Exhibit 99.1

GOLD RESERVE INC.

TECHNICAL REPORT ON THE SIEMBRAMINERA PROJECT, BOLIVAR STATE, VENEZUELA

NI 43-101 Report

Qualified Persons:

Richard J. Lambert, P.E., P.Eng. Hugo Miranda, C.P.

José Texidor Carlsson, P.Geo. Kathleen A. Altman, Ph.D., P.E. Grant A. Malensek, P.Eng.

March 16, 2018

RPA Inc.55 University Ave. Suite 501 I Toronto, ON, Canada M5J 2H7 IT+ 1 (416) 947 0907www.rpacan.com

| www.rpacan.com | |||

| Report Control Form | |||

| Document Title | Technical Report on the Siembra Minera Project, Bolivar | ||

| State, Venezuela | |||

| Client Name & Address | Gold Reserve Inc. | ||

| 999 W. Riverside Ave, Suite 401 | |||

| Spokane, WA 99201. | |||

| Document Reference | Status & | FINAL | |

| Project #2832 | Issue No. | Version | |

| Issue Date | March 16, 2018 | ||

| Lead Author | Richard J. Lambert | (Signed) | |

| José Texidor Carlsson | (Signed) | ||

| Hugo M. Miranda | (Signed) | ||

| Kathleen A. Altman | (Signed) | ||

| Grant A. Malensek | (Signed) | ||

| Peer Reviewer | Richard J. Lambert | (Signed) | |

| Luke Evans | (Signed) | ||

| Project Manager Approval | Richard J. Lambert | (Signed) | |

| Project Director Approval | Richard J. Lambert | (Signed) | |

Report Distribution

Name

No. of Copies

Client

RPA Filing

1 (project box)

Roscoe Postle Associates Inc.

55 University Avenue, Suite 501

Toronto, ON M5J 2H7

Canada

Tel: +1 416 947 0907

Fax: +1 416 947 0395

mining@rpacan.com

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page i |

www.rpacan.com

| TABLE OF CONTENTS | |

| PAGE | |

| 1 SUMMARY | 1-1 |

| Executive Summary | 1-1 |

| Economic Analysis | 1-8 |

| 2 INTRODUCTION | 2-1 |

| 3 RELIANCE ON OTHER EXPERTS | 3-1 |

| 4 PROPERTY DESCRIPTION AND LOCATION | 4-1 |

| Land Tenure | 4-1 |

| 5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND | |

| PHYSIOGRAPHY | 5-1 |

| 6 HISTORY | 6-1 |

| 7 GEOLOGICAL SETTING AND MINERALIZATION | 7-1 |

| Regional Geology | 7-1 |

| Mineralization at Brisas | 7-12 |

| Mineralization at Cristinas | 7-14 |

| 8 DEPOSIT TYPES | 8-1 |

| Brisas | 8-1 |

| Cristinas | 8-2 |

| 9 EXPLORATION | 9-1 |

| Exploration Potential | 9-1 |

| 10 DRILLING | 10-1 |

| General | 10-1 |

| Brisas Concessions | 10-5 |

| Cristinas Concessions | 10-8 |

| 11 SAMPLE PREPARATION, ANALYSES AND SECURITY | 11-1 |

| Brisas Concessions | 11-1 |

| Cristinas Concessions | 11-5 |

| Review of the QA/QC Results | 11-10 |

| 12 DATA VERIFICATION | 12-1 |

| PAH Data Verification - Brisas Concessions | 12-1 |

| MDA Data Verification - Cristinas Concessions | 12-3 |

| RPA Audit of Drill Hole Database | 12-5 |

| 13 MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 |

| Brisas | 13-3 |

| Cristinas | 13-5 |

| Results and Conclusions | 13-14 |

| 14 MINERAL RESOURCE ESTIMATE | 14-1 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page i |

| www.rpacan.com | |

| Summary | 14-1 |

| Drill Hole Database | 14-4 |

| Topography | 14-4 |

| Geological Interpretation | 14-5 |

| Statistical Analysis | 14-11 |

| Capping of High Grades | 14-13 |

| Compositing | 14-19 |

| Variography | 14-22 |

| Densities | 14-25 |

| Block Model Construction | 14-28 |

| Classification | 14-31 |

| Net Smelter Return | 14-33 |

| Cut-Off Grade | 14-34 |

| Treatment of ArtisAnal Miner Activity | 14-34 |

| Block Model Validation | 14-39 |

| Open Pit Optimization | 14-43 |

| Mineral Resource Estimate | 14-43 |

| Sensitivity Analysis | 14-47 |

| 15 MINERAL RESERVE ESTIMATE | 15-1 |

| 16 MINING METHODS | 16-1 |

| Production Schedule | 16-4 |

| Mine Equipment | 16-12 |

| 17 RECOVERY METHODS | 17-1 |

| Introduction | 17-1 |

| Oxide Cyanidation Plant | 17-1 |

| Flotation Concentrator | 17-5 |

| Plant Transitions and Reconfiguration | 17-10 |

| 18 PROJECT INFRASTRUCTURE | 18-1 |

| Highway Access Roads | 18-1 |

| Oxide Plant | 18-3 |

| Flotation Plant | 18-3 |

| Tailings | 18-4 |

| 19 MARKET STUDIES AND CONTRACTS | 19-1 |

| Markets | 19-1 |

| Contracts | 19-2 |

20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT

20-1

| Environmental Studies | 20-1 |

| Permitting: Regulatory Approval Process | 20-8 |

| Closure and Reclamation Plan | 20-12 |

| Waste Management Plan | 20-12 |

| Environmental and Social Summary | 20-13 |

| 21 CAPITAL AND OPERATING COSTS | 21-1 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page ii |

www.rpacan.com

| Capital Costs | 21-1 | |

| Operating Costs | 21-7 | |

| 22 ECONOMIC ANALYSIS | 22-1 | |

| Sensitivity Analysis | 22-11 | |

| 23 ADJACENT PROPERTIES | 23-1 | |

| 24 OTHER RELEVANT DATA AND INFORMATION | 24-1 | |

| 25 INTERPRETATION AND CONCLUSIONS | 25-1 | |

| 26 RECOMMENDATIONS | 26-1 | |

| 27 REFERENCES | 27-1 | |

| 28 DATE AND SIGNATURE PAGE | 28-1 | |

| 29 CERTIFICATE OF QUALIFIED PERSON | 29-1 | |

| 30 APPENDIX 1 | 30-1 | |

| Cash Flow Projection | 30-1 | |

| LIST OF TABLES | ||

| PAGE | ||

| Table 1-1 | Proposed Program | 1-8 |

| Table 1-2 | Royalties and Government Payments | 1-10 |

| Table 1-3 | Income Taxes, Working Capital, and Other | 1-11 |

| Table 1-4 | Indicative Project Economics | 1-15 |

| Table 1-5 | All-in Sustaining Costs Composition | 1-16 |

| Table 1-6 | Pre-tax Sensitivity Analysis | 1-19 |

| Table 1-7 | Summary of Mineral Resources – December 31, 2017 | 1-25 |

| Table 1-8 | Capital Cost Summary | 1-29 |

| Table 1-9 | Estimated LoM Operating Costs | 1-30 |

| Table 4-1 | UTM Coordinates of Economic Zone | 4-2 |

| Table 7-1 | Regional Stratigraphy and Broad Description | 7-10 |

| Table 10-1 | Summary of GRI Drilling-Brisas Concessions | 10-2 |

| Table 10-2 | Summary of Placer and Crystallex Drilling-Cristinas Concessions | 10-2 |

| Table 11-1 | Material Densities and Moisture | 11-5 |

| Table 11-2 | Summary of Placer’s Assaying Procedures, Cristinas Concessions | 11-6 |

| Table 11-3 | Summary of Available QA/QC Data, Cristinas Concessions | 11-11 |

| Table 11-4 | Summary of Available QA/QC Data, Brisas Concessions | 11-13 |

| Table 11-5 | Summary of Blank Sample Analysis, Brisas Concessions | 11-14 |

| Table 11-6 | Average Grade And Standard Deviation Of Available Standards Submitted At | |

| Las Cristinas | 11-16 | |

| Table 11-7 | Expected Value and Accepted Range of Standard Material, Brisas Concessions | |

| 11-17 | ||

| Table 11-8 | Comparative Statistics of Pulp Duplicate Samples at Brisas | 11-21 |

| Table 12-1 | Summary of Twin Hole Gold Data, Brisas Concessions | 12-3 |

| Table 12-2 | Comparison of Twin Hole Copper Data, Brisas Concessions | 12-3 |

| Table 13-1 | Summary of Resources and Grades by Area | 13-2 |

| Table 13-2 | Current Summary of Rock Types and Grades | 13-2 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page iii |

| www.rpacan.com | ||

| Table 13-3 | Summary of Locked Cycle Test Data | 13-5 |

| Table 13-4 | Placer Gold Recovery Estimate for Sulphide Saprolite | 13-8 |

| Table 13-5 | Placer Gold Recovery Estimate for Hard Rock | 13-9 |

| Table 13-6 | Placer Comminution Data | 13-9 |

| Table 13-7 | Cristinas Comminution Data | 13-12 |

| Table 13-8 | Cristinas Carbon Elution Assays | 13-13 |

| Table 13-9 | Recovery Estimates for PEA | 13-15 |

| Table 14-1 | Summary of Mineral Resources – December 31, 2017 | 14-1 |

| Table 14-2 | Summary of Mineral Resources by Material Type – December 31, 2017 | 14-2 |

| Table 14-3 | Summary of Mineral Resources by Zone – December 31, 2017 | 14-3 |

| Table 14-4 | Descriptive Statistics of Uncapped Gold Assay Values by Domain | 14-12 |

| Table 14-5 | Descriptive Statistics of Uncapped Copper Assay Values by Domain | 14-13 |

| Table 14-6 | Summary of Gold and Copper Capping Values | 14-16 |

| Table 14-7 | Descriptive Statistics of Gold Capped Assay Values by Domain | 14-18 |

| Table 14-8 | Descriptive Statistics of Copper Capped Assay Values by Domain | 14-19 |

| Table 14-9 | Descriptive Statistics of Capped, Composited Copper Values | 14-20 |

| Table 14-10 | Descriptive Statistics of Capped, Composited Gold Values by Domain | 14-21 |

| Table 14-11 | Density Statistics for the Brisas Concessions, by Mineralized Domain and | |

| Study | 14-27 | |

| Table 14-12 | Density Statistics for the Cristinas Concessions, by Mineralized Domain and | |

| Study | 14-27 | |

| Table 14-13 | Density Statistics for the Mesones Area, Cristinas Concessions, by Mineralized | |

| Domain and Study | 14-27 | |

| Table 14-14 | Block Model Setup | 14-28 |

| Table 14-15 | Block Model Attribute Descriptions | 14-28 |

| Table 14-16 | Gold Sample Selection Strategy | 14-29 |

| Table 14-17 | Copper Sample Selection Strategy | 14-31 |

| Table 14-18 | Key Assumptions for Calculation of NSR Factors | 14-33 |

| Table 14-19 | Summary of NSR Factors | 14-34 |

| Table 14-20 | Comparison Between OK and NN Grades | 14-39 |

| Table 14-21 | Summary of Mineral Resources – December 31, 2017 | 14-43 |

| Table 14-22 | Summary of Mineral Resources by Material Type – December 31, 2017 | 14-44 |

| Table 14-23 | Summary of Mineral Resources by Zone – December 31, 2017 | 14-44 |

