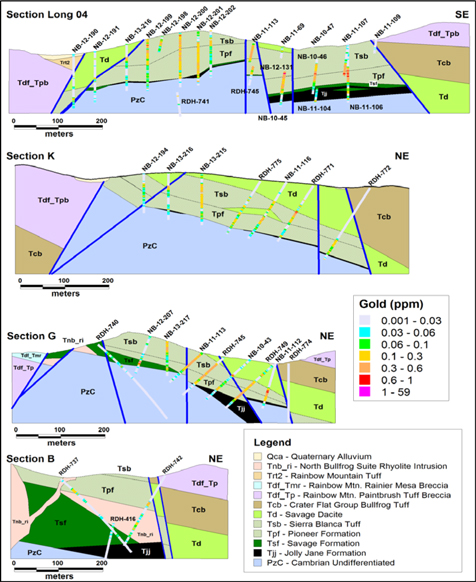

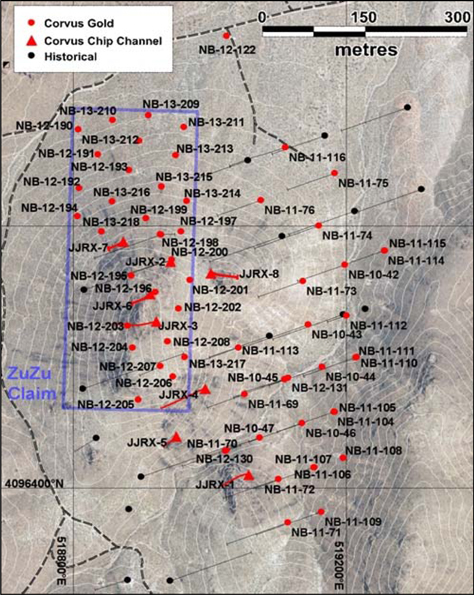

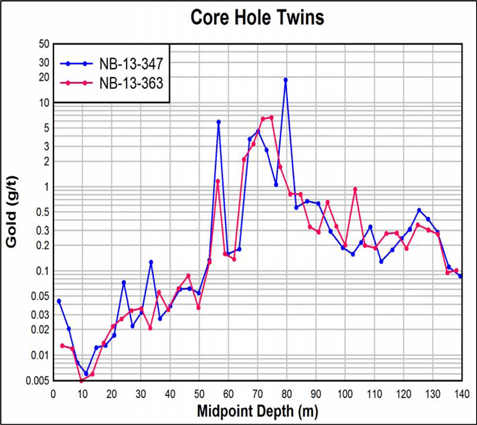

The authors have produced a Mineral Resource Estimate for the NBP with an effective date of June 16, 2015. The estimate is based on 664 holes comprising 113,492 metres of length, 72,655 Au samples and 64,200 Ag samples, completed through the effective date of this report. The Project has been modelled using the NAD 27 CONUS, ZONE 11 UTM coordinate grid system.

| 1.2 | PROPERTY DESCRIPTION AND OWNERSHIP |

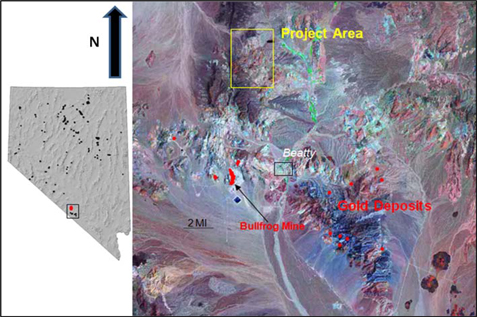

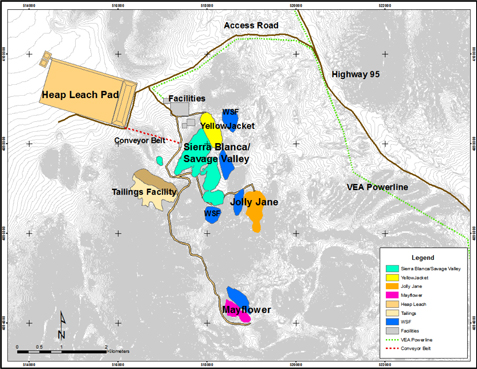

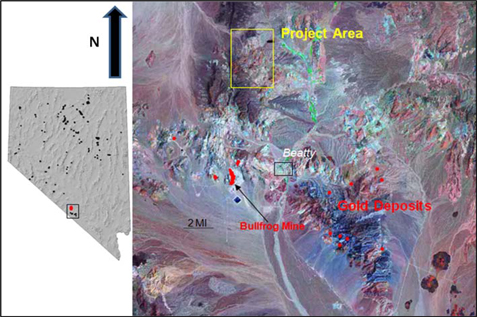

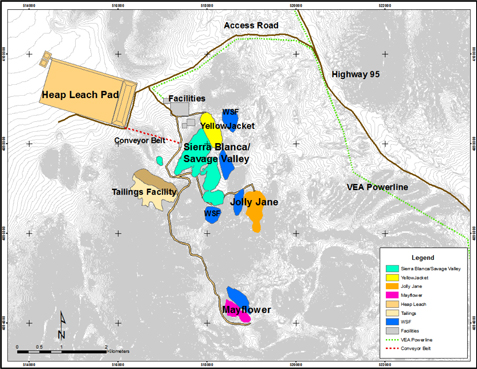

The NBP is located in the Bullfrog Hills of northwestern Nye County, Nevada (Figure 4-1).

Corvus’ property covers approximately 7,223 hectares of patented and unpatented lode mining claims in Sections 20, 21, 25, 26, 27, 28, 29, 32, 33, 34, 35, and 36 of T10S, R46E; sections 1, 2, 11, 12, 13, and 14 of T11S, R46E; section 31 of T10S, R47E; and section 6, 9, 15, 16 and 17 of T11S, R47E, MDBM. The NBP is accessible as a two and one half hour (260 km) drive north of Las Vegas Nevada along US Highway 95. US 95 is the major transportation route between Las Vegas, Reno Nevada and Boise Idaho. Las Vegas is serviced by a major international airport. The Project lies immediately to the west of the highway. Beatty, Nevada is the closest town to the Project with a population of about 1,100 and contains most basic services. Access around the Project is by a series of reasonably good gravel roads that extend to most of the important exploration areas.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 28 |

Corvus controls the Project through a number of private land leases and unpatented federal load claims listed in Table 4.1, Table 4.3 and Table 4.4 of Section 4. Corvus owns and leases several patented lode mining claims as well as maintaining a large contiguous block of federal unpatented lode mining claims. In 2014 Corvus purchased 162 hectares of surface lands in Sarcobatus Flats approximately 26 km north of the NBP, which included water rights for 1,600 acre feet per year.

