Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended: December 31, 2011

OR

o TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission File Number: 1-14066

SOUTHERN COPPER CORPORATION

(Exact name of registrant as specified in its charter)

Delaware | | 13-3849074 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

1440 East Missouri Avenue Suite C-175 Phoenix, AZ | | 85014 |

(Address of principal executive offices) | | (Zip code) |

Registrant’s telephone number, including area code: (602) 264-1375

Securities registered pursuant to Section 12(b) of the Act:

Title of each class: | | Name of each exchange on which registered: |

Common stock, par value $0.01 per share | | New York Stock Exchange Lima Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No o

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes o No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer x | | Accelerated filer o |

| | |

Non-accelerated filer o | | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes o No x

At January 31, 2012, there were of record 840,980,000 shares of common stock, par value $0.01 per share, outstanding.

The aggregate market value of the shares of common stock (based upon the closing price at June 30, 2011 as reported on the New York Stock Exchange - Composite Transactions) of Southern Copper Corporation held by non affiliates was approximately $5,438 million.

PORTIONS OF THE FOLLOWING DOCUMENTS ARE INCORPORATED BY REFERENCE:

Part III: | Proxy statement for 2012 Annual Meeting of Stockholders |

| |

Part IV: | Exhibit Index is on Page 170 through 179 |

Table of Contents

PART I.

ITEM 1. BUSINESS

THE COMPANY

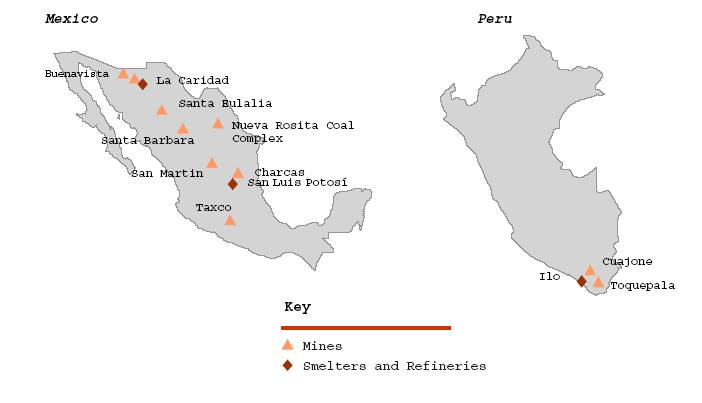

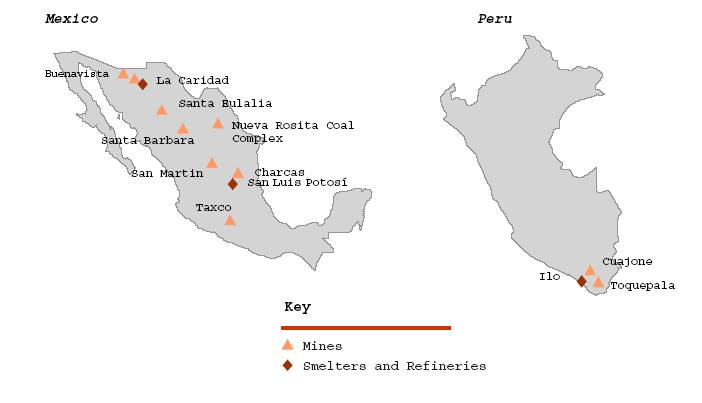

Southern Copper Corporation (“SCC”, “Southern Copper” or the “Company”) is one of the largest integrated copper producers in the world. We produce copper, molybdenum, zinc and silver. All of our mining, smelting and refining facilities are located in Peru and Mexico and we conduct exploration activities in those countries and in Argentina, Chile and Ecuador. See Item 2 “Properties - Review of Operations” for maps of our principal mines, smelting facilities and refineries. Our operations make us one of the largest mining companies in Peru and also in Mexico. We believe we have the largest copper reserves in the world. We were incorporated in Delaware in 1952 and have conducted copper mining operations since 1960. Since 1996, our common stock has been listed on both the New York and Lima Stock Exchanges.

Our Peruvian copper operations involve mining, milling and flotation of copper ore to produce copper concentrates and molybdenum concentrates; the smelting of copper concentrates to produce anode copper; and the refining of anode copper to produce copper cathodes. As part of this production process, we also produce significant amounts of molybdenum concentrate and refined silver. Additionally, we produce refined copper using SXEW technology. We operate the Toquepala and Cuajone mines high in the Andes Mountains, approximately 860 kilometers southeast of the city of Lima, Peru. We also operate a smelter and refinery west of the Toquepala and Cuajone mines in the coastal city of Ilo, Peru.

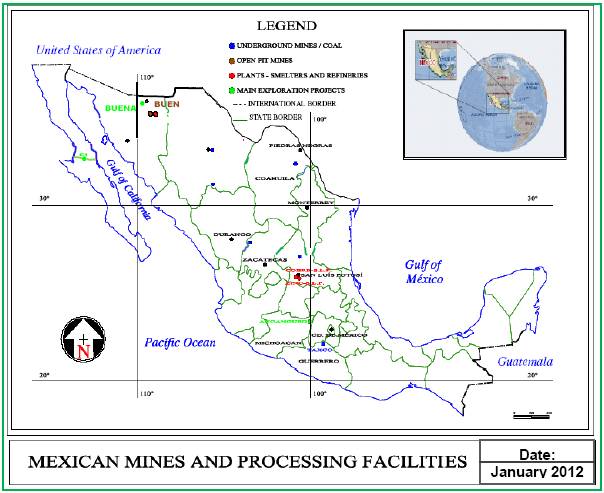

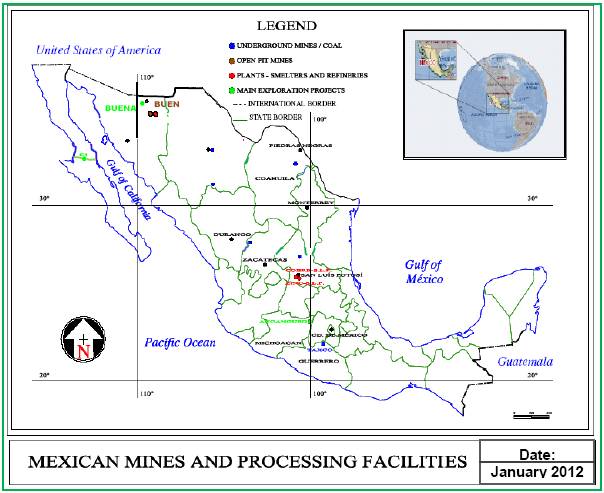

Our Mexican operations are conducted through our subsidiary, Minera Mexico S.A. de C.V. (“Minera Mexico”), which we acquired in 2005. Minera Mexico engages primarily in the mining and processing of copper, molybdenum, zinc, silver, gold and lead. Minera Mexico operates through subsidiaries that are grouped into three separate units. Mexicana de Cobre S.A. de C.V. (together with its subsidiaries, the “Mexcobre unit”) operates La Caridad, an open-pit copper mine, a copper ore concentrator, a SXEW plant, a smelter, refinery and a rod plant. Operadora de Minas e Instalaciones Mineras S.A de C.V. ( the “Buenavista unit”) operates Buenavista, formerly named Cananea, an open-pit copper mine, which is located at the site of one of the world’s largest copper ore deposits, a copper concentrator and two SXEW plants. The Buenavista mine was operated until December 11, 2010 by Mexicana de Cananea S.A. de C.V. and by Buenavista del Cobre S.A. de C.V. from that date until July 2011. Industrial Minera Mexico, S.A. de C.V. (together with its subsidiaries, the “IMMSA unit”) operates five underground mines that produce zinc, lead, copper, silver and gold, a coal mine and a zinc refinery. Effective February 1, 2012, Minerales Metalicos del Norte S.A was merged with Industrial Minera Mexico S.A. de C.V. (IMMSA). IMMSA absorbed Minerales Metalicos del Norte S.A.

We utilize modern, state of the art mining and processing methods, including global positioning systems and computerized mining operations. Our operations have a high level of vertical integration that allows us to manage the entire production process, from the mining of the ore to the production of refined copper and other products and most related transport and logistics functions, using our own facilities, employees and equipment.

The sales prices for our products are largely determined by market forces outside of our control. Our management, therefore, focuses on cost control and production enhancement to remain profitable. We endeavor to achieve these goals through capital spending programs, exploration efforts and cost reduction programs. Our focus is on seeking to remain profitable during periods of low copper prices and maximizing results in periods of high copper prices. For additional information on the sale prices of the metals we produce, please see “Metal prices” in this Item 1.

