INVESTOR PRESENTATION April 2017

These slides contain (and the accompanying oral discussion will contain, where applicable) “forward- looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. These statements involve known and unknown risks, uncertainties and other factors that could cause the actual results of the Company to differ materially from the results expressed or implied by these statements, including health issues, litigation and regulation relating to our business, our ability to achieve and/or maintain profitability, significant cyclical fluctuations in our customers’ businesses, competitive substitutes for our products, risks associated with our international operations, including foreign currency rate fluctuations, energy costs and the availability and prices of raw materials, and other factors disclosed in periodic reports filed with the Securities and Exchange Commission. Consequently, these forward- looking statements should be regarded as the Company’s current plans, estimates and beliefs. The Company does not undertake and specifically declines any obligation to publicly release the results of any revisions to these forward-looking statements that may be made to reflect any future events or circumstances after the date of such statements or to reflect the occurrence of anticipated or unanticipated events. These slides include certain non-GAAP financial measures as defined by the rules and regulations of the Securities and Exchange Commission. A reconciliation of those measures to the most directly comparable GAAP equivalent is provided in the Appendix to this presentation. Forward-looking Statements 2

Making advanced materials that improve the world Materion: Our Purpose 3

Materion at a Glance 4 Adjusted EPS1 $1.32 Adjusted EBITDA1 $81M Market cap @ 12/31/16 $791M Debt-to-capitalization1 1% Operating cash flow $67M Revenues $969M Value-added sales1 $600M 2016 ~1% Dividend yield 1 Non-GAAP, excludes special items. Refer to the Appendix for additional detail.

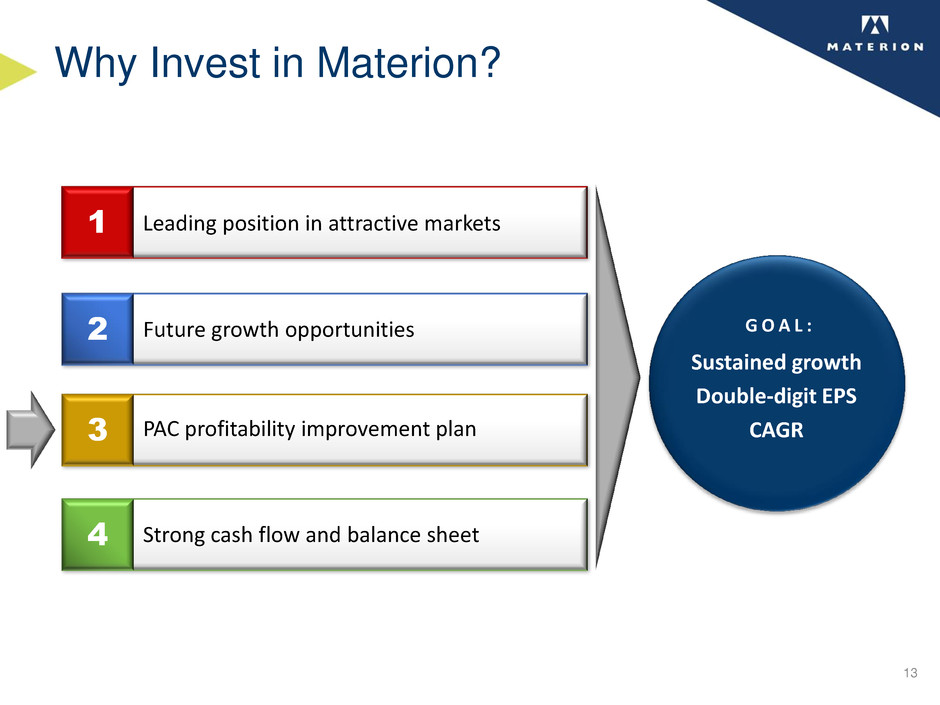

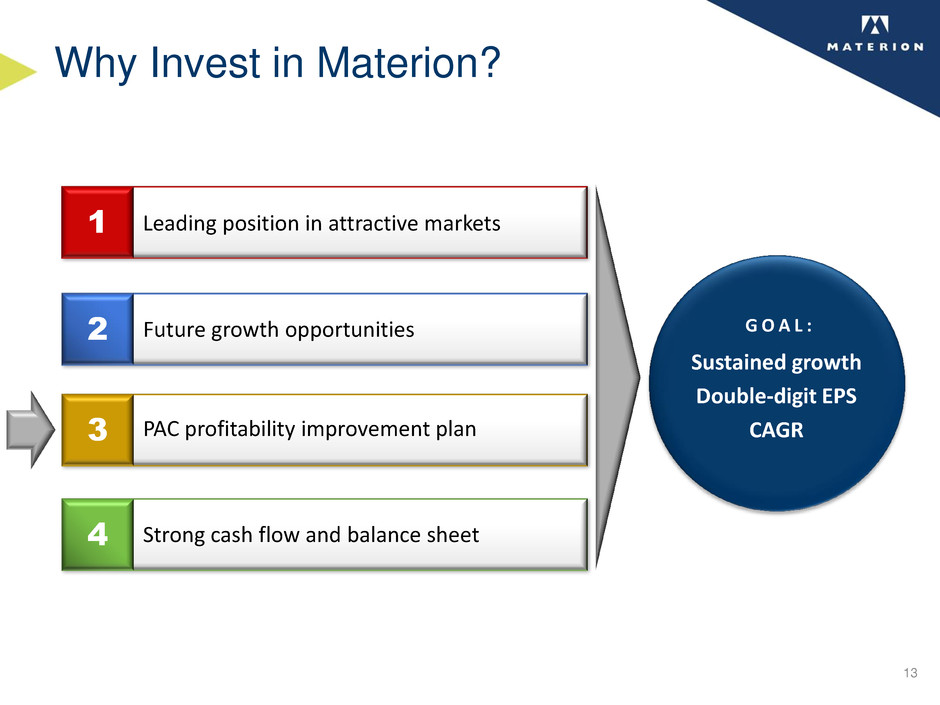

Why Invest in Materion? 5 G O A L : Sustained growth Double-digit EPS CAGR Leading position in attractive markets 1 Future growth opportunities 2 Strong cash flow and balance sheet 4 3 PAC profitability improvement plan

