| | Listed on the NASDAQ Price (03/31/2008)Revenues (ttm to 12/31/2007)Net Income (ttm to 12/31/2007)Market Capitalization52-Week High/LowShares Outstanding (as of 12/31/2007)Fiscal YearCorporate HeadquartersWebsite | | CPSL $3.80$65.7 million$7.7 million$174.4 million$12.65 / $2.5845.89 millionJune 30thShanghai, Chinahttp://www.chinaprecisionsteelinc.com |

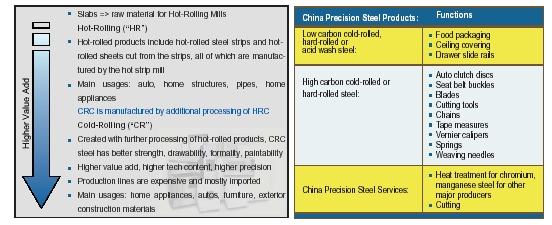

China Precision Steel (CPS) is a niche and high value-added steel processing company that takes commodity steel and creates a specialty premium steel which yields above industry gross margins. The Company produces and sells high precision ultra-thin (7.5 mm ~ 0.03 mm) cold-rolled steel products and provides heat treatment and cutting for medium and high carbon hot-rolled steel strips. Specialty precision steel pertains to the precision of measurements and tolerances of thickness, shape, width, surface finish, and other special quality features of highly engineered end use applications such as automobile components, saw blades, weaving needles, packing and containers, and microelectronics. CPS primarily sells its products domestically, but has recently begun exporting to Nigeria, Thailand, Indonesia and the Philippines and plans to continue building its export business in order to become recognized as an international competitor in ultra-thin steel.

| | |

| | | |

| | Rapidly Growing Niche Segment - For the past five years, demand for precision steel has been growing 20% annually. Export demand coupled with nationwide demand for automobile parts and components, saw blades, weaving needles, microelectronics, packing and containers in China's booming economy are expected to continue, which will result in increasing demand for high precision steel products. Moreover, new applications of steel products are continually being developed. For instance, in the automobile industry, thinner sheets of high strength steel are increasingly being used to reduce a vehicle’s weight without compromising its safety. |

| | | |

| | Developing Leadership Position in China - Specialty precision steel is a relatively new industry in China with the majority of precision steel imported from Japan, Korea, the European Union and the United States. As a result, the average quality and standards of China's high precision steel industry lags behind the international norm. CPS has taken the leadership position in China for producing specialty precision steel similar to international standards. It represents 50-70% of the market share from domestic companies and about 10% of the total market. The Company has invested in state-of-the-art patented technology process which enables it to produce high quality products as it builds a nationally recognized brand. |

| | | |

| | Focus on High Margin Products - CPS has increased its gross margin from 5.8% in 2004 to 20% in the first quarter of 2008. The average gross margin of its high carbon steel is 20-40% and for its low carbon steel products is 10-30%. In addition, the Company provides additional services such as heat treatment and cutting which further enhance their margins. The high gross margins are sustainable despite fluctuations in steel prices because of the specialty of the end product which allows price increases of raw material to be passed directly to the client. |

| | | |

| | Expanding Manufacturing - CPS completed a 1400 mm cold rolling mill in August, 2006. The Company plans to commence the installation of a second 1700 mm cold rolling mill by the first calendar quarter of 2008. The two mills will increase CPS’s capacity by 300,000 tons per year bringing total annual capacity to 400,000 tons (actual tonnage may vary depending on the product mix due to different processing time). Both rolling mills will produce high quality and more complex precision cold-rolled steel products. |

| | Competitive Internationally--High Barriers to Entry for Domestic Competitors - CPS has strong advantages over both its international and domestic competitors. CPS is committed to providing high value-added specialty steel products that are not only manufactured using an advance patented technology process but are also developed in close association with their customers creating high barriers to entry. Few domestic companies have the technology and experience to provide high quality cold-rolled steel. Moreover, CPS is the only domestic company with the ability to produce sheets with width greater than 1000 mm and 2.5 mm in thickness. Compared to other international companies, CPS’s lower costs allow it to sell its products on average 10% less than its international competitors with shorter delivery time and custom specifications. |

