IMPORTANT NOTICE

This report was prepared as a National Instrument 43-101 Technical Report, in accordance with Form 43-101F1, for Idaho-Maryland Mining Corporation (Idaho-Maryland) Doublestar Resources Ltd.by AMEC Americas Limited (AMEC). The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in AMEC’s services, based on: i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended to be used by Idaho-Maryland subject to the terms and conditions of its contract with AMEC. That contract permits Idaho-Maryland to file this report as a Technical Report with Canadian Securities Regulatory Authorities pursuant to provincial securities laws. Any other use of this report by any third party is at that party’s sole risk. |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| | | | | |

| | | | | |

| 1.0 | SUMMARY | 1-1 | |

| | 1.1 | Introduction | 1-1 | |

| | 1.2 | Geology and Mineral Resource | 1-2 | |

| | | 1.2.1 Geological Setting | 1-2 | |

| | | 1.2.2 Summary of Industrial Mineral Resource (Ceramics Feedstock) | 1-3 | |

| | | 1.2.3 Gold Resource | 1-4 | |

| | 1.3 | Exploration | 1-4 | |

| | | 1.3.1 Industrial Minerals Resource Exploration | 1-4 | |

| | | 1.3.2 Gold Exploration | 1-5 | |

| | 1.4 | Property Description and Tenure | 1-6 | |

| | 1.5 | Mining | 1-6 | |

| | 1.6 | Process | 1-7 | |

| | | 1.6.1 Mineral Processing | 1-7 | |

| | | 1.6.2 Crushing, Drying, and Grinding | 1-7 | |

| | | 1.6.3 Ceramics Production | 1-8 | |

| | | 1.6.4 Gold Processing (Future) | 1-9 | |

| | 1.7 | Site Facilities | 1-9 | |

| | 1.8 | Permit Application Requirements and Status | 1-11 | |

| | 1.9 | Environmental Considerations | 1-12 | |

| | 1.10 | Marketing and Sales Approach | 1-13 | |

| | 1.11 | Capital Cost Estimate | 1-13 | |

| | 1.12 | Operating Cost Estimate | 1-14 | |

| | 1.13 | Financial Analysis | 1-16 | |

| | 1.14 | Project Schedule | 1-16 | |

| | 1.15 | Conclusions and Recommendations | 1-17 | |

| 2.0 | INTRODUCTION AND TERMS OF REFERENCE | 2-1 | |

| | 2.1 | Introduction | 2-1 | |

| | 2.2 | Terms of Reference | 2-2 | |

| 3.0 | DISCLAIMER | 3-1 | |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 4-1 | |

| | 4.1 | Location | 4-1 | |

| | 4.2 | Jurisdictions | 4-1 | |

| | 4.3 | Permitting History | 4-4 | |

| | 4.4 | Environmental Laws | 4-5 | |

| | 4.5 | Permit Requirements | 4-7 | |

| | | 4.5.1 Permitting History | 4-7 | |

| | | 4.5.2 Annexation and Permitting Authority | 4-8 | |

| | | 4.5.3 Use Permit for Exploratory Work | 4-8 | |

| | | 4.5.4 Use Permit for Mineral Resource Development | 4-9 | |

| | | 4.5.5 Permitting Period | 4-10 | |

| | 4.6 | Environmental Status | 4-11 | |

| | | |

Project No. 146357 | TOC i | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| | | | |

| | | | |

5.0 | ACCESSIBILITY, CLIMATE, AND PHYSIOGRAPHY | 5-1 | |

6.0 | HISTORY | 6-1 | |

7.0 | GEOLOGICAL SETTING | 7-1 | |

| 7.1 | Regional Geology | 7-1 | |

| | 7.1.1 Structural Setting | 7-4 | |

| 7.2 | Property Geology | 7-5 | |

| | 7.2.1 Fiddle Creek Complex | 7-6 | |

| | 7.2.2 Lake Combie Complex | 7-6 | |

| | 7.2.3 Spring Hill Tectonic Mélange | 7-7 | |

| | 7.2.4 Tectonic Mélange – Weimar Fault Zone | 7-9 | |

| | 7.2.5 Dioritic Intrusions | 7-9 | |

| 7.3 | Property Structural Geology | 7-10 | |

| | 7.3.1 Weimar Fault Zone (6-3 Fault) | 7-10 | |

| | 7.3.2 Spring Hill Mélange | 7-11 | |

| | 7.3.3 Idaho Deformation Corridor | 7-13 | |

| | 7.3.4 Morehouse Fault | 7-13 | |

| | 7.3.5 The Brunswick 20 Series Faults | 7-15 | |

| | 7.3.6 The Brunswick Stacked Faults | 7-16 | |

8.0 | DEPOSIT TYPES | 8-1 | |

9.0 | MINERALIZATION | 9-1 | |

| 9.1 | Gold Mineralization | 9-1 | |

| | 9.1.1 Gold-Quartz Veins | 9-1 | |

| | 9.1.2 Mineralized Black Slate Deposits | 9-3 | |

| | 9.1.3 Mineralized Diabasic Slabs | 9-3 | |

| | 9.1.4 Mineralized Phyllonites | 9-5 | |

| 9.2 | Industrial Minerals Resources (Ceramics Feedstock Material) | 9-5 | |

| | 9.2.1 Meta-Andesite | 9-6 | |

| | 9.2.2 Meta-Diabase | 9-6 | |

| | 9.2.3 Meta-Gabbro | 9-6 | |

10.0 | EXPLORATION | 10-1 | |

| 10.1 | Evaluation Data | 10-1 | |

| 10.2 | Gold Mineralization | 10-2 | |

| | 10.2.1 Data Review Results | 10-2 | |

| | 10.2.2 Discussion | 10-3 | |

11.0 | DRILLING | 11-1 | |

| 11.1 | Historic Drilling | 11-1 | |

| 11.2 | 2003 / 2004 Drilling | 11-1 | |

| | 11.2.1 Gold Mineralization Targets | 11-3 | |

| | 11.2.2 Geotechnical Drilling (Ceramics Feedstock Definition) | 11-5 | |

12.0 | SAMPLING METHOD AND APPROACH | 12-1 | |

| 12.1 | Gold Mineralization | 12-1 | |

| 12.2 | Ceramic Feedstock | 12-1 | |

13.0 | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 13-1 | |

| 13.1 | 2003 – 2004 Gold Exploration Samples | 13-1 | |

| 13.2 | Historic Gold Samples | 13-2 | |

| | | |

Project No. 146357 | TOC ii | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| | | | |

