| NI 43-101 Pre-Feasibility Study of the Mineral |

| Resources of the Borealis Gold Project Located in |

| Mineral County, Nevada, USA |

| July 20, 2009 |

Prepared by:

John R. Danio, P.E.

Senior Associate

Telesto Nevada, Inc.

Reno, Nevada

Telephone: 775-853-7776

| Roger C. Steininger, Ph.D., CPG | Jaye T. Pickarts, P.E. |

| Chief Consulting Geologist | Knight Piésold and Co. |

| Gryphon Gold Corporation | Denver, Colorado |

| Reno, Nevada | Telephone: 303-629-8788 |

| Telephone: 775-742-6333 | |

| Steven D. Craig, CPG | Kim Drossulis |

| Senior Consulting Geologist | Senior Mine Engineer |

| Gryphon Gold Corporation | Telesto Nevada, Inc. |

| Reno, Nevada | Reno, Nevada |

| Telephone: 775-742-6333 | Telephone: 775-853-7776 |

Table of Contents

| 1.0 Executive Summary | 1 |

| 1.1 Introduction | 1 |

| 1.1.1 Terms of Reference | 1 |

| 1.1.2 Basis of Study | 2 |

| 1.2 Project Description and Location | 2 |

| 1.2.1 Land Status and Ownership | 3 |

| 1.2.2 Royalty | 4 |

| 1.3 Access, Climate, Local Resources, and Infrastructure | 4 |

| 1.4 Property History | 5 |

| 1.5 Geology and Mineralization | 6 |

| 1.6 History of Exploration Activities | 8 |

| 1.7 Drill Hole Database | 10 |

| 1.8 Sample Preparation, Analysis, and Security | 10 |

| 1.8.1 Historical | 10 |

| 1.8.2 Recent Programs | 11 |

| 1.9 Data Limitations | 11 |

| 1.10 Mineral Processing and Metallurgical Testing | 12 |

| 1.10.1 Processing | 13 |

| 1.11 Mineral Resource Estimates | 13 |

| 1.11.1 Mineral Resource Model | 14 |

| 1.12 Other Important Considerations | 17 |

| 1.12.1 Permitting | 17 |

| 1.13 Financial Model Results | 17 |

| 1.14 Sensitivity | 18 |

| 1.15 Conclusions and Recommendations | 20 |

| 2.0 Introduction and Terms of Reference | 21 |

| 3.0 Reliance on Other Experts | 29 |

| 4.0 Property Description and Location | 31 |

| 4.1 Location | 31 |

| 4.2 Study Area Boundaries | 32 |

| 4.3 Property Description and Ownership | 32 |

| 4.3.1 General Property Description | 32 |

| 4.3.2 Ownership, Purchase Agreement, and Mining Lease | 33 |

| 4.3.3 Royalty | 34 |

| 5.0 Accessibility, Climate, Local Resources, Infrastructure, and Physiography | 35 |

| 5.1 Access | 35 |

| 5.2 Climate and Physiography | 35 |

| 5.3 Existing Site Conditions, Infrastructure, and Available Services | 35 |

i

| 6.0 History | 39 |

| 6.1 History of the District | 39 |

| 6.2 Past Production | 41 |

| 6.3 Borealis Property Development Background | 41 |

| 6.4 Previous Mineral Resource Estimates | 43 |

| 7.0 Geologic Setting | 47 |

| 7.1 Introduction | 47 |

| 7.2 Regional Geology | 47 |

| 7.3 Local Geology | 49 |

| 7.4 Miocene and Younger Rocks | 50 |

| 7.5 Structure | 52 |

| 8.0 Deposit Types | 55 |

| 8.1 Hydrothermal Gold Deposits | 55 |

| 8.2 Graben Breccias | 57 |

| 8.3 Gold in Alluvium | 58 |

| 9.0 Mineralization | 59 |

| 9.1 Introduction | 59 |

| 9.2 Oxidized Gold Mineralization | 59 |

| 9.3 Gold-Sulfide Mineralization | 60 |

| 10.0 Exploration | 63 |

| 10.1 Introduction | 63 |

| 10.2 Historical Exploration | 63 |

| 10.2.1 Borealis Extension Deposit | 64 |

| 10.2.2 Graben Deposit | 64 |

| 10.2.3 North Graben Prospect | 65 |

| 10.2.4 Sunset Wash Prospect | 65 |

| 10.2.5 Boundary Ridge/Bullion Ridge Prospect | 66 |

| 10.2.6 Central Pediment (Lucky Boy) Prospect | 66 |

| 10.3 Activities Planned to Expand Mineralized Zones and Explore Prospects | 67 |

