|

Nova Gold Resources Inc.

Donlin Creek Gold Project,

Alaska, USA

NI 43-101 Technical Report

Prepared for Nova Gold Resources Inc. by:

Kirk Hanson P.E.

Gordon Seibel M.AusIMM.

Simon Allard, P.Eng.

Gregory Wortman P.Eng.

Alexandra Kozak P.Eng.

Effective Date: 1 April, 2009

160638

![]()

CERTIFICATE OF QUALIFIED PERSON

Kirk Hanson, P.E.

AMEC E&C Services, Inc.

780 Vista Blvd., Suite 100

Sparks, NV., 89434

Tel 775 997 6559

Fax: 775-331-4153

E-mail: kirk.hanson@amec.com

I, Kirk Hanson, P.E., am employed as a Principal Engineer with AMEC E&C Services Inc.

This certificate applies to the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” dated 1 April 2009 (the Technical Report).

I am a registered Professional Engineer in the states of Idaho (11063) and Nevada (10640).

I graduated with a B.Sc. degree from Montana Tech of the University of Montana, Butte, Montana in 1989 and from Boise State University, Boise, Idaho with a MBA in 2003.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101Standards of Disclosure for Mineral Projects(NI 43–101).

I visited the Donlin Creek Gold Project on 1 October 2008.

I am responsible for Sections 1, 2, 3, 4, 5, 6, 17.2, 18.1 to 18.8, 19, 20, 21, 22, and 23 and those portions of the summary, conclusions and recommendations that pertain to those sections of the Technical Report.

I am independent of NovaGold Resources Inc. as independence is described by Section 1.4 of NI 43–101.

I have been involved with the Donlin Creek Gold Project since October 2008 as part of preparation of this Technical Report.

I have read NI 43–101 and this Technical Report has been prepared in compliance with that Instrument.

As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

“signed and sealed”

Kirk Hanson, P.E.

Dated: 2 June 2009

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CERTIFICATE OF QUALIFIED PERSON

Gordon Seibel, M.AusIMM..

AMEC E&C Services, Inc.

780 Vista Blvd., Suite 100

Sparks, NV., 89434

Tel 775 997 6559

Fax: 775-331-4153

E-mail: gordon.seibel@amec.com

I, Gordon Seibel, M.AusIMM, am employed as a Principal Geologist with AMEC E&C Services Inc..

This certificate applies to the Technical report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” dated 1 April 2009 (the Technical Report).

I am a Corporate Member of the Australasian Institute of Mining and Metallurgy (AusIMM # 223092). I graduated from the University of Colorado with a Bachelor of Arts degree in Geology in 1980. In addition, I obtained a Masters of Science degree in Geology from Colorado State University in 1991.

I have practiced my profession for 29 years. I have been directly involved in the development of resource models and mineral resource estimation for gold projects in Colorado, Nevada, California, Canada, Mexico, Peru, and Australia since 1991.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101Standards of Disclosure for Mineral Projects(NI 43–101).

I visited the Donlin Creek property on 1 October 2008.

I am responsible for Sections 7, 8, 9, 10, 11, 12, 13, 14, 15, 17.1 and those portions of the summary, conclusions and recommendations that pertain to those sections of the Technical Report.

I am independent of NovaGold Resources Inc. as independence is described by Section 1.4 of NI 43–101.

I have been involved with the Donlin Creek Gold Project since October 2008 as part of preparation of this Technical Report.

I have read NI 43–101 and this Technical Report has been prepared in compliance with that Instrument.

As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

“Signed”

Gordon Seibel, M.AusIMM

Dated: 2 June 2009

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CERTIFICATE OF QUALIFIED PERSON

Simon Allard, P.Eng.

AMEC Americas Limited

111 Dunsmuir Street, Suite 400

Vancouver, BC

Tel: (604) 664-4578

Fax: (604) 664-3057

simon.allard@amec.com

I, Simon Allard P.Eng, am employed as a Financial Analyst with AMEC Americas Limited.

This certificate applies to the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” dated 1 April 2009 (the Technical Report).

I am a registered Professional Engineer in the Province of British Columbia. I graduated from Université Laval in 2004 with a Baccalauréat coopératif en génie des mines et de la minéralurgie degree.

I have practiced my profession for five years. I have been directly involved in cash-flow modelling, risk evaluation, real-options valuation, financial analysis, marketing studies and financial review of mines including Araguaia (base metals) in Brazil, Oyu Tolgoi (copper-gold) in Mongolia, Gibellini (vanadium) in Nevada, Bisha (polymetallic) in Eritrea, Gaho Kue (diamonds) in NWT and Gurupi (gold) in Brazil.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101Standards of Disclosure for Mineral Projects(NI 43–101).

I have not visited the Donlin Creek Gold Project.

I am responsible for Sections 18.9 to 18.12, and those portions of the summary, conclusions and recommendations that pertain to those sections of the technical report titled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”).

I am independent of NovaGold Resources Inc. as independence is described by Section 1.4 of NI 43–101.

I have been involved with the Donlin Creek Gold Project since October 2008 as part of preparation of this Technical Report.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I have read NI 43–101 and this Technical Report has been prepared in compliance with that Instrument.

As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

“Signed and sealed”

Simon Allard, P.Eng.

Dated: 2 June 2009

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CERTIFICATE OF QUALIFIED PERSON

Gregory Wortman, P.E.

AMEC International (Chile) S.A

Americo Vespucio Sur 100, Oficina 203

Las Condes, Santiago, Chile

Tel: (562) 210-9500

Fax: (562) 210-9510

gregory.wortman@amec.com

I, Gregory Wortman, P.Eng., am employed as a Technical Director, Process with AMEC Americas Limited..

This certificate applies to the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” dated 1 April 2009 (the Technical Report).

I am a member of Professional Engineers, Ontario. I graduated from the Technical University of Nova Scotia in 1968.

I have practiced my profession for 40 years. I have been directly involved in design and operation of a number of pressure oxidation autoclave hydrometallurgical facilities during that period.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101Standards of Disclosure for Mineral Projects(NI 43–101).

I have not visited the Donlin Creek Gold Project.

I am responsible for Section 16.1.3 of the Technical Report.

I am independent of NovaGold Resources Inc. as independence is described by Section 1.4 of NI 43–101.

I have been involved with the Donlin Creek Gold Project since October 2008 as part of preparation of this Technical Report.

I have read NI 43–101 and this Technical Report has been prepared in compliance with that Instrument.

As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

“Signed and sealed”

Gregory Wortman, P.Eng.

Dated: 2 June 2009

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CERTIFICATE OF QUALIFIED PERSON

Alexandra J. Kozak, P.Eng.

AMEC Americas Limited

111 Dunsmuir Street, Suite 400

Vancouver, BC

Tel: (604) 664-4578

Fax: (604) 664-3057

alexandra.kozak@amec.com

I, Alexandra J. Kozak, P.Eng., am employed as Manager, Process Engineering with AMEC Americas Limited.

This certificate applies to the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” dated 1 April 2009 (the Technical Report).

I am a member of the Association of Professional Engineers and Geoscientists of British Columbia (APEGBC). I graduated from the University of Alberta with a Bachelor of Science degree in Mineral Process Engineering in 1985.

I have practiced my profession continuously since 1985 and have been involved in operations in Canada and Guyana and preparation of scoping, pre-feasibility, and feasibility level studies for gold, base metals and diamond properties in Canada, United States, Peru, Mexico, Mongolia, Ghana, and New Guinea. I am currently a Consulting Engineer and have been so since September 1996.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101Standards of Disclosure for Mineral Projects(NI 43–101).

I have not visited the Donlin Creek Gold Project.

I am responsible for Sections 16.1.1, 16.1.2, and 16.1.4 to 16.3 of the Technical Report and those portions of the summary, conclusions and recommendations that are based on that section.

I am independent of NovaGold Resources Inc. as independence is described by Section 1.4 of NI 43–101.

I have been involved with the Donlin Creek Gold Project since October 2008 as part of preparation of this Technical Report.

I have read NI 43–101 and this Technical Report has been prepared in compliance with that Instrument.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

As of the date of this certificate, to the best of my knowledge, information and belief, the Technical Report contains all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

“Signed and sealed”

Alexandra J. Kozak, P.Eng.

Dated: 2 June 2009

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CONSENT OF QUALIFIED PERSON

Kirk Hanson, P.E.

AMEC E&C Services, Inc.

780 Vista Blvd., Suite 100

Sparks, NV., 89434

Tel 775 997 6559

Fax: 775-331-4153

kirk.hanson@amec.com

| To: | Securities Regulatory Authority |

| British Columbia Securities Commission | |

| Alberta Securities Commission | |

| Saskatchewan Financial Services Commission | |

| Manitoba Securities Commission | |

| Ontario Securities Commission | |

| Autorité des marchés financiers du Quebec | |

| New Brunswick Securities Commission | |

| Nova Scotia Securities Commission | |

| Securities Office, Prince Edward Island | |

| Securities Commission of Newfoundland and Labrador |

Re: NovaGold Resources Inc., Press Release Dated 28 April 2009 Entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”

I, Kirk Hanson, P.E. consent to the public filing of Sections 1, 2, 3, 4, 5, 6, 17.2, 18.1 to 18.8, 19, 20, 21, 22, and 23 and those portions of the summary, conclusions and recommendations that pertain to those sections, of the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”).

I consent to extracts from, or a summary of, the Technical Report in the NovaGold Resources Inc. press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves” (the “Press Release”) and dated 28 April 2009.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I confirm that I have read the Press Release and that it fairly and accurately represents the information in the Technical Report that supports the disclosure.

“signed and sealed”

| Kirk Hanson | 2 June, 2009 |

| Signed | Dated |

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CONSENT OF QUALIFIED PERSON

Gordon Seibel, M.AusIMM..

AMEC E&C Services Inc.