| 13.3 | Ceramics Feedstock Samples | 13-3 | |

14.0 | DATA VERIFICATION | 14-1 | |

| 14.1 | Historic Data | 14-1 | |

| 14.2 | 2003 and 2004 Data | 14-1 | |

15.0 | ADJACENT PROPERTIES | 15-1 | |

16.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 16-1 | |

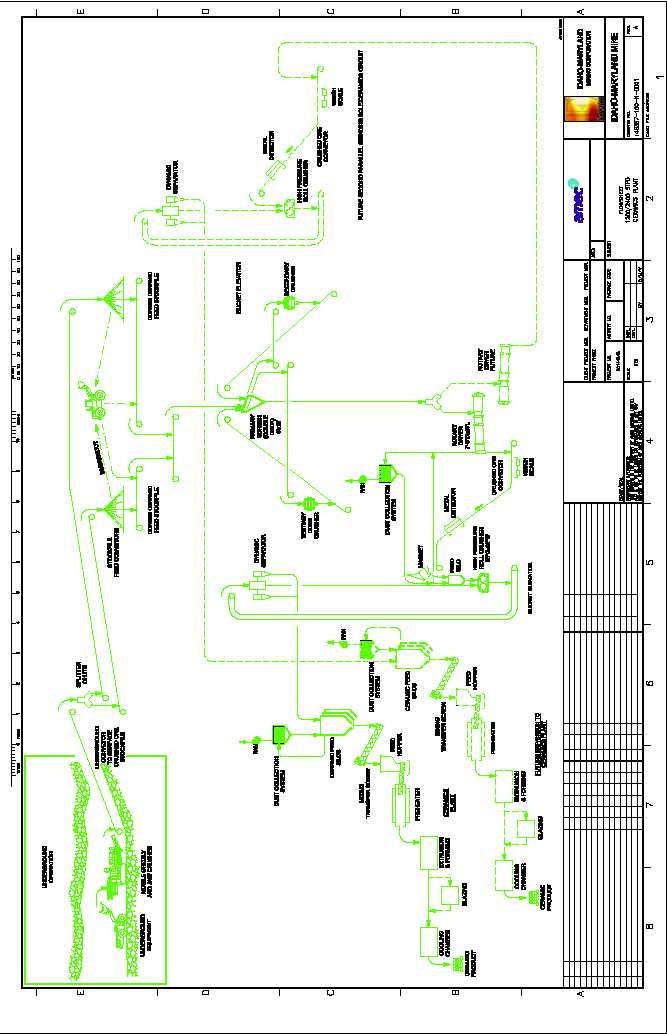

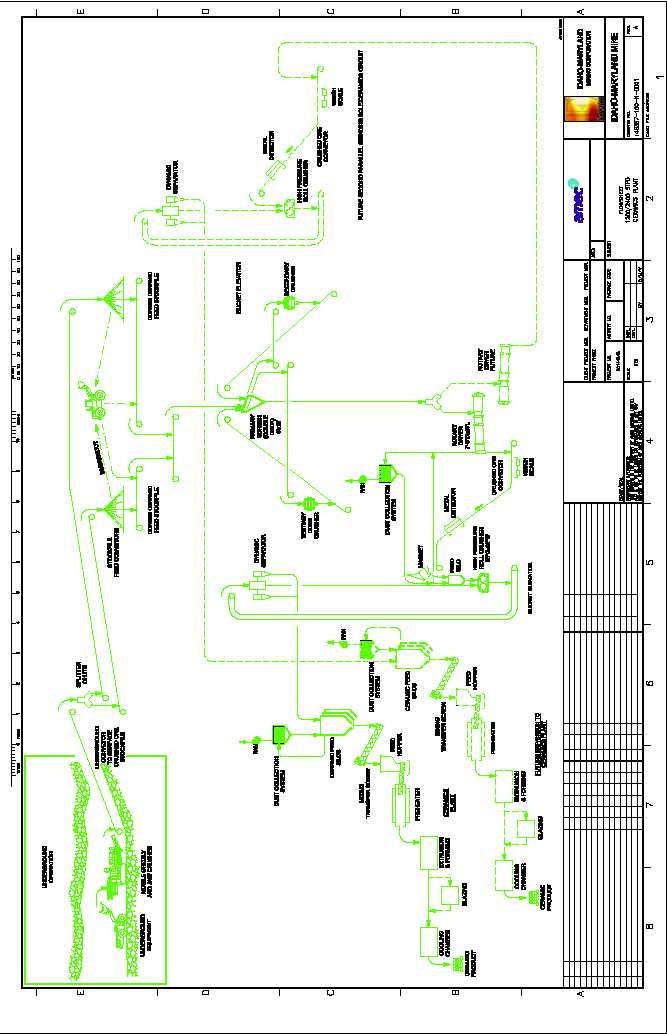

| 16.1 | Process Description | 16-1 | |

| | 16.1.1 Crushing, Drying, and Grinding | 16-1 | |

| | 16.1.2 Ceramics Manufacturing | 16-2 | |

| | 16.1.3 Gold Processing Plant (Future) | 16-3 | |

| 16.2 | Development Plan and Production Rate | 16-4 | |

| | 16.2.1 Equipment Capacity | 16-4 | |

| | 16.2.2 Materials Handling – Surface | 16-4 | |

| 16.3 | Metallurgical and Process Testwork | 16-5 | |

| | 16.3.1 Feed Material Evaluation for the Ceramext™ Process | 16-5 | |

| | 16.3.2 Gold Recovery Testwork | 16-6 | |

| 16.4 | Process Operating Basis | 16-7 | |

| 16.5 | Equipment List | 16-8 | |

17.0 | MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | 17-1 | |

| 17.1 | Idaho-Maryland Gold Mineral Resource | 17-1 | |

| | 17.1.1 Structural and Mineralization Continuity | 17-3 | |

| | 17.1.2 Data Analysis | 17-3 | |

| | 17.1.3 Mine Call Factor | 17-4 | |

| | 17.1.4 Resource Estimation | 17-5 | |

| | 17.1.5 Resource Classification and Summary | 17-6 | |

| 17.2 | Idaho-Maryland Ceramics Industrial Mineral Resource | 17-7 | |

| | 17.2.1 Mineral Resource Quality | 17-8 | |

| | 17.2.2 Resource Estimate and Classification | 17-8 | |

| 18.0 | OTHER RELEVANT DATA AND INFORMATION | 18-1 | |

| 19.0 | REQUIREMENTS FOR TECHNICAL REPORTS ON PRODUCTION AND | | |

| DEVELOPMENT PROPERTIES | 19-1 | |

| 19.1 | Mine Plan | 19-1 | |

| | 19.1.1 Introduction | 19-1 | |

| | 19.1.2 Mine Mobile Equipment | 19-4 | |

| | 19.1.3 Project Schedule | 19-6 | |

| | 19.1.4 Ground Conditions | 19-8 | |

| | 19.1.5 Mine Access | 19-11 | |

| | 19.1.6 Mining of the Industrial Minerals (Ceramics Feedstock) Resource | 19-14 | |

| | 19.1.7 Exploration of the Gold Resource | 19-14 | |

| | 19.1.8 New Brunswick Shaft | 19-18 | |

| | 19.1.9 Mining Risks and Opportunities | 19-23 | |

| 19.2 | Site Facilities | 19-26 | |

| | 19.2.1 Site Layout | 19-26 | |

| | 19.2.2 Noise Suppression and Dust Control | 19-26 | |

| | 19.2.3 Decline Portal | 19-27 | |

| | 19.2.4 Truckshop and Warehouse Building | 19-28 | |

| | | |

Project No. 146357 | TOC iii | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| | 19.2.5 Administration Office/Changehouse | 19-28 | |

| | 19.2.6 Power Supply | 19-29 | |

| | 19.2.7 Natural Gas Supply | 19-29 | |

| | 19.2.8 Fresh and Process Water Supply | 19-29 | |

| | 19.2.9 Sewage Services | 19-30 | |

| 19.3 | Market Evaluation | 19-30 | |

| | 19.3.1 World Market for Ceramic Products | 19-32 | |

| | 19.3.2 Ceramic Tile | 19-33 | |

| | 19.3.3 Ceramic Roof Tile | 19.35 | |

| | 19.3.4 Ceramic Brick | 19-36 | |

| | 19.3.5 Other Ceramic Products | 19-36 | |

| | 19.3.6 Market Summary | 19-37 | |

| | 19.3.7 Marketing Channels | 19-37 | |

| | 19.3.8 Production Costs | 19-37 | |

| 19.4 | Capital Cost Estimate | 19-38 | |

| | 19.4.1 Summary | 19-38 | |

| | 19.4.2 Mine Capital Costs | 19-39 | |

| | 19.4.3 Process Plant and Ancillary Facilities | 19-42 | |

| | 19.4.4 Basis of Estimate | 19-42 | |

| 19.5 | Operating Cost Estimate | 19-46 | |

| | 19.5.1 Summary | 19-46 | |

| | 19.5.2 Mine Operating Costs | 19-46 | |

| | 19.5.3 Process Operating Costs | 19-49 | |

| | 19.5.4 General and Administration Costs | 19-50 | |

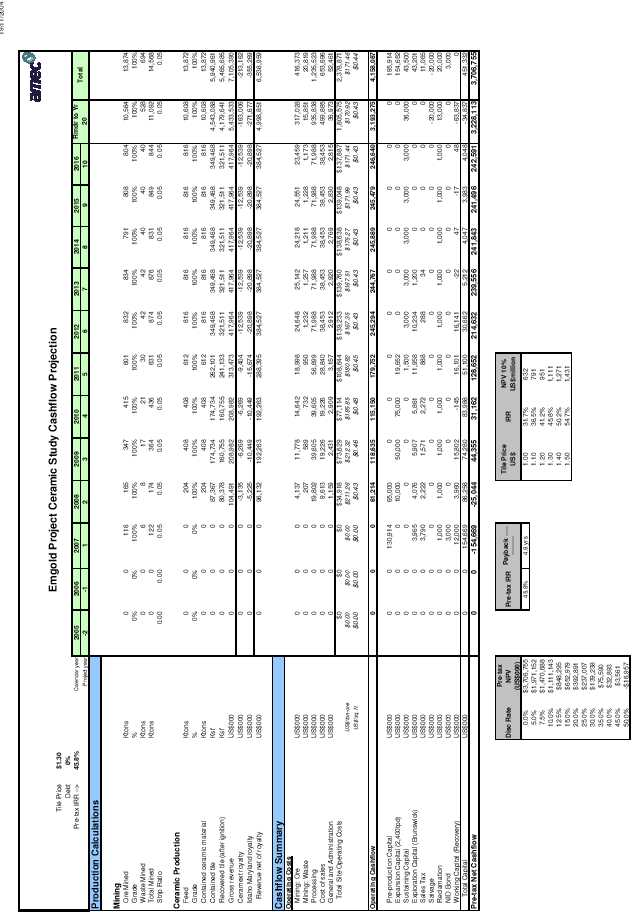

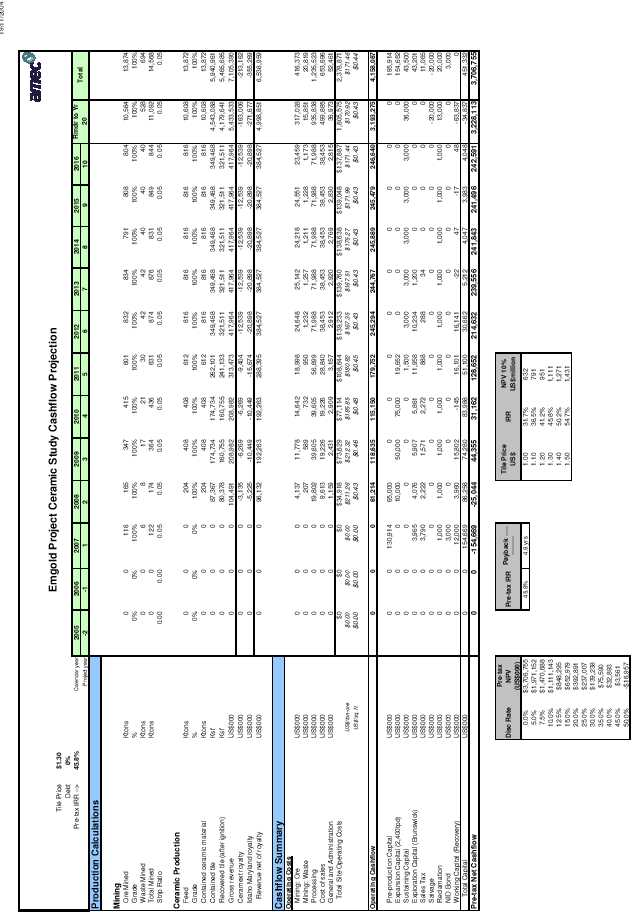

| 19.6 | Financial Analysis | 19-51 | |

| | 19.6.1 Summary | 19-51 | |

| | 19.6.2 Sensitivity Analysis | 19-51 | |

| | 19.6.3 Valuation Methodology | 19-51 | |

| | 19.6.4 Ceramics Marketing | 19-52 | |

| | 19.6.5 Taxation | 19-53 | |

| | 19.6.6 Royalties | 19-53 | |

| | 19.6.7 Other Assumptions | 19-53 | |

| 19.7 | Manpower | 19-54 | |

| | 19.7.1 Mine Labor | 19-54 | |

| | 19.7.2 Process Plant Labor | 19-56 | |

| | 19.7.3 General and Administration Manpower | 19-57 | |

| 19.8 | Project Schedule | 19-58 | |

| 20.0 | CONCLUSIONS AND RECOMMENDATIONS | 20-1 | |

| 20.1 | Conclusions | 20-1 | |

| 20.2 | Recommendations | 20-1 | |

| | 20.2.1 Mining | 20-1 | |

| | 20.2.2 Process | 20-1 | |

| | 20.2.3 Crushing and Grinding | 20-2 | |

| | 20.2.4 Ceramics Manufacture | 20-2 | |

| | 20.2.5 Ceramics Marketing | 20-2 | |

| | 20.2.6 Dewatering of Historic Mine Workings | 20-3 | |

| | 20.2.7 Site Assessment | 20-3 | |

| | 20.2.8 Gold Processing (Future) | 20-3 | |

| | 20.2.9 Financial Evaluation | 20-4 | |

| 21.0 | REFERENCES | 21-1 | |

| | | |

Project No. 146357 | TOC iv | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| | | | |

| T A B L E S | - | - | |

| | | | |

| Table 1-1: | Summary of Ceramics Feedstock Resources, 5 November 2004 | 1-4 | |

| Table 1-2: | Gold Resources, 20 September 2004 | 1-4 | |

| Table 1-3: | Operating Costs by Year $/ton of Feed Processed | 1-15 | |

| Table 1-4: | Operating Costs by Year $/ft2 of Ceramic Product | 1-15 | |

| Table 1-5: | Scenario A NPV at Varying Discount Rates and IRR) | 1-16 | |

| Table 1-6: | Idaho-Maryland Estimated Capital, Annual Production Costs and Sales at | | |

| | Average Conditions | 1-16 | |

| Table 4-1: | Permits | 4-8 | |

| Table 11-1: | Idaho-Maryland Project 2003 and 2004 Drill Holes | 11-2 | |

| Table 11-2: | Significant Gold Mineralized Intersections, 2003 – 2004 Drill Campaigns | 11-5 | |

| Table 16-1: | Process Operating Basis | 16-7 | |

| Table 17-1: | Idaho-Maryland Project Gold Mineral Resource Summary, 20 September 2004 | 17-7 | |

| Table 17-2: | Idaho-Maryland Project Ceramics Feedstock Mineral Resource Summary, 5 | | |

