Exhibit 99.2

TECHNICAL REPORT on the RESOURCES of the

SILVER-ZINC SIERRA MOJADA PROJECT

COAHUILA, MEXICO

NAD 27 Zone 13 Mexico

Latitude 27°24' North and Longitude 103°43' West (Centre of Project)

Report Date: April 30, 2013

Effective Date: March 18, 2013

Prepared for:

Silver Bull

RESOURCES INC.

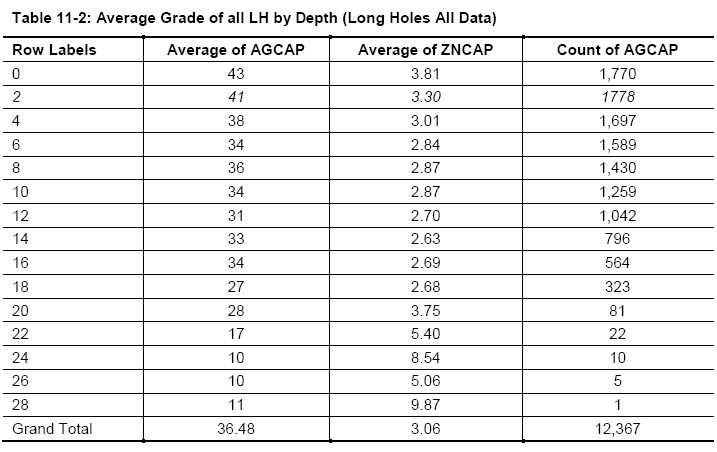

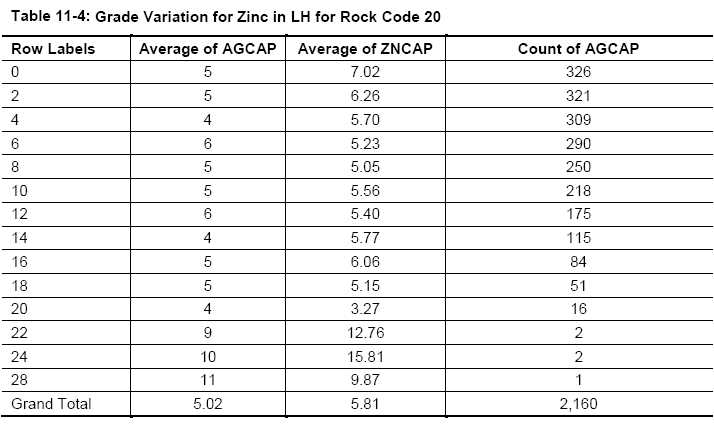

Silver Bull Resources Inc.

Suite 1908, 925 West Georgia St,

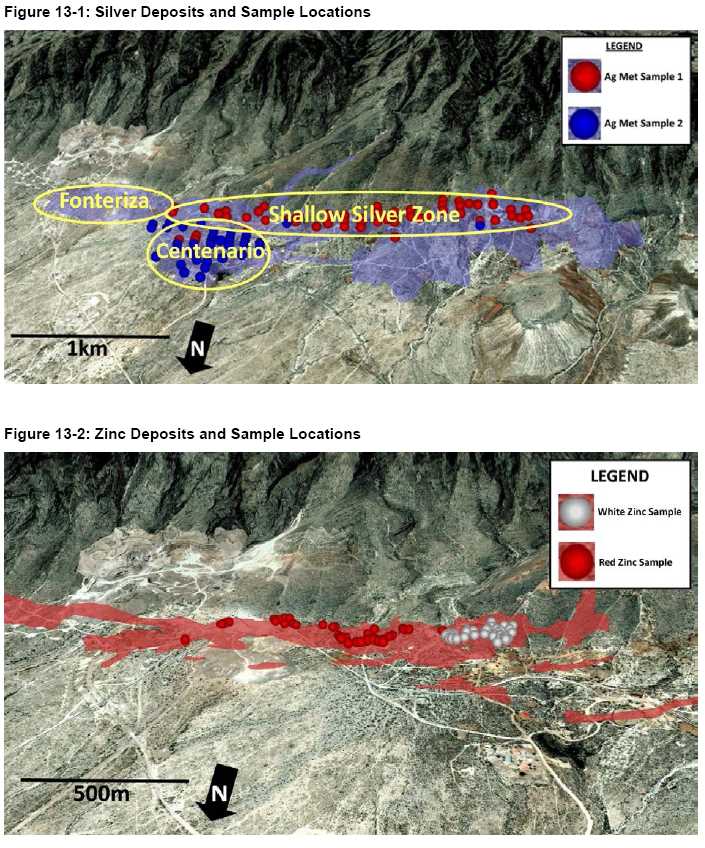

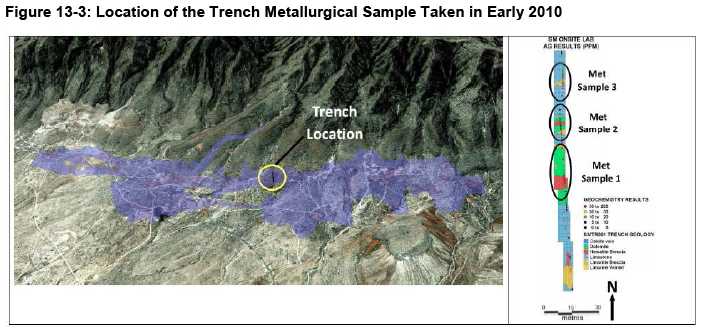

Vancouver, BC, Canada

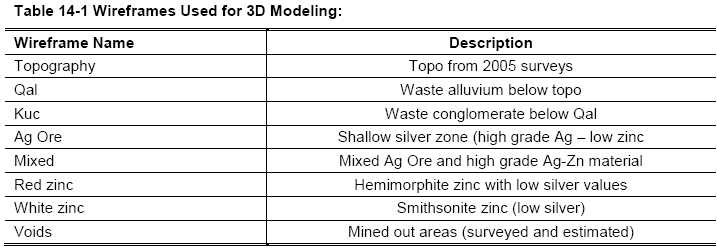

V6C 3L2

Ph: (604) 687-5800

Qualified Persons Mr. Allan Reeves, P.Geo. Mr. Gilles Arseneau, Ph.D., P.Geo. | Company JDS Energy & Mining Inc. SRK Consulting (Canada) Inc.

|

Vancouver Office T 604.687.7545 F 604.689.5041 #860 - 625 Howe Street Vancouver, BC V6C 2T6 | Jdsmining.ca Kelowna Office T 250.763.6369 F 250.763.6302 #200 - 532 Leon Avenue, Kelowna, BC V1Y 6J6 |

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

NOTICE

This report was prepared as a National Instrument 43-101 Technical Report, in accordance with Form 43- 101F1, for Silver Bull Resources Inc. The quality of information, conclusions and estimates contained herein is based on: (i) information available at the time of preparation; (ii) data supplied by outside sources, and (iii) the assumptions, conditions and qualifications set forth in this report.

Silver Bull Resources Inc. is authorized to file this report as a Technical Report with the Canadian Securities Regulatory Authorities pursuant to provincial securities legislation. Except for the purposes legislated under provincial securities law, any other use of this report by any third party is at that party's sole risk.

Report Date: April 30, 2013

Effective Date: March 18, 2013

This Technical Report dated April 30, 2013, was prepared by JDS Energy & Mining Inc. (JDS) for Silver Bull Resources Inc. (Silver Bull or SBR) to provide a NI-43-101 compliant technical report (Technical Report) of the updated mineral resources at the Sierra Mojada Project in Coahuila state, Mexico.

Mr. Allan Reeves, P.Geo. of JDS managed the report preparation. Dr. Gilles Arseneau, P.Geo., of SRK Consulting (Canada) Inc. prepared the Termite/Long Hole Comparison Section 11.3.

The mineral resource estimate in this report replaces the mineral resource estimate from SRK Consulting Inc. (SRK) in July 2012. This report focuses on both the near surface silver mineralization that has been referred to as the "Shallow Silver Zone" (SSZ) and the historic red and white zinc zones that had been historically mined. Significant work has been done on structural and geologic mapping; modeling of the deposit and follow-up on previous work recommendations.

The Sierra Mojada Project has been the subject of previous technical reports which disclosed mineral resource estimates for the Shallow Silver Zone and the Red Zinc Zone respectively:

| ▪ | SRK in July 2012 and November of 2011 |

| ▪ | John Nilsson (and Ronald Simpson) in April 2011 |

| ▪ | Pincock Allan & Holt (PAH) in January 2010. |

This Technical Report was prepared in compliance with the requirements of the Canadian Securities Administrators' NI 43-101 and Form 43-101F1.

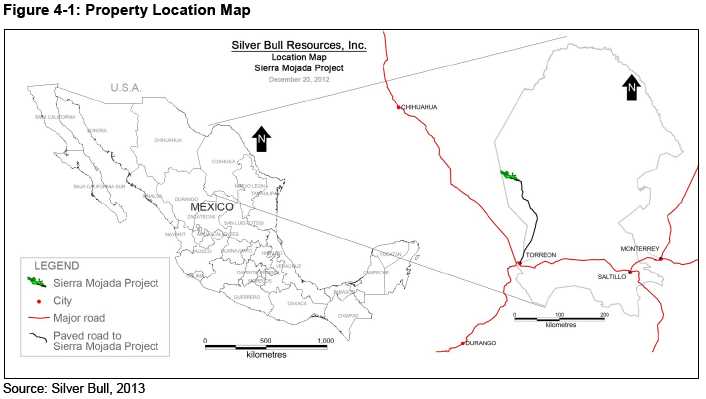

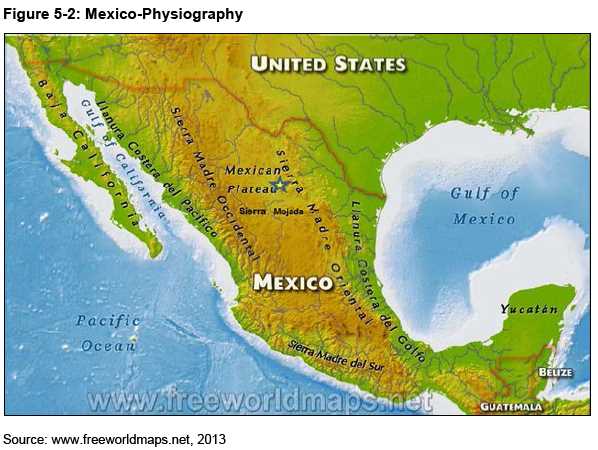

The Sierra Mojada Project is located in the northwestern part of Coahuila State, Mexico, close to the border with Chihuahua State.

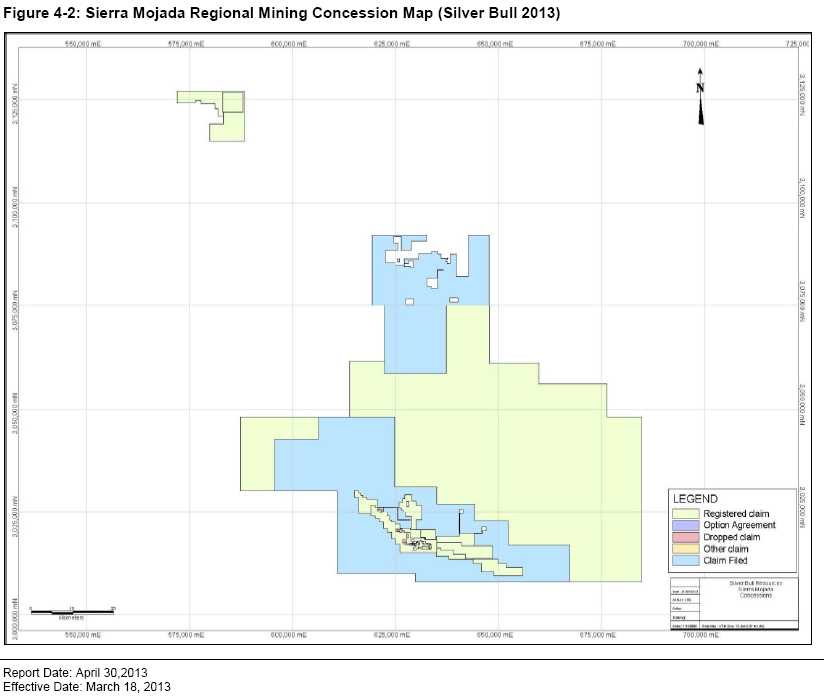

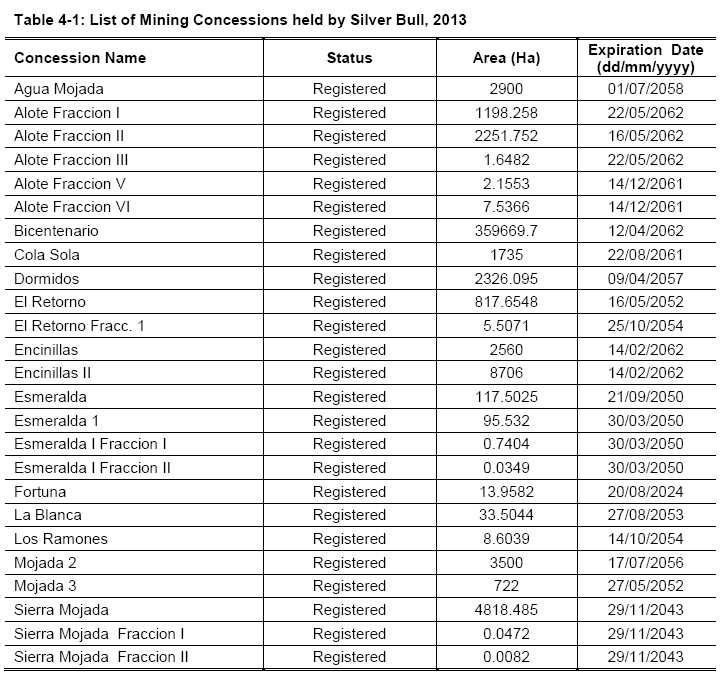

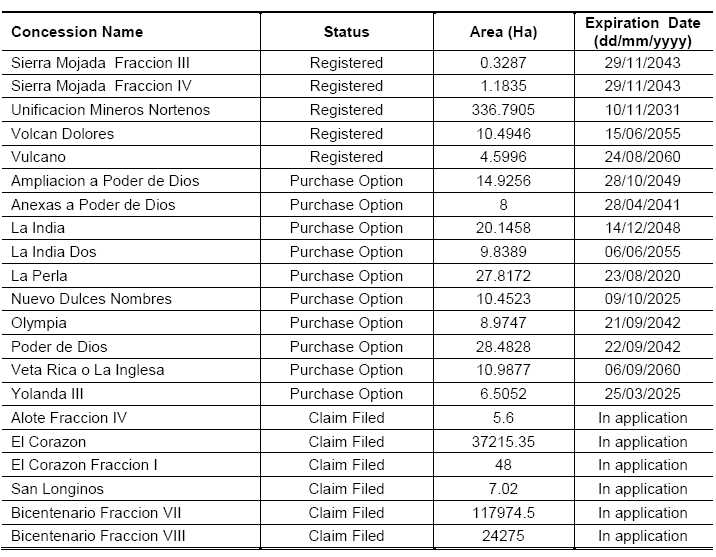

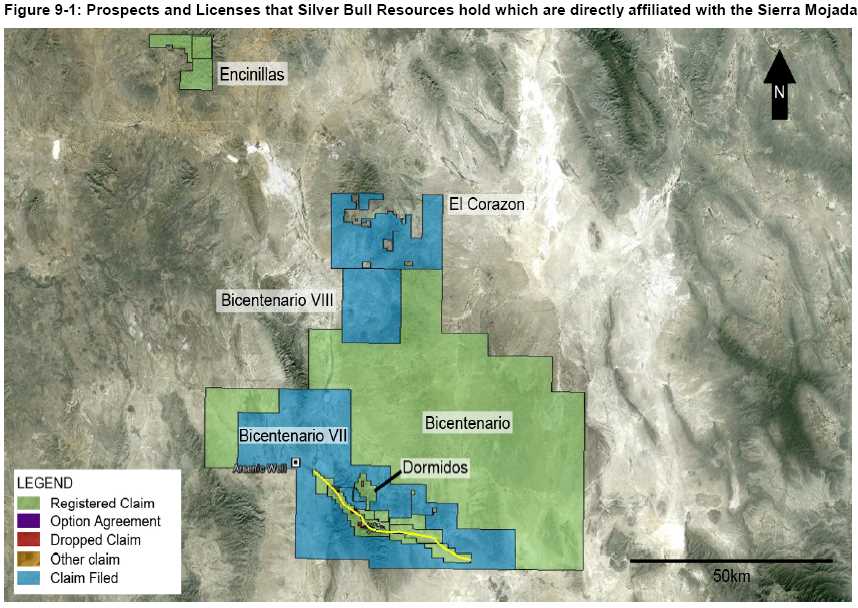

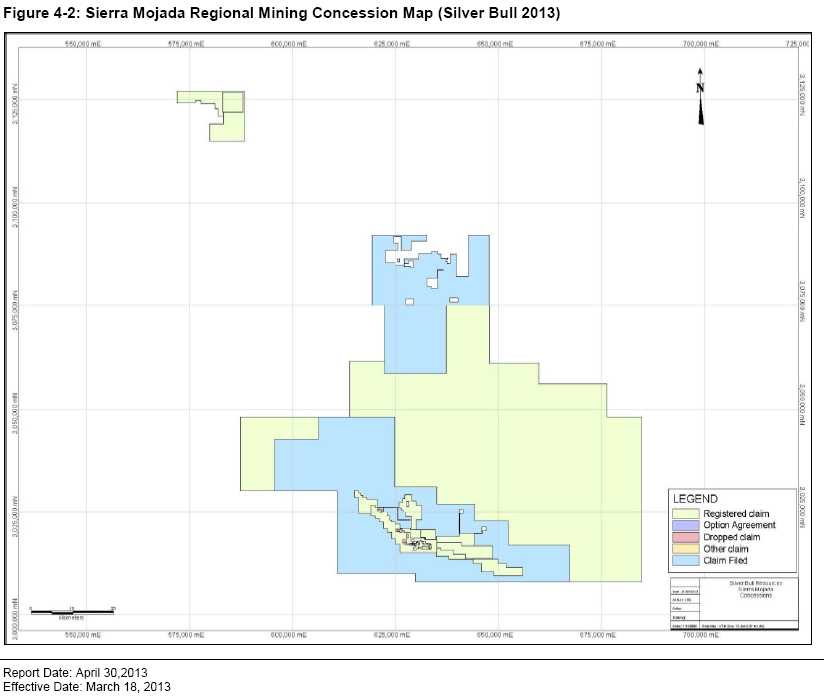

Silver Bull has 30 registered concessions, 10 concessions under option purchase agreements, and 6 concessions with claims filed for a total of 46 concessions. Total area for the mining concessions currently held by Silver Bull, excluding the "claim filed" concessions is 391,991.21 ha.

Silver Bull operates in Mexico through a wholly owned Mexican subsidiary; Minera Metalin S.A. de C.V. All minerals in Mexico are owned by the federal government and mineral rights are granted by soliciting mining concessions, which by law have priority over surface land use, but in practice the concessions owner must have an agreement with the surface owner.

As previously described by SRK (2012):

Report Date: April 30, 2013

Effective Date: March 18, 2013

"The Sierra Mojada Project area is situated in the northwestern part of Coahuila State, Mexico at latitude 27°24' North and longitude 103°43' West, close to the border with Chihuahua State, south of the village of Esmeralda. It is accessible by paved roads from the city of Torreon, Coahuila which lies about 250km to the southwest.

Most of the area adjacent to the project site is used for cattle ranching, however; the southeastern boundary of the project abuts the Penoles dolomite extraction and processing facility. The Penoles quarrying facility contains associated waste piles and a 1km long conveyor belt transporting crushed dolomitic carbonate aggregate of specific magnesium carbonate grade to the railroad spur for transportation to the Penoles process plant known locally as Quimica del Rey.

