[GRAPHIC]

[LOGO]

Raymond James

IT Supply Chain Conference

December 8, 2004

Safe Harbor Provision

[LOGO]

During the course of this presentation, we will make projections or other forward-looking statements regarding future events or the future financial performance of the Company. We wish to caution you that such statements reflect only our current expectations, and that actual events or results may differ materially.

We refer you to the risk factors and cautionary language contained in the documents that the Company files from time to time with the Securities and Exchange Commission, specifically the Company’s most recent S-3 Registration Statement and Form 10-K. Such documents contain and identify important factors that could cause the actual results to differ materially from those contained in our projections or forward-looking statements. We undertake no obligation to update such projections or such forward-looking statements in the future.

2

Company Overview

TTM is a leading provider of time-critical and technologically complex printed circuit boards to the world’s leading electronic equipment designers and manufacturers

[GRAPHIC]

• “Pure Play” printed circuit board (PCB) manufacturer

• Focused on time (24 hrs to 10 days) & technology service segments

• Three integrated, mission-focused production facilities:

• Santa Ana, CA

• Redmond, WA

• Chippewa Falls, WI

• $181.5 million in YTD 04* sales

• 1,643 employees

* Jan-Sept 2004

3

Investment Highlights

Focused Strategy & Leading Market Position

• Leader in most attractive PCB segments – time & technology

• Mission-focused facilities – speed, flexibility and technology

Demonstrated Execution Excellence

• Strong relationships with leading OEM and EMS customers

• Proven ability to integrate acquisitions

• Cross-selling efforts leading to success

Industry Leading Financial Performance

• Profitable business model across cycle

• Strong balance sheet

Market Leadership. . .Focus. . . Execution. . . Performance

4

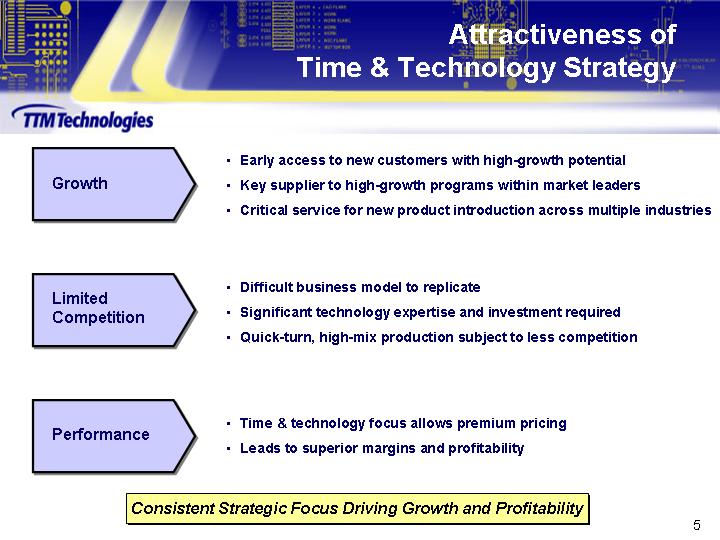

Attractiveness of

Time & Technology Strategy

Growth

• Early access to new customers with high-growth potential

• Key supplier to high-growth programs within market leaders

• Critical service for new product introduction across multiple industries

Limited Competition

• Difficult business model to replicate

• Significant technology expertise and investment required

• Quick-turn, high-mix production subject to less competition

Performance

• Time & technology focus allows premium pricing

• Leads to superior margins and profitability

Consistent Strategic Focus Driving Growth and Profitability

5

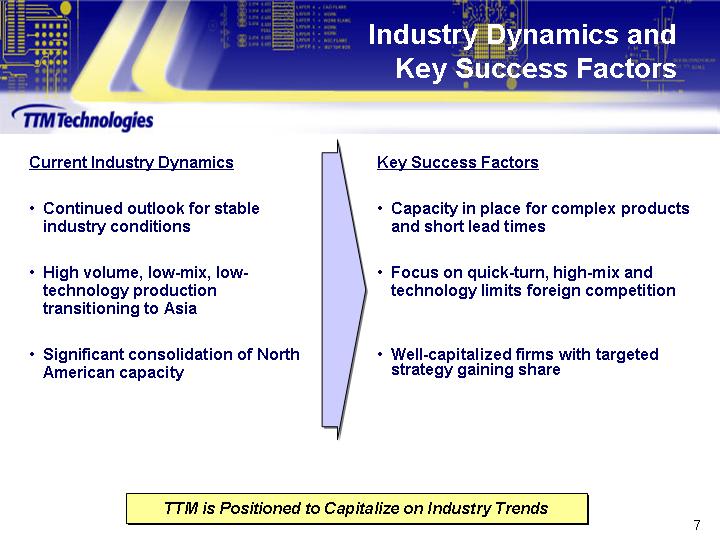

Industry Dynamics and

Key Success Factors

Current Industry Dynamics | | Key Success Factors |

| | |

• Continued outlook for stable industry conditions | | • Capacity in place for complex products and short lead times |