780 Vista Blvd., Suite 100

Sparks, NV., 89434

Tel (775) 331 2375

Fax (775) 331 4153

E-mail: gordon.seibel@amec.com

| To: | Securities Regulatory Authority |

| British Columbia Securities Commission | |

| Alberta Securities Commission | |

| Saskatchewan Financial Services Commission | |

| Manitoba Securities Commission | |

| Ontario Securities Commission | |

| Autorité des marchés financiers du Quebec | |

| New Brunswick Securities Commission | |

| Nova Scotia Securities Commission | |

| Securities Office, Prince Edward Island | |

| Securities Commission of Newfoundland and Labrador |

Re: NovaGold Resources Inc., Press Release Dated 28 April 2009 Entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”

I, Gordon Seibel, M.AusIMM, consent to the public filing of Sections 7, 8, 9, 10, 11, 12, 13, 14, 15, and 17.1, and those portions of the summary, conclusions and recommendations that pertain to those sections of the technical report titled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”).

I consent to extracts from, or a summary of, the Technical Report in the NovaGold Resources Inc. press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves” (the “Press Release”) and dated 28 April 2009.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I confirm that I have read the Press Release and that it fairly and accurately represents the information in the Technical Report that supports the disclosure.

“signed”

| Gordon Seibel, M.AusIMM | 2 June 2009 |

| Signed | Dated |

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CONSENT OF QUALIFIED PERSON

Simon Allard, P.Eng.

AMEC Americas Limited

111 Dunsmuir Street, Suite 400

Vancouver, BC

Tel: (604) 664-4578

Fax: (604) 664-3057

simon.allard@amec.com

| To: | Securities Regulatory Authority |

| British Columbia Securities Commission | |

| Alberta Securities Commission | |

| Saskatchewan Financial Services Commission | |

| Manitoba Securities Commission | |

| Ontario Securities Commission | |

| Autorité des marchés financiers du Quebec | |

| New Brunswick Securities Commission | |

| Nova Scotia Securities Commission | |

| Securities Office, Prince Edward Island | |

| Securities Commission of Newfoundland and Labrador |

Re: NovaGold Resources Inc., Press Release Dated 28 April 2009 Entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”

I, Simon Allard, P.Eng. consent to the public filing of Sections 18.9 to 18.12, and those portions of the summary, conclusions and recommendations that pertain to that section of the technical report titled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”).

I consent to extracts from, or a summary of, the Technical Report in the NovaGold Resources Inc. press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves” (the “Press Release”) and dated 28 April 2009.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I confirm that I have read the Press Release and that it fairly and accurately represents the information in the Technical Report that supports the disclosure.

“signed and sealed”

| Simon Allard, P.Eng. | 2 June, 2009 |

| Signed | Dated |

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CONSENT OF QUALIFIED PERSON

Gregory Wortman, P.E.

AMEC International (Chile) S.A

Americo Vespucio Sur 100, Oficina 203

Las Condes, Santiago, Chile

Tel: (562) 210-9500

Fax: (562) 210-9510

gregory.wortman@amec.com

| To: | Securities Regulatory Authority |

| British Columbia Securities Commission | |

| Alberta Securities Commission | |

| Saskatchewan Financial Services Commission | |

| Manitoba Securities Commission | |

| Ontario Securities Commission | |

| Autorité des marchés financiers du Quebec | |

| New Brunswick Securities Commission | |

| Nova Scotia Securities Commission | |

| Securities Office, Prince Edward Island | |

| Securities Commission of Newfoundland and Labrador |

Re: NovaGold Resources Inc., Press Release Dated 28 April 2009 Entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”

I, Gregory Wortman, P.E. consent to the public filing of Section 16.1.3 and those portions of the summary, conclusions and recommendations that pertain to that section, of the Technical Report entitled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”).

I consent to extracts from, or a summary of, the Technical Report in the NovaGold Resources Inc. press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves” (the “Press Release”) and dated 28 April 2009.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I confirm that I have read the Press Release and that it fairly and accurately represents the information in the Technical Report that supports the disclosure.

“signed and sealed”

| Gregory Wortman | 2 June, 2009 |

| Signed | Dated |

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

CONSENT OF QUALIFIED PERSON

Alexandra J. Kozak, P.Eng.

AMEC Americas Limited

111 Dunsmuir Street, Suite 400

Vancouver, BC

Tel: (604) 664-4578

Fax: (604) 664-3057

alexandra.kozak@amec.com

| To: | Securities Regulatory Authority |

| British Columbia Securities Commission | |

| Alberta Securities Commission | |

| Saskatchewan Financial Services Commission | |

| Manitoba Securities Commission | |

| Ontario Securities Commission | |

| Autorité des marchés financiers du Quebec | |

| New Brunswick Securities Commission | |

| Nova Scotia Securities Commission | |

| Securities Office, Prince Edward Island | |

| Securities Commission of Newfoundland and Labrador |

Re: NovaGold Resources Inc., Press Release Dated 28 April 2009 Entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”

I, Alexandra Kozak, P.Eng. consent to the public filing of Sections 16.1.1, 16.1.2, and 16.1.4 to 16.3, and those portions of the summary, conclusions and recommendations that pertain to that section of the technical report titled “NovaGold Resources Inc., Donlin Creek Gold Project, Alaska, USA, NI 43-101 Technical Report” and dated 1 April 2009, (the “Technical Report”)..

I consent to extracts from, or a summary of, the Technical Report in the NovaGold Resources Inc. press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves” (the “Press Release”) and dated 28 April 2009.

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

![]()

I confirm that I have read the Press Release and that it fairly and accurately represents the information in the Technical Report that supports the disclosure.

“signed and sealed”

| Alexandra Kozak, P.Eng. | 2 June 2009 |

| Signed | Dated |

| AMEC E&C Services, Inc. | ||

| 780 Vista Boulevard | ||

| Sparks, NV, 89434 | ||

| Tel (775) 331 2375 | ||

| Fax (775) 331 4153 | www.amec.com |

IMPORTANT NOTICE

This report was prepared as a National Instrument 43-101 Technical Report for NovaGold Resources Inc. (NovaGold) by AMEC Americas Limited (AMEC). The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in AMEC’s services, based on: i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by NovaGold subject to the terms and conditions of its contract with AMEC. This contract permits NovaGold to file this report as a Technical Report with Canadian Securities Regulatory Authorities pursuant to National Instrument 43-101,Standards of Disclosure for Mineral Projects. Except for the purposes legislated under provincial securities law, any other uses of this report by any third party is at that party’s sole risk.

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| CO N T E N T S |

| Project No.: 160638 | ||

| April 2009 | TOC i |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Project No.: 160638 | ||

| April 2009 | TOC ii |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Project No.: 160638 | ||

| April 2009 | TOC iii |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Project No.: 160638 | ||

| April 2009 | TOC iv |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| TA B L E S |

| Project No.: 160638 | ||

| April 2009 | TOC v |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| FI G U R E S |

| Project No.: 160638 | ||

| April 2009 | TOC vi |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Project No.: 160638 | ||

| April 2009 | TOC vii |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 1.0 | SUMMARY | ||

AMEC Americas Limited (AMEC) was commissioned by NovaGold Resources Inc. (NovaGold), to provide an independent Qualified Person’s Review and Technical Report (the Report) for the Donlin Creek Gold Project (the Project) located in Alaska, USA. | |||

AMEC understands that this Report will be used by NovaGold in support of a NovaGold press release dated 28 April 2009, entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”. | |||

The Project is a joint venture between NovaGold Resources Alaska, Inc., a wholly owned subsidiary of NovaGold, and Barrick Gold U.S. Inc., a wholly-owned subsidiary of Barrick Gold Corporation. For the purposes of this report, the name “NovaGold” refers interchangeably to the NovaGold subsidiary and parent companies; and the name “Barrick” refers interchangeably to the Barrick subsidiary and parent companies. During 2006, Barrick acquired Placer Dome Inc., which had held an interest in the Project between 1995 and 2006 through its wholly-owned subsidiary, Placer Dome US Inc. For the purposes of this report, the name “Barrick” also refers interchangeably to Placer Dome Inc. and to Placer Dome US Inc. when reference is made to the manager of work undertaken on the Project between 1995 and 2000, and between 2003 and 2006. On 1 December 2007, NovaGold entered into a limited liability company agreement with Barrick that provided for the conversion of the Project into a new limited liability company, the Donlin Creek LLC (DCLLC), which is jointly owned by NovaGold and Barrick on a 50/50 basis. The limited liability company agreement provides that information obtained in connection with the performance of the agreement, which includes information developed by, or on behalf of the DCLLC, may be disclosed by either NovaGold or Barrick, or affiliates of either, where such disclosure is required by law or to meet stock exchange requirements, including for purposes of a technical report required under National Instrument 43–101, Standards of Disclosure for Mineral Projects (NI 43–101). | |||

| 1.1 | Principal Outcomes | ||

Proven and Probable Mineral Reserves estimated for 29.3 Moz contained gold: | |||

– | Proven Mineral Reserves: 8.4 Mt at 2.59 g/t Au (0.7 Moz contained gold) | ||

– | Probable Mineral Reserves: 375 Mt at 2.37 g/t Au (28.6 Moz contained gold) | ||

| Project No.: 160638 | ||

| April 2009 | Page 1-1 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

21 year mine life at 53,500 t/d throughput | |||

| Average annual gold production: | |||

– | 1.25 Moz over the projected life of mine | ||

– | 1.5 Moz over the first full 10 years | ||

– | 1.6 Moz over the first full 5 years | ||

Total predicted total cash costs: | |||

| – | $467/oz1 gold over the life of mine | ||

| – | $442/oz over the first full 10 years | ||

| – | $394/oz over the first full 5 years | ||

| Cumulative net present after-tax cash flow (net present value (NPV) 5%) | |||

| – | At $725/oz gold price (Base Case) minus $733 million | ||

| – | At $900/oz gold price (Alternative Case 1) $829 million | ||

| – | At $1,000/oz gold price (Alternative Case 2) $1,674 million | ||

| Average annual cash flow for first full five years of production2 | |||

| – | At $725/oz gold price $521 million | ||

| – | At $900/oz gold price $790 million | ||

| – | At $1,000/oz gold price $944 million | ||

| At $725/oz gold price, undiscounted cumulative pre-tax net cash flow is $1.5 billion, pre-tax NPV 5% is minus $592 million, with a pre-tax internal rate of return (IRR) of 3% | ||

| At current gold prices of $900/oz, undiscounted cumulative pre-tax net cash flow is $5.9 billion, pre-tax NPV 5% is $1.5 billion with a pre-tax IRR of 9.4% | ||

| At a gold price of $1,000/oz, undiscounted cumulative pre-tax net cash flow is $8.4 billion, pre-tax NPV 5% is $2.7 billion with a pre-tax IRR of 12.3% | ||

| Increase in contained gold ounces of 3.6 Moz in Proven and Probable Mineral Reserve and Measured and Indicated Mineral Resources over the previous Measured and Indicated Mineral Resource estimate of 10 June 2008 |