| 10.3.1 Area Geophysical Surveys | 67 |

| 10.3.2 Applied Reflectance Spectroscopy and Geochemical Analyses | 69 |

| 10.3.3 Freedom Flats Section | 70 |

| 10.3.4 Central Graben Section | 71 |

| 10.3.5 Conclusions and Recommendations | 71 |

| 11.0 Drilling | 73 |

| 11.1 Gryphon Gold Drilling | 73 |

| 11.2 Historical Exploration Drill Hole Database | 73 |

| 11.3 Historical Blast Hole Database | 74 |

| 12.0 Sampling Method and Approach | 77 |

ii

| 12.1 General | 77 |

| 12.1.1 Freedom Flats Example | 78 |

| 12.2 Sampling of Existing Heaps and Dumps – Spring 2004 | 79 |

| 12.3 Drill Hole Database for Mineral Resource Model | 79 |

| 13.0 Sample Preparation, Analysis, and Security | 81 |

| 13.1 Previous Mining Operations and Exploration | 81 |

| 13.1.1 Analysis and Quality Control | 81 |

| 13.1.2 Security | 82 |

| 13.2 Heap and Dump Drilling and Sampling Program - Spring 2004 | 82 |

| 13.2.1 Sampling, Analysis, and Quality Control - Heap and Dump Drilling | 82 |

| 13.2.2 Security | 85 |

| 13.3 2005 Through Late-2007 Reverse Circulation Drilling | 85 |

| 13.3.1 2005-2007 Analytical Program | 86 |

| 13.3.2 Outside Lab Check | 87 |

| 13.3.3 Change of Labs | 87 |

| 13.4 Quality Assurance and Quality Control (“QA/QC”) Conclusions | 87 |

| 14.0 Data Verification | 89 |

| 14.1 Historical Exploration Drill Hole Data | 89 |

| 14.2 Semi-Quantitative Check Sampling | 89 |

| 14.3 Database Verification | 90 |

| 15.0 Adjacent Properties | 91 |

| 16.0 Mineral Processing and Metallurgical Testing | 93 |

| 16.1 Introduction | 93 |

| 16.2 Metallurgical History | 93 |

| 16.3 Previous Metallurgical Investigation | 94 |

| 16.4 Current Metallurgical Investigation | 95 |

| 16.4.1 Sample Description | 95 |