| 1.3 | GEOLOGY AND MINERALIZATION |

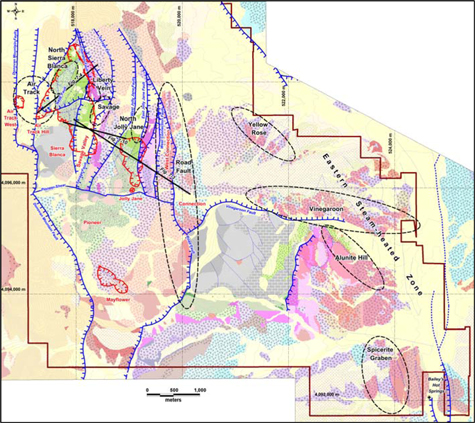

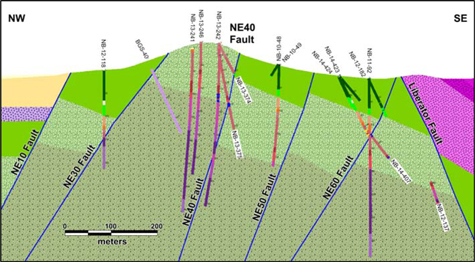

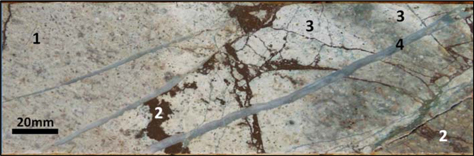

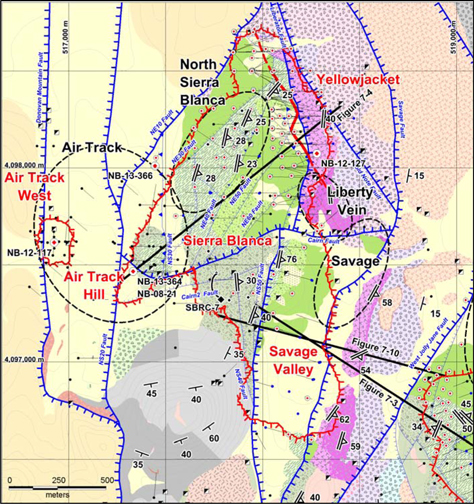

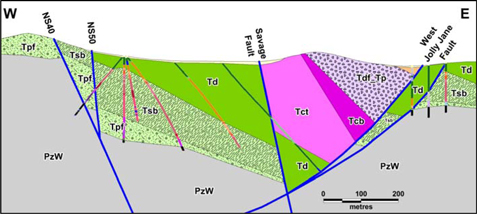

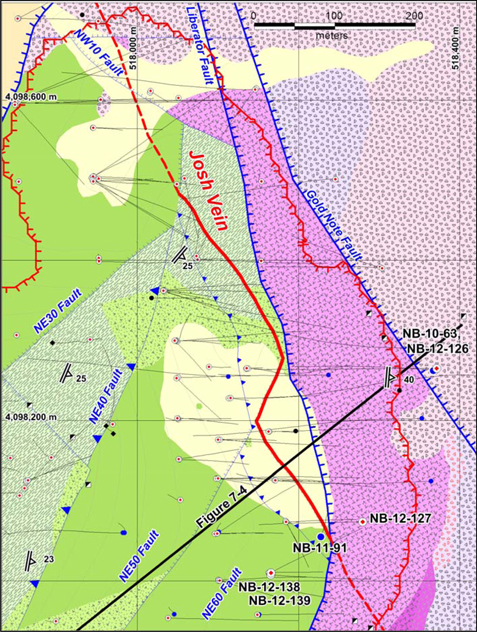

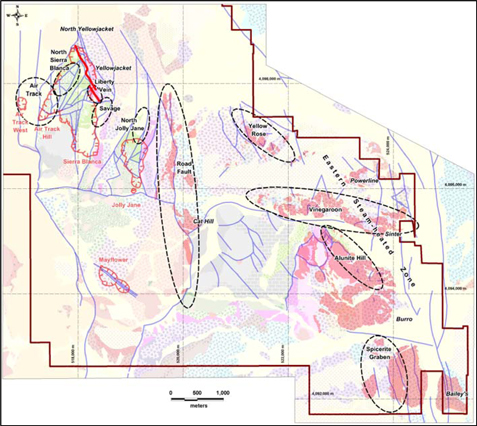

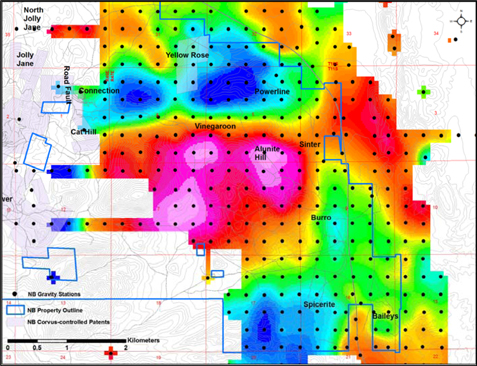

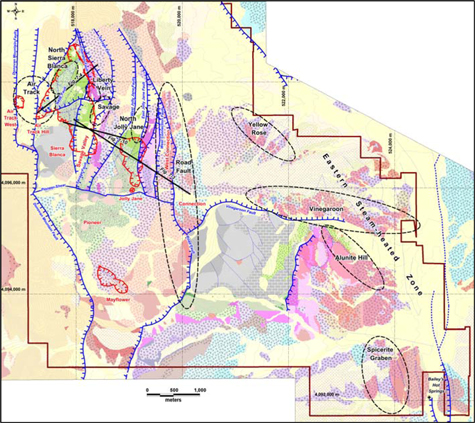

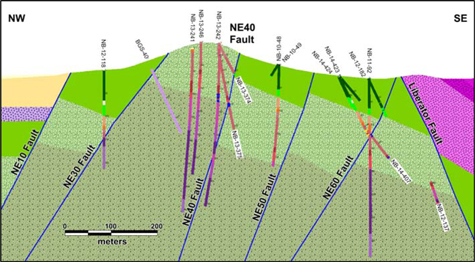

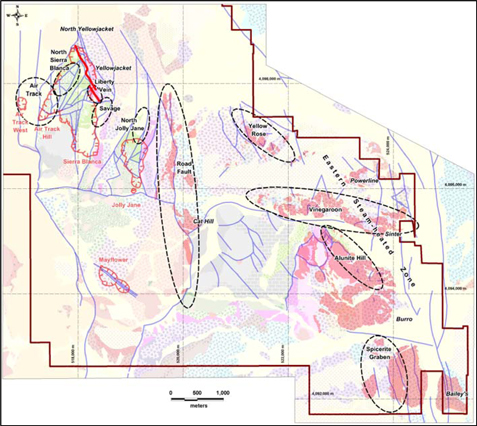

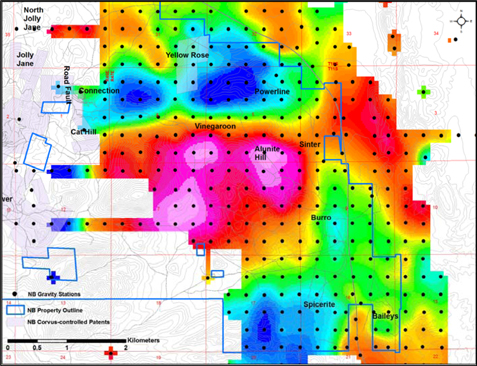

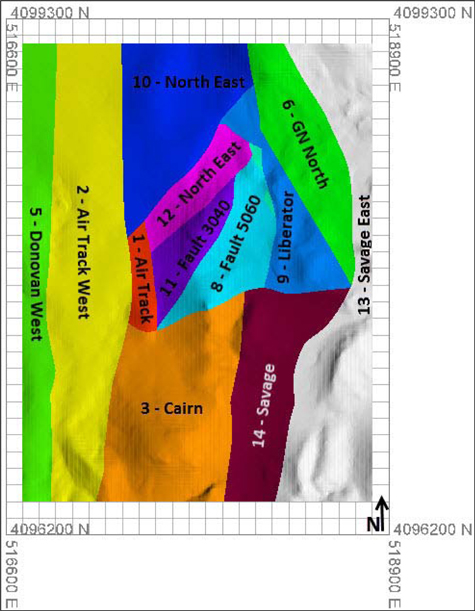

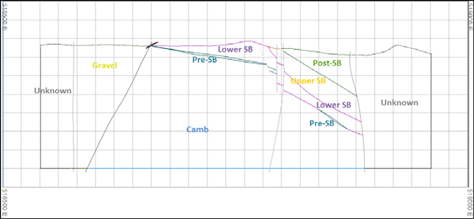

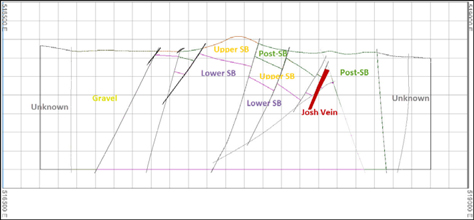

Gold mineralization in the NBP is primarily hosted in the middle Miocene Sierra Blanca Tuff. Gold mineralization is also hosted to a lesser extent in monolithic and heterolithic debris-flow deposits, as well as in felsic dikes and plugs. Two district-scale north striking normal faults are the dominant structural features in the Project area, but several smaller-scale faults between them are important controls for distribution of hydrothermal alteration and gold mineralization.

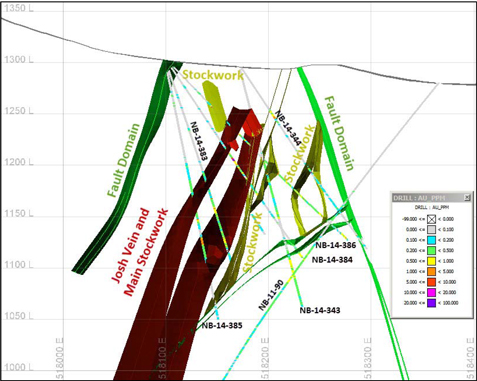

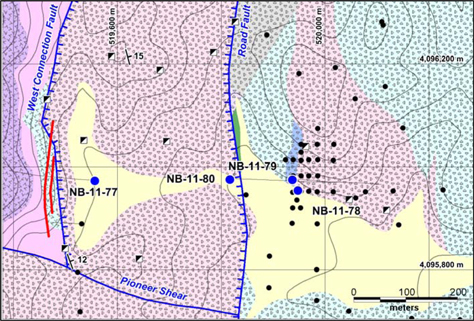

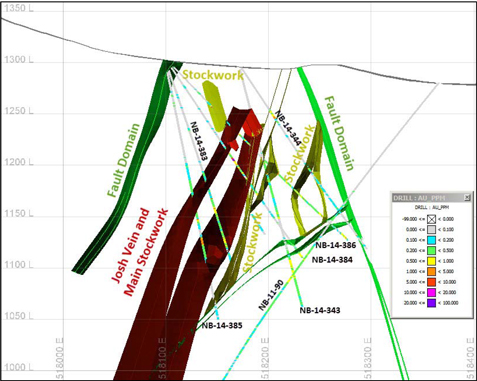

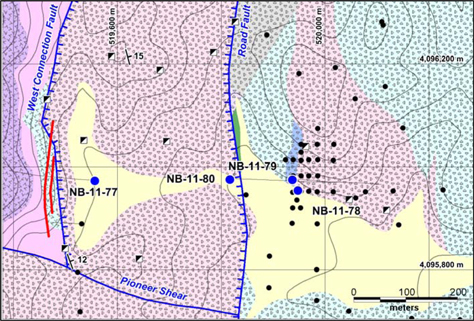

Two styles of precious metal epithermal mineralization are present at the NBP: 1) high-grade, structurally controlled fissure veins and associated stockwork zones, and 2) low-grade disseminated or replacement deposits within altered volcanic rocks. Historic drilling (pre-NI 43-101) outlined areas of important mineralization at the NBP. Drilling by International Tower Hill Mines Ltd. (“ITH”), Corvus predecessor-in-interest, was used to develop initial resource estimates, to better understand precious metal mineralization at Air Track Hill, and as initial tests at the Sierra Blanca, Pioneer, Savage and YellowJacket targets.

| 1.3.1 | METALLURGICAL TESTING |

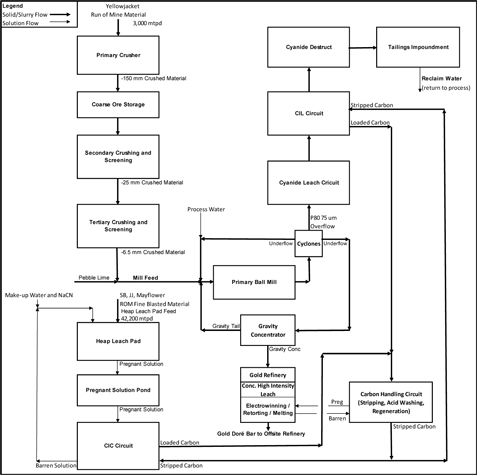

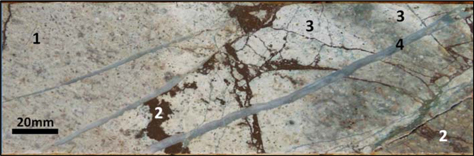

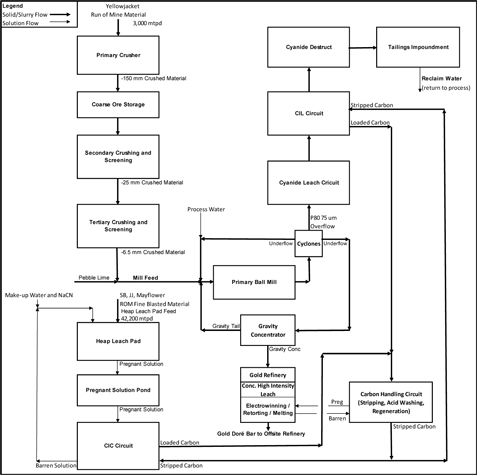

During 2012-2013 metallurgical testing was performed using composite samples developed from PQ core materials produced at Mayflower, Sierra Blanca, Savage Valley and Jolly Jane. Column leach testing on up to P80 minus 19mm indicated relatively high gold recoveries in the range of 80%, and confirmed the suitability of heap leach processing on disseminated mineralization. In 2014-2015, composite samples of PQ core materials were developed from YellowJacket vein and stockwork mineralization. Those tests indicate high solubility of contained gold in cyanide leach testing at P80minus 150 microns, but reduced gold recoveries at heap leach size particles. These tests indicate that mill processing would be required on YellowJacket mineralization. Further testing of composite samples, using gravity concentration, intense cyanide leaching of gravity concentrate and cyanide leaching of the gravity tails, indicate gold recoveries in the range of 90% and silver recoveries in the range of 70%.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 29 |

| 1.3.2 | CURRENT EXPLORATION AND DEVELOPMENT |

Currently, Corvus drilling is focused on the identification of other structurally controlled high-grade vein/stockwork mineralization similar to YellowJacket and historic Bullfrog deposit. This exploration is currently focused along the YellowJacket structural zone and other similar structural zones in the immediate area of the Sierra Blanca and Jolly Jane deposits. The YellowJacket zone is open to the north, south and at depth so additional drilling would be required to close off the zone. In addition exploration drilling will test several vein system targets in the newly discovered Eastern Steam-heated zone along the eastern boundary of the property. This new emerging exploration area is essentially untested and covers an area three times the size of the current area hosting the projects resource base. An RC drilling program to test a number of the targets in the greater YellowJacket and Eastern Steam Heated zones will take place over the remainder of 2015.

