Exhibit 99.2

| FOR IMMEDIATE RELEASE | February 10, 2012 |

MICROMEM RELEASES SPEED CONTROL CIRCUIT STAGE ONE TEST

Toronto, ONTARIO, NEW YORK, February 10, 2012 –Micromem Technologies Inc. [the “Company”] [OTC BB: MMTIF, CNSX: MRM], through its wholly owned subsidiary Micromem Applied Sensor Technologies Inc. (“MAST”), releases Speed Control Circuit Stage one test results.

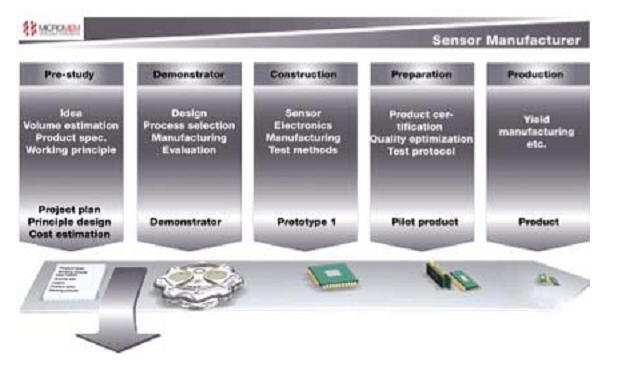

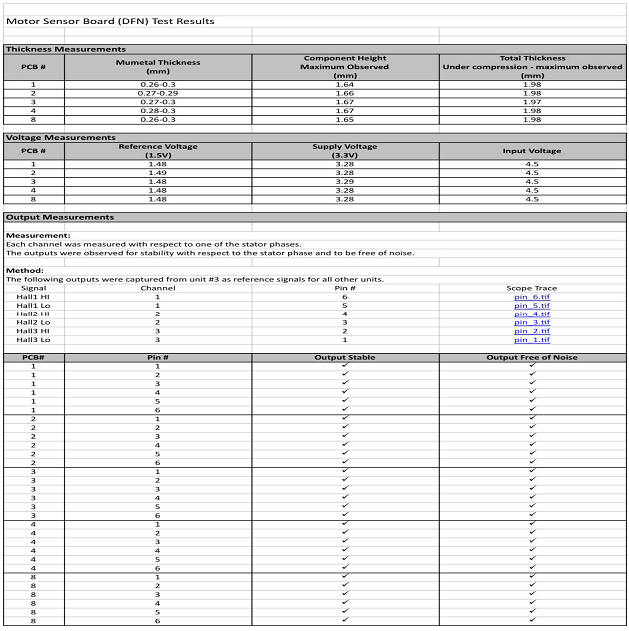

On February 6, 2012 we announced our successful shipping of a MAST product for final performance testing to GSI Westwind, the results of the stage one tests are in the chart above. This performance indicates that all mechanical and electrical requirements were met on 100% of the boards.

The Company would like to take this opportunity to describe the process taken to end up with a solution our clients can attribute business value to. It cannot be overemphasized that Micromem products are unique to our clients predicated upon an exchange of technical and business challenges unique to them.

The Company is a solution provider who benefits from a patent portfolio of sensing technology. While the Company is enjoying the benefits of its magnetic sensors based upon size, speed, sensitivity, ease of manufacturing and low cost of production, Micromem has amalgamated a skills base which includes nanofabrication, MEMS, photonics, electro-magnetics, bio and chemical sensor integration, signal processing, simulation, and electronics design, packaging and industrial sustainability.

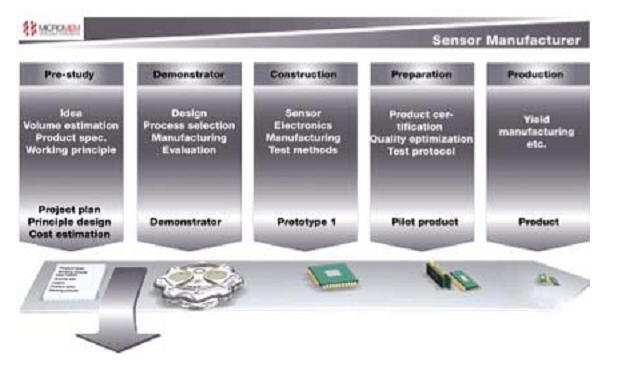

It is with this technology base that the Company is presently delivering proposals, or proof of concepts to diverse industry segments such as oil production, medical, automotive, automated electronics manufacturing and high voltage transmission and distribution. See the process on all client engagements outlined in the‘MAST Client Engagement Process’ captioned chart attached.