| Table 14-24 | M&I Sensitivity to Au Cut-off Grade by Concession | 14-48 |

| Table 14-25 | M&I Sensitivity to Au Cut-off Grade | 14-49 |

| Table 16-1 | PEA Open Pit Optimization Parameters | 16-2 |

| Table 16-2 | Mine Plan Open Pit Optimization | 16-5 |

| Table 16-3 | Mine Phases Summary | 16-7 |

| Table 16-4 | Waste Dump Capacity | 16-9 |

| Table 16-5 | Mine Production Schedule | 16-10 |

| Table 16-6 | Process Production Schedule | 16-11 |

| Table 16-7 | Major Mine Equipment Requirements | 16-13 |

| Table 18-1 | Tailings Management Facility Capacity | 18-4 |

| Table 21-1 | Development Capital Cost Summary | 21-2 |

| Table 21-2 | Development Capital Direct Cost Details | 21-3 |

| Table 21-3 | Development Capital Indirect Cost Details | 21-4 |

| Table 21-4 | Development Capital Contingency Details | 21-5 |

| Table 21-5 | Sustaining Capital Cost Summary | 21-5 |

| Table 21-6 | Operating Cost Summary | 21-7 |

| Table 21-7 | Year 5 Annual Headcount Detail | 21-8 |

| Table 21-8 | Mine Unit Operating Costs ($/t) | 21-9 |

| Table 21-9 | Reagent and Consumables Costs for Leaching Oxide Saprolite | 21-9 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page iv |

| www. | rpacan.com |

| Table 21-10 | Reagent and Consumables Costs for Leaching Sulphide Saprolite | 21-10 |

| Table 21-11 | Reagent and Consumables Costs for Leaching | 21-11 |

| Table 21-12 | Reagent and Consumables Costs for Flotation of Sulphide Saprolite and Hard | |

| Rock | 21-11 | |

| Table 21-13 | Summary of Process Labour Costs | 21-12 |

| Table 21-14 | Summary of Power Consumption Estimates | 21-14 |

| Table 21-15 | Summary of Average Annual Power Costs | 21-15 |

| Table 21-16 | Summary of Process Operating Costs ($/t) | 21-15 |

| Table 21-17 | Summary of G&A Operating Costs ($/t) | 21-16 |

| Table 21-18 | Summary of Other Infrastructure Operating Costs ($/t) | 21-16 |

| Table 22-1 | Royalties and Government Payments | 22-3 |

| Table 22-2 | Income Taxes, Working Capital, and Other | 22-4 |

| Table 22-3 | Indicative Project Economics | 22-8 |

| Table 22-4 | All-in Sustaining Costs Composition | 22-9 |

| Table 22-5 | Pre-tax Sensitivity Analysis | 22-12 |

| Table 26-1 | Proposed Program | 26-4 |

| LIST OF FIGURES | ||

| PAGE | |

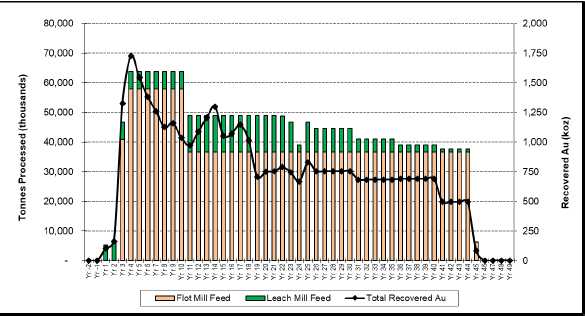

| Figure 1-1 Mine vs. Mill Production | 1-13 |

| Figure 1-2 Mill Production Profile by Plant | 1-14 |

| Figure 1-3 Project Pre-tax Metrics Summary | 1-14 |

| Figure 1-4 Annual AISC Curve Profile | 1-17 |

| Figure 1-5 Pre-tax NPV 10% Sensitivity Analysis | 1-20 |

| Figure 1-6 Pre-tax IRR Sensitivity Analysis | 1-20 |

| Figure 1-7 Pre-tax Discount Rate Sensitivity Analysis | 1-21 |

| Figure 1-8 After-tax Discount Rate Sensitivity Analysis | 1-21 |

| Figure 4-1 Project Location | 4-3 |

| Figure 4-2 Map of Economic Zone | 4-4 |

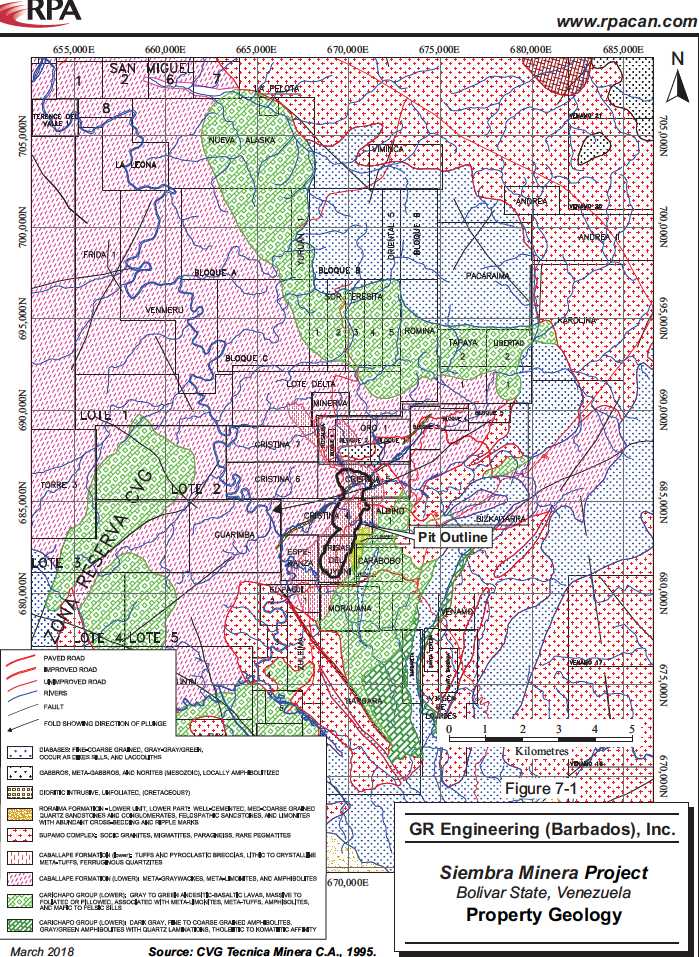

| Figure 7-1 Property Geology | 7-4 |

| Figure 7-2 Ternary Diagram for Classification of Tuffaceous Units | 7-7 |

| Figure 9-1 Exploration Target Areas | 9-2 |

| Figure 10-1 Drill Hole Location Map | 10-4 |

| Figure 11-1 Sample Preparation Flow Sheet, Brisas Concessions | 11-3 |

| Figure 11-2 Sample Preparation Flow Sheet, Cristinas Concessions | 11-7 |

| Figure 11-3 Control Chart of Blank Samples (Gold), Cristinas Concessions | 11-14 |

| Figure 11-4 Control Chart of Blank Samples (Gold), Brisas Concessions | 11-15 |

| Figure 11-5 Control Chart of Gold STD – 1Y | 11-18 |

| Figure 11-6 Control Chart of Copper STD – 1Y | 11-19 |

| Figure 11-7 Scatter Plot of Pulp Duplicate Samples, Cristinas Concessions | 11-20 |

