Exhibit 99.2

| | | |

| | National Instrument 43-101

Preliminary Feasibility Study |

| | | Technical Report of the |

| | | Getty Copper Project |

| | | | |

| | | Kamloops Mining Division |

| | | British Columbia, Canada |

| | | | |

| | | WCE File ID# GET100-001-07 |

| | | | |

| | | June 9, 2009 |

| | | |

|

| | | Prepared For: | Getty Copper Inc. |

| | | | 1000 Austin Avenue |

| | | | Coquitlam, British Columbia |

| | | | Canada V3K 3P1 |

| | | | |

| 1838 Eastman Avenue | | | |

| Suite 200 | | | |

| Ventura, CA 93003 | | Prepared by: | Craig L. Parkinson, PG |

| Phone 805/644-7976 | | | West Coast Environmental and |

| Fax 805/644-5929 | | | Engineering |

| | | | 101 Providence Mine Road, Ste 105 |

| 101 Providence Mine Road | | | Nevada City, California 95959 |

| Suite 105 | | | |

| Nevada City, CA 95959 | | | Todd S. Fayram, QP |

| Phone 530/470-0215 | | | 1300 West Copper Street |

| Fax 530/687-9399 | | | Butte, Montana 59701 |

| | | | |

www.wcenviro.com

| | | |

| |

| Nevada City |

| 101 Providence Mine Road, Suite 105 |

| Nevada City, CA 95959 |

| Phone 530/470-0215 Fax 530/687-9399 |

| |

| Ventura |

| 1838 Eastman Avenue, Suite 200 |

| Ventura, CA 93003 |

| Phone 805/644-7976 Fax 805/644-5929 |

| www.wcenviro.com |

Preliminary Feasibility Study

Technical Report of the

Getty Copper Project

WCE File ID# GET100-001-07

June 9, 2009

| | |

| get100-001_pre-fs_9june09a | i | West Coast Environmental and |

| | | Engineering |

| |

| Nevada City |

| 101 Providence Mine Road, Suite 105 |

| Nevada City, CA 95959 |

| Phone 530/470-0215 Fax 530/687-9399 |

| |

| Ventura |

| 1838 Eastman Avenue, Suite 200 |

| Ventura, CA 93003 |

| Phone 805/644-7976 Fax 805/644-5929 |

| www.wcenviro.com |

TABLE OF CONTENTS

| | | | |

| 1.0 | SUMMARY | | 1 |

| 1.1 | Getty North Deposit | 1 |

| 1.2 | Getty South Deposit | 2 |

| 1.3 | Summary of Getty Project Mineral Resource and Reserve Estimates | 3 |

| 1.4 | Summary of Getty Project Economics | 4 |

| |

| 2.0 | INTRODUCTION AND TERMS OF REFERENCE | 4 |

| 2.1 | Author Background Information | 5 |

| 2.2 | Unit Conversions | 7 |

| |

| 3.0 | RELIANCE ON OTHER EXPERTS | 7 |

| |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 8 |

| 4.1 | Getty North Deposit | 9 |

| 4.2 | Getty South Deposit | 10 |

| 4.3 | Permitting Status | 17 |

| |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE ANDPHYSIOGRAPHY | 17 |

| 5.1 | Access | 17 |

| 5.2 | Climate | 17 |

| 5.3 | Local Resources and Infrastructure | 17 |

| 5.4 | Physiography | 18 |

| |

| 6.0 | HISTORY | | 18 |

| 6.1 | Getty North | 18 |

| 6.2 | Getty South | 19 |

| |

| 7.0 | GEOLOGIC SETTING | 19 |

| 7.1 | Regional Geology | 19 |

| 7.2 | Local Geology | 20 |

| | 7.2.1 | Getty North Deposit | 20 |

| | 7.2.2 | Getty South Deposit | 25 |

| |

| 8.0 | DEPOSIT TYPE | 29 |

| 8.1 | Getty North Deposit | 30 |

| 8.2 | Getty South Deposit | 30 |

| | |

| get100-001_pre-fs_9june09a | ii | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | | | |

| 9.0 | MINERALIZATION | 30 |

| 9.1 | Getty North Deposit | 30 |

| | 9.1.1 | Gold and Silver Mineralization | 31 |

| 9.2 | Getty South Deposit | 32 |

| | 9.2.1 | Gold and Silver Mineralization | 33 |

| 9.3 | Getty Project Gold and Silver Mineralization | 33 |

| |

| 10.0 | EXPLORATION | 35 |

| 10.1 | Getty North Deposit | 35 |

| 10.2 | Getty South Deposit | 35 |

| 10.3 | Summary of Mineralized Zones | 40 |

| |

| 11.0 | DRILLING | 42 |

| 11.1 | Getty North Deposit | 42 |

| 11.2 | Getty South Deposit | 45 |

| |

| 12.0 | SAMPLING METHOD AND APPROACH | 48 |

| 12.1 | Getty North Deposit | 48 |

| 12.2 | Getty South Deposit | 48 |

| |

| 13.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 49 |

| 13.1 | Sample Preparation | 49 |

| 13.2 | Copper Assay Analysis | 49 |

| 13.3 | Getty North Deposit | 50 |

| 13.4 | Getty South Deposit | 51 |

| |

| 14.0 | DATA VERIFICATION | 51 |

| 14.1 | Getty North Deposit | 52 |

| | 14.1.1 | Database Update | 53 |

| | 14.1.2 | Mine Model Data | 54 |

| 14.2 | Getty South Deposit | 54 |

| | 14.2.1 | Database Update | 54 |

| | 14.2.2 | Mine Model Data | 55 |

| |

| 15.0 | ADJACENT PROPERTIES | 55 |

| |

| 16.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 57 |

| 16.1 | Previous Engineering Studies | 58 |

| | 16.1.1 | Getty North Deposit | 58 |

| | 16.1.2 | Getty South Deposit | 60 |

| | 16.1.3 | Getty Project | 60 |

| 16.2 | Getty Project Processing Plan | 61 |

| 16.3 | Metallurgical Testwork and Flowsheet Development | 62 |

| | 16.3.1 | Testing | 63 |

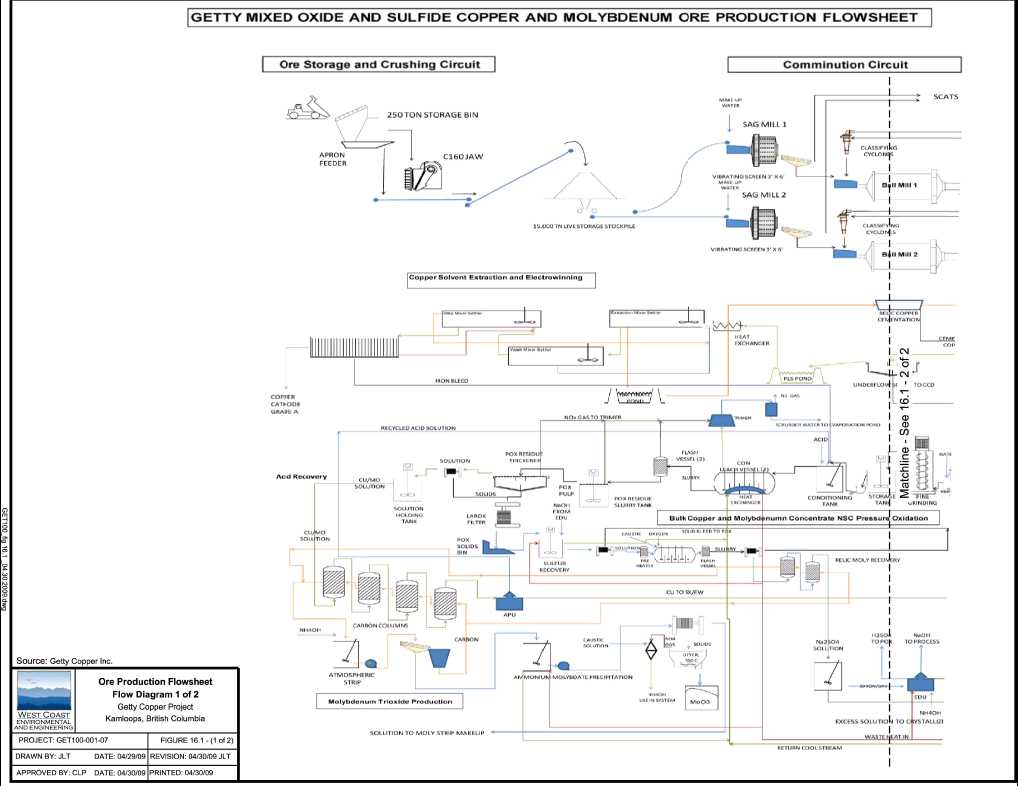

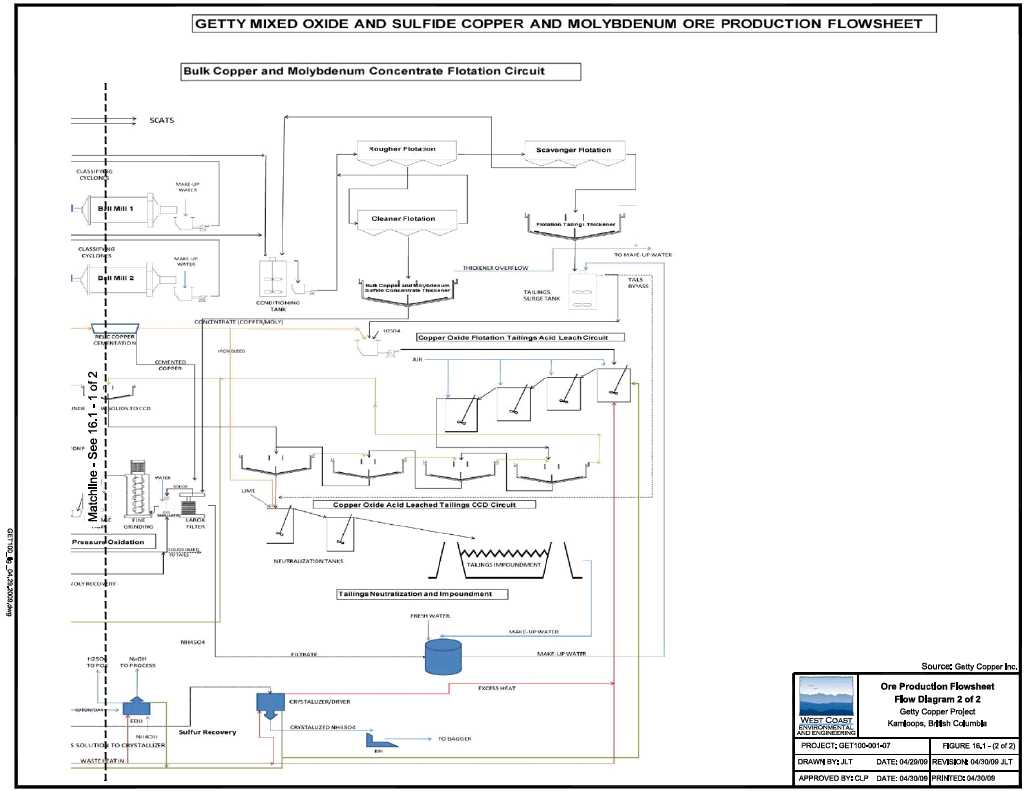

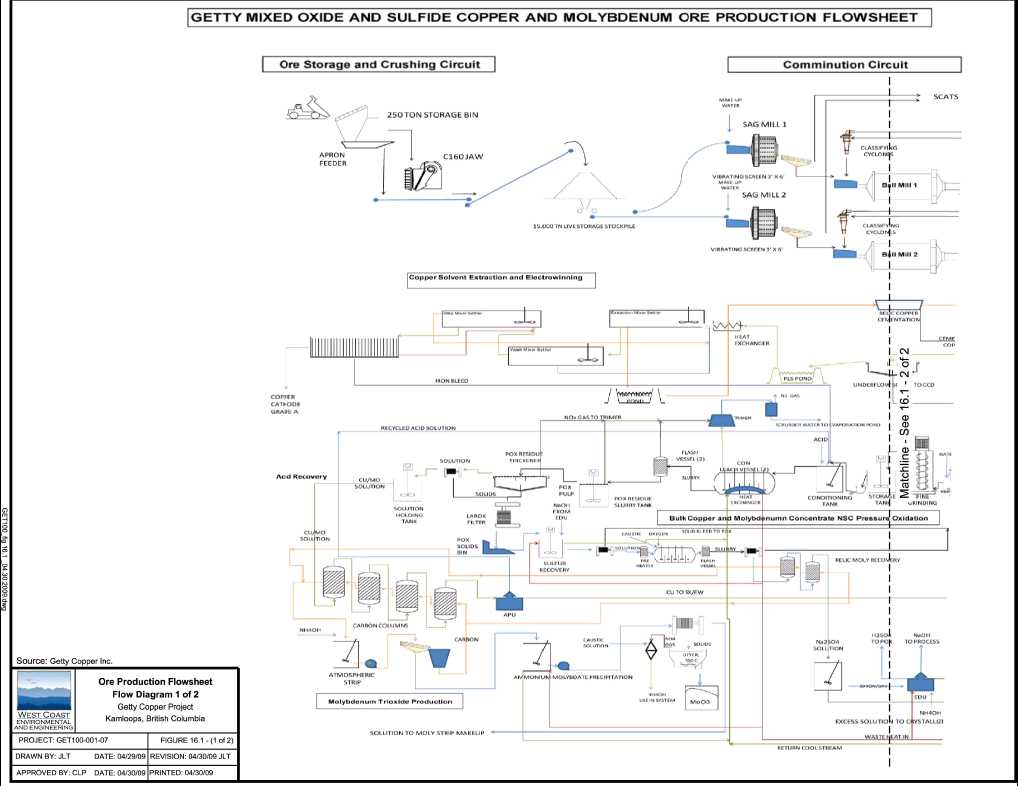

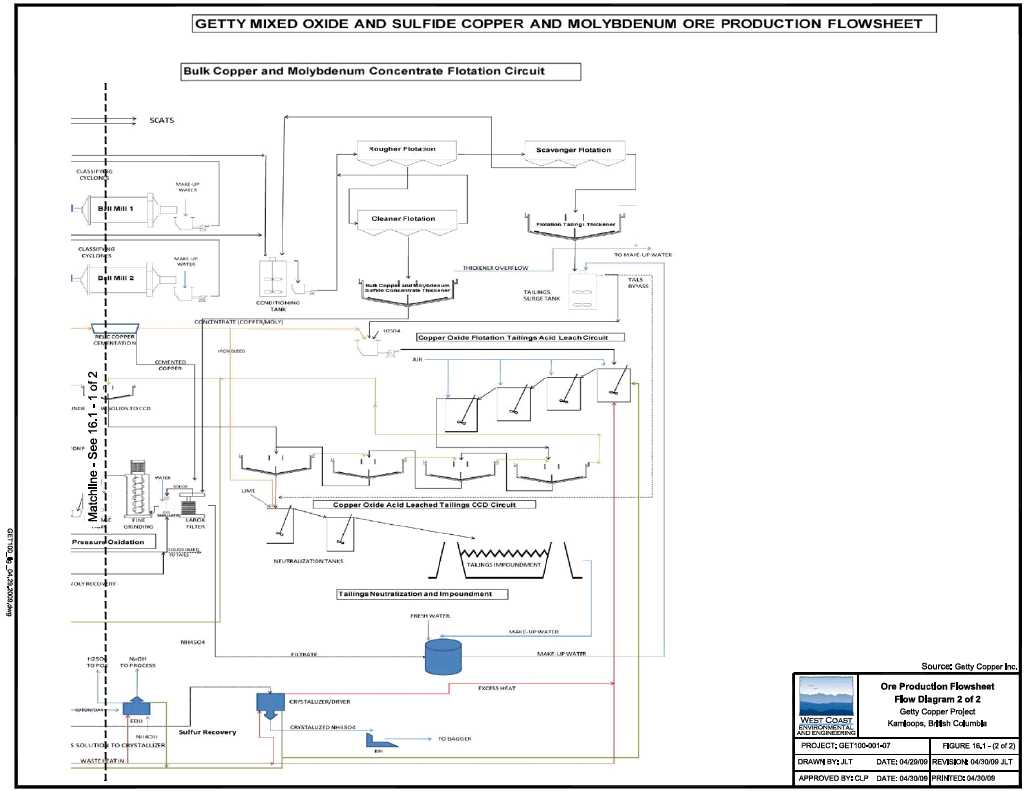

| 16.4 | Flowsheet Development | 67 |

| | 16.4.1 | Overview | 67 |

| | 16.4.2 | Thickening | 70 |

| | |

| get100-001_pre-fs_9june09a | iii | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | | | |

| | 16.4.3 | Filtration | 71 |

| | 16.4.4 | Concentrate Leaching | 71 |

| | 16.4.5 | Flowsheet | 73 |

| 16.5 | Process Plant Design | 76 |

| 16.6 | Process Design Review | 89 |

| 16.7 | Capital Costs | 92 |

| 16.8 | Operating Costs | 101 |

| 16.9 | Processing Operating Costs | 104 |

| 16.10 | Recommendations | 106 |

| |

| 17.0 | MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | 108 |

| 17.1 | Historical Resource Evaluations | 108 |

| 17.2 | Recent Resource Evaluations | 109 |

| | 17.2.1 | Getty North Deposit | 109 |

| | 17.2.2 | Getty South Deposit | 111 |

| 17.3 | Mineral Resource and Reserve Classifications | 113 |

| | 17.3.1 | Mineral Resources | 113 |

| | 17.3.2 | Mineral Reserves | 115 |

| 17.4 | Current Copper and Molybdenum Mineral Resource and Reserve Estimates | 116 |

| | 17.4.1 | General Model Parameters | 116 |

| | 17.4.2 | Model Input Parameters | 118 |

| | 17.4.3 | Model Results | 120 |

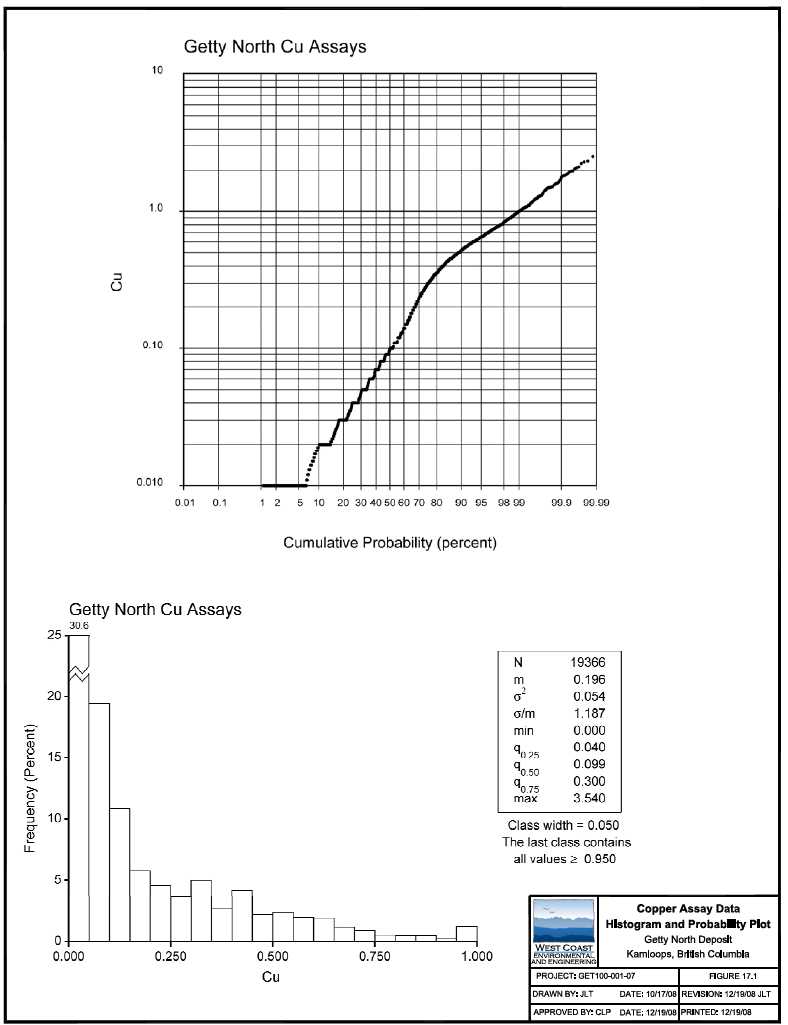

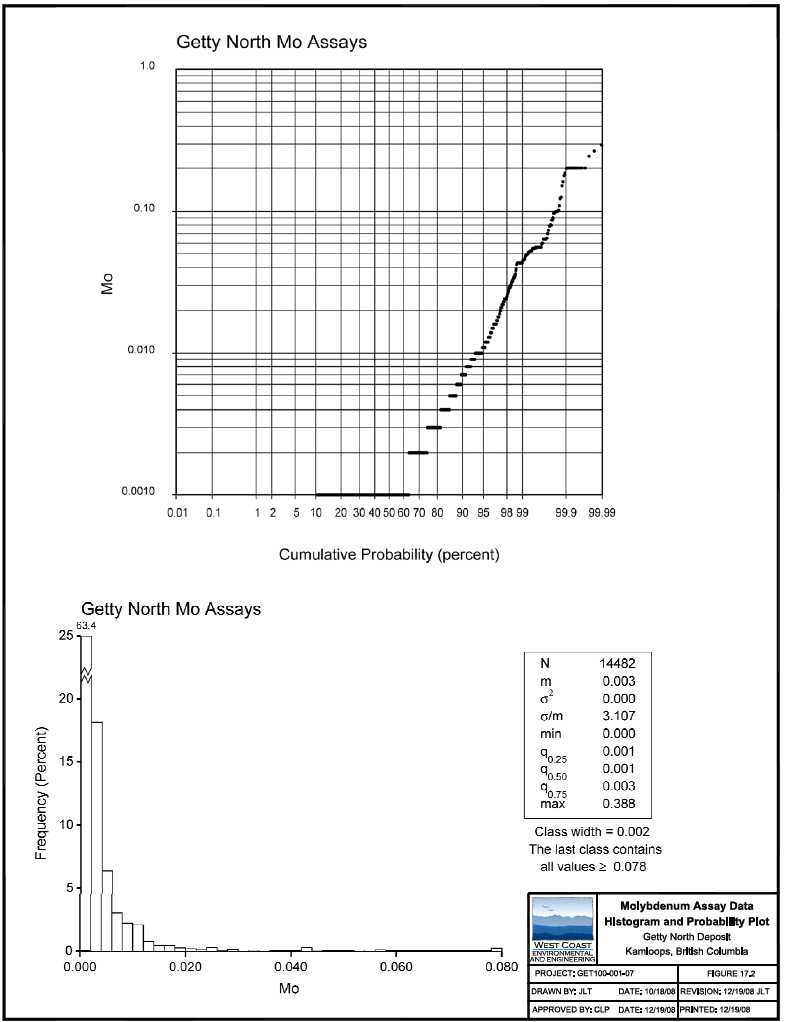

| | 17.4.4 | Model Statistics | 121 |

| | 17.4.5 | Model Sections and 3D Perspectives | 126 |

| | 17.4.6 | Mineral Reserves Classification Methodology | 137 |

| |

| 18.0 | OTHER RELEVANT DATA AND INFORMATION | 139 |

| 18.1 | Local Land Use Zoning, Planning, Bylaws and Development Plans | 139 |

| 18.2 | Environmental Considerations | 140 |

| | 18.2.1 | Environmental Scenario or Setting | 141 |

| | 18.2.2 | Tailings and Mine Rock Management | 144 |

| 18.3 | Pertinent Mining Laws | 147 |

| | 18.3.1 | Applicable Laws | 148 |

| 18.4 | Mine Reclamation and Closure | 149 |

| |

| 19.0 | ADDITIONAL REQUIREMENTS FOR DEVELOPMENT PROPERTIES ANDPRODUCTION PROPERTIES | 154 |

| 19.1 | Open Pit Mining Plan | 156 |

| 19.3 | Open Pit Mine Plan Parameters | 157 |

| 19.3 | Economics | 166 |

| | 19.3.1 | Introduction | 166 |

| | 19.3.2 | Basis | 166 |

| | 19.3.3 | Base Case Cash Flow Analysis | 166 |

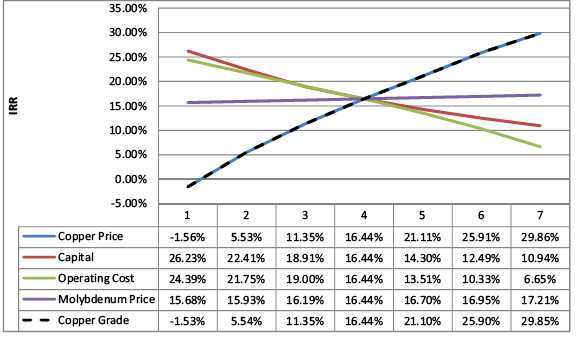

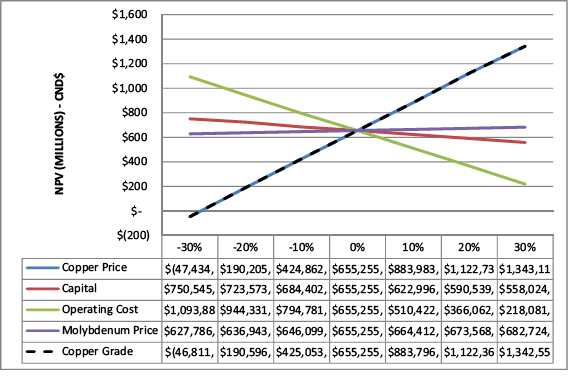

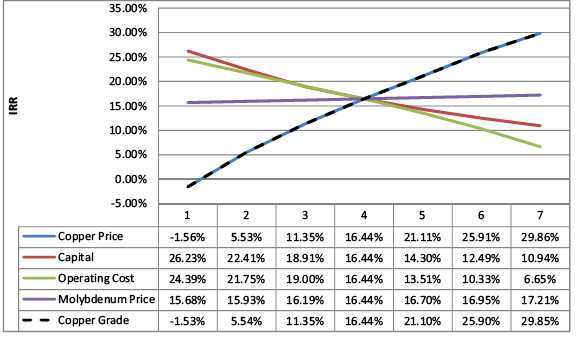

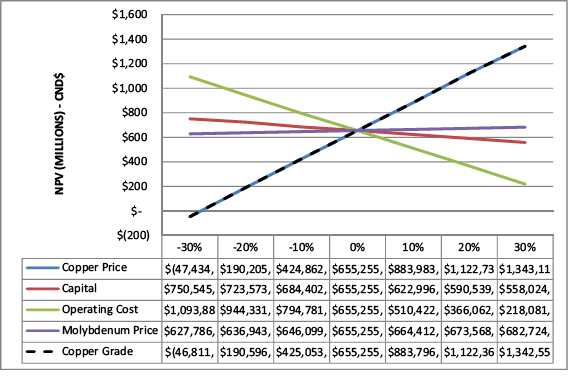

| 19.4 | Sensitivity Analysis | 172 |

| 19.5 | Economic Parameters | 176 |

| | Sodium Sulfate Production | 176 |

| | Revenue | 176 |

| | Operating Costs | 176 |

| | |

| get100-001_pre-fs_9june09a | iv | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | | | |