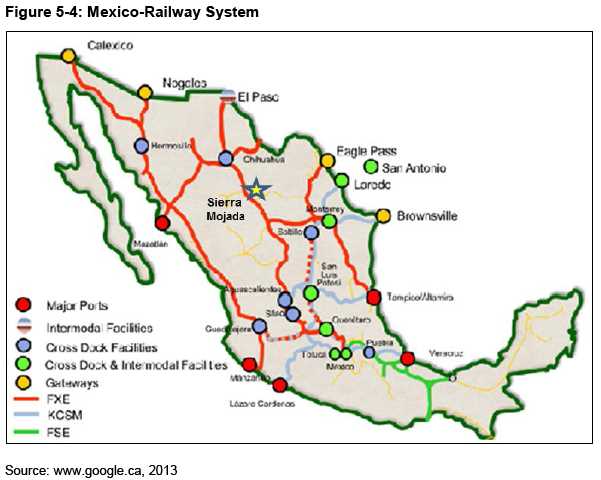

A rail line utilized by Penoles to transport material to its chemical plant extends west to La Esmeralda. The remains of an older section extend right up to old workings and a loading facility located south of La Mesa Blanca right in the center of the Sierra Mojada Camp. The spur line connects the main national line which connects Escalon and Monclova. Rail traffic to the east is through Frontera to the United States via Eagle Pass, Texas, or southward to Monterrey or the seaport at Altamira. Service to the west is available as well as to the western USA via El Paso, or to points south connected through Torreon. Although power levels are sufficient for current operations and exploration, any development of the project would potentially require additional power supplies to be sourced

Silver and lead were first discovered by a foraging party in 1879, and mining to 1886 consisted of native silver, silver chloride, and lead carbonate ores. After 1886 silver-lead-zinc-copper sulphate ores within limestone and sandstone units were produced. No accurate production history has been found for historical mining during this period."

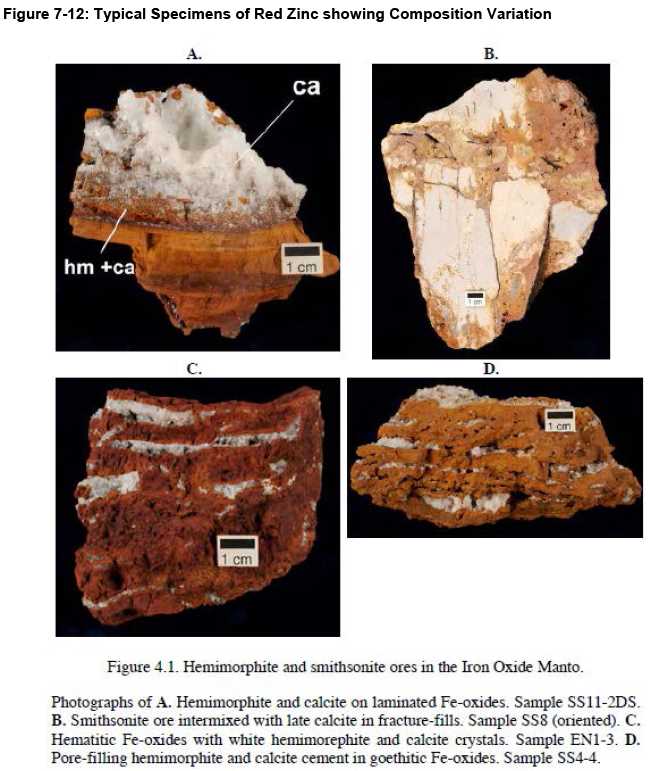

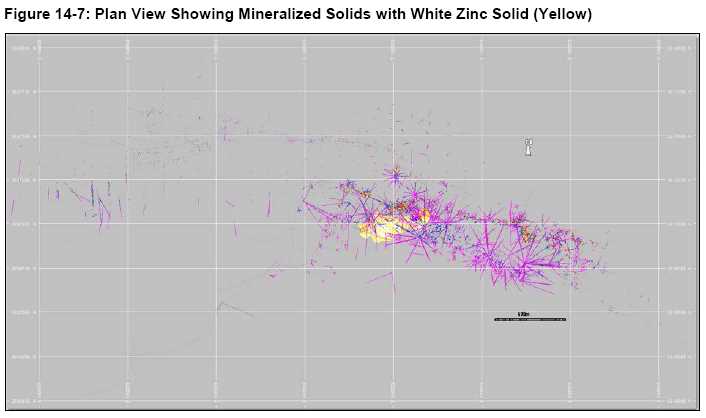

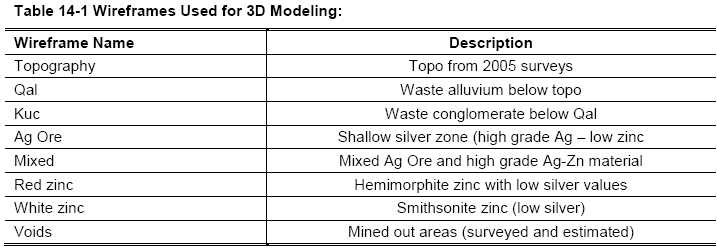

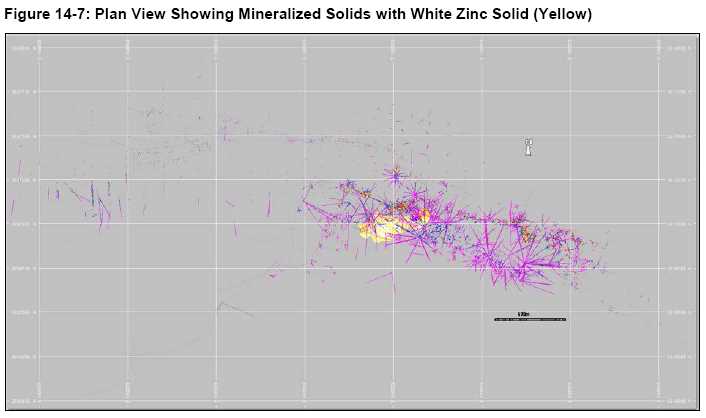

The Sierra Mojada project area is host to several mineralized zones varying from the 'red zinc' (hemimorphite-rich) manto; a 'white zinc' (smithsonite-rich) manto; and silver-lead rich zones. As reported by SRK (2012):

"Approximately 120 years ago, zinc silicate and zinc carbonate minerals (Zinc Manto Zone) were discovered underlying the silver-lead mineralized horizon. The zinc Manto is predominantly zinc dominated, but with subordinate lead-rich manto and is principally situated in the footwall rocks of the Sierra Mojada Fault System. Since discovery and up to 1990; zinc, silver, and lead ores were mined from various mines along the strike of the deposit, including from the Sierra Mojada property. Ores mined from within these areas were hand sorted and the concentrate shipped mostly to smelters in the United States.

Metalline Mining Company (Metalline) entered into a Joint Exploration and Development Agreement with USMX in July 1996, involving USMX's Sierra Mojada concessions. In October 1999, Metalline entered into a joint venture with North Limited of Melbourne, Australia (now Rio Tinto). Exploration by North Limited consisted of underground channel samples in addition to surface RC and diamond drilling. North Limited withdrew from the joint venture in October 2000.

Report Date: April 30, 2013

Effective Date: March 18, 2013

A joint venture agreement was made with Penoles in November 2001. The agreement allowed Penoles to acquire 60% of the project by completing a bankable Feasibility Study and making annual payments to Metalline.

During 2002, Penoles conducted an underground exploration program consisting of driving raises through the oxide zinc Manto, diamond drilling, continuation of the percussion drilling and channel sampling of the oxide zinc workings (stopes and drifts) previously started by Metalline in 1999, and continued by North in 2000 and Metalline during 2001.

In December 2003, the joint venture was terminated by mutual consent between Penoles and Metalline. Since 2003, Metalline continued sampling numerous underground workings through channel and grab samples.

In April 2010, Metalline merged with Dome Ventures, retaining the name Metalline Mining Inc. Subsequently, in April 2011, the company changed name to Silver Bull Resources. Silver Bull continued to diamond drill the project until June of 2012."

JDS has been providing project management services to the Sierra Mojada Project since the merger of Metalline Mining Inc. and Dome Ventures Inc. in 2010.

| 1.4 | Geology and Mineralization |

Sierra Mojada is located in the Eastern Tectonic Zone of Mexico, which represents a passive plate margin relative to the Western Zone which documents a convergent plate margin. The boundary between the Eastern and Western terrains is in Chihuahua State, just west of the Sierra Mojada project area. Within the Eastern Zone, the project is located in the Coahuila terrain which is composed of moderately metamorphosed flysch and un-metamorphosed andesitic volcanic rocks cut by granite and granodiorite intrusives of Permian to Triassic age. The district is located on passive margin type Cretaceous platform carbonate rocks of the Sabinas Basin, which have been structurally prepared from Jurassic through Tertiary time by the complex San Marcos fault system.

Along the San Marcos fault system are one or more mineralizing intrusions which are inferred from direct and indirect evidence in the district leading to the identification of the district as being a CRD (Carbonate Replacement Deposit). The district shows a complex history of hypogene sulfide mineralization followed by oxidation and supergene alteration of the mineral profile. Hydrothermal alteration follows a clear sequence of dolomitization, carbonate and silica alteration; followed by late carbonate, silica, argillic, and iron oxide alterations related to the oxidation-supergene events. Approximately 80% of the district mineralization is hosted by dolomite and the remainder in limestone.

The alteration-mineralizing events have generated two types of mineralization in the Sierra Mojada district; The Shallow Silver Zone (SSZ) and the Base Metal Manto Zone (BMM). Mineralization in the Shallow Silver Zone is dominated by acanthite, the silver halide solid solution of bromargyrite-chloragyrite, and tennantite. Silver occurs in early to late high grade structures,

Report Date: April 30, 2013

Effective Date: March 18, 2013

karst breccias, low-angle fault breccias, and mantos, and as disseminated replacements in porous hydrothermally altered dolomites.

The Base Metal mineralization is dominated by hemimorphite in the Red Zinc Zone and smithsonite in the White Zinc Zone. Mineralization primarily occurs as replacement of karst breccia and accessory faults which feed the breccia zones. Non-sulfide base metal mineralization is a result of oxidation and supergene enrichment of an original zone of semi-to massive pyrite-sphalerite-galena ore largely located in the Lead zone manto mineralization.

The result is a silver (copper) rich polymetallic zone of mineralization overlaying a large non- sulfide zinc-lead resource, both forming a linear zone of manto shaped mineralization which is cross cut by mineralized structures.

| 1.5 | Exploration Status & Drilling |

Since the previous technical report, underground geological and structural mapping has been completed to improve geological modeling and planning of exploration drill programs. Exploration drilling has been limited to an underground core drilling program intended to verify long hole assays from previous years. While designed to verify historic sludge sampled drill holes, some drill holes were added to supplement existing interpretations and improve grade estimation in areas that had been under-sampled.

| 1.6 | Sample Preparation, Analyses and Data Verification |

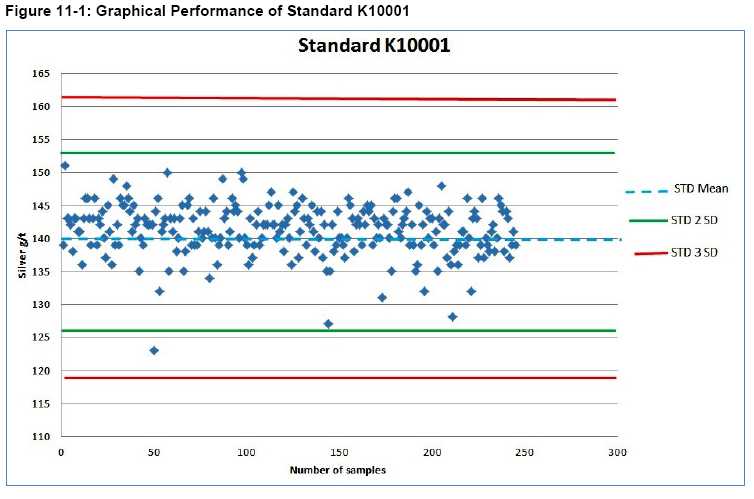

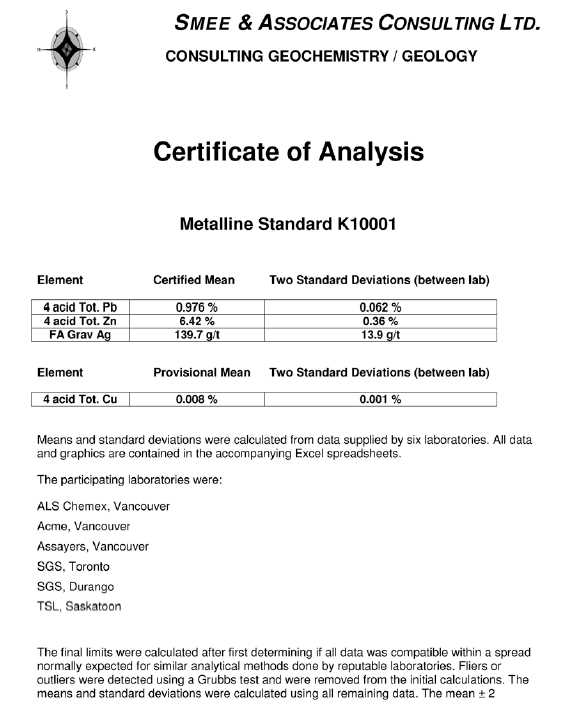

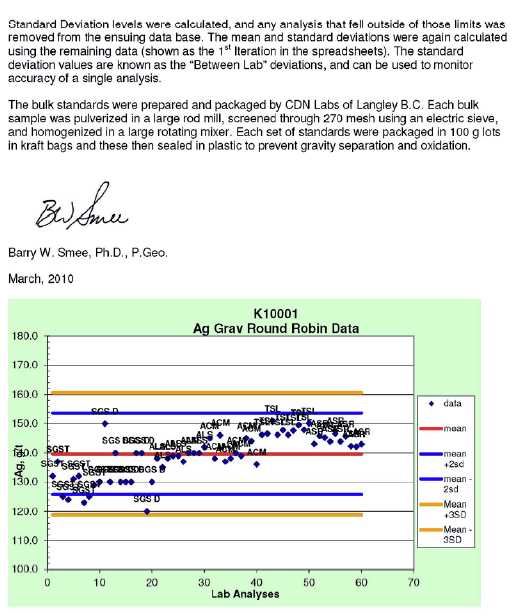

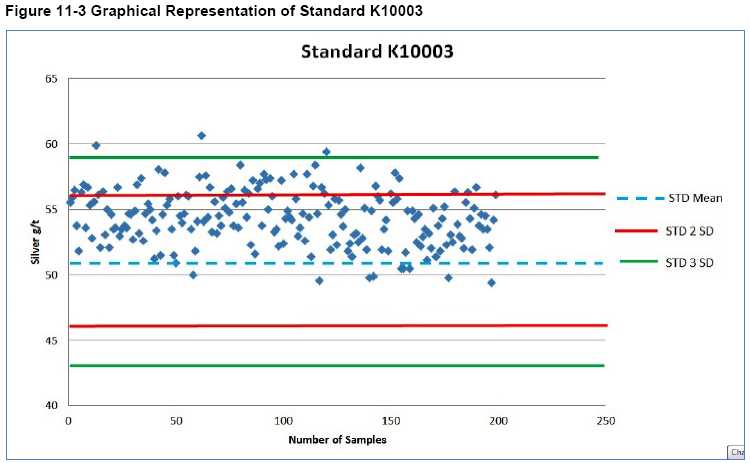

In the time JDS has provided management services there has been no change in the methodology of sample preparation and chain-of-custody. In 2010, the onsite assay lab was decommissioned to eliminate any questions of sampling bias. As noted by SRK (2012):

"All analytical work used in the project has been performed in the ALS laboratory ("ALS") in Vancouver, BC, Canada. ALS is a leading provider of assaying and analytical testing services for mining and exploration companies. The laboratory is ISO 9001:2000 and ISO/IEC 1702S:2005 certified. SRK is of the opinion that the sample preparation, security and analysis meets or exceeds industry standards and is adequate to support a mineral resource estimate as defined under NI43-101, but that better care should be taken in reviewing and analyzing the QA/QC.

SRK downloaded all available data from ALS and compared the digital database supplied by Silver Bull against original assay data provided by ALS. A total of 37,100 assays were checked against the digital database; about 23% of the total assay population. While some discrepancies were observed, most of the errors were considered not material and most were easily explained. A few samples that did not agree with the assay certificates were not used for the resource estimate."

JDS has been direct email copied from ALS-Chemex (now ALS-Global) with the assays and has had the opportunity to verify the assays against the loaded data. In addition, in 2011 IoGlobal (based in Australia) provided data verification services to Silver Bull Resources. For this

