Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-Q

x Quarterly Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

For the quarterly period ended September 30, 2013

OR

o Transition Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

Commission File Number 0-21719

Steel Dynamics, Inc.

(Exact name of registrant as specified in its charter)

Indiana | | 35-1929476 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

7575 West Jefferson Blvd, Fort Wayne, IN | | 46804 |

(Address of principal executive offices) | | (Zip Code) |

Registrant’s telephone number, including area code: (260) 969-3500

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company (see definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act).

(Check one): | | Large accelerated filer x | | Accelerated filer o | | Non-accelerated filer o | | Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No x

As of October 31, 2013, Registrant had 221,984,201 outstanding shares of common stock.

Table of Contents

STEEL DYNAMICS, INC.

CONSOLIDATED BALANCE SHEETS

(in thousands, except share data)

| | September 30, | | December 31, | |

| | 2013 | | 2012 | |

| | (unaudited) | | | |

Assets | | | | | |

Current assets | | | | | |

Cash and equivalents | | $ | 370,056 | | $ | 375,917 | |

Investments in short-term commercial paper | | — | | 31,520 | |

Accounts receivable, net | | 722,867 | | 599,499 | |

Accounts receivable-related parties | | 50,006 | | 42,864 | |

Inventories | | 1,192,032 | | 1,202,507 | |

Deferred income taxes | | 25,228 | | 23,449 | |

Other current assets | | 25,126 | | 20,469 | |

Total current assets | | 2,385,315 | | 2,296,225 | |

| | | | | |

Property, plant and equipment, net | | 2,241,067 | | 2,231,198 | |

| | | | | |

Restricted cash | | 23,016 | | 27,749 | |

Intangible assets, net | | 393,531 | | 416,635 | |

Goodwill | | 733,650 | | 738,542 | |

Other assets | | 97,726 | | 105,067 | |

Total assets | | $ | 5,874,305 | | $ | 5,815,416 | |

| | | | | |

Liabilities and Equity | | | | | |

Current liabilities | | | | | |

Accounts payable | | $ | 411,201 | | $ | 344,953 | |

Accounts payable-related parties | | 15,205 | | 15,144 | |

Income taxes payable | | 7,649 | | 16,941 | |

Accrued payroll and benefits | | 79,589 | | 85,802 | |

Accrued interest | | 23,060 | | 35,306 | |

Accrued expenses | | 82,157 | | 81,900 | |

Current maturities of long-term debt | | 335,341 | | 29,631 | |

Total current liabilities | | 954,202 | | 609,677 | |

| | | | | |

Long-term debt | | | | | |

Term note | | 226,875 | | 247,500 | |

Senior notes | | 1,500,000 | | 1,600,000 | |

Convertible senior notes | | — | | 287,496 | |

Other long-term debt | | 46,744 | | 37,610 | |

Total long-term debt | | 1,773,619 | | 2,172,606 | |

| | | | | |

Deferred income taxes | | 565,798 | | 537,304 | |

Other liabilities | | 22,898 | | 19,173 | |

Commitments and contingencies | | | | | |

Redeemable noncontrolling interests | | 110,054 | | 98,814 | |

| | | | | |

Equity | | | | | |

Common stock voting, $.0025 par value; 900,000,000 shares authorized; 257,314,197 and 255,592,901 shares issued; and 221,349,383 and 219,522,655 shares outstanding, as of September 30, 2013 and December 31, 2012, respectively | | 641 | | 637 | |

Treasury stock, at cost; 35,964,814 and 36,070,246 shares, as of September 30, 2013 and December 31, 2012, respectively | | (718,373 | ) | (720,479 | ) |

Additional paid-in capital | | 1,060,780 | | 1,037,687 | |

Retained earnings | | 2,149,389 | | 2,087,620 | |

Total Steel Dynamics, Inc. equity | | 2,492,437 | | 2,405,465 | |

Noncontrolling interests | | (44,703 | ) | (27,623 | ) |

Total equity | | 2,447,734 | | 2,377,842 | |

Total liabilities and equity | | $ | 5,874,305 | | $ | 5,815,416 | |

See notes to consolidated financial statements.

1

Table of Contents

STEEL DYNAMICS, INC.

CONSOLIDATED STATEMENTS OF INCOME (UNAUDITED)

(in thousands, except per share data)

| | Three Months Ended | | Nine Months Ended | |

| | September 30, | | September 30, | |

| | 2013 | | 2012 | | 2013 | | 2012 | |

Net sales | | | | | | | | | |

Unrelated parties | | $ | 1,838,464 | | $ | 1,624,561 | | $ | 5,302,285 | | $ | 5,359,753 | |

Related parties | | 73,274 | | 68,829 | | 206,489 | | 225,480 | |

Total net sales | | 1,911,738 | | 1,693,390 | | 5,508,774 | | 5,585,233 | |

| | | | | | | | | |

Costs of goods sold | | 1,714,546 | | 1,536,989 | | 4,987,626 | | 5,045,432 | |

Gross profit | | 197,192 | | 156,401 | | 521,148 | | 539,801 | |

| | | | | | | | | |

Selling, general and administrative expenses | | 67,553 | | 62,984 | | 198,171 | | 188,603 | |

Profit sharing | | 8,469 | | 3,954 | | 19,891 | | 20,237 | |

Amortization of intangible assets | | 7,897 | | 8,848 | | 24,075 | | 26,831 | |

Impairment charges | | — | | 7,894 | | 308 | | 7,894 | |

Total selling, general and administrative expenses | | 83,919 | | 83,680 | | 242,445 | | 243,565 | |

| | | | | | | | | |

Operating income | | 113,273 | | 72,721 | | 278,703 | | 296,236 | |

| | | | | | | | | |

Interest expense, net of capitalized interest | | 30,970 | | 41,490 | | 97,064 | | 123,708 | |

Other expense (income), net | | (1,852 | ) | 24,010 | | (4,144 | ) | 32,366 | |

| | | | | | | | | |

Income before income taxes | | 84,155 | | 7,221 | | 185,783 | | 140,162 | |

Income taxes | | 33,065 | | 1,116 | | 70,168 | | 52,975 | |

| | | | | | | | | |

Net income | | 51,090 | | 6,105 | | 115,615 | | 87,187 | |

| | | | | | | | | |

Net loss attributable to noncontrolling interests | | 6,396 | | 6,728 | | 19,044 | | 15,793 | |

| | | | | | | | | |

Net income attributable to Steel Dynamics, Inc. | | $ | 57,486 | | $ | 12,833 | | $ | 134,659 | | $ | 102,980 | |

| | | | | | | | | |

Basic earnings per share attributable to Steel Dynamics, Inc. stockholders | | $ | 0.26 | | $ | 0.06 | | $ | 0.61 | | $ | 0.47 | |

| | | | | | | | | |

Weighted average common shares outstanding | | 220,926 | | 219,191 | | 220,464 | | 219,097 | |

| | | | | | | | | |

Diluted earnings per share attributable to Steel Dynamics, Inc. stockholders, including the effect of assumed conversions when dilutive | | $ | 0.25 | | $ | 0.06 | | $ | 0.59 | | $ | 0.47 | |

| | | | | | | | | |

Weighted average common shares and share equivalents outstanding | | 239,001 | | 220,044 | | 238,497 | | 236,536 | |

| | | | | | | | | |

Dividends declared per share | | $ | 0.11 | | $ | 0.10 | | $ | 0.33 | | $ | 0.30 | |

See notes to consolidated financial statements.

2

Table of Contents

STEEL DYNAMICS, INC.

CONSOLIDATED STATEMENTS OF CASH FLOWS (UNAUDITED)

(in thousands)

| | Three Months Ended | | Nine Months Ended | |

| | September 30, | | September 30, | |

| | 2013 | | 2012 | | 2013 | | 2012 | |

Operating activities: | | | | | | | | | |

Net income | | $ | 51,090 | | $ | 6,105 | | $ | 115,615 | | $ | 87,187 | |

| | | | | | | | | |

Adjustments to reconcile net income to net cash provided by operating activities: | | | | | | | | | |

Depreciation and amortization | | 58,202 | | 58,953 | | 172,089 | | 170,027 | |

Equity-based compensation | | 2,515 | | 738 | | 9,612 | | 9,463 | |

Impairment charges | | — | | 7,894 | | 308 | | 7,894 | |

Deferred income taxes | | 9,861 | | 34,633 | | 31,608 | | 54,464 | |

(Gain) loss on disposal of property, plant and equipment | | 1,739 | | (152 | ) | 944 | | (565 | ) |

Changes in certain assets and liabilities: | | | | | | | | | |

Accounts receivable | | 254 | | 2,690 | | (130,510 | ) | 15,604 | |

Inventories | | (23,648 | ) | 43,005 | | 10,360 | | 6,702 | |

Other assets | | (1,727 | ) | (7,484 | ) | 8,414 | | (4,917 | ) |

Accounts payable | | 59,801 | | 6,920 | | 52,419 | | (19,015 | ) |

Income taxes receivable/payable | | 16,354 | | 25,993 | | (9,972 | ) | 16,917 | |

Accrued expenses and liabilities | | 8,825 | | (61,929 | ) | (15,196 | ) | (104,375 | ) |

Net cash provided by operating activities | | 183,266 | | 117,366 | | 245,691 | | 239,386 | |

| | | | | | | | | |

Investing activities: | | | | | | | | | |

Purchases of property, plant and equipment | | (52,162 | ) | (58,342 | ) | (146,744 | ) | (158,686 | ) |

Proceeds from maturity of short-term commercial paper | | — | | 9,998 | | 31,520 | | 84,830 | |

Other investing activities | | 844 | | 655 | | 4,121 | | (20,379 | ) |

Net cash used in investing activities | | (51,318 | ) | (47,689 | ) | (111,103 | ) | (94,235 | ) |

| | | | | | | | | |

Financing activities: | | | | | | | | | |

Issuance of current and long-term debt | | 9,526 | | 760,000 | | 418,819 | | 1,049,969 | |

