Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Fiscal Year Ended December 31, 2004

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Transition Period from to

Commission File Number 333-69826

Hornbeck Offshore Services, Inc.

(Exact Name of Registrant as Specified in Its Charter)

| Delaware | 72-1375844 | 4424 | ||

| (State or other jurisdiction of incorporation or organization) | (I.R.S. Employer Identification Number) | (Primary Standard Industrial Classification Code Number) |

103 Northpark Boulevard, Suite 300

Covington, Louisiana 70433

(985) 727-2000

(Address, including zip code, and telephone number, including area code, of registrant’s principal executive offices)

Securities registered pursuant to Section 12(b) of the Act:

Title of each class | Name of exchange, on which registered | |

Common Stock, $0.01 par value | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None.

Indicate by check mark whether the Registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yesx No¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of the Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. Yes¨ Nox

Indicate by check mark whether the Registrant is an accelerated filer (as defined in Exchange Act Rule

12b-2). Yes¨ Nox

The aggregate market value of the Common Stock held by non-affiliates computed by reference to the price at which the Common Stock was last sold as of the last day of registrant’s most recently completed second fiscal quarter is $158,294,678.

The number of outstanding shares of Common Stock as of March 1, 2005 is 20,823,428 shares.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Registrant’s definitive 2005 proxy statement, anticipated to be filed with the Securities and Exchange Commission within 120 days after the close of the Registrant’s fiscal year, are incorporated by reference into Part III of this Form 10-K.

Table of Contents

HORNBECK OFFSHORE SERVICES, INC. AND SUBSIDIARIES

FORM 10-K

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2004

| 1 | ||

| 1 | ||

| 1 | ||

| 2 | ||

| 8 | ||

| 13 | ||

| 15 | ||

| 17 | ||

| 18 | ||

| 19 | ||

| 23 | ||

| 24 | ||

| 24 | ||

| 24 | ||

Availability of Reports, Certain Committee Charters and Other Information | 25 | |

| 25 | ||

| 25 | ||

| 26 | ||

Item 5—Market for the Registrant’s Common Stock and Related Stockholder Matters | 26 | |

| 27 | ||

Item 7—Management’s Discussion and Analysis of Financial Condition and Results of Operations | 29 | |

| 30 | ||

| 33 | ||

| 36 | ||

| 42 | ||

| 44 | ||

| 45 | ||

| 45 | ||

| 46 | ||

Item 7A—Quantitative and Qualitative Disclosures About Market Risk | 47 | |

| 48 | ||

Item 9—Changes in and Disagreements with Accountants on Accounting and Financial Disclosures | 48 | |

| 48 | ||

| 49 | ||

| 50 | ||

| 50 | ||

| 50 | ||

| 50 |

i

Table of Contents

| 50 | ||

| 50 | ||

| 51 | ||

Item 15—Exhibits, Financial Statement Schedules and Reports on Form 8-K | 51 | |

| F-1 | ||

| S-1 | ||

| E-1 |

ii

Table of Contents

Items 1 and 2.—Business and Properties

Hornbeck Offshore Services, Inc. was incorporated under the laws of the State of Delaware in 1997. In this annual report on Form 10-K, “company,” “we,” “us” and “our” refers to Hornbeck Offshore Services, Inc. and its subsidiaries, except as otherwise indicated. References in this annual report on Form 10-K to “OSVs” mean offshore supply vessels; to “deepwater” mean offshore areas, generally 1,000' to 5,000' in depth, and ultra-deepwater areas, generally more than 5,000' in depth; to “deep well” mean a well drilled to a true vertical depth of 15,000' or greater; and to “new generation,” when referring to OSVs, mean modern, deepwater-capable vessels subject to the regulations promulgated under the International Convention on Tonnage Measurement of Ships, 1969, which was adopted by the United States and made effective for all U.S.-flagged vessels in 1992 and foreign-flagged equivalent OSVs.

BUSINESS

We are a leading provider of technologically advanced, new generation OSVs serving the offshore oil and gas industry, primarily in the U.S. Gulf of Mexico and in select international markets. The focus of our OSV business is on complex exploration and production activities, which include deepwater, deep well and other logistically demanding projects. We are also a leading transporter of petroleum products through our tug and tank barge segment serving the energy industry, primarily in the northeastern United States and Puerto Rico.

In the mid-1990s, oil and gas producers began seeking large hydrocarbon reserves at deeper well depths using new, specialized drilling and production equipment. We recognized that the existing fleet of conventional 180' OSVs operating in the U.S. Gulf of Mexico was not designed to support these more complex projects or to operate in the challenging environments in which they were conducted. Therefore, in 1997, we began a program to construct new generation OSVs based upon our proprietary designs. Since that time, we have constructed 17 new generation OSVs using these proprietary designs, and expanded our fleet with the acquisitions of a total of six additional new generation OSVs, one fast supply vessel and one anchor-handling towing supply vessel, or AHTS. Our OSV fleet is among the youngest in the industry with an average age of approximately four years. We are the only publicly traded company with a significant fleet of U.S.-flagged, new generation OSVs.

Our OSVs were purposefully designed with the flexibility to meet the diverse needs of our clients in all stages of their exploration and production activities. As a result, all of our OSVs have enhanced capabilities that allow them to more effectively support premium drilling equipment required for deep drilling and related specialty services. In contrast to conventional 180' OSVs, our vessels have dynamic positioning capability, as well as greater storage and off-loading capacity. We are capable of providing OSV services to our customers anywhere in the world and we are actively pursuing additional contracts in select international markets.

Historically, demand for our OSV services has been primarily driven by the drilling of deep wells, whether in the deepwater or on the U.S. Continental Shelf, and other complex

1

Table of Contents

exploration and production projects that require specialized drilling and production equipment. In addition, our new generation OSVs are increasingly in demand by our customers for conventional drilling projects. Our customers are willing to pay more than the prevailing dayrates for conventional 180' OSVs for such projects because of the ability of our OSVs to reduce overall offshore logistics costs through the vessels’ greater capacities and operating efficiencies.

According to the Minerals Management Service, or MMS, in 2003 the deepwater region accounted for 62% of total U.S. Gulf of Mexico oil production and 43% of total U.S. Gulf of Mexico natural gas production, up substantially from 4% and 1%, respectively, in 1990. In addition, the MMS estimates that deep reservoirs on the Continental Shelf may hold up to 55 tcf of undiscovered natural gas. This potential reserve base compares favorably to the current total of approximately 26 tcf of proven natural gas reserves in the entire U.S. Gulf of Mexico. Our new generation OSVs are also well suited for drilling in logistically demanding projects and frontier areas, where support infrastructure is severely limited.

Our tug and tank barge fleet consists of 14 ocean-going tugs and 13 active ocean-going tank barges. As of March 1, 2005, we had five double-hulled tank barges under construction, which will add new barrel-carrying capacity and replace barrel-carrying capacity lost when we retired three of our 15 single-hulled tank barges from service at the end of 2004 as mandated by the Oil Pollution Act of 1990, or OPA 90. We believe our tug and tank barge business complements our OSV business by providing additional revenue and geographic diversification, while allowing us to offer another line of services to integrated oil and gas companies. Demand for our tug and tank barge services is primarily driven by the level of refined petroleum product consumption in the northeastern United States and Puerto Rico, our core operating markets. The Energy Information Administration, or EIA, projects that refined petroleum product consumption in the East Coast region of the United States will increase by an average of 1.7% per year from 2002 to 2010. Demand for refined petroleum products is primarily driven by population growth, the strength of the U.S. economy, seasonal weather patterns, oil prices and competition from alternate energy sources.

The OSV Industry

OSVs primarily serve exploratory and developmental drilling rigs and production facilities and support offshore construction and subsea maintenance activities. OSVs differ from other types of marine vessels in their cargo carrying flexibility and capacity. In addition to transporting deck cargo, such as pipe or drummed material and equipment, OSVs also transport liquid mud, potable and drilling water, diesel fuel, dry bulk cement and personnel between shore bases and offshore rigs and facilities. In general, demand for OSVs, as evidenced by dayrates and utilization rates, is primarily related to offshore oil and natural gas exploration, development and production activity, which in turn is influenced by a number of factors, including oil and natural gas prices and the drilling budgets of offshore exploration and production companies.

