Use these links to rapidly review the document

TABLE OF CONTENTS

PART IV

Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| | |

ý |

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended September 30, 2013, |

or |

o |

|

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

|

Commission file number 1-32459

HEADWATERS INCORPORATED

(Exact name of registrant as specified in its charter)

| | |

Delaware

(State or other jurisdiction of

incorporation or organization) | | 87-0547337

(I.R.S. Employer

Identification No.) |

10653 South River Front Parkway, Suite 300

South Jordan, Utah

(Address of principal executive offices) |

|

84095

(Zip Code) |

(801) 984-9400

(Registrant's telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

None

Securities registered pursuant to Section 12(g) of the Act:

Common Stock, $.001 par value

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes o No ý

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes o No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company.

| | | | | | |

| Large accelerated filer ý | | Accelerated filer o | | Non-accelerated filer o

(Do not check if a

smaller reporting company) | | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes o No ý

The aggregate market value of the common stock held by non-affiliates of the registrant as of March 31, 2013 was $773,903,761, based upon the closing price on the New York Stock Exchange reported for such date. This calculation does not reflect a determination that persons whose shares are excluded from the computation are affiliates for any other purpose.

The number of shares outstanding of the registrant's common stock as of October 31, 2013 was 73,155,132.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant's definitive proxy statement to be issued in connection with registrant's annual meeting of stockholders to be held in 2014 are incorporated by reference into Part III of this Report on Form 10-K.

Table of Contents

TABLE OF CONTENTS

| | | | | | |

| |

| | Page | |

|---|

PART I | | | | | | |

ITEM 1. | | BUSINESS | | | 4 | |

ITEM 1A. | | RISK FACTORS | | | 20 | |

ITEM 1B. | | UNRESOLVED STAFF COMMENTS | | | 37 | |

ITEM 2. | | PROPERTIES | | | 37 | |

ITEM 3. | | LEGAL PROCEEDINGS | | | 37 | |

ITEM 4. | | MINE SAFETY DISCLOSURES | | | 37 | |

PART II | | | | | | |

ITEM 5. | | MARKET FOR REGISTRANT'S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES | | | 38 | |

ITEM 6. | | SELECTED FINANCIAL DATA | | | 39 | |

ITEM 7. | | MANAGEMENT'S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS | | | 40 | |

ITEM 7A. | | QUANTITATIVE AND QUALITATIVE DISCLOSURES ABOUT MARKET RISK | | | 58 | |

ITEM 8. | | FINANCIAL STATEMENTS AND SUPPLEMENTARY DATA | | | 59 | |

ITEM 9. | | CHANGES IN AND DISAGREEMENTS WITH ACCOUNTANTS ON ACCOUNTING AND FINANCIAL DISCLOSURE | | | 59 | |

ITEM 9A. | | CONTROLS AND PROCEDURES | | | 59 | |

ITEM 9B. | | OTHER INFORMATION | | | 61 | |

PART III | | | | | | |

ITEM 10. | | DIRECTORS, EXECUTIVE OFFICERS AND CORPORATE GOVERNANCE | | | 62 | |

ITEM 11. | | EXECUTIVE COMPENSATION | | | 62 | |

ITEM 12. | | SECURITY OWNERSHIP OF CERTAIN BENEFICIAL OWNERS AND MANAGEMENT AND RELATED STOCKHOLDER MATTERS | | | 62 | |

ITEM 13. | | CERTAIN RELATIONSHIPS AND RELATED TRANSACTIONS, AND DIRECTOR INDEPENDENCE | | | 62 | |

ITEM 14. | | PRINCIPAL ACCOUNTING FEES AND SERVICES | | | 62 | |

PART IV | | | | | | |

ITEM 15. | | EXHIBITS, FINANCIAL STATEMENT SCHEDULES | | | 63 | |

SIGNATURES

|

|

|

69 |

|

Forward-looking Statements

This Annual Report on Form 10-K contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 regarding future events and our future results that are based on current expectations, estimates, forecasts, and projections about the industries in which we operate and the beliefs and assumptions of our management. Actual results may vary materially from such expectations. In some cases, words such as "may," "should," "intends," "plans," "expects," "anticipates," "targets," "goals," "projects," "believes," "seeks," "estimates," "forecasts," or variations of such words and similar expressions, or the negative of such terms, may help to identify such forward-looking statements. In addition, any statements that refer to projections of our future financial performance, our anticipated growth and trends in our businesses, and other characterizations of future events or circumstances, are forward-looking. For a discussion of the factors that could cause actual results to differ from expectations, please see the risk factors described in Item 1A hereof. There can be no assurance that our results of operations will not be

2

Table of Contents

adversely affected by such factors. Unless legally required, we undertake no obligation to revise or update any forward-looking statements for any reason. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date of this report.

Our internet address is www.headwaters.com. There we make available, free of charge, our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and any amendments to those reports, as soon as reasonably practicable after we electronically file such material with, or furnish it to, the Securities and Exchange Commission (SEC). Our reports can be accessed through the investor relations section of our web site. The information found on our web site is not part of this or any report we file with or furnish to the SEC.

3

Table of Contents

PART I

ITEM 1. BUSINESS

General Development of Business

Headwaters Incorporated ("Headwaters") is a building products company providing products and services in the light and heavy building materials sectors. Our vision is to improve lives through innovative advancements in construction materials. We sell building products such as manufactured architectural stone, siding accessory products and concrete block. We market coal combustion products ("CCPs"), including fly ash which is primarily used as a partial replacement for portland cement in concrete. We also provide services to electric utilities related to the management of CCPs. We intend to expand our light building products and heavy construction materials businesses through growth of existing operations and commercialization of new technologies and products. We are involved in the energy industry through selling catalytic materials to certain refineries engaged in heavy oil upgrading. We have pursued divestiture of non-core businesses in our energy segment and have sold the business of reclaiming waste coal which is presented as a discontinued operation.

We conduct our business primarily through the following three reporting segments: light building products, heavy construction materials, and energy technology.

Light Building Products. We compete in the light building products industry, which is currently our largest reporting segment based on revenue. Our light building products segment has leading positions in several light building product categories.

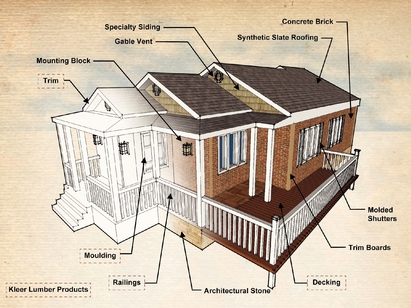

We are a leading designer, manufacturer and marketer of siding accessories used in residential repair and remodeling and new residential construction applications. Our siding accessories include decorative window shutters, gable vents, mounting blocks, and window and door trim products. We also market functional shutters, specialty siding products, specialty roofing products and window wells. Our siding accessory sales are primarily driven by the residential repair and remodeling market and, to a lesser extent, by the new residential construction market. In December 2012 we acquired the assets of Kleer Lumber, Inc. located in Westfield, Massachusetts. Kleer Lumber has added cellular PVC trim board and moulding products to our light building products segment, enhancing our market position and product offerings.

We are a leading producer of manufactured architectural stone. Eldorado Stone, our largest stone brand by revenue, is designed and manufactured to be one of the most realistic manufactured architectural stone products in the world. Our two additional brands are marketed at different price points in the manufactured architectural stone market, allowing us to compete across a broad spectrum of customer profiles. Our manufactured stone sales are driven by new residential construction demand and residential repair and remodeling, as well as commercial construction markets.

