Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 20-F

| ¨ | REGISTRATION STATEMENT PURSUANT TO SECTION 12(b) OR (g) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2007

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| ¨ | SHELL COMPANY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission file number 333-146371

ARCELORMITTAL

(Exact name of Registrant as specified in its charter)

ARCELORMITTAL

(Translation of Registrant’s name into English)

(Jurisdiction of incorporation or organization)

19, Avenue de la Liberté, L-2930 Luxembourg,

Grand Duchy of Luxembourg

(Address of Registrant’s principal executive offices)

Henk Scheffer, 19, Avenue de la Liberté, L-2930 Luxembourg, Grand Duchy of Luxembourg. Fax: 011 352 4792 2675

(Name, Telephone, E-mail and/or Facsimile number and Address of Company Contact Person)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

Title of each class | Name of each exchange on which registered | |

| Common Shares | New York Stock Exchange |

Securities registered or to be registered pursuant to Section 12(g) of the Act:

None

Securities for which there is reporting obligation pursuant to Section 15(d) of the Act:

None

Indicate the number of outstanding shares of the issuer’s classes of capital or common stock as of the close of the period covered by the annual report:

Common Shares

1,421,570,646

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes x No ¨

If this report is an annual or transition report, indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934.

Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act.

Large accelerated filer x Accelerated filer ¨ Non-accelerated filer ¨

Indicate by check mark which basis of accounting the registrant has used to prepare the financial statements included in this filing:

U.S. GAAP ¨ International Financial Reporting Standards as issued by the International Accounting Standards Board x Other ¨

If “Other” has been checked in response to the previous question, indicate by check mark which financial statement item the registrant has elected to follow.

Item 17 ¨ Item 18 ¨

If this is an annual report, indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes ¨ No x

Table of Contents

i

Table of Contents

ii

Table of Contents

PRESENTATION OF FINANCIAL AND CERTAIN OTHER INFORMATION

Definitions and Terminology

Unless indicated otherwise, or the context otherwise requires, references herein to “ArcelorMittal”, “we”, “us”, “our” and “the Company” or similar terms are to ArcelorMittal, formerly known as Mittal Steel Company N.V. (“Mittal Steel”) or as Ispat International N.V., and its subsidiaries (which include LNM Holdings N.V. and its subsidiaries and International Steel Group Inc. and its subsidiaries).

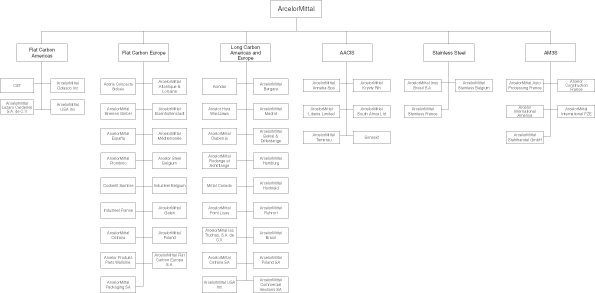

All references herein to “Arcelor” refer to Arcelor, asociété anonyme incorporated under Luxembourg law, which was acquired by Mittal Steel on August 1, 2006, having its registered office at 19, avenue de la Liberté, L-2930 Luxembourg, Grand Duchy of Luxembourg, and, where the context requires, its consolidated subsidiaries. All references herein to “Arcelor Brasil” refer to the former Arcelor Brasil S.A. (the current ArcelorMittal Brasil S.A.), a majority-owned subsidiary of Arcelor. All references herein to “Sicartsa” refer to the operations of ArcelorMittal las Truchas S.A. de C.V. (formerly Siderurgia Lázaro Cárdenas las Truchas S.A. de C.V.) in Mexico, which was acquired by the Company on April 20, 2007. All references herein to “ArcelorMittal Kryviy Rih” refer to the operations of Kryvorizhstal in the Ukraine, which was acquired by the Company on November 25, 2005. “ISG” refers to International Steel Group Inc. and its subsidiaries as it existed prior to its acquisition by Mittal Steel on April 15, 2005. Following the acquisition of ISG by Mittal Steel, ISG’s name was changed to “Mittal Steel USA ISG Inc.”, the operations were merged with Ispat Inland on December 31, 2005 and the name of the surviving entity was changed to Mittal Steel USA Inc and then to ArcelorMittal USA following Mittal Steel’s acquisition of Arcelor. ArcelorMittal’s principal subsidiaries, categorized by operating segment and location, are as follows. For the purposes of this annual report, the abbreviated names of the following ArcelorMittal subsidiaries will be used where applicable.

Name of Subsidiary | Abbreviation | Country | ||

Flat Carbon Americas | ||||

ArcelorMittal USA Inc. | ArcelorMittal USA | USA | ||

Companhia Siderúrgica de Tubarão S.A. | CST | Brazil | ||

ArcelorMittal Dofasco Inc. | Dofasco | Canada | ||

ArcelorMittal Lázaro Cárdenas S.A. de C.V. | ArcelorMittal Lázaro Cárdenas | Mexico | ||

Flat Carbon Europe | ||||

Aceria Compacta de Bizkaia S.A. | Aceria Compacta de Bizkaia | Spain | ||

Arcelor Produits Plats Wallonie | Arcelor Produits Plats Wallonie | Belgium | ||

Arcelor Steel Belgium N.V. | Arcelor Steel Belgium | Belgium | ||

ArcelorMittal Atlantique et Lorraine SAS | ArcelorMittal Atlantique et Lorraine | France | ||

ArcelorMittal Bremen GmbH | ArcelorMittal Bremen | Germany | ||

ArcelorMittal Eisenhüttenstadt GmbH | ArcelorMittal Eisenhüttenstadt | Germany | ||

ArcelorMittal España S.A. | ArcelorMittal España | Spain | ||

ArcelorMittal Flat Carbon Europe | AMFCE | Luxembourg | ||

ArcelorMittal Galati S.A. | ArcelorMittal Galati | Romania | ||

ArcelorMittal Méditerranée SAS | ArcelorMittal Méditerranée | France | ||

ArcelorMittal Ostrava a.s. | ArcelorMittal Ostrava | Czech Republic | ||

ArcelorMittal Packaging SA | ArcelorMittal Packaging | France | ||

ArcelorMittal Piombino S.p.a. | ArcelorMittal Piombino | Italy | ||

ArcelorMittal Poland S.A. | ArcelorMittal Poland | Poland | ||

Cockerill Sambre S.A. | Cockerill Sambre | Belgium | ||

Industeel Belgium S.A. | Industeel Belgium | Belgium | ||

Industeel France S.A. | Industeel France | France | ||

1

Table of Contents

Name of Subsidiary | Abbreviation | Country | ||

Long Carbon Americas and Europe | ||||

Acindar Industria Argentina de Aceros S.A. | Acindar | Argentina | ||

Arcelor Huta Warszawa Sp.z.o.o. | Arcelor Huta Warszawa | Poland | ||

ArcelorMittal Belval & Differdange SA | ArcelorMittal Belval & Differdange | Luxembourg | ||

ArcelorMittal Bergara, S.A. | ArcelorMittal Bergara | Spain | ||

ArcelorMittal Brasil S.A. | ArcelorMittal Brasil | Brazil | ||

ArcelorMittal Commercial Sections SA | ArcelorMittal Commercial Sections | Luxembourg | ||

ArcelorMittal Hamburg GmbH | ArcelorMittal Hamburg | Germany | ||

ArcelorMittal Hochfeld GmbH | ArcelorMittal Hochfeld | Germany | ||

ArcelorMittal Madrid, S.L. | ArcelorMittal Madrid | Spain | ||

ArcelorMittal Olaberría, S.L. | ArcelorMittal Olaberría | Spain | ||

ArcelorMittal Ostrava a.s. | ArcelorMittal Ostrava | Czech Republic | ||

ArcelorMittal Point Lisas Ltd. | ArcelorMittal Point Lisas | Trinidad and Tobago | ||

ArcelorMittal Poland S.A. | ArcelorMittal Poland | Poland | ||

ArcelorMittal Rodange & Schifflange S.A. | ArcelorMittal Rodange | Luxembourg | ||

