IMPORTANT NOTICE

This report was prepared as National Instrument 43-101 Technical Report for Golden Queen Mining Co., Inc. (GQM) by Norwest Corporation (Norwest) and AMEC E&C Services Inc. (AMEC).

The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in Norwest’s and AMEC’s services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report.

This report is intended for use by GQM and subject to terms and conditions of its respective contracts with AMEC and Norwest. Except for the purposes legislated under Canadian provincial and territorial securities law, any other uses of this report by any third party is at that party’s sole risk.

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

TABLEOFCONTENTS

| October 2012 | i |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| October 2012 | ii |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| October 2012 | iii |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| October 2012 | iv |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Note

Text that appears in italics is taken from AMEC’s resource report dated:

February 29, 2012

| October 2012 | v |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

LIST OFTABLES

| October 2012 | vi |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

LIST OFFIGURES

| October 2012 | vii |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| October 2012 | viii |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 1 | SUMMARY |

| | |

| Golden Queen Mining Co., Ltd. requested Norwest Corporation (Norwest) and AMEC E&C Services Inc. (AMEC) prepare a report (the Report) with results from updated Mineral Resources and Mineral Reserves estimates based on in-fill and step-out drilling and an updated feasibility study for the Soledad Mountain Project (the Project). |

| | |

| The Report has been submitted as a NI 43-101 compliant Technical Report and this is availableon SEDAR and on the Company’s website atwww.goldenqueen.com. |

| Text shown in italicshasbeenextractedfromtheAMECresourcereportdatedFebruary 29, 2012. |

1.1 Key Outcomes

| | • | Total Proven and Probable Mineral Reserves of 66,808 ktons grading 0.0188 oz/ton Au and 0.343 oz/ton Ag. |

| | | |

| | • | Capital cost of US $119 million. |

| | | |

| | • | Operating costs of $32 million per year; $7.58 per ton leached |

| | | |

| | • | The pre-tax net present value (NPV) at 8 percent discount rate is $787 million and the internal rate of return (IRR) is 82.9 percent. |

| | | |

| | • | Payback for the Project is less than two years on an after-tax basis. |

1.2 Location, Access and Climate

The Project is located in Kern County in southern California, approximately 5 miles south of the town of Mojave. The metropolitan areas of Rosamond and Lancaster lie approximately 9 miles and 20 miles to the south respectively. Los Angeles is about 70 miles south of Mojave.

Access to site is from State Route 14 and Silver Queen Road, an existing paved County road. Silver Queen Road will be the primary access to site.

The Mojave region is generally characterized as arid, with a wet season from December through March. Rainfall events tend to be short lived and of high intensity. Mojave experiences high summer temperatures up to 113°F. The minimum temperature may reach 20°F. Maximum wind speed is 90mph with Exposure C for design purposes. Mean recorded annual rainfall is 6.14 inches with a mean maximum month of 1.11 inches.

1.3 Land Status

The land status is described in sub-section 4.2.

| October 2012 | 1-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

GQM acquired its initial property interests in 1985. GQM purchased fee land or entered into mining lease agreements from the 1990’s onwards and is continuing to add to its land position in the area. GQM only purchases and does not lease fee land in an ongoing effort to ensure a secure land position.

The land required for the Project, which has been included within the Approved Project Boundary, has either been secured under one of the mining lease agreements referred to in subsection 1.4 below or is held by GQM through ownership of the land in fee or as patented and unpatented mining claims or millsites.

The fee land surrounding the patented and unpatented mining claims in Section 6 and Section 5 and the millsites in Section 32 is required for the construction of the ancillary facilities for the mining operation, for the construction of the heap leach pads and for construction of a pad for the storage of quality waste rock and for the aggregate production facilities.

1.4 Mineral Tenure and Mining Lease Agreements

Mineral tenure and mining lease agreements are described in Section 4.3

GQM holds directly or controls via mining lease agreements with landholders a total of 33 patented lode mining claims, 134 unpatented lode mining claims, 1 patented millsite, 12 unpatented millsites, and 1 unpatented placer claim and upward of 980 acres of fee land, collectively referred to as the Property.

1.5 Royalties

Royalties are described in Section 4.4.

GQM is required to pay advance, minimum royalties under the mining lease agreements. In some instances, the Company will receive a credit for the advance minimum royalty payments made on commencement of commercial production. Weighted average royalty rates on production will range from a low of 1.0% to a high of 5.0% depending upon the area being mined and gold and silver prices.

Royalty calculations from production will be complex. Norwest has developed a model for an accurate royalty calculation and this is attached to the cash flow model.

State royalties for payable gold and silver are charged at the following rates:

| | • | Gold royalty = $5.00/oz gold (post-smelter) |

| | | |

| | • | Silver royalty = $0.10/oz silver (post-smelter) |

The mining lease agreements also typically provide for an additional royalty if non-mineral commodities, such as aggregates, are produced and sold.

| October 2012 | 1-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

1.6 Approvals and Permits

1.6.1 Land Use - Conditional Use Permits

Environmental issues were fully addressed in the Supplemental Environmental Impact Report (SEIR) and this is described in sub-section 21.1.

The Kern County Planning Commission formally considered the Project on April 8, 2010. At the meeting, the Planning Commission, consisting of a panel of three commissioners, unanimously approved the Project. The Planning Commission certified the SEIR and adopted a Mitigation Measures Monitoring Program and a set of Conditions of Approval for the Project. The Mitigation Measures Monitoring Program and Conditions of Approval for the Project were amended by Planning Commission Resolution No. 171-10 adopted on October 28, 2010 and are now final.

The Bureau of Land Management confirmed that its Record of Decision approving the Plan of Operations under NEPA in November 1997 remains valid.

1.6.2 Water Quality– Waste Discharge Requirements

The Lahontan Regional Water Quality Control Board (the Board) unanimously approved Waste Discharge Requirements and a Monitoring and Reporting Program for the Project at a public hearing held in South Lake Tahoe on July 14, 2010. The Board order was subsequently signed by the Executive Officer of the Board and is now in effect.

1.6.3 Air Quality– Authority to Construct and Permit to Operate

The Air Quality and Health Risk Assessments for the Project were completed and submitted to the Planning Department and the Eastern Kern Air Pollution Control District (EKAPCD) on July 21, 2009. This report was approved by the Planning Commission on April 8, 2010, as part of the certification of the SEIR.

Ten applications for Authority to Construct permits were submitted to the EKAPCD in February 2011. The EKAPCD confirmed that the information required to support the applications was complete. The draft Authority to Construct permits were received in September 2011. The

Company’s consulting engineers and legal counsel completed their review of the draft Authority to Construct permits in January 2012. The Authority to Construct permits were issued by EKAPCD on February 8, 2012.

The Authority to Construct approvals will be converted to a Permit to Operate after construction has been completed and subject to inspection by EKAPCD.

1.7 Considerations of Social and Community Impacts

The impact of the Project on Mojave and the surrounding areas is described in Section 21.3.

| October 2012 | 1-3 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Mojave and the surrounding areas are areas of relatively high unemployment and employment has not recovered since the start of the financial downturn in 2008. The Project has therefore had a positive response from the local communities.

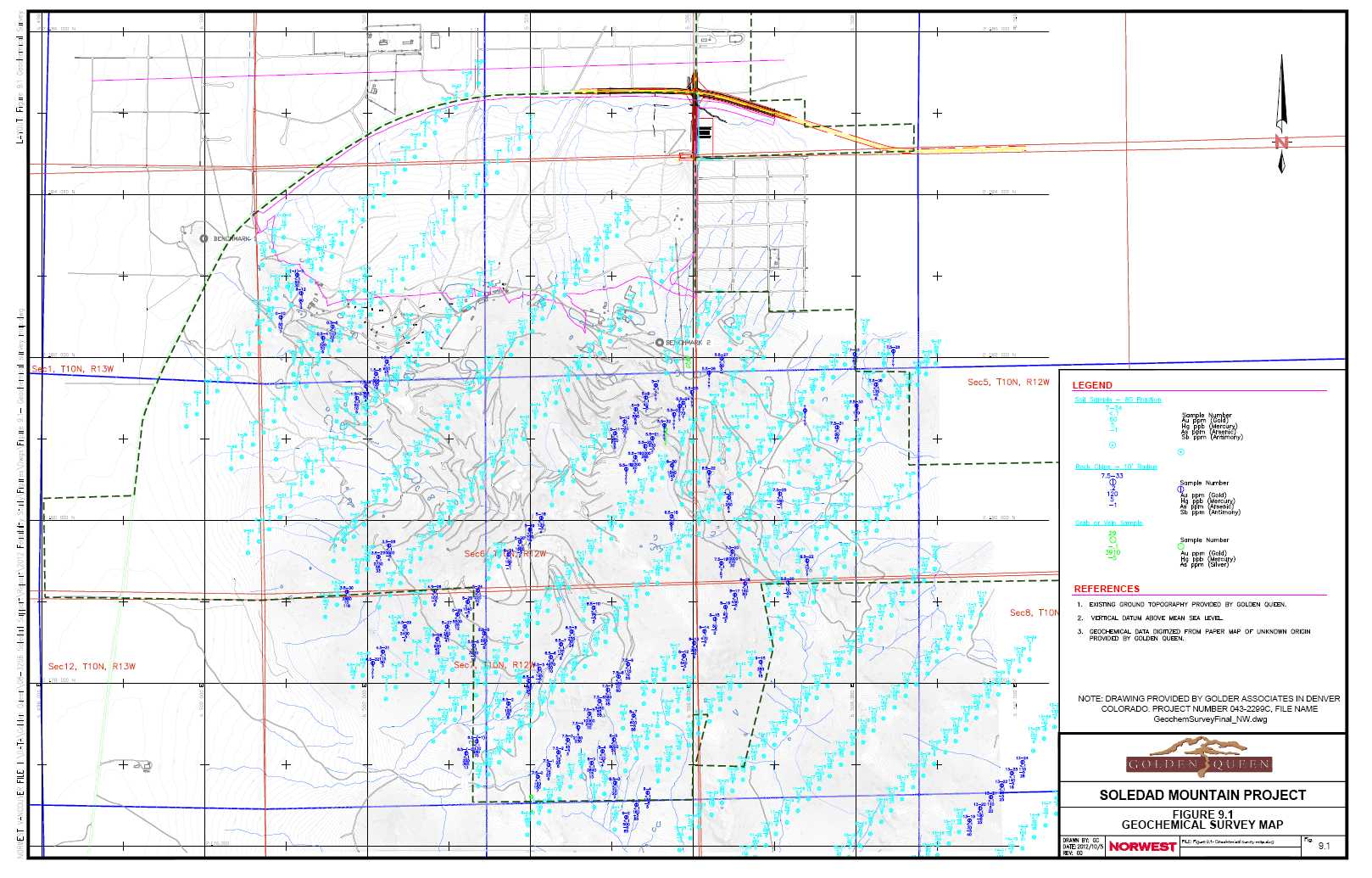

1.8 Geology and Mineralization

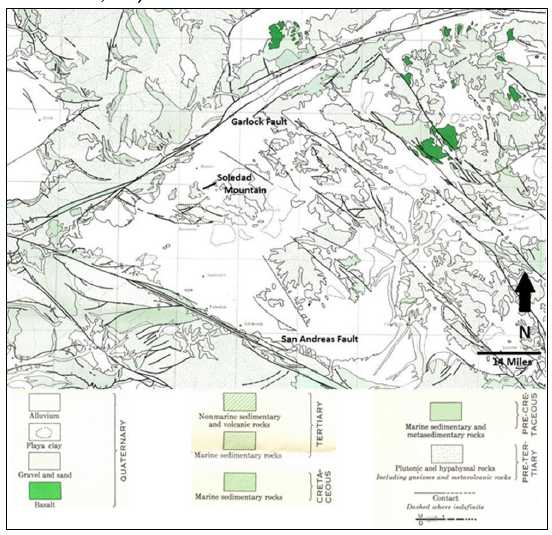

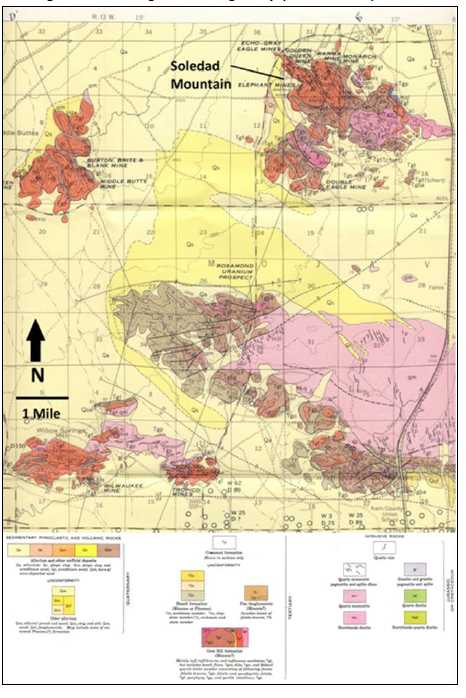

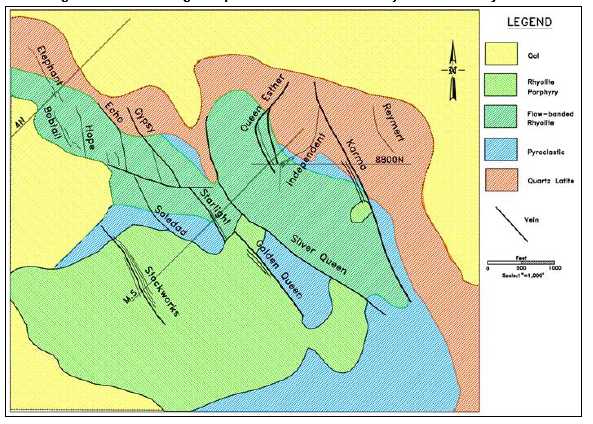

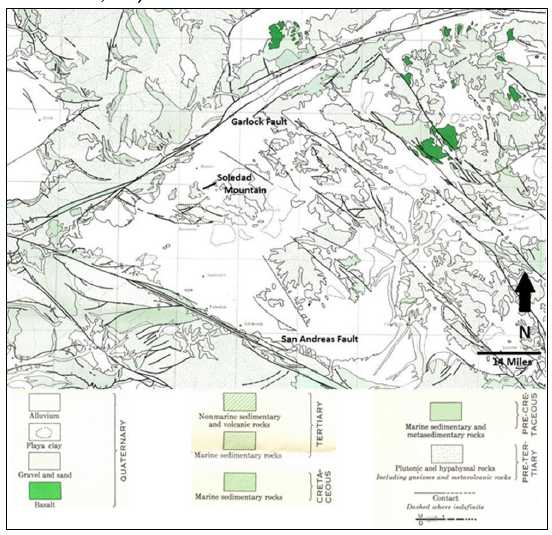

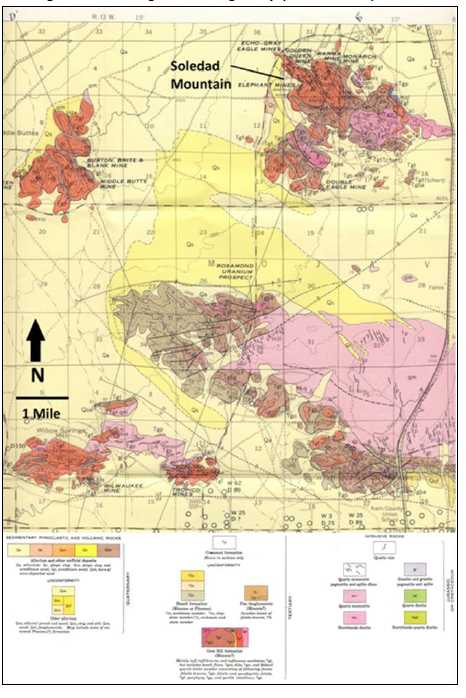

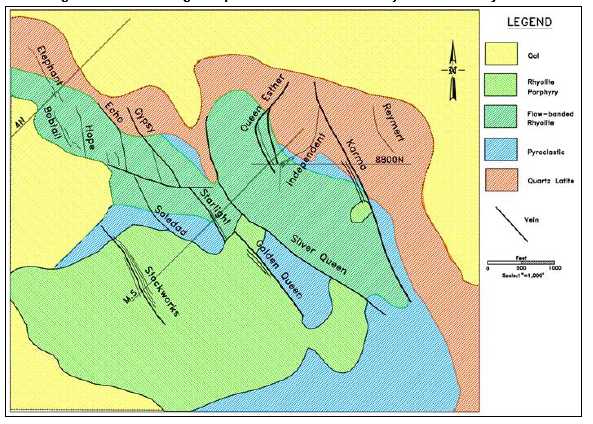

Soledad Mountain is located within the Mojave structural block, a triangular-shaped area bounded to the east by the northwest-trending San Andreas Fault and to the north by the northeast-trending, Garlock Fault. The Mojave block is broken into an orthogonal pattern of N50E to N60E and N40W to N50W fracture systems. These fracture zones likely developed as the result of Late Cretaceous compressional stresses that were present prior to formation of the Garlock and San Andreas Faults. Gold and silver mineralization at Soledad Mountain is hosted by northwest-trending, en-echelon faults and fracture systems. Cretaceous quartz monzonite forms the basement of stratigraphic sequences in the Mojave block. The quartz monzonite is overlain by Miocene-age, quartz latite and rhyolitic volcanic rocks. Volcanic centers appear to have formed at intersections of the northeast and northwest-trending fracture systems. Major volcanic centers are present at Soledad Mountain, Willow Springs and Middle Buttes. These volcanic centers consist generally of initial, widespread sheet flows and pyroclastics of quartz latite, followed by restricted centers of rhyolitic flows and rhyolite porphyry intrusives. Rhyolitic flows and intrusives are elongated somewhat along northwest-trending vents and feeder zones. Gold deposits in the Mojave block include Soledad Mountain, Standard Hill, Cactus and Tropico. Of these gold deposits, only Soledad Mountain is in the Project area. At Soledad Mountain gold mineralization occurs in low-sulfidation style, quartz-adularia veins and stockworks that strike northwest. Gold mineralization at Standard Hill, located 1 mile northeast of Soledad, consists of north to northwest-striking quartz veins in Cretaceous quartz monzonite and Tertiary, quartz latite volcanic rocks. At the Cactus Gold Mine, 5 miles west of Soledad, gold occurs in northwest and northeast-striking quartz veins, breccias and irregular zones of silicification in quartz latite, rhyolitic flows and rhyolitic intrusive breccias.

At least 14 separate vein systems and related vein splits occur at Soledad Mountain. Veins generally strike N20-40W and dip at high angles either to the northeast or to the southwest. Separate, parallel or en-echelon vein systems are present over a total strike length of 6,000 ft. trending northwest and a total width of 4,500 ft. Veins and zones are from 5 ft. to 150 ft. thick, 325 ft. to 3,000 ft. long and from 300 ft. to 1,000 ft. deep along dip. The horizontal distance between individual veins is from 50 ft. to over 400 ft. Mineralization consists of fine-grained pyrite, covellite, chalcocite, tetrahedrite, acanthite, native silver, pyrargyrite, polybasite, native gold and electrum within discrete quartz veins, veinlets, stockworks and irregular zones of silicification. Electrum is about 25% silver.

1.9 Golden Queen Mining Co., Inc.

Golden Queen Mining Co. Ltd. was formed in November 1985 to acquire Golden Queen Mining Co., Inc. (GQM), a California corporation, which had secured, by agreement, a core group ofclaims on Soledad Mountain. Golden Queen Mining Co, Ltd. Is a Canadian public company listed on the Toronto Stock Exchange and is registered with the U.S. Securities And Exchange Commission as a foreign, private issuer.

| October 2012 | 1-4 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

The mine operator is Golden Queen Mining Co., Inc., the wholly-owned subsidiary of Golden Queen Mining Co. Ltd. The Project has California Mine ID #91-15-0098.

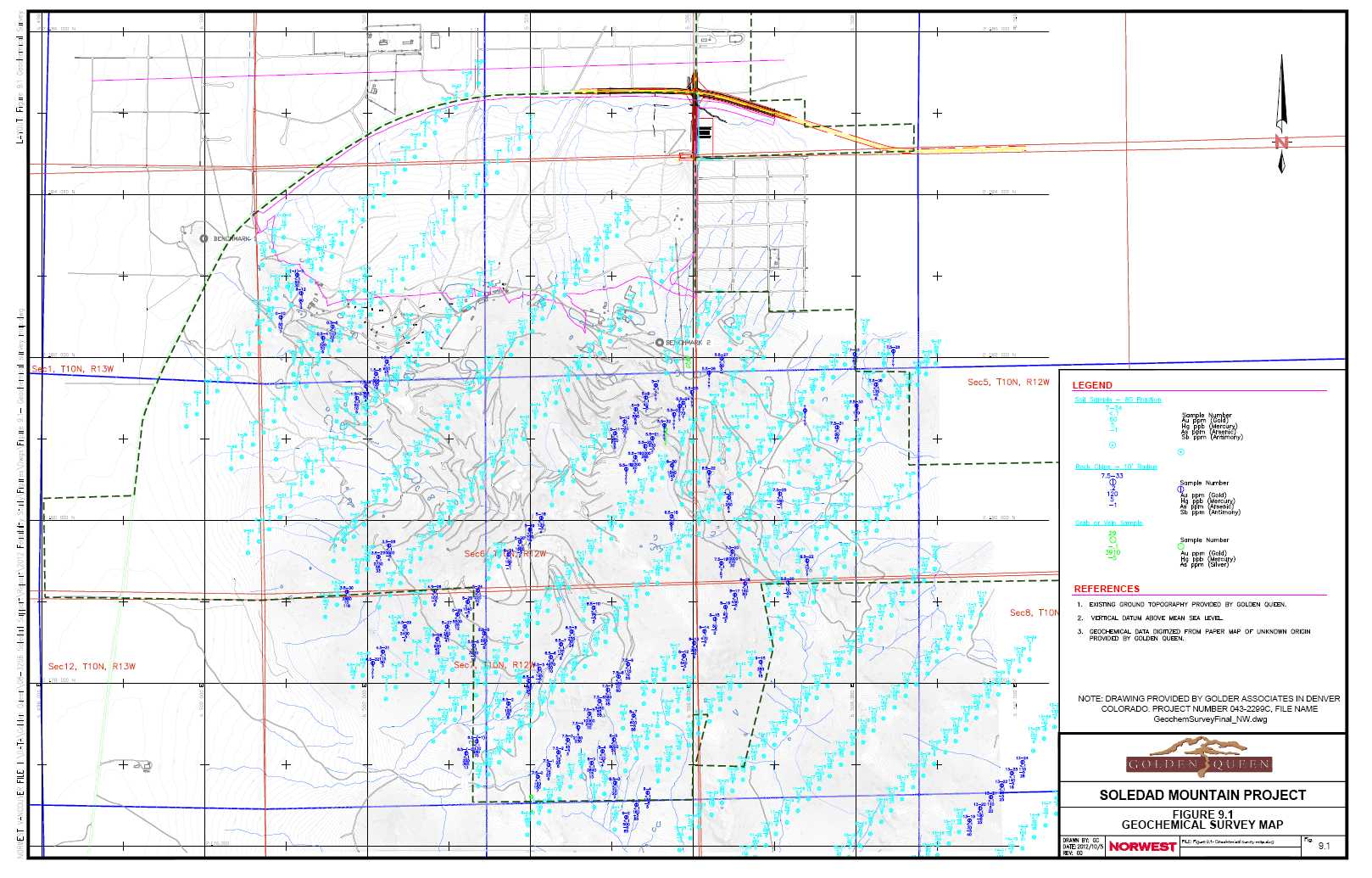

GQM’s activities have included construction of infrastructure to support exploration activities, reconnaissance and geological mapping, aerial photography; rock chip and soil sampling, geophysical surveys, reverse-circulation and core drilling, underground channel sampling, condemnation drilling, metallurgical test work, geotechnical studies, baseline environmental and a range of other studies, mine design, community consultations and permit applications and a range of mineral resource and mineral reserve estimates. Feasibility studies were done in 1996 (Pincock Allen & Holt, 1996), 1998 (M3 Engineering & Technology Corp., 1998), 2000 (Golden Queen Mining Co., Inc., 2000), 2008 (Norwest Corporation, 2008), 2011 (Norwest Corporation, 2011) with the current update prepared as a NI 43-101 Technical Report.

1.10 Exploration Potential

Exploration and exploration potential are described in Section 9 and sub-section 9.8 respectively.

A number of areas with exploration potential have been identified. The Hope Cabin area has good potential for vein-type mineralization under alluvial cover and the Alphson areas may contain stockwork vein-type mineralization south of existing planned open pits. In addition, gold and silver mineralization extends at depth below the bottom of designed open pits and in areas immediately adjacent to the East Pit high walls along strike.

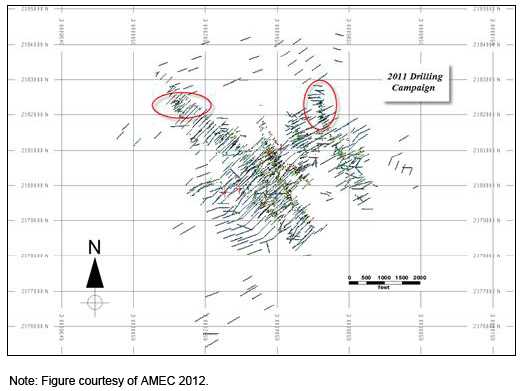

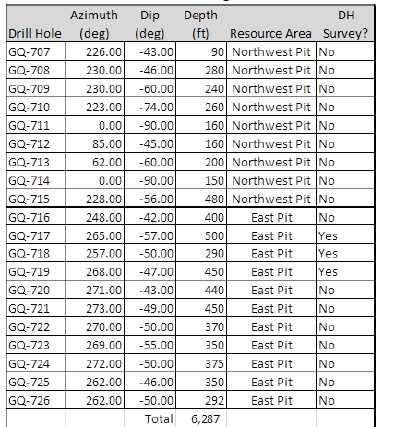

1.11 Drilling

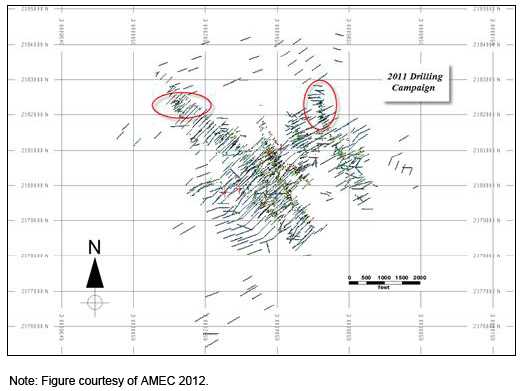

Data from 1,374 reverse-circulation (RC) holes, diamond core holes and underground cross-cut channels was loaded into the MineSight® files for a total of 379,326.4 ft. of data. Approximately 86.5% of the drilling in the database wascompleted during GQM’s ownership from 1986 to2011. The remaining 13.5% of the drilling was conducted by Gold Fields America Development Co (GFA) , Shell/Billiton, and Noranda.

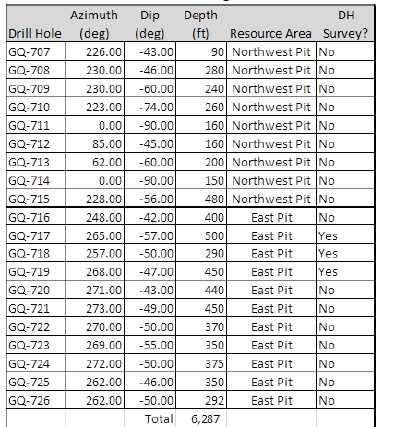

Twenty- holes were drilled for a total of 6,932 ft. in 2011.

Core sizes used on the Project include AQ (27mm) for core drilling done by GFA and HQ (63.5mm) core drilling completed by GQM. RC bit sizes used by GQM ranged from 4.0 inch to 5.5 inch.

Industry standard logging and sampling conventions were used to capture information from the RC chips, diamond drill core and underground, cross-cut channel samples. Data logged included lithology, alteration, mineralization, structural, oxidation state, and geotechnical data.

| October 2012 | 1-5 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Recovery was not recorded for diamond core holes DDH 1-16. Only general comments regarding recovery were made for holes DDH 17-21. 100% recovery was noted for most mineralized intervals except in drill hole DDH 21, which experienced recoveries as low as 25%. All remaining drill logs recorded measured recoveries for each cored interval. The number of mineralized intervals with poor core recovery is relatively small for the 43 core holes that have recovery information ranging from 10 to 70%. Mineral Resources Development Inc. (MRDI)(2000) reports that recovery appears to have been adequate to meet industry standards for holes DDH 22through DDH97-10.

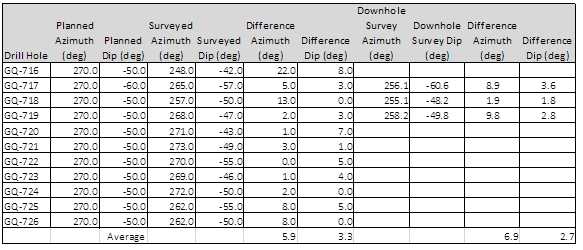

GQM drill-hole collar locations during 1986-2000 were surveyed relative to the historical mine grid by DeWalt Corporation of Bakersfield, California. Surveys were carried out using either a Total Station Wild TC-1610 theodolite or Trimble 4000 SSI RTK Global Positioning System. Drill hole collar locations of GQM holes drilled in 2011 were surveyed by Quality Surveying, Inc. of Lancaster, California.

The positions of underground cross-cut samples were located by GQM by using historical transit surveys of underground workings. Portal elevations were corrected during surface surveying of drill sites.

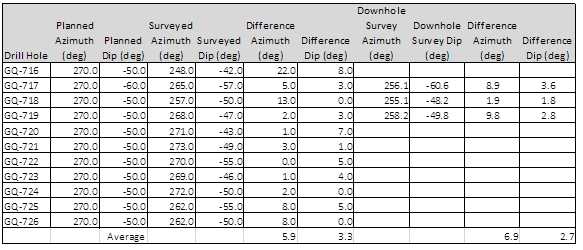

Down-hole surveys were not performed for holes drilled prior to 1994. RC holes GQ-1 to GQ-475 and core holes DDH-1 to DDH-16 were not surveyed. GQM imposed an average downward deviation adjustment on these holes. Diamond drill holes DDH-17 through DDH-42 and DDH 97-1 through DDH 97-10 were surveyed for dip and azimuth using a Baker Hughes/Inteq Magnetic Single Shot Survey Tool. RC holes GQ-475 through GQ-632 were surveyed for dip using a MD-Totco Special Operating Unit Deviation Tool. Inclined RC holes show a downward deviation of from 1.5 to 3 degrees per 100 ft. The lateral deviations in azimuth are unknown. Drill holes for the 2011 program were down-hole surveyed by Golder Associates Inc. (Golder) Golder used a Mount Sopris Instruments 2DVA-1000 (deviation) borehole logging probe mounted on an 4MXB-1000 winch with approximately 410 meters of 1/8-inch single-conductor wireline and controlled using an MGXII control console. Only three out of twenty drill holes were down-hole surveyed due to holes being blocked.

1.12 Sample Analysis and Security

A number of commercial assay laboratories were contracted to assay GQM samples for gold and silver from 1986-2000. The assay labs that GQM used were Jacobs, in Tucson, Bondar-Clegg in Sparks, Barringer in Sparks, GSI, Skyline, Mountain States Research, and American Assay in Sparks, and ALS Chemex, Reno.

