CAUTIONARY STATEMENT FOR PURPOSES OF THE “SAFE HARBOR” PROVISIONS OF

THE PRIVATE SECURITIES LITIGATION REFORM ACT OF 1995

Except for historical matters, the matters discussed in this Annual Report on Form 20-F are forward-looking statements that are subject to a number of significant risks and uncertainties and are based on information as of the date hereof. These statements are generally indicated by the use of forward-looking terminology such as the words “anticipate”, “believe”, “estimate”, “expect”, “intend”, “may”, “plan”, “project”, “will”, “could”, “might”, “should” and other words and phrases of similar import that express an indication of actions or results of actions that may or are expected to occur in the future. These statements appear in a number of places throughout this Annual Report on Form 20-F and include statements regarding our intentions, beliefs or current expectations concerning, among other things, our results of operations, financial condition, liquidity, prospects, growth, strategies and the industries in which we operate.

By their nature, forward-looking statements involve risks and uncertainties because they relate to events and depend on circumstances that may or may not occur in the future. Forward-looking statements are not guarantees of future performance and our actual results of operations, financial condition and liquidity, and the development of the industries in which we operate may differ materially from those made in or suggested by the forward-looking statements contained in this Annual Report on Form 20-F. Important factors that could cause those differences include, but are not limited to:

•the volatility of the semiconductor industry and the market for end-user applications for semiconductor products;

•overcapacity in the semiconductor assembly and testing markets;

•the increased competition from other companies and our ability to retain and increase our market share;

•our ability to successfully develop new technologies and remain a technological leader;

•our ability to maintain control over capacity expansion and facility modifications;

•our ability to generate growth or profitable growth;

•our ability to hire and retain qualified personnel;

•our ability to acquire required equipment and supplies to meet customer demand;

•our ability to raise debt or equity financing as required to meet certain existing obligations;

•our reliance on the business and financial condition of certain major customers;

•the success of any of our future acquisitions, investments or joint ventures;

•the outbreak of contagious disease and occurrence of earthquakes, typhoons and other natural disasters, as well as industrial accidents;

•the political stability of the regions in which we conduct operations;

•general local and global economic and financial conditions;

•the potential impact of the Coronavirus Disease 2019 (“COVID-19”) pandemic on our operations or the operations of our supply chain or our customers; and

•other factors set forth under the heading “Item 3. Key Information—Risk Factors” of this Annual Report on Form 20-F.

The factors identified above are believed to be important factors (but not necessarily all of the important factors) that could cause actual results to differ materially from those expressed in any forward-looking statement made by us. Other factors not discussed herein could also have material adverse effects on us. All forward-looking statements included in this Annual Report on Form 20-F are expressly qualified in their entirety by the foregoing cautionary statements. We undertake no obligation to update any forward-looking statement (or its associated cautionary language), whether as a result of new information or future events.

Forward-looking statements include, but are not limited to, statements regarding our strategy and future plans, future business condition and financial results, our capital expenditure plans, our capacity expansion plans, our investments in Mainland China, technological upgrades, investment in research and development, future market demand, future regulatory or other developments in our industry. Please see “Item 3. Key Information—Risk Factors” for a further discussion of certain factors that may cause actual results to differ materially from those indicated by our forward-looking statements.

EXCHANGE RATES

References to “US$” and “US dollars” are to United States dollars and references to “NT$” and “NT dollars” are to New Taiwan dollars. This Annual Report on Form 20-F contains translations of certain NT dollar amounts into US dollars at specified rates solely for the convenience of the reader. Unless otherwise noted, all translations from NT dollars to US dollars and from US dollars to NT dollars were made at the noon buying rate in the City of New York for cable transfers in NT dollars per US dollar as certified for customs purposes by the Federal Reserve Bank of New York as of December 29, 2023, which was NT$30.62 to US$1.00. We make no representation that the NT dollar or US dollar amounts referred to in this Annual Report on Form 20-F could have been or could be converted into US dollars or NT dollars, as the case may be, at any particular rate or at all.

PART I

Item 1. Identity of Directors, Senior Management and Advisers

Not applicable.

Item 2. Offer Statistics and Expected Timetable

Not applicable.

Item 3. Key Information

Capitalization and Indebtedness

Not applicable.

Reasons for the Offer and Use of Proceeds

Not applicable.

Risk Factors

Risks Relating to Economic Conditions and the Financial Markets

Global inflation and financial markets disruptions could materially and adversely affect our business and results of operations.

Disruptions in global inflation, interest rate rising, financial markets and trade tensions may occur that causes diminished liquidity and limited availability of credit, reduced consumer confidence, reduced economic growth, increased unemployment rates and uncertainty about economic stability. Limited availability of credit in financial markets may lead consumers and businesses to postpone spending. This in turn may cause our customers to cancel, decrease or delay their existing and future orders with us. Particularly, the economics uncertainty caused by trade tensions and inflation, which led the weakness of macro-economic environment, will impact the end product market demand. The softness in broader market demand including smart phones, TVs, PC/servers and other consumer products, directly affects the inventory elimination of our customers. The decrease in segment revenue was principally due to the weakness of macro-economic environment, softness in market demand and customer adjustment of inventory levels, all of which led to the decreased utilization rate of our production lines since the second half of 2022 till the first half of 2023.

Financial difficulties experienced by our customers or suppliers as a result of these conditions could lead to production delays and delays or defaults in payment of accounts receivable. We are not able to predict the occurrence, frequency, duration or extent of disruptions in global inflation and financial markets, or when the trade tensions could be settled down. These conditions increase the difficulty of accurately forecasting and planning our business activities. If these conditions and uncertainties occur or continue, or if credit and financial markets and confidence in economic conditions deteriorate, our business and results of operations could be materially and adversely affected.

Risks Relating to Our Industry

Because we depend on the highly cyclical semiconductor industry, which is characterized by significant and sometimes prolonged downturns from time to time, our revenue and earnings may fluctuate significantly, which in turn could adversely affect our results of operations and could cause the market price of our common shares or of our ADSs to decline.

Because our business is, and will continue to be, dependent on the requirements of semiconductor companies for independent assembly and testing services, any downturn in the highly cyclical semiconductor industry may reduce demand for our services and adversely affect our results of operations. All of our customers operate in this industry and variations in order levels and in service fee from our customers may result in volatility in our revenue and earnings. For instance, during periods of decreased demand for assembled semiconductors, some of our customers may simplify, delay or forego final testing of certain types of semiconductors, such as dynamic random access memory or DRAM and NAND Flash, which in turn may result in reduced demand for our services, adversely affecting our results of operations. From time to time, the semiconductor industry has experienced significant, and sometimes prolonged, downturns which have adversely affected our results of operations. We cannot give any assurances that there will not be any downturn in the future or that any future downturn will not materially and adversely affect our results of operations.

Any deterioration in the market for end-user applications for semiconductor products would reduce demand for our services and may result in a decrease in our earnings.

Market conditions in the semiconductor industry track, to a large degree, those for their end-user applications. Any deterioration in the market conditions for the end-user applications of semiconductors we test and assemble could reduce demand for our services and, in turn, could materially adversely affect our financial condition and results of operations. Our revenue is largely attributable to fees derived from testing and assembling semiconductors for use in personal computers, communications equipment, consumer electronic products and display applications. A significant decrease in demand for products in these markets could put pricing pressure on our assembly and testing services and negatively affect our revenue and earnings. The LCD driver market often aligns with broader economic trend, we cannot give any assurances that there will not be any downturn in the future or that any future downturn will not affect our results of operations. Any significant decrease in demand for end-user applications of semiconductors will negatively affect our revenue and earnings.

A decline in average selling prices for our services could result in a decrease in our earnings.

Historically, prices for our assembly and testing services in relation to any given semiconductor tend to decline over the course of its product and technology life cycle. See also “— A decrease in market demand for LCD, OLED, automotive panel and other display panel driver semiconductors may adversely affect our capacity utilization rates and thereby negatively affect our profitability”. If we cannot reduce the cost of our assembly and testing services, or introduce higher-margin assembly and testing services for new package types, to offset the decrease in average selling prices for our services, our earnings could decrease.

A reversal or slowdown in the outsourcing trend for semiconductor assembly and testing services could reduce our profitability.

