As filed with the Securities and Exchange Commission on July 24, 2003

Registration No. 333-106916

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

AMENDMENT NO. 1

TO

FORM S-4

REGISTRATION STATEMENT

UNDER THE SECURITIES ACT OF 1933

The Premcor Refining Group Inc.

(Exact Name of Registrant as Specified in Its Charter)

| Delaware | | 2911 | | 43-1491230 |

(State or Other Jurisdiction of Incorporation or Organization) | | (Primary Standard Industrial Classification Code Number) | | (I.R.S. Employer Identification Number) |

Michael D. Gayda, Esq.

1700 East Putnam Avenue

Suite 400

Old Greenwich, Connecticut 06870

(203) 698-7500

(Name, Address, Including Zip Code, and Telephone Number, Including Area Code, of Agent For Service)

With a copy to:

Martin H. Neidell, Esq.

Stroock & Stroock & Lavan LLP

180 Maiden Lane

New York, New York 10038

(212) 806-5836

Facsimile: (212) 806-7836

Approximate date of commencement of proposed sale to the public: As soon as practicable after this Registration Statement becomes effective.

If the securities being registered on this form are being offered in connection with the formation of a holding company and there is compliance with General Instruction G, check the following box. ¨

If this form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, check the following box and list the Securities Act Registration number of the earlier effective Registration Statement for the same offering. ¨ _________

If this form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act Registration number of the earlier effective Registration Statement for the same offering. ¨ __________

The Registrant hereby amends this Registration Statement on such date or dates as may be necessary to delay its effective date until the Registrant shall file a further amendment which specifically states that this Registration Statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933, as amended, or until this Registration Statement shall become effective on such date as the Commission, acting pursuant to said Section 8(a), may determine.

The information in this prospectus is not complete and may be changed. We may not sell these securities until the registration statement filed with the Securities and Exchange Commission is effective. This prospectus is not an offer to sell securities and we are not soliciting offers to buy these securities in any state where the offer or sale is not permitted.

SUBJECT TO COMPLETION, DATED JULY 24, 2003

Prospectus

$300,000,000

The Premcor Refining Group Inc.

Offer to exchange all outstanding 7 1/2% Senior Notes due 2015 for 7 1/2% Senior Notes due 2015, which have been registered under the Securities Act of 1933.

| The Exchange Offer | | Broker Dealers |

| |

• We will exchange all outstanding notes that are validly tendered and not validly withdrawn for an equal principal amount of exchange notes that are freely tradeable. • You may withdraw tenders of outstanding notes at any time prior to the expiration of the exchange offer. • The exchange offer expires at 5:00 p.m., New

York City time, August 28, 2003, unless extended. We do not currently intend to extend the expiration date. The Exchange Notes • The terms of the exchange notes to be issued in the exchange offer are substantially identical to the outstanding notes, except that the exchange notes will be freely tradeable. | | • Each broker-dealer that receives exchange notes for its own account in the exchange offer must acknowledge that it will deliver a prospectus in connection with any resale of those exchange notes. The letter of transmittal states that, by so acknowledging and delivering a prospectus, a broker-dealer will not be deemed to admit that it is an “underwriter” within the meaning of the Securities Act. • This prospectus, as it may be amended or supplemented from time to time, may be used by a broker-dealer in connection with resales of exchange notes received in exchange for outstanding notes where the outstanding notes were acquired by the broker-dealer as a result of market-making activities or other trading activities. • We have agreed that, for a period of 90 days after the consummation of this exchange offer, we will make this prospectus available to any broker-dealer for use in connection with the resale of exchange notes. See “Plan of Distribution.” |

You should consider carefully the risk factors beginning on page 13 of this prospectus before participating in the exchange offer.

Neither the Securities and Exchange Commission nor any state securities commission has approved or disapproved of these securities or determined if this prospectus is truthful or complete. Any representation to the contrary is a criminal offense.

The date of this prospectus is , 2003.

WHERE YOU CAN FIND ADDITIONAL INFORMATION

We have filed with the Securities and Exchange Commission, or SEC, a registration statement on Form S-4 with respect to the exchange notes offered in this prospectus. This prospectus is a part of the registration statement and, as permitted by the SEC’s rules, does not contain all of the information presented in the registration statement. Whenever a reference is made in this prospectus to one of our contracts or other documents, please be aware that this reference is not necessarily complete and that you should refer to the exhibits that are a part of the registration statement for a copy of the contract or other document. You may review a copy of the registration statement, including exhibits to the registration statement, at the SEC’s public reference rooms referred to below. Please call the SEC at 1-800-SEC-0330 for further information on the operation of the public reference room. Our filings with the SEC are also available to the public through the SEC’s internet site athttp://www.sec.gov.

We are subject to the informational requirements of the Securities Exchange Act of 1934, and in accordance with the Exchange Act have filed annual, quarterly and current reports with the SEC. The Exchange Act file number for our SEC filings is 1-11392. You may read and copy any document we file at the following SEC public reference room:

| Judiciary Plaza |

| 450 Fifth Street, N.W. |

| Rm. 1200 |

| Washington D.C. 20549 |

You may request copies of the filings, at no cost, by telephone at (203) 698-7500 or by mail at: The Premcor Refining Group Inc., 1700 East Putnam Avenue, Suite 400, Old Greenwich, Connecticut 06870, Attention: Investor Relations.

In order to obtain timely delivery, you must request documents from us no later than August 22, 2003.

Our investor relations website iswww.premcor.com. We make available, free of charge, under “Investor Relations—SEC Filings,” via a link to a third-party website at www.corporate-ir.net, our annual reports on Form 10-K, our quarterly reports on Form 10-Q, our current reports on Form 8-K, Forms 3, 4 and 5 filed via Edgar by our directors and executive officers and various other SEC filings, including amendments to these reports, as soon as reasonably practicable after we electronically file or furnish such reports to the SEC. The information on our website, or on the site of our third-party service provider, is not incorporated by reference into this report.

We have agreed that, if we are subject to the informational requirements of Sections 13 or 15(d) of the Exchange Act, we will furnish to holders and beneficial owners of the notes and to prospective purchasers designated by such holders the information required to be delivered pursuant to Rule 144(A)(d)(4) under the Securities Act to permit compliance with Rule 144A in connection with resales of the notes.

i

TABLE OF CONTENTS

You should rely only on the information contained in this document or to which we have referred you. We have not authorized anyone to provide you with information that is different from that contained in this document. This document may be used only where it is legal to sell these securities. The information in this document may be accurate only on the date of this document.

ii

PROSPECTUS SUMMARY

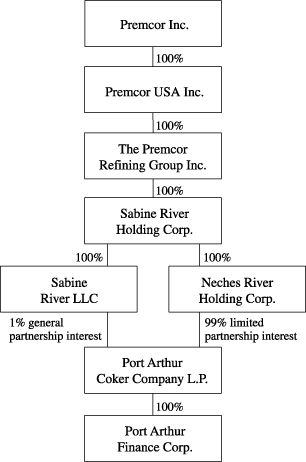

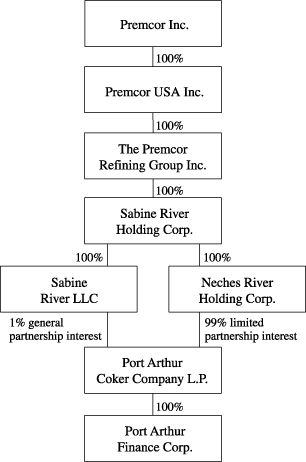

This summary may not contain all the information that may be important to you. You should read the entire prospectus, including the “Risk Factors” section and our financial statements and notes to those statements, before deciding whether to invest in the notes. As used in this prospectus, the terms “we,” “our,” or “us” refer to The Premcor Refining Group Inc. and its consolidated subsidiaries, including Sabine River Holding Corp., Sabine River LLC, Neches River Holding Corp., Port Arthur Coker Company L.P. and Port Arthur Finance Corp., taken as a whole, and its predecessors, unless the context otherwise indicates. Because of the technical nature of our industry, we have included a Glossary of Selected Terms that explains many of the terms we use in this prospectus.