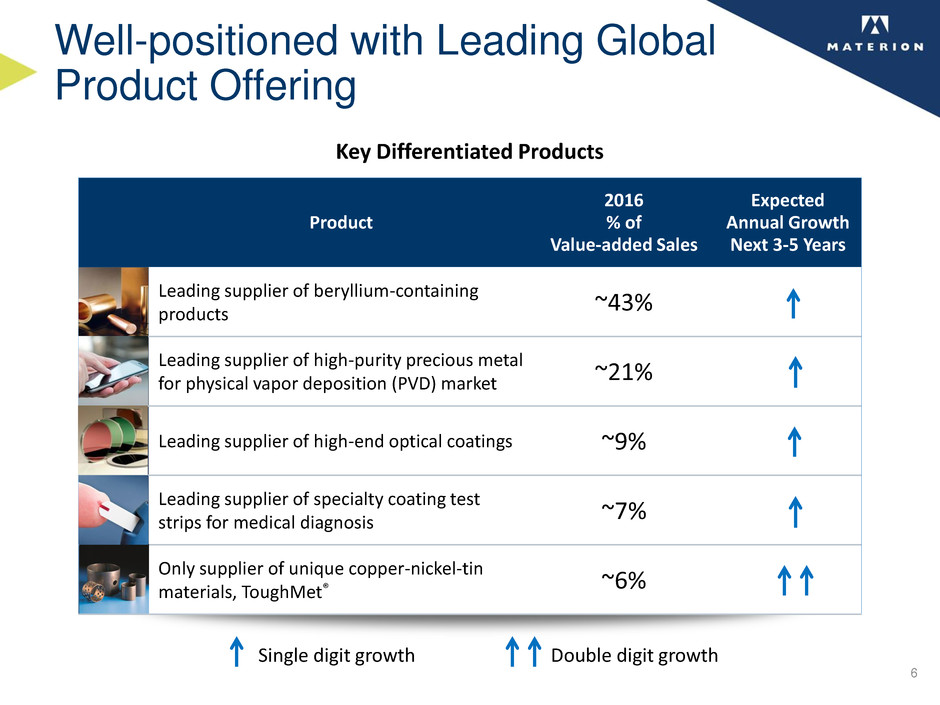

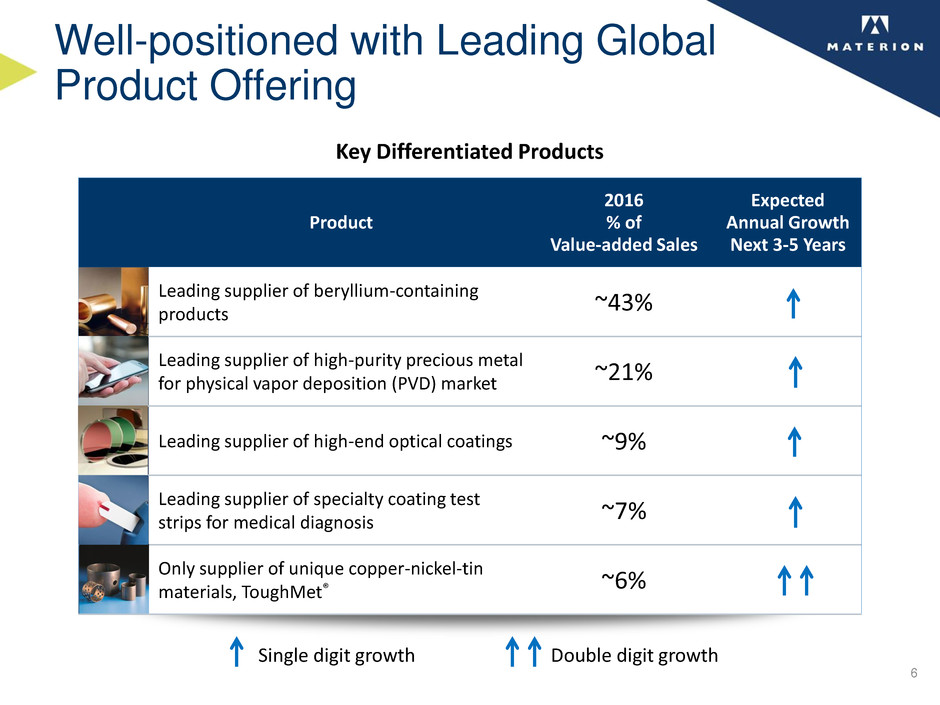

Well-positioned with Leading Global Product Offering 6 Product 2016 % of Value-added Sales Expected Annual Growth Next 3-5 Years Leading supplier of beryllium-containing products ~43% Leading supplier of high-purity precious metal for physical vapor deposition (PVD) market ~21% Leading supplier of high-end optical coatings ~9% Leading supplier of specialty coating test strips for medical diagnosis ~7% Only supplier of unique copper-nickel-tin materials, ToughMet® ~6% Double digit growth Single digit growth Key Differentiated Products

