UNITED STATESSECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

☒ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGEACT OF 1934

For the fiscal year ended December 31, 2013

OR

☐ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIESEXCHANGE ACT OF 1934

For the transition period from _______ to ________

Commission File Number: 001-35902

Insys Therapeutics, Inc.

(Exact name of registrant as specified in its charter)

Delaware | 51-0327886 |

(State or Other Jurisdiction of | (I.R.S. Employer |

Incorporation) | Identification No.) |

444 South Ellis St., Chandler, Arizona | 85224 |

(Address of Principal Executive Offices) | (Zip Code) |

(602) 910-2617

(Registrant’s Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act:

Title Of Each Class | Name Of Each Exchange On Which Registered |

Common Stock, $0.0002145 Par Value Per Share | The NASDAQ Global Market LLC |

Securities Registered Pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☐ No ☑

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☑

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☑ No ☐

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ☑ No ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment of this Form 10-K. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer ☐ | Accelerated filer ☐ | Non-accelerated filer ☐ | Smaller reporting company ☑ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☑

The aggregate market value of the voting and non-voting common equity held by non-affiliates of the registrant was approximately $73.4 million as of June 30, 2013 based on the closing sales price of the common stock on the NASDAQ Global Market.

There were 22,273,494 shares of the registrant’s common stock issued and outstanding as of February 26, 2014.

Documents Incorporated by Reference

Portions of the registrant's Proxy Statement relating to its 2014 Annual Meeting of Stockholders, to be filed with the Securities and Exchange Commission (“SEC”) pursuant to Regulation 14A within 120 days after the registrant’s fiscal year ended December 31, 2013, are incorporated by reference in Part III of this Form 10-K.

TABLE OF CONTENTS

| | Page

Numbers |

PART I |

| | |

Item 1. | Business | 2 |

| | | |

Item 1A. | Risk Factors | 23 |

| | | |

Item 1B. | Unresolved Staff Comments | 59 |

| | | |

Item 2. | Properties | 59 |

| | | |

Item 3. | Legal Proceedings | 59 |

| | | |

Item 4. | Mine Safety Disclosures | 59 |

| | |

PART II |

| | |

Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters, and Issuer Purchases of Equity Securities | 60 |

| | | |

Item 6. | Selected Financial Data | 60 |

| | | |

Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations | 61 |

| | | |

Item 7A. | Quantitative and Qualitative Disclosures About Market Risk | 76 |

| | | |

Item 8. | Financial Statements and Supplementary Data | 77 |

| | | |

Item 9. | Changes in and Disagreements With Accountants on Accounting and Financial Disclosure | 101 |

| | | |

Item 9A. | Controls and Procedures | 101 |

| | | |

Item 9B. | Other Information | 101 |

| | | |

| PART III |

| |

Item 10. | Directors, Executive Officers and Corporate Governance | 102 |

| | | |

Item 11. | Executive Compensation | 102 |

| | | |

Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 102 |

| | | |

Item 13. | Certain Relationships and Related Transactions, and Director Independence | 102 |

| | | |

Item 14. | Principal Accountant Fees and Services | 102 |

| | | |

PART IV |

| | | |

Item 15. | Exhibits, Financial Statement Schedules | 103 |

| | | |

SIGNATURES | 105 |

PART I

ITEM 1. BUSINESS

Overview

As used in this Form 10-K, “we,” “us,” and “our” refer to Insys Therapeutics, Inc.

We are a commercial-stage specialty pharmaceutical company that develops and commercializes innovative supportive care products. We have two marketed products: Subsys, a proprietary sublingual fentanyl spray for breakthrough cancer pain, or BTCP, in opioid-tolerant patients and Dronabinol SG Capsule, a generic equivalent to Marinol (dronabinol), an approved second-line treatment of chemotherapy-induced nausea and vomiting, or CINV, and anorexia associated with weight loss in patients with AIDS. We market Subsys through an incentive-based sales model.

Insys Therapeutics, Inc. was incorporated in Delaware in June 1990, and we maintain headquarters in Chandler, Arizona. We were in the development stage through December 31, 2011. The year 2012 is the first year during which we were considered an operating company and was no longer in the development stage. We completed our initial public offering of common stock in May 2013. On November 8, 2010, we effected a merger with NeoPharm, Inc., or NeoPharm, in a transaction accounted for as a reverse acquisition, or the NeoPharm merger. All of our outstanding share capital was exchanged for newly-issued shares of common stock and convertible preferred stock of NeoPharm. As a result of the NeoPharm merger, we became a wholly-owned subsidiary of NeoPharm and changed our name to Insys Pharma, Inc., or Insys Pharma. NeoPharm then changed its name to Insys Therapeutics, Inc. Since Insys Pharma, formerly known as Insys Therapeutics, Inc., was the acquiring entity for accounting purposes, the financial statements included in this report for all periods up to and including the November 8, 2010 NeoPharm merger date are the financial statements of the entity that is now the subsidiary, Insys Pharma. The financial statements for all periods subsequent to the November 8, 2010 NeoPharm merger date are the consolidated financial statements of Insys Therapeutics, Inc. and Insys Pharma.

Information about our company and communities is provided on our Internet website at www.insys.com. The information contained on our website is not considered part of this Annual Report on Form 10-K. Our periodic and current reports, including any amendments, filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended are available, free of charge, on our website as soon as reasonably practicable after they are electronically filed with or furnished to SEC. These filings are also available on the SEC’s website atwww.sec.gov. Information contained on our website it not considered part of this annual report.

We are leveraging our capabilities in dronabinol formulation and manufacturing, as well as our sublingual spray drug delivery technology, to develop a robust portfolio of differentiated, wholly-owned product candidates. Our lead product candidate is Dronabinol Oral Solution, a proprietary, orally administered liquid formulation of dronabinol, which will be our second branded supportive care product, if it successfully obtains all required regulatory approvals. We believe this product candidate may provide increased flexibility in dosing for doctors and more convenient delivery and an improved absorption profile for patients, which may ultimately increase patient compliance because of more rapid onset of action and less dose-to-dose variability and allow us to further penetrate and potentially expand the market for the use of dronabinol. We intend to market Dronabinol Oral Solution and any other future supportive care products, if approved, through our commercial organization.

Our Products and Product Candidates

Subsys is a proprietary, single-use product that delivers fentanyl, an opioid analgesic, for transmucosal absorption underneath the tongue. We filed our New Drug Application, or NDA, in March 2011 and received marketing approval for Subsys from the U.S. Food and Drug Administration, or FDA, in January 2012 for the treatment of BTCP. BTCP is characterized by sudden, often unpredictable, episodes of intense pain which can peak in severity at three to five minutes despite background pain medication. We believe Subsys is an important, differentiated treatment option for patients and physicians relative to other transmucosal immediate-release fentanyl, or TIRF, products due to its rapid onset of action, improved bioavailability, most complete range of dosage strengths and ease of administration. Our product label includes data from our pivotal clinical trial demonstrating that Subsys provides pain relief at five minutes, which represents the most rapid onset of action in the TIRF class of products. Also, in a head-to-head study, Subsys demonstrated 76% bioavailability versus 51% for Actiq, which is the current market-leading TIRF product (including its generic equivalents). Further, Subsys offers the most complete range of dosage strengths in the TIRF class of products, consisting of 100 to 1,600 microgram, or mcg, doses. Patients can administer Subsys in less than one minute while Actiq and Fentora, the leading branded TIRF products, can require 14 to 30 minutes to administer.