The Premcor Refining Group Inc.

Overview

We are one of the largest independent petroleum refiners and suppliers of unbranded transportation fuels, heating oil, petrochemical feedstocks, petroleum coke and other petroleum products in the United States. We currently own and operate three refineries, which are located in Port Arthur, Texas; Memphis, Tennessee; and Lima, Ohio, with a combined crude oil volume processing capacity, known as throughput capacity, of approximately 610,000 barrels per day, or bpd. In late September 2002, we ceased refining operations at our Hartford, Illinois refinery. In the first quarter of 2003, we signed a memorandum of understanding with ConocoPhillips for a sale of refining assets and certain storage and distribution assets related to the Hartford refinery for $40 million. We sell petroleum products in the Midwest, the Gulf Coast, Eastern and Southeastern United States. We sell our products on an unbranded basis to approximately 1,200 distributors and chain retailers through our own product distribution system and an extensive third-party owned product distribution system, as well as in the spot market.

For the twelve months ended March 31, 2003, highly refined products, known as light products, such as transportation fuels, petrochemical feedstocks and heating oil, accounted for approximately 91% of our total product volume. For the same period, high-value, premium product grades, such as high octane and reformulated gasoline, low sulfur diesel and jet fuel, which are the most valuable types of light products, accounted for approximately 38% of our total product volume.

We source our crude oil on a global basis through a combination of long-term crude oil purchase contracts, short-term purchase contracts and spot market purchases. The long-term contracts provide us with a steady supply of crude oil, while the short-term contracts and spot market purchases give us flexibility in obtaining crude oil. Since all of our refineries have access, either directly or through pipeline connections, to deepwater terminals, we have the flexibility to purchase foreign crude oils via waterborne delivery or domestic crude oils via pipeline delivery. Our Port Arthur refinery, which possesses one of the world’s largest coking units, can process 80% heavy sour crude oil. Approximately 80% of the crude oil supply to our Port Arthur refinery is lower cost heavy sour crude oil from Mexico, called Maya.

Recent Developments

In May 2003, we announced plans to expand our Port Arthur refinery. The plans include increasing the refinery’s crude oil throughput capacity from its current rate of 250,000 bpd to approximately 325,000 bpd. In addition, the refinery’s coker unit, already one of the largest in the world, will be expanded from its current rated capacity of 80,000 bpd to 105,000 bpd, which will further increase our ability to process lower cost, heavy sour crude oil. The project, which is estimated to cost between $200 million and $220 million, is expected to be completed in the fourth quarter of 2005.

1

In June 2003, we completed a private placement offering of $300 million in senior notes, due 2015, bearing interest at 7.5% per annum. The proceeds from this offering will be used for capital expenditures, including the plans to expand our Port Arthur, Texas refinery, for acquisitions and for working capital and general corporate purposes.

The Transformation of Premcor Inc.

Beginning in early 1995 and continuing after Blackstone Capital Partners III Merchant Banking Fund L.P. and its affiliates, or Blackstone, acquired its controlling interest in Premcor Inc., our ultimate parent company, in 1997, we completed several strategic initiatives that have significantly enhanced our competitive position, the quality of our assets, and our financial and operating performance. For example:

| | • | | We divested non-core assets during 1998 and 1999, generating net proceeds of approximately $325 million, which we reinvested into our refining business. |

| | • | | We increased our crude oil throughput capacity from approximately 130,000 bpd to 610,000 bpd after closing two refineries, by acquiring our Port Arthur, Lima and Memphis refineries and subsequently upgrading our Port Arthur refinery. |

| | • | | We implemented capital projects to increase throughput and premium product yields and to reduce operating expenses within our refining asset base. These projects, together with our acquisitions, increased our coking capacity from 18,000 bpd to 113,000 bpd, increased our cracking capacity from 70,000 bpd to 246,000 bpd, and increased our capacity to process heavy sour crude oil from 45,000 bpd to 200,000 bpd. |

| | • | | We expanded and enhanced our capabilities to supply fuels, on an unbranded basis, to include the Midwest, Gulf Coast, eastern and southeastern United States. |

In February 2002, Premcor Inc. recruited Mr. Thomas D. O’Malley, a chief executive officer with a proven track record of successfully operating businesses and growing and enhancing shareholder value. Since then, Mr. O’Malley has assembled a management team of energy and refining industry veterans to lead Premcor Inc. and our competitive position has continued to improve as a result of the following:

| | • | | Premcor Inc. raised $481.7 million in an initial public offering of 20.7 million shares of common stock and a concurrent private placement of 850,000 shares of common stock in May 2002. |

| | • | | We completed an internal restructuring in June 2002, which resulted in Sabine River Holding Corp. becoming our wholly-owned subsidiary. |

| | • | | We ceased refining operations at our Hartford, Illinois refinery in late September 2002 after concluding it was uneconomical to reconfigure the refinery to meet new federally mandated fuel specification standards. |

| | • | | Premcor Inc. raised $305.9 million in a public offering of 13.1 million of its shares of common stock and a concurrent private placement of 2.9 million shares of common stock in January and February 2003. |

| | • | | We raised $825 million in two private offerings of senior notes in February 2003 and June 2003. |

| | • | | We completed the acquisition of a Memphis, Tennessee refinery and related supply and distribution assets from The Williams Companies, Inc. and certain of its subsidiaries in the beginning of March 2003. |

2

| | • | | We have taken, and are continuing to take, steps to reduce our cost structure. |

For further detail on our transformation, see “Business—The Transformation of Premcor Inc.”

Market Trends

Industry refining margins and crude oil differentials have declined in the second quarter of 2003 compared to the first quarter of 2003, and prices for natural gas, an important component of our refining cost structure, have increased. However, we believe that the longer term outlook for the United States refining industry is attractive due to certain significant trends that we have identified. We believe that:

| | • | | The supply and demand fundamentals for refined petroleum products have improved since the late 1990s and will continue to improve. |

| | • | | Increasing worldwide supplies of lower-cost sour and heavy sour crude oil will provide an increasing cost advantage to those refineries with complex configurations that are able to process these crude oils. |

| | • | | Products meeting new and evolving fuel specifications will account for an increasing share of total fuel demand, which will benefit refiners possessing the capabilities to blend and process these fuels. |

| | • | | The continuing consolidation in the refining industry will create attractive opportunities to acquire competitive refining capacity. |

See, however, “Risk Factors—Risks Related to our Business and our Industry—Volatile margins in the refining industry may negatively affect our future operating results and decrease our cash flow.”

For further detail on market trends, see “Business—Market Trends.”

Competitive Strengths

As a result of our transformation, we have developed the following strengths:

| | • | | As a “pure-play” refiner, which is a refiner without crude oil exploration and production or retail sales operations, we are free to supply our products to markets having the greatest profit potential and focus our management attention and capital solely on refining. |

| | • | | Our three refineries are logistically well-located modern facilities of significant size and scope with access to a wide variety of crude oils and product distribution systems. |

| | • | | Our Port Arthur, Texas refinery has significant heavy sour crude oil processing capacity, giving us a cost advantage over other refiners that are not able to process high volumes of these less expensive crude oils. |

| | • | | We have a long-term heavy sour crude oil supply agreement with an affiliate of Petroleos Mexicanos, or PEMEX, the Mexican state oil company, that provides a stable and secure supply of Maya crude oil. |

| | • | | We have an experienced and committed management team led by Mr. Thomas D. O’Malley, a refining industry veteran with a proven track record of growing businesses and shareholder value through acquisitions. |

For further detail on our competitive strengths, see “Business—Competitive Strengths.”