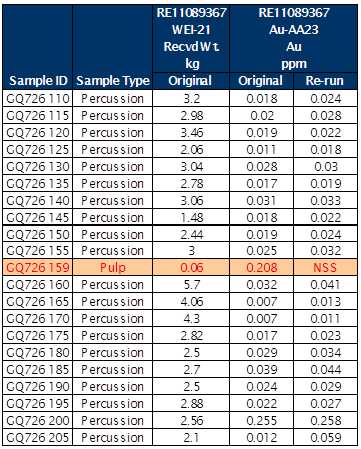

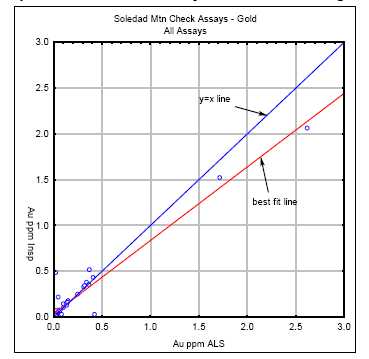

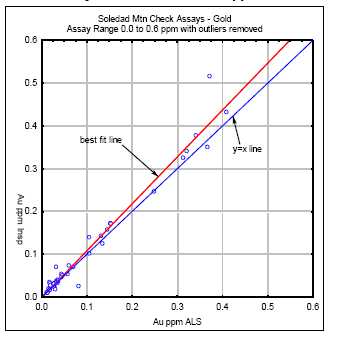

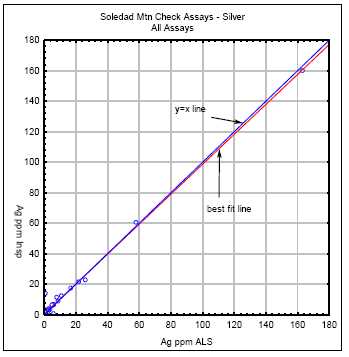

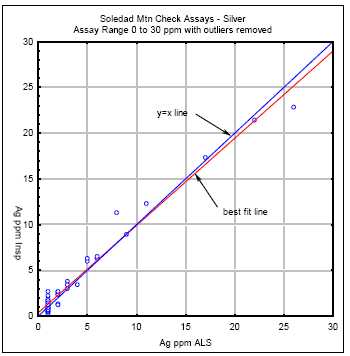

The GQM 2011 RC samples were analysed by ALS Chemex, a well-established and recognized assay and geochemical analytical services company. Samples were weighed upon receipt at the laboratory, dried, crushed to 70% passing 2 mm, riffle split to obtain a nominal 250 g subsample, and this subsample was pulverized to 85% passing 75 µm. Gold was assayed by conventional fire assay of a 30 g split of pulverized material, then determined by atomic absorptionspectrometry (ALS Chemex code Au-AA23). Silver was assayed by aqua-regia digestion and atomic absorption spectrometry (ALS Chemex code Ag-AA62). Those samples returning greater than two ppm gold (> 2.0 ppm Au) by method Au-AA23 were reassayed by fire assay of a 30 g subsample with a gravimetric finish (ALS Chemex code Au-GRA21).

| October 2012 | 1-6 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

No information is available documenting sample security procedures prior to 1994. Since 1994, sample security measures include moving core from the drill site to a locked storage warehouse on the Project site at the end of each shift. RC cuttings were allowed to dry at the drill site before being locked in a semi-trailer to be shipped to the laboratory. Access roads into the Project site are locked with either a gate across the road or padlocked with a heavy metal chain across the road. GQM is of the opinion that sample storage is sufficiently secure.

1.13 Data Verification

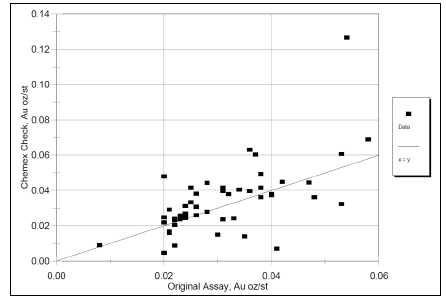

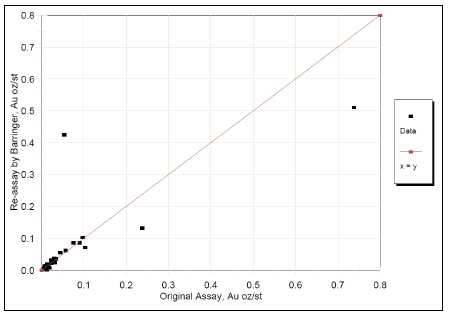

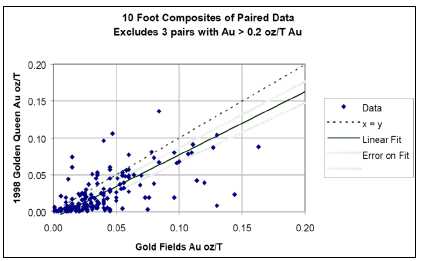

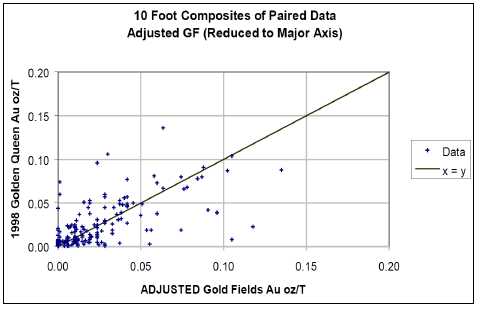

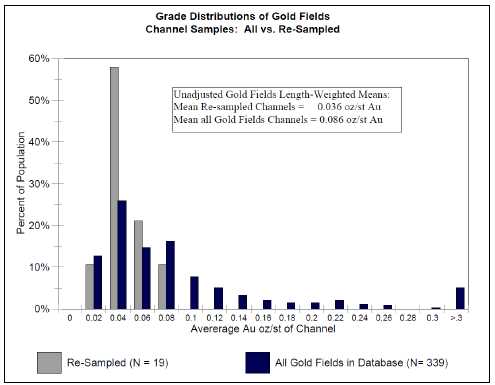

A series of data audits and verification programs have been conducted over the Project’s history,in support of mining studies and technical reports. Checks were performed in 1998 by Mine Reserve Associates, in 2000 by MRDI, and in 2006 by Steffen, Robertson & Kirsten (U.S.), Inc. (SRK).

Database audit of the 2011 drilling showed 0% error in assay records and a 0.4% error rate in lithology and oxidation codes. AMEC typically uses a criterion of less than 1.0% errors to determine whether or not a database is acceptably error-free.

AMEC is of the opinion that the database is sufficiently error free and acceptable for Mineral Resources and Mineral Reserve estimation.

1.14 Process Development

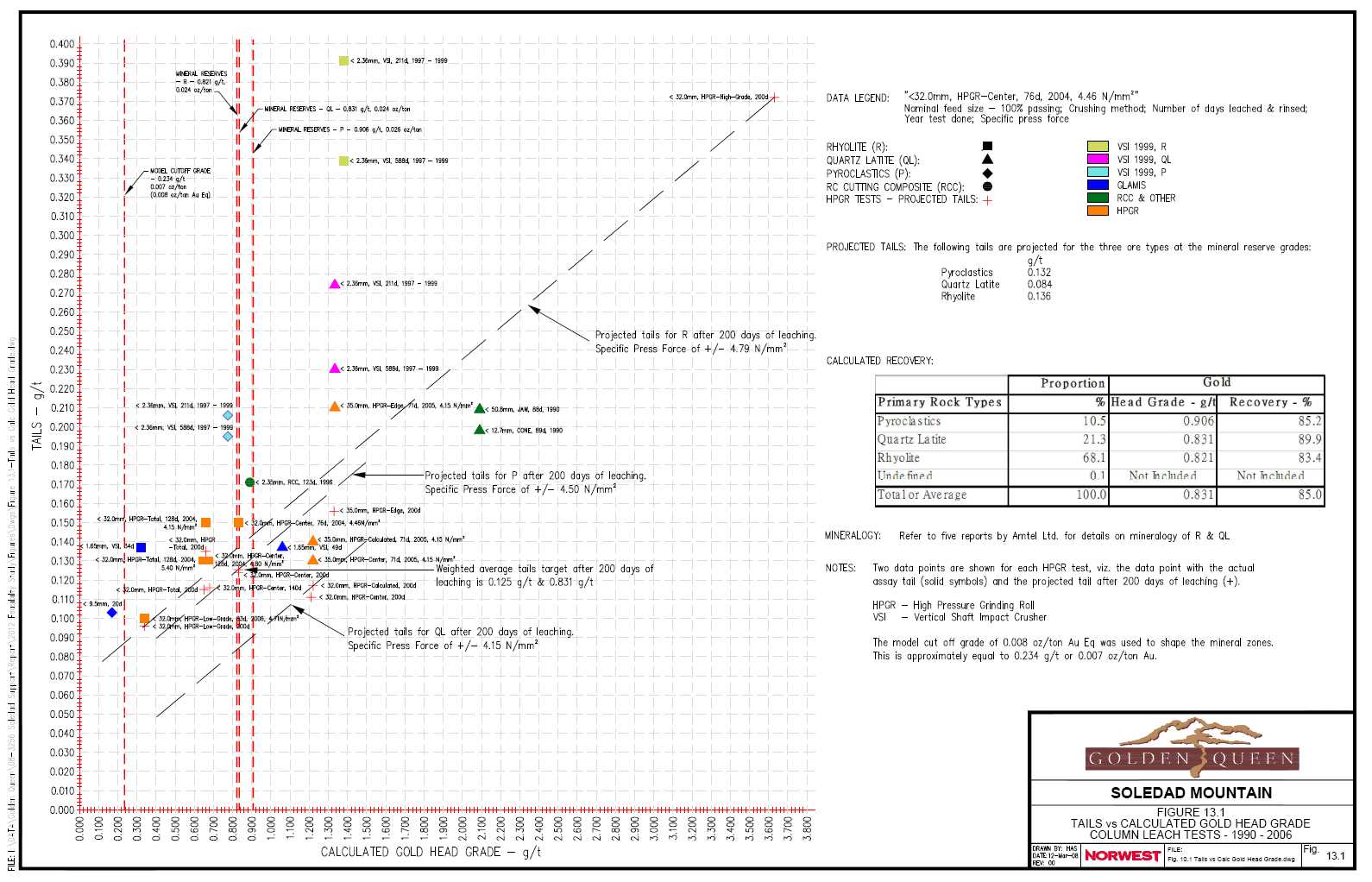

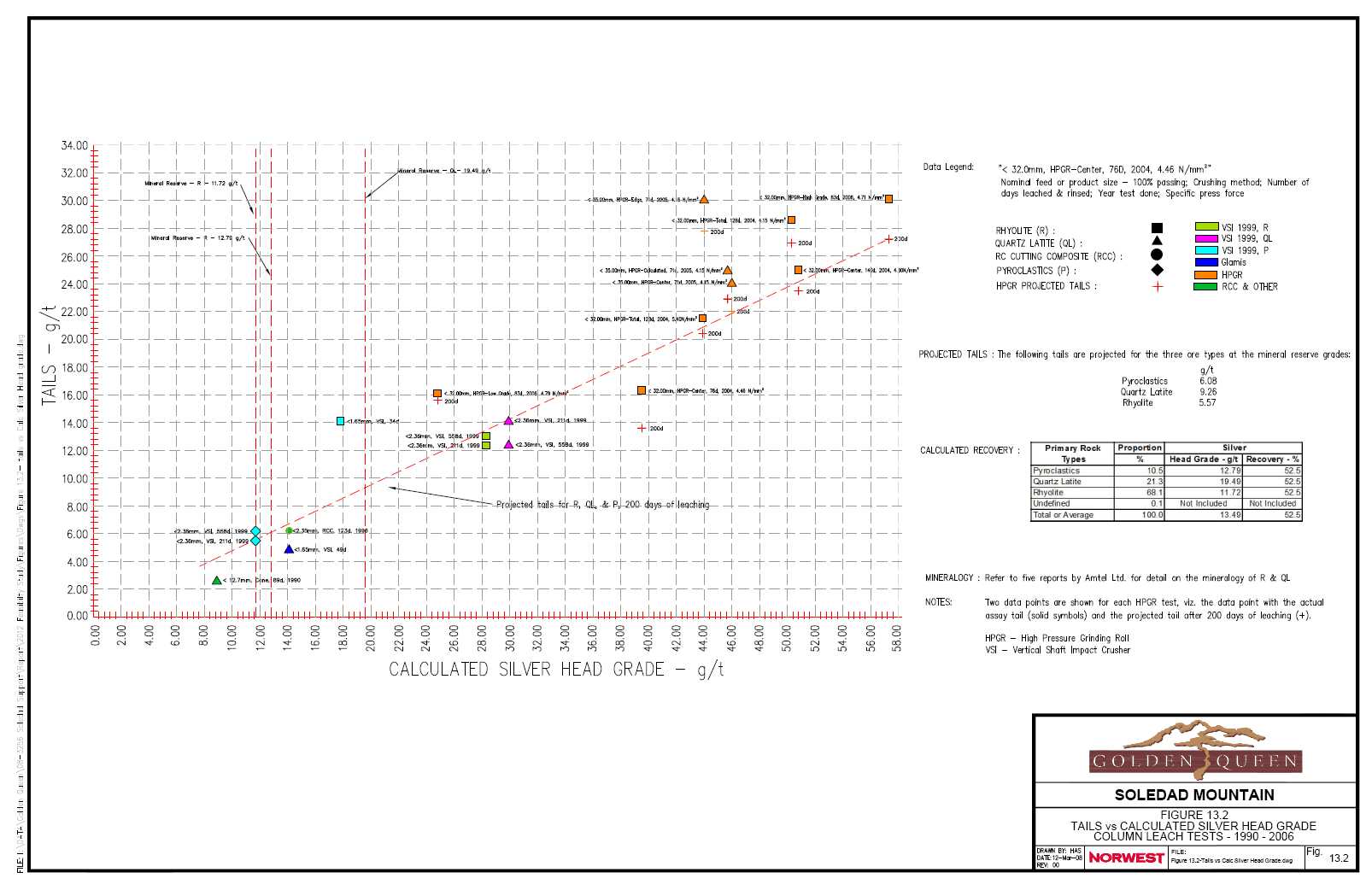

Process development and the extensive metallurgical test work done between 1998 and 2007 are described in Section 13.

The primary ore types that will be mined are rhyolite porphyry and flow-banded rhyolite, pyroclastics and quartz latite porphyry representing approximately 70%, 10% and 20% of the ore tonnage respectively. Minor quantities of siliceous vein material (0.1%) will also be mined.

Extensive test work and process development work done on the Project ore types from 1988 to 2007 show that these ores are readily amenable to heap leaching provided the material is crushed to relatively small sizes. The test work for a total of 45 column leach tests is well documented and the test results have been used in a number of feasibility studies. Parameters such as agglomerate strength, percolation rate, cyanide consumption and cement and/or lime required for pH control were also determined in numerous tests.

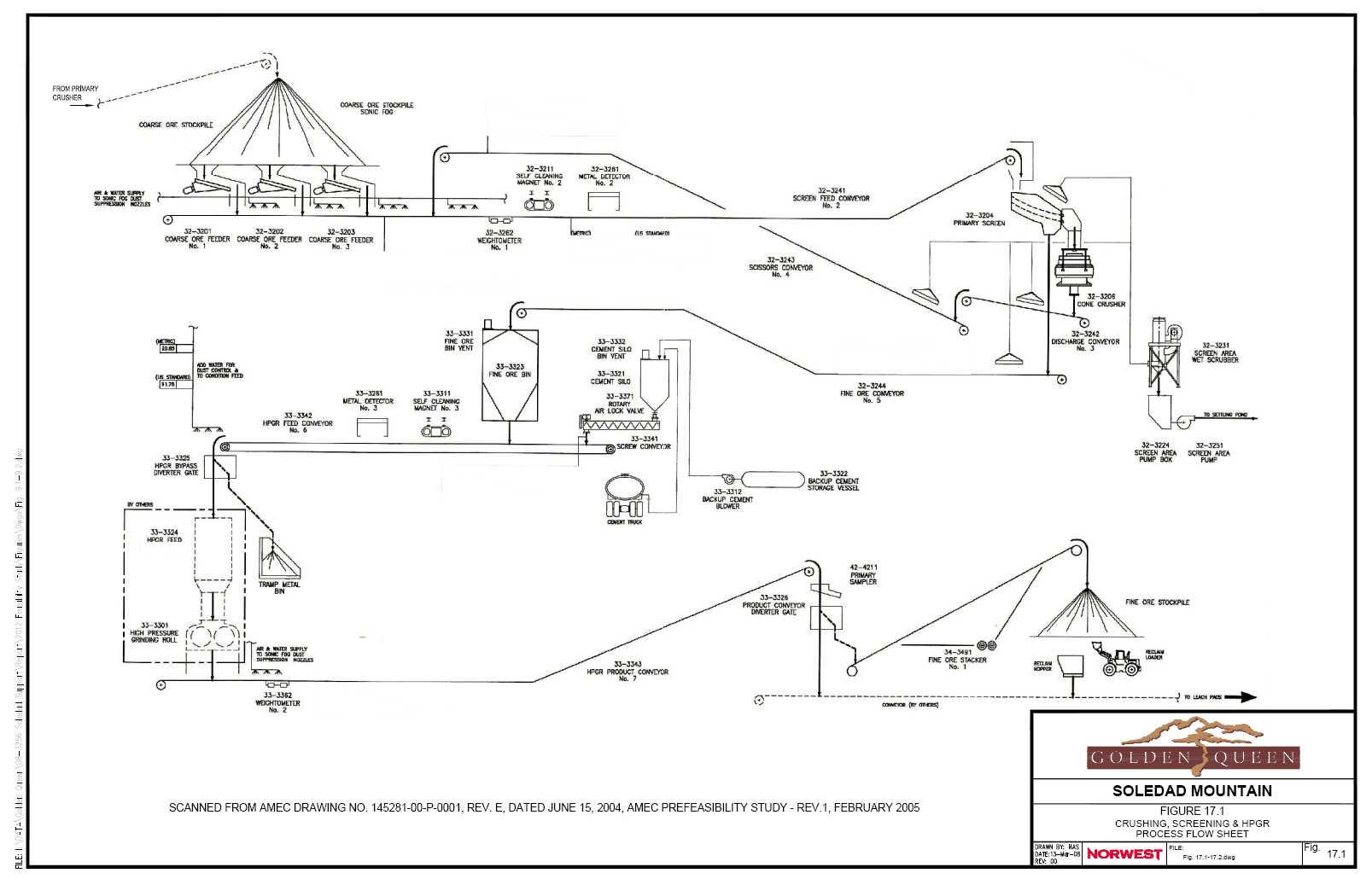

A series of tests using a high-pressure grinding roll (HPGR) and bottle roll and column leach tests was performed between 2003 and 2007 to confirm the flow sheet and to provide design criteria for the design of the crushing-screening plant.

| October 2012 | 1-7 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

The test work shows that the HPGR will have distinct advantages over conventional crushing and screening in preparing particles for heap leaching in this particular application.

Tests completed in 2006 were performed on a low-grade and a high-grade rhyolite sample to test the range of grades that is expected in the commercial operation. The test on rhyolite with a lower head grade in the 0.3 g/t (0.009 oz/ton) range is especially important to give an indication of the tail grade and thus the recovery that should be used when doing cut-off grade analyses. No new column leach tests have been done on pyroclastic ore since the 1997-1999 tests.

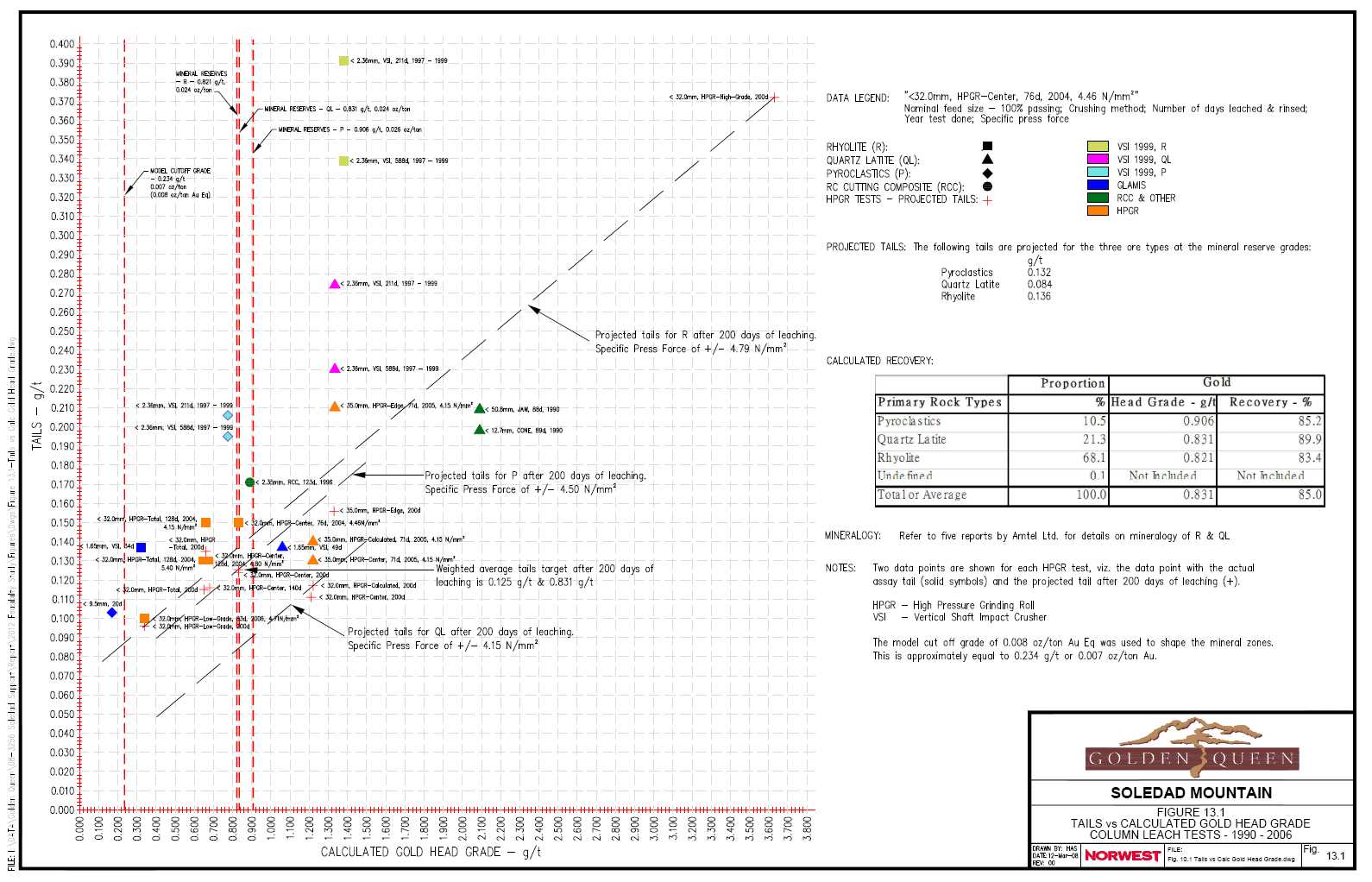

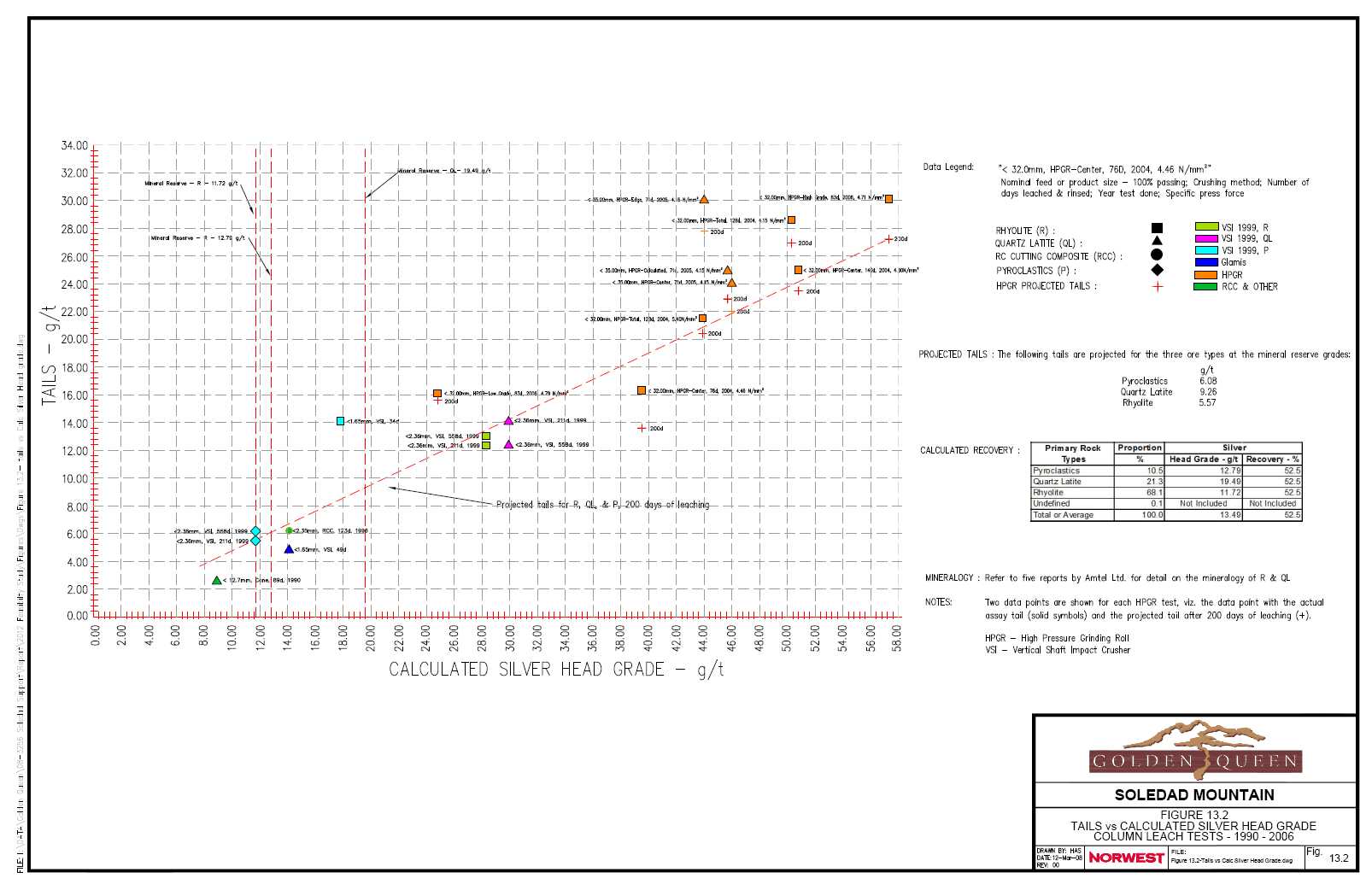

Recoveries for gold and silver are based upon tails obtained in HPGR-based column leach tests. The recovery analysis for gold and the recovery analysis for silver are described in detail in subsection 13.5 and sub-section 13.6 respectively. The projected recoveries based upon the tails analysis are shown below.

Recoveries for Gold & Silver

| | | Gold | Silver |

| | Proportion | Head Grade | Recovery | Head Grade | Recovery |

| Primary Rock Types | % | g/t | % | g/t | % |

| Pyroclastics | 10.5 | 0.906 | 85.2 | 12.79 | 52.5 |

| Quartz Latite | 21.3 | 0.831 | 89.9 | 19.49 | 52.5 |

| Rhyolite | 68.1 | 0.821 | 83.4 | 11.72 | 52.5 |

| Undefined | 0.1 | 0.870 | Not included | 15.75 | Not Included |

| Total & Average | 100.00 | 0.831 | 85.0 | 13.49 | 52.5 |

An extensive characterization program using bottle roll tests on reverse circulation drill cuttings was completed by an independent consulting engineer in 1995. The deposit was divided into six areas, four rock types and three vertical zones for this program and 46 standard bottle roll tests were performed. An analysis of the results showed that there was no discernible difference in metallurgical response for a particular rock type from area to area and from strata to strata.

The final product that will be produced in the refinery on site is a dorè. There is no indication of deleterious elements in the dorè. Allowance has been made for 1.5% of minor metals in the dorè.

1.15 Mineral Resources

The updated mineral resources study to determine mineral resources was supervised by Mark Hertel, Principal Geologist, with AMEC.

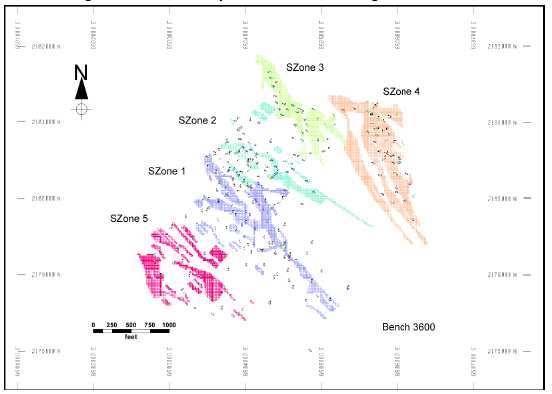

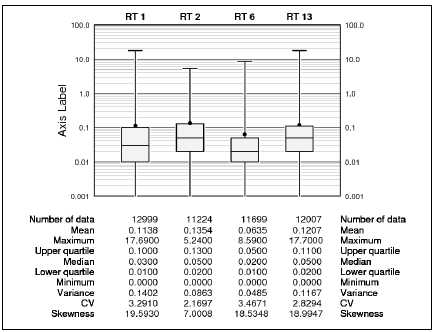

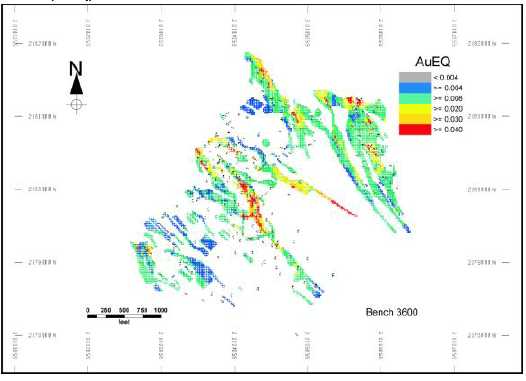

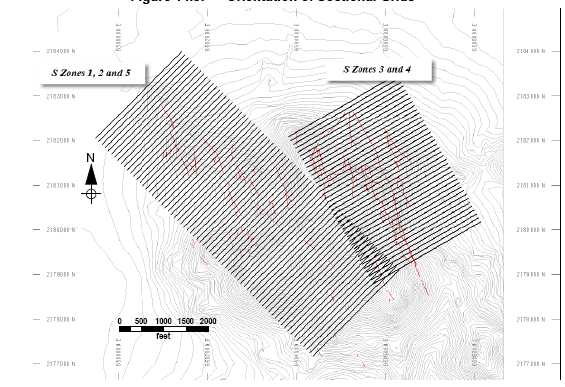

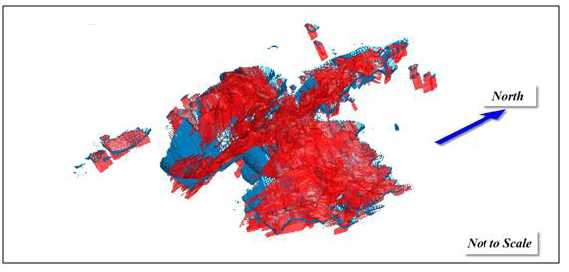

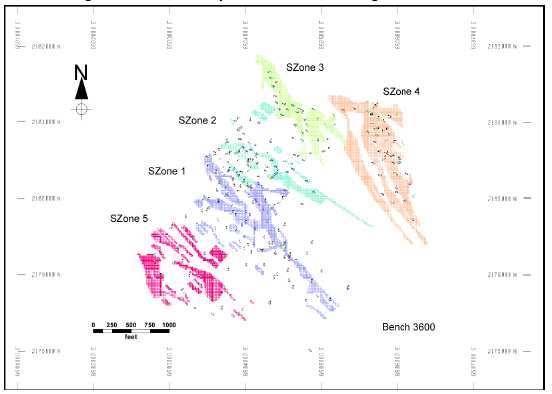

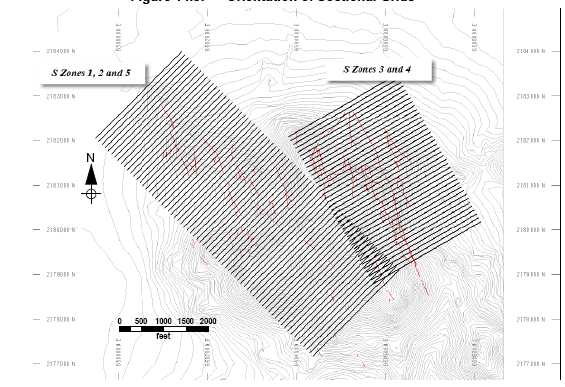

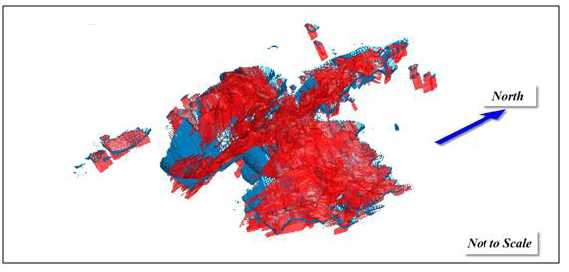

Geologic and grade shell polygons were created in cross-sections and level plans and used to create three-dimensional solids. The block model was assigned two mineralized domains, four rock type domains and five structural domains.

| October 2012 | 1-8 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Three tonnage factors were assigned based on rock type: 13.76 cubic yard/ton for pyroclastics, 13.86 cubic yard/ton for quartz latite, and 13.94 cubic yard/ton for rhyolite.