| · China’s Steel Industry | | |

| | | |

| | | In 2006, China strengthened its position as the largest steel producing country in the world, increasing its crude steel production by 17.7% to a record 418.8 million tones, more than three and a half times the second larger steel producer, Japan. In 2006, Japan’s production of crude steel was 116.2 million tones. In the first months of 2007, China’s steel production was 408.5 million tones. While China is a net exporter of crude steel with 4.5 million tons exported in 2006, it is a net importer of higher value precision steel and ultra-thin steel. |

| | | |

| | | Steel products are categorized as low-end (long products such as pipes, tubes, wires and rods) and high end (flat products such as hot-rolled steel or cold-rolled steel sheets). Based on information derived from China Metallurgical Institute (CMI), about 65% of China’s steel production is low-end long products with the balance of 35% being high-end high-value cold-rolled steel sheets. |

| | | |

| | | Demand for ultra-thin steel products is estimated to be about 2 million metric tons. Because precision steel is a relatively new industry in China, the average quality and standards of China’s high precision steel production lag behind the international norm. China's manufacturers subsequently have to import millions of tons of cold-rolled steel rolls and sheets from Japan, Korea, the European Union and the United States. Imports represent the majority of China’s cold-rolled steel market at 85% - 90% with domestic companies representing less than 15% of the market. |

| | | |

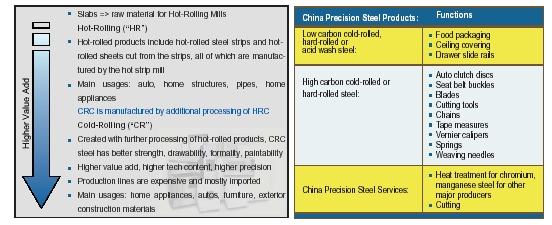

| | | · Low carbon steel - is steel with carbon content of less than 0.1%. It is a very versatile and useful material, easily worked into complex shapes and has low cost and good mechanical properties. · Medium carbon steel - is steel with carbon content of 0.3% and is a typical engineered steel product. · High carbon steel - is hard-rolled or cold-rolled steel with a carbon content of 0.8% or more. The increased strength is in direct relation to the carbon content. This precision steel product is very hard, quite brittle and much less ductile than low carbon steel. High carbon steel has good wear resistance, and is used for railways as well as for cutting tools. |

| | | |

| · Growth Strategy | | |

| | | |

| | | China Precision Steel has switched from producing lower priced steel products to higher priced, higher margin specialty steel products as a result of continuous R&D and accumulated experience. The ultra-thin cold-rolled precision steel strips are produced using a patented technology process and range from a thickness of 7.5 mm to 0.03 mm, or as thin as a third of a human hair, and a width of 1000 mm to 1400 mm. The Company’s heat treatment and cutting is for medium and high carbon hot-rolled steel strips not exceeding 3.0 millimeters. |

| | | |

| | | One of CPS competitive strengths is that it is the only company in the world that manufactures ultra-thin steel with a width of 1400 mm. Width is an important differentiation factor because certain end products such as washers and automobiles require materials with a certain minimum width. Although materials with smaller width could also be used for these applications through jointing, this increases production cost. Wider products therefore are more flexible and cost efficient which further reduces the end user’s overall cost. |

| | | CPS has established relationships with major steel companies such as Baosteel, POSCO and JFE for hot-rolled steel. Boasteel is a strategic long-term supplier as well as customer of CPS. Currently, CPS's specialty precision products are mainly used in the manufacturing of automobile parts and components, saw blades, weaving needles, microelectronics, packing and containers. |

| | | |

| | | CPS’s growth is derived from multiple sources, including: |

| | | |

| | · Increased orders from current customers · Taking market share from international competitors · Developing new products for use in automobiles. Specifically, it is developing steel products for vibration damping pads and seat belt springs, both of which require more sophisticated processing and generate higher margins · Increasing exports |