We launched Subsys as a commercial product in March 2012. Subsys is the fourth new branded product in the TIRF market over the last four years. Within the first four weeks of product launch, Subsys realized greater market share than the previous three branded products combined at their respective peak market penetration levels to date according to Source Healthcare Analytics. In December 2013, Subsys was the most prescribed branded TIRF product with 28.3% market share on a prescription basis according to Source Healthcare Analytics. Through our ongoing commercial initiatives, we believe we can continue to grow our market share and net revenue for Subsys. According to Source Healthcare Analytics, in 2013, TIRF products generated $421.2 million in annual U.S. product sales. The physician prescriber base for TIRF products is concentrated with approximately 1,850 physicians writing 90% of all TIRF product prescriptions in 2013, according to Source Healthcare Analytics. As a result, our commercial organization is able to promote Subsys using a highly targeted approach designed to maximize impact with physicians.

Subsys utilizes our proprietary sublingual spray technology consisting of a small, single-unit device that delivers our proprietary formulation of drug particles via a fine mist disbursed across a broad surface area of the highly permeable membrane underneath the tongue. This delivery platform is suitable for other molecules for which there may be a benefit to a greater rate and extent of absorption, which could lead to a more rapid onset of action and enhanced bioavailability versus other oral preparations and routes of administration. We are developing our proprietary sublingual spray technology in other product applications in order to expand our portfolio of product candidates.

Dronabinol SG Capsule is a dronabinol soft gelatin capsule that is a generic equivalent to Marinol, an approved second-line treatment for CINV and anorexia associated with weight loss in patients with AIDS. Dronabinol, the active ingredient in Marinol, is a synthetic cannabinoid whose chemical name is delta-9-tetrahydrocannabinol, or THC. Dronabinol SG Capsule was the first approved product in our family of dronabinol product candidates that we are developing. We commercialize Dronabinol SG Capsule through our exclusive supply and distribution agreement with Mylan Pharmaceuticals Inc. We believe that Marinol and its generic equivalents have limitations in their current formulations. Marinol is characterized by a highly variable bioavailability and an onset of action that ranges from 30 minutes to one hour. We are developing additional proprietary formulations of dronabinol, the most advanced of which is Dronabinol Oral Solution, to address these limitations.

Our lead product candidate is Dronabinol Oral Solution, a proprietary, orally administered liquid formulation of dronabinol, which has yet to be approved for commercialization. Dronabinol Oral Solution has demonstrated more rapidly detectable blood levels and a more reliable absorption profile than Marinol in our clinical studies. In 2012, we completed a pre-NDA meeting with the FDA and a pivotal bioequivalence study. Our pivotal bioequivalence study measured the pharmacokinetics, or PK, of Dronabinol Oral Solution versus Marinol. This PK study demonstrated that 100% of subjects receiving Dronabinol Oral Solution achieved detectable plasma levels at 15 minutes compared to less than 25% of subjects receiving Marinol. In this study, Dronabinol Oral Solution also demonstrated a 44% decrease in the patient coefficient of variation for area under the curve, or AUC, which is indicative of greater patient exposure to drug. We believe these product attributes could result in Dronabinol Oral Solution capturing a significant share of the existing U.S. market for dronabinol products, which was $134.7 million in 2013, according to IMS Health, and potentially expanding the usage of dronabinol-based products.

The Potential Market for BTCP Management

The National Cancer Institute estimates that, as of January 1, 2009, there were approximately 12.5 million people in the United States who had been diagnosed or were living with cancer. According to the American Cancer Society, the number of patients with cancer continues to increase as the population ages and diagnosis, treatment and survival rates improve due to higher standards of care and greater patient access to health care. Cancer patients often suffer from symptoms such as pain, nausea, vomiting, fatigue, weight loss and anemia as a result of their cancer or radiation and chemotherapy treatments intended to eradicate or inhibit the growth of cancerous cells and tumors. Pain is a widely prevalent symptom of cancer patients, an estimated 50% to 90% of whom also suffer from BTCP. We believe that the acute pain episodes of BTCP patients are not adequately managed by oncologists and pain specialists, creating an opportunity for us to educate these medical professionals and promote effective BTCP management using Subsys. According to a 2004 study by the American Society of Clinical Oncology, it is estimated that 60% to 80% of all cancer patients who receive chemotherapy experience nausea and vomiting associated with their therapy. We believe current therapies do not adequately address the needs of many of these patients. Supportive care is an important component in the treatment of cancer patients, as suggested by an August 2010 article in theNew England Journal of Medicine indicating that improved supportive care in cancer patients prolonged median survival by over two months. By focusing on supportive care products, we believe we can contribute to the improvement of cancer patient outcomes and survival rates.

Strategy

Grow Subsys market share and revenues. We launched Subsys as a commercial product in March 2012. By December 2013, we had a 28.3% share of the overall TIRF market, according to Source Healthcare Analytics. We believe that we can continue to increase Subsys net product revenue through further market penetration and educating the medical community to ensure that patients are titrated to an effective dose of Subsys and have access to Subsys. In addition, we may conduct post-marketing clinical trials to seek to establish incremental uses for Subsys in the supportive care market or other advantages that Subsys may have over existing fentanyl products.

Achieve FDA approval for Dronabinol Oral Solution and advance our synthetic cannabinoid product pipeline. We believe there is an unmet patient need for a more reliable synthetic THC for treating CINV and anorexia associated with weight loss in patients with AIDS. In a pivotal bioequivalence study, our Dronabinol Oral Solution product candidate has demonstrated rapid and more reliable absorption, which we believe represents an attractive product profile relative to Marinol. We are also evaluating proprietary sublingual spray, inhaled and intravenous formulations of dronabinol in preclinical testing. We also have the capability to manufacture synthetic cannabidiol (CBD) and we intend to pursue clinical studies that could result in future commercial products containing CBD.

Continue to leverage our cost-efficient commercial organization to market Subsys and, if approved, Dronabinol Oral Solution and other complementary products. We commercialize Subsys through a cost-efficient commercial organization utilizing an incentive-based sales model similar to that employed by Sciele Pharma and other companies previously led by members of our board of directors, including our founder and Executive Chairman. We intend to market Dronabinol Oral Solution and other proprietary supportive care products, if approved, using the same approach and our commercial organization. We target our product detailing efforts primarily towards oncologists, pain specialists and centers that focus on supportive care. We may also pursue opportunities to acquire commercial products or product candidates that could further leverage our supportive care commercial organization.

Use our core competencies and expertise to expand our dronabinol and cannabidiol manufacturing capabilities. Since dronabinol is difficult to import, procure and produce, we have a U.S.-based, state-of-the-art dronabinol manufacturing facility, which we anticipate will be able to supply the active pharmaceutical ingredient, or API, for Dronabinol SG Capsule and initial launch quantities of Dronabinol Oral Solution, if approved. We are currently constructing a second manufacturing facility that will enable us to supply sufficient commercial quantities of dronabinol API for our continued commercialization of Dronabinol SG Capsule and for the commercialization of our proprietary synthetic cannabinoid product candidates, if approved.

Research and develop additional sublingual spray product candidates. We believe that the delivery of certain pharmaceutical products using our sublingual spray platform technology could have significant advantages over other methods of delivery. Our technology delivers drug product directly to the sublingual mucosa for rapid and efficient absorption into the bloodstream. This process is accomplished by delivering a ready-to-be absorbed formulation across the sublingual mucosa. The sublingual mucosa is an efficient medium for the delivery of certain drugs because this membrane is highly permeable with a high density of blood vessels, which allows for the portion of the drug absorbed to bypass first-pass metabolism in the liver. Certain drug products delivered utilizing our sublingual spray technology can be absorbed quickly and take effect more rapidly than many other forms of administration. We are developing several product candidates, including buprenorphine, buprenorphine with naloxone, ondansetron, sildenafil, diclofenac and ketorolac, where we believe our proprietary sublingual spray technology has the potential to provide a clinically meaningful therapeutic advantage over existing delivery methods.