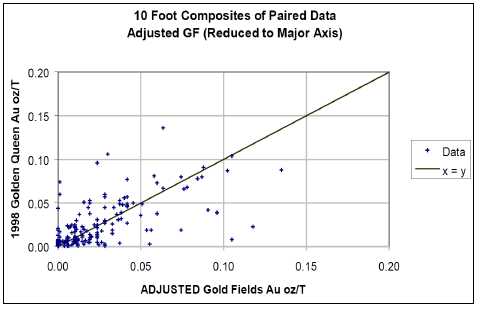

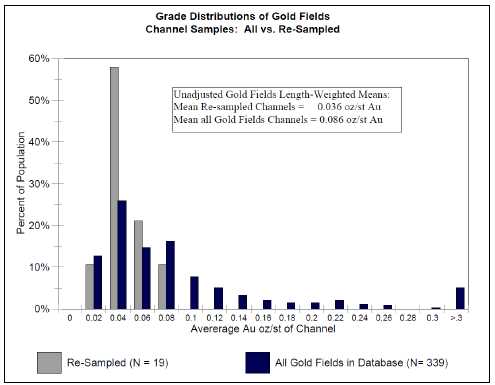

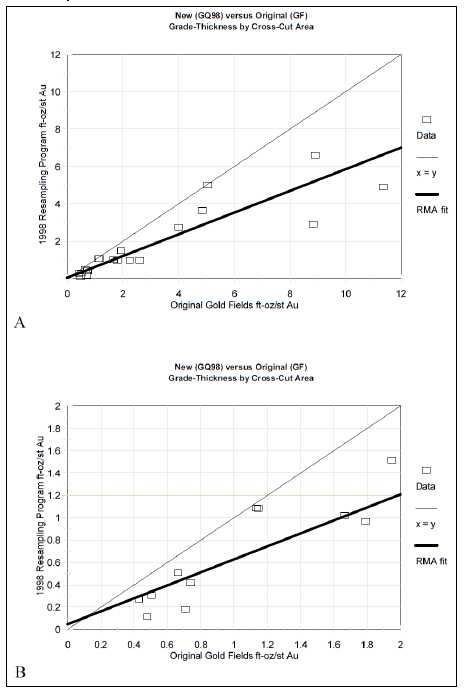

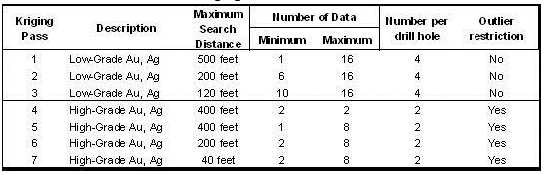

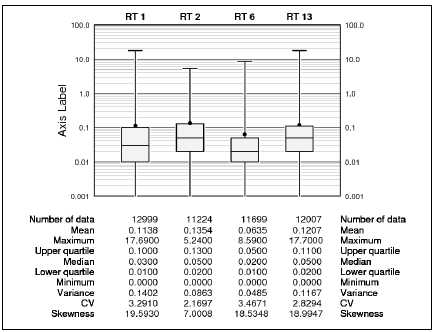

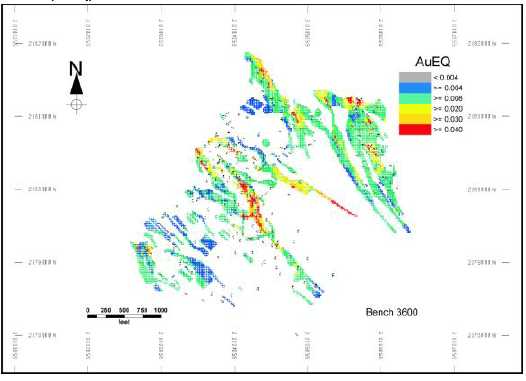

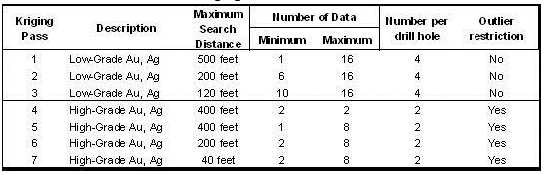

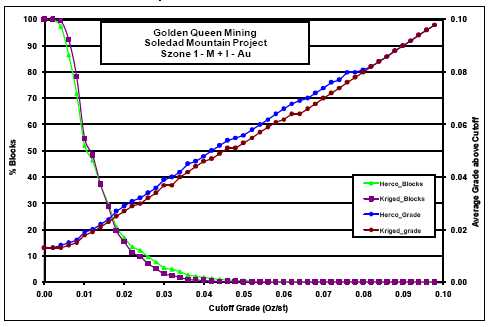

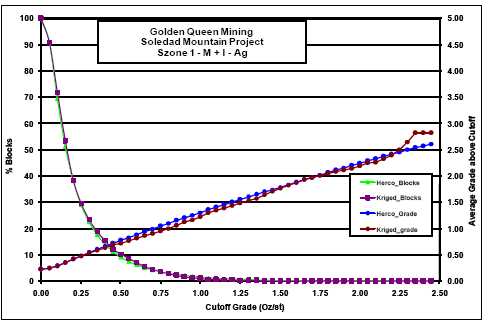

Composites were created on 10 ft. intervals along the drill hole trace. A minimum of two composites were required to develop a low-grade grade shell polygon. The low-grade mineralization was based on a gold equivalent grade of >0.003 oz/ton. The high-grade grade shell only required a single ten foot composite >=0.100 oz/ton Au for modeling. The influence of high-grade gold and silver composites on grade estimation was confined by high-grade shells and range-restricted by the use of outlier restrictions. Ordinary Kriging was used to estimate gold and silver except for one structural zone which used Inverse distance.

Interpolation of grade into the blocks was conducted on three passes based upon increasing search distances out to 500 ft. Gold and silver grades were estimated separately by structural domains within low-grade mineralized solids and within high-grade mineralized solids. High-grade composites were identified as >=0.100 oz/ton gold.

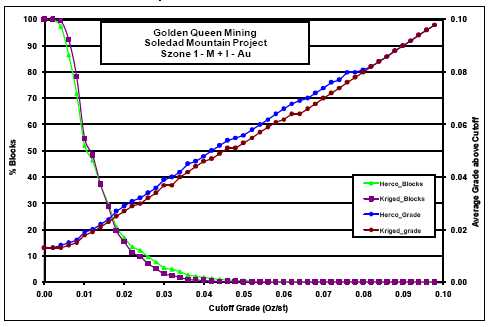

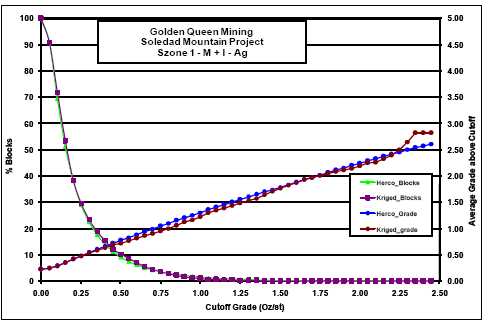

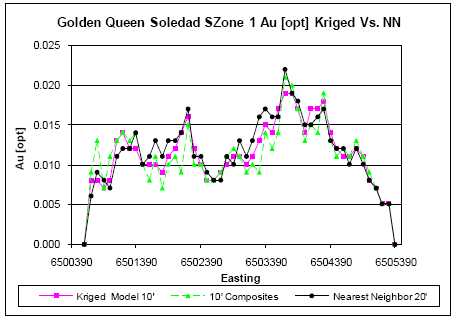

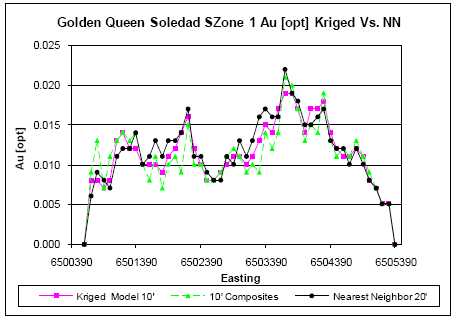

Gold and silver block model grades were validated visually against drill holes and composites in section and plan. A nearest-neighbour block was based on 20 foot down the hole composite. Grade profile plots were created on the 20 ft. x 20 ft. x 20 ft. Measured and Indicated resource block and no estimation biases were noted.

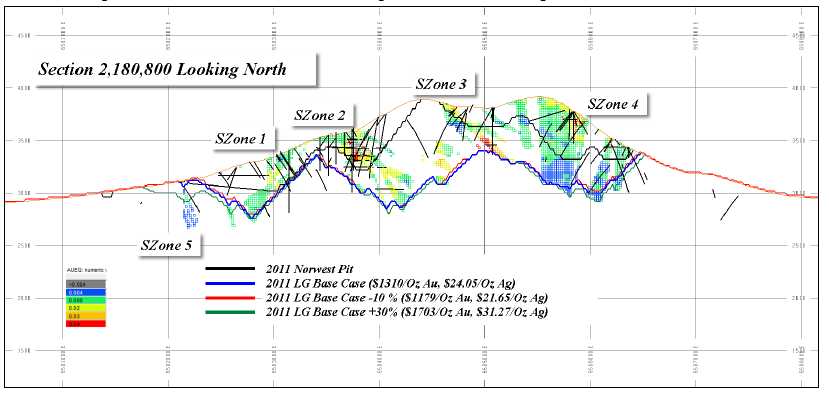

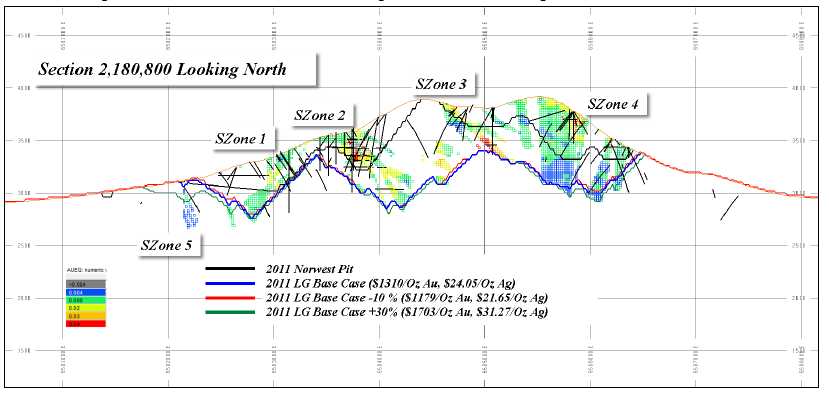

AMEC constrained the Mineral Resources within a economic pit based on a mining costs cost of $1.25/ton, a processing cost including G&A of $4.98/ton processed, pit wall slope angles of 55o, and gold recoveries ranging from 83.4 to 89.9% and silver recoveries of 53.5% . Gold price was set at $1,310/oz Au and silver price was set at $24.05/oz Ag.

Factors which may affect the conceptual pit shells used to constrain the mineral resources, and therefore the Mineral Resources include changes to the following assumptions and parameters:

| | • | Commodity price assumptions |

| | | |

| | • | Mining and processing cost assumptions |

| | | |

| | • | Metallurgical recovery assumptions |

| | | |

| | • | Pit slope angles used for the mine design |

| | | |

| | • | Assignment of SG values |

1.16 Mineral Resources Statement

The QP for the Mineral Resources is Mark Hertel, Principal Geologist, R.M. SME Registered Member, and an employee of AMEC. Mineral Resources are reported in Table 1.1 with gold and silver prices of $1,310/oz and $24.05/oz respectively, have an effective date of February 29, 2012, and are inclusive of Mineral Reserves. Mineral Resources take into account geologic, mining, processing and economic constraints, and have been confined within appropriate Lerchs-Grossman pit shells, and therefore are classified in accordance with the 2010 CIM Definition Standards for Mineral Resources and Mineral Reserves.

| October 2012 | 1-9 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Table 1.1 Mineral Resources

Effective Date February 29, 2012, Mark Hertel, SME Registered Member

| | | | In-situ Grade | Contained Metal |

| | | | Gold | Silver | Gold | Silver |

| Classification | tonnes | ton | g/t | oz/ton | g/t | oz/ton | oz | oz |

| Measured | 26,727,000 | 29,400,000 | 0.850 | 0.025 | 13.29 | 0.39 | 729,000 | 11,403,000 |

| Indicated | 118,090,000 | 129,900,000 | 0.442 | 0.013 | 8.53 | 0.25 | 1,675,000 | 32,301,000 |

| Total & Average | 144,817,000 | 159,300,000 | 0.517 | 0.015 | 9.42 | 0.27 | 2,404,000 | 43,704,000 |

| Inferred | 14,545,000 | 16,000,000 | 0.362 | 0.011 | 7.89 | 0.23 | 169,000 | 3,681,000 |

Notes to Accompany Soledad Mountain Mineral Resources Table:

| 1. | Mineral Resources are inclusive of Mineral Reserves. |

| | |

| 2. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| | |

| 3. | Mineral Resources are reported at a 0.004 oz/ton (0.137 g/t) AuEq cut-off. |

| | |

| 4. | Mineral Resources are reported as undiluted. |

| | |

| 5. | Mineral Resources are reported within a conceptual pit shell that has been merged with the 2012 Mineral Reserve pit. |

| | |

| 6. | Mineral Resources are reported using a long-term Au price of US$1310/oz, silver price of $24.05/oz, mining and processing costs and variable recoveries that are based on rock type classification. |

| | |

| 7. | Gold equivalent grades were calculated based on the equation: |

| AuEq(oz/ton) = Au(oz/ton) + (Ag(oz/ton) * [(Ag price(US$/oz)/Au price(US$/oz)) * (Ag recovery(%)/Au recovery(%)]) |

| | |

| 8. | Rounding as required by reporting guidelines may result in apparent summation differences between tons, grade and contained metal content. |

| | |

| 9. | Tonnage and grade measurements are in US and metric units. Grades are reported in troy ounces per short tons and in grams per tonne. |

| | |

| 10. | Mineral zones were shaped manually with a cutoff grade of 0.004 oz/ton (0.137 g/t) AuEq. |

1.17 Mineral Reserves

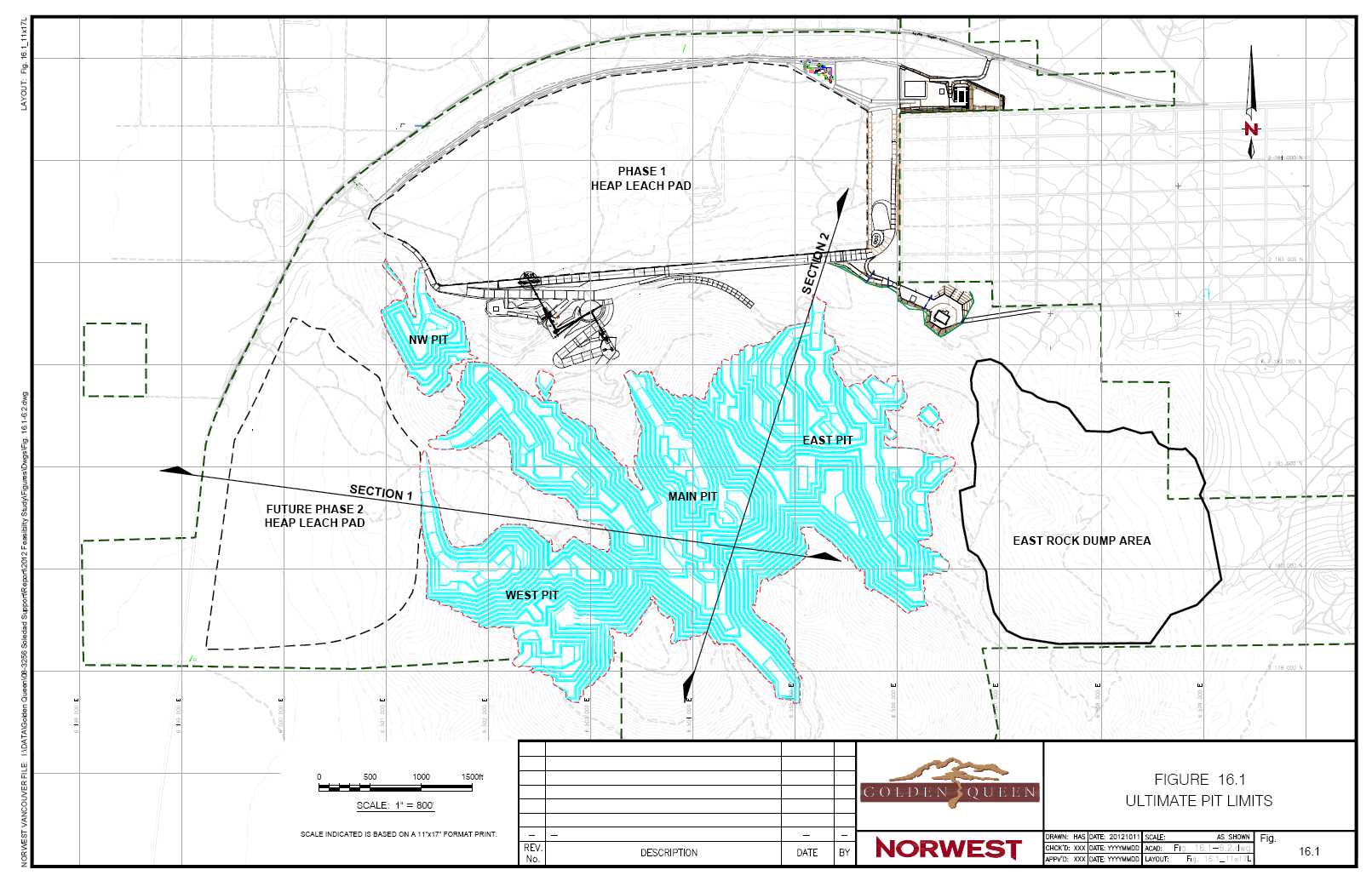

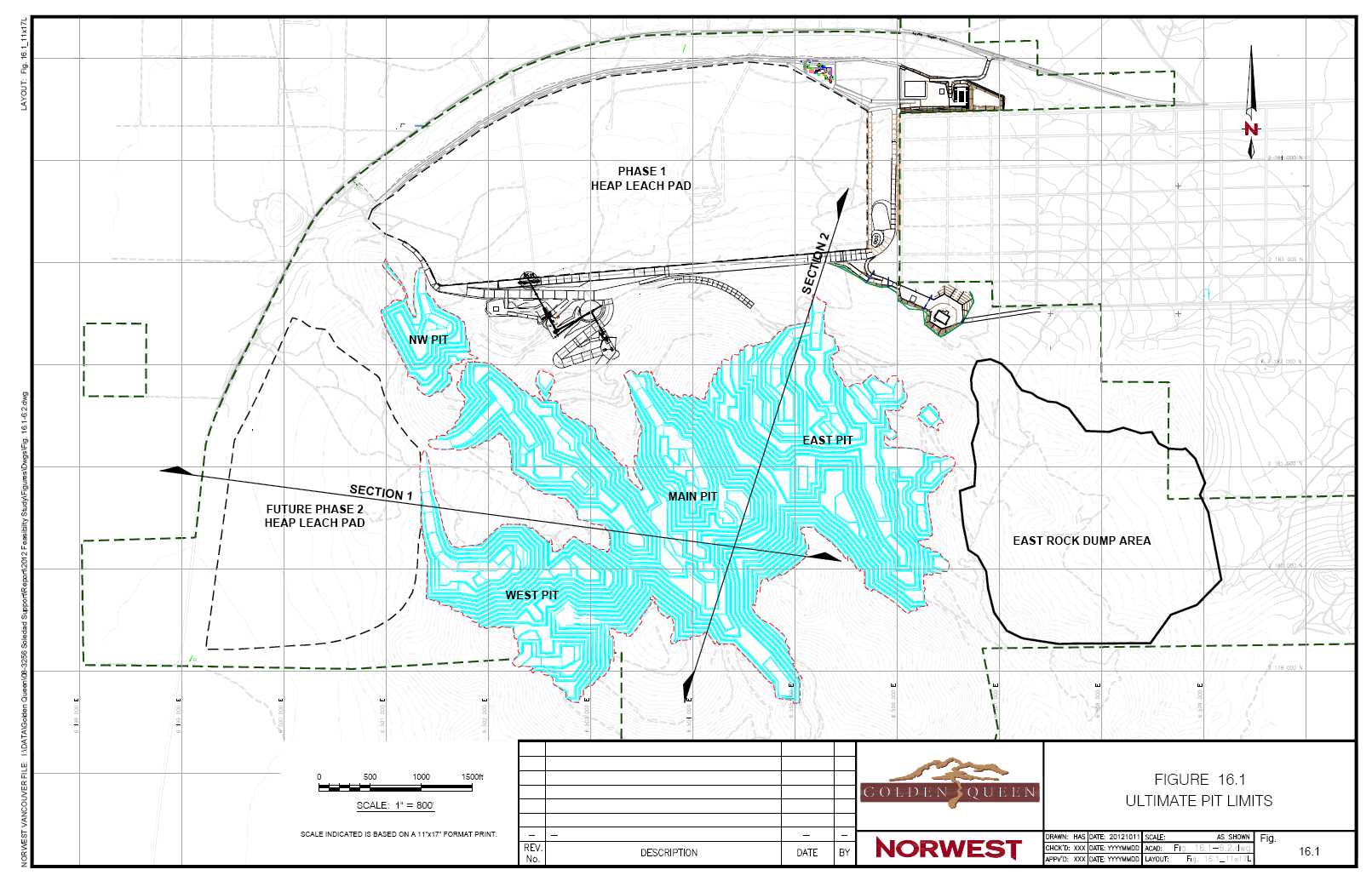

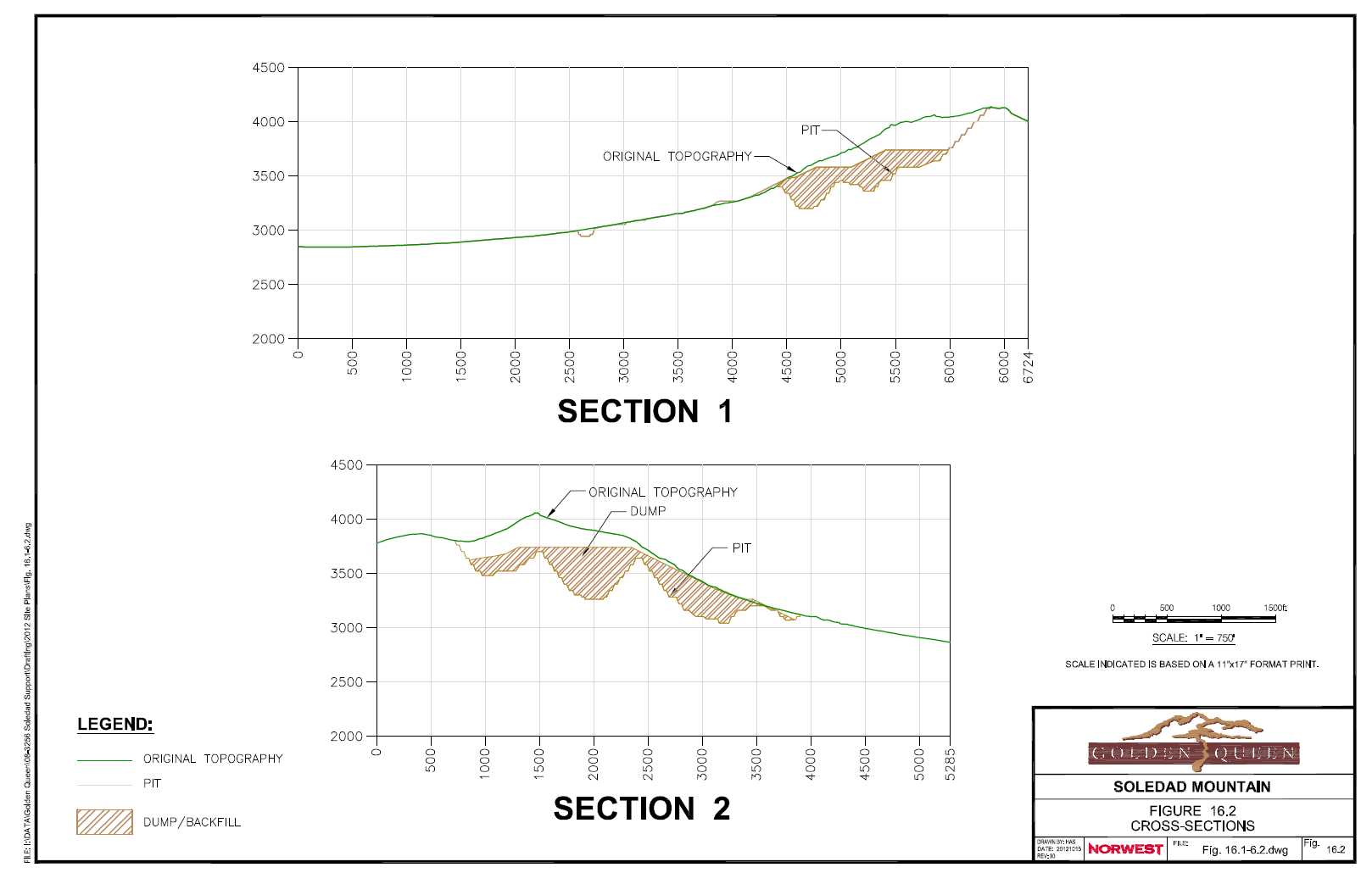

The mine design is described in Section 16.3.

Norwest accepted the geological and block model provided by AMEC and relied upon these in the preparation of the mine plan for the Project. The mine plan was based upon a series of Lerchs Grossman pit optimization studies.

The MineSight 3D (Mintec©) software was used to carry out the detailed mine design.

1.18 Mineral Reserves Statement

The QP for the Mineral Reserves is Sean Ennis, Vice President, Mining, P.Eng. APEGBC Registered Member, and an employee of Norwest. Mineral Reserves are reported in Table 1.2 and have an effective date of August 31, 2012.

| October 2012 | 1-10 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Table 1.2: Mineral Reserves

| | | | In-Situ Grade | Contained Metal |

| | | | Gold | Silver | Gold | Silver |

| Reserve Category | tonnes | tons | g/t | oz/ton | g/t | oz/ton | oz | oz |

| Proven | 18,371,000 | 20,250,000 | 0.910 | 0.027 | 14.49 | 0.423 | 537,700 | 8,558,500 |

| Probable | 42,237,000 | 46,558,000 | 0.529 | 0.015 | 10.58 | 0.309 | 717,900 | 14,372,500 |

| Total & Average | 60,608,000 | 66,808,000 | 0.644 | 0.019 | 11.77 | 0.343 | 1,255,600 | 22,931,000 |

Note: Gold equivalent cut-off grade= 0.240g/t or 0.007 oz/ton was used.

