U.S. Concrete, Inc. (“USCR”) Investor Presentation March 2021 Orca Quarry, Polaris Materials

Disclaimer CAUTIONARY STATEMENT REGARDING FORWARD-LOOKING STATEMENTS Certain statements and information provided in this presentation are “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. These forward-looking statements include, without limitation, statements concerning plans, objectives, goals, projections, outlook, strategies, future events or performance, and underlying assumptions and other statements, which are not statements of historical facts. In some cases, you can identify forward-looking statements by terminology such as “may,” “will,” “intend,” “should,” “expect,” “plan,” “target”, “anticipate,” “believe,” “estimate,” “outlook,” “predict,” “potential” or “continue,” the negative of such terms or other comparable terminology. These forward-looking statements, which are subject to risks, uncertainties and assumptions about us, may include projections of our future financial performance, our anticipated growth strategies and anticipated trends in our business. These statements are predictions based on our current expectations and projections about future events which we believe are reasonable. Actual events or results may differ materially. By their nature, forward-looking statements involve risks and uncertainties because they relate to events and depend on circumstances that may or may not occur in the future. We believe that these risks and uncertainties include, but are not limited to: general economic and business conditions, which will, among other things, affect demand for new residential and commercial construction; our ability to successfully identify, manage, and integrate acquisitions; the cyclical nature of, and changes in, the real estate and construction markets, including pricing changes by our competitors; governmental requirements and initiatives, including those related to mortgage lending, financing or deductions, funding for public or infrastructure construction, land usage, and environmental, health, and safety matters; disruptions, uncertainties or volatility in the credit markets that may limit our, our suppliers’ and our customers’ access to capital; our ability to successfully implement our operating strategy; weather conditions; our substantial indebtedness and the restrictions imposed on us by the terms of our indebtedness; the effects of currency fluctuations on our results of operations and financial condition; our ability to maintain favorable relationships with third parties who supply us with equipment and essential supplies; our ability to retain key personnel and maintain satisfactory labor relations; and product liability, property damage, results of litigation and other claims and insurance coverage issues. These risks and uncertainties also include the effects of COVID-19; the length and severity of the COVID-19 pandemic; the pace of recovery following the COVID-19 pandemic; our ability to implement cost containment strategies; and the adverse effects of COVID-19 on our business, the economy and the markets we serve. Although we believe that the expectations reflected in the forward-looking statements are reasonable, we cannot guarantee future results, levels of activity, performance or achievements. Moreover, neither we nor any other person assumes responsibility for the accuracy and completeness of the forward-looking statements. All written and oral forward-looking statements made in connection with this press release that are attributable to us or persons acting on our behalf are expressly qualified in their entirety by the “Risk Factors” in our Annual Report on Form 10-K and our Quarterly Reports on Form 10-Q filed with the Securities and Exchange Commission. We are under no duty to update any of the forward-looking statements after the date of this press release to conform such statements to actual results or to changes in our expectations, except as required by federal securities laws. There can be no assurance that other factors will not affect the accuracy of these forward-looking statements or that our actual results will not differ materially from the results anticipated in such forward-looking statements. Unpredictable or unknown factors we have not discussed in this press release also could have material effects on actual results or matters that are the subject of our forward-looking statements. We undertake no obligation to, and do not intend to, update our description of important factors each time a potential important factor arises. Non-GAAP Financial Measures. Included in this presentation are certain non-GAAP financial measures that we believe are useful for investors. These non-GAAP financial measures may not be comparable to similarly titled measures other companies report and are not intended to be used as an alternative to any measure of our performance in accordance with GAAP. Please see the appendix to this presentation reconciliations. Industry and Market Data. This presentation includes industry data that we obtained from various third-party sources, including periodic industry publications, data compiled by the United States Census Bureau, and industry reports produced by consultants and trade associations. These third-party sources generally include a statement that the information contained therein has been obtained from sources believed to be reliable. However, industry and market data is subject to change and cannot always be verified with certainty due to limits on the availability and reliability of raw data, the voluntary nature of the data gathering process and other limitations and uncertainties inherent in any statistical survey. Neither we nor the initial purchasers have independently verified any of the data from third-party sources nor have we or the initial purchasers ascertained the underlying economic assumptions relied upon therein. As a result, you should be aware that industry, market and other similar data set forth herein, and estimates and beliefs based on such data, might not be accurate. 2

U.S. Concrete Overview Manhattan, NY 3

Investment Growth and Value Proposition Long-term opportunities from Aggregates and Technology investments U.S. Concrete has a defensible, strategic network of ready-mixed concrete plants in high growth areas. Where’s My Concrete?™ provides a competitive advantage through optimizing workflow - from quoting a job to pouring on a job site. USCR continually invests in technology that is superior in quality to industry standards, and creates revenue diversification. USCR continues to grow its aggregates segment which is a significant component of the Company’s long- term value proposition. USCR has an extensive, successful track record of acquisitions and greenfield development to drive growth and value. READY MIX TECHNOLOGYAGGREGATES 4

West Region Market Driver: Technology 28 1 2 East Region Market Driver: Financial Services / Government 38 5 5 Central Region Market Driver: Diversified 128 14 2011 2020 113 7 0 194 20 7 Ready-Mixed Concrete Operating Facilities Aggregates Producing Facilities Aggregates Distribution Terminals (1) Source: U.S. Census Bureau 2019 population statistics. (2) As of December 31, 2020, calculated on an LTM basis. Company Total 5 Large, High Quality, Vertically Integrated Asset Base USCR operates in markets with 20% of U.S. population, and in 5 of 10 largest MSAs(1) Ready-Mixed Concrete Market Aggregates Market 30% 37% 33% 1% % of USCR Revenue(2)%

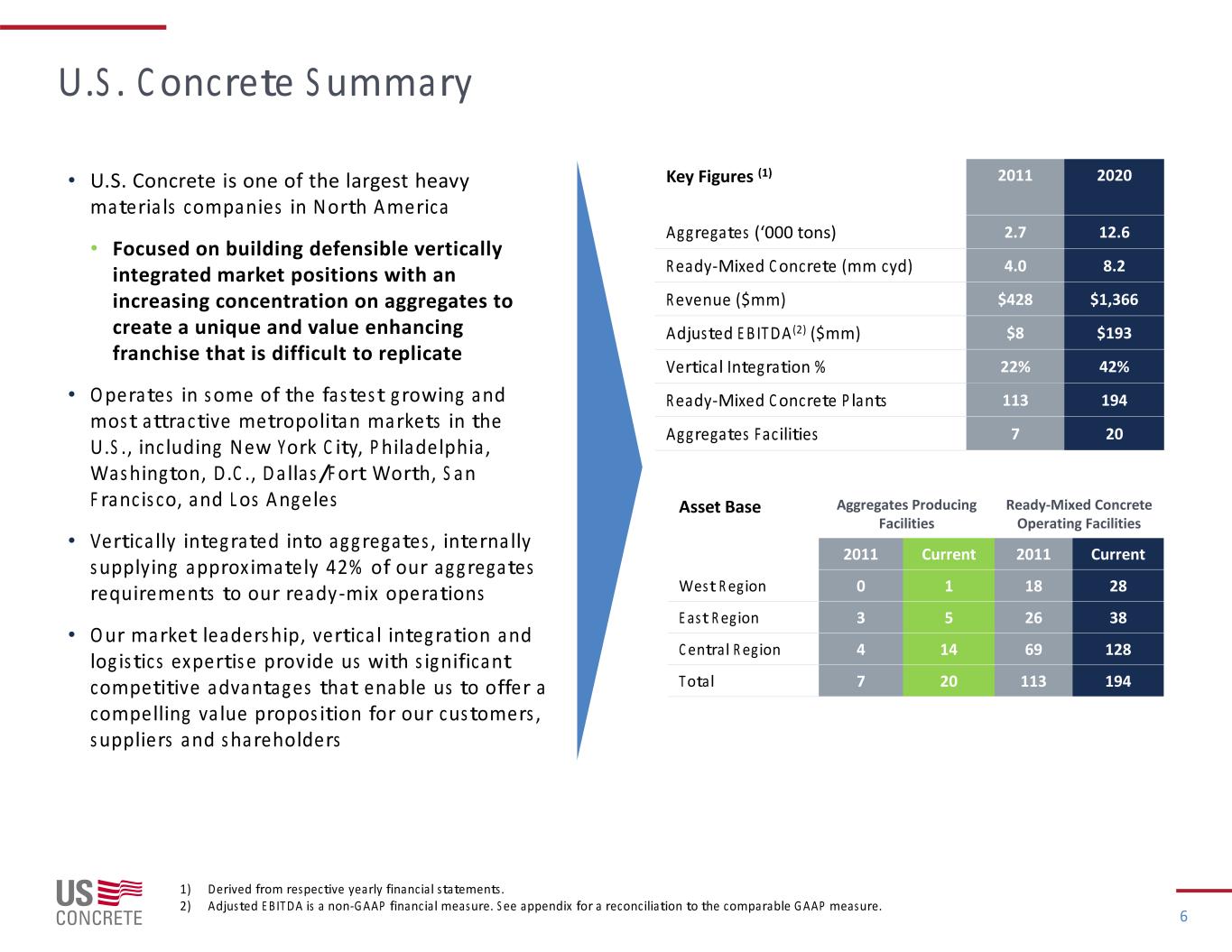

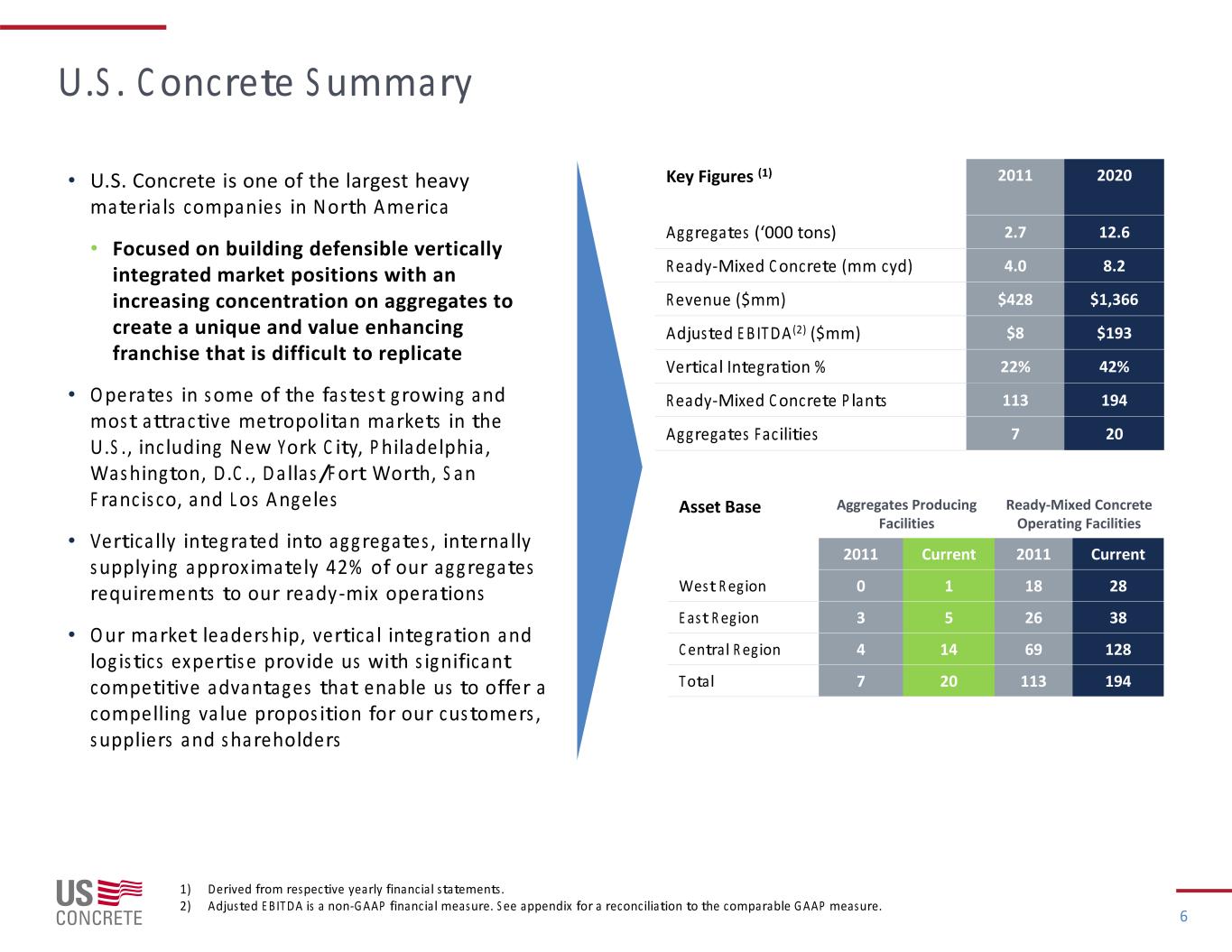

• U.S. Concrete is one of the largest heavy materials companies in North America • Focused on building defensible vertically integrated market positions with an increasing concentration on aggregates to create a unique and value enhancing franchise that is difficult to replicate • Operates in some of the fastest growing and most attractive metropolitan markets in the U.S., including New York City, Philadelphia, Washington, D.C., Dallas/Fort Worth, San Francisco, and Los Angeles • Vertically integrated into aggregates, internally supplying approximately 42% of our aggregates requirements to our ready-mix operations • Our market leadership, vertical integration and logistics expertise provide us with significant competitive advantages that enable us to offer a compelling value proposition for our customers, suppliers and shareholders 1) Derived from respective yearly financial statements. 2) Adjusted EBITDA is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. U.S. Concrete Summary Key Figures (1) 2011 2020 Aggregates (‘000 tons) 2.7 12.6 Ready-Mixed Concrete (mm cyd) 4.0 8.2 Revenue ($mm) $428 $1,366 Adjusted EBITDA(2) ($mm) $8 $193 Vertical Integration % 22% 42% Ready-Mixed Concrete Plants 113 194 Aggregates Facilities 7 20 Asset Base Aggregates Producing Facilities Ready-Mixed Concrete Operating Facilities 2011 Current 2011 Current West Region 0 1 18 28 East Region 3 5 26 38 Central Region 4 14 69 128 Total 7 20 113 194 6

7 Portfolio Diversity Enhances Value Revenue Mix by Region Ready-Mixed Volume by End Market Reported Segment Adj. EBITDA Central: 37% East: 33% Commercial & Industrial: 58% Infrastructure: 16% Residential: 26% Aggregates: 35% Ready-mixed Concrete: 65% West: 30% Diverse Geography: Diverse Project Type: Diverse Sources: Operating assets across major metropolitan markets that represent over 20% of the population in the United States Agility to support all projects in our markets with our expertise in materials sourcing, mix design, relationships and plant locations Robust aggregates portfolio provides vertical integration for our ready-mixed assets including terminals near major markets Note: Fiscal Year 2020 results.

