Exhibit 99.1

AMC Mining Consultants (Canada) Ltd. BC0767129 — 200 Granville Street, Suite 202 Vancouver BC V6C 1S4 CANADA — T +1 604 669 0044 F +1 604 669 1120 E vancouver@amcconsultants.com W amcconsultants.com |  |

Technical Report

MAG Silver Juanicipio NI 43-101 Technical Report

MAG Silver Corp

Zacatecas State, Mexico

In accordance with the requirements of National Instrument 43-101 “Standards of Disclosure for Mineral Projects” of the Canadian Securities Administrators

Qualified Persons:

A. Ross, Ph.D., P.Geo. (BC, AB)

G. Methven, P.Eng. (BC)

H. Muller, MAusIMM, CP

C. Kottmeier, P.Eng. (BC)

AMC Project 717002

Effective date 21 October 2017

Adviser of choice to the world’s minerals industry

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

This Technical Report (the Report) provides an update of the Mineral Resource estimate and Preliminary Economic Assessment (2017 PEA) of the Mineral Resources identified within the Minera Juanicipio Property (the Property) in Zacatecas State, Mexico. The Report has been prepared by AMC Mining Consultants (Canada) Ltd. (AMC) of Vancouver, Canada on behalf of MAG Silver Corp. (MAG Silver).

MAG Silver owns 44% of Minera Juanicipio S.A. de C.V. (Minera Juanicipio), a Mexican incorporated joint venture company, which owns (100%) of the Property. Fresnillo plc (Fresnillo) holds the remaining 56% interest in the joint venture and is the project operator. The Report has been prepared in accordance with the requirements of National Instrument 43-101 (NI 43-101), “Standards of Disclosure for Mineral Projects” of the Canadian Securities Administrators (CSA) for lodgement on CSA’s “System for Electronic Document Analysis and Retrieval” (SEDAR).

The economic analysis in the 2017 PEA is preliminary in nature and is based, in part, on Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves. There is no certainty that the PEA will be realized.

The monetary values shown in the Report are in US dollars ($).

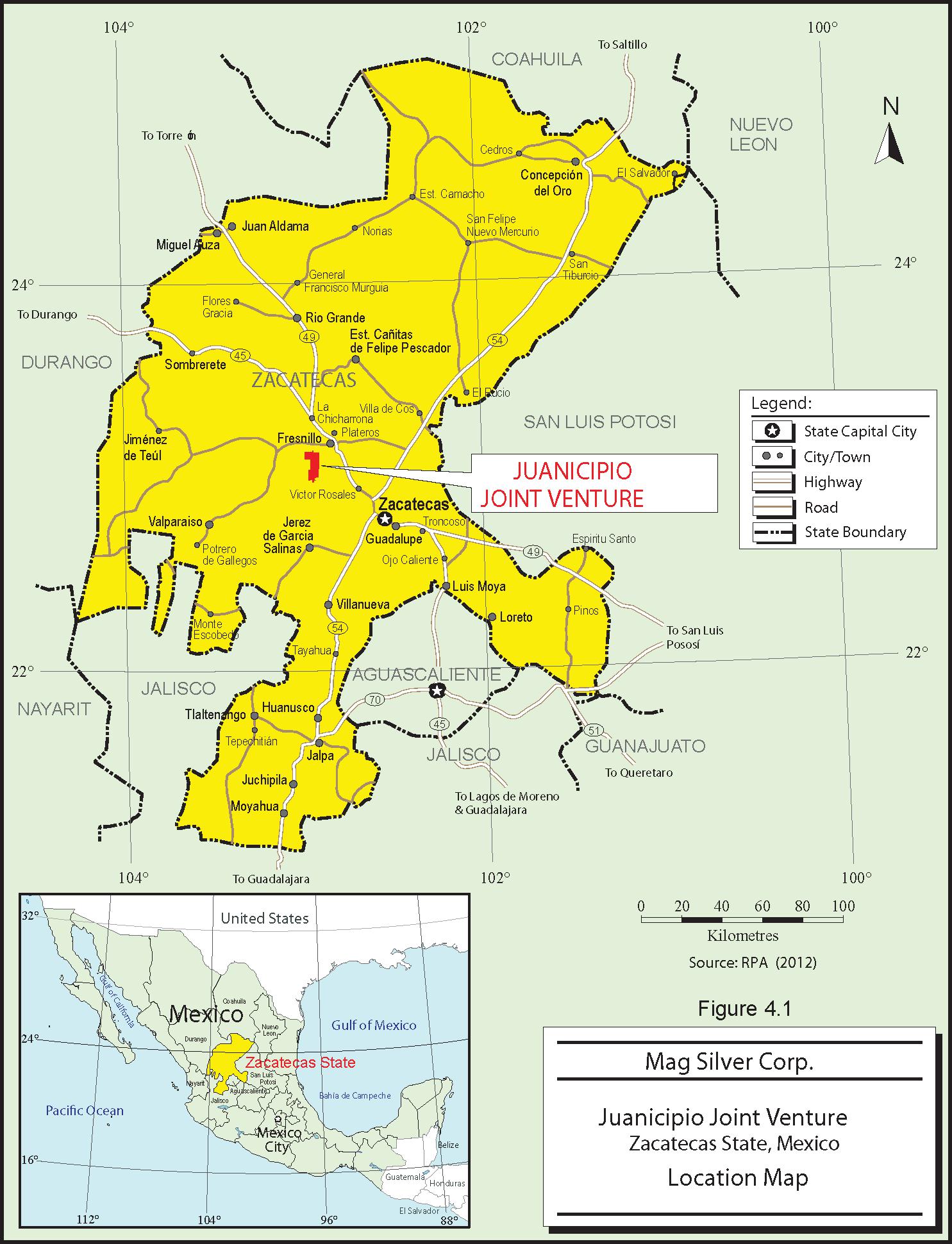

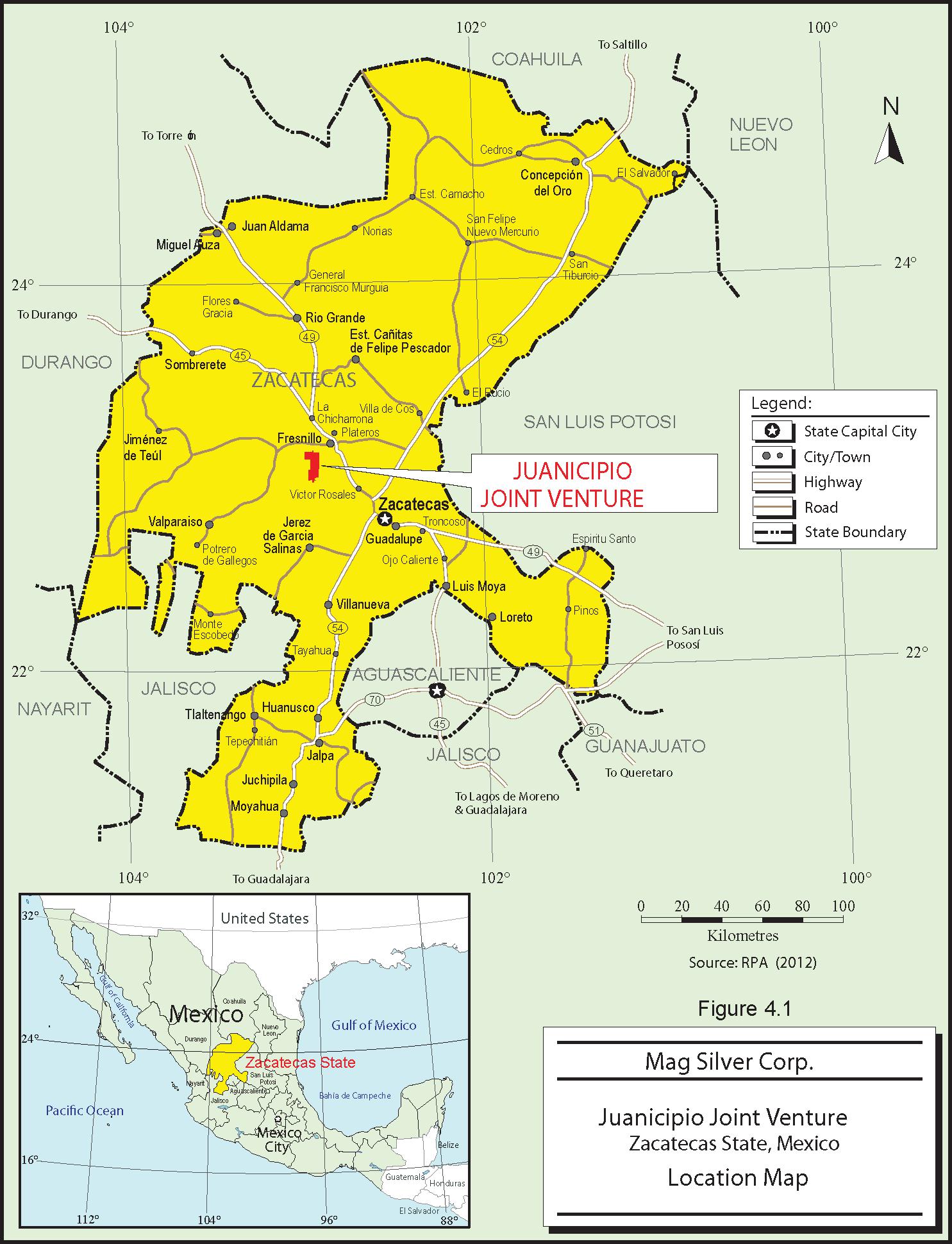

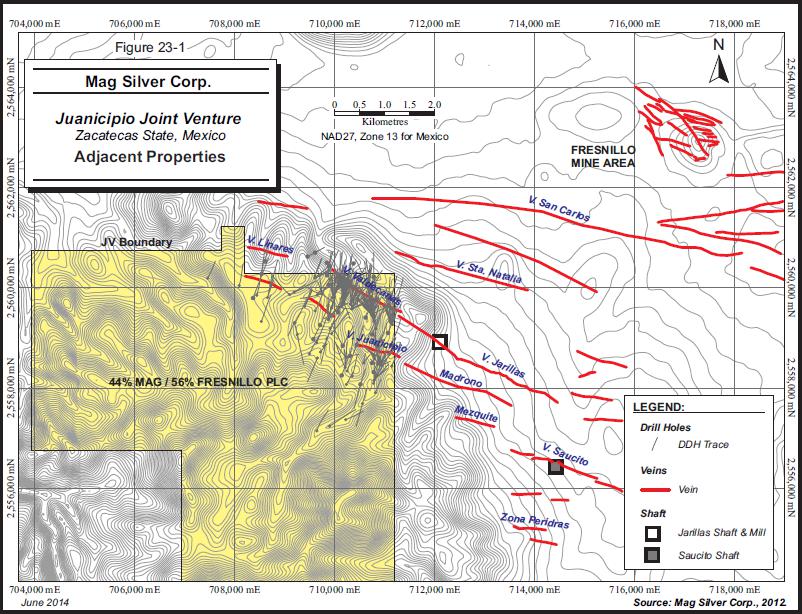

The Juanicipio deposit consists of two main vein systems that lie in the north-eastern part of the Property, which is situated about 6 km to the south-west of the city of Fresnillo, a town located about 60 km north-west of the state capital, Zacatecas City. Zacatecas City has a population of approximately 140,000 and is located about 550 km northwest of Mexico City. Zacatecas City is serviced by daily flights from Mexico City. Surface rights to the part of the Property where mineral resources have been identified are held by Minera Juanicipio.

| 1.3 | Geology and mineralization |

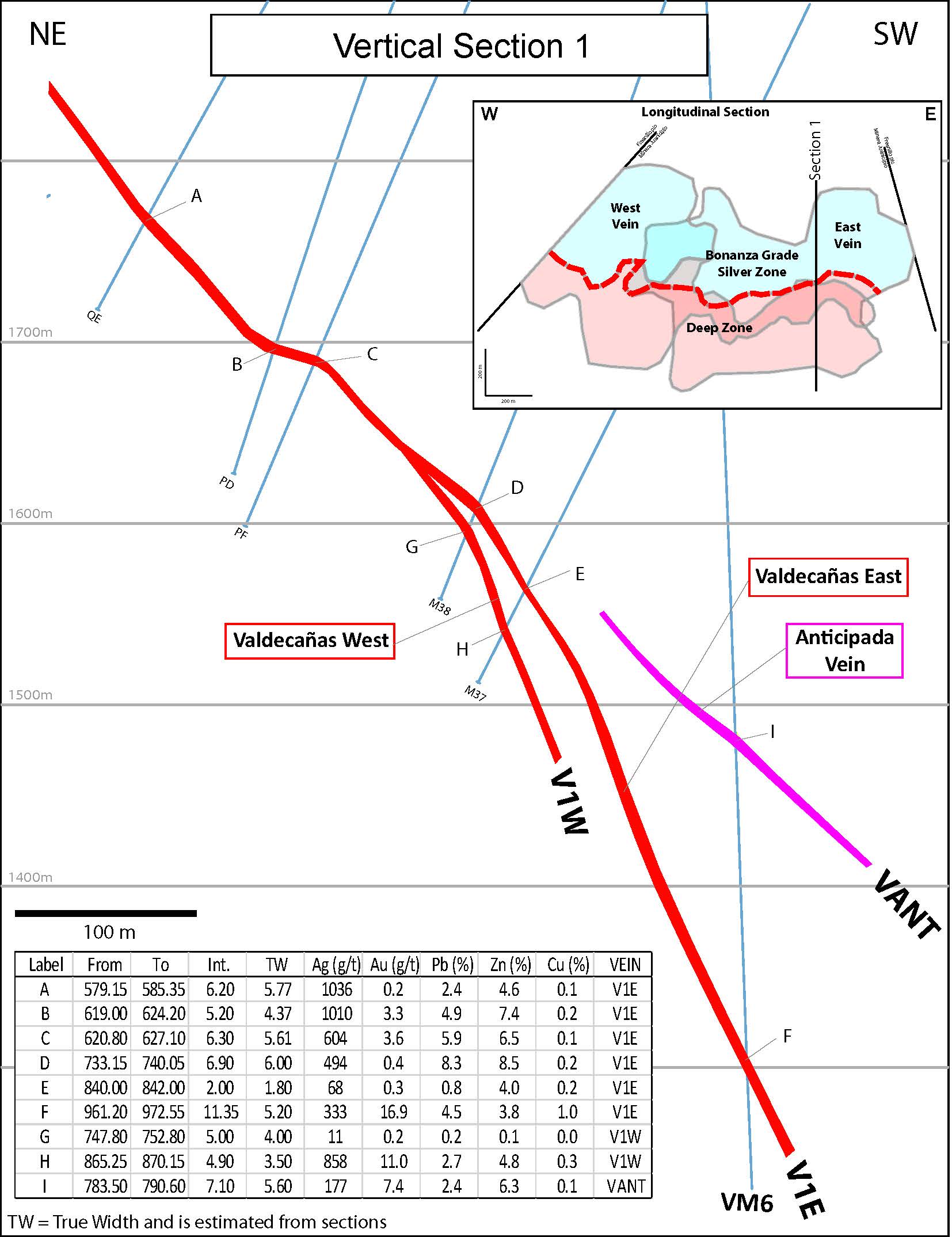

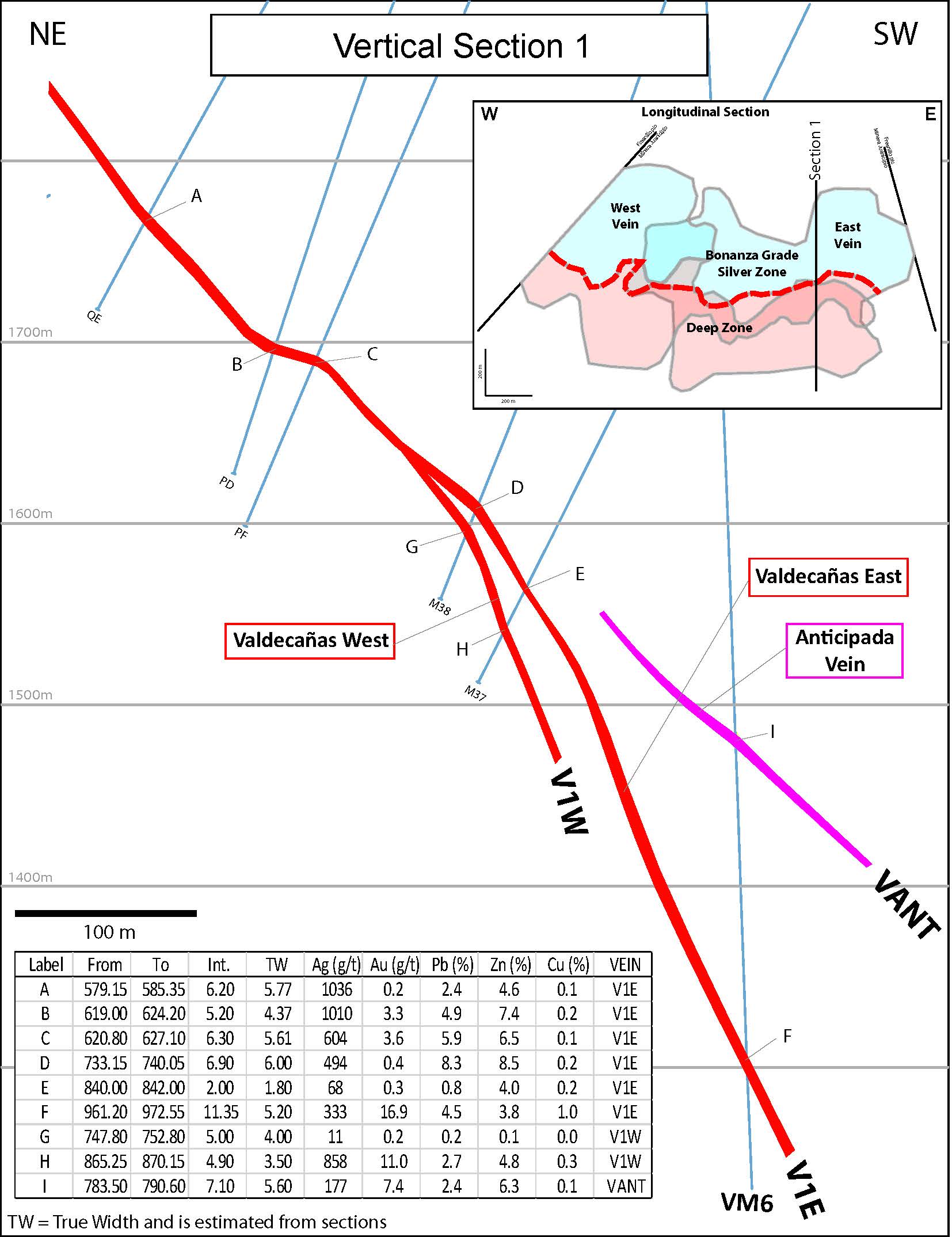

The Juanicipio deposit consists of two main vein systems, the Valdecañas vein system and the Juanicipio vein, which are significant silver-gold epithermal structures. The Valdecañas vein system consists of five veins (V1E, V1W, HW1, VANT, and V2W) and the Juanicipio vein (VJUA). Both systems strike east-southeast and dip 35° to 70° with an average dip of about 58° southwest. The Valdecañas vein system displays the metal zonation typical of the Fresnillo District and epithermal veins in general, of an upper precious metal zone (Bonanza Zone) grading downwards into a deeper base metal zone (Deep Zone). There is significant evidence for a repeat of this zonation in the deeper reaches, perhaps reflecting “stacked” boiling levels (Buchanan, 1981). The Valdecañas structure hosts the majority of the Mineral Resources currently estimated on the Property.

The Juanicipio vein is located some 1,100 m to the south of the Valdecañas vein. Thirty-five drillholes contribute to the definition of this vein. Overall, Juanicipio is a much thinner vein and appears to have a higher gold content; however, this interpretation is based on a limited number of overall samples. Mineralization styles and host rocks are the same as those for Valdecañas.

The Valdecañas vein system has undergone multiple mineralizing events as suggested by various stages of brecciation and quartz sealing, local rhythmic microcrystalline quartz-pyrargyrite-acanthite banding, and open-space cocks-comb textures and vuggy silica. The vein system exhibits the characteristic metal zoning of the principal veins in the Fresnillo district, observed as a change from silver- and gold-rich zones at the top (Bonanza Zone) to increased lead and zinc in the deeper reaches (Deep Zone), with copper coming in at the deepest levels.

Mineralization in the Bonanza Zone consists of precious metal-rich, banded, or brecciated quartz-pyrargyrite-acanthite-polybasite-galena-sphalerite veins. Mineralization in the Deep Zone consists of base metal-rich, banded, or brecciated quartz-galena-sphalerite-chalcopyrite veins with lesser acanthite and pyrargyrite. Portions of the veins in the Deep Zone show skarn minerals, including garnets, pyroxenes, ilvaite and axinite within and surrounding the veins. Retrograde hydration of these minerals to chlorite and hydrogrossular is pervasive and widespread.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

In December 2016, MAG Silver commissioned AMC to prepare an independent estimate of the Mineral Resources of the Property, to be compiled using exploration data available up to 31 December 2016. The updated global Mineral Resource estimate is summarized in Table 1.1. The Mineral Resources are based on a cut-off Net Smelter Return (NSR) value of $55/t.

| Table 1.1 | Summary of Global Mineral Resources as of 21 October 2017 |

| Resource Category | Tonnes (Mt) | Ag (g/t) | Au (g/t) | Pb (%) | Zn (%) | Cu (%) | Metal contained in Mineral Resources |

| Ag (Moz) | Au (koz) | Pb (Mlbs) | Zn (Mlbs) | Cu (Mlbs) |

| Indicated | 12.83 | 427 | 2.10 | 2.11 | 3.68 | 0.13 | 176 | 867 | 598 | 1041 | 38 |

| Inferred | 12.13 | 232 | 1.44 | 2.46 | 4.68 | 0.27 | 91 | 562 | 658 | 1252 | 71 |

Notes: CIM Definition Standards were used for reporting the Mineral Resources.

Dr A. Ross, Ph.D., P.Geo. of AMC is the Qualified Person under NI 43-101 and takes responsibility for the Mineral Resource estimate.

Mineral Resources are estimated at a resource NSR cut-off value of $55 per tonne.

Resource NSR values are calculated in US$ using factors of $0.61 per g/t Ag, $34.27 per g/t Au, $19.48 per % Pb, and $19.84 per % Zn. These factors are based on metal prices of $20/oz Ag, $1,300/oz Au, $0.95/lb Pb, and $1.00/lb Zn and estimated recoveries of 82% Au, 95% Ag, 93% Pb, 90% Zn. The Mineral Resource NSR does not include offsite costs.

Drilling results up to 31 December 2016.

The numbers may not compute exactly due to rounding.

Source: AMC Mining Consultants (Canada) Ltd.

The Valdecañas vein system displays the vertical grade transition from upper silver-rich zones to deep base metal dominant areas that is typical of Fresnillo District veins and epithermal silver veins in general. The Mineral Resource estimate was manually divided into the Bonanza Grade Silver (BGS) Zone and the Deep Zone to highlight differing metal content within the two zones. Parts of the Juanicipio vein are included in the BGS Zone as well as the silver-rich portions of the other veins. The BGS Zone terminology was used in the previous report and is kept for continuity. The results are shown in Table 1.2.

| Table 1.2 | Mineral Resource by Bonanza and Deep Zones as of 21 October 2017 |

| Zone | Resource category | Tonnes (Mt) | Ag (g/t) | Au (g/t) | Pb (%) | Zn (%) | Cu (%) | Ag (Moz) | Au (koz) | Pb (Mlbs) | Zn (Mlbs) | Cu (Mlbs) |

| BGS Zone | Indicated | 8.17 | 550 | 1.94 | 1.63 | 3.08 | 0.08 | 145 | 509 | 294 | 554 | 14 |

| Inferred | 1.98 | 648 | 0.81 | 1.32 | 2.80 | 0.06 | 41 | 52 | 58 | 123 | 3 |

| Deep Zone | Indicated | 4.66 | 209 | 2.39 | 2.96 | 4.73 | 0.23 | 31 | 359 | 304 | 486 | 24 |

| Inferred | 10.14 | 151 | 1.57 | 2.69 | 5.05 | 0.31 | 49 | 510 | 601 | 1129 | 69 |

Notes: See footnotes under Table 1.1.

Mineral Resources do not have demonstrated economic viability. Additionally, it cannot be assumed that Inferred Mineral Resources will be upgraded to a higher mineral resource category.

| 1.5 | Geotechnical considerations |

Following the 2012 PEA, Minera Juanicipio conducted additional exploration drilling and captured further geotechnical data from the drill core. This data was used to complement the existing data, and a re-assessment of conceptual stope dimensions, ground support requirements and vertical development stability analyses was conducted. The assessment findings were recorded in a Preliminary Geotechnical Report compiled in September 2015.

Subsequently, AMC was requested to further review the available geotechnical information and to undertake underground visits to neighbouring mines and the existing decline at Juanicipio. These visits afforded AMC’s geotechnical engineers the opportunity to take relevant measurements, obtain an appreciation of the geotechnical environment in which the mining operation is expected to take place, assess the stability of existing underground excavations taking cognisance of installed support systems, and liaise with technical services personnel.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

AMC also assisted the Minera Juanicipio geologists in reviewing the existing geotechnical model, and a new 3D geotechnical model was developed by AMC for Juanicipio. The new geotechnical model takes cognisance of the additional laboratory-conducted rock strength testing recommended by AMC.

| 1.5.1 | Rock mass properties and hydrogeology |

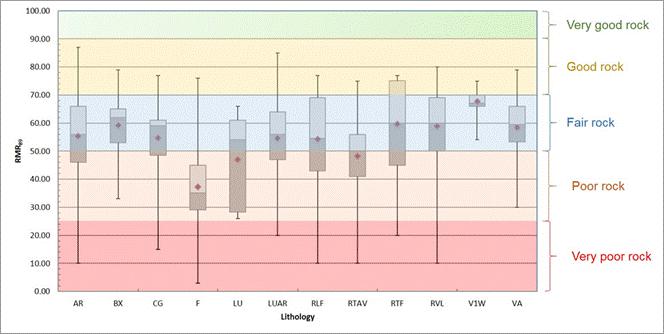

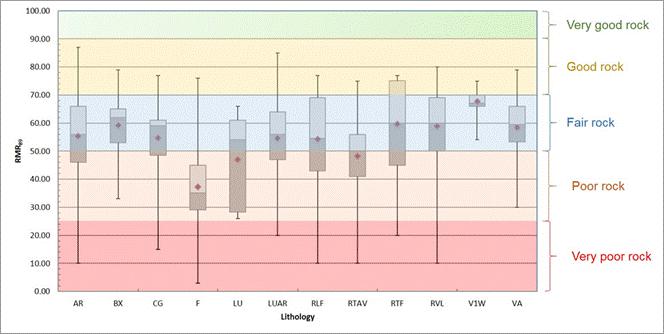

A total of 20 drillholes has been geotechnically logged for the Juanicipio project area. The results indicate that the quality of the host rock can be anticipated to be Fair; and that there will be some areas where Poor ground conditions could be expected, these being in the vicinity of faults and intersections with rhyolite tuff agglomerate or shale.

