Exhibit 99.1

|

| Canadian National Instrument 43-101 Technical Report |

| in Support of the Preliminary Assessment on the |

| Development of the Los Azules Project, San Juan |

| Province, Argentina |

| |

| Effective Date: March 19, 2009 |

| |

| Prepared for: | Prepared by: |

| |

| Minera Andes, Inc. | Samuel Engineering, Inc. |

| 111 East Magnesium Road, Suite A | 8450 East Crescent Parkway, Suite 200 |

| Spokane, Washington 99208 USA | Greenwood Village, Colorado 80111 USA |

| |

| Qualified Persons (Contributors) |

| |

| Randolph P. Schneider, MAusIMM | William L. Rose, P.E. |

| Robert Sim, P.Geo | Scott Elfen, P.E. |

| Bruce Davis, PhD., FAusIMM | |

Exhibit 99.1

|

|

| | | |

| Table of Contents |

| |

| 3.0 | SUMMARY | 1 |

| 3.1 | OVERVIEW OF THE STUDY | 2 |

| 3.2 | PROPERTY DESCRIPTION AND OWNERSHIP, LOCATION, INFRASTRUCTURE AND HISTORY | 2 |

| 3.2.1 | Property Description and Ownership | 2 |

| 3.2.2 | Property Location | 4 |

| 3.2.3 | Infrastructure | 4 |

| 3.2.4 | Property History | 4 |

| 3.3 | GEOLOGY AND RESOURCES | 5 |

| 3.3.1 | Regional Geology | 5 |

| 3.3.2 | Property Geology | 5 |

| 3.3.3 | Resources | 5 |

| 3.3.4 | Resource Classification | 6 |

| 3.3.5 | Resources within Designed Pit Phases | 7 |

| 3.4 | METALLURGY | 8 |

| 3.5 | PROCESS | 8 |

| 3.5.1 | Process Description | 8 |

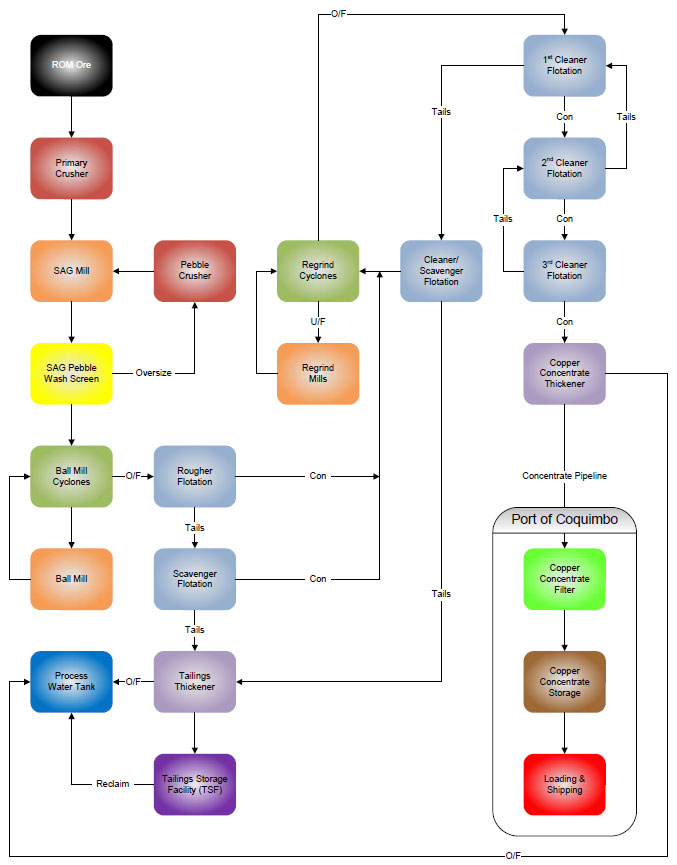

| 3.5.2 | Process Block Flow Diagram | 10 |

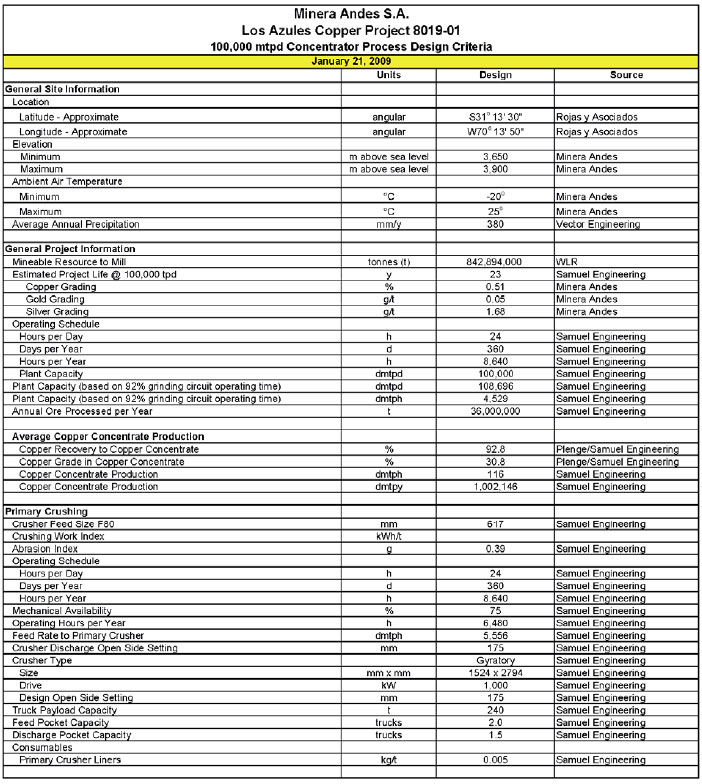

| 3.5.3 | Basic Process Design Criteria | 11 |

| 3.6 | TAILINGS STORAGE FACILITY (“TSF”) | 12 |

| 3.7 | WASTE ROCK DISPOSAL FACILITY (“WRDF”) | 12 |

| 3.8 | MINE PLAN | 13 |

| 3.9 | OPERATING COSTS | 15 |

| 3.10 | CAPITAL COSTS | 16 |

| 3.11 | PROJECT ECONOMICS | 17 |

| 3.12 | CONCLUSIONS & RECOMMENDATIONS | 19 |

| 4.0 | INTRODUCTION | 20 |

| 4.1 | PURPOSE OF TECHNICAL REPORT | 21 |

| 4.2 | SOURCES OF INFORMATION | 21 |

| 4.3 | SITE VISIT | 23 |

| 5.0 | RELIANCE ON OTHER EXPERTS | 24 |

| 5.1 | RELIANCE ON OTHER EXPERTS | 25 |

| 5.2 | PREVIOUS TECHNICAL REPORTS | 25 |

| 6.0 | PROPERTY DESCRIPTION AND LOCATION | 26 |

| 6.1 | LOCATION | 28 |

| 6.2 | PROPERTY AND TITLE IN ARGENTINA | 28 |

| 6.2.1 | Cateo | 28 |

| 6.2.2 | Mina | 29 |

| 6.2.3 | Estaca Minas | 30 |

| 6.2.4 | Provincial Reserve Areas | 30 |

| 6.3 | OWNERSHIP OF THE LOS AZULES PROJECT | 30 |

| 6.4 | TERMS OF LOS AZULES OPTION AGREEMENT AND UNDERLYING AGREEMENTS | 34 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

i

Exhibit 99.1

|

|

| | | |

| 6.5 | ENVIRONMENTAL BASELINE STUDIES | 35 |

| 6.5.1 | Physical components | 35 |

| 6.5.2 | Biological components | 36 |

| 6.6 | ENVIRONMENTAL LIABILITIES | 37 |

| 6.6.1 | Veranadas | 37 |

| 6.6.2 | Existing Exploration Roads | 37 |

| 6.7 | PERMITTING REQUIREMENTS | 38 |

| 6.7.1 | Exploration and Prospecting Requirements | 38 |

| 6.7.2 | Requirements to Proceed to Prefeasibility Study Phase | 38 |

| 6.8 | PERMITTING REGULATIONS | 38 |

| 6.8.1 | Environmental Regulation | 38 |

| 6.8.2 | Mine Regulation | 39 |

| 6.8.3 | Hazardous Waste and Health and Safety Regulation | 39 |

| 7.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 42 |

| 7.1 | ACCESSIBILITY | 43 |

| 7.1.1 | General | 43 |

| 7.1.2 | Surface Rights | 43 |

| 7.2 | CLIMATE | 43 |

| 7.3 | LOCAL RESOURCES AND INFRASTRUCTURE | 46 |

| 7.3.1 | Proximity of Property to Population Centers | 46 |

| 7.3.2 | Power | 47 |

| 7.4 | PHYSIOGRAPHY | 51 |

| 8.0 | HISTORY | 52 |

| 8.1 | PROPERTY HISTORY | 53 |

| 9.0 | GEOLOGICAL SETTING | 54 |

| 9.1 | REGIONAL GEOLOGY | 55 |

| 9.1.1 | Pre-Jurassic Basement | 55 |

| 9.1.2 | Mesozoic Sequence | 55 |

| 9.1.3 | Cenozoic Sequence | 55 |

| 9.1.4 | Quaternary | 58 |

| 9.2 | PROPERTY GEOLOGY | 58 |

| 9.2.1 | Lithology | 60 |

| 9.2.2 | Alteration | 63 |

| 10.0 | DEPOSIT TYPES | 66 |

| 10.1 | INTRODUCTION | 67 |

| 10.2 | TYPICAL PORPHYRY COPPER SYSTEM | 67 |

| 10.3 | LOS AZULES DEPOSIT | 69 |

| 11.0 | MINERALIZATION | 71 |

| 12.0 | EXPLORATION | 74 |

| 12.1 | EXPLORATION HISTORY | 75 |

| 12.2 | SUBSEQUENT EXPLORATION | 76 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

