Exhibit 99.1

| Steve Winter President & COO Baird’s 2007 Growth Stock Conference: May 9, 2007 |

| Safe Harbor Statement Statements in this presentation that express our intentions, hopes, beliefs, indications, expectations, forecasts or predictions of the future constitute forward-looking statements. They include, without limitation, statements about: maintaining or improving our revenues, gross margins or profits, for the current period or any future period; competing effectively with our current products and planned products, and introducing new products; completing restructuring activities; maintaining or reducing expenses; increasing product development capacity; and using our research and development investment to generate future revenue. Forward-looking statements involve and are dependent upon certain risks and uncertainties and are not guarantees of future performance. We undertake no obligation to publicly update or revise any forward-looking statement after the date on which it is made, for any reason. A more complete description of what we consider to be forward looking statements, and about the factors that could cause our actual results to differ materially from those expressed or implied in a forward-looking statement, is contained in our press releases and in our SEC filings, including Form 10-K for the year ended December 31, 2006, and our subsequent reports on Form 10-Q. Copies of these filings may be obtained by contacting us or the SEC. |

| The Technology Leader in Transition |

| Data Capture Core Technologies Conventional AIDC: Laser Scanning Linear Imaging Area Imaging Emerging Technology: RFID |

| Major Performance Improvement in Laser Scanning Enabled Transition from Competitor Supplied Product Advantages of MEMS: Speed Maintainability Ease of Use Micro-Electromechanical Systems (“MEMS”) |

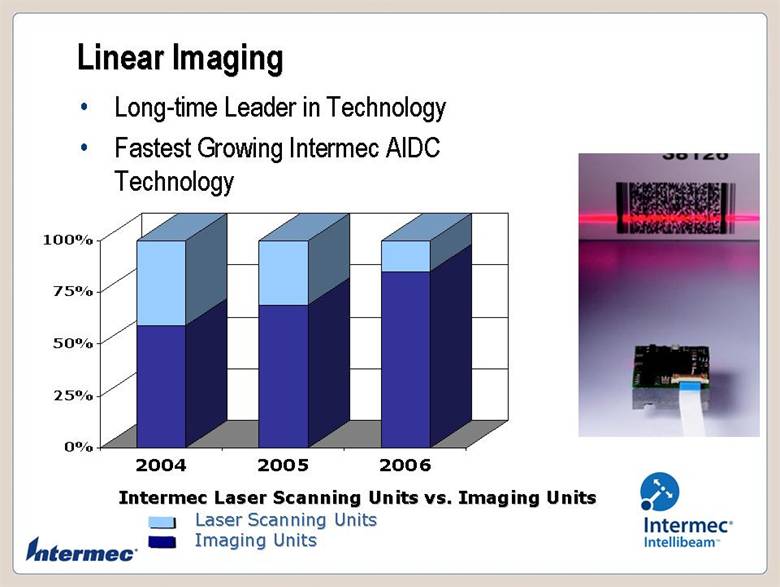

| Long-time Leader in Technology Fastest Growing Intermec AIDC Technology Linear Imaging Intermec Laser Scanning Units vs. Imaging Units Laser Scanning Units Imaging Units 0% 25% 50% 75% 100% 2004 2005 2006 |

| Area Imaging Accommodates Rising Popularity of 2D & Increasing Data Content Image Capture Capability feeds need for Contextual Information Can Read and Decode Bar Codes in any Orientation Reduces worker fatigue and increases productivity Auto-Focus dramatically expands Read Ranges |

| Transferring Technology Leadership Product Innovation Most Integrated Radio Options Available GPRS & CDMA WWAN WiFi WLAN Bluetooth GPS 2D Imager & Color Camera CN3 Rugged Mobile Computer |

| Best in class flexibility, delivers real-time wireless supply chain management Smallest full-screen footprint Improves forklift safety by increasing driver visibility CV30 – Rugged Fixed Mount Computer Transferring Technology Leadership Product Innovation |

| Transferring Technology Leadership Product Innovation First near-far scan engine to read 1D, 2D, composite and postal codes, eliminating need for multiple scanners Imaging capabilities capture photos of damaged, expired or unsealed goods and proof-of-delivery documents EX25 - Area Imaging Technology |

| Transferring Technology Leadership Product Innovation “Store & Forward” Capabilities Ensure Data Won’t Be Lost Intel Celeron Processor – Ample Storage to Run Complex RFID Applications Host Applications Written in Java, Java Script or C# . Net Based on EPCglobal Certified Radio IF61 - RFID Enterprise Reader |