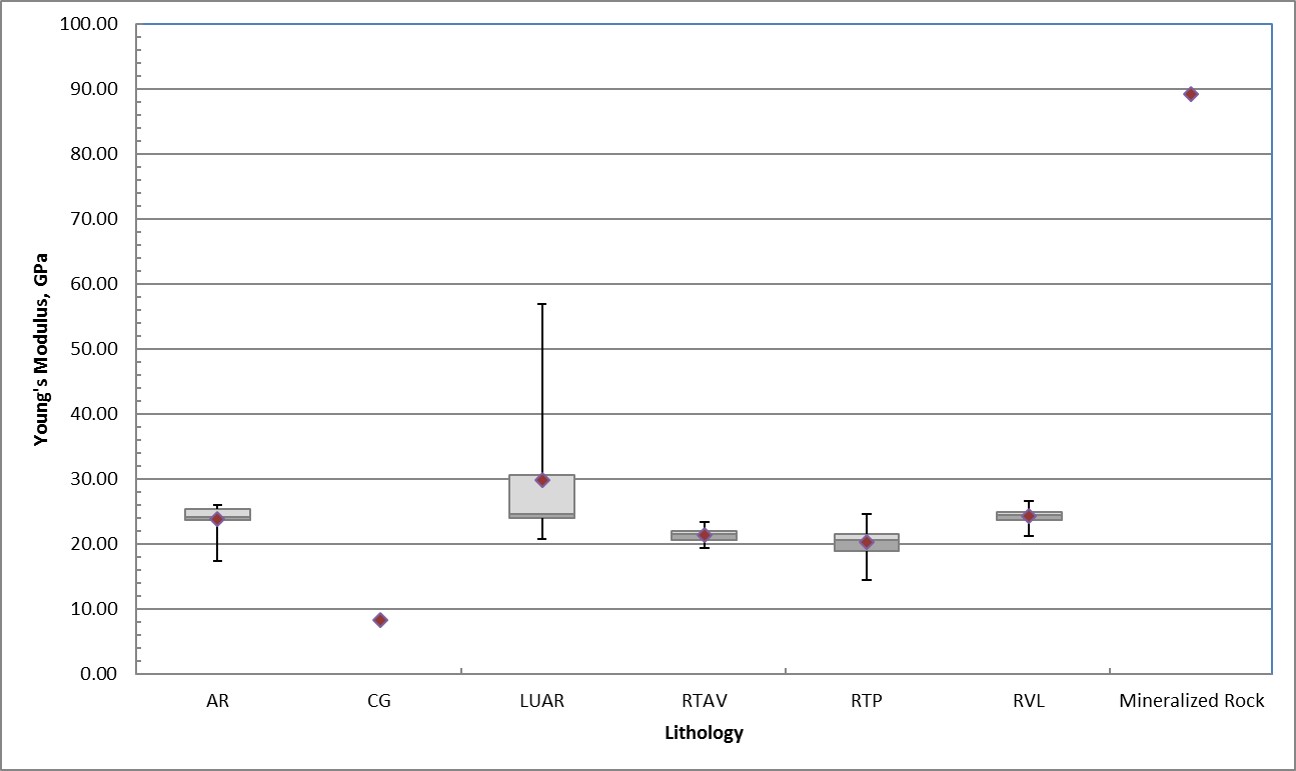

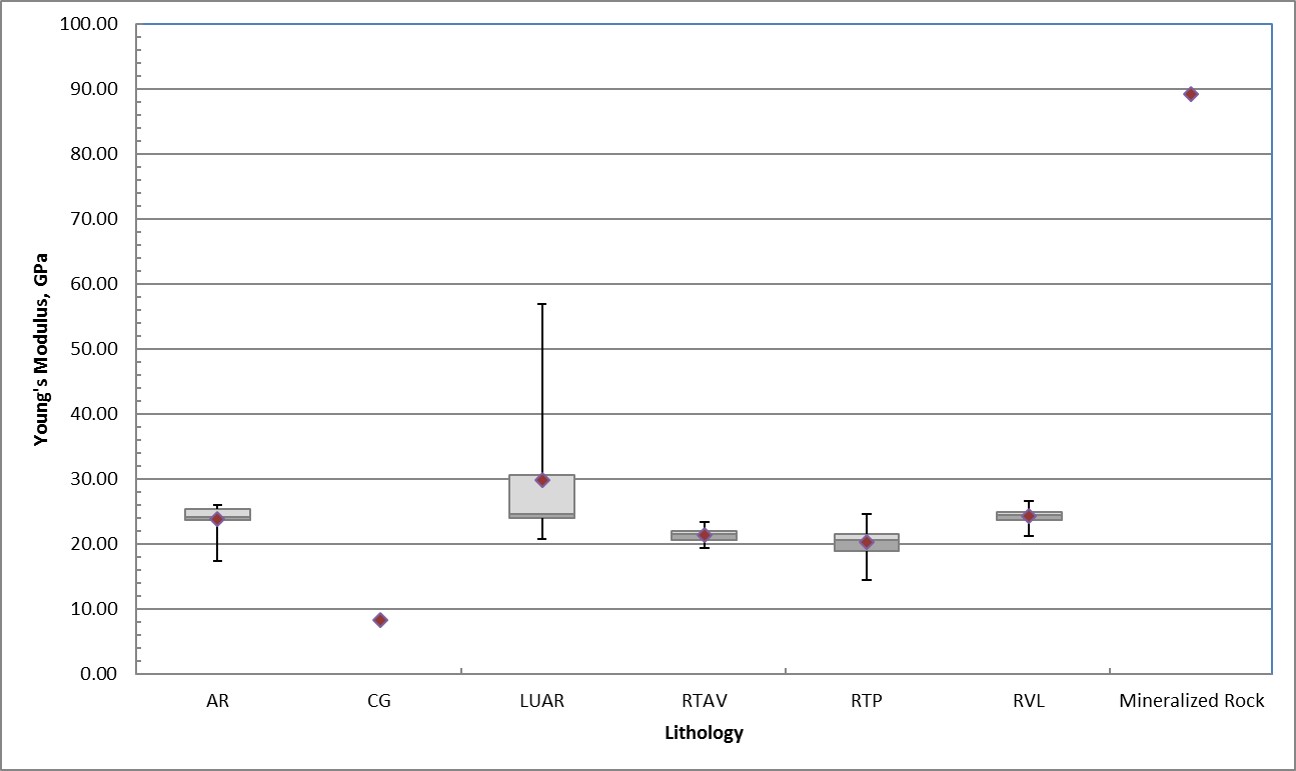

The Deformation Modulus (Young’s Modulus) is an indication of the stiffness of the rock type. The host rock at Juanicipio is fairly soft, implying that deformation can be expected when subjected to large loads / stress.

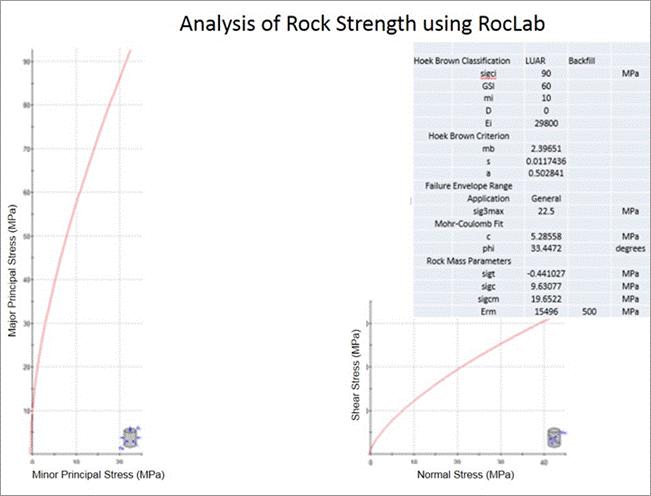

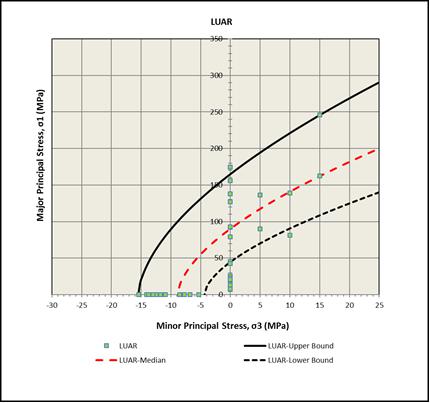

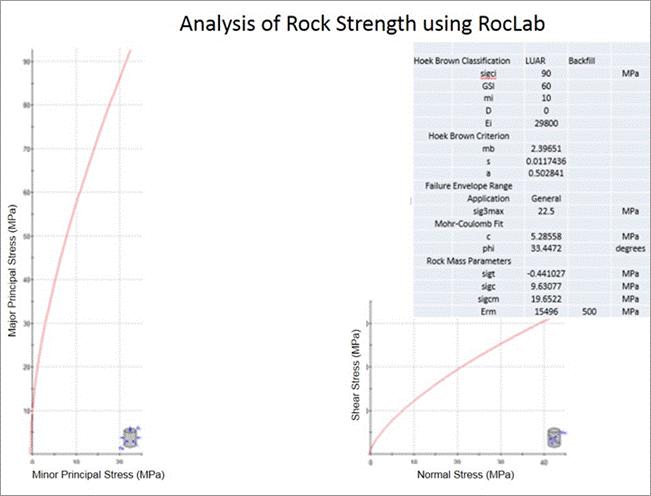

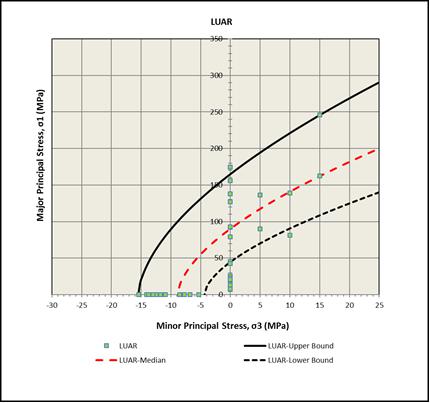

To assess the rock mass properties, the results of data reduction analyses were input into Rocscience’s RocLab software package. Only the LUAR rock mass properties were evaluated, reflecting both the predominance of the LUAR lithology as the host rock for the mineralized vein and the quantity and type of available rock strength test data. The results of the rock mass property analysis indicate that the waste rock strength is Fair to Good. The single sample for vein mineralization indicated a Uniaxial Compressive Strength (UCS) of 178 MPa or Good classification.

Based on limited data, the depth of weathering appears to vary significantly across the site. Depths of weathering down to 400 m below surface have been recorded.

There have been no detailed investigations carried out on the hydrogeology of the Juanicipio area. AMC recommends that hydrogeological investigations be carried out, taking particular cognisance of any further available relevant information from other mines close by. The strategy adopted for mine planning is to have the main development (ramps and footwall access) ahead of the stope mining front. This strategy will assist in dewatering levels prior to stoping.

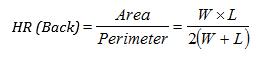

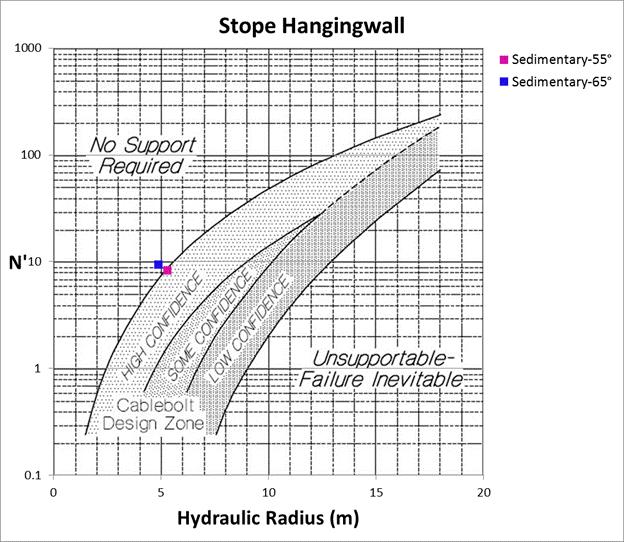

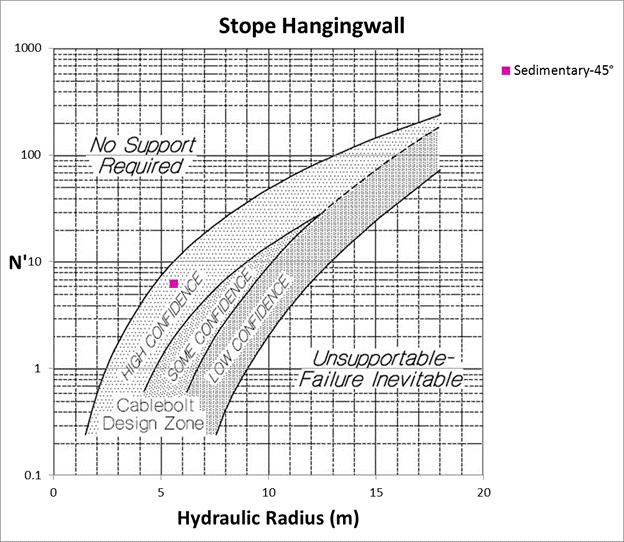

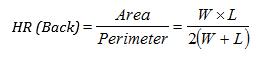

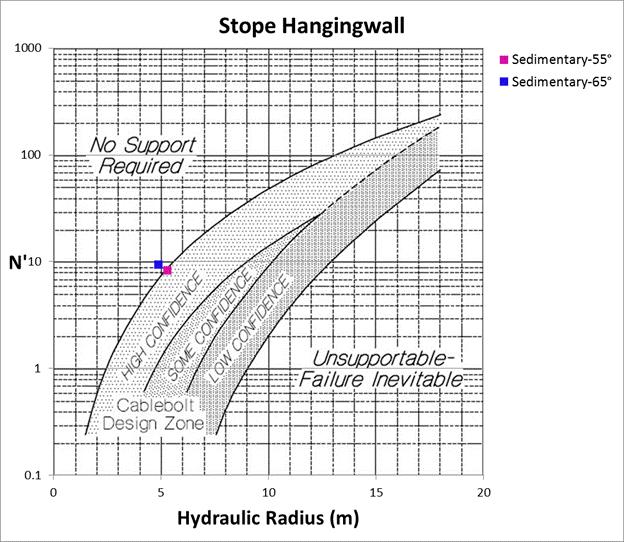

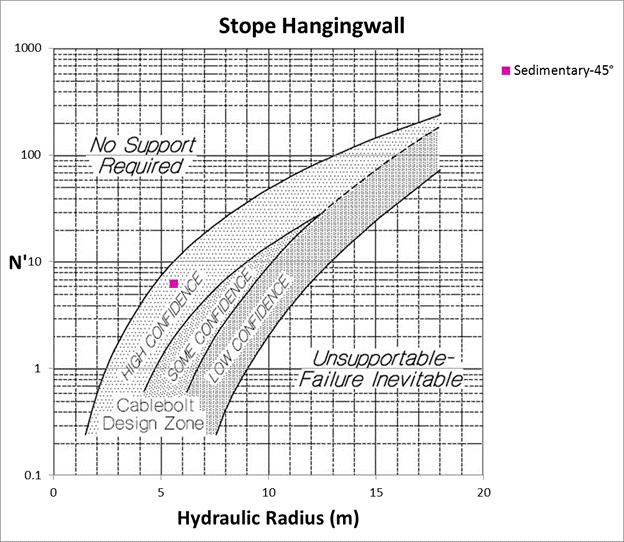

No additional detailed geotechnical core logging has been conducted on drillhole core since the assessment of potential stope panel dimensions and vertical development recommendations were made in 2015. The results of the stope stability assessments for the Juanicipio project using the empirical Stability Graph Method (Mathews et al. 1981; Potvin, Y. 1988) indicate that hangingwall stability is strongly influenced by vein dip. At a 65° dip a vertical stope height of 21.8 m is projected to be stable without support. At lower dip angles cable bolt support may be needed, especially in the volcanic lithologies. At a 45° dip and in the volcanic lithology, a 15 m or greater vertical height is projected to require hangingwall support for stability.

| 1.5.3 | Stope dilution estimation |

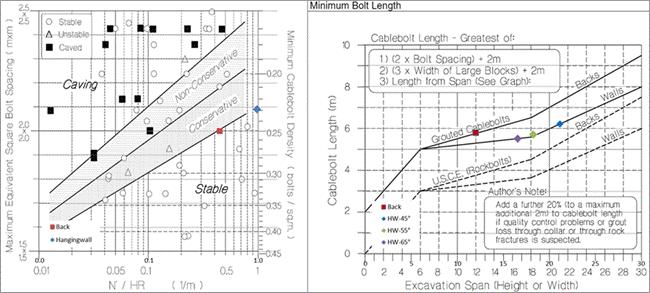

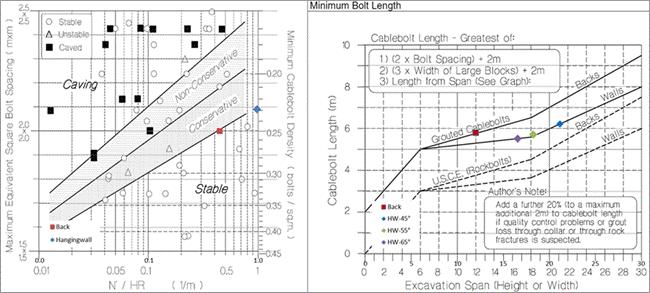

Dilution for Long Hole Open Stopes (LHOS) has been geotechnically estimated using the equivalent linear overbreak slough (ELOS) technique (Clark and Pakalnis, 1997). This empirical method estimates the overbreak based on recorded case histories and established design curves relating the modified stability number N’ and the hydraulic radius. Stopes are considered likely to be sensitive to overbreak to some degree given the blocky ground conditions. The dilution estimation indicates an anticipated dilution of ~0.55 m from a sedimentary hangingwall dipping at 55°.

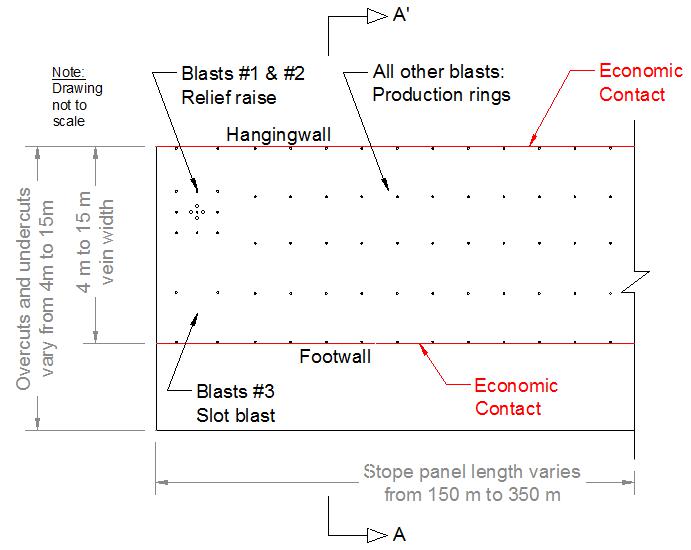

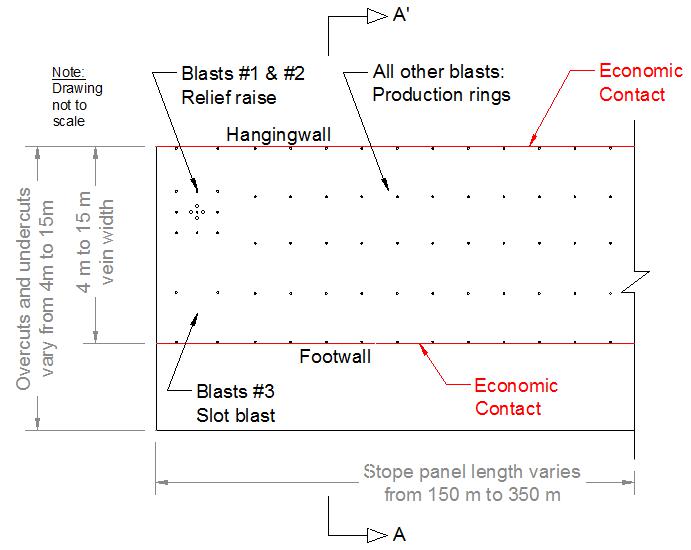

A number of mining method studies have been carried out to identify suitable design strategies for the project. The studies include identification of the most suitable stoping method, production rate, backfilling method, and haulage method for the mine. Methods that provide high mining recovery and lower dilution have been assessed against other methods that may be cheaper, but result in greater loss or dilution of mineralization.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

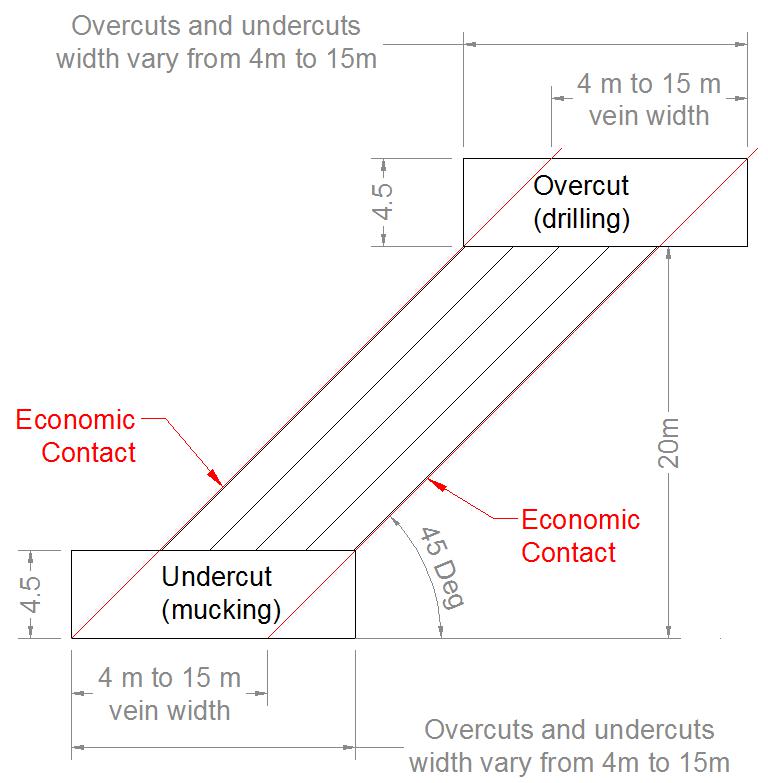

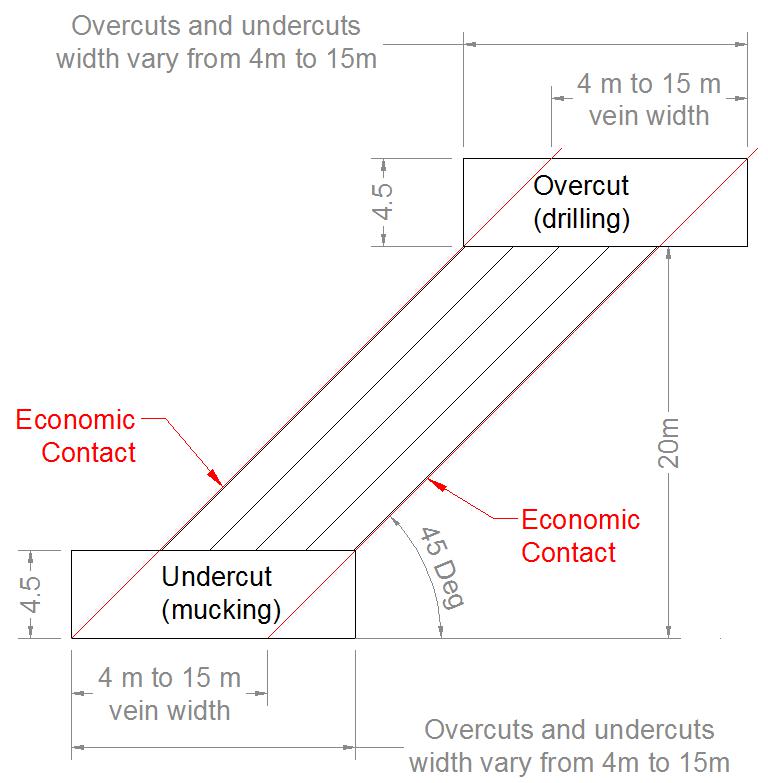

The 2012 PEA study considered a longhole stoping mining method with pastefill and a production rate of 2,650 tpd. AMC undertook several site visits to other operating mines in the area to review the details of the mining methods used and the application of rock fill. The primary mining method continues to be longhole stoping, but at an increased production rate of 4,000 tpd. Some cost savings and production efficiencies have been identified with the use of waste rock fill, which is now considered as the primary backfill; in the wider stopes where more than one longitudinal pass is required, cemented rock fill will be utilized.

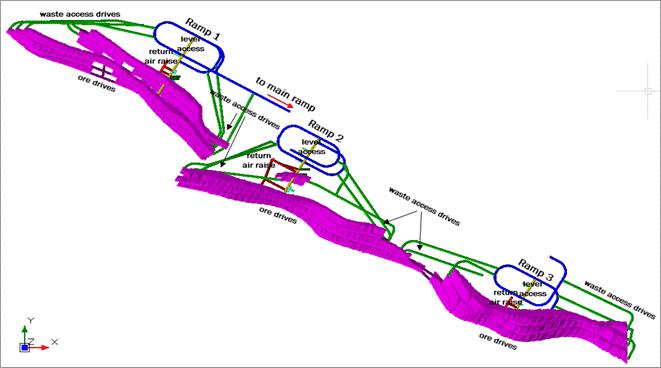

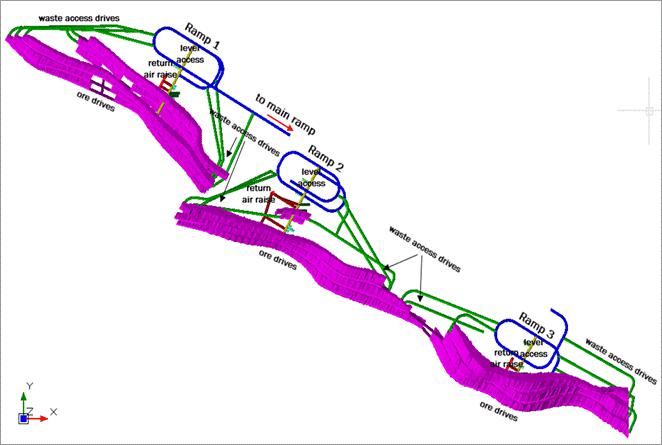

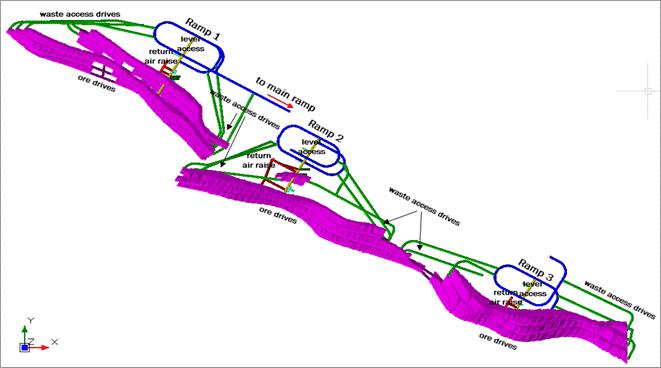

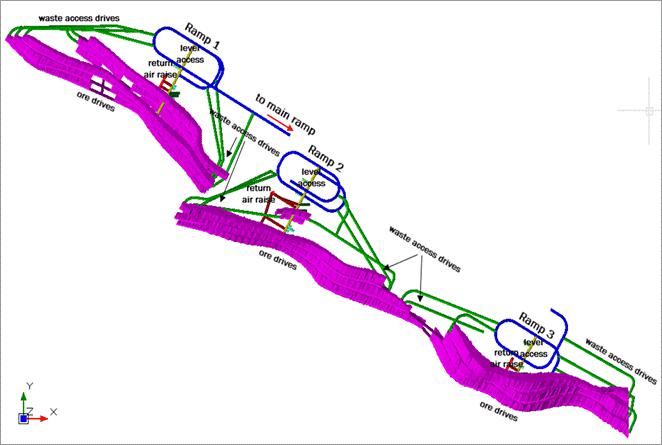

The proposed mining method employs zone access via three internal ramps on 20 m sub-levels, as well as footwall access to the extents of the mineralization to allow placement of rock fill. Stopes 20 m high (floor to floor) are mined from the extents back to the central access (on retreat) with rock fill placed within 20 m of the blasting face.

In the lower levels of the vein, the vein widens out to a maximum thickness of approximately 30 m. In these areas, the vein will be mined in two longitudinal passes with a maximum width of 15 m. The footwall stope will be taken first over the full strike length, followed by the hangingwall stope. Cemented rock fill will be used in the footwall stope to prevent waste entering the hanging wall stope.