We are the largest manufacturer of concrete block in the Texas market, which we believe to be one of the largest concrete block markets in the United States. We offer a variety of concrete based masonry unit products and employ a regional branding and distribution strategy. A large portion of our concrete block sales are generated from the institutional construction markets in Texas, including school construction.

We have a large customer base for our building products that includes many siding and roofing wholesalers in the United States and a large number of retail customers and lumber yards across the country. Sales are broadly diversified by serving a large variety of customers in various distribution channels. We believe we attract a large base of customers because we emphasize customer satisfaction, high quality and innovative products.

Heavy Construction Materials. We also compete in the heavy construction materials industry. We are the national leader in the management and marketing of fly ash and other CCPs, procuring fly ash

4

Table of Contents

from coal-fueled electric generating utilities and supplying it to our customers as a mineral admixture used as a partial replacement for portland cement in the production of concrete. CCPs, such as fly ash and bottom ash, are the non-carbon components of coal that remain after coal is burned.

Fly ash is most valuable when it is used as a mineral admixture to replace a portion of the portland cement used in concrete. Concrete made with fly ash has better performance characteristics than concrete made only from portland cement, including improved durability, decreased permeability and enhanced corrosion resistance. Further, concrete made with CCPs typically is easier to work with than concrete made only with portland cement, due in part to its better pumping and forming properties. Because fly ash can be substituted for a portion of the portland cement used in concrete and is generally less expensive per ton than portland cement, the total per cubic yard cost of concrete made with fly ash can be lower than the cost of concrete made exclusively with portland cement. According to a 2011 report sponsored by us from the American Road and Transportation Builders Association, the recycling of fly ash into concrete saves federal and state governments more than $5 billion annually in infrastructure costs, based on the initial price savings of fly ash relative to portland cement and the longer durability of concrete made with fly ash.

In order to ensure a steady and reliable supply of CCPs, we enter into long-term and exclusive management contracts with coal-fueled electric generating utilities, maintain stand-alone CCP distribution terminals across North America, as well as plant-site supply facilities. With our extensive distribution network, we can transport CCPs significant distances to states that have limited coal-fueled electric utilities producing CCPs yet historically have been high volume CCP markets.

A substantial majority of our CCP revenue comes from sales to an extensive customer base that uses fly ash as a mineral admixture for the partial replacement for portland cement in concrete. These customers are primarily ready mix producers, but also include paving contractors and other manufacturers of concrete products. Although our customers typically operate in limited regions because of the high cost of transporting concrete and concrete products, we sell fly ash in multiple regions across the country utilizing our broad sources of supply and our efficient distribution system.

We plan to grow our heavy construction materials business by increasing the percentage of fly ash used as a mineral admixture for the partial replacement of portland cement and expanding the use of CCPs through market recognition of the performance, economic and environmental benefits of CCPs. Based on Portland Cement Association and American Coal Ash Association data, we estimate that for calendar 2011, fly ash replaced approximately 19% of the portland cement that otherwise would have been used in concrete produced in the United States.

Energy Technology. We are involved in heavy oil upgrading processes and liquefaction of coal into liquid fuels. We formerly owned and operated 11 coal cleaning facilities capable of separating ash from waste coal to provide a refined coal product that is higher in Btu value and lower in impurities than the feedstock coal and which can generate refined coal tax credits under Internal Revenue Code Section 45. In September 2011 we committed to a plan to sell all of our coal cleaning facilities. During fiscal 2012 we sold one facility, in October 2012 we sold two more facilities and in January 2013 we sold the remaining eight facilities.

Headwaters was incorporated in Delaware in 1995. Our stock trades under the New York Stock Exchange symbol "HW."

As used herein, "Headwaters," "combined company," "we," "our" and "us" refer to Headwaters Incorporated and its consolidated subsidiaries, including Tapco International Corporation and its subsidiaries, Headwaters Construction Materials, Inc. and its subsidiaries, Eldorado Stone LLC, and its subsidiaries and affiliates (operating in our light building products segment); Headwaters Resources, Inc. and its subsidiaries (operating in our heavy construction materials segment); Headwaters Plant Services, Inc. (operating in our heavy construction materials segment); Headwaters

5

Table of Contents

Heavy Oil, LLC and Headwaters Technology Innovation Group, Inc. ("HTI," operating in our energy technology segment); and Headwaters Energy Services Corp. and its subsidiaries (formerly operating in our energy technology segment); unless the context otherwise requires. As used in this report, Headwaters Building Products or "HBP" refers to Tapco International Corporation and its subsidiaries and to Headwaters Construction Materials, Inc., together with its subsidiaries including "Eldorado", which refers to Eldorado Stone LLC and its subsidiaries and affiliates); "HRI" refers to Headwaters Resources, Inc. and its consolidated subsidiaries; "HPS" refers to Headwaters Plant Services, Inc.; "HTI" refers to Headwaters Heavy Oil, LLC and Headwaters Technology Innovation Group, Inc.; and "HES" refers to Headwaters Energy Services Corp., together with its consolidated subsidiaries and affiliates; unless the context otherwise requires.

Light Building Products

We operate leading businesses in siding accessories, manufactured architectural stone and concrete blocks. We manufacture and distribute nationally siding accessories (such as window shutters, gable vents, mounting blocks, trim, moulding, simulated wood shake siding, and composite roofing), and professional tools used in exterior residential remodeling and construction. Our manufactured architectural stone and building accessories products have a national presence in commercial, residential and remodeling markets. We also are a leading supplier of concrete blocks and specialty blocks in Texas. We believe our traditional building products and new product offerings position us for significant growth as residential remodeling and construction activity in the United States continues to improve.

Siding and Exterior Siding Accessories. We are a leading designer, manufacturer and marketer of resin-based siding accessories and professional tools used in exterior residential home improvement and construction under multiple brands. These products, which are either injection-molded or extruded, enhance the appearance of homes and include decorative window shutters, gable vents, and mounting blocks for exterior fixtures, roof ventilation, trim board and moulding products, specialty siding products, synthetic roofing tiles, and window well systems. Professional tools include portable cutting and shaping tools used by contractors, on-site, to fabricate customized aluminum shapes that complement the installation of exterior siding.

6

Table of Contents

We market our injection-molded building product accessories to retailers and mass merchandisers through our Builders Edge and Vantage brands and to the manufactured housing market through the MHP brand. In addition, we market tools through the Tapco brand, functional shutters through the Atlantic Premium Shutters brand, specialty siding products through the Foundry brand, specialty roofing products through the InSpire brand, window wells under the WellCraft brand, and cellular PVC trim board and moulding under the Kleer Lumber brand.

These building products principally serve applicator needs for siding and roofing. Our injection-molded products are designed to enhance the exterior appearance of the home while delivering durability at a lower cost compared to similar aluminum, wood and slate products.

In December 2012 we acquired the assets of Kleer Lumber, Inc. located in Westfield, Massachusetts. Kleer Lumber has added cellular PVC trim board and moulding products to our light building products business, enhancing our market position and product offerings.

