UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, DC 20549

þ Annual report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

For the fiscal year ended December 31, 2007

¨ Transition report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

For the transition period from ______________ to ______________

Commission file number 000-24293

| LMI AEROSPACE, INC. |

| (Exact Name of Registrant as Specified in Its Charter) |

| Missouri | | 43-1309065 |

| (State or Other Jurisdiction of | | (IRS Employer |

| Incorporation or Organization) | | Identification No.) |

411 Fountain Lakes Blvd., St. Charles, Missouri | | 63301 |

| (Address of Principal Executive Officer) | | (Zip Code) |

| (636) 946-6525 |

| (Registrant’s Telephone Number, Including Area Code) |

Securities registered pursuant to Section 12(b) of the Act:

Common stock, $0.02 par value, The NASDAQ Stock Market LLC

Securities registered pursuant to Section 12(g) of the Act:

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.¨YESþNO

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.¨YESþNO

Note—Checking the box above will not relieve any registrant required to file reports pursuant to Section 13 or 15(d) of the Exchange Act from their obligations under those Sections.

Indicate by check mark whether registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. þYES ¨NO

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definitions of “accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer¨ Accelerated filerþ

Non-accelerated filer¨ Smaller reporting company¨

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act).

¨YES þNO

The aggregate market value of the voting common equity held by non-affiliates computed by reference to the price at which the common equity was last sold as of the last business day of the registrant’s most recently completed second fiscal quarter ended June 30, 2007, was $196,419,743.

There were 11,505,949 shares of common stock outstanding as of March 6, 2008.

DOCUMENTS INCORPORATED BY REFERENCE

Part III incorporates by reference portions of the Proxy Statement for the Registrant’s 2008 Annual Meeting.

TABLE OF CONTENTS

| Item No. | Page |

| | |

| PART I |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | | |

| PART II |

| | | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | | |

| PART III |

| | | |

| | |

| | |

| | |

| | |

| | |

| | | |

| PART IV |

| | | |

| | |

| | | |

| |

| | |

| |

Forward-Looking Information

The Private Securities Litigation Reform Act of 1995 provides a “safe harbor” for forward-looking statements. The Company makes forward-looking statements in this Annual Report on Form 10-K and in the public documents that are incorporated herein by reference, which represent the Company’s expectations or beliefs about future events and financial performance. When used in this report and the documents incorporated herein by reference, the words “expect,” “believe,” “anticipate,” “goal,” “plan,” “intend,” “estimate,” “may,” “will” or similar words are intended to identify forward-looking statements. These forward-looking statements are based on estimates, projections, beliefs and assumptions and are not guarantees of future events or results. Such statements are subject to known and unknown risks, uncertainties and assumptions, including those referred to under “Risk Factors” in this Annual Report on Form 10-K and otherwise described in the Company’s periodic filings and current reports filed with the Securities and Exchange Commission.

All predictions as to future results contain a measure of uncertainty, and accordingly, actual results could differ materially. Among the factors that could cause actual results to differ from those contemplated, projected or implied by the forward-looking statements (the order of which does not necessarily reflect their relative significance) are:

| | l | the financial well-being of Gulfstream Aerospace Corporation, Boeing Company, Spirit AeroSystems, Vought Aircraft Industries and Sikorsky, orders from which comprise a majority of the Company’s consolidated revenues; |

| | l | the effect of terrorism and other factors that adversely affect the commercial travel industry; |

| | l | difficulties with the implementation of the Company’s growth strategy, such as acquisition integration problems and unanticipated costs relating to the Company’s manufacture of new parts for its current customers and new customers; |

| | l | competitive pressures, such as pricing pressures relating to low-cost foreign labor and industry participation commitments made by the Company’s customers to foreign governments; |

| | l | changes in the quality, costs and availability of the Company’s raw materials, principally aluminum; |

| | l | the Company’s ability to stay current with technological changes, such as advancements in semiconductor and laser component technology and the development of alternative aerospace materials; |

| | l | governmental funding for certain military programs that utilize the Company’s products; |

| | l | asserted and unasserted claims, and in particular, the Company’s ability to successfully negotiate claims relating to cost over-runs of work performed on certain customer contracts; |

| | l | changes in employee relations; |

| | l | changes in accounting principles or new accounting standards; and |

| | l | compliance with laws and regulations. |

In light of these risks, uncertainties and assumptions, the forward-looking events discussed may not occur. Accordingly, investors are cautioned not to place undue reliance on the forward-looking statements. Except as required by law, the Company undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise. Investors should, however, review additional disclosures made by the Company from time to time in its periodic filings with the Securities and Exchange Commission.

This Annual Report on Form 10-K and the documents incorporated herein by reference should be read completely and with the understanding that the Company’s actual future results may be materially different from what the Company expects. All forward-looking statements made by the Company in this Annual Report on Form 10-K and in the Company’s other filings with the Securities and Exchange Commission are qualified by these cautionary statements.

PART I

General Overview

LMI Aerospace, Inc. is a leading provider of structural components, assemblies and kits to the aerospace, defense and technology industries. On July 31, 2007 we acquired all of the capital stock of D3 Technologies, Inc., a premier design and engineering services firm, for $65.0 million. With our acquisition of D3 Technologies, we now provide a complete range of design, engineering and program management services for the aerospace and defense industries.

Our current growth strategy focuses on being well positioned to meet the more demanding requirements of original equipment manufacturers, referred to as OEMs, and Tier 1 aerospace providers for more complex products, using both metal and non-metal technologies, and for related services. We believe that OEMs and Tier 1 aerospace providers will continue to outsource the design and manufacturing of components, assemblies and sub-systems to fewer preferred suppliers. In addition, these companies have formed relationships with an increasingly smaller number of preferred suppliers in order to improve quality and service levels while reducing purchasing costs. Accordingly, we continue to focus on remaining well positioned to benefit from these trends by:

| · | Leveraging Strong Customer Relationships. We plan to continue to strengthen our relationships with current customers by expanding our product and service offerings. With our breadth of capabilities and track record of performance, we believe that we can capture additional outsourcing opportunities in the design, engineering, fabrication and assembly of aircraft components, assemblies and sub-systems with our existing customers. We will continue to seek to formalize our customer relationships through long-term agreements. |

| · | Pursuing Design-Build Opportunities. We intend to leverage our highly complementary design, engineering and fabrication capabilities to offer design-build solutions to our customers. We plan to integrate these core competencies to ultimately develop proprietary engineering designs for increasingly complex sub-systems work from OEMs and Tier 1 aerospace providers. |

| · | Expanding Value-Added Services and Solutions. We intend to grow by increasing the array of value-added services and solutions that we offer our customers. By expanding our capability to integrate components into higher level aerospace assemblies and providing point of use kitting for our customers, we believe we will enhance our reputation as a preferred supplier to aerospace manufacturers and improve our position in the aerospace supply chain. As OEMs and Tier 1 aerospace suppliers continue to outsource production of components and assemblies, we believe that we are well positioned to capture additional sales and become an increasingly important provider to new and existing customers. |

| · | Expanding into More Complex Metal and Non-Metal Technologies. We are planning to apply our expertise in metals and close tolerance manufacturing to emerging materials and techniques. We believe we can take advantage of opportunities in related metal technologies, including high speed machining of hard metals. We intend to expand our fabrication capabilities to include composite materials, as composite structures are being used more frequently for aerospace applications. |

We believe that implementation of this growth strategy will enhance our ability to successfully compete in the future. Our plans for the implementation of this strategy include:

| · | Continued investment in production efficiencies and capacity. We remain focused on targeted investment in our domestic production capabilities, while seeking more cost solutions by expanding into lower labor cost areas through direct investment in facilities or augmenting our supply chain. We expect that additional future cost-saving opportunities will arise from increased productivity, further improvements to quality, continued outsourcing of non-core activities and investment in human resources, software and improved processes designed to better manage supply chain procurement. |

| · | Pursuing strategic acquisitions. We will continue to explore acquisition opportunities that would enhance our strategic position as a preferred supplier in the aerospace industry. We believe we are well-positioned to take advantage of acquisition opportunities as consolidation trends continue in the aerospace industry. We believe that our ability to integrate strategic acquisitions with our current capabilities will enable us to capture additional market share and diversify our current businesses. |

With our acquisition of D3 Technologies, we operate in two business segments consisting of our Aerostructures segment, comprised of all of LMI’s operations other than D3 Technologies, and our Engineering Services segment, comprised of the operations of D3 Technologies.