| | Metal Shipping and Refining | 176 |

| | Reclamation Costs | 176 |

| | Royalties | 176 |

| 19.6 | Capital and Other Costs | 177 |

| | Pre-production Costs | 177 |

| | Operation and Maintenance Supply Inventory | 177 |

| | Working Capital Requirement | 177 |

| | Sustaining Capital | 177 |

| 19.7 | Taxes | 178 |

| | Federal Taxes | 178 |

| | Provincial Income Tax | 178 |

| | Provincial Mining Tax | 178 |

| | Property Tax | 178 |

| | Depreciation | 178 |

| |

| 20.0 | INTERPRETATIONS AND CONCLUSIONS | 179 |

| 20.1 | Getty North Deposit | 179 |

| 20.2 | Getty South Deposit | 179 |

| 20.3 | Getty Copper Project | 180 |

| | 20.3.1 | Project Economic Feasibility | 180 |

| |

| 21.0 | RECOMMENDATIONS | 180 |

| 21.1 | Getty North Deposit | 180 |

| 21.2 | Getty South Deposit | 182 |

| 21.3 | Getty Copper Project | 183 |

| |

| 22.0 | REFERENCES | 186 |

| |

| 23.0 | CERTIFICATES OF QUALIFIED PERSONS | 193 |

| |

| 24.0 | GLOSSARY | 196 |

| 24.1 | Definitions of Terms | 196 |

| 24.2 | Abbreviations | 198 |

| | |

| get100-001_pre-fs_9june09a | v | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | |

| TABLES | | |

| Table 1-1 | Summary of Getty Indicated and Inferred Mineral Resource Estimates | 3 |

| Table 1-2 | Summary of Getty Probable Mineral Reserve Estimates | 3 |

| Table 4-1 | Getty North Property Claim Data | 14 |

| Table 4-2 | Getty South Property Lot Data | 17 |

| Table 10-1 | Getty South Trenching Summary | 39 |

| Table 10-2 | Getty South Summary of Mineralization within Underground Workings | 41 |

| Table 11-1 | Getty North Deposit Drilling Summary | 44 |

| Table 11-2 | Getty South Deposit Drilling Summary | 47 |

| Table 13-1 | ICP-MS Detection Limits | 50 |

| Table 14-1 | Data Verification – Getty North Eco Tech Assay Results | 53 |

| Table 16-1 | Net Acid Consumption for Vat Leach Results (AMEC – September 2003) | 65 |

| Table 16-2 | Cytec Vat Leaching Flowsheet Design Review | 70 |

| Table 16-3 | NSC Leaching Parameters | 72 |

| Table 16-4 | POX Leaching Parameters | 72 |

| Table 16-5 | Ore Characteristics | 77 |

| Table 16-6 | Primary Crushing Circuit | 78 |

| Table 16-7 | Coarse Ore Stockpile | 78 |

| Table 16-8 | Grinding Circuit | 78 |

| Table 16-9 | Primary Grinding Circuit – SAG | 79 |

| Table 16-10 | Sag Mill Discharge Screen | 79 |

| Table 16-11 | Secondary Grinding Circuit | 79 |

| Table 16-12 | Secondary Classification Circuit | 80 |

| Table 16-13 | Flotation Circuit | 80 |

| Table 16-14 | Oxide Tailings Leach Circuit | 81 |

| Table 16-15 | Copper Recovery Circuit | 81 |

| Table 16-16 | Solvent Extraction Circuit | 82 |

| Table 16-17 | Stripping Section | 82 |

| Table 16-18 | Organic Phase | 83 |

| Table 16-19 | Mixer Settlers | 83 |

| Table 16-20 | Electrolyte Preparation | 84 |

| Table 16-20 | Electrolyte Preparation continued | 85 |

| Table 16-21 | Pressure Concentrate Leach Circuit | 85 |

| Table 16-22 | Nitrogen Species Catalyzed Pressure Leach | 86 |

| Table 16-22 | Nitrogen Species Catalyzed Pressure Leach continued | 87 |

| Table 16-23 | Molybdenum Recovery | 87 |

| Table 16-23 | Molybdenum Recovery continued | 88 |

| Table 16-24 | NSC POX Leached Residue Sulfur Recovery | 88 |

| Table 16-25 | Relic Copper Recovery | 89 |

| Table 16-26 | Mineral Processing Capital Cost Estimate* | 94 |

| Table 16-27 | Mineral Processing Capital Cost Estimate | 101 |

| Table 16-28 | Average Unit Operating Costs – Life of Mine | 102 |

| Table 16-29 | Mill Management Labor | 103 |

| Table 16-30 | Mill Operation Labor | 103 |

| Table 16-31 | Processing Power Load and Consumption | 104 |

| Table 16-32 | Steel Consumption and Cost* | 105 |

| Table 16-33 | Chemical Usage Flotation | 105 |

| Table 16-34 | Chemical Usage Tails Leach | 105 |

| Table 16-35 | Chemical Usage Concentrate Leach | 106 |

| Table 17-1 | Getty North Mineral Resource Estimates – February 2008 | 111 |

| | |

| get100-001_pre-fs_9june09a | vi | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | |

| Table 17-2 | Getty South Inferred Mineral Resource Estimates- June 2007 | 113 |

| Table 17-3 | Summary of Getty Project Indicated and Inferred Mineral Resources | 120 |

| Table 17-4 | Summary of Getty Project Probable Mineral Reserves | 121 |

| Table 19-1 | Open Pit Mine Plan Parameters | 159 |

| Table 19-2 | Getty Copper Project Pre-Production and Production Forecast | 160 |

| Table 19-3 | Salary and Hourly Personnel Wages | 161 |

| Table 19-4 | Equipment Capital Costs | 162 |

| Table 19-5 | Equipment Operating Costs | 163 |

| Table 19-6 | Consumable Supply Prices | 164 |

| Table 19-7 | Supplies and Materials Unit and Daily Costs | 164 |

| Table 19-8 | Operating Cost Summary | 164 |

| Table 19-9 | Mining Operations Capital Cost Estimate Summary | 165 |

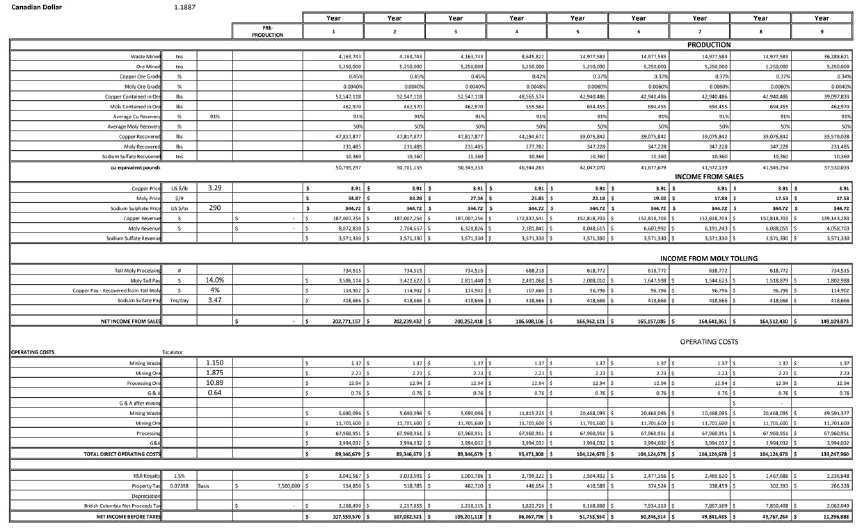

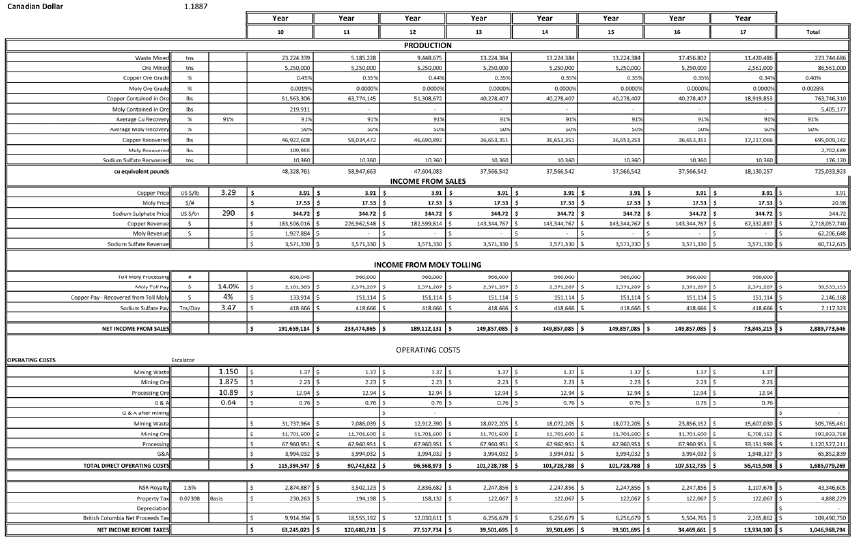

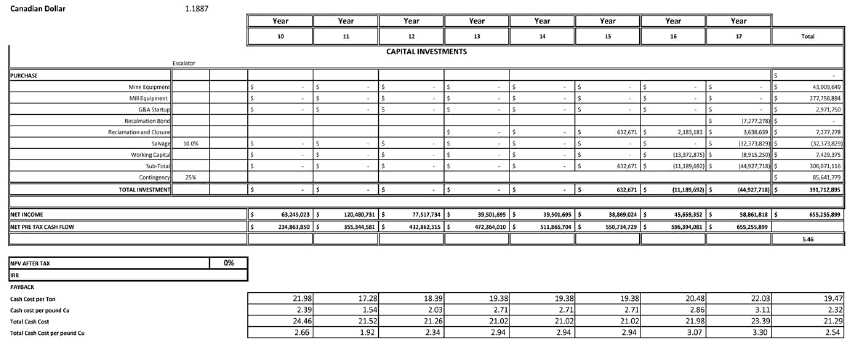

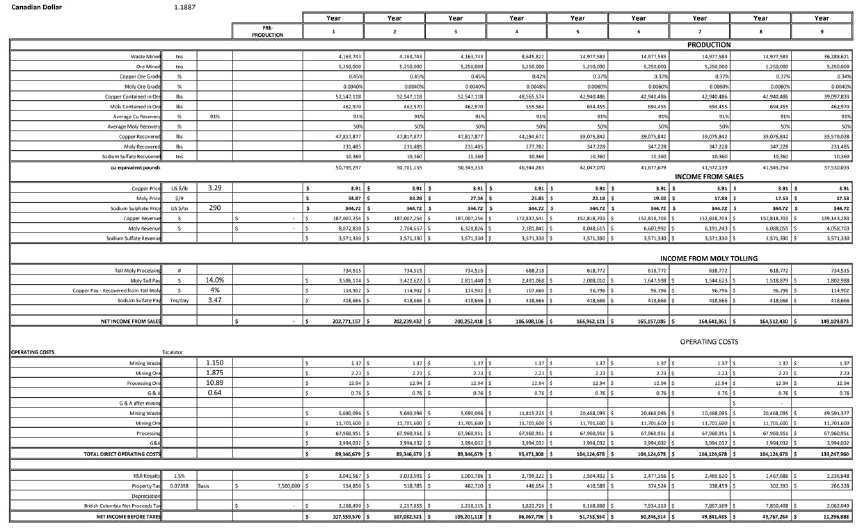

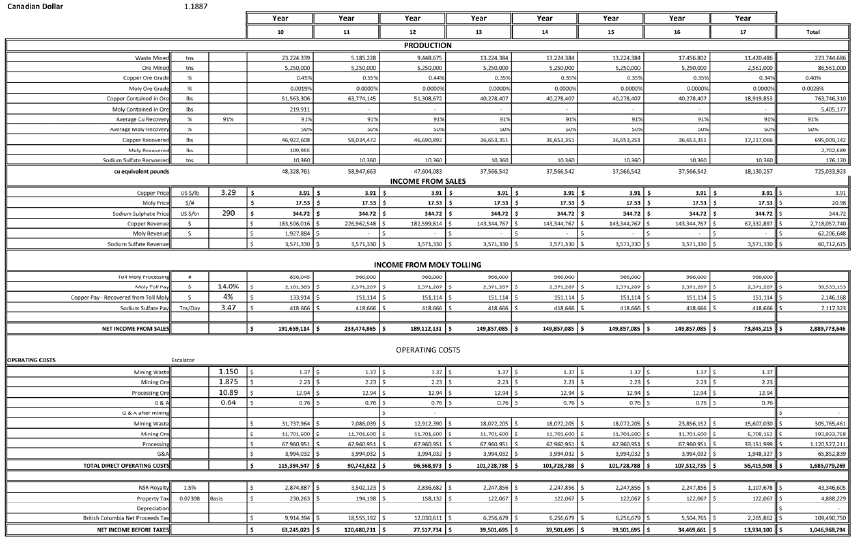

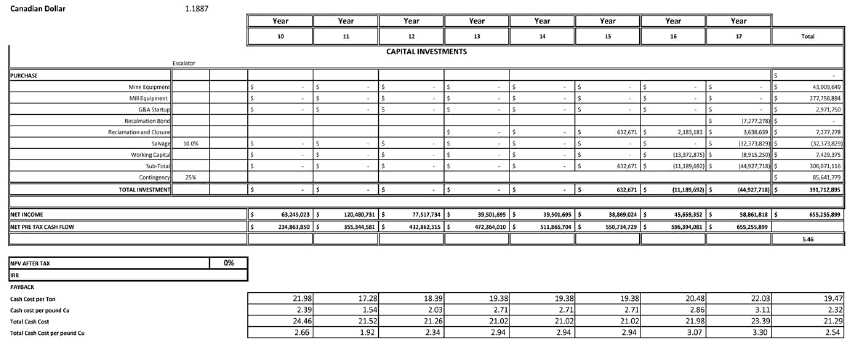

| Table 19-10 | Pro Forma Cash Flow Table - Pre-tax, 100% Equity, with Contingency | 168 |