ii

Exhibit 99.1

|

|

| | | |

| 13.0 | DRILLING | 77 |

| 13.1 | DRILLING HISTORY | 78 |

| 13.2 | CURRENT DRILLING | 79 |

| 14.0 | SAMPLING METHOD AND APPROACH | 82 |

| 15.0 | SAMPLE PREPARATION, ANALYSIS AND SECURITY | 84 |

| 15.1 | INTRODUCTION | 85 |

| 15.2 | SAMPLE PREPARATION | 85 |

| 15.2.1 | Core Sampling | 86 |

| 15.2.2 | QC Sample Insertion | 86 |

| 15.2.3 | Chain of Custody | 86 |

| 15.3 | SAMPLE CONTROL STANDARDS | 87 |

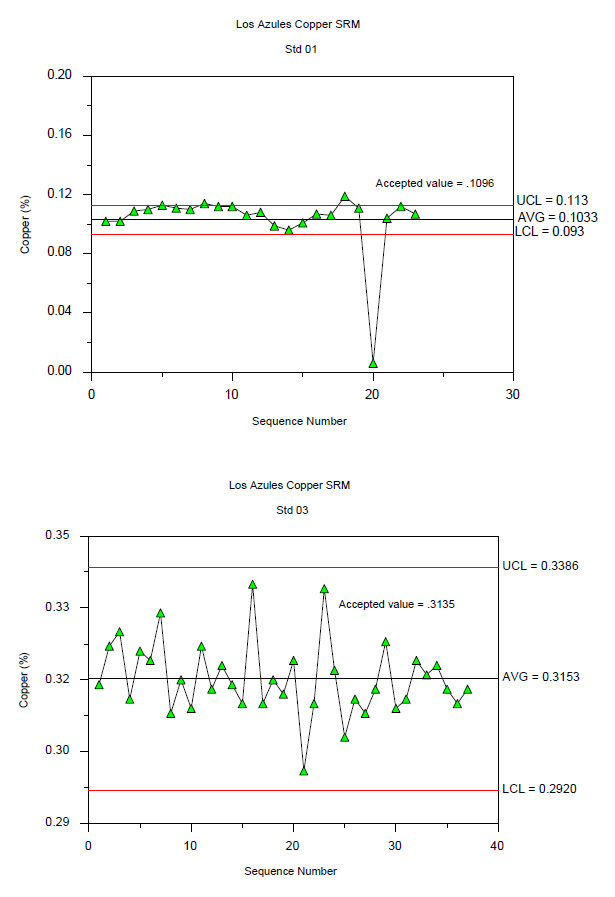

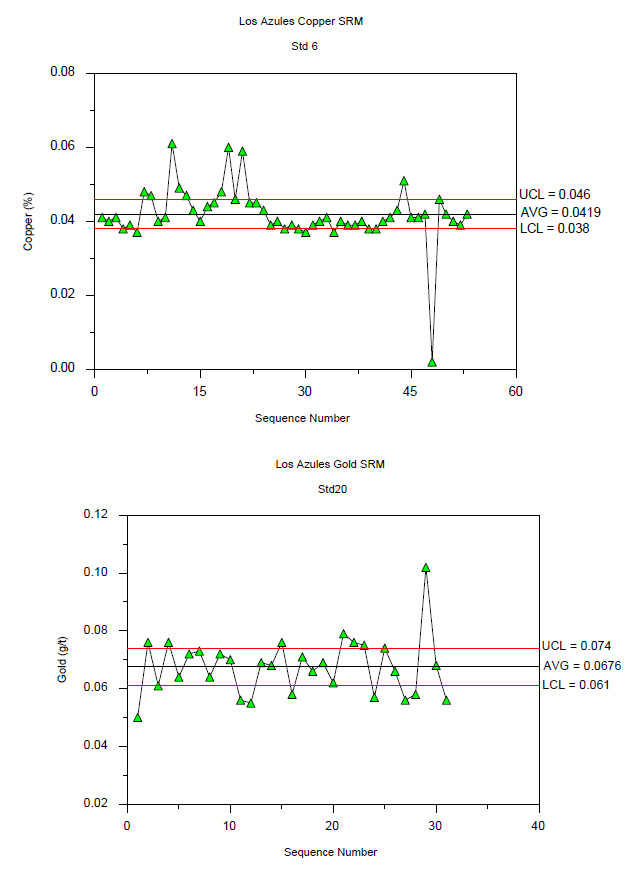

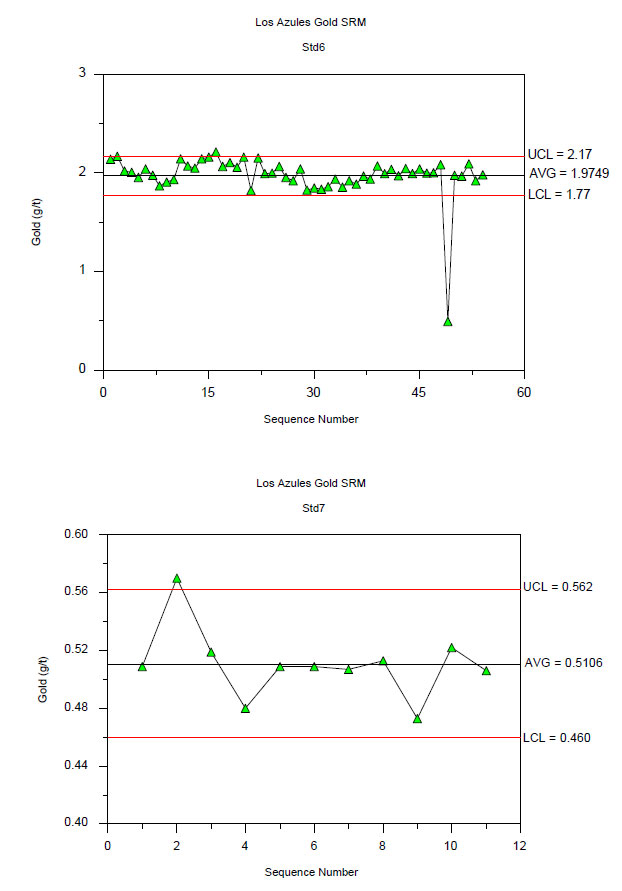

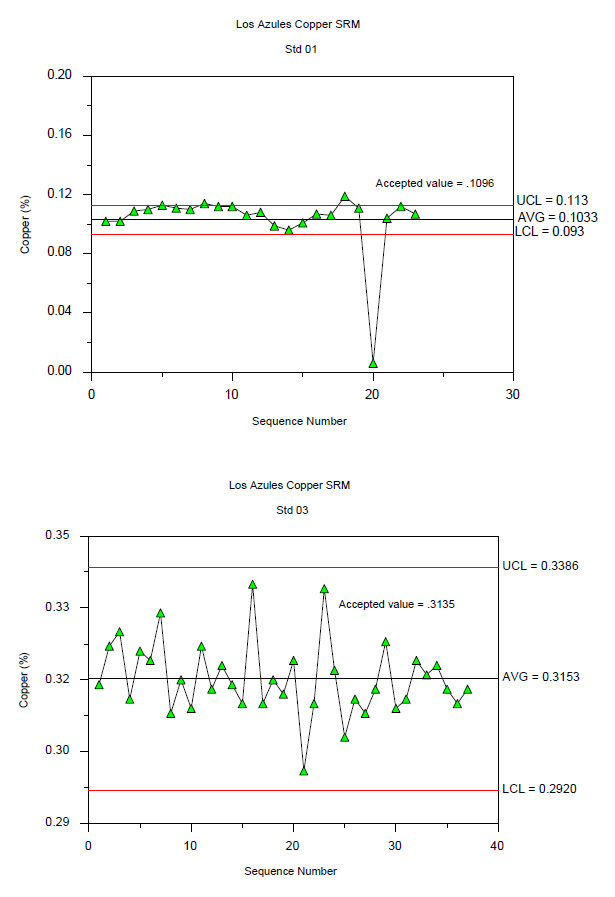

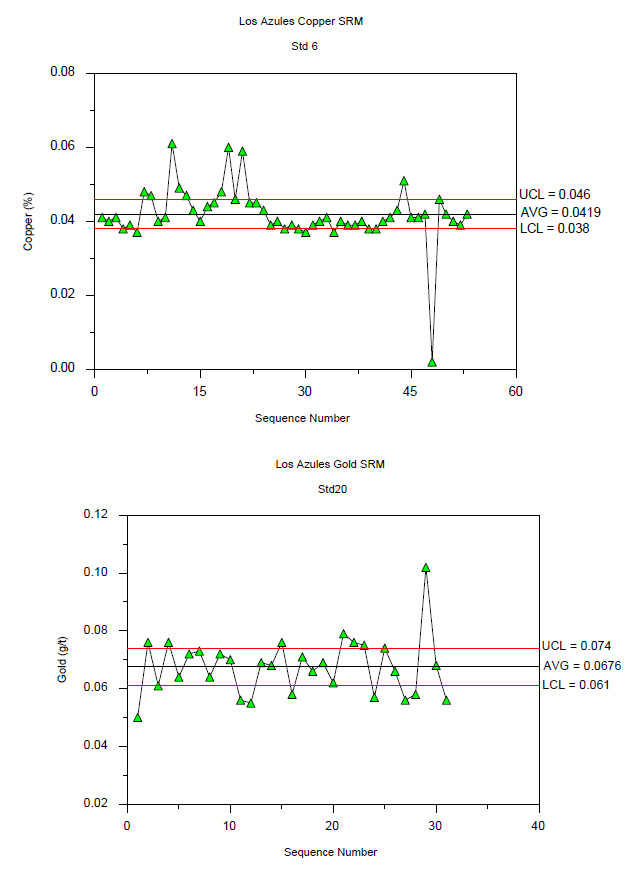

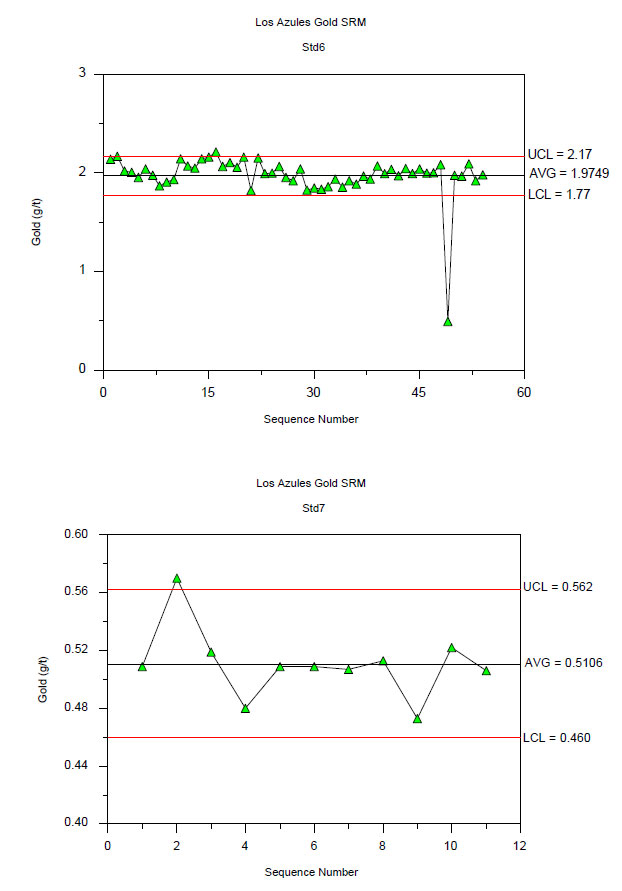

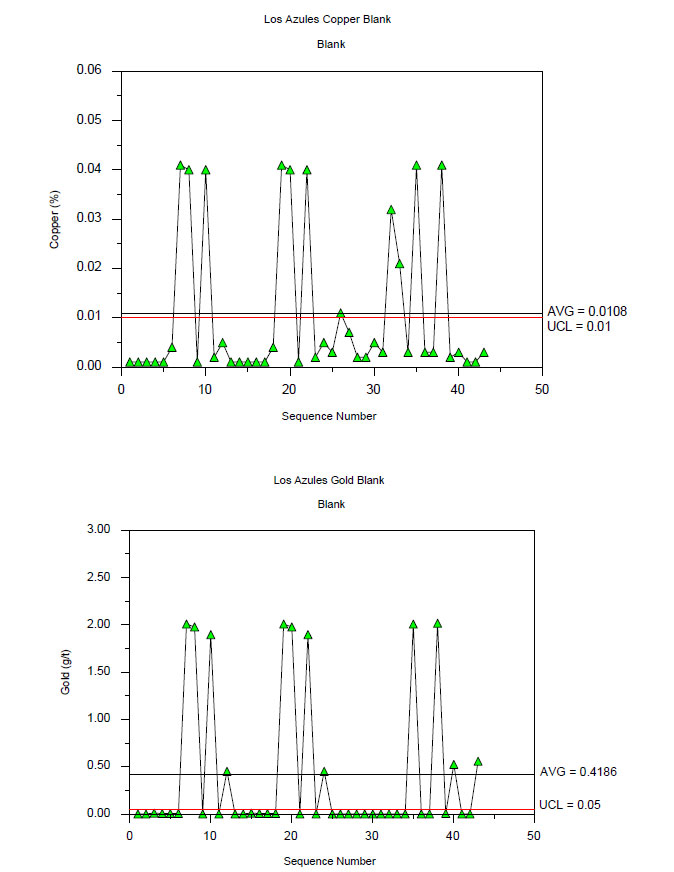

| 15.3.1 | Sample Standards | 87 |

| 15.3.2 | Control Sample Performance | 88 |

| 15.3.3 | Blank Sample Performance | 92 |

| 15.3.4 | Coarse Duplicate Sample Performance | 92 |

| 15.3.5 | Pulp Duplicate Sample Performance | 92 |

| 15.4 | CONCLUSIONS | 94 |

| 16.0 | DATA VERIFICATION | 95 |

| 16.1 | VERIFICATION OF GEOLOGIC DATA | 96 |

| 16.1.1 | Database Verification | 96 |

| 16.1.2 | Site Visit Validation | 97 |

| 16.1.3 | Conclusions | 97 |

| 16.2 | VERIFICATION OF ANALYTICAL DATA | 97 |

| 17.0 | ADJACENT PROPERTIES | 98 |

| 18.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 100 |

| 18.1 | INTRODUCTION | 101 |

| 18.2 | REVIEW OF METALLURGICAL TEST WORK | 101 |

| 18.2.1 | Summary | 101 |

| 18.2.2 | Bottle Roll Leaching Tests | 101 |

| 18.2.3 | Grinding | 101 |

| 18.2.4 | Flotation | 102 |

| 18.3 | PROCESS INTRODUCTION | 103 |

| 18.4 | PROCESS FLOWSHEET DEVELOPMENT | 103 |

| 18.5 | PROCESS PLANT SITING CONSIDERATIONS | 103 |

| 18.6 | PROCESS BLOCK FLOW DIAGRAM | 105 |

| 18.7 | PROCESS DESCRIPTION | 106 |

| 18.7.1 | Crushing and Coarse Ore Stockpile | 106 |

| 18.7.2 | Grinding | 106 |

| 18.7.3 | Flotation and Regrind | 106 |

| 18.7.4 | Concentrate Thickening | 107 |

| 18.7.5 | Concentrate Transportation | 107 |

| 18.7.6 | Concentrate Filtration and Storage | 108 |

| 18.7.7 | Filtrate Handling | 108 |

| 18.7.8 | Tailings | 110 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

iii

Exhibit 99.1

|

|

| | | |

| 18.7.9 | Reagents | 111 |

| 18.7.10 | Water Treatment, Dust and Emissions Control | 111 |

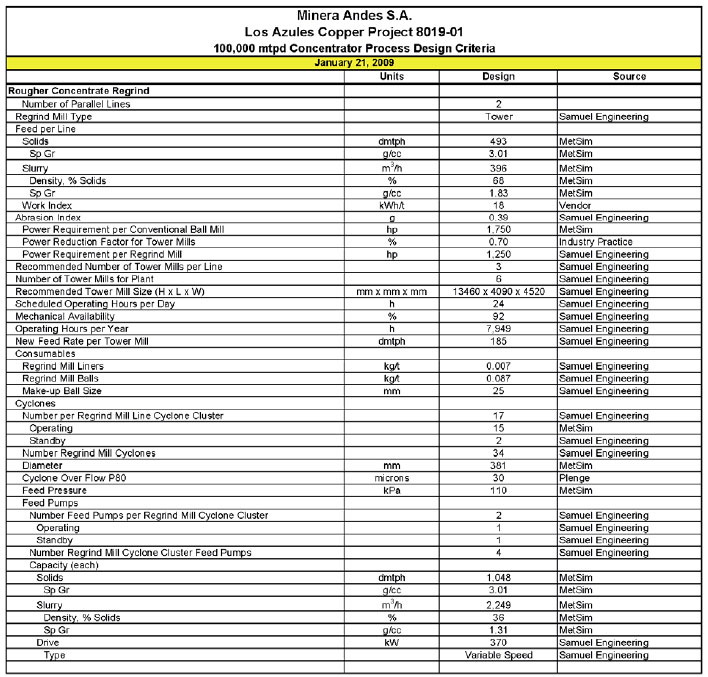

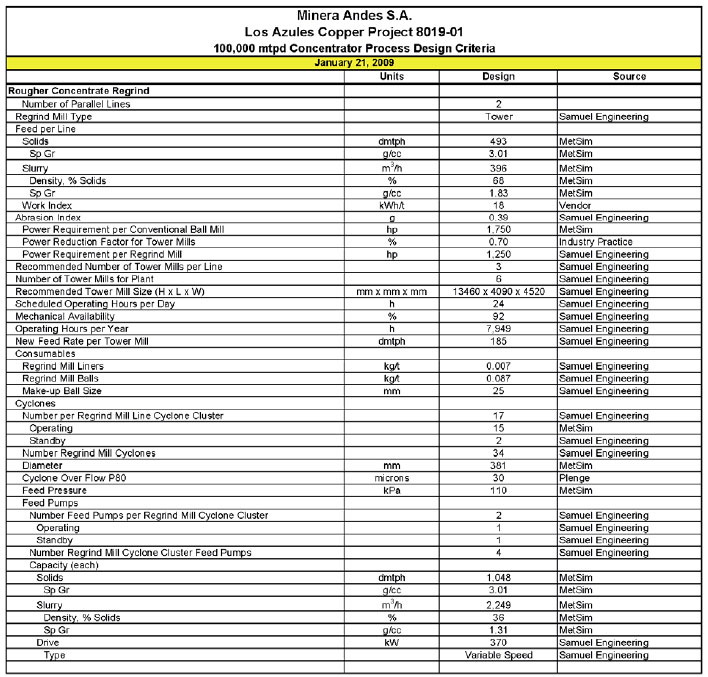

| 18.7.11 | Process Design Criteria | 111 |

| 19.0 | MINERAL RESOURCE ESTIMATE | 122 |

| 19.1 | INTRODUCTION | 123 |

| 19.2 | GEOLOGIC MODEL, DOMAINS AND CODING | 123 |

| 19.3 | DATABASE | 125 |

| 19.4 | COMPOSITING | 126 |

| 19.5 | STATISTICAL DATA ANALYSIS | 127 |

| 19.5.1 | Basic Statistics by Domain | 127 |

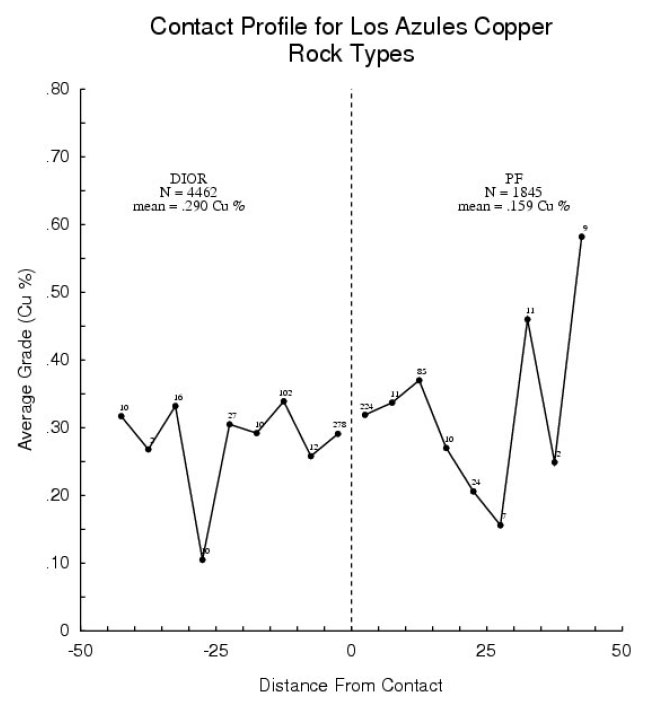

| 19.5.2 | Contact Profiles | 127 |

| 19.5.3 | Conclusions and Modeling Implications | 128 |

| 19.5.4 | Secondary Elements | 131 |

| 19.6 | BULK DENSITY DATA | 132 |

| 19.7 | EVALUATION OF OUTLIER GRADES | 132 |

| 19.8 | VARIOGRAPHY | 132 |

| 19.9 | THREE-DIMENSIONAL MODEL | 133 |

| 19.10 | PROBABILITY SHELL | 134 |

| 19.11 | INTERPOLATION PARAMETERS | 134 |

| 19.12 | VALIDATION | 137 |

| 19.12.1 Visual Inspection | 137 |

| 19.12.2 Model Checks for Change of Support | 137 |

| 19.12.3 Comparison of Interpolation Methods | 138 |

| 19.12.4 Swath Plots (Drift Analysis) | 139 |

| 19.13 | RESOURCE CLASSIFICATION | 139 |

| 19.14 | MINERAL RESOURCES | 143 |

| 19.15 | PIT LIMIT ANALYSIS | 143 |

| 19.16 | PIT DESIGN | 146 |

| 19.17 | MINERAL RESOURCES WITHIN DESIGNED PIT/PHASES | 146 |

| 20.0 | OTHER RELEVANT DATA AND INFORMATION | 148 |

| 20.1 | MINING OPERATIONS | 149 |

| 20.1.1 | Mine Production Schedule | 149 |

| 20.1.2 | Mine Equipment Selection and Fleet Requirements | 153 |

| 20.1.3 | Mine Personnel | 154 |

| 20.2 | INFRASTRUCTURE | 159 |

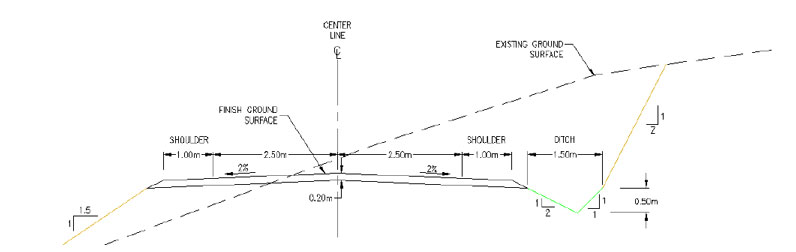

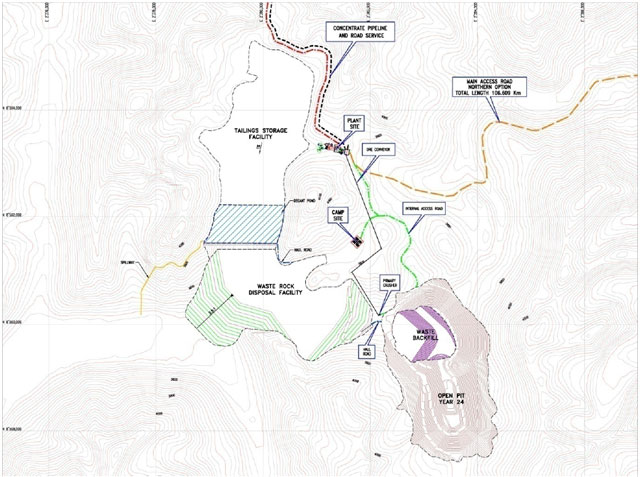

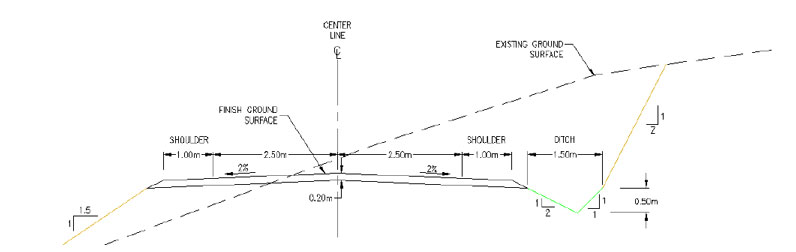

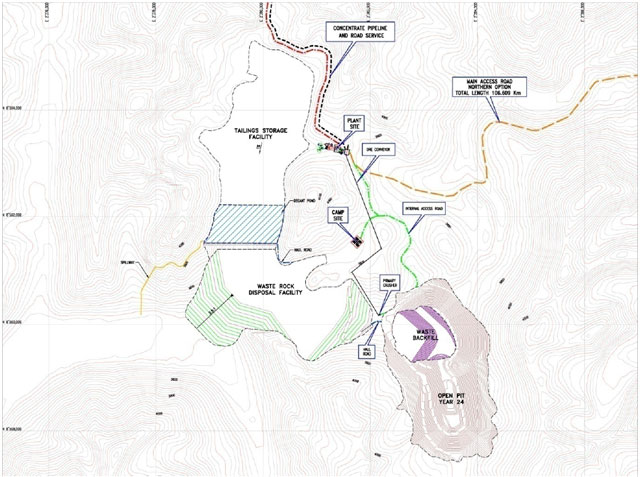

| 20.2.1 | Mine Access Road | 159 |

| 20.2.2 | Waste Rock Disposal Facility (“WRDF”) | 163 |

| 20.2.3 | Tailings Storage Facility (“TSF”) | 167 |

| 20.2.4 | Mancamp Facilities | 173 |

| 20.2.5 | Employee Housing and Transportation | 173 |

| 20.2.6 | Water Supply | 173 |

| 20.3 | RECLAMATION AND MINE CLOSURE | 182 |

| 20.4 | SEISMICITY | 183 |

| 20.5 | RECOVERIES | 186 |

| 20.6 | MARKETS | 186 |

| 20.7 | CONTRACTS | 186 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

iv

Exhibit 99.1

| | | |

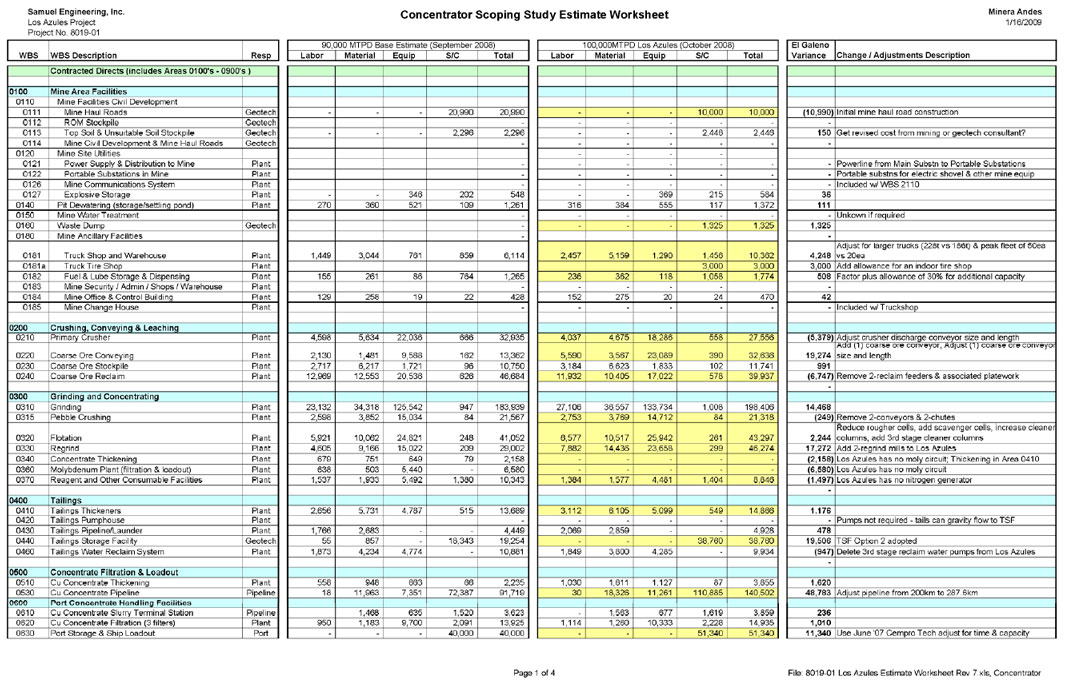

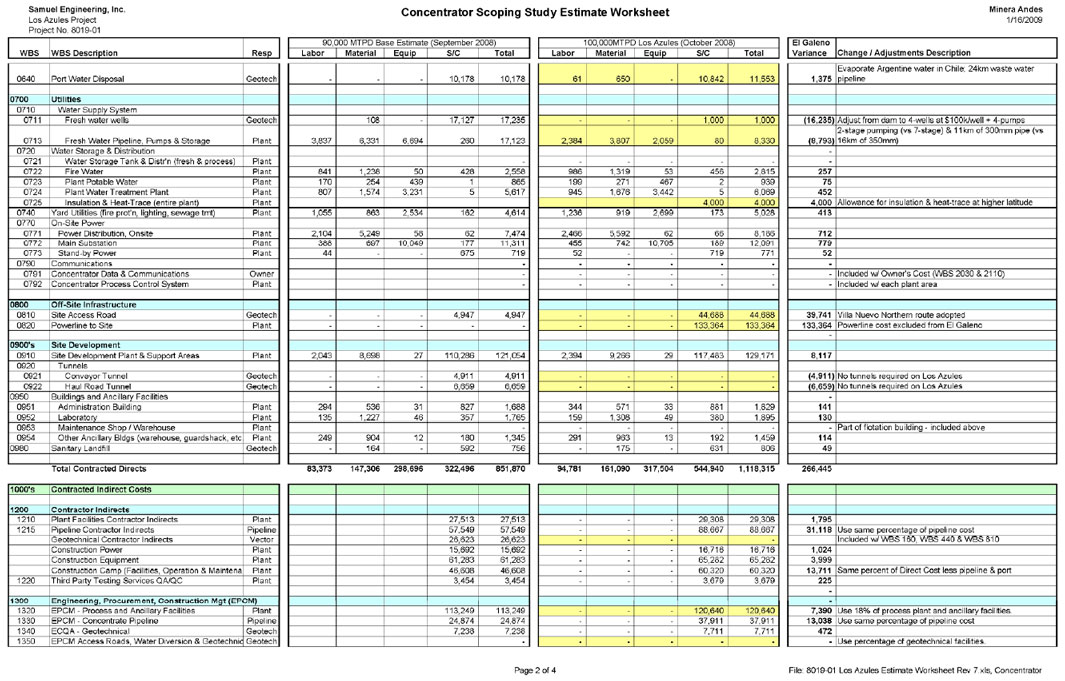

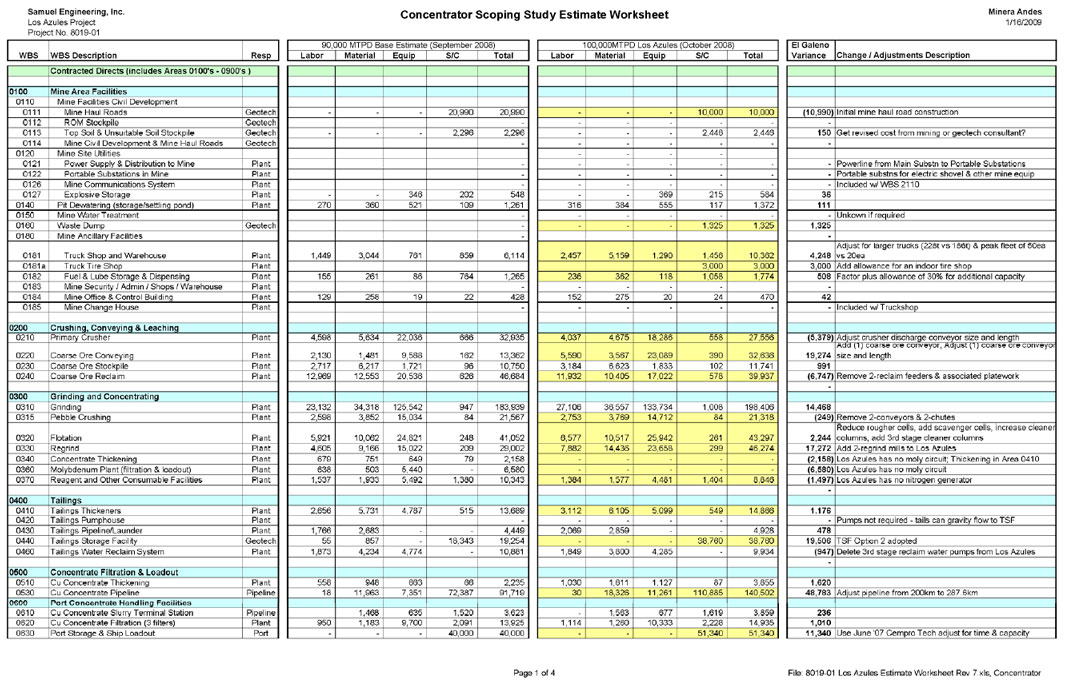

| 20.8 | CAPITAL COSTS | 186 |

| 20.8.1 | Objective and Summary | 186 |

| 20.8.2 | Accuracy | 188 |

| 20.8.3 | Currency | 188 |

| 20.8.4 | Scope | 189 |

| 20.8.5 | Exclusions | 189 |

| 20.8.6 | Estimating Methodology | 190 |

| 20.8.7 | General Risk Factors | 193 |

| 20.8.8 | Estimate Cost by Area | 194 |

| 20.9 | OPERATING COSTS | 194 |

| 20.9.1 | Mining Costs | 194 |

| 20.9.2 | Process and G&A Costs | 196 |

| | |

| 20.10 ECONOMIC ANALYSIS | 196 |

| 20.10.1 Introduction | 196 |

| 20.10.2 Model Inputs | 197 |

| 20.11 MINE LIFE AND CAPITAL PAYBACK | 204 |

| 21.0 | INTERPRETATION AND CONCLUSIONS | 205 |

| 21.1 | INTERPRETATIONS AND CONCLUSIONS | 206 |

| 22.0 | RECOMMENDATIONS | 209 |

| 22.1 | GEOLOGY, GEOCHEMISTRY, AND GEOCHRONOLOGY | 210 |

| 22.2 | GEOTECHNICAL | 213 |

| 22.3 | MINING | 213 |

| 22.4 | RECLAMATION AND MINE CLOSURE | 213 |

| 22.5 | SAMPLE PREPARATION, ANALYSIS AND SECURITY | 214 |

| 22.6 | ENVIRONMENTAL | 214 |

| 22.7 | HYDROGEOLOGICAL AND HYDROLOGIC | 215 |

| 22.8 | WATER DISPOSAL ALTERNATIVES | 216 |

| 22.9 | SOCIAL | 216 |

| 22.10 GENERAL PROJECT RECOMMENDATIONS | 216 |

| 23.0 | REFERENCES | 217 |

| 23.1 | REFERENCES | 218 |

| 23.2 | GLOSSARY | 218 |

| 23.3 | LIST OF ABBREVIATIONS | 224 |

| 23.4 | MEASUREMENT UNITS AND SYMBOLS | 226 |

| 24.0 | DATE AND SIGNATURE PAGE | 231 |

| 25.0 | ADDITIONAL REQUIREMENTS FOR TECHNICAL REPORTS ON DEVELOPMENT PROPERTIES AND PRODUCTION PROPERTIES | 233 |

| 25.1 | ADDITIONAL INFORMATION | 234 |

| 26.0 | ILLUSTRATIONS | 235 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

v

Exhibit 99.1

|

|

| |

| List of Figures |

| |

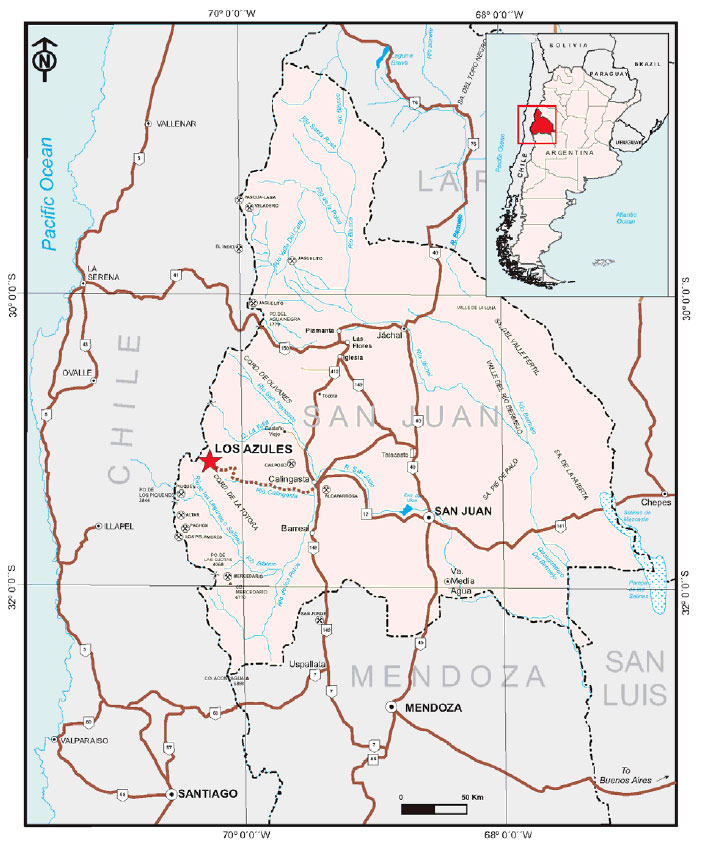

| Figure 3.1 – Project Location | 3 |

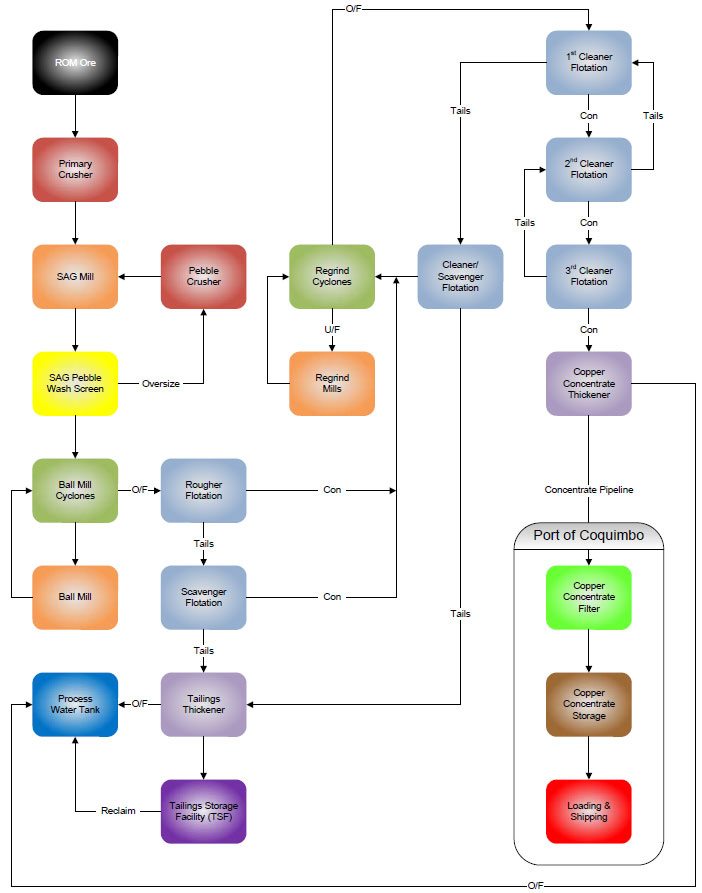

| Figure 3.2 – Process Block Flow Diagram | 10 |

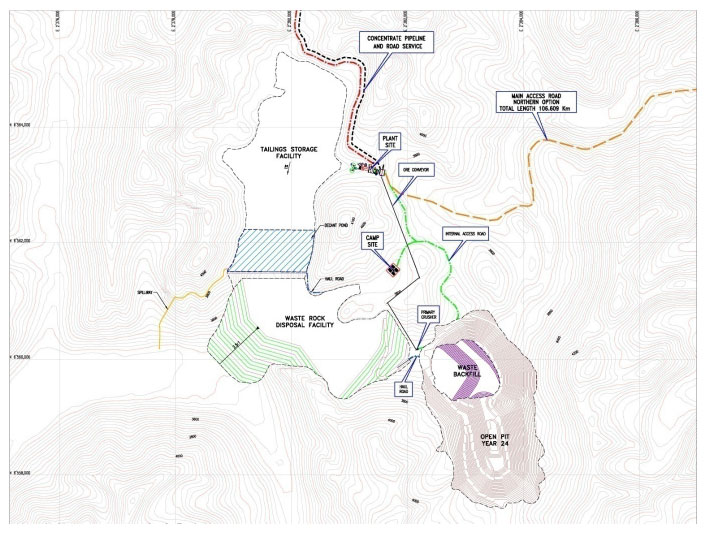

| Figure 3.3 – General Arrangement Plan | 13 |

| Figure 3.5 – Foreign Currency Conversion Rates | 17 |

| Figure 6.1 - Project Location | 27 |

| Figure 9.1 – Regional Geomorphology | 56 |

| Figure 9.2 – Regional Geology | 57 |

| Figure 9.3 – Local Geology and Structure | 59 |

| Figure 9.4 – Lithology Plan View at 3600 masl | 62 |

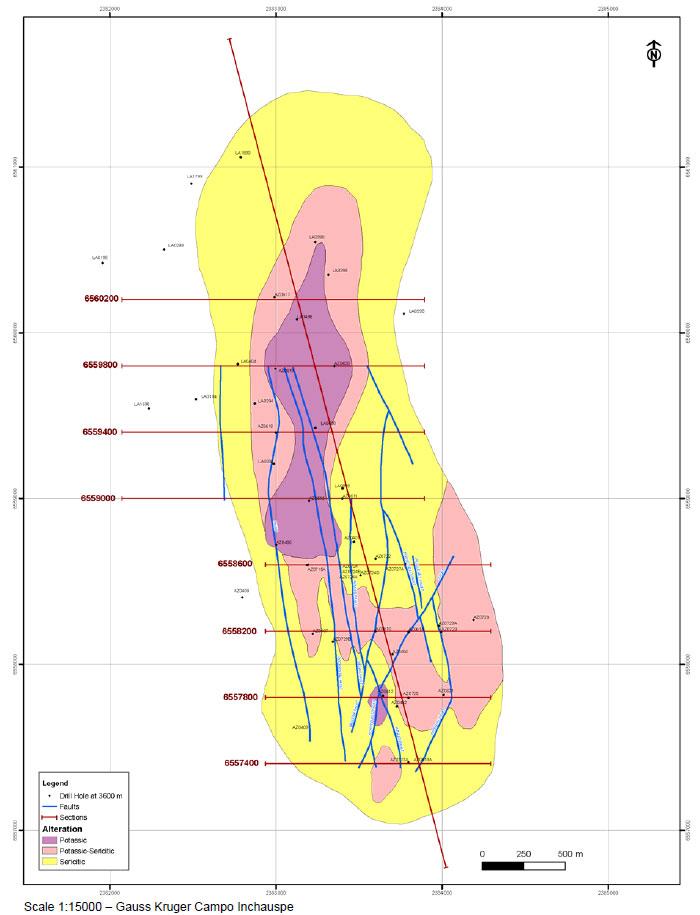

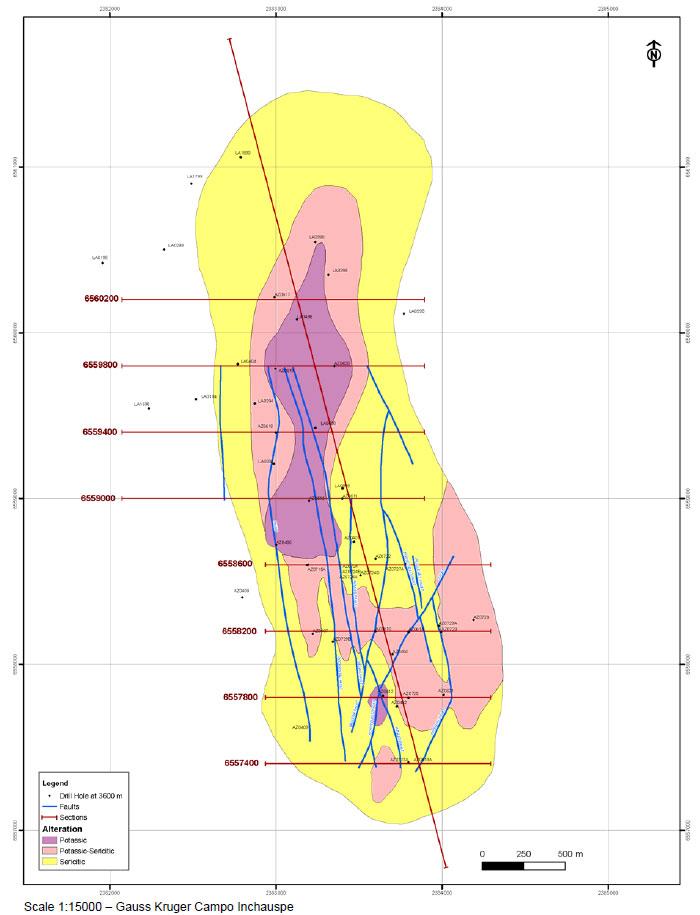

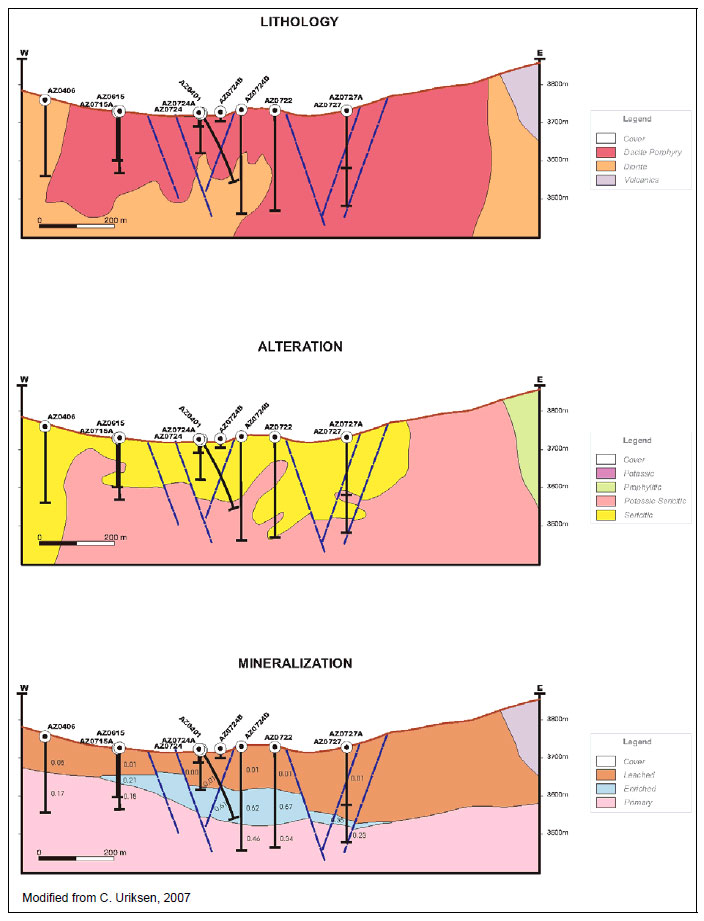

| Figure 9.5 – Alteration Plan View at 3600 masl | 64 |

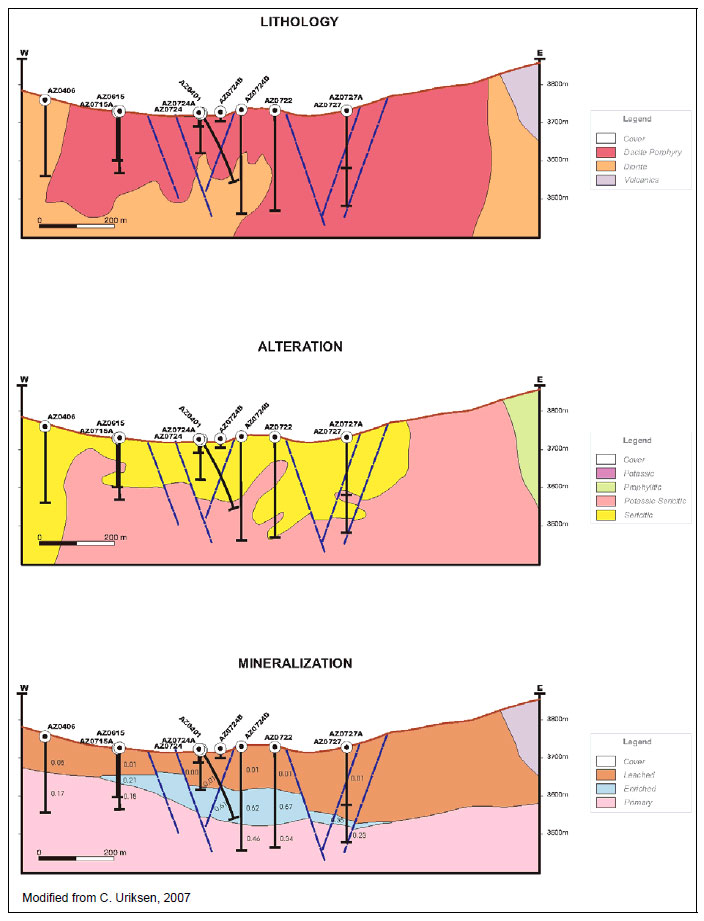

| Figure 9.6 – Representative Cross Section (N6558600) | 65 |

| Figure 10.1 – Typical Porphyry Copper Deposit | 68 |

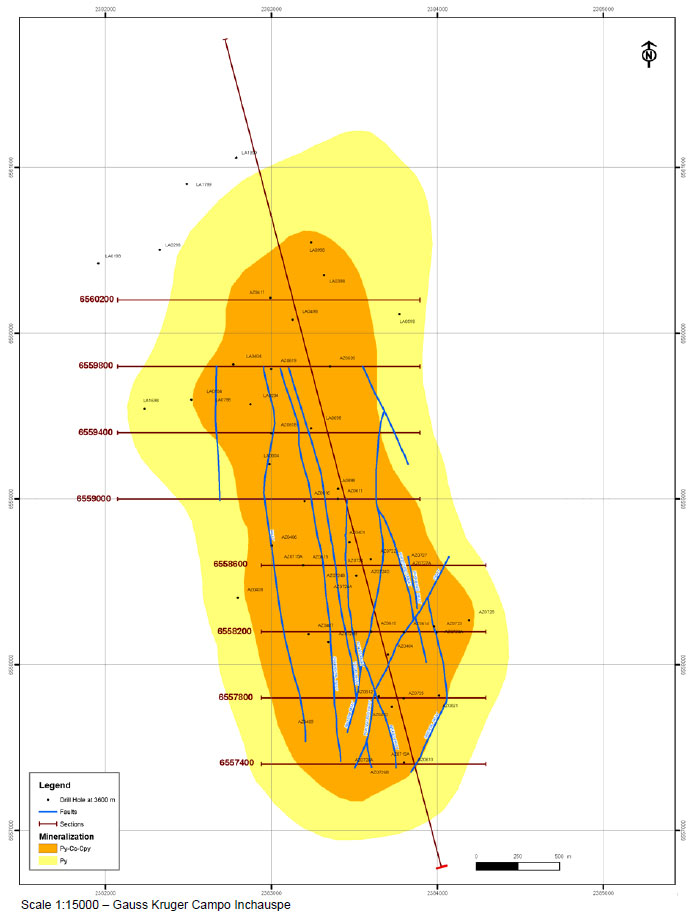

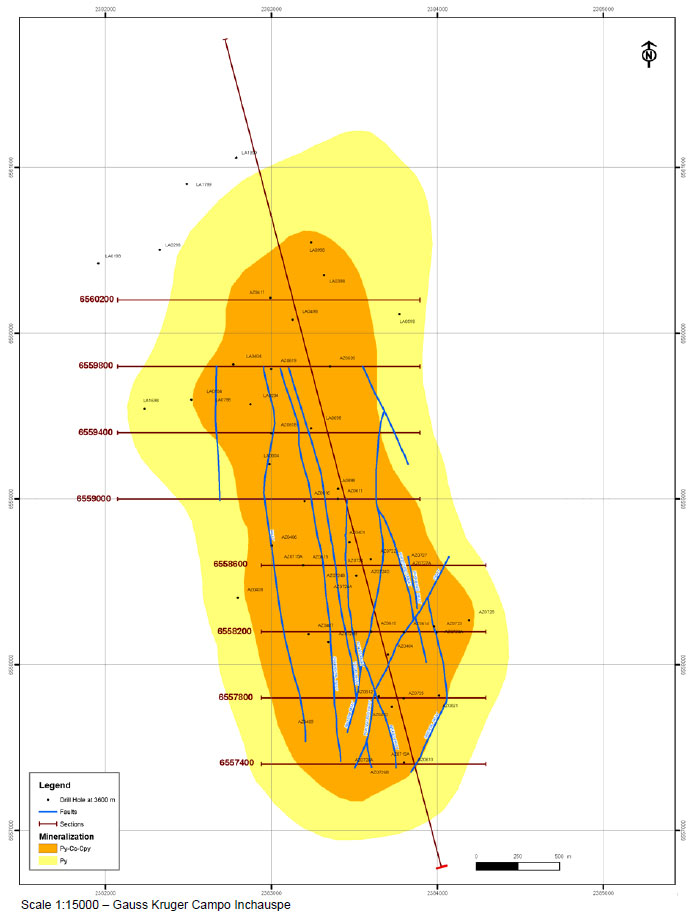

| Figure 11.1 – Mineralization Plan View 3600 masl | 73 |

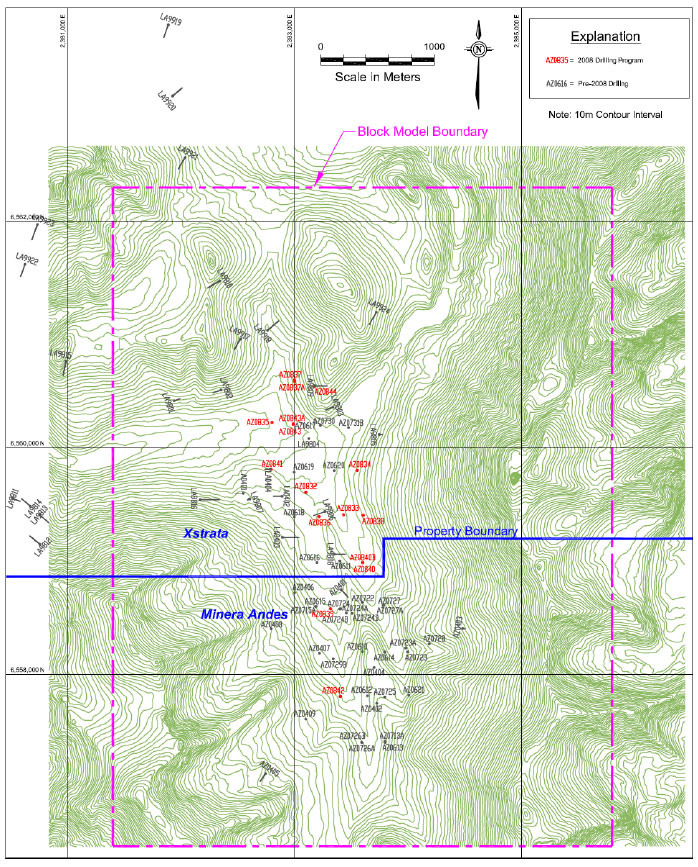

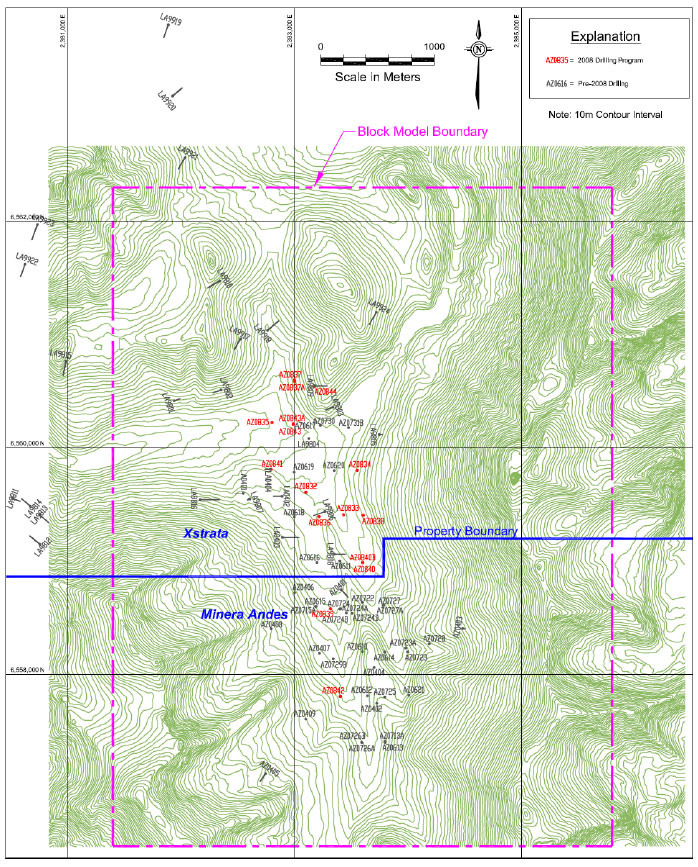

| Figure 13.1 – Drill Hole Locations | 80 |

| Figure 15.1 – Copper Sample Control (Std01, Std03) Performance Charts | 89 |

| Figure 15.2 – Copper and Gold Sample Control (Std6, Std20) Performance Charts | 90 |

| Figure 15.3 – Gold Sample Control (Std6, Std7) Performance Charts | 91 |

| Figure 15.4 – Copper and Gold Blank Sample Control Performance Charts | 93 |

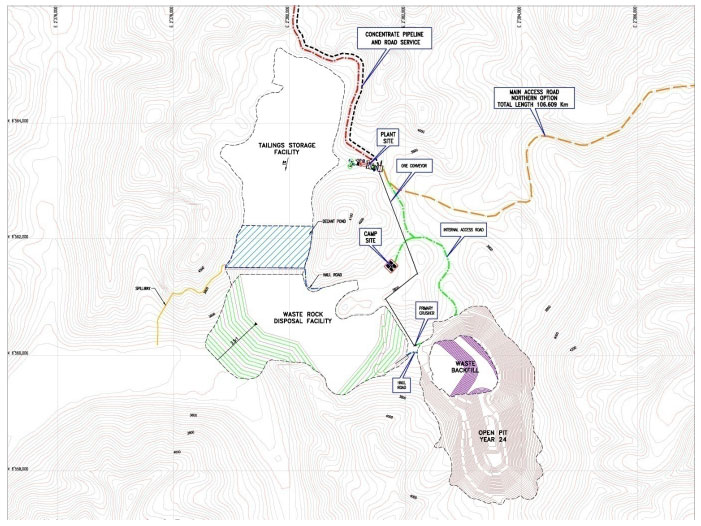

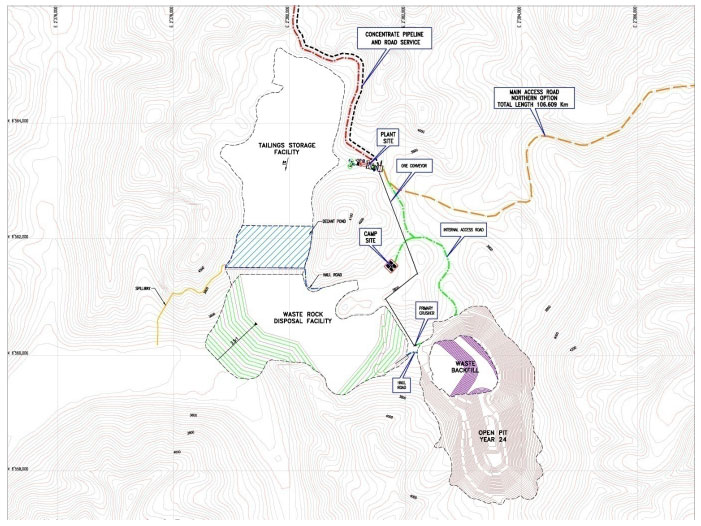

| Figure 18.1 – Mine Site General Arrangement Plan | 104 |

| Figure 18.2 – Process Block Flow Diagram | 105 |

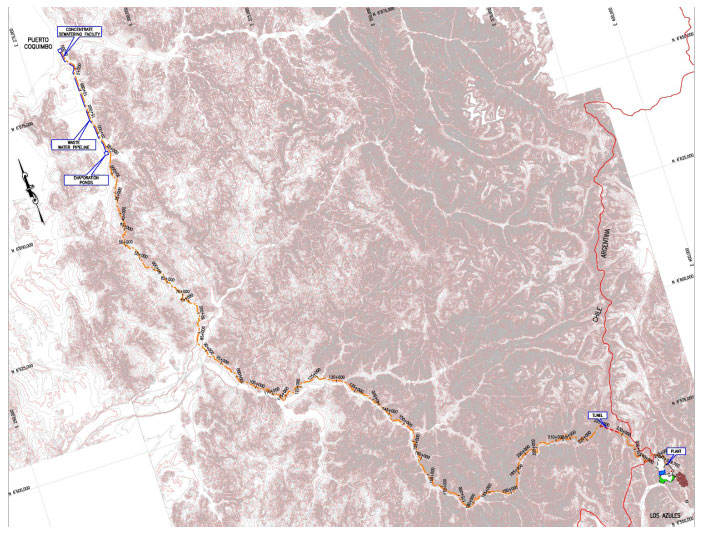

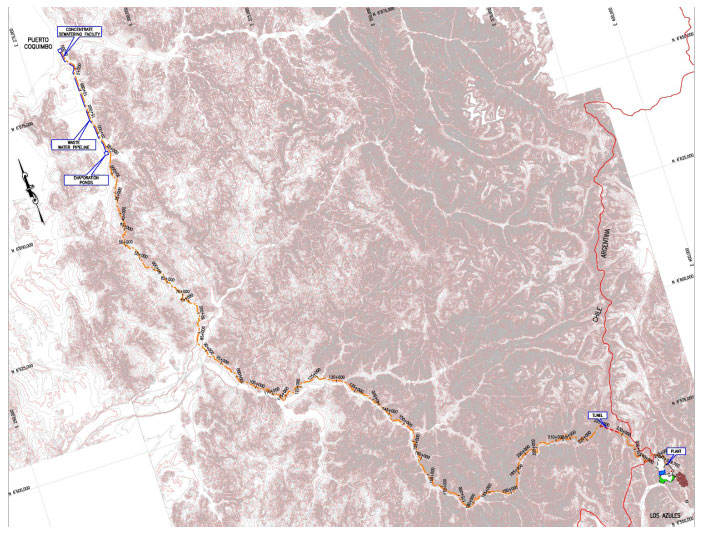

| Figure 18.3 – Concentrate Pipeline from Los Azules Mine Site to the Port facility | 108 |

| Figure 18.4 – Potential Concentrate Water Evaporation Sites | 109 |

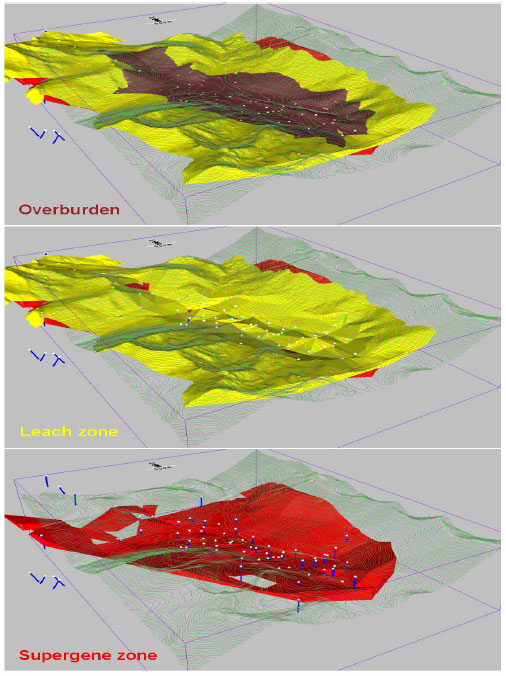

| Figure 19.1 – Mineral Zone Domains | 124 |

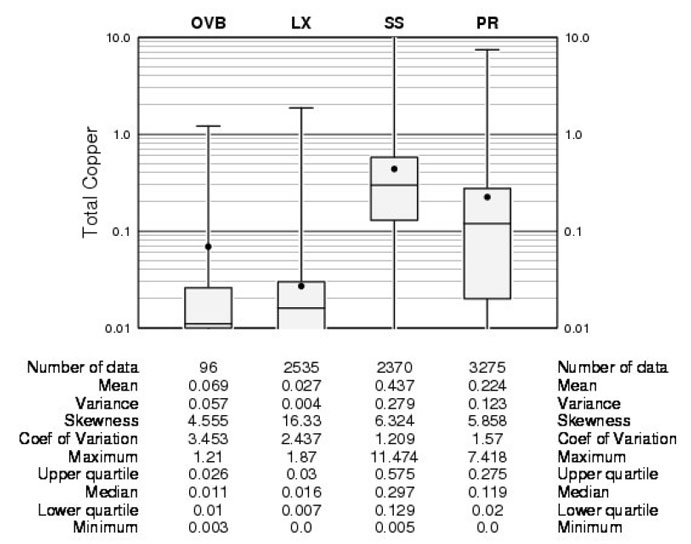

| Figure 19.3 – Boxplot Cu by Mineral Zone | 129 |

| Figure 19.4 – Contact Profile for Rock Types | 130 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