| Figure 11-8 Scatter Plot of Pulp Duplicate Samples at Brisas | 11-21 |

| Figure 11-9 Quantile-Quantile Plot of Check Assay Samples at Brisas | 11-23 |

| Figure 13-1 Brisas Metallurgical Sample Locations | 13-4 |

| Figure 13-2 Cristinas Metallurgical Sample Locations | 13-6 |

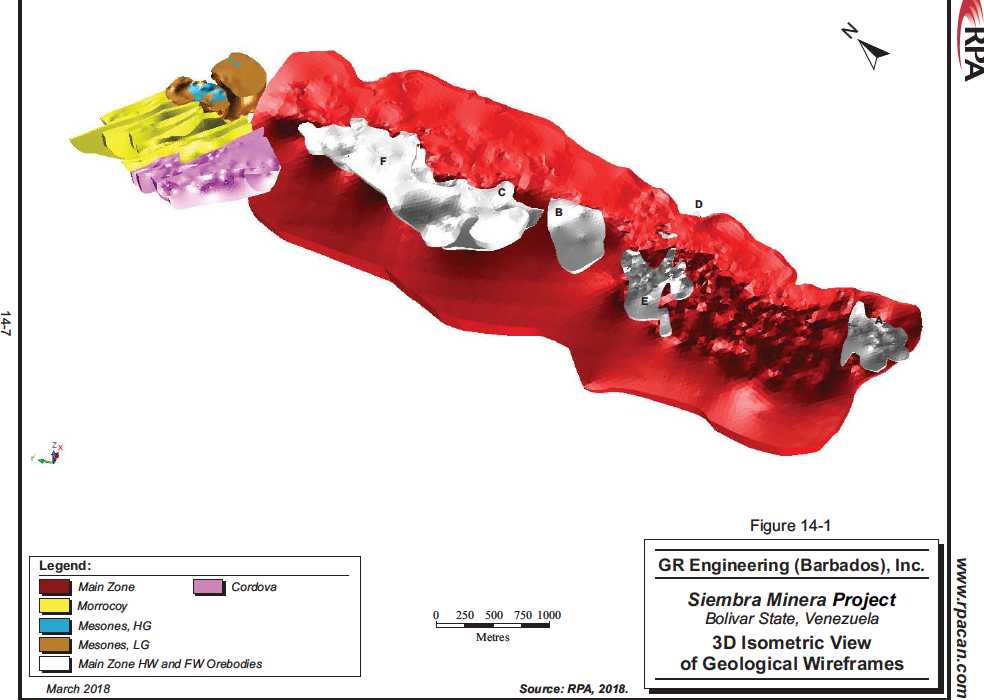

| Figure 14-1 3D Isometric View of Geological Wireframes | 14-7 |

| Figure 14-2 Example Section of Mineralization, Section 682,800N | 14-8 |

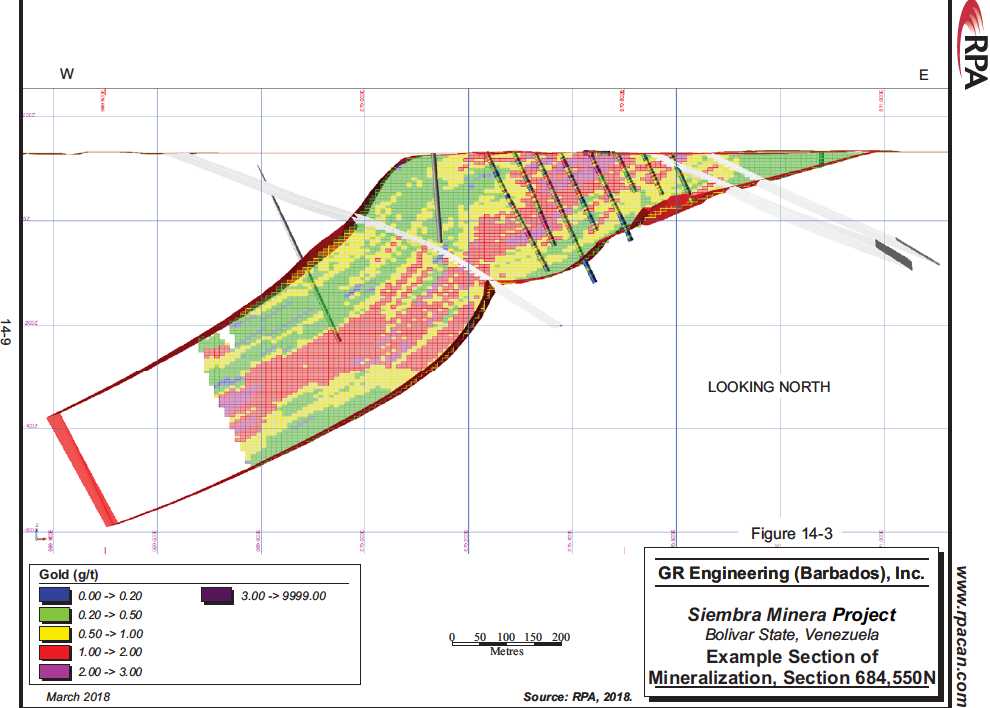

| Figure 14-3 Example Section of Mineralization, Section 684,550N | 14-9 |

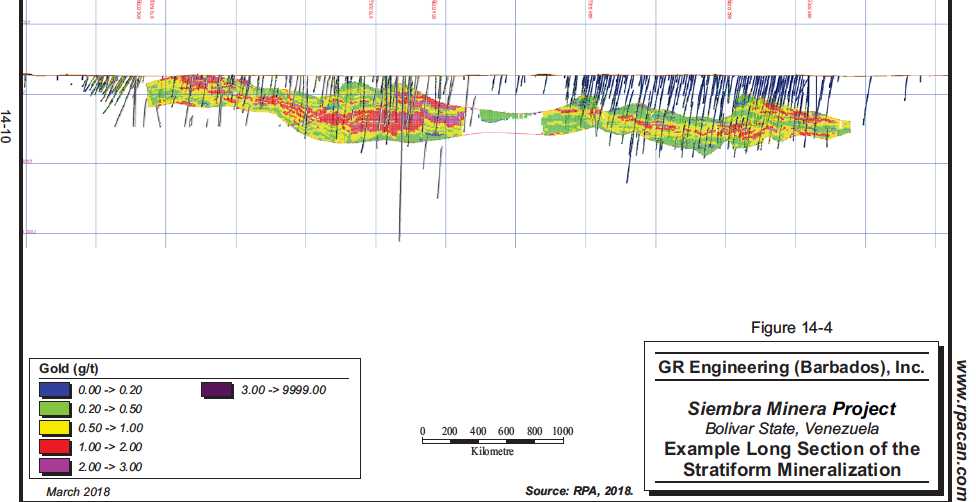

| Figure 14-4 Example Long Section of the Stratiform Mineralization | 14-10 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page v |

| www. | rpacan.com |

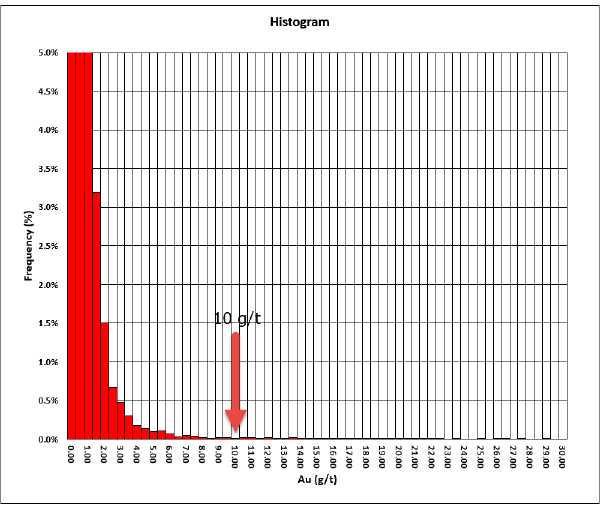

| Figure 14-5 | Frequency Histogram of the Gold Values for Brisas Main Zone | 14-14 |

| Figure 14-6 | Frequency Histogram of the Gold Values for Cristinas Main Zone | 14-15 |

| Figure 14-7 | Probability Plots of the Gold Values for Brisas Main | 14-16 |

| Figure 14-8 | Probability Plots of the Gold Values for Cristinas Main Zone | 14-17 |

| Figure 14-9 | Histogram of Sample Lengths, All Domains Combined | 14-20 |

| Figure 14-10 | Au Variograms for Brisas | 14-23 |

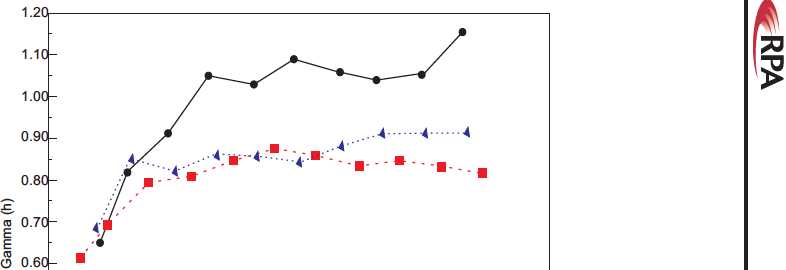

| Figure 14-11 | Au Variograms for Cristinas | 14-24 |

| Figure 14-12 | Brisas Density Statistics by Historic Oxidation Domain | 14-26 |

| Figure 14-13 | Isometric View of Resource Classification | 14-32 |

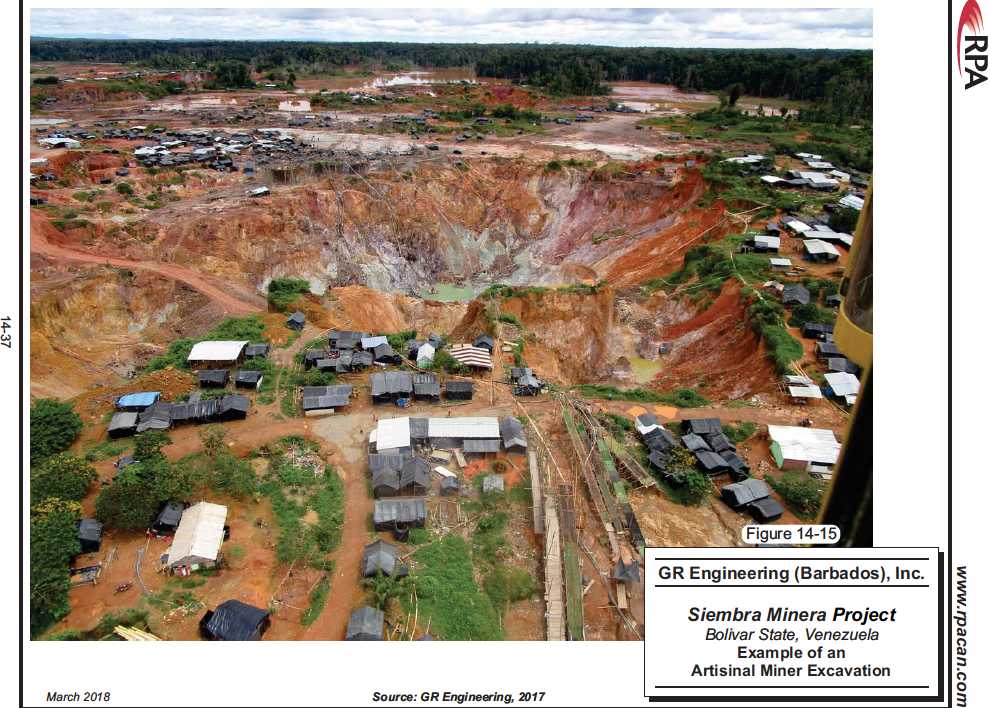

| Figure 14-14 | Overview of Artisanal Miner Excavations | 14-36 |

| Figure 14-15 | Example of an Artisanal Miner Excavation | 14-37 |

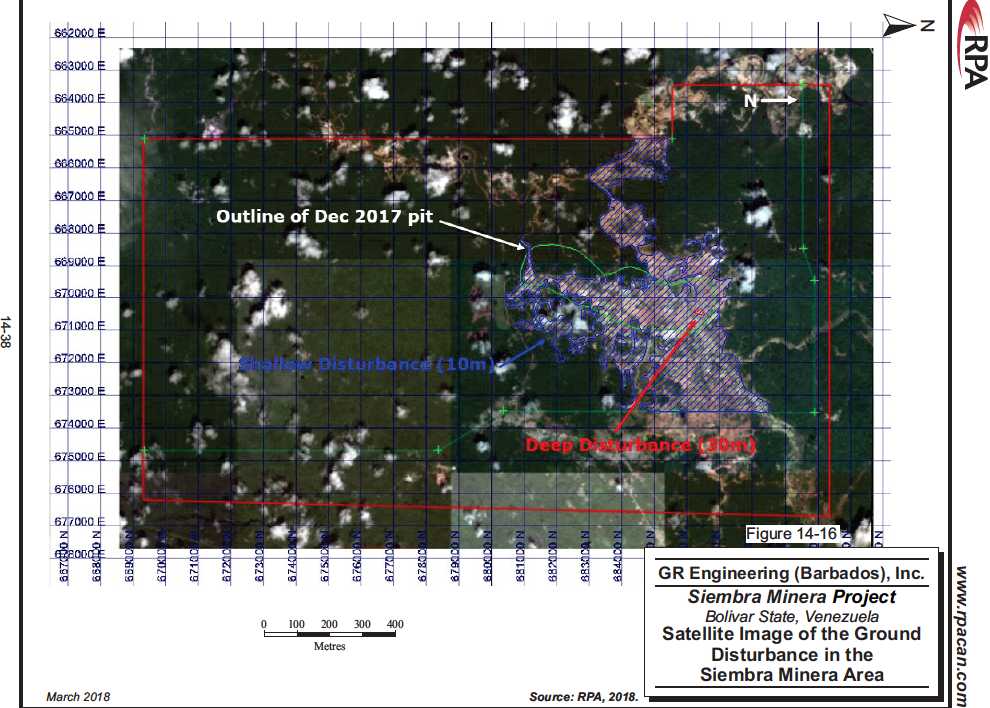

| Figure 14-16 | Satellite Image of the Ground Disturbance in the Siembra Minera Area | 14-38 |

