UNITED STATESSECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 20-F

| o | | REGISTRATION STATEMENT PURSUANT TO SECTION 12(b) OR 12(g) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| | For the fiscal year ended December 31, 2014 |

OR

| o | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| o | SHELL COMPANY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission file number: 001-16125

(Exact name of Registrant as specified in its charter)

Advanced Semiconductor Engineering, Inc.

(Translation of Registrant’s Name into English)

REPUBLIC OF CHINA

(Jurisdiction of Incorporation or Organization)

26 Chin Third Road

Nantze Export Processing Zone

Nantze, Kaohsiung, Taiwan

Republic of China

(Address of Principal Executive Offices)

Joseph Tung

Room 1901, No. 333, Section 1 Keelung Rd.

Taipei, Taiwan, 110

Republic of China

Tel: 886-2-8780-5489

Fax: 882-2-2757-6121

Email: ir@aseglobal.com

(Name, Telephone, Email and/or Facsimile number and Address of Company Contact Person)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

| Title of Each Class | Name of Each Exchange on which Registered |

| | |

| Common Shares, par value NT$10.00 each | The New York Stock Exchange* |

*Traded in the form of American Depositary Receipts evidencing American Depositary Shares, each representing five Common Shares

Securities registered or to be registered pursuant to Section 12(g) of the Act:

None

Securities for which there is a reporting obligation pursuant to Section 15(d) of the Act:

None

Indicate the number of outstanding shares of each of the issuer’s classes of capital or common stock as of the close of the period covered by the annual report:

7,860,491,546 Common Shares, par value NT$10 each**

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes x No o

If this report is an annual or transition report, indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934.

Yes o No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days.

Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

Yes o No x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer x Accelerated filer o Non-accelerated filer o

Indicate by check mark which basis of accounting the registrant has used to prepare the financial statements included in this filing:

o U.S. GAAP x International Financial Reporting Standards as issued by the International Accounting Standards Board o Other

If “Other” has been checked in response to the previous question, indicate by check mark which financial statement item the registrant has elected to follow:

Item 17 o Item 18 o

If this is an annual report, indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes o No x

** As a result of the exercise of employee stock options subsequent to December 31, 2014, as of January 31, 2015, we had 7,866,207,746 shares outstanding.

Page

Unless the context otherwise requires, references in this annual report to:

| | · | “2014 Bonds” are to RMB150.0 million 3.125% Guaranteed Bonds due September 22, 2014, issued by Anstock Limited, our wholly owned subsidiary incorporated in the Cayman Islands; |

| | · | “2016 Bonds” are to RMB500.0 million 4.250% Guaranteed Bonds due September 20, 2016, issued by Antock Limited; |

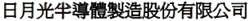

| | · | “ASE,” the “Company,” “ASE Group,” “ASE Inc.,” “we,” “us,” or “our” are to Advanced Semiconductor Engineering, Inc. and, unless the context requires otherwise, its subsidiaries; |

| | · | “ASE Chung Li” are to ASE (Chung Li) Inc., a company previously incorporated under the laws of the ROC that merged into ASE Inc. on August 1, 2004; |

| | · | “ASE Electronics” are to ASE Electronics Inc., a company incorporated under the laws of the ROC; |

| | · | “ASE Japan” are to ASE Japan Co. Ltd., a company incorporated under the laws of Japan; |

| | · | “ASE Korea” are to ASE (Korea) Inc., a company incorporated under the laws of the Republic of Korea; |

| | · | “ASE Material” are to ASE Material Inc., a company previously incorporated under the laws of the ROC that merged into ASE Inc. on August 1, 2004; |

| | · | “ASE Shanghai” are to ASE (Shanghai) Inc., a company incorporated under the laws of the PRC; |

| | · | “ASE Test” are to ASE Test Limited, a company incorporated under the laws of Singapore; |

| | · | “ASE Test Malaysia” are to ASE Electronics (M) Sdn. Bhd., a company incorporated under the laws of Malaysia; |

| | · | “ASE Test Taiwan” are to ASE Test, Inc., a company incorporated under the laws of the ROC; |

| | · | “ASEKS” are to ASE (KunShan) Inc., a company incorporated under the laws of the PRC; |

| | · | “ASEN” are to Suzhou ASEN Semiconductors Co., Ltd., a company incorporated under the laws of the PRC; |

| | · | “ASESH AT” are to ASE Assembly & Test (Shanghai) Limited, formerly known as Global Advanced Packaging Technology Limited, or GAPT, a company incorporated under the laws of the PRC; |

| | · | “ASEWH” are to ASE (Weihai), Inc., a company incorporated under the laws of the PRC; |

| | · | “Bonds” are to the 2014 Bonds and 2016 Bonds; |

| | · | “California case” are to the complaint Tessera filed against the Company and its U.S. Subsidiary, ASE (U.S) Inc. in 2006, but was later dismissed in October 2014; |

| | · | “Capital Increase” are to issuance of 130,000,000 common shares for public subscription which was effected by way of an increase in the authorized share capital in the amount of NT$1,300.0 million of the Company in September 2013; |

| | · | “Corporate Bonds” are to NT$8.0 billion 1.450% secured corporate bonds with five year term issued in August 2011 by the Company; |

| | · | “Deposit Agreement” are to deposit agreement dated September 29, 2000 among Citibank, N.A., as depositary, holders and beneficial owners of ADSs and us, which was filed as an exhibit to our registration statement on post-effective amendment No. 2 to Form F-6 on September 16, 2003, and its two amendments, which were filed as an exhibit to our registration statement on post-effective amendment No. 1 to Form F-6 on April 3, 2006 and our registration statement on post-effective amendment No. 2 to Form F-6 on October 25, 2006; |

| | · | “EEMS Test Singapore” are to EEMS Test Singapore Pte. Ltd., a company incorporated under the laws of Singapore, which changed its name to ASE Singapore II Pte. Ltd. and was subsequently merged into ASE Singapore Pte. Ltd. on January 1, 2011; |

| | · | the “Exchange Act” are to the U.S. Securities Exchange Act of 1934, as amended; |

| | · | “FSC” are to the Financial Supervisory Commission of the Republic of China. |

| | · | “Green Bonds” are to US$300.0 million 2.125% Guaranteed Bonds due July 24, 2017, offered by Anstock II Limited, our wholly owned subsidiary incorporated in the Cayman Islands; |

| | · | “Hung Ching” are to Hung Ching Development & Construction Co. Ltd., a company incorporated under the laws of the ROC; |

| | · | “IFRS” are to International Financial Reporting Standards, International Accounting Standards and Interpretations as issued by the International Accounting Standards Board; |

| | · | “ISE Labs” are to ISE Labs, Inc., a corporation incorporated under the laws of the State of California; |

| | · | “ITC” are to the United States International Trade Commission; |

| | · | “Korea” or “South Korea” are to the Republic of Korea; |

| | · | “Mainland Investors Regulations” are to the Regulations Governing Securities Investment and Futures Trading in Taiwan by Mainland Area Investors; |

| | · | “MOEAIC” are to Investment Commission of the ROC Ministry of Economic Affairs; |

| | · | “PowerASE” are to PowerASE Technology, Inc., a company incorporated under the laws of the ROC which was merged into ASE Inc. in May 2012; |

| | · | “PRC” are to the People’s Republic of China and excludes Taiwan, Macau and Hong Kong; |

| | · | “PRC Regulations” are to the Regulations Governing Mainland China Investors’ Securities Investments and Futures Trading in Taiwan; |

| | · | “QDII” are to qualified domestic institutional investors; |

| | · | “Republic of China,” the “ROC” and “Taiwan” are to the Republic of China, including Taiwan and certain other possessions; |

| | · | “ROC GAAP” are to generally accepted accounting principles in the ROC; |

| | · | the “SEC” are to the Securities and Exchange Commission of the U.S.; |

| | · | the “Securities Act” are to the U.S. Securities Act of 1933, as amended; |