| | | |

| · Products | | |

| | | |

| | | Cold-rolled steel products represent hot-rolled de-scaled (pickled) steel coils which have been processed by cold reduction through a cold-rolling mill to the desired thinness. The primary feature of cold reduction is to reduce the thickness of the steel coils. There is no heating involved. Because the cold reduction operation induces very high strains (work hardening) into the steel sheet, the precision steel sheet not only becomes thinner, but also becomes much harder, less ductile and very difficult to form. Thus cold-reduced steel products are annealed (heated to high temperatures) to become soft and formable. Cold-rolled sheet products are used in a wide variety of end applications such as appliances (refrigerators, washers, dryers, and other small appliances), automobiles (exposed as well as unexposed parts), electric motors and bathtubs. |

| | | |

| | | Hard-rolled steel represents steel products manufactured from cold reduction to the desired thinness without annealing. The product is very stiff; it is intended for flat work where deformation is very minimal. This type of hard-rolled steel is most often applied to further processing for applications such as continuous galvanizing. |

| | | |

| | | Acid wash steel is also known as the acid pickling and refers to the process of using liquid acids, for example hydrochloric acid, to remove rust or oxides from the surface of steel which prepares the surface for a protective coating. |

| | | |

| | | CPS manufactures approximately 40 different types of precision steel products with a range of over one hundred specifications. |

| | | |

· Expanding Capacity | | |

| | | |

| | At the start of 2006, CPS had an annual production capacity of approximately 100,000 tons. In August 2006, CPS completed a new production facility which increased the production area by approximately 10,000 m2. At that time, CPS also installed a 1400 mm cold-rolling mill at its new production facilities which added an additional 150,000 tons to the annual production capacity. The Company intends to install another 1700 mm width cold-rolling mill by the end of 2007. Once all of the equipment (1400 mm width and 1700 mm width cold-rolling mills) is installed in the new production facilities, CPS's annual production capacity will increase to 400,000 tons. The increased production capacity is expected to be fully utilized within two to three years after commencement of operation. The two additional rolling mills are able to produce high carbon, high strength cold-rolled steel products and more complex precision steel products. |

| | | |

· Research and Development | | |

| | | |

| | China Precision Steel’s research and development is focused on advancing processing techniques and production of ultra thin, high strength cold-rolled precision steel product with a ratio of width to thickness of 10,000 times. The Company protects its processing techniques through a combination of patented bearing and internal know-how. In addition to traditional research and development activities, the engineers constantly interact with customers to detect changing patterns in end products and develop products to customer’s specifications. |

| | | |

· Quality Control | | |

| | | |

| | Following the accreditation of the International Organization for Standardization ("ISO") Technical Standards ("TS") 16949 on October 8, 2004, CPS implemented the Quality Handbook in October 2004. This Quality Handbook was prepared on the basis and standards of ISO/TS 16949, which are compatible with existing American (QS-9000), German (VDA6.1), French (EAQF) and Italian (AVSQ) automotive quality system standards within the global automotive industry. Together with ISO 9001:2000, ISO/TS 16949 specifies the quality system requirements for the design, development, production, installation and servicing of automotive related products. |

| | | |

· Sales and Marketing | | |

| | | |

| | China Precision Steel’s high precision steel products are sold directly to the end users in various parts of China. Due to the nature of the industry, CPS does very little marketing. The majority of new orders come from current customers reducing imports and new customers who contact CPS based the Company’s industry reputation. All of CPS’s production is based on confirmed sales orders. Generally, an initial deposit (approximately 30% of the aggregate contracted sales amount) is pre-paid when the contract is signed. CPS has approximately 200 major customers who are primarily located in East China. CPS’s location in Shanghai is particularly advantageous in that customers can easily meet with the Company to discuss product design and the delivery time is shorter with lower associated cost than international competitors. The Company intends to increase its customer base by expanding into the lucrative markets in Guangdong Province where there is a heavy concentration of light industries and into the Northeastern region of China where the automotive industries are concentrated. |