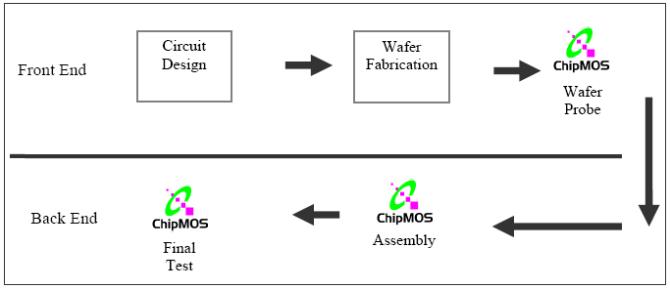

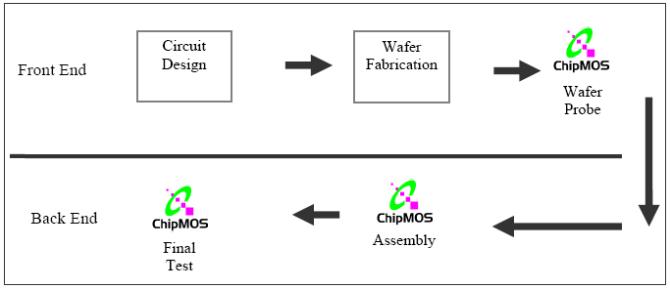

Integrated device manufacturers, or IDMs, continue to increasingly outsource stages of the semiconductor production process, including assembly and testing, to independent companies like us to shorten production cycles. In addition, the availability of advanced independent semiconductor manufacturing services has also enabled the growth of so-called “fabless” semiconductor companies that focus exclusively on design and marketing and outsource their manufacturing, assembly and testing requirements to independent companies. A substantial portion of our revenue is indirectly generated from providing semiconductor assembly and testing services to these IDMs and fabless companies. We cannot assure you that these companies will continue to outsource their assembly and testing requirements to independent companies like us. A reversal of, or a slowdown in, this outsourcing trend could result in reduced demand for our services, which in turn could reduce our profitability.

Risks Relating to Our Business

If we are unable to compete effectively in the highly competitive semiconductor assembly and testing markets, we may lose customers and our income may decline.

The semiconductor assembly and testing markets are very competitive. We face competition from a number of IDMs with in-house assembly and testing capabilities and other independent semiconductor assembly and testing companies. Our competitors may have access to more advanced technologies and greater financial and other resources than we do. Many of our competitors have shown a willingness to reduce prices quickly and sharply in the past to maintain capacity utilization in their facilities during periods of reduced demand. In addition, an increasing number of our competitors conduct their operations in lower cost centers in Asia such as Mainland China. Any renewed or continued erosion in the prices or demand for our assembly and testing services as a result of increased competition could adversely affect our profits.

We are highly dependent on the market for memory products. A downturn in market prices for these products could significantly reduce our revenue and profit.

A significant portion of our revenue is derived from testing and assembling memory semiconductors. In the past, our service fees for testing and assembling memory semiconductors were sharply reduced in tandem with the decrease in the average selling price of DRAM and NAND Flash in the semiconductor industry. Oversupply of DRAM or NAND Flash products and weak demand in the DRAM or NAND Flash market may result in significant reductions in the price of DRAM or NAND Flash products, which in turn may drive down the average prices for our assembly and testing services for DRAM and NAND Flash products and further reduce our revenue and profit. We cannot assure you that there will not be further downturns in DRAM or NAND Flash prices in the future.

A decrease in market demand for LCD, OLED, automotive panel and other display panel driver semiconductors may adversely affect our capacity utilization rates and thereby negatively affect our profitability.

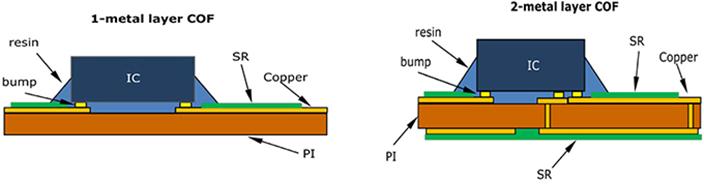

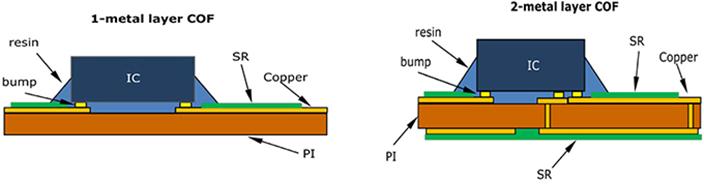

Our assembly and testing services for Display panel driver semiconductors generated revenue of NT$8,211 million, NT$7,289 million and NT$7,822 million (US$255 million) in 2021, 2022 and 2023, respectively. We invested NT$2,749 million, NT$2,677 million and NT$1,757 million (US$57 million) in 2021, 2022 and 2023, respectively, on equipment for chip-on-film, or COF and chip-on-glass, or COG, technologies, which are used in assembly and testing services for LCD, OLED, automotive panel and other display panel driver semiconductors. Most of this equipment may not be used for technologies other than COF or COG. The market demand for LCD, OLED, automotive panel and other display panel driver semiconductors increased in 2018 particularly the wafer test for TDDI in the second half of 2020. Then demand went down in second half of 2022 due to customer inventory adjustment for market weakness. However, we observed some rebound sign for OLED, TDDI, and large panel driver IC demand since Lunar New Year holiday 2023 but it is still fluctuation except OLED and automotive panel in 2023. Any significant decrease in demand for these products and our related services would significantly impact our capacity utilization rates. That may result in our inability to generate sufficient revenue to cover the depreciation expenses for the equipment used in testing and assembling LCD, OLED, automotive panel and other display panel driver semiconductors, thereby negatively affecting our profitability. See also “—Because of our high fixed costs, if we are unable to achieve relatively high capacity utilization rates, our earnings and profitability may be adversely affected”.

Our significant amount of indebtedness and interest expense will limit our cash flow and could adversely affect our operations.

We have a significant level of debt and interest expense. As of December 31, 2023, we had approximately NT$14,912 million (US$487 million) outstanding long-term indebtedness. Our long-term indebtedness as of December 31, 2023, represented bank loans with an interest rate from 1.2% to 1.75%. As of December 31, 2023, NT$11,271 million (US$368 million) of our indebtedness was secured by collateral comprised of our assets.

Our significant indebtedness poses risks to our business, including the risks that:

•we may have to use a substantial portion of our consolidated cash flow from operations to pay principal and interest on our debt, thereby reducing the funds available for working capital, capital expenditures, acquisitions and other general corporate purposes;

•insufficient cash flow from operations may force us to sell assets, or seek additional capital, which we may be unable to do at all or on terms favorable to us;

•our ability to sell assets or seek additional capital may be adversely affected by security interests in our assets granted to our lenders as collateral; and

•our level of indebtedness may make us more vulnerable to economic or industry downturns.

For additional information on our indebtedness, see “Item 5. Operating and Financial Review and Prospects—Liquidity and Capital Resources”.

Our results of operations may fluctuate significantly and may cause the market price of our common shares or of our ADSs to be volatile.

Our results of operations have varied significantly from period to period and may continue to vary in the future. Among the more important factors affecting our quarterly and annual results of operations are the following:

•our ability to accurately predict customer demand, as we must commit significant capital expenditures in anticipation of future orders;

•our ability to quickly adjust to unanticipated declines or shortfalls in demand and market prices for our assembly and testing services, due to our high percentage of fixed costs;

•changes in prices for our assembly and testing services;

•volume of orders relative to our assembly and testing capacity;

•capital expenditures and production uncertainties relating to the roll-out of new assembly and testing services;

•our ability to obtain adequate assembly and testing equipment on a timely basis;

•changes in costs and availability of raw materials, equipment and labor;

•changes in our product mix; and

•earthquakes, global new virus epidemic, climate change and other natural disasters, as well as industrial accidents.

Because of the factors listed above, our future results of operations or growth rates may be below the expectations of research analysts and investors. If so, the market price of our common shares or of our ADSs, and the market value of your investment, may fall.

We rely on key customers for a substantial portion of our revenue and a loss of, or deterioration of the business from, or delayed payment by, any one of these customers could result in decreased revenue and materially adversely affect our results of operations and financial condition.

We rely on a small group of customers for a substantial portion of our business. In 2023, our top five customers collectively accounted for 61% of our revenue. As part of our strategy, we have been focusing on sales to key customers through long-term service agreements. We also focus on our business with smaller customers and customers who do not place orders on a regular basis. We expect that we will continue to rely on a relatively limited number of customers for a significant portion of our revenue. Any adverse development in our key customers’ operations, competitive position or customer base could materially reduce our revenue and materially adversely affect our business and profitability.