Through our Aerostructures segment, we fabricate, machine, finish and integrate formed, close tolerance aluminum and specialty alloy components and sheet metal products primarily for large commercial, corporate, regional and military aircraft. We manufacture more than 30,000 products for integration into a variety of aircraft platforms manufactured by leading OEMs, and Tier 1 aerospace suppliers, including Gulfstream Aerospace Corporation, Boeing Company, Spirit AeroSystems, Sikorsky, Vought Aircraft and Bombardier. We are the sole-source provider, under long-term agreements, for many of the products that we provide. Our primary aerospace products include:

· leading edge wing slats and flapskins;

· winglets and related wing modification kits;

· detail interior components;

· helicopter cabin components and assemblies;

· helicopter aft components and assemblies;

· wing panels;

· door components, assemblies and floorbeams;

· thrust reversers and engine nacelles/cowlings;

· cockpit window frames and landing light lens assembly;

· fuselage and wing skin;

· structural sheet metal and extruded components;

· auxiliary power unit components;

· fans, heat exchangers and various assemblies;

· housings and assemblies for gun turrets; and

· various components and assemblies.

We also offer our customers value-added services related to the design, production, assembly and distribution of aerospace components, as well as deliver kits of products directly to customer points of use. We believe these value-added services strengthen our position as a preferred supplier by improving overall production efficiencies and value for our customers. These services include:

· kitting and distribution;

· assembly;

· just-in-time delivery;

· warehousing;

· engineered tool fabrication and repair;

· prototyping and manufacturing producibility design;

· polishing and painting;

· heat treating and aging of components;

· chemical milling; and

· metal finishing.

In addition to aerospace products, we produce components and assemblies for laser equipment used by semiconductor and medical equipment manufacturers in the technology industry.

Our Engineering Services segment provides prototyping and complex design and engineering services to the aerospace industry. It supports both military and commercial aircraft lifecycles from conceptual design, analysis and certification through production support, fleet support and service life extensions via a complete turnkey engineering solution, including:

· structural design and analysis;

· systems design and integration;

· tool design and fabrication;

· certification planning and support;

· logistics and fleet maintainability;

· complex program management support; and

· avionics and tactical software development.

Through our Engineering Services segment, we offer a complete range of design, engineering and program management services. This capability, added through our acquisition of D3 Technologies, enhances our ability to provide timely, complete turnkey solutions to our customers. Our team of engineers has extensive experience across multiple disciplines, enabling us to creatively address the needs of our customers throughout the life cycle of our customers’ programs. We have the ability to work with OEM customers to launch new programs by assisting in the preliminary and conceptual design, certification planning support, risk mitigation and producibility trade studies, and development of high level program schedule and resource planning. This early stage work better positions us to provide tooling design support in the fabrication stage, as well as modifications and upgrades throughout the platform’s life cycle.

We were organized as a Missouri corporation in 1948. Our principal executive offices are located at 411 Fountain Lakes Blvd., St. Charles, Missouri 63301. Our Internet address is www.lmiaerospace.com. Interested readers can access our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and any amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 19334, as amended, through the Securities and Exchange Commission website at www.sec.gov. Such reports are generally available on the day they are filed. Additionally, we will furnish interested readers a paper copy of such reports, upon request, free of charge.

Customers and Products

Customers

Our principal customers are primarily leading OEMs and Tier 1 suppliers in the corporate and regional, large commercial and military aircraft markets of the aerospace industry. Through December 31, 2007, direct sales to our top three customers (Gulfstream Aerospace Corporation, Spirit AeroSystems, and Boeing Company) accounted for a total of approximately 53% of our sales. The loss of any of these customers could materially affect our sales and profitability.

We have entered into long-term agreements with our customers whereby the customer generally commits to purchase all of its requirements of a particular component from us, subject to termination rights. When operating under these agreements, our customers issue purchase orders or provide a shipment signal to schedule delivery of products at a previously negotiated price. Our products sold outside of long-term agreements are based upon previously negotiated pricing and specific terms and conditions on purchase orders.

See “Item 1A. Risk Factors. Risks Related to Our Business. Sales to a limited number of customers represent a significant portion of our revenues, and our long-term agreements with these customers are generally terminable upon written notice.”

Products & Services

Our Aerostructures segment fabricates, machines and integrates formed, close tolerance aluminum and specialty alloy components for use by the aerospace, defense and technology industries. All of our components and assemblies are based on designs and specifications prepared and furnished by our customers. Our Engineering Services segment provides a complete range of design, engineering and program management services for the aerospace industries. Because we manufacture thousands of components and provide design services on various programs, no one component or service program accounts for a significant portion of our sales. The following table describes some of the principal products we manufacture and the structural design services we provide, as well as the models into which they are integrated:

Product & Services | Models |

| Aerostructures Segment | |

| Leading edge wing slats and flapskins | - Gulfstream: G-450 - Boeing: 737, 777, 787 - Bombardier: Learjet 45 & 60, Challenger 604/605, Dash-8, CRJ 200/700/900 - Cessna: Citation X |

| Winglets | - Boeing: 737, 757 |

Detail interior components | - Gulfstream: G-350, G-450, G-550 - Boeing: 727, 737, 747, 757, 767, 777 - Lockheed: C-130 |

Helicopter cabin components and assemblies | - Sikorsky: UH-60 Black Hawk |

Helicopter aft section components and assemblies | - Sikorsky: UH-60 Black Hawk |

Wing panels | - Boeing: 747 - Bombardier: CRJ 200/700/900 |

Door components, assemblies and floorbeams | - Gulfstream: G-450 - Boeing: 737, 747, 757 - Bombardier: Challenger 604 - Lockheed: F-16 Fighting Falcon, C-130 Hercules |

Thrust reversers and engine nacelles/cowlings | - Gulfstream: G-450 - Boeing Commercial: 737, 747, 777 - Boeing Defense: B-52 Buffalo |

Cockpit window frames and landing light lens assembly | - Gulfstream: G-350, G-450 - Boeing: 737, 747, 767, 777, MD-80, KC-10 - Bombardier: Learjet 45 & 60, Challenger 300 - Lockheed: F-16 Fighting Falcon - Cessna: Citation III, VII and Excel |

Product & Services | Models |

Fuselage and wing skin | - Gulfstream: G-350, G-450, G-550 - Boeing: 717, 737, 747, 757, 767, 777, 787 - Bombardier: Learjet 45 & 60, Dash-8, CRJ 200/700/900 - Lockheed: F-16 Fighting Falcon, C-130 Hercules - Cessna: Citation III |

Structural sheet metal and extruded components | - Gulfstream: G-350, G-450, G-550 - Boeing Commercial: 727, 737, 747, 757, 767, 777 - Boeing Defense: F-15 Eagle, F/A-18 Hornet, C-17 Globemaster - Bombardier: CRJ 200/700/900 - Lockheed: F-16 Fighting Falcon, C-130 Hercules |

Auxiliary power unit components | - Gulfstream: G-550 - Boeing: V-22 Osprey |

Fans, heat exchangers, and various assemblies | - Cymer: ELS 7000, ELS 6010 and XLA 100 |