Repayment of current and long-term debt | | (4,097 | ) | (946,858 | ) | (512,100 | ) | (1,252,202 | ) |

Debt issuance costs | | — | | (11,625 | ) | (6,192 | ) | (13,813 | ) |

Proceeds from exercise of stock options, including related tax effect | | 7,925 | | 583 | | 18,516 | | 2,021 | |

Contributions from noncontrolling investors, net | | 5,275 | | 16,320 | | 10,972 | | 30,943 | |

Dividends paid | | (24,274 | ) | (21,915 | ) | (70,464 | ) | (65,710 | ) |

Net cash used in financing activities | | (5,645 | ) | (203,495 | ) | (140,449 | ) | (248,792 | ) |

| | | | | | | | | |

Increase (decrease) in cash and equivalents | | 126,303 | | (133,818 | ) | (5,861 | ) | (103,641 | ) |

Cash and equivalents at beginning of period | | 243,753 | | 420,938 | | 375,917 | | 390,761 | |

| | | | | | | | | |

Cash and equivalents at end of period | | $ | 370,056 | | $ | 287,120 | | $ | 370,056 | | $ | 287,120 | |

| | | | | | | | | |

Supplemental disclosure information: | | | | | | | | | |

Cash paid for interest | | $ | 40,075 | | $ | 42,413 | | $ | 107,390 | | $ | 123,973 | |

Cash paid for federal and state income taxes, net | | $ | 3,022 | | $ | 3,629 | | $ | 41,547 | | $ | 43,976 | |

See notes to consolidated financial statements.

3

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 1. Description of the Business and Significant Accounting Policies

Description of the Business

Steel Dynamics, Inc. (SDI), together with its subsidiaries (the company), is a domestic manufacturer of steel products and metals recycler. The company has three reporting segments: steel operations, metals recycling and ferrous resources operations, and steel fabrication operations.

Steel Operations. Steel operations include the company’s Flat Roll Division, Structural and Rail Division, Engineered Bar Products Division, Roanoke Bar Division, Steel of West Virginia (SWVA) and The Techs operations. These operations consist of mini-mills, producing steel from steel scrap, using electric arc furnaces, continuous casting, automated rolling mills, and downstream finishing facilities. The company’s steel operations sell directly to end users and service centers. These products are used in numerous industry sectors, including the automotive, construction, commercial, transportation and industrial machinery markets. Steel operations accounted for approximately 61% and 62% of the company’s external net sales during the three-month periods ended September 30, 2013 and 2012, respectively, and 60% and 62% of the company’s external net sales during the ninth-month periods ended September 30, 2013 and 2012, respectively.

Metals Recycling and Ferrous Resources Operations. Metals recycling and ferrous resources operations include OmniSource Corporation (OmniSource), the company’s metals recycling, steel scrap procurement, and processing locations, and our two ironmaking initiatives: Iron Dynamics (IDI), a liquid pig iron production facility; and our Minnesota iron operations, an iron nugget production facility and operations to supply the nugget facility with its primary raw material, iron concentrate. Metals recycling and ferrous resources operations accounted for approximately 32% and 31% of the company’s external net sales during the three-month periods ended September 30, 2013 and 2012, respectively, and 33% and 32% of the company’s external net sales during the nine-month periods ended September 30, 2013 and 2012, respectively.

Steel Fabrication Operations. Steel fabrication operations include the company’s New Millennium Building Systems plants located throughout the United States and Northern Mexico. Revenues from these plants are generated from the fabrication of trusses, girders, steel joists and steel decking used within the non-residential construction industry. Steel fabrication operations accounted for approximately 6% and 6% of the company’s external net sales during the three-month periods ended September 30, 2013 and 2012, respectively, and 6% and 5% of the company’s external net sales during the nine-month periods ended September 30, 2013 and 2012, respectively.

Significant Accounting Policies

Principles of Consolidation. The consolidated financial statements include the accounts of SDI, together with its wholly and majority-owned or controlled subsidiaries, after elimination of significant intercompany accounts and transactions. Noncontrolling interests represent the noncontrolling owner’s proportionate share in the equity, income, or losses of the company’s majority-owned or controlled consolidated subsidiaries.

Use of Estimates. These financial statements are prepared in conformity with accounting principles generally accepted in the United States and, accordingly, include amounts that require management to make estimates and assumptions that affect the amounts reported in the financial statements and in the notes thereto. Significant items subject to such estimates and assumptions include the carrying value of property, plant and equipment, intangible assets and goodwill; valuation allowances for trade receivables, inventories and deferred income tax assets; income taxes; unrecognized income tax benefits; potential environmental liabilities; and litigation claims and settlements. Actual results may differ from these estimates and assumptions.

In the opinion of management, these financial statements reflect all normal recurring adjustments necessary for a fair presentation of the interim period results. These financial statements and notes should be read in conjunction with the audited financial statements and notes thereto included in the company’s Annual Report on Form 10-K for the year ended December 31, 2012.

Goodwill. The company’s goodwill is allocated to the following reporting units at September 30, 2013, and December 31, 2012, (in thousands):

| | September 30, | | December 31, | |

| | 2013 | | 2012 | |

OmniSource — Metals Recycling/Ferrous Resources Segment | | $ | 559,901 | | $ | 564,793 | |

The Techs — Steel Segment | | 142,783 | | 142,783 | |

Roanoke Bar Division — Steel Segment | | 29,041 | | 29,041 | |

New Millennium Building Systems — Fabrication Segment | | 1,925 | | 1,925 | |

| | $ | 733,650 | | $ | 738,542 | |

OmniSource goodwill decreased $4.9 million from December 31, 2012 to September 30, 2013, in recognition of the 2013 tax benefit related to the amortization of the component of OmniSource tax-deductible goodwill in excess of book goodwill.

4

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 2. Earnings Per Share

Basic earnings per share is based on the weighted average shares of common stock outstanding during the period. Diluted earnings per share assumes the weighted average dilutive effect of common share equivalents outstanding during the period applied to the company’s basic earnings per share. Common share equivalents represent potentially dilutive stock options, restricted and deferred stock units, restricted shares, and dilutive shares related to the company’s 5.125% convertible senior notes. Common share equivalents are excluded from the computation in periods in which they have an anti-dilutive effect. Options to purchase 2.4 million and 6.5 million shares were anti-dilutive at September 30, 2013 and 2012, respectively. The computation of diluted earnings per share for the three-month period ended September 30, 2012 did not include the after-tax equivalent of interest of $2.4 million for the company’s 5.125% senior convertible notes, due 2014 and the related weighted average equivalent of 16.6 million shares, as the result would have been anti-dilutive.

The following table presents a reconciliation of the numerators and the denominators of the company’s basic and diluted earnings per share computations for net income attributable to Steel Dynamics, Inc. (in thousands, except per share data):

| | Three Months Ended September 30, | |

| | 2013 | | 2012 | |

| | Net Income

(Numerator) | | Shares

(Denominator) | | Per Share

Amount | | Net Income

(Numerator) | | Shares

(Denominator) | | Per Share

Amount | |

Basic earnings per share | | $ | 57,486 | | 220,926 | | $ | 0.26 | | $ | 12,833 | | 219,191 | | $ | 0.06 | |

Dilutive common share equivalents | | — | | 1,366 | | | | — | | 853 | | | |

5.125% convertible senior notes, net of tax | | 2,358 | | 16,709 | | | | — | | — | | | |

Diluted earnings per share | | $ | 59,844 | | 239,001 | | $ | 0.25 | | $ | 12,833 | | 220,044 | | $ | 0.06 | |

| | Nine Months Ended September 30, | |

| | 2013 | | 2012 | |

| | Net Income

(Numerator) | | Shares

(Denominator) | | Per Share

Amount | | Net Income

(Numerator) | | Shares

(Denominator) | | Per Share

Amount | |

Basic earnings per share | | $ | 134,659 | | 220,464 | | $ | 0.61 | | $ | 102,980 | | 219,097 | | $ | 0.47 | |

Dilutive common share equivalents | | — | | 1,363 | | | | — | | 908 | | | |

5.125% convertible senior notes, net of tax | | 7,074 | | 16,670 | | | | 7,074 | | 16,531 | | | |

Diluted earnings per share | | $ | 141,733 | | 238,497 | | $ | 0.59 | | $ | 110,054 | | 236,536 | | $ | 0.47 | |

Note 3. Inventories

Inventories are stated at lower of cost or market. Cost is determined using a weighted average method for scrap, and a first-in, first-out basis for all other inventories. Inventories consisted of the following (in thousands):

| | September 30, | | December 31, | |

| | 2013 | | 2012 | |

Raw materials | | $ | 583,335 | | $ | 594,388 | |

Supplies | | 280,841 | | 278,494 | |

Work-in-progress | | 97,508 | | 82,934 | |

Finished goods | | 230,348 | | 246,691 | |

Total inventories | | $ | 1,192,032 | | $ | 1,202,507 | |

Note 4. Debt

On March 26, 2013, the company issued $400.0 million of 51/4% Senior Notes due 2023 (2023 Notes). Interest on the 2023 Notes is due semiannually on April 15 and October 15, with the first payment due on October 15, 2013. The 2023 Notes are redeemable at any time after April 15, 2018. The redemption price (expressed as a percentage of principal amount) is 102.625% during the period April 15, 2018 to April 14, 2019; 101.750% during the period April 15, 2019 to April 14, 2020; 100.875% during the period April 15, 2020 to April 14, 2021; and 100% on and after April 15, 2021, plus accrued interest to the redemption date. In addition, at any time before April 15, 2016, the company may redeem up to 35% of the principal amount of the 2023 Notes with the net cash proceeds from one or more sales of the company’s common stock at a redemption price (expressed as a percentage of principal amount) of 105.250%, plus accrued interest to the redemption date. The 2023 Notes are unsecured and rank pari passu with all existing and future senior unsubordinated unsecured indebtedness and senior in right of payment to all subordinated indebtedness.