1.19 Open Pit Operation

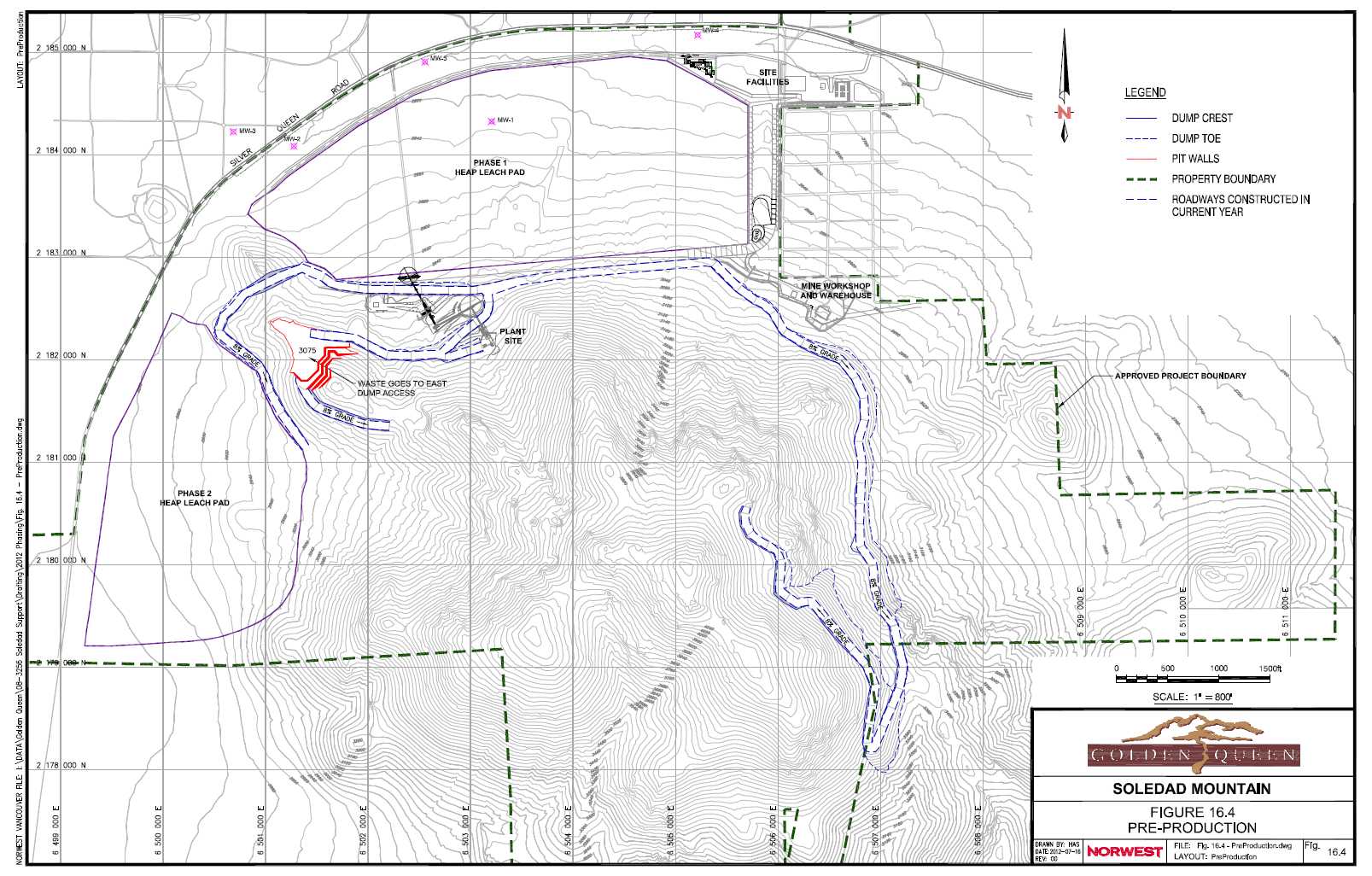

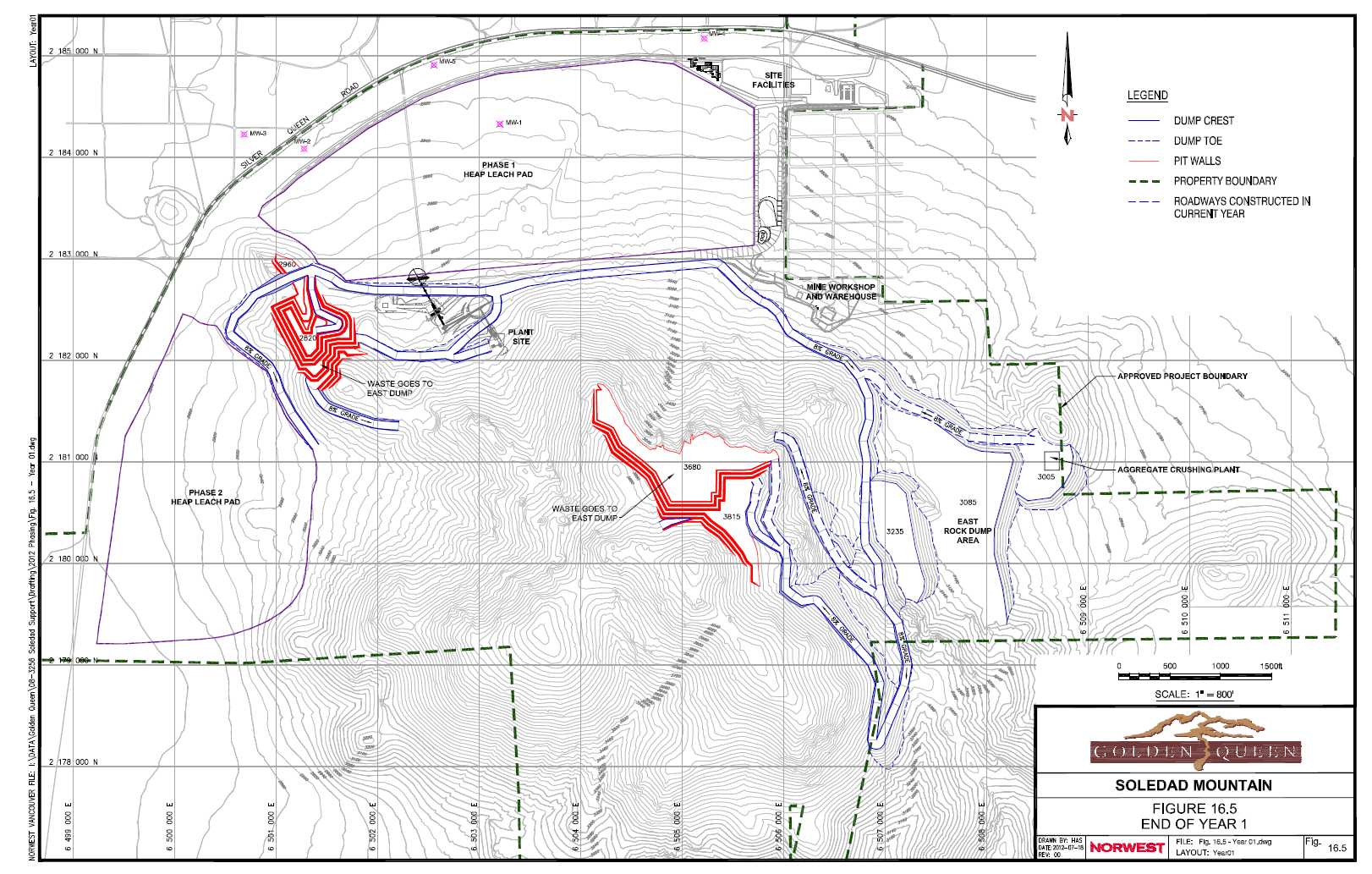

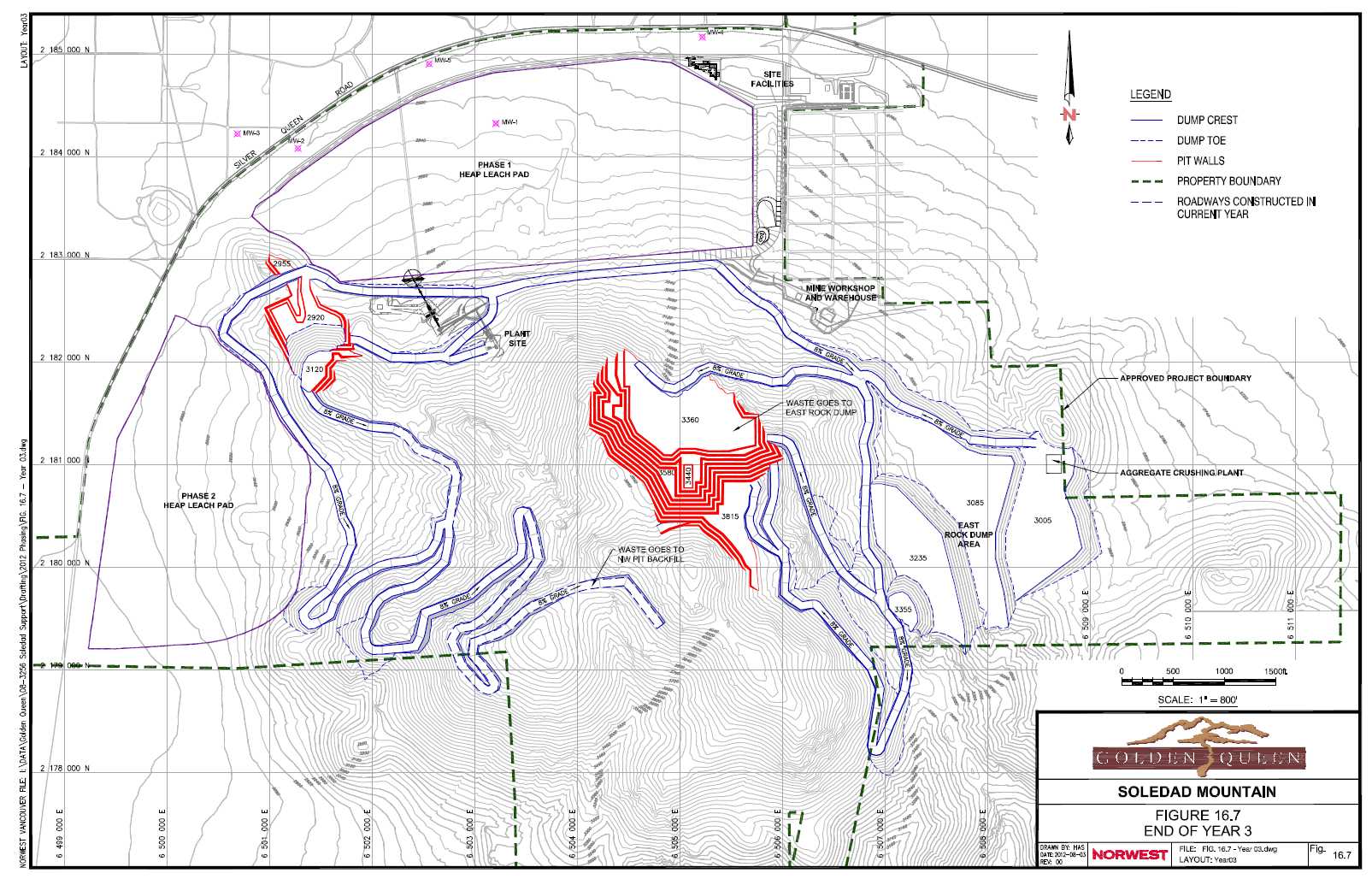

The open pit operation is described in Section 16.

The operation will be an open pit operation. Wheel loaders and haul trucks with a capacity of 90 tonnes (100 ton) will be used as the primary mining equipment. Smaller equipment will be used for pioneering access roads, mining narrower benches, and final ore extraction at the bottom of the various mining phases. Support equipment such as a grader, a water truck and tracked dozers and a wheel dozer will be used for road and bench maintenance, dust control and work in the waste rock disposal areas.

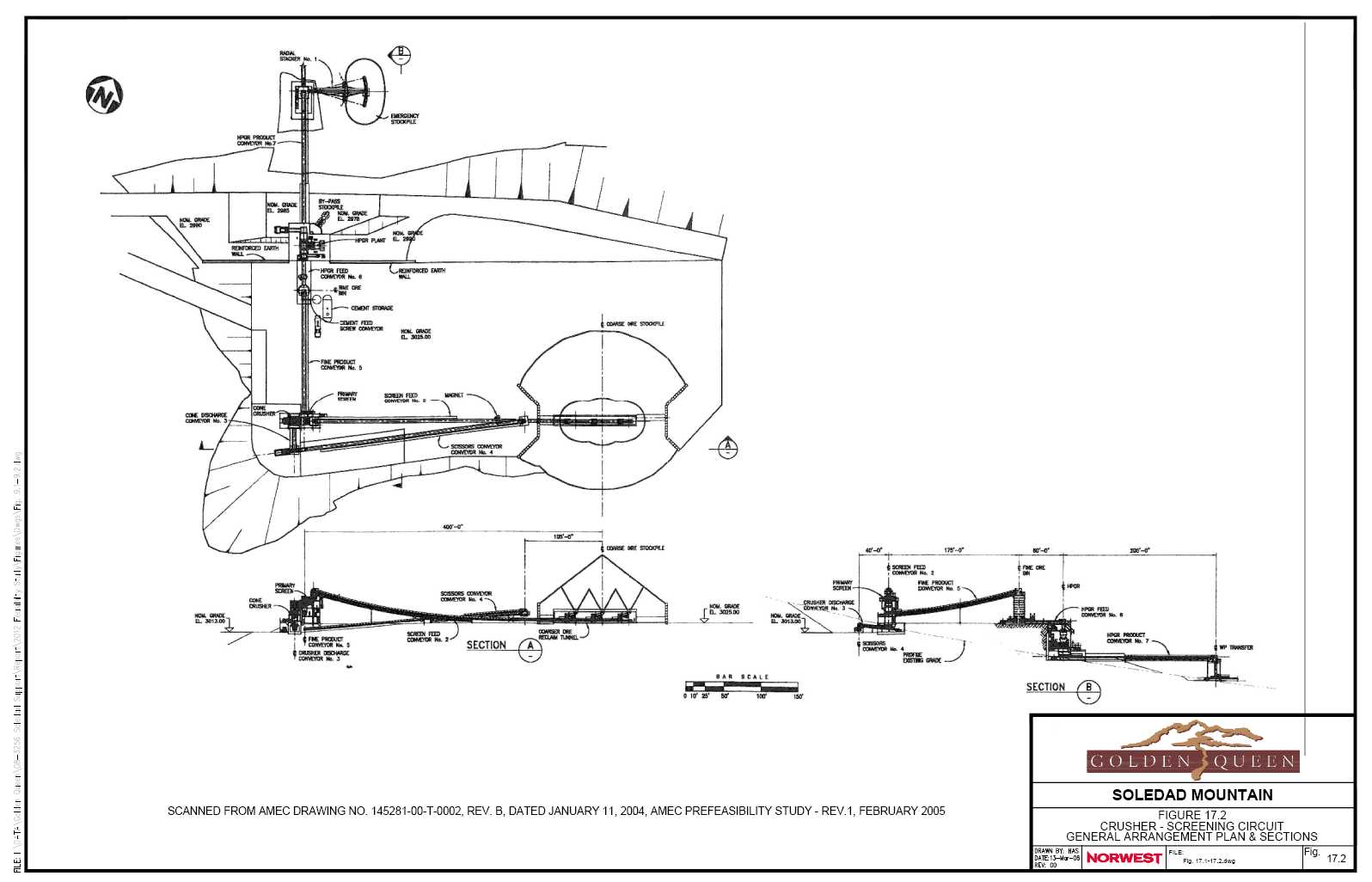

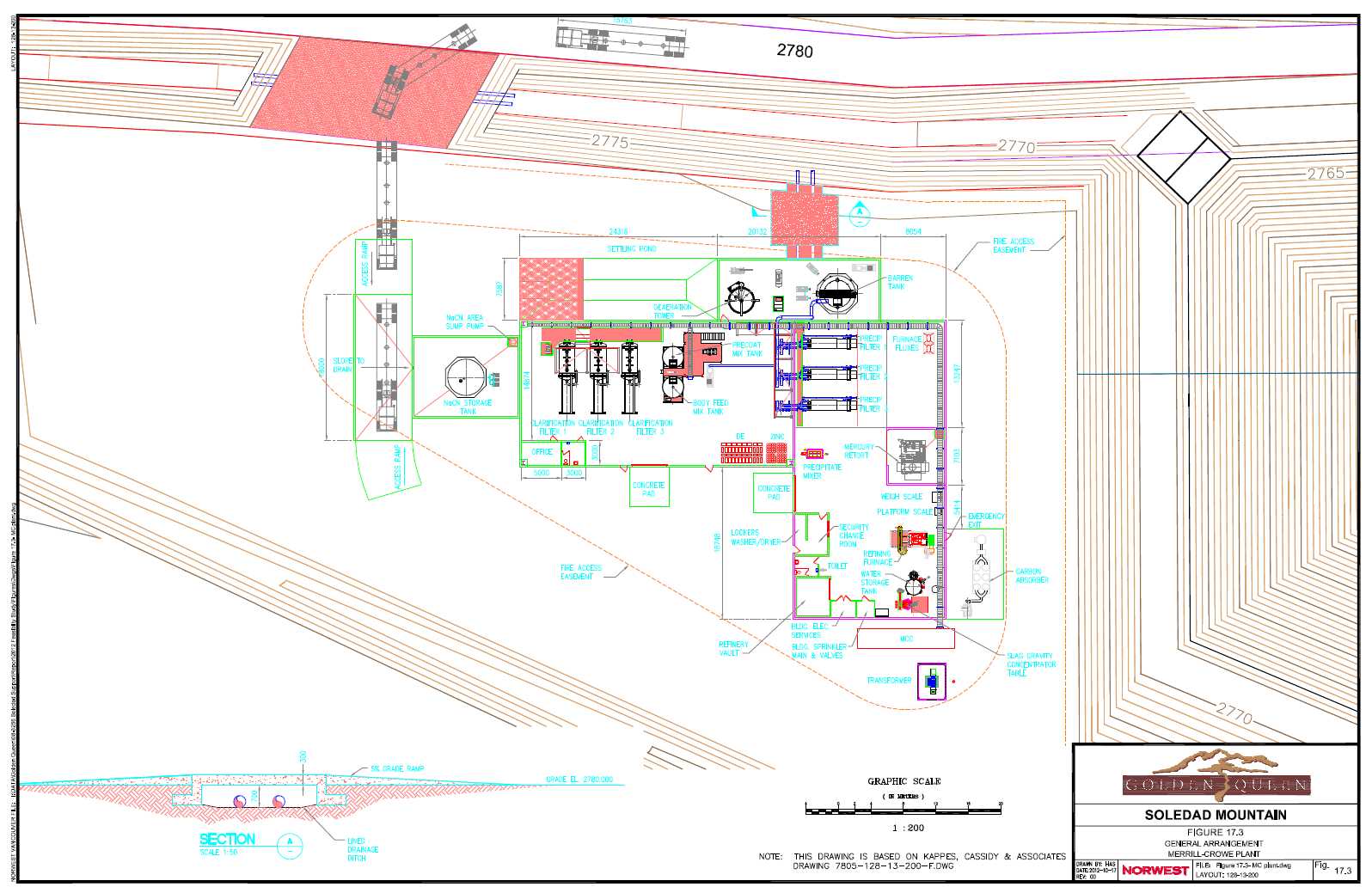

1.20 Production of Gold and Silver

The operation has been designed to mine approximately 5.1 million tons (4.6 Mtonnes) of ore and the associated waste rock per year. Ore will be fed to a crushing-screening plant. The crushing-screening plant includes a primary and secondary cone crusher, primary screen, a high-pressure grinding roll (HPGR) as the key comminution device and the required ore chutes and conveyors. Crushed and agglomerated ore will be stacked on two heap leach pads. A dilute sodium cyanide solution will be used to leach gold and silver from the ore. Leach solutions will flow to the toe of the heap and from there to a pump box. The Merrill-Crowe process will be used to precipitate gold and silver from the pregnant solution. The precipitate will be further processed in a refinery on site to produce a dorè.

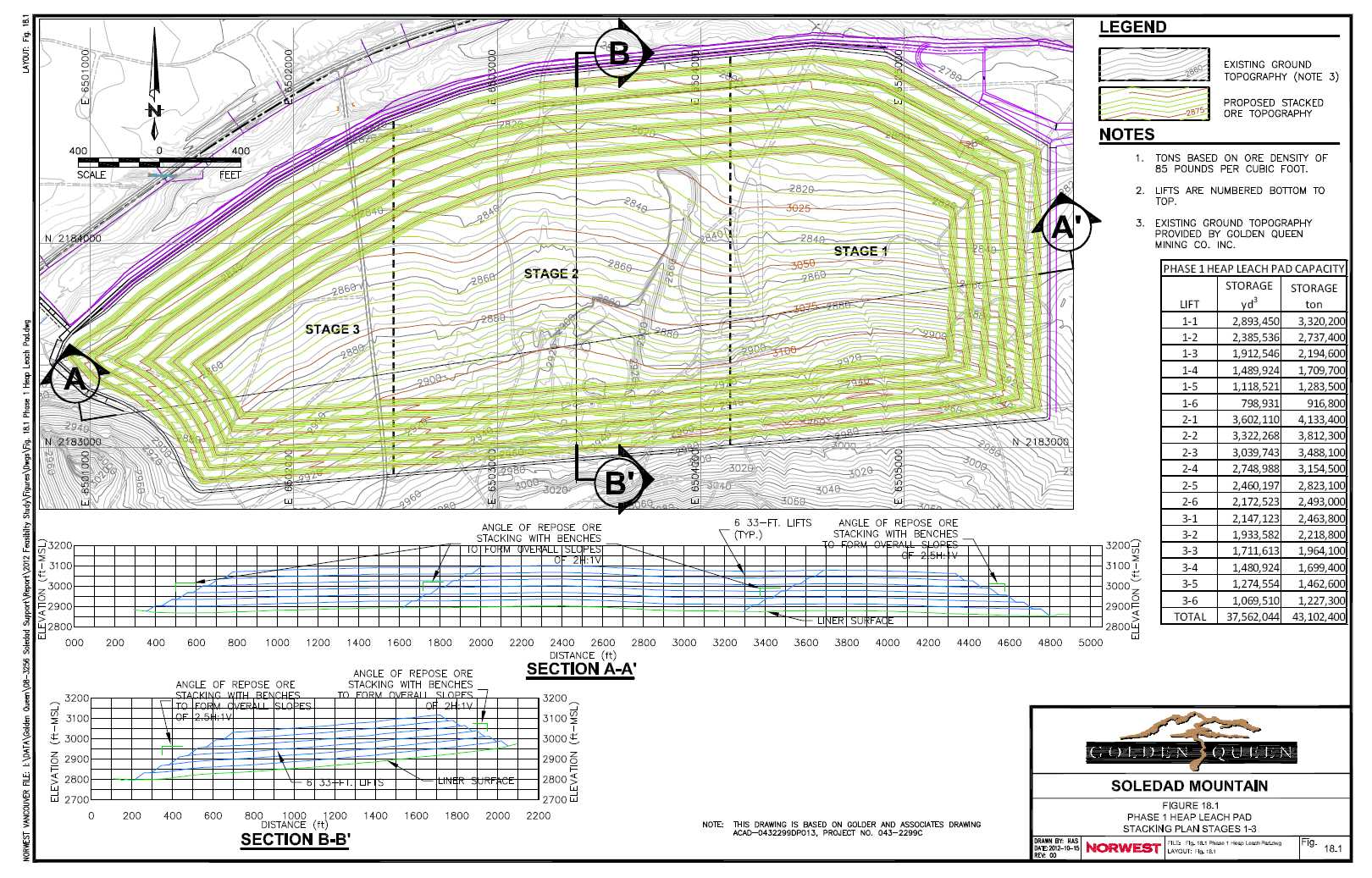

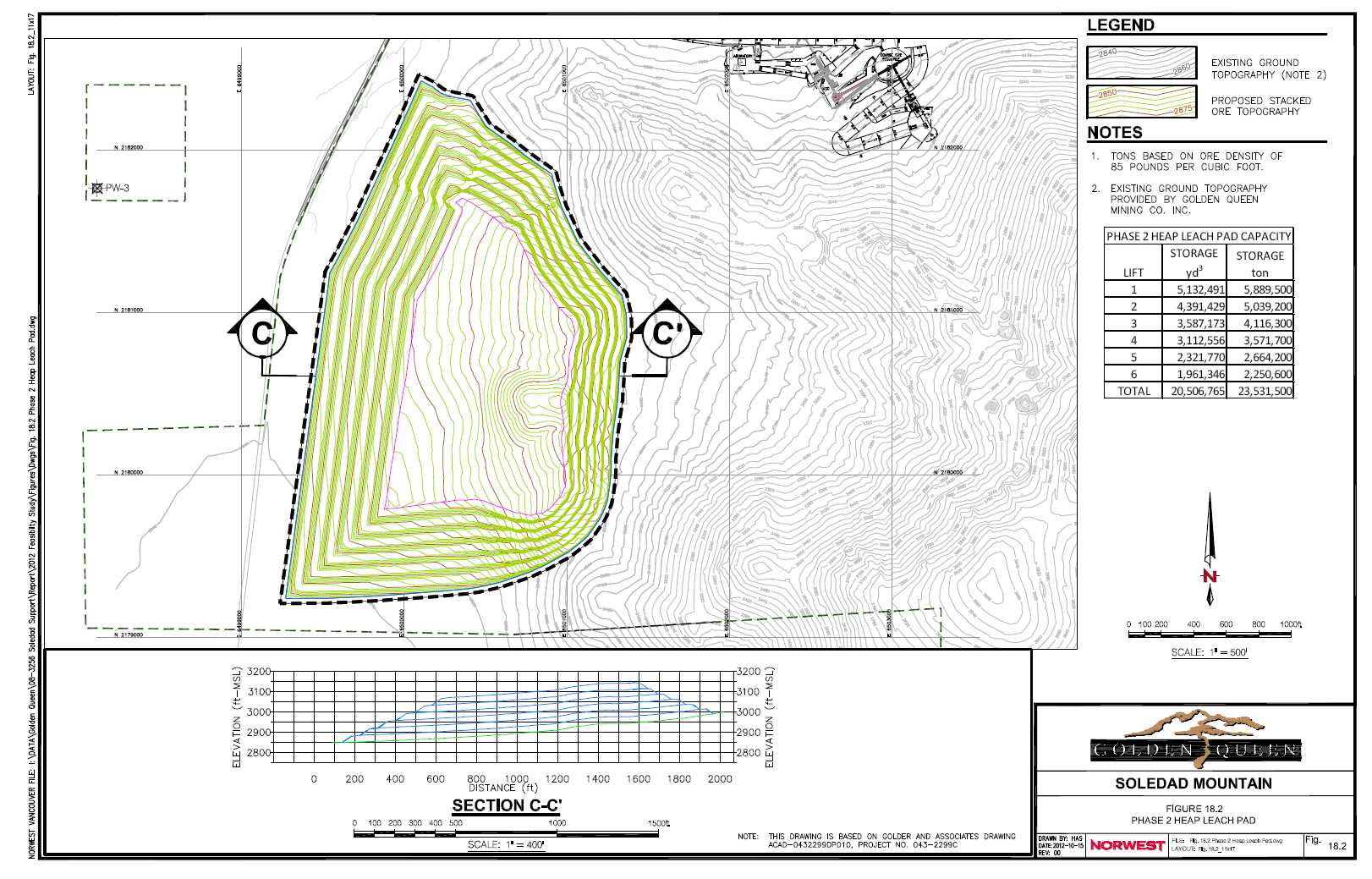

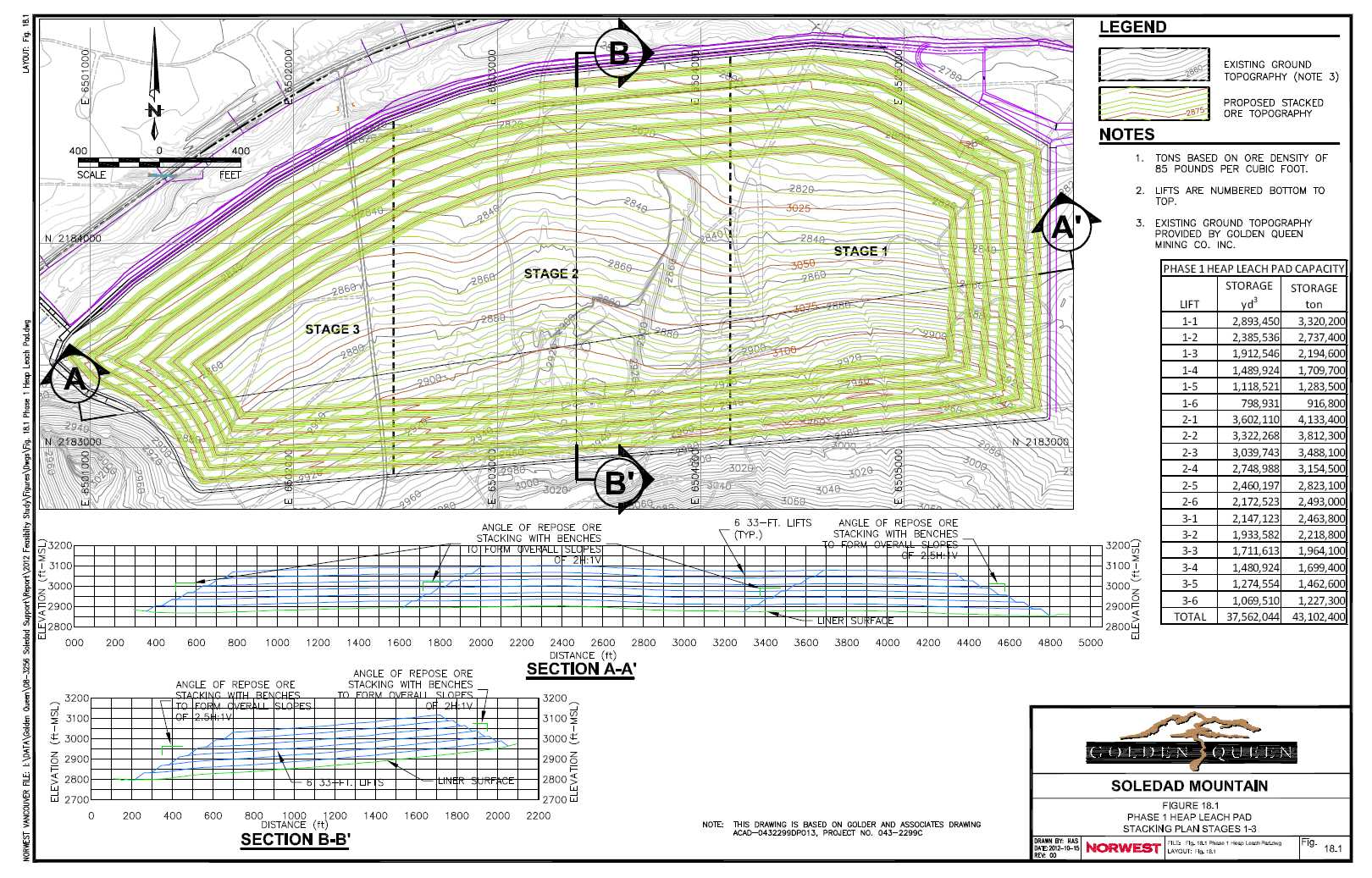

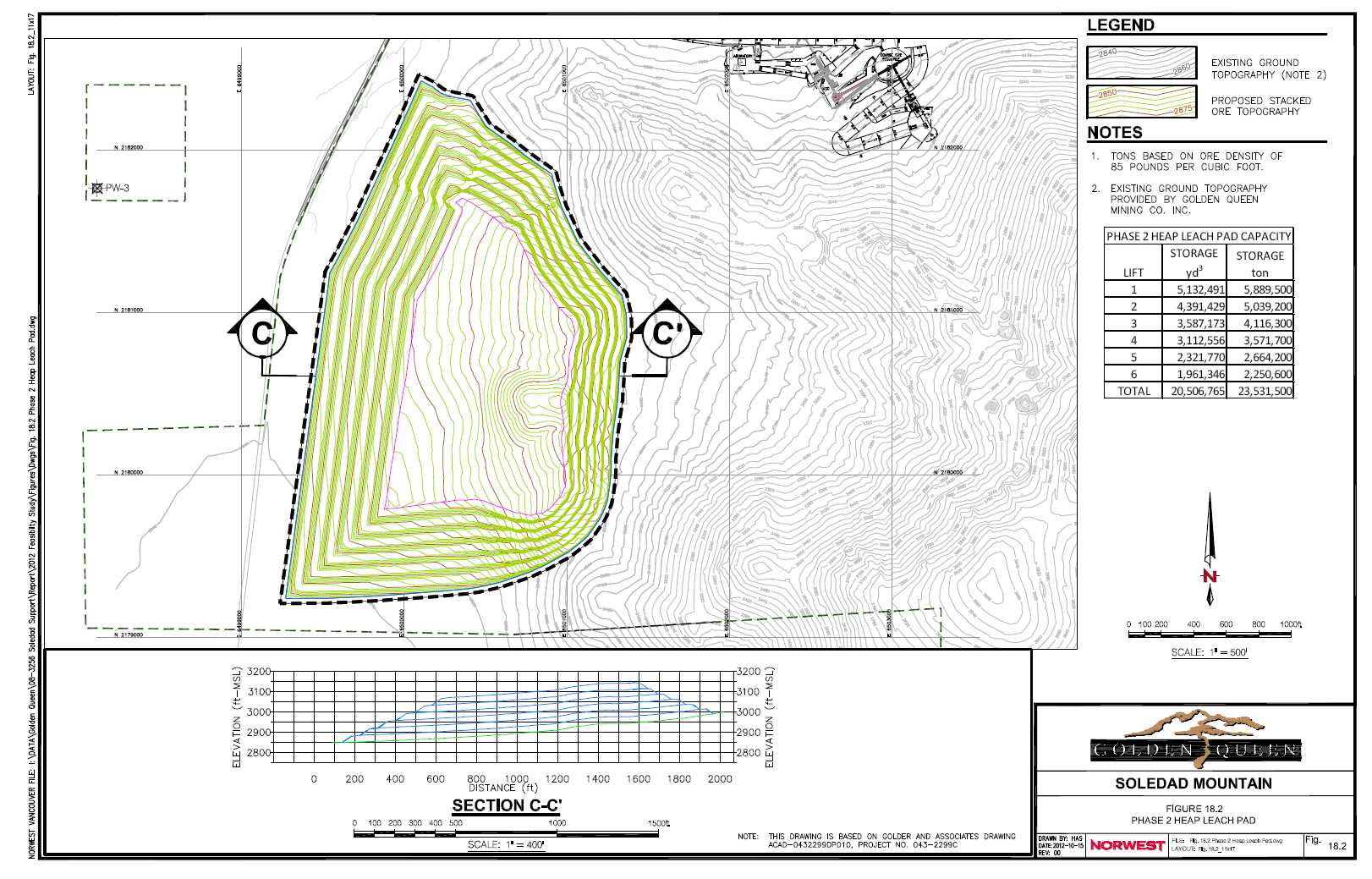

The design, construction and operation of the heap leach facilities are described in Section 18.

1.21 Local Resources and Infrastructure

Services such as a hospital, ambulance, fire-protection, garbage and hazardous waste disposal, schools, motels and housing, shopping, airport and recreation are available in Mojave and its surroundings. Telephone and internet service are available on site. Mojave is a railroad hub for the Burlington Northern/Santa Fe and Union Pacific/Southern Pacific railroad lines.

