1934 ACT FILE NO. 001-15264 SECURITIES AND EXCHANGE COMMISSION FORM 6-K Report of Foreign Private IssuerPursuant to Rule 13a-16 or 15d-16 of For the month of April 2017 Aluminum Corporation of China Limited No. 62 North Xizhimen Street Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F. Form 20-F X Form 40-F Indicate by check mark if the registrant is submitting the Form 6-K in papers as permitted by Regulation S-T Rule 101(b)(1): __________ Indicate by check mark if the registrant is submitting the Form 6-K in papers as permitted by Regulation S-T Rule 101(b)(7): __________ Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing the information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934. Yes No X If "Yes" is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b): 82- |

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| Aluminum Corporation of China Limited (Registrant) | |

Date April 27, 2017 |

By /s/ Zhang Zhankui |

Certain statements contained in this announcement may be regarded as "forward-looking statements" within the meaning of the U.S. Securities Exchange Act of 1934, as amended. Such forward-looking statements involve known and unknown risks, uncertainties and other factors, which may cause the actual performance, financial condition or results of operations of the Company to be materially different from any future performance, financial condition or results of operations implied by such forward-looking statements. Further information regarding these risks, uncertainties and other factors is included in the Company's filings with the U.S. Securities and Exchange Commission. The forward-looking statements included in this announcement represent the Company's views as of the date of this announcement. While the Company anticipates that subsequent events and developments may cause the Company's views to change, the Company specifically disclaims any obligation to update these forward-looking statements, unless required by applicable laws. These forward-looking statements should not be relied upon as representing the Company's views as of any date subsequent to the date of this announcement. |

|

(Stock Code: 2600) 2016 ENVIRONMENTAL, SOCIAL AND GOVERNANCE REPORT |

Contents |

2 | Chairman's Statement |

3 | About this Report |

6 | 2. | About Us |

6 | 2.1 | Company Profile | |

6 | 2.2 | Core Philosophy | |

7 | 2.3 | Honors and Awards |

8 | 3. | Governance: Deepen Reform and Integrate Resources |

8 | 3.1 | Corporate Governance | |

10 | 3.2 | Integrity and Compliance | |

11 | 3.3 | Advancing Quality and Efficiency | |

14 | 3.4 | Responsibility Management |

21 | 4. | Environment: Save Energy and Respect Nature |

21 | 4.1 | Save Energy and Reduce Consumption for Green Production | |

26 | 4.2 | Respect Nature and Improve Resource Use | |

28 | 4.3 | Turn Trash into Treasure and Advocate the Cycle Mode | |

32 | 4.4 | Sustainable Mining to Maintain the Ecological Environment |

36 | 5. | Collaboration: Win-win Journey and Achieve Joint Progress |

36 | 5.1 | Improve the Management to Establish a Sustainable Supply Chain | |

40 | 5.2 | Strengthen Client Relationship | |

45 | 5.3 | Encourage Innovations and Promote Industry Development |

49 | 6. | Employees: Caring for Employees and Grow Together |

49 | 6.1 | Optimize Management and Maximum Talents of Employees | |

53 | 6.2 | Ensure the Occupational Health and Safety | |

54 | 6.3 | Care for Employees and Their Happiness |

57 | 7. | Community: Contribute to Harmonious Community |

57 | 7.1 | Fixed-Point Poverty Alleviation | |

58 | 7.2 | Volunteer Activities |

60 | 8. | Outlook of 2017 |

61 | HKEx Guide ESG Reference |

64 | 9. | Your Feedback |

Chairman's Statement |

INNOVATING DEVELOPMENT CONCEPTS AND LEADING THE FUTURE OF THE INDUSTRY |

As the price of global bulk commodity plummeted in the early 2016, aluminum price had dropped to the level that of 20 years ago, causing widespread losses of China's and even global aluminum industry. |

Facing the severe and complicated external environment, under the tremendous pressure from the market's widespread pessimism due to the aluminum price dropped below 10,000 RMB per ton in the beginning of the year. Chalco didn't step away from the challenge. By adhering to the development concepts of "Innovation, Coordination, Green, Openness and Sharing", we adopted approaches of "improvement of weakness, reduction of un-functional business, development through innovation, and capitalization of resources". With persisting in idea of "Doing one thing and getting it done well", we have been making up where we were weak and gathering new momentum for development. By following approach of "using minor earthquakes to neutralizing major ones", we cut down zombie companies to usher in a new frontier. In belief of "innovation-driven development", we have strengthened our leadership position in the industry by advancing technologies and through innovation. Following the working idea of "limited resources but unlimited creativity", we turned resources into capitals to maximize benefits. At the same time, Chalco breaks stereotyped mindset, and makes its management more innovative. We have been decreasing cost to cope with market, and enforcing reforms to ensure our cost maintaining low. Because of drastically cutting down of the full costs of leading products, we have avoided the negative impact of market price drop and significantly strengthened our competitiveness. |

In 2016, Chalco bucked the trend and made breakthrough development. We achieved the best business performance in the recent years. Our efforts were highly recognized by our shareholders, society and capital markets. |

Ao Hong |

Secretary of Party committee and Chairman |

Chalco |

About this Report |

REPORTING PERIOD |

1 January 2016–31 December 2016. Some content exceeds this scope. |

REPORTING CYCLE |

The Environmental, Social and Governance Report (Corporate Social Responsibility Report) of Aluminum Corporation of China Limited is an annual report. It is regularly released. This report is our ninth report. |

SCOPE OF THE REPORT |

Unless otherwise stated, this report includes Aluminum Corporation of China Limited and all its subsidiaries. |

REPORTING REFERENCE |

This report is prepared with reference to The Environmental, Social and Governance Reporting Guide of The Stock Exchange of Hong Kong Limited, notice on Strengthening Listed Companies' Undertaking of Social Responsibilities and Issuance of 'Guidelines on Environmental Information Disclosure by Companies Listed on the Shanghai Stock Exchange', Sustainability Reporting Guidelines (G4) issued by the Global Reporting Initiative (GRI), and the ISO26000 Social Responsibility Guideline. |

REPORTING SPECIFICATION |

For the convenience of reading, Aluminum Corporation of China Limited hereinafter is referred to as "Chalco", "the Company" and "We". The group of Aluminum Corporation of China is referred to as "Chinalco". Other definitions are as follows: |

Shanxi Branch | refers to | Chalco Shanxi Branch |

Guangxi Branch | refers to | Chalco Guangxi Branch |

Guizhou Branch | refers to | Chalco Guizhou Branch |

Zhengzhou Institute | refers to | Chalco Zhengzhou Research Institute of Non-ferrous Metal |

Henan Branch | refers to | Chalco Henan Branch |

Liancheng Branch | refers to | Chalco Liancheng Branch |

Chalco Shandong | refers to | Chalco Shandong Co., Ltd |

Zhongzhou Aluminum | refers to | Chalco Zhongzhou Aluminum Co., Ltd. |

Ningxia Energy | refers to | Chalco Ningxia Energy Group Co., Ltd. |

Maliantai Power Plant | refers to | Maliantai Power Plant of Chalco Ningxia Energy Group Co., Ltd |

Chalco Logistics | refers to | China Aluminum Logistics Group Corporation Co., Ltd. |

Chalco Mining | refers to | Chalco Mining Co., Ltd. |

Baotou Aluminum | refers to | Baotou Aluminum Co., Ltd. |

Chalco Trading | refers to | China Aluminum International Trading Co., Ltd. |

Shandong Huayu | refers to | Shandong Huayu Alloy Materials Co., Ltd. |

Shanxi Huaze | refers to | Shanxi Huaze Aluminum & Power Co., Ltd. |

Shanxi Huaxing | refers to | Shanxi Huaxing Aluminum Co., Ltd. |

REPORT DATA SPECIFICATION |

The financial data referred shall be subject to the Company's financial report in case of any discrepancy with the annual report. The Chinese currency, Yuan, is used as the unit for the financial data in the report, unless other indicated. |

ACCESS TO THE REPORT |

This report is published both in Chinese and English, the electronic one is available as follows: |

The Website of Hong Kong Exchanges and Clearing Limited | http://sc.hkex.com.hk |