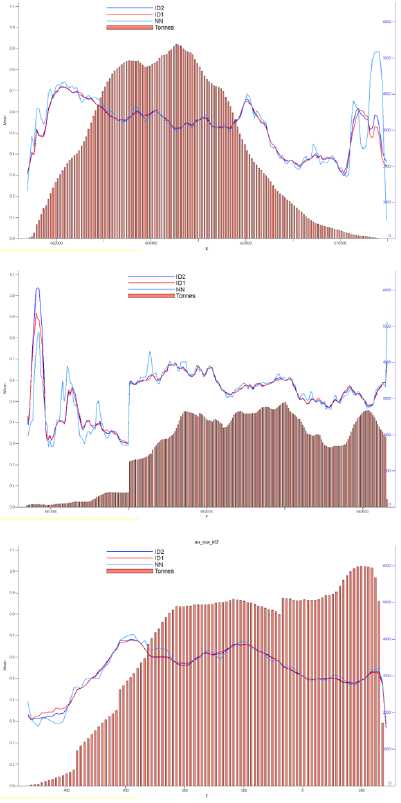

| Figure 14-17 | Validation of Local Bias for Au in Brisas | 14-40 |

| Figure 14-18 | Validation of Local Bias for Au in Cristinas | 14-41 |

| Figure 14-19 | Visual Inspection of Composite Grades vs. Block Grades for Au in Section | |

| 682250 | 14-42 | |

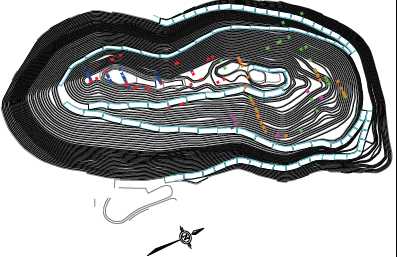

| Figure 16-1 | Resource Pit Geometry | 16-3 |

| Figure 16-2 | Pit by Pit Graph with NPV | 16-6 |

| Figure 16-3 | Final Pit Design | 16-8 |

| Figure 17-1 | Simplified Process Flowsheet for the Oxide Cyanidation Plant | 17-2 |

| Figure 17-2 | Simplified Process Flowsheet for the Flotation Concentrator | 17-6 |

| Figure 18-1 | General Site Layout | 18-2 |

| Figure 22-1 | Mine vs. Mill Production | 22-6 |

| Figure 22-2 | Mill Production Profile by Plant | 22-7 |

| Figure 22-3 | Project Pre-tax Metrics Summary | 22-7 |

| Figure 22-4 | Annual AISC Curve Profile | 22-10 |

| Figure 22-5 | Pre-tax NPV 10% Sensitivity Analysis | 22-13 |

| Figure 22-6 | Pre-tax IRR Sensitivity Analysis | 22-13 |

| Figure 22-7 | Pre-tax Discount Rate Sensitivity Analysis | 22-14 |

| Figure 22-8 | After-tax Discount Rate Sensitivity Analysis | 22-14 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page vi |

www.rpacan.com

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by Gold Reserve Inc.(GRI), and its wholly owned subsidiary GR Engineering Barbados, Inc. (GRE) to prepare an independent Technical Report on the Siembra Minera Project (the Project), located in Bolivar State, Venezuela. The operating company Empresa Mixta Ecosocialista Siembra Minera, S.A. (Siembra Minera), which holds the rights to the Siembra Minera Project, is a mixed capital company with 55% being owned by a Venezuelan state entity [owned by the Bolivarian Republic of Venezuela through the Corporación Venezolana de Minería (CVM)] and 45% by GR Mining Barbados, Inc. (GRM), a wholly-owned subsidiary of GRI. GRE has been set up to perform engineering, procurement, construction, and operation of the Project.

The Project is a combination of the Brisas and Cristinas properties into a single project now called the Siembra Minera Project. The purpose of this report is to provide GRI and GRE with an initial assessment of the Siembra Minera Project including a resource estimate, conceptual mine plan, and a preliminary economic review. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the Project on September 19, 2017.

The Siembra Minera Project is a gold-copper deposit located in the Kilometre 88 mining district of Bolivar State in southeast Venezuela. Local owners and illegal miners have worked the property for many years. Shallow pitting and hydraulic methods were used to mine the upper saprolite zone, and coarse gold was recovered by gravity concentration and amalgamation with mercury. Most of the large-scale exploration work at Cristinas was performed by Placer Dome Inc. (Placer), which worked on the property from 1991 to 2001. At Brisas, GRI carried out the exploration program on the concession from 1992 to 2005. The most recent Technical Report for Cristinas is dated November 7, 2007, which is based on a feasibility study and includes historic mineral reserves. The most recent Technical Report for Brisas is dated March 31, 2008, which is also based on a feasibility study and includes historic mineral reserves.

RPA has relied on data derived from work completed by previous owners on the Cristinas concessions and by GRI on the Brisas concessions. The current resources for Cristinas were estimated by RPA based on the drill hole data supplied by Corporación Venezolana de

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-1 |

www.rpacan.com

Guayana (CVG) to GRI in 2002. The database had 1,174 drill holes and 108 trenches which were included in the Cristinas database. Hard copies of the assay data sheets were not available, however, GEOLOG data files from Placer were provided including assay data, geological descriptions, structural data, geotechnical data, and check sample data. The current resources for Brisas were estimated by RPA based on drill hole data supplied by GRI in Geovia GEMS format which formed the basis of the last Technical Report by Pincock Allen & Holt (PAH) in 2008.

This report is considered by RPA to meet the requirements of a Preliminary Economic Assessment (PEA) as defined in Canadian NI 43-101 regulations. The mine plan and economic analysis contained in this Technical Report are based, in part, on Inferred Mineral Resources, and are preliminary in nature. Inferred Mineral Resources are considered too geologically speculative to have mining and economic considerations applied to them that would enable them to be categorized as Mineral Reserves. There is no certainty that economic forecasts on which this PEA is based will be realized.

CONCLUSIONS

RPA offers the following conclusions by area.

GEOLOGY AND MINERAL RESOURCES

- A number of exploration programs completed by Placer and GRI were successful inlocating and defining the extents of the various mineralized zones on each of theirrespective property holdings. The recently established Siembra Minera EconomicZone has unified the land tenure.

- The geology of the deposit is well understood in general. RPA is of the opinion thatthe distribution of high grade areas in the Main Zone should be studied in more detail.

In the southern two-thirds of the Cristinas concessions and the entirety of the Brisasconcessions, the mineralization occurs in a large tabular body, which strikesapproximately north-south and dips moderately to the west. In the northern third of theCristinas concessions, the mineralization can occur as pipe-shaped forms, and asthinner tabular forms with sub-vertical dips and strikes to the southeast. - The large tabular, strataform mineralized zone (referred to herein as the Main Zone)forms most of the Mineral Resource. The Main Zone has a minimum thickness of 10m at the south end and reaches a maximum thickness of 350 m. The average thicknessis approximately 200 m. While the southern limits of the Main Zone have been outlinedby the existing drilling pattern with a reasonable degree of confidence, the down-diplimits have not been defined by drilling. The northern limits of the Main Zone are alsoreasonably well defined by the existing drilling pattern.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-2 |

www.rpacan.com

- The drill hole information collected by Placer and GRI was merged into one masterdatabase that was then used to prepare the Mineral Resource estimate. Additional drillhole information collected by Crystallex International Corporation (Crystallex) on theCristinas concessions could not be used to prepare the current estimate of the MineralResources, as the detailed information required was not available. The drill hole datafrom Placer contained drilling information and analytical results up to 1997 while thedrill hole data from GRI included information up to 2006.

- In RPA’s opinion, the drill hole data is adequate for use in the preparation of MineralResource estimates.

- The outline of the gold mineralization was created by drawing wireframes usingapproximately a 0.20 g/t Au cut-off grade and the copper mineralization was outlinedusing broad wireframes based on approximately a 0.04% Cu cut-off grade.A total of24 wireframes were constructed to represent the gold mineralization zones and sixwireframes to represent the copper mineralization zones. RPA also preparedwireframe surfaces to represent the three main weathering profiles for the mineralizedzones: oxide saprolite, sulphide saprolite, and hard rock.

- RPA applied variable capping values for gold and copper grades for each of themineralized wireframe domains. The capped assay values were composited into threemetre lengths. The composites were then used to estimate the gold and copper gradesinto a grade-block model that used block sizes of 10 m by 10 m by 6 m. Gold andcopper grades were estimated into blocks using inverse distance squared and dynamicanisotropy with the Surpac v.6.8 software package. The estimated gold and coppergrades were used to calculate Net Smelter Return (NSR) values for each mineralizedblock.

- Mineral Resources were prepared using an NSR cut-off value of US$7.20/t for theoxide saprolite and US$5.00/t for the sulphide saprolite and fresh rock. An open pitshell was created using the Whittle software package to constrain reporting of theMineral Resources.

- The Mineral Resource estimate conforms to Canadian Institute of Mining, Metallurgyand Petroleum (CIM) Definition Standards for Mineral Resources and MineralReserves dated May 10, 2014 (CIM, 2014).

- The Mineral Resources are estimated at 10 million tonnes at an average grade of 1.02g/t Au and 0.18% Cu containing 318,000 ounces of gold and 17,000 tonnes of copperin the Measured category, 1.17 billion tonnes at an average grade of 0.70 g/t Au and0.10% Cu containing 26.5 million ounces of gold and 1.2 million tonnes of copper inthe Indicated category. Mineral Resources in the Inferred category are estimated at1.30 billion tonnes at an average grade of 0.61 g/t Au and 0.08% Cu containing 25.4million ounces of gold and 1.0 million tonnes of copper.

MINING

- Mine production is scheduled to be carried out at a maximum mining rate ranging from330 ktpd to 380 ktpd of total material.

- Stripping ratios are expected to average 1.16 over the Life of Mine (LoM) plan

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-3 |

www.rpacan.com

- A separate equipment fleet of smaller excavators and articulated dump trucks isincluded in the mining capital for saprolite mining in the first 10 years. Typically,undisturbed saprolite material can be difficult to mine as the moisture creates operationproblems. As the Project area has essentially been disturbed, RPA has assumed mostsaprolite is handled by the larger equipment fleet. The larger mine fleet is moreproductive and prior experience at Cristinas shows that rigid frame trucks can operatein the saprolite.

- Stockpiles are required for blending the process feed to achieve sufficient coppergrades in flotation to produce a copper concentrate above 20%. Stockpiles fluctuateyear to year, but achieve maximum capacity of just over 70 million tonnes.

MINERAL PROCESSING

- Both Brisas and Cristinas were developed to the feasibility-level stage and beyond in2006 to 2007 so the quantity of information available is greater than would typically beavailable at the PEA stage of a project.

- The material to be mined from Siembra Minera is demonstrated to be amenable to bothcyanide leaching and to sulphide flotation. For materials that contain lowerconcentrations of copper, cyanide leaching is more cost effective and for material thatcontains higher concentrations of copper, sulphide flotation is more cost effective.

- The prior metallurgical test work met industry standards at the time the studies werecompleted, however, technology has progressed in the subsequent ten plus years andindustry standards have evolved. Current standards include testing of a large numberof variability samples and development of geometallurgical models, as opposed totesting composite samples to represent “average” material to be processed, which wasthe emphasis for the Brisas test program.

ENVIRONMENT

- GRE is in the process of preparing environmental reports and programs to meetmunicipal, provincial, and national regulatory requirements, as well as generallyaccepted international standards.

- Two separate but parallel Environmental and Social Impact Assessments (ESIA) arebeing prepared for the Project, one that meets Venezuelan regulatory requirementsand one that meets international standards and guidelines.

- A conceptual plan for small-scale mining management is in place. The conceptual planincludes relocation of the artisanal miners away from the active, large scale miningoperations and establishment of an oxide saprolite processing and stockpile area withconcrete tailings ponds that collect and transport tailings from the artisanal miningoperations to the Project tailings management facility (TMF).

RECOMMENDATIONS

Given the positive economic results presented in this report, RPA recommends that the Project be advanced to the next stage of engineering study and permitting.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-4 |

www.rpacan.com

RPA offers the following recommendations.