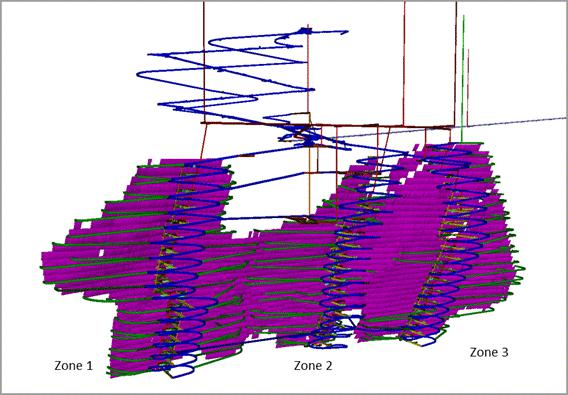

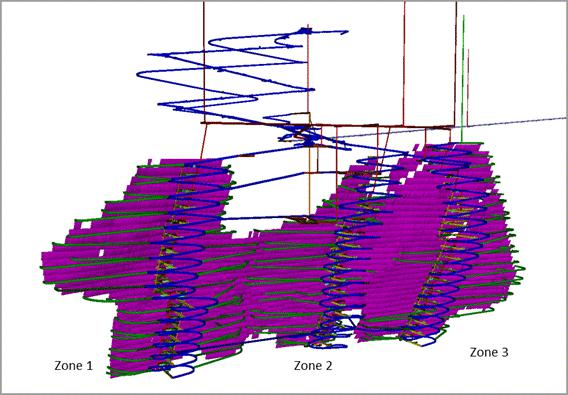

A composite plan view of the mine design showing the general layout of ramps and footwall drives for backfill access is shown in Figure 1.1.

| Figure 1.1 | Composite plan view of mine design |

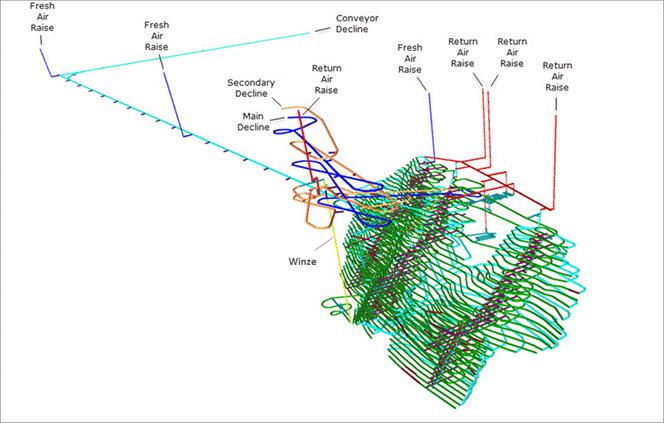

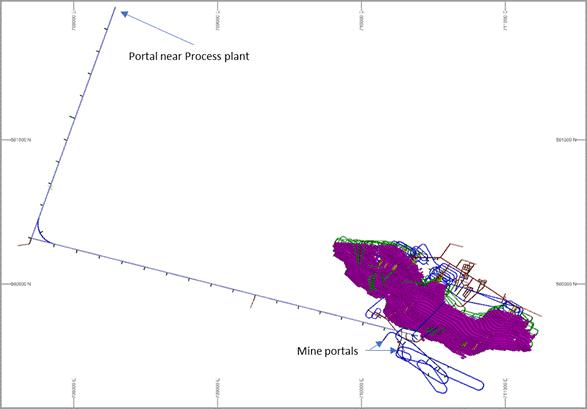

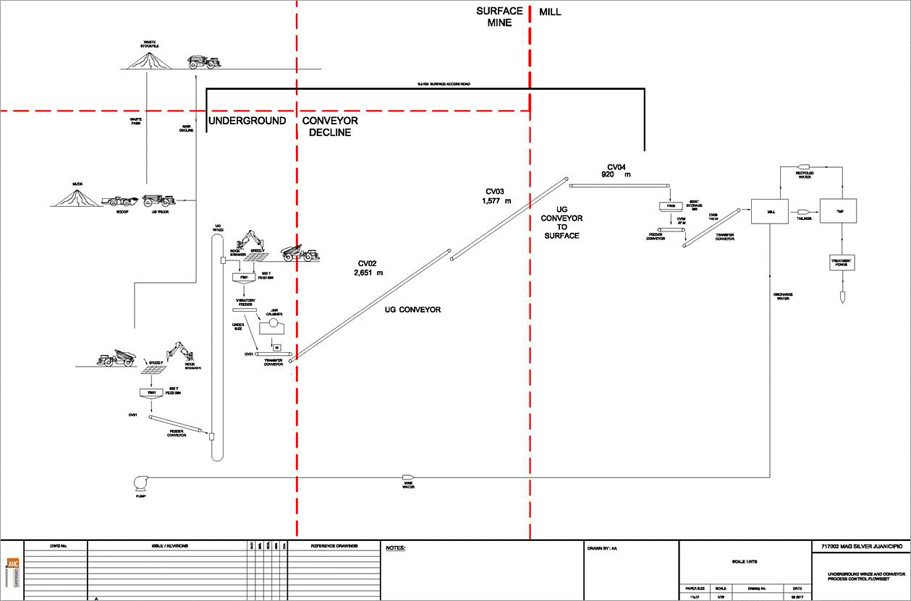

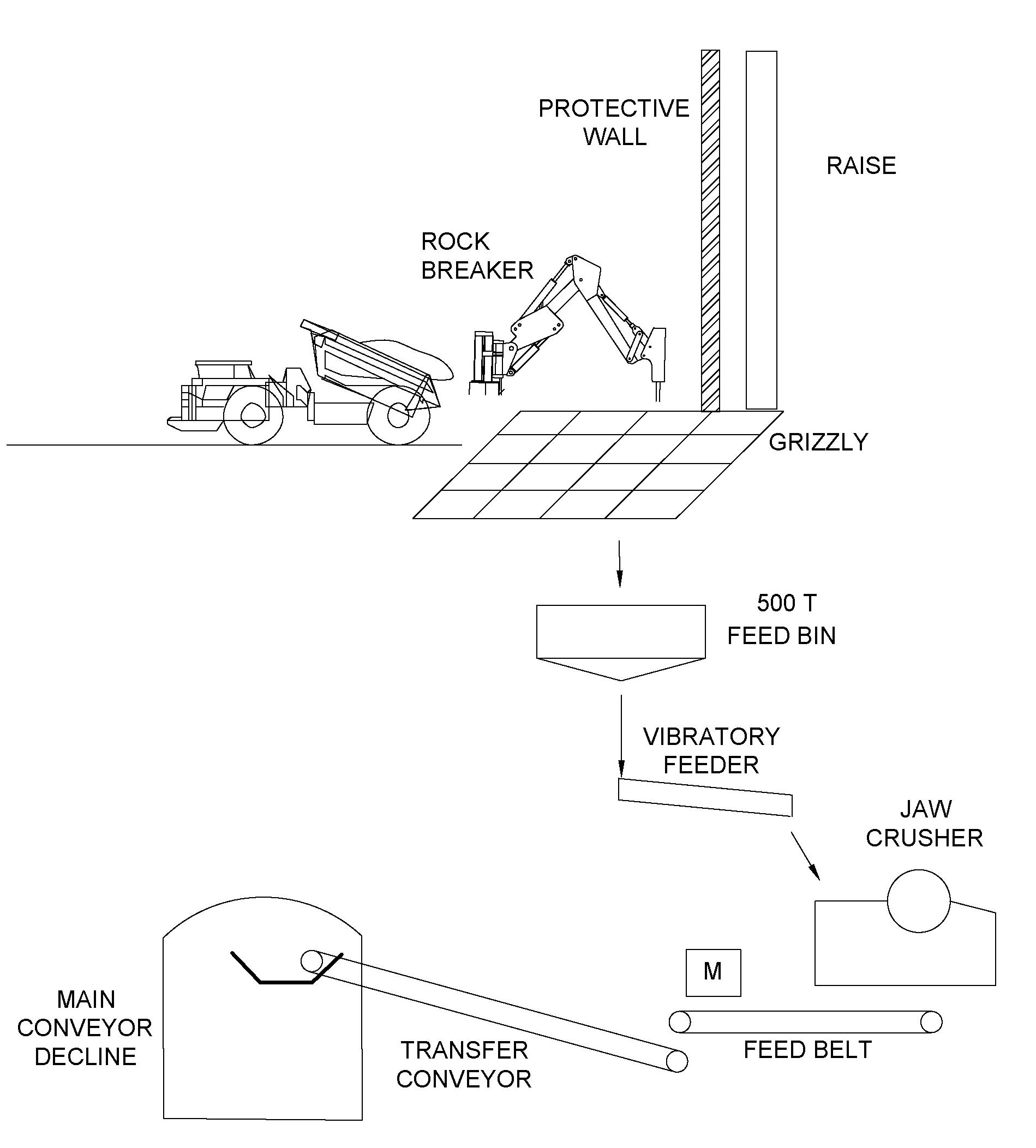

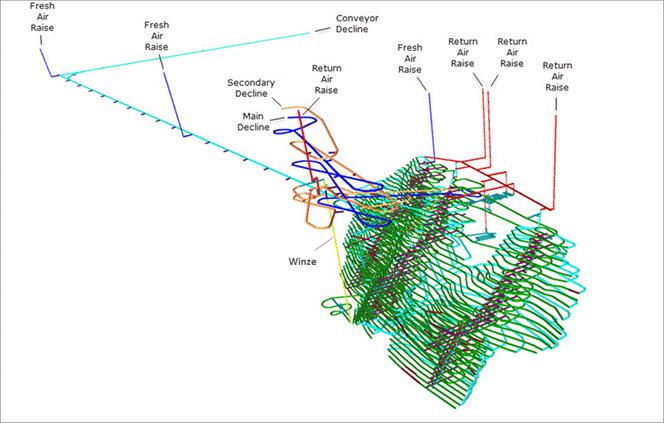

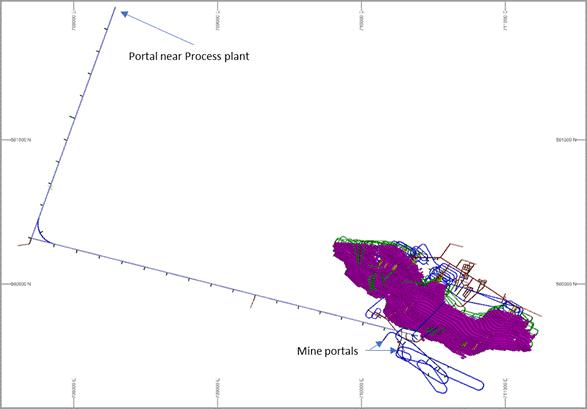

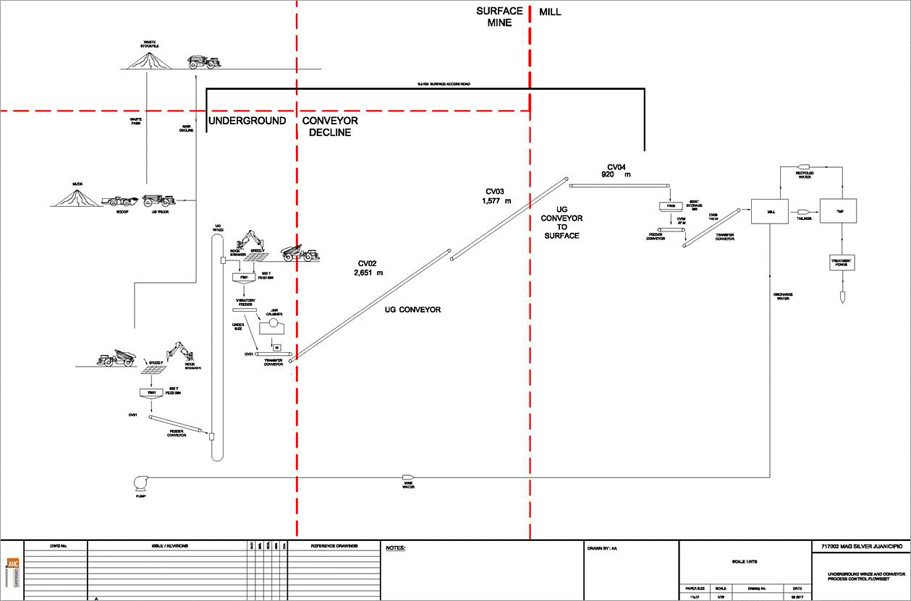

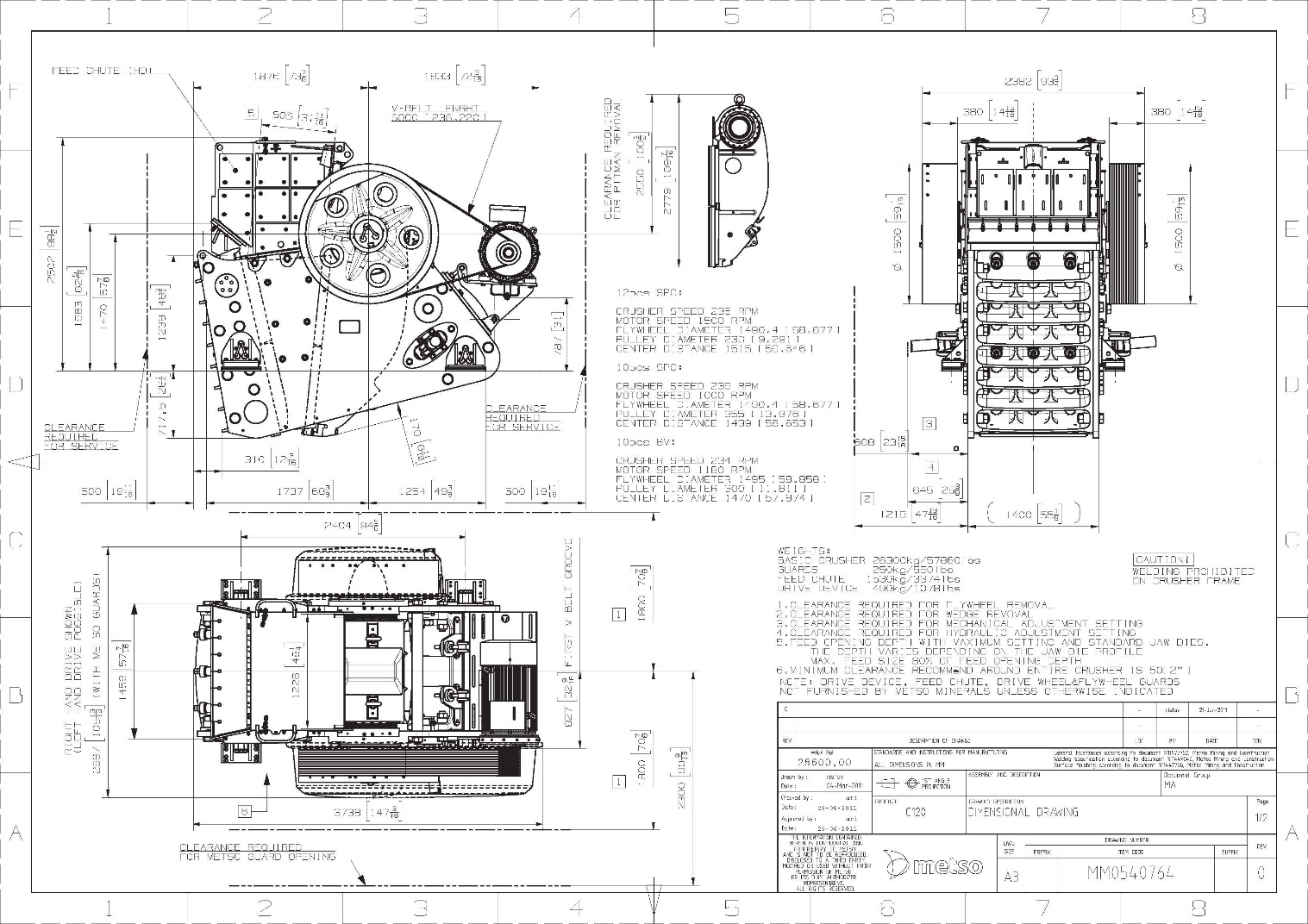

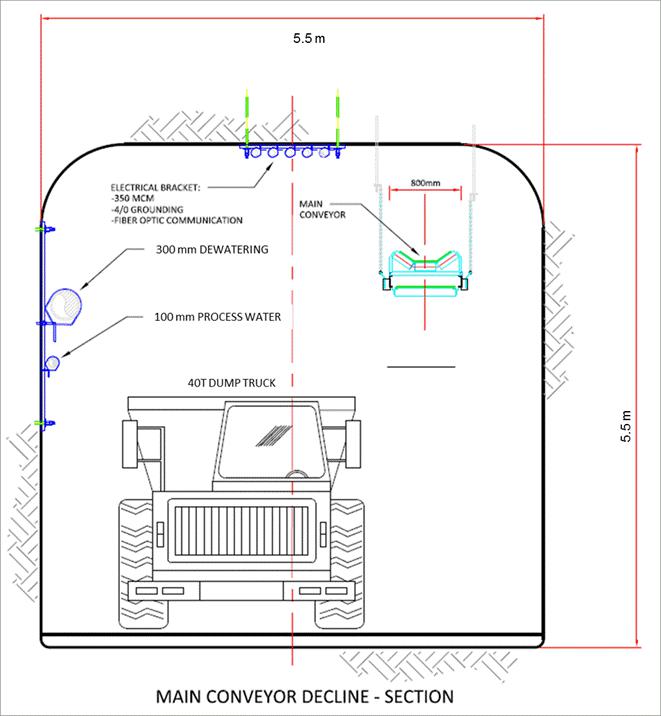

Truck haulage, shaft hoisting, and conveying have been considered for transferring mineralized rock and waste from the mine workings to surface. All waste not placed directly in stopes will be trucked to surface via twin access declines, where it will be stockpiled and later used for backfilling stopes as they are mined out. In early mining, mineralized rock from development and stoping will be trucked to a rock pass feeding the underground crusher. The crusher station is located on 1950 RL, from where the mineralized rock will be transferred to surface via a main conveyor (base at 1940 RL). The decline portal for the conveyor is near the projected processing plant location.

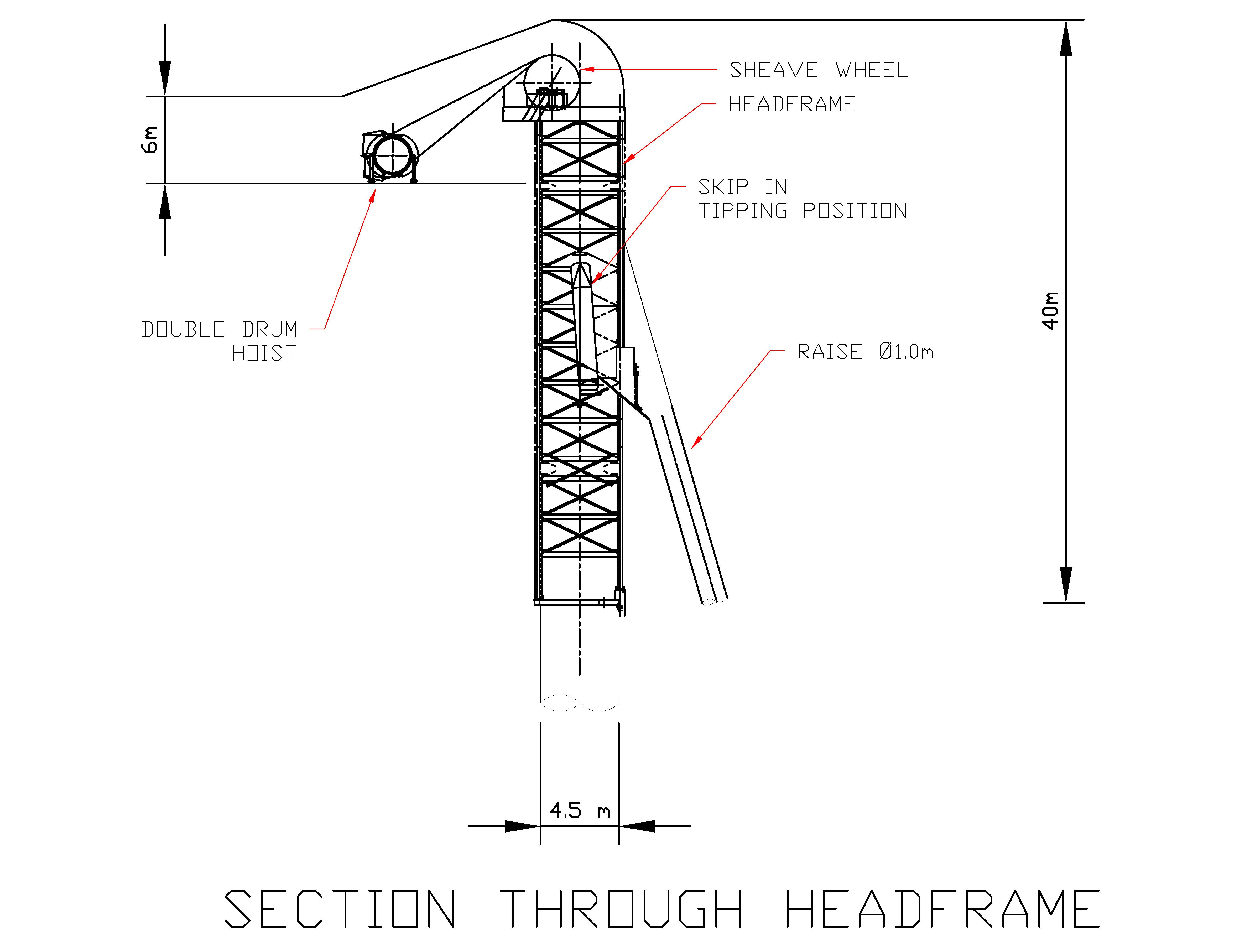

An underground winze (780 m in length) will be sunk in the hangingwall of the mineralization. The winze is planned to eventually hoist (after Year 8) mineralized rock from the loading station on 1300 RL to the top of the shaft on 2040 RL. Mineralized rock is transferred directly from the skips to the decline conveyor via a rock pass and loading station.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

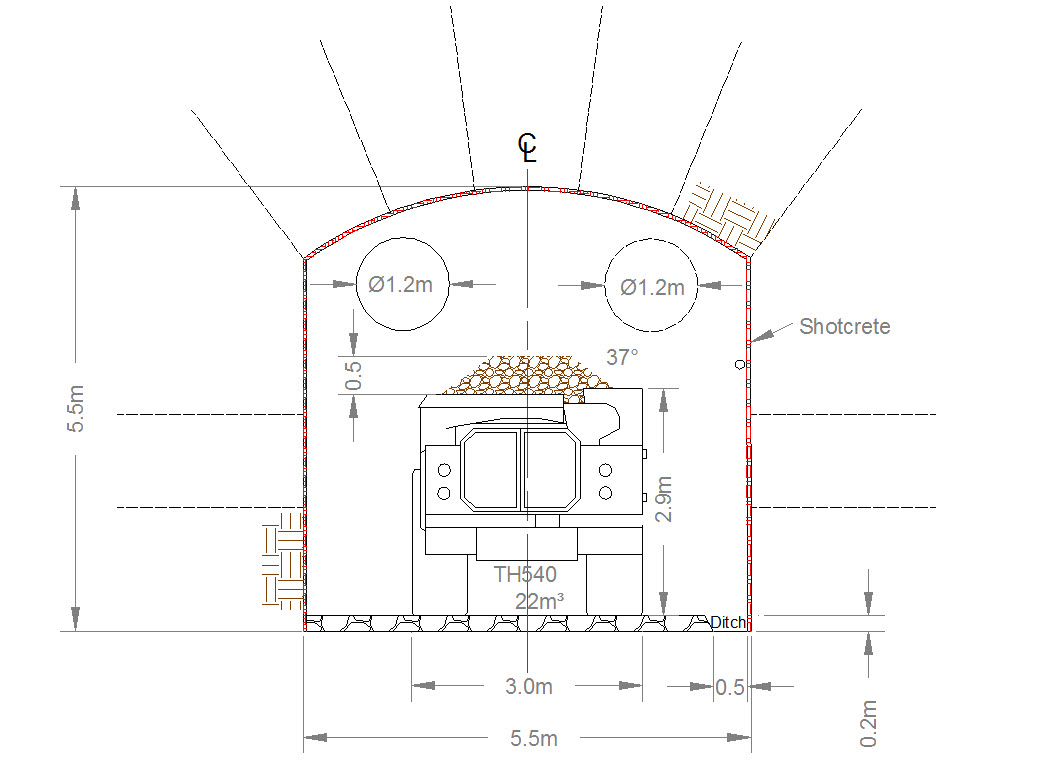

It is envisaged that mining will be carried out using modern trackless mining equipment. The proposed mine ventilation circuit will include a number of ventilation raises, raise-bored from surface.

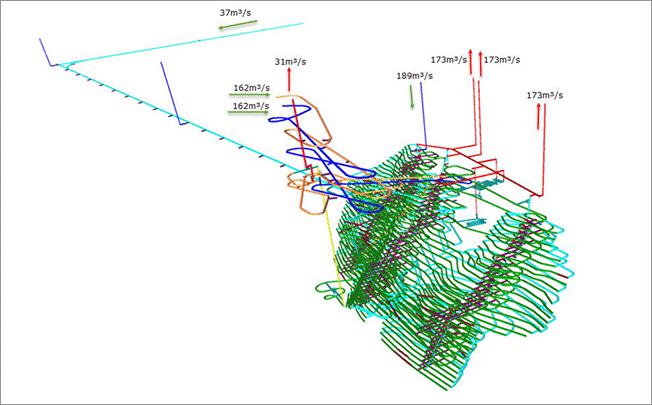

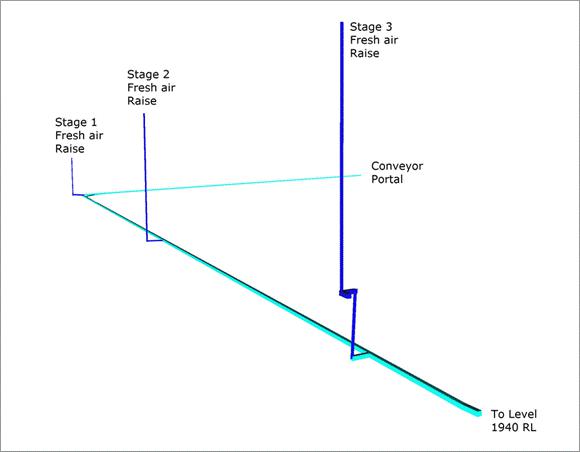

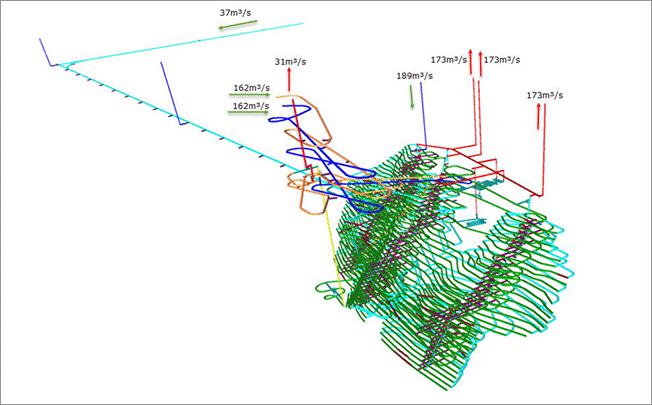

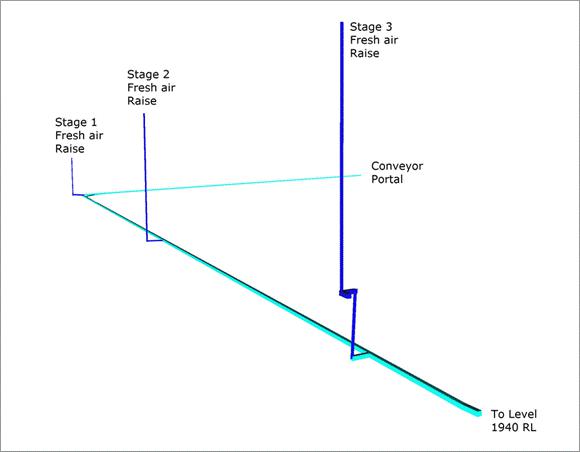

Figure 1.2 is an illustration of the mine as a whole, showing the ventilation layout, the conveyor route to surface, and the winze.

| Figure 1.2 | Overall mine layout |

Metallurgical test work was carried out between 2008 and 2015 on metallurgical samples composited from 67 drillhole samples taken from the Valdecañas vein system.

The proposed process plant consists of a comminution circuit followed by the sequential flotation of a silver-rich lead concentrate, a zinc concentrate, and a gold-rich pyrite concentrate.

It is envisaged that crushed mineralized rock will be delivered to a stockpile located near the mill and will feed directly to the mill via transfer conveyors.

The proposed milling circuit comprises a semi-autogenous grinding mill and ball mill, producing feed to the flotation circuit. Separate lead, zinc, and pyrite concentrates would be thickened, filtered, and stockpiled for dispatch by truck directly to customers or for onward shipment. It is noted that, although Cu is estimated in the Mineral Resource, it is not considered in this study, additional mineral processing work being required to establish prospects for reasonable extraction.

It is envisaged that the process plant will ramp up operations over a three year period to a steady state throughput rate of 1.4 Mtpa. Estimated mill recoveries are summarized in Table 1.3.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | Gold | Silver | Lead | Zinc |

| Mill recovery | 82% | 95% | 93% | 90% |

| 1.8 | Project infrastructure |

A 6.5 km access road, mostly over hilly terrain, will be required to access the main decline portal site from the mill. A two-lane sealed road suitable for use by heavy vehicles is proposed.

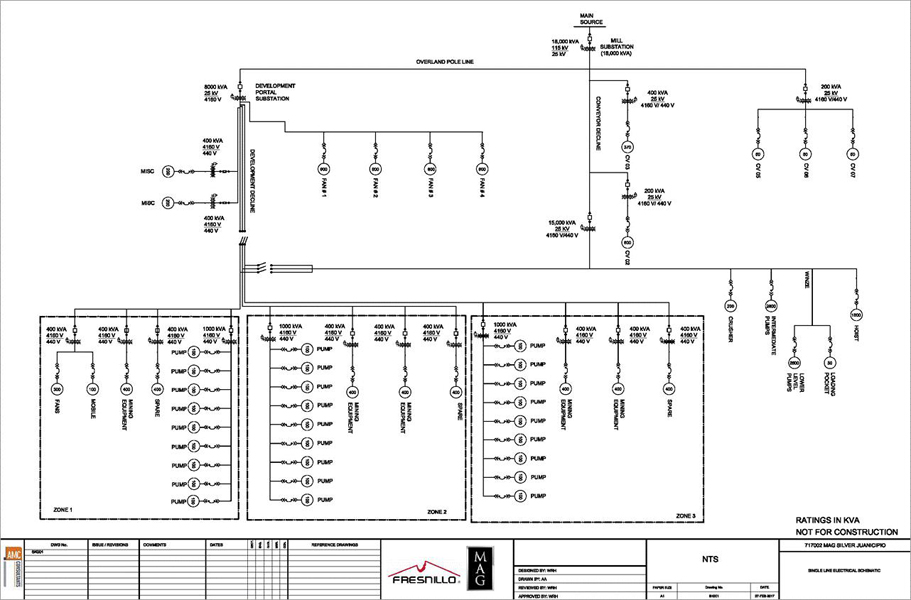

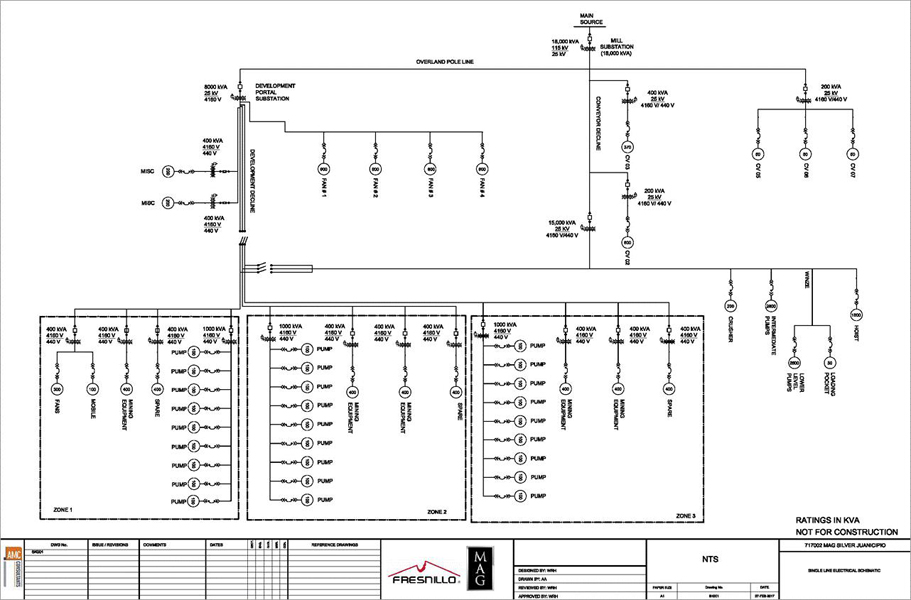

Power would be supplied to a main substation at the site via a 115 kV overhead power line supplied from the local grid. The line would have a length of approximately 1.5 km to the main processing plant sub-station.

The electrical supply system for the Juanicipio project will be developed in stages as the project develops. An initial system, with power sourced from a nearby mine, has been used for the initial decline development. This power will eventually be disconnected and the supply switched over to the permanent mine system, which originates at the mill substation.

The permanent system will have power feeding the underground and surface facilities from the mill substation. There will be two feeders for the mine: a power line that will follow the access road to deliver power from the mill to the current portal and surface ventilation fans, and a second power line going down the conveyor decline.

It is anticipated that water will initially be provided via a pipeline from a neighbouring mine that has excess water from ground water inflow. This water will be supplemented by any water from dewatering the underground workings at Juanicipio.