The Website of Shanghai Stock Exchange | www.sse.com.cn |

The Website of Aluminum Corporation of China Limited | www.chalco.com.cn |

The Securities Times | http://www.stcn.com/ |

2. About Us | |

2.1 | COMPANY PROFILE |

Aluminum Corporation of China Limited was incorporated on 10 September, 2001 in China, Aluminum Corporation of China is its controlling shareholder. Chalco is a leading company in China's non-ferrous industry, with a strong portfolio of assets among global competitors. Chalco has been listed in the Stock Exchange of Hong Kong, The New York Stock Exchange, and the Shanghai Stock Exchange. | |

Chalco is also the only large company in China's aluminum industry that is engaged in the whole value chain, from exploration and mining of bauxite and coal, the production, R&D of alumina, primary aluminum and aluminum alloy products, to international trade, logistics, and power generation from both fossil fuels and sustainable energy. By the end of 2016, Chalco has 49 subsidiaries, including 10 branches, 18 wholly owned and 21 controlled ones. | |

Chalco has made its mission to safeguard development and utilization of national strategic resources. The company plays an essential role in the application of aluminum in the aeronautics and space industry, rail transport, and the production of high-end alloys for civil purposes. The Company has provided a large number of high quality key materials for products including China's first man-made satellite, Long March rockets, Shenzhou spacecrafts, Chang'e lunar probes, commercial airplanes, high-speed trains and that of other construction and transportation industries. | |

2.2 | CORE PHILOSOPHY |

Our vision: | To become a world-class global company with innovative capability and international competitiveness |

Our mission: | Benefits shareholders, employees, clients, communities and environment |

Core values: | Responsibility, Integrity, Openness and Excellence |

Corporate spirit: | Striving for better performance and innovating for prosperity |

Management philosophy: | Striving for excellence and collaborating for efficiency |

Operation philosophy: | Creating values and maximizing returns |

Responsibility philosophy: | Turning stone into gold and benefiting mankind |

Corporate culture: | Transparency, Honesty, Simplicity and Open-mindedness |

Business concept: | Work without corruption and perform with virtues |

2.3 | HONORS AND AWARDS |

* | The Most Competitive Alumina Producer in 2015–2016 by 2016 China Aluminum Summit | |

* | The Most Competitive Electrolytic Aluminum Producer in 2015–2016 by 2016 China Aluminum Summit | |

* | Award for Outstanding Contribution of Mother Earth-Water Conservancy Project on the fifth anniversary of the project | |

* | Excellence Award of the eighteenth China Patent Award by the State Intellectual Property Office and the World Intellectual Property Organization | |

* | 2016 China Patent Excellence Award | |

* | Won one first prize, four second prize, five third Prize of the China Nonferrous Metals Industry Science and Technology Award | |

* | Won 11 Science and Technology Progress Awards | |

* | Best Investor relationship Award of Listed Companies' Awards by China Financing | |

3.Governance: Deepen Reform and Integrate Resources |

The Company adheres to the principles of integrity and compliance, continuously improves the management level of the Company's social responsibility work in order to ensure the efficient operation of the Company. In 2016, taking "Advancing quality and efficiency, reform and innovation, transformation and upgrading" as main work idea, Chalco raised its profitability to create more value for stakeholders, such as shareholders, employees, clients and communities by further deepening reform, integrating quality resources, reducing costs, increasing benefits, strengthening cost budgeting control, and reducing the cost of main products substantially. |

3.1 | CORPORATE GOVERNANCE |

Chalco strictly follows the laws, regulations and regulatory rules of securities in the listing locations of Shanghai, Hong Kong and New York City, continues to improve the Company's governance structure and regulate the work flow and management process of the Company's operations through a governance structure called "Three Boards and One Layer" to form an operation and management framework that is featured in explicit authority and responsibilities, clear and separate roles, inter-coordination, effective checks and balance, scientific decision-making and standardized operations of/among its staff or departments/offices. | |

| |

General Meeting | |

The general meeting is the highest authority of Chalco, legally exercising its rights to decide on the Company's management principles investment plans, review and approve the Company's profit distribution and loss recovery plans, revise the Company's constitution and rule of procedures for the general meeting, Board of Directors and Board of Supervisors. During the reporting period, Chalco has held three general meetings and reviewed 20 proposals. | |

Board of Directors | |

Board of Directors is the operating decision-making body of Chalco, answers to the general meeting. The Board of Directors legally exercises its duties including but not limited to the following items: executing the resolutions of general meetings, deciding on the Company's development strategies, business plans and investment plans, formulating the Company's annual financial budget plan and financial statement plan, profit distribution plan and loss recovery plan, the Company's plan for increasing or decreasing the registered capital, and its basic management system, as well as supervising the implementation of various regulations, deciding on the Company's policies for risk management, compliance and internal control, and making related systems of internal control and compliance management and equity incentive plans, etc. | |

In 2016, the Company's 6th session of Board of Directors consists of nine directors with chairman and non-executive Director, Mr. Yu Dehui, executive Director Mr. Ao Hong, non-executive Director Mr. Liu Caiming, executive Directors, namely Mr. Lu Dongliang and Mr. Jiang Yinggang, non-executive Director Mr. Wang Jun, and independent non-executive Directors, namely Ms. Chen Lijie, Mr. Hu Shihai and Mr. Li Dazhuang. During the reporting period, the Board has held 13 meetings and reviewed 62 proposals. | |

Board of Supervisors | |

Board of Supervisors is the Company's supervisory body, and answers to the general meeting. The Board of Supervisors legally exercises its duties to inspect and investigate the Company's financial and risk management and internal control, supervise and appraise the performance of the Board of Directors, senior management and their members, as well as give their opinions and make recommendations. During the reporting period, the board, consists of three supervisors with two supervisors on behalf of shareholders, one supervisor on behalf of employees, has held five meetings, reviewed and approved 11 proposals. | |

Management | |

The main functions of management include being in charge of the Company's production, operation and management, organizing the implementation of the Board of Directors' resolutions and the Company's development strategies, annual business plan, investment plan, financial budget plan, as well as formulating and carrying out the performance appraisal and remuneration incentive scheme. The Board of Directors would review the functions and performance of the management to ensure the interest of the Group as a whole. The Company's management would report on the signing and implementation of major contracts, the use of funds and its profit and loss situation. | |

In 2016, the Company's key management includes: Mr. Ao Hong, President; Mr. Lu Dongliang, Senior Vice President; Mr. Jiang Yinggang, Vice President; Mr. Xu Bo, Vice President; Zhang Zhankui, Chief Financial Officer and the Company's Secretary (Board Secretary); Mr. Leng Zhengxu, Vice President. For specific information on senior management, please see the Company's website: http://www.chalco.com.cn/chalco/gsgk/glry/A120110web_1.htm. | |

3.2 | INTEGRITY AND COMPLIANCE |

Chalco follows the laws and regulations, abides by business ethics, continuously improves its internal control and risk management system, and develops a system of prevention and punishment, thus nipping evils in the bud to ensure a regular and legal operation and management of the Company. | |

3.2.1 | Total Risk Management | |

Chalco raised the principle of "strengthening internal auditing as an opportunity to effectively prevent internal control risks, strengthen internal control system and consistently build the capacity of risk warning and the level of management", putting risk awareness into every operational activity ranging from strategic management to day-to-day operations and doing a best job on the prevention of risks, especially striving to minimize the risk to the extent that the company can withstand. | ||

To maintain an effective operation of risk management, Chalco actively takes on comprehensive risk management ground work, and builds warning indicator system for major risks. By monitoring the indicators, the Company analyzes the current risk situation, predicts risk trends and submits periodic quality risk management reports. In 2016, the Internal Auditing Department, staffed with full-time risk management professionals, was officially launched for the completion of risk management system, further improving the Company's risk management structure, and providing organizational and personnel guarantee for better development of risk management in the Company. Workshops on risk management were held within the Company to raise the heads of departments' and branches' awareness of risk and compliance. | ||