| | |

• High volume, low-mix, low-technology production transitioning to Asia | | • Focus on quick-turn, high-mix and technology limits foreign competition |

| | |

• Significant consolidation of North American capacity | | • Well-capitalized firms with targeted strategy gaining share |

TTM is Positioned to Capitalize on Industry Trends

7

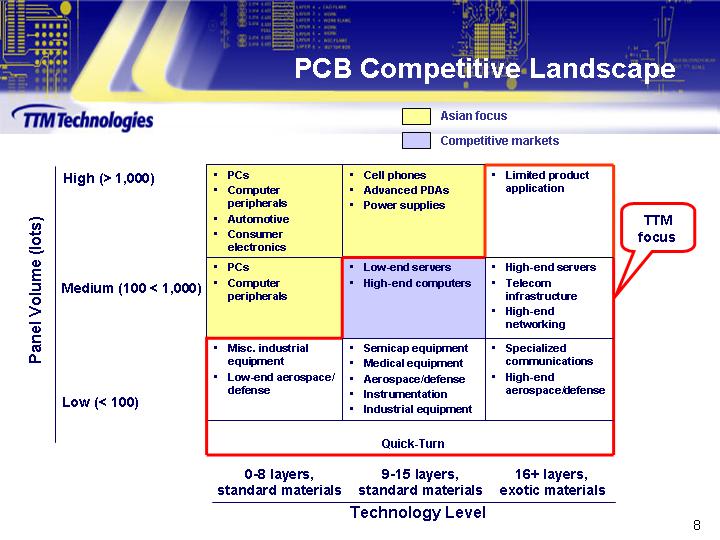

PCB Competitive Landscape

| | | Asian focus |

| | | |

| | | Competitive markets |

Panel Volume (lots) | | | | | | | |

| | | | | | | |

High (> 1,000) | | • PCs • Computer peripherals • Automotive • Consumer electronics | | • Cell phones • Advanced PDAs • Power supplies | | • Limited product application | |

| | | | | | | |

Medium (100 < 1,000) | | • PCs • Computer peripherals | | • Low-end servers • High-end computers | | • High-end servers • Telecom infrastructure • High-end networking | TTM

focus |

| | | | | | | |

Low (< 100) | | • Misc. industrial equipment • Low-end aerospace/defense | | • Semicap equipment • Medical equipment • Aerospace/defense • Instrumentation • Industrial equipment | | • Specialized communications • High-end aerospace/defense | |

| | | |

| | Quick-Turn | |

| | | |

| | 0-8 layers, | | 9-15 layers, | | 16+ layers, | |

| | standard materials | | standard materials | | exotic materials | |

| | | | | | | |

| | | | Technology Level | | | |

8

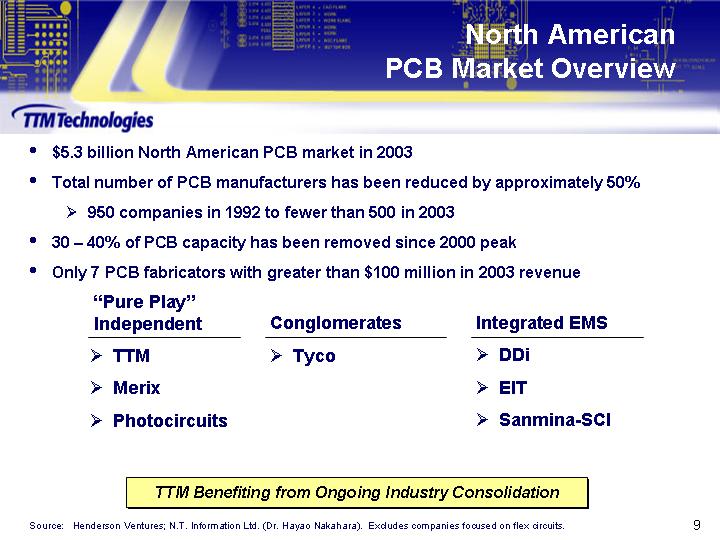

North American

PCB Market Overview

• $5.3 billion North American PCB market in 2003

• Total number of PCB manufacturers has been reduced by approximately 50%

• 950 companies in 1992 to fewer than 500 in 2003

• 30 – 40% of PCB capacity has been removed since 2000 peak

• Only 7 PCB fabricators with greater than $100 million in 2003 revenue

“Pure Play”

