MAG SILVER CORP.

TECHNICAL REPORT ON THE

UPPER MANTO DEPOSIT,

CHIHUAHUA, MEXICO

NI 43-101 Report

Qualified Person:

David Ross, M.Sc., P.Geo.

November 14, 2012

| RPA Inc. 55 University Ave. Suite 501 | | Toronto, ON, Canada M5J 2H7 | | T +1 (416) 947 0907 www.rpacan.com |

Report Control Form

| Document Title | | Technical Report on the Upper Manto Deposit, Chihuahua, Mexico |

| | | |

Client Name & Address | | MAG Silver Corp. #770 - 800 West Pender Street Vancouver, British Columbia V6C 2V6 |

| | | |

| Document Reference | | Project #1938 | | Status & Issue No. | | FINAL Version | 1 |

| | | | |

| Issue Date | | November 14, 2012 | |

| | | | |

| Lead Author | | David Ross, P.Geo. | | (Signed) |

| | | | | |

| Peer Reviewer | | Luke Evans, P.Eng. | | (Signed) |

| | | | | |

| Project Manager Approval | | David Ross, P.Geo. | | (Signed) |

| | | | | |

| Project Director Approval | | Deborah McCombe, P.Geo. | | (Signed) |

| | | | | |

| Report Distribution | | Name | No. of Copies |

| | | | |

| | | Client | 2 |

| | | | |

| | | RPA Filing | 1 (project box) |

| | Roscoe Postle Associates Inc. 55 University Avenue, Suite 501 Toronto, ON M5J 2H7 Canada Tel: +1 416 947 0907 Fax: +1 416 947 0395 mining@rpacan.com |

| www.rpacan.com |

TABLE OF CONTENTS

| | PAGE |

| 1 SUMMARY | 1-1 |

| Executive Summary | 1-1 |

| Technical Summary | 1-3 |

| 2 INTRODUCTION | 2-1 |

| 3 RELIANCE ON OTHER EXPERTS | 3-1 |

| 4 PROPERTY DESCRIPTION AND LOCATION | 4-1 |

| 5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-1 |

| 6 HISTORY | 6-1 |

| 7 GEOLOGICAL SETTING AND MINERALIZATION | 7-1 |

| Regional Geology | 7-1 |

| Local Geology | 7-4 |

| Property Geology | 7-6 |

| Mineralization | 7-8 |

| 8 DEPOSIT TYPES | 8-1 |

| 9 EXPLORATION | 9-1 |

| 10 DRILLING | 10-1 |

| 11 SAMPLE PREPARATION, ANALYSES AND SECURITY | 11-1 |

| Quality Assurance and Quality Control | 11-3 |

| 12 DATA VERIFICATION | 12-1 |

| Site Visit and Drill Core Review | 12-1 |

| Database Review | 12-1 |

| Assay Table Verification | 12-1 |

| 13 MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 |

| 14 MINERAL RESOURCE ESTIMATE | 14-1 |

| Resource Database | 14-1 |

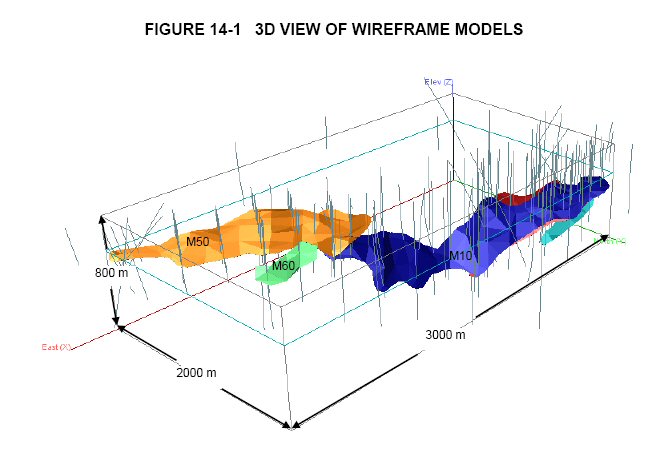

| Geological Interpretation and 3D Solids | 14-2 |

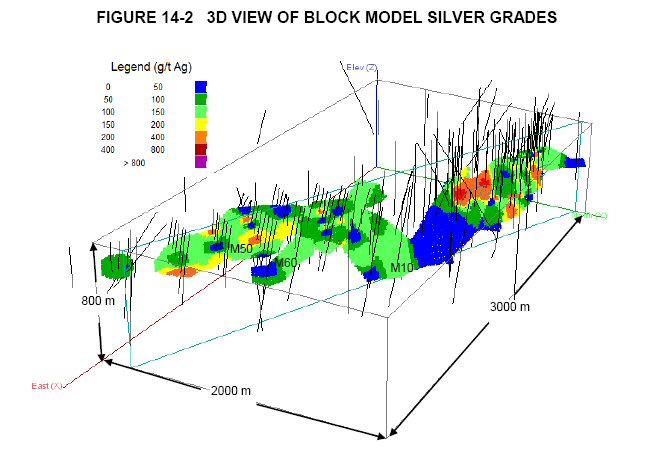

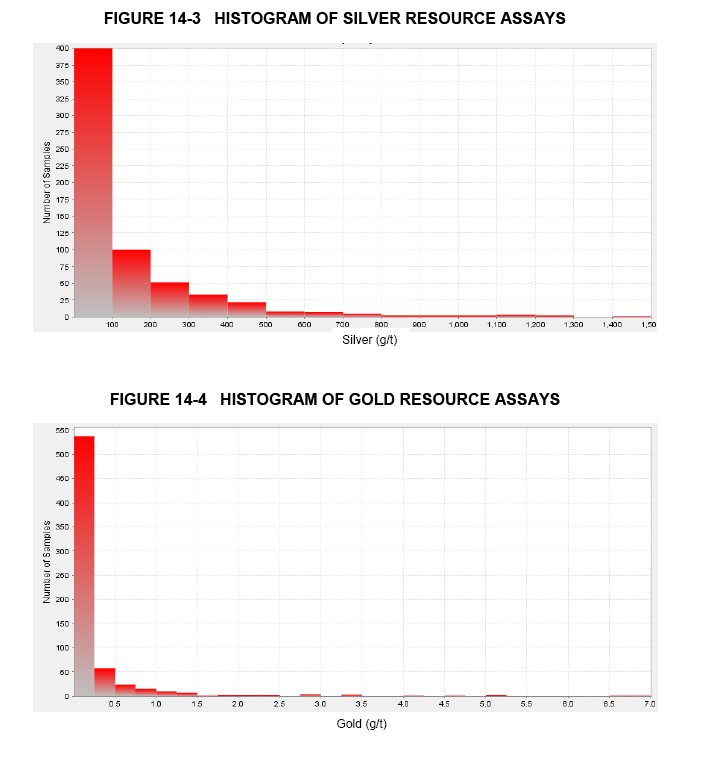

| Statistical Analysis | 14-5 |

| Cutting High-Grade Values | 14-6 |

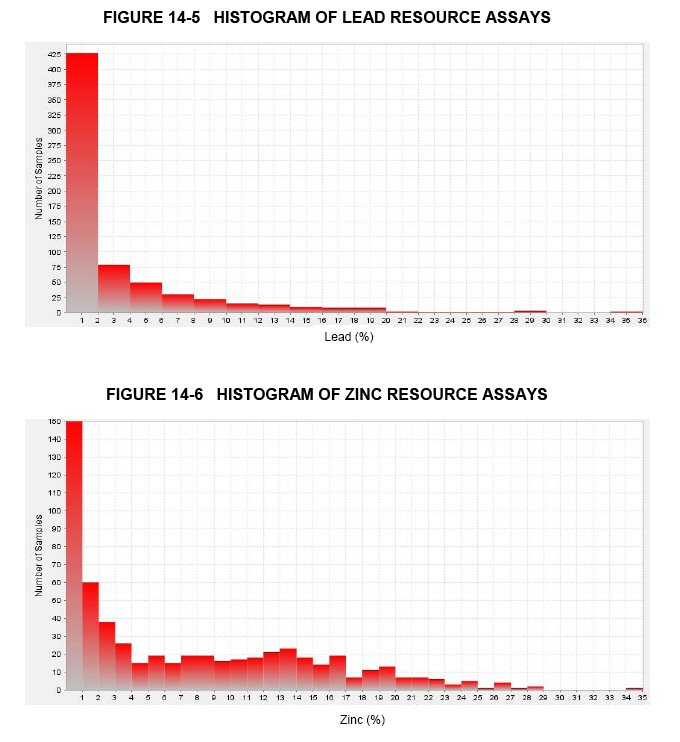

| Compositing | 14-10 |

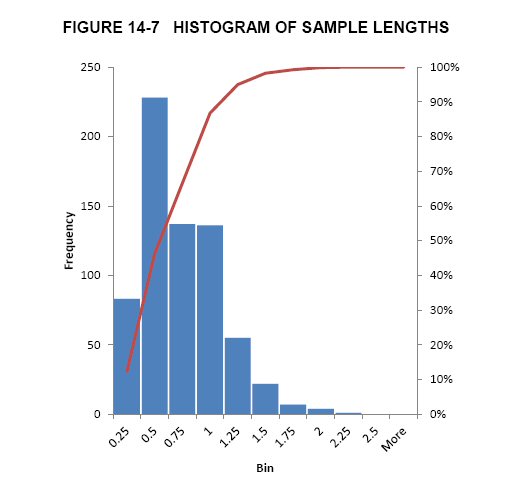

| Interpolation Parameters | 14-12 |

| Density | 14-18 |

| Block Model | 14-18 |

| NSR Cut-off Value | 14-19 |

| Classification | 14-20 |

| Mineral Resource Reporting | 14-20 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page i |

| www.rpacan.com |

| Mineral Resource Validation | 14-21 |

| Pozo Seco Mineral Resource Estimate | 14-22 |

| 15 MINERAL RESERVE ESTIMATE | 15-1 |

| 16 MINING METHODS | 16-1 |

| 17 RECOVERY METHODS | 17-1 |

| 18 PROJECT INFRASTRUCTURE | 18-1 |

| 19 MARKET STUDIES AND CONTRACTS | 19-1 |

| 20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 20-1 |

| 21 CAPITAL AND OPERATING COSTS | 21-1 |

| 22 ECONOMIC ANALYSIS | 22-1 |

| 23 ADJACENT PROPERTIES | 23-1 |

| 24 OTHER RELEVANT DATA AND INFORMATION | 24-1 |

| 25 INTERPRETATION AND CONCLUSIONS | 25-1 |

| 26 RECOMMENDATIONS | 26-1 |

| 27 REFERENCES | 27-1 |

| 28 DATE AND SIGNATURE PAGE | 28-1 |

| 29 CERTIFICATE OF QUALIFIED PERSON | 29-1 |

LIST OF TABLES

| | PAGE |

| Table 1-1 Proposed Budget | 1-2 |

| Table 1-2 Inferred Mineral Resources by Manto – September 1, 2012 | 1-5 |

| Table 4-1 List of Concessions | 4-1 |

| Table 7-1 Stratigraphic Section | 7-5 |

| Table 10-1 Summary of Drilling at the Upper Manto Deposit | 10-1 |

| Table 10-2 Select Mineralized Intercepts | 10-4 |

| Table 11-1 Summary Statistics for Duplicates | 11-9 |

| Table 11-2 Expected Values and Ranges of CRMs | 11-11 |

| Table 14-1 Descriptive Statistics of Resource Assay Values | 14-5 |

| Table 14-2 Descriptive Statistics of Cut Resource Assay Values | 14-9 |

| Table 14-3 Descriptive Statistics of Composite Values | 14-11 |

| Table 14-4 Comparison Statistics of Density Measurements and Block Estimates | 14-18 |

| Table 14-5 Inferred Mineral Resources by Manto – September 1, 2012 | 14-21 |

| Table 14-6 Mineral Resources by NSR Cut-off Value | 14-21 |

| Table 14-7 Volume Comparison | 14-22 |

| Table 14-8 Pozo Seco Mineral Resource Estimate – July 12, 2010 | 14-23 |

| Table 26-1 Proposed Budget | 26-1 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page ii |

