Use these links to rapidly review the document

TABLE OF CONTENTS

Item 8. Financial Statements and Supplementary Data

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 10-K

| | |

ý |

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended April 3, 2010 |

or |

o |

|

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

|

Commission file number: 001-34133

GT Solar International, Inc.

(Exact name of registrant as specified in its charter)

| | |

Delaware

(State or other jurisdiction of

incorporation or organization) | | 03-0606749

(I.R.S. Employer

Identification No.) |

243 Daniel Webster Highway

Merrimack, New Hampshire 03054

(Address of principal executive offices, including zip code)

(603) 883-5200

(Registrant's telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

| | |

| Title of each class | | Name of each exchange on which registered |

|---|

| Common stock, $0.01 par value | | The NASDAQ Global Select Market |

Securities registered pursuant to Section 12(g) of the Act:None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes o No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes o No ý

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes o No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act. (Check one):

| | | | | | |

| Large accelerated filer o | | Accelerated filer ý | | Non-accelerated filer o

(Do not check if a

smaller reporting company) | | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No ý

The aggregate market value of the registrant's common stock, $0.01 par value per share, held by non-affiliates of the registrant on September 26, 2009, the last business day of the registrant's most recently completed second fiscal quarter, was approximately $212.0 million (based on the closing sales price of the registrant's common stock on that date). As of May 28, 2010, 143,974,904 shares of the registrant's common stock, $0.01 par value per share, were issued and outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

The information required by Part III of this Annual Report on Form 10-K, to the extent not set forth herein, is incorporated by reference from the registrant's definitive proxy statement relating to the Annual Meeting of Shareholders to be held in 2010, which will be filed with the Securities and Exchange Commission within 120 days after the end of the fiscal year to which this Annual Report on Form 10-K relates.

Table of Contents

GT Solar International, Inc.

Form 10-K

Year Ended April 3, 2010

TABLE OF CONTENTS

| | | | |

Item | |

| | Page |

|---|

| | PART I

| | |

Item 1. | | Business | |

5 |

Item 1A. | | Risk Factors | | 16 |

Item 1B. | | Unresolved Staff Comments | | 36 |

Item 2. | | Properties | | 36 |

Item 3. | | Legal Proceedings | | 37 |

Item 4. | | (Removed and Reserved) | | 38 |

| | PART II | | |

Item 5. | | Market for Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | |

39 |

Item 6. | | Selected Consolidated Financial Data | | 41 |

Item 7. | | Management's Discussion and Analysis of Financial Condition and Results of Operations | | 43 |

Item 7A. | | Quantitative and Qualitative Disclosures about Market Risk | | 69 |

Item 8. | | Financial Statements and Supplementary Data | | 71 |

Item 9. | | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | | 110 |

Item 9A. | | Controls and Procedures | | 110 |

Item 9B. | | Other Information | | 113 |

| | PART III | | |

Item 10. | | Directors, Executive Officers and Corporate Governance | |

113 |

Item 11. | | Executive Compensation | | 113 |

Item 12. | | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | | 113 |

Item 13. | | Certain Relationships and Related Transactions, and Director Independence | | 114 |

Item 14. | | Principal Accountant Fees and Services | | 114 |

| | PART IV | | |

Item 15. | | Exhibits and Financial Statement Schedules | |

114 |

Signatures | | 115 |

Exhibit Index | | 117 |

2

Table of Contents

Cautionary Statements Concerning Forward-Looking Statements

This Annual Report on Form 10-K contains "forward-looking statements" that involve risks and uncertainties, as well as assumptions that, if they never materialize or prove incorrect, could cause our results to differ materially from those expressed or implied by such forward-looking statements. The statements contained in this Annual Report on Form 10-K that are not purely historical are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. Forward-looking statements are often identified by the use of words such as, but not limited to, "anticipate," "believe," "continue," "could," "estimate," "expect," "intend," "may," "will," "plan," "target," "continue," and similar expressions or variations intended to identify forward-looking statements. These statements are based on the beliefs and assumptions of our management based on information currently available to management. Such forward-looking statements are subject to risks, uncertainties and other important factors that could cause actual results and the timing of certain events to differ materially from future results expressed or implied by such forward-looking statements. Factors that could cause or contribute to such differences include, but are not limited to, the following factors and any other factors discussed under the heading titled "Risk Factors" included elsewhere in this Annual Report on Form 10-K:

- •

- the potential adverse impact of general economic conditions on demand for our products;

- •

- current future credit and financial market conditions;

- •

- the failure of amounts in our order backlog to result in actual revenue or to translate into profits;

- •

- our dependence on a small number of customers;

- •

- our dependence on the sale of a limited number of products;

- •

- our dependence on a limited number of third party suppliers;

- •

- product liability claims and/or claims in relation to third party equipment;

- •

- loss of any of our management team or our inability to attract and retain key employees or integrate new employees into our management team;

- •

- our inability to attract, train and retain technical personnel;

- •

- our inability to protect our intellectual property and the possibility of litigation to protect our intellectual property rights;

- •

- risks associated with the international nature of our business, including of unfavorable political, regulatory, labor and tax conditions in foreign countries;

- •

- claims relating to the infringement, misappropriation or other violation of proprietary manufacturing expertise, technological innovation and other intellectual property rights;

- •

- compliance with legal systems in other countries in which we offer and sell our products;

- •

- commercial, jurisdictional and legal risks associated with our business in China and the increase in those risks as we expand our operations in China;

- •

- concentration of credit risk related to our cash equivalents and short term investments;

- •

- our inability to comply with covenants in our credit facilities;

- •

- our exposure to warranty claims;

- •

- our exposure to exchange rate fluctuations;

- •

- the effect of increases in interest rates or the reduced availability of financing on demand for our products;

3

Table of Contents

- •

- the securities class action lawsuits relating to our initial public offering;

- •

- the effect that the interpretation of existing or new accounting pronouncements could have on our revenue recognition and operating results;

- •

- our lack of ownership of the technology underlying our CVD reactor;

- •

- factors that impact revenue recognition of our polysilicon business, some of which are beyond our control;

- •

- cyclicality in the market for polysilicon and variation in demand for products sold in our polysilicon business;

- •

- direct and indirect competition for our polysilicon production equipment;

- •

- our reliance on a limited number of suppliers and manufacturers for our polysilicon business;

- •

- competition from other manufacturers of photovoltaic products;

- •

- the loss of or changes in government subsidiaries or economic incentives for on-grid solar electricity applications;

- •

- existing regulations and policies or changes to regulations and policies relating to the electric utility industry;

- •

- inability of the photovoltaic industry to compete successfully with conventional power generation or other sources of renewable energy; and

- •

- technological changes in the photovoltaic industry that render existing products and technologies uncompetitive or obsolete.

The foregoing factors should not be construed as exhaustive and should be read in conjunction with the other statements that are included under the heading "Risk Factors" included in this Annual Report on Form 10-K. Forward-looking statements speak only as of the date of this report. We undertake no obligation to publicly update or review any forward-looking statements to reflect events or circumstances after the date of such statements.

4

Table of Contents

PART I

Item 1. Business

Our Company

GT Solar International, Inc., through its subsidiaries (referred to collectively herein as "we," "us" and "our") is a leading global provider of polysilicon production technology, crystalline ingot growth systems and related photovoltaic manufacturing services for the solar industry. Our customers include several of the world's largest solar companies as well as companies in the chemical industry.