Currency Information:

Unless stated otherwise, all our financial information is presented in U.S. dollars and any reference herein to “U.S. dollars”, “dollars”, or “$” are to U.S. dollars; references to “S/.”, “nuevo sol” or “nuevos soles”, are to Peruvian nuevos soles; and references to “peso”, “pesos”, or “Ps.”, are to Mexican pesos.

3

Table of Contents

Unit Information:

Unless otherwise noted, all tonnages are in metric tons. To convert to short tons, multiply by 1.102. All ounces are troy ounces. All distances are in kilometers. To convert to miles, multiply by 0.621. To convert hectares to acres, multiply by 2.47.

ORGANIZATIONAL STRUCTURE

The following chart describes our organizational structure, starting with our controlling stockholders, as of December 31, 2011. For clarity of presentation, the chart identifies only our main subsidiaries and eliminates intermediate holding companies.

We are a majority-owned, indirect subsidiary of Grupo Mexico S.A.B. de C.V. (“Grupo Mexico”). Through its wholly-owned subsidiaries, Grupo Mexico as of December 31, 2011 owns 80.9% of our capital stock. Grupo Mexico’s principal business is to act as a holding company for shares of other corporations engaged in the mining, processing, purchase and sale of minerals and other products and railway and other related services.

We conduct our operations in Peru through a registered branch (the “SPCC Peru Branch”, “Branch” or “Peruvian Branch”). The SPCC Peru Branch comprises substantially all of our assets and liabilities associated with our copper operations in Peru. The SPCC Peru Branch is not a corporation separate from us and, therefore, obligations of SPCC Peru Branch are direct obligations of SCC and vice-versa. It is, however, an establishment, registered pursuant to Peruvian law, through which we hold assets, incur liabilities and conduct operations in Peru. Although it has neither its own capital nor liability separate from us, it is deemed to have equity capital for purposes of determining the economic interests of holders of our investment shares, (See Note 13 “Non-controlling interest” of our consolidated financial statements).

On April 1, 2005, we acquired Minera Mexico, the largest mining company in Mexico on a stand-alone basis, from Americas Mining Corporation (“AMC”), a subsidiary of Grupo Mexico, our controlling stockholder. Minera Mexico is a

4

Table of Contents

holding company and all of its operations are conducted through subsidiaries that are grouped into three units: (i) the Mexcobre unit (ii) the Buenavista unit and (iii) the IMMSA unit. We own 99.95% of Minera Mexico.

In 2011, our Board of Directors increased from $500 million to $1billion the share repurchase program authorized in 2008. Pursuant to this program, we purchased 42.5 million shares of our common stock at a cost of $730.7 million. These shares are available for general corporate purposes. We may purchase additional shares from time to time, based on market conditions and other factors. This repurchase program has no expiration date and may be modified or discontinued at any time.

REPUBLIC OF PERU AND MEXICO

Our revenues are derived primarily from our operations in Peru and Mexico. Risks related to our operations in both countries include those associated with economic and political conditions, effects of currency fluctuations and inflation, effects of government regulations and the geographic concentration of our operations.

AVAILABLE INFORMATION

We file annual, quarterly and current reports, proxy statements and other information with the U.S. Securities and Exchange Commission (“SEC”). You may read and copy any document we file at the SEC’s Public Reference Room at 100 F Street NE, Washington, D.C. 20549. Please call the SEC at 1-800-SEC-0330 for information on the Public Reference Room. The SEC maintains a website that contains annual, quarterly and current reports, proxy statements and other information that issuers (including Southern Copper Corporation) file electronically with the SEC. The SEC’s website is www.sec.gov.

Our Internet address is www.southerncoppercorp.com. Commencing with the Form 8-K dated March 14, 2003, we have made available free of charge on this internet address our annual, quarterly and current reports, as soon as reasonably practical after we electronically file such material with, or furnish it to, the SEC. Our website includes the Corporate Governance guidelines and the charters of our most significant Board Committees. However, the information found on our website is not part of this or any other report.

CAUTIONARY STATEMENT

Forward-looking statements in this report and in other Company statements include statements regarding expected commencement dates of mining or metal production operations, projected quantities of future metal production, anticipated production rates, operating efficiencies, costs and expenditures, including taxes, as well as projected demand or supply for the Company’s products. Actual results could differ materially depending upon certain factors, including the risks and uncertainties relating to general U.S. and international economic and political conditions, the cyclical and volatile prices of copper, other commodities and supplies, including fuel and electricity, the availability of materials, insurance coverage, equipment, required permits or approvals and financing, the occurrence of unusual weather or operating conditions, lower than expected ore grades, water and geological problems, the failure of equipment or processes to operate in accordance with specifications, failure to obtain financial assurance to meet closure and remediation obligations, labor relations, litigation and environmental risks, as well as political and economic risk associated with foreign operations. Results of operations are directly affected by metals prices on commodity exchanges, which can be volatile.

Additional business information follows:

COPPER BUSINESS

Copper is the world’s third most widely used metal, after iron and aluminum, and an important component in the world’s infrastructure. Copper has unique chemical and physical properties, including high ductility, malleability, and thermal and electrical conductivity, and resistance to corrosion that has made it a superior material for use in electrical and electronic products, including power transmission and generation, which accounts for about three quarters of its global copper use,

5

Table of Contents

telecommunications, building construction, transportation and industrial machinery businesses. Copper is also an important metal in non-electrical applications such as plumbing and roofing and, when alloyed with zinc to form brass, in many industrial and consumer applications.

Copper is an internationally traded commodity with prices principally determined by the major metal exchanges, the Commodities Exchange, or “COMEX”, in New York and the London Metal Exchange or “LME”. Copper is usually found in nature in association with sulfur. Pure copper metal is generally produced from a multistage process, beginning with the mining and concentrating of low-grade ores containing copper sulfide minerals, and followed by smelting and electrolytic refining to produce a pure copper cathode. An increasing share of copper is produced from acid leaching of oxidized ores. Copper is one of the oldest metals ever used and has been one of the important materials in the development of civilization.

Copper industry fundamentals, including copper demand, price levels and stocks, strengthened in late 2003 and copper prices continued to improve into the third quarter of 2008, from the 15-year price lows set during 2002. Late in the third quarter of 2008 the price of copper, as well as the price of other commodities, suffered a brief temporary decline as a consequence of the world financial crisis reaching price lows of $1.30 per pound in the fourth quarter of 2008. However, since 2009 the price of copper has improved, closing at year-end 2011 at $3.43 per pound on both the LME and COMEX.

BUSINESS REPORTING SEGMENTS:

Our management views Southern Copper as having three reportable segments and manages it on the basis of these segments.

The three segments identified are groups of individual mines, each of which constitutes an operating segment with similar economic characteristics, type of products, processes and support facilities, regulatory environments, employee bargaining contracts and currency risks. In addition, each mine within the individual group earns revenues from similar type of customers for their products and services and each group incurs expenses independently, including commercial transactions between groups.

Inter-segment sales are based on arm’s-length prices at the time of sale. These may not be reflective of actual prices realized by the Company due to various factors, including additional processing, timing of sales to outside customers and transportation cost. Added to the segment information is information regarding the Company’s sales. The segments identified by our Company are:

1. Peruvian operations, which include the Toquepala and Cuajone mine complexes and the smelting and refining plants, industrial railroad and port facilities which service both mines. Sales of its products are recorded as revenue of our Peruvian mines. The Peruvian operations produce copper, with production of by-products of molybdenum, silver and other material.

2. Mexican open-pit operations, which include the La Caridad and Buenavista mine complexes and the smelting and refining plants and support facilities which service both mines. Sales of its products are recorded as revenue of our Mexican mines. The Mexican open-pit operations produce copper, with production of by-products of molybdenum, silver and other material.

3. Mexican underground mining operations, which include five underground mines that produce zinc, copper, silver and gold, a coal mine which produces coal and coke, and a zinc refinery. This group is identified as the IMMSA unit and sales of its products are recorded as revenue of the IMMSA unit.

Financial information is regularly prepared for each of the three segments and the results are reported to the Chief Operating Officer on a segment basis. The Chief Operating Officer focuses on operating income and on total assets as measures of performance to evaluate different segments and to make decisions to allocate resources to the reported segments. These are common measures in the mining industry.

