UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, DC 20549

FORM 10-K

(Mark One)

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended: December 31, 2007

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission File No.: 000-26175

CHINA WATER GROUP, INC.

(Exact Name of Registrant as Specified in Its Charter)

| Nevada | | 88-0409151 |

| (State or Other Jurisdiction of Incorporation | | (I.R.S. Employer Identification No.) |

| or Organization) | | |

SUITE 7A01, BAICHENG BUILDING

584 YINGBIN ROAD

DASHI, PANYU DISTRICT

GUANGZHOU, GUANGDONG, CHINA

(Address of Principal Executive Offices)

(86-20) 3479 9768

(Registrant’s Telephone Number, Including Area Code)

Securities registered pursuant to Section 12(b) of the Act: None

Securities registered pursuant to Section 12(g) of the Act: Common Stock, par value $0.001

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ¨ No x

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (s 229.405) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company filer. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer o Accelerated filer o Non-accelerated Filer o Smaller reporting company x

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act).

Yes ¨ No x

The aggregate market value of the voting and non-voting common equity held by non-affiliates of the registrant as of May 10 , 2009: $2,787,669.

The number of shares of the registrant’s common stock outstanding as of April 15 , 2009: 139,383,450.

INDEX TO FORM 10-K ANNUAL REPORT

| | | Page |

| | | |

| PART I | | |

| | | |

| Item 1. | Business | 3 |

| | | |

| Item 1A. | Risk Factors | 19 |

| | | |

| Item 1B. | Unresolved Staff Comments | 24 |

| | | |

| Item 2. | Properties | 24 |

| | | |

| Item 3. | Legal Proceedings | 25 |

| | | |

| Item 4. | Submission of Matters to a Vote of Security Holders | 25 |

| | | |

| PART II | | |

| | | |

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters and Issurer Purchases of Equity Securities | 25 |

| | | |

| Item 6. | Selected Financial Data | 26 |

| | | |

| Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations | 26 |

| | | |

| Item 7A. | Quantitative and Qualitative Disclosures about Market Risk | 32 |

| | | |

| Item 8. | Financial Statements and Supplementary Data | 32 |

| | | |

| Item 9. | Changes in and Disagreements with Accountants on Accounting and Financial Disclosure | 32 |

| | | |

| Item 9A(T) | Controls and Procedures | 32 |

| | | |

| Item 9B | Other Information | 38 |

| | | |

| PART III | | |

| | | |

| Item 10. | Directors, Executive Officers and Corporate Governance | 38 |

| | | |

| Item 11. | Executive Compensation | 39 |

| | | |

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 41 |

| | | |

| Item 13. | Certain Relationships and Related Transactions, and Director Independence | 42 |

| | | |

| Item 14. | Principal Accountant Fees and Services | 43 |

| | | |

| PART IV | | |

| | | |

| Item 15. | Exhibits and Financial Statement Schedules | 44 |

| | | |

| | Signatures | 45 |

| | | |

| | Financial Statements | F-1 |

EXPLANATORY NOTE

We, China Water Group, Inc., are filing this Annual Report on Form 10-KSB for the year ended December 31, 2007 during calendar 2009 as an initial step in our efforts to become current in our filing obligations under the Securities Exchange Act of 1934, as amended. We will endeavor to file additional periodic reports to become current in our filings as expeditiously as the limited size of our staff allows. Except where a date after April 2009 is specifically mentioned, this report is written as though it had been prepared during the first four months of calendar 2008.

Unless otherwise indicated, all references to our company include our wholly and majority owned subsidiaries.

All of our sales and nearly all our expenses are denominated in renminbi (“RMB”), the national currency of the People’s Republic of China (the “PRC”). Solely for the convenience of the reader, certain financial information as of and for the years ended December 31, 2006 and 2007 have been converted into United States dollars. Assets and liabilities are translated at the exchange rate in effect at period end. Income statement accounts are translated at the average rate of exchange prevailing during the period. No representation is made that the RMB amounts could have been, or could be, converted into United States dollars at that rate or at any other certain rate as of the respective dates or at any other date.

The statements contained in this report that are not historical are “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), including statements, without limitation, regarding our expectations, beliefs, intentions or strategies regarding the future. We intend that such forward-looking statements be subject to the safe-harbor provided by the Private Securities Litigation Reform Act of 1995. Such forward-looking statements relate to, among other things: (1) expected revenue and earnings growth; (2) estimates regarding the size of target markets; and (3) regulation of our industries and markets by the Chinese government. These statements are qualified by important factors that could cause our actual results to differ materially from those reflected by the forward-looking statements. Such factors include, but are not limited to, those risk factors described elsewhere in this annual report.

Part I

Item 1. Description of Business.

We are a waste water engineering company based in the PRC. Through our majority-owned subsidiaries, we are engaged in the design, construction, implementation and management of industrial and municipal waste water treatment facilities throughout the PRC.

We provide turn-key waste water treatment engineering design and contracting. From 2000 to 2007 we completed the following turn-key projects: Yongji Development Zone Wastewater Treatment Plant (Phase 1), Guangdong Nanhai City Jinsha Town Wastewater Treatment Plant, Guangdong Sanshui Baini Wastewater Treatment Plant and Guangzhou Yantang Wastewater Treatment Plant, Tianjin City Meichang Town Wastewater Treatment Plant,Yongji Development Zone Wastewater Treatment Plant (Phase 2), China Environment Industrial Park Wastewater Treatment Plant, Huangzhuang Industrial Park Wastewater Treatment Plant and Tian Jin WuQing No.1 Waste Water Treatment Factory.

We hold 90% and 35%, respectively, of the equity interest in the following two water treatment facilities operated through build, operate and transfer (“BOT”) arrangements with the PRC government: (i) Tian Jin Shi Sheng Water Treatment Company Limited (“TianJin”), which commissioned water treatment in November 2003 and has a daily treatment capacity of approximately 10,000 tons; and (ii) Xin Le Sheng Mei Water Purifying Company Limited (“XinLe”), which also commissioned water treatment in November 2003 and has a daily treatment capacity of 40,000 tons. We have been retained as the manager to manage both TianJing and XinLe. The fees from XinLe and TianJing did not represent a significant portion of our revenue during 2007.

We also developed a BOT water treatment facility project in Hai Yang City under our subsidiary Hai Yang City Sheng Shi Environment Protection Company Limited (“HaiYang”) with capacity of 20,000 tons per day. We began construction of this project in April 2004 and completed the project and commenced water treatment in June 2005. We also developed another BOT water treatment facility project in Beijing under our subsidiary Bei Jing Hao Tai Shi Yuan Water Purifying Company Limited (“Beijing HaoTai”) with planned capacity of 20,000 tons per day. We began construction of this project in July 2004 completed approximately 90% till December, 2006. We retained a 90% interest in this facility until we disposed of it in December 2006 for a total consideration of US$1,442,567 realizing a gain of US$44,872 . In July 2005, we started construction of a BOT water treatment facility project for the Handan Fengfeng Mining Area in the Hebei Province under our subsidiary Han Dan Cheng Sheng Water Affairs Company Limited (“HanDan”) with capacity of 33,000 tons per day. The project was completed in December 2007. The fees from these projects are expected to strengthen our net sales in the future.

Our predecessor in interest, Discovery Investments, Inc. (“Discovery”) was incorporated on September 10, 1996, under the laws of the State of Nevada to engage in any lawful corporate activity. Discovery had been in the development stage and was not active until October 26, 1999.