5

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 4. Debt (Continued)

A portion of the proceeds from the issuance of the 2023 Notes was used to fund the March 26, 2013 purchase of $301.7 million (plus accrued interest) of the company’s 63/4% Senior Notes due 2015 (2015 Notes) pursuant to a tender offer. On April 9, 2013, the company used the remaining proceeds from the issuance of the 2023 Notes, along with available cash, to repay the remaining outstanding 2015 Notes due at a price of 100% of the principal amount of $198.3 million (plus accrued interest). As a result of the tender offer to purchase the 2015 Notes in March and the early payoff of the remaining balance of the 2015 Notes in April, the company recorded expenses related to tender premiums, unamortized debt issuance costs write-off, and tender expenses of $2.6 million, which is reflected in other expenses in the consolidated statement of income for the nine-month period ended September 30, 2013.

Note 5. Changes in Equity

The following table provides a reconciliation of the beginning and ending carrying amounts of total equity, equity attributable to stockholders of Steel Dynamics, Inc. and equity and redeemable amounts attributable to the noncontrolling interests (in thousands):

| | Stockholders of Steel Dynamics, Inc. | | | | | | | |

| | Common | | Additional

Paid-In | | Retained | | Treasury | | Noncontrolling | | Total | | Redeemable

Noncontrolling | |

| | Stock | | Capital | | Earnings | | Stock | | Interests | | Equity | | Interests | |

Balances at January 1, 2013 | | $ | 637 | | $ | 1,037,687 | | $ | 2,087,620 | | $ | (720,479 | ) | $ | (27,623 | ) | $ | 2,377,842 | | $ | 98,814 | |

Proceeds from the exercise of stock options, including related tax effect | | 4 | | 18,512 | | — | | — | | — | | 18,516 | | — | |

Dividends declared | | — | | — | | (72,860 | ) | — | | — | | (72,860 | ) | — | |

Equity-based compensation and issuance of restricted stock | | — | | 6,813 | | (30 | ) | 2,106 | | — | | 8,889 | | — | |

Acquisition of noncontrolling interest | | — | | (2,232 | ) | — | | — | | 2,232 | | — | | — | |

Contributions from noncontrolling investors | | — | | — | | — | | — | | 126 | | 126 | | 11,240 | |

Distributions to noncontrolling investors | | — | | — | | — | | — | | (394 | ) | (394 | ) | — | |

Net income (loss) | | — | | — | | 134,659 | | — | | (19,044 | ) | 115,615 | | — | |

Balances at September 30, 2013 | | $ | 641 | | $ | 1,060,780 | | $ | 2,149,389 | | $ | (718,373 | ) | $ | (44,703 | ) | $ | 2,447,734 | | $ | 110,054 | |

Note 6. Derivative Financial Instruments

The company is exposed to certain risks relating to its ongoing business operations. The company utilizes derivative instruments to mitigate interest rate risk, foreign currency exchange rate risk, and commodity margin risk. Interest rate swaps may be entered into to manage interest rate risk associated with the company’s fixed and floating-rate borrowings. Forward exchange contracts on various foreign currencies may be entered into to manage foreign currency exchange rate risk as necessary. No interest rate swaps or significant forward exchange contracts on foreign currency existed for the periods presented. The company routinely enters into forward exchange traded futures and option contracts to manage the price risk associated with nonferrous metals inventory as well as purchases and sales of nonferrous metals (specifically aluminum, copper, nickel and silver). The company offsets fair value amounts recognized for derivative instruments executed with the same counterparty under master netting agreements. The company began to designate certain of its nonferrous metals, forward exchange futures contracts as fair value hedges of inventory and firm sales commitments in January 2013.

Commodity Futures Contracts. If the company is “long” on futures contracts, it means the company has more futures contracts purchased than futures contracts sold for the underlying commodity. If the company is “short” on futures contracts, it means the company has more futures contracts sold than futures contracts purchased for the underlying commodity. The following summarizes the company’s futures contract commitments as of September 30, 2013 (MT represents metric tons and Lbs represents pounds):

Commodity Futures | | Long/Short | | Total | | | |

Aluminum | | Long | | 2,300 | | MT | |

Aluminum | | Short | | 2,225 | | MT | |

Copper | | Long | | 2,710 | | MT | |

Copper | | Short | | 8,448 | | MT | |

Silver | | Short | | 686 | | Lbs | |

6

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 6. Derivative Financial Instruments (Continued)

The following summarizes the location and amounts of the fair values and gains or losses related to derivatives included in the company’s financial statements as of September 30, 2013, and December 31, 2012, and for the three and nine-month periods ended September 30, 2013 and 2012 (in thousands):

| | Asset Derivatives | | Liability Derivatives | |

| | | | Fair Value | | Fair Value | |

| | Balance sheet location | | September 30,

2013 | | December 31, 2012 | | September 30,

2013 | | December 31, 2012 | |

Derivative instruments designated as fair value hedges - | | | | | | | | | | | |

Commodity futures | | Other current assets | | $ | 413 | | | | $ | 660 | | | |

| | | | | | | | | | | |

Derivative instruments not designated as hedges - | | | | | | | | | | | |

Commodity futures | | Other current assets | | $ | 285 | | $ | 4,024 | | $ | 625 | | $ | 1,854 | |

| | | | | | | | | | | |

Total derivative instruments | | | | $ | 698 | | $ | 4,024 | | $ | 1,285 | | $ | 1,854 | |

| | Location of gain | | Amount of gain (loss) recognized in

income on derivatives for the three

months ended | | Hedged items | | Location of gain (loss) | | Amount of gain (loss) recognized in

income on related hedged items for

the three months ended | |

| | (loss) recognized in

income on derivatives | | September 30,

2013 | | September 30,

2012 | | in fair value hedge

relationships | | recognized in income on

related hedged item | | September 30,

2013 | | September 30,

2012 | |

Derivatives in fair value hedging relationships - | | | | | | | | | | | | | | | |

Commodity futures | | Costs of goods sold | | $ | 381 | | | | Firm commitments | | Costs of goods sold | | $ | (1,736 | ) | | |

| | | | | | | | Inventory | | Costs of goods sold | | 364 | | | |

| | | | | | | | | | | | $ | (1,372 | ) | | |

| | | | | | | | | | | | | | | |

Derivatives not designated as hedging instruments - | | | | | | | | | | | | | | | |

Commodity futures | | Costs of goods sold | | $ | (2,836 | ) | $ | (9,085 | ) | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | Location of gain | | Amount of gain (loss) recognized in

income on derivatives for the nine

months ended | | Hedged items | | Location of gain (loss) | | Amount of gain (loss) recognized in

income on related hedged items for

the nine months ended | |

| | (loss) recognized in

income on derivatives | | September 30,

2013 | | September 30,

2012 | | in fair value hedge

relationships | | recognized in income on

related hedged item | | September 30,

2013 | | September 30,

2012 | |

Derivatives in fair value hedging relationships - | | | | | | | | | | | | | | | |

Commodity futures | | Costs of goods sold | | $ | 7,773 | | | | Firm commitments | | Costs of goods sold | | $ | 877 | | | |

| | | | | | | | Inventory | | Costs of goods sold | | (8,458 | ) | | |

| | | | | | | | | | | | $ | (7,581 | ) | | |

| | | | | | | | | | | | | | | |

Derivatives not designated as hedging instruments - | | | | | | | | | | | | | | | |

Commodity futures | | Costs of goods sold | | $ | 3,793 | | $ | (6,810 | ) | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

Derivatives accounted for as fair value hedges had ineffectiveness resulting in losses of $312,000 and $199,000 during the three- and nine-month periods ended September 30, 2013, respectively; and a loss excluded from hedge effectiveness testing of $678,000 that increased costs of goods sold during the three-month period ended September 30, 2013, and a gain of $392,000 that reduced costs of goods sold during the nine-month period ended September 30, 2013.

7

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 7. Fair Value Measurements

FASB accounting standards provide a comprehensive framework for measuring fair value and set forth a definition of fair value and establish a hierarchy prioritizing the inputs to valuation techniques, giving the highest priority to quoted prices in active markets for identical assets and liabilities and the lowest priority to unobservable value inputs. Levels within the hierarchy are defined as follows:

· Level 1—Unadjusted quoted prices for identical assets and liabilities in active markets;

· Level 2—Quoted prices for similar assets and liabilities in active markets (other than those included in Level 1) which are observable for the asset or liability, either directly or indirectly; and

· Level 3—Valuations derived from valuation techniques in which one or more significant inputs or significant value drivers are unobservable.

The following table sets forth financial assets and liabilities measured at fair value in the consolidated balance sheets and the respective levels to which the fair value measurements are classified within the fair value hierarchy as of September 30, 2013, and December 31, 2012 (in thousands):

| | Total | | Quoted Prices in

Active Markets

for Identical

Assets

(Level 1) | | Significant

Other

Observable

Inputs

(Level 2) | | Significant

Unobservable

Inputs

(Level 3) | |

September 30, 2013 | | | | | | | | | |

Commodity futures — financial assets | | $ | 698 | | $ | — | | $ | 698 | | $ | — | |

Commodity futures — financial liabilities | | 1,285 | | — | | 1,285 | | — | |

| | | | | | | | | |

December 31, 2012 | | | | | | | | | |

Investments in short-term commercial paper | | $ | 31,520 | | $ | — | | $ | 31,520 | | $ | — | |

Commodity futures — financial assets | | 4,024 | | — | | 4,024 | | — | |

Commodity futures — financial liabilities | | 1,854 | | — | | 1,854 | | — | |

The carrying amounts of financial instruments including cash and equivalents approximate fair value. The fair values of short-term commercial paper and commodity futures and options contracts are estimated by the use of quoted market prices, estimates obtained from brokers, and other appropriate valuation techniques based on references available. The fair value of long-term debt, including current maturities, as determined by quoted market prices (Level 2), was approximately $2.2 billion and $2.3 billion (with a corresponding carrying amount in the consolidated balance sheets of $2.1 billion and $2.2 billion) at September 30, 2013 and December 31, 2012, respectively.