3.2.2 | Anti-corruption | |

Chalco continues to improve the related regulations and supervisory mechanism on anti-corruption and work without corruption. The Company has done its job on anti-corruption to build a mechanism and system in which no one dares, can and wants to corrupt. Chalco starts with an education on clean governance culture with a focus on anti-corruption awareness rising. The Company intensifies its anti-corruption campaign by continuing to launch its Anti-corruption-themed Education Month, and send anti-corruption-themed reminders by texts and WeChat, watch anti-corruption-themed videos, visit anti-corruption-themed education bases, hold workshops on anti-corruption and its laws in the party school, print and distribute anti-corruption-themed case studies and sign letters of anti-corruption commitment, etc. to ensure the anti-corruption training reaches the grass-roots and covers all 797 anti-corruption-themed lectures had been held throughout the year with 35,089 people directly benefited. | ||

Case: Figures of Anti-corruption Workshops in the Party School | ||

|

| ||

Capacity Building for Secretary of Commission for Discipline Inspection | Team Leader Training in Branches of the Company |

3.3 | ADVANCING QUALITY AND EFFICIENCY |

Chalco pushes forward the "improvement of weakness, reduction of un-functional business, development through innovation, and capitalization of resources" reform and achieves reducing costs and increasing benefits through precision management, which would be a modern management model and system that ranges from production process, finance, capital operation, investment proposals to internal coordination, marketing and logistics, safety and stability, etc. | |

In 2016, supported and coordinated by its branches and all the departments of headquarters, Chalco launched "Advancing quality and efficiency" special campaign in a comprehensive way as its main working idea, which led it to withstand market pressure, cool-headedly rise to all the challenges and finally realized its business goal of this year. | |

1. | The launch of "advancing quality and efficiency" initiative across the company has led the overall development of the Company. In 2016, the initiative that is featured in all staff participation, whole process control and full efforts from all, further specified the objectives and responsibilities of the Company's leaders, competent departments and business entities respectively. The Company optimized technology indicators, grasped the opportunity of electric power system reform, and worked on those restructuring and upgrading key projects in an orderly manner. In 2016, the Company beat the market due to its cost reduction and efficiency improvement, which savings and earned revenue have overall surpassed the amount of lost profit that was affected by the reduced products prices. | |

2. | The Company grasped the opportunity of electric power system reform and reduced its electric power cost. Directed by the concept of building the large energy system for reducing costs, the Company grasped the opportunity of national electric power system reform and implemented fine management. As results, unplanned stopping operation of self-provided power plants were reduced, and correspondingly coal consumption and power generation cost were cut; some enterprises under Chalco realized the integration of aluminum and power as well as replacement of sustainable energy. In 2016, the reduction rate of the Company's electricity cost is about 13%. | |

3. | Chalco strengthened market research and optimized its marketing strategy. Relying on the collection and analysis of new trends of the industry, the Company grasped market principles and market opportunities and then developed a marketing strategy aiming at stabilizing clients by a rapid response, rapid decision-making, and change-to-change model. Based on the overall analysis of market supply and demand, the Company continued to intensify centralized procurement and adjust the inventory of the bulk of raw and auxiliary materials. The Company achieved good results of reducing costs and increasing benefits by selecting outstanding suppliers and enhancing their shares of direct supply. | |

4. | Driven by the two wheels – investment and technology, the development of the Company was full of vitality. Following its concept – "investing one project, making it successful, and getting profit", the Company accelerated restructuring and upgrading of mines and key projects, which enhanced the capability of mining security and making profits. In 2016, with implementation of technological R&D projects, breakthrough of several key technology, and demonstrative projects of new technology industrialization into service, technological innovation and theoretical achievements conversion provided strong technical support for the Company's enhancing quality and efficiency as well as its restructuring and upgrading. | |

5. | The Company continued to run precise management and optimize technical indicators. In 2016, the operation monitoring center and command system of safety production and emergency & rescue for coal mine and power plant were put into use. Based on daily morning meeting system, the Company closely combined management instruction with process supervision, and improved business efficiency by grasping the hot, key and difficult issues during operation. In addition, the Company started a mining improvement project to untangle and inspect problems for reducing costs and increasing benefits. Through multifaceted and whole process precise management, 19 key indicators were significantly improved and 634 rectification measures for "precise indemnification and elimination of waste" were completed, which significantly raised quality and efficiency. | |

6. | Those companies in difficulty were reborn by creatively adopting "larger, efficient, stronger and dynamic" approaches. Chalco made "one policy for one company", which vitalized those companies in difficulty through relocation and transformation. Meanwhile, by benchmarking advanced level of labor productivity in this industry, the Company further optimized allocation of employees and dramatically increased labor productivity. As results, labor productivity increased 56% and 20% in companies majoring in alumina and companies in aluminum respectively. | |

3.4 | RESPONSIBILITY MANAGEMENT |

Chalco promotes its management level and continuously moves forward to fulfill its sustainable objectives by combining its management of Corporate Social Responsibility (CSR) with its main businesses and advancing the efficiency of resource utilization in its work. | |

3.4.1 | Social Responsibility | |

The responsibility concept with the social responsibility view of "turning stone into gold and benefiting mankind" at the core have won wide recognition in the Company and been treated as their objectives and pursuits by the Company's staff. They put both the Company and the society on the path to the sustainable development by making unstoppable efforts to innovate and practice. | ||

Turning stone:utilizing the resources in an ethical and equal way; | ||

Becoming gold: utilizing the resources in a green, highly efficient, low-carbon and responsible way to create wealth and promote value; | ||

Benefiting mankind: utilizing the global resources to serve the global economy and bringing benefits to future generations by means of creation; | ||

Turning stone into gold and benefiting mankind: is the Company's promise to smelt the ore into gold and turn the stone into treasure and bring benefits to the next generations of mankind. | ||

3.4.2 | Social Responsibility Management System | |

To guarantee that the Company meets its social responsibility's objectives and requirements, Chalco has established and improved its long-term working mechanism of CSR. Chalco classified the work content and duty according to the guideline of Hong Kong Stock Exchange and with the reference to ISO26000 international standard. It continues to improve the Company's social responsibility management system from three layers – strategy, operation and basis, while integrating its CSR into the Company's management system and making the relevant departments accountable for the results by forming five fields – company's governance, environment, employment and employee rights, operating practices and community as the main structure, therefore achieving the effective integration of social responsibility work and operating management. |

Responsibilities | Departments in Duty |

Governance | President's Office (Office of Board of Directors); Human Resources Department; Financial Management Department | ||

Environment | Corporate Management Department; Energy Management Department; Sci-Tech Management Department | ||

Employment and Labor | Human Resource Department; Culture Department; Labor Union | ||

Operating Practices | President's Office; Marketing & Procurement Department; Investment Management Department; Internal Audit Department; Supervision Department | ||

Community | President's Office (Office of Board of Directors); Culture Department; Labor Union |

Chalco set up a leadership group for CSR with Chairman of the Board of Directors as the group leader and President as the representative of the CSR management. The Company's leadership group has its own CSR office while all its branches set up their own leadership group and their offices of CSR correspondingly, in charge of their work in this respect. | ||

| ||

The Company's Leadership Group for CSR is a senior managing and coordinating body. It is in charge of the review of strategic CSR planning, making the Company's CSR policies and systems, releasing the Company's CSR reports and inspecting and supervising the implementation of the planning. The Company's CSR office is a daily office for the leadership group, whose responsibilities include: implementing the resolutions made by the leadership group, compiling the Company's planning and work plans for CSR, conducting training on social responsibility, coordinating the relevant work for social responsibility across the Company, managing the CSR on a daily basis, compiling and releasing CSR reports, doing research and surveys on social responsibility and practice, and strengthening communications among stakeholders. | ||

3.4.3 | Stakeholders Communication | |

Chalco actively carries out social responsibility communication work in order to enhance the performance of social responsibility, improve the transparency of the Company and build a harmonious stakeholder relationship. It continues to improve stakeholder communication mechanism, communication channels, communication measures, and constantly improves the effectiveness of communication by receiving visitors, answering the question of investors, overseas road show, displaying innovative results, etc. | ||