U.S. Concrete Fiscal Year 2020 Results Cash Flow Generation Cost Controls Operating Margins Safety & Health 8 • COVID-19 protocols allowed us to operate as an essential service, subject to compliance with applicable safety and health restrictions • Two of our key markets, New York City and Dallas-Fort Worth, were the top two markets in terms of construction starts in 2020 according to Dodge Data • Resilient and improving aggregates and concrete average selling prices (“ASP”) and operating margins during a challenging market environment • Continued ready-mix segment margin improvement, despite cement supply challenges in the West region and COVID-19 related disruptions which lowered ready-mix volumes • Consolidated Adjusted EBITDA(1) margin of 14.1% for FY’20, a 160 basis point improvement over FY’19 • Record Adjusted Free Cash Flow(1) of $158.6MM generated during FY’20, a $53.6MM increase over FY’19 (1) See appendix for reconciliation of non-GAAP measures

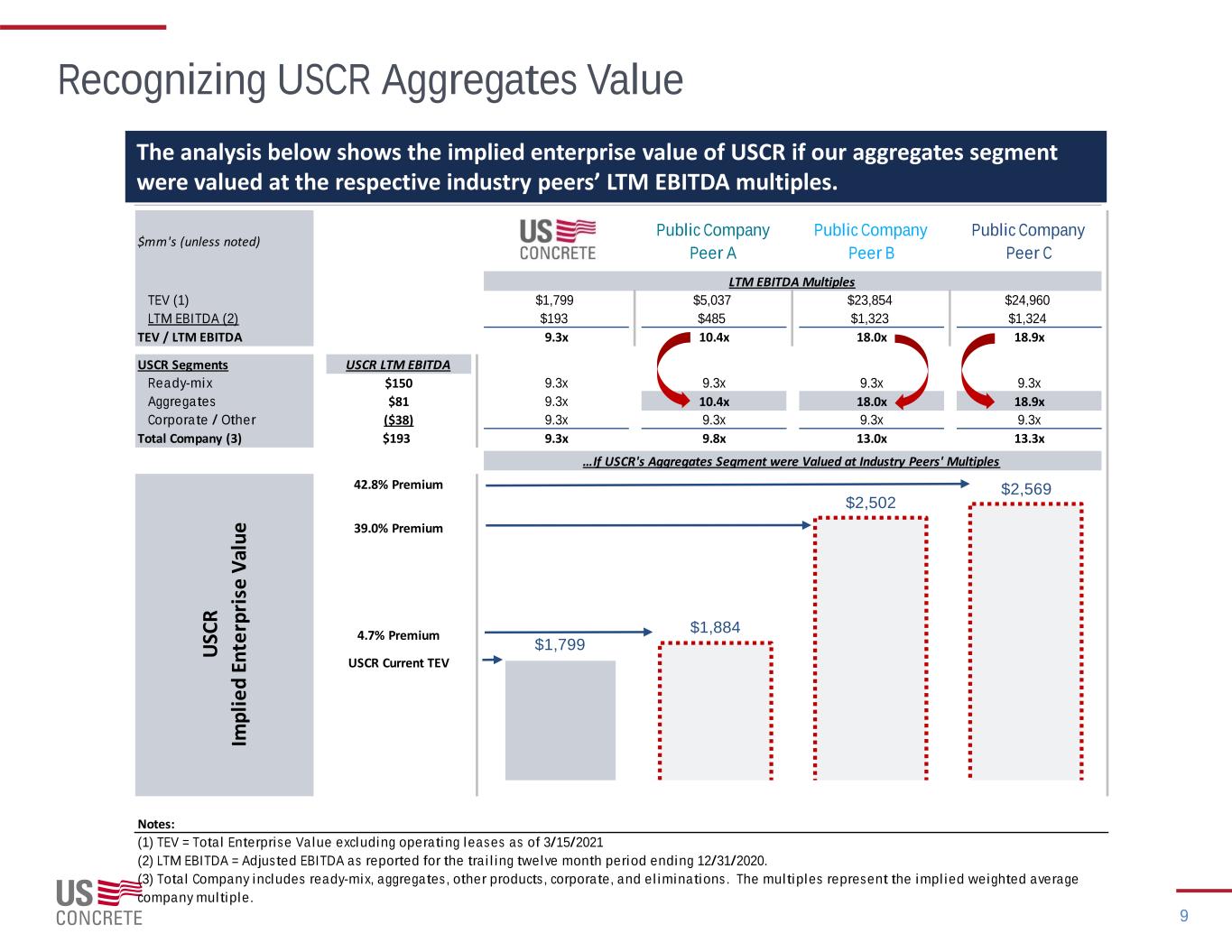

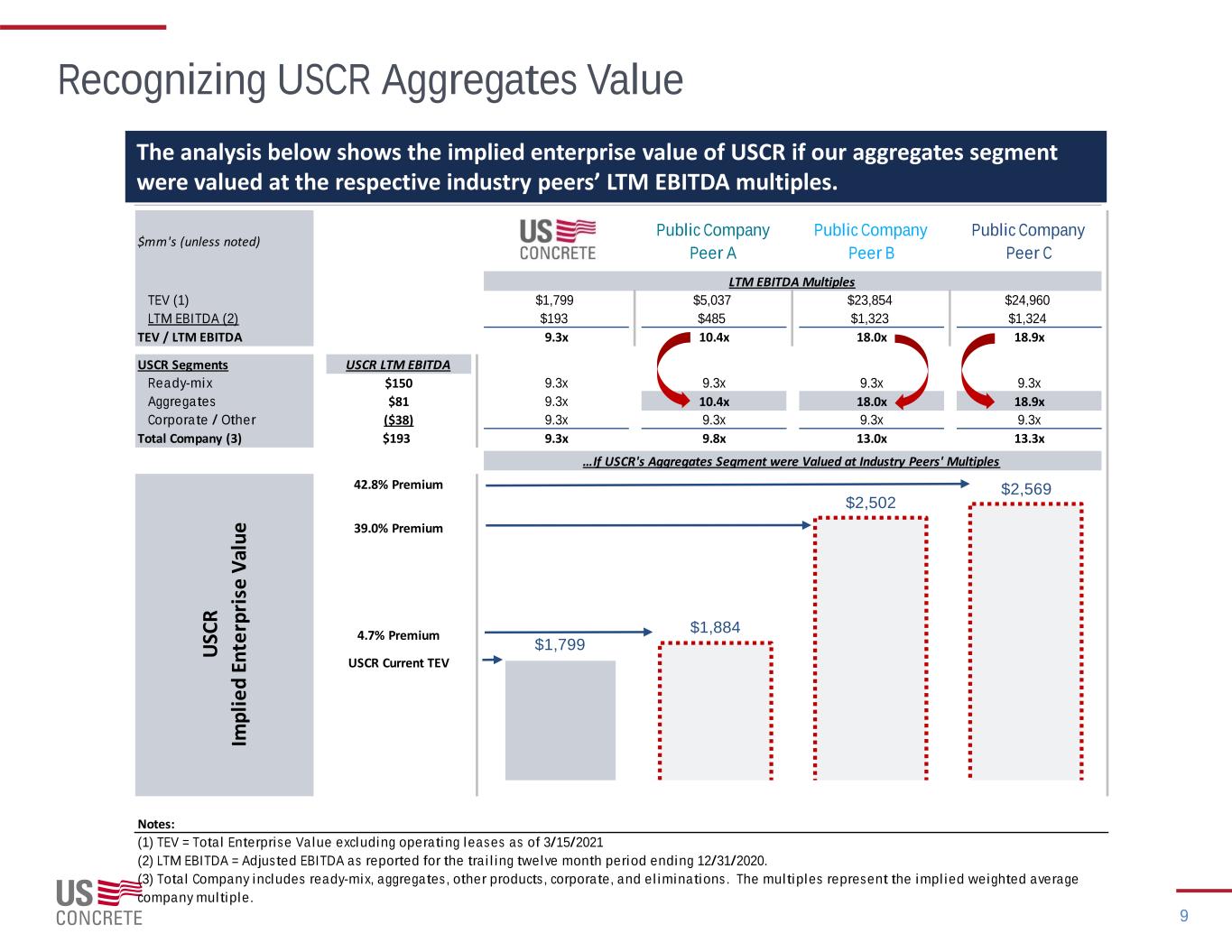

9 Recognizing USCR Aggregates Value The analysis below shows the implied enterprise value of USCR if our aggregates segment were valued at the respective industry peers’ LTM EBITDA multiples. $mm's (unless noted) Public Company Peer A Public Company Peer B Public Company Peer C LTM EBITDA Multiples TEV (1) $1,799 $5,037 $23,854 $24,960 LTM EBITDA (2) $193 $485 $1,323 $1,324 TEV / LTM EBITDA 9.3x 10.4x 18.0x 18.9x USCR Segments USCR LTM EBITDA Ready-mix $150 9.3x 9.3x 9.3x 9.3x Aggregates $81 9.3x 10.4x 18.0x 18.9x Corporate / Other ($38) 9.3x 9.3x 9.3x 9.3x Total Company (3) $193 9.3x 9.8x 13.0x 13.3x …If USCR's Aggregates Segment were Valued at Industry Peers' Multiples 42.8% Premium 39.0% Premium 4.7% Premium USCR Current TEV Notes: (1) TEV = Total Enterprise Value excluding operating leases as of 3/15/2021 (2) LTM EBITDA = Adjusted EBITDA as reported for the tra i l ing twelve month period ending 12/31/2020. (3) Total Company includes ready-mix, aggregates , other products , corporate, and el iminations . The multiples represent the impl ied weighted average company multiple. U S C R Im p li e d E n te rp ri se V a lu e $1,799 $1,884 $2,502 $2,569