| 1.3.3 | NORTH BULLFROG RESOURCE ESTIMATE |

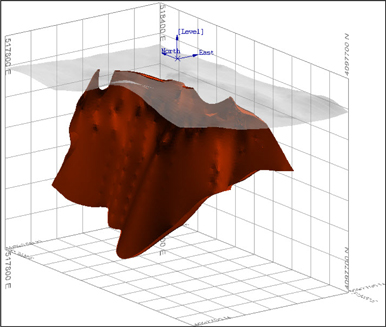

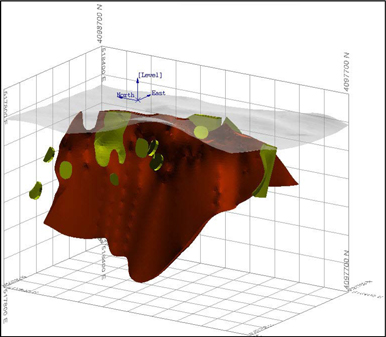

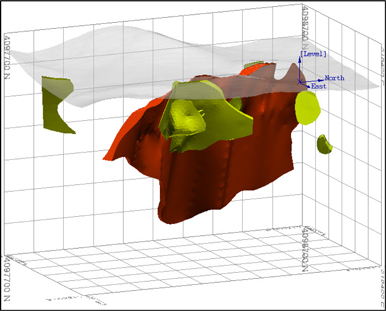

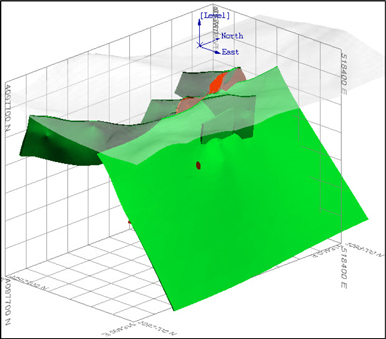

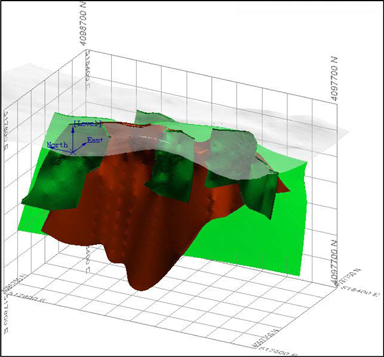

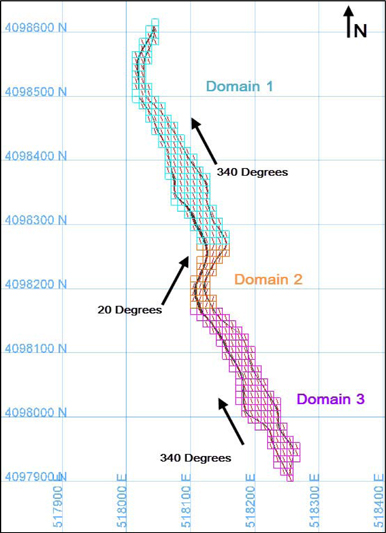

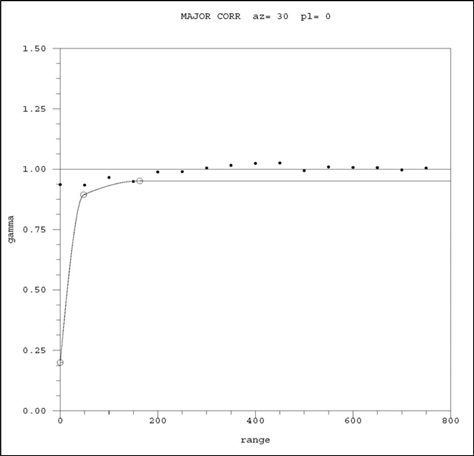

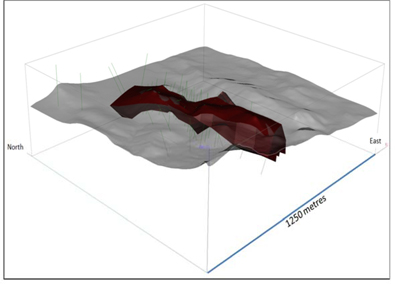

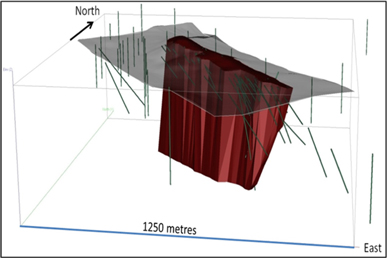

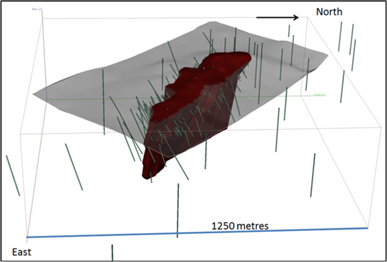

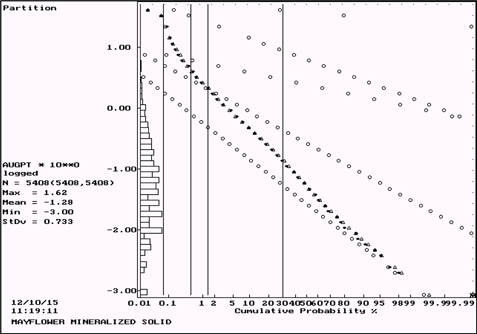

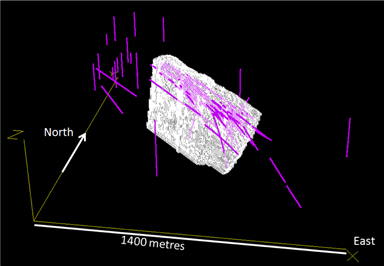

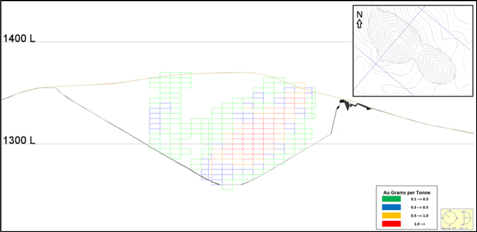

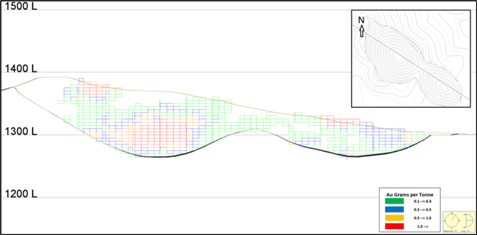

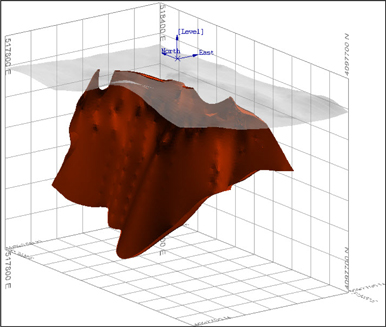

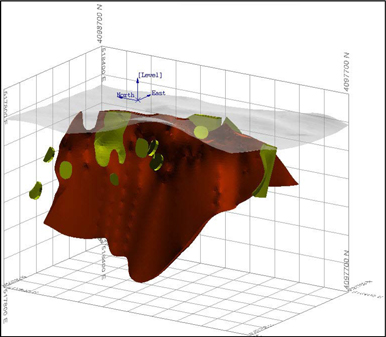

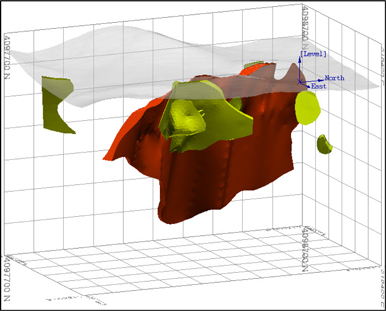

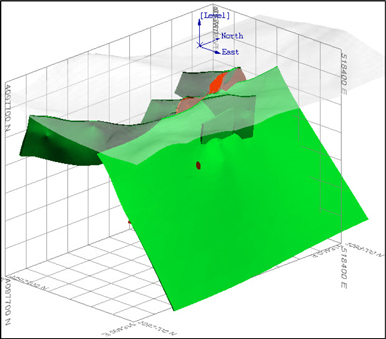

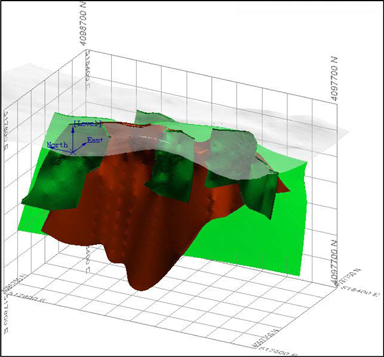

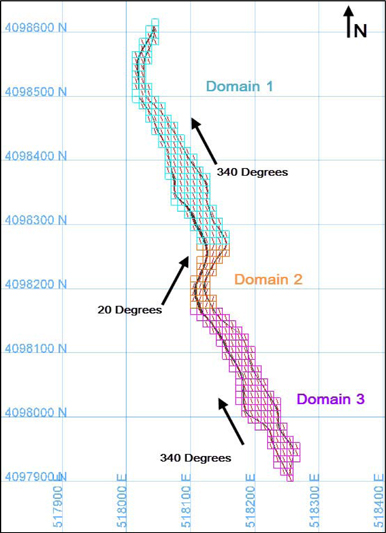

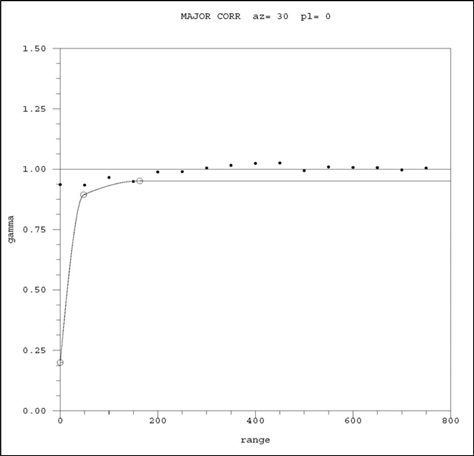

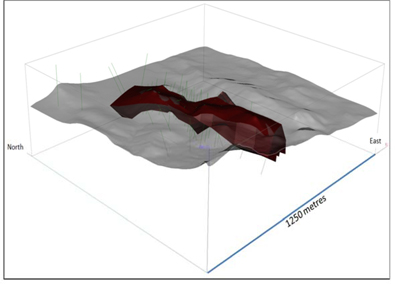

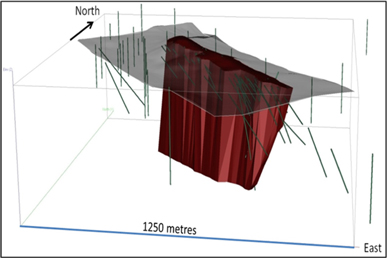

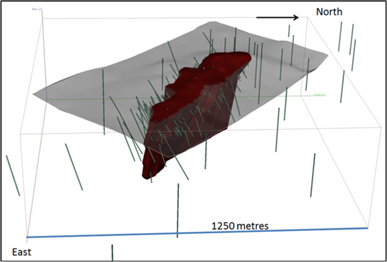

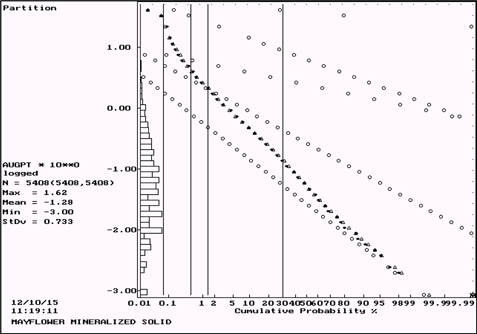

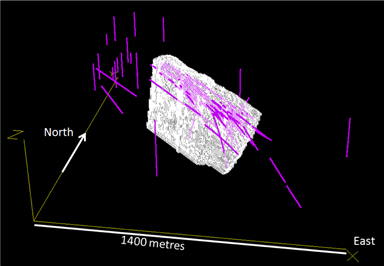

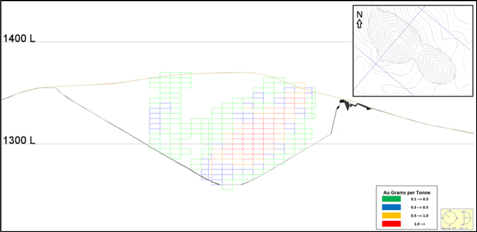

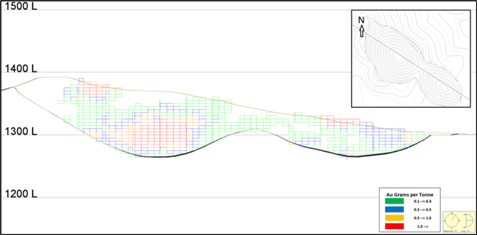

The basis for the mineral resource estimates at the NBP are geologic models interpreted by Corvus geologists and constructed in Vulcan Software by MMC. Geostatistics and estimates of mineralization were prepared by MMC. The current mineralization update focused on updating the YellowJacket Zone drilling which was completed throughout 2014. Geologic logs, alteration, geochemical data and cyanidation leach indicators were used to define the mineralized zones, and were the limiting factor for gold distribution for the resource estimations. Industry accepted grade estimation techniques were used to develop global mineralization block models. Table 1-3 lists the Measured, Indicated and Inferred Mineral Resources at various cut-off grades effective as of June 16, 2015.