Independent | | Conglomerates | | Integrated EMS | |

• TTM | | • Tyco | | • DDi | |

• Merix | | | | • EIT | |

• Photocircuits | | | | • Sanmina-SCI | |

TTM Benefiting from Ongoing Industry Consolidation

Source: Henderson Ventures; N.T. Information Ltd. (Dr. Hayao Nakahara). Excludes companies focused on flex circuits.

9

TTM’s Strategy

| Customers / End Markets • Diverse base of industry leading customers • Early access to emerging customers and niche end-markets • Global sales reach | |

| | |

Technology • High performance, technologically complex PCBs • Advanced manufacturing processes & technology expertise | Industry Leading

Execution and

Financial Results | Time • Dedicated ultra-short lead time capability (<24 hours available) • Dedicated, highly flexible, ramp-to-volume production in <10 days |

• Industry leading avg. layer count of 20+ at Chippewa Falls facility | Strong Long-Term

Outlook | • High-mix complex technology production with standard delivery |

| | |

| Financial Strength • Focus on operational excellence • Superior asset management and strong balance sheet • Successful integration of opportunistic acquisitions | |

11

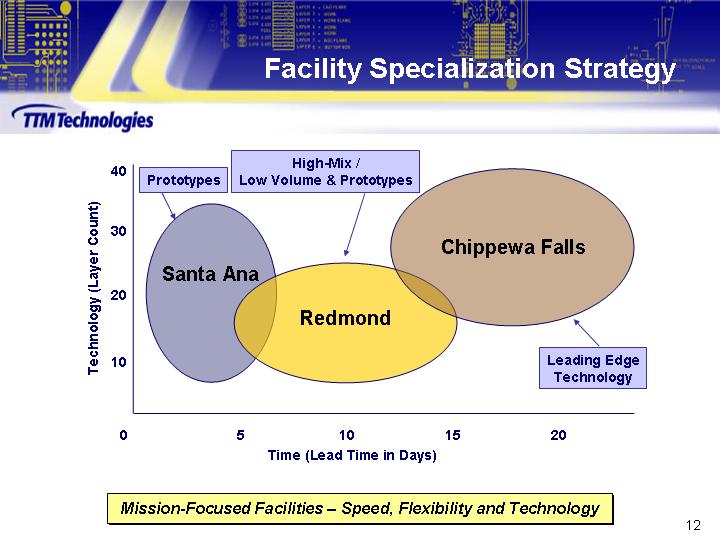

Facility Specialization Strategy

[CHART]

Mission-Focused Facilities – Speed, Flexibility and Technology

12

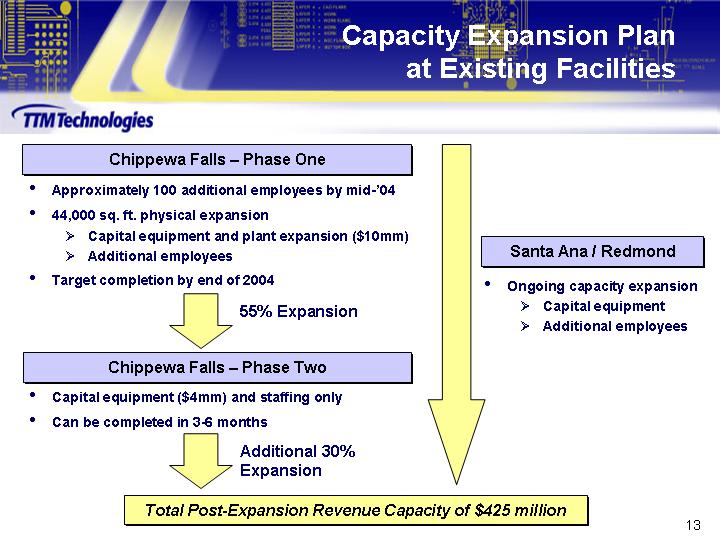

Capacity Expansion Plan

at Existing Facilities

Chippewa Falls – Phase One • Approximately 100 additional employees by mid-’04 • 44,000 sq. ft. physical expansion • Capital equipment and plant expansion ($10mm) • Additional employees • Target completion by end of 2004 55% Expansion Chippewa Falls – Phase Two • Capital equipment ($4mm) and staffing only • Can be completed in 3-6 months Additional 30% Expansion | | Santa Ana / Redmond • Ongoing capacity expansion • Capital equipment • Additional employees |