Segment information is included in Item 2 “Properties”, under the captions — “Metal production by segments” and “Ore Reserves.” More information on business segment and segment financial information is included in Note 20 “Segment and Related Information” of our consolidated financial statements.

6

Table of Contents

CAPITAL INVESTMENT PROGRAM

For a description of our capital investment program, see Item 7 “Management’s Discussion and Analysis of Financial Condition and Results of Operations” — “Capital Investment Program.”

EXPLORATION ACTIVITIES

We are engaged in ongoing extensive exploration to locate additional ore bodies in Peru, Mexico, Argentina, Ecuador and Chile. We also conduct exploration in the areas of our current mining operations. We invested $37.5 million in exploration programs in 2011, $34.3 million in 2010 and $24.6 million in 2009 and we expect to spend approximately $44.8 million in exploration programs in 2012.

Currently in Peru, we have direct control of 145,064 hectares of mineral rights. In Mexico, we currently hold 176,250 hectares of exploration concessions. We also currently hold 21,068 hectares, 35,958 hectares and 2,544 hectares of exploration concessions in Argentina, Chile and Ecuador, respectively.

Peru

Los Chancas. The Los Chancas project, located in the department of Apurimac in southern Peru, is a copper and molybdenum porphyry deposit. As a result of the pre-feasibility studies and after the preliminary design of the pit, estimates show 355 million tons of mineralized material with a copper content of 0.62%, molybdenum content of 0.05% and 0.039 grams of gold per ton. During 2011, we completed the pre-feasibility study and we plan to conduct a feasibility study of the project in 2012.

Tantahuatay. The Tantahuatay mine located in the department of Cajamarca in northern Peru, started operations in July 2011. Please see “Capital Investment Programs” under Item 7 for further information.

Other Peruvian Prospects. As part of the 2011 exploration program, we concluded a program of 1,652 meters of diamond drilling at the Huallas (Chinchinga) project (a skarn of copper-lead-zinc) located in the department of Ayacucho and 6,268 meters of diamond drilling at the Clara project (copper porphyry) located in southern Peru. These prospects are on hold as we evaluate the results of the drilling program.

For 2012 we are considering developing a diamond drilling program of approximately 30,000 meters for some prospects located in the northern and southern parts of Peru, including at El Penon, a copper and gold project, located in the north. We will continue with the regional exploration program at several other Peruvian mineralized zones.

Mexico

In addition to exploratory drilling programs at existing mines, we are currently conducting exploration to locate mineral deposits at various other sites in Mexico. The following are some of the more significant exploration projects:

El Arco. The El Arco site is a copper deposit located in the state of Baja California in Mexico. Exploration work at the site indicates approximately 1,207 million tons of mineralized sulfide material with an average copper content of 0.5% and 0.125 grams of gold per ton and 290 million tons of copper oxide with 0.35% copper grade. In 2010, a deep drilling program of 1,214 meters indicated approximately 390 million tons of mineralized material with 0.62% of copper content below the current pit limits. As we have a large mineralized material database for this project, we decided to postpone the deep drilling program to the future, consequently no drilling was done in 2011 and none is planned for 2012.

A water source for the leaching operation was identified in 2009 and in 2010 four new production wells were drilled and confirmed an underground water availability of 300 liters per second in the area. During 2011, all documentation required to obtain a water concession for 300 liters per second was filed. We expect to receive the title for these water rights in the first half of 2012.

The feasibility study performed in 2010 was completed in 2011. During the last year most of our activities were related to infrastructure issues such as land, power and port facilities. We expect to resolve these issues in 2012.

7

Table of Contents

Angangueo. The Angangueo site is located in the state of Michoacan in Mexico. A deposit of 13 million tons of mineralized material has been identified with diamond drilling. Testing indicates that the deposit has mineralized material containing 0.16 grams of gold and 262 grams of silver per ton, with 0.79% lead, 0.97% copper and 3.5% zinc. In 2011, we concluded the feasibility study and in October 2011 an investment of $130.7 million was approved for the development of the Angangueo mine. Please see “Capital Investment Programs” under Item 7 for further information.

Buenavista-Zinc (formerly named Buenavista). The Buenavista-Zinc site is located in the state of Sonora, Mexico and forms part of the Buenavista ore body. Drilling and metallurgical studies have shown that the zinc-copper deposit contains approximately 36 million tons of mineralized material containing 29 grams of silver per ton, 0.69% copper and 3.3% zinc. A new “scoping level” study indicates that Buenavista-Zinc may be an economic deposit. Due to labor strike activities at the Buenavista mine no work was performed from 2008 through 2010. In 2011, 11,956 meters of diamond drilling were executed to confirm grade and acquire geotechnical information. In 2012, the Buenavista-Zinc mine plan will be integrated with the overall mine plan of the Buenavista pit. Also we expect to conclude the final metallurgical testing and the feasibility study in 2012.

Carbon Coahuila. In Coahuila, an intensive exploration program of diamond drilling has identified two additional areas, Esperanza with a potential for more than 30 million tons of “in place” mineralized coal and Guayacan with a potential for 15 million tons of “in place” mineralized coal, that could be used for a future coal-fired power plant. During 2010, 1,213 meters of diamond drilling were completed at the Rosita pit area and with this drilling, 10,100 tons of mineralized coal were added to the mineralized material estimates for this open pit project. In 2011, 2,640 meters distributed in 68 drilling holes were executed. This resulted in an increase of 178,000 tons of new mineralized material at the Nueva Rosita pit. For 2012, a 5,000 meters drilling program is planned for the La Conquista pit.

The Chalchihuites. The Chalchihuites site is located in the state of Zacatecas. It is a replacement deposit with mixed oxides and sulfides of lead, copper, zinc and silver. A drilling program, in the late 1990s, defined 16 million tons of mineralized material containing 95 grams of silver, 0.36% lead, 0.69% copper and 3.08% zinc per ton. Preliminary metallurgical testing indicates that a leaching precipitating-flotation recovery process can be applied to this ore. In 2009, we started a prefeasibility study which is expected to be completed by the end of the second quarter 2012. In 2010 and 2011, we added several claims and performed a 9,386 meters drilling program that indicated at least seven million tons of mineralized material containing 979 grams of silver, 0.41% lead, 0.52% copper and 2.53% zinc. During 2012, we plan to continue the drilling program, metallurgical testing and related studies.

Pilares. Located in the state of Sonora, Pilares is ten kilometers from the town of Nacozari de Garcia and six straight line kilometers from our La Caridad mine. In 2008, we acquired 100% ownership of Pilares, with the intention of operating it as an open pit facility. In October 2011, an investment of $136.3 million was approved for the development of the second stage of the Pilares mine. Please see “Capital Investment Programs” under Item 7 for further information.

Sierra de Lobos. This project is located southwest of the city of Leon, Guanajuato. Drilling in 2008 confirmed the presence of copper and zinc mineralization, but an economic deposit has not yet been identified. Due to the changes in our investment program priorities, no work was performed in 2009, 2010 and 2011. We expect to resume drilling activities in the second quarter of 2012.

Chile

Ticnamar. The Ticnamar prospect, located in northern Chile, has been explored as a deposit with copper-molybdenum porphyric veins. In 2011, a diamond drilling program of 1,124 meters was completed. For 2012 we plan to continue exploration with a diamond drilling program of 3,000 meters.

Catanave. Located in northern Chile (Arica), Catanave belongs to a mineralized epithermal system of gold and silver. In 2010, the environmental impact study was approved and during 2011, 2,189 meters of diamond drilling were completed. This prospect has good possibilities and for 2012 we plan to continue exploration with a diamond drilling program of 3,000 meters.

Santa Marta. Located in the Atacama region, Santa Marta is being explored for copper and molybdenum porphyry. During 2011 and 2010, we diamond drilled 2,837 meters and 3,318 meters, respectively, showing promising results. Exploration will continue in 2012, with a diamond drilling program of 4,000 meters.

8

Table of Contents

San Benito. Located in the Atacama region, San Benito was explored for copper and molybdenum porphyry. In 2010, a diamond drilling program of 3,241 meters was completed. The prospect is currently pending further evaluation.

El Salado. A copper-gold prospect located in the Atacama region, northern Chile. During 2011, we evaluated the information available for the prospect in order to plan the work to be done in the next stage. For 2012, we plan a diamond drilling program of 5,000 meters and metallurgical testing laboratory.

