WEYERHAEUSER INVESTOR MEETING December 13, 2016 | New York

FORWARD-LOOKING STATEMENTS AND NON-GAAP FINANCIAL MEASURES 2 This presentation contains statements that are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, as amended, including, without limitation, with respect to future prospects, business strategies, revenues, earnings, cash flow, taxes, funds available for distribution, pricing, production, supply, dividend levels, share repurchases, business priorities, performance, cost reductions, operational excellence initiatives, costs and operational synergies, demand drivers and levels, margins, growth, housing markets, capital structure, credit ratings, capital expenditures, cash position, debt levels, and harvests and export markets. Forward-looking statements can be identified by the fact that they do not relate strictly to historical or current facts. Forward-looking statements may be identified by our use of certain words in such statements, including without limitation words such as “anticipate,” “believe,” “continue,” “continued,” “could,” “forecast,” “estimate,” “outlook,” “goal,” “will,” “plan,” “expect,” “target,” “would” and similar words and terms and phrases using such terms and words. We may refer to assumptions, goals or targets, or we may reference expected performance through, or events to occur by or at, a future date, and such references may also constitute forward-looking statements. Forward-looking statements are based on management’s current expectations and assumptions concerning future events and are inherently subject to uncertainties and factors relating to our operations and business environment that are difficult to predict and often beyond the company’s control. Many factors could cause, among other things, one or more of our expectations to be unmet, one or more of our assumptions to be materially inaccurate or actual results to differ materially from those expressed or implied in these forward-looking statements. Such factors include, without limitation: our ability to successfully integrate the Plum Creek merger; our ability to successfully execute our performance plans, including cost reductions and other operational excellence initiatives; the effect of general economic conditions, including employment rates, housing starts, interest rate levels, availability of financing for home mortgages and the strength of the U.S. dollar; market demand for our products, including demand for our timberland properties with higher and better uses, which in turn is related to the strength of various U.S. business segments and U.S. and international economic conditions; domestic and foreign competition; raw material prices; energy prices; the effect of weather; the risk of loss from fires, floods, windstorms, hurricanes, pest infestation and other natural disasters; transportation availability and costs; federal tax policies; the effect of forestry, land use, environmental and other governmental regulations; legal proceedings; performance of pension fund investments and related derivatives; the effect of timing of retirements and changes in market price of our common stock on charges for share-based compensation; changes in accounting principles; and the other risk factors described in filings we make from time to time with the Securities and Exchange Commission, including without limitation risk factors described in our annual report on Form 10-K for the year ended December 31, 2015. There is no guarantee that any of the anticipated events or results articulated in this presentation will occur or, if they occur, what effect they will have on the company’s results of operations or financial condition. The forward-looking statements contained herein apply only as of the date of this presentation and we do not undertake any obligation to update these forward-looking statements. Nothing on our website is intended to be included or incorporated by reference into, or made a part of, this presentation. Also included in this presentation are certain non-GAAP financial measures, which management believes complement the financial information presented in accordance with U.S. generally accepted accounting principles. Management believes such non-GAAP measures may be useful to investors. Our non-GAAP financial measures may not be comparable to similarly named or captioned non-GAAP financial measures of other companies due to potential inconsistencies in how such measures are calculated. A reconciliation of each presented non-GAAP measure to its most directly comparable GAAP measure is provided in the appendices to this presentation.

INTRODUCTION DOYLE SIMONS President and CEO 3

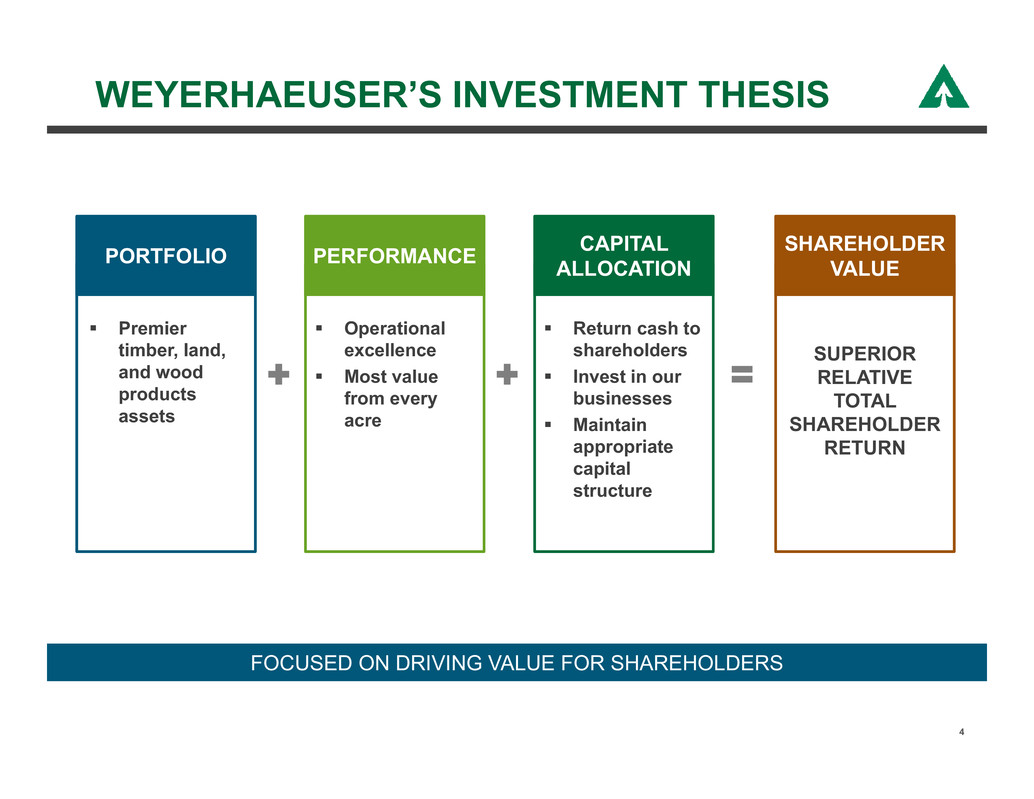

WEYERHAEUSER’S INVESTMENT THESIS FOCUSED ON DRIVING VALUE FOR SHAREHOLDERS Operational excellence Most value from every acre Return cash to shareholders Invest in our businesses Maintain appropriate capital structure Premier timber, land, and wood products assets SUPERIOR RELATIVE TOTAL SHAREHOLDER RETURN PORTFOLIO PERFORMANCE CAPITAL ALLOCATION SHAREHOLDER VALUE 4

FOCUSED PORTFOLIO OF SCALE ASSETS 6 7 13 0% 20% 40% 60% 80% 100% 2012 2013 2016 MILLION ACRES MILLION ACRES MILLION ACRES Timberlands Wood Products Cellulose Fibers WRECO Timberlands Wood Products Cellulose Fibers WRECO Timberlands Wood Products INCREASING FOCUS UNMATCHED SCALE AND QUALITY WE ARE ONE OF THE LARGEST REITS IN THE U.S. OUR TIMBERLANDS ASSETS ARE WORLD CLASS OUR WOOD PRODUCTS MANUFACTURING FACILITIES ARE LOW COST & INDUSTRY LEADING T i m b e r l a n d s % o f B u s i n e s s A s s e t s 5

PERFORMANCE: Achieving 2016 Commitments 6 HARD DOLLAR COST SYNERGIES $100 million OPERATIONAL SYNERGIES $130-140 million WOOD PRODUCTS OPX $60 million ACCELERATED SHARE REPURCHASE $2 billion AT LEAST $40 MILLION IN 2016 ON TRACK FOR $125 MILLION COMPLETED IN UNDER 6 MONTHS ON TRACK AVO process MAXIMIZE VALUE OF EVERY ACRE COMPLETE FOR ALL SOUTHERN TIMBERLANDS C O M M I T M E N T T A R G E T S T A T U S

▪ Retained strengths of both organizations ▪ Placed high potential individuals in key roles ▪ Good mix from both companies on operating teams ▪ Selected leaders who excel at execution and know how to build a common culture RIGHT PEOPLE IN THE RIGHT ROLES 7

8

TIMBERLANDS RHONDA HUNTER Senior Vice President, Timberlands 9

STRATEGY FOR SUCCESS Timberlands 10 BEST TIMBERLANDS Superior quality and productivity Unmatched diversity Unparalleled scale Sustainably certified RIGHT PEOPLE IN THE RIGHT ROLES DRIVE RESULTS WINNING INDUSTRY- LEADING EBITDA PER ACRE BEST EXECUTION Operational synergies from merger Ongoing operational excellence initiatives Targeted capital investments

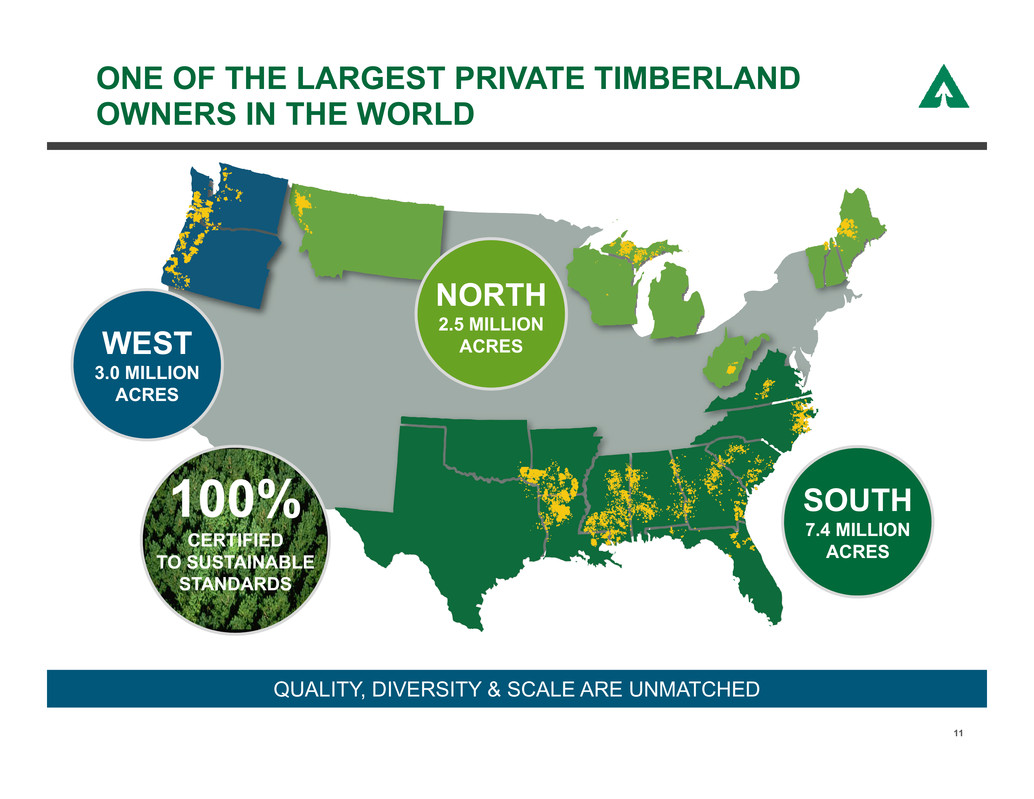

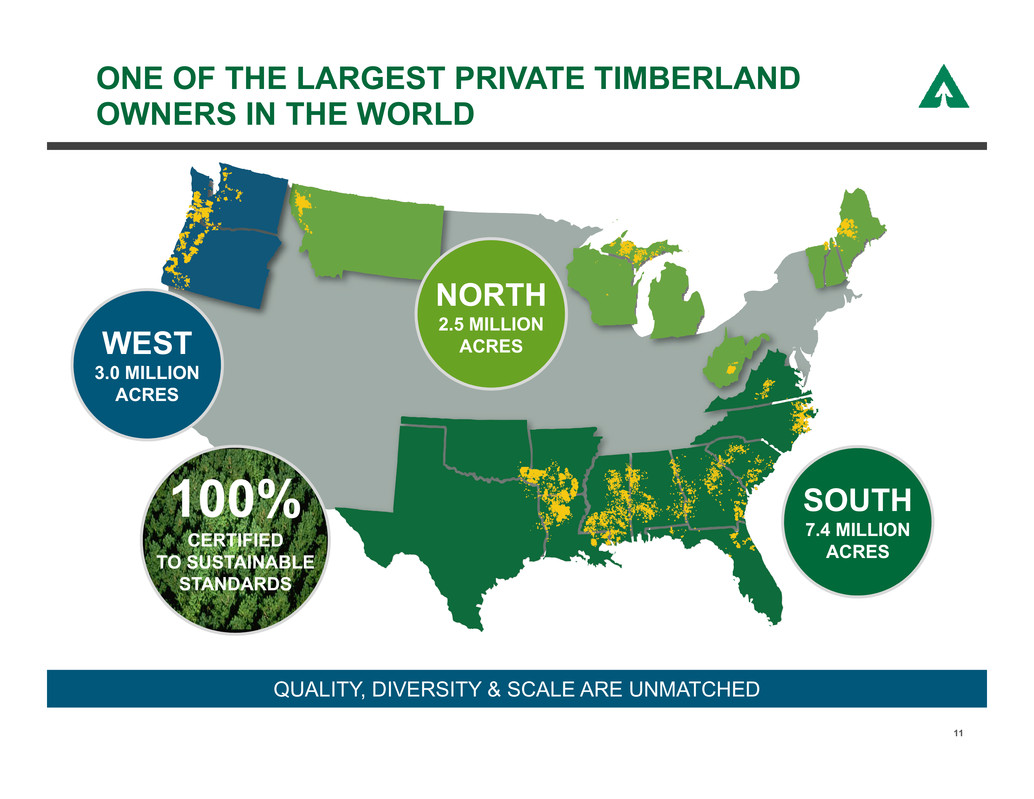

ONE OF THE LARGEST PRIVATE TIMBERLAND OWNERS IN THE WORLD 11 QUALITY, DIVERSITY & SCALE ARE UNMATCHED NORTH 2.5 MILLION ACRESWEST 3.0 MILLION ACRES SOUTH 7.4 MILLION ACRES 100% CERTIFIED TO SUSTAINABLE STANDARDS

US WEST TIMBERLANDS Export Other Export Japan Domestic Sales Internal Sales UNPARALLELED SCALE UNMATCHED DIVERSITYSUPERIOR QUALITY #1 Private timberlands owner Largest export log facility in U.S. Well-balanced age-class Three diverse market drivers Unique access to premium export market AGE CLASS IN YEARS T O N S O F S O F T W O O D I N M I L L I O N S 0 10 20 30 40 50 60 0-19 20-29 30-39 40-49 50-59 60-89 90+ 0 20 40 60 80 100 120 140 Average Douglas fir WY Exhibited Douglas fir S I T E I N D E X I N F E E T 30% higher site index Inventory represents WY and PCL softwood standing inventory as of 12/31/2015. Inventory charted includes all conservation and set aside areas. Share of revenue for 2016 Q3 YTD 12 Site index for U.S. Western timberlands represents average dominant tree height at age 50. Source: USDA Natural Resources Conservation Service, Weyerhaeuser

US SOUTH TIMBERLANDS UNPARALLELED SCALE UNMATCHED DIVERSITYSUPERIOR QUALITY Favorable age-class inventory End-to-end market knowledge in every major wood market AGE CLASS IN YEARS #1 Private timberlands owner Scale operations in every region Superior efficiency in planning, infrastructure and delivery 0 20 40 60 80 100 0-9 10-19 20-29 30+ 0 15 30 45 60 75 Average Southern Yellow Pine WY Exhibited Southern Yellow Pine Nearly 25% higher site index S I T E I N D E X I N F E E T 13 Site index for U.S. Southern timberlands represents average tree height at age 25. Source: USDA Natural Resources Conservation Service, Weyerhaeuser T O N S O F S O F T W O O D I N M I L L I O N S Inventory represents WY and PCL softwood standing inventory as of 12/31/2015. Inventory charted includes all conservation and set aside areas.

US NORTH TIMBERLANDS UNPARALLELED SCALE UNMATCHED DIVERSITYSUPERIOR QUALITY #1 Private timberland owner in Northern hardwood Well developed merchandising program to maximize value of every log 15% premium value hardwood sawlogs Proximate to key markets Nearly 80% of hardwood pulpwood sold under supply agreements Grow 50 species Market 130 product grades 14

SUSTAINABLE AND GROWING HARVEST M I L L I O N S O F T O N S 0 5 10 15 20 25 30 35 40 45 2016 2017-2021 2022-2026 2027-2031 SOUTH WEST NORTH Projected harvest levels exclude Uruguay operations and may change as a result of future acquisitions or dispositions of timberlands, including activity within our Real Estate segment. 15 PROJECTED AVERAGE ANNUAL HARVEST VOLUMES

TIMBERLANDS: Relative Performance ADJUSTED EBITDA* / ACRE OWNED U.S. WEST ADJUSTED EBITDA* / ACRE OWNED U.S. SOUTH Source for competitor data: public SEC filings, National Council of Real Estate Investment Fiduciaries (NCREIF). *Adjusted EBITDA. See appendix for reconciliation to GAAP amounts. **WY excludes Real Estate, Energy & Natural Resources and includes Plum Creek Washington, Oregon and Southern operations for all periods. Longview Timber included beginning in 2014. ***Pope Resources results exclude significant land sales in 2014 Q3 and Q4. Including these sales, 2014 EBITDA/acre = $263. ****Deltic EBITDA calculated as Woodlands operating income plus Woodlands depreciation, amortization and cost of fee timber harvested. $45 $95 $145 $195 $245 2011 2012 2013 2014 2015 2016 Q3 LTM $0 $20 $40 $60 $80 2011 2012 2013 2014 2015 2016 Q3 LTM WY Timberlands, including Plum Creek** NCREIF Rayonier Pope Resources*** Deltic**** 16

TIMBERLANDS: OpX Performance OPERATIONAL EXCELLENCE 2 0 1 4 - 1 5 2 0 1 6 PROGRESS GOAL $64 MM $40 MM OUTLOOK $200 MM TOTAL GOAL KEY INITIATIVES Capture operational synergies ̶ Optimize wood flows to minimize costs and increase realizations ̶ Optimize silviculture: cost and value creation ̶ Best practices in harvesting and transportation Continue with OpX focus and expand to larger footprint ̶ Steep slope logging technologies ̶ Central truck dispatch $40 MM GOAL 2 0 1 7 17

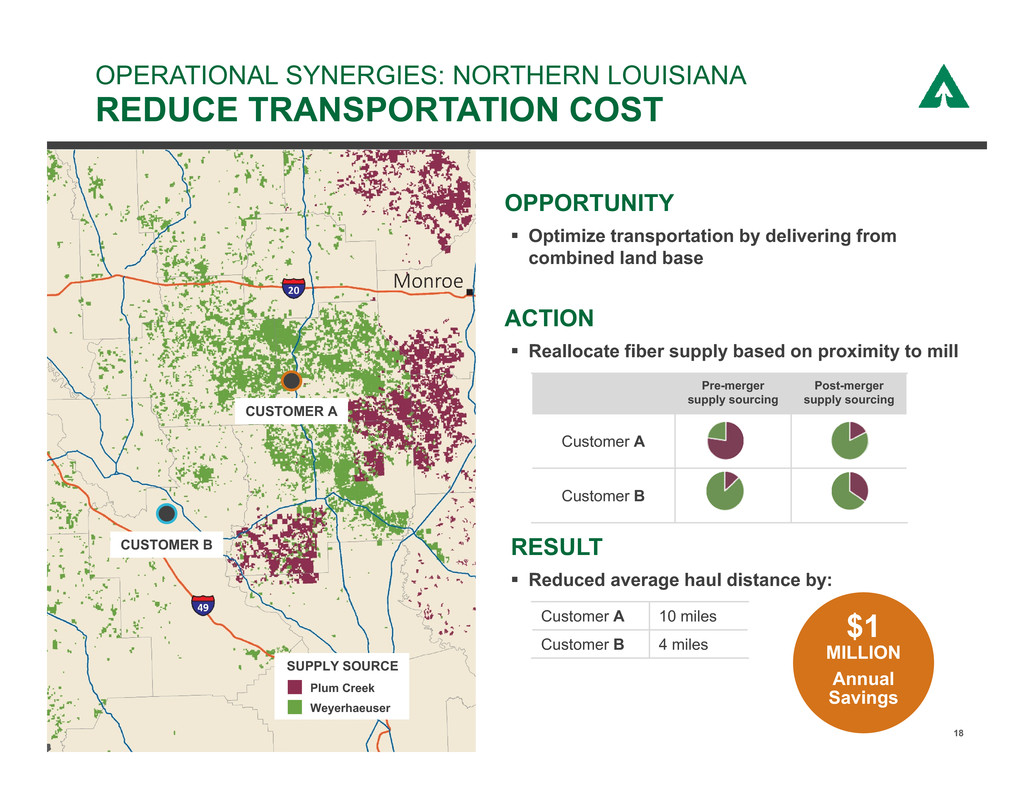

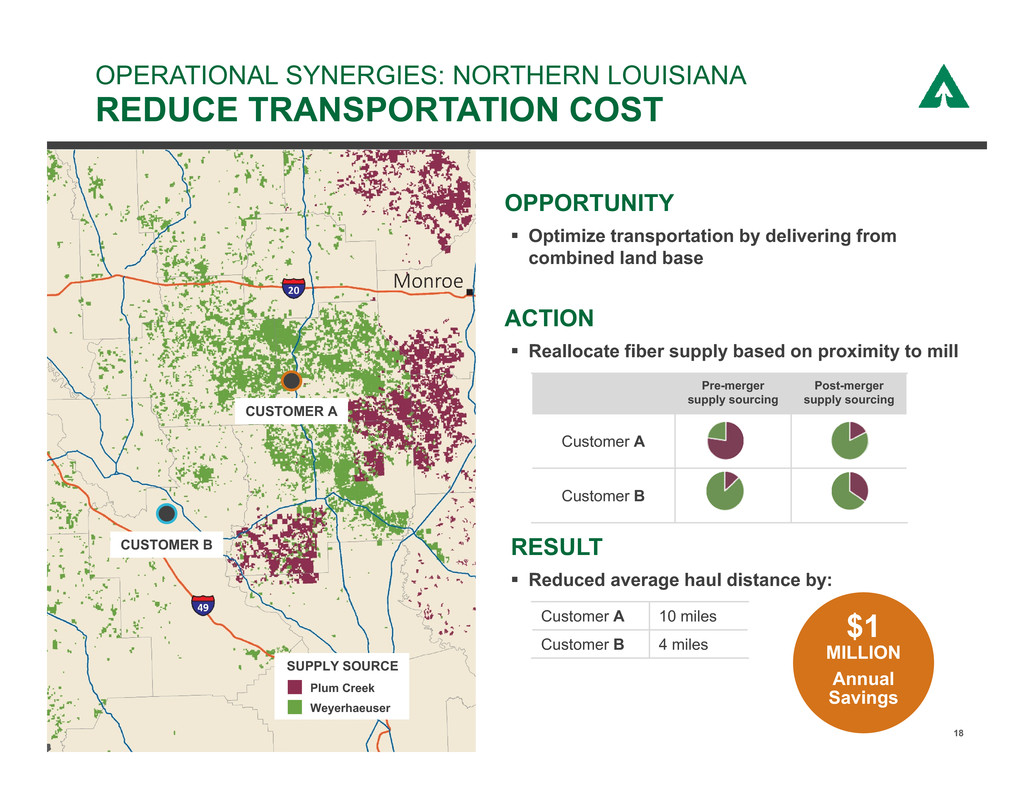

OPERATIONAL SYNERGIES: NORTHERN LOUISIANA REDUCE TRANSPORTATION COST 18 OPPORTUNITY Optimize transportation by delivering from combined land base ACTION Reallocate fiber supply based on proximity to mill RESULT Reduced average haul distance by: CUSTOMER A CUSTOMER B Customer A 10 miles Customer B 4 miles Pre-merger supply sourcing Post-merger supply sourcing Customer A Customer B Plum Creek Weyerhaeuser SUPPLY SOURCE $1 MILLION Annual Savings