| www.rpacan.com |

LIST OF FIGURES

| | PAGE |

| Figure 4-1 Location Map | 4-3 |

| Figure 4-2 Concession Map | 4-4 |

| Figure 7-1 Simplified Regional Geology | 7-2 |

| Figure 7-2 CRD Occurrences in the Chihuahua Trough | 7-3 |

| Figure 7-3 Property Geology | 7-7 |

| Figure 7-4 Cross Section of an Idealized CRD | 7-10 |

| Figure 8-1 CRD Deposit Model for Cinco de Mayo | 8-39 |

| Figure 10-1 Drill Hole Plan Map | 10-3 |

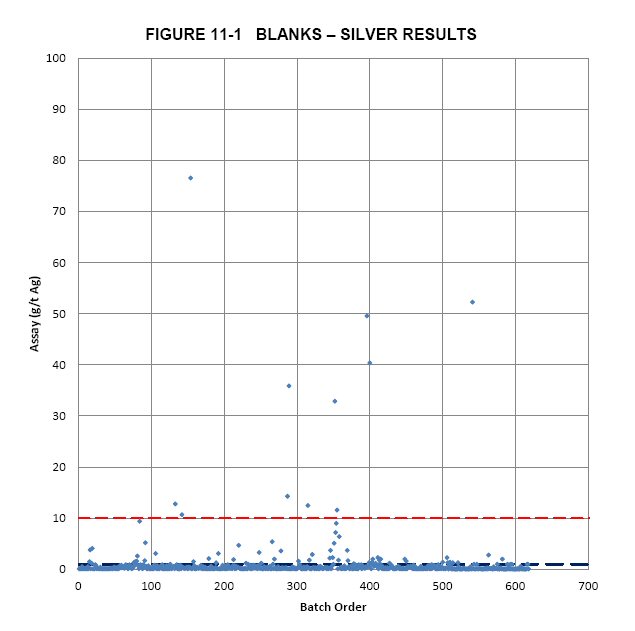

| Figure 11-1 Blanks – Silver Results | 11-5 |

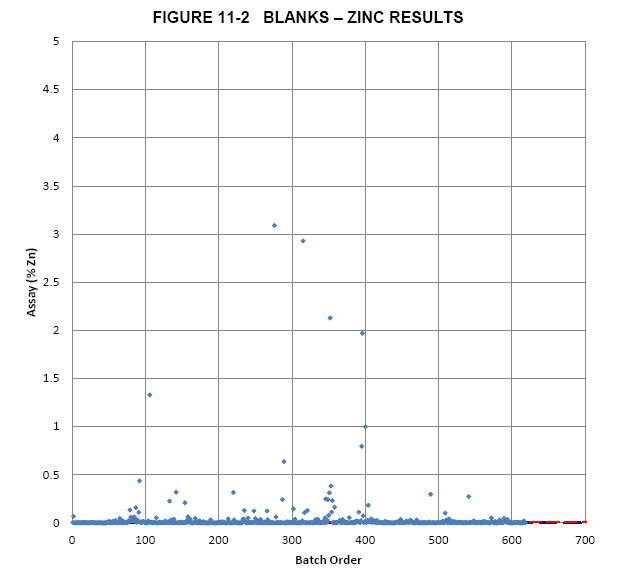

| Figure 11-2 Blanks – Zinc Results | 11-6 |

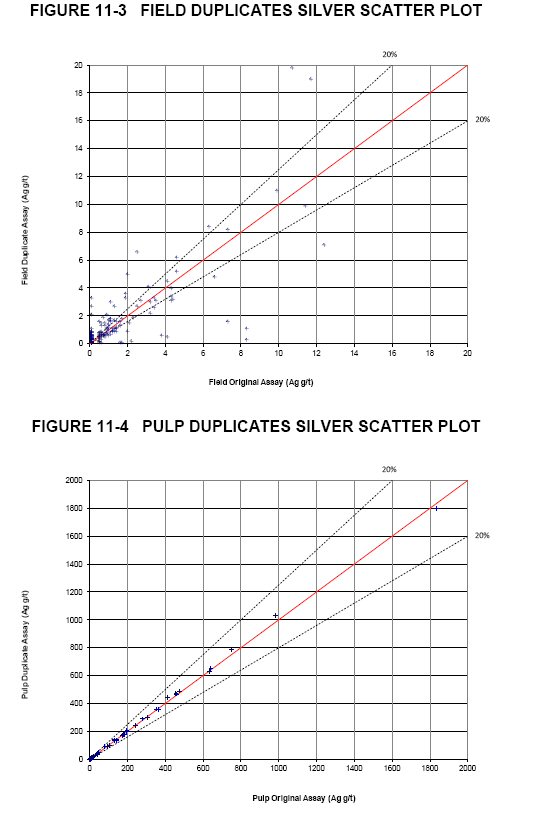

| Figure 11-3 Field Duplicates Silver Scatter Plot | 11-7 |

| Figure 11-4 Pulp Duplicates Silver Scatter Plot | 11-7 |

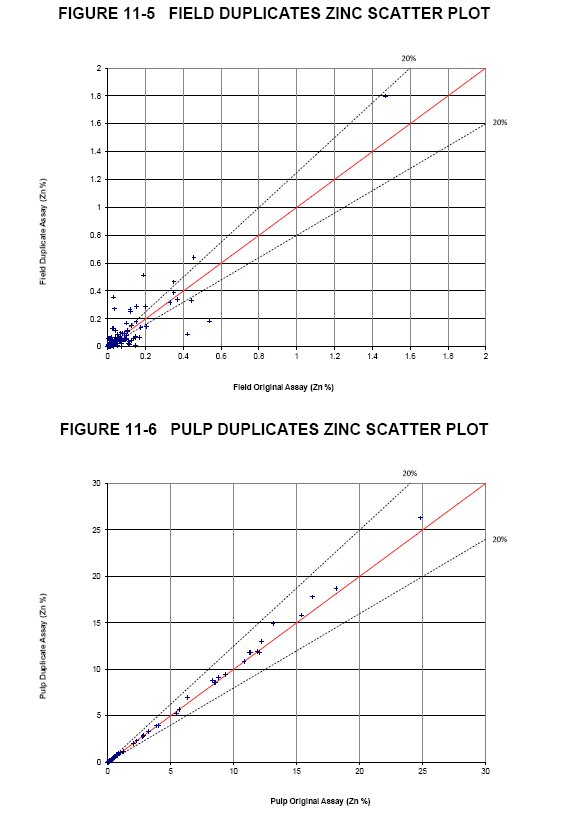

| Figure 11-5 Field Duplicates Zinc Scatter Plot | 11-8 |

| Figure 11-6 Pulp Duplicates Zinc Scatter Plot | 11-8 |

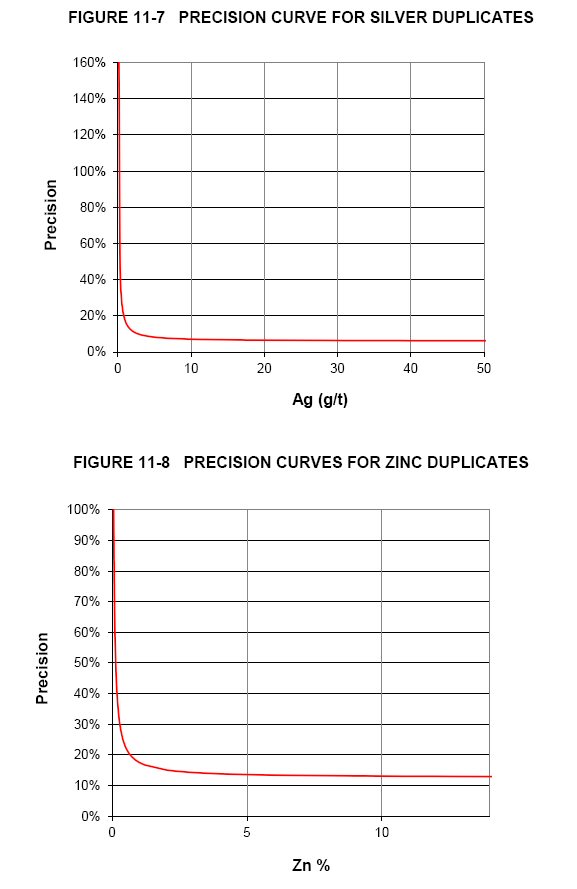

| Figure 11-7 Precision Curve for Silver Duplicates | 11-10 |

| Figure 11-8 Precision Curves for Zinc Duplicates | 11-10 |

| Figure 11-9 CRM GBM999-3 – Silver | 11-12 |

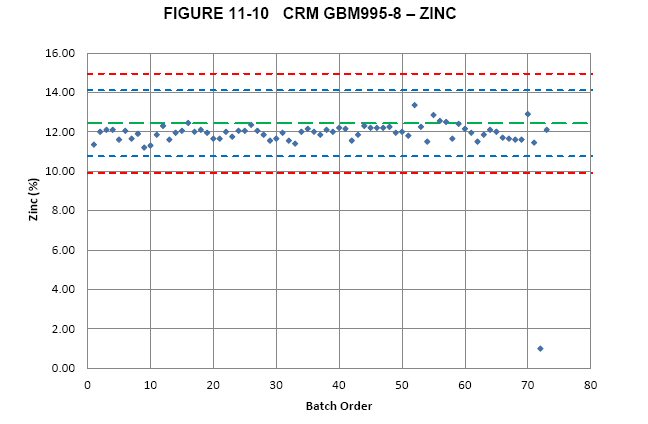

| Figure 11-10 CRM GBM995-8 – Zinc | 11-13 |

| Figure 14-1 3D View of Wireframe Models | 14-3 |

| Figure 14-2 3D View of Block Model Silver Grades | 14-4 |

| Figure 14-3 Histogram of Silver Resource Assays | 14-7 |

| Figure 14-4 Histogram of Gold Resource Assays | 14-7 |

| Figure 14-5 Histogram of Lead Resource Assays | 14-8 |

| Figure 14-6 Histogram of Zinc Resource Assays | 14-8 |

| Figure 14-7 Histogram of Sample Lengths | 14-10 |

| Figure 14-8 Vertical Section 10000BZ | 14-13 |

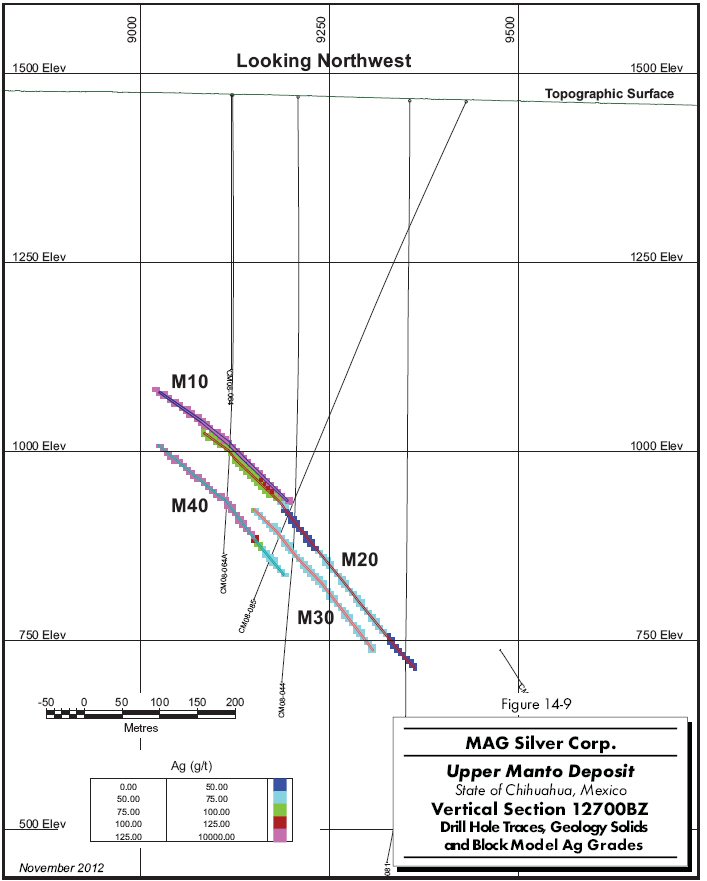

| Figure 14-9 Vertical Section 12700BZ | 14-14 |

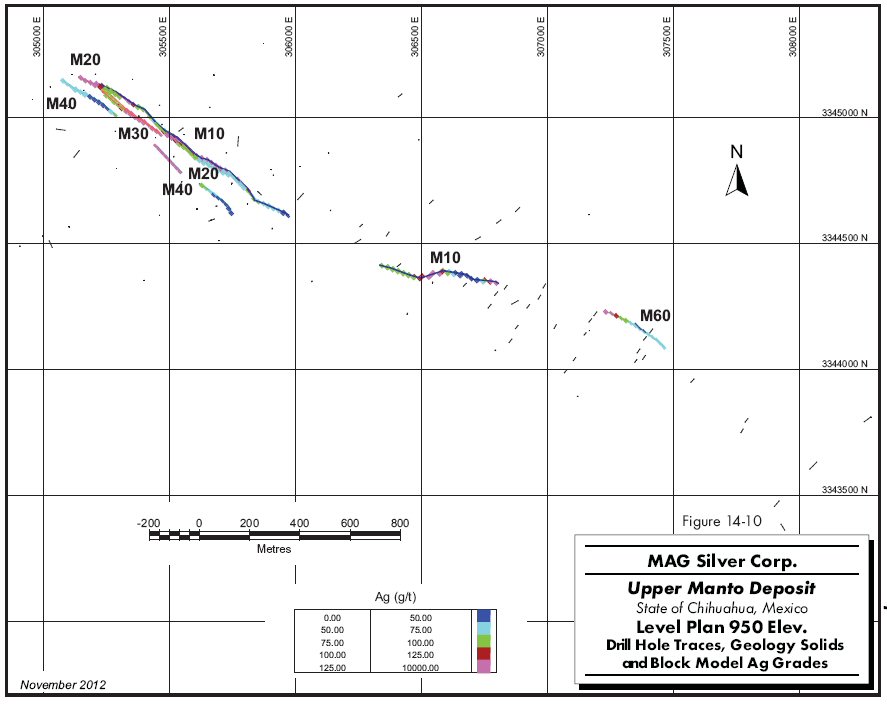

| Figure 14-10 Level Plan 950 Elev | 14-15 |

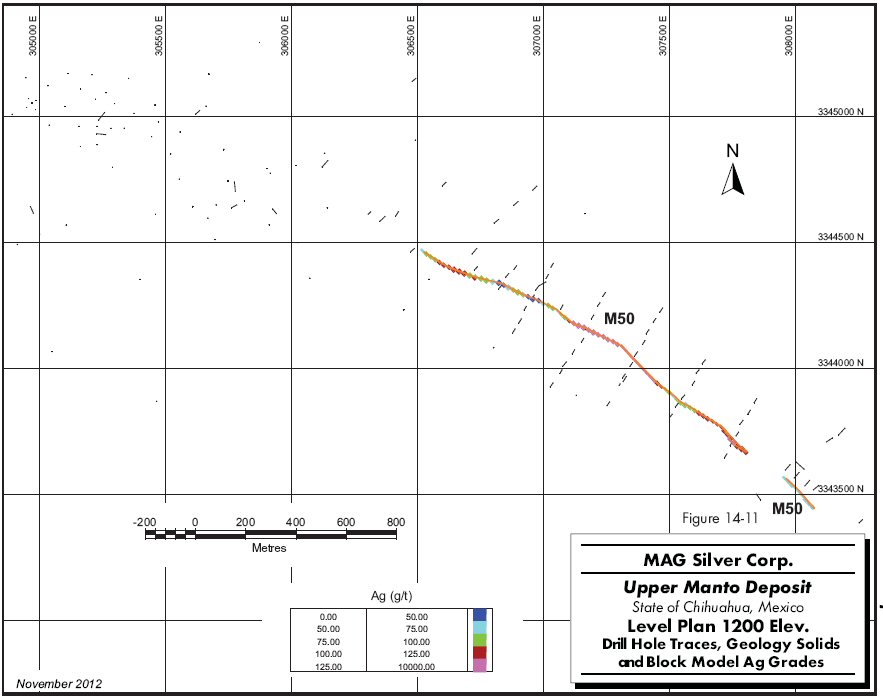

| Figure 14-11 Level Plan 1200 Elev | 14-16 |

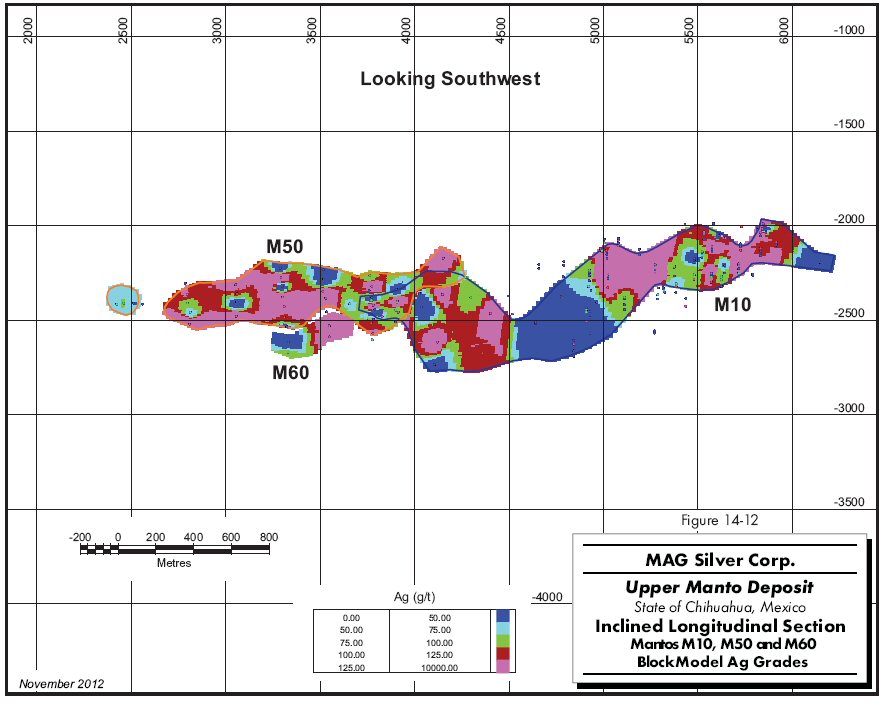

| Figure 14-12 Inclined Longitudinal Section | 14-17 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page iii |

| www.rpacan.com |

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by MAG Silver Corp. (MAG) to prepare an independent Technical Report on the Upper Manto deposit (the Project), located on MAG’s 25,000 ha Cinco de Mayo property (the Property), Chihuahua, Mexico. The purpose of this report is to support the Mineral Resource estimate prepared by RPA and disclosed by MAG in a press release dated October 3, 2012. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the Property most recently on October 2 and 3, 2012.