Since semiconductor companies generally rely on service providers with whom they have established relationships to meet their assembly and testing needs for their applications and new customers usually require us to pass a lengthy and rigorous qualification process, if we lose any of our key customers, we may not be able to replace them in a timely manner. If any of our key customers reduces or cancels its orders or terminates existing contractual arrangements, and if we are unable to attract new customers and establish new contractual arrangements with existing or new customers, our revenue could be reduced and our business and results of operations may be materially adversely affected.

Because of our high fixed costs, if we are unable to achieve relatively high capacity utilization rates, our earnings and profitability may be adversely affected.

Our operations are characterized by a high proportion of fixed costs. For memory and logic/mixed-signal semiconductor testing services, our fixed costs represented 49%, 52% and 50% of our total cost of revenue in 2021, 2022 and 2023, respectively. For memory and logic/mixed-signal semiconductor assembly services, our fixed costs represented 19%, 22% and 26% of our total cost of revenue in 2021, 2022 and 2023, respectively. For Display panel driver semiconductor assembly and testing services, our fixed costs represented 59%, 61% and 59% of our total cost of revenue in 2021, 2022 and 2023, respectively. For bumping services, our fixed costs represented 19%, 21% and 19% of our total cost of revenue in 2021, 2022 and 2023, respectively. Our profitability depends in part not only on absolute pricing levels for our services, but also on the utilization rates for our assembly and testing equipment, commonly referred to as “capacity utilization rates”. Increases or decreases in our capacity utilization rates can significantly affect our gross margins as unit costs generally decrease as the fixed costs are allocated over a larger number of units. In the past, our capacity utilization rates have fluctuated significantly as a result of the fluctuations in the market demand for semiconductors. If we fail to increase or maintain our capacity utilization rates, our earnings and profitability may be adversely affected. In addition, the long-term assembly and testing services agreements we entered with certain customers may require us to incur significant capital expenditures. If we are unable to achieve high capacity utilization rates for the equipment purchased pursuant to these agreements, our gross margins may be materially and adversely affected.

The assembly and testing process is complex and our production yields and customer relationships may suffer as a result of defects or malfunctions in our testing and assembly equipment and the introduction of new packages.

Semiconductor testing and assembly are complex processes that require significant technological and process expertise. Semiconductor testing involves sophisticated test equipment and computer software. We develop computer software to test our customers’ semiconductors. We also develop conversion software programs that enable us to test semiconductors on different types of testers. Similar to most software programs, these software programs are complex and may contain programming errors or bugs. In addition, the testing process is subject to human error by our employees who operate our test equipment and related software. Any significant defect in our testing or conversion software, malfunction in our test equipment or human error could reduce our production yields and damage our customer relationships.

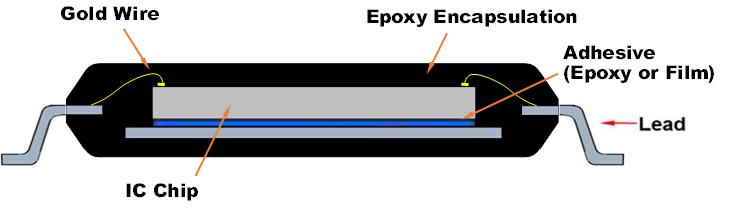

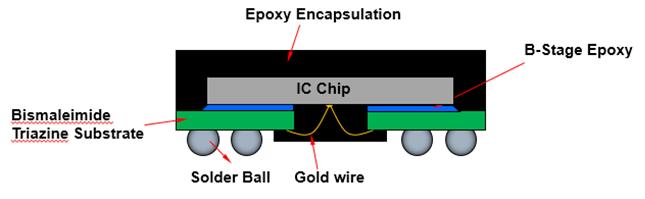

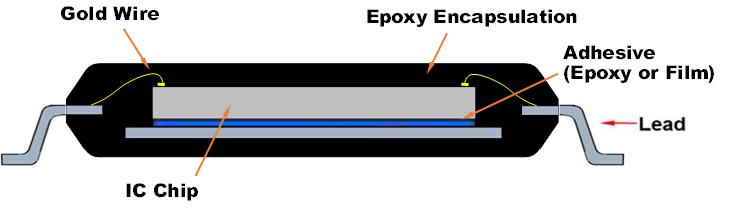

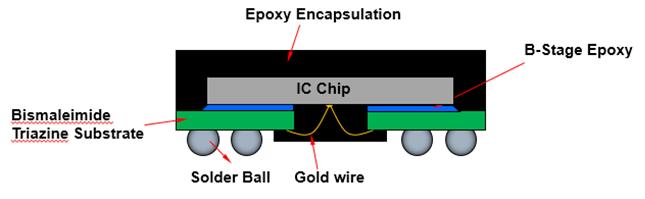

The assembly process involves a number of steps, each of which must be completed with precision. Defective packages primarily result from:

•contaminants in the manufacturing environment;

•defective raw materials; or

•defective plating services.

These and other factors have, from time to time, contributed to lower production yields. They may do so in the future, particularly as we expand our capacity or change our processing steps. In addition, to be competitive, we must continue to expand our offering of packages. Our production yields on new packages typically are significantly lower than our production yields on our more established packages. Our failure to maintain high standards or acceptable production yields, if significant and prolonged, could result in a loss of customers, increased costs of production, delays, substantial amounts of returned goods and related claims by customers. Further, to the extent our customers have set target production yields, we may be required to compensate our customers in a pre-agreed manner. Any of these problems could materially adversely affect our business reputation and result in reduced revenue and profitability.

Because of the highly cyclical nature of our industry, our capital requirements are difficult to plan. If we cannot obtain additional capital when we need it, we may not be able to maintain or increase our current growth rate and our profits will suffer.

As our industry is highly cyclical and rapidly changing, our capital requirements are difficult to plan. To remain competitive, we may need capital to fund the expansion of our facilities as well as to fund our equipment purchases and research and development activities. To meet our liquidity, capital spending and other capital needs, we have taken and plan to take certain measures to generate additional working capital and to save cash. See “Item 5. Operating and Financial Review and Prospects—Liquidity and Capital Resources”. We cannot assure you that these plans and measures will be implemented or will provide sufficient sources of capital.

In addition, future capacity expansions or market or other developments may require additional funding. Our ability to obtain external financing in the future depends on a number of factors, many of which are beyond our control. They include:

•our future financial condition, results of operations and cash flows;

•general market conditions for financing activities by semiconductor assembly and testing companies; and

•economic, political and other conditions in Taiwan and elsewhere.

If we are unable to obtain funding in a timely manner or on acceptable terms, our growth prospects and potential future profitability will suffer.

Disputes over intellectual property rights could be costly, deprive us of technologies necessary for us to stay competitive, render us unable to provide some of our services and reduce our opportunities to generate revenue.

Our ability to compete successfully and achieve future growth will depend, in part, on our ability to protect our proprietary technologies and to secure, on commercially acceptable terms, critical technologies that we do not own. We cannot assure you that we will be able to independently develop, or secure from any third party, the technologies required for our assembly and testing services. Our failure to successfully obtain these technologies may seriously harm our competitive position and render us unable to provide some of our services.

Our ability to compete successfully also depends on our ability to operate without infringing upon the proprietary rights of others. The semiconductor assembly and testing industry is characterized by frequent litigation regarding patent and other intellectual property rights. We may incur legal liabilities if we infringe upon the intellectual property or other proprietary rights of others. We are not able to ascertain what patent applications have been filed in the United States or elsewhere, however, until they are granted. If any third party succeeds in its intellectual property infringement claims against us or our customers, we could be required to:

•discontinue using the disputed process technologies, which would prevent us from offering some of our assembly and testing services;

•pay substantial monetary damages;

•develop non-infringing technologies, which may not be feasible; or

•acquire licenses to the infringed technologies, which may not be available on commercially reasonable terms, if at all.

Any one of these developments could impose substantial financial and administrative burdens on us and hinder our business. We are, from time to time, involved in litigation in respect of intellectual property rights. Any litigation, whether as plaintiff or defendant, is costly and diverts our resources. If we fail to obtain necessary licenses on commercially reasonable terms or if litigation, regardless of the outcome, relating to patent infringement or other intellectual property matters occurs, our costs could be substantially increased to impact our margins. Any such litigation could also prevent us from testing and assembling particular products or using particular technologies, which could reduce our opportunities to generate revenue.

If we are unable to obtain raw materials and other necessary inputs from our suppliers in a timely and cost-effective manner, our production schedules would be delayed and we may lose customers and growth opportunities and become less profitable.