Our Products and Product Candidates

The following table summarizes certain information regarding our marketed products and most advanced product candidates:

Franchise | | Product or

Product Candidate | | Regulatory

Pathway | | Indication | | Status |

| | | | | | | | | |

Spray | | Subsys | | 505(b)(2) | | BTCP in Opioid-Tolerant Patients | | Marketed |

| | | | | | | | | |

Dronabinol | | Dronabinol SG Capsule | | ANDA | | CINV and Anorexia Associated with Weight Loss in Patients with AIDS | | Marketed(1) |

| | Dronabinol Oral Solution | | 505(b)(2)(2) | | | | Pre-NDA(3) |

| | Dronabinol Line Extensions | | 505(b)(2)(2) | | | | Preclinical |

______________________________

(1) | Marketed in the United States under an exclusive distribution agreement with Mylan Pharmaceuticals Inc. |

(2) | Anticipated regulatory pathway. A 505(b)(2) New Drug Application (NDA) relies for its approval upon studies that were not conducted by or for the applicant, and for which the applicant has not obtained a right of reference. The applicant may rely on the FDA’s findings of safety and/or effectiveness for a previously approved drug (the “reference drug”). However, the applicant must still provide any additional preclinical or clinical data necessary to ensure that differences from the reference drug do not compromise safety and effectiveness. For Dronabinol Oral Solution and our Dronabinol Line Extensions, we expect to use Marinol as the reference drug. |

(3) | Completed a pre-NDA meeting and pivotal bioequivalence study in 2012 and expect to submit an NDA in the second half of 2014. |

Additionally, we are focused on the development of other earlier stage product candidates. Specifically, we are currently completing preclinical work on three products that utilize our proprietary spray technology platform and will expand our supportive care franchise:

● | Buprenorphine (semi-synthetic opioid to treat moderate and acute chronic pain) |

● | Buprenorphine/Naloxone (opioid antagonist to treat addiction) |

● | Ondansetron (serotonin 5-HT3 receptor antagonist used mainly as an antiemetic to treat nausea and vomiting following chemotherapy) |

We have also initiated preclinical development of three additional sublingual spray candidates:

● | Sildenafil (the active ingredient in Viagra) |

● | Diclofenac (a non-steroidal anti-inflammatory drug (NSAID) taken or applied to reduce inflammation and as an analgesic reducing pain) |

● | Ketorolac (for short-term management of moderate to moderately severe pain requiring analgesia at the opioid level) |

Further, we have the ability to manufacture pure, synthetic cannabidiol and are evaluating the potential utility of this in a variety of indications.

We intend to file one NDA and at least three IND’s with the FDA in 2014.

Subsys Sublingual Fentanyl Spray

Subsys is a proprietary, single-use product that delivers fentanyl, an opioid analgesic, for transmucosal absorption underneath the tongue. We received marketing approval for Subsys from the FDA on January 4, 2012 for the treatment of BTCP. BTCP is characterized by sudden, often unpredictable, episodes of intense pain which can peak in severity at three to five minutes despite background pain medication. We believe Subsys is an important, highly differentiated treatment option for patients and physicians relative to other TIRF products due to its rapid onset of action, improved bioavailability, most complete range of dosage strengths and ease of administration. According to Source Healthcare Analytics, TIRF products generated $421.2 million in U.S. sales in 2013.

Fentanyl is an opioid analgesic approved in the United States for acute and chronic pain management. Depending upon the type of pain, physicians currently prescribe fentanyl in three forms of administration: injectable, transmucosal, or delivery by diffusion through the mucous membranes of the mouth, and transdermal, or delivery through the skin. Fentanyl imitates natural biochemicals found in the body that moderate pain and block the transmission of pain signals that travel along nerves to the brain. We believe these properties make fentanyl a potent and effective therapy for use in patients with cancer who suffer from acute or breakthrough episodes of pain.

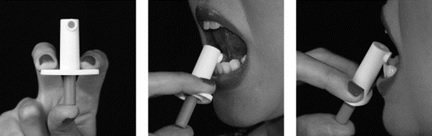

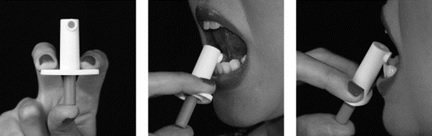

Subsys is a proprietary, single-use product developed to treat BTCP through the delivery of a liquid fentanyl formulation in 100, 200, 400, 600, 800, 1,200 and 1,600 mcg dosages. The 1,200 and 1,600 mcg doses of Subsys are achieved by administering two 600 and 800 mcg doses, respectively. The mechanism by which the liquid is delivered is a highly consistent, one-step process in which a plume of fentanyl is generated by the actuation of the device. The plume disperses a small volume of liquid across the surface area of the sublingual mucosa and facilitates rapid absorption by the body.

Cancer Pain Market Overview

Cancer pain can occur as a result of tumors pressing on nerves, damage caused by cancer cells in bone and treatments for cancer such as chemotherapy, radiation therapy or surgery. Many cancer patients experiencing pain suffer from two types of pain: (1) persistent or continuous pain, which is typically managed by long-acting or sustained-release drugs taken by patients on a regular schedule, and (2) breakthrough pain, which can be severe and sudden, and may require a stronger, fast-acting medication. Opioids are the most widely-prescribed treatment for cancer pain followed by medications commonly used to treat inflammatory pain, such as corticosteroids, anesthetics, non-steroidal anti-inflammatory drugs, anticonvulsants and antidepressants. A report published by Worldwide Marketing Research estimated that the value of the U.S. cancer pain market was $3.1 billion in 2008 and will increase to $5.3 billion by 2018.

Following rapid onset that peaks in three to five minutes, BTCP episodes can last several minutes to an hour, and usually occur several times per day. Pain is a widely prevalent symptom of cancer patients, an estimated 50% to 90% of whom suffer from BTCP, which is particularly difficult to treat due to its severity, rapid onset and the often unpredictable nature of its occurrence. Physicians typically treat BTCP with a variety of short-acting opioid medications, including morphine, morphine and codeine derivatives and fentanyl.

Morphine and codeine derivatives have been available for decades in immediate-release forms of tablets, capsules or liquids that are ingested by the patient. More recently-approved short-acting opioid-based fentanyl formulations utilize transmucosal delivery in an attempt to improve upon existing fentanyl therapies. Teva Pharmaceutical Industries Ltd.’s Actiq, approved by the FDA in 1998 and currently available in several generic options, is an oral transmucosal lozenge, and Fentora, the leading branded TIRF product, approved by the FDA in 2006, is a fentanyl buccal tablet. Three other companies have received approval for branded TIRF products since 2009 including BioDelivery Sciences International, Inc.’s Onsolis, a soluble film placed on the buccal area after wetting the inside of the cheek with saliva or water, Galena Pharmaceutical’s Abstral, an immediate-release transmucosal sublingual tablet, and Depomed’s Lazanda, a nasal spray. According to Source Healthcare Analytics, TIRF products generated $421.2 million in 2013 U.S. sales. Although these existing therapies provide improvements over oral opioids, we believe that Subsys market adoption to date demonstrates that the current treatment options have limitations and that there remains a significant unmet need for therapies that provide faster pain relief, more convenient dose administration and a better PK profile.