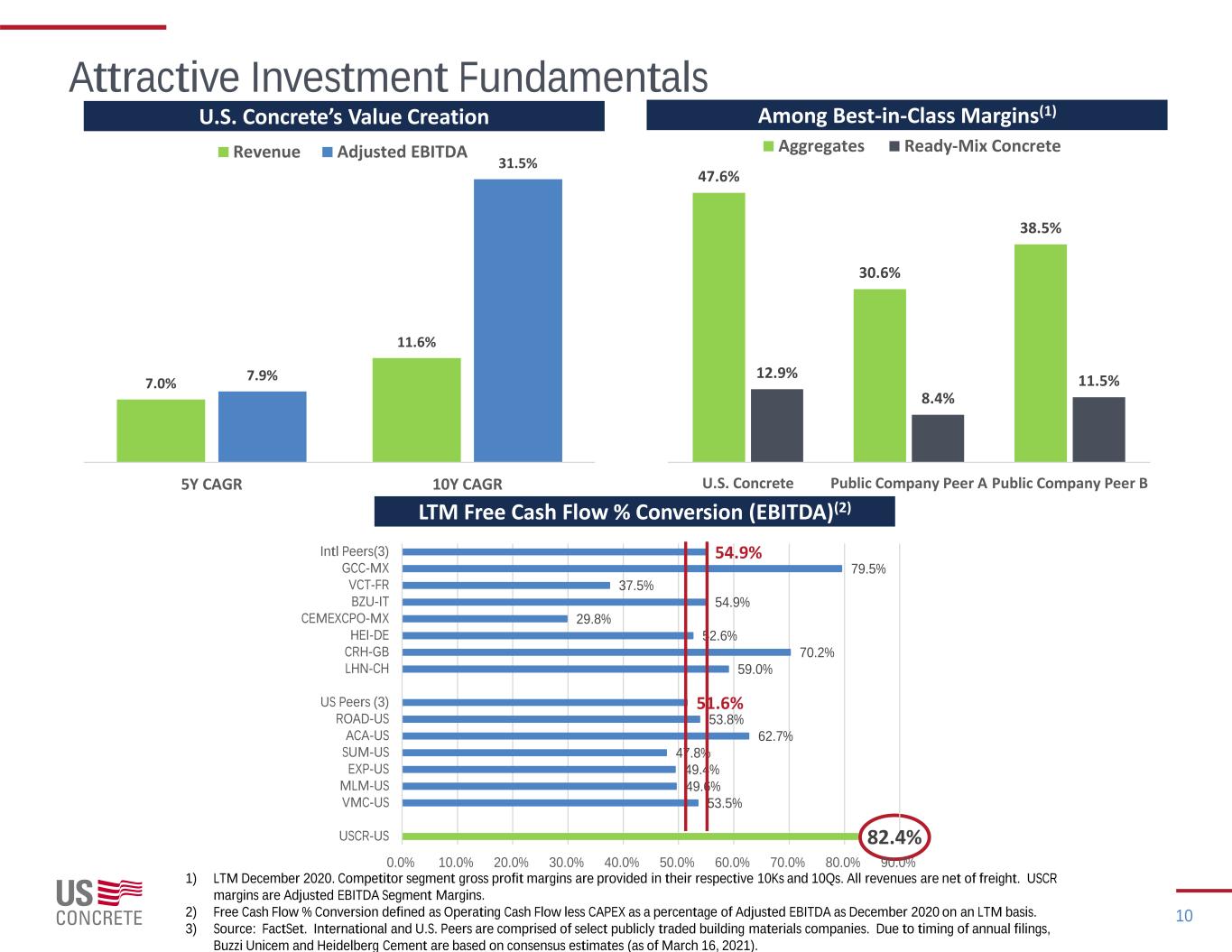

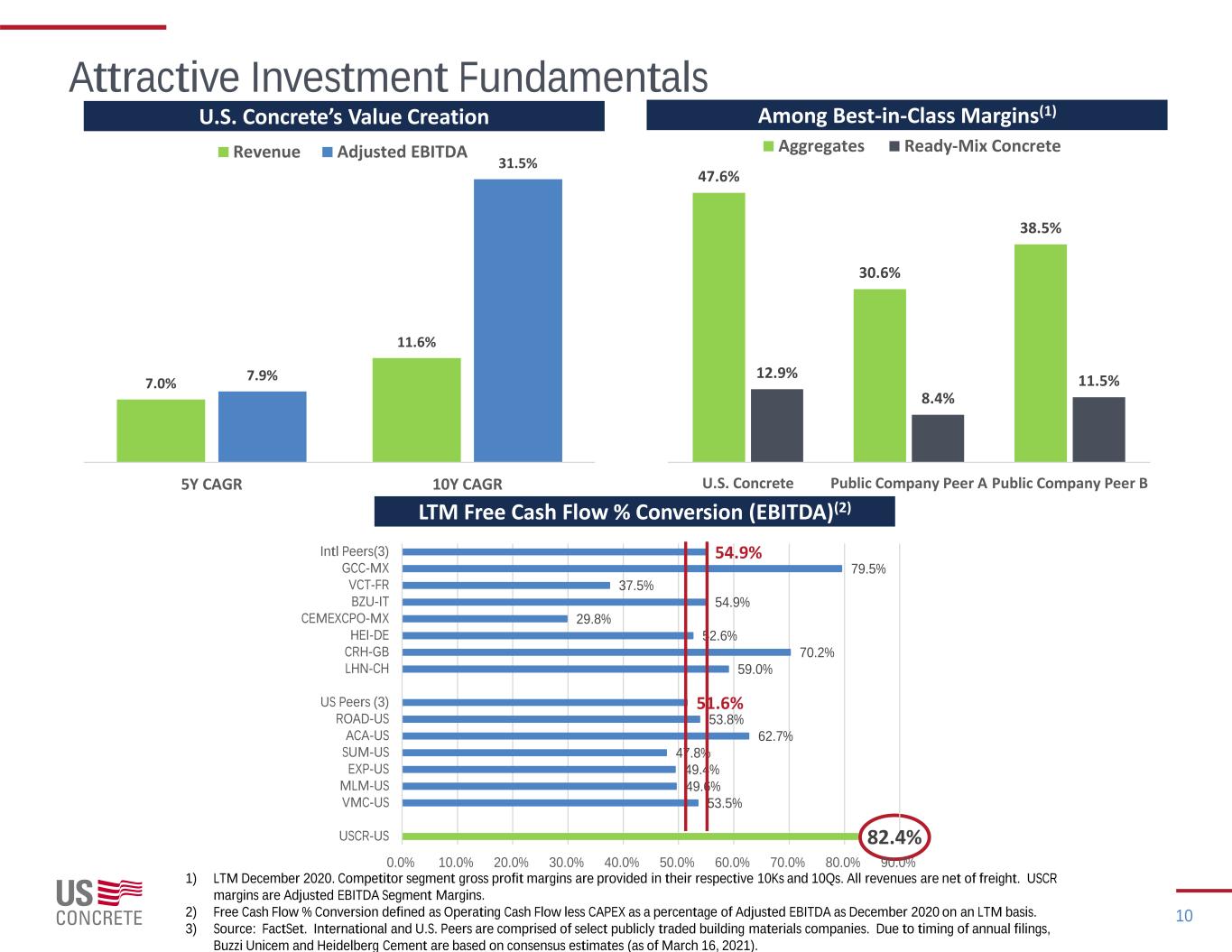

Attractive Investment Fundamentals 1) LTM December 2020. Competitor segment gross profit margins are provided in their respective 10Ks and 10Qs. All revenues are net of freight. USCR margins are Adjusted EBITDA Segment Margins. 2) Free Cash Flow % Conversion defined as Operating Cash Flow less CAPEX as a percentage of Adjusted EBITDA as December 2020 on an LTM basis. 3) Source: FactSet. International and U.S. Peers are comprised of select publicly traded building materials companies. Due to timing of annual filings, Buzzi Unicem and Heidelberg Cement are based on consensus estimates (as of March 16, 2021). 10 Among Best-in-Class Margins(1)U.S. Concrete’s Value Creation LTM Free Cash Flow % Conversion (EBITDA)(2) 7.0% 11.6% 7.9% 31.5% 5Y CAGR 10Y CAGR Revenue Adjusted EBITDA 47.6% 30.6% 38.5% 12.9% 8.4% 11.5% U.S. Concrete Public Company Peer A Public Company Peer B Aggregates Ready-Mix Concrete 82.4% 53.5% 49.6% 49.4% 47.8% 62.7% 53.8% 51.6% 59.0% 70.2% 52.6% 29.8% 54.9% 37.5% 79.5% 54.9% 0.0% 10.0% 20.0% 30.0% 40.0% 50.0% 60.0% 70.0% 80.0% 90.0% USCR-US VMC-US MLM-US EXP-US SUM-US ACA-US ROAD-US US Peers (3) LHN-CH CRH-GB HEI-DE CEMEXCPO-MX BZU-IT VCT-FR GCC-MX Intl Peers(3)

Historical Financial Results 1) Adjusted EBITDA is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. 2) Adjusted EBITDA Margin is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. 3) Adjusted Free Cash Flow is a non-GAAP financial measure and is defined as net cash provided by operating activities less purchases of property, plant and equipment, less purchases of environmental credits, plus proceeds from the disposal of businesses and property, plant and equipment, eminent domain matter and property insurance claims. See appendix for a reconciliation to the comparable GAAP measure. 11 Revenue ($MM) Adjusted EBITDA(1) ($MM) and % Margin(2) Capital Expenditures ($MM)Adjusted Free Cash Flow(3) ($MM) $132 $160 $192 $194 $184 $193 13.5% 13.7% 14.4 % 12.8 % 12.5 % 14.1 % 2015 2016 2017 2018 2019 2020 Adjusted EBITDA(1) Adjusted EBITDA Margin(2) $975 $1,168 $1,336 $1,506 $1,479 $1,366 2015 2016 2017 2018 2019 2020 $25 $40 $43 $40 $43 $24 2015 2016 2017 2018 2019 2020 $82 $81 $56 $103 $105 $159 2015 2016 2017 2018 2019 2020

Historical Financial Results 1) Adjusted EBITDA is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. 2) Adjusted EBITDA Margin is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. 12 ($ in Millions except ASP) FY'11 FY'17 FY'18 FY'19 FY'20 Total Revenue $ 495 $ 1,336 $ 1,506 $ 1,479 $ 1,366 Segment Volumes Aggregates (MM tons) 2.7 6.2 11.1 11.4 12.6 Ready-Mixed Concrete (MM cyds) 4.0 9.0 9.5 9.2 8.2 Segment ASP Aggregates ($/ton) $ 7.46 $ 12.92 $ 11.28 $ 11.93 $ 13.08 Ready-Mixed Concrete ($/cyds) $ 94.48 $ 134.86 $ 136.42 $ 138.97 $ 140.69 Segment Revenues Aggregates $ 21 $ 81 $ 129 $ 143 $ 170 Ready-Mixed Concrete $ 388 $ 1,213 $ 1,307 $ 1,279 $ 1,161 Segment Adjusted EBITDA Aggregates $ 3 $ 27 $ 42 $ 54 $ 81 Ready-Mixed Concrete $ 22 $ 186 $ 179 $ 158 $ 150 Segment Adjusted EBITDA Margin Aggregates 14.3% 33.5% 32.2% 37.6% 47.6% Ready-Mixed Concrete 5.7% 15.3% 13.7% 12.3% 12.9% Adjusted EBITDA (1) $ 8 $ 192 $ 194 $ 184 $ 193 Adjusted EBITDA Margin (2) 1.5% 14.4% 12.8% 12.5% 14.1%

Aggregates Overview Orca Quarry, British Columbia, CA 13

Aggregates: Successful Record of Acquisitions Coram Overview: Acquired in 2020 • Coram Materials is a premier provider of high-quality sand and gravel products located on Long Island, NY with above average margin contributions • Coram owns and controls approximately 49.4 million tons of proven reserves and excavates the material using two state-of- the-art floating barges equipped with clam shell buckets that feed conveyor lines to wet and dry processing plants • Current annualized Adjusted EBITDA run rate is on target to achieve a post synergy multiple of 7 times Cumulative M&A Spend by Segment ~$500mm Invested in Aggregates Segment Polaris Overview: Acquired in 2017 • Polaris Materials develops, produces and distributes high- performance construction aggregates to the United States and Canada • Increased production from 3 million tons at acquisition to approximately 5 million tons per annum. Orca Quarry production and export permits increased from 6.6 to 9.6 million tons per annum to facilitate growth plans • Increased Adjusted EBITDA almost 7 times acquisition level • Doubled Long Beach terminal capacity to 2 million tons per annum • Black Bear expansion provides up to 4 million tons of capacity per annum in aggregates to allow for greater flexibility in meeting market specific demands Coram Materials, Long Island, NY 14 0.0% 10.0% 20.0% 30.0% 40.0% 50.0% 60.0% 70.0% 80.0% 90.0% 100.0% 2012 2013 2014 2015 2016 2017 2018 2019 2020 % o f C u m u la ti ve S p e n d Ready-mix Aggregates