| 16.4.2 Bottle Roll Tests | 96 |

| 16.4.3 Column Test Work | 97 |

| 16.5 Reagent Consumption | 98 |

| 16.6 Summary of Results | 99 |

| 16.7 Bulk Density and Tonnage Factor | 100 |

| 16.8 Heap Leach Processing Alternatives | 102 |

| 16.8.1 Heap Leach Plus Gravity | 102 |

| 16.8.2 Heap Leach Plus Gravity (Screen out the Low Grade) | 103 |

| 17.0 Mineral Reserve Estimate | 105 |

| 17.1 Introduction | 105 |

| 17.2 Evaluations | 105 |

| 17.2.1 Resource Evaluation | 105 |

iii

| 17.2.2 Optimization Analysis | 105 |

| 17.3 Existing Heaps, ROM COG | 106 |

| 17.4 Mineral Reserves | 107 |

| 17.5 Pit Design Parameters | 108 |

| 17.6 General Statement | 108 |

| 17.6.1 Independent Review | 109 |

| 17.7 Mineral Resource Model | 110 |

| 17.7.1 Resource Block Model Size and Location | 110 |

| 17.7.2 Production Drill Hole Data | 112 |

| 17.7.2 Compositing | 119 |

| 17.7.3 Topographic Data and Models | 119 |

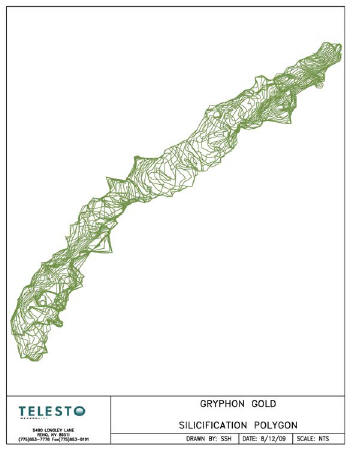

| 17.7.4 Geological Modeling 2008 and 2009 | 122 |

| 17.7.5 Geologic Model for the Thickness of the QAL and TCV Formations | 122 |

| 17.7.6 Model of the Depth of Oxidation and Partial Oxidation | 123 |

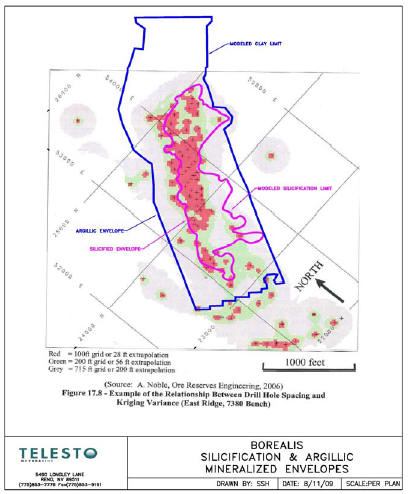

| 17.7.7 Grade Zone Models and Basic Statistics | 124 |

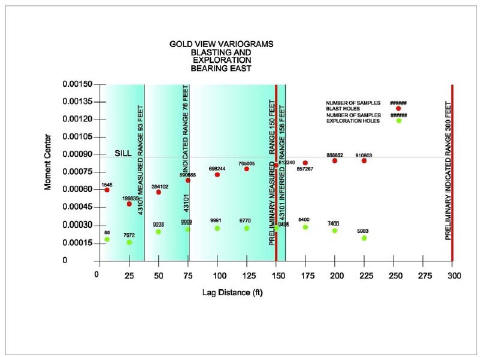

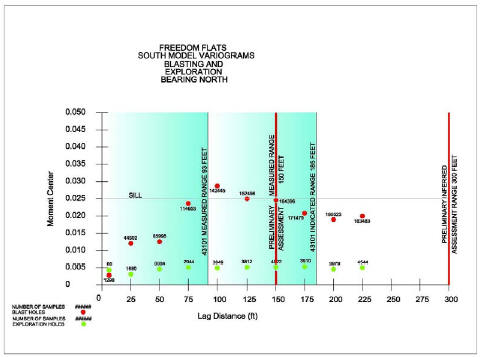

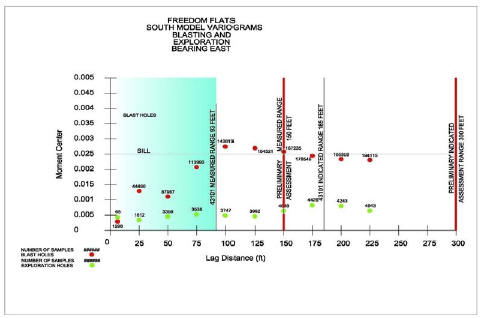

| 17.7.8 Variograms | 131 |

| 17.7.9 Grade Estimation and Mineral Resource Classification | 136 |

| 17.7.10 2009 Revisions to the Relationships of Drill Spacing and Resource Classification | 143 |

| 17.7.11 Jackknife Analysis | 146 |

| 17.7.12 Comparison of Mineral Resource Estimates to Previous Production | 146 |