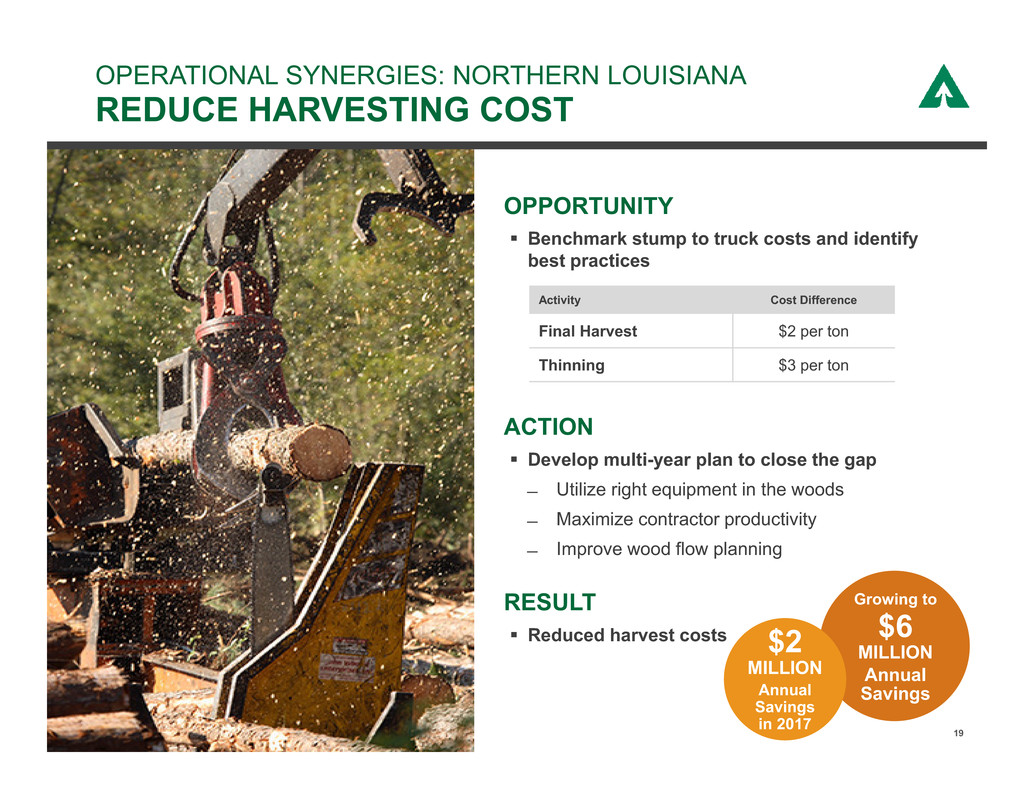

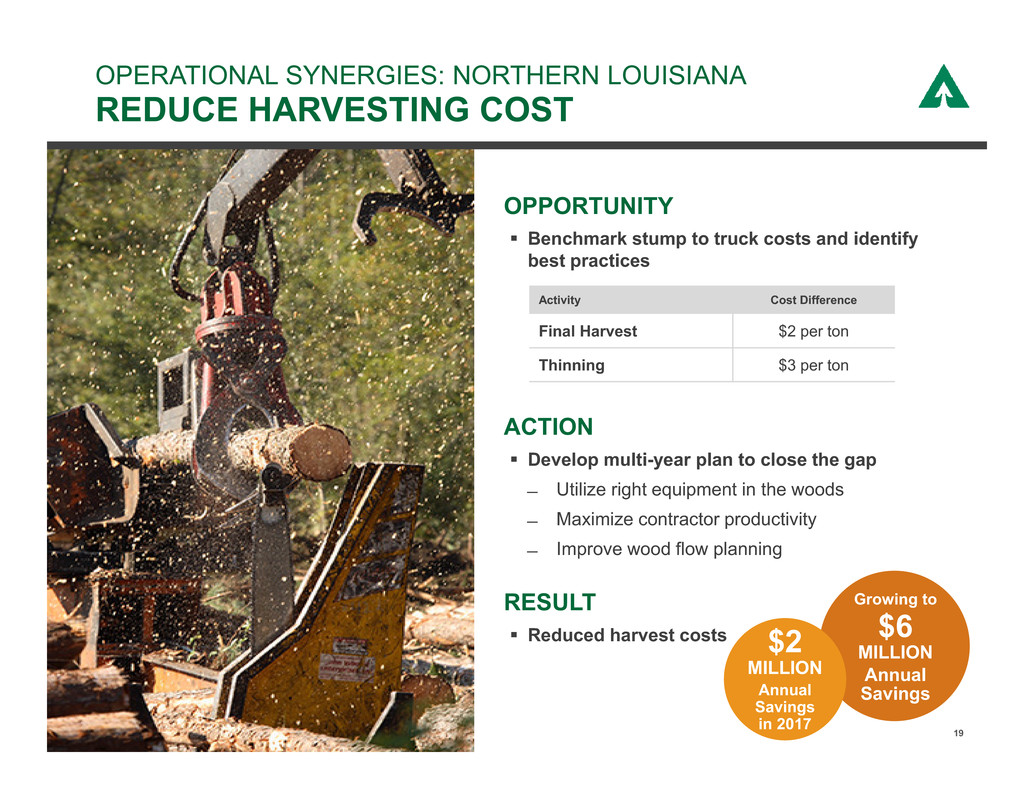

OPERATIONAL SYNERGIES: NORTHERN LOUISIANA REDUCE HARVESTING COST 19 OPPORTUNITY Benchmark stump to truck costs and identify best practices ACTION Develop multi-year plan to close the gap ̶ Utilize right equipment in the woods ̶ Maximize contractor productivity ̶ Improve wood flow planning RESULT Reduced harvest costs Growing to $6 MILLION Annual Savings Activity Cost Difference Final Harvest $2 per ton Thinning $3 per ton $2 MILLION Annual Savings in 2017

OPERATIONAL SYNERGIES: NORTHERN LOUISIANA MERCHANDISE TO EXTRACT VALUE OPPORTUNITY Benchmark merchandising practices to capture value extraction Combined land base creates better scale and proximity to serve high value customers ACTION Capture opportunities to merchandise higher value log mix Serve new customers by delivering from combined land base RESULT More valuable product mix drives margin uplift Average value uplift by grade P E R T O N CUSTOMER $0 $10 $20 $30 $40 Pulp Chip N Saw Sawlog Veneer Pole 20 $1 MILLION Uplift Improve Mix 1%

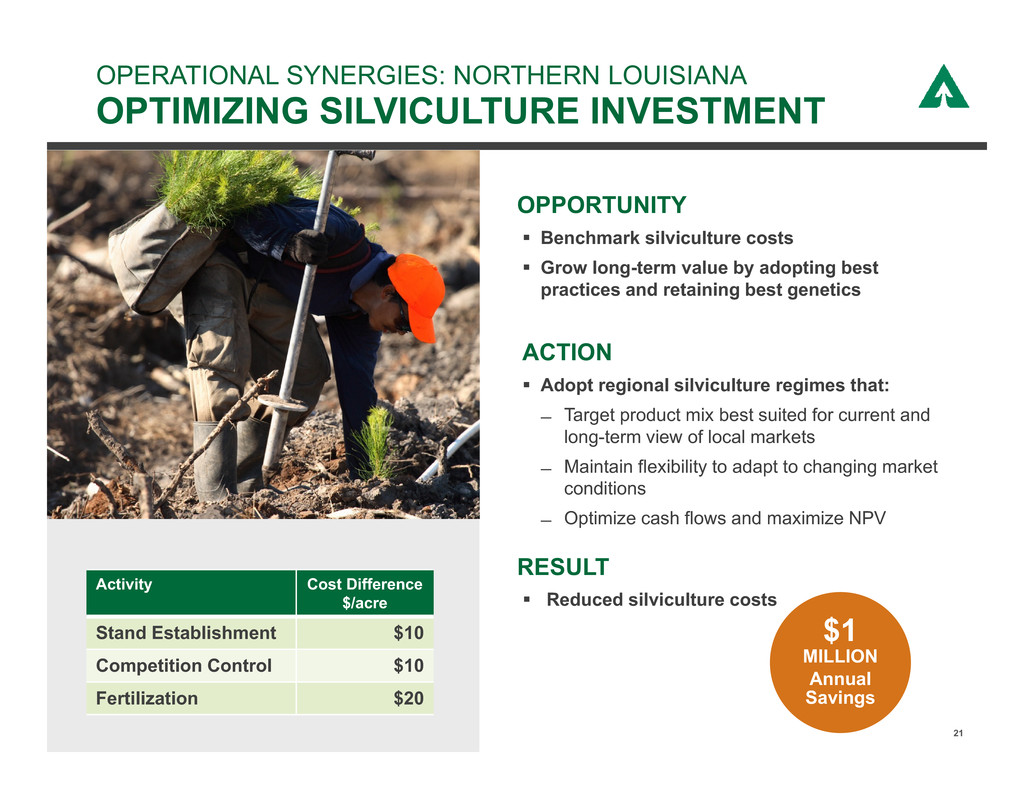

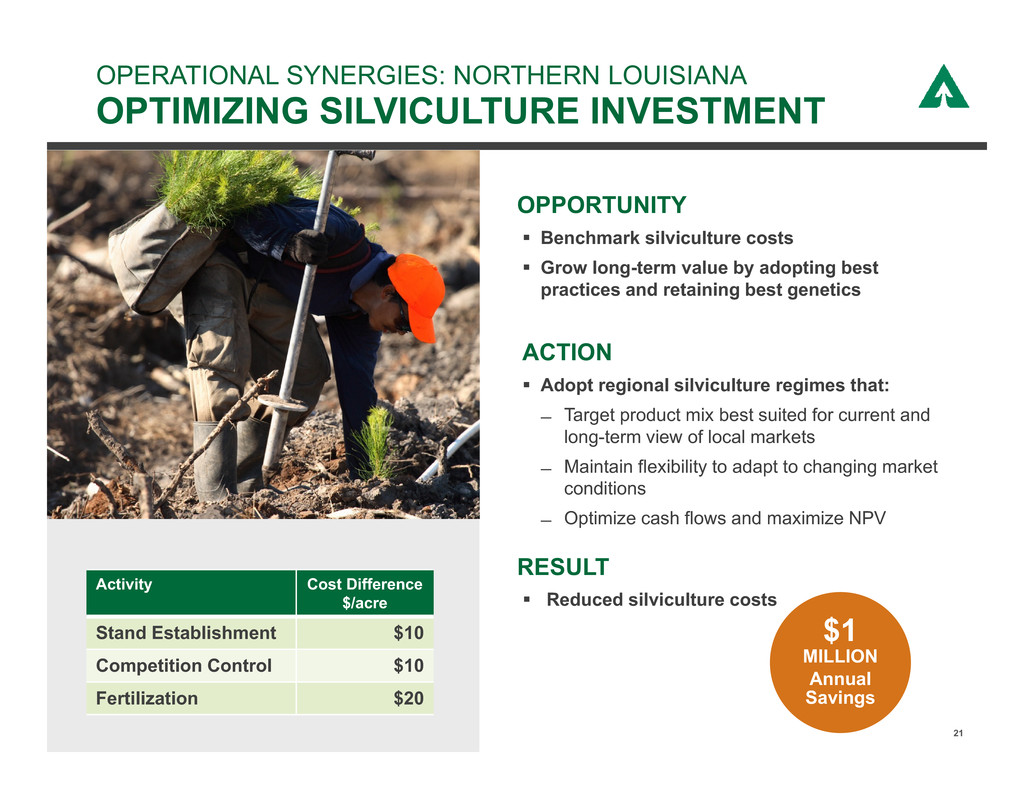

21 Activity Cost Difference $/acre Stand Establishment $10 Competition Control $10 Fertilization $20 OPPORTUNITY Benchmark silviculture costs Grow long-term value by adopting best practices and retaining best genetics ACTION Adopt regional silviculture regimes that: ̶ Target product mix best suited for current and long-term view of local markets ̶ Maintain flexibility to adapt to changing market conditions ̶ Optimize cash flows and maximize NPV RESULT Reduced silviculture costs $1 MILLION Annual Savings OPERATIONAL SYNERGIES: NORTHERN LOUISIANA OPTIMIZING SILVICULTURE INVESTMENT

22 OPPORTUNITY Utilize new cable-assist technology to mechanize harvest on steep slopes Reduce reliance on manual labor and high cost equipment to improve safety and productivity ACTION Expand use of steep slope technologies across ̶ Western footprint ̶ Previously inoperable acres in Maine Will take multiple years to fully implement RESULT Reduced harvest costs OPERATIONAL EXCELLENCE: STEEP SLOPE LOGGING TECHNOLOGY Growing to $12-15 MILLION Annual Savings $4 MILLION Annual Savings in 2016

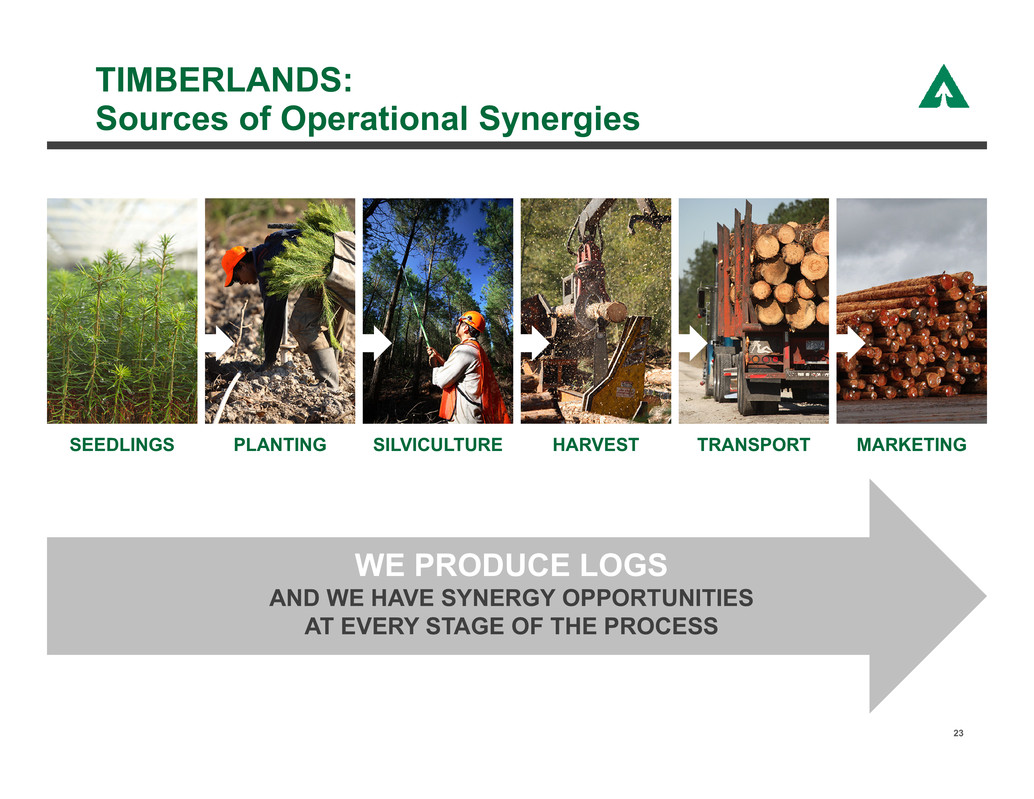

TIMBERLANDS: Sources of Operational Synergies 23 WE PRODUCE LOGS AND WE HAVE SYNERGY OPPORTUNITIES AT EVERY STAGE OF THE PROCESS SEEDLINGS PLANTING SILVICULTURE HARVEST TRANSPORT MARKETING

STRATEGY FOR SUCCESS Timberlands 24 BEST TIMBERLANDS Superior quality and productivity Unmatched diversity Unparalleled scale Sustainably certified RIGHT PEOPLE IN THE RIGHT ROLES DRIVE RESULTS WINNING INDUSTRY- LEADING EBITDA PER ACRE BEST EXECUTION Operational synergies from merger Ongoing operational excellence initiatives Targeted capital investments

REAL ESTATE AND ENERGY & NATURAL RESOURCES JIM KILBERG Senior Vice President, Real Estate and Energy & Natural Resources 25

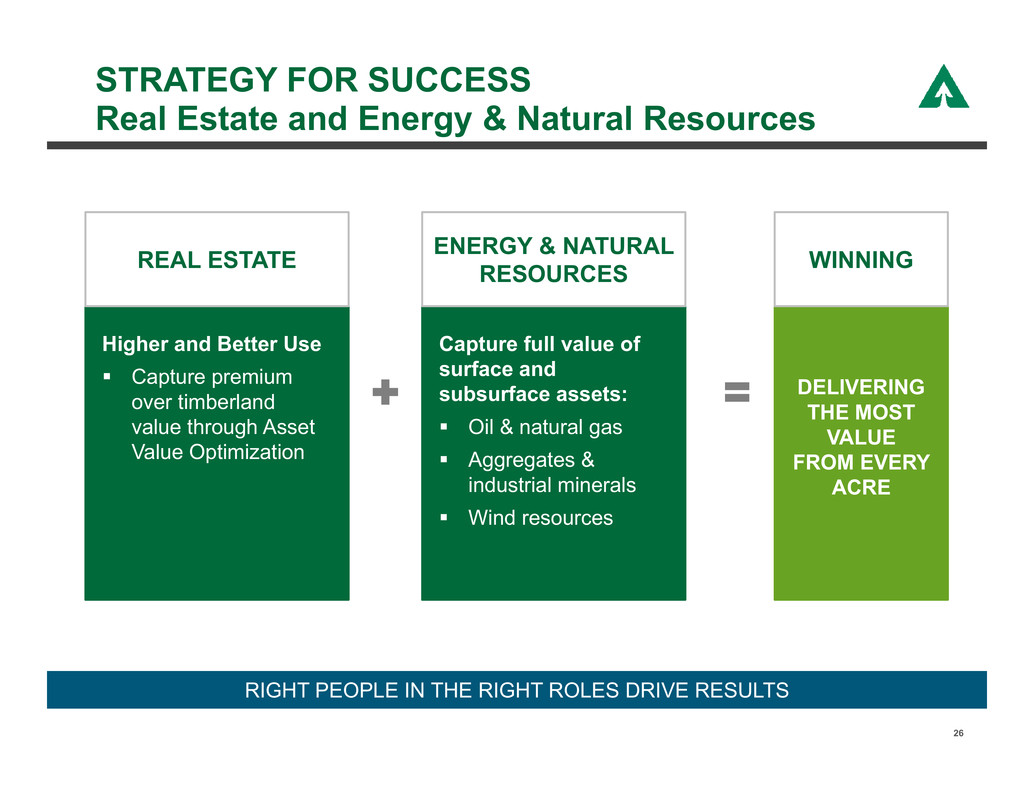

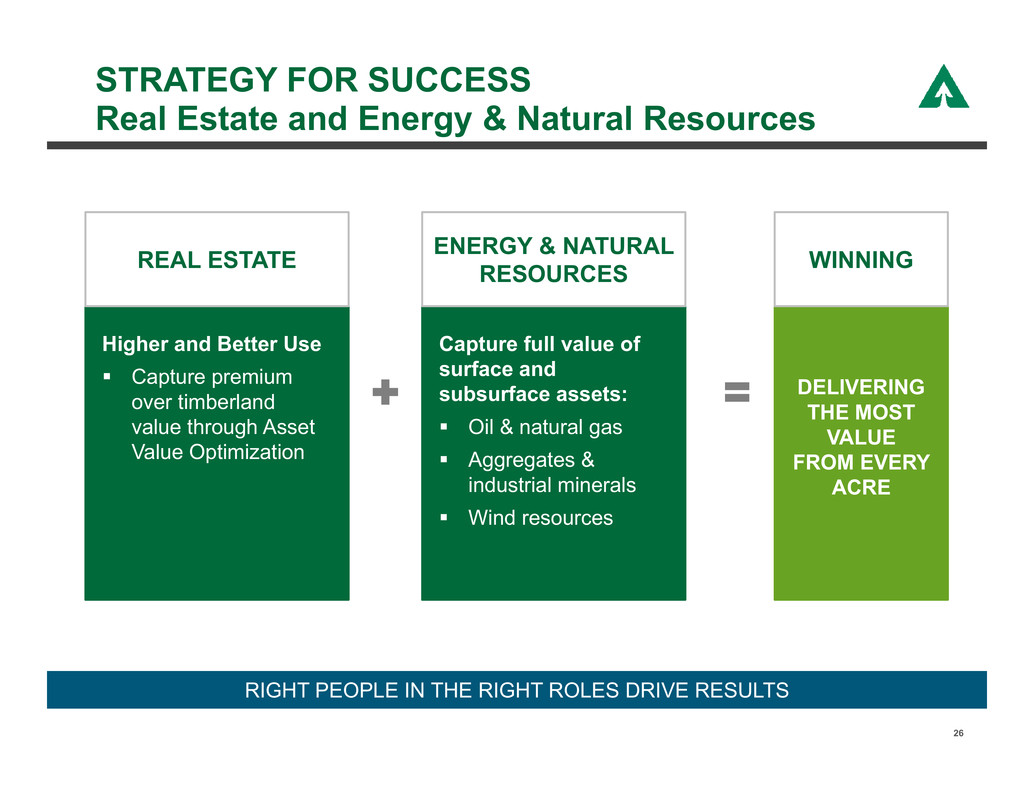

STRATEGY FOR SUCCESS Real Estate and Energy & Natural Resources 26 REAL ESTATE Higher and Better Use Capture premium over timberland value through Asset Value Optimization RIGHT PEOPLE IN THE RIGHT ROLES DRIVE RESULTS WINNING DELIVERING THE MOST VALUE FROM EVERY ACRE ENERGY & NATURAL RESOURCES Capture full value of surface and subsurface assets: Oil & natural gas Aggregates & industrial minerals Wind resources