____________________________________________

1 All dollar figures quoted in this summary are in U.S. dollars.

2 Total revenues minus total operating costs and royalties before interest, taxes, depreciation and amortization.

| Project No.: 160638 | ||

| April 2009 | Page 1-2 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 1.2 | Location and Access |

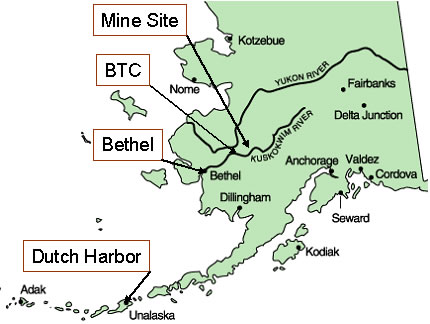

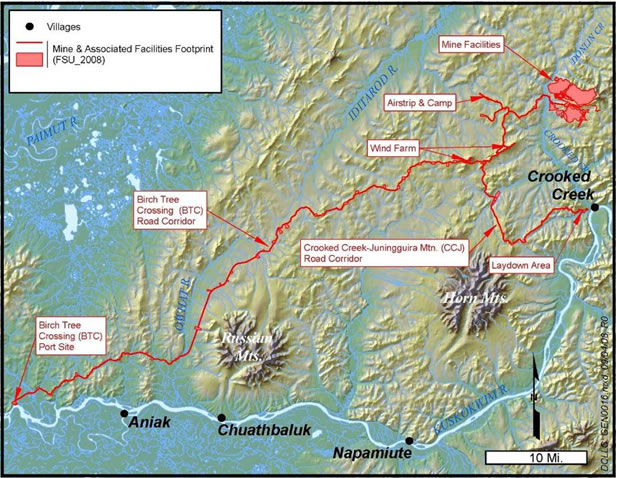

Donlin Creek is located in southwest Alaska in the United States of America, approximately 80 km northeast of Aniak, a regional hub, and approximately 20 km north of the village of Crooked Creek on the Kuskokwim River. The Kuskokwim River is a regional transportation route and is serviced by commercial barge lines. | |

There is no road or rail access to the site and therefore all personnel and supplies are transported by air. An airstrip 1,500 m long is located adjacent the exploration camp and is capable of handling aircraft as large as C-130 Hercules. The project can be serviced directly by charter air facilities out of both Anchorage and Aniak. | |

At present, the project is isolated from power and all other public infrastructure. Planned infrastructure to support proposed mining operations will include, in addition to the future plant site at the mine, a wind farm, an airstrip, barge terminals at Bethel and Birch Tree Crossing (BTC), construction of major receiving, storage, and transfer facilities at different locations in Alaska en-route to the mine, mine access road development, and a fuel pipeline. |

| 1.3 | Tenure and Surface Rights |

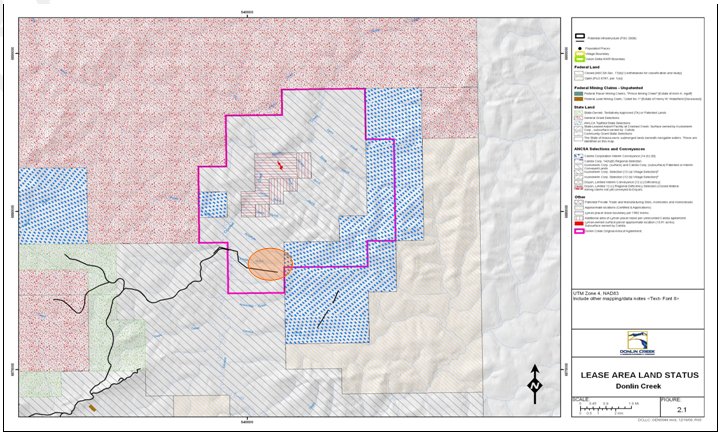

The Donlin Creek exploration and mining lease currently includes a total of 42 sections leased from Calista Corporation (Calista), a regional Native corporation. Calista holds the subsurface (mineral) estate for Native-owned lands in the region. Title to all these sections was conveyed to Calista by the Federal Government. Calista owns the surface estate on nine of these 42 sections. A separate surface use agreement for access and surface rights is in place with The Kuskokwim Corporation (TKC) that owns the majority of the surface estate of the remaining 33 sections. The surface use agreement grants non-exclusive surface use rights to the DCLLC. All of these sections have now been conveyed to Calista/TKC by the Federal Government. | |

The currently identified Mineral Resource and the bulk of the primary infrastructure sites (mill and waste rock facilities) are located on leased lands that were conveyed. Lands required for the BTC port site, access road, wind farm power facilities, tailings storage facility in Anaconda Creek, and airstrip are located on a combination of Native-conveyed, Native-selected, and State of Alaska-selected lands, and additional negotiations will be required. A right-of-way will also be required from the State of Alaska for the proposed road alignment where it crosses State lands. |

| Project No.: 160638 | ||

| April 2009 | Page 1-3 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 1.4 | Agreements |

The DCLLC operates under an exploration and mining lease from the Calista Corporation. A separate Surface Use Agreement with the TKC grants non-exclusive surface use rights to the DCLLC. This can be converted to an exclusive use right under the existing agreement. | |

The Calista agreement includes staged royalty provisions, with payments tied to various stages of Project development and production. Calista also has the right to acquire an equity interest in the Project of up to 15%. Calista shareholders have a hiring preference and Calista has a 5% bidding preference on competitive contracts for all work on or for the project. | |

The TKC agreement provides for an annual aggregate surface use fee of $50,000. Once exclusive-use lands are identified, payment of an annual exclusive-use fee of 10% of the fair market value of the property is required. At TKC’s request, this may be converted into an outright property purchase. | |

Lyman Resources has existing placer mining leases covering approximately four square miles within the Donlin lease area. |

All exploration activities on leased lands are covered under the terms of the lease agreement with Calista and the surface use agreement with TKC. Activities on Native-owned lands not currently within the agreement, or on state and federal lands, are permitted on an individual basis as required. Drilling operations on the project are covered under the Alaska Placer Mining Application process and related permits. | |

The proposed Donlin Creek operation will require a considerable number of permits and authorizations from both federal and state agencies. | |

| 1.5 | Environmental Studies |

Baseline environmental studies commenced in 1996, comprising water quality studies, meteorology, aquatic studies in the main drainages, wetlands delineation in the areas of the Mineral Resource estimates and some waste rock characterization. During 2003, the baseline program was expanded, and included ambient air monitoring, terrestrial wildlife and avian surveys, groundwater monitoring, detailed aquatic studies, cultural site surveys, detailed waste rock characterization and additional wetlands delineation. Feedback from regulatory and public consultation resulted in additional studies to review the impact of mercury use and the impact of barge traffic on subsistence fishing and river erosion. |

| Project No.: 160638 | ||

| April 2009 | Page 1-4 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

The Environmental Management System (EMS) and permit review process will determine the precise number of management plans required to address all aspects of the project to ensure compliance with environmental design and permit criteria. | |