Resguardo de la Costa. A copper-gold prospect located in northern Chile (Atacama area). This prospect is on hold, pending further evaluation.

Other Chilean Prospects. For 2012, we plan to continue with a regional exploration program oriented to locate systems mainly of porphyritics of copper and molybdenum.

Ecuador

In 2011, we started exploration activities in Ecuador. For 2012, we expect to begin exploration work on the Chaucha prospect, located south of Guayaquil. The mineralization is characteristic of a copper-molybdenum porphyry system. In 2012, we plan a program of 10,000 meters of diamond drilling to evaluate the deposit.

Argentina

In the last quarter of 2011, we started exploration activities in Argentina. We plan to carry out explorations in the south of Argentina, where mineralization for porphyry copper, epithermal gold and silver and polymetallic skarns is expected.

PRINCIPAL PRODUCTS AND MARKETS

The principal uses of copper are in the building and construction industry, electrical and electronic products and, to a lesser extent, industrial machinery and equipment, consumer products and the automotive and transportation industries. Molybdenum is used to toughen alloy steels and soften tungsten alloy and is also used in fertilizers, dyes, enamels and reagents. Silver is used for photographic, electrical and electronic products and, to a lesser extent, brazing alloys and solder, jewelry, coinage, silverware and catalysts. Zinc is primarily used as a coating on iron and steel to protect against corrosion. It is also used to make die cast parts, in the manufacturing of batteries and in the form of sheets for architectural purposes.

Our marketing strategy and annual sales planning emphasize developing and maintaining long-term customer relationships, and thus acquiring annual or other long-term contracts for the sale of our products is a high priority. Approximately 80% of our metal production for the years 2011, 2010 and 2009, was sold under annual or longer-term contracts. Sales prices are determined based on prevailing commodity prices for the quotation period according to the terms of the contract.

We focus on the ultimate end-user customers as opposed to selling on the spot market or to trading companies. In addition, we devote significant marketing effort to diversifying our sales both by region and by customer base. We strive to provide superior customer service, including timely deliveries of our products. Our ability to consistently fulfill customer demand is supported by our substantial production capacity.

For additional information on sales please see Revenue recognition in Note 3 “Summary of significant accounting policies” and Note 20 “Segment and related information” of our consolidated financial statements.

9

Table of Contents

METALS PRICES

Prices for our products are principally a function of supply and demand and, except for molybdenum, are established on COMEX and LME, the two most important metal exchanges in the world. Prices for our molybdenum products are established by reference to the publication Platt’s Metals Week. Our contract prices also reflect any negotiated premiums and the costs of freight and other factors. From time to time, we have entered into hedging transactions to provide partial protection against future decreases in the market price of metals and we may do so under certain market conditions. We entered into copper derivative contracts in 2011 and 2010. During 2009, we did not hold any metal derivative contracts. For a further discussion of derivative instruments, see Item 7A “Quantitative and Qualitative Discussion about Market Risk.” For a further discussion of our products market prices, please see Item 7 “Management’s Discussion and Analysis of Financial Condition and Results of Operations” — “Metal Prices.”

The table below shows the high, low and average COMEX and LME copper prices during the last 15 years:

| | Copper (COMEX) | | Copper (LME) | |

Year | | High | | Low | | Average | | High | | Low | | Average | |

1997 | | 1.23 | | 0.76 | | 1.04 | | 1.23 | | 0.77 | | 1.03 | |

1998 | | 0.86 | | 0.64 | | 0.75 | | 0.85 | | 0.65 | | 0.75 | |

1999 | | 0.85 | | 0.61 | | 0.72 | | 0.84 | | 0.61 | | 0.71 | |

2000 | | 0.93 | | 0.74 | | 0.84 | | 0.91 | | 0.73 | | 0.82 | |

2001 | | 0.87 | | 0.60 | | 0.73 | | 0.83 | | 0.60 | | 0.72 | |

2002 | | 0.78 | | 0.65 | | 0.72 | | 0.77 | | 0.64 | | 0.71 | |

2003 | | 1.04 | | 0.71 | | 0.81 | | 1.05 | | 0.70 | | 0.81 | |

2004 | | 1.54 | | 1.06 | | 1.29 | | 1.49 | | 1.06 | | 1.30 | |

2005 | | 2.28 | | 1.40 | | 1.68 | | 2.11 | | 1.39 | | 1.67 | |

2006 | | 4.08 | | 2.13 | | 3.10 | | 3.99 | | 2.06 | | 3.05 | |

2007 | | 3.75 | | 2.40 | | 3.23 | | 3.77 | | 2.37 | | 3.23 | |

2008 | | 4.08 | | 1.25 | | 3.13 | | 4.08 | | 1.26 | | 3.16 | |

2009 | | 3.33 | | 1.38 | | 2.35 | | 3.33 | | 1.38 | | 2.34 | |

2010 | | 4.44 | | 2.76 | | 3.43 | | 4.42 | | 2.76 | | 3.42 | |

| | | | | | | | | | | | | | |

2011-1st Q | | | 4.62 | | 4.13 | | 4.39 | | 4.60 | | 4.07 | | 4.38 | |

2011-2nd Q | | | 4.50 | | 3.90 | | 4.16 | | 4.46 | | 3.87 | | 4.15 | |

2011-3rd Q | | | 4.47 | | 3.15 | | 4.07 | | 4.46 | | 3.16 | | 4.08 | |

2011-4th Q | | | 3.70 | | 3.05 | | 3.41 | | 3.65 | | 3.08 | | 3.40 | |

2011 | | 4.62 | | 3.05 | | 4.01 | | 4.60 | | 3.08 | | 4.00 | |

The per pound COMEX copper price during the last 5, 10 and 15 year periods averaged $3.23, $2.37 and $1.85, respectively. The per pound LME copper price during the last 5, 10 and 15 year periods averaged $3.23, $2.37 and $1.85, respectively.

10

Table of Contents

The table below shows the high, low and average market prices for our three principal by-products during the last 15 years:

| | Zinc(LME) | | Silver (COMEX) | | Molybdenum (Dealer Oxide Platt’s

Metals Week) | |

Year | | High | | Low | | Average | | High | | Low | | Average | | High | | Low | | Average | |

1997 | | 0.80 | | 0.47 | | 0.60 | | 6.31 | | 4.16 | | 4.87 | | 4.75 | | 3.59 | | 4.31 | |

1998 | | 0.52 | | 0.42 | | 0.46 | | 7.26 | | 4.61 | | 5.53 | | 4.48 | | 2.10 | | 3.42 | |

1999 | | 0.56 | | 0.41 | | 0.49 | | 5.76 | | 4.87 | | 5.22 | | 2.80 | | 2.52 | | 2.66 | |

2000 | | 0.58 | | 0.46 | | 0.51 | | 5.55 | | 4.56 | | 4.97 | | 2.92 | | 2.19 | | 2.56 | |

2001 | | 0.48 | | 0.33 | | 0.40 | | 4.81 | | 4.03 | | 4.36 | | 2.58 | | 2.19 | | 2.35 | |

2002 | | 0.38 | | 0.33 | | 0.35 | | 5.11 | | 4.22 | | 4.60 | | 7.90 | | 2.43 | | 3.76 | |

2003 | | 0.46 | | 0.34 | | 0.38 | | 5.98 | | 4.35 | | 4.89 | | 7.60 | | 3.28 | | 5.29 | |

2004 | | 0.58 | | 0.43 | | 0.48 | | 8.21 | | 5.51 | | 6.68 | | 32.38 | | 7.35 | | 16.20 | |

2005 | | 0.87 | | 0.53 | | 0.63 | | 9.00 | | 6.43 | | 7.32 | | 39.25 | | 25.00 | | 31.99 | |

2006 | | 2.10 | | 0.87 | | 1.49 | | 14.85 | | 8.82 | | 11.54 | | 28.20 | | 21.00 | | 24.75 | |

2007 | | 1.93 | | 1.00 | | 1.47 | | 15.50 | | 11.47 | | 13.39 | | 33.75 | | 24.50 | | 30.19 | |

2008 | | 1.28 | | 0.47 | | 0.85 | | 20.69 | | 8.80 | | 14.97 | | 33.88 | | 8.75 | | 28.42 | |

2009 | | 1.17 | | 0.48 | | 0.75 | | 19.30 | | 10.42 | | 14.67 | | 18.00 | | 7.83 | | 10.91 | |