Our operations require us to obtain sufficient quantities of raw materials at acceptable prices in a timely and cost-effective manner. We source most of our raw materials, including critical materials like leadframes, organic substrates, epoxy, gold wire and molding compound for assembly, and tapes for COF, from a limited group of suppliers. We purchase all of our materials on a purchase order basis and have no long-term contracts with any of our suppliers. From time to time, suppliers have extended lead times, increased the price or limited the supply of required materials to us because of market shortages. Consequently, we may, from time to time, experience difficulty in obtaining sufficient quantities of raw materials on a timely basis. In addition, from time to time, we may reject materials that do not meet our specifications, resulting in declines in output or yield. Although we typically maintain at least two suppliers for each key raw material, we cannot assure you that we will be able to obtain sufficient quantities of raw materials and other supplies of an acceptable quality in the future. It usually takes from three to six months to switch from one supplier to another, depending on the complexity of the raw material. If we are unable to obtain raw materials and other necessary inputs in a timely and cost-effective manner, we may need to delay our production and delivery schedules, which may result in the loss of business and growth opportunities and could reduce our profitability.

If we are unable to obtain additional assembly and testing equipment or facilities in a timely manner and at a reasonable cost, we may be unable to fulfill our customers’ orders and may become less competitive and less profitable.

The semiconductor testing and assembly business is capital intensive and requires significant investment in expensive equipment manufactured by a limited number of suppliers. The market for semiconductor assembly and testing equipment is characterized, from time to time, by intense demand, limited supply and long delivery cycles. Our operations and expansion plans depend on our ability to obtain equipment from a limited number of suppliers in a timely and cost-effective manner. We have no binding supply agreements with any of our suppliers and we acquire our assembly and testing equipment on a purchase order basis, which exposes us to changing market conditions and other significant risks. Semiconductor assembly and testing also requires us to operate sizable facilities. If we are unable to obtain equipment or facilities in a timely manner, we may be unable to fulfill our customers’ orders, which could negatively impact our financial condition and results of operations as well as our growth prospects. Currently, we do not have any long-term service agreements that require our commitment to acquire additional assembly and testing equipment or facilities. We cannot assure you, however, that such commitment will not be made in the future. See “Item 4. Information on the Company—Customers”.

If we are unable to manage the expansion of our operations and resources effectively, our growth prospects may be limited and our future profitability may be reduced.

We expect to continue to expand the operations and to increase the number of employees. Rapid expansion puts a strain on our managerial, technical, financial, operational and other resources. As a result of our expansion, we will need to implement additional operational and financial controls and hire and train additional personnel. We cannot assure you that we will be able to do so effectively in the future, and our failure to do so could jeopardize our expansion plans and seriously harm our operations.

Laws of the Republic of China may be less protective of shareholder rights than laws of the United States or other jurisdictions.

Our corporate affairs are governed by our Articles of Incorporation and laws governing corporations incorporated in the Republic of China (“ROC”). The rights of our shareholders to bring shareholders’ suits against us or our Board of Directors under the ROC law are more limited than those of the shareholders of U.S. corporations. For example, the ROC Company Act requires that a shareholder that continuously holds at least 1% of our issued and outstanding shares for at least 6 months may request our audit committee to institute an action against a director on the Company’s behalf. In addition, the controlling shareholders of U.S. corporations owe fiduciary duties to minority shareholders, while controlling shareholders in ROC corporations do not. Therefore, our shareholders may be less able under the ROC law than they would be under the laws of the United States or other jurisdictions to protect their interests in connection with actions by our management, members of our Board of Directors or our controlling shareholder.

It may be difficult to bring and enforce lawsuits against us in the United States.

We are incorporated in the ROC and a majority of our directors and most of our officers are not residents of the United States. A substantial portion of our assets is located outside the United States. As a result, it may be difficult for our shareholders to serve notice of a lawsuit on us or our directors and officers within the United States. Because most of our assets are located outside the United States, it may be difficult for our shareholders to enforce in the United States judgments of United States courts. Any United States judgments obtained against us will not be enforced by ROC courts if any of the following situations shall apply to such final judgment:

•the court rendering the judgment does not have jurisdiction over the subject matter under the ROC law;

•the judgment was rendered by default, except where the summons or order necessary for the commencement of the action was duly served on us within the jurisdiction of the court rendering the judgment within a reasonable period of time and in accordance with the laws and regulations of such jurisdiction, or with judicial assistance of the ROC;

•the judgment or the court procedures resulting in the judgment are contrary to the public order or good morals of the ROC; or

•the judgments of ROC courts are not recognized and enforceable in the jurisdiction of the court rendering the judgment on a reciprocal basis.

Investor confidence and the market price of our common shares or ADSs may be adversely impacted if we are unable to maintain effective Internal Control over Financial Reporting in accordance with Section 404 of the Sarbanes-Oxley Act of 2002.

We are required to comply with the ROC and US securities laws and regulations in connection with internal controls. As a public company in the United States, our management is required to assess the effectiveness of our internal control over financial reporting using the criteria established in Internal Control – Integrated Framework (2013) issued by Committee of Sponsoring Organization of the Treadway Commission (COSO), as required by Section 404 of the Sarbanes-Oxley Act of 2002. We carried out an evaluation, under the supervision and with the participation of management, including our President, the principal executive officer and Vice President of the Finance and Accounting Management Center, the principal financial officer of the effectiveness of the design and operation of our internal controls over financial reporting as of December 31, 2023, and concluded those internal controls over financial reporting were effective as of that date. See “Item 15. Controls and Procedures” for more information. Moreover, even if our management concludes that our internal controls over our financial reporting are effective, our independent public registered accounting firm may disagree. If our independent public registered accounting firm is not satisfied with our internal controls over our financial reporting or the level at which our controls are documented, designed, operated or reviewed, or if the independent public registered accounting firm interprets the requirements, rules or regulations differently from us, it may decline to attest our effectiveness of internal controls over financial reporting or may issue an adverse opinion in the future. Any of these possible outcomes could result in an adverse reaction in the financial marketplace due to a loss of investor confidence in the reliability of our consolidated financial statements, which ultimately could negatively impact the market prices of our common shares or ADSs.

Any environmental claims or failure to comply with any present or future environmental regulations, or any new environmental regulations, may require us to spend additional funds, may impose significant liability on us for present, past or future actions, and may dramatically increase the cost of providing our services to our customers.

We are subject to various laws and regulations relating to the use, storage, discharge and disposal of chemical by-products of, and water used in, our assembly and gold bumping processes. Although we have not suffered material environmental claims in the past, a failure or a claim that we have failed to comply with any present or future regulations could result in the assessment of damages or imposition of fines against us, suspension of production or a cessation of our operations or negative publicity. New regulations could require us to acquire costly equipment or to incur other significant expenses. Any failure on our part to control the use of, or adequately restrict the discharge of, hazardous substances could subject us to future liabilities that may materially reduce our earnings.

Fluctuations in exchange rates could result in foreign exchange losses.

Currently, we are nearly 60% of revenue denominated in US dollars. Our cost of revenue and operating expenses, on the other hand, are incurred in several currencies, including NT dollars, Japanese yen and US dollars. In addition, a substantial portion of our capital expenditures, primarily for the purchase of LCD, OLED, automotive panel and other display panel driver semiconductor, assembly and testing equipment, has been, and is expected to continue to be, denominated in Japanese yen with much of the remainder in US dollars. We also have debt denominated in NT dollars, Japanese yen, and US dollars. Fluctuations in exchange rates, primarily among the US dollar, the NT dollar and the Japanese yen, will affect our costs and operating margins in NT dollar terms. In addition, these fluctuations could result in exchange losses and increased costs in NT dollar terms. Despite selective hedging and other techniques implemented by us, fluctuations in exchange rates have affected, and may continue to affect, our financial condition and results of operations.

We may not be successful in our acquisitions, investments, joint ventures and dispositions, and may therefore be unable to implement fully our business strategy.