Total Post-Expansion Revenue Capacity of $425 million

13

Price by Delivery Time

[CHART]

Quick-Turn Revenue (10 days or less)

• ~27% 2003

• ~23% YTD 04*

Quick-Turn Service Allows Premium Pricing

*Jan-Sept 2004

14

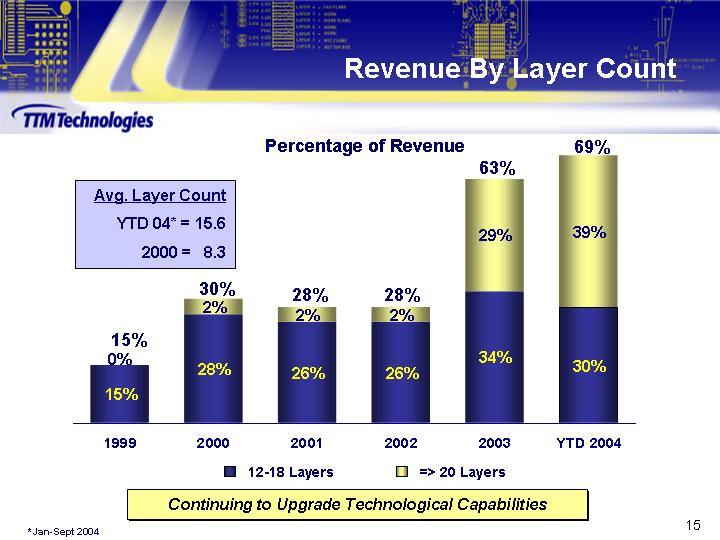

Revenue By Layer Count

[CHART]

Percentage of Revenue

Avg. Layer Count

YTD 04* = 15.6

2000 = 8.3

Continuing to Upgrade Technological Capabilities

*Jan-Sept 2004

15

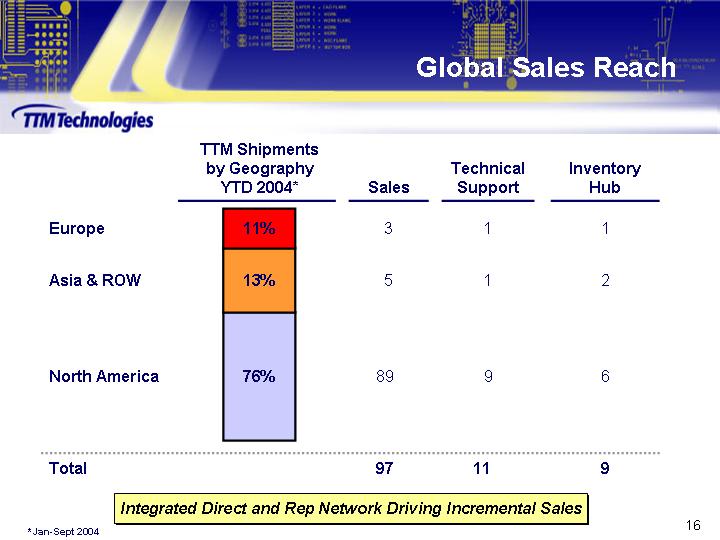

Global Sales Reach

[CHART]

Integrated Direct and Rep Network Driving Incremental Sales

*Jan-Sept 2004

16

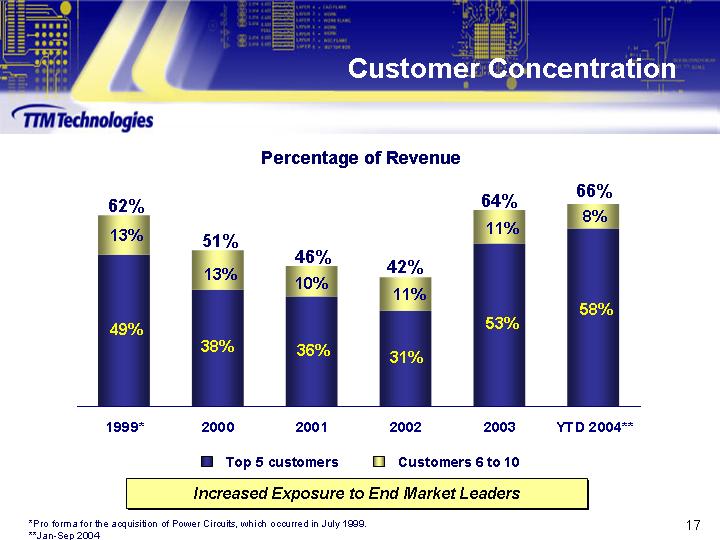

Customer Concentration

Percentage of Revenue

[CHART]