The Upper Manto Pb-Zn-Ag (Au) deposit, formerly known as the Jose Manto-Bridge Zone deposit, consists of two parallel and overlapping manto deposits referred to as the Jose Manto and the Bridge Zone. The Property also hosts the Pozo Seco Mo-Au deposit, however, this Technical Report focuses solely on the Upper Manto deposit. A separate Technical Report on the Pozo Seco deposit was prepared in 2010 and remains current since the two deposits host distinctly different mineralization with different commodities, are separated by four kilometres and small mountain range, will potentially be mined by different methods, underground for Upper Manto and open pit for Pozo Seco, and have no significant synergies between them.

CONCLUSIONS

MAG has made a major carbonate replacement deposit (CRD) discovery at its 100% owned Cinco de Mayo Property in northern Chihuahua, Mexico. Diamond drilling has outlined manto mineralization with three-dimensional continuity, and size and grades that can potentially be extracted economically. MAG’s protocols for drilling, sampling, analysis, security, and database management meet industry accepted practices. The drill hole database was verified by RPA and is suitable for Mineral Resource estimation work.

RPA estimated Mineral Resources for the Upper Manto deposit using drill hole data available as of September 1, 2012. At an NSR cut-off of US$100/t, Inferred Mineral Resources are estimated to total 12.45 million tonnes of 132 g/t Ag, 0.24 g/t Au, 2.86% Pb, and 6.47% Zn. The total contained metals in the resource are 52.7 million ounces of silver, 785 million pounds of lead, 1,777 million pounds of zinc, and 96,000 ounces of gold. Drill sections were spaced at 100 m to 250 m along strike with intercepts on each section averaging 50 m apart down dip. The resource remains open in several directions. There are no Mineral Reserves estimated on the Property.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 1-1 |

| www.rpacan.com |

The 61.6 m of massive sulphide intercept, known as the Pegaso Zone, located deeper in hole CM-12-431 was not included in this resource estimate. That intercept indicates excellent potential for a much larger resource at depth, however, additional drilling is required to establish the geometry of the Pegaso Zone.

A significant exploration budget is warranted.

RECOMMENDATIONS

The Upper Manto deposit hosts a significant silver-zinc-lead-gold deposit and merits considerable work. RPA recommends a Phase 1 budget of US$12.1 million (Table 1-1) to advance the Project and explore elsewhere on the Property. Work should include:

| · | 50,000 m of infill drilling at the Upper Manto deposit. |

| · | 7,500 m of drilling at the Pegaso Zone to explore for extensions of the known mineralization. |

| · | 2,000 m of drilling for a property-wide exploration program including mapping, and drilling of new targets. |

| TABLE 1-1 PROPOSED BUDGET |

| MAG Silver Corp. – Upper Manto Deposit |

| Item | US$ |

| Infill drilling at Upper Manto (50,000 m at $150 m) | 7,500,000 |

| Exploration drilling at Pegaso (7,500 m at $180/m) | 1,350,000 |

| Exploration drilling elsewhere on property (2,000 m at $150/m) | 300,000 |

| Geophysics (seismic survey) | 1,000,000 |

| Metallurgical testwork | 100,000 |

| Other engineering studies | 250,000 |

| Operating costs/office | 500,000 |

| Sub-total | 11,000,000 |

| Contingency (10%) | 1,100,000 |

| Total | 12,100,000 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page1-2 |

| www.rpacan.com |

The recommended Phase 2 budget of US$10 million would be contingent of Phase 1 results. Work would include additional drilling at Pegaso, metallurgical testwork, and a Preliminary Economic Assessment.

TECHNICAL SUMMARY

PROPERTY DESCRIPTION AND LAND TENURE

The Upper Manto deposit is located on MAG’s Cinco de Mayo Property in north central Chihuahua State, 190 km northwest of the state capital of Chihuahua City. Chihuahua City is a major city with a population of approximately 750,000. The Property is located immediately west of the village of Benito Juárez, accessible along dirt roads. The Property is centred at 305,000mE, 3,340,000mN (NAD 27 Mexico, Zone 13).

The Project consists of 29 concessions totalling 25,113.2049 ha located in the Municipio de Buenaventura. The concessions are wholly owned by MAG subject to a 2.5% net smelter return (NSR) royalty due to Minera Cascabel S.A. de C.V. (Cascabel). MAG has indicated that there are no outstanding environmental liabilities associated with the Project or the Property.

HISTORY

Small scale mining took place in the Property area in at least twelve locations sometime prior to the 1990s. In the mid-1990s, an affiliate of Industrias Peñoles S.A. de C.V. (Peñoles) drilled six reverse circulation holes for a total of 1,368 m to test several silicified zones. In 1992, the area was visited by Peter Megaw on behalf of Teck Corporation (Teck) as part of a reconnaissance program in Chihuahua State carried out from 1991 to 1994. Megaw determined that the area exhibited characteristics favourable for large CRDs. Teck’s field work included reconnaissance mapping and detailed sampling of the jasperoid veins along Cinco de Mayo Ridge. Teck transferred the Property to Cascabel in early 2000 with no retained interest. Cascabel continued to stake claims until 2003. In 2004, MAG optioned the ground from Cascabel.

GEOLOGY AND MINERALIZATION

Cinco de Mayo is located on the western margin of the Chihuahua Trough, the same environment which hosts several other important CRDs in Mexico. The Chihuahua Trough is a Jurassic marine basin generally composed of evaporites, clastic sedimentary rocks, and carbonates.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 1-3 |

| www.rpacan.com |

The Property is dominated by the Sierra Santa Lucia, a northwest-trending 600 m high limestone range roughly 3.5 km wide and 12 km long. Cinco de Mayo Ridge is an elongate limestone ridge, 400 m wide by 2,000 m long off the east side of the Sierra Santa Lucia. The Sierra Santa Lucia lies directly above the western bounding fault of the Chihuahua Trough and there is strong local evidence that this fault functioned subsequently as a major shear zone. There are numerous mineralization and alteration occurrences associated with this fault zone throughout the Sierra Santa Lucia and adjacent hills.

The Upper Manto Pb-Zn-Ag (Au) deposit consists of two parallel overlapping manto deposits referred to as Jose Manto and the Bridge Zone. There are four styles of mineralization at the Upper Manto deposit including manto mineralization, massive sulphide mineralization, garnet-pyroxene skarn, and vein and veinlet mineralization.

EXPLORATION

Work by MAG began in mid-2004 with preliminary regional geological mapping, followed by geochemical, biogeochemical, and geophysical surveys in 2005 to 2009. Combining the geological, geochemical, biogeochemical, and geophysical data and interpretations, MAG developed a series of drill targets along a prominent northwest trending fault zone that cuts strongly folded massive limestone and limestone-rich sedimentary rocks.

As of September 1, 2012, 445 holes totalling 213,591 m have been drilled on the Property. Of these, 151 holes totalling 97,610 m are located at or nearby the Upper Manto deposit and were used to model the mineralization.

MINERAL RESOURCE ESTIMATE

RPA prepared a Mineral Resource estimate for the Upper Manto deposit based on drilling results available up to September 1, 2012 (Table 1-2). There are no Mineral Reserves estimated for the Project at this time.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 1-4 |

| www.rpacan.com |

| TABLE 1-2 INFERRED MINERAL RESOURCES BY MANTO – SEPTEMBER 1, 2012 |

| MAG Silver Corp. – Upper Manto Deposit |

| Manto | Tonnage | Gold | Silver | Zinc | Lead | AgEq | Gold | Silver | Zinc | Lead |

| | (Mt) | (g/t) | (g/t) | (%) | (%) | (g/t) | (oz) | (Moz) | (Mlb) | (Mlb) |

| M10 | 4.89 | 0.32 | 142 | 6.56 | 2.74 | 396 | 50,000 | 22.4 | 708 | 296 |

| M20 | 1.48 | 0.20 | 129 | 5.97 | 2.24 | 350 | 9,000 | 6.1 | 195 | 73 |

| M30 | 0.93 | 0.07 | 122 | 6.97 | 2.65 | 378 | 2,000 | 3.7 | 143 | 54 |

| M40 | 1.45 | 0.24 | 133 | 6.18 | 3.52 | 400 | 11,000 | 6.2 | 198 | 113 |

| M50 | 3.29 | 0.18 | 122 | 6.84 | 3.11 | 392 | 19,000 | 12.9 | 496 | 225 |

| M60 | 0.41 | 0.34 | 100 | 4.22 | 2.63 | 293 | 4,000 | 1.3 | 38 | 24 |

| Total | 12.45 | 0.24 | 132 | 6.47 | 2.86 | 385 | 96,000 | 52.7 | 1,777 | 785 |

Notes:

| 1. | CIM definitions were followed for the classification of Mineral Resources. |

| 2. | Mineral Resources are estimated at an NSR cut-off value of US$100 per tonne. |

| 3. | NSR values are calculated in US$ using factors of $0.60 per g/t Ag, $12.32 per g/t Au, $18.63 per % Pb and $14.83 per % Zn. These factors are based on metal prices of US$27.00/oz Ag, US$1,500/oz Au, $1.15/lb Pb, and $1.20/lb Zn and estimated recoveries and smelter terms. |

| 4. | The Mineral Resource estimate uses drill hole data available as of September 1, 2012. |

| 5. | Totals may not add correctly due to rounding |

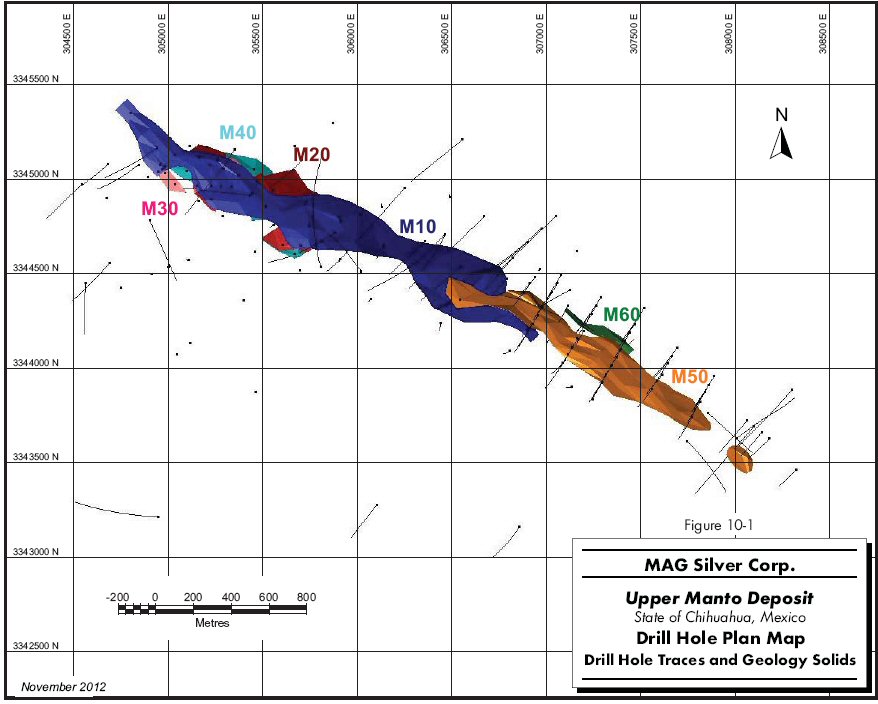

A total of six zones were modelled, with the largest, Manto M10, extending from the northwest part of the Jose Manto deposit to partway into the Bridge Zone and measuring 2,500 m long by 350 m down dip by 1.5 m to 9 m thick. The zones extend from surface to a depth of 950 m below surface.

Grade interpolations for silver, gold, lead, zinc, and density were made using inverse distance cubed with a minimum of one to a maximum of twelve composites per block estimate. Hard boundaries were used to limit the use of composites between mantos. The search ellipse was 250 m by 250 m by 100 m oriented in the plane of the mantos. Gold values greater than 1 g/t were restricted to a maximum of 75 m.

Mineral Resources were classified entirely as Inferred based on drill hole spacing and the apparent continuity of mineralization. Drill sections were spaced 100 m to 250 m along strike with intercepts on each section averaging 50 m apart down dip. The resource remains open in several directions.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 1-5 |

| www.rpacan.com |

The Property also hosts the Pozo Seco Mo-Au deposit, for which RPA prepared a Mineral Resource estimate in 2010. At a cut-off grade of 0.022% Mo, the Indicated Mineral Resources were estimated at 29.1 million tonnes grading 0.147% Mo and 0.25 g/t Au, containing 94.0 million pounds Mo and 230,000 ounces Au. Inferred Mineral Resources were estimated at 23.4 million tonnes grading 0.103% Mo and 0.17 g/t Au, containing 53.2 million pounds Mo and 129,000 ounces Au. The estimate was constrained within a preliminary pit optimization using assumed costs, recoveries, and metal prices. A separate Technical Report on the Pozo Seco deposit prepared in 2010 remains current since the two deposits host distinctly different mineralization with different commodities, are separated by four kilometres and small mountain range, will potentially be mined by different methods, underground for Upper Manto and open pit for Pozo Seco, and have no significant synergies between them.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 1-6 |

| www.rpacan.com |

2 INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by MAG Silver Corp. (MAG) to prepare an independent Technical Report on the Upper Manto deposit (the Project), located on MAG’s 25,000 ha Cinco de Mayo property (the Property), Chihuahua, Mexico. The purpose of this report is to support the Mineral Resource estimate prepared by RPA and disclosed by MAG in a press release dated October 3, 2012. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the Property most recently on October 2 and 3, 2012.