Our principal products are:

- •

- Chemical vapor deposition (CVD) reactors and related equipment used to produce polysilicon, the key raw material used in silicon-based solar wafers and cells; and

- •

- Directional solidification systems (DSS) furnaces and related equipment used to cast multicrystalline ingots by melting and cooling polysilicon in a precisely controlled process. These ingots are used to make photovoltaic (PV) wafers which are, in turn, used to make solar cells.

Our business was founded in 1994. Effective January 1, 2006, our business was acquired (the "Acquisition") by GT Solar Holdings, LLC, a newly formed company controlled by investment funds affiliated with G3W Ventures LLC, or "G3W", a private equity investment firm focused on the energy sector, and Oaktree Capital Management, L.P., or "OCM", a global alternative and non-traditional investment manager. We use the term "Predecessor" to refer to the operations of our predecessor for accounting purposes, GT Equipment Technologies, Inc. (now known as GT Solar Incorporated), for periods prior to the Acquisition by GT Solar Holdings, LLC on January 1, 2006 and the term "GT Solar" to refer to us with respect to our results of operations for periods following the Acquisition.

GT Solar International, Inc. was originally incorporated in Delaware in September 2006. On September 27, 2006, we completed an internal reorganization through which GT Solar International, Inc. became the parent company of GT Solar Incorporated, our principal operating subsidiary.

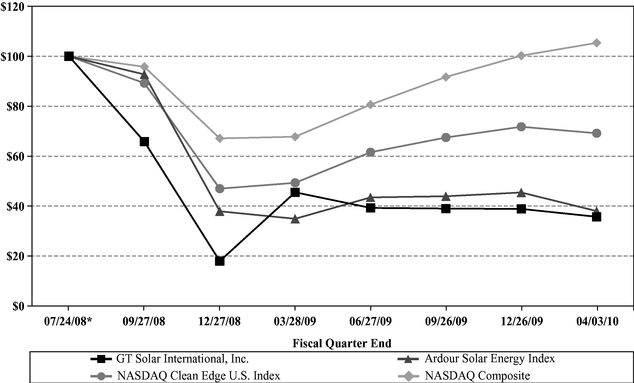

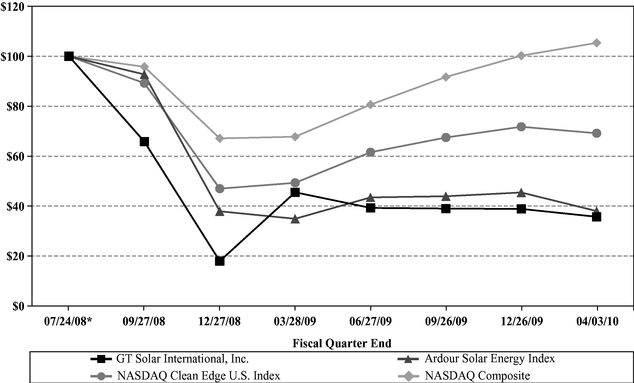

In July 2008, we completed an initial public offering of 30,300,000 shares of common stock by GT Solar Holdings, LLC. In March 2010, we completed a secondary public offering of 28,750,000 shares of common stock by GT Solar Holdings, LLC.

Industry Overview

Today, the majority of the world's electricity supply is generated by fossil fuels such as oil, coal and natural gas. Volatile global energy prices, increasing demand for electricity, particularly in developing economies, growing environmental awareness of the consequences of fossil fuel-based energy sources and the desire for energy security are driving the growth of renewable energy sources such as solar systems. Solar systems are used in industrial, commercial and residential applications to convert sunlight directly into electricity. Today, electricity costs generated from solar PV energy are higher than electricity generated by traditional energy sources. To offset the higher costs associated with solar energy and to encourage the adoption of alternative energy supplies, governments around the world have implemented various tax credits and other incentives.

According to Solarbuzz, the global PV market, as measured by total customer installations, grew at a compound annual growth rate of 50% between 2005 and 2009. The global economic recession which began in 2008 slowed expansion of the solar industry through the middle of 2009 when the industry began to experience an increase in demand. According to Solarbuzz, annual PV installations at end-user sites worldwide for 2009 were an estimated 7,300 megawatts (MW) with global PV industry revenues of approximately $38.5 billion for 2009. In its "Green World" scenario, Solarbuzz estimates

5

Table of Contents

that in 2014 the annual PV installations at end-user sites may reach approximately 24,700 MW with global PV industry revenues of approximately $78 billion for 2009.

The anticipated long-term growth of the solar PV industry is expected to increase investment in manufacturing capacity by polysilicon producers and solar manufacturing companies. Total capital expenditures associated with new manufacturing capacity for the production of mono-crystalline and multicrystalline silicon PV products in 2009 was approximately $17.0 billion, according to Solarbuzz, of which approximately $10.0 billion was spent on new polysilicon production capacity. In its "Green World" scenario, Solarbuzz estimates that, excluding emerging technologies, approximately 173,000 metric tons (MT) of polysilicon production capacity will be added from 2009 to 2014.

Information regarding markets, market size, market growth rates, forecasts and other industry data contained in this Annual Report on Form 10-K consists of estimates based on data and reports compiled by professional organizations, industry consultants and analysts, on data from other external sources, and on our knowledge and internal surveys of the solar and polysilicon industries. Marketbuzz 2010, an annual report dated March 2010 prepared by Solarbuzz LLC, an international solar energy market research and consulting company, was the primary source for third party industry data and forecasts.

In view of the emerging nature of the solar and polysilicon industries and the absence of publicly available information on most of the PV equipment and polysilicon manufacturers (including, without limitation, their existing production capacity, business plans and strategies), the estimates for the size of the solar and polysilicon markets and their projected growth rates set out in this Annual Report on Form 10-K should be considered with caution. Certain market share information and other statements in this Annual Report on Form 10-K regarding the solar and polysilicon industries and our position relative to our competitors is not based on published statistical data or information obtained by independent third parties. Rather, such information and statements reflect our management's best estimates based upon information obtained from trade and industry organizations and associations and other contacts within the solar and polysilicon industries. While we believe our internal estimates to be reasonable, they have not been verified by independent sources.

Manufacturing Trends

Manufacturers across the various segments comprising the PV manufacturing process are lowering their manufacturing costs and improving cell efficiency in an effort to make solar generated electricity more price competitive with electricity generated from traditional sources. According to the Solarbuzz Marketbuzz 2010 report, solar module prices have fallen from an average of $3.30 per watt in the fourth quarter of 2008 to an estimated $2.14 per watt in the first quarter of 2010. In the absence of a significant reduction in the cost of electricity generated from traditional sources, we believe that end user demand for solar energy will increase as production costs for solar energy decrease.

China continues to be one of the fastest growing global regions for PV manufacturing and polysilicon production. According to the Solarbuzz Marketbuzz 2010 report, at the end of 2009, 65% of the world's PV silicon wafer production capacity was located in China (including Taiwan) , up from 59% in 2008. Economic incentives offered by the Chinese government and the availability of low cost labor have accelerated the expansion of PV manufacturing capacity within the country. As a result, demand for PV capital equipment into the region is increasing and demand in traditional solar PV capital equipment markets such as Europe is decreasing. As a result of this trend, some capital equipment suppliers to the global PV manufacturing industry are choosing to locate manufacturing and operations to Asia. In the fiscal year ended April 3, 2010, 81% of our revenue was from existing or new customers in Asia, with 63% generated from customers in China.