| | November 2004 | 17-8 | |

| Table 19-1: | Relative Depths and Elevations of Underground Infrastructure | 19-3 | |

| Table 19-2: | Parameters Used for Mine Design | 19-3 | |

| Table 19-3: | Mobile Equipment Acquisition Schedule | 19-5 | |

| Table 19-4: | Estimated Range of Rock Quality Values Expected for Mining in Andesite | | |

| | using Barton’s Rock Tunneling Designation | 19-9 | |

| Table 19-5: | Cost Summary, Gold Exploration, and Shaft Rehabilitation | 19-18 | |

| Table 19-6: | New Brunswick Shaft Rehabilitation and Gold Exploration | 19-24 | |

| Table 19-7: | Worldwide Ceramic Tile Consumption in 2001 | 19-33 | |

| Table 19-8: | Ceramic Production | 19-37 | |

| Table 19-9: | Capital Cost Estimates (x 000) | 19-38 | |

| Table 19-10: | Underground Capital Costs for Ceramics Feedstock Mining | 19-40 | |

| Table 19-11: | Underground Mobile Equipment Acquisition Schedule for Ceramics Feedstock Mining | 19-41 | |

| Table 19-12: | Estimated Direct Capital Costs (x 000) | 19-42 | |

| Table 19-13: | Operating Costs by Year $/ton of Feed Processed | 19-47 | |

| Table 19-14: | Operating Costs by Year $/ft2 of Ceramic Product | 19-47 | |

| Table 19-15: | Underground Operating Costs for Ceramics Feedstock Mining | 19-48 | |

| Table 19-16: | Process Operating Costs ($/ton) | 19-49 | |

| Table 19-17: | G&A Operating Costs | 19-50 | |

| Table 19-18: | Variation in NPV with Discount Rate and IRR | 19-51 | |

| Table 19-19: | Underground Operating Labor Productivities and Manpower | 19-55 | |

| Table 19-20: | Process Labor | 19-56 | |

| Table 19-21: | G&A Manpower | 19-58 | |

| | | |

Project No. 146357 | TOC v | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

| F IGURES | - | - | |

| | | | |

| Figure 4-1: | Project Location Map | 4-2 | |

| Figure 4-2: | Mine Location Map | 4-3 | |

| Figure 7-1: | Regional Geology | 7-2 | |

| Figure 7-2: | Regional Lithologic Units | 7-3 | |

| Figure 7-3: | Property Structural Geology – Plan View | 7-12 | |

| Figure 7-4: | Geologic Cross Section – Plane of Section No. 20 E, Looking West, Sections C | | |

| | – C1 | 7-14 | |

| Figure 7-5: | Idaho Deformation Corridor | 7-15 | |

| Figure 8-1: | Idaho-Maryland Mineralization Types | 8-1 | |

| Figure 9-1: | Mineralized Black Slate Deposits – Br 16 Vein Area | 9-4 | |

| Figure 11-1: | Drill Hole Cross Section – Looking S40E | | 11-4 | |

| Figure 13-1: | Sample Preparation and Assay Procedure Flowchart, Primary Laboratory | 13-1 | |

| Figure 17-1: | Idaho-Maryland Project Gold Resource Summary, 5 November 2004 | 17-2 | |

| Figure 19-1: | Mine Access and Location of Room-and-Pillar Mining Looking Southwest | 19-2 | |

| Figure 19-2: | Project Schedule Underground Development | | 19-7 | |

| Figure 19-3: | RQD Results from Seven Holes, 2,500 ft of Drilling (excludes all data from | | |

| | surface to 150 ft depth) | | 19-8 | |

| Figure 19-4: | Core Sample Typical of Andesite | | 19-8 | |

| Figure 19-5: | Stress Fields Modeled | | 19-10 | |

| Figure 19-6: | Pillar Stability | | 19-10 | |

| Figure 19-7: | Start of Decline | | 19-12 | |

| Figure 19-8: | Cross Section of Portal | | 19-13 | |

| Figure 19-9: | Dual Decline | | 19-13 | |

| Figure 19-10: | Room-and-Pillar Benching | | 19-14 | |

| Figure 19-11: | General View of Ceramics Feedstock Resource Room-and-Pillar Stoping Area | ..19-15 | |

| Figure 19-12: | Gold Resource Blocks Identified from Previous Mining* | 19-16 | |

| Figure 19-13: | View of Brunswick and Idaho Mine Levels Looking North showing Decline and | | |

| | Gold Resource Blocks Identified from Previous Mining | 19-17 | |

| Figure 19-14: | Schedule for New Brunswick Shaft and Gold Exploration | 19-19 | |

| Figure 19-15: | Consumption of Ceramic Tile in the USA, 1980 to 2003 | 19-30 | |

| Figure 19-16: | Comparison of Per Capita Tile Consumption by Country in 2001 | 19-31 | |

| Figure 19-17: | Ceramic Tile Consumption in Top Ten States in USA (1998) | 19-32 | |

| Figure 19-18: | Ceramic Tile Production by Major Producing Countries in 2001 | 19-34 | |

| Figure 19-19: | Chinese Ceramic Tile Production, 1999 to 2002 | | 19-35 | |

| Figure 19-20: | Sensitivity of NPV | | 19-52 | |

| Figure 19-21: | Overall Project Schedule | | 19-60 | |

| | | |

Project No. 146357 | TOC vi | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

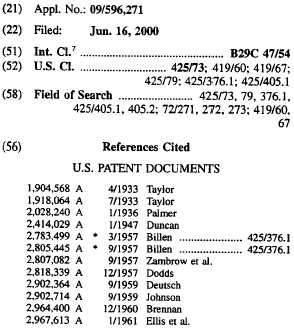

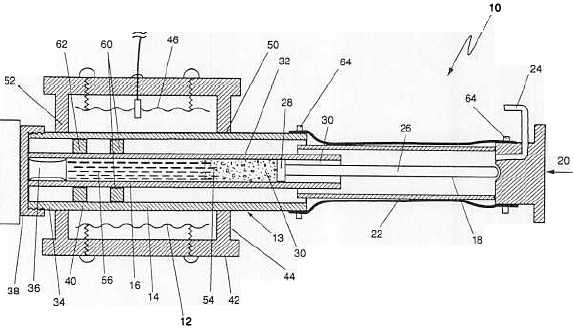

APPENDICES

Appendix A

Patents

Appendix B

Site Plan

Appendix C

Geochemistry

Appendix D

Sample Protocols and Testing

Appendix E

Flowsheet, Plant Layout, and Equipment List

Appendix F

Cash Flow Model

| | | |

Project No. 146357 | TOC vii | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

1.0

SUMMARY

1.1

Introduction

The Idaho-Maryland Mining Corporation (Idaho-Maryland) is a wholly owned subsidiary of Emgold Mining Corporation (Emgold). Idaho-Maryland holds a mining lease and option to purchase the Idaho-Maryland property. The property encompasses a previously mined gold deposit suitable for further gold exploration and a recently defined industrial minerals deposit that may be suitable for the production of ceramic products. The Idaho-Maryland property is located near the eastern side of the City of Grass Valley, Nevada County, within the State of California.

The overall development plan for the Idaho-Maryland project envisions the following three major components:

1.

Development of a decline to access underground drill stations for gold exploration

2.

Construction of a commercial ceramics production facility which will utilize development rock from the decline and rock from an underground room-and-pillar mine as feed material

3.

Upon confirmation of an economic gold resource, establishment of a commercial gold mine and processing operation, integrated with the ceramics process so that gold process tailings and development rock would become the feedstock for the ceramic process

This technical assessment specifically evaluates the development of the decline plus the establishment of a stand-alone industrial minerals mine and ceramics production facility and describes further exploration potential for gold at the Idaho-Maryland project.

The establishment of a gold mine and processing operation is contingent on successful gold exploration. A stand-alone gold mine and process plant has been assessed in previous AMEC reports and is not specifically addressed in this Preliminary Assessment.

Previous work by Emgold focused on identifying and developing the gold resource at the property with the objective of establishing a commercial gold mine. Idaho-Maryland has stated that it plans to continue development of the gold resources and a significant underground gold exploration program is planned. The exploration program will require development of a long decline to access underground drill stations. In driving the decline, and if a commercial gold mining operation is ultimately established, Idaho-Maryland will not be able to obtain sufficient nearby land holdings to construct both a long-term waste rock and tailings storage facility. Operations will eventually entail disposal of waste material off

| | | |

Project No. 146357 | Page 1-1 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