OSVs operate worldwide, but are generally concentrated in relatively few offshore regions with high levels of exploration and development activity such as the Gulf of Mexico, the North Sea, Southeast Asia, West Africa, Latin America and the Middle East. While there

2

Table of Contents

is some vessel migration between regions, key factors such as mobilization costs, vessel suitability and government statutes prohibiting foreign-flagged vessels from operating in certain waters generally limit such migration.

According to the MMS the U.S. Gulf of Mexico is a critical oil and natural gas supply basin for the United States, and it predicts that new incentives offered to energy companies to explore and develop hard-to-reach areas of the U.S. Gulf of Mexico may boost peak oil and natural gas production by 43% and 13%, respectively, over the next decade. Offshore oil and natural gas drilling and production in the U.S. Gulf of Mexico occurs on the Continental Shelf and in the deepwater. Drilling activity on the Continental Shelf has historically been limited to shallow wells, or wells with true vertical depths of less than 15,000'. However, with the advent of improved technology and higher oil and gas prices, operators have begun to increasingly focus exploratory efforts on deep wells and natural gas reserves located below 15,000'. These deep prospects are largely undeveloped, but are believed to contain significant reserves.

While the shallow waters of the Continental Shelf have been actively explored for decades, relatively few deep wells have been drilled historically due to the high cost associated with these wells. The dry hole cost of a typical Continental Shelf well drilled from 8,000' to 12,000' generally ranges from $4 million to $8 million, while the dry hole cost for a deep well drilled in a similar location but to 15,000' or more can range from $10 million to $75 million. The higher costs associated with the drilling of deep wells can be attributed to, among other things, the need for specialized, high-end drilling rigs and related equipment, greater volumes of downhole materials such as liquid mud, tubular products and cement, and longer drilling times.

Despite the higher costs associated with deep well Continental Shelf drilling, operators, especially those in search of natural gas, have continued to demonstrate interest. This interest is driven by, among other things, the potential for the discovery of significant natural gas reserves. The MMS estimates that there may be up to 55 tcf of undiscovered, conventionally recoverable, deep well natural gas on the Continental Shelf. Moreover, the abundance of existing platforms, production facilities and pipelines on the Continental Shelf allow new deep gas to flow quickly to market. In addition, MMS data indicates that higher natural gas production rates can be expected from wells drilled on the Continental Shelf below 16,000'. Furthermore, the MMS royalty relief programs enacted in 2001, and expanded in August 2003 and again in January 2004, have stimulated interest by reducing the development costs of these deep wells. The combination of these factors partly compensates for the higher drilling costs of deep wells on the Continental Shelf and can allow operators to commercially produce discovered reserves in this market. While overall drilling on the Continental Shelf has declined from 2001 levels, gas production data from 2000 to 2003 provided by IHS Energy, an energy research company, suggests an increasing focus on deep wells in shallow waters. From 2000 to 2003, gas production from deep wells as a percentage of total wells on the Continental Shelf increased from 22% to 30%.

Recent discoveries of large hydrocarbon reserves in deepwater fields in the Gulf of Mexico and at deeper well depths on the Continental Shelf have resulted in increased developmental and exploratory drilling activities in these areas. The deepwater region of the U.S. Gulf of Mexico is an increasingly important source of oil and natural gas production with

3

Table of Contents

many unexplored areas of potential oil and natural gas reserves. According to the 2004 Deepwater and Ultra Deepwater Report of Infield Systems Limited, an international energy research firm, the U.S. Gulf of Mexico had 58 deepwater projects developed between 1999 and 2003, and an additional 79 deepwater projects have been identified for development between 2004 and 2008.

Because oil and natural gas exploration, development and production costs in the shallow well Continental Shelf market are generally lower than those in the deepwater or deep well environments, shallow well drilling activity on the Continental Shelf is typically more sensitive to fluctuations in commodity prices, particularly the price of natural gas. Accordingly, actual or anticipated decreases in oil and natural gas prices generally result in reduced offshore drilling activity and correspondingly lower demand for the conventional 180' OSVs serving the shallow well Continental Shelf market. This causes a corresponding decline in OSV dayrates and utilization rates in that market. In contrast, the relatively larger capital commitments and longer lead times and investment horizons associated with deepwater, particularly ultra-deepwater, and deep well developments make it less likely that an operator will abandon such projects in response to a short-term decline in oil or natural gas prices. Dayrates and utilization rates for new generation OSVs that serve the deepwater and deep well markets are, therefore, generally less sensitive to short-term commodity price fluctuations and tend to be more stable than dayrates and utilization rates for OSVs serving the shallow well Continental Shelf market.

According to our analysis of the industry and data compiled from various industry sources, including the U.S. Coast Guard, we estimate that the U.S.-flagged OSV fleet currently totals 386 vessels, substantially all of which are located in the Gulf of Mexico. Of this total, 249, or 65% are conventional 180' OSVs that primarily operate on the Continental Shelf. The remaining 137 vessels are U.S. flagged, new generation OSVs, with 115 currently operating in the U.S. Gulf of Mexico. However, during soft markets conditions in the deepwater, these modern vessels have increasingly migrated at premium dayrates to conventional drilling environments, such as the U.S. Continental Shelf, Mexico and Trinidad & Tobago. Of the conventional OSV fleet, a significant number are currently cold-stacked. Vessels that are cold-stacked have generally been removed from active service by the operator due to lack of demand. In contrast, we believe there are currently no new generation OSVs cold-stacked.

The Market for New Generation OSVs

Complex exploration and production projects require specialized equipment and higher volumes of supplies to meet the more difficult operating environment associated with such offshore developments. In order to better serve these projects and meet customer demands, new generation OSVs, including our entire OSV fleet, are designed with larger capacities, including greater liquid mud and dry bulk cement capacities, as well as larger areas of open deck space than conventional 180' OSVs. These features are essential to the effective servicing of deepwater drilling projects, which are often distant from shore-based support infrastructure, because they allow a vessel to make fewer trips to supply the liquid mud, drilling water, dry bulk cement and other needs of the customer. In addition, OSVs operating in deepwater environments generally require dynamic positioning, or anchorless station-keeping capability, primarily because customers’ safety procedures preclude OSVs from tying

4

Table of Contents

up to deepwater installations, and to enable continued operation in adverse weather conditions. We believe that conventional 180' OSVs, substantially all of which lack dynamic positioning capability and sufficient on-deck or below-deck cargo capacity, are not capable of operating effectively or economically in the deepwater market. In addition, certain ports have draft or other logistical impediments, which limit the pool of new generation vessels capable of servicing such ports. Our proprietary vessels were designed to work under these shallow draft and logistically demanding conditions.

As a result of recent deepwater and deep well drilling activity, utilization rates for new generation OSVs in the U.S. Gulf of Mexico have averaged approximately 86% over the last two years while the average utilization rate for the conventional 180' OSV fleet over the same period has been approximately 72%, not taking into account cold-stacked conventional 180' OSVs. Taking such cold-stacked vessels into account, we believe that the average utilization rate for U.S. flagged conventional 180' OSVs is less than 50%. Additional utilization for new generation OSVs has come from increasing demand for these vessels in support of conventional shelf drilling projects. Moreover, during the same two-year period, average dayrates for new generation OSVs were generally more than double the average dayrates of conventional 180' OSVs. We believe that demand is beginning to outpace the supply of new generation OSVs in the U.S. Gulf of Mexico. We base our belief on the recent and expected drilling activity in all sectors of the U.S. Gulf of Mexico and the departure of certain new generation OSVs to foreign markets, after taking into account vessels currently available and vessels being constructed under announced construction plans. Furthermore, although U.S.-flagged vessels operating in overseas locations may be remobilized to the U.S. Gulf of Mexico, historically such re-mobilization has been limited.