Limitations of Competing TIRF Therapies

We believe that the BTCP market is underserved due to the limitations of the current market-leading TIRF therapies, which include:

● | Time until statistically significant pain relief: Patients suffering from BTCP require rapid pain relief as peak intensity of episodic breakthrough pain can occur between three and five minutes from the onset of pain symptoms. The peak effect of Actiq and Fentora may be delayed as it may take up to 14 to 30 minutes for the lozenge or tablet to fully dissolve and be absorbed. In addition, oral immediate-release opioids are metabolized in the liver and consequently may take up to 30 to 45 minutes to become effective. |

● | Pharmacokinetic profile: Actiq and its generic equivalents achieve bioavailability of approximately 50% and require 15 to 30 minutes for absorption. Up to half of the delivered dose of competing TIRF treatments is swallowed and is absorbed slowly through the gastrointestinal, or GI tract, which we believe may delay the onset of pain relief and contribute to side effects. |

● | Inconvenient delivery: We believe competing commercially available therapies do not adequately address patient ease of use and convenience needs. Competing TIRF therapies can require an administration period of several minutes, disrupt daily activities and cause patient discomfort. For example, Actiq requires patients to place a lozenge between their cheeks and lower gums and rub the lozenge from side to side over a 15-minute period. In addition, patients with dry mouth and oral mucositis may experience difficulty in using Actiq and other commercially available therapies. |

● | Limited dosage forms: Actiq and its generic equivalents are available in six dosage strengths ranging from 200 to 1,600 mcg. No other commercially available TIRF therapies are offered in the 1,200 and 1,600 mcg dosage range. According to Source Healthcare Analytics, approximately 47% of the U.S. dollar sales of Actiq in 2012 were in the 1,200 and 1,600 mcg doses. |

Our Solution

We believe Subsys’ proprietary formulation and sublingual delivery mechanism offer several advantages over other FDA-approved TIRF products, and these advantages may lead to improved patient compliance and expanded medical use of fentanyl for BTCP. Such advantages include:

● | Statistically significant pain relief in five minutes: Subsys is the only product to show statistically significant pain relief when measuring the sum of pain intensity difference, SPID, at five minutes in a Phase 3 BTCP clinical trial using fentanyl. We believe that Subsys is able to achieve this rapid delivery of fentanyl through sublingual delivery because there is a high density of blood vessels beneath the tongue and the thin layer in the mucosa enables higher absorption. The product sprays in a manner that is designed to maximize the area covered by the product. |

● | One-step administration: Subsys is administered in one step using a small handheld delivery system that sprays fentanyl beneath the patient’s tongue. This delivery mechanism allows for administration in less than one minute, rather than the 14 to 30 minutes required for Actiq and Fentora. Further, Subsys can be administered without moistening the tongue or cheek, allowing for administration in cancer patients suffering from dry mouth and oral mucositis. |

● | Superior pharmacokinetic profile. As compared to Actiq’s PK profile, Subsys’ PK profile is characterized by higher peak blood concentrations, which are achieved at a more rapid rate. This profile is, in part, due to greater than 85% absorption occurring transmucosally, resulting in higher bioavailability. Because a small volume of liquid is sprayed on to the sublingual mucosa, we believe this method of administration reduces the amount of liquid swallowed and subsequently absorbed via the digestive system. As a result, we believe that less fentanyl is exposed to first-pass metabolism in the liver. |

● | Broad spectrum of dosage strengths allows for proper titration and better pain relief. Subsys is available in the most complete range of dosage strengths in the TIRF market, at 100, 200, 400, 600, 800, 1,200 and 1,600 mcg. We believe it is important to offer a product in all dose ranges for the treatment of BTCP, as all branded products without generic equivalents, and, to our knowledge, all product candidates currently in development, are not, or will not be, available in the 1,200 and 1,600 mcg dosage strengths. |

Subsys Market Experience to Date

Prescription Trends: Monthly prescription data through February 2014 shows that approximately 39,000 prescriptions of Subsys have been dispensed since launch in March 2012. Subsys’ total prescription share of the TIRF market has increased each quarter since launch. In December 2013, Subsys was the most prescribed branded TIRF product with 28.3% market share.

Physician Prescriber Base: Approximately 1,850 physicians were responsible for 90% of all TIRF prescriptions dispensed in 2013, according to Source Healthcare Analytics. We have targeted our initial commercialization efforts towards the majority of these high prescribers. As of December 2013, there were approximately 1,140 unique physician prescribers of Subsys, according to the TIRF risk evaluation mitigation strategy, or REMS, database. As of December 2013, approximately 81% of the top 118 TIRF prescribers had prescribed Subsys. These physicians accounted for 30% of TIRF prescriptions, according to Source Healthcare Analytics.

Patient Use: Patient data generated by the TIRF REMS database demonstrates that the number of Subsys-experienced patients has increased steadily since launch with over 7,100 unique patients as of December 2013. Importantly, the proportion of Subsys prescriptions written for repeat Subsys patients has continued to increase since July 2012 from 50% of prescriptions to over 80% of prescriptions as of December 2013. Generally, repeat Subsys patients receive higher doses of Subsys on average than first-time patients, as patients are titrated from a starter dose of Subsys to their effective dose in accordance with the REMS protocol.

Patient Access: Subsys is a Tier 3 medication available under nearly all major commercial health insurance plans. Some third-party payors require usage and failure on cheaper generic versions of Actiq prior to providing reimbursement for Subsys and other branded TIRF products. We believe that physicians and payors will develop greater familiarity with both the differentiated features of Subsys and the process to achieve patient access to the product from continued and broader usage of Subsys by their patients. We offer patients a free trial of Subsys to allow for titration to their effective dose and bridge the prior authorization process. Once third-party payor reimbursement is in place, we offer patients coupons to reduce out of pocket costs.

Dronabinol Product Family

We have one approved dronabinol product and are developing several innovative dronabinol product candidates for the second-line treatment of CINV and anorexia associated with weight loss in patients with AIDS. We received FDA approval for Dronabinol SG Capsule in 2011, and we currently commercialize this product in the United States through our exclusive distribution agreement with Mylan. We believe a significant unmet medical need exists for formulations of dronabinol that act more rapidly, are subject to less variable patient absorption and allow for more flexible dosing. Our lead proprietary dronabinol product candidate is Dronabinol Oral Solution. We completed a pivotal bioequivalence study for Dronabinol Oral Solution in 2012. In addition, we are evaluating proprietary sublingual spray, inhaled and intravenous formulations of dronabinol in preclinical studies.

Dronabinol, the active ingredient in Marinol, is a synthetic form of THC. THC is an orally active cannabinoid which, like other cannabinoids, has complex effects on the central nervous system. Approved by the FDA in 1985, Marinol is indicated for the treatment of CINV in patients who have failed to respond adequately to conventional treatments, as well as for the treatment of anorexia associated with weight loss in patients with AIDS. Marinol is formulated in sesame oil and encapsulated in soft gelatin capsules and must be stored in cool storage conditions or in a refrigerator.

Market Overview

CINV is a commonly known side effect of chemotherapy that can have a significant negative impact on quality of patient life. CINV is classified into five categories:

● | Acute: Occurs within 24 hours of chemotherapy administration. |

● | Delayed: Occurs more than 24 hours after chemotherapy administration, with peak intensity two to three days post-administration and duration of up to one week. |

● | Anticipatory: Occurs prior to treatment. |

● | Breakthrough: Occurs after use of antiemetic agents. |

● | Refractory: Occurs after failed use of breakthrough therapy. |

The majority of chemotherapy patients experience at least one type of CINV. The National Comprehensive Cancer Network estimates that 70% to 80% of patients undergoing chemotherapy experience vomiting, with 10% to 44% experiencing anticipatory vomiting. Predictive factors for developing CINV can include: age of less than 50 years, female gender, vomiting during previous chemotherapy, pregnancy-induced nausea/vomiting, history of motion sickness and anxiety. In addition to generally affecting patient quality of life, CINV can result in weakness, weight loss, electrolyte imbalance, dehydration or anorexia. According to a study published by Ballatori, et al in 2007, 90% of patients who experienced CINV reported an impact on daily activities.