Increased Exposure to End Market Leaders

*Pro forma for the acquisition of Power Circuits, which occurred in July 1999.

**Jan-Sep 2004

17

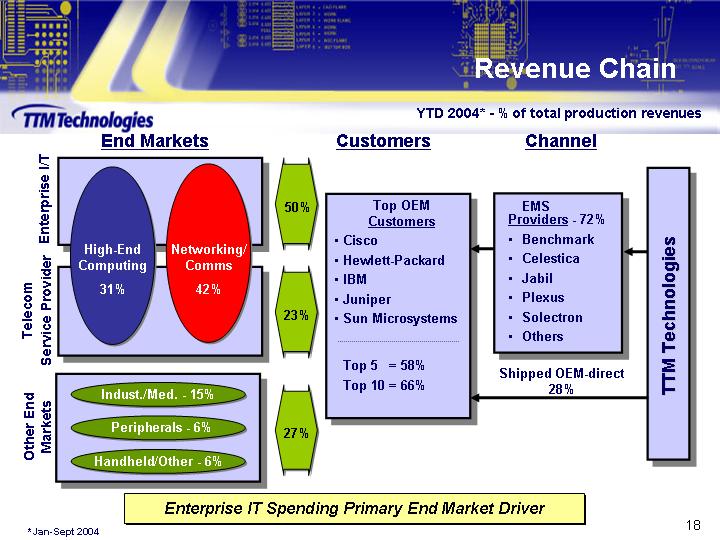

Revenue Chain

YTD 2004* - % of total production revenues

End Markets

Enterprise I/T | | High-End

Computing

31% | | Networking /

Comms

42% | | 50% | |

| | | | | |

Telecom Service Provider | | | | 23% | |

| | | | | | | |

Other End Markets | | Industrial & Med. - 15%

Peripherals - 6%

Handheld & Other - 6% | | 27% | |

Customers

Top OEM

Customers

• Cisco

• Hewlett-Packard

• IBM

• Juniper

• Sun Microsystems

EMS

Providers - 72%

• Benchmark

• Celestica

• Jabil

• Plexus

• Solectron

• Others

Shipped OEM-direct

28%

TTM Technologies

Enterprise IT Spending Primary End Market Driver

*Jan-Sept 2004

18

Key Customers by

End Market

Percentage of Revenue by End Market – YTD 2004*

Networking & Communications | | 42 | % | [LOGOS] | |

| | | | | |

High-End Computing | | 31 | % | [LOGOS] | |

| | | | | |

Industrial & Medical | | 15 | % | [LOGOS] | |

| | | | | |

Computer Peripherals | | 6 | % | [LOGOS] | |

| | | | | |

Handheld & Other | | 6 | % | [LOGOS] | |

Leading Positions with Industry Leaders. . .

Approximately 600 Active Customers

*Jan-Sept 2004

19

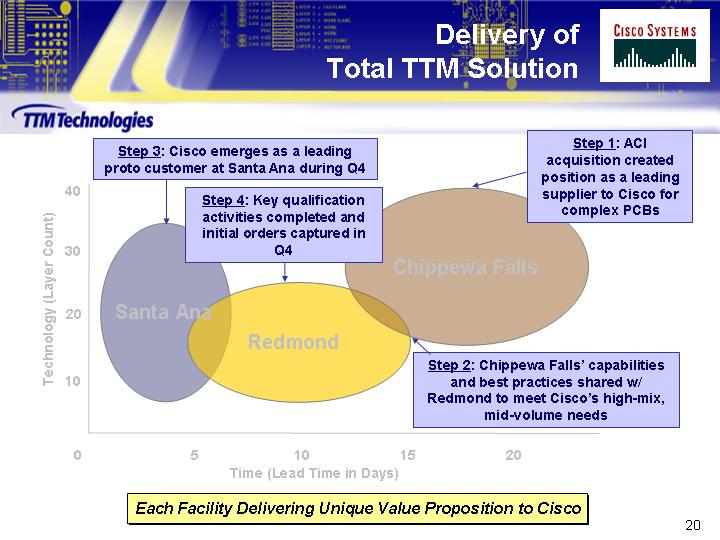

Delivery of

Total TTM Solution

[CHART]