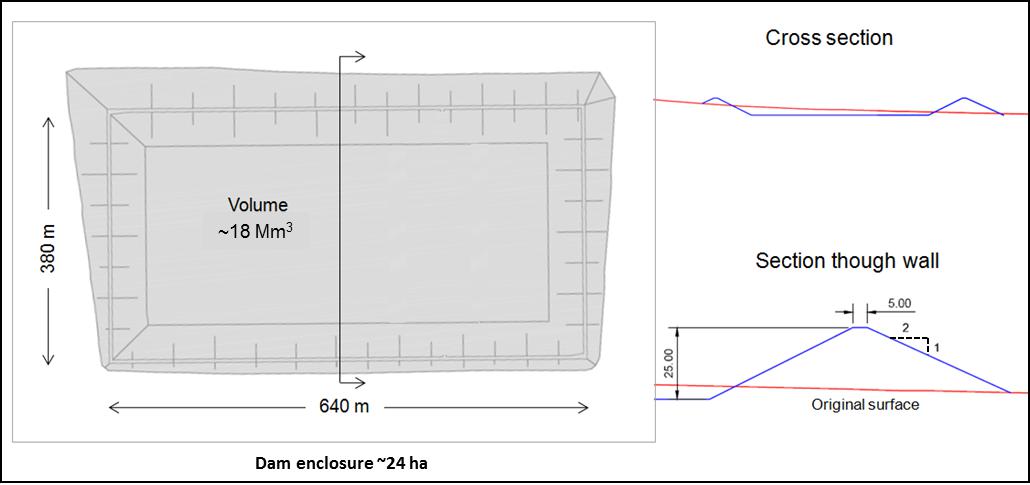

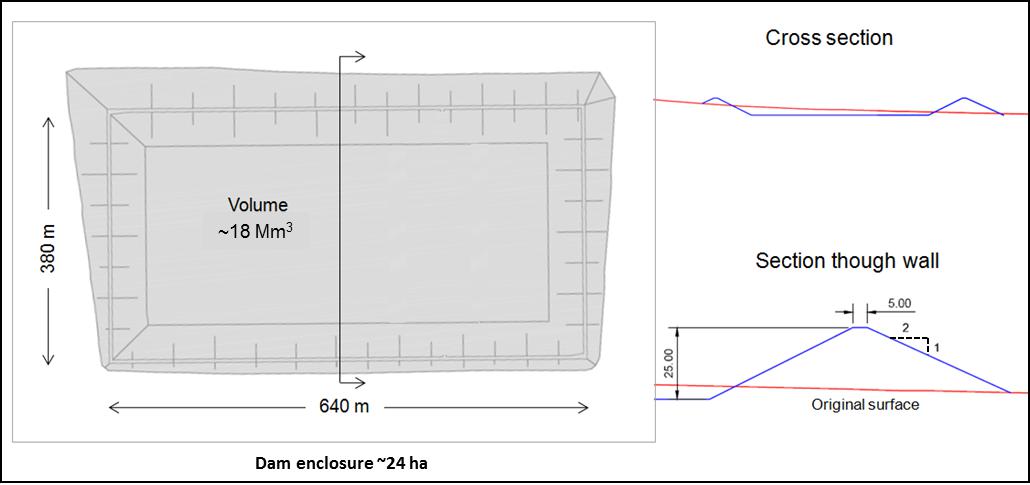

It is envisaged that all mill tailings will be discharged to a tailings storage facility (TSF) with a total volume of approximately 18 Mm3. No detailed environmental or geotechnical studies have been carried out on suitable sites for the TSF for the project. Nevertheless, several sites have been considered, including a location adjacent to the proposed mill site.

| 1.9 | Underground infrastructure |

The handling system for mineralized material is based around a nominal 4,000 tpd capacity, approximately equivalent to 216 tph over a 24-hour period, based on a capacity factor of 1.3. This allows for excess capacity in the mineralized material handling system relative to any potential disconnection between the mine and mill. Initially mineralized material transport from various mining levels will be by truck haulage to the crusher on 1950 RL. The crushed material is then placed on a load-out belt feeding two sequential conveyors to the surface stockpile adjacent to the mill.

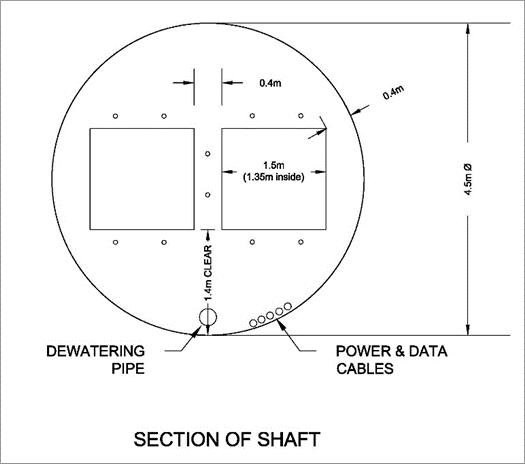

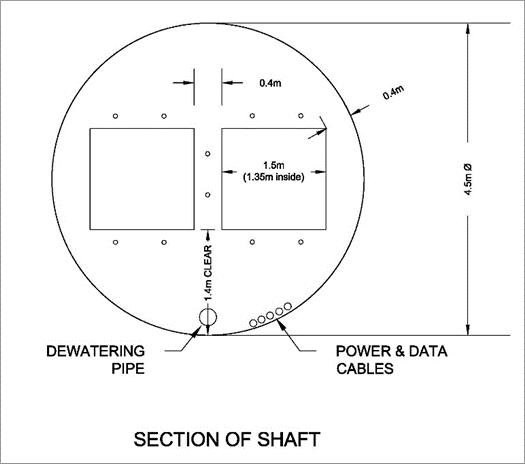

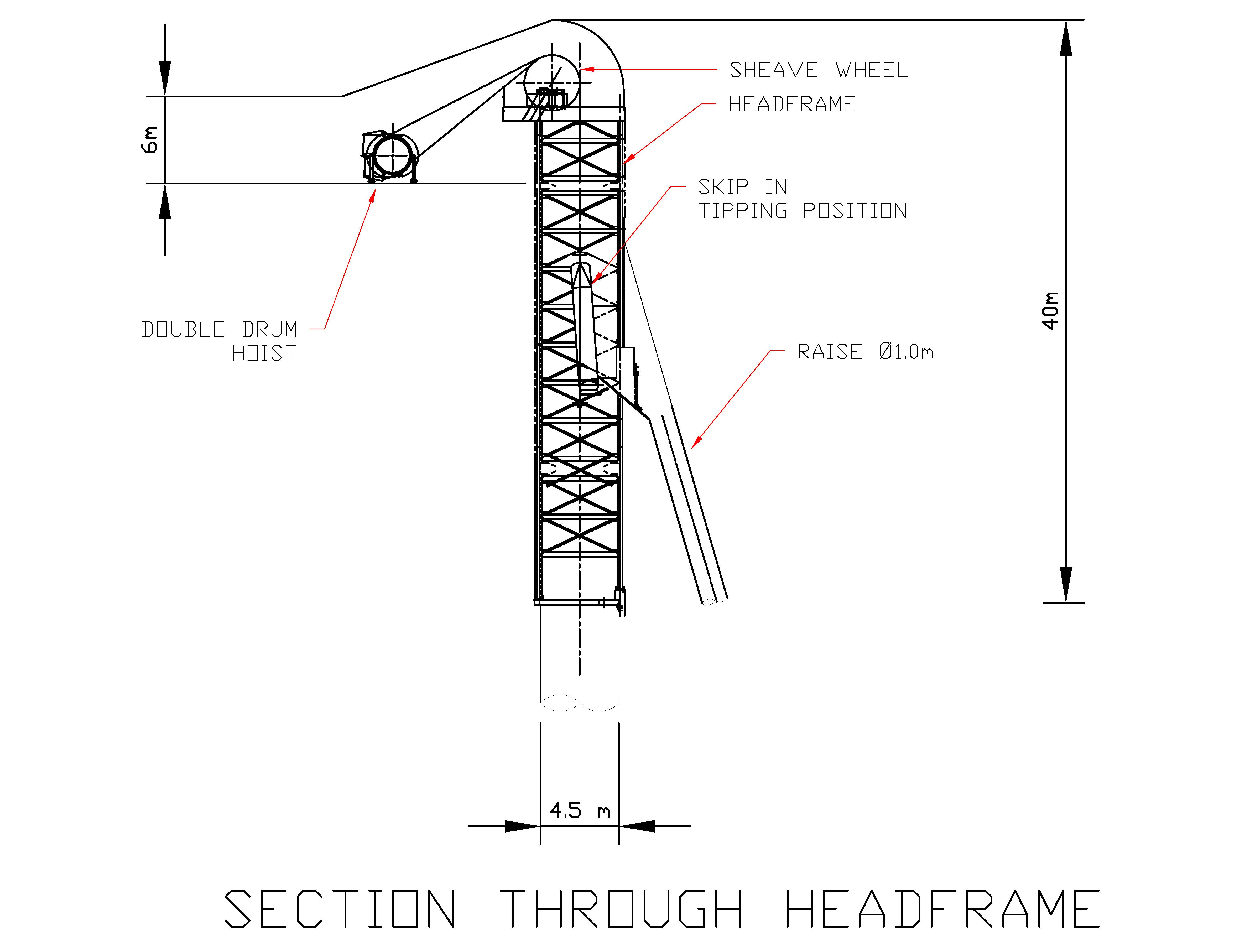

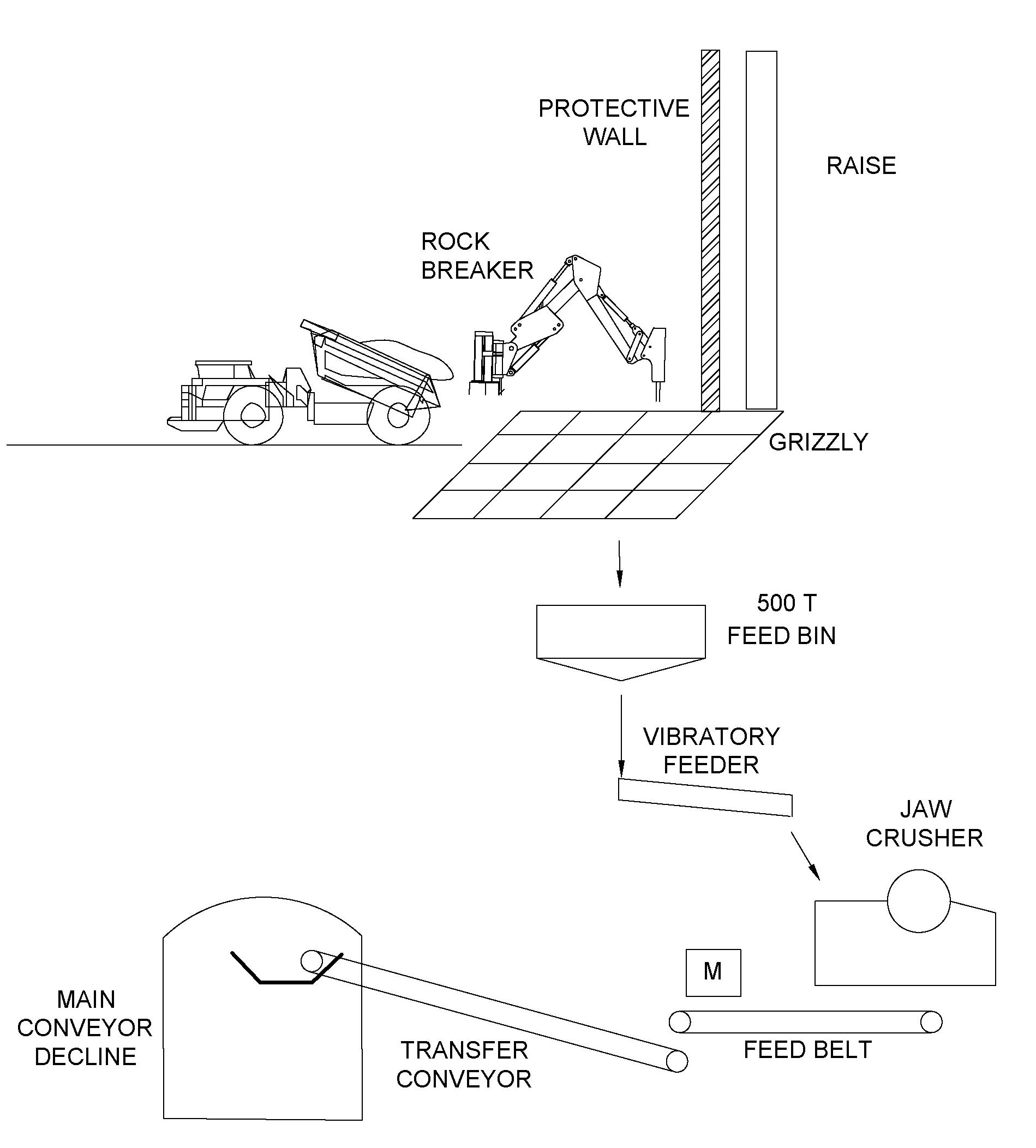

Later in the mine life, an internal winze is projected to be sunk to allow the hoisting of mineralized material from the loading pocket on 1300 RL up to the crusher on 1950 RL. From there, the material will be conveyed out of the mine via the existing conveyor system. The winze hoist consists of a double drum, dual skip system with rope guides. The hoist is mounted at the head of the winze excavation in a chamber above the skip dumps. The skips are discharged via pneumatic self-discharge systems into a raise that leads to a 500 t storage bin. Mineralized material that is delivered to the bin will be sized to minus 200 mm. The storage bin discharges into a jaw crusher that sizes the material to minus 100 mm. The hoist is designed to accommodate the production capacity of 1.4 Mtpa, however there is some spare capacity built in through potential minor adjustments in hoisting schedules or skip sizes.

Development waste is either hauled to surface by trucks via the twin access declines, or placed directly into stopes as backfill. All waste hauled to surface will be stored near the current portal. Waste required for subsequent backfilling will be delivered down a waste pass driven as close to the deposit as practicable, and then distributed to the stopes.

Two bays will be provided for the storage of bulk emulsion, each containing one 24,000 L storage tank and a storage area. A third bay will be designated for the storage of detonators on wooden shelves. A powder bay will be designated for the storage of all other explosive products (other than the bulk emulsion and the detonators) on wooden shelves. A concrete wall with a steel door will separate this bay from the rest of the mine workings. All explosives bays will be located on 1920 RL.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

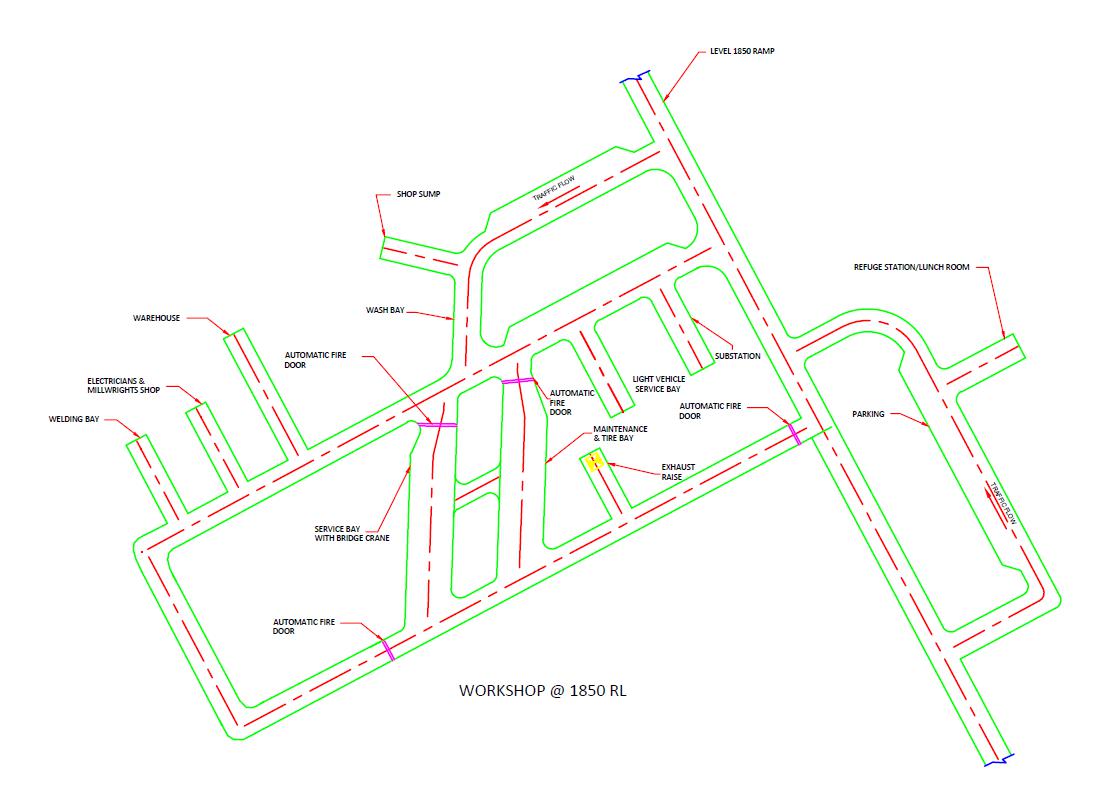

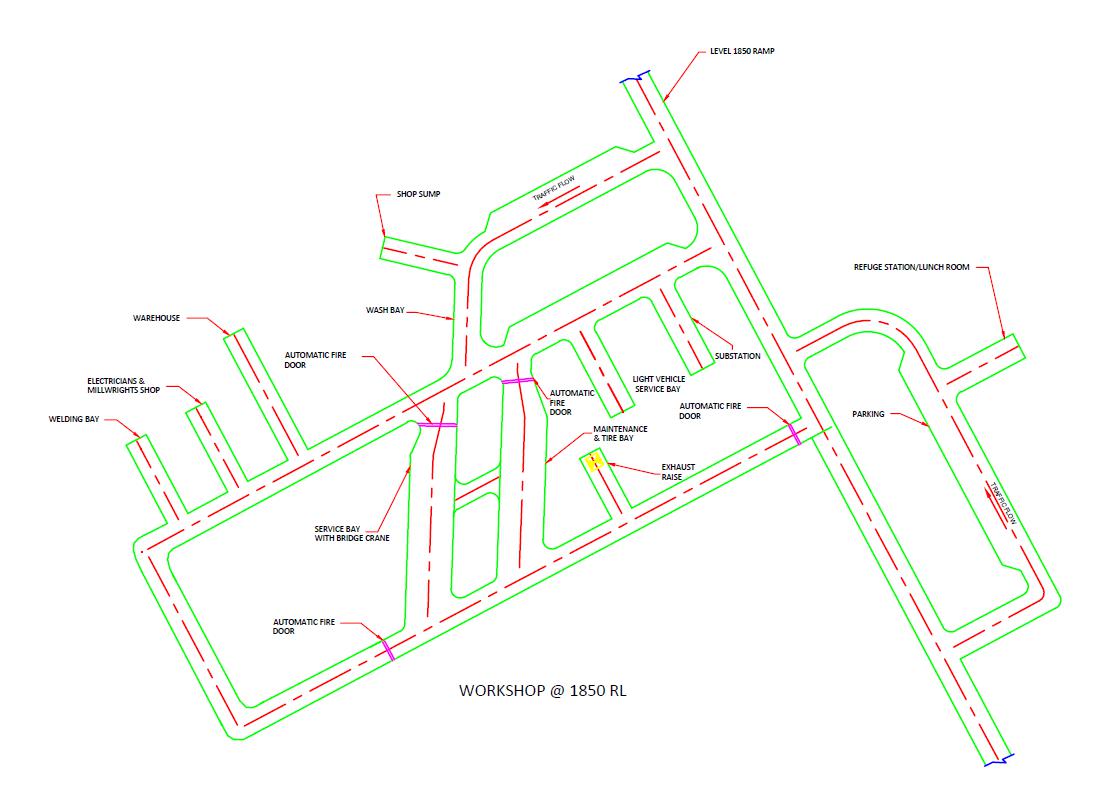

The main maintenance area will be located on surface. All major scheduled planned maintenance and rebuilds will take place in the surface workshop. Two small service bays will be located underground for low-level maintenance such as lubrication and small repairs. To reduce the quantity of fuel and oils stored underground, it is envisaged that the truck fleet and most utility vehicles will be fuelled on surface and maintained in a surface heavy equipment workshop. Only vehicles and equipment not travelling to surface as part of their daily routine will be fuelled underground.

Local area compressors will supply compressed air for the underground maintenance and service bay area, with compressed air lines from the air receiver routed to convenient locations in the area. All mobile drilling equipment, including jumbos, longhole drills, bolters, and cable bolters will be equipped with on-board compressors. ITH drills will have portable adjacent compressors to meet their elevated pressure requirements. Two units are required for this purpose.

Refuge station chambers with 30-person capacity will be used for emergencies; these chambers will be portable for flexibility of location at the most appropriate areas of the mine.

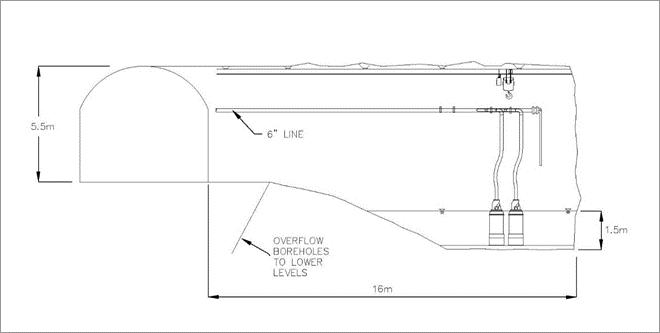

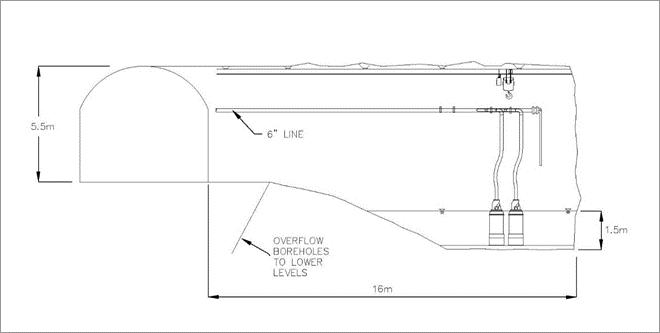

The ground water inflow into the mine has been estimated using information from nearby mines and is not based on a hydrogeological model. The hydrology data available at the time of this report is not sufficiently detailed to fully understand the likely magnitude of water inflow into the mine along faults or other geological features. AMC understands that other mines in the area are currently experiencing a steady mine inflow of the order of 190 L/s in similar geological structures and lithologies to those that will be encountered at Juanicipio. Relating the strike length of the Juanicipio mineralization to other mineralization strike lengths in the area has allowed a design criterion for long term steady state inflow of 95 L/s to be projected. The mine dewatering system will be sized to handle twice this amount as the peak outflow.

The overall dewatering strategy largely depends on accessing the lower levels of the mine well ahead of stope production. This early development approach provides a means for installing a series of dewatering sumps that will dewater sections of the mine prior to production mining. The risk of flooding will be partially mitigated by this early development strategy and by the provision of spare pumping capacity.

| 1.10 | Project development and production schedule |

Minera Juanicipio is currently developing an access decline to the mineralization, which is at approximately 1920 RL as of the time of this Report. It is estimated that it will take approximately two years to extract first mineralization and commence concentrate production. Key milestones relating to the project development are shown in Table 1.4.

| Table 1.4 | Project development milestones |

| Milestone | Start | Finish |

| Decline development | Year 1 | Year 8 |

| Conveyor decline | Year 1 | Year 2 |

| Internal winze, engineering, and construction | Year 3 | Year 9 |

| Processing plant | Year 1 | Year 3 |

| Full production (ramp up to 1.4 Mtpa) | Year 2 | Year 5 |

Year 1 is assumed to be 2018.

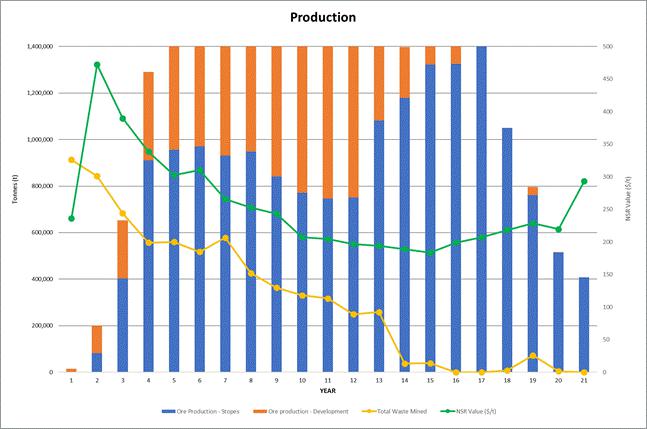

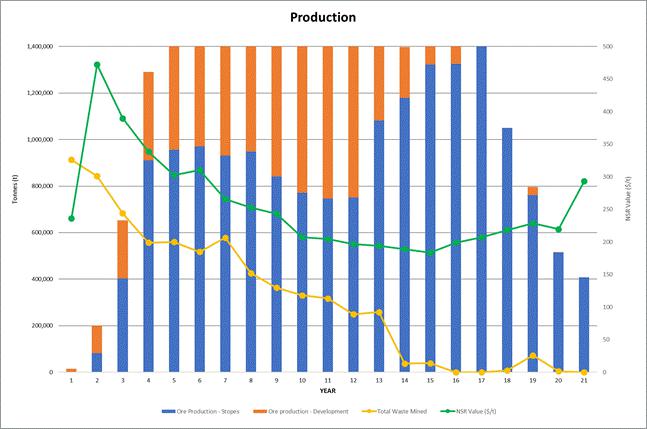

The estimated LOM production tonnage and grade that forms the basis for the economic assessment is set out in Table 1.5. Mill feed from vein development comprises approximately 25% of total mill feed, with the remainder from stoping operations.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| Table 1.5 | Material projected to be mined and processed as a basis for the economic assessment |

| | Grade | Contained metal |

| Tonnes | Ag (g/t) | Au (g/t) | Pb (%) | Zn (%) | Ag (Moz) | Au (koz) | Pb (Mlbs) | Zn (Mlbs) |

| 23,123,706 | 282 | 1.37 | 1.84 | 3.43 | 210 | 1,019 | 938 | 1,748 |

The tonnage and grades shown in Table 1.5 have resulted from the mine design and scheduling process conducted on the Mineral Resource estimate and block model prepared by AMC and described in this Report. A $55 Net Smelter Return (NSR) cut-off was applied to the resource model, stope shapes have been projected, and estimated dilution and mining losses have been accounted for. Metal prices used in the NSR calculation were $1,225 per ounce gold, $17.30 per ounce silver, $0.87 per pound lead, and $0.94 per pound zinc. An exchange rate of 18.46 Mexican pesos to one US dollar was assumed.

In developing the tonnage and grade estimates, stope blocks that were in contact with the property boundaries were excluded and zero grade has been assumed for the dilution material. Approximately 38% of the tonnage and 22% of the silver content of the material that forms the basis of the economic assessment is derived from Inferred Mineral Resources. Inferred Mineral Resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves.

| 1.11 | Project capital costs |

Project capital is estimated at $840M; pre-production capital (Year 1 to Q1 Year 3 inclusively) is estimated to be $360M. Sustaining capital ($480M) is defined as all capital following pre-production and includes ongoing mine development after concentrate production commences, and mobile and fixed equipment replacements and rebuilds over the mine life. A summary of projected capital costs is shown in Table 1.6.

| Table 1.6 | Summary of projected capital costs |

| | Capital ($) | Pre-production capital ($) |

| Item | Total LOM | Y01 | Y02 | Y03* |

| Underground development | 226,272,930 | 25,243,270 | 32,209,310 | 5,241,840 |

| Mine equipment | 161,878,000 | 0 | 7,284,510 | 4,249,300 |

| Winze | 64,044,740 | 0 | 0 | 0 |

| Material movement - trucking development waste | 46,949,770 | 1,778,840 | 2,082,660 | 1,414,330 |

| Road and powerline to portal | 5,914,000 | 5,914,000 | 0 | 0 |

| Process plant | 91,877,700 | 23,902,690 | 38,244,310 | 9,561,080 |

| Surface infrastructure | 68,138,330 | 13,865,330 | 13,865,330 | 13,865,330 |

| UG infrastructure | 65,830,930 | 19,276,980 | 19,276,980 | 19,276,980 |

| Capitalized operating costs | 22,770,790 | 5,149,800 | 14,096,800 | 3,524,200 |

| EPCM | 24,956,260 | 8,318,750 | 8,318,750 | 8,318,750 |

| Owners cost | 16,377,420 | 5,459,140 | 5,459,140 | 5,459,140 |

| Contingency | 45,157,810 | 15,052,600 | 15,052,600 | 9,572,230 |

| Total | 840,168,680 | 123,961,400 | 155,890,390 | 80,483,180 |

| Pre-production capital | 360,334,970 | | | |

| Sustaining capital | 479,833,710 | | | |

Totals do not necessarily equal the sum of the components due to rounding adjustments.