Although the pathophysiology of CINV is not clearly understood, it is thought that chemotherapeutic agents cause vomiting by activating neurotransmitter receptors located in the chemoreceptor trigger zone, GI tract, and vomiting center, or VC. Activation of the VC directly or through the chemoreceptor trigger zone results in stimulation of the salivation and respiratory centers as well as control of the pharyngeal, GI and abdominal muscles. This stimulation can trigger the body to retch and vomit.

Treatment of CINV is highly patient-specific and is based on the emetogenic potential of the chemotherapy regimen. According to IMS Health, U.S. sales for drugs treating CINV were $1.1 billion in 2012, though published reports suggest that current therapies are not entirely effective. A 2004 report published in Cancer estimated that approximately 35% of patients treated with CINV therapies continue to experience acute nausea, with 13% of CINV patients experiencing acute vomiting after first-line treatment.

Limitations of Existing Therapies

We believe that the synthetic cannabinoid market is underserved due to the limitations of existing therapies, which include:

● | Delayed absorption: Marinol is only available in a capsule formulation, which must be dissolved and digested before it is metabolized in the patient’s liver, where the drug is broken down by enzymes. We believe that this capsule formulation and digestion process delays onset of action and relief of nausea and vomiting. After oral administration, Marinol has an onset of action of approximately 30 minutes to one hour and peak effect at two to four hours. |

● | Lower level of efficacy: Due to the capsule formulation and digestion process of Marinol, only 10% to 20% of an administered dose of Marinol reaches the systemic circulation in the body. This poor absorption profile significantly reduces the bioavailability of the API in patients using its capsule formulation which may result in lower efficacy. |

● | Lack of flexibility in dosing: Marinol and its generic equivalents are only available in 2.5, 5.0 and 10.0 milligram, or mg, soft-gelatin capsules. The fixed dosage amounts may cause patients to ingest more or less drug than necessary, which can result in increased side effects and/or a lower level of efficacy. |

● | Variable patient absorption: The uptake of Marinol into systemic circulation varies widely from dose-to-dose and patient-to-patient. In general, this level of variability is atypical relative to approved pharmaceutical products. As such, physicians are unable to predict the level of efficacy or side effects that an individual patient might experience relative to other patients or even to a patient’s own last dose of dronabinol. |

Our Solutions

We believe our proprietary dronabinol product candidates have the potential to address many of the limitations that exist in synthetic cannabinoid products by providing a number of key advantages, including:

● | Faster absorption: Dronabinol Oral Solution is a liquid solution and is absorbed faster than a capsule formulation which has to dissolve in the GI tract. We believe that quicker absorption may lead to faster onset of action for an oral solution product. Separately, we believe that our proprietary sublingual spray, inhalation and intravenous dronabinol formulations, currently in preclinical studies, may further accelerate dronabinol’s onset of action due to their route of delivery bypassing first-pass metabolism in the liver. |

● | Level of efficacy: By bypassing first-pass metabolism in the liver, we believe our proprietary sublingual spray, inhalation and intravenous dronabinol formulations may demonstrate lower dose-to-dose variability compared to Marinol and, as a result, more reliable efficacy. |

● | Flexibility in dosing: Dronabinol Oral Solution allows for greater flexibility across the dosing range versus the fixed dosing necessitated by Marinol. We believe that offering physicians and patients an improved formulation with the opportunity to more precisely titrate may increase market acceptance of dronabinol. |

● | Reduced dose-to-dose variability: Based on our pivotal bioequivalence and PK studies, we believe Dronabinol Oral Solution has lower dose-to-dose variability which could lead to more consistent intra-patient responses in each successive dose. Due to the higher anticipated absorption rates for our dronabinol inhalation formulation, we believe that lower dosages of this formulation may be required as compared to Marinol. |

Dronabinol SG Capsule

Dronabinol SG Capsule is our generic version of Marinol approved by the FDA in August 2011. Dronabinol SG Capsule is a simple solution of dronabinol in sesame oil that is encapsulated in soft gelatin. Dronabinol SG Capsule is supplied in 2.5, 5.0 and 10.0 mg dosage strengths. We launched Dronabinol SG Capsule in the United States through our exclusive distribution partner, Mylan, in December 2011.

Dronabinol Oral Solution

Dronabinol Oral Solution is a proprietary synthetic THC in an oral liquid formulation, which contains ingredients to enhance absorption. We believe that this product candidate may provide increased flexibility in dosing, more convenient delivery and an improved absorption profile in patients. We believe these attributes may ultimately increase patient compliance because of more rapid onset of action and less dose-to-dose variability, which we believe will allow us to further penetrate and potentially expand the market for the medical use of dronabinol.

We completed a pre-NDA meeting with the FDA on April 17, 2012 and subsequently in 2012 completed a pivotal bioequivalence study for Dronabinol Oral Solution. Our pivotal bioequivalence study was a 52-patient crossover bioavailability and PK clinical trial comparing Dronabinol Oral Solution with Marinol. In the study, 100% of subjects receiving Dronabinol Oral Solution achieved detectable plasma levels at 15 minutes compared to less than 25% of the subjects receiving Marinol, and Dronabinol Oral Solution demonstrated a more than 60% decrease in dose-to-dose drug exposure variability as measured by patient coefficient of variation for AUC. We expect to submit an NDA for Dronabinol Oral Solutionby the second half of 2014.

Other Product Candidates

Our other product candidates include other dronabinol line extensions and sublingual spray product candidates.

Future Cannabinoid Line Extensions. As described above, we plan to develop additional dronabinol delivery systems, including proprietary sublingual spray, inhalation and intravenous dronabinol formulations. All of these product candidates are in preclinical development. We have also submitted a supplemental Abbreviated New Drug Application, or ANDA, for a room temperature stable version of our dronabinol soft gel capsule, which we refer to as Dronabinol RT Capsule. We also have the capability to manufacture synthetic cannabidiol and intend to work with medical researchers to determine its viability.

Sublingual Spray Product Candidates. As described above, we are conducting preclinical development for multiple well-known, approved molecules for delivery through our sublingual drug delivery technology. We intend to evaluate these and other products that we believe could have a differentiated efficacy and/or safety profile if formulated by us and delivered via a sublingual spray.

Sales and Marketing

Key members of our management and board have extensive experience in building and implementing cost-efficient, incentive-based commercial organizations as well as commercializing supportive care products, including dronabinol. We currently market Subsys and intend to commercialize Dronabinol Oral Solution and future supportive care products, if approved, through our U.S.-based commercial organization focused on supportive care. Specifically, we currently market Subsys in the United States through our commercial organization. We have built this commercial organization utilizing an incentive-based model similar to that employed by Sciele Pharma and other companies previously led by members of our board, including our founder, Executive Chairman and principal stockholder. This model employs a pay structure where a significant component of the compensation paid to sales representatives comes in the form of potential bonuses based on sales performance. Our product detailing efforts focus primarily on oncologists, pain specialists and centers that cater to supportive care.

We do not currently have sales and marketing capabilities outside of the United States. In international markets, we plan to enter into arrangements with third parties to pursue requisite regulatory approvals and market and sell our products.

We believe some of the key factors in generating continued growth in Subsys usage include taking market share from leading TIRF products and expanding the usage of Subsys for BTCP by building awareness among oncologists of its rapid onset of action, improved bioavailability, most complete range of dosage strengths and ease of administration relative to other TIRF products. To successfully commercialize our family of proprietary dronabinol products, we intend to focus our commercial efforts on taking market share from Marinol and its generic alternatives as well as further expanding into a broader segment of the CINV market by developing awareness of our product attributes relative to currently available dronabinol products.