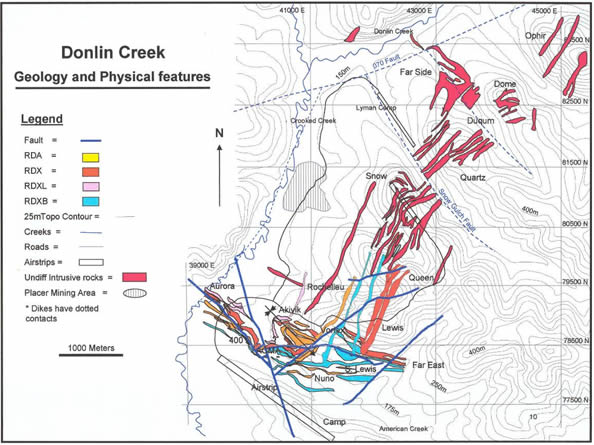

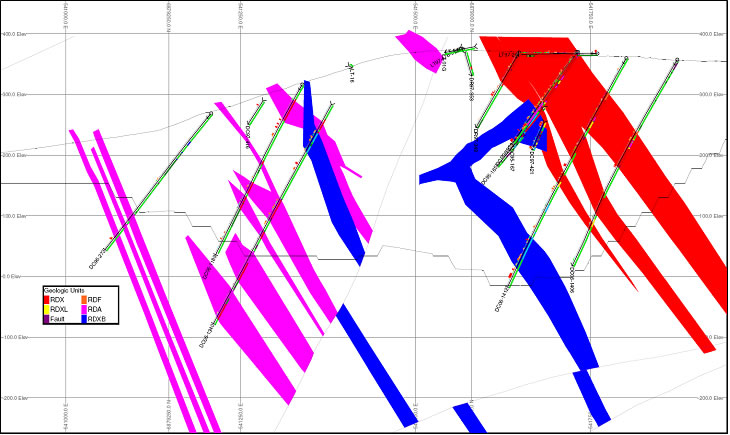

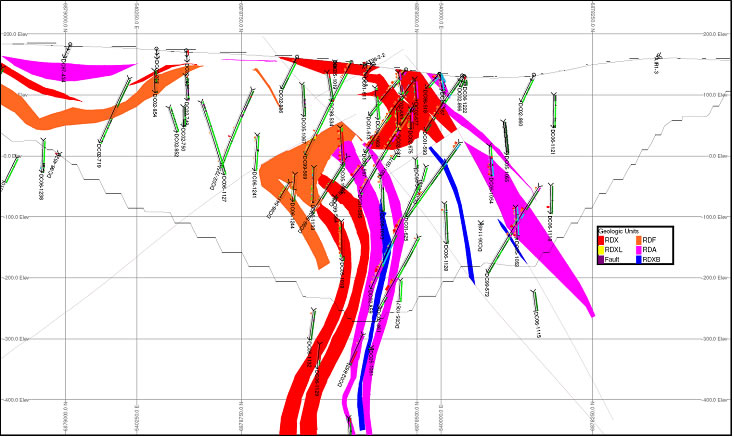

| 1.6 | Geology and Mineralization |

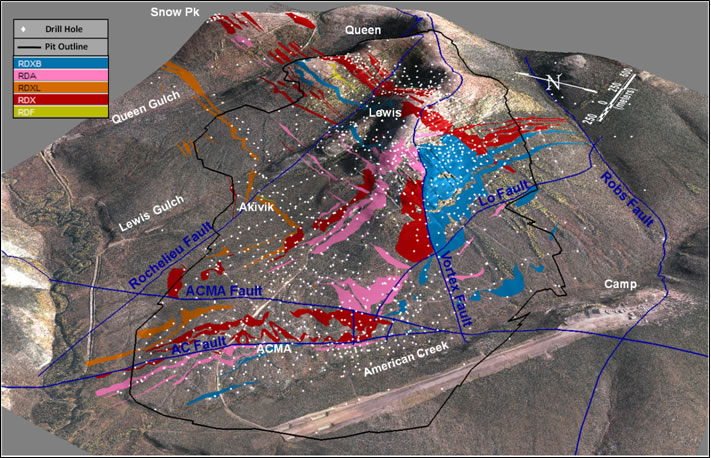

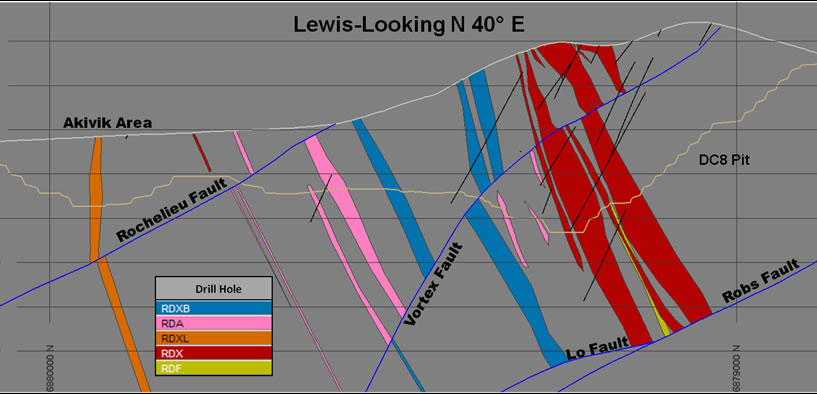

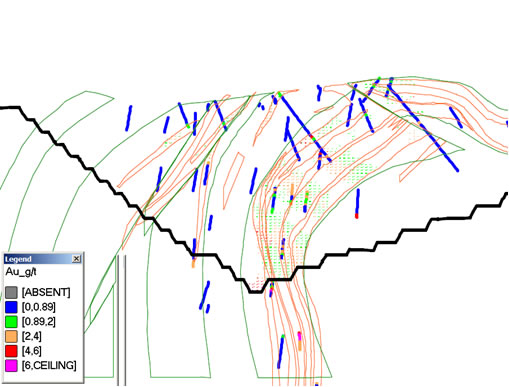

The Kuskokwim region of southwestern Alaska is predominantly underlain by rocks of the Upper Cretaceous Kuskokwim Group that filled a subsided northeast-trending strike-slip basin between a series of amalgamated terranes. Undivided Kuskokwim Group sedimentary rocks and granite porphyry complexes are the main rock units. Greywacke is dominant in the northern part of the area (“northern resource area” comprising Lewis, Queen, Rochelieu, and Akivik), while shale-rich units are common in the southern part of the area (“southern resource area” comprising South Lewis and ACMA). Overall, sedimentary structure in the northern resource area is monoclinal, whereas sedimentary rocks in the southern resource area display open easterly trending folds. | |

The Donlin Creek deposits lie between two regional, northeast-trending faults, in an area that contains numerous northeast to east–northeast- and northwest to west–northwest-trending lineaments that probably represent steeply-dipping strike-slip faults. Locally, intermediate composition volcano-plutonic complexes intrude and overlie Kuskokwim Group rocks throughout the region. |

Gold deposits are associated with an extensive Late Cretaceous gold–arsenic–antimony–mercury hydrothermal system. Gold-bearing zones exhibit strong structural and host rock control along north–northeast-trending fracture zones and are best developed where those zones intersect relatively competent host rocks. Mineralized material is most abundant in the igneous rocks, but sedimentary rocks are also mineralized within strong fracture zones. | |

Two distinct styles of gold-rich mineralization (ACMA–Lewis style and Dome–Duqum style) occur within the Donlin Creek trend. The ACMA–Lewis style of mineralization, a later low-temperature, low-sulphidation epithermal system, constitutes the main mineralizing system within the Donlin Creek property. This is the sole style of mineralization within the current resource area. The ACMA–Lewis style consists of sheeted quartz, quartz–carbonate and sulphide-only veins characterized by a gold–arsenic–antimony–mercury geochemical signature. The bulk of the gold occurs in the lattice structure of arsenopyrite. Stibnite, realgar and native arsenic are commonly observed associated with zones of higher-grade gold mineralization but do not appear to host any significant gold mineralization compared to arsenopyrite. Disseminated gold-bearing arsenopyrite can also be found typically adjacent to veins and vein zones. |

| Project No.: 160638 | ||

| April 2009 | Page 1-5 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

Mineralization is best developed in all intrusive rocks, and to a lesser extent, sedimentary rocks (mainly greywacke). Sedimentary units in areas of ACMA–Lewis mineralization typically show no contact metasomatic effects. The Dome–Duqum prospect is best characterized as an early, higher-temperature porphyry style of mineralization with fracture-controlled stockwork, and laminated quartz-only veins containing varying proportions of copper, zinc, bismuth, silver, tellurium, selenium and local native gold mineralization. | |

| 1.7 | Exploration History |

Gold was discovered in the Donlin Creek area in 1909, and placer production of about 30,000 ounces of gold occurred between 1909 and 1956. From 1956 to 1988, exploration comprised reconnaissance efforts, focusing on first-pass evaluation of ridge tops and outcrops, to determine the lode source of the placer gold. | |

Exploration in the period 1988 to 2005 comprised airborne geophysical surveys, geological reconnaissance, rock chip, soil and auger sampling, trenching, RC and diamond drilling, environmental studies, petrographic, fluid inclusion and metallurgical studies. Eight prospects, Snow, Dome, Quartz, Carolyn, Queen, Upper Lewis, Lower Lewis, and Rochelieu, were initially identified, followed by the discovery of the ACMA deposit in 1996. |

The 2002 work program culminated in a preliminary assessment study, and first time disclosure of Mineral Resources under NI 43-101. An updated Mineral Resource estimate was prepared by Barrick (formerly Placer Dome) during 2005 and SRK Consulting subsequently prepared a preliminary assessment study on behalf of NovaGold, confirming that deposit was amenable to conventional open pit mining operation. | |

From 2006 to 2008 work programs focused on infill, geotechnical and condemnation drilling, water geochemical studies, peat exploration, wind power generation studies, metallurgical studies, and project economic reviews. The work culminated in an updated feasibility study, completed January 2009 that indicated positive project economics. | |

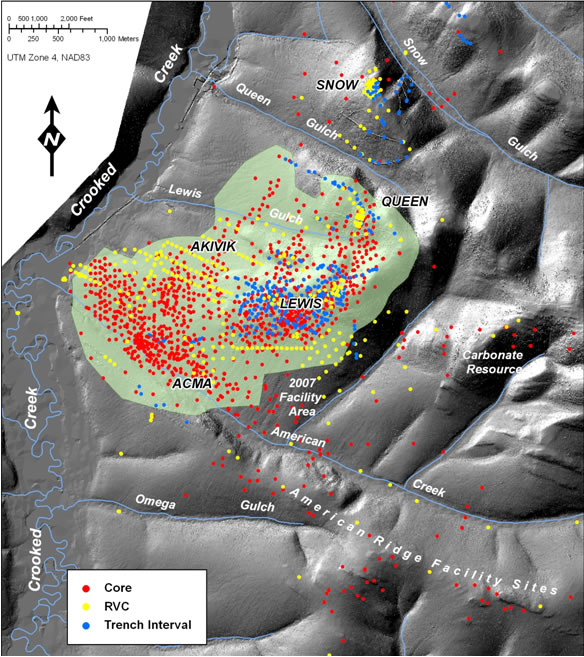

| 1.8 | Drilling |

Approximately 1,676 exploration and development core (88%) and reverse circulation (RC) (12%) drill holes, totalling 392,937 m were completed from 1988 through 2007. All but 8% (district exploration, carbonate resource, geotechnical, waste rock, condemnation, and hydrology) of this drilling was utilized for the feasibility study |

| Project No.: 160638 | ||

| April 2009 | Page 1-6 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| resource model. Approximately 50% of the core and 40% of the holes were drilled during the 2006–2007 period. An additional 108 core holes totalling 33,425 m were added in 2008 to explore near-pit expansions and satellite deposits, and for facility related condemnation and geotechnical studies. | |

Recoveries were not routinely measured for RC drilling; core recoveries typically ranged between 80% to 100%. | |