vi

Exhibit 99.1

|

|

| |

| Figure 19.5 – Contact Profile for Mineral Zones | 131 |

| Figure 19.6 – Probability Plot TCu% in SS and PR Zone | 135 |

| Figure 19.7 – Isometric View Of Probability Shell in SS + PR Zone | 136 |

| Figure 19.8 – Recovered Copper (20x20x15 SMU) | 138 |

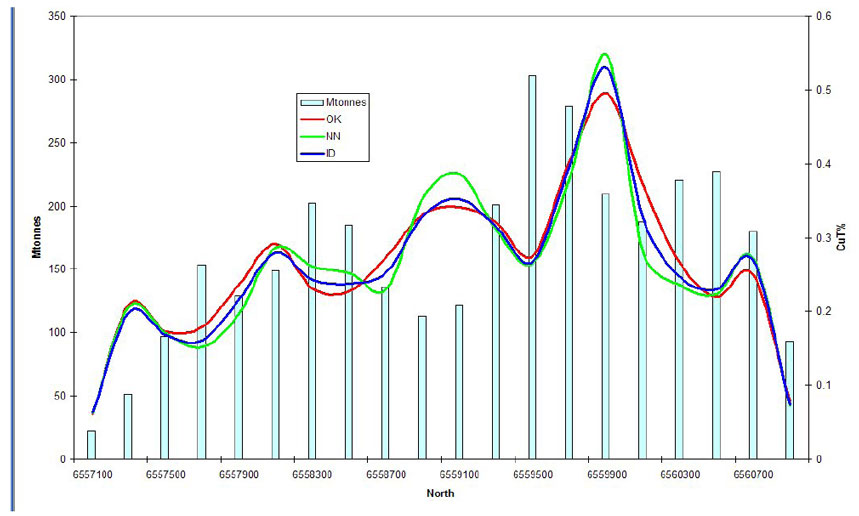

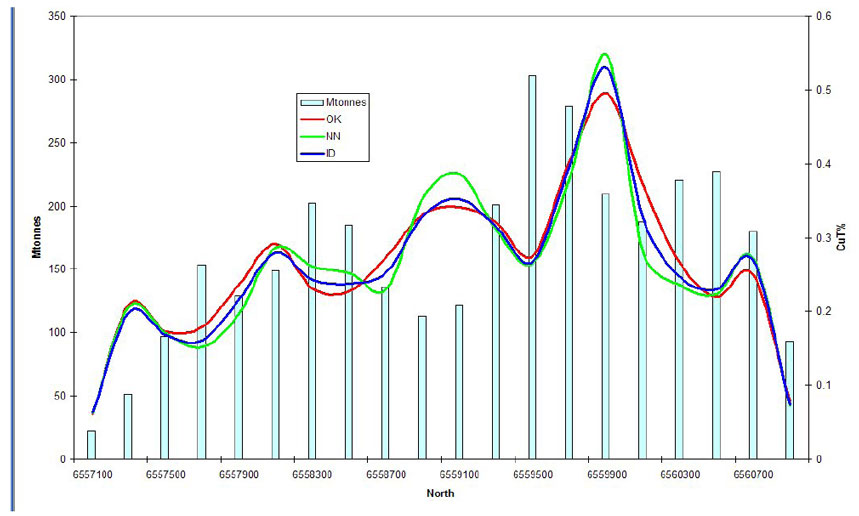

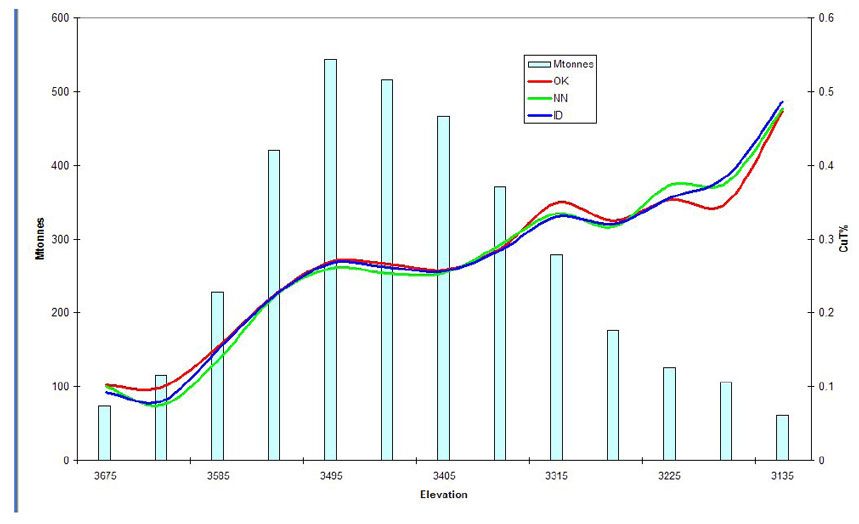

| Figure 19.9 – Comparison of OK, ID, NN Models | 140 |

| Figure 19.10 – East-West Swath | 140 |

| Figure 19.11 – North-South Swath | 141 |

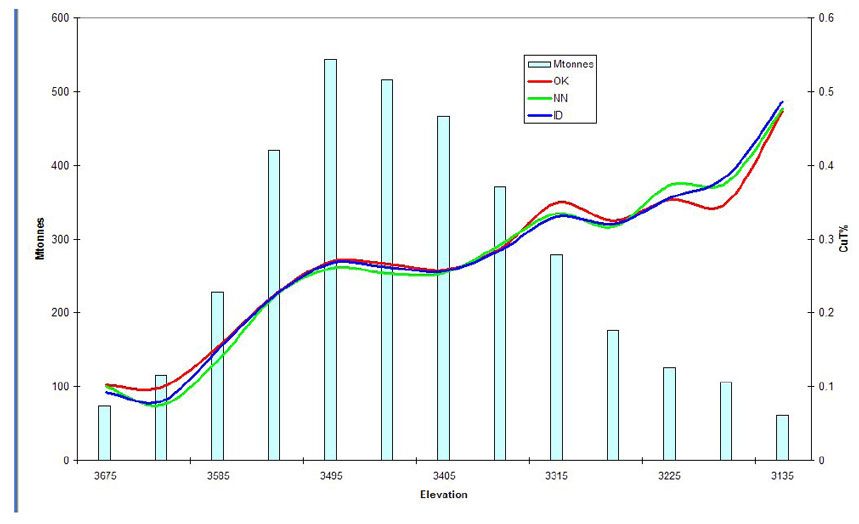

| Figure 19.12 – Vertical Swath | 141 |

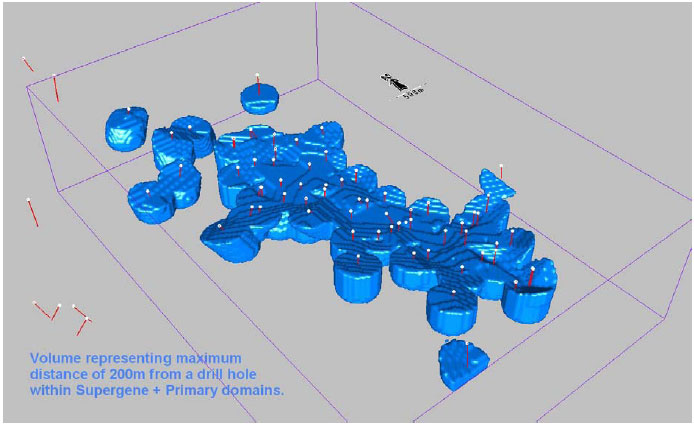

| Figure 19.13 – Volume Classified as Inferred Resources within SS + PR Domains | 142 |

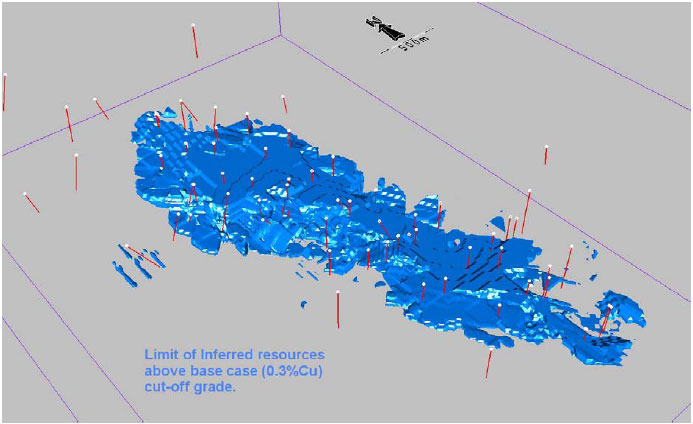

| Figure 19.14 – Inferred Resources Above 0.3% Cu Cutoff Grade | 142 |

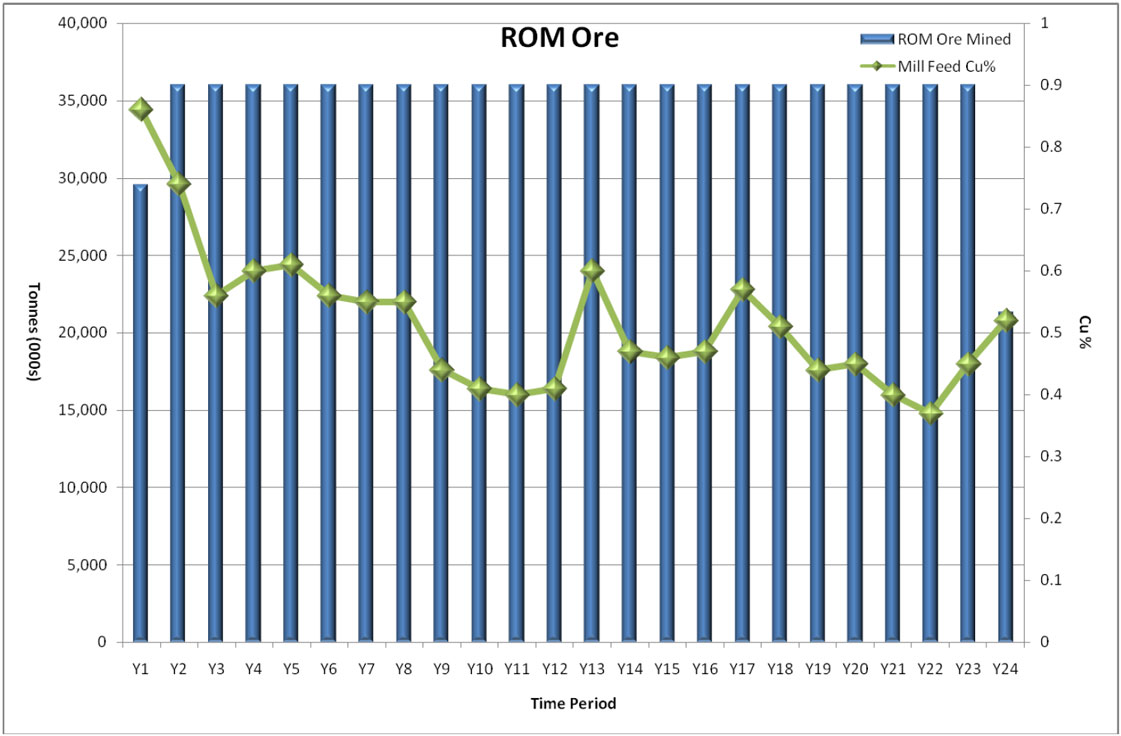

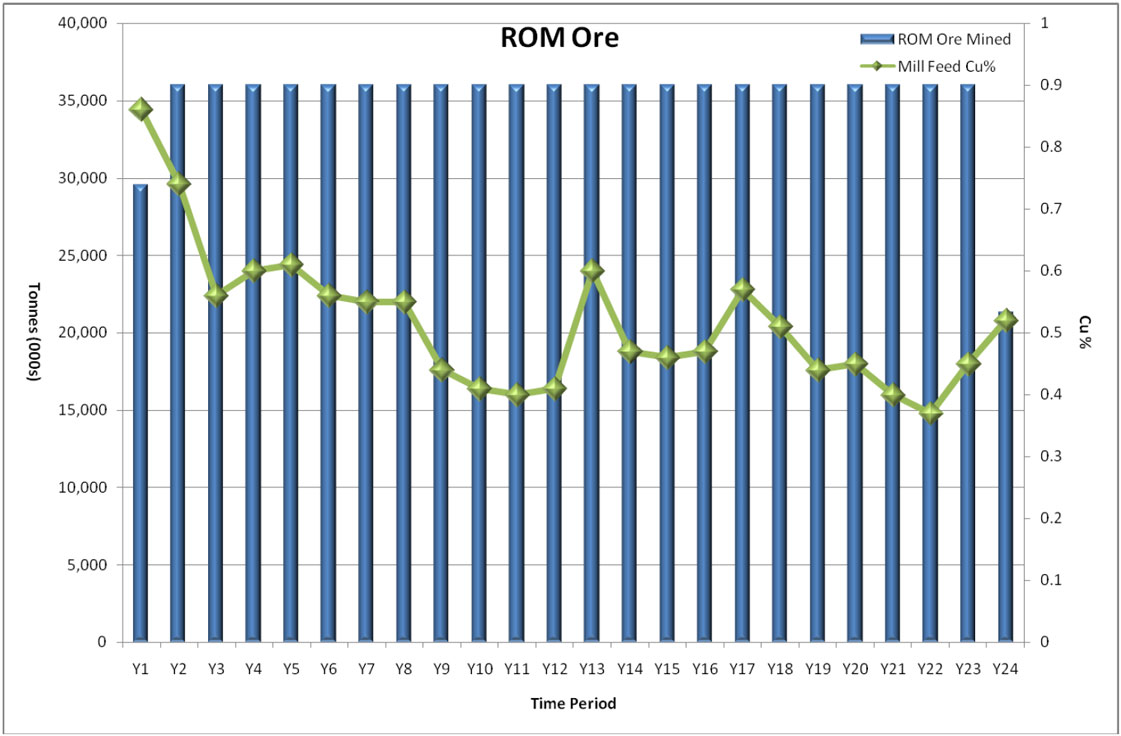

| Figure 20.1 – ROM Mineralized Material Source and Mill Feed Copper Grade | 151 |