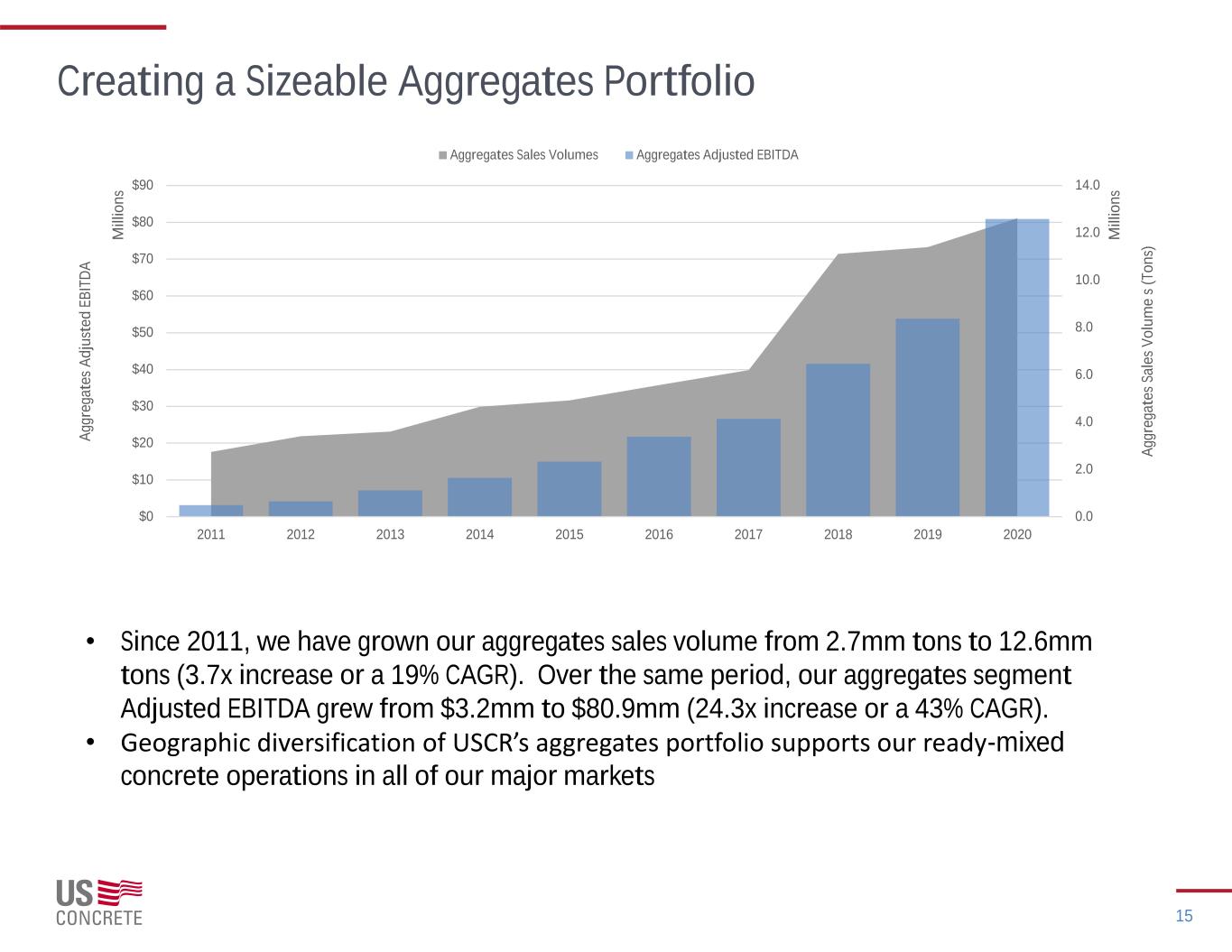

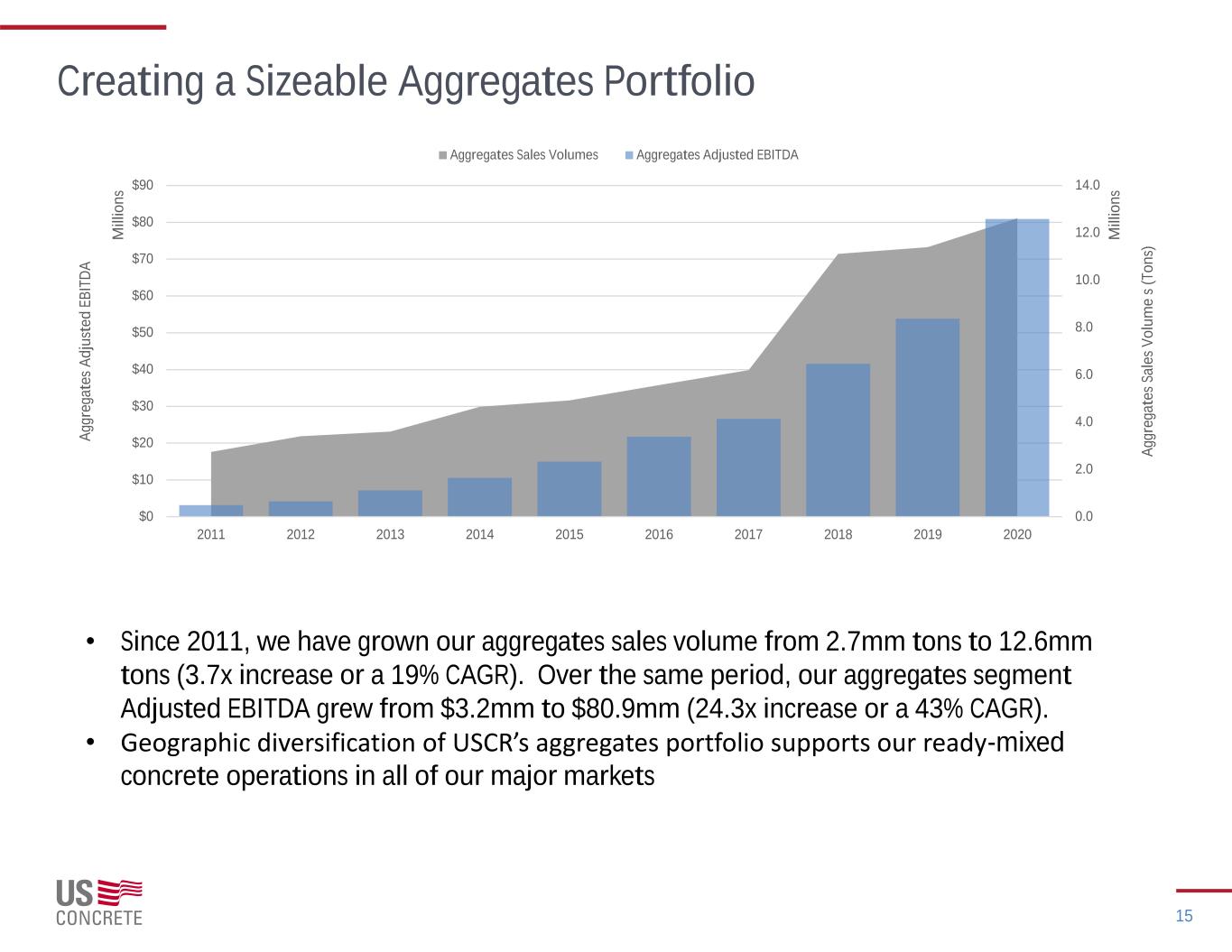

Creating a Sizeable Aggregates Portfolio 15 • Since 2011, we have grown our aggregates sales volume from 2.7mm tons to 12.6mm tons (3.7x increase or a 19% CAGR). Over the same period, our aggregates segment Adjusted EBITDA grew from $3.2mm to $80.9mm (24.3x increase or a 43% CAGR). • Geographic diversification of USCR’s aggregates portfolio supports our ready-mixed concrete operations in all of our major markets 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 $0 $10 $20 $30 $40 $50 $60 $70 $80 $90 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 A g g re g a te s S a le s V o lu m e s ( T o n s) M il li o n s A g g re g a te s A d ju st e d E B IT D A M il li o n s Aggregates Sales Volumes Aggregates Adjusted EBITDA

Ready-Mixed Concrete Overview The Campus at Lawson Lane, Santa Clara, CA (Largest single placement of CarbonCure in the Country - 7,665 cubic yards) 16

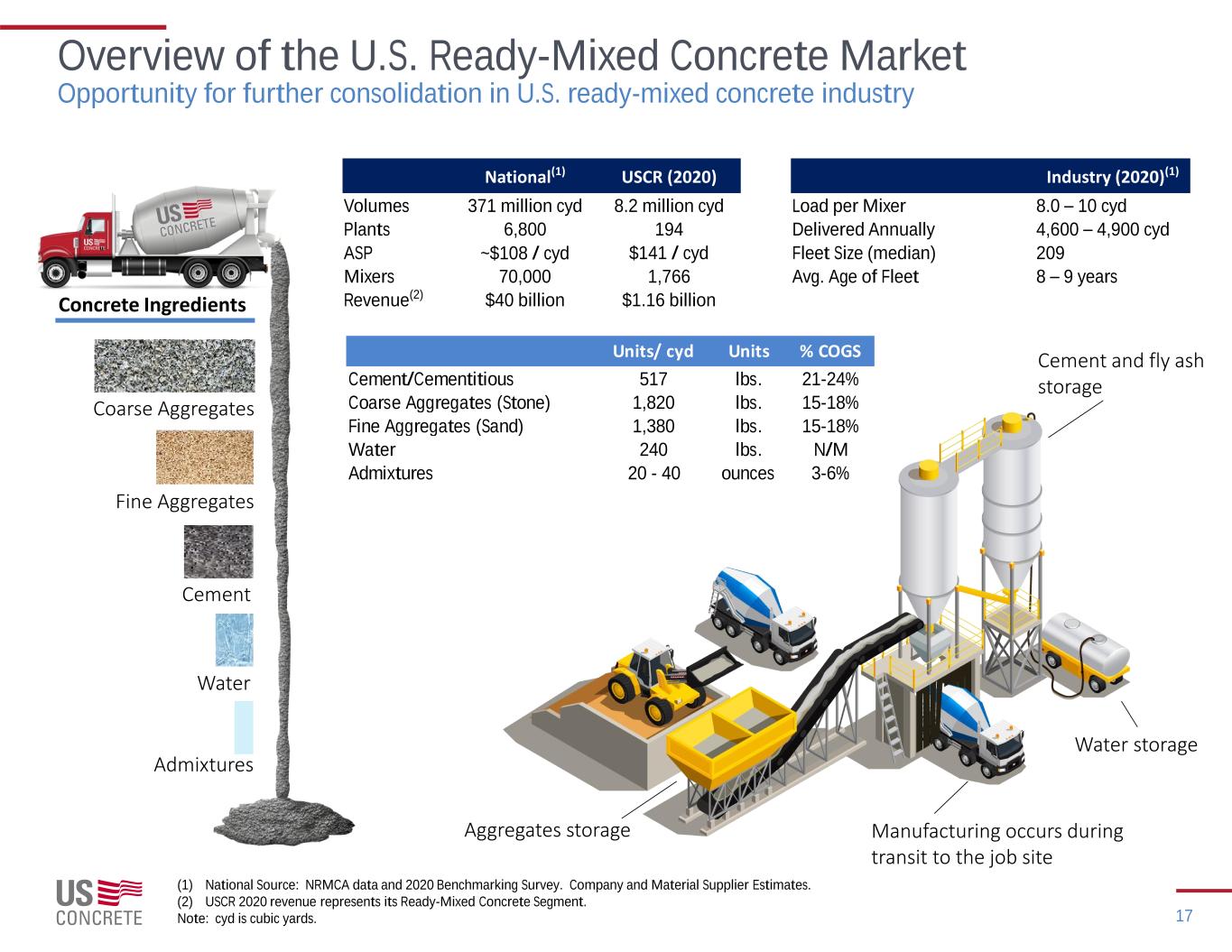

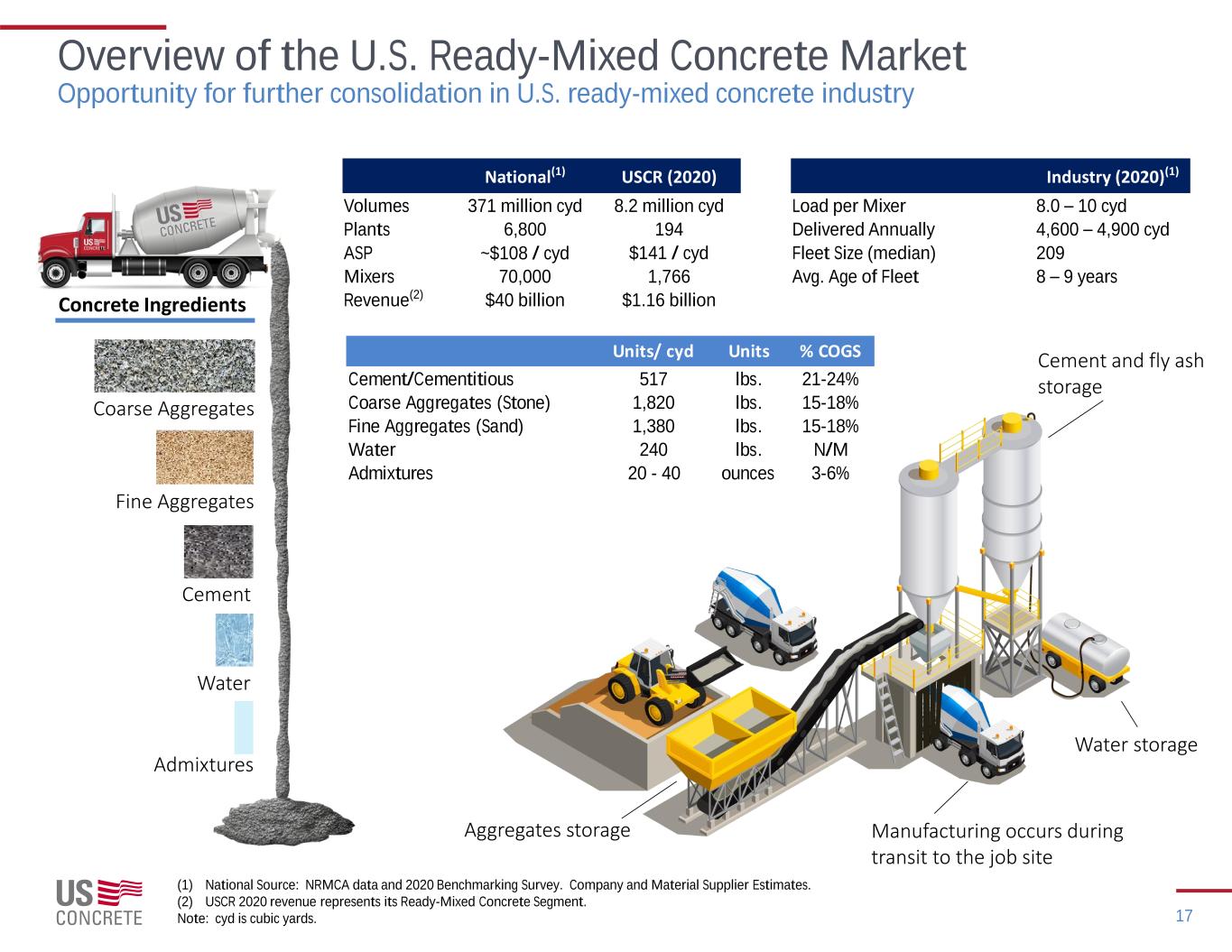

Overview of the U.S. Ready-Mixed Concrete Market Opportunity for further consolidation in U.S. ready-mixed concrete industry 17 (1) National Source: NRMCA data and 2020 Benchmarking Survey. Company and Material Supplier Estimates. (2) USCR 2020 revenue represents its Ready-Mixed Concrete Segment. Note: cyd is cubic yards. Concrete Ingredients Coarse Aggregates Fine Aggregates Water Cement Admixtures Aggregates storage Cement and fly ash storage Water storage Manufacturing occurs during transit to the job site Units/ cyd Units % COGS Cement/Cementitious 517 lbs. 21-24% Coarse Aggregates (Stone) 1,820 lbs. 15-18% Fine Aggregates (Sand) 1,380 lbs. 15-18% Water 240 lbs. N/M Admixtures 20 - 40 ounces 3-6% National(1) USCR (2020) Industry (2020)(1) Volumes 371 million cyd 8.2 million cyd Load per Mixer 8.0 – 10 cyd Plants 6,800 194 Delivered Annually 4,600 – 4,900 cyd ASP ~$108 / cyd $141 / cyd Fleet Size (median) 209 Mixers 70,000 1,766 Avg. Age of Fleet 8 – 9 years Revenue(2) $40 billion $1.16 billion

18 High Rise (e.g. Hudson Yards – NYC) 60,000 cyd 6,500 Loads Wind Farm (West Texas) 40,000 cyd Portable plant used for 24/7 availability House Slab 150 cyd ~15 Loads Warehouse 25,000-40,000 cyd 2,800-4,400 Loads Ready-Mixed Concrete 101 2nd Most Consumed Material in the World (After Water) Breadth of Products 3,000 psi Residential Use 27,000 psi High-rise and specialty use Diverse Uses Specifically designed for engineering mix: end use, ground condition, exposure, and strength Infrastructure (Highway) 2,400 cyd per single lane mile Portable plant or multiple fixed plants used 25 miles in any direction Limited product lifespan Note: cyd is cubic yards and psi is pounds per square inch.

Diverse Customer Base and Diverse Project Base A Top Supplier to Large and Complex Commercial Projects Project List as of March 16, 2021. Customer Base and Project Base calculated on an LTM basis as of December 31, 2020. 19 Customer Base Project Base Total Active Customers 10,000+ Total Projects - LTM December 2020 17,000 Top 20 Customers - % of Work 25% Top 100 Projects - % of Work 37% Project Location Cubic Yards Status LaGuardia Airport Queens, New York 355,000 In Progress Newark Airport Terminal A - Paving Newark, New Jersey 142,156 In Progress Charles Schwab Westlake Campus Westlake, Texas 141,526 Completed TXDOT Tarrant County 1-35W Tarrant County, Texas 101,244 In Progress 1 Journal Square Jersey City, New Jersey 100,000 Upcoming 66 Hudson Blvd Manhattan, New York 90,000 In Progress Adobe North Tower Office Building San Jose, California 83,000 In Progress 200 Park Avenue San Jose, California 81,506 In Progress Google Caribbean Mt. View Mt. View, California 75,000 Upcoming 55-15 Grand Avenue Manhattan, New York 70,000 New - In Progress UTSW BICC, Dallas-Vaughn Dallas, Texas 65,010 In Progress I680 / SR 4 Interchange Martinez, California 65,000 In Progress Columbus Hi Rise Jersey City, New Jersey 65,000 In Progress 50 Hudson Yards Manhattan, New York 64,529 New - In Progress LGA Airside Civil Queens, New York 64,500 New - In Progress Omni PGA Frisco, Texas 60,000 New - In Progress 1900 Crystal Drive Arlington, Virginia 58,171 Upcoming Harborside 8 Jersey City, New Jersey 55,976 Upcoming Texas Instruments RFA2 Richardson, Texas 50,000 In Progress Amazon Project Amarillo, Texas 50,000 New - In Progress Amazon Project Roanoke, Texas 50,000 New - In Progress Genesis Marina Brisbane, California 47,000 New - In Progress Journal Square - Phase 2 Jersey City, New Jersey 46,408 New - In Progress