2010 | | 1.14 | | 0.72 | | 0.98 | | 30.91 | | 14.82 | | 20.18 | | 18.60 | | 11.75 | | 15.60 | |

| | | | | | | | | | | | | | | | | | | |

2011-1st Q | | 1.15 | | 1.01 | | 1.09 | | 37.87 | | 26.81 | | 31.74 | | 17.88 | | 16.40 | | 17.17 | |

2011-2nd Q | | 1.13 | | 0.95 | | 1.02 | | 48.58 | | 33.49 | | 38.42 | | 17.15 | | 15.55 | | 16.50 | |

2011-3rd Q | | 1.13 | | 0.84 | | 1.01 | | 43.32 | | 29.93 | | 38.76 | | 15.05 | | 14.40 | | 14.44 | |

2011-4th Q | | 0.93 | | 0.79 | | 0.86 | | 35.27 | | 27.19 | | 31.81 | | 14.10 | | 12.70 | | 13.20 | |

2011 | | 1.15 | | 0.79 | | 0.99 | | 48.58 | | 26.81 | | 35.18 | | 17.88 | | 12.70 | | 15.33 | |

The per pound LME zinc price during the last 5, 10 and 15 year periods averaged $1.01, $0.84 and $0.72, respectively. The per ounce COMEX silver price during the last 5, 10 and 15 year periods averaged $19.68, $13.34 and $10.56, respectively. The per pound Platt’s Metals Week Dealer Oxide molybdenum price during the last 5, 10 and 15 year periods averaged $20.09, $18.24 and $13.18, respectively.

COMPETITIVE CONDITIONS

Competition in the copper market is primarily on a price and service basis, with price being the most important consideration when supplies of copper are ample. Our products compete with other materials, including aluminum and plastics. For additional information, see “Item 1A Risk Factors — The copper mining industry is highly competitive.”

EMPLOYEES

As of December 31, 2011, we had 12,145 employees, approximately 70.3% of whom are covered by labor agreements with eleven different labor unions. During the last several years, we have experienced strikes or other labor disruptions that have had an adverse impact on our operations and operating results. Our Taxco and San Martin mines in Mexico have been on strike since July 2007, our Buenavista mine was on strike from July 2007 through June 6, 2010.

Peru

Approximately 61% of our 4,159 Peruvian workers were unionized at December 31, 2011, represented by eight separate unions. Three of these unions, one at each major production area, represent the majority of the Company’s workers. In September 2010, we reached a collective bargaining agreement with these three unions which will expire on August 31, 2012. This agreement includes, among other things, a 5% annual salary increase and a signing bonus of approximately $6,700 for each of the workers (approximately 2,000). In addition, this agreement provides a productivity bonus program for the departments that reach certain goals.

In addition, there are five smaller unions, representing the balance of workers. Collective bargaining agreements with these unions will expire in November 2012. We expect that negotiations with all eight unions will likely continue throughout the first quarter of 2013.

11

Table of Contents

There were no strikes during 2011 and 2010.

Employees of the Toquepala and Cuajone units reside in townsites, where we have built 3,700 houses and apartments. In 1998, Company housing at our Ilo unit was sold to workers at nominal prices. We still hold 90 houses at Ilo for staff personnel. Housing, together with maintenance and utility services, is provided at minimal cost to most of our employees. Our townsite and housing complexes include schools, medical facilities, churches, social clubs and recreational facilities. We also provide shopping, banking and other services at the townsites.

Mexico

Approximately 75% of our 7,975 Mexican workers were unionized at December 31, 2011, represented by three separate unions. Under Mexican law, the terms of employment for unionized workers is set forth in collective bargaining agreements. Mexican companies negotiate the salary provisions of collective bargaining agreements with the labor unions annually and negotiate other benefits every two years. We conduct negotiations separately at each mining complex and each processing plant.

In recent years the Buenavista mine experienced several labor stoppages. The latest labor stoppage started in July 2007 and finished in June 2010. We began the rehabilitation of the Buenavista mine during the second half of 2010 and in 2011 we restored full capacity.

Currently, the Buenavista operations have a work force of 2,100 workers that are operating the mine and plants as well as developing the $3.7 billion expansion program, which is expected to increase its production capacity from 180,000 tons of copper per year to 488,000 tons. On June 6, 2011, the Confederation of Mexican Workers (“CTM”) was awarded the collective bargaining agreement of the Buenavista del Cobre’s union by the Federal Board of Conciliation and Arbitration. CTM now represents around 780 workers of this mine.

Additionally, the San Martin and Taxco mines have been on strike since July 2007. On December 10, 2009, a federal court confirmed the legality of the San Martin strike. In order to recover the control of the San Martin mine and resume operations, on January 27, 2011, we filed a court petition requesting that the court establish our responsibility for the strike and that it define the termination payment for each unionized worker. The court denied the petition alleging that according to federal labor law, the union was the legitimate party to file the petition. On appeal by us, on May 13, 2011, the Mexican federal tribunal accepted our petition. In July 2011, the union appealed the favorable court decision before the Supreme Court. At December 31, 2011, resolution of the appeal was pending.

In the case of the Taxco mine, following the workers refusal to allow exploration of new reserves, we commenced litigation seeking to terminate the labor relationship with workers of the Taxco mine (including the related collective bargaining agreement). On September 1, 2010, the federal labor court issued a ruling approving the termination of the collective bargaining agreement and all the individual labor contracts of the workers affiliated with the Mexican mining union at the Taxco mine. The ruling was based upon the resistance of the mining union to allow us search for reserves at the Taxco mine. If sustained, this ruling will also have the effect of terminating the protracted strike at the Taxco unit. The mining union appealed the labor court ruling before a federal court. In September 2011, the federal court accepted the union’s appeal and requested that the federal labor court review the procedure and to take into account all the evidence to issue a new resolution. On January 3, 2012, the federal labor court again issued a new resolution, approving the termination of the collective bargaining agreement and all the individual labor contracts of the workers affiliated with the Mexican mining union at the Taxco mine. On January 25, 2012, the mining union appealed the resolution before the federal court. The resolution of the appeal is expected to be issued within the next months.

It is expected that operations at these mines will remain suspended until these labor issues are resolved.

Employees of the Mexcobre and Buenavista units reside in townsites at La Caridad and Buenavista, where we have built approximately 2,000 houses and apartments and 275 houses and apartments, respectively. Most of the employees of the IMMSA unit reside on the grounds of the mining or processing complexes in which they work and where we have built approximately 900 houses and apartments. Housing, together with maintenance and utility services, is provided at minimal cost to most of our employees. Our townsites and housing complexes include educational and, in some units, medical facilities, churches, social clubs, shopping centers, banking and other services. Through 2007, the Buenavista unit (at that

12

Table of Contents

time Cananea) provided health care services free of charge to employees and retired unionized employees and their families through its own hospital at the Buenavista unit. In 2011, we signed an agreement with the Secretary of Health of the State of Sonora to continue providing these services to our retired workers and their families. The new workers of the Buenavista unit will receive health services from the Mexican Institute of Social Security as do all Mexican workers.

FUEL, ELECTRICITY AND WATER SUPPLIES

The principal raw materials used in our operations are fuels, electricity and water. We use natural gas to power boilers and generators and for metallurgical processes at our Mexican operations and diesel fuel for mining equipment. We believe that supplies of fuel, electricity and water are readily available. Although the prices of these raw materials may fluctuate beyond our control, we focus our efforts to reduce these costs through cost and energy saving measures.

Peru

In Peru, electric power for our operating facilities is generated by two thermal electric plants owned and operated by Enersur S.A., an independent power company (“Enersur”), a diesel and waste heat boilers plant located adjacent to the Ilo smelter and a coal plant located south of Ilo. Power generation capacity for Peruvian operations is currently 344 megawatts. Enersur is building a 400 megawatt power plant close to the current coal plant, which will provide additional power reserves in the south of Peru. We believe the plant is scheduled to commence operations in 2013.

In addition, we have nine megawatts of power generation capacity from two small hydro-generating installations at Cuajone. Power is distributed over a 224-kilometer closed loop transmission circuit, which is interconnected with the Peruvian network. We obtain fuel in Peru primarily from a local producer.

In 1997, we sold our Ilo power plant to Enersur. In connection with the sale, a power purchase agreement was also completed under which we agreed to purchase all of our power needs for our Peruvian operations from Enersur for twenty years, commencing in 1997. In 2003, the agreement was amended releasing Enersur from its obligation to construct additional capacity to meet our increased electricity requirements and changing the power tariff as called for in the original agreement.