On December 10, 1999, Discovery entered into a Plan and Agreement of Reorganization (the “Plan”) with LLO-Gas, Inc. and John Castellucci. On October 26, 1999, LLO-Gas had acquired certain ARCO facilities and a so-called card lock facility and commenced operations. LLO-Gas was incorporated in July 1998 under the laws of the State of Delaware. On December 20, 1999, there was a closing under the Plan and LLO-Gas, Inc. became a wholly-owned subsidiary of Discovery and there was a change of control of Discovery. Between December 20, 1999 and August 10, 2000, differences of opinion as to matters of fact and as to matters of law had arisen by and between certain of the shareholders of Discovery, who were shareholders prior to the closing, and between Discovery, John Castellucci and LLO-Gas, Inc.

On June 7, 2000, LLO-Gas, Inc. filed a Voluntary Petition under Chapter 11 of the Bankruptcy Code in the United States Bankruptcy Court, Central District of California, San Fernando Valley Division, case number SV 00-15398-AG. On December 1, 2000, the United States Bankruptcy Court converted the pending matter into a Chapter 7 liquidation. Said Chapter 7 effected LLO-Gas, Inc. and not Discovery.

On August 10, 2000, Discovery entered into a Mutual Rescission Agreement and Mutual Release with John Castellucci which provided, inter alia, that Discovery consented and agreed to rescind said Plan with John Castellucci consenting and agreeing to the rescission. The parties mutually agreed to forego all rights and benefits provided to each other thereunder.

On August 9, 2001, Discovery filed a voluntary petition under Chapter 11 of the Bankruptcy Code in the United States Bankruptcy Court, District of Nevada, Case Number BK-S-01-18156-RCJ. On September 24, 2001, the Bankruptcy Court confirmed the Disclosure Statement and Plan of Reorganization submitted by Discovery and Discovery was thereafter released from Bankruptcy.

On April 29, 2002, Discovery entered into a Plan and Agreement of Reorganization with Bycom Media Inc., an Ontario, Canada corporation (“Bycom”). Pursuant to this agreement, Discovery acquired all the outstanding shares of Bycom for 4,800,000 shares of Common Stock. On October 5, 2002, Bycom became a wholly-owned subsidiary of Discovery and there was a change of control.

Bycom was engaged in multimedia applications for internet-based business. Utilizing business search tools and databases, Bycom intended to be able to locate and access global business information for a fee, or was to act as an “out-source provider” of information. Bycom currently is an inactive, wholly owned subsidiary of the Company.

On September 4, 2002, Discovery completed a transaction set out in a Plan and Agreement of Reorganization dated June 13, 2002, pursuant to which Discovery acquired all of the outstanding shares of Cavio Corporation, a Washington corporation, (“Cavio”) in exchange for 14 million share of Discovery common stock. Due to poor market conditions and Discovery’s inability to seek adequate financing from third parties to properly finance the operations of Cavio, on December 2, 2002 Discovery’s board of directors approved, subject to receiving the approval of a majority of the shareholders, to unwind the acquisition of Cavio in cancellation of the shares of common stock issued.

On December 2, 2002, Discovery unanimously approved the disposition of its interest in Cavio and thereafter received the consent of a majority of the outstanding shares of the company’s common stock. Discovery determined the effective date for the divestiture to be June 30, 2003.

For the two years prior to a reverse acquisition in September 2004, we had not generated significant revenues and were considered a development stage company as defined in Statement of Financial Accounting Standards No. 7. We were seeking business opportunities or potential business acquisitions. Pursuant to a securities purchase agreement and plan of reorganization dated September 9, 2004, as amended, between our company, Evergreen Asset Group Limited, an International Business Company organized under the laws of the British Virgin Islands (“Evergreen” or “EGAG”), and the stockholders of Evergreen, we acquired 100% of the issued and outstanding shares of Evergreen’s capital stock. We issued 83,500,000 shares of our common stock in exchange for all the 300 issued and outstanding shares of Evergreen capital stock which had an estimated value of $4.24 million at the time of such issuance, valued based on the fair market value of the net assets of Evergreen. Since the stockholders of Evergreen acquired approximately 83.5% of our outstanding shares and the Evergreen management team and board of directors became the management team and board of directors of our company, according to FASB Statement No. 141 - “ Business Combinations ”, this acquisition has been treated as a recapitalization for accounting purposes, in a manner similar to reverse acquisition accounting. In accounting for this transaction:

| • | Evergreen is deemed to be the purchaser and surviving company for accounting purposes. Accordingly, its net assets are included in the balance sheet at their historical book values and the results of operations of Evergreen have been presented for the comparative prior period; |

| • | Control of the net assets and business of our company was acquired effective October 15, 2004. This transaction has been accounted for as a purchase of the assets and liabilities of our company by Evergreen. The historical cost of the net liabilities assumed was $0.00. |

As a result of the transaction described above we changed our name from Discovery Investments, Inc. to China Evergreen Environmental Corporation.

Due to the reverse acquisition mentioned above, EGAG, pursuant to a group reorganization which was completed in July 2004, acquired 90% equity interests in each of XinXingmei, XianYang, HaiYang and BeijingHaoTai for cash consideration of RMB12,601,000 (approximately $1,521,860), RMB18,000,000 (approximately $2,173,913), RMB2,700,000 (approximately $326,087) and RMB1,800,000 (approximately $217,391) respectively, all of which are domestic incorporated companies established in the PRC with limited liability.

In March 2003, GDXS entered into a BOT agreement with Xian Yang City Environment Protection Bureau. The BOT agreement was later transferred to Xian Yang Bai Sheng Water Purifying Company Limited (“XianYang”), after XianYang was incorporated. The construction of the wastewater plant of XianYang started in the beginning of 2004. Due to the group reorganization in July 2004, 90% of GDXS’s interest in XianYang was transferred to EGAG. In October 2004, EGAG entered into a tri-party framework agreement with True Global Limited (“TGL”), an independent party and Guang Dong Xin Sheng Environmental Protection Company Limited (“GDXS”) for the disposal of its 90% interest in XianYang to TGL at a total consideration of $13,246,377. A gain on disposal of $5,220,299 was recorded in 2004 for the disposal of our entire 90% attributable interest in XianYang to TGL.The gain represents the difference between the disposal proceeds and our attributable share of net assets of XianYang at the date of disposal.

In April 2005, we conducted a private placement of 20 investment units, at $25,000 per unit, for gross proceeds of $500,000. Each unit consisted of (a) one 12% convertible debenture in the original principal amount of $25,000, convertible into shares of our common stock at the rate of the lesser of (i) $0.20 per share or (ii) a 10% discount to the price per share of common stock (or conversion price per share of common stock) of the next private placement conducted by us prior to any conversion of the debenture, and (b) 125,000 detachable warrants to purchase one share each of our common stock at an exercise price of $0.20 per share, expiring ten years from their date of issuance. The debentures were due and payable August 1, 2005. The debenture holders, however, extended the payment period to September 30, 2005. We granted the investors limited registration rights for the common shares underlying their debentures and warrants. Westminster Securities Corporation acted as placement agent for this offering on our behalf. All the debenture holders have converted the debentures into 3,703,701 shares of our common stock on October 1, 2005.

On September 14, 2005, we closed the private placement sale to accredited investors of units consisting of shares of our common stock and warrants to purchase shares of our common stock for aggregate gross proceeds of $4.83 million. Pursuant to the subscription agreements entered into with the investors, we issued to the investors 161 units at a price of $30,000 per unit. Each unit consisted of 200,000 shares of our common stock, priced at $0.15 per share, and warrants to purchase 200,000 shares of our common stock over a five-year period at an exercise price of $0.20 per share. Pursuant to the terms of the subscription agreements, we granted the investors limited registration rights for all common shares comprising the units, including the common shares issuable on exercise of the warrants.