| | · | “SiP” are to system-in-package; |

| | · | “Taiwan-IFRS” are to the Regulations Governing the Preparation of Financial Reports by Securities Issuers, the IFRS as well as related guidance translated by Accounting Research and Development Foundation and endorsed by the FSC. |

| | · | “Tessera” are to Tessera, Inc., a company which filed a suit against the Company and its U.S. subsidiary, ASE (U.S.) Inc.; |

| | · | “UGJQ” are to Universal Global Technology (Shanghai) Co., Ltd., a company incorporated under the laws of the PRC; |

| | · | “UGKS” are to Universal Global Technology (Kunshan) Co. Ltd., a company incorporated under the laws of the PRC; |

| | · | “UGTW” are to Universal Global Scientific Industrial Co. Ltd., a company incorporated under the laws of the ROC; |

| | · | “Universal Scientific” or “USI” are to Universal Scientific Industrial Co., Ltd., a company incorporated under the laws of the ROC, and, unless the context requires otherwise, “Universal Scientific Group” are to Universal Scientific, and its directly and indirectly held subsidiaries; |

| | · | “Universal Scientific Shanghai” are to Universal Scientific Industrial (Shanghai) Co., Ltd., a company incorporated under the laws of the PRC; |

| | · | “U.S.” refers to United States of America; |

| | · | “US GAAP” are to accounting principles generally accepted in the U.S.; |

| | · | “USI, Inc.” are to a new corporation, which is expected to be incorporated under ROC law on a spin-off record date once the proposed USI Spin-Off transaction is approved by the MOEAIC; |

| | · | “USI Spin-Off transaction” are to the proposed spin-off transaction whereby Universal Scientific proposes to spin-off and assign its investment businesses to a new entity, and the proposed transaction is currently being reviewed by the MOEAIC; |

| | · | “USI Mexico” are to Universal Scientific Industrial De Mexico S.A. DE C.V., a company incorporated under the laws of Mexico; |

| | · | “USISZ” are to Universal Electronics (Shenzhen) Co. Ltd., a company incorporated under the laws of the PRC; |

| | · | “Wuxi Tongzhi” are to Wuxi Tongzhi Microelectronics Co., Ltd., a company incorporated under the laws of the PRC; and |

| | · | “Yang Ting” are to Yang Ting Tech Co., Ltd., a company incorporated under the laws of the ROC which was merged into ASE Inc. in August 2013. |

We publish our financial statements in New Taiwan dollars, the lawful currency of the ROC. In this annual report, references to “United States dollars,” “U.S. dollars” and “US$” are to the currency of the United States; references to “New Taiwan dollars,” “NT dollars” and “NT$” are to the currency of the ROC; references to “RMB” are to the currency of the PRC; references to “JP¥” are to the currency of Japan; references to “MYR” are to the currency of Malaysia; references to “SGD” are to the currency of Republic of Singapore; references to “KRW” are to the currency of Republic of Korea; and references to “EUR” are to the currency of the European Union. Unless otherwise noted, all translations from NT dollars to U.S. dollars were made at the exchange rate as set forth in the H.10 weekly statistical release of the Federal Reserve System of the United States (the “Federal Reserve Board”) as of December 31, 2014, which was NT$31.60 = US$1.00, and all translations from RMB to U.S. dollars were made at the exchange rate as set forth in the H.10 weekly statistical release of the Federal Reserve Board as of December 31, 2014, which was RMB6.2046 = US$1.00. All amounts translated into U.S. dollars in this annual report are provided solely for your convenience and no representation is made that the NT dollar/RMB or U.S. dollar amounts referred to herein could have been or could be converted into U.S. dollars or NT dollars/RMB, as the case may be, at any particular rate or at all. On March 13, 2015, the exchange rate between NT dollars and U.S. dollars as set forth in the H.10 weekly statistical release by the Federal Reserve Board was NT$31.71 = US$1.00. On March 13, 2015, the exchange rate between RMB and U.S. dollars as set forth in the H.10 weekly statistical release by the Federal Reserve Board was RMB6.2585 = US$1.00.

This annual report on Form 20-F contains “forward-looking statements” within the meaning of Section 27A of the Securities Act and Section 21E of the Exchange Act. Although these forward-looking statements, which may include statements regarding our future results of operations, financial condition or business prospects, are based on our own information and information from other sources we believe to be reliable, you should not place undue reliance on these forward-looking statements, which apply only as of the date of this annual report. The words “anticipate,” “believe,” “estimate,” “expect,” “intend,” “plan” and similar expressions, as they relate to us, are intended to identify these forward-looking statements in this annual report. Our actual results of operations, financial condition or business prospects may differ materially from those expressed or implied in these forward-looking statements for a variety of reasons, including risks associated with cyclicality and market conditions in the semiconductor or electronics industry; changes in our regulatory environment, including our ability to comply with new or stricter environmental regulations and to resolve environmental liabilities; demand for the outsourced semiconductor packaging, testing and electronic manufacturing services we offer and for such outsourced services generally; the highly competitive semiconductor or manufacturing industry we are involved in; our ability to introduce new technologies in order to remain competitive; international business activities; our business strategy; our future expansion plans and capital expenditures; the strained relationship between the ROC and the PRC; general economic and political conditions; the recent global economic crisis; possible disruptions in commercial activities caused by natural or human-induced disasters; fluctuations in foreign currency exchange rates; and other factors. For a discussion of these risks and other factors, see “Item 3. Key Information—Risk Factors.”

Not applicable.

Not applicable.

The selected consolidated statements of comprehensive income data and cash flow data for the years ended December 31, 2012, 2013 and 2014, and the selected consolidated balance sheet data as of December 31, 2013 and 2014, set forth below are derived from our audited consolidated financial statements included in this annual report and should be read in conjunction with, and are qualified in their entirety by reference to, these consolidated financial statements, including the notes thereto. Our consolidated financial statements as of and for the years ended December 31, 2012, 2013 and 2014 have been prepared and presented in accordance with IFRS. The selected consolidated balance sheet data as of December 31, 2012, set forth below, is derived from our audited consolidated financial statements not included herein.

We have adopted IFRS for certain filings with the SEC, starting from the filing of our annual report on Form 20-F for the year ended December 31, 2013. Historical financial results as of and for the year ended December 31, 2012 included herein have been adjusted and presented in accordance with IFRS, which differs from the results included in our annual report on Form 20-F for the year ended December 31, 2012. Meanwhile, as required by the FSC, we adopted Taiwan-IFRS for reporting of our annual and interim consolidated financial statements in the ROC beginning on January 1, 2013. Taiwan-IFRS differs from IFRS in certain respects, including, but not limited to the extent that any new or amended standards or interpretations applicable under IFRS may not be timely endorsed by the FSC. See “Item 3. Key Information—Risk Factors—Risks Relating to Our Business—Our adoption of new financial reporting standards, effective January 1, 2013, may have material impact on our financial statements thereafter” for more information.