Two specific gravity values have been used, 2.65 for the mineralized intrusive units, and 2.71 for the mineralized sedimentary units, based on wet immersion measurements. | |

| 1.9 | Sample Preparation and Analysis |

The majority of sample preparation for the Donlin Creek Project has taken place at a facility at the Donlin Creek camp. Sample preparation was performed by employees of Barrick or NovaGold, depending on who had project management at the time of sample preparation. |

A number of laboratories have performed sample analysis, including Barrick’s internal laboratory, and Bondar Clegg/ALS Chemex. The majority of assays in the database were supplied by Bondar Clegg/ALS Chemex. | |

Gold is typically fire assayed primarily using a fire assay-atomic absorption spectroscopy (AAS) method. The major proportion of trace and major element data for drill holes located within the resource model boundary was acquired prior to the 2005 program by various laboratories using industry standard acid digestions followed by atomic absorption (AA) or inductively coupled plasma (ICP) instrumental determinations. | |

Standard reference materials were used to monitor the performance of gold analysis. Overall the results were consistent with current industry standards. Blank sample submission indicates limited contamination of samples during the analysis procedures. | |

| 1.10 | Data Verification |

The data verification process has included internal and external reviews. | |

The drill hole database is considered sufficiently free from error to support Mineral Resource and Mineral Reserve estimation. |

| Project No.: 160638 | ||

| April 2009 | Page 1-7 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

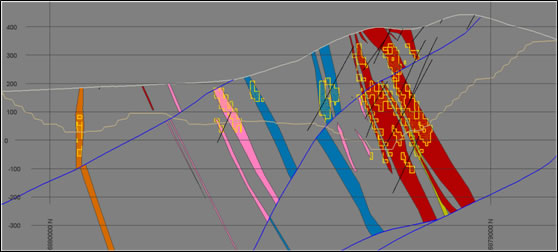

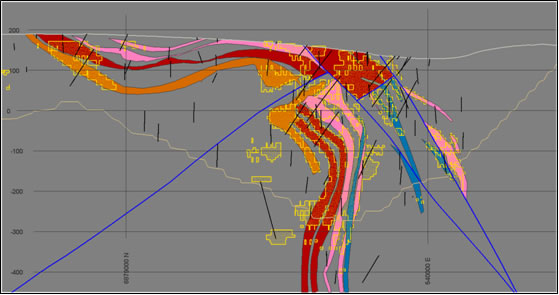

| 1.11 | Mineral Resource and Mineral Reserve Estimation |

The Mineral Resource block model consists of 6 m x 6 m x 6 m blocks estimated using inverse-distance to the third-power methodology into gold and sulphur discriminator models. The discriminator models were generated by an inverse-distance-squared method to calculate probabilities, which define blocks both internal and external to a probable mineralized envelope. Grades were estimated from multiple passes on each of the major rock groups (intrusive rocks, shale, greywacke), both internal and external to the probable mineralized envelope. Search distances increased with each successive pass. | |

Variogram ranges were found to be 30 m at 80% of the sill variance and 45 m at 90% of the sill variance. Based on these ranges, the discriminator model, estimation pass, and distance to nearest composite sample were used to classify the blocks to resource confidence categories. | |

Mineral Resources are based on a Lerchs-Grossmann pit optimized for all Measured, Indicated, and Inferred blocks assuming: |

| A gold selling price of US$850/oz | ||

Mill recoveries in the pit optimization varied by rock type, domain, and degree of oxidation, and ranged from 86.66% to 94.17% | ||

| ||

Administrative costs estimated at $1.56/t | ||

| ||

Refining, freight and marketing (selling costs) were estimated at $0.573/oz recovered | ||

| ||

A royalty of 3.75%, based on the Au price minus the selling cost. |

The Mineral Reserves, were subtracted from the total Mineral Resources reported from this pit optimization to determine the reported Mineral Resources that are exclusive of Mineral Reserves. During Whittle® pit optimization, incremental cut-offs can be applied to determine whether material within a pit shell is classed as potentially economic mineralization or as waste. The cut-offs assume that all material within a pit will be mined, but that at the top of the exit ramp of a pit, a choice must be made between what will report to the mill as potentially economic mineralization, and what will be sent to dumps as waste. To be considered potentially economic mineralization, the net smelter return (NSR) must pay back the incremental processing cost plus US$0.01/t.

Mineral Resources were classified using criteria appropriate under the 2005 CIM Definition Standards for Mineral Resources and Mineral Reserves by application of the

| Project No.: 160638 | ||

| April 2009 | Page 1-8 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

NSR-based cut-off grade that incorporated mining and recovery parameters, and constraint of the Mineral Resources to a pit shell based on commodity prices. Mineral Resources have an effective date of 31 December 2008.

Mineral Resources are summarized in Table 1-1. AMEC cautions that Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

Table 1-1: | Mineral Resource Statement, Effective Date 31 December 2008,Gordon Seibel, M.AusIMM |

| Tonnage | Au | Contained Au | ||||||||

| Category | (Mt) | (g/t) | (Moz) | |||||||

| Measured | 1.2 | 2.19 | 0.08 | |||||||

| Indicated | 93.4 | 1.97 | 5.92 | |||||||

| Total Measured and Indicated | 94.6 | 1.98 | 6.01 | |||||||

| Inferred | 54.5 | 2.29 | 4.02 |

| Note: | ||

| 1) | Mineral Resources are exclusive of Mineral Reserves, and are reported on a 100% basis | |

| 2) | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability | |

| 3) | Mineral Resources are reported to an Au price of US$850/oz | |

| 4) | Sums may not agree due to rounding | |

Mineral Reserves were estimated based on a series of Lerchs–Grossmann pit shells, established following a number of throughput rationalization studies. The pit shell considered Measured and Indicated Resources. The base case parameters used in the optimizations were:

Throughput of 53.5 kt/d and 20 year mine life | ||

Conventional open pit mining using a combined bulk mining (12 m benches) and selective mining (6 m benches) approach | ||

A long-term gold price assumption of US$725/oz | ||

Mill recoveries in the pit optimization varied by rock type, domain, and degree of oxidation, and ranged from 86.66% to 94.17% | ||

Slopes were determined by geotechnical domain, with bench face angle recommendations ranging from 43° to 65°, inter-ramp slope angles from 26° to 50°, and overall slope angles ranging between 26° and 47° | ||

General and administrative (G&A) costs were estimated at $1.61/t | ||

Refining, freight and marketing (selling costs) were $0.573/oz recovered | ||

A royalty of 3.75%, based on the Au price minus the selling cost. |

| Project No.: 160638 | ||

| April 2009 | Page 1-9 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

Because of narrow mineralized zones, the deposits were initially modelled with relatively small blocks to ensure that sufficient resolution was available to ensure adequate characterization.

Dilution and ore selectivity was determined using a program “SMUman,” developed in-house by Barrick and NCL Ingineria y Construccion S.A. Practical mining areas were designated for selective mining if a significant NSR dollar per tonne benefit over bulk mining was demonstrated. This significant benefit was chosen as being approximately 5%. In general, this benefit occurred in the ACMA deposit, which includes flatter dipping areas and is less contiguous than the Lewis deposit.

Additional Inferred Mineral Resource tonnes were added to the optimization resource base by to the reclassification of Inferred Mineral Resources to Measured or Indicated Mineral Resources during the “SMUman” 12 m block category allocation. The material was included in the Proven and Probable Mineral Reserve statement, the mining plan, and the financial analysis, and was subtracted from the Mineral Resources tabulations.

The base mining cost (before incremental mining cost with depth) was $1.68/t, the average processing cost was $15.97/t, and the G&A cost was $1.61/t.

Mineral Reserves were classified using criteria appropriate under the 2005 CIM Definition Standards for Mineral Resources and Mineral Reserves, and have an effective date of 31 December 2008. Mineral Reserves are summarized in Table 1-2.

Table 1-2: | Proven and Probable Mineral Reserve Statement, Effective Date 31December 2008, Kirk Hanson, P.E. |

| Tonnes | Au | Contained Au | ||||||||

| Category | (Mt) | (g/t) | (Moz) | |||||||

| Proven | 8.4 | 2.59 | 0.70 | |||||||

| Probable | 375.4 | 2.37 | 28.57 | |||||||

| Total | 383.8 | 2.37 | 29.27 |

| Note: | ||

| 1) | Mineral Reserves reported to an Au price of US$725/oz | |

| 2) | Mineral Reserves are reported on a 100% basis | |

| 3) | Sums may not agree due to rounding | |

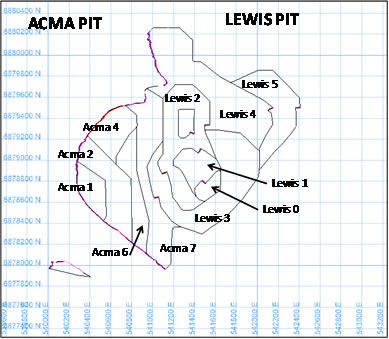

| 1.12 | Open Pit Mine Plan |

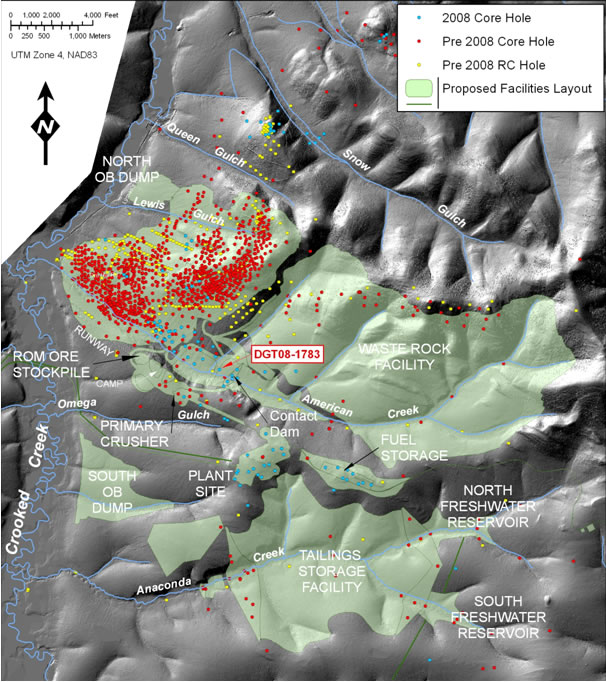

The mine will be an open pit operation and is proposed to be mined by a combination of bulk and selective mining methods using owner-operated large-scale equipment. | |