Table 1-3 North Bullfrog Project Pit Constrained Mineral Resource Estimate (MMC, Scott Wilson, C.P.G.).

| Resource Area | Classification | Cutoff | Tonnes (Mt) | Au (g/t) | Ag (g/t) | Contained

Au (000’s) | Contained

Ag (000’s) |

| YellowJacket Mill | Measured | 0.56 | 3.86 | 2.55 | 19.70 | 316.51 | 2,445.23 |

| Indicated | 1.81 | 1.53 | 10.20 | 89.09 | 593.25 |

| Inferred | 1.48 | 0.83 | 4.26 | 39.36 | 203.35 |

| Sierra Blanca and YellowJacket Heap Leach | Measured | 0.15 | 0.30 | 0.25 | 2.76 | 2.34 | 26.28 |

| Indicated | 0.13 | 0.25 | 1.99 | 1.07 | 8.56 |

| Inferred | 168.40 | 0.19 | 0.68 | 1,041.80 | 3,664.32 |

| Jolly Jane Heap Leach | Indicated | 0.15 | 17.60 | 0.25 | 0.43 | 141.44 | 240.99 |

| Inferred | 7.95 | 0.20 | 0.54 | 51.00 | 137.33 |

| Mayflower Heap Leach | Indicated | 0.20 | 5.13 | 0.47 | 0.41 | 77.26 | 68.27 |

Mineral resources are not mineral reserves and do not demonstrate economic viability. There is no certainty that all or any part of the mineral resource will be converted to mineral reserves. Quantity and grade are estimates and are rounded to reflect the fact that the resource estimate is an approximation.

Corvus has invested considerable effort and investment in the advancement of the North Bullfrog Project through drilling, permitting, technical and metallurgical evaluations, internally and with the assistance of reputable consulting firms. This evaluation indicates a strong positive and robust performance of a combination heap leaching and milling facility at the Project at the current metal price environment. The project performance is most sensitive to gold price and gold recovery. Metallurgical data to this point indicates economic extraction of metals is not complicated.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 30 |

The project economics suggest that this is a project that can be put into production for a total capital investment of approximately US $258.7 million and with the initial capital being paid back within 2.2 years of startup. Good potential exists for the discovery of additional mill and heap leach Mineral Resources at exploration target areas identified within the Project claim block.

MMC is of the opinion that the current Mineral Resource at North Bullfrog is sufficient to warrant continued planning and effort to explore, permit, and develop the Project.

MMC believes there is sufficient data to support continued exploration, geologic modeling and continuing development of the project..

The PEA results, for the combined mill and heap leach configuration, indicate the substantial financial impact on project performance of the higher grade vein and vein stockwork mineralization. Therefore it is recommended that future exploration should focus on the identification and development of other structural related mineralization. These recommended activities are:

| · | Drill structures identified in the Eastern Steam-heated Alteration Zone |

| · | Explore Structural Targets around the YellowJacket-Sierra Blanca and Jolly Jane deposits |

| · | Continue Baseline project development Data Collection |

The projected costs for the next phase of this program are outlined in Table 1-4.

Table 1-4 Proposed Budget to Support Recommended Program at NBP.

| Activity | Amount |

| Exploration Drilling and Data Management | US$ 0.9 M |

| Baseline Data Collection | US$ 0.1 M |

| Total | US$ 1.0M |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 31 |

Corvus Gold Inc. is a North American gold exploration and development company, focused on its near-term gold-silver mining project at North Bullfrog, Nevada. Corvus is listed on the TSX as “KOR”. This report is being prepared to incorporate recent drilling geological and metallurgical data developed in 2014 and 2015 on the YellowJacket zone into an updated Mineral Resource Estimate. A Preliminary Economic Assessment of the North Bullfrog Project based on combined mill processing of Mineral Resources from YellowJacket and heap leaching of lower grade disseminated mineralization in Sierra Blanca, Jolly Jane and Mayflower has also been performed.

The report has been amended and restated on May 18, 2016 to correct some of the information in Table 22-4 and in Table 16- 2 that was found to be in error. None of the results or conclusions of the report were effected.

The Authors used various forms of digital data in the Technical Report including geologic models based on surface mapping and drilling, assay data, and metallurgical testing data developed by Corvus, MMC, SBBM, HCO and PCI.

The NBP is located in northwestern Nye County, Nevada, in the Northern Bullfrog Hills about 15 km North of Beatty (Figure 2-1). The Project lies within the Walker Lane structural terrain about 12 km North of the Bullfrog mine where Barrick Gold Corp. (and predecessor companies) produced about 2.31 million ounces of gold and 3.0 million ounces of silver from 1989 through 1999 (NBMG MI-2000, page 34). The NBP contains numerous epithermal low-sulfidation volcanic rock-hosted gold showings that had limited historic production.

Corvus controls the Project through a number of private land leases with various land owners (Table 4-1 and Figure 4-1) and through numerous federal unpatented lode mining claim holdings. In 2006, Redstar Gold Corp (“RGC”) initially assembled 213 unpatented lode mining claims and 33 patented lode mining claims through six option agreements, which were the property subject to the original joint venture agreement between RGC and ITH (called the North Bullfrog Project Joint Venture – “NBPJV”). ITH leased an additional 11 patented lode mining claims in the Mayflower area, which became subject to the NBPJV agreement. ITH earned into the NBPJV when in August 2009 they negotiated an agreement to purchase RGC’s interest in the joint venture property. ITH spun out Corvus on August 26, 2010 as the controlling entity of the North Bullfrog property. Corvus completed one additional option agreement on patented lode mining claims in the Jolly Jane area in March 2011, for a total of eight option agreements on private lands. Corvus also expanded the North Bullfrog property in early 2012 by staking a total of 511 federal unpatented lode mining claims. In late 2012 Corvus staked an additional 297 unpatented lode mining claims to the north and east (Figure 4-1) bringing the total unpatented lode mining claim holdings to 808. All of these claims are in good standing with the BLM and Nye County.

On March 23, 2013 Corvus announced the purchase of surface rights only to five patented lode mining claims from Mr. and Mrs. Gordon Millman to facilitate shorter overburden haul distances for development of the Mayflower deposit. The terms of the purchase as outlined in the Corvus press release (February 21, 2013) are, “USD 160,000, payable at closing. The terms also include payment by Corvus Nevada of a fee of USD 0.02 per ton of overburden to be stored on the property, subject to payment for a minimum of 12 million short tons. The minimum tonnage fee (USD 240,000) bears an interest at 4.2% per annum from closing and is evidenced by a promissory note due on the sooner of the beginning of production or December 31, 2015.”

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 32 |

Figure 2-1 Regional Location Maps of the NBP; Nevada Map Shows Productive Gold Deposits in Black and Location of Enlarged Area with False-Color Remote Sensing Image Backdrop Showing the Project Area in Yellow and the Productive Gold Deposits in Red

Corvus requested that this Technical Report be prepared to support a revised Mineral Resource estimate to include the YellowJacket mineralization outlined in 2013-2014 drilling. This report also updates material changes in the NBP ownership, land position, metallurgical data and drilling data completed since the 2014 NI 43-101 report (Wilson et. al., 2014), as well as recommendations for the next phase of evaluation of the Project. This report outlines the geology, exploration history, and potential of the Project based on possible exploitation of mineralized areas. Mr. Scott E. Wilson (MMC), Mr. Stephen Batman (SBBM), Mr. Herbert Osborne (HCO) and Mr. William Pennstrom (PCI) were commissioned by Corvus to prepare this report.

The principal author, Mr. Scott E. Wilson, CPG #10965, and a Registered Member of SME, member number 4025107RM, as an independent Qualified Person, was responsible for the overall preparation of this report and specifically for Sections 1 through 12, Section 14, Section 20 and Sections 23 through 27 of the report. Mr. Wilson visited the North Bullfrog Site on January 30 and 31, 2013, March 24, 2014 and November 2 and 3, 2014. Mr. Wilson is independent of Corvus applying all of the tests in Section 1.5 of NI 43-101.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 33 |

Mr. Stephen Batman, SME Registered Member 181580RM, was responsible for the preparation of Sections 15 and 16 and relevant parts of Sections 1, 21 and 25. Mr. Batman visited the site on March 12, 2015. Mr. Batman is independent of Corvus applying all of the tests in Section 1.5 of NI 43-101.

Mr. Herbert Osborne, Consulting Metallurgical Engineer and a Registered Member of SME, member number 2430050RM, as an independent Qualified Person, was responsible for Section 13 and Section 17 and relevant portions of Sections 1 and Sections 25. Mr. Osborne has not visited the NBP as a site visit was not required for the purposes of his participation. Mr. Osborne is independent of Corvus applying all of the tests in Section 1.5 of NI 43-101.

Mr. William J. Pennstrom, Jr., Consulting Metallurgical Engineer and Registered Member of SME, member number 2503900RM, as an independent Qualified Person, was responsible for Sections 18, 19, 22, and portions of Sections 21, and relevant parts of Sections 1 and 25 of the technical report. Mr. Pennstrom last visited the site on March 12, 2015. Mr. Pennstrom is independent of Corvus applying all of the tests in Section 1.5 of NI 43-101.