Following our adoption of IFRS for SEC filing purposes, pursuant to the rule amendments adopted by the SEC which became effective on March 4, 2008, we were no longer be required to reconcile our consolidated financial statements with U.S. GAAP.

| | | As of and for the Year Ended December 31, | |

| | | | | | | | | | |

| | | NT$ | | | NT$ | | | NT$ | | | US$ | |

| | | (in millions, except earnings per share and per ADS data) | |

Statement of Comprehensive Income Data: | | | | | | | | | | | | |

| Operating revenues | | | 193,972.4 | | | | 219,862.4 | | | | 256,591.4 | | | | 8,120.0 | |

| Operating costs | | | (157,342.7 | ) | | | (177,040.4 | ) | | | (203,002.9 | ) | | | (6,424.1 | ) |

| Gross profit | | | 36,629.7 | | | | 42,822.0 | | | | 53,588.5 | | | | 1,695.9 | |

| Operating expenses | | | (18,922.6 | ) | | | (20,760.4 | ) | | | (23,942.7 | ) | | | (757.7 | ) |

| Other income and expenses, net | | | 83.2 | | | | (1,348.2 | ) | | | 228.7 | | | | 7.2 | |

| Profit from operations | | | 17,790.3 | | | | 20,713.4 | | | | 29,874.5 | | | | 945.4 | |

| Non-operating expense, net | | | (1,181.6 | ) | | | (1,343.6 | ) | | | (1,339.4 | ) | | | (42.4 | ) |

| Profit before income tax | | | 16,608.7 | | | | 19,369.8 | | | | 28,535.1 | | | | 903.0 | |

| Income tax expense | | | (2,960.4 | ) | | | (3,499.6 | ) | | | (5,666.0 | ) | | | (179.3 | ) |

| Profit for the year | | | 13,648.3 | | | | 15,870.2 | | | | 22,869.1 | | | | 723.7 | |

| Attributable to | | | | | | | | | | | | | | | | |

| Owners of the Company | | | 13,191.6 | | | | 15,404.5 | | | | 22,228.6 | | | | 703.4 | |

| Non-controlling interests | | | 456.7 | | | | 465.7 | | | | 640.5 | | | | 20.3 | |

| | | | 13,648.3 | | | | 15,870.2 | | | | 22,869.1 | | | | 723.7 | |

| Other comprehensive income (loss), net of income tax | | | (3,830.7 | ) | | | 3,233.3 | | | | 5,504.4 | | | | 174.2 | |

| Total comprehensive income for the year | | | 9,817.6 | | | | 19,103.5 | | | | 28,373.5 | | | | 897.9 | |

| Attributable to | | | | | | | | | | | | | | | | |

| Owners of the Company | | | 9,420.4 | | | | 18,509.6 | | | | 27,394.3 | | | | 866.9 | |

| | | As of and for the Year Ended December 31, | |

| | | | | | | | | | |

| | | NT$ | | | NT$ | | | NT$ | | | US$ | |

| | | (in millions, except earnings per share and per ADS data) | |

| Non-controlling interests | | | 397.2 | | | | 593.9 | | | | 979.2 | | | | 31.0 | |

| | | | 9,817.6 | | | | 19,103.5 | | | | 28,373.5 | | | | 897.9 | |

Earnings per common share(1): | | | | | | | | | | | | | | | | |

| Basic | | | 1.77 | | | | 2.05 | | | | 2.89 | | | | 0.09 | |

| Diluted | | | 1.73 | | | | 1.99 | | | | 2.79 | | | | 0.09 | |

Dividends per common share(2) | | | 2.05 | | | | 1.05 | | | | 1.29 | | | | 0.04 | |

Earnings per equivalent ADS(1): | | | | | | | | | | | | | | | | |

| Basic | | | 8.86 | | | | 10.26 | | | | 14.46 | | | | 0.46 | |

| Diluted | | | 8.65 | | | | 9.96 | | | | 13.93 | | | | 0.44 | |

Number of common shares(3): | | | | | | | | | | | | | | | | |

| Basic | | | 7,445.5 | | | | 7,508.5 | | | | 7,687.9 | | | | 7,687.9 | |

| Diluted | | | 7,568.2 | | | | 7,747.6 | | | | 8,220.7 | | | | 8,220.7 | |

| Number of equivalent ADSs | | | | | | | | | | | | | | | | |

| Basic | | | 1,489.1 | | | | 1,501.7 | | | | 1,537.6 | | | | 1,537.6 | |

| Diluted | | | 1,513.6 | | | | 1,549.5 | | | | 1,644.1 | | | | 1,644.1 | |

| Balance Sheet Data: | | | | | | | | | | | | | | | | |

| Current assets | | | 97,495.6 | | | | 132,176.5 | | | | 159,955.2 | | | | 5,061.9 | |

Investments- non-current(4) | | | 2,267.8 | | | | 2,345.5 | | | | 2,409.3 | | | | 76.2 | |

| Property, plant and equipment, net | | | 127,197.8 | | | | 131,497.3 | | | | 151,587.1 | | | | 4,797.1 | |

| Intangible assets | | | 12,361.3 | | | | 11,953.6 | | | | 11,913.3 | | | | 377.0 | |

| Long-term prepayment for lease | | | 4,164.1 | | | | 4,072.3 | | | | 2,586.0 | | | | 81.8 | |

Others(5) | | | 4,236.0 | | | | 4,676.9 | | | | 5,267.9 | | | | 166.7 | |

| Total assets | | | 247,722.6 | | | | 286,722.1 | | | | 333,718.8 | | | | 10,560.7 | |

| Short-term borrowings | | | 36,884.9 | | | | 44,618.2 | | | | 41,176.0 | | | | 1,303.1 | |

| Current portion of long-term debts | | | 3,213.8 | | | | 6,016.5 | | | | 2,835.5 | | | | 89.7 | |

Long-term debts(6) | | | 44,591.7 | | | | 50,166.5 | | | | 55,375.8 | | | | 1,752.4 | |

Other liabilities(7) | | | 53,211.8 | | | | 60,176.9 | | | | 78,640.1 | | | | 2,488.6 | |

| Total liabilities | | | 137,902.2 | | | | 160,978.1 | | | | 178,027.4 | | | | 5,633.8 | |

| Share capital | | | 76,047.7 | | | | 78,180.3 | | | | 78,715.2 | | | | 2,491.0 | |

| Non-controlling interests | | | 3,505.7 | | | | 4,128.4 | | | | 8,209.9 | | | | 259.8 | |

| Equity attributable to owners of the Company | | | 106,314.7 | | | | 121,615.6 | | | | 147,481.5 | | | | 4,667.1 | |

| Cash Flow Data: | | | | | | | | | | | | | | | | |

| Capital expenditures | | | (39,029.5 | ) | | | (29,142.7 | ) | | | (39,599.0 | ) | | | (1,253.1 | ) |

| Depreciation and amortization | | | 23,435.9 | | | | 25,470.9 | | | | 26,350.8 | | | | 833.9 | |

| Net cash inflow from operating activities | | | 33,038.0 | | | | 41,296.0 | | | | 45,863.5 | | | | 1,451.4 | |

| Net cash outflow from investing activities | | | (43,817.8 | ) | | | (29,925.8 | ) | | | (38,817.9 | ) | | | (1,228.4 | ) |

| Net cash inflow (outflow) from financing activities | | | 8,455.8 | | | | 12,794.9 | | | | (2,797.0 | ) | | | (88.5 | ) |

| Segment Data: | | | | | | | | | | | | | | | | |

| Operating revenues: | | | | | | | | | | | | | | | | |

| Packaging | | | 104,298.3 | | | | 112,603.9 | | | | 121,336.5 | | | | 3,839.8 | |

| Testing | | | 22,657.0 | | | | 24,732.2 | | | | 25,874.7 | | | | 818.8 | |

| Electronic manufacturing services | | | 62,747.7 | | | | 78,530.6 | | | | 105,784.4 | | | | 3,347.6 | |

| Others | | | 4,269.4 | | | | 3,995.7 | | | | 3,595.8 | | | | 113.8 | |

| Gross profit: | | | | | | | | | | | | | | | | |

| Packaging | | | 19,812.5 | | | | 23,673.7 | | | | 33,040.2 | | | | 1,045.6 | |

| Testing | | | 7,601.0 | | | | 9,079.4 | | | | 9,632.0 | | | | 304.8 | |

| Electronic manufacturing services | | | 7,241.3 | | | | 8,054.3 | | | | 9,118.9 | | | | 288.6 | |

| Others | | | 1,974.9 | | | | 2,014.6 | | | | 1,797.4 | | | | 56.9 | |

| (1) | The denominators for diluted earnings per common share and diluted earnings per equivalent ADS are calculated to account for the potential diluted factors, such as the exercise of options and conversion of our convertible bonds into our common shares. |

| (2) | Dividends per common share issued as a cash dividend, a stock dividend and distribution from capital surplus. |

| (3) | Represents the weighted average number of shares after retroactive adjustments to give effect to stock dividends. Common shares held by consolidated subsidiaries are classified as “treasury stock,” and are deducted from the number of common shares outstanding. |

| (4) | Including available-for-sale financial assets — non-current and investments accounted for using the equity method. |

| (5) | Including deferred tax assets, other financial assets — non-current and other non-current assets. |

| (6) | Including bonds payable, long-term borrowings and capital lease obligations. |

| (7) | Including (x) current liabilities other than short-term borrowings and current portion of long-term debts and (y) non-current liabilities other than long-term debts. |