Our OSV Business

We currently own and operate a fleet of 24 new generation OSVs, which includes one AHTS vessel that is primarily operating as a supply vessel and towing jack-up rigs. We also own and operate one fast supply vessel. We engineered and supervised the construction of 17 of our OSVs expressly to meet the demands of deepwater regions and other complex drilling projects, based on our proprietary designs. Drawing from the vessel operating experience of our in-house engineers, we work closely with potential charterers to design vessels specifically to meet their anticipated needs. This is particularly the case when the charterer will operate a project that could have a duration of more than 20 years and require expenditures exceeding $1 billion. Our 17 proprietary OSVs have up to three times the dry bulk capacity and deck space, two to ten times the liquid mud capacity and two to four times the deck tonnage compared to conventional 180' OSVs. The advanced cargo handling systems of our proprietary OSVs allow for dry bulk and liquid cargos to be loaded and unloaded three times faster than conventional 180' OSVs, while the solid state controls of their engines typically result in a 20% greater fuel efficiency than vessels powered by conventional engines. In addition, our larger classes of proprietary OSV designs, designated by us as our 240 ED and 265 classes, were designed, in part, to supply the substantially greater liquid mud volume and other cargo capacity required for ultra-deepwater drilling. We believe that our customers’ recognition of the superior capabilities of our proprietary OSVs has contributed to our ability to achieve higher dayrates and utilization rates and increased overall operating cost efficiencies than our competitors.

5

Table of Contents

All of our new generation OSVs are equipped with dynamic positioning systems and controllable pitch thrusters, which allow our vessels to maintain position with minimal variance, and state-of-the-art safety, emergency power, fire alarm and fire suppression systems and systems monitoring equipment. The unique hull design and integrated rudder and thruster system of our 17 proprietary OSVs provide for a more maneuverable vessel. These proprietary vessels also have double-bottomed and double-sided hulls that minimize environmental impact in the event of vessel collisions or groundings, solid state controls that minimize visible soot and polluting gases and zero discharge sewage and waste systems that minimize the impact on marine environments. In addition, these 17 vessels are either fully SOLAS (Safety of Life at Sea) certified or SOLAS ready. SOLAS is the international convention that regulates the technical characteristics of vessels for purposes of ensuring international standards of safety for vessels engaged in commerce between international ports. These features allow us to market our proprietary OSVs for service in international waters.

Our technologically advanced, new generation OSVs are also capable of providing specialty services in support of certain of our customers, including well stimulation, remotely operated vehicles, or ROVs, used in oilfield subsea construction and maintenance, underwater inspections, marine seismic operations, and certain non-energy applications such as fiber optics cable installation, military work and containerized cargo transportation. Compared to conventional 180' OSVs, our OSVs have more dead weight capacity, deck space, and berthing accommodations, improved maneuverability and greater fuel efficiency. We believe these characteristics strengthen demand for our OSVs in specialty situations. Two of our vessels, theHOS Innovatorand theHOS Dominator,currently provide ROV subsea construction and maintenance support for a large oilfield service company under contracts that each have an initial term of three years. TheBJ Blue Rayprovides deepwater well stimulation support services for another large oilfield service company under a contract with a five-year initial term. This vessel was the first U.S.-flagged well stimulation vessel to receive the American Bureau of Shipping WS and DPS2 class notations. We believe theBJ Blue Rayis one of the most technologically sophisticated well stimulation vessels in the world.

On June 26, 2003, we acquired five 220' new generation OSVs from Candy Marine Investment Corporation, an affiliate of Candy Fleet Corporation, or Candy Fleet. Following the completion in July 2003 of a private placement of our common stock and satisfaction of certain other conditions, on August 6, 2003 we acquired an additional 220' new generation OSV from Candy Fleet. These six vessels complement our existing OSV fleet and have allowed us to expand our service offerings to clients, particularly those drilling wells on the Continental Shelf.

In January 2005, we acquired a new generation AHTS vessel from a private owner. This vessel, which will be renamed theHOS Saylor, is our first foreign-flagged vessel. Upon acquisition, we immediately deployed theHOS Saylor on a time charter with one of our OSV customers in Trinidad & Tobago. This strategic vessel acquisition complements our growing market presence in international waters. While this vessel has anchor-handling capabilities, we are currently using it primarily as a supply vessel and for towing jack-up rigs.

6

Table of Contents

The following table provides information, as of, March 1, 2005, regarding our fleet of vessels that serve our OSV customers.

Offshore Supply Vessels

Name | Class | Current Service Function | Built (Acquired) | Deadweight (long tons) | Brake Horsepower | |||||

Offshore Supply Vessels: | ||||||||||

BJ Blue Ray | 265 | Well Stimulation | November 2001 | 3,756 | 6,700 | |||||

HOS Brimstone | 265 | Supply | June 2002 | 3,756 | 6,700 | |||||

HOS Stormridge | 265 | Supply | August 2002 | 3,756 | 6,700 | |||||

HOS Sandstorm | 265 | Supply | October 2002 | 3,756 | 6,700 | |||||

HOS Bluewater | 240 ED | Supply | March 2003 | 2,850 | 4,000 | |||||

HOS Gemstone | 240 ED | Supply | June 2003 | 2,850 | 4,000 | |||||

HOS Greystone | 240 ED | Supply | September 2003 | 2,850 | 4,000 | |||||

HOS Silverstar | 240 ED | Supply | January 2004 | 2,850 | 4,000 | |||||

HOS Innovator | 240 E | ROV Support(1) | April 2001 | 2,380 | 4,500 | |||||

HOS Dominator | 240 E | ROV Support(1) | February 2002 | 2,380 | 4,500 | |||||

HOS Deepwater | 240 | Supply | November 1999 | 2,250 | 4,500 | |||||

HOS Cornerstone | 240 | Supply | March 2000 | 2,250 | 4,500 | |||||

HOS Explorer | 220 | Supply | February 1999 (June 2003) | 1,607 | 3,900 | |||||

HOS Express | 220 | Supply | September 1998 (June 2003) | 1,607 | 3,900 | |||||

HOS Pioneer | 220 | Supply | June 2000 (June 2003) | 1,607 | 4,200 | |||||

HOS Trader | 220 | Supply | November 1997 (June 2003) | 1,607 | 3,900 | |||||

HOS Voyager | 220 | Supply | May 1998 (June 2003) | 1,607 | 3,900 | |||||

HOS Mariner | 220 | Supply | September 1999 (August 2003) | 1,607 | 3,900 | |||||

HOS Crossfire | 200 | Supply | November 1998 | 1,750 | 4,000 | |||||

HOS Super H | 200 | Supply | January 1999 | 1,750 | 4,000 | |||||

HOS Brigadoon | 200 | Supply | March 1999 | 1,750 | 4,000 | |||||

HOS Thunderfoot | 200 | Supply | May 1999 | 1,750 | 4,000 | |||||

HOS Dakota | 200 | Supply | June 1999 | 1,750 | 4,000 | |||||

Anchor-Handling Towing Supply Vessel: | ||||||||||

HOS Saylor (2) | 240 | Towing/Supply | October 1999 (January 2005) | 3,321 | 8,000 | |||||

Fast Supply Vessel: | ||||||||||

HOS Hotshot | 165 | Fast Supply | April 2003 (May 2004) | 260 | 6,200 | |||||

| (1) | The term “ROV” means remotely operated vehicle. |

| (2) | We acquired theHOS Saylor, a foreign-flagged vessel, in January 2005 from a private owner. We are currently using theHOS Saylor primarily for its OSV capabilities and for towing jack-up rigs. |

7

Table of Contents

We have designed and constructed five distinct classes of proprietary OSVs and added a sixth class, through the acquisitions of six OSVs from Candy Fleet, to meet the diverse needs of the offshore oil and gas industry. The following table provides a comparison of certain specifications and capabilities of our new generation OSVs to conventional 180' OSVs.

| Conventional 180' OSV(1) | Our Proprietary Design OSV Classes | Acquired OSVs | ||||||||||||

| 200 | 240 | 240 E | 240 ED | 265 | 220(2) | |||||||||

Size | ||||||||||||||

Class length overall (ft.) | 180 | 200 | 240 | 240 | 240 | 265 | 220 | |||||||

Breadth (ft.) | 40 | 54 | 54 | 54 | 54 | 60 | 46 | |||||||

Depth (ft.) | 14 | 18 | 18 | 18 | 20 | 22 | 17 | |||||||

Maximum draft (ft.) | 12 | 13 | 13 | 13 | 14.5 | 16 | 13.7 | |||||||

Deadweight (long tons) | 950 | 1,750 | 2,250 | 2,380 | 2,850 | 3,756 | 1,607 | |||||||