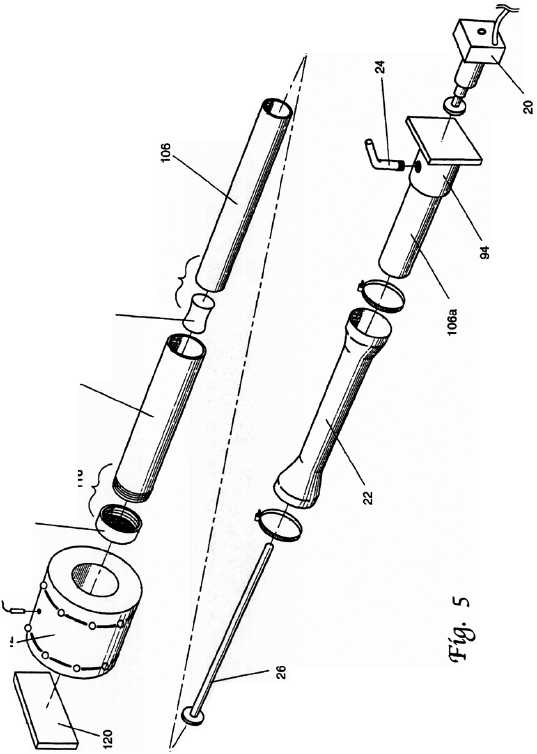

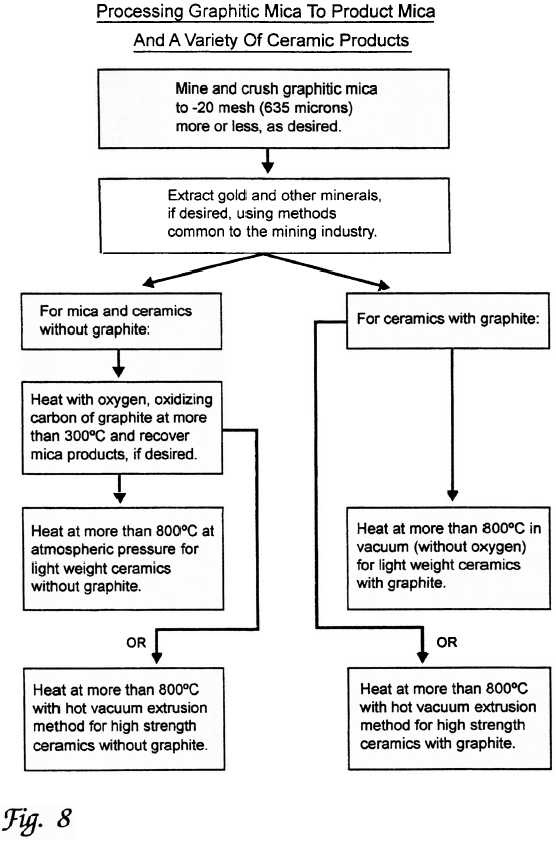

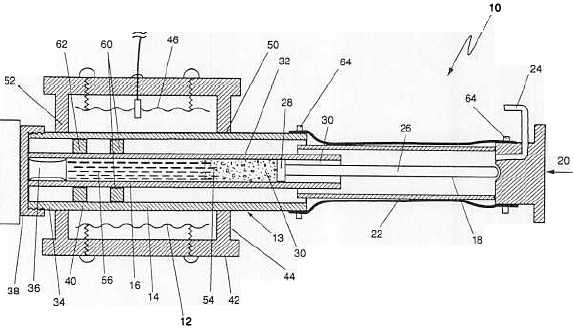

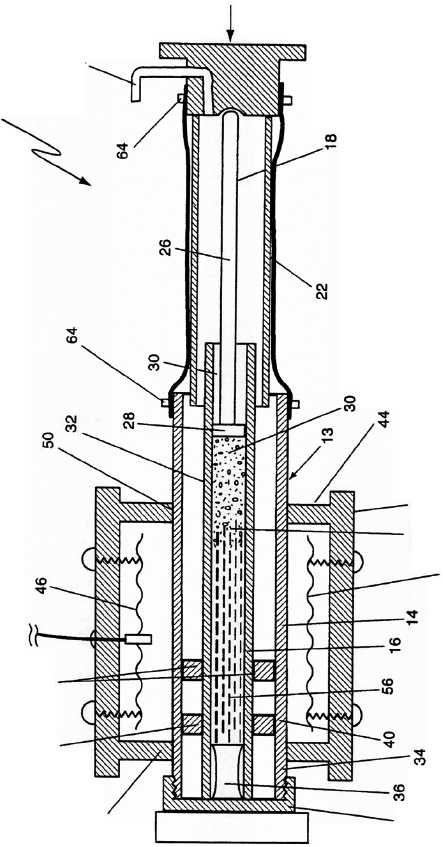

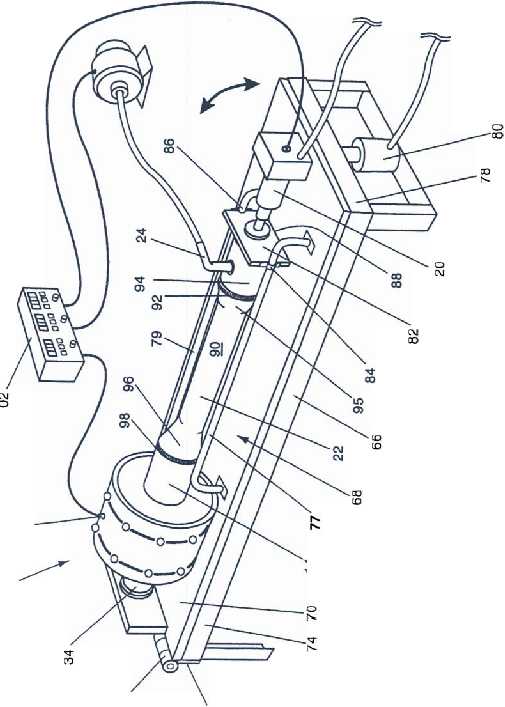

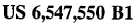

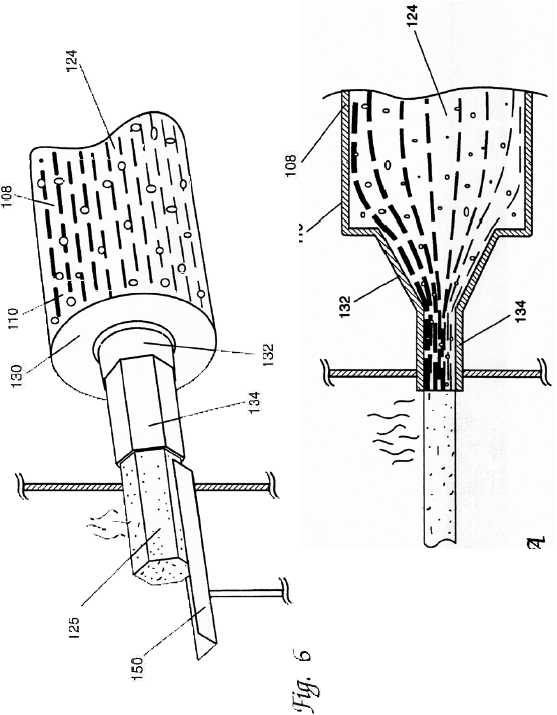

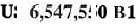

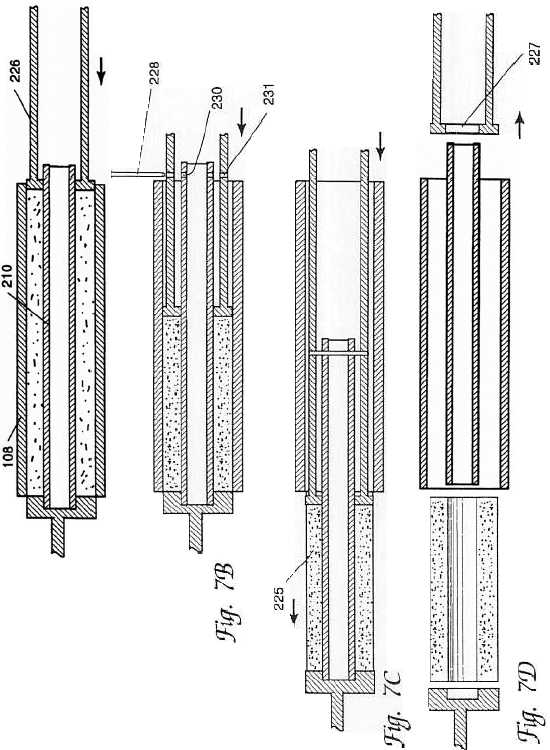

site. The permitting, logistics and financial effects caused by ongoing off-site waste disposal will likely impact the project to the extent that it may no longer be feasible. In response to this, Idaho-Maryland management identified and licensed a new technology that offers the potential to utilize the development rock and gold process tailings for the production of ceramic building products. The trade name for the technology is Ceramext™. The Ceramext™ process is a new, patented, and proprietary process for the manufacture of ceramic products. The process has been tested at the lab and pilot-plant scale currently, there are no full-scale commercial operations utilizing the process. Implications for scale-up to commercial application, including technical and economic parameters, are still to be determined. Larg e domestic and international markets exist for quality ceramics products, but acceptance of Ceramext™ ceramic products will ultimately depend on quality and price. Successful application of the Ceramext™ technology is projected to consume all the mine waste rock and process tailings thereby eliminating the requirement for long-term surface storage of these materials.

The successful production and sales of ceramic materials would allow Idaho-Maryland to continue with exploration of additional gold targets, then pre-production development, with the objective to define an economic gold reserve while generating positive cash flow from the ceramics production.

1.2

Geology and Mineral Resource

1.2.1

Geological Setting

The Idaho-Maryland mine and the Grass Valley Mining District are situated in the northern portion of the Sierra Nevada Foothills Gold Belt. This belt averages 50 miles in width and extends for 320 miles in a north-northwest orientation along the western slope of the Sierra Nevada range. The extent of the Sierra Nevada Foothills Gold Belt coincides closely with the outcrop area of the Sierra Nevada Foothills Metamorphic Belt.

The rocks underlying the Idaho-Maryland mine property are divisible into five separate units ranging in age from early to late Jurassic:

1.

Early Jurassic meta-sediments of the Fiddle Creek Complex

2.

Early Jurassic meta-volcanics and interflow sediments of the Lake Combie Complex

3.

Middle Jurassic ophiolitic assemblage of the Spring Hill Tectonic Mélange

4.

Discontinuous later Jurassic Tectonic Mélange of the Weimar Fault Zone

5.

Late Jurassic dioritic intrusives.

| | | |

Project No. 146357 | Page 1-2 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

The most important of these units with respect to the feed material for the ceramics manufacturing process are the Jurassic meta-volcanics. With regard to exploration for gold mineralization, the Spring Hill Tectonic mélange is the unit of primary interest.

The Idaho-Maryland property hosts a structurally controlled deformation zone terminated at its eastern end by a regional fault. Within this deformation corridor, large dismembered clasts of predominantly ophiolitic igneous origin are present in a foliated serpentinite melange matrix. These large clasts are referred to as slabs in Idaho-Maryland company reports. Identified slabs consist of albitized (sausserite) meta-gabbro, massive antigorite serpentinite, meta-diabase, meta-diorite, slates, and basaltic to dacitic meta-volcanics.

The largest slab of metavolcanic rocks on the property is the Brunswick Slab, which is 1.5 miles in length, approximately 0.6 miles in width, elongated in an eastward direction, and open at depth. This slab is interpreted to be derived from the Lake Combie Complex, and the industrial minerals resource is a block within this slab.

The industrial minerals feedstock deposit consists mostly of metamorphosed andesite, dacite, diabase and gabbro correlative with the Lake Combie Complex. These rocks were observed in drill core and outcropping on the surface as well.

1.2.2

Summary of Industrial Mineral Resource (Ceramics Feedstock)

The industrial minerals ceramics feedstock resource was delineated by seven geotechnical core holes drilled at inclinations of 40° and 45°, one exploration core hole, seven surface sample sites, and certain geologic data from historical underground mine drifts. The top boundary of the resource is 200 ft below the ground surface (due to depth of mineral rights). Drill hole spacing ranged from 80 ft to 1,200 ft. The lower boundary of the resource is based on the bottom of the drill holes, since drilling ended within Lake Combie Complex igneous rock units. The west boundary is where the amount of gabbro and ultramafic rocks begin to increase. The east boundary is based on the limit of geotechnical drilling and surface sampling.

The Idaho-Maryland project has measured, indicated, and inferred industrial minerals (ceramics) feedstock resources, as summarized in Table 1-1.

| | | |

Project No. 146357 | Page 1-3 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

Table 1-1:

Summary of Ceramics Feedstock Resources, 5 November 2004

Classification | Tons |

Measured mineral resources | 48,817,000 |

Indicated mineral resources | 122,685,000 |

Measured + Indicated mineral resources | 171,502,000 |

Inferred mineral resources | 358,112,000 |

1.2.3

Gold Resource

The Idaho-Maryland property hosts a significant gold deposit first discovered in 1851. Gold mining commenced in 1862 and continued until 1954. The Idaho-Maryland was the second largest underground gold producer in California.

The varying styles of mineralization present at the Idaho-Maryland project are typical of those commonly found in mesothermal lode gold deposits worldwide. At least four basic types of mineralization have been recognized to contain significant gold deposits. In order of importance these include: 1) gold-quartz veins, 2) mineralized black slate bodies, 3) mineralized diabasic slabs, and 4) altered, mineralized phyllonites. The veins consist primarily of quartz, which is milky white, massive to banded, sheared, and brecciated. Gold occurs as native gold, ranging from very fine grains within the quartz to leaves or sheets along fractures.