* Assumed to be Q1 2020

Total site operating costs have been estimated at $58.67/t milled. The unit costs are broken down as follows:

| · | Milling: $20.37/t milled |

| · | General and Administration: $3.34/t milled |

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

Key factors relating to the operating cost estimate include:

| · | Some unit mine operating costs from the 2012 PEA were updated for inflation. |

| · | Revised costs were estimated for trucking, conveying and hoisting activities. Costs relating to labour, equipment and power were also updated to reflect the current production schedule. |

| · | Power costs were estimated based on updated infrastructure needs and a unit cost of $0.0834/kWh. |

| · | A waste rock backfill operating cost of $0.87/t mineralized material for imported waste rock fill from surface was estimated from first principles. |

| · | Ore drift development cost per metre was based on a single-face average advance rate of 100 m/month. The labour component (~30%) of unit costs was scaled-up from the 2012 PEA to reflect this (2012 PEA assumed 120 m/month single-face advance). Unit ore development costs were also projected 10% higher for 100 m/month compared to the 2012 PEA. Unit development rates reflect current contractor pricing. |

| · | Variable processing unit costs ($/t milled) remained the same as for the 2012 PEA to reflect inflation, but also taking account of the savings due to economies of scale. Fixed processing costs ($/year) for items such as salaries, mill maintenance and other fixed costs, were escalated by the 6 / 10 power rule to account for the higher mill throughput rate, and suitable cost inflation was also applied. |

| · | Fixed general and administration (G&A) costs ($/year) for items including site administration, human resources, finance and purchasing, general maintenance, safety and environment, were escalated by the 6 / 10 power rule to account for the higher production rate, and suitable cost inflation was also applied. |

| · | Operating costs were estimated for the underground conveyor at $0.59/t and for the winze and crusher at $1.22/t. These costs include labour, energy, and maintenance. |

A summary of the annual operating costs over the life of mine is provided in Table 1.7.

| Table 1.7 | Summary of life of mine site operating costs |

| Year | Date | Operating cost $M |

| Year 1 | 2018 | n/a – capitalized as pre-operative capital |

| Year 2 | 2019 | n/a – capitalized as pre-operative capital |

| Year 3 | 2020 | 48 |

| Year 4 | 2021 | 79 |

| Year 5 | 2022 | 83 |

| Year 6 | 2023 | 85 |

| Year 7 | 2024 | 84 |

| Year 8 | 2025 | 87 |

| Year 9 | 2026 | 85 |

| Year 10 | 2027 | 85 |

| Year 11 | 2028 | 87 |

| Year 12 | 2029 | 89 |

| Year 13 | 2030 | 80 |

| Year 14 | 2031 | 78 |

| Year 15 | 2032 | 74 |

| Year 16 | 2033 | 74 |

| Year 17 | 2034 | 73 |

| Year 18 | 2035 | 57 |

| Year 19 | 2036 | 48 |

| Year 20 | 2037 | 34 |

| Year 21 | 2038 | 29 |

| Total | | 1,357 |

Note: Totals do not necessarily equal the sum of the components due to rounding adjustments.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| 1.13 | Offsite costs (Concentrate transport, treatment, and refining costs) |

No detailed market studies have been undertaken at this stage of the project. Lead and zinc concentrates are commonly sold as part of the world’s mining and metals industries. It is envisaged that silver-rich lead concentrate and zinc concentrate may be sold to smelters in the Asian region. Lead concentrate could potentially be sold to a smelter in Mexico or exported to offshore smelters. If sold to a local smelter, transport costs could be reduced.

For purposes of its analysis, AMC has assumed that both the lead and zinc concentrates will be treated in Asia, with lead and zinc treatment charges of $235/dry metric tonne of concentrate, silver refining charges equivalent to 4% of the silver price, gold refining charges of $5/oz and, subject to a transport cost of $115/wet metric tonne. Treatment and other terms for lead and zinc concentrates were suggested by Neil S. Seldon & Associates Ltd. (NSA, 2016). Both lead and zinc concentrates are projected to incur minor treatment penalties for impurities. The pyrite concentrate is expected to be of high value and it is assumed that it will be sold to a Mexican smelter, but other alternatives are expected to be available.

Total off-site costs have been estimated at $41.32/t milled.

Income and other taxes presented in the PEA are based on Mexican legislated tax rates and do not reflect any tax planning opportunities. The tax provisions include a conventional profit based tax using the 30% corporate tax rate currently in effect, a 7.5% special mining duty applied on earnings before amortization and taxes, and a 0.5% gross revenue royalty on all gold and silver revenues. Employee profit sharing (PTU) is not included in the financial estimates and the net present value (NPV) and internal rate of return (IRR) of the project may fluctuate depending on how the project is structured once it is in operation.

Project economics have been assessed using the following metal prices (Base Case Prices), which were selected after discussion with MAG Silver and referencing current market and recent historical prices, values used in other recent projects, and forecasts in the public domain:

| · | Silver price = $17.90/oz |

It is envisaged that a silver-rich zinc concentrate will be sold primarily to smelters in the Asian region. Lead concentrate could potentially be sold to a smelter in Mexico or exported to offshore smelters. It is envisaged that the gold-rich pyrite concentrate will be sold to a customer able to recover gold and silver using a conventional cyanide leach process.

All currency is in US dollars ($) unless otherwise stated. The cost estimate was prepared with a base date of Year 1 and does not include any escalation beyond this date. For net present value (NPV) estimation, all costs and revenues are discounted at 5% from the base date. An exchange rate of MXP18.46:US$1 and a corporate tax rate of 30% have been assumed.

AMC conducted a high level economic assessment of the conceptual underground operation of the Juanicipio deposit. The mine is projected to generate approximately $1,860M pre-tax NPV and $1,138 M post-tax NPV at 5% discount rate, pre-tax IRR of 64.5% and post-tax IRR of 44.5%. Project capital is estimated at $840 M with a payback period of 3.4 years (undiscounted pre-tax cash flow from Year 1).

Table 1.8 provides a summary of the key inputs and results of the economic analysis. The results of the 2017 PEA compare favorably with the previous 2012 PEA, which projected a post-tax NPV at 5% discount rate of $1,233M and post-tax IRR of 43%.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| Table 1.8 | Key inputs and results of economic analysis |

| Juanicipio deposit | Unit | Value(7) |

| Total mineralized rock | tonnes | 23,123,706 |

| Total waste production | tonnes | 6,758,008 |

| Production tonnage silver grade(1) | g/t | 282 |

| Production tonnage gold grade(1) | g/t | 1.37 |

| Production tonnage zinc grade(1) | % | 3.43 |

| Production tonnage lead grade(1) | % | 1.84 |

| Silver recovery(1) | % | 94.8 |

| Gold recovery(1) | % | 81.6 |

| Zinc recovery(1) | % | 89.8 |

| Lead recovery(1) | % | 92.8 |

| Silver price | $/oz | $17.90 |

| Gold price | $/oz | $1,250 |

| Zinc price | $/lb | $0.95 |

| Lead price | $/lb | $1.00 |

| Silver payable(2) | % | 87 |

| Gold payable(2) | % | 73 |

| Zinc payable(2) | % | 76 |

| Lead payable(2) | % | 86 |

| Payable silver metal | oz | 182,789,511 |

| Payable gold metal | oz | 747,417 |

| Payable zinc metal | lb | 1,326,904,724 |

| Payable lead metal | lb | 811,923,951 |

| Revenue split by commodity | Silver | 51.90% |

| Revenue split by commodity | Gold | 14.82% |

| Revenue split by commodity | Zinc | 21.05% |

| Revenue split by commodity | Lead | 12.23% |

| Gross revenue | $ (M) | $6,304 |

| Capital costs | $ (M) | 840 |

| Operating costs (total)(3) | $ (M) | 1,357 |

| Mine operating costs(4) | $/t | 34.95 |

| Processing costs | $/t | 20.37 |

| Operating costs (total)(3) | $/t | 58.67 |

| Operating cash cost (Ag) | $/oz Ag | (3.94) |

| Total all-in sustaining cost (Ag) | $/oz Ag | 5.02 |

| Payback period from plant start up(5) | Years | 1.8 |

| Cumulative net cash flow(6) | $ (M) | 3,152 |

| Pre-tax NPV @5% discount rate | $ (M) | 1,860 |

| Pre-tax IRR | % | 64.5 |

| Post-tax NPV @5% discount rate | $ (M) | 1,138 |

| Post-tax IRR | % | 44.5 |

1. LOM average.

2. Overall payable % includes recoveries, treatment, transport, refining costs and selling costs.

3. Includes mine operating costs, milling, and mine G&A.

4. Underground mining costs only.

5. Values are post-tax from projected plant start up.

6. Pre-tax and undiscounted.

7. The results are preliminary in nature and include Inferred Mineral Resources that are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the PEA will be realized.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

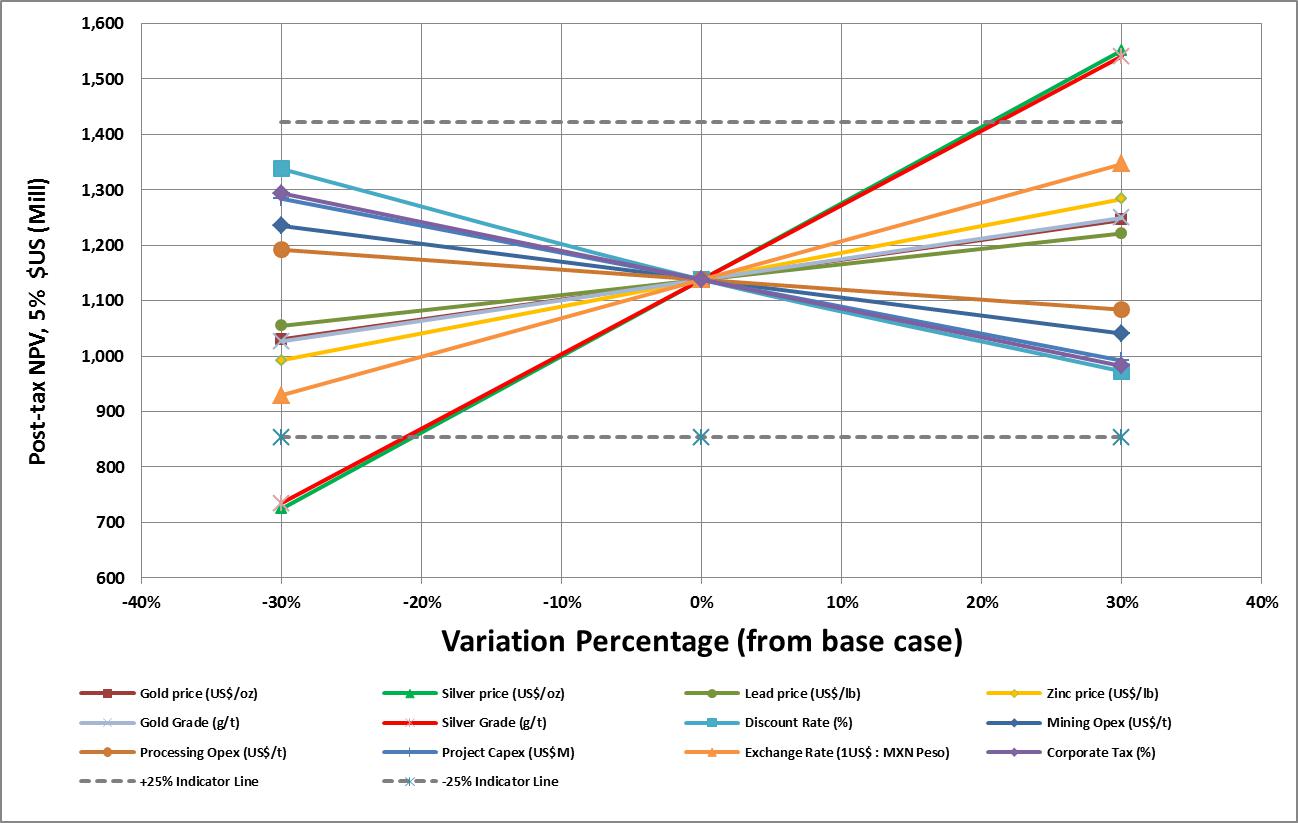

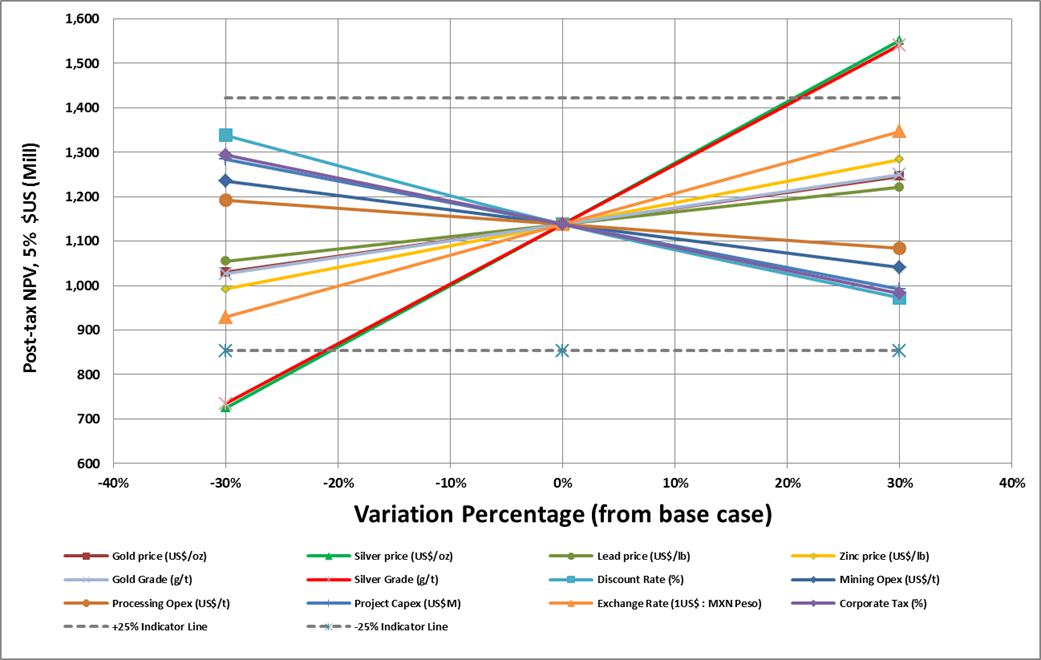

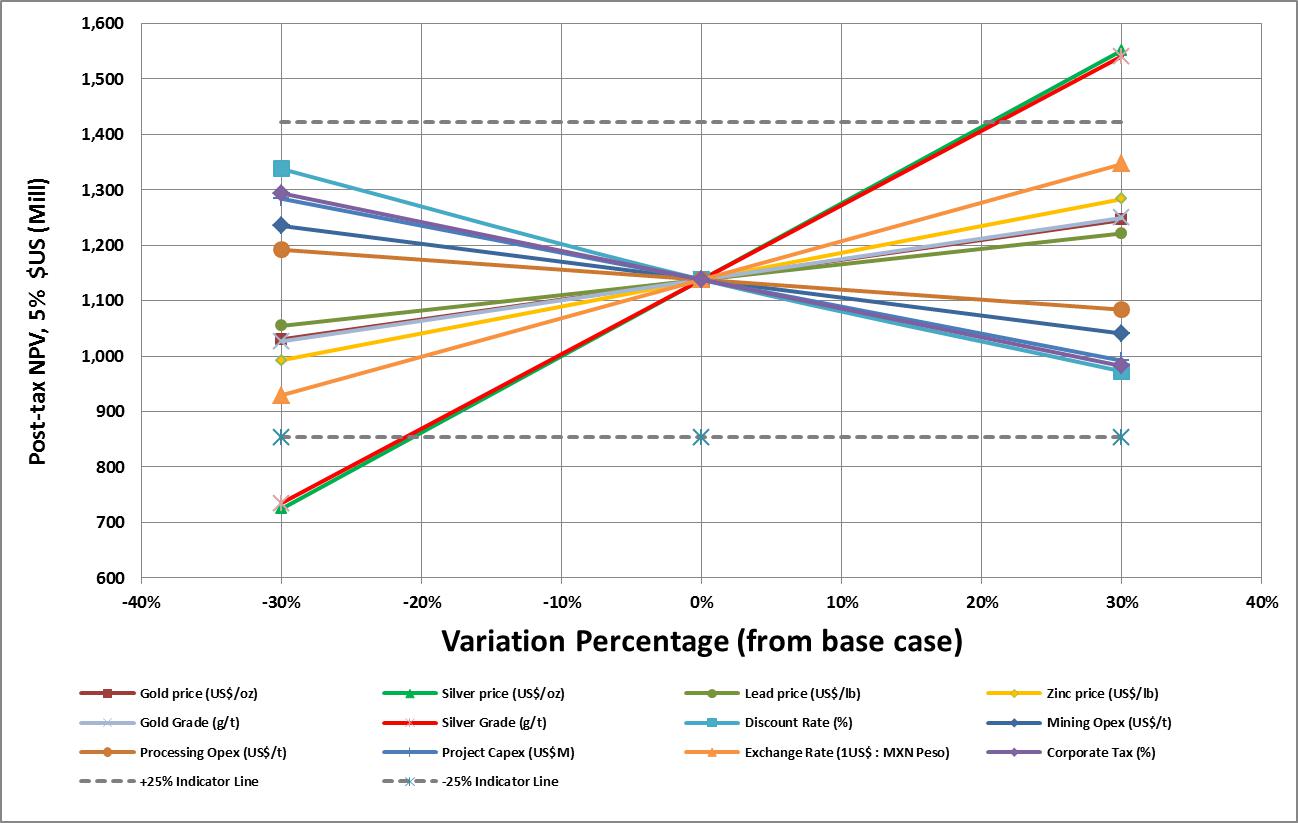

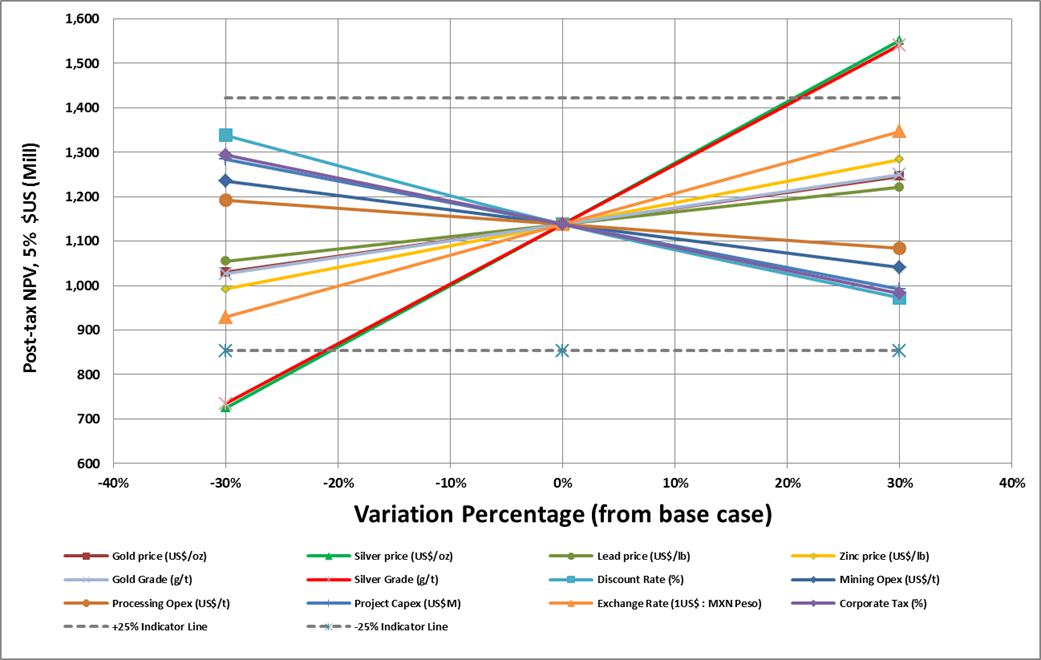

AMC has carried out a sensitivity analysis of the project economics. The sensitivity analysis examined the impact on the post-tax NPV (at 5% discount rate) of a 30% positive or negative change in metal prices, operating costs, capital costs, corporate tax rate, foreign exchange rate (MXN Peso:$) and the discount rate. The results (Figure 1.3) show that the post-tax NPV is very positive and remains so for the range of sensitivities evaluated.

| Figure 1.3 | Sensitivity analysis – post-tax NPV at 5% discount rate |

| 1.18.1 | Mineral Resource estimate |

AMC makes the following observations and conclusions:

| · | Indicated tonnes have increased by 27%, while Inferred tonnes have increased by 138%. |

| · | Both Indicated and Inferred grades have decreased for silver and increased for base metals. |

| · | Average gold grades have increased in the Indicated category and decreased in Inferred category. |

| · | The net result in the Indicated category has been an increase in contained silver of 6% and an increase in contained gold of 59%. The increases in contained lead and zinc are 43% and 34% respectively. |

| · | The net result in the Inferred category has been an increase in contained silver of 48% and an increase in contained gold of 76%. Contained lead and zinc show increases of 226% and 295% respectively. |

| · | Although not a significant part of the total Mineral Resource, copper is quoted for the first time as a result of high copper values being intercepted at depth in the new drilling. |

Reasons for the differences in grade, tonnes and contained metal include Mineral Resource addition down-dip and conversion to higher categories arising from the new drilling. The most significant change from the previous estimate is the increase in extent of the Deep Zone mineralization as a result of the new drilling. This is in keeping with the increase in tonnes seen in the 2017 AMC estimate. Also, the overall decrease in average precious metal grades and increase in average base metal grades reflects the new drilling targeting the deeper base metal rich zones.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| · | The mine will be accessed by twin declines and a conveyor decline. |

| · | Mechanized longhole stoping with waste backfill has been selected as the mining method. This offers good productivity while maintaining selectivity. |

| · | Trade-off studies have identified that conveying the mineralized rock directly to the relocated process plant from underground is economically and operationally superior to other arrangements. |

| · | Evaluation of the planned production rate and scheduling of the deposit indicates that the deposit supports 1.4 Mtpa. |

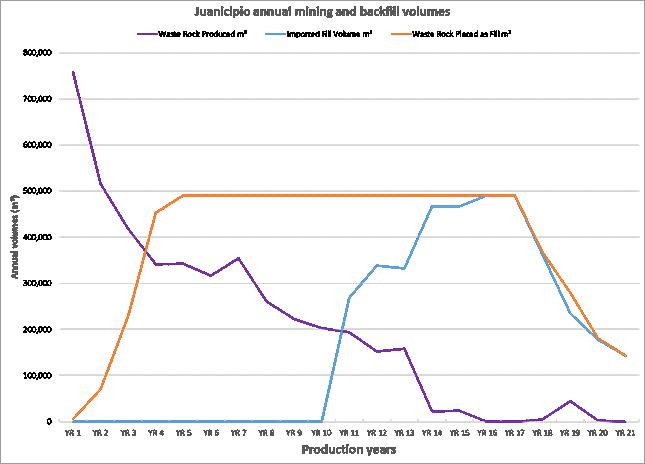

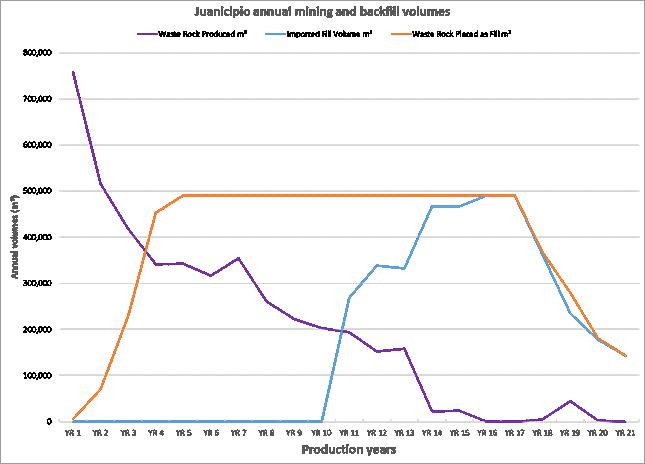

| · | All waste will be tipped directly into stopes or trucked to surface. There will be a deficit in the amount of waste required for backfilling, projected to be in Year 11. It is assumed that waste will be mined from a small pit and dropped down a waste pass for distribution to the stopes. |

| · | A 780 m long winze will be developed to handle the mineralized material at depth. The winze will commence hoisting in Year 8. |

| · | A 1.5 km paved access road is required from the main highway to the process plant. A 6.5 km access road, mostly over hilly terrain, will be required to access the main portal site from the plant. A two-lane sealed road suitable for use by heavy vehicles is proposed. |

| · | Power would be supplied to a main substation at the site via a 115 kV overhead power line from an existing power line located to the north of the property. The line would have a length of approximately 2 km to the main processing plant sub-station. |

| · | It is anticipated that mine service water will initially be provided via a pipeline from a neighbouring mine that has excess water from groundwater inflow. This water will be supplemented by any water from dewatering the underground workings at Juanicipio (see final point below). |

| · | It is envisaged that all mill tailings will be discharged to a tailings storage facility (TSF) with a total volume of approximately 18 Mm3. |

| · | No detailed environmental or geotechnical studies have been carried out on suitable sites for the TSF for the project. |

| · | Extensive groundwater is anticipated at Juanicipio. Currently there has not been a detailed hydrogeological study for the mine; this may be considered a risk. |

| · | A third metallurgical laboratory test program was undertaken during 2013, building on the two previous programs. Locked cycle flotation tests confirmed that the flotation circuit will be viable and good recoveries of silver (80.1%), lead (92.8%), and copper (38.4%) to the lead concentrate were achieved. Recoveries to zinc concentrate were 4.9% for gold, 6.8% for silver, 43.9% for copper, and 89.8% for zinc. Gold recoveries of 22.1% to pyrite concentrate were also achieved, along with 9.9% of the silver and 58.1% of the iron. Losses to final tails were reasonable, with metal grades observed in the final tails stream of 0.2 g/t gold, 24 g/t silver, 0.11% lead, 0.01% copper, and 0.11% zinc. Cyanidation of the pyrite concentrate demonstrated good gold and silver recoveries of 52% and 80% respectively. |

| · | The proposed flowsheet is designed to treat a nominal 4,000 tpd of feed and consists of a comminution circuit, with underground primary crushing, secondary crushing and milling on surface, followed by sequential flotation to produce a silver-rich lead concentrate; followed by production of a zinc concentrate and a gold-containing pyrite concentrate. The flowsheet is conventional for lead-zinc operations, with the pyrite flotation circuit providing a variation to the most commonly used circuits. Test work supports the selection and design of the flotation circuits. |

| · | The location of the processing plant has changed from previous studies to a large flat area suitable for construction and of sufficient size to accommodate the processing plant and tailings facility. |

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

The preliminary economic assessment clearly indicates that the Juanicipio Project has the potential to be developed into an economically positive, high-grade underground silver mine. Further drilling and investigation work aimed at upgrading Inferred Mineral Resources and increasing the geotechnical and hydrogeological understanding of the deposit is recommended to augment the next stage of project design and evaluation.

Mineral resources are not Mineral Reserves and do not have demonstrated economic viability. There is a degree of uncertainty attributable to the estimation of Mineral Resources. Until resources are actually mined and processed, the quantity of mineralization and grades must be considered as estimates only. Any material change in quantity of resources, mineralization, or grade may affect the economic viability of the project.

| 1.18.6 | Opportunities for further consideration currently excluded from project scope |

Potential opportunities for the project include:

| · | Significant exploration potential within a large land package and a number of high priority drill targets. |

| · | The Valdecañas vein system, including the new Anticipada Vein, is largely open at depth. |

| · | Deep zone is open to the east and west boundaries of the joint venture property. |

| · | Juanicipio vein open to the west and to depth for further exploration. |

| · | This 2017 PEA only considers the identified Mineral Resources within the Valdecañas vein system, the Juanicipio vein is not considered at this time. |

| · | Further analysis to determine the metal grade of the diluting material from the Hangingwall and Footwall over blast. |

| · | A characterization study of the planned dilution and dilution grade. |

| · | Lease versus purchase analysis of equipment, considering equipment availability and tax benefits of leasing. |

| · | Assess the ability to increase the recoverability and payability of Ag and Au with a gravity circuit. |

| · | Potential recoverability of copper to be considered and assessed. |

| | |

| · | An opportunity exists to commence negotiations with potential smelters to possibly capitalize on lower lead and zinc treatment charges, and possibilities to reduce transportcosts ofconcentrate. |

| 1.19 | Recommendations for further work |

AMC recommends the following additional work:

| · | In-fill drilling to convert Inferred Mineral Resources to Indicated Mineral Resources in the Valdecañas vein system. |

| · | Step-out drilling to expand the Deep Zone in the Valdecañas vein system and to delineate the western extent and depth of the Juanicipio vein. |

| · | Undertake surface exploration and drilling programs on targets outside of the existing Mineral Resource area, as only 5% to 10% of the overall property has been drill tested and numerous targets for drill-based exploration have been identified. |

| · | Continue with relevant mapping, sampling and geophysical surveys to assist in identification of new drill targets. |

| · | Undertake a hydrogeological study to reduce risks associated with ground water and better define the dewatering strategy. |

| · | Undertake a geotechnical data collection program to include an appropriate number of laboratory-conducted rock strength tests on all lithological units that are expected to be intersected by underground mining. |

| · | Geotechnically log the centreline of the planned winze and conduct a geophysical survey of the proposed shaft centreline using an optical and acoustic televiewer. |

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| · | Create a more detailed cost estimate and life of mine production plan for the next phase of the project. Assess potential to optimize lateral and vertical development quantities. The depth of the winze may need to be re-evaluated if the Mineral Resource extends further at depth. |

| · | Optimization of the lead flotation circuit should be investigated to improve the lead grade of the concentrate without compromising recoveries. It has been shown that up to 37% of the gold and 28% of the silver in feed could be recovered to a gravity concentrate, which could improve project economics and potentially eliminate the requirement for a pyrite flotation circuit. More test work will be required to demonstrate the viability of including a gravity circuit in the final process design. An overall cost benefit study of the pyrite flotation circuit should be undertaken. |

| · | The potential impact of variability within the ore body has not been demonstrated and more variability work may be required to ensure that projected grades and recoveries can be reasonably assumed to be consistently achievable over the life of the operation. |

| · | Detailed mass and water balances should be generated to confirm metal deportment throughout the processing circuit, process water requirements and, as necessary, water discharge requirements. Similarly, energy requirements for processing operations should be further evaluated. |

| · | Discussions with potential customers are recommended to better define likely concentrate payment terms. The discussions should be directed towards establishing provisional concentrate off-take agreements. |

| · | Undertake further work to identify and establish firm contracts for water supply either with a neighbouring mine or from an alternative source. Further understanding of the likely quantity of ground water will be gained from a hydrogeological study; this together with catchment dams could be an alternative solution. |

It is recommended that further work be carried out as part of a structured program that includes completion of a more detailed project feasibility study (FS). The estimated cost of this program is $15.2M.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