In 2009, we signed a Memorandum of Understanding (“MOU”) with Enersur regarding its power supply agreement. The MOU contains new economic terms that we believe better reflect current economic conditions in the power industry and in Peru. The new economic conditions agreed in the MOU have been applied by Enersur to its invoices to us since May 2009. Additionally, the MOU includes an option for providing power for the Tia Maria project. The MOU also established a time frame during which Enersur and we must negotiate in good faith to settle certain pending issues, including agreeing on a power purchase agreement for the Tia Maria project. During 2010 and 2011, we continued our negotiation with Enersur but negotiations are currently suspended due to the delay of the Tia Maria project. See “Other legal matters -Tia Maria” in note 14 “Commitment and Contingencies” to our consolidated financial statements for further information.

In Peru, we have water rights or licenses for up to 1,950 liters per second from well fields at the Huaitire, Vizcachas and Titijones aquifers and also surface water from the Suches lake and two small water courses, namely Quebrada Honda and Quebrada Tacalaya, which together are sufficient to supply the needs of our two operating units at Toquepala and Cuajone. At Ilo, we have desalinization plants that produce water for industrial and domestic use that we believe are sufficient for our current and projected needs.

Mexico

Besides electric energy, the principal raw materials used in our operations are fuels. Natural gas is used for metallurgical processes, to power furnaces, converters, casting wheels, boilers and electric generators. Diesel oil is a backup for all these uses. Also at our operations we use diesel oil for mining equipment. Fuel, electricity and water supplies are readily available. The prices of these materials may fluctuate beyond our control since the only supplier is the Mexican government. We therefore focus our efforts to reduce these costs through cost and energy saving measures.

In Mexico, fuel is purchased directly from Petroleos Mexicanos, (“PEMEX”), the state oil monopoly. Electricity for our Mexican operations, which is used as the main energy source at our mining complexes, is purchased from the Comision Federal de Electricidad, the Federal Electricity Commission, or CFE, the state’s electrical power producer. In addition, we recover some energy from waste heat boilers at the La Caridad smelter. Accordingly, a significant portion of our operating

13

Table of Contents

costs in Mexico are dependent upon the pricing policies of PEMEX and CFE, which reflect government policy, as well as international market prices for crude oil, natural gas and conditions in the refinery markets.

The Mexcobre unit imports natural gas from the U.S. through its pipeline (between Douglas, Arizona and Nacozari, Sonora). This permits us to import natural gas from the United States at market prices and thereby reduce operating costs. Several contracts with PEMEX and the United States provide us with the option of using a monthly fixed price or daily fixed prices for our natural gas purchases.

From time to time we enter into gas swap contracts to protect part of our gas consumption. The gain or losses obtained are included in the production cost. During all of 2010 and 2011 and at December 31, 2011, we did not hold any gas swap contracts. During 2009, we entered into gas swap contracts to protect 306,000 MMBTUs of our gas consumption at a fixed price of $3.6350.

Energy is the principal cost in mining, therefore the concern for its conservation and efficient usage is very relevant. We have an energy management committee at most of our mines. The committees meet periodically to discuss consumptions and to develop measures directed at saving energy. Also, alternative sources are being analyzed at the corporate level, both from traditional and renewable energy sources. This has helped us develop a culture of energy conservation directed at the sustainability of our operations.

In Mexico, water is a national property and industries not connected to a public services water supply must obtain a water concession from Comision Nacional del Agua (the “National Water Commission”, or “CNA”). Water usage fees are established in the Ley Federal de Derechos (the Federal Law of Rights), which distinguishes several availability zones with different fees per unit of volume according to each zone. All of our operations have one or several water concessions and, with the exception of Mexicana de Cobre, pump out the required water from one or several wells. Mexicana de Cobre pumps water from the La Angostura dam, which is close to the mine and plants. At our Buenavista facility, we maintain our own wells and pay the CNA for water usage. Water conservation committees have been established in each plant in order to conserve and recycle water. Water usage fees are updated on a yearly basis and have been increasing in recent years.

ENVIRONMENTAL MATTERS

For a discussion of environmental matters reference is made to the information contained under the caption “Environmental matters” in Note 14 “Commitments and Contingencies” of the consolidated financial statements.

MINING RIGHTS AND CONCESSIONS

Peru

We have 196,800 hectares in concessions from the Peruvian government for our exploration, exploitation, extraction and/or production operations, distributed among our various sites as follows:

| | Toquepala | | Cuajone | | Ilo | | Other | | Total | |

| | (hectares) | |

Plants | | 300 | | 456 | | 421 | | — | | 1,177 | |

Operations | | 24,045 | | 17,111 | | 9,403 | | — | | 50,559 | |

Exploration | | 4,800 | | — | | 4,600 | | 135,664 | | 145,064 | |

Total | | 29,145 | | 17,567 | | 14,424 | | 135,664 | | 196,800 | |

We believe that our Peruvian concessions are in full force and in effect under applicable Peruvian laws and that we are in compliance with all material terms and requirements applicable to these concessions. The concessions have indefinite terms, subject to our payment of concession fees of up to $3.00 per hectare annually for the mining concessions and a fee based on nominal capacity for the processing concessions. Fees paid during 2011, 2010 and 2009, were approximately $1.2 million, $1.1 million and $1.1 million, respectively. We have two types of mining concessions in Peru: metallic and non-metallic concessions. We also have water concessions for well fields at Huaitire, Titijones and Vizcachas and surface water rights from the Suches Lake, which together are sufficient to supply the needs of our Toquepala and Cuajone

14

Table of Contents

operating units.

In 2004, the Peruvian Congress enacted legislation imposing a royalty charge to be paid by mining companies in favor of the regional governments and communities where mining resources are located. Under this law, we were subject to a 1% to 3% charge, based on sales, and calculated on the value of the concentrates produced at our Toquepala and Cuajone mines. We made provisions of $52.5million, $65.5 million and $43.7 million in 2011, 2010 and 2009, respectively, for this charge.

In September 2011, the Peruvian Congress approved an amendment to the mining royalty charge. The new mining royalty charge is based on operating income margins with graduated rates ranging from 1% to 12%, with a minimum royalty charge assessed at 1% of net sales. If the operating income margin is 10% or less, the royalty charge is 1% and for each 5% increment in the operating income margin, the royalty charge rate increases by 0.75%, up to a maximum of 12%. In the last quarter of 2011, we made provisions of $19.3 million for this charge.

At the same time, the Peruvian Congress enacted a new tax for the mining industry. This tax is also based on operating income with rates ranging from 2% to 8.4%. It begins at 2% for the first 10% of operating income margin and for each additional 5% of operating income margin is increased by an additional rate of 0.4% until 85% of operating income margin is reached. In the last quarter of 2011, we made provisions of $16.4 million for this tax.

Mexico

In Mexico we have approximately 379,103 hectares in concessions from the Mexican government for our exploration and exploitation activities as outlined in the table below.

| | Underground

Mines | | La Caridad | | Buenavista | | Projects | | Total | |

| | (hectares) | |

Mine concessions | | 88,439 | | 96,588 | | 17,826 | | 176,250 | | 379,103 | |

We believe that our Mexican concessions are in full force and in effect under applicable Mexican laws and that we are in compliance with all material terms and requirements applicable to these concessions. Under Mexican law, mineral resources belong to the Mexican nation and a concession from the Mexican federal government is required to explore or mine mineral reserves. Mining concessions have a 50-year term that can be renewed for another 50 years. Holding fees for mining concessions can be from $0.4 to $8.9 per hectare depending on the beginning date of the mining concession. Fees paid during 2011, 2010 and 2009 were approximately $3.5 million, $2.9 million and $2.5 million, respectively. In addition, all of our operating units in Mexico have water concessions that are in full force and effect. We generally own the land to which our Mexican concessions relate, although ownership is not required in order to explore or mine a concession. We also own all of the processing facilities of our Mexican operations and the land on which they are constructed.

15

Table of Contents

ITEM 1A. RISK FACTORS:

Every investor or potential investor in Southern Copper Corporation should carefully consider the following risk factors.

General Risks Relating to Our Business

Our financial performance is highly dependent on the price of copper and the other metals we produce.