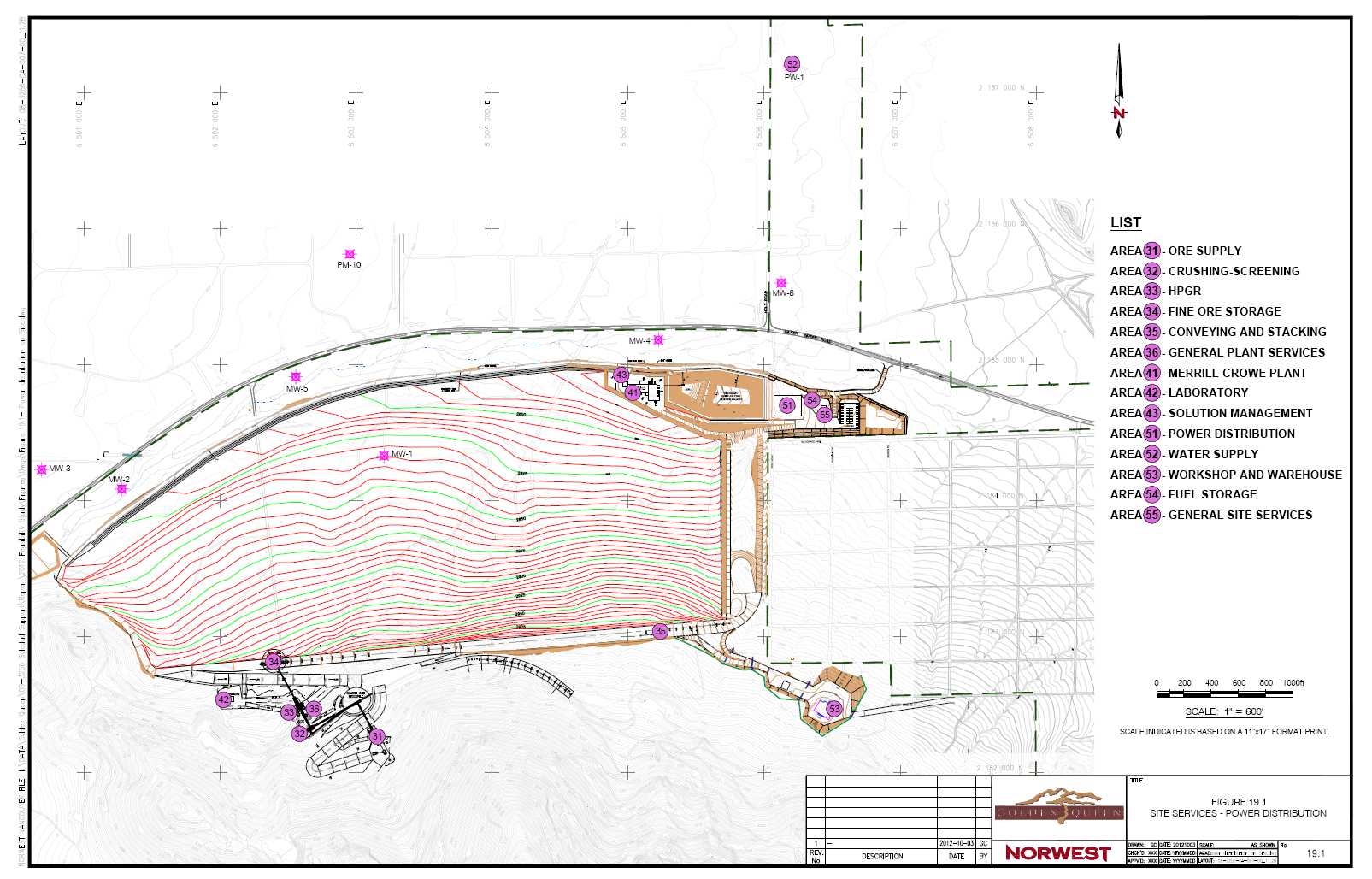

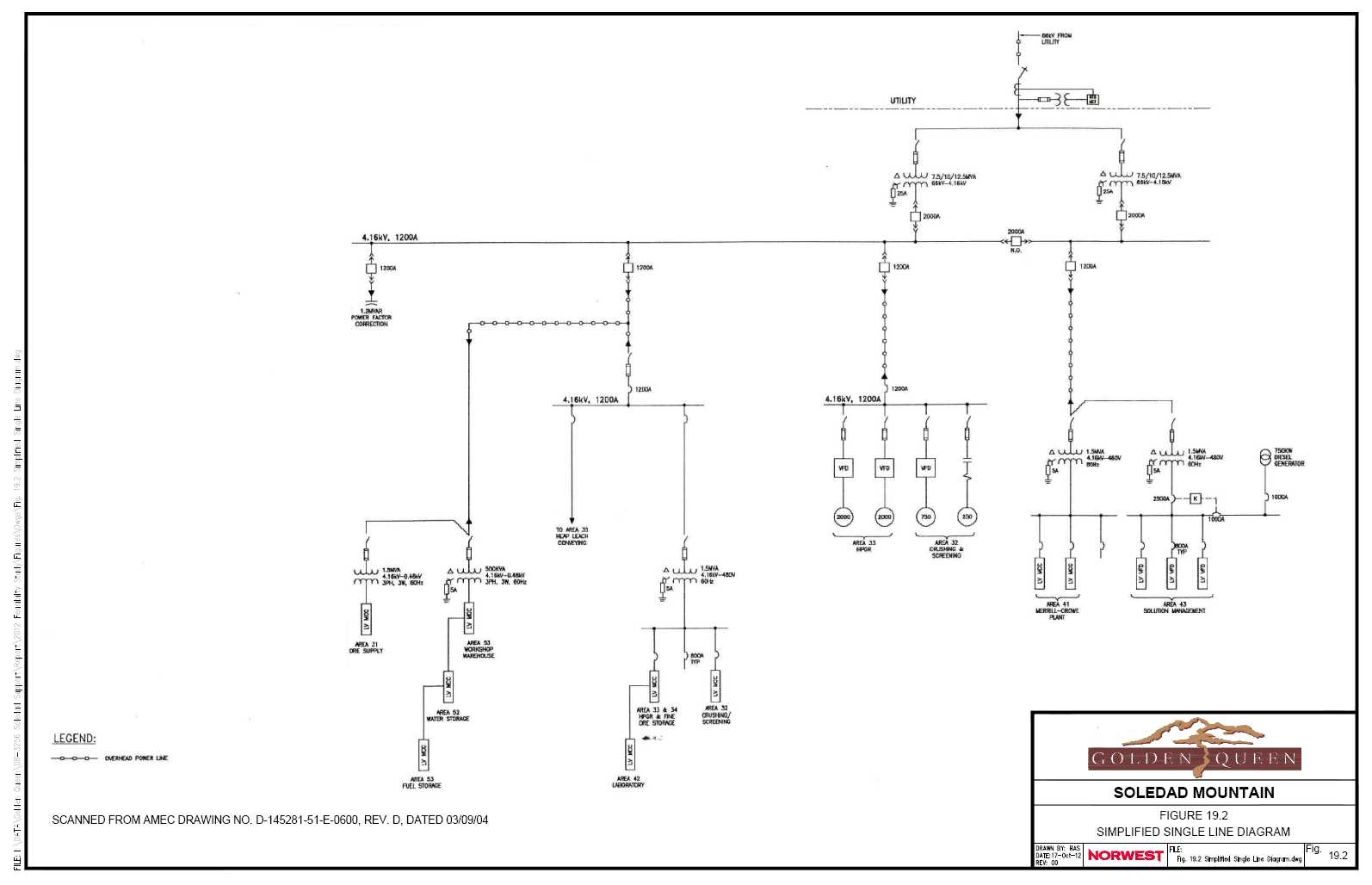

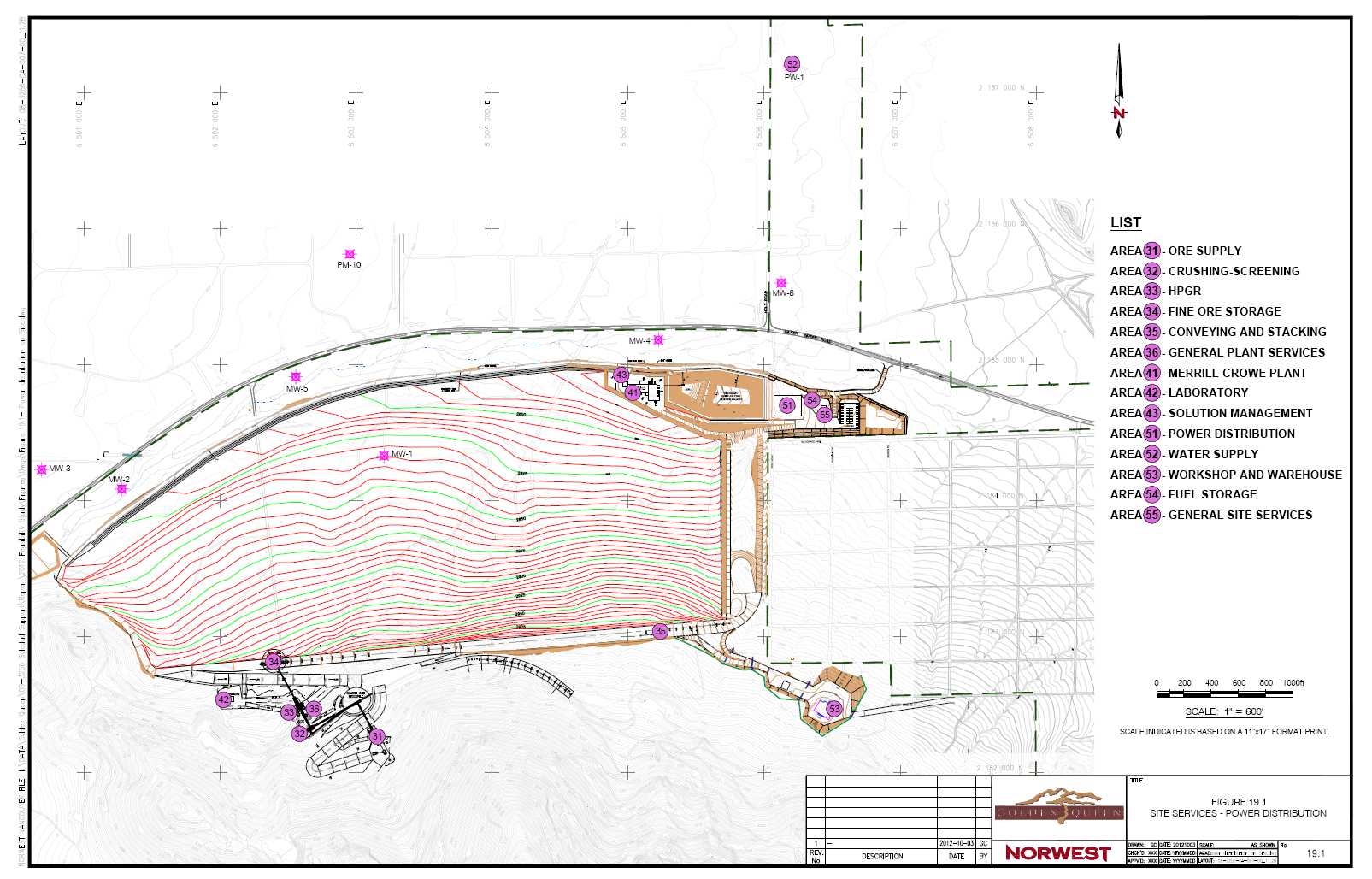

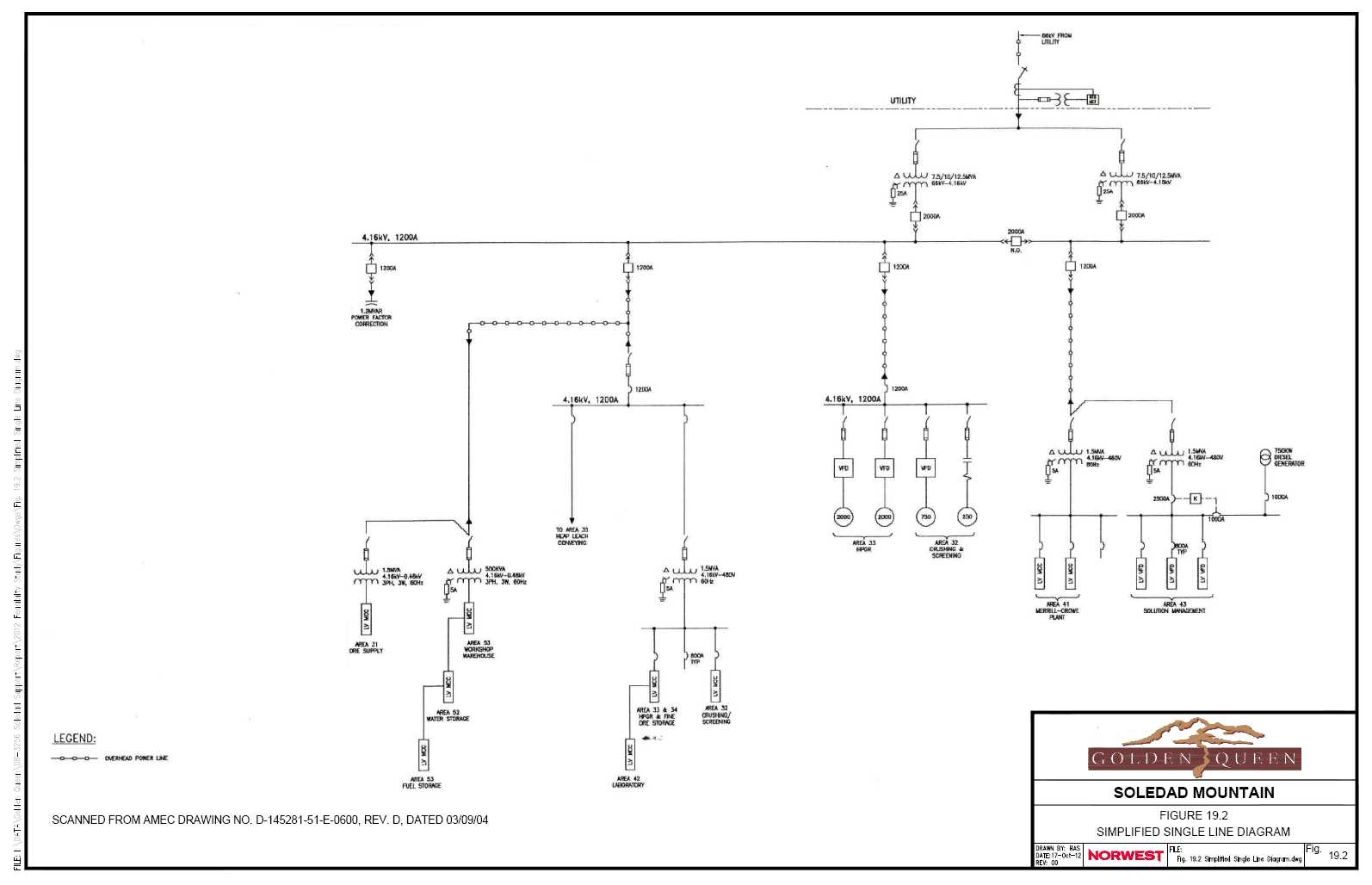

Infrastructure is described in Section 19 and this includes both on-site and off-site infrastructure.

| October 2012 | 1-11 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Off-site infrastructure such as the availability of power and a backup water supply are described in sub-section 19.3.

1.22 Market Studies

A dorè will be produced in the refinery on site. It is expected that the dorè will be shipped to the refinery owned by Johnson Matthey Inc. in Salt Lake City, Utah. The dorè will be smelted and refined to produce saleable gold and silver. The gold and silver will be sold by Johnson Matthey Inc. at spot price on the day it is produced. That is the conventional and generally accepted procedure for dealing with gold and silver produced by a smaller heap leach operation such as the Project.

GQM has therefore not entered into any agreement for selling refined gold and silver. GQM has also stated in its public documents such as the Form 10-K dated March 29, 2012 that it is not expected that GQM will hedge any of its gold or silver production. Refer to sub-section 1.27 for a comment on the aggregate component of the Project.

1.23 Capital Cost Estimates

Capital costs are described in sub-section 22.2 and summarized in sub-section 22.2.8.

Engineering has been substantially completed for all major components of the Project and this includes the design of the crushing-screening plant with the HPGR as the key comminution device by a Vancouver-based consulting engineering firm. Capital cost estimates are based upon quotes for construction from a number of key vendors and contractors based in southern California. The capital cost required is estimated to be $108.5 million and this includes unallocated costs of $12.5 million. It is estimated that a further $10.5 million will be required as working capital. Total estimated capital costs are therefore $119 million. The company is evaluating a leasing agreement for major mine equipment which reduce initial capital costs to $107 million however this case has not been used as the base case for financial evaluation.

The sustaining capital is estimated to be a further $30.6 million over the life of the gold and silver heap leach operation with detail provided in Table 16.7. The bulk of the sustaining capital will be required for construction of the second and third stages of the heap leach pad and for major equipment replacement.

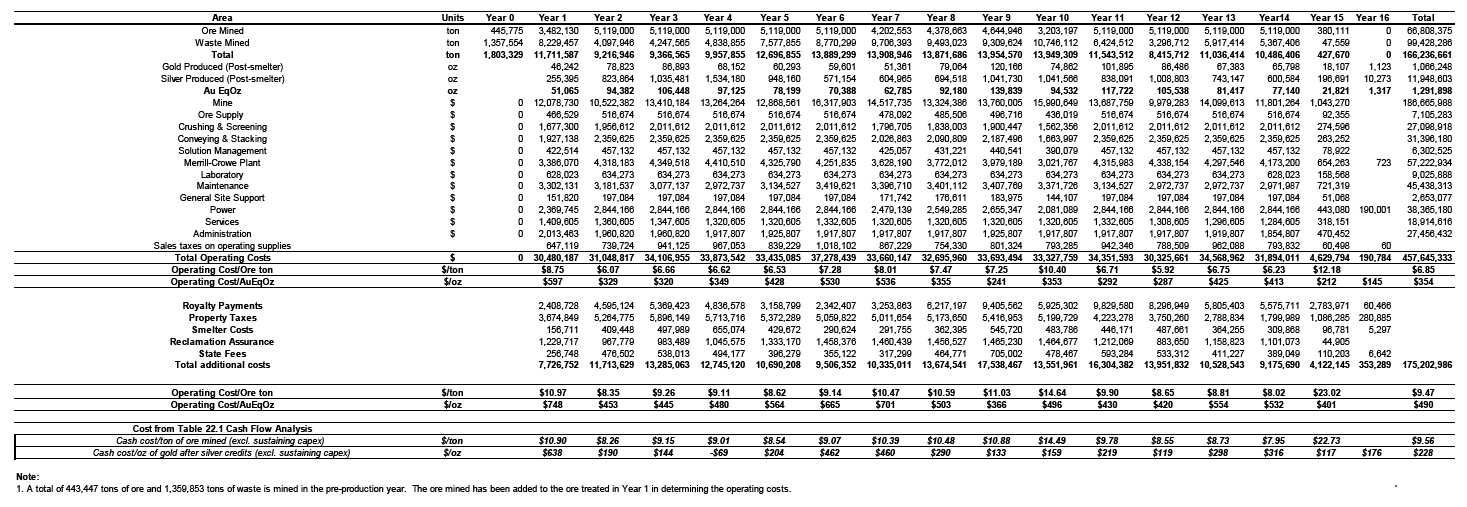

1.24 Operating Cost Estimates

Operating costs are described in sub-section 22.4 and summarized in sub-section 22.4.6.

Detailed operating cost estimates have been prepared with information provided by independent consulting engineers and vendors of services and supplies such as diesel fuel and explosives, reagents such as cement and sodium cyanide and operating supplies and spare parts for both the major mining equipment and support equipment and equipment in the various processing facilities.

| October 2012 | 1-12 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

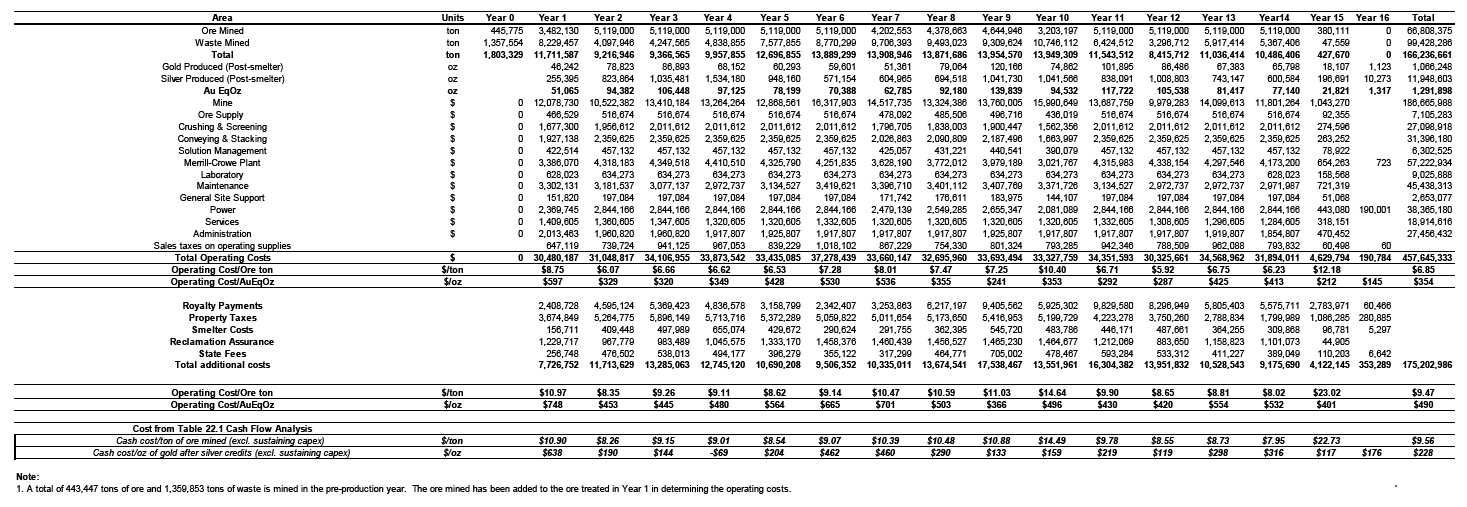

The all-inclusive average cash operating cost is projected at $10.02/ton of ore mined for the life of the gold and silver heap leach operation. There is no allowance for escalation or inflation in the operating cost estimates from the third quarter 2012 onwards. Operating costs for the life of the mine are summarized in Table 22.6.

Note that an allowance for unallocated costs has been added to the operating cost estimates in the cash flow model.

1.25 Financial Analysis

1.25.1Pre-tax Cash Flow Analysis

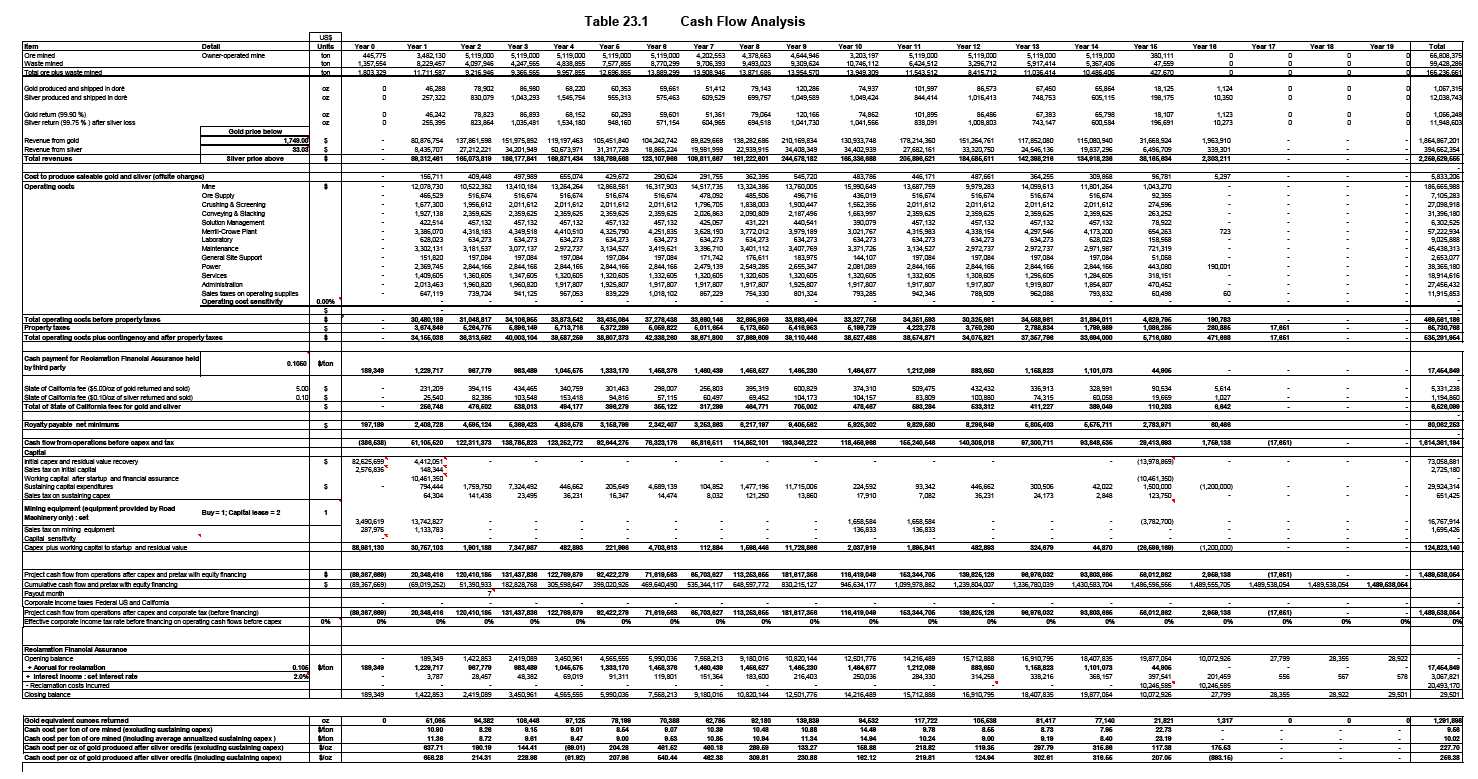

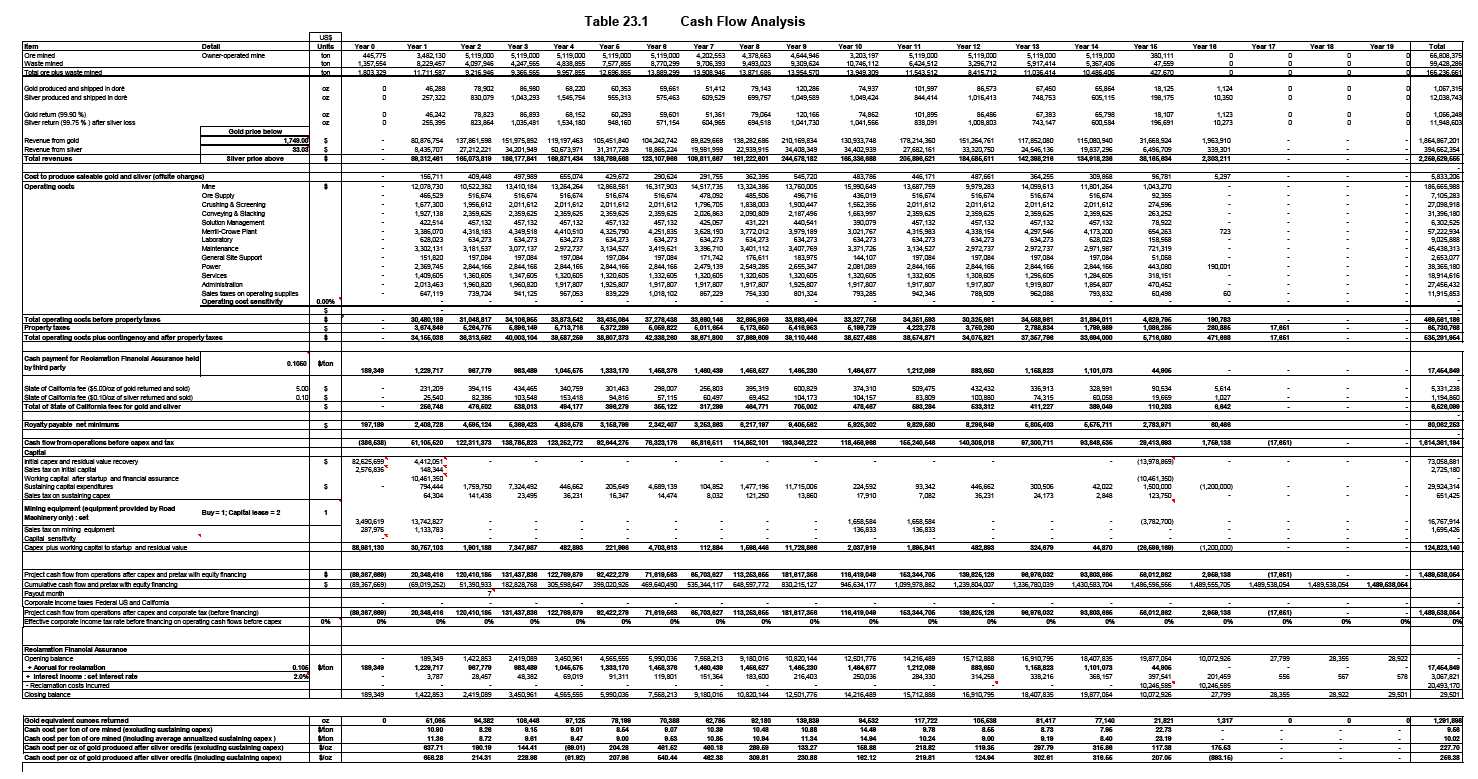

The pre-tax cash flow analysis is described in sub-section 23.4.1. This analysis includes detail on a number of items that make up the cash flow model.

The base cash flow analysis is done on a constant United States dollar, pre-tax, stand-alone project basis.

The Project has an indicated internal rate of return (IRR) on capital employed of 82.9% . The net present value (NPV) is $787 million with a discount rate of 8.0% and the undiscounted, cumulative net cash flow is approximately $1.49billion. For comparison, at a 5% discount rate the NPV is $986 million. The indicated contribution of gold and silver to gross revenues is 83% and 17% respectively at current gold and silver prices with an all-inclusive, average cash cost per ounce of gold produced, net of silver credits, of $256/oz. Gold and silver prices used to model the cash flows were $1,749.00 and $33.03 respectively, the London fix for precious metals on October 17, 2012.

1.26 Sensitivity Analysis

Sensitivity analyses are described in sub-section 23.4.2.

If gold and silver prices are reduced by 10% from current levels, the indicated IRR is 72.4 %, the NPV is $669 million with a discount rate of 8% and the undiscounted, cumulative net cash flow is $1.28 billion. The all-inclusive, average cash cost per ounce of gold produced, net of silver credits, increases from $256/oz to $275/oz at these lower gold and silver prices.

When trailing 36-month average gold and silver prices of $1,438/oz and $27.65/oz respectively to the end of September, 2012 are used to model the cash flows, the indicated IRR is 64.4% before taxes, the NPV is $580 million with a discount rate of 8% and the undiscounted, cumulative net cash flow is $1.13 billion. The all-inclusive, average cash cost per ounce of gold produced, net of silver credits, increases further to $285/oz. The trailing 36-month average precious metals prices are accepted by the U.S. Securities And Exchange Commission when reporting mineral reserves.

| October 2012 | 1-13 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

1.27 Aggregate

GQM expects to develop a by-product aggregate and construction materials business once the heap leach operation is in full production, based on the location of the Project in southern California with close proximity to major highways and railway lines. The source of raw materials will be suitable quality waste rock specifically stockpiled for this purpose. The waste rock can be classified into a range of products such as riprap, crushed stone and sand with little further processing. Test work done in the 1990s confirmed the suitability of waste rock as aggregate and construction material. GQM also plans to process and sell leached and rinsed residues from the heap leach operation for a range of uses to local and regional markets. It is intended that these products will be sold over an extended mine life beyond the current planned gold and silver production periodbut no contributions from the sale of such products will be included in the cash flow projections until long term contracts for the sales of these products are secured.