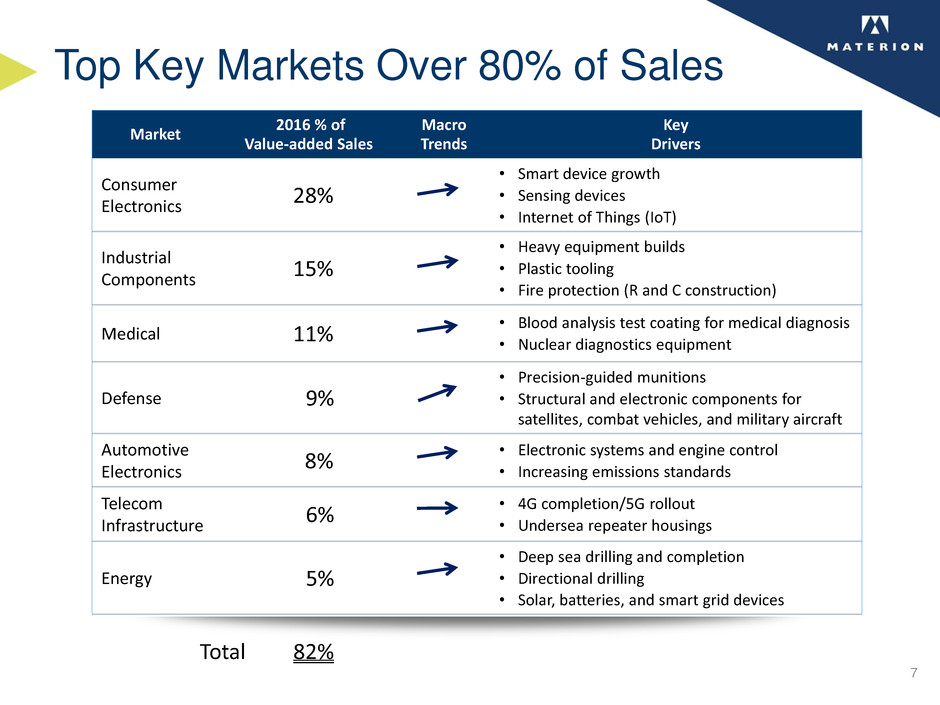

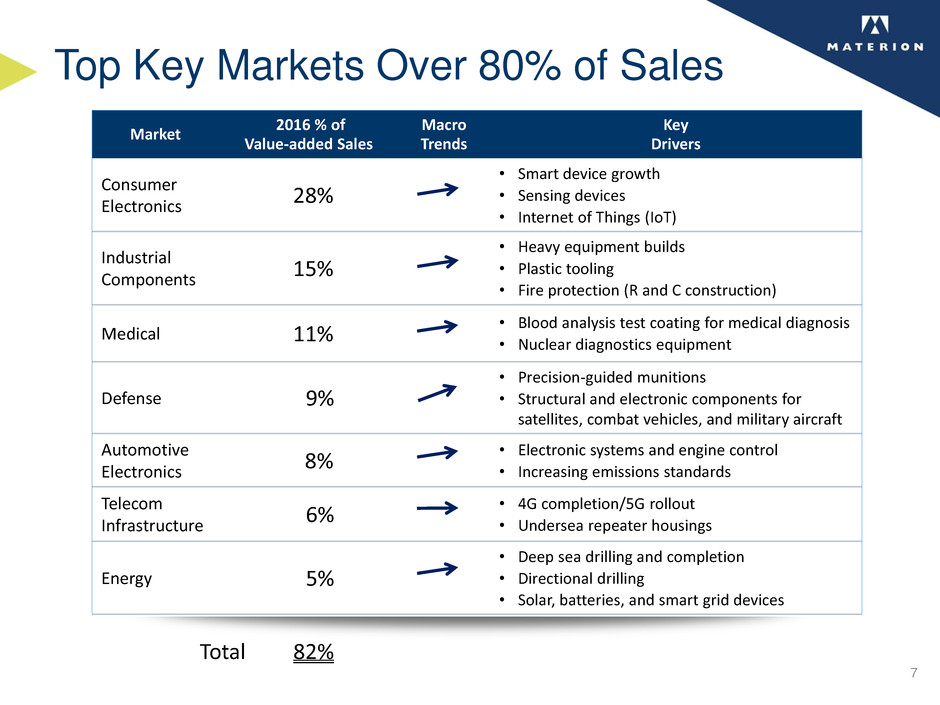

Market 2016 % of Value-added Sales Macro Trends Key Drivers Consumer Electronics 28% • Smart device growth • Sensing devices • Internet of Things (IoT) Industrial Components 15% • Heavy equipment builds • Plastic tooling • Fire protection (R and C construction) Medical 11% • Blood analysis test coating for medical diagnosis • Nuclear diagnostics equipment Defense 9% • Precision-guided munitions • Structural and electronic components for satellites, combat vehicles, and military aircraft Automotive Electronics 8% • Electronic systems and engine control • Increasing emissions standards Telecom Infrastructure 6% • 4G completion/5G rollout • Undersea repeater housings Energy 5% • Deep sea drilling and completion • Directional drilling • Solar, batteries, and smart grid devices Top Key Markets Over 80% of Sales 7 Total 82%

Why Invest in Materion? 8 G O A L : Sustained growth Double-digit EPS CAGR Leading position in attractive markets 1 Future growth opportunities 2 Strong cash flow and balance sheet 4 3 PAC profitability improvement plan

Global Megatrends Play to our Strengths 9 Key Trends • Miniaturization of electronics/IOT • Additional electronic instruments for autos, aircraft • Expanding high performance optical device opportunities • Innovation in medical diagnostics and sensors • Extraction of oil and gas from previously inaccessible locations • Alternative energy • New aircraft builds and retrofits • Advancements in lighting (LED) Characteristics of our Materials Conductivity Corrosion resistance Weight savings (lighter) Purity Wavelength management Thermal management Lubricity Reliability Durability Miniaturization Strength

9.7% 11.2% 11.6% 14.1% 2013 2014 2015 2016 Innovation Leading to Organic Growth 10 New Product Value-added Sales as % of Total Noteworthy New Products Offerings Phosphor Wheel • Provides high brightness, longer life • Offers low noise characteristics, individual precision balancing, and stable colors Dovetail Clad® • Best solution for laser welding of Li-Ion batteries • Lowest cost assembly eStainless® • Thermally conductive replacement for conventional stainless steels • Manages higher heat of today’s processing technology ToughMet Couplings • Copper-nickel-tin alloy that resists mechanical wear, thread damage, corrosion, and erosion • Maximizes oilfield production