Report Date: April 30, 2013

Effective Date: March 18, 2013

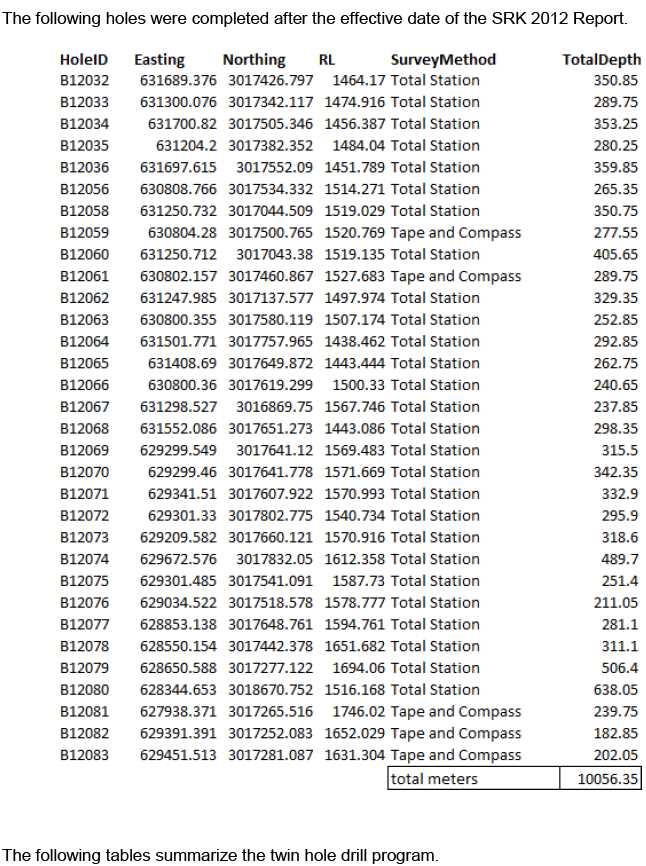

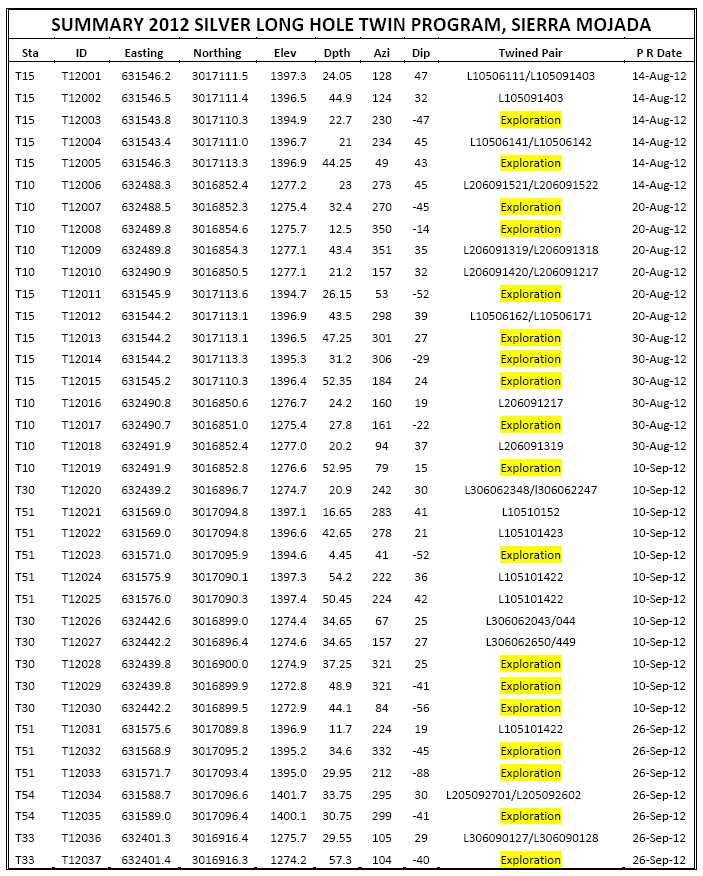

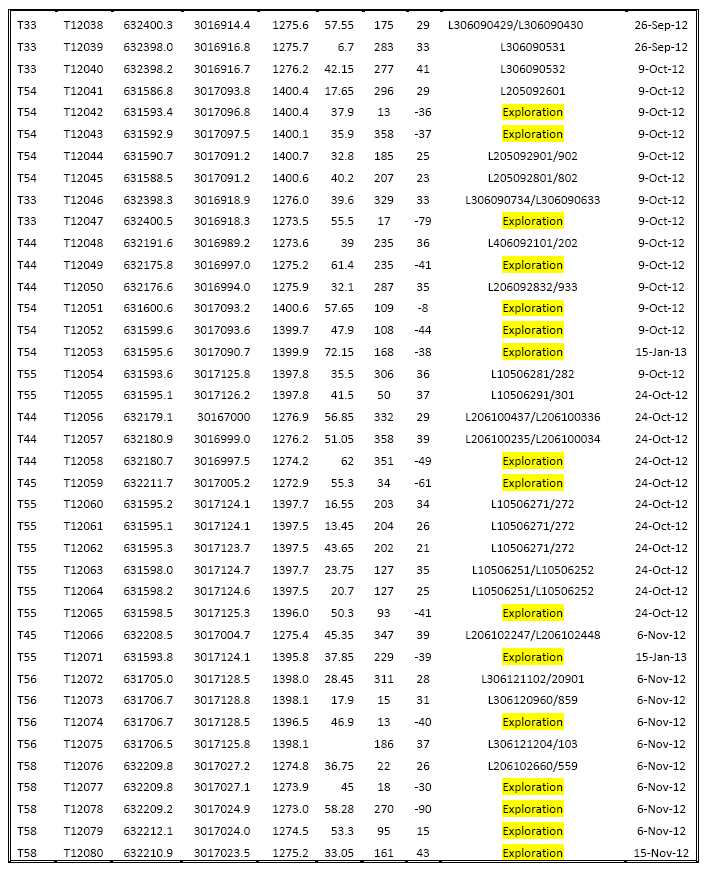

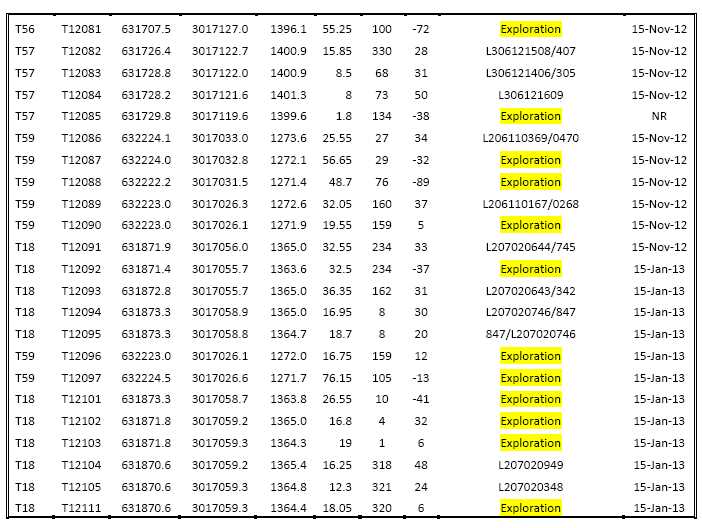

program, emphasis has been upon verification of assays arising from the surface drilling (B-series 2012 holes not included by SRK, and the T-series 2012 holes (used for twinning and exploration).

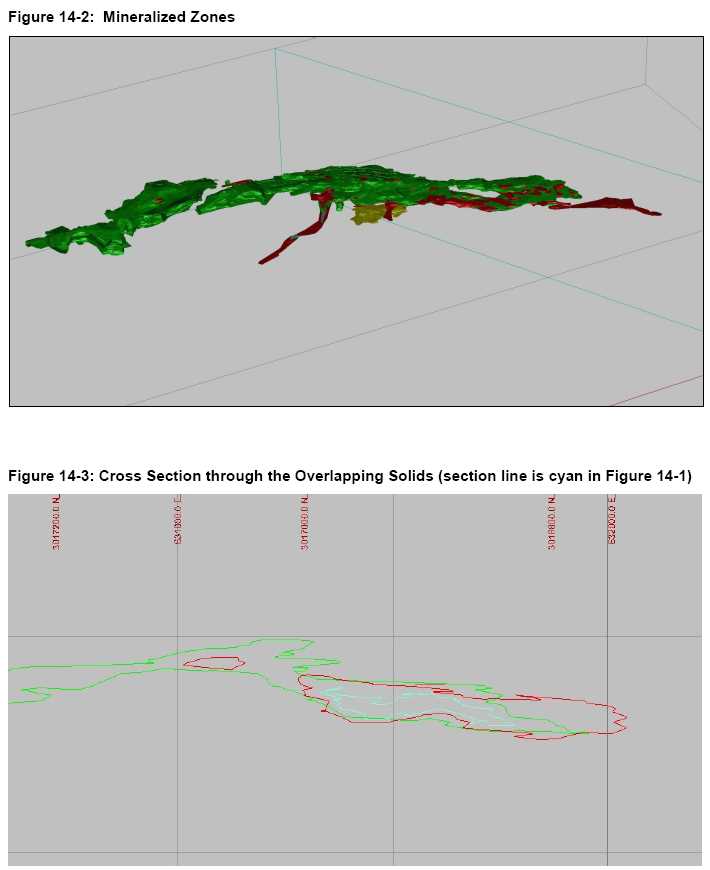

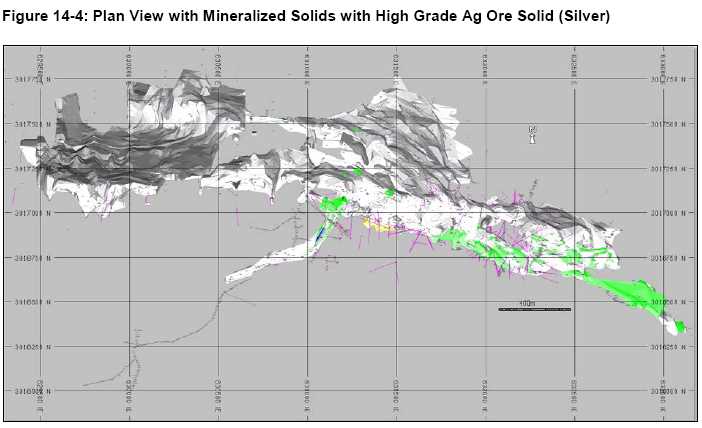

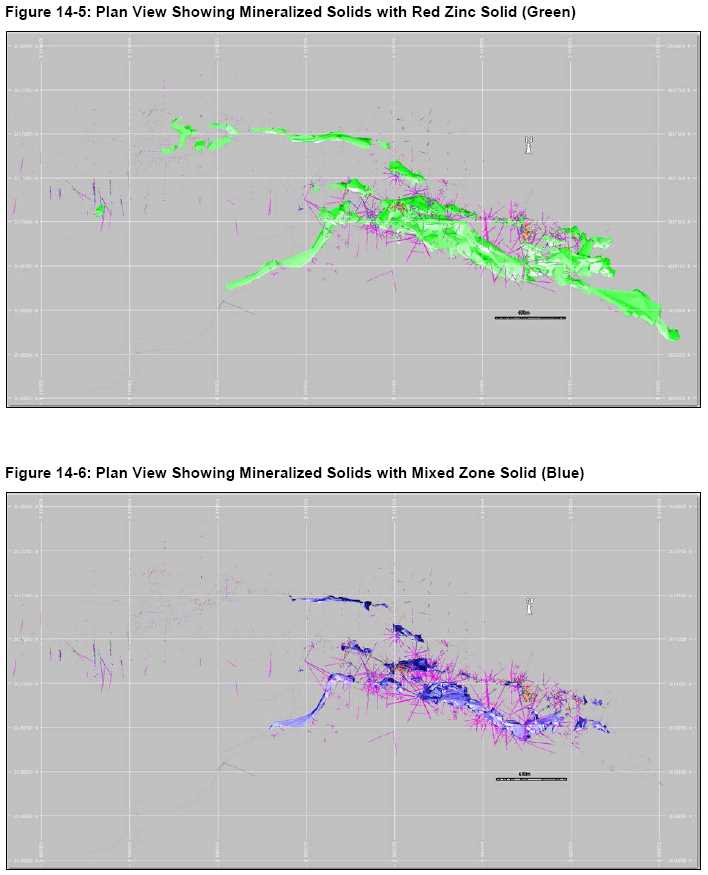

JDS also examined the updated wireframing, and although some "roughness" is present, the wireframes are a reasonable representation of what has been observed underground and modified from previous modeling work.

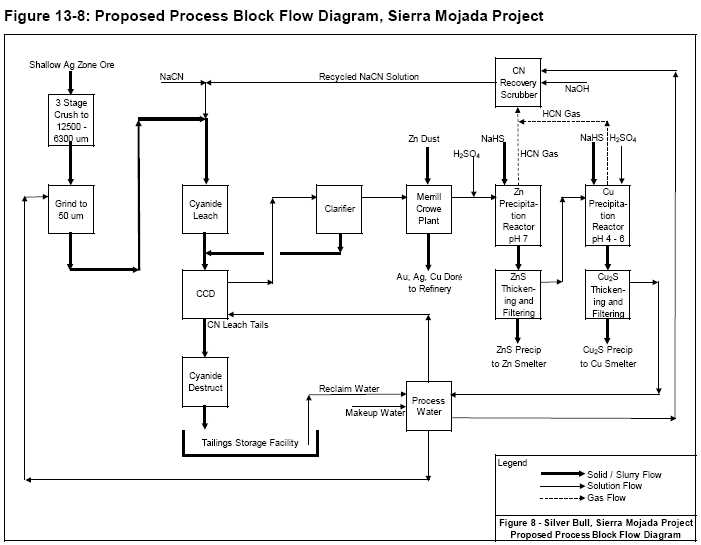

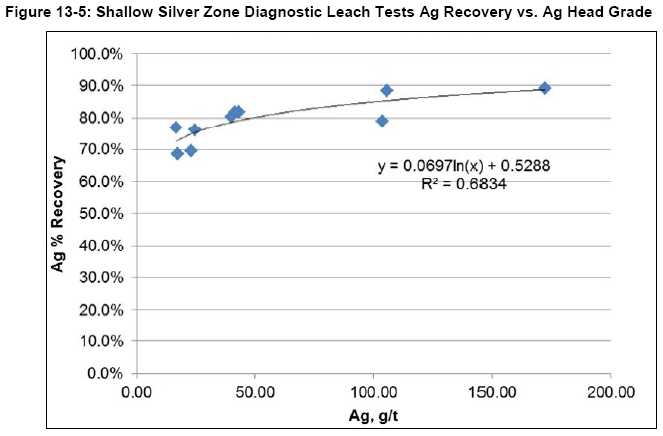

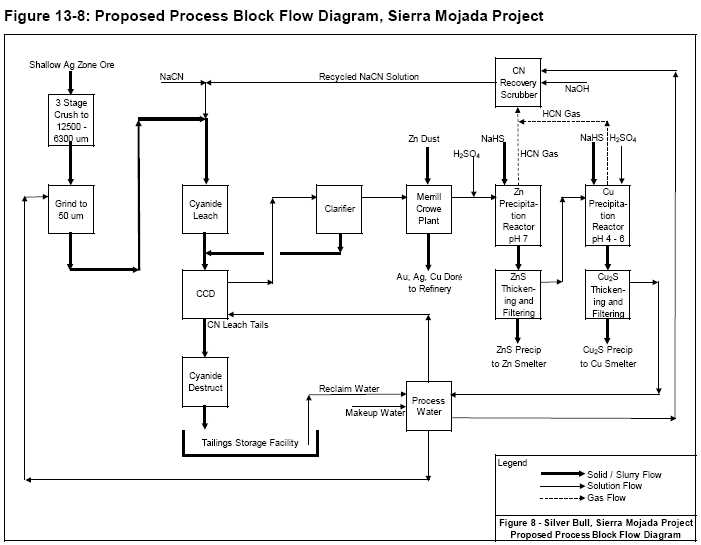

Metallurgical testing of the mineralization at Sierra Mojada in the early years of Metalline Mining Co. work focused on the oxidized zinc mineralization. Poor recoveries and low metal prices persuaded Silver Bull to consider newer technologies. Mr. Bill Pennstrom examined the SART Process and its application to Sierra Mojada Project mineralization. Improved recoveries and the ability to recover/reduce cyanide consumption suggest improved economics that will be further evaluated.

Classification has been done adhering to CIM Standards as defined below.

Mineral Resources are sub-divided, in order of increasing geological confidence, into Inferred, Indicated and Measured categories. An Inferred Mineral Resource has a lower level of confidence than that applied to an Indicated Mineral Resource. An Indicated Mineral Resource has a higher level of confidence than an Inferred Mineral Resource but has a lower level of confidence than a Measured Mineral Resource.

A Mineral Resource is a concentration or occurrence of diamonds, natural solid inorganic material, or natural solid fossilized organic material including base and precious metals, coal, and industrial minerals in or on the Earth's crust in such form and quantity and of such a grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge.

The term Mineral Resource covers mineralization and natural material of intrinsic economic interest which has been identified and estimated through exploration and sampling and within which Mineral Reserves may subsequently be defined by the consideration and application of technical, economic, legal, environmental, socio-economic and governmental factors. The phrase 'reasonable prospects for economic extraction' implies a judgement by the Qualified Person in respect of the technical and economic factors likely to influence the prospect of economic extraction. A Mineral Resource is an inventory of mineralization that under realistically assumed and justifiable technical and economic conditions might become economically extractable. These assumptions must be presented explicitly in both public and technical reports.

Report Date: April 30, 2013

Effective Date: March 18, 2013

1.8.1.2 Indicated Mineral Resource

An 'Indicated Mineral Resource' is that part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed.

Mineralization may be classified as an Indicated Mineral Resource by the Qualified Person when the nature, quality, quantity and distribution of data are such as to allow confident interpretation of the geological framework and to reasonably assume the continuity of mineralization. The Qualified Person must recognize the importance of the Indicated Mineral Resource category to the advancement of the feasibility of the project.

All silver and zinc resources are classified as Indicated while lead and copper are classified as Inferred. Although the lead and copper resources are within the distance and spacing criteria, the authors believe further work is required to develop confidence in the source data and economics prior to classifying these resources as Indicated.

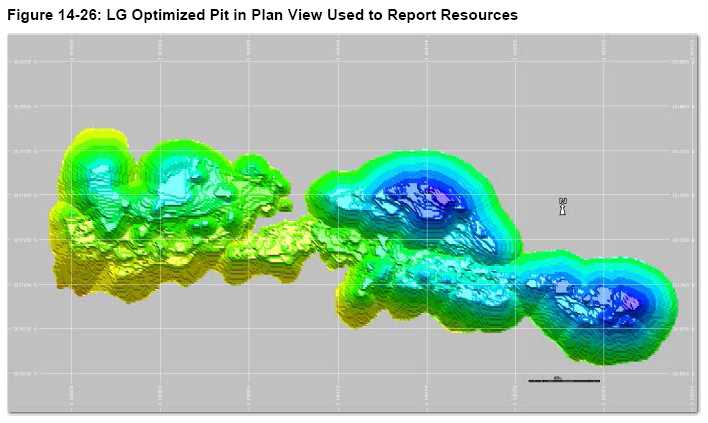

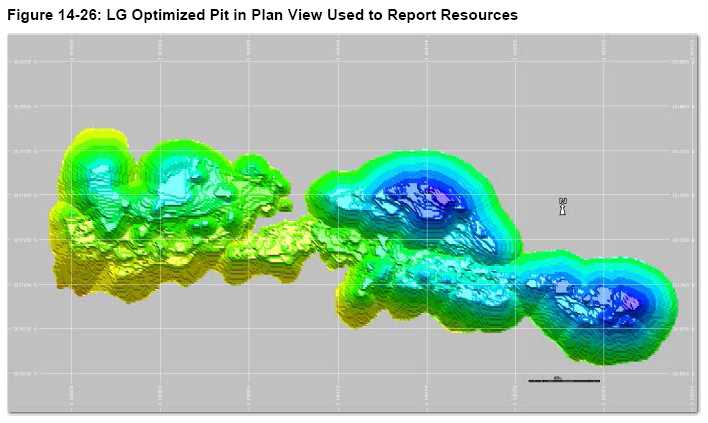

The mineral resources are confined within an optimized Lerchs-Grossman (LG) pit shell to ensure reasonable prospects of economic extraction. The pit shell was generated using a silver, zinc, lead and copper prices of $29.20 per ounce silver, $0.95 per pound zinc, $1.00 per pound lead and $3.70 per pound copper, as defined by the 3-year trailing average as on January 31, 2013. Mining costs (ore and waste) of US$1.50/tonne, processing costs of US$13.00/tonne (including G&A) and an overall pit slope of 50° were used for the pit optimizations. Recoveries were assumed to be 100%.

For the purposes of determining a cutoff grade, JDS used a silver Recovery of 75% and a dilution factor of 80% with the following calculation:

(Processing Costs+ G&A Costs)/[(Ag Price)/31.1035 * %Rec * %Dilution]

Thus the Cut-off calculation is:

(12.00 - 1.00)/[29.20/31.104 * 75% *80%] = 23.08 g/t => USE 25.0 g/t

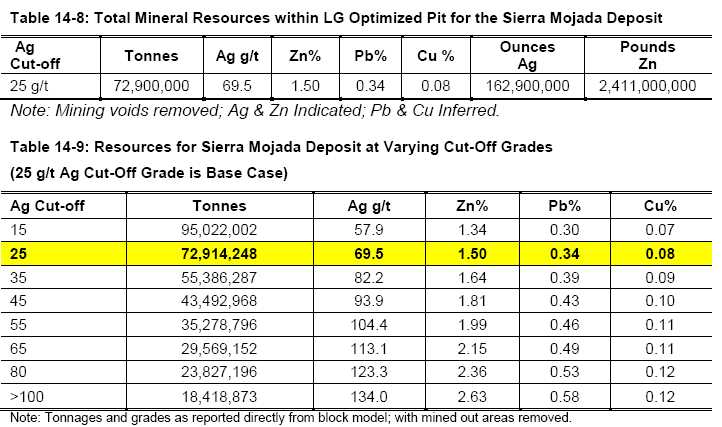

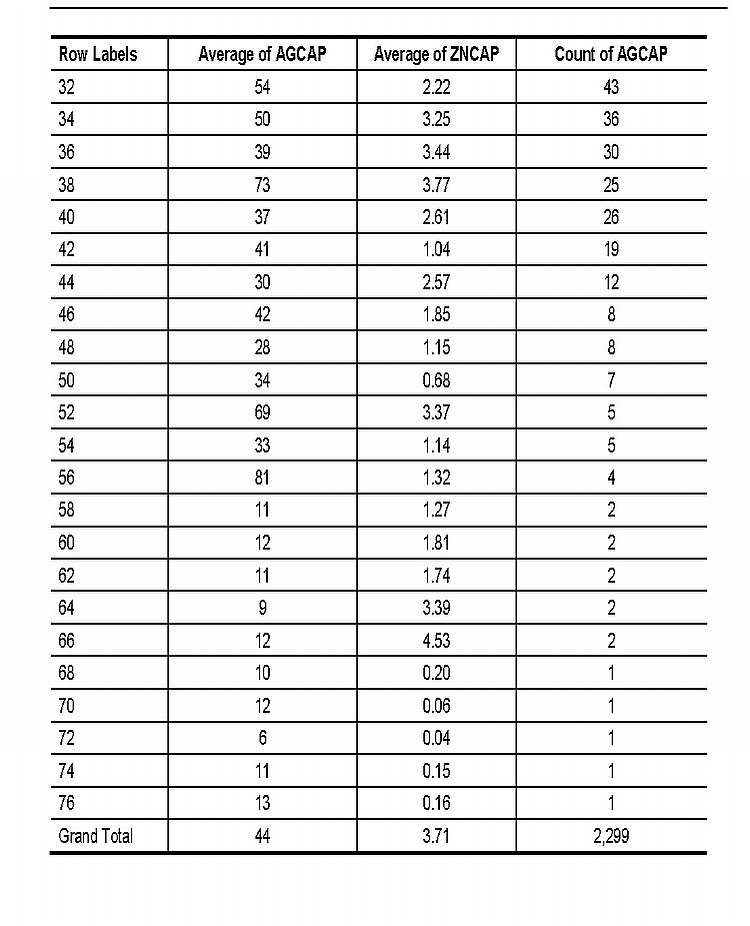

The combined mineral resources are listed at this base case cut-off grade of 25g/t Ag as shown in Table 1-1. In addition, Table 14-9 tabulates the resources at varying silver cut-off grades.