Manufactured Architectural Stone. Under the Eldorado Stone, Dutch Quality Stone and StoneCraft brands, we offer a wide variety of high-quality manufactured architectural stone products to meet a variety of design needs and price points. Our manufactured architectural stone siding incorporates several key features, including high aesthetic quality, ease of installation, durability, low maintenance, attractive cost relative to other siding materials and widespread availability in the marketplace. Our largest brand by revenue, the Eldorado Stone brand is designed and manufactured to be one of the most realistic manufactured architectural stone products in the world. Our manufactured architectural stone siding is a lightweight, adhered siding product recommended or used by national, regional and local architectural firms, real estate developers, contractors, builders and homeowners. Our stone products are used in construction projects ranging from large-scale residential housing developments and commercial projects to do-it-yourself home improvement jobs. In addition, our manufactured stone product lines are used in a variety of external and internal home applications such as walls, archways, fireplaces, patio kitchens, and landscaping. We continually introduce new products in order to improve our offering, such as Farmledge panelized stone. We believe that our focus on product quality, breadth and innovation, combined with a geographically diversified manufacturing platform, provides us with significant marketing advantages over traditional materials such as natural stone, brick or stucco.

Concrete Block. We are one of the largest manufacturers and sellers of concrete block in the Texas market, one of North America's largest markets. We offer a variety of concrete-based masonry products including standard grey block, split faced block, ground face block, polished block and textured block. Our product offerings allow us to meet a range of architectural specifications for concrete block and other products. We employ a regional branding and distribution strategy. In 2012 we began producing a polished block that we expect will allow us to further expand marketing beyond the Texas market. A large portion of our concrete block sales are generated from institutional construction markets in Texas, including school construction. Fly ash is used in the manufacturing process for concrete block.

We conduct manufacturing, distribution and sales operations for resin-based siding accessories and ancillary products through five facilities. Manufacturing assets include more than 100 injection molding presses, many of which are automated through robotics or conveyor systems which have reduced cycle times and have helped to reduce waste. Nonconforming output is reused as raw material, further minimizing waste.

Our manufactured architectural stone brands are currently manufactured through a network of six plants. We reduced our manufacturing footprint in recent years as a result of the residential construction down cycle. We remain focused on improving product quality while reducing the cost of the manufactured architectural stone we produce.

7

Table of Contents

We operate six modern concrete block manufacturing facilities. Our block operations are located to provide coverage of all the key metropolitan areas in Texas and Baton Rouge, Louisiana, and to lower transportation costs and gain efficiencies by concentrating the manufacturing of specific products in fewer facilities.

Our resin-based siding products' sales and marketing organization supports the one-step, two-step distribution, and retail channels through various networks of sales support that include approximately 100 independent sales representatives and a group of business development managers, regional sales managers and sales executives.

Our manufactured architectural stone products sales force works directly with wholesale customers as well as architects and contractors to provide information concerning the attributes and ease of installation of our manufactured stone product and to promote market acceptance over traditional building materials. Similarly, our block sales personnel work with architects and contractors to have our products specified on construction projects.

We maintain relationships with local contractors, professional builders, and other end-users by participating each year in many local and national shows. Local shows, sponsored by local distributors, enable us to promote our products through hands-on comparisons to competing products. These shows enable us to receive useful feedback from local contractors, which may lead to new product ideas as well as significant goodwill within the trade.

Resin-based siding accessories and our ancillary products are distributed throughout the United States and Canada through five primary distribution channels: one-step distributors that sell directly to contractors, two-step distributors that sell our products to lumber yards and one-step distributors, retail home centers/mass merchandisers, direct sales to lumber yards, and manufactured housing. In connection with our December 2012 acquisition of the assets of Kleer Lumber, Inc., we have begun introducing Kleer Lumber's product offerings into our larger distribution network, thus expanding point of sale locations. In addition, Kleer Lumber primarily distributes its products to independent lumber yards and home improvement centers located in the Northeast and Mid-Atlantic states. Increased access to the Kleer Lumber distribution channel for our existing products expands our light building products distribution network.

Manufactured architectural stone is distributed throughout North America, Europe and Asia primarily on a wholesale basis through a network of distributors, including masonry and stone suppliers, roofing and siding materials distributors, fireplace suppliers and other contractor specialty stores. We also distribute some brands through national retail home centers.

We distribute our concrete block products through national and regional retail home centers as well as through direct sales to masonry contractors and general contractors.

We have a large customer base for our light building products in the residential home improvement and new home construction markets that include many retail customers and siding wholesalers across North America and to a lesser extent, in Europe and Asia. Sales are diversified across customers and ship-to locations, mitigating the impact of regional economic circumstances.

8

Table of Contents

The primary raw materials purchased for resin-based siding products are polypropylene and PVC which are available for purchase from multiple suppliers. We also use comparatively small amounts of styrene. From time to time, prices for some of the raw materials used in production/assembly processes fluctuate significantly. Although we do not have any long-term contracts with suppliers and we purchase supplies on a purchase order basis, we occasionally make volume purchases of materials at fixed prices.

We purchase cement, sand and aggregates as primary raw materials for our concrete-based products. We do not have long-term contracts for the supply of these materials and demand for these materials can be volatile while supplies are constrained to local sources because of transportation costs. Our costs to purchase raw materials have risen in some regions for certain materials. However, we have not suffered from any long-term shortages and believe that supplies will be adequate in the future.

We have a leading market position in our siding accessories business because of our strong ability to manufacture and distribute a broad range of products economically and rapidly. However, our resin-based siding accessory business' strong market position suggests that its future growth will come largely from improved demand for building products as the construction sector of the economy continues to strengthen, not from increasing market share in the siding accessories industry. We have developed a recognized name in the manufactured architectural stone industry and a strong market share because our products have excellent authenticity and broad selection alternatives. Our architectural stone business has a multi-channel distribution network, but faces strong competition from producers that may be closer to certain end markets. Our block business is not national in breadth, although it enjoys a strong regional market position in Texas and Louisiana, facing competition from other Texas and Louisiana block businesses.

Our primary competition for resin-based siding products includes Ply Gem, Royal, and Alpha in the siding accessories market, Azek in the trimboard market, and CertainTeed in the specialty siding market. Notwithstanding our national position as a leading producer of manufactured architectural stone, we face significant competition from other national and regional producers of similar products, such as Boral Material Technologies Inc. and Coronado Stone Products. With respect to concrete masonry units, national and regional competition includes Featherlite, IPC Building Products, Pavestone, Revels Block & Brick and Jewell Concrete Products, some of which are larger manufacturers of concrete masonry units than us. Many of our competitors have greater financial and other resources and may be able to take advantage of acquisitions and other opportunities more readily than we can.

Heavy Construction Materials—Coal Combustion Products

We are the nation's largest manager and marketer of CCPs, including fly ash, a mineral admixture that may be used as a partial replacement for portland cement in concrete. In order to help protect our supply of CCPs, we have formed numerous long-term exclusive management contracts with coal-fueled electric generating utilities throughout the United States and maintain stand-alone CCP distribution terminals across North America, as well as plant-site supply facilities. With our extensive distribution network, we can transport CCPs significant distances to states that have limited coal-fueled electric utilities producing CCPs yet historically have been high volume CCP markets.

CCPs are varying types of inorganic residuals from burning coal. CCPs have been an environmental and economic burden for power generators; however, when properly managed CCPs can be valuable products. Of the different CCPs, we sell fly ash (captured from the flue gas) which is used

9

Table of Contents

primarily as a mineral admixture for the partial replacement for portland cement in a wide variety of concrete applications, including infrastructure, commercial, and residential construction. We believe we are currently the largest manager and marketer of CCPs in the United States; we also conduct business in Canada. We have a number of long-term, exclusive management contracts with coal-fueled, electric generating utilities throughout the United States and provide CCP management services at plant-site supply locations.