Table 1-2:

Gold Resources, 20 September 2004

| | True Thickness

(ft) | Tonnage

(tons) | Gold Grade

(oz/ton) | Gold

(oz) | Gold Grade

(oz/ton)

1.44 MCF | Gold

(oz)

1.44 MCF1 |

Idaho-Maryland Project 2 |

|

| |

| |

|

Measured Mineral Resource 1 | 13.3 | 271,000 | 0.22 | 59,000 | 0.31 | 85,000 |

Measured Mineral Resource 2 | 70.7 | 831,000 | 0.15 | 127,000 | 0.15 | 127,000 |

Indicated Mineral Resource | 8.1 | 489,000 | 0.35 | 172,000 | 0.50 | 243,000 |

Measured + Indicated Mineral Resources | 41.1 | 1,666,000 | 0.22 | 375,000 | 0.28 | 472,000 |

Inferred Mineral Resources | 9.3 | 2,526,000 | 0.26 | 666,000 | 0.38 | 952,000 |

1. MCF = Mine Call Factor (not applicable to Waterman Group resources). 2. Idaho-Maryland measured resources are split into two categories: 1. the Eureka, Idaho, Dorsey, and Brunswick Groups, and 2. the Waterman Group (stockwork/slate type ore).

1.3

Exploration

1.3.1

Industrial Minerals Resource Exploration

Emgold, initiated exploration of the Idaho-Maryland property in 1993. Emgold’s wholly owned subsidiary, Idaho-Maryland has continued exploration to the present. The primary

| | | |

Project No. 146357 | Page 1-4 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

focus has been to identify gold mineralization with the objective of developing a mineable gold resource.

More recently, Emgold identified and secured rights to a new potentially commercial ceramics manufacturing process and realized that the Idaho-Maryland property may host mineral resources suitable as feedstock for the process. Initial investigations of the meta-volcanic rock were begun in June 2004 with a geotechnical drilling program designed to obtain data for the design of a mine access ramp. Geological information from this program was also analyzed to determine if the rock excavated during ramp construction would be suitable feedstock for the ceramics process. The analysis included surface geologic mapping, outcrop sampling, sampling of the diamond drill core, and testing of samples to assess their suitability for ceramics manufacture. The result of these analyses was the definition of a large volume of igneous rocks of similar composit ion that were considered satisfactory as an industrial mineral resource suitable for ceramics manufacture.

The industrial rock resource is adequately defined by core drilling, but further testing, marketing, and production of ceramic products using the Ceramext™ Process, and the beginning of underground development will be necessary to upgrade industrial rock resources into reserves. No further core drilling of the meta-volcanics is planned until access is developed underground.

1.3.2

Gold Exploration

The gold exploration program has consisted of an extensive geologic evaluation of the historical mine records plus additional diamond drilling from surface. This rather unique program was possible because of the excellent and comprehensive preservation of the historical Idaho-Maryland mine and mill records. Idaho-Maryland has indicated this data is exhaustive and essentially complete, and was used to generate a consistent, property-wide structural geology model and vein set definition and chronology. Unmined mineralization was identified along underground workings and in historical diamond drill holes. Interpretation of the updated geologic model defined new vein sets and extensions of known vein sets. These were categorized for mineral resource estimates, future exploration, and expansion.

There is potential to identify additional gold resources on the Idaho-Maryland property, and Idaho-Maryland management has indicated its intent to continue with an ongoing gold exploration program. An access ramp is planned to establish underground drilling stations for further drill testing of key gold target areas, plus definition and expansion of known gold resources.

| | | |

Project No. 146357 | Page 1-5 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

1.4

Property Description and Tenure

The Idaho-Maryland property is 1.5 miles from the center of Grass Valley, Nevada County, in north-central California. The property comprises approximately 2,750 acres of mineral lands, with 37 acres of surface rights centered around the New Brunswick shaft, 101 acres of surface rights west of the Idaho shaft, and a one-acre easement on the Round Hole Shaft property. The 101 acre site is called the Idaho-Maryland property. The mineral rights are defined as sub-parcels in a Quit Claim Deed. The mineral rights are restricted to a variable depth from surface and are generally contiguous below 200 ft from surface. Idaho-Maryland has an agreement with the mineral rights holders (BET Group) that include a mining lease and an option to purchase both the 56 and 37 acre properties. The term of the lease agreement is five years commen cing 1 June 2002. During the term of the lease agreement, any production from the property will be subject to a 3% Net Smelter Royalty (NSR).

1.5

Mining

An underground mine plan has been developed to extract the industrial minerals resource at the Idaho-Maryland mine using modern mining methods and simultaneously provide access to underground gold exploration targets and known gold resources.

Feed material for ceramics production will come primarily from room-and-pillar stopes located 500 ft or more below surface. The decline and ancillary development will also provide ceramic feed material. The decline has been placed such that it will also provide an excellent drill platform for exploration of the known gold resources and additional exploration targets within and adjacent to the historic Idaho-Maryland workings.

The ramp access will be driven as two declines separated by a 60 ft pillar. This will allow one decline to be used for fresh air and the other for exhaust, providing ample ventilation without the need for a major ventilation raise until a connection can be established with the Brunswick mine workings.

To reduce the potential for higher noise levels on surface, a temporary crusher for ceramic feed material and development rock will be installed underground at 1,000 ft from the portal and within a year after portal excavation begins. Until this time, movement of trucks and crushing of ceramic feed material on surface will be confined mostly to daylight hours.

The temporary crusher will supply the surface stockpiles until a permanent crusher can be located at greater depth. The permanent crushing installation will be operational roughly three years after the start of the decline at a depth of 900 ft below surface. Like the temporary crusher, it will supply surface stockpiles via a 36" conveyor. Also, in

| | | |

Project No. 146357 | Page 1-6 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

consideration of noise levels on surface, the underground coarse ore bin and crusher have been sized to supply full production feed operating one shift per day.

Ground conditions in the area of the ceramics feedstock resource are expected to be very good. Room-and-pillar mining has been selected as the long-term mining method because it is responsive to changes in ground conditions, and the equipment and workforce requirements are similar to those for tunneling. The method is based on personnel entry so the underground openings will be smaller than with other bulk mining methods.

No backfill is planned after extraction of the ceramics feedstock/industrial minerals resource. Pillars have therefore been designed with high safety factors, and recovery is planned at roughly 25% of the resource. Rock pillars have been designed to remain stable indefinitely.

Room-and-pillar mining for ceramic plant feed may start at 500 ft below surface roughly three years after the start of the underground decline. By this time, the permanent crushing and conveying installation will be operational. Ceramics production is scheduled to ramp up gradually from 1,200 ton/d to 2,400 ton/d over the course of three years from initial plant start up.

The dewatering of the mine workings from the New Brunswick Shaft will be required to eliminate the risk of water pressure transmitted through diamond drill holes penetrating areas close to the old mine workings and will be required in advance of a breakthrough into old mine workings.

Surface exposure of underground workings will be limited to the portal, which will be covered with a culvert and four raises for ventilation and emergency exit from the mine.

1.6

Process

1.6.1

Mineral Processing

The development scenario for the Idaho-Maryland ceramics project will see an initial production rate of 1,200 ton/d, increasing to 2,400 ton/d at the start of Year 4 after initial plant start-up.

1.6.2

Crushing, Drying, and Grinding

The feed material for the ceramic production will consist primarily of meta-volcanics. Run-of-mine (ROM) ceramics plant feed material will be crushed in an underground crusher and conveyed to two crushed material stockpiles on surface adjacent to the process plant. Crushed ore will be drawn from the stockpiles by reclaim feeders and fed to the

| | | |

Project No. 146357 | Page 1-7 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

secondary/tertiary crushing plant. Crushing circuit product will then be passed through a rotary kiln drier to reduce the moisture content to 1% prior to a single stage of grinding in a high-pressure-grinding roll (HPGR). The ground product will be classified in a dynamic separator with a target final product particle size of 80% passing 150 µm. The sized product will be conveyed to a series of storage silos adjacent to the ceramics plant and will be segregated depending on the mineralogical composition and the final ceramic product required.

Although the initial Phase 1 ceramic plant capacity will be 1,200 ton/d, the secondary and tertiary crushing circuit will be constructed with a capacity of 2,400 ton/d, which will be sufficient for Phase 2 ceramic production rate. The initial high-pressure grinding roll will have a capacity of 1,200 ton/d, and a second grinding roll circuit will be installed for the expansion to 2,400 ton/d. Primary underground crushing and conveyor transport to the surface stockpile will take place on dayshift only to minimize noise levels during non-daylight hours. The secondary/tertiary crushing and grinding circuits will be completely enclosed in an insulated building to minimize external noise levels. This will permit these circuits to operate 24 h/d.