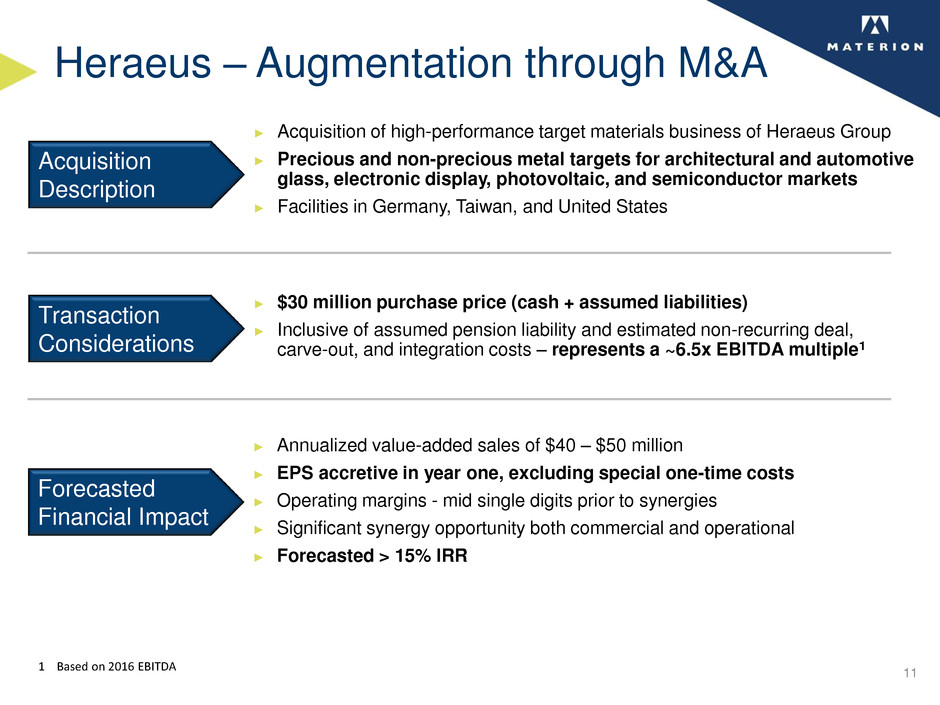

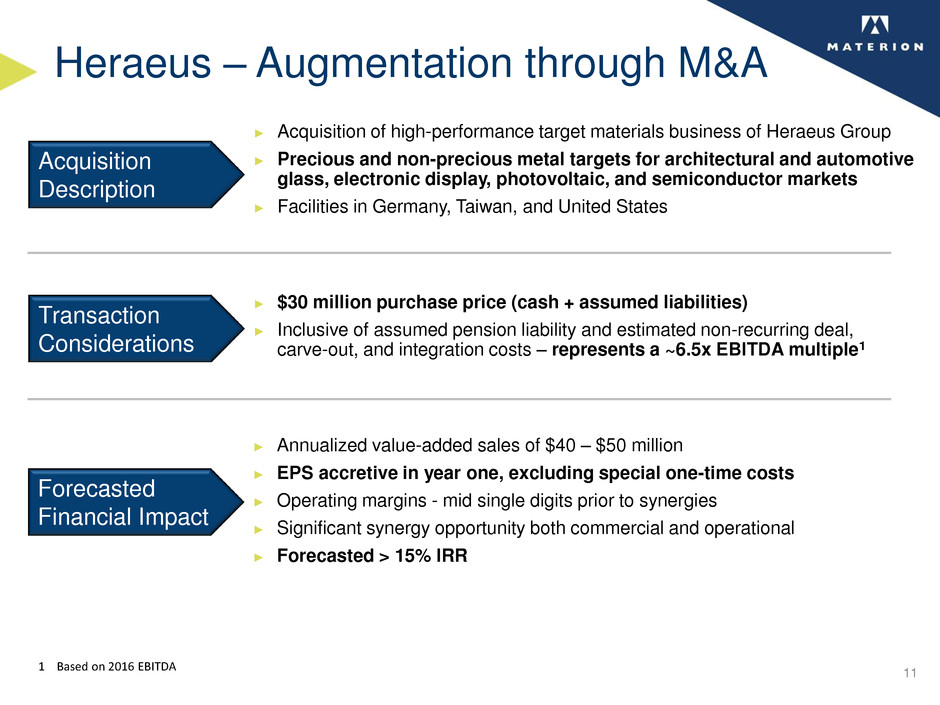

Heraeus – Augmentation through M&A 11 Acquisition Description ► Acquisition of high-performance target materials business of Heraeus Group ► Precious and non-precious metal targets for architectural and automotive glass, electronic display, photovoltaic, and semiconductor markets ► Facilities in Germany, Taiwan, and United States Transaction Considerations ► $30 million purchase price (cash + assumed liabilities) ► Inclusive of assumed pension liability and estimated non-recurring deal, carve-out, and integration costs – represents a ~6.5x EBITDA multiple1 Forecasted Financial Impact ► Annualized value-added sales of $40 – $50 million ► EPS accretive in year one, excluding special one-time costs ► Operating margins - mid single digits prior to synergies ► Significant synergy opportunity both commercial and operational ► Forecasted > 15% IRR 1 Based on 2016 EBITDA

► Accelerates and solidifies global precious metal position in growth portfolio (semiconductor) ► Provides broader market, technology, and geographic diversification to increase growth platforms and effectively compete worldwide ► Achieves economies of scale in cost-sensitive targets business ► Improves our global footprint in Europe and Asia ► Improves organizational strength through complementary technical talent Heraeus – A Compelling Strategic Fit for Materion 12

Why Invest in Materion? 13 G O A L : Sustained growth Double-digit EPS CAGR Leading position in attractive markets 1 Future growth opportunities 2 Strong cash flow and balance sheet 4 3 PAC profitability improvement plan

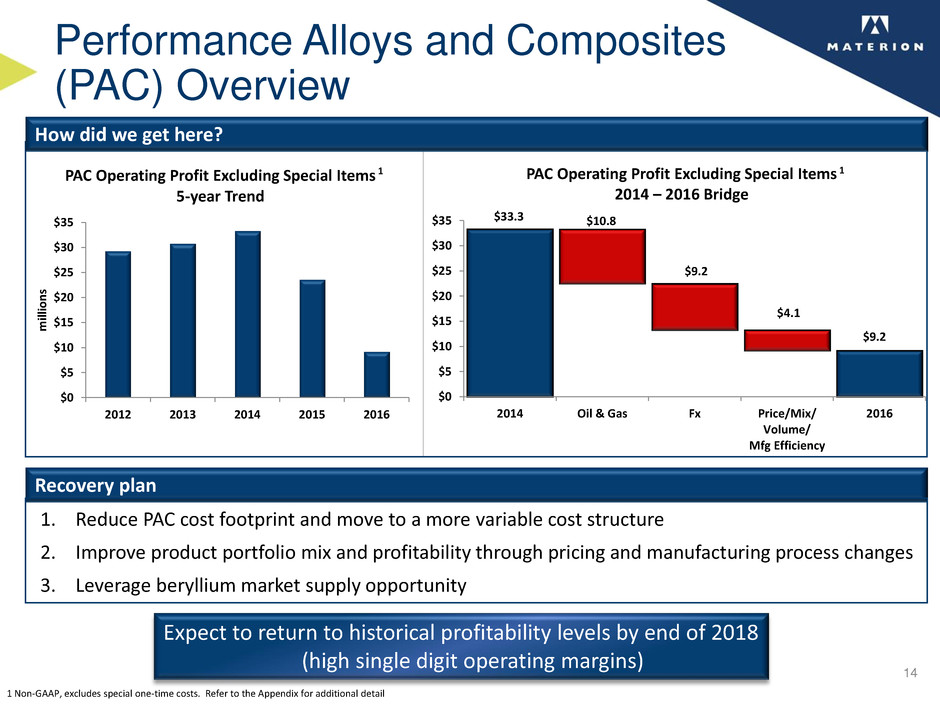

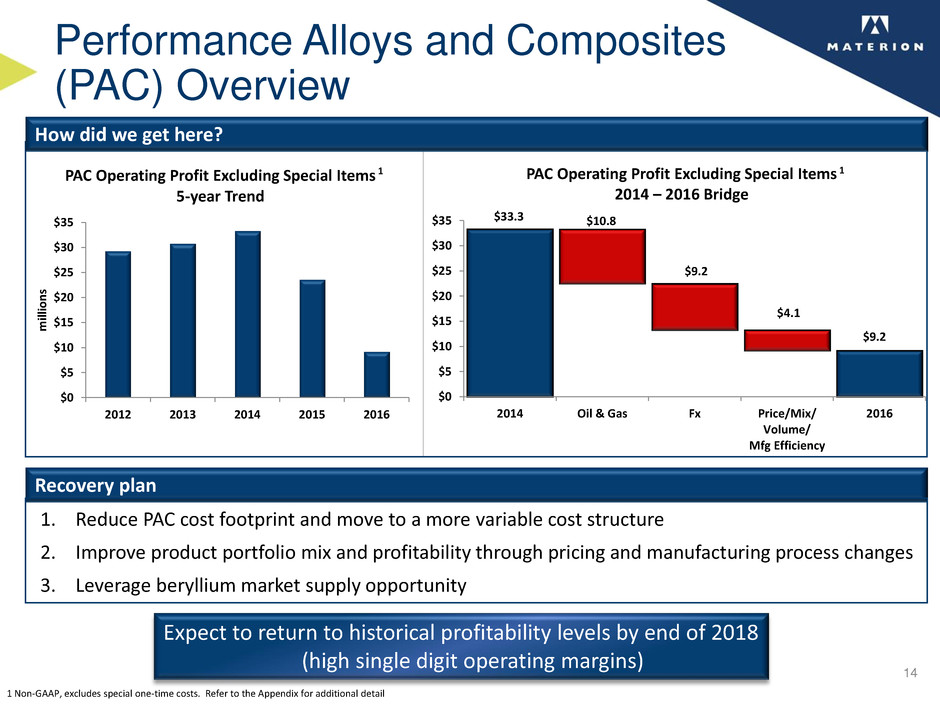

Performance Alloys and Composites (PAC) Overview 14 1. Reduce PAC cost footprint and move to a more variable cost structure 2. Improve product portfolio mix and profitability through pricing and manufacturing process changes 3. Leverage beryllium market supply opportunity $0 $5 $10 $15 $20 $25 $30 $35 2012 2013 2014 2015 2016 m ill io n s PAC Operating Profit Excluding Special Items 5-year Trend $33.3 $9.2 $10.8 $9.2 $4.1 $0 $5 $10 $15 $20 $25 $30 $35 2014 Oil & Gas Fx Price/Mix/ Volume/ Mfg Efficiency 2016 PAC Operating Profit Excluding Special Items 2014 – 2016 Bridge Expect to return to historical profitability levels by end of 2018 (high single digit operating margins) 1 Non-GAAP, excludes special one-time costs. Refer to the Appendix for additional detail 1 1 How did we get here? Recovery plan

► Reduce cost footprint - exit service center in Fukaya, Japan ► Service large Japanese customers out of U.S. ► Transfer smaller customers to local distributors ► Lower in-country headcount and investments ► Reduces annual costs by $2.0 million ► Continue exploring other structural cost reduction options ► Aggressive pricing initiatives bearing fruit PAC Margin Improvement Plan 15