Note 8. Commitments and Contingencies

The company is involved in various routine litigation matters, including administrative proceedings, regulatory proceedings, governmental investigations, environmental matters, and commercial and construction contract disputes, none of which are expected to have a material impact on our financial condition, results of operations, or liquidity.

The company is involved, along with eight other steel manufacturing companies, in a class action antitrust complaint filed in federal court in Chicago, Illinois in September 2008, which alleges a conspiracy to fix, raise, maintain and stabilize the price at which steel products were sold in the United States starting in 2005, by artificially restricting the supply of such steel products. All but one of the Complaints were brought on behalf of a purported class consisting of all direct purchasers of steel products between January 1, 2005, and the present. The other Complaint was brought on behalf of a purported class consisting of all indirect purchasers of steel products within the same time period. In addition, in December 2010, we and the other co-defendants were served with a substantially similar complaint in the Circuit Court of Cocke County, Tennessee, purporting to be on behalf of indirect purchasers of steel products in Tennessee. That case has been removed to the federal court in Chicago that is hearing the main complaint. All Complaints seek treble damages and costs, including reasonable attorney fees, pre- and post-judgment interest and injunctive relief. In January 2009, Steel Dynamics and the other defendants filed a Joint Motion to Dismiss all of the direct purchaser lawsuits, but this motion was denied in June 2009. Following a period of preliminary discovery relating to class certification matters, Plaintiffs filed their Motion for Class Certification in May 2012, and on February 28, 2013, Defendants filed their Joint Memorandum in Opposition to Plaintiffs’ Motion for Class Certification, together with joint motions to exclude the expert opinions of both of Plaintiffs’ two retained experts. On October 15, 2013, Plaintiffs submitted their Reply papers, together with responses to Defendants’ Daubert motions. Additional briefing is anticipated on all issues related to the pending motions. Due to the uncertain nature of litigation, we cannot presently determine the ultimate outcome of this litigation. However, we have determined, based on the information available at this time, that there is not presently a “reasonable possibility” (as that term is defined in ASC 450-20-20), that the outcome of these legal proceedings would have a material impact on our financial condition, results of operations, or liquidity.

Although not presently necessary or appropriate to make a dollar estimate of exposure to loss, if any, in connection with the above matter, we may in the future determine that a loss accrual is necessary. Although we may make loss accruals, if and as warranted, any amounts that we may accrue from time to time could vary significantly from the amounts we actually pay, due to inherent uncertainties and the inherent shortcomings of the estimation process, the uncertainties involved in litigation and other factors. Additionally, an adverse result could have a material effect on our financial condition, results of operations and liquidity.

8

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 9. Segment Information

The company has three reportable segments: steel operations, metals recycling and ferrous resources operations, and steel fabrication operations. These operations are described in Note 1 to the financial statements. Revenues included in the category “Other” are from subsidiary operations that are below the quantitative thresholds required for reportable segments and primarily consist of further processing, slitting, and sale of certain steel products and the resale of certain secondary and excess steel products. In addition, “Other” also includes certain unallocated corporate accounts, such as the company’s senior secured credit facilities, senior notes and convertible senior notes, certain other investments, and certain profit sharing expenses.

The company’s operations are primarily organized and managed by operating segment. Operating segment performance and resource allocations are primarily based on operating results before income taxes. The accounting policies of the reportable segments are consistent with those described in Note 1 to the financial statements. Intra-segment and intra-company sales and any related profits are eliminated in consolidation. Refer to the company’s Annual Report on Form 10-K for the year ended December 31, 2012, for more information related to the company’s segment reporting. The company’s segment results for the three and nine-month periods ended September 30, 2013 and 2012 are as follows (in thousands):

For the three months ended | | | | Metals Recycling / | | Steel Fabrication | | | | | | | |

September 30, 2013 | | Steel Operations | | Ferrous Resources | | Operations | | Other | | Eliminations | | Consolidated | |

| | | | | | | | | | | | | |

Net Sales | | | | | | | | | | | | | |

External | | $ | 1,102,048 | | $ | 557,765 | | $ | 119,134 | | $ | 24,593 | | $ | — | | $ | 1,803,540 | |

External Non-U.S. | | 60,381 | | 47,616 | | — | | 201 | | — | | 108,198 | |

Other segments | | 54,537 | | 313,113 | | 134 | | 7,918 | | (375,702 | ) | — | |

| | 1,216,966 | | 918,494 | | 119,268 | | 32,712 | | (375,702 | ) | 1,911,738 | |

Operating income (loss) | | 146,564 | | (17,135 | ) | 3,265 | | (17,274 | )(1) | (2,147 | )(2) | 113,273 | |

Income (loss) before income taxes | | 133,041 | | (24,567 | ) | 1,751 | | (23,922 | ) | (2,148 | ) | 84,155 | |

Depreciation and amortization | | 26,815 | | 27,713 | | 2,219 | | 1,506 | | (51 | ) | 58,202 | |

Capital expenditures | | 33,985 | | 17,385 | | 297 | | 495 | | — | | 52,162 | |

| | | | | | | | | | | | | |

As of September 30, 2013 | | | | | | | | | | | | | |

Assets | | 2,581,798 | | 2,530,979 | | 272,786 | | 699,244 | (3) | (210,502 | )(4) | 5,874,305 | |

Liabilities | | 533,966 | | 593,674 | | 22,908 | | 2,366,273 | (5) | (200,304 | )(6) | 3,316,517 | |

| | | | | | | | | | | | | | | | | | | |

Footnotes related to the three months ended September 30, 2013 segment results (in millions):

(1) Corporate SG&A | | $ | (9.2 | ) |

Company-wide equity-based compensation | | (2.1 | ) |

Profit sharing | | (7.4 | ) |

Other, net | | 1.4 | |

Total | | $ | (17.3 | ) |

(2) Gross profit reduction from intra-company sales | | $ | (2.1 | ) |

(3) Cash and equivalents | | $ | 325.8 | |

Deferred income taxes | | 25.2 | |

Property, plant and equipment, net | | 72.9 | |

Debt issuance costs, net | | 27.7 | |

Intra-company debt | | 153.6 | |

Other | | 94.0 | |

Total | | $ | 699.2 | |

(4) Elimination of intra-company receivables | | $ | (46.9 | ) |

Elimination of intra-company debt | | (153.6 | ) |

Other | | (10.0 | ) |

Total | | $ | (210.5 | ) |

(5) Accounts payable | | $ | 43.1 | |

Income taxes payable | | 7.7 | |

Accrued interest | | 22.9 | |

Debt | | 2,041.8 | |

Deferred income taxes | | 204.6 | |

Other | | 46.2 | |

Total | | $ | 2,366.3 | |

(6) Elimination of intra-company payables | | $ | (47.3 | ) |

Elimination of intra-company debt | | (153.6 | ) |

Other | | 0.6 | |

Total | | $ | (200.3 | ) |

9

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 9. Segment Information (Continued)

For the three months ended | | | | Metals Recycling / | | Steel Fabrication | | | | | | | |

September 30, 2012 | | Steel Operations | | Ferrous Resources | | Operations | | Other | | Eliminations | | Consolidated | |

| | | | | | | | | | | | | |

Net Sales | | | | | | | | | | | | | |

External | | $ | 985,524 | | $ | 475,547 | | $ | 102,401 | | $ | 17,156 | | $ | — | | $ | 1,580,628 | |

External Non-U.S. | | 65,825 | | 46,684 | | — | | 253 | | — | | 112,762 | |

Other segments | | 48,157 | | 268,137 | | 41 | | 4,864 | | (321,199 | ) | — | |

| | 1,099,506 | | 790,368 | | 102,442 | | 22,273 | | (321,199 | ) | 1,693,390 | |

Operating income (loss) | | 106,927 | | (15,697 | ) | 3,141 | | (17,759 | )(1) | (3,891 | )(2) | 72,721 | |

Income (loss) before income taxes | | 88,394 | | (24,829 | ) | 1,225 | | (53,678 | ) | (3,891 | ) | 7,221 | |

Depreciation and amortization | | 25,937 | | 26,449 | | 2,100 | | 4,518 | | (51 | ) | 58,953 | |

Capital expenditures | | 14,625 | | 42,370 | | 1,005 | | 342 | | — | | 58,342 | |

| | | | | | | | | | | | | |

As of September 30, 2012 | | | | | | | | | | | | | |

Assets | | 2,523,616 | | 2,586,568 | | 249,988 | | 597,297 | (3) | (181,953 | )(4) | 5,775,516 | |

Liabilities | | 482,348 | | 507,367 | | 18,143 | | 2,505,036 | (5) | (170,206 | )(6) | 3,342,688 | |

| | | | | | | | | | | | | | | | | | | |

Footnotes related to the three months ended September 30, 2012 segment results (in millions):

(1) Corporate SG&A | | $ | (7.6 | ) |

Profit sharing | | (2.9 | ) |

Impairment charges | | (7.9 | ) |

Other, net | | 0.6 | |

Total | | $ | (17.8 | ) |

(2) Gross profit reduction from intra-company sales | | $ | (3.9 | ) |

(3) Cash and equivalents | | $ | 246.8 | |

Income taxes receivable | | 0.9 | |

Deferred income taxes | | 28.2 | |

Property, plant and equipment, net | | 75.7 | |

Debt issuance costs, net | | 29.4 | |

Intra-company debt | | 129.1 | |

Other | | 87.2 | |

Total | | $ | 597.3 | |

(4) Elimination of intra-company receivables | | $ | (35.8 | ) |

Elimination of intra-company debt | | (129.1 | ) |

Other | | (17.1 | ) |

Total | | $ | (182.0 | ) |

(5) Accounts payable | | $ | 32.3 | |

Income taxes payable | | 12.7 | |

Accrued interest | | 28.9 | |

Accrued profit sharing | | 15.5 | |

Debt | | 2,156.2 | |

Deferred income taxes | | 240.9 | |

Other | | 18.5 | |

Total | | $ | 2,505.0 | |

(6) Elimination of intra-company payables | | $ | (39.0 | ) |

Elimination of intra-company debt | | (129.1 | ) |

Other | | (2.1 | ) |

Total | | $ | (170.2 | ) |

10

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 9. Segment Information (Continued)