Two pits are planned, at ACMA and Lewis. A set of 14 mining phases were designed, eight in the ACMA pit and six in the Lewis pit. |

| Project No.: 160638 | ||

| April 2009 | Page 1-10 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

This sequence aims to deplete ACMA as early as possible to maximize use of the waste backfill dump designed inside the pit while minimizing deviation from the optimal economic mining sequence. The initial phases of the two pits are independent, but they partially merge later in the mine life. | |

Open pit mining on both 6 m and 12 m high benches provided the best project economics. About 22% of the total tonnage is planned to be selectively mined on 6 m benches. Blasting will be required. | |

The operating life-of-mine (LOM) is estimated to be 20 years based on a nominal processing rate of 53.5 kt/d. Mine start-up is assumed to commence in 2014, and cease in 2034. The processing rate is variable from period to period as a function of sulphur grade and ore hardness. | |

To maximize plant utilization, long-term ore stockpiling is required to balance sulphur feed grades. Short-term stockpiling will also be required to handle crusher downtime and production fluctuations in the pit. | |

Preproduction covers the first 15 months of the mine plan, when mining activities will focus on providing sufficient ore exposure for plant start-up. Mining is initially focused on the ACMA pit to access the highest-value ore. |

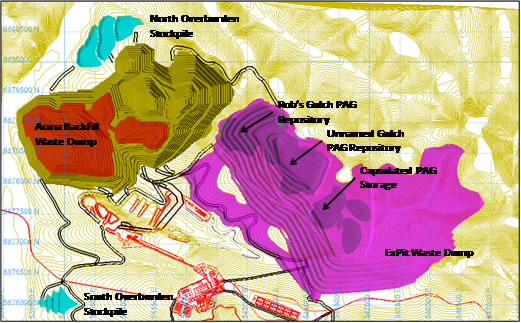

Waste rock from open pit mining will be placed in an ex-pit waste rock facility (WRF), in the American Creek valley, east of the pit area, or in a backfill dump in ACMA. Sufficient allocation was made in the WRF design to accommodate non-acid generating (NAG) and potentially acid generating (PAG) rock from the ACMA and Lewis pits. A total of 1.69 Gt of waste will be stored in the WRF and another 404 Mt in the ACMA backfill dump. An engineered rock dam is planned downstream of the WRF to support higher water discharge events. | ||

A proposed tailings storage facility (TSF) in the Anaconda Creek basin will be a fully lined impoundment with cross-valley dams at both the upstream (“upper dam,” comprising upper north and upper south) and downstream (“main” dam) ends. The TSF will have an ultimate capacity of 311.43 Mm3, corresponding to an ultimate impoundment surface area of 549 ha. The total catchment area of the TSF will be 705 ha. | ||

The main objectives of the water management plan for the Donlin Creek project are to minimize or eliminate the need for treatment and discharge of contact water during mine construction, operations, and closure; to achieve the pit-slope depressurization requirements; and to provide adequate quantity and quality of water supply to the mill. | ||

| Project No.: 160638 | ||

| April 2009 | Page 1-11 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Contact water will be stored behind a dam in American Creek, and tailings will be stored in the adjacent Anaconda Creek basin. | ||

| Staged diversion structures will be required to divert fresh water out of the project area during construction, operations, and closure. | ||

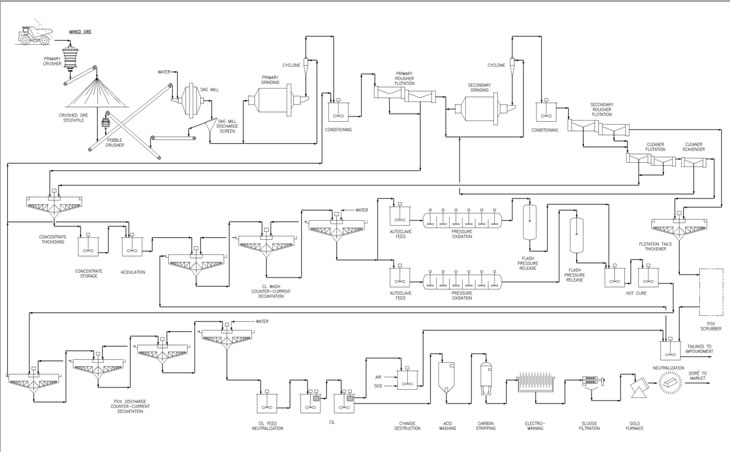

| 1.13 | Process and Process Plant | |

Key testwork programs were conducted on Donlin Creek ores at a number of laboratories over a period of approximately eight years, including: | ||

| Mineralogy | ||

| Direct leach/carbon-in-leach (CIL) testwork | ||

| Comminution tests | ||

| Flotation | ||

| Pressure oxidation | ||

| CIL and gold recovery testwork | ||

| Environmental considerations. | ||

The testing has shown that the ores require pre-treatment ahead of cyanidation to recover the gold. The preferred method of pre-treatment is pressure oxidation of the sulphide concentrate produced from flotation. Overall gold recovery is estimated to be 89.5%, based on the combined LOM average recovery of 92.6% from flotation and 96.6% from pressure oxidation of the concentrate. | ||

The process plant is designed to recover a sulphide flotation product and to oxidize the refractory gold concentrate in a pressure oxidation circuit before cyanidation. Key features of the plant are:

Gyratory crusher feeding a covered stockpile. Design operating times are 65% for the primary crusher and 93% for the process plant. | ||

Mill–chemical–float–mill–chemical–float (MCF2) grinding and flotation circuit. A single semi-autogenous grind (SAG) mill will operate in closed circuit with parallel cone crushers, followed by a primary ball mill in closed circuit with cyclones. Primary ball mill product reports to primary rougher flotation. Rougher flotation tailings report to the secondary ball mill circuit, while in closed circuit with cyclones. Secondary ball mill product at P80 50 µm reports to secondary rougher flotation. Secondary rougher flotation concentrate reports to cleaner flotation. A cleaner scavenger flotation circuit treats the cleaner flotation tailings. |

| Project No.: 160638 | ||

| April 2009 | Page 1-12 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

Combined flotation concentrates from primary rougher and cleaner flotation are dewatered in a thickener before acidulation and counter-current decant (CCD) washing to remove solubilised ions from the concentrate. It was shown that high levels of certain soluble ions in the feed to the autoclave have detrimental effects on the pressure oxidation (POX) / CIL gold recovery. The flotation circuit has a concentrate storage option. | ||

The autoclave circuit includes two autoclaves operating in parallel. Thickened flotation tailings slurry is used as a cooling medium in the autoclave letdown circuit. | ||

Flotation tailings are combined with the flotation concentrate wash solution product to neutralize the acidic solution before discharge to the tailings storage facility. The carbonate in the flotation tailings slurry will provide primary neutralization. The final pH level will be adjusted by adding slaked lime. | ||

Flashed and cooled autoclave discharge slurry is cured before POX discharge to CCD. The acidic solution recovered by CCD is recycled to acidulation and flotation feed conditioning. | ||

POX CCD product slurry is neutralized with lime ahead of cyanidation. | ||

The CIL circuit will operate at pH 9.0. The CIL tanks are fully enclosed and vented to a caustic scrubbing system to recover cyanide and recycle it back to the CIL circuit. Carbon will be handled with in-tank revolving screens. |

The carbon-handling area for the loaded carbon consists of an acid wash circuit and a modified pressure Zadra circuit for stripping carbon. Carbon is reactivated in an electric kiln. | ||

Gold is recovered in an electrowinning circuit. The electrowinning sludge is treated in a retort before being melted in an induction furnace. The final product is doré bars. | ||

Mercury that evolves in the process plant will be captured in a number of mercury abatement systems to treat the following streams: autoclave flash vent, regeneration kiln feed and discharge vents, electrowinning vents, retort furnace exhaust, induction furnace vent, and general refinery area ventilation stream. |

| Project No.: 160638 | ||

| April 2009 | Page 1-13 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 1.14 | Cost Estimates |

The total estimated cost to design and build the Donlin Creek Project is $4,481 million, including an Owner-provided mining fleet and self-performed pre-development (Table 1-3). Sustaining capital requirements total $803 million. The feasibility capital cost estimate was developed in accordance with AACE Class 3 requirements, consisting of semi-detailed unit costs and assembly line items. All costs are expressed in third-quarter (3Q) 2008 U.S. dollars but with a de-escalation allowance applied subsequently to adjust the estimate to fourth-quarter (4Q) 2008 U.S. dollars. |

| Table 1-3: Summary of Capital Costs by Major Discipline | |||

| Cost | |||

| Discipline | ($000) | ||

| Direct Costs | |||

| Civil | 383,298 | ||

| O/L Piping | 124,804 | ||

| Mining | 431,636 | ||

| Concrete | 183,043 | ||

| Structural | 181,293 | ||

| Architectural | 105,990 | ||

| Mechanical | 1,104,979 | ||

| Piping | 190,137 | ||

| Electrical | 360,026 | ||

| Instrumentation | 60,641 | ||

| Coatings | 14,986 | ||

| Total Direct Costs | 3,140,833 | ||

| Indirect Costs | |||

| Owner’s Costs | 191,921 | ||

| Project Indirect Costs | 925,821 | ||

| Total Indirect Costs | 1,117,742 | ||

| Subtotal | 4,258,575 | ||

| Contingency @ P50 | 394,625 | ||

| Total Project Cost | 4,653,200 | ||

| De-escalation @ P50 | (172,600 | ) | |

| Net Project Cost | 4,480,600 |

No allowances are included for escalation through construction, interest during construction, taxes, or duties. Life-of-mine operating costs, including allocations for mining, processing, administration and refining are estimated at $30.03/t milled, $4.60/t mined, and approximately $440/oz overall (Table 1-4).