ArcelorMittal Ruhrort GmbH | ArcelorMittal Ruhrort | Germany | ||

ArcelorMittal USA Inc. | ArcelorMittal USA | USA | ||

Mittal Canada Inc. | Mittal Canada | Canada | ||

ArcelorMittal las Truchas, S.A. de C.V. | Sicartsa | Mexico | ||

Asia, Africa and CIS (AACIS) | ||||

ArcelorMittal Annaba Spa | ArcelorMittal Annaba | Algeria | ||

ArcelorMittal South Africa Ltd. | ArcelorMittal South Africa | South Africa | ||

ArcelorMittal Temirtau | ArcelorMittal Temirtau | Kazakhstan | ||

Mittal Steel Liberia Limited | Mittal Steel Liberia | Liberia | ||

OJSC ArcelorMittal Kryviy Rih | ArcelorMittal Kryviy Rih | Ukraine | ||

Société Nationale de Sidérurgie, S.A. | Sonasid | Morocco | ||

Stainless Steel | ||||

ArcelorMittal Inox Brasil S.A. | Acesita or ArcelorMittal Inox Brasil | Brazil | ||

ArcelorMittal Stainless Belgium | AMSB | Belgium | ||

ArcelorMittal Stainless France | AMSF | France | ||

Arcelor Mittal Steel Solutions and Services (AM3S) | ||||

ArcelorMittal Construction France | ArcelorMittal Construction France | France | ||

Arcelor International America, LLC | Arcelor International America | USA | ||

ArcelorMittal Auto Processing France SAS | ArcelorMittal Auto Processing France | France | ||

ArcelorMittal International FZE | ArcelorMittal International FZE | United Arab Emirates | ||

ArcelorMittal Stahlhandel Gmbh | ArcelorMittal Stahlhandel | Germany | ||

In addition, unless we have indicated otherwise, or the context otherwise requires, references in this annual report to:

| • | “production capacity” are to the annual production capacity of plant and equipment based on existing technical parameters as estimated by management; |

| • | “steel products” are to finished and semi-finished steel products and exclude direct reduced iron (DRI), hot metal, coke, etc.; |

| • | “sales” include shipping and handling fees and costs billed to a customer in a sales transaction; |

2

Table of Contents

| • | “tons”, “net tons” or “ST” are to short tons and are used in measurements involving steel products, (short ton is equal to 907.2 kilograms or 2000 pounds); |

| • | “tonnes” or “MT” are to metric tonnes and are used in measurements involving steel products, as well as crude steel, iron ore, iron ore pellets, DRI, hot metal, coke, coal, pig iron and scrap (a metric tonne is equal to 1,000 kilograms or 2,204.62 pounds); |

| • | “Articles of Association” are to the amended and restated articles of association of ArcelorMittal, dated November 5, 2007; |

| • | “crude steel” are to the first solid steel product upon solidification of liquid steel, including ingots from conventional mills and semis (e.g., slab, billet and blooms) from continuous casters; |

| • | “gigajoules” is equivalent to 1,000,000,000 joules (where joules is a measure of energy); |

| • | “megajoules” is equivalent to 1,000,000 joules (where joules is a measure of energy); |

| • | measures of distance are stated in kilometers, each of which equals approximately 0.62 miles, or in meters, each of which equals approximately 3.28 feet; |

| • | “DMTU” or “dmtu” stands for dry metric tonne unit; |

| • | “real”, “reais” or “R$” are to Brazilian reais, the official currency of Brazil; |

| • | “US$”, “$”, “dollars”, “USD” or “U.S. dollars” are to United States dollars; |

| • | “C$” or “CAD” are to Canadian dollars; |

| • | “Rs” are to Indian rupees; |

| • | “HK$” are to Hong Kong Dollars; |

| • | “downstream” are to finishing operations, for example in the case of flat products the process after the production of hot rolled coil/plates, and in case of long products the process after the production of blooms/billets; |

| • | “upstream” are to operations that precede downstream steel-making, such as mining, coke, sinter, DRI, blast furnace, blast oxygen furnace (“BOF”), electric arc furnace (“EAF”), casters & hot rolling/plate mill; |

| • | “euro”, “euros”, “EUR” or “€” are to the currency of the European Union member states participating in the European Monetary Union; |

| • | “Significant shareholder” are to Mr. Lakshmi N. Mittal and his wife, Mrs. Usha Mittal, who together own approximately 44% of Mittal Steel’s outstanding voting equity as at December 31, 2007; |

| • | “brownfield project” means the expansion of an existing operation; |

| • | “greenfield project” means the development of a new project; |

| • | “coking coal”, by virtue of its coking properties, is used in the manufacture of coke, which is used in the steelmaking process; |

| • | “direct reduced iron” (“DRI”) is metallic iron formed by removing oxygen from iron ore without the formation of, or passage through, a smelting phase. DRI can be used as feedstock for steel production; |

| • | “energy coal” is used as a fuel source in electrical power generation, cement manufacture and various industrial applications. Energy coal may also be referred to as steam or thermal coal; |

| • | “metallurgical coal” is a broader term than coking coal which includes all coals used in steelmaking, such as coal used for the pulverised coal injection process; |

| • | “hot briquetted iron” (“HBI”) is densified direct reduced iron where the densification is carried out at a temperature greater than 650 degrees Celsius. The resultant product has density greater than 5g/cm3. HBI can be used as feedstock for steel production; |

3

Table of Contents

| • | “BRICET” means the countries of Brazil, Russia, India, China, Eastern Europe and Turkey; |

| • | “take or pay” means an obligation on a customer to pay for an agreed minimum quantity of a commodity even if it fails to “take” that agreed minimum quantity; and |

| • | the “Spanish Stock Exchanges” refer to the stock exchanges of Madrid, Barcelona, Bilbao and Valencia. |

Financial Information

This annual report contains the audited consolidated financial statements of ArcelorMittal (of which Mittal Steel Company N.V. is the predecessor) and its consolidated subsidiaries, including the consolidated balance sheets as of December 31, 2006 and 2007, and the consolidated statements of income, changes in equity and cash flows for each of the years ended December 31, 2005, 2006 and 2007, which we refer to as the ArcelorMittal Consolidated Financial Statements. The ArcelorMittal consolidated financial statements were prepared in accordance with International Financial Reporting Standards as issued by the International Accounting Standards Board (“IFRS”).

ArcelorMittal’s significant acquisitions in 2005, 2006 and 2007, including in particular Arcelor, ISG, Kryvorizhstal and Sicartsa, have been accounted for using the purchase method of accounting, with ArcelorMittal as the acquiring entity in accordance with IFRS 3 (“Business Combinations”).

Our results of operations and financial conditions as of and for the years ended December 31, 2006 and 2007, and the comparability between them, have been significantly affected by our August 2006 acquisition of Arcelor. For purposes of comparing our 2006 and 2007 results, we have prepared unaudited pro forma financial information for the year ended December 31, 2006 that present our results of operations as if the acquisition had taken place on January 1, 2006, as described under “Item 5. Operating and Financial Review and Prospects.”

The financial information and certain other information presented in a number of tables in this annual report have been rounded to the nearest whole number or the nearest decimal. Therefore, the sum of the numbers in a column may not conform exactly to the total figure given for that column. In addition, certain percentages presented in the tables in this annual report reflect calculations based upon the underlying information prior to rounding and, accordingly, may not conform exactly to the percentages that would be derived if the relevant calculations were based upon the rounded numbers.

Market Information

This annual report includes industry data and projections about our markets obtained from industry surveys, market research, publicly available information and industry publications. Statements on ArcelorMittal’s competitive position contained in this annual report are based primarily on public sources including, but not limited to, publications of the International Iron and Steel Institute. Industry publications generally state that the information they contain has been obtained from sources believed to be reliable but that the accuracy and completeness of such information is not guaranteed and that the projections they contain are based on a number of significant assumptions. We have not independently verified this data or determined the reasonableness of such assumptions. In addition, in many cases we have made statements in this annual report regarding our industry and our position in the industry based on internal surveys, industry forecasts and market research, as well as our own experience. While these statements are believed to be reliable, they have not been independently verified, and we do not make any representation or warranty as to the accuracy or completeness of such information set forth in this annual report.