Housings and assemblies for gun turrets | - Boeing: AH-64 Apache |

Various components and assemblies | - Gulfstream: G-550 - Cymer: IntraLase FS Laser |

| Engineering Services Segment | |

| Structural Design and Analysis | |

· Wing/wingbox, fuselage, empennage design | - Boeing Commercial: 737, 767, 777, 747-8, 787 Dreamliner - Lockheed: JSF F-35, C-130 Hercules, P-3 Orion - Airbus: A-330 - Gulfstream: G-500 - Aviation Technologies Group: Javelin Mark-10 |

· Winglet design | - Boeing Commercial: 737, 757, 767 |

· Nacelle, engine cowl, thrust reverser design | -Gulfstream: G200/G300 - Boeing Commercial: 727 |

· Weight improvement engineering | - Boeing Commercial: 787 Dreamliner, 747-8 - Lockheed: JSF F-35 |

· Aircraft modification engineering | - Boeing Commercial: 727, 757, 767, 777 - Lockheed: C-130 Hercules - Boeing Defense: F/A-18 Hornet - Airbus: A-330 |

Products & Services | Models |

| Systems design and integration | - Boeing Commercial: 757, 777, 747-8, 787 Dreamliner - Airbus: A-380 - Lockheed: JSF F-35 - Lockheed ADP: C-130 Hercules - Northrop Grumman: C-2A Greyhound - Eclipse: Eclipse 500 - Gulfstream: G-350 - GE Aviation: CF34-8 |

| Tool design and fabrication | - Boeing Commercial: 737, 757, 767, 777, 747-8, 787 Dreamliner - Boeing Defense: MMA, F/A-18 Hornet, Delta IV Rocket, C-17 Globemaster, 737 Wedgetail - Lockheed: JSF F-35, F-22, F-16 Fighting Falcon, P-3, C-130 Hercules, C-5 Galaxy, Titan Rocket - Hawker: Hawker 800 - Northrop Grumman: Global Hawk - Gulfstream: G-350 - Lockheed: JSF F-35, Titan IV Rocket |

See “Management’s Discussion and Analysis of Financial Condition and Results of Operations, Overview” for detailed information regarding the revenues contributed by each of the corporate and regional, large commercial, military and technology product sectors. Also refer to Note 16 to Consolidated Financial Statements for business segment information.

Manufacturing Process

We organize our manufacturing facilities by work centers focusing on a particular manufacturing process. Depending on the component, we utilize either a forming process or a machining process. Each work center is staffed by a team of operators who are supported by a supervisor, lead operators and quality inspectors. Throughout each stage of the manufacturing and finishing processes, we collect, maintain and evaluate data, including customer design inputs, process scheduling, material inventory, labor, inspection results and completion and delivery dates. Our information systems employ this data to provide accurate pricing and scheduling information to our customers as well as to establish production standards used to measure internal performance.

We use several different processes in manufacturing components, including:

· fluid cell press;

· sheet metal and extrusion stretch;

· skin stretch;

· stretch draw;

· hot joggle;

· machining and turning;

· brake forming; and

· roll forming.

These processes shape or form aluminum, stainless steel or titanium sheet metal and extrusion, known as a work piece, into components by applying pressure through impact, stretching or pressing, which causes the work piece to conform to a die. The shapes may be simple with a single angle, bend or curve, or may be complex with compound contours having multiple bends and angles. Some processes incorporate heat to soften the metal prior to or during forming.

We also produce components using close tolerance machining methods. These methods involve the machining of various metals, such as stainless steel, aluminum, monel, kevlar and numerous varieties of steel and castings. We have the capability of machining steel and castings in both heat-treated and non-heat-treated conditions. The parts we manufacture using these close-tolerance machining methods are typically small to medium sized parts.

We process parts through conventional and computer numerical control machining methods, also known as CNC, from raw material or castings up to and including assembly processes. In addition, complex machining of parts is accomplished through the use of engineering set-ups to produce intricate and close tolerances with very restrictive finish requirements. Each machining facility is also set up to complete turnkey, research and development projects to better support engineering changes from customers.

Value-Added Services

In addition to the products we sell, each segment offers various value-added services that are intended to result in both cost and time savings. These services include:

· kitting;

· assembly;

· just-in-time delivery;

· warehousing;

· engineered tool design, fabrication and repair;

· prototyping and manufacturing producibility design;

· polishing and painting;

· heat treating and aging of components;

· chemical milling; and

· metal finishing.

Also, our distribution facilities in Savannah, Georgia and Tulsa, Oklahoma are designed to kit manufactured components and deliver to customer points of use in a just-in-time manner.

Backlog

Our Engineering Services segment does not utilize backlog to monitor its operations. Our Aerostructures segment’s backlog is displayed in the following table:

| | | As of December 31, ($ in millions) | |

| | | 2007 | | | 2006 | |

| Total | | $ | 160.9 | | | $ | 139.9 | |

| Portion deliverable within 12 months | | $ | 126.0 | | | $ | 99.2 | |

Our customers often modify purchase orders to accelerate or delay delivery dates. The level of unfilled orders at any given time during the year will be materially affected by our customers’ provisioning policies, the timing of our receipt of orders and the speed with which those orders are filled. Moreover, sales during any period may include sales that are not part of the backlog at the end of the prior period. See “Item 1A. Risk Factors, Risks Related to Our Business – We may not realize all of the sales expected from our existing backlog.”

Raw Materials and Procurement Practices

We manufacture the majority of our components from aerospace quality aluminum sheet metal and extrusion. We also use steel, titanium, inconel, monel and other metals to support the balance of our components. We purchase the majority of these materials through contracts we have negotiated with a distributor and a mill as well as contracts certain of our customers have negotiated with distributors. These contracts are designed to provide an adequate supply of material at predictable pricing levels. If supply is not available or we need a product that is not covered under these agreements, we use a variety of mills and distributors to support our needs. We believe that currently there are adequate alternative sources of supply.

In line with our customers’ demands for more sophisticated and complex products, we have focused our attention on operational execution of an unprecedented number of assembled products. As a result, we anticipate a greater use of third party suppliers for strategic components. To meet this challenge, we established a management procurement process designed to develop strategic relationships with key suppliers and to manage the supply chain to ensure the timely delivery of quality components.

During 2007, we purchased approximately 31% of the materials used in production from three suppliers.

Quality Assurance and Control

Our Aerospace Quality Systems are continuously reviewed and updated to comply with the requirements of ISO9001-2000/AS9100 Revision B and Nadcap (National Aerospace and Defense Contractors Accreditation Program) special processes quality requirements. The continuous review and updating of our processes have allowed our fabrication facilities, with third party ISO9001-2000/AS9100 registrations from National Quality Assurance, USA and Perry Johnson Registrars and Performance Review Institute, to maintain those certifications for 2008 and beyond. Our Engineering Services segment’s quality management system is continuously reviewed and updated to comply with the requirements of ISO9001-2000/A/AS9100 Revision B.

This attention to quality system and business processes has allowed us to remain an approved supplier for many of the leading OEM and Tier 1 suppliers such as Gulfstream, Boeing, Bombardier, Sikorsky Aircraft, Spirit AeroSystems, Lockheed Martin, Cessna, Raytheon, Goodrich and others.

Our quality systems include the quality review of work order masters and outside purchase orders to ensure that the flow-down of our customer’s requirements is being addressed both internally and externally. The quality review of the work order master also ensures that the necessary inspection operations are properly located within the work order to verify and control the outcome of the fabrication processes. We use an ongoing employee training program and lean manufacturing techniques to assist employees in becoming familiar with any changes in our procedures or special customer requirements. We use a robust internal auditing program for each of the facilities to ensure that the training is effective and to ensure ongoing compliance to industry and customer required standards. The internal auditing is provided by a combination of Quality Engineer/Auditors located in some of our facilities or by Corporate Quality Engineer/Auditors traveling to our individual facilities from our headquarters to perform internal audits. All of our quality auditors have completed Registrar Accreditation Board approved Lead Auditor training and have been observed by a Corporate Quality Engineer/Auditor.