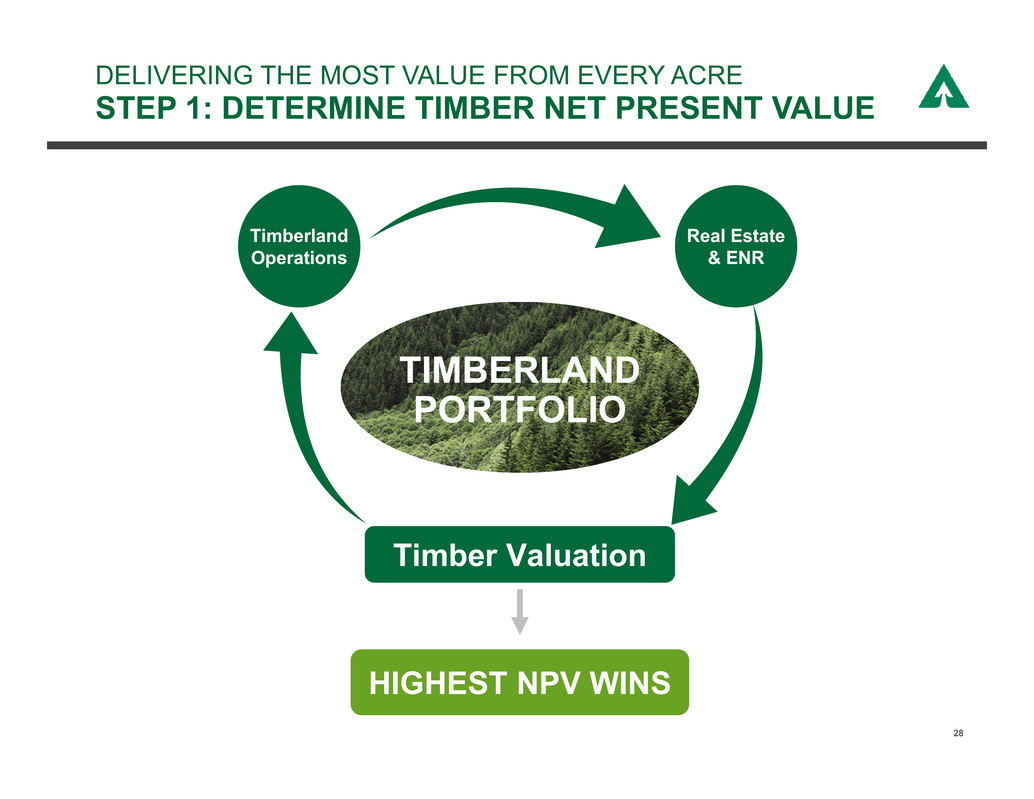

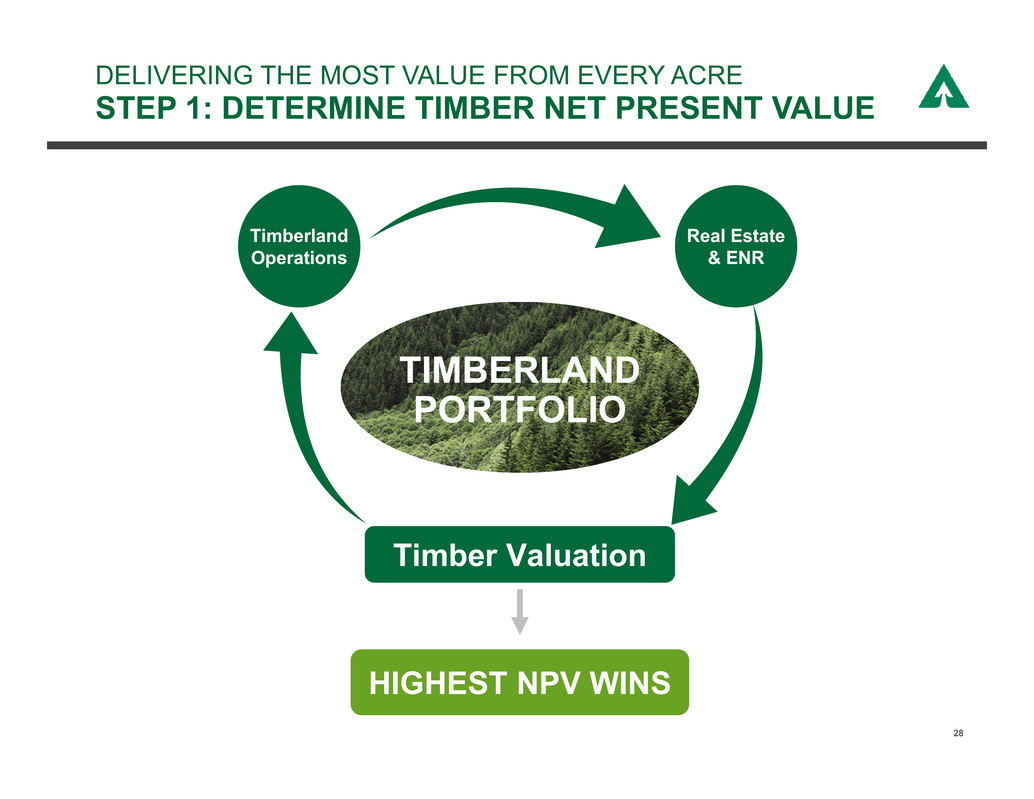

Identify opportunities to capture premium value (Asset Value Optimization — AVO) REAL ESTATE: Delivering the most value from every acre 27 Determine timber net present value for each acre Deliver a premium to timber net present value 2 3 1

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 1: DETERMINE TIMBER NET PRESENT VALUE 28 TIMBERLAND PORTFOLIO Timber Valuation Real Estate & ENR Timberland Operations HIGHEST NPV WINS

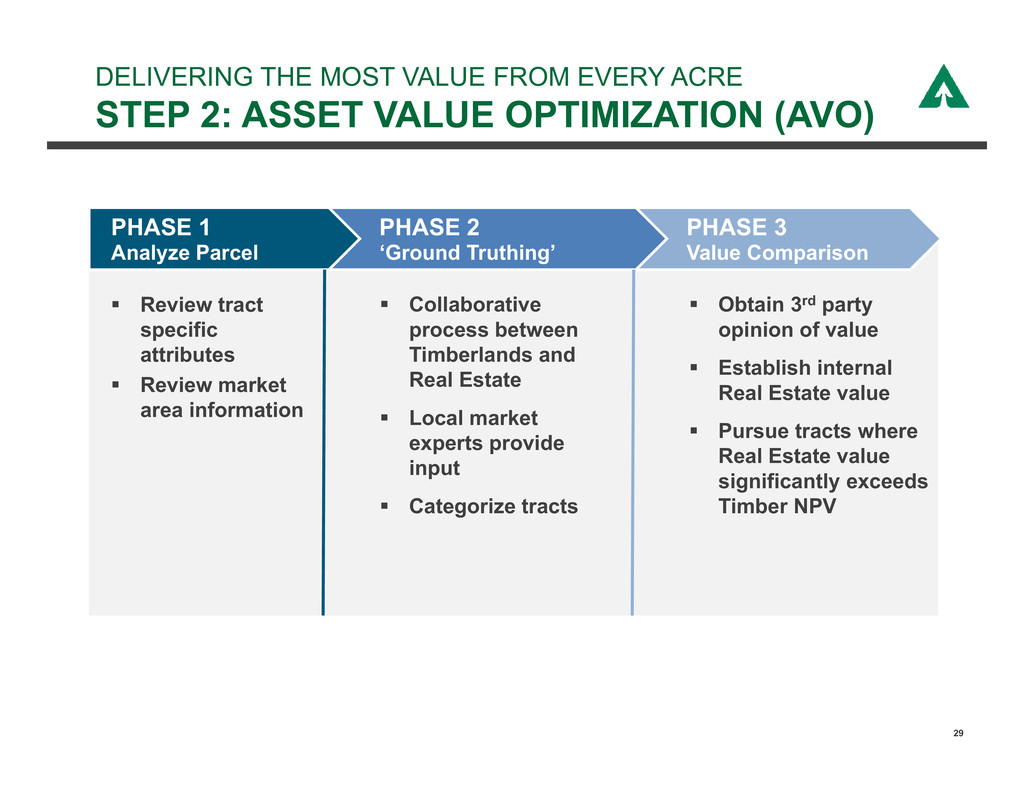

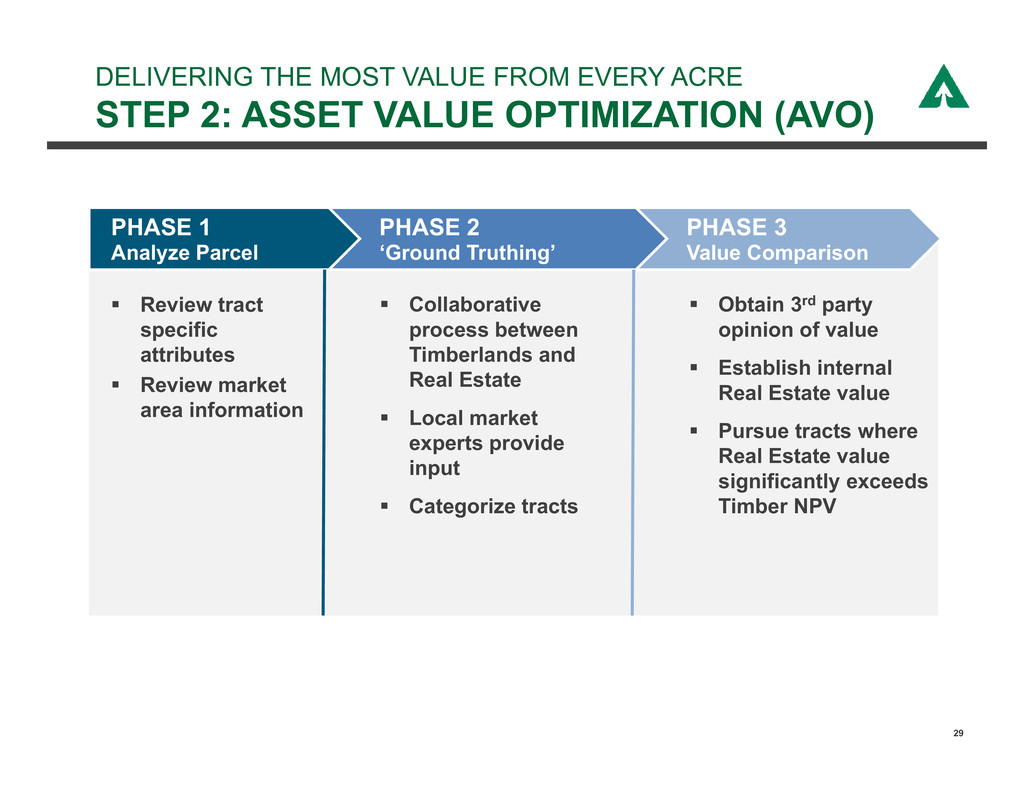

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 2: ASSET VALUE OPTIMIZATION (AVO) 29 Review tract specific attributes Review market area information PHASE 1 Analyze Parcel PHASE 2 ‘Ground Truthing’ PHASE 3 Value Comparison Collaborative process between Timberlands and Real Estate Local market experts provide input Categorize tracts Obtain 3rd party opinion of value Establish internal Real Estate value Pursue tracts where Real Estate value significantly exceeds Timber NPV

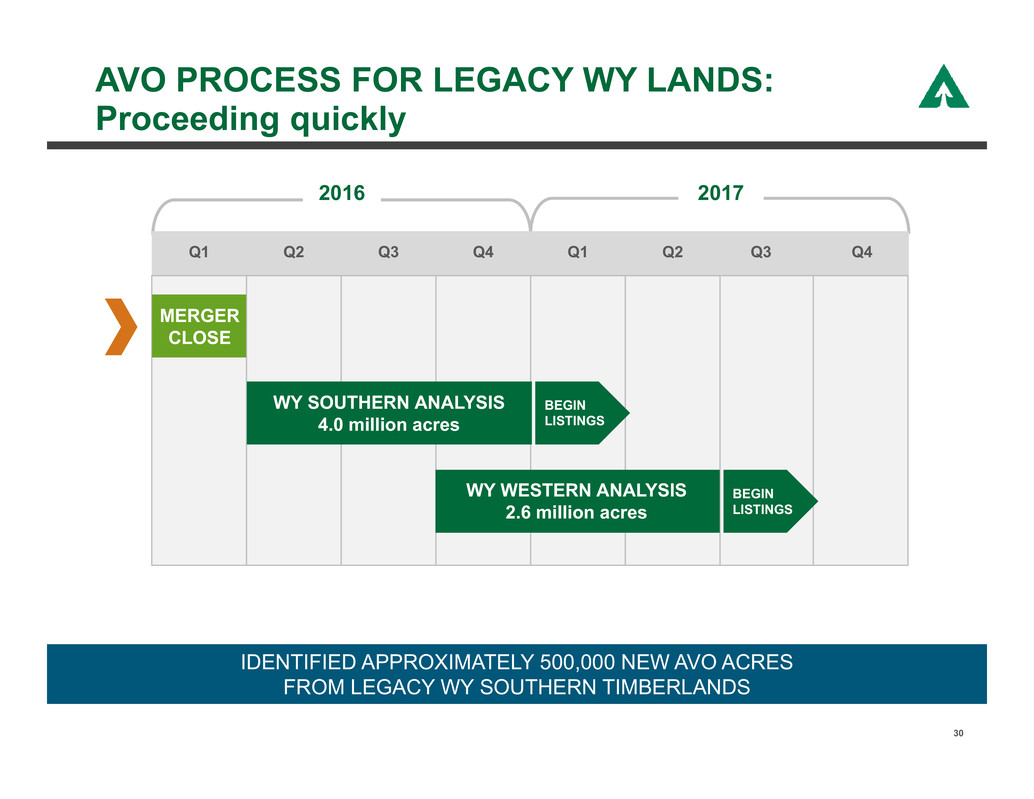

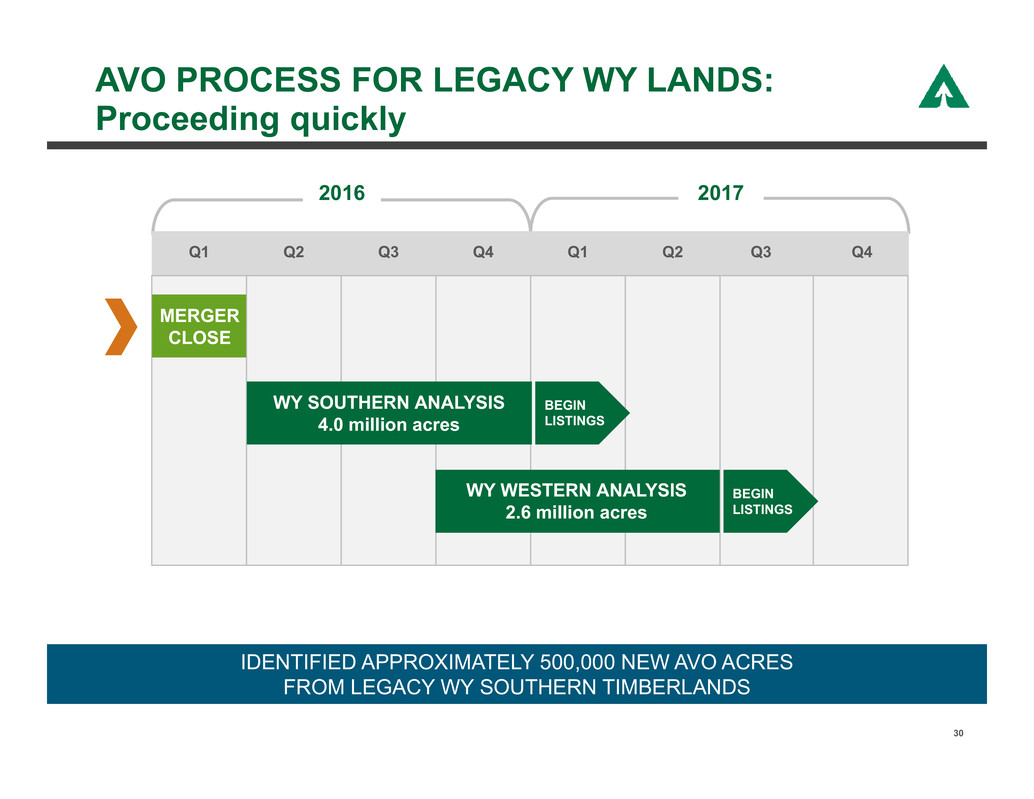

AVO PROCESS FOR LEGACY WY LANDS: Proceeding quickly 30 2016 2017 Q1 Q2 Q3 Q4 Q1 Q2 MERGER CLOSE WY SOUTHERN ANALYSIS 4.0 million acres WY WESTERN ANALYSIS 2.6 million acres BEGIN LISTINGS Q3 Q4 BEGIN LISTINGS IDENTIFIED APPROXIMATELY 500,000 NEW AVO ACRES FROM LEGACY WY SOUTHERN TIMBERLANDS

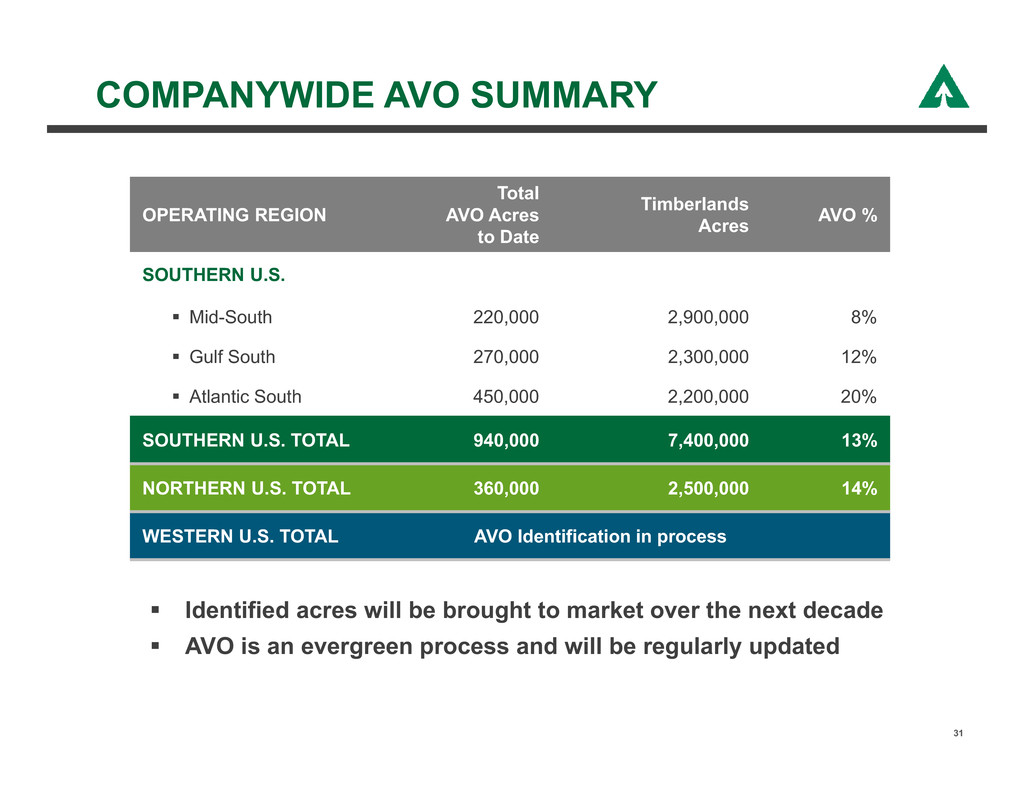

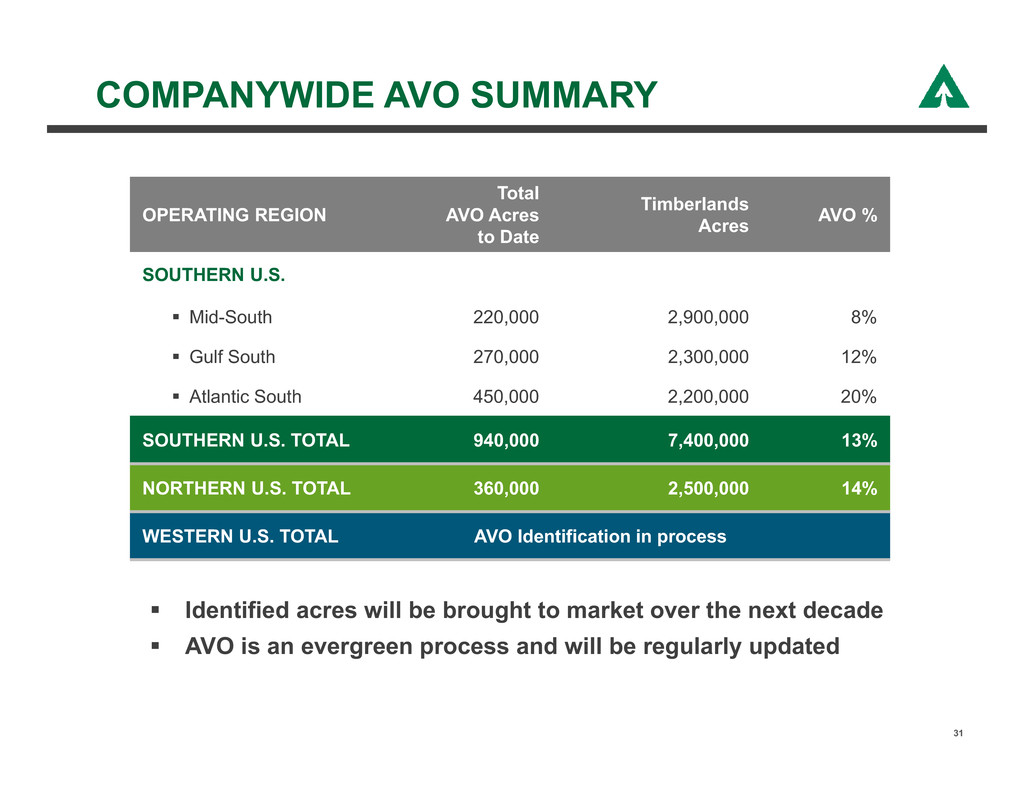

OPERATING REGION Total AVO Acres to Date Timberlands Acres AVO % SOUTHERN U.S. Mid-South 220,000 2,900,000 8% Gulf South 270,000 2,300,000 12% Atlantic South 450,000 2,200,000 20% SOUTHERN U.S. TOTAL 940,000 7,400,000 13% NORTHERN U.S. TOTAL 360,000 2,500,000 14% WESTERN U.S. TOTAL AVO Identification in process COMPANYWIDE AVO SUMMARY 31 Identified acres will be brought to market over the next decade AVO is an evergreen process and will be regularly updated