All dollar amounts in this document are United States dollars unless otherwise noted.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 34 |

| 3 | RELIANCE ON OTHER RELEVANT EXPERTS |

Richard DeLong

Mr. Delong is the founder of Enviroscientists, Inc. a well-respected business known throughout the Northern Nevada mining community. Enviroscientists is a leading property development and permit acquisition firm that specializes in assisting natural resource development industries with property development needs, evaluation of environmental effects, and compliance with governing regulations. Mr. Delong is not a Qualified Person as defined by NI43-101. However, Mr. Delong’s opinions regarding regulatory compliance are widely sought after and his recommendations are typically followed. The author knows of Mr. Delong’s reputation, and has relied on Mr. Delong’s contributions to and review of Section 20.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 35 |

| 4 | PROPERTY DESCRIPTION AND LOCATION |

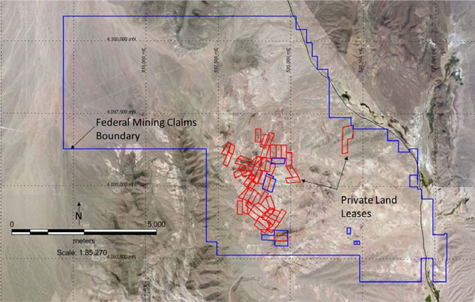

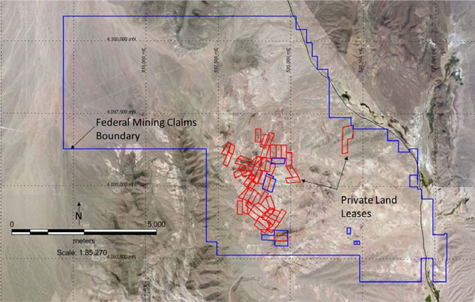

The NBP is located in the Bullfrog Hills of northwestern Nye County, Nevada. A map of the NBP property is presented in Figure 4-1, which shows the boundary defined by unpatented lode mining claims in blue and private land patented claims in red. Location of the property is indicated by the coordinate grid on the map which is in the UTm NAD27, Zone 11 coordinate system. The Project covers about 7,223 of patented and unpatented lode mining claims in Sections 20, 21, 25, 26, 27, 28, 29, 32, 33, 34, 35, and 36 of T10S, R46E; sections 1, 2, 11, 12, 13, and 14 of T11S, R46E; section 31 of T10S, R47E; and section 6,9,15,16 and 17, T11S, R47E, MDBM. A summarized list of the claims covered by the NBP is given in Table 4-2 and Table 4-4 in this section. Corvus has a total of nine option/lease agreements in place that give it control of 51 patented lode mining claims which are summarized in Table 4-1 below.

Figure 4-1 Property Map of the NBP (Blue). Leased Private Land Identified in Red (UTm NAD 27 Zone 11).

The claims and lease agreements give Corvus the right to explore the property and mine locatable minerals subject to required regulatory permits which are described in Section 20. Corvus currently has permits for exploration of the public and private land (Bureau of Land Management (BLM) and Nevada Department of Environmental Protection (NDEP)). The permits allow non-exclusive access to Corvus and its contractors, exploration drilling and sampling, geologic mapping, engineering characterization, baseline environmental data collection and new surface disturbance as defined by the permits. The leases and claims give Corvus the rights to conduct mining operations to extract the Mineral Resources subject to future permits described in Section 20.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 36 |

| 4.2 | REDSTAR OPTION/JOINT VENTURE/ITH PURCHASE OF LAND |

RGC originally staked 213 unpatented lode mining claims and optioned 21 patented lode mining claims from six private parties in 2006. ITH optioned the original NBP land package from RGC in 2006, creating the NBPJV. ITH added 11 patented lode mining claims (the Mayflower property) to the NBPJV in 2007 under the Greenspun lease agreement. RGC added 12 patented lode mining claims (the Connection and adjacent properties) to the NBPJV in 2008 under the lease agreement with Lunar Landing LLC. In August 2009 ITH purchased 100% interest in the NBPJV from RGC by paying RGC CAD$250,000 and issuing 200,000 ITH common shares (News Release, August 4, 2009). These holdings were then transferred to Corvus during the spin out. Corvus completed one additional option agreement on two patented lode mining claims in the Jolly Jane area in March 2011. In May 2014, Corvus amended its existing lease agreement with Kolo Corp. to add the Yellowrose and Yellowrose No. 1 claims. In March 2015 Corvus added a second option agreement with Lunar Landing LLC, to lease the Sunflower, Sunflower No. 1 and Sunflower No. 2 claims for a total of nine option agreements on private land. Corvus has added an additional 808 federal unpatented lode mining claims which were staked in 2012, and added an additional 57 federal unpatented lode mining claims which were staked in 2015. Table 4-1 summarizes the obligations of the nine leases which are part of Corvus’ responsibilities on the Project and Table 4-2 lists the individual claim names and U.S Bureau of Land Management serial numbers for the nine lease obligations. The principal author has verified that all lease obligations have been met and are paid in full as of the date of this report.

All of these properties are held through CGN, which was a wholly owned subsidiary of ITH and was transferred to Corvus in connection with the spinout on August 26, 2010.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 37 |

Table 4-1 Summary of Lease Obligations That Are Part of the Corvus Spin out (All Funds USD).

| Party | Area | Claims/Acres | Next

Payment | Property

Taxes | NSR | Signing Date | Term

(yrs) | Term

Extension | Option to

Purchase

Property | Option to

Purchase

Royalty | NSR

Option

Term |

| Gregory | North Pioneer | 1/8.2 | $3,600 | na | 2% | 6/16/2006 | 10 | yes | no | $1 M/% | na |

| Hall | Savage | 3/45.7 | $8,600 | na | 2% | 5/22/2006 | 5 | yes | no | $1 M/% | na |

| Kolo Corp | Jolly Jane & Yellowrose | 4/81.7 | $6,000 | $258 | 3% | 5/8/2006 | 10 | yes | no | $0.85/% | na |

| Milliken | Pioneer | 3/24.5 | $5,400 | na | 2% | 5/8/2006 | 10 | yes | no | $1M/% | na |

| Pritchard | Pioneer | 12/203.0 | $20,000 | na | 4% | 5/16/2006 | 10 | yes | no | $1M/% | na |

| Lunar Landing LLC | Connection | 12/195.0 | $16,200 | $207 | 4% | 10/27/2008 Amended 5/28/2014 | 10 | yes | $1 M | $1M/% | 35 yrs |

| Lunar Landing LLC | Sunflower | 3/59.2 | $5,000 | $180 | 4% | 3/30/2015 | 4 | 7yrs | $0.3 M | $0.5/% | 35 yrs |

| Greenspun1 | Mayflower | 11/183.05 | $10,0001 | $214 | 4% | 12/1/2007 | See Table 4-3 |

| Sussman | Jolly Jane | 2/37.4 | $30,000 | $113 | 2% | 3/14/2011 | 10 | 10 yrs | Inclusive in Royalty Purchase | $1M/% | na |

| Total | - | 51/748.7 | $104,800 | $972 | - | - | - | - | | - | - |

1Plus 50,000 ITH shares and 25,000 Corvus shares

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 38 |

ITH, through its Talon Gold Nevada Inc. subsidiary (now called “Corvus Gold Nevada Inc.” and owned by Corvus (“CGN”), entered into a mining lease with option to purchase with the Greenspun Group for 183 acres of patented lode mining claims that cover much of the Mayflower prospect. The Mayflower lease requires Corvus to make payments and complete work programs as outlined in Table 4-3. During the term of the lease any production from the Mayflower property is subject to a sliding scale royalty, also outlined in Table 4-3. Corvus has the right to purchase a 100% interest in the Mayflower property for $7.5 million plus a 0.5% NSR (if gold is less than $500) or 1.0% (if gold is above $500) at any time during the term of the lease (subject to escalation for inflation if the option is exercised after the 10th year of the lease). The annual property taxes to be paid by Corvus for the Mayflower property are $214. On February 11, 2015, the Mayflower mining lease with option to purchase was amended with the addition of an anti-dilute clause applying to the ITH shares and with an increase in the annual payment to include 25,000 Corvus shares.

On February 21, 2013, Corvus signed a purchase agreement, which was subsequently closed on March 27, 2013, for the surface rights only to five patented lode mining claims owned by Mr. and Mrs. Gordon Millman and located east of the Mayflower deposit. This ground could be used for potential overburden storage at the Mayflower deposit as well as improving access to the Mayflower deposit in general. Corvus purchased the surface rights for $160,000. Additionally, Corvus agreed to pay the Millmans a fee of $0.02 per ton of any potential overburden storage subject to a minimum storage of 12 million short tons of material. The minimum storage fee of $240,000 bears interest at 4.2% per annum from the closing date and is due on December 31, 2015.

| 4.4 | OTHER PROPERTY CONSIDERATIONS |

All of the unpatented lode mining claims are on U.S. public land administered by the Bureau of Land Management (“BLM”). These claims give Corvus the right to explore for and mine mineral which include the metal gold and silver, subject to the necessary permits described in Section 20. The current exploration permits from BLM and NDEP allow Corvus surface access, maintenance of roads, drilling and sampling, and a defined amount of accompanying surface disturbance. The unpatented lode mining claims require payment of yearly maintenance fees to the BLM and Nye County (recording fees) of an aggregate of $147,953 (estimated for 2015). Annual property taxes to be paid by Corvus for some of the properties subject to the original six RGC leases and subsequent leases are tabulated in Table 4-1.

Current exploration activities are covered by a Plan of Operations (NVN-83002) with the BLM. Two Plans of Operation are in place with the Nevada Department of Environmental Protection (“NDEP”) (NDEP#0280 and #0290) that fulfill the State of Nevada permitting obligations on private and public lands, respectively. Reclamation bonds, related to environmental liabilities to which the NBP is subject, are in place to cover activities on the property. Corvus’s reclamation liabilities are covered by surety bonds issued by Lexon Insurance Company in the amount of $341,341 for 103 acres of disturbance on public land with the BLM and $209,070 for 20.3 acres of disturbance on private land with NDEP. Additional permits and bonding will be required for the expanded exploration program outlined in the Recommendation Section of this report.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 39 |

In December 2013, the Company completed the purchase of a 160 ha fee simple parcel of land 16 km north of the NBP which carries with it 1,600 acre feet of irrigation water rights within the Sarcobatus Flats water basin. Cost of the land was USD 1,000,000. The Company has registered the purchase of water rights with the Nevada State Engineer (“NSE”) and will make application to the NSE to move the production point to NBP, and change the application to mining. The water right requires annual renewal and has currently been extended through June 11, 2016.

None of the authors knows of any other significant factors and risks that may affect access or title to the NBP, or the right or ability to perform work on the Project.

Table 4-4 summarizes the unpatented lode mining claims on U.S. public land at the NBP.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 40 |

Table 4-2 Summary of Patented Claims in the Nine NBP Lease Agreements

| Lease | Claim Name | U.S. Bureau of Land Management Serial Number |

| Gregory | Jim Dandy | 448055 |

| Hall | Gold Basin | 330227 |

| Hall | Savage | 330227 |

| Hall | Savage 2 | 330227 |

| KoloCorp. | Black Jack | 163170 |

| Kolo Corp | ZuZu | 261838 |

| Kolo Corp | Sunflower | 369130 |

| Kolo Corp | Sunflower No.1 | 369130 |

| Kolo Corp | Sunflower No. 2 | 369130 |

| Milliken | Indiana 1 | 245488 |

| Milliken | Indiana 2 | 245488 |

| Milliken | Indiana 3 | 245488 |

| Pritchard | Banker's Life | 493623 |

| Pritchard | Bimettalic 1 | 46204 |

| Pritchard | Bimettalic 2 | 46204 |

| Pritchard | Bimettalic 3 | 46205 |

| Pritchard | Bluff | 493623 |

| Pritchard | Conservative | 611953 |

| Pritchard | KK1 | 504301 |

| Pritchard | Mutual | 493623 |

| Pritchard | Penn Mutual | 493623 |

| Pritchard | Prudential | 493623 |

| Pritchard | Sunrise 1 | 114544 |

| Pritchard | Sunrise 2 | 114544 |

| Lunar Landing LLC | Dewey Bailey | 269019 |

| Lunar Landing LLC | Four Aces | 269019 |

| Lunar Landing LLC | Parson Haskins | 269019 |

| Lunar Landing LLC | Bull Con | 269019 |

| Lunar Landing LLC | Ugly | 296019 |

| Lunar Landing LLC | Hardtack | 341527 |

| Lunar Landing LLC | Connection Mine | 342533 |

| Lunar Landing LLC | Equity | 342533 |

| Lunar Landing LLC | Geraldine 3 | 342533 |

| Lunar Landing LLC | Grey Eagle 2 | 342533 |

| Lunar Landing LLC | Grey Eagle 4 | 342533 |

| Lunar Landing LLC | Vinegarroan | 342533 |

| Lunar Landing LLC | Yellowrose | 369130 |

| Lunar Landing LLC | Yellowrose No. 1 | 369130 |

| Greenspun | Mayflower Lode Mining Claim | 2548 |

| Greenspun | Mayflower No. 1 Lode Mining Claim | 2548 |

| Greenspun | Mayflower No. 2 Lode Mining Claim | 2548 |

| Greenspun | Mayflower No. 3 Lode Mining Claim | 2548 |

| Greenspun | Moonlight Lode Mining Claim | 2640 |

| Greenspun | Moonlight No. 1 Lode Mining Claim | 2640 |

| Greenspun | Moonlight No. 2 Lode Mining Claim | 2640 |

| Greenspun | Starlight No. 4 Lode Mining Claim | 2640 |

| Greenspun | Starlight No. 5 Lode Mining Claim | 2640 |

| Greenspun | Starlight No. 6 Lode Mining Claim | 2640 |

| Greenspun | Starlight No. 7 Lode Mining Claim | 2640 |

| Sussman | Jolly Jane | 402672 |

| Sussman | Valley View | 402672 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 41 |