Utilities produce CCPs year-round. In comparison, sales of CCPs and building products produced using CCPs are seasonal, following construction market demands. CCPs must be disposed of or stored in terminals during the off-peak sales periods as well as transported to where they are needed for use. Due to transportation costs, the CCP market is generally regional, with product transportation to areas that have scarce supply of coal-fueled electric utilities producing high quality CCPs. As the largest manager and marketer of CCPs in the United States, we benefit from contractual supplies and our extensive distribution system. We maintain stand-alone CCP distribution terminals across North America, as well as plant-site supply facilities. In addition, we have area managers and technical sales representatives nationwide to provide customer support.

We provide services as an integrated component of our work with coal-fueled utilities and their production of CCPs. We focus on providing industrial services to utilities that include constructing and managing landfill operations, operating and maintaining material handling systems and equipment maintenance. These are services that enhance our reputation in the marketing of fly ash and that strategically position us as an integrated manager of CCPs. We have more than three decades of experience designing, permitting, constructing, operating and closing solid waste disposal operations for utilities and other industrial clients. We currently provide such services to some of the largest utilities in the United States.

The complexity of CCP disposal operations is expected to increase as new environmental regulations are adopted. Many utilities may be forced to upgrade disposal practices or convert to new types of disposal. As new disposal regulations are adopted, we plan to use our experience with landfill operations, pond cleanouts, converting disposal operations from wet to dry handling, designing and managing systems for handling flue gas desulphurization materials, and deploying systems for improving fly ash quality to expand our business. By providing such services to utilities, we expect to improve our position as the leading manager and marketer of fly ash in the United States.

The benefits of CCP use in construction applications include improved product performance, cost savings and positive environmental effect. Fly ash improves both the chemical and physical performance of concrete, decreasing permeability and enhancing durability while providing environmental benefits. Fly ash utilization conserves landfill space as well as conserves energy and reduces greenhouse gas emissions. According to the U.S. Environmental Protection Agency ("EPA"), one ton of fly ash used as a mineral admixture in the partial replacement of portland cement eliminates approximately one ton of carbon dioxide emissions associated with cement production. The value of utilizing fly ash in concrete has been recognized by a number of federal agencies, including the U.S. Department of Energy, the U.S. Department of Transportation, and the U.S. Environmental Protection Agency. Today almost all states specify or recommend the use of fly ash in state and federal transportation projects. In June 2010, the EPA issued a proposed rule to regulate the disposing of CCPs which, if adopted is likely to increase the cost of managing and disposing of CCPs and which may have an adverse effect on beneficial use and sales of CCPs (see "Business—Regulation" and "Risk Factors").

Higher-quality fly ash and other high-caliber CCPs possess greater value than low quality CCPs because of their diverse, higher-margin commercial uses. The quality of fly ash produced by the combustion process at coal-fueled facilities varies widely and is affected by the type of coal feedstock used and the boilers maintained by the utilities. We assist our utility clients in their efforts to improve the production of high-value CCPs at their facilities. Our quality control system ensures customers

10

Table of Contents

receive their specified quality of CCPs while our relationships with utilities, transportation equipment and terminal facilities provide stable and reliable supply.

Expansion of Market Awareness of CCPs' Benefits. Customer demands for quality and reliability drive our CCP marketing and sales program. Our marketing efforts emphasize the performance value and environmental benefits of CCP usage. We participate in a variety of marketing activities to increase fly ash sales, including professional outreach, technical publications, relationships with industry organizations, and involvement in legislative and regulatory initiatives planned to lead to greater use of CCPs.

New Technologies for CCP Utilization. Our research and development activities focus on expanding the use of CCPs and decreasing landfill disposal. For example, although generally unsuitable for use in traditional concrete applications, we developed and offer for sale two products that utilize the type of fly ash generated at fluidized bed combustion ("FBC") power plants. Stabil-Mix, a mixture of fly ash and lime used for roadbed stabilization, may be custom blended for optimum results in varying soil conditions. Pozzalime takes advantage of the lower SO3 and free lime content of some sources of FBC ash to create a product suited for use as a partial cement replacement in the manufacture of concrete masonry units.

Technologies to Improve Fly Ash Quality. We have also developed technologies that maintain and improve the quality of CCPs, further enhancing their marketability. Today, many utilities are switching fuel sources, changing boiler operations and introducing activated carbon and ammonia into the exhaust gas stream in an effort to meet increasingly stringent emissions control regulations. While these factors may negatively affect fly ash quality, we are addressing these challenges with the development and commercialization of two technologies—carbon fixation, which pre-treats unburned carbon particles in fly ash to minimize the particles' adverse effects; and ammonia slip mitigation, which counteracts the effect of ammonia contaminants in fly ash.

Most of our heavy construction materials customers purchase CCPs for beneficial use. A substantial majority of our CCP revenue comes from sales to customers who use fly ash as a mineral admixture for the partial replacement of portland cement in concrete. These customers are primarily ready mix producers, but also include paving contractors and manufacturers of concrete products, with some customers using CCPs for soil stabilization, road base or other applications. Although our customers typically operate in limited regions because of the high cost of transporting concrete and concrete products, we sell CCPs to many customers in various regions across the country utilizing our extensive distribution system. No customer represents more than 10% of our heavy construction materials segment revenue.

Coal is the largest indigenous fossil fuel resource in the United States. The U.S. Energy Information Administration estimates that in 2012 coal was used to produce approximately 37% of the electricity generated in the United States. The combustion of coal results in a high percentage of residual materials which serve as the "raw material" for the CCP industry. According to the American Coal Ash Association, in 2011 about 57 million tons of the approximately 130 million tons of U.S. CCPs generated were efficiently utilized. As long as a significant amount of electricity is created using coal-fueled generation, we believe there will be significant supplies of CCP raw materials. However, as Clean Air Act, Resource Conservation and Recovery Act ("RCRA") and other environmental rules are implemented, the efforts of coal-fueled electric power producers to comply with tighter regulatory

11

Table of Contents

requirements may have a serious adverse effect on the supply of CCPs. Increasingly strict requirements make coal burning less attractive for utilities. Faced with the prospect of more stringent regulations, litigation by environmental groups and a decrease in the cost of natural gas, some electric utilities are reducing their portfolio of coal powered energy facilities. In recent years, multiple companies have announced plans to close coal-fired power plant units, or dropped plans to open new plants. While the current level of reduced use of coal in power generation has not materially impacted our fly ash supply, significant diminished use of coal in the future could reduce our supply of CCP raw materials. (See "Business—Regulation" and "Risk Factors.")

The business of marketing traditional CCPs is highly competitive but we have a strong competitive position due to our long-term utility contracts for the supply of fly ash and our extensive distribution system. Our nationwide CCP distribution system not enjoyed by our competition allows us to effectively compete for long-term exclusive supply contracts with utilities. However, our CCP business is sometimes adversely affected by inclement weather slowing construction using concrete, the largest market for certain high quality CCPs. We also face increasingly aggressive competition in marketing and sales of CCPs.