On November 7, 2006, China Evergreen Environmental Corporation changed its name to China Water Group, Inc. to reflect its focus on China’s water treatment and supply needs and on build-operate-transfer(BOT), Transfer-operate-transfer(TOT), and turnkey wastewater treatment facilities in China, at the same time, bottled water is considered.

On December 29, 2007, China Water Group Inc. signed a contract with Fortune Luck Global International Limited to acquire 90 percent of the equity interest of Aba Xinchen Dagu Glacier Spring Co., Limited through its subsidiary Guangzhou Xinchen Water Company. The assignment is at the consideration of 13.45 million dollars, of which 7.5 million dollars will be paid in cash, and the remaining 5.95 million dollars will be in shares.

Our executive offices are located at Suite 7A01, Baicheng Building, 584 Yingbin Road, Dashi, Panyu District, Guangzhou, Guangdong, China; telephone number (86-20) 3479 9768.

Our Business

General

We are a waste water engineering company based in the PRC. Through our majority-owned subsidiaries, we are engaged in the design, construction, implementation and management of industrial and municipal waste water treatment facilities throughout the PRC. We are also exploring the viability of entering the bottled water business in the PRC.

Our business was originally established in 1999 by our Chairman, Mr. Chong Liang Pu, with a focus on developing innovative biochemical technologies and processes for waste water treatment. We have the exclusive rights to MHA biological treatment processes technologies (“MHA”) and GM Bio-carriers. Both are the subject of patents owned by our Chairman, Mr. Pu, and we have acquired the exclusive rights pursuant to a license agreement with Mr. Pu. Both technologies were developed to improve the efficiency and effectiveness of waste water treatment processes and reduce the initial investment and on-going operating cost of waste water treatment facilities.

We have applied biotechnological processes to waste water treatment and have developed relationships with the PRC environmental authorities at both national and provincial levels throughout the PRC. Since 2000, we have successfully completed the design and construction of over 15 waste water facilities across China with total daily capacity of over 130,000 tons (inclusive of five BOT waste water treatment facilities with daily capacity of 123,000 tons). Our customers include municipal governments, food processing and beverage companies and industrial companies.

Because of these achievements, we have been recognized as a “Key Enterprise in Environmental Industry in the PRC” by the General Bureau of Environmental Protection of China and are viewed as a “High-Tech Enterprise” by the Bureau of Science and Technology of Guangzhou, PRC.

Industry Background

Waste Water Treatment Markets in the PRC . The waste water treatment business is in a developmental stage in China. Following decades of rapid industrialization and urbanization resulting from PRC’s breakneck economic expansion, demands for urban and industrial waste water treatment are immense. In 2002, total volume of municipal and industrial waste water produced reached 23 billion and 26 billion tons, respectively, of which only approximately 25% was treated in some form. The PRC government, which views environmental issues as a policy priority, has targeted a 90% treatment ratio by 2030. This targeted growth, combined with a policy of privatizing all existing government facilities, is resulting in extraordinarily high levels of expansion in an industry that did not effectively exist until the 1980s.

In order to promote investment in the waste water treatment industry, the central government has created incentives such as tax relief and higher throughput fees which can improve the profitability of certain municipal projects.

Under the tax regulations in the PRC, companies providing water purification are exempted from business tax on the collection of waste water treatment fees. The PRC government also gives tax relief in the form of reduction in or exemption from value-added tax and income tax to encourage treated water to be reused in residential, agricultural, commercial or industrial sectors.

The PRC government introduced a new policy in relation to the water supply tariff management methods for the water-resource system which became effective in January 2004. The new policy prescribes a water tariff approach, comprising of water production costs, expenses, profit, and tax. Pertinent pricing is expected to be in accord with local market demand.

Before the 1990s, water tariffs were extremely low, and there were no wastewater discharge fees. People were more concerned with water quality than with the price and quantity they used. As citizens now pay closer attention to water quality, they expect higher prices to accompany water quality improvements. Therefore, water tariff and wastewater treatment throughput fees, especially in the cities, are rising to rational levels.

Fresh Water Markets . Before 2003, the facilities for fresh water supply in the PRC were owned and operated by the agencies of local governments. As industrial, economic and population growth and chronic pollution have placed intense demands on the water supply in China, the fresh water supply has had a serious shortage. Similar to the waste water treatment industry, the PRC government has opened up the fresh water supply business to private sector and international operators.

Bottled Water Markets . The bottled water industry in PRC is in the process of rapid and continuous growth and development. Globally, according to recently published data from consultancy firm Beverage Marketing Corporation(BMC), from 2002 to 2007 PRC was the fastest growing country in the world in terms of consumption of bottled water, showing a compound annual growth rate of 17.5%, double the next fatest growing country, the United States. With the growth in demand and addition of new industry participants offering new and varied bottled water products, the Chinese bottled water industry is poised for significant growth.

Our Business Activities

There are different types and quantities of pollutants in water due to the environment, conditions and purpose for which the water is used. Municipal water has organic matters including nitrogen and phosphorus. The composition of such municipal wastewater is relatively stable. In contrast, pollutants in water discharged from industries include organic pollutants, inorganic matters, metal ions and salt ion. We adopt varying treatment processes for different industrial wastewater.

We provide turn-key engineering, equipment and chemical sales for industrial and municipal waste water treatment facilities in the PRC. We also invest in, manage and operate our own water treatment facilities through BOT arrangements in the PRC.

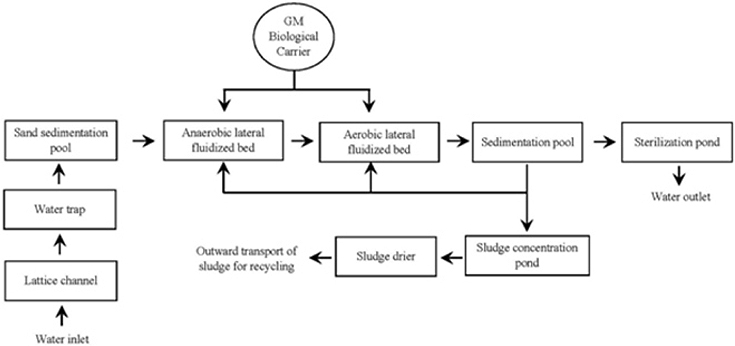

The following chart describes the waste water treatment process that we service:

Turn-Key Waste Water Engineering. We provide turn-key waste water treatment engineering services to both public and private sectors. Our public sector clients include municipal governments at the city, district and town levels. Our private sector clients include heavy industries, such as steel, car manufacturing, electronic; light industries, such as chemical, food and beverage, paper, printing and breweries; and others, including hospitals and the pharmaceutical industry. The industrial wastewater qualities differ due to the different industrial products and manufacturing processes.

These contracts are awarded either by public tender or by direct contract. A typical turn-key waste water treatment project can be classified into three phases; (1) survey and design, (2) construction and equipment installation, and (3) operation and management services.