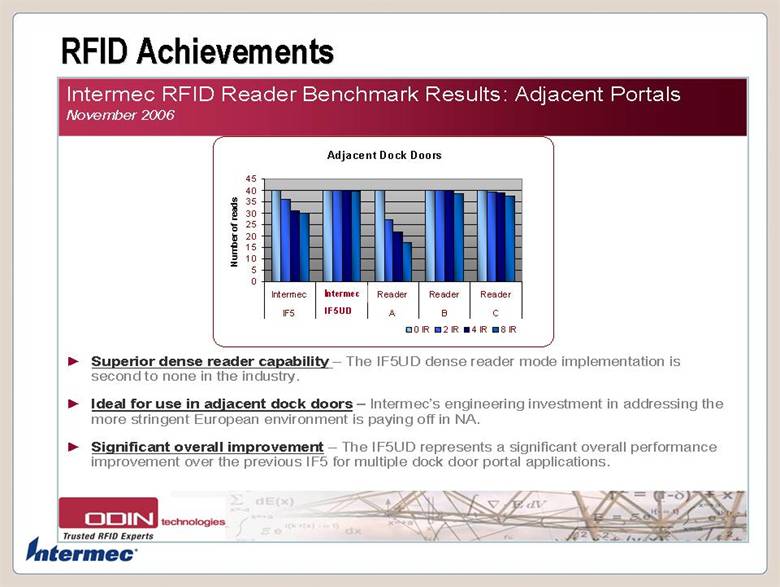

| RFID Achievements Intermec RFID Reader Benchmark Results: Adjacent Portals November 2006 Superior dense reader capability – The IF5UD dense reader mode implementation is second to none in the industry. Ideal for use in adjacent dock doors – Intermec ’ s engineering investment in addressing the more stringent European environment is paying off in NA. Significant overall improvement – The IF5UD represents a significant overall performance improvement over the previous IF5 for multiple dock door portal applications. Adjacent Dock Doors 0 5 10 15 20 25 30 35 40 45 Intermec Intermec Reader Reader Reader IF5 IF5-2 A B C Number of reads 0 IR 2 IR 4 IR 8 IR IF5UD Intermec |