We utilize a first part buy-off at each operation during the fabrication process as well as a 100% final inspection of parts to verify their compliance with the customer’s configuration requirements.

We use the AS9102 Rev A standard and forms to perform First Article Inspections. Our Corporate Quality Group maintains our Approved Supplier List (“ASL”) for all facilities. This includes reviewing surveys, performing on-site audits and constant monitoring of customer ASL’s to verify that suppliers are maintaining their customers’ direct approvals.

Our Engineering Services segment’s quarterly management review meetings are performed with the segment’s executive level team on all internal processes and performance to ensure that we meet expectations with positive measurable results. All suppliers of our Engineering Services segment are approved through our supplier rating system and are maintained in our ASL database. All fabrications suppliers of our Engineering Services segment are reviewed on a continual basis with documented quality performance reviews and quality deliverable reviews. All certification documentation is reviewed through preliminary design reviews and critical design reviews by our engineering department and is routed through our internal quality design verification group for verification and validation of data. All Engineering Services sites are required to go through a robust quality assurance internal audit program every year to ensure the effectiveness of our quality management system structure. All final audit reports are reviewed by each Engineering Services site director and the internal audit team to assess required process improvements.

Sales and Marketing

Our Aerostructures sales and marketing group targets four market sectors: corporate and regional aircraft, large commercial aircraft, military aircraft and non-aerospace. We utilize five Program Managers to support these sectors. At each of our facilities, customer service representatives establish and maintain a business relationship between customers and our production and fabrication business units with a focus on customer satisfaction. Additionally, we retain two independent sales representatives.

Awards of new work are generally preceded by receipt of a request for quotation, referred to as an RFQ. Upon receipt, the RFQ is preliminarily reviewed by a team consisting of members of senior management, a program manager, an estimator, engineering personnel and plant management. If our team determines that the program is adequately compatible with our capabilities and objectives, we prepare a formal response. A substantial percentage of new programs are awarded on a competitive bid basis. Following award, the same team reviews the work statement for consistency with the bid and changes are coordinated with the customer. Communication with the customer is performed by the Program Manager.

Our Engineering Services segment utilizes a central marketing and business development team whose main area of responsibility is to establish and maintain ongoing business relationships with our engineering services customer base. In addition, the directors of engineering, operations and program management organization, as well as the organizations they oversee, directly engage with existing customers and programs. All internal organizations within our Engineering Services segment work together to maintain and expand customer relationships with new and existing customers. The segment’s marketing and business development team serves as the main focus for sales and marketing activities relating to design-build programs, working in conjunction with the Program Managers and other LMI corporate staff to assure seamless customer service.

Competition

Our competitors in the aerospace industry consist of a large fragmented group of companies, including certain business units or affiliates of our customers. However, we are unaware of any single company in the aerospace industry that competes in all of our processes. We believe competition within the aerospace industry will increase substantially as a result of industry consolidation, trends favoring greater outsourcing of components and design engineering, the reduction of the number of preferred suppliers and increased capabilities of foreign sources. We also believe participants in the aerospace industry compete primarily with respect to delivery, price and quality.

Unlike the aerospace industry, we believe there are only a few producers of components similar to the principal technology components we manufacture. We believe engineering capability, responsiveness and price are key aspects of competition in the technology industry.

In all of our industries, some of our competitors, including business units affiliated with our customers, have substantially greater financial, production and other resources than we have. We also believe that foreign aerospace manufacturers and engineering service providers are becoming an increasing source of competition, due largely to foreign manufacturers’ access to low-cost labor. Within the aerospace industry, the prevalence of industry participation commitments, pursuant to which domestic OEMs agree to award production work to manufacturers from a foreign country in order to obtain orders from that country, is also driving this trend.

Governmental Regulations and Environmental Compliance

Our operations are subject to extensive and frequently changing federal, state and local laws and substantial regulation by government agencies, including the United States Environmental Protection Agency, the United States Occupational Safety and Health Administration and the Federal Aviation Administration. Among other matters, these agencies impose requirements that regulate the handling, transportation and disposal of hazardous materials generated or used by us during the normal course of our operations, govern the health and safety of our employees and require that we meet standards and licensing requirements for aerospace components. This extensive regulatory framework imposes significant compliance burdens and risks and, as a result, may substantially affect our operational costs.

In addition, we may become liable for the costs of removal or remediation of hazardous substances released on or in our facilities without regard to whether we knew of, or caused, the release of such substances. Furthermore, we are subject to U.S. Export Regulations, including the Arms Export Control Act (AECA), associated International Traffic in Arms Regulations (ITAR), as well as other federal regulations promulgated by various departments within the U.S. Government.

We believe that we are currently in material compliance with applicable laws and regulations and we are not aware of any material environmental violations at any of our current or former facilities. There can be no assurance, however, that our prior activities did not create a material environmental situation for which we could be responsible or that future uses or conditions (including, without limitation, changes in applicable environmental laws and regulations, or an increase in the amount of hazardous substances generated or used by our operations) will not result in any material environmental liability to us or result in a material adverse effect to our financial condition or results of operations.

Employees

As of December 31, 2007, we had 1,338 permanent employees, of whom 32 served in executive positions, approximately 400 were engineers and engineering-related personnel, approximately 160 served in administrative positions and 746 were engaged in manufacturing operations. In addition, we also used the services of approximately 119 temporary employees. None of our employees are subject to a collective bargaining agreement, and we have not experienced any material business interruption as a result of labor disputes since our inception. We believe we have an excellent relationship with our employees.

We strive to continuously train and educate our employees, which enhances the skill and flexibility of our work force. Through the use of internally developed programs, which include formal classroom and on-the-job, hands-on training, lean manufacturing training developed jointly with external resources and tuition reimbursement programs we fund, we seek to attract, develop and retain the personnel necessary to achieve our growth and profitability objectives.

Seasonality

We do not generally experience any seasonality in the demand for our products.

Geographic Operations

We derive less than ten percent of our sales from foreign sources.

You should carefully consider the following risks and other information contained in or incorporated by reference in this Annual Report on Form 10-K when evaluating our business and financial condition. Although the risks described below are the risks that we believe are material, there may also be risks of which we are currently unaware, or that we currently regard as immaterial based on the information available to us that later prove to be material. These risks may adversely affect our business, financial condition and operating results.

Risks Related to Our Business

Sales to a limited number of customers represent a significant portion of our revenues, and our long-term agreements with these customers are generally terminable upon written notice.

As of December 31, 2007, 53% of our aggregate sales were dependent upon relationships with three major customers: Gulfstream Aerospace Corporation, Spirit AeroSystems, and Boeing Company. Although a majority of our sales, including sales to these customers, are made pursuant to long-term agreements, these agreements are generally terminable upon written notice by the customer and typically do not require the customer to purchase any specific quantity of products. As a result, our sales under these agreements may not continue for the full term of the agreements or be consistent with historical sales levels. Additionally, the loss of any one of these customers, or a significant reduction in the amount of orders received from any one of these customers, could cause a significant decrease in our net sales and profitability. We anticipate that a small number of large customers will continue to represent a significant portion of our sales for the foreseeable future. See “Item 1. Business — Customers.”

We may experience cost over-runs related to orders for new products and changes to existing products, and we may be unable to recoup the resulting increased costs.

We generally sell our components, kits and assemblies under multi-year firm agreements on a fixed-price basis, regardless of our production costs. As a result, factors such as inaccurate pricing, manufacturing inefficiencies, start-up costs and increases in the cost of labor, materials or overhead may result in cost over-runs and losses on those agreements. We may not succeed in obtaining the agreement of a customer to reprice a particular product, and we may not be able to recoup previous losses resulting from incomplete or inaccurate engineering data or out-of-tolerance tooling.