Our CCP business has substantial competition in two main areas: obtaining CCP management contracts with utility and other industrial companies and marketing CCPs and related industrial materials. Our CCP business has a presence in every region in the United States but, because the market for the management of CCPs is fragmented and because the costs of transportation are high relative to sales prices, most of the competition in the CCP management industry is regional. There are many local, regional and national companies that compete for market share with similar CCP products and with numerous other substitute products. Although we have a number of long-term CCP management contracts with our clients, some of these contracts allow for the termination of the contract at the convenience of the utility company upon a specified notice. Our major competitors include Lafarge North America Inc., Boral Material Technologies Inc. and Cemex. Many of our competitors have greater financial, management and other resources and may be able to take advantage of potential acquisitions and other opportunities more readily than we can.

Energy Technology

In our energy technology segment, we are focused on increasing the value of low value oil through a technology that improves conversion of petroleum refinery vacuum residuals into higher-value products. In September 2011 we committed to a plan to sell our facilities that use coal cleaning processes to upgrade waste coal by separating ash from the coal, resulting in a coal product lower in ash, including sulfur, mercury and other impurities, and higher in Btu value. During fiscal year 2012 we sold one facility, in October 2012 we sold two more facilities, and in January 2013 we sold the remaining eight facilities. The financial results of our former coal cleaning business is classified as a discontinued operation.

We continue to develop for commercialization the following businesses and technologies:

Heavy Oil Upgrading Technology. We own patents and know-how related to the HCAT® Technology. HCAT is a unique heavy oil upgrading technology for the addition of hydrogen to heavy residual oils such as petroleum vacuum residue (so-called "bottom of the barrel") and tar sand bitumen into lighter, more valuable petroleum materials. The proprietary HCAT process uses a highly active, molecular-scale catalyst to more efficiently convert heavy oils, including the asphaltenic components, into more valuable products, such as diesel fuel. We now supply our catalyst precursor to the heavy oil

12

Table of Contents

upgrading units at two refineries. We will continue to develop the long sale cycle opportunities for HCAT with additional refineries through the efforts of our own small group of sales executives and through marketing cooperation with established industry participants.

Coal Liquefaction. Our technology for producing liquid fuels from coal was licensed in 2002 to the Shenhua Group, China's largest coal company, for a direct coal liquefaction ("DCL") project in Majiata, China. We have also entered into several development and/or study agreements for coal liquefaction during the last several years.

In September 2011 we decided to focus on our core light building products and heavy construction materials businesses and therefore committed to a plan to sell our coal cleaning business comprised primarily of 11 coal cleaning facilities and associated assets. In a series of transactions in 2012 and 2013, we sold our coal cleaning business. The financial results of our former coal cleaning business are presented in our statements of operations as a discontinued operation.

Each of our energy businesses experiences competition. Our heavy oil upgrading, coal liquefaction and catalyst technologies experience competition from many of the world's major petroleum, chemical and energy companies. Those companies are actively engaged in research and development activities that could result in a competitive slurry catalyst system. For example, Chevron has recently begun marketing a catalyst system that could be competitive with HCAT. Many of our competitors have greater financial and other resources and may be able to take advantage of acquisitions and other opportunities more readily.

With respect to discontinued coal cleaning operations, the purchasers of our former coal cleaning facilities face competition from numerous operators of run-of-mine coal production facilities, some of which also prepare and co-produce product from waste or low value coal streams. Our receipt of future income and avoidance of certain contingent liabilities depends upon the successful operation by the purchasers of the coal cleaning facilities against such competition.

Segments and Major Customers

We operate in three business segments, light building products, heavy construction materials and energy technology. Additional information about segments is presented in Note 3 to our audited consolidated financial statements. No customer accounted for more than 10% of total revenue from 2011 through 2013.

Research and Development

We maintain a staff of engineers, scientists and technicians with expertise in the design and operation of high-pressure and temperature process plants at our Lawrenceville, New Jersey pilot plant and laboratory facilities. Our staff is focused on improving the HCAT technology and pursuing additional applications beyond use as an additive in ebullated bed reactors. Our light building products business conducts limited research for the development of potential new products and the improvement of existing products. Our heavy construction materials business conducts research on improvements to CCP quality, such as carbon fixation in fly ash, and CCP beneficial uses.

13

Table of Contents

The following table presents our approximate research and development expenses for the past three fiscal years:

| | | | |

2011 | | $ | 6.5 million | |

2012 | | $ | 8.0 million | |

2013 | | $ | 7.3 million | |

Seasonality

Our light building products and heavy construction materials segments experience seasonal changes in revenue. Construction of new homes, repair and remodeling, and commercial and infrastructure projects slow during winter conditions and increase during temperate seasons. Because our products are used in construction projects, our revenues increase in the spring, are strong in the summer and fall, and drop significantly in the winter months, typically making our second fiscal quarter our lowest revenue quarter.

Intellectual Property

As of September 30, 2013, we had approximately 300 U.S. and foreign counterpart patents and approximately 72 U.S. and foreign counterpart patents pending. Additionally, we have approximately 229 U.S. and foreign trademarks and approximately 63 U.S. and foreign trademark applications pending. The following table lists the number of patents and trademarks, U.S. and foreign, by segment:

| | | | | | | | | | | | | |

| | Patents | | Trademarks | |

|---|

| | Issued | | Pending | | Issued | | Pending | |

|---|

Light Building Products | | | 138 | | | 8 | | | 214 | | | 63 | |

Heavy Construction Materials | | | 24 | | | 1 | | | 13 | | | 0 | |

Energy Technology and Corporate | | | 138 | | | 63 | | | 2 | | | 0 | |

Collectively, the intellectual property is important to us, but except in energy technology, there is no single patent or trademark that is itself material to us at the present time. In our energy segment, we have patents protecting our heavy oil upgrading technology that are material to that business.

There can be no assurance as to the scope of protection afforded by the patents. In addition, there are other technologies in use and others may subsequently be developed, which do not, or will not, utilize processes covered by the patents. There can be no assurance that our patents will not be infringed or challenged by other parties or that we will not infringe on patents held by other parties. Because some of these patents represent new technology, the importance of the patents to our business will depend on our ability to commercialize these technologies successfully, as well as our ability to protect our technology from infringement or challenge by other parties. Patents may expire before they are a commercial success.

In addition to patent protection, we also rely on trade secrets, know-how and confidentiality agreements to protect technologies. Despite these safeguards, such methods may not afford complete protection and there can be no assurance that others will not either independently develop such know-how or obtain access to our know-how, concepts, ideas, and documentation. Since our proprietary information is important to our business, failure to protect ownership of our proprietary information would likely have a material adverse effect on us.

Regulation

Environmental. Our operations and those of our suppliers and customers involved in coal-based energy generation, primarily utilities, are subject to federal, state and local environmental regulations. Our coal-based operations and those of our customers, including our recently sold coal cleaning

14

Table of Contents

operations, are subject to regulations that impose limits on the discharge of air and water pollutants and establish standards for the treatment, storage and disposal of solid and hazardous waste materials and the reclamation of land. Compliance with the applicable regulations adds to the cost of doing business and may expose us to potential fines for non-compliance or may require us to spend money to investigate or remediate contaminated facilities or reclaim disturbed land. Moreover, in order to establish and operate power plants, our operations to collect and transport CCPs and our former coal cleaning facilities, we and our customers have obtained various federal, state and local permits and must comply with processes and procedures that have been approved by regulatory authorities. Compliance with permits, regulations and approved processes and procedures helps protect the environment and is critical to our business. Any failure to comply could result in the issuance of substantial fines and penalties and may cause us to incur environmental or reclamation liabilities or subject us to third party claims.