3

Business Strategies

Our goal is to be a premier independent refiner and supplier of unbranded petroleum products in the United States and to be an industry leader in growing shareholder value. We intend to accomplish this goal, grow our business, enhance earnings and improve our return on capital by executing the following strategies:

| | • | | We intend to grow through timely and cost-effective acquisitions and by undertaking discretionary capital projects to improve, upgrade and potentially expand our refineries. |

| | • | | We will continue to promote excellence in safety and reliability at our operations. |

| | • | | We intend to create an organization in which employees are highly motivated to enhance earnings and improve return on capital. |

For further detail on our business strategies, see “Business—Business Strategies.”

Risks Relating to Our Business

As part of your evaluation of our company, you should take into account the risks we face in our business and not solely our outlook for the refining industry, our competitive strengths and our business strategies. For example, our position as a “pure-play” refiner exposes us to volatility in refining industry margins; our long-term heavy sour crude oil supply agreement renders us highly dependent upon that supply, which could be interrupted by events beyond our control or that of the supplier; and our strategy of growing through acquisitions and by undertaking discretionary capital projects involves many factors beyond our control. See “Risk Factors” for a more detailed discussion of factors you should carefully consider before deciding to invest in the notes.

* * * *

Our principal executive offices are located at 1700 E. Putnam Avenue, Suite 400, Old Greenwich, CT 06870 and our telephone number is (203) 698-7500.

4

Summary of Terms of the Exchange Offer

References to “notes” in this prospectus are references to both the outstanding notes and the exchange notes.

In connection with the issuance of the notes, we entered into a registration rights agreement with the initial purchasers in which we agreed to deliver to you this prospectus and complete the exchange offer. If the exchange offer is not consummated within 270 days following June 10, 2003, then the per annum interest rate on the notes will increase. In the exchange offer, you are entitled to exchange your outstanding notes for exchange notes which are identical in all material respects to the outstanding notes except that:

| | • | | the exchange notes have been registered under the Securities Act, |

| | • | | the exchange notes are not entitled to all registration rights under the registration rights agreement, and |

| | • | | some of the contingent interest rate provisions of the registration rights agreement are no longer applicable. |

The Exchange Offer | | We are offering to exchange up to $300 million aggregate principal amount of exchange 7 1/2% senior notes due 2015 for up to $300 million aggregate principal amount of outstanding 7 1/2% senior notes due 2015. Outstanding notes may be exchanged only in integral multiples of $1,000. |

Resale | | Based on an interpretation by the staff of the SEC set forth in no-action letters issued to third parties, we believe that the exchange notes issued in the exchange offer in exchange for outstanding notes may be offered for resale, resold and otherwise transferred by you without compliance with the registration and prospectus delivery provisions of the Securities Act, provided that: |

| | | • you are acquiring the exchange notes in the ordinary course of your business; • you have not engaged in, do not intend to engage in, and have no arrangement or understanding with any person to participate in the distribution of exchange notes; and • you are not an “affiliate” of ours within the meaning of Rule 405 of the Securities Act. |

| | | Each participating broker-dealer that receives exchange notes for its own account during the exchange offer in exchange for shares of outstanding notes that were acquired as a result of market-making or other trading activity must acknowledge that it will deliver a prospectus in connection with any resale of the exchange notes. Prospectus delivery requirements are discussed in greater detail in the section captioned “Plan of Distribution.” |

5

| | | Any holder of outstanding notes who: |

| |

| | | • is an affiliate of ours, |

| |

| | | • does not acquire exchange notes in the ordinary course of its business, or |

| |

| | | • tenders in the exchange offer with the intention to participate, or for the purpose of participating, in a distribution of exchange notes, cannot rely on the position of the staff of the SEC enunciated in Exxon Capital Holdings Corporation, Morgan Stanley & Co. Incorporated or similar no-action letters and, in the absence of an exemption, must comply with the registration and prospectus delivery requirements of the Securities Act in connection with the resale of the exchange notes. |

| |

Expiration Date; Withdrawal of

Tenders | |

The expiration date of the exchange offer will be at 5:00 p.m., New York City time, on August 28, 2003, or such later date and time to which we extend it. A tender of outstanding notes in connection with the exchange offer may be withdrawn at any time prior to the expiration date. Any outstanding notes not accepted for exchange for any reason will be returned without expense to the tendering holder promptly after the expiration or termination of the exchange offer. |

| |

Conditions to the Exchange Offer | | The exchange offer is subject to customary conditions, which we may waive. Please read the section captioned “The Exchange Offer—Conditions to the Exchange Offer” of this prospectus for more information regarding the conditions to the exchange offer. |

| |

Procedures for Tendering Outstanding Notes | |

If you wish to accept the exchange offer, you must complete, sign and date the accompanying letter of transmittal, or a facsimile of the letter of transmittal, according to the instructions contained in this prospectus and the letter of transmittal. You must also mail or otherwise deliver the letter of transmittal, or a facsimile of the letter of transmittal, together with the outstanding notes and any other required documents to the exchange agent at the address set forth on the cover page of the letter of transmittal. If you hold outstanding notes through The Depository Trust Company, or DTC, and wish to participate in the exchange offer, you must comply with the Automated Tender Offer Program procedures of DTC, by which you will agree to be bound by the letter of transmittal. By signing, or agreeing to be bound by, the letter of transmittal, you will represent to us that, among other things: |

| |

| | | • any exchange notes that you receive will be acquired in the ordinary course of your business; |

| |

| | | • you have no arrangement or understanding with any person or entity to participate in the distribution of the exchange notes; |

| |

| | | • if you are a broker-dealer that will receive exchange notes for your own account in exchange for outstanding notes that were acquired as |

6

| | | a result of market-making activities, that you will deliver a prospectus, as required by law, in connection with any resale of the exchange notes; and |

| |

| | | • you are not an “affiliate,” as defined in Rule 405 of the Securities Act, of ours or, if you are an affiliate, you will comply with any applicable registration and prospectus delivery requirements of the Securities Act. |

| |

Special Procedures for Beneficial

Owners | |

If you are a beneficial owner of outstanding notes which are not registered in your name, and you wish to tender outstanding notes in the exchange offer, you should contact the registered holder promptly and instruct the registered holder to tender on your behalf. If you wish to tender on your own behalf, you must, prior to completing and executing the letter of transmittal and delivering your outstanding notes, either make appropriate arrangements to register ownership of the outstanding notes in your name or obtain a properly completed bond power from the registered holder. |

| |

Guaranteed Delivery Procedures | | If you wish to tender your outstanding notes and your outstanding notes are not immediately available or you cannot deliver your outstanding notes, the letter of transmittal or any other documents required by the letter of transmittal or comply with the applicable procedures under DTC’s Automated Tender Offer Program prior to the expiration date, you must tender your outstanding notes according to the guaranteed delivery procedures set forth in this prospectus under “The Exchange Offer—Guaranteed Delivery Procedures.” |

| |

Consequences of Failure to

Exchange | |

All untendered outstanding notes will continue to be subject to the restrictions on transfer provided for in the outstanding notes and in the indenture. In general, the outstanding notes may not be offered or sold, unless registered under the Securities Act, except in compliance with an exemption from, or in a transaction not subject to, the Securities Act and applicable state securities laws. Other than in connection with the exchange offer, we do not currently anticipate that we will register the outstanding notes under the Securities Act. |

| |

U.S. Federal Income Tax

Considerations | |

The exchange of outstanding notes for exchange notes in the exchange offer will not be a taxable event for U.S. federal income tax purposes. Please read the section of this prospectus captioned “U.S. Federal Income Tax Consequences of the Exchange Offer” for more information on tax consequences of the exchange offer. |

| |

Use of Proceeds | | We will not receive any cash proceeds from the issuance of exchange notes in the exchange offer. |

| |

Shelf Registration Statement | | Under certain circumstances, certain holders of outstanding notes (including holders who are not permitted to participate in the exchange offer or who may not freely resell registered notes received in the |