From 2000 to 2007, we completed the following turn-key projects: Yongji Development Zone Wastewater Treatment Plant (Phase 1), Guangdong Nanhai City Jinsha Town Wastewater Treatment Plant, Guangdong Sanshui Baini Wastewater Treatment Plant and Guangzhou Yantang Wastewater Treatment Plant, Tianjin City Meichang Town Wastewater Treatment Plant,Yongji Development Zone Wastewater Treatment Plant (Phase 2), China Environment Industrial Park Wastewater Treatment Plant ,Huangzhuang Industrial Park Wastewater Treatment Plant and Tian Jin WuQing No.1 Waste Water Treatment Factory.

We financed our turn-key projects through progressive payments from our customers as stipulated in the agreements for these projects.

Investment in BOT Waste Water Treatment Facilities. We also invest in waste water treatment facilities through BOT arrangements. BOT projects provide us with a stable income source under a long-term (usually 20-30 year) contract granted by municipal governments to build and operate waste water plants. BOT project land is typically contributed by the municipal government with the operator providing investment and daily management. After the contract period, the project is transferred to the local government. After we secure a contract for a BOT project from a municipal government and the financing for such project is in place, we will proceed to construct the facility. After the completion of construction and testing and commissioning, we will operate the waste water treatment facility for a period of 20-25 years as stipulated in the BOT contract.

The following table sets forth the BOT projects which we have completed:

| BOT Projects | | Cost of investment | | Capacity/ Per Day | | Operation Period | | Date of commencement of operation |

| Waste water treatment plant of TianJing | | US $ | 1.09 million | | | 10,000 tons | | 20 years | | November 2003 |

| Waste water treatment plant of XinLe | | US $ | 4.11 million | | | 40,000 tons | | 22 years | | October 2003 |

| Waste water treatment plant of HaiYang | | US $ | 3.62 million | | | 20,000 tons | | 22 years | | June 2005 |

| Waste water treatment plant of HanDan | | US $ | 3.53 million | | | 33,000 tons | | 22 years | | December 2007 |

As of December 31, 2007, the waste water treatment plants of TianJin, XinLe and HaiYang were operational and have been providing waste water treatment services. The HanDan waste water treatment plant began to operate during January 2008.

We have been financing the BOT projects of TianJing, XinLe and HaiYang through capital injections and funds generated from our operations. We will finance the remaining capital expenditure of HanDan of approximately $2 million through funds generated from our operations.

Our Production Process

Though the chemicals used for treating municipal and industrial wastewater qualities are different due to the different sources of wastewater for municipal wastewater treatment and different industrial product and manufacturing process for industrial wastewater treatment, the treatment processes are largely similar.

During the wastewater treatment process, the wastewater is first collected by a pipeline network system and then transported to a sand sedimentation pool. The wastewater will then go through the MHA waste water treatment process, which is a natural, chemical-free, biological and mineral-based process that facilitates the rapid growth of bacteria in order to improve the efficiency of degrading the micro-organism materials in the wastewater and for more efficient operation and reduced energy consumption. After the MHA waste water treatment process, the wastewater is then transported to the sedimentation pool to remove the fine particles in the wastewater. The wastewater will then be sterilized in the sterilization pool and be transported to the water outlet.

Our Project Management Process

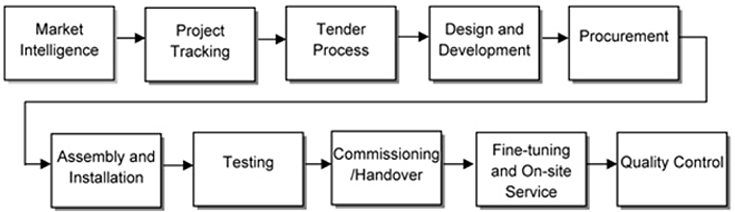

The following is the flow chart of our project management process for both turn-key wastewater engineering projects and BOT projects:

Market Intelligence . The starting point for all our projects is market intelligence so that our management is able to decide which projects they wish to secure for the benefit of the company. Our marketing personnel are in charge of market information on potential projects on a regular and ad-hoc basis. Our management is able to identify and decide on projects which we may potentially bid for.

Project Tracking . Based on the information gathered through market intelligence and the subsequent comprehensive analysis conducted on such information, our management will decide on which projects to pursue. We carry out internal evaluations which consist of three steps: initial evaluation, revaluation and valuation by professionals. We also engage external advisors to carry out external evaluation. We will then embark on determining what the tender rules and conditions are and the capital requirements and technologies used for the project. Project tracking allows us to plan ahead and make the necessary cost planning.

Tender Process . Once we decide to proceed to tender for a particular project, we will form a tender committee comprising marketing personnel and technical personnel, who will be responsible for compiling the tender documents to be submitted for tender within the stipulated deadline. The tender committee will compile internal costing and budgetary estimates of labor and material costs based on quotations from the relevant suppliers and factor in a suitable profit margin in determining our tender pricing.

Design and Development. After signing of the contract, we will appoint a project team to be responsible for the execution of the project, including an ad-hoc research and development team to handle the design and development of that particular project. The research and development team will follow our overall guidelines to analyze, assess and determine the design and specifications of a system which will ensure that all of our customers’ requirements are met. The design and development process includes collection of information, site survey, key design concept, design specification, individual design, evaluation, revaluation and issue for construction. In addition to our own design and development capabilities, we have also entered into collaboration arrangements with other parties to test our equipment to ensure its suitability and effectiveness.

Procurement. After the necessary design and analysis, the specifications of the system are confirmed, and our procurement department will proceed to purchase all the materials and equipment required or appoint appropriate sub-contractors to carry out certain parts of the project.

Construction . The construction process includes sub-contracting and site supervision. During construction, we will send site representatives to control and supervise the construction.

Assembly and Installation . We will carry out assembly and installation of equipment and/or system and coordinate the assembly and installation fully with the construction process to ensure all equipment and/or system are properly assembled and installed. We will send technical staff to assist and guide the assembly and installation.

Testing . After the equipment and/or system has been assembled and installed, we will test the system in accordance with industrial and national rules and regulations formulated by the relevant PRC authorities.

Commissioning and Fine-Tuning . For turn-key projects, should the system pass all tests, we will proceed to hand over the system to our customers. 5%-10% of the total contract value will be treated as retention monies during the warranty period of up to 12 months requirement. Our technical personnel will carry out fine-tuning and on-site services. After successful commissioning of the entire system, the retention monies will be paid by our customers to us after the warranty period of up to 12 months. For BOT projects, the plant will start operation after passing all tests. The technical team will carry out fine-tuning and on-site services. The operation team will follow the operational guidelines and monitor the quality of treated water.

Competition

We believe our main competitor is Beijing Capital Co., Ltd. (“Beijing Capital”), a subsidiary of Capital Group, which has identified investment, development, operation and management in the PRC water industry as its core business. Beijing Capital provides environment management services. We also compete with many other environmental and water treatment companies. We believe that we compete primarily on the basis of contract pricing and capital. Though many of our competitors offer similar but less cost-effective services, they may have greater financial resources and hence be able to secure contracts with reduced operating margins but more competitive pricing. However, we believe that as a result of our cost efficiency through our patented technologies, we are able to offer even more competitive pricing. In addition, having access to the capital markets in the United States through our public listing will help to differentiate us from our competition. Another area of competition comes from local protectionism where local governments wish to protect local environmental businesses. In order for us to overcome this kind of competition, we rely on our financial and technical resources.

Our Competitive Strengths

Key elements of our competitive strengths include:

Capital Resources. The threshold of capital requirements for entering the waste water treatment segment and the initial capital investment of waste water treatment facilities and projects, especially BOT projects, is relatively high. Based on our good track record and relationships with local governments in the PRC, we believe we are capable of obtaining sufficient capital resources to fund our operation of projects and expansion plan.