We believe that all required permits to construct and operate facilities have been or will be obtained and believe all of our current facilities are in substantial compliance with, and our former facilities during our period of ownership or operation were in substantial compliance with, all relevant environmental laws and regulations governing our operations.

In spite of safeguards, our operations entail risks of regulatory noncompliance or accidental discharge that could create an environmental liability, because regulated materials are used or stored during normal business operations, including in our CCP and former coal cleaning operations. Moreover, we use regulated chemicals in operations involving distillation to purify products, analysis, packaging of chemicals and the selling, warehousing and manufacturing of organic chemicals in small research volumes. We also use facilities to perform research and development activities involving coal, oil, chemicals and industrial gases such as hydrogen. As a result, petroleum and other hazardous materials have been and are present in and on our properties. We generally hire independent contractors to transport and dispose of any wastes we generate during such activities and send the wastes to approved facilities for disposal.

Our HRI business is dependent upon the recovery and processing of CCPs from our customers, typically coal-burning power plants. Coal-burning power plants and the coal industry generally are highly regulated under federal and state law. Environmental regulation affecting this industry is ever-evolving, including the following:

- •

- The federal Clean Air Act of 1970 and subsequent amendments, particularly the Clean Air Act Amendments of 1990. Regulation by the U.S. Environmental Protection Agency ("EPA") and corresponding state laws and regulations, limit the emission of air pollutants such as sulfur oxides ("SOx"), nitrogen oxides ("NOx") and particulate matter ("PM"). In January 2013, the EPA finalized a more stringent ambient air quality standard for fine PM. EPA is also expected to propose more stringent standards for ozone by the end of 2013 and for NOx in early 2016. To meet emissions limits, utilities have been required to make changes such as changing their fuel sources, installing expensive pollution control equipment and, in some cases, shutting down a plant. In addition, in July 2011, the EPA adopted the Cross-State Air Pollution Rule ("CSAPR"), a cap-and-trade type program requiring utilities to make substantial reductions in SOx and NOx emissions that contribute to ozone and fine particulate matter pollution in order to reduce the interstate transport of such pollution. CSAPR was challenged by industry and vacated by the D.C. Circuit in August 2012. The case will be heard by the Supreme Court in December 2013. These emission control requirements can impact the quantity and quality of CCPs produced at a power plant, can add to the costs of operating a power plant and could make coal a less attractive fuel alternative in the planning and building of utility power plants in the future.

- •

- Certain environmental laws, including the Comprehensive Environmental Response, Compensation and Liability Act ("CERCLA") and similar state laws, impose strict, joint and

15

Table of Contents

several liability on responsible parties for investigation and remediation of regulated materials at contaminated sites. CCPs may contain materials such as metals that are regulated materials under these laws. Land application of CCPs as a beneficial use is regulated by a variety of federal and state statutes, which impose testing and management requirements to ensure environmental protection. However, mismanagement of CCPs can give rise to liability under CERCLA and similar laws.

- •

- Under its Mercury and Air Toxics Standards for Power Plants rule, in February 2012 the EPA promulgated final limits on mercury and other toxic chemicals from new and modified power plants. In April 2013, the EPA finalized updates to certain limits for new power plants. The requirements to control mercury emissions could result in implementation of additional technologies at power plants that could negatively affect fly ash quality.

- •

- Some states have adopted legislation and regulatory programs to reduce greenhouse gas ("GHG") emissions, either directly or through mechanisms such as renewable portfolio standards for electric utilities. These programs could require electric utilities to increase their use of renewable energy such as solar and wind power. Federal GHG legislation appears unlikely in the near term. However, in the absence of federal GHG legislation, the EPA has taken several recent steps to regulate GHG emissions using existing Clean Air Act authorities, including setting GHG emission thresholds for determining when new and existing power plants must obtain permits. EPA's authority to regulate GHGs in this manner has been challenged and the case is set to be heard by the Supreme Court in early 2014. In addition, EPA is crafting New Source Performance Standards for GHG emissions from new and existing fossil-fuel fired electric power plants. The proposed rule for existing power plants is expected to be released by June 1, 2014.

- •

- The EPA is addressing water quality impacts from coal-burning power plants and coal mining operations. In 2011, the EPA issued new guidance that recommended strict new discharge limits in Clean Water Act permits for mountaintop removal and surface mining and established "enhanced coordination procedures" for permits issued by the U.S. Army Corps of Engineers. In June 2013, EPA issued proposed effluent limitation guidelines for steam electric power generating facilities which would require these utilities to meet specific discharge requirements. More stringent regulation of coal-burning power plants and coal mining operations could increase the cost for utilities and thus indirectly impact the availability and cost of fly ash for HRI's CCP activities.

Although our business managing CCPs for utility customers may benefit from opportunities to manage compliance with certain of the new regulatory requirements, increasingly strict requirements such as those described above generally will increase the cost of doing business and may make coal burning less attractive for utilities. Faced with the prospect of more stringent regulations, litigation by environmental groups, and a decrease in the cost of natural gas, some electric utilities are reducing their portfolio of coal powered energy facilities. For example, in recent years, multiple companies announced plans to close coal-fired power plant units, or dropped plans to open new plants, citing the cost of compliance with pending or new environmental regulations. The potential impact on job prospects in the utility and mining industries, already weakened by the economic downturn, has prompted considerable concern in Congress, leading to calls to restrict the EPA's regulatory authority. The outcome of these developments cannot be predicted. To date, our business has not had a significant impact from plant closures because our national footprint allows us to move fly ash to satisfy demand; however, if the rate of coal-powered plant closures increases, we may be adversely affected in the future. Nevertheless, we believe that reliance on coal for a substantial amount of electric power generation in the United States is likely to continue for the foreseeable future. For example, the Energy Information Administration's Annual Energy Outlook for 2013 indicates that coal will continue to be the predominant fuel used for the production of electricity through 2040.

16

Table of Contents

HRI manages, stores, transports and sells fly ash, and some products manufactured and sold by HRI contain fly ash. Currently, fly ash is not regulated as "hazardous waste" under Subtitle C of the federal Resource Conservation and Recovery Act ("RCRA"). However, in June 2010, the EPA proposed two alternative rules to regulate CCPs generated by electric utilities and independent power producers. One proposed option would classify CCPs disposed of in surface impoundments or landfills as "special wastes" subject to federal hazardous waste regulation under Subtitle C of RCRA. The second proposed option would instead regulate CCPs as non-hazardous waste under Subtitle D of RCRA, with states retaining the lead authority on regulating their handling, storage and disposal. Under both options, the current exemption from hazardous waste regulation for CCPs that are used for beneficial purposes would remain in effect. However, the EPA has received comments on refining the definition of beneficial use subject to the exception, which could result in the narrowing of the scope of exempt uses in the final rule to certain encapsulated uses. Both rule options are controversial and EPA has delayed its rulemaking to request and consider additional data. In June 2013, in a separate rulemaking on effluent limitation guidelines for steam electric power generating facilities, EPA suggested that new information developed in the effluent limitation guidelines rulemaking could provide strong support for regulating CCPs under Subtitle D. However, EPA has not yet made a final decision. Meanwhile, environmental groups, members of industry (including HRI) and other parties filed suit against the EPA alleging that the EPA failed to timely take action on regulations applicable to the disposal of coal ash. On October 29, 2013, the United States District Court for the District of Columbia issued an order giving EPA 60 days in which to advise the court when it proposes to complete review and revision of its regulations concerning coal ash.