Stakeholders | Expectation and requirements | Communication channels |

Government | Tax payment | Participate in meeting |

Regulatory authorities | Compliant operation | Information disclosure |

Shareholders | Maintenance and | Results announcement |

Clients and Suppliers | Sincere cooperation | User forum |

Employees | Protection of the legitimate | Company internal publications |

Industry | Industry standard setting | New technology seminar |

| Environment | Resource conservation | Environmental protection forum |

Community | Civilized production | Green Reclamation |

3.4.4 | Materiality Analysis | |

Chalco collected stakeholders' concerns and topics by stakeholder interviews and online retrieval. With reference to the "Environmental, Social and Governance Reporting Guide" released by the Stock Exchange of Hong Kong Limited and ISO26000 International Standards of Social Responsibility, combining with the review of company's current operational management and development strategy, it evaluated the material issues of social responsibility, ensured that the Company can disclose the important information as accurately as possible in terms of stakeholders concern. | ||

Screening Flow on Material Topics of Environmental, Social and Governance | ||

Sources of Topics | |||

– Corporate Development Strategy | |||

| – Corporate Management Suggestions | ||

– Stakeholder Analysis | |||

– Main Business Features of the Company | |||

–Environmental, Social and Governance Reporting Guide, by the Stock Exchange of Hong | |||

– ISO26000 | |||

– United Nations Millennium Development Goals – Industry Development Trends | |||

– National and International Peer Companies Benchmark Study | |||

–Environmental Protection Law of the People's Republic of China | |||

–Management Measures for Environment Monitoring | |||

–Codes of the Aluminum Industry, by Ministry of Industry and Information Technology | |||

Screening Standard | |||

– Contribution to Sustainable Development | |||

– Stakeholders' Concerns | |||

– Request by Social Responsibility Guidelines | |||

– Accordance with the Needs of Corporate Strategic Development |

Screening Flow on Material Topics of Environmental, Social and Governance | ||

Results of Materiality Analysis | ||

| ||

4. Environment: Save Energy and Respect Nature |

As a large-scale resource-based enterprise, Chalco pursues a coordinated development between business operations and environmental protection. Chalco implements sustainable development through every single link of its production and operation from four major aspects, including energy saving and emissions reduction, resource utilization improving, waste recycling and reusing as well as sustainable mining. |

In order to reduce the environmental impact of the company's production and operations strengthen the protection of the environment, the company strictly abides by relevant state laws and regulations. It stipulated the relevant policies and regulations, such as "The internal safety and environmental protection responsibility system of Chalco (Trial)", "Environmental protection management measures in Chalco", "The disposal plan of Emergency Environmental Information Event in Chalco", "The contingency plan of Environmental Administrative penalty in Chalco", etc. |

4.1 | SAVE ENERGY AND REDUCE CONSUMPTION FOR GREEN PRODUCTION |

Chalco has implemented environmental management responsibility system based on its environmental management system. Environmental protection indicators are introduced in Chalco's development planning and production & operation plans. It standardizes and normalizes energy saving and emissions reduction in a planned and targeted manner by implementing the three-step energy saving and emission reduction system. The three-step system includes "Layered target decomposition", "Reducing costs and increasing benefits for large-scale energy", and "Energy saving and consumption reduction by everyone". | |

1. Classify and | 2. Carry out reducing costs and | 3. Implement energy saving and consumption |

Plans for energy saving and emissions reduction are developed annually with the overall target allocated to the entities. Each subsidiary and branch shall take measures based on its actual situation to decompose the tasks to ensure the successful completion of Chalco's energy saving targets. | Carry out reducing costs and increasing benefits for large-scale energy activities; reduce energy consumption by properly balancing the mediums of energy resources such as water, electricity, wind, gas, and oil and consumption control. Bridge the gap of insufficient essential energy factors by technical innovation, reform, and upgrading projects; Reduce energy consumption by improving the energy structure; and manage energy in all aspects for the purpose of sustainable reduction in energy consumption by standardization, supervision, and inspection of the management of energy-consuming units, and comprehensive use of energy base data, flow charts, data statistics and other means. | Carry out activities such as Energy-Saving Awareness Week and National Low-Carbon Day to disseminate knowledge of energy saving and emission reduction, such as energy-efficient "leader", energy saving technologies, energy performance contracting and carbon emission management; Organize energy saving inspection, including on-site energy use, "gas escape, water emitting, liquid dropping, and leakage" of energy mediums, irrational use of energy mediums, and idle running of belt, fan and pump and other equipment; and to guide employees to carry out the "five small activities" involving "small reforms", "small inventions", "small transformations", "small designs", and "small suggestions" by carrying out "fulfillment of new ideas and making achievements in the 'Thirteenth Five-Year Plan'" themed competition and other activities, for the purpose of achieving energy saving and consumption reduction by relying on employee's wisdom. |

4.1.1 | Energy Consumption Reduction | |

Chalco encourages (R&D), demonstration and promotion of new technologies to support energy saving and environmental protection. It focuses on energy consumption in all aspects of production, in order to reduce losses, eliminate squander and utilize energy effectively. | ||

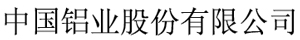

In 2016, the comprehensive energy consumption of all alumina and electrolytic aluminum enterprises was about 16.59 million tons of standard coal, the synthetic energy consuming per 10,000 Yuan of GDP was 2.71 tons of standard coal; purchase electricity was 22.3 billion degrees, the total coal consumption was 15.5 million tons. | ||

In recent years, Chalco has made great progress by implementing its energy saving measures. From 2014 to 2016, Chalco's comprehensive energy consumption decreased successively year by year. In 2016, the year-on-year energy consumption (compared to 2014) decreased by 11.57%. By taking measures such as production equipment update and technical transformation, the energy savings totaled 2.2854 million tons of standard coal. The overall energy consumption of alumina also declined year by year with a cumulative reduction by 19.59%, reaching a leading level in the world. | ||

| ||

Note: | comprehensive energy consumption = the sum of the actual consumption of various energy sources in industrial production activities (converted into standard coal) – the sum of the energy conversion process of the enterprise's energy output (converted into standard coal) – the sum of recycling energy (converted into standard coal) | Note: | The comprehensive energy consumption data has been converted into standard coal | ||

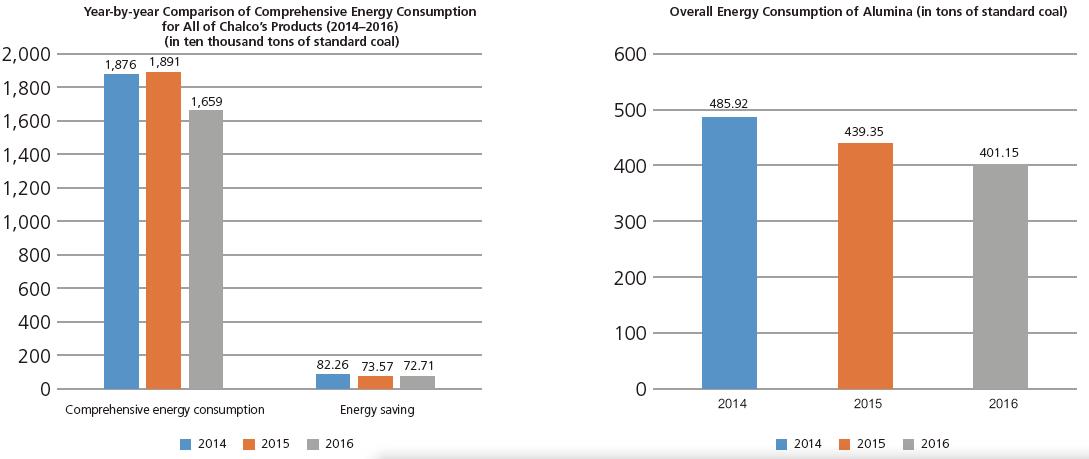

The energy consumption for the production of the two major products – alumina and electrolytic – decreased successively in recent five years. The coal consumed for power generation has been significantly reduced. The standard coal consumption of power supply for alumina, standard coal consumption of heating supply for alumina, and the coal consumption of power supply for electrolytic aluminum are also declining steadily. | ||

| ||

4.1.2 | High Thermal Efficiency of CHP | |

To improve the quality of heating, save fuel consumption significantly and reduce impacts on the environment, the Combined Heat and Power (CHP) mode is adopted in all of Chalco's heating and power plants for alumina enterprise. The high-pressure steam produced by boilers works through the stream turbine for energy consumption of production. In addition, the waste heat is re-used to provide heating for the living quarter of employees. It realized the gradient utilization (step-wise utilization) of energy. By this approach the heat efficiency reached more than 70%, far higher than that of traditional condensation thermal power plants. | ||