Strategy Overview 20 Residential Project, Millsap, TX

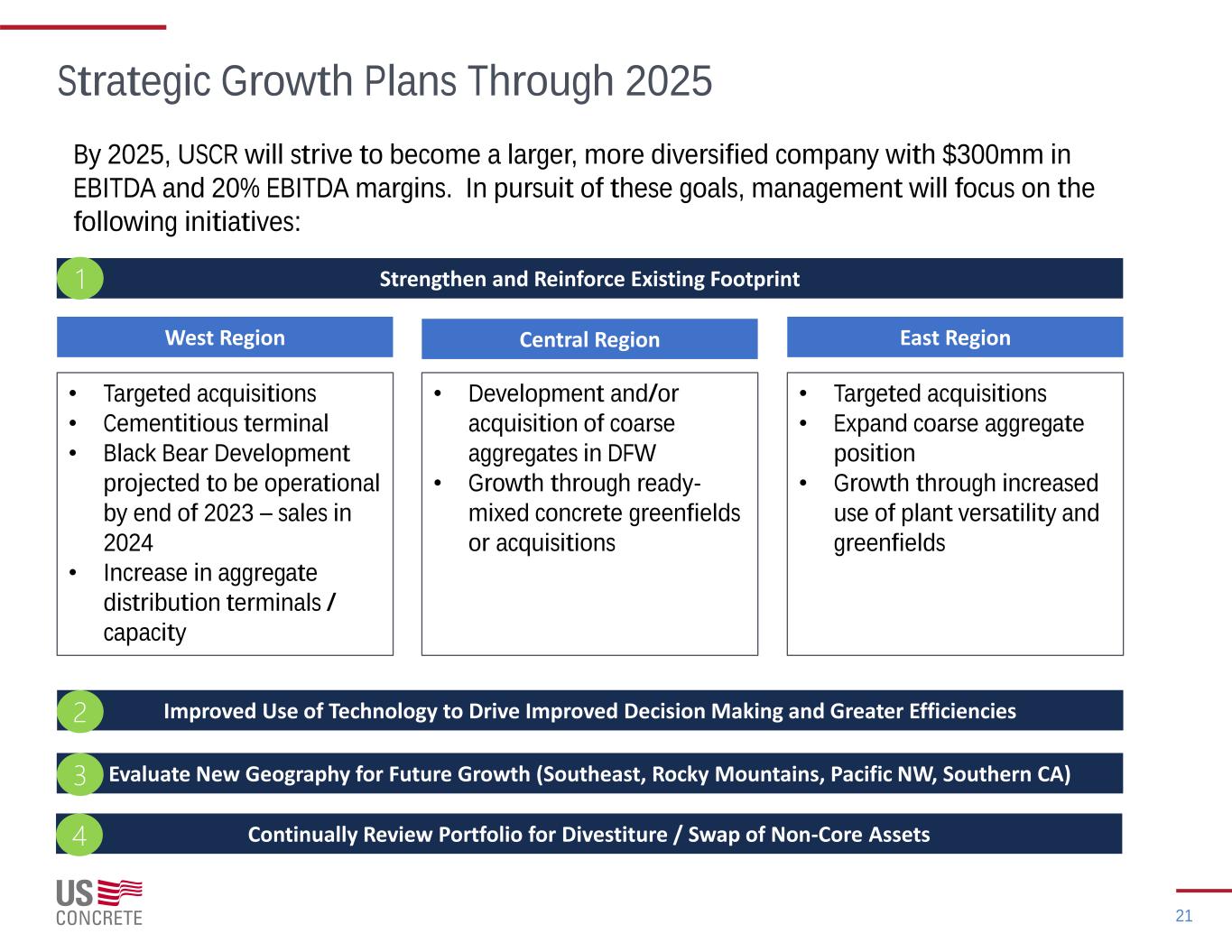

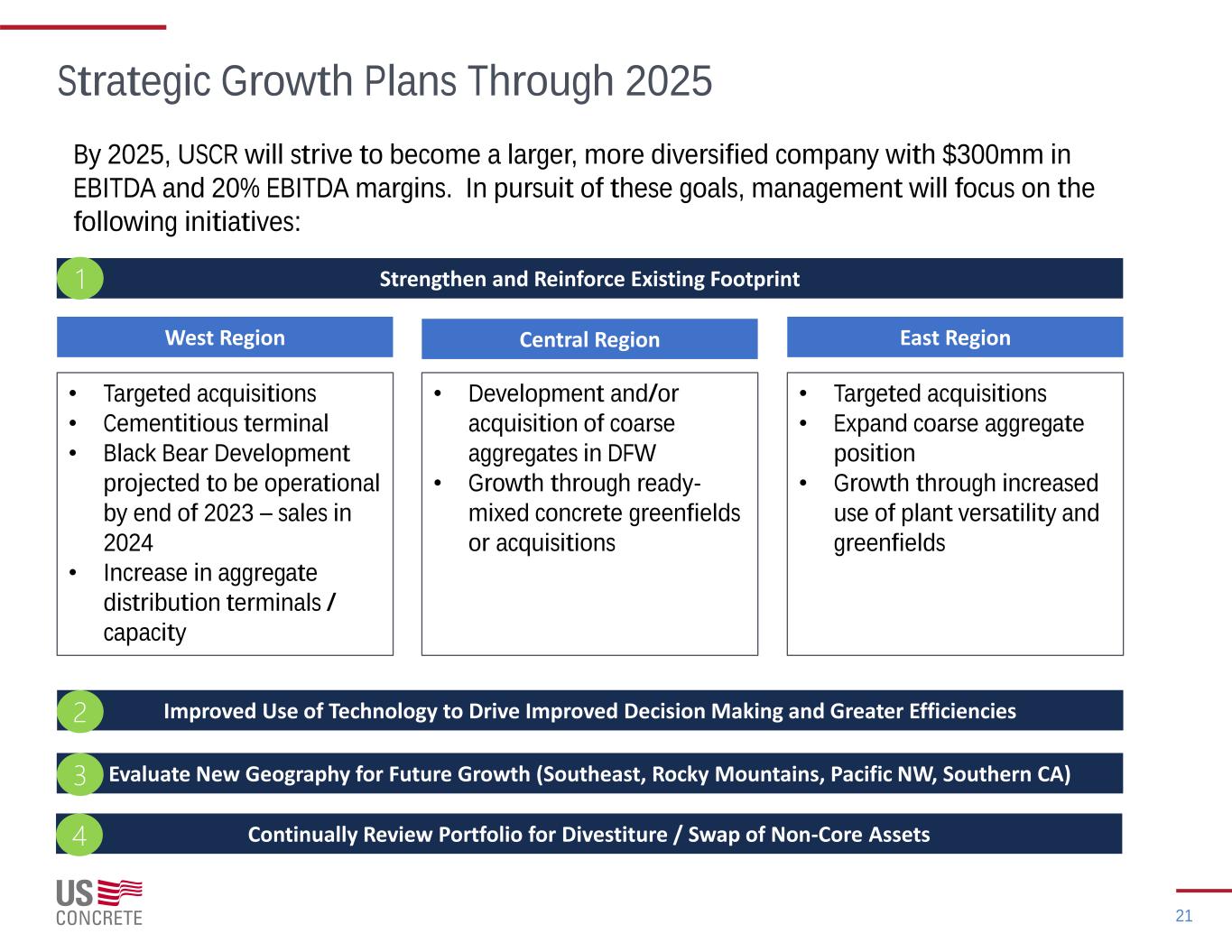

Strategic Growth Plans Through 2025 21 By 2025, USCR will strive to become a larger, more diversified company with $300mm in EBITDA and 20% EBITDA margins. In pursuit of these goals, management will focus on the following initiatives: West Region Central Region East Region • Targeted acquisitions • Cementitious terminal • Black Bear Development projected to be operational by end of 2023 – sales in 2024 • Increase in aggregate distribution terminals / capacity • Development and/or acquisition of coarse aggregates in DFW • Growth through ready- mixed concrete greenfields or acquisitions • Targeted acquisitions • Expand coarse aggregate position • Growth through increased use of plant versatility and greenfields Improved Use of Technology to Drive Improved Decision Making and Greater Efficiencies Evaluate New Geography for Future Growth (Southeast, Rocky Mountains, Pacific NW, Southern CA) Strengthen and Reinforce Existing Footprint1 2 3 Continually Review Portfolio for Divestiture / Swap of Non-Core Assets4

Technology Strategy Dallas, TX 22

Logistical Expertise with Continued Investments in Technology U.S. Concrete owns and licenses the Where’s My Concrete?™ technology platform providing a distinct competitive advantage in the international marketplace Anywhere, Anytime Access Dispatch • Paperless tickets: savings from electronic billing • Driver able to clock in and out at the cab • Focus on truck efficiency and driver performance Customer App • Reduces calls to dispatch with direct chatting feature • Provides electronic ordering • Enhances customer service Sales • Reduces time to quote on a job: 5 min vs 45 min • Enables sales team’s ability to focus on relationships • Streamlined approval process • Increased efficiency in labor and operations • Reduction in third party IT investment and infrastructure Analytics 23

Growing Influence of Technology Where’s My Concrete?™ and its Integration into the Ready-Mixed Concrete business 24 • Pipeline Management • CRM System, including Pricing and Quoting Jobs Sales and Marketing • Mix Design, LabQuality Control • Highly Automated ProcessBatchers • Digital Ticketing • KPI’s Plant Labor • Real Time Inventory • Fully linked to Mid Office Materials Purchasing • Order Details including Mix Design, Pour Rate Analysis • Customer Chat Feature with Dispatch Dispatch and Ordering • Digital Ticketing • Clock in at the Cab Delivery/Drivers • KPI’s – Better VisibilityR&M • Highly Automated • Front Office and Back Office Alignment Mid Office • View Jobs and Orders • Track Delivery Status in Real-Time Customer App SALES ANALYTICS CUSTOMERS DISPATCH DRIVERS TICKETS

ESG Update – Governance • 6 of 8 board members are independent • Independent Chairman • 2 new board members added in the last two years • Susan Ball – 2019: CFO, Executive Vice President and Treasurer of Team, Inc. (NYSE: TISI) • Rajan Penkar – 2020: Previous experience includes: SVP and President, Supply Chain of Sears Holding Corporation (OTC: SHLDQ) and President, Customer Solutions of United Parcel Service, Inc. (NYSE: UPS) Toyota Headquarters, Plano, TX 25

Environmental Leadership and Social Responsibility • Pioneered technology for low CO2 concrete • Our national research laboratory was featured in a New York Times article August 2020 about industry innovation • Reduced Levi’s Stadium carbon footprint by an estimated 23 million lbs. of carbon emissions and reduced Nvidia’s Endeavor building by an estimated 6.7 million lbs. of carbon emissions • First company in the U.S. ready-mixed concrete industry to adopt the 2030 Challenge to develop Environmental Product Declarations (“EPD”) • USCR has over 15,000 EPDs nationwide • Integrating Climate Earth’s EPD tool in our submittal process, thereby delivering on-demand EPDs for every product offering. • Strategic investments in technology to recycle CO2 to reduce carbon footprint while positively affecting product performance, further enhancing value proposition • CarbonCure has been retrofitted into existing concrete plants • Created discipline for workforce safety and harmony around the disciplines in Courage, Compassion and Credibility • Regular communication and town halls are held to reinforce these values Levi’s Stadium, Santa Clara, CA Central Concrete, San Francisco, CA 26

Summary San Francisco, CA 27

Experienced Management Team Driving Sustainable Business Improvement 28 Name Position Year Joined Relevant Experience Ronnie Pruitt President and Chief Executive Officer 2015 27 years John Kunz Senior Vice President - Chief Financial Officer 2017 30 years Paul Jolas Senior Vice President - General Counsel 2013 30 years David Behring Senior Vice President - Operational Accounting 1991 29 years Daren Lesley Vice President - Aggregates 2017 31 years Matt Emmert Vice President and General Manager - East Region 2012 23 years Jeffrey Roberts Vice President and General Manager - Central Region 1994 31 years Herb Burton Vice President and General Manager - West Region 1999 23 years Gib Dawson Vice President - Chief Accounting Officer 2017 33 years Sharon Ellis Vice President - Investor Relations 2020 30 years Toni Heaps Vice President - Tax 2019 35 years Brian Mahavier Vice President - Strategy and Development 2013 20 years Terry Marshall Vice President - Chief Information Officer 2016 32 years Mark Peabody Vice President - Human Resources 2012 29 years Thomas Byrnes Chief of Staff 2014 27 years