The Upper Manto deposit, formerly known as the Jose Manto-Bridge Zone deposit, consists of two parallel and overlapping manto deposits referred to as the Jose Manto and the Bridge Zone. The Property also hosts the Pozo Seco Mo-Au deposit, however, this Technical Report focuses solely on the Upper Manto deposit. A separate Technical Report on the Pozo Seco deposit (Ross, 2010) remains current since the two deposits host distinctly different mineralization with different commodities, are separated by four kilometres and small mountain range, will be potentially mined by different methods, underground for Upper Manto and open pit for Pozo Seco, and have no significant synergies between them.

MAG is listed on the Toronto Stock Exchange and on the NYSE Amex Equities. MAG’s major assets are the Cinco de Mayo Property and a 44% interest in the Juanicipio Joint Venture Project located in Zacatecas State, Mexico.

SOURCES OF INFORMATION

A site visit to the Project was carried out by David Ross, M.Sc., P.Geo., Principal Geologist with RPA, on July 5 to 7, 2010, and again on October 2 and 3, 2012. He examined several outcrops, reviewed logging and sampling methods, and inspected core from drill holes.

Discussions on site and thereafter were held with:

| · | Mr. Dan MacInnis, President and CEO, MAG |

| · | Mr. Mike Petrina, Vice President Operations, MAG |

| · | Dr. Peter Megaw, C.P.G., President of International Mineral Development and Exploration, Inc. (IMDEX), Director of MAG, and discoverer of the Project. |

| · | Mr. James McGlasson, Technical Services Director, IMDEX |

| · | Mr. Lyle Hanson, M.Sc., Regional Geologist, MAG |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 2-1 |

| www.rpacan.com |

The documentation reviewed, and other sources of information, are listed at the end of this report in Section 27 References.

LIST OF ABBREVIATIONS

Units of measurement used in this report conform to the Metric system. All currency in this report is US dollars (US$) unless otherwise noted.

| a | annum | | kWh | kilowatt-hour |

| A | ampere | | L | litre |

| bbl | barrels | | lb | pound |

| btu | British thermal units | | L/s | litres per second |

°C | degree Celsius | | m | metre |

| C$ | Canadian dollars | | M | mega (million); molar |

| CRD | carbonate replacement deposit | | m2 | square metre |

| cfm | cubic feet per minute | | m3 | cubic metre |

| cm | centimetre | | µ | micron |

cm2 | square centimetre | | MASL | metres above sea level |

| d | day | | µg | microgram |

| dia | diameter | | m3/h | cubic metres per hour |

| dmt | dry metric tonne | | mi | mile |

| dwt | dead-weight ton | | min | minute |

°F | degree Fahrenheit | | µm | micrometre |

| ft | foot | | mm | millimetre |

ft2 | square foot | | mph | miles per hour |

ft3 | cubic foot | | MVA | megavolt-amperes |

| ft/s | foot per second | | MW | megawatt |

| g | gram | | MWh | megawatt-hour |

| G | giga (billion) | | oz | Troy ounce (31.1035g) |

| Gal | Imperial gallon | | oz/st, opt | ounce per short ton |

| g/L | gram per litre | | ppb | part per billion |

| Gpm | Imperial gallons per minute | | ppm | part per million |

| g/t | gram per tonne | | psia | pound per square inch absolute |

gr/ft3 | grain per cubic foot | | psig | pound per square inch gauge |

gr/m3 | grain per cubic metre | | RL | relative elevation |

| ha | hectare | | s | second |

| hp | horsepower | | st | short ton |

| hr | hour | | stpa | short ton per year |

| Hz | hertz | | stpd | short ton per day |

| in. | inch | | t | metric tonne |

in2 | square inch | | tpa | metric tonne per year |

| J | joule | | tpd | metric tonne per day |

| k | kilo (thousand) | | US$ | United States dollar |

| kcal | kilocalorie | | USg | United States gallon |

| kg | kilogram | | USgpm | US gallon per minute |

| km | kilometre | | V | volt |

km2 | square kilometre | | W | watt |

| km/h | kilometre per hour | | wmt | wet metric tonne |

| kPa | kilopascal | | wt% | weight percent |

| kVA | kilovolt-amperes | | yd3 | cubic yard |

| kW | kilowatt | | yr | year |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 2-2 |

| www.rpacan.com |

3 RELIANCE ON OTHER EXPERTS

This report has been prepared by RPA for MAG. The information, conclusions, opinions, and estimates contained herein are based on:

| · | Information available to RPA at the time of preparation of this report, |

| · | Assumptions, conditions, and qualifications as set forth in this report, and |

| · | Data, reports, and other information supplied by MAG and other third party sources. |

For the purpose of this report, RPA has relied on ownership information provided by MAG. MAG has relied on an opinion by Creel, Garcia-Cuellar, Aiza y Enriquez, S.C. dated September 5, 2012, entitled Cinco de Mayo Property, and this opinion is relied on in Section 4 and the Summary of this report. RPA has not researched property title or mineral rights for the Cinco de Mayo Property and expresses no opinion as to the ownership status of the Property.

Except for the purposes legislated under provincial securities laws, any use of this report by any third party is at that party’s sole risk.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 3-1 |

| www.rpacan.com |

4 PROPERTY DESCRIPTION AND LOCATION

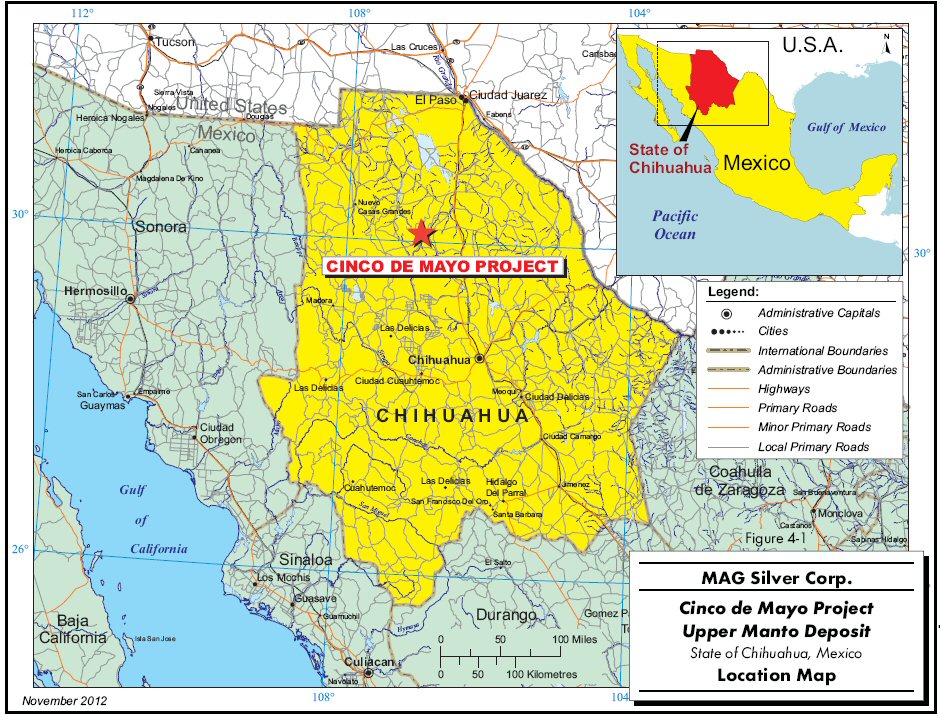

The Upper Manto deposit is located on MAG’s Cinco de Mayo Property in north central Chihuahua State, 190 km northwest of the state capital of Chihuahua City (Figure 4-1). Chihuahua City is a major city with a population of approximately 750,000. The Property is located immediately west of the village of Benito Juárez, accessible along dirt roads. The Property is centred at 305,000mE, 3,340,000mN (NAD 27 Mexico, Zone 13).

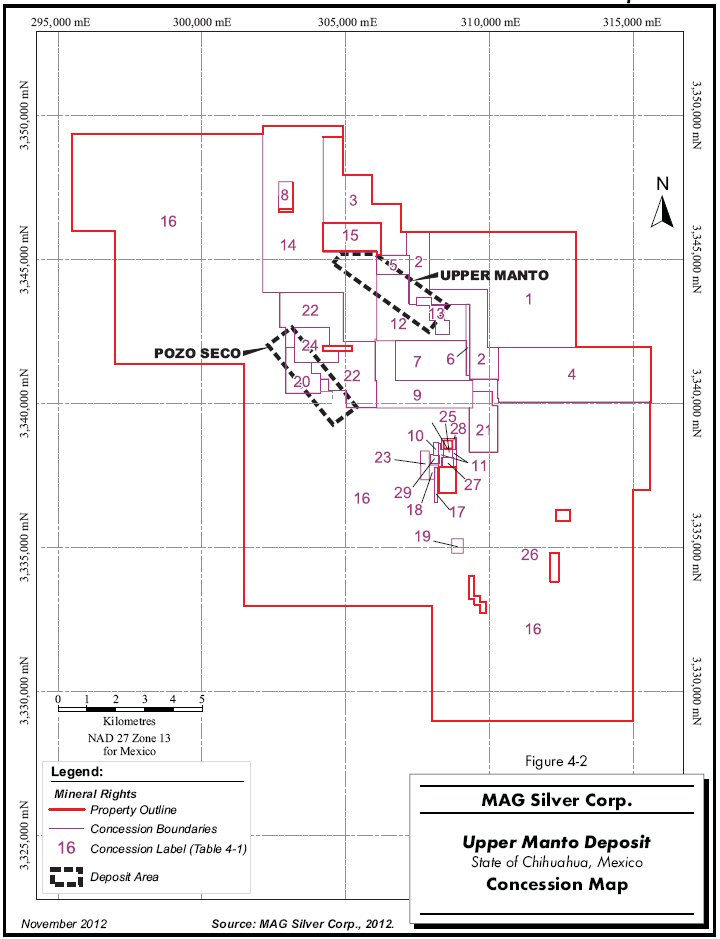

The Project consists of 29 concessions totalling 25,113.2049 ha located in the Municipio de Buenaventura (Figure 4-2). Table 4-1 lists the subject concessions along with their information including number, date of issue, expiry dates, and surface areas.

| TABLE 4-1 LIST OF CONCESSIONS |

| MAG Silver Corp. – Upper Manto Deposit |

Figure Label | Concession Name | Title Number | Date of Issue | Expiration Date | Area (ha) |

| 1 | DON JOSE | 222251 | 22-Jun-04 | 21-Jun-54 | 1,640.0000 |

| 2 | DON JOSE II | 235685 | 16-Feb-10 | 15-Feb-60 | 469.9433 |

| 3 | DON JOSE II FRACC. 1 | 235711 | 19-Feb-10 | 18-Feb-60 | 536.1942 |

| 4 | DON JOSE II FRACC. 2 | 235712 | 19-Feb-10 | 18-Feb-60 | 1,005.5683 |

| 5 | DON JOSE III | 224331 | 26-Apr-05 | 25-Apr-55 | 78.7872 |

| 6 | DON JOSE III FRACC. 2 | 209293 | 30-Mar-99 | 29-Mar-49 | 32.7879 |

| 7 | DON JOSE IV REDUCCION | 218474 | 31-Oct-00 | 30-Oct-50 | 348.5547 |

| 8 | DON JOSE V | 212878 | 13-Feb-01 | 12-Feb-46 | 47.7166 |

| 9 | DON JOSE VI | 234414 | 30-Jun-10 | 29-Jun-60 | 412.2388 |

| 10 | DON JOSE VII | 237045 | 22-Oct-10 | 21-Oct-60 | 8.4199 |

| 11 | DON JOSE VIII | 237692 | 26-Apr-11 | 25-Apr-61 | 18.3534 |

| 12 | DON ROBERTO | 224252 | 22-Apr-05 | 21-Apr-55 | 453.4431 |

| 13 | CINCO DE MAYO | 216086 | 09-Apr-02 | 08-Apr-48 | 65.0000 |

| 14 | DANIEL | 229222 | 27-Mar-07 | 26-Mar-57 | 1,653.9137 |

| 15 | DANIEL 1 | 229249 | 28-Mar-07 | 27-Mar-57 | 4.8630 |

| 16 | INDEPENDENCIA | 229744 | 13-Jun-07 | 12-Jun-57 | 17,096.9082 |

| 17 | LA MARY | 230455 | 04-Sep-07 | 03-Sep-57 | 12.0000 |

| 18 | LA AMISTAD | 230454 | 04-Sep-07 | 03-Sep-57 | 11.4935 |

| 19 | EL PLOMO | 230475 | 06-Sep-07 | 05-Sep-57 | 20.0000 |

| 20 | LA FORTUNA | 228746 | 18-Jan-07 | 17-Jan-57 | 132.9008 |

| 21 | LA SINFOROSA | 228747 | 18-Jan-07 | 17-Jan-57 | 192.5727 |

| 22 | EL CHINACATE | 228723 | 17-Jan-07 | 16-Jan-57 | 651.9335 |

| 23 | CAMARADA | 228487 | 24-Nov-06 | 23-Nov-56 | 29.8687 |

| 24 | TRES AMIGOS | 228148 | 06-Oct-06 | 05-Oct-56 | 150.8245 |

| 25 | LA FORTUNA | 220802 | 08-Oct-03 | 07-Oct-51 | 8.6804 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 4-1 |

| www.rpacan.com |

Figure Label | Concession Name | Title Number | Date of Issue | Expiration Date | Area (ha) |

| 26 | LA FORTUNA I | 221879 | 07-Apr-04 | 06-Apr-52 | 0.6584 |

| 27 | JOSEFINA I | 221881 | 07-Apr-04 | 06-Apr-52 | 12.0000 |

| 28 | CRIPTO | 221884 | 07-Apr-04 | 06-Apr-52 | 9.0000 |

| 29 | EL MANZANILLO | 221877 | 07-Apr-04 | 06-Apr-52 | 8.5801 |

| | Total | | | | 25,113.2049 |

Unlike many jurisdictions, Mexican mining law does not distinguish between exploration and exploitation type mineral concessions. Applicants are granted a single type of mining concession (exploration and exploitation) with a 50 year life from the date of registration in the Public Registry of Mines. Concessions are renewable for an equal term so long as the concession is not cancelled by any act or omission sanctioned by the Mining Act and an application is filed within five years prior to its expiration.