Exchange Rates

Fluctuations in the exchange rate between NT dollars and U.S. dollars will affect the U.S. dollar equivalent of the NT dollar price of our common shares on the Taiwan Stock Exchange and, as a result, will likely affect the market price of the ADSs. Fluctuations will also affect the U.S. dollar conversion by the depositary under our ADS deposit agreement referred to below of cash dividends paid in NT dollars on, and the NT dollar proceeds received by the depositary from any sale of, common shares represented by ADSs, in each case, according to the terms of the deposit agreement dated September 29, 2000 and as amended and supplemented from time to time among us, Citibank N.A., as depositary, and the holders and beneficial owners from time to time of the ADSs, which we refer to as the deposit agreement.

The following table sets forth, for the periods indicated, information concerning the number of NT dollars for which one U.S. dollar could be exchanged. The exchange rates reflect the exchange rates set forth in the H.10 statistical release of the Federal Reserve Board.

| | | | |

| | | | | | | | | | | | | |

| 2010 | | | 31.40 | | | | 32.43 | | | | 29.14 | | | | 29.14 | |

| 2011 | | | 29.42 | | | | 30.67 | | | | 28.50 | | | | 30.27 | |

| 2012 | | | 29.47 | | | | 30.28 | | | | 28.96 | | | | 29.05 | |

| 2013 | | | 29.73 | | | | 30.20 | | | | 28.93 | | | | 29.83 | |

| 2014 | | | 30.38 | | | | 31.80 | | | | 29.85 | | | | 31.60 | |

| September | | | 30.13 | | | | 30.47 | | | | 29.89 | | | | 30.44 | |

| October | | | 30.40 | | | | 30.49 | | | | 30.31 | | | | 30.45 | |

| November | | | 30.73 | | | | 30.99 | | | | 30.48 | | | | 30.99 | |

| December | | | 31.35 | | | | 31.80 | | | | 31.03 | | | | 31.60 | |

| 2015 | | | | | | | | | | | | | | | | |

| January | | | 31.64 | | | | 32.00 | | | | 31.06 | | | | 31.75 | |

| February | | | 31.55 | | | | 31.76 | | | | 31.31 | | | | 31.44 | |

| March (through March 13, 2015) | | 31.54 | | | 31.71 | | | 31.35 | | | 31.71 | |

| (1) | Annual averages were calculated by using the average of the exchange rates on the last day of each month during the relevant year. Monthly averages were calculated by using the average of the daily rates during the relevant month. |

On March 13, 2015, the exchange rate as set forth in the H.10 weekly statistical release by the Federal Reserve Board was NT$31.71 = US$1.00.

Not applicable.

Not applicable.

Risks Relating to Our Business

Since we are dependent on the highly cyclical semiconductor and electronics industries and conditions in the markets for the end-use applications of our products, our revenues and net income may fluctuate significantly.

Our business is affected by market conditions in the highly cyclical semiconductor and electronics industries. Most of our customers operate in this industry, and variations in order levels from our customers and service fee rates may result in volatility in our revenues and net income. From time to time, the semiconductor and electronics industries have experienced significant, and sometimes prolonged, downturns. As our business is, and will continue to be, dependent on the requirements for independent packaging, testing and electronic manufacturing services, any future downturn in the industry would reduce demand for our services. For example, in the fourth quarter of 2008, the global economic crisis resulted in a significant deterioration in demand for our customers’ products, which in turn affected demand for our services and adversely affected our operating results. Although demand has recovered, we expect there to be continued downward pressure on our average selling prices and continued volatility with respect to our sales volumes in the future. If we cannot reduce our costs or adjust our product mix to sufficiently offset any decline in sales volumes, our profitability will suffer, and we may incur losses.

Market conditions in the semiconductor and electronics industries depend to a large degree on conditions in the markets for the end-use applications of various products, such as communications, computing and consumer electronics products. Any deterioration of conditions in the markets for the end-use applications would reduce demand for our services, and would likely have a material adverse effect on our financial condition and results of operations. In 2014, approximately 53.3%, 11.6% and 34.7% of our operating revenues from packaging and testing were attributed to the packaging and testing of semiconductors used in communications, computing and consumer electronics/industrial/automotive applications, respectively. In the same year, approximately 55.6%, 18.0%, 8.9%, 10.3% and 6.3% of our operating revenues from electronic manufacturing services were attributed to the communications, computing, consumer electronics applications, industrial and automotive applications, respectively. Each of the markets for end-use applications is subject to intense competition and significant shifts in demand, which could put pricing pressure on our services and adversely affect our revenues and net income.

A reversal or slowdown in the outsourcing trend for semiconductor packaging and testing services and electronic manufacturing services could adversely affect our growth prospects and profitability.

Semiconductor manufacturers that have their own in-house packaging and testing capabilities, known as integrated device manufacturers and original equipment manufacturers, have increasingly outsourced stages of the production process, including packaging, testing, electronic manufacturing and assembly, to independent companies in order to reduce costs, eliminate product complexity and meet fast-to-market requirements. In addition, the availability of advanced independent semiconductor manufacturing services has also enabled the growth of so-called “fabless” semiconductor companies that focus exclusively on design and marketing and outsource their manufacturing, packaging and testing requirements to independent companies. We cannot assure you that these manufacturers and companies will continue to outsource their packaging, testing and manufacturing requirements to third parties like us. Furthermore, during an economic downturn, these integrated device manufacturers typically rely more on their own in-house packaging and testing capabilities, therefore decreasing their need to outsource. A reversal of, or a slowdown in, this outsourcing trend could result in reduced demand for our services and adversely affect our growth prospects and profitability.

Any global economic downturn could adversely affect the demand for our products and services, and a protracted global economic crisis would have a material adverse effect on us.

The global financial markets experienced significant disruptions in 2008 and the United States, Europe and other economies went into recession. The recovery from the lows of 2008 and 2009 was uneven and it is facing new challenges, including a European sovereign debt crisis that began in 2011 and continuing high unemployment rates in much of the world. It is unclear what the long-term impact of the European sovereign debt crisis will be and uncertainty remains over the long-term effects of the expansionary monetary and fiscal policies that have been adopted by the central banks and financial authorities of some of the world’s leading economies. Any economic downturn or crisis may cause our customers to do the following:

| | · | cancel or reduce planned expenditures for our products and services; |

| | · | seek to lower their costs by renegotiating their contracts with us; |

| | · | consolidate the number of suppliers they use which may result in our loss of customers; and |

| | · | switch to lower-priced products or services provided by our competitors. |

Any uncertainty or significant volatility in global economic conditions may also make it difficult for our customers to accurately forecast and plan future business activities and may have a material adverse effect on us.

If we are unable to compete favorably in the highly competitive markets of semiconductor packaging and testing and electronic manufacturing services, our revenues and net income may decrease.