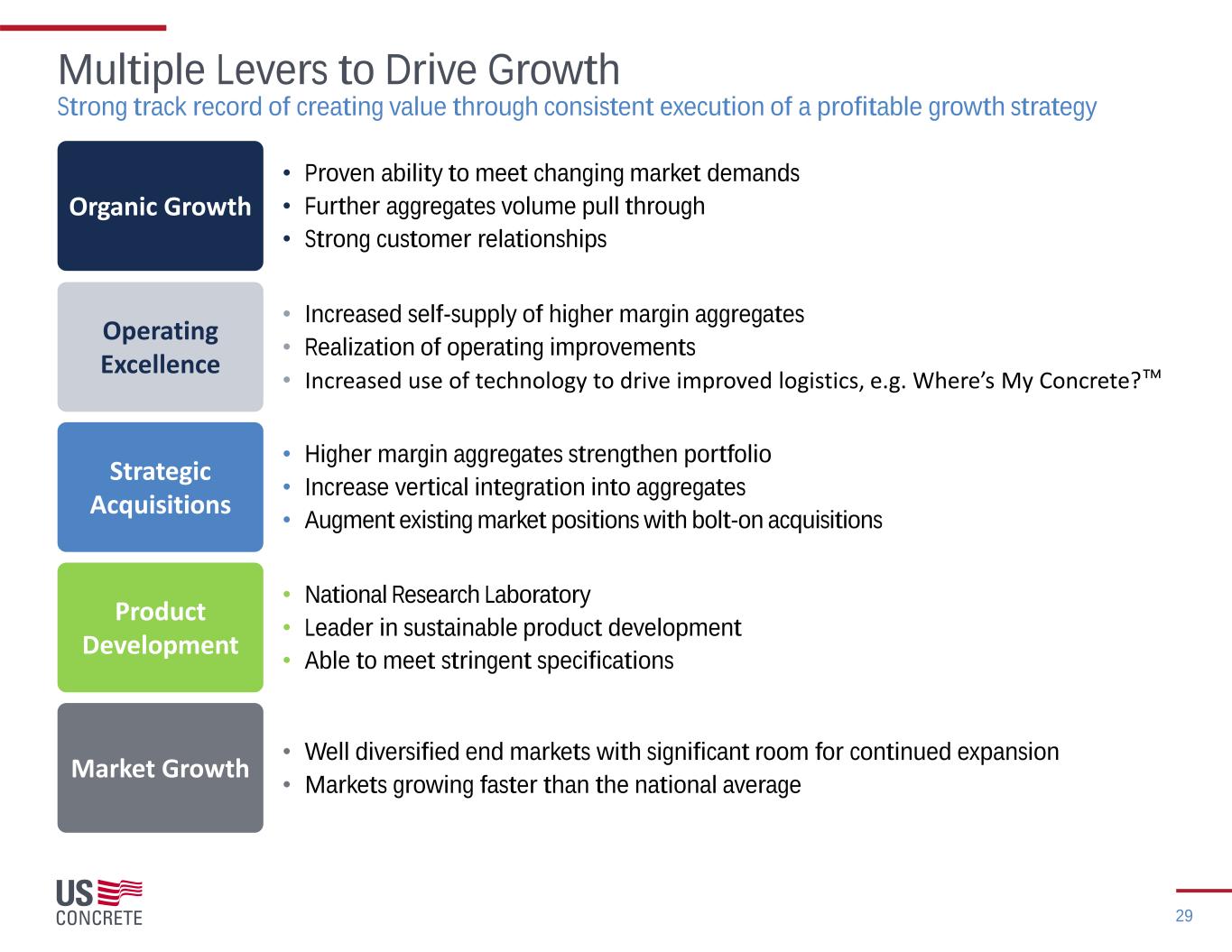

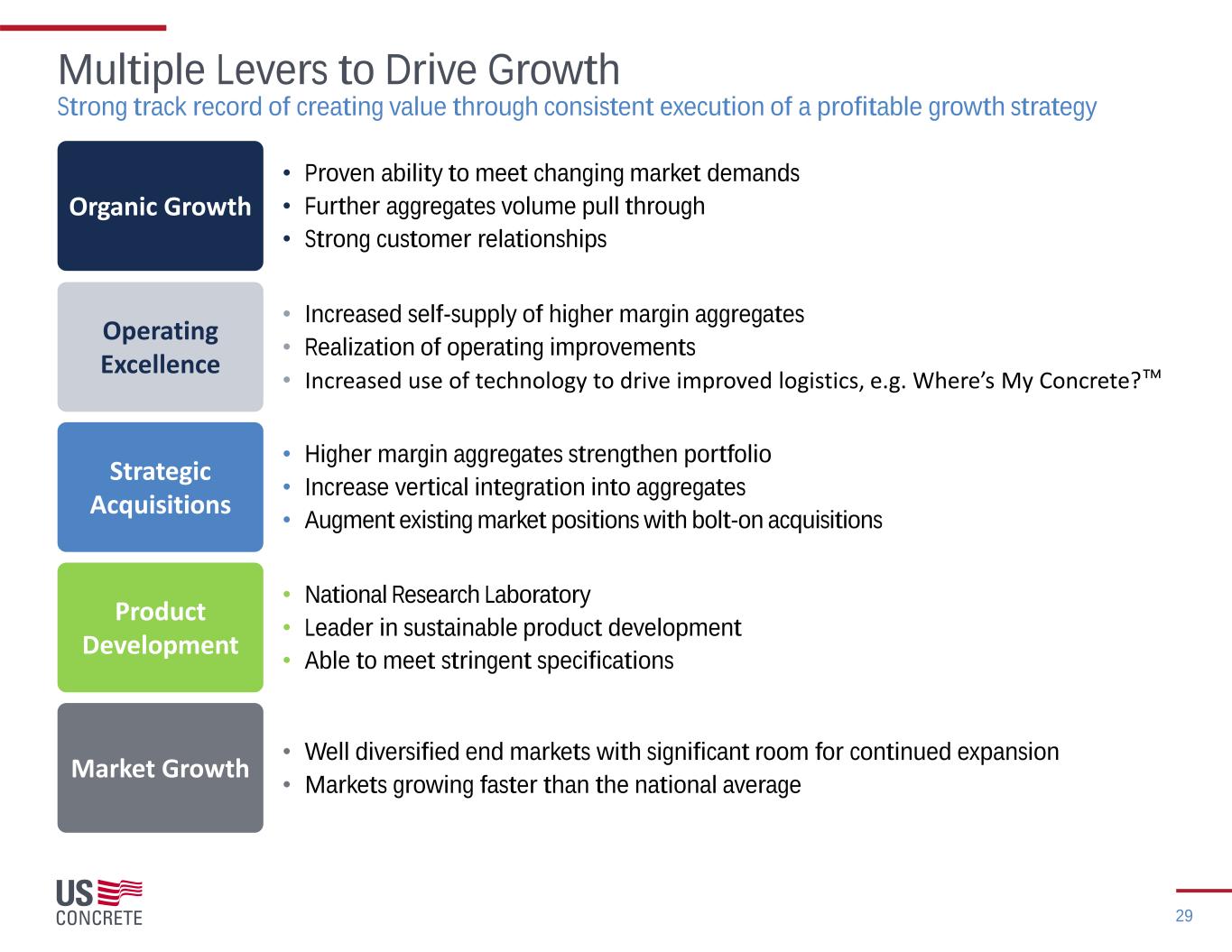

Multiple Levers to Drive Growth Strong track record of creating value through consistent execution of a profitable growth strategy Operating Excellence Strategic Acquisitions Product Development Market Growth • Increased self-supply of higher margin aggregates • Realization of operating improvements • Increased use of technology to drive improved logistics, e.g. Where’s My Concrete?™ • Higher margin aggregates strengthen portfolio • Increase vertical integration into aggregates • Augment existing market positions with bolt-on acquisitions • National Research Laboratory • Leader in sustainable product development • Able to meet stringent specifications • Well diversified end markets with significant room for continued expansion • Markets growing faster than the national average Organic Growth • Proven ability to meet changing market demands • Further aggregates volume pull through • Strong customer relationships 29

30 Increasing Vertical Integration into Aggregates Enhances Value Chain Logistical Expertise with Continued Investments in Technology Creating Value through Acquisitions with Track Record of Successful Integrations Solid Balance Sheet and Ample Liquidity ($420 million as of December 31, 2020)(1) Market Leader in Favorable Geographic Markets(2) Large, High Quality, Vertically Integrated Asset Base Diverse Board Advising on Strategy, Overseeing Risk and Supporting Long Term Value Creation A Compelling Long-Term Investment Growth Value 1) Liquidity is defined as available borrowing under our ABL Revolving Credit Facility and Delayed Draw Term Loan Facility, plus Cash & Cash Equivalents. See Appendix. 2) Based on Management estimates.