The primary concessions of the Cinco de Mayo Property were acquired by way of an option agreement with Minera Cascabel S.A. de C.V. (Cascabel) dated February 26, 2004. Under the terms of the agreement, MAG acquired a 100% interest in the Cinco de Mayo Property, subject to a 2.5% net smelter return (NSR) royalty. During the year ended December 31, 2008, MAG acquired a 100% interest in certain additional concessions internal to the Cinco de Mayo Property from two separate vendors. MAG made a one-time payment of $350,000 for these concessions. During the year ended December 31, 2009, MAG acquired a 100% interest in certain additional concessions internal or adjacent to the Cinco de Mayo Property from three separate vendors. MAG made a one-time payment of $362,000 for these concessions. During the year ended December 31, 2009, MAG also purchased surface rights in the Cinco de Mayo area for $660,000. During the year ended December 31, 2010, MAG entered into two option agreements to earn a 100% interest in five additional concessions adjacent to the Cinco de Mayo Property, and paid $40,000 upon executing the agreements. In order to earn its 100% interest on these additional five concessions, MAG must pay an additional $156,000 in stages through 2015. The 2.5% net smelter royalty due to Cascabel applies to these claims acquired subsequent to the original option.

At the time of writing, MAG had applied for, but had not yet received, exploration permits for the next round of drilling. MAG has indicated that there are no outstanding environmental liabilities associated with the Property.

The Property is surrounded by the 9,673,536 ha Juárez Asignación Minera Nacional, a large regional mining assignment established in 2006 by the Mexican geological service.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 4-2 |

| www.rpacan.com |

| www.rpacan.com |

| www.rpacan.com |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

ACCESSIBILITY

The Project is located in north central Chihuahua State, approximately 190 km northwest of the state capital of Chihuahua City. The Property is accessible by driving north from Chihuahua City on Federal Highway 45D for approximately 92 km to Highway 7D, then driving northwesterly for approximately 108 km to the town of Ricardo Flores Magón. MAG’s base of operations is located in Ejido Benito Juarez, a distance of about 20 km north of Ricardo Flores Magón along Highway 10. The Property is located immediately west of Benito Juárez and is accessible along dirt roads.

The closest railway access is 80 km to the east at Villa Ahumada. International airport services are in Chihuahua City and Ciudad Juarez.

CLIMATE

The climate is dry to semi-arid. The average annual temperature is 20°C. Annual rainfall ranges from 220 mm to 1,000 mm.

LOCAL RESOURCES

The closest full service town, Nuevo Casas Grandes, is located approximately 100 km to the northwest from the Property. Nuevo Casas Grandes has a population of approximately 55,000 and has most services including medical services and accommodations. A greater range of services is available at Chihuahua City located about a two and a half hour drive by paved highway.

The closest airport with daily service to Mexico City, Dallas-Fort Worth, and Houston is located at Chihuahua City. Daily service to Mexico City and other cities in Mexico is also available nearby at Juarez City.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 5-1 |

| www.rpacan.com |

INFRASTRUCTURE

Other than exploration drill roads used to access drill sites, there is currently no permanent infrastructure on the Property.

A potential mining development on the Property would likely have access to electric power from the Mexican national transmission grid. A high tension power line bisects the southern part of the Property, approximately eight kilometres south of the Project (Figure 4-2).

PHYSIOGRAPHY

The Sierra Santa Lucia is the most prominent physiographic feature on the Property. It is a northwest-trending 600 m high limestone range roughly 12 km long by 3.5 km wide. Elevations range from 1,330 MASL in the valley floor west of the Sierra Santa Lucia to 1,940 MASL along the Sierra Santa Lucia. Cinco de Mayo Ridge is an elongate limestone ridge, 400 m wide by 2,000 m long off the east side of the Sierra Santa Lucia. The Upper Manto deposit is located on the plain along the east side of the Sierra Santa Lucia, whereas Pozo Seco Mo-Au deposit is located on the west side.

Vegetation is sparse and consists of range grass and scattered cacti and other shrubs with occasional mesquite trees.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 5-2 |

| www.rpacan.com |

6 HISTORY

Small scale mining took place in the Property area in at least twelve locations sometime prior to the 1990s (Figure 4-2). There are no known records describing this historic production. A series of small claims in these areas were previously held by Mexican individuals.

In the mid-1990s, an affiliate of Industrias Peñoles S.A. de C.V. (Peñoles) drilled six reverse circulation holes for a total of 1,368 m to test several silicified zones.

The area was visited by Peter Megaw in 1992 on behalf of Teck Corporation (Teck) as part of a reconnaissance program in Chihuahua State carried out from 1991 to 1994. Megaw determined that the area exhibited characteristics favourable for large carbonate replacement deposits (CRD) and that Cinco de Mayo looked very much like the distal portions of the Santa Eulalia deposit (Megaw, 1997). Teck’s field work included reconnaissance mapping and detailed sampling of the jasperoid veins along Cinco de Mayo Ridge. Teck chose to drop its interest in the Property and transferred the Property to Cascabel in early 2000 with no retained interest. Cascabel continued to stake claims until 2003.

In 2004, MAG optioned the ground from Cascabel. The agreement is summarized in Section 4 of this report.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 6-1 |

| www.rpacan.com |

7 GEOLOGICAL SETTING AND MINERALIZATION

The descriptions of geological setting and mineralization provided below are derived primarily from the work of Peter Megaw and James Lyons.

REGIONAL GEOLOGY

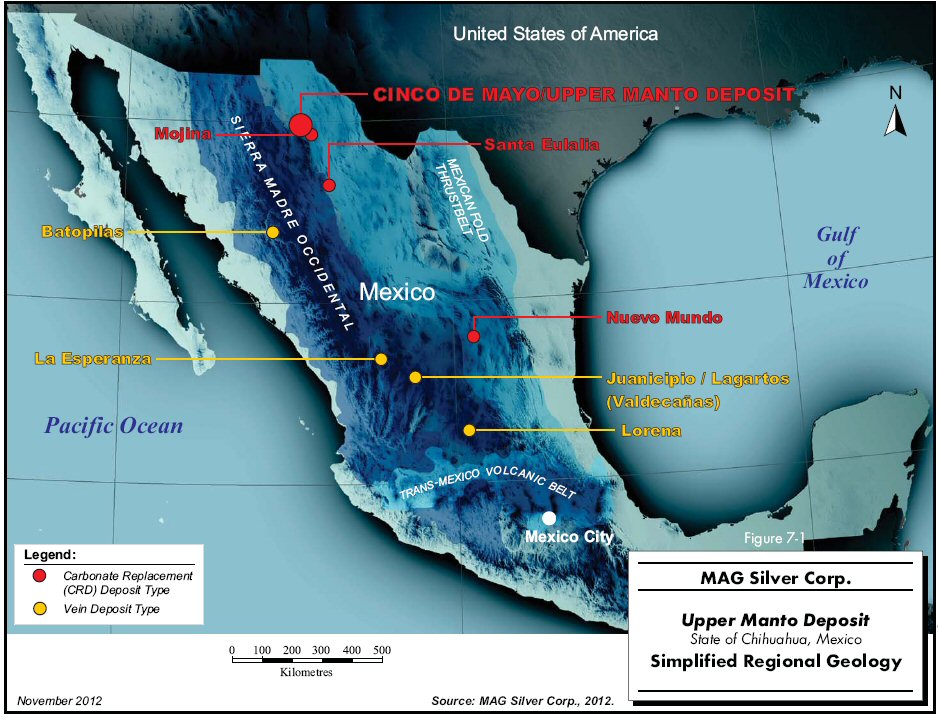

The Property is located along the junction of the Sierra Madre Occidental and the Mexican fold thrust belt (Figure 7-1). The Sierra Madre Occidental is a large silicic igneous province formed during Cretaceous-Cenozoic magmatic and tectonic episodes. The Mexican fold thrust belt is mostly composed of thick sections of Cretaceous carbonate rocks deposited in linear, fault-bounded basins and deformed during the Laramide Orogeny at the end of the Cretaceous.

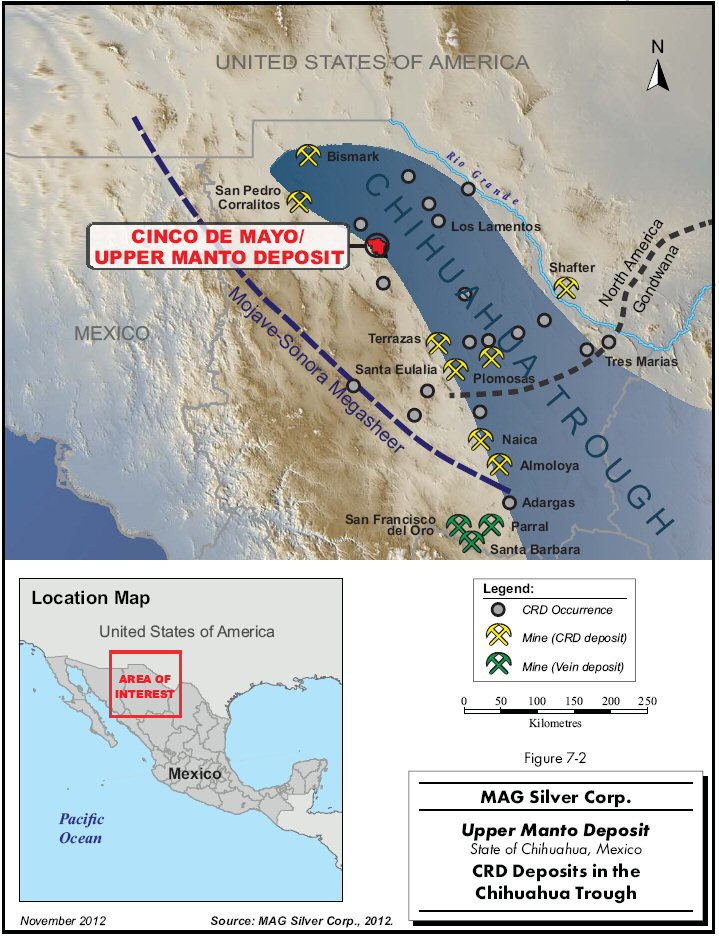

Cinco de Mayo is also located on the western margin of the Chihuahua Trough, the same environment which hosts several other important CRDs (Figure 7-2). The Chihuahua Trough is a Jurassic marine basin generally composed of (from oldest to youngest) evaporites, clastic sedimentary rocks, and carbonates (Haenggi, 2002). The Jurassic evaporate rocks are gypsum, anhydrite, and salt. The clastic sedimentary rocks are conglomeratic sandstone, pebble conglomerates, siltstone, and shale. The Cretaceous carbonate rocks are mostly limestone, with some intercalated shale units. The Chihuahua Trough is generally interpreted to be the result of a Jurassic extensional event related to the opening of the proto-Atlantic Ocean and formation of the Gulf of Mexico. The Property (especially Cerro Cinco de Mayo, Sierra Santa Lucia, and Sierra Ruso) is dominated by Cretaceous limestones.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-1 |

| www.rpacan.com |

| www.rpacan.com |

| www.rpacan.com |

LOCAL GEOLOGY

The structural style at Cinco de Mayo indicates that the district is favourably situated on the west margin of the Jurassic Chihuahua Trough. This location has proven to be a good regional environment for CRDs in Mexico (Megaw et al., 1988). Evidence of fluid flow includes silica replaced structures, silica replaced pipes, fluorite-barite veins, sulphide mantos, sulphide filled faults, and disseminated sulphides in marble.

STRATIGRAPHY

The exposed stratigraphy is highly thrusted, with three to four repeated/stacked sections of the Lower Cretaceous (Early and Middle Albian) limestone-shale section. The units mapped on the surface range from Cuchillo Formation (limestone and shale) at the base, up through the Benigno Formation (limestone) to the Lagrima Formation (shale), all of which underlie the Finlay Formation (limestone). The estimated thicknesses in Table 7-1 are approximate because of structural thickening and thinning obvious throughout the district.

The Finlay Formation, the principal host to known mineralization, is a fossiliferous cherty limestone with high energy beach zones at the base, and abundant rudist reefs (common Mesozoic bivalve). The Finlay Formation is overlain by two different shale units: the Benavides Shale and the Ojinaga Formation. The Benavides Formation (Lower Cretaceous) overlies the Finlay in depositional contact on the east side of Sierra Santa Lucia. On the east side of the range, the Finlay is observed in drill core in thrust contact with the Upper Cretaceous (late Cenomanian) Agua Nueva or Ojinaga Formation. The Late Albian Loma de Plata, and Early Cenomanian Del Rio and Buda Formations, which should be present, remain unobserved at Cinco de Mayo and may have been faulted out of the section or eroded prior to late Cretaceous deposition. Two Late Cretaceous units are observed in the region. First is the Late Cenomanian Indidura equivalent which outcrops 15 km north-northeast of Cinco de Mayo, adjacent to an alteration inducing intrusive. The other is the Ojinaga Formation which outcrops 5.5 km east-northeast of Cinco de Mayo. Drill holes located on the northeast side of Cinco de Mayo Ridge were apparently collared in the Ojinaga Formation. The volcanically derived sandstones of the Ojinaga Formation probably account for the prominent fold observed in the magnetic survey northeast of the Sierra Santa Lucia. Lower Tertiary volcanic rocks, ranging from dacite to rhyolite in composition, crop out in an arcuate band across the eastern, northern, and western fringes of the Project area.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-4 |

| www.rpacan.com |

| TABLE 7-1 STRATIGRAPHIC SECTION |

| MAG Silver Corp. – Upper Manto Deposit |

| Age | Label | Formation | Description | Thickness (m) |

| Tertiary | Tv | Volcanic Rocks | Dacite to Rhyolitic welded tuffs | |

| Cenomanian | Ko | Ojinaga | Sandstones and Shale | +1,000 |

| Cenomanian | Kin | Indidura | Finely Laminated siltstone | ? |

| Late Albian | Klp | Loma de Plata | Bedded Fossiliferous Cherty Limestone | ? |

| Late Albian | Kbe | Benavides | Marl and Calcareous Shale | ~300-400 |

| Middle Albian | Kf | Finlay | Bedded Fossiliferous Cherty Limestone | ~100 |

| Middle Albian | Kl | Lagrima | Marl and Calcareous Shale | 30-50 or more |

| Early Albian | Kbg | Benigno | Bedded Fossiliferous Cherty Limestone | ~150-200 |

| Aptian | Kcu | Cuchillo | Interbedded Limestone and Shale | ~1 to 2 |

STRUCTURAL GEOLOGY

The oldest structures interpreted in the Property area are the north-northwest trending Late Triassic and Early Jurassic extensional basin-controlling structures of the Chihuahua Trough that defined the basin in which the thick Lower Cretaceous carbonate sequence was deposited. The Upper Cretaceous platform sediments (shales and sandstones) subsequently covered the basin structures and obscured the feature. The basin structures were reactivated during the compressional Late Cretaceous-Early Tertiary Laramide Orogeny and were extended upwards through the Late Cretaceous platform sedimentary units. The west-directed folding and thrust faulting related to the Laramide compression produced the dominant structural fabric seen in the area. These prominent folds and thrusts are “escape structures” created during structural narrowing of the basin. Their geometry suggests that they lie above the ancient basin-controlling faults. These structures appear to be favourable hosts of mineralization and apparently were reopened during the subsequent mid-Tertiary extension which characterizes the region and coincides with mineralization-related magmatism (Megaw et al., 1996).