4.1.3 | Emission Reduction through Scientific Research and Technological Reform | |

Chalco has always valued the R&D improvement and application of environmental protection technologies in production processes to reduce production consumption, emissions, costs as well as the impact on the environment. In 2016, the Company totally had 45,075,090,000 cubic meters of emissions, 41,187 tons of sulfur dioxide,1,140,781 tons of nitrogen oxides, and 180,906 tons of soot. In 2016, Chalco made great achievements in reducing emissions, including 254,441 tons of SO2, 44,062 tons of nitrogen oxides and 2,032,731 tons of soot. | ||

Case: Research & Transformation of Desulphurization and Denitrification Technologies in Chalco | ||

Chalco has initiated the research on the integrated technology in flue gas desulfurization, associated denitration and mercury removal since 2013. A number of achievements have been made, such as the integrated wet desulfurization, associated denitration and mercury removal technology, the new dual-alkali desulfurization technology adopted in Shanxi Huaxing, and the dry non-catalytic reduction denitration technology. In addition, these achievements have been widely used in the flue gas control and treatment regarding circulating fluidized bed boilers (CFBBs), pulverized coal furnaces, coal-water slurry boilers (CWF boilers), chain boilers and daily glass furnaces. By doing so the flue gas treatment indicators have achieved China's requirements of ultra-low emissions and the investment and operating costs have been reduced by more than 20% compared with the existing conventional technologies, reaching an internationally leading level. |

| ||

The New Dual-Alkali Desulfurization Technology Adopted in Shanxi Huaxing | |||

Case: High Efficiency of Flue Gas Purification | ||

The flue gas of electrolytic aluminum plant is mainly produced by CO2 based anode gas on the anode. The electrolytic pot emits flue gas which is mainly fluoride, dust, etc. They are collectively referred to as the main components of electrolysis flue gas. Fluoride and dust are harmful components. The company's electrolytic aluminum enterprises generally adopt dry purification technology, and it makes the total fluorine emissions of flue gas≤1mg/Nm3, dust emission of flue gas≤5mg/Nm3, much lower than the national emission standards (total fluoride emissions≤3mg/Nm3, dust emission≤10, key areas/20mg/Nm3). | ||

Chalco's flue gas treatment technology has high purification efficiency and is featured by a simple process, no wastewater, and no secondary pollution. The technology not only allows Chalco to meet the national standards of dust emissions, it also recovers the water in flue gas as electrolytic raw materials in the electrolytic cell. It effectively turns the hazard into the benefit and achieves comprehensive utilization. | ||

4.2 | RESPECT NATURE AND IMPROVE RESOURCE USE |

In line with the principles of economizing resources, Chalco transferred production modes fundamentally. It improved process technologies, the tailings recovery and comprehensive utilization ratio of ores for rational mining of resources and efficient use. At the same time, Chalco also actively researches on and develops new technologies regarding the recycling of renewable resources and reducing environmental pollution. | |

4.2.1 | Raising Mining Rate | |

In the process of resource mining, Chalco uses the smart mining platform for precise, dynamic, digital, and real-time management, which provides conditions for building resource-saving and environment-friendly green mines. | ||

Case: Online Mine Smart Mining System has improved the efficiency of resource utilization and | ||

Chalco's Online Mine Smart Mining System integrates resource dynamic management, resource mining planning, large homogeneous ore blending, mining design, centralized dispatching based on production visualization, safety supervising and monitoring and many other subsystems. It also integrates information digitization, real-time production process, management and control, and decision-making processing. The system has greatly promoted the comprehensive and precise management of mining, a traditionally complicated production system. It has enhanced the efficiency of resource utilization and effectively reduced the costs for mining. This technology was applied in the phase III mining of our Guangxi Branch. It has improved the production information level and the labor production efficiency, reduced the rate of ore loss by 0.20% and the dilution rate by 0.10%, lowered fuel consumption and achieved the goal of improving the efficiency of resource utilization. | ||

| ||

Online Smart Mining System Applied in three phases Mining of Guangxi Branch | ||

4.2.2 | Comprehensive Reuse of Water Resources | |

Adhering to the water-saving principle of "water conservation and comprehensive utilization", Chalco never stops to develop new technologies to reduce the consumption of new water from the source, to promote the construction of non-leaking plants, and to encourage the use of recycled water. Multiple measures have been taken to strengthen water conservation management. In 2016, total water consumption was 25.7 tons, and water consumption of ten thousand Yuan output value was 1.547 tons. | ||

Currently, Chalco has 52 sets of wastewater treatment facilities with a daily wastewater treatment capacity of 362 thousand tons. All of Chalco's alumina and aluminum plants are adopting "zero" discharge of wastewater technology. In 2016 Chalco recycled 2.7 billion tons of wastewater. | ||

Case: Integrated Water Purification Plant Put into Operation in Zhongzhou Aluminum, Massive Industrial | ||

Zhongzhou Company carried out scientific treatment of industrial wastewater and tailings backwater by means of the operation and control of the integrated water purification plant. In 2016, 6.7086 million tons of industrial wastewater was recycled. The Company carried out a number of labor competitions such as "water management by alkali test" and "improve boilers' consumption of backwater". It had made a good progress and greatly reduced the pollution of "alkali leakage" accidents on water systems. The average consumption of backwater of boilers was increased to 500 tons per hour in 2015 from 276 tons per hour in 2015, which was a great breakthrough. | ||

|

| ||

Reciprocating Flocculation Tank of Integrated Water Purification Plant in Zhongzhou Aluminum | Swash Plate Sedimentation Tank of Integrated Water Purification Plant in Zhongzhou Aluminum | ||

Case: All-round Water-saving Initiatives in Chalco Shandong | ||

Chalco Shandong set up a water-saving team in which the Company's leader served as the team leader. In line with the principles of action – "make full use of condensate water, priority of using external drainage, reasonable control of new water, and reduce reverse osmosis water", it carried out a system-wide water balance test. A total of 35 improvement initiatives were prepared for alumina production process, such as improvement of the recycling rate and utilization of condensate water in evaporator, comprehensive treatment and utilization of industrial wastewater, control and treatment of gas escape, water emitting, liquid dropping, and leakage, and further improvement of pipe network facilities. | ||

Case: Two Pronged Remediation of Illegal Water Consumption and Pipe Network in Guangxi Branch | ||

Guangxi Branch perseveres in inspection on water consumption in the surrounding area irregularly and more than twice a month. The branch carries out on-site inspection with the focus of the amount of consumed water and private or nonconformance water pipe pipes access. 14 illegal accesses to water were identified and removed in the year. The Company re-installed water meters and signed agreements with four villages which illegally used water. Guangxi Branch strengthened water supply pipe network management and set up a special team regarding "improve water supply stability and reduce the consumption of new water" to check, control and manage potential leakage of pipe network and to provide effective remediation to pipe explosion emergency response. In 2016, the Company identified a total of 5 severe potential leaks, 2 illegal overflow drainage; and carried out remediation accordingly. It saved new water consumption of about 6,000 cubic meters per day after remediation. | ||

4.3 | TURN TRASH INTO TREASURE AND ADVOCATE THE CYCLE MODE |

In 2015, China put forward the "Made in China 2025" program aimed at creating an internationally competitive manufacturing industry. As one of the world's largest producers of electrolytic aluminum, China's electrolytic aluminum industry is one of the most important strategic industries in the "Made in China 2025" program. | |

Wastewater, waste gas and waste solid produced in the production process of electrolytic aluminum are the main factors imposing negative impacts on the environment. Chalco strictly abides by the relevant national laws and regulations. Under the premise of making its pollutants reach the standard of discharge, it also explores the methods and approaches to comprehensively utilize the "three wastes" to minimum the discharge of them. Chalco has developed a variety of technologies to advocate and practice the mode of industry recycling, such as establishing aluminum plants, purchasing and use of petrochemical wastes (such as petroleum coke) from CNPC and SNP, reducing the discharge of aluminum and alumina wastes, and implementing resource utilization. Chalco firmly believes that technological innovation is fundamental while innovative and high-tech production modes will become the fundamental driving force of green production for China's electrolytic aluminum. | |