For the nine months ended | | | | Metals Recycling / | | Steel Fabrication | | | | | | | |

September 30, 2013 | | Steel Operations | | Ferrous Resources | | Operations | | Other | | Eliminations | | Consolidated | |

| | | | | | | | | | | | | |

Net Sales | | | | | | | | | | | | | |

External | | $ | 3,152,111 | | $ | 1,653,975 | | $ | 316,526 | | $ | 64,792 | | $ | — | | $ | 5,187,404 | |

External Non-U.S. | | 162,646 | | 158,026 | | — | | 698 | | — | | 321,370 | |

Other segments | | 168,482 | | 865,143 | | 1,276 | | 20,198 | | (1,055,099 | ) | — | |

| | 3,483,239 | | 2,677,144 | | 317,802 | | 85,688 | | (1,055,099 | ) | 5,508,774 | |

Operating income (loss) | | 351,410 | | (34,210 | ) | 7,125 | | (48,147 | )(1) | 2,525 | (2) | 278,703 | |

Income (loss) before income taxes | | 309,780 | | (56,860 | ) | 2,475 | | (72,136 | ) | 2,524 | | 185,783 | |

Depreciation and amortization | | 79,698 | | 81,553 | | 6,455 | | 4,536 | | (153 | ) | 172,089 | |

Capital expenditures | | 93,244 | | 49,999 | | 2,000 | | 1,501 | | — | | 146,744 | |

| | | | | | | | | | | | | | | | | | | |

Footnotes related to the nine months ended September 30, 2013 segment results (in millions):

(1) Corporate SG&A | | $ | (26.3 | ) |

Company-wide equity-based compensation | | (7.3 | ) |

Profit sharing | | (16.5 | ) |

Other, net | | 2.0 | |

Total | | $ | (48.1 | ) |

(2) Gross profit increase from intra-company sales | | $ | 2.5 | |

For the nine months ended | | | | Metals Recycling / | | Steel Fabrication | | | | | | | |

September 30, 2012 | | Steel Operations | | Ferrous Resources | | Operations | | Other | | Eliminations | | Consolidated | |

| | | | | | | | | | | | | |

Net Sales | | | | | | | | | | | | | |

External | | $ | 3,279,344 | | $ | 1,643,522 | | $ | 273,060 | | $ | 54,071 | | $ | — | | $ | 5,249,997 | |

External Non-U.S. | | 166,025 | | 168,818 | | — | | 393 | | — | | 335,236 | |

Other segments | | 148,839 | | 1,009,604 | | 45 | | 12,290 | | (1,170,778 | ) | — | |

| | 3,594,208 | | 2,821,944 | | 273,105 | | 66,754 | | (1,170,778 | ) | 5,585,233 | |

Operating income (loss) | | 380,832 | | (30,905 | ) | 666 | | (49,294 | )(1) | (5,063 | )(2) | 296,236 | |

Income (loss) before income taxes | | 325,521 | | (57,932 | ) | (4,408 | ) | (117,956 | ) | (5,063 | ) | 140,162 | |

Depreciation and amortization | | 78,405 | | 78,114 | | 6,007 | | 7,654 | | (153 | ) | 170,027 | |

Capital expenditures | | 26,848 | | 127,133 | | 3,502 | | 1,203 | | — | | 158,686 | |

| | | | | | | | | | | | | | | | | | | |

Footnotes related to the nine months ended September 30, 2012 segment results (in millions):

(1) Corporate SG&A | | $ | (22.4 | ) |

Company-wide stock option expense | | (5.7 | ) |

Profit sharing | | (15.3 | ) |

Impairment charges | | (7.9 | ) |

Other, net | | 2.0 | |

Total | | $ | (49.3 | ) |

(2) Gross profit reduction from intra-company sales | | $ | (5.1 | ) |

11

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 10. Condensed Consolidating Information

Certain 100%-owned subsidiaries of SDI have fully and unconditionally guaranteed all of the indebtedness relating to the issuance of the company’s senior notes due 2014, 2019, 2020, 2022 and 2023. Following are the company’s condensed consolidating financial statements, including the guarantors, which present the financial position, results of operations and cash flows of (i) SDI (in each case, reflecting investments in its consolidated subsidiaries under the equity method of accounting), (ii) the guarantor subsidiaries of SDI, (iii) the non-guarantor subsidiaries of SDI, and (iv) the eliminations necessary to arrive at the information on a consolidated basis. The following statements should be read in conjunction with the accompanying consolidated financial statements and the company’s Annual Report on Form 10-K for the year ended December 31, 2012.

Condensed Consolidating Balance Sheets (in thousands)

| | | | | | Combined | | Consolidating | | Total | |

As of September 30, 2013 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Cash and equivalents | | $ | 322,212 | | $ | 37,710 | | $ | 10,134 | | $ | — | | $ | 370,056 | |

Investments in short-term commercial paper | | — | | — | | — | | — | | — | |

Accounts receivable, net | | 311,333 | | 900,928 | | 35,210 | | (474,598 | ) | 772,873 | |

Inventories | | 622,008 | | 471,537 | | 102,803 | | (4,316 | ) | 1,192,032 | |

Other current assets | | 57,805 | | 7,301 | | 3,987 | | (18,739 | ) | 50,354 | |

Total current assets | | 1,313,358 | | 1,417,476 | | 152,134 | | (497,653 | ) | 2,385,315 | |

Property, plant and equipment, net | | 1,042,112 | | 634,552 | | 566,873 | | (2,470 | ) | 2,241,067 | |

Intangible assets, net | | — | | 393,531 | | — | | — | | 393,531 | |

Goodwill | | — | | 733,650 | | — | | — | | 733,650 | |

Other assets, including investments in subs | | 2,621,656 | | 25,367 | | 8,266 | | (2,534,547 | ) | 120,742 | |

Total assets | | $ | 4,977,126 | | $ | 3,204,576 | | $ | 727,273 | | $ | (3,034,670 | ) | $ | 5,874,305 | |

| | | | | | | | | | | |

Accounts payable | | $ | 155,868 | | $ | 257,009 | | $ | 83,830 | | $ | (70,301 | ) | $ | 426,406 | |

Accrued expenses | | 119,919 | | 105,444 | | 10,014 | | (42,922 | ) | 192,455 | |

Current maturities of long-term debt | | 312,076 | | 300 | | 46,060 | | (23,095 | ) | 335,341 | |

Total current liabilities | | 587,863 | | 362,753 | | 139,904 | | (136,318 | ) | 954,202 | |

Long-term debt | | 1,732,445 | | — | | 202,825 | | (161,651 | ) | 1,773,619 | |

Other liabilities | | 164,381 | | 1,968,990 | | 44,567 | | (1,589,242 | ) | 588,696 | |

| | | | | | | | | | | |

Redeemable noncontrolling interests | | — | | — | | 110,054 | | — | | 110,054 | |

| | | | | | | | | | | |

Common stock | | 641 | | 33,896 | | 18,121 | | (52,017 | ) | 641 | |

Treasury stock | | (718,373 | ) | — | | — | | — | | (718,373 | ) |

Additional paid-in-capital | | 1,060,780 | | 117,737 | | 525,230 | | (642,967 | ) | 1,060,780 | |

Retained earnings (deficit) | | 2,149,389 | | 721,200 | | (268,725 | ) | (452,475 | ) | 2,149,389 | |

Total Steel Dynamics, Inc. equity | | 2,492,437 | | 872,833 | | 274,626 | | (1,147,459 | ) | 2,492,437 | |

Noncontrolling interests | | — | | — | | (44,703 | ) | — | | (44,703 | ) |

Total equity | | 2,492,437 | | 872,833 | | 229,923 | | (1,147,459 | ) | 2,447,734 | |

Total liabilities and equity | | $ | 4,977,126 | | $ | 3,204,576 | | $ | 727,273 | | $ | (3,034,670 | ) | $ | 5,874,305 | |

12

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 10. Condensed Consolidating Information (Continued)

| | | | | | Combined | | Consolidating | | Total | |

As of December 31, 2012 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Cash and equivalents | | $ | 322,707 | | $ | 41,675 | | $ | 11,535 | | $ | — | | $ | 375,917 | |

Investments in short-term commercial paper | | 31,520 | | — | | — | | — | | 31,520 | |

Accounts receivable, net | | 277,428 | | 772,868 | | 11,293 | | (419,226 | ) | 642,363 | |

Inventories | | 564,882 | | 536,331 | | 107,422 | | (6,128 | ) | 1,202,507 | |

Other current assets | | 51,268 | | 7,253 | | 4,006 | | (18,609 | ) | 43,918 | |

Total current assets | | 1,247,805 | | 1,358,127 | | 134,256 | | (443,963 | ) | 2,296,225 | |

Property, plant and equipment, net | | 1,017,587 | | 664,332 | | 551,903 | | (2,624 | ) | 2,231,198 | |

Intangible assets, net | | — | | 416,635 | | — | | — | | 416,635 | |

Goodwill | | — | | 738,542 | | — | | — | | 738,542 | |

Other assets, including investments in subs | | 2,768,360 | | 30,862 | | 9,189 | | (2,675,595 | ) | 132,816 | |

Total assets | | $ | 5,033,752 | | $ | 3,208,498 | | $ | 695,348 | | $ | (3,122,182 | ) | $ | 5,815,416 | |

| | | | | | | | | | | |

Accounts payable | | $ | 150,191 | | $ | 219,415 | | $ | 56,472 | | $ | (65,981 | ) | $ | 360,097 | |