We also believe that the desire to reduce overall cost is driving the growth of PV manufacturing and polysilicon production in China and is creating a trend towards PV manufacturers vertically

6

Table of Contents

integrating and expanding manufacturing capacity. Larger, better capitalized manufacturers improve their competitive position by controlling a greater range of the PV manufacturing process. The expanded scale of their operations enhances their ability to control costs, preserve margins, and manage through the volatility in raw material prices. We have provided equipment to four of the five largest PV manufacturers in China based on wafer manufacturing capacity, according to Solarbuzz data.

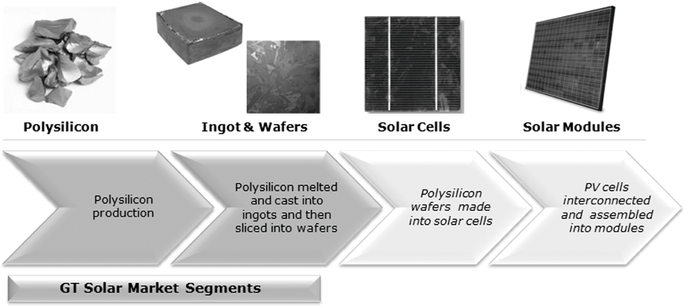

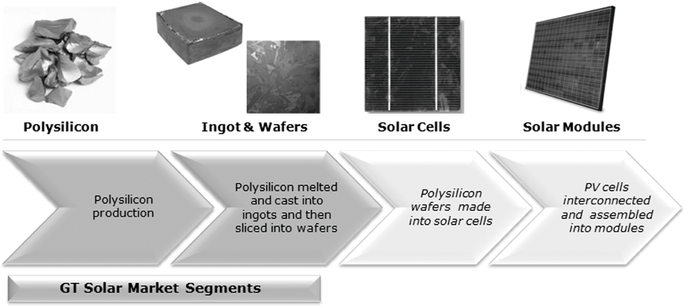

The PV Manufacturing Process

The production of multicrystalline-based PV modules includes a number of manufacturing steps. The first step involves the production of raw polysilicon using one of several production techniques. Raw polysilicon is then cast into a multicrystalline ingot in a DSS furnace. The ingot then moves into the wafering operation where it is sawed into bricks and the bricks are then sawed into thin wafers. Next the wafers are processed into solar cells through a series of etching, doping, coating and electrical contact processes. The next step involves interconnecting and assembling solar cells into solar modules. Finally, solar modules along with other system components such as batteries and inverters are installed as solar power systems.

We design and sell capital equipment and related services used in both the polysilicon production and ingot production segments of the PV manufacturing process.

Our Business Segments

Polysilicon Business

Polysilicon is a highly purified form of silicon that is a key raw material used to produce solar wafers. The same material is also used to make semiconductor wafers for microelectronic applications. Our polysilicon business offers CVD reactors and related equipment engineering services such as trichlorosilane (TCS) and silane engineering services to existing polysilicon producers and new market entrants. Our CVD reactors utilize the non-proprietary Siemens process, a widely used and proven polysilicon production process which has been in existence for nearly fifty years. In July 2006, our polysilicon business received its first order for CVD reactors from OCI Company, Ltd. (formerly DC Chemical Co., Ltd.,) a leading Korean chemical company. From July 31, 2007 through April 3, 2010 we shipped over 170 CVD reactors representing over 45,000 metric tons (MT) of polysilicon capacity.

7

Table of Contents

CVD reactors—We sell CVD reactors that produce polysilicon. We market our CVD reactors under the names SDR200 and SDR300. We began offering these products commercially in April 2006. Our SDR200 CVD reactors are producing at levels of approximately 200 MT of polysilicon annually and our SDR300 CVD reactors, which were introduced during our fiscal year ended March 31, 2008, are producing at levels of approximately 300 MT of polysilicon annually.

Customers for our polysilicon products include chemical companies and power generation companies that are entering the polysilicon market and solar wafer and cell manufacturers that are vertically integrating the production of polysilicon into their operations to become more cost competitive and meet their own production needs. All of the components for our CVD reactors are manufactured by third parties using our designs. Our personnel focus on product design, engineering services and project management providing technical know-how and process development related to the commissioning and production of polysilicon.

Polysilicon services, parts and other—In addition to CVD reactors for polysilicon manufacturing, we also provide technology and engineering services for the commissioning, start-up and optimization of our equipment and technology. We provide the basic engineering packages and process licenses for the production and purification of trichlorosilane and silane. We recently began offering hydrochlorination technology which lowers the capital costs and power consumption of polysilicon production. Hydrochlorination technology eliminates the need for silicon tetrachloride converters which are required when using other technology. Our personnel also support the commissioning and startup of our equipment and technology.

Photovoltaic Business

The primary focus of our PV business includes the manufacture and sales of DSS crystallization furnaces and ancillary equipment required in the operation of DSS crystallization furnaces to cast multicrystalline silicon ingots. We believe we have established a leading position in the market for specialized furnace technology for the production of multicrystalline solar wafers. From April 1, 2005 through April 3, 2010, we shipped over 1,450 DSS crystallization furnaces representing approximately 7 gigawatts of ingot production capacity.

DSS crystallization furnaces—Our DSS furnace is a specialized furnace used to melt polysilicon and cast multicrystalline ingots. Polysilicon is placed into a quartz crucible and the crucible is then loaded into the chamber of the DSS furnace where it is cast into multicrystalline ingots under precise heating and cooling conditions. Multicrystalline ingots are used to produce solar wafers, which ultimately become solar cells. Solar cells made from multicrystalline wafers represented approximately 46% of all solar cells produced in 2009 according to Solarbuzz. Our DSS crystallization furnaces are capable of applying precise incremental temperature changes, which is critical to forming quality ingots required for high efficiency solar cells. We have developed proprietary control software systems to automate the operation of the furnace during all stages of the crystal growth process. Our DSS furnaces share a common architecture, which allows customers to efficiently upgrade systems thus protecting their investment and increasing their return on investment. We market our DSS crystallization furnaces under the names DSS240, DSS450, and DSS450HP.

All of the components and assemblies for our DSS furnaces are manufactured by third parties using our designs. Our manufacturing personnel focus on final assembly, integration and testing of the DSS furnace prior to shipping the product to the customer. We also provide engineering and product design, quality control, process engineering and engineering services related to the operation of our DSS furnaces.

Ancillary equipment—Our largest capacity DSS furnaces, the DSS450 and DSS450HP are capable of producing ingots that weigh up to 450 kilograms. Our ancillary equipment provides operators with

8

Table of Contents

material handling assistance during the preparation of the crucible before it is loaded with silicon and during the loading and unloading of the crucible into the DSS furnace chamber at the start of the growth process and out of the DSS furnace chamber at the conclusion of the ingot growth process. Our ancillary equipment includes crucible coating stations, crucible manipulators, extraction tools and other material handling systems required to safely transport material during the ingot growth process. We report ancillary equipment revenue as other PV equipment.