Table 4-3 Summary of the Terms for the Mayflower/Greenspun Group Lease

| Term: Five Years Beginning December 1, 2007 |

| Five additional years with an additional five year period, plus an additional 3 year period or so long thereafter as commercial production continues |

| Lease Payments: Due on Each Anniversary Date of the Lease |

On regulatory acceptance - US$5,000 and 25,000 ITH shares Each of first – fourth anniversaries, US$ 5,000 and 20,000 ITH shares Each of fifth – ninth anniversaries,US$10,000 ,50,000 ITH shares and 25,000 Corvus shares |

| Work Commitments: Excess Expenditures in Any Year Can Be Carried Forward, or if under Spent the Unspent Portion Paid to Greenspun Group |

Years 1-3 US$100,000 each year the lease is in effect Years 4-6 US$200,000 each year the lease is in effect Years 7-10 US$300,000 each year the lease is in effect |

| Retained Royalty: Production Sliding Scale Net Smelter Return Based on Price of Gold Each Quarter |

2% if gold is less than US$300 per ounce 3% if gold is between US$300 and US$500 per ounce 4% if gold is more than US$500 per ounce |

| Advance Minimum Royalty Payments (if not in commercial production by the tenth anniversary, in order to extend lease for an additional three years) |

| Years 11-13 US$100,000 each year the lease is in effect and commercial production has not been achieved |

| PurchaseOption: |

During first 10 years property can be purchased for US$ 7.5 million plus an 0.5% NSR (if gold is less than US$ 500) or 1.0% (if gold is above US$ 500) After the tenth anniversary the US$ 7.5 million purchase price escalates by the Consumer Price Index, using the CPI immediately prior to the tenth anniversary as a base |

Table 4-4 Summary of the Unpatented Lode Mining Claims on U.S. Public Land at the NBP

| Land Holder | Claim Name | US Bureau of Land Management Serial

Number |

| Corvus Gold Nevada Inc. | NB 1 – NB 149 | 922928 – 923076 |

| Corvus Gold Nevada Inc. | NB 150 | 943108 |

| Corvus Gold Nevada Inc. | NB-151A | 1078379 |

| Corvus Gold Nevada Inc. | NB 152 – NB 154 | 943110 - 943112 |

| Corvus Gold Nevada Inc. | NB-155A | 1078381 |

| Corvus Gold Nevada Inc. | NB 156 – NB 161 | 943114 - 943119 |

| Corvus Gold Nevada Inc. | NB 162 – NB 213 | 989863 – 989914 |

| Corvus Gold Nevada Inc. | NB 214 – NB 510 | 1069332 - 1069628 |

| Corvus Gold Nevada Inc. | NB 511 | 1078379 |

| Corvus Gold Nevada Inc. | NB 512 – NB 808 | 1085130 - 1085426 |

| Corvus Gold Nevada Inc. | NB 809 – NB865 | 1109343 – 1109399 |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 42 |

| 5 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY |

The NBP is accessible as a two and one half hour (209 km, 130 mile) drive north of Las Vegas Nevada along US Highway 95. US 95 is the major transportation route between Las Vegas, Reno Nevada and Boise Idaho. Las Vegas is serviced by a major international airport. The Project lies immediately to the west of the highway. Beatty, Nevada is the closest town to the Project with a population of about 1,100 and contains most basic services. Access around the Project is by a series of reasonably good gravel and dirt roads that extend to most of the important exploration areas.

The NBP is in Western Nevada’s high desert which receives about 15 cm of precipitation per year, mostly as modest snow fall in the winter and thunderstorms in the summer. The average daily temperature (F) varies from a low of 40.8° in January to a high of 80.8° in July. Due to the mild climate at the NBP the operating season is year round. Occasional thunderstorms may prohibit drilling for periods of an hour or so due to safety concerns about lightning strikes.

The hills at the Project are covered with sparse low brush including creosote, four-wing saltbush, rabbit brush and Nevada ephedra. The Project is in the Basin and Range province, but the local topographic relief is only a few hundred feet. The elevation of the Project ranges from 1,100m (3,600 feet) to 1,500m (4,800 feet). Most of the Project is characterized by low hills separated by modest width valleys (Figure 5-1).

As described in Section 4, Corvus maintains sufficient surface rights to support mining operations; including potential waste disposal areas, tailings storage areas, heap leach pads and potential mill sites. Claim blocks are contiguous, power is readily accessible and Corvus has secured access rights to water. The towns of Beatty, Pahrump and Tonopah support an ample population for mining personnel.

Figure 5-1 Mayflower Ridge Looking to the Northwest

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 43 |

The NBP is in the Bullfrog Mining District. Gold was discovered at what was to become the Original Bullfrog mine by Frank “Shorty” Harris and Ernest Cross on August 9, 1904 (Elliott, 1966). Two periods of mining activity account for the majority of production from the District. Lincoln (1923) reported 111,805 ounces of gold and 868,749 ounces of silver were produced between 1905 and 1921, after which there was little production until the 1980s. In early 1982 geologists from St. Joe America became interested in the District. They conducted extensive exploration in the area of the Montgomery-Shoshone and Senator Stewart mines, resulting in the discovery of the Bullfrog deposit in mid-1986. Several company acquisitions resulted in Barrick Gold Corporation being the final owner of the mine. The Bullfrog mine produced gold and silver from three separate deposits including: 1) main Bullfrog (open pit and underground); 2) Montgomery-Shoshone (open pit); and 3) Bonanza Mountain (open pit). Between 1989 and 1999, the Bullfrog mine produced 2.31 Moz of gold and 3.0 Moz of silver (NBMG MI-2000, page 34).

The early history of the NBP property is comingled with the greater Bullfrog Mining District. The Pioneer and Mayflower were the principal mines in the northern part of the district. The Pioneer mine was most active between 1909 and 1926 with about 15,000 feet of underground workings, all being developed within 330 feet of the surface. There are no accurate production figures, but limited records suggest that head grades were about one quarter ounce of gold per ton. The Mayflower mine was probably active during the same time, but again there are no reliable production records. Underground development at Sierra Blanca, Jolly Jane, Savage Valley, and Yellow Jacket also attest to historic mining and production, probably during the same period.

Modern exploration started in the early 1970s and, as outlined in Table 6-1, consisted of a number of companies with focuses on different parts of the Project. These programs consisted of a variety of activities including surface mapping and sampling, underground mapping and sampling, and drilling.

Table 6-1 Summary of Companies That Explored NBP.

| Company | Years of Activity | Principal Target |

| Cordex | 1974-1982 | Connection, Pioneer |

| US Borax | 1982 | Mayflower |

| Gexa/Galli | 1984-1991 | Pioneer, Connection |

| CR Exploration | 1984-1985 | Mayflower |

| Western States | 1987 | West Mayflower |

| Sunshine/Bond Gold JV | 1988-1994 | Sierra Blanca, Yellow Jacket |

| Pathfinder | 1991, 1992 | Pioneer |

| Barrick | 1995-1996 | Jolly Jane, Sierra Blanca, Mayflower |

Through the Barrick program approximately 249 rotary and reverse-circulation drill holes were drilled on the Project (see Section 10 for detailed description of these programs).

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 44 |

With the downturn in gold price at the start of the 21st Century interest in the Project was essentially nonexistent. RGC became attracted to the North Bullfrog area in late 2005, and started staking unpatented lode mining claims and acquiring leases on patented lode mining claims. In March 2007, RGC granted ITH the right to earn an interest in the NBP and thereafter form the NBPJV. In December 2007 ITH completed a lease of the Mayflower property, which was included in the NBPJV. Following the execution of the NBPJV option/joint venture agreement, ITH commenced active exploration on the NBP. In October 2008, RGC completed a lease of the Connection property, which was also included in the NBPJV. On August 4, 2009, ITH purchased RGC’s interests in the property and continued the exploration program as sole owner/lessor. On August 26, 2010 ITH spun out Corvus as a separate public company in a transaction which resulted in Corvus owning CGN, through which all interest in the NBP was held, thus resulting in Corvus indirectly acquiring all of the interest in and responsibilities for the NBP property.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 45 |

| 7 | GEOLOGICAL SETTING AND MINERALIZATION |

| 7.1 | REGIONAL GEOLOGICAL SETTING |

The NBP is within the Walker Lane structural province and the Southwestern Nevada Volcanic Field (“SWNVF”). The Project lies approximately ten kilometres west of the western margin of the middle Miocene Timber Mountain caldera complex, which is the source of the voluminous ash flow tuffs of the SWNVF. Many of the volcanic units exposed at the NBP originated from the caldera complex. However, some of the most important host rocks for the mineralization at NBP are apparently locally derived and are currently known as the North Bullfrog Hills Volcanic Complex (“NBHVC”). The NBHVC rocks are slightly older than the main ash flows erupted from the Timber Mountain Caldera.

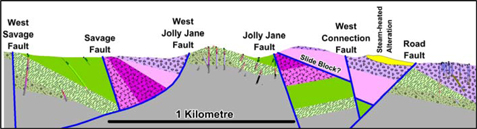

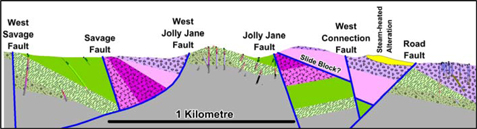

The region is underlain by Paleozoic sedimentary rocks, which form the basement for the mid-Miocene ash flow tuffs, lavas and lesser sedimentary rocks that comprise the SWNVF. The region was subjected to extensional faulting which was contemporaneous with SWNVF volcanism. As a result, fault-bounded sedimentary basins formed and filled with and basement debris, volcanic debris, and pyroclastic deposits. Multiple episodes of extension have been documented. Most of the major fault zones have northerly strikes with normal displacement down-to-the west. However, hanging wall antithetic faults are also present. Some of the major faults are interpreted to have listric shapes similar to the MP fault at the Bullfrog mine, and likely sole into a district-scale, low-angle detachment fault at depth. During younger periods of extension, many of the older faults in the hanging walls of these listric structures have experienced significant rotation and reactivation. The topography of the North Bullfrog District is a series of low rolling hills and ridges, separated by gravel filled valleys (see Section 5).