7

| |

| | | exchange offer) may, by giving us written notice, require us to file, and cause to become effective, a shelf registration statement under the Securities Act, which would cover resales of outstanding notes by these holders. See “Description of Notes—Registration Rights Agreement”. |

| |

Exchange Agent | | Deutsche Bank Trust Company Americas is the exchange agent for the exchange offer. The address and telephone number of the exchange agent are set forth in the section captioned “Exchange Offer—Exchange Agent” of this prospectus. |

8

Summary of Terms of the Exchange Notes

Issuer | The Premcor Refining Group Inc. |

Securities Offered | $300 million in principal amount of 7 1/2% senior notes due 2015. As of the date of this prospectus, $300 million aggregate principal amount of the notes are outstanding. |

Maturity Date | June 15, 2015. |

Interest Payment Dates | June 15 and December 15 of each year, beginning December 15, 2003. |

Optional Redemption | We may redeem any of the notes beginning on June 15, 2008. The redemption price for the notes will decline each year after June 15, 2008 and will be 100% of their principal amount, plus accrued interest, beginning on June 15, 2011. See “Description of Notes—Optional Redemption.” |

| | In addition, until June 15, 2006, we may redeem up to 35% of the aggregate principal amount of the notes with the net proceeds of certain public offerings of common stock by us, Premcor USA Inc., our direct parent, or Premcor Inc. at a redemption price equal to 107.500% of the principal amount, plus accrued and unpaid interest, of the notes being redeemed. We may make such redemption only if, after any such redemption, at least 65% of the aggregate principal amount of notes originally issued remains outstanding. |

Change of Control | Upon a change of control that results in a rating decline with respect to the notes (as defined under “Description of Notes”), we will be required to make an offer to purchase the notes at a purchase price of 101% of the principal amount of the notes on the date of purchase plus accrued interest. We may not have sufficient funds available at that time to make any required debt repayment (including purchases of the notes), and certain provisions of our other debt agreements (including our credit agreement) may further limit our ability to make these purchases. |

Ranking | The notes are our senior unsecured obligations. They rank equal in right of payment with any of our existing and future senior unsecured indebtedness and other liabilities and senior in right of payment to any of our future subordinated indebtedness. Because the notes are unsecured, obligations under our credit agreement effectively rank senior to the senior notes offered hereby. The notes are structurally subordinated to all indebtedness and other liabilities of our subsidiaries. We and our subsidiaries may incur additional debt, subject to the limits of the indenture, and our subsidiaries may incur other liabilities without limit by the indenture. |

9

Certain Covenants Before an Investment Grade Rating Event | The terms of the notes restrict our ability and the ability of certain of our subsidiaries (as described in “Description of Notes”) to: |

| | • | | incur or guarantee additional indebtedness; |

| | • | | pay dividends on and redeem capital stock; |

| | • | | sell assets and capital stock; |

| | • | | enter into transactions with affiliates; |

| | • | | engage in mergers and consolidations; and |

| | • | | transfer substantially all of our assets to another person. |

| | However, these limitations are subject to a number of important qualifications and exceptions. |

Certain Covenants After an Investment Grade Rating Event | After an investment grade rating event (as defined under “Description of Notes”), certain of the covenants described in the preceding paragraph will cease to exist or will be modified. The terms of the notes will then restrict our ability and the ability of certain of our subsidiaries to: |

| | • | | create liens with respect to certain assets; |

| | • | | enter into sale-leaseback transactions; and |

| | • | | engage in certain mergers and consolidations. |

Registration Rights | Upon consummation of the exchange offer, holders of notes will no longer have any rights under the registration rights agreement, except to the extent that we have continuing obligations to file a shelf registration statement. |

10

Summary Financial Information

The following table presents summary financial and other data about us. The summary statement of earnings and cash flow data for the years ended December 31, 2000, 2001 and 2002 are derived from our audited consolidated financial statements, including the notes thereto, appearing elsewhere in this prospectus. The summary statement of earnings and cash flow data set forth below for the three months ended March 31, 2002 and 2003 and the balance sheet data as of March 31, 2003 are derived from our unaudited condensed consolidated financial statements, including the notes thereto, appearing elsewhere in this prospectus. The interim information was prepared on a basis consistent with that used in preparing our audited financial statements with only such recurring adjustments as are necessary, in management’s opinion, for a fair statement of the results for the periods presented. The as adjusted balance sheet data give effect to the private offering of the notes and the use of proceeds as if it had occurred on March 31, 2003. The historical earnings, cash flow and balance sheet data referred to above have been restated to give retroactive effect to the contribution by Premcor Inc. of the common stock of Sabine River Holding Corp. to us. This table should be read in conjunction with “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and our financial statements, including the notes thereto, appearing elsewhere in this prospectus. We have provided selected operating and other data under the heading “Key operating statistics”.

| | | Year Ended December 31,

| | | Three Months Ended March 31,

| |

| | | 2000

| | | 2001

| | | 2002

| | | 2002

| | | 2003

| |

| | | | | | (unaudited) | |

| | | (in millions, except as noted) | |

Statements of operations data: | | | | | | | | | | | | | | | | | | | | |

Net sales and operating revenues | | $ | 7,301.7 | | | $ | 6,417.5 | | | $ | 6,772.6 | | | $ | 1,228.3 | | | $ | 2,375.8 | |

Cost of sales | | | 6,564.1 | | | | 5,253.2 | | | | 6,106.0 | | | | 1,062.0 | | | | 2,109.6 | |

| | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

Gross margin | | | 737.6 | | | | 1,164.3 | | | | 666.6 | | | | 166.3 | | | | 266.2 | |

Operating expenses (1) | | | 466.7 | | | | 466.9 | | | | 431.5 | | | | 114.4 | | | | 116.7 | |

General and administrative expenses (1) | | | 52.7 | | | | 63.1 | | | | 51.5 | | | | 14.4 | | | | 11.7 | |

Stock-based compensation | | | — | | | | — | | | | 14.0 | | | | 1.9 | | | | 4.3 | |

Depreciation and amortization (2) | | | 71.7 | | | | 91.9 | | | | 88.9 | | | | 22.2 | | | | 24.0 | |

Refinery restructuring and other charges | | | — | | | | 176.2 | | | | 168.7 | | | | 142.0 | | | | 15.0 | |

| | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

Operating income (loss) | | $ | 146.5 | | | $ | 366.2 | | | $ | (88.0 | ) | | $ | (128.6 | ) | | $ | 94.5 | |

| | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

Net income (loss) | | $ | 83.8 | | | $ | 140.9 | | | $ | (114.4 | ) | | $ | (95.5 | ) | | $ | 38.8 | |

| | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

Cash flow and other data: | | | | | | | | | | | | | | | | | | | | |

Cash flow from operating activities | | $ | 141.4 | | | $ | 440.0 | | | $ | 30.9 | | | $ | 11.2 | | | $ | 117.4 | |

Cash flow from investing activities | | | (375.3 | ) | | | (153.4 | ) | | | (141.3 | ) | | | (39.1 | ) | | | (503.0 | ) |

Cash flow from financing activities | | | 200.1 | | | | (55.3 | ) | | | (252.4 | ) | | | (94.6 | ) | | | 521.7 | |

EBITDA (3) | | | 218.2 | | | | 458.1 | | | | 0.9 | | | | (106.4 | ) | | | 118.5 | |

Interest expense and finance income, net (4) | | | (64.3 | ) | | | (122.3 | ) | | | (92.1 | ) | | | (28.3 | ) | | | (25.1 | ) |

Capital expenditures for property, plant and equipment | | | 390.7 | | | | 94.5 | | | | 114.3 | | | | 14.8 | | | | 22.0 | |