| Table 19-11 | IRR Sensitivity, Pre-Tax | 174 |

| Table 19-12 | NPV @ 0% Discount Rate, Pre-Tax | 174 |

| | |

| FIGURES | | |

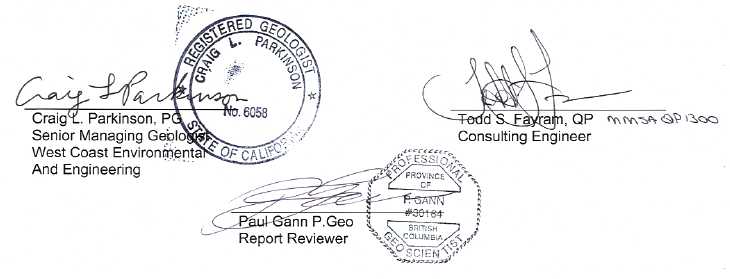

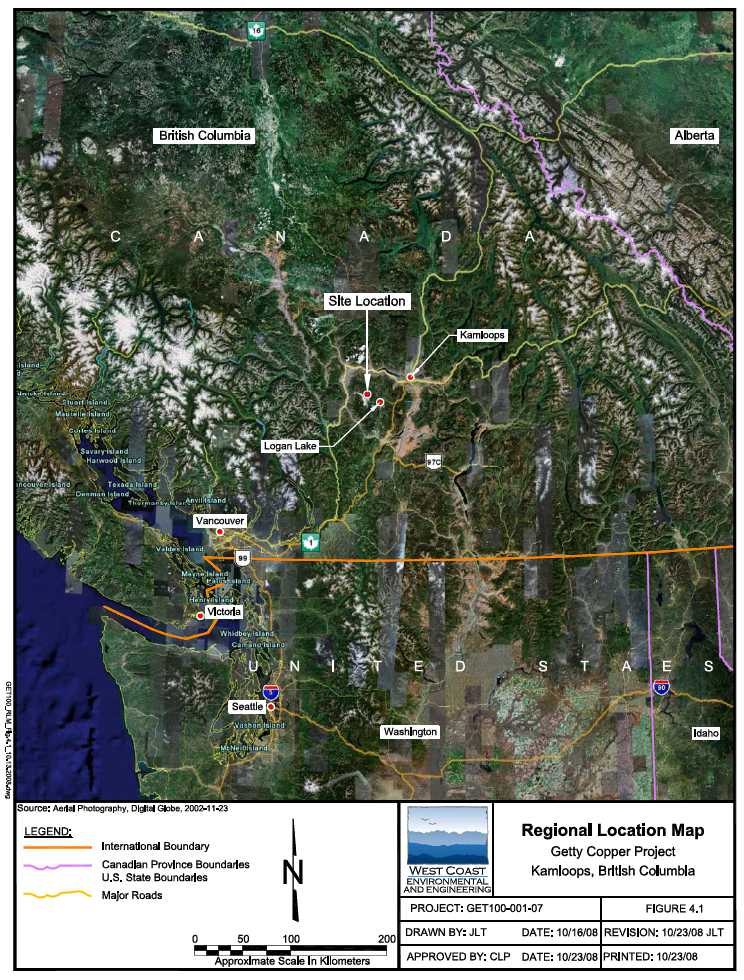

| Figure 4.1 | Regional Location Map | 11 |

| Figure 4.2 | Property Location Map | 12 |

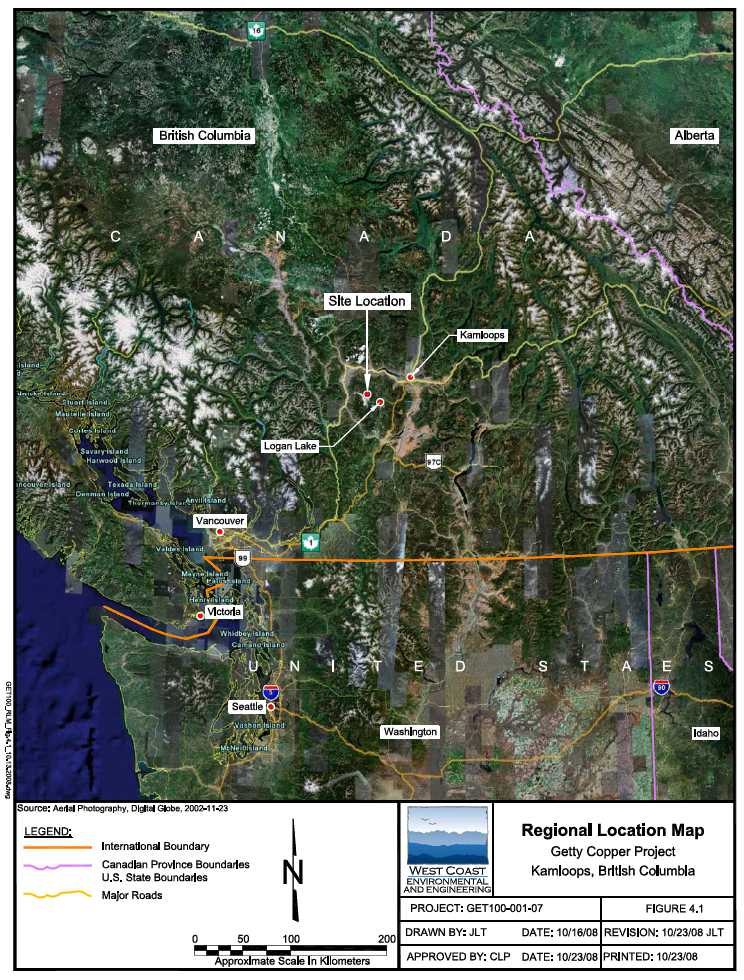

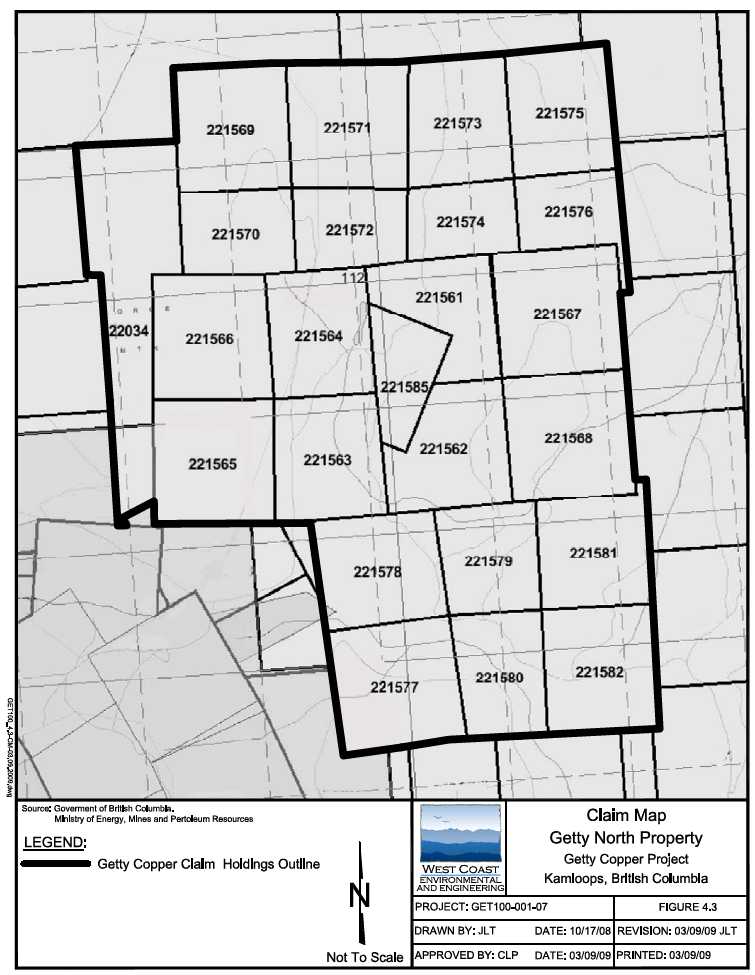

| Figure 4.3 | Claim Map Getty North Property | 13 |

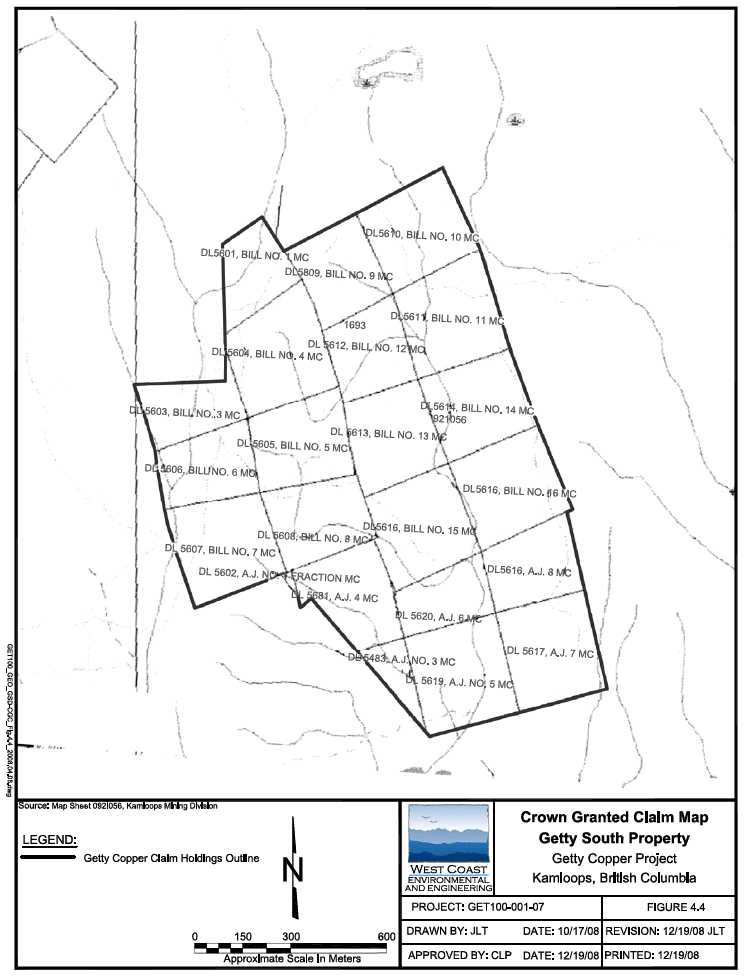

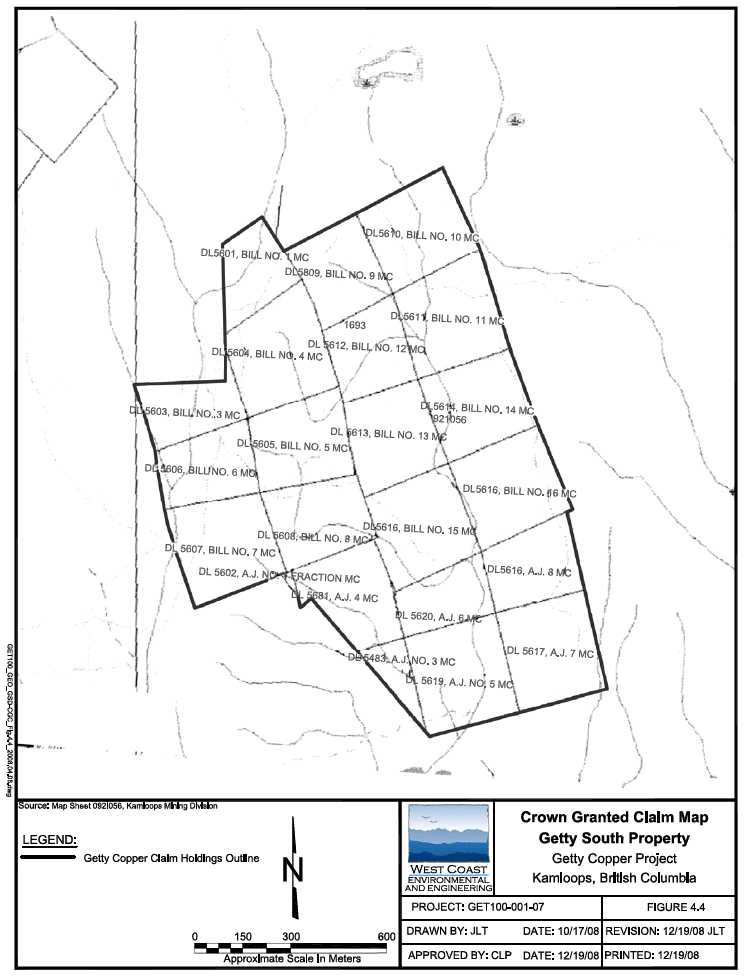

| Figure 4.4 | Crown Granted Claim Map Getty South Property | 15 |

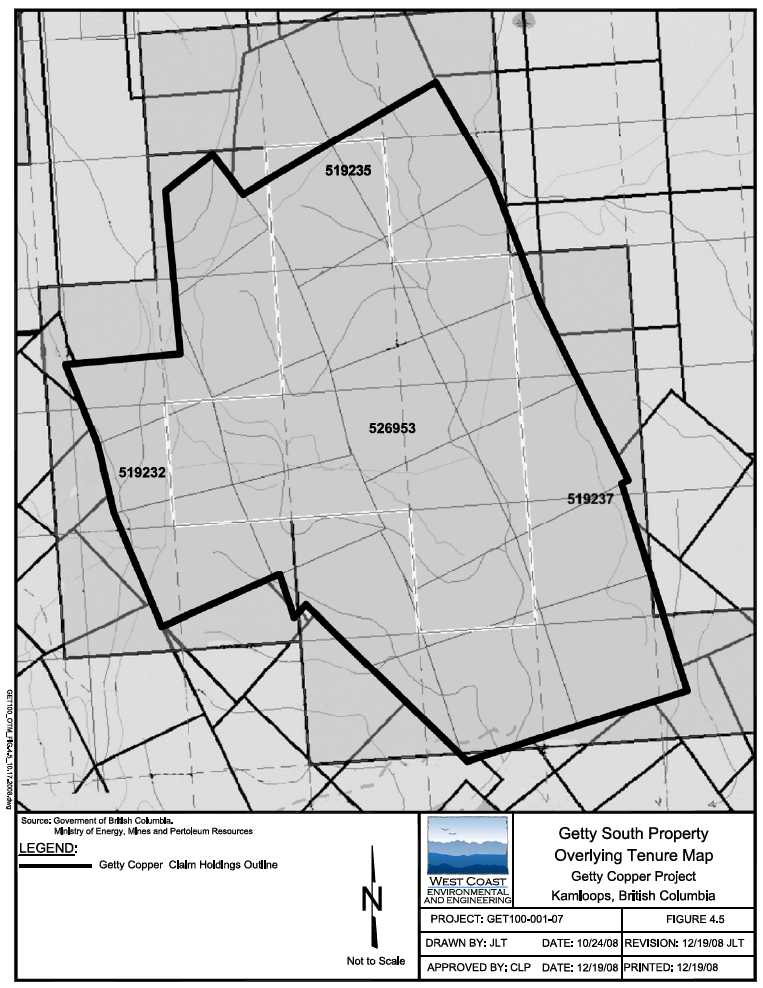

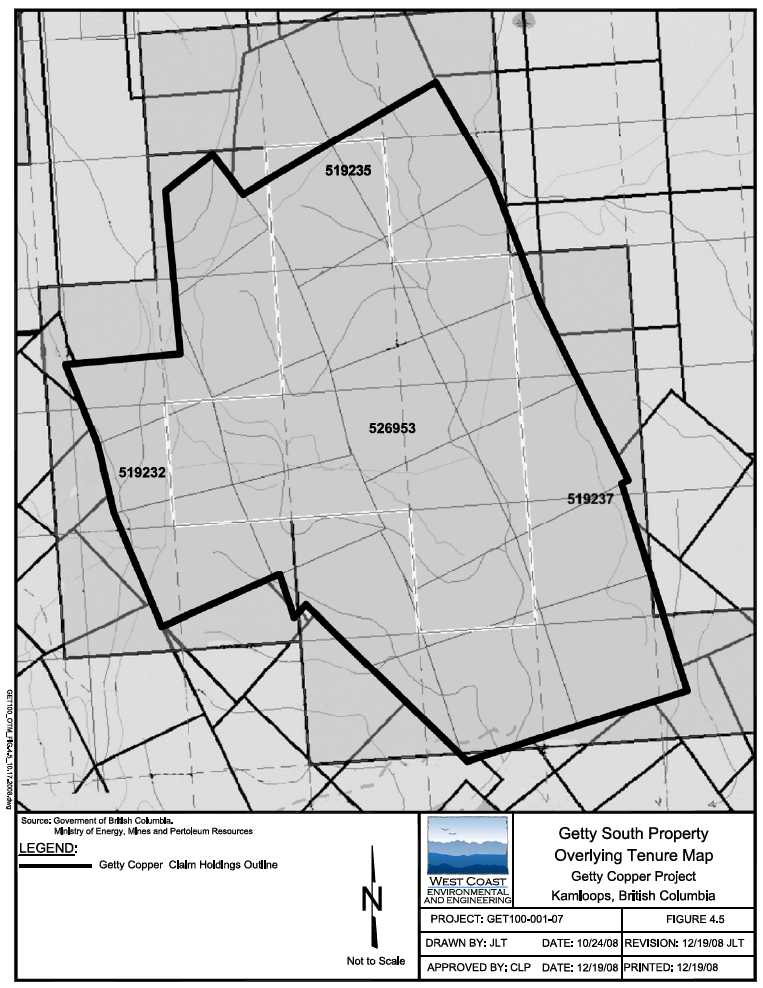

| Figure 4.5 | Getty South Property Overlying Tenure Map | 16 |

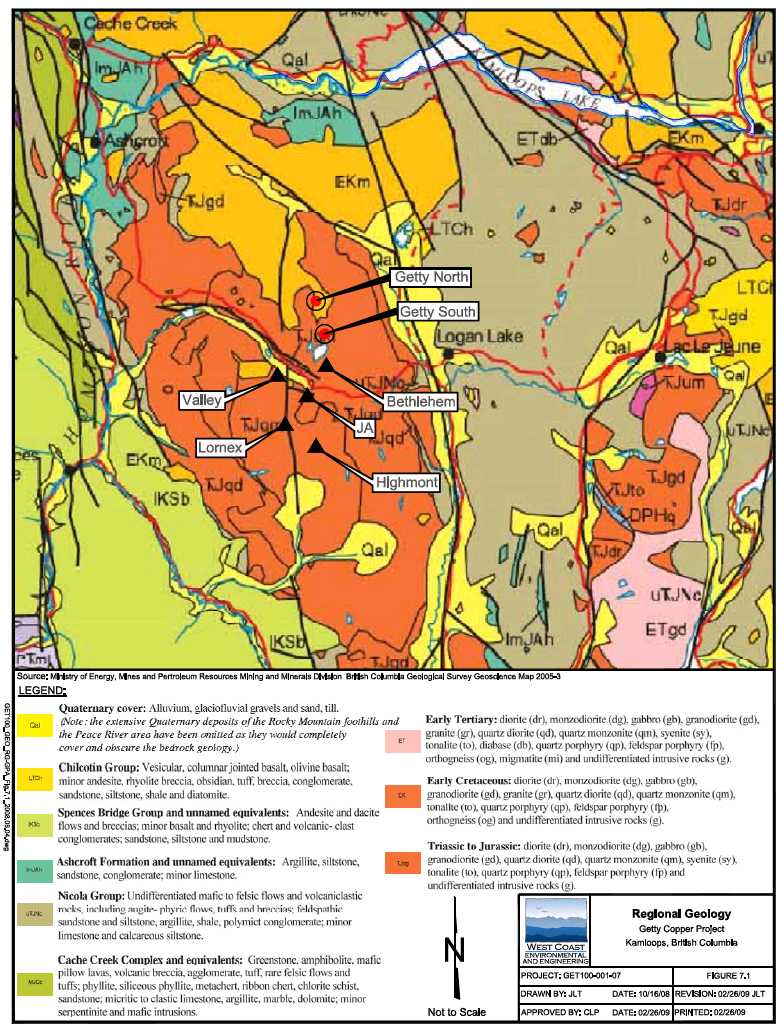

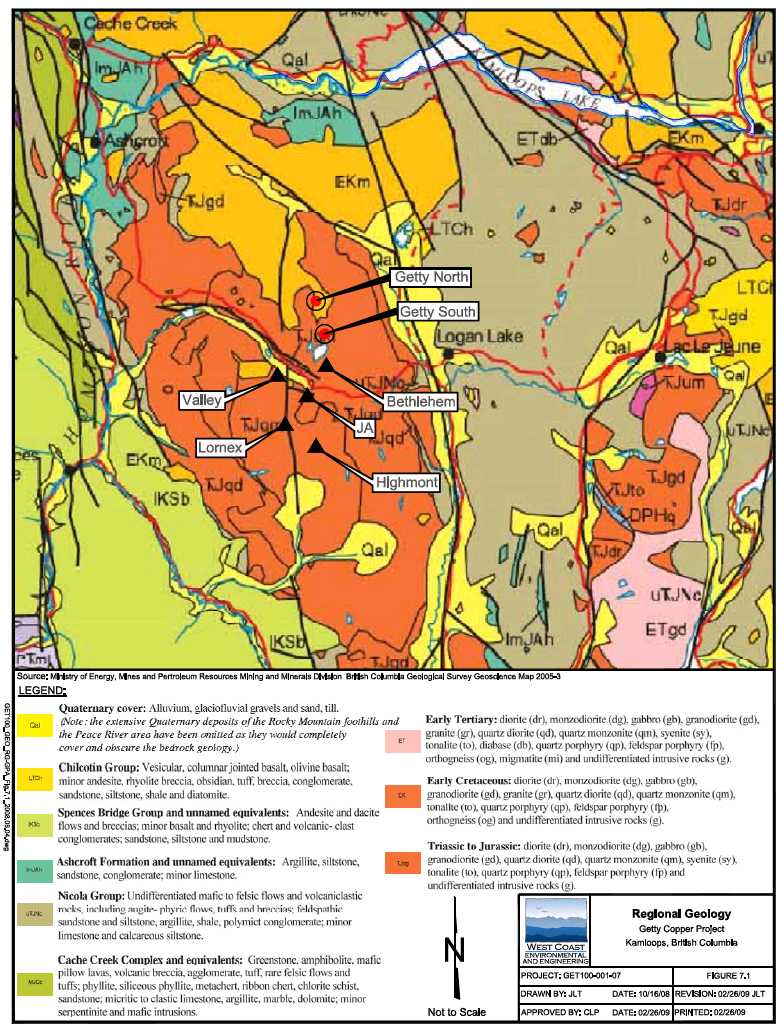

| Figure 7.1 | Regional Geology | 21 |

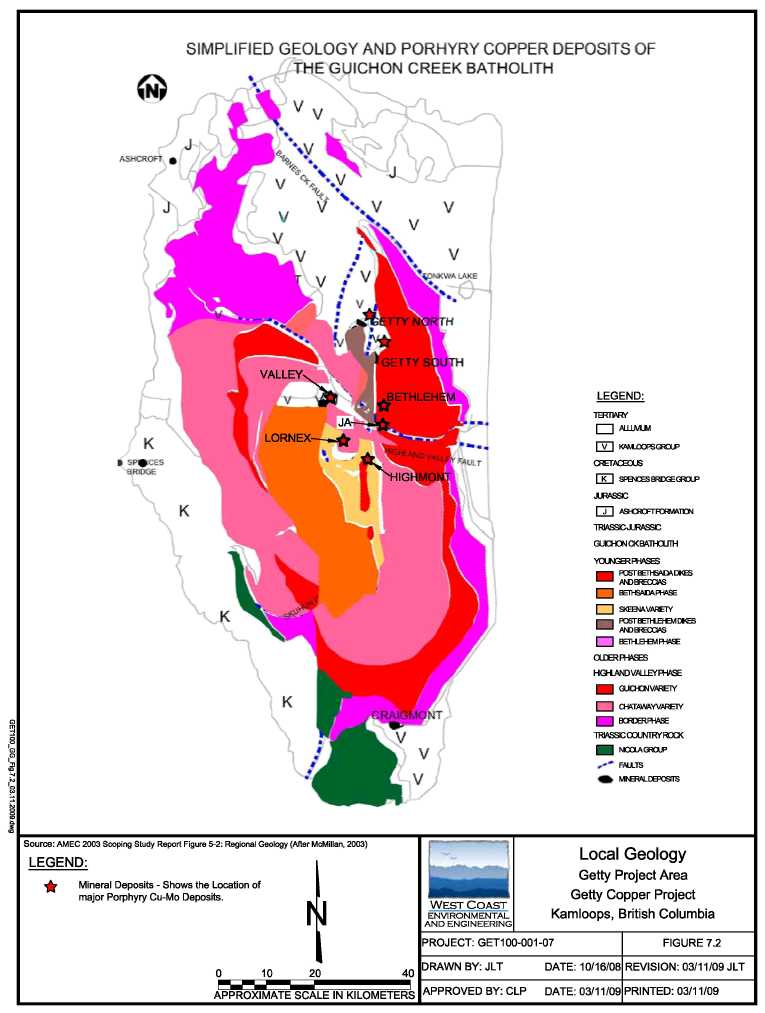

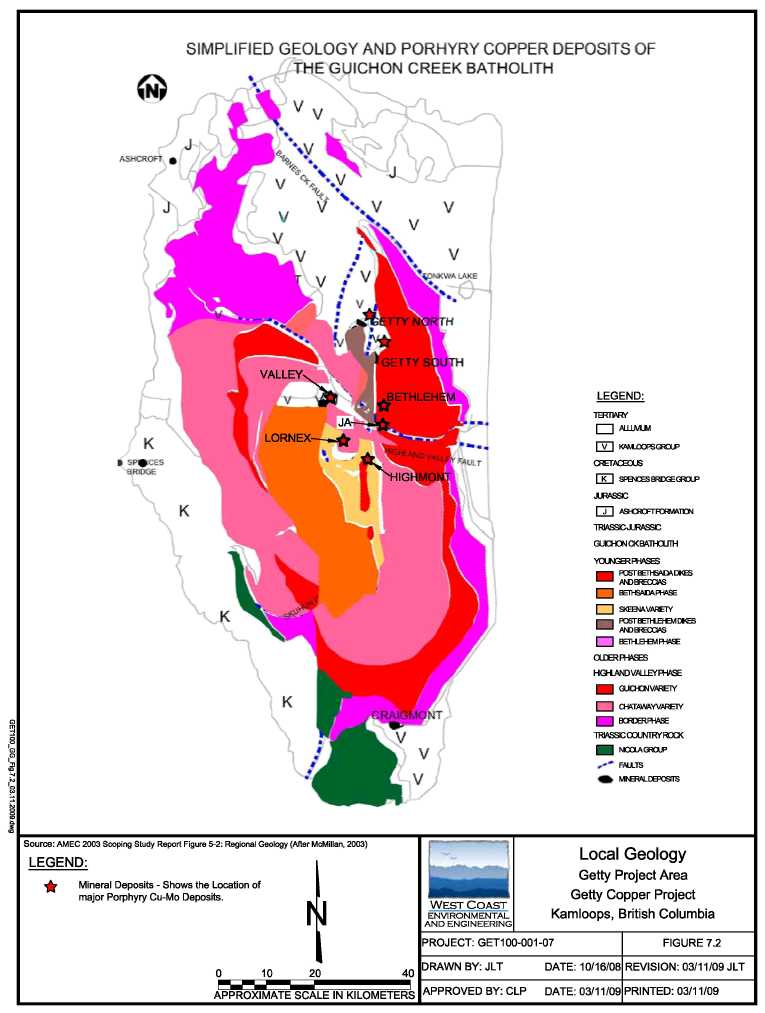

| Figure 7.2 | Local Geology, Getty Project Area | 22 |

| Figure 7.3 | Geology, Getty North Deposit | 23 |

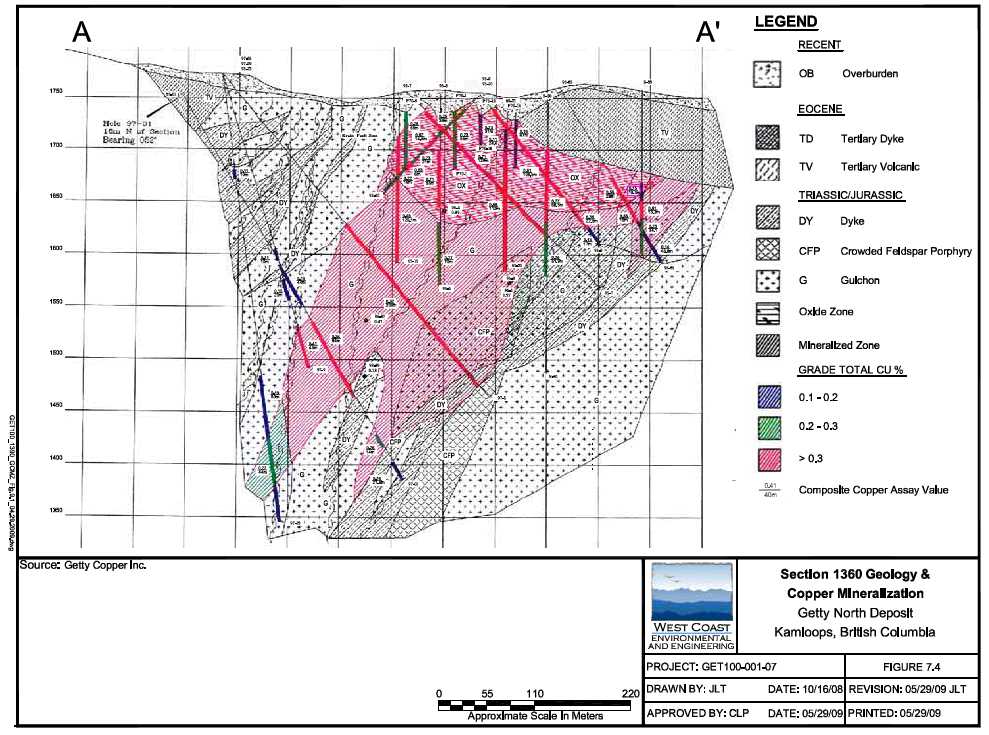

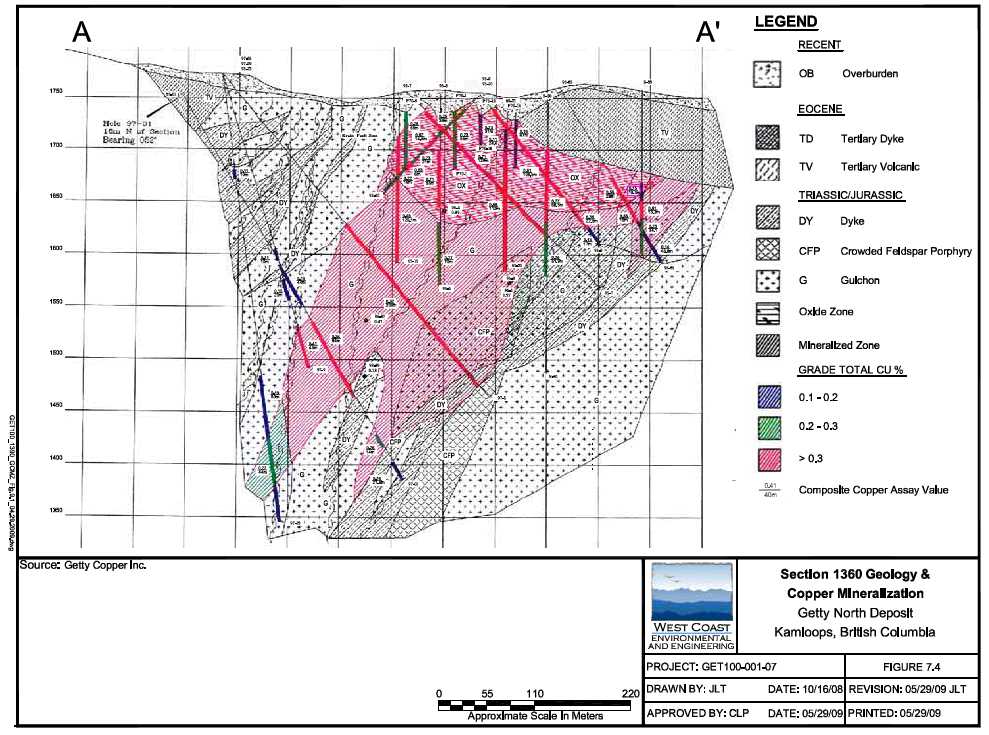

| Figure 7.4 | Section 1360 Geology and Copper Mineralization, Getty North Deposit | 24 |