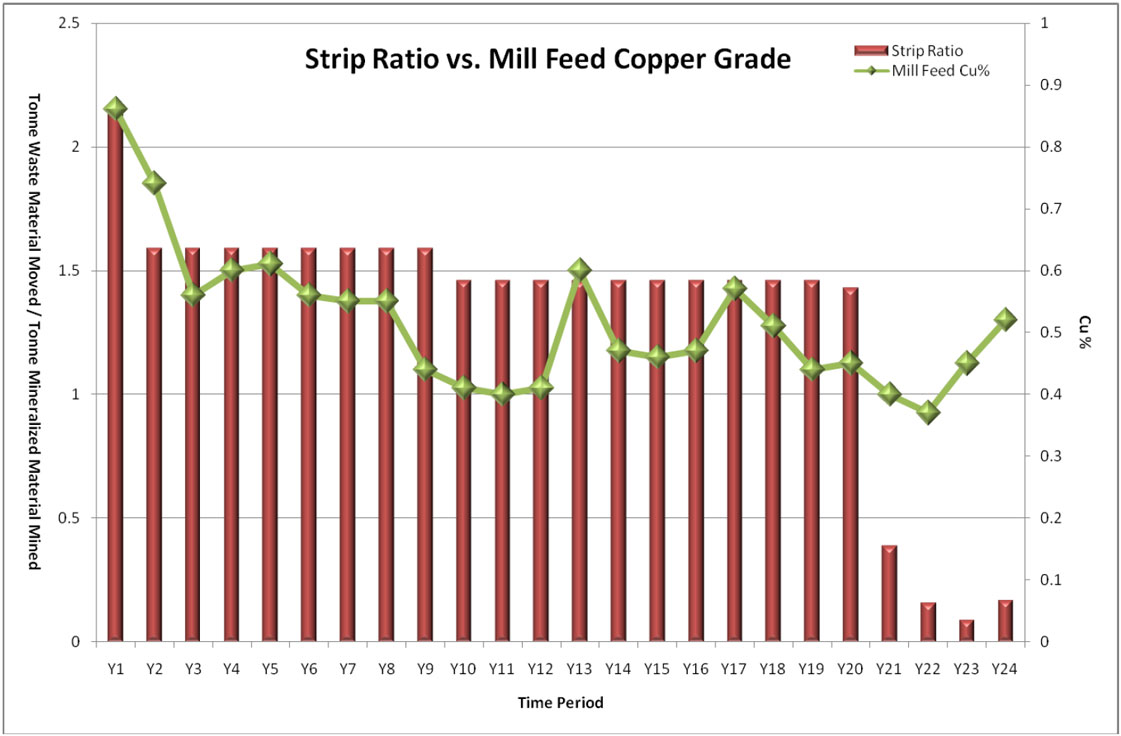

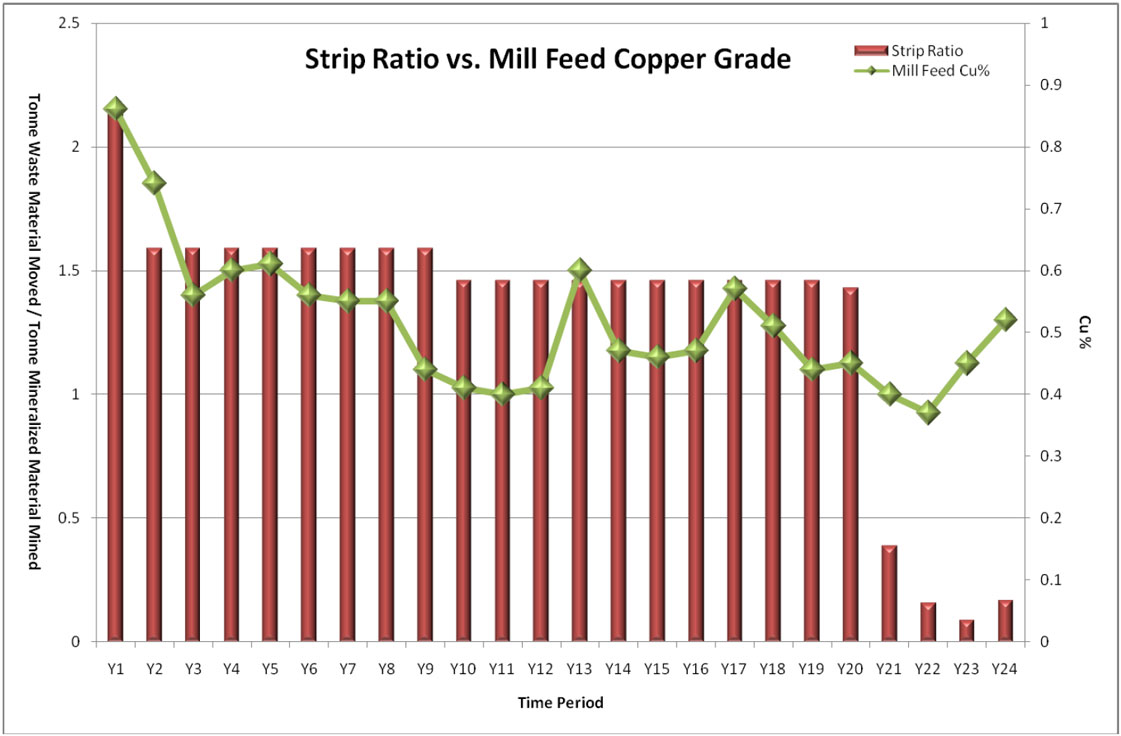

| Figure 20.2 – Strip Ratio and Mill Feed Copper Grade | 152 |

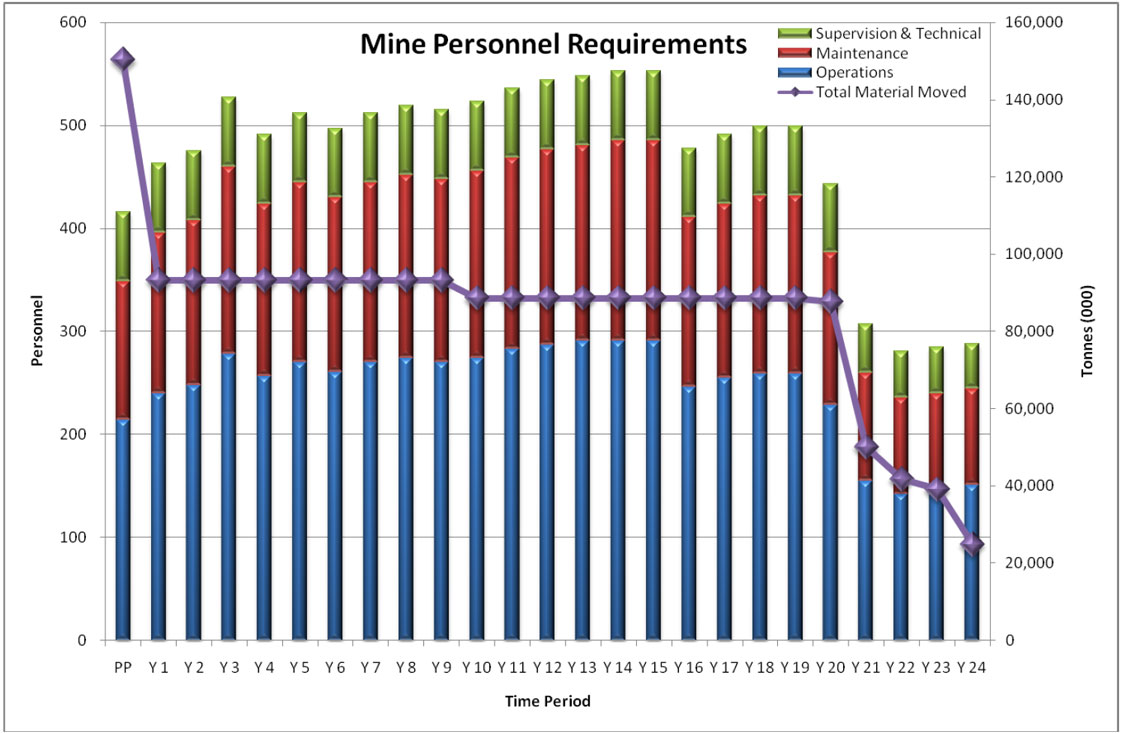

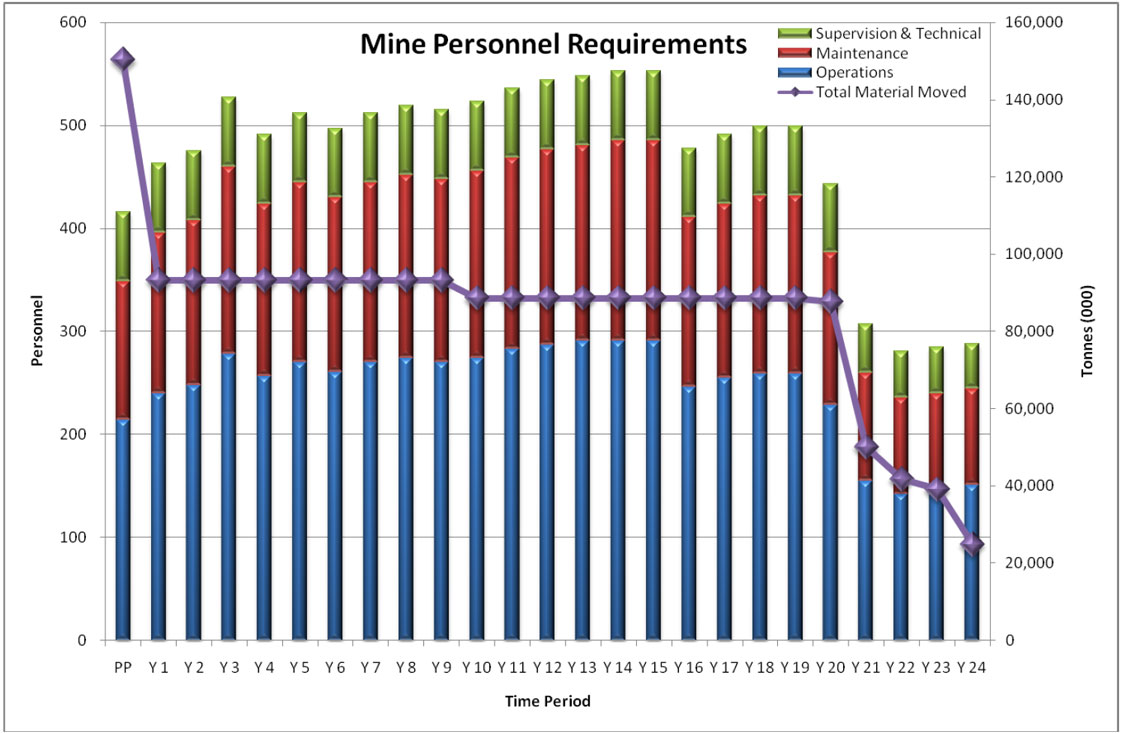

| Figure 20.3 – Mine Personnel Requirements | 158 |

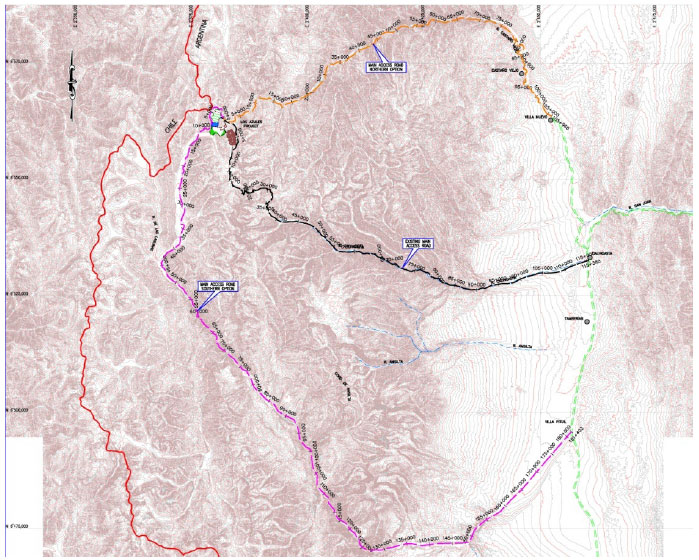

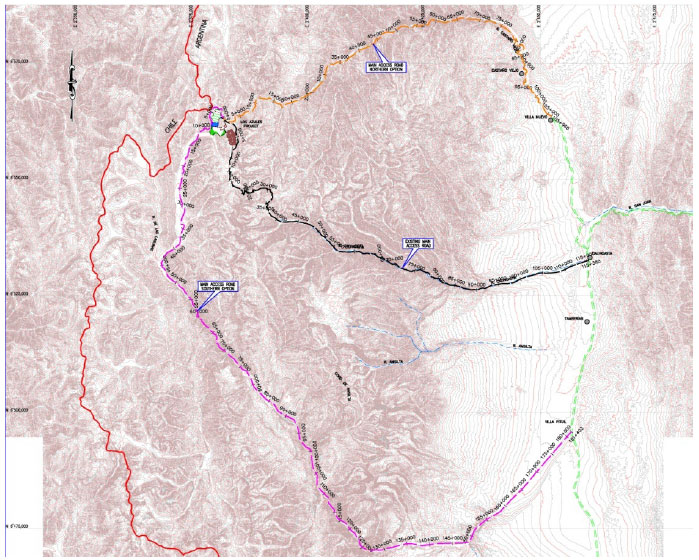

| Figure 20.4 – Potential Mine Access Routes | 159 |

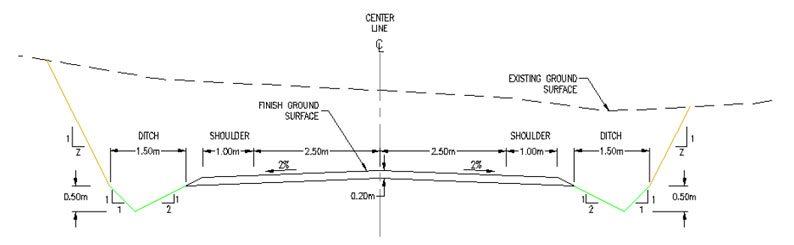

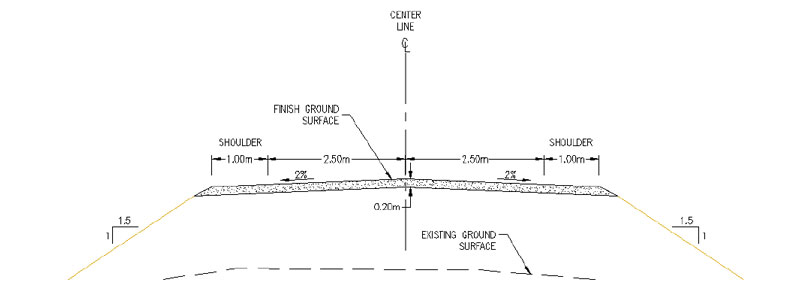

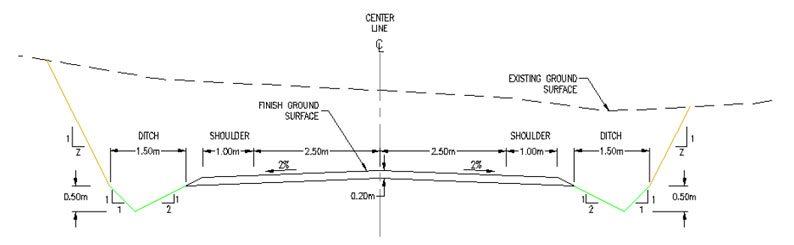

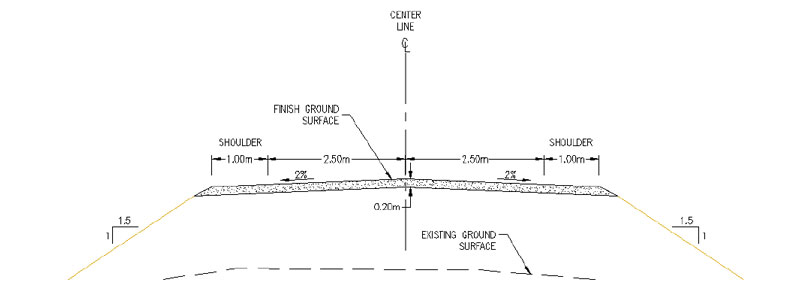

| Figure 20.5 – Typical Cut Cross Section | 162 |

| Figure 20.6 – Typical Cut and Fill Cross Section | 162 |

| Figure 20.7 – Typical Fill Section | 162 |

| Figure 20.8 – General Arrangement Plan | 163 |

| Figure 20.9 – TSF and WRDF Siting Map | 168 |

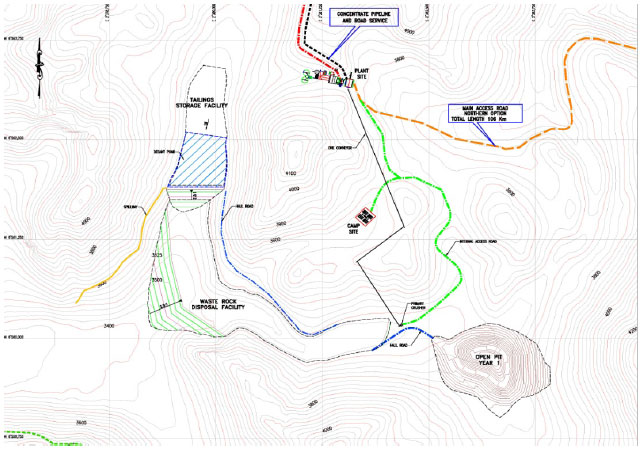

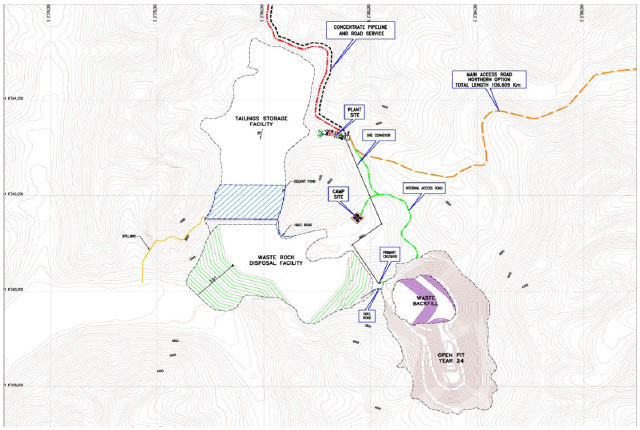

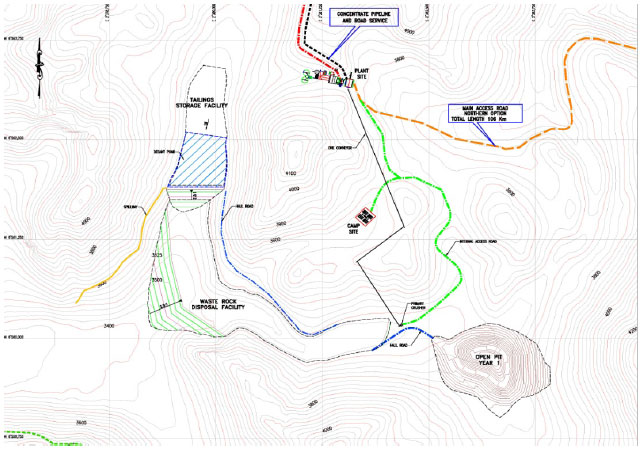

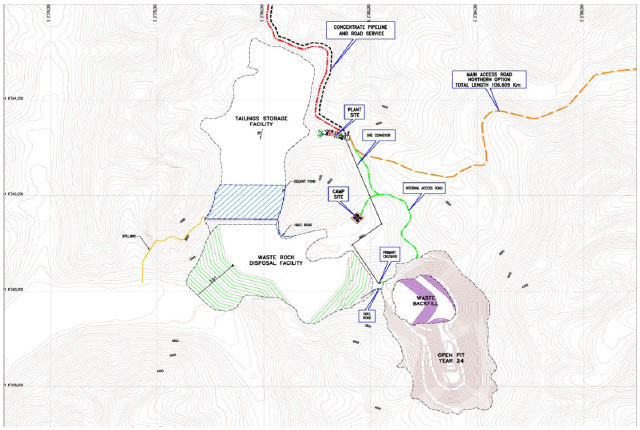

| Figure 20.10 – General Initial Facility Arrangement | 170 |

| Figure 20.11 – General Ultimate Facility Arrangement | 170 |

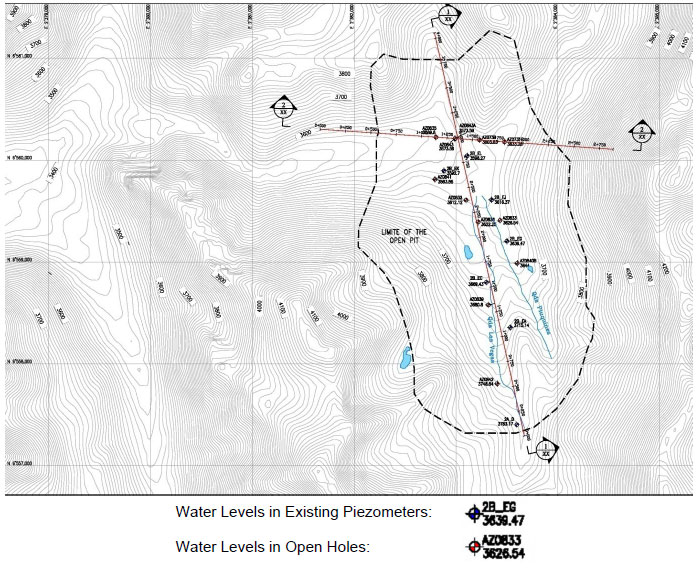

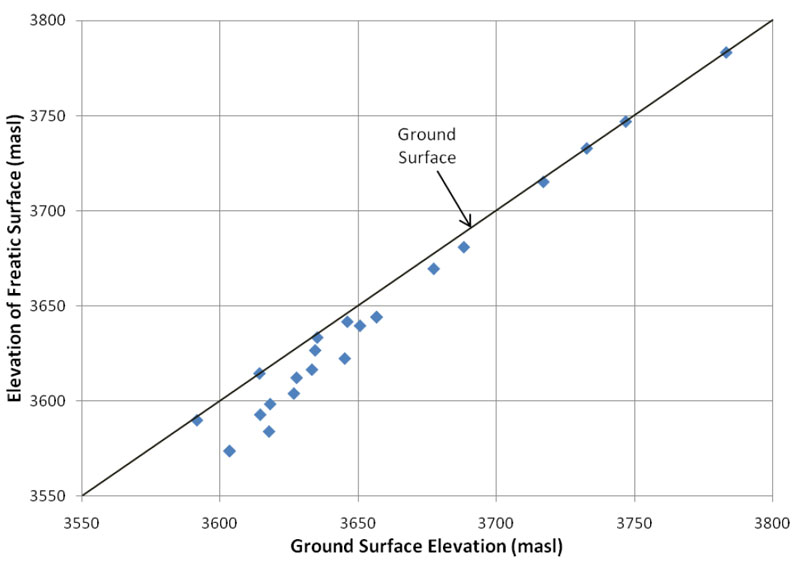

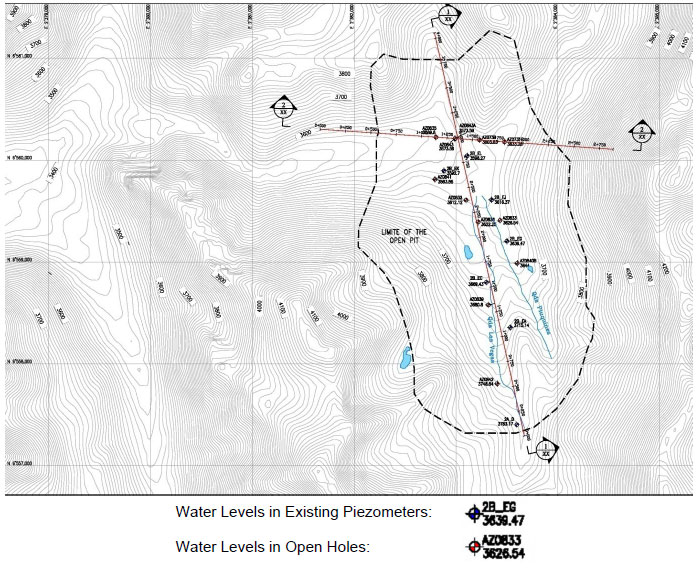

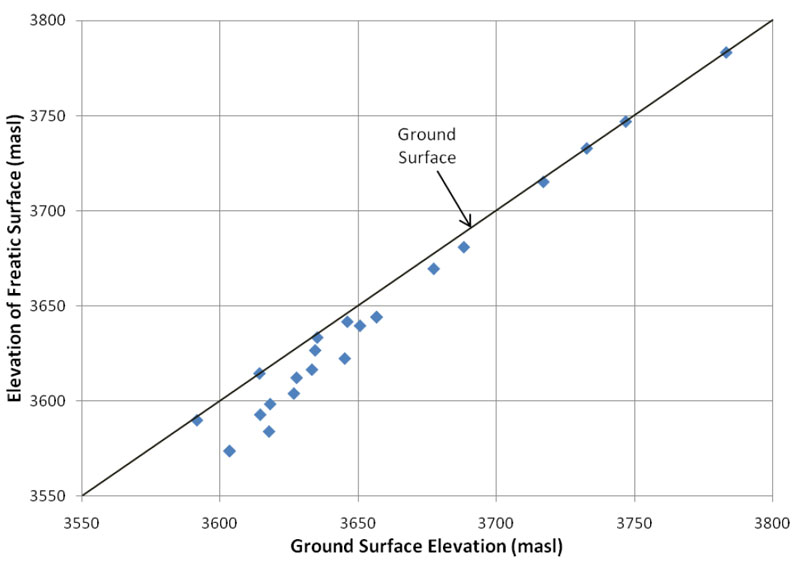

| Figure 20.12 – Groundwater Levels on Los Azules Site | 175 |

| Figure 20.13 – Relationship of Groundwater Depth to Surface Elevation | 176 |

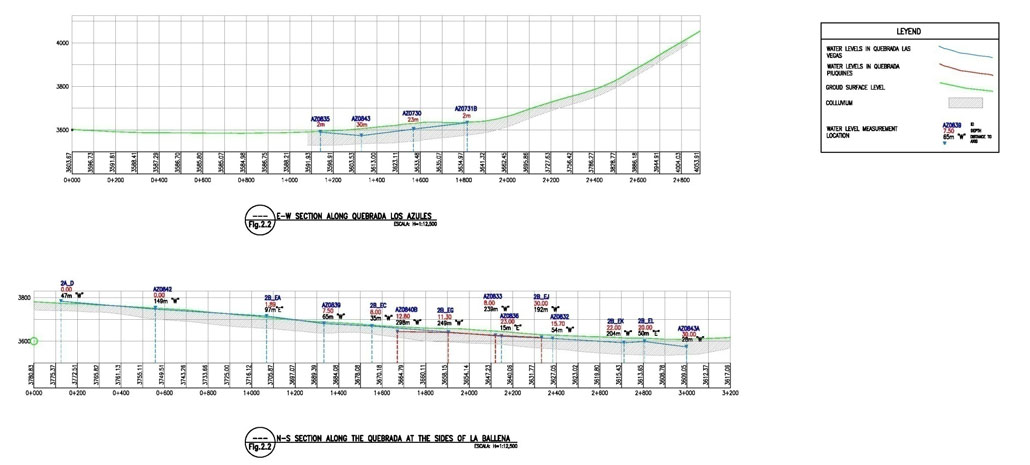

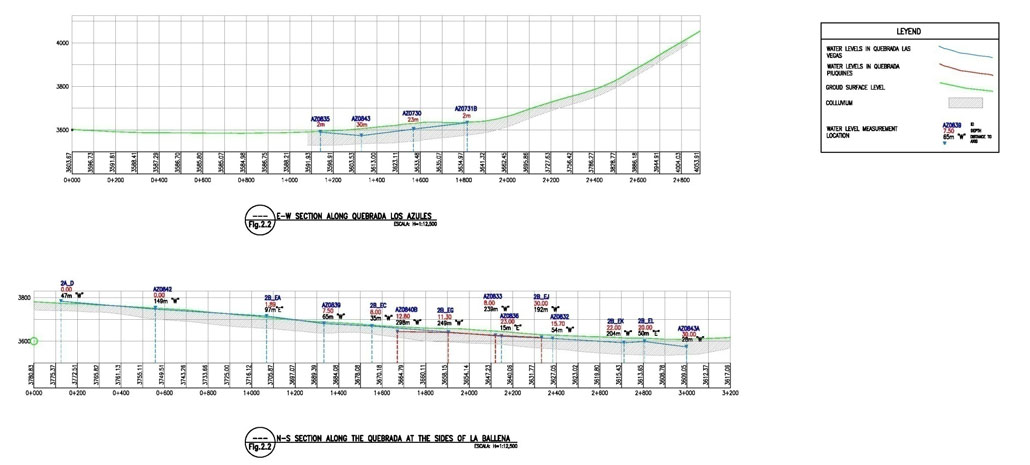

| Figure 20.14 – Cross Section of Los Azules Site | 177 |

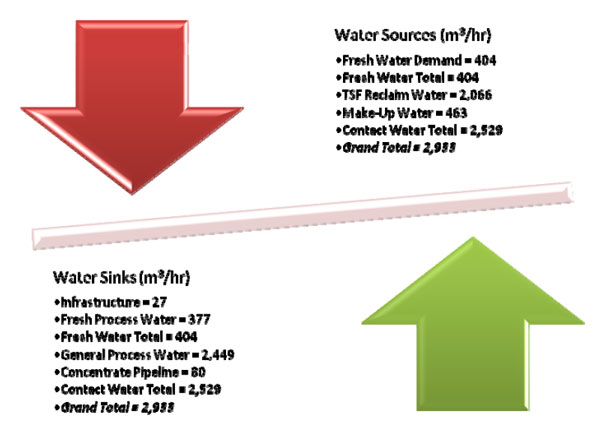

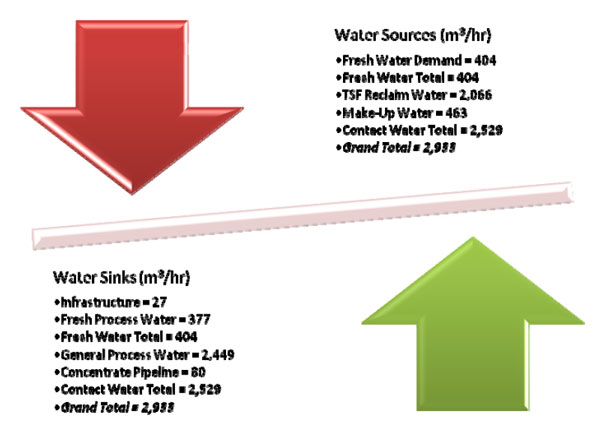

| Figure 20.15 – Site Water Balance | 180 |

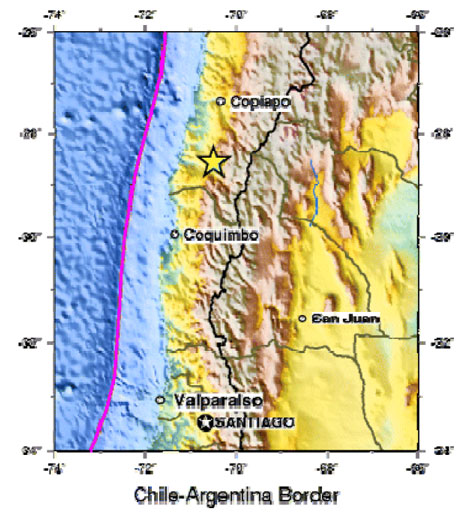

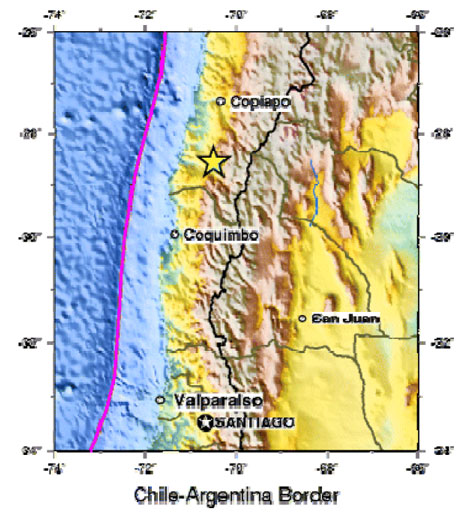

| Figure 20.16 – Location of the 1992 Earthquake Epicenter | 184 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

vii

Exhibit 99.1

| |

| Figure 20.17 – Western Argentina Seismic Hazard Map (Peak Ground Ac3celeration in m/s2with 10% Probability of Exceedance in 50 Years) | 185 |