Capital expenditures for turnaround | | | 31.5 | | | | 49.2 | | | | 34.3 | | | | 27.5 | | | | 8.8 | |

Refinery acquisition expenditures | | | — | | | | — | | | | — | | | | — | | | | 474.8 | |

Key operating statistics: | | | | | | | | | | | | | | | | | | | | |

Production (000 barrels per day) | | | 477.3 | | | | 463.4 | | | | 438.2 | | | | 444.2 | | | | 455.3 | |

Crude oil throughput (000 barrels per day) | | | 468.0 | | | | 439.7 | | | | 412.8 | | | | 434.2 | | | | 430.1 | |

Total crude oil throughput (in millions of barrels) | | | 171.3 | | | | 160.5 | | | | 150.7 | | | | 39.1 | | | | 38.7 | |

Per barrel of crude oil throughput ($ per barrel) | | | | | | | | | | | | | | | | | | | | |

Gross margin | | $ | 4.31 | | | $ | 7.25 | | | $ | 4.42 | | | $ | 4.25 | | | $ | 6.88 | |

Operating expenses | | | 2.72 | | | | 2.91 | | | | 2.86 | | | | 2.93 | | | | 3.02 | |

| | | As of March 31, 2003

|

| | | Actual

| | As Adjusted

|

| | | (unaudited) |

| | | (in millions) |

Balance sheet data: | | | | | | |

Cash, cash equivalents and short-term investments (5) | | $ | 311.3 | | $ | 606.3 |

Working capital | | | 530.5 | | | 825.5 |

Total assets | | | 3,129.3 | | | 3,429.3 |

Total debt | | | 1,165.2 | | | 1,465.2 |

Stockholder’s equity | | | 931.9 | | | 931.9 |

11

| (1) | | Certain reclassifications have been made to our prior period amounts to conform them to current period presentation. |

| (2) | | Amortization includes amortization of turnaround costs. However, this may not be permitted under generally accepted accounting principles, or GAAP, in future periods. |

| (3) | | EBITDA is earnings before interest, taxes, depreciation and amortization. EBITDA is a commonly used non-GAAP financial measure but should not be construed as an alternative to operating income or net income as an indicator of our performance, or as an alternative to cash flow from operating activities, investing activities or financing activities as a measure of liquidity, in each case as such measures are determined in accordance with GAAP. EBITDA is presented because we believe that it is a useful indicator of a company’s ability to incur and service debt. EBITDA, as we calculate it, may not be comparable to similarly-titled measures reported by other companies. Our calculations are as follows: |

| | | Year Ended December 31,

| | | Three Months

Ended March 31,

|

| | | 2000

| | 2001

| | 2002

| | | 2002

| | | 2003

|

| | | (in millions, unaudited) |

Operating income (loss) | | $ | 146.5 | | $ | 366.2 | | $ | (88.0 | ) | | $ | (128.6 | ) | | $ | 94.5 |

Depreciation and amortization | | | 71.7 | | | 91.9 | | | 88.9 | | | | 22.2 | | | | 24.0 |

| | |

|

| |

|

| |

|

|

| |

|

|

| |

|

|

EBITDA | | $ | 218.2 | | $ | 458.1 | | $ | 0.9 | | | $ | (106.4 | ) | | $ | 118.5 |

| | |

|

| |

|

| |

|

|

| |

|

|

| |

|

|

| (4) | | Interest expense and finance income, net, includes amortization of debt issuance costs of $11.8 million, $14.3 million, $12.1 million, $3.5 million and $2.4 million for the years ended December 31, 2000, 2001, and 2002, and for the three months ended March 31, 2002 and 2003, respectively. Interest expense and finance income, net, also includes interest on all indebtedness, net of capitalized interest and interest income. |

| (5) | | Cash, cash equivalents and short-term investments includes $53.8 million of cash and cash equivalents restricted for debt service as of March 31, 2003. |

12

RISK FACTORS

An investment in our notes involves risk. You should consider carefully, in addition to the other information contained in this prospectus, the following risk factors before deciding to invest in the notes.

Risks Related to our Business and our Industry

Volatile margins in the refining industry may negatively affect our future operating results and decrease our cash flow.

Our financial results are primarily affected by the relationship, or margin, between refined product prices and the prices for crude oil and other feedstocks. The cost to acquire our feedstocks and the price at which we can ultimately sell refined products depend upon a variety of factors beyond our control. Historically, refining margins have been volatile, and they are likely to continue to be volatile in the future. Future volatility may negatively affect our results of operations, since the margin between refined product prices and feedstock prices may decrease below the amount needed for us to generate net cash flow sufficient for our needs.

Specific factors, in no particular order, that may affect our refining margins include:

| | • | | accidents, interruptions in transportation, inclement weather or other events that cause unscheduled shutdowns or otherwise adversely affect our plants, machinery, pipelines or equipment, or those of our suppliers or customers; |

| | • | | changes in the cost or availability to us of transportation for feedstocks and refined products; |

| | • | | failure to successfully implement our planned capital projects or to realize the benefits expected for those projects; |

| | • | | changes in fuel specifications required by environmental and other laws, particularly with respect to oxygenates and sulfur content; |

| | • | | rulings, judgments or settlements in litigation or other legal matters, including unexpected environmental remediation or compliance costs at our facilities in excess of any reserves, and claims of product liability or personal injury; and |

| | • | | aggregate refinery capacity in our industry to convert heavy sour crude oil into refined products. |

Other factors that may affect our margins, as well as the margins in our industry in general, include, in no particular order:

| | • | | domestic and worldwide refinery overcapacity or undercapacity; |

| | • | | aggregate demand for crude oil and refined products, which is influenced by factors such as weather patterns, including seasonal fluctuations, and demand for specific products such as jet fuel, which may themselves be influenced by acts of God, nature and acts of terrorism; |

| | • | | domestic and foreign supplies of crude oil and other feedstocks and domestic supply of refined products, including from imports; |

| | • | | price fluctuations between the time we enter into domestic crude oil purchase commitments and the time we actually process the crude oil into refined products (approximately one month) and the effect of any related hedging transactions; |

| | • | | the ability of the members of the Organization of Petroleum Exporting Countries, or OPEC, to maintain oil price and production controls; |

| | • | | political conditions in oil producing regions, including the Middle East, Africa and Latin America; |

| | • | | refining industry utilization rates; |

| | • | | pricing and other actions taken by competitors that impact the market; |

| | • | | price, availability and acceptance of alternative fuels; |

13

| | • | | adoption of or modifications to federal, state or foreign environmental, taxation and other laws and regulations; |

| | • | | price fluctuations in natural gas, as our refineries purchase and consume significant amounts of natural gas to fuel their operations; and |

| | • | | general economic conditions. |

A significant interruption or casualty loss at any of our refineries could reduce our production, particularly if not fully covered by our insurance.

Our business currently consists of owning and operating three refineries. As a result, our operations could be subject to significant interruption if any of our refineries were to experience a major accident, be damaged by severe weather or other natural disaster, or otherwise be forced to shut down or curtail production due to unforeseen events, such as acts of God, nature and acts of terrorism. Any such shutdown would reduce the production from that refinery. For example, our Port Arthur refinery is located in the Gulf Coast region of the United States, which is susceptible to seasonal hurricanes and other weather related problems. There is also risk of mechanical failure and equipment shutdowns both in general and following unforeseen events. Further, in such situations, undamaged refinery processing units may be dependent on or interact with damaged sections of our refineries and, accordingly, are also subject to being shut down. In the event any of our refineries is forced to shut down for a significant period of time, it would have a material adverse effect on our earnings, our other results of operations and our financial condition as a whole. Furthermore, if any of the above events were not fully covered by our insurance, it could have a material adverse effect on our earnings, our other results of operations and our financial condition.

Disruption of our ability to obtain crude oil could reduce our margins and our other results of operations.