OUTSOURCED MODEL PROVIDES OPERATING LEVERAGE DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 3: DELIVERING THE PREMIUM TO TIMBER VALUE 32 MASTER BROKER + REGIONAL TRANSACTION MANAGERS INDEPENDENT LOCAL BROKERS (100+) LAND ASSET MANAGEMENT TEAM REAL ESTATE / BROKER PARTNERSHIP

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 1: DETERMINE TIMBER NET PRESENT VALUE 33 TIMBER VALUATION Cover type Acres Pine Plantation 165 Hardwood & Bottomland 80 Non Productive 15 TOTAL ACRES 260 TIMBER NPV IS CALCULATED AT THE STAND LEVEL TIMBER NPV = $455,000 HBU PARCEL – Riverbend Sold in 2016

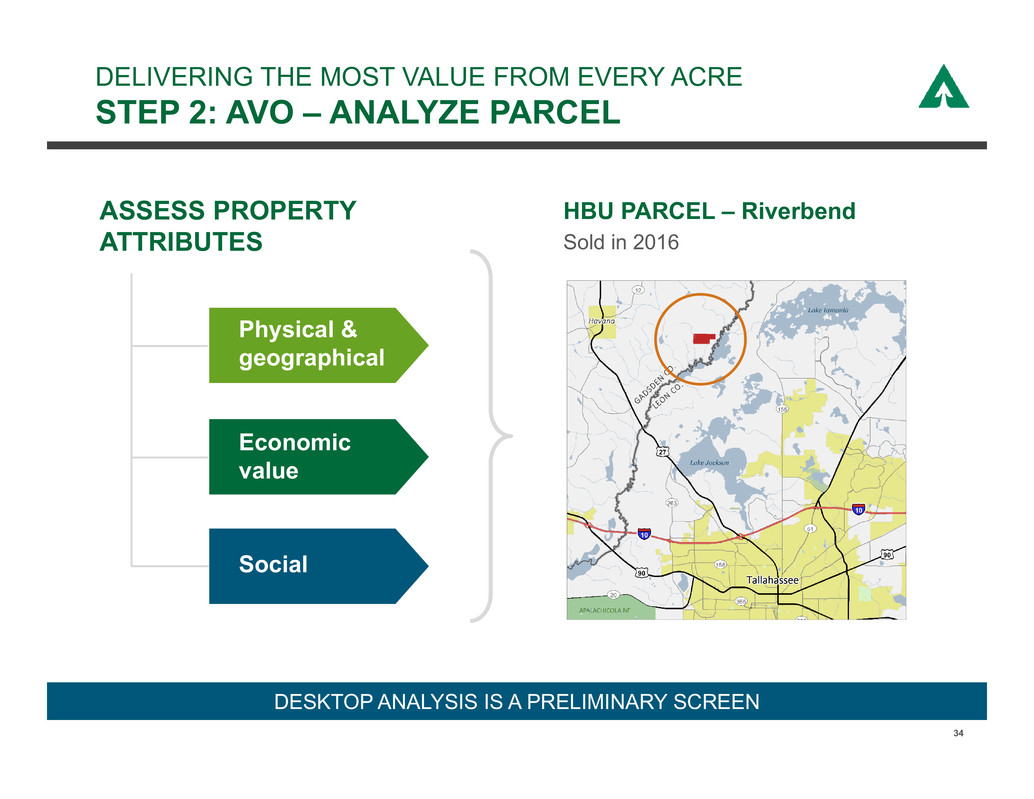

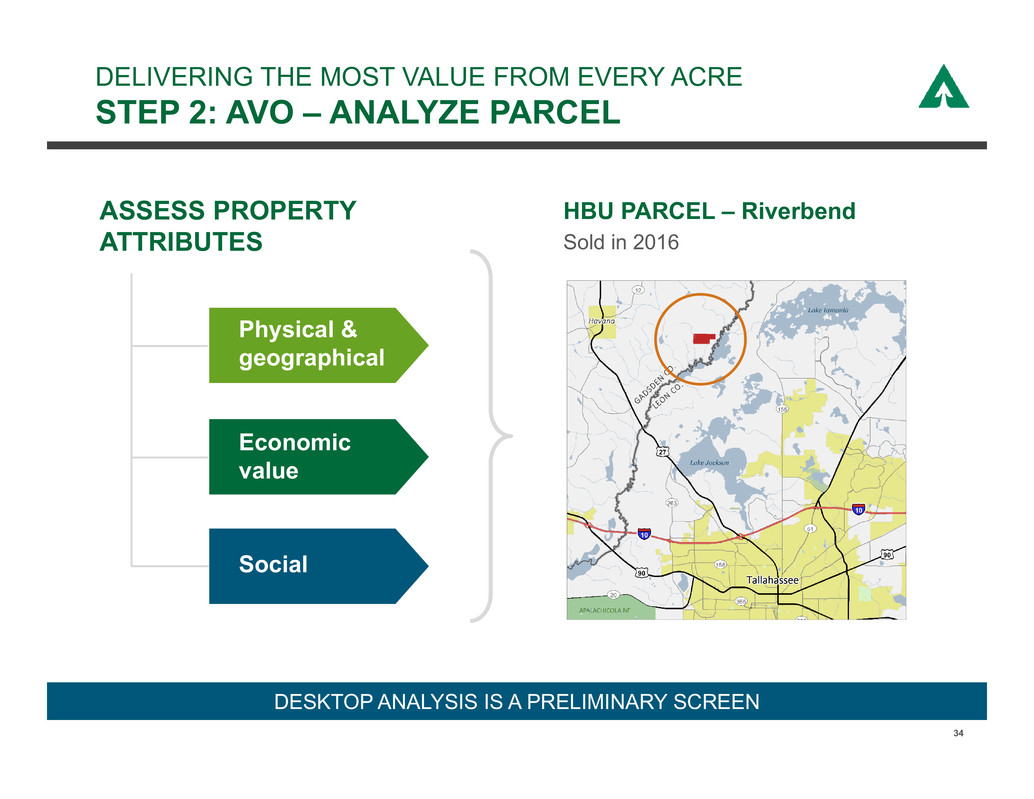

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 2: AVO – ANALYZE PARCEL 34 DESKTOP ANALYSIS IS A PRELIMINARY SCREEN Physical & geographical Social Economic value ASSESS PROPERTY ATTRIBUTES HBU PARCEL – Riverbend Sold in 2016

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 2: AVO – GROUND TRUTHING 35 VERIFY ATTRIBUTES ▪ Proximity to Tallahassee ▪ Near Ochlockonee River ▪ Diverse age class & forest cover type attractive for recreation ▪ Improving recreation markets in local area GROUND TRUTHING VERIFIES PARCEL CHARACTERISTICS HBU PARCEL – Riverbend Sold in 2016

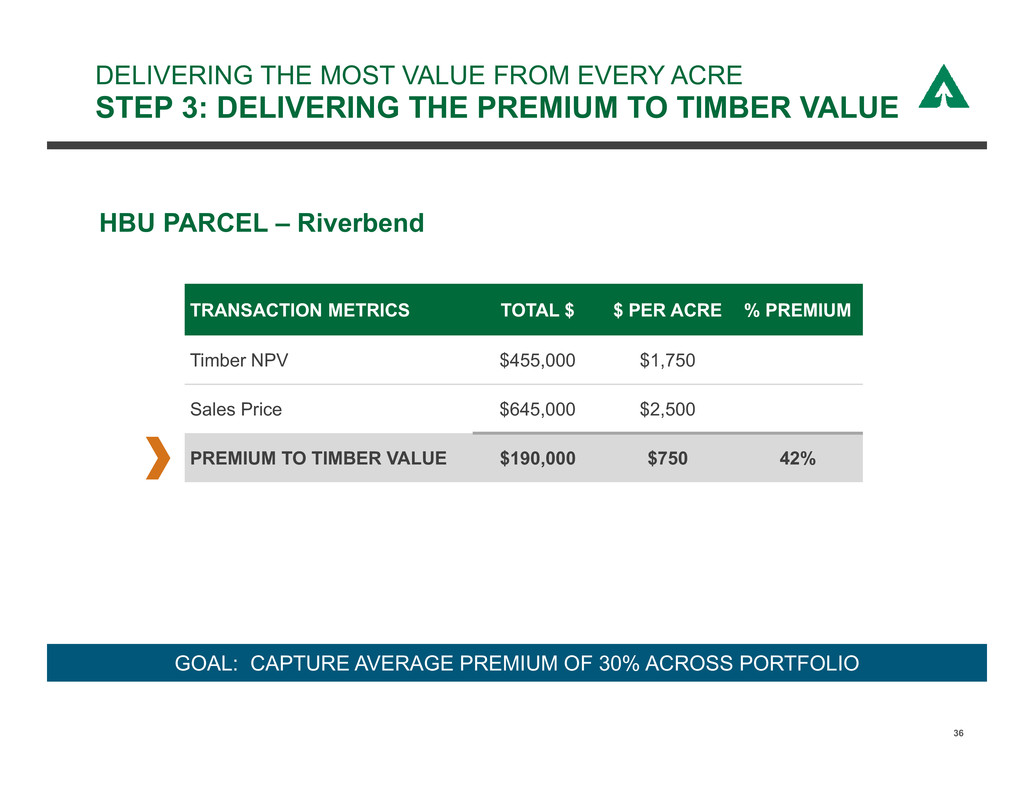

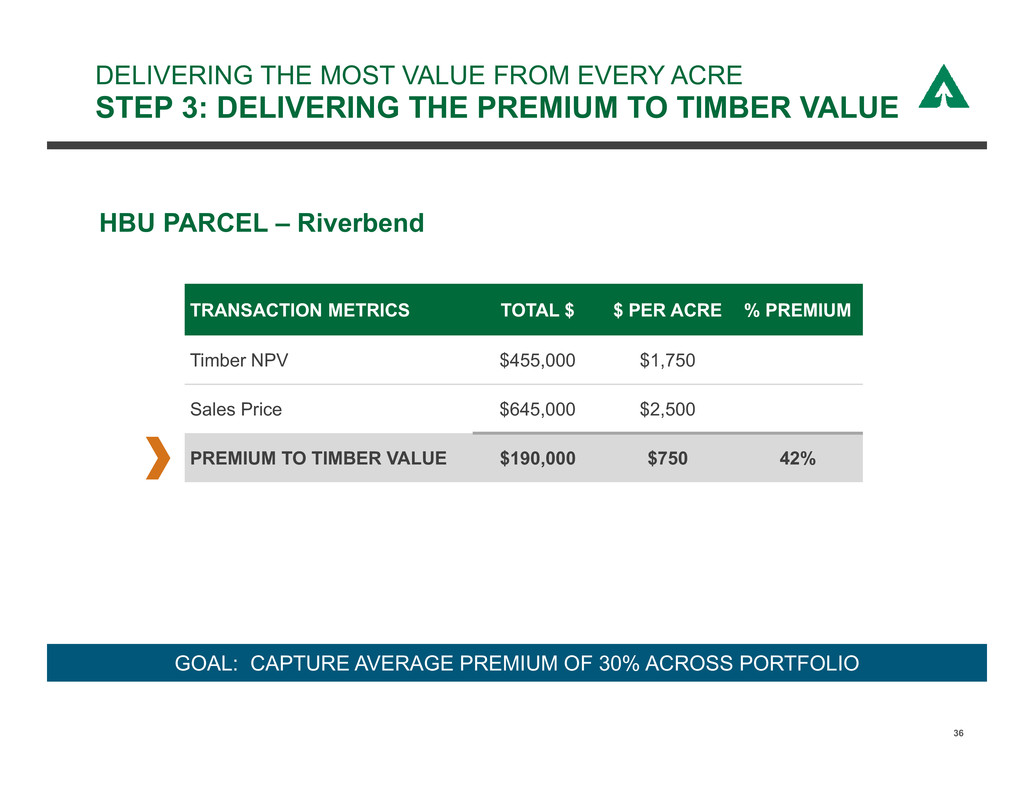

DELIVERING THE MOST VALUE FROM EVERY ACRE STEP 3: DELIVERING THE PREMIUM TO TIMBER VALUE 36 GOAL: CAPTURE AVERAGE PREMIUM OF 30% ACROSS PORTFOLIO TRANSACTION METRICS TOTAL $ $ PER ACRE % PREMIUM Timber NPV $455,000 $1,750 Sales Price $645,000 $2,500 PREMIUM TO TIMBER VALUE $190,000 $750 42% HBU PARCEL – Riverbend

▪ Activity remains strong, especially in the South ▪ Buyers targeting recreation tracts with investment potential ▪ Conservation interest remains solid REAL ESTATE: Buyer profile Adjacent Landowner Recreation/ Investment Conservation Second Home or Cabin Other BUYER’S INTENDED USE 37

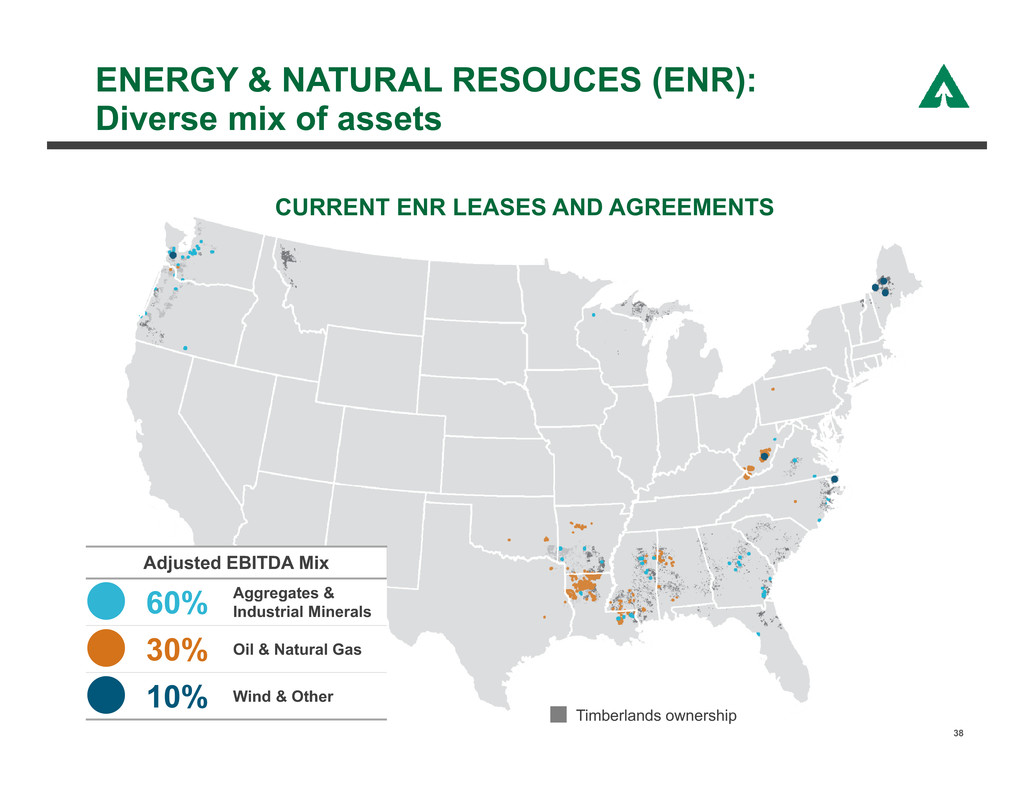

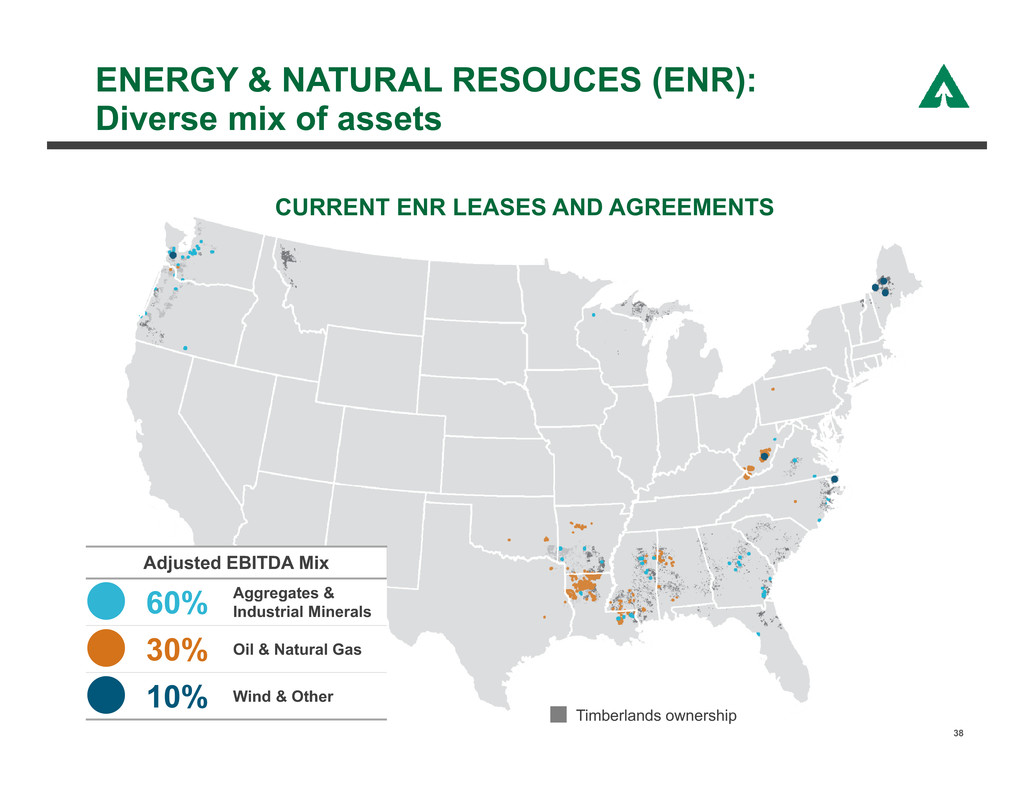

ENERGY & NATURAL RESOUCES (ENR): Diverse mix of assets 38 Adjusted EBITDA Mix 60% Aggregates & Industrial Minerals 30% Oil & Natural Gas 10% Wind & Other CURRENT ENR LEASES AND AGREEMENTS Timberlands ownership

ENR PROVIDES GROWING SOURCE OF STABLE, ONGOING ROYALTY STREAMS 39 263 MW of wind energy operating Over 260 MW more constructed by end of 2018 REAL ESTATE, ENERGY & NATURAL RESOURCES WOOD PRODUCTS 610,000 acres leased for exploration and development Royalty interest in over 3,000 oil and gas wells OIL AND N TURAL GAS RENEWABLE ENERGY Interests in 400+ million tons of producing reserves Over 50 producing projects in 9 states AGGREGATES AND INDUSTRIAL MINERALS

STRATEGY FOR SUCCESS Real Estate and Energy & Natural Resources 40 REAL ESTATE Higher and Better Use Capture premium over timberland value through Asset Value Optimization RIGHT PEOPLE IN THE RIGHT ROLES DRIVE RESULTS WINNING DELIVERING THE MOST VALUE FROM EVERY ACRE ENERGY & NATURAL RESOURCES Capture full value of surface and subsurface assets: Oil & natural gas Aggregates & industrial minerals Wind resources

LUMBER ORIENTED STRAND BOARD ENGINEERED WOOD DISTRIBUTION WOOD PRODUCTS ADRIAN BLOCKER Senior Vice President, Wood Products 41

INDUSTRY LEADING NORTH AMERICAN WOOD PRODUCTS PRODUCER 42 LUMBER PRODUCTION 3rd OSB PRODUCTION 4th ENGINEERED WOOD REVENUE 1st DISTRIBUTION FACILITIES (not shown) 17 EACH BUSINESS HAS SCALE AND DIVERSITY $4.3 Revenue represents Wood Products revenue for 2016 Q3 LTM. BILLION REVENUE 4 VENEER / PLYWOOD MILLS 6 ENGINEERED WOOD MILLS 19 LUMBER MILLS 6 ORIENTED STRAND BOARD MILLS 1 MEDIUM DENSITY FIBERBOARD MILL WY OWNED AND LICENSED TIMBERLANDS