Clear deck area (sq. ft.) | 3,450 | 6,580 | 8,836 | 8,100 | 8,100 | 9,212 | 5,472 | |||||||

Capacity | ||||||||||||||

Fuel capacity (gallons) | 79,400 | 90,000 | 151,800 | 135,100 | 104,210 | 151,800 | 114,490 | |||||||

Fuel pumping rate (gallons per minute) | 275 | 550 | 550 | 550 | 550 | 500 | 380 | |||||||

Drill water capacity (gallons) | 120,000 | 240,000 | 240,000 | 240,000 | 311,000 | 413,000 | 99,000 | |||||||

Dry bulk capacity (cu. ft.) | 4,000 | 7,000 | 8,400 | 8,400 | 6,000 | 10,800 | 8,040 | |||||||

Liquid mud capacity (barrels) | 1,200 | 3,640 | 6,475 | 6,475 | 8,300 | 10,500 | 2,955 | |||||||

Liquid mud pumping rate (gallons per minute) | 250 | 500 | 1,000 | 1,000 | 1,000 | 1,000 | 1,200 | |||||||

Potable water capacity (gallons) | 11,500 | 52,200 | 52,200 | 52,200 | 30,400 | 20,430 | 26,800 | |||||||

Machinery | ||||||||||||||

Main engines (horsepower) | 2,250 | 4,000 | 4,000 | 4,000 | 4,000 | 6,700 | 3,900 | |||||||

Auxiliaries (number) | 2 | 3 | 3 | 3 | 3 | 3 | 2 | |||||||

Total rating (kw) | 200 | 750 | 750 | 750 | 750 | 860 | 250 | |||||||

Bow thruster (horsepower) | 325 | 800 | 1,600 | 1,600 | 1,600 | 2,400 | 530 | |||||||

Type of Pitch | Fixed | Controllable | Controllable | Controllable | Controllable | Controllable | Fixed | |||||||

Stern thruster (horsepower) | None | 300 | 300 | 800 | 800 | 1,600 | 300 | |||||||

Type of Pitch | — | Controllable | Controllable | Controllable | Controllable | Controllable | Fixed | |||||||

Fire fighting (gallons per minute) | None | 1,250 | 2,700 | 2,700 | 2,700 | 2,700 | 2,600 | |||||||

Dynamic positioning(3) | None | DP0,1 | DP1 | DP2 | DP2 | DP2,3 | DP0,1 | |||||||

Crew Requirements | ||||||||||||||

Number of personnel(4) | 5 | 6 | 6 | 7 | 7 | 8 | 6 | |||||||

| (1) | Statistics are for a typical 180' class vessel. Actual specifications and capabilities may vary from vessel to vessel. |

| (2) | Excludes theHOS Saylor,which is a foreign-flagged AHTS vessel. |

| (3) | Dynamic positioning permits a vessel to maintain position without the use of anchors. The numbers “0,” “1,” “2” and “3” refer to increasing levels of technical sophistication and system redundancy features. |

| (4) | Regulatory manning requirements; depending on the services provided, operators may man vessels with more crew than required by regulations. |

Additional information with respect to our OSV segment can be found in Note 14 of our consolidated financial statements.

The Tug and Tank Barge Industry

Introduction. The domestic tank barge industry provides marine transportation of crude oil, petroleum products and petrochemicals by tug and tank barge, and is a critical link in the U.S. petroleum distribution chain. Petroleum products are transported in the northeastern United States through a vast network of terminals, tankers and pipelines. We believe, based

8

Table of Contents

upon our analysis of the industry, that in the northeastern United States approximately 430 million barrels of petroleum products are transported annually by tank barges. Additionally, the EIA estimates that in Puerto Rico, our other core area of operation, approximately 70 million barrels of petroleum products are transported annually.

Demand for tug and tank barge services in the northeastern United States is primarily driven by population growth, the strength of the U.S. economy, seasonal weather patterns, oil prices and competition from alternate energy sources. According to the EIA, demand for petroleum products in the northeastern United States is expected to increase approximately 1.7% annually through 2010, which we believe will generate steadily increasing demand for the tank barge industry.

The largest tank barge market in the northeastern United States is New York Harbor. Imported petroleum products are primarily delivered to New York Harbor as it has the capacity to receive products in cargo lots of 50,000 tons or more per tanker. By contrast, draft limitations in most New England ports and drawbridge limitations in Boston and Portland, Maine limit the average cargo carrying capacity of direct imports into many of the largest New England ports to about 30,000 tons per tanker. As a result, ships importing directly into New England must frequently discharge in multiple ports or terminals or transfer cargos to tank barges. As existing single-hulled tankers are retired due to age or as mandated under OPA 90, they are typically replaced by larger tankers. These larger-sized tankers are being built to facilitate the importation of crude oil and petroleum products into the United States. The volume of imported crude oil and petroleum products is expected to grow at a compound annual rate of 2.4% through 2025, according to the EIA. As larger petroleum tankers are being built, we believe that direct delivery into New York Harbor will generate increased tank barge demand for lightering services and further shipment to New England, the Hudson River and Long Island.

9

Table of Contents

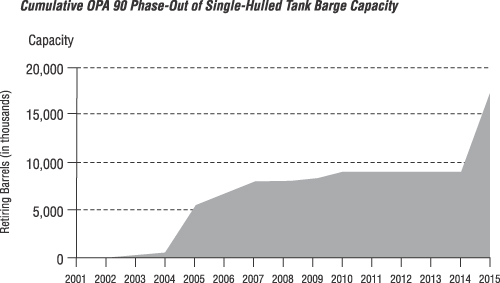

Oil Pollution Act of 1990. OPA 90 mandates that all single-hulled tank vessels operating in U.S. waters be removed from service according to a set time schedule. Data provided by a U.S. Coast Guard report dated September 2001 indicates that 5.5 million barrels of single-hulled tank barge capacity would be retired by 2005 and an additional 3.5 million barrels by 2010, as mandated by OPA 90. According to the report, this represented on a cumulative basis as of each such retirement date, 22% and 36%, respectively, of the total 24.9 million barrel single- and double-hulled tank barge capacity that existed in 2001. The following chart illustrates the capacity of tank vessels that must be removed from service from 2000 through 2014. We believe that, absent a substantial increase in the number of double-hulled vessels constructed in the industry, this reduction in capacity, assuming steady demand, may favorably impact dayrates and utilization of the remaining tank barges, including our own.

Based on data contained in the United States Coast Guard Report to Congress on the Progress to Replace Single Hull Tank Vessels with Double Hull Tank Vessels, dated September 2001.

Additionally, OPA 90 requires that owners or operators of tankers operating in U.S. waters submit vessel spill response plans to the U.S. Coast Guard for approval and operate according to the plans upon approval. Our vessel response plans have been approved by the U.S. Coast Guard, and all of our crew members have been trained to comply with these guidelines. For further discussion of OPA 90 see“—Environmental and Other Governmental Regulation”below.

Our Tug and Tank Barge Business

We provide marine transportation, distribution and logistics services primarily in the northeastern United States and Puerto Rico with our fleet of 14 ocean-going tugs and 13 active ocean-going tank barges. As of March 1, 2005, we had five double-hulled tank barges under construction, which will add new barrel-carrying capacity and replace barrel-carrying capacity lost when we retired three of our 15 single-hulled tank barges from service at the end of 2004, as mandated by OPA 90. We provide our services to major oil companies, refineries

10

Table of Contents

and oil traders. Generally, a tug and tank barge work together as a “tow” to transport refined or bunker grade petroleum products. Our tank barges carry petroleum products that are typically characterized as either “clean” or “dirty”. Clean products are primarily gasoline, home heating oil, diesel fuel and jet fuel. Dirty products are mainly crude oils, residual crudes and feedstocks, heavy fuel oils and asphalts.