GEOLOGY AND MINERAL RESOURCES

| Acquire new topographic data. | ||

| Drill approximately 150 to 200 drill holes totalling approximately 75 km to 100 km. This drilling would have a number of objectives including: | ||

| o | Conversion of Inferred Mineral Resources to Indicated with priority set on Inferred Mineral Resources situated in the 5 and 10-year pit shells. | |

| o | Drilling to determine the extent of mineralization at depth in the Main Zone as this will determine the limits of the largest possible pit and help with the location of features such as dumps and roads. | |

| o | Better definition of the copper mineralization in the Main Zone footwall. | |

| o | Improving preliminary artisanal mining sterilization assumptions. | |

| o | Condemnation drilling of proposed waste rock storage sites. | |

| o | Closer spaced drilling in the El Potaso area between Brisas and Cristinas concession areas. | |

| o | Drilling on the northwest extensions of the mineralization in the Morrocoy and Cordova areas. | |

| o | Drilling on the Cristinas Main Zone for density measurements. | |

| Improve understanding of the geological and structural controls on the shapes and local trends of high grade lenses in the Main Zone. Northwest striking cross-faults need to be identified and modelled and structural sub-domains built to improve future variography studies and dynamic anisotropy trend surfaces. This will improve the local accuracy of future gold and copper grade models. | ||

| Carry out additional 3D mineralization trend analysis studies, domain modelling, and variography work for the gold and copper mineralization. This will also assist in evaluating if additional 5-spot drill holes are needed to support the Indicated classification in some areas with more complex geology. | ||

| Depending on the outcome of new variography work, build gold and copper models | ||

| using | ordinary kriging. | |

| Develop a new lithology model once new drill holes have been drilled so that an improved material densities model can be created. | ||

| Build a structural model. | ||

| For the proposed drilling, implement field and coarse duplicate sampling programs at Siembra Minera at a rate of approximately 1 in 50. | ||

| Acquire three or four matrix matched certified reference materials that approximate the cut-off grade, average grade, and high grades and insert them in all future drill programs at the Project at a rate of approximately 1 in 25. | ||

| Implement external laboratory check assays at a rate of approximately 1 in 20. | ||

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-5 |

www.rpacan.com

MINING

- RPA is of the opinion that one of the most important factors influencing mining will bethe amount of water entering the pit. RPA recommends contracting a groundwaterhydrologist to evaluate the combined Project based on past work.

- A LoM schedule should be generated for the mining and processing of the SiembraMinera mineralized material. This study should include optimization and blending ofthe materials to achieve a sufficiently high copper grade to produce a copperconcentrate grade above 20%.

- A trade-off study should be completed for the backfilling of the open pit with waste rockand/or neutralized tailings.

- A geotechnical investigation program should be carried out to confirm the subsurfaceconditions under the proposed new open pit, waste dump locations, and stabilityanalysis undertaken to verify design recommendations.

MINERAL PROCESSING

| Every effort should be made to acquire access to the detailed metallurgical and plant | ||

| data | for Cristinas. In the absence of that data, detailed metallurgical sampling and | |

| testing are required to provide the information required to design the oxide leaching | ||

| plant. | ||

| Additional test work should be conducted for the flotation plant using variability samples | ||

| taken | from throughout the deposits with particular emphasis on Cristinas where limited | |

| variability testing was done using the flotation flowsheet. Currently, industry standard emphasizes the use of variability samples as opposed to the composite samples that | ||

| were | predominantly used in previous flotation testing. | |

| RPA is of the opinion that there is considerable potential for optimization of the flowsheet of the Siembra Minera Project. Examples include: | ||

| o | Increased efficiency if larger equipment sizes are utilized in the design. Due to cost savings and enhanced performance, the sizes for grinding mills and flotation cells have increased substantially. As examples, semi-autogenous grinding (SAG) mills that are now available are as large as 12.2 m diameter by 8.8 m long as opposed to the 11.6 m by 6.7 m that are in the current design and flotation cells now have capacities of 600 m3instead of the 160 m3that are in the current design. The larger pieces of equipment result in a reduced footprint and fewer pieces of equipment and, therefore, lower installed costs. | |

| o | The use of an adsorption desorption recovery (ADR) that is designed for the combined Project will probably result in less cost than merely doubling the size of the current design. In addition to this, consolidating the ADR from the oxide leach plant into a plant that can later be expanded to process the doré from the flotation plant has the potential to not only cut costs but also reduce security concerns and efforts. | |

| RPA is of the opinion that the current conceptual design for the oxide leach plant does not include the best options for Siembra Minera. Areas that require detailed evaluations include: | ||

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-6 |

www.rpacan.com

| o | Use of carbon-in-leach (CIL) instead of carbon-in-pulp (CIP) particularly since the plant designs for both Cristinas and Brisas were changed to CIL from CIP during previous studies. | ||

| o | Investigate elimination of the copper circuits. Data from the Cristinas feasibility | ||

| study | shows that copper is only soluble in the sulphide saprolite and that it is | ||

| not soluble in material that has lower copper concentrations. Therefore, the copper circuit should not be needed as the sulphide saprolite that contains higher concentrations of copper will be processed in the flotation plant and not in the oxide leach plant. | |||

| o | Changes to the gravity separation circuit. The use of continuous centrifugal concentrators instead of batch units to eliminate manual labour and reduce potential for theft. Use intensive cyanide leaching to process the gravity gold concentrate instead of shaking tables. Prior studies showed that intensive cyanide leaching was preferable for treatment of the gravity concentrate for both Brisas and Cristinas. | ||

| o | Selection of designs that are appropriate for processing clay-like saprolitic material, including: | ||

| § | Appropriate tank sizing using slurry densities that are consistent with the material that has a low specific gravity and is viscous in nature | ||

| § | Proper agitator selection | ||

| § | Selection of pumps and design of piping | ||

| Design of the TMF for the combined Project is preliminary. Further detailed geotechnical work is required to complete a design for the final tailings. Preliminary | |||

| plans | are to use the feasibility level design from the SNC-Lavalin 2007 study as Stage | ||

| 1 of construction with the final tailings inundating the Stage 1 structure. | |||

ENVIRONMENT

- GRI has held discussions with the small miners, indigenous groups, and local people.RPA recommends continuing discussions with these groups.

- Due to the increase in mineral resources, additional work is required for the increasedwaste rock dump (WRD) and TMF, and redesign/update of the acid rock drainage(ARD) mitigation measures.

- A new ESIA will be required for the combined project with an updated project plan andin conjunction with detail design and feasibility study.

COSTS AND ECONOMICS

- After the designs are complete for the Siembra Minera Project, a new capital andoperating cost estimate should be completed.

- An updated copper concentrate marketing study should be completed. Recentchanges in the world copper concentrate supply have reduced treatment and refiningcharges for copper and reduced participation charges.

PROPOSED PROGRAM AND BUDGET

RPA’s proposed program for the next stage of study is summarized in Table 1-1.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-7 |

www.rpacan.com

TABLE 1-1 PROPOSED PROGRAM

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Description | Cost |

| (US$ M) | |

| Drilling to upgrade Inferred Mineral Resources – 150 to 200 holes | 20 |

| Geotechnical Studies | 2 |

| Hydrogeology Study | 1 |

| Metallurgical Studies | 2 |

| Pre-feasibility/Feasibility Study | 5 |

| ESIA and Permitting | 2 |

| Total | 32 |

ECONOMIC ANALYSIS

The economic analysis contained in this report is based, in part, on Inferred Mineral Resources, and is preliminary in nature. Inferred Mineral Resources are considered too geologically speculative to have mining and economic considerations applied to them that would enable them to be categorized as Mineral Reserves. There is no certainty that economic forecasts on which this PEA is based will be realized.

A Cash Flow Projection has been generated from the LoM production schedule and capital and operating cost estimates, and is summarized in Table 1-4. All currency is in US dollars (US$ or $). A summary of the key criteria is provided below.

ECONOMIC CRITERIA

PRODUCTION

- The LoM production plan assumes that leach plant detailed engineering/earlyearthworks will commence in Q1 of Year -2.

- The LoM production plan assumes concentrator plant detailed engineering willcommence in Q1 of Year -2.

- A 2-year pre-production period for the leach plant, 2 additional years for completion ofthe flotation concentrator, and a 45 year overall mine life.

- The leach plant has nameplate capacity of 15,000 tpd from year 1 through year 10,which increases in year 11 to 35,000 tpd through year 45 (End of Mine, or EoM) (5.8Mtpa to 12.25 Mtpa, respectively).

- The concentrator plant has nameplate capacity of 140,000 tpd from year 3 through year10, which decreases in year 11 to 105,000 tpd through year 45 EoM (58 Mtpa to 36.75Mtpa, respectively).

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-8 |

www.rpacan.com

- Total combined leach and concentrator production is 2.0 billion tonnes, at a grade of0.70 g/t Au, 0.50 g/t Ag, and 0.090% Cu.

- The copper head grades in the mine plan are 302 Mt at 0.017% Cu and 1,703 Mt at0.106% Cu for the leach and concentrator plants, respectively. However, the leachplant does not recover copper, thus the overall average copper head grade in the totalmill feed is 2,005 Mt at 0.090% Cu.

- Average overall metal recovery of 84% Au, 53% Ag, and 84% Cu.

- Total recovered metal of 38.1 Moz Au, 17.1 Moz Ag, and 3.3 billion lb Cu.

- Average LoM annual recovered metal production of 847 koz Au, 380 koz Ag, and 78million lb Cu.

- Average annual recovered metal production in Years 3 through 18 of 1,229 koz Au,469 koz Ag, and 77 million lb Cu.

- Average annual recovered metal production in Years 19 through 45 EoM of 674 kozAu, 353 koz Ag, and 78 million lb Cu.

REVENUE

| Doré payable factors at refinery are 99.9% Au and 98% Ag. | |||

| Copper concentrate average payable factors at smelter are 98% Au, 97% Ag, and 95.8% Cu. | |||

| Payable metal sales for the Project total 37.6 Moz Au, 16.6 Moz Ag, and 3.2 billion lb Cu split as follows: | |||

| o | From Doré: 14.4 Moz Au and 4.1 Moz Ag. | ||

| o | From Concentrate: 23.2 Moz Au, 12.5 Moz Ag, and 3.2 billion lb Cu. | ||

| Metal prices: US$1,300 per troy ounce Au; US$17 per troy ounce Ag and US$3.00 per pound Cu. | |||

| NSR for doré includes transport and refining costs of $0.50 per ounce doré and $6 per ounce gold/$0.40 per ounce silver, respectively. | |||

| NSR for copper concentrate includes: | |||

| o | Cost Insurance and Freight (CIF) charge of $103 per wet tonne concentrate | ||

| (8% | moisture content) consisting of: | ||

| § | Road Transport (350 km one way): $11/t | ||

| § | Port Charges (Puerto Ordaz) : $17/t | ||

| § | Ocean Transport (Europe): $75/t. | ||

| o | Smelter treatment charge of $95 per dry tonne concentrate. | ||

| o | Smelter refining charges of $0.095/lb Cu, $6/oz Au, and $0.40/oz Ag. | ||

| o | Copper price participation is not included. | ||

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-9 |

www.rpacan.com

COSTS

- Pre-production period to CIP plant First Production: 24 months (January Year -2 toDecember Year -1).

- Pre-production period to concentrator First Production: 48 months (January Year -2 toDecember Year 2).

- Project development capital totals $2.57 billion, including $459 million in contingency(22% of direct and indirect capital).

- Sustaining capital of $1.42 billion.

- Average unit operating costs in $/t milled over the mine life:

| o | Mine ($1.36/t mined): | 2.89 | |

| o | Process: | 4.93 | |

| o | G&A: | 1.32 | |

| o | Other Infrastructure: | 0.14 | |

| o | Direct Operating Costs | 9.29 | |

| o | Concentrate Freight | 0.36 | |

| o | Off-site Costs | 0.54 | |

| o | Total | $ | 10.19 |

ROYALTIES AND GOVERNMENT PAYMENTS

Royalties and other government payments total $5.6 billion, or $2.77/t milled, over the LoM as shown in Table 1-2.