1.6.3

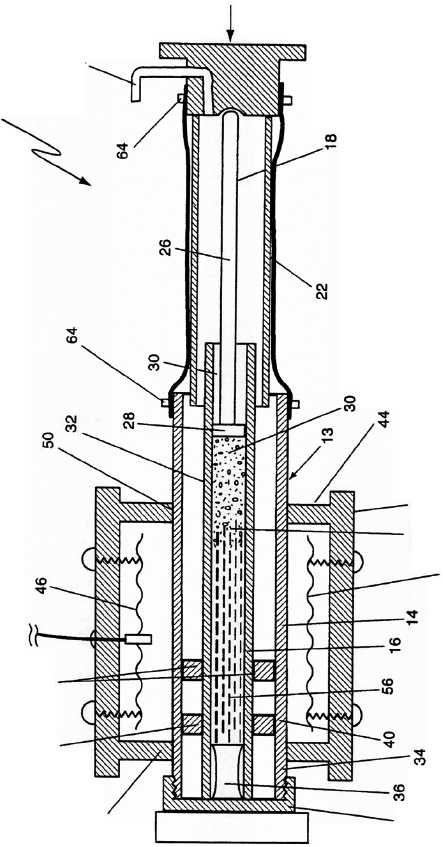

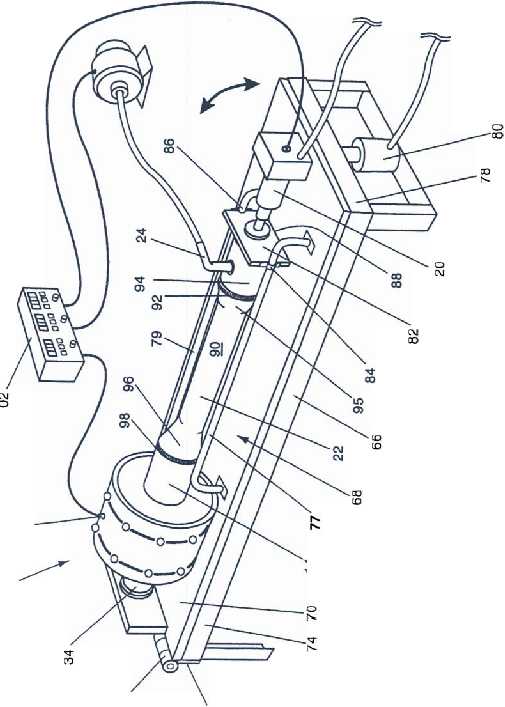

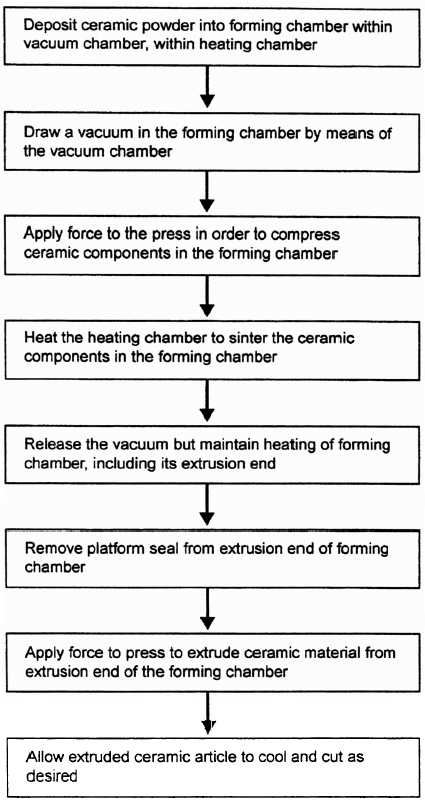

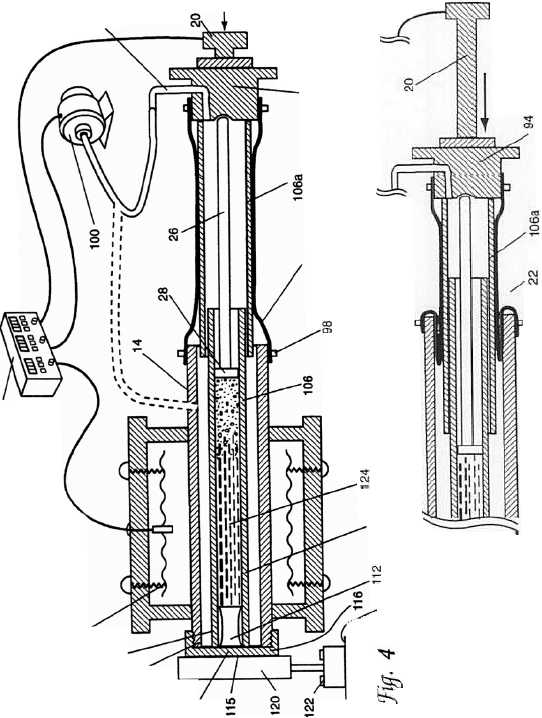

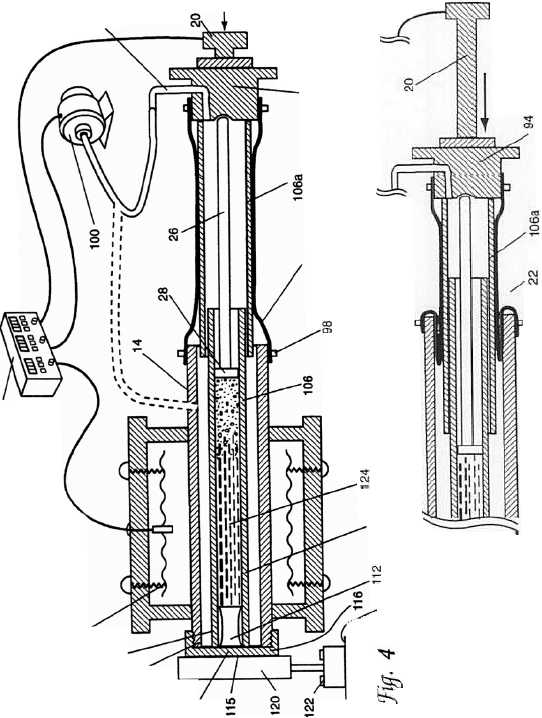

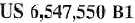

Ceramics Production

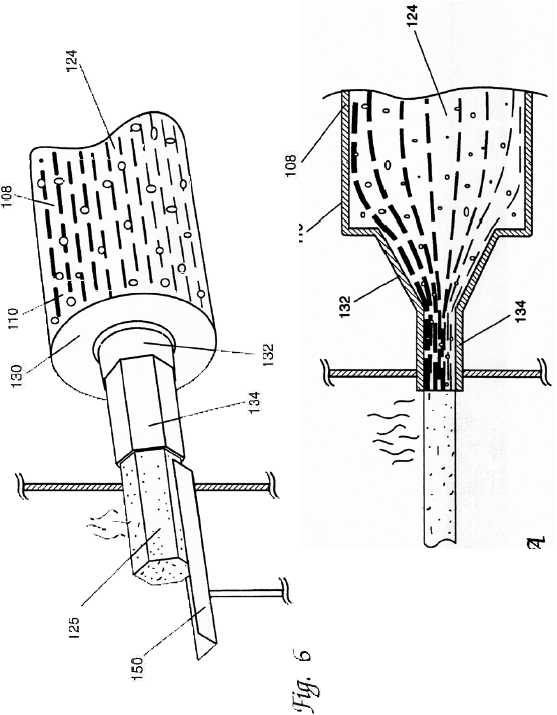

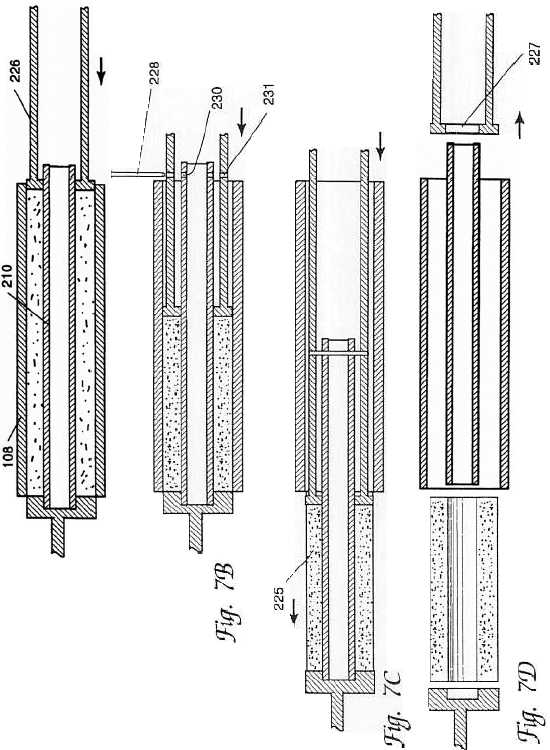

Ceramics manufacturing will utilize the proprietary Ceramext™ process, which is based on high temperature vacuum extrusion to produce high-strength, low porosity industrial ceramics such as floor tile, roof tile, brick, and other construction materials. Ceramic feed material will be drawn from the silos and conveyed to a set of blenders used to mix predetermined quantities of feed material for different end products. From the blenders, the feed material will be conveyed to screw feeders used to meter feed material to a bank of pre-heaters. Each pre-heater will feed multiple ceramic manufacturing lines and will serve to drive off remaining moisture as well as heating the material for the ceramics process. Upon exiting the pre-heaters, the material will be fed into the extrusion and forming process. From t he extrusion and forming process, the shaped pieces will be directed to a glazing process or to the cooling furnaces. The cooling furnaces provide a controlled temperature environment to reduce the ceramic product to ambient temperature.

From the cooling furnaces, products will be machine stacked. Flat tile products will be boxed, strapped, and palletized. Shaped tile products, brick pavers, and block will be strapped and palletized. All packaging operations will be fully automated. Packaged products will be delivered to either indoor or outdoor storage to await customer delivery. The Ceramext™ equipment is patented, the process patent is pending and additional patents are being prepared for further protection and commercialization of the intellectual property. A copy of the patent is in Appendix A. The Ceramext™ process has been successfully tested at the pilot plant level. However, at this point, there is no full-scale production unit in operation.

| | | |

Project No. 146357 | Page 1-8 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

Dr. Carl Frahme, an independent consultant and the designated Qualified Person for the ceramic portion of the project, has evaluated the technical and economic aspects of the Ceramext™ project. He has concluded that the Ceramext™ process is technologically sound, that its basic premise of high temperature extrusion has been validated and demonstrated, and that production of competitive ceramic has the potential to be feasible. His economic evaluation indicates that the process may achieve lower production costs and produce superior products when compared to existing technology currently in use, and is economically attractive and viable. He also evaluated the market for products that could be produced by the process, and has determined that the markets are large and that market entry and penetration do not offer large obstacles.

1.6.4

Gold Processing (Future)

Should a commercial gold resource ultimately be defined, the crushing and grinding circuits installed for the ceramics process will also serve to crush and grind ore for the gold recovery process. Furthermore, the overall process route would be modified so that the product from the grinding circuit would report first to the gold recovery circuit. The final process tails from the gold circuit would then be treated to remove residual cyanide, dewatered, dried, and then fed to the ceramics process.

The gold ore would be crushed and then ground to 80% passing 150 µm particle size. Gravity concentration and flotation circuits would be used to produce gold concentrates. The concentrates would be leached in an intensive cyanidation circuit to extract gold, and the gold would be recovered from the leach solutions by precipitation in an electrowinning circuit. The gold would be smelted on site to produce doré, which would then be transported off-site to a custom refiner to produce refined bullion. Barren solid residue from the intensive leach process would be rinsed to remove residual cyanide, and then transported off site to a custom treatment facility.

Tailings from the process plant would be dewatered to recover water for reuse in the process. All material that has come into contact with cyanide would be treated to destroy any remaining cyanide. Dewatered tailings material in excess of that required for backfill in the gold mine would be used for ceramics production.

As the process tailings would be consumed in the ceramics manufacturing process or used for backfill in the underground mine, there would be no need for a surface tailings containment system.

1.7

Site Facilities

The Idaho-Maryland project consists of three general areas: the 101 acre Idaho-Maryland site property adjacent to the Idaho shaft, the 37 acre Brunswick property surrounding the

| | | |

Project No. 146357 | Page 1-9 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

New Brunswick shaft, and the 1 (one) acre easement on the Round Hole Shaft property. The bulk of the new facilities will be constructed on the Idaho-Maryland property. These facilities will include the decline portal, vent raise, escape raise, ore stockpiles, storm water detention and mine water sedimentation ponds, process plants, warehouse, truck shop, electrical substation, mine dry, administration building and visitors center.

It is planned to construct certain facilities on the Brunswick property as part of the proposed gold exploration program. These facilities will include hoist house, headframe and hoist, pump system for mine dewatering, mine water treatment system, power supply substation and emergency generator/compressor house.

The Round Hole shaft may be used in the future as a ventilation shaft and emergency access shaft.

The proposed location of the decline portal is toward the west side of the Idaho-Maryland property. Services feeding the decline will be electric power, fresh water, discharge water, communications lines, and compressed air pipelines. The escape raise will be positioned in the southeast corner of the Idaho-Maryland property, and the ventilation shaft will be located in the northeast corner.