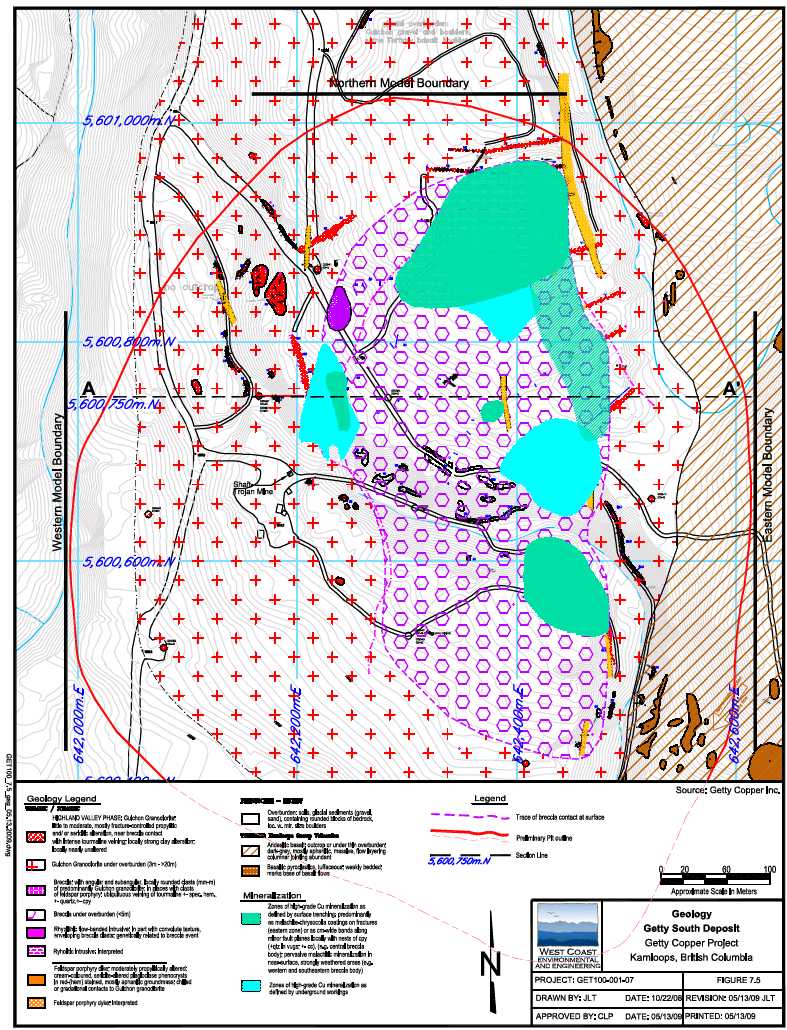

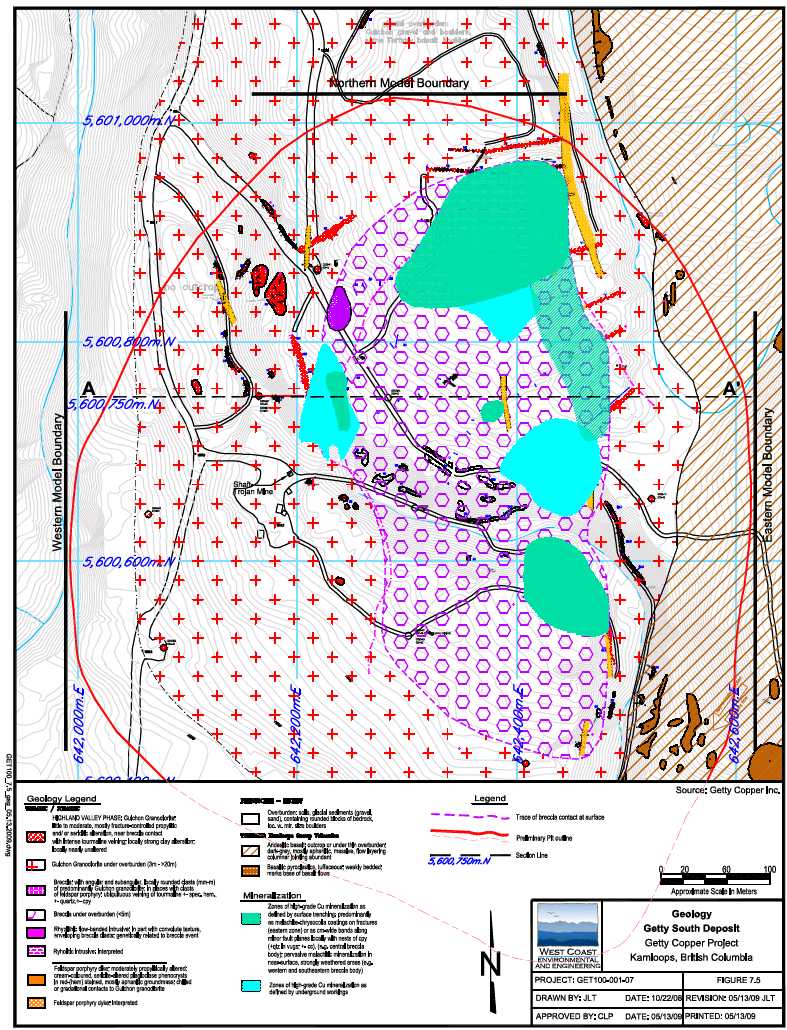

| Figure 7.5 | Geology, Getty South Deposit | 27 |

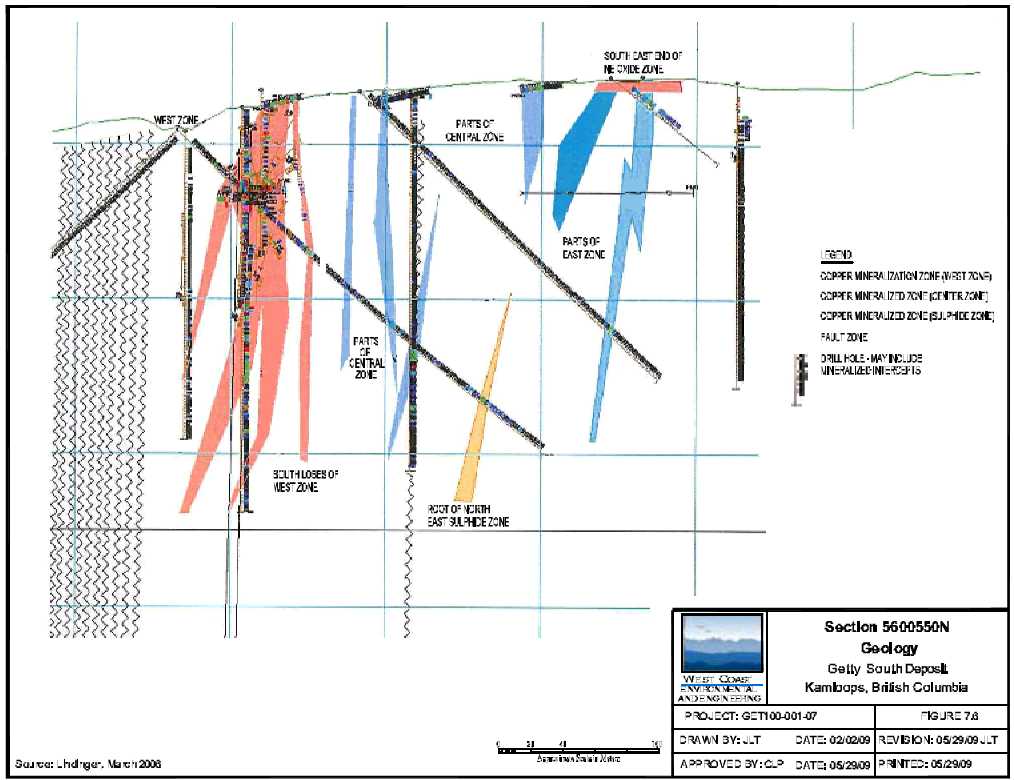

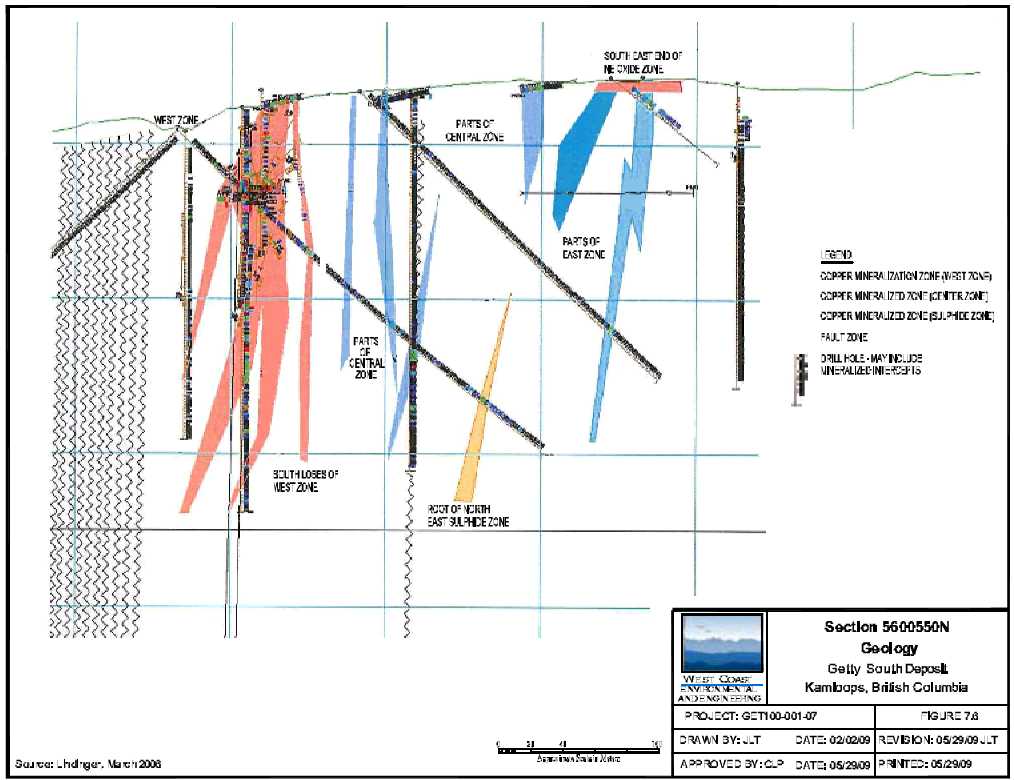

| Figure 7.6 | Section 5600550N, Getty South Deposit | 28 |

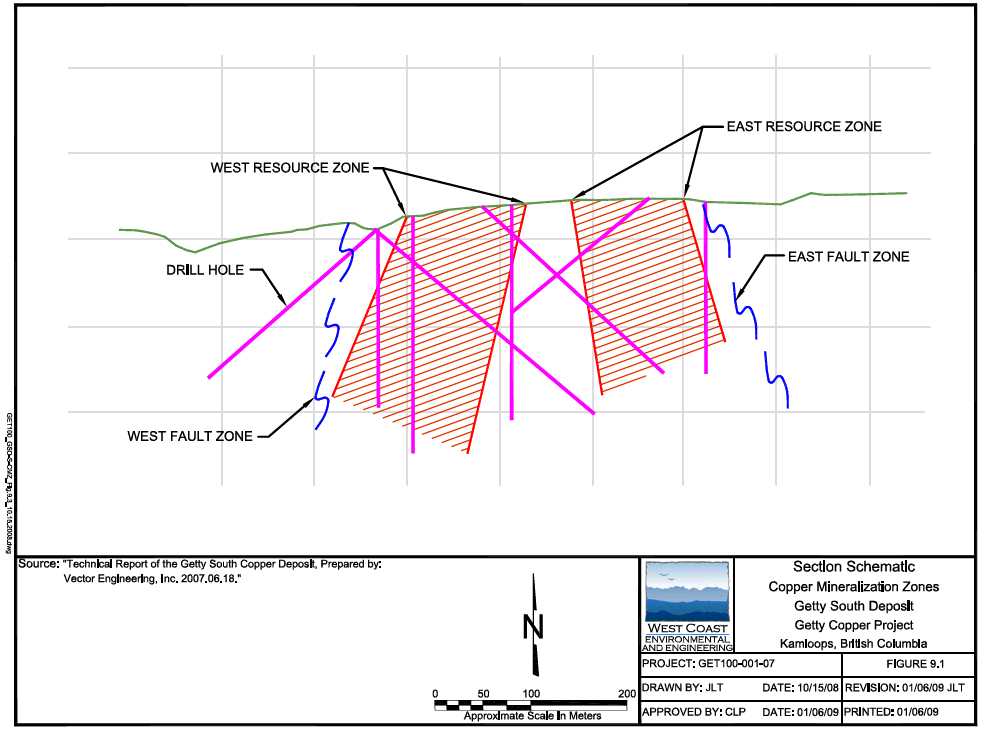

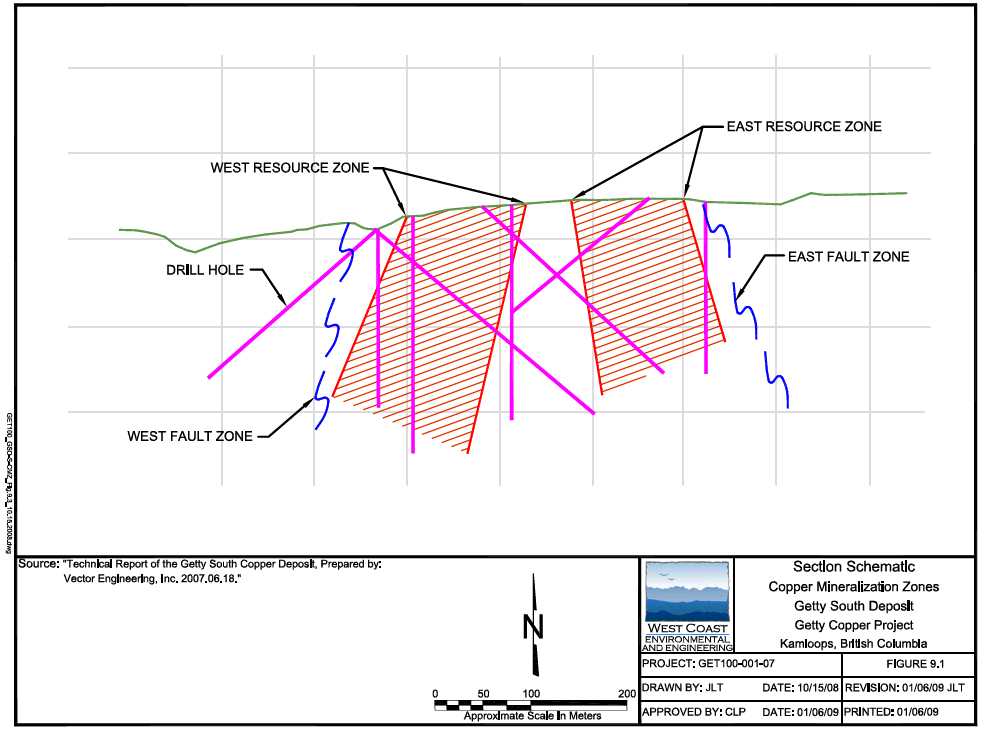

| Figure 9.1 | Section Schematic, Copper Mineralization Zone Getty South Deposit | 34 |

| Figure 10.1 | Map of 1997 Trenching, Getty South Property | 37 |

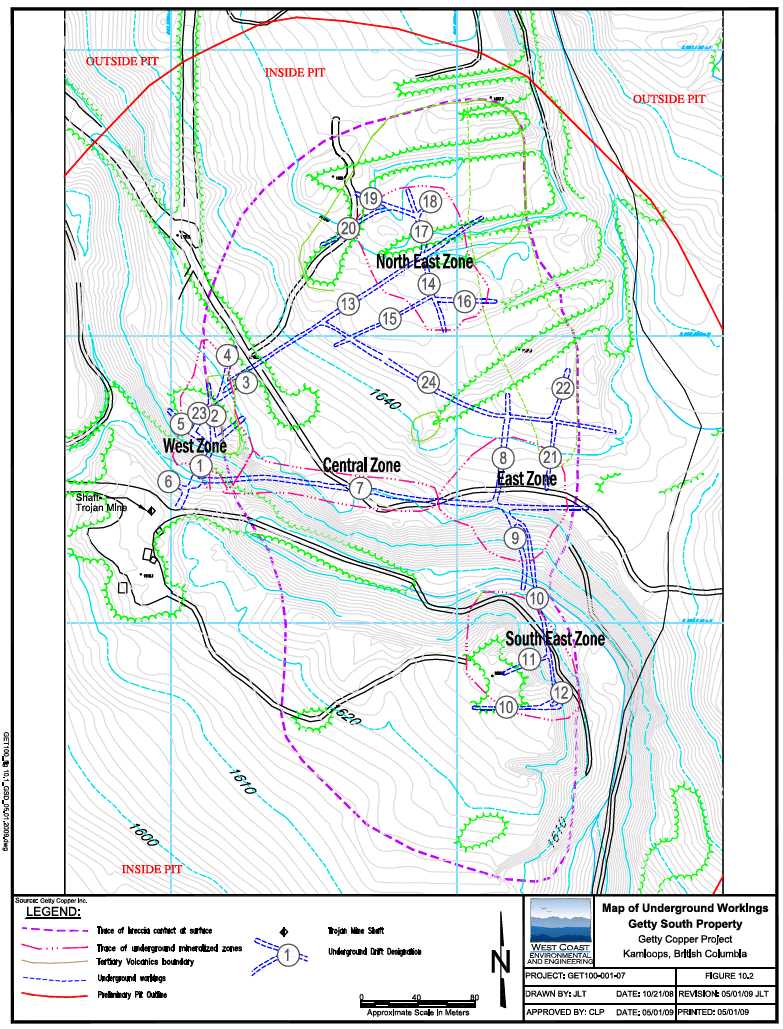

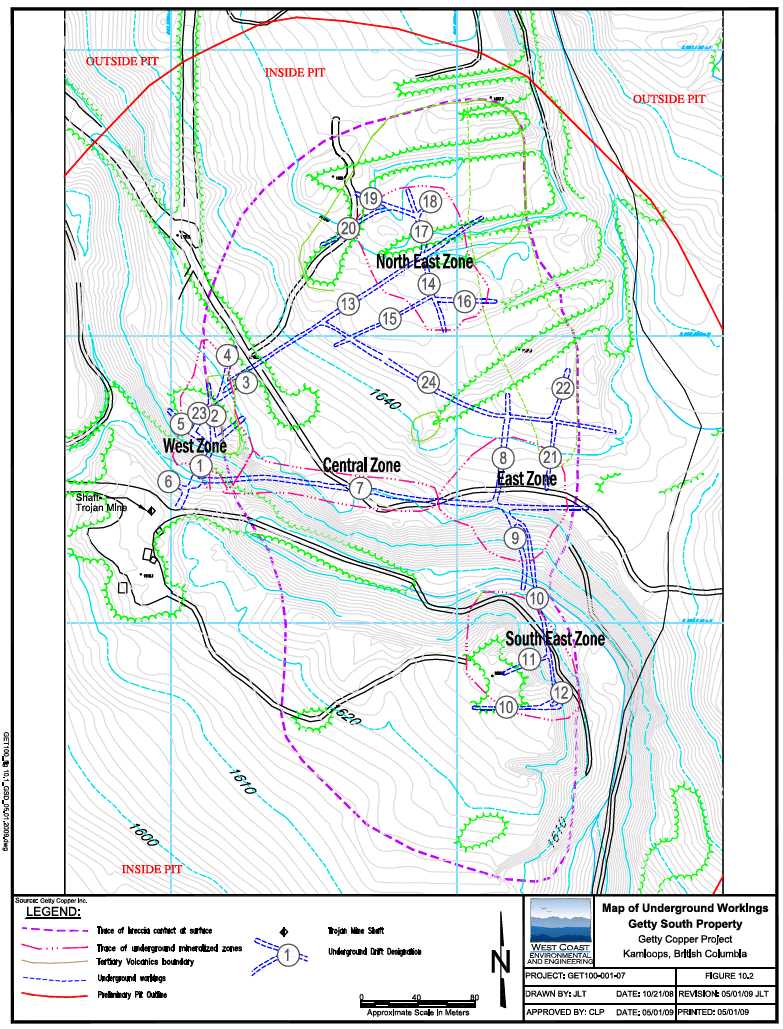

| Figure 10.2 | Map of Underground Workings, Getty South Property | 38 |

| Figure 11.1 | Locations of Drill Holes, Getty North Property | 43 |

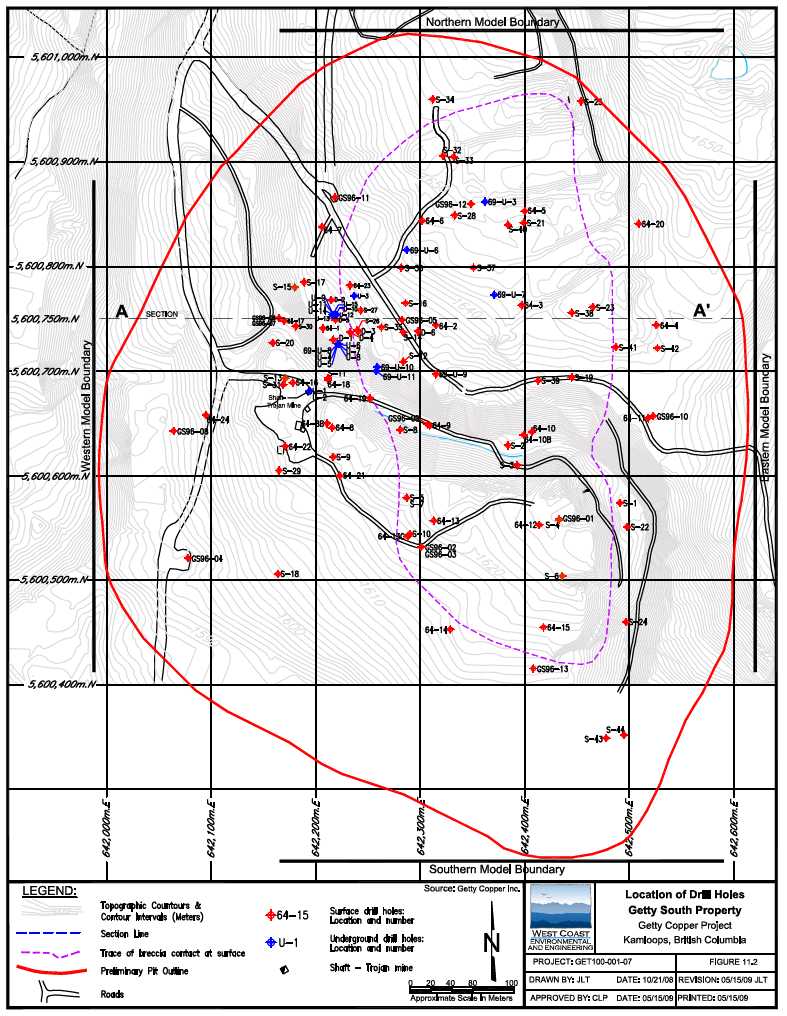

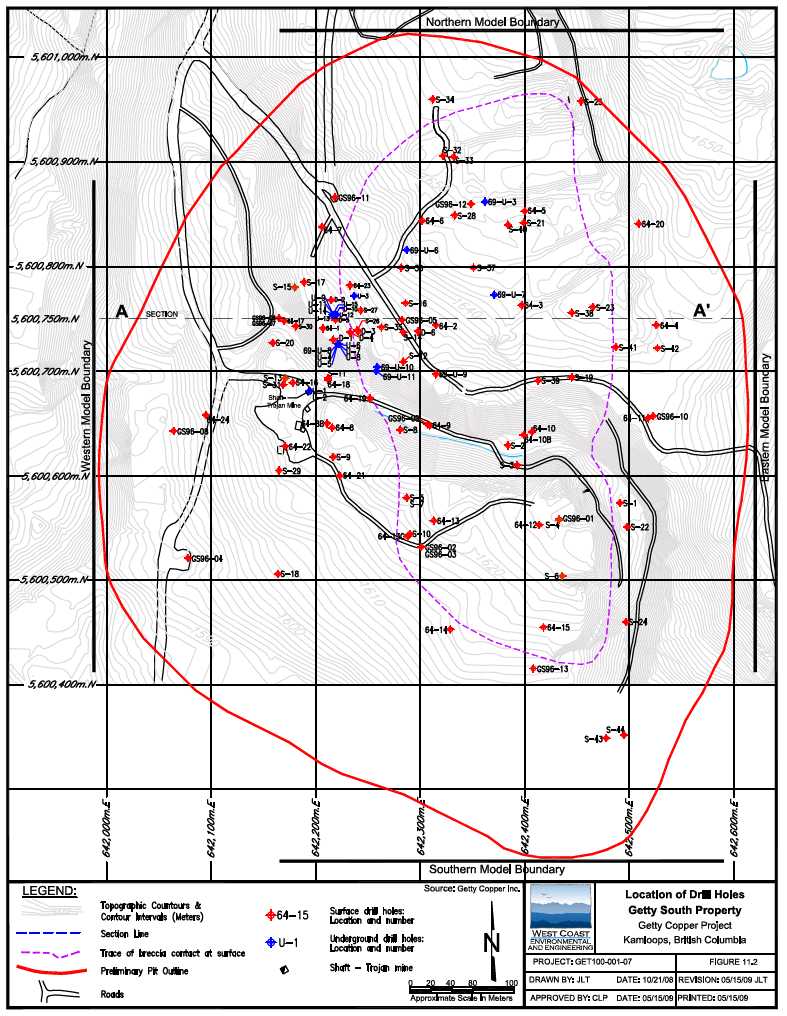

| Figure 11.2 | Location of Drill Holes, Getty South Property | 46 |

| Figure 16.1 | Ore Production Flowsheet | 74 |

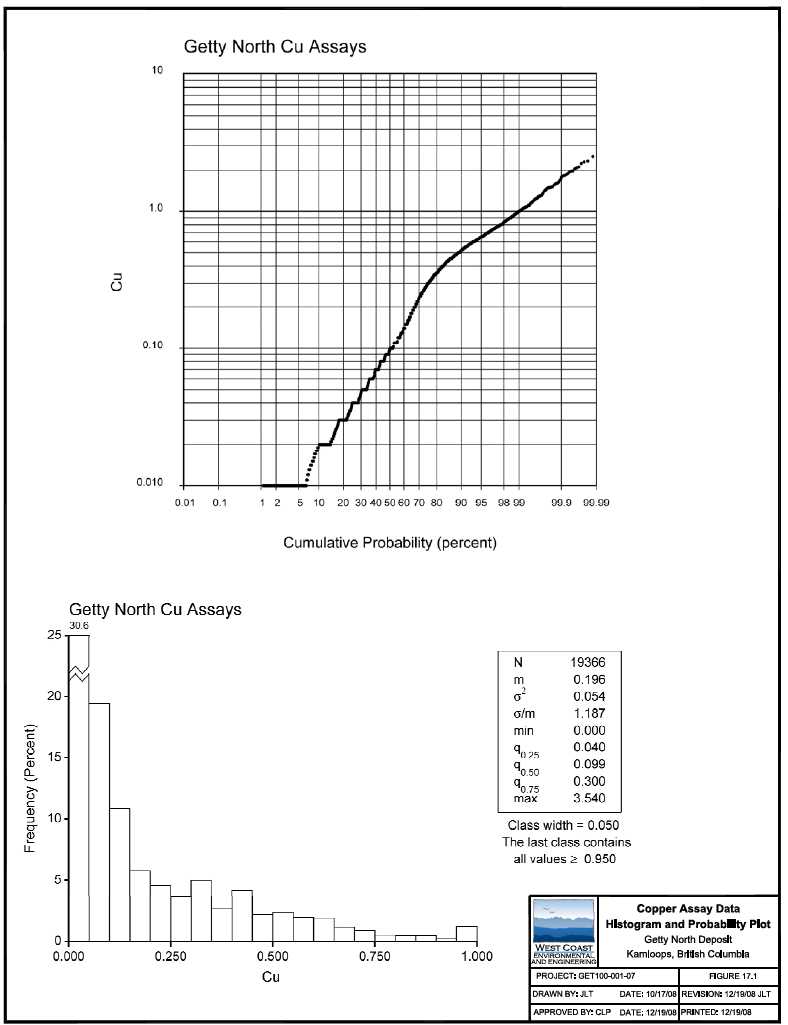

| Figure 17.1 | Getty North Cu Assay Frequency Histogram & Cumulative Probabilty Plot | 123 |

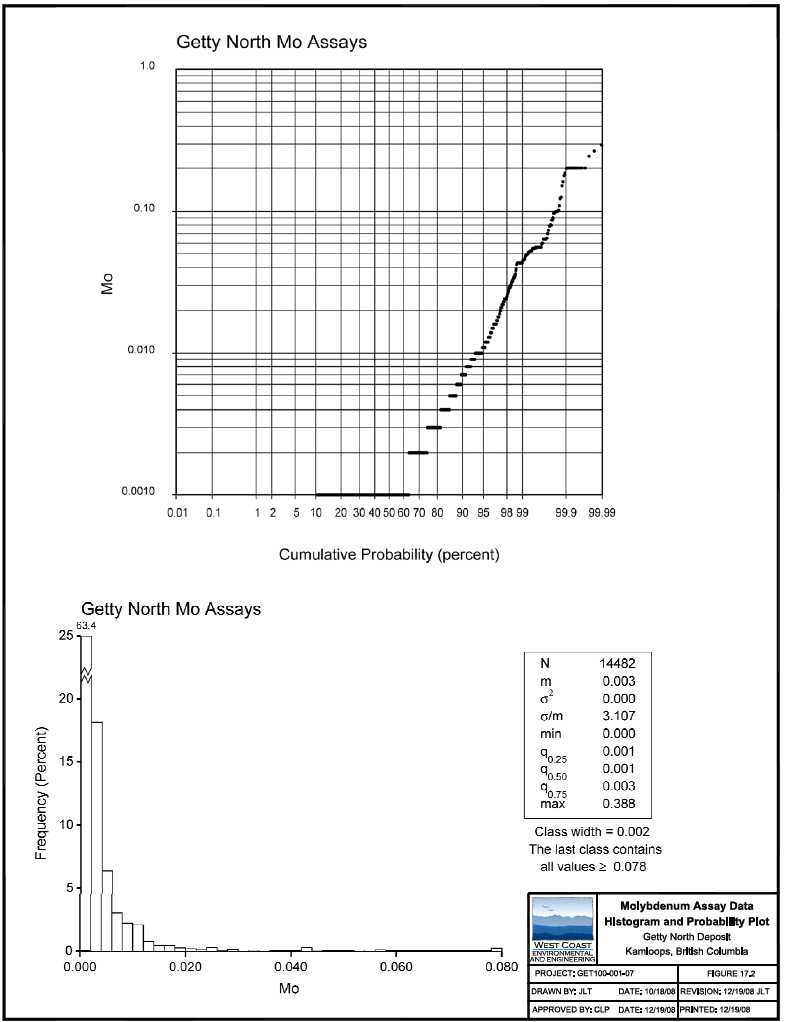

| Figure 17.2 | Getty North Mo Assay Frequency Histogram & Cumulative Probability Plot | 124 |

| Figure 17.3 | Getty South Cu Assay Frequency Histogram & Cumulative Probability Plot | 125 |