4

Table of Contents

CAUTIONARY STATEMENT REGARDING FORWARD-LOOKING STATEMENTS

This annual report and the documents incorporated by reference in this annual report contain forward-looking statements based on estimates and assumptions. This annual report contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include, among other things, statements concerning the business, future financial condition, results of operations and prospects of ArcelorMittal, including its acquired subsidiaries. These statements usually contain the words “believes”, “plans”, “expects”, “anticipates”, “intends”, “estimates” or other similar expressions. For each of these statements, you should be aware that forward-looking statements involve known and unknown risks and uncertainties. Although it is believed that the expectations reflected in these forward-looking statements are reasonable, there is no assurance that the actual results or developments anticipated will be realized or, even if realized, that they will have the expected effects on the business, financial condition, results of operations or prospects of ArcelorMittal.

These forward-looking statements speak only as of the date on which the statements were made, and no obligation has been undertaken to publicly update or revise any forward-looking statements made in this annual report or elsewhere as a result of new information, future events or otherwise, except as required by applicable laws and regulations. In addition to other factors and matters contained or incorporated by reference in this annual report, it is believed that the following factors, among others, could cause actual results to differ materially from those discussed in the forward-looking statements:

| • | ArcelorMittal’s ability to manage its growth; |

| • | ArcelorMittal’s ability fully to realize anticipated cost savings, revenue enhancements and other benefits from the acquisition by Mittal Steel of Arcelor; |

| • | Mr. Lakshmi N. Mittal’s ability to exercise significant influence over the outcome of shareholder voting; |

| • | any loss or diminution in the services of Lakshmi N. Mittal, ArcelorMittal’s President and Chief Executive Officer; |

| • | any downgrade of ArcelorMittal’s credit rating; |

| • | ArcelorMittal’s ability to operate within the limitations imposed by its financing arrangements; |

| • | ArcelorMittal’s ability to refinance existing debt and obtain new financing on acceptable terms to finance its growth; |

| • | mining risks; |

| • | the risk that non-fulfillment or breach of transitional arrangements may result in the recovery of aid granted to some of ArcelorMittal’s subsidiaries; |

| • | ArcelorMittal’s ability to fund under-funded pension liabilities; |

| • | increased cost of wages and the risk of labor disputes; |

| • | general economic conditions, whether globally, nationally or in the markets in which ArcelorMittal conducts business; |

| • | the risk of disruption or volatility in the economic, political or social environment in the countries in which ArcelorMittal conducts business; |

| • | fluctuations in currency exchange rates, commodity prices, energy prices and interest rates; |

| • | the risk of disruptions to ArcelorMittal’s operations; |

| • | the risk of unfavorable changes to, or interpretations of, the tax laws and regulations in the countries in which ArcelorMittal operates; |

5

Table of Contents

| • | the risk that ArcelorMittal may not be able fully to utilize its deferred tax assets; |

| • | damage to ArcelorMittal’s production facilities due to natural disasters; |

| • | the risk that ArcelorMittal’s insurance policies may provide limited coverage; |

| • | the risk of product liability claims adversely affecting ArcelorMittal’s operations; |

| • | international trade actions or regulations; |

| • | the risk that U.S. investors may have difficulty enforcing civil liabilities against ArcelorMittal and its directors and senior management; |

| • | the risk that a downturn in global economic conditions may have an adverse effect on the results of ArcelorMittal; |

| • | ArcelorMittal’s ability to operate successfully within a cyclical industry; |

| • | the risk that changes in demand for and supply of steel products in China and other developing economies may result in falling steel prices; |

| • | the risk of significant supply shortages and increasing costs of raw materials, energy and transportation; |

| • | increased competition from substitute materials, such as aluminum; and |

| • | legislative or regulatory changes, including those relating to protection of the environment and health and safety, and those resulting from international agreements and treaties related to trade, accession to the European Union (“EU”) or otherwise. |

Some of these factors are discussed in more detail in this annual report, including under “Item 3D—Key Information—Risk Factors”.

6

Table of Contents

ITEM 1. IDENTITY OF DIRECTORS, SENIOR MANAGEMENT AND ADVISERS

Not applicable.

ITEM 2. OFFER STATISTICS AND EXPECTED TIMETABLE

Not applicable.

The following tables present selected consolidated financial information of ArcelorMittal and, where relevant, of its predecessor company Mittal Steel Company N.V., as of and for the years ended December 31, 2004, 2005, 2006 and 2007, prepared in accordance with IFRS. Mittal Steel Company N.V. did not prepare financial statements in accordance with IFRS in 2003. This selected consolidated financial information should be read in conjunction with the ArcelorMittal Consolidated Financial Statements, including the notes thereto, included elsewhere herein.

| Statement of Income Data | ||||||||||||||||

| (Amounts in $ millions except per share data and percentages) | ||||||||||||||||

| For the year ended December 31, | ||||||||||||||||

| 2004 | 2005 | 2006(7) | 2007 | |||||||||||||

Sales(1) | $ | 20,612 | $ | 28,132 | $ | 58,870 | $ | 105,216 | ||||||||

Cost of sales (including depreciation and impairment)(2)(3) | 14,422 | 22,341 | 48,378 | 84,953 | ||||||||||||

Selling, general and administrative | 676 | 1,062 | 2,960 | 5,433 | ||||||||||||

Operating income | 5,514 | 4,729 | 7,532 | 14,830 | ||||||||||||

Operating income as percentage of Sales | 26.8 | % | 16.8 | % | 12.8 | % | 14.1 | % | ||||||||

Other income—net | 1,143 | 214 | 49 | — | ||||||||||||

Income from equity method investments | 149 | 86 | 301 | 985 | ||||||||||||

Financing costs—net | (214 | ) | (353 | ) | (654 | ) | (927 | ) | ||||||||

Income before taxes | 6,592 | 4,676 | 7,228 | 14,888 | ||||||||||||

Net income (including minority interest) | 5,625 | 3,795 | 6,106 | 11,850 | ||||||||||||

Net income attributable to equity holders of the parent | 5,210 | 3,301 | 5,247 | 10,368 | ||||||||||||

Basic earnings per common share(4) | $ | 8.10 | $ | 4.80 | $ | 5.31 | $ | 7.41 | ||||||||

Diluted earnings per common share(4) | $ | 8.10 | $ | 4.79 | $ | 5.30 | $ | 7.40 | ||||||||

Dividends declared per share(5) | — | $ | 0.30 | $ | 0.50 | $ | 1.30 | |||||||||

| Balance Sheet Data | ||||||||||||||||

| (Amounts in $ millions except share data) | ||||||||||||||||

| As of December 31, | ||||||||||||||||

| 2004 | 2005 | 2006(7) | 2007 | |||||||||||||

Cash and cash equivalents, including short-term investments and restricted cash | $ | 2,634 | $ | 2,149 | $ | 6,146 | $ | 8,105 | ||||||||

Property, plant and equipment | 11,058 | 19,045 | 54,573 | 61,994 | ||||||||||||

Total assets | 21,692 | 33,867 | 112,681 | 133,625 | ||||||||||||

Short-term debt and current portion of long-term debt | 341 | 334 | 4,922 | 8,542 | ||||||||||||

Long-term debt, net of current portion | 1,639 | 7,974 | 21,645 | 22,085 | ||||||||||||

Net assets | 11,079 | 15,457 | 50,228 | 61,535 | ||||||||||||

Basic weighted average common shares outstanding (millions) | 643 | 687 | 988 | 1,399 | ||||||||||||

Diluted weighted average common shares outstanding (millions) | 643 | 689 | 989 | 1,401 | ||||||||||||

7

Table of Contents

| Other Data | ||||||||||||||||

| (Amounts in $ millions except volume data) | ||||||||||||||||

| For the year ended December 31, | ||||||||||||||||

| 2004 | 2005 | 2006(7) | 2007 | |||||||||||||

Net cash provided by operating activities | $ | 4,300 | $ | 3,874 | $ | 7,122 | $ | 16,532 | ||||||||