A high voltage powerline located within a quarter mile of the Idaho property will supply the site with power. The average power demand for the mine, ceramics manufacturing plant and ancillary facilities will be approximately 9200 kW at the 1,200 ton/d production rate. At the increased production rate of 2,400 ton/d the power demand will increase to 18,500 kW. Natural gas for the rotary kilns and ceramics process heating will be supplied via a pipeline to the site.

Fresh water will be supplied from the Nevada Irrigation District (NID) water supply. Process water will be drawn as reclaim water from the mine dewatering system.

The existing mine workings will be dewatered via a pumping system in the New Brunswick shaft. The water will be treated to remove dissolved iron and manganese and any other metals, and will meet state and federal water quality standards prior to release to the South Fork Wolf Creek. Iron and manganese residues recovered during water treatment will be collected for recycle to the ceramics process.

Other metal residues, if present, will be collected and transported off-site for treatment and/or storage.

| | | |

Project No. 146357 | Page 1-10 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

1.8

Permit Application Requirements and Status

A Conditional Mine Use Permit (use permit) is required in order for Idaho-Maryland to continue with the underground exploration, and development of the Idaho-Maryland deposit.

Emgold through its subsidiary, Idaho-Maryland Mining Corporation has been successful in obtaining all permits applied for to date regarding the exploration and development of the Idaho-Maryland project. Idaho-Maryland is currently preparing separate applications for permits to further exploration, development and operation of the mine.

Idaho-Maryland is currently applying for a use permit to conduct another surface core drilling exploration program. Surface exploration programs have and will continue to consist of diamond drilling to expand the understanding of the project geology and identify underground exploration targets. Separate drilling permits will be required to conduct the surface exploration drilling programs.

A use permit will be required to conduct the underground diamond drilling exploration and mine development programs. This use permit will also include the construction of the decline, dewatering of existing mine workings, mine development, construction of surface facilities including processing and support facilities, and ultimately closure and reclamation activities. The application for the use permit will incorporate a phased development program in order to streamline the permitting process while at the same time, retaining the option to evaluate the project on completion of underground drilling and exploration activities. If the results from both the surface and underground exploration meets expectations, Idaho-Maryland may proceed with further development, production and operation under the same use permit.

Granting of the use permit for the mineral resource development program will require a zoning designation and general plan amendment from the City of Grass Valley to allow for mining operations. Such actions require a use permit application be submitted to the lead agency, which will trigger the California Environmental Quality Act (CEQA) process.

In addition to CEQA, the following environmental laws are applicable to the project: Surface Mining and Reclamation Act (SMARA, 1975), Clean Water Act (CWA, 1972), and Clean Air Act (CAA, 1972).

Idaho-Maryland commissioned MACTEC Engineering and Consulting, Inc. (MACTEC) of Petaluma, California, to complete a Conceptual Development Review Application for the Idaho-Maryland mine project. This document was completed on 28 July 2004 and has been received by Idaho-Maryland management. This document was submitted to the City of Grass Valley on 30 July 2004. An initial response from the City of Grass Valley has

| | | |

Project No. 146357 | Page 1-11 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

been received by Idaho-Maryland and Idaho-Maryland is now preparing the final conditional mine use permit application for submission to the City of Grass Valley.

1.9

Environmental Considerations

Idaho-Maryland contracted MACTEC to complete a Phase 1 Environmental Site Assessment of the WestBet property (also referred to as the Idaho-Maryland). The investigation did not identify evidence of recognized environmental conditions. A due diligence site investigation was completed by MACTEC on the adjoining Brenner property (formerly known as the Lausman) and evidence of recognized environmental conditions was observed. The environmental concerns on the Lausman property relate to a log pond and an underground fuel storage tank. Subsequent to the performance of the investigation, Idaho-Maryland purchased the property under a joint venture agreement with Milco Development. Under the terms of the agreement, Idaho-Maryland owns the southern 45 acres of the 67 acre property and Milco owns the remaining portion. The log pond is locat ed entirely on the Milco property. The underground fuel storage is located entirely on the Idaho-Maryland property. Remediation of the underground fuel storage is currently underway.

The Phase I Environmental Site Assessment is preliminary in scope and MACTEC recommends more detailed assessment including testing on samples of soil and groundwater.

Virtually all of the building structures related to the historic mine operations on the Idaho-Maryland property have been removed. The only physical structures remaining are two concrete towers previously used for the deposition of mine tailings. Idaho-Maryland management has stated that the company may be responsible for any environmental liabilities pertaining to the former mine operations.

Due to its proximity to the City of Grass Valley, the proposed design has taken into consideration noise levels generated by the operation. During the initial development of the underground mine access, haul trucks will transport rock to a temporary primary crusher on surface for a period of approximately one year. Hauling and crushing activities will be restricted to daylight hours during this period. The primary crusher will be relocated underground and a conveyor installed once sufficient mine development has been completed. Conveying of rock to surface will be conducted only during daylight hours.

Once the surface plant facilities are constructed, most of the industrial operations with the exception of the crushed rock stockpiles will be housed within fully enclosed and insulated buildings. This will serve to maintain low external noise levels. As the mine is underground, virtually all mine-related operations will be underground and noise will not be a factor.

| | | |

Project No. 146357 | Page 1-12 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

Significant effort will be made to minimize the physical and visual impact of the project on the environment and community. Existing waterways will be preserved. Impact on existing vegetation will be minimized. Current architectural codes will be strictly adhered to. Visual sight lines will be taken into account in the layout of the project site. Surface exposure of underground workings will be limited to the portal, which will be covered with a culvert, and four raises required for ventilation and emergency exit from the mine.

1.10

Marketing and Sales Approach

Based on the 1,200 ton/d feed rate, the ceramics plant could produce approximately 160 Mft2/yr of tile. This represents approximately 5% of 2003 US tile consumption and 35% of 2003 California consumption. The second stage of mine development would double this production level to approximately 320 Mft2/yr.

Given the superior properties of tile and other products expected using Ceramext™ technology, the proposed market strategy would be to compete in the higher ends of the marketplace. For ceramic tile, this would include vitrified floor tile and porcelain tile products. These products command higher retail prices and represent the major share of the market growth in recent years. Target markets would include large commercial projects (malls, commercial office space, restaurants, civic projects) and upscale home floor, wall, and countertop installations, for both new construction and renovation. Factory selling prices in the $1.00/ft2 to $1.50/ft2 are expected based on current market experience.

A number of marketing and sales channels are available, including factory direct showrooms, independent distributors, and large retail stores. An assessment of the marketing channels is warranted to identify the optimum marketing and sales approach.

1.11

Capital Cost Estimate

The estimated capital cost for development of the mining, process, and ancillary facilities to achieve a production rate of 1,200 ton/d is $195,914,000. The estimated additional capital cost for the expansion of the mine and process plant to achieve a production rate of 2,400 ton/d is $154,652,000. The total estimated mine and plant capital cost is $350,566,000. The costs are based on 4th quarter 2004 US dollars. The estimate should be considered as conceptual with a probable accuracy of ±35%.

The capital cost estimate includes:

| | | |

Project No. 146357 | Page 1-13 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

contingency

Owner’s costs

working capital.

Separate from the ceramic mine and plant project cost, an additional $43,000,000 has been included to complete dewatering and rehabilitation of the Brunswick mine workings, and to perform a gold exploration program primarily in the areas of the previous Brunswick and Idaho-Maryland workings, and complete a feasibility study on the gold project.

The total project capital cost including mine, plant, mine dewatering, rehabilitation of existing Idaho-Maryland mine workings, and gold exploration program is $393,566,000.

1.12

Operating Cost Estimate

The estimated project operating costs are presented in Tables 1-3 and 1-4. The mine operating costs are based on unit costs and manpower levels typical of other underground mines of similar scope with the notable exception that access drives provide feed to the process plant and therefore the cost per ton is much lower. The processing costs are comprised of two major components; 1) crushing, drying, and grinding; 2) ceramics processing. The crushing, drying, and grinding costs are based on typical industry costs for plants of similar scope. The ceramics processing costs have been provided by Idaho-Maryland and must be considered conceptual, as there are no plants in operation using this technology on which to base the estimated costs. The G&A costs have been based on other mining projects of similar size.

| | | |

Project No. 146357 | Page 1-14 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

Table 1-3:

Operating Costs by Year $/ton of Feed Processed

| Pre-Production | | Expansion | | Full Production |

| Year 1 | Year 2 Q1 + Q2 | | Year 2 Q3 + Q4 | Year 3 | Year 4 | Year 5 Q1 + Q2 | | Year 5 Q3 + Q4 | Year 6 | Year 7 | Year 8 | Year 9 | Year 10 |

Tons/d | | | | 1,200 t * | 1,200 t * | 1,200 t * | 1,200 t * | | 2,400 t * | 2,400 t | 2,400 t | 2,400 t | 2,400 t | 2,400 t |

Mining | - | - | | 20.28 | 28.87 | 34.90 | 40.93 | | 26.10 | 30.21 | 30.81 | 29.68 | 30.09 | 28.75 |

Process | - | - | | 97.07 | 97.07 | 97.07 | 97.07 | | 90.22 | 88.22 | 88.22 | 88.22 | 88.22 | 88.22 |

G&A | - | - | | 7.01 | 7.01 | 7.01 | 7.01 | | 3.50 | 3.50 | 3.50 | 3.50 | 3.50 | 3.50 |

Total | - | - | | 124.36 | 132.95 | 139.97 | 145.01 | | 119.82 | 121.93 | 122.53 | 121.40 | 121.81 | 120.47 |

* plant feed is combination of mined production and temporary stockpile reclaim

Table 1-4:

Operating Costs by Year $/ft2 of Ceramic Product

| Pre-Production | | Expansion | | Full Production |

| Year 1 | Year 2 Q1 + Q2 | | Year 2 Q3 + Q4 | Year 3 | Year 4 | Year 5 Q1 + Q2 | | Year 5 Q3 + Q4 | Year 6 | Year 7 | Year 8 | Year 9 | Year 10 |

Tile production | | 160,754,000 ft²/yr | | 321,507,000 ft²/yr |

Mining | - | - | | 0.05 | 0.07 | 0.09 | 0.10 | | 0.07 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Process | -

| - | | 0.25 | 0.25 | 0.25 | 0.25 | | 0.23 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 |

G&A | -

| - | | 0.02 | 0.02 | 0.02 | 0.02 | | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

Total | - | - | | 0.32 | 0.34 | 0.36 | 0.37 | | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 |

| | | |

Project No. 146357 | Page 1-15 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

1.13

Financial Analysis

The preliminary financial analysis for this project is presented in Tables 1-5 and 1-6. Based on the parameters and assumptions incorporated into this assessment, the analysis indicates a positive financial return on this project. California sales tax has been included in the analysis.

The inputs to the model were generated by AMEC and Idaho-Maryland to a scoping study level of accuracy. The model used a discounted cash flow (DCF) analysis to determine the pre-tax net present value (NPV) and the pre-tax internal rate of return (IRR) for the project.