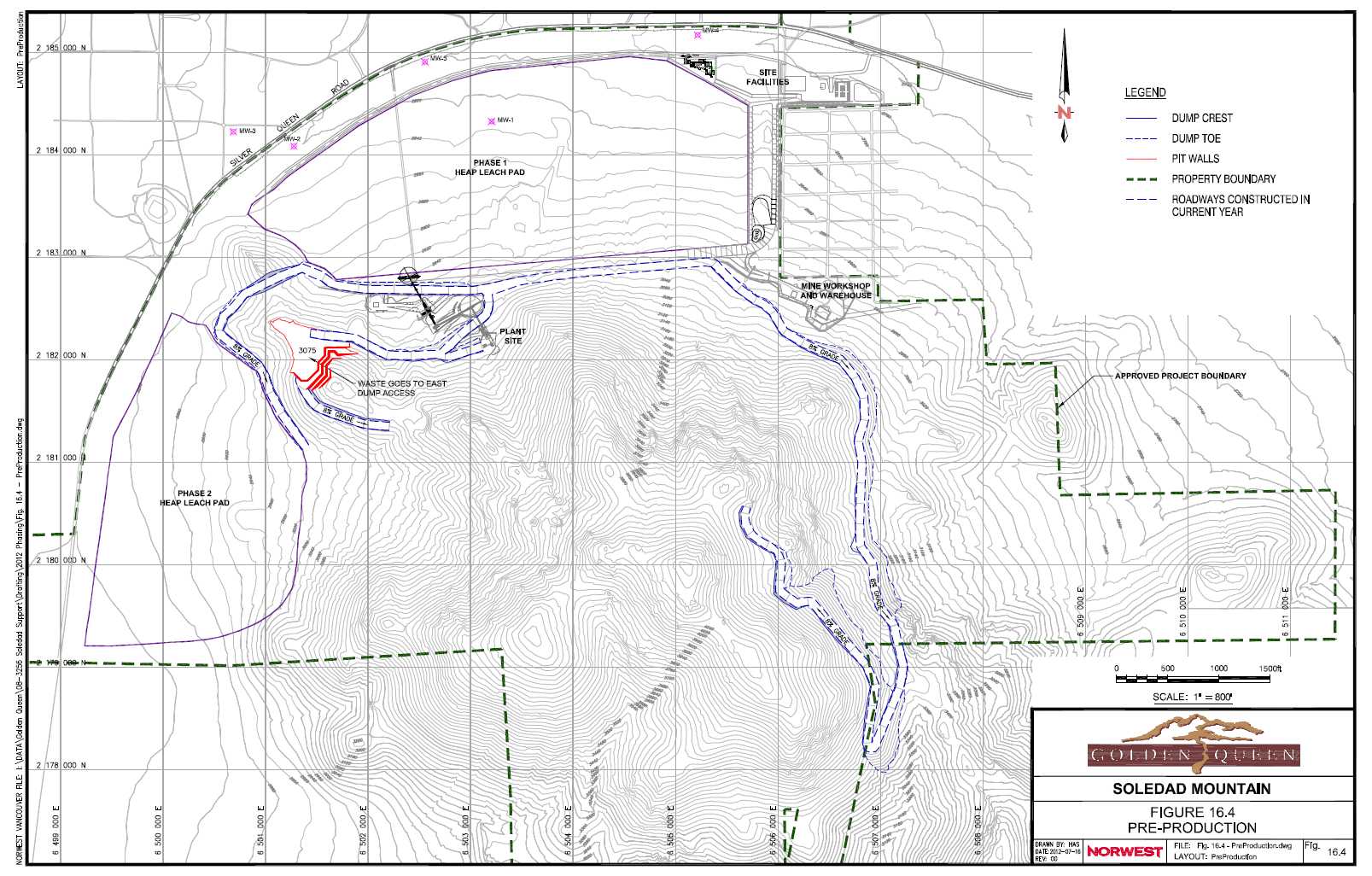

1.28 Project Schedule

The Company now has final approvals in place for the Project. The Company is therefore continuing with the design of the Phase 1, Stage 1 heap leach pad and the associated site drainage plans, design of a number of site grading plans, design of the sub-station required for the distribution of power to the operating facilities and all of these designs are being done for construction

Once a production decision is made, the Company will need significant additional financing to develop the Project into an operating mine. The Company is evaluating various financing options for the Project and these may be combined:

| | a. | An equity financing; |

| | | |

| | b. | A combination of equity and debt and |

| | | |

| | c. | A merger with an established mining company. |

The Company estimates that construction can be completed in approximately fifteen months once project financing has been secured. The target for the start of production is therefore the first quarter of 2014.

1.29 Interpretation and Conclusions

1.29.1Interpretation and Conclusions by Norwest

The Norwest QP finds the following:

| | 1. | The Project utilizes standard mining and processing methods which are well understood in the region. |

| October 2012 | 1-14 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| | 2. | The development plan follows a reasonable timeline for construction and production ramp-up. |

| | | |

| | 3. | The Project has a robust cash flow with a relatively low sensitivity to increases in the capital and operating costs. |

| | | |

| | 4. | There is sufficient area within the Project to host an open pit mining operation including any proposed open pit, waste dumps, and leach pads |

| | | |

| | 5. | The current mine plan includes mining and dumping activities beyond areas currently within the permitted limits. Norwest understands that GQM owns or is in negotiations with landholders to secure access however failure to do so could affect the current mine plan. |

| | | |

| | 6. | The current pit configuration is constrained by permit backfill requirements rather than economic strip ratio limits. The potential to expand the mineable ore tonnage exists if the constraints related to backfilling can be mitigated. |

1.29.2 Interpretation and Conclusions by AMEC

In the opinion of AMEC E&C QPs, the following interpretations and conclusions, based on the Feasibility Study Report, can be reached:

| | • | The project geology and mineralization is sufficiently well established and understood to support mineral resource estimation. |

| | | |

| | • | Completed exploration programs were appropriate to the mineralization style. |

| | | |

| | • | Work programs included geological mapping, geochemical sampling, channel sampling, petrography, mineralogical studies, and drilling. |

| | | |

| | • | Drill data collected by GQM meets industry standards for exploration of gold and silver deposits. No material factors were identified with the drill data collection that could affect Mineral Resource estimation. Drill hole sampling employed by GQM is in line with industry norms. Sample preparation for samples that support Mineral Resource estimation has followed a similar procedure for the GQM programs. The GQM drill samples were analyzed by reputable independent, accredited laboratories using analytical methods appropriate to the gold and silver concentration. Drill data are typically verified by AMEC prior to Mineral Resource estimation, by running a software program check. |

| | | |

| | • | Drill sampling has been adequately spaced to first define, then infill, gold and silver anomalies to produce prospect-scale and deposit-scale drill data. Drill hole spacing varies with depth. Drill hole spacing increases with depth as the number of holes decrease and holes deviate apart. |

| | | |

| | • | Sample data collected adequately reflect deposit dimensions, true widths of mineralization, and the style of the deposits. |

| October 2012 | 1-15 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| | • | Gold grades were estimated inside a grade shell using primarily ordinary kriging and inverse distance. Mineralization was confined within a conceptual open pit shell, which used economic parameters developed by Norwest from first principles. AMEC has reviewed the economic parameters used in the Mineral Resource and is of the opinion that they are reasonable for supporting Mineral Resource declaration within a conceptual open pit shell. |

1.30 Cautionary Statement

As noted in Section 1.6, the Project has been approved by the Kern County Planning Commission and the Kern Country Planning and Community Development Department. The Commission accepted the project plan subject to a number of Conditions of Approval. A number of these conditions specifically address issues related to reclamation of the property including backfilling and restoration to approximate pre-mining topography.

The mine plan presented in this document represents best efforts by Norwest to develop a mine plan which maximizes in-pit backfill while not unduly penalizing the Project’s economic viability. The pit shells used as a basis for this feasibility were selected based on consideration of both economic and waste volume considerations with the goal of developing pit configurations which balanced ore tonnage against waste quantities.

In order for the current mine plan to meet all the conditions laid out by the County, approximately 19 million tons of waste rock must be sold as aggregate and removed from site prior to final reclamation. In addition, all the leached residues must be either permitted to remain in place or be sold as aggregate. If this quantity cannot be sold, the necessity of handling this additional volume as part of the reclamation plan will affect the overall ore tonnage that can be mined at site. While no costs or revenues associated with aggregate production using this material, have been included in the Project economic analysis, removal of these materials is an integral component of the integrated mining and backfilling plan. If these quantities of material remain onsite, it will require revision of the mining plan in order to meet the backfill requirements which could reduce the life of the heap leach operation by up to 5 years.

Norwest has worked with GQM to develop a scenario which limits the effect of this on the mine life and GQM has had promising discussions with a local aggregate contractor regarding the saleability of the waste rock and leached residues into the regional market. However, there is still a potential risk that meeting the requirements of the Conditions of Approval could affect the overall mine life.

The current mine plan includes mining and dumping activities beyond areas currently within the permitted limits. Norwest understands that GQM owns or is in negotiations with landholders to secure access and to expand the permit boundary however failure to do so could affect the current mine plan.

| October 2012 | 1-16 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

2.1 Terms of Reference

GQM engaged Norwest Corporation (Norwest) and AMEC to prepare an updated NI 43-101 compliant Technical Report to assess mineral reserves for the Project as part of an independent feasibility study based upon technical work and engineering designs completed up to monthend May 2012. The results of the Norwest study were disclosed in a press release on September 6, 2012.

The geological model for the Project was developed by AMEC effective February 29, 2012. Norwest has used this model as a basis for pit optimization and the development of the mining plan in the feasibility study.

Detailed studies have been completed by GQM internally under the guidance of Lutz Klingmann, P.Eng., President of GQM. Norwest has incorporated the findings of many of the engineering and technical studies commissioned by GQM as these studies have been completed by qualified independent third parties. These studies are referenced in this feasibility report and a list of all references is included. Where revisions have been made to previous work they are noted (example: capital and operating cost updates).

2.2 Qualified Persons

The following people served as the QPs as defined in National Instrument 43-101, Standards of Disclosure for Mineral Projects, and in compliance with Form 43-101F1:

| | • | Mark Hertel, SME Registered Member, Principal Geologist, AMEC Mesa, AZ. |

| | | |

| | • | Sean Ennis, APEGBC Registered Member, Vice President, Mining, Norwest Corporation, Vancouver BC. |

2.3 Site Visits and Scope of Personal Inspections

AMEC’s QP conducted a site visit as shown in Table 2.1.

| October 2012 | 2-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Table 2.1 QPs Areas of Report Responsibility and Site Visits

| Qualified Person | Site Visits | Report Sections of Responsibility(or Shared Responsibility) |

| Sean Ennis | | Sections 1.1 – 1.7, 1.9, 1.14, 1.17-1.30, 2, 3, 4, 5, 9.6-9.7, 13,15, 16, 17, 18, 19, 20, 21, 22, 23, 25, 26.3-26.4, 27.2-27.3 |

| Jay Horton | November 4 -5, 2010 | - |

| Mark Hertel | July 26, 2011 | Sections 1.8, 1.10, 1.11, 1,12, 1,13, 1,15, 1.16, 1.29.2, 6, 7, 8, 9.1, 9.2, 9.3, 9.4, 9.5, 9.8, 9.9, 10, 11, 12, 14, 24, 26.1, 26.2, 26.4, and 27.1. |

Mr. Hertel inspected surface geology, drill hole collars, drill core and RC chip trays, logging procedures, sampling protocols, proposed open pit location, and sites amenable for locating infrastructure.

Jay Horton, a Norwest QP conducted his most recent site visit as shown in Table 2.1. Mr. Horton observed the proposed pit, dump and leach pad areas. He reviewed the site configuration to confirm the reasonableness of planned pre-development and mining assumptions.

2.4 Effective Dates

The Report has a number of effective dates as follows:

| | • | Effective date of the database closeout for Soledad Mountain for the purposes of estimation of Mineral Resources: 31 December 2011 |

| | | |

| | • | Effective date of the Mineral Resources for Soledad Mountain: 29 February 2012 |

| | | |

| | • | Effective date of the mineral tenure and surface rights data: October, 10, 2012 |

| | | |

| | • | Effective date of the mineral reserves: August 31, 2012 |

| | | |

| | • | Effective date of the financial analysis: October 17, 2012 |

| | | |

| | • | Effective date of the final report: October, 17, 2012 |

There has been no material change to the scientific and technical information on the Project between the effective date of the Report, and the signature date.

2.5 Information Sources and References

Reports and documents listed in Section 3 Reliance on Other Experts and Section 28 References were also used to support preparation of the Report. Additional information was provided by GQM personnel where required.

2.6 Previous Technical Reports

GQM has previously filed the following technical reports:

| October 2012 | 2-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Table 2.2 Previously Filed Technical Reports

| Name of Report | | Date of Report | Date Filed onSEDAR | Category Filed onSEDAR |

| | | | |

| Soledad Mountain Feasibility Study (Prepared by Norwest Corporation) | | May 2, 2011 | May 17, 2011 | Other |

| | | | | |

| Technical Report Soledad Mountain Project (Prepared by Norwest Corporation) | | January 23, 2008 | January 31, 2008 | Technical Report NI 43-101 |

| | | | | |

| NI 43-101 Technical Report Soledad Mountain Project (Prepared by SRK Consulting U.S., Inc.) | | March 2006 | March 21, 2006 | Technical Report NI 43-101 |

| | | | | |

| Soledad Mountain Project Technical Report (Prepared by John Barton Fairbairn) | | June 20, 1997 | August 26, 1997 | Other |

| October 2012 | 2-3 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 3 | RELIANCE ON OTHER EXPERTS |

| | |

| AMEC and Norwest QP have relied upon and disclaim responsibility for information derived from reports pertaining to mineral tenure, surface rights, water rights, environmental approvals and permits. |

3.1 Mineral Tenure and Royalties

The AMEC QP has not independently verified the legal status of ownership of land within the Approved Project Boundary. AMEC has fully relied upon, and disclaims responsibility for information provided by GQM staff and experts retained by GQM for information relating to mineral tenure, landholders’ title to properties, and mining lease agreements GQM has with landholders. The following document was referred to with respect to mineral ownership and royalty rights:

Letter from E.E. Riffenburgh, Gresham Savage, Attorneys at Law, October, 10, 2012.

Detail is provided in Section 4.3 and 4.4. This information is used in Sections 4.3, 4.4, and 14.

3.2 Surface and Water Rights

The AMEC QP has fully relied upon and disclaims responsibility for information provided by GQM staff and experts retained by GQM for information relating to surface rights and water rights in California. The following document was referred to with respect to current surface and water rights:

Independent California legal counsel, Paul Singarella, Esq., Latham & Watkins LLP, Costa Mesa, California, prepared a document titled “Memorandum, July 18, 2007, Initial Diligence Report and Potential Action Items – Golden Queen Mining’s Soledad Mountain Project”.

Kern County Board of Supervisors approved a water entitlement of 170 m3/h (750 gal/min) in the CUPs issued in 1997

An assessment of surface rights and water rights is provided in Sections 4.5, 4.6 and 5.5 of the Report. This information is used in Sections 4.5, 4.6, 5.5, 14 and 15.

3.3 Environmental Studies and Approvals and Permits

The AMEC QP has fully relied upon and disclaims responsibility for information provided by GQM staff and experts retained by GQM for information relating to the environmental studies performed and approvals and permits obtained for the Project. The following documents were referred to with respect to environmental studies, approvals and permits.

“California Regional Water Quality Control Board, Lahontan Region, Board Order No. R6V-2012-0031, Waste Discharge Requirements, July 23, 2012.”

| October 2012 | 3-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

A Supplemental Environmental Impact Report (SEIR) was issued by GQM in January 2010. The Kern County Planning Commission formally considered the Project at its regularly scheduled meeting in Bakersfield on April 8, 2010. The Planning Commission certified the SEIR, adopted a Mitigation Measures Monitoring Program and Conditions of Approval for the Project which define conditions and performance standards which the mining operation must meet. The Mitigation Measures Monitoring Program and Conditions of Approval for the Project were amended by Planning Commission Resolution No. 171-10 adopted on October 28, 2010

Detail is provided in Section 21 of the Report. This information was used in Section 14 of this report.

| October 2012 | 3-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 4 | PROPERTY DESCRIPTION AND LOCATION |

4.1 Location

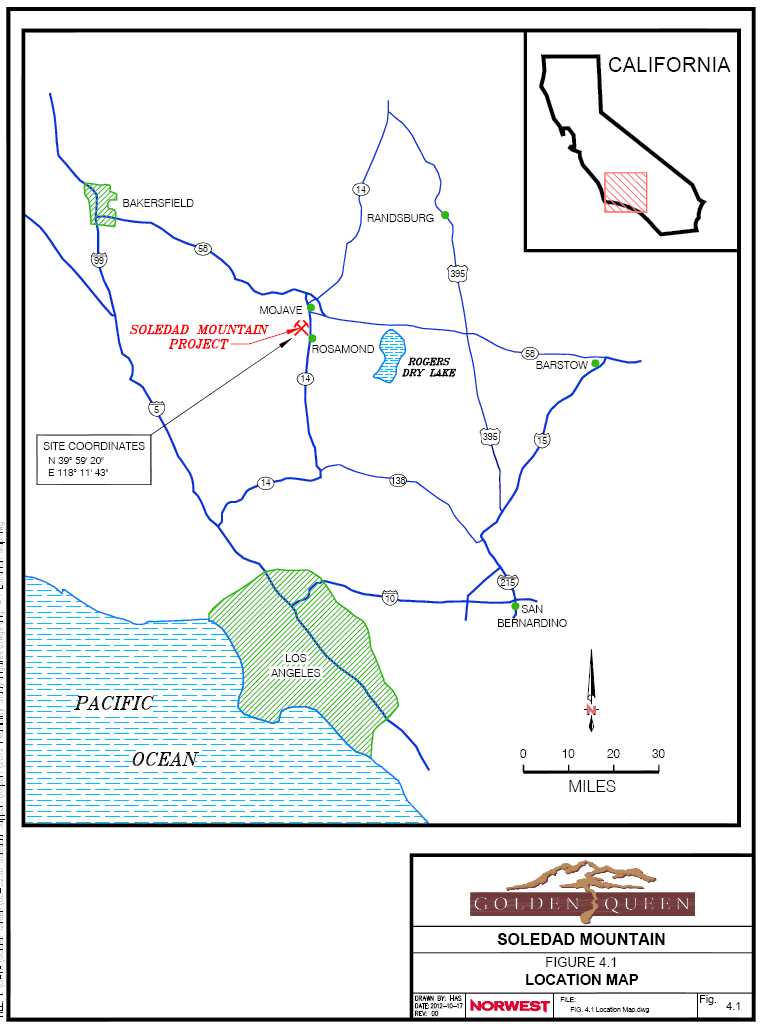

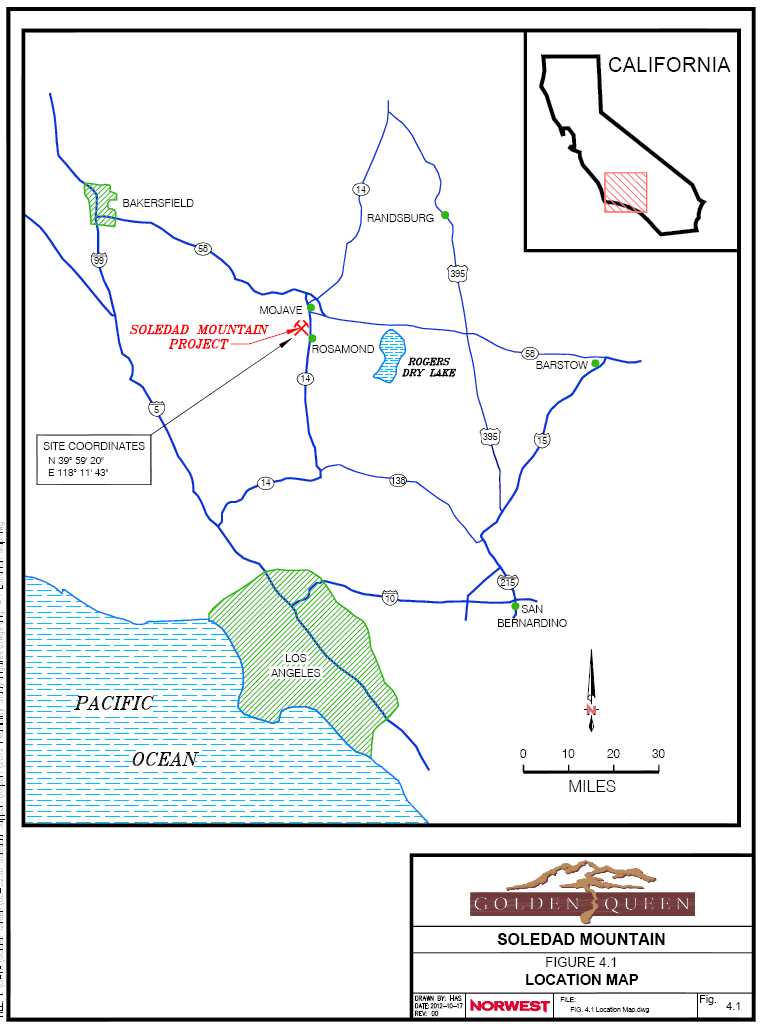

The Project is located in Kern County in southern California as shown in Figure 4.1. The Project is located approximately 5 miles south of the town of Mojave. The metropolitan areas of Rosamond and Lancaster lie approximately 9 miles and 20 miles to the south respectively. Los Angeles is about 70 miles south of Mojave. California City lies approximately 10 miles northeast of Mojave.

The project coordinates are N 39º 59’ 20” and E 118º 11’ 43”.

The Project is within the Mojave Mining District along with the former Cactus Gold Mine, Standard Hill Mine and Tropico Mine. These former operating mines are located within a radius of five miles of the site.