Even though both EPA options continue to exempt beneficial uses of CCPs from hazardous waste rules, users of fly ash and other CCPs are likely to attach a stigma to material that is identified as "hazardous waste" and may seek alternative products. Several bills were introduced in Congress in 2012 attempting to block EPA from regulating coal ash as a hazardous waste under RCRA Subtitle D, but were unsuccessful. In July 2013, the U.S. House of Representatives passed H.R. 2218, the "Coal Residuals Reuse and Management Act of 2013", which would authorize states to implement and enforce CCP permit programs meeting minimum federal standards, allow EPA to implement and enforce a CCP permit program only where a state does not do so, and prohibit EPA from finalizing its June 2010 proposed CCP rule. H.R. 2218 is currently on the Senate calendar. Whether regulated by EPA or expanded state programs, the complexity and cost of managing and disposing of CCPs could increase.

If the EPA determines to regulate CCPs as hazardous waste under RCRA Subtitle C, CCPs would become subject to a variety of regulations governing the handling, transporting, storing and disposing of hazardous waste, increasing the regulatory burden and costs of fly ash management for the utility industry and for HRI. The regulations could require modifications to or closure of disposal facilities, modifications to equipment used to handle, store and transport fly ash, additional training for personnel, new permitting requirements, increased recordkeeping and reporting requirements, as well as increased disposal costs at landfills. There can be no guarantee that such regulations would not reduce or eliminate our supply or our ability to market fly ash and other CCPs which would have a material adverse impact on our operations and financial condition.

Regulation of CCPs as hazardous waste would likely have an adverse effect on beneficial use and sales of CCPs and HRI's relationship with utilities, if users of fly ash and other CCPs seek alternative products to avoid material that is identified as "hazardous waste." Moreover, some environmental groups are urging the EPA to restrict some beneficial uses of CCPs, such as in cement, concrete and road base, alleging that contaminants may leach into the environment. This could reduce the demand for fly ash and other CCPs which would have an adverse effect on our CCP revenues. In addition, regulation of CCPs as hazardous waste would likely cause utilities and power producers to impose greater restrictions on the use of CCPs by HRI and its customers. Restrictions imposed by utilities may

17

Table of Contents

narrow the types of potential customers to which HRI can market CCPs and limit their uses of CCPs, reducing HRI's sales opportunities. Utilities are also likely to negotiate to shift actual or perceived liabilities associated with CCPs and their use to HRI through more onerous contract and indemnity obligations. This could harm HRI's business by reducing the number of CCP management contracts or by increasing HRI's exposure to the contingent risks associated with any new regulation of CCPs.

HRI manages a number of landfill and pond operations that may be affected by new Clean Water Act requirements, as well as RCRA regulations. In June 2013, the EPA issued a proposed rule for Clean Water Act effluent limitation guidelines for steam electric power generating facilities which requires discharges from waste streams and surface impoundments to meet certain limits. If adopted, this rule would phase in between 2017 and 2022, and would require HRI to implement pollution control measures to reduce discharges. EPA is also developing new regulations to minimize adverse environmental impacts from cooling water intake structures, which would apply to existing electric generating and manufacturing plants. These regulations are expected to be finalized in November 2013 and would require specified controls at all existing facilities to prevent impingement and entrainment of fish.

At HTI, we have worked at the molecular level in the use of nano-sized metal crystals on substrate materials for nanocatalysts. A number of agencies are studying the potential implications of nanotechnology and manufactured nanomaterials on human health and the environment, including the National Toxicology Program, the National Institute for Safety and Health, the National Science Foundation and the EPA. In September 2010, the EPA adopted its first rule regulating carbon nanomaterials under the Toxic Substances Control Act ("TSCA") and is considering other rulemaking in this area. While these developments demonstrate increasing interest in this area, at this time it is not certain what nanotechnology regulations may be adopted and how they may affect our business.

Section 45. Our discontinued coal cleaning operations generated tax credits subject to compliance with the terms of Section 45 for the production and sale of refined coal. For facilities placed in service before January 1, 2009, the term "refined coal" means a fuel which (i) is a liquid, gaseous, or solid fuel produced from coal (including lignite) or high carbon fly ash, including such fuel used as a feedstock, (ii) is sold by the taxpayer with the reasonable expectation that it will be used for purpose of producing steam, (iii) is certified by the taxpayer as resulting (when used in the production of steam) in a reduction of at least 20% of the emissions of NOx and either SOx or mercury released when burning the refined coal (excluding any dilution caused by materials combined or added during the production process), as compared to the emissions released when burning the feedstock coal or comparable coal predominantly available in the marketplace as of January 1, 2003, and (iv) is produced in such a manner as to result in an increase of at least 50% in the market value of the refined coal (excluding any increase caused by materials combined or added during the production process), as compared to the value of the feedstock coal. In order to qualify for the Section 45 tax credits using the foregoing criteria, the refined coal facility must have been placed in service after October 22, 2004 and before January 1, 2009. In addition, a refined coal production facility does not include any facility the production from which was allowed as a credit under Section 45K.

Section 45 provides a tax credit for refined coal produced by the taxpayer at a refined coal facility during the 10-year period beginning on the date the facility was originally placed in service and sold by a taxpayer to an unrelated party during such 10-year period. The credit amount is adjusted each year for inflation and for 2013 is $6.59 per ton of refined coal.

18

Table of Contents

In September 2010, the IRS issued Notice 2010-54 ("Notice") giving some public guidance about how this tax credit program is administered and some of the restrictions on the availability of such credits. Among other things, the Notice requires that for coal cleaning operations to qualify for Section 45 credits, the facilities must have been placed in service for the purpose of producing refined coal from waste coal and the taxpayer must obtain a "verification of waste coal supply" from a "qualified person." In addition, the Notice provides guidance about the testing that must be conducted to certify the emissions reduction required by Section 45. Based on the language of Section 45 and the Notice, we believe that our sold coal cleaning facilities were eligible for Section 45 refined coal tax credits during the periods we owned and operated them, and as a result, have recognized a benefit for such credits. Our ability to claim tax credits is dependent upon a number of conditions in our former coal cleaning operations, including, but not limited to:

- •

- Placement of facilities in service after October 22, 2004 and before January 1, 2012;

- •

- Production of fuel from waste coal that is lower in NOx and either SOx or mercury emissions by the specified amount as compared to the emissions of the feedstock;

- •

- Production of fuel at least 50% more valuable than the waste coal feedstock; and

- •

- Having sold the fuel to a third party for the purpose of producing steam.

We are subject to audit by the IRS with respect to Section 45 tax credits we claim. There are multiple bases upon which the IRS may challenge the tax credits, including whether our facilities were placed in service for the purpose of producing refined coal, whether the facilities use waste coal as a feedstock, and whether the testing methods and certifications adequately demonstrate the required emissions reductions. In addition, Congress may modify or repeal Section 45 so that these tax credits may not be available in the future.

Employees

As of September 30, 2013, we employed approximately 2,355 full-time employees, including approximately 50 who work under collective bargaining agreements.