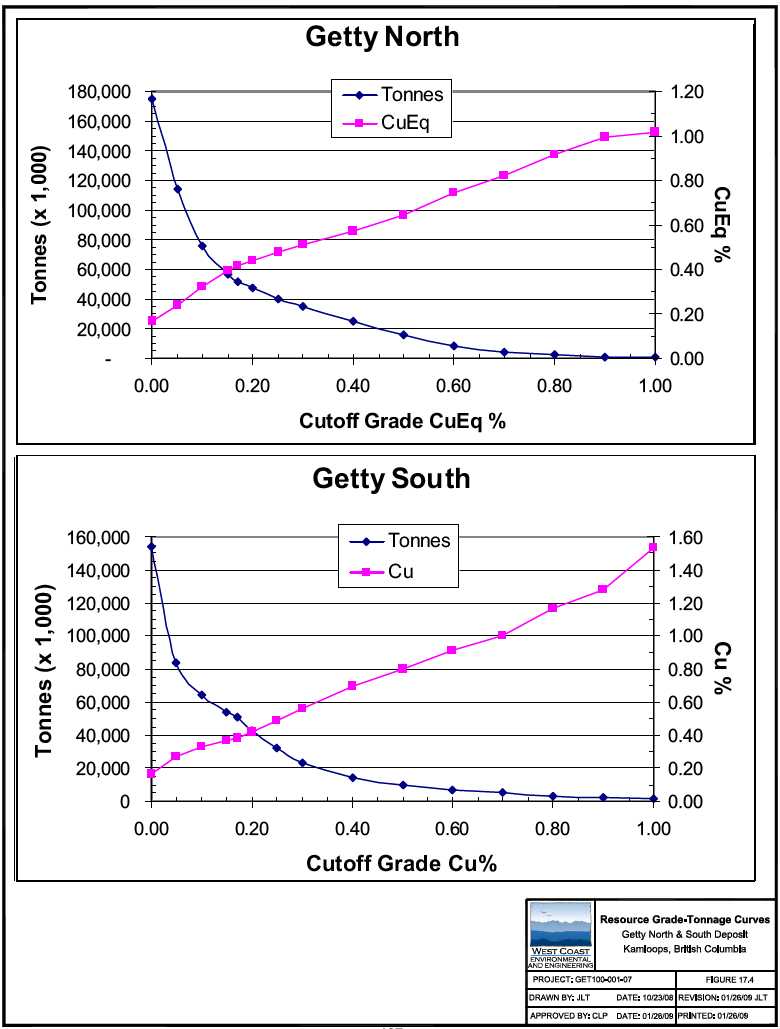

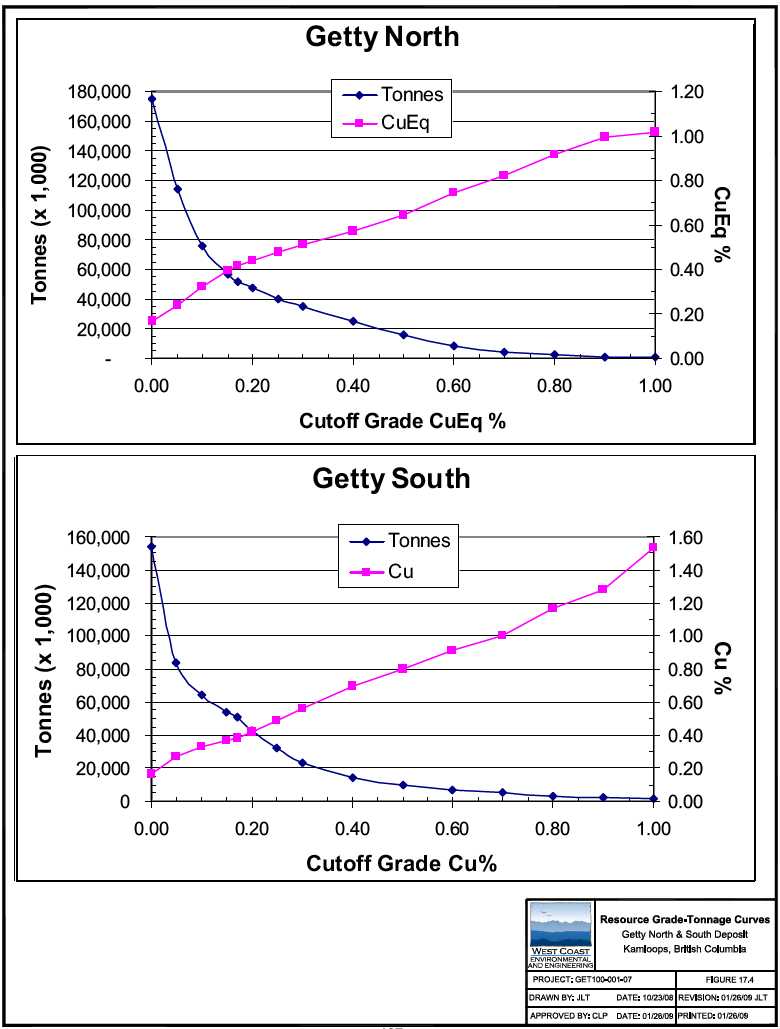

| Figure 17.4 | Resource Tonnes and Grade Distribution | 127 |

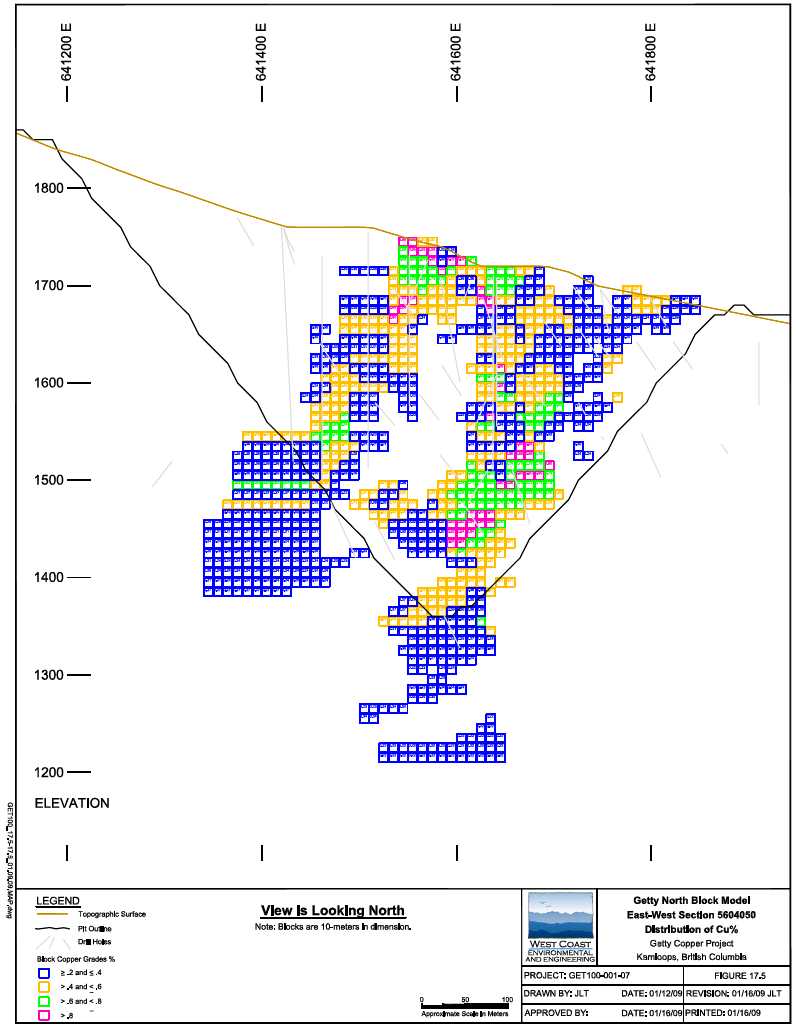

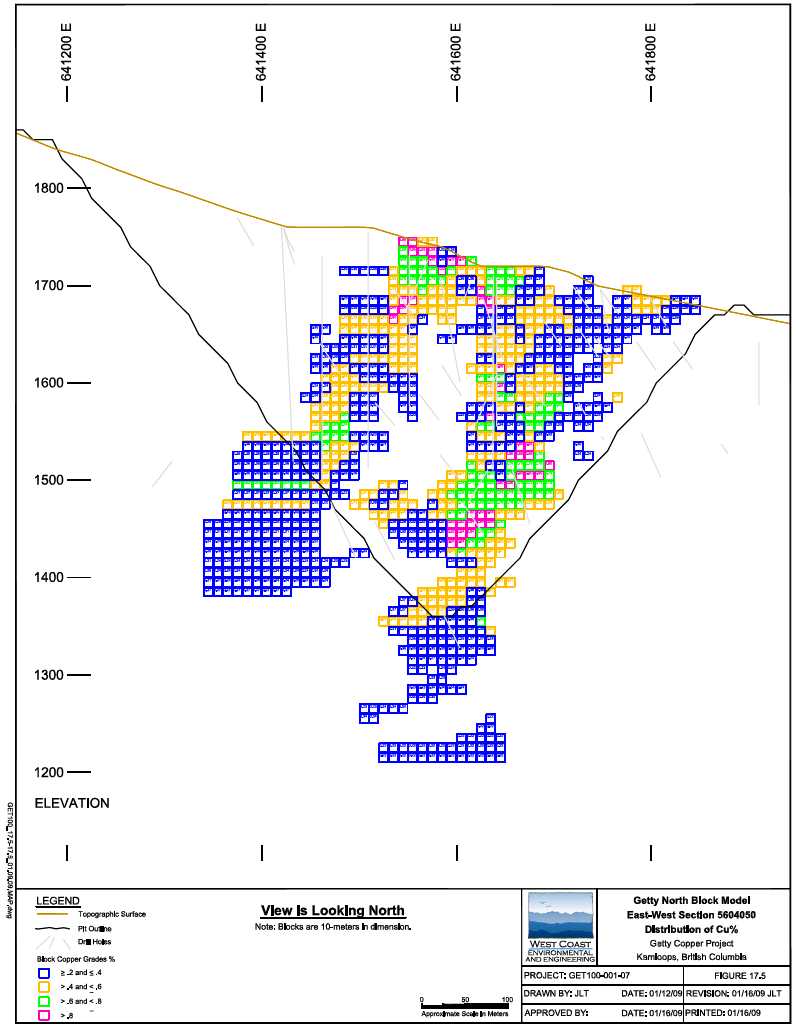

| Figure 17.5 | Getty North Block Model East-West Section 5604050 | 128 |

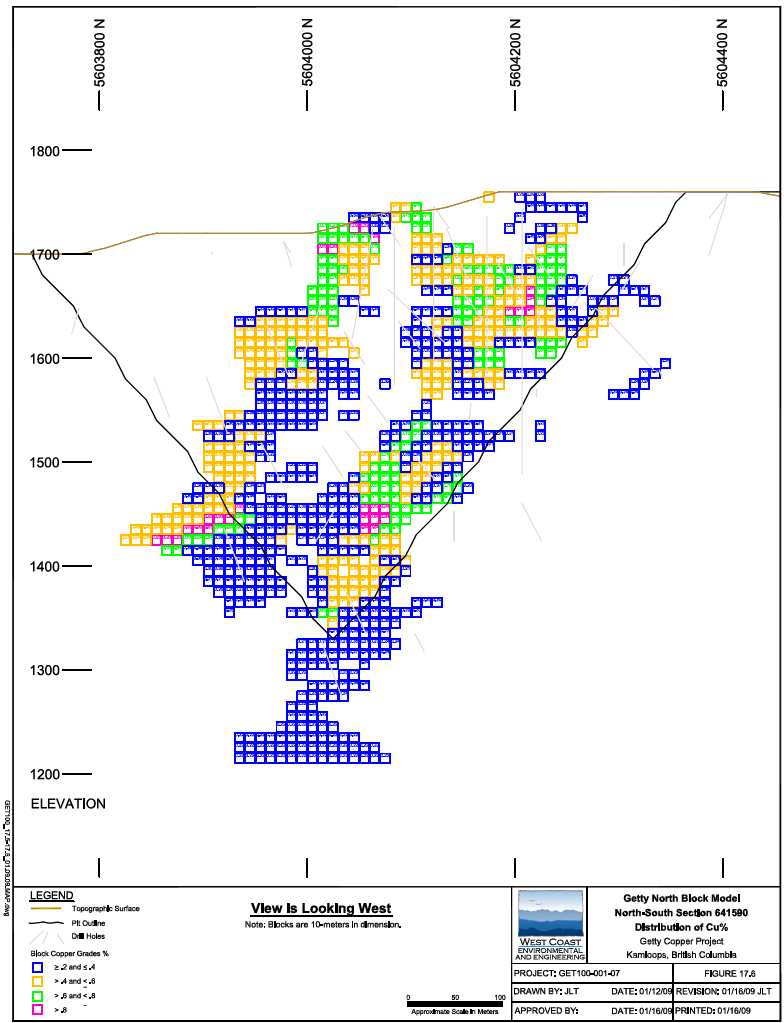

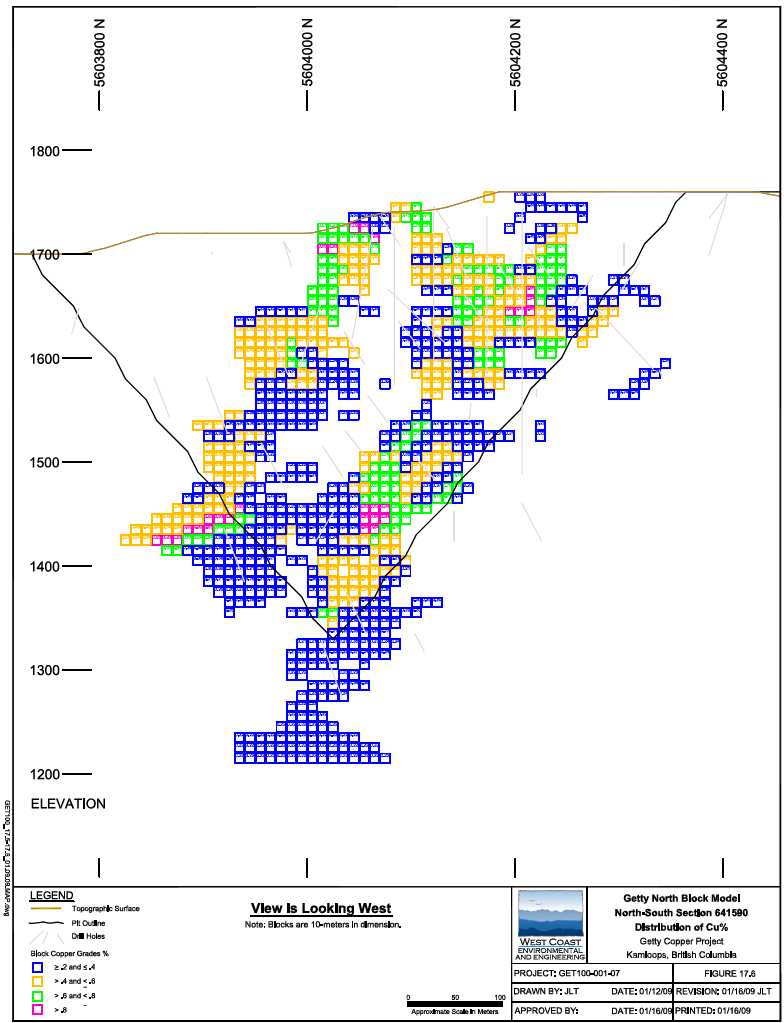

| Figure 17.6 | Getty North Block Model North-South Section 641590 | 129 |

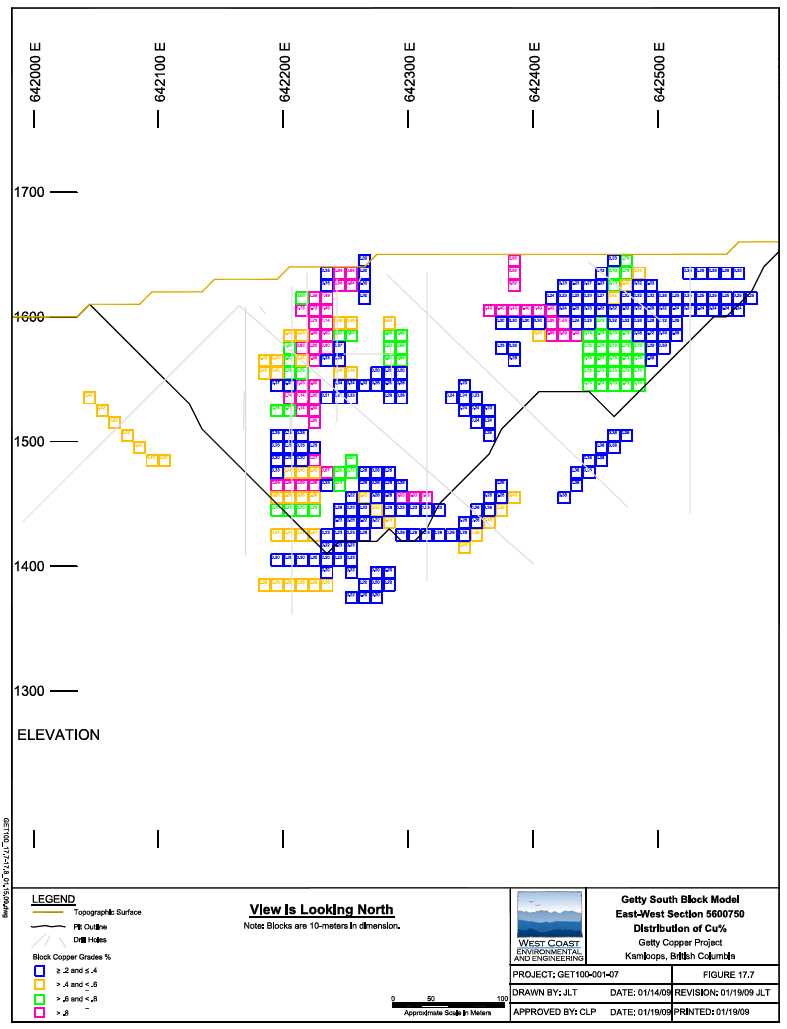

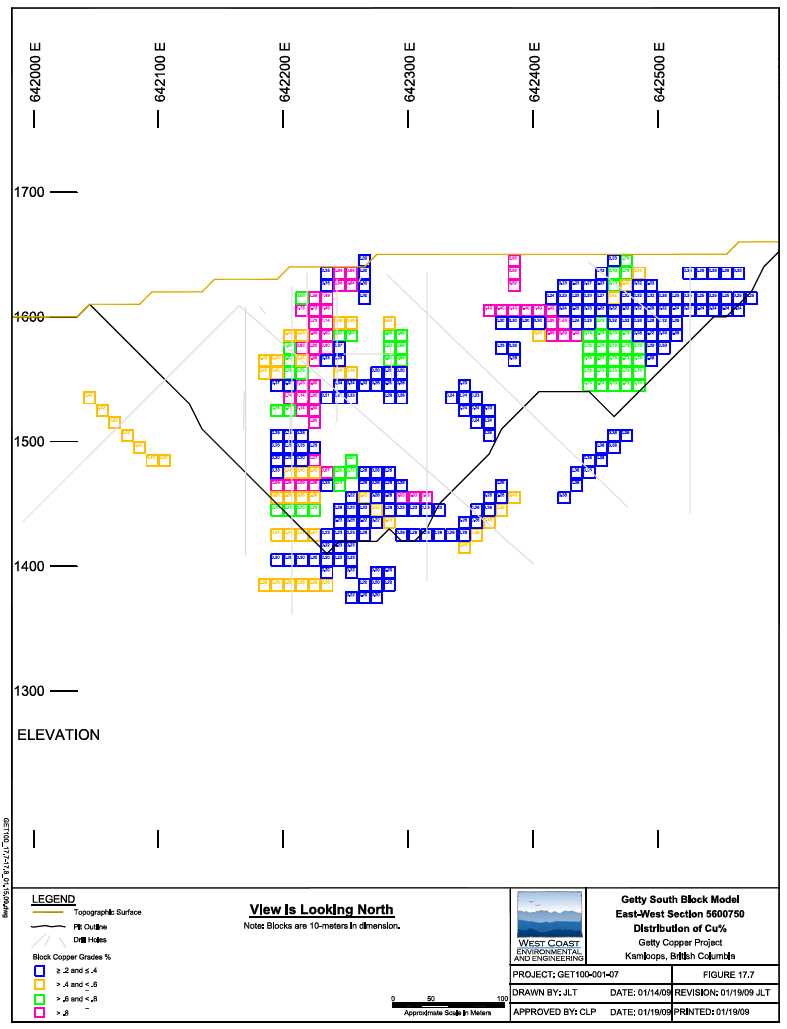

| Figure 17.7 | Getty South Block Model East-West Section 5600750 | 130 |

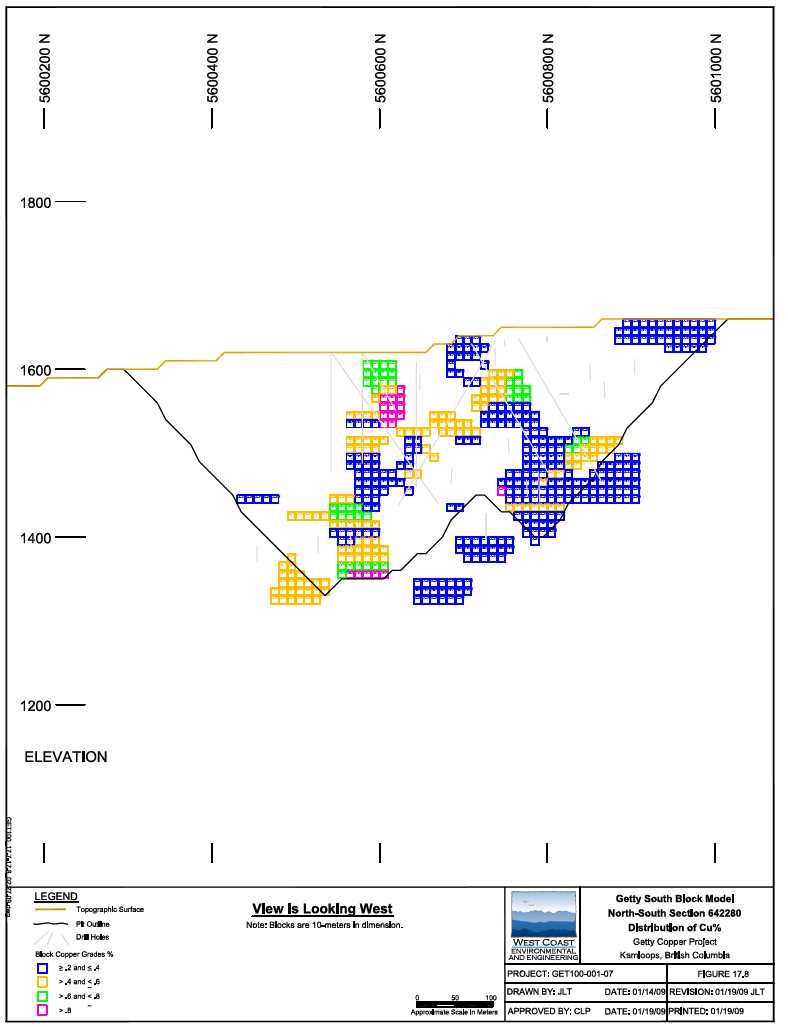

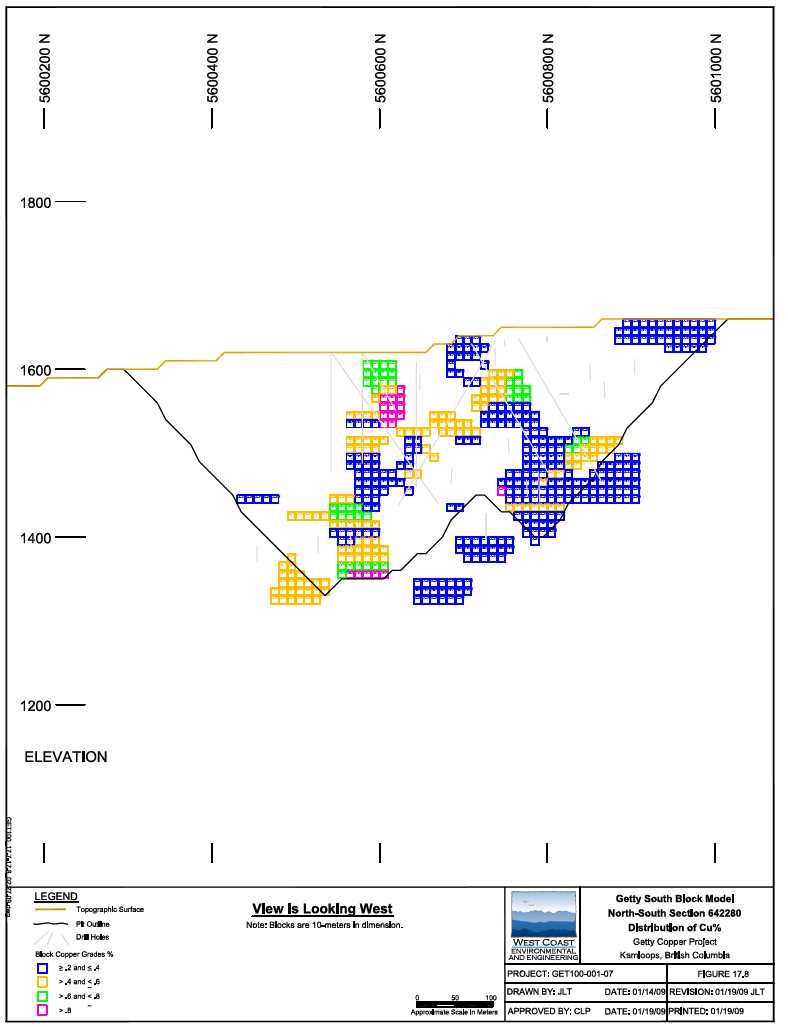

| Figure 17.8 | Getty South Block Model North-South Section 642280 | 131 |

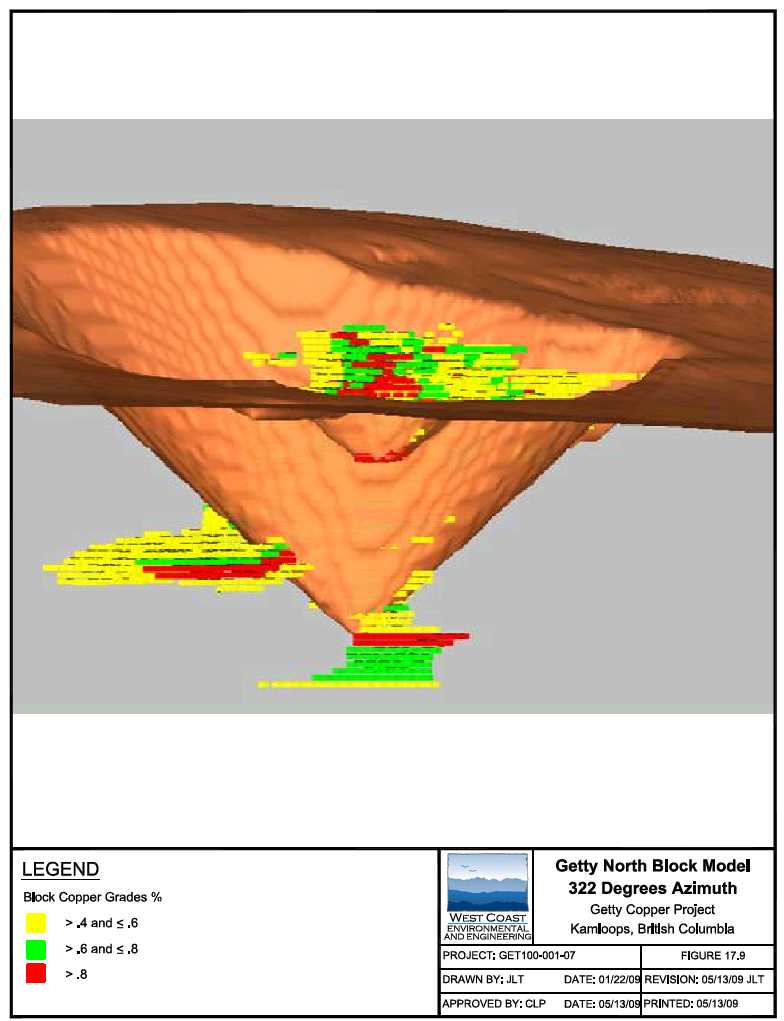

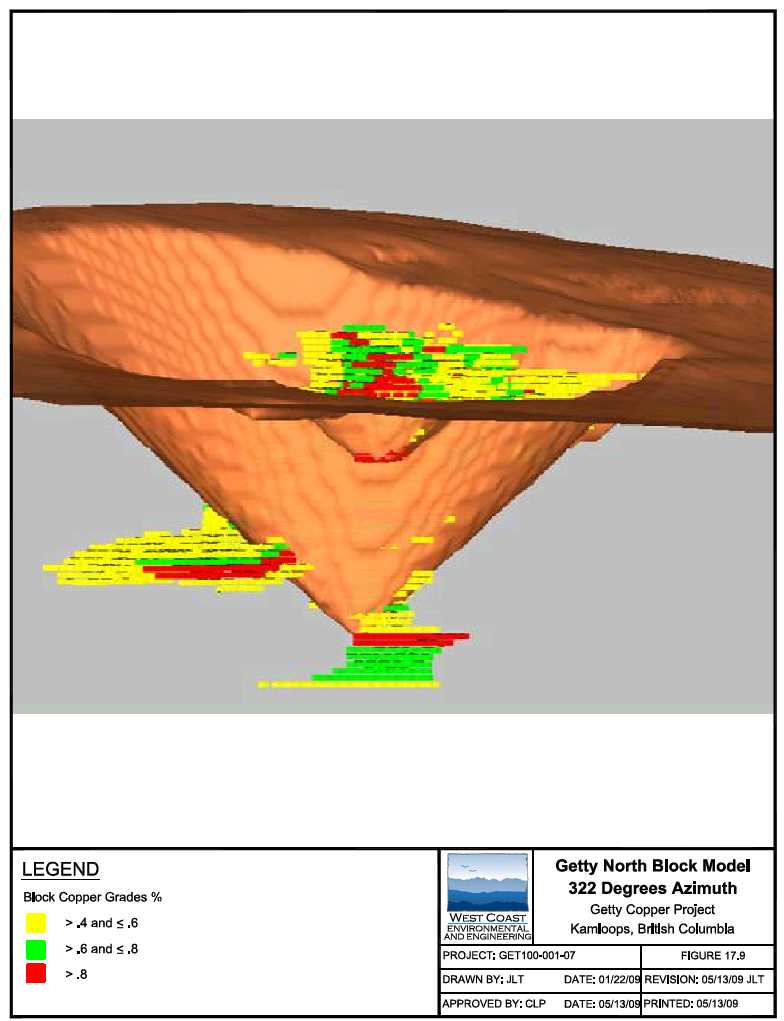

| Figure 17.9 | Getty North Block Model 322 Azimuth 3D Perspective | 132 |