Net cash (used in) investing activities | (656 | ) | (7,512 | ) | (8,576 | ) | (11,909 | ) | ||||||||

Net cash (used in) provided by financing activities | (2,118 | ) | 3,349 | 5,445 | (3,417 | ) | ||||||||||

Total production of crude steel (thousands of tonnes) | 39,362 | 48,916 | 85,620 | 116,415 | ||||||||||||

Total shipments of steel products (thousands of tonnes)(6) | 35,067 | 44,614 | 78,950 | 109,724 | ||||||||||||

| (1) | Including $2,235 million, $2,339 million, $3,847 million and $4,767 million of sales to related parties for the years ended December 31, 2004, 2005, 2006 and 2007, respectively. (see Note 12 to the ArcelorMittal Consolidated Financial Statements). |

| (2) | Including $1,021 million, $914 million, $1,740 million and $2,408 million of purchases from related parties for the years ended December 31, 2004, 2005, 2006 and 2007, respectively. |

| (3) | Including depreciation and impairment of $734 million, $1,113 million, $2,324 million and $4,570 million for the years ended December 31, 2004, 2005, 2006 and 2007, respectively. |

| (4) | Earnings per common share are computed by dividing net income attributable to equity holders of ArcelorMittal by the weighted average number of common shares outstanding during the periods presented considering retroactively the shares issued by Mittal Steel in connection with the acquisition of LNM Holdings. |

| (5) | This does not include the dividends declared by LNM Holdings to its shareholder prior to its acquisition by Ispat International. |

| (6) | Shipment volumes of steel products for the operations of the Company include certain inter-company shipments. |

| (7) | As required by IFRS, the 2006 information has been adjusted retrospectively for the finalization of the allocation of purchase price of Arcelor (see Note 3 to the ArcelorMittal Consolidated Financial Statements). |

B. Capitalization and Indebtedness

Not applicable.

C. Reasons for the Offer and Use of Proceeds

Not applicable.

Our business, financial condition, results of operations or prospects could be materially adversely affected by any of the risks and uncertainties described below.

Risks related to ArcelorMittal.

ArcelorMittal results from a recent merger of two companies and has continued to grow through acquisitions subsequently and expects to continue to do so. The failure to manage the company’s recent and expected future growth could significantly harm ArcelorMittal’s future results and require significant expenditures to address the additional operational and control requirements of this growth.

ArcelorMittal results from Mittal Steel Company N.V.’s acquisition of Arcelor, a company of approximately equivalent size, in August 2006 and the subsequent merger of the two companies in 2007. The combined company has continued, as did its predecessor companies, to make numerous and substantial acquisitions, with numerous transactions announced in 2007, and acquisitions and investments for a total value of $12.3 billion (including cash purchase price, assumed net debt and shares issued at fair market value) completed

8

Table of Contents

in 2007. ArcelorMittal’s growth strategy includes the acquisitions of complementary companies. Such growth entails significant investment and increased operating costs. Overall growth in ArcelorMittal’s business also requires greater allocation of management resources away from daily operations. In addition, managing this growth (including managing multiple operating assets) requires, among other things, the continued development of ArcelorMittal’s financial and management information control systems, the ability to integrate newly acquired assets with existing operations, the ability to attract and retain sufficient numbers of qualified management and other personnel, the continued training and supervision of such personnel and the ability to manage the risks and liabilities associated with the acquired businesses. Failure to manage such growth, while at the same time maintaining adequate focus on the existing assets of ArcelorMittal, could have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects.

The former Mittal Steel and Arcelor may not successfully integrate their business operations to the fullest extent, which could result in ArcelorMittal’s failure to realize anticipated cost savings, revenue enhancements and other benefits expected from the acquisition.

Since the acquisition by Mittal Steel of Arcelor, the combined company has reached significant milestones in its operational integration process, having consolidated support functions, optimized its supply chain and procurement structure, and leveraged research and development services across a larger base, thereby achieving cost savings and revenue synergies, as well as other synergistic benefits. As of December 31, 2007, ArcelorMittal had realized $1.4 billion in synergies from the merger, as compared to the expected $1.6 billion in synergies to be achieved by the end of 2008 announced by Mittal Steel at the time of its acquisition of Arcelor. While the integration process has so far proceeded smoothly, further integration steps may not be achieved to the fullest extent or within the timeframe expected, which could have a material adverse effect on ArcelorMittal’s results of operations.

In particular, ArcelorMittal is continuing to integrate manufacturing best practices and to standardize management information systems across the ArcelorMittal group. The integration of these functions could interfere with the activities of one or more of the businesses of ArcelorMittal and may divert management’s attention from the daily operations of ArcelorMittal’s core businesses. If the combined company is unable to continue to integrate effectively its operations, technologies and personnel in a timely and efficient manner, then it may not fully realize the benefits expected from the acquisition. In particular, if the continued integration is not successful, ArcelorMittal’s operating results may be harmed, it may lose key personnel and key customers, it may not be able to retain or expand its market position, and the market price of its shares may decline.

Mr. Lakshmi N. Mittal has the ability to exercise significant influence over the outcome of shareholder voting.

As of December 31, 2007, Mr. Lakshmi N. Mittal owned 623,285,000 of ArcelorMittal’s outstanding common shares, representing approximately 44% of ArcelorMittal’s outstanding voting shares. Consequently, Mr. Lakshmi N. Mittal has the ability to influence significantly the decisions adopted at the ArcelorMittal general meetings of shareholders, including matters involving mergers or other business combinations, the acquisition or disposition of assets, issuances of equity and the incurrence of indebtedness. Mr. Lakshmi N. Mittal also has the ability to significantly influence a change of control of ArcelorMittal.

The loss or diminution of the services of the President and Chief Executive Officer of ArcelorMittal could have a material adverse effect on its business and prospects.

The President and Chief Executive Officer of ArcelorMittal has for over a quarter of a century contributed significantly to shaping and implementing the business strategy of Mittal Steel and subsequently ArcelorMittal. His strategic vision was instrumental in the creation of the world’s largest and most global steel group. The loss or any diminution of the services of the President and Chief Executive Officer could have a material adverse effect on ArcelorMittal’s business and prospects. ArcelorMittal does not maintain key man life insurance on its President and Chief Executive Officer.

9

Table of Contents

ArcelorMittal has a substantial amount of indebtedness. Credit rating downgrades, which could result from, among other things, substantial debt-financed acquisitions or cyclical downturns in the steel industry, could significantly harm ArcelorMittal’s refinancing capacity and increase its cost of funding. ArcelorMittal’s level of indebtedness, including the consequential high financing costs and restrictive covenants, could also limit its flexibility in managing its business.

As of December 31, 2007, ArcelorMittal had total debt outstanding of $30.6 billion, consisting of $8.5 billion of short-term indebtedness (including payables to banks and the current portion of long-tem debt) and $22.1 billion of long-term indebtedness. As of December 31, 2007, ArcelorMittal had $8.1 billion of cash and cash equivalents, including short-term investments and restricted cash, and, for the year ended December 31, 2007, ArcelorMittal recorded operating income of $14.8 billion.

Some of Mittal Steel’s credit ratings were put on ratings watch for possible downgrades following its acquisition of Arcelor in 2006. In late 2007 and early 2008, however, Standard & Poor’s Ratings Services raised its long-term corporate credit rating for ArcelorMittal to “BBB+” from “BBB” with a stable outlook, Fitch Ratings affirmed its rating of ArcelorMittal at “BBB” and revised its long-term Issuer Default Rating (IDR) outlook to Positive from Stable, and Moody’s Investors Service upgraded its rating of ArcelorMittal from Baa3 to Baa2.

Future downgrades resulting from factors specific to ArcelorMittal could be experienced. Credit rating downgrades could also result from a cyclical downturn in the steel industry, as ArcelorMittal has experienced in the past. Any decline in its credit rating would increase ArcelorMittal’s cost of borrowing and could significantly harm its financial condition, results of operations and profitability, including its ability to refinance its existing indebtedness.