· Management Team | | |

| | | |

| | Mr. Wo Hing Li. Chairman and Executive Director |

| | | |

| | Mr. Li has been the Chairman and Executive Director of China Precision Steel and its subsidiaries since their formation in July 2002. Mr. Li is also a Non-executive Director of China Petrotech Holdings Limited, an oil software and exploration company listed on the Singapore Stock Exchange. Since October 2001, Mr. Li has served as a director of Medical China Limited, a company listed on the GEM Board of Hong Kong Stock Exchange. From 1997 to 2001, Mr. Li served as a director of Teda (HK) Holdings Limited. Mr. Li served in various positions within the Grand Finance Group between 1984 and 1997, serving the last seven years as the General Manager of its subsidiary, Grand International (China) Investment Holding Co., Limited. Mr. Li has an MBA from Murdoch University of Australia, and a PhD in Management, a program co-organized by the University of International Business & Economics of China and the European University of Ireland. |

| | | |

| | | Mr. Hai Sheng Chen, Executive Director and General Manager |

| | | |

| | | Mr. Chen is one of the founders of CPS and has been the General Manager since July 2002. From July 2001 to July 2002, Mr. Chen was the Managing Director of Shanghai Krupp Stainless Steel Co. Limited, a steel processing company. From August 1999 to May 2001, Mr. Chen was the Deputy General Manager of PuDong Steel Co. Limited, a subsidiary of the Baosteel Group, a major steel processing company. Mr. Chen has an Executive MBA Degree from China Europe International Business School and a Bachelors Degree in Metallic Pressure Processing from the Beijing University of Science and Technologies. |

| | | |

| | | Leada Tak Tai Li, Chief Financial Officer |

| | | |

| | | Ms. Li is responsible for overseeing the financial and administrative matters of CPS. From June 2004 to October 2005, Ms. Li was Assistant to the Chairman of STAR Pharmaceutical Limited, a pharmaceutical manufacturing company listed on the main board of the Singapore Stock Exchange. At STAR Pharmaceutical Limited, Ms. Li was responsible for investor relations and assisting in the annual audits. From November 2003 to May 2004, Ms. Li was an audit assistant at KPMG, Hong Kong. From January 2002 to September 2002, Ms. Li was an Investment Analyst at Suez Asia Holdings (HK) Limited. Ms. Li holds a Bachelor of Commerce Degree with a dual major in Accounting and Finance from the University of Melbourne in Australia and a Master of Science Degree in Accounting and Finance from the Napier University in the United Kingdom. |

| | | |

| | | Gou Di Lu, Deputy General Manager |

| | | |

| | | Mr. Lu has been the Assistant to the General Manager of CPS since July 2002. Mr. Lu served as Department Head of the Quality Control Department of Shanghai Pudong Steel Group, Ltd. from November 1998 to July 2002. Mr. Lu holds a Bachelor Degree in Business Administration from Shanghai No. 2 University of Industry and a Bachelor Degree in metallic pressure processing from Shanghai Metallurgical College. |

· Selected Financial Data

| | | Six Months Ended December 31 | | Year Ended June 30, | |

| | 2007 | | 2006 | | 2007 | | 2006 | | 2005 | |

| | unaudited | | unaudited | | | | | | | |

Sales | | $ | 37,226,416 | | $ | 25,510,930 | | $ | 53,960,243 | | $ | 34,881,141 | | $ | 53,144,601 | |

| Cost of goods sold | | | 28,773,987 | | | 18,394,950 | | | 38,925,987 | | | 24,892,154 | | | 45,562,070 | |

Gross Profit | | | 8,452,429 | | | 7,115,980 | | | 15,034,256 | | | 9,988,987 | | | 7,582,531 | |

| Selling Expenses | | | 281,449 | | | 104,390 | | | 245,695 | | | 122,220 | | | 86,592 | |

| G&A Expenses | | | 1,332,595 | | | 684,925 | | | 1,863,994 | | | 505,764 | | | 544,171 | |

| Provision for bad debts | | | 651,780 | | | | | | 3,775,645 | | | | | | | |

| Depreciation and amortization | | | 29,430 | | | 21,262 | | | 44,375 | | | 40,005 | | | 142,127 | |

| Total Expenses | | | 2,295,254 | | | 810,577 | | | 5,929,709 | | | 667,989 | | | 772,890 | |