Although we have one long-term crude oil supply contract, the majority of our crude oil supply is acquired under short-term contractual arrangements or in the spot market. Our short-term crude oil supply contracts are terminable on one to three months’ notice. Further, a significant portion of our feedstock requirements is supplied from Latin America, Africa and the Middle East (including Iraq), and we are subject to the political, geographic and economic risks attendant to doing business with suppliers located in those regions. For example, on April 8, 2002 Iraq announced that it was halting all oil exports for a 30-day period. In the event that one or more of our supply contracts is terminated, we may not be able to find alternative sources of supply. If we are unable to obtain adequate crude oil volumes or are only able to obtain such volumes at unfavorable prices, our margins and our other results of operations could be materially adversely affected.

Our Port Arthur refinery is highly dependent upon a PEMEX affiliate for its supply of heavy sour crude oil, which could be interrupted by events beyond the control of PEMEX.

During 2002, we sourced approximately 83% of our Port Arthur refinery’s crude oil from P.M.I. Comercio Internacional, S.A. de C.V., or PMI, an affiliate of PEMEX. Therefore, a large proportion of our crude oil needs is influenced by the adequacy of PEMEX’s crude oil reserves, the estimates of which are not precise and are subject to revision at any time. In addition, in connection with our recently announced plans to expand our Port Arthur refinery, we will require additional heavy sour crude oil. We intend to seek an increase in our heavy sour crude oil supply agreement with the PEMEX affiliate and/or alternative supply sources to provide for our incremental requirements. There are no assurances that the PEMEX affiliate will agree to an increase in our crude oil supply agreement or that alternative sources can be obtained at terms as favorable as those negotiated with PEMEX’s affiliate. In the event that PEMEX’s affiliate were to terminate our crude oil supply agreement or default on its supply obligations, we would need to obtain heavy sour crude oil from another supplier and would lose the potential benefits of the coker gross margin support mechanism contained in the supply agreement. Alternative supplies of crude oil may not be available or may not be on terms as favorable as those negotiated

14

with PEMEX’s affiliate. In addition, the processing of oil supplied by a third party may require changes to the configuration of our Port Arthur refinery, which could require significant unbudgeted capital expenditures.

Furthermore, the obligation of PEMEX’s affiliate to deliver heavy sour crude oil under the agreement may be delayed or excused by the occurrence of conditions and events beyond the reasonable control of PEMEX, such as:

| | • | | extreme weather-related conditions; |

| | • | | production or operational difficulties and blockades; |

| | • | | embargoes or interruptions, declines or shortages of supply available for export from Mexico, including shortages due to increased domestic demand and other national or international political events; and |

| | • | | certain laws, changes in laws, decrees, directives or actions of the government of Mexico. |

The government of Mexico may direct a reduction in our supply of crude oil, so long as that action is taken in common with proportionately equal supply reductions under its long-term crude oil supply agreements with other parties and the amount by which it reduces the quantity of crude oil to be sold to us shall first be applied to reduce quantities of crude oil scheduled for sale and delivery to our Port Arthur refinery under any other crude oil supply agreement with us or any of our affiliates. Mexico is not a member of OPEC, but in 1998 it agreed with the governments of Saudi Arabia and Venezuela to reduce Mexico’s exports of crude oil by 200,000 bpd. In March 1999, Mexico further agreed to cut exports of crude oil by an additional 125,000 bpd. As a consequence, during 1999, PEMEX reduced its supply of oil under some oil supply contracts by invoking an excuse clause based on governmental action similar to one contained in our long-term crude oil supply agreement. It is possible that PEMEX could reduce our supply of crude oil by similarly invoking the excuse provisions in the future.

Competitors who produce their own supply of feedstocks, have extensive retail outlets, make alternative fuels or have greater financial resources than we do may have a competitive advantage over us.

The refining industry is highly competitive with respect to both feedstock supply and refined product markets. We compete with numerous other companies for available supplies of crude oil and other feedstocks and for outlets for our refined products. We are not engaged in the petroleum exploration and production business and therefore do not produce any of our crude oil feedstocks. We do not have a retail business and therefore are dependent upon others for outlets for our refined products. We do not have any long term arrangements for much of our production, and our contracts to supply jet fuel to Federal Express in Memphis will expire in 2004. Many of our competitors, however, obtain a significant portion of their feedstocks from company-owned production and have extensive retail outlets. Competitors that have their own production or extensive retail outlets, with brand-name recognition, are at times able to offset losses from refining operations with profits from producing or retailing operations, and may be better positioned to withstand periods of depressed refining margins or feedstock shortages. A number of our competitors also have materially greater financial and other resources than we possess. These competitors have a greater ability to bear the economic risks inherent in all phases of the refining industry. In addition, we compete with other industries that provide alternative means to satisfy the energy and fuel requirements of our industrial, commercial and individual consumers. If we are unable to compete effectively with these competitors, both within and outside of our industry, our financial condition and results of operations, as well as our business prospects, could be materially adversely affected.

Our substantial indebtedness may limit our financial flexibility.

Our substantial indebtedness has significantly affected our financial flexibility historically and may significantly affect our financial flexibility in the future. As of March 31, 2003, after giving effect to the

15

June 2003 private notes offering, we would have had total consolidated long-term debt, including current maturities, of $1,465.2 million, cash, short-term investments and cash restricted for debt service of $606.3 million, and stockholder’s equity of $931.9 million, resulting in a total debt to total capitalization ratio of 61.1%. We may also incur additional indebtedness in the future, although our ability to do so will be restricted by the terms of our existing indebtedness. The indenture governing the notes will permit us to incur significant additional indebtedness. We are continually evaluating all available refinery acquisitions, some of which may be significant. Any significant acquisition would require us to incur additional indebtedness in order to finance all or a portion of such acquisition. The level of our indebtedness has several important consequences for our future operations, including that:

| | • | | a significant portion of our cash flow from operations will be dedicated to the payment of principal of, and interest on, our indebtedness and will not be available for other purposes; |

| | • | | covenants contained in our existing debt arrangements require us to meet or maintain certain financial tests, which may affect our flexibility in planning for, and reacting to, changes in our industry, such as being able to take advantage of acquisition opportunities when they arise; |

| | • | | our ability to obtain additional financing for working capital, capital expenditures, acquisitions, general corporate and other purposes may be limited; |

| | • | | we may be at a competitive disadvantage to those of our competitors that are less leveraged; and |

| | • | | we may be more vulnerable to adverse economic and industry conditions. |

We have significant principal payments due under our debt instruments. As of March 31, 2003, after giving effect to the June 2003 private notes offering, we are required to make the following principal payments on our long-term debt: $10.4 million in 2003; $25.8 million in 2004; $38.5 million in 2005; $46.4 million in 2006; $318.4 million in 2007; and $1,026.8 million in the aggregate thereafter. Our ability to meet our principal obligations will be dependent upon our future performance, which in turn will be subject to general economic conditions, industry cycles and financial, business and other factors affecting our operations, many of which are beyond our control. Our business may not continue to generate sufficient cash flow from operations to repay our substantial indebtedness. If we are unable to generate sufficient cash flow from operations, we may be required to sell assets, to refinance all or a portion of our indebtedness or to obtain additional financing. Refinancing may not be possible and additional financing may not be available on commercially acceptable terms, or at all.

Restrictive covenants in our debt instruments limit our ability to move funds and assets among our subsidiaries and may limit our ability to undertake certain types of transactions.

Various covenants in our and our subsidiaries’ debt instruments and other financing arrangements may restrict our and our subsidiaries’ financial flexibility in a number of ways. Our indebtedness subjects us to significant financial and other restrictive covenants, including restrictions on our ability to incur additional indebtedness, place liens upon assets, pay dividends or make certain other restricted payments and investments, consummate certain asset sales or asset swaps, enter into certain transactions with affiliates, make certain payments to Premcor Inc. or Premcor USA, enter into sale and leaseback transactions, conduct businesses other than our current businesses, merge or consolidate with any other person or sell, assign, transfer, lease, convey or otherwise dispose of all or substantially all of our assets. Some of the debt instruments also require us and our subsidiaries to satisfy or maintain certain financial condition tests. Our credit agreement only allows us to incur $15 million of additional debt after the June 2003 private notes offering. Our ability and the ability of our subsidiaries to meet these financial condition tests can be affected by events beyond our control and we may not meet such tests.