4.3.1 | Electrolytic Aluminum Scrap Recycling | |

With years of accumulated technologies, Chalco has developed "Spent Potlining (SPL) Wet Processing Technology". The traditional aluminum electrolytic pot has problems like occupying large space, threatening the surrounding environment, and causing a high maintenance cost. The "SPL Wet Processing Technology" not only improved the hazard-free treatment efficiency of aluminum spent potlining, but also realized the recycle of aluminum scrap. The waste residues from the hazard-free treatment are to be recycled as brick building and road fill materials. | ||

Case: In March 2017, this technology conducted an industrial "Spent Potlining (SPL) Wet Processing | ||

| ||

The production demonstration line of "Spent Potlining (SPL) Wet Processing Technology" in Baotou Branch | ||

4.3.2 | Treatment of Bauxite residue Discharge | |

Chalco developed a number of innovative technologies for the soil treatment in terms of flue gas, sewage, and heavy metals and strives to realize safe storage and reuse of bauxite residue. | ||

Along with reducing the discharge of bauxite residue and ensuring safe storage, Chalco is more active in exploring the effective utilization of bauxite residue resources, increasing the utilization amount of bauxite residue, expanding the applications of bauxite residue and tailings in soil improvement, industrial waste treatment, and industrial water purification agent and other fields. In 2016, Chalco achieved resource utilization with a total of 798 thousand tons of bauxite residue and developed four aspects of the utilization as a resource. | ||

Four ways of red mud resources utilization in Chalco: | ||

1. Boiler Desulfurization Applied to Bauxite residue | ||

• | Zhengzhou Institute has completed the bauxite residue desulfurization industrial test for 5 tons per hour coal-fired boilers. Bauxite residue is used for desulfurization of coal-fired flue gas, greatly reducing the SO2 concentration contained to the national ultra-low emission standards. The implementation of this technology can make 1 ton of dry bauxite residue to absorb 180–180kg carbon dioxide, and the bauxite residue utilization rate can increase to 10%–15%. It reduces the alkalinity of bauxite residue during the desulfurization. The pH value of the bauxite residue used for the desulfurization also meets China's requirements for industrial solid wastes. The desalination rate of bauxite residue desulfurization liquid is 70% or more, and meets national requirements after purification. The Company is currently working on a boiler of 75 tons per hour for industrial application of the technology. | ||

2. Industrialization of Selection of Iron Ore in Bauxite residue Project | ||

• | In 2016, Guangxi Branch, Huaxing Aluminum and and Shandong Branch, etc. recycled iron ore in bauxite residue by way of magnetic separation according to the characteristics of bauxite residue. In 2016, the three companies produced 660 thousand tons, 120 thousand tons and 18 thousand tons of iron ore concentrate, respectively. It reached recycling of resources. | ||

3. Industrial Wastewater Purification Agent Production | ||

• | Shandong Branch adopts Bayer process for the development and production of industrial wastewater purification products with bauxite residue. In 2016 it produced and sold thousands of tons of such purification agent based on a pilot line. The 10 thousand tons liquid purification agent production line is about to be completed and moving into trial production and commissioning. | ||

4. Bauxite residue Soil Conditioners | ||

• | Zhongzhou Aluminum has developed a bauxite residue soil conditioner. The product is a high molecular space material with stable structure that can reduce cadmium, lead and other heavy metals in the soil. A 20 thousand soil conditioner production line has been built and is to be put into trial production in June this year. It will reach the production requirements in August. | ||

4.3.3 | Fly Ash Recycling | |

Chalco adheres to the recycling of fly ash for the production of lightweight insulation bricks, turning waste into treasure. In 2016, Shanxi Branch comprehensively utilized 120 thousand tons of fly ash and slag with a total of 73,792.7 thousand bricks produced, including 59,769.2 thousand standard fly ash bricks and 140,235 thousand special-shaped bricks (converted into standard bricks). | ||

|

| ||

Fly Ash Brick Production site of Shanxi Branch | Fly Ash Brick Production line of Shanxi Branch | ||

|

| ||

Autoclaved Fly Ash Perforated Bricks Made by Shanxi Branch | Autoclaved Fly Ash Hollow Bricks Made by Shanxi Branch | ||

4.3.4 | Packing Materials Recycling | |

Chalco advocates reducing disposable packaging. Chalco Logistics recycles alumina packaging materials from the clients for reuse. In order to further reduce the consumption of disposable materials, such as plastics, Chalco starts to use recyclable aluminum packing container which suitable for short distance transportation in 2016. Except that it could be recycled and reused repeatedly, the aluminum packing container is easy for storage and inventory and greatly enhances the supply and transportation efficiency. | ||

4.4 | SUSTAINABLE MINING TO MAINTAIN THE ECOLOGICAL ENVIRONMENT |

Chalco adheres to the concept of "responsible mining development" and adopts scientific and orderly mining for protection of mining ecology and reducing impacts of production on the mining and neighboring environment. Chalco has established a long-term mechanism for the ecological environment management and land reclamation in the mining area. The integrated "Separation-Mining-Reclamation" mining technology and "Ladder Leveling-Landfilling of Surface Tillage Soil", "Bulldozer-Front Loader-Car" and other land reclamation processes suitable to the actual conditions are used. These measures can simultaneously implement separation, mining and reclamation which effectively shorten the cycle of land reclamation and realize the effective combination of engineering reclamation and ecological reclamation. In 2016, a total of more than 8,000 mu of land in mining areas were reclaimed. | |

Case: To Build "a National Green Mine" | ||

Guangxi Branch adheres to building a green mine and comprehensively carries out the construction of a demonstration base for comprehensive utilization of mineral resources. In September 2014, the mine passed the acceptance inspection of green mine and was officially named "National Green Mine". Guangxi Branch was also won several awards, such as the "Aluminum Corporation of China Limited President Special Award – Mine Demonstration Base Award" in 2016 and 2016 Aluminum Corporation of China Limited "Model Mine". |

| |

Mining reclaimed by Guangxi Branch |

Case: Ecology Farm – Sprouting on the Reclaimed Land | |

Chalco's Xiangcaowa Mine has built more than 500 mu of ecological farms in the goaf. Walnut trees, poplar, vegetables, chrysanthemum and other cash crops are planted on the reclaimed land both to develop the local economy as well as improving the environment. On November 15 this year, the Xiazhou District TV Station of Sanmenxia City made a special report The Green Farm in the Mine. On December 14 China Center Television (CCTV) Financial Channel made a follow-up coverage, and on December 24, Fifth Edition of Chalco Newspaper also reported the story. | |

|

| |

Ecological Farm in Aluminum Mine of Xiangcaowa, | Soil Reclaimed in Aluminum Mine of Xiangcaowa, | |

Case: Houwucheng Mine Built an Overall Reclamation System | |

Houwucheng Mine adheres to paying equal attention to reclamation and mining production. It also established a supportive system for reclamation plan, technology, funds, and organization. It set up an integrated mine separation-mining-reclamation process system. Over the years, Houwucheng Mine has accumulated experiences in remedial works on waste dump, biological planting experiments, and planting land crops on reclaimed lands. Part of the land has been cultivated by local villagers with main species including corn, millet, wheat, beans and potatoes. Some land is for walnut trees and other cash crops. This contributes to promote local farmers to get rich and create a harmonious relation between the enterprise and the local community. | |

|

| |

Reclaimed Houwucheng Mine area | Crop planting in reclaimed Houwucheng Mine area | |

Case: Joint Efforts in Land Reclamation with Gongyi Government | |

On December 23, 2016, theLand Reclamation Development Project of Fengmenggou Village, Xiaoguan Town, Gongyi City jointly built by Xiaoguan Mine of Chalco and the government passed the acceptance of Gongyi City Government. | |