Photovoltaic parts and services—The use of our products requires substantial technical know-how and many of our customers rely on us to design and optimize their production processes as well as train their employees in the use of our equipment. We sell replacement parts and consumables used in our DSS furnaces and other PV equipment. We also offer a range of services in connection with the sale of equipment, including facility design, equipment installation and integration, technical training and manufacturing process optimization. We typically charge for these services separately from the price of our equipment. As the number of our installed DSS crystallization furnaces continues to expand, we believe that sales of upgrades, parts and services will grow as well. We report revenue from PV parts and services as PV services, parts and other.

Turnkey integration services—We offer complete turnkey integration services, using third party wafer, cell and module production equipment designed to produce a specified level of output. These services are sold to new market entrants in connection with the construction of new PV manufacturing facilities. Most of our turnkey revenues have historically been from sales of wafer production lines, which provide additional sales opportunities for our DSS crystallization furnaces. We report turnkey revenue, exclusive of the DSS units, as other PV equipment. Our market for turnkey services has substantially decreased in recent years due to the maturity of the industry. As our activity in this area has correspondingly decreased, we have limited our marketing and sales efforts to identifying only highly qualified prospects that are well capitalized. We are reviewing our turnkey integration services and our plans with regards to this business will depend on the success of our current marketing efforts.

Our Competitive Strengths

We believe that our competitive strengths include:

- •

- Large and growing presence in China, a major growth market for solar manufacturing—Today, many of the world's leading solar manufacturing companies are based in China (including Taiwan), which according to Solarbuzz, accounted for approximately 65% of the world's solar wafer manufacturing capacity in 2009. We have provided equipment to four of the top five leading PV manufacturers in China based on wafer manufacturing capacity, according to Solarbuzz data.

We have been doing business in China since 2002 and are continuing to expand our base of operations to better serve the growing number of our China-based customers. In September 2009, we opened our Shanghai production facility to provide spare parts inventory, a demo and training center and other customer service capabilities for our Asia-based customers. We are also establishing our new Asia subsidiary, based in Hong Kong, which will become our new Asia headquarters. We expect this new facility to be operational in 2010. We believe that our relationships with leading Chinese solar companies and our expanding base of operations in China will enhance our ability to compete against the lower cost Chinese PV capital equipment companies in our markets.

- •

- Leading market position in crystal growth equipment for the multicrystalline solar industry—We believe our DSS crystallization furnaces are the most widely used furnaces for casting multicrystalline ingots in the solar industry. Since the introduction of our DSS240 in 2005, we have shipped over 1,450 furnaces to customers worldwide, the majority of which were to

9

Table of Contents

Our Growth Strategies

The significant components of our strategy include the following:

- •

- Better serve our customers by expanding our customer service and sales operations in Asia—Approximately 81% of our revenue for the fiscal year ended April 3, 2010 was generated from customers located in Asia, with the highest percentage of those customers located in China. To better serve their needs, we are establishing a new base of operations located in Hong Kong. We expect to commence operations there in 2010. We believe that expanding our Asia operations will allow us to improve our competitiveness against other low cost capital equipment suppliers based primarily in China. It will also allow us to be more responsive to our customers when they require service. Our Shanghai facility will continue to provide rapid shipment of replacement parts to customers when service is required, which will minimize our customers' production downtime.

10

Table of Contents

- •

- Protect our customers' investments in capital equipment by providing technical improvements for existing products that enhance their productivity and efficiency—As a capital equipment supplier we believe product innovation and technology research and development are critical to preserving our market leadership. Our strategy is to offer improvements on our products in terms of performance and cost reductions which help our customers lower their manufacturing costs and improve their return on investment.

During the fiscal year ended April 3, 2010, we began offering equipment and engineering services to assist companies with the production of trichlorosilane ("TCS"), an essential raw material in both the semiconductor and solar industries and introduced the DSS450HP, our latest version of the DSS450 product architecture. We also offer DSS450HP upgrades for sale which allows customers to achieve productivity increases of approximately 15% using their current DSS450 and approximately 50% using their current DSS240. We intend to continue to introduce new products that protect our customers' capital equipment investment and that lower their PV manufacturing costs.

- •

- Develop or acquire complementary technologies or businesses—We believe that the solar PV market is still fragmented but is moving toward higher levels of vertical integration throughout the PV manufacturing process. We believe our expertise in crystallization technology and the consolidation of the PV manufacturing industry will lead to opportunities for us to expand our product offerings through selective acquisitions. We will look for opportunities that build upon our core strengths in crystallization technologies.

Competition

We compete on the basis of reputation, technology, delivery, service (both installation and aftermarket) and price. While our turnkey business participates in all stages of the PV manufacturing process, we principally compete with equipment manufacturers in markets for CVD reactors for the production of polysilicon and DSS furnaces for the production of multicrystalline ingots.

Polysilicon business—Our CVD reactor products and other related services face direct competition from a small number of new entrants to the polysilicon production market. These competitors include MSA Apparatus Construction for Chemical Equipment Ltd, Centrotherm Elektrische Anlagen GmbH & Co., Morimatsu Industry Co. Ltd. and Poly Plant Project, Inc. We also face indirect competition from large, well-established companies that produce polysilicon primarily for the semiconductor industry. These companies have developed polysilicon production technology for their own use which they do not market to third parties. These indirect competitors include Hemlock Semiconductor Corporation, Wacker Chemie AG, Tokuyama Corporation, MEMC Electronic Materials, Inc., Renewable Energy Corporation ASA and M Setek Company Ltd.

Photovoltaic business—Over the past several years, we have seen the emergence of new, low-cost competitors to our DSS crystallization furnaces. These competitors include ALD Vacuum Technologies AG, JYT Corporation, Ferrotec Corporation, PVA TePla AG, Centrotherm Elektrische Anlagen GmbH & Co., Jing Gong Technology as well as a number of other furnace manufacturers. Several of these competitors, such as Centrotherm and Ferrotec are large integrated manufacturers with significant resources capable of competing for business globally.

Customers

We sell our products and services globally to polysilicon producers and solar wafer, cell and module manufacturers. Our customers include, or are suppliers to, some of the world's leading solar wafer and cell manufacturers.

11

Table of Contents

In any one year, we typically have a small number of customers, with any one customer representing a significant percentage of our total revenue. However, our customers and/or their contribution to our revenue typically change from year to year, as different customers replace equipment and undertake projects to add manufacturing capacity. The following customers comprised 10% or more of the Company's total net revenues for the fiscal years ended April 3, 2010, March 28, 2009 and March 31, 2008:

| | | | | | | | | | | | | | | | | |

| | Fiscal Year Ended | |

|---|

| | April 3, 2010 | | March 28, 2009 | | March 31, 2008 | |

|---|

| | Revenue | | % of

Total | | Revenue | | % of

Total | | Revenue | | % of

Total | |

|---|

| | (dollars in thousands)

| |

|---|

LDK Solar Co., Ltd | | $185,249 | | | 34 | % | $ | 108,781 | | | 20 | % | $152,271 | | | 62 | % |

OCI Company Ltd (formerly DC Chemical Co. Ltd) | | * | | | * | % | | 92,544 | | | 17 | % | * | | | * | % |

Baoding Tianwei, Yingli New Energy Resources Co., Ltd | | * | | | * | % | | 74,533 | | | 14 | % | * | | | * | % |

Glory Silicon Energy Co., Ltd | | * | | | * | % | | 57,896 | | | 11 | % | * | | | * | % |

- *

- Revenue from these customers was either zero or less than 10% of the total revenue during the period.