ArcelorMittal’s principal financing facilities (that is, the $3.2 billion term and revolving credit facility, which was amended on February 6, 2007 (the “2005 Credit Facility”), the $800 million committed multi-currency letter of credit facility (the “Letter of Credit Facility”) and the €17 billion (approximately $22 billion) term and revolving credit facility entered into on November 30, 2006 (the “€17 Billion Facility”), contain provisions that limit encumbrances on the assets of ArcelorMittal and its subsidiaries and limit the ability of ArcelorMittal’s subsidiaries to incur debt. The Letter of Credit Facility requires compliance with a minimum interest coverage ratio. The 2005 Credit Facility and the €17 Billion Facility require compliance with a maximum gearing ratio. Limitations arising from these credit facilities could adversely affect ArcelorMittal’s ability to maintain its dividend policy and make additional strategic acquisitions.

The level of debt outstanding could have adverse consequences to ArcelorMittal, including impairing its ability to obtain additional financing for working capital, capital expenditures, acquisitions, general corporate purposes or other purposes, and limiting its flexibility to adjust to changing market conditions or withstand competitive pressures, resulting in greater vulnerability to a downturn in general economic conditions.

ArcelorMittal’s debt facilities and its guarantees have provisions whereby a default by any borrower within the ArcelorMittal group could, under certain circumstances, lead to defaults under other ArcelorMittal credit facilities. Any possible invocation of these cross-default clauses could cause some or all of the other guaranteed debt to accelerate, creating severe liquidity pressures.

Furthermore, most of ArcelorMittal’s current borrowings are at variable rates of interest and thereby expose ArcelorMittal to interest rate risk. Generally, ArcelorMittal does not use financial instruments to hedge a significant portion of its interest rate exposure. If interest rates rise, ArcelorMittal’s debt service obligations on its variable rate indebtedness would increase even if the amount borrowed remained the same, resulting in higher interest costs.

A substantial portion of ArcelorMittal’s debt is denominated in euro. Accordingly, ArcelorMittal is exposed to fluctuations in the exchange rates between the U.S. dollar and the euro. Any such fluctuations in the euro and, in particular, a further marked appreciation of the euro to the U.S. dollar would mechanically increase ArcelorMittal’s indebtedness.

10

Table of Contents

Because ArcelorMittal is a holding company, it depends on the earnings and cash flows of its operating subsidiaries, which may not be sufficient to meet future needs.

Because ArcelorMittal is a holding company, it is dependent on the earnings and cash flows of, and dividends and distributions from, its operating subsidiaries to pay expenses, meet its debt service obligations, and pay any cash dividends or distributions on its common shares. Some of these operating subsidiaries have debt outstanding or are subject to acquisition agreements that impose restrictions or prohibitions on such operating subsidiaries’ ability to pay dividends.

Under the laws of Luxembourg, the combined company will be able to pay dividends or distributions only to the extent that it is entitled to receive cash dividend distributions from its subsidiaries, recognize gains from the sale of its assets or record share premium from the issuance of shares.

The significant capital expenditure and other commitments ArcelorMittal has made in connection with past acquisitions may limit its operational flexibility and add to its financing requirements.

In connection with the acquisition of some of its operating subsidiaries, ArcelorMittal has made significant capital expenditure commitments and other commitments with various governmental bodies involving expenditures required to be made over the next few years. In 2007, capital expenditures amounted to $5.4 billion. As of December 31, 2007, ArcelorMittal and its subsidiaries had capital commitments outstanding of approximately $1.9 billion under privatization and other major contracts. ArcelorMittal expects to fund these capital expenditure commitments and other commitments primarily through internal sources, but ArcelorMittal cannot assure you that it will be able to generate or obtain sufficient funds to meet these requirements or to complete these projects on a timely basis or at all. In addition, completion of these projects may be affected by factors that are beyond the control of ArcelorMittal. See “Item 5F—Operating and Financial Review and Prospects—Tabular Disclosure of Contractual Obligations” and Note 22 to the ArcelorMittal Consolidated Financial Statements.

ArcelorMittal has also made commitments relating to employees at some of its operating subsidiaries. It has agreed, in connection with the acquisition of interests in these subsidiaries, including the acquisition of Arcelor, that it will not make collective dismissals for certain periods. These periods generally extend several years following the date of acquisition. The inability to make such dismissals may affect ArcelorMittal’s ability to coordinate its workforce and efficiently manage its business in response to changing market conditions in the areas affected.

ArcelorMittal may not be able to remain in compliance with some or all of these requirements in the future. Failure to remain in compliance may result in forfeiture of part of ArcelorMittal’s investment and/or the loss of tax and regulatory benefits.

ArcelorMittal’s mining operations are subject to mining risks.

ArcelorMittal has substantial mining operations and has recently increased their scope and intends to continue to do so. Mining operations are subject to hazards and risks normally associated with the exploration, development and production of natural resources, any of which could result in production shortfalls or damage to persons or property. In particular, hazards associated with open-pit mining operations include, among others:

| • | flooding of the open pit; |

| • | collapse of the open-pit wall; |

| • | accidents associated with the operation of large open-pit mining and rock transportation equipment; |

| • | accidents associated with the preparation and ignition of large-scale open-pit blasting operations; |

| • | production disruptions due to weather; and |

11

Table of Contents

| • | hazards associated with the disposal of mineralized waste water, such as groundwater and waterway contamination. |

Hazards associated with underground mining operations include, among others:

| • | underground fires and explosions, including those caused by flammable gas; |

| • | cave-ins or falls of ground; |

| • | discharges of gases and toxic chemicals; |

| • | flooding; |

| • | sinkhole formation and ground subsidence; |

| • | other accidents and conditions resulting from drilling; and |

| • | blasting and removing, and processing material from, an underground mine. |

ArcelorMittal is at risk of experiencing any or all of these hazards. For example, in September 2006, a methane gas explosion at ArcelorMittal’s Lenina mine in Kazakhstan resulted in 41 fatalities, and a production shutdown of two days to fully investigate the incident and in January 2008, a methane gas explosion at ArcelorMittal’s Abaiskaya mine in Kazakhstan resulted in 30 fatalities. It is estimated that it will take approximately six months before another unit is ready for production at the mine. The occurrence of any of these hazards could delay production, increase production costs and result in death or injury to persons, damage to property and liability for ArcelorMittal, some or all of which may not be covered by insurance.

Some of ArcelorMittal’s subsidiaries benefited from state aid granted prior to, or in connection with, their respective privatizations, the granting of which is subject to transitional arrangements under the respective treaties concerning the accession of these countries to the European Union. Non-fulfillment or breach of the transitional arrangements and related rules may result in the recovery of aid granted pursuant to the transitional arrangements.

ArcelorMittal has acquired formerly state-owned companies in the Czech Republic, Poland and Romania, some of which benefited from state aid granted prior to, or in connection with, their respective privatization and restructuring. Moreover, the restructuring of the steel industries in each of the Czech Republic, Poland and Romania is subject to transitional arrangements and related rules that determine the legality of restructuring aid. The transitional arrangements form part of the respective treaties concerning the accession of the Czech Republic, Poland and Romania to the European Union. See “Item 4B—Information on the Company—Business Overview—Government Regulations—State Aid”. Non-fulfillment or breach of the transitional arrangements and related rules may nullify the effect of the transitional arrangements and may result in the recovery of aid granted pursuant to the transitional arrangements that have been breached.

Under-funding of pension and other post-retirement benefit plans at some of ArcelorMittal’s operating subsidiaries, and the possible need to make substantial cash contributions to pension plans or to pay for healthcare, which may increase in the future, may reduce the cash available for ArcelorMittal’s business.