| Figure 20.18 – Foreign Currency Conversion Rates | 188 |

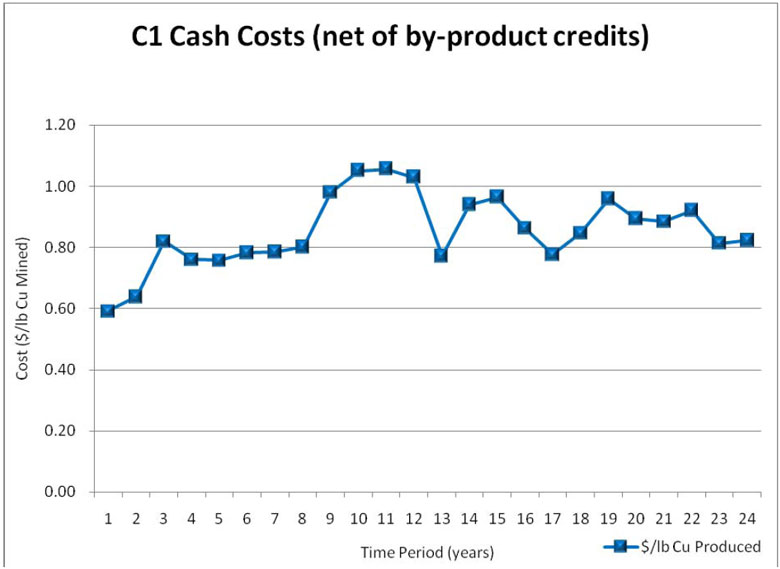

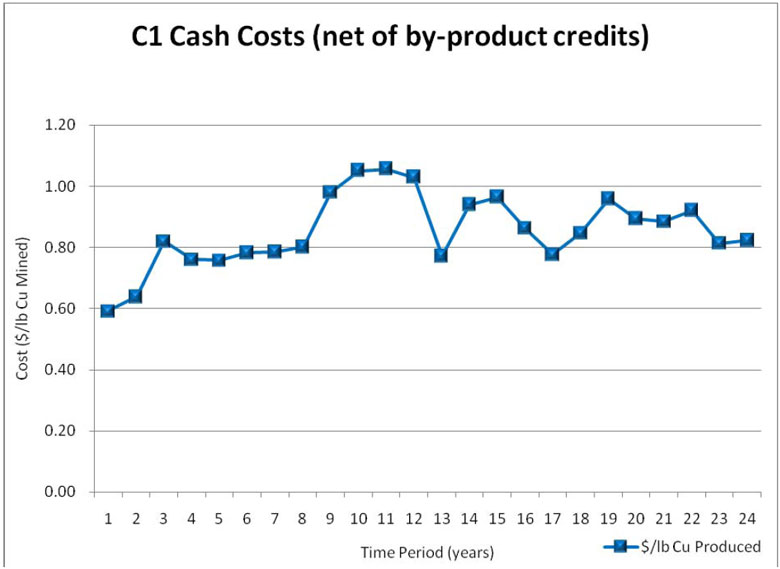

| Figure 20.20 – C1 Cash Costs (Net of By-Product Credits) | 201 |

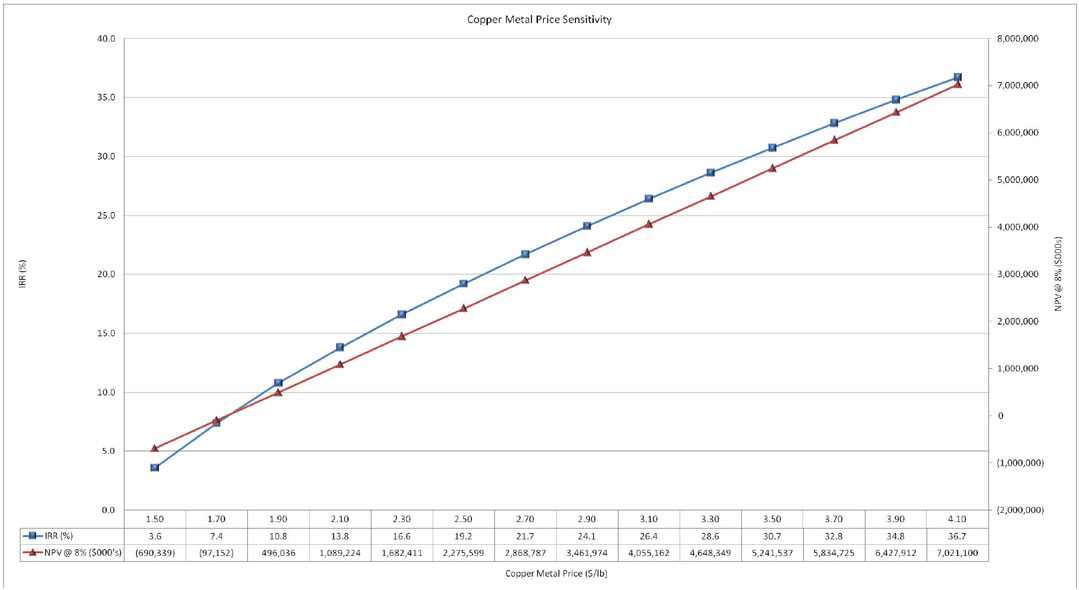

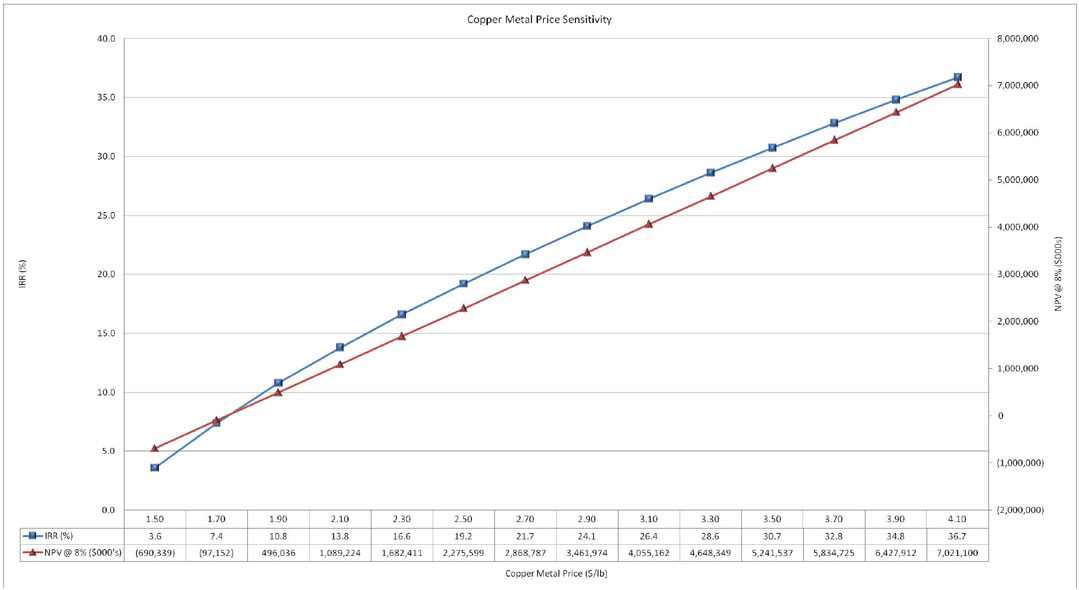

| Figure 20.21 – Copper Metal Price Sensitivity | 203 |

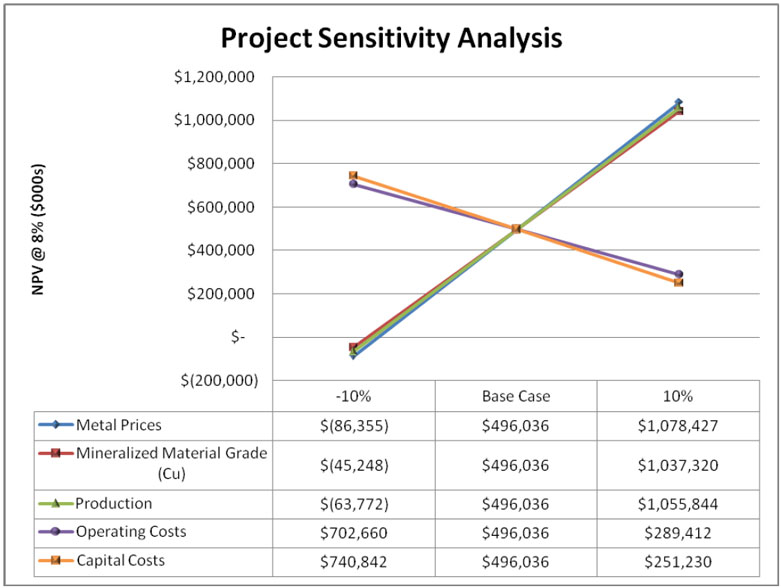

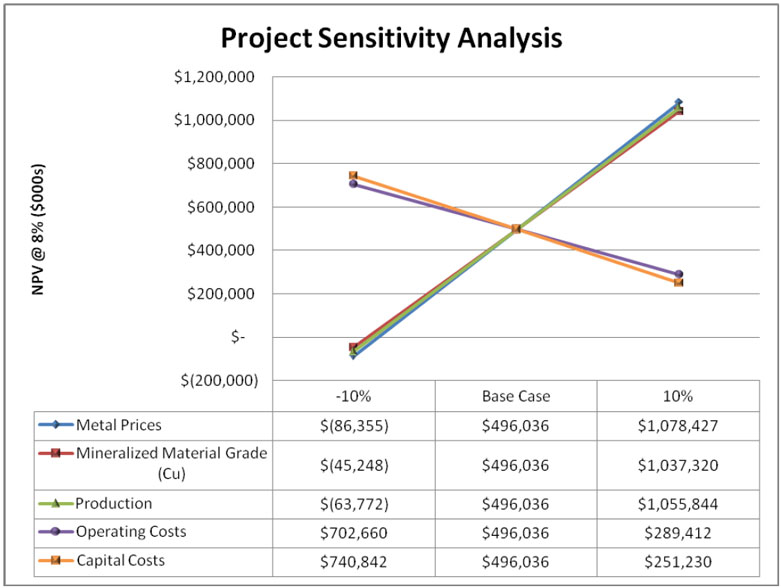

| Figure 20.22 – Project Sensitivity Analysis | 204 |

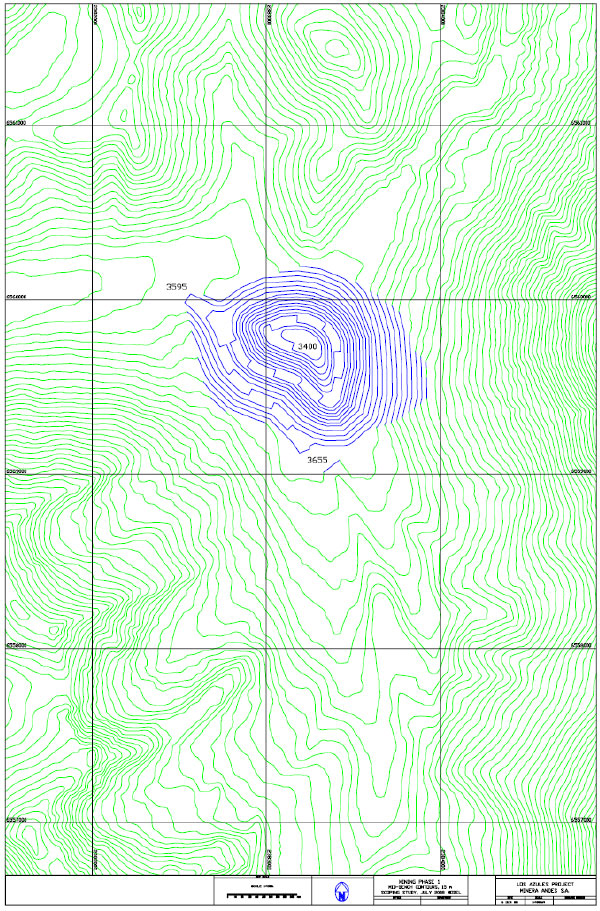

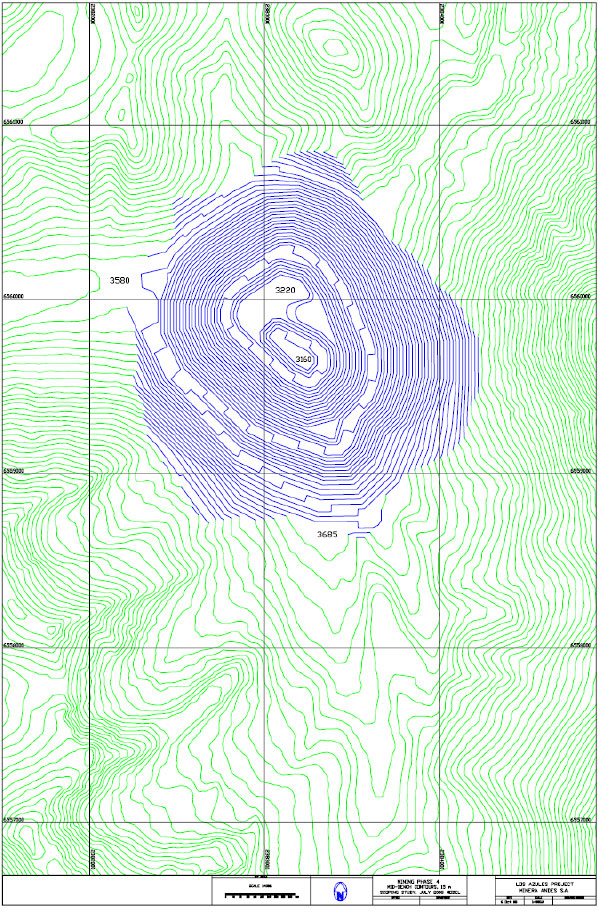

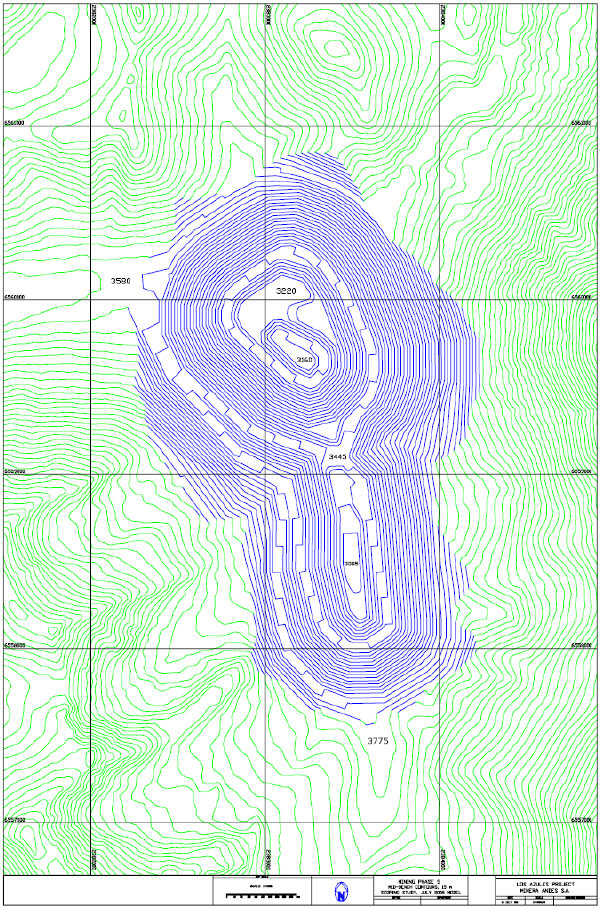

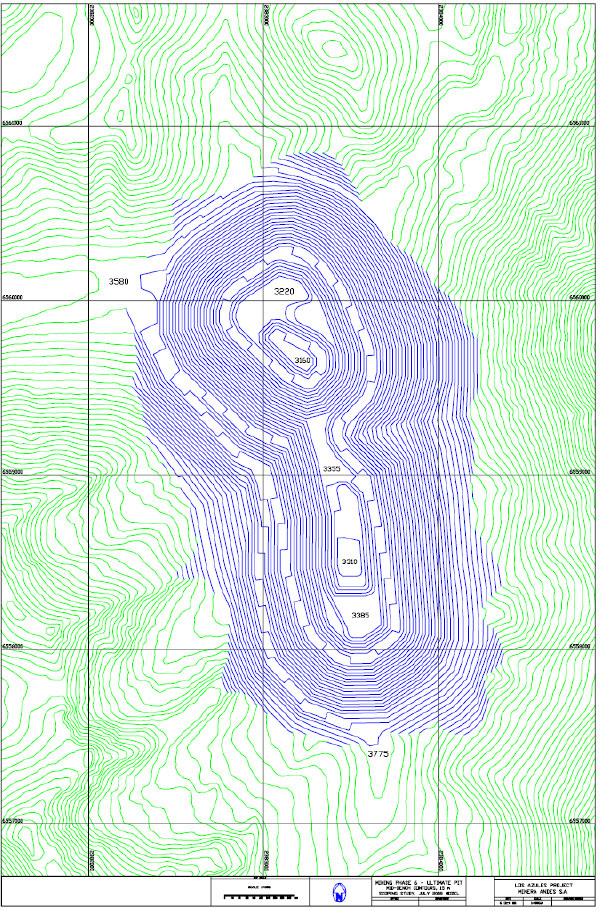

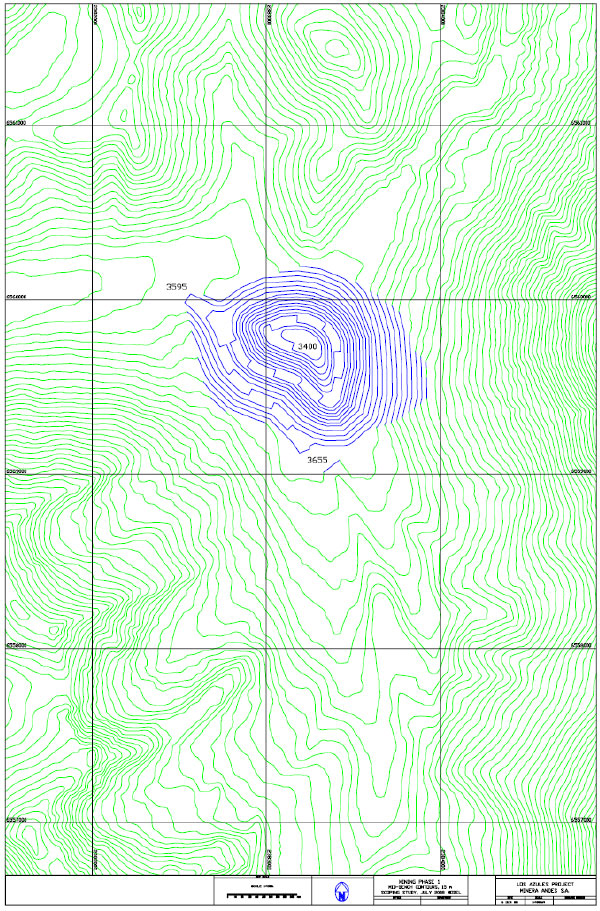

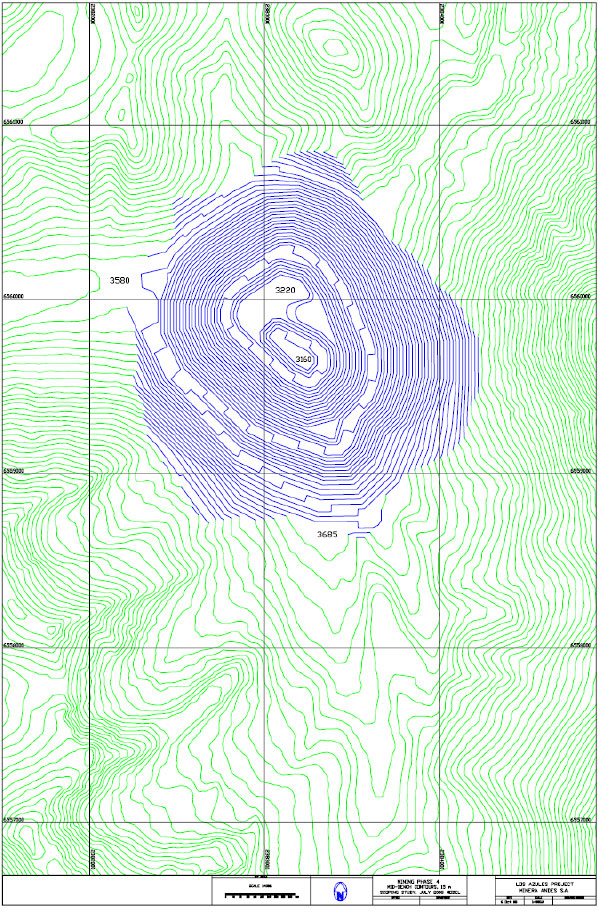

| Figure 26.1 – Mining Phase 1 | 236 |

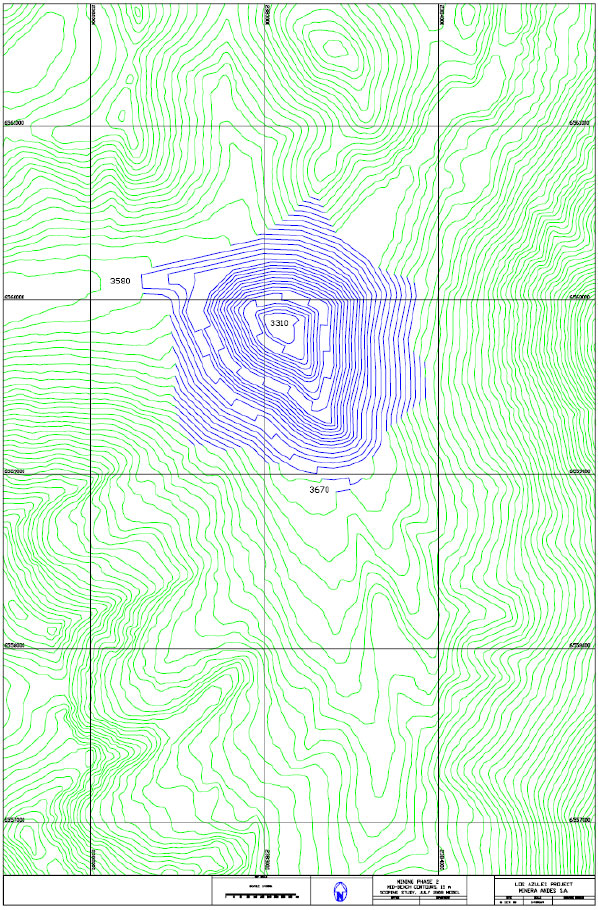

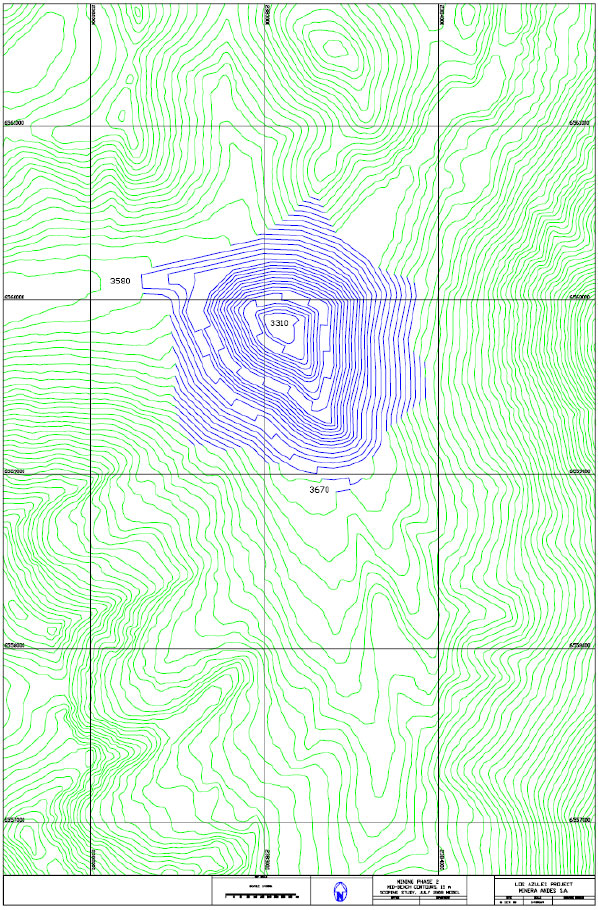

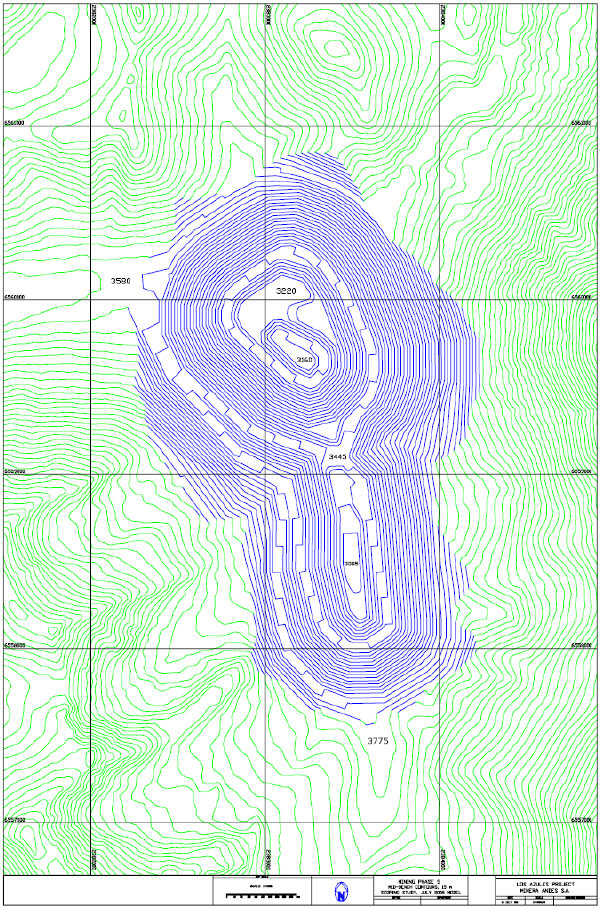

| Figure 26.2 – Mining Phase 2 | 237 |

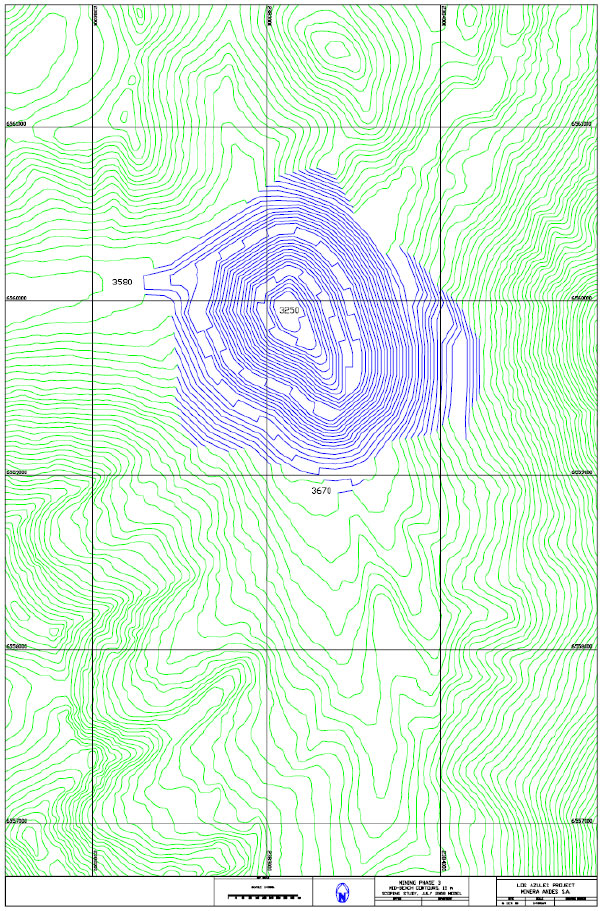

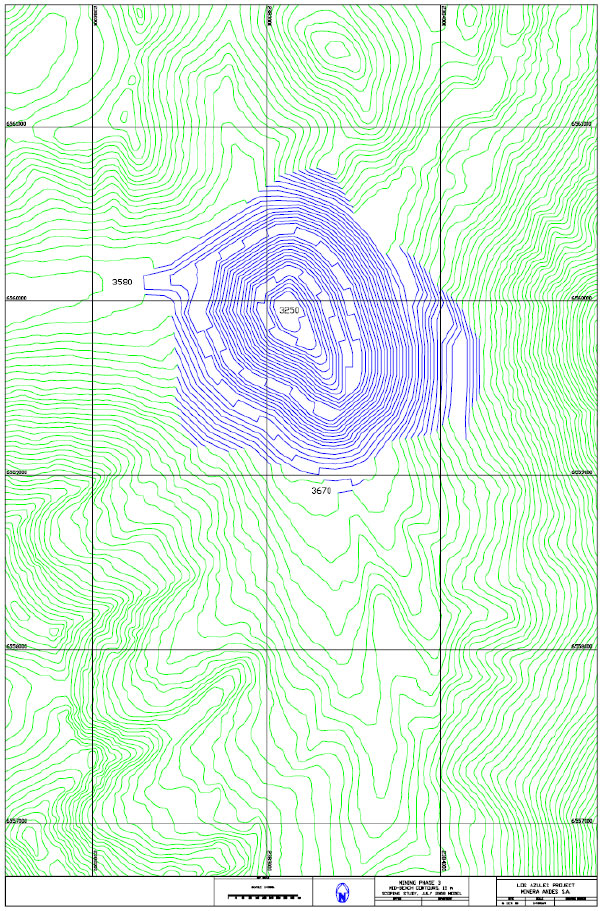

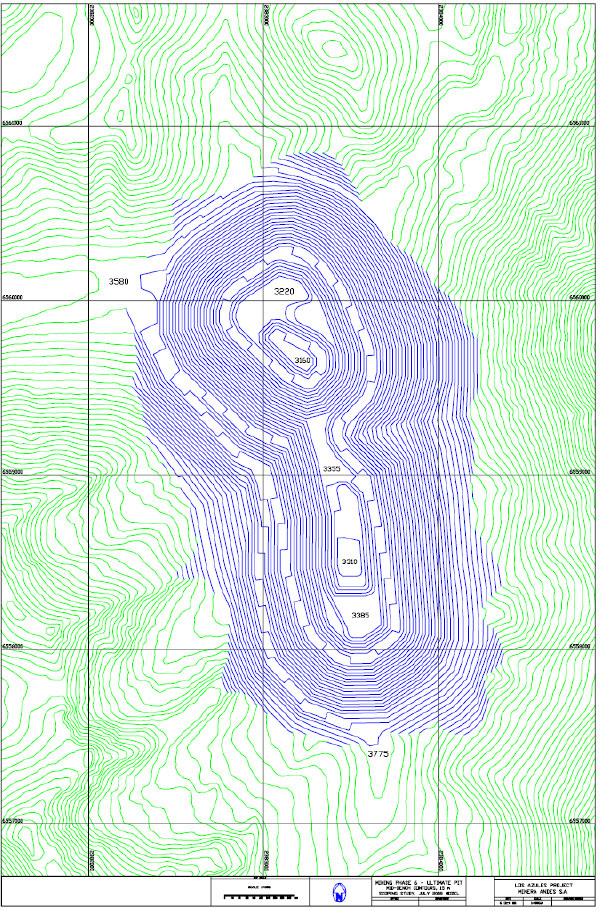

| Figure 26.3 – Mining Phase 3 | 238 |

| Figure 26.4 – Mining Phase 4 | 239 |

| Figure 26.5 – Mining Phase 5 | 240 |

| Figure 26.6 – Mining Phase 6 (Ultimate Pit) | 241 |

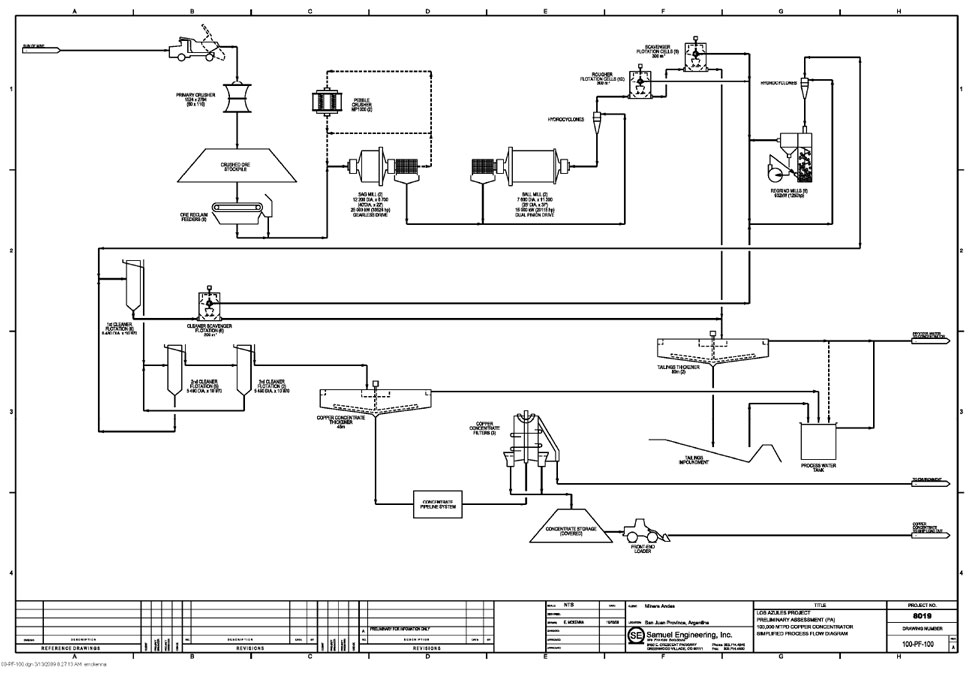

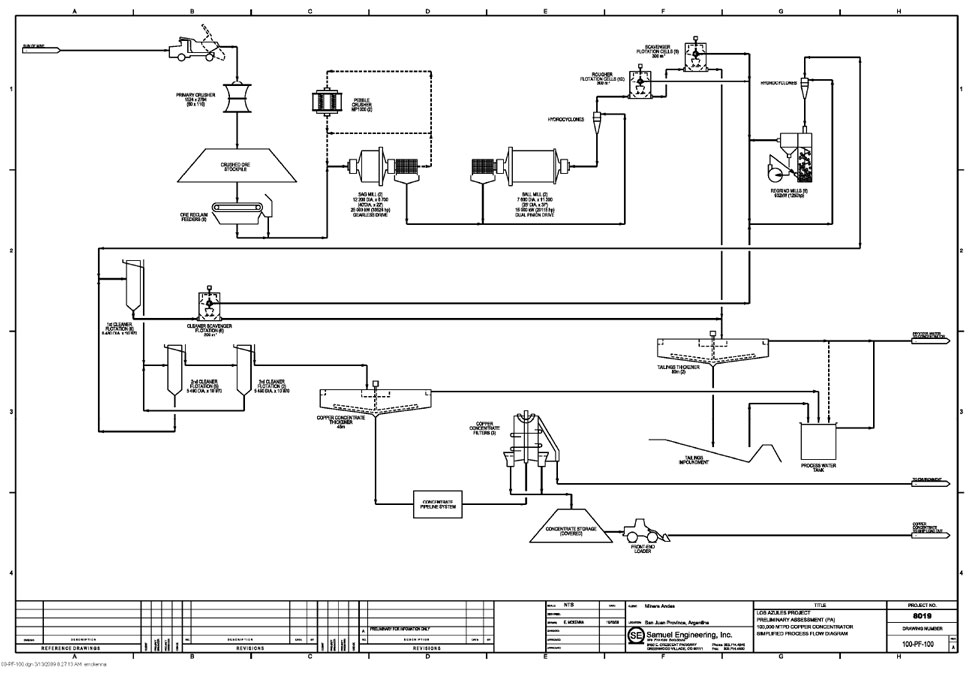

| Figure 26.7 – Simplified Process Flow Diagram | 242 |

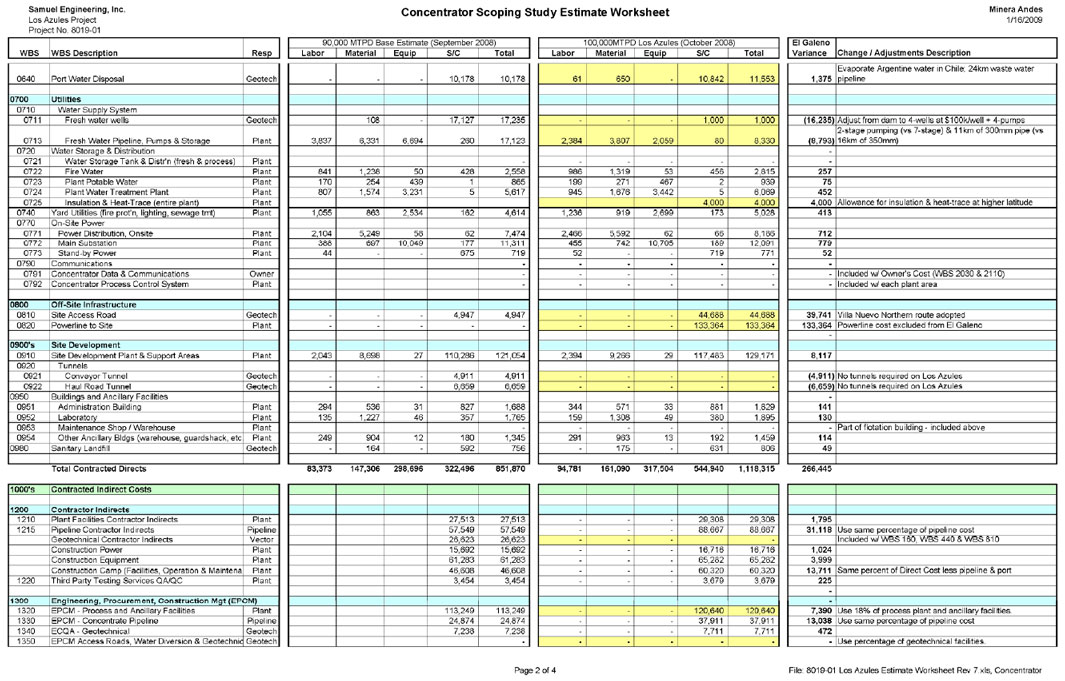

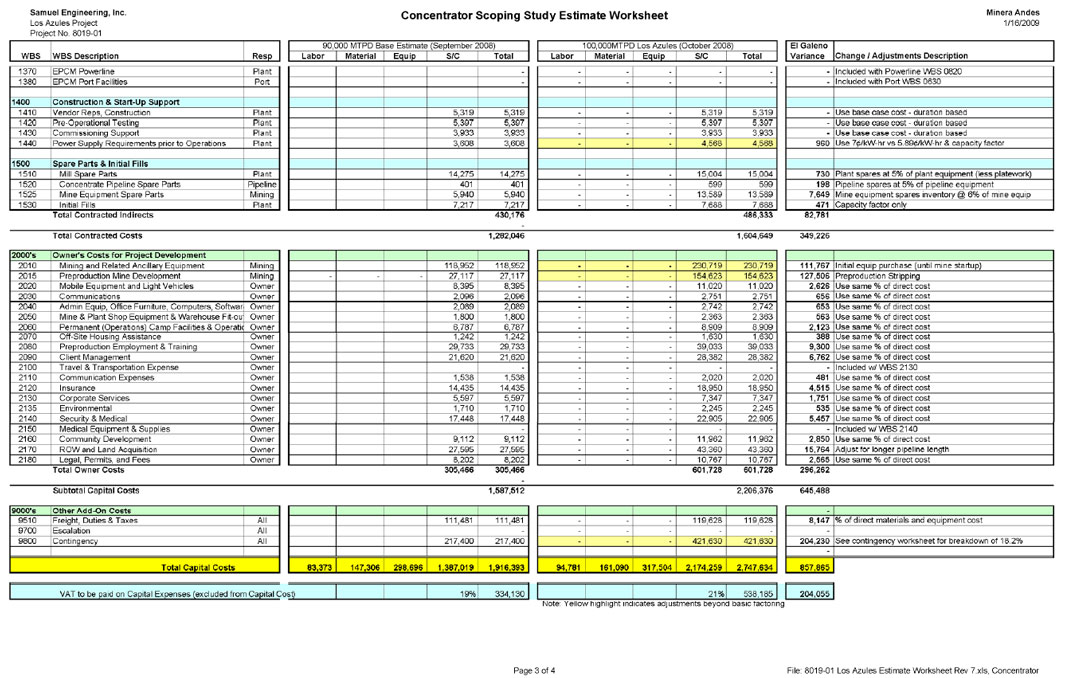

| Figure 26.8 – Work Breakdown Structure (WBS) – Page 1 | 243 |

| Figure 26.9 – Work Breakdown Structure (WBS) – Page 2 | 244 |

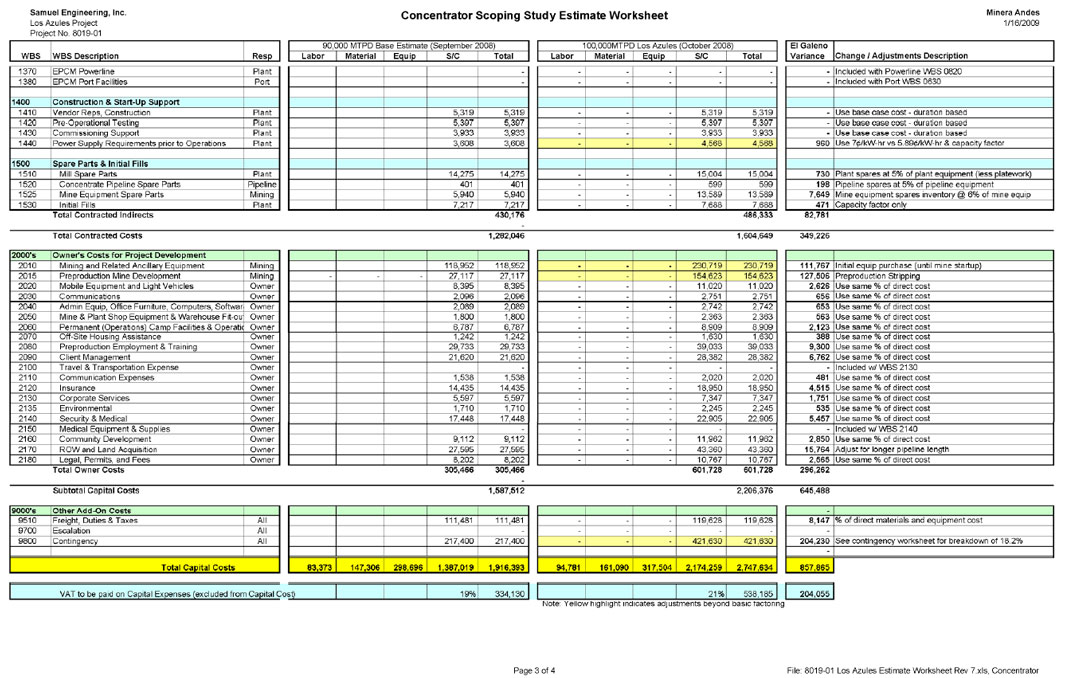

| Figure 26.10 – Work Breakdown Structure (WBS) – Page 3 | 245 |

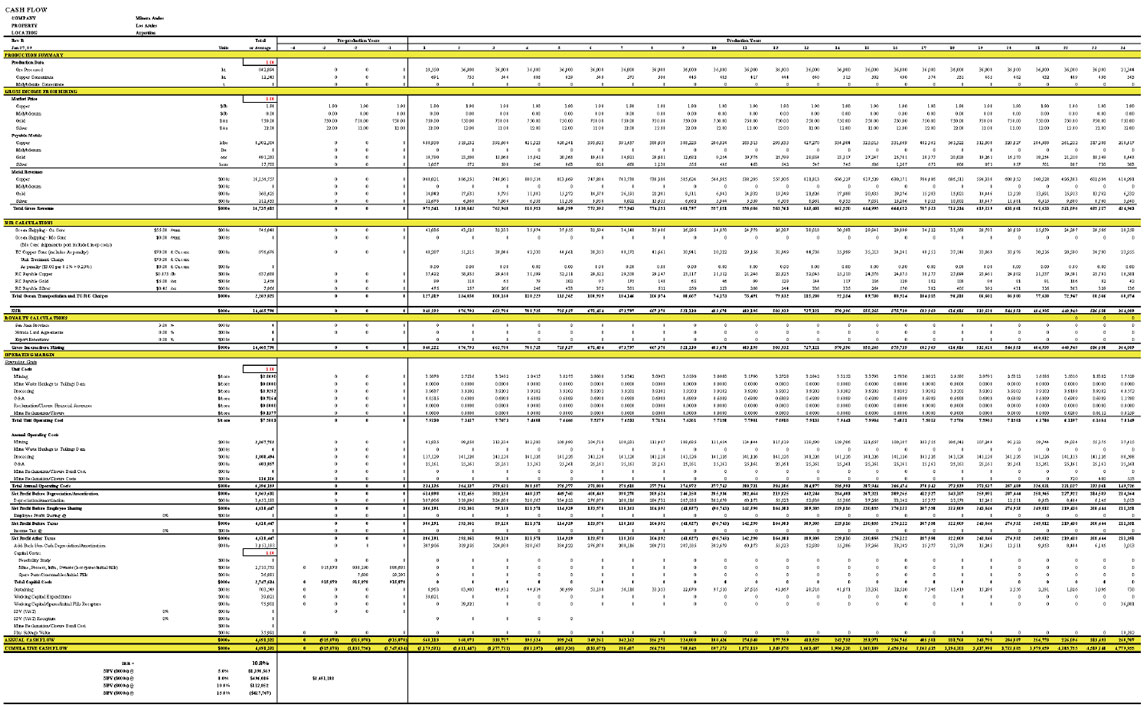

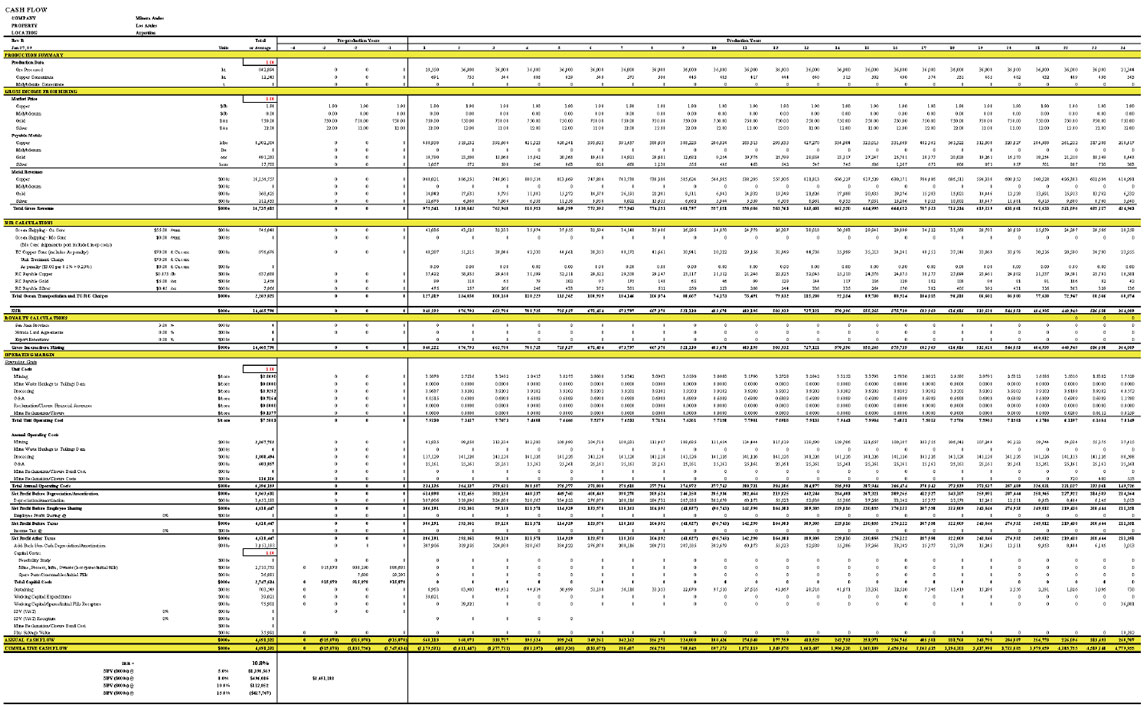

| Figure 26.11 – Pro Forma Cash Flow | 246 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

viii

Exhibit 99.1

|

|

| |

| List of Tables |

| |

| Table 3.1 Inferred Mineral Resources | 6 |

| Table 3.2 Inferred Mineral Resources Contained Within Designed Pit / Phases | 7 |

| Table 3.3 Locked-Cycle Test Work Results | 8 |

| Table 3.4 Basic Design Criteria | 11 |

| Table 3.6 LoM Operating Cost Summary | 15 |

| Table 3.7 LoM Capital Cost Summary | 16 |

| Table 3.8 Production, Metal Prices, Royalties and Smelting-Refining (“TC-RC”) Terms | 18 |

| Table 3.9 Concentrate Productions & Payable Metals | 19 |

| Table 4.1 List of Contributing Authors | 22 |

| Table 6.1 Los Azules Property Claim Status | 31 |

| Table 6.2 MIM Property Claim Status | 32 |

| Table 6.3 List of Main Permits by Stages of the Life of Mine | 40 |

| Table 7.2 Site Climate Data | 45 |

| Table 7.3 Neighboring Projects | 49 |

| Table 7.4 Estimated Cost of Power Supply Components | 49 |

| Table 7.5 Estimated Cost of Power Supply Options | 50 |

| Table 13.1 Exploration Drilling by Year and by Company | 78 |

| Table 13.2 Significant Drilling Results | 81 |

| Table 15.1 Sample Control Standards (2006 – 2007) | 87 |

| Table 18.1 Locked-Cycle Test Work Results | 102 |

| Table 18.2 Evaporation Site Location | 109 |

| Table 19.1 Mineral Zone Domains and Coding | 125 |

| Table 19.2 Mineral Zone Domains and Coding | 128 |

| Table 19.3 Variogram Parameters for Copper | 133 |

| Table 19.4 Block Model Limits | 133 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

ix

Exhibit 99.1

|

|

| |

| Table 19.5 Interpolation Parameters for Copper | 136 |

| Table 19.6 Inferred Mineral Resources | 143 |

| Table 19.7 Base Case Economic Parameters | 144 |

| Table 19.8 Floating Cone Results | 145 |

| Table 19.9 Open Pit Design Parameters | 146 |

| Table 19.10 Inferred Mineral Resources Contained Within Designed Pit / Phases | 147 |

| Table 20.1 Mine Production Scheduling Parameters | 149 |

| Table 20.2 Mine Production Schedule Based on Inferred Mineral Resources | 150 |

| Table 20.3 Major Mining Equipment Fleet Requirements | 155 |

| Table 20.4 Mine Personnel Requirements | 156 |

| Table 20.5 Main Access Road Design Criteria | 161 |

| Table 20.6 Acid Generation Potential Testing Sample Points | 165 |

| Table 20.7 Acid Generation Potential Testwork Parameters of Interest – ABA Testing Program | 166 |

| Table 20.8 Classification of ABA Test Results | 166 |

| Table 20.9 TSF Design Criteria | 169 |

| Table 20.10 Tailings – Comparative Analysis of Important ARD and Leaching Parameters | 172 |

| Table 20.11 Specific Hydraulic Yields – San Juan River Basin | 174 |

| Table 20.12 Preproduction Capital Cost Estimate Summary | 187 |

| Table 20.13 Summary of Mine Capital Expenditures | 195 |

| Table 20.14 Production, Metal Prices, Royalties and Smelting-Refining (“TC-RC”) Terms | 197 |

| Table 20.15 Concentrate Productions & Payable Metals | 198 |

| Table 20.16 LoM Capital Cost Summary | 199 |

| Table 20.17 LoM Operating Cost Summary | 200 |

| Table 20.18 Project Economic Summary | 202 |

| Table 21.1 Budget Estimate for Work Plan | 207 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

x

Exhibit 99.1

| Table 23.1 SI Base Units | 226 |

| Table 23.2 Permitted Base Units | 226 |

| Table 23.3 SI Prefixes | 227 |

| Table 23.4 Derived SI Units of Special Name | 228 |

| Table 23.5 Units in Use | 228 |

| Table 23.6 Common Derived Units (Select List Only) | 229 |

| Table 23.7 Abbreviations of Other Terms | 230 |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

xi

Exhibit 99.1

3.0

Summary

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

1

3.1

Overview of the Study

Minera Andes, Inc. (“MAI”) commissioned a Preliminary Assessment (“PA”) for its Los Azules project in 2008. The PA was prepared to define the overall scope of the Los Azules project, perform preliminary mine planning, report on metallurgical testwork and process design, estimate capital and operating costs and estimate the economics of developing the project as an open pit mine and mill facility. All monetary amounts presented in this report are in US$ unless specified otherwise.

The results of the PA were announced by MAI by way of news release dated February 5, 2009. This technical report has been prepared pursuant to section 4.2(j)(i) of National Instrument 43-101 “Standards of Disclosure for Mineral Projects” (“NI 43-101”) and in accordance with NI 43-101F1.

As a result, this report discloses a preliminary assessment that includes inferred mineral resources. Inferred mineral resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that the preliminary assessment will be realized. The basis for the preliminary statements and the qualifications and assumptions made by the authors of this report are set out herein.

3.2

Property Description and Ownership, Location, Infrastructure and History

3.2.1

Property Description and Ownership

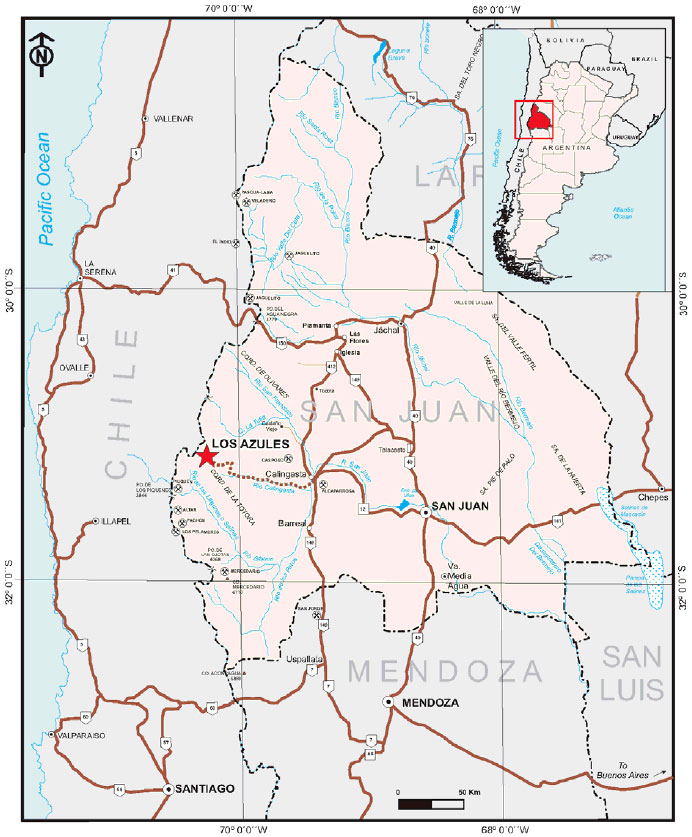

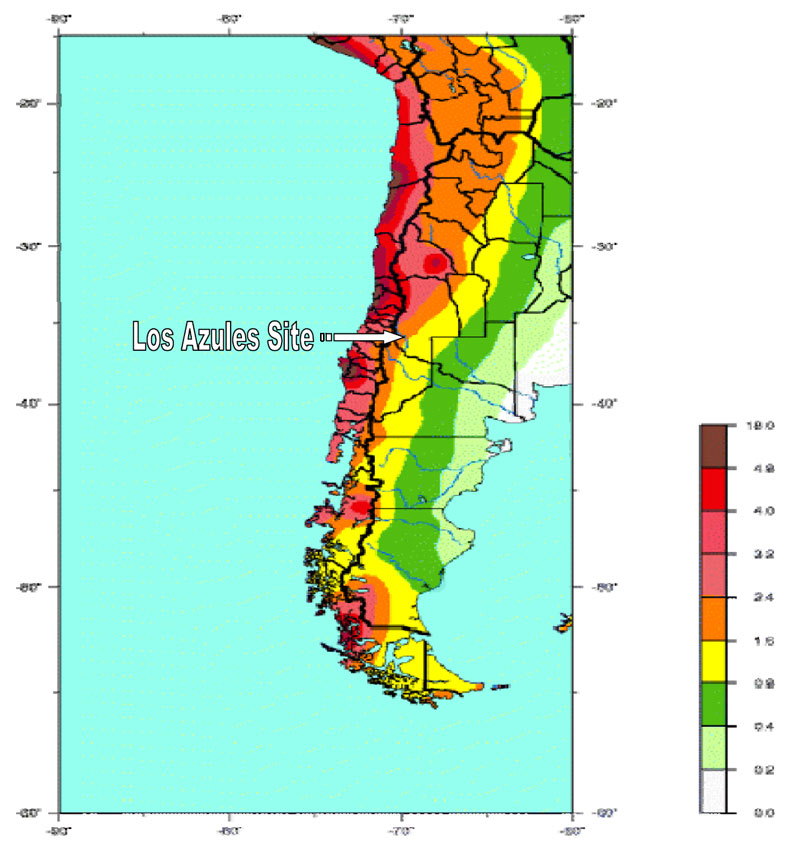

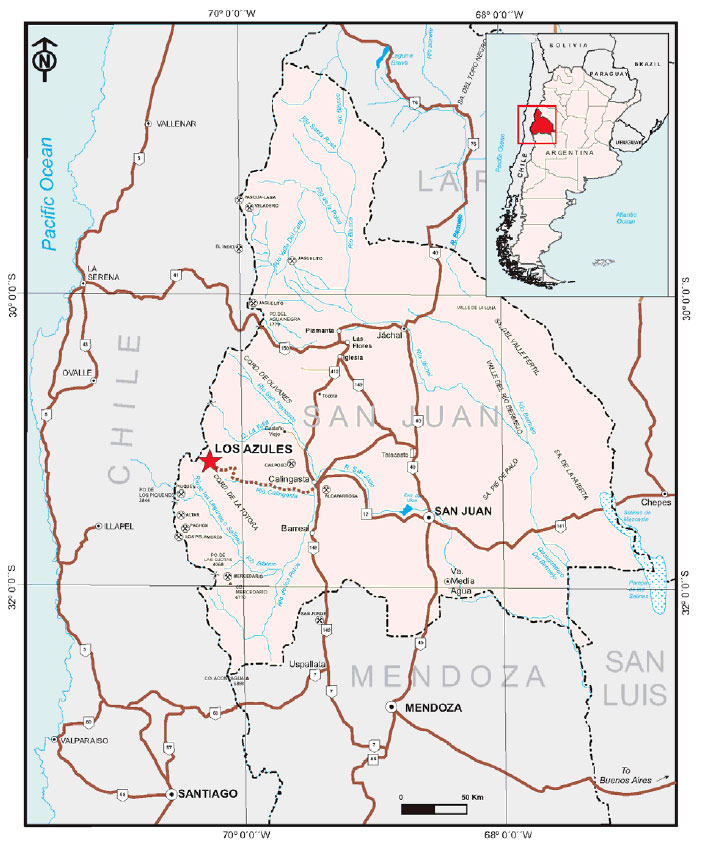

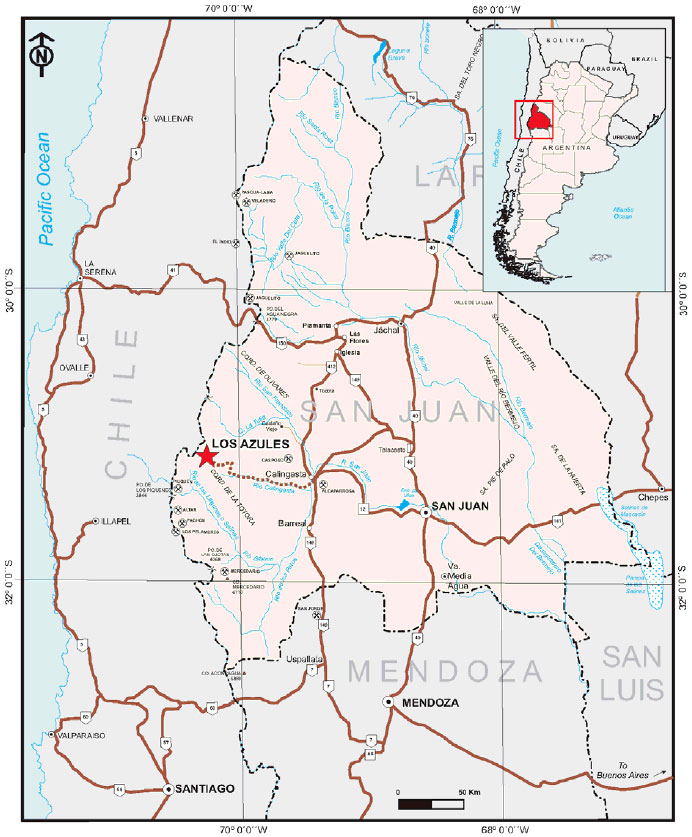

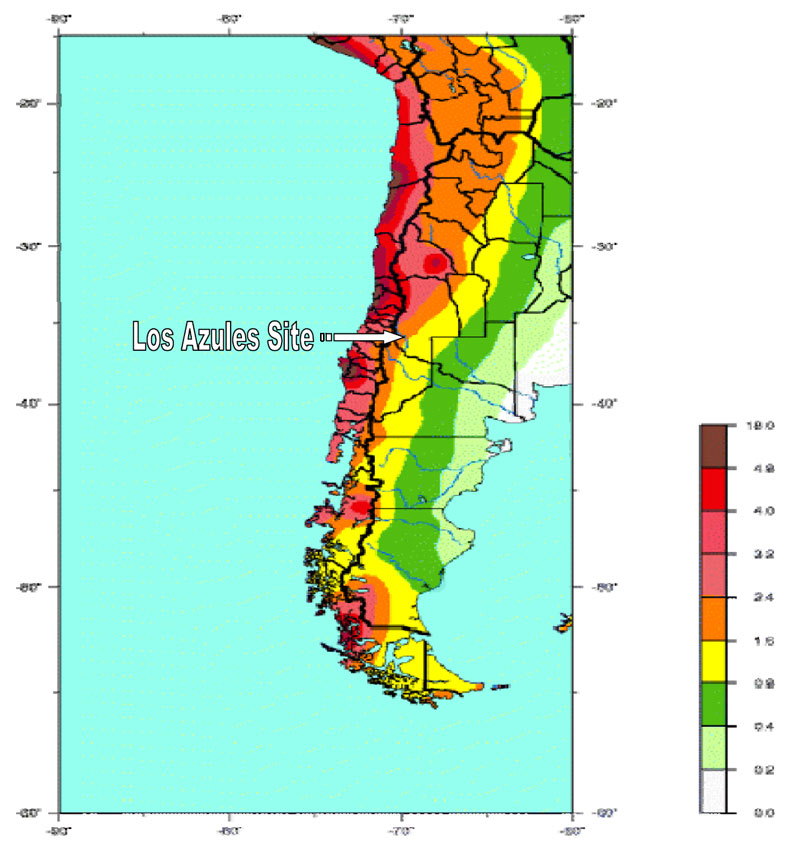

The Los Azules project is located near 31° 13' 30" south latitude and 70° 13' 50" west longitude in the western portion of San Juan Province, Calingasta Department, adjacent to the Argentina/Chilean border as shown in Figure 3.1.

The Los Azules project is about 20,612 ha (50,933 acres) and was discovered by MAI geologists through regional exploration in the Andes. The project is situated between two prolific mineral belts and is held by two “Manefestaciones de Discubrimiento”.

The project’s mineralized area straddles property currently held by Xstrata Copper to the north and MAI to the south. MAI has held the southern portion of the property since 1994. Xstrata Copper and MAI have entered into an Option and Joint Venture Agreement dated November 2, 2007 governing exploration of the properties held by each of them comprising the Los Azules project (the “Los Azules Option Agreement”).

The hydrothermal system at Los Azules is an altered area approximately 8 km (N-S) by 5 km (E-W) surrounding a core mineralized porphyry target that is about 3 km by 1 km in size. Initial exploration efforts have been typical for a porphyry type deposit and have used a hole spacing of 400 m (N-S) and 200 m (E-W). Now that mineralization has been confirmed, MAI is continuing to infill drill the grid spacing in order to upgrade the mineral resource estimate from an Inferred status to an Indicated and Measured status in preparation for a Prefeasibility Study.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

2

Figure 3.1 – Project Location

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

3

3.2.2

Property Location

The Los Azules project is west and slightly north of the town Calingasta, in the San Juan Province of Argentina. The project site is accessed by 120 km of unimproved dirt road with eight river crossings and two mountain passes (both above 4,100 m elevation). Calingasta is located west of the city of San Juan along Route 12.

At the Los Azules project, elevation ranges between 3,500 m and 4,500 m above mean sea level. The climate is tundra-like (semiarid/cold) with abundant snowfall during winter and temperatures as low as -30°C. Frequent northwesterly winds can approach 120 km/hr.

Exploration work typically commences in November and terminates in early April.

3.2.3

Infrastructure

The Los Azules project area is quite remote and therefore, no infrastructure is present. In addition, there are no nearby towns and/or settlements. Exploration operations are carried by means of a man-camp near the project area.

The Calingasta substation is the nearest source of power to the Los Azules project; however, it is isolated from the provincial network. Power supply to the region is currently satisfied by means of local hydro or thermal generation.