The Pre-study phase sets the tone for the engagement. It involves a complete understanding of the operational and business issues that the client is facing. In the case of our recent market release of the Motor Speed Control Circuit, it was at this point in the client engagement that we understood the limited space we had to fit the electronics, the operational challenges of working with the current solution being used and generally the technical challenges of integrating the proposed solution into the client’s high speed precision product line.

Based upon a complete understanding of the client’s requirements the Company designed a solution that formed a demonstrator for the client. Micromem utilized computerized circuit simulation software that demonstrated how the proposed product would not only fit in the very limited space but how it would operate over the entire speed range of the client’s product.

Once the simulation results were shared by the client and signed off the Company proceeded with the manufacturing of some prototypes of the circuit board. Micromem utilized its ISO certified manufacturing partner in China who was chosen based on their ability to generate rapid prototype products with extremely high quality control standards. This process is iterative in nature and must be managed over several time zones. See‘Rapid Prototype Circuit Board Manufacturing’ photo attached.

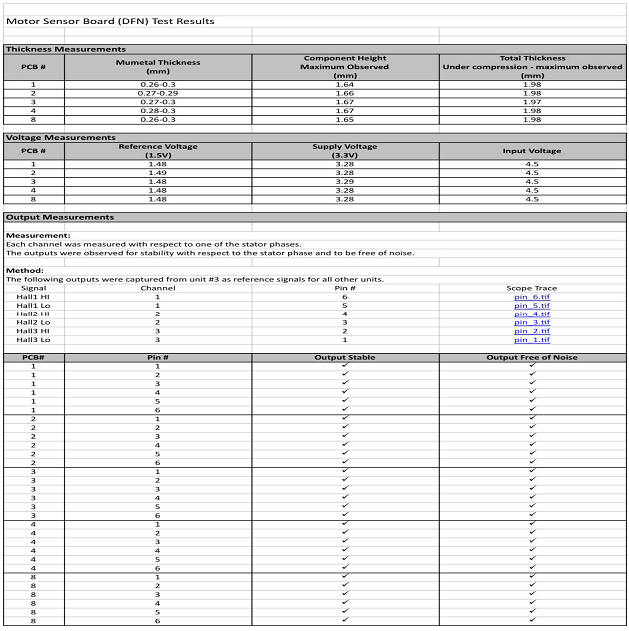

As is the typical case minor changes to the circuit had to be made based on actual testing prior to shipping to the client. The goal at this stage is to provide a stable prototype that can be sent to the client who can perform some initial testing to advise if the design was tracking their requirements. At this stage we also designed and manufactured a Mu-metal shield that functions as a shield to the electronics when installed in the inner workings of a high speed circuit. See‘Circuit Boards validated through Stage One Testing’ and‘MAST designed Mu-Metal Electronic Shielding’ photos attached.

Prototypes were sent to the client for testing, in this case both for mechanical fit and electronic operation. During the back and forth with the client, issues were expected and resolved.