The following table lists the approximate number of employees by business segment at September 30, 2011, 2012, and 2013:

| | | | | | | | | | |

| | 2011 | | 2012 | | 2013 | |

|---|

Light Building Products | | | 1,670 | | | 1,395 | | | 1,400 | |

Heavy Construction Materials | | | 895 | | | 980 | | | 875 | |

Discontinued Operations | | | 120 | | | 70 | | | 0 | |

Energy Technology | | | 30 | | | 35 | | | 35 | |

Corporate | | | 35 | | | 40 | | | 45 | |

| | | | | | | | |

Total | | | 2,750 | | | 2,520 | | | 2,355 | |

| | | | | | | | |

19

Table of Contents

ITEM 1A. RISK FACTORS

Risks Relating to Our Business

The building products industry is experiencing a slow recovery and recent improvements in some of our end markets may not continue. Because the markets for our building products are heavily dependent on residential construction and remodeling, our revenues could flatten or decrease as a result of events outside our control that impact home construction and home improvement activity, including economic factors specific to the building products industry and severe weather.

Our residential building products business relies upon the home improvement and remodeling markets as well as new construction. Between 2007 and 2011, there was a severe slowing of new housing and remodeling and we experienced a significant slowdown in sales activity during these years. Although residential construction and remodeling activity has somewhat improved during 2012 and 2013 in certain regions of the United States, the homebuilding industry continues to experience activity below historical levels. Consumer and builder confidence, unemployment rates, limits on credit availability, and other factors may adversely affect homeowners' and homebuilders' ability or desire to engage in construction or remodeling, resulting in continued slow improvement or a further slowdown in new construction or remodeling and repair activities.

We, like many others in the building products industry, experienced a large drop in orders and a reduction in our margins in 2008 through 2012, relative to prior years. In 2007-2009, we recorded significant goodwill impairments associated with our building products business. While some increased market activity occurred in 2012 and 2013, we can provide no assurances that the building products market will further improve in the near future.

The construction markets are seasonal and generally dependent on temperate weather conditions. The majority of our building products sales are in the residential construction market, which tends to slow down in the winter months. If there are severe weather events such as hurricanes or flooding, or other events outside of our control, construction activities will slow and there may be a negative effect on our revenues. For the winter months of late 2013 and early 2014, our decreased seasonal revenues from our light building products and heavy construction materials businesses may result in negative cash flow.

The tight financial markets could continue to negatively affect our business, results of operations, and financial condition. Market conditions in the mortgage lending and mortgage finance industries deteriorated significantly starting in 2008, which continues to adversely affect the availability of credit for builders, home purchasers and remodelers in 2013 and 2014.

The financial crisis of the banking system and financial markets beginning in 2008 and the going concern threats to banks, governments, and other financial institutions has resulted in continued tight credit markets, including mortgages and home equity loans, low liquidity in many financial markets, and heavy volatility in credit and equity markets. A continuation of poor borrowing markets or a further tightening of construction or mortgage lending requirements could adversely affect the availability of credit for purchasers of our products and thereby reduce our sales.

There could be a number of follow-on effects from the continued poor credit availability on our business, including the reduced ability of builders, prospective homebuyers or remodelers to obtain credit to finance the purchase of our building products. These and other similar factors could:

- •

- cause delay or decisions to not undertake new home construction or improvement projects,

- •

- cause our customers to delay or decide not to purchase our building products,

- •

- lead to a decline in customer transactions and our financial performance.

20

Table of Contents

Our building products business has been strengthened by the sales growth of new products. If we are unable to offer new products and expand our new product sales, our revenue growth may be adversely affected.

Part of our light building products revenues has come from sales in new product categories. New products require innovation, research, capital for development, manufacturing, and acquisition activities. If we are unable to sustain new product sales growth, whether for lack of new product development, access to adequate capital or for other reasons, sales will follow the general industry slowdown in new residential construction and remodeling activity, which will negatively affect our revenue and growth.

Demand for our building products may decrease because of changes in customer preferences or because competing products gain price advantages. If demand for our products declines, our revenues will decrease.

Our building products are subject to reductions in customer demand for reasons such as changes in preferred home sizes, styles and appearances. Many of our resin-based siding accessory products are complementary to an owner's choice of vinyl as a siding material. If sales of vinyl siding decrease, sale of our accessories will also decrease. Similarly, sales of our manufactured architectural stone products are dependent on the continuing popularity of stone finishes.

Demand for our building products can also decline if competing products become relatively less expensive. For example, if costs of petroleum-based resins that are used to make vinyl siding and accessories increase faster than the costs of stucco, then stucco products, which we do not sell, will become more attractive from a price standpoint, and our vinyl siding and accessory sales may decrease. Similarly, manufactured architectural stone could lose price competitiveness compared to other finishes. If demand for our building products declines because of changes in the popularity or price advantages of our products, our revenues will be adversely affected.

A significant increase in the price of materials used in the production of our building products that cannot be passed on to customers could have a significant adverse effect on our operating income. Furthermore, we depend upon limited sources for certain key production materials, the interruption of which would materially disrupt our ability to manufacture and supply products, resulting in lost revenues and the potential loss of customers.

Our manufactured architectural stone and concrete block manufacturing processes require key production materials including cement, manmade and natural aggregates, oxides, packaging materials, and certain types of rubber-based products. The suppliers of these materials may experience capacity or supply constraints in meeting market demand that limit our ability to obtain needed production materials on a timely basis or at expected prices. We do not have long-term contracts with such suppliers. We do not currently maintain large inventories of production materials and alternative sources meeting our requirements could be difficult to arrange in the short term. A significant increase in the price of these materials that cannot be passed on to customers could have a significant adverse effect on our cost of sales and operating income. Additionally, our manufacturing and ability to provide products to our customers could be materially disrupted if this supply of materials was interrupted for any reason. Such an interruption and the resulting inability to supply our manufactured architectural stone customers with products could adversely impact our revenues and our relationships with our customers.

Certain of our home siding accessory products are manufactured from polypropylene and PVC, a large portion of which material is sold to us by single suppliers. The prices of polypropylene and PVC are primarily a function of manufacturing capacity, demand and the prices of petrochemical feedstocks, crude oil and natural gas liquids. Historically, the market prices of polypropylene and PVC have fluctuated, and significantly increased in 2011. A significant increase in the price of polypropylene or PVC that cannot be passed on to customers could have a significant adverse effect on our cost of sales

21

Table of Contents

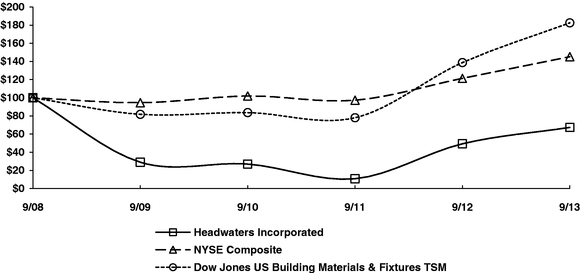

and operating income. We do not have long-term contracts with our polypropylene or PVC suppliers. We do not maintain large inventories of polypropylene or PVC and alternative sources could be difficult to arrange in the short term. Therefore, our manufacturing and ability to provide products to our customers could be materially disrupted if our supply of polypropylene or PVC were interrupted for any reason. Such an interruption and the resulting inability to supply our resin-based siding accessory customers with products could adversely impact our revenues and potentially our relationships with our customers.