| Figure 17.10 | Getty South Block Model 376 Azimuth 3D Perspective | 133 |

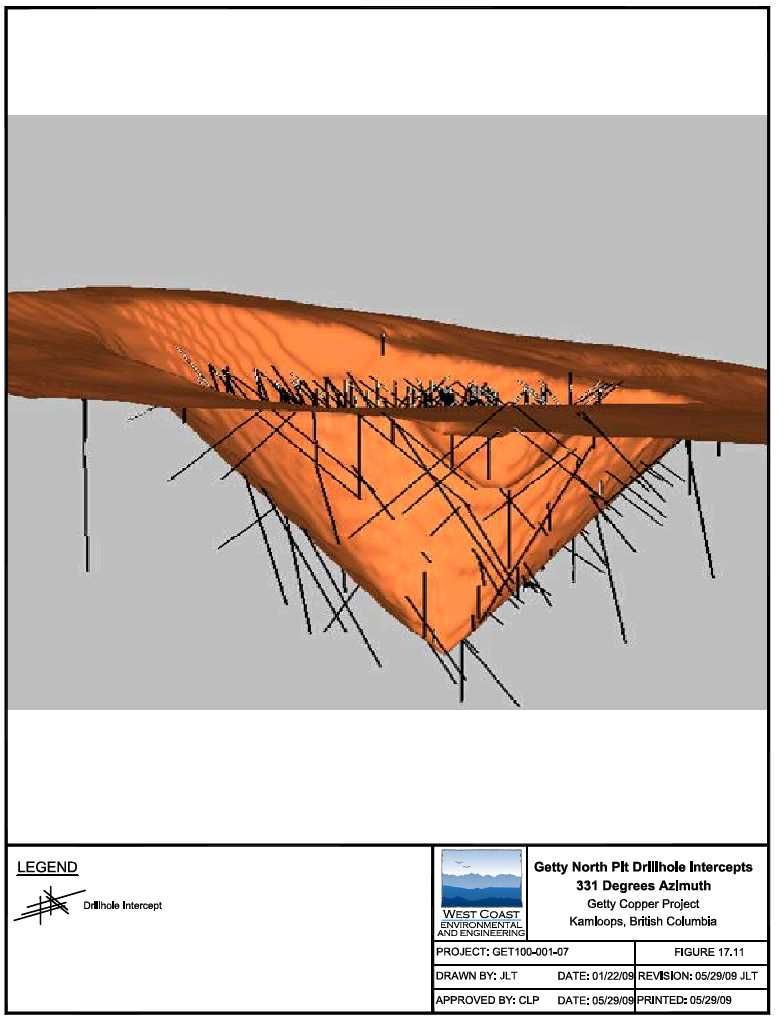

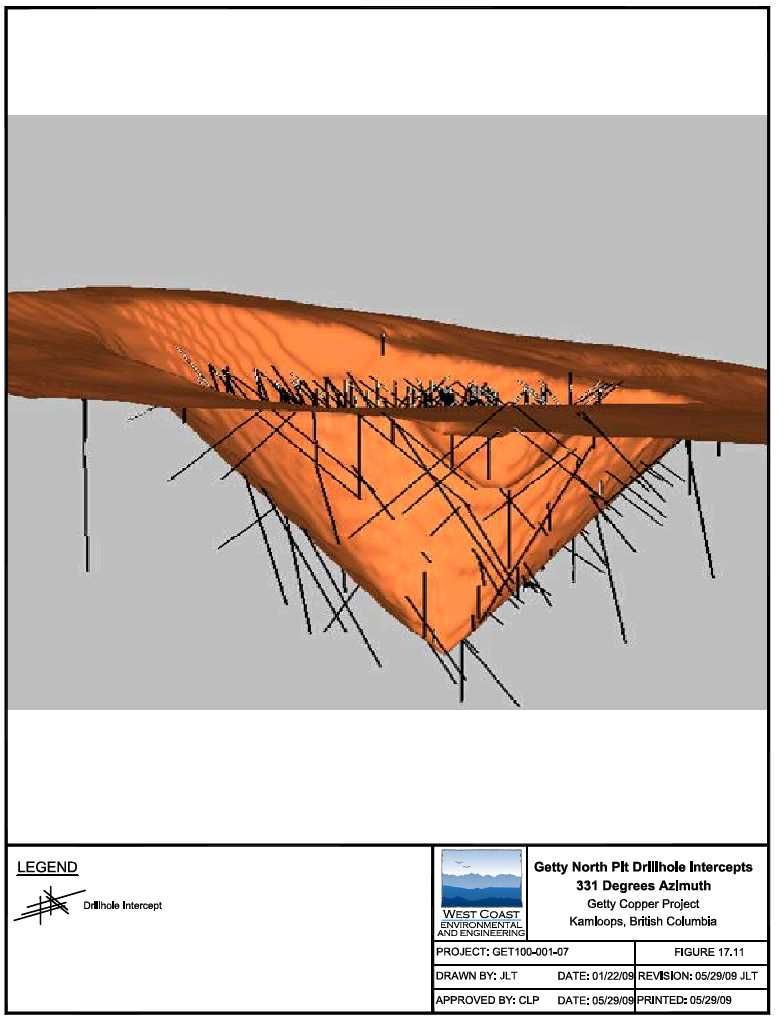

| Figure 17.11 | Getty North Model Drillhole Intercepts 331 Azimuth | 134 |

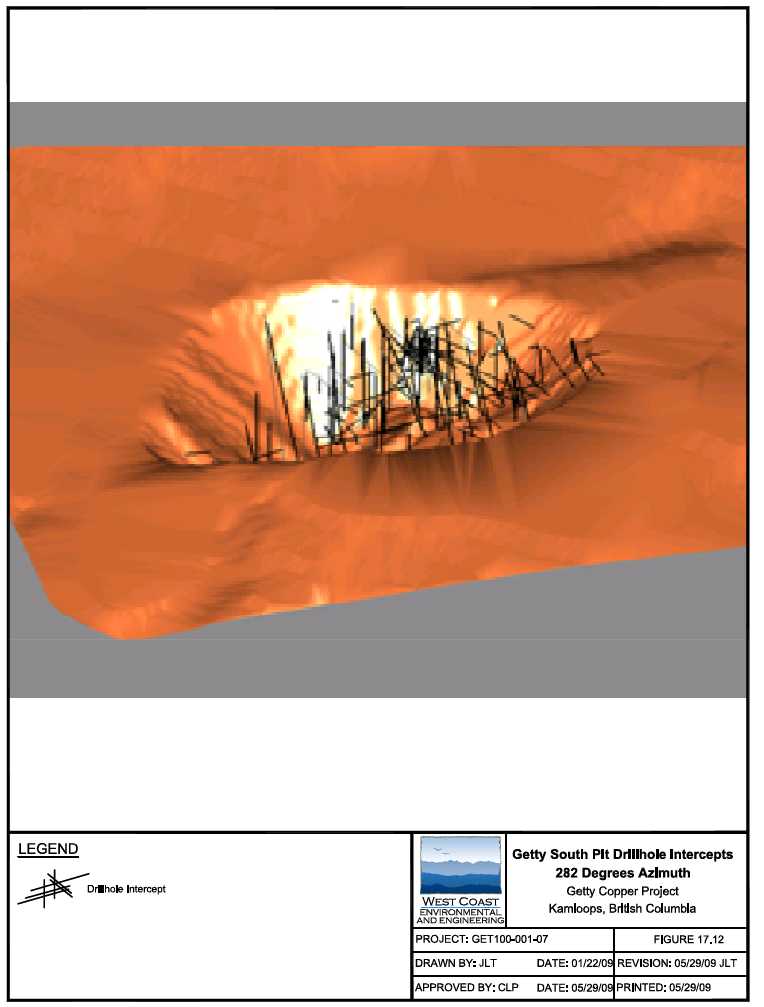

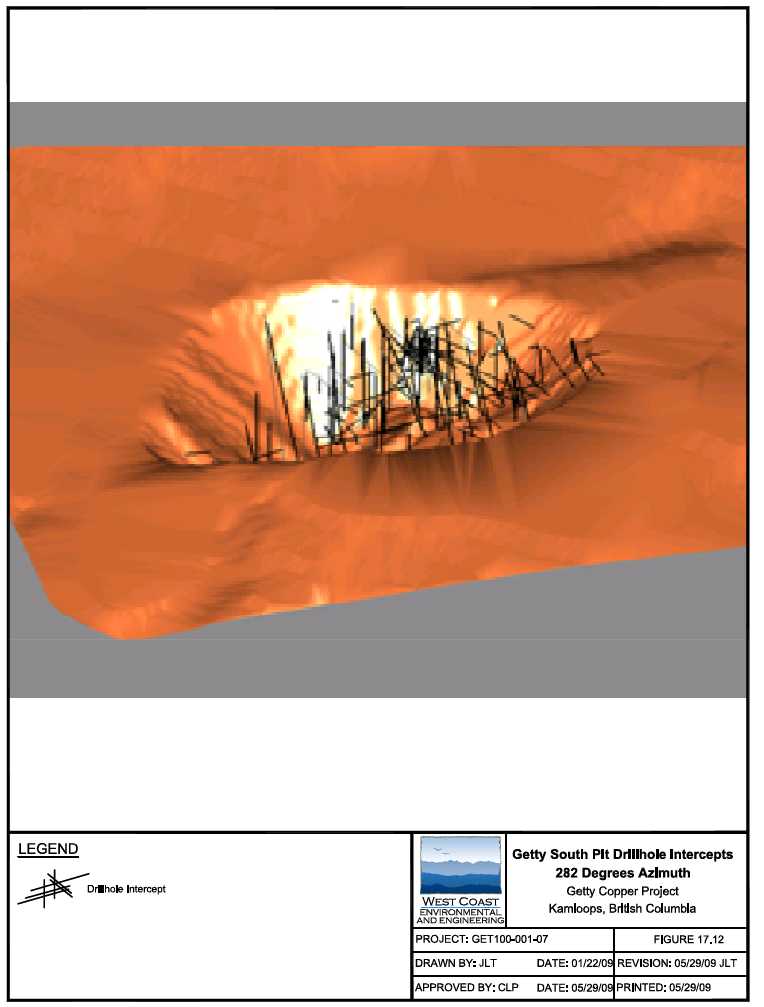

| Figure 17.12 | Getty South Model Drillhole Intercepts 274 Azimuth | 135 |

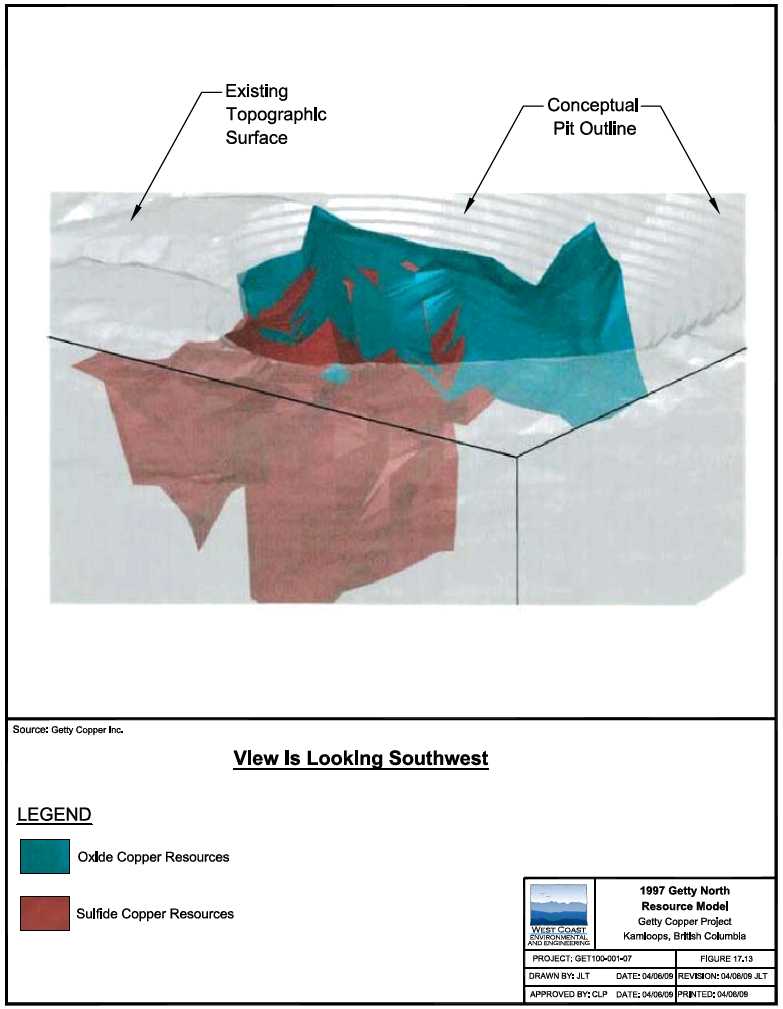

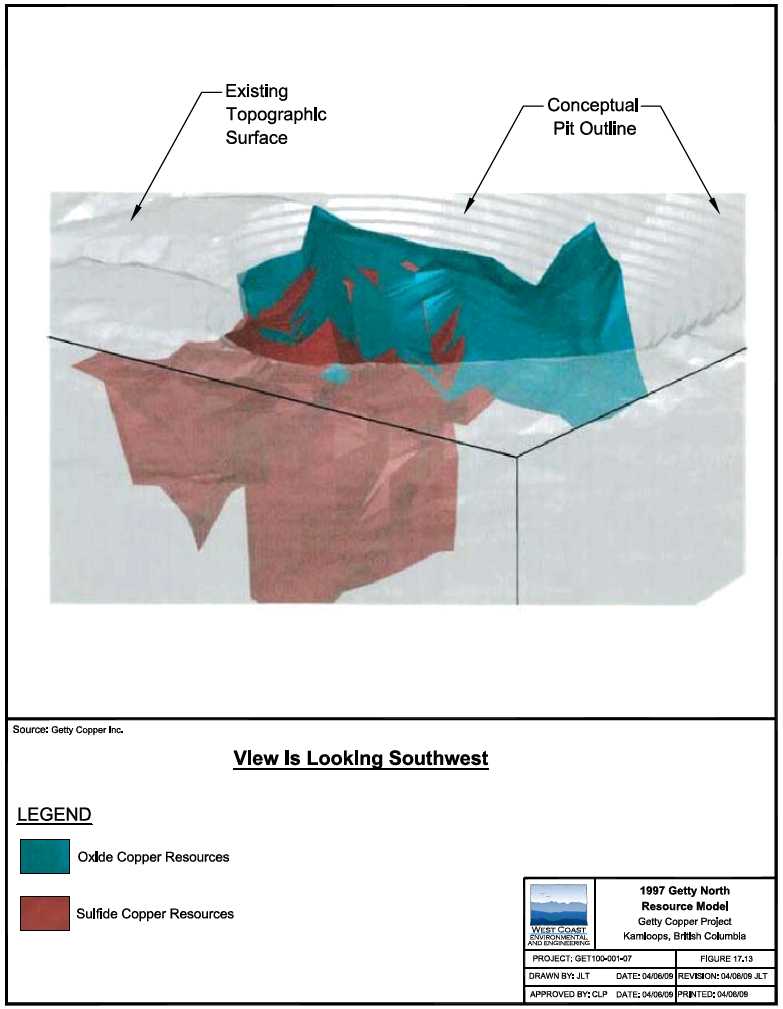

| Figure 17.13 | 1997 Getty North Resource Model | 136 |

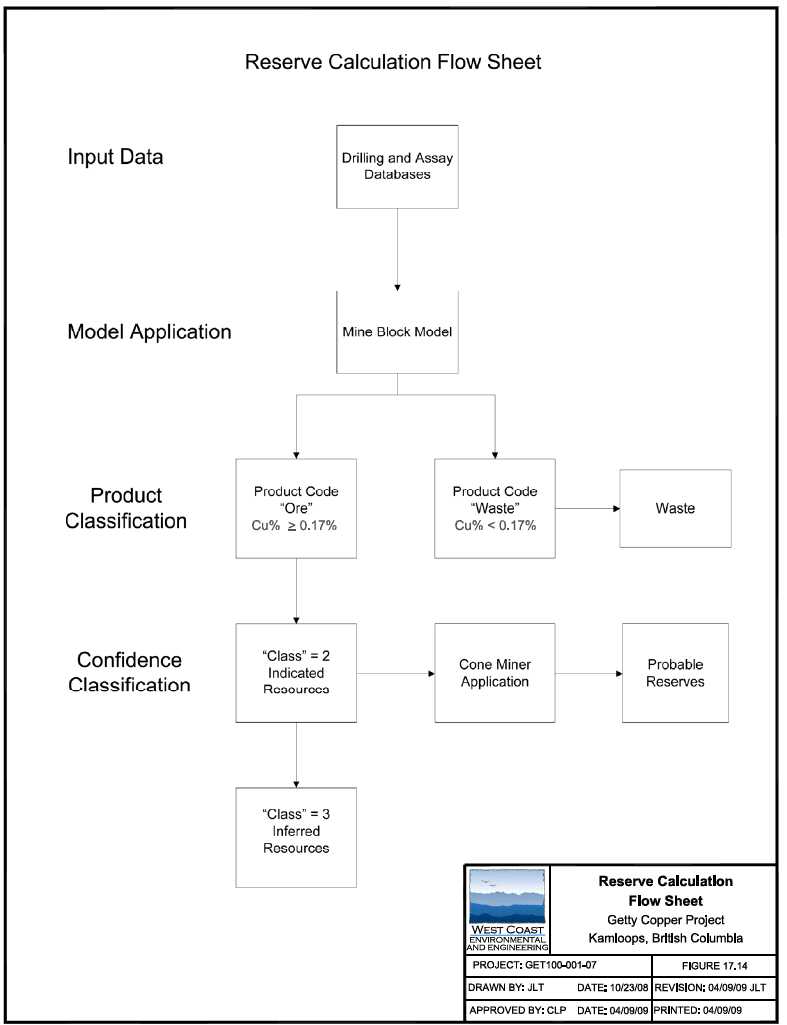

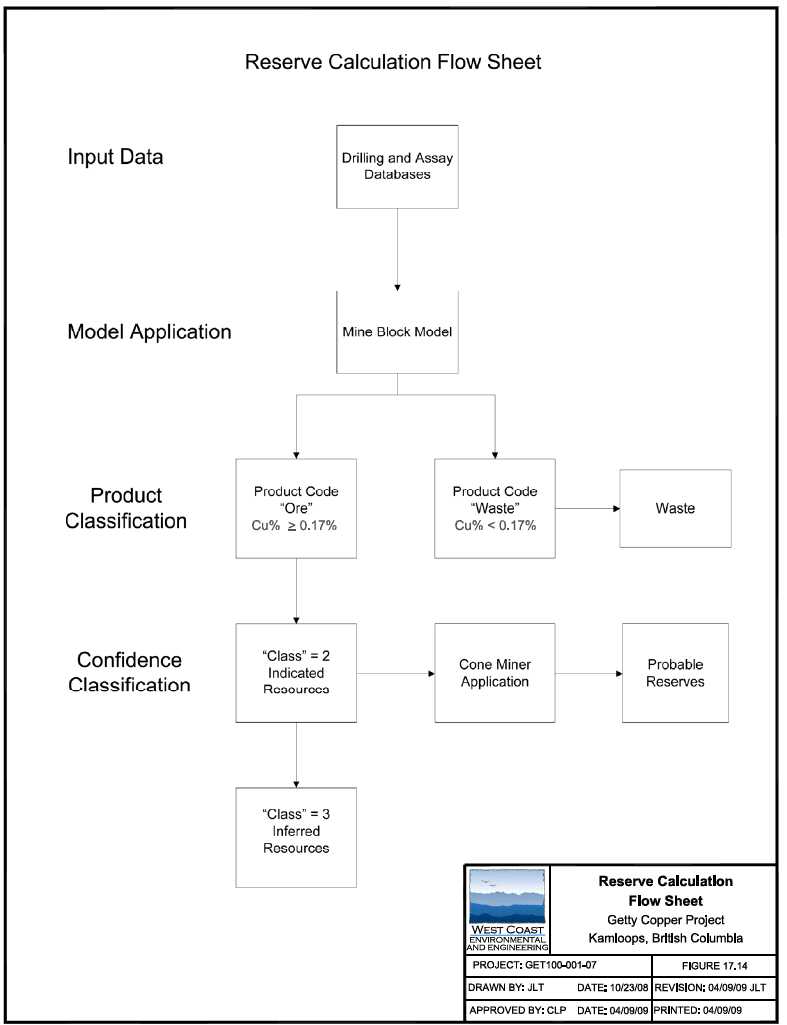

| Figure 17.14 | Reserve Calculation Flow Sheet | 138 |

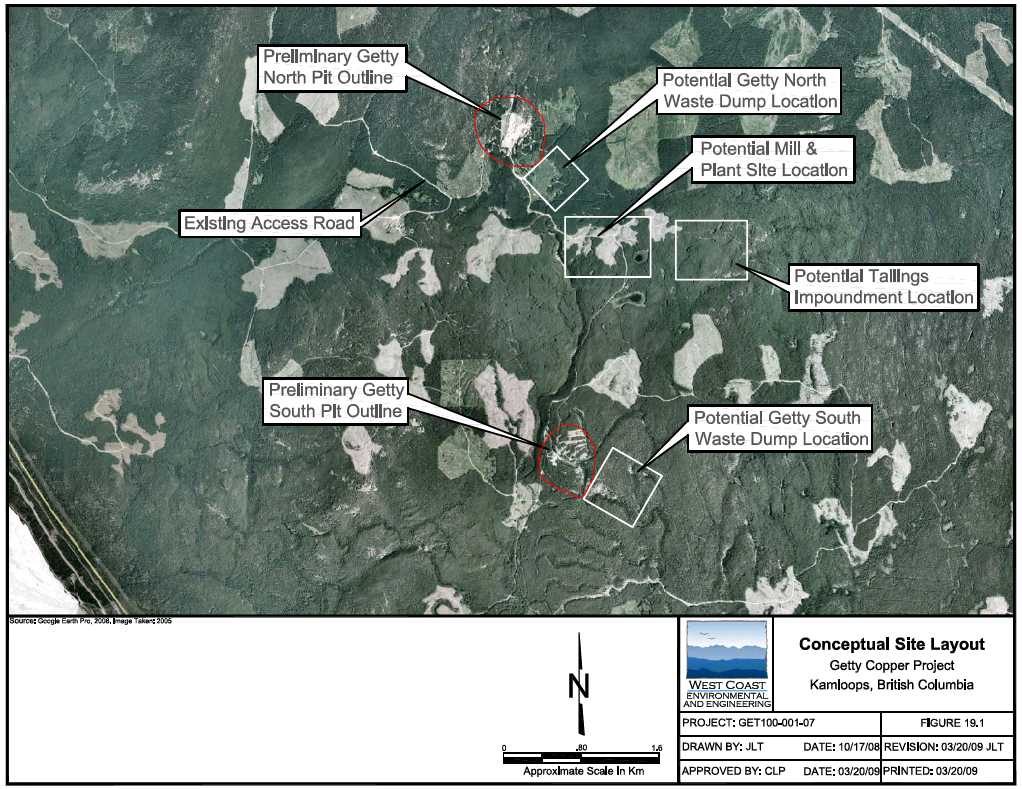

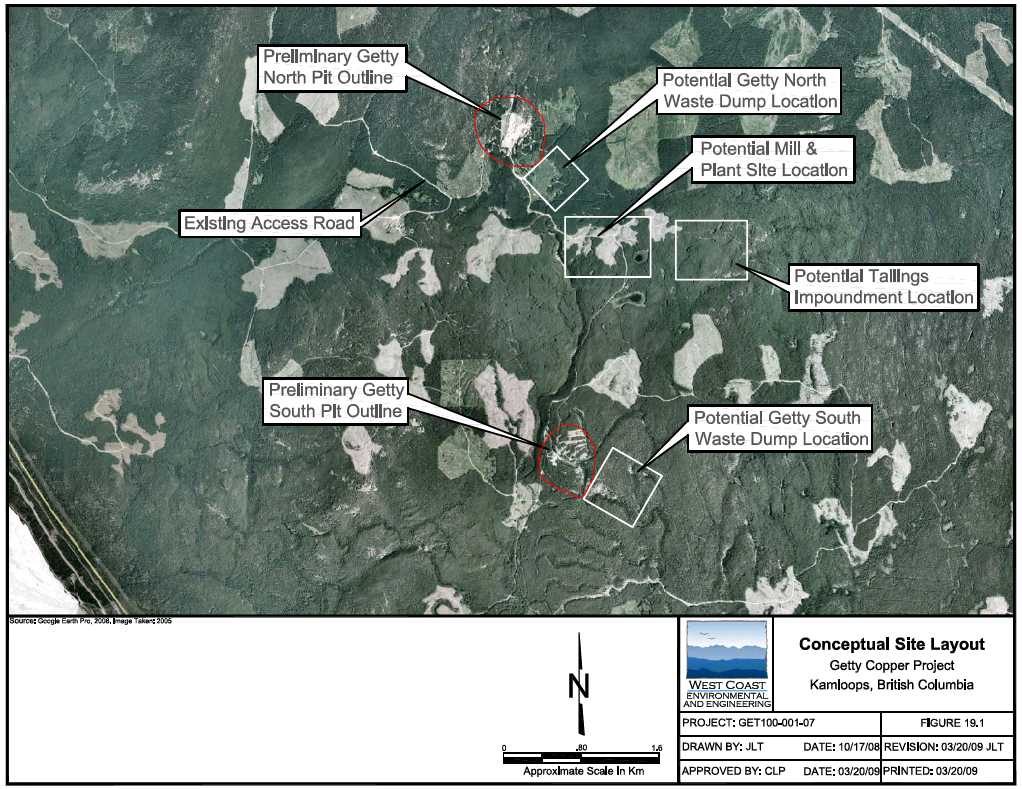

| Figure 19.1 | Conceptual Site Layout Map | 155 |

| | |

| get100-001_pre-fs_9june09a | vii | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| | |