Demand for our defense-related products depends upon government spending.

A material portion of our sales is derived from the military market. The military market is largely dependent upon government budgets, particularly the U.S. defense budget. The funding of government programs is subject to Congressional appropriation. Although multi-year contracts may be authorized in connection with major procurements, Congress generally appropriates funds on a fiscal year basis, even though a program may be expected to continue for several years. Consequently, programs, including those that require our components, may be only partially funded or never enter full-scale production as expected. As a result, future U.S. defense spending may not be allocated to programs that would benefit our business or at levels that we had anticipated. A decrease in levels of defense spending or the government’s termination of, or failure to fully fund, one or more of the contracts for the programs in which we participate would adversely impact our revenues and cash flow.

We may not realize all of the sales expected from our existing backlog.

At December 31, 2007, we had approximately $161 million of order backlog. We consider backlog to be firm customer orders for future delivery. From time to time, our OEM customers provide projections of components and assemblies that they anticipate purchasing in the future under new and existing programs. These projections are not included in our backlog unless we have received a firm purchase order or order commitment from our customers. Our customers may have the right, under certain circumstances and with certain penalties or consequences, to terminate, reduce or defer firm orders that we have in backlog. If our customers terminate, reduce or defer firm orders, we may be protected from certain costs and losses, but our sales will nevertheless be adversely affected.

Given the nature of our industry and customers, there is always a risk that orders may be cancelled or rescheduled due to fluctuation in our customers’ business needs, purchasing budgets or inventory management practices. Moreover, our realization of sales from new and existing programs is inherently subject to a number of important risks and uncertainties, including the possibility that our customers will not launch programs on time, or at all, the number of units that our customers will actually produce will change and the timing of production will be altered. Also, until firm orders are pledged, our customers generally have the right to discontinue a program or replace us with another supplier at any time without penalty. Our failure to realize sales from new and existing programs would adversely impact our net sales, results of operations and cash flow.

We may be required to risk our capital to continue existing partnerships or develop new strategic partnerships with OEMs.

Many OEMs are moving toward developing strategic, and sometimes risk-sharing, partnerships with their larger suppliers. Each strategic partner provides an array of integrated services including purchasing, warehousing and assembly for OEM customers. We have been designated as a strategic partner by some OEMs and are striving to become a strategic partner of other OEMs. In order to maintain our current strategic partnerships and establish new ones, we will likely need to expand our existing capacities or capabilities. We may not, however, have the financial ability or technical expertise to do so.

Our long-term success and growth strategy depend on our senior management and our ability to attract and retain qualified personnel.

We have written employment agreements with certain of our senior management that expire on December 31, 2009 and 2010. We also maintain key man life insurance policies on the lives of certain members of senior management. The loss of service of one or more of our senior management personnel, however, could result in a loss of leadership and an inability to successfully pursue our long-term success and growth strategy.

Our success and future growth also depend on management’s ability to attract, hire, train, integrate and retain qualified personnel in all areas of our business. Competition for such personnel is intense, and our inability to adequately staff our operations with qualified personnel could render us less efficient and decrease our rate of production. For example, our Engineering Services segment competes in a highly competitive market to attract and retain highly qualified and well-trained engineers. Such a competitive market could put upward pressure on labor costs for engineering talent. Although we have historically been able to pass through increases in engineering labor costs to our customers, there can be no assurance that we will be able to do so in the future.

In addition, rising costs associated with certain employee benefits, in particular employee health coverage, could limit our ability to provide certain employee benefits in the future. If we are unable to provide a competitive employee benefits package, recruiting and retaining qualified personnel may become more difficult.

We use sophisticated equipment that is not easily repaired or replaced, and therefore equipment failures could cause us to be unable to meet quality or delivery expectations of our customers.

Many of our manufacturing processes are dependent on sophisticated equipment used to meet the strict tolerance requirements of our customers. Because sophisticated equipment generally is not easily repaired or replaced, unexpected failures of this equipment could result in production delays or the manufacturing of defective products. Our ability to meet the expectations of our customers with respect to on-time delivery of quality products is critical. Our failure to meet the quality or delivery expectations of our customers could lead to the loss of one or more of our significant customers.

The use by end-users of the product platforms into which our components are integrated could expose us to product liability claims.

We may be exposed to possible claims of personal injury, death, grounding costs, property damage or other liabilities that result from the failure or malfunction of any component or assembly fabricated or designed by us. We currently have in place policies for products liability and premises insurance, which we believe provide adequate coverage in amounts and on terms that are generally consistent with industry practice. Nevertheless, to the extent a claim is made against us that is not covered in whole or in part by our current insurance, we may be subject to a material loss. Moreover, any claims that are covered by our policies would likely cause our premiums to increase, and we might not be able to maintain adequate insurance coverage levels in the future.

Our long-term growth strategy depends on our ability to maintain a robust and effective supply chain management system.

As we pursue our long-term growth strategy, we will be providing to our customers increasingly sophisticated components, value-added services and design-build programs. In addition, many OEMs are moving toward developing strategic partnerships with their larger suppliers, which are providing purchasing, warehousing and assembly services. The increased complexity of our products, the expected increased outsourcing of non-core activities and the value-added services we are providing to our customers require us to maintain and manage an effective supply chain to assure timely delivery to us of quality components needed to meet our delivery schedules. Failure to procure from our suppliers quality components on a timely basis could decrease customer satisfaction, and thus our competitiveness, and could also result in loss revenue due to contractual penalties or lost sales.

Our facilities are located in regions that are affected by natural disasters.

Several of our facilities are located in regions that have an increased risk of earthquake activity, and one of our facilities has experienced damage due to floods. Although we maintain earthquake and flood loss insurance where necessary, an earthquake, flood or other natural disaster could disrupt our business, result in significant recovery costs and cause our productivity to decrease.

We may be required to record material impairment charges for goodwill, which would reduce our net income and earnings per share.

Current accounting standards require a periodic review of goodwill for impairment in value if circumstances indicate that the carrying amount will not be recoverable. In assessing the recoverability of our goodwill, management is required to make certain critical estimates and assumptions, particularly as to manufacturing efficiency, the achievement of reductions in operating costs, and increased sales and backlog. If any of these or other estimates and assumptions are not realized in the future, we may be required to record impairment charges for goodwill, which charges would reduce net income and earnings per share.

Risks associated with acquisitions could result in increased costs and production inefficiencies.

A key element of our growth strategy continues to be expansion of our business through the acquisition of complementary businesses involved in the aerospace industry and strategic acquisitions that would provide us with access to new industries, product lines and technology. Our ability to expand by acquisition is dependent upon, and may be limited by, the availability of suitable acquisition candidates and our capital resources. Acquisition risks include:

| · | difficulties in assimilating the operations and personnel of acquired companies; |

| · | difficulties associated with implementing and integrating new product lines and meeting new tolerance requirements; |

| · | difficulties in accurately pricing new products; |

| · | the failure to realize potential cost savings or other financial and strategic benefits; |

| · | the incurrence of substantial unanticipated integration costs; |

| · | the potential loss of key employees of the acquired companies; |

| · | the incurrence of substantial, additional indebtedness in funding such acquisitions; |

| · | significant strain on our managerial, financial and other resources; and |

| · | potential goodwill impairment. |

Furthermore, although we will investigate the business operations and assets of entities that we acquire, there may be liabilities that we fail or are unable to discover and for which we, as a successor owner or operator, may be liable. Also, the necessity of integrating our internal controls over financial reporting with businesses acquired by us in order to meet the requirements of Section 404 of the Sarbanes - Oxley Act of 2002 will add additional cost and expense to acquisitions and expose us to the risk that we may not be successful in integrating our internal control over financial reporting with that of the acquired business on a timely basis.