Our tugs and tank barges serve the northeastern U.S. coast, primarily New York Harbor, by transporting both clean and dirty petroleum products to and from refineries and distribution terminals. Our tugs and tank barges also transport both clean and dirty petroleum products from refineries and distribution terminals in Puerto Rico to the Puerto Rico Electric Power Authority and to utilities located on other Caribbean islands. In addition, we provide ship lightering, bunkering and docking services in these markets and are well positioned to provide such services to the increasing number of new tankers that are too large to make direct deliveries to distribution terminals and refineries.

On May 31, 2001, we acquired nine ocean-going tugs and nine ocean-going tank barges from the Spentonbush/Red Star Group, composed of certain affiliates of Amerada Hess, as well as the business related to these tugs and tank barges, greatly expanding our capacity in the northeastern United States and increasing our market share of the coastwise trade on the U.S. upper east coast. As part of the acquisition, Amerada Hess entered into a long-term contract of affreightment with us pursuant to which Amerada Hess has committed to use us as its exclusive marine logistics provider and transporter of liquid petroleum products by tank barge in the northeastern United States. Under this contract, Amerada Hess has committed to ship a minimum of 45 million barrels annually for an initial period from June 1, 2001 through March 31, 2006, which can be extended for subsequent periods by mutual agreement. Also under the contract, we have the opportunity, on a reasonable commercial efforts basis, to coordinate the marine logistics for Amerada Hess in the southeastern United States, subject to Amerada Hess’s right to cancel within 30 days after December 31 of each year of the contract. The contract of affreightment will provide us with a significant source of revenues over the life of the contract. Our contract of affreightment allows Amerada Hess to reduce its minimum annual cargo volume commitment subject to significant adjustment penalties. Because the tank barge market in the northeastern United States is currently operating at or near capacity, we believe that we would be able to replace through other customers any volumes that Amerada Hess does not transport as contemplated by the contract.

One of our tank barges is double-hulled and is not subject to OPA 90 retirement dates. Ten of our 12 active single-hulled tank barges are not required under OPA 90 to be retired or double-hulled until 2015. The two other single-hulled tank barges are required to be retired from service in 2009. As required under OPA 90, we have previously retired from service three single-hulled tank barges at the end of 2004. In anticipation of their retirement, we commenced construction of five double-hulled, ocean-going tank barges, two of which are expected to be delivered by the end of the second quarter of 2005 and the other three in the fourth quarter of 2005. Our coastwise tanker is not subject to OPA 90 retirement dates. Based on the remaining lives of the majority of our tank barge fleet under OPA 90 and our recent construction program, we believe we are well positioned to obtain additional customers in the northeastern United States, as a large portion of currently available capacity in that market was required to be removed from service or be substantially reconstructed by 2005.

11

Table of Contents

The following tables provide information, as of March 1, 2005, regarding the tugs, tank barges and coastwise tanker that we own, as well as the five double-hulled tank barges under construction at that date.

Ocean-Going Tugs

Name | Gross Tonnage | Length (feet) | Year Built | Brake Horsepower | ||||

Freedom Service(1) | 180 | 126 | 1982 | 6,140 | ||||

Liberty Service(1) | 180 | 126 | 1982 | 6,140 | ||||

Ponce Service | 190 | 107 | 1970 | 3,900 | ||||

Caribe Service | 194 | 111 | 1970 | 3,900 | ||||

Atlantic Service | 198 | 105 | 1978 | 3,900 | ||||

Brooklyn Service | 198 | 105 | 1975 | 3,900 | ||||

Gulf Service | 198 | 126 | 1979 | 3,900 | ||||

Tradewind Service | 183 | 105 | 1975 | 3,200 | ||||

Yabucoa Service | 183 | 105 | 1975 | 3,000 | ||||

Spartan Service | 126 | 102 | 1978 | 3,000 | ||||

Sea Service | 173 | 109 | 1975 | 2,820 | ||||

North Service | 187 | 100 | 1978 | 2,200 | ||||

Bayridge Service | 194 | 100 | 1981 | 2,000 | ||||

Stapleton Service | 146 | 78 | 1966 | 1,530 |

| (1) | These vessels have been substantially retrofitted since their purchase in June 2004 to provide power for the new double-hulled tank barges under construction. |

Ocean-Going Tank Barges and Coastwise Tanker

Name | Barrel Capacity | Length (feet) | Year Built | OPA 90 Date(1) | |||||

Active: | |||||||||

Ocean-Going Tank Barges: | |||||||||

Energy 13501 | 135,000 | est. | 450 | TBD(2) | DH | ||||

Energy 13502 | 135,000 | est. | 450 | TBD(2) | DH | ||||

Energy 11101 | 111,844 | 420 | 1979 | 2009 | |||||

Energy 11102 | 111,844 | 420 | 1979 | 2009 | |||||

Energy 11103 | 110,000 | est. | 390 | TBD(2) | DH | ||||

Energy 11104 | 110,000 | est. | 390 | TBD(2) | DH | ||||

Energy 11105 | 110,000 | est. | 390 | TBD(2) | DH | ||||

Energy 8001 | 81,364 | 350 | 1996 | DH | |||||

Energy 7002 | 72,693 | 351 | 1971 | 2015 | |||||

Energy 7001 | 72,016 | 300 | 1977 | 2015 | |||||

Energy 6504 | 66,333 | 305 | 1958 | 2015 | |||||

Energy 6505 | 65,710 | 328 | 1978 | 2015 | |||||

Energy 6503 | 65,145 | 327 | 1988 | 2015 | |||||

Energy 6502 | 64,317 | 300 | 1980 | 2015 | |||||

Energy 6501 | 63,875 | 300 | 1974 | 2015 | |||||

Energy 5501 | 57,848 | 341 | 1969 | 2015 | |||||

Energy 2201 | 22,556 | 242 | 1973 | 2015 | |||||

Energy 2202 | 22,457 | 242 | 1974 | 2015 | |||||

Inactive: | |||||||||

Ocean-Going Tank Barges: | |||||||||

Energy 9801 | 97,432 | 390 | 1967 | (3) | |||||

Energy 9501 | 94,442 | 346 | 1972 | (3) | |||||

Energy 8701 | 86,454 | 360 | 1976 | (3) | |||||

Coastwise Tanker: | |||||||||

Energy Service 9001(4) | — | 402 | 1992 | N/A | |||||

12

Table of Contents

| TBD: | To be determined. |

| DH: | OPA 90 limitations are not applicable to these double-hulled vessels. |

| (1) | Prior to January 1 of the year indicated (except for theEnergy 11101 for which the date is June 1), according to OPA 90, the vessel must be refurbished as a double hull or be retired from service in U.S. waters. For a discussion of OPA 90 see “—Environmental and Other Governmental Regulation” below. |

| (2) | TheEnergy 13501 andEnergy 11103 are under construction with delivery anticipated by the end of the second quarter of 2005. TheEnergy 13502,Energy 11104 andEnergy 11105 are also under construction with delivery anticipated in the fourth quarter of 2005. |

| (3) | TheEnergy 9801,Energy 9501 andEnergy 8701 were removed from service for the transport of petroleum products in navigable waters of the United States prior to January 1, 2005 due to OPA 90. These vessels are currently inactive. |

| (4) | This coastwise tanker, formerly known as theM/V W.K. McWilliams, Jr., acquired on November 15, 2001, is not currently certified to transport petroleum products and, therefore, barrel capacity is not applicable to this vessel. This vessel is currently inactive. |

Additional information with respect to our tug and tank barge segment can be found in Note 14 of our consolidated financial statements.

Technologically Advanced Fleet of New Generation OSVs. Our technologically advanced, new generation OSVs were designed with the specifications necessary for operations in complex and challenging drilling environments, including deepwater, deep well and other logistically demanding projects. Our new generation OSVs have significantly more capacity and operate more efficiently than conventional 180' OSVs. While operators are especially concerned with a vessel’s ability to avoid collisions with multi-million dollar drilling rigs or production platforms during adverse weather conditions, they are hesitant to stop operations under such conditions due to the high daily cost of halting such complex operations. Our proprietary vessels incorporate sophisticated technologies and are designed specifically to operate safely in complex exploration and production environments. These technologies include dynamic positioning, roll reduction systems and controllable pitch thrusters, which allow our vessels to maintain position with minimal variance, and our unique cargo handling systems, which permit high volume transfer rates of liquid mud and dry bulk. We believe that we earn higher average dayrates and maintain higher utilization rates than our competitors due to the superior capabilities of our OSVs, our seven-year track record of safe and reliable performance and the collaborative efforts of our in-house design team in providing marine engineering solutions to our customers.