The San Juan provincial government is planning to expand the existing 500 kV network, by among other things, building new 500/220 kV El Rodeo and Calingasta substations. In addition, a 500/220 kV San Juan substation, a 165 km San Juan to El Rodeo transmission line (“TL”) and a 160 km El Rodeo to Calingasta TL will also be constructed. Finally, the existing Gran Mendoza to San Juan TL will need to be upgraded from 220 kV to 500 kV.

3.2.4

Property History

On June 21, 2000 Battle Mountain Gold Corporation (“BMGC”) merged with Newmont Mining Corporation (“NMC”). Prior to the merger, BMGC explored a block of claims on the Chile-Argentine border and discovered a large hydrothermal alteration zone associated with dacite porphyry intrusions and stockwork structural zones, which was drilled with reverse circulation holes during 1998 and 1999. This discovery led to the recognition that the suggested porphyry copper-gold deposit area was not entirely contained within the lands controlled by BMGC. The merger with NMC failed and the BMGC properties were subsequently acquired by Sr. Bosque and Solitario Argentina S.A. (“SASA”) and later by MIM Argentina S.A. (“MIM”). Xstrata succeeded MIM and in 2007, signed an agreement with MASA optioning of the Los Azules lands now held by MAI (Section 6.4).

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

4

3.3

Geology and Resources

3.3.1

Regional Geology

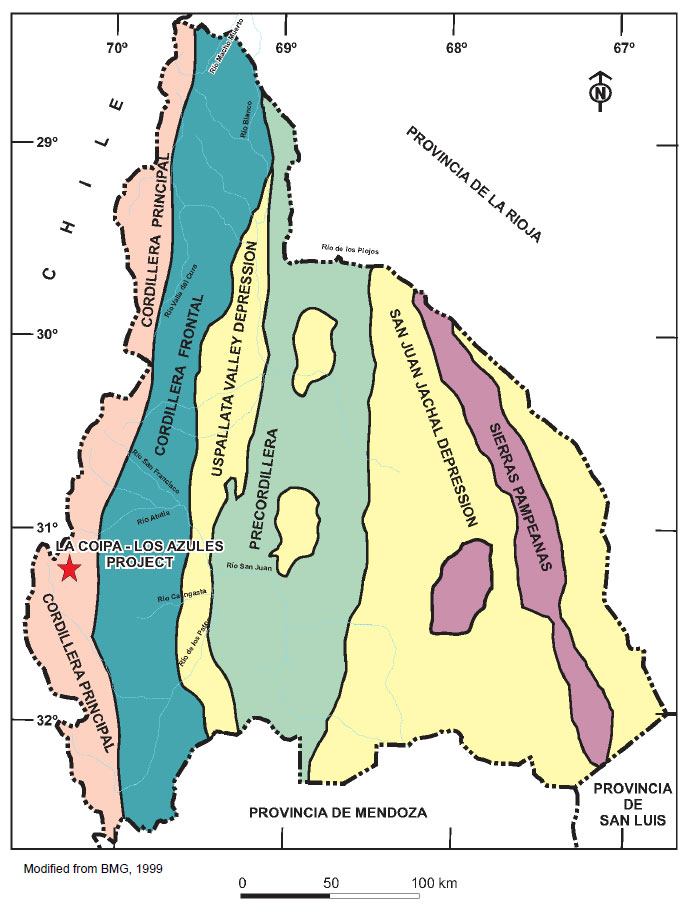

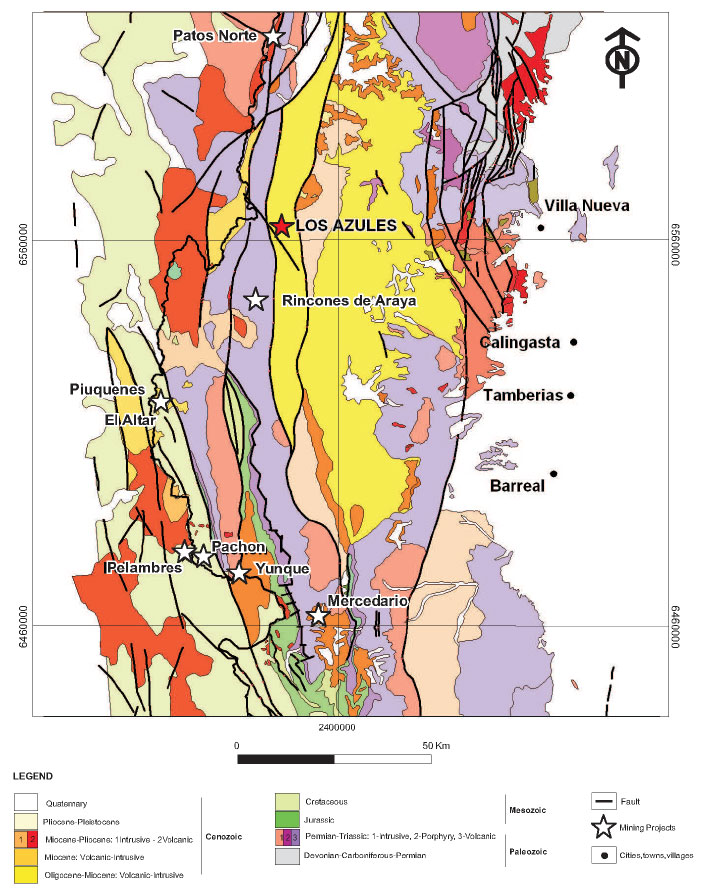

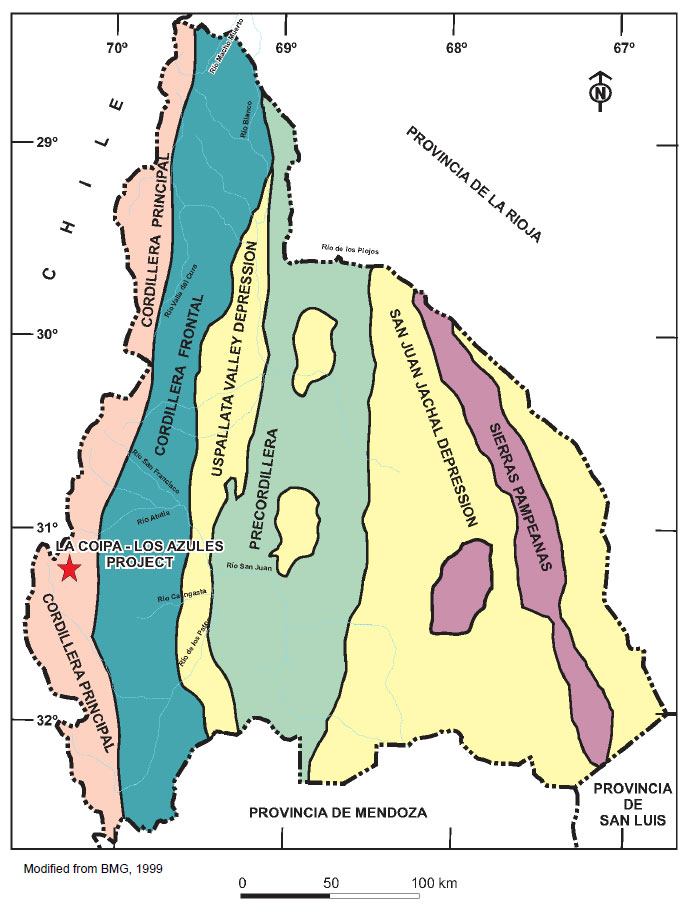

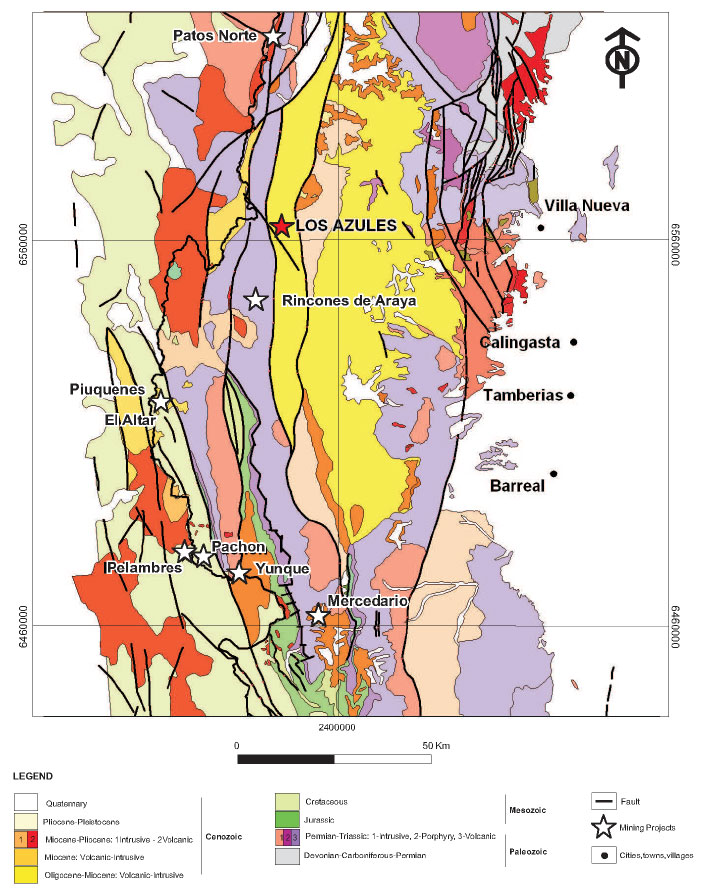

The property is located in a geological province known as the Cordillera Frontal, a mountainous region situated between the Pre-Cordillera and the Cordillera Principal. This region, located along the western side of Argentina and adjacent to the Chilean border, covers the provinces of Catamarca, La Rioja, San Juan and Mendoza between latitude 21°00’ south and 36°46’ south.

During Middle to Lower Miocene times, active volcanism resulted in a geographically broad distribution of porphyry-type copper-gold epithermal gold-silver deposits over 250 km wide zone from the Andean Cordillera through the Pampean ranges.

3.3.2

Property Geology

The Los Azules project is based on a NNW-SSW-trending ridge (“La Ballena”) that exists at the southern end of a hydrothermally altered system approximately 8 km long (N-S) by 5 km wide (E-W), which surrounds a core mineralized porphyry target that is about 3 km long by 1 km wide.

Previous work recognizes two principal geological groups at Los Azules: an upper volcanic suite and a lower intrusive complex. The volcanic suite comprises a basal rhyolitic unit overlain by dacitic pyroclastics and andesitic flows. The lower suite is described as diorite-tonalite in composition with a dacite porphyry core. In addition, a rhyolitic-dacitic pyroclastic and volcaniclastic suite, interpreted to be part of the Choiyoi Group (Permian- Triassic) form the known basement rocks in the Los Azules area.

3.3.3

Resources

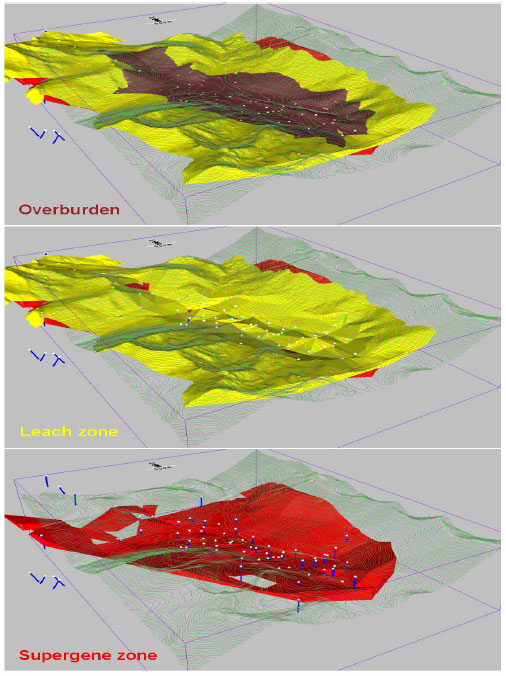

There appears to have been a very minor degree of near-surface remobilization of copper due to acidic fluids created from the breakdown of pyrite in this reducing environment. These mechanisms are well documented in relation to many porphyry copper deposits, often developing a high-grade blanket of “supergene” enrichment, which is overlain by a “leach” cap and is essentially void of contained metals. It is apparent that both of these types of mineralization zones (“Minzone”) have been developed at Los Azules and are underlain by primary sulfide mineralization comprised of pyrite, chalcopyrite and bornite.

Separate domains have been interpreted for overburden (“OVB”), leached (“LX”) and supergene (“SS”) zones using a combination of mineral zone logging (visual observation of enrichment minerals such as chalcocite and/or covellite) and assay grades. In many areas, the base of the SS zone is defined at the interval where the ratio of cyanide soluble copper (“CSCu”) to total copper (“TCu”) is greater than 60 percent. Soluble copper assay data is not present in all drill holes and hence, visual observation is utilized in these cases.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

5

Overburden is thickest in the valley floor and thins as the slopes steepen to the west and east. Thicknesses are variable and range up to 100 m in some locations but average approximately 60 m in thickness above the zone of mineralization. The Leached zone is also locally variable in thickness from non-existent in some drill holes to almost 200 m thick in others. The average thickness of the Leach zone above the deposit is approximately 40 m. The underlying Supergene zone is also somewhat variable with thicknesses ranging from zero to over 250 m with an average of approximately 70 m.

3.3.4

Resource Classification

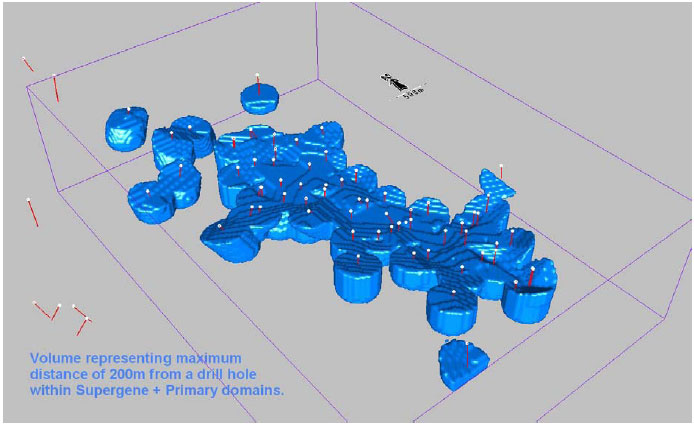

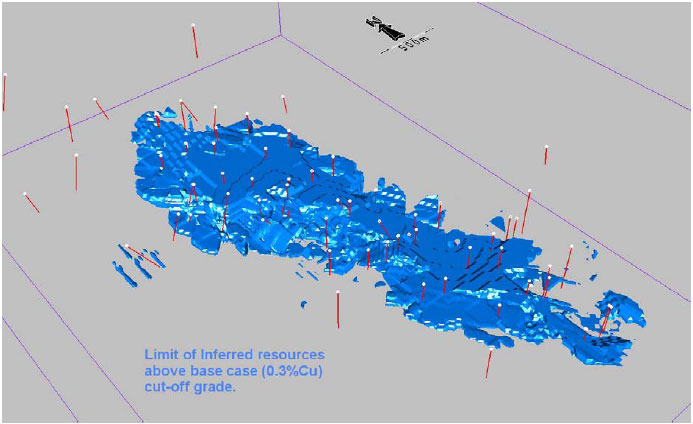

The mineral resources at the Los Azules deposit have been classified in accordance with the CIM definition standards for mineral resources and mineral reserves (CIM, 2005). At this stage of the project, the relative number and density of drill holes does not support the classification of resources in the measured or indicated categories. The classification parameters for inferred resources are defined in relation to the distance to sample data and are intended to encompass zones of reasonably continuous mineralization.

Inferred Mineral Resources are blocks in the supergene and primary domains which are a maximum distance of 200 m from a drill hole.

The Los Azules mineral resources are summarized in Table 3.1 at a series of copper cutoff grades. These cutoff grades are presented for comparison purposes only. In order to comply with CIM definitions regarding selection of a “base case”, a base case was selected at a cutoff grade of 0.35% copper, which is consistent with other operations exhibiting similar characteristics, potential scale of operation and location.

| | |

Table 3.1

Inferred Mineral Resources |

Cutoff Grade (TCu%) | Million Tonnes | TCu% |

0.30 | 1,171 | 0.50 |

0.35 | 922 | 0.55 |

0.40 | 727 | 0.60 |

0.50 | 451 | 0.69 |

0.60 | 273 | 0.78 |

0.70 | 161 | 0.87 |

0.80 | 93 | 0.97 |

Note: Mineral Resources do not have demonstrated economic viability. |

There are no known factors related to environmental, permitting, legal, title, taxation, socioeconomic, marketing or political issues which could materially affect the mineral resource.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

6

3.3.5

Resources within Designed Pit Phases

Inferred mineral resources contained within each of the mining phases were based on an internal cutoff grade of 0.22% Cu. No dilution has been included in the estimates of mineral resources beyond that incorporated into the block model grades. Tonnages were based on an in-situ material density of 2.45 t/m3. An extraction rate of 100% was applied to the model tonnage estimates. Table 3.2 summarizes the estimated tonnage and grade of contained inferred mineral resources by mining phase.

| | | | | | | | |

Table 3.2

Inferred Mineral Resources Contained Within Designed Pit / Phases |

Phase | Mineral Resources* (>= 0.22% Cu Cutoff) | Waste (Million t) | Total (Million t) | Strip Ratio |

(Million t) | Cu (%) | Mo (%) | Au (g/t) | Ag (g/t) |

1 | 59 | 0.83 | 0.003 | 0.08 | 2.13 | 148 | 207 | 2.52 |

2 | 100 | 0.60 | 0.004 | 0.05 | 1.66 | 124 | 224 | 1.24 |

3 | 125 | 0.55 | 0.004 | 0.06 | 1.85 | 141 | 266 | 1.13 |

4 | 257 | 0.45 | 0.003 | 0.05 | 1.36 | 324 | 582 | 1.26 |

5 | 150 | 0.51 | 0.002 | 0.05 | 1.95 | 300 | 450 | 1.99 |

6 | 152 | 0.42 | 0.002 | 0.04 | 1.65 | 236 | 387 | 1.55 |

Total | 843 | 0.51 | 0.003 | 0.05 | 1.68 | 1,273 | 2,116 | 1.51 |

Inferred mineral resources have a great amount of uncertainty as to their existence and as to whether they can be mined legally or economically. It cannot be assumed that all or any part of inferred mineral resources will ever be upgraded to a higher category. |

The designed Los Azules ultimate pit is nearly six percent larger than the base case floating cone pit shell, which is within acceptable limits. This slight expansion is due to pit wall smoothing and the inclusion of haulage ramps within the pit design.

The ultimate pit contains approximately 843 million tonnes of potentially economic inferred mineral resources (above a 0.22% Cu internal cutoff) grading 0.51% Cu and has an estimated stripping ratio of about 1.5:1 (tonnes waste per tonne of mineralized material). Contained metal is estimated at 9.5 billion pounds of copper, 56 million pounds of molybdenum (molybdenum recovery is not being considered at the time of this report), 1.5 million troy ounces of gold and 46 million troy ounces of silver. Of the 843 million tonnes of inferred mineral resources, about 402 million tonnes are secondary sulfides grading 0.55% Cu and 441 million tonnes are primary sulfides grading 0.48% Cu.

This Technical Report supports a preliminary assessment within the meaning of NI 43-101 which includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

7

3.4

Metallurgy

The scope of the metallurgical testing program was to determine the flotation response of Los Azules mineralized material samples and provide data for the design of the grinding and flotation circuits.

The metallurgical testwork indicated the flotation response on the samples tested are typical of ore deposits for the recovery of copper, gold and silver. Two composites and 16 drill core samples were sent to CH Plenge & Cia. for the metallurgical test work. Composite No. 1 is a secondary strong enrichment composite with 17% of the copper in chalcopyrite, while composite No. 2 is a primary weak enrichment composite with 49% of the copper in chalcopyrite. A small amount of high grade sample (No. 3) of primary sulfide with 75% of the copper in chalcopyrite was also sent to Plenge for metallurgical test work and it was confirmed that the high grade sample responded well to copper recovery by flotation.

Locked-cycle tests were performed on each of the two composites and Sample 3. The results of the locked-cycle tests are shown in Table 3.3.

| | | | | | |

Table 3.3

Locked-Cycle Test Work Results |

Composite | Concentrate Assay | Metal Recoveries (%) |

Copper (%) | Silver (g/t) | Gold (g/t) | Copper | Silver | Gold |

1 – Strong Enrichment | 35 | 101 | 2.7 | 94.1 | 70 | 56 |

2 – Weak Enrichment | 31 | 80 | 3.9 | 94.7 | 62 | 66 |

Sample 3 – High-grade Primary Sulfide | 34 | 84 | 2.4 | 95.1 | 83 | 74 |

These results were factored for use in the process design to relate laboratory results to expected industry capabilities. In this, composite No. 1 concentrate is 34% copper with 92% copper recovery, composite No. 2 is 30% copper with 93% copper recovery and sample No. 3 is 33% copper with 93% copper recovery. From the results of these two composites and sample a weighted final concentrate copper grade of 30.8% copper and a recovery of 92.8% copper were applied to the process design.

3.5

Process

3.5.1

Process Description

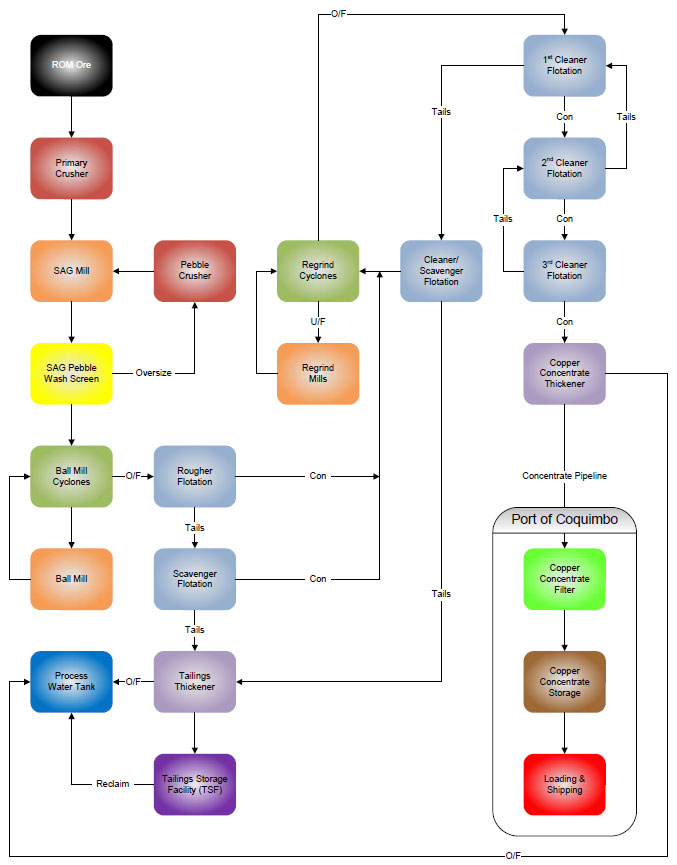

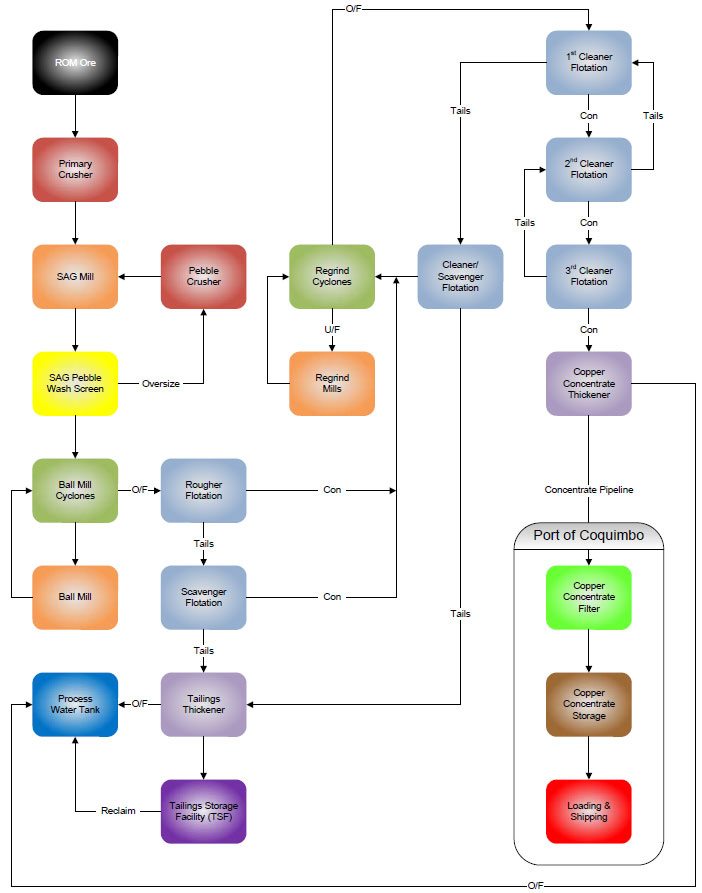

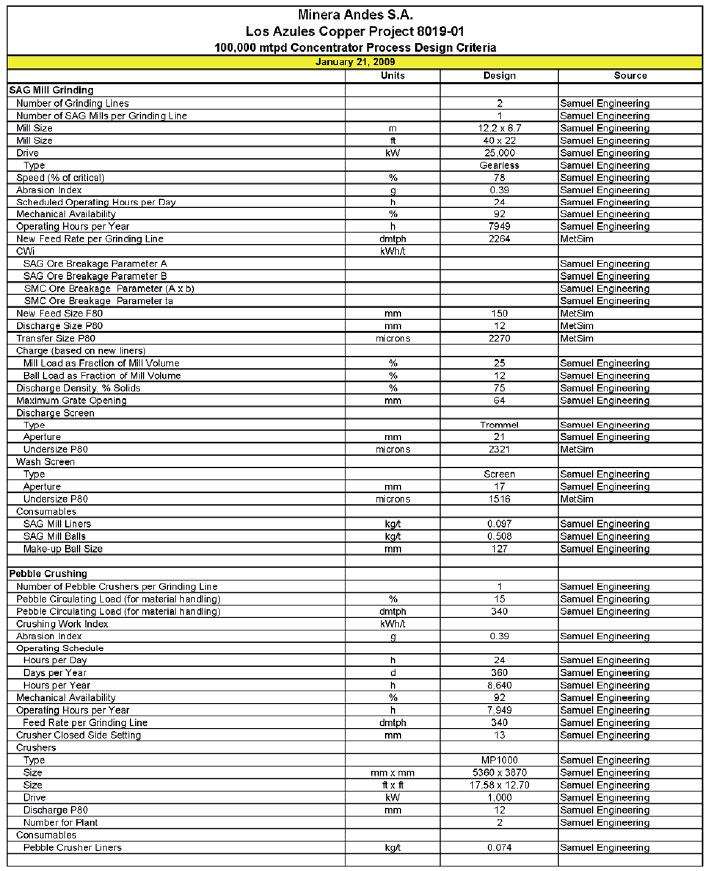

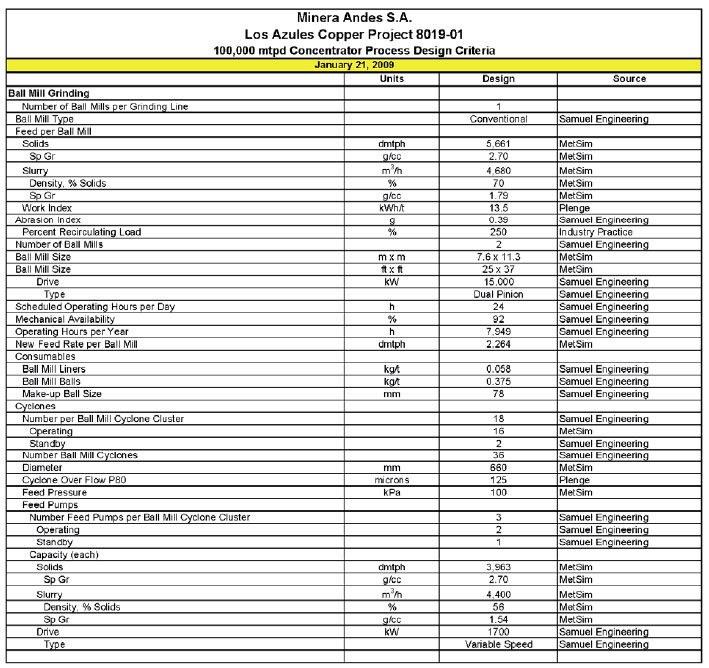

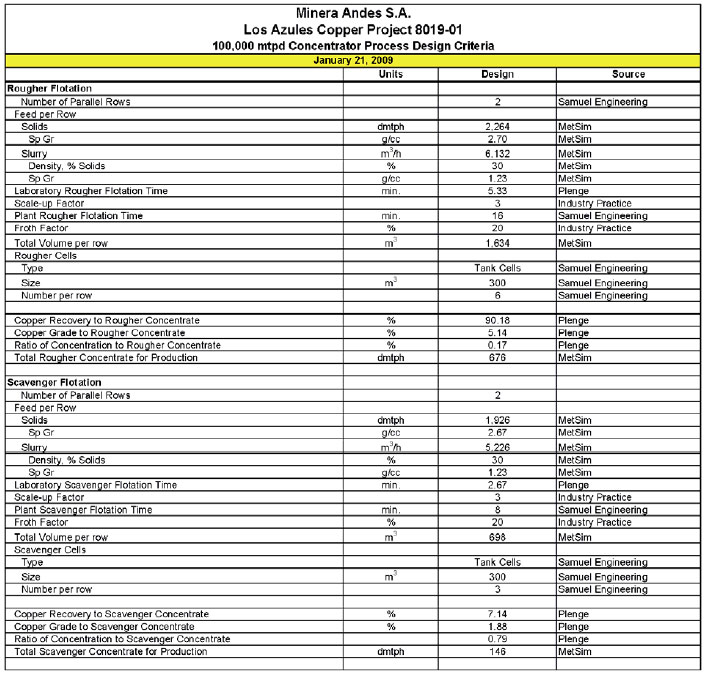

The process flow sheet (Figure 26.7) and the process block flow diagram (Figure 3.2) show a plant design representative of a conventional flotation concentrator.

The Los Azules concentrator will have an annual throughput of 36,000,000 tonnes, based on an average daily throughput of 100,000 tonnes and 360 operating days per annum. The concentrator on site will include a comminution circuit followed by a flotation circuit and a copper circuit with thickener, filtration and concentrate load out and shipping. Tailings thickener, tailings storage, and water reclaim are part of the tailings storage facilities (“TSF”). This circuit will have a design capacity of 108,696 tonnes per day (“tpd”) and the aforementioned nominal capacity of 100,000 tpd.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

8

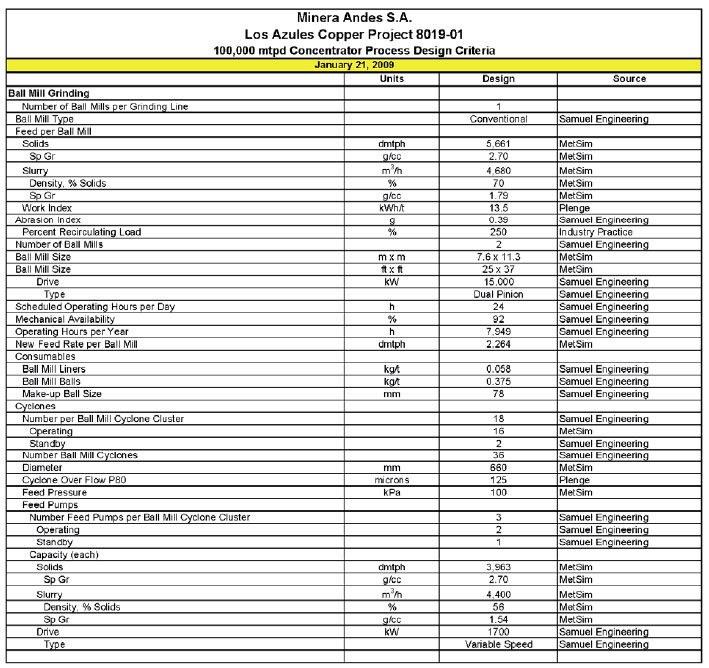

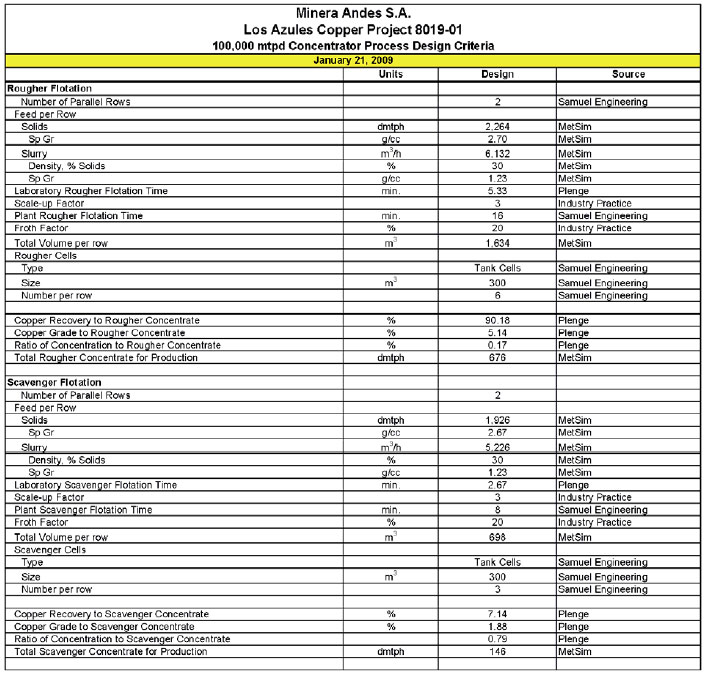

The 1524 mm x 2794 mm (60 inch x 110 inch) primary gyratory crusher will produce a 175 mm (7 inch) feed which will be conveyed to a coarse material stockpile with a live capacity of 100,000 tonnes. Material from the stockpile is reclaimed and transported by conveyor to two (2) parallel grinding lines.

Each grinding line is comprised of one (1) 12.2 m diameter x 6.7 m long (40 ft x 22 ft) semi-autogenous grinding (“SAG”) mill powered by an 25 MW gearless drive, and one (1) 7.6 m diameter x 11.3 m long (25 ft x 37 ft) ball mill powered by a 15 MW dual pinion drive. The two (2) SAG mills discharge through trommel screens and the screens oversize (“critical”) report to two (2) 5.36 m x 3.87 m (17.6 ft x 12.7 ft) pebble crushers, each driven by a 1.0 MW motor, before returning to the SAG mills. Cyclone classification is employed to produce the required particle size distribution at P80 of 125 microns (“µm”).

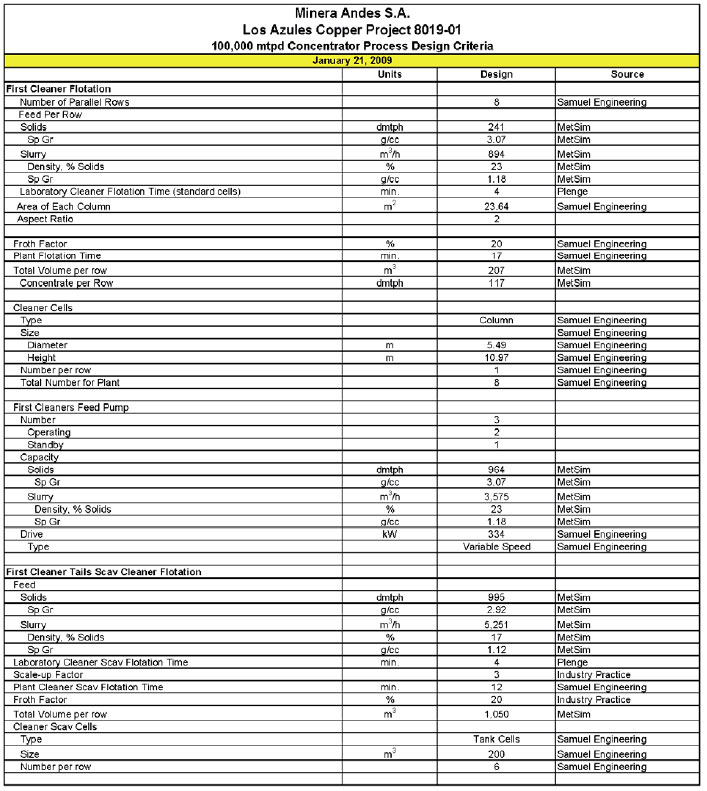

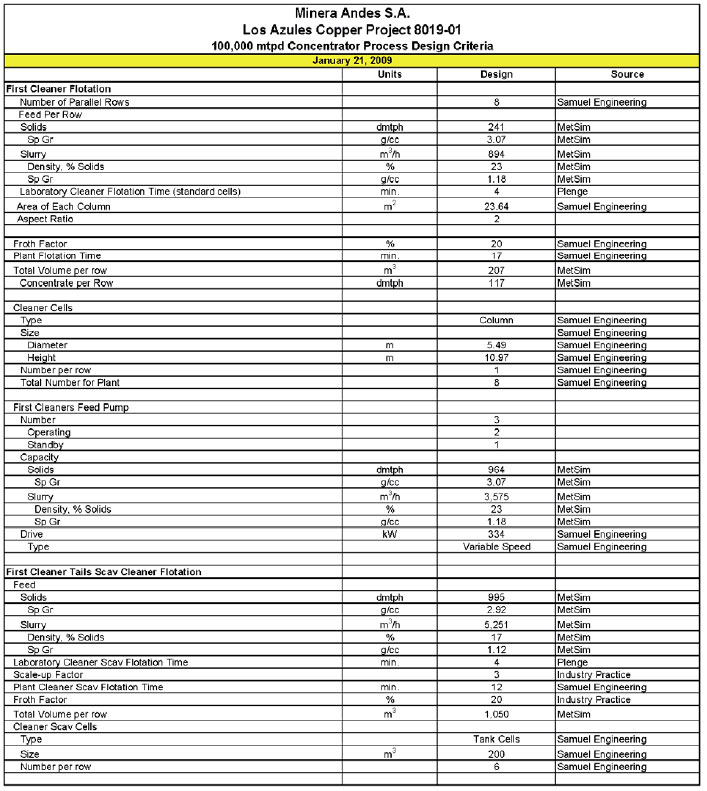

This overflow will be fed to two (2) rougher flotation circuits. Tailings from the rougher flotation circuits will be combined and sent to two (2) scavenger flotation banks, while the concentrate from the scavenger circuit will be combined with the rougher concentrate and both will report to a regrind circuit, and the tails will report to the tailings thickener.