| Project No.: 160638 | ||

| April 2009 | Page 1-14 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Table 1-4: LOM Operating Costs (US$000) | ||||||||||||

| Area | Total LOM | $/t Milled | $/t Mined | $/oz | ||||||||

| Mine Operations | 5,226,143 | 13.62 | 2.08 | 200 | ||||||||

| Processing Operations | 5,664,194 | 14.76 | 2.26 | 216 | ||||||||

| Administration | 589,596 | 1.54 | 0.24 | 23 | ||||||||

| Refining | 43,858 | 0.11 | 0.02 | 2 | ||||||||

| Total | 11,523,790 | 30.03 | 4.60 | 440 |

The operating cost estimates were assembled by area and component, based on estimated staffing levels, consumables, and expenditures, according to the mine plan and process design. Operating costs were prepared in fourth-quarter 2008 U.S. dollars with no allowances for escalation, sales tax, import duties, or contingency.

| 1.15 | Financial Analysis |

The results of the economic analysis represent forward-looking information that are subject to a number of known and unknown risks, uncertainties and other factors that may cause actual results to differ materially from those presented here. |

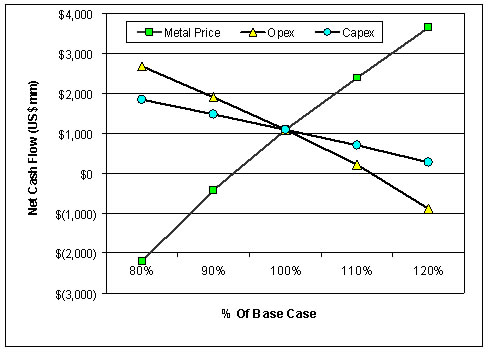

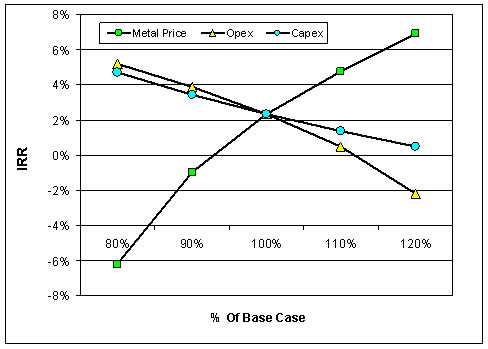

The overall economic viability of the project was evaluated by both discounted and undiscounted cash flow analyses. The Project is expected to generate net cash flows of $1.1 billion and yield an internal rate of return (IRR) of 2.3%, under a long-term gold price assumption of $725/oz.

The base case after-tax net present value at 5% (NPV 5%) of the Project is a negative $733 million (Table 1-5). At recent gold prices of $900/oz, (Alternative Case 1) the Project has an after-tax NPV (5%) of $829 million and an after-tax internal rate of return (IRR) of 7.7% (Table 1-6). The Project is particularly sensitive to the gold price. For the purposes of the sensitivity analysis, DCLLC assumed that the Project sensitivity to changes in gold grades was mirrored by the sensitivity of the Project to changes in the gold price.

The Project requires a gold price of $670/oz to break even at an oil price of $75/barrel. From the base case of gold at $725/oz and oil at $75/barrel, each $1/barrel increase in the price of oil requires approximately a $1.50/oz increase in the price of gold to offset the impact (Table 1-7).

| Project No.: 160638 | ||

| April 2009 | Page 1-15 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

Table 1-5: Donlin Creek Project Financial Summary (Base Case US$725/oz)

| Item | Unit | LOM | $/oz | $/t milled | $/t mined | |||||||||||

| Total Mined | Mt | 2,567.7 | - | - | - | |||||||||||

| Ore Milled | Mt | 383.8 | - | - | - | |||||||||||

| Strip Ratio (waste tonnes:ore tonnes) | t:t | 5.69 | - | - | - | |||||||||||

| Gold Grade | g/t | 2.37 | - | - | - | |||||||||||

| Contained Gold | Moz | 29.269 | - | - | - | |||||||||||

| Gold Recovery | % | 89.5 | - | - | - | |||||||||||

| Recovered Gold | Moz | 26.184 | - | - | - | |||||||||||

| Mine Life | Years | 21 | ||||||||||||||

| Oil Price | $/barrel | 75 | ||||||||||||||

| Revenue | $M | 18,983 | 725 | |||||||||||||

| Mining Costs | $M | 5,226 | 200 | 13.62 | 2.08 | |||||||||||

| Processing Costs | $M | 5,664 | 216 | 14.76 | 2.26 | |||||||||||

| G&A | $M | 590 | 23 | 1.54 | 0.24 | |||||||||||

| Refining | $M | 44 | 2 | 0.11 | 0.02 | |||||||||||

| Operating Costs | $M | 11,524 | 440 | 30.03 | 4.60 | |||||||||||

| Royalties | $M | 693 | 26 | 1.81 | 0.28 | |||||||||||

| Total Cash Costs | $M | 12,217 | 467 | 31.84 | 4.87 | |||||||||||

| Other Revenue | $M | (156 | ) | (6 | ) | (0.41 | ) | (0.06 | ) | |||||||

| Depreciation (Excluding Sunk Costs) | $M | 5,242 | 200 | 13.66 | 2.09 | |||||||||||

| Trust Fund | $M | 179 | 7 | 0.47 | 0.07 | |||||||||||

| Total Production Costs | $M | 17,481 | 668 | 45.55 | 6.97 | |||||||||||

| Cash Taxes | $M | 402 | 15 | 1.04 | 0.16 | |||||||||||

| Working Capital, Net | $M | (2 | ) | - | (0.01 | ) | 0.00 | |||||||||

| Total Costs, Including Taxes and Working Capital* | $M | 17,881 | 683 | 46.59 | 7.13 |

Table 1-6: Project Sensitivity to Gold Price (US$)

| Item | Unit | Base Case | Alternative Case 1 | Alternative Case 2 | |||||||||

| Gold Price | $/oz | 725 | 900 | 1,000 | |||||||||

| Oil Price | $/barrel | 75 | 75 | 75 | |||||||||

| Undiscounted Cumulative Net Cash Flow Pre-tax | $ | 1,504 | 5,915 | 8,435 | |||||||||

| Undiscounted Cumulative Net Cash Flow After-tax | $ | 1,103 | 4,166 | 5,876 | |||||||||

| NPV (5%) Pre-tax | $ | (592 | ) | 1,525 | 2,735 | ||||||||

| NPV (5%) After-tax | $ | (733 | ) | 829 | 1,674 | ||||||||

| IRR Pre-tax | % | 3.0 | 9.4 | 12.3 | |||||||||

| IRR After-tax | % | 2.3 | 7.7 | 10.2 | |||||||||

| Payback | Years | 15 | 7 | 5 | |||||||||

| Note: NPV = net present value, IRR = internal rate of return | |||||||||||||

Table 1-7: Project Sensitivity to Oil Price (US$725/oz Au price)

| Oil Price | Net Cash Flow | NPV @ 5% | IRR | ||||||||

| ($/barrel) | ($M) | ($M) | (%) | ||||||||

| 35 | 2,106 | (236 | ) | 4.2 | |||||||

| 50 | 1,744 | (415 | ) | 3.5 | |||||||

| 75 | 1,103 | (733 | ) | 2.3 | |||||||

| 100 | 430 | (1,069 | ) | 0.9 | |||||||

| Note: NPV = net present value, IRR = internal rate of return | |||||||||||

| Project No.: 160638 | ||

| April 2009 | Page 1-16 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 1.16 | Recommendations |

A recommended work program was budgeted in two phases, and totals $2.5 million. The work primarily involves additional studies and design to support Project advancement. |

| Project No.: 160638 | ||

| April 2009 | Page 1-17 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 2.0 | INTRODUCTION |

AMEC Americas Limited (AMEC) was commissioned by NovaGold Resources Inc. (NovaGold), to provide an independent Qualified Person’s Review and Technical Report (the Report) for the Donlin Creek Gold Project (the Project) located in Alaska, USA (Figure 2-1). | |

The Report was prepared in compliance with National Instrument 43-101, Standards of Disclosure for Mineral Projects (NI 43-101) and documents the results of an updated feasibility study on the Project. AMEC understands that this Report will be used by NovaGold in support of a press release entitled “Donlin Creek Feasibility Study Adds 14.7 Mozs to NovaGold’s Reserves”, dated 28 April 2009. | |

The Project is a joint venture between NovaGold Resources Alaska, Inc., a wholly-owned subsidiary of NovaGold Resources Inc., and Barrick Gold U.S. Inc., a wholly-owned subsidiary of Barrick Gold Corporation. For the purposes of this report, the name “NovaGold” refers interchangeably to the NovaGold subsidiary and parent companies; and the name “Barrick” refers interchangeably to the Barrick subsidiary and parent companies. During 2006, Barrick acquired Placer Dome Inc., which had held an interest in the Project between 1995 and 2006 through its wholly-owned subsidiary, Placer Dome US Inc. For the purposes of this report, the name “Barrick” also refers interchangeably to Placer Dome Inc. and to Placer Dome US Inc. when reference is made to the manager of work undertaken on the Project between 1995 and 2000, and between 2003 and 2006. | |

On 1 December 2007, NovaGold entered into a limited liability company agreement with Barrick that provided for the conversion of the Project into a new limited liability company, the Donlin Creek LLC (DCLLC), which is jointly owned by the NovaGold and Barrick on a 50/50 basis. The limited liability company agreement provides that information obtained in connection with the performance of the agreement, which includes information developed by, or on behalf of the DCLLC, may be disclosed by either NovaGold or Barrick, or affiliates of either, where such disclosure is required by law or to meet stock exchange requirements, including for purposes of a technical report required under NI 43-101. The Project is located in the USA, which uses U.S. Imperial measurements. Unless specified, all measurements in this Report were converted to the metric system. The Report currency throughout the Report is expressed in U.S. dollars; the Report uses Canadian English. |

| Project No.: 160638 | ||

| April 2009 | Page 2-1 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

Figure 2-1: Location Map

Note: Figure courtesy DCLLC

| Project No.: 160638 | ||

| April 2009 | Page 2-2 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 2.1 | Qualified Persons | |