Income from Operations | | | 6,157,175 | | | 6,305,403 | | | 9,104,547 | | | 9,320,998 | | | 6,809,641 | |

| Other revenues | | | 792,410 | | | | | | 103,388 | | | | | | 12,077 | |

| Interest and finance costs | | | (759,001 | ) | | (318,082 | ) | | (312,222 | ) | | (271,693 | ) | | (455,277 | ) |

| Other expenese | | | | | | | | | (1,362 | ) | | | | | | |

| Total other income (expenses) | | | 33,409 | | | (318,082 | ) | | (210,196 | ) | | (271,693 | ) | | (443,200 | ) |

EBT | | | 6,190,584 | | | 5,987,321 | | | 8,894,351 | | | 9,049,305 | | | 6,366,441 | |

| Provision for taxes | | | 928,989 | | | 809,908 | | | 1,421,690 | | | 1,535,204 | | | | |

| Net income before discontinued operations | | | 5,261,595 | | | 5,177,413 | | | 7,472,661 | | | 7,514,101 | | | 6,366,441 | |

| Net income from discontinued operations | | | | | | 639,072 | | | 831,448 | | | 900,469 | | | (340,586 | ) |

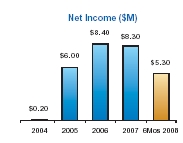

Net Income | | $ | 5,261,595 | | $ | 5,816,485 | | $ | 8,304,109 | | $ | 8,414,570 | | $ | 6,025,855 | |

| Basic earnings per share | | | 0.13 | | | 0.22 | | | 0.29 | | | 0.35 | | | 0.25 | |

| Basic weighted average shares outstanding | | | 40,204,745 | | | 26,981,916 | | | 28,438,313 | | | 24,283,725 | | | 24,283,725 | |

| Diluted earnings per share | | | 0.13 | | | 0.22 | | | 0.29 | | | 0.35 | | | 0.25 | |

| Diluted weighted average shares outstanding | | | 40,809,437 | | | 26,981,916 | | | 28,759,553 | | | 24,283,725 | | | 24,283,725 | |

Selected Balance Sheet Data | | 30-Dec-07 | | 30-Sep-07 | |

| | unaudited | | unaudited | |

| Cash and equivalents | | | 40,205,111 | | | 6,049,792 | |

| Total current assets | | | 97,269,778 | | | 54,399,585 | |

| Total assets | | | 142,974,646 | | | 96,111,876 | |

| Total current liabilities | | | 40,446,345 | | | 35,204,175 | |

| Working capital | | | 56,823,433 | | | 19,195,410 | |

| Total stockholders' equity | | | 100,213,232 | | | 54,898,812 | |

· For Further Information

| Company Contact | | Investor Relations Contact | | |

| Leada Li | | Crocker Coulson | | Leslie Richardson |

| Chief Financial Officer | | President | | Financial Writer |

| Email: leadali@biznetvigator.com | | Tel: +1-646-213-1915 | | Tel: +1-310-231-8600 |

| | | Email: crocker.coulson@ccgir.com | | Email: leslie.richardson@ccgir.com |

| Business Risks and Forward-Looking Statements |

| |

| Safe Harbor Statement Under the Private Securities Litigation Reform Act of 1995: Any statements set forth above that are not historical facts are forward looking statements that involve risks and uncertainties that could cause actual results to differ materially from those in the forward-looking statements, which may include, but are not limited to, such factors as industry cyclicality and over capacity, increased price of raw materials, increased cost related to environmental compliance, ability to compete with international steel companies, and other information detailed from time to time in the Company’s filings and future filings with the United States Securities and Exchange Commission. |

| | |

| Readers are advised that this information is intended for the use of investment professionals. Anyone interested in obtaining information on the Company should contact China Precision Steel or CCG, as set forth above, to receive the Company’s most recent financial reports. This Financial Profile of China Precision Steel was developed by the Company and is intended solely for informational purposes and is not to be construed as an offer to sell or the solicitation of an offer to buy the Company’s stock. This Profile is based upon information available to the public, as well as other information from sources which management believes to be reliable, but is not guaranteed by China Precision Steel as being accurate nor does it purport to be complete. Opinions expressed herein are those of management as of the date of publication and are subject to change without notice. |