Accrued expenses | | 144,719 | | 98,484 | | 9,877 | | (33,131 | ) | 219,949 | |

Current maturities of long-term debt | | 14,237 | | 300 | | 52,595 | | (37,501 | ) | 29,631 | |

Total current liabilities | | 309,147 | | 318,199 | | 118,944 | | (136,613 | ) | 609,677 | |

Long-term debt | | 2,140,958 | | — | | 169,223 | | (137,575 | ) | 2,172,606 | |

Other liabilities | | 178,182 | | 2,087,957 | | 41,581 | | (1,751,243 | ) | 556,477 | |

| | | | | | | | | | | |

Redeemable noncontrolling interests | | — | | — | | 98,814 | | — | | 98,814 | |

| | | | | | | | | | | |

Common stock | | 637 | | 33,896 | | 18,121 | | (52,017 | ) | 637 | |

Treasury stock | | (720,479 | ) | — | | — | | — | | (720,479 | ) |

Additional paid-in-capital | | 1,037,687 | | 117,737 | | 476,677 | | (594,414 | ) | 1,037,687 | |

Retained earnings (deficit) | | 2,087,620 | | 650,709 | | (200,389 | ) | (450,320 | ) | 2,087,620 | |

Total Steel Dynamics, Inc. equity | | 2,405,465 | | 802,342 | | 294,409 | | (1,096,751 | ) | 2,405,465 | |

Noncontrolling interests | | — | | — | | (27,623 | ) | — | | (27,623 | ) |

Total equity | | 2,405,465 | | 802,342 | | 266,786 | | (1,096,751 | ) | 2,377,842 | |

Total liabilities and equity | | $ | 5,033,752 | | $ | 3,208,498 | | $ | 695,348 | | $ | (3,122,182 | ) | $ | 5,815,416 | |

13

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 10. Condensed Consolidating Information (Continued)

Condensed Consolidating Statements of Operations (in thousands)

For the three months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2013 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net sales | | $ | 902,280 | | $ | 2,136,327 | | $ | 91,198 | | $ | (1,218,067 | ) | $ | 1,911,738 | |

Costs of goods sold | | 760,589 | | 2,025,470 | | 114,408 | | (1,185,921 | ) | 1,714,546 | |

Gross profit (loss) | | 141,691 | | 110,857 | | (23,210 | ) | (32,146 | ) | 197,192 | |

Selling, general and administrative | | 30,073 | | 55,348 | | 2,622 | | (4,124 | ) | 83,919 | |

Operating income (loss) | | 111,618 | | 55,509 | | (25,832 | ) | (28,022 | ) | 113,273 | |

Interest expense, net of capitalized interest | | 19,733 | | 10,561 | | 1,915 | | (1,239 | ) | 30,970 | |

Other (income) expense, net | | (2,423 | ) | 631 | | (1,301 | ) | 1,241 | | (1,852 | ) |

Income (loss) before income taxes and equity in net loss of subsidiaries | | 94,308 | | 44,317 | | (26,446 | ) | (28,024 | ) | 84,155 | |

Income taxes (benefit) | | 24,930 | | 16,579 | | 2,004 | | (10,448 | ) | 33,065 | |

| | 69,378 | | 27,738 | | (28,450 | ) | (17,576 | ) | 51,090 | |

Equity in net loss of subsidiaries | | (11,892 | ) | — | | — | | 11,892 | | — | |

Net loss attributable to noncontrolling interests | | — | | — | | 6,396 | | — | | 6,396 | |

Net income (loss) attributable to Steel Dynamics, Inc. | | $ | 57,486 | | $ | 27,738 | | $ | (22,054 | ) | $ | (5,684 | ) | $ | 57,486 | |

For the three months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2012 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net sales | | $ | 785,168 | | $ | 1,918,774 | | $ | 48,167 | | $ | (1,058,719 | ) | $ | 1,693,390 | |

Costs of goods sold | | 685,074 | | 1,823,447 | | 69,520 | | (1,041,052 | ) | 1,536,989 | |

Gross profit (loss) | | 100,094 | | 95,327 | | (21,353 | ) | (17,667 | ) | 156,401 | |

Selling, general and administrative | | 19,927 | | 53,023 | | 14,032 | | (3,302 | ) | 83,680 | |

Operating income (loss) | | 80,167 | | 42,304 | | (35,385 | ) | (14,365 | ) | 72,721 | |

Interest expense, net of capitalized interest | | 27,153 | | 13,997 | | 1,619 | | (1,279 | ) | 41,490 | |

Other (income) expense, net | | 23,345 | | 434 | | (1,046 | ) | 1,277 | | 24,010 | |

Income (loss) before income taxes and equity in net income of subsidiaries | | 29,669 | | 27,873 | | (35,958 | ) | (14,363 | ) | 7,221 | |

Income taxes (benefit) | | (2,771 | ) | 8,668 | | 73 | | (4,854 | ) | 1,116 | |

| | 32,440 | | 19,205 | | (36,031 | ) | (9,509 | ) | 6,105 | |

Equity in net loss of subsidiaries | | (19,607 | ) | — | | — | | 19,607 | | — | |

Net loss attributable to noncontrolling interests | | — | | — | | 6,728 | | — | | 6,728 | |

Net income (loss) attributable to Steel Dynamics, Inc. | | $ | 12,833 | | $ | 19,205 | | $ | (29,303 | ) | $ | 10,098 | | $ | 12,833 | |

14

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 10. Condensed Consolidating Information (Continued)

For the nine months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2013 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net sales | | $ | 2,566,286 | | $ | 6,150,327 | | $ | 245,607 | | $ | (3,453,446 | ) | $ | 5,508,774 | |

Costs of goods sold | | 2,220,737 | | 5,840,025 | | 318,163 | | (3,391,299 | ) | 4,987,626 | |

Gross profit (loss) | | 345,549 | | 310,302 | | (72,556 | ) | (62,147 | ) | 521,148 | |

Selling, general and administrative | | 83,675 | | 164,104 | | 7,433 | | (12,767 | ) | 242,445 | |

Operating income (loss) | | 261,874 | | 146,198 | | (79,989 | ) | (49,380 | ) | 278,703 | |

Interest expense, net of capitalized interest | | 61,927 | | 33,351 | | 5,405 | | (3,619 | ) | 97,064 | |

Other (income) expense, net | | (4,776 | ) | 645 | | (3,633 | ) | 3,620 | | (4,144 | ) |

Income (loss) before income taxes and equity in net loss of subsidiaries | | 204,723 | | 112,202 | | (81,761 | ) | (49,381 | ) | 185,783 | |

Income taxes (benefit) | | 41,945 | | 41,712 | | 4,085 | | (17,574 | ) | 70,168 | |

| | 162,778 | | 70,490 | | (85,846 | ) | (31,807 | ) | 115,615 | |

Equity in net loss of subsidiaries | | (28,119 | ) | — | | — | | 28,119 | | — | |

Net loss attributable to noncontrolling interests | | — | | — | | 19,044 | | — | | 19,044 | |

Net income (loss) attributable to Steel Dynamics, Inc. | | $ | 134,659 | | $ | 70,490 | | $ | (66,802 | ) | $ | (3,688 | ) | $ | 134,659 | |

For the nine months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2012 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net sales | | $ | 2,625,152 | | $ | 6,408,166 | | $ | 131,024 | | $ | (3,579,109 | ) | $ | 5,585,233 | |

Costs of goods sold | | 2,275,227 | | 6,106,504 | | 189,477 | | (3,525,776 | ) | 5,045,432 | |

Gross profit (loss) | | 349,925 | | 301,662 | | (58,453 | ) | (53,333 | ) | 539,801 | |

Selling, general and administrative | | 72,196 | | 160,513 | | 20,940 | | (10,084 | ) | 243,565 | |

Operating income (loss) | | 277,729 | | 141,149 | | (79,393 | ) | (43,249 | ) | 296,236 | |

Interest expense, net of capitalized interest | | 81,583 | | 41,208 | | 5,068 | | (4,151 | ) | 123,708 | |

Other (income) expense, net | | 31,419 | | (436 | ) | (2,767 | ) | 4,150 | | 32,366 | |

Income (loss) before income taxes and equity in net income of subsidiaries | | 164,727 | | 100,377 | | (81,694 | ) | (43,248 | ) | 140,162 | |

Income taxes (benefit) | | 31,809 | | 36,354 | | 444 | | (15,632 | ) | 52,975 | |

| | 132,918 | | 64,023 | | (82,138 | ) | (27,616 | ) | 87,187 | |

Equity in net loss of subsidiaries | | (29,938 | ) | — | | — | | 29,938 | | — | |

Net loss attributable to noncontrolling interests | | — | | — | | 15,793 | | — | | 15,793 | |

Net income (loss) attributable to Steel Dynamics, Inc. | | $ | 102,980 | | $ | 64,023 | | $ | (66,345 | ) | $ | 2,322 | | $ | 102,980 | |

15

Table of Contents

STEEL DYNAMICS, INC.