16

Compliance with, and changes in, environmental laws could adversely affect our results of operations and our financial condition.

We are subject to extensive federal, state and local environmental laws and regulations, including those relating to the discharge of materials into the environment, waste management, pollution prevention, remediation of contaminated sites and the characteristics and composition of gasoline and diesel fuels. In addition, some of these laws and regulations require our facilities to operate under permits that are subject to renewal or modification. These laws and regulations and permits can often require expensive pollution control equipment or operational changes to limit the impact or potential impact on the environment and/or human health. Violations of these laws and regulations or permit conditions can result in substantial fines, criminal sanctions, permit revocations and/or facility shutdowns. Compliance with environmental laws and regulations significantly contributes to our operating costs. In addition, we have made and expect to make substantial capital expenditures on an ongoing basis to comply with environmental laws and regulations.

In addition, new laws, new interpretations of existing laws, increased governmental enforcement of environmental laws or other developments could require us to make additional unforeseen expenditures. These expenditures or costs for environmental compliance could have a material adverse effect on our financial condition, results of operations and cash flow. For example, the United States Environmental Protection Agency, or EPA, has promulgated new regulations under the federal Clean Air Act described below that establish stringent sulfur content specifications for gasoline and low-sulfur highway, or “on-road” diesel fuel designed to reduce air emissions from the use of these products.

In February 2000, the EPA promulgated the Tier 2 Motor Vehicle Emission Standards Final Rule for all passenger vehicles, establishing standards for sulfur content in gasoline. These regulations mandate that the average sulfur content of gasoline for highway use produced at any refinery not exceed 30 ppm during any calendar year by January 1, 2006, phasing in beginning on January 1, 2004. We currently expect to produce gasoline under the new sulfur standards at our Port Arthur refinery prior to January 1, 2004 and at our Memphis refinery in the first quarter of 2004. As a result of the corporate pool averaging provisions of the regulations, we believe that we will be able to defer a significant portion of the investment required for compliance for our Lima refinery until the end of 2005 through the purchase of sulfur allotments and credits which arise from a refiner producing gasoline with a sulfur content below specified levels prior to the end of 2005, the end of the phase-in period. There is no assurance that the averaging provisions of the regulations will allow for a deferral of compliance at our Lima refinery or that sufficient allotments or credits to defer investment at our Lima refinery will be available, or if available, that they will be cost effective. We believe, based on current estimates and on a January 1, 2004 compliance date for all three refineries, that compliance with the new Tier 2 gasoline specifications will require capital expenditures in the aggregate through 2004 of approximately $335 million. This estimate reflects an increase from 2001 year-end estimates of $80 million for the newly acquired Memphis refinery and $79 million for revised cost estimates at our Lima and Port Arthur refineries based on completed detailed engineering studies and refined implementation plans. Future revisions to these cost estimates may be necessary. We are reviewing the current plans for Tier 2 compliance at the Memphis refinery and believe there may be opportunities for significant cost savings based on a revised project design. We have entered into contracts totaling $126 million related to the design and construction activity at our Port Arthur and Lima refineries for the Tier 2 gasoline compliance.

In January 2001, the EPA promulgated its on-road diesel regulations, which will require a 97% reduction in the sulfur content of diesel fuel sold for highway use by June 1, 2006, with full compliance by January 1, 2010. We estimate that capital expenditures required to comply with the on-road diesel standards at all three of our refineries in the aggregate through 2006 is approximately $347 million, an increase from previous estimates of $100 million for the newly acquired Memphis refinery and of $20 million for revised cost estimates at our Lima and Port Arthur refineries. The revised estimate is based on additional engineering studies and may be revised further as we move towards finalization of our implementation strategy. More than 95% of the projected investment is expected to be incurred during 2004 through 2006 with the greatest concentration of spending

17

occurring in 2005. Since the Lima refinery does not currently produce diesel fuel to on-road specifications, we are considering an acceleration of the low-sulfur diesel investment at the Lima refinery in order to capture this incremental product value. If the investment is accelerated, production of the low-sulfur fuel is possible by the first half of 2005.

In April 2002, the EPA promulgated regulations to implement Phase II of the petroleum refinery Maximum Achievable Control Technology rule under the federal Clean Air Act, referred to as MACT II, which regulates emissions of hazardous air pollutants from certain refinery units. We expect to spend approximately $25 million in the next two years related to these new regulations.

We have additional capital needs for which our internally generated cash flow may not be adequate; we may have insufficient liquidity to meet those needs.

In addition to the capital expenditures we will make to comply with Tier 2 gasoline standards, on-road diesel regulations and MACT II regulations, we have additional short-term and long-term capital needs. Our short-term working capital needs are primarily crude oil purchase requirements, which fluctuate with the pricing and sourcing of crude oil. Our internally generated cash flow and availability under our working capital facilities may not be sufficient to meet these needs. We also have significant long-term needs for cash. We estimate that mandatory capital and turnaround expenditures, excluding the non-recurring capital expenditures required to comply with Tier 2 gasoline standards, on-road diesel regulations and MACT II regulations described above, will average approximately $150 million per year from 2003 through 2006. Our internally generated cash flow may not be sufficient to support such capital expenditures.

We may not be able to implement successfully our discretionary capital expenditure projects.

We could undertake a number of discretionary capital expenditure projects designed to increase the productivity and profitability of our refineries such as our recently announced plans to expand our Port Arthur refinery. Many factors beyond our control may prevent or hinder our undertaking of some or all of these projects, including compliance with or liability under environmental regulations, a downturn in refining margins, technical or mechanical problems, lack of availability of capital and other factors. Failure to successfully implement these profit-enhancing strategies may adversely affect our business prospects and competitive position in the industry.

Environmental clean-up and remediation costs of our sites and environmental litigation could decrease our net cash flow, reduce our results of operations and impair our financial condition.

We are subject to liability for the investigation and clean-up of environmental contamination with respect to each of the properties that we own or operate, certain properties we formerly owned or operated and at off-site locations where we arranged for the disposal of hazardous substances. We are involved in several proceedings or other projects relating to our liability for the investigation and clean-up of such sites. We may become involved in further litigation or other proceedings. If we were to be held responsible for damages in any existing or future litigation or proceedings, such costs may not be covered by insurance and may be material. For example, there is extensive contamination at our Port Arthur refinery site and contamination at our Lima refinery site. Chevron Products Company, the former owner of the Port Arthur refinery, has retained environmental remediation obligations regarding pre-closing contamination for all areas of the refinery except those under or within 100 feet of active processing units, and BP has retained liability for certain environmental costs relating to operations of, or associated with, the Lima refinery site prior to our acquisition of that facility. However, if either of these parties fails to satisfy its obligations for any reason, or if significant liabilities arise in the areas in which we assumed liability, we may become responsible for the remediation. In addition, in May 2003, the State of Illinois filed a lawsuit against us and a prior owner of the Hartford refinery seeking injunctive relief, recovery of removal costs and monetary penalties with regard to subsurface contamination in the village of Hartford, Illinois. If we are forced to assume liability for the cost of this remediation or other remediation relating to our current or former facilities, such liability could have a material adverse effect on our financial condition. As a result, in

18

addition to making capital expenditures or incurring other costs to comply with environmental laws, we also may be liable for significant environmental litigation or remediation costs and other liabilities arising from the ownership or operation of these assets by prior owners, which could materially adversely affect our financial condition, results of operations and cash flow.