Appendix 31 Fannie Mae Headquarters, Reston, VA

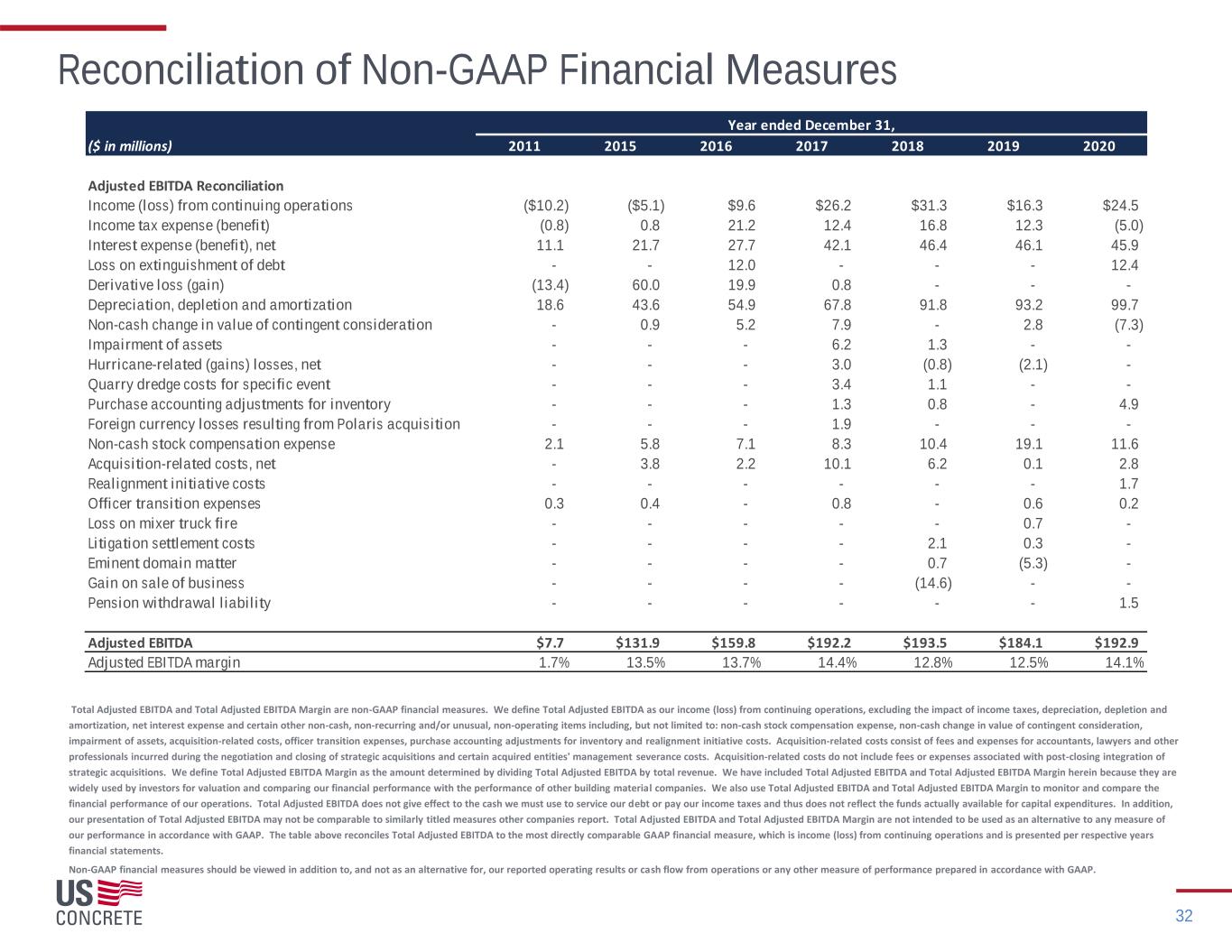

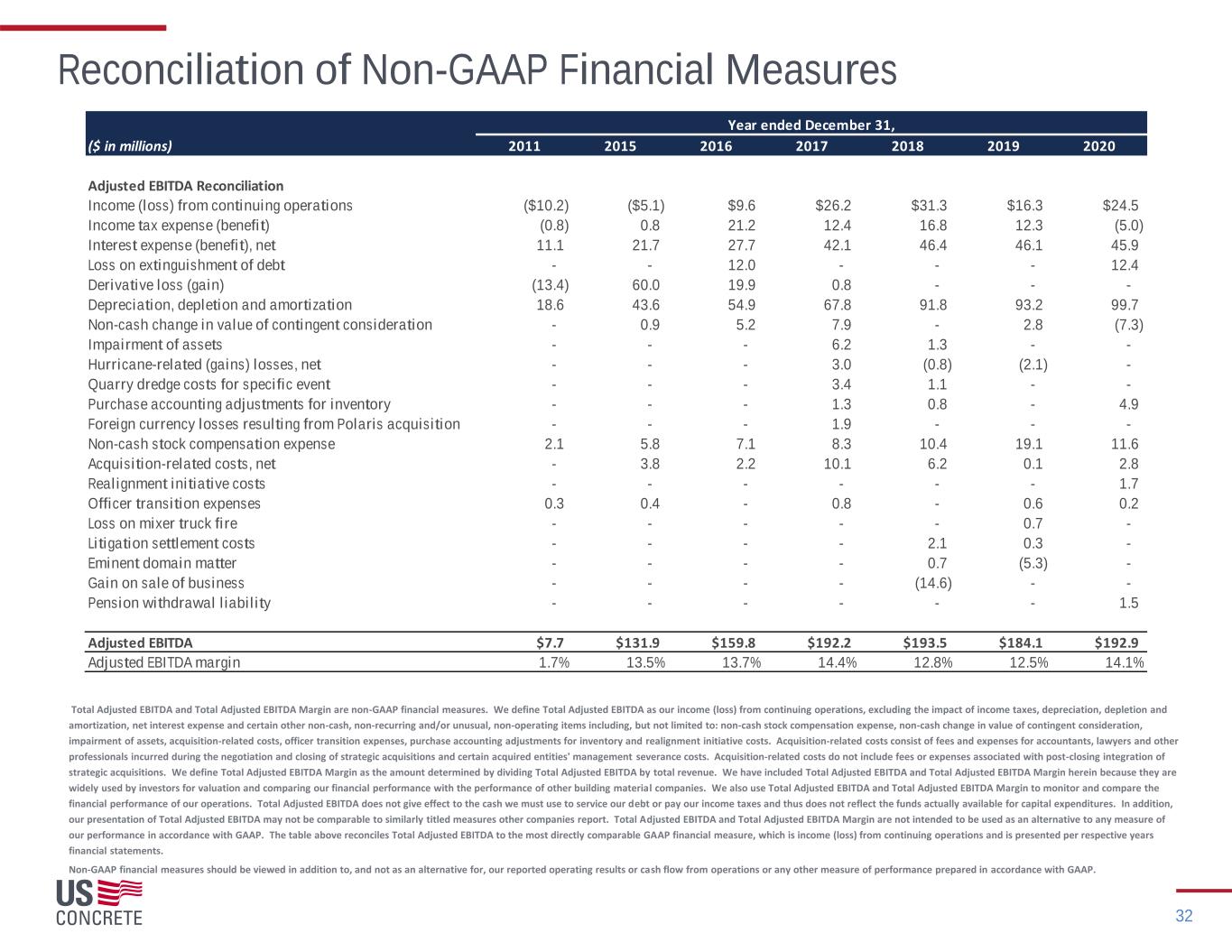

Reconciliation of Non-GAAP Financial Measures Total Adjusted EBITDA and Total Adjusted EBITDA Margin are non-GAAP financial measures. We define Total Adjusted EBITDA as our income (loss) from continuing operations, excluding the impact of income taxes, depreciation, depletion and amortization, net interest expense and certain other non-cash, non-recurring and/or unusual, non-operating items including, but not limited to: non-cash stock compensation expense, non-cash change in value of contingent consideration, impairment of assets, acquisition-related costs, officer transition expenses, purchase accounting adjustments for inventory and realignment initiative costs. Acquisition-related costs consist of fees and expenses for accountants, lawyers and other professionals incurred during the negotiation and closing of strategic acquisitions and certain acquired entities' management severance costs. Acquisition-related costs do not include fees or expenses associated with post-closing integration of strategic acquisitions. We define Total Adjusted EBITDA Margin as the amount determined by dividing Total Adjusted EBITDA by total revenue. We have included Total Adjusted EBITDA and Total Adjusted EBITDA Margin herein because they are widely used by investors for valuation and comparing our financial performance with the performance of other building material companies. We also use Total Adjusted EBITDA and Total Adjusted EBITDA Margin to monitor and compare the financial performance of our operations. Total Adjusted EBITDA does not give effect to the cash we must use to service our debt or pay our income taxes and thus does not reflect the funds actually available for capital expenditures. In addition, our presentation of Total Adjusted EBITDA may not be comparable to similarly titled measures other companies report. Total Adjusted EBITDA and Total Adjusted EBITDA Margin are not intended to be used as an alternative to any measure of our performance in accordance with GAAP. The table above reconciles Total Adjusted EBITDA to the most directly comparable GAAP financial measure, which is income (loss) from continuing operations and is presented per respective years financial statements. Non-GAAP financial measures should be viewed in addition to, and not as an alternative for, our reported operating results or cash flow from operations or any other measure of performance prepared in accordance with GAAP. 32 ($ in millions) 2011 2015 2016 2017 2018 2019 2020 Adjusted EBITDA Reconciliation Income (loss) from continuing operations ($10.2) ($5.1) $9.6 $26.2 $31.3 $16.3 $24.5 Income tax expense (benefit) (0.8) 0.8 21.2 12.4 16.8 12.3 (5.0) Interest expense (benefit), net 11.1 21.7 27.7 42.1 46.4 46.1 45.9 Loss on extinguishment of debt - - 12.0 - - - 12.4 Derivative loss (gain) (13.4) 60.0 19.9 0.8 - - - Depreciation, depletion and amortization 18.6 43.6 54.9 67.8 91.8 93.2 99.7 Non-cash change in value of contingent consideration - 0.9 5.2 7.9 - 2.8 (7.3) Impairment of assets - - - 6.2 1.3 - - Hurricane-related (gains) losses, net - - - 3.0 (0.8) (2.1) - Quarry dredge costs for specific event - - - 3.4 1.1 - - Purchase accounting adjustments for inventory - - - 1.3 0.8 - 4.9 Foreign currency losses resulting from Polaris acquisition - - - 1.9 - - - Non-cash stock compensation expense 2.1 5.8 7.1 8.3 10.4 19.1 11.6 Acquisition-related costs, net - 3.8 2.2 10.1 6.2 0.1 2.8 Realignment initiative costs - - - - - - 1.7 Officer transition expenses 0.3 0.4 - 0.8 - 0.6 0.2 Loss on mixer truck fire - - - - - 0.7 - Litigation settlement costs - - - - 2.1 0.3 - Eminent domain matter - - - - 0.7 (5.3) - Gain on sale of business - - - - (14.6) - - Pension withdrawal l iability - - - - - - 1.5 Adjusted EBITDA $7.7 $131.9 $159.8 $192.2 $193.5 $184.1 $192.9 Adjusted EBITDA margin 1.7% 13.5% 13.7% 14.4% 12.8% 12.5% 14.1% Year ended December 31,

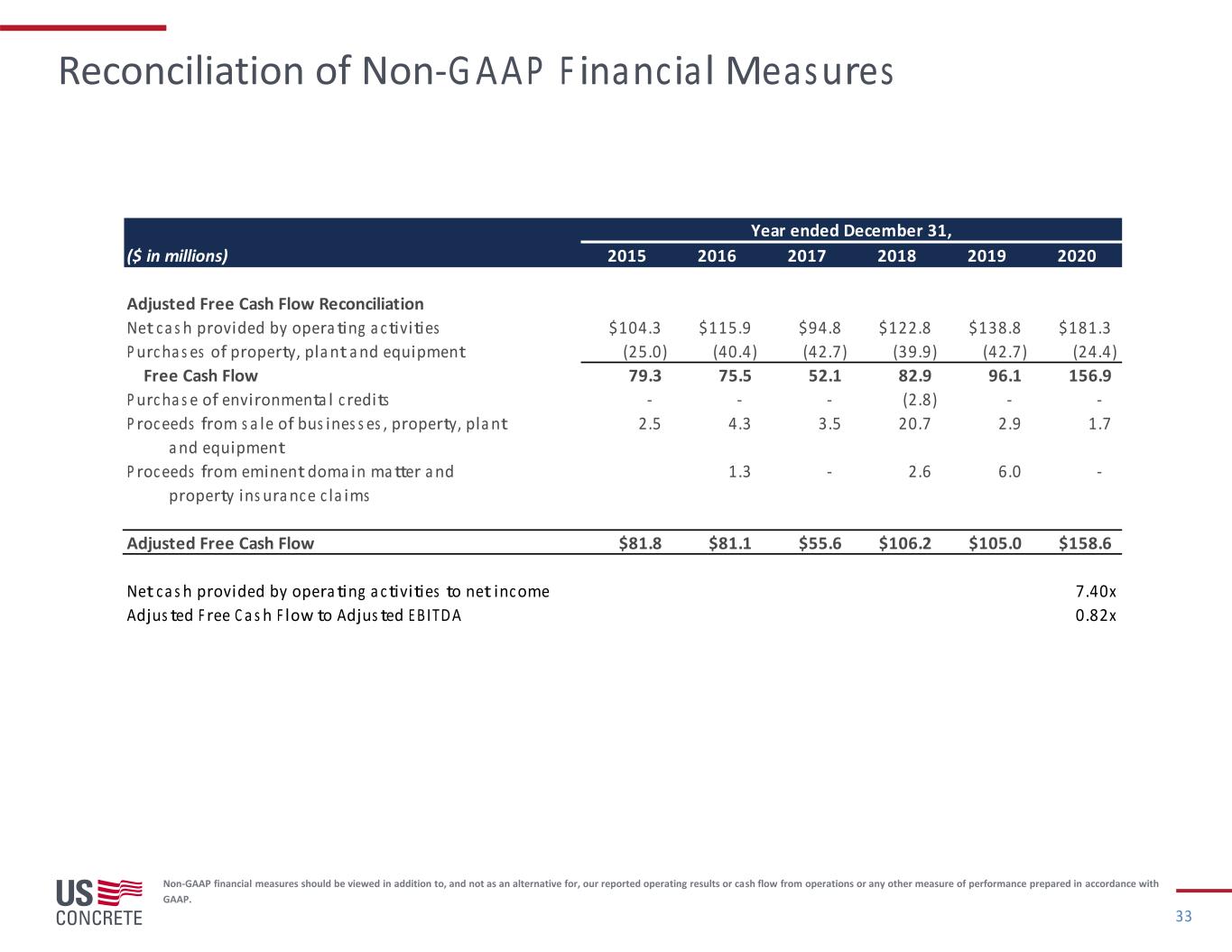

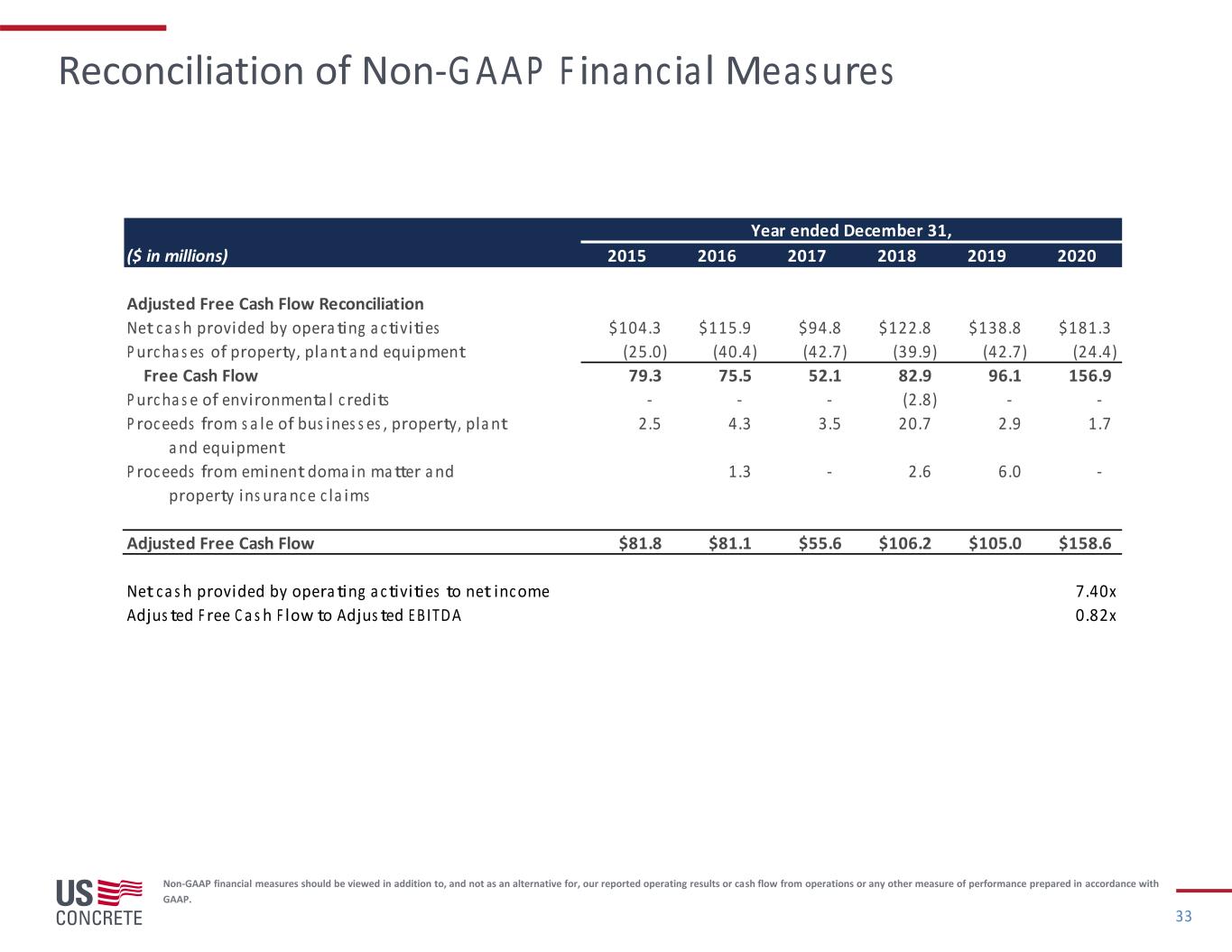

Reconciliation of Non-GAAP Financial Measures Non-GAAP financial measures should be viewed in addition to, and not as an alternative for, our reported operating results or cash flow from operations or any other measure of performance prepared in accordance with GAAP. 33 ($ in millions) 2015 2016 2017 2018 2019 2020 Adjusted Free Cash Flow Reconciliation Net cash provided by operating activities $104.3 $115.9 $94.8 $122.8 $138.8 $181.3 Purchases of property, plant and equipment (25.0) (40.4) (42.7) (39.9) (42.7) (24.4) Free Cash Flow 79.3 75.5 52.1 82.9 96.1 156.9 Purchase of environmental credits - - - (2.8) - - Proceeds from sale of businesses, property, plant 2.5 4.3 3.5 20.7 2.9 1.7 and equipment Proceeds from eminent domain matter and 1.3 - 2.6 6.0 - property insurance claims Adjusted Free Cash Flow $81.8 $81.1 $55.6 $106.2 $105.0 $158.6 Net cash provided by operating activities to net income 7.40x Adjusted Free Cash Flow to Adjusted EBITDA 0.82x Year ended December 31,