Experienced Management Team and Strong Research and Development Capability. We have a qualified and experienced management team and staff who possess strong technical capabilities and who specialize in project management, project design and research and development in relation to the water purification and wastewater treatment industry. Among our senior management, most possess degrees or senior technical qualifications. Members of our senior management team also have prior experience in managing large corporations and are familiar with all levels of management. Most of our management and staff have strong technical expertise and are professionally trained.

We place great emphasis on technical research and development, and typically set up research and development teams for specific projects to handle the design, development and improvement of such projects.

We also keep track of the latest developments in water treatment technology through our advisors and consultants who are experts in the water purification and waste water treatment industry. We have established a long-term cooperation with the Chinese Academy of Science at Guangdong and a number of universities to maintain its superiority in developing innovative wastewater treatment technology.

We believe that our management experience and our strong technical capabilities provide us with a competitive edge over our competitors.

Good Track Record and Professional Quality. We believe that our good track record and goodwill that we have built up in the provision of water treatment systems for the municipal government and industrial waste water treatment give us an edge over our competitors. Due to our strong track record, we have been awarded various certifications by different environmental institutions, including certifications of Quality Facility for Environmental Protection, Gold Price of 2 nd Chinese Patent Technology Fair, World Chinese Scientific and Technology Invention Prize, certificates of “Quality Branded Environmental Protection” and “Asia International Scientific and Technology Improvement Prize”. These certificates typically strengthen our ability to tender for BOT projects with the municipal government and also turn-key projects for industrial waste water treatment.

Effective Market Network. We emphasize the importance of marketing and have people specialized in promotion of our company and securing projects. We have marketing networks in Shangdong, Tianjin, Beijing, Handan Hebei, Xianyang Shangxi and Guangdong, where we have BOT projects. Such offices provide feedback on market intelligence and deal with existing and potential customers. Project selection is partially based on intelligence feedback from these networks. We retain a team of former senior government officials with considerable influence on local and central governments in the PRC. We identify this team through introduction and conferences/conventions that we attend. This team identifies and helps to secure major environmental projects for the group. The team also provides timely feedback of market conditions and deals with our existing and potential customers regularly. Though we do not have any contract with this team, we give incentives/commissions for each successful project secured.

Long-Term Relationships with Academic Institutions. We have good long-term relationships with Guangdong Province Environmental Protection Design Institute and North-Eastern Environmental Protection Design Institute, who provide important technical support in design and project execution. North-Eastern Environmental Protection Design Institute will provide technical support in the design of waste water treatment facilities and preparation for the tendering of projects while Guangdong Province Environmental Protection Design Institute will evaluate the feasibility and acceptability of the blue prints of the facilities. Compensation for both institutions are based on amount of work done.

Customers, Sales and Marketing

Many of our principal customers are local governments, food and beverage processing companies and industrial companies that use our technologies to treat their waste water.

In 2007, the Group’s major customers were Tianjin City Wuqing Zone Environment Protection Bureau and Hai Yang City Zoning and Construction Management Bureau, both independent third parties, which, accounted for approximately 43.3% and 38.3%, respectively, of the Group’s total revenue of 2007. Revenue from Tianjin City Wuqing Zone Environment Protection Bureau was in relation to the turn-key projects of Tianjin City Wuqing Economic Development Zone Wastewater Treatment Plant while revenue from Hai Yang City Zoning and Construction Management Bureau was for the BOT wastewater treatment services of Haiyang City Wastewater Treatment Plant.

We market and sell our products through our direct sales force and independent sales representatives throughout the PRC. Our sales and marketing team is responsible for evaluating the marketplace, generating leads and creating sales programs. We use a “Project-Company” strategy for each BOT project, establishing a company in the location of the project, responsible for construction and operation of the project. Through establishing a good relationship with the local government, the Project-Company markets its business in the location. Our on-site direct service organization provides ongoing services to customers using our products.

In order to compete effectively, we focus on projects of a scale between 10,000 tons and 50,000 tons of waste water per day, where we can achieve a balance between economies of scale arising from our technology and our available capital base.

Research and Development

Our research and development efforts are directed toward enhancing our existing technology and products and developing our next generation of technology.

We have the exclusive rights to MHA biological treatment processes technologies (“MHA”) and GM Bio-carriers. Both are the subject of patents owned by our Chairman, Mr. Pu, and we have acquired the exclusive rights pursuant to a license agreement with Mr. Pu. We have applied both technologies to improve the efficiency and effectiveness of waste water treatment processes as well as to reduce the initial investment and on-going operating cost of waste water treatment facilities. The advantages of MHA are:

| • | Proprietary design of water flow control mixer to ensure even distribution of waste treatment bacteria in the treatment facility. |

| • | Proprietary design of no-oxygen, low-oxygen and oxygen tanks to reduce energy consumption and ensure low sludge build up in the treatment process. |

| • | Proprietary blend of waste water treatment bacteria (i.e., photosynthetic, lactobacillus, yeast, streptonyces, etc.) of over 50 types of different degradation and effectiveness to achieve toxic, aromatic and micro-organism-free water of release. |

GM Bio-carrier is a natural, chemical-free, biological and mineral-based process that facilitates the rapid growth of bacteria in order to improve the efficiency of degrading the micro-organism materials in the waste water. Installation of such carriers into the waste treatment process facilitates bacterial growth for more efficient operation and reduced energy consumption.

Currently we are developing technology with universities and research institutions in Guangdong Province and have on staff a chief scientist, who is a researcher in the field of environmental protection, and two research fellows. The technology that we are developing with these universities and research institutions is for the improvement of quality of treated water, increase in efficiency, reduction in costs in the waste water treatment process and to further enhance the current technologies that we have.

Quality Control

Our quality control department is headed by Luo Huizhong, who has more than 15 years of relevant experience. Mr. Luo has been a chief engineer at several companies, and Vice general engineer of our company, and he is familiar with resource allocation, quality control and environmental facility management control.

To ensure the quality of our products and services, we carry out stringent quality control checks at every stage of project execution.

Quality Control During Design, Research and Development. The design of every project is carried out by our experienced staff following strict guidelines. We have also established a three-tier examination and verification system. A strict examination and approval system is also adopted in respect of any design changes.

Quality Control During Procurement. To ensure the quality of equipment and materials procured, we maintain a list of suppliers and sub-contractors whose goods and services meet our quality control standards. We purchase our materials and equipment only from these suppliers, and such materials and equipment are subject to further inspection and checks by our quality control staff upon arrival at our production facilities. Goods which do not meet our quality control standards are rejected.

Quality Control During Assembly and Integration. As a general policy, our sub-contractors selected and appointed by us to carry out engineering, assembly and integration works should be long established and have good track records.

Quality Control During Delivery and Installation. To ensure that our qualified sub-contractors comply with our quality control standards during delivery and installation, we also task our engineers with formulating a quality control and progress plan, and to identify the key quality control points of the delivery and installation procedure. Such engineers will supervise our sub-contractors during delivery and installation.

Quality Control During Operation for BOT Projects. Our operation team starts their training prior to the commencement of operation. After test run and commissioning, the operation team will take over the operation. We have very strict guidelines for the operating team to ensure quality of clean water. A production report is to be faxed to the head office everyday and we will perform regular tests to ensure the treated water meet high quality standard. We also conduct regular training to ensure that our operation teams are equipped with the latest know-how.