STRATEGY FOR SUCCESS Wood Products 43 RIGHT ALIGNMENT RIGHT COST RIGHT CUSTOMERS INDUSTRY LEADER INDUSTRY LEADING MARGINS AND BLACK AT THE BOTTOM Top-quartile cost structure Preferred supplier for targeted markets and customers Strong alignment with fiber supply

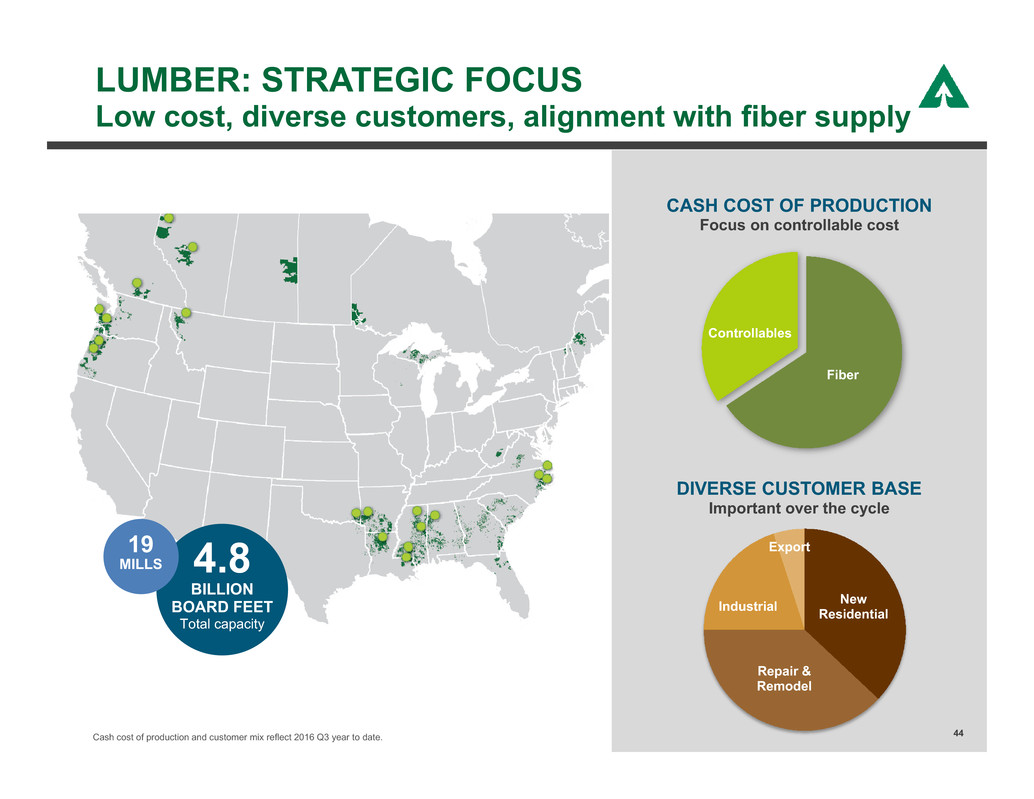

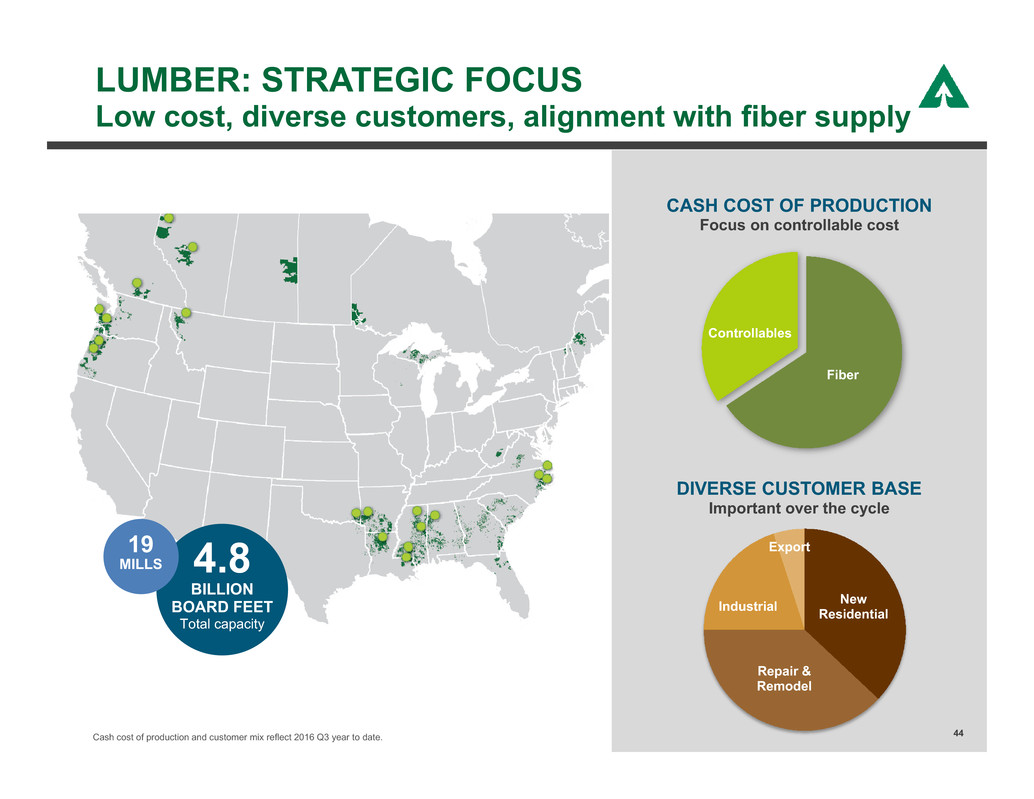

LUMBER: STRATEGIC FOCUS Low cost, diverse customers, alignment with fiber supply 44 Fiber Controllables CASH COST OF PRODUCTION Focus on controllable cost New Residential Repair & Remodel Industrial Export DIVERSE CUSTOMER BASE Important over the cycle 4.8 BILLION BOARD FEET Total capacity 19 MILLS Cash cost of production and customer mix reflect 2016 Q3 year to date.

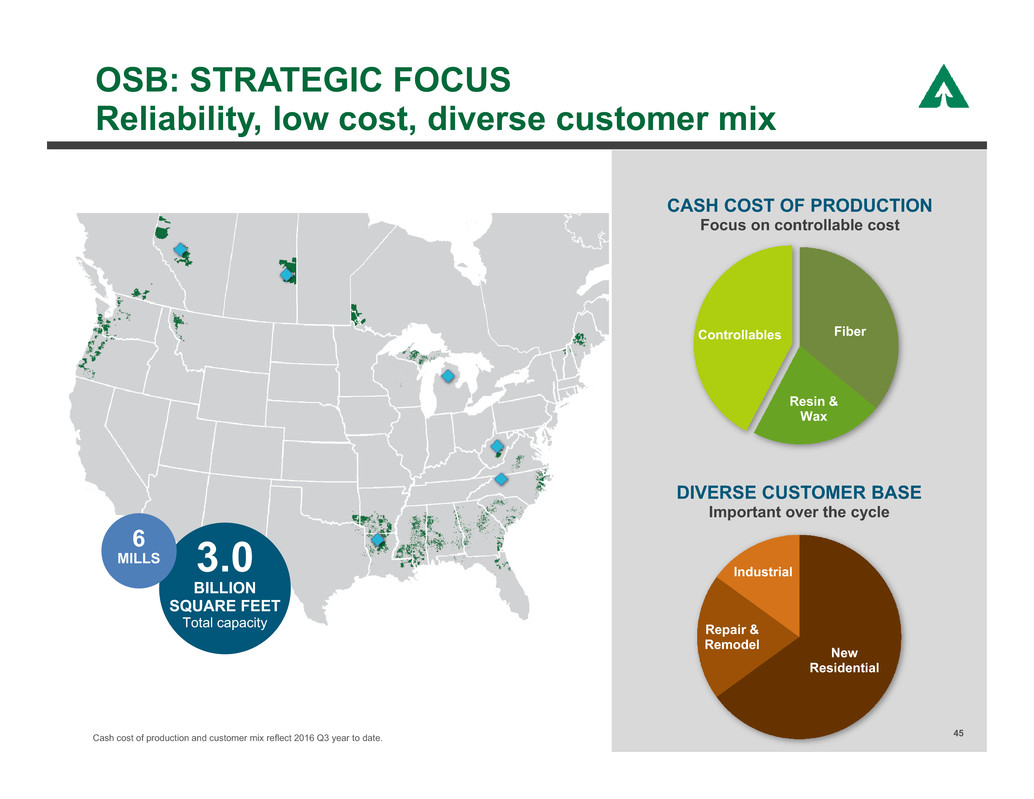

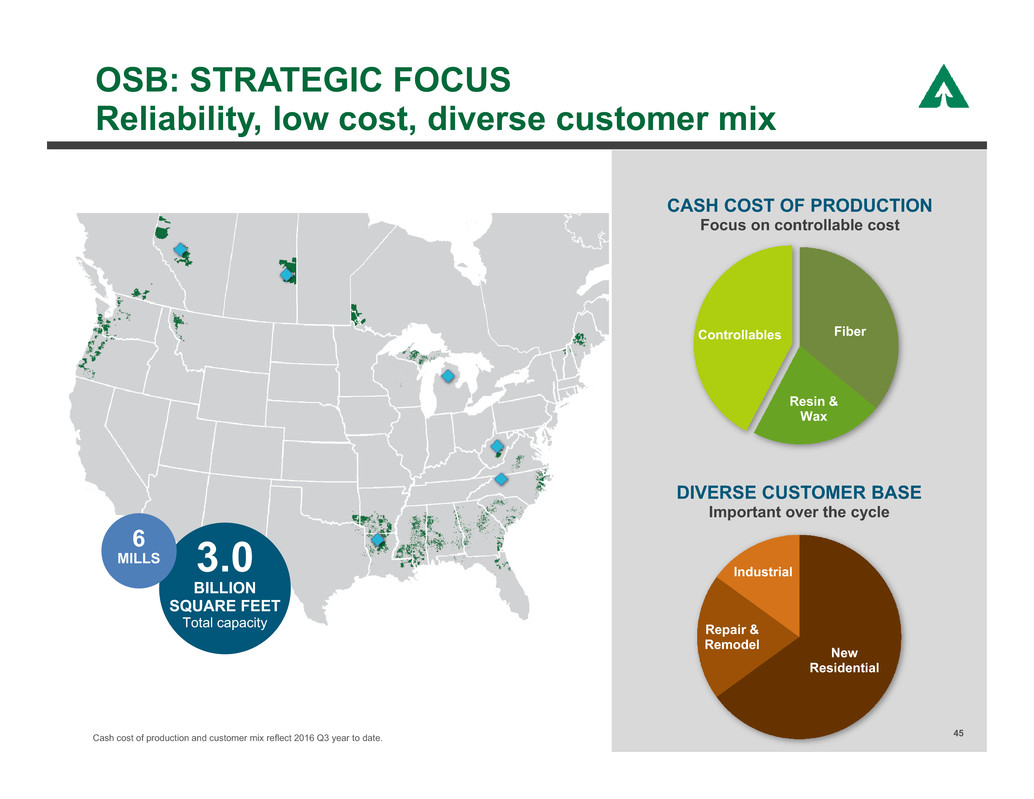

OSB: STRATEGIC FOCUS Reliability, low cost, diverse customer mix 45 New Residential Repair & Remodel Industrial DIVERSE CUSTOMER BASE Important over the cycle Fiber Resin & Wax Controllables CASH COST OF PRODUCTION Focus on controllable cost 3.0 BILLION SQUARE FEET Total capacity 6 MILLS Cash cost of production and customer mix reflect 2016 Q3 year to date.

ENGINEERED WOOD: STRATEGIC FOCUS Low cost, end-market alignment, diverse customer mix 46 3rd Party Distributor New Residential WY Distribution New Residential Industrial Export Repair & Remodel Other DIVERSE CUSTOMER BASE Distributors are key OSB Fiber Resin Controllables CASH COST OF PRODUCTION Focus on controllable cost Source: US Census OF U.S. STARTS 50% OF U.S. STARTS 25% WEST SOUTH 4 VENEER / PLYWOOD FACILITIES → 610 million square feet plywood capacity 6 ENGINEERED WOOD MILLS → 43 million cubic feet solid section capacity* 1 MEDIUM DENSITY FIBERBOARD MILL → 265 million square feet capacity Cash cost of production and customer mix reflect 2016 Q3 year to date. * Capacity if mills produce exclusively solid section product. Three engineered wood products facilities also produce engineered I-Joists to meet market demand. 2015 production of I-Joists was 185 million lineal feet.

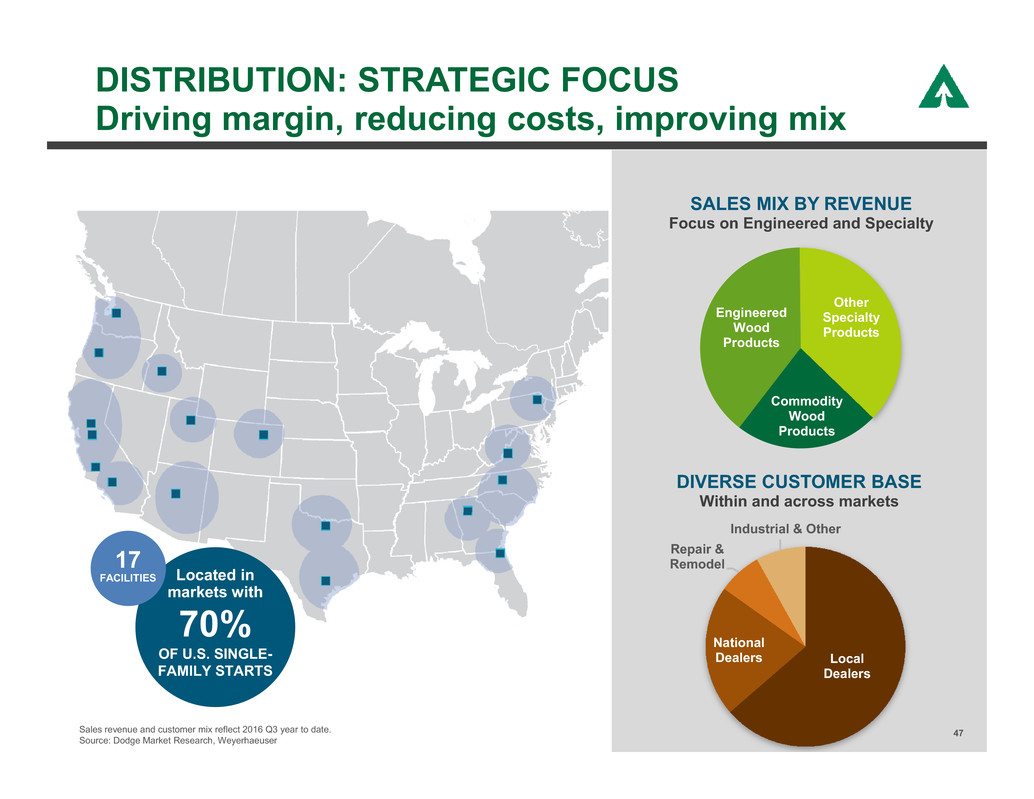

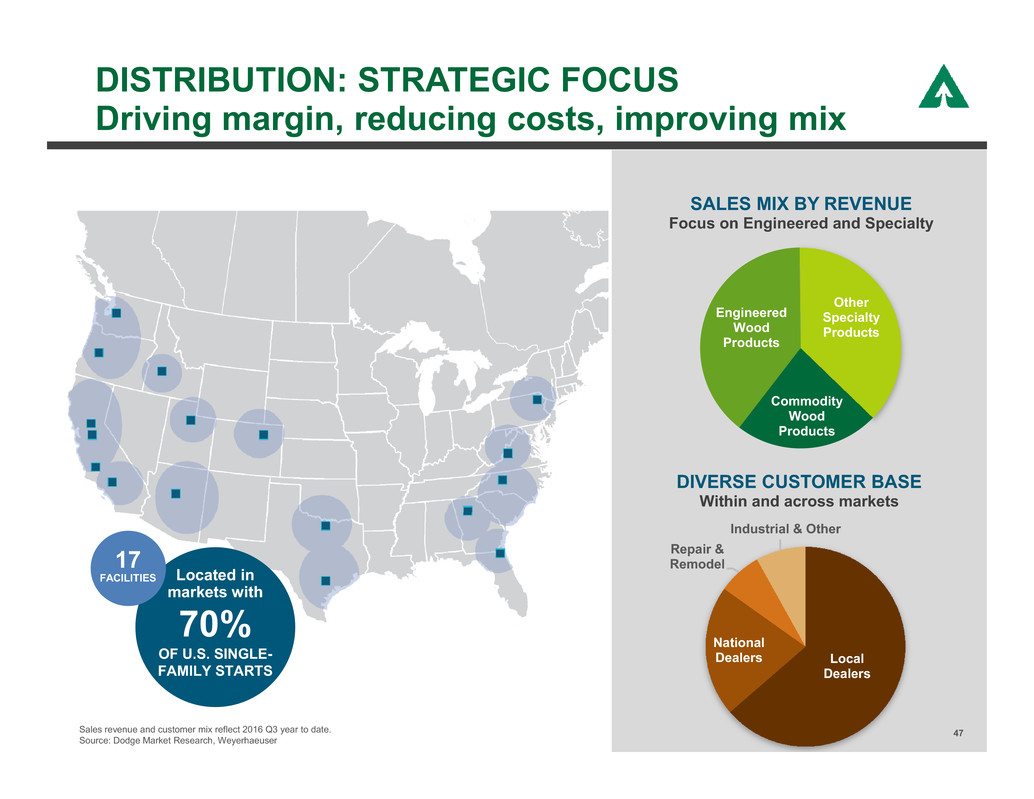

DISTRIBUTION: STRATEGIC FOCUS Driving margin, reducing costs, improving mix 47 Local Dealers National Dealers Repair & Remodel Industrial & Other DIVERSE CUSTOMER BASE Within and across markets Commodity Wood Products Engineered Wood Products Other Specialty Products SALES MIX BY REVENUE Focus on Engineered and Specialty Sales revenue and customer mix reflect 2016 Q3 year to date. Source: Dodge Market Research, Weyerhaeuser Located in markets with 70% OF U.S. SINGLE- FAMILY STARTS 17 FACILITIES

DEVELOPING A ROADMAP TO TOP QUARTILE 48 BENCHMARK COSTS IDENTIFY GAPS EARN THE RIGHT TO CAPITAL NON-CAPITAL IMPROVEMENTS 1 2 3 DISCIPLINED CAPEX 4 5 WINNING

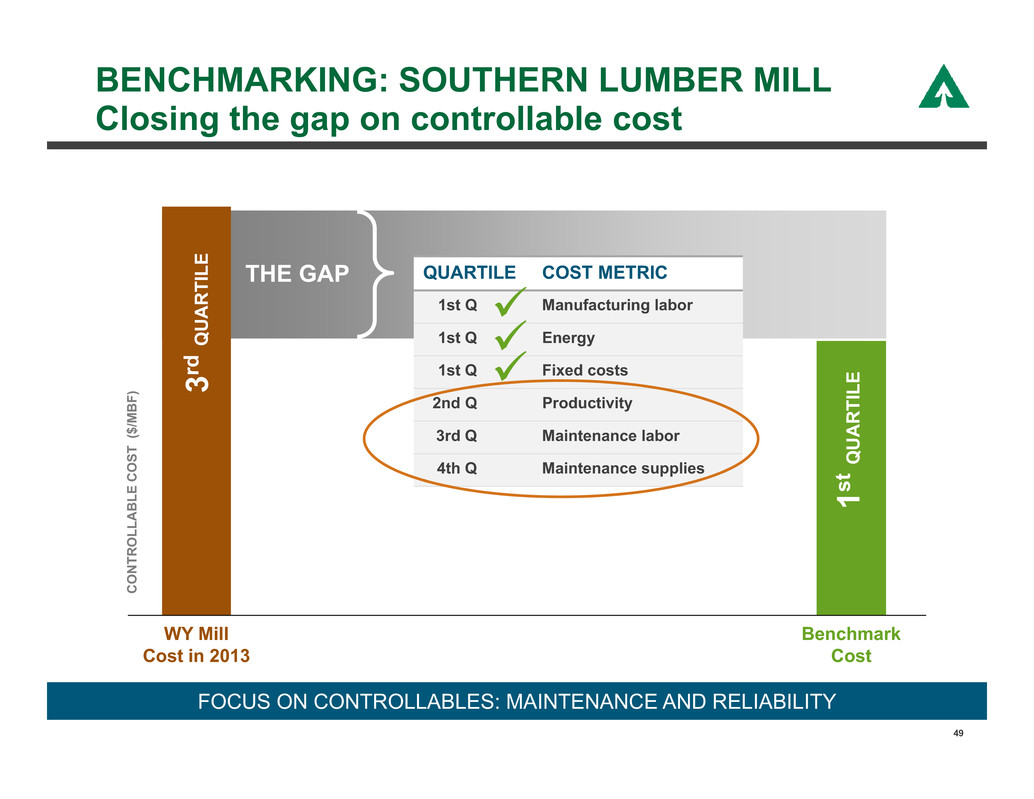

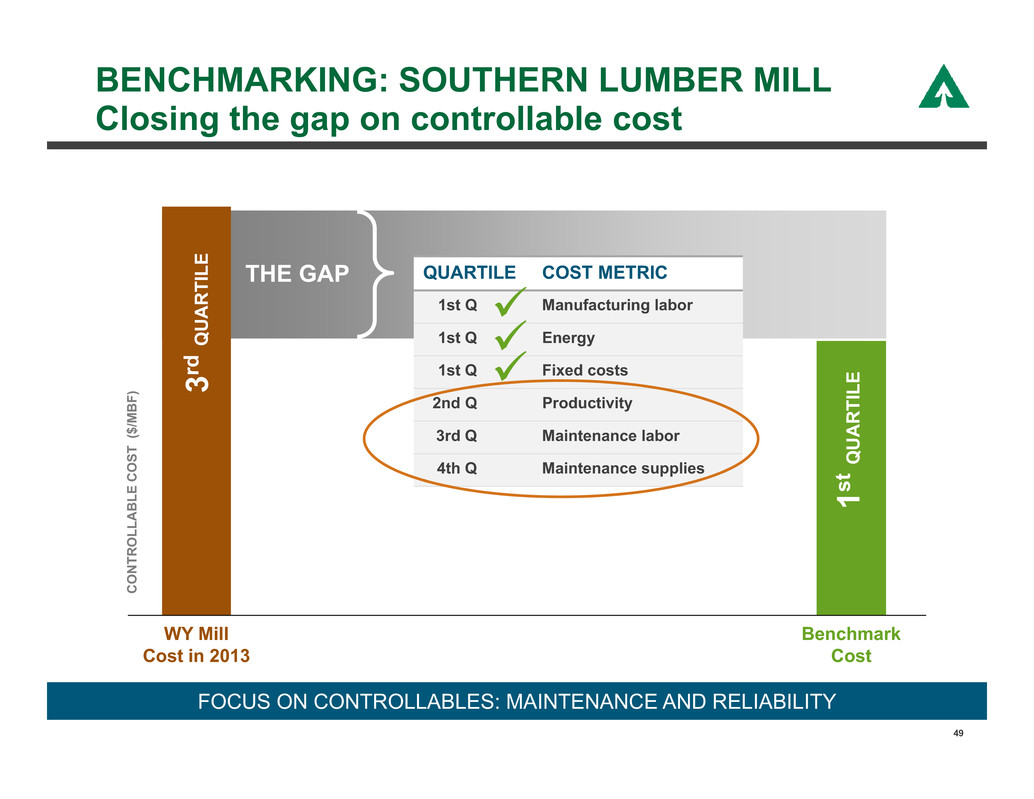

BENCHMARKING: SOUTHERN LUMBER MILL Closing the gap on controllable cost 49 WY Mill Cost in 2013 Benchmark Cost FOCUS ON CONTROLLABLES: MAINTENANCE AND RELIABILITY C O N T R O L L A B L E C O S T ( $ / M B F ) 3 r d Q U A R T I L E 1 s t Q U A R T I L E THE GAP QUARTILE COST METRIC 1st Q Manufacturing labor 1st Q Energy 1st Q Fixed costs 2nd Q Productivity 3rd Q Maintenance labor 4th Q Maintenance supplies