Our financial performance is significantly affected by the market prices of the metals that we produce, particularly the market prices of copper, molybdenum, zinc and silver. Historically, prices of the metals we produce have been subject to wide fluctuations and are affected by numerous factors beyond our control, including international economic and political conditions, levels of supply and demand, the availability and costs of substitutes, inventory levels maintained by users, actions of participants in the commodities markets and currency exchange rates. In addition, the market prices of copper and certain other metals have on occasion been subject to rapid short-term changes.

During the last 15-year period the yearly average price of copper per pound on the COMEX ranged from a low $0.72 in 1999 and 2002, to a high $4.01 in 2011. In 2011, the COMEX copper price decreased from a quarterly high of $4.39 per pound in the first quarter to a quarterly low of $3.41 per pound in the fourth quarter and closed the year at $4.01 per pound. The LME copper prices during these periods, while slightly different, closely paralleled the COMEX prices. Molybdenum, zinc and silver during the same 15-year period showed average highs and lows as follows: molybdenum $2.35 per pound, low in 2001 and $31.99 per pound, high in 2005; zinc $0.35 per pound, low in 2002 and $1.49 per pound, high in 2006; and silver $4.36 per ounce, low in 2001 and $35.18 per ounce high in 2011.

We cannot predict whether metals prices will rise or fall in the future. Future declines in metals prices and, in particular, copper or molybdenum prices, will have an adverse impact on our results of operations and financial condition, and we might, in very adverse market conditions, consider curtailing or modifying certain of our mining and processing operations.

Changes in the level of demand for our products could adversely affect our product sales.

Our revenue is dependent on the level of industrial and consumer demand for the concentrates and refined and semi-refined metal products we sell. Changes in technology, industrial processes and consumer habits may affect the level of that demand to the extent that changes increase or decrease the need for our metal products. A change in demand, including any change resulting from economic slow-downs or recessions, could impact our results of operations and financial condition.

Our actual reserves may not conform to our current estimates of our ore deposits and we depend on our ability to replenish ore reserves for our long-term viability.

There is a degree of uncertainty attributable to the calculation of reserves. Until reserves are actually mined and processed, the quantity of ore and grades must be considered as estimates only. The proven and probable ore reserves data included in this report are estimates prepared by us based on evaluation methods generally used in the mining industry. We may be required in the future to revise our reserves estimates based on our actual production. We cannot assure you that our actual reserves conform to geological, metallurgical or other expectations or that the estimated volume and grade of ore will be recovered. Market prices of our metals, increased production costs, reduced recovery rates, short-term operating factors, royalty charges and other factors may render proven and probable reserves uneconomic to exploit and may result in revisions of reserves data from time to time. Reserves data are not indicative of future results of operations. Our reserves are depleted as we mine. We depend on our ability to replenish our ore reserves for our long-term viability. We use several strategies to replenish and increase our ore reserves, including exploration and investment in properties located near our existing mine sites and investing in technology that could extend the life of a mine by allowing us to cost-effectively process ore types that were previously considered uneconomic. Acquisitions may also contribute to increased ore reserves and we review potential acquisition opportunities on a regular basis. However, we cannot assure you that we will be able to continue with our strategy to replenish reserves indefinitely.

16

Table of Contents

Our business requires levels of capital expenditures which we may not be able to maintain.

Our business is capital intensive. Specifically, the exploration and exploitation of copper and other metal reserves, mining, smelting and refining costs, the maintenance of machinery and equipment and compliance with laws and regulations require significant capital expenditures. We must continue to invest capital to maintain or to increase the amount of copper reserves that we exploit and the amount of copper and other metals we produce. We cannot assure you that we will be able to maintain our production levels to generate sufficient cash, or that we have access to sufficient financing to continue our exploration, exploitation and refining activities at or above present levels.

Restrictive covenants in the agreements governing our indebtedness and the indebtedness of our Minera Mexico subsidiary may restrict our ability to pursue our business strategies.

Our financing instruments and those of our Minera Mexico subsidiary include financial and other restrictive covenants that, among other things, limit our and Minera Mexico’s abilities to incur additional debt and sell assets. If either we or our Minera Mexico subsidiary do not comply with these obligations, we could be in default under the applicable agreements which, if not addressed or waived, could require repayment of the indebtedness immediately. Our Minera Mexico subsidiary is further limited by the terms of its outstanding notes, which also restrict the Company’s applicable incurrence of debt and liens. In addition, future credit facilities may contain limitations on our incurrence of additional debt and liens, on our ability to dispose of assets, or on our ability to pay dividends to our common stockholders.

Applicable law restricts the payment of dividends from our Minera Mexico subsidiary to us.

Our subsidiary, Minera Mexico, is a Mexican company and, as such, may pay dividends only out of net income that has been approved by the shareholders. Shareholders must also approve the actual dividend payment, after mandatory legal reserves have been created and losses for prior fiscal years have been satisfied. As a result, these legal constraints may limit the ability of Minera Mexico to pay dividends to us, which in turn, may have an impact on our ability to pay stockholder dividends or to service debt.

Through 2011, our management set aside $2.0 billion of unremitted earnings of its Mexican subsidiary, Minera Mexico, as appropriated retained earnings. It is our intention to indefinitely invest these funds in Mexico. These amounts are earmarked for the Company’s Mexican expansion program.

Our operations are subject to risks, some of which are not insurable.

The business of mining, smelting and refining copper, zinc and other metals is subject to a number of risks and hazards, including industrial accidents, labor disputes, unusual or unexpected geological conditions, changes in the regulatory environment, environmental hazards and weather and other natural phenomena, including earthquakes. Such occurrences could result in damage to, or destruction of, mining operations resulting in monetary losses and possible legal liability. In particular, surface and underground mining and related processing activities present inherent risks of injury to personnel and damage to equipment. We maintain insurance against many of these and other risks, which may not provide adequate coverage in certain circumstances. Insurance against certain risks, including certain liabilities for environmental damage or hazards as a result of exploration and production, is not generally available to us or other companies within the mining industry. Nevertheless recent environmental legal initiatives have considered future regulations regarding environmental damage insurance. In case such regulations come into force, we will have to analyze the need to obtain such insurance. We do not have, and do not intend to obtain, political risk insurance. These or other uninsured events may adversely affect our financial condition and results of operations.

Deliveries under our copper sales agreements can be suspended or cancelled by our customers in certain cases.

Under our sales agreements, we or our customers may suspend or cancel delivery of copper during a period of force majeure. Events of force majeure under these agreements include acts of nature, labor strikes, fires, floods, wars, transportation delays, government actions or other events that are beyond the control of the parties. Any suspension or cancellation by our customers of deliveries under our sales contracts that are not replaced by deliveries under new contracts or sales on the spot market would reduce our cash flow and could adversely affect our financial condition and results of operations.

17

Table of Contents

The copper mining industry is highly competitive.

We face competition from other copper mining and producing companies around the world. We cannot assure you that competition from lower cost producers will not adversely affect us in the future.

In addition, mines have limited lives and, as a result, we must periodically seek to replace and expand our reserves by acquiring new properties. Significant competition exists to acquire properties producing or capable of producing copper and other metals.

The mining industry has experienced significant consolidation in recent years, including consolidation among some of our main competitors, as a result of which an increased percentage of copper production is from companies that also produce other products and may, consequently, be more diversified than we are. We cannot assure you that the result of current or future consolidation in the industry will not adversely affect us.

Potential changes to international trade agreements, trade concessions or other political and economic arrangements may benefit copper producers operating in countries other than Peru and Mexico, where our mining operations are currently located. We cannot assure you that we will be able to compete on the basis of price or other factors with companies that in the future may benefit from favorable trading or other arrangements.

Interruptions of energy supply or increases in energy costs and other production costs may adversely affect our results of operations.

We require substantial amounts of fuel oil, electricity and other resources for our operations. Fuel, gas and power costs constituted approximately 37.0% and 36.0% of our total production cost in 2011 and 2010, respectively. We rely upon third parties for our supply of the energy resources consumed in our operations. The prices for and availability of energy resources may be subject to change or curtailment, respectively, due to, among other things, new laws or regulations, imposition of new taxes or tariffs, interruptions in production by suppliers, worldwide price levels and market conditions. Disruptions in energy supply or increases in costs of energy resources or increases of other production costs could have a material adverse effect on our financial condition and results of operations.

Shortages of water supply, critical parts, equipment and skilled labor may adversely affect our operations and development projects.