Cooperative Partners and Suppliers

We outsource the design and construction of our subsystems to a number of cooperative partners and key suppliers and maintain close relationships with them. Our cooperative partners include North-Eastern Environmental Protection Design Institute, Guangdong Province Environmental Protection Design Institute, and the 20 th Group of China Railway Company. We have signed cooperative agreements with these cooperative partners. North-Eastern Environmental Protection Design Institute provides technical support in the design of waste water treatment facilities and preparation for the tendering of projects, 20 th Group of China Railway Company evaluates all documents and information required for tendering while Guangdong Province Environmental Protection Design Institute evaluates feasibility and acceptability of the blue prints of the facilities. Compensation for our cooperative partners are based on amount of work done.

North-Eastern Environmental Protection Design Institute was established in 1961 in the city of Changchun. The institute focuses on design of, research in and provision of consultancy services for municipal infrastructure construction works including water supply, waste water treatment, waste treatment, energy supply, construction of road and bridges, public transport and afforestation of city etc. The institute also provides other services in relation to civil construction works for municipal projects like feasibility studies for projects, evaluation of projects, project management and project supervision.

The Guangdong Province Environmental Protection Design Institute was established in 1990. Over the years, the institute has gained experiences in the design, management, treatment and turn-key engineering of waste water, air pollution, noise pollution and waste residue. The institute has achieved remarkable results especially in waste water treatment for the printing and dyeing, electroplating, brewing, pharmaceutical, chemical and food & beverages industries.

The 20 th Group of China Railway is a large-scale construction company in the PRC. The history of the 20 th Group of China Railway dated back to the year 1949. The company has enormous experience in the construction of railway systems in the PRC and related infrastructure including road construction, water supply, energy supply, waste water treatment, urban and rural planning, municipal projects etc. The company is also involved in many large scale construction projects overseas.

There are three main types of equipment for our waste water treatment and potable water projects: (i) electrical equipment which includes various types of sewage pumps, slush pumps and other water pumps, separators, sludge scrapers, mixers, air compressors, filters, dehydrators, blow fans, etc; (ii) automated control systems and electrical parts; and (iii) various test, analysis, detection and monitoring instruments. All purchases from foreign companies are made through their authorized dealers/agents in the PRC. We adhere closely to the principles of total quality management. Our customers, suppliers and employees are encouraged to provide feedback and suggestions for improvements in products and services.

The following table sets forth our major suppliers of equipment and materials:

Component, Raw Materials and Equipments | | Our Major Suppliers |

| Waste water treatment analytical instruments | | Hach Company |

| | | |

| Blow fan systems | | HV-Turbo A/S |

| | | |

| Sewage pumps, slush pumps, other water pumps and mixers | | Nanjing Airs Pump Industry Group |

| | | |

| PLC automated control systems | | Mitsubishi Electric |

| | | |

| Electrical parts | | Schneider Electric Low Voltage (Tianjin) Co. |

| | | |

| Automated systems | | GuangZhou SaiDi Automated Engineering Company |

Intellectual Property

We seek to protect our intellectual property by way of our license rights to patents on proprietary features of our advanced bio-chemical treatment technology and processing systems for waste water treatment and by challenging third parties that we believe infringe on our licensed patents. We have obtained the exclusive right to use two patents owned by our Chairman, Mr. Pu, for our MHA and GM Bio-carriers technologies. We also protect our intellectual property rights with nondisclosure and confidentiality agreements with employees, consultants and key customers.

Specifically, we have registered the following patents with the State Intellectual Property Office of the PRC:

| • | MHA biological treatment process technology (PRC Patent No. ZL 01 1 07637.2) applied on March 14, 2001, declared effective on March 3, 2004 with a duration of 20 years from the date of application; and |

| • | GM Bio carriers (PRC Patent No. ZL 01 1 07624.0) applied on March 8, 2001, declared effective on September 10, 2003 with a duration of 20 years from the date of application. |

Employees

As of December 31, 2007, we had 36 employees, of whom 3 were engaged in sales, marketing and service, 6 in research, development and engineering, 12 in finance and administration and 15 in operations. None of our employees is represented by a collective bargaining agreement, and we believe that we have satisfactory relations with our employees.

Environmental

One of our core values is protecting the environment in which we operate and the environment in which our equipment operates. Compliance with laws and regulations regarding the discharge of materials into the environment, or otherwise relating to the protection of the environment, has not had any material effect on our capital expenditures, earnings or competitive position. We do not anticipate any material capital expenditures for environmental control facilities in 2008 .

The PRC’s numerous ongoing water reforms are moving toward a user-pay, market-driven sector. Legislation serves as the basis to regulate and enforce these reforms. The Water Resource Law, amended and put into effect on October 1, 2002, significantly changes water resource management systems, water resource protection, water conservation, and legal responsibilities.

Environmental Laws and Regulations

In the PRC, environmental laws and regulations are stipulated and implemented through legislation and through administrative authorities at various levels of government. Current environmental laws and regulations can be classified into two categories: environmental management and environmental pollution prevention and control. All environmental laws and regulations are stipulated on the basis of the Environmental Protection Law (EPL). EPL, effective in December 1989, sets the framework for environmental management and pollution control legislation in the PRC.

Environmental Management Law and Regulation . The PRC’s environmental management measures include environmental impact assessment (EIA), the Three Synchronies Policy, permitting requirements, and reporting requirements. Each of these is described below:

| 1. | Environmental impact assessment . The 1989 Environmental Impact Assessment Law was revised in October 2002. These revisions became effective in September 2003 and apply to all construction projects that may negatively impact the environment. An EIA must be prepared during the project feasibility stage to assess the project’s environmental impact. EIA approval is necessary to secure a construction and operating permit. |

| 2. | Three Synchronies Policy . Article 26 of the EPL defines the Three Synchronies Policy as the installation of pollution prevention and control facilities in a construction project to be undertaken concurrently with the main construction phase. The pollution prevention and control facilities are to be installed and commissioned only after they are inspected and approved by the Environmental Protection Bureau (EPB). |

| 3. | Permitting requirements . Pollution discharges in the PRC are subject to registration and permitting requirements. The EPL defines requirements for pollution discharge registration and permits. Pollution discharges must be registered with the relevant environmental authority. A pollution discharge permit is issued after registration. The Management Regulation on the Registration of Discharged Pollutants, issued by the State Environmental Protection Administration (SEPA), effective Oct. 1, 1992, details requirements for pollution discharge registration. At the state level, the Department of Pollution Control under SEPA implements pollution discharge registration and permitting policies. Pollution control departments under local EPBs are in charge of the registration procedures and issue a pollution discharge permit. |

| 4. | Reporting requirements. According to Article 31 of the EPL, any organization that causes or has a potential to cause an accident resulting in environmental pollution must promptly take measures to prevent and control the pollution hazard and notify the relevant authorities. In addition, enterprises and institutions that have a greater likelihood to cause severe pollution accidents must adopt effective pollution prevention measures. |

Environmental Pollution Law and Regulation . Environmental pollution prevention and control measures in the PRC apply to various environmental media, including water, water supply, wastewater discharge, air emissions, hazardous waste management, noise, and soil and groundwater. In November 2004, the management rules regarding environmental pollution prevention facilities operation permit was enacted and it set forth the requirements for getting a permit and how the facilities must be operated.