Beryllium Market Supply Opportunity 16 Materion – leading position in beryllium market • Only global integrated producer – minimum of 75 years of proven reserves in Utah mine – supplies over 70% of world’s mined beryllium • 40% of company sales include beryllium in some form Signs of shortage ahead • Global stockpiled sources depleting • No other commercially active bertrandite ore mine • Materion positioned to support world demand • Significant incremental profit potential

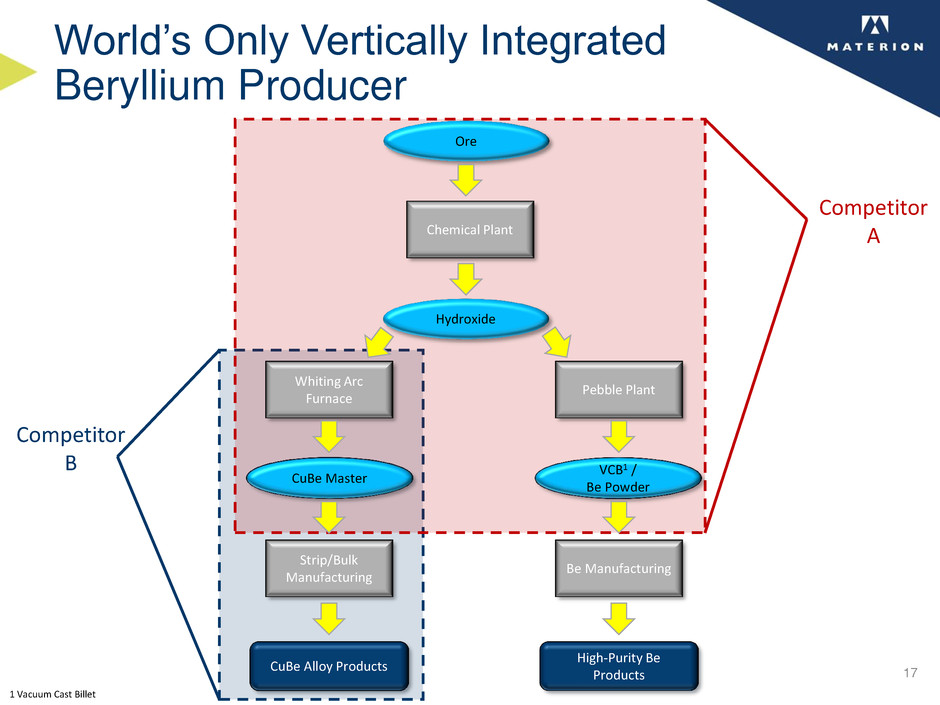

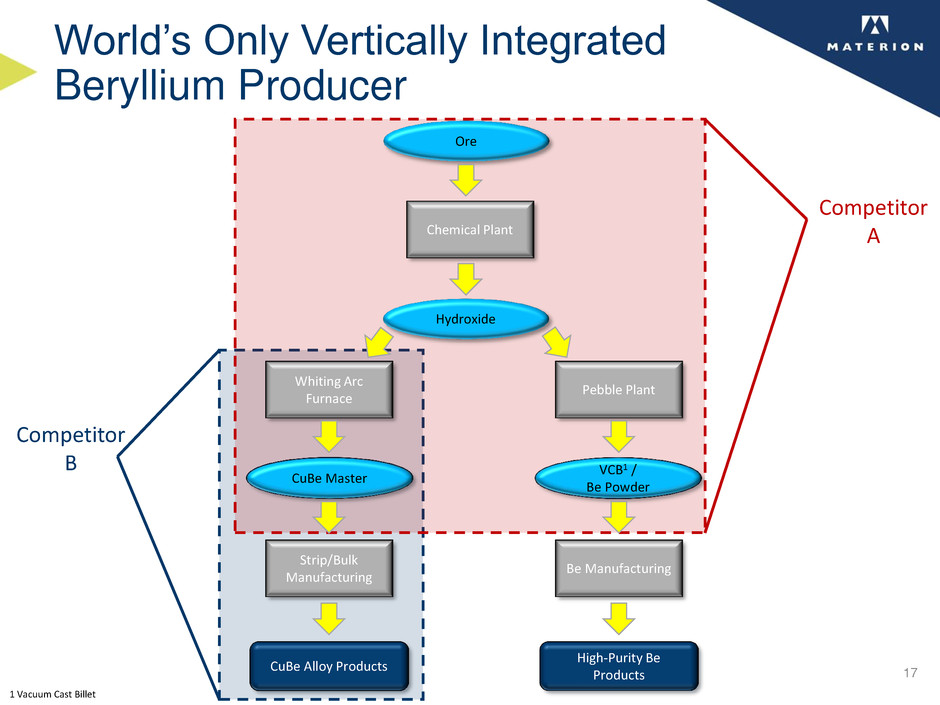

World’s Only Vertically Integrated Beryllium Producer 17 Ore Chemical Plant Hydroxide Whiting Arc Furnace Pebble Plant CuBe Master VCB1 / Be Powder CuBe Alloy Products High-Purity Be Products Strip/Bulk Manufacturing Be Manufacturing Competitor B Competitor A 1 Vacuum Cast Billet

Why Invest in Materion? 18 G O A L : Sustained growth Double-digit EPS CAGR Leading position in attractive markets 1 Future growth opportunities 2 Strong cash flow and balance sheet 4 3 PAC profitability improvement plan

2016 2018 (F) 25% 28% $0 $10 $20 $30 $40 $50 $60 $70 $80 $90 $100 2013 2014 2015 2016 Cash Flow from Operations ($ in millions) Free Cash Flow Capital Expenditures Cash Flow and Working Capital Efficiency Focus 19 Improve Working Capital3 Efficiency Working capital % of net sales 1 Free Cash Flow calculated as cash flow from operations less capital expenditures 2 Capital Expenditures includes mine development costs 3 Working capital is calculated as accounts receivable plus inventory less accounts payable. $- $0.10 $0.20 $0.30 $0.40 2012 2013 2014 2015 2016 Dividends per share $75.9 $60.3 $90.2 $67.2 1 2