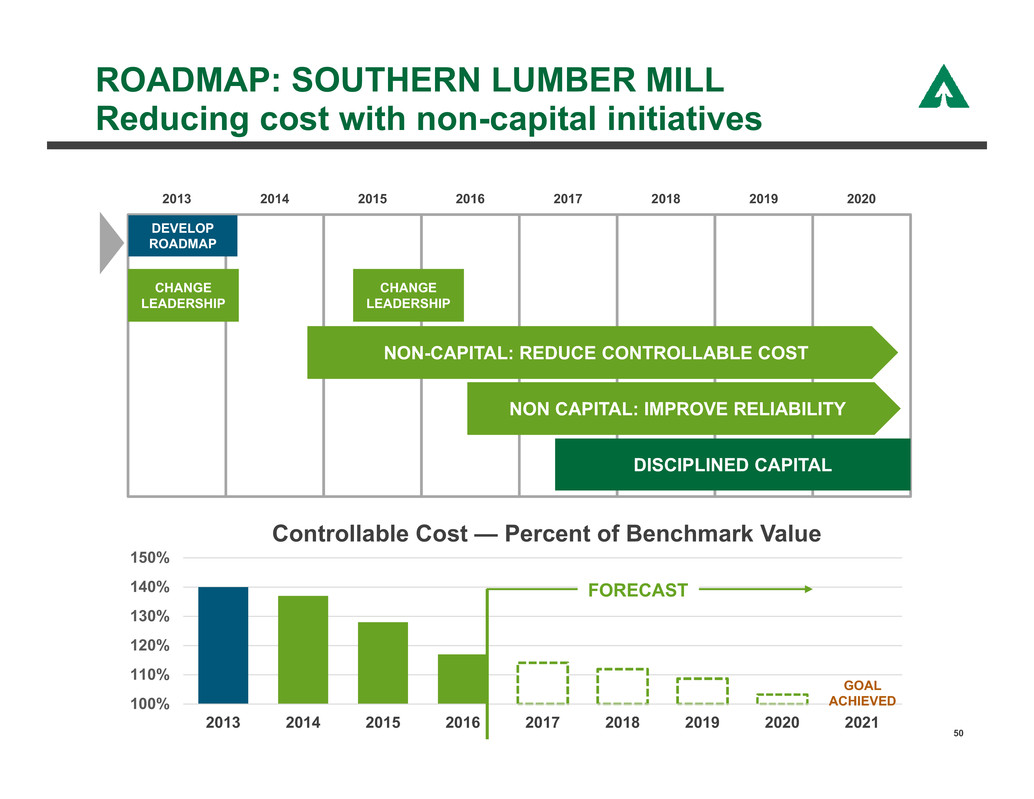

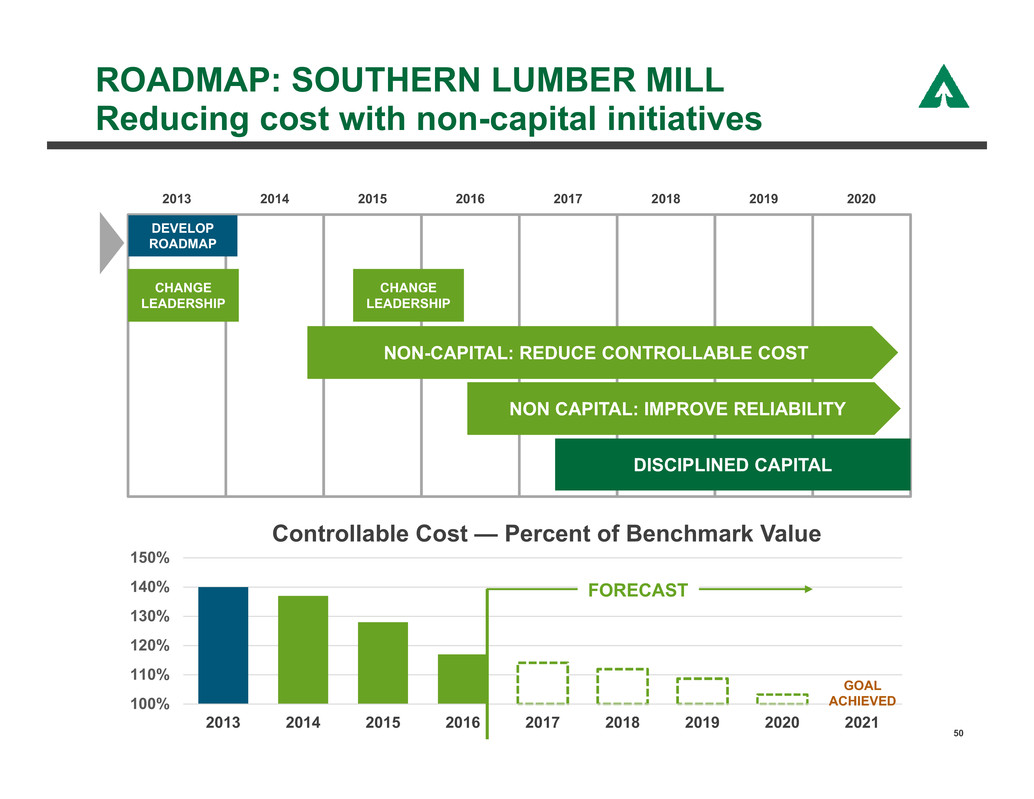

2013 2014 2015 2016 2017 2018 2019 2020 DEVELOP ROADMAP NON CAPITAL: IMPROVE RELIABILITY DISCIPLINED CAPITAL ROADMAP: SOUTHERN LUMBER MILL Reducing cost with non-capital initiatives 50 100% 110% 120% 130% 140% 150% 2013 2014 2015 2016 2017 2018 2019 2020 2021 Controllable Cost — Percent of Benchmark Value NON-CAPITAL: REDUCE CONTROLLABLE COST CHANGE LEADERSHIP CHANGE LEADERSHIP GOAL ACHIEVED FORECAST

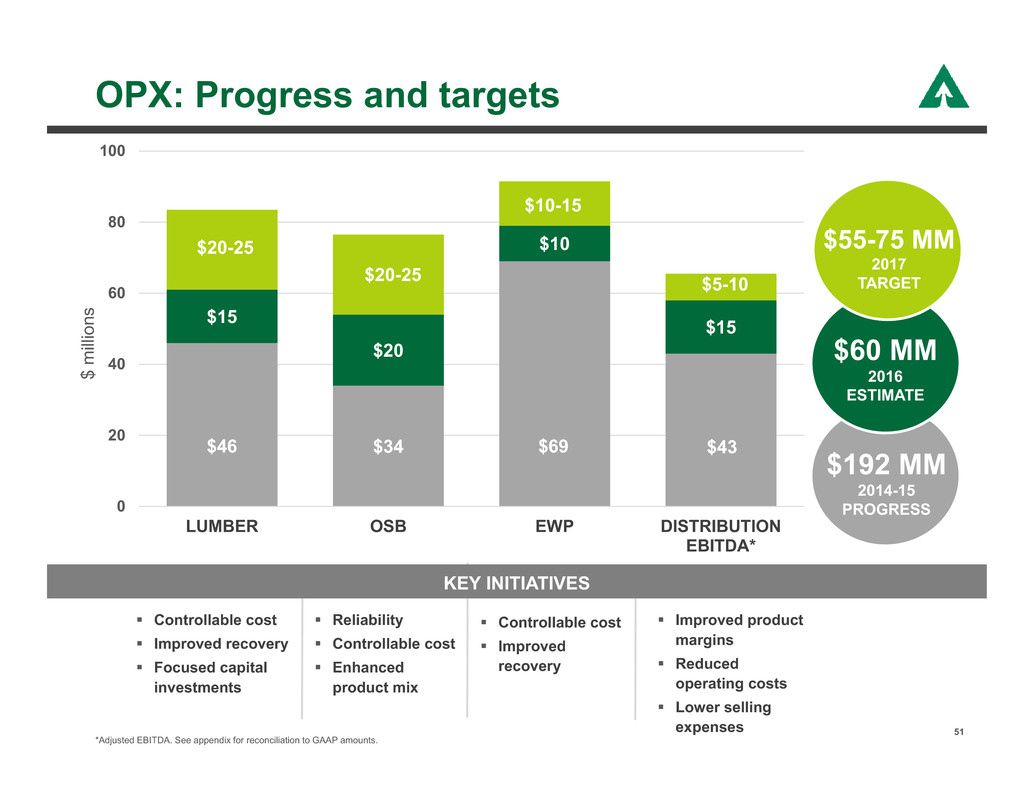

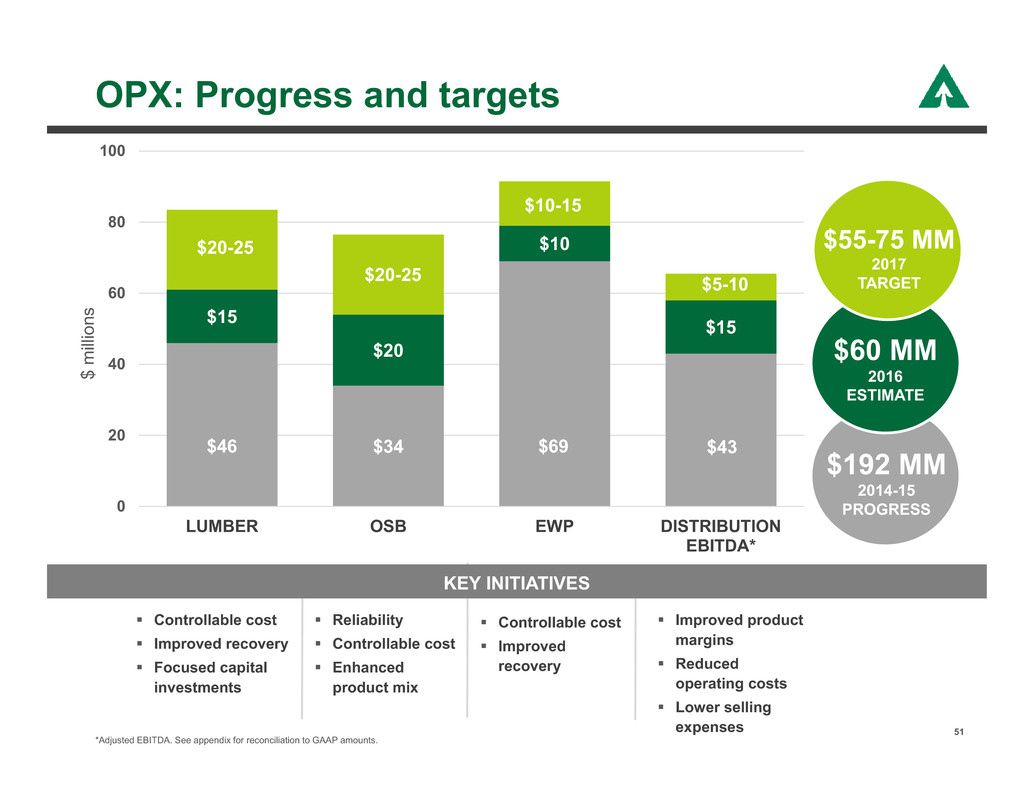

OPX: Progress and targets Controllable cost Improved recovery Focused capital investments Reliability Controllable cost Enhanced product mix Controllable cost Improved recovery Improved product margins Reduced operating costs Lower selling expenses *Adjusted EBITDA. See appendix for reconciliation to GAAP amounts. KEY INITIATIVES $46 $34 $69 $43 $15 $20 $10 $15 0 20 40 60 80 100 LUMBER OSB EWP DISTRIBUTION EBITDA* $ m i l l i o n s $20-25 $20-25 $5-10 $10-15 $192 MM 2014-15 PROGRESS $60 MM 2016 ESTIMATE $55-75 MM 2017 TARGET 51

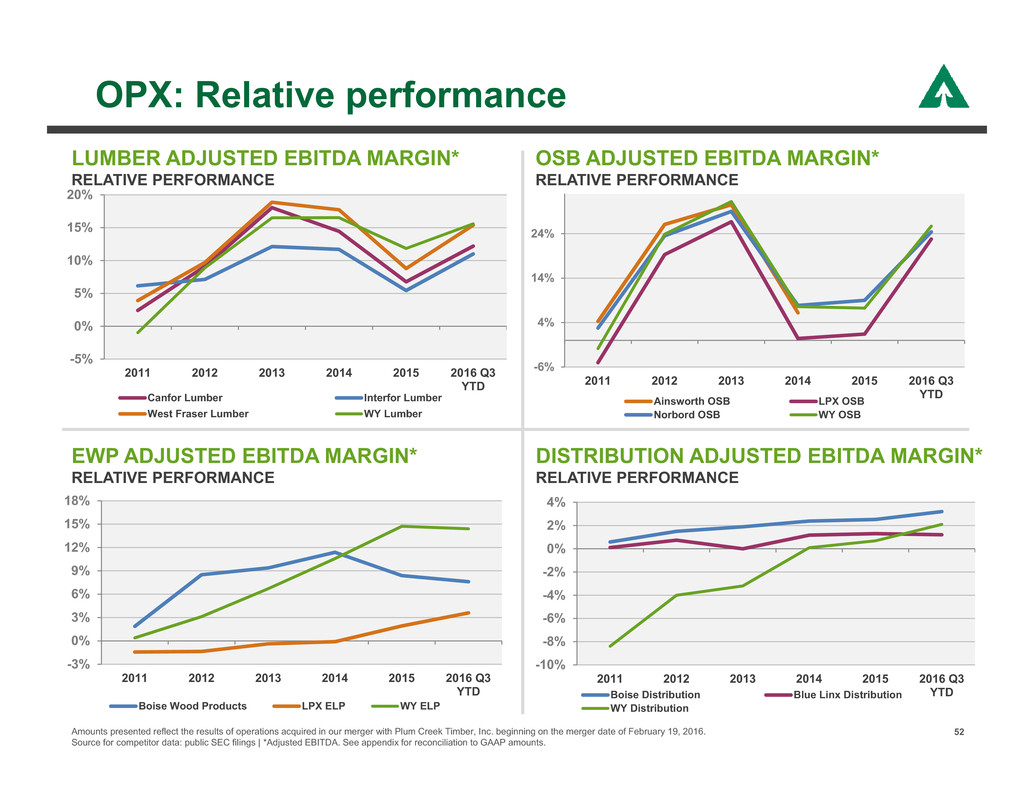

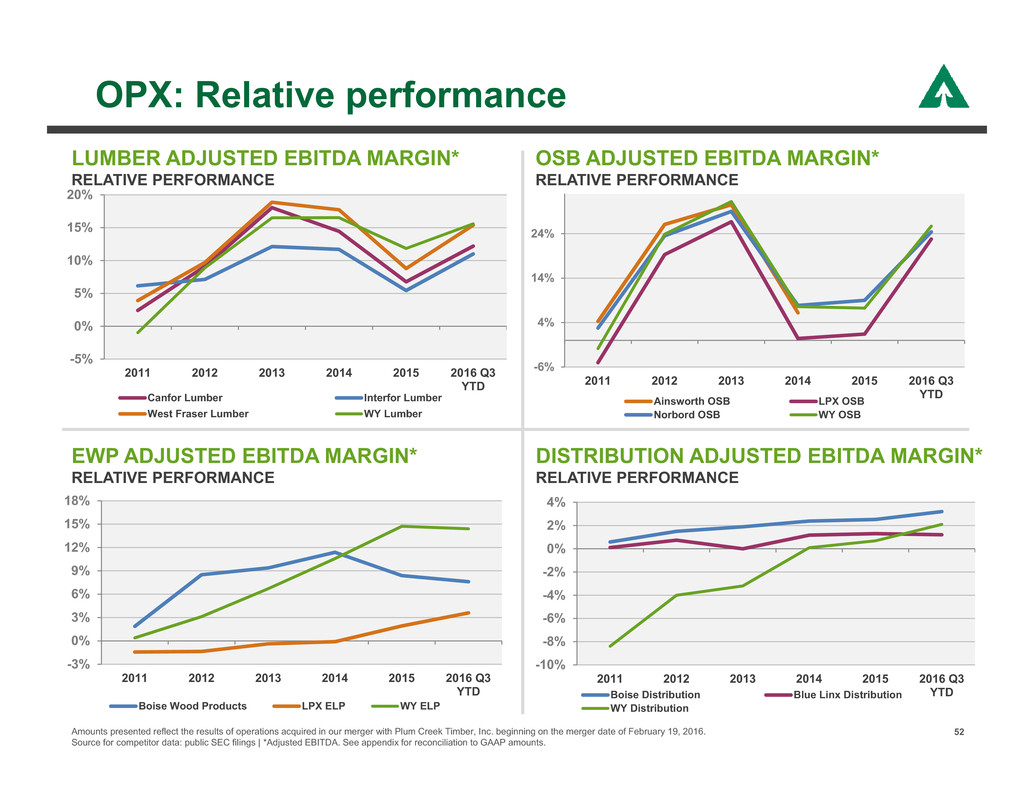

OPX: Relative performance 52 LUMBER ADJUSTED EBITDA MARGIN* RELATIVE PERFORMANCE -5% 0% 5% 10% 15% 20% 2011 2012 2013 2014 2015 2016 Q3 YTD Canfor Lumber Interfor Lumber West Fraser Lumber WY Lumber EWP ADJUSTED EBITDA MARGIN* RELATIVE PERFORMANCE -3% 0% 3% 6% 9% 12% 15% 18% 2011 2012 2013 2014 2015 2016 Q3 YTD Boise Wood Products LPX ELP WY ELP -6% 4% 14% 24% 2011 2012 2013 2014 2015 2016 Q3 YTD Ainsworth OSB LPX OSB Norbord OSB WY OSB OSB ADJUSTED EBITDA MARGIN* RELATIVE PERFORMANCE DISTRIBUTION ADJUSTED EBITDA MARGIN* RELATIVE PERFORMANCE -10% -8% -6% -4% -2% 0% 2% 4% 2011 2012 2013 2014 2015 2016 Q3 YTDBoise Distribution Blue Linx Distribution WY Distribution Amounts presented reflect the results of operations acquired in our merger with Plum Creek Timber, Inc. beginning on the merger date of February 19, 2016. Source for competitor data: public SEC filings | *Adjusted EBITDA. See appendix for reconciliation to GAAP amounts.

2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 Q3 LTM OUR GOAL is to be black at the bottom of the cycle $250 MILLION OF OPX ACHIEVED THROUGH 2016 53 SIGNIFICANT PROGRESS TOWARDS “BLACK AT THE BOTTOM” WE ARE 70% of the way there 2017 OPX ADDS 10% WE ARE 70% OF THE WAY THERE 2017 OPX ADDS ANOTHER 15% ($343) A D J U S T E D E B I T D A * I N $ M I L L I O N S *See appendix for reconciliation to GAAP amounts.