Step 1: ACI acquisition created position as a leading supplier to Cisco for complex PCBs

Step 2: Chippewa Falls’ capabilities and best practices shared w/Redmond to meet Cisco’s high-mix, mid-volume needs

Step 3: Cisco emerges as a leading proto customer at Santa Ana during Q4

Step 4: Key qualification activities completed and initial orders captured in Q4

Each Facility Delivering Unique Value Proposition to Cisco

20

Compelling

Growth Opportunities

• One-stop manufacturing solution with numerous cross-selling opportunities

• Quick-turn capabilities for attracting emerging high-growth customers

• Leadership in technology and advanced manufacturing processes

• Capacity available through low risk, low cost expansion plan

• Successful track record of completing and integrating acquisitions

21

Annual Sales

[CHART]

Sales ($mm)

22

Quarterly Sales

[CHART]

Sales ($mm)

23

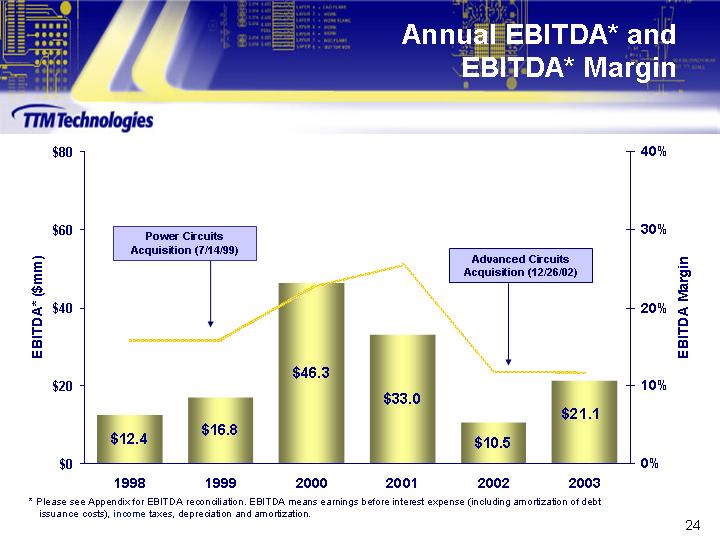

Annual EBITDA* and

EBITDA* Margin

[CHART]

* Please see Appendix for EBITDA reconciliation. EBITDA means earnings before interest expense (including amortization of debt issuance costs), income taxes, depreciation and amortization.

24

Quarterly EBITDA* and

EBITDA* Margin

[CHART]

* Please see Appendix for EBITDA reconciliation. EBITDA means earnings before interest expense (including amortization of debt issuance costs), income taxes, depreciation and amortization.

25

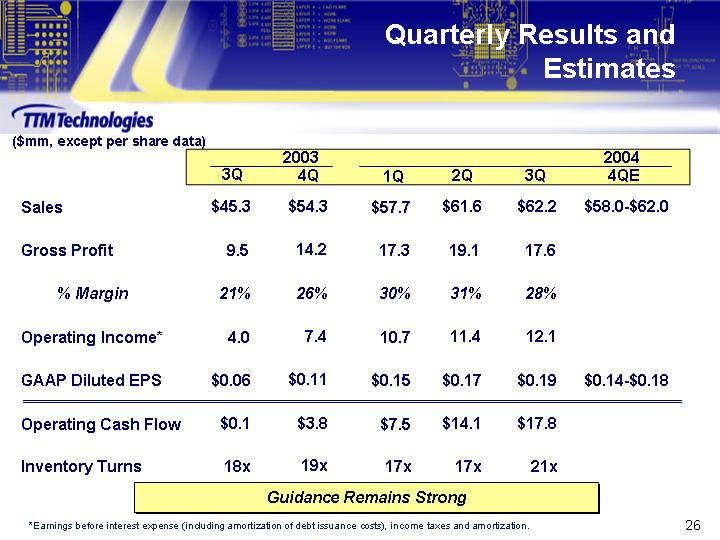

Quarterly Results and

Estimates

($mm, except per share data)