Contents

| 1 Summary | 1 |

| 1.1 Introduction | 1 |

| 1.2 Location | 1 |

| 1.3 Geology and mineralization | 1 |

| 1.4 Mineral Resources | 2 |

| 1.5 Geotechnical considerations | 2 |

| 1.5.1 Rock mass properties and hydrogeology | 3 |

| 1.5.2 Stable stope spans | 3 |

| 1.5.3 Stope dilution estimation | 3 |

| 1.6 Mining concept | 3 |

| 1.7 Mineral processing | 5 |

| 1.8 Project infrastructure | 6 |

| 1.9 Underground infrastructure | 6 |

| 1.10 Project development and production schedule | 7 |

| 1.11 Project capital costs | 8 |

| 1.12 Site operating costs | 8 |

| 1.13 Offsite costs (Concentrate transport, treatment, and refining costs) | 10 |

| 1.14 Taxes | 10 |

| 1.15 Project revenue | 10 |

| 1.16 Economic analysis | 10 |

| 1.17 Sensitivity | 12 |

| 1.18 Conclusions | 12 |

| 1.18.1 Mineral Resource estimate | 12 |

| 1.18.2 Mining | 13 |

| 1.18.3 Processing | 13 |

| 1.18.4 Economics | 14 |

| 1.18.5 Risks | 14 |

| 1.18.6 Opportunities for further consideration currently excluded from project scope | 14 |

| 1.19 Recommendations for further work | 14 |

| 2 Introduction | 25 |

| 2.1 Purpose | 25 |

| 2.2 Terms of reference | 25 |

| 2.3 Sources of information | 25 |

| 2.4 Qualified Persons | 25 |

| 2.5 Units of measure and currency | 26 |

| 3 Reliance on other experts | 27 |

| 4 Property description and location | 28 |

| 4.1 Land tenure | 28 |

| 5 Accessibility, climate, local resources, infrastructure, and physiography | 31 |

| 5.1 Accessibility | 31 |

| 5.2 Climate | 31 |

| 5.3 Local resources | 31 |

| 5.4 Infrastructure | 31 |

| 5.5 Physiography | 31 |

| 6 History | 32 |

| 6.1 Prior ownership | 32 |

| 6.2 Exploration history | 32 |

| 6.3 Previous Mineral Resource estimates | 32 |

| 6.4 Scoping study – 2009 | 33 |

| 6.5 PEA study – 2012 | 33 |

| 6.6 RPA Technical Report June 2014 | 34 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| 7 Geological setting and mineralization | 35 |

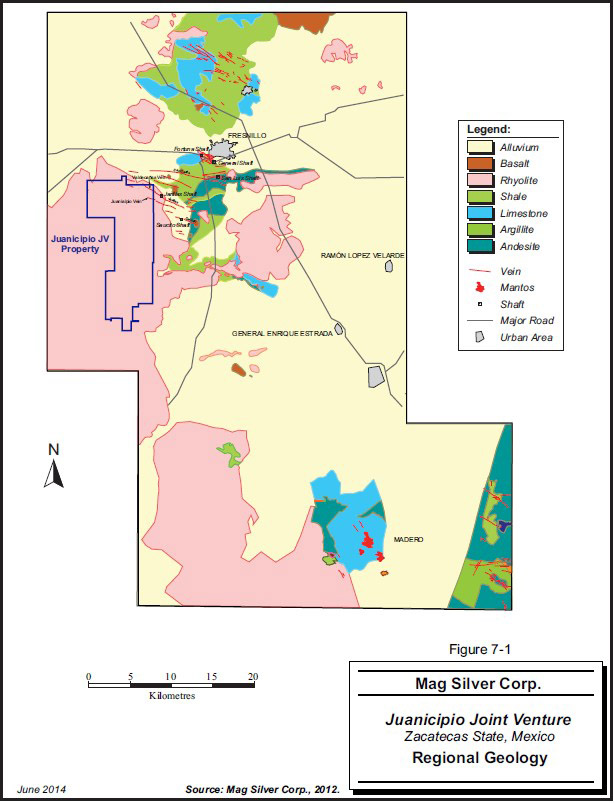

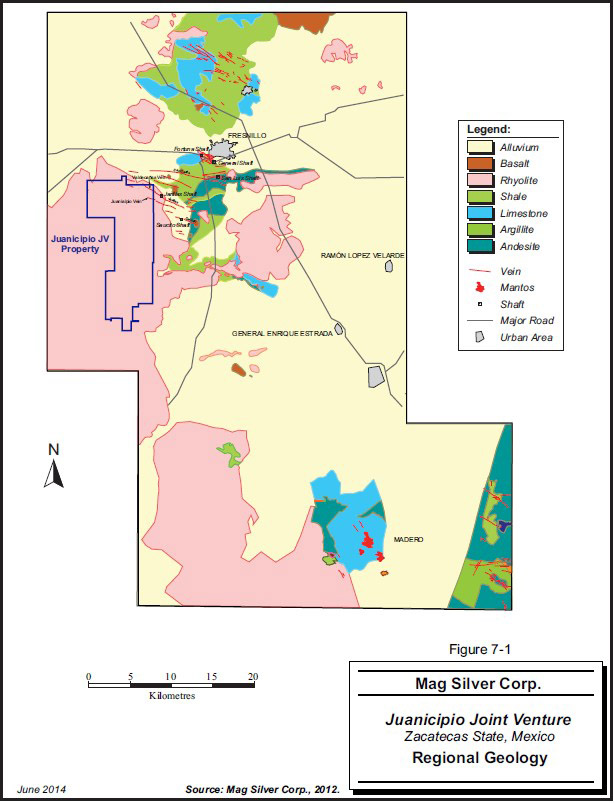

| 7.1 Regional geology | 35 |

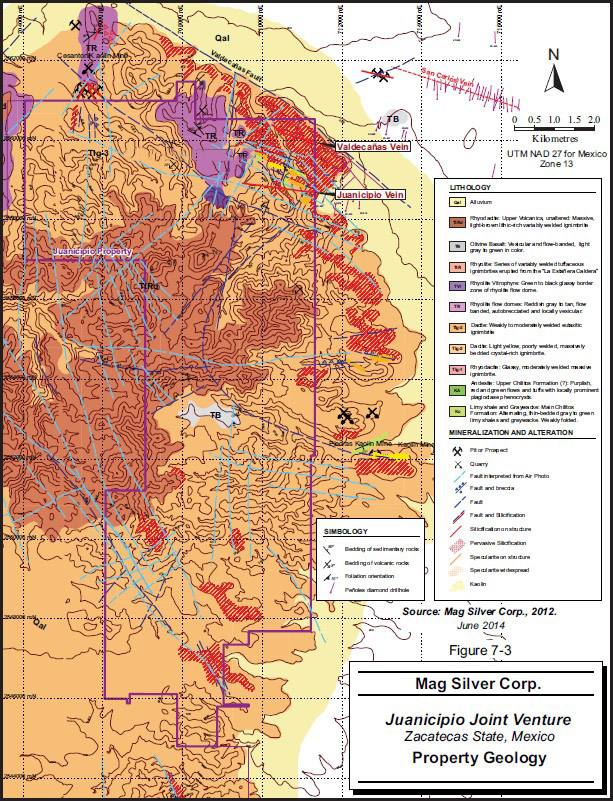

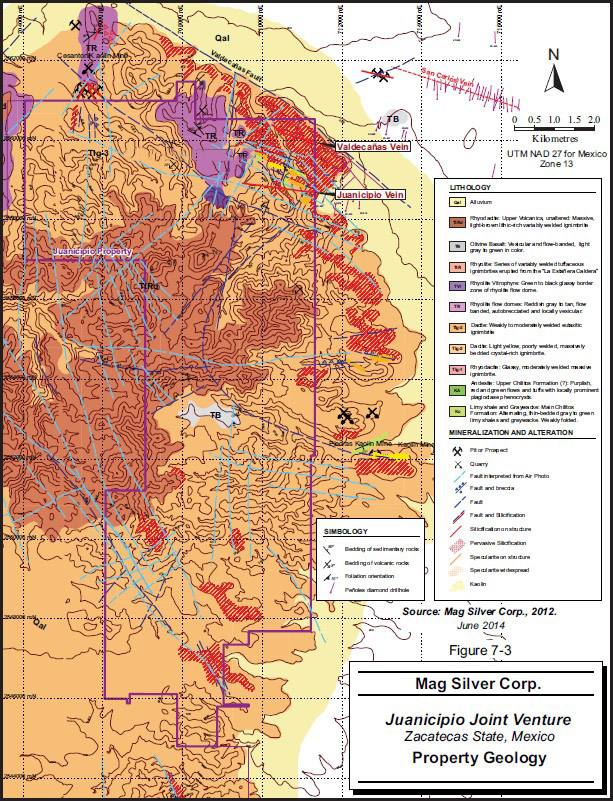

| 7.2 Property geology | 39 |

| 7.2.1 Mesozoic rocks | 39 |

| 7.2.2 Tertiary igneous rocks | 39 |

| 7.2.3 Upper Tertiary rocks | 39 |

| 7.2.4 Structural geology | 40 |

| 7.3 Mineralization | 42 |

| 7.3.1 Valdecañas vein system | 42 |

| 7.3.2 Juanicipio vein | 43 |

| 7.3.3 Other known mineralization | 43 |

| 8 Deposit types | 44 |

| 9 Exploration | 45 |

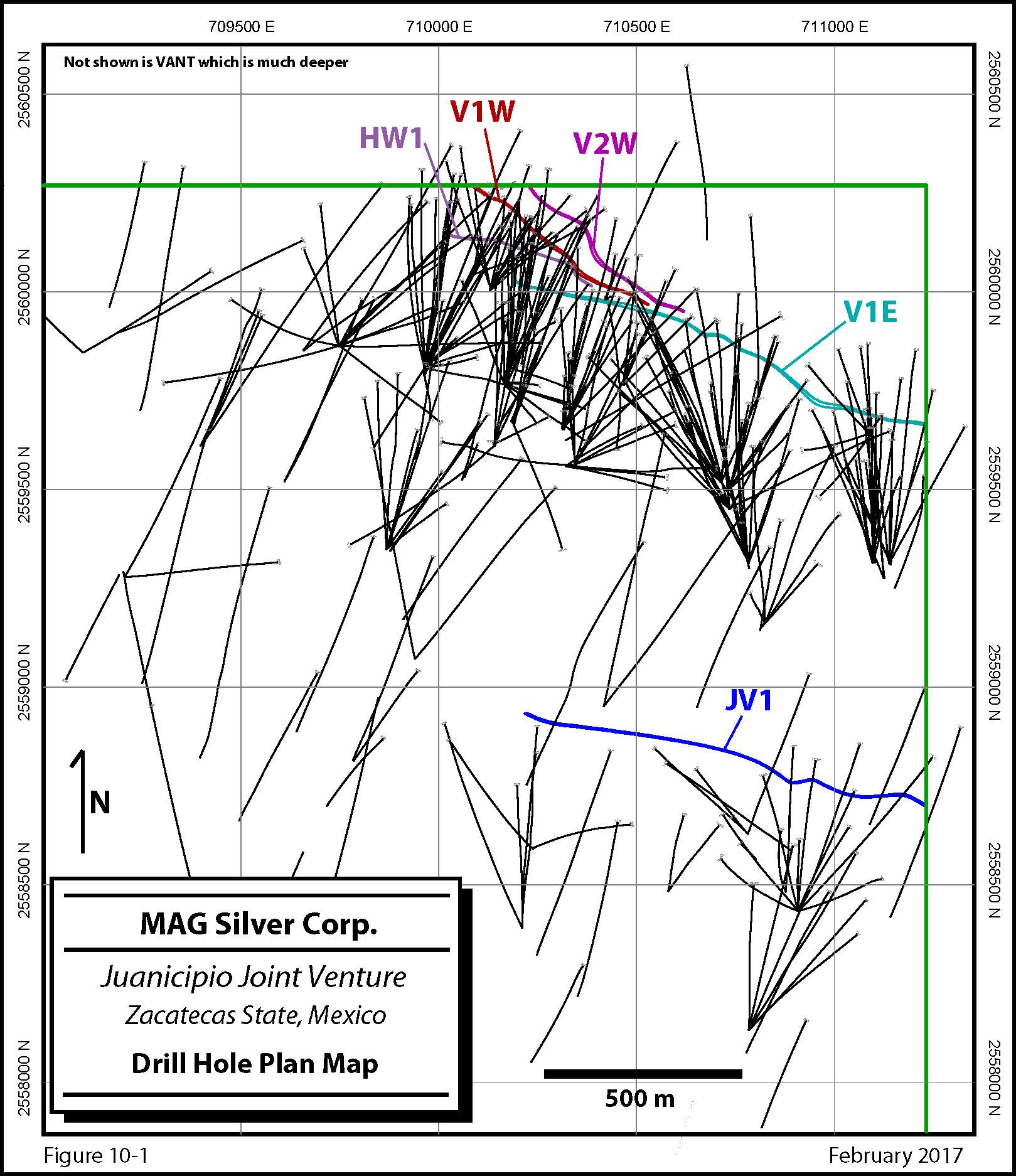

| 10 Drilling | 46 |

| 10.1 Introduction | 46 |

| 10.2 Drilling progress | 46 |

| 10.3 Procedures | 46 |

| 10.3.1 Sampling by MAG Silver (2004) | 46 |

| 10.3.2 Sampling by Fresnillo (2005-2016) | 46 |

| 10.4 Drilling results | 47 |

| 11 Sample preparation, analyses, and security | 53 |

| 11.1 Sample preparation and analysis | 53 |

| 11.1.1 MAG Silver samples (2005) | 53 |

| 11.1.2 Fresnillo samples (2005-2016) | 53 |

| 11.2 Quality assurance and quality control | 53 |

| 11.2.1 Assay results of standards | 53 |

| 11.2.2 Assay results of blank samples | 56 |

| 11.2.3 Assay results of duplicates | 57 |

| 11.2.4 Assay results of umpire data | 57 |

| 11.3 Core storage and security | 59 |

| 12 Data verification | 60 |

| 12.1 Previous work | 60 |

| 12.1.1 Wardrop 2009 | 60 |

| 12.1.2 Strathcona 2011 | 60 |

| 12.1.3 AMC 2012 | 60 |

| 12.1.4 RPA 2014 | 60 |

| 12.2 AMC verification | 61 |

| 13 Mineral processing and metallurgical testing | 62 |

| 13.1 Metallurgical testing | 62 |

| 13.2 Sample preparation | 62 |

| 13.3 Head assays | 63 |

| 13.4 Mineralogical characterization | 63 |

| 13.4.1 Mineral composition and species distribution | 63 |

| 13.4.2 Mineral liberation | 65 |

| 13.5 Flotation tests | 65 |

| 13.5.1 Open circuit flotation test work | 65 |

| 13.5.2 Locked cycle flotation test work | 68 |

| 13.6 Cyanidation of pyrite concentrate | 70 |

| 13.7 Gravity recoverable gold and silver | 70 |

| 13.8 Ball mill work indexes | 71 |

| 13.9 Metal recoveries and concentrate grade | 71 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| 14 Mineral Resource estimates | 72 |

| 14.1 Data used | 73 |

| 14.1.1 Drillhole database | 73 |

| 14.1.2 Bulk density | 74 |

| 14.2 Domain modelling | 75 |

| 14.2.1 Lithological domains | 75 |

| 14.2.2 Mineralization domains | 75 |

| 14.3 Statistics and compositing | 76 |

| 14.4 Block model | 80 |

| 14.4.1 Block model parameters | 80 |

| 14.4.2 Variography and grade estimation | 80 |

| 14.4.3 Resource classification | 80 |

| 14.4.4 Block model validation | 80 |

| 14.4.5 Mineral Resource estimation | 82 |

| 14.5 Comparison with previous Mineral Resource estimate | 84 |

| 15 Mineral Reserve estimates | 86 |

| 16 Mining method | 87 |

| 16.1 Geotechnical considerations | 87 |

| 16.1.1 Rock mass properties | 87 |

| 16.1.2 Stable stope spans – geotechnical analysis | 94 |

| 16.1.2.1 Stability number (N’) | 94 |

| 16.1.3 Stope dilution estimation | 97 |

| 16.1.3.1 Stope design parameters | 98 |

| 16.1.3.2 Stope back design parameters | 100 |

| 16.1.4 Tunnel support design | 100 |

| 16.1.4.1 General ground support | 101 |

| 16.1.5 Vertical development support design | 101 |

| 16.2 Mineral Resource and PEA | 102 |

| 16.3 Stope optimization | 102 |

| 16.4 Net Smelter Return (NSR) | 103 |

| 16.5 Production rate | 104 |

| 16.6 Mineralized rock and waste handling | 104 |

| 16.7 Access development | 104 |

| 16.8 Mine design | 106 |

| 16.9 Tonnage and grade of projected material to be mined and milled | 108 |

| 16.10 Mining factors | 108 |

| 16.11 Backfilling method | 109 |

| 16.12 Ventilation | 110 |

| 16.12.1 Design criteria | 111 |

| 16.12.2 Airflow determination | 112 |

| 16.12.2.1 Airflow for underground infrastructure | 112 |

| 16.12.2.2 Airflow determination based on diesel fleet size | 112 |

| 16.12.2.4 Total airflow requirement | 113 |

| 16.12.3 Ventilation modelling | 114 |

| 16.12.4 Ventilation control and distribution | 114 |

| 16.12.5 Ventilation circuit operability | 114 |

| 16.12.6 Primary fan duties | 115 |

| 16.12.7 Auxiliary ventilation | 115 |

| 16.12.8 Ventilating the conveyor decline | 116 |

| 16.12.8.1 Conveyor decline airflow requirement | 117 |

| 16.12.8.2 Conveyor risk of fire | 117 |

| 16.13 Stope drill and blast design | 118 |

| 16.13.1 Drill selection for stoping | 118 |

| 16.13.2 Stope layout and design | 118 |

| 16.16 Project development and production schedule | 120 |

| 16.17 Production and development schedule | 120 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

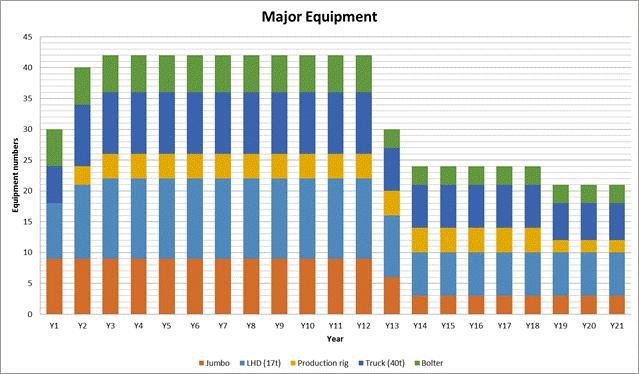

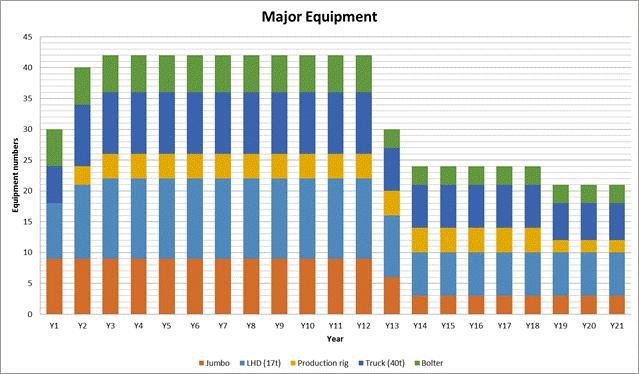

| 16.18 Mobile equipment | 123 |

| 17 Recovery methods | 128 |

| 17.1 Ore transport | 128 |

| 17.2 Ore stockpile | 128 |

| 17.3 Grinding and classification | 128 |

| 17.4 Lead flotation circuit | 128 |

| 17.5 Zinc flotation circuit | 129 |

| 17.6 Pyrite flotation circuit | 129 |

| 17.7 Thickening of lead concentrate | 129 |

| 17.8 Surge tank for lead concentrate | 130 |

| 17.9 Lead concentrate filtration | 130 |

| 17.10 Thickening of zinc concentrate | 130 |

| 17.11 Surge tank for zinc concentrate | 130 |

| 17.12 Filtration of zinc concentrate | 130 |

| 17.13 Thickening of pyrite concentrate | 130 |

| 17.14 Surge tank for pyrite concentrate | 130 |

| 17.15 Thickening of final tails | 130 |

| 17.16 Shipment of lead and zinc concentrate | 131 |

| 17.17 Tailings storage facility | 131 |

| 17.18 Mineral processing schedule and recovery | 133 |

| 18 Project infrastructure | 134 |

| 18.1 Site layout | 134 |

| 18.2 Access road | 134 |

| 18.3 Power supply | 136 |

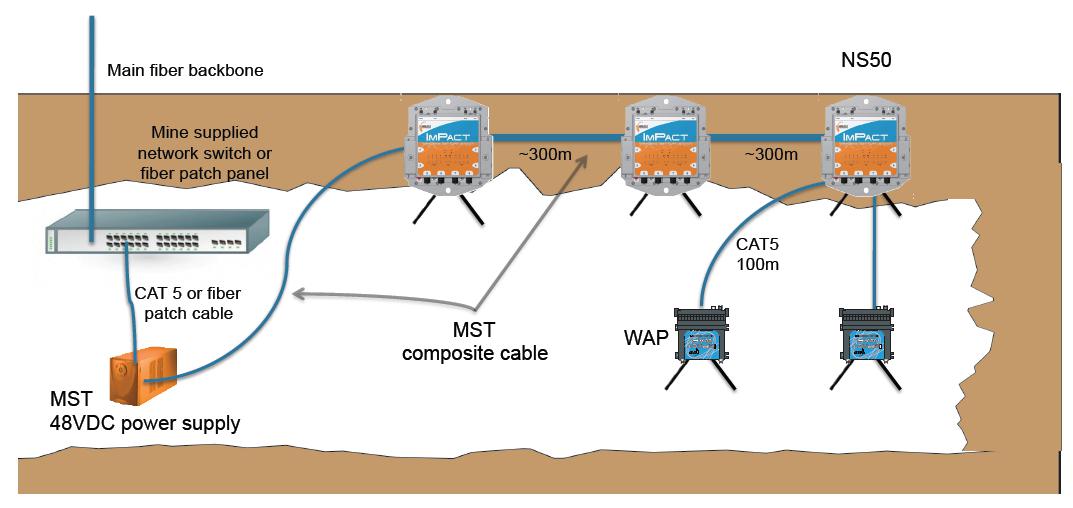

| 18.4 Communications systems | 139 |

| 18.4.1 Personnel and equipment tracking | 139 |

| 18.4.2 Fixed plant monitoring and control | 140 |

| 18.5 Water supply | 140 |

| 18.6 Stockpiles | 140 |

| 18.7 Tailings storage | 141 |

| 18.8 Other surface facilities | 141 |

| 18.8.1 Offices and change house | 141 |

| 18.8.2 Workshops and fuel storage | 142 |

| 18.9 Underground infrastructure | 142 |

| 18.9.1 Haulage and mineralized material and waste handling system | 142 |

| 18.9.2 Winze mineralized material handling | 144 |

| 18.9.3 Crusher and conveyor belt mineralized material handling | 148 |

| 18.10 Underground conveyor system | 151 |

| 18.11 Magazines | 153 |

| 18.12 Underground workshops and warehouse | 156 |

| 18.13 Fuel storage | 156 |

| 18.14 Compressed air requirements | 157 |

| 18.15 Refuge stations, emergency egress, and other emergency provisions | 157 |

| 18.15.2 Emergency egress | 158 |

| 18.15.3 Stench system | 158 |

| 18.15.4 Fire doors | 158 |

| 18.16.4 Zones 1, 2, and 3 dewatering system | 160 |

| 19 Market studies and contracts | 165 |

| 19.1 Metal prices | 165 |

| 19.2 Marketing | 165 |

| 20 Environmental studies, permitting, and social or community impact | 167 |

| 21 Capital and operating costs | 168 |

| 21.1 Capital costs | 168 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| 21.1.1 Total capital cost estimate for the mine | 168 |

| 21.1.2 Underground mine capital cost estimate | 170 |

| 21.1.2.1 Underground development capital costs | 170 |

| 21.1.2.2 Underground mobile equipment capital costs | 171 |

| 21.1.2.3 Winze capital costs | 171 |

| 21.1.2.4 Underground infrastructure capital costs | 171 |

| 21.1.3 Process plant capital costs | 172 |

| 21.1.4 Surface infrastructure capital costs | 172 |

| 21.1.4.1 Access road and powerline capital costs | 173 |

| 21.1.5 Indirect capital costs | 173 |

| 21.1.6 Capital contingency | 173 |

| 21.2 Operating costs | 174 |

| 21.2.1 Mine site operating costs | 174 |

| 21.2.2 Underground mine operating costs | 175 |

| 21.2.3 Process plant operating costs | 176 |

| 21.2.4 General and administration operating cost | 176 |

| 21.2.5 Estimated annual power costs | 177 |

| 22 Economic analysis | 178 |

| 22.1 Assumptions | 178 |

| 22.2 Economic analysis | 178 |

| 22.3 LOM payable metal | 181 |

| 22.4 Taxes | 181 |

| 22.5 Overall cash operating cost (on-site and off-site costs) | 181 |

| 22.6 Economic sensitivity analysis | 185 |

| 23 Adjacent properties | 187 |

| 24 Other relevant data and information | 189 |

| 25 Interpretation and conclusions | 190 |

| 25.1 Mineral Resource estimate | 190 |

| 25.2 Mining | 190 |

| 25.3 Processing | 191 |

| 25.4 Economics | 191 |

| 25.4.1 Risks | 191 |

| 25.4.2 Opportunities for further consideration currently excluded from project scope | 191 |

| 26 Recommendations | 192 |

| 27 References | 193 |

| 28 QP Certificates | 195 |

Tables

| Table 1.1 Summary of Global Mineral Resources as of 21 October 2017 | 2 |

| Table 1.2 Mineral Resource by Bonanza and Deep Zones as of 21 October 2017 | 2 |

| Table 1.3 Mill recoveries | 6 |

| Table 1.4 Project development milestones | 7 |

| Table 1.5 Material projected to be mined and processed as a basis for the economic assessment | 8 |

| Table 1.6 Summary of projected capital costs | 8 |

| Table 1.7 Summary of life of mine site operating costs | 9 |

| Table 1.8 Key inputs and results of economic analysis | 11 |

| Table 2.1 Persons who prepared or contributed to this technical report | 26 |

| Table 4.1 Tenure data | 28 |

| Table 7.1 Stratigraphy of the Fresnillo district | 38 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| Table 10.1 Bulk density results by vein | 47 |

| Table 10.2 Vein intercept results for holes shown in Figure 10.3 | 51 |

| Table 11.1 Internal standards and Certified Reference Material | 54 |

| Table 11.2 Assay results of Certified Reference Material (November 2014 – December 2016) | 54 |

| Table 11.3 Assay results of blank material | 56 |

| Table 11.4 Results of blank materials above two standard deviations | 56 |

| Table 13.1 Metallurgical samples - head assay | 63 |

| Table 13.2 Head sample - minerals composition | 64 |

| Table 13.3 Elemental metal distribution by mineralogical species | 64 |

| Table 13.4 Tests 1 to 5 - calculated head grades | 66 |

| Table 13.5 Tests 1 to 5 - Pb concentrate grades and recoveries | 66 |

| Table 13.6 Tests 1 to 5 - Zn concentrate grades and recoveries | 66 |

| Table 13.7 Tests 1 to 5 - tails grades and recoveries | 66 |

| Table 13.8 Tests 6 and 13 - calculated head grades | 67 |

| Table 13.9 Tests 6 and 13 - Pb concentrate grades and recoveries | 67 |

| Table 13.10 Tests 6 and 13 - Zn concentrate grades and recoveries | 67 |

| Table 13.11 Tests 6 and 13 - Pyrite concentrate grades and recoveries | 67 |

| Table 13.12 Tests 6 and 13 - Tails grades and recoveries | 67 |

| Table 13.13 Flotation circuit metallurgical balance | 69 |

| Table 13.14 Gravity recoverable gold and silver test results | 70 |

| Table 13.15 Metal recovery and concentrate grade | 71 |

| Table 14.1 Summary of Global Mineral Resources as of 21 October 2017 | 72 |

| Table 14.2 Mineral Resources as of 21 October 2017 by vein | 73 |

| Table 14.3 Mineral Resource by metal zone 1 September 2017 | 73 |

| Table 14.4 Drillhole data used in the estimate | 74 |

| Table 14.5 Comparative statistics of bulk density measurements and estimates | 75 |

| Table 14.6 Grade capping summary | 77 |

| Table 14.7 Statistics of raw, composited, and capped assay data | 78 |

| Table 14.8 Block model parameters | 80 |

| Table 14.9 Minimum and maximum sample parameters | 80 |

| Table 14.10 Statistical comparison of capped assay data and block model | 81 |

| Table 14.11 Input parameters in calculating resource NSR | 83 |

| Table 14.12 Juanicipio underground Mineral Resource estimates at a range of cut-off values | 83 |

| Table 14.13 Comparison of 2013 and 2017 Mineral Resource estimates | 84 |

| Table 16.1 Lithology code definitions | 89 |

| Table 16.2 Summary of laboratory-conducted rock strength tests | 90 |

| Table 16.3 Assessment of stability number (N’) for the hangingwall (dip-55°) and vein back | 94 |

| Table 16.4 Assessment of unsupported stope height for the hangingwall | 96 |

| Table 16.5 Assessment of unsupported stope width for the back | 96 |

| Table 16.6 Assessment of supported stope heights for the hangingwall | 96 |

| Table 16.7 Assessment of supported stope width for the back | 96 |

| Table 16.8 Stope design parameters for vein inclinations of 55° and 65° (unsupported) | 98 |

| Table 16.9 Stope design parameters for vein inclinations of 45° to 55° (with cable bolt support) | 99 |

| Table 16.10 Tendon support requirements for Juanicipio Mine | 101 |

| Table 16.11 MSO parameters used to estimate economically viable mineralization | 103 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| Table 16.12 NSR calculation assumptions | 103 |

| Table 16.13 Development quantities (m) for access design | 105 |

| Table 16.14 Tonnage and grade of projected material to be mined and milled | 108 |