As of December 31, 2013, there were approximately 8,500 physicians enrolled in the TIRF REMS program. Enrollment in this class-wide REMS program is required by the FDA as of March 2012 in order to prescribe TIRF products. Approximately 1,850 physicians comprise 90% of TIRF prescriptions dispensed in 2013, according to Source Healthcare Analytics. Our sales and marketing efforts have primarily targeted approximately 90% of these top 1,850 prescribing physicians with a focus on the highest prescribers. As of December 2013, 81% of the top 118 physician prescribers had prescribed Subsys. These physicians accounted for 30% of all U.S. TIRF prescriptions. We believe that key factors for driving future Subsys growth include increasing the number of prescriptions written by those physicians who currently prescribe Subsys, increasing the number of physicians who prescribe Subsys, and allowing sufficient time for physicians and patients to identify their effective Subsys dose among our broad spectrum of dosage strengths.

We entered into a supply and distribution agreement effective as of May 20, 2011 with Mylan, pursuant to which we engaged Mylan to exclusively distribute our Dronabinol SG Capsule within the United States. The agreement has a seven-year term, which commenced in December 2011 upon the first commercial sale of the Dronabinol SG Capsule product and which will automatically renew for an additional one-year term, following the initial term, unless we or Mylan give the other party 180 days’ prior written notice of its desire to terminate the agreement. Under the terms of the agreement, we are obligated to pay Mylan a royalty between 10% and 20% on Mylan’s net Dronabinol SG Capsule sales, and a single digit percentage fee on such sales for distribution and storage services. See Note 8 under the heading “-Legal Matters” of the Notes to our Consolidated Financial Statements for a discussion on our ongoing dispute with Mylan.

Manufacturing and Supply

We produce dronabinol, the API in our dronabinol product family, including Dronabinol SG Capsule and our proprietary dronabinol product candidates, internally at our U.S.-based, state-of-the-art manufacturing facility. We believe that this facility has the capacity to supply sufficient commercial quantities of dronabinol API for Dronabinol SG Capsule and initial launch quantities of Dronabinol Oral Solution, if approved, as well as to support the continued development of our other dronabinol product candidates in the near-term. We believe this facility gives us a significant competitive advantage since dronabinol API is a Schedule I material and consequently is subject to annual production limits set by quota for each individual facility, cannot be readily procured, is difficult to import into the United States and has a limited number of suppliers domestically.

For our long-term needs, we have commenced construction of a second dronabinol manufacturing facility, which we anticipate will enable us to supply sufficient commercial quantities of dronabinol API for our continued commercialization of Dronabinol SG Capsule and for the commercialization of our proprietary dronabinol product candidates, if approved. We expect to initiate manufacturing activities in the new facility in the fourth quarter of 2014.

The chemical materials for dronabinol API are sourced from independent suppliers and are manufactured utilizing well-established chemical techniques. Our manufacturing facility utilizes these chemical materials to produce dronabinol through a series of synthetic reactions and purification cycles. We believe that our suppliers are equipped to meet our current and future chemical material needs for the continued commercialization of Dronabinol SG Capsule and the development and commercialization of our dronabinol-based product candidates.

On March 21, 2011, we entered into a commercial manufacturing and packaging agreement with Catalent Pharma Solutions, LLC, or Catalent, pursuant to which we engaged Catalent on an exclusive basis to provide processing and packaging services with respect to our Dronabinol SG Capsule. Pursuant to the terms of the agreement, which was amended on March 5, 2012, we are required to supply Catalent with the API for our Dronabinol SG Capsule and are required to purchase a minimum number of units of our Dronabinol SG Capsule pursuant to annual purchase orders. For units ordered, we are required to pay Catalent a per-unit fee, plus annual product maintenance fees. The initial term of the agreement is five years, unless earlier terminated, and annually renews for additional periods of two years, unless we or Catalent give the other party at least 12 months’ prior written notice of our, or their, desire to terminate the agreement.

Subsys is manufactured by contract manufacturers and sub-component fabricators. AptarGroup, Inc., or Aptar, a dispensing system company based in Illinois, developed the sublingual spray device we use for Subsys. We entered into a supply agreement effective as of March 7, 2011 with Aptar pursuant to which Aptar supplies us with the delivery system to administer Subsys. We are required to provide Aptar with rolling quarterly forecasts of our requirement for Subsys drug delivery systems. Under certain circumstances, such forecasts are non-binding; however, some portions of such forecasts may constitute a firm commitment to purchase delivery systems. The agreement has a term of five years from the effective date, subject to early termination clauses.

We entered into a manufacturing agreement effective as of May 24, 2011 with DPT Lakewood, LLC, or DPT, pursuant to which we engaged DPT on an exclusive basis to provide processing and packaging services with respect to Subsys. The contract requires us to provide rolling quarterly forecasts, a portion of which constitute firm purchase commitments. Unless terminated earlier, the initial term of the agreement will continue until December 31, 2017, subject to automatic extension and early termination clauses.

Aptar and DPT have been selected for their specific competencies in manufacturing, product design and materials. FDA regulations require that materials be produced under current Good Manufacturing Practices, or cGMPs, or quality system regulations, as required for the respective unit operation within the manufacturing process. We believe both key suppliers have sufficient capacity to meet our projected product requirements.

Competition

Our industry is characterized by rapidly advancing technologies, intense competition and a strong emphasis on proprietary products. We face competition from many different sources, such as pharmaceutical companies, including generic drug companies, biotechnology companies, drug delivery companies and academic and research institutions. We believe the key competitive factors that will affect the commercial success of our products and the development of our product candidates include, but are not limited to, onset of action, bioavailability, efficacy, cost, convenience of dosing, safety, and tolerability profile. Many of our potential competitors have substantially greater financial, scientific, technical, intellectual property, regulatory and human resources than we do, and greater experience than we do commercializing products and developing product candidates, including obtaining FDA and other regulatory approvals for product candidates. Consequently, our competitors may develop products for the treatment of BTCP, CINV and anorexia associated with weight loss in patients with AIDS, or other indications we pursue that are more effective, better tolerated, more widely-prescribed or accepted, more useful and less costly, and they may also be more successful in manufacturing and marketing their products. We also face competition from third parties in obtaining allotments of fentanyl and dronabinol under applicable U.S. Drug Enforcement Administration, or DEA, quotas, recruiting and retaining qualified personnel, establishing clinical trial sites and enrolling patients for clinical trials and in identifying and acquiring or in-licensing new products and product candidates.

Subsys

Subsys competes against numerous branded and generic products already being marketed and potentially those which are or will be in development. Subsys is the fourth new product in the TIRF market over the last four years. In the BTCP market, physicians often treat patients with a variety of short-acting opioid medications, including morphine, morphine and codeine derivatives and fentanyl. Some currently marketed products against which we directly compete include Teva Pharmaceutical Industries Ltd’s Fentora and Actiq, Galena Biopharma Inc.’s Abstral, Depomed Inc.’s Lazanda and BioDelivery Science International, Inc.’s Onsolis. Some generic fentanyl products against which Subsys competes are marketed by Mallinckrodt, Inc., Par Pharmaceutical Companies and Actavis, Inc. In addition, we are aware of numerous companies developing other treatments and technologies for rapid delivery of opioids to treat BTCP, including transmucosal, transdermal, nasal spray, inhaled delivery systems and sublingual delivery systems, among others.