The reclaimed land was used for the construction of 12 multi-story residential buildings and 56 low-rise residences by the Company and the government, covering a total area of 75,000 square meters. The public facilities are readily available, including a large square, cultural center, nursing home, viewing pavilion, clinic, supermarket, fitness equipment, and stone stools and tables, providing a fresh environment surrounded by green trees and red flowers. The villagers living conditions have been significantly improved. | |

| |

The comparison of reclaiming before and after | |

5. Collaboration: Win-win Journey and Achieve Joint Progress |

With the development of the business and the expansion of the market, the environmental and social factors affected by Chalco's supply chain are also increasing. At the same time, Chalco is expected to take more necessary social responsibilities. Chalco also faces new opportunities brought by industrial upgrading and innovative development. |

With the close communication with partners and assistance in regulating the social responsibility management of suppliers, as well as assistance in further optimization of the industrial supply chain by means of technological innovation, enhancing resource efficiency and reducing impacts on the environment, Chalco guides the upstream and downstream enterprises of the supply chain to understand and fulfill their appropriate responsibilities regarding the environment and society for mutual benefits, win-win cooperation, and common progress. |

5.1 | IMPROVE THE MANAGEMENT TO ESTABLISH A SUSTAINABLE SUPPLY CHAIN |

In the course of its own development, Chalco strengthens the management of upstream and downstream suppliers and contractors of the supply chain. Chalco extends the management requirements of social responsibilities to the supply chain, and helps the supply chain grow stronger in the spirit of win-win cooperation for the purpose of creating a sustainable supply chain. By the end of 2016, Chalco has 4,204 domestic suppliers and 42 overseas suppliers. | |

5.1.1 | Well-Established Management Procedure | |

As for the selection of suppliers, the potential supplier not only need to meet the basic compliance requirements, but also required to have the qualifications regarding dangerous chemicals, special manufacturing industry. They need to provide proof of quality or production sales certificates granted by the manufacturer. They also shall comply with the requirements specified in Confidential Terms of the Chalco Electronic Procurement Platform and participate in the corresponding business skills training. | ||

In addition, Chalco has a well-established supplier evaluation system: Chalco is responsible for establishing supplier files which regularly record suppliers' strength, supply share, performance of contract and supplier rewards and discipline In the supplier annual evaluation report, it shows new suppliers and eliminated ones in the year, including suppliers' annual comprehensive evaluation results, rectification measures and recommendations, etc. Ultimately in accordance with the evaluation results, outstanding suppliers will be selected and withdrawn suppliers will be determined from the directory by the Company. | ||

5.1.2 | Suppliers Communication | |

Chalco has established three main ways of supplier maintenance when strengthening the daily communication with suppliers: 1) centralized purchasing from annual supplier meetings for raw and auxiliary materials, exchanging market information, and organizing market analysis of major products such as coal, caustic soda and petroleum coke; 2) selecting excellent suppliers on the basis of summarizing the procurement work in 2016 and consulting relevant opinions from them; 3) participating in the national coal trade fairs for thorough consultation and communication with coal enterprises. | ||

|

| ||

"Seminar for Chalco Key Suppliers and Market" Held in | Twenty-Three Companies Awarded to | ||

5.1.3 | Suppliers Support | |

The supplier is an important partner to Chalco. In line with the purposes of "long-term cooperation, mutual support, complementary advantages, and seeking common development", Chalco carries out all-round and multi-angle cooperation with its suppliers. At the same time, Chalco ensures long-term stable supply of raw materials and reduces purchasing costs. We also provides support and assistance to suppliers who are faced with difficulties on the basis of win-win cooperation. | ||

Case: Baotou Aluminum Gives Priority to Purchase Coal from Sujiagou Coal Mine | ||

In March 2016, because of the replacement of Sujiagou Coal Mine's replacement of its working area and the continuous slump in the coal market prices, Sujiagou Coal Mine faced poor production and management situations. In the understanding of its specific circumstances and according to the actual business development and the market-oriented principle, Baotou Aluminum, a subsidiary of Chalco purchased 60 thousand tons of coal from Sujiagou Coal Mine for two consecutive months. In addition to reducing the inventory pressure of Sujiagou Coal Mine and providing financial support for its replacement of working area, Baotou Aluminum also established a strategic partnership with Sujiagou Coal Mine. In August 2016, when Baotou Aluminum was facing a tight coal supply which might impose a serious threat to production safety, Sujiagou Coal Mine started a new working area and supplied 70% of its monthly coal production to Baotou Aluminum, which guaranteed the safe and stable production of Baotou Aluminum. | ||

5.1.4 | Supply Chain Management | |

In addition to strengthening the supervision and control of its own production and operation safety and environmental protection facilities, Chalco also set up requirements for the production and operation safety for the contractors of its construction projects. With the issuance and implementation of the Measures for Production and Operation Safety of Chalco and specific rules and regulations provided for the safety production management of construction projects, it has played a positive role in raising the safety and environmental awareness of suppliers, preventing occupational diseases and ensuring the safety and successful implementation of construction projects. | ||

Case: Chalco Trading Raw Material Center Promotes and Applies the Social Responsibility Management | ||

Chalco Trading Raw Material Center affiliated to Chalco adheres to the implementation and promotion of the social responsibility management module for the supply chain to promote the supply chain members to jointly fulfill their social responsibilities. The module requires suppliers to include social responsibilities into their daily work, to sign the Letter of Responsibility for Integrity, to strictly abide by the social responsibility management system and Chalco's related management systems. At the same time, it also carries forward the spirit of the contract and actively promotes the business philosophy. It gives full play to the advantages of a centralized purchasing and ensures the stable operation of enterprises. It also regulates the supplier access mechanism and raises the awareness of the concept of social responsibilities. | ||

|

| ||

The signing ceremony between Chalco Trading and | Suppliers site visit in Liancheng Branch | ||

5.2 | STRENGTHEN CLIENT RELATIONSHIP |

Chalco always adheres to the client-oriented principle and carries out in-depth and strengthened communication with clients to understand their needs and provide them with high quality and efficient services. At the same time, Chalco takes helping clients' development as one important goal of serving clients, facing the ever-changing market environment together with clients. It provides customized high quality products in accordance with client demands, jointly developing new aluminum products with products for mutual benefits and common growth. | |

Chalco conducts centralized and unified management to our main products such as aluminum and alumina, and separating management responsibility and operation responsibility for marketing. We strictly comply with the national product quality related regulations and our internal industrial standards for aluminum and alumina, to ensure our products quality. Our headquarters set up marketing & purchasing department to be responsible for making relevant guidelines of marketing, establishing marketing management system, making sales plan, risk control and coordination of marketing operations. | |

5.2.1 | Provide High Quality Products | |

Chalco has a well-established quality management system involving all links, including procurement of materials, production and manufacturing, and ex-factory and after-sale services to ensure reliable and high quality of products. In addition, Chalco also entrusts the National Light Metal Quality Supervision and Inspection Center to entrust the national quality inspection authorities to carry out field visit at production sites for equipment detection, implementation of standards, and integrity of original records, sampling and other aspects to verify the quality of products. The focus of the spot checks includes finished alumina, prebaked anode, cathode carbon block, remelting aluminum ingot, quality of aluminum and aluminum alloy ingot and alumina analysis and test capabilities of electrolytic aluminum companies. Twelve spot checks are arranged for alumina production companies, including 6 on-site checks at the production company and 6 at the user company. One spot check is arranged for other products. | ||

In 2016, Chalco's first-grade rate of alumina reached 96.72%, an increase of 5.81% compared to 2015; the second-grade rate reached 100%; the alumina-45um rate reached 15.86%, which has superior to the indicators of the first-grade metallurgical alumina in the nonferrous metals industry. In 2016, Chalco's 99.70% or above original liquid of electrolytic aluminum reached 96.67%, an increase of 2.11% compared to 2015. 99.9% above aluminum ingot reached 99.9%; Fe content of the original aluminum liquid was gradually reduced to 0.132%, which was 0.005% less than that in 2015. | ||

|

| ||

A Discussion Meeting between Chalco and | Alumina Contract Signing Ceremony for Chalco Trade | ||