The last tectonic event to affect the region was mid-late Tertiary extension. This extension was directed opposite to the Laramide compression and created the classic north-northwest linear alternation of ranges and basins that define the Basin and Range Province

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-5 |

| www.rpacan.com |

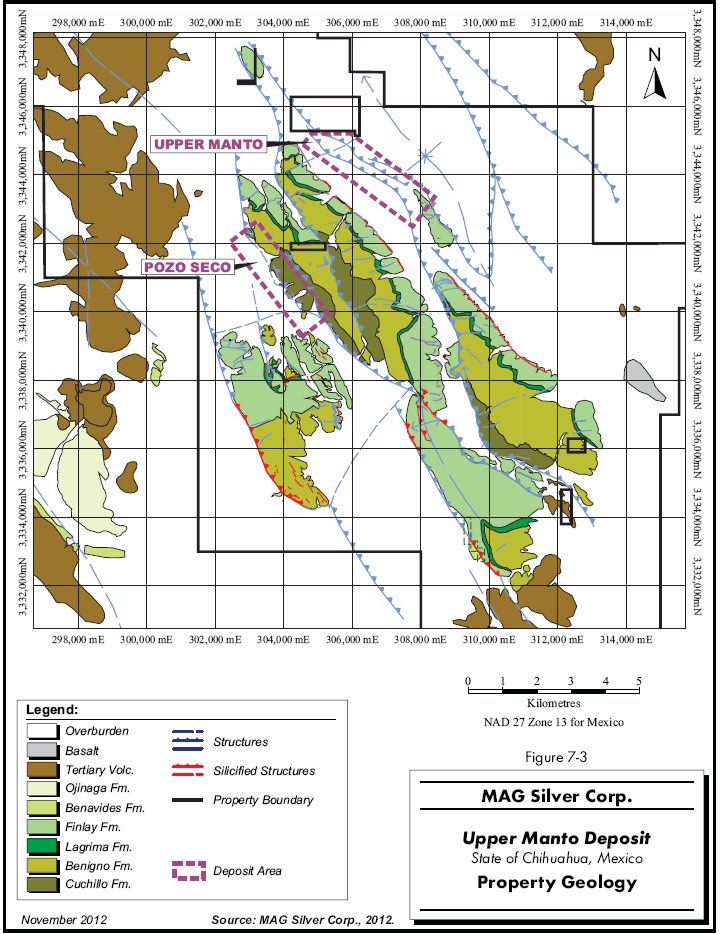

PROPERTY GEOLOGY

The Property is dominated by the Sierra Santa Lucia, a northwest-trending 600 m high limestone range roughly 3.5 km wide and 12 km long. Cinco de Mayo Ridge is an elongate limestone ridge, 400 m wide by 2,000 m long off the east side of the Sierra Santa Lucia. Both are separated and flanked by broad alluvium mantled valleys. Drilling, PEMEX geophysical data, and outcrop reconnaissance indicate that the alluvial cover is thin and that a thick section of carbonate host rocks lies immediately beneath the cover in many areas. The structural complexity of the Sierra Santa Lucia indicates that it lies directly above the western bounding fault of the Chihuahua Trough and there is strong local evidence that this fault functioned subsequently as a major shear zone, with strands passing along the immediate flanks of the Sierra Santa Lucia and probably carving off the north-northwest trending Cinco de Mayo Ridge from the body of the range. Surface mapping and drilling suggest that the principal thrust and shear offsets are pre-mineral in age, with mineralization-related intrusions and mineralizing fluids exploiting these zones of weakness.

There are numerous mineralization and alteration occurrences associated with this fault zone throughout the Sierra Santa Lucia and adjacent hills. These include the prospects and small mines at Abundancia, Celia, Cinco Ridge, and Orientales and a host of unnamed occurrences dominated by iron-rich jasperoids with strongly anomalous Pb-Zn-Ag-As (Au) signatures, particularly along the base of the ridge. Little is known of the historic mining at Cinco de Mayo Ridge, but there are two old mines at opposite ends of the ridge that probably produced small amounts of high-grade silver and base metal mineralization. These historic mines helped draw early exploration work to the area, but it was rapidly recognized that the entire ridge is cut by northeast-southwest and northwest-southeast structures that host both mineralization and metal-bearing jasperoid alteration. The jasperoids were the focus of a systematic mapping and sampling program in 1998, which revealed a number of geochemical “hot-spots” along certain structural corridors leading towards the adjacent covered areas that are in turn underlain by highly favourable host rocks.

The property geology map is shown in Figure 7-3.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-6 |

| www.rpacan.com |

| www.rpacan.com |

MINERALIZATION

The two deposits on the Property with estimated Mineral Resources are the Upper Manto Pb-Zn-Ag CRD located on the east side of Sierra Santa Lucia, and the Pozo Seco Mo-Au deposits located on the west side of Sierra Santa Lucia. The Upper Manto deposit, formerly known as the Jose Manto-Bridge Zone deposit, consists of two parallel overlapping manto deposits referred to as Jose Manto and the Bridge Zone. This report focuses on the Upper Manto deposit; however, the Pozo Seco is briefly mentioned for completeness. The Pozo Seco deposit is described in a separate NI 43-101 report (Ross, 2010).

UPPER MANTO DEPOSIT

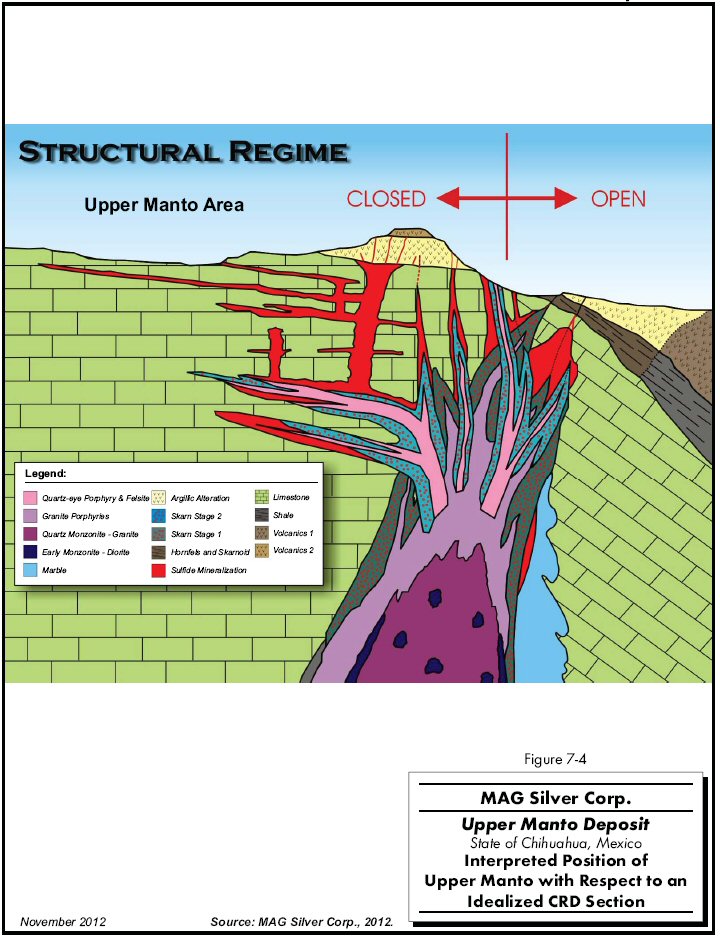

The description of the mineralization for the Upper Manto deposit comes from Dr. Peter Megaw (personnel communication) and was verified by the author in 2012. There are four styles of mineralization at the Upper Manto deposit including manto mineralization, massive sulphide mineralization, garnet-pyroxene skarn, and vein and veinlet mineralization. Each is described below.

| · | Manto mineralization represents relatively flat-lying to inclined tabular bodies consisting of medium to coarse grained massive pyrite, pyrrhotite, galena, and sphalerite with minor acanthite (Ag2S). The sulphides are commonly brecciated and re-mineralized by later sulphide and in-filling events. Sphalerite colour varies by event from honey to brown to nearly black. Sulphides are commonly banded, locally reflecting the shapes of partially replaced limestone domains, but generally highly contorted with no apparent relationship to any pre-existing opening or domain shape which is typical of CRDs. Pyrite replacements after platy pyrrhotite are common. Gangue is dominated by calcite, with minor fluorite. The mineralization is locally siliceous. Fragments of limestone are common within the manto. Alteration of the surrounding limestone is generally limited to a narrow recrystallized and bleached selvage, with local silicification. |

| · | Massive sulphide mineralization, consisting of the same sulphide assemblage as manto mineralization, occurs as layers and veins from 30 cm to three metres thick within hornfelsed shale rich units. Sphalerite in this environment is commonly dark amber in colour. The hornfels consists of very fine grained pyroxenes and garnets, with local zones showing garnet crystal faces up to 0.5 mm across indicating transition to skarn conditions. |

| · | Garnet-pyroxene skarn mineralized with galena, sphalerite, chalcopyrite, scheelite, and gold was intersected in several deep holes. Skarn mineralization was intercepted in the Pegaso Zone in the deeper intercepts of hole CM-12-431 (hole 431), where the garnets are thoroughly retrograde altered (hydrated) to hydrogrossular and clays. Garnets can display zoning from yellowish green to dark brown, with the dark brown commonly being earlier. Pyroxene content appears to increase with depth. Several of the skarn drill hole intercepts contain felsic dykes beneath the Upper Manto that are themselves largely converted to calc-silicates. Sphalerite-dominant sulphide and scheelite mineralization is common in the skarns. The skarn zones are surrounded by variably developed recrystallization and marble, with zones of 10 m to 30 m of coarse grained marble intersected in the deeper holes. Pegaso hole 431 shows notably thicker skarn, marble and hornfels, reaching a thickness of over 300 m. No intrusive rock was cut by hole 431 despite the greatly increased strength of thermal metamorphism and metasomatism. Sulphides in this area occur with skarn silicates but do not replace them. |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-8 |

| www.rpacan.com |

| · | Vein and veinlet mineralization consists of high-angle calcite veins with 5 vol.% to 50 vol.% very coarse grained sulphides occurring as linings on the vein walls, breccia fragments surrounded by later calcite, and as veinlets replacing massive vein calcite. The veins clearly were repeatedly brecciated, filled with calcite and subsequently remineralized. The calcite has a characteristic strong orange-red fluorescence under ultraviolet light, indicating the presence of significant manganese in the calcite crystal structure. This is characteristic of “fugitive calcite” veining, which represents calcite dissolved by the sulphide mineralizing replacement process and reprecipitated in fractures outboard of the sulphide zone with various trace metals present in the “spent” mineralizing fluids. Manganese is abundant in these “spent” fluids and its characteristic response to ultraviolet light makes “fugitive calcite” veins easy to detect and discriminate from calcite veinlets of other origins. |

A schematic cross section showing the mineralization and alteration at the Upper Manto deposit is shown in Figure 7-4.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-9 |

| www.rpacan.com |

| www.rpacan.com |

POZO SECO

Pozo Seco molybdenum-gold mineralization is primarily hosted in brecciated Upper Cuchillo limestone. Brecciation is most intense along the Lucia Fault over a strike length of two kilometres and extends up to 300 m east of the fault in a tabular body up to 100 m thick. Veining related to the brecciation is dominated by white calcite and dark chalcedony. Average grades range from 0.1% Mo to 0.2% Mo and 0.15 g/t Au to 0.25 g/t Au. Pyrite, galena, and sphalerite are found in a core of the high-grade oxide mineralization and within deeper veins.

The main molybdenum mineral is powellite (calcium molybdate) and is easily recognized by its yellow-orange fluorescence under an ultraviolet light. Powellite occurs as late stage vein-fracture fill and banded open space coatings on brecciated rock. Other recognized molybdenum minerals include ferrimolybdite and ilsemanite. The mineralogical site of the anomalous arsenic present has not been determined. The limited sulphide core has evidence of precursor molybdenite.

Textures and geochemistry suggest mineralization occurred in a boiling environment. The multiple brecciation stages could result from explosive boiling repeatedly breaking a developing silica seal to the system during coeval faulting. The tabular form could be a result of brecciation and later solution along a precursor low angle fault or a result of explosive fracturing, silica healing, and re-fracturing by boiling at the paleo-phreatic level.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 7-11 |

| www.rpacan.com |

8 DEPOSIT TYPES

The description provided below is derived from Megaw et al., 1988, Megaw et al., 1996, and Megaw, 1998.

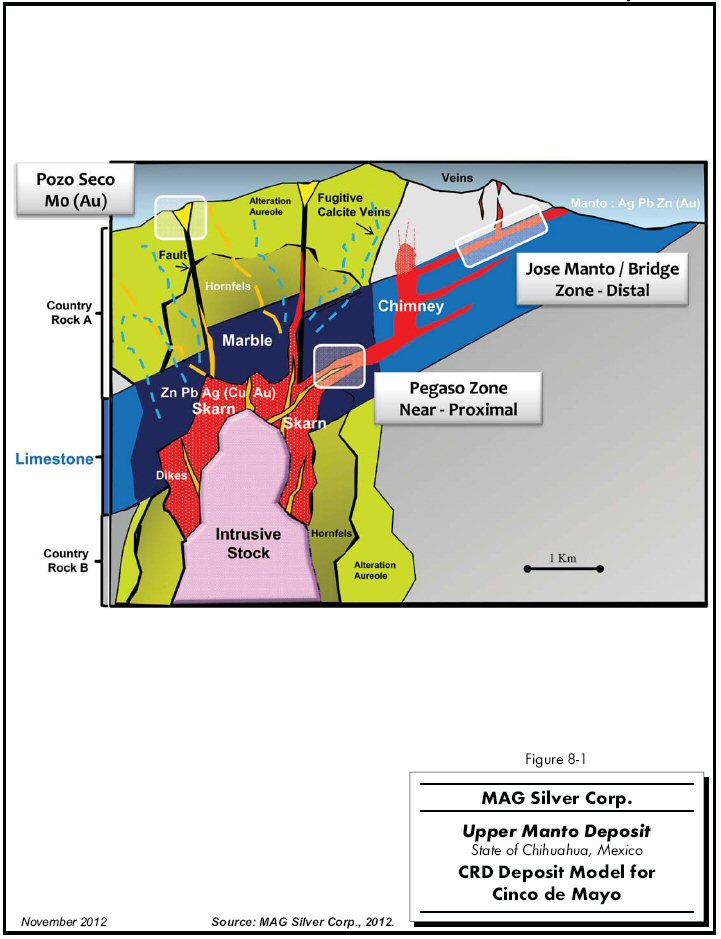

Carbonate replacement deposits (CRDs) are Phanerozoic, high-temperature (>250oC) deposits consisting of major pod, lens, and pipe-shaped Pb-Zn-Ag-Cu-Au skarn and massive sulphide bodies which transgress the stratigraphy of their host carbonate rocks and are commonly associated with igneous intrusive and extrusive rocks. Limestone, dolomite, and dolomitized limestones are the common hosts with minor deposits in calcareous sediments of other lithologies. They are dominantly composed of a simple assemblage of metal sulphides with subordinate carbonate, sulphate, fluorite, and quartz gangue. Calc-silicate or iron-calcic skarn may or may not be present and important. Both sulphide and skarn contacts with carbonate wallrocks are sharp. Evidence for replacement greatly outweighs evidence for open-space filling or syngenetic deposition.