TABLE 1-2 ROYALTIES AND GOVERNMENT PAYMENTS

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Item | US$ M | US$/t milled |

| NSR Royalty | 3,262.8 | 1.63 |

| Special Advantages Tax | 1,710.0 | 0.85 |

| Science, Technology and Innovation Contributions | 588.1 | 0.29 |

| Total | 5,560.9 | 2.77 |

The Project will pay an annual NSR royalty to Venezuela on the sale of gold, copper, and silver and any other strategic minerals of 5% for the first ten years of commercial production and 6% thereafter.

The Project is subject to an additional 3% NSR annual royalty called Special Advantages Tax which is a national social welfare fund.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-10 |

www.rpacan.com

The Project is subject to a 1% gross revenue levy as part of the Science, Technology and Innovation Contributions fund (LOCTI).

Customs duties and Value Added Taxes (VAT) are assumed to be waived for the Project.

INCOME TAXES, WORKING CAPITAL, AND OTHER

Income taxes/contributions, upfront working capital, and reclamation/closure costs total $8.3 billion as shown in Table 1-3. Withholding taxes on corporate dividends and interest payments are not incorporated into the Project economic analysis.

TABLE 1-3 INCOME TAXES, WORKING CAPITAL, AND OTHER

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Item | US$ M |

| Anti-Drug Contributions | 283.9 |

| Sports Contributions | 283.9 |

| Corp. Income Taxes Paid | 7,373.8 |

| Upfront Working Capital (Yrs 1-4) | 195.4 |

| Reclamation and Closure | 150.0 |

| Salvage Value | 0 |

| Total | 8,286.9 |

Anti-drug and Sport Contributions

These profit-based taxes are assessed at 1% of current year and previous year operating income, respectively. The annual operating margin is calculated by taking annual gross revenues and deducting all operating costs and depreciation/amortization allowances.

Corporate Income Tax

The Project economic analysis incorporates a sliding scale of tax rates applicable on income based on Project phases starting in Year 1 of commercial production as follows:

- Years 1 through 5: 14%

- Years 6 through 10: 19%

- Years 11 through 15: 24%

- Years 16 through 20: 29%

- Years 21+: 34%

Year 1 is the first year of gold production, after commissioning of the 15,000 tpd oxide plant.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-11 |

www.rpacan.com

Deductions from income for the purpose of estimating income subject to tax include the following items:

| Operating Expense | ||

| Expensed operating costs are deducted 100% in year incurred. | ||

| Stockpile adjustments | ||

| As a result of large stockpiles of mill feed being generated during the life of the mine, the Project economic analysis includes annual adjustments to EBITDA to match mining | ||

| costs | with recognized revenue. The net effect of these adjustments over the life of the | |

| mine | is zero but the adjustments increase EBITDA in years where stockpiling exceeds | |

| processing and inversely decrease EBITDA when processing stockpile material exceeds stockpile placement amounts. | ||

| Depreciation/Amortization | ||

| o | All prior expenditures before January 2018 are considered sunk with respect to this analysis. | |

| o | Depreciation commences once the facilities are placed into service and the mine and mill are operating. | |

| o | Heavy mine fleet equipment capital is depreciated using 8-year straight line (SL) method. Light vehicle capital is depreciated using 5-year SL method. | |

| o | All process and infrastructure capital are depreciated using the Units of Production (UoP) method. | |

| o | Capitalized pre-production activities such as pre-stripping and water management are amortized the UoP method. | |

| o | The Project economic analysis incorporates an accelerated depreciation methodology which combines the first 12 years of annual SL depreciation allowances with the standard UoP cost basis. The resulting combined UoP/SL basis is then re-calculated using the UoP method. After 12 years, the depreciation allowances come directly from each UoP or SL category. | |

| o | Reclamation costs are amortized during the LoM by an annual accrual of $0.035/t mined ($150 million cost divided by 4.33 billion tonnes mined). This allowance is adjusted annually by periodic reclamation capital expenditures during the LoM. | |

| Other Deductions | ||

| Other | deductions from income for the purposes of estimating taxable income include | |

| management fees which amount to 5% of annual operating and capital costs. The annual management fees derived from operating costs are within the G&A opex category and thus expensed 100% in the year incurred while the annual fees derived | ||

| from | capital costs are amortized using the UoP method starting in the year they are | |

| incurred. | ||

| Loss Carryforwards | ||

| Income tax losses may be carried forward indefinitely but may not be used for prior tax years. | ||

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-12 |

www.rpacan.com

Upfront Working Capital

A total of $195 million has been allocated for upfront working capital in Years 1 to 4. This amount covers year over year changes in accounts receivable and payable plus consumable inventory.

Reclamation/Closure Costs

The Project economic analysis has a $150 million LoM closure cost estimate.

Salvage

No salvage value was estimated as part of the Project economic analysis.

CASH FLOW ANALYSIS

The Project as currently designed has significant variations in the mining schedule, processing methods, and head grades over its planned 45-year life. These variations are shown in Figures 1-1 and 1-2 and the resulting impact on the pre-tax free cash flow profile is shown in Figure 1-3.

FIGURE 1-1

MINE VS. MILL PRODUCTION

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-13 |

www.rpacan.com

FIGURE 1-2 MILL PRODUCTION PROFILE BY PLANT

FIGURE 1-3 PROJECT PRE-TAX METRICS SUMMARY

Table 1-4 shows the LoM total metrics for the Project as currently designed. Due to the length of the 45-year mine life, the full annual cash flow model is presented in Appendix 1.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-14 |

www.rpacan.com

TABLE 1-4 INDICATIVE PROJECT ECONOMICS

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Item | Unit | Value | |

| Realized Market Prices | |||

| Au | US$/oz | 1,300 | |

| Ag | US$/oz | 17.00 | |

| Cu | US$/lb | 3.00 | |

| Payable Metal | |||

| Au | Moz | 37.6 | |

| Ag | Moz | 16.6 | |

| Cu | Mlb | 3,197.6 | |

| Total Gross Revenue | US$ M | 58,806.2 | |

| Mining Cost | US$ M | (5,790.9 | ) |

| Process Cost | US$ M | (9,881.0 | ) |

| G & A Cost | US$ M | (2,653.6 | ) |

| Other Infrastructure Cost | US$ M | (288.9 | ) |

| Concentrate Freight Cost | US$ M | (728.0 | ) |

| Off-site Costs | US$ M | (1,076.5 | ) |

| NSR Royalty Cost | US$ M | (3,262.8 | ) |

| Special Advantages Tax Cost | US$ M | (1,710.0 | ) |

| Science (LOCTI) Contributions | US$ M | (588.1 | ) |

| Total Operating Costs | US$ M | (25,979.7 | ) |

| Operating Margin (EBITDA) | US$ M | 32,826.5 | |

| Anti-Drug Contributions | US$ M | (283.9 | ) |

| Sport Contributions | US$ M | (283.9 | ) |

| Effective Tax Rate | % | 22.5 | % |

| Income Tax | US$ M | (7,373.8 | ) |

| Total Taxes | US$ M | (7,941.5 | ) |

| Working Capital ($195 M in Years 1 to 4) | US$ M | 0 | |

| Operating Cash Flow | US$ M | 24,885.0 | |

| Development Capital | US$ M | (2,570.6 | ) |

| Sustaining Capital | US$ M | (1,941.7 | ) |

| Closure/Reclamation Capital | US$ M | (150.0 | ) |

| Total Capital | US$ M | (4,662.3 | ) |

| Pre-tax Free Cash Flow | US$ M | 28,164.2 | |

| Pre-tax NPV @ 5% | US$ M | 11,209.4 | |

| Pre-tax NPV @ 10% | US$ M | 5,534.5 | |

| Pre-tax IRR | % | 36.8 | % |

| After-tax Simple Payback | Years | 3.8 | |

| After-tax Free Cash Flow | US$ M | 20,222.7 | |

| After-tax NPV @ 5% | US$ M | 8,101.2 | |

| After-tax NPV @ 10% | US$ M | 3,930.1 | |

| After-tax IRR | % | 31.1 | % |

| After-tax Simple Payback | Years | 4.1 | |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-15 |

www.rpacan.com

On a pre-tax basis, the undiscounted cash flow totals $28,164 million over the mine life. The pre-tax Internal Rate of Return (IRR) is 36.8%, and simple payback from start of commercial production occurs in 3.8 years. The pre-tax Net Present Values (NPV) are:

- $11,209 million at a 5% discount rate.

- $5,534 million at a 10% discount rate.

On an after-tax basis, the undiscounted cash flow totals $20,223 million over the mine life, the IRR is 31.1%, and simple payback from start of commercial production occurs in 4.1 years. The after-tax NPVs are:

- $8,101 million at a 5% discount rate.

- $3,930 million at a 10% discount rate.

The average annual gold sales during the forty-five years of operation is 836 koz per year (37.6 Moz over the LoM) at an average all in sustaining cost (AISC) of US$483 per ounce. Table 1-5 shows the AISC build up which is net of a US$262/oz copper and silver by-product credit (nbp).

TABLE 1-5 ALL-IN SUSTAINING COSTS COMPOSITION

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Item | US$M | US$/oz Au | ||

| Mining | 5,790.9 | 154 | ||

| Process | 9,881.0 | 263 | ||

| G & A | 2,653.6 | 71 | ||

| Other Infrastructure | 288.9 | 8 | ||

| Subtotal Site Costs | 18,614.3 | 495 | ||

| Transportation | 728.0 | 19 | ||

| Off-site Treatment | 1,076.5 | 29 | ||

| Subtotal Off-site Costs | 1,804.5 | 48 | ||

| Direct Cash Costs | 20,418.8 | 542 | ||

| Ag and Cu By-Product Credit | (9,875.4 | ) | (262 | ) |

| Total Direct Cash Costs (nbp) | 10,543.4 | 280 | ||

| NSR Royalty | 3,262.8 | 87 | ||

| Special Advantages Tax | 1,710.0 | 45 | ||

| STI Contributions | 588.1 | 16 | ||

| Total Indirect Cash Costs | 5,560.9 | 148 | ||

| Total Production Costs | 16,104.3 | 428 | ||

| Sustaining Capital Cost | 1,941.7 | 52 |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-16 |

| www.rpacan.com | ||

| Item | US$M | US$/oz Au |

| Closure/Reclamation Capital | 150.0 | 4 |

| Corporate G&A | 0.0 | 0 |

| Off-mine Exploration | 0.0 | 0 |

| Total Sustaining Costs | 2,091.7 | 56 |

| Total All-in Sustaining Costs | 18,196.0 | 483 |

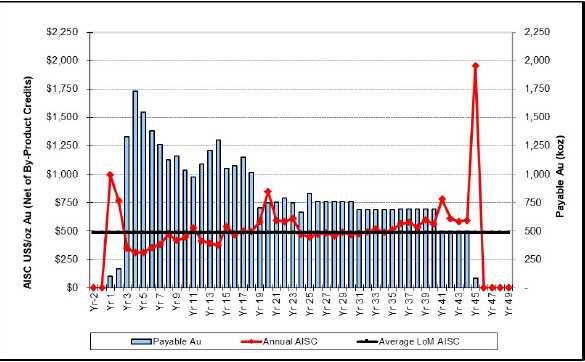

Figure 1-4 shows the annual AISC trend during the mine operations against an overall average AISC of US$483/payable oz over the 45-year LoM at an annual production rate of 836 koz Au per year. The AISC variations are mainly driven changes in grades, mine schedule, and processing methods. The AISC metric can range from US$309/oz to US$992/oz Au in a given year (excluding final year spike in Year 45 of $1,956/oz) but can be subdivided into three distinct phases:

- Phase 1: Years 1 and 2 (CIP only) - 133 koz/yr Au at $853/oz.