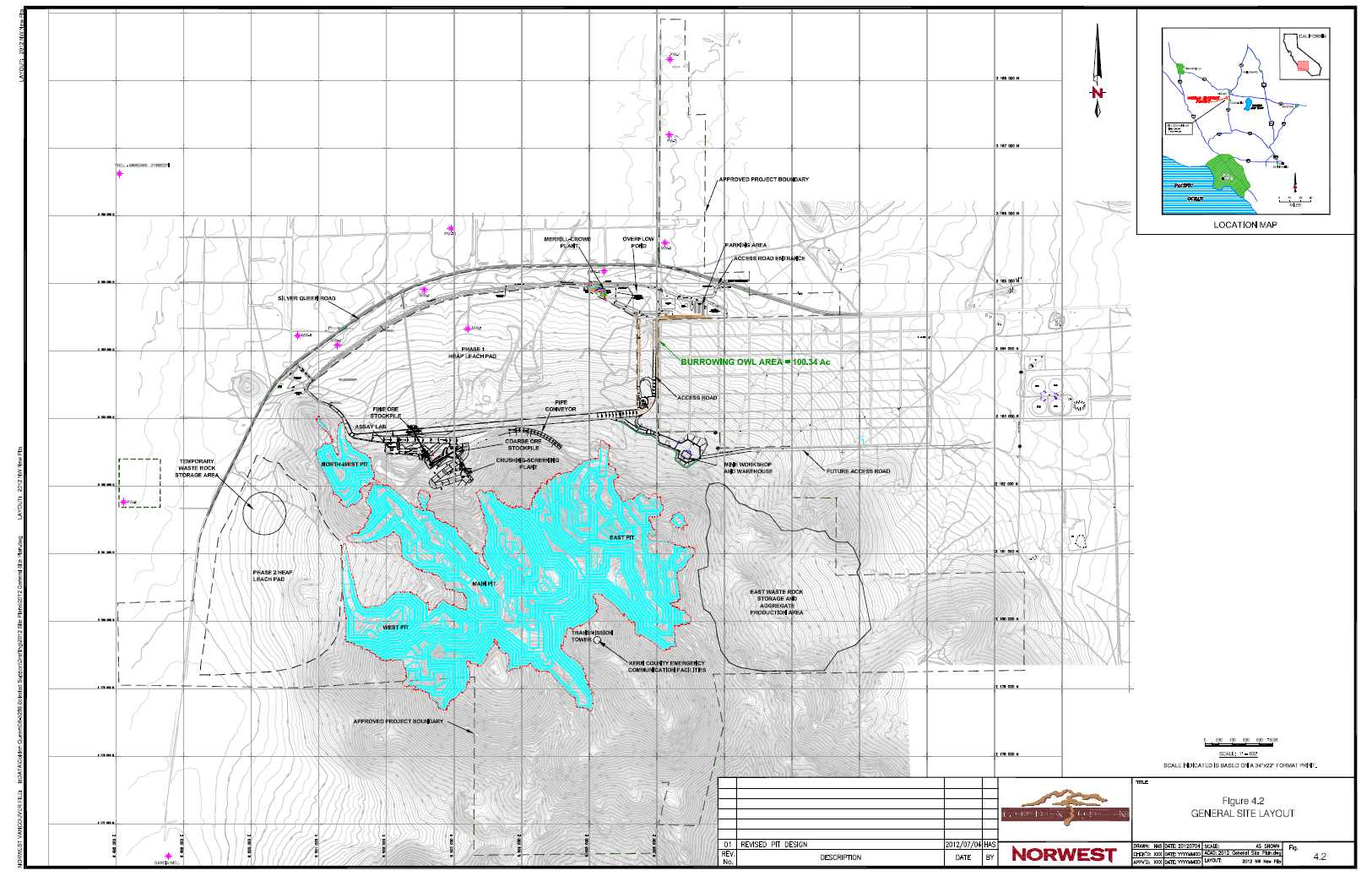

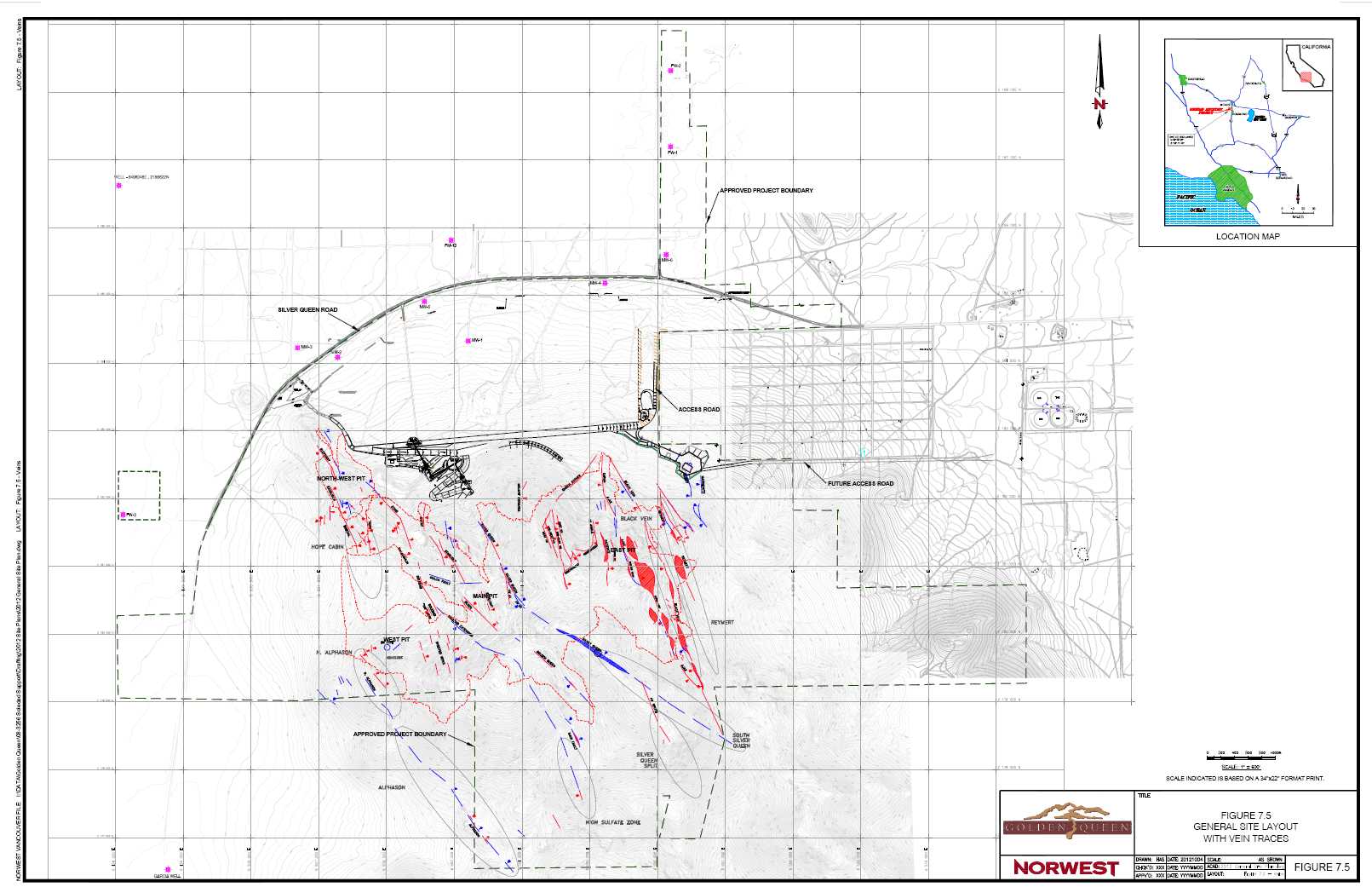

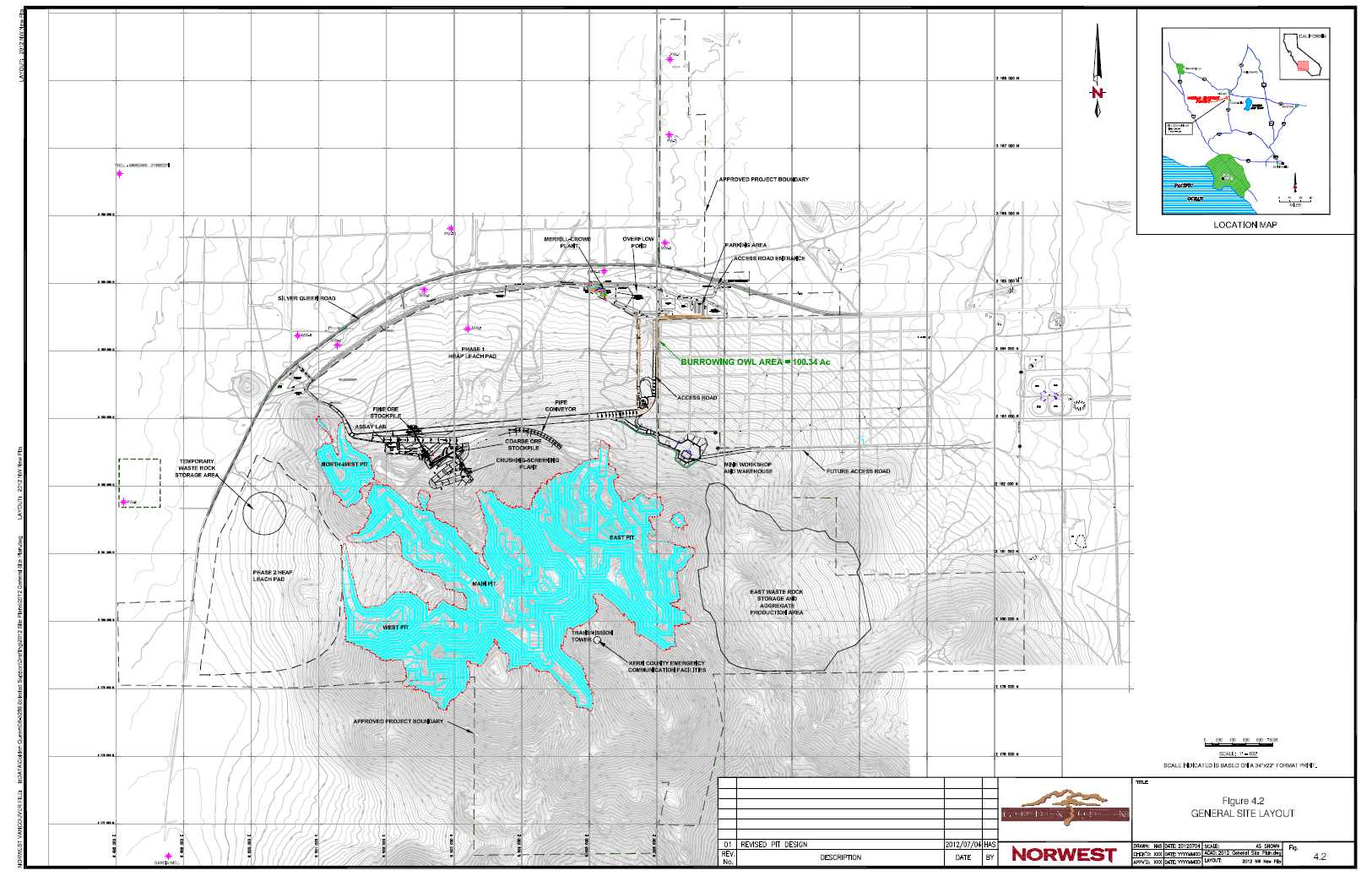

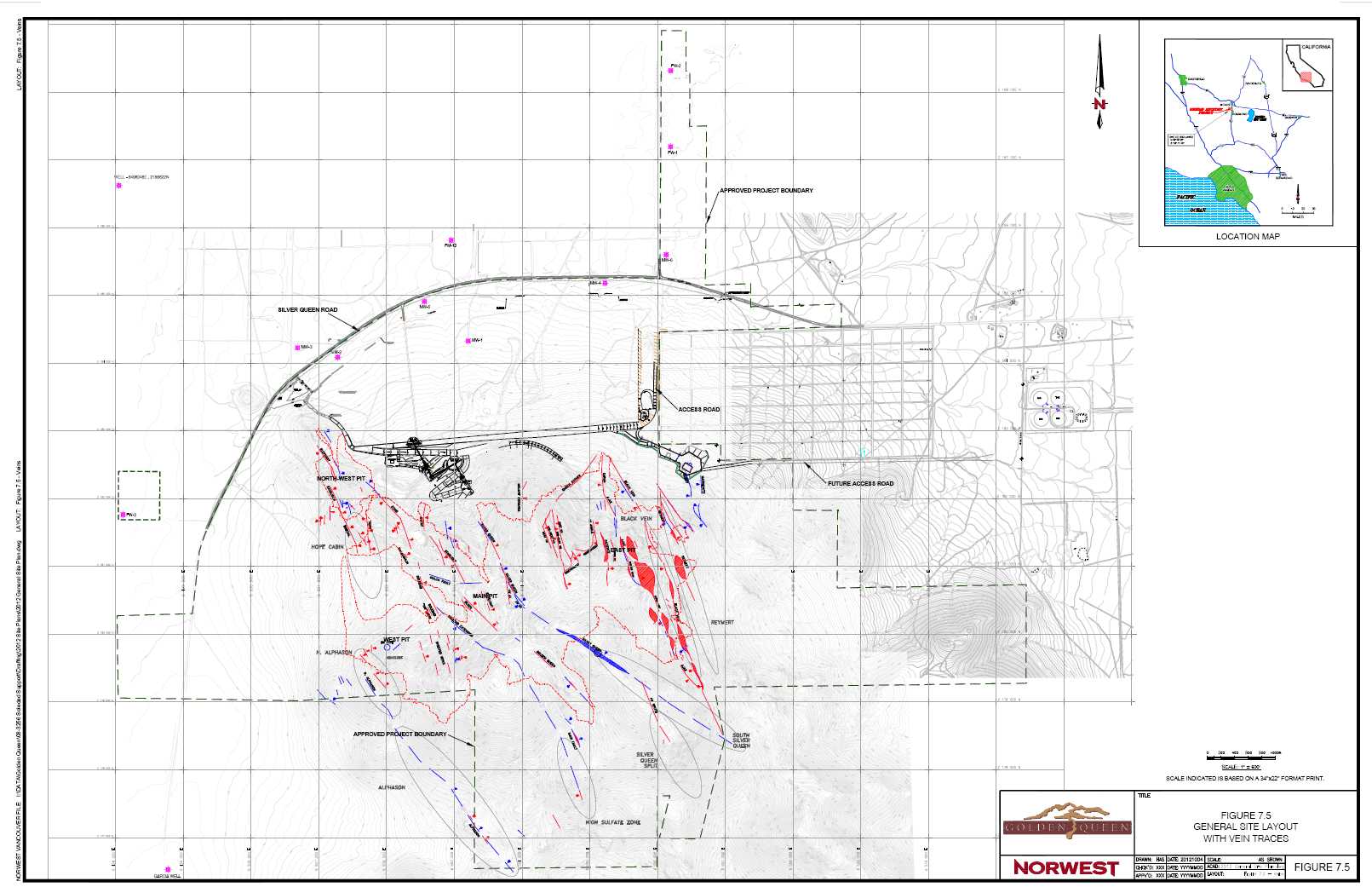

A general site layout is shown in Figure 4 2.

4.2 Land Holdings

GQM controls approximately 2,500 acres (1,000 hectares) of land in the area, consisting of private (fee land and patented lode mining claims and millsites) and federal lands (unpatented mining claims and millsites) administered by the BLM, collectively referred to as the Property. The total area required for the Project, which is surrounded by an Approved Project Boundary, is approximately 1,400 acres (600 hectares) in size. The actual area that will be disturbed by mining, waste rock disposal, the construction of the heap leach pads and the heap and the facilities will be approximately 912 acres (369 hectares) in size of which approximately 835 acres (338 hectares) will be reclaimed during and at the end of the mine life.

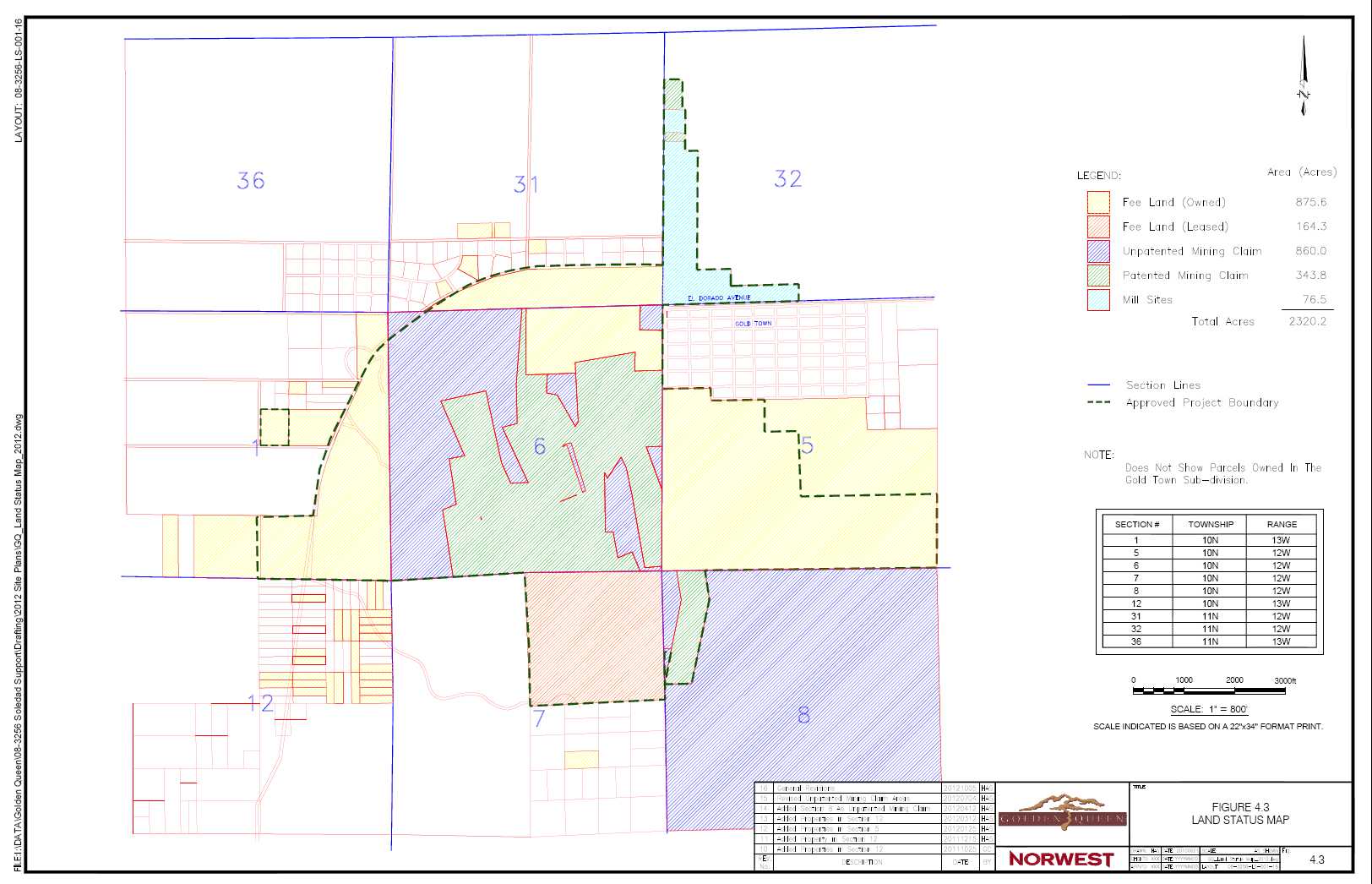

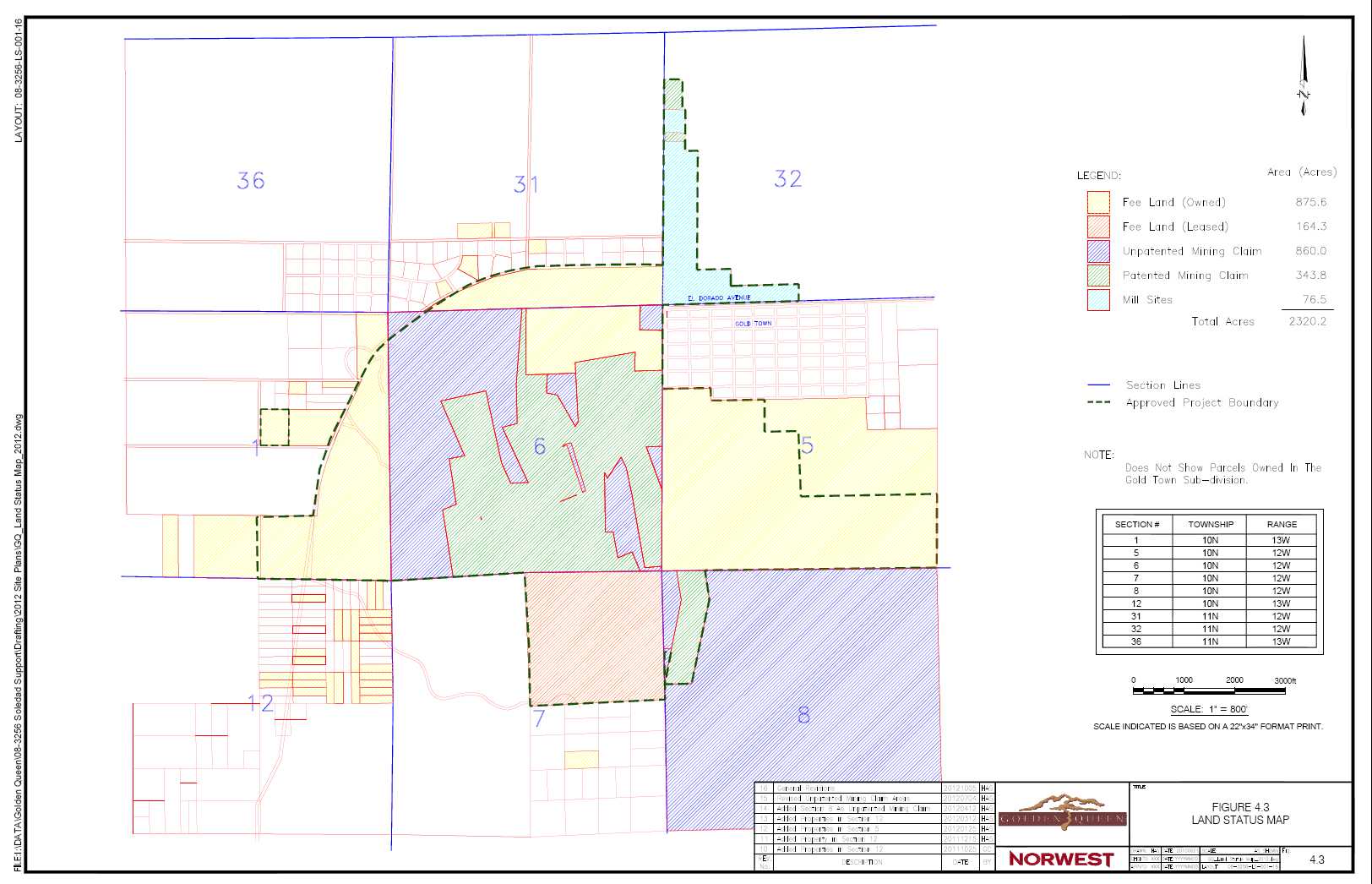

The Property is located west of California State Highway 14 and largely south of Silver Queen Road in Kern County, California, and covers all of Section 6 and portions of Sections 5, 7 and 8 in Township 10 North (T10N), Range 12 West (R12W), portions of Sections 1 and 12 in T10N, R13W, portions of Section 18 in T9N, R12W, and portions of Section 32 in T11N, R12W, all from the San Bernardino Baseline and Meridian. The Project facilities will be located in Section 6 of T10N, R12W. Two water production wells have been drilled in Section 32, T11N, R12W, on land controlled by GQM. A third water production well was drilled in Section 1, T11N, R12W, on land controlled by GQM in 2008.

4.3 Mineral Tenure and Mining Lease Agreements

GQM holds or controls via agreement 33 patented lode mining claims, 134 unpatented lode mining claims, 1 patented millsite, 12 unpatented millsites, 1 unpatented placer claim and 867 acres of fee land. A summary of the land held or controlled by GQM is shown in Table 4.1. As noted above, additional land is held by GQM which may be incorporated into the project area in the future if required. The land status is shown in Figure 4.3.

| October 2012 | 4-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Table 4.1 Land Status

| Land Status | Acres | Hectares |

| Fee Land (Owned) | 875.6 | 354.3 |

| Unpatented Mining Claims | 860.0 | 348.0 |

| Patented Mining Claims | 343.8 | 139.1 |

| Fee Land (Leased) | 164.3 | 66.5 |

| Millsites | 76.5 | 31.0 |

| Total | 2320.2 | 938.9 |

GQM holds or controls the properties under mining leases with 53 individual landholders, two groups of landholders and 2 incorporated entities. Contact information for the landholders is available on file at the GQM offices in Vancouver. Length of the agreements varies and the current approach is to have agreements extend to the year 2045.

GQM believes that all the land required for the Project either has been secured under a mining lease or is held by GQM through ownership of the land in fee or via unpatented mining claims. GQM executed land purchases or entered into agreements from 1990 onwards, and is continuing to add to its land position in the area.

A formal title review was done by Gresham Savage Nolan & Tilden, a firm with experience in title matters. The report was dated September 6, 1996 and was updated to April 26, 1999. This title review was done to provide confirmation that titles remained valid. Work on mining lease agreements and confirmation of titles is on-going and is being done by GQM’s “Legal Counsel, Gresham, Savage, Nolan and Tilden”.

A formal title review was again done by an independent landman, Sylvia Good, in May 2004.

4.4Royalties

Royalties paid to third party landholders and the State are shown as line items in the Project cash flows in Table 22.1.

There are multiple third party landholders and the royalty formula applied to mine production varies with each property. This leads to a complex set of royalty calculations. A standard net smelter return per ton formula has been applied to the cash flows to calculate the estimated royalty payable. The estimated royalty payable over the Project’s life is approximately $80million for the base case.

State royalties for payable gold and silver have been applied at the following rates:

| | • | Gold royalty = $5.00/oz gold (post-smelter) |

| | | |

| | • | Silver royalty = $0.10/oz silver (post-smelter) |

| October 2012 | 4-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

The estimated combined gold and silver royalty paid to the State over the Project’s life is $6.4 million for the base case.

4.5 Surface Rights

About 45% of the land in California is controlled by the Federal Government; most of this land is administered by the US Bureau of Land Management (BLM), the US Forest Service, the National Park Service, or the US Department of Defense. Much of the land controlled by the BLM and Forest Service is open to prospecting and claim location. The distribution of public lands in California is shown on the BLM “Land Status Map of California” (1990) at scales of 1:500,000 and 1:1,000,000.

Bureau of Land Management regulations regarding surface disturbance and reclamation require that a notice be submitted to the appropriate Field Office of the Bureau of Land Management for exploration activities in which five acres or fewer are proposed for disturbance (43 CFR 3809.1 -1 through 3809.1 -4). A Plan of Operations is needed for all mining and processing activities, plus all activities exceeding five acres of proposed disturbance. A Plan of Operations is also needed for any bulk sampling in which 1,000 or more tons of presumed ore are proposed for removal (43 CFR 3802.1 through 3802.6, 3809.1 -4, 3809.1 -5). The BLM also requires the posting of bonds for reclamation for any surface disturbance caused by more than casual use (43 CFR 3809.500 through 3809.560.

4.6 Water Rights

Independent California legal counsel (“Memorandum, July 18, 2007, Initial Diligence Report and Potential Action Items – Golden Queen Mining’s Soledad Mountain Project”, Prepared by Paul Singarella, Esq., Latham & Watkins LLP, Costa Mesa, California.) did an analysis of water rights in California on a confidential basis. The following are key points:

| | a. | California does not regulate the use of groundwater under a state-wide administrative permit program; |

| | | |

| | b. | A land holder with land overlying groundwater does not need to have the right to pump water verified before the land holder can drill wells and pump water; |

| | | |

| | c. | Groundwater rights rules include a hierarchy of rights under which the rights of the overlying users are paramount; |

| | | |

| | d. | When a groundwater basin is in an overdraft condition, competing water uses will frequently initiate judicial proceedings to test the claims of competing rights; |

| | | |

| | e. | Groundwater rights can be determined, and pumping limited, through court adjudications; |

| | | |

| | f. | The Project will draw groundwater from the Fremont Valley groundwater basin and this basin is separated from other basins by significant geological features; |

| October 2012 | 4-3 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| | g. | Ongoing monitoring will be required to ensure that the groundwater immediately underlying the Project is not in an overdraft condition; |

| | | |

| | h. | If the Project’s groundwater demands were to contribute to an overdraft condition, GQM would be bound by the correlative rights doctrine, which provides that as between overlying owners, all have equal rights to the water and must share in any water shortages; |

| | | |

| | i. | An adjudication of groundwater resources in the Antelope Valley is ongoing and this also needs ongoing monitoring to confirm that the Fremont Valley groundwater basin is not drawn into this adjudication and |

| | | |

| | j. | Under Article X, Section 2 of the California Constitution, water must be put to |

| | | |

| | | “reasonable and beneficial use” and the California Code of Regulations expressly defines “beneficial uses” to include mining. |

Kern County Board of Supervisors approved a water entitlement of 170 m3/h (750 gal/min) in the CUPs issued in 1997.

Water required for the Project and alternative water supplies are described in Section 19.3.3, 19.4.3 and 19.4.4.

4.7 Reclamation and Reclamation Financial Assurance

GQM has provided reclamation financial assurance in the form of an Irrevocable Standby Letter Of Credit backed by a Certificate Of Deposit with Union Bank of California in the amount of US$286,653.00. This is the current estimate for reclamation of historical disturbances on the property and this is reassessed annually.

GQM prepared detailed cost estimates for ongoing reclamation and reclamation at the end of the life of the mine and these cost estimates were included in the Application for a revised Surface Mining Reclamation Plan. GQM will provide the necessary financial assurance as required by the regulatory authorities. Cost estimates for site reclamation are included in the discussion of the project economics and operating costs.

A number of additional approvals and permits will be required as project development proceeds, as detailed below:

| | • | Storm water permit; |

| | | |

| | • | Kern County building permits to include all applicable California codes and |

| | | |

| | • | Permit to store and dispense fuel onsite with provision for gasoline vapor recovery. |

Newly implemented security requirements make contract blasting a preferred option and a contract blasting service will be used. The contractor will be required to obtain the necessary approvals and permits.

| October 2012 | 4-4 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Conditions GQM must meet both before the start of construction, during operations and after operations have ended are set out in the Mitigation Measures Monitoring Program and Conditions of Approval.

4.8 Cautionary Statement

As noted in Section 1.6, the Project has been approved by the Kern County Planning Commission and the Kern Country Planning and Community Development Department. The Commission accepted the project plan subject to a number of Conditions of Approval. A number of these conditions specifically address issues related to reclamation of the property including backfilling and restoration to approximate pre-mining topography.

The mine plan presented in this document represents best efforts by Norwest to develop a mine plan which maximizes in-pit backfill while not unduly penalizing the Project’s economic viability. The pit shells used as a basis for this feasibility study were selected based on consideration of both economic and waste volume considerations with the goal of developing pit configurations which balanced ore tonnage against waste quantities.

In order for the current mine plan to meet all the conditions laid out by the County, approximately 19 million tons of waste rock must be sold as aggregate and removed from site prior to final reclamation. In addition, all the leached residues must be either permitted to remain in place or be sold as aggregate. If this quantity cannot be sold, the necessity of handling this additional volume as part of the reclamation plan will affect the overall ore tonnage that can be mined at site. While no costs or revenues associated with aggregate production using this material, have been included in the Project economic analysis, removal of these materials is an integral component of the integrated mining and backfilling plan. If these quantities of material remain onsite, it will require revision of the mining plan in order to meet the backfill requirements which could reduce the life of the heap leach operation by up to 5 years.

Norwest has worked with GQM to develop a scenario which limits the effect of this on the mine life and GQM has had promising discussions with a local aggregate contractor regarding the saleability of the waste rock and leached residues into the regional market. However, there is still a potential risk that meeting the requirements of the Conditions of Approval could affect the overall mine life.

The current mine plan includes mining and dumping activities beyond areas currently within the permitted limits. Norwest understands that GQM owns or is in negotiations with landholders to secure access and to expand the permit boundary however failure to do so could affect the current mine plan.

| October 2012 | 4-5 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| October 2012 | 4-6 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 5 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

5.1 Access

Refer to sub-section 19.1 for a detailed description of access to site.

Access to site is from State Route 14 and Silver Queen Road, an existing paved county road. Access also exists from the south via Mojave Tropico Road, an existing paved county road. State Route 14 is the major highway, which connects Mojave, Rosamond, Lancaster and Palmdale to the greater Los Angeles area.

The Kern County Planning Department has assigned a new street address for the Project – 2818 Silver Queen Road, Mojave, CA 93501.

5.2 Climate

The Mojave region is generally characterized as arid, with a wet season from December through March. Rainfall events tend to be short-lived and of high intensity. Mojave experiences high summer temperatures up to 113°F. The minimum temperature may reach 20°F. Maximum wind speed is 90mph with Exposure C for design purposes. Mean recorded annual rainfall is 6.14 inch with a mean maximum month of 1.11 inch.

Exploration is possible year round, though snow in winter and wet conditions can make travel on unimproved dirt roads difficult. It is also expected that mining operations will be conducted year round.

5.3 Local Resources

Services such as a hospital, ambulance, fire-protection, garbage and hazardous waste disposal, schools, motels and housing, shopping, airport and recreation are available in Mojave and its surroundings. Telephone and internet service are available on site.

Mojave is a railroad hub for the Burlington Northern/Santa Fe and Union Pacific/Southern Pacific railroad lines.

Off-site infrastructure such as the availability of power and a backup water supply is described in sub-section 19.3.

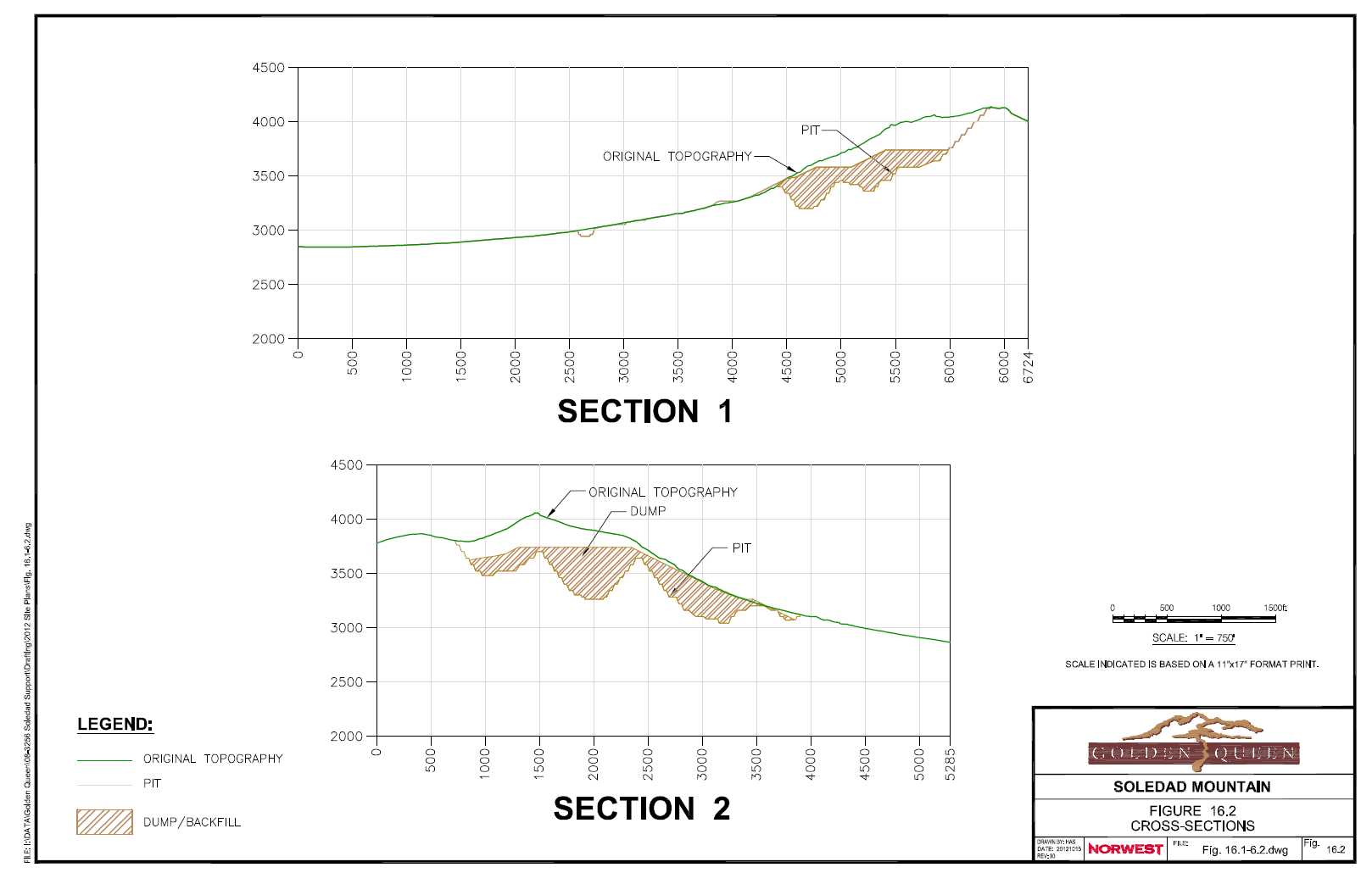

5.4 Physiography

The Soledad Mountain gold-silver deposit is hosted in a volcanic sequence of rhyolite porphyries, quartz latites and bedded pyroclastics that form a large dome-shaped feature, called Soledad Mountain, along the margins of a collapsed caldera. The deposit is located on the central-northeast flank of Soledad Mountain. The mountain has a domal form that is a reflection of an original, dome-shaped volcanic center. The Project is located on the flanks of Soledad Mountain. Elevations range from 4,180 ft. above mean sea level at the highest point of Soledad Mountain to 2,840 ft. above mean sea level at the valley floor north of the mountain. The topographic relief ranges from moderate to steep.

| October 2012 | 5-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

Vegetation is typical of the Basin and Range physiographic province. The lower slopes of Soledad Mountain are covered by sagebrush, grass, and various desert shrubs. Fauna that have been observed in the Project area are typical of those of the Great Basin area.

5.5 Sufficiency of Surface Rights

The Kern County Planning Commission formally considered the Project on April 8, 2010. At the meeting, the Commission, consisting of a panel of three commissioners, unanimously approved the Project. The Planning Commission certified the Supplemental Environmental Impact Report (SEIR) and adopted a Mitigation Measures Monitoring Program and a set of Conditions of Approval for the Project. The Mitigation Measures Monitoring Program and Conditions of Approval for the Project were amended by Commission Resolution No. 171-10 adopted on October 28, 2010 and are now final. The Approved Plan for the Project includes an Approved Project Boundary with a legal description checked and confirmed by the Kern County Engineering, Surveying & Permit Services Department.

GQM believes that the land required for the Project, which has been included within the Approved Project Boundary, has either been secured under a mining lease or is held by GQM through ownership of the land in fee or via patented and unpatented lode mining claims or millsites. Detail on the SEIR is provided in sub-section 21.1.1.

The current mine plan includes mining and dumping activities beyond areas currently within the permitted limits. Norwest understands that GQM owns or is in negotiations with landholders to secure access and to expand the permit boundary however failure to do so could affect the current mine plan.

5.6 Comments on Section 5

In the opinion of the Norwest QP:

The proposed project site is located in an area with access and services that can support the development and operation of the configuration and scale currently planned by GQM.

| October 2012 | 5-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 6 | HISTORY | |

| | |

| The first recorded mining activity in the Mojave Mining District occurred on March 8, 1894,when W.W. Bowers discovered gold on a promontory south of Mojave, then named Bowers' Hilland now known as Standard Hill. This soon led to the discovery of the Exposed Treasure vein onthe same hill.Later that year gold was found on Tropico Hill, in the Rosamond Hills.Prospecting also started on Soledad Mountain and gold was found on the Queen Esther, Karma,Echo, Elephant and Gray Eagle properties. |

| | |

| The first mill was built at the Exposed Treasure Mine in 1901. This mill had 20 stamps and acyanide plant. Construction of other mills followed rapidly - the Echo mill in 1902 with 10stamps, the Queen Esther mill in 1903 and the Karma mill in 1904 with 20 stamps. Of theseproperties, the Exposed Treasure, with production equivalent to 3,260 kg or 105,000 oz of gold,was the largest; the Queen Esther, with production equivalent to 1,930 kg or 62,000 oz ofgold,was second and the Karma third with production equivalent to 1,150 kg or 37,000 oz ofgold.The last of these early mills was shut down in 1914 when the readily available ore wasexhausted. |

| | |

| The district attracted brief attention eight years later with a find of rich ore on the Yellow Dogclaim located on a small butte near Bowers' Hill, but interest soon waned as the deposit proved tobe small. |

| | |

| The revival of the district is attributable in part to the Burton Brothers, who, as owners of theTropico mine and mill, assisted lessors in the district by grub-staking prospectors and providinga mill for the treatment of lessees' ore. Lessees looking for a new area to work (George Holmes)found some float that led to the discovery of the Silver Queen vein system on Soledad Mountain in1933.Claims were staked and exploration was done. The property was sold to a syndicate(Golden Queen Mining Co.) headed by Gold Fields America Development Co. (GFA) in January1933. |

| | |

| GFA did extensive exploration on the property in the next few years, which resulted in a largeincrease in ore reserves. The Golden Queen vein was also discovered at that time. During thisperiod of exploration on the Golden Queen vein, an area south and west of the Golden Queenvein was also explored and a large vein was discovered on the Starlight claim. The SoledadExtension vein, west of the Starlight vein was also discovered. The Lodestar Mining Co. obtainedcontrol of this area. |

| | |

| GFA built a 300 ton/d mill on the property and production started in October 1935. The mill wasthen expanded to 400 ton/d. Ore was extracted from the Silver Queen, Golden Queen, Soledad,Queen Esther and Karma veins plus ore was custom-milled from other properties in the area.Tailings from smaller, historical mining operations were also retreated. Production continueduntil the mine was closed by Order L-208 of the War Production Board in 1942. Althoughrecords are incomplete, it is estimated that 1.3 million ton of ore was mined and milled withaverage grades of 9.5 g/t gold or 0.277 oz/ton gold and 223 g/t silver or 6.5 oz/ton silver. The mine did not resume production after the war although some exploration and development work was done. GFA returned the property to its former owners in 1953 and the company was dissolved. |

| October 2012 | 6-1 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

It is estimated that a total of 8,030 ton of ore was mined in the Project area by lessors in the early 1950s.