The Qualified Persons (QPs), as defined in NI 43–101 and in compliance with Form 43–101F1 Technical Report, responsible for the preparation of the Report include: | ||

Gordon Seibel, M.AusIMM., Principal Geologist (AMEC, Reno) | ||

Kirk Hanson, P.E., Principal Mining Engineer, (AMEC, Reno) | ||

Simon Allard, P.Eng., Senior Financial Analyst (AMEC, Vancouver) | ||

Greg Wortman, P.Eng., Technical Director, Process (AMEC, Santiago) | ||

Alexandra Kozak, P.Eng., Manager, Process Engineering (AMEC, Vancouver) | ||

| 2.2 | Site Visits | |

AMEC QPs have conducted site visits to the Donlin Creek Project as shown in Table 2-1. | ||

| Table 2-1: Dates of Site Visits and Areas of Responsibility | |||

| QP Name | Site Visit Date | Area of Responsibility | |

| Kirk Hanson | 1 October 2008 | Sections 1, 2, 3, 4, 5, 6, 17.2, 18.1 to 18.8, 19, 20, 21, 22 and 23 and those portions of the summary, conclusions and recommendations that pertain to those sections. | |

| Gordon Siebel | 1 October 2008 | Sections 7, 8, 9, 10, 11, 12, 13, 14, 15, 17.1 and those portions of the summary, conclusions and recommendations that pertain to those sections. | |

| Simon Allard | No site visit | Sections 18.9 to 18.12 and those portions of the summary, conclusions and recommendations that pertain to those sections. | |

| Greg Wortman | No site visit | Section 16.1.3 and those portions of the summary, conclusions and recommendations that pertain to that section. | |

| Alexandra Kozak | No site visit | Sections 16.1.1, 16.1.2, 16.1.3 to 16.3 and those portions of the summary, conclusions and recommendations that pertain to those sections. | |

| 2.3 | Effective Dates |

The Report has a number of effective dates. The effective date for the Mineral Resources and Mineral Reserves is 31 December, 2008. The feasibility study update completion date for financial information included in the Report is 24 February 2009. The date of last supply of significant information to the Report, comprising Project tenure details, was 1 April 2009. The effective date for the Report is therefore 1 April 2009. There were no material changes to the information on the Project between the effective date and the signature date of the Report. |

| Project No.: 160638 | ||

| April 2009 | Page 2-3 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 2.4 | Previous Technical Reports |

A number of previous Technical Reports were filed on the Donlin Creek Project: |

Francis, K., 2007: Donlin Creek Project, NI 43-101 Technical Report, Southwest Alaska, U.S: unpublished NI43-101F1 Technical Report to NovaGold Resources Inc., 8 February 2008

Dodd, S., Francis, K. and Doerksen, G., 2006: Preliminary Assessment Donlin Creek Gold Project Alaska, USA, unpublished NI43-101F1 Technical Report to NovaGold Resources Inc. by SRK Consulting (US), Inc., 20 September 2006

Dodd, S., 2006: Donlin Creek Project 43-101 Technical Report, unpublished NI43-101F1 Technical Report to NovaGold Resources Inc. by NovaGold Resources Inc., 19 January 2006

Juras, S. and Hodgson, S., 2002: Technical Report, Preliminary Assessment, Donlin Creek Project, Alaska, unpublished NI43-101F1 Technical Report to NovaGold Resources Inc. by MRDI, March 2002

Juras, S., 2002: Technical Report, Donlin Creek Project, Alaska, unpublished NI43-101F1 Technical Report to NovaGold Resources Inc. by MRDI, 24 January 2002

AMEC has sourced information from these reports and other reference documents are as cited in the text and summarized in Section 22 of this Report. Additional information was sourced from, and provided by, NovaGold and the DCLLC. AMEC has relied upon other experts in the fields of mineral tenure, surface rights, permitting, and environmental as outlined in Section 3.

| 2.5 | Technical Report Sections and Required Items under NI 43-101 |

Table 2-2 relates the sections as shown in the contents page of this Report to the Prescribed Items Contents Page of NI 43-101. |

| Project No.: 160638 | ||

| April 2009 | Page 2-4 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| Table 2-2: Contents Page Headings in Relation to NI 43-101 Prescribed Items—Contents | |||

| NI 43-101 Item Number | NI 43-101 Heading | Report Section Number | Report Section Heading |

| Item 1 | Title Page | Cover page of Report | |

| Item 2 | Table of Contents | Table of contents | |

| Item 3 | Summary | Section 1 | Summary |

| Item 4 | Introduction | Section 2 | Introduction |

| Item 5 | Reliance on Other Experts | Section 3 | Reliance on Other Experts |

| Item 6 | Property Description and Location | Section 4 | Property Description and Location |

| Item 7 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | Section 5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

| Item 8 | History | Section 6 | History |

| Item 9 | Geological Setting | Section 7 | Geological Setting |

| Item 10 | Deposit Types | Section 8 | Deposit Types |

| Item 11 | Mineralization | Section 9 | Mineralization |

| Item 12 | Exploration | Section 10 | Exploration |

| Item 13 | Drilling | Section 11 | Drilling |

| Item 14 | Sampling Method and Approach | Section 12 | Sampling Method and Approach |

| Item 15 | Sample Preparation, Analyses and Security | Section 13 | Sample Preparation, Analyses and Security |

| Item 16 | Data Verification | Section 14 | Data Verification |

| Item 17 | Adjacent Properties | Section 15 | Adjacent Properties |

| Item 18 | Mineral Processing and Metallurgical Testing | Section 16 | Mineral Processing and Metallurgical Testing |

| Item 19 | Mineral Resource and Mineral Reserve Estimates | Section 17 | Mineral Resource and Mineral Reserve Estimates |

| Item 20 | Other Relevant Data and Information | Section 19 | Other Relevant Data and Information |

| Item 21 | Interpretation and Conclusions | Section 20 | Interpretation and Conclusions |

| Item 22 | Recommendations | Section 21 | Recommendations |

| Item 23 | References | Section 22 | References |

| Item 24 | Date and Signature Page | Section 23 | Date and Signature Page |

| Item 25 | Additional Requirements for Technical Reports on Development Properties and Production Properties | Section 18 | Additional Requirements for Technical Reports on Development Properties and Production Properties |

| Item 26 | Illustrations | Incorporated in Report under appropriate section number | |

| Project No.: 160638 | ||

| April 2009 | Page 2-5 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 3.0 | RELIANCE ON OTHER EXPERTS |

The QPs, authors of this Report, state that they are qualified persons for those areas as identified in their respective “Certificate of Qualified Person” attached to this Report. The authors have relied upon and disclaim responsibility for information derived from the following expert reports pertaining to mineral rights, surface rights, and permitting issues. | |

| 3.1 | Mineral Tenure |

AMEC QPs have not reviewed the mineral tenure, nor independently verified the legal status or ownership of the Project area or underlying property agreements. AMEC has fully relied upon legal experts for this information through the following document: |

Reeves Amodio LLC, 2009: Title Opinion: unpublished document prepared for Donlin Creek LLC, Barrick Gold US Inc., and NovaGold Alaska Inc., 23 February 2009, 49 p

This information was used in Sections 4.2.2 to 4.2.4 and Section 4.3.6 of the Report. | |

| 3.2 | Surface Rights, Access, and Permitting |

AMEC QPs have fully relied on information regarding the status of the current Surface Rights, Road Access and Permits through opinions and data supplied by legal experts through the following document: |

Reeves Amodio LLC, 2009: Title Opinion: unpublished document prepared for Donlin Creek LLC, Barrick Gold US Inc., and NovaGold Alaska Inc., 23 February 2009, 49 p

Donlin Creek Feasibility Study Update, Section 2, Introduction: unpublished report to the DCLLC, 21 May, 2009

Donlin Creek Feasibility Study Update, Section 13 Environmental and Permitting: unpublished report to the DCLLC, 21 May, 2009

This information was used in Sections 4.2.2 to 4.2.4 and Section 4.4 of the Report.

| Project No.: 160638 | ||

| April 2009 | Page 3-1 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 3.3 | Environmental and Permitting |

AMEC QPs have fully relied on information regarding the environmental and permitting status of the Project through opinions and data supplied by independent experts to the DCLLC as part of the feasibility study update, through the following: |

Donlin Creek Feasibility Study Update, Section 2, Introduction: unpublished report to the DCLLC, 21 May, 2009

Donlin Creek Feasibility Study Update, Section 13 Environmental and Permitting: unpublished report to the DCLLC, 21 May, 2009

This information was used in Sections 4.2.2 to 4.2.4, Section 4.4, Section 4.5 and Section 18.8 of the Report. | |

| 3.4 | Reclamation and Closure |

AMEC QPs have fully relied on information regarding the reclamation and closure proposals for the Project through opinions and data supplied by independent experts to the DCLLC as part of the feasibility study update, through the following: |

Donlin Creek Project Feasibility Study Update, Section 14 Closure Plan: unpublished report to the DCLLC, 21 May, 2009

This information was used in Sections 4.5 and Section 18.8 of the Report.

| Project No.: 160638 | ||

| April 2009 | Page 3-2 |

| NovaGold Resources Inc. Donlin Creek Gold Project, Alaska, USA NI 43-101 Technical Report |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION |

| 4.1 | Location |

Donlin Creek is located in southwest Alaska in the United States of America, approximately 80 km northeast of Aniak, a regional hub (see Figure 2-1). The property consists of about 109 km2of privately-owned Native Alaskan land. Calista Corporation (Calista), a regional Native corporation, owns the subsurface rights, and The Kuskokwim Corporation (TKC), a village corporation, owns the majority of the surface rights. | |