Report Date: April 30, 2013

Effective Date: March 18, 2013

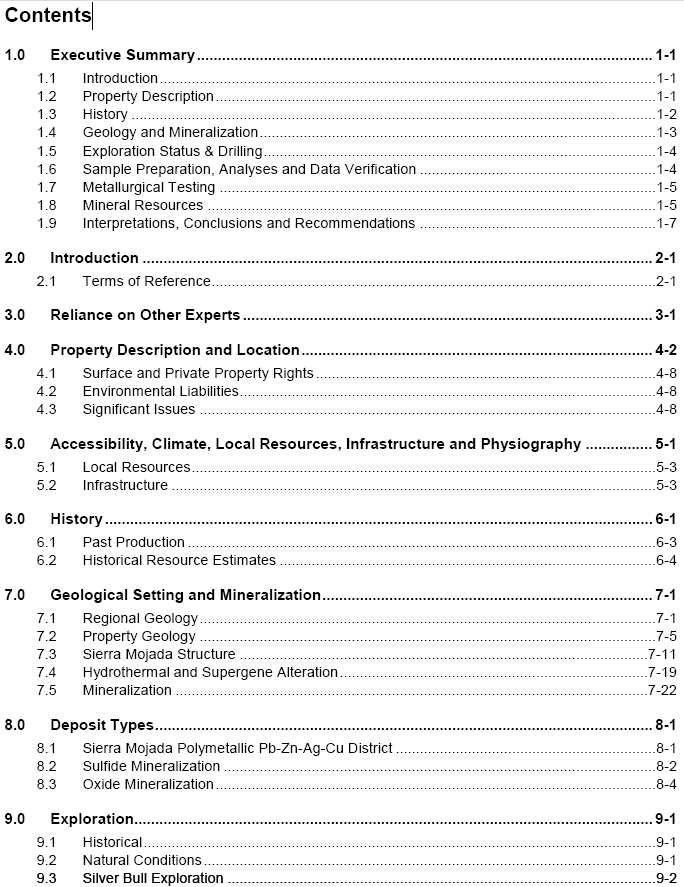

Table 1-1 Mineral Resources within LG Optimized Pit Shell

Ag Cut Off | Tonnes | Ag g/t | Zn% | Pb% | Cu % | Ounces Ag | Pounds Zn |

| 25 g/t | 72,900,000 | 69.5 | 1.50 | 0.34 | 0.08 | 162,900,000 | 2,411,000,000 |

Note: Mining voids removed. Ag & Zn are Indicated; Pb & Cu are inferred.

1.9 Interpretations, Conclusions and Recommendations

JDS recommends that Silver Bull Resources:

| ● | Continue to drill-test the silver zones at the west end of the Sierra Mojada property. |

| ● | The next phase work program should include geotechnical drilling to confirm appropriate slope angles for future open pit design work. |

| ● | Continue to do limited programs of duplicate channel sampling to help eliminate the possibility that the channel sample bias is a result of a sampling bias. |

| ● | Complete the SART process metallurgical test work and confirm recovery parameters. |

| ● | Continue work on improved interpretation and modeling of domains. |

| ● | Revise the underground mined out solids and voids. |

| ● | Collect additional SG data. |

| ● | Detail power and water sources, requirements, and begin permit process |

| ● | Conduct a Preliminary Economic Assessment (PEA). |

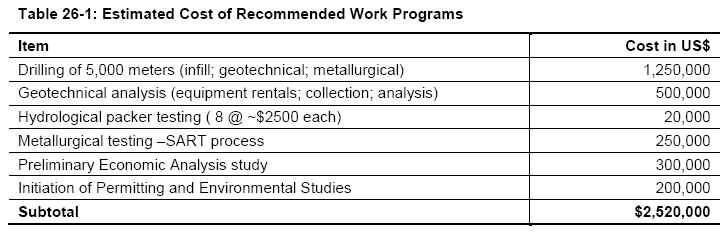

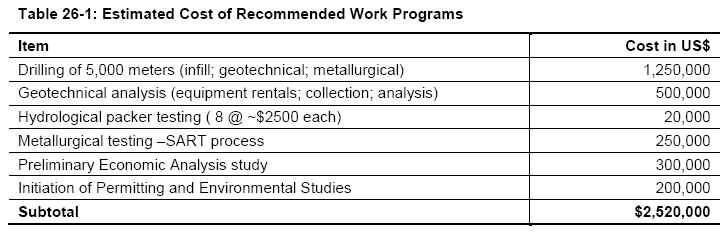

JDS estimates that the total cost of the next phase work program is approximately US$2.5M.

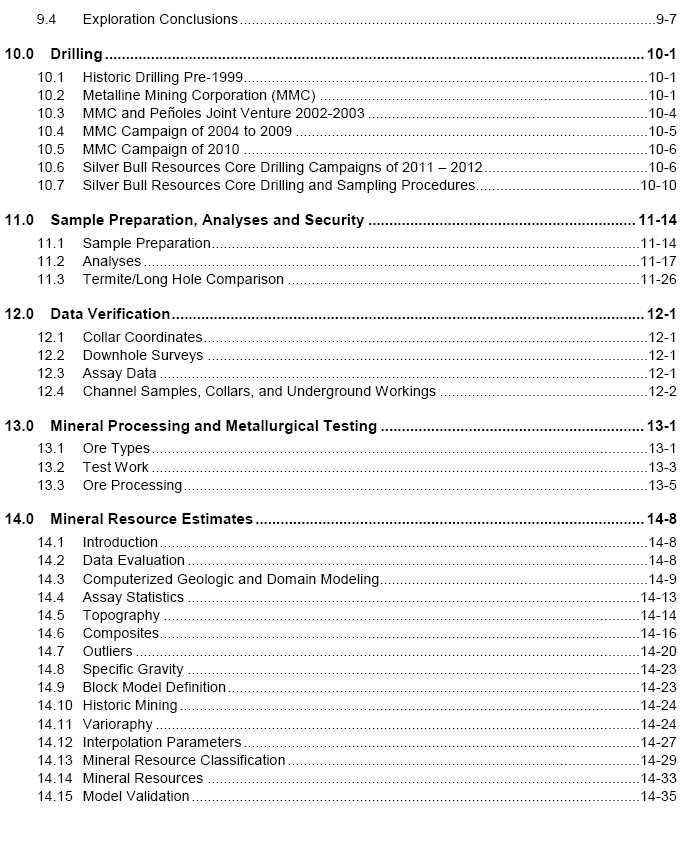

Table 1-2: Estimated Cost of Recommended Work Programs

| Item | | Cost in US$ | |

| 5,000 meters of drilling (infill; geotechnical; metallurgical) | | | 1,250,000 | |

| Geotechnical analysis (equipment rentals; collection; analysis) | | | 500,000 | |

| Hydrological packer testing ( 8 @ ~$2500 each) | | | 20,000 | |

| Metallurgical testing -SART process | | | 250,000 | |

| Preliminary Economic Analysis study | | | 300,000 | |

| Initiation of Permitting and Environmental Studies | | | 200,000 | |

| Subtotal | | $ | 2,520,000 | |

Report Date: April 30, 2013

Effective Date: March 18, 2013

This Technical Report dated April 30, 2013, was prepared by JDS to provide a NI-43-101 compliant technical report (Technical Report) of the updated resources at the Sierra Mojada Project in Mexico. Silver Bull Resources Inc. (Silver Bull) has a 100% interest in the 46 concessions.

Mr. Allan Reeves, P.Geo., of JDS managed the report preparation. Dr. Gilles Arseneau, P.Geo., of SRK Consulting (Canada) Inc. prepared the Termite/Long Hole Comparison Section 11.3.

This Technical Report was prepared in compliance with the requirements of the Canadian Securities Administrators' NI 43-101 and Form 43-101F1.

The current mineral resource estimate presented in this report replaces the previous mineral resource estimate from SRK Consulting Inc. (SRK) in July 2012. JDS Energy & Mining Inc. has provided project management services since July 2010 and as part of these services have been further commissioned to prepare this NI 43-101 Resource Technical report, and a follow-up Preliminary Economic Assessment.

| 2.3 | Statement of Independence |

Neither JDS nor any of the authors of this Report have any beneficial interest in the outcome of the technical assessment being capable of affecting its independence. JDS's fee for completing this Report is based on its normal professional rates plus reimbursement of incidental expenses. The payment of that professional fee is not contingent upon the outcome of the Report.

Mr. Allan Reeves, P.Geo, a qualified person under the terms of NI 43-101, has spent a considerable amount of time at the Sierra Mojada site in the role of project manager and resource consultant. It is estimated that the time totalled: 62 days in 2010; 108 days in 2011; and 80 days in 2012.

The purpose of Mr. Reeves site visits varied from coverage as site manager during the Dome Ventures-Metalline Mining Company transition period; QA/QC review of data collection methods and quality; the implementation of safety systems and protocols; and to assist on surface/underground tours for visitors.

Silver Bull allowed JDS access to all digital and paper copy data collected over the years. JDS also had many opportunities to review the geology and mineralization encountered both on surface and underground as well as examining random drill core.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Mr. Gilles Arseneau, P.Geo., has visited the site on July 27 and 28, 2011, on October 1 to October 3, 2011 and on February 21 to 23, 2012.

Unless otherwise stated all units used in this report are metric. Assay values are reported in grams per metric tonne (g/t) unless some other unit is specifically stated. The US$ is used throughout this report.

This report is based, in part, on internal Company technical reports, and maps, published government reports, Company letters and memoranda, and public information as listed in the References Section 27.0 at the conclusion of this Technical Report.

The Sierra Mojada Project has been the subject of two previous NI 43-101 compliant technical reports by SRK Consulting Inc. (SRK). Both reports were prepared by Dr. Gilles Arseneau, with the first in November 2011 and an update in July 2012.

Earlier reports consisted of the Nilsson report in April 2011 (authored by Ronald Simpson and John Nilsson). In January 2010 Pincock Allan & Holt (PAH) prepared a report which disclosed mineral resource estimates for the Shallow Silver Zone and the Red Zinc Zone respectively.

JDS has relied upon some of the previously disclosed reports along with newly collected information provided by Silver Bull Resources.

JDS has not conducted detailed land status evaluations, and has relied upon previous qualified reports, public documents and statements by the Company regarding Property status and legal title to the Sierra Mojada Project.

| 2.7 | Units of Measure, Calculations & Abbreviations |

A list of the main units, abbreviations and acronyms used throughout this report is presented in Table 2-2.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Table 2-1: Units of Measure & Abbreviations Units of Measure

| um | Micron (micrometre) |

| Amp | Ampere |

| cm | Centimetre |

| g/t | Gram per tonne |

| hr | Hour |

| ha | Hectare |

| hp | Horsepower |

| kg | Kilogram |

| km | Kilometre |

km2 | Square kilometer |

| KPa | Kilopascal |

| kt | Thousand tonnes |

| Kw | Kilowatt |

| KWh | Kilowatt hour |

| L | Litre |

| lb or lbs | Pound(s) |

| m | Metre |

| M | Million |

| m2 | Square metre |

m3 | Cubic metre |

| min | Minute |

| mm | Millimetre |

| Mpa | Mega Pascal |

| mph | Miles per hour |

| Mtpa | Million tonnes per annum |

| Mt | Million tonnes |

| °C | Degree Celsius |

| oz | Troy ounce |

| ppb | Parts per billion |

| ppm | Parts per million |

| s | Second |

| t | Metric tonne |

| tpd | Tonnes per day |

| tph | Tonnes per hour |

| V | Volt |

| W | Watt |

| wmt | Wet metric tonne |

Report Date: April 30, 2013

Effective Date: March 18, 2013

Abbreviations & Acronyms

| % or pct | Percent |

| AAS | Atomic absorption spectrometer |

| Ag | Silver |

| Amsl | Above mean sea level |

| As | Arsenic |

| Au | Gold |

| C | Carbon |

| CAPEX | Capital Costs |

| CFE | Comision Federal de Electricidad |

| CIL | Carbon-in-leach |

| CIM | Canadian Institute of Mining |

| Elev | Elevation above sea level |

| GPS | Global positioning system |

| HG | High Grade |

| H:V | Horizontal to vertical |

| JDS | JDS Energy & Mining Inc. |

| LG | Low Grade |

| Ma | Million years ago |

| MMC | Metalline Mining Company |

| MXP | Mexican pesos |

| N,S,E,W | North, South, East, West |

| NPV | Net Present Value |

| NSR | Net Smelter Return |

| NI 43-101 | National Instrument 43-101 |

| OPEX | Operating costs |

| PA | Preliminary Assessment |

| PAX | Potassium Amyl Qanthate |

| Pb | Lead |

| PEA | Preliminary Economic Assessment |

| PFS | Prefeasibility Study |

| QA/QC | Quality Assurance/Quality Control |

| QMS | Quality Management System |

| RC | Reverse circulation |

| S | Sulfur |

| SEMARNAT | Secretaria de medio ambiente y recursos naturales |

| S.G. | Specific gravity |

| SBR | Silver Bull Berources Inc. |

| SRK | SRK Consulting Inc. |

| US$ | US dollars |

| Whittle | Gemcom Whittle- Strategic Mine Planning TM |

| X,Y,Z | Cartesian Coordinates, also Easting, Northing and Elevation |

| Zn | Zinc |

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 3.0 | Reliance on Other Experts |

Independent metallurgical consultant Mr. William J. Pennstrom Jr., M.A.; QPMMSA of Pennstrom Consulting Inc. was contracted by Silver Bull to review the metallurgical testing programs conducted. Mr. Pennstrom's work was provided to JDS by Silver Bull and forms the basis of Section 13 - Mineral Processing and Metallurgical Testing. Responsibility for his work has been undertaken by Mr. Allan Reeves, a Qualified Person.

Although copies of the tenure documents, operating licenses, permits, and work contracts were reviewed, an independent verification of land title and tenure was not performed. JDS has not verified the legality of any underlying agreement(s) that may exist concerning the licenses or other agreement(s) between third parties but has relied on Silver Bull's solicitor to have conducted the proper legal due diligence. Information on tenure and permits was obtained from Silver Bull.

Based on Silver Bull's legal opinion the current mining law in Mexico allows for the concession to be issued for 50 years. This law was made effective April 29, 2005 and concessions issued prior to this change in mining law will have the expiration date of the concession amended to reflect the 50-year period. JDS has relied on representations and legal opinions provided by Silver Bull regarding the legal disposition of mining concessions.

JDS has relied completely on Silver Bull regarding all information related to the environmental, political and tax information about the project.

Report Date: April 30, 2013

Effecitve Date: March 18, 2013

| 4.0 | Property Description and Location |

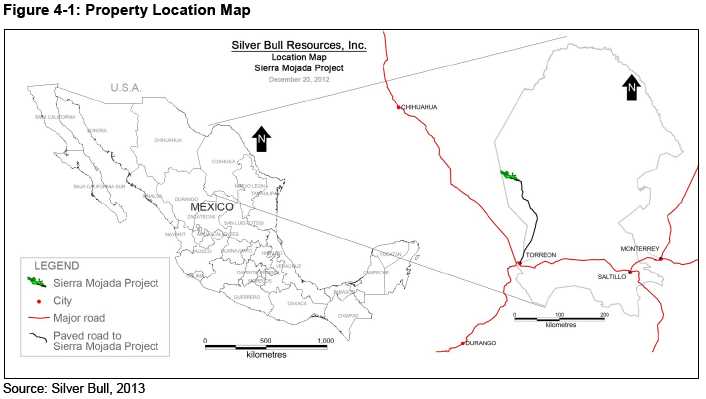

The Sierra Mojada project is located in the northwestern part of Coahuila State, Mexico, close to the border with Chihuahua State (Figure 4-1). Access is by paved Highway from the city of Torreon about 250km southwest of the project. The project site is situated about one km south of the village of Esmeralda.

The Sierra Mojada Project abuts a major escarpment that forms the northern margin of the Sierra Mojada range. The average elevation at the site is 1,500masl and is at latitude 27°24' North and longitude 103°43' West. Silver Bull Resources employs the NAD 27 Zone 13 survey coordinate system on the project.

Silver Bull operates in Mexico through a wholly owned Mexican subsidiary; Minera Metalin S.A. de C.V. All minerals in Mexico are owned by the federal government and mineral rights are granted by soliciting mining concessions, which by law have priority over surface land use, but in practice the concessions owner must have an agreement with the surface owner. See Figure 4-2 for the location of the regional concessions.

JDS understands that all necessary agreements are in place and that the mining concessions are in good standing for the resource estimates presented in this report.

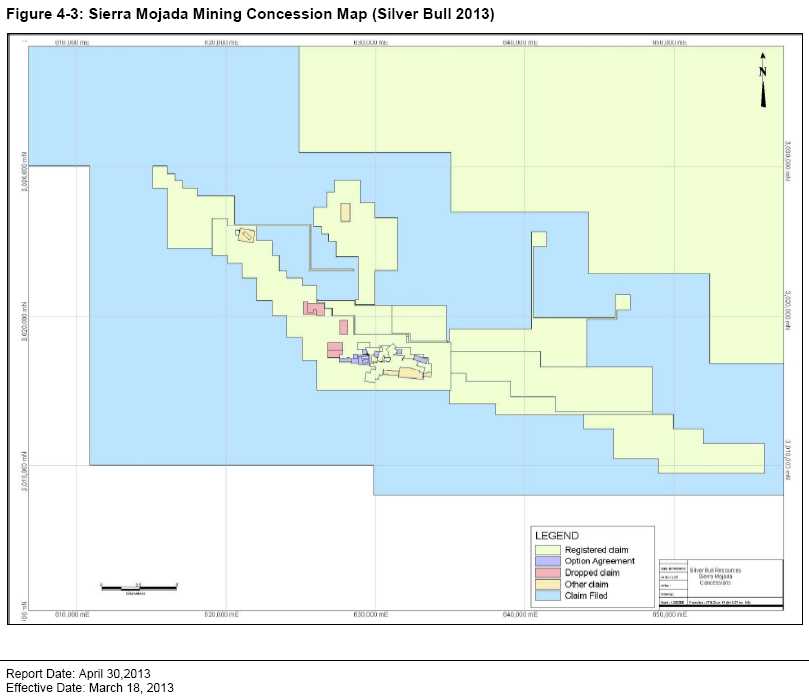

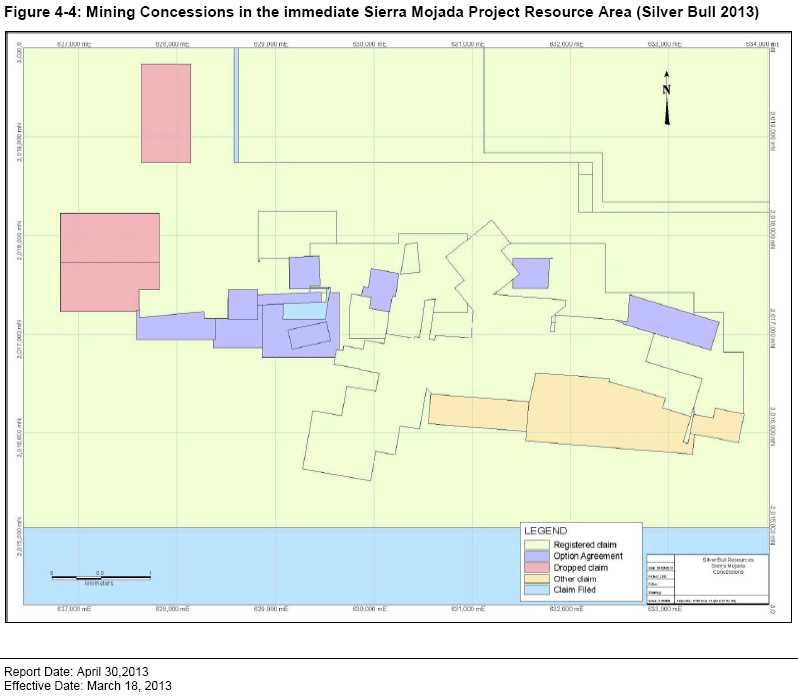

The Sierra Mojada Project contains all of the known reported historical silver-zinc resources in the area, and is composed of a number of mining concessions. Local mining concessions are shown in Figures 4-2, 4-3, and 4-4.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

The mining concessions held by Silver Bull cover all the mineralized zones. No mining operations are currently active within the area, except for a dolomite quarry operated by Penoles near Esmeralda.