CRDs have contributed 40% of Mexico's historic silver production, making them second only to epithermal veins. Currently, they provide most of the zinc and lead that put Mexico in fifth and sixth place respectively in world production. The largest CRDs in Mexico range from 10 million tonnes to over 100 million tonnes in size and define a belt measuring 2,200 km long by 20 km to 50 km wide. The Upper Manto deposit represents a new major discovery along this trend. CRDs are commonly mined at rates of 2,500 tpd to over 6,000 tpd, with mining depths in several exceeding 1,200 m below surface.

Mexico's CRDs occur along the intersection of the Laramide-aged Mexican Thrust Belt and the Tertiary volcanic plateau of the Sierra Madre Occidental, a zone where structurally prepared carbonate host rocks were intruded by metal-rich magmas (Figure 8-1). The Project area lies on the western bounding fault of the Chihuahua Trough, the same structure that hosts major CRDs, such as Santa Eulalia (MAG's Guigui property), Naica, San Pedro Corralitos, and Terrazas (see Figure 7-2). This ancient crustal break first controlled deposition of a thick section of carbonate host rocks and then later movements created abundant structural fluid pathways, guiding metal-rich magmas into place for optimal mineral deposition. These are essential elements of the mineralization model (Megaw et al., 1988 and 1996).

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 8-1 |

| www.rpacan.com |

CRDs are zoned over thousands of metres laterally and hundreds to thousands of metres vertically from central intrusions with mineralized skarn lenses along their flanks to mineralized skarns along dike or sill offshoots; to vertical to steeply oriented tabular or tubular “chimneys” composed dominantly of massive sulphides; to flat-lying tabular elongate "mantos" composed of massive sulphides; to a distinctive series of alteration styles that may extend for additional hundreds of metres from sulphide mineralization (Figure 8-1). The dominant metals change with distance from the source intrusion, with the highest silver grades occurring in the distal manto-dominated components of the system. Mineralization is typically continuous from the source intrusion to the fringes of the system, with the largest mines exhibiting the full range of mineralization styles. Distinct alteration and mineralization patterns characterize each zone and can be used to trace mineralization from one zone to another. Large CRDs are characteristically multi-stage systems showing evidence for multiple intrusion, mineralization, and alteration events. This results in overprinting of the various stages and creates complex, but substantial mineralized bodies.

CRD exploration focuses on position within the "CRD Belt" and recognition of where exposed mineralization lies with respect to this zoning spectrum. Mantos are traced to chimneys and from there to skarn and source intrusion, or vice versa. Early systematic regional exploration work and the results of initial drilling show that Cinco de Mayo has many geological and mineralogical characteristics in common with the largest CRDs in Mexico. MAG believes its current exploration discoveries in the Upper Manto deposit are in the distal manto part of the system, with Pegaso representing a nearer source (“near-proximal”) environment.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 8-2 |

| www.rpacan.com |

| www.rpacan.com |

9 EXPLORATION

Most work on the Cinco de Mayo Property is done by IMDEX and Cascabel under contract to MAG. IMDEX and Cascabel are related privately held geological consulting companies providing a range of contract exploration services to the mining industry in Mexico. All airborne and ground geophysical surveys conducted on the Project since late 2006 were directly contracted and supervised by MAG. Work on the Property prior to MAG’s involvement is covered in Section 6, History.

Work by MAG began in mid-2004 with preliminary regional geological mapping. Work continued in early 2005 with the completion of an orientation biogeochemical survey that revealed strong linear zinc and copper anomalies coincident with structural lineaments exposed along the eastern edge of Sierra Santa Lucia.

In late 2005, Zonge Engineering & Research Organization, Inc. (Zonge) completed a five line natural source audio magnetotelluric (NSAMT) survey. Based on the initial results, Zonge completed an additional seven lines in 2006. In total, 45 line kilometres using 50 m dipoles were completed. The survey lines were oriented in a northwest direction, parallel to Cinco de Mayo Ridge, and northeast direction, across the ridge and parallel to a jasperoid vein system. In all, data from 902 stations were acquired in 180 setups.

The strongest anomalies were detected off the northeast flank of the ridge, where most of the historic prospecting has taken place. A series of anomalies on the southwest side of the ridge corresponded closely with jasperoid veinlet system (Van Reed and Liu, 2006).

In December 2006, Aeroquest Surveys (Aeroquest) completed a 450 line-kilometre combined magnetic and electromagnetic helicopter-borne survey. The survey was flown using Aeroquest’s AeroTEM II time domain electromagnetic system in conjunction with a high-sensitivity cesium vapour magnetometer at 100 m line spacings.

Geotech Ltd. (Geotech) flew a Versatile Time Domain Electromagnetic (VTEM) survey in February 2009. A total of 1,920 line kilometres at 125 m spacing were flown for a total area of 217.5 km2. Also in February 2009, Geotech flew a Z-Axis, Tipper Electromagnetic Airborne Survey (ZTEM). A total of 413 line kilometres at 250 m spacing were flown for a total area of 103 km2.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 9-1 |

| www.rpacan.com |

Combining the geological, geochemical, biogeochemical, and geophysical data and interpretations, MAG developed a series of drill targets along a prominent northwest trending fault zone that cuts strongly folded massive limestone and limestone-rich sedimentary rocks. The sulphide-rich manto was first identified in hole CM07-20, which was collared to test the projection of a mineralized thrust fault exposed at the base of the Sierra Santa Lucia and a target identified by the airborne geophysical survey.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 9-2 |

| www.rpacan.com |

10 DRILLING

As of September 1, 2012, the effective date of the current Upper Manto deposit Mineral Resource estimate, 445 holes totalling 213,591 m have been drilled on the Cinco de Mayo Property. Of these, 151 holes totalling 97,610 m are located at or nearby the Upper Manto deposit and were used to model the mineralization (Table 10-1). The Jose Manto is mostly intersected by holes drilled in 2006 to 2009. The Bridge Zone is interested by holes drilled in 2011 and 2012. Drilling was not underway during the October 2012 site visit.

| TABLE 10-1 SUMMARY OF DRILLING AT THE UPPER MANTO DEPOSIT |

| MAG Silver Corp. – Upper Manto Deposit |

| Year | No. Holes | Total (m) | Average Length (m) |

| 2006 | 6 | 3,347 | 558 |

| 2007 | 6 | 3,102 | 517 |

| 2008 | 60 | 40,282 | 671 |

| 2009 | 13 | 10,456 | 804 |

| 2010 | 0 | 0 | 0 |

| 2011 | 12 | 7,428 | 619 |

| 2012 | 54 | 33,067 | 611 |

| Total | 151 | 97,682 | 646 |

Drilling is contracted to Major Drilling de Mexico, S.A. de C.V. (Major) of Hermosillo. At the time of a prior site visit in July 2010, Major was operating two drills on the Pozo Seco deposit. Diamond drill holes were collared using HQ (63.5 mm core diameter) equipment and reduced to NQ (47.6 mm core diameter) or BQ as drilling conditions dictated. The collar location was surveyed by differential GPS instrumentation using the coordinate system UTM Zone 13, NAD27 for Mexico. The orientation of the drill head was set by compass and down hole deviation was monitored using an Icefield instrument with readings taken at intervals varying from 10 m to 30 m. Most holes were inclined towards the southwest.

A Cascabel project geologist was at the drill to end each hole. Once the hole was completed, the casing was pulled and the collar was identified with labelled cement monuments. The site was then revegetated according to local regulations and standards.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 10-1 |

| www.rpacan.com |

Drill sections were spaced at 100 m to 250 m along strike, with intercepts on each section averaging 50 m apart down dip. Drill hole recovery was good except for the occasional fault zone. The resource remains open in several directions.

Table 10-2 lists the collar location, hole orientation, thicknesses, and average grades of select mineralized intercepts. Prior to calculating the length weighted average grades, high grade assay values were cut to 1,000 g/t Ag, 4 g/t Au, 24% Zn, and 18% Pb. True thickness was calculated using an average strike direction of 300° and a dip of 50° to the southwest. True thicknesses range from 65% to 100% of the core sample length with an overall average of 80%.

The 61.6 m of massive sulphide intercept, known as the Pegaso Zone, located deeper in hole CM12-431 was not included in Table 10-2 since that intercept was not included as part of the Mineral Resource estimate. Additional drilling is recommended to establish the geometry of the Pegaso Zone. The 61.6 m intercept has an average grade of 89 g/t Ag, 0.78 g/t Au, 0.13% Cu, 2.1% Pb, and 7.3% Zn, including 31.9 m that grades 117 g/t Ag, 1.13 g/t Au, 0.16% Cu, 2.7% Pb, and 9.3% Zn.

There did not appear to be any drilling, sampling, or recovery factors that could materially affect the accuracy or reliability of the results. The resource modelling method used by RPA manages the relationship between core length and true thickness. A more detailed description of the grade, thickness, depth, and general geometry of the various lenses is provided in Section 14 under Geological Interpretation.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 10-2 |

| www.rpacan.com |

| www.rpacan.com |

TABLE 10-2 SELECT MINERALIZED INTERCEPTS

MAG Silver Corp. – Upper Manto Deposit

| Hole | Collar X (m) | Collar Y (m) | Collar Z (m) | Hole Length (m) | Azimuth (deg) | Dip (deg) | From (m) | To (m) | Core Length (m) | True Thickness (m) | Au (g/t) | Ag (g/t) | Zn (%) | Pb (%) |

| CM06-001 | 308,102 | 3,343,688 | 1,455 | 950 | 221 | - 60 | 320.57 | 323.12 | 2.55 | 2.38 | 0.08 | 50 | 8.05 | 2.01 |

| CM06-007 | 308,143 | 3,343,656 | 1,454 | 465 | 221 | - 60 | 321.87 | 326.17 | 4.15 | 4.01 | 0.15 | 82 | 2.56 | 3.03 |

| CM06-008 | 308,184 | 3,343,624 | 1,453 | 433 | 221 | - 60 | 320.12 | 322.99 | 2.87 | 2.59 | 0.12 | 53 | 3.30 | 2.37 |

| CM07-020 | 305,353 | 3,345,153 | 1,463 | 747 | 211 | - 55 | 474.97 | 477.74 | 2.77 | 2.69 | 0.15 | 419 | 11.45 | 10.47 |

| CM08-022 | 305,229 | 3,344,961 | 1,468 | 490 | 1 | - 90 | 401.10 | 403.88 | 2.78 | 1.79 | 0.05 | 195 | 5.82 | 5.73 |

| CM08-023 | 305,157 | 3,344,962 | 1,469 | 389 | 1 | - 90 | 381.60 | 384.22 | 2.62 | 1.69 | 0.03 | 129 | 3.68 | 3.57 |

| CM08-027 | 305,101 | 3,345,041 | 1,468 | 509 | 1 | - 90 | 443.05 | 445.61 | 2.56 | 1.65 | 0.10 | 108 | 6.51 | 2.51 |

| CM08-028 | 305,298 | 3,345,051 | 1,465 | 732 | 1 | - 90 | 483.42 | 487.42 | 4.00 | 2.57 | 0.26 | 170 | 10.78 | 3.96 |

| CM08-029 | 305,265 | 3,345,094 | 1,465 | 680 | 1 | - 90 | 487.13 | 490.69 | 3.56 | 2.29 | 0.04 | 91 | 3.24 | 1.83 |

| CM08-035 | 305,283 | 3,344,956 | 1,468 | 515 | 1 | - 90 | 413.17 | 415.75 | 2.58 | 1.71 | 0.57 | 88 | 2.98 | 1.73 |

| CM08-037 | 305,438 | 3,344,909 | 1,470 | 668 | 279 | - 55 | 470.75 | 473.04 | 2.29 | 1.59 | 0.01 | 147 | 2.63 | 5.18 |

| CM08-038 | 305,223 | 3,345,070 | 1,466 | 607 | 1 | - 90 | 461.25 | 463.75 | 2.50 | 1.62 | 0.03 | 66 | 3.42 | 1.29 |

| CM08-039 | 305,374 | 3,345,015 | 1,466 | 671 | 1 | - 90 | 520.15 | 523.61 | 3.46 | 2.34 | 0.06 | 510 | 12.90 | 11.16 |

| CM08-040 | 305,471 | 3,344,985 | 1,467 | 753 | 1 | - 90 | 550.94 | 555.64 | 4.70 | 3.20 | 0.04 | 114 | 10.73 | 3.09 |

| CM08-041 | 305,166 | 3,345,110 | 1,466 | 567 | 1 | - 90 | 454.58 | 457.00 | 2.42 | 1.56 | 0.14 | 330 | 13.38 | 5.57 |

| CM08-044 | 305,558 | 3,344,938 | 1,469 | 775 | 1 | - 90 | 603.23 | 605.85 | 2.55 | 1.85 | 0.02 | 69 | 6.00 | 1.72 |

| CM08-046 | 306,545 | 3,344,358 | 1,475 | 812 | 1 | - 90 | 480.06 | 482.44 | 2.38 | 1.61 | 0.19 | 139 | 3.61 | 1.57 |

| CM08-047 | 305,458 | 3,345,046 | 1,465 | 719 | 1 | - 90 | 650.50 | 653.07 | 2.57 | 1.80 | 0.03 | 216 | 13.70 | 2.64 |

| CM08-048 | 305,915 | 3,344,774 | 1,471 | 960 | 1 | - 90 | 748.99 | 751.59 | 2.60 | 1.84 | 2.49 | 218 | 5.98 | 10.70 |

| CM08-051 | 305,039 | 3,345,122 | 1,468 | 501 | 1 | - 90 | 397.21 | 399.57 | 2.37 | 1.55 | 0.06 | 116 | 2.13 | 2.23 |

| CM08-052 | 306,144 | 3,344,642 | 1,472 | 965 | 1 | - 90 | 731.91 | 740.16 | 8.25 | 6.03 | 0.36 | 22 | 2.49 | 1.75 |

| CM08-055 | 305,813 | 3,344,666 | 1,476 | 911 | 1 | - 90 | 493.28 | 496.59 | 3.31 | 2.25 | 0.27 | 77 | 4.95 | 1.16 |

| CM08-056 | 306,019 | 3,344,807 | 1,470 | 1,061 | 1 | - 90 | 807.36 | 810.57 | 3.21 | 2.07 | 0.94 | 187 | 10.48 | 1.75 |