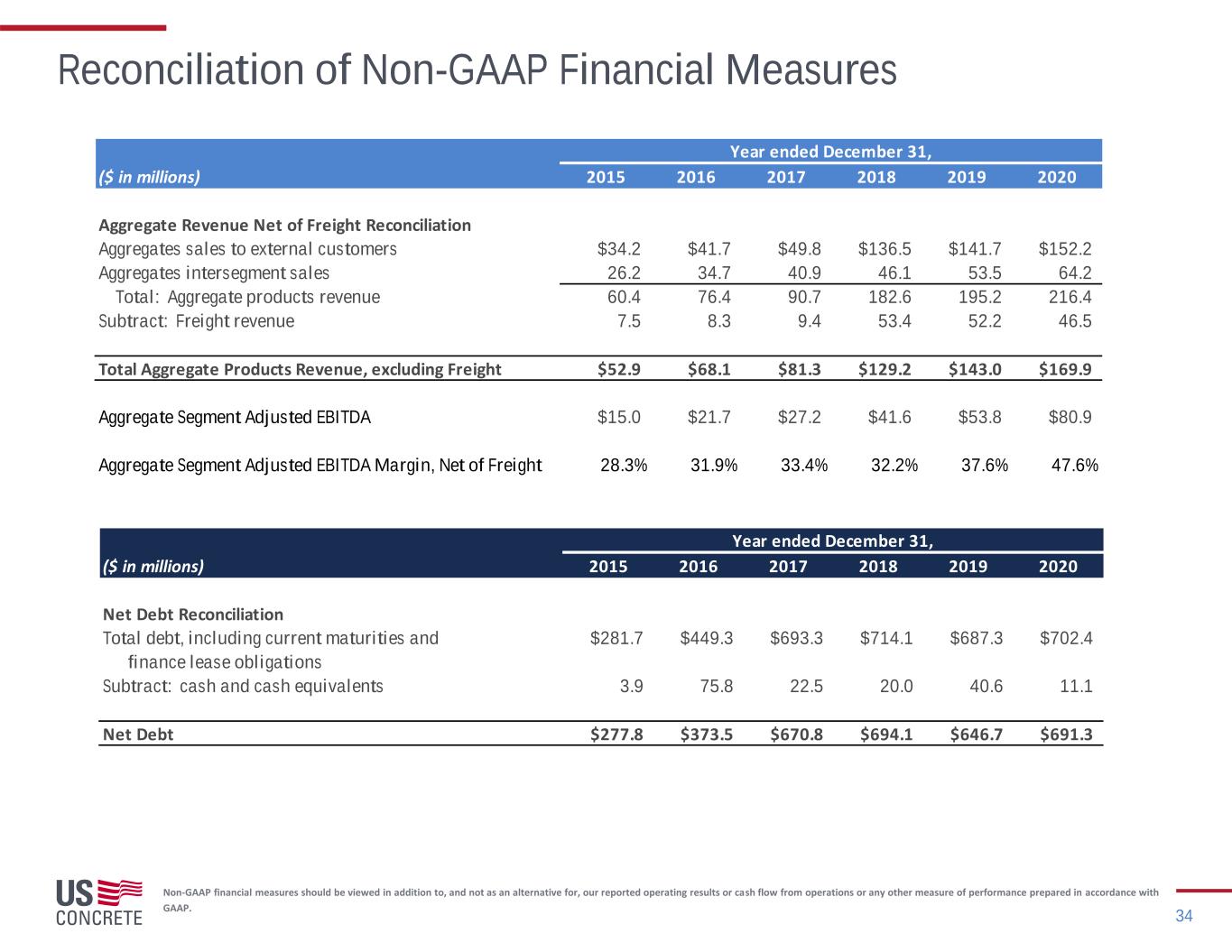

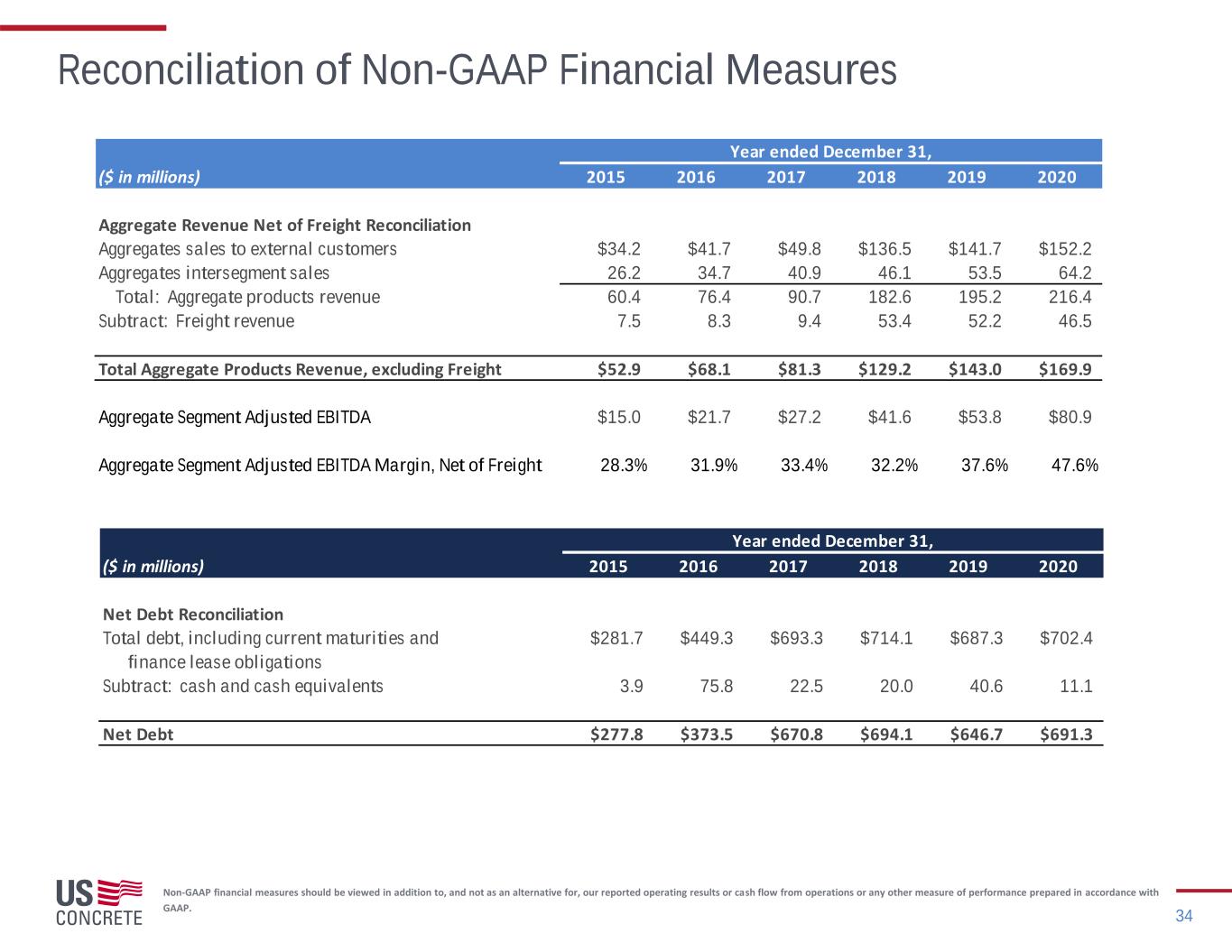

Reconciliation of Non-GAAP Financial Measures Non-GAAP financial measures should be viewed in addition to, and not as an alternative for, our reported operating results or cash flow from operations or any other measure of performance prepared in accordance with GAAP. 34 ($ in millions) 2015 2016 2017 2018 2019 2020 Aggregate Revenue Net of Freight Reconciliation Aggregates sales to external customers $34.2 $41.7 $49.8 $136.5 $141.7 $152.2 Aggregates intersegment sales 26.2 34.7 40.9 46.1 53.5 64.2 Total: Aggregate products revenue 60.4 76.4 90.7 182.6 195.2 216.4 Subtract: Freight revenue 7.5 8.3 9.4 53.4 52.2 46.5 Total Aggregate Products Revenue, excluding Freight $52.9 $68.1 $81.3 $129.2 $143.0 $169.9 Aggregate Segment Adjusted EBITDA $15.0 $21.7 $27.2 $41.6 $53.8 $80.9 Aggregate Segment Adjusted EBITDA Margin, Net of Freight 28.3% 31.9% 33.4% 32.2% 37.6% 47.6% Year ended December 31, ($ in millions) 2015 2016 2017 2018 2019 2020 Net Debt Reconciliation Total debt, including current maturities and $281.7 $449.3 $693.3 $714.1 $687.3 $702.4 finance lease obligations Subtract: cash and cash equivalents 3.9 75.8 22.5 20.0 40.6 11.1 Net Debt $277.8 $373.5 $670.8 $694.1 $646.7 $691.3 Year ended December 31,

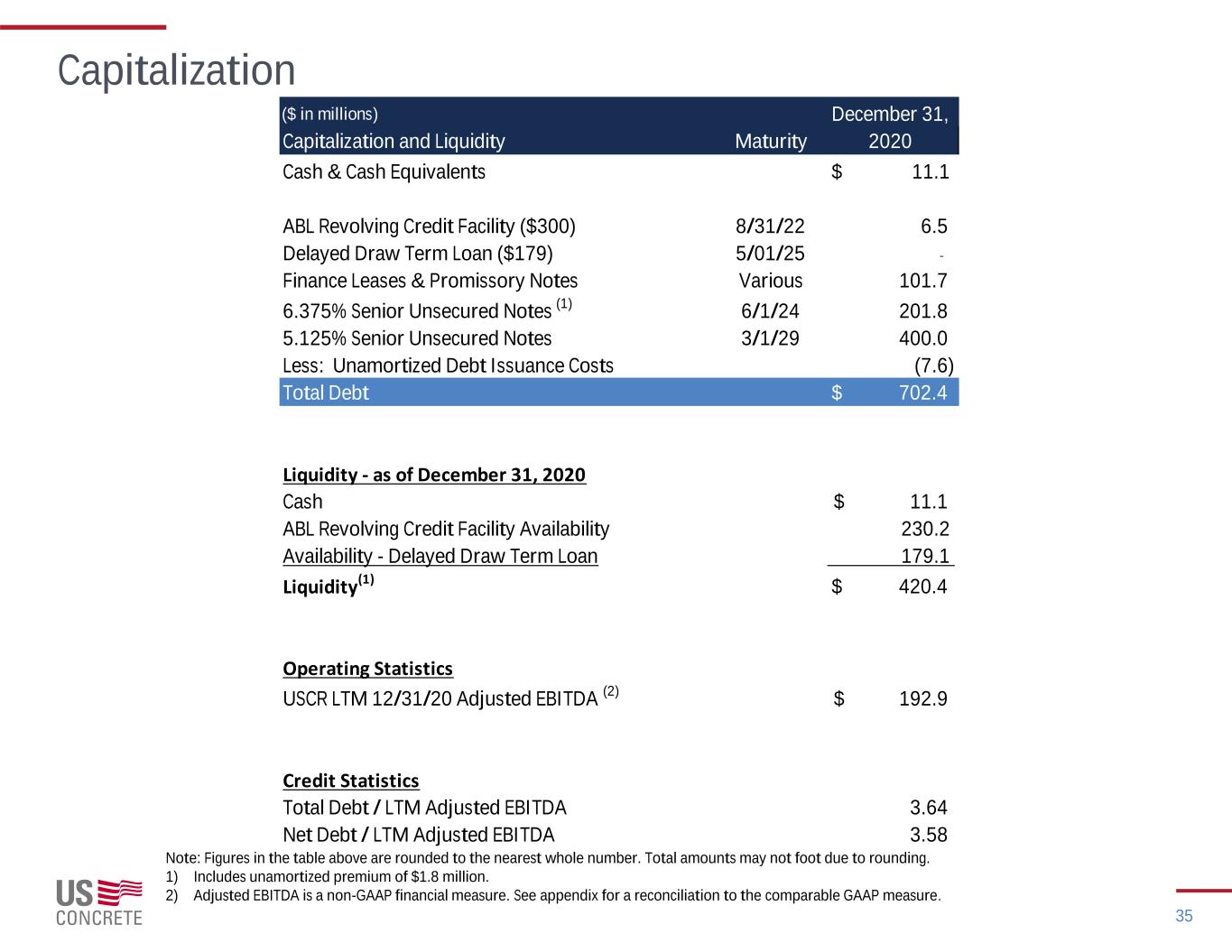

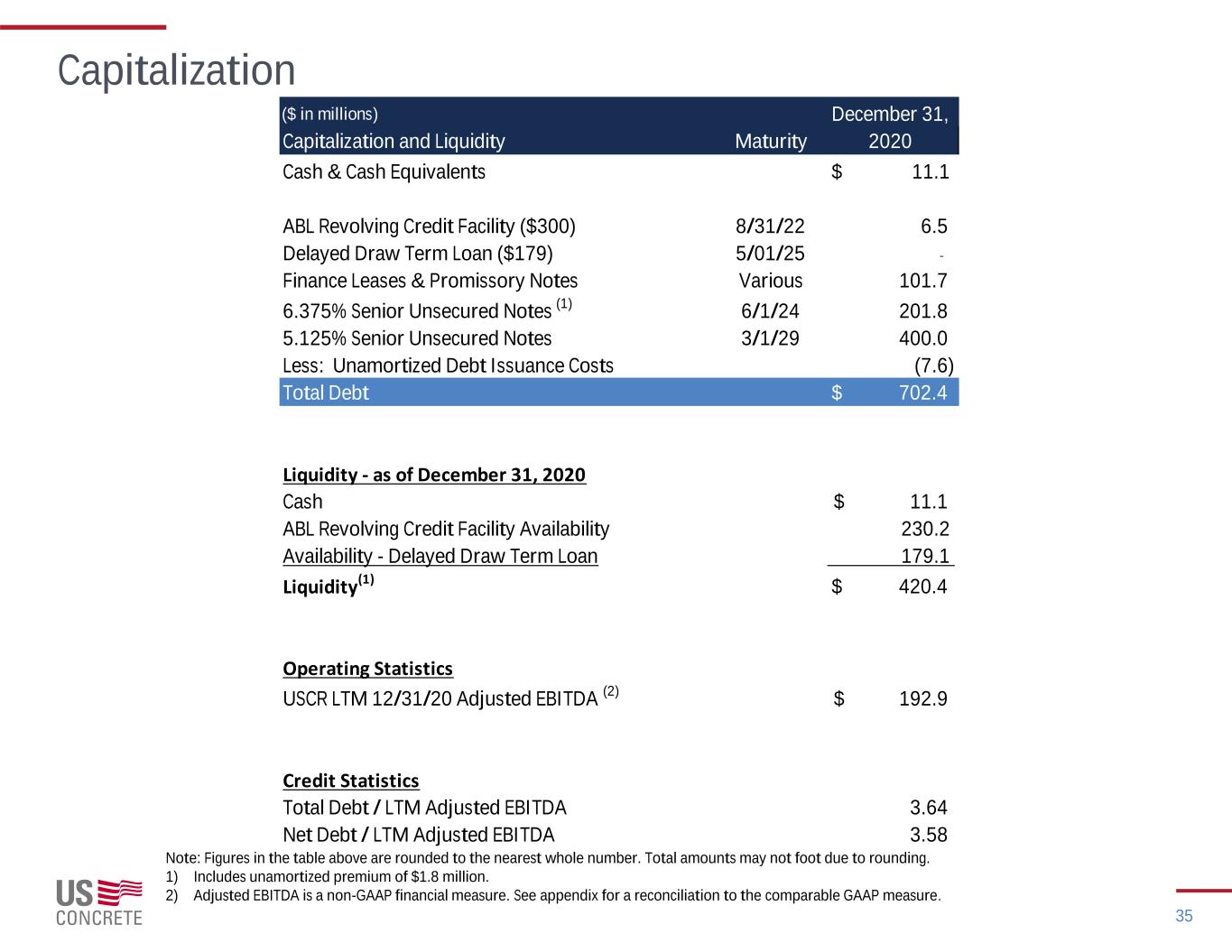

Capitalization Note: Figures in the table above are rounded to the nearest whole number. Total amounts may not foot due to rounding. 1) Includes unamortized premium of $1.8 million. 2) Adjusted EBITDA is a non-GAAP financial measure. See appendix for a reconciliation to the comparable GAAP measure. 35 ($ in millions) Capitalization and Liquidity Maturity Cash & Cash Equivalents $ 11.1 ABL Revolving Credit Facility ($300) 8/31/22 6.5 Delayed Draw Term Loan ($179) 5/01/25 - Finance Leases & Promissory Notes Various 101.7 6.375% Senior Unsecured Notes (1) 6/1/24 201.8 5.125% Senior Unsecured Notes 3/1/29 400.0 Less: Unamortized Debt Issuance Costs (7.6) Total Debt $ 702.4 Liquidity - as of December 31, 2020 Cash 11.1$ ABL Revolving Credit Facility Availability 230.2 Availability - Delayed Draw Term Loan 179.1 Liquidity (1) $ 420.4 Operating Statistics USCR LTM 12/31/20 Adjusted EBITDA (2) 192.9$ Credit Statistics Total Debt / LTM Adjusted EBITDA 3.64 Net Debt / LTM Adjusted EBITDA 3.58 December 31, 2020

Thank You 331 North Main Street Euless, TX 76039 844.828.4774 www.us-concrete.com ir@us-concrete.com