Table 4-1 shows the mining concessions currently held by Silver Bull. Total area for these licences excluding the "claim filed" concessions is 391,991.21 ha.

The "registered" concessions are 100% owned by a Silver Bull's wholly owned Mexican subsidiary; Minera Metalin S.A. de C.V. (Minera Metalin). In the concessions with the "purchase option" status, Minera Metalin has a 100% interest, and the "claim filed" concessions will be 100% owned once granted by the Mexican authorities.

Report Date: April 30, 2013

Effective Date: March 18, 2013

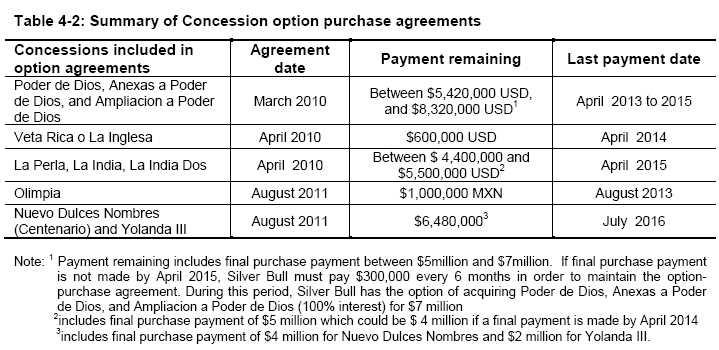

The Sierra Mojada property is subject to five concession option purchase agreements listed in the table below. Table 4-2 summarizes the obligations of each agreement.

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 4.1 | Surface and Private Property Rights |

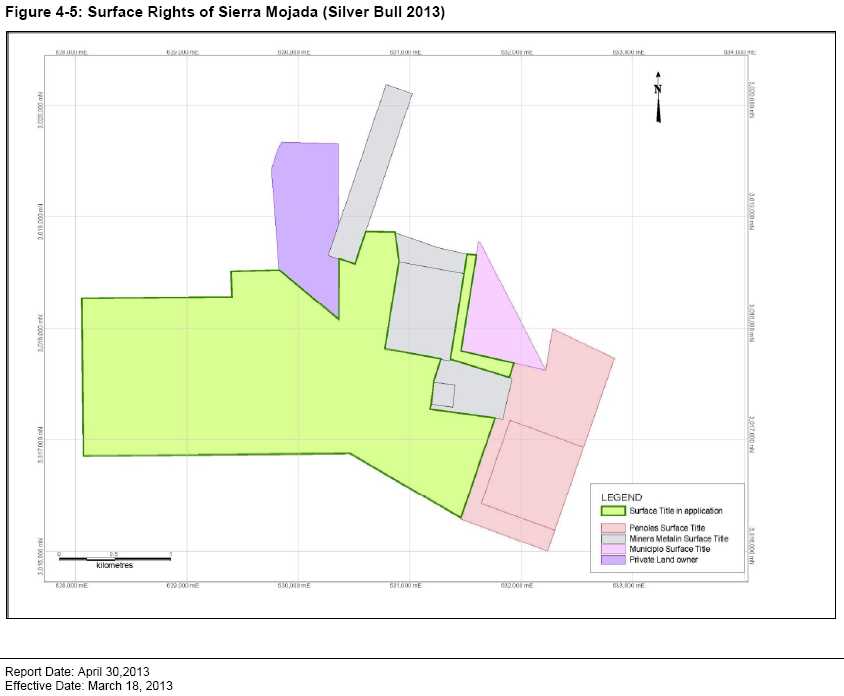

Approximately 80% of the area of interest labelled "Surface in Application" on Figure 4-5 (in green is currently owned by the Federal Government. The Municipality has applied to the Federal Government in order for the Federal Government to cede the rights to the Municipality (a formality since the Federal Government is not allowed to sell surface rights according to Mexican law). Silver Bull is already in discussions with the municipality of Sierra Mojada for acquisition of the surface rights once ceded. All of Silver Bull's fixed assets, including offices and buildings, are on land owned by Silver Bull.

| 4.2 | Environmental Liabilities |

There are no known environmental liabilities on the Sierra Mojada Project, and all necessary work permits are in good standing.

There are no known significant issues on the Sierra Mojada property.

I've brought this issue up before. We need to divulge the presence of an historic lead smelter under section 4.2 and the positive security situation under section 4.3.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

The climate is arid and warm. Rainfall is scarce but more prominent in summer, whilst temperatures are very hot by day and cool at night. The average annual temperature is 14 °C to 16 °C, with rainfall of 400 to 500mm per year.

The highest daily temperatures are generally recorded in May, with maximum temperatures being moderated somewhat by rainfall during June through October. Freezing occurs from time to time during the winter - particularly in January and February - although this occurs less than 20 days out of the year in most years. Occasionally there is snow as can be seen in Figure 5-1.

Winds are highly variable, but strong southerly winds coming down from the mountains are common. Streams are ephemeral and wells with acceptable water quality are tens to hundreds of meters deep. (SRK 2012)

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

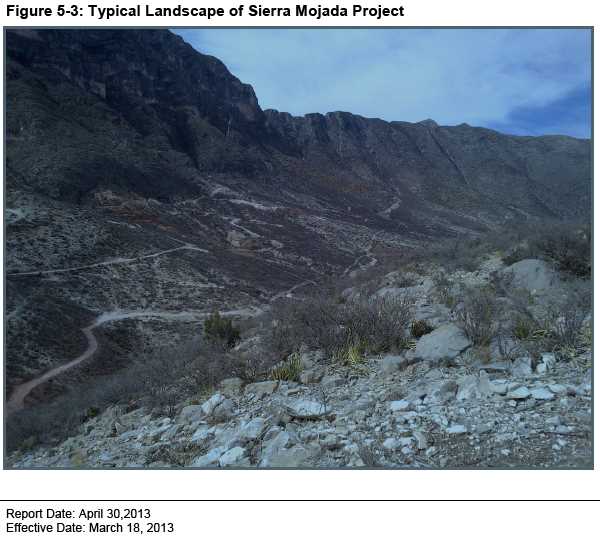

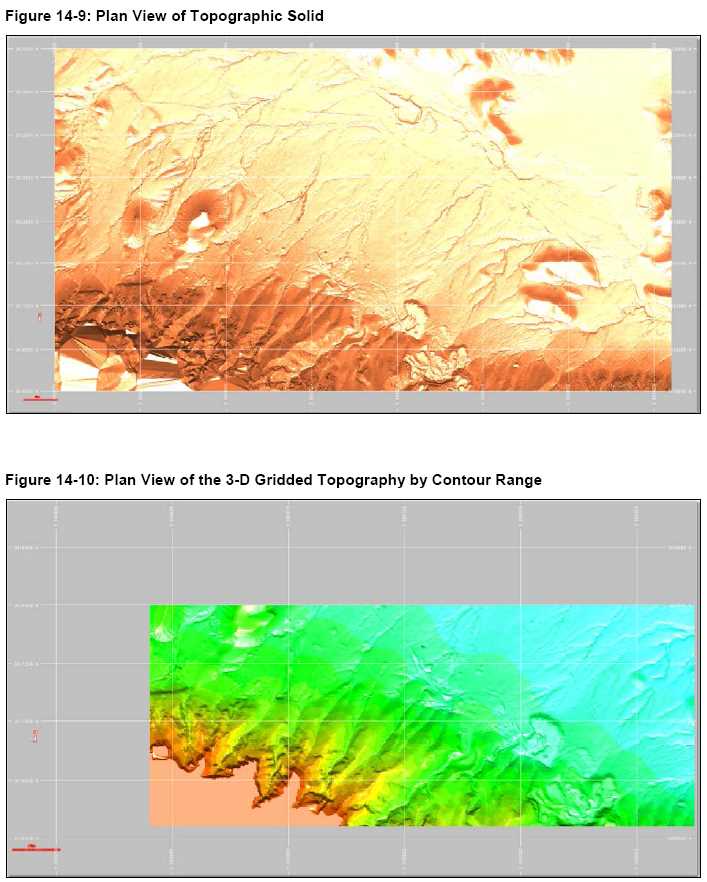

The project is located west of Sierra Madre Oriental on the Mexican Plateau as shown on Figure 5-2. The terrain is generally flat, with prominent relief formations of up to 1,500m along the southern boundary of the project site as shown on Figure 5-3.

The majority of the mineral concessions are located in areas at the base of the cliffs where there is moderate relief with numerous stream forming gullies that erode the surface alluvium. The area is high desert covered by scrub vegetation; comparable to the Basin and Range in Nevada. Mining operations are viable throughout the year (SRK 2012).

While most of the area peripheral to the project site is used for cattle ranching, the village of La Esmeralda and the town of Sierra Mojada (about 4km west of the project camp) can provide local workforce and minor supplies. Both communities offer basic services and for the project and are linked by paved road.

Mina Dolomita, the Penoles dolomite extraction and crushing facility is located at the southeastern boundary of the project. The mine contains waste piles and a 1km long conveyor belt that transports crushed dolomitic carbonate aggregate of specific magnesium carbonate grade to their railroad spur for bi-weekly transportation to the Penoles Quimica Del Rey plant in Laguna Del Rey.

A rail line utilized by Penoles to transport material to its chemical plant extends west to La Esmeralda. The remains of an older section extend right up to old workings and loading facility located south of La Mesa Blanca right in the center of the Sierra Mojada Camp. The spur line connects the main national line which connects Escalon and Monclova. Rail traffic to the east is through Frontera to the United States, via Eagle Pass, Texas, southward to Monterrey, or via the seaport at Altamira/Tampico (Figure 5-3). Service to the west is also available, as well as to the western USA via El Paso, or to points south connected through Torreon.

Although power levels are sufficient for current operations and exploration, any development of the project would potentially require additional power supplies to be sourced. The Comision Federal de Electricidad (English: Federal Electricity Commission) is the Mexican state-owned electricity monopoly, widely known as CFE, which provides service to the area.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

The following historical summary has been extracted from previous technical reports and information provided by Silver Bull.

Silver and lead were first discovered by a foraging party in 1879, and mining to 1886 consisted of native silver, silver chloride, and lead carbonate ores. Alter 1886, silver-lead-zinc-copper sulphate ores within limestone and sandstone units were produced. No accurate production history has been found for historical mining during this period.

Approximately 90 years ago, zinc silicate and zinc carbonate minerals ("Zinc Manto Zone") were discovered underlying the silver-lead mineralized horizon. The Zinc Manto Zone is predominantly zinc dominated, but with subordinate Lead - rich manto and is principally situated in the footwall rocks of the Sierra Mojada Fault System. Since discovery and up to 1990; zinc, silver, and lead ores were mined from various mines along the strike of the deposit including from the Sierra

Report Date: April 30, 2013

Effective Date: March 18, 2013

Mojada property. Ores mined from within these areas were hand sorted and the concentrate shipped mostly to smelters in the United States.

Activity during the period of 1956 to 1990 consisted of operations by the Mineros Nortenos Cooperativa and operations by individual owners and operators of pre-existing mines. The Mineros Nortenos operated the San Salvador, Encantada, Fronteriza, Esmeralda, and Parrena mines, and shipped oxide zinc ore to Zinc National's smelter in Monterrey, while copper and silver ore were shipped to smelters in Mexico and the United States.

The principal mines operated by individuals and lessors were the Veta Rica, Deonea, Juarez, Volcan I and II, Once, San Antonio, San Jose, San Buena, Monterrey, Vasquez III, Tiro K, El Indio and Poder de Dios. The individual operators were mainly local residents, such as the Farias, Espinoza, and Valdez families.

In the early 1990's, Kennecott Copper Corporation ("Kennecott") had a joint venture agreement involving USMX's Sierra Mojada concessions. Kennecott terminated the joint venture in approximately 1995.

Metalline entered into a Joint Exploration and Development Agreement with USMX in July 1996 involving USMX's Sierra Mojada concessions. In 1998, Metalline purchased the Sierra Mojada and the USMX concessions and the Joint Exploration and Development Agreement was terminated. Metalline also purchased the Esmeralda, Esmeralda I, Unificacion Mineros Nortenos, Volcan, La Blanca and Fortuna concessions, and conducted exploration for copper and silver mineralization from 1997 through 1999. During this period, exploration consisted of reverse circulation ("RC") drilling which intersected significant zinc mineralization.

In October of 1999, Metalline entered into a joint venture with North Limited of Melbourne, Australia (now Rio Tinto). Exploration by North Limited consisted of underground channel samples in addition to surface RC and diamond drilling. North Limited withdrew from the joint venture in October 2000.

A joint venture agreement was made with Penoles in November 2001. The agreement allowed Penoles to acquire 60% of the project by completing a bankable Feasibility Study and making annual payments to Metalline.

During 2002, Penoles conducted an underground exploration program consisting of driving raises through the oxide Zinc Manto, diamond drilling, continuation of the percussion drilling, and channel sampling of the oxide zinc workings (stopes and drifts) previously started by Metalline in 1999 and continued by North in 2000 and Metalline during 2001.

The workings operated by the Nortenos Cooperativa in the Zinc Manto allow access to the entire Zinc Manto in the San Salvador, Encantada, and Fronteriza mine operations. The objective of Penoles's 2002 program, in addition to evaluating the Zinc Manto mineralization, was to compare the quality and consistency of sampling methods. Penoles developed diamond drill sites in the San Salvador and Encantada mines. It also developed raises through the vertical extent of the Zinc Manto. Bulk samples of raise muck and channel samples of the raise walls were collected at

Report Date: April 30, 2013

Effective Date: March 18, 2013

one meter intervals. Percussion and diamond drill holes were drilled parallel to the raises and also sampled at one meter intervals.

The Penoles 2003 program continued the underground channel sampling and included percussion and diamond drilling from the surface. In addition to drilling the manto along its extent in the three mines, Penoles conducted step out drilling to the east and west. Penoles drilled holes on fences spaced 200 m apart east of the Fronteriza mine toward the Oriental mine, a distance of nearly 2 km. The holes were spaced 50 to 100 m in a north-south direction along the fences. To the west Penoles followed up the North Limited drilling in the vicinity of the San Antonio mine, 2 km west, which confirmed and extended the mineralization.

In December 2003, the joint venture was terminated by mutual consent between Penoles and Metalline. Penoles had other projects it preferred to fund and Metalline was interested in reacquiring a 100% interest in the project. From 2003 to April 2010, Metalline continued sampling numerous underground workings through channel and grab samples as well as completing underground and surface drill holes exploring the zinc-silver mineralization.

Subsequent to the merger with Dome Ventures in April 2010 underground exploration of the Zinc Zone was terminated. Focus was switched to a surface diamond drill program exploring near surface low grade bulk tonnage silver-zinc mineralization or the same style of mineralization above and up-dip from the hemimorphite zinc mineralization. (SRK 2012)