In addition, at the closed Blue Island, Illinois and Hartford, Illinois refineries, we are required to conduct environmental assessment and remediation. We are currently assessing our remedial obligations at these closed facilities and have an aggregate reserve of $49.0 million as of March 31, 2003. Also, in connection with our sale of certain retail properties and product terminals in 1999, we agreed to indemnify the purchasers for certain environmental conditions arising during our ownership and operation of these assets. Clean-up costs may exceed our estimates, which could, in turn, have a material adverse effect on our financial condition, results of operations and cash flow.

We may also face liability arising from current or future claims alleging personal injury or property damage due to exposure to chemicals or other hazardous substances, such as asbestos and benzene and petroleum hydrocarbon, at or from our facilities. We may also face liability for personal injury, property damage, natural resource damage or clean-up costs for the alleged release or migration of contamination or hazardous substances from our currently or formerly owned properties. In June 2003, approximately 700 residents of Port Arthur, Texas filed a lawsuit against us and five other companies alleging personal injuries and property damage from emissions from refining and chemical facilities in the area. The plaintiffs are seeking class certification, unspecified damages and the establishment of a trust fund for health concerns. A significant increase in the number or success of these claims could materially adversely affect our financial condition, results of operations and cash flow.

We may assume significant lease and environmental clean-up obligations as a result of the bankruptcy filing of the purchaser of our former retail properties.

In 1999, we sold the majority of our former retail properties to Clark Retail Enterprises, Inc., or CRE, which, together with its parent company, Clark Retail Group, Inc. filed for Chapter 11 bankruptcy protection in October 2002. In addition to our obligations under the environmental indemnities discussed above, we may be jointly and severally liable for CRE’s obligations under approximately 150 retail leases that were assigned to CRE as part of the sale, including payment of rent and taxes. We may also incur other significant liabilities for environmental obligations at these sites. CRE rejected approximately 30 of these leases in connection with bankruptcy hearings held in January, February and March 2003. We recorded an after-tax charge of $4.3 million in the first quarter of 2003 representing the estimated net present value of our remaining liability under these leases, net of estimated sub-lease income. In May 2003, CRE announced that it would conduct an orderly sale of its retail assets, including the lease sites which have not been rejected. We are participating with CRE in the sale process. The remaining future lease payments on these properties is currently estimated as follows: 2003—$9.8 million; 2004—$10.1 million; 2005—$10.5 million; 2006—$10.9 million; 2007—$11.3 million; and in the aggregate thereafter—$84.2 million. It is possible that we may incur additional liability for CRE lease obligations or other costs as CRE finalizes the disposition of the properties; however, the amounts are not estimable at this time and could be material.

A substantial portion of our workforce is unionized and we may face labor disruptions that would interfere with our refinery operations.

As of March 31, 2003, we employed approximately 1,700 people, approximately 59% of whom were covered by collective bargaining agreements. The collective bargaining agreements covering employees at our Port Arthur and Memphis refineries expire in January 2006 and the agreement covering employees at our Lima refinery expires in April 2006. Our relationships with the relevant unions at our current facilities have been good and we have never experienced a work stoppage as a result of labor disagreement. However, we cannot assure you that this situation will continue. A labor disturbance at any of our refineries could have a material adverse effect on that refinery’s operations.

19

We have not fully developed or implemented a disaster recovery plan for our information systems, which could adversely affect business operations should a major physical disaster occur.

We are dependent upon functioning information systems to conduct business. A system failure or malfunction may result in an inability to process transactions or lead to a disruption of operations. Although we regularly backup our programs and data, we do not currently have a comprehensive disaster recovery plan providing a hot site facility for immediate system recovery should a major physical disaster occur at our general office, our executive office or at one of our refineries. A comprehensive disaster recovery plan is currently being developed, with completion targeted in the fourth quarter of 2003.

Our federal income tax carryforward attributes could be substantially limited if our parent, Premcor Inc., experiences an ownership change as defined in the Internal Revenue Code.

Our consolidated group had federal income tax net operating loss carryforwards of approximately $478.5 million, and we had net operating loss carryforwards of $372.1 million, at December 31, 2002. These net operating loss carryforwards will begin to terminate with the year ending December 31, 2011, to the extent they have not been used to reduce taxable income prior to such time. Our consolidated group’s ability to use these net operating loss carryforwards to reduce taxable income and to utilize other losses and certain tax credits is dependent upon, among other things, our parent, Premcor Inc., not experiencing an ownership change of more than 50% during any three-year testing period as defined in the Internal Revenue Code. Premcor Inc. has had significant changes in the ownership of its common stock in the three-year period immediately prior to this exchange offer. Accordingly, future changes, even slight changes, in the ownership of Premcor Inc.’s common stock (including, among other things, the exercise of compensatory options) could result in an aggregate change in ownership of more than 50% as defined in the Internal Revenue Code, which could substantially limit the availability of these net operating loss carryforwards, other losses and tax credits.

Risks Related to Future Acquisitions

We may not be able to consummate future acquisitions.

A substantial portion of our growth over the last several years has been attributed to acquisitions. A principal component of our strategy going forward is to continue to selectively acquire refining assets in order to increase cash flow and earnings. Our ability to do so will be dependent upon a number of factors, including our ability to identify acceptable acquisition candidates, consummate acquisitions on favorable terms, successfully integrate acquired businesses and obtain financing to support our growth and many other factors beyond our control. We may not be successful in implementing our acquisition strategy and, even if implemented, such strategy may not improve our operating results. In addition, the financing of future acquisitions may require us to incur additional indebtedness, which could limit our financial flexibility.

We may not be able to successfully integrate future acquisitions into our business.

In connection with future acquisitions, we may experience unforeseen operating difficulties as we integrate the acquired assets into our existing operations. These difficulties may require significant management attention and financial resources that would otherwise be available for the ongoing development or expansion of existing operations. Any future acquisitions involve risks, including:

| | • | | unexpected losses of key employees, customers and suppliers of the acquired operations; |

| | • | | difficulties in integrating the financial, technological and management standards, processes, procedures and controls of the acquired business with those of our existing operations; |

| | • | | challenges in managing the increased scope, geographic diversity and complexity of our operations; and |

| | • | | mitigating contingent liabilities. |

20

Risks Related to this Offering

There is no existing market for the exchange notes, and we cannot assure you that an active trading market will develop for the exchange notes or that you will be able to sell your exchange notes.

There is no existing market for the exchange notes, and there can be no assurance as to the liquidity of any markets that may develop for the exchange notes, your ability to sell your exchange notes or the prices at which you would be able to sell your exchange notes. Future trading prices of the exchange notes will depend on many factors, including, among other things, prevailing interest rates, our operating results and the market for similar securities. The initial purchasers of the outstanding notes are not obligated to make a market in the exchange notes and any market making by them may be discontinued at any time without notice. We do not intend to apply for a listing of the exchange notes on any securities exchange or on any automated dealer quotation system.

Historically, the market for non-investment grade debt has been subject to disruptions that have caused volatility in prices. It is possible that the market for the exchange notes will be subject to disruptions. Any such disruptions may have a negative effect on you, as a holder of the exchange notes, regardless of our prospects and financial performance.

Despite our level of indebtedness, we and our subsidiaries may be able to incur substantially more debt, which could exacerbate the risks described above.

We and our subsidiaries may be able to incur substantial additional indebtedness in the future. Although the indenture governing the notes and our other debt instruments and financing arrangements contain restrictions on the incurrence of additional indebtedness, these restrictions are subject to a number of qualifications and exceptions, and the indebtedness incurred in compliance with these restrictions could be substantial. To the extent new debt is added to our currently anticipated debt levels, the substantial leverage risks described above would increase. Also, these restrictions do not prevent us from incurring obligations that do not constitute indebtedness. See “Description of Indebtedness” and “Description of Notes.”

The notes are not secured.