| Table 16.15 Key assumptions for surface waste mining | 109 |

| Table 16.16 Ventilation velocity criteria | 112 |

| Table 16.17 Infrastructure airflow allowance | 112 |

| Table 16.18 Airflow requirements | 113 |

| Table 16.19 Total airflow allowance | 113 |

| Table 16.20 Airway dimensions and friction factors | 114 |

| Table 16.21 Design powder factors for LHOS and development | 120 |

| Table 16.22 Project development milestones | 120 |

| Table 16.23 PEA LOM production schedule | 122 |

| Table 16.24 Equipment list | 123 |

| Table 16.25 Mine personnel requirements | 125 |

| Table 17.1 Metal recoveries adopted for the PEA | 133 |

| Table 17.2 Annual processing throughput | 133 |

| Table 18.1 Estimated site power demand | 136 |

| Table 18.2 Estimate of site water usage | 140 |

| Table 19.1 Lead concentrate treatment terms | 165 |

| Table 19.2 Zinc concentrate treatment terms | 165 |

| Table 19.3 Pyrite concentrate treatment terms | 166 |

| Table 19.4 Concentrate transport costs | 166 |

| Table 21.1 Total capital cost estimate | 169 |

| Table 21.2 Annual capital expenditure | 169 |

| Table 21.3 Underground capital costs | 170 |

| Table 21.4 Capital mine development unit rates | 171 |

| Table 21.5 Underground mobile equipment capital costs | 171 |

| Table 21.6 Winze capital costs | 171 |

| Table 21.7 Underground infrastructure capital costs | 172 |

| Table 21.8 Process plant capital costs | 172 |

| Table 21.9 Surface infrastructure capital costs | 172 |

| Table 21.10 Indirect capital costs | 173 |

| Table 21.11 Owner’s and EPCM capital cost details | 173 |

| Table 21.12 Capital contingency | 174 |

| Table 21.13 Summary of life of mine site operating costs | 174 |

| Table 21.14 Summary of life of mine site operating costs | 175 |

| Table 21.15 Unit site operating costs | 175 |

| Table 21.16 Life of mine underground mine operating costs | 176 |

| Table 21.17 Life of mine process plant operating costs (variable and fixed) | 176 |

| Table 21.18 Annual and life of mine general and administration operating costs | 177 |

| Table 21.19 Estimated life of mine and annual power costs at steady state production | 177 |

| Table 22.1 Key economic assumptions and results | 178 |

| Table 22.2 Metal price sensitivity analysis | 180 |

| Table 22.3 Impact of varying silver and zinc pricing on after-tax NPV and IRR(1) | 180 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| Table 22.4 Estimated LOM payable production by metal including silver equivalent ounces (AgEq. oz.) | 181 |

| Table 22.5 Cash costs, total cash costs and AISC per oz of silver (base case) | 181 |

| Table 22.6 LOM undiscounted cash flow, revenue and cost summary | 182 |

| Table 22.7 Juanicipio PEA LOM production and cash flow forecast | 183 |

| Table 22.8 Economic sensitivity analysis (post-tax) | 185 |

| Table 26.1 Cost breakdown of recommended further work for the FS | 192 |

Figures

| Figure 1.1 Composite plan view of mine design | 4 |

| Figure 1.2 Overall mine layout | 5 |

| Figure 1.3 Sensitivity analysis – post-tax NPV at 5% discount rate | 12 |

| Figure 4.1 Location map | 29 |

| Figure 4.2 Claim map and surface rights on the Property | 30 |

| Figure 7.1 Regional geology | 36 |

| Figure 7.2 Regional stratigraphy | 37 |

| Figure 7.3 Property geology | 41 |

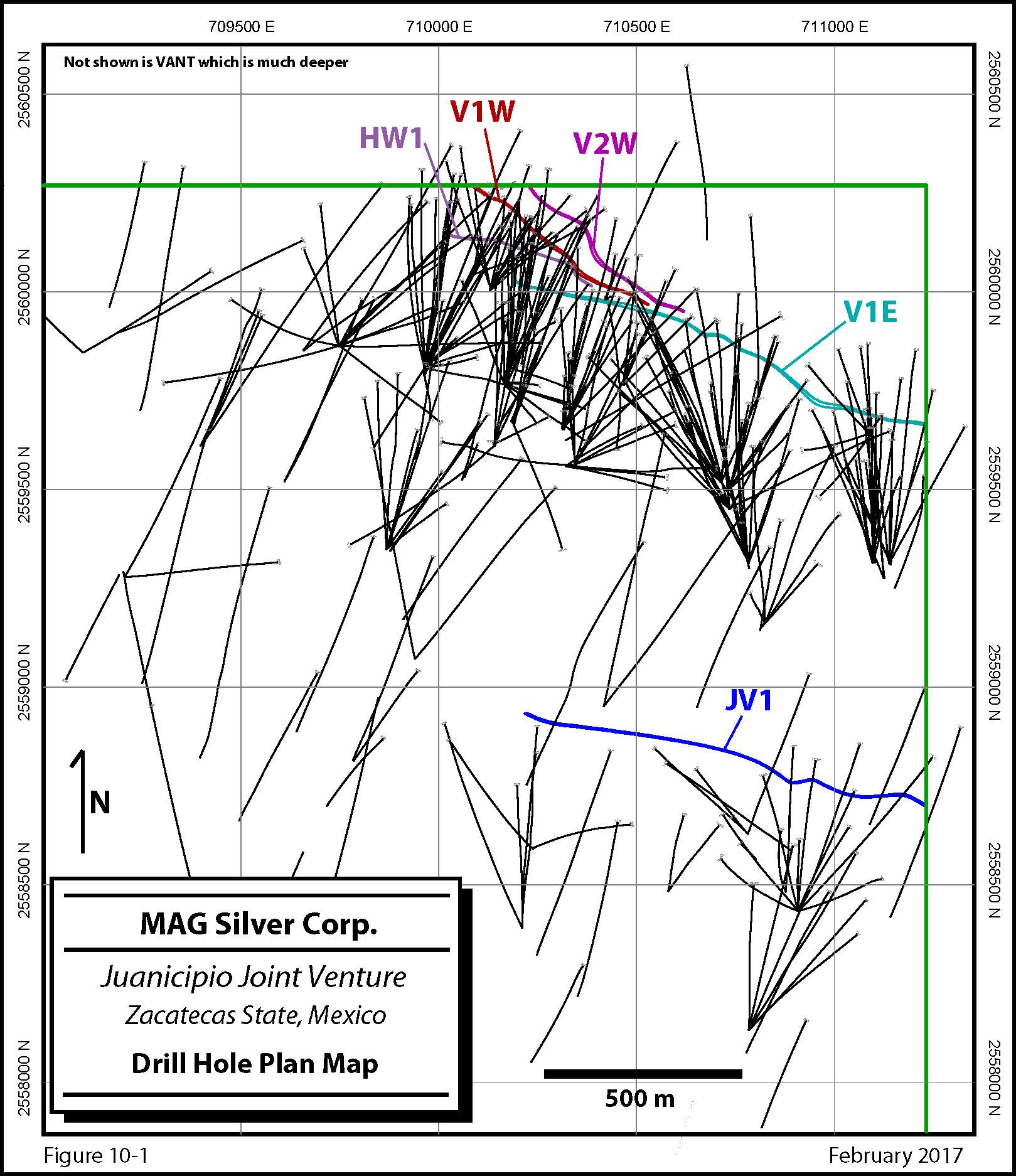

| Figure 10.1 Drillhole plan map | 48 |

| Figure 10.2 Eastern cross section through the Valdecañas vein system | 49 |

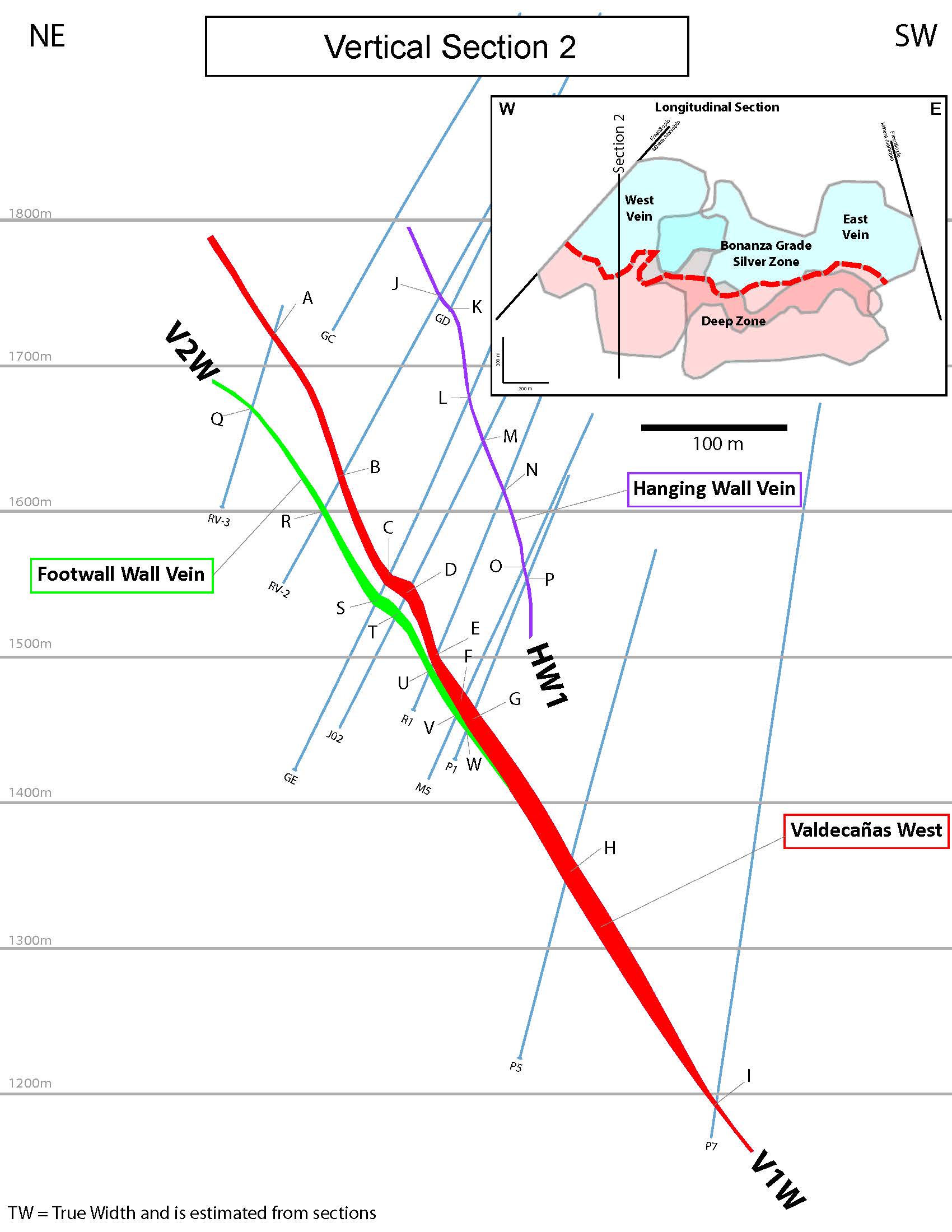

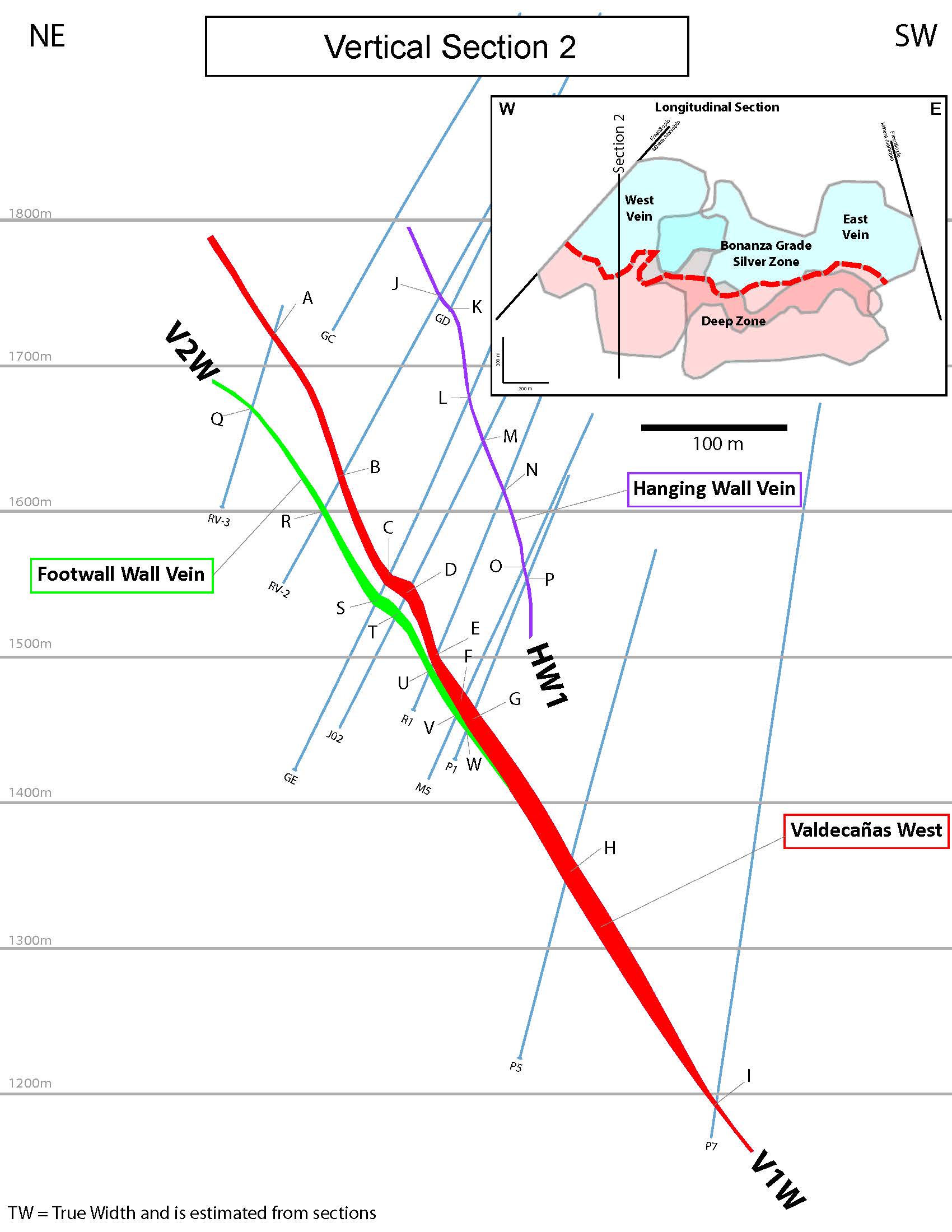

| Figure 10.3 Western cross section through the Valdecañas vein system | 50 |

| Figure 10.4 Cross section through the Juanicipio vein system | 52 |

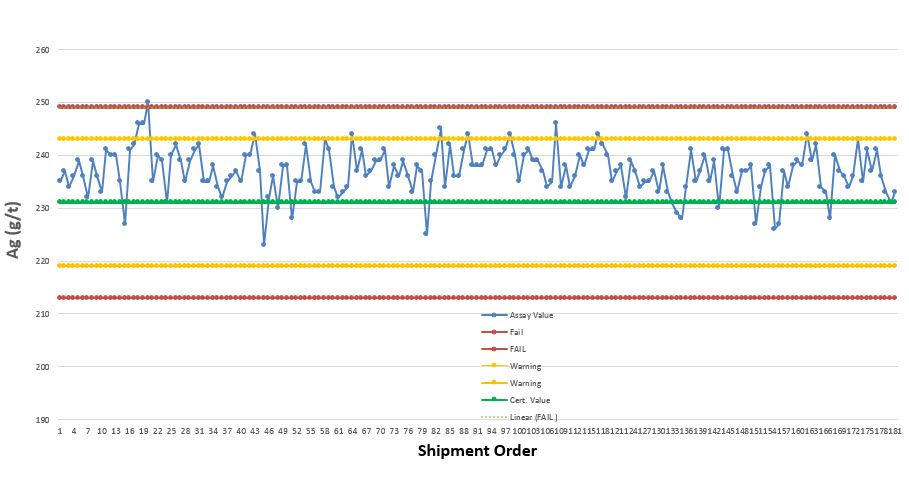

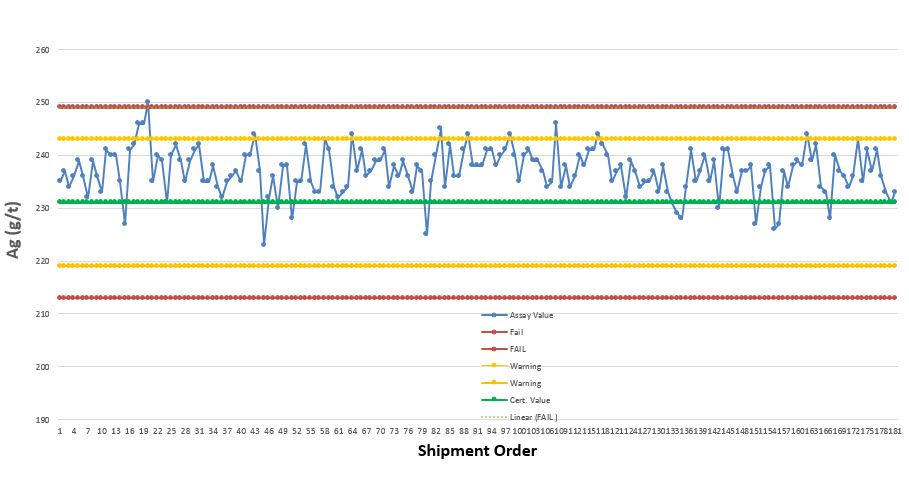

| Figure 11.1 Control chart for CRM CDN-ME-1305 (silver) | 55 |

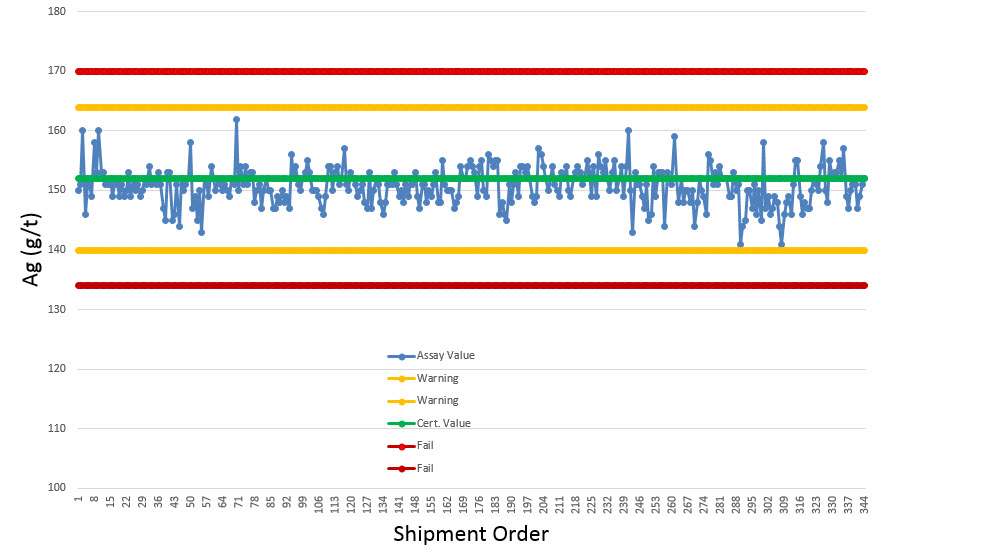

| Figure 11.2 Control chart for CRM CDN-ME-1303 (silver) | 55 |

| Figure 11.3 Control chart for blank material (silver) | 57 |

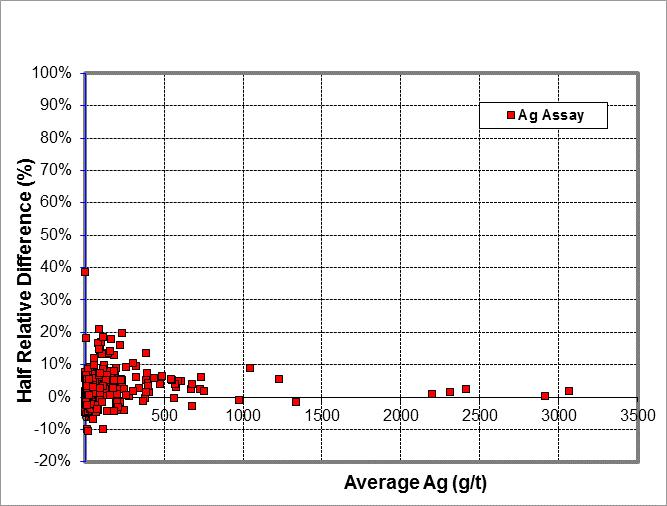

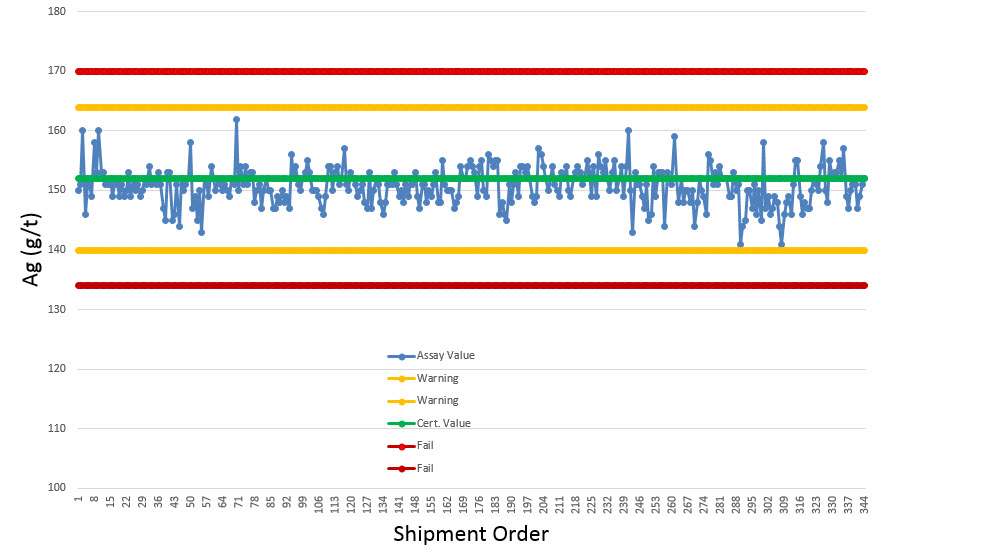

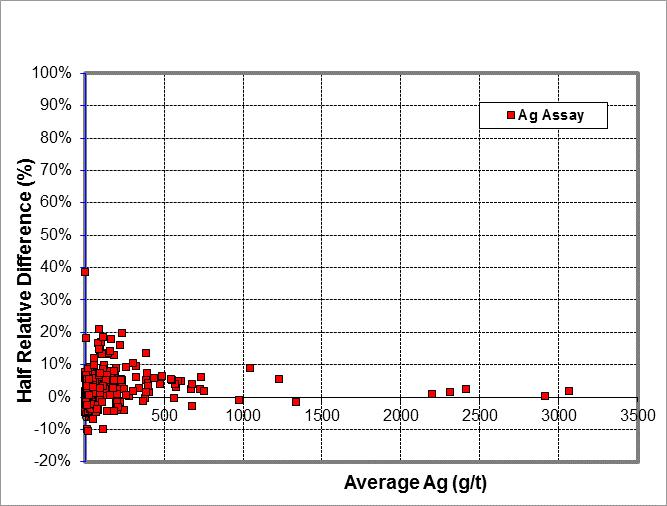

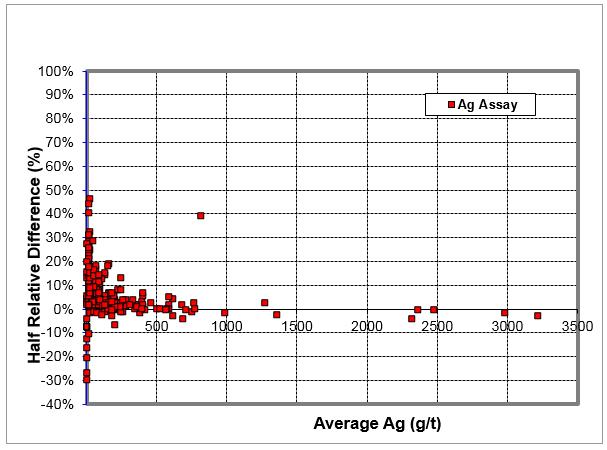

| Figure 11.4 Control chart for IPL versus ALS duplicates (silver) | 58 |

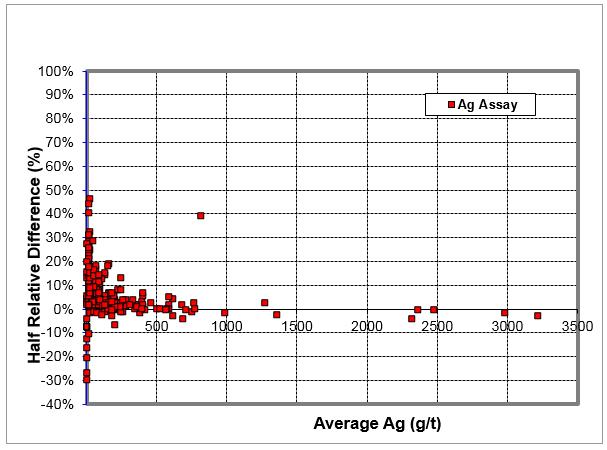

| Figure 11.5 Control chart for SGS versus ALS duplicates (silver) | 59 |

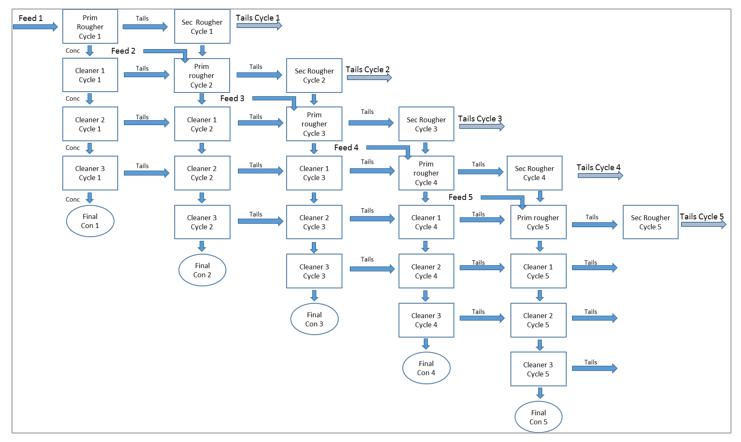

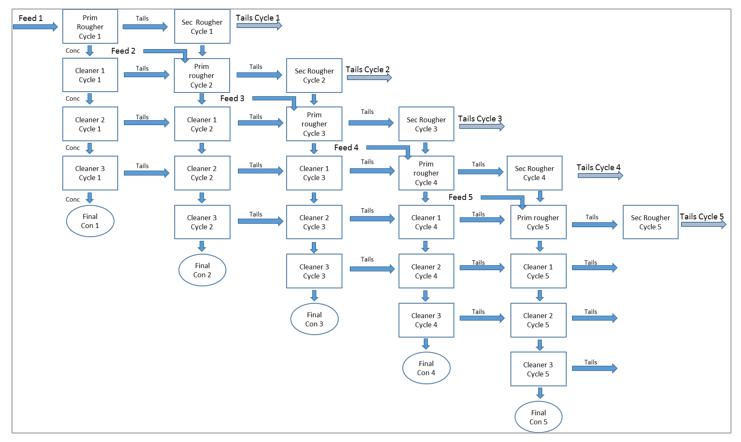

| Figure 13.1 Lead flotation locked cycle test work flowsheet | 69 |

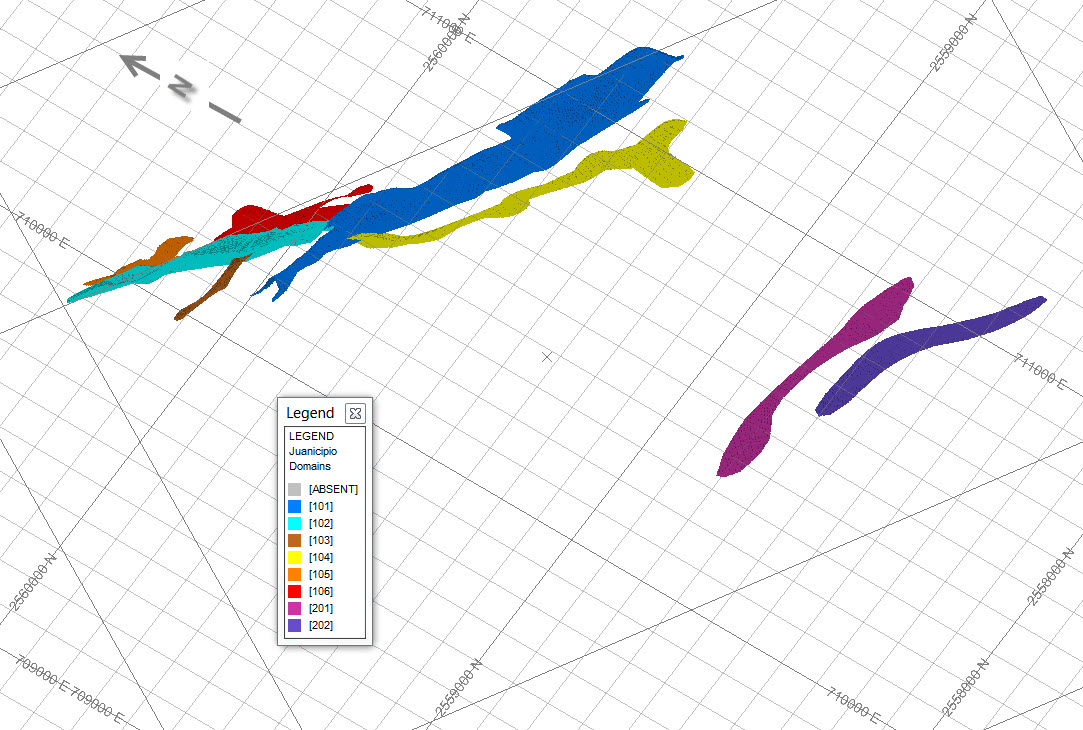

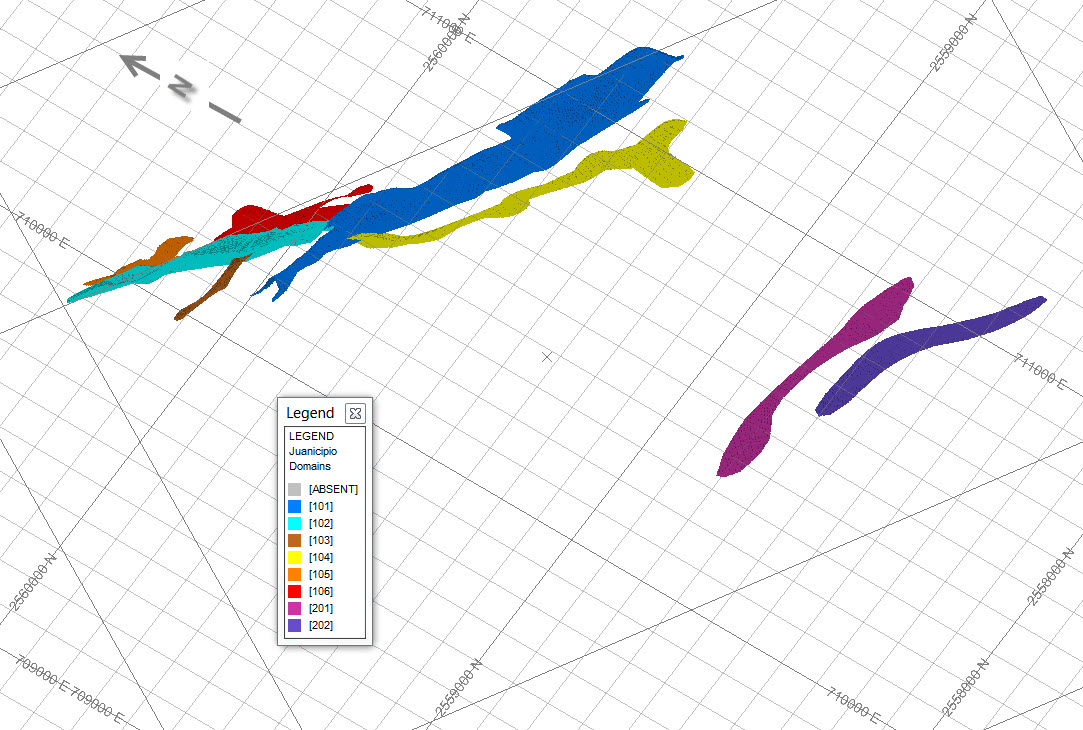

| Figure 14.1 3-dimensional view of mineralization domains looking northeast | 76 |