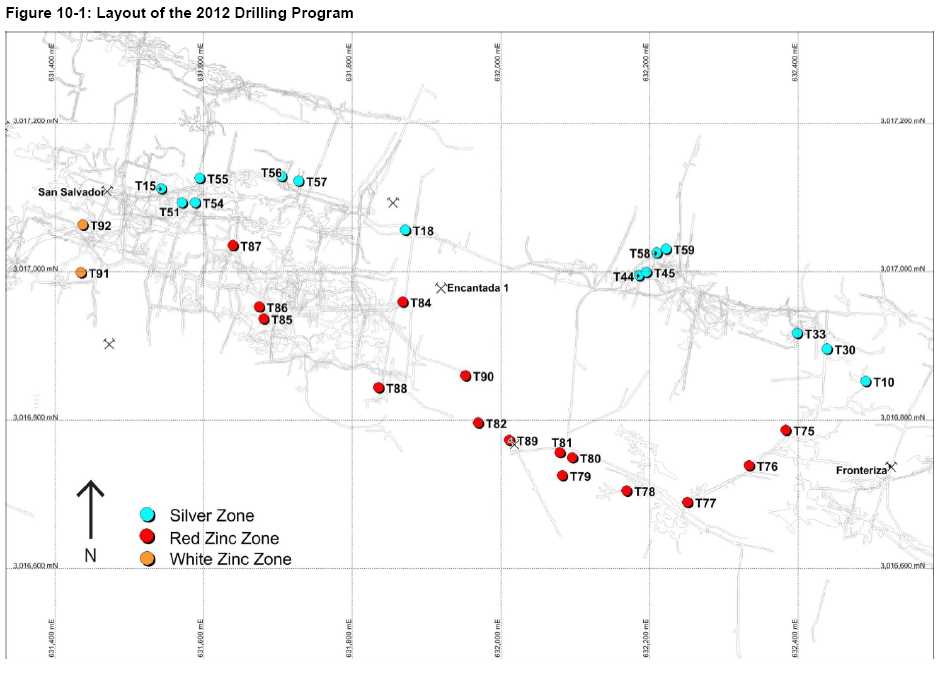

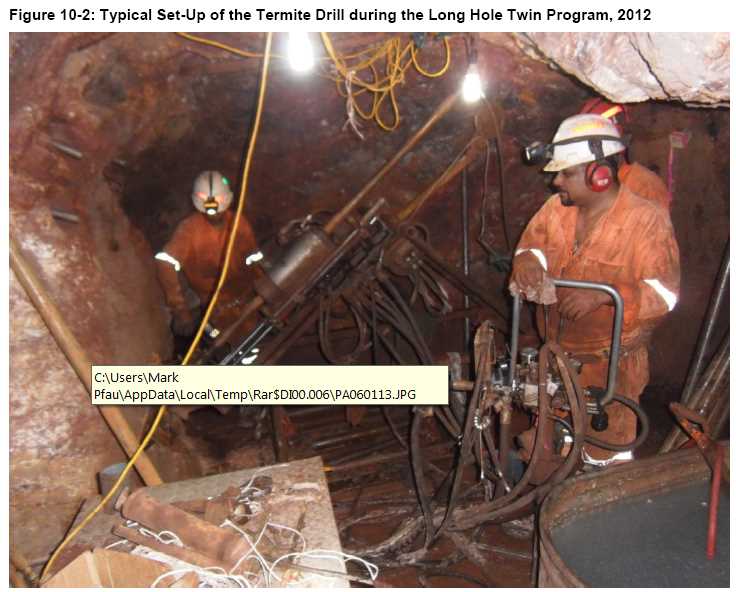

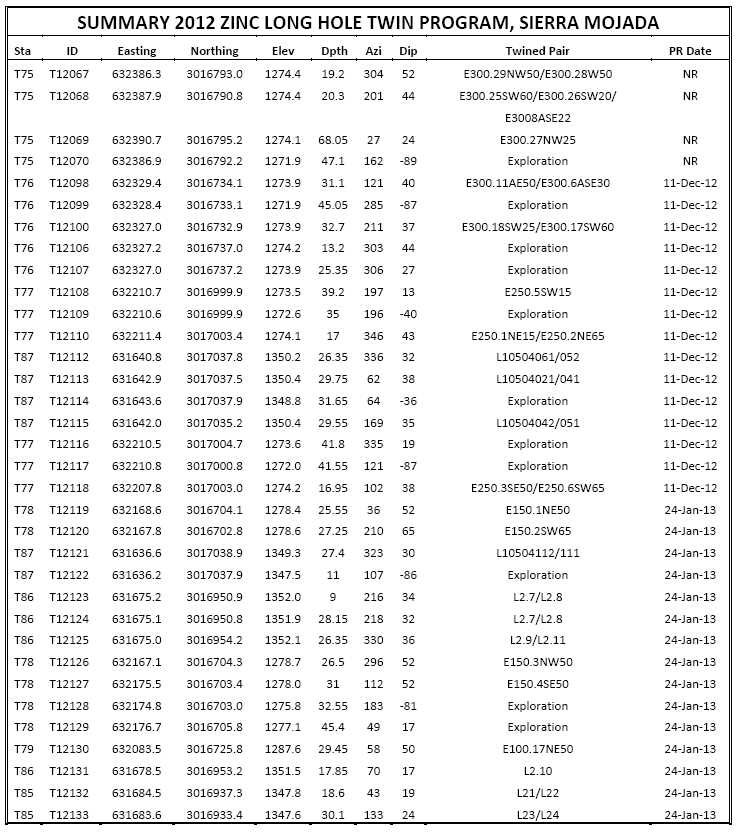

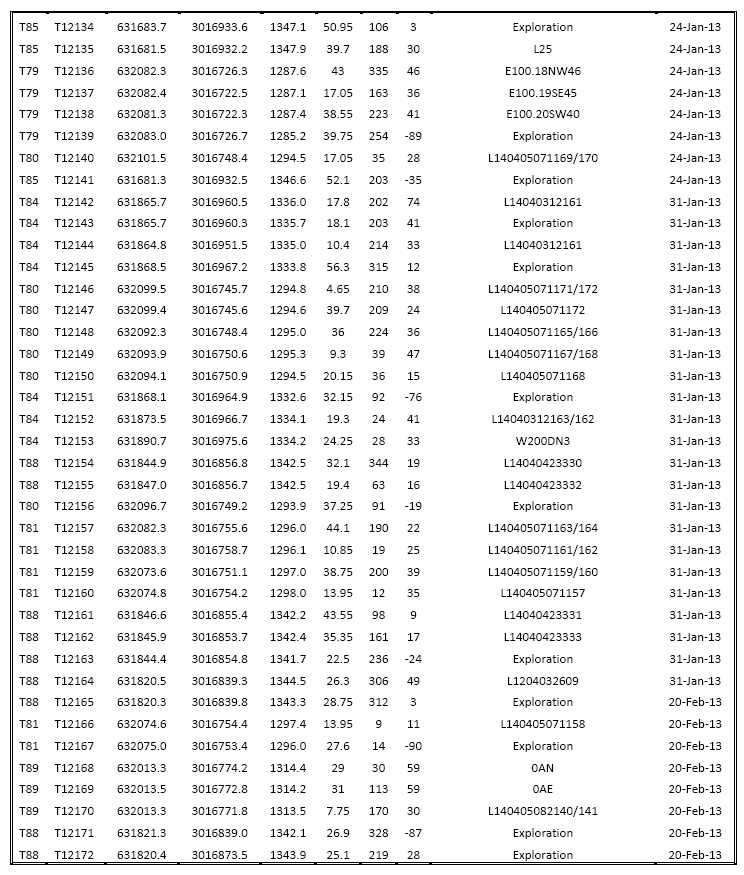

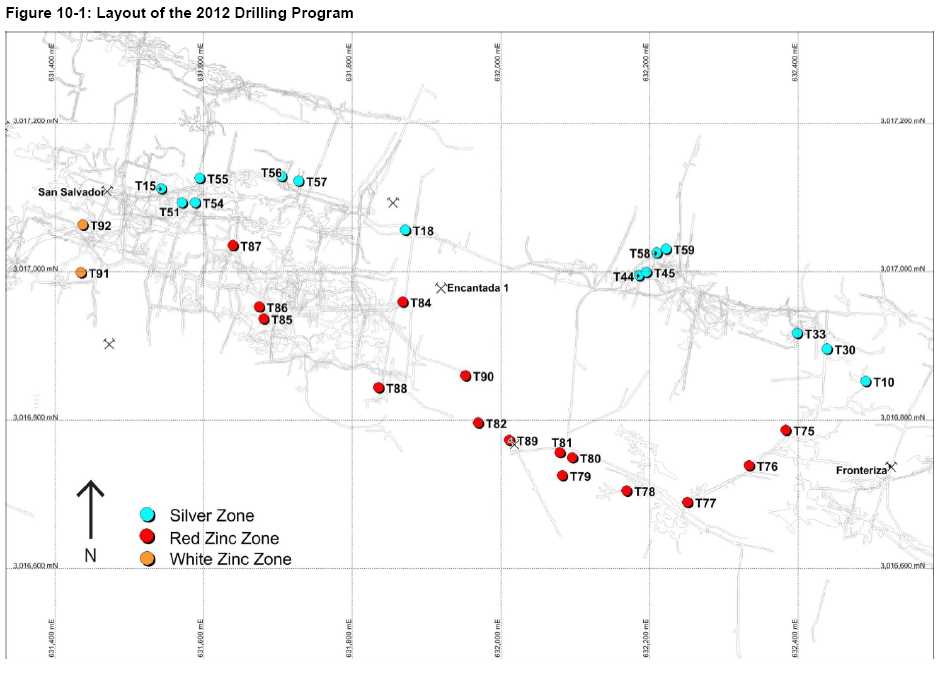

During the second half of 2012, assays from the remaining surface drill holes (B12-series) that had not made it into the last SRK technical report, were supplemented by a combined underground twin hole and exploration drill program in the silver, mixed Ag-Zn, and red zinc (hemimorphite) zones. Further u/g drill exploration of high grade silver areas to the west (Veta Rica) is planned for 2013.

To date Silver Bull has estimated that over 150km of underground workings have been surveyed on the project. This represents approximately 4 million tonnes of development and 10 million short tons of silver, zinc, lead, and copper ores.

Estimates from 1931 put production along the mineralized trend, of which the Sierra Mojada property is a subset, at approximately 5 million short tons (all of the following will be short tons). That compares with Shaw, who in his 1922 AIME paper estimated that production to 1920 was 3 to 3.5 million tons of lead-silver ores; and 1.5 to 2 million tons of Ag and Cu-Ag ores. Based on fragmented records, anecdotal evidence and stope volumes, perhaps 900,000 tons of additional oxide zinc may have been mined from Red Zinc and White Zinc areas on the Sierra Mojada property. Significant production occurred between 1920 and 1950 from the district with the involvement of major international mining companies operating small daily tonnage mines during that period. (SRK 2012)

Most of the workings are accessed through vertical shafts although there are a few adits and open stopes also present. For safety reasons, shafts have been barricaded and locations

Report Date: April 30, 2013

Effective Date: March 18, 2013

surveyed. The head frames at San Salvador, Frontireza and Centenario have been maintained and are used regularly.

| 6.2 | Historical Resource Estimates |

While the area has hosted prolonged but small scale mining activity for over 100 years there is no existing reliable historical resource estimate for the various manto deposits.

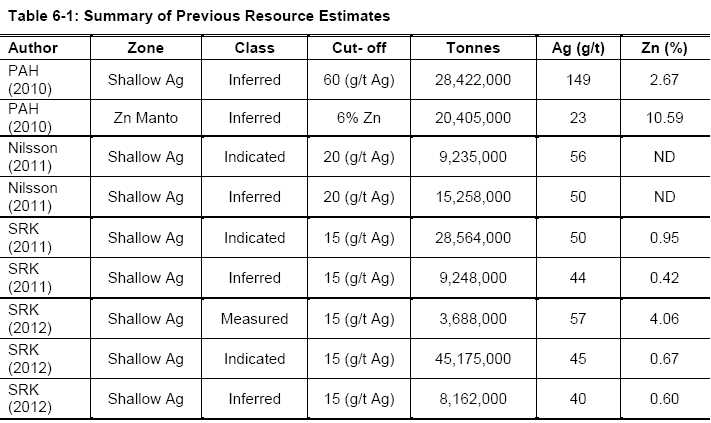

Prior NI 43-101 compliant mineral resources have been prepared for the property; namely a mineral resource prepared by PAH in January 2010 covering the Shallow Silver Zone and the Zinc Manto Zone and a mineral resource estimate prepared by Simpson and Nilsson in April 2011 covering the Shallow Silver Zone only (Table 6-1). These estimates are documented in technical reports listed in the Reference section of this report and available on SEDAR. The estimates are reliable and relevant to the property. The Zinc Manto has been partially re-estimated by SRK, as such the PAH estimate for the Zinc Manto is no longer considered current and should not be relied upon. (SRK 2012)

From 1897 to about 1905, small quantities of lead ore were smelted on site, and remnants of the smelter are still visible near the core logging facility. At various times historically, zinc oxides ores were shipped to fertilizer plants in the U.S. and Mexico.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 7.0 | Geological Setting and Mineralization |

The Chapters 7.1 through 7.3 have information modified from Stockhausen (2012), King (2012), Gryger (2010), Hodder (2010), Thorson (2010), and McKee (1990) with the original references cited within; as well as internal investigations conducted by Silver Bull Resources. Chapters 7.4 through 7.5 have information taken or modified from Stockhausen (2012), Megaw (1988, 1996, 2007), SRK (2012) and PAH (2010); as well as internal investigations conducted by Silver Bull Resources.

The Sierra Mojada Project is located in the Eastern Zone, one of the three principal geologic zones of Mexico defined by age, tectonics, and lithologies. The other two zones are the Western Zone and the Trans Mexican Volcanic belt. The Eastern Zone represents a passive plate margin relative to the Western Zone which documents a convergent plate margin, and is composed of three major lithostratigraphic terrains; the Coahuila, Maya, and Sierra Madre. The boundary between the Eastern and Western terrains is in Chihuahua just west of the Sierra Mojada project area. Within the Eastern Zone, the project is located in the Coahuila terrain.

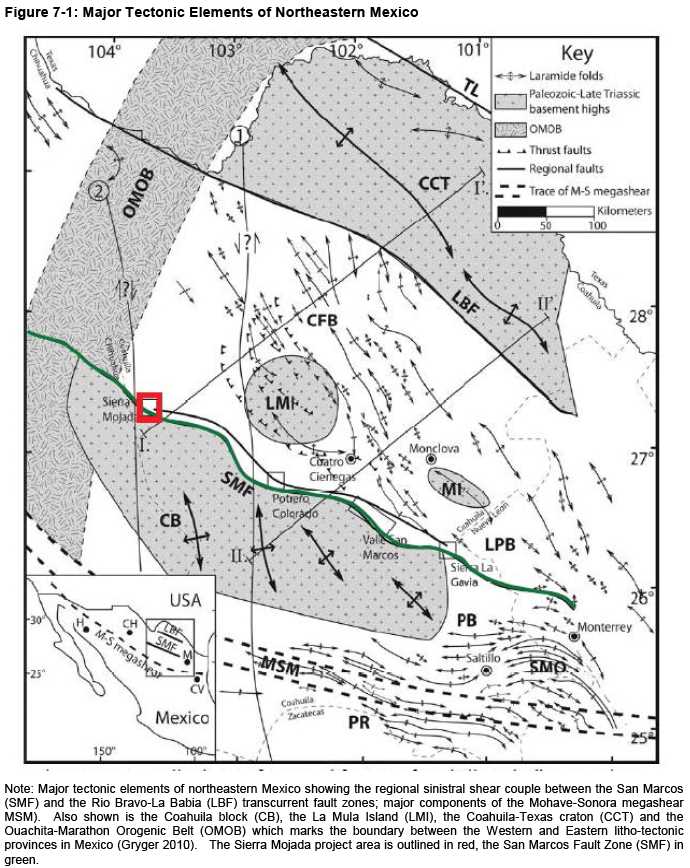

Basement rocks in the portion of the Coahuila terrain containing the Sierra Mojada district are Late Paleozoic in age. The Coahuila basement block is composed of moderately metamorphosed flysch and unmetamorphosed andesitic volcanic rocks, cut by granite and granodiorite intrusive rocks of Permian to Triassic age The Coahuila block is bounded to the northeast by the San Marcos fault system and to the south by the Torreon-Monterrey lineament, parallel to the Sonora-Mojave megashear (Figure 7-1).

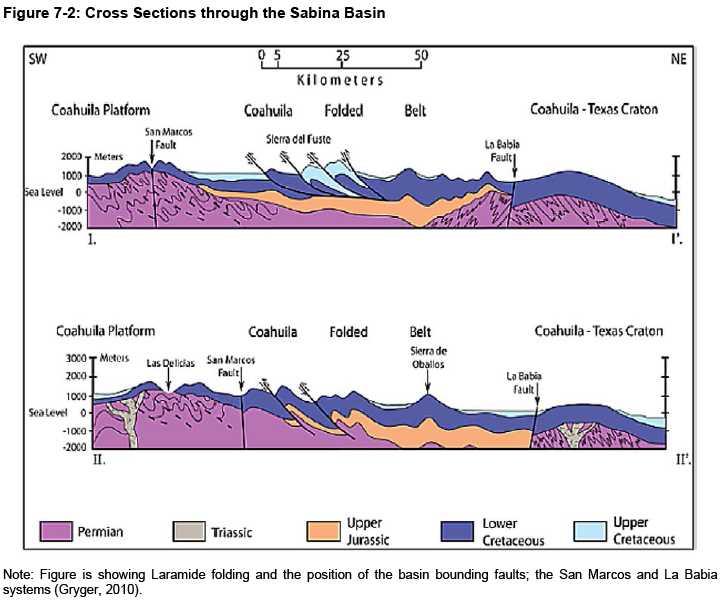

The basement rocks of the Coahuila block were cut by Permian to Triassic aged granitic and granodioritic intrusions. These intrusive units represent the roots of an island arc system produced south of the Ouachita-Marathon orogenic belt. Permian-Triassic intrusive rocks of similar composition to those found within the Coahuila block occur within the Sabinas basin along the La Mula and Monclava uplifts. The intrusive units likely acted as basement high within the basin during the Jurassic and Cretaceous. The Coahuila block was the source of siliciclastic detritus deposited along the Jurassic and Early Cretaceous in the Sabinas Basin following regional deformation along the San Marcos fault system (Figure 7-2).

The Sabinas basin formed during the Jurassic opening of the Gulf of Mexico and contains over 6,000 m of Jurassic to Cretaceous continental redbeds, evaporites, and carbonate rocks. The basin formed between the Coahuila block to the south and the Coahuila-Texas craton to the northeast. A post-rifting marine transgression resulted in deposition of extensive Middle Jurassic to Late Cretaceous carbonate rocks throughout the region. Although the orientations of sedimentary basins in northeastern Mexico were structurally controlled, basin-bounding structures were likely inactive during the time of carbonate deposition.

Report Date: April 30, 2013

Effective Date: March 18, 2013

The Sabinas Basin is prolific in its production and potential of hydrocarbon, primarily natural gas, coal, and coal-bed methane. It is also the source of metal-bearing brines linked to lead-zinc, copper- silver, barite, strontium, and fluorine mineralization in SEDEX related mineral deposits; in skarn related mineral deposits and Laramide age intrusive rocks; and in CRD type replacement deposits. The potential for sulfur and potash remains speculative.

The Coahuila region contains three major northwest-trending structures as presented in Figure 7-1 and 7-2:

| ● | Mojave-Sonora megashear |

| ● | Torreon-Monterrey lineament |

| ● | San Marcos-Rio Bravo (Babia) shear couple |

The Mojave-Sonora megashear was proposed by Silver and Anderson (1974) to explain an 800 km sinistral offset between basement rocks in northern Mexico and southern California. This shear zone is interpreted to have formed from a series of intracontinental transform faults that were active during the Late Triassic to Middle Jurassic.

The Torreon-Monterrey lineament is a west-northwest-trending structure that forms the southern boundary of the Coahuila basement block and is the southeastern extension of the Mojave-Sonora megashear. It displays regional scale left-lateral displacement of up to 400 km Movement along the Torreon-Monterrey lineament appears to have occurred primarily between the Middle Triassic and Late Jurassic.

The north-northwest striking San Marcos-Rio Bravo sinistral shear couple was active during the Jurassic, Early Cretaceous, and Tertiary and has a surface trace length of at least 1000km according to Flotte, et al 2008. This shear couple is responsible for a distinct system of conjugate normal faults in the region which strike north-south to north 70 degrees east.

The San Marcos fault component of this system exhibits a minimum of four recorded movements and begins with an early normal movement with later left-lateral strike-slip reverse movements beginning in the early Tertiary. Initial movement along the San Marcos fault has been attributed to deformation along the Torreon-Monterrey lineament and the Mojave-Sonora megashear together with subsequent isostatic adjustment due to crustal thickening during the Jurassic. The thrust component of the San Marcos fault is locally referred to as the Sierra Mojada thrust and the corresponding thrust movement on the Rio Bravo fault to the north is referred to as the Babia thrust zone. The San Marcos fault is northeast dipping and is believed to cut the entire crust while documented off sets are about 100m in the Sierra Mojada district, but variable region wide.

Movement along the San Marcos fault system resulted in the deposition of Cretaceous age continental redbed and carbonate units north of the fault. The redbed units include the San Marcos Formation and the Upper Conglomerate units. The carbonate units include the La Pena and Aurora

Report Date: April 30, 2013

Effective Date: March 18, 2013

Formation, all in the Sierra Mojada district. Reactivation of the San Marcos fault occurred during the Early Pliocene and resulted in a series of secondary faults with east-west to north-south orientations in western Coahuila and southeastern Chihuahua.

The deep seated San Marcos fault zone has also been the structural guide to Laramide - Pleistocene age igneous activity along its length including the Carmago volcanic field 100 km to the northwest of the Sierra Mojada district, the Quatro Cienegas thermal area 150 km to the southeast of the Sierra Mojada, as well as the igneous intrusions believed to be the source of the mineralization in the Sierra Mojada district.

The Seveir-Laramide orogeny marks a period of major mountain building along a northwest trending front throughout the North American continent. The timing of the Laramide orogeny varies across North America, but it is broadly attributed to the late Cretaceous to early Paleocene. In northeastern Mexico, the Laramide orogeny resulted in the reactivations of Early Mesozoic rift-related basement faults. Cretaceous strata situated on the Coahuila block experienced low intensity deformation forming a broad, southeast-plunging anticlinal dome. Laramide deformation also formed the Sierra Madre Oriental fold and thrust belt to the south of the Coahuila block and the Coahuila fold belt to the north of the Coahuila block in the Sabinas Basin

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 7.2.1 | Sierra Mojada Stratigraphy |

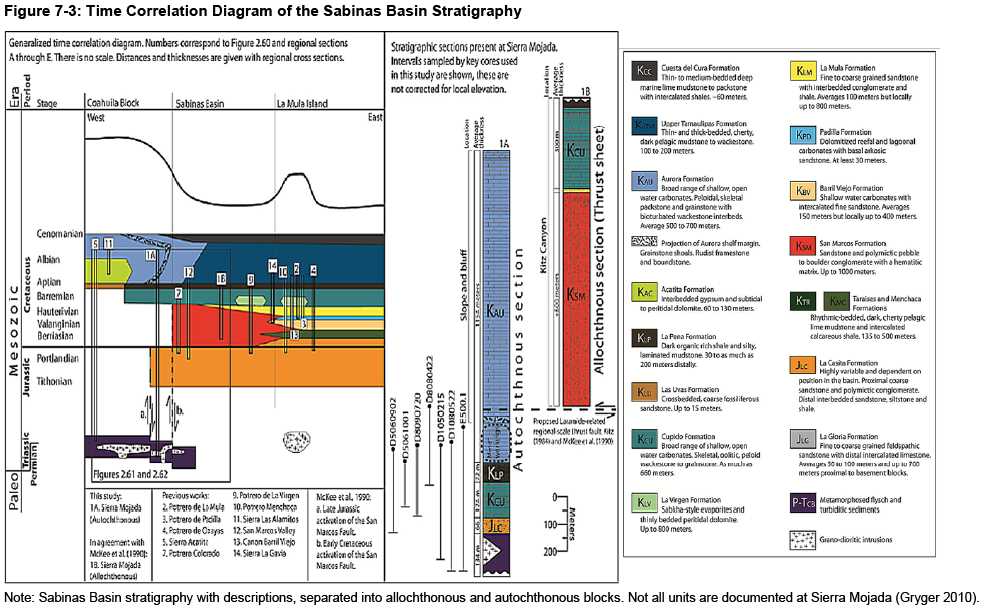

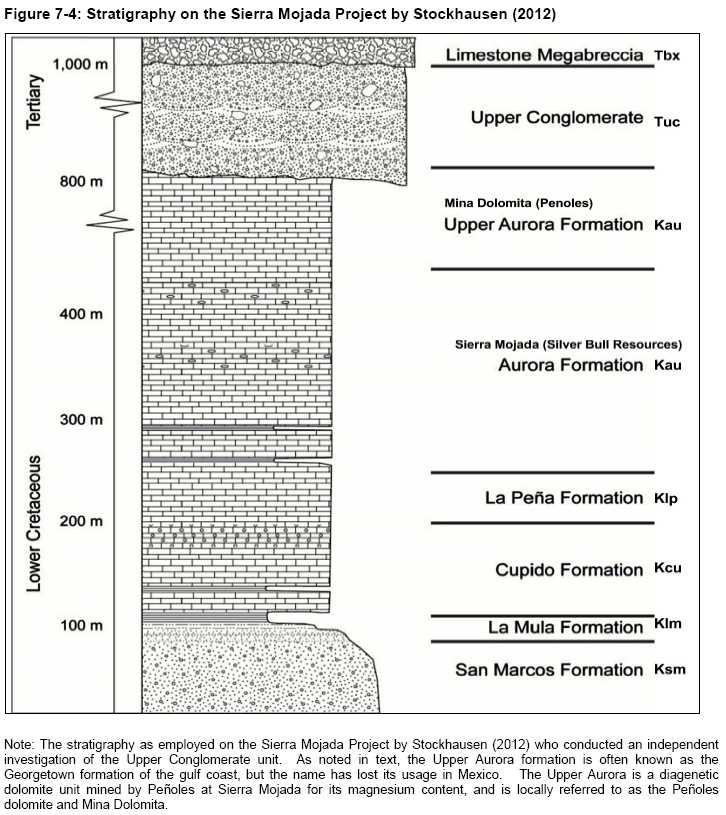

The rocks at Sierra Mojada record an Early Cretaceous transgression beginning with subaerial redbeds and near shore beach sandstones followed by carbonate rocks deposited in shoal, lagoonal, shelf, and platform environments. At Sierra Mojada, Lower Cretaceous rocks are overlain by younger redbed and breccia units as shown by Gryger in Figure 7-3, which separates the regional stratigraphy into the allochthonous and autochthonous blocks.