The markets of semiconductor packaging and testing and electronic manufacturing services are very competitive. We face competition from a number of sources, including other independent semiconductor packaging and testing companies, especially those that offer turnkey packaging and testing services, and other electronic manufacturing services providers with large-scale manufacturing capabilities who can quickly react to market changes. We believe that the principal competitive factors in our industry are:

| | · | technological expertise; |

| | · | the ability to provide total solutions to our customers, including integrated design, manufacturing, packaging and testing and electronic manufacturing services; |

| | · | ability to offer interconnect technologies at an optimal scale for our businesses; |

| | · | range of package types and testing platforms available; |

| | · | the ability to work closely with our customers at the product development stage; |

| | · | responsiveness and flexibility; |

| | · | fast-to-market product development; |

| | · | diversity in facility locations; and |

We face increasing competition, as most of our customers obtain services from more than one source. Rapid technological advances and aggressive pricing strategies by our competitors may continue to increase competition. Our ability to compete depends on factors both within and outside of our control and may be constrained by the distinct characteristics and production requirements of individual products. We cannot assure you that we will be able to continue to improve production efficiency and maintain reasonable profit for all of our products.

In addition, some of our competitors may have superior financial, marketing, manufacturing, research and development and technological resources than we do. For example, the central government of the PRC as well as provincial and municipal governments have provided various incentives to domestic companies in the semiconductor industry. Increase in competition may lead to declines in product prices and profitability could have a material adverse effect on our business, financial condition, results of operations and future prospects.

Our profitability depends on our ability to respond to rapid technological changes in the semiconductor industry.

The semiconductor industry is characterized by rapid increases in the diversity and complexity of semiconductors. As a result, we expect that we will need to constantly offer more sophisticated packaging and testing technologies and processes in order to respond to competitive industry conditions and customer requirements. We have successfully combined our packaging, testing and materials technologies with the expertise of Universal Scientific at the systems level to develop our SiP business. Success of a new product depends on a number of factors such as product acceptance by the market. New products are developed in anticipation of future demand. We cannot assure you that the launch of any new product will be successful, or that we will be able to produce sufficient quantities of these products to meet market demand. If we fail to develop, or obtain access to, advances in packaging or testing technologies or processes, we may become less competitive and less profitable. In addition, advances in technology typically lead to declining average selling prices for semiconductors packaged or tested with older technologies or processes. As a result, if we cannot reduce the costs associated with our services, the profitability of a given service and our overall profitability may decrease over time.

Our operating results are subject to significant fluctuations, which could adversely affect the market value of your investment.

Our operating results have varied significantly from period to period and may continue to vary in the future. Downward fluctuations in our operating results may result in decreases in the market price of our common shares and the ADSs. Among the more important factors affecting our quarterly and annual operating results are the following:

| | · | changes in general economic and business conditions, particularly the cyclical nature of the semiconductor and electronics industries and the markets served by our customers; |

| | · | our ability to quickly adjust to unanticipated declines or shortfalls in demand and market prices; |

| | · | changes in prices for our products or services; |

| | · | volume of orders relative to our packaging, testing and manufacturing capacity; |

| | · | changes in costs and availability of raw materials, equipment and labor; |

| | · | our ability to obtain or develop substitute raw materials with lower cost; |

| | · | our ability to successfully develop or market new products or services; |

| | · | our ability to successfully manage product mix in response to changes in market demand and differences in margin associated with different products; |

| | · | timing of capital expenditures in anticipation of future orders; |

| | · | our ability to acquire or design and produce advanced and cost-competitive interconnect materials, and provide integrated solutions for electronic manufacturing services; |

| | · | fluctuations in the exchange rate between the NT dollar and foreign currencies, especially the U.S. dollar; and |

| | · | typhoons, earthquakes, drought, epidemics, tsunami and other natural disasters, as well as industrial and other incidents such as fires and power outages. |

Due to the factors listed above, our future operating results or growth rates may be below the expectations of research analysts and investors. If so, the market price of our common shares and the ADSs, and thus the market value of your investment, may fall.

If we are not successful in maintaining our in-house interconnect materials capabilities, our margins and profitability may be adversely affected.

We expect that we will need to maintain our interconnect materials designs and production processes in order to respond to competitive industry conditions and customer requirements. In particular, our competitive position will depend on our ability to design and produce interconnect materials that are comparable to or better than those produced by independent suppliers and others. Many of these independent suppliers have dedicated greater resources than we have for the research and development and design and production of interconnect materials. In addition, we may not be able to acquire the technology and personnel that would enable us to maintain our in-house expertise and our design and production capabilities. For more information on our interconnect materials operations, see “Item 4. Information on the Company—Business Overview—Principal Products and Services—Packaging Services—Interconnect Materials.” If we are unable to maintain our in-house interconnect materials expertise to offer interconnect materials that meet the requirements of our customers, we may become less competitive and our margins and profitability may suffer as a result.

Due to our high percentage of fixed costs, we may be unable to maintain our gross margin at past levels if we are unable to achieve relatively high capacity utilization rates.

Our operations, in particular our testing operations, are characterized by relatively high fixed costs. We expect to continue to incur substantial depreciation and other expenses in connection with our acquisitions of equipment and facilities. Our profitability depends not only on the pricing levels for our services or products, but also on utilization rates for our machinery and equipment, commonly referred to as “capacity utilization rates.” In particular, increases or decreases in our capacity utilization rates can significantly affect gross margins since the unit cost generally decreases as fixed costs are allocated over a larger number of units. In periods of low demand, we experience relatively low capacity utilization rates in our operations, which leads to reduced margins. For example, in the fourth quarter of 2008, we experienced lower than anticipated utilization rates in our operations due to a significant decline in worldwide demand for our packaging and testing services, which resulted in reduced margins during that period. Although capacity utilization rates have recovered since 2009, we cannot assure you that we will be able to maintain or surpass our past gross margin levels if we cannot consistently achieve or maintain relatively high capacity utilization rates.

If we are unable to manage our expansion or investments effectively, our growth prospects may be limited and our future profitability and core business operations may be adversely affected.

We have significantly expanded our operations through both organic growth and acquisitions in recent years. For example, we acquired the controlling interest of Universal Scientific through a tender offer in February 2010 and EEMS Test Singapore in August 2010 (EEMS Test Singapore was subsequently merged into ASE Singapore Pte. Ltd. on January 1, 2011). We also acquired Yang Ting in January 2012 and merged our subsidiary PowerASE into ASE Inc. in May 2012 (Yang Ting was subsequently merged into ASE Inc. in August 2013). In addition, we acquired Wuxi Tongzhi in May 2013 and Universal Scientific Group established UGJQ in September 2013. We expect that we will continue to expand our operations in the future. The purpose of our expansion is mainly to provide total solutions to existing customers or to attract new customers and broaden our product range for a variety of end-use applications. However, rapid expansion may place a strain on our managerial, technical, financial, operational and other resources. As a result of our expansion, we have implemented and will continue to implement additional operational and financial controls and hire and train additional personnel. Any failure to manage our growth effectively could lead to inefficiencies and redundancies and result in reduced growth prospects and profitability.

In addition, we have recently made investments in real estate development businesses mostly in China. The PRC property market is volatile and may experience undersupply or oversupply and property price fluctuations. The central and local governments frequently adjust monetary and other fiscal policies to prevent and curtail the overheating of the economy. Such policies may lead to changes in market conditions, including price instability and imbalance of supply and demand in respect of office, residential, retail, entertainment, cultural and intellectual properties. We may continue to make investments in this area in the future and our diversification in this industry may put pressure on our managerial, financial, operational and other resources. Our exposure to risks related to real estate development may also increase over time as a result of our expansion into such a business. There can be no assurance that our investments in such a business will yield the anticipated returns and that our expansion into such a business, including the resulting diversion of management’s attention, will not adversely affect our core business operations.

The packaging and testing businesses are capital intensive. If we cannot obtain additional capital when we need it, our growth prospects and future profitability may be adversely affected.

The packaging and testing businesses are capital intensive. We will need capital to fund the expansion of our facilities as well as fund our research and development activities in order to remain competitive. We believe that our existing cash, marketable securities, expected cash flow from operations and existing credit lines under our loan facilities will be sufficient to meet our capital expenditures, working capital, cash obligations under our existing debt and lease arrangements, and other requirements for at least the next twelve months. However, future capacity expansions or market or other developments may cause us to require additional funds. Our ability to obtain external financing in the future is subject to a variety of uncertainties, including:

| | · | our future financial condition, results of operations and cash flows; |

| | · | general market conditions for financing activities by semiconductor or electronics companies; and |

| | · | economic, political and other conditions in Taiwan and elsewhere. |

If we are unable to obtain funding in a timely manner or on acceptable terms, our result of operations and financial conditions may be materially and adversely affected.