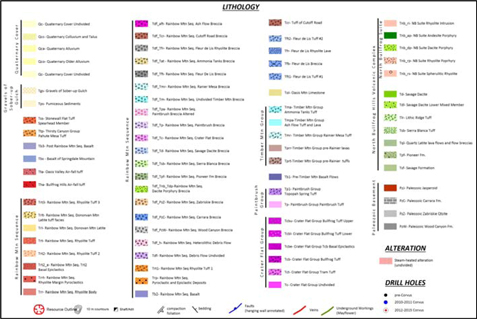

| 7.2.1.1 | LOCAL STRATIGRAPHY |

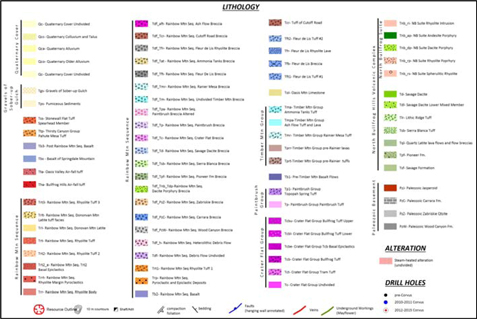

The stratigraphy of the Northern Bullfrog Hills (“NBH”) was most recently described by Connors et al. (1998) who mapped the area between 1989 and 1991. Based on the extensive drilling and geochronology studies conducted by Corvus, the local stratigraphy has been refined enough to warrant the identification of the NBHVC (Table 7-1).

As far as possible the terminology of Connors et al. (1998) has been preserved. New geochronology has shown that some units were incorrectly correlated and these have been given new names. The most significant examples are the Sierra Blanca Tuff and the Pioneer Formation, which were previously included in the Crater Flat Group. Brief descriptions of the Tertiary units which are present in the NBP area are given below.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 46 |

Table 7-1 Overview of the stratigraphy of the North Bullfrog Hills.

| Major Unit Name | Symbol | Formation | Lithodeme | Major Unit Description | |

| Quaternary Cover | Qc | | | Unconsolidated Quaternary alluvium, colluvium, talus, and mine dumps | |

| Gravels of Sober-up Gulch | Tgs | | | Semi-consolidated boulder gravels | |

| Pumiceous Sediments | Tps | | | Light colored tuffaceous sandstone and pebble conglomerate with pumice clasts | |

| Rainbow Mountain Sequence | Trl | Donovan Mountain Latite | | Latite and quartz latite | |

| lava flows and flow breccias | |

| Trt & Trr | Tuffs and Lavas of Rainbow Mountain | | Non-welded crystal-lithic rhyolite tuff and aphanitic flow-banded rhyolite flows and domes with minor sedimentary interbeds. | |

| Tdf | Rainbow Mountain Debris Flow Sequence | | A sequence of intercalated heterolithic and monolithic debris flow breccias derived from local volcanic and sedimentary units. Heterolithic sequences are bedded but poorly sorted, consisting of sand- to large boulder-size clasts of predominantly volcanic rocks. Monolithic breccias are interpreted as landslide megabreccia deposits that were shed off local fault scarps. | |

| Timber Mountain Group | Tma | Ammonia Tanks Tuff | North Bullfrog Suite: rhyolite and dacite dikes, sills and plugs as well as rhyolite domes of ambiguous origin | Single cooling unit of poorly to densely welded crystal-rich rhyolite ash-flow tuff. | |

| Tmr | Rainier Mesa Tuff | Single cooling unit of slightly to densely welded crystal-rich rhyolite ash flow tuff | |

| Tprr | Pre-Ranier Rhyolite | Flow-banded to massive rhyolite lava flows | |

| Tprt | Pre-Ranier Tuff | Rhyolitic surge and ash-flow deposits | |

| Paintbrush Group | Tp | Paintbrush Tuff | Aphanitic shard-rich, phenocryst-poor welded rhyolite tuff. Regionally subdivided into the Topopah Springs and Tiva Canyon Tuffs but these are not distinguished in the NBH | |

| Rater Flat Group | Tcb | Bullfrog Tuff | Variably welded crystal-lithic rhyolite tuffs. Possible equivalents of Tram and Bullfrog Members of the Crater Flat Group | |

| Tcb | Tram Tuff | |

| North Bullfrog Hills Volcanic Complex | Td | Savage Valley Dacite | Intercalated lava flows, breccias and pyroclastics of dacitic to andesitic composition. Probable stratigraphic correlation to Tr1g quartz latite unit in Southern Bullfrog Hills | |

| |

| Lower Member may be complex mixture of rhyolitic to andesitic lava flows, tuffs, domes, breccias and sedimentary rocks covering post-Sierra Blanca surface | |

| |

| North Bullfrog Hills Volcanic Complex | Tsb | Sierra Blanca Tuff | Large compound cooling unit of variably welded crystal-lithic rhyolite tuff. Probable equivalent of the Upper Tuff of Sawtooth Mountain. | |

| |

| Tpf | Pioneer Formation | Upper Mixed Epiclastic Member: zone may be heterogeneous zone with tuffs and welded tuffs mixed with poorly sorted silty, sandy, pebbly and cobbly sediments | |

| "Green tuff" of Sierra Blanca; rhyolitic tuffs; heterogeneous non-welded to semi-welded, lithic-poor to lithic-rich crystal tuff with scattered intervals of bedded tuff and epiclastics. Possible equivalent of the Lower Tuff of Sawtooth Mountain. | |

| |

| Tnb | | |

| Tsf | Savage Formation | Sequence of intercalated lava flows, intrusives and epiclastic debris of dacitic to rhyolitic composition. | |

| |

| Tjj | Jolly Jane Formation | Heterogeneous sedimentary sequence consisting of mudstone, siltstone, sandstone and conglomerate accumulated in localized structural basins. | |

| |

| Paleozoic Basement | PzC | Carrara Limestone | Micritic to and argillaceous carbonaceous limestone | |

| PzZ | Zabriskie Quartzite | Massive marine quartzite | |

| PzW | Wood Canyon Formation | Quartz-rich calcareous siltstone, sandstone, quartzite | |

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 47 |

7.2.1.1.1 PALEOZOIC BASEMENT

7.2.1.1.1.1 WOOD CANYON FORMATION – PZW

The Wood Canyon Formation is Lower Cambrian in age and made up of shale, siltstone and sandstone with occasional beds of finely laminated limestone. The minimum thickness is believed to be 350m (Connors, et al. (1998).

7.2.1.1.1.2 ZABRISKIE QUARTZITE – PZZ

The Zabriskie Quartzite is Lower Cambrian in age and generally consists of fine- to medium-grained ortho-quartzite with poorly preserved bedding. Its minimum thickness is believed to be around 370 meters (Connors, et al. (1998).

7.2.1.1.1.3 CARRARA FORMATION – PZC

The Carrara Formation is Middle to Lower Cambrian in age and is made up of thin to medium bedded limestone. The lower parts of the Formation contain argillaceous and siliciclastic interbeds. The minimum thickness is around 280 meters (Connors, et al. (1998)

7.2.1.1.2 NORTH BULLFROG HILLS VOLCANIC COMPLEX

The North Bullfrog Hills Volcanic Complex is a name that has been given to a sequence of locally derived lavas and pyroclastic rocks that were in-part previously incorrectly correlated with the Crater Flat Group by Connors, et al. (1998). The subdivisions identified here are based primarily on stratigraphic data obtained from drilling that has helped clarify both the stratigraphic sequence and distribution of different units.

7.2.1.1.2.1 JOLLY JANE FORMATION – TJJ

The Jolly Jane Formation is consists of a basal Tertairy conglomerate, overlain by a heterogeneous sequence of sedimentary rocks including mudstone, siltstone and sandstone. The basal conglomerate is a time transgressive unit which characteristically contains abundant clasts of pre-Tertiary basement rocks. It is the litho-stratigraphic equivalent, but probably not the time-stratigraphic equivalent, to the Titus Canyon Formation of Connors et al. (1998).

The type locality for this unit is known from drilling in the Jolly Jane area and consists of up to 50 metres of heterogeneous sediments, which appear to have accumulated in isolated structural basins prior to and during the onset of volcanism. Sandstone, siltstone, shale and calcareous volcaniclastic sediments are typically hematitic and may be locally carbonaceous. It is common to see tuffaceous sediments in the upper portions of the sand and shale sequences. The thickness and composition of the Jolly Jane Formation is highly variable. It is interpreted to have been deposited on a Tertiary erosional unconformity of significant relief.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 48 |

7.2.1.1.2.2 SAVAGE FORMATION – TSF

The Savage Formation consists of locally-sourced lava domes, flows, pyroclastics and associated intrusive rocks of dacitic to rhyolitic composition. The type locality for these rocks is the southern end of Savage Valley. The Savage Formation may also include intercalated epiclastic intervals of re-worked dacite and locally carbonaceous sediments. The unit overlies and intertongues with the Jolly Jane Formation. The thickness of the Savage Formation varies greatly from 0-100 metres, possibly reflecting both fault-bounded basins and the areal distribution of individual domes, flows and epiclastic intervals. Two distinct compositions can be identified on the basis of the Zr/Nb ratio. While these compositions have been recently mapped, no definitive patterns have yet been derived from their distribution. The Savage Formation is correlative to the lower portion of the Tr1 unit as described in the Southern Bullfrog Hills by Eng et.al. (1996). Tsf is locally mineralized in the Sierra Blanca and Jolly Jane areas.

7.2.1.1.2.3 NORTH BULLFROG DOMES AND INTRUSIVE –SUITE

The North Bullfrog Domes and Intrusive Suite (Tnb) consists of rhyolitic and dacitic bodies including plugs, domes, dikes and possibly sills that are recognized over much of the NBP. Tnb has been found in rocks ranging in age from the Paleozoic through the Pre-Timber Mountain Rhyolites. The Tnb unit has been separated into a lithodeme in order to deal with the ambiguity about the emplacement mechanism and relative age of many of these bodies (Table 7-1).

Plug or dome-like bodies of rhyolite and dacite are present at both the south end of Savage Valley and at Jolly Jane. In both cases, they are surrounded by pyroclastic rocks of the Savage or Pioneer Formations. Field relationships suggest that these bodies are intrusive into the pyroclastic Pioneer Formation, however, there does not appear to be a significant age difference between the two suites of rocks and for the most part they are geochemically indistinguishable (see Section 7.2.1.2).

There is one suite of rhyolite bodies that have no compositionally similar pyroclastic rocks. These rhyolites are relatively depleted in light rare earths such as cerium and lanthanum compared to the other rhyolites. They occur as intrusive plugs and flow-domes both above and below the Sierra Blanca Tuff. These rhyolites are important mineralization hosts particularly in the northern parts of Sierra Blanca where they frequently host higher-grade gold mineralization. Their genetic association with the mineralization events in the North Bullfrog District has yet to be determined.

7.2.1.1.2.4 PIONEER FORMATION – TPF

The Pioneer Formation consists of relatively monotonous lithic-lapilli tuffs which show marked variations in grain-size and clast composition ranging from coarse breccias to sandy facies. The type locality for this Formation is the prominent topographic high to the north of the Pioneer Mine. In the subsurface north of Sierra Blanca, the Pioneer Formation is mixed or interbedded with rhyolite bodies of a variety of textures which appear to be coeval with the pyroclastic deposits. Locally bedded epiclastic intervals have been observed throughout the unit. Near the upper contact of the unit, the lithic composition becomes quite heterogeneous with coarse epiclastic debris that creates the Upper Mixed Epiclastic Member, a semi-continuous marker horizon below base of the Sierra Blanca Tuff.