Stockhausen (2012) refines the local stratigraphy as employed on the Sierra Mojada Project in Figure 7-4 and renames a distinct and local portion of what was historically called the Cretaceous San Marcos formation, as the Tertiary Upper Conglomerate.

Report Date: April 30, 2013

Effective Date: March 18, 2013

7.2.2 | Allochthonous Stratigraphy |

The San Marcos Formation has been described throughout Coahuila and has been the focus of several investigations in the Sierra Mojada district as noted by Stockhausen (2012). Regionally within the Coahuila terrain, the San Marcos Formation is up to 1,000m thick with the thickest sections present north of the San Marcos fault which indicates that this fault was active during deposition of the unit. In the Sierra Mojada district, the San Marcos Formation has a thickness of approximately 70m in drill core. The unit consists of Lower Cretaceous alluvial strata composed of conglomerates containing andesitic volcanic pebbles within a siliceous matrix and several meter thick siltstone units (Figure 7-4).

The La Mula Formation occurs throughout northeastern Mexico and forms an unconformable surface above the San Marcos Formation. The La Mula is believed to represent a change from an alluvial depositional environment to a near shore beach environment. In the Sierra Mojada district the La Mula Formation is known as the Sierra Mojada Sandstone (Figure 7-4). It crops out within an overturned sequence south of the town of Sierra Mojada and consists of fine- to medium-grained, subrounded to rounded, well sorted quartz sandstone up to 25m in thickness. The siliciclastic rocks of the La Mula and San Marcos Formations have been historically targeted for sediment-hosted stratiform copper deposits by several companies.

The Cupido Formation is the lowest stratigraphic carbonate unit of Mesozoic age throughout much of northeastern Mexico. In the Sierra Mojada district the contact between the La Mula Formation and the overlying Cupido Formation is gradational and is approximately 90m thick. The basal portion of the unit contains medium grey colored skeletal grainstone and wackestone with local mudstones that display a moderate degree of bioturbation. These strata are thought to have been deposited in restricted lagoonal and peritidal environments. The upper portion of the Cupido Formation at Sierra Mojada contains brown-grey packstones and grainstones with some oolitic lenses suggestive of deposition in a high energy shoal depositional environment.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 7.2.2.4 | Upper Conglomerate |

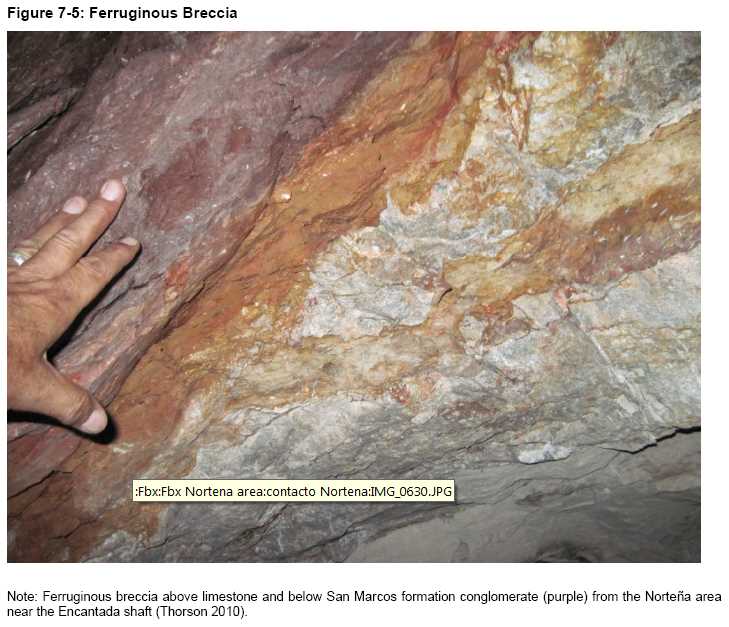

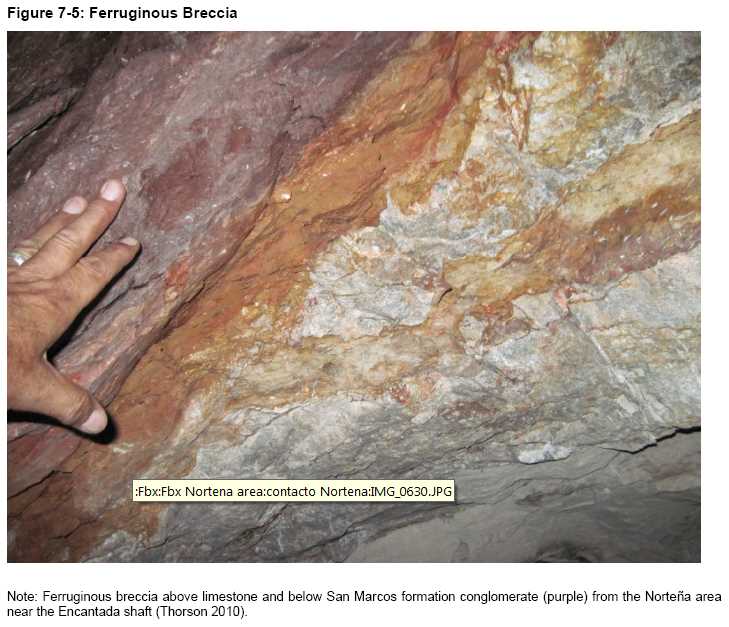

The Tertiary age Upper Conglomerate unit is arguably the most controversial lithology in the district (Figure 7-4). Various companies and authors have referred to the unit as the Menchaca formation, Upper San Marcos formation, ferrunginous breccia, limonite breccia, residual breccia, Ralph and "X". On the project, the Upper Conglomerate is defined and logged separately from the generic ferruginous breccia (Fbx) which is described as an alteration facies under section 7.4. The unit is significant in that it is a major host rock to high grade silver-copper mineralization in the Sierra Mojada district, Figure 7-5.

Stockhausen (2012) and Thorson (2010) refer to the Upper Conglomerate as an unconformable surface and interpret the unit to be a local scale, surface karst feature. Observations underground though, show a consistent association with low angle faulting. An alternative interpretation is that the unit is a karst surface-fault breccia related to the low-angle movement of the Sierra Mojada thrust (see section 7.3), with thicker sections represented by low-angle dilatational tension zones.

| 7.2.2.5 | Limestone Megabreccia |

The Limestone Megabreccia is the youngest stratigraphic unit observed at Sierra Mojada (Figure 74). The unit is a clast-supported breccia composed of variably weathered, angular to subrounded, pebble to boulder sized clasts of Aurora Formation and Upper Aurora Formation limestone in a matrix of calcite with lesser quartz. The Limestone Megabreccia differs from the Cretaceous carbonate units in displaying highly variable orientations of the limestone clasts and abundant joints, but does not appear to be cut by faults. Unlike Quaternary alluvium in the district, the Limestone Megabreccia contains only limestone blocks, lacks well-rounded clasts, contains minor to no shale to silt matrix material, and has a much higher resistance to weathering. It is separated from the Upper Conglomerate by a detachment or low angle fault.

| 7.2.3 | Autochthonous Stratigraphy |

| 7.2.3.1 | Coahuila Basement Complex |

Within the Coahuila basement complex at Sierra Mojada, the project lies at the juxtaposition of three important litho-tectonic elements; the Permian-Triassic Coahuila basement block, the Cretaceous Sabinas Basin, and the San Marcos-Rio Bravo Triassic-Tertiary transcurrent fault zone and associated conjugate structures. The Rio Bravo fault zone is also known as the La Babia fault zone.

The La Casita formation is not known in the Sierra Mojada district, but is well- known in the regional stratigraphy.

Report Date: April 30, 2013

Effective Date: March 18, 2013

The Cupido formation in the autochthonous block is the same lagoonal-peritidal facies as in the allochthonous block.

The La Pena Formation overlies the Cupido Formation throughout northern Mexico. In the Sierra Mojada district the formation consists of a series of coarsening-upward cyclical limestone units. The base of each cycle is typically a dark grey to black colored carbonaceous mudstone. Tops of individual cycles generally are brownish grey packstone or wackstone with coarser-grained strata and often contain large fossils. The upper portion of the La Pena Formation is less fossiliferous and consists of thick beds of light grey packstone and wackestone. The total thickness of the La Pena

Report Date: April 30, 2013

Effective Date: March 18, 2013

Formation at Sierra Mojada is approximately 60m. The cyclical nature and relative abundance of argillaceous material in the La Pena Formation carbonate rocks at Sierra Mojada suggest that they were deposited in a lagoonal environment.

The overlying Aurora Formation is the principal host rock for the sulfide and oxide mineral deposits at Sierra Mojada (Figure 7-4). The Aurora Formation crops out along the cliffs at the southern boundary of the Sierra Mojada valley. Structural deformation of the Aurora Formation at Sierra Mojada has made it difficult to determine the total thickness of the unit and it is thermally metamorphosed in thin section throughout the district. However geological mapping and drill sections suggest it has a thickness of approximately 500m. The basal portion of the Aurora Formation contains mostly grey to brown micritic mudstone and wackestone with some fine-grained fossil debris. The basal portion of the formation grades upwards to distinctly more fossiliferous, medium grey wackestone and grainstone with discontinuous intervals containing lobate chert nodules and minor mudstone. The Aurora Formation sequence is typical of open marine platform to shallow slope environments.

The Aurora Formation at Sierra Mojada is overlain by the Upper Aurora Formation. This unit contains fossiliferous grainstone and wackestone similar to much of the limestone in the Aurora Formation. The unit has previously been termed the Georgetown Formation in some reports (Hodder, 2001, internal report.). However, the Georgetown Formation is the stratigraphic equivalent to the Upper Aurora Formation along the Texas Gulf coast and this nomenclature is general not utilized in northeastern Mexico The Upper Aurora is regionally a diagenetic dolomite and is locally referred to as the Penoles Dolomite due to the local open pit magnesia mine operated by Penoles known as Mina Dolomita. There is no metallic mineralization know to be associated with this unit besides the magnesium.

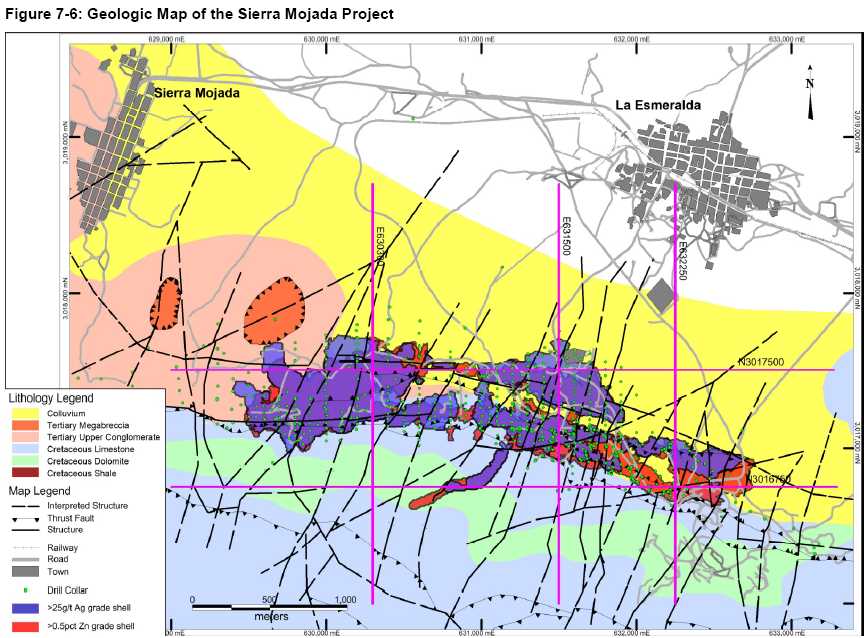

| 7.3 | Sierra Mojada Structure |

The Sierra Mojada district is dominated by three sets of structures, each with a unique influence on the geology and mineralization of the project. These structures are related to the San Marcos-La Babia shear couple regionally and later basin-and-range extension (Figure 7-6) and locally present a structurally "dense" architecture which has had a profound influence in the amount and styles of mineralization present.

The San Marcos fault zone is the oldest fault present in the district. The San Marcos, regionally, records at least four separate movements from the Jurassic to the early Tertiary. From Jurassic through early Cretaceous time, the San Marcos recorded three separate periods of normal movement, down-dip and stepping basin-ward towards the north. In the Sierra Mojada district, the San Marcos faults strike N78 West and dips at 65 degrees to the North. The northern most, and most recent step records a 100m down-drop.

Report Date: April 30, 2013

Effective Date: March 18, 2013

During the Laramide Orogeny the San Marcos reactivated as a reverse fault, with left lateral-oblique slip movement from the northeast. Locally, this reverse movement is referred to as the Sierra Mojada thrust fault, due to the prominent exposures underground. Some observers have suggested that the low-angle structures represent a detachment surface. In the Sierra Mojada district, the reverse movement surface varies from 0 to 60 degrees to the north and "roles" in several locations, along with back thrusts dipping to the south. Offsets are from 6 to 45 meters. The early normal faults related to the San Marcos system are thus over-ridden by the later reverse movements. This period of reverse movement was noted on the La Babia fault zone on the north side of the Sabinas Basin.

Cutting the San Marcos structures are a series of northeast trending structures exemplified by the Callavasas, Parrena, and Veta Rica faults, which are believed to be conjugate structures related to the San Marcos-La Babia shear couple. Throughout northern Mexico, northeast structures are associated with mineralization from depth and at Sierra Mojada these northeast structures are believed to be the original sources of hydrothermal mineralization in the district. The northeast structures a typically normal and high angle, dipping 90 to 65 degrees and down-dropped to the southeast. Off sets are not well documented due to later structural off sets and mineralization.

The youngest structures in the district are normal high angle structures varying from 0 to 20 degrees strike, 90 to 55 degrees dip and are down-dropped to the east and west, forming a series of horst and graben structures across the district. These structures a believed to be related to basin-and- range movements and typically show offsets of 5 to 25 meters. The North-South structures are important at Sierra Mojada as they are a major inheritor of remobilized supergene and oxide mineralization and many of the historic workings trace these structures.

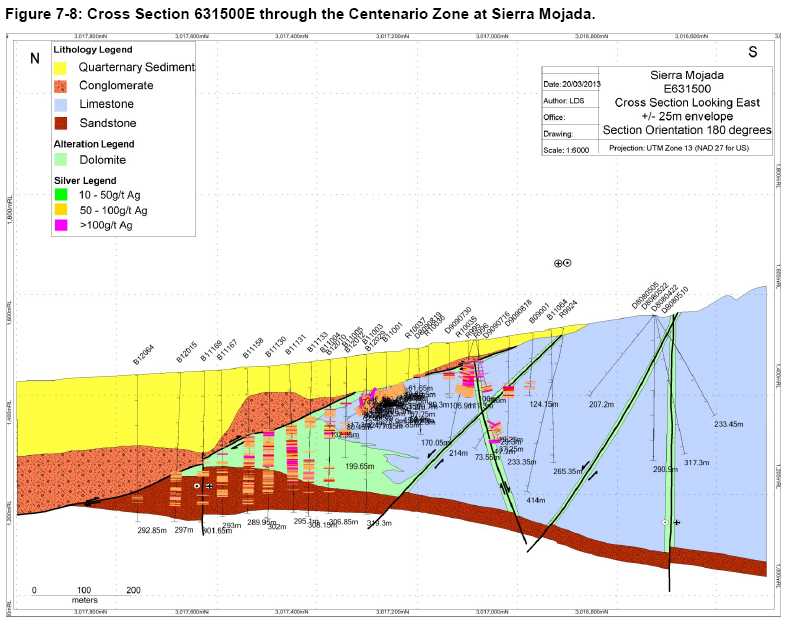

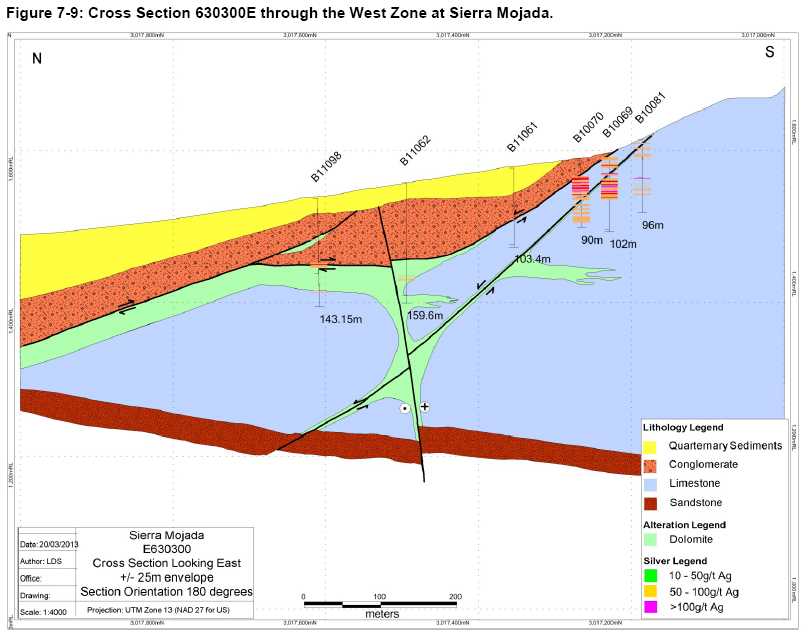

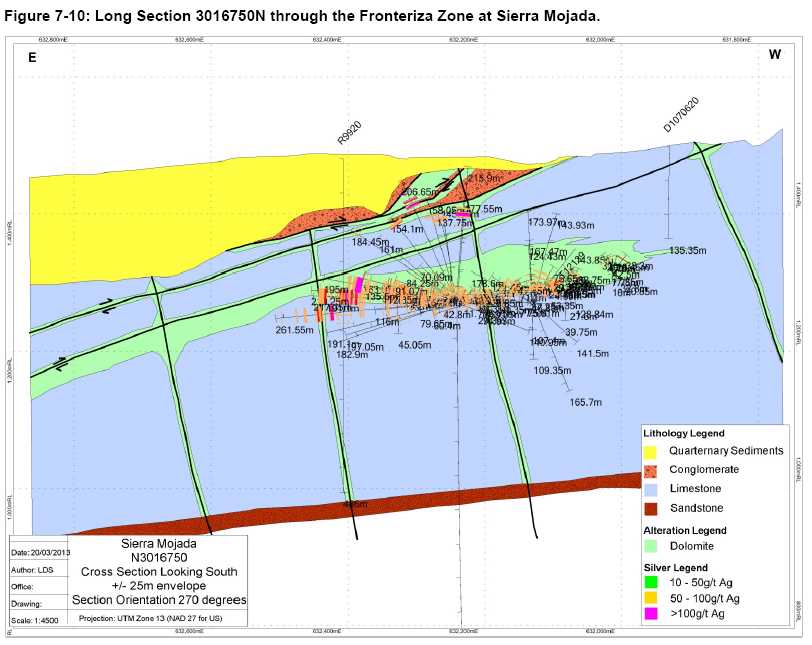

Figures 7-6 through 7-11 include a new and revised geologic map of the district with representative cross sections and long section through each of the three main portions of the mineralization.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

Report Date: April 30, 2013

Effective Date: March 18, 2013

| 7.4 | Hydrothermal and Supergene Alteration |

Diagenetic dolomite is well documented in the petroleum literature of northeastern Mexico, particularly in the Cretaceous section, and is of interest to petroleum and metals resource explorers due to the fact that the dolomitization process can increase the porosity of the unit by 15-20%. Against this backdrop, mineralization at Sierra Mojada is directly associated with extensive, hydrothermal dolomitization and moderate to strong silicification, both of which occurred prior to and during primary hypogene sulfide mineralization. The hydrothermal alteration observed at Sierra Mojada is typical of many high-temperature, carbonate-hosted Ag-Pb-Zn-(Cu) deposits in northern Mexico (Megaw et al., 1988). Stockhausen (2012) documents distinct zones of intense sericite alteration associated with sulfide mineralization. This has been interpreted to represent the distal expression of felsite intrusive activity.