We believe that our sales to customers in Asia will continue to be a significant portion of sales over the next several years as polysilicon and PV manufacturing continues to grow in that region. For more information about our revenue by geographic region and our revenue, gross profit and assets by segment, please refer to Note 16 in our Consolidated Financial Statements included elsewhere in this Annual Report on Form 10-K.

Sales, Marketing and Customer Support

We market our products principally through a direct sales force, as well as through regional indirect sales representatives who solicit orders and identify potential sales opportunities in markets where our business is less established. All sales are made directly by us to the customer and our indirect sales representatives are not authorized to enter into sales contracts on our behalf.

We have established standard terms and conditions of sale for our products; however, sales contracts and prices can vary and are generally negotiated on a case-by-case basis. Customers are generally required to make a cash deposit when the order is placed. Customers occasionally require us to provide a standby letter of credit to secure the cash deposit. In addition to cash deposits, customers are also generally required to either post a letter of credit or make advance payments of typically 90% of the value of the equipment prior to shipment. The balance, typically 10%, is paid upon customer acceptance of the products sold, which typically occurs within a two to twelve month period after shipping based upon contract terms. Because of the longer production times associated with our CVD reactors, customers are also required to make a series of installment payments as production milestones are achieved in addition to the initial cash deposit. In the event market conditions deteriorate, our existing terms and conditions may not be sustainable.

Our polysilicon products are generally sold with a standard warranty typically for a period not exceeding twenty-four months from delivery. Our PV products are generally sold with a standard

12

Table of Contents

warranty for technical defects for a period equal to the shorter of: (i) twelve months from the date of acceptance by the customer; or (ii) fifteen months from the date of shipment. The warranty is typically provided on a repair or replacement basis and includes both products we manufacture and products that we supply our customers from other manufacturers. Our warranty expenses were $1.1 million for the fiscal year ended April 3, 2010, $2.3 million for the fiscal year ended March 28, 2009, and $1.9 million for the fiscal year ended March 31, 2008.

Our polysilicon production equipment and crystallization furnaces are critical to the operation of our customers manufacturing operations. Prior to an order being placed, a customer service representative advises the customer with respect to its facilities requirements and undertakes modeling of expected operating costs. Following delivery, our engineers assist with installation and integration of equipment at the customer's facility. After the sale is complete we often provide support services for a fee. As the number of our product installations increases, we will continue to enhance our service and support.

Manufacturing and Suppliers

Our manufacturing model is different from many capital equipment manufacturers in that we outsource most of the components used in our PV equipment. Our factory focuses on assembly operations and the production of proprietary components. Nearly all of the components of our polysilicon products are shipped directly from our qualified vendors to the customer installation site. Components for our DSS crystallization furnaces are shipped to our facility in Merrimack, New Hampshire, where they are integrated into the final system prior to shipping to the customer. This model results in a highly flexible cost structure, modest working capital and physical plant requirements and a relatively small number of manufacturing employees. Our flexible model provides a strategic advantage during downward market swings because it creates a low cost structure for our operations.

Our DSS manufacturing operation uses a "forecast manufacturing" methodology to project our raw material needs sufficiently in advance of manufacturing lead times, diminishing the threat of spot price volatility and generally minimizing the effect of supply shortages and disruptions. We believe this approach reduces product delivery times and increases scalability and factory utilization. Our polysilicon and turnkey operations procure materials when customer orders are received.

We purchase a range of materials and components for use in our products from other manufacturers. We also purchase equipment from third party manufacturers for resale as part of our turnkey solutions. Many component parts purchased by us are made to our specifications and under appropriate confidentiality arrangements. Purchased components represented approximately 87%, 85%, and 81% of cost of goods sold in the fiscal year ended April 3, 2010, March 28, 2009, and March 31, 2008, respectively. We attempt to secure multiple suppliers of our components to ensure adequate supply. In addition, we do not use any single supplier to produce all of the components for any single product in order to reduce the risk that a supplier could replicate our products. We believe that these materials and components are readily available from multiple sources and that we are not dependent on any single supplier or limited group of suppliers. We have well-established relationships with various domestic and foreign suppliers of the components used in our products. We generally are required to make a series of pre-payments to these vendors, which we fund from the deposits we receive from customers.

Research, Development and Engineering

Our research and development activities are focused on advancing, developing and improving technologies for the markets we serve. We also have cooperative research and development agreements

13

Table of Contents

with certain universities, customers and suppliers. Our research and development expense was $21.4 million in the fiscal year ended April 3, 2010; $18.3 million in the fiscal year ended March 28, 2009; and $10.5 million in the fiscal year ended March 31, 2008.

Intellectual Property

We believe that our competitive position depends, in part, on our ability to protect our intellectual property resulting from our research, development, engineering, manufacturing, marketing, and technical and customer service activities. Under our intellectual property strategy we protect our proprietary technology through a combination of patents, trademarks, copyrights, know-how, trade secrets, as well as employee and third party confidentiality and assignment of rights agreements. We focus on developing, identifying and protecting our technology and resulting intellectual property in a manner that supports our overall business and technology objectives. Although we rely on intellectual property that is primarily developed in-house for our solar and polysilicon equipment and related products, we also enter into patent and/or technology licenses with other parties when such licenses would advance or complement our products and technology or would otherwise be in our best interest.

One of the principal means of protecting our proprietary technology, including technical processes and equipment designs, is through trade secret protection and confidentiality agreements. Our personnel, including our research and development personnel, enter into confidentiality agreements and non-competition agreements with us. These agreements further address intellectual property protection issues and require our employees to assign to us, among other things, all of the inventions, designs and technologies they develop during the course of their employment with us. We also generally require our customers and business partners to enter into confidentiality agreements before we disclose any sensitive aspects of our technology or business plans.

We seek patent protection in various countries when it is consistent with our strategy and the protection afforded justifies the required disclosure costs associated with the filing. We own, or have applied for, various patents and patent applications in the United States and other countries relating to our products, product uses and manufacturing processes. The patents and patent applications vary in scope and duration. As of April 3, 2010, we owned twelve issued patents in the PV and semiconductor fields in the United States and had held seven patents in other jurisdictions. Although the products made, sold or used under our patents or technology licenses are important to us, we believe at this time that our business as a whole is not materially dependent on any particular patent or technology license, or on the licensing of our patents or technology to third parties, other than our customers.

We have not been subject to any material claims for infringement, misappropriation or other violation of intellectual property rights, claims for compensation by employee inventors or claims disputing ownership of our proprietary technologies.