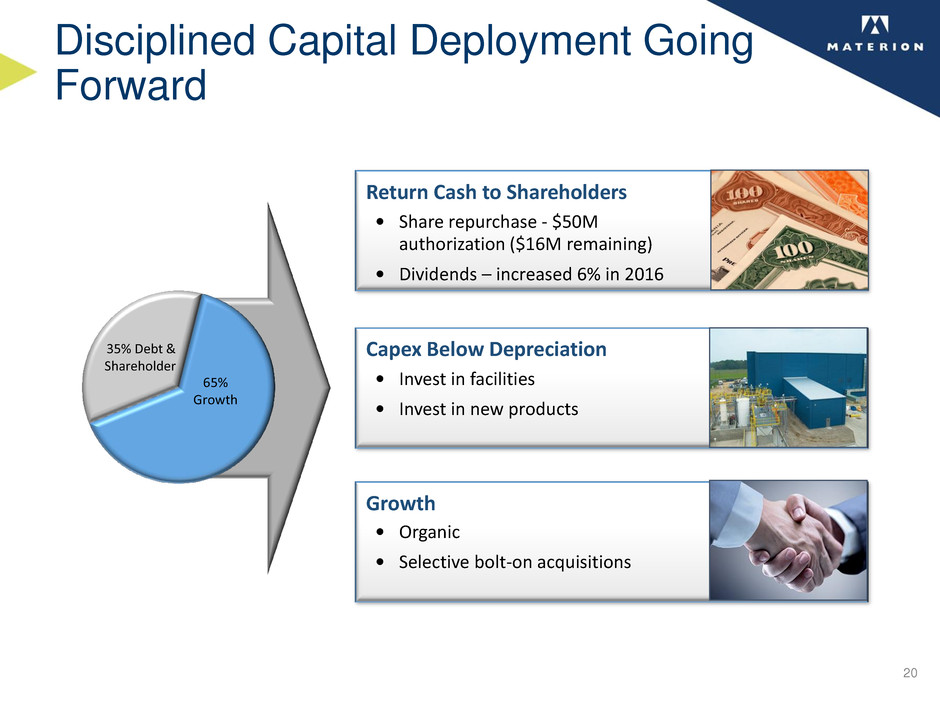

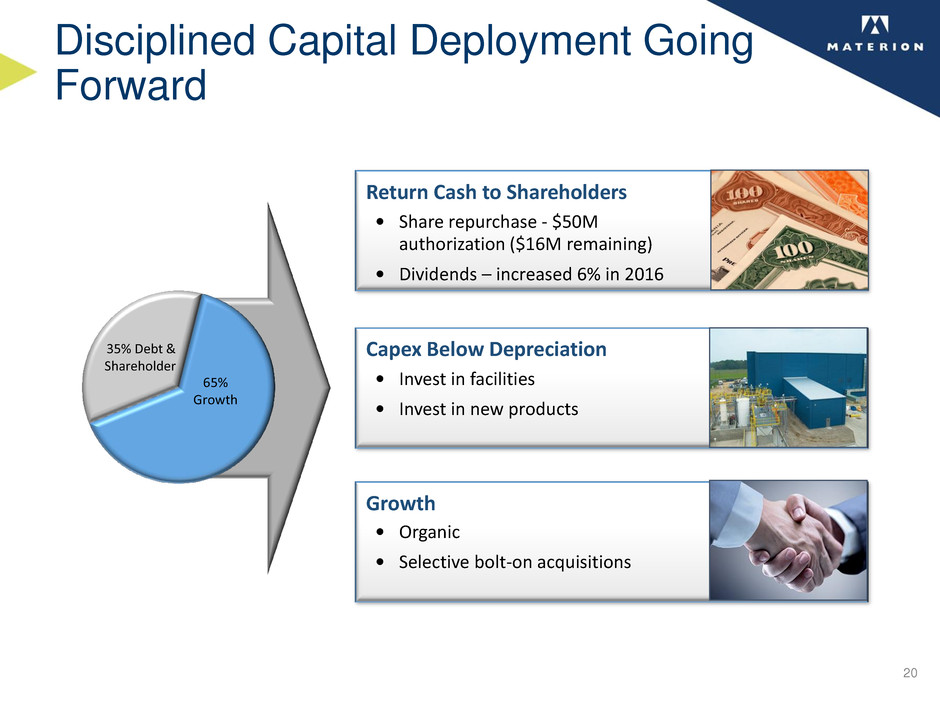

Disciplined Capital Deployment Going Forward 20 Return Cash to Shareholders • Share repurchase - $50M authorization ($16M remaining) • Dividends – increased 6% in 2016 Capex Below Depreciation • Invest in facilities • Invest in new products Growth • Organic • Selective bolt-on acquisitions 35% Debt & Shareholder 65% Growth

Appendix

Performance Alloys and Composites 55% Advanced Materials 29% Precision Coatings 16% Consumer Electronics 28% Industrial Components 15% Medical 11% Defense 9% Automotive Electronics 8% Telecom Infrastructure 6% Energy 5% 0 82% Materion: Mission Critical Advanced Materials A Balanced Portfolio % of Value-added Sales 2016 A-1

Performance Alloys and Composites A-2 Clad Strip 12% ToughMet 11% CuBe 52% Be - Alloys 9% Be – High Purity 14% Europe 20% United States 55% Rest of World 1% Asia 24% Telecom Infrastructure 9% Automotive Electronics 14% Defense 11% Industrial Components 19% Medical 2% Other 18% Consumer Electronics 21% Energy 6% 0% 2% 4% 6% 8% 10% 12% 14% $100 $150 $200 $250 $300 $350 $400 2012 2013 2014 2015 2016 $337 $340 $359 $335 $332 Product Mix1 Geographic Mix1 Value-added Sales by Market1 New product development • New proprietary non-Be alloys with improved durability & weight-to-strength ratio • New heat dissipating clad material • Improving customer yields with “near net shape” products New application development • Clad material serving the renewable energy market • Precision rolling to thinner strips opening new application opportunities • ToughMet couplings serving the oil and gas production market resist mechanical wear, thread damage, corrosion, and erosion Changing beryllium demand • World’s only fully integrated producer • Minimum of 75 years of proven mine reserves in Delta, UT • Primary Be competitor is consuming stockpiled ore Growth Drivers Value-added Sales O P % o f V A S al e s V A S al es ($ m ill io n s) Hydroxide 2% 1 Reflects 2016 mix by market, geography, and product

0% 5% 10% 15% 20% 25% 30% $100 $125 $150 $175 $200 2012 2013 2014 2015 2016 Advanced Materials A-3 Services 15% Packaging 10% Targets 57% Chemicals 18% Europe 6% United States 78% Rest of World 1% Asia 15% Telecom Infrastructure 5% Defense 4% Other 18% Medical 7% Consumer Electronics 46% Industrial Components 13% Energy 7% $172 $169 $181 $183 $176 Product Mix1 Geographic Mix1 Value-added Sales by Market1 Growth Drivers Value-added Sales O P % o f V A S al e s V A S al es ($ m ill io n s) 1 Reflects 2016 mix by market, geography, and product New product development • Highly technical advanced chemicals, pure metals, and alloys, including evaporation materials and large PVD targets • High-value products with capacity to scale Semiconductor • Long-term high growth market • Heraeus acquisition further accelerates position in this market • Full suite of best in class ultra-pure, clean room ready products • Quality and reliability highly valued Growth opportunities • Continued product and market diversification • Continued geographic diversification specifically in Asia and Europe • Asia is a high growth region where customers are exploiting excess fab capacity and use our current material set

New product development • New precious metal coating stacks • Novel electrode alloys • Gesture control sensing • Phosphor wheel and thermal imaging New market development • Expanding into Asia with blood glucose test strips • New applications for medical sensing films • Growing demand for optical filters in consumer electronics and automotive sensors Expanded service offering • Optical coating is the critical sensor assembly application • Gettering capabilities for wafer level processing • Laser patterning • Precision film slitting & sheeting 0% 4% 8% 12% 16% 20% 24% $60 $70 $80 $90 $100 $110 $120 2012 2013 2014 2015 2016 Precision Coatings A-4 BGTS 42% Projection Display Components 19% Optical Filters & Arrays 39% Europe 11% United States 74% Rest of World 1% Asia 14% Automotive Electronics 3% Defense 14% Other 9% Medical 50% Consumer Electronics 20% Industrial Components 4% $106 $104 $102 $102 $98 Product Mix1 Geographic Mix1 Value-added Sales by Market1 Growth Drivers Value-added Sales O P % o f V A S al e s V A S al es ($ m ill io n s) 1 Reflects 2016 mix by market, geography, and product