The following is a summary of environmental pollution laws and regulations regarding water, water supply and waste water discharge in the PRC:

Three laws apply to the water sector:

| 1. | The Water Resources Law emphasizes the uniform management of river basins and the macro-management of water distribution and consumption. In addition, the law identifies a water quality management system. |

| 2. | The 1984 Water Pollution Prevention and Control Law (WPL) applies to discharges to rivers, lakes, canals, reservoirs, and groundwater. The WPL contains sections pertaining to water quality and discharge standards, pollution prevention, surface water, and groundwater. Amendments in 1996 introduced further controls on river basins, including requirements for cities and towns to establish central sewage treatment plants and to set treatment fees, mass-loading controls, provisions for strengthening the supervision and management of water pollution, and non-point-source pollution controls. |

| 3. | The Implementation Regulation of Water Pollution Prevention and Control Law was enacted on March 20, 2000. This law regulates the supervision and management of surface and ground water pollution, prevention, and control measures. |

Water supply . In urban areas, water is usually supplied by the municipal water utility companies, which are responsible for ensuring that water quality complies with the National Drinking Water Standard (GB5749-85). A groundwater abstraction permit is required if any company intends to use groundwater directly. In the northern part of the PRC, however, the use of groundwater is strictly controlled because of significant water shortages and ground settlement issues. Users must apply to provincial or higher level administrative committees for a groundwater abstraction permit.

Wastewater discharge . Two types of wastewater discharge systems are defined in the PRC: (1) polluted wastewater discharges (typically industrial and domestic wastewater) and (2) non-polluted wastewater discharges (for example, storm water). Separate drainage systems for polluted and non-polluted discharges are required for a facility in which a municipal sewer system is available.

Environmental Enforcement

In the PRC, methods of enforcing environmental legislation include discharge fees, surcharge fees, fines, and administrative sanctions. Pollutant discharge activity is subject to a discharge permit, which must be registered and obtained before the pollutants are generated.

In major pollution control areas, such as Shanghai and Beijing, mass-loading targets are established and allocated to major emission facilities by the local EPB. In some pilot locations, emission quotas can be traded among facilities.

In areas with significant pollution problems, such as those impacted by sulfur dioxide emissions, acid rain, and water quality deterioration, specific discharge limitations are adopted to prevent further degradation.

There are specific items within the Constitution of the People’s Republic of China and the PRC Criminal Law to strengthen the enforcement of environmental legislation by disciplinary sanction, civil liability, and even criminal liability. Disciplinary sanctions may come in the form of a warning, a fine, a requirement to install environmental protection equipment, or a requirement to cease operations. Criminal liability can also be passed on to the legal representative of an enterprise if the polluting activity caused severe damage to property, health, or interests of the state or its citizens. In these cases, the individual deemed responsible may be prosecuted. Civil liability also exists and is aimed at activities that may result in civil disputes. Generally, the dispute may be settled through financial compensation by the facility that caused the damage.

PROPOSED NEW LINE OF BUSINESS

In 200 7_ we entered into an agreement with _Fortune Luck Global International Limited_____ to secure a high quality source of drinking water from the __Dagu___ glacier. During calendar 2007 we conducted a limited test market of bottled water in _Guangzhou. Management was satisfied with the results of the test market of the bottled water and intends to expand this business to make it the main business of the Company in the future.

Currently, the industry of waste water treatment is facing more intense competition. The industry itself requires large investment in capital coupled with low rates of return over long periods. We have determined that we lack the available capital resources and support to expand our business in waster water treatment. Management believes it is in the shareholders’ interest to switch our business line from waster water treatment to bottled water mining, distribution and sales as there is currently no premium national bottled glacier water brand in the PRC creating a market opportunity for the Company.

The Global Industry for Bottled Water.

According to Datamonitor, the global bottled water market reached a value of $61.0 billion in 2006 and is forecasted to have a value of $86.4 billion in 2011, an increase of 41.6%. In 2006, global volume of bottled water was 115.4 billion liters and is expected to be 174.2 billion liters in 2011, an increase of 51.0%. On a consumption per capita basis, United Arab Emirates holds the leading position with 260 liters of bottled water consumption per capita in 2007, followed by Mexico and Italy. The global average consumption per capita is 29 liters, but China consumes only approximately 14 liters of bottled water per capita. If China's consumption per capita grew to the global average of 29 liters, it would represent a 110% increase (or an additional 20 billion liters) in consumption of bottled water. If China's consumption per capita grew to the average consumption per capita of the top 10 countries, it would represent over a 1,000% increase (or an additional 184 billion liters) in consumption of bottled water.

The Chinese Bottled Water Industry.

In China, water resources per capita are only 28% of the world average. Compounding the lack of water resources, the State Environment Protection Administration of China estimated in 2007 that tap water in one-half of China's major cities was polluted by industrial chemicals and agriculture fertilizers. A large amount of wastewater is directly discharged into water bodies, and industrial wastewater treatment has not been completely established, resulting in serious water pollution problems. Safe drinking water is a priority in China, and given the lack of wastewater treatment plants, the drinking water issues are not likely to be solved in the near future.China's bottled water industry started to grow as drinking water quality in China began to deteriorate. The market grew at a compound rate of around 37% yearly from 1994 to 2005. According to the Beverage Marketing Corporation, China was the fastest growing consumer of bottled water in the world with a 17.5% compounded annual growth rate from 2002 to 2007, double the next fastest growing country, the United States. Although China was the fastest growing and third largest consumer of bottled water, it represented less than one-half of the world's per capita average of liters consumed and only 11% of the per capita average of liters consumed of the top 20 countries.

Item 1A. Risk Factors.

You should carefully consider the risks described below, which constitute the material risks facing us. If any of the following risks actually occur, our business could be harmed. You should also refer to the other information about us contained in this Form 10-K, including our financial statements and related notes.

Risks Related to Our Business

We are dependent on the state of the PRC’s economy as all of our business is conducted in the PRC . All of our business operations are conducted in the PRC and all of our customers are also located in the PRC. Accordingly, any significant slowdown in the PRC economy may cause the waste water treatment industry to reduce expenditure or delay the building of new facilities or projects for waste water treatment. This may in turn lead to a decline in the demand for our products and services, and may reduce our profitability and the return on your investment.

We may not be able to secure new customers . Our business is project-based, though our BOT projects customers are bound to us for the contractual periods of twenty to twenty five years, our other customers are non-recurring customers and we do not expect them to continue to be our customers because of the nature of the industry. If we fail to secure projects from new customers, our revenues and profitability may decline and the return on your investment may be reduced.

Our business could be affected by cost overruns, project delays and/or incorrect estimation of project costs . As our business is project-based, it is important that we manage our projects efficiently in terms of time, procurement of materials and allocation of resources. If our initial cost estimates are incorrect or delays occur in a project resulting in cost overruns, the profitability of that project will be adversely affected. Currently, we offer some of our customers a warranty period of up to 12 months after the commissioning of the water treatment projects, during which we are obliged to provide free rectification work against any manufacturing defects. Cost overruns due to additional rectification work and delays in completion of projects would adversely affect our profitability. We may also face potential liability from legal suits brought against us by our customers for causing loss due to any delay in completing a project. Mismanagement of or mistakes made during our projects will adversely affect our profitability as well as our reputation among our customers. We may also face potential liability from legal suits brought against us by our customers who have suffered loss due to such mismanagement or mistakes. This would also reduce our profitability and the return on your investment.

Failure to retain services of key personnel will affect our operations and results . Our success to date has been largely due to the contributions of our executive officers. The continued success of our business is very much dependent on the goodwill that they have developed in the industry over the past several years.

Our continued success is dependent, to a large extent, on our ability to retain the services of our executive officers. The loss of any of our executive officers’ services due to resignation, retirement, illness or otherwise without suitable replacement or the inability to attract and retain qualified personnel would affect our operations and may reduce our profitability and the return on your investment.