Order Backlog

Our order backlog consists of signed purchase orders or other written contractual commitments. The table below sets forth our order backlog as of April 3, 2010 and March 28, 2009 by product category:

| | | | | | | | | | | | | |

| | April 3, 2010 | | March 28, 2009 | |

|---|

Product Category | | Amount | | % of

Backlog | | Amount | | % of

Backlog | |

|---|

| | (dollars in millions)

| |

|---|

Photovoltaic business | | $ | 441 | | | 49 | % | $ | 341 | | | 29 | % |

Polysilicon business | | | 465 | | | 51 | % | | 836 | | | 71 | % |

| | | | | | | | | | |

Total | | $ | 906 | | | 100 | % | $ | 1,177 | | | 100 | % |

| | | | | | | | | | |

14

Table of Contents

Our order backlog as of April 3, 2010, included deferred revenue of $82.1 million related to our photovoltaic business and $252.2 million related to our polysilicon business. Deferred revenue represents equipment that had been shipped to customers but not yet recognized as revenue. Cash received in deposits related to our order backlog were $119.6 million as of April 3, 2010, and substantially all of the contracts in our order backlog require the customer to either post a standby letter of credit in our favor or make advance payment prior to shipment of equipment. From the date of a written commitment, we generally would expect to deliver PV products over a period ranging from three to nine months and polysilicon products over a period ranging from twelve to eighteen months, although portions of the related revenue are expected to be recognized over longer periods in many cases. Disregarding the effect of any contract terminations or modifications, we would expect to convert approximately 50% of our April 3, 2010 order backlog into revenue during fiscal year 2011, and approximately 50% during fiscal 2012 and 2013. Although, most of our orders require substantial non-refundable deposits, our order backlog as of any particular date should not be relied upon as indicative of our revenues for any future period. We began tracking our backlog as a performance measure on a consistent basis during 2007.

If a customer fails to perform on a timely basis, and such failure continues after notice of breach and a cure period, we may terminate the contract. Our contracts do not contain cancellation provisions and in the event of a customer breach, the customer may be liable for contractual damages. During the fiscal year ended April 3, 2010, we terminated or modified contracts resulting in a $105 million reduction in our order backlog (95% of the reduction was from 9 contracts) as compared to the fiscal year ended March 28, 2009, during which we terminated or modified contracts resulting in a $39 million reduction in our order backlog (95% of the reduction was from 7 contracts). During the fiscal years ended April 3, 2010 and March 28, 2009 we recorded revenues of $21.1 million and $4.0 million, respectively, from terminated contracts.

Although we have a reasonable expectation that most of our customers will substantially perform on their contractual obligations, we monitor those contracts that we believe to be at risk which include contracts with customers to whom we have sent notices of breach for failure to provide letters of credit or to make payments when due. We conduct negotiations with certain customers who have requested that we extend their delivery schedules or make other contract modifications or who have not provided letters of credit or made payments in accordance with the terms of their contracts. We engage in a certain level of these negotiations in the ordinary course. We monitor the effect, if any, that these negotiations may have on our future revenue recognition. If we cannot come to an agreement with these customers, our order backlog could be reduced.

As a result of the economic downturn that began during the fiscal year ended March 28, 2009, we experienced an increase in the amount of backlog that we considered to be at risk which was substantially higher than in prior periods. As a result of contract terminations which occurred during the fiscal year ended April 3, 2010 and the satisfactory resolution of other contracts that were considered at risk, our assessment of the risk in our order backlog as of April 3, 2010 is substantially lower than our estimates in prior interim periods. However, other customers with contracts in our order backlog that are not currently under negotiation may approach us with similar requests in the future, or may fail to provide letters of credit or to make payments when due, which could further reduce our order backlog. If we cannot come to an agreement with these customers, our order backlog could be further reduced.

As of April 3, 2010, our order backlog consisted of contracts with 26 PV customers, 14 of which have orders of $3 million or greater and contracts with 7 polysilicon customers, 6 of which have orders of $3 million or greater. Our order backlog as of April 3, 2010, included $619 million attributed to three customers each representing 10% or more our order backlog.

15

Table of Contents

Employees

As of April 3, 2010, we employed 384 full-time employee equivalents and contract personnel, consisting of 121 engineering and research and development employees; 41 customer service representatives; 8 executives; 18 sales and marketing employees; 85 finance, general and administrative employees; 101 manufacturing staff; and 10 information technology employees. As of April 3, 2010, 268 employees were located at our headquarters in New Hampshire, 57 employees were located at our Montana facility and 70 employees were located at our Asia facilities. None of our employees are currently represented by labor unions or covered by a collective bargaining agreement. We believe that relations with our employees are satisfactory.

Environmental Matters

Our facility in Merrimack, New Hampshire is subject to an industrial user discharge permit governing the discharge of wastewater to the Merrimack sewer system. There are no further environmental related permits required by us that are material to our business. We are not aware of any environmental issues that would have a material adverse effect on our operations generally.

Available Information

Our internet website address is http://www.gtsolar.com. Through our website, we make available, free of charge, our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and any amendments to those reports, as soon as reasonably practicable after such materials are electronically filed, or furnished to, the Securities & Exchange Commission ("SEC"). These SEC reports can be accessed through the investor relations section of our website. The information found on our website is not part of this or any other report we file with or furnish to the SEC.

The charters of our Audit Committee, Compensation Committee, Nominating and Corporate Governance Committee, as well as our Code of Conduct and Code of Ethics for Senior Financial Officers, and Corporate Governance Guidelines are available on our website at www.gtsolar.com under "Corporate Governance". These items are also available in print to any stockholder who requests them by calling (603) 883-5200. This information is also available by writing to us, attention: Corporate Secretary, at the address on the cover of this Annual Report on Form 10-K.

Item 1A. Risk Factors

Our business, operating results and cash flows can be impacted by a number of factors, any one of which could cause our actual results to vary materially from recent results or from our anticipated future results. You should carefully consider the risks described below and the other information in this report before deciding to invest in shares of our common stock. These are the risks and uncertainties we believe are most important for you to consider. Additional risks and uncertainties not presently known to us, which we currently deem immaterial or which are similar to those faced by other companies in our industry or business in general, may also impair our business operations. If any of the following risks or uncertainties actually occurs, our business, financial condition and operating results would likely suffer. In that event, the market price of our common stock could decline and an investor in our common stock could lose all or part of their investment.

Risks Related to Our Business Generally

General economic conditions may have an adverse impact on demand for our products.

Demand for products requiring significant capital expenditures, such as our DSS units and CVD reactors, is affected by general economic conditions. A downturn in the global construction market reduces demand for solar panels in new residential and commercial buildings, which in turn reduces

16

Table of Contents

demand for our products that are used in the manufacture of PV wafers, cells and modules and polysilicon for the solar power industry. Uncertainties about economic conditions, negative financial news, tighter credit markets and declines in asset values have caused our customers to postpone making purchases of capital equipment. Increasing budgetary pressures could reduce or eliminate government subsidies and economic incentives for on-grid solar electricity applications. A prolonged downturn in the global economy could have a material adverse effect on our business in a number of ways, including decreased demand for our products, which would result in lower sales and reduced backlog.

Uncertainty about future economic conditions makes it challenging for us to forecast our operating results, make business decisions and identify the risks that may affect our business. If we are not able to timely and appropriately adapt to changes resulting from the difficult macroeconomic environment, our business, results of operations and financial condition may be materially and adversely affected.

Current or future credit and financial market conditions could materially and adversely affect our business and results of operations in several ways.

As widely reported, financial markets in the United States, Europe and Asia experienced extreme disruption recently, including, among other things, extreme volatility in security prices, severely diminished liquidity and credit availability, rating downgrades of certain investments and declining valuations of others. There can be no assurance that there will not be further deterioration in credit and financial markets and confidence in economic conditions. These economic developments affect businesses such as ours in a number of ways. The current tightening of credit in financial markets has resulted in reduced funding worldwide and a higher level of uncertainty for solar module manufacturers. As a result, some of our customers have been delayed in securing or prevented from securing funding adequate to honor their existing contracts with us or to enter into new contracts to purchase our products. We believe the reduced availability of funding for new manufacturing facilities and facility expansions, together with reduced demand for solar panels, has caused a decrease in orders for our products. We currently require most of our customers to prepay a portion of the purchase price of their orders. We use these customer deposits to prepay our suppliers to reduce the need to borrow to cover our cash needs for working capital. This practice may not be sustainable if the recent market conditions continue. Some of our customers who have become financially distressed have failed to provide letters of credit or make payments in accordance with the terms of their existing contracts. If customers fail to post letters of credit or make payments, and we do not agree to revised terms, it could have a significant impact on our business, results of operations and financial condition.