Applications

► Advanced chemicals for OLED applications ► Multiple product offerings for smartphones, including connector material and voice coil motor (auto focus lens stabilizer) ► Phosphor wheel and opto-ceramic coatings for laser projectors ► Wafer level optical coatings for electronic devices ► 3D/gesture control optical filter capability ► Semiconductor targets for Tier 1 suppliers Consumer Electronics A-6

► Precious metal blood glucose test strips for diabetes testing ► Be material for x-ray equipment applications ► Narrow-band optical filters for spectroscopy ► Continuous glucose monitoring (CGM) electrodes for type 2 diabetes Medical 28 A-7

► Infrared sensors for fighter jet, unmanned aerial vehicle optical targeting ► Optical filters for precision-guided munitions ► Structural components for combat vehicles and aircraft ► Optical, structural, and electronic components for satellites Defense 29 A-8

► Connector material for battery and high temperature applications ► High-performance alloys (i.e., CuBe, ToughMet®) for the powertrain ► Metal matrix composites (i.e., SupremEx®) for chassis, suspension, and braking component applications ► Optical filters: night vision, speed control, sensors, camera applications Automotive Electronics 30 A-9

► ToughMet couplings for oil production ► ToughMet components for oil drilling applications ► Connector materials (i.e., Dovetail®) for fuel cell batteries ► Precious metal targets for coatings on construction glass Energy 31 A-10

Financial Information

Reconciliation for Value-Added Sales A-12 $ in millions Value-added sales is a non-GAAP measure that removes the impact of pass-through metal costs and allows for analysis without the distortion of the movement or volatility in metal prices. Internally, we manage our business on this basis, and a reconciliation of net sales to value-added sales is included herein. Q1 2017 2016 2015 2014 2013 2012 Net Sales Performance Alloys and Composites 92.6$ 387.5$ 394.8$ 433.3$ 422.9$ 424.4$ Advanced Materials 114.7 437.2 482.3 547.3 592.0 694.8 Precision Coatings 33.4 144.5 148.4 147.7 152.3 153.0 Other - - (0.2) (1.4) (0.3) 0.9 Total 240.7$ 969.2$ 1,025.3$ 1,126.9$ 1,166.9$ 1,273.1$ Less: pass-through metal costs Performance Alloys and Composites 13.4$ 55.5$ 59.7$ 74.8$ 83.0$ 87.4$ Advanced Materials 67.4 260.9 299.5 366.3 423.4 522.7 Precision Coatings 10.1 46.8 46.6 45.3 48.0 46.7 Other 0.8 6.1 2.3 3.4 3.3 0.7 Total 91.7$ 369.3$ 408.1$ 489.8$ 557.8$ 657.5$ Value-added sales Performance Alloys and Composites 79.2$ 332.0$ 335.1$ 358.5$ 339.9$ 337.0$ Advanced Materials 47.3 176.3 182.8 181.0 168.6 172.1 Precision Coatings 23.3 97.7 101.8 102.4 104.2 106.4 Other (0.8) (6.1) (2.5) (4.8) (3.6) 0.1 Total 149.0$ 599.9$ 617.2$ 637.1$ 609.1$ 615.6$

Reconciliation for Adjusted EPS A-13 As detailed in the above reconciliation, we have adjusted the results for certain special items, such as cost reduction initiatives (i.e., asset impairment charges and severance), legacy legal and environmental costs, CEO transition costs, merger and acquisition costs, and certain income tax items from the applicable GAAP measure. Internally, management reviews the results of operations without the impact of these costs in order to assess the profitability from ongoing activities. We are providing this information because we believe it will assist investors in analyzing our financial results and, when viewed in conjunction with the GAAP results, provide a more comprehensive understanding of the factors and trends affecting our operations. $ in millions, except per share amounts Q1 2017 2016 2015 2014 2013 2012 GAAP As Reported Operating Profit 3.4$ 27.1$ 45.3$ 57.6$ 27.6$ 36.2$ Net Income 3.1 25.7 32.2 42.1 20.2 24.3 Weighted average diluted shares outstanding 20.375 20.213 20.402 20.852 20.943 20.740 EPS - Diluted 0.15$ 1.27$ 1.58$ 2.02$ 0.97$ 1.17$ Operating Profit Special Items Cost reductions 0.7$ 2.6$ 1.9$ (1.6)$ 4.9$ -$ Legacy legal & environmental costs (benefits) 0.2 1.4 (1.4) (6.9) - 7.4 CEO transition 1.7 - - - - - Acquisition costs 1.7 3.9 - - - - Total operating profit special items 4.3$ 7.9$ 0.5$ (8.5)$ 4.9$ 7.4$ Operating Profit Special Items - net of tax 2.8$ 5.1$ 0.3$ (5.6)$ 3.4$ 4.8$ Tax Special Item -$ (4.2)$ 0.2$ (1.8)$ -$ -$ Non-GAAP Measures - Adjusted Profitability Operating Profit 7.7$ 35.0$ 45.8$ 49.1$ 32.5$ 43.6$ Net Income 5.9 26.6 32.7 34.7 23.6 29.1 EPS - Diluted 0.29$ 1.32$ 1.60$ 1.67$ 1.13$ 1.40$

Other Non-GAAP Items A-14 Adjusted EBITDA is calculated by adding depreciation, depletion, and amortization and certain special items such as cost reduction initiatives (i.e., asset impairment charges and severance), legacy legal and environmental costs, CEO transition costs, merger and acquisition costs, and certain income tax items to our operating profit. Internally, management reviews the results of operations without the impact of these costs in order to assess the profitability from ongoing operations. Debt-to-capitalization is our total debt divided by net debt plus shareholders’ equity. Net debt (cash) is a non-GAAP measure calculated by subtracting cash & cash equivalents from our total outstanding debt. We are providing this information because we believe it is more indicative of our overall financial position. It is also a measure our management uses to assess financing and other decisions. $ in millions 2014 2013 Operating Profit 3.4$ 27.1$ 45.3$ 57.6$ 27.6$ Special Items 4.3 7.9 0.5 (8.5) 4.9 Adjusted Operating Profit 7.7$ 35.0$ 45.8$ 49.1$ 32.5$ Depreciation, depletion, and amortization 10.1 45.6 37.8 42.7 41.6 Adjusted EBITDA 17.8$ 80.6$ 83.6$ 91.8$ 74.1$ Total Debt 32.6$ 4.6$ 13.6$ 24.3$ 64.8$ Less: Cash & Cash Equivalents 16.3 31.5 24.2 13.1 22.8 Net Debt (Cash) 16.3$ (26.9)$ (10.6)$ 11.2$ 42.0$ Total Shareholders' Equity 497.1$ 494.1$ 483.0$ 459.0$ 464.4$ Debt-to-Capitalization 6% 1% 3% 5% 13% 2016 2015Q1 2017