We may not be able to protect our processes, technologies and systems against claims by other parties . Although we have two registered patents in respect of the processes, technologies and systems we use frequently in our systems, we have not purchased or applied for any patents other than these as we are of the view that it may not be cost-effective to do so. For such other processes, technologies and systems for which we have not applied for or purchased or been licensed to use patents, we may have no legal recourse to protect our rights in the event that they are replicated by other parties. If our competitors are able to replicate our processes, technologies and systems at lower costs, we may lose our competitive edge and our profitability may be reduced.

We may face claims for infringement of third-party intellectual property rights . We may face claims from third parties in respect of the infringement of any intellectual property rights owned by such third parties. There is no assurance that third parties will not assert claims to our processes, technologies and systems. In such an event, we may need to acquire licenses to, or to contest the validity of, issued or pending patents or claims of third parties. There can be no assurance that any license acquired under such patents would be made available to us on acceptable terms, if at all, or that we would prevail in any such contest. In addition, we would incur substantial costs and spend substantial amounts of time in defending ourselves in or contesting suits brought against us for alleged infringement of another party’s patent rights. As such, our operations and business may be adversely affected by such civil actions.

We rely on trade secrets, technology and know-how, which we seek to protect, in part, by confidentiality provisions in contracts with our customers and our employees. There can be no assurance that these agreements will not be breached, or that we will have adequate remedies for any breach, or that other parties may not obtain knowledge of our trade secrets and processes, technology and systems. Should these events occur, our business would be affected and hence, our profitability, may be reduced.

We may require additional funding for our future growth . Our future growth will depend, to a large extent, on our ability to secure and invest in BOT projects which require a higher amount of capital investment. In order to obtain additional capital to develop these growth opportunities, we may issue additional shares of our equity securities. If new shares placed to new and/or existing shareholders are issued, they may be priced at a discount to the then prevailing market price of our shares, in which case, existing shareholders’ equity interests may be diluted. If we fail to utilize the new equity to generate a commensurate increase in earnings, our earnings per share will be diluted, and this could lead to a decline in our share price. Any additional debt financing may, apart from increasing interest expense, contain restrictive covenants with respect to dividends, future fund-raising exercises and other financial and operational matters.

Our customers may make claims against us and/or terminate our services, in whole or in part, prematurely should we fail to implement projects that fully satisfy their requirements and expectations . Failure to implement projects that fully satisfy the requirements and expectations of our customers or defective system structure or products as a result of design or workmanship or due to acts of nature may lead to claims against us and/or termination of our services, in whole or in part, prematurely. This may arise from a variety of factors including unsatisfactory design or implementation, staff turnover, human errors or misinterpretation of and failure to adhere to regulations and procedures. This may adversely affect our reputation and may reduce our profitability.

We are still exposed to credit risks of our customers. Defaults in payment by our customers will affect our financial position and our profitability within in a reduced extend compared to 2006 . As of December 31, 2007, accounts receivables of $ 0.52 million accounted for approximately 3.2% of our current asset. Generally, our credit terms vary from 90 days to 180 days. Defaults in payment by our customers would adversely affect our profitability and cash flow. There was no allowance for doubtful amounts for the years ended December 31, 2006 and 2007. We are unable to provide assurance that risks of default by our customers would not increase in the future, or that we will not experience cash flow problems as a result of such defaults. Should these develop into actual events, our operations will be adversely affected and our profitability may be reduced.

We are reliant on a few major suppliers . We are dependent on our major suppliers for the timely delivery of materials and equipment that we require for the equipment and systems we install. Should our major suppliers fail to deliver the materials and equipment on time, and if we are unable to source these materials and equipment from alternative suppliers on a timely basis, our project timeline will be delayed, thereby affecting delivery to our customers. This, in turn, would adversely affect our reputation if our customers lose confidence in our services and as a result, reduce our revenue and profitability.

We are subject to risks relating to BOT projects in which we have started to invest . We have begun to invest capital in BOT projects which require high up-front capital expenditures. Our returns from BOT projects are derived from fees paid by the PRC government and such BOT projects are able to generate a steady and recurring source of income for us over a sustained period of time between 20 and 25 years. However, our BOT projects are exposed to risks such as the occurrence of natural disasters or the imposition of more stringent government regulations, which may result in the disruption of our BOT projects. Our investment returns from these BOT projects may thus be reduced should any of such risks materialize.

We rely on subcontractors for our projects . As we may, from time to time, subcontract some parts of our projects to subcontractors, such as engineering, assembly and integration works, we face the risk of unreliability of work performed by our subcontractors. Should our subcontractors default on their contractual obligations and work specifications, our ability to deliver the end product or service to our customers in accordance with quality and/or timing specifications may, in turn, be compromised. Furthermore, if we are unable to secure competitive rates from our subcontractors, our profitability may be reduced.

The registered capital of our PRC subsidiaries may, in some cases, limit the size of the projects we bid for . We tender for projects in the normal course of business. There are instances where the projects that we intend to tender for require tendering companies to have a minimum registered share capital which is more than the registered share capital of our PRC subsidiaries. Under applicable PRC law, registered capital is defined as the total amount of capital contributions subscribed to by the parties and registered with the PRC authorities. Therefore, the quantum of our capital contributions to the PRC subsidiaries may limit the size of the projects that we are able to successfully tender for, even if we could show that we have other sources of fund. Although some customers may take into account other factors like our trading status and our track record, we are unable to assure you that we would be able to secure projects which are valued at more than our registered capital. Consequently, our revenue, business and financial results may decline.

We are subject to foreign exchange risks . Our dominant transactional currency is the Chinese RMB, including the cost of materials which are imported by our suppliers. With costs mainly denominated in RMB, our transactional foreign exchange exposure for the past few years has been insignificant. However, as our suppliers take into account the fluctuations in foreign exchange rates when they price the imported materials which we procure from them, such fluctuations in foreign exchange rates may result in changes in the purchase price of imported materials. Any future significant fluctuations in foreign exchange rates may have a material impact on our financial performance in the event that we are unable to transfer the increased costs to our customers.

We may be adversely affected by slow downs in the PRC economy owing to unforeseen circumstances, such as an outbreak of infectious diseases . Our business is dependent on the number of contracts we are able to secure from our customers. Unforeseen circumstances such as an outbreak of infectious diseases may lead to a decline in global and regional business, which may, in turn, lead to a decline in demand for our services.

Furthermore, should such unforeseen circumstances cause disruptions to our customers’ operations, they may undertake cost-cutting measures such as cutting capital expenditure and deferring projects such as installation of water treatment systems. The demand for our business may decline as a result of such cost-cutting measures.

Since our subsidiaries, operations and significant assets are located in the PRC, shareholders may find it difficult to enforce a U.S. judgment against the assets of our company, our directors and executive officers . Our subsidiaries’ operations and significant assets are located in the PRC. In addition, all of our executive officers and our directors are non-residents of the U.S., and substantially all the assets of these persons are located outside the U.S. As a result, it could be difficult for investors to effect service of process in the U.S., or to enforce a judgment obtained in the U.S. against us or any of these persons.

Our operations could be adversely affected by changes in the political and economic conditions in the PRC . The PRC is our main market and accounted for all of our revenue in 2006. Therefore, we face risks related to conducting business in the PRC. Changes in the social, economic and political conditions of the PRC may adversely affect our business. Unfavorable changes in government policies, political unrest and economic developments may also have a negative impact on our operations.