Young OSV Fleet with Lower Cost of Ownership. We believe that we operate one of the youngest fleets of U.S.-flagged OSVs. While the average age of the conventional 180' U.S.-flagged OSV fleet is approximately 24 years, the average age of our OSV fleet is approximately four years. Newer vessels generally experience less downtime and require significantly less maintenance and scheduled drydocking costs compared to older vessels. The average intermediate drydocking for recertification for one of our OSVs generally lasts five to ten days in the shipyard and costs approximately $0.3 million. In contrast, the typical drydocking for recertification of a conventional 180' OSV may last up to 90 days in the shipyard and can cost as much as $1.5 million. We believe that our operation of new, technologically advanced OSVs gives us a competitive advantage in obtaining long-term contracts for our vessels and in attracting and retaining crews. Since we accepted delivery of our first OSV in November 1998, the average utilization rate for our OSVs has been approximately 93%. According to ODS-Petrodata, the U.S. Gulf of Mexico industry average was approximately 73% over the same time period, based on vessels available for service. We expect that our newer, larger, faster and more cost-efficient vessels will remain in high demand as deepwater and other complex and challenging exploration, development and production activities continue to increase globally.

13

Table of Contents

Commitment to Safety and Quality. As part of our commitment to safety and quality, we have voluntarily pursued and received certifications that are not generally held by other companies in our industry. We have maintained certifications to the requirements of the International Standards Organization, or ISO, Standards 9002 and 14000 for quality and environmental management, respectively, with respect to the eight tugs and nine tank barges acquired from the Spentonbush/Red Star Group. We are one of the few OSV companies operating in the U.S. Gulf of Mexico that is approved under the U.S. Coast Guard’s Streamlined Inspection Program in which we and the Coast Guard cooperate to develop training, inspection and compliance processes, with our personnel conducting periodic examinations of vessel systems to the requirements of the vessels’ Coast Guard certifications, and taking corrective actions where necessary. Both of our principal office locations in Covington, Louisiana and Brooklyn, New York, as well as the majority of our vessels, including all of our OSVs and our tugs and tank barges acquired from the Spentonbush/Red Star Group, are also certified under the International Safety Management Code, or ISM Code, developed by the International Maritime Organization to provide internationally recognized standards for the safe management and operation of ships and for pollution prevention. We are currently combining the ISO and ISM certification of our fleetwide operations to standards of the American Bureau of Shipping’s Safety, Quality and Environmental Certification, or ABS SQE, which integrates the elements of these certifications into a single program. Quality, Safety and Environmental Certificates are an increasingly important consideration for both our OSV and tank barge customers due to the environmental and regulatory sensitivity associated with offshore drilling and production activity and waterborne transportation of petroleum products, respectively. We believe that customers recognize our commitment to safety and that our strong reputation and performance history provide us with a competitive advantage.

Leading Market Presence in Core Target Markets. Our 23 U.S.-flagged OSVs comprise the second largest fleet of technologically advanced, new generation OSVs qualified for work in the U.S. Gulf of Mexico. Currently, 18 of our 23 U.S.-flagged OSVs operate in that area. We also operate one of the largest fleets of tugs and tank barges for the transportation of petroleum products in Puerto Rico and believe that we are the fourth largest tank barge transporter of petroleum products in New York Harbor. We believe that having scale in our selected markets benefits our customers and provides us with operating efficiencies.

Successful Track Record of Vessel Construction and Acquisitions. Our management has significant naval architecture, marine engineering and shipyard experience. We believe we are unique in the manner in which we design our own vessels and work closely with our contracted shipyards in their construction. We typically source and supply many of the manufactured components (owner-furnished equipment), comprising a large portion of the aggregate cost of a vessel, directly from vendors rather than through the shipyard. In addition to substantial cost savings, we believe our approach enables us to better control the construction process, resulting in a higher quality vessel and an enhanced level of service from these vendors during the applicable warranty periods. We believe that our history of designing and constructing 17 new generation OSVs on time and on budget provides us with a competitive advantage in obtaining contracts for our vessels prior to their actual delivery. Our company has designed its operations and management systems in contemplation of additional growth through new vessel construction and acquisitions. To date, we have successfully completed and integrated five acquisitions involving 15 ocean-going tugs and 13

14

Table of Contents

ocean-going tank barges, one acquisition of a coastwise tanker, two acquisitions involving six 220' new generation OSVs, one acquisition of a 165’ fast supply vessel, and one acquisition of an AHTS vessel.

Favorable OPA 90 Fleet Status. Data provided by a U.S. Coast Guard report dated September 2001 indicates that 5.5 million barrels of single-hulled tank barge capacity would need to be retired by 2005 and an additional 3.5 million barrels by 2010, as mandated by OPA 90. According to the report, this represented on a cumulative basis as of each such retirement date, 22% and 36%, respectively, of the total 24.9 million barrel single- and double-hulled tank barge capacity that existed in 2001. Because 10 of our 12 active single-hulled tank barges are not required to be replaced or retrofitted with double hulls until 2015, we believe we have a competitive advantage over operators who have a higher percentage of single-hulled tank barges that must be retired or modified to add double hulls before 2010.

Experienced Management Team with Proven Track Record. Our executive management team has an average of 21 years of domestic and international marine transportation industry-related experience. We believe that our team has successfully demonstrated its ability to grow our fleet through new construction and strategic acquisitions and to secure profitable contracts for our vessels in both favorable and unfavorable market conditions. Moreover, our in-house engineering team has significant operating experience that enables us to more effectively design and manage our new vessel construction program, adapt our vessels for specialized purposes, oversee and manage the drydocking process and provide custom marine engineering solutions to our customers. We believe this will continue to result in a lower overall cost of ownership over the life of our vessels compared to our competitors, as well as a competitive advantage in securing contracts for our OSVs as the benefits of our proprietary designs and in-house engineering capabilities are recognized by our customers.

Apply Existing and Develop New Technologies to Meet our Customers’Vessel Needs. Our new generation OSVs are designed to meet the higher capacity and performance needs of our clients’increasingly more complex drilling and production programs. In addition, our proprietary double-hulled tank barges currently under construction are designed to maximize transit speed, improve cargo through-put rates and enhance crew safety features. Our new generation OSVs are equipped with sophisticated propulsion and cargo handling systems, dynamic positioning capabilities and have larger capacities than conventional 180' OSVs. We are committed to applying existing and developing new technologies to maintain a technologically advanced fleet that will enable us to continue to provide a high level of customer service and meet the developing needs of our customers for OSVs and ocean-going tugs and tank barges, as well as other types of vessels that complement our two business segments. Improvements in exploration and production technologies have enabled operators to pursue larger scale, more complex drilling programs in remote locations and under more challenging operating conditions. We believe that the trend toward increasingly more complex projects will increase the demand for our technologically advanced fleet of new generation OSVs. Oil and natural gas exploration and development activity in these regions has increased recently as a result of several factors, including world-class exploration potential, improvements in exploration and production technologies for deepwater projects,

15

Table of Contents

and slowing or declining production from onshore and shallow water fields. We believe that deepwater regions worldwide and deep well drilling on the Continental Shelf will continue to be active areas for exploration and development in the foreseeable future, and that demand for our OSVs, which are uniquely equipped to serve the current and planned drilling programs in these markets, will continue to be strong.

Expand Fleet Through Newbuilds and Strategic Acquisitions. We plan to expand our fleet through construction of new vessels, including construction of new generation OSVs and double-hulled tank barges as market conditions warrant, retrofitting of certain vessels and through strategic acquisitions. Market demand for vessels, including demand for new generation OSVs in domestic and international markets, will be the main determinant of the level and timing of construction of additional vessels. We believe that acquisition opportunities are likely to arise as consolidation continues in our two industry segments. We intend to use our expertise and experience to evaluate and execute strategic acquisitions where the opportunity exists to expand our service offerings in our core markets and create or enhance long-term client relationships. As of March 1, 2005, we have completed ten acquisitions involving 37 vessels and have constructed 17 proprietary OSVs, with five additional double-hulled tank barges expected for delivery during 2005.