Dronabinol Product Family

With respect to our Dronabinol SG Capsule and our dronabinol product candidates, the market in which we compete is challenging in part because generic products generally face greater price competition than branded products. With respect to Dronabinol SG Capsule and any of our dronabinol product candidates, if approved, the competition from generic products which we encounter, or will encounter with respect to our dronabinol product candidates, may have an effect on our product prices, market share, revenues and profitability. We or our distributor may not be able to differentiate any products that we may market from those of our competitors, successfully develop or introduce new products that are less costly or offer better performance than those of our competitors, or offer purchasers of our products payment and other commercial terms as favorable as those offered by our competitors. In addition, there are a number of established therapies and products already commercially available and under development by other companies that treat the indications which Dronabinol SG Capsule and our dronabinol product candidates are intended to treat. Specifically, Dronabinol SG Capsule and, if approved, our dronabinol product candidates, will compete against therapies and products such as AbbVie, Inc.’s Marinol and Marinol generics. Par Pharmaceutical Companies markets an approved generic version of Marinol, and Actavis, Inc. markets an authorized generic version of Marinol. Moreover, our dronabinol products may compete with non-synthetic cannabinoid drugs, including therapies such as GW Pharmaceuticals plc’s Sativex, especially in many countries outside of the United States where non-synthetic cannabinoids are legal. In addition, literature has been published arguing the benefits of natural cannabis, or marijuana, over dronabinol, and there are a number of states that have already enacted laws legalizing medicinal and recreational marijuana. There is some support in the United States for further legalization of marijuana. We also cannot assess the extent to which patients utilize marijuana illegally to alleviate CINV, instead of using prescribed therapies such as approved dronabinol products. Furthermore, in the treatment of CINV, physicians typically offer conventional anti-nausea agents prior to initiating chemotherapy, such as Sanofi’s Anzemet, Eisai Inc./Helsinn Group’s Aloxi, Roche Holding AG’s Kytril, Par Pharmaceutical Companies’s Zuplenz and GlaxoSmithKline plc’s Zofran, as well as Neurokinin 1 receptor antagonists on the market including Kyowa Hakko Kirin Co., Ltd.’s Sancuso and Merck & Co., Inc.’s Emend. To the extent that Dronabinol SG Capsule and our dronabinol product candidates compete in a broader segment of the CINV market, we will also face competition from these products.

Additionally, we are aware of companies in late stage development for CINV product candidates, including A.P. Pharma, Inc.’s APF530 (Phase 3) Aphios Corp.’s Zindo (Phase 2/3), Tesaro, Inc.’s Rolapitant (Phase 3) and Roche Holding/Helsinn Group’s netupitant (Phase 3). If these products are successfully developed and approved over the next few years, they could represent significant competition for Dronabinol SG Capsule and, if approved, our dronabinol product candidates.

Intellectual Property

The success of most of our product candidates will depend in large part on our ability to:

● | obtain and maintain patent and other legal protections for the proprietary technology, inventions and improvements we consider important to our business; |

● | prosecute our patent applications and defend our issued patents; |

● | preserve the confidentiality of our trade secrets; and |

● | operate without infringing the patents and proprietary rights of third parties. |

We intend to continue to seek appropriate patent protection for certain of our product candidates, drug delivery systems, molecular modifications, as well as other proprietary technologies and their uses by filing patent applications in the United States and selected other countries. We intend for these patent applications to cover, where possible, claims for medical uses, processes for preparation, processes for delivery and formulations.

As of December 31, 2013, we owned or licensed from third parties a total of nine issued U.S. utility patents and ten pending U.S. utility patent applications. These U.S. patents and patent applications will expire between 2015 and 2034. Some of the issued patents and pending applications, if issued, may also be eligible for patent term adjustment and patent term restoration, thereby extending their patent terms.

Subsys

Our SUBSYS patent portfolio currently consists of two Orange Book listed (with the F.D.A.) U.S. Patent Nos. 8,486,972 ('972 patent) and 8,486,973 ('973 patent) and two pending U.S. patent applications. Both of these patents cover SUBSYS brand fentanyl and will expire no sooner than 2030. The '972 patent covers the SUBSYS sublingual fentanyl spray formulation, while the '973 patent covers the use of the SUBSYS sublingual fentanyl spray for the treatment of pain. The SUBSYS sublingual fentanyl spray is useful for delivering fentanyl directly to the sublingual mucosa to achieve appreciable plasma concentration levels within five minutes and differs from other fentanyl formulations in that it is readily absorbed bringing quick and effective pain relief to the patient without the need for injections or IVs. We also currently have seven issued foreign patents and 11 pending foreign patent applications covering at least formulations and methods of use relating to SUBSYS. Any patents that issue from our pending foreign patents and applications are expected to expire no earlier than 2027.

Dronabinol

Our dronabinol patent portfolio currently consists of two issued U.S. patents, two pending U.S. patent applications and one P.C.T. patent application. The claims of the patents and applications are directed to formulations of dronabinol and methods of manufacturing and packaging dronabinol. The issued dronabinol patents will expire in 2028. Any patents that issue from our pending patent applications will likely expire between 2028 and 2033.

Other

The rest of our patent portfolio relates to patents and applications owned or licensed by us and directed to other potential product candidates.

Although we believe our rights under these patents and patent applications provide a competitive advantage, the patent positions of pharmaceutical and biotechnology companies are highly uncertain and involve complex legal and factual questions. We may not be able to obtain issued patents from pending applications. Even if patents are granted, the allowed claims may not be sufficient to adequately protect the technology owned by or licensed to us. Any patents or patent rights that we obtain carry some risk of being circumvented, challenged or invalidated by our competitors. As described in the section entitled “Legal Proceedings,” a former officer of Insys Pharma has sought to rescind his assignment of his inventions concerning fentanyl and dronabinol patent applications described above. Ownership and inventorship disputes may arise for other patents and applications that we own or license.

We also rely on trade secrets, proprietary know-how and continuing innovation to develop and maintain our competitive position, especially when we do not believe that patent protection is appropriate or can be obtained. We require each of our employees, consultants and advisors to execute proprietary information and inventions assignment agreement before they begin providing services to us. Among other things, this agreement obligates each employee, consultant or advisor to refrain from disclosing any of our confidential information received during the course of providing services and, with some exceptions, to assign to us any inventions conceived or developed during the course of these services. We also require confidentiality agreements from third parties that receive our confidential information.

The biotechnology and biopharmaceutical industries are characterized by the existence of a large number of patents and frequent litigation based on allegations of patent infringement. As our current and potential product candidates and others based upon our proprietary technologies progress toward commercialization, the possibility of an infringement claim against us increases. While we attempt to be certain that our products and proprietary technologies do not infringe other parties’ patents and other proprietary rights, competitors or other parties may assert that we infringe on their proprietary rights.

We have conducted certain clearance searches of issued U.S. patents for our fentanyl formulations but we have not conducted extensive clearance searches for our other product candidates, and cannot guarantee that the searches we have done were comprehensive and, therefore, whether Subsys or any of our product candidates, delivery devices, or methods of using, making or delivering our product candidates infringe the patents searched, or that other patents do not exist that cover Subsys or product candidates, delivery devices or these methods. Interpreting patent claims involves complex legal and scientific questions and it is difficult to assess whether or not our product candidates would infringe any patent. Likewise, it is difficult to predict whether or not third-party patent applications will issue and what claim scope they may obtain. If we conclude that any identified patents, or patent applications once they issue as patents cover Subsys or our product candidates, we cannot guarantee that we will be able to formulate around such patents at all or without material delay or whether we can obtain reasonable license terms from the patent owners, if at all. There may also be other pending patent applications that are unknown to us and, if granted, may prevent us from making, using or selling Subsys or our product candidates. Other product candidates that we may develop, either internally or in collaboration with others, could be subject to similar uncertainties. If a product is found to infringe a third-party patent, we could be prevented from developing and selling that product. Please see the section entitled “Risk Factors — Risks Relating to Intellectual Property.”

Environmental and Safety Matters

We use hazardous materials, including chemicals, biological agents and compounds that could be dangerous to human health and safety or the environment. Our operations also produce hazardous waste products. Federal, state and local laws and regulations govern, among other things, the use, generation, manufacture, storage, handling and disposal of these materials and wastes. Compliance with applicable environmental laws and regulations may be expensive, and current or future environmental laws and regulations may impair our product development efforts.