During the fiscal years ended April 3, 2010 and March 28, 2009, some of our customers failed to make deposits when due under their contracts, and we terminated those contracts. In addition, certain customers requested extensions of delivery dates and other modifications. The resulting contract modifications included lower pricing and reductions in the number of units deliverable under the contracts, thereby reducing our order backlog. As a result of these terminations and other contract modifications, our order backlog was reduced by $105 million during the fiscal year ended April 3, 2010 and by $39 million during the fiscal year ended March 28, 2009.

As a result of customer delays or contract terminations, we often reschedule or cancel purchase orders with our vendors to procure materials and reimburse the vendor for costs incurred to the date of termination plus predetermined profits. In cases where we are not able to cancel or modify purchase orders impacted by customer delays or terminations, our purchase commitments may exceed our order backlog requirements and we may be unable to redeploy the undelivered equipment. For example, during the year ended March 28, 2009, we rescheduled and/or cancelled commitments to our vendors as a result of customer delays, contract modifications and terminations and we recorded losses of $11.3 million relating to expected forfeitures of vendor advances and reserves against advances on inventory purchases with vendors that had become financially distressed.

17

Table of Contents

Delays in deliveries could cause us to have inventories in excess of our short-term needs and may delay our ability to recognize revenue on contracts in our order backlog. Additional contract breaches or cancellation of orders would prevent us from recognizing revenue on contracts in our order backlog and may require us to reschedule and/or cancel additional commitments to vendors in the future.

Such credit and financial market conditions may similarly affect our suppliers. We may lose advances we make to our suppliers in the event they become insolvent because our advances are not secured or backed by letters of credit. The inability of our suppliers to obtain credit to finance development or manufacture our products could result in delivery delays or prevent us from delivering our products to our customers. In addition, the volatility in the credit markets has severely diminished liquidity and capital availability. While the ultimate outcome of the disruptions in the credit markets cannot be predicted, they may result in events that could prevent us from obtaining new financing on commercially acceptable terms.

We are unable to predict the likely duration and severity of the disruption in financial markets and adverse worldwide economic conditions and any resulting effects or changes, including those described above, may have a material and adverse effect on our business, results of operations and financial condition.

Amounts included in our order backlog may not result in actual revenue or translate into profits.

Although our order backlog is based on signed purchase orders or other written contractual commitments, we cannot guarantee that our order backlog will result in actual revenue in the originally anticipated period or at all. In addition, the contracts included in our order backlog may not generate margins equal to our historical operating results. We began to track our order backlog on a consistent basis as a performance measure in 2007, and as a result, we do not have significant experience in determining the level of realization that we will actually achieve on our backlog. Our customers may experience project delays or defaults on the terms of their contracts with us as a result of external market factors and economic or other factors beyond our control. If a customer fails to perform its contractual obligations and we do not reasonably expect such customer to perform its obligations, we may terminate the contract. In addition, our backlog is at risk to varying degrees to the extent customers request that we extend the delivery schedules and make other modifications under their contracts in our order backlog. Any contract modifications that we negotiate could likely include an extension of delivery dates, and could result in lower pricing or in a reduction in the number of units deliverable under the contract, thereby reducing our order backlog. Our order backlog includes contracts with customers to whom we have sent notices of breach for failure to provide letters of credit or to make payments when due. If we cannot come to an agreement with these customers, it could result in a further reduction of our order backlog. Other customers with contracts in our order backlog that are not currently under negotiation may approach us with requests for delays in the future, or may fail to make payments when due, which could further reduce our order backlog. As a result of terminations and other contract revisions, our order backlog was reduced by $105 million during the fiscal year ended April 3, 2010 and by $39 million during the fiscal year ended March 28, 2009. If our order backlog fails to result in revenue in a timely manner, or at all, we could experience a reduction in revenue, profitability and liquidity.

18

Table of Contents

We currently depend on a small number of customers in any given fiscal year for a substantial part of our sales and revenue.

In each fiscal year, we depend on a small number of customers for a substantial part of our sales and revenue. For example, in the fiscal year ended April 3, 2010, one customer accounted for 34% of our revenue, in the fiscal year ended March 28, 2009, four customers accounted for 62% of our revenue and in the fiscal year ended March 31, 2008, one customer accounted for 62% of our revenue. In addition, as of April 3, 2010, we had a $907 million order backlog of which $619 million was attributable to three customers. As a result, the default in payment by any of our major customers, the loss of existing orders or lack of new orders in the future, or a change in the product acceptance schedule by such customers could significantly reduce our revenues and have a material adverse effect on our financial condition, results of operations, business and/or prospects. We anticipate that our dependence on a limited number of customers in any given fiscal year will continue for the foreseeable future. There is a risk that existing customers will elect not to do business with us in the future or will experience financial difficulties. Furthermore, many of our customers are at an early stage and many are dependent on the equity capital markets to finance their purchase of our products. As a result, these customers could experience financial difficulties and become unable to fulfill their contracts with us. There is also a risk that our customers will attempt to impose new or additional requirements on us that reduce the profitability of sales to those customers for us. If we do not develop relationships with new customers, we may not be able to increase, or even maintain, our revenue, and our financial condition, results of operations, business and/or prospects may be materially adversely affected.

Our success depends on the sale of a limited number of products.

A significant portion of our operating profits has historically been derived from sales of DSS units, CVD reactors and STC converters, which sales accounted for 91% of our revenue for the fiscal year ended April 3, 2010, 89% of our revenue in the fiscal year ended March 28, 2009 and 79% of our revenue in the fiscal year ended March 31, 2008. There can be no assurance that DSS units and CVD reactors sales will increase beyond, or be maintained at, past levels. We believe that sales of our STC converters will be substantially lower in the future due to changes in technology. Factors affecting the level of future sales of these products include factors beyond our control, including, but not limited to, demand for solar products and competing product offerings by other equipment manufacturers. There can be no assurance that we will be able to successfully diversify our product offering and thereby increase our revenue and/or maintain our profits in the event of a decline in DSS units and CVD reactors sales. If sales of these products decline for any reason, our financial condition, results of operations, business and/or prospects could be materially adversely affected.

We depend on a limited number of third party suppliers.

We use component parts supplied by a small number of third party suppliers in our products and source most equipment used in our turnkey solutions from third party suppliers. Our supplier agreements are typically short-term in nature, which leaves us vulnerable to the risk that our suppliers may change the terms on which they have previously supplied products to us or cease supplying products to us at any time and for any reason. There is no guarantee that we will maintain relationships with our existing suppliers or develop new relationships with other suppliers. In addition, many of our suppliers are small companies that may cease operations for any reason, including financial viability reasons, and/or may be unable to meet increases in our demand for component parts and equipment, as we expand and grow our business. We are also dependent on our suppliers to maintain the quality of the components we use and the increased demands placed on these suppliers as we continue to grow may result in quality control problems. We may be unable to identify replacement or additional suppliers or qualify their products in a timely manner and on commercially reasonable terms. Component parts supplied by new suppliers may also be less suited to our products than the

19

Table of Contents

component parts supplied by our existing suppliers. Certain of the component parts used in our products have been developed, made or adapted specifically for us. Such parts are not generally available from many vendors and could be difficult to obtain elsewhere. As a result, there may be a significant time lag in securing an alternative source of supply.