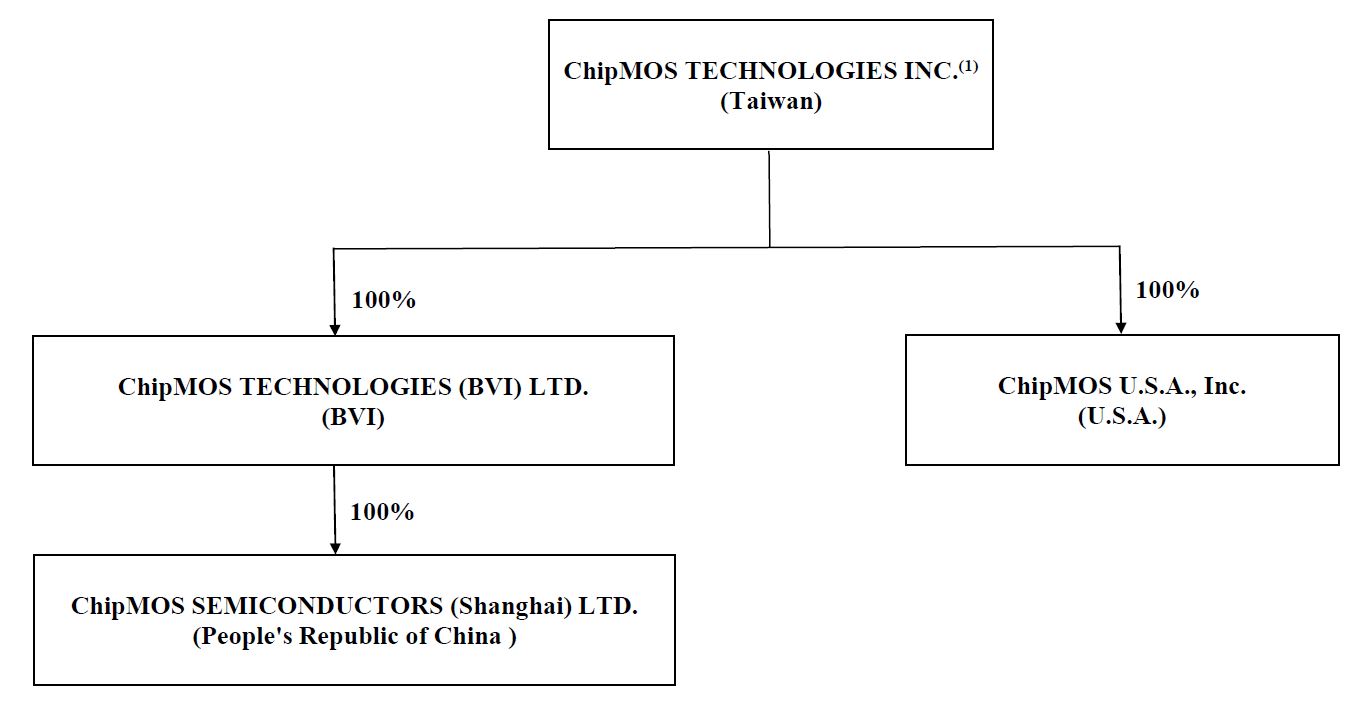

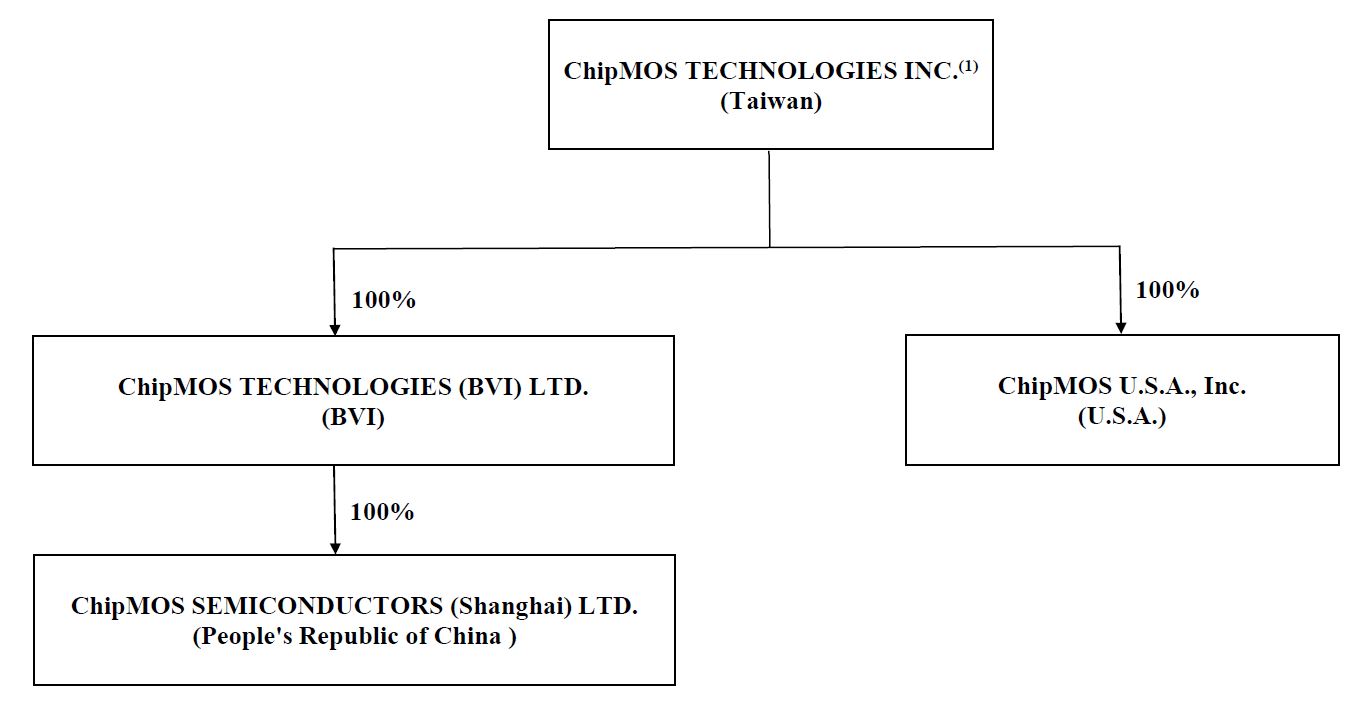

To implement our business strategy requires us to enter into acquisition, investment, joint venture and disposition transactions. These transactions may not be successful to maintain or grow our business. On December 21, 2023, the Company’s Board of Directors approved its wholly-owned subsidiary, ChipMOS TECHNOLOGIES (BVI) LTD., (“ChipMOS BVI”) to sell its entire 45.0242% equity interests in Unimos Microelectronics (Shanghai) Co., Ltd. (“Unimos Shanghai”) for a total sale price of RMB 979.3 million in cash. Under the proposed agreement, ChipMOS BVI will sell its entire remaining 45.0242% equity interests in Unimos Shanghai to Suzhou Oriza PuHua ZhiXin Equity Investment Partnership (L.P.) and other local Chinese investment management companies. The equity interest transfer is expected to be completed in the first half of 2024. Please see “Item 5. Operating and Financial Review and Prospects—Recent Acquisition” for additional information.

The success of our acquisitions, investments, joint ventures and dispositions depends on a number of factors, including:

•our ability to identify suitable investment, acquisition, joint venture or disposition opportunities;

•our ability to reach an agreement for an acquisition, investment, joint venture or disposition opportunity on terms that are satisfactory to us or at all;

•the extent to which we are able to exercise control over the acquired or joint venture company;

•our ability to align the economic, business or other strategic objectives and goals of the acquired company with those of our company; and

•our ability to successfully integrate the acquired or joint venture company or business with our company.

If we are unsuccessful in our acquisitions, investments, joint ventures and dispositions, we may not be able to implement fully our business strategy to maintain or grow our business.

We rely on key personnel, and our revenue could decrease and our costs could increase if we lose their services.

We depend on the continued service of our executive officers and skilled engineering, technical and other personnel. We will also be required to hire a substantially greater number of skilled employees in connection with our expansion plans. In particular, we depend on a number of skilled employees in connection with our LCD, OLED, automotive panel and other display panel driver semiconductor assembly and testing services, and the competition for such employees in Taiwan is intense. We may not be able to either retain our present personnel or attract additional qualified personnel as and when needed. Moreover, we do not carry key person insurance for any of our executive officers nor do we have employment contracts with any of our executive officers. If we lose any of our key personnel, it could be very difficult to find and integrate replacement personnel, which could affect our ability to provide our services, resulting in reduced revenue and earnings. In addition, we may need to increase employee compensation levels in order to retain our existing officers and employees and to attract additional personnel. As of February 29, 2024, 22% of the workforce at our facilities are foreign workers employed by us under work permits that are subject to government regulations on renewal and other terms. Consequently, if the regulations in Taiwan relating to the employment of foreign workers were to become significantly more restrictive or if we are otherwise unable to attract or retain these workers at reasonable cost, we may be unable to maintain or increase our level of services and may suffer reduced revenue and earnings.