| 17.7.13 Summary of Model Results | 147 |

| 17.8 Mineable Reserves | 150 |

| 17.9 Mineral Resources from Existing Heaps and Stockpiles | 151 |

| 17.10 Mine Plan | 154 |

| 18.0 Other Relevant Data and Information | 155 |

| 18.1 Permitting | 155 |

| 18.2 Permit Summary | 155 |

| 18.3 Background and Status of Permits | 157 |

| 18.3.1 Approved Plan of Operations | 157 |

| 18.3.2 Water Pollution Control Permit (WPCP) | 158 |

| 18.3.3 Reclamation Permit | 159 |

| 18.3.4 Closure Plans | 159 |

| 18.3.5 Air Quality Permit | 160 |

| 18.3.6 Storm Water Permit | 161 |

| 18.3.7 Spill Prevention, Control, and Countermeasure Plan (SPCC) | 161 |

| 18.3.8 Emergency Release, Response, and Contingency Plan (ERRCP) | 161 |

| 18.3.9 Threatened and Endangered Species Act | 161 |

| 18.3.10 Historical Preservation Act | 162 |

iv

| 18.3.11 Water Rights | 163 |

| 18.4 Other Minor Permits and Authorizations | 163 |

| 18.5 Other Information | 165 |

| 19.0 Interpretation and Conclusions | 167 |

| 19.1 Geology | 167 |

| 19.2 Geophysics | 167 |

| 19.3 Gold Deposits | 167 |

| 19.4 Mineral Resources | 168 |

| 19.5 Mining | 168 |

| 19.6 District Exploration | 168 |

| 20.0 Recommendations | 171 |

| 21.0 References | 173 |

| 22.0 Certificate of Author | 177 |

| 23A.0 Additional Requirements for Development Properties | 187 |

| 23A.1 Mining Operations | 187 |

| 23A.2 Contract Mining | 192 |

| 23A.2.1 Maintenance and Fuel Storage Facilities | 192 |

| 23A.2.2 Explosive Storage | 192 |

| 23A.2.3 Mine Personnel | 192 |

| 23A.2.4 Blasting Design | 192 |

| 23A.2.5 Grade Control Procedures | 193 |

| 23A.2.6 Stockpiles and Waste Dumps | 193 |

| 23A.2.7 Ore Dilution | 194 |

| 23A.3 Organization | 194 |

| 23A.3.1 General Management | 194 |

| 23A.3.2 Finance and Accounting | 195 |

| 23A.3.3 Human Resources | 195 |

| 23A.3.4 Purchasing and Materials Management | 195 |

| 23A.3.5 Public Relations | 195 |

| 23A.3.6 Environmental and Permitting | 195 |

| 23A.3.7 Health and Safety | 195 |

| 23A.3.8 Corporate Support | 195 |

| 23A.3.9 Emergencies | 195 |

| 23A.3.10 Compensation Plan Structure | 196 |

| 23A.3.11 Training | 196 |

| 23B.0 Recoverability | 197 |

| 23B.1 Introduction | 197 |

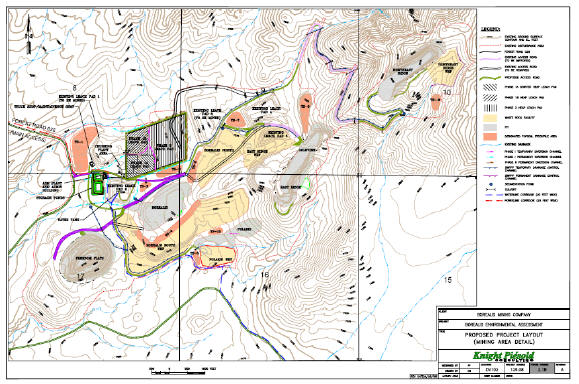

| 23B.2 Site Layout Considerations | 198 |

| 23B.3 Process Description | 198 |

v

| 23B.3.1 Design Criteria | 198 |

| 23B.3.2 Crushing, Screening, and Agglomeration | 198 |

| 23B.3.3 Heap Leaching | 199 |

| 23B.3.4 ADR Process Plant | 199 |

| 23B.3.5 Reagents and Utilities | 200 |

| 23B.3.6 Utilities | 200 |

| 23B.4 Plant Operation and Instrumentation | 200 |

| 23B.5 Plant Services | 201 |

| 23B.5.1 Mobile Equipment | 201 |

| 23B.5.2 Building | 201 |

| 23B.5.3 Assay/Metallurgical Laboratories | 201 |

| 23B.6 Process Personnel | 201 |

| 23B.6.1 Salaried Staff | 201 |

| 23B.6.2 Hourly Staff | 201 |

| 23B.7 Heap Leach Pad and Pond Design | 202 |

| 23B.7.1 Introduction | 202 |

| 23B.7.2 Heap Leach Pad Grading Plan | 202 |

| 23B.7.3 Heap Leach Pad Liner System | 202 |

| 23B.7.4 Process Component Monitoring System | 204 |

| 23B.7.5 Loading Plan | 204 |

| 23B.7.6 Recycle/Storm Water Pond LCRS | 204 |