Certain newer aircraft platforms include fewer metal products and could, over time, limit our ability to grow.

Newer military aircraft, such as the Lockheed F-35 Series, and newer aircraft designs for large commercial aircraft, such as the Boeing 787, include more composite and other non-metal components than previous models. Additionally, redesigns of existing platforms could include greater amounts of non-metal components. Although we are in the process of developing and/or acquiring non-metalic production capabilities, we currently do not have the capability to produce non-metal components. If we are unsuccessful in developing and/or acquiring such production expertise, the trend toward the use of non-metal components could limit our opportunities for new work, cause the loss of certain existing work and increase the competitive environment with other suppliers of metal components.

Anti-takeover provisions and our organizational documents may discourage our acquisition by a third party, which could limit your opportunity to sell your shares at a premium.

Our restated articles of incorporation and amended and restated bylaws contain certain provisions that reduce the probability of a change of control or acquisition of our company. These provisions include, among other things:

| · | the ability of our board to issue preferred stock in one or more series with such rights, obligations and preferences as the board may determine, without any further vote or action by our shareholders; |

| · | advanced notice procedures for shareholders to nominate candidates for election of directors and for shareholders to submit proposals for consideration at shareholders’ meetings; |

| · | the staggered election of our directors; and |

| · | restrictions on the ability of shareholders to call special meetings of shareholders. |

In addition, we are subject to Section 459 of the General and Business Corporation Law of Missouri, which, under certain circumstances, may prohibit a business combination with any shareholder holding 20% or more of our outstanding voting power. This provision may have the effect of delaying, deterring or preventing certain potential acquisitions or a change of control of our company.

If our directors and executive officers choose to act together, they will exercise voting control over matters requiring approval by our shareholders.

As of December 31, 2007, our directors and executive officers beneficially owned approximately 28% of our common stock. As a result, these shareholders, acting together, would be able to effectively control all matters requiring approval by our shareholders, including the election of our directors and any merger, sale of assets or other change of control transaction.

Risks Related to Our Industry

We are subject to the cyclical nature of the aerospace industry, and any future downturn in the aerospace industry or general economic conditions could cause our sales and operating income to decrease.

We derive approximately 92% of our revenue from the sale of services and components for the aerospace industry. Consequently, our business is directly affected by certain characteristics and trends of the aerospace industry or general economic conditions that affect our customers, such as:

| · | fluctuations in the aerospace industry’s business cycle; |

| · | varying fuel and labor costs; |

| · | intense price competition and regulatory scrutiny; |

| · | certain trends, including a possible decrease in aviation activity, a decrease in outsourcing by aircraft manufacturers or the failure of projected market growth to materialize or continue; and |

| · | changes in military budgeting and procurement for certain military aircraft. |

In the event that these characteristics and trends were to adversely affect customers in the aerospace industry, they would reduce the overall demand for our products and services, thereby decreasing our sales and operating income.

Terrorist attacks could reduce demand for our large commercial, corporate and regional products and services.

Acts of sabotage or terrorism or adverse results to the U.S. and its military conflicts, such as the current conflict in Iraq, would likely have an adverse impact on the large commercial, corporate and regional aircraft industries, which could lead to reduced demand for our products and services. Prior industry downturns caused by such acts or results have negatively affected our net Aerostructures segment’s sales, gross margin, net income and cash flow. In particular, we and the aerospace industry suffered significantly as a result of the events of September 11, 2001, the events of which caused a substantial downturn in new large commercial aircraft deliveries and order cancellations or deferrals by major domestic and international air carriers.

We may not be able to maintain or improve our competitive position because of the intense competition in the markets we serve.

Our competitors in the aerospace industry consist of a large fragmented group of companies, including certain business units or affiliates of our customers. We believe that competition within the aerospace industry will increase substantially as a result of industry consolidation, trends favoring greater outsourcing of components and a decrease in the number of preferred suppliers. We also believe foreign aerospace manufacturers and engineering service providers will become an increasing source of competition, due largely to foreign manufacturers’ access to low-cost labor and the increased prevalence of industry participation commitments, pursuant to which domestic OEMs agree to award production work to manufacturers from a foreign country in order to obtain orders from that country. Some of our competitors have substantially greater financial, production and other resources than we have. These competitors may have:

| · | the ability to adapt more quickly to changes in customer requirements and industry conditions or trends; |

| · | greater access to capital; |

| · | stronger relationships with customers and suppliers; and |

| · | greater name recognition. |

Decreases in the availability or increases in the cost of our raw materials would increase our operating costs.

Most of our components are manufactured from aluminum products. From time to time, we, and the aerospace components industry as a whole, have experienced shortages in the availability of aerospace quality aluminum. In addition, we utilize certain materials in the manufacture of our non-aerospace products that, in some cases, may be provided by a limited number of suppliers. Raw material shortages could limit our ability to meet our production needs and adversely affect our ability to deliver products to our customers on a timely basis. Also, raw material shortages and capacity constraints at our raw material producers are outside of our control and can cause the price of aluminum to increase. Any significant shortage or price escalation of raw materials such as aluminum could increase our operating costs, which would likely reduce our profits.

OEMs in the aerospace industry have significant pricing leverage over suppliers such as ourselves, and may be able to achieve price reductions over time, which could adversely impact our profitability.

There is substantial and continuing pressure from OEMs in the aerospace industry on suppliers such as ourselves, to reduce prices for products and services. If we are unable to absorb OEM price reductions through operating cost reductions and other methods, our gross margins, profitability and cash flows could be reduced.

Compliance with and changes in environmental, health and safety laws and other laws that regulate the operation of our business and industry standards could increase the cost of production and expose us to regulatory claims.

Our operations are subject to extensive and frequently changing federal, state and local laws and substantial regulation by government agencies, including the United States Environmental Protection Agency, the United States Occupational Safety and Health Administration and the Federal Aviation Administration. Among other matters, these agencies impose requirements that:

| · | regulate the operation, handling, transportation and disposal of hazardous materials generated or used by us during the normal course of our operations; |

| · | govern the health and safety of our employees; and |

| · | require that we meet standards and licensing requirements for aerospace components. |

In particular, we use and generate hazardous waste in our operations. Consequently, we monitor hazardous waste management and applicable environmental permitting and reporting for compliance with applicable laws at our locations in the ordinary course of our business. We may be subject to potential material liabilities relating to any investigation and cleanup of our locations or properties where we deliver hazardous waste for handling or disposal that may be contaminated and to claims alleging personal injury. In addition, we have incurred, and expect to continue to incur, costs to comply with environmental laws and regulations. The adoption of new laws and regulations, stricter enforcement of existing laws and regulations, the discovery of previously unknown contamination or the imposition of new cleanup requirements could require us to incur costs and become subject to new or increased liabilities that could increase our operating costs and adversely affect the manner in which we conduct our business.

While we require Federal Aviation Administration certifications only to a limited extent, we typically are required to maintain third-party registration to industry specification standards, such as AS9100 and National Aerospace and Defense Contractors Accreditation Program, for our quality systems and processes. In fact, many individual OEMs and Tier 1 suppliers require certifications or approvals of our work for them based on third-party registrations in order to engineer and serve the systems and components used in specific aircraft models. If material OEM certifications or approvals were revoked or suspended, OEMs may cease purchasing our products.

We are also subject to U.S. Export Regulations, including the Arms Export Control Act (AECA) and associated International Traffic in Arms Regulations (ITAR).

Moreover, if in the future new or more stringent governmental regulations are adopted, or industry oversight heightened, such action could result in our incurrence of significant additional costs.

None.