Pursue Optimal Mix of Long-Term and Short-Term Contracts. We seek to balance our portfolio of customer contracts by entering into both long-term and short-term charters. Long-term charters, which contribute to higher utilization rates, provide us with more predictable cash flow. Most of our long-term charters contain annual dayrate escalation provisions. Short-term charters provide the opportunity to benefit from increasing dayrates in favorable market cycles. We plan our mix of long-term and spot market contracts with respect to our OSVs based on anticipated market conditions. Our contract of affreightment with Amerada Hess for the services of tugs and tank barges in the northeastern United States has an initial term of June 1, 2001 through March 31, 2006. Our other tug and tank barge contracts typically have been renewed annually over the last several years. By design, substantially all of our tank barges operate under long-term contracts.

Build Upon Existing Customer Relationships. We intend to build upon existing customer relationships by expanding the services we offer to those customers with diversified marine transportation needs. Many integrated oil and gas companies require OSVs to support their exploration and production activities and ocean-going tugs and tank barges to support their refining, trading and retail distribution activities. Moreover, many of our customers that conduct operations internationally have expressed interest in chartering our OSVs in such markets. We now have 28% of our supply vessel fleet, with five OSVs in Trinidad & Tobago and one OSV and our fast supply vessel offshore Mexico, chartered for use in international markets. Our management team has significant international experience and will continue to evaluate such opportunities.

Optimize Tug and Tank Barge Operations. Due to OPA 90 phase-out requirements of single-hulled barges, the total barrel-carrying capacity of existing tank vessels transporting petroleum products domestically is projected to decline from its current level without a commensurate increase in newbuildings and retrofittings. In addition, the energy industry is increasingly outsourcing its marine transportation requirements and focusing on safety and reliability as a key determinant in awarding new business. We believe that these trends will

16

Table of Contents

improve the balance of supply and demand, and result in improved tank barge utilization and dayrates.

Major oil companies, large independent oil and gas exploration, development and production companies and large oil service companies constitute the majority of our customers for our OSV services, while refining, marketing and trading companies constitute the majority of our customers for our tug and tank barge services. The percentage of revenues attributable to a customer in any particular year depends on the level of oil and natural gas exploration, development and production activities undertaken or refined petroleum products or crude oil transported by a particular customer, the availability and suitability of our vessels for the customer’s projects or products and other factors, many of which are beyond our control. For the year ended December 31, 2004, Amerada Hess Corporation accounted for more than 10% of our total revenues. Under the terms of our contract of affreightment with Amerada Hess, we are required to meet certain performance criteria and, if we fail to meet such criteria, Amerada Hess would be entitled to terminate the contract. Our contract of affreightment provides for minimum annual cargo volumes to be transported and allows Amerada Hess to reduce its minimum commitment, subject to significant adjustment penalties. Because the tank barge market in the northeastern United States is currently operating at or near capacity, we believe that we would be able to replace through other customers any volumes that Amerada Hess does not transport as contemplated by the contract. For a discussion of significant customers in prior periods, see Note 13 of the notes to our consolidated financial statements.

We enter into a variety of contract arrangements with our customers, including spot and time charters, contracts of affreightment and consecutive voyage contracts. Our contracts are obtained through competitive bidding or, with established customers, through negotiation.

Most of the contracts for our OSVs contain early termination options in favor of the customer; however some have substantial early termination penalties designed to discourage the customers from exercising such options. Similarly, 11 of our 13 active tank barges provide services under long-term contracts with initial terms of one year or longer. Since we commenced operations, our OSVs have performed services for more than 60 different customers, and our tugs and tank barges have performed services for more than 250 different customers. Because of the variety and number of customers historically using the services of our fleet, and the approximate balance between supply and demand in both the OSV and tug and tank barge markets, we believe that the loss of any one customer would not have a material adverse effect on our business.

Because we have established a reputation for on-time delivery and reliability, charterers have contacted us in certain circumstances to construct vessels to meet their needs. In such circumstances, we have generally contracted these specially designed vessels for three to five years, with renewal options, before construction is completed. Although we will design vessels to meet the specific needs of a charterer, we ensure in our design that customization does not preclude efficient operation of these vessels for other customers, for other purposes or in other situations.

17

Table of Contents

We operate in a highly competitive industry. Competition in the OSV and ocean-going tug and tank barge segments of the marine transportation industry primarily involves factors such as:

| • | quality and capability of the vessels; |

| • | ability to meet the customer’s schedule; |

| • | safety record; |

| • | reputation; |

| • | price; and |

| • | experience. |

The terms of the Jones Act restrict the ability of vessels that are not built in the United States, documented under the laws of the United States and controlled by U.S. citizens to engage in the coastwise trade in the United States and Puerto Rico. See“—Environmental and Other Governmental Regulation”for a more detailed discussion of the Jones Act.

We do not anticipate significant competition in the near term from pipelines as an alternative method of petroleum product delivery in the northeastern United States or Puerto Rico. No pipelines are currently under construction that could provide significant competition to tank barges in the northeastern United States or Puerto Rico, nor are any new pipelines likely to be built in the near future due to cost constraints and logistical and environmental requirements.

We believe that only 30% of the new generation OSVs currently operating in the U.S. Gulf of Mexico are owned by publicly-traded companies. We believe we operate the second largest fleet of new generation OSVs in the U.S. Gulf of Mexico, and are the only publicly traded company with a significant fleet of U.S.-flagged, new generation OSVs. In contrast, approximately 75% of the conventional 180’ OSVs operating on the Continental Shelf of the U.S. Gulf of Mexico are owned by publicly-traded companies. We operate one of the largest tank barge fleets in Puerto Rico and we believe that we are the fifth largest transporter by tank barge of petroleum products in New York Harbor. Most of our competitors in the tug and tank barge industry are privately held.

Although some of our principal competitors are larger and have greater financial resources and, with respect to OSVs, extensive international operations, we believe that our operating capabilities and reputation enable us to compete effectively with other fleets in the market areas in which we operate. In particular, we believe that the relatively young age and advanced features of our OSVs provide us with a competitive advantage. The ages of our OSVs range from eleven months to seven years, while the average age of the industry’s conventional 180’ U.S.-flagged OSV fleet is approximately 25 years. Retirement of older vessels has already commenced and we believe that many more of these older vessels will be retired in the next few years. The young age of our fleet, together with the advanced capabilities of our vessels, position us to take advantage of the expanding deepwater, deep well and other logistically demanding exploration and production projects in the U.S. Gulf of Mexico and around the world. In addition, our new generation OSVs are also increasingly in

18

Table of Contents

demand by our customers for conventional drilling projects because of the ability of our OSVs to reduce overall offshore logistics costs for the customer through the vessels’ greater capacities and operating efficiencies.

Environmental and Other Governmental Regulation

Our operations are significantly affected by a variety of federal, state, local and international laws and regulations governing worker health and safety and the manning, construction and operation of vessels. Certain U.S. governmental agencies, including the Department of Homeland Security and agencies under its auspices (such as the U.S. Coast Guard and the U.S. Customs and Border Protection), the National Transportation Safety Board, and the Maritime Administration of the U.S. Department of Transportation, have jurisdiction over our operations. In addition, private industry organizations such as the American Bureau of Shipping oversee aspects of our business. The U.S. Coast Guard and the National Transportation Safety Board establish safety criteria and are authorized to investigate vessel accidents and recommend improved safety standards.

The U.S. Coast Guard regulates and enforces various aspects of marine offshore vessel operations. Among these are classification, certification, routes, drydocking intervals, manning requirements, tonnage requirements and restrictions, hull and shafting requirements and vessel documentation. Coast Guard regulations require that each of our vessels be drydocked for inspection at least twice within a five-year period.