ArcelorMittal’s principal operating subsidiaries in Brazil, Canada, Europe, and the United States provide defined benefit pension plans to their employees. Some of these plans are currently under-funded. At December 31, 2007, the value of ArcelorMittal USA’s pension plan assets was $2,627 million, while the projected benefit obligation was $3,078 million, resulting in a deficit of $451 million. At December 31, 2007, the value of the pension plan assets of ArcelorMittal’s Canadian subsidiaries was $2,707 million, while the projected benefit obligation was $3,034 million, resulting in a deficit of $327 million. At December 31, 2007, the value of the pension plan assets of ArcelorMittal’s European subsidiaries was $623 million, while the projected benefit obligation was $2,486 million, resulting in a deficit of $1,863 million. ArcelorMittal USA also had an under-funded post-employment benefit obligation of $1,181 million relating to life insurance and medical benefits as of

12

Table of Contents

December 31, 2007. ArcelorMittal’s Canadian subsidiaries also had an under-funded post-employment benefit obligation of $983 million relating to life insurance and medical benefits as of December 31, 2007. ArcelorMittal’s European subsidiaries also had an under-funded post-employment benefit obligation of $507 million relating to life insurance and medical benefits as of December 31, 2007. See Note 18 to the ArcelorMittal Consolidated Financial Statements.

ArcelorMittal’s funding obligations depend upon future asset performance, the level of interest rates used to discount future liabilities, actuarial assumptions and experience, benefit plan changes and government regulation.

Because of the large number of variables that determine pension funding requirements, which are difficult to predict, as well as any legislative action, future cash funding requirements for ArcelorMittal’s pension plans and other post-employment benefit plans could be significantly higher than currently estimated amounts. These funding requirements could have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects.

ArcelorMittal could experience labor disputes that could disrupt its operations and its relationships with its customers.

A majority of the employees of ArcelorMittal and of its contractors are represented by labor unions and are covered by collective bargaining or similar agreements, which are subject to periodic renegotiation. Strikes or work stoppages could occur prior to, or during, the negotiations leading to new collective bargaining agreements, during wage and benefits negotiations or during other periods for other reasons. ArcelorMittal has experienced strikes and work stoppages at various facilities in recent years. Any such breakdown leading to work stoppage and disruption of operations could have an adverse effect on the operations and financial results of ArcelorMittal.

ArcelorMittal is subject to economic risks and uncertainties in the countries in which it operates or proposes to operate. Any deterioration or disruption of the economic environment in those countries may have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects.

In recent years, many of the countries in which ArcelorMittal operates, or proposes to operate, have experienced economic growth and improved economic stability. For example, Eastern European countries, such as Poland, the Czech Republic and Romania, have initiated free-market economic reforms in connection with or in anticipation of their accession to the European Union. Others, such as Algeria, Argentina and South Africa, have attempted to reinforce political stability and improve economic performance after recent periods of political instability. Ukraine and Kazakhstan have implemented free-market economic reforms. ArcelorMittal’s business strategy was developed partly on the assumption that such economic growth and the modernization, restructuring and upgrading of the physical infrastructure in the developing countries in which it invested will continue, thus creating increased demand for ArcelorMittal’s steel products and maintaining a stable level of steel prices both in these countries and in other key product markets. While the demand in these countries for steel and steel products has gradually increased, this trend will not necessarily continue. In addition, the legal systems in some of the countries in which ArcelorMittal operates remain underdeveloped, particularly with respect to bankruptcy proceedings, and the prospect of widespread bankruptcy, mass unemployment and the deterioration of various sectors of these economies still exists. Reform policies may not continue to be implemented and, if implemented, may not be successful. In addition, these countries may not remain receptive to foreign trade and investment. Any slowdown in the development of these economies or any reduction in the investment budgets of governmental agencies and companies responsible for the modernization of such physical infrastructure could also have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects.

13

Table of Contents

ArcelorMittal is subject to political, social and legal uncertainties in some of the developing countries in which it operates or proposes to operate. Any disruption or volatility in the political or social environment in those countries may have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects.

ArcelorMittal operates, or proposes to operate, in a number of developing countries. Some of the countries in which it currently operates, such as Romania and the Ukraine, have been undergoing substantial political transformations from centrally controlled command economies to pluralist market-oriented democracies. Political and economic reforms necessary to complete such transformation may not continue. On occasion, ethnic, religious, historical and other divisions have given rise to tensions and, in certain cases, wide-scale civil disturbances and military conflict, as in Algeria, Bosnia and Herzegovina, China, India, Liberia, Russia, South Africa and Turkey. The political systems in these and other developing countries may be vulnerable to the populations’ dissatisfaction with reforms, social and ethnic unrest and changes in governmental policies, any of which could have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects and its ability to continue to do business in these countries.

In addition, ArcelorMittal may encounter difficulties in enforcing court judgments or arbitral awards in some countries in which it operates because those countries may not be parties to treaties that recognize the mutual enforcement of court judgments.

A current example of these risks is the situation in Kazakhstan, where the government has placed into question certain development deals negotiated in the early years of the country’s independence. Following the Abaiskaya mine accident in Kazakhstan, the second mine accident at ArcelorMittal Temirtau in two years, the government of Kazakhstan has threatened to remove ArcelorMittal Temirtau’s operating license. In addition, tax claims (amounting to $2.5 billion including administrative charges) have been brought against ArcelorMittal Temirtau, despite ArcelorMittal Temirtau’s tax obligations being capped under the privatization agreements under which it was acquired from the government of Kazakhstan. The revocation of the operating license of ArcelorMittal Temirtau could disrupt ArcelorMittal’s operations and final assessment of tax payments in the amounts claimed would have a material adverse effect on ArcelorMittal’s results of operations.

ArcelorMittal may experience currency fluctuations and become subject to exchange controls that could adversely affect its business, financial condition, results of operations or prospects.

ArcelorMittal operates and sells products in a number of countries, and, as a result, its business, financial condition, results of operations or prospects could be adversely affected by fluctuations in exchange rates. Major changes in exchange rates, particularly changes in the value of the U.S. dollar against the currencies of the countries in which ArcelorMittal operates, could have an adverse effect on its business, financial condition, results of operations or prospects.

Some operations involving the South African rand, Kazakh tenge, Brazilian real, Argentine peso, Algerian dinar and Ukrainian hryvnia are subject to limitations imposed by their respective central banks. The imposition of exchange controls or other similar restrictions on currency convertibility in the countries in which ArcelorMittal operates could adversely affect its business, financial condition, results of operations or prospects.

Disruptions to ArcelorMittal’s manufacturing processes could adversely affect ArcelorMittal’s operations, customer service levels and financial results.

Steel manufacturing processes are dependent on critical steel-making equipment, such as furnaces, continuous casters, rolling mills and electrical equipment (such as transformers), and such equipment may incur downtime as a result of unanticipated failures or other events, such as fires or furnace breakdowns. ArcelorMittal’s manufacturing plants have experienced, and may in the future experience, plant shutdowns or periods of reduced production as a result of such equipment failures or other events. To the extent that lost

14

Table of Contents

production as a result of such a disruption could not be compensated for by unaffected facilities, such disruptions could have an adverse effect on ArcelorMittal’s operations, customer service levels and financial results.

Natural disasters could significantly damage ArcelorMittal’s production facilities.

Natural disasters could significantly damage ArcelorMittal’s production facilities and general infrastructure. In particular, a new plant planned in Mozambique is in a natural flood zone. In addition, ArcelorMittal Lázaro Cárdenas’s production facilities are located in Lázaro Cárdenas, Michoacán, Mexico and ArcelorMittal Temirtau is located in the Karaganda region of the Republic of Kazakhstan, both of which are areas that have historically experienced earthquakes of varying magnitude. Extensive damage to these facilities, or any other major production complexes, whether as a result of a flood, earthquake, hurricanes, tsunami or other natural disaster, could, to the extent that lost production as a result of such a disaster could not be compensated for by unaffected facilities, severely affect ArcelorMittal’s ability to conduct its business operations and, as a result, reduce its future operating results.

ArcelorMittal’s insurance policies provide limited coverage, potentially leaving it uninsured against some business risks.