If our security measures are breached and unauthorized access is obtained to our information technology systems, we may lose proprietary data.

Our security measures could be compromised by various factors, including computer hackers, employee errors, and unfavorable actions by suppliers, resulting in unauthorized access to our or our customers’ data, including our intellectual property, other confidential business information, or information technology systems.

Due to the frequent evolution of information technology and hacker techniques, we may be unable to anticipate these methods or implement adequate preventive measures. Any security vulnerability could lead to the disclosure of our trade secrets, confidential customer, supplier, or employee data. This could result in legal liability, damage to our reputation, and other harm to our business.

If our information technology systems succumb to cyberattacks by third parties, our business and operations may be severely interrupted or even shut down, and our results of operations, financial condition, prospects and reputation may also be materially and adversely affected.

Regarding the defense and strengthening of internal and external cybersecurity, we outline as follows:

Internal cybersecurity reinforcement: We've established an Information Security Management Committee dedicated to maintaining and promoting information security. Annual management review meetings are held regularly to review yearly tasks, including project execution, risk assessment, document compliance, education and training, significant information security incidents, key performance indicators in information security, information security attack prevention, internal and external concerns, disaster recovery drills, and the effectiveness report of company-wide phishing drills. Adhering to ISO 27001 principles, we implement various enhancements and improvements in information security. Additionally, we reinforce the Company’s information security through recommendations from the Management Review Committee, continually introducing effective and secure information security protection equipment or mechanisms to enhance information security awareness among all employees and foster professional information security personnel.

External cybersecurity defense: We periodically replace EOS devices, hire consultants for vulnerability scanning, penetration testing, and source code detection. We implement WAF to strengthen application web security, examining internal security through external intelligence collection. In the event of a network attack, although business operations may be interrupted, we strive to ensure data security for post-attack recovery. Should there be a leakage of business secrets or customer data, our commitments to customers and other stakeholders might suffer significant damage, potentially impacting our business performance, financial condition, prospects, and reputation negatively.

Risks Relating to Countries in Which We Conduct Operations

The operations we conduct through our affiliated companies that we do not fully own may be limited by legal duties owed to other shareholders of such companies.

Certain of our operations are conducted through companies that we do not fully own. For example, since March 31, 2017, the Company has owned 45.0242% equity interests of Unimos Shanghai through its wholly-owned subsidiary ChipMOS BVI. We also conduct other activities through our affiliated entities. See also “—Risks Relating to Our Common Shares or ADSs—The Company’s ability to maintain its listing and trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq Stock Market (“Nasdaq”) is dependent on factors outside of the Company’s control and satisfaction of stock exchange requirements. The Company may not be able to overcome such factors that disrupt its trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq or satisfy other eligibility requirements that may be required of it in the future” and “Item 7. Major Shareholders and Related Party Transactions—Related Party Transactions”.

In accordance with the various laws of the relevant jurisdictions in which our subsidiaries and affiliates are organized, each of our subsidiaries and affiliates and their respective directors owe various duties to their respective shareholders. As a result, the actions we wish our subsidiaries or affiliates to take could be in conflict with their or their directors’ legal duties owed to their other shareholders. When those conflicts arise, our ability to cause our subsidiaries or affiliates to take the action that we desire may be limited.

Any future outbreak of health epidemics and outbreaks of contagious diseases may materially affect our operations and business.

Any future outbreak of contagious diseases, such as avian influenza virus subtypes H5N1, H9N2 and H7N9 and swine influenza virus subtypes H1N1 and H3N2, New Influenza A or more commonly known as the “bird flu” and “swine flu”, Severe Acute Respiratory Syndrome (“SARS”), Middle East respiratory syndrome coronavirus (“MERS-CoV”), or COVID-19, for which there is inadequate treatment or no known cure or vaccine, may potentially result in a quarantine of infected employees and related persons, or even significant governmental measures being implemented to control the spread, including, among others, restrictions on travel, manufacturing and the movement of employees in many regions of the world. The occurrence could adversely affect our operations at one or more of our facilities or the operations of our customers or suppliers.

We cannot predict the impact that any further future outbreak of the aforementioned viruses or other diseases could have on our business and results of operations. If any of our employees is suspected of having contracted any contagious disease, we may, under certain circumstances, be required to quarantine such employees and the affected areas of our premises, or adhere to governmental measures to control the spread. As a result, we may have to suspend part or all of our operations temporarily, or may experience delays in product development, a decreased ability to support our customers, and overall lack of productivity. Our customers may also experience closures of their manufacturing facilities or inability to obtain other components, either of which could negatively impact demand for our solutions. In addition, any future outbreak may restrict the level of economic activity in affected regions, which may also adversely affect our businesses. As a result, there is no assurance that any future outbreak of contagious diseases would not have a material adverse effect on our business, financial condition and results of operations.

We face substantial political risk associated with doing business in the ROC, particularly due to the strained relations between the ROC and the PRC, which could negatively affect our business and the market price of our common shares or ADSs.

Our principal executive offices and our assembly and testing facilities are located in the ROC. As a result, our business, financial condition and results of operations and the market price of our common shares or ADSs may be affected by changes in the ROC governmental policies and the political relationship between the ROC and the PRC, as well as social instability and diplomatic and social developments in or affecting the ROC which are beyond our control. The ROC has a unique international political status. The PRC government regards Taiwan as a province and does not recognize the legitimacy of the ROC as an independent country. Although significant economic and cultural relations have been positively strengthened in recent years between the ROC and the PRC, relations have often been strained. In March 2005, the PRC government enacted the “Anti-Secession Law” codifying its policy of retaining the right to use military force to gain control over Taiwan, particularly under what it considers as highly provocative circumstances, such as a declaration of independence by Taiwan or the refusal by the ROC to accept the PRC’s stated “One China” principle.

In 2024, the pro-independence Democratic Progressive Party (“DPP”) won Taiwan’s Presidential Election. The President-Elect, Lai Ching-te, stressed that he would maintain the status quo with the PRC. However, the PRC continues to ramp up pressures through various means on the DPP administration for their refusal to accept the “One China” principle. It is uncertain how these different measures may affect our financial condition and results of operations, and there is no assurance that any future measures imposed by the PRC or ROC would not adversely affect our financial condition or results of operations.

Past developments related to the interaction between the ROC and the PRC have on occasion depressed the market prices of the securities of Taiwanese or Taiwan-related companies, including our own. We cannot assure you any contentious situations between the ROC and the PRC will resolve in maintaining the current status quo or remain peaceful. Relations between the ROC and the PRC and other factors affecting military, political or economic stability in Taiwan could have a material adverse effect on our financial condition and results of operations, as well as the market price and the liquidity of our common shares or ADSs.

The business and operations of our business associates and our own business operations are vulnerable to disruptions that may be caused by natural disasters and other events.

The frequency and severity of catastrophic events, including natural disasters and severe weather has been increasing, in part due to climate change or systemic regional geological changes that manifest in damaging earthquakes. ChipMOS has manufacturing and other operations in locations susceptible to natural disasters, such as flooding, earthquakes, tsunamis, typhoons, and droughts that may cause interruptions or shortages in the supply of utilities, such as water and electricity that could disrupt operations. In addition, ChipMOS’s suppliers and customers also have operations in such locations. We currently provide most of our testing services through our facilities in the Hsinchu Science Park and the Hsinchu Industrial Park in Taiwan, and all of our assembly services through our facility in the Southern Taiwan Science Park, which are susceptible to earthquakes, tsunamis, flooding, typhoons, and droughts from time to time that may cause shortages in electricity and water or interruptions to our operations. Significant damage or other impediments to these facilities as a result of natural disasters, industrial strikes or industrial accidents could significantly increase our operating costs.

The production facilities of many of our suppliers, customers and providers of complementary semiconductor manufacturing services, including foundries, are located in Taiwan. If our customers are adversely affected by natural disasters or other events occurring in or affecting these geographic areas, it could result in a decline in the demand for our assembly and testing services. If our suppliers and providers of complementary semiconductor manufacturing services are affected by such events, our production schedule could be halted or delayed. As a result, a major earthquake, other natural disaster, industrial strike, industrial accident or other disruptive event occurring in or affecting Taiwan could severely disrupt our normal operation of business and have a material adverse effect on our financial condition and results of operations.