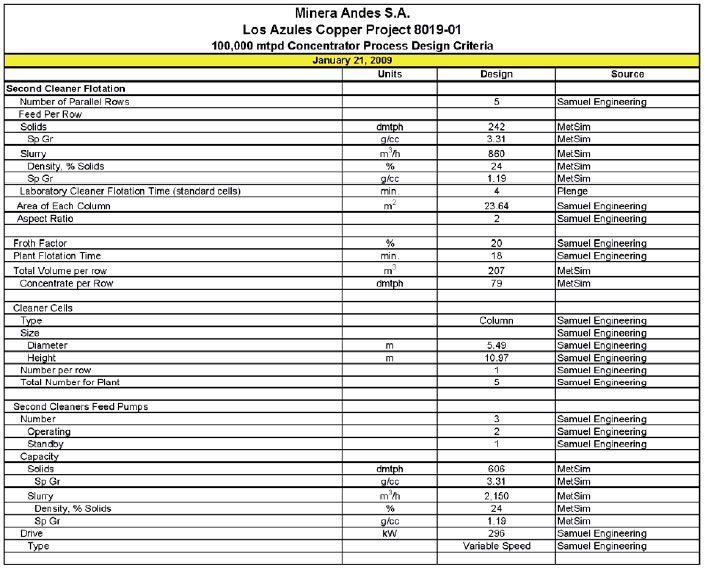

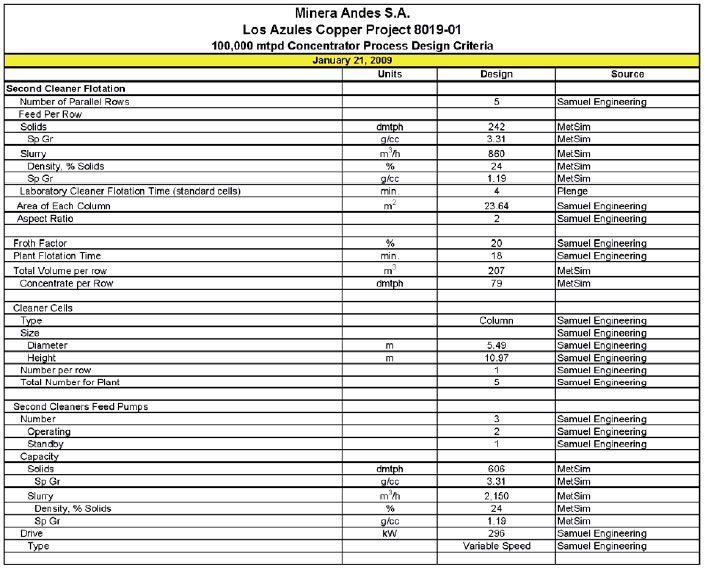

The combined rougher and scavenger concentrates are reduced to a P80 of 30 µm in six (6) 1,250 hp tower mills before being pumped to the 3-stage cleaner circuit.

The 1st cleaner underflow is transferred to the cleaner/scavenger flotation circuit and the reclaimed concentrate is sent back to the regrind circuit. The tailings from the cleaner/scavenger are then joined by the rougher and scavenger flotation tailings and transferred to two (2) 80 m (263 ft) diameter tailings thickeners.

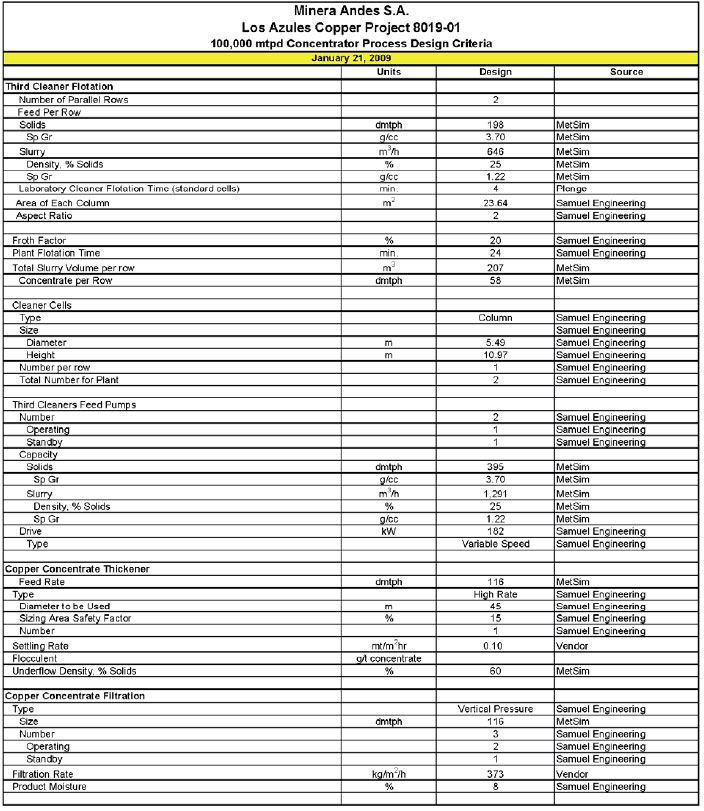

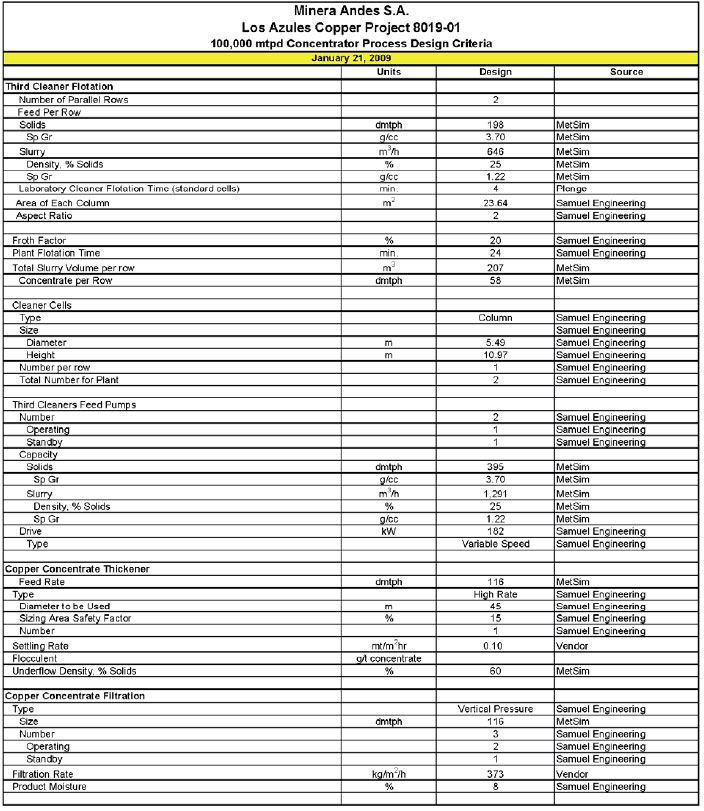

The concentrate from the 1st cleaner flotation cells transfers to the 2nd cleaner flotation circuit. Tails from the 2nd cleaner circuit will be sent back to the 1st cleaner circuit. Concentrate from the 2nd cleaner will report to the 3rd cleaner flotation circuit.

Tails from the 3rd cleaner circuit report back to 2nd cleaner flotation. Concentrate from the 3rd cleaner reports to the copper concentrate thickener.

Final copper concentrate at 25% solids from the 3rd cleaner flotation concentrate stream will be thickened to 60% solids in one (1) 45 m (148 ft) diameter thickener. The copper concentrate thickener overflow reports back to the process water tank for reuse, while the thickened copper concentrate will be pumped via pipeline to the port facility of Coquimbo, Chile, which houses three (3) vertical pressure type dewatering filters. The filter cake containing 8% moisture reports to the covered copper concentrate stockpile for loading by a front-end loader to copper concentrate transport ships destined for smelters in the Orient. The filtrate will be pumped to an evaporation pond for final disposal.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

9

3.5.2

Process Block Flow Diagram

Figure 3.2 – Process Block Flow Diagram

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

10

3.5.3

Basic Process Design Criteria

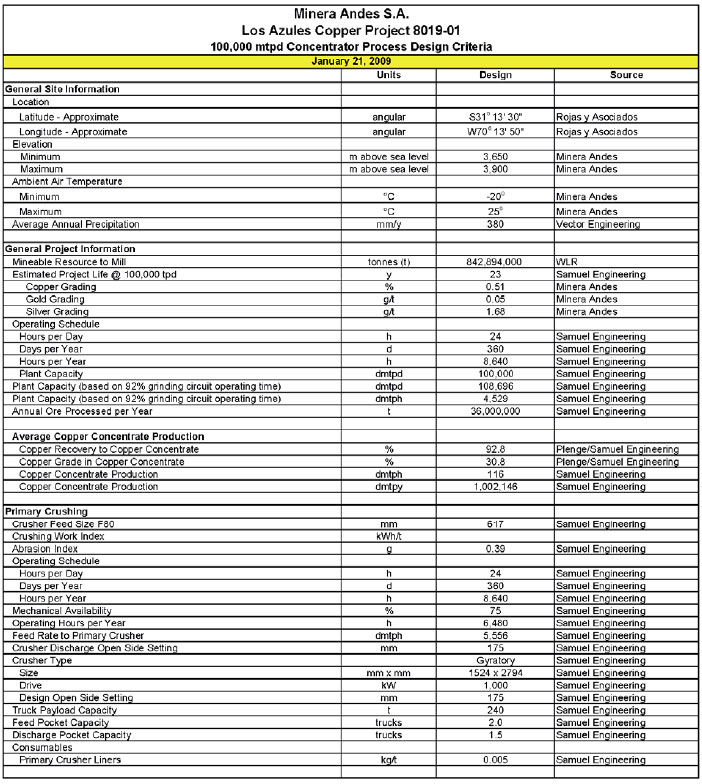

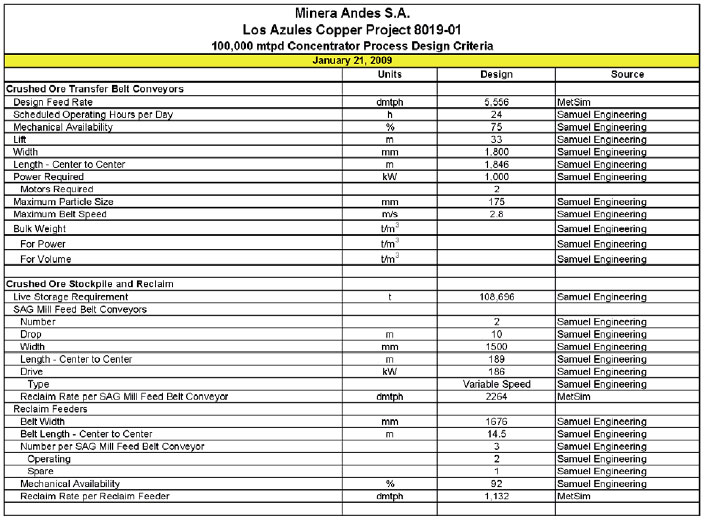

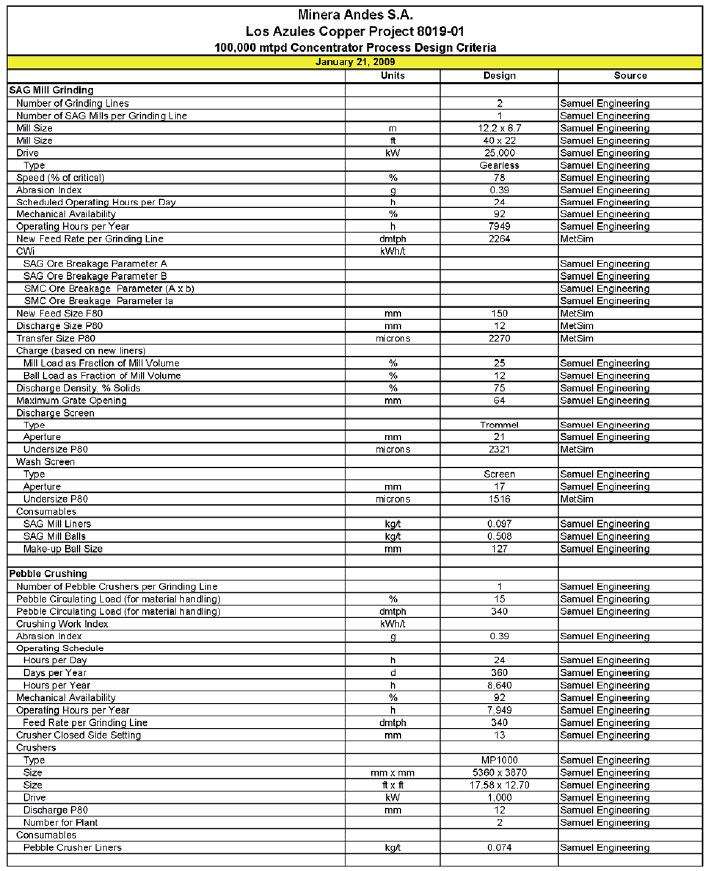

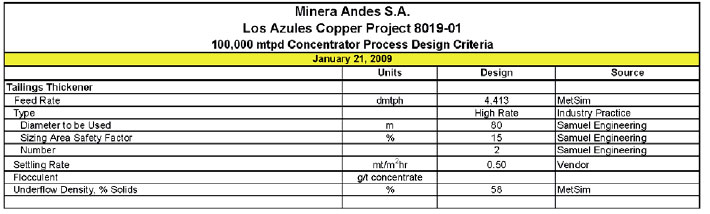

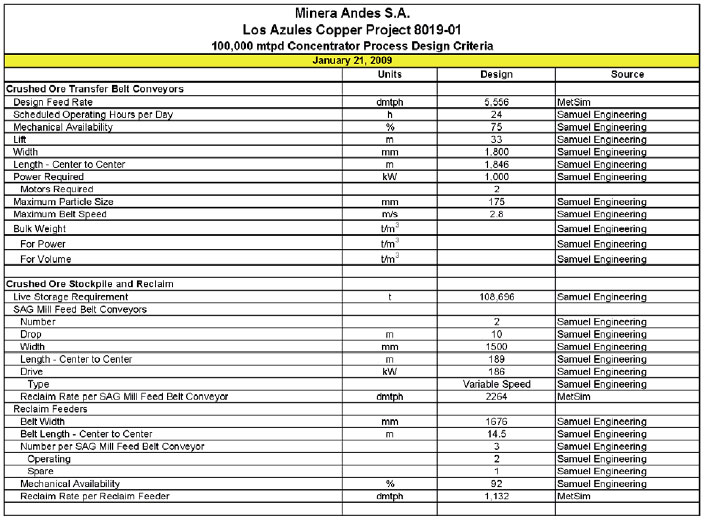

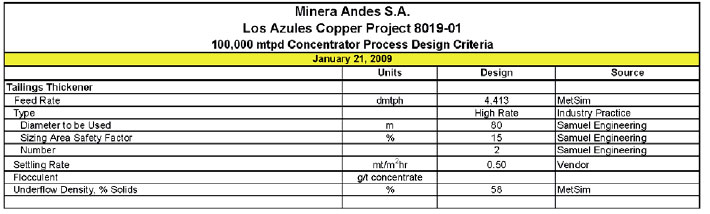

Table 3.4 shows the design criteria used to establish the process for a 100,000 tonnes per day operation process facility.

| | | |

Table 3.4

Basic Design Criteria |

| Units | Design | Source |

General Site Information |

Location | | | |

Latitude - Approximate | angular | S31o13' 30" | Rojas y Asociados |

Longitude - Approximate | angular | W70o13' 50" | Rojas y Asociados |

Elevation | | | |

Minimum | masl | 3,650 | Minera Andes |

Maximum | masl | 3,900 | Minera Andes |

Ambient Air Temperature | | | |

Minimum | °C | -20o | Minera Andes |

Maximum | °C | 25o | Minera Andes |

Average Annual Precipitation | mm/y | 380 | Vector Engineering |

General Project Information |

Mineable Resource to Mill | tonnes (“t”) | 842,894,000 | WLR |

Estimated Project Life @ 100,000 tpd | y | 23.6 | Samuel Engineering |

Copper Grading | % | 0.51 | Minera Andes |

Gold Grading | g/t | 0.05 | Minera Andes |

Silver Grading | g/t | 1.68 | Minera Andes |

Operating Schedule | | | |

Hours per Day | h | 24 | Samuel Engineering |

Days per Year | d | 360 | Samuel Engineering |

Hours per Year | h | 8,640 | Samuel Engineering |

Plant Capacity | dmtpd | 100,000 | Samuel Engineering |

Based on a 92% grinding circuit operating time | dmtpd | 108,696 | Samuel Engineering |

Based on a 92% grinding circuit operating time | dmtph | 4,529 | Samuel Engineering |

Annual Mineralized Material Processed per Year | t | 36,000,000 | Samuel Engineering |

Copper Concentrate Production |

Copper Recovery to Copper Concentrate | % | 92.8 | Plenge/Samuel Engineering |

Copper Grade in Copper Concentrate | % | 30.8 | Plenge/Samuel Engineering |

Copper Concentrate Production | dmtph | 116 | Samuel Engineering |

Copper Concentrate Production | dmtpy | 1,002,146 | Samuel Engineering |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

11

3.6

Tailings Storage Facility (“TSF”)

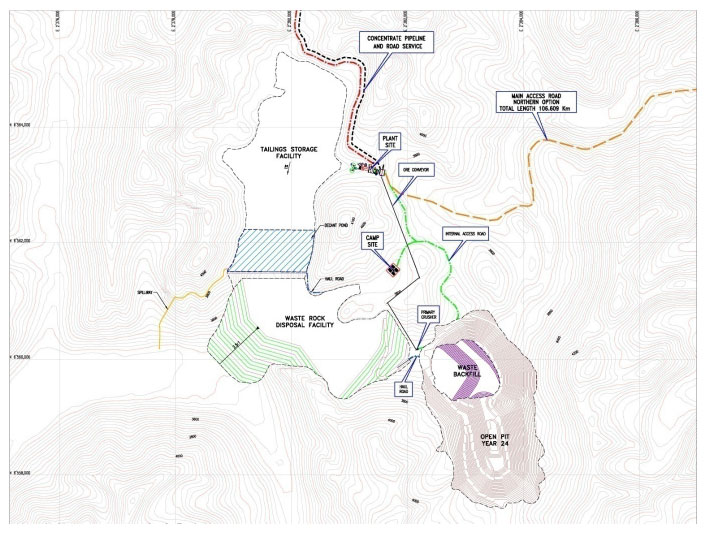

The mine plan estimates mine life at approximately 24 years with a production rate of approximately 100,000 tpd. It is estimated that approximately 98% of mineralized material fed into the process plant will be discharged as gangue (tailings) and co-disposed of into the TSF and waste rock disposal facility (“WRDF”). Current estimates show that approximately 80% [663 million tonnes (dry)] of the tailings will enter the TSF, while the remaining 20% [166 million tonnes (dry)] will be diverted to the WRDF. At an estimated average dry density of 1.3 tonnes/m3, this equates to approximately 510 million m3 placed in the TSF and 128 million m3 placed in the WRDF.

Tailings will be discharged by gravity from the process plant into the impoundment as slurry, a mixture of pulverized rock and water, estimated to contain 55% solids. In addition to the tailings, the TSF will hold ponded water which includes water that separates from the tailings slurry, incident rainfall, rainfall runoff from the surrounding catchment and water pumped into the TSF from other sources such as pit dewatering.

3.7

Waste Rock Disposal Facility (“WRDF”)

During 24 years of mining operations, it is calculated that approximately 1,272.7 million tonnes of waste rock will be generated from the open pit.

The WRDF will be located immediately west and downstream of the pit in Los Azules Valley and extend into the confluences with Embarrada Valley, and the Salinas Valley. It will ultimately buttress the TSF embankment located in the Embarrada Valley. Approximately 236 million tonnes of waste rock will be placed in the northern end of the pit. In-pit waste disposal will start in Year 16 of operation based on the current mine plan.

The total capacity of the WRDF is reduced by 389 million tonnes due to requirements for the construction of the TSF embankment and in-pit filling operations.

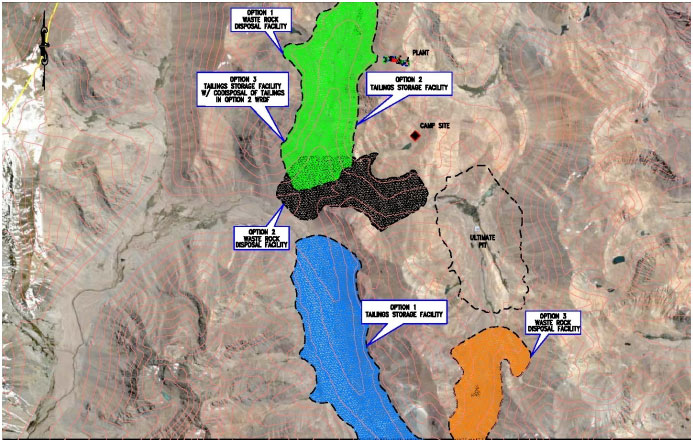

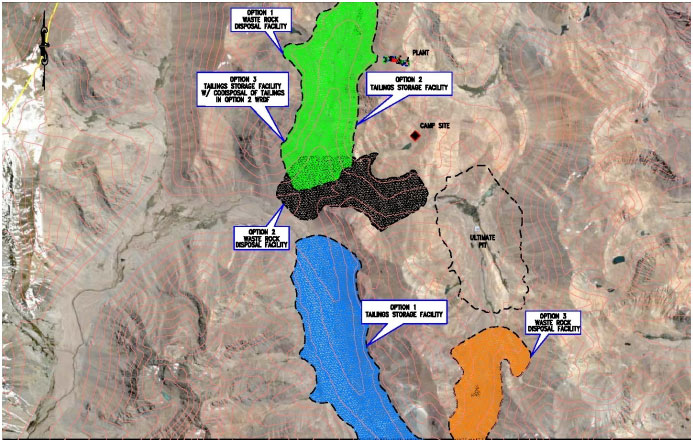

Figure 3.3 shows the general arrangement of the Los Azules project site components.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

12

Figure 3.3 – General Arrangement Plan

3.8

Mine Plan

An allowance of five days per annum was made for weather delays and/or shutdowns for holidays. Otherwise, pit operations would be scheduled around the clock. Mineralized material feed for the first year of concentrator operations was limited to 29.55 million tonnes to account for a gradual ramp-up of milling rates during the first seven months after startup.

Only primary and secondary sulfide mineral resources above a 0.22% Cu cutoff were considered as mineralized material for purposes of developing the mine production schedule. Advanced stripping needed to maintain adequate mineralized material exposure was estimated for the above milling rates. A proprietary scheduling program sequenced the necessary material by bench, by phase, for each time period. Mining phases were processed in order, from the upper most benches downward. Concurrent phase mining was allowed for advanced stripping purposes, subject to the restriction that previous phases cannot be undercut by subsequent pushbacks. Table 3.5 summarizes the resulting mine production schedule.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

13

|

|

| | | | | | | | |

Table 3.5

Mine Production Schedule Based on Inferred Mineral Resources |

Time Period | Mineral Resources* (>= 0.22% Cu Cutoff) | Waste (Million t) | Total (Million t) | Strip Ratio |

(Million t) | Cu (%) | Mo (%) | Au (g/t) | Ag (g/t) |

PP | 2.874 | 0.67 | 0.002 | 0.080 | 2.67 | 147.397 | 150.271 | 51.29 |

Y1* | 29.55 | 0.86 | 0.003 | 0.079 | 2.59 | 63.65 | 93.2 | 2.15 |

Y2 | 36.0 | 0.74 | 0.004 | 0.071 | 1.60 | 57.2 | 93.2 | 1.59 |

Y3 | 36.0 | 0.56 | 0.002 | 0.047 | 1.38 | 57.2 | 93.2 | 1.59 |

Y4 | 36.0 | 0.60 | 0.005 | 0.052 | 1.44 | 57.2 | 93.2 | 1.59 |

Y5 | 36.0 | 0.61 | 0.005 | 0.057 | 2.10 | 57.2 | 93.2 | 1.59 |

Y6 | 36.0 | 0.56 | 0.003 | 0.057 | 1.69 | 57.2 | 93.2 | 1.59 |

Y7 | 36.0 | 0.55 | 0.004 | 0.076 | 1.59 | 57.2 | 93.2 | 1.59 |

Y8 | 36.0 | 0.55 | 0.004 | 0.065 | 2.35 | 57.2 | 93.2 | 1.59 |

Y9 | 36.0 | 0.44 | 0.003 | 0.039 | 1.26 | 57.2 | 93.2 | 1.59 |

Y10 | 36.0 | 0.41 | 0.002 | 0.033 | 1.12 | 52.6 | 88.6 | 1.46 |

Y11 | 36.0 | 0.40 | 0.003 | 0.047 | 1.15 | 52.6 | 88.6 | 1.46 |

Y12 | 36.0 | 0.41 | 0.003 | 0.054 | 1.32 | 52.6 | 88.6 | 1.46 |

Y13 | 36.0 | 0.60 | 0.004 | 0.066 | 1.87 | 52.6 | 88.6 | 1.46 |

Y14 | 36.0 | 0.47 | 0.003 | 0.053 | 1.72 | 52.6 | 88.6 | 1.46 |

Y15 | 36.0 | 0.46 | 0.004 | 0.058 | 1.45 | 52.6 | 88.6 | 1.46 |

Y16 | 36.0 | 0.47 | 0.003 | 0.060 | 2.27 | 52.6 | 88.6 | 1.46 |

Y17 | 36.0 | 0.57 | 0.002 | 0.058 | 1.57 | 52.6 | 88.6 | 1.46 |

Y18 | 36.0 | 0.51 | 0.002 | 0.053 | 1.85 | 52.6 | 88.6 | 1.46 |

Y19 | 36.0 | 0.44 | 0.002 | 0.046 | 1.83 | 52.6 | 88.6 | 1.46 |

Y20 | 36.0 | 0.45 | 0.002 | 0.045 | 1.90 | 51.627 | 87.627 | 1.43 |

Y21 | 36.0 | 0.40 | 0.002 | 0.044 | 1.52 | 14.07 | 50.07 | 0.39 |

Y22 | 36.0 | 0.37 | 0.002 | 0.046 | 1.67 | 5.749 | 41.749 | 0.16 |

Y23 | 36.0 | 0.45 | 0.002 | 0.045 | 1.69 | 3.126 | 39.126 | 0.09 |

Y24 | 21.344 | 0.52 | 0.001 | 0.043 | 1.49 | 3.522 | 24.866 | 0.17 |

Total | 845.767 | 0.51 | 0.003 | 0.050 | 1.68 | 1,272.743 | 2,118.51 | 1.50 |

* Includes rehandling 2.874 million t of stockpiled ROM mineralized material during Year 1. |

Mineralized material feed to the mills would total 842,894 kt over the life of the mine, which is projected at 23.6 years. About 2,874 kt of run-of-mine (“ROM”) mineralized material stockpiled during preproduction stripping would be reclaimed and hauled to the primary crusher during Year 1.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

14

Peak material handling rates from Years 2-9 would average nearly 259,000 tpd, before settling back to about 246,000 tpd from Year 10 through late Year 20. Over 150 million tonnes of waste rock and mineralized material would be stripped during preproduction to expose sufficient mineralized material for the concentrator startup. Preproduction stripping operations would last approximately two years.

A rotating, four-crew system would be used to staff mine operations and maintenance craft labor positions. These crews would work 12-hour shifts. Peak manpower levels of 595 are projected for Years 12-14.

3.9

Operating Costs

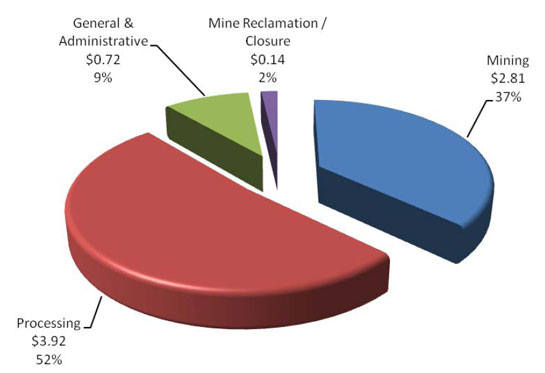

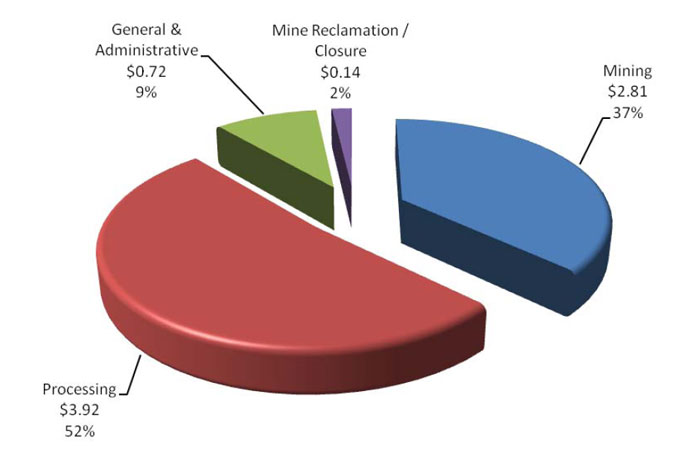

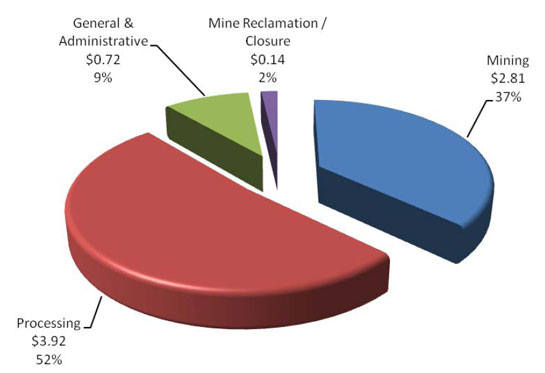

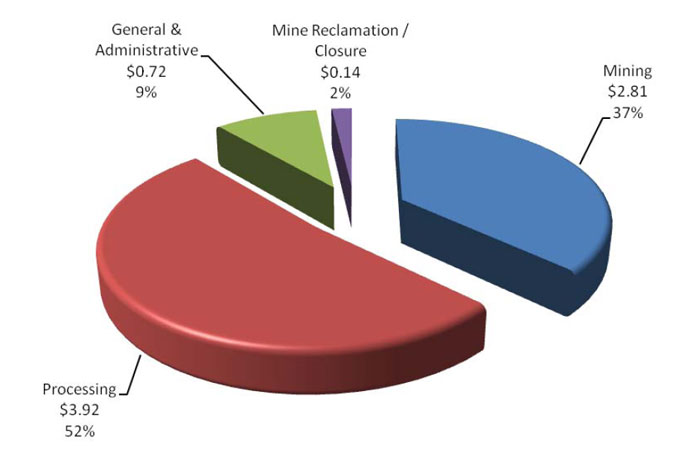

The total life-of-mine (“LoM”) operating cost is estimated at $6.40 billion, or $7.59/t mineralized material as summarized in Table 3.6. Figure 3.4 shows the percentage of each operating cost component.

| | |

Table 3.6

LoM Operating Cost Summary |

Description | LoM Cost ($000s) | LoM Cost/t Mineralized Material ($) |

Mining | 2,367,702 | 2.81 |

Processing | 3,308,494 | 3.92 |

General & Administrative | 603,857 | 0.72 |

Mine Reclamation / Closure | 116,106 | 0.14 |

LoM Operating Cost | 6,396,159 | 7.59 |

Figure 3.4 – LoM Operating Costs per Tonne Mineralized Material

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

15

3.10

Capital Costs

The total capital cost is estimated at $3.49B, being comprised of $2.75B during preproduction, $39.0M for working capital, and $704M in sustaining capital over the LoM. The estimate is summarized in Table 3.7.

| | |

Table 3.7

LoM Capital Cost Summary |

Description | Units | LoM Cost |

Mine Area Facilities | $000s | 31,332 |

Mineralized Material Storage, Handling and Crushing | $000s | 111,870 |

Grinding and Concentrating | $000s | 318,141 |

Tailings | $000s | 68,487 |

Concentrate Transport | $000s | 144,357 |

Port Concentrate Handling Facilities | $000s | 81,687 |

Utilities | $000s | 49,229 |

Off-site Infrastructure | $000s | 178,052 |

Site Development | $000s | 135,160 |

Contracted Indirects | $000s | 486,333 |

Owner Directs | $000s | 414,758 |

Owner Indirects | $000s | 186,970 |

Freight, Duties & Taxes | $000s | 119,628 |

Contingency | $000s | 421,630 |

Total Preproduction Capital | $000s | 2,747,634 |

Sustaining | $000s | 703,549 |

Working Capital | $000s | 39,021 |

Total LoM Capital | $000s | 3,490,204 |

The accuracy target for this capital cost estimate is intended to be plus or minus 35%. Most of the costs have been derived using a recently completed estimate for a similar plant, located in the Peruvian Andes, and making adjustment for project specific requirements and differences.

The costs presented in this document are based on estimates prepared as of December 2008 and no provision has been included to offset future escalation in prices.

Where source information was provided in other currencies, these amounts have been converted at rates shown in Figure 3.5.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

16

Figure 3.5 – Foreign Currency Conversion Rates

The rate of foreign currency exchange could have a serious impact on the value of labor and materials obtained in the local market (including freight, duties, and taxes). In addition, the value of the U.S. dollar against other world currencies could also influence future project cost if equipment is purchased in Europe or elsewhere. No funds have been allocated in the estimate to offset potential future currency fluctuations.

3.11

Project Economics

The PA set out herein is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the PA will be realized.

The project before-tax pro forma cash flow (Figure 26.11) shows an 10.8% IRR and a $496 million NPV at an 8% discount rate.

The pro forma cash flow used the following conventional methodology:

·

unleveraged 100% equity basis (no project financing or debt);

·

stand-alone project basis;

·

no export retentions;

·

before-tax determination of project economics;

·

annual cash flows discounted on end of year basis;

·

costs in third quarter 2008 U.S. Dollars (US$); and

·

no employee profit sharing.

The general parameters used in the economic analysis are shown in Table 3.8. The preproduction period is estimated at four years including one year for preparation of a feasibility study and three years for project development and construction.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

17

| |

Table 3.8

Production, Metal Prices, Royalties and Smelting-Refining (“TC-RC”) Terms |

Parameter | Data |

General |

Estimate Basis | Third quarter 2008 |

Preproduction Period | Three years |

Mine Production Life | 23.6 years |

Inferred Mineral Resources (Contained within Designed Pit) | 842,894,000 t |

Annual Mineralized Material Production Capacity | 36,000,000 t |

Market Prices |

Copper Price | $1.90/lb |

Gold Price | $750.00/oz |

Silver Price | $12.00/oz |

Royalties |

San Juan Province | 3.00% |

Xstrata Land Agreements | 0.00% |

Transportation, Smelting, and Refining Charges and Terms |

Copper Concentrate Transportation – Ocean Shipping | $55/wmt Cu conc. |

Copper Concentrate Treatment Charge | $70/dmt conc. |

Copper Refining Charge | $0.075/lb (payable) |

Gold Refining Charge | $5.00/oz (payable) |

Silver Refining Charge | $0.45/oz (payable) |

Copper Payfor | 96.5% |

Gold Payfor (net of deductions) | 54.9% |

Silver Payfor (net of deductions) | 59.4% |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

18

Table 3.9 summarizes the LoM concentrate productions and payable metals.

| | |

Table 3.9

Concentrate Productions & Payable Metals |

Description | Units | Value |

Copper Concentrate |

Copper Concentrate | t | 12,542,753 |

Copper Concentrate Grade | % | 31.9 |

Contained Copper | t | 4,002,595 |

Gold Content | g/t | 2.22 |

Contained Gold | oz | 895,231 |

Silver Content | g/t | 74.0 |

Contained Silver | oz | 29,827,136 |

Payable Metals |

Copper | t | 3,856,672 |

Gold | oz | 491,233 |

Silver | oz | 17,702,746 |

The Los Azules Project is at the exploration stage of investigation; consequently, this study is at the scoping level of accuracy, preliminary in nature, and includes inferred mineral resources in the conceptual mine plan and the mine production schedule. Inferred mineral resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves under the standards set forth in NI 43-101. There is no certainty that the preliminary assessment will be realized. |

3.12

Conclusions & Recommendations

The total project capital cost is estimated at $3.49 billion, being comprised of $2.75 billion during preproduction, $39.0 million for working capital, and $704 million in sustaining capital over the LoM. The total LoM operating cost is estimated at $6.40 billion, or $7.59/t mineralized material.

The project before-tax pro forma cash flow shows an 10.8% IRR and a $496 million NPV at an 8% discount rate.

The deposit is open-ended, and further drilling will be required to fully define the limits of the mineralization, especially along strike to the north and at depth.

The deposit requires further drilling to achieve the drill hole density required to support an indicated resource prior to a prefeasibility study.