| Figure 19.2 | Sensitivity Analysis IRR (Pre-Tax) | 175 |

| Figure 19.3 | Sensitivity Analysis NPV(0%) (Pre-Tax) | 175 |

| | |

| get100-001_pre-fs_9june09a | viii | West Coast Environmental and |

| | | Engineering |

| |

| Nevada City |

| 101 Providence Mine Road, Suite 105 |

| Nevada City, CA 95959 |

| Phone 530/470-0215 Fax 530/687-9399 |

| |

| Ventura |

| 1838 Eastman Avenue, Suite 200 |

| Ventura, CA 93003 |

| Phone 805/644-7976 Fax 805/644-5929 |

| www.wcenviro.com |

Preliminary Feasibility Study

Technical Report of the

Getty Copper Project

West Coast Environmental and Engineering (WCE) was commissioned by Getty Copper Inc. (Getty Copper) to prepare a Preliminary Feasibility Study compliant with National Instrument 43-101 (NI 43-101). The Getty North and South deposits constitute the focus of this Preliminary Feasibility Study and are collectively termed herein the Getty Project.

The purpose of this report is to provide estimates of copper and molybdenum resources and reserves within the Getty North and South deposits, prepare preliminary mining and processing plans, and perform subsequent economic analysis to determine the project feasibility. The resources are classified as inferred based on the sample density and geological modeling. The reserves are classified as probable based on current metal prices, mining and processing costs, and computer based mine modeling. A summary of the resources and reserves are provided in Tables 1-1 and 1-2 below.

The Getty Copper Project is located in the Kamloops Mining Division of British Columbia, Canada and consists of both the Getty North and Getty South Deposits. The area has historically produced appreciable amounts of copper and molybdenum.

Miles and Associates (2002) conducted a hydrometric study of the Getty North area during 1998 to 2001, during a period in which stream flows were identified as being smaller than average. They did not indicate water supply would be an issue with the Getty Project, and stated the results of their analysis should be adequate for initial mine site design and permitting requirements.

The Getty North property was acquired from Robak Industries Ltd. and Masco Capital Inc. in 1992. Past exploration efforts on the Getty North project have included induced polarization (IP) and ground magnetometer surveys, geochemical sampling surveys, trenching, exploratory diamond drilling, preparation of level plans, and geological mapping.

The Getty North property is comprised of 26 mineral claims located in south central British Columbia, Canada near latitude 50° 34' 15" North and longitude 121° 0' 3" West. The claims which cover the Getty North Property are located in the Highland Valley Mining camp, approximately six kilometers north of the former Bethlehem Copper Corp Mine.

The property has been explored intermittently since the 1950’s with work consisting of surface trenching and surface bulk sampling, aerial photographic surveys and base map production, diamond and percussion drilling, geological mapping, assaying, IP and magnetics geophysical surveys, soil geochemical surveys and metallurgical testing. To date, diamond drilling on the Getty North property totals approximately 46,490 meters in 210 holes, and percussion drilling totals approximately 5724 meters in 74 holes. In addition, 23 kilometers of induced polarization surveys, 23 kilometers of geochemical soil sampling surveys, and detailed geological mapping have been conducted.

| | |

| get100-001_pre-fs_9june09a | 1 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Getty North deposit is situated within the upper Triassic Guichon Batholith which is part of the Nicola Group of the Quesnel Terrane. The Quesnel Terrane is a west-facing volcanic island-arc sequence that was accreted to the North American plate during the Jurassic age. The Guichon Batholith, located 60 kilometers southwest of Kamloops, is an elongated intrusion 25 kilometers wide by 40 kilometers long which hosts several large low-grade porphyry copper deposits.

The Getty North property is largely underlain by granodiorite cut by a series of porphyry dikes that are most likely derived from the Bethlehem phase of the batholith. Porphyry style hypogene mineralization within the study area consists mostly of chalcopyrite and lesser bornite in fractures and veins, as disseminations, and in breccia bodies. Oxidized mineralization is also present near the Kamloops unconformity.

Development of the Getty North deposit is recommended, particularly laterally to the west, southwest, and northeast of the deposit and also in the deeper sulfide zone. The deeper resources appear to occur within continuous shoots that are amenable to open pit mining followed by rubber-tire underground mining methods. Additional drilling and sampling will likely increase the tonnage and grade estimates, as well as raise the resources to a higher category.

The Getty South property is currently 50% owned and controlled by Getty Copper Inc. and 50% owned by Robak Industries Ltd. Past exploration efforts on the property include IP and ground magnetometer surveys, geochemical sampling surveys, trenching, exploratory drilling, geological mapping, and development of underground workings.

The Getty South Property is comprised of 22 Crown Granted mining claims, located in south central British Columbia, Canada on map sheet 92I/056 near latitude 50º 32’ 32” North and longitude 120º 59’ 28” West, in the Kamloops Mining Division. The claims are located in the Highland Valley Mining camp, five kilometers north of the former Bethlehem Copper Corp Mine.

As with the Getty North Deposit, the Getty South property has been explored intermittently since the 1950’s with work consisting of surface trenching and surface and underground bulk sampling, underground workings, aerial photographic surveys and base map production, diamond and percussion drilling, geological mapping, assaying, IP and magnetics geophysical surveys, soil geochemical surveys and metallurgical testing. The Getty South property has been examined with almost 4000 meters of surface trenching, approximately 20,353 meters of diamond drilling from surface and underground sites, and 1,719 meters of underground workings. Most recently, an exploration program composed of 13 reconnaissance diamond drill holes and 15 surface trenches with a total length of 1,572 meters were completed in 1996 and 1997.

The Getty South deposit is also situated within the upper Triassic Guichon Batholith. The deposit is a composite breccia zone of what was originally Guichon quartz diorite that was intruded by andesite, rhyolite and porphyritic dikes and related phreato-magmatic breccias.

| | |

| get100-001_pre-fs_9june09a | 2 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Development of the Getty South deposit is recommended, with particular attention given to the west, northeast, and southeast areas to fill in gaps identified in the mine model that would potentially increase the probable reserves of the deposit. The deeper resources appear to occur within continuous shoots that should be amenable to open pit mining followed by rubber-tire underground mining methods. Proper in-fill drilling, trenching and bulk sampling should be conducted to reclassify the resource at a potentially higher category. Additional deep-level in-fill and exploratory drilling is also recommended to examine the vertical and lateral extent of copper mineralization in the underlying sulfide zone.

| |

| 1.3 | Summary of Getty Project Mineral Resource and Reserve Estimates |

A summary of the copper and molybdenum Indicated and Inferred Mineral Resource estimates for the Getty North and Getty South deposits are provided below in Table 1-1. A summary of the copper and molybdenum Probable Mineral Reserve estimates for the Getty North and Getty South deposits is provided in Table 1-2.

Table 1-1 Summary of Getty Indicated and Inferred Mineral Resource Estimates

| | | | |

| Deposit | Indicated Resources | | Grade | |

| (millions of tonnes) | | |

| | | Cu% | CuEq% | Mo% |

| North | 49.691 | 0.397 | 0.442 | 0.005 |

| South | 36.870 | 0.405 | --- | No Data |

| Total | 86.561 | 0.400 | 0.426 | --- |

| Deposit | Inferred Resources | | Grade | |

| (millions of tonnes) | | |

| | | Cu% | CuEq% | Mo% |

| North | 8.089 | 0.419 | 0.464 | 0.005 |

| South | 14.008 | 0.314 | --- | No Data |

| Total | 22.097 | 0.352 | 0.369 | --- |

The authors have not identified any environmental, permitting, legal, title, taxation, socioeconomic, marketing or political factors that might impact the estimate of mineral resources identified in this Technical Report. Because this is an historic mining area that has produced in the past, no unusual mining constraints are anticipated to exist. This Preliminary Feasibility Study did not identify any mining, metallurgical, infrastructure or other relevant factors that may materially affect the estimates of mineral resources.

Table 1-2 Summary of Getty Probable Mineral Reserve Estimates

| | | | |

| Deposit | Probable Reserves | | Grade | |

| (millions of tonnes) | | |

| | | Cu% | CuEq% | Mo% |

| North | 49.691 | 0.397 | 0.442 | 0.005 |

| South | 36.870 | 0.405 | --- | No Data |

| Total | 86.561 | 0.400 | 0.426 | --- |

| | |

| get100-001_pre-fs_9june09a | 3 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards state a Mineral Resource is an occurrence of natural solid material in the Earth’s crust in such form, quantity, and quality (grade) that the material has a reasonable prospect for economic extraction.

A Mineral Reserve is the economically mineable part of a Measured or Indicated Mineral Resource demonstrated by at least a Preliminary Feasibility Study. The study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A Mineral Reserve includes diluting materials and allowances for losses that may occur when the material is mined.

The location, quantity, grade, continuity, and geologic characteristics of the Getty Project mineral resources and reserves are sufficiently defined and have been adequately interpreted from the available geologic evidence, data, and analytical test results. The Getty Project mineral resources and reserves have a reasonable prospect for economic extraction by modern surface and underground mining methods given the current metal prices and economic conditions.

| |

| 1.4 | Summary of Getty Project Economics |

The financial aspects and economic indicators for the project have been determined by using cash flow analysis to evaluate the capital and operating costs generated for the development, operation, and closure of the Getty Project. A 12-month pre-production period is proposed to allow for capital outlay, pre-stripping and mine development. The mine will have an estimated life of 17 years given the reserves described in this report assuming a nominal 15,000 tonnes ore per day mining operation.

Revenue from copper and molybdenum oxide sales are based upon an overall metallurgical grade recovery rate of 91% Cu and 50% Mo over the LoM, and a copper and molybdenum market price of CD$ 3.91 and CD$ 34.87 per pound respectively (CD$8.61 and CD$76.89 per kilogram respectively), and molybdenum deescalating to a final price of CD$ 17.53 per pound (CD$38.65 per kilogram). Operating costs, including mining, processing, and support, are estimated at CD$ 19.47 per tonne of ore. Copper and Molybdenum Trioxide will be refined on site and sold FOB mine site based on selling LME Grade 1 Copper and High Grade Molybdenum Oxide. Additional revenue will be generated from sales of sodium sulfate production as a byproduct of copper and molybdenum production.

Capital cost for the project is estimated at CD$ 428.2 million initially, with CD$ 18.2 million in sustaining capital required over the life of the mine. The project has a pre-tax NPV of CD $655.3 million at a 0% discount rate. Estimated time to payback is about 5.46 years at no imputed interest. Total Cash Flow for the project is estimated CD$655.3 million.

| |

| 2.0 | INTRODUCTION AND TERMS OF REFERENCE |

West Coast Environmental and Engineering (WCE), was commissioned by Getty Copper Inc. (Getty Copper) to prepare a National Instrument 43-101 (NI 43-101) compliant Preliminary Feasibility Study (PFS) of the Getty Copper Project (Getty Project) in Logan Lake, British Columbia Canada. WCE is a consulting and engineering firm comprised of personnel with multiple disciplines who are professionally registered and certified. WCE follows industry trends and standards by active participation in many industry associations. This PFS is intended for the use of Getty Copper Inc. for the further development and advancement of the Getty Project towards the production stage, including a subsequent Feasibility Study. This PFS report meets the requirements for NI 43-101, and the Resource and Reserves definitions are as set forth in the Appendix to Companion Policy 43-101CP, Canadian Institute of Mining, Metallurgy, and Petroleum (CIM) – Definitions Adopted by CIM Council, Nov ember 2005.

| | |

| get100-001_pre-fs_9june09a | 4 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

| |

| 2.1 | Author Background Information |

The principal author of this Technical Report is Craig L. Parkinson, PG of Penn Valley, California. Mr. Parkinson is a Certified Professional Geologist (CPG #10098) with the American Institute of Professional Geologists (AIPG) and a California Registered Professional Geologist (PG #6058), and meets the requirements of a Qualified Person as specified by NI 43-101. Mr. Parkinson is the Project Manager for WCE on the Getty Project and his professional experience dates to 1981 in the fields of exploring, developing, and producing precious metals, base metals, industrial minerals, and aggregates. Mr. Parkinson holds a Master of Science Degree in Hydrogeology from the University of Nevada-Reno School of Mines, Master of Science Degree in Mining Geology from the University of Idaho College of Mines, and Bachelor of Science Degree in Geology from Cornell College, Iowa. Mr. Parkinson has authored NI 43-101 technical reports for mining projects in the United States, Mexico , Peru, and British Columbia.

Richard A. Lopez of Pahrump, Nevada developed and expanded the drillhole assay database and modified the mining plan used in preparation of the mineral resource and reserve models. Mr. Lopez performed a review of the metallurgical processing plan, preliminary mining plan, and project economic feasibility analysis. He also developed the mine reclamation and closure cost estimate, provided mining engineering technical expertise as needed, and facilitated with preparation of the technical report. Mr. Lopez is a Mining Engineer for WCE and a Montana certified Engineer-In-Training (EIT). Mr. Lopez holds a Bachelor of Science Degree in Mining Engineering from Montana Tech and has over 10 years of varied experience in surface and underground surveying and mining, tunneling, and earth-works construction projects.

Todd S. Fayram of Butte, Montana prepared the metallurgical processing and economic analysis sections of the Technical Report, and assisted with the mine planning section. Mr. Fayram holds a Bachelor of Science in Mineral Processing Engineering from Montana Tech, and is a Qualified Professional Member of the Mining and Metallurgical Society of America (MMSA #1300QP). Mr. Fayram is a consulting metallurgical engineer with over 21 years diversified experience managing, operating and consulting for various mining and milling operations in North and South America and Australia. His experience includes: project and construction management; planning, design and engineering of precious and base metal heap leach and milling operations; project evaluation for pre-feasibility, feasibility and bankable documents; and metallurgical interpretation of numerous mineral deposits.

J. Ed Switzer of South Jordan, Utah prepared the geological and mineral resource models and associated resource and reserve estimates. He holds a Bachelor of Science Degree in Civil Engineering from Utah State University. Mr. Switzer is a mine development and design specialist with 33 years experience in precious metals and base metals development in the western United States and worldwide. Mr. Switzer has 17 years experience in a technical environment involving engineering and computer programming, and 16 years of subsequent on-site experience including five years as Chief Engineer of an operating minerals producing property. In addition, Mr. Switzer has considerable experience in mine planning and computer modeling. Mr. Switzer previously prepared the mine model for a NI 43-101 technical report for a mining project in Idaho.

| | |

| get100-001_pre-fs_9june09a | 5 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Michael J. Skopos, CPG of Sacramento, California performed a detailed analysis of the available drill assay data, and reviewed the drilling and assay data records on file at the Getty Copper Logan Lake Office in British Columbia. Mr. Skopos is a Certified Professional Geologist (CPG #05999) with the American Institute of Professional Geologists. He is an exploration and mining geologist and mine development-design specialist with 50 years experience in precious-metal and base-metal operations worldwide. Mr. Skopos served as the Chief Geologist at the nearby Lornex Mine from 1969 to 1973.

Paul Gann of New Westminster BC is a registered geologist with the Association of Professional Geologists of British Columbia, Canada (License # 30164) and a Fellow of the Geological Association of Canada and meets the requirements of a Qualified Person as specified by NI 43-101. Mr Gann is the QP on the Getty Copper Project. His professional experience dates from 1982 in the fields of exploration and production of base and precious metals. Mr Gann holds a Bachelors of Science Degree in Geology from the University of Calgary. He has been previously employed by Atomic Energy of Canada Ltd at the Underground Research Laboratory and INCO as a mine geologist at the T1 mine in Thompson Manitoba. He has been involved in consulting for 18 years.

This PFS has been prepared based on a technical and economic review by a team of consultants sourced principally from WCE’s office in Nevada City, California. These consultants are specialists in the fields of geology, exploration, mineral resource-reserve estimation and classification, surface and underground mining, mineral processing, and mineral economics. Neither WCE nor any of its employees and associates employed in the preparation of this report has any beneficial interest in Getty Copper and thus WCE is independent of Getty Copper. WCE was paid a fee for their work completed in accordance with normal professional consulting practice.

This PFS Technical Report is primarily based on review of information supplied by Getty Copper or gathered from technical reports and published papers on the Getty and Highland Valley region and reconnaissance. Mr. Parkinson visited the Getty South property on May 7, 2007 and conducted an examination of the geology, infrastructure, and diamond drill core. Plans, maps, and documents present in the Getty Copper offices at Logan Lake and Coquitlam, British Columbia were also examined on May 7 and 8, 2007. Mr. Parkinson visited the Getty Project site again during August 19 through 22, 2008 and conducted an additional examination of the geology, infrastructure, and access, and also examined various plans, maps, and documents in the Getty Copper office at Logan Lake.

Mr. Parkinson previously prepared and was the principal author of a NI 43-101 Technical Report on the Getty North Deposit while employed with WCE in 2008. That technical report was titled “National Instrument 43-101 Technical Report of the Getty North Copper Deposit, Kamloops Mining Division, British Columbia, Canada”, and was dated February 21, 2008.

Mr. Parkinson was the principal author of a NI 43-101 Technical Report on the Getty North Deposit while employed with Vector Engineering, Inc. (Vector) in 2007. That technical report was titled “National Instrument 43-101 Technical Report of the Getty North Copper Deposit, Kamloops Mining Division, British Columbia, Canada”, and was dated August 22, 2007. Getty Copper provided WCE with a copy of the Vector 2007 report and Mr. Parkinson modified that report with the inclusion of molybdenum resources for preparation of the Getty North 2008 Technical Report.

| | |

| get100-001_pre-fs_9june09a | 6 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Mr. Parkinson had also previously prepared and was the principal author of a NI 43-101 Technical Report on the Getty South Deposit while employed with Vector in 2007. That technical report was titled “National Instrument 43-101 Technical Report of the Getty South Copper Deposit, Kamloops Mining Division, British Columbia, Canada”, and was dated June 18, 2007. A copy of this technical report was also obtained from Getty Copper for review.

Units of measure used in the report, except where otherwise stated, are based on the metric system. Various conversion factors from metric units to Imperial measures are given below:

| | |

| Linear | | |

| 1 centimeter | = 0.394 inch | |

| 1 meter | = 3.281 feet | = 1.094 yards |

| 1 kilometer | = 0.625 mile | |

| |

| Area | | |

| 1 hectare | = 2.471 acres | |

| 1 square kilometer | = 0.386 square mile | |

| |

| Weight | | |

| 1 tonne | = 1.103 short tons | = 2205 pounds (avdp) |

| 1 kilogram | = 2.205 pounds (avdp) | |

| |

| Assay Values | | |

| 1 gram/tonne | = 0.0292 ounce per ton | = 1 ppm |

| 1 gram | = 0.0322 troy ounce | |

| |

| 3.0 | RELIANCE ON OTHER EXPERTS |

WCE’s opinion contained herein is based on information independently obtained by WCE and their sub-consultants, and based on data provided to WCE by Getty Copper throughout the course of WCE’s investigations. The sources of information utilized in this study include data and reports supplied by Getty personnel, as well as documents referenced in Section 22.

WCE used its experience to determine if the information from previous reports was suitable for inclusion in this PFS, and if required WCE modified the information. Revisions to previous data were based on research, recalculations, and information from other similar projects. The level of detail utilized on the project was deemed appropriate for this level of study.

In preparing this document, the authors did not check title to the claims and hereby disclaim any responsibility for such matters. Getty Copper has had qualified persons establish the validity of the various claims that make up the Getty North and Getty South properties. To the best of our knowledge, there are no environmental liabilities or other potential liens against the property. The authors are familiar with the rock descriptions, geologic model, and assay database used in the resource model and metallurgical testing.

Based on review of the available information sample preparation and assay procedures from historical drilling and other sample-collection programs, including laboratory assay quality assurance/quality control checks, appear to have been carried out appropriately by qualified individuals, firms, and laboratories to industry standards. Previous authors have performed laboratory assay quality assurance/quality control checks. In 1996 and 1997, Getty Copper used Eco Tech Laboratory Ltd in Kamloops (Eco Tech) and ALS Chemex Lab in North Vancouver, and in 2005 Getty Copper used Eco Tech and Acme Analytical Lab. ALS Chemex and Acme laboratories conducted trace element and ore grade analytical testing for copper mineralization, and Eco Tech performed testing for the presence of base metals and precious metals, and environmental quality of soil and water.

| | |

| get100-001_pre-fs_9june09a | 7 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

In the preparation of this NI 43-101 Technical Report, WCE incorporated information from many previous technical reports prepared on the Highland Valley Project area. These reports are referenced in Section 22. This report includes technical information which required subsequent calculations to derive subtotals, totals, and weighted averages. Such calculations inherently involve a degree of rounding and consequently can introduce a margin of error. Where these rounding errors occur, WCE does not consider them to be material.

| |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION |

The Getty Project is situated at an elevation between 1400 and 1830 meters in the Kamloops Mining Division of British Columbia, Canada. A regional location map is provided in Figure 4.1 and a property location map is provided in Figure 4.2. The project area is developed with surface and underground exploration drill holes, surface trenches, shafts and underground workings, and sample storage areas. The Getty Copper mineral property is located in the Highland Valley, an area with a long history of natural resource based activities which historically have provided the economic base of the region. Copper mining is the principal activity in the immediate vicinity of Getty Copper's tenure with a $1 billion per year industry at the adjacent Highland Valley Copper Mine (Cominco, Teck, Rio Algom). The entire Getty Highland Valley property consists of 301 contiguous claims which cover a total area of 29,025 hectares (approximately 200 square kilometers, or 80 square miles ). The Getty claims are subject to a 1.5% NSR in favor of Robak Industries.

Mineral exploration and mining have been major economic activities in the copper-rich Highland Valley for more than four decades. In the early part of the century, early miners and prospectors shipped hand-picked high grade copper ore to the Tacoma smelter via rail to Vancouver from the town of Ashcroft, 40 km to the northwest. In 1962 the Highland Valley gained international prominence as one of Canada's principal copper producing districts as a result of the opening of the Bethlehem Mine, Canada's first open pit porphyry copper mine. The larger Lornex, Highmont and Valley deposits were discovered soon thereafter and were quickly brought into production resulting in the building of the town of Logan Lake.