Restrictive covenants and broad default provisions in our existing debt agreements may materially restrict our operations as well as adversely affect our liquidity, financial condition and results of operations.

We are a party to numerous loans and other agreements relating to the incurrence of debt, many of which include restrictive covenants and broad default provisions. In general, covenants in the agreements governing our existing debt, and debt we may incur in the future, may materially restrict our operations, including our ability to incur debt, pay dividends, make certain investments and payments, other than in connection with restructurings of consolidated entities, and encumber or dispose of assets. In addition, any global economic deterioration or ineffective expansion may cause us to incur significant net losses or force us to assume considerable liabilities. We cannot assure you that we will be able to remain in compliance with our financial covenants which, as a result, may lead to a default. This may thereby restrict our ability to access unutilized credit facilities or the global capital markets to meet our liquidity needs. Furthermore, a default under one agreement by us or one of our subsidiaries may also trigger cross-defaults under our other agreements. In the event of default, we may not be able to cure the default or obtain a waiver on a timely basis. An event of default under any agreement timely governing our existing or future debt, if not cured or waived, could have a material adverse effect on our liquidity, financial condition and results of operations.

We have on occasion failed to comply with certain financial covenants in some of our loan agreements. Such non-compliance may also have, through broadly worded cross-default provisions, resulted in default under some of the agreements governing our other existing debt. For example, we failed to comply with certain financial covenants in some of our loan agreements as a result of our acquisition of the controlling interest of Universal Scientific in February 2010, for which we have timely obtained waivers from our counterparties. If we are unable to timely remedy any of our non-compliance under such loan agreements or obtain applicable waivers or amendments, we would breach our financial covenants and our financial condition would be adversely affected. As of December 31, 2014, we were not in breach of any of the financial covenants under our existing loan agreements, although we cannot provide any assurance that we will not breach any of such financial covenants in the future.

We depend on select personnel and could be affected by the loss of their services.

We depend on the continued service of our executive officers and skilled technical personnel. Our business could suffer if we lose the services of any of these personnel and cannot adequately replace them. Although some of these management personnel have entered into employment agreements with us, they may nevertheless leave before the expiration of these agreements. We are not insured against the loss of the services of any of our personnel. In addition, these proceedings may divert these and other employees’ attention from our business operations.

In addition, we may be required to increase substantially the number of these employees in connection with our expansion plans, and there is intense competition for their services in this industry. We may not be able to either retain our present personnel or attract additional qualified personnel as and when needed. In addition, we may need to increase employee compensation levels in order to attract and retain our existing officers and employees and the additional personnel that we expect to require. Furthermore, a portion of the workforce at our facilities in Taiwan are foreign workers employed by us under work permits which are subject to government regulations on renewal and other terms. Consequently, our business could also suffer if the Taiwan regulations relating to the employment of foreign workers were to become significantly more restrictive or if we are otherwise unable to attract or retain these workers at a reasonable cost.

If we are unable to obtain additional packaging and testing equipment or facilities in a timely manner and at a reasonable cost, our competitiveness and future profitability may be adversely affected.

The semiconductor packaging and testing businesses are capital intensive and require significant investment in expensive equipment manufactured by a limited number of suppliers. The market for semiconductor packaging and testing equipment is characterized, from time to time, by intense demand, limited supply and long delivery cycles. Our operations and expansion plans depend on our ability to obtain a significant amount of such equipment from a limited number of suppliers. From time to time we have also leased certain equipment. We have no binding supply agreements with any of our suppliers and acquire our packaging and testing equipment on a purchase order basis, which exposes us to changing market conditions and other substantial risks. For example, shortages of capital equipment could result in an increase in the price of equipment and longer delivery times. Semiconductor packaging and testing also require us to operate sizeable facilities. If we are unable to obtain equipment or facilities in a timely manner, we may be unable to fulfill our customers’ orders, which could adversely affect our growth prospects as well as financial condition and results of operations. See “Item 4. Information on the Company—Business Overview—Equipment.”

Fluctuations in exchange rates could result in foreign exchange losses.

Currently, the majority of our revenues are denominated in U.S. dollars, with a portion denominated in NT dollars and Japanese yen. Our operating costs and operating expenses, on the other hand, are incurred in several currencies, primarily NT dollars, U.S. dollars, RMB, Japanese yen, Korean won, as well as, to a lesser extent, Singapore dollars and Malaysian ringgit. In addition, a substantial portion of our capital expenditures, primarily for the purchase of packaging and testing equipment, has been, and is expected to continue to be, denominated in U.S. dollars, with the remainder in Japanese yen. Fluctuations in exchange rates, primarily among the U.S. dollar against the NT dollar, the Japanese yen and RMB, will affect our costs and operating margins. In addition, these fluctuations could result in exchange losses and increased costs in NT dollar and other local currency terms. Despite hedging and mitigating techniques implemented by us, fluctuations in exchange rates have affected, and may continue to affect, our financial condition and results of operations. We recognized net foreign exchange gains of NT$965.4 million, net foreign exchange losses of NT$276.2 million and net foreign exchange losses of NT$1,222.0 million (US$38.7 million) in 2012, 2013 and 2014, respectively. We cannot assure you that we will achieve foreign exchange gains in the future. See “Item 11. Quantitative and Qualitative Disclosures about Market Risk—Market Risk—Foreign Currency Exchange Rate Risk.”

The loss of a large customer or disruption of our strategic alliance or other commercial arrangements with semiconductor foundries and providers of other complementary semiconductor manufacturing services may result in a decline in our revenues and profitability.

Although we have a large customer base, we have derived and expect to continue to derive a large portion of our revenues from a small group of customers during any particular period due in part to the concentration of market share in the semiconductor and electronics industries. Our five largest customers together accounted for approximately 31.2%, 37.2% and 40.3% of our operating revenues in 2012, 2013 and 2014, respectively. Although no single customer accounted for more than 10.0% of our operating revenues in 2012, one customer did account for more than 10.0% of our operating revenues in 2013 and 2014. The demand for our services from a customer is directly dependent upon that customer’s level of business activity, which could vary significantly from year to year. Our key customers typically operate in the cyclical semiconductor and electronic business and, in the past, have varied, and may vary in the future, order levels significantly from period to period. Some of these companies are relatively small, have limited operating histories and financial resources, and are highly exposed to the cyclicality of the industry. We cannot assure you that these customers or any other customers will continue to place orders with us in the future at the same levels as in past periods. The loss of one or more of our significant customers, or reduced orders by any one of them, and our inability to replace these customers or make up for such orders could adversely affect our revenues and profitability. In addition, we have in the past reduced, and may in the future be requested to reduce, our prices to limit the level of order cancellations. Any price reduction would likely reduce our margins and profitability.

Since 1997, we have maintained a strategic alliance with Taiwan Semiconductor Manufacturing Company Limited, or TSMC, one of the world’s largest dedicated semiconductor foundries. TSMC designates us as their non-exclusive preferred provider of packaging and testing services for semiconductors manufactured by TSMC. Any strategic alliances, as well as our other commercial arrangements with providers of other complementary semiconductor manufacturing services, enable us to offer total semiconductor manufacturing solutions to our customers. Any strategic alliances and our other commercial arrangements may be terminated at any time. Any such termination, and our failure to enter into substantially similar strategic alliances or commercial arrangements, may adversely affect our competitiveness and our revenues and profitability.

Our revenues and profitability may decline if we are unable to obtain adequate supplies of raw materials in a timely manner and at a reasonable price.