ChipMOS has occasionally suffered power outages or surges in Taiwan caused by difficulties encountered by its electricity supplier, the Taiwan Power Company, or other power consumers on the same power grid, which have resulted in interruptions to our operations. Such shortages or interruptions in electricity supply could further be exacerbated by changes in the energy policy of the government which intends to make Taiwan a nuclear-free country. If we are unable to secure reliable and uninterrupted supply of electricity to power our manufacturing fabs within Taiwan, our ability to fill customers’ orders would be severely jeopardized. Also, in 2020 and 2021, Taiwan has faced one of the worst droughts in decades. Government imposes restrictions on the supply and usage of water by industrial companies like us as responses, it could disrupt our operations. We maintain a comprehensive risk management system dedicated to the safety of people, the conservation of natural resources, and the protection of property. In order to effectively handle emergencies and natural disasters, at each facility management has developed comprehensive plans and procedures that focus on risk prevention, emergency response, crisis management and business continuity. All ChipMOS manufacturing factories have been ISO 14001 certified (environmental management system) and ISO 45001 certified (occupational health and safety management system).

ChipMOS pays special attention to preparedness of emergency response to disasters, such as typhoons, floods and droughts caused by climate change, earthquakes and disruptions to water, electricity and other public utilities. We have established a company-wide taskforce dedicated to managing the risk of a water or electricity shortage that might arise due to climate change. Despite our preparedness, there is no assurance that any such natural disaster would not severely disrupt our normal operation of business and have a material adverse effect on our financial condition and results of operations.

Systemic political, economic and financial crises could negatively affect our business

In recent years, several major systemic political, economic and financial crises negatively affected global business, banking and financial sectors, including the semiconductor industry and markets.

Since 2018, there have been political and trade tensions among many of the world’s major economies. These tensions have resulted in the imposition of tariff, non-tariff trade barriers and sanctions, including export control restrictions and sanctions against certain countries and individual companies. These trade barriers and other measures have particularly impacted the semiconductor industry and related markets. Prolonged or increased use of trade barriers and such measures may result in a decrease in the growth of the global economy and the semiconductor industry, causing disturbance in global markets that often result in declines in electronic products sales from which we generate our income through our products and services. Also, any increase in the use of export control restrictions and sanctions to target certain countries and entities, any expansion of the extraterritorial jurisdiction of export control laws, or complete or partial ban on semiconductor products sales to certain entities could impact not only our ability to continue supplying products to those customers, but also our customers’ demand for our products, and could even lead to changes in semiconductor supply chains.

Conversely, measures adopted by an affected country to counter the impacts of another country’s actions or regulations could lead to significant legal liability to multinational corporations including our own. For example, the PRC Ministry of Commerce promulgated the Provisions on the Unreliable Entity List and the Blocking Statute in September 2020 and January 2021, and in furtherance of that, the “Anti-Foreign Sanctions Law” was promulgated by the PRC government on June 10, 2021 to systematize the ad hoc sanctions imposed by the PRC government on foreign individuals and organizations that, among other matters, entitles Chinese entities incurring damages from a multinational’s compliance with foreign laws to seek civil remedies. The imposition of trade sanctions or other regulations or the loss of “normal trade relations” status with the PRC could significantly increase our production cost and harm our business. As of the date of this annual report, our current results of operations have not been materially affected by the expanded export control regulations or the novel rules or measures adopted to counteract them. Nevertheless, depending on future developments of global trade tensions, such regulations, rules, or measures may have an adverse effect on our business and operations, and we may incur significant legal liability and financial losses as a result.

Further, changes in PRC’s economic, political or social conditions or government policies could adversely impact our business and operations. Some of the governmental measures implemented by the Chinese government may help China achieve its carbon peaking and neutrality goals as well as energy and climate goals, but may have a negative effect on us or our suppliers or customers in China. For example, China has implemented the dual-control policy on energy consumption and intensity to reduce energy intensity and to limit total energy consumption and to accelerate the elimination of outdated and inefficient excess production capacity. Despite a policy tool implemented in 2016, on June 3 and August 12, 2021, the National Development and Reform Commission issued the quarterly reviews of the target achievement for the first time, with progress alerts upon provinces. On September 16, 2021, the policymaker released “The Scheme to Refine Dual-Control of Energy Intensity and Total Energy Consumption”, which clarified the overall arrangement, working principles, as well as tasks and measures of the dual control system, and drew a roadmap for the development of the dual control system. Just days after that, some provinces with “progress alerts” started to employ power rationing and production curbs. From 2022, the severe situation of dual-control of energy consumption and intensity has been mitigated to some extent. For example, on February 18, 2022, the National Development and Reform Commission, the Ministry of Industry and Information Technology, the Ministry of Finance, and other Departments issued the Notice on Several Policies for Promoting the Steady Growth of Industrial Economy, requiring the people’s government to optimize the assessment frequency of total energy consumption control policies, to carry out overall assessment of energy intensity targets in the 14th Five-Year Plan period, and to avoid restricting enterprises' normal energy use due to the reason to achieve the targets of the energy consumption intensity. Further, on March 5, 2022, the Chinese Premier Li, Keqiang delivered the 2022 Government Work Report at the fifth session of the 13th National People’s Congress, emphasizing again that the targets of the energy consumption intensity in the 14th Five-Year Plan period should be assessed as a whole with appropriate flexibility, and further proposing to promote the transformation from the dual control of energy consumption and intensity to the dual control of total carbon emissions and intensity and to accelerate the formation of an incentive and restraint mechanism for reducing pollution and carbon. As a result, the impact of the dual control of energy consumption and intensity on the economy and the normal production and operation of enterprises might be less compared to prior years. Nevertheless, under the existence of dual-control policy of energy consumption and intensity, our suppliers or customers in China may be adversely affected. Consequently, our businesses, financial condition and results of operations may be materially and adversely affected.

Any future outbreak of radiation-related disease as a result of nuclear power plant reactors damage caused by the Great East Japan Earthquake of 2011 may materially adversely affect our operations and business.

The Great East Japan Earthquake of 2011 raises tremendous concerns about the possible effects of radiation emission from the damaged nuclear power plants. Japanese official authorities are working with experts in assessing the risk and determining the best courses of actions to implement to escape harmful radiation. The potential health effects due to exposure to harmful radiation may be temporary or permanent harmful effects in nature.

Multiple radioactive gases could possibly be emitted in a situation where uranium attains a “meltdown” state, which is a severe overheating of the core of a nuclear reactor, in which the core melts and radiation and heat are caused to escape. This would occur if the containment system partially or fully fails. The particles that are released with the gases due to the meltdown would be the spewed particles of iodine-131, strontium-90 and cesium-137. These might enter into a human by being swallowed, absorbed through the skin, or inhaled. Depending on the chemical characteristics of each of these and their predilection for certain body tissues, they could cause cancers of such organs as bones, soft tissues near bones, thyroid gland, and the bone marrow (typically known as leukemia).

Acute or very high level radiation exposure can cause a person to become very ill or to die quickly. Ionizing radiation, which is defined as high-energy particles or electromagnetic waves that can break chemical bonds, damage humans by disrupting cellular function, particularly in tissues with rapid growth and turnover of cells. Intense, high level and/or excessive radiation exposure may result in acute radiation syndrome whereby harmful effects to the human body may be evidenced by skin burns, internal organ deterioration, bleeding, vomiting, bone marrow distortion and deaths. If the radiation exposure is less intense and/or more prolonged at a lower level, then the central nervous system, kidneys, thyroid gland, and liver may be affected. Cancer is the most well-known effect, and may affect virtually any significantly exposed tissue.

Certain health effects due to exposure to harmful radiation does not have adequate treatment or known cure or vaccine, consequently, may potentially result in a quarantine of infected employees and related persons, and adversely affect our operations at one or more of our facilities or the operations of our customers or suppliers. We cannot predict the probability of any future outbreak of radiation related diseases as a possible result of nuclear power plants damage caused by the Great East Japan Earthquake of 2011 or the extent of the material adverse impact that this could have on our business and results of operations.

Risks Relating to Our Common Shares or ADSs

The Company’s ability to maintain its listing and trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq Stock Market is dependent on factors outside of the Company’s control and satisfaction of stock exchange requirements. The Company may not be able to overcome such factors that disrupt its trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq Stock Market or satisfy other eligibility requirements that may be required of it in the future.

The Company became listed and commenced trading its common shares on the main board of Taiwan Stock Exchange (“TWSE”) on April 11, 2014 and its ADSs on the Nasdaq on November 1, 2016. For a TWSE-listed and Nasdaq-listed company to continue trading on the main board of TWSE and Nasdaq depends in part on market conditions and other factors that may not within the control of the Company. For these reasons there can be no assurance that the Company’s shares will continue to be listed or traded on the TWSE or ADSs will continue to be listed or traded on the Nasdaq.