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS (UNAUDITED)

Note 10. Condensed Consolidating Information (Continued)

Condensed Consolidating Statements of Cash Flows (in thousands)

For the nine months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2013 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net cash provided by (used in) operating activities | | $ | 126,404 | | $ | 164,383 | | $ | (56,636 | ) | $ | 11,540 | | $ | 245,691 | |

Net cash used in investing activities | | (115,979 | ) | (28,654 | ) | (20,230 | ) | 53,760 | | (111,103 | ) |

Net cash provided by (used in) financing activities | | (10,920 | ) | (139,694 | ) | 75,465 | | (65,300 | ) | (140,449 | ) |

Decrease in cash and equivalents | | (495 | ) | (3,965 | ) | (1,401 | ) | — | | (5,861 | ) |

Cash and equivalents at beginning of period | | 322,707 | | 41,675 | | 11,535 | | — | | 375,917 | |

Cash and equivalents at end of period | | $ | 322,212 | | $ | 37,710 | | $ | 10,134 | | $ | — | | $ | 370,056 | |

For the nine months ended, | | | | | | Combined | | Consolidating | | Total | |

September 30, 2012 | | Parent | | Guarantors | | Non-Guarantors | | Adjustments | | Consolidated | |

Net cash provided by (used in) operating activities | | $ | 145,121 | | $ | 128,705 | | $ | (39,928 | ) | $ | 5,488 | | $ | 239,386 | |

Net cash used in investing activities | | (19,249 | ) | (74,342 | ) | (81,123 | ) | 80,479 | | (94,235 | ) |

Net cash provided by (used in) financing activities | | (183,982 | ) | (86,072 | ) | 107,229 | | (85,967 | ) | (248,792 | ) |

Decrease in cash and equivalents | | (58,110 | ) | (31,709 | ) | (13,822 | ) | — | | (103,641 | ) |

Cash and equivalents at beginning of period | | 301,073 | | 58,699 | | 30,989 | | — | | 390,761 | |

Cash and equivalents at end of period | | $ | 242,963 | | $ | 26,990 | | $ | 17,167 | | $ | — | | $ | 287,120 | |

16

Table of Contents

ITEM 2. MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

Forward-Looking Statements

This report contains some predictive statements about future events, including statements related to the steel and recycled metals markets, our revenues, costs of purchased materials, future profitability and earnings, and the operation of new or existing facilities. These statements are intended to be made as “forward-looking,” subject to many risks and uncertainties, within the safe harbor protections of the Private Securities Litigation Reform Act of 1995. Some factors that could cause such forward-looking statements to turn out differently than anticipated include: (1) the effects of a recurrent slowing in industrial demand; (2) changes in economic conditions, either generally or in any of the steel or scrap-consuming sectors which affect demand for our products, including the strength of the non-residential and residential construction, automotive, appliance, and other steel-consuming industries; (3) fluctuations in the cost of key raw materials (including steel scrap, iron units, and energy costs) and our ability to pass-on any cost increases; (4) the impact of domestic and foreign import price competition; (5) risks and uncertainties involving product and/or technology development; and (6) occurrences of unexpected plant outages or equipment failures.

More specifically, we refer you to the sections titled Special Note Regarding Forward-Looking Statements and Risk Factors in our annual report on Form 10-K for the year ended December 31, 2012, as well as in other reports which we file with the Securities and Exchange Commission, for a more detailed discussion of some of the many factors, variable risks and uncertainties that could cause actual results to differ materially from those we may have expected or anticipated. These reports are available publicly on the SEC web site, www.sec.gov, and on our web site, www.steeldynamics.com. Forward-looking or predictive statements we make are based upon information and assumptions, concerning our businesses and the environments in which they operate, which we consider reasonable as of the date on which these statements are made. Due to the foregoing risks and uncertainties however, as well as, matters beyond our control which can affect forward-looking statements, you are cautioned not to place undue reliance on these predictive statements, which speak only as of the date of this report. We undertake no duty to update or revise any forward-looking statement, whether as a result of new information, future events or otherwise.

Operating Statement Classifications

Net Sales. Net sales from our operations are a factor of volumes shipped, product mix and related pricing. We charge premium prices for certain grades of steel, product dimensions, certain smaller volumes, and for value-added processing or coating of the steel products. Except for our steel fabrication operations segment, we recognize revenue from sales and the allowance for estimated costs associated with returns from these sales at the time the title of the product is transferred to the customer. Provision is made for estimated product returns and customer claims based on estimates and actual historical experience. Net sales from steel fabrication operations are recognized from construction contracts utilizing a percentage-of-completion method, which is based on the percentage of steel consumed to date as compared to the estimated total steel required for each contract.

Costs of Goods Sold. Our costs of goods sold represent all direct and indirect costs associated with the manufacture of our products. The principal elements of these costs are scrap and scrap substitutes (which represent the most significant single component of our consolidated costs of goods sold), steel, direct and indirect labor and related benefits, alloys, zinc, transportation and freight, repairs and maintenance, utilities (most notably electricity and natural gas), and depreciation.

Selling, General and Administrative Expenses. Selling, general and administrative expenses consist of all costs associated with our sales, finance and accounting, and administrative departments. These costs include, among other items, labor and related benefits, professional services, insurance premiums, property taxes, profit sharing, and amortization of intangible and other assets.

Interest Expense, net of Capitalized Interest. Interest expense consists of interest associated with our senior credit facilities and other debt net of interest costs that are required to be capitalized during the construction period of certain capital investment projects.

Other Expense (Income), net. Other income consists of interest income earned on our temporary cash deposits and investments; any other non-operating income activity, including gains on certain short-term investments; and income from non-consolidated investments accounted for under the equity method. Other expense consists of any non-operating costs, such as certain financing expenses.

17

Table of Contents

Overview

Net income was $57.5 million, or $0.25 per diluted share, during the third quarter of 2013, compared with net income of $12.8 million, or $0.06 per diluted share, during the third quarter of 2012, and net income of $29.0 million, or $0.13 per diluted share, during the second quarter of 2013. Our net sales increased $218.3 million, or 13%, to $1.9 billion in the third quarter of 2013 versus the third quarter of 2012, while net sales increased $110.4 million, or 6%, versus the second quarter of 2013. Our gross profit percentage was 10% for the third quarter of 2013 as compared to 9% for the third quarter of 2012 and 8% for the second quarter of 2013.

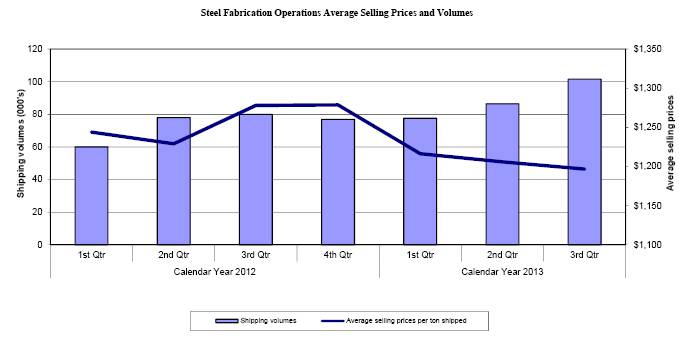

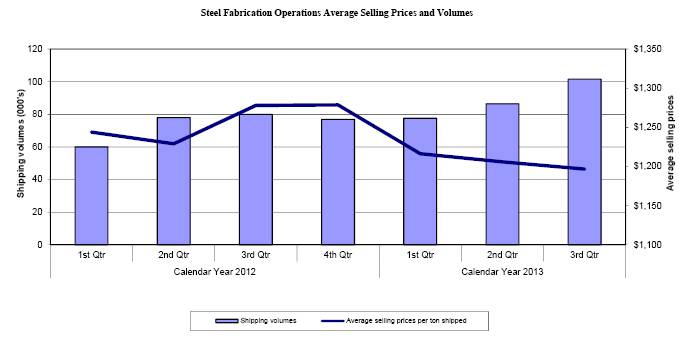

Third quarter 2013 external steel shipments increased 13% as compared to the third quarter of 2012 (with total sheet products shipments increasing 14% and long products shipments increasing 12%), and external ferrous scrap shipments increased 4% and external nonferrous scrap shipments increased 7%. Additionally, steel fabrication external shipments increased 27% in the third quarter of 2013 compared to the same period in 2012. Operating income increased 56% to $113.3 million in the third quarter 2013, as compared to the same period in 2012, due primarily to increased operating income from our steel operations due to higher steel sales volumes and improved gross margins.

Comparing the third quarter of 2013 to the second quarter of 2013, external steel shipments increased 5% while external ferrous and nonferrous scrap shipments increased 1% and 5%, respectively. Steel fabrication continued its trend of increasing external shipments, showing an 18% sequential-quarter gain. Consolidated quarterly operating income increased 64% sequentially, due primarily to increased volume in our steel operations segment coupled with higher steel sheet metal spreads resulting from increased steel sheet selling prices.

Segment Operating Results 2013 vs. 2012 (dollars in thousands)

| | Three Months Ended | | Second | | Sequential | | Nine Months Ended | |

| | September 30, | | Quarter | | Quarter | | September 30, | |

| | 2013 | | %

Change | | 2012 | | 2013 | | %

Change | | 2013 | | %

Change | | 2012 | |

| | | | | | | | | | | | | | | | | |

Net sales: | | | | | | | | | | | | | | | | | |

Steel | | $ | 1,216,966 | | 11 | % | $ | 1,099,506 | | $ | 1,143,913 | | 6 | % | $ | 3,483,239 | | (3 | )% | $ | 3,594,208 | |

Metals recycling and ferrous resources | | 918,494 | | 16 | % | 790,368 | | 861,158 | | 7 | % | 2,677,144 | | (5 | )% | 2,821,944 | |

Steel fabrication | | 119,268 | | 16 | % | 102,442 | | 104,159 | | 15 | % | 317,802 | | 16 | % | 273,105 | |

Other | | 32,712 | | 47 | % | 22,273 | | 28,122 | | 16 | % | 85,688 | | 28 | % | 66,754 | |

| | 2,287,440 | | | | 2,014,589 | | 2,137,352 | | | | 6,563,873 | | | | 6,756,011 | |

Intra-company | | (375,702 | ) | | | (321,199 | ) | (336,012 | ) | | | (1,055,099 | ) | | | (1,170,778 | ) |

Consolidated | | $ | 1,911,738 | | 13 | % | $ | 1,693,390 | | $ | 1,801,340 | | 6 | % | $ | 5,508,774 | | (1 | )% | $ | 5,585,233 | |

| | | | | | | | | | | | | | | | | |

Operating income (loss): | | | | | | | | | | | | | | | | | |

Steel | | $ | 146,564 | | 37 | % | $ | 106,927 | | $ | 85,545 | | 71 | % | $ | 351,410 | | (8 | )% | $ | 380,832 | |