To the east of the Sierra Mojada district the carbonate section has been pervasively dolomitized, apparently along northeast-trending faults. This area is the site of the active Penoles dolomite quarry. The Aurora Formation is also pervasively dolomitized in the western portion of the district, in the area of overturned section near the Sierra Mojada village. Diagenetic dolomitization represents the introduction of brines from adjacent evaporite-rich basins and is not known to carry base or precious metal mineralization but is believed to be part of the host rock preparation stage for later metals mineralization.

Irregular pods of completely hydrothermally altered dolomitized limestone surrounded by zones of partially diaigenetic dolomitized limestone occur in outcrop throughout the Sierra Mojada district. These dolomitized zones may be up to tens of meters thick and occur both along northeast- trending faults and along the upper contact of the carbonate section with overlying Upper Conglomerate. The Sierra Mojada sulfide bodies occur primarily but not exclusively within dolomitized horizons. Hydrothermal dolomite represents the influx of higher temperature hydrothermal fluids prior to and during hypogene sulfide mineralization. At Sierra Mojada, hydrothermal dolomitization is expressed by a distinct tan to pink colored, fracture controlled alteration throughout the district.

Two phases of silicification are noted at Sierra Mojada, an early pre- sulfide mineral phase, and a late syn- to post sulfide mineral phase. The early phase affects carbonate rocks throughout the Sierra Mojada district, especially those within or adjacent to fault zones, and display varying degrees of silicification and jasparoid development. Limestone clasts in tectonic, dolomite, and karst breccias are frequently pervasively replaced by very fine-grained, light grey to dark blue, anhedral quartz, something noted in all petrographic work conducted on the project.

Report Date: April 30, 2013

Effective Date: March 18, 2013

Early fine-grained silicified limestone is locally cut by later medium- to coarse-grained, subhedral quartz veins that occur along faults and at the contact with the Upper Conglomerate. This coarsegrained quartz is commonly associated with lead, zinc, silver, copper, and iron sulfide and oxide minerals and is spatially associated with zones containing iron- and magnesium-rich replacive carbonate minerals and sulfides or their oxidized products. Typically there is a decrease in silica content moving outward from the structures, something noted in the district dating back to 1901 (Chisholm 1901)

Silicification is not common within high-temperature, carbonate-hosted Ag-Pb-Zn-(Cu) deposits in northern Mexico and is only noted at the Charcas, Santa Eulalia, La Encantada, and Sierra Mojada deposits (Megaw et al., 1988).

Sericite is commonly present in the ferruginous breccia and within the Upper Conglomerate. Areas containing abundant sericite occur above northeast-trending faults near the historic Veta Rica workings and in the deeper working below the San Salvador and Fronteriza shaft areas. The formation of sericitized zones well-up into the Upper Conglomerate indicates that this alteration clearly post-dates the major period of sulfide mineralization at Sierra Mojada. Sericitization of the Upper Conglomerate and ferruginous breccia may represent continued movement of hydrothermal fluids, or a second phase of hydrothermal alteration, along and above major structural pathways.

Sericitization is relatively uncommon in the Mexican high-temperature, carbonate-hosted Ag-Pb- Zn-(Cu) deposits. One of the few deposits with significant sericitization is Santa Eulalia where igneous rocks along mineralized faults are altered to massive sericite with arsenopyrite (Megaw, pers. comm.).

Two phases of carbonate alteration are noted at Sierra Mojada, and early pre-and syn-mineral phase and a late phase associated with ongoing supergene processes. The hydrothermal dolomite found throughout the district is cut by a later assemblage of ferroan to magnesian-rich replacement carbonate minerals, which occur along northeast-trending faults and at the upper contact of the carbonate section. This assemblage of ankerite, siderite, and magnesite locally cuts and replaces diagenetic dolomite and previously undolomitized limestone.

The carbonate minerals are fine-grained and are relatively similar in grain size to earlier diagenetic dolomite. They display pink to red colors at surface but have a pale grey color where unoxidized. These carbonate minerals also may be enriched in lead and strontium and commonly display abundant very fine-grained dendritic manganese oxide minerals. The iron- and magnesium-rich carbonate minerals are intergrown with iron and base metal sulfides and barite indicating they were precipitated during the initial mineralization event (Renaud and Pietrzak, 2010,). The red and pink carbonate minerals are commonly intergrown with iron- and zinc-oxide minerals.

Report Date: April 30, 2013

Effective Date: March 18, 2013

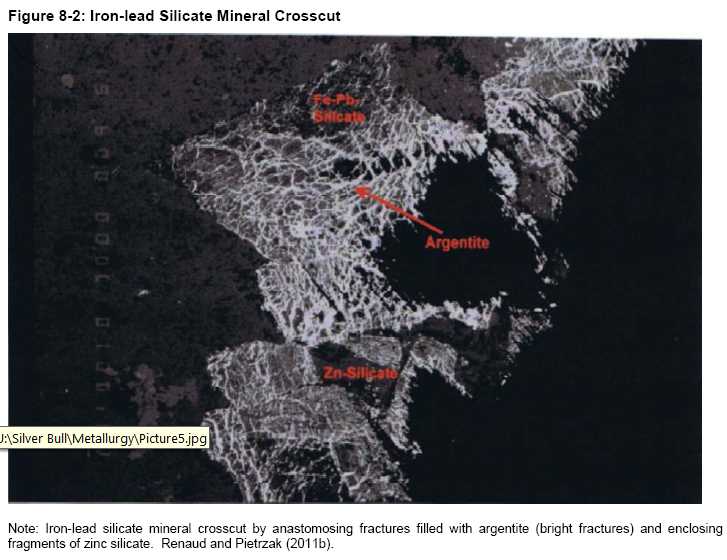

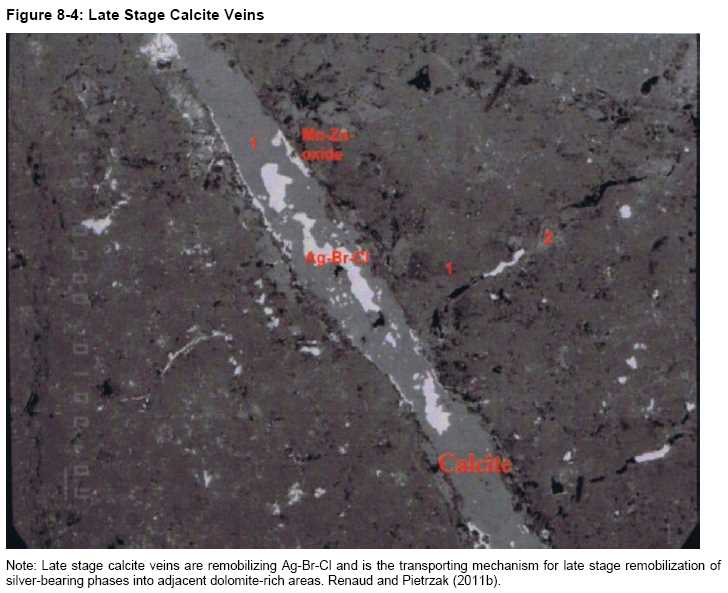

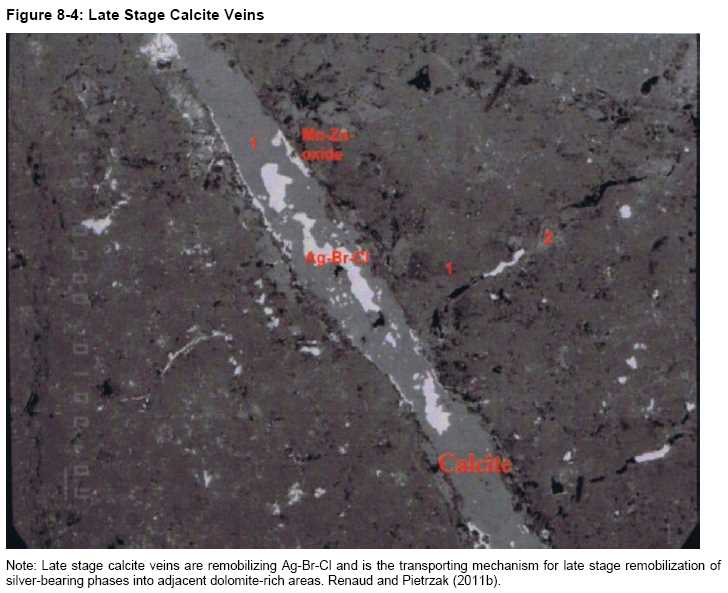

Late calcite veinlets occur throughout the Sierra Mojada district, but are most prevalent along the Sierra Mojada fault zone. The calcite veinlets are typically 1-20cm wide and cut carbonate rocks, the ferruginous breccia, and the Upper Conglomerate. The calcite in these veinlets is fine-grained, anhedral, and commonly intergrown with zinc-, lead-, and iron oxide minerals and acanthite; it may contain inclusions of barite (Renaud and Pietrzak, 2011). Coarse-grained calcite with normal to zincian compositions also locally replaces limestone, silicified limestone, dolomite, and iron- and magnesium-rich replacive carbonate rocks, as well as the matrix of the ferruginous breccia adjacent to zones containing late calcite veinlets. Calcite veinlets crosscut sericitized Upper Conglomerate rocks indicating that this alteration event occurred after sericitization. These calcite veinlets and replacive calcite zones were just recently formed and are interpreted to be ongoing supergene processes.

Argillic alteration zones are found throughout the Sierra Mojada district at the contact between Cretaceous carbonate rocks and the Upper Conglomerate. These light grey and tan to tan-brown zones are clay-rich. Based on x-ray diffraction (XRD) analyses these zones are composed of kaolinite, illite, and halloysite in addition to fine-grained quartz, limonite, hematite, and calcite. Tan- brown intervals contain more abundant clay relative to the light grey colored, fine-grained quartz- rich material. The ferruginous breccia contains varying abundances of interstitial kaolinite and illite with minor halloysite surrounding quartz and carbonate rock clasts, however the timing of formation of the ferruginous breccia and clay is unclear (Renaud and Pietrzak, 2010).

The Ferruginous Breccia is treated here as a distinct alteration facies even though in core logging it is treated as a separate lithology, due to its direct association with mineralization. The unit may actually be comprised of a mixture of Upper Conglomerate, Aurora Formation dolomite and limestone, karst breccia, and limonite breccia. Clasts of medium- to coarse-grained, sub-rounded limonite after sulfide contain elevated concentrations of silver and zinc. Clast shape suggests that they are detrital rather than representing in-situ sulfide precipitation. The presence of both sulfide- rich and oxide-rich clasts indicates that the ferruginous breccia formed after both the hydrothermal event responsible for sulfide precipitation and supergene weathering of portions of the sulfide replacement bodies.

The base of the ferruginous breccia is commonly highly irregular. Ferruginous breccia also fills fractures extending downward approximately 7m into the carbonate sequence. These fractures may contain large, angular, cobble-sized limestone and replacive carbonate mineral clasts. Additionally, the ferruginous breccia contains silicified carbonate clasts indicating that this finegrained silicification event took place prior to karstification. The ferruginous breccia also occurs beneath fine-grained travertine in karst cavities within the limestone sequence. Thus, the ferruginous breccia appears to represent both a surficial deposit formed by chemical and mechanical weathering of carbonate rocks and karst-fill material (Thorson, 2010).

Report Date: April 30, 2013

Effective Date: March 18, 2013

The ferruginous breccia is commonly overlain by the Upper Conglomerate. In some areas lenses of ferruginous breccia are interlayered with lenses of Upper Conglomerate suggesting these units formed synchronously. The ferruginous breccia has not been identified outside of the Sierra Mojada district.

The ferruginous breccia at Sierra Mojada is interpreted to represent surficial oxidation of exposed sulfide replacement bodies in the carbonate sequence as well as infill of karst cavities formed by both normal weathering and acid generated during sulfide oxidation.

Sierra Mojada consists of two important and diverse mineralizing models, accentuated by a locally dense structural architecture and are detailed in Chapter 8.0, Deposit Type:

| ● | Development of a major Carbonate Replacement Deposit (CRD) of lead-zinc-silver (copper), distal to the source intrusion. |

| ● | The oxidation, supergene enrichment, and second oxidation of the original sulfide deposit leading to the mineralization of current interest and resource development. |

There are essentially two overlapping mineralized sections to the Sierra Mojada district:

| ● | The Shallow Silver Zone (SSZ), also known as the Polymetallic manto of historic reference. |

| ● | The Base Metal Mantos (BMM). The BMM is subdivided into three further zones for descriptive purpose; the Pb Manto (Carbonate Manto of historic reference), the Red Zinc Manto (Iron Oxide Manto of historic reference), and the White Zinc Manto. |

The Shallow Silver Zone (SSZ), outcrops on the surface on the west end of the district and dips under colluvial cover towards the east at about 10-degrees. The zone is 3.3km in length, up to 1km in width, and 100 to 300m thick. The SSZ is hosted in breccias of the Tertiary Upper Conglomerate unit, the ferruginous breccia, and in reactive dolomite and limestone of the Cretaceous Aurora Formation. Significantly, mineralization is also controlled by the dense array of structures in the district. Due to these structural and lithologic controls, mineralization develops into four configurations:

| ● | Stratiform mantos, primarily in reactive dolomite horizons and associated karst breccia features. |

| ● | High-grade (>100g/t) veins, primarily faults and chimneys related to the mixed structural architecture of low angle and high angle faults. |

| ● | Unconformity controlled breccia mineralization related to the Cretaceous-Tertiary weathering surface, although the unconformity demonstrates low-angle movement in many localities. |

| ● | Disseminated replacement mineralization between the mantos and structures. |

Report Date: April 30, 2013

Effective Date: March 18, 2013

Silver mineralization is dominated by acanthite, the silver halide solid solution bromargyite - clorargyrite, and argentiferous tennantite. Silver mineralization shows a close affinity to the gangue minerals of barite, and celestine. As noted by Wyss (2013) the bromargyrite grains are consistently larger than the acanthite grains varying according to location in the three mineralized silver zones of Fronteriza, Centenario, and the West End.

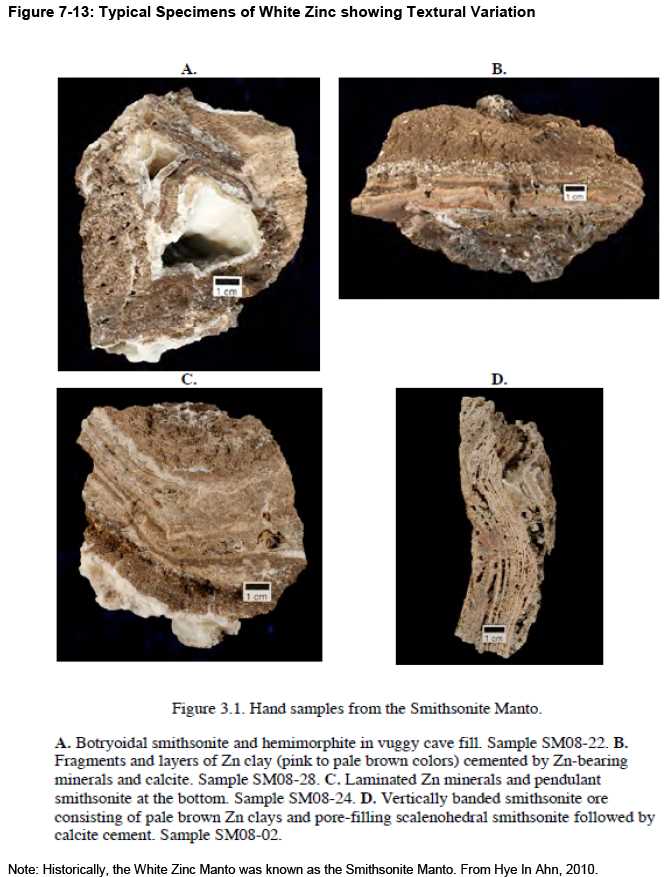

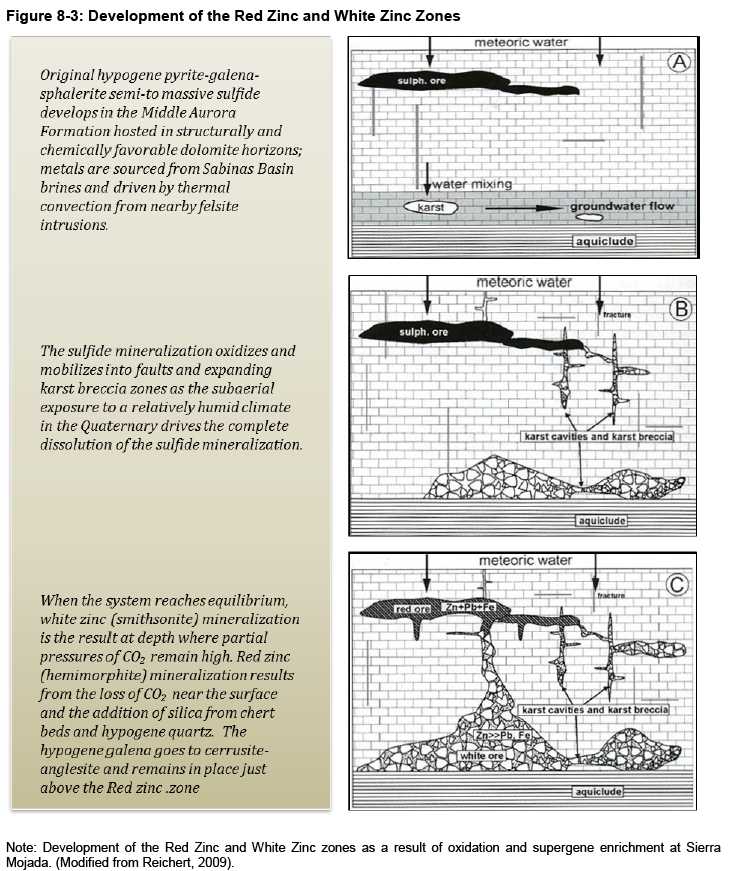

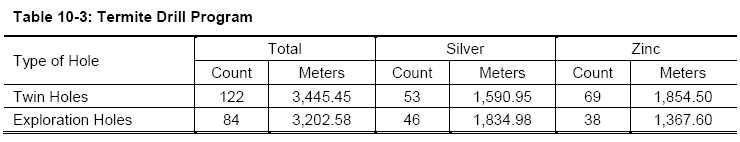

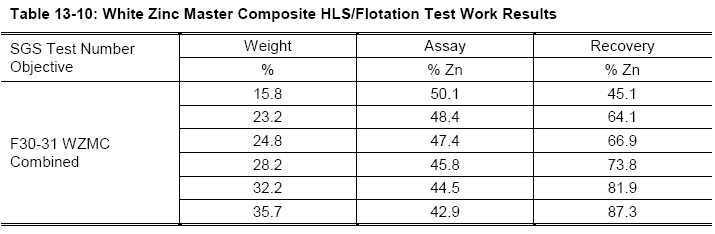

| 7.5.2 | Base Metal Mineralization |