Facilities

The following table provides certain information with respect to our headquarters and manufacturing, and engineering centers:

| Location | Principal Use | Square Footage | Interest |

| Aerostructures Segment | | | |

3600 Mueller Road St. Charles, Missouri | Administrative Offices and Manufacturing Center | 62,585 | Leased(1) |

411 Fountain Lakes Blvd. St. Charles, Missouri | Executive and Administrative Offices and Manufacturing Center | 65,580 | Leased(2) |

3030-3050 N. Hwy 94 St. Charles, Missouri | Manufacturing Center and Storage | 92,736 | Leased(3) |

3000-3010 N. Hwy 94 St. Charles, Missouri | Assembly and Storage | 30,074 | Leased(4) |

101 Western Ave. So. Auburn, Washington | Manufacturing Center | 79,120 | Leased(5) |

2629-2635 Esthner Ct. Wichita, Kansas | Manufacturing Center | 31,000 | Leased(6) |

2621 W. Esthner Ct. Wichita, Kansas | Manufacturing Center and Administrative Offices | 39,883 | Leased(7) |

2104 N. 170th St. E. Ave. Tulsa, Oklahoma | Finishing and Manufacturing Facility | 75,000 | Leased(8) |

5270 N Skiatook Road Catoosa, Oklahoma | Distribution Center | 80,000 | Leased(9) |

2205 and 2215 River Hill Rd. Irving, Texas | Machining Facility | 8,400 | Leased(10) |

101 Coleman Blvd. Pooler, Georgia | Distribution | 76,600 | Leased(11) |

A.V. Eucalipto, #2351 Col. Rivera Modula Cy D, C.P. 21259 Mexicali, Baja California, Mexico | Manufacturing Center | 34,857 | Leased(12) |

8866 Laurel Canyon Blvd. Sun Valley, California | Office and Manufacturing | 26,200 | Leased(13) |

11011-11021 Olinda Street Sun Valley, California | Office, Manufacturing and Storage | 22,320 | Leased(14) |

1377 Specialty Drive Vista, California | Office and Manufacturing | 85,004 | Leased(15) |

| Engineering Services Segment | | | |

4838 Ronson Court San Diego, California | Administrative Offices and Engineering | 16,359 | Leased(16) |

8217 44th Ave. West Mukilteo, Washington | Engineering | 18,054 | Leased(17) |

8223 44th Ave. West Mukilteo, Washington | Engineering | 9,890 | Leased(18) |

| Location | Principal Use | Square Footage | Interest |

68 Global Dr., Suite 101 Greenville, South Carolina | Engineering | 8,762 | Leased(19) |

860 W. Airport Frwy, #600 Hurst, Texas | Engineering | 7457 | Leased(20) |

1616 H St. NW, Suite 206 Washington, DC | Administrative Office | 314 | Leased(21) |

__________________________________

| (1) | Subject to graduated yearly rent payments of $373,376 to $549,581 during the lease term. The lease expires on February 28, 2025, subject to our option to extend the lease for three additional five-year terms. |

| (2) | On March 9, 2007, we relocated our principal executive offices to this location which also provides additional manufacturing space. The graduated yearly rent payments are between $397,567 and $528,727 over the ten-year lease term and we have the options for two additional three-year terms. |

| (3) | Subject to graduated yearly rent payments of $244,384 to $359,715 during the lease term. The lease expires on February 28, 2025, subject to our option to extend the lease for three additional five-year terms. |

| (4) | Month to month lease with monthly rent of $10,022. |

| (5) | Subject to yearly rent payments of $444,000 through June 30, 2008 and $492,000 through lease expiration date of June 30, 2011; we retain the option to extend the lease for two additional three-year terms. |

| (6) | Subject to graduated yearly rent payments of $119,574 to $176,003 during the lease term. The lease expires on February 28, 2025, subject to our option to extend the lease for three additional five-year terms. |

| (7) | Subject to yearly rent payments of $148,620 and expires on July 1, 2009; we retain an option to extend the lease term for an additional five years. |

| (8) | Subject to graduated yearly rent payments of $152,740 to $224,822 during the lease term. The lease expires on February 28, 2025, subject to our option to extend the lease for three additional five-year terms. |

| (9) | Subject to yearly rent payments of $329,436 and expires on April 30, 2014. |

| (10) | Subject to yearly rent payments of $45,000 and expires on October 31, 2008. |

| (11) | Subject to yearly rent payments of $421,300 through November 30, 2014; we retain the option to extend the lease for three additional five-year terms. |

| (12) | Subject to graduated monthly rent payments of $13,594 to $15,755 during the lease term and the lease expires on March 31, 2012. |

| (13) | Subject to yearly rent payments of $182,352 and expires on March 31, 2009; we retain an option to extend the lease for two additional terms, which consist of three years and two years, respectively. |

| (14) | Subject to yearly rent payments of $160,704 and expires on March 31, 2009. |

| (15) | Subject to graduated yearly rent payments of $455,166 to $572,304 during the lease term. The lease expires on September 30, 2013, subject to our option to extend the lease for two additional five-year terms. |

| (16) | Subject to graduated yearly rent payments of $206,076 to $222,892 during the lease term. The lease expires on March 31, 2009. |

| (17) | Subject to graduated yearly rent payments of $132,200 to $261,192 during the lease term. The lease expires on December 31, 2011, subject to our option to extend the lease for four additional one-year terms. |

| (18) | Subject to graduated yearly rent payments of $120,000 to $127,920 during the lease term. The lease expires on December 31, 2008, subject to our option to extend the lease for two additional three-year terms. |

| (19) | Subject to graduated yearly rent payments of $61,334 to $63,175 during the lease term. The lease expires on August 31, 2011, subject to our option to extend the lease for three additional five-year terms. |

| (20) | Subject to graduated yearly rent payments of $57,045 to $123,040 during the lease term. The lease expires on January 31, 2012, subject to our option to extend the lease for one additional five-year term. |

| (21) | Subject to graduated yearly rent payments of $10,200 to $10,610 during the lease term. The lease expires on October 31, 2009, subject to our option to extend the lease for one additional two-year term. |

We are not a party to any legal proceedings, other than routine claims and lawsuits arising in the ordinary course of our business. We do not believe such claims and lawsuits, individually or in the aggregate, will have a material adverse effect on our business.

None.

PART II

Market Information

The Company’s common stock is traded on The NASDAQ Stock Market LLC under the symbol “LMIA.” The following table sets forth the range of high and low sales prices for the Company’s common stock for the periods indicated during the Company’s past two fiscal years:

| Period | | High | | | Low | |

| | | | | | | |

| Fiscal 2007 | | | | | | |

1st quarter | | $ | 20.80 | | | $ | 15.48 | |

2nd quarter | | $ | 25.50 | | | $ | 17.76 | |

3rd quarter | | $ | 27.20 | | | $ | 19.69 | |

4th quarter | | $ | 30.91 | | | $ | 22.66 | |

Fiscal 2006 | | | | | | | | |

1st quarter | | $ | 19.13 | | | $ | 12.39 | |

2nd quarter | | $ | 22.78 | | | $ | 15.21 | |

3rd quarter | | $ | 23.86 | | | $ | 16.91 | |

4th quarter | | $ | 21.37 | | | $ | 15.10 | |

Holders

As of March 6, 2008, there were approximately 142 holders of record of the Company’s common stock.

Dividends

We have not historically declared or paid cash dividends on our common stock and we do not anticipate paying any cash dividends in the foreseeable future. Our credit facility with Wachovia Bank, National Association prohibits us from declaring a dividend with respect to our common stock without the lender’s approval. We currently intend to retain our earnings, if any, and reinvest them in the development of our business.