Our operations, such as packaging operations, substrate operations and electronic manufacturing services, require that we obtain adequate supplies of raw materials on a timely basis. Shortages in the supply of raw materials have in the past resulted in occasional price increases and delivery delays. In addition, the operations of some of our suppliers are vulnerable to natural disasters, such as earthquakes and typhoons, the occurrences of which may deteriorate and prolong the shortage or increase the uncertainty of the supply of raw materials. For example, on March 11, 2011, a major earthquake occurred off the coast of Japan resulting in a large tsunami and radiation leak at the Fukushima nuclear power plant. We experienced a disruption to the supply of raw materials from Japan for about three to four weeks due to the fear of radiation contamination and the reduction or postponement in production by some of our Japanese suppliers. Although the purchase of supplies from Japan has been restored to the previous level, we cannot assure you that we will not suffer long-term from the impact of the earthquake and the tsunami. In addition, further earthquakes, aftershocks thereof or other disasters in Japan or affecting any regions in which we operate may cause a decline in our sales. Any of the above events or developments may have a material adverse effect on our business, results of operations and financial condition.

Raw materials such as advanced substrates are prone to supply shortages since such materials are produced by a limited number of suppliers such as Nanya Printed Circuit Board Corporation, Kinsus Interconnect Technology Corporation, Samsung Electro-Mechanics Co., Ltd and Unimicron Technology Corp. Our operations conducted through our wholly-owned subsidiaries ASE Electronics and ASE Shanghai have improved our ability to obtain advanced substrates on a timely basis and at a reasonable cost. In 2014, our interconnect materials operations supplied approximately 31.7% of our consolidated substrate requirements by value. We do not expect that our internal interconnect materials operations will be able to meet all of our interconnect materials requirements. Consequently, we will remain dependent on market supply and demand for our raw materials. In addition, recent fluctuations in prices of precious metals, such as gold, have also affected the price at which we have been able to purchase the principal raw materials we use in our packaging processes. We cannot guarantee that we will not experience shortages in the near future or that we will be able to obtain adequate supplies of raw materials in a timely manner or at a reasonable price. Our revenues and net income could decline if we are unable to obtain adequate supplies of high quality raw materials in a timely manner or if there are significant increases in the costs of raw materials that we cannot pass on to our customers.

New regulations related to conflict minerals could adversely affect our business, financial condition and results of operations.

The Dodd-Frank Wall Street Reform and Consumer Protection Act contains provisions to improve transparency and accountability concerning the supply of certain minerals, known as conflict minerals, which are defined as cassiterite, columbite-tantalite, gold, wolframite or their derivatives and other minerals determined by the U.S. government to be financing conflict in the Democratic Republic of Congo and adjoining countries. As a result, in August 2012 the SEC adopted annual disclosure and reporting requirements for those companies who use conflict minerals in their products. These rules require companies that manufacture or contract to manufacture products for which conflict minerals are necessary to the functionality or production to begin scrutinizing the origin of conflict minerals in their products starting from January 1, 2013, and file a new form, Form SD, containing the conflict

minerals disclosure by May 31 for the prior calendar year, beginning May 31, 2014. We filed a specialized disclosure report on Form SD for the year ended December 31, 2013 on May 30, 2014. Our specialized disclosure report on Form SD for the year ended December 31, 2013 disclosed that we were unable to determine the origin of the sources of gold, tantalum, tin and tungsten used in our products. Therefore, pursuant to the SEC rules governing conflict minerals disclosures, we have engaged an independent auditing firm to conduct audits on our due diligence framework to provide a private sector report for our specialized disclosure report on Form SD for the year ended December 31, 2014. As a result, there will be costs associated with complying with these disclosure requirements, including costs for diligence to determine the sources of conflict minerals used in our products and other potential changes to products, processes or sources of supply as a consequence of such verification activities. The implementation of these rules could adversely affect the sourcing, supply and pricing of materials used in our products. As there may be only a limited number of suppliers offering “conflict free” minerals, we cannot be sure that we will be able to obtain necessary “conflict free” minerals from such suppliers in sufficient quantities or at competitive prices. Also, we may face adverse effects to our reputation if we determine that certain of our products contain minerals not determined to be conflict free or if we are unable to sufficiently verify the origins for all conflict minerals used in our products through the procedures we may implement.

System security risks, data protection breaches or unexpected system outage or failures could harm our business, financial condition and results of operations.

We rely on the efficient and uninterrupted operation of complex information technology applications, systems and networks to operate our business. Our systems are vulnerable to damage or interruption from earthquakes, terrorist attacks, floods, fires, power loss, telecommunications failures, cyber-attacks, computer viruses, computer denial of service attacks or other attempts to harm our system, and similar events. In recent years, the risks that we face from cyber-attacks have increased significantly. Some of these attacks may originate from well-organized, highly skilled organizations. Although there have not been reported major cyber-attacks against our systems in the recent years, any such attack or system or network disruption could result in a loss of our intellectual property, the release of commercially sensitive information, customer or employee personal data. Failures to protect the privacy of customer and employee confidential data against breaches of network security could result in damage to our reputation.

Furthermore, some of our data centers are located in areas with a high risk of major earthquakes. Our data centers are also subject to break-ins, sabotage and intentional acts of vandalism, and to potential disruptions if the operators of these facilities have financial difficulties. Some of our systems are not fully redundant, and our disaster recovery planning cannot account for all eventualities. The occurrence of a natural disaster, a decision to close a facility we are using without adequate notice for financial reasons or other unanticipated problems at our data centers could result in loss of production capabilities and lengthy interruptions in our service. Any damage to or failure of our systems could result in interruptions in our service. Interruptions in our service could materially and adversely affect our business, financial condition and results of operations.

Any environmental claims or failure to comply with any present or future environmental regulations, as well as any fire or other industrial accident, may require us to spend additional funds and may materially and adversely affect our financial condition and results of operations.

We are subject to various laws and regulations relating to the use, storage, discharge and disposal of chemical by-products of, and water used in, our packaging and interconnect materials production processes, and the emission of volatile organic compounds and the discharge and disposal of solid industrial wastes from electronic manufacturing services operations. In the recent years, we have been subject to environmental administrative actions and judicial proceedings related to certain wastewater discharge incidents that occurred at our facilities. As a result of these proceedings, we have been subject to monetary fines as well as sanctions, including orders to suspend or limit our operations and criminal charges against us.

In December 2013, the Kaohsiung City Environmental Protection Bureau ordered us to suspend the operations at our K7 Plant’s wafer-level process where nickel is used for alleged wastewater discharge violations and fined us NT$110.1 million for which we recognized as other income and expenses in December 2013 and paid in full in January 2014. In April 2014, the amount of the fine was reduced to NT$109.4 million (US$3.5 million) by the Kaohsiung City Environmental Protection Bureau. We received the refund of NT$0.7 million (US$0.02 million) and recorded the reversal of loss in September 2014. We have been actively working with the Kaohsiung City Environmental Protection Bureau and implemented improvement plans to enhance our wastewater discharge processes since this incident. Following a series of examinations, hearings and trial runs as ordered by the Kaohsiung City Environmental Protection Bureau during 2014, in December 2014, the Kaohsiung City Environmental Protection Bureau lifted the suspension order and approved the full resumption of operation of our K7 Plant. Although our K7 Plant has resumed full operation, we may be subject to other new environmental claims, charges or investigations on our K7 Plant or other facilities which may cause similar or more sever interruptions to our business and operations.