STRATEGY FOR SUCCESS Wood Products 54 RIGHT ALIGNMENT RIGHT COST RIGHT CUSTOMERS INDUSTRY LEADER INDUSTRY LEADING MARGINS AND BLACK AT THE BOTTOM Top-quartile cost structure Preferred supplier for targeted markets and customers Strong alignment with fiber supply

FINANCIAL ITEMS 55 RUSSELL HAGEN Senior Vice President and Chief Financial Officer

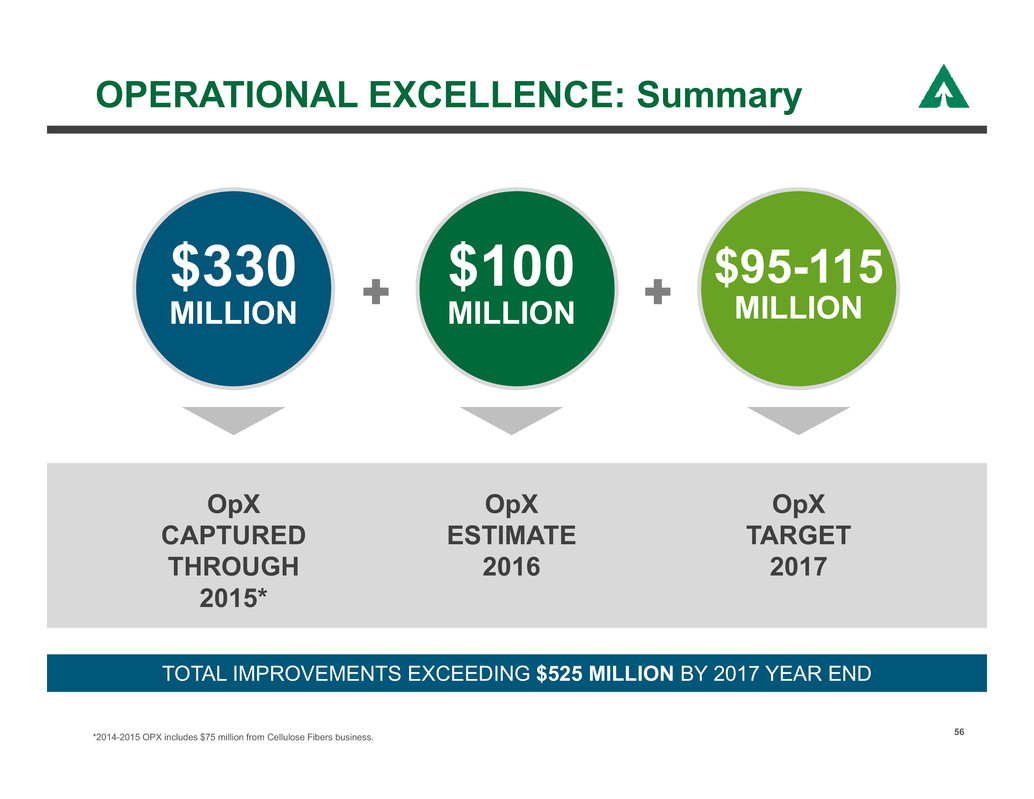

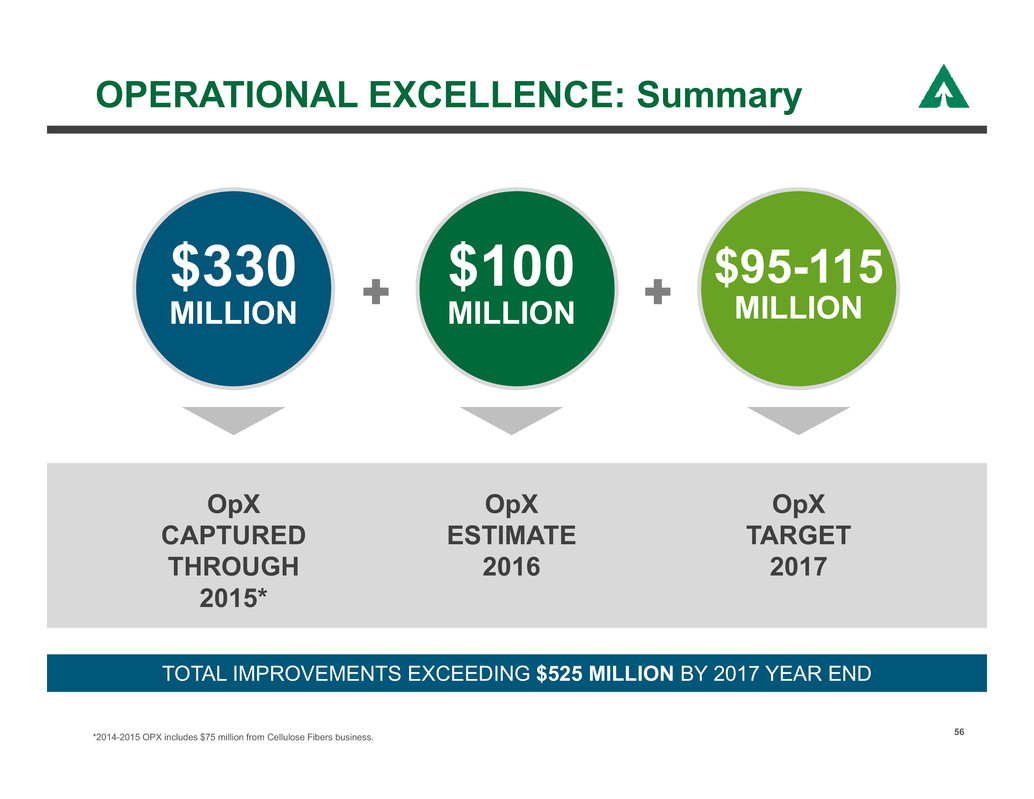

OPERATIONAL EXCELLENCE: Summary 56*2014-2015 OPX includes $75 million from Cellulose Fibers business. OpX CAPTURED THROUGH 2015* $330 MILLION $100 MILLION OpX ESTIMATE 2016 $95-115 MILLION OpX TARGET 2017 TOTAL IMPROVEMENTS EXCEEDING $525 MILLION BY 2017 YEAR END

REAL ESTATE & ENR SEGMENT RAMPING UP 57 Expect approximately $250 million Adjusted EBITDA in 2017 Some further upside in 2018 and beyond Real Estate business part of continual portfolio management ̶ AVO process captures premium over timberland values ̶ Ongoing acquisition of quality, core timberlands $250 Million ADJUSTED EBITDA REAL ESTATE & ENR 2016 2017 $175 MM $250 MM NEARLY 45% INCREASE

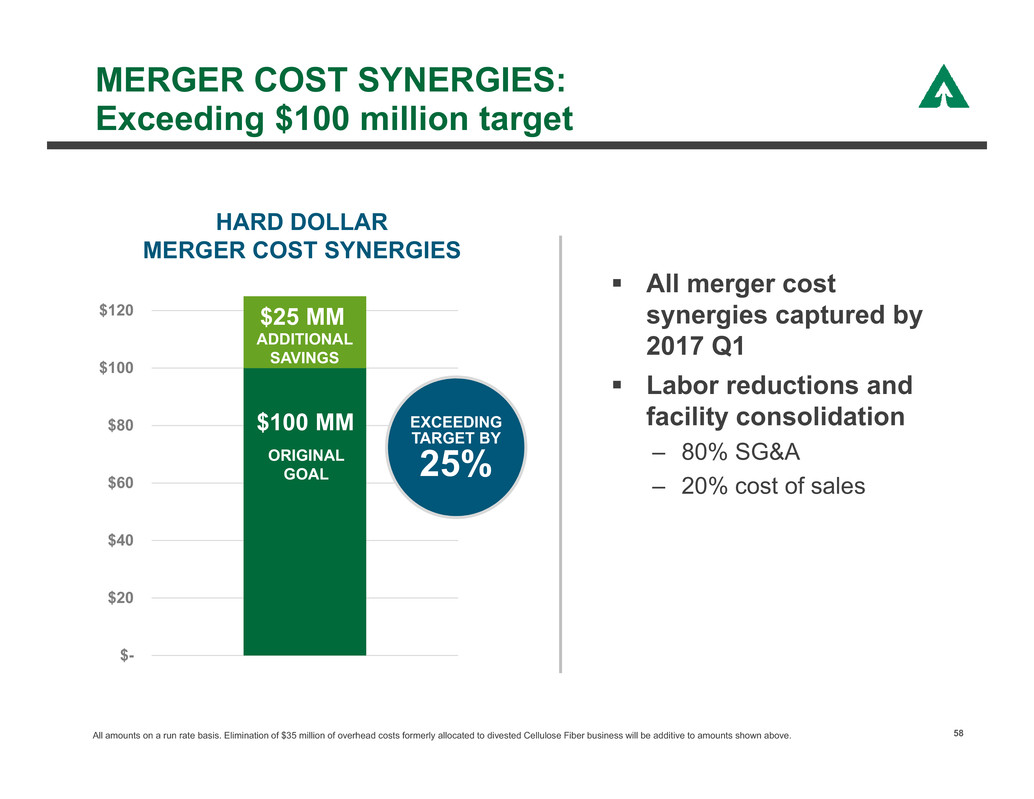

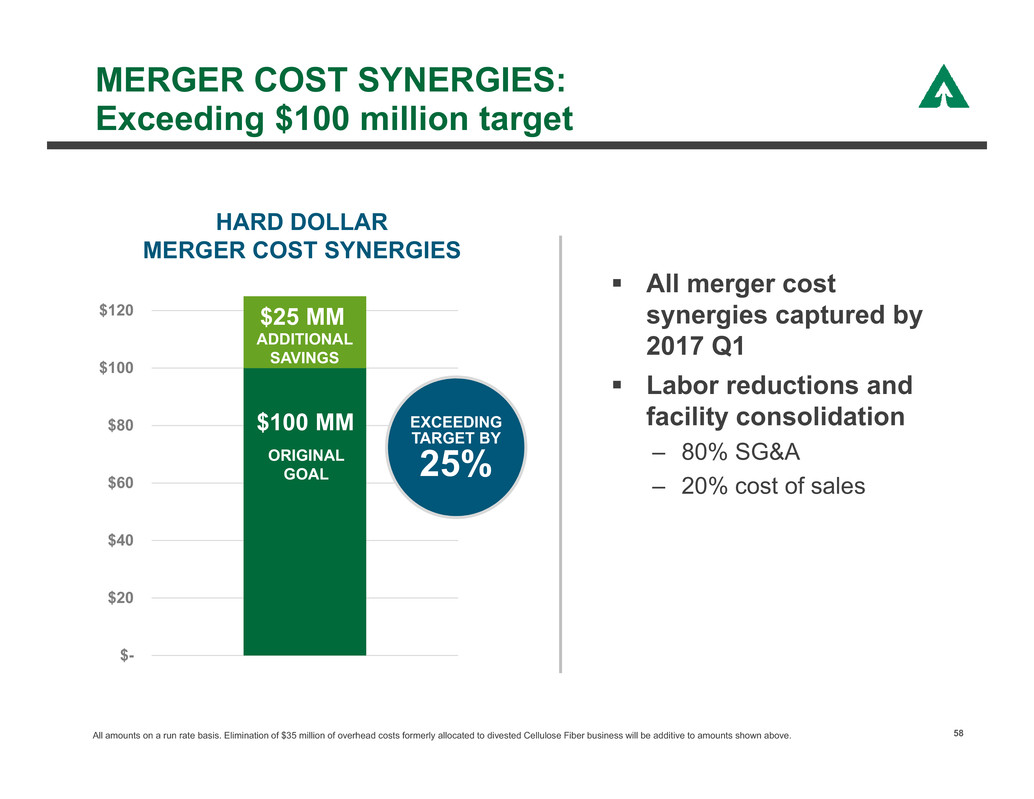

MERGER COST SYNERGIES: Exceeding $100 million target 58 MILLION MILLION MILLION All merger cost synergies captured by 2017 Q1 Labor reductions and facility consolidation – 80% SG&A – 20% cost of sales HARD DOLLAR MERGER COST SYNERGIES All amounts on a run rate basis. Elimination of $35 million of overhead costs formerly allocated to divested Cellulose Fiber business will be additive to amounts shown above. $- $20 $40 $60 $80 $100 $120 $100 MM $25 MM EXCEEDING TARGET BY 25%ORIGINAL GOAL ADDITIONAL SAVINGS

Q4 Outlook Update 59 FINANCIAL ITEMS

Market Outlook 60 FINANCIAL ITEMS

CONTINUED GROWTH IN U.S. HOUSING MARKET 61 U.S. HOUSING STARTS SEASONALLY ADJUSTED ANNUAL RATE Growth supported by: ̶ Rising employment and wages ̶ Historically low mortgage rates ̶ Demographics ̶ Pent-up housing demand Current supply constraints: ̶ Mortgage availability ̶ Labor shortages ̶ Lot availability0.0 0.5 1.0 1.5 2.0 2.5 2000 2002 2004 2006 2008 2010 2012 2014 2016 2018 2020 M I L L I O N S QUARTERLY Multi-family Single-family Source: Bureau of Census, *FEA, *RISI Forecast* RISI FEA ANTICIPATE NEARLY 1.3 MILLION STARTS IN 2017 AND IMPROVING SINGLE-FAMILY SHARE

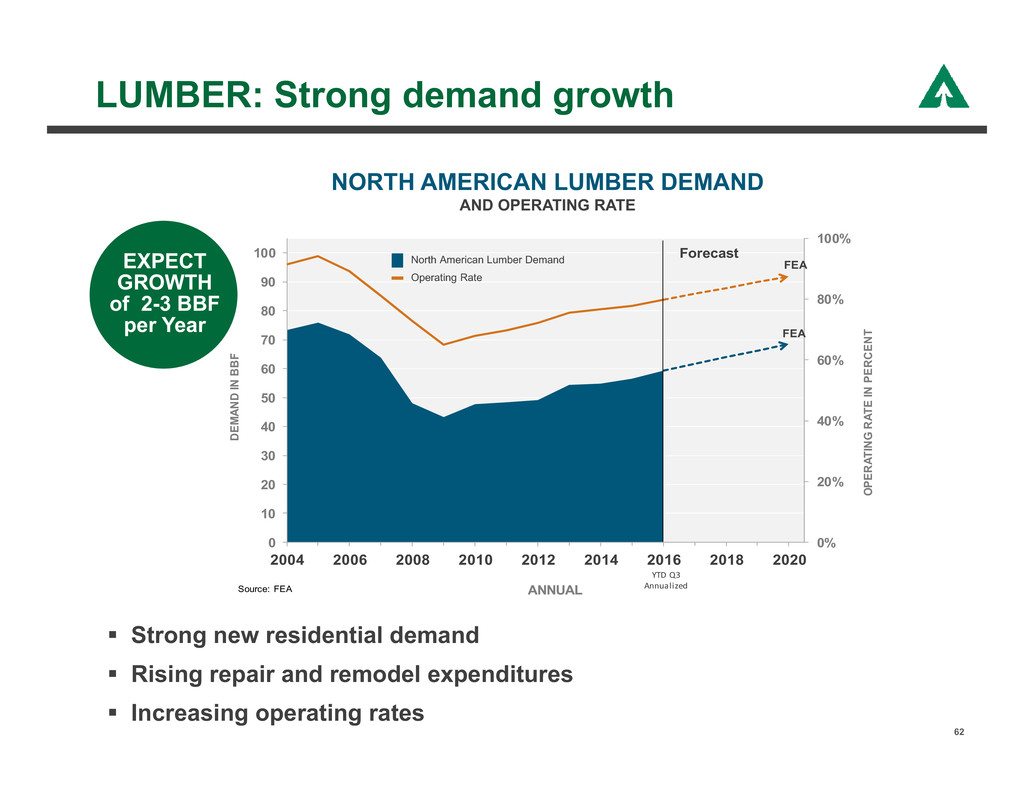

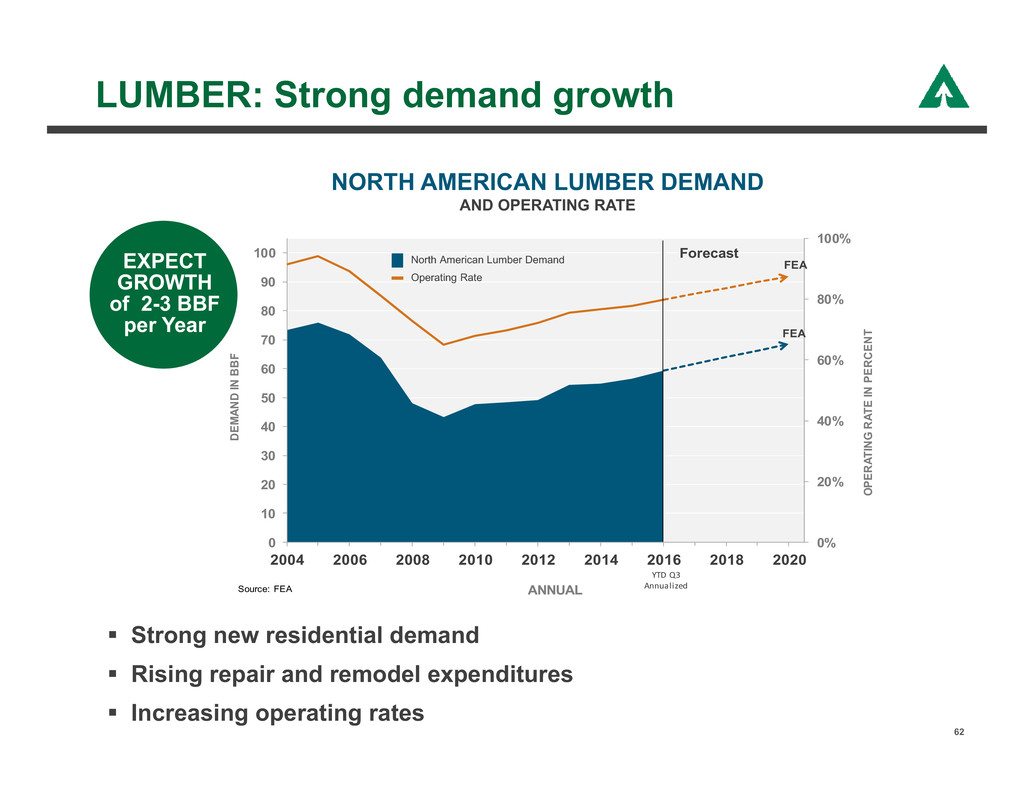

0% 20% 40% 60% 80% 100% 0 10 20 30 40 50 60 70 80 90 100 2004 2006 2008 2010 2012 2014 2016 2018 2020 O P E R A T I N G R A T E I N P E R C E N T D E M A N D I N B B F ANNUAL Forecast Source: FEA FEA FEA YTD Q3 Annualized LUMBER: Strong demand growth 62 EXPECT GROWTH of 2-3 BBF per Year NORTH AMERICAN LUMBER DEMAND AND OPERATING RATE Strong new residential demand Rising repair and remodel expenditures Increasing operating rates North American Lumber Demand Operating Rate

0% 5% 10% 15% 20% 25% 30% 35% 40% 0 5 10 15 20 25 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 S H A R E O F C O N S U M P T I O N I N P E R C E N T E X P O R T S I N B B F ANNUALSource: Random Lengths, FEA YTD Q3 Annualized 0 5 10 15 20 2004 2006 2008 2010 2012 2014 2016 2018 2020 B B F O F L U M B E R ANNUALSource: Census, WWPA, COFI, *FEA YTD Q3 Annualized Forecast* FEA LUMBER: Canadian exports constrained; Southern production rising 63 U.S. SOUTH LUMBER PRODUCTION Canadian market share to decline: ̶ Pine beetle and AAC reductions limit harvest ̶ Softwood lumber dispute Southern lumber production to exceed prior peak ̶ Implied annual growth of 5-10% to meet rising U.S. demand ̶ Southern mills continue to recapitalize and expand production capacity CANADIAN LUMBER EXPORTS TO U.S. Canadian Lumber Exports to U.S. Canadian Share of U.S. Consumption SENSITIVITY 2% CANADIAN SHARE ≈ 1 BBF LUMBER DEMAND

LUMBER: Pricing remains strong 64 Continued growth in U.S. housing and repair & remodel Declining Canadian lumber production Rising operating rates PRICING OUTLOOK FRAMING LUMBER COMPOSITE 150 200 250 300 350 400 450 500 2005 2007 2009 2011 2013 2015 2017 2019 $ / M B F QUARTERLYSources: Random Lengths, *RISI, *FEA Forecast* RISI FEA SENSITIVITY $10/MBF ≈ $45 million EBITDA

20 30 40 50 60 70 1996 1998 2000 2002 2004 2006 2008 2010 2012 2014 2016 2018 2020 $ / G R E E N T O N ANNUAL Forecast* Source: Timber Mart-South, *FEA, *RISI RISI FEA YTD Nov SOUTHERN SAWLOGS: Improving demand and pricing 65 Lumber production increasing in the U.S. South Constrained Canadian lumber supply and reduced market share Supply and demand to come into balance PRICING OUTLOOK DELIVERED SOUTHERN AVG PINE SAWLOG SENSITIVITY $5/ton ≈ $75 million EBITDA

WESTERN SAWLOGS: Strong demand from export and domestic markets 66 Steady demand for premium Japanese logs ̶ Wooden housing starts up nearly 9% 2016 YTD ̶ Favorable mortgage rates Chinese economic growth supports continued demand for US logs Western domestic demand increasing 0 100 200 300 400 500 600 700 800 900 1996 1998 2000 2002 2004 2006 2008 2010 2012 2014 2016 2018 2020 $ / M B F ANNUAL Forecast* Source: Log Lines, *FEA, *RISI RISI FEA YTD Nov WESTERN PRICING OUTLOOK DELIVERED DOUGLAS FIR #2 SENSITIVITY $20/MBF ≈ $30 million EBITDA 0.0 0.3 0.5 0.8 1.0 1.3 1.5 1.8 2.0 2.3 2000 2002 2004 2006 2008 2010 2012 2014 2016 B B F S C R I B N E R Korea China Japan WEST COAST SOFTWOOD LOGS EXPORTS TO ASIA

100 150 200 250 300 350 400 450 2005 2007 2009 2011 2013 2015 2017 2019 $ / M S F QUARTERLYSources: Random Lengths, *RISI, *FEA Forecast* RISI FEA OSB: Continued strong markets 67 Demand increasing steadily, driven by ̶ Single-family starts ̶ Repair & remodel Industry capacity additions will meet rising demand Anticipate continued strong operating ratesPRICING OUTLOOK NORTH CENTRAL OSB SENSITIVITY $10/MSF ≈ $30 million EBITDA 0% 20% 40% 60% 80% 100% 0 5 10 15 20 25 30 35 O P E R A T I N G R A T E I N P E R C E N T D E M A N D I N B S F 3 / 8 " B A S I S ANNUAL Forecast Source: FEA FEA YTD Nov Annualized FEA NORTH AMERICAN OSB DEMAND AND OPERATING RATE North American OSB Demand Operating Rate 2006 2008 2010 2012 2014 2016 2018 2020

TIMBERLAND MARKETS REMAIN STRONG 68 Investment in industrial timberlands remains competitive Continued interest from institutional investors and REITs Deal flow remains robust Recent transactions support continued solid timberland valuations