A review of alternatives to reduce capital and operating costs at the prefeasibility stage of the project would provide opportunities to improve project economics.

A detailed list of additional recommendations for future work and studies can be found in Section 22.0 of this report.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

19

4.0

Introduction

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

20

4.1

Purpose of Technical Report

Minera Andes, Inc. (“MAI”) commissioned a Preliminary Assessment (“PA”) for its Los Azules project in 2008. The scope of the study was to assist management of MAI in making decisions with respect to the potential development of the Los Azules project. The PA was prepared to define the overall scope of the Los Azules project, perform preliminary mine planning, report on metallurgical test work and process design, estimate capital and operating costs and determine the economics to develop the project as an open pit mine and mill facility.

The results of the PA were announced by MAI in a press release dated February 5, 2009. As a result, this report was prepared pursuant to Section 4.2(j)(i) of National Instrument 43-101 under the direction of Randolph P. Schneider, MAusIMM, Project Manager, SE, as an independent “Qualified Person” as defined in the Instrument.

This report is intended to be read as a whole, and sections should not be read or relied upon out of context. This report contains the expression of the professional opinions of the contributors to this report and other consultants, based upon information available at the time of preparation. The quality of the information, conclusions and estimates contained herein is consistent with the intended level of accuracy as set out in this report, as well as the circumstances and constraints under which the report was prepared which are also set out herein.

4.2

Sources of Information

This report is the product of technical contributions from the consultants listed below and in Table 4.1:

·

Randolph P. Schneider, MAusIMM – IQP, Study Manager, Samuel Engineering, Inc.

·

Robert Sim, P.Geo – QP, Consulting Geologist, SIM Geological, Inc.

·

Bruce Davis, PhD, FAusIMM – QP, Consulting Geostatistician, BD Resource Consulting, Inc.

·

William L. Rose, P.E. – QP, Consulting Mining Engineer, WLR Consulting, Inc.

·

Scott C. Elfen, P.E. – QP, Consulting Civil Engineer, Vector Perú S.A.C.

·

Kenneth Rippere – Geotechnical Consultant

MAI contracted MTB Project Management Professionals, Inc. (“MTB”) to be the project manager and Samuel Engineering, Inc. (“SE”) to produce the PA. MTB contributed to infrastructure, and capital and operating costs; WLR Consulting contributed mineral reserve, mining and production schedule estimates, and mining capital and operating costs; Kenneth Rippere performed the geotechnical review and analysis of pit slopes; CH Plenge & Cia. performed metallurgical testwork; SE contributed the process engineering, capital and operating costs, and the cash flow modeling and valuation; and Vector Engineering was responsible for tailings and waste rock with associated capital and operating costs, and baseline environmental and socioeconomic studies.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

21

|

|

| | | |

Table 4.1

List of Contributing Authors |

Section No. | Section Name | Company | Responsible Party |

1 | Title Page | SE | Randolph P. Schneider, MAusIMM |

2 | Table of Contents | SE | Randolph P. Schneider, MAusIMM |

3 | Summary | SE | Randolph P. Schneider, MAusIMM |

4 | Introduction | SE | Randolph P. Schneider, MAusIMM |

5 | Reliance on Other Experts | SE | Randolph P. Schneider, MAusIMM |

6 | Property Description and Location | SE VEC | Randolph P. Schneider, MAusIMM Scott C. Elfen, P.E. |

7 | Accessibility, Climate, Local Resources, Infrastructure, and Physiography | SE VEC | Randolph P. Schneider, MAusIMM Scott C. Elfen, P.E. |

8 | History | SE | Randolph P. Schneider, MAusIMM |

9 | Geological Setting | SE | Randolph P. Schneider, MAusIMM |

10 | Deposit Types | SE | Randolph P. Schneider, MAusIMM |

11 | Mineralization | SE | Randolph P. Schneider, MAusIMM |

12 | Exploration | SE | Randolph P. Schneider, MAusIMM |

13 | Drilling | SE | Randolph P. Schneider, MAusIMM |

14 | Sampling Method and Approach | SE | Randolph P. Schneider, MAusIMM |

15 | Sample Preparation, Analysis and Security | SIM BDRC | Robert Sim, P.Geo Bruce Davis, PhD, FAusIMM |

16 | Data Verification | SE SIM | Randolph P. Schneider, MAusIMM Robert Sim, P.Geo |

17 | Adjacent Properties | SE | Randolph P. Schneider, MAusIMM |

18 | Mineral Processing and Metallurgical Testing | SE VEC | Randolph P. Schneider, MAusIMM Scott C. Elfen, P.E. |

19 | Mineral Resource Estimate | SIM BDRC WLR | Robert Sim, P.Geo Bruce Davis, PhD, FAusIMM William L. Rose, P.E. |

20 | Other Relevant Data and Information | ALL | ALL |

21 | Interpretations and Conclusions | ALL | ALL |

22 | Recommendations | ALL | ALL |

23 | References | ALL | ALL |

24 | Date and Signature Pages | ALL | ALL |

25 | Additional Requirements for Technical Reports on Development Properties and Production Properties | SE | Randolph P. Schneider, MAusIMM |

26 | Illustrations | SE WLR | Randolph P. Schneider, MAusIMM William L. Rose, P.E. |

Abbreviations: ALL – All QP Contributors; BDRC – BD Resource Consulting; MAI – Minera Andes, Inc. (Client); MTB – MTB Project Management Professionals, Inc.;

SE – Samuel Engineering, Inc.; SIM – SIM Geological, Inc.; VEC – Vector Engineering, Inc.; WLR – WLR Consulting, Inc. |

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

22

4.3

Site Visit

Randolph P. Schneider, MAusIMM, Project Manager, Mining & Minerals, of Samuel Engineering visited the project site February 19-21, 2008. The primary focus of the site visit was to evaluate site layout options for the mine shop, primary crusher, conveyor, mill site, tailings pond, waste rock, and topsoil material. In addition, observe first-hand the project site and drilling activities and to talk with various site personnel.

Robert Sim, P.Geo, of SIM Geological, Inc. visited the project site from March 30 to April 1, 2008 to observe first-hand the project site, observe drilling/sampling/logging practices, and to examine available drill core. In addition, available reports, cross sections, geologic interpretations and other relevant geologic data were reviewed and discussed with Minera Andes geology personnel.

Scott C. Elfen, General Manager, of Vector Perú S.A.C. visited the project site on February 21, 2008. The primary focus of the site visit was to observe first-hand the project site and gain an understanding of potential siting facility issues from a geotechnical and hydrology design point for the general infrastructure, open pit, tailings storage facility, waste rock disposal facility, access road, and pipeline corridor.

Bruce Davis, PhD, FAusIMM, of BD Resource Consulting, has not visited the project site since it is not necessary to do so in order to apply geostatistical analysis and co-develop the resource estimate along with Robert Sim.

William L. Rose, P.E. of WLR Consulting, Inc., has not visited the project site since the mine plan and mine production schedule were developed exclusively from the resource estimate provided by Robert Sim and Bruce Davis.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

23

5.0

Reliance on Other Experts

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

24

5.1

Reliance on Other Experts

The contributors to this report have, in the preparation of Sections 6.2 and 6.3 of this report, relied upon an opinion on current validity of the Los Azules mineral concessions held by Minera Andes, Inc. (“MAI”) expressed by the Argentinean lawyer, Mr. Jose Maria Sayavedra, on behalf of MAI, in a letter dated January 14, 2009. Samuel Engineering, Inc. (“SE”) has not conducted a legal review of the land ownership or property boundaries and is relying on the legal opinion of Mr. Sayavedra. Each of the contributors to this report hereby disclaims liability for Sections 6.2 and 6.3 of this report as they relate to title.

Randolph Schneider, the Study Manager, has not conducted an independent verification of geologic data used in the mineral resource estimate and is relying upon information provided by Robert Sim, P.Geo in the preparation of Section 16.0.

5.2

Previous Technical Reports

Information set out in Sections 6 to 17 of this report can be found in the report titled, “Los Azules Copper Project, San Juan Province, Argentina” prepared by Donald B. Tschabrun, MAusIMM, Tetra Tech, Golden, CO, USA with a revised date of January 8, 2009. Section 6.4 was updated by the title opinion presented in Section 5.1 above.

Information forming the basis of Section 9.0 can be found in the report titled, “Technical Report – Los Azules – February 2008”, prepared by Nivaldo Rojas of Rojas y Asociados, Mendoza, Argentina. This report was also used to prepare the Tetra Tech report above.

Information set out in Section 7.3.2 of this report can be found in the report titled, “Los Azules Mining Project Pre-Feasibility Study – Electric Energy Supply Study”, prepared by SIEye and HGF & Asociados.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

25

6.0

Property Description and Location

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

26

Figure 6.1 - Project Location

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

27

6.1

Location

The Los Azules project is located in the Frontal Cordillera of Argentina near 31° 13' 30" south latitude and 70° 13' 50" west longitude in the western portion of San Juan Province, Calingasta Department, adjacent to the Argentina/Chilean border as shown in Figure 6.1. Elevation ranges from 2,500 m to 5,500 m with moderate to high relief.

The Los Azules project is about 20,612 ha (50,933 acres) and was discovered by Minera Andes, Inc. (“MAI”) geologists through regional exploration in the Andes. The project is situated in Argentina near the Argentina/Chile border between two prolific mineral belts that straddle the border. To the north of the property, the El Indio gold belt is host to multi-million ounces of gold, and includes significant gold discoveries such as Veladero, Sancarron, Pascua and El Indio-El Tambo. The property lies in a belt of porphyry copper prospects such as El Pachón (Xstrata), El Altar (Rio Tinto), Los Piuquenes (Rio Tinto) and Rincones de Araya (Tenke).

The project’s mineralized area straddles property currently held by Xstrata Copper to the north and MAI to the south. MAI has held the southern portion of the property since 1994. The northern portion of the property has been held and explored by Battle Mountain Gold Corporation (“BMGC”) from 1994 - 1999 and by Mount Isa Mines (“MIM”), now Xstrata Copper, from 2004 to the present time.

The hydrothermal system at Los Azules is an altered area approximately 8 km (N-S) by 5 km (E-W) surrounding a core mineralized porphyry target that is about 3 km by 1 km in size.

Aerial photographic analysis and global positioning were utilized to locate the property boundaries.

6.2

Property and Title in Argentina

The laws, procedures and terminology regarding mineral title in Argentina differ considerably from those in the United States and in Canada. Mineral rights in Argentina are separate from surface ownership and are owned and administered by the provincial governments. The following summarizes some of the Argentinean mining law terminology in order to aid in understanding the MAI land holdings in Argentina.

6.2.1

Cateo

A cateo is an exploration concession which does not permit mining but gives the owner a preferential right to a mining concession for the same area. Cateos are measured in 500 ha unit areas. A cateo cannot exceed 20 units (10,000 ha). No person may hold more than 400 units in a single province. The term of a cateo is based on its area: 150 days for the first unit (500 ha) and an additional 50 days for each unit thereafter. After a period of 300 days, 50% of the area over four units (2,000 ha) must be dropped. At 700 days, 50% of the area remaining must be dropped. At each stage the land can be converted to one or more “Manifestaciones de Discubrimiento” (“MD”).Time extensions may be granted to allow for bad weather and difficult access. Cateos are identified by a file number or "expediente" number.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

28

Cateos are awarded by the following process:

·

Application for a cateo covering a designated area. The application describes a minimum work program for exploration;

·

Approval by the province and formal placement on the official map or graphic register;

·

Publication in the provincial official bulletin;

·

A period following publication for third parties to oppose the claim;

·

Awarding of the cateo.

The length of this process varies depending on the province, and commonly takes up to two years. Accordingly, cateo status is divided into those that are in the application process and those that have been awarded. If two companies apply for cateos on the same land, the first to apply has the superior right. During the application period, the first applicant has rights to any mineral discoveries made by third parties in the cateo without its prior consent. While it is theoretically possible for a junior applicant to be awarded a cateo, because applications can be denied, MAI knows of no instances where this has happened.

Applicants for cateos may be allowed to explore on the land pending formal award of the cateo, with the approval of the surface owner of the land. The time period after which the owner of a cateo must reduce the quantity of land held does not begin to run until 30 days after a cateo is formally awarded.

The mining act requires that a canon fee of ARS$400 be paid upon application for the cateo. This is paid only once.

6.2.2

Mina

To convert an exploration concession to a mining concession, some or all of the area of a cateo must be converted to a mina. Minas are mining concessions which permit mining on a commercial basis. The area of a mina is measured in "pertenencias". Each mina may consist of two or more pertenencias. "Common pertenencias" are six ha and "disseminated pertenencias" are 100 ha (relating to disseminated deposits of metals rather than discrete veins). Once granted, minas have an indefinite term assuming exploration development or mining is in progress. An annual canon fee of ARS$800 per pertenencia is payable to the province.

Minas are obtained by the following process:

·

Declaration of MD, in which a point within a cateo is nominated as a discovery point. The MD is used as a basis for location of pertenencias of the sizes described above. MDs do not have a definite area until pertenencias are proposed. Within a period following designation of a MD, the claimant may do further exploration, if necessary, to determine the size and shape of the mineralized material.

·

Survey (mensura) of the mina. Following a publication and opposition period and approval by the province, a formal survey of the pertenencias (together forming the mina) is completed before the granting of a mina. The status of a surveyed mina provides the highest degree of mineral land tenure and rights in Argentina.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

29

6.2.3

Estaca Minas

These are six-hectare extensions to existing surveyed minas that were granted under previous versions of the mining code. Estaca minas are equivalent to minas. New Estaca minas were eliminated from the mining code in August 1996.

6.2.4

Provincial Reserve Areas

Provinces are allowed to withdraw areas from the normal cateo/mina process. These lands may be held directly by the province or assigned to provincial companies for study or exploration and development.

All mineral rights described above are considered forms of real property and can be sold, leased or assigned to third parties on a commercial basis. Cateos and minas can be forfeited if minimum work requirements are not performed or if annual payments are not made. Generally, notice and an opportunity to cure defaults is provided to the owner of such rights.

Grants of mining rights, including water rights, are subject to the rights of prior users. Further, the mining code contains environmental and safety provisions administered by the provinces. Prior to conducting operations, miners must submit an environmental impact report to the provincial government describing the proposed operation and the methods to be used to prevent undue environmental damage. The environmental impact report must be updated biennially, with a report on the results of the protection measures taken. If protection measures are deemed inadequate, additional environmental protection may be required. Mine operators are liable for environmental damage. Violators of environmental standards may be caused to shut down mining operations.

6.3

Ownership of the Los Azules Project

The Los Azules project is comprised of properties owned by Minera Andes S.A. (“MASA”) and Andes Corporacion Minera S.A. (“ACMSA”), both affiliates of Minera Andes (the “MASA Properties”) and adjoining properties owned by Xstrata Copper, one of the commodity business units within Xstrata plc (London Stock Exchange: XTA.L and Zurich Stock Exchange: XTRZn.S), through Mount Isa Mines Argentina Exploraciones S.A. (“MIM” and the “MIM Properties”).

Both the MASA Properties and the MIM Properties are subject to the terms of the Los Azules Option Agreement (described in Section 6.4).

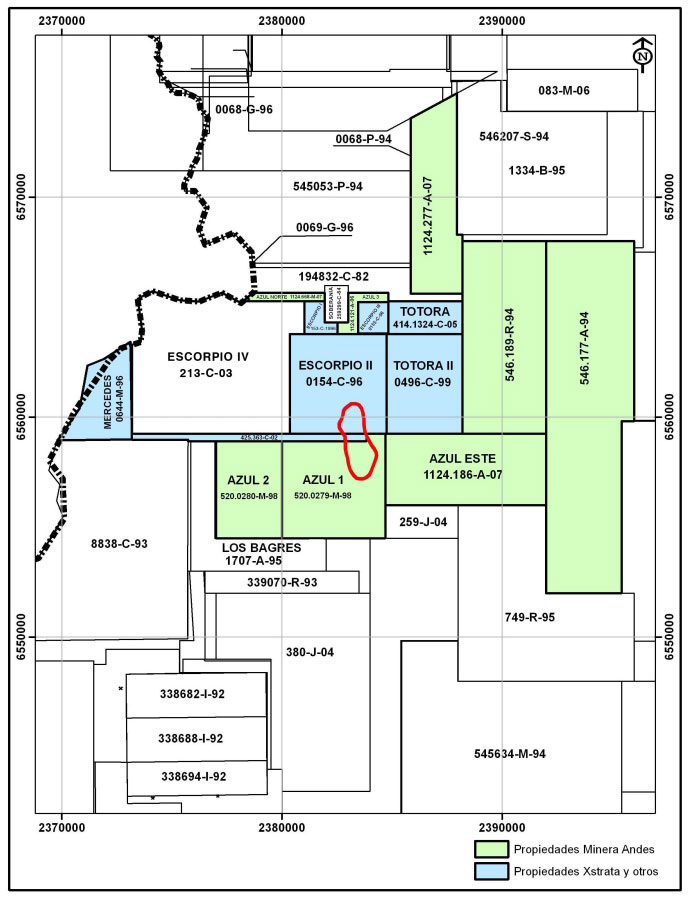

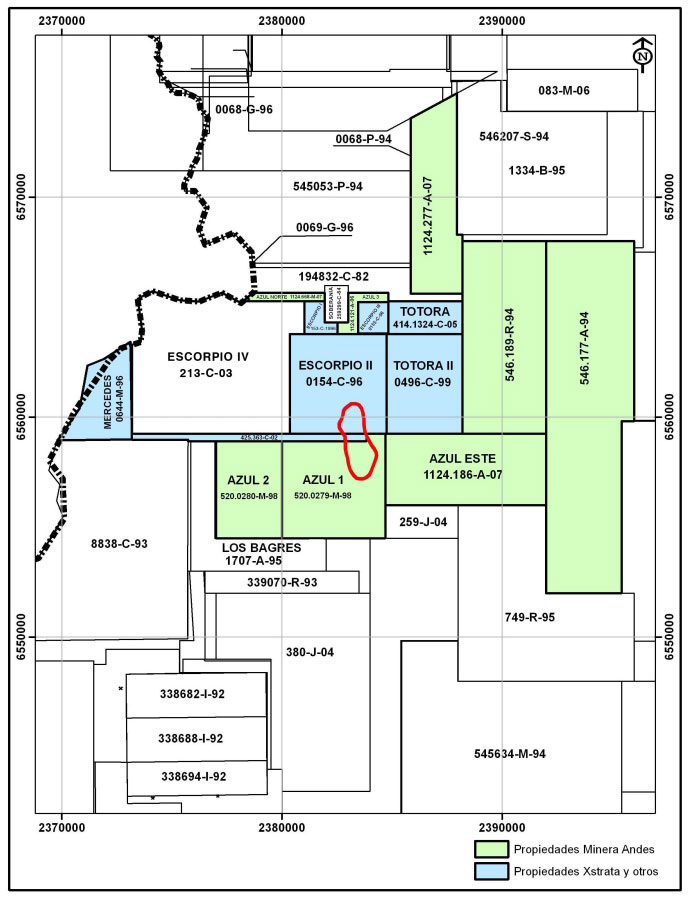

In 1994, MASA was granted the Cordon de Los Azules Cateo 545.957-D-94. This cateo was divided and converted into two MDs on October 17, 1998, known as Azul 1 and Azul 2. These MDs cover part of the southern portion of the Los Azules project. MASA owns a 100% interest in its lands that make up the Azul 1 and Azul 2 MDs, subject to the terms of the Los Azules Option Agreement.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

30

Additional Peripheral Land Holdings (“PLH”) consisting of cateo applications and MDs were acquired by MASA and ACMSA from 2006 to 2008 (see Table 6.1). MASA and ACMSA have acquired cateo applications, applied for cateos, and filed MDs for the rights to acquire a 100% interest in the lands that make up the PLH subject to the terms of the Los Azules Option Agreement. Some of the lands that make up the PLH are in the process of being perfected including being registered, surveyed and some lands may overlap other lands. These factors may potentially change which lands and the size of the lands that will be awarded the MASA or ACMSA, as applicable.

An amendment or other acknowledgement is being prepared to formally include the PLH registered to MASA and ACMSA under the terms of the Los Azules Option Agreement.

Table 6.1 shows the current land status of the MASA Properties.

| | |

Table 6.1

MASA Property Claim Status |

Name | File Number | Hectares (ha) |

Principal Land Holdings |

Azul 1 (“MD”) | 520-0279-M98 | 2,054.2 |

Azul 2 (“MD”) | 520-0280-M98 | 1,320.0 |

Peripheral Land Holdings |

No name (Cateo application) | 546.189-R-94 | 5,697.50 |

No name (Cateo application) | 546.177-A-94 | 5,954.15 |

No name (Cateo application) | 1124.277-A-07 | 1,860.91 |

Azul 3 (“MD”) | 1124.121-A-06 | 166.76 |

Azul Este (“MD”) | 1124.186-A-07 | 2,372.50 |

Azul Norte (“MD”) | 1124.668-M-07 | 131.94 |

Azul 4 (“MD”) | 1124.473-M-08 | 1,054 |

MIM owns a 100% interest in its lands that make up the MIM Properties, subject to the terms of the Los Azules Option Agreement and the two underlying option agreements described in Section 6.4.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

31

Table 6.2 shows the current land status of the MIM Properties.

| | |

Table 6.2

MIM Property Claim Status |

Name | File Number | Estimated Hectares (ha) |

Escorpio I | 153-C-1996 | 170 |

Escorpio II | 0154-C-96 | 1,997 |

Escorpio III | 0155-C-96 | 199 |

Totora | 414.1324-C-05 | 492 |

Totora II | 0496-C-99 | 1,570 |

| 425.363-C-02 | 365 |

Mercedes | 0644-M-96 | 930 |

The red line in Figure 6.2 represents the extent of the inferred resource.

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

32

Figure 6.2 - Property Claims Map

Los Azules Preliminary Assessment Technical Report

SE Project No. 8019-01

33

6.4

Terms of Los Azules Option Agreement and Underlying Agreements

On November 2, 2007, Minera Andes and MASA entered into the Los Azules Option Agreement with Xstrata Copper, through Xstrata Queensland Limited and MIM, in respect of the MASA Properties and the adjoining MIM Properties. Under the Los Azules Option Agreement, MASA has an option, exercisable until November 24, 2010 to acquire a 100% interest in the MIM Properties (the “MASA Option”). If MASA exercises the MASA Option, MIM has the option to back-in to the Combined Property for a 51% interest.

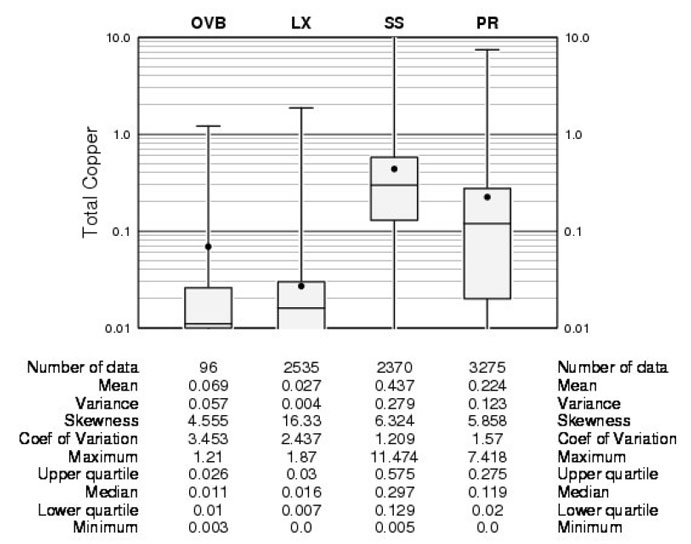

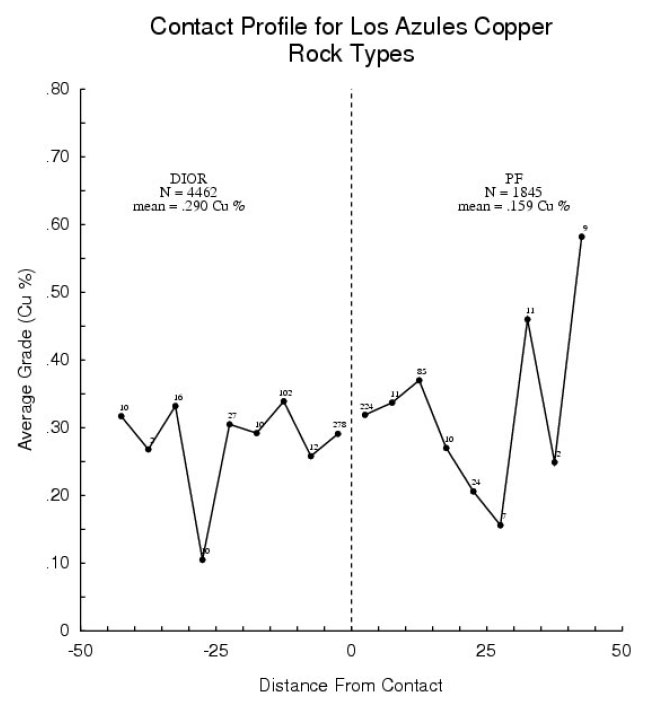

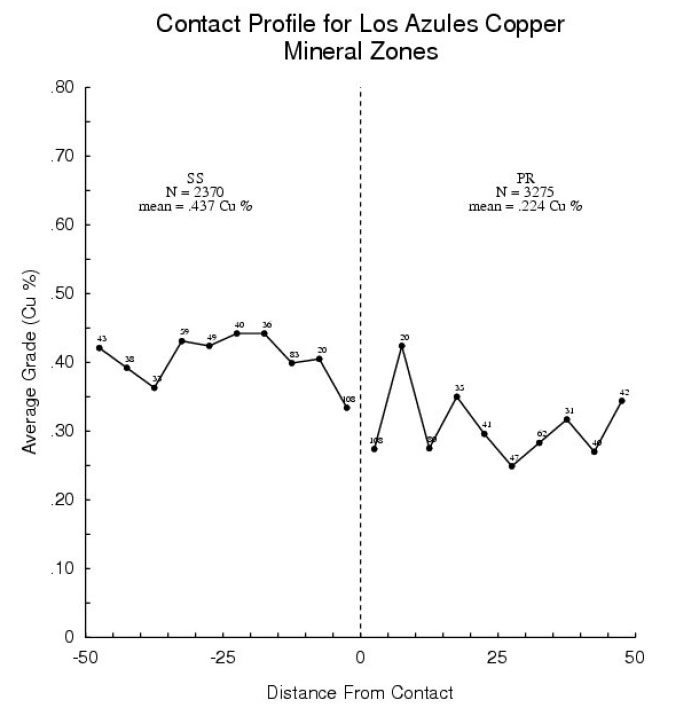

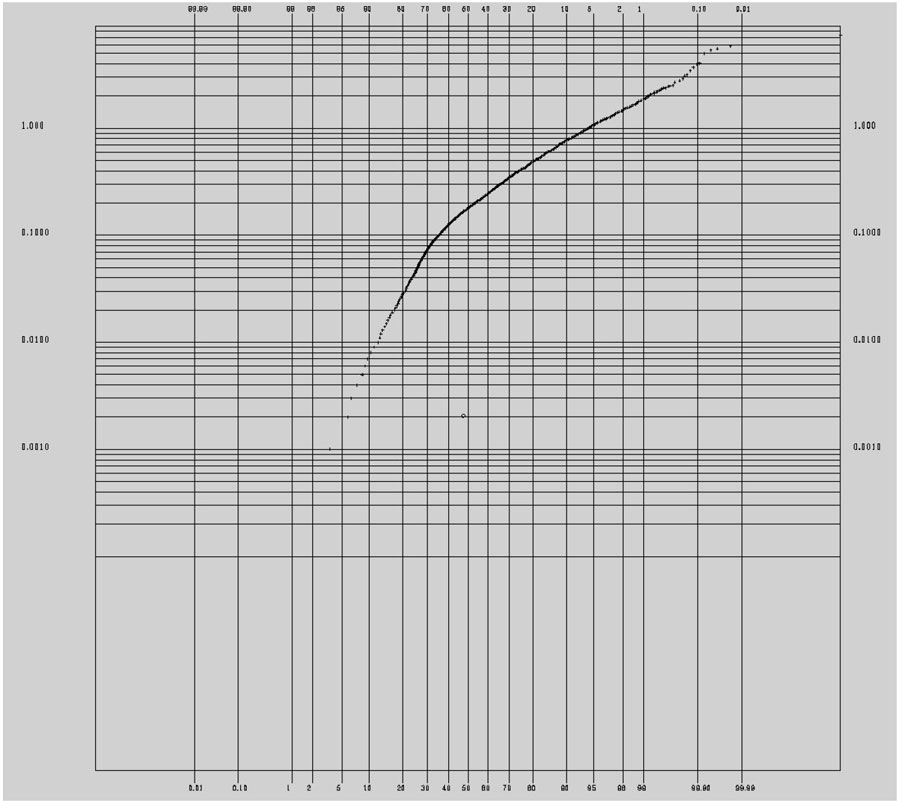

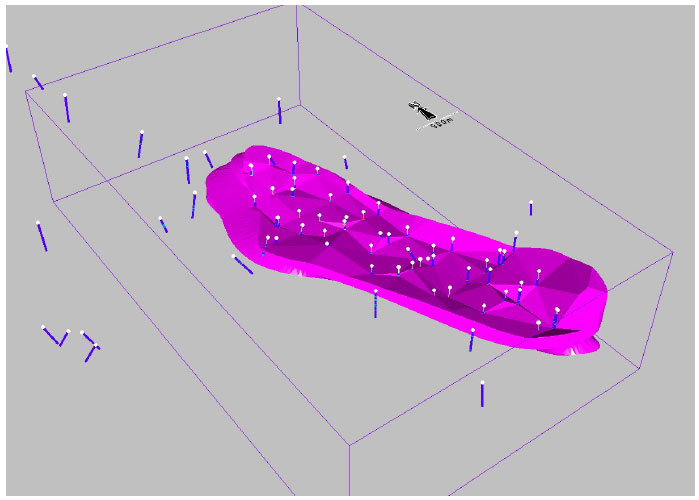

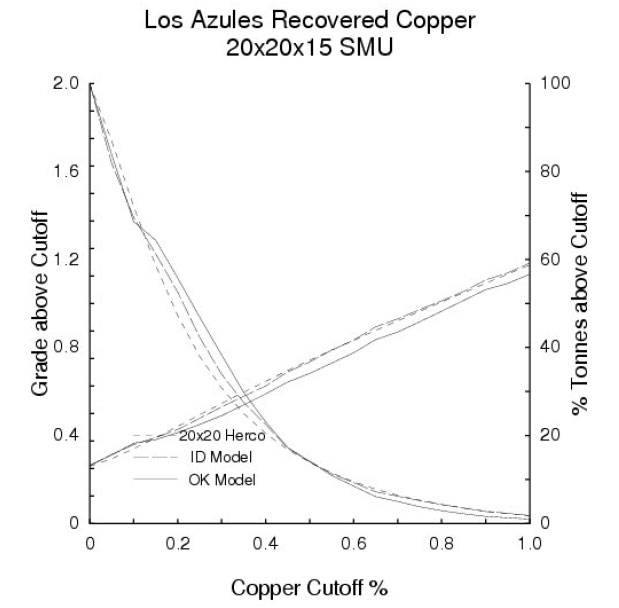

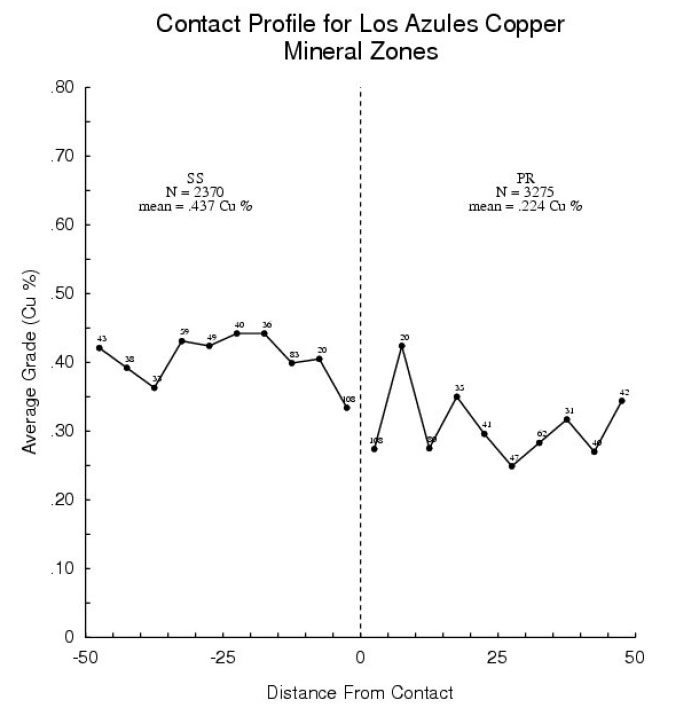

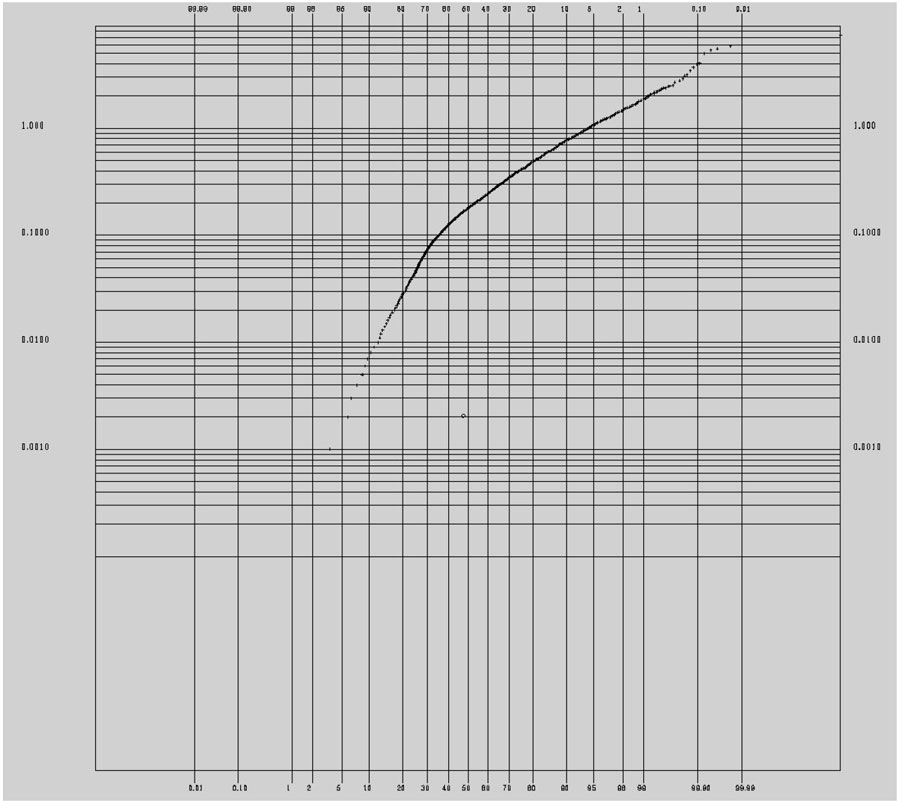

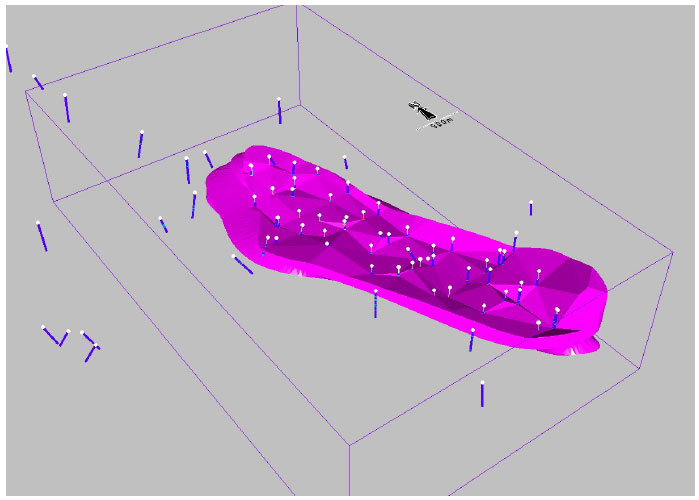

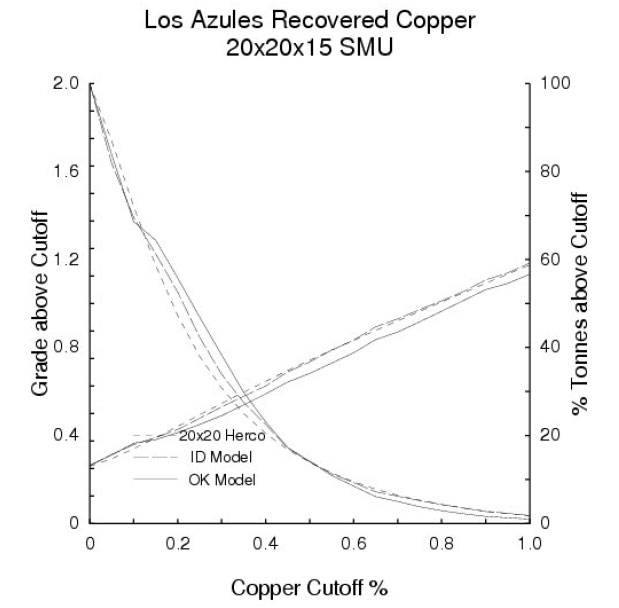

In order to exercise the MASA Option, MASA must incur US$1 million in expenditures on the MIM Properties, deliver to MIM an independent scoping study and technical report in respect of the Combined Property (the “Los Azules Preliminary Assessment”) and deliver a notice of exercise.