Highland Valley remains British Columbia's premier copper producing district with a total production to date of more than eight billion pounds (3,628 tonnes) of copper from nearly one billion tonnes of ore mined. Teck Cominco’s Highland Valley Copper (HVC) mine, one of the world's largest, treats approximately 120,000 tonnes of ore per day with a skilled labor force of more than 1,100 employees. Of these employees, approximately 75% reside in Kamloops and Logan Lake with the remainder residing in Ashcroft, Merritt and Cache Creek. The town of Logan Lake owes its origin to the Highland Valley area copper mines. Since its founding some 25 years ago, this modern community of 2,600 residents have relied on copper mining in the nearby Highland Valley for its existence.

| | |

| get100-001_pre-fs_9june09a | 8 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Forest harvesting is also an established economic activity in this area but, in sharp contrast with mining, all sawmills and other related plants, including a major pulp mill, are located in Kamloops, Merritt, Cache Creek and Savona. Timber leases held by Weyerhaeuser and Ainsworth Lumber overlap the Getty Copper mineral tenure, so the Getty North and Getty South deposits are within an area where timber rights are maintained by both Weyerhaeuser and Ainsworth. Recent clear-cut logging was performed on Getty Copper's mineral tenure, including the immediate vicinity of the Getty North and Getty South deposits. In 1996, Getty clear-cut the Getty North property for further development and projected open-pit mining. According to the Ministry of Forests, no substantial clear cut logging activities by the forest industry are anticipated on Getty Copper's mineral tenure for at least five years, since the most valuable timber has already been removed by the logging compan ies.

Cattle ranching is the third long-established principal activity in the region. Range leases cover most of the crown land on the Thompson Plateau. Range leases overlap the Getty Copper mineral tenure and the nearby HVC Mine. Large scale mining and cattle ranching have productively co-existed in the Highland Valley for the past 35 years. In fact, as part of their ongoing reclamation program, HVC, in cooperation with B.C. Cattleman's Association and Agriculture Canada, is concluding a four-year research project designed to determine the suitability of grazing cattle on pasture reclaimed from copper mining operations. Results of this study have shown that the test herd performed like a normal herd with no health problems and consistently produced meat considered safe for human consumption.

Recreational activities in the general area include hunting, fishing, swimming, cross-country skiing and camping. With the exception of hunting, none of these activities take place within Getty Copper's mineral tenure, as no streams or lakes are present in the area that are suitable for fishing or swimming. Also, the densely wooded areas and clear-cut portions of the countryside are not attractive to recreational campers or cross-country skiers. There are no extraordinary scenic views present at any location on Getty Copper's mineral tenure.

The Getty North copper deposit is located on British Columbia Geographic Systems (BCGS) Map Sheet 92I/056 near latitude 50° 34' 15" North and longitude 121° 0' 3" West in the Kamloops Mining Division of British Columbia, Canada. There are 26 claims (covering an area of 1,600 hectares) that form the Getty North copper property, which is part of 301 contiguous claims. Figure 4.3 is a claim map of the property and Table 4-1 lists the claim data. The Getty North property was originally called the Krain property and many historical documents refer to the property as Krain.

The Getty North property hosts two adits as a result of historical minor exploration work. The Getty North property is located just north of the past-producing Bethlehem Mine property and a few kilometers north of the Teck Highland Valley Mine property.

Getty Copper Inc. acquired the Getty North property from Robak Industries Ltd and Masco Capital Inc pursuant to an Agreement of Purchase and Sale, dated June 30, 1992, as amended September 30, 1992, subject to 1.5% net smelter return royalty reserved in favor of Robak. Getty Copper issued escrow 5,000,000 Common Shares to Robak and 5,000,000 Common Shares to Masco as consideration for the property. After the release of the escrow shares in 1999, title to the Getty North property was fully vested in Getty Copper Inc.

| | |

| get100-001_pre-fs_9june09a | 9 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Getty South deposit property consists of 371.19 hectares of land and its location is documented on BCGS Map Sheet 92I/056 near latitude 50º 32’ 32” North and longitude 120º 59’ 28” West, in the Kamloops Mining Division, British Columbia. The property is located just south of the Getty North property and just north of the Bethlehem Mine property.

The Getty South deposit is located in the Highland Valley area on portions of adjoining Crown Granted mineral claims Bill 3, 4, 5, 6, 7 and 8, designated as District Lots 5603 to 5608 inclusive, Kamloops Division, Yale District. Figure 4.4 is a map of the Crown Granted claims and Table 4-2 lists the property lot data. Maintenance of the claims is achieved by paying an annual cash payment to the Minister of Finance of the Province of British Columbia. The Crown Granted claims are owned and controlled 50% by Getty Copper Inc. and 50% by Robak Industries Ltd. The heart of the Crown Granted mineral claims is overlain by mineral tenures 526953, 519232, 519235, and 519237 which are 100% owned by Getty Copper, and which form the central part of the property.

These tenures were staked under the new Map Selection Procedure using a provision that allows Crown Granted claims to be overstaked. The overlying tenures are shown in Figure 4.5. This procedure is valid because the new Mineral Tenure Act allows natural materials not covered under the previous Acts to be described as “minerals,” and thus available for “acquisition” under the new Act. These claims are also subject to normal assessment requirements as provided under statutes of the current Mineral Tenure Act.

The new Act of January 12, 2005 does not allow the performance of exploration and mining work on Crown Grants to be applied for assessment credit on adjoining mineral tenures, only on overlying tenures. Therefore, the only process available for mineral exploration expenditures completed on Crown Grants for assessment credit on adjoining tenures is to have both overlying and adjoining tenure.

Exploration is being conducted under Ministry of Energy and Mines Exploration Permit MX 3-151. Sufficient bonding is in place to conduct a surface exploration program for preliminary trenching and drilling. To conduct a large-scale trenching or underground exploration program, the bond required would have to be increased.

| | |

| get100-001_pre-fs_9june09a | 10 | West Coast Environmental and |

| | | Engineering |

11

12

13

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Table 4-1 Getty North Property Claim Data

| | | |

| Tenure Number | Claim Name | Tenure Number | Claim Name |

| 221561 | Getty #1 | 221574 | Getty #14 |

| 221562 | Getty #2 | 221575 | Getty #15 |

| 221563 | Getty #3 | 221576 | Getty #16 |

| 221564 | Getty #4 | 221577 | Getty #17 |

| 221565 | Getty #5 | 221578 | Getty #18 |

| 221566 | Getty #6 | 221579 | Getty #19 |

| 221567 | Getty #7 | 221580 | Getty #20 |

| 221568 | Getty #8 | 221581 | Getty #21 |

| 221569 | Getty #9 | 221582 | Getty #22 |

| 221570 | Getty #10 | 221585 | Getty A fraction |

| 221571 | Getty #11 | 322034 | GTY #1 |

| 221572 | Getty #12 | 322035 | GTY #2 |

| 221573 | Getty #13 | 322036 | GTY #3 |

| | |

| get100-001_pre-fs_9june09a | 14 | West Coast Environmental and |

| | | Engineering |

15

16

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Table 4-2 Getty South Property Lot Data

| | | |

| Lot # | Name | Lot # | Name |

| 5483 | A.J. No. 3 | 5611 | BILL No. 11 |

| 5601 | BILL No. 1 | 5612 | BILL No. 12 |

| 5602 | A.J. No. 1 FRACTION | 5613 | BILL No. 13 |

| 5603 | BILL No. 3 | 5614 | BILL No. 14 |

| 5604 | BILL No. 4 | 5615 | BILL No. 15 |

| 5605 | BILL No. 5 | 5616 | BILL No. 16 |

| 5606 | BILL No. 6 | 5617 | A.J. No. 7 |

| 5607 | BILL No. 7 | 5618 | A.J. No.8 |

| 5608 | BILL No. 8 | 5619 | A.J. No. 5 |

| 5609 | BILL No. 9 | 5620 | A.J. No. 6 |

| 5610 | BILL No. 10 | 5621 | A.J. No. 4 |

For the Getty North and Getty South properties, WCE believes there are no known factors relating to permitting that might negatively impact the proposed development of the Getty Project. Because this is a historic producing mining area, no unusual mining constraints are anticipated to exist.

| |

5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

Logan Lake is the closest supporting community to the properties and is about 15 kilometers to the east of the project area. Access to the properties is via the Bose Lake Road from the paved Bethlehem Mine Road, and forestry and drill roads provide easy access to the claims. The nearest domestic airport is located in the City of Kamloops, approximately 54 kilometers northeast of Getty North. The nearest major city is Vancouver, which is situated approximately 330 kilometers to the southwest, and is accessed by the Coquihalla Highway. The City of Vancouver hosts an international airport and seaport.

The climate is characteristic of the “dry belt” of the British Columbia Interior Plateau where average annual precipitation is about 23 centimeters. The seasonal climatic conditions are generally moderate and general mining activities can likely proceed year round. Severe weather conditions can occur for isolated periods in the winter, although snowfall is usually moderate and the mean winter temperature is -6.6°C in January. Summer temperatures are cool to warm and mean temperatures are 14.1°C in July.

| |

| 5.3 | Local Resources and Infrastructure |

In light of the current cycle of elevated metal prices, and given the history of mining in the Highland Valley area, it is likely that mining infrastructure and a skilled labor force are available within the immediate surrounding region. It is believed that all necessary assets such as water, power and access will be available for future mining activities at the property. A 500 KVA power line crosses the property and telephone service is available in Logan Lake and at nearby mines. The regional surface-water supply is limited and previous mine operators in the Highland Valley area have used groundwater for mining operation water supplies.

| | |

| get100-001_pre-fs_9june09a | 17 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Getty South and North properties are located near Forge Mountain at elevations between 1400 and 1830 meters. The topographic relief is moderate and the ground surface is typically mantled by glacial deposits cut by recent stream channels. Small topographic highs are generally immediately underlain by glacial drift and Tertiary volcanic cover.

The Getty North property was originally staked in about 1907 and minor exploration work was performed in two adits at the same elevation and about 42 meters apart. In 1960, Rio Tinto Canadian Exploration Limited obtained an option and conducted a geophysical survey and 161 meters of diamond drilling in one hole. Pentland (1965) indicated assay results of two drill holes conducted by North Pacific Mines Ltd. Showed an estimated “ore reserve” of 8,543,000 tons grading 0.50% copper. In 1966, Canex Aerial Exploration Ltd (Placer Development) completed 2,015 meters of diamond drilling in 16 holes. In 1969, Brameda Resources Ltd and Noranda Exploration Company Ltd. performed geochemical and geophysical surveys, and 957 meters of diamond drilling in seven holes. Percussion drilling in 1970 by North Pacific Mines consisted of 1,149 meters in 25 holes drilled within the oxide zone to collect samples for leaching tests.

In 1971, Getty Pacific Mining Limited, a subsidiary of Getty Oil Company, optioned the property. Work by Getty Pacific Mining during 1971 and 1972 included induced polarization (IP) surveys over 27 line kilometers, resistivity surveys over nine line kilometers, a geochemical survey over the Krain claims, 635 meters of diamond drilling, and percussion drilling consisting of 1,765 meters in 16 drill holes. The Getty option was terminated in 1974.

In 1975, three percussion drill holes totaling 171 meters were drilled on the Getty 17 and Getty 19 claims located approximately one kilometer south of the mineralized zone. Work conducted in 1976 consisted of drilling by W.R. Financial Consultants Ltd. which included 540 meters of percussion drilling in seven holes. TRV Minerals Corporation optioned the property in May 1980. During 1978 to 1982, TRV or its associates W.R. Financial Consultants and New Minex Resources conducted 302 meters of diamond drilling in one hole and a magnetometer survey over 90 kilometers on the Krain (Getty North) and adjacent Trojan (Getty South) property. In 1984, Robak performed a geochemical survey that included the collection of 119 soil, six rock, and three silt samples from across the Getty North property.

From January 1993 to November 1997, Getty Copper conducted 36,348 meters of diamond drilling in 143 drill holes. Thus, the Getty North deposit has been systematically drilled on northeast-oriented sections 30 meters apart. In December 1997, Getty Copper retained Bateman Engineering Inc. of Denver, Colorado (“Bateman”) to perform a feasibility outlook study for the oxidized part of the Getty North deposit and the proposed Getty North copper plant. Bateman used a resource model developed by KHA Resource Modeling Inc. for the preliminary mine design evaluation. Based on these results, Bateman recommended a full feasibility study for the Getty North deposit and additional leach and assay comparison tests that might increase the mineral resource estimates. Most recently, in 2004 and 2005 Getty Copper drilled several geophysical targets adjacent to the Getty North property.

| | |

| get100-001_pre-fs_9june09a | 18 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Early work in the Getty South area was reported by the B.C. Minister of Mines for the years 1902, 1907, and 1915, under the heading of the Albatross and Canopus groups. The work consisted of open cuts and short adits in the breccia zones with reported assay results varying between 0.5 to 0.9% copper.

Several adits were reportedly driven in the 1920’s, and during 1954 key claims were staked by local prospectors which were then purchased by Trojan in 1955. Development work commenced and the property was optioned to Chimo Gold Mines Limited in early 1956, which completed 7620 meters of diamond drilling. The 1957 to 1958 phase of underground development was primarily directed at determining the size and grade of the West Zone mineralized breccia pipe on the west side of the Getty South breccia body, also known in the literature as the Trojan and Shaft Zone

Various types of exploration activities including drill programs, IP surveys, surface mapping-trenching-sampling programs, geochemical sampling surveys, and underground exploration projects were conducted on the Getty South property from the 1950’s to present. Pentland (1967) concluded that results of the underground and diamond drilling sampling assays showed there is a high-grade zone near the Trojan Mine shaft that contains “indicated ore reserves” estimated at 17,422,000 tons grading 0.75% copper. Livgard (1979) observed that the west, east, and northwest zones bordering the main Getty South breccia contained copper grades of 0.638% to 3.07%, which would constitute “reserves” under the right conditions and could be mined and then treated by the producing mines in the vicinity.

In 1996, Getty Copper drilled 3236 meters in 13 widely-spaced reconnaissance diamond drill holes on the Getty South Property. In 1997, Getty Copper completed 1572 meters of track-hoe trenching on the Getty South breccia zone. In this program, the northeast oxide zone was systematically sampled and many older trenches were opened up and re-sampled.

To date, exploration work totals 19,003 meters of surface diamond drilling, 1158 meters of underground diamond drilling, 319 meters of underground Jackleg drill holes, 69.3 line kilometers of IP surveying, 1719 meters of underground drifting and a two-compartment shaft with a total depth of 49 meters. All underground development has been confined to the 49-meter level (“150 Level”).

The Highland Valley porphyry deposits are within the Guichon Creek batholith, which is one of a series of plutons associated and possibly comagmatic with the Nicola Group. The Nicola Group is a succession of Late Triassic island-arc volcanic rocks within the southern portion of the Quesnel Trough in the Intermontane belt. The Nicola Group volcanic rocks form part of a 30-km to 60-km wide northwest-trending belt extending from southern B.C. into the southern Yukon. This belt is enclosed by older rocks and intruded by batholiths and smaller intrusive rocks.

| | |

| get100-001_pre-fs_9june09a | 19 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Guichon Creek batholith is a large, composite intrusion with a surface area of about 1,000 square kilometers. A cluster of nine major porphyry copper deposits lie within a 15 square kilometer zone in the center of the batholith. The Getty Project is situated just north of these deposits. Figure 7.1 shows the regional geology and Figure 7.2 shows the local geology of the Getty Project Area.

The batholith is a semi-concordant composite intrusive that is elliptical and elongated slightly west of north. A central, steeply plunging root or feeder zone is inferred under Highland Valley, and the major deposits lie around the projection of the feeder zone to the surface. The batholith has intruded and metamorphosed island-arc volcanic and associated sedimentary rocks of the Nicola Group, and a metamorphic halo up to 500 meters wide is developed adjacent to the contact.

Rocks along the edge of the batholith are older and more mafic, and successive phases moving inward toward the core are younger and more felsic. Although contacts can be sharp, they are generally gradational and chilled contacts are not common. Variations in the batholith geochemistry indicate local areas of assimilated country rock in the border zone and roof pendants in the intrusion. Outcrop areas have inclusions of amphibolite and “granitized” metamorphic rocks and compositional variations.

Two younger volcanic-dominated successions are important in the area. First, a northwest trending belt of Cretaceous continental volcanic and sedimentary rocks of the Spences Bridge Group unconformably overlie both the Nicola Group country rock and intrusive rocks along the southwest flank of the batholith. Distribution of the Spences Bridge Group rocks was locally controlled by reactivation of older faults that were important mineralization conduits in the batholith, such as the Lornex fault. Second, continental volcanic and sedimentary rocks of the Tertiary Kamloops Group cover extensive areas of the batholith and also overlie Triassic and Jurassic rocks from north of Highland Valley to the Thompson River. These also form isolated outliers and local intrusive centers south of the Highland Valley.

The Getty North deposit lies along the southern boundary of an extensive area composed of post-mineral cover consisting of continental volcanic and interbedded sedimentary rocks of the Eocene Kamloops Group (Figure 7.3). These rocks overlie plutonic rocks of the Guichon Creek batholith. Mineralization occurs within quartz diorite rocks of the Highland Valley phase (Guichon variety) of the batholith, and within younger small stocks and anastomosing dikes. The stocks and dikes resemble quartz diorite of the Bethlehem phase of the batholith. The Kamloops Group rocks cover the northern half of the mineralized zone. There is an older well-developed oxidized cap which extends to a depth of more than 150 meters.

Fractures and faults are prominent, and the areas of highest fracture density are also the zones of higher-grade mineralization. The areas of higher fracture density are adjacent to the stock and associated with sets of steeply dipping north and northeast trending faults that have dominantly formed post-mineralization. Kamloops Group rocks are restricted almost entirely to down-faulted blocks and associated vertical offsets that have been identified by drilling. Figure 7.4 depicts the geology and copper mineralization of the Getty North Deposit along representative Section 1360, the location of which is shown on Figure 7.3.

| | |

| get100-001_pre-fs_9june09a | 20 | West Coast Environmental and |

| | | Engineering |

21

22

23

24

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Getty South deposit is located immediately west of a regional north-south striking structure locally called the Jersey Fault. A similar parallel-striking fault, termed the Bethlehem Fault by previous authors, is located near the east side of the breccia. The Bethlehem Fault is interpreted by previous workers as a major structural break. The geology of the Getty South Deposit is shown in Figure 7.5, and representative Section 5600550N is shown in Figure 7.6.

The Getty South breccia is thought to occur immediately east of a regional north-south striking structure locally called the South Krain Fault (Gower 1992). A similarly parallel striking fault is thought to be located near the east side of the breccia, termed by many previous authors as the Bethlehem Fault and interpreted as a major structural break (Coveney, P.Eng., 1969)

The breccia that defines the Getty South deposit is a polyphase composite. The breccia includes three main types of fragmentation, which are composed of the Guichon quartz diorite, rhyolite porphyry, and brown porphyry. All three may be present together or, alternatively, one or other of the porphyries may be lacking. Parts of the breccia body, especially near its walls, consist of weakly brecciated quartz diorite traversed by widely-spaced veins in which porphyry fragments are rare or absent.

Rhyolitic porphyry sheets and angular fragments commonly exhibit a strong alteration, which colors them variously pink, buff and light-green and the alteration was effected prior to brecciation. X-ray identification of the fine grained argillic products of this alteration confirmed the presence of abundant sericite and chlorite, which are predominantly accompanied by quartz.

The matrix of the breccia is diversely altered and varies considerably in composition. In the brecciated rhyolite porphyry the matrix consists largely of fine grained quartz and sericite, with some rare quartz grains as large as two millimeters in size. The differences in fabric and composition of the Trojan breccia suggest that its origin was complex and possibly occurred in multiple stages. The brown porphyry undoubtedly preceded the rhyolite porphyry, and it evidently was emplaced in fractured quartz diorite and may have caused a first stage of brecciation.

The structural geological setting of the Getty South deposit consists of elongated, en-echelon, rectangular, faulted blocks displaced to the south, which is typical of the eastern portion of the Guichon Batholith. The Getty South deposit appears to be influenced by two key strike-slip fault zones, which are the western-most Getty North (Krain) Fault located just west of the Getty South Shaft Zone and the main West Breccia Zone, and to the east the Bethlehem Fault (also known as the Jersey Fault). The rotational deformation which has occurred between these two faults has generated both sinistral displacement influencing the clockwise movement of the main West Breccia Zone, and dextral or counterclockwise movement by the Bethlehem (Jersey) Fault located east of the shaft.

These two key faults have introduced a 180-degree change in the dips of the most prominent fracture density copper patterns. As a result, the copper values have also been offset within each block. A few key diamond core drill holes will likely confirm this rotation and establish the geologic structural model of the Getty South deposit. It appears the main Breccia Zone hosting the deposit may be increasing in width at depth. This may be due to the divergence of the key strike slip fault zones and the associated copper mineralization within these zones.

| | |

| get100-001_pre-fs_9june09a | 25 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The various breccia zones involving the Main West, Southwest, Northeast and Southeast exhibit high copper values at 300 meters and are open to depth. Both the Getty South and Getty North deposits appear to have northeast-trending structures that actively control mineralization. The deposits appear to share the same structural controls and appear to be similarly mineralized.

| | |

| get100-001_pre-fs_9june09a | 26 | West Coast Environmental and |

| | | Engineering |

27

28

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

Significant porphyry deposits in the Guichon Creek batholith are confined to the central part of the intrusion. Previous authors relate mineralization to water saturation in the evolving crystallizing magma that allowed separation of a fluid phase. The metals and other mobile elements were scavenged/enriched into this late phase fluid. The first mineralizing event also corresponds with the first major episode of dike emplacement and breccia-pipe formation in the batholith. The second and most significant mineralizing event followed emplacement of the youngest major phase of the batholith. Some dikes and breccia formed during this event, but large zones of shattering that host mineralization are more significant.

The following description on deposit types is excerpted from McMillan (2003):

“…Significant porphyry deposits in the Guichon Creek batholith are confined to the central part of the intrusion. McMillan (1976, 1982) and others (Westerman, 1970; Olade 1974; Johan and McMillan, 1980) present evidence to relate mineralization to water saturation in the evolving, crystallizing magma that allowed separation of a fluid phase. Metals and other mobile elements were scavenged into this fluid. Significantly, the first mineralizing event also corresponds with the first major episode of dyking and breccia pipe formation in the batholith. The Bethlehem deposits, Krain, South Seas (Trojan) and other deposits resulted. The second, and most significant mineralizing event, which formed the Valley, Lornex, Highmont, JA and several smaller deposits, followed emplacement of the Bethesda phase, the youngest major phase of the batholith. Some dyking and breccia formation occurred related to this event, but large zones of shattering that host mineralization are more important.”

Most copper and molybdenum mineralization in the Highland Valley deposits is fracture controlled. As a generalization, better grades occur where fracture density is higher or where several sets of fractures overlap. Disseminated mineralization is present and sulfide minerals also occur in alteration zones that fringe the veins and fractures.

The batholith is internally subdivided into segments by north- to northwest-striking faults. The major north-striking structures are the Lornex and bounding Guichon Creek faults, and the major northwest-striking structures occupy from south to north the Skuhun Creek, Highland Valley, and Barnes Creek faults. Large-scale tension fractures have orientations similar to those of the faults, such as the northwest-striking Gnawed Mountain dike and the northwest-striking zone of dike swarms extending from the Skuhun Creek fault to the Barnes Creek fault.

Northerly, northwesterly and northeasterly striking faults and fractures dominate the structural fabric of the region. The faults developed prior to mineralization and have been periodically reactivated. They apparently channeled hydrothermal fluids into faulted, fractured and brecciated sites where they deposited metallic minerals. Tertiary block faulting created a horst and graben pattern that controlled development of the present landscape. This pattern also controlled the level of erosion and consequently the depth of exposure of the ore deposits. Depth of emplacement of the deposits was inferred based on the characteristics of the host rocks, variations in the intensity of alteration, and the presence of porphyry dike swarms and breccias.

| | |

| get100-001_pre-fs_9june09a | 29 | West Coast Environmental and |

| | | Engineering |

| |

| Getty Copper, Inc. | Preliminary Feasibility Study |

| | Technical Report of the Getty Copper Project |

| | June 9, 2009 |

The Getty North deposit occurs as a partially buried porphyry copper system at least 350 meters wide, at least 1000 meters long, and with a depth of at least 450 meters. Primary mineralization consists of chalcopyrite, bornite, chalcocite, molybdenite, and pyrite which occur as disseminations, specks, and fracture fillings within Guichon Quartz Diorite that has been intruded by younger porphyry. The copper zone is cylindrical in plan view with its axis plunging to the southeast. An oxide zone forms a cap of secondary copper minerals at and near the surface in the northern part of the deposit. The copper mineralization in the Getty North Deposit forms a mineralized body over 450 meters thick. Mineralization in the west side of the deposit dips steeply to the west, and mineralization in the east side dips steeply to the east. Faulting has extended the copper and molybdenum mineralization to the southeast, which offer targets for exploration.

The Getty South deposit contains a series of closely spaced (10-meter to 50-meter separation) sub-parallel and inter-intruded intermediate to felsic dikes that grade upward into different breccia phases. Structural control appears strong for dike, breccia, and copper mineralization. Previous authors concluded there are two major structural orientations at Getty South: north-northeast (NNE) dipping steeply to the west, and west-northwest (WNW) dipping steeply to the east (E). Geological maps from underground workings also identify northeast-trending shears and faults that appear to displace north-trending mineralized zones with apparent left-lateral displacement. There are also east and southeast dipping shears with right lateral displacement. Similar to Getty North, the Getty South mineralization in the west side of the deposit dips steeply to the west, and mineralization in the east side dips steeply to the east.

Overview

The Guichon Creek Batholith contains more porphyry copper deposits in a specific area than any other location in Canada. The aggregate tonnage of the Guichon deposits exceeds 1.6 billion tonnes of ore grading 0.45% copper within 15 separate deposits, all of which are hosted by batholithic rocks with a common age of around 195 million years old. There are nine copper deposits near the center of the Guichon batholith. The sulfide mineralogy and alteration suites are similar to that occurring in other porphyry copper deposits. The sulfide assemblage consists of chalcopyrite accompanied by bornite and commonly molybdenite, and occurs in and adjacent to quartz-sericite filled fractures and disseminated between fractures within breccia pipes.

The Getty North deposit occurs within a broad northwest-trending zone characterized by numerous sub-parallel northwest-trending porphyry dikes. There are also prominent fracture-related, non-pervasive, chlorite-epidote-chalcopyrite+/-pyrite and bornite hydrothermal veins and fracture selvage assemblages. Smaller zones of pervasive chlorite-clay alteration, some containing strong chalcopyrite mineralization, occur frequently at the margins of the porphyry dikes.

Mineralization and alteration are closely associated with an elongated 1000 meter by 200 meter dike-like stock, which is exposed at the center of the deposit. The exposed portion appears to be a cupola-like projection which developed above the stock. To the northwest and southeast along strike, the apex of the stock plunges gently away from the Getty North deposit and the lateral contacts dip about 70 degrees southwestward. Fracturing, brecciation, alteration, and mineralization are developed in and around the central cupola-like core and along the upper surface of the stock.

| | |