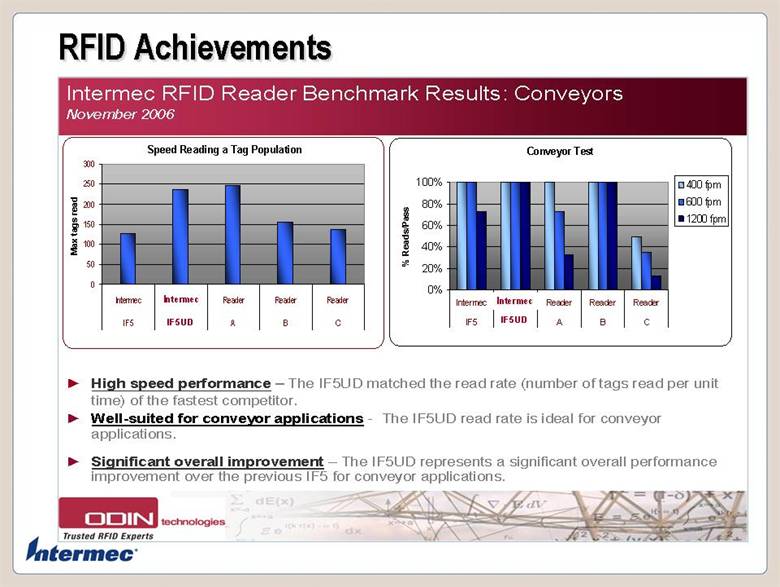

| RFID Achievements Intermec RFID Reader Benchmark Results: Conveyors November 2006 High speed performance – The IF5UD matched the read rate (number of tags read per unit time) of the fastest competitor. Well-suited for conveyor applications - The IF5UD read rate is ideal for conveyor applications. Significant overall improvement – The IF5UD represents a significant overall performance improvement over the previous IF5 for conveyor applications. IF5UD Intermec IF5UD Intermec Speed Reading a Tag Population Max tags read 300 250 200 150 100 50 0 Intermec IF5 Intermec IF5UD Reader A Reader B Reader C Conveyor Test % Reads/Pass 100% 80% 60% 40% 20% 0% Intermec IF5 Intermec IF5UD Reader A Reader B Reader C 400 fpm 600 fpm 1200 fpm |

| RFID Market Observations Compliance mandates remain in place Standards progress Vendors supporting EPC Gen 2 8 Reader companies & 5 Silicon companies with EPC Gen2 certified products to date Retailers committing to EPC Gen 2 |

| RFID Market Observations (cont.) Product prices are dropping Product performance and quality improving Standards beginning on item, sensors, and active tags ROI’s Developing with compliance projects Rapidly developing with closed loop applications |

| Highlight on Recent Wins Hong Kong Airport Authority (CL Systems – Intermec partner) RFID bag tag application Intermec selected in a competitive performance evaluation for project roll out Canadian RFID Centre (Intermec & IBM) Loblaw’s sponsoring retailer Food track and trace pilot involving Maple Leaf Foods, General Mills, Scott Paper and Unilever |

| Highlight on Recent Wins (cont.) Grupo Familia Wal-Mart compliance supplier South America’s largest Consumer Goods company 6 Major distribution centers 6 million pallets & 15 million cartons annually DaimlerChrysler (Quanta, Inc. / System Concepts – Intermec partners) Intermec readers and tags selected for manufacturing process application |

| Highlight on ROI Data Partners: Quanta Inc. / System Concepts Customer: Daimler Chrysler Application: Tracking conveyor carriers to reduce body shop process bottlenecks, overtime labor and downtime Summary: Utilized Intermec RFID equipment to implement a conveyor carrier PM system to plan downtime and remove process bottlenecks Result: Reduced labor overtime cost by $1.1 million annually, producing a 4 month payback ROI: 354% |

| Intermec – Gen2 Supply Chain METRO Group Sole source award for case level trials Selected IF5 and Intermec enclosure portal systems Achieving 100% read rates on pure pallets & >98% on mixed mode “We have a clear commitment to be the technology leader. We need technology vendors with the same strategy. We believe in Intermec’s capabilities.” - Dr. Gerd Wolfram |

| Highlight on Gen 2 Products Intermec Gen 2 Rigid Tag Released Gen 2 compliant and interoperability certified Excellent solution for asset tagging and reusable container tracking projects Intermec IM5 Release 2 Released Gen 2 compliant and interoperability certified Integrated with IF5 reader, IV7 mobile reader, PM4i and PF2i RFID printer series Significant performance improvements Speed (tags per second) Receiver sensitivity (read rates) |