Under Section 27 of the Merchant Marine Act of 1920, also known as the Jones Act, the privilege of transporting merchandise or passengers for hire in the coastwise trade in U.S. domestic waters is restricted to only those vessels that are controlled by U.S. citizens and are built in and documented under the laws of the United States. To engage in coastwise trade, a corporation is not considered a U.S. citizen unless, among other things:

| • | the corporation is organized under the laws of the United States or of a state, territory or possession of the United States; |

| • | at least 75% of the ownership of voting interests with respect to its capital stock is held by U.S. citizens; |

| • | the corporation’s chief executive officer, president and chairman of the board are U.S. citizens; and |

| • | no more than a minority of the number of directors necessary to constitute a quorum for the transaction of business are non-U.S. citizens. |

We meet all of the foregoing requirements. If we should fail to comply with these requirements, our vessels would lose their eligibility to engage in coastwise trade within U.S. domestic waters. To facilitate compliance, our certificate of incorporation:

| • | limits ownership by non-U.S. citizens of any class of our capital stock (including our common stock) to 20%, so that foreign ownership will not exceed the 25% permitted; |

| • | permits withholding of dividends and suspension of voting rights with respect to any shares held by non-U.S. citizens that exceed 20%; |

| • | permits a stock certification system with two types of certificates to aid tracking of ownership; |

19

Table of Contents

| • | permits our board of directors to redeem any shares held by non-U.S. citizens that exceed 20%; and |

| • | permits our board of directors to make such determinations to ascertain ownership and implement such measures as reasonably may be necessary. |

Jones Act restrictions have been challenged by interests seeking to facilitate foreign competition for coastwise trade. Historically, their efforts have been defeated by large margins when considered by the U.S. Congress. Industry associations and participants actively responded to and successfully defeated the latest challenges involving the nature, extent and availability of lease-finance alternatives permitted by a 1996 amendment of the Jones Act. Under the provisions of that amendment, certain foreign interests operated and proposed to operate in the U.S. coastwise trade.

On August 9, 2004, following an initiative by the U.S. marine industry interested in protecting the Jones Act, Congress enacted and the President signed into law Public Law No. 108-293. Section 608 of that law amends the lease financing criteria of such Act, adding new requirements that effectively eliminate the ability of foreign interests engaged in the marine business to control vessels engaged in U.S. coastwise trade by structuring lease-finance transactions. In addition, the legislation requires the United States Coast Guard to, by August 9, 2007, revoke the authorization of any offshore service vessel that received an endorsement to engage in coastwise trade utilizing the challenged lease-finance structure, unless the vessel otherwise complies with the Jones Act’s U.S.-control requirements. Following enactment of the foregoing legislation, we are aware of one foreign marine interest that is subject to the three-year sunset provision and another foreign marine interest that had announced its intention to avail itself of the lease-finance structure, but aborted its plan. Instead, the latter is now utilizing a foreign mortgage-finance structure covering 100% of the construction costs of its vessels, which is currently being challenged by the U.S. marine industry. Should foreign competition be permitted to enter the U.S. coastwise market to any significant extent, it could have an adverse effect on the U.S. OSV industry and on us.

Our operations are also subject to a variety of federal, state, local and international laws and regulations regarding the discharge of materials into the environment or otherwise relating to environmental protection. The requirements of these laws and regulations have become more complex and stringent in recent years and may, in certain circumstances, impose strict liability, rendering a company liable for environmental damages and remediation costs without regard to negligence or fault on the part of such party. Aside from possible liability for damages and costs including natural resource damages associated with releases of hazardous materials including oil into the environment, such laws and regulations may expose us to liability for the conditions caused by others or even acts of ours that were in compliance with all applicable laws and regulations at the time such acts were performed. Failure to comply with applicable laws and regulations may result in the imposition of administrative, civil and criminal penalties, revocation of permits, issuance of corrective action orders and suspension or termination of our operations. Moreover, it is possible that changes in the environmental laws, regulations or enforcement policies that impose additional or more restrictive requirements or claims for damages to persons, property, natural resources or the environment could result in substantial costs and liabilities to us. We believe that we are in substantial compliance with currently applicable environmental laws and regulations.

20

Table of Contents

OPA 90 and regulations promulgated pursuant thereto impose a variety of regulations on “responsible parties” related to the prevention of oil spills and liability for damages resulting from such spills. A “responsible party” includes the owner or operator of an onshore facility, pipeline or vessel or the lessee or permittee of the area in which an offshore facility is located. OPA 90 assigns liability to each responsible party for oil removal costs and a variety of public and private damages. Under OPA 90, “tank vessels” of over 3,000 gross tons that carry oil or other hazardous materials in bulk as cargo, a term, which includes our tank barges, are subject to liability limits of the greater of $1,200 per gross ton or $10 million. For any vessels, other than “tank vessels,” that are subject to OPA 90, the liability limits are the greater of $500,000 or $600 per gross ton. A party cannot take advantage of liability limits if the spill was caused by gross negligence or willful misconduct or resulted from violation of a federal safety, construction or operating regulation. If the party fails to report a spill or to cooperate fully in the cleanup, the liability limits likewise do not apply. Moreover, OPA 90 imposes on responsible parties the need for proof of financial responsibility to cover at least some costs in a potential spill. We have provided satisfactory evidence of financial responsibility to the U.S. Coast Guard for all of our vessels over 300 tons.

OPA 90 also imposes ongoing requirements on a responsible party, including preparedness and prevention of oil spills, preparation of an oil spill response plan and proof of financial responsibility (to cover at least some costs in a potential spill) for vessels in excess of 300 gross tons. We have engaged the National Response Corporation to serve as our independent contractor for purposes of providing stand-by oil spill response services in all geographical areas of our fleet operations. In addition, our Oil Spill Response Plan has been approved by the U.S. Coast Guard.

OPA 90 requires that all newly-built tank vessels used in the transport of petroleum products be built with double hulls and provides for a phase-out period for existing single hull vessels. Modifying existing vessels to provide for double hulls will be required of all tank barges and tankers in the industry by the year 2015. We are in a favorable position concerning this provision because a significant number of vessels in our fleet of tank barges measure less than 5,000 gross tons. Vessels of such tonnage may continue to operate without double hulls through the year 2015. Under existing legal requirements, therefore, we will be required to modify or replace only two of our existing tank barges before 2015. We previously retired from service three single-hulled tank barges at the end of 2004 pursuant to OPA 90. Although we are not aware of anything that would lead us to believe this current schedule will change, it remains possible that a change in the law affecting the requirement for double hulls or other aspects of our operations may occur that would require us to modify or replace our existing tank barge fleet earlier than currently anticipated.

The Clean Water Act imposes strict controls on the discharge of pollutants into the navigable waters of the United States. The Clean Water Act also provides for civil, criminal and administrative penalties for any unauthorized discharge of oil or other hazardous substances in reportable quantities and imposes substantial liability for the costs of removal and remediation of an unauthorized discharge. Many states have laws that are analogous to the Clean Water Act and also require remediation of accidental releases of petroleum in reportable quantities. Our OSVs routinely transport diesel fuel to offshore rigs and platforms and also carry diesel fuel for their own use. Our OSVs also transport bulk chemical materials used in drilling activities and liquid mud, which contain oil and oil by-products. In addition, our

21

Table of Contents

tank barges are specifically engaged to transport a variety of petroleum products. We maintain vessel response plans as required by the Clean Water Act to address potential oil and fuel spills.

The Comprehensive Environmental Response, Compensation, and Liability Act of 1980, also known as “CERCLA” or “Superfund,” and similar laws impose liability for releases of hazardous substances into the environment. CERCLA currently exempts crude oil from the definition of hazardous substances for purposes of the statute, but our operations may involve the use or handling of other materials that may be classified as hazardous substances. CERCLA assigns strict liability to each responsible party for all response and remediation costs, as well as natural resource damages and thus we could be held liable for releases of hazardous substances that resulted from operations by third parties not under our control or for releases associated with practices performed by us or others that were standard in the industry at the time.

The Resource Conservation and Recovery Act regulates the generation, transportation, storage, treatment and disposal of onshore hazardous and non-hazardous wastes and requires states to develop programs to ensure the safe disposal of wastes. We generate non-hazardous wastes and small quantities of hazardous wastes in connection with routine operations. We believe that all of the wastes that we generate are handled in all material respects in compliance with the Resource Conservation and Recovery Act and analogous state statutes.