The occurrence of an event that is uninsurable or not fully insured could have a material adverse effect on ArcelorMittal’s business, financial condition, results of operations or prospects. ArcelorMittal maintains insurance on property and equipment in amounts believed to be consistent with industry practices but it may not be fully insured against some business risks. The former Mittal Steel’s insurance policies cover physical loss or damage to its property and equipment on a reinstatement basis arising from a number of specified risks and certain consequential losses, including business interruption arising from the occurrence of an insured event under the policies. The former Arcelor maintained similar coverage, which will be fully consolidated under appropriate group-wide policies, which include insurance for property damage and business interruption, by June 1, 2008. Under these policies, damages and losses caused by certain natural disasters, such as earthquakes, floods and windstorms, are also covered. The coverage for the former Arcelor plants was similar to the coverage for ArcelorMittal’s plants, except as to natural hazards, earthquakes and windstorms, for which Arcelor relied on self-insurance where external insurance cover was not legally required, as its exposure to those risks was considered to be limited. Each of the operating subsidiaries of ArcelorMittal also maintains various other types of insurance, such as workmen’s compensation insurance and marine insurance. Notwithstanding the insurance coverage that ArcelorMittal and its subsidiaries carry, the occurrence of an accident that causes losses in excess of limits specified under the relevant policy, or losses arising from events not covered by insurance policies, could materially harm ArcelorMittal’s financial condition and future operating results.

Product liability claims could adversely affect ArcelorMittal’s operations.

ArcelorMittal sells products to major manufacturers who are engaged to sell a wide range of end products. Furthermore, ArcelorMittal’s products are also sold to, and used in, certain safety-critical applications. If ArcelorMittal were to sell steel that is inconsistent with the specifications of the order or the requirements of the application, significant disruptions to the customer’s production lines could result. There could also be significant consequential damages resulting from the use of such products. ArcelorMittal has a limited amount of product liability insurance coverage, and a major claim for damages related to products sold could leave ArcelorMittal uninsured against a portion or all of the award and, as a result, materially harm its financial condition and future operating results.

International trade actions or regulations and trade-related legal proceedings could reduce or eliminate ArcelorMittal’s access to steel markets.

ArcelorMittal has international operations and makes sales throughout the world, and, therefore, its businesses have significant exposure to the effects of trade actions and barriers. Various countries, including the United States and Canada, have in the past instituted, or are currently contemplating the institution of, trade actions and barriers.

15

Table of Contents

ArcelorMittal cannot predict the timing and nature of similar or other trade actions by the United States, Canada or any other country. Because of the international nature of ArcelorMittal’s operations, it may be affected by any trade actions or restrictions introduced by any country in which it sells, or has the potential to sell, its products. Any such trade actions could materially and adversely affect ArcelorMittal’s business by reducing or eliminating ArcelorMittal’s access to steel markets.

In addition to the more general trade barriers described above, if ArcelorMittal were party to a regulatory or trade-related legal proceeding that was decided adversely to it, its business, financial condition, results of operations or prospects could be adversely affected.

See “Item 4B—Information on the Company—Business Overview—Government Regulations”.

The income tax liability of ArcelorMittal may substantially increase if the tax laws and regulations in countries in which it operates change or become subject to adverse interpretations or inconsistent enforcement.

Taxes payable by companies in many of the countries in which ArcelorMittal operates are substantial and include value-added tax, excise duties, profit taxes, payroll-related taxes, property taxes and other taxes. Tax laws and regulations in some of these countries may be subject to frequent change, varying interpretation and inconsistent enforcement. Ineffective tax collection systems and continuing budget requirements may increase the likelihood of the imposition of arbitrary or onerous taxes and penalties, which could have a material adverse effect on ArcelorMittal’s financial condition and results of operations. In addition to the usual tax burden imposed on taxpayers, these conditions create uncertainty as to the tax implications of various business decisions. This uncertainty could expose ArcelorMittal to significant fines and penalties and to enforcement measures despite its best efforts at compliance, and could result in a greater than expected tax burden. See Note 19 to the ArcelorMittal Consolidated Financial Statements.

In addition, many of the jurisdictions in which ArcelorMittal operates have adopted transfer pricing legislation. If tax authorities impose significant additional tax liabilities as a result of transfer pricing adjustments, it could have a material adverse effect on ArcelorMittal’s financial condition and results of operations.

It is possible that tax authorities in the countries in which ArcelorMittal operates will introduce additional revenue raising measures. The introduction of any such provisions may affect the overall tax efficiency of ArcelorMittal and may result in significant additional taxes becoming payable. Any such additional tax exposure could have a material adverse effect on its financial condition and results of operations.

ArcelorMittal may face a significant increase in its income taxes if tax rates increase or the tax laws or regulations in the jurisdictions in which it operates, or treaties between those jurisdictions, are modified in an adverse manner. This may adversely affect ArcelorMittal’s cash flows, liquidity and ability to pay dividends.

If ArcelorMittal were unable to utilize fully its deferred tax assets, its profitability could be reduced.

At December 31, 2007, ArcelorMittal had $1,629 million recorded as deferred tax assets on its balance sheet. These assets can be utilized only if, and only to the extent that, ArcelorMittal’s operating subsidiaries generate adequate levels of taxable income in future periods to offset the tax loss carry forwards and reverse the temporary differences prior to expiration.

At December 31, 2007, the amount of future income required to recover ArcelorMittal’s deferred tax assets was approximately $5,072 million at certain operating subsidiaries. For each of the years ended December 31, 2006 and 2007, these operating subsidiaries generated approximately 43% and 29%, respectively, of ArcelorMittal’s consolidated income before tax of $7,228 million and $14,888 million respectively.

16

Table of Contents

ArcelorMittal’s ability to generate taxable income is subject to general economic, financial, competitive, legislative, regulatory and other factors that are beyond its control. If ArcelorMittal generates lower taxable income than the amount it has assumed in determining its deferred tax assets, then the value of deferred tax assets will be reduced. See “Item 5A—Operating and Financial Review and Prospects—Operating Results—Year Ended December 31, 2007 Compared to Year Ended December 31, 2006—Income Tax”.

U.S. investors may have difficulty enforcing civil liabilities against ArcelorMittal and its directors and senior management.

ArcelorMittal is organized under the laws of the Grand Duchy of Luxembourg with its principal executive offices and corporate seat in Luxembourg. The majority of ArcelorMittal’s directors and senior management are residents of jurisdictions outside the United States. The majority of ArcelorMittal’s assets and the assets of these persons are located outside the United States. As a result, U.S. investors may find it difficult to effect service of process within the United States upon ArcelorMittal or these persons or to enforce outside the United States judgments obtained against ArcelorMittal or these persons in U.S. courts, including actions predicated upon the civil liability provisions of the U.S. federal securities laws. Likewise, it may also be difficult for an investor to enforce in U.S. courts judgments obtained against ArcelorMittal or these persons in courts in jurisdictions outside the United States, including actions predicated upon the civil liability provisions of the U.S. federal securities laws. It may also be difficult for a U.S. investor to bring an original action in a Luxembourg court predicated upon the civil liability provisions of the U.S. federal securities laws against ArcelorMittal’s directors and senior management and non-U.S. experts named in this annual report.

ArcelorMittal’s inability to successfully centralize various corporate and management functions could adversely affect its productivity and profitability.

ArcelorMittal is centralizing various corporate and management functions at its corporate headquarters in Luxembourg. These functions include the central sale of raw materials, purchase and sale of finished products, research and development functions as well as other functions. The process of centralizing these functions and of making changes to the Company’s existing operational business model may have various efficiency, organizational, operational and tax consequences. If ArcelorMittal is not able to centralize its functions successfully, this could adversely affect its productivity and profitability.

ArcelorMittal may not be able to realize the full book value of its assets held for sale.

ArcelorMittal has assets held for sale. If ArcelorMittal cannot sell them at their full book value, this would negatively affect its cash flow and consequently could affect its financial results.

Risks related to the steel industry.

A downturn in global economic conditions may have a material adverse effect on the results of ArcelorMittal.

ArcelorMittal’s activities and results are affected by international, national and regional economic conditions. In 2007, growing fears of an economic downturn affected consumer confidence and reduced the intensity of demand for steel products. If macroeconomic conditions worsen, the performance of steel producers could be affected. In particular, fears of a recession in the United States, sparked by uncertainty in the credit markets, have grown, as have concerns as to the effect a U.S. recession would have in Europe and elsewhere. Despite ArcelorMittal’s size and global breadth, regional declines in consumption caused by a recession in one or more major markets may have a material adverse effect on demand for its products and hence on its results.