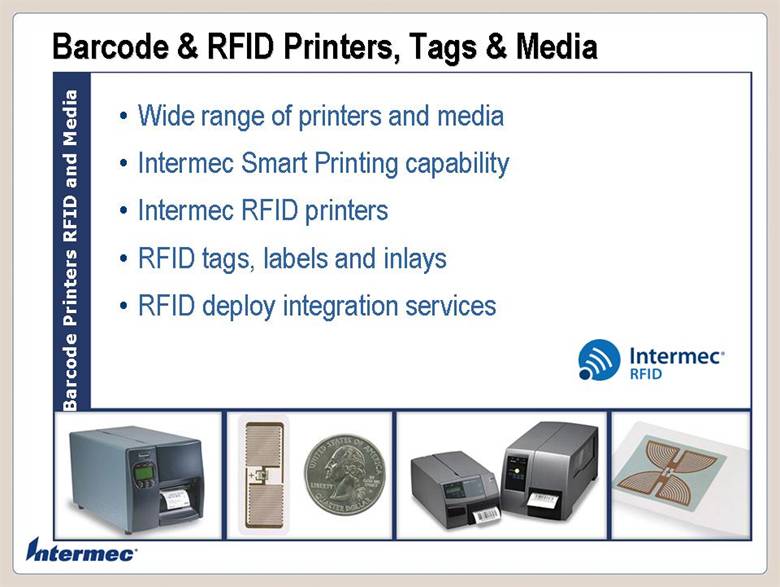

| Barcode & RFID Printers, Tags & Media Wide range of printers and media Intermec Smart Printing capability Intermec RFID printers RFID tags, labels and inlays RFID deploy integration services Barcode Printers RFID and Media |

| Wireless Network Intermec partners with Cisco Cisco AP Features Best-In-Class partner Service and Support Intermec Solutions |

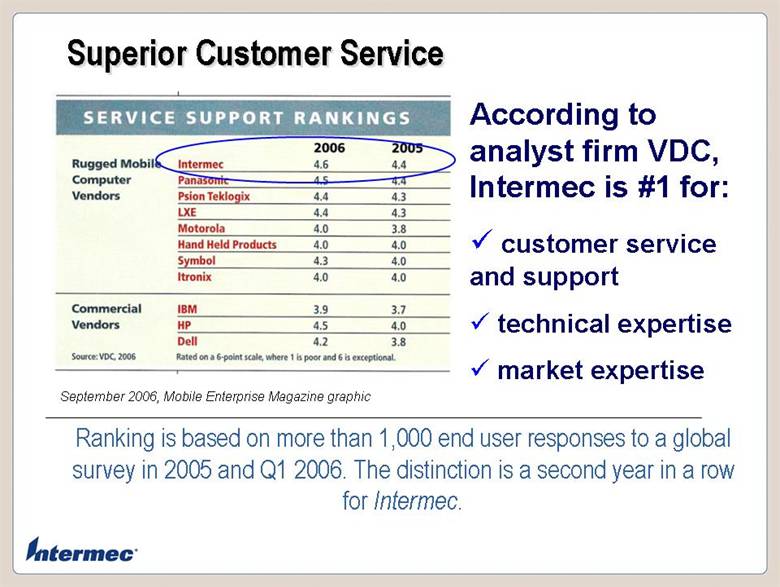

| According to analyst firm VDC, Intermec is #1 for: customer service and support technical expertise market expertise September 2006, Mobile Enterprise Magazine graphic Ranking is based on more than 1,000 end user responses to a global survey in 2005 and Q1 2006. The distinction is a second year in a row for Intermec. Superior Customer Service |

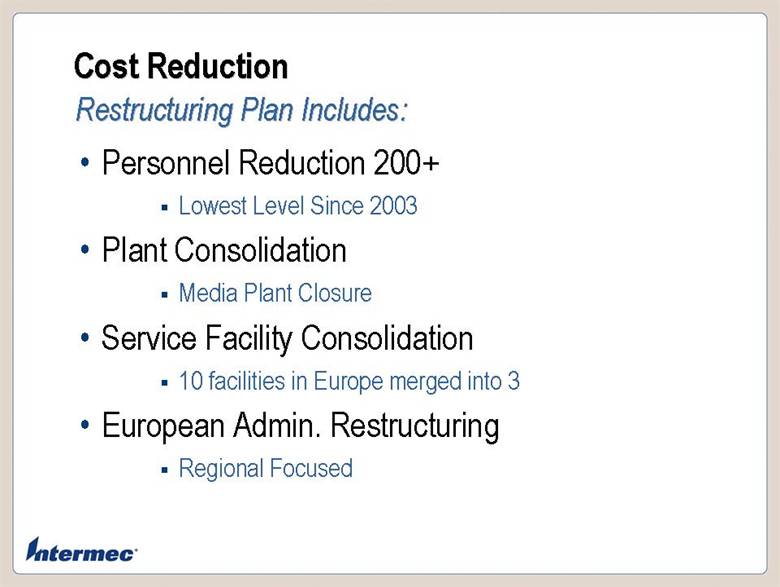

| Cost Reduction Restructuring Plan Includes: Personnel Reduction 200+ Lowest Level Since 2003 Plant Consolidation Media Plant Closure Service Facility Consolidation 10 facilities in Europe merged into 3 European Admin. Restructuring Regional Focused |