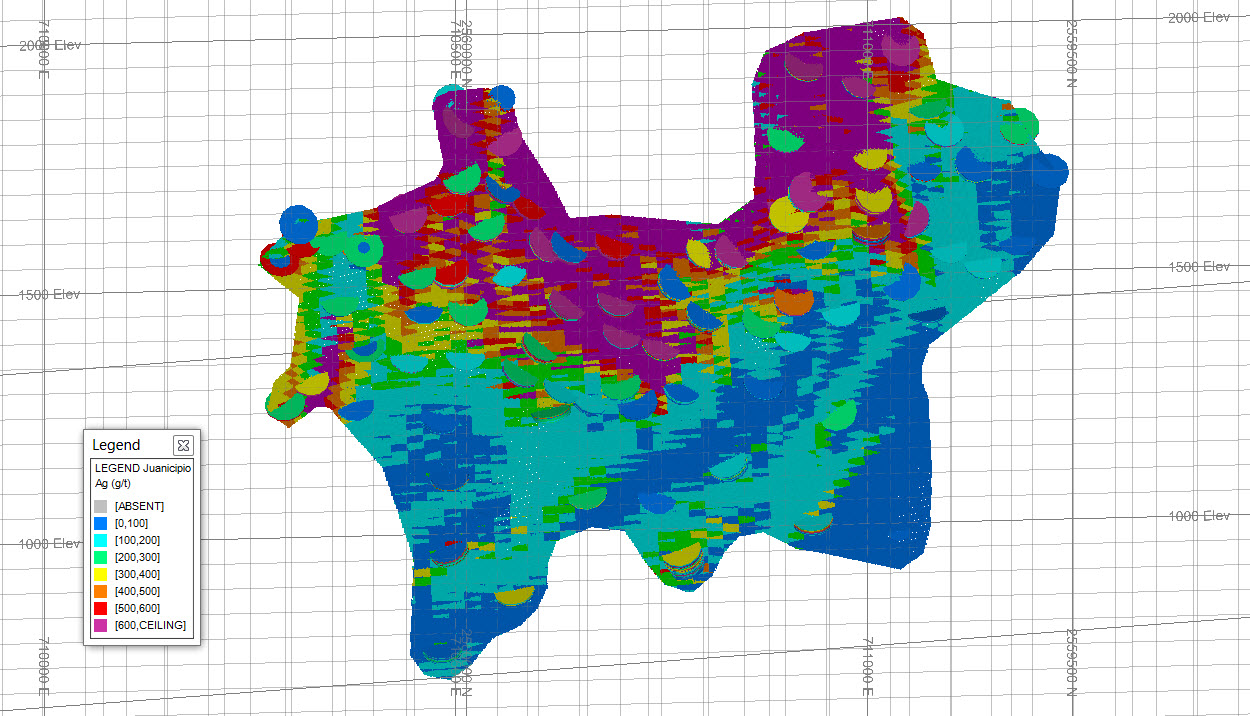

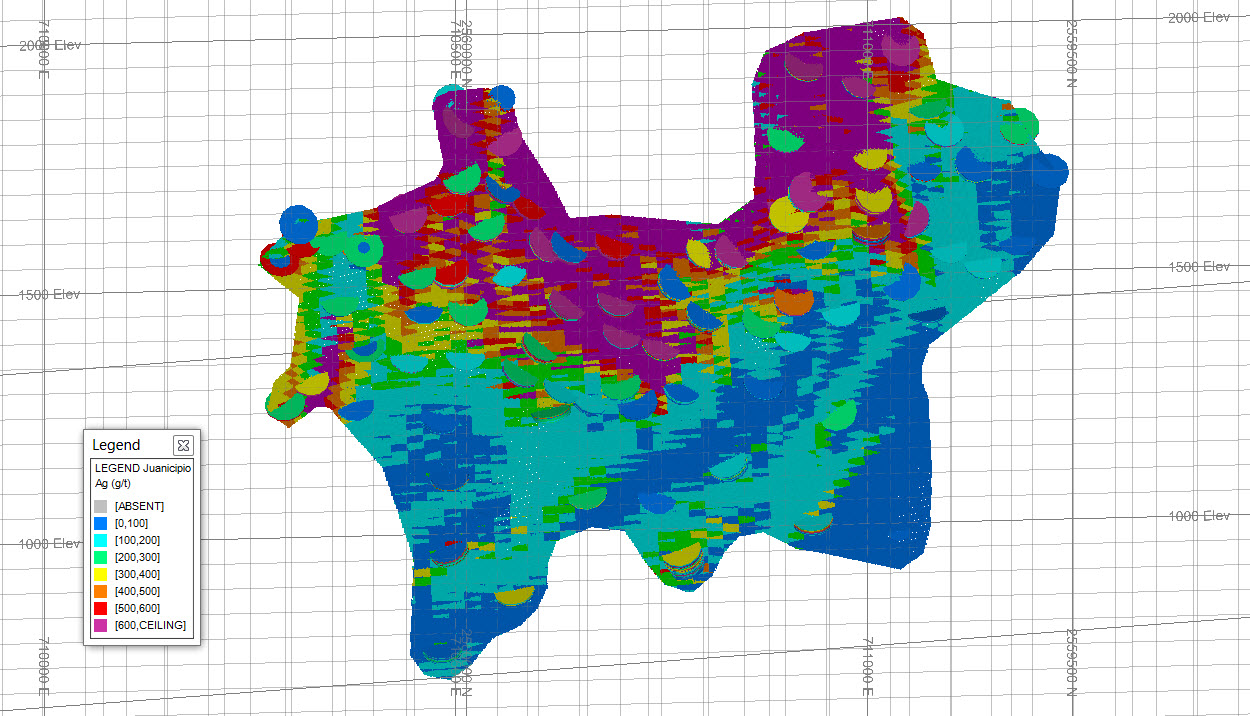

| Figure 14.2 Silver grade longitudinal projection vein V1E | 81 |

| Figure 14.3 Copper grade longitudinal projection vein V1E | 85 |

| Figure 16.1 Longhole stoping with rock fill general layout | 87 |

| Figure 16.2 Location of drillholes geotechnically logged for the Juanicipio project area | 88 |

| Figure 16.3 Average RMR89 values determined from geotechnical logging of the borehole cores | 89 |

| Figure 16.4 Average intact rock strength (± standard deviation) | 90 |

| Figure 16.5 Data reduction results of Young’s Modulus (obtained from the UCS tests) | 91 |

| Figure 16.6 Rock mass strength parameter determination results | 92 |

| Figure 16.7 Determination of mi from the LUAR triaxial test results | 93 |

| Figure 16.8 Stability graph results for the stope HW (vein dip-55°) and stope back | 95 |

| Figure 16.9 Recommended spacing and minimum length for cable bolts | 97 |

| Figure 16.10 Stope dilution estimated for the HW (dip 55°) | 98 |

| Figure 16.11 Stability graph results for vein inclinations of 55° to 65° | 99 |

| Figure 16.12 Stability graph results for vein inclinations of 45° to 55° | 100 |

| Figure 16.13 Access development composite plan layout (over three production levels) | 105 |

| Figure 16.14 Composite plan view of the underground mine design | 106 |

| Figure 16.15 Long-section view of the underground mine design | 107 |

| | |

|

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| | |

| Figure 16.16 Long-section view of the access development and underground infrastructure | 108 |

| Figure 16.17 Waste rock fill production and demand | 110 |

| Figure 16.18 Ventilation system overview* | 111 |

| Figure 16.19 Steady state ventilation configuration | 115 |

| Figure 16.20 Cross section of decline development | 116 |

| Figure 16.21 Conveyor decline development ventilation strategy | 117 |

| Figure 16.22 LHOS plan view | 119 |

| Figure 16.23 LHOS cross section view of production rings | 119 |

| Figure 16.24 Projected production profile | 123 |

| Figure 16.25 Major equipment required over LOM | 124 |

| Figure 16.26 Personnel profile over LOM | 127 |

| Figure 17.1 Process flow sheet | 132 |

| Figure 18.1 Site layout concept | 135 |

| Figure 18.2 Single line diagram – electrical distribution | 137 |

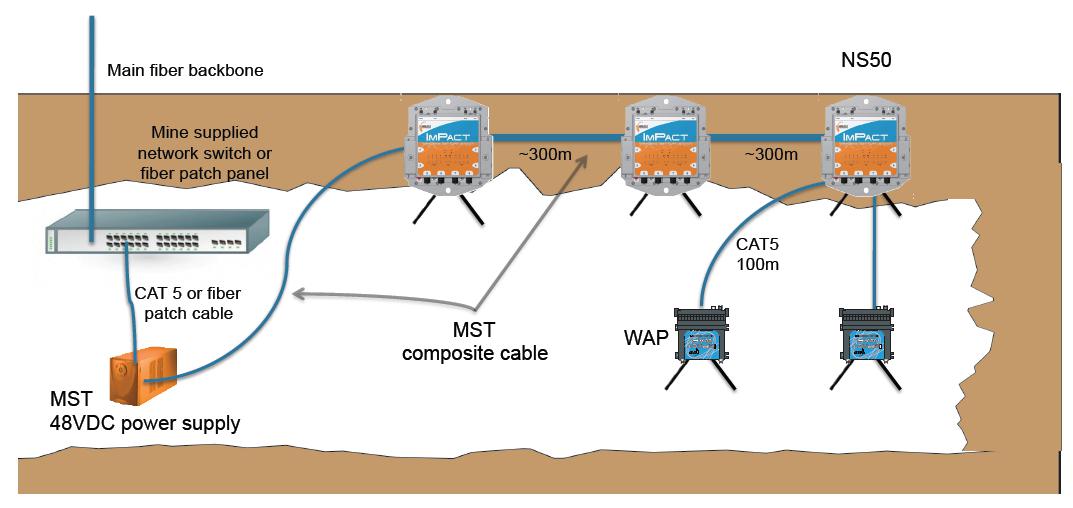

| Figure 18.3 Underground communications system schematic | 139 |

| Figure 18.4 Concept design of tailings storage facility | 141 |

| Figure 18.5 Flow sheet showing the mineralized material and waste handling system | 143 |

| Figure 18.6 Loading pocket general arrangement | 145 |

| Figure 18.7 Shaft section schematic | 146 |

| Figure 18.8 Winze performance | 147 |

| Figure 18.9 Winze headframe and transfer conveyor arrangement | 148 |

| Figure 18.10 Schematic of upper dump | 149 |

| Figure 18.11 Feeder schematic | 150 |

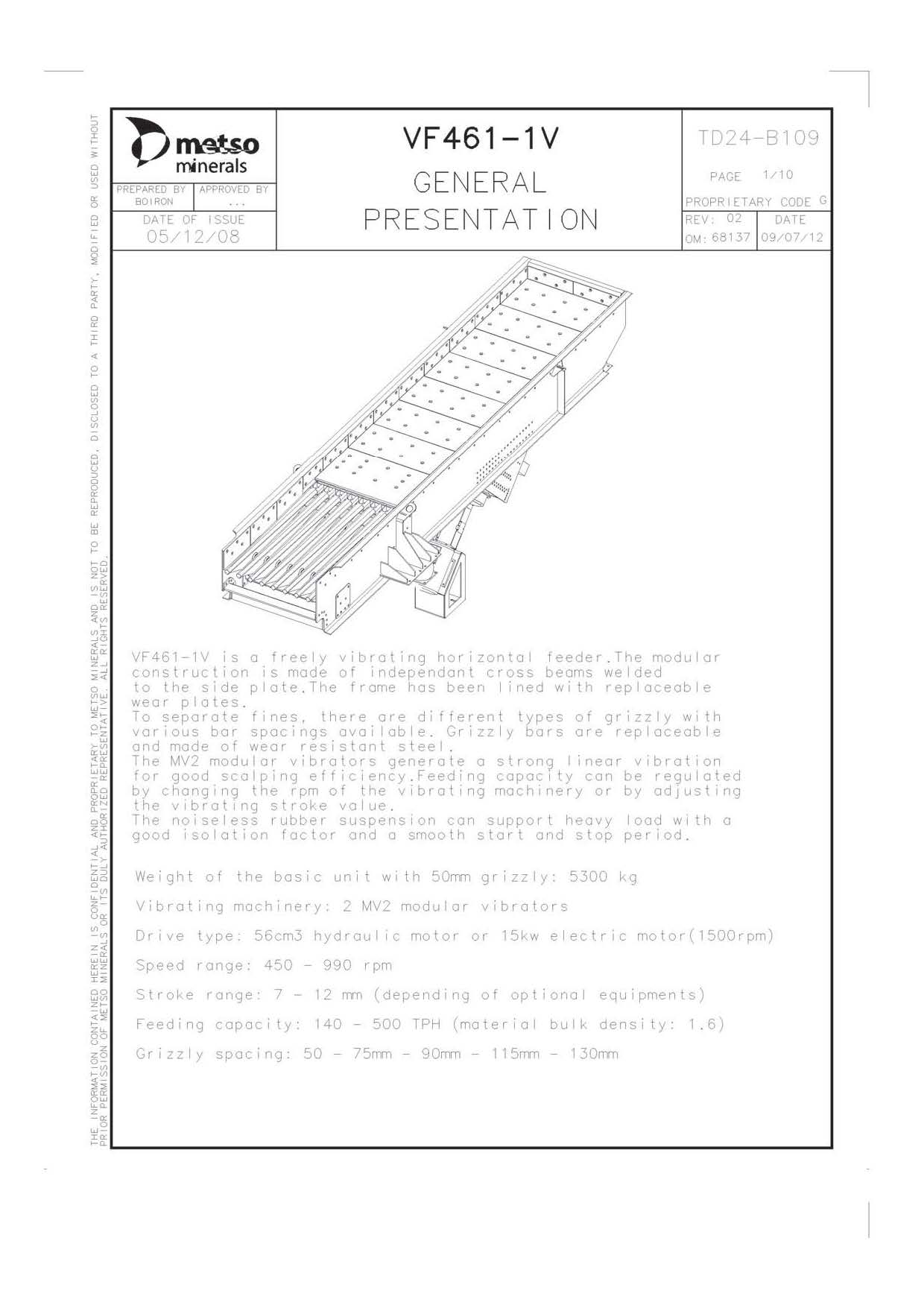

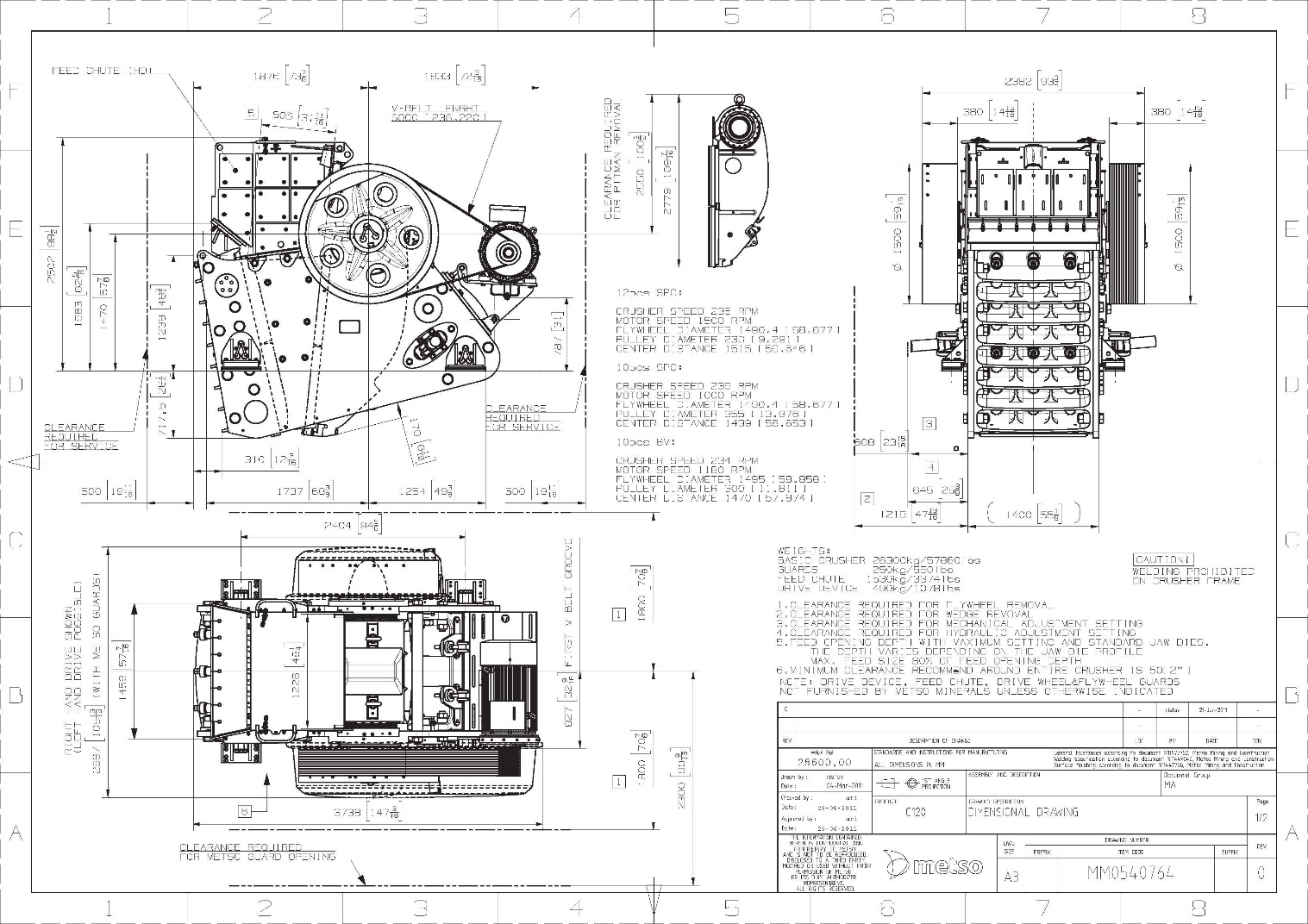

| Figure 18.12 Jaw crusher | 151 |

| Figure 18.13 Underground conveyor arrangement | 152 |

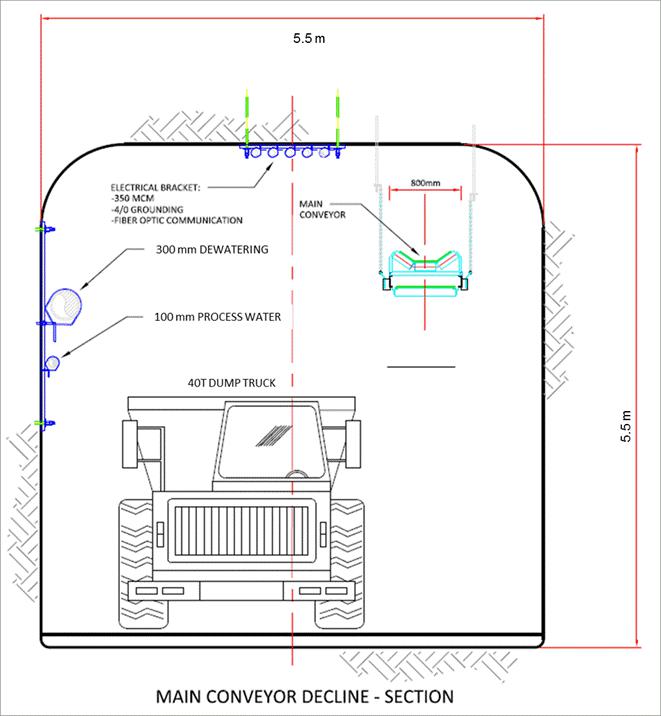

| Figure 18.14 Cross section of the conveyor decline | 153 |

| Figure 18.15 Bulk emulsion storage - plan and sections | 155 |

| Figure 18.16 Underground workshop and related services | 156 |

| Figure 18.17 Overall mine dewatering schematic | 160 |

| Figure 18.18 Dirty water sump arrangement | 161 |

| Figure 18.19 Intermediate sump arrangement | 162 |

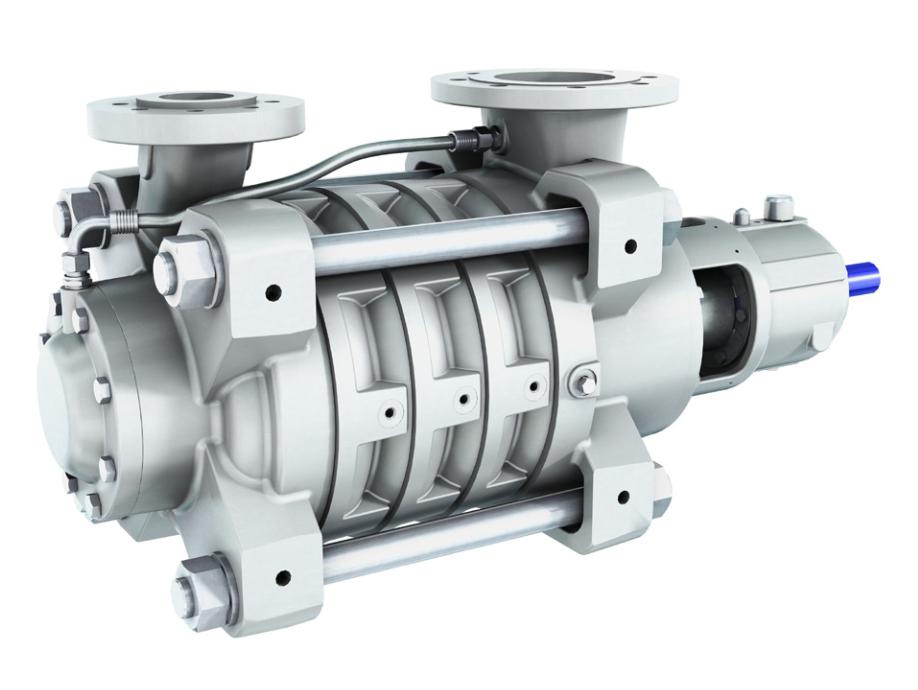

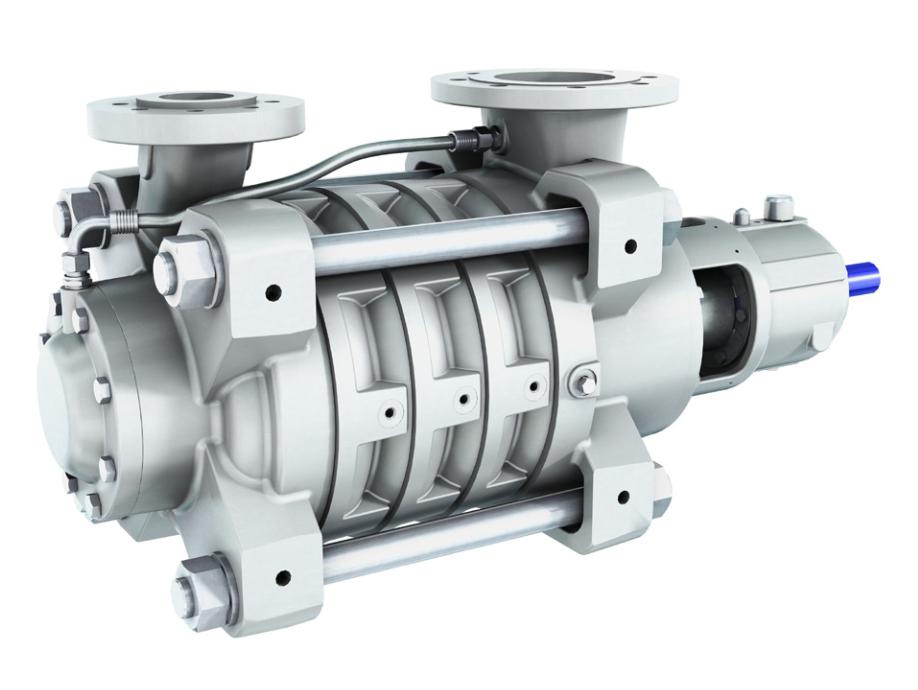

| Figure 18.20 Stacked impeller mine dewatering pump | 164 |

| Figure 22.1 Sensitivity analysis – post-tax NPV at 5% discount rate | 186 |

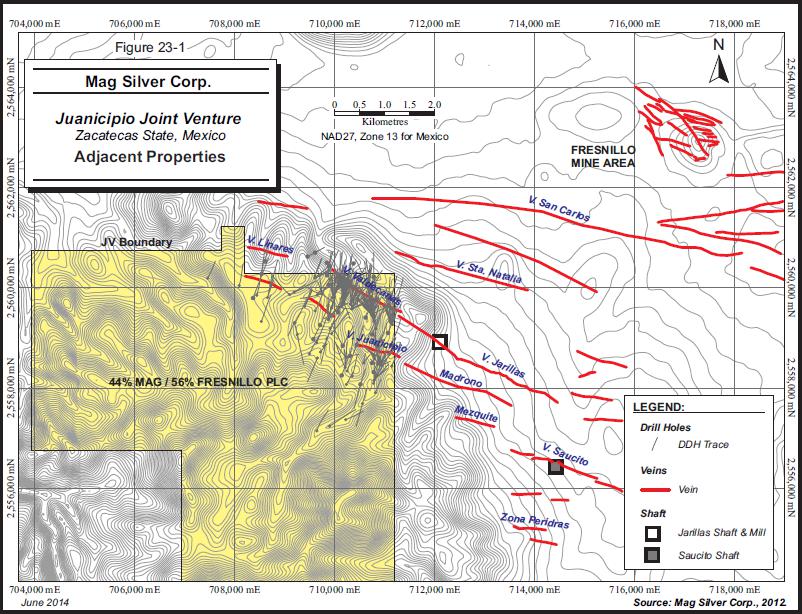

| Figure 23.1 Adjacent properties | 188 |

Distribution list

1 e-copy to George Paspalas, MAG Silver

1 e-copy to AMC Vancouver office

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

This Technical Report (Report) provides an update of the Mineral Resource estimate and Preliminary Economic Assessment (2017 PEA) of the Mineral Resources identified within the Minera Juanicipio Property (Property) in Zacatecas State, Mexico. The Report has been prepared by AMC Mining Consultants (Canada) Ltd. (AMC) of Vancouver, Canada on behalf of MAG Silver Corp (MAG Silver).

MAG Silver owns 44% of Minera Juanicipio S.A. de C.V. (Minera Juanicipio), a Mexican incorporated joint venture company, which owns (100%) and operates the Property. Fresnillo plc (Fresnillo) holds the remaining 56% interest in the joint venture and is the project operator. The Report has been prepared in accordance with the requirements of National Instrument 43-101 (NI 43-101) “Standards of Disclosure for Mineral Projects” of the Canadian Securities Administrators (CSA) for lodgement on CSA’s “System for Electronic Document Analysis and Retrieval” (SEDAR).

In December 2016, MAG Silver commissioned AMC to prepare an independent estimate of the Mineral Resources of the Property, to be compiled using exploration data available up to December 2016. This Mineral Resource estimate is the basis for the 2017 PEA. The Mineral Resource estimate was prepared by Ms A. Ross, Ph.D., P.Geo. (BC and AB).

The 2017 PEA considers the identified Mineral Resources within the Valdecañas vein system only, the Juanicipio vein is not considered at this time. The 2017 PEA has been carried out on the assumption that this vein system will be exploited as a stand-alone project. All mining and processing facilities are to be contained within the property boundary. Access roads and other surface infrastructure are to be restricted to areas over which Minera Juanicipio can reasonably be expected to secure surface tenure or access rights.

AMC’s scope of work included determination of appropriate methods for mining and processing the resource. Plans, schedules, and cost estimates for the mine and infrastructure development concepts were prepared for input to an economic model with which to carry out the economic assessment.

Projected risks and opportunities associated with the project were compiled together with a list of recommendations for further project development activities, including resource drilling, geotechnical and hydrogeological investigations, and metallurgical test work.

| 2.3 | Sources of information |

Key sources of information include the diamond drill hole database, metallurgical test work reports, and marketing information gained with the assistance of MAG Silver. A full reference list is included at the end of the Report. The most recent report often referred to is: Technical Report on the Mineral Resource Update for the Juanicipio Joint Venture, Zacatecas State, Mexico (Roscoe Postle Associates Inc. (RPA) 2014 Technical Report).

A listing of the authors of the Report, together with the sections for which they are responsible, is shown in Table 2.1.

| MAG Silver Juanicipio NI 43-101 Technical Report | |

| MAG Silver Corp. | 717002 |

| Table 2.1 | Persons who prepared or contributed to this technical report |