Table 1-5:

Scenario A NPV at Varying Discount Rates and IRR)

| | 0% | 10% | 20% | 30% | 40% |

NPV (US$ ‘000) | 3,706,755 | 1,111,143 | 392,891 | 139,238 | 32,893 |

IRR (%) | 45.8 | - | - | - | - |

Table 1-6:

Idaho-Maryland Estimated Capital, Annual Production Costs and Sales at Average Conditions

Daily

Feed Rate

(ton/d) | Capital

Expense

(US$ M) | Estimated Tile

Production

(Mft2) | Projected

Sales1

(US$ M) | Production

Costs

(US$ M) | Direct Profit2

(US$ M) |

1,200 | 196 | 160 | 192 | 77 | 115 |

2,400 | 155 | 320 | 384 | 139 | 245 |

CA Sales Tax | 10 | - | - | - | - |

Total |

| - | - | - | - |

Note: 1 $1.30 ft2. 2 Excludes income taxes, dewatering and rehabilitation of existing Idaho-Maryland mine workings and gold exploration.

1.14

Project Schedule

The project schedule consists of five distinct stages: 1) securing permits and completion of feasibility study, 2) detail engineering, 3) driving of a decline to the industrial minerals mining area and development of initial mine excavation areas and exploration drill stations, 4) construction of the surface process and ancillary facilities, and 5) expansion of the mine production and surface process plant capacities.

Securing of permits and completion of a feasibility study is expected to require up to 24 months after submittal of the Conditional Mine Use Permit application. Detail engineering and development of the mine, construction of the surface plant and facilities is scheduled to require an additional 18 months. Overall, the implementation is estimated to be 36 to 42

| | | |

Project No. 146357 | Page 1-16 | ![[techreport054.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport054.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

months from submittal of the permit application to the start of production for the 1,200 ton/d project.

The expansion to 2,400 ton/d is projected to be completed 36 months after the initial start of the 1,200 ton/d processing plant.

1.15

Conclusions and Recommendations

This Preliminary Assessment Report was completed to assess at the conceptual level the economic potential to develop an industrial minerals mine and establish an associated ceramics production facility while providing underground access for gold exploration and resource definition. A key parameter to the viability of the project is the commercial application of the new, proprietary CeramextTM technology. The findings of this preliminary assessment are based entirely on the assumption that the technology may ultimately be successfully applied in a commercial application.

Recognizing the assumption and limitation stated above, the findings of the Preliminary Assessment indicate that the general concept of development of an industrial minerals mine and an associated ceramics production facility appears to warrant further development and study.

AMEC has identified a number of recommendations for this project. The recommendations are presented in Section 20.2.

| | | |

Project No. 146357 | Page 1-17 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

2.0

INTRODUCTION AND TERMS OF REFERENCE

2.1

Introduction

Idaho-Maryland retained the services of AMEC Americas Limited (AMEC) to evaluate the potential of a ceramics project on the Idaho-Maryland property and to report the findings in a Preliminary Assessment report. AMEC has completed two previous evaluations of the property based on the gold mining potential. The first was an independent Qualified Person’s review and evaluation in the form of a Technical Report as defined in National Instrument 43-101, Standards of Disclosure for Mineral Projects in November 2002. The second was a Scoping Study, dated January 2003.

The overall development plan for the Idaho-Maryland project envisions the following three major components:

1.

Development of a decline to access underground drill stations for gold exploration

2.

Construction of a commercial ceramics production facility which will utilize development rock from the decline and rock from an underground room-and-pillar mine as initial feed material

3.

Upon delineation of an economic gold resource, establishment of a gold mining and processing operation, integrated with the ceramics process so that gold process tailings would combine with mine rock as the feedstock for the ceramic process

Previous work by Emgold focused on identifying and developing the gold resource at the property with the objective of establishing a commercial gold mine. Idaho-Maryland management plans to continue pursuing development of the gold resources through further surface and underground exploration; however, underground exploration can only proceed after a Conditional Mine Use Permit is received from the City of Grass Valley. Obtaining this permit depends on acceptance of the project by the City of Grass Valley and Nevada County. In the event of planning and establishing a mining operation, the satisfactory management and treatment of all development rock and tailings from any underground exploration, mining, and recovery process would be critical to this acceptance.

In response to this, Idaho-Maryland management identified and licensed a new technology that offers the potential to utilize the decline development rock and gold process tailings for the production of ceramic building products. The trade name for the technology is Ceramext™. Successful application of the Ceramext™ technology would see all the mine development rock and gold process tailings consumed thereby eliminating the requirement for long-term surface storage of these materials.

| | | |

Project No. 146357 | Page 2-1 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

Upon identification of the Ceramext™ technology, Idaho-Maryland technical personnel also investigated the possibility of establishing a commercial industrial minerals mine on the Idaho-Maryland property. Their investigation led to the identification of a significant mineral deposit, the Brunswick Slab, within the Idaho-Maryland property boundaries that would provide suitable feed for the Ceramext™ process.

Application of the Ceramext™ technology combined with the suitability of the Brunswick Slab rock as feed material to the ceramics process may provide a business case for production of high-quality ceramic building materials. The successful production and sales of ceramic materials would allow Idaho-Maryland to continue with exploration, definition, and development of potential gold targets, with the objective to identify an economic gold reserve while generating positive cash flow from the ceramics development.

The industrial minerals mine will have an initial production rate of 1,200 ton/d, expanding in stages to an ultimate capacity of 2,400 ton/d by the end of the third year.

This study may be used to guide future work on the development of the project as well as to provide a development scenario for preparation of the use permit application. The study has been completed to a scoping level of accuracy. Facilities included in the scope are underground mine operations, a ceramics manufacturing facility, and ancillary plant and infrastructure.

Emgold through its wholly owned subsidiary, Golden Bear Ceramics Company, has signed an exclusive world-wide license agreement with Ceramext™, LLC to develop and use the Ceramext™ Process to convert mine development rock, tailings, waste and other naturally occurring materials into high quality ceramics. The Ceramext™ Process is a patented, energy-efficient, one-step technology capable of converting a wide variety of raw materials, including mine tailings and fly ash into high-strength, low-porosity, industrial ceramics such as floor tile, roof tile, brick, construction materials and other industrial and commercial products.

2.2

Terms of Reference

AMEC obtained information and data for the study from the Idaho-Maryland project site during visits between 3 and 11 October 2002, 3 and 4 June 2004, 24 August to 1 September 2004, and on 29 October 2004. Information was also obtained from a Scoping Study completed by AMEC in January 2003 for Emgold, which assessed the potential to establish a gold mining and processing operation. Additional information was obtained from Emgold’s head office in Vancouver, BC.

Idaho-Maryland and Emgold provided AMEC with the following information:

| | | |

Project No. 146357 | Page 2-2 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

overall project scope

capital and operating costs for the Ceramext™ process and plant facilities

manpower level for the Ceramext™ manufacturing facility

general and administration (G&A) costs

property ownership and location details

historical and current gold resource and industrial minerals resource data

labor rates as determined by Western Compensation and Benefits Consultants.

Pertinent data were reviewed in sufficient detail for the preparation of this document. The following AMEC personnel provided Qualified Person review:

Sean Waller, M. Sc., P. Eng. Acted as study manager and provided input and/or review on crushing and grinding process design, capital and operating cost estimates relating to crushing, grinding, certain infrastructure and site services (Sections 16, Sections 19.3 to 19.5, and Sections 19.7.1 and 19.7.2). Mr. Waller has not visited the site.

Stephen Juras, Ph. D., P. Geol. Reviewed geologic data, mineralogy and resource estimates as well as sample handling protocols (Sections 7 – 13, Section 17). Dr. Juras also visited the site on 3 to 4 June 2004 and 29 October 2004 as part of this preliminary Assessment. Dr. Juras had previously visited the site during the period of 3 to 11 October 2002 as part of a previous Preliminary Assessment performed by AMEC.

Mr. Joe Ringwald, P. Eng. Reviewed the underground mine design and costs (Sections 19.1, 19.3, 19.4, and 19.7.1). Mr. Ringwald has not visited the site.

Additional Qualified Person assistance was provided by the following persons:

For all technical, financial and marketing information pertaining to the CeramextTM technology and process, and ceramics marketing, AMEC has relied on information supplied by Dr. Carl Frahme, Ph.D. (Sections 16.1.2,16.3.1, 19.3.3, 19.4.3, 19.7.2) AMEC understands Dr. Frahme is an independent consultant with recognized expertise in ceramics manufacture and marketing. Dr. Frahme is currently an independent consultant to Idaho-Maryland and Golden Bear Ceramics Company.

For environmental information pertaining to the project site, AMEC has relied on information supplied by Patricia Nelson, Thomas Graham and Matthew Walraven of MACTEC Engineering and Consulting, Inc. AMEC understands that Ms. Nelson, Mr. Graham and Mr. Walraven are suitably qualified environmental scientists and that MACTEC is a recognized consulting firm with expertise in the environmental sciences. Ms. Nelson visited the site on numerous occasions. Mr. Walraven visited the site on September 13, 2004 and Mr. Graham visited the site on 2 and 3 August 2004. (Section 4.0).

| | | |

Project No. 146357 | Page 2-3 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

The CeramextTM process is a key parameter to the potential technical and economic viability of the project. This is a new, proprietary, patented process currently under development but at this point not proven in a commercial application. All information and data concerning the CeramextTM process were provided by Emgold, Idaho-Maryland management, and Dr. Carl Frahme, independent consultant of Emgold’s wholly owned subsidiary Golden Bear Ceramics Company.

Unless otherwise stated, all costs in this report are expressed in 4th quarter US dollars.

| | | |

Project No. 146357 | Page 2-4 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

3.0

DISCLAIMER

The CeramextTM technology is a new, patented and proprietary technology. At this point, there are no commercial installations utilizing this technology. With regard to all aspects of the CeramextTM technology, Ceramext™ costing and ceramic products marketing, AMEC has relied on information provided by Dr. Carl Frahme, an independent consultant with specific expertise in ceramics manufacturing and marketing. AMEC has done so under the assumption that Dr. Frahme is a Qualified Person under NI 43-101 guidelines. Furthermore, AMEC has relied on information provided by Dr. Frahme for the definition of mineralogy suitable for processing with the CeramextTM technology.

For environmental information pertaining to the project site, AMEC has relied on information supplied by Patricia Nelson and Thomas Graham of MACTEC Engineering and Consulting, Inc. AMEC understands that Patricia Nelson and Thomas Graham are suitably qualified environmental scientists and that MACTEC is a recognized consulting firm with expertise in the environmental sciences.

AMEC also relied on a legal report entitled “Legal Title Opinion prepared for the Core Area Properties of the Idaho-Maryland Mine Project, Grass Valley Mining District, Nevada County, California” (Galati & Associates, 1997) for its review of title and mineral rights. The report was used based on the assumption it was prepared by a Qualified Person.

| | | |

Project No. 146357 | Page 3-1 | ![[techreport004.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport004.gif)

|

November 2004 | |

![[techreport003.gif]](https://capedge.com/proxy/20FR12G/0001137171-05-001000/techreport003.gif)

| IDAHO-MARYLAND MINING CORPORATION |

PRELIMINARY ASSESSMENT TECHNICAL REPORT IDAHO-MARYLAND MINE, GRASS VALLEY, CALIFORNIA |

4.0

PROPERTY DESCRIPTION AND LOCATION

4.1

Location