Corvus Gold Corp. Technical Report – North Bullfrog Project |  | Page | 49 |

The thickness of the Pioneer Formation varies from several hundred metres north of Sierra Blanca to just a few metres at the south end of Savage Valley. Divergence of compaction foliation directions between the Pioneer Formation and the Sierra Blanca Tuff at Sierra Blanca seems to indicate that tilting and erosion took place prior to the eruption of the Sierra Blanca Tuff. The Pioneer Formation is widely mineralized but is generally lower grade than the overlying Sierra Blanca Tuff.

7.2.1.1.2.5 SIERRA BLANCA TUFF – TSB

The Sierra Blanca Tuff is a large cooling unit of rhyolitic ash flow tuff that blankets the entire Project area with the type locality being Sierra Blanca. This unit varies in thickness from 70 metres at Jolly Jane to 170 metres at North Sierra Blanca. It is likely that the deposit was sourced outside of the North Bullfrog Hills and it may be the equivalent of the Upper Tuff of Sawtooth Mountain (see 7.2.1.2 Geochronology). No definitive study has been done to confirm that correlation.

The Sierra Blanca Tuff has a very distinct geochemical stratigraphy, but macroscopically is difficult to subdivide. There is a distinctive, shard and pumice-rich interval in the basal 10-20 metres which is referred to as the lower Pumice Marker (Tsb1). Above that the tuff is a relatively homogeneous densely welded crystal tuff with variably developed compaction foliation.

At Jolly Jane there appears to be an interval of Savage Valley Dacite within the middle of the Sierra Blanca Tuff. While the Sierra Blanca Tuff appears to be a single cooling unit, there may have been enough time during the regional-scale eruptive cycle for a simultaneous local dacitic eruption to have occurred. The result is a lense of Savage Valley Dacite within the Sierra Blanca Tuff.

The brittle nature of the densely welded middle Sierra Blanca tuff allowed for significant fracturing. The increased permeability from brittle fracturing likely played a significant role in focusing hydrothermal fluids through the Sierra Blanca Tuff making it one of the more important hosts for both disseminated and vein style mineralization.

7.2.1.1.2.6 SAVAGE VALLEY DACITE – TD

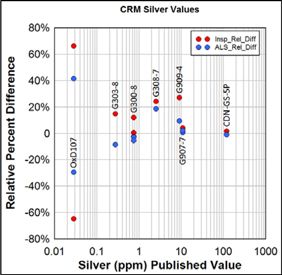

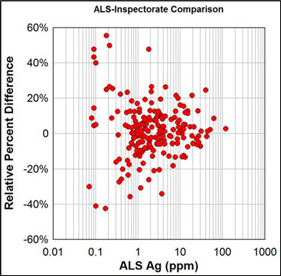

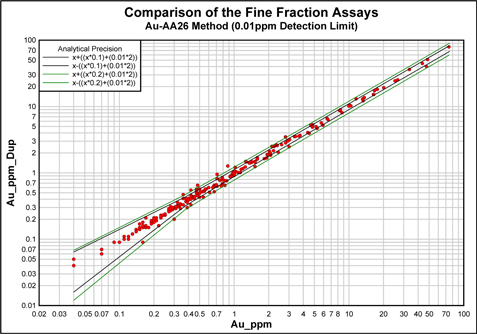

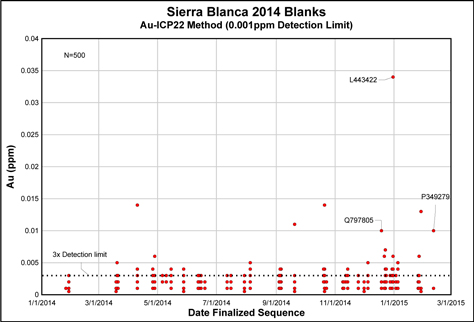

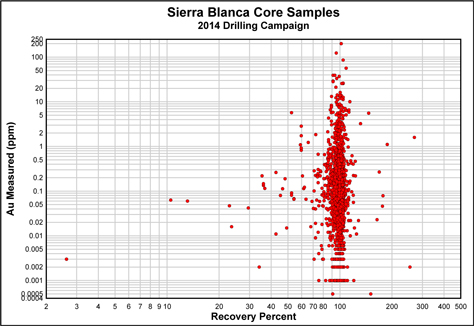

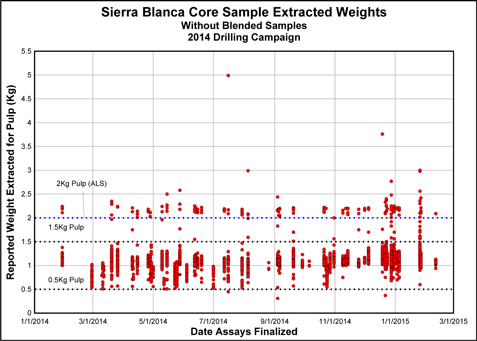

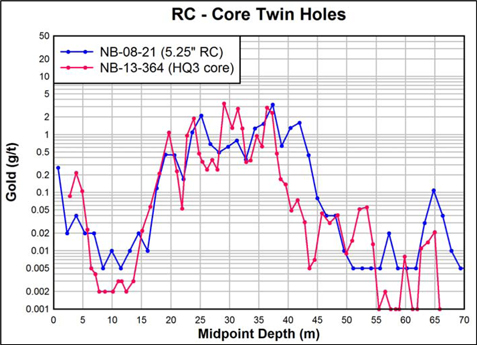

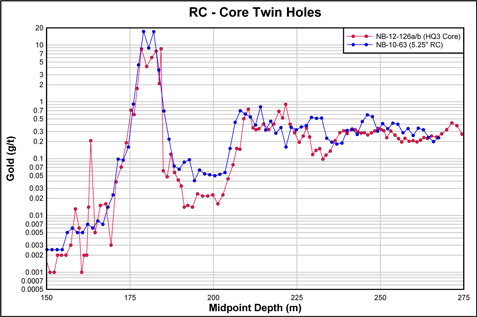

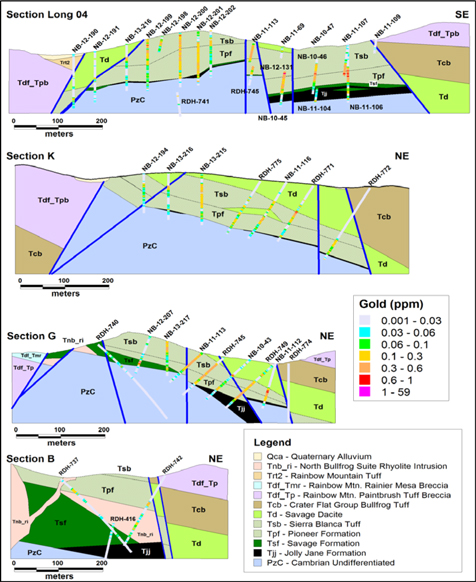

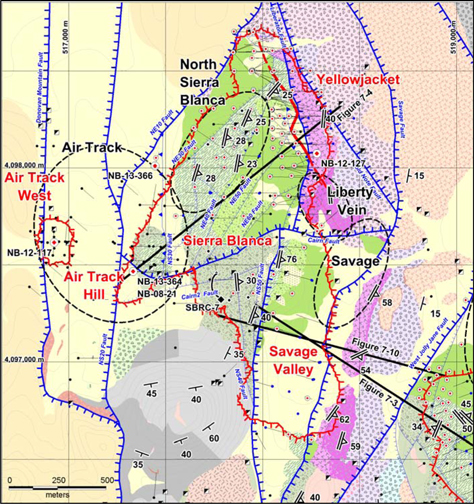

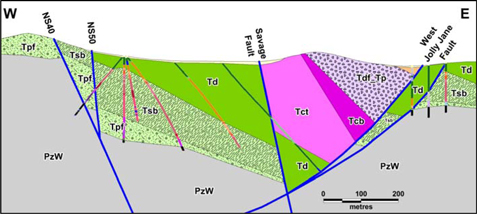

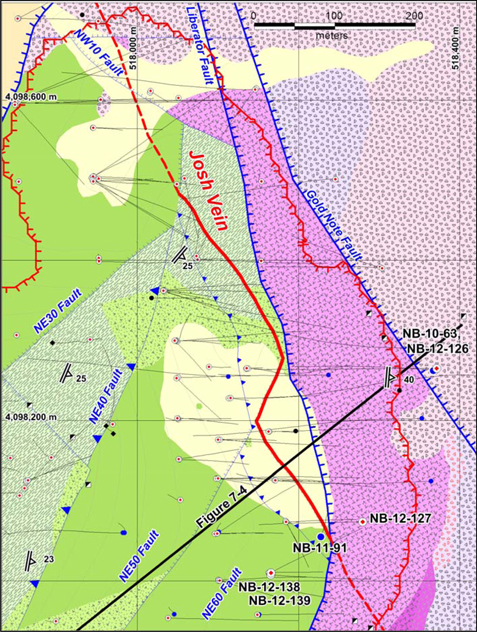

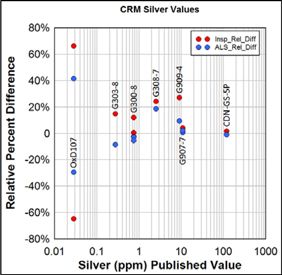

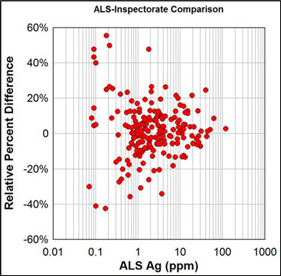

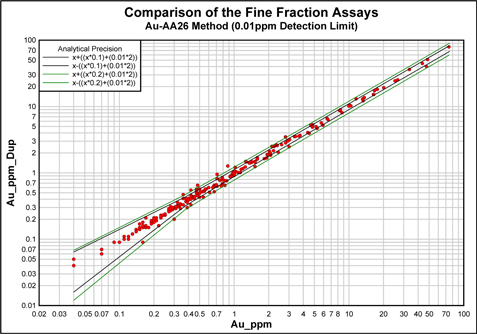

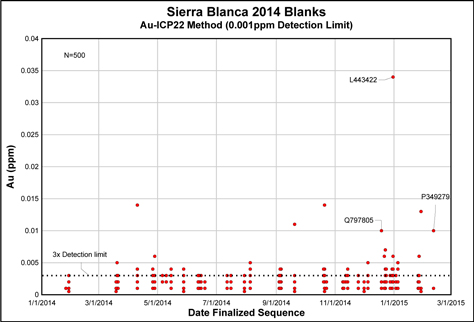

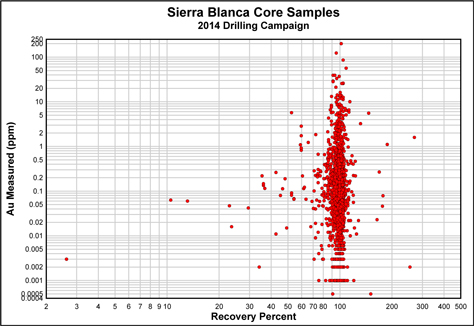

The Savage Valley Dacite represents another sequence of locally-sourced volcanics. At the base of the unit there is a rather heterogeneous and somewhat discontinuous sequence of rhyolitic flow domes, pyroclastics and epiclastics deposits, which grades upward into lavas and pyroclastics of dacitic composition. The upper part of the unit is dominated by relatively homogenous, typically magnetic lavas and lesser pyroclastic rocks of dacitic to andesitic composition.