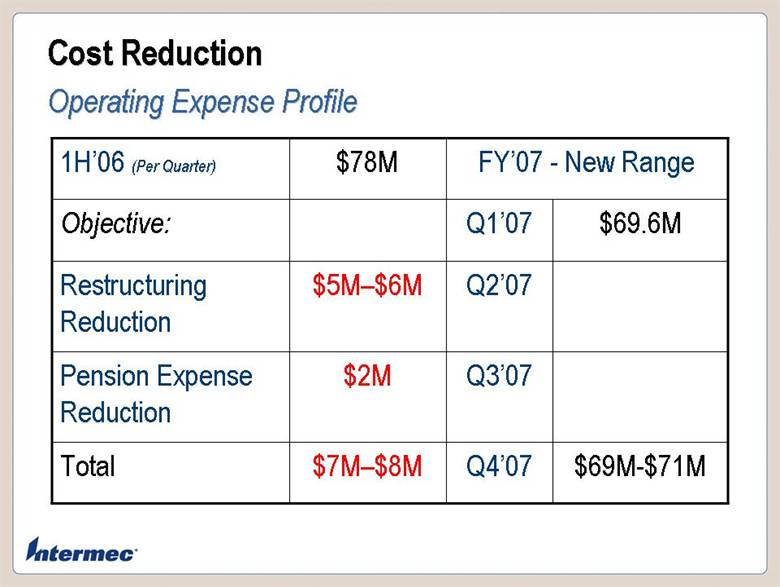

| Cost Reduction Operating Expense Profile $69M-$71M Q4’07 $7M–$8M Total Q3’07 $2M Pension Expense Reduction Q2’07 $5M–$6M Restructuring Reduction $69.6M Q1’07 Objective: FY’07 - New Range $78M 1H’06 (Per Quarter) |

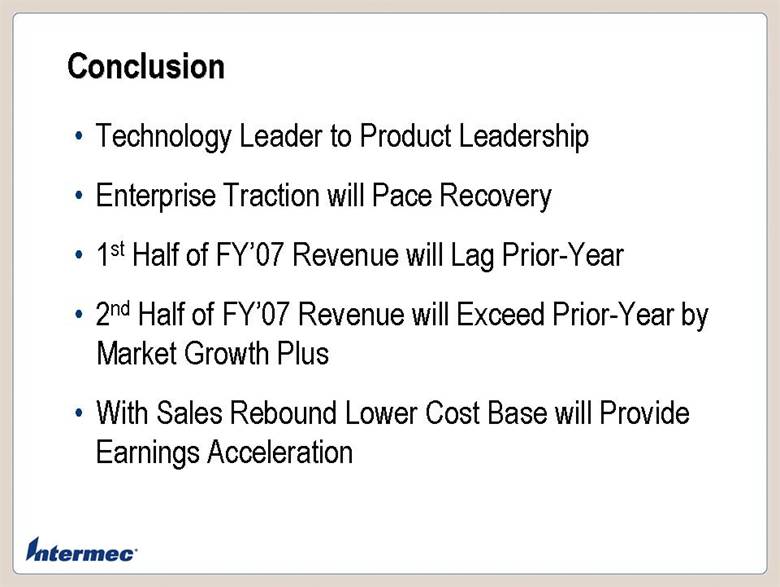

| Conclusion Technology Leader to Product Leadership Enterprise Traction will Pace Recovery 1st Half of FY’07 Revenue will Lag Prior-Year 2nd Half of FY’07 Revenue will Exceed Prior-Year by Market Growth Plus With Sales Rebound Lower Cost Base will Provide Earnings Acceleration |

| Thank you |