In addition, we cannot entirely eliminate the risk of accidental injury or contamination from these materials or wastes. If one of our employees was accidentally injured as a result of the use, storage, handling or disposal of these materials or wastes, the medical costs related to his or her treatment is within the coverage terms of our workers’ compensation insurance policy. However, we do not carry specific biological or hazardous waste insurance coverage and our property and casualty and general liability insurance policies specifically exclude coverage for damages and fines arising from biological or hazardous waste exposure or contamination. Accordingly, in the event of contamination or injury, we could be held liable for damages or penalized with fines in an amount exceeding our resources, and our clinical trials or regulatory approvals could be suspended.

Government Regulation

FDA Approval Process

In the United States, pharmaceutical products are subject to extensive regulation by the FDA. The Federal Food, Drug, and Cosmetic Act, or the FDCA, and other federal and state statutes and regulations, govern, among other things, the research, development, testing, manufacture, storage, recordkeeping, approval, labeling, promotion and marketing, distribution, post-approval monitoring and reporting, sampling, and import and export of pharmaceutical products. Failure to comply with applicable U.S. requirements may subject a company to a variety of administrative or judicial sanctions, such as FDA refusal to approve pending investigational New Drug Applications, or INDs, and NDAs or the issuance of warning letters, product recalls, product seizures, total or partial suspension of production or distribution, injunctions, fines, civil penalties and criminal prosecution.

FDA approval is required before any new unapproved drug or dosage form, including a new use of a previously approved drug, can be marketed in the United States. Pharmaceutical product development in the United States typically involves, among other things, preclinical laboratory and animal tests, the submission to the FDA of an IND, which must become effective before clinical testing may commence, and adequate and well-controlled clinical trials to establish the safety and effectiveness of the drug for each indication for which FDA approval is sought. Satisfaction of FDA pre-market approval requirements typically takes many years and the actual time required may vary substantially based upon the type, complexity and novelty of the product or disease indicated for treatment.

Preclinical tests include laboratory evaluation of product chemistry, stability, formulation and toxicity, as well as animal trials to assess the characteristics and potential safety and efficacy of the product. The conduct of the preclinical tests must comply with federal regulations and requirements including good laboratory practices. The results of preclinical testing are submitted to the FDA as part of an IND along with other information including information about product chemistry, manufacturing and controls and a proposed clinical trial protocol. Certain nonclinical tests, such as animal tests of reproductive toxicity and carcinogenicity, may be conducted after the IND is submitted. A 30-day waiting period after the submission of each IND is required prior to the commencement of clinical testing in humans. If the FDA has not placed a clinical hold on the IND within this 30-day period, the clinical trial proposed in the IND may begin.

Clinical trials involve the administration of the investigational new drug to healthy volunteers or patients under the supervision of a qualified investigator. Clinical trials must be conducted in compliance with federal regulations, good clinical practices, or GCP, which include the requirement that all research subjects provide their informed consent in writing for their participation in any clinical trial, as well as under protocols detailing the objectives of the trial, the parameters to be used in monitoring safety and the effectiveness criteria to be evaluated. Each protocol involving testing in U.S. patients and subsequent protocol amendments must be submitted to the FDA as part of the IND. The FDA may order the temporary or permanent discontinuation of a clinical trial at any time or impose other sanctions if it believes that the clinical trial is not being conducted in accordance with FDA requirements or presents an unacceptable risk to the clinical trial patients. The study protocol and informed consent information for patients in clinical trials must also be submitted to an institutional review board, or IRB, for approval. An IRB may also require the clinical trial at the site to be halted, either temporarily or permanently, for failure to comply with the IRB’s requirements, or may impose other conditions.

Clinical trials to support NDAs for marketing approval are typically conducted in three sequential phases, but the phases may overlap. In Phase 1, the initial introduction of the drug into healthy human volunteers, the drug is tested to assess safety, metabolism, PK, pharmacological actions, side effects associated with increasing doses and, if possible, early evidence of effectiveness. Phase 2 usually involves trials in a limited patient population to evaluate the effectiveness of the drug for a particular indication or indications, dosage tolerance and optimum dosage, and identify possible adverse effects and safety risks. If a compound demonstrates evidence of effectiveness and an acceptable safety profile in Phase 2 evaluations, Phase 3 trials are undertaken to obtain additional information about clinical efficacy and safety in a larger number of patients, typically at geographically dispersed clinical trial sites, to establish the overall benefit-risk relationship of the drug and to provide adequate information for the labeling of the drug. In some cases, the FDA may condition approval on the sponsor’s agreement to conduct additional clinical trials to further assess the drug’s safety and effectiveness after approval. Such post-approval studies are typically referred to as Phase 4 studies.

The current FDA standards for approving new pharmaceutical products are more stringent than those that were applied in the past. These standards were not applied to many established products currently on the market, including certain opioid products. As a result, the FDA does not have as extensive safety databases on these products as on some products developed more recently. The FDA has recently expressed an intention to develop safety data for certain products, including many opioids. In particular, the FDA has expressed interest in specific impurities that may be present in a number of opioid narcotic APIs, such as oxycodone. Based on certain structural characteristics, these impurities may have the potential to cause mutagenic effects. If, after testing, such effects are ultimately demonstrated to exist, more stringent controls on the levels of these impurities may be required for FDA approval of products containing these impurities, such as oxymorphone. Any additional testing or remedial measures that may be necessary could result in increased costs for, or delays in, obtaining approval for certain of our products in development.

After completion of the required clinical testing, an NDA is prepared and submitted to the FDA. FDA approval of the NDA is required before marketing of the product may begin in the United States. The NDA must include the results of all preclinical, clinical and other testing and a compilation of data relating to the product’s pharmacology, chemistry, manufacture and controls, and proposed labeling, among other things. The cost of preparing and submitting an NDA is substantial. Under federal law, the submission of most NDAs is additionally subject to a substantial application user fee, and the manufacturer and/or sponsor under an approved NDA are also subject to annual product and establishment fees per product and per establishment. These fees are typically increased annually.

The FDA has 60 days from its receipt of an NDA to determine whether the application will be accepted for filing based on the agency’s threshold determination that it is sufficiently complete to permit substantive review. Once the submission is accepted for filing, the FDA begins an in-depth review. Under the Prescription Drug User Fee Act the FDA has agreed to certain performance goals in the review of NDAs. The FDA has a goal of reviewing applications for non-priority drug products within 12 months of NDA submission. The review process may be extended by the FDA for three additional months to consider certain information or clarification regarding information already provided in the submission. The FDA may also refer applications for novel drug products or drug products which present difficult questions of safety or efficacy to an advisory committee, typically a panel that includes clinicians and other experts, for review, evaluation and a recommendation as to whether the application should be approved. The FDA is not bound by the recommendations of an advisory committee, but it considers such recommendations carefully when making decisions. Additionally, the FDA will inspect the facility or the facilities at which the drug is manufactured. The FDA will not approve the product unless the facility demonstrates compliance with current cGMPs and the NDA contains data that provides substantial evidence that the drug is safe and effective for the indication sought in the proposed labeling. Additionally, the FDA will typically inspect one or more clinical trial sites to assure compliance with GCPs before approving an NDA.

After the FDA evaluates the NDA and the manufacturing facilities, it may issue an approval letter, or a complete response letter. A complete response letter generally outlines the deficiencies in the submission and may require substantial additional testing or information in order for the FDA to reconsider the application. If and when those deficiencies have been addressed to the FDA’s satisfaction in a resubmission of the NDA, the FDA will issue an approval letter. The FDA has committed to reviewing such resubmissions in two to six months depending on the type of information included.