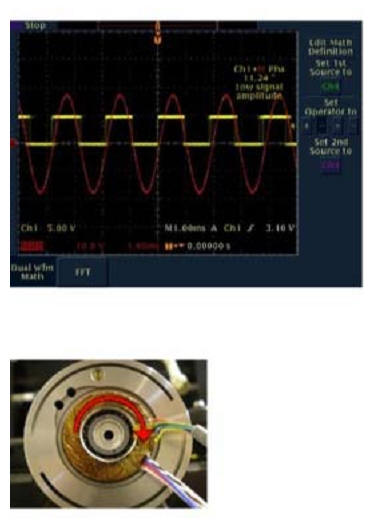

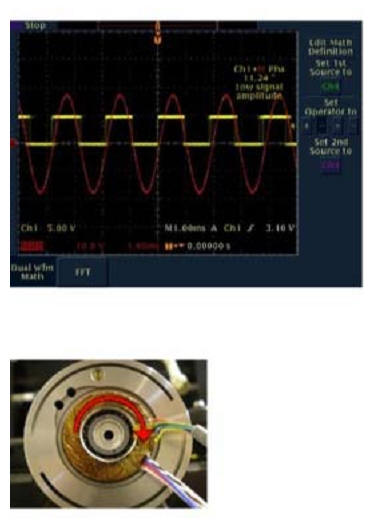

With the client feedback integrated into the design the product is sent back to the manufacturing partner in China and produced again. At this point MAST begins extensive electronic testing. The boards were run through several levels of testing and data evaluation. As is shown in the following performance display, on a three phase motor, it is critical for very accurate motor speed control to position each of three magnetic sensors in precise relationship to each other. The Company’s ability to position its very small magnetic sensors close to the magnetic portion of the motor, allows us to output from our board extremely accurate rotational positioning data. See‘Client Directed Speed Testing’ photo attached.

Discussions on the speed control circuit began November 2010 and work began in February of 2011 and has been a progressive set of milestones demonstrating Micromem’s ability to create a solution utilizing its patented sensor technology. The Company’s final deliverable to the client solved their space issue, their speed of response issue and it is anticipated it will reduce the man-hours to assemble and setup their final product

GSI Westwind will be releasing to Micromem the results of the final series of evaluation tests utilizing other parameters shortly. This will close the development contract where Micromem will receive the 3rd and final payment for the development agreement and take us to the commercial sales portion of this new product.

About Micromem, MASTInc

MASTInc is a wholly owned U.S.-based subsidiary of Micromem Technologies Inc., a publicly traded (OTC BB: MMTIF, CNSX: MRM) company. MASTInc responsibly analyzes the specific industry sectors to create intelligent game-changing applications that address unmet market needs. By leveraging its expertise and experience with sophisticated magnetic sensor applications, MASTInc successfully powers the development and implementation of innovative solutions for healthcare/biomedical, natural resource exploration, government, information technology, manufacturing, and other industries. Visitwww.micromeminc.comwww.mastinc.com.

Safe Harbor Statement

This press release contains forward-looking statements. Such forward-looking statements are subject to a number of risks, assumptions and uncertainties that could cause the Company’s actual results to differ materially from those projected in such forward-looking statements. In particular, factors that could cause actual results to differ materially from those in forward looking statements include: our inability to obtain additional financing on acceptable terms; risk that our products and services will not gain widespread market acceptance; continued consumer adoption of digital technology; inability to compete with others who provide comparable products; the failure of our technology; the infringement of our technology with proprietary rights of third parties; inability to respond to consumer and technological demands; inability to replace significant customers; seasonal nature of our business; and other risks detailed in our filings with the Securities and Exchange Commission. Forward-looking statements speak only as of the date made and are not guarantees of future performance. We undertake no obligation to publicly update or revise any forward-looking statements. When used in this document, the words “believe,” “expect,” “anticipate,” “estimate,” “project,” “plan,” “should,” “intend,” “may,” “will,” “would,” “potential,” and similar expressions may be used to identify forward-looking statements.

The CNSX or any other securities regulatory authority has not reviewed and does not accept responsibility for the adequacy or accuracy of this press release that has been prepared by management.

###

Listing: NASD OTC-Bulletin Board - Symbol: MMTIF

CNSX - Symbol: MRM

Shares issued: 118,231,407

SEC File No: 0-26005

Investor Contact: Jason Baun, Chief Information Officer Tel. 416-364-2023

MAST Client Engagement Process

Rapid Prototype Circuit Board Manufacturing

Circuit Boards validated through Stage One Testing

MAST designed Mu-metal Electronic Shielding

Client Directed Speed Testing