Metals recycling and ferrous resources | | (17,135 | ) | (9 | )% | (15,697 | ) | (7,251 | ) | (136 | )% | (34,210 | ) | (11 | )% | (30,905 | ) |

Steel fabrication | | 3,265 | | 4 | % | 3,141 | | 2,330 | | 40 | % | 7,125 | | 970 | % | 666 | |

Other | | (17,274 | ) | 3 | % | (17,759 | ) | (14,434 | ) | (20 | )% | (48,147 | ) | 2 | % | (49,294 | ) |

| | 115,420 | | 51 | % | 76,612 | | 66,190 | | 74 | % | 276,178 | | (8 | )% | 301,299 | |

Eliminations | | (2,147 | ) | | | (3,891 | ) | 3,008 | | | | 2,525 | | | | (5,063 | ) |

Consolidated | | $ | 113,273 | | 56 | % | $ | 72,721 | | $ | 69,198 | | 64 | % | $ | 278,703 | | (6 | )% | $ | 296,236 | |

| | | | | | | | | | | | | | | | | | | | | | | |

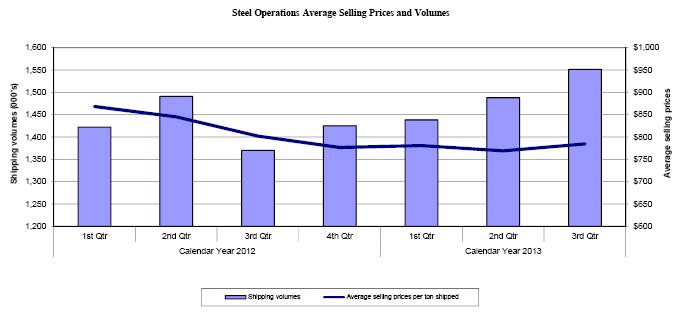

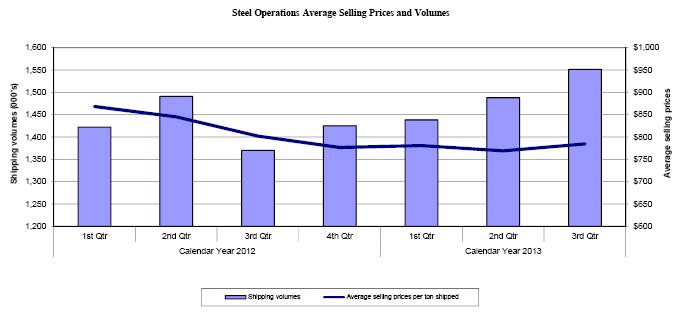

Steel Operations. Steel operations consist of our five electric arc furnace mini-mills, producing steel from steel scrap, utilizing continuous casting, automated rolling mills, and various downstream finishing facilities, including The Techs operations. Collectively, our steel operations sell directly to end users and service centers. These products are used in numerous industry sectors, including the automotive, construction, commercial, transportation, agriculture and industrial machinery markets. In the third quarter of 2013 and 2012, our steel operations accounted for 61% and 62% of our external net sales, respectively. Operating income for the steel segment increased $39.6 million, or 37%, to $146.6 million in the third quarter of 2013, compared to the same period of 2012. The increase in operating income is primarily due to a 13% increase in segment shipments and improved gross margins. Decreased metal spreads, caused by average segment selling prices per ton shipped decreasing $18 versus only a $3 per ton decrease in the average cost of ferrous scrap consumed, were more than offset by cost compression derived in part from increased production volumes. Continued domestic oversupply caused selling values to decrease more than raw material costs, resulting in the compressed metal spreads.

18

Table of Contents

Operating income for the steel segment decreased $29.4 million, or 8%, to $351.4 million in the first nine months of 2013, compared to the same period of 2012. Despite a more than 4% increase in steel segment shipments, gross margin and correspondingly operating income, decreased 6%, primarily due to a $61 decrease in average segment selling prices per ton shipped versus only a $38 per ton decrease in average ferrous scrap cost melted in the first nine months of 2013, as compared to the first nine months of 2012.

Steel Operations Shipments (tons)

| | Three Months Ended | | | | Second | | | | Nine Months Ended | | | |

| | September 30, | | | | Quarter | | | | September 30, | | | |

| | 2013 | | | | 2012 | | | | 2013 | | | | 2013 | | | | 2012 | | | |

| | | | | | | | | | | | | | | | | | | | | |

Flat Roll Division | | 740,279 | | | | 638,776 | | | | 720,582 | | | | 2,165,151 | | | | 2,004,225 | | | |

The Techs | | 176,713 | | | | 167,982 | | | | 179,217 | | | | 507,067 | | | | 484,034 | | | |

Sheet products | | 916,992 | | 58 | % | 806,758 | | 57 | % | 899,799 | | 59 | % | 2,672,218 | | 58 | % | 2,488,259 | | 57 | % |

| | | | | | | | | | | | | | | | | | | | | |

Structural and Rail Division | | 315,808 | | | | 255,533 | | | | 286,974 | | | | 883,679 | | | | 769,063 | | | |

Engineered Bar Products Division | | 127,788 | | | | 113,327 | | | | 123,919 | | | | 364,528 | | | | 437,024 | | | |

Roanoke Bar Division | | 144,323 | | | | 152,922 | | | | 134,001 | | | | 418,274 | | | | 453,228 | | | |

Steel of West Virginia | | 80,214 | | | | 76,481 | | | | 77,975 | | | | 238,896 | | | | 228,149 | | | |

Long products | | 668,133 | | 42 | % | 598,263 | | 43 | % | 622,869 | | 41 | % | 1,905,377 | | 42 | % | 1,887,464 | | 43 | % |

| | | | | | | | | | | | | | | | | | | | | |

Total shipments | | 1,585,125 | | | | 1,405,021 | | | | 1,522,668 | | | | 4,577,595 | | | | 4,375,723 | | | |

Intra-segment shipments | | (33,778 | ) | (2 | )% | (34,594 | ) | (2 | )% | (35,031 | ) | (2 | )% | (100,899 | ) | (2 | )% | (92,211 | ) | (2 | )% |

Segment shipments | | 1,551,347 | | | | 1,370,427 | | | | 1,487,637 | | | | 4,476,696 | | | | 4,283,512 | | | |

Intra-company shipments | | (87,480 | ) | (6 | )% | (71,195 | ) | (5 | )% | (91,257 | ) | (6 | )% | (272,017 | ) | (6 | )% | (214,629 | ) | (5 | )% |

External shipments | | 1,463,867 | | | | 1,299,232 | | | | 1,396,380 | | | | 4,204,679 | | | | 4,068,883 | | | |

Sheet Products. Our Flat Roll Division sells a broad range of sheet steel products, such as hot rolled, cold rolled and coated steel products, including a large variety of specialty products such as light gauge hot rolled, galvanized, Galvalume® and painted products. The Techs operations, comprised of three galvanizing lines, also sells specialized galvanized sheet steels used in non-automotive applications.

Long Products. Our Structural and Rail Division sells structural steel beams and pilings to the construction market, as well as standard-grade rail to the railroad industry. Our Engineered Bar Products Division primarily sells engineered, special-bar-quality and merchant bar quality rounds, and round-cornered squares. Our Roanoke Bar Division primarily sells merchant steel products, including angles, plain rounds, flats and channels. Steel of West Virginia primarily sells merchant beams, channels and specialty structural steel sections.

Net sales for the steel segment increased $117.5 million, or 11%, in the third quarter of 2013 when compared to the third quarter of 2012, as a 13% increase in segment shipments more than offset a 2%, or $18 per ton, decrease in average selling prices. Increased shipments were somewhat consistent between sheet and long product, as sheet products shipments increased 14%, and long product shipments increased 12%, with the most notable increase in structural steel. Net sales for the steel segment decreased $111.0 million, or 3%, in the first nine months of 2013 when compared to the first nine months of 2012, as an almost 5% increase in segment shipments was offset by selling price decreases of more than 7%, or $61 per ton.

19

Table of Contents

Metallic raw materials used in our electric arc furnaces represent our single most significant manufacturing cost. Our metallic raw material cost per net ton consumed in our steel operations decreased $3 in the third quarter of 2013, compared with the third quarter of 2012. During the third quarter of 2013 and 2012, respectively, our metallic raw material costs represented 65% and 64% of our steel operations’ manufacturing costs, excluding the operations of The Techs, which purchases, rather than produces, the steel it further processes. Our metallic raw material cost per net ton consumed in our steel operations decreased $38 in the first nine months of 2013 compared with the first nine months of 2012, and represented 65% of our steel operations’ manufacturing costs, excluding the operations of The Techs, in each nine-month period.

Metals Recycling and Ferrous Resources Operations |

Metals Recycling and Ferrous Resources Operations. This operating segment primarily includes our metals recycling operations (OmniSource); our liquid pig iron production facility, Iron Dynamics (IDI); and our Minnesota iron operations. Our metals recycling and ferrous resources operations segment accounted for 32% and 31% of our external net sales in the third quarter of 2013 and 2012, respectively. Operating loss for the metals recycling and ferrous resources operations segment increased $1.4 million compared to the third quarter of 2012, due primarily to decreased ferrous metal spreads in metals recycling which more than offset increases in ferrous and nonferrous selling volumes. Operating loss for metals recycling and ferrous resources operations segment decreased $3.3 million in the first nine months of 2013 to $34.2 million compared to the first nine months of 2012.

20

Table of Contents

Metals Recycling and Ferrous Resources Operations Shipments

| | Three Months Ended | | Second | | Nine Months Ended | |

| | September 30, | | Quarter | | September 30, | |

| | 2013 | | 2012 | | 2013 | | 2013 | | 2012 | |

Ferrous metal (gross tons) | | | | | | | | | | | |