Our failure to obtain sufficient component parts and/or third party equipment that meet our requirements in a timely manner and on commercially reasonable terms could interrupt or impair our ability to assemble our products and provide turnkey solutions, and may adversely impact our plans to expand and grow our business, as well as result in a loss of market share. Further, such failure may prevent us from delivering our products as required by the terms of our contracts with our customers, and may harm our reputation and result in breach of contract and other claims being brought against us by our customers. Any changes to our current supply arrangements, whether to the terms of supply from existing suppliers or a change in our suppliers, may also increase our costs.

As a result of any of the foregoing factors, our financial condition, results of operations, business and/or prospects could be materially adversely affected.

We may face product liability claims and/or claims in relation to third party equipment.

It is possible that our products could result in property damage and/or personal injury, whether by product malfunctions, defects, improper use or installation or other causes. We cannot predict whether or not product liability claims will be brought against us or the effect of any resulting negative publicity on our business, which may include loss of existing customers, failure to attract new customers and a decline in sales. The successful assertion of product liability claims against us could result in potentially significant monetary damages being payable by us, and we may not have adequate resources to satisfy any judgment against us. Furthermore, it may be difficult to determine whether any damage or injury was due to product malfunction or operator error. For example, two of our customers have experienced accidents at their respective facilities involving our DSS units, one of which occurred in December 2006, and resulted in two deaths. To date, we have not received any product liability or other claims with respect to these or any other accidents. The bringing of product liability claims against us, whether ultimately successful or not, could have a material adverse effect on our financial condition, results of operations, business and/or prospects.

We provide third party equipment in connection with both turnkey solutions and stand-alone sales. There can be no guarantee that such third party equipment will function in accordance with our intended or specified purpose or that the customer's personnel, in particular those who are inexperienced in the use of the specialized equipment sold by us, will be able to install and operate it, which may result in the return of products and/or claims by the customer against us. In the event of a claim against us, there is no guarantee that we will be able to recover all or any of our loss from the third party equipment provider. Any such claim, in particular in the case of a turnkey solution where the customer may return other equipment sold by us or cancel related orders, could have a material adverse effect on our financial condition, results of operations, business and/or prospects.

Our future success depends on our management team and on our ability to attract and retain key employees and to integrate new employees into our management team successfully.

We are dependent on the services of our management team. Although certain of these individuals are subject to service agreements with us, any and all of them may choose to terminate their employment with us on thirty or fewer days' notice. The loss of any member of the management team could have a material adverse effect on our financial condition, results of operations, business and/or prospects. There is a risk that we will not be able to retain or replace these or other key employees. Integrating new employees into our management team could prove disruptive to our daily operations, require a disproportionate amount of resources and management attention and ultimately prove

20

Table of Contents

unsuccessful. This may have a material adverse effect on our financial condition, results of operations, business and/or prospects.

We may be unable to attract, train and retain technical personnel.

Our future success depends, to a significant extent, on our ability to continue to develop and improve our technology and to attract, train and retain experienced and knowledgeable technical personnel. Recruiting and retaining capable personnel, particularly those with expertise in the polysilicon or solar products industries, is vital to our success. There is substantial competition for qualified technical personnel, and qualified personnel are currently, and for the foreseeable future are likely to remain, a limited resource. Locating candidates with the appropriate qualifications can be costly, time-consuming and difficult. There can be no assurance that we will be able to attract new, or retain existing, technical personnel. We may need to provide higher compensation or increased training to our personnel than current levels. If we are unable to attract and retain qualified personnel, or are required to change the terms on which our personnel are employed, our financial condition, results of operations, business and/or prospects may be materially adversely affected.

We may be unable to protect our intellectual property adequately and may face litigation to enforce our intellectual property rights.

Our ability to compete effectively against other solar equipment manufacturers will depend, in part, on our ability to protect our current and future proprietary technologies, product designs, product uses and manufacturing processes under relevant intellectual property laws including, but not limited, to laws relating to patents and trade secrets.

We own various patents and patent applications in the United States and other countries relating to our products, product uses and manufacturing processes. To the extent that we rely on patent protection, our patents may provide only limited protection for our technology and may not be sufficient to provide competitive advantages to us. For example, competitors could develop similar or more advantageous technologies or design around our patents or otherwise employ alternative products, equipment or processes that may successfully compete with our products and technology. In addition, patents are of limited duration. Any issued patents may also be challenged, invalidated or declared unenforceable. If our patents are challenged, invalidated or declared unenforceable, other companies will be better able to develop products that compete with ours, which could adversely affect our competitive business position, business prospects and financial condition. Further, we may not have, or be able to obtain, effective patent protection in all of our key sales territories. Our patent applications may not result in issued patents and, even if they do result in issued patents, the patents may not include rights of the scope that we seek. The patent position of technology-oriented companies, including ours, is uncertain and involves complex legal and factual considerations. Accordingly, we do not know what degree of protection we will obtain from our proprietary rights or the breadth of the claims allowed in patents issued to us or to others. Further, given the costs of obtaining patent protection, we may choose not to protect certain innovations that later turn out to be important to our business.

Third parties may infringe, misappropriate or otherwise violate our proprietary technologies, product designs, manufacturing processes and our intellectual property rights therein, which could have a material adverse effect on our financial condition, results of operations, business and/or prospects. Because the laws and enforcement mechanisms of various countries that we seek protection in may not allow us to adequately protect our intellectual property rights, the strength of our intellectual property rights will vary from country to country. Litigation to prevent, or seek compensation for such infringement, misappropriation or other violation may be costly and may divert management attention and other resources away from our business without any guarantee of success.

21

Table of Contents

We also rely upon proprietary manufacturing expertise, continuing technological innovation and other know-how or trade secrets to develop and maintain our competitive position. While we generally enter into confidentiality and non-disclosure agreements with our employees and third parties to protect our intellectual property, such confidentiality and non-disclosure agreements could be breached and are limited, in some instances, in duration and may not provide meaningful protection for the trade secrets or proprietary manufacturing expertise that we hold. We have had in the past and may continue to have certain of our employees terminate their employment with us to work for one of our customers or competitors. Adequate or timely remedies may not be available in the event of misappropriation, unauthorized use or disclosure of our manufacturing expertise, technological innovations and trade secrets. In addition, others may obtain knowledge of our manufacturing expertise, technological innovations and trade secrets through independent development or other legal means and, in such cases, we may not be able to assert any trade secret rights against such a party.

We may face claims in relation to the infringement or misappropriation of third-party intellectual property rights.

Notwithstanding our intellectual property rights, we may be subject to claims that our products, processes or product uses infringe the intellectual property rights of others. These claims, even if meritless, could be expensive and time consuming to defend. In addition, if we are not successful in our defense of such claims, we could be subject to injunctions and/or damages, or be required to enter into licensing arrangements requiring royalty payments and/or use restrictions. In some instances, licensing arrangements may not be available to us or, if available, may not be available on acceptable terms.