- Phase 2: Years 3 through 18 (mining highest grades) - 1,191 koz/yr Au at $411/oz.

- Phase 3: Years 19 through 45 EoM (mining lower grades) - 665 koz/yr Au at $554/oz.

FIGURE 1-4

ANNUAL AISC CURVE PROFILE

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-17 |

www.rpacan.com

SENSITIVITY ANALYSIS

Project risks can be identified in both economic and non-economic terms. Key economic risks were examined by running cash flow sensitivities:

- Head grade

- Gold recovery

- Gold price

- Operating costs

- Capital costs

- Discount rates

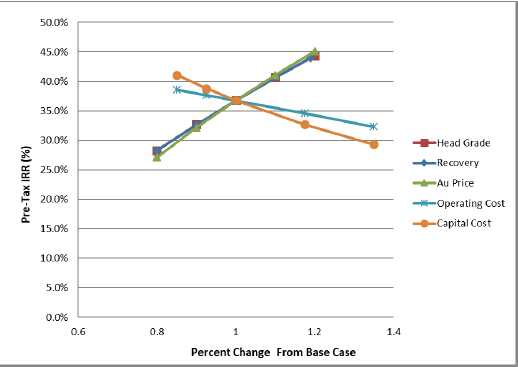

Pre-tax NPV and IRR sensitivities over the base case has been calculated for -20% to +20% variations metal-related categories. For operating costs and capital costs, the sensitivities over the base case has been calculated at -15% to +35% variation. The sensitivities are shown in Table 1-6 and in Figures 1-5 and 1-6, respectively.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-18 |

www.rpacan.com

TABLE 1-6 PRE-TAX SENSITIVITY ANALYSIS

GR Engineering (Barbados), Inc. – Siembra Minera Project

| Factor Change | Head Grade (g/t Au) | NPV at 10% | IRR | ||

| (US$ M) | (%) | ||||

| 0.8 | 0.56 | 3,477.3 | 28.3 | % | |

| 0.9 | 0.63 | 4,505.8 | 32.7 | % | |

| 1 | 0.70 | 5,534.5 | 36.8 | % | |

| 1.1 | 0.78 | 6,563.2 | 40.6 | % | |

| 1.2 | 0.85 | 7,591.9 | 44.3 | % | |

| Recovery | NPV at 10% | IRR | |||

| Factor Change | (% Au) | (US$ M) | (%) | ||

| 0.8 | 67 | 3,477.3 | 28.3 | % | |

| 0.9 | 76 | 4,505.8 | 32.7 | % | |

| 1 | 84 | 5,534.5 | 36.8 | % | |

| 1.1 | 92 | 6,563.2 | 40.6 | % | |

| 1.2 | 100 | 7,489.0 | 44.0 | % | |

| Metal Price | NPV at 10% | IRR | |||

| Factor Change | (US$/oz Au) | (US$ M) | (%) | ||

| 0.8 | 1,040 | 3,166.4 | 27.2 | % | |

| 0.9 | 1,170 | 4,350.4 | 32.2 | % | |

| 1 | 1,300 | 5,534.5 | 36.8 | % | |

| 1.1 | 1,430 | 6,718.5 | 41.1 | % | |

| 1.2 | 1,560 | 7,902.5 | 45.1 | % | |

| Factor Change | Operating Costs | NPV at 10% | IRR | ||

| (US$/t milled) | (US$ M) | (%) | |||

| 0.85 | $ | 11.57 | 6,068.2 | 38.6 | % |

| 0.93 | $ | 12.27 | 5,801.3 | 37.7 | % |

| 1.00 | $ | 12.96 | 5,534.5 | 36.8 | % |

| 1.18 | $ | 14.59 | 4,911.7 | 34.6 | % |

| 1.35 | $ | 16.21 | 4,289.0 | 32.3 | % |

| Capital Costs | NPV at 10% | IRR | |||

| Factor Change | (US$ M) | (US$ M) | (%) | ||

| 0.85 | $ | 4,222 | 5,812.0 | 41.1 | % |

| 0.93 | $ | 4,385 | 5,673.2 | 38.8 | % |

| 1.00 | $ | 4,547 | 5,534.5 | 36.8 | % |

| 1.18 | $ | 4,927 | 5,210.7 | 32.7 | % |

| 1.35 | $ | 5,306 | 4,886.9 | 29.3 | % |

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-19 |

www.rpacan.com

FIGURE 1-5 PRE-TAX NPV 10% SENSITIVITY ANALYSIS

FIGURE 1-6 PRE-TAX IRR SENSITIVITY ANALYSIS

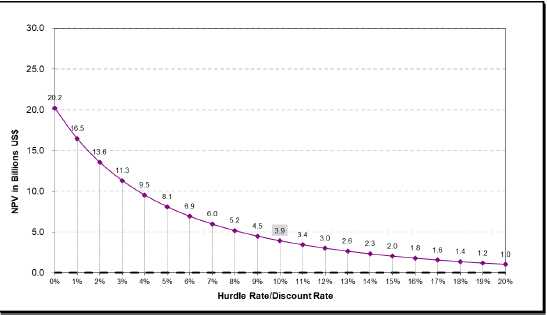

A sensitivity analysis of discount rates is presented in Figure 1-7 and 1-8 and shows that the Project as currently designed would be NPV positive through a 20% discount rate.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-20 |

www.rpacan.com

FIGURE 1-7 PRE-TAX DISCOUNT RATE SENSITIVITY ANALYSIS

FIGURE 1-8 AFTER-TAX DISCOUNT RATE SENSITIVITY ANALYSIS

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-21 |

www.rpacan.com

TECHNICAL SUMMARY

PROPERTY DESCRIPTION AND LOCATION

The Siembra Minera Project is located in the Kilometre 88 mining district of Bolivar State, in southeast Venezuela at Latitude 6° 11’ North and Longitude 61° 28’ West. The property is approximately 3.5 km west of Highway 10. Las Claritas is the closest town to the property.

The Project site is located in the Guyana region, which covers approximately one-third of Venezuela’s national territory. The closest nearby large city is Ciudad Guayana, with approximately 1,050,000 inhabitants (2001), situated on the Orinoco River near its confluence with the Caroní River. Ciudad Guayana consists of the old town of San Félix to the east and the new town of Puerto Ordaz to the west. Puerto Ordaz is home to most of the major industrial facilities such as aluminum smelters and port facilities. Puerto Ordaz has major port facilities accessible to ocean-going vessels from the Atlantic Ocean via the Orinoco River, a distance of approximately 200 km. There is regularly scheduled commercial airline service to Puerto Ordaz from Caracas.

Highway 10 provides paved access from Ciudad Guayana, which is 373 km northwest of the property, to within 3.5 km of the Project site. Unpaved roads provide the remaining 3.5 km of access.

The Project area encompasses approximately 18,951 ha and has been designated as an Economic Zone by the Venezuelan Government.

HISTORY

Gold in the Siembra Minera region was first discovered in 1920. Gold mining in the Project area was initiated in the 1930s and continued sporadically on a minor scale until the early 1980s when a gold rush occurred. Approximately 5,000 to 7,000 small miners worked alluvial and saprolite-hosted gold deposits using hydraulic mining techniques. The amount of gold recovered is unknown and much of the area of the concessions is now covered with tailings.

Placer conducted essentially all of the modern exploration on Cristinas during its tenure on the property from 1991 to 2001. Placer completed line cutting, mapping, rock and soil sampling, geophysics, and drilling of 1,174 drill holes for a total of 158,738 m of drilling. In 2003, Crystallex undertook drilling of 12 holes totalling 2,199 m to confirm the tenor of mineralization

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-22 |

www.rpacan.com

presented in the pre-existing database and also assayed check samples. Between 2003 and 2007, Crystallex released at least two feasibility studies and several resource and reserve estimates for Cristinas, all of which are historic in nature and should not be relied upon.

The Brisas concession was acquired by GRI in August 1992 with the acquisition of Compañia Aurifera Brisas del Cuyuni C.A. A large stratabound gold-copper mineralization was discovered in both alluvial and hard rock material by a drilling program in 1993. A majority of the exploration and development drilling took place in 1996 and 1997, with additional drilling completed in 1999, 2003, 2004, and 2005. As of 2005, 802 exploration holes had been drilled including 186,094 m of core drilling and 189,985 m of exploration core and auger drilling. In 2005-2006, an additional 76 holes were drilled on the Brisas concessions for geotechnical and other studies. A number of resource estimates have been completed for the Brisas deposit, all of which are superseded by the current Mineral Resource estimate in this report. A pre-feasibility study was carried out in 1998 and a feasibility study in 2005, with a feasibility update in 2008, all including historic reserve estimates.

GEOLOGY

The Siembra Minera Project is within the Guyana Shield in northern South America. The shield covers easternmost Colombia, southeastern Venezuela, Guyana, Suriname, French Guiana, and northeastern Brazil. The Venezuelan portion of the shield is subdivided into five geological provinces with different petrological, structural and metallogenic characteristics. The provinces are, from oldest to youngest, Imataca, Pastora, Cuchivero, Roraima, and Parguaza. Only the Imataca, Pastora and Roraima provinces are found in the vicinity of the Siembra Minera deposit.

The Siembra Minera deposit lies within a portion of the lower Caballape Formation volcanic and volcanic-related sedimentary rocks. The units present are (1) andesitic to rhyolitic tuffaceous volcanic beds, (2) related sedimentary beds, and (3) a tonalitic intrusive body. All rocks have been tilted and subjected to lower greenschist facies metamorphism. It is thought, based on information from nearby properties, that the Siembra Minera Project occupies one limb of a large regional fold. Limited direction-indicating structures show the strata to be top-up. In the main mineralized trend, moderate to strong foliation is oriented N10°E and dipping 30° to 55° northwest. This foliation appears to be parallel to the original bedding and tends to

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-23 |

www.rpacan.com

be strongest in the finer-grained rocks. A much weaker foliation orientation appears in outcrop exposures, striking north-northwest and dipping to the southwest.

There are four distinct types of gold and copper mineralization present at Brisas, defined by geometry, associated minerals, and the gold-copper ratio. These zones are the Blue Whale body, disseminated gold+pyrite (± copper), disseminated high copper, and shear-hosted gold. Only the first three types are encountered within the proposed pit geometry.

Two distinct styles of mineralization are present at Cristinas: hydrothermal breccia-hosted mineralization at Mesones-Sofia and stratiform mineralization at Conductora, Morrocoy, and Cordova. The vast majority (approximately 95%) of the gold at Cristinas is contained in the stratiform mineralized zone.

EXPLORATION STATUS

Drilling at Brisas was carried out by GRI from late 1992 to 2006 and consisted of 975 drill holes totalling approximately 207,000 m. In addition, four trenches were dug for a total of 60 m. At Cristinas, drilling was carried out by Placer from 1992 to 1997, consisting of 1,182 drill holes totalling approximately 155,000 m, and by Crystallex from 2003 to 2007, consisting of 90 holes totalling approximately 28,000 m. The Crystallex drill hole data was not available for RPA’s resource modelling work.

The Siembra Minera mineralization is open down dip in all zones and along strike to the northwest in Morrocoy and Cordova because of insufficient drilling. Current plans for exploration are based on brownfield expansion of the existing deposit. As the Project advances, GRE proposes to carry out approximately 75,000 m to 100,000 m of new drilling.