With respect to the NT$109.4 million (US$3.5 million) administrative penalty imposed on us by the Kaohsiung City Environmental Protection Bureau, we appealed the case to the Kaohsiung High Administrative Court in August 2014 to revoke the Kaohsiung City Government’s decision and to lift the administrative penalty. In connection with the same alleged wastewater discharge violations at our K7 plant, the Kaohsiung District Court ruled against us and imposed on us a criminal penalty of NT$3.0 million (US$0.1 million) for which we recognized as other income and expenses in October 2014. We appealed the case to the Taiwan High Court Kaohsiung District Branch in November 2014. While we are defending these proceedings vigorously, the ultimate outcome of the matter is uncertain. For additional details of these administrative actions and judicial proceedings related to our K7 Plant see “Item 4. Information on the Company—Business Overview—Environmental Matters,” “Item 4. Information on the Company—Property, Plants and Equipment” and “Item 8. Financial Information—Consolidated Statements and Other Financial Information—Legal Proceedings.” Defending against any of these pending or future actions will likely be costly and time-consuming and could significantly divert management’s efforts and resources. The ultimate outcome of these proceedings cannot be predicted with certainty. Any penalties, fines, damages or settlements made in connection with these criminal, civil, and/or administrative investigations and/or lawsuits may have a material adverse effect on our business, results of operations and future prospects.

We have made, and expect to continue to make, expenditures to maintain strict compliance with such environmental laws and regulations. For example, in order to demonstrate our commitment to environmental protection, in December 2013, our board of directors approved contributions to environmental protection efforts in Taiwan in a total amount of not less than NT$3,000.0 million, to be made in the next 30 years. For the year ended December 31, 2014, we have made contributions in the amount of NT$100.0 million (US$3.2 million) through ASE Cultural and Educational Foundation to fund various environmental projects and our board of directors have resolved in a resolution in January 2015 to contribute NT$100.0 million (US$3.2 million) through ASE Cultural and Educational Foundation in environmental projects in 2015. The costs of current and future compliance with environmental laws and regulations could require us to acquire costly equipment or to incur other significant expenses that may have a material adverse effect on our financial condition and results of operations.

Negative publicity may adversely affect our brand and reputation, which may result in a material adverse impact on our business, results of operations and prospects and cause fluctuations in the price of our common shares and ADSs.

Any negative publicity may damage our brand and reputation, harm our ability to attract and retain customers and result in a material adverse impact on our results of operations and prospects as well as cause fluctuations in the trading price of our common shares and ADSs. In addition, any change in policy or directions in which we carry out our corporate social responsibility or corporate sustainability activities may also have an adverse effect on our reputation. Furthermore, in recent years, we have experienced and may continue to experience negative publicity in connection with administrative penalties and criminal charges related to alleged violations of environmental regulations and laws. For further details, see “—Any environmental claims or failure to comply with any present or future environmental regulations, as well as any fire or other industrial accident, may require us to spend additional funds and may materially and adversely affect our financial condition and results of operations,” “Item 4. Information on the Company—Business Overview—Environmental Matters,” “Item 4. Information on the Company—Property, Plants and Equipment” and “Item 8. Financial Information—Consolidated Statements and Other Financial Information—Legal Proceedings.”

Climate change, other environmental concerns and green initiatives also presents other commercial challenges, economic risks and physical risks that could harm our results of operations or affect the manner in which we conduct our business.

Increasing climate change and environmental concerns could affect the results of our operations if any of our customers request that we exceed any standards set for environmentally compliant products and services, or if raw materials and/or products are required to meet strict inspection standards with respect to any radioactive contamination as a result of concerns arising from radiation leaking incidents, such as the radiation leak which occurred in March 2011 in Japan. If we are unable to offer such products or offer products that are compliant, but are not as reliable due to the lack of reasonably available alternative technologies, it may harm our results of operations.

Furthermore, energy costs in general could increase significantly due to climate change regulations. Therefore, our energy costs may increase substantially if utility or power companies pass on their costs, fully or partially, such as those associated with carbon taxes, emission cap and carbon credit trading programs.

We may be subject to intellectual property rights disputes, which could materially adversely affect our business.

Our ability to compete successfully and achieve future growth depends, in part, on our ability to develop and protect our proprietary technologies and to secure on commercially acceptable terms certain technologies that we do not own. We cannot assure you that we will be able to independently develop, obtain patents for, protect or secure from any third party, the technologies required.

Our ability to compete successfully also depends, in part, on our ability to operate without infringing the proprietary rights of others. In particular, the semiconductor and electronics industries are characterized by frequent litigation regarding patent and other intellectual property rights. In February 2006, Tessera filed a suit against us and others alleging patent infringement. In February 2014, ASE Inc. and our U.S. subsidiary, ASE (U.S.) Inc. reached a term sheet agreement with Tessera to fully resolve the remaining legal proceedings between each other, under which we would pay a total of US$30.0 million to Tessera (which was fully recognized by us in the fourth quarter of 2013) and both Tessera and we would dismiss all pending claims against each other. The final settlement agreement was entered into among the parties in October 2014 and the final settlement amount was reduced to US$27.0 million. In October 2014, the United States District Court for the Northern District of California dismissed all claims between Tessera and us. We have fully paid the settlement amount in January 2015 and reversed the settlement amount of US$3.0 million in the fourth quarter of 2014. See “Item 8. Financial Information—Consolidated Statements and Other Financial Information—Legal Proceedings.”

Any litigation, whether as plaintiff or defendant and regardless of the outcome, is costly and diverts company resources. Any of the foregoing could harm our competitive position and render us unable to provide some of our services operations.

Our major shareholders may take actions that are not in, or may conflict with, our public shareholders’ best interest.

Members of the Chang family own, directly or indirectly, a significant interest in our outstanding common shares. See “Item 7. Major Shareholders and Related Party Transactions—Major Shareholders.” Accordingly, these shareholders will continue to have the ability to exercise a significant influence over our business, including matters relating to:

| | · | our management and policies; |

| | · | the timing and distribution of dividends; and |

| | · | the election of our directors and supervisors. |

Members of the Chang family may take actions that you may not agree with or that are not in our or our public shareholders’ best interests.

We are an ROC company and, because the rights of shareholders under ROC law differ from those under U.S. law and the laws of certain other countries, you may have difficulty protecting your shareholder rights.

Our corporate affairs are governed by our Articles of Incorporation and by the laws governing corporations incorporated in the ROC. The rights of shareholders and the responsibilities of management and the members of the board of directors under ROC law are different from those applicable to a corporation incorporated in the United States and certain other countries. As a result, public shareholders of ROC companies may have more difficulty in protecting their interests in connection with actions taken by management or members of the board of directors than they would as public shareholders of a corporation in the United States or certain other countries.

We have made investments in, and are exploring the possibility of expanding our businesses and operations to, or making additional investments in, the PRC, which may expose us to additional political, regulatory, economic and foreign investment risks.

We operate packaging and testing facilities and electronic manufacturing services in the PRC primarily through our PRC subsidiaries such as ASESH AT and Universal Scientific Shanghai, among others. We also made substantial investments in PRC real estate development through our subsidiaries in the PRC. Under PRC laws and regulations, foreign investment projects, such as our subsidiaries, must obtain certain approvals from the relevant governmental authorities in the provinces or special economic zones in which they are located and, in some circumstances, from the relevant authorities in the PRC’s central government. Foreign investment projects must also comply with certain regulatory requirements. However, PRC laws and regulations are often subject to varying interpretations and means of enforcement, and additional approvals from the relevant governmental authorities may be required for the operations of our PRC subsidiaries. If required, we cannot assure you that we will be able to obtain these approvals in a timely manner, if at all. Because the PRC government holds significant discretion in determining matters relating to foreign investment, we cannot assure you that the relevant governmental authorities will not take action that is materially adverse to our PRC operations.

In addition, the PRC stock market is subject to extreme price and volume fluctuations. We are the controlling shareholder of Universal Scientific Shanghai, which is an entity currently listed on the Shanghai Stock Exchange. The PRC securities markets have recently experienced, and may experience in the future, significant price declines and volatility. Any volatility may have a significant effect on Universal Scientific Shanghai’s share price and may indirectly affect the market price of our common shares and ADSs.

Our global manufacturing and sales activities subject us to risks associated with legal, political, economic or other conditions or developments in various jurisdictions, including in particular the ROC and the PRC, which could negatively affect our business and financial status and therefore the market value of your investment.