| CM08-062 | 305,446 | 3,344,919 | 1,469 | 636 | 1 | - 90 | 454.75 | 457.82 | 3.06 | 1.97 | 0.01 | 81 | 2.46 | 1.78 |

| CM08-064A | 305,520 | 3,344,852 | 1,472 | 607 | 1 | - 90 | 537.31 | 540.05 | 2.74 | 1.90 | 0.02 | 220 | 4.81 | 5.62 |

| CM08-066 | 305,734 | 3,344,874 | 1,470 | 939 | 1 | - 90 | 645.02 | 647.75 | 2.73 | 1.96 | 0.02 | 24 | 9.42 | 0.09 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 10-4 |

| www.rpacan.com |

| Hole | Collar X (m) | Collar Y (m) | Collar Z (m) | Hole Length (m) | Azimuth (deg) | Dip (deg) | From (m) | To (m) | Core Length (m) | True Thickness (m) | Au (g/t) | Ag (g/t) | Zn (%) | Pb (%) |

| CM08-084 | 305,748 | 3,344,745 | 1,473 | 948 | 1 | - 90 | 484.87 | 487.59 | 2.72 | 1.83 | 0.02 | 463 | 13.60 | 9.50 |

| CM08-085 | 305,713 | 3,345,099 | 1,463 | 716 | 221 | - 65 | 594.13 | 596.49 | 2.35 | 2.03 | 0.04 | 236 | 4.56 | 4.85 |

| CM09-098 | 305,606 | 3,344,647 | 1,478 | 701 | 128 | - 90 | 453.68 | 456.45 | 2.77 | 1.81 | 0.07 | 164 | 6.03 | 3.41 |

| CM09-103 | 305,705 | 3,344,643 | 1,478 | 689 | 1 | - 90 | 427.86 | 431.24 | 3.38 | 2.28 | 0.04 | 37 | 7.90 | 0.30 |

| CM09-106 | 305,883 | 3,344,712 | 1,473 | 921 | 231 | - 65 | 518.22 | 520.26 | 2.04 | 1.71 | 0.05 | 53 | 1.09 | 1.24 |

| CM11-370 | 307,116 | 3,344,327 | 1,462 | 692 | 206 | - 70 | 299.62 | 302.16 | 2.54 | 2.18 | 0.28 | 71 | 16.09 | 2.96 |

| CM11-377 | 307,166 | 3,344,154 | 1,466 | 573 | - | - 90 | 253.25 | 258.50 | 5.25 | 3.37 | 0.22 | 201 | 6.25 | 4.45 |

| CM11-380 | 307,421 | 3,344,142 | 1,460 | 454 | 211 | - 70 | 297.21 | 302.86 | 5.65 | 4.90 | 0.46 | 267 | 11.51 | 6.18 |

| CM11-381 | 307,643 | 3,344,020 | 1,459 | 454 | 211 | - 70 | 351.29 | 354.92 | 3.63 | 3.08 | 0.61 | 191 | 12.05 | 6.54 |

| CM11-382 | 307,843 | 3,343,869 | 1,456 | 451 | 211 | - 70 | 339.74 | 342.11 | 2.37 | 2.08 | 0.04 | 51 | 3.18 | 1.79 |

| CM11-383 | 306,916 | 3,344,446 | 1,463 | 579 | 216 | - 70 | 316.03 | 320.22 | 4.19 | 3.60 | 0.06 | 183 | 12.32 | 6.84 |

| CM12-385 | 307,445 | 3,344,185 | 1,458 | 555 | 211 | - 70 | 335.00 | 339.92 | 4.92 | 4.22 | 0.31 | 103 | 12.68 | 3.28 |

| CM12-386 | 307,401 | 3,344,098 | 1,463 | 421 | 211 | - 70 | 256.02 | 259.15 | 3.13 | 2.71 | 0.22 | 191 | 7.79 | 5.00 |

| CM12-389 | 307,470 | 3,344,226 | 1,456 | 567 | 211 | - 70 | 387.67 | 390.68 | 3.01 | 2.59 | 0.10 | 31 | 5.24 | 1.57 |

| CM12-390 | 307,349 | 3,344,011 | 1,466 | 277 | 211 | - 70 | 174.80 | 182.88 | 8.08 | 6.94 | 0.71 | 257 | 17.18 | 5.22 |

| CM12-391 | 307,349 | 3,344,011 | 1,466 | 326 | 211 | - 55 | 154.81 | 156.79 | 1.98 | 1.91 | 0.02 | 12 | 5.32 | 0.12 |

| CM12-393 | 307,492 | 3,344,269 | 1,455 | 719 | 211 | - 70 | 493.89 | 496.49 | 2.61 | 2.23 | 0.57 | 13 | 10.18 | 0.34 |

| CM12-397 | 307,201 | 3,344,190 | 1,464 | 710 | 211 | - 70 | 245.15 | 250.80 | 5.65 | 4.81 | 0.79 | 160 | 10.96 | 4.81 |

| CM12-399 | 306,907 | 3,344,664 | 1,463 | 838 | 228 | - 65 | 675.21 | 678.57 | 3.36 | 2.87 | 2.12 | 150 | 15.93 | 3.32 |

| CM12-403 | 307,269 | 3,344,327 | 1,459 | 616 | 211 | - 70 | 409.25 | 416.35 | 7.10 | 5.94 | 0.33 | 127 | 2.71 | 3.26 |

| CM12-405 | 307,142 | 3,344,109 | 1,467 | 460 | 211 | - 70 | 158.43 | 160.44 | 2.01 | 1.79 | 0.01 | 40 | 15.36 | 1.46 |

| CM12-409 | 306,958 | 3,344,274 | 1,468 | 582 | 211 | - 70 | 187.92 | 192.35 | 4.43 | 3.83 | 0.04 | 75 | 2.90 | 1.35 |

| CM12-411 | 306,981 | 3,344,315 | 1,466 | 583 | 211 | - 70 | 238.05 | 243.90 | 5.85 | 5.00 | 0.02 | 236 | 9.70 | 4.19 |

| CM12-414 | 307,820 | 3,343,820 | 1,457 | 459 | 211 | - 70 | 295.22 | 297.46 | 2.24 | 1.94 | 0.07 | 77 | 0.42 | 0.54 |

| CM12-415 | 307,033 | 3,344,399 | 1,462 | 625 | 211 | - 70 | 316.80 | 319.85 | 3.05 | 2.62 | 0.23 | 161 | 10.84 | 4.05 |

| CM12-416 | 307,562 | 3,343,887 | 1,463 | 369 | 211 | - 70 | 232.13 | 234.90 | 2.77 | 2.36 | 0.05 | 212 | 3.52 | 1.79 |

| CM12-417 | 307,588 | 3,343,932 | 1,461 | 427 | 216 | - 70 | 263.25 | 265.35 | 2.10 | 1.81 | 0.01 | 104 | 2.83 | 4.31 |

| CM12-418 | 307,793 | 3,343,780 | 1,458 | 384 | 211 | - 70 | 260.29 | 269.47 | 9.18 | 7.84 | 0.04 | 131 | 6.84 | 4.58 |

| CM12-424 | 307,064 | 3,344,446 | 1,459 | 716 | 211 | - 70 | 454.05 | 459.65 | 5.60 | 4.85 | 0.09 | 120 | 4.07 | 4.42 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 10-5 |

| www.rpacan.com |

| Hole | Collar X (m) | Collar Y (m) | Collar Z (m) | Hole Length (m) | Azimuth (deg) | Dip (deg) | From (m) | To (m) | Core Length (m) | True Thickness (m) | Au (g/t) | Ag (g/t) | Zn (%) | Pb (%) |

| CM12-427 | 307,128 | 3,344,409 | 1,460 | 695 | 241 | - 60 | 554.60 | 556.66 | 2.06 | 1.83 | 0.24 | 136 | 5.13 | 2.58 |

| CM12-428 | 306,977 | 3,344,735 | 1,460 | 948 | 226 | - 65 | 798.89 | 802.21 | 3.31 | 2.86 | 0.01 | 39 | 4.28 | 0.16 |

| CM12-429 | 307,083 | 3,344,490 | 1,458 | 695 | 211 | - 70 | 513.10 | 516.09 | 2.99 | 2.59 | 0.05 | 145 | 1.60 | 3.52 |

| CM12-430 | 306,944 | 3,344,477 | 1,461 | 594 | 216 | - 70 | 354.13 | 365.92 | 11.79 | 10.19 | 0.11 | 84 | 10.21 | 1.59 |

| CM12-431 | 306,675 | 3,344,800 | 1,460 | 1,356 | 226 | - 70 | 817.55 | 827.55 | 10.00 | 8.81 | 1.38 | 139 | 11.71 | 2.62 |

| CM12-432 | 307,291 | 3,344,370 | 1,460 | 945 | 211 | - 70 | 496.11 | 500.05 | 3.94 | 3.39 | 0.26 | 144 | 2.47 | 3.43 |

| CM12-433 | 307,520 | 3,344,314 | 1,460 | 1,155 | 211 | - 70 | 575.34 | 579.42 | 4.08 | 3.59 | 0.17 | 92 | 2.68 | 2.95 |

| JM11-378 | 305,669 | 3,344,600 | 1,479 | 881 | - | - 90 | 457.71 | 460.11 | 2.40 | 1.57 | 0.01 | 13 | 3.43 | 0.11 |

| JM12-392 | 306,468 | 3,344,701 | 1,465 | 969 | 206 | - 70 | 648.37 | 655.67 | 7.30 | 6.35 | 1.11 | 138 | 1.50 | 1.45 |

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 10-6 |

| www.rpacan.com |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY

MAG and Cascabel use industry standard sample preparation, analysis, data management and security procedure for the Project. In summary, RPA concurs with the adequacy of the samples taken, the security of the storage and shipping procedures, the sample preparation, analytical procedures used, and data management practices.

SAMPLING METHOD AND APPROACH

Drill core is transported by Cascabel personnel twice daily to MAG’s core handling facility in Benito Juárez. Geotechnicians check depth markers, box numbers, reconstruct the core, and calculate core recovery.

The core is descriptively logged and marked for sampling by Cascabel geologists. All core is also logged under an ultraviolet light. Logging and sampling data are entered into HP iPAQ Pocket PCs using GeoInfo Mobile software by Geo-Information Solutions of Tucson, Arizona. Data are later transferred to customized GeoInfo Tools Database software, also by Geo-Information Solutions. Core is photographed before sampling.

Sample intervals are selected based on visible mineralization and geological contacts. Sample lengths of the mineralized intervals in the Upper Manto deposit area vary from a minimum of 9 cm to 2.12 m. Barren samples are commonly taken to shoulder both ends of mineralized zones and are typically one metre in length. Core marked for sampling is sawn, with half returned to the box and the other half placed in plastic sample bags. Core samples are tracked using three part ticket books. Assay intervals and sample numbers are marked on core boxes with marker. One tag is placed in the sample bag along with the sample and the last tag is kept for MAG’s records. Core trays are marked with aluminum tags as well as felt marker. The plastic sample bags are placed in larger rice bags and sealed for shipping. Mineralized core is stored in a secure building in Benito Juárez. Unmineralized core is cross-piled at two different secure locations also in Benito Juárez.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 11-1 |

| www.rpacan.com |

DENSITY MEASUREMENTS

MAG measures the density of all samples submitted for chemical analysis. Several measurement methods have been used over the history of the Project, including a graduated cylinder to estimate volume and a digital scale for mass, the "weight in air" versus "weight in water" method (Archimedes method), and a water displacement method. The Archimedes method is currently used to measure the density of samples from 2012 drilling. Porous material is sealed with paraffin wax.

SAMPLE SECURITY

Core samples for analysis are stored in a secure warehouse in Benito Juárez prior to shipping. The warehouse is either locked or under direct supervision of the geological staff. Prior to shipping, drill core samples are placed in large rice bags and sealed. A sample transmittal form is prepared that identifies each batch of samples. The samples are transported directly to ALS Chemex facilities in Chihuahua for sample preparation. ALS Chemex forwards sample pulps to its laboratory facility in North Vancouver, British Columbia, Canada, for analysis.

SAMPLE ANALYSIS

ALS Chemex laboratories in North America are registered to ISO 9001:2000 for the provision of assay and geochemical services by QMI Quality Registrars. In addition, ALS Chemex’s main North American laboratory in North Vancouver is accredited by the Standards Council of Canada (SCC) for specific tests listed in their Scope of Accreditation No. 579. This accreditation is based on international standards (ISO 17025) and involves extensive site audits and on-going performance evaluations.

Upon receipt at the laboratory, samples are assigned bar codes for tracking. Sample preparation includes weighing, drying, fine crushing of the sample to a minimum of 75% passing a minus 10 mesh, splitting the sample through a riffle splitter, and pulverizing 250 g to a minimum of 95% passing a minus 150 mesh. For the Bridge Zone samples, barren silica sand was used to help clean the crushing and pulverizing equipment.

Following a four-acid digestion, samples were analyzed for Ag, As, Cu, Pb, and Zn using Atomic Adsorption (ALS Chemex method code AA61), with overlimits being analyzed by method AA62. If the overlimit for AA62 was reached, silver was analyzed by fire assay/gravimetric method and overlimits for Cu, Pb, and Zn are analyzed by ALS Chemex’s CON02 method. For samples with greater than 2% sulphides, the current system is to skip the AA61 method by going directly to the AA62 method.

| MAG Silver Corp. – Upper Manto Deposit, Project #1938 Technical Report NI 43-101 – November 14, 2012 | Page 11-2 |

| www.rpacan.com |

Gold is analyzed by 30 g digestion fire assay with an AAS finish (ALS Chemex code AA23). The prepared sample is fused with a mixture of lead oxide, sodium carbonate, borax, silica, and other reagents as required, inquarted with 6 mg of gold-free silver and then cupelled to yield a precious metal bead. The bead is digested in 0.5 mL dilute nitric acid in the microwave oven, 0.5 mL concentrated hydrochloric acid is then added, and the bead is further digested in the microwave oven. The digested solution is cooled, diluted to a total volume of 4 mL with de-mineralized water, and analyzed by AAS against matrix-matched standards.

A few gold and silver values were assayed using a gravimetric method. A prepared sample is fused with a mixture of lead oxide, sodium carbonate, borax, silica, and other reagents in order to produce a lead button. The lead button containing the precious metals is cupelled to remove the lead. The remaining gold and silver bead is parted in dilute nitric acid, annealed and weighed as gold. Silver is determined by the difference in weights.

Once sample analyses are finalized, the MAG project manager downloads the results from ALS Chemex’s Webtrieve system. Results are imported into GeoInfo Tools Database software using routines that strip and match header information. All data are indexed on sample number and batch ID. Results from the different analytical methods are stored in separate fields and later compiled into a “final” field using a set of precedence. The “final” field was imported into Gemcom for resource modelling.

QUALITY ASSURANCE AND QUALITY CONTROL