Capital Allocation 69 FINANCIAL ITEMS

CAPITAL ALLOCATION PRIORITIES 70 Sustainable and growing dividend Opportunistic share repurchases INVEST IN OUR BUSINESSES Timberlands ̶ Improve productivity ̶ Optimize portfolio Wood Products ̶ Reduce costs MAINTAIN APPROPRIATE CAPITAL STRUCTURE Committed to a solid investment grade rating RETURN CASH TO SHAREHOLDERS

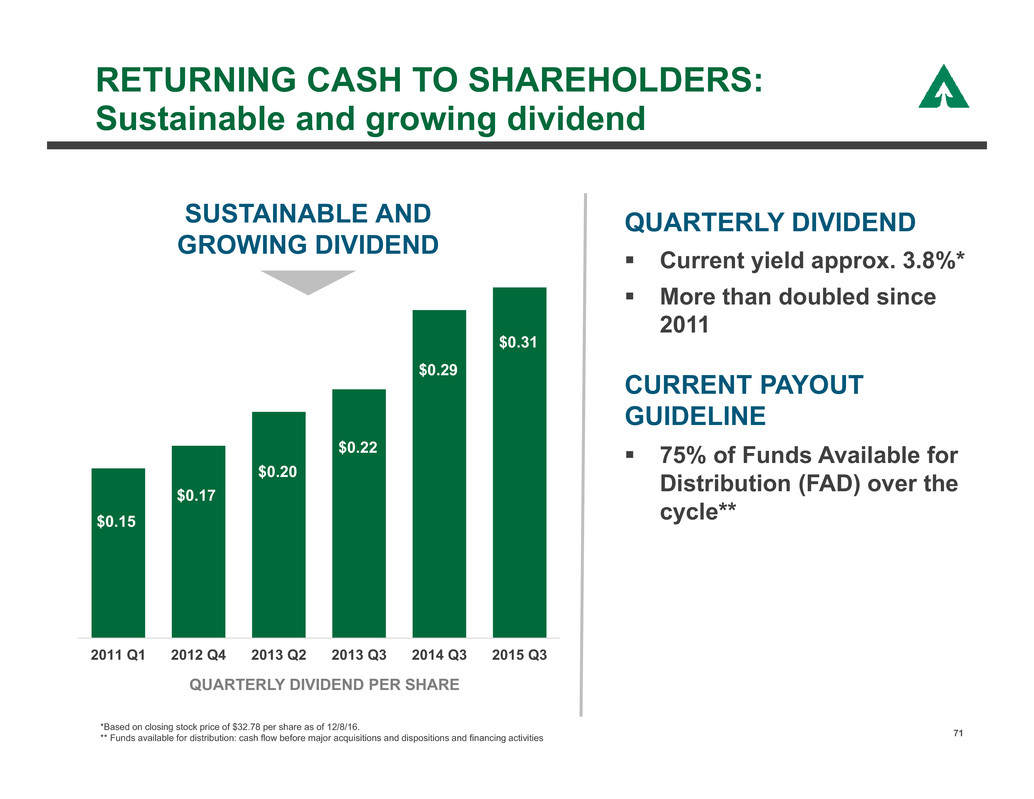

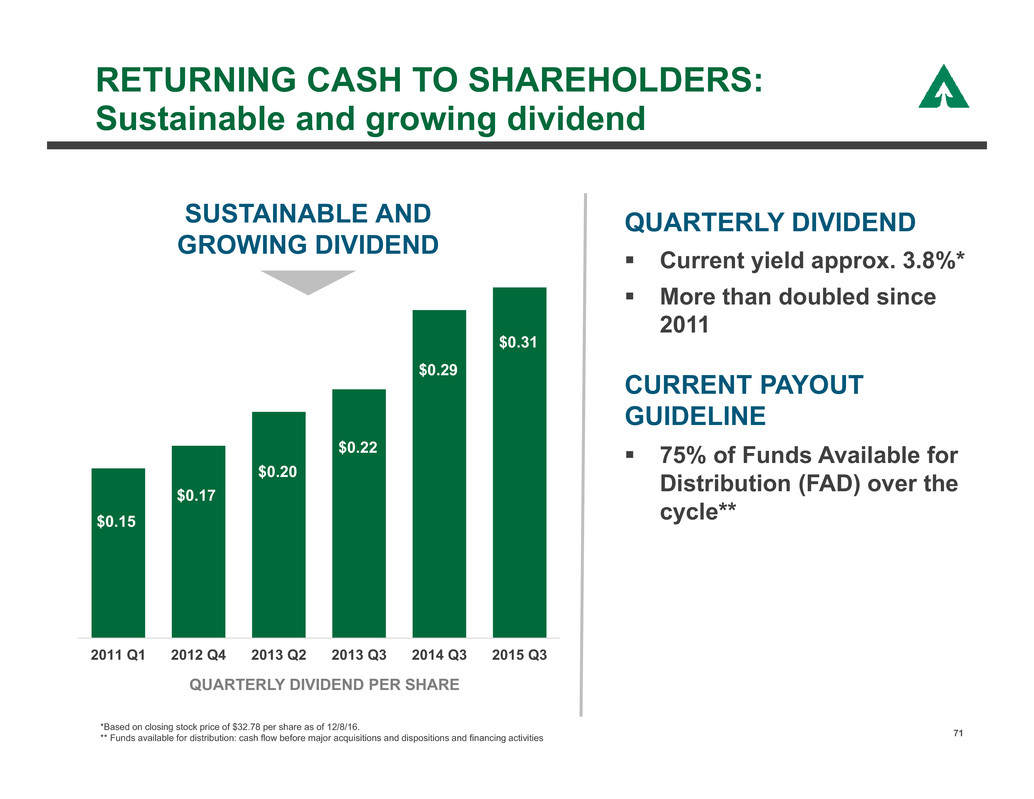

RETURNING CASH TO SHAREHOLDERS: Sustainable and growing dividend 71 $0.15 $0.17 $0.20 $0.22 $0.29 $0.31 2011 Q1 2012 Q4 2013 Q2 2013 Q3 2014 Q3 2015 Q3 QUARTERLY DIVIDEND PER SHARE SUSTAINABLE AND GROWING DIVIDEND Current yield approx. 3.8%* More than doubled since 2011 QUARTERLY DIVIDEND 75% of Funds Available for Distribution (FAD) over the cycle** CURRENT PAYOUT GUIDELINE *Based on closing stock price of $32.78 per share as of 12/8/16. ** Funds available for distribution: cash flow before major acquisitions and dispositions and financing activities

RETURNING CASH TO SHAREHOLDERS: Share repurchase 72 $2.5 BILLION SHARE REPURCHASE $2 BILLION ACCELERATED Completed in less than 6 months Repurchased 68 million shares at an average price of $29.49 per share $500 MILLION REMAINING Complete on an opportunistic basis Evaluate in context of overall capital allocation program $500 MILLION REMAINING COMPLETED $2.0 BILLION ACCELERATED

INVESTING IN OUR BUSINESSES: Disciplined capital expenditures for 2017 73 TIMBERLANDS * Excludes $5 million for Corporate and Other Reduce costs and improve productivity Maintenance capex Silviculture Roads and infrastructure 2 0 1 7 C A P E X * FOCUS WOOD PRODUCTS REAL ESTATE, ENERGY & NATURAL RESOURCES Primarily entitlement activities $130 MILLION $300 MILLION MINIMAL

▪ Comprehensive review of timberland portfolio to identify ̶ Value of every acre ̶ Areas for strategic investment ̶ Non-strategic timberlands ▪ Continue to strategically upgrade portfolio ̶ Silvicultural investments to improve productivity ̶ Divest less productive or non-strategic timberlands ̶ Reinvest in more productive lands in strategic markets ▪ Goal is the most valuable timberland portfolio, not necessarily the biggest OPTIMIZE TIMBERLAND PORTFOLIO 74 WEYERHAEUSER TIMBERLANDS = UNMATCHED IN SCALE, PRODUCTIVITY AND VALUE

▪ $1.7 billion term loan balance repaid December 1, 2016 ▪ Solid investment grade credit rating of Baa2 / BBB- stable ▪ Target net debt / Adjusted EBITDA < 3.5x ▪ Net Debt to Enterprise Value 18%* CAPITAL STRUCTURE 75 $0 $400 $800 $1,200 $1,600 $2,000 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 $ M I L L I O N S Legacy WY Debt Legacy PCL Debt LONG-TERM DEBT APPROXIMATELY $6.6 BILLION** *Based on closing stock price of $32.78 per share as of 12/8/16. **Weighted average cost of $6.6 billion long-term debt approx. 6.0%.

SUMMARY 76 DOYLE SIMONS President and CEO

HEADQUARTERS MOVE TO SEATTLE 77

WEYERHAEUSER’S INVESTMENT THESIS FOCUSED ON DRIVING VALUE FOR SHAREHOLDERS Operational excellence Most value from every acre Return cash to shareholders Invest in our businesses Maintain appropriate capital structure Premier timber, land, and wood products assets SUPERIOR RELATIVE TOTAL SHAREHOLDER RETURN PORTFOLIO PERFORMANCE CAPITAL ALLOCATION SHAREHOLDER VALUE 78

WEYERHAEUSER INVESTOR MEETING December 13, 2016 | New York

BIOGRAPHIES 80

DOYLE SIMONS 81 President and CEO Doyle R. Simons has been President and Chief Executive Officer since August 1, 2013. He has been a director of the company since June 2012 and was appointed as Chief Executive Officer Elect and an executive officer of the company June 17, 2013. He served as Chairman and Chief Executive Officer of Temple-Inland, Inc. from 2008 to February 2012 when it was acquired by International Paper. Previously, he held various management positions with Temple-Inland, including Executive Vice President from 2005 to 2007 and Chief Administrative Officer from 2003 to 2005. Prior to joining Temple-Inland in 1992, he practiced real estate and banking law with Hutcheson and Grundy, L.L.P. Simons also serves on the board of directors for Fiserv, Inc.; is a member of the board of visitors for the University of Texas M. D. Anderson Cancer Center, and the Baylor University Hankamer School of Business Advisory Board; and serves on the board of directors for United Way of King County.

RHONDA HUNTER 82 Senior Vice President, Timberlands Rhonda D. Hunter has been Senior Vice President, Timberlands, since January 1, 2014. Prior to her current position, she was Vice President, Southern Timberlands, from 2010 to 2014. She held a number of leadership positions in the Southern Timberlands organization with experience in inventory and planning, regional timberlands management, environmental and work systems, finance, and land acquisition. She joined Weyerhaeuser in 1987 as an accountant. She holds a Bachelor of Science in Accounting from Henderson State University.

JAMES KILBERG 83 Senior Vice President, Real Estate, Energy and Natural Resources James A. Kilberg was named Weyerhaeuser's senior vice president, real estate, energy and natural resources in April 2016. In this position, he oversees the company’s non-timber businesses, including real estate development, land asset management, conservation, mitigation banking, recreational lease management, oil and gas, construction materials, heavy minerals, wind and water. Kilberg began his career serving in a variety of marketing positions with IBM and AT&T. In 1983, he joined Trammell Crow Company where he held roles of increasing responsibility in the development business. In 1987, he became divisional partner and later served as executive vice president of asset management for the southeastern United States. In 1992, Kilberg became senior director of the Pizza Hut division of PepsiCo. He later became an officer and vice president of the division. In 1995, he joined Pep Boys as vice president of real estate. In 1998, he returned to Trammell Crow Company as an Executive Vice President to oversee the company’s national retail practice. In 2001, he became managing director for the global services business. He remained in this role until joining Plum Creek as vice president, land management in January 2003. In 2006, Kilberg became Plum Creek’s senior vice president, real estate, energy and natural resources. Kilberg earned a Bachelor of Science degree in marketing from Washington University in St. Louis, Missouri. He also received a master’s degree in business management from Georgia State University and a master’s degree in corporate real estate from the National Association of Corporate Real Estate. He currently serves on the board of the Georgia Chamber of Commerce and the Alliance Theater, as well as the Corporate Council of the Land Trust Alliance.

ADRIAN BLOCKER 84 Senior Vice President, Wood Products Adrian M. Blocker has been Senior Vice President, Wood Products, since Jan. 1, 2015. Prior to this role, he was Senior Vice President, Lumber, from August 2013 to December 2014. He joined Weyerhaeuser in May 2013 as Vice President, Lumber. Before joining the company, he served as CEO of the Wood Products Council and Chairman. Throughout his career in the industry, Blocker held numerous leadership positions at West Fraser, International Paper, and Champion International focused on wood products manufacturing, forest management, fiber procurement, consumer packaging, strategic planning, and business development. He holds an MBA and Bachelor of Science degrees in Business and Forestry from Mississippi State University.

RUSSELL HAGEN 85 Senior Vice President and Chief Financial Officer Russell S. Hagen has been Senior Vice President and Chief Financial Officer since February 19, 2016. Previously, he was Senior Vice President, Business Development at Plum Creek, overseeing the company’s business development activities, including acquisitions and dispositions, while continuing to manage the energy and natural resource business. Hagen began his career in 1988 with Coopers & Lybrand where he was a certified public accountant and led the audits of public clients in the technology, banking and natural resource industries. He joined Plum Creek in 1993 as Manager of Internal Audit and held director-level positions in accounting, financial operations, risk management and information technology. Prior to his last role, he was Vice President, Real Estate Development, overseeing the development activities of the company's real estate, oil and gas, construction materials and bioenergy businesses. He received a Bachelor of Science in business and accounting from Seattle University. He serves on the Board of Advisors of the Seattle University business school where he has also been an adjunct lecturer.

APPENDIX 86

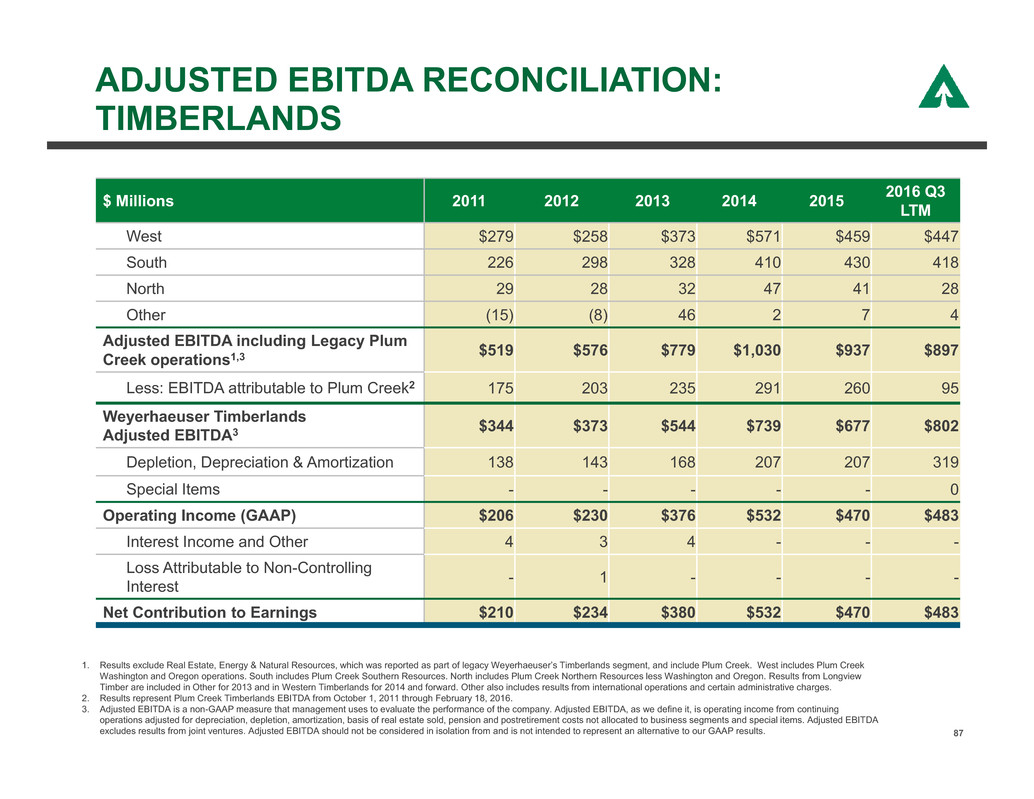

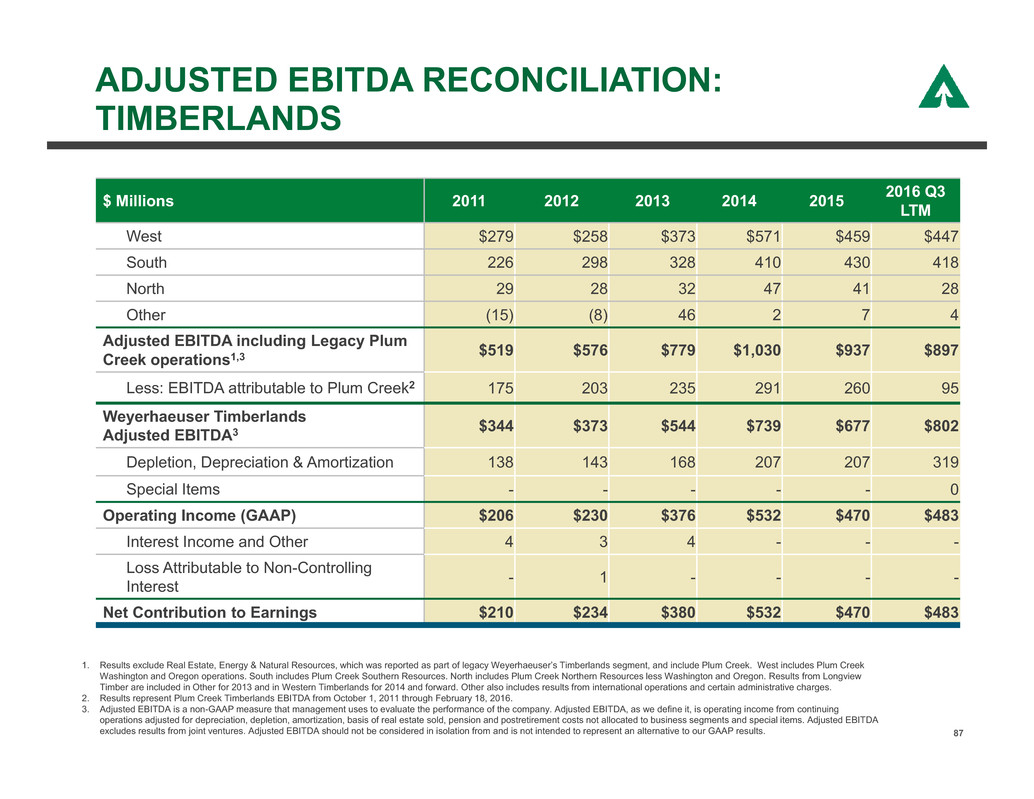

ADJUSTED EBITDA RECONCILIATION: TIMBERLANDS 87 $ Millions 2011 2012 2013 2014 2015 2016 Q3 LTM West $279 $258 $373 $571 $459 $447 South 226 298 328 410 430 418 North 29 28 32 47 41 28 Other (15) (8) 46 2 7 4 Adjusted EBITDA including Legacy Plum Creek operations1,3 $519 $576 $779 $1,030 $937 $897 Less: EBITDA attributable to Plum Creek2 175 203 235 291 260 95 Weyerhaeuser Timberlands Adjusted EBITDA3 $344 $373 $544 $739 $677 $802 Depletion, Depreciation & Amortization 138 143 168 207 207 319 Special Items - - - - - 0 Operating Income (GAAP) $206 $230 $376 $532 $470 $483 Interest Income and Other 4 3 4 - - - Loss Attributable to Non-Controlling Interest - 1 - - - - Net Contribution to Earnings $210 $234 $380 $532 $470 $483 1. Results exclude Real Estate, Energy & Natural Resources, which was reported as part of legacy Weyerhaeuser’s Timberlands segment, and include Plum Creek. West includes Plum Creek Washington and Oregon operations. South includes Plum Creek Southern Resources. North includes Plum Creek Northern Resources less Washington and Oregon. Results from Longview Timber are included in Other for 2013 and in Western Timberlands for 2014 and forward. Other also includes results from international operations and certain administrative charges. 2. Results represent Plum Creek Timberlands EBITDA from October 1, 2011 through February 18, 2016. 3. Adjusted EBITDA is a non-GAAP measure that management uses to evaluate the performance of the company. Adjusted EBITDA, as we define it, is operating income from continuing operations adjusted for depreciation, depletion, amortization, basis of real estate sold, pension and postretirement costs not allocated to business segments and special items. Adjusted EBITDA excludes results from joint ventures. Adjusted EBITDA should not be considered in isolation from and is not intended to represent an alternative to our GAAP results.

ADJUSTED EBITDA RECONCILIATION: WOOD PRODUCTS 88 $ Millions 2009 2010 2011 2012 2013 2014 2015 2016 Q3 YTD1 Lumber ($7) $130 $317 $319 $212 $232 OSB (4) 143 247 46 41 137 EWP 6 17 45 79 114 119 Distribution (37) (29) (33) 2 10 20 Other (1) (15) (2) - (5) 1 Adjusted EBITDA2 ($343) ($85) ($43) $246 $574 $446 $372 $509 Depletion, Depreciation & Amortization (198) (177) (151) (133) (123) (119) (106) (96) Special Items (194) (51) (52) 6 (10) - (8) - Operating Income (GAAP) ($735) ($313) ($246) $119 $441 $327 $258 $413 Interest Income and Other 2 3 3 1 - - - - Net Contribution to Earnings ($733) ($310) ($243) $120 $441 $327 $258 $413 1. Amounts presented reflect the results of operations acquired in our merger with Plum Creek Timber, Inc. beginning on the merger date of February 19, 2016. 2. Adjusted EBITDA is a non-GAAP measure that management uses to evaluate the performance of the company. Adjusted EBITDA, as we define it, is operating income from continuing operations adjusted for depreciation, depletion, amortization, basis of real estate sold, pension and postretirement costs not allocated to business segments and special items. Adjusted EBITDA excludes results from joint ventures. Adjusted EBITDA should not be considered in isolation from and is not intended to represent an alternative to our GAAP results.