MINERAL RESOURCE ESTIMATES

A Mineral Resource estimate, dated December 31, 2017, was completed by RPA using the Surpac and Leapfrog Geo software packages. Wireframes for geology and mineralization were constructed in Leapfrog Geo based on geology sections, assay results, lithological information, and structural data. Assays were capped to various levels based on exploratory data analysis and then composited to three metre lengths. Wireframes were filled with blocks measuring 10 m by 10 m by 6 m (length, width, height). Block grades were estimated using dynamic anisotropy and inverse distance squared algorithms. Block estimates were validated

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-24 |

www.rpacan.com

using industry standard validation techniques. Classification of blocks was based on drill hole spacing distances and other criteria.

A summary of the Mineral Resources at the Project is provided in Table 1-7.

| TABLE 1-7 | SUMMARY OF MINERAL RESOURCES – DECEMBER 31, 2017 | |||||

| GR Engineering (Barbados), Inc. – Siembra Minera Project | ||||||

| Category | Tonnes | Grade | Grade | Contained Gold | Contained Copper | |

| (Mt) | (g/t Au) | (% Cu) | (koz Au) | (kt Cu) | (Mlb Cu) | |

| Measured | 10 | 1.02 | 0.18 | 318 | 17 | 38 |

| Indicated | 1,174 | 0.70 | 0.10 | 26,504 | 1,202 | 2,649 |

| Total Measured | ||||||

| + Indicated | 1,184 | 0.70 | 0.10 | 26,823 | 1,219 | 2,687 |

| Inferred | 1,291 | 0.61 | 0.08 | 25,389 | 1,044 | 2,300 |

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated at an NSR cut-off value of US$7.20 per tonne for oxide-saprolite material and US$5.00 per tonne for sulphide-saprolite and fresh rock material. |

| 3. | Mineral Resources are constrained by a preliminary pit shell created using the Whittle software package. |

| 4. | Mineral Resources are estimated using a long-term gold price of US$1,300 per ounce, and a copper price of US$3.00 per pound. |

| 5. | Bulk density varies by material type. |

| 6. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 7. | Numbers may not add due to rounding. |

RPA is not aware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other relevant factors that could materially affect the Mineral Resource estimate.

MINING

The Siembra Minera Project is an open pit gold-copper mining project that will utilize 30 m3hydraulic shovels and 236-tonne trucks as the primary mining equipment.

The resource pit optimization was developed by RPA based on the RPA Mineral Resource estimate (Table 1-7). Blocks classified as Measured, Indicated, and Inferred Mineral Resources were included in the resource pit optimization process for the Siembra Minera deposit. The resource pit is approximately 6,000 m long and 1,900 m wide with a maximum depth of approximately 700 m. The pit slope on the east wall follows the mineralization with slopes from 36° to 38°, while the west wall final pit has overall pit slopes ranging from 48° to 50°.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-25 |

www.rpacan.com

Mine production is scheduled to be carried out at a maximum mining rate ranging from 330 ktpd to 380 ktpd of total material. Stripping ratios are expected to average 1.16 over the LoM plan. The production schedule was produced using Whittle software to guide the mining sequence, Vulcan to design phases, waste dumps and the final pit, and XPAC to schedule the phases following the processing requirements.

During the first ten years of the Project, 5.8 million tonnes per annum (Mtpa) of oxide saprolite that does not require grinding will be processed in the oxide saprolite plant. The flotation plant starts two years after the oxide plant. Feed to the flotation mill is scheduled for 58.0 Mtpa for years 3 to10, while softer high copper sulphide saprolite material is available. In year 11, one quarter of the flotation grinding mill (12.25 Mtpa) is converted to oxide to accommodate the harder low-copper sulphide saprolite and low-copper hard rock materials. The other 36.75 Mtpa of capacity in the grinding mill are used for the harder higher-copper material in the flotation. The oxide plant will start processing with a combination of saprolite and low copper hard rock using the leach tanks from the oxide saprolite plant and additional leach tanks required for processing. The hard rock and sulphide saprolite was divided into high copper and low copper using a 0.02% Cu threshold.

In order to supply the processing input required in the first 10 years of production, the total material mined must achieve up to 120 Mtpa from a combination of the mining phases. The mining rate will change depending on stockpile size, increasing total mining rate to 140 Mtpa in year 20.

Total resources potentially mineable by open pit are estimated at approximately 2.0 billion tonnes of mineralized material at a gold grade of 0.705 g/t and a copper grade of 0.1% with 2.3 billion tonnes of waste for a stripping ratio of 1.16 tonnes of waste per tonne of mineralized material.

All of the waste rock, except that used for TMF construction, will be disposed of in the WRD facilities located to the north, west, and south of the pit. It appears that a portion of the Siembra Minera pit could be backfilled with waste rock, however, further investigation into tailings disposal and pit backfill opportunities are recommended.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-26 |

www.rpacan.com

MINERAL PROCESSING AND METALLURGICAL TESTING

The Siembra Minera Project consists of three rock types. Hard rock ore comprises approximately 87% of the material that will be processed. The remaining 13% of the mineralized material is saprolite with a split composed of approximately 43% oxide saprolite and 57% sulphide saprolite. Metallurgical test work was conducted on hard rock that contains higher and lower copper concentrations, and on blends that simulate the blends projected for the plant operation.

Based on the results of metallurgical testing, the conceptual processes selected for the combined project include a cyanide leach plant to process oxide saprolite and sulphide saprolite that contains low concentrations of copper to recover gold as doré from gravity concentration and cyanide leaching plus a flotation concentrator to process sulphide saprolite and hard rock that contain higher concentrations of copper. The flotation concentrator will recover copper and gold into a copper flotation concentrate and gold as doré utilizing gravity concentration and cyanide leaching of cleaner scavenger tailings.

The production schedule for this PEA is based on initially processing oxide saprolite through a 15,000 tpd cyanide leach plant. The crushing and screening plant feed is designed to process approximately 10% higher assuming that some of the material will be rejected due to oversize and/or rock material. Starting in year 7, the majority of the oxide saprolite is depleted and sulphide saprolite that contains low concentrations of copper will also be fed to the plant. In years 9 and 10, only low copper sulphide saprolite will be fed to the oxide plant.

In year 4, the flotation concentrator will be commissioned. The feed to the plant includes sulphide saprolite that contains higher concentration of copper and a combination of high and low copper hard rock material at a nominal rate of 140,000 tpd although the actual feed rate is higher in the early years due to the presence of sulphide saprolite which is easier to grind.

In year 11, the quantity of hard rock with suitable copper grades to produce acceptable concentrate grades in the flotation plant diminishes so the plant will be re-configured to process less material through the flotation plant and additional material through the oxide leach plant. The conceptual plan, at this early stage of the Project development, is to reduce the feed to the flotation concentrator to approximately 105,000 tpd and increase the tonnage to the oxide leach plant to 35,000 tpd. The low copper hard rock material will be ground in the existing milling circuit in the flotation plant and the leach plant will be expanded to accommodate the

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-27 |

www.rpacan.com

higher tonnage of material. The ball mill in the oxide leach plant, which is only sized to process saprolite, can be decommissioned or used to grind saprolite that is pumped from the open pit mine to the oxide leach plant.

ENVIRONMENT

Two separate, but parallel ESIA are being prepared for the Project. One ESIA is intended to meet Venezuelan regulatory requirements and the second one, international standards and guidelines. The Venezuelan ESIA is expected to be completed and submitted to the Ministry of People’s Power for Ecosocialism and Water (MINEA) in 2018; and the International ESIA will be completed soon thereafter.

Prior to submission of the ESIA, an Authorization to Occupy the Territory (AOT) must be obtained and a Term of Reference (TDR) approved. The AOT certifies that the proposed use of the land by the Project is compatible with the land use designation of the area and the TDR defines the scope and contents of the ESIA. Both AOT and TDR must be submitted to MINEA. GRE has submitted the application for an AOT, and the TDR for the Project will be submitted as soon as the AOT is approved. Upon the approval of the TDR, GRE will prepare and submit the ESIA to MINEA. An application for the Authorization to Affect Natural Resources (AANR), a permit for exploitation, will be submitted as soon as the Project ESIA is approved, which is expected to be in 2018.

In addition to the ESIAs, GRE is in the process of developing a series of environmental and social management plans and programs. Thousands of small-scale miners are actively working in the Project area and adequate management of small-scale mining is critical to the success of the Project. A conceptual plan for small-scale mining management has been developed by GRE to relocate these miners to the Oro concession area.

Based on the current Project design, reclamation activities will commence soon after construction begins, and will continue throughout the life of the Project. Closure activities will continue for three years after the end of the mine life in year 27. Some intermittent reclamation would also take place before year 23, when areas are no longer needed for mine operation activities. Total expenditures for reclamation and closure are currently estimated to be approximately US$150 million.

| Gold Reserve Inc. – Siembra Minera Project, Project #2832 | |

| Technical Report NI 43-101 – March 16, 2018 | Page 1-28 |

www.rpacan.com

CAPITAL COST ESTIMATE

A summary of capital costs is shown in Table 1-8.

| TABLE 1-8 CAPITAL COST SUMMARY | ||||||

| GR Engineering (Barbados), Inc. – Siembra Minera Project | ||||||

| Description | Development | Sustaining | LoM Total | |||

| Mineral Reserve Definition | 0.0 | 100.0 | 100.0 | |||

| Mining | 436.6 | 1,212.6 | 1,649.2 | |||

| Processing - CIP | 97.0 | 0.0 | 97.0 | |||

| Processing - Concentrator | 696.8 | 11.0 | 707.8 | |||

| Processing - Tailings Dam | 54.9 | 322.5 | 377.4 | |||

| Processing - Port/Diversion/Vehicles | 74.8 | 34.2 | 109.0 | |||

| Processing - CIP Plant Conversion to 35 ktpd | 0.0 | 35.0 | 35.0 | |||

| Engineering & Geology | 15.9 | 30.1 | 46.0 | |||

| ARD Plant | 2.3 | 0.0 | 2.3 | |||

| Site Infrastructure | 111.8 | 9.5 | 121.3 | |||

| Subtotal Direct Cost | 1,490.1 | 1,754.9 | 3,245.0 | |||

| Indirects - CIP | 34.3 | 0.0 | 34.3 | |||

| Indirects - Concentrator | 278.1 | 0.0 | 278.1 | |||

| Indirects - Owner's Cost | 310.4 | 150.6 | 461.0 | |||

| Total Cost Before Contingency | 2,112.8 | 1,905.5 | 4,018.3 | |||

| Contingency - Mining | 30.0 | 0.0 | 30.0 | |||

| Contingency - CIP | 26.3 | 0.0 | 26.3 | |||

| Contingency - Concentrator | 238.6 | 0.0 | 238.6 | |||

| Contingency - TMF | 16.5 | 0.0 | 16.5 | |||

| Contingency - Port/Diversion/Vehicles | 18.2 | 0.0 | 18.2 | |||

| Contingency - Infrastructure | 35.2 | 0.0 | 35.2 | |||

| Contingency - Owner's Cost | 93.1 | 36.2 | 129.3 | |||

| Total Contingency | 457.8 | 36.2 | 494.0 | |||

| % Contingency | 21.7 | % | 1.9 | % | 12.3 | % |

| Total Capital Cost | 2,570.6 | 1,941.7 | 4,512.3 | |||

| Reclamation/Closure Cost | 0.0 | 150.0 | 150.0 | |||

| Total Capital Cost excl. Working Capital | 2,570.6 | 2,091.7 | 4,662.3 | |||

| Working Capital1 | 195.4 | 0.0 | 195.4 | |||

| Total LoM Capital Cost | 2,766.0 | 2,091.7 | 4,857.7 | |||

| Notes: | ||||||