Securities Authorized for Issuance Under Equity Compensation Plans

On July 7, 2005, our shareholders approved the LMI Aerospace, Inc. 2005 Long-term Incentive Plan (the “2005 Plan”). The 2005 Plan replaced the Amended and Restated LMI Aerospace, Inc. 1998 Stock Option Plan (the “1998 Plan”) as the Company’s only compensation plan under which the Company’s common stock is authorized for issuance to employees or directors. The 2005 Plan provides for the grant of non-qualified stock options, incentive stock options, shares of restricted stock, restricted stock units, stock appreciation rights, performance awards, and other stock-based awards and cash bonus awards. Up to 1,200,000 shares of common stock are authorized for issuance under the 2005 Plan.

The following table summarizes information about our equity compensation plan as of December 31, 2007. All outstanding awards relate to the Company’s common stock.

Equity Compensation Plan Information

| Plan Category | Number of Securities to be Issued upon Exercise of Outstanding Options, Warrants and Rights | Number of Unvested Restricted Stock Issued | Weighted-Average Exercise Price of Outstanding Options, Warrants and Rights | Weighted-Average Grant-Date Fair Value of Restricted Stock | Number of Securities Remaining Available for Future Issuance Under Equity Compensation Plans (excluding securities reflected in columns (a) and (b)) |

| | (a) | (b) | (c) | (d) | (e) |

Equity compensation plans approved by security holders: | | | | | |

2005 Long-Term Incentive Plan | 131,790 | 273,876 | $3.23 | $21.27 | 727,850 |

Equity compensation plans not approved by security holders | - | - | - | - | - |

| Total | 131,790 | 273,876 | $3.23 | $21.27 | 727,850 |

Issuer Purchases of Equity Securities

In 1998, the Company’s Board of Directors authorized the repurchase of up to 1,100,000 shares. As of December 31, 2007, the Company had purchased 960,520 shares under this arrangement, but the Company made no purchases of stock under this arrangement during 2007.

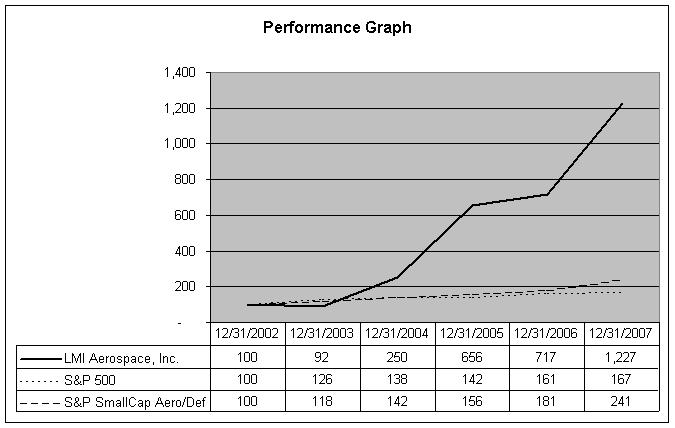

Performance Graph

Set forth below is a line graph presentation comparing the yearly percentage change in cumulative total shareholder returns since December 31, 2002 on an indexed basis with the S & P 500 Index and the S&P Small Cap Aerospace/Defense Index, which is a nationally recognized industry standard index.

The following graph assumes the investment of $100 in LMI Aerospace, Inc. Common Stock, the S & P 500 Index and the S&P Small Cap Aerospace/Defense Index as well as the reinvestment of all dividends. There can be no assurance that the performance of the Company’s stock will continue into the future with the same or similar trend depicted in the graph below.

The selected financial data set forth below for each of the five years ended December 31, 2007, should be read in conjunction with “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations,” the consolidated financial statements, related notes and other financial information included herein. The financial data for the years ended December 31, 2003 through 2007 was derived from our consolidated financial statements for those periods that were audited by BDO Seidman, LLP, independent registered public accounting firm.

(Dollar amounts in thousands, except share and per share data)

| | | | | | | | | | | | | | | | |

| | | 2007 (1) | | | 2006 | | | 2005 | | | 2004 | | | 2003 | |

| Statement of Operations Data: | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | |

| Net sales | | $ | 168,502 | | | $ | 122,993 | | | $ | 101,073 | | | $ | 85,908 | | | $ | 75,855 | |

| Cost of sales | | | 123,588 | | | | 89,527 | | | | 76,326 | | | | 69,510 | | | | 67,485 | |

| Gross profit | | | 44,914 | | | | 33,466 | | | | 24,747 | | | | 16,398 | | | | 8,370 | |

| Selling, general & administrative expenses (2) | | | 23,466 | | | | 17,243 | | | | 14,474 | | | | 13,870 | | | | 13,423 | |

| Income (loss) from operations | | | 21,448 | | | | 16,223 | | | | 10,273 | | | | 2,528 | | | | (5,053 | ) |

| Interest expense | | | (902 | ) | | | (93 | ) | | | (2,019 | ) | | | (2,175 | ) | | | (1,645 | ) |

| Other (expense) income, net | | | (20 | ) | | | (121 | ) | | | 30 | | | | 313 | | | | 306 | |

| Income (loss) before income taxes | | | 20,526 | | | | 16,009 | | | | 8,284 | | | | 666 | | | | (6,392 | ) |

| Provision for (benefit of) income taxes | | | 7,369 | | | | 5,334 | | | | 3,133 | | | | 236 | | | | (2,411 | ) |

| Net income (loss) | | $ | 13,157 | | | $ | 10,675 | | | $ | 5,151 | | | $ | 430 | | | $ | (3,981 | ) |

| | | | | | | | | | | | | | | | | | | | | |

| Amounts per common share: | | | | | | | | | | | | | | | | | | | | |

| Net income (loss) | | $ | 1.18 | | | $ | 1.02 | | | $ | 0.62 | | | $ | 0.05 | | | $ | (0.49 | ) |

| Net income (loss) – assuming dilution | | $ | 1.17 | | | $ | 1.01 | | | $ | 0.61 | | | $ | 0.05 | | | $ | (0.49 | ) |

| Weighted average common shares outstanding | | | 11,157,396 | | | | 10,494,747 | | | | 8,291,337 | | | | 8,186,158 | | | | 8,181,786 | |

| Weighted average dilutive common shares outstanding | | | 11,288,486 | | | | 10,615,251 | | | | 8,401,426 | | | | 8,200,114 | | | | 8,181,786 | |

| | | | | | | | | | | | | | | | | | | | | |

| Other Financial Data: | | | | | | | | | | | | | | | | | | | | |

| Capital expenditures | | $ | 6,570 | | | $ | 6,671 | | | $ | 2,903 | | | $ | 1,266 | | | $ | 1,001 | |

| Cash flows from operating activities | | | 3,166 | | | | 6,160 | | | | 5,342 | | | | 7,426 | | | | 1,011 | |

| Cash flows used by investing activities | | | (56,055 | ) | | | (4,964 | ) | | | (2,786 | ) | | | (314 | ) | | | (371 | ) |

| Cash flows from (used by) financing activities | | | 28,560 | | | | 23,180 | | | | (2,935 | ) | | | (7,119 | ) | | | (1,412 | ) |

| Gross profit margin | | | 26.7 | % | | | 27.2 | % | | | 24.5 | % | | | 19.1 | % | | | 11.0 | % |

| | | | | | | | | | | | | | | | | | | | | |

| Balance Sheet Data | | | | | | | | | | | | | | | | | | | | |

| Cash and equivalents | | $ | 82 | | | $ | 24,411 | | | $ | 35 | | | $ | 414 | | | $ | 441 | |

| Working capital | | | 55,256 | | | | 65,411 | | | | 28,941 | | | | 25,593 | | | | 25,919 | |

| Total assets | | | 166,118 | | | | 108,610 | | | | 71,957 | | | | 65,381 | | | | 70,519 | |

| Total long-term debt, excluding current portion | | | 29,106 | | | | 583 | | | | 15,462 | | | | 18,583 | | | | 21,756 | |

| Stockholders' equity | | | 104,827 | | | | 90,510 | | | | 39,832 | | | | 34,352 | | | | 33,792 | |