17

Table of Contents

ArcelorMittal is susceptible to the cyclicality of the steel industry, making ArcelorMittal’s results of operations unpredictable.

The steel industry has historically been highly cyclical and is affected significantly by general economic conditions and other factors such as worldwide production capacity, fluctuations in steel imports/exports and tariffs. Steel prices are also sensitive to trends in cyclical industries, such as automotive, construction, appliance, machinery, equipment and transportation industries, which are the significant markets for ArcelorMittal’s products. Steel markets have been experiencing larger and more pronounced cyclical fluctuations, driven recently by the substantial increase in steel production and consumption in China. This trend, combined with the rising costs of key inputs, mainly metallics, energy, transportation and logistics, presents an increasing challenge for steel producers.

The volatility and the length and nature of business cycles affecting the steel industry have historically been unpredictable, and the recurrence of another major downturn in the industry would negatively impact ArcelorMittal’s results of operations and profitability.

See “Item 5—Operating and Financial Review and Prospects—Overview—Key Factors Affecting Results of Operations” and “—Consolidation in the Steel Industry”.

Rapidly growing supply of steel products in China and other developing economies, which may increase faster than increases in demand, may result in additional excess worldwide capacity and falling steel prices.

Over the last several years, steel consumption in China and other developing economies such as India has increased rapidly. Steel companies have responded by developing steel production capabilities in these countries. Steel production, especially in China, has been expanding significantly and China is now the largest worldwide steel producer by a significant margin. In 2006, China became a net exporter of steel, exerting downward pressure on steel prices in the European and American markets in that year. Chinese steel exports slowed in 2007 due to, among other things, rising input prices, Chinese government policies, growing internal demand and slowing worldwide economic growth. In the future, any significant excess Chinese capacity could have a major impact on world steel trade and prices if this excess production is exported to other markets.

Developments in the competitive environment in the steel industry could have an adverse effect on ArcelorMittal’s competitive position and hence its business, financial condition, results of operations or prospects.

The markets in which steel companies conduct business are highly competitive. Competition could cause ArcelorMittal to lose market share, increase expenditures or reduce pricing, any one of which could have a material adverse effect on its business, financial condition, results of operations or prospects. The global steel industry has historically suffered from substantial over-capacity. This has led to substantial price decreases during periods of economic weakness that have not been offset by commensurate price increases during periods of economic strength. Excess capacity in some of the products sold by ArcelorMittal will intensify price competition for such products. This could require ArcelorMittal to reduce the price for its products and, as a result, may have a material adverse effect on its business, financial condition, results of operations or prospects.

ArcelorMittal may encounter increases in the cost and shortages in the supply of raw materials, energy and transportation.

Steel production requires substantial amounts of raw materials and energy, including iron ore, coking coal, zinc, scrap, electricity, natural gas, coal and coke. Currently, there is a worldwide shortage of coke and coal, mainly as a result of the rapid growth in the demand for steel globally. In recent years, and particularly in 2006 and 2007, there was a sharp rise in the cost of a number of commodities essential for the process of steel-making. In particular, the prices of zinc and nickel fluctuated substantially, while the price of iron ore rose 65%, due

18

Table of Contents

among other things to dynamics of supply (including downstream concentration) and demand (including the surge in Chinese and Indian demand). The current concentration in the mining industry, as well as possible further consolidation (in particular the possible combination of BHP Billiton and Rio Tinto), has fostered and may also lead to further price increases in iron ore and other raw materials. The availability and prices of raw materials may be negatively affected by, among other factors, new laws or regulations; suppliers’ allocations to other purchasers; interruptions in production by suppliers; accidents or other similar events at suppliers’ premises or along the supply chain; wars, natural disasters and other similar events; changes in exchange rates; consolidation in steel-related industries; the bargaining power of raw material suppliers; worldwide price fluctuations; and the availability and cost of transportation. Any prolonged interruption in the supply of raw materials or energy, or substantial increases in their costs that steel companies are not able to pass on to customers, could adversely affect the business, financial condition, results of operations or prospects of steel companies.

In addition, energy costs, including the cost of electricity and natural gas, make up a substantial portion of the cost of goods sold by steel companies. The price of energy has varied significantly in the past several years and may vary significantly in the future largely as a result of market conditions and other factors beyond the control of steel companies, including significant increases in oil prices. Because the production of direct reduced iron and the re-heating of steel involve the use of significant amounts of natural gas, steel companies are sensitive to the price of natural gas.

ArcelorMittal will not necessarily be able to procure adequate supplies in the future. A portion of ArcelorMittal’s raw materials are obtained under contracts that are either short-term or are subject to periodic price negotiations. Any prolonged interruption, discontinuation or other disruption in the supply of raw materials or energy, or substantial increases in their costs, may harm ArcelorMittal’s business, financial condition, and results of operations or prospects.

Competition from other materials could significantly reduce market prices and demand for steel products and thereby reduce ArcelorMittal’s cash flow and profitability.

In many applications, steel competes with other materials that may be used as steel substitutes, such as aluminum (particularly in the automobile industry), cement, composites, glass, plastic and wood. Additional substitutes for steel products could significantly reduce market prices and demand for steel products and thereby reduce ArcelorMittal’s cash flow and profitability.

ArcelorMittal is subject to stringent environmental and health and safety regulations that give rise to significant costs and liabilities, including those arising from environmental remediation programs.

ArcelorMittal is subject to a broad range of environmental and health and safety laws and regulations in each of the jurisdictions in which it operates. These laws and regulations, as interpreted by relevant agencies and the courts, impose increasingly stringent environmental and health and safety protection standards regarding, among other things, air emissions, wastewater storage, treatment and discharges, the use and handling of hazardous or toxic materials, waste disposal practices, worker health and safety and the remediation of environmental contamination. The costs of complying with, and the imposition of liabilities pursuant to, environmental and health and safety laws and regulations could be significant, and failure to comply could result in the assessment of civil and criminal penalties, the suspension of permits or operations, and lawsuits by third parties.

Compliance with environmental obligations may require additional capital expenditures or modifications in operating practices, particularly at steel companies operating in countries that have recently joined the European Union. For example, U.S. laws and regulations and EU Directives, as well as any new or additional environmental compliance requirements that may arise out of the implementation by different countries of the Kyoto Protocol (United Nations Framework on Climate Change, 1992) and future, more stringent greenhouse gas

19

Table of Contents

restrictions and emissions trading schemes, may require changes to the operations of steel facilities, further reductions in emissions, and the purchase of emission rights.

ArcelorMittal also incurs costs and liabilities associated with the assessment and remediation of contaminated sites. In addition to the impact on current facilities and operations, environmental remediation obligations can give rise to substantial liabilities with respect to divested assets and past activities. ArcelorMittal could become subject to further remediation obligations in the future, as additional contamination is discovered or cleanup standards become more stringent.

Under certain circumstances, authorities could require ArcelorMittal facilities to curtail or suspend operations based on environmental or health and safety concerns. For example, following accidents in 2006 and 2007 that resulted in numerous fatalities, the Kazakh government has threatened to revoke the operating license of ArcelorMittal Temirtau unless certain additional safety measures are implemented at its facilities. Similarly, exceedance of ambient air quality standards or other environmental limitations can lead to sanctions including imposition of penalties or operational restrictions, particularly where human health may be compromised.

See “Item 4B—Information on the Company—Business Overview—Government Regulations—Environmental Laws and Regulations” and “Item 8A—Financial Information—Consolidated Statements and Other Financial Information—Legal Proceedings”.

ITEM 4. INFORMATION ON THE COMPANY

A. History and Development of the Company

ArcelorMittal Overview

ArcelorMittal is the world’s largest and most global steel producer. It results from the combination in 2006 of Mittal Steel and Arcelor, at the time respectively the world’s largest and second largest steel companies by production volume.