The only exploration of note in the project area between 1953 and 1985 was undertaken by Rosario Exploration and Shell/Billiton and is further discussed in Section 10.2.

The Cactus Gold Mine, Standard Hill Mine and Tropico Mine are also located in the Mojave Mining District. These former operating mines are located within a 5 mile radius of Soledad Mountain.

| October 2012 | 6-2 |  |

| Soledad Mountain Project

Kern County, CA, USA

Technical Report |

| 7 | GEOLOGICAL SETTING AND MINERALIZATION |

| | |

| Ttwo evaluations of the geology of the Soledad Mountain area were carried out, the first by MRDI and the second by SRK, who issued a NI 43-101 compliant Technical Report in March 2006, which is available on SEDAR and on the GQM website at www.goldenqueen.com. |

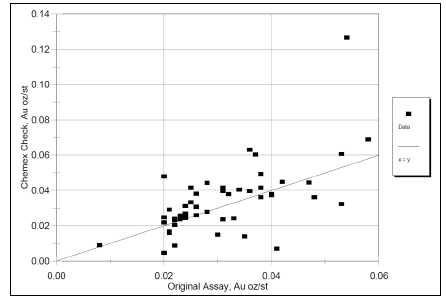

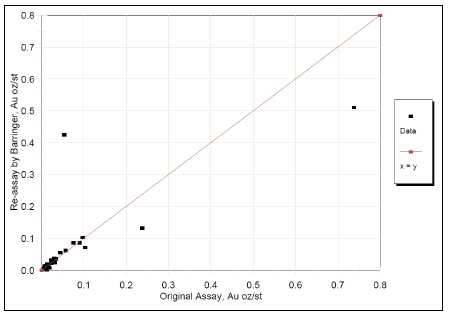

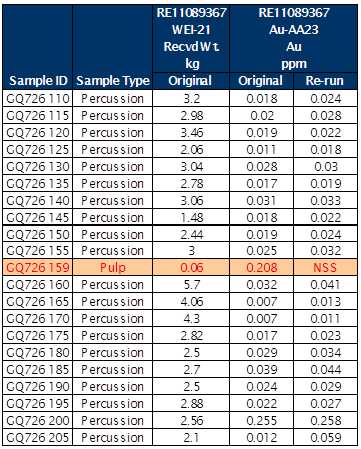

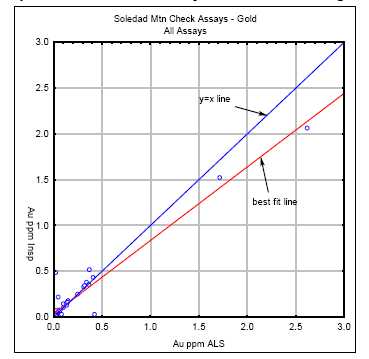

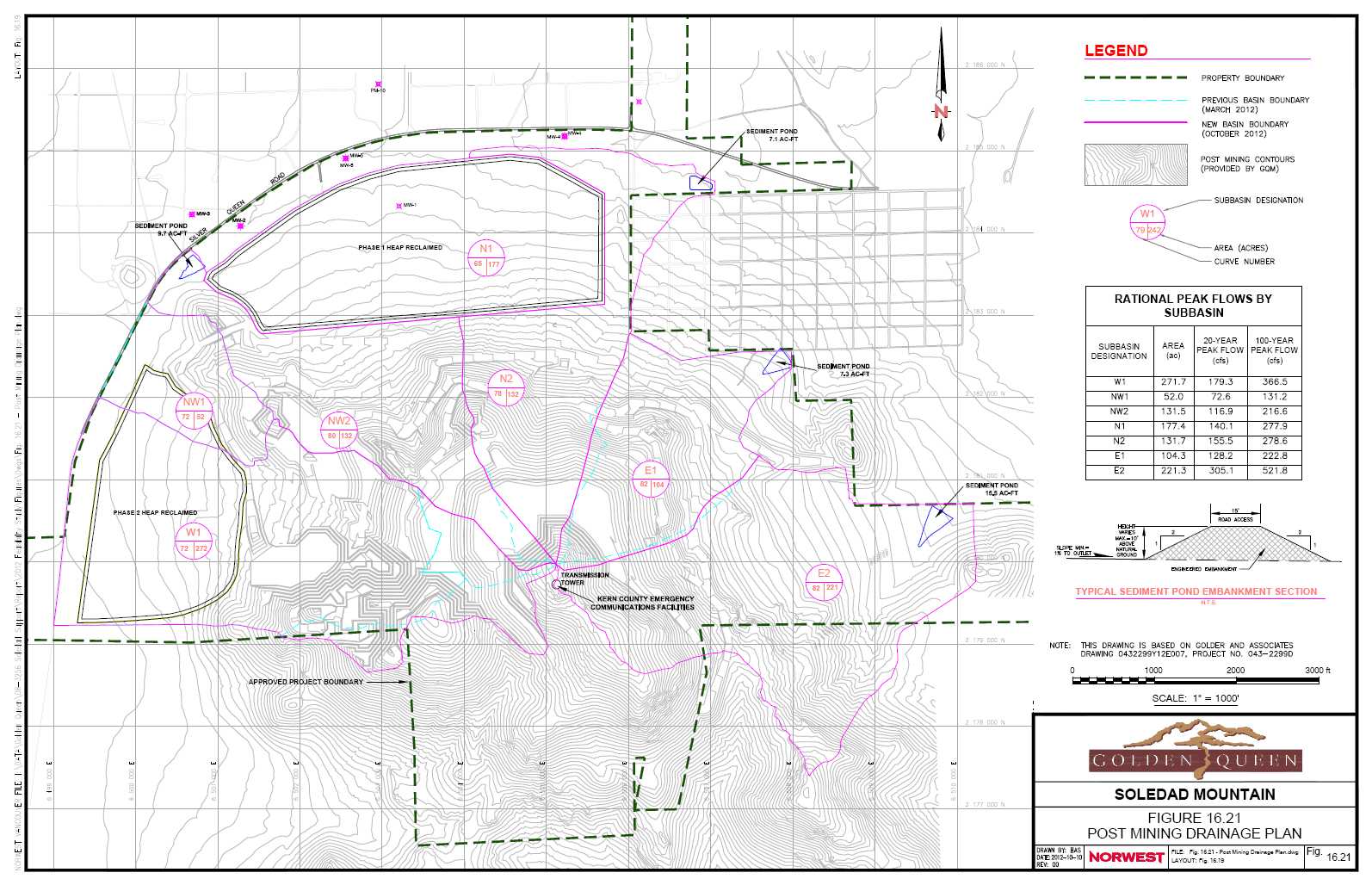

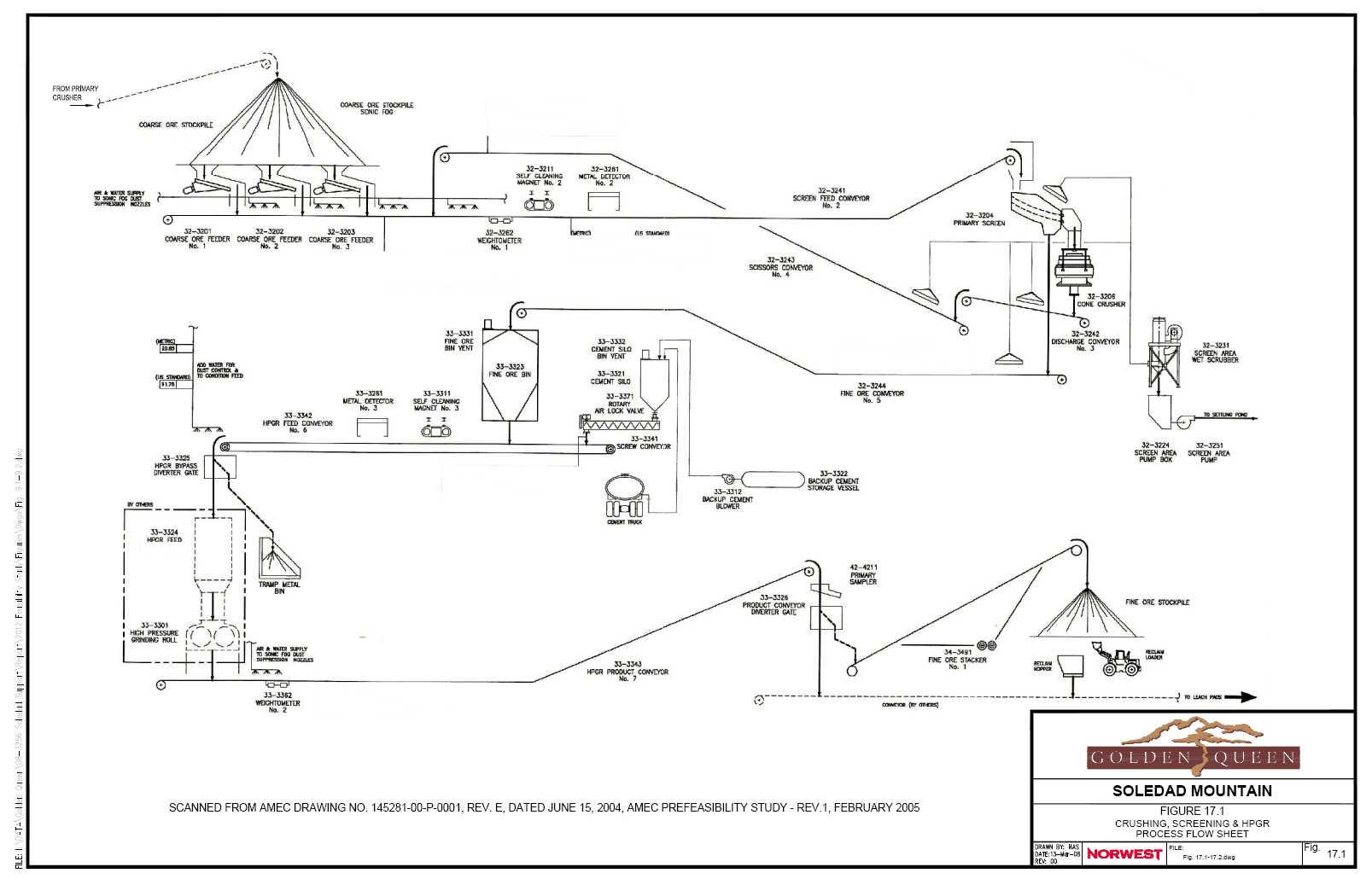

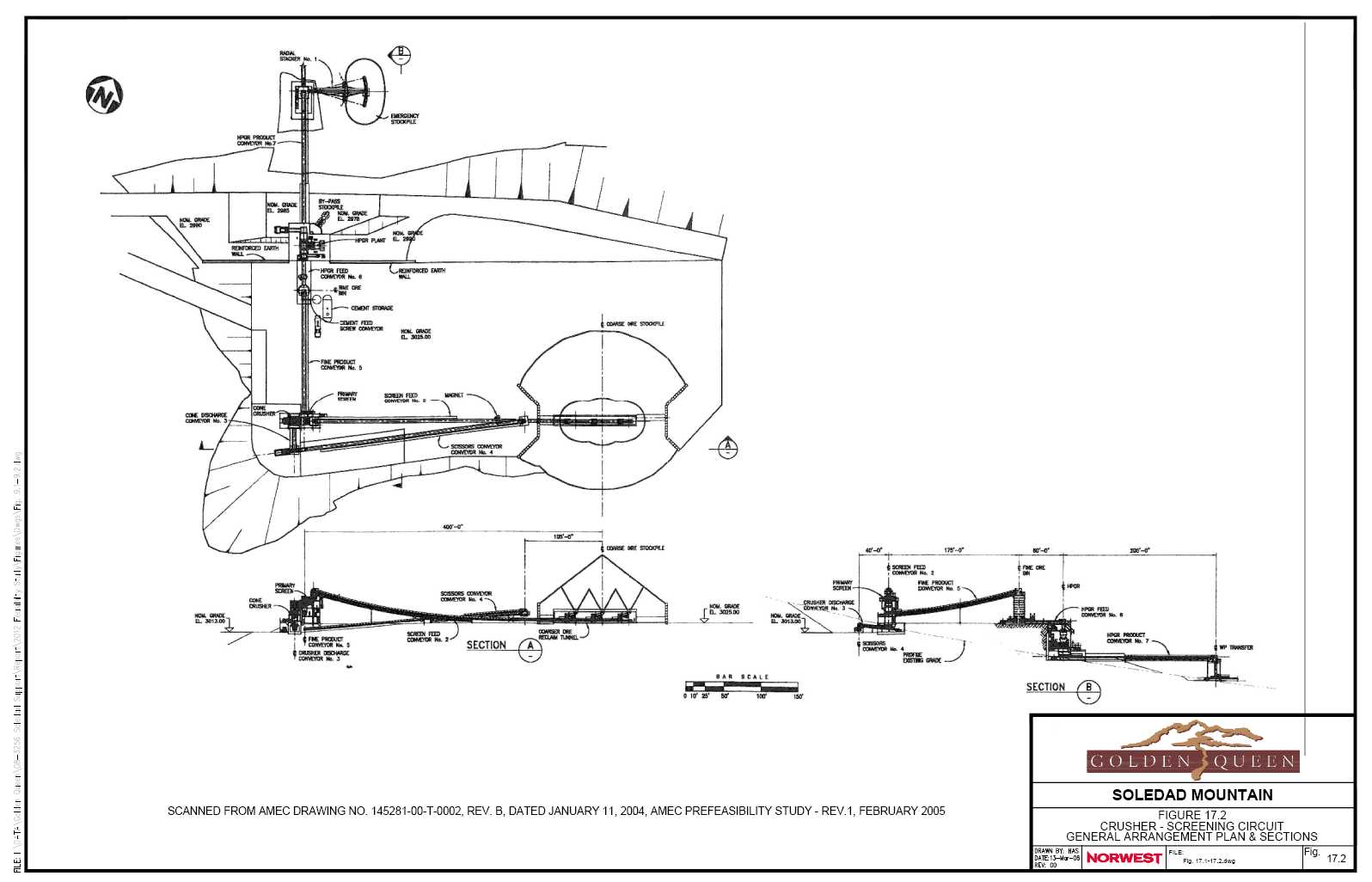

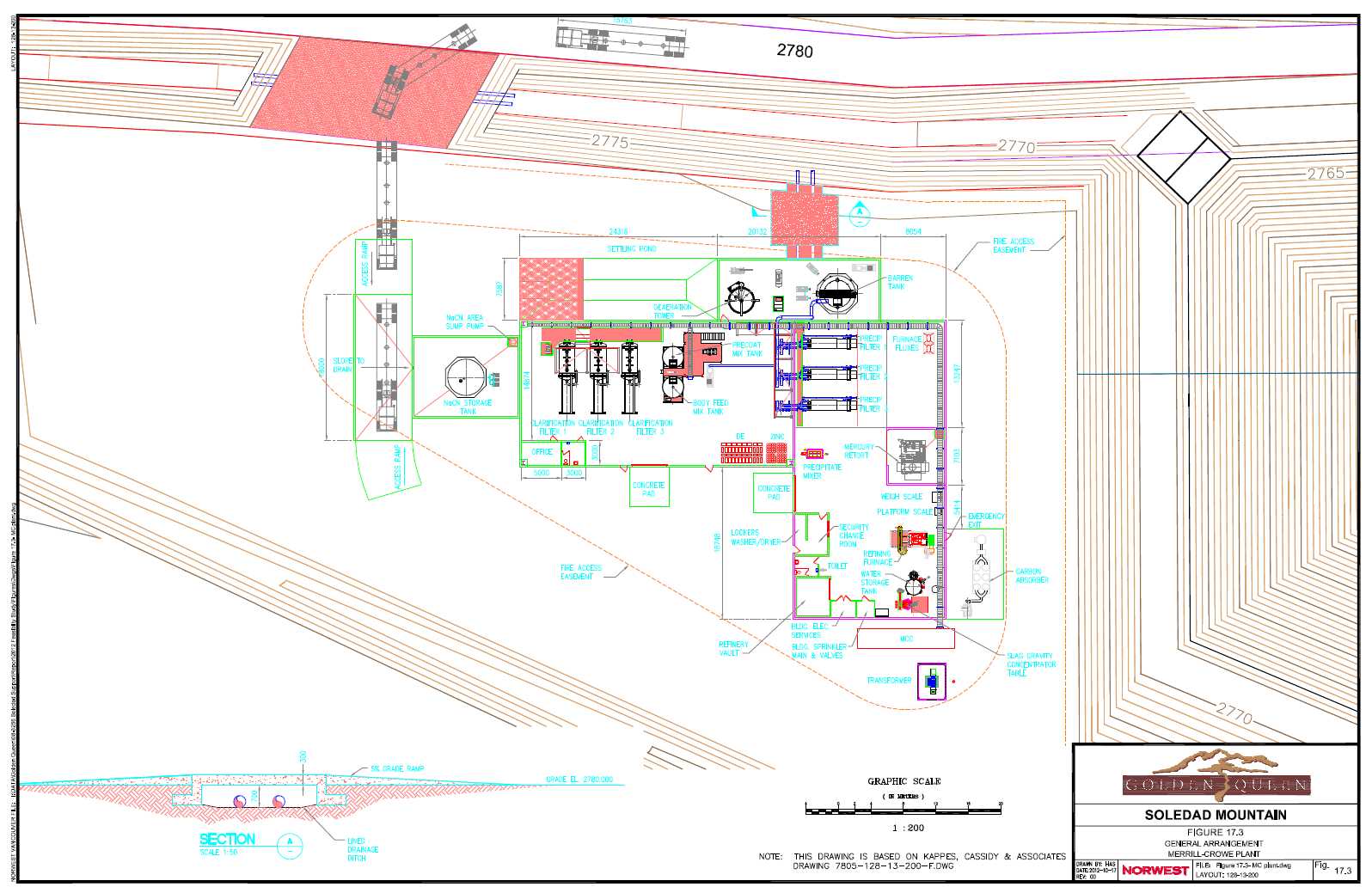

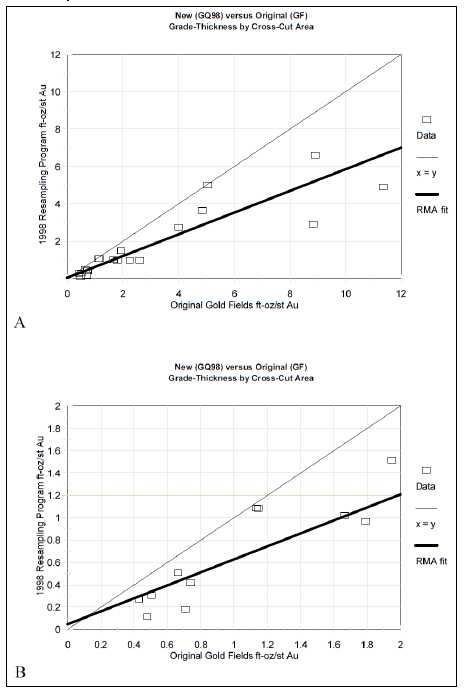

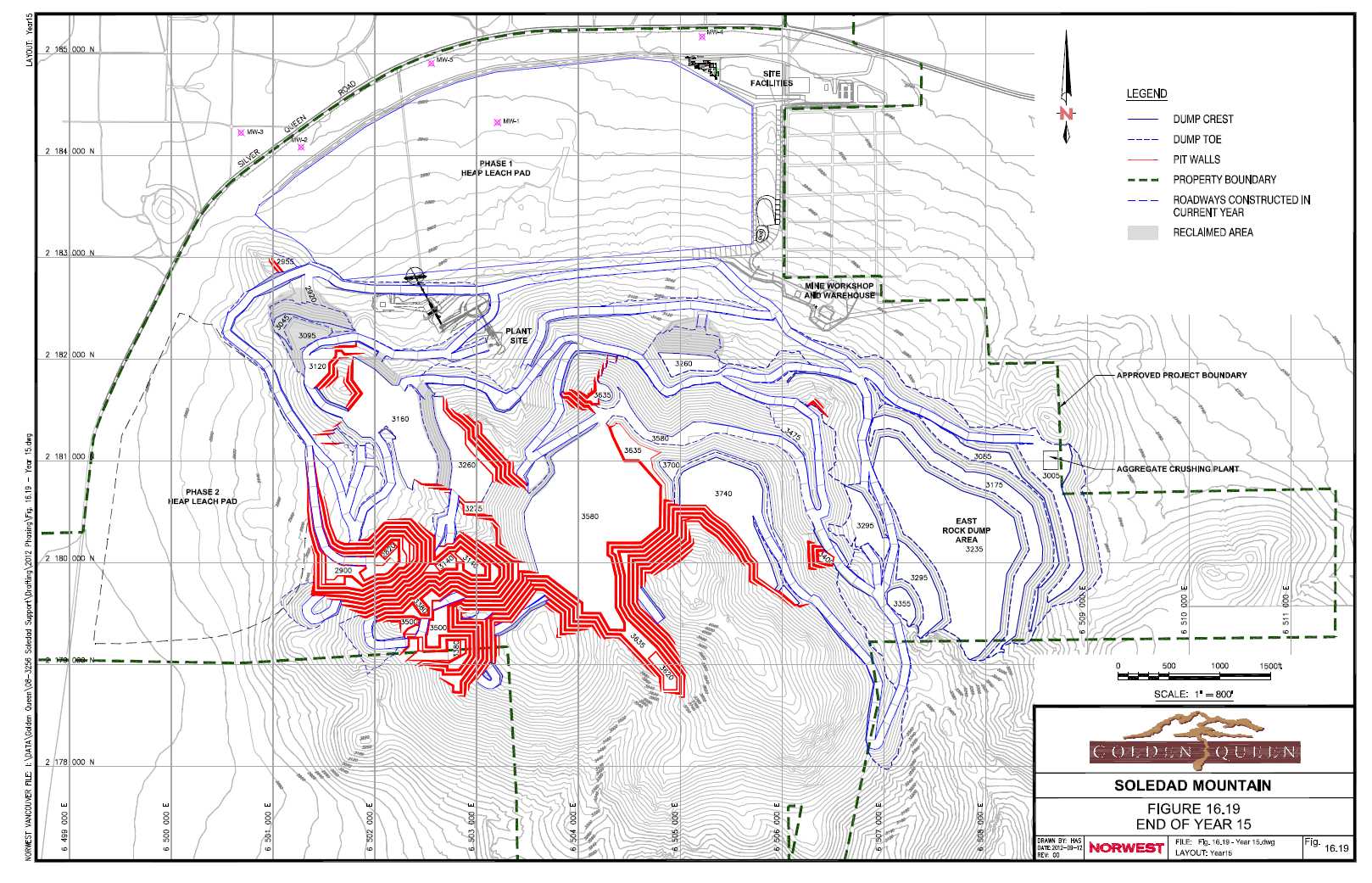

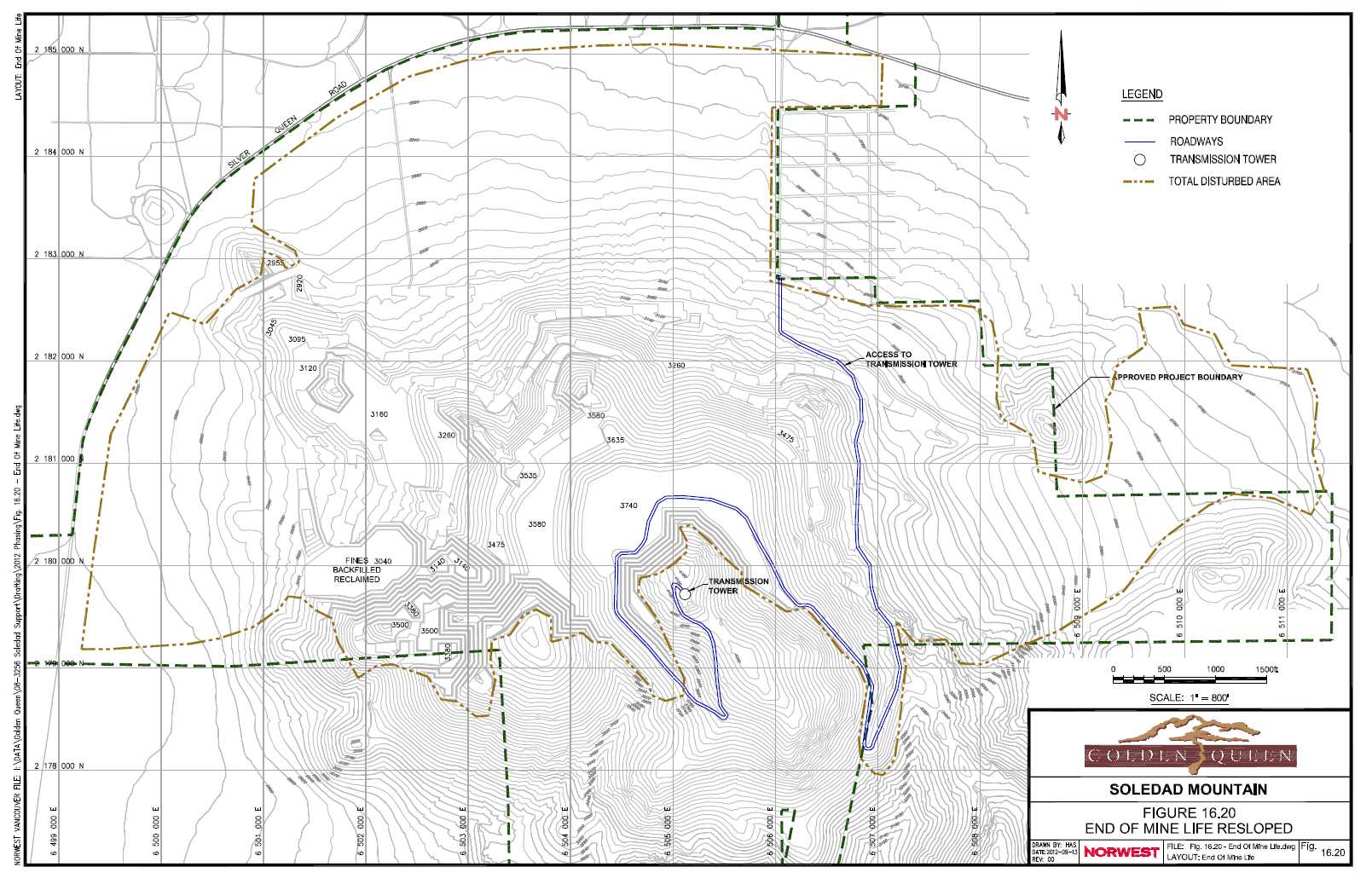

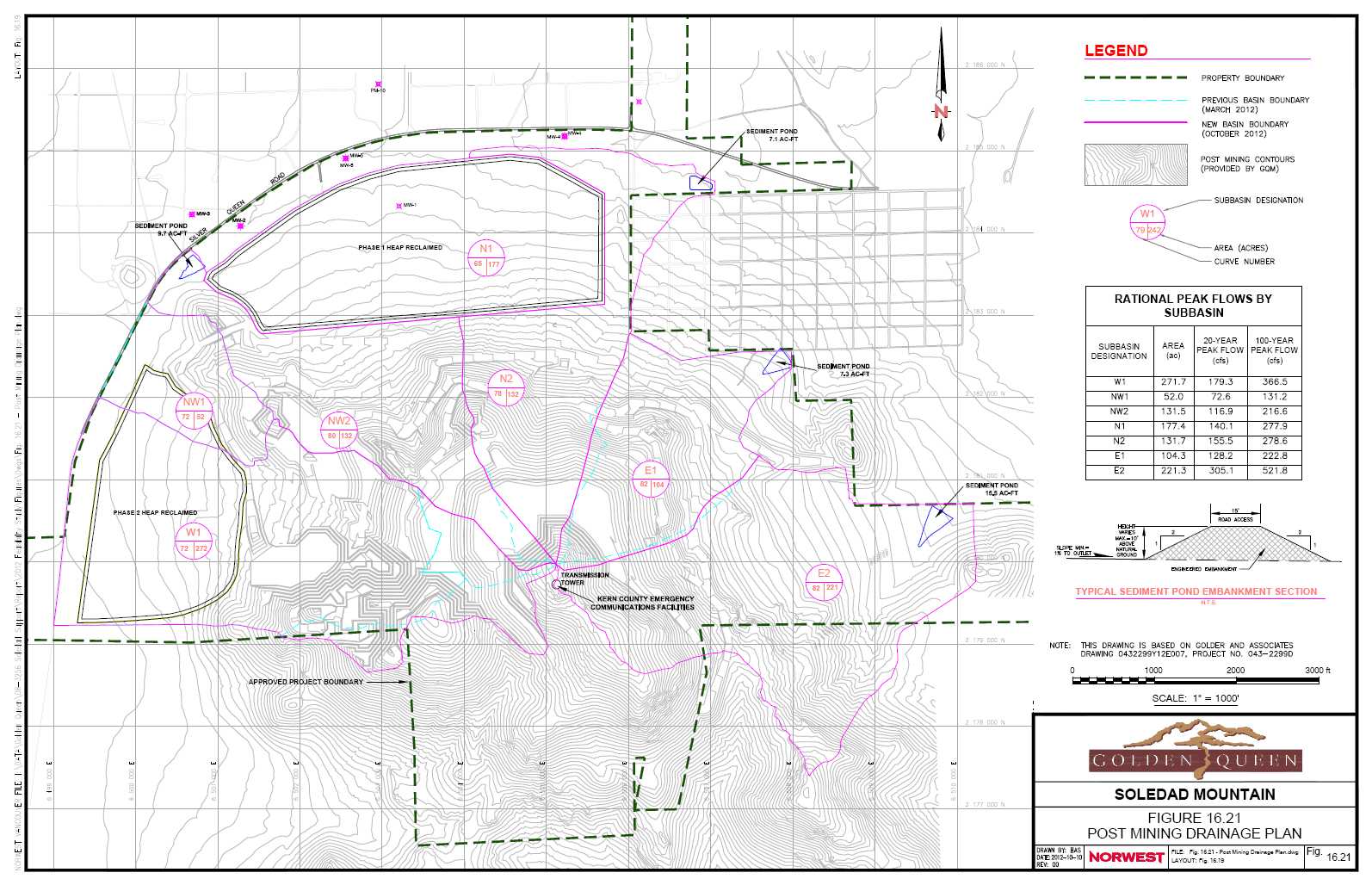

7.1 Regional Geology