Our mining operations require significant quantities of water for mining, ore processing and related support facilities. Although each operation currently has sufficient water rights to cover its operational demands, the loss of some or all water rights for any of our mines or operations, in whole or in part, or shortages of water to which we have rights could require us to curtail or shut down mining production and could prevent us from pursuing expansion opportunities. Additionally, we have not yet secured adequate water rights to support all of our announced expansion projects, and our inability to secure those rights could prevent us from pursuing some of those opportunities. In addition, future shortages of critical parts, equipment and skilled labor could adversely affect our operations and development projects.

Our results and financial condition are affected by global and local market conditions.

We are subject to the risks arising from adverse changes in domestic and global economic and political conditions. Our industry is cyclical by nature and fluctuates with economic cycles, including the current global economic instability.

The weakness in the global economy has been marked by, among other adverse factors, lower levels of consumer and corporate confidence, decreased business investment and consumer spending, increased unemployment, reduced income and asset values in many areas, currency volatility and limited availability of credit and access to capital.

If the United States and the world-wide economic recovery continues to be weak or deteriorates or if Chinese economic growth weakens, it could have an impact on our business and our financial condition. We cannot predict if the administrative and legislative actions taken in the United States and elsewhere in the world to address this situation will be successful in reducing the severity or duration of the economic instability. The continuation or intensification of the slow global economic recovery and the sovereign debt crisis in Europe or elsewhere may prompt banks to limit or deny lending to us or to our customers, which may have an adverse effect on our liquidity and on our ability to carry out our announced

18

Table of Contents

capital investment programs. Additionally, concerns over the slow recovery in the United States and elsewhere in the world may prompt our customers to slow down or reduce the purchase of our products. We may experience longer sales cycles, difficulty in collecting sales proceeds, and lower prices for our products. A change in the demand of our products could impact our results of operations and financial condition. We cannot provide any assurance that any of these events will not have a material adverse effect on market conditions, prices of our securities, our ability to obtain financing, and our results of operations and financial condition.

Environmental, health and safety laws, regulatory response to climate change, and other regulations may increase our costs of doing business, restrict our operations or result in operational delays.

Our exploration, mining, milling, smelting and refining activities are subject to a number of Peruvian and Mexican laws and regulations, including environmental laws and regulations, as well as certain industry technical standards. Additional matters subject to regulation include, but are not limited to, concession fees, transportation, production, water use and discharge, power use and generation, use and storage of explosives, surface rights, housing and other facilities for workers, reclamation, taxation, labor standards, mine safety and occupational health.

We are required to comply with occupational health and safety laws and regulations in Peru and Mexico where our operations are subject to periodic inspections by the relevant governmental authorities. These laws and regulations govern, among others, health and safety work place conditions, including high risk labor and the handling, storage and disposal of chemical and other hazardous substances. We believe our operations are in compliance in all material respects with applicable health and safety laws and regulations in the countries in which we operate. Compliance with these laws and regulations and new or existing regulations that may be applicable to us in the future could increase our operating costs and adversely affect our financial results of operations and cash flows.

We regularly monitor occupational health and safety performance and compliance through programs, reports and activities at our operations. Accidents are reported to Mexican and Peruvian authorities as required. In 2011, we had one fatality in Mexico, one contractor employee, and two fatalities in Peru, two Company employees. In 2010, we had eight fatalities in Mexico, four Company employees and four contractor employees and two fatalities in Peru, one Company employee and one contractor employee. The amounts paid to the Mexican and Peruvian authorities for reportable accidents did not have a material impact on our results. Under Mexican and Peruvian law penalties and fines for safety violations are generally monetary, but in certain cases may lead to the temporary or permanent shutdown of the affected facility or the suspension or revocation of permits or licenses. In 2010 and 2011, we were not subject to material penalties or sanctions and we did not experience any shutdowns of our work areas.

Environmental regulations in Peru and Mexico have become increasingly stringent over the last decade and we have been required to dedicate more time and money to compliance and remediation activities. Furthermore, Mexican authorities have become more rigorous and strict in enforcing Mexican environmental laws. We expect additional laws and regulations will be enacted over time with respect to environmental matters.

On January 28, 2011, Article 180 of the Mexican Federal General Law of Ecological Balance and Environmental Protection (the “General Law”) was amended. This amendment, gives an individual or entity the ability to contest administrative acts, including environmental authorizations, permits or concessions granted, without the need to demonstrate the actual existence of harm to the environment, natural resources, flora, fauna or human health, because it will be sufficient to argue that the harm may be caused.

As a result of the amendment, more legal actions supported or sponsored by non-governmental groups, interested in halting projects, and not necessarily in protecting the rights of affected communities may be filed against companies operating in all industrial sectors, including the mining sector.

In addition, on August 30, 2011, amendments to the Civil Federal Procedures Code (“CFPC”) were published in the Official Gazette and will be effective on February 29, 2012. These amendments establish three categories of collective actions, by means of which 30 or more people claiming injury derived from environmental, consumer protection, financial services and economic competition issues will be considered to be sufficient in order to have a legitimate interest to seek through a civil procedure restitution or economic compensation or suspension of the activities from which the alleged injury derived. The amendments to the CFPC may result in more litigation, with plaintiffs seeking remedies, including suspension of the activities alleged to cause harm.

19

Table of Contents

On December 5, 2011, the Senate Chamber approved the Environmental Liability Federal Law which establishes general guidelines in order to determine which environmental actions will be considered to cause environmental harm that will give rise to administrative responsibilities (remediation or compensations) and criminal responsibilities. Also economic fines could be established. This initiative has been turned to lower chamber for discussion and voting. The law will be in force once approved by the lower chamber and signed by the president.

In 2003 and 2005, Peruvian environmental laws imposing closure and remediation obligations on the mining industry were enacted. Additionally, future changes to environmental laws and regulations could increase the extent of reclamation and remediation work required to be performed by us. Any such increases in future costs could materially impact the amounts charged to operations for reclamation and remediation. We further discuss these obligations in our Note 10 “Asset Retirement Obligation” to our consolidated financial statements. Moreover, our Mexican operations are also subject to the environmental agreement entered into by Mexico, the United States and Canada in connection with the North American Free Trade Agreement. This agreement, as well as new international treaties regarding human rights, contains environmental provisions and initiatives. We believe our operations are in material compliance with all environmental laws and regulations within the areas we operate.

Regulatory response to climate change, restrictions, caps, taxes, or other controls on emissions of greenhouse gasses, including on emissions from the combustion of carbon-based fuels, could significantly increase our operating costs. Restrictions on emissions could also affect our customers. A number of governments or governmental bodies have introduced or are contemplating regulatory changes in response to the potential impacts of climate change. These regulatory initiatives will be either voluntary or mandatory and may impact our operations directly or through our suppliers or customers.

The potential physical impacts of climate change on our operations are highly uncertain, and would be particular to the geographic circumstances of our facilities. These may include changes in rainfall patterns, water shortages, changing sea levels, changing storm patterns and intensities, and changing temperatures. These effects may adversely impact the cost, production and financial performance of our operations.

The development of more stringent environmental protection programs in Peru and Mexico and in relevant trade agreements could impose constraints and additional costs on our operations and require us to make significant capital expenditures in the future. We cannot assure you that current or future legislative, regulatory or trade developments will not have an adverse effect on our business, properties, operating results, financial condition or prospects.

Our metals exploration efforts are highly speculative in nature and may be unsuccessful.

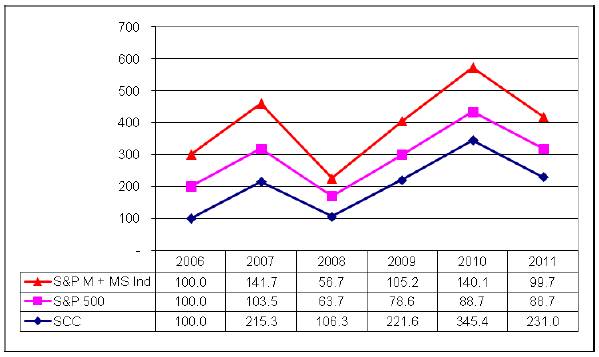

Metals exploration is highly speculative in nature, involves many risks and is frequently unsuccessful. Once mineralization is discovered, it may take a number of years from the initial phases of drilling before production is possible, during which time the economic feasibility of production may change. Substantial expenditures are required to establish proven and probable ore reserves through drilling, to determine metallurgical processes to extract the metals from the ore and, in the case of new properties, to construct mining and processing facilities. We cannot assure you that our exploration programs will result in the expansion or replacement of current production with new proven and probable ore reserves.