5.2.2 | Improve Client Service | |

Chalco pays high attention to strengthen and deepen the communication with clients. It is stably based on different needs and characteristics to deepen their awareness of our existing products and to better understand their needs for the purpose of improving client service experience. Chalco has established five online and offline client communication channels: regular holding of key client summit forum for alumina and aluminum products to understand customer needs, communicating how to respond to market changes and consolidate the relationship; setting up "Aluminum Daniu Offer" WeChat Public Account to push daily offers for aluminum ingot; relying on brand benefits of Chalco, it is to raise the public awareness of our products via Chalco's official website, the third-party platform websites, mailing of brochures, and promotional videos, etc; participating in professional exhibitions for thorough communication with upstream and downstream clients; to maintain client relationship by attending in specific business activities, telephone publicity, client visit, and field visits of downstream clients' production sites. | ||

At the same time, Chalco has set up pre-sale, sale and after-sales service management system to improve consumer complaints and solutions channels, working with clients to solve problems, and strives to enhance client satisfaction by providing good products and services. In addition, we also investigate client satisfaction in the form of questionnaires in line with ISO9001 management system. The enterprise and clients could have regular communication and exchange their opinions when they meet some problem during the cooperation. The feasible solutions and measures can be proposed by discussion. It also consolidates and develops cooperation between both sides, and builds a solid foundation for the development of enterprise. | ||

Case: Baotou Aluminum Improved the Client Service Mode | ||

During the process of market development, according to a client's special demands, Baotou Aluminum improved its service mode, including removing rust of packing steel strip before product delivery, changing ingot shape for adapting to the fork truck, controlling trace elements (Mg), transportation cycle, delivery methods, etc. Multiple return visits after the sale of the product and timely on-site service had been highly recognized by users. The volume of monthly order increased gradually from 300 tons to 1,800–2,000 tons, it achieved win-win effect. | ||

|

| ||

Client Communication in Baotou Branch | Client's on-the-spot investigation in Batou Branch's warehouse | ||

5.2.3 | Grow with Clients | |

Chalco profoundly investigated client demands and jointly developed suitable products for clients in different fields. It continuously improves product technologies to meet market demands. At the same time of achieving sales growth, it also promotes the market to apply aluminum products for common development with clients. | ||

Case: Shandong Huayu and Suzhou Institute of Nonferrous Metals Co., Ltd. Worked Together and Successfully | ||

Shandong Huayu and Suzhou Institute of Nonferrous Metals Co., Ltd. carried out a research on 6000 series aluminum alloy in 2016. They overcame the "black line" – an industrial difficulty and successfully developed the high-end 6000 series aluminum alloy including the surface material for mobile phones. It was put into mass production in April for supply. With continuous subsequent improvement, the conformance rate climbed and ultimately reached a stable rate of 95% or more. In 2016, a total of 4,713 tons was sold. | ||

|

| ||

6000 Series Aluminum Alloy for Mobile Phone Shell Jointly Made by Shandong Huayu | |||

Case: Guizhou Branch and Shanxi Huaze Worked with Chalco-Sapa and Developed Large-Diameter Aluminum | ||

In 2016, Guizhou Branch and Shanxi Huaze made a breakthrough regarding the production of large-sized alloy rods upon the requests of Chalco Sapa Special Aluminum (Chongqing) Co., Ltd. They successfully developed the large-diameter aluminum alloy rods for track and construction, respectively. The new products have extended the industrial chain, improved the market competitiveness, and achieved common growth with clients. In 2016, 1,013 tons and 1,796 tons alloy were sold respectively by Guizhou Branch and Shanxi Huaze. | ||

| ||

Products of Guizhou Branch | ||

| ||

Products of Shanxi Huaze | ||

5.3 | ENCOURAGE INNOVATIONS AND PROMOTE INDUSTRY DEVELOPMENT |

In 2016, Chalco has achieved fruitful science and technology outcomes by insisting on the scientific and technological development as the driving force, continuing to improve the Company's science and technology innovation system, strengthening its independent innovation capacity, and improving its capacity to transfer its science and technology research results into actual practice. Although the Company has reached the international leading level in its production technologies in the field of aluminum smelt, the Company tries to make good use of technological innovations to support its industry upgrading, structural adjustment and strategy transformation, therefore laying a solid technological foundation for the Company to become a world's top-tier global company with innovative capability and international competitiveness. | |

5.3.1 | Participation in the Industry Standard Setting | |

Since Chalco was founded, Chalco has always deemed its duty to lead the industry to develop in an orderly and regular fashion, participating in the industry standard setting and amendments for many times. In 2016, Chalco has set and amended 37 standards and participated in the setting and amendments of 14 national and industry standards. | ||

Case: Chalco Participated in the Amendment of National Standard Aluminum Alloy Ingots for Casting | ||

As the only guiding fundamental standard in the casting aluminum alloy industry, the GB/T8733-2016 Aluminum Alloy Ingots for Casting could not meet the needs of the market in terms of its content and varieties covered due to the development of foundry industry and higher market demands. In 2016, Chalco led other domestic institute to make amendments to the GB/T8733Aluminum Alloy Ingots for Casting and set the new standard GB/T8733-2016. The new standard, which had been promulgated and implemented, has strengthened requirements for performance of casting aluminum alloy in China, improved the quality, mechanical properties, and test level of aluminum alloy ingots for casting, as well as expanded its use in the automobile industry, therefore promoting China's international status in the casting aluminum alloy industry, and the competitiveness of China's casting aluminum alloy companies and their relevant companies. | ||

Case: Chalco Participated in Amending the Industry Standard The Test Methods of Carbon Materials for | ||

Chalco led and completed the amendment to the original YS/T63.3-2006Test Methods of Carbon Materials for Aluminum Part 3: Comparison of Determination of Thermal Conductivity and set the new standard YS/T63.3-2015. The new standard, which had been promulgated and implemented, has expanded the scope of determination of thermal conductivity in carbon materials for aluminum, as well as been applied in the determination of thermal conductivity for common carbon block, high graphite and graphitized cathode carbon block, therefore meeting the needs of our nation's electrolytic aluminum companies, carbon production and trade, and promoting the product upgrading and technological progress in the carbon industry. | ||

5.3.2 | Achievement of National Major Science and Technology Awards | |

Chalco has made a range of major science and technology achievements with independent intellectual property rights by improving its science and technology innovation system, and strengthening its independent innovation capacity. In 2016, the Company has filed 109 patent applications, 41 of which belonged to major projects and 88 were granted. By the end of 2016, the Company had possessed 1,472 granted patents. In the meantime, the Company has won multiple national and the industry's major science and technology awards. In 2016, the Company has been awarded one China Patent Award, one first prize, four second prize, five third prize of the China Nonferrous Metals Industry Science and Technology Award. It also has won 11 Science and Technology Progress Awards as a cooperation unit by the same industry above. | ||

Case: "The Development, Spread and Application of New Type Constant-Current and Well-Insulated Energy | ||

This newly-developed technology established the constant-current model of aluminum liquid, cathode block, steel bar and their assembly's synchronized and optimized combination, created a new design thinking for electrolytic cells' energy balance, developed a constant-current high conductivity steel bar for the first time, and solved the technological problems in that 1) aluminum electrolytic cells are hard to arrive at high current efficiency at low voltages; 2) electrolytes are difficult to maintain and operate with high probability of early damage and short live of cells. In addition, this technology has achieved excellent energy-saving results in a variety of aluminum electrolytic cells with technological maturity and strong applicability, therefore having a high application value. This technology has significantly reduced not only the DC power consumption of aluminum liquid, but also the emission of carbon dioxide, further promoting our nation's energy-saving and environmental protection technical level, and the international competitiveness of Chalco. Having been applied in the entire industry with capacity at 32 million tons, it could directly produce the energy-saving benefit at 7.68 billion Yuan per year with the CO2 emission reduction equivalency at the amount of 16.8 million tons per year, which would be of strategic significance in terms of the nation's energy conservation and emissions reduction, environmental protection and science development. | ||

The technology has formed 12 patents, 10 of which are patents for invention, and the remaining two are utility model patents. Nine research papers have been published in the core journals. The Company's chief engineer team led more than 40 researchers to work on this new technology with more than 30 million Yuan spent on it. | ||