($ in millions, except per share data) 2017 Q1 Q2 Q3 Q4 2014 Q1 Q2 Q3 Q4 2015 Q1 Q2 Q3 Q4 2016 Q1 Sales PAC 97.2$ 109.6$ 114.2$ 112.3$ 433.3$ 103.3$ 107.7$ 93.6$ 90.3$ 394.8$ 90.6$ 97.7$ 103.7$ 95.5$ 387.5$ 92.6$ AM 129.3 145.0 137.6 135.3 547.3 149.9 131.4 113.6 87.4 482.3 108.1 113.6 107.2 108.3 437.2 114.7 PC 33.9 34.1 39.9 39.7 147.7 36.6 38.3 37.2 36.4 148.4 36.8 38.5 38.7 30.5 144.5 33.4 Other (1.5) (0.7) (0.1) 1.1 (1.4) 0.2 (0.5) - - (0.2) - - - - - - Consolidated MTRN 258.9 288.0 291.6 288.4 1,126.9 290.0 276.9 244.4 214.0 1,025.3 235.5 249.8 249.6 234.3 969.2 240.7 VA PAC 80.0 89.9 94.7 93.9 358.5 85.6 91.5 79.6 78.4 335.1 78.2 83.4 87.2 83.2 332.0 79.2 AM 41.7 45.0 46.1 48.3 181.0 51.7 46.7 44.5 39.8 182.8 42.1 47.0 46.0 41.2 176.3 47.3 PC 23.9 24.9 27.0 26.5 102.4 24.6 25.2 25.7 26.4 101.8 24.6 25.1 25.8 22.2 97.7 23.3 Other (0.7) (0.2) (2.2) (1.7) (4.8) 0.7 (1.0) (1.0) (1.2) (2.5) (1.0) (1.6) (2.0) (1.5) (6.1) (0.8) Consolidated MTRN 144.9 159.6 165.6 167.0 637.1 162.6 162.4 148.8 143.4 617.2 143.9 153.9 157.0 145.1 599.9 149.0 Gross Margin PAC 22.7 24.6 26.8 26.8 100.9 23.1 25.5 18.0 17.9 84.6 17.7 16.3 20.6 19.0 73.6 16.3 AM 16.1 17.6 19.3 20.6 73.6 20.7 18.8 17.1 15.5 72.1 15.8 19.1 20.0 16.7 71.6 18.4 PC 7.1 7.7 9.0 9.6 33.3 8.3 7.5 9.2 9.1 34.1 10.0 9.5 10.7 7.6 37.8 8.3 Other (0.4) (0.1) (0.3) (1.1) (1.9) 0.3 (0.5) (0.3) 0.6 - (0.1) 0.4 (0.5) 0.8 0.5 - Consolidated MTRN 45.5 49.8 54.8 55.8 205.9 52.4 51.3 44.0 43.1 190.8 43.4 45.3 50.8 44.1 183.5 43.0 Gross Margin as a % of VA PAC 28% 27% 28% 29% 28% 27% 28% 23% 23% 25% 23% 20% 24% 23% 22% 21% AM 39% 39% 42% 43% 41% 40% 40% 38% 39% 39% 38% 41% 43% 41% 41% 39% PC 30% 31% 33% 36% 33% 34% 30% 36% 34% 33% 41% 38% 41% 34% 39% 36% Other N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M Consolidated MTRN 31% 31% 33% 33% 32% 32% 32% 30% 30% 31% 30% 29% 32% 30% 31% 29% Operating Profit PAC 6.2 6.3 10.8 9.9 33.3 6.8 9.3 4.5 2.9 23.6 1.5 0.2 4.4 0.5 6.6 0.2 AM 5.1 12.5 7.8 7.2 32.7 8.9 7.4 7.0 4.5 27.8 5.2 7.3 8.3 5.5 26.3 6.4 PC 4.1 0.5 2.1 2.5 9.3 1.7 0.6 2.3 3.0 7.5 4.1 2.3 3.4 1.8 11.6 2.2 Other (3.9) (5.4) (3.0) (5.2) (17.7) (4.2) (4.2) (2.9) (2.3) (13.6) (3.3) (4.0) (5.9) (4.2) (17.4) (5.4) Consolidated MTRN 11.6 13.9 17.7 14.4 57.6 13.2 13.1 10.9 8.1 45.3 7.5 5.8 10.2 3.6 27.1 3.4 Special Items - OP PAC - - - - - - - - - - - - - 2.6 2.6 0.5 AM 0.4 (5.4) - - (5.1) - - - - - - - - - - 1.0 PC (2.6) 0.1 - - (2.5) - - 1.3 0.1 1.4 - - - - - - Other 0.2 1.5 (2.7) (0.9) (2.1) - 0.5 0.7 (0.9) - 2.3 2.0 1.0 5.3 2.8 Consolidated MTRN (2.0) (3.8) (2.7) - (8.5) (2.1) - 1.8 0.8 0.5 - 2.3 2.0 3.6 7.9 4.3 Operating Profit ex Spec Items PAC 6.2 6.3 10.8 9.9 33.3 6.8 9.3 4.5 2.9 23.6 1.5 0.2 4.4 3.1 9.2 0.7 AM 5.5 7.1 7.8 7.2 27.6 8.9 7.4 7.0 4.5 27.8 5.2 7.3 8.3 5.5 26.3 7.4 PC 1.6 0.6 2.1 2.5 6.8 1.7 0.6 3.6 3.1 8.9 4.1 2.3 3.4 1.8 11.6 2.2 Other (3.7) (3.9) (5.7) (5.2) (18.6) (6.3) (4.2) (2.4) (1.6) (14.5) (3.3) (1.7) (3.9) (3.2) (12.1) (2.6) Consolidated MTRN 9.7 10.1 15.0 14.4 49.1 11.1 13.1 12.7 8.9 45.8 7.5 8.1 12.2 7.2 35.0 7.7 OP ex Spec Items as a % of VA PAC 7.8% 7.1% 11.4% 10.5% 9.3% 7.9% 10.2% 5.7% 3.7% 7.0% 1.9% 0.2% 5.0% 3.7% 2.8% 0.9% AM 13.2% 15.8% 16.9% 14.9% 15.2% 17.2% 15.8% 15.7% 11.3% 15.2% 12.4% 15.5% 18.0% 13.3% 14.9% 15.6% PC 6.5% 2.4% 7.8% 9.4% 6.6% 6.9% 2.4% 14.0% 11.7% 8.7% 16.7% 9.2% 13.2% 8.1% 11.9% 9.4% Other N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M N/M Consolidated MTRN 6.7% 6.4% 9.1% 8.6% 7.7% 6.8% 8.1% 8.5% 6.2% 7.4% 5.2% 5.3% 7.8% 5.0% 5.8% 5.2% 2014 2015 2016 1 Internally, management reviews the results of operations without the impact of special one-time costs in order to assess the profitability from ongoing activities. Refer to the note on page A-13 for a full reconciliation of adjusted earnings. Historical Financials A-15 1 1 1

►Full Year Guidance ► Adjusted EPS of $1.45 - $1.60 ► Operating cash $50M - $60M ► Capex approximately $25M - $30M ► Mine development capital expenditures <$3M ► Depreciation and amortization expense of $43M - $45M ► Effective tax rate excluding special items 18% - 20% 2017 Forecasted Financial Guidance A-16