| | 2003 | | 2004 | |

| | 3Q | | 4Q | | 1Q | | 2Q | | 3Q | | 4QE | |

Sales | | $ | 45.3 | | $ | 54.3 | | $ | 57.7 | | $ | 61.6 | | $ | 62.2 | | $58.0-$62.0 | |

| | | | | | | | | | | | | |

Gross Profit | | 9.5 | | 14.2 | | 17.3 | | 19.1 | | 17.6 | | | |

| | | | | | | | | | | | | |

% Margin | | 21 | % | 26 | % | 30 | % | 31 | % | 28 | % | | |

| | | | | | | | | | | | | |

Operating Income* | | 4.0 | | 7.4 | | 10.7 | | 11.4 | | 12.1 | | | |

| | | | | | | | | | | | | |

GAAP Diluted EPS | | $ | 0.06 | | $ | 0.11 | | $ | 0.15 | | $ | 0.17 | | $ | 0.19 | | $0.14-$0.18 | |

| | | | | | | | | | | | | |

Operating Cash Flow | | $ | 0.1 | | $ | 3.8 | | $ | 7.5 | | $ | 14.1 | | $ | 17.8 | | | |

| | | | | | | | | | | | | |

Inventory Turns | | 18 | x | 19 | x | 17 | x | 17 | x | 21 | x | | |

Guidance Remains Strong

*Earnings before interest expense (including amortization of debt issuance costs), income taxes and amortization.

26

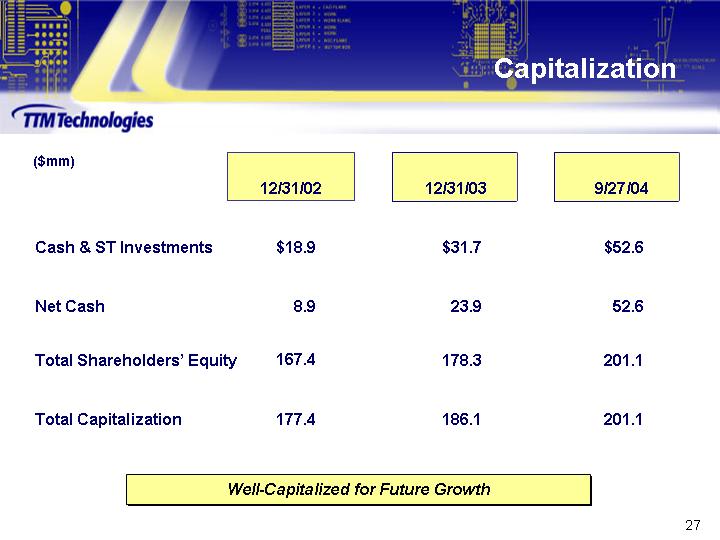

Capitalization

($mm)

| | 12/31/02 | | 12/31/03 | | 9/27/04 | |

| | | | | | | |

Cash & ST Investments | | $ | 18.9 | | $ | 31.7 | | $ | 52.6 | |

| | | | | | | |

Net Cash | | 8.9 | | 23.9 | | 52.6 | |

| | | | | | | |

Total Shareholders’ Equity | | 167.4 | | 178.3 | | 201.1 | |

| | | | | | | |

Total Capitalization | | 177.4 | | 186.1 | | 201.1 | |

| | | | | | | | | | |

Well-Capitalized for Future Growth

27

Conclusion

• Solid industry fundamentals

• Focused strategy and strong market position

• Demonstrated execution excellence

• Industry leading financial performance

28

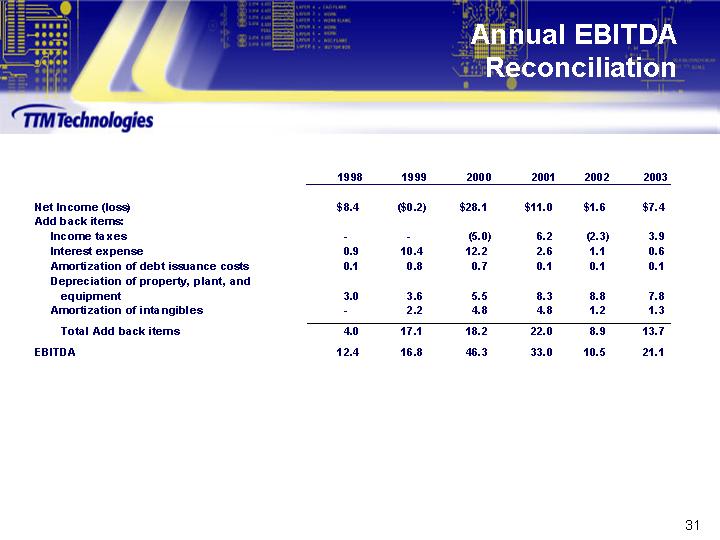

Annual EBITDA

Reconciliation

| | 1998 | | 1999 | | 2000 | | 2001 | | 2002 | | 2003 | |

| | | | | | | | | | | | | |

Net Income (loss) | | $ | 8.4 | | $ | (0.2 | ) | $ | 28.1 | | $ | 11.0 | | $ | 1.6 | | $ | 7.4 | |