Volatility in the price of our common shares or ADSs may result in shareholder litigation that could in turn result in substantial costs and a diversion of our management’s attention and resources.

The financial markets in the United States and other countries have experienced significant price and volume fluctuations, and market prices of technology companies have been and continue to be extremely volatile. Volatility in the price of our common shares or ADSs may be caused by factors outside of our control and may be unrelated or disproportionate to our results of operations. Shareholders of public companies such as the Company frequently institute securities class action litigations against companies following periods of volatility in the market price of public company securities including common shares and ADSs. Litigation of this kind against the Company could result in substantial costs and a diversion of our management’s attention and resources.

Certain provisions in our constitutive documents and in our severance agreements with our executive officers make the acquisition of us by another company more difficult and costly and therefore may delay, defer or prevent a change of control.

We entered into change in control severance agreements with certain management pursuant to which we agreed to pay certain severance payments if a change in control event (as defined in the change in control severance agreements) occurs and the employment of such executive officer is terminated by our company other than for cause or by such executive officer for good reasons within two years following the occurrence of the change in control event. These agreements may increase the cost of a party seeking to effect a change in control of our company.

Future sales, pledge or issuance of common shares or ADSs by us or our current shareholders could depress our share price or ADSs price and you may suffer dilution.

Sales of substantial amounts of common shares or ADSs in the public market, the perception that future sales may occur, or the pledge of a substantial portion of our common shares or ADSs could depress the prevailing market price of our common shares or ADSs. See “Item 7. Major Shareholders and Related Party Transactions—Major Shareholders” for further information about our major shareholders.

The Company was listed and commenced trading of common shares on the main board of TWSE on April 11, 2014. See “—Risks Relating to Our Common Shares or ADSs—The Company’s ability to maintain its listing and trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq is dependent on factors outside of the Company’s control and satisfaction of stock exchange requirements. The Company may not be able to overcome such factors that disrupt its trading status of common shares on the Taiwan Stock Exchange or ADSs on the Nasdaq or satisfy other eligibility requirements that may be required of it in the future” for additional information on the Company’s listing on the main board of TWSE. We plan to issue, from time to time, additional shares in connection with employee compensation and to finance possible future capital expenditures, investments or acquisitions. The issuance of additional shares may have a dilutive effect on other shareholders and may cause the price of our common shares or ADSs to decrease.

Holders of Our ADSs do not have the same voting rights as holders of our common shares.

Under the ROC Company Act, except under limited circumstances, shareholders have one vote for each common share held. See “Item 10. Additional Information—Voting Rights” for a discussion of voting rights of holders of our common shares. Holders of our ADSs do not have the same voting rights as holders of our common shares. Instead, the voting rights of a holder of our ADSs are governed by the Deposit Agreement and are able to exercise voting rights on an individual basis as follows: if a holder of our ADSs outstanding at the relevant record date instructs the depositary to vote in a particular manner for or against a resolution, including the election of directors, the depositary will cause all the shares represented by such holder’s ADSs to be voted in that manner. If the depositary does not receive timely instructions from a holder of our ADSs outstanding at the relevant record date to vote in a particular manner for or against any resolution, including the election of directors, such holders of our ADSs will be deemed to have instructed the depositary or its nominee to give a discretionary proxy to a person designated by the Company to vote all the shares represented by such holder’s ADSs at the discretion of such person, which may not be in the interest of holders of our ADSs.

If a non-ROC holder of our ADSs withdraws and holds our shares, such holder of our ADSs will be required to appoint a tax guarantor, local agent and custodian in the ROC and register with the TWSE in order to buy and sell securities on the TWSE.

When a non-ROC holder of our ADSs elects to withdraw and hold our shares represented by our ADSs, such holder of our ADSs will be required to appoint an agent for filing tax returns and making tax payments in the ROC. Such agent will be required to meet the qualifications set by the ROC Ministry of Finance and, upon appointment, will become the guarantor of the withdrawing holder’s tax payment obligations. Evidence of the appointment of a tax guarantor, the approval of such appointment by the ROC tax authorities and tax clearance certificates or evidentiary documents issued by such tax guarantor may be required as conditions to such holder repatriating the profits derived from the sale of our shares. We cannot assure you that a withdrawing holder will be able to appoint, and obtain approval for, a tax guarantor in a timely manner.

In addition, under the current ROC law, such withdrawing holder is required to register with the TWSE and appoint a local agent in the ROC to, among other things, open a bank account and open a securities trading account with a local securities brokerage firm, pay taxes, remit funds and exercise such holder’s rights as a shareholder. Furthermore, such withdrawing holder must appoint a local bank or local securities firm to act as custodian for confirmation and settlement of trades, safekeeping of securities and cash proceeds and reporting and declaration of information. Without satisfying these requirements, non-ROC withdrawing holders of our ADSs would not be able to hold or otherwise subsequently sell our shares on TWSE or otherwise. Appointment of an agent or a tax guarantor might also incur additional costs.

Pursuant to Mainland investors regulations, only qualified domestic institutional investors (the “QDIIs”, each a “QDII”) or persons that have otherwise obtained the approval from the Ministry of Economic Affairs, ROC (the “MOEA”) and registered with the TWSE are permitted to withdraw and hold our shares from a depositary receipt facility. In order to hold our shares, such QDIIs are required to appoint an agent and custodian as required by the Mainland investors regulations. If the aggregate amount of our shares held by any QDII or shares received by any QDII upon a single withdrawal accounts for 10.0% of our total issued and outstanding shares, such QDII must obtain the prior approval from the MOEA. We cannot assure you that such approval would be granted.

Restriction on the ability to deposit our shares into our ADR facility may adversely affect the liquidity and price of our ADSs.

The ability to deposit our shares into our ADR facility is restricted by the ROC law. Under the current ROC law, no person or entity, including you and the Company, may deposit our shares into our ADR facility without specific approval of the Financial Supervisory Commission of the ROC, or the FSC, unless:

(1)the Company pays stock dividends on our shares;

(2)the Company makes a free distribution of our shares;

(3)holders of our ADSs exercise preemptive rights in the event of capital increases; or

(4)to the extent permitted under the Deposit Agreement and the relevant custody agreement and within the amount of depositary receipts which have been withdrawn, investors purchase our shares, directly or through the depositary, on the TWSE, and deliver our shares to the custodian for deposit into our ADR facility, or our existing shareholders deliver our shares to the custodian for deposit into our ADR facility.

With respect to item (4) above, the depositary may issue our ADSs against the deposit of our shares only if the total number of our ADSs outstanding following the deposit will not exceed the number of our ADSs previously approved by the FSC, plus any our ADSs issued pursuant to the events described in items (1), (2) and (3) above.

In addition, in the case of a deposit of our shares requested under item (4) above, the depositary will refuse to accept deposit of such our shares if such deposit is not permitted under any legal, regulatory or other restrictions notified by the Company to the depositary from time to time, which restrictions may include blackout periods during which deposits may not be made, minimum and maximum amounts and frequency of deposits.

The rights of holders of our ADSs to participate in our rights offerings are limited, which could cause dilution to your holdings.

The Company may from time to time distribute rights to its shareholders, including rights to acquire its securities. Under the Deposit Agreement, the depositary will not offer holders of our ADSs those rights unless both the distribution of the rights and the underlying securities to all our ADS holders are either registered under the Securities Act or exempt from the registration under the Securities Act. Although the Company may be eligible to take advantage of certain exemptions under the Securities Act available to certain foreign issuers for rights offering, the Company can give no assurances that it will be able to establish an exemption from registration under the Securities Act, and it is under no obligation to file a registration statement for any of these rights. Accordingly, holders of our ADSs may be unable to participate in our rights offerings and may experience dilution of their holdings.

If the depositary is unable to sell rights that are not exercised or not distributed or if the sale is not lawful or reasonably practicable, it will allow the rights to lapse, in which case holders of our ADSs will receive no value for these rights.

Changes in exchanges controls which restrict your ability to convert proceeds received from your ownership of our ADSs may have an adverse effect on the value of your investment.

Under the current ROC law, the depositary may, even without obtaining approvals from the Central Bank of the Republic of China (Taiwan) or any other governmental authority or agency of the ROC, convert NT dollars into other currencies, including US dollars, for:

•the proceeds of the sale of common shares represented by ADSs or received as stock dividends from our shares and deposited into the depositary receipt facility; and

•any cash dividends or cash distributions received.