Add back items: | | | | | | | | | | | | | |

Income taxes | | — | | — | | (5.0 | ) | 6.2 | | (2.3 | ) | 3.9 | |

Interest expense | | 0.9 | | 10.4 | | 12.2 | | 2.6 | | 1.1 | | 0.6 | |

Amortization of debt issuance costs | | 0.1 | | 0.8 | | 0.7 | | 0.1 | | 0.1 | | 0.1 | |

Depreciation of property, plant, and equipment | | 3.0 | | 3.6 | | 5.5 | | 8.3 | | 8.8 | | 7.8 | |

Amortization of intangibles | | — | | 2.2 | | 4.8 | | 4.8 | | 1.2 | | 1.3 | |

Total Add back items | | 4.0 | | 17.1 | | 18.2 | | 22.0 | | 8.9 | | 13.7 | |

EBITDA | | 12.4 | | 16.8 | | 46.3 | | 33.0 | | 10.5 | | 21.1 | |

| | | | | | | | | | | | | | | | | | | |

31

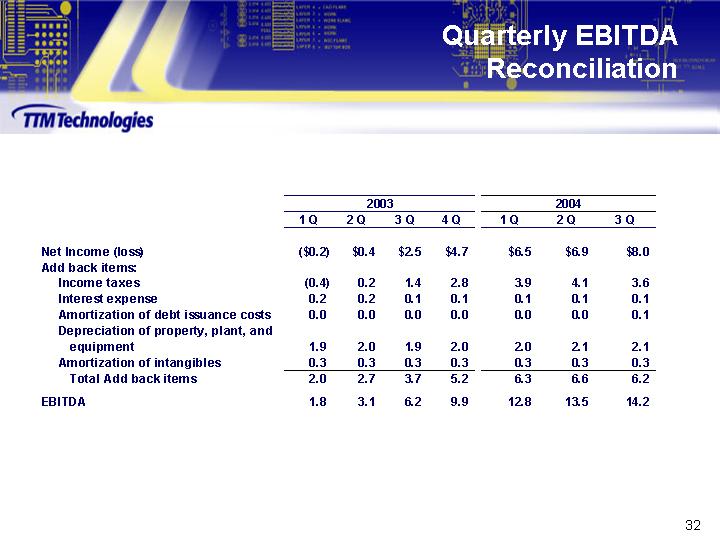

Quarterly EBITDA

Reconciliation

| | 2003 | | 2004 | |

| | 1 Q | | 2 Q | | 3 Q | | 4 Q | | 1 Q | | 2 Q | | 3 Q | |

| | | | | | | | | | | | | | | |

Net Income (loss) | | $ | (0.2 | ) | $ | 0.4 | | $ | 2.5 | | $ | 4.7 | | $ | 6.5 | | $ | 6.9 | | $ | 8.0 | |

Add back items: | | | | | | | | | | | | | | | |

Income taxes | | (0.4 | ) | 0.2 | | 1.4 | | 2.8 | | 3.9 | | 4.1 | | 3.6 | |

Interest expense | | 0.2 | | 0.2 | | 0.1 | | 0.1 | | 0.1 | | 0.1 | | 0.1 | |

Amortization of debt issuance costs | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | 0.0 | | 0.1 | |

Depreciation of property, plant, and equipment | | 1.9 | | 2.0 | | 1.9 | | 2.0 | | 2.0 | | 2.1 | | 2.1 | |

Amortization of intangibles | | 0.3 | | 0.3 | | 0.3 | | 0.3 | | 0.3 | | 0.3 | | 0.3 | |

Total Add back items | | 2.0 | | 2.7 | | 3.7 | | 5.2 | | 6.3 | | 6.6 | | 6.2 | |

EBITDA | | 1.8 | | 3.1 | | 6.2 | | 9.9 | | 12.8 | | 13.5 | | 14.2 | |

| | | | | | | | | | | | | | | | | | | | | | |

32