| 23B.7.7 Water Balance | 205 |

| 23B.7.8 Monitoring Wells | 206 |

| 23B.8 Infrastructure | 207 |

| 23B.8.1 Site Access | 207 |

| 23B.8.2 Site Improvements | 207 |

| 23B.8.3 Office, ADR Change House, Assay Laboratory, and Surveying | 207 |

| 23B.8.4 Water Supply Distribution | 208 |

| 23B.8.5 Power Distribution | 208 |

| 23B.8.6 Process Area | 208 |

| 23B.8.7 Crushing Area | 208 |

| 23B.8.8 Haul Roads | 210 |

| 23B.8.9 Perimeter Roads | 210 |

| 23B.8.10 Fire Protection | 210 |

| 23B.8.11 Fencing and Access | 210 |

| 23B.8.12 Propane | 210 |

| 23B.8.13 Site Radios | 210 |

| 23B.8.14 Site Phones | 210 |

| 23C.0 Markets | 211 |

vi

| 23D.0 Contracts | 213 |

| 23E.0 Reclamation and Closure | 215 |

| 23E.1 Introduction | 215 |

| 23E.2 Surface Reclamation and Revegetation Plan | 215 |

| 23E.2.1 Soils and Soil Availability for Reclamation | 215 |

| 23E.2.2 Surface Reclamation | 215 |

| 23E.2.3 Revegetation | 215 |

| 23E.2.4 Heap Leach Pads | 216 |

| 23E.2.5 Storage Ponds and ADR Plant | 216 |

| 23E.2.6 Open Pits | 217 |

| 23E.2.7 Waste Rock Facilities | 217 |

| 23E.2.8 Roads and Drainages | 218 |

| 23E.2.9 Exploration Activities | 218 |

| 23E.2.10 Buildings and Infrastructure | 219 |

| 23E.3 Monitoring and Reporting | 219 |

| 23E.4 Reclamation Schedule and Cost | 220 |

| 23E.5 Reclamation and Closure Risk | 220 |

| 23F.0 Taxes and Royalties | 223 |

| 23G1.0 Capital Cost Estimate | 225 |

| 23G1.1 Introduction | 225 |

| 23G1.2 Basis of Estimate | 225 |

| 23G1.2.1 Cost Areas | 226 |

| 23G1.2.2 Indirect Costs | 227 |

| 23G1.3 Contingency | 227 |

| 23G1.4 Summary | 227 |

| 23G1.5 Owner’s Costs | 228 |

| 23G1.6 Exclusions, Clarification, and Qualifications | 229 |

| 23G1.6.1 Exclusions | 229 |

| 23G1.6.2 Clarifications and Qualifications | 229 |

| 23G2.0 Operating Cost Estimate | 231 |

| 23G2.1 Introduction | 231 |

| 23G2.2 Mining | 231 |

| 23G2.3 Crushing, Agglomeration, and Heap Stacking | 233 |

| 23G2.4 Processing | 234 |

| 23G2.4.1 Labor | 234 |

| 23G2.5 Reagents, ADR supplies | 234 |

| 23G2.6 Processing Cost Summary | 235 |

| 23G2.7 General and Administrative (G & A) | 235 |

| 23G2.8 Operating Cost Summary | 236 |

vii

| 23G3.0 Project Execution | 241 |

| 23G3.1 Engineering, Procurement and Construction Management | 241 |

| 23G3.2 Procurement Plan | 241 |

| 23G3.2.1 Purchasing | 241 |

| 23G3.2.2 Expediting | 242 |

| 23G3.2.3 Inspections | 242 |

| 23G3.2.4 Traffic and Logistics | 242 |

| 23G3.3 Engineering | 242 |

| 23G3.3.1 Electrical, Control Systems, and Instrumentation | 243 |

| 23G3.3.2 Structural Design | 243 |

| 23G3.4 Project Schedule | 244 |

| 23G3.5 Construction Labor Force | 244 |

| 23G3.6 Start-up and Commissioning | 245 |

| 23H.0 Economic Analysis | 247 |

| 23H.1 Introduction | 247 |

| 23H.2 Production Schedule and Assumptions | 247 |

| 23H.3 Sales and Revenue | 247 |

| 23H.4 Cash Flow Projections | 247 |

| 23H.4.1 Capital Costs | 247 |

| 23H.4.2 Sustaining Capital | 248 |

| 23H.4.3 Owner’s Costs | 248 |

| 23H.4.4 Working Capital | 248 |

| 23H.4.5 Operating Costs | 248 |

| 23H.5 Depreciation, Taxes, and Royalties | 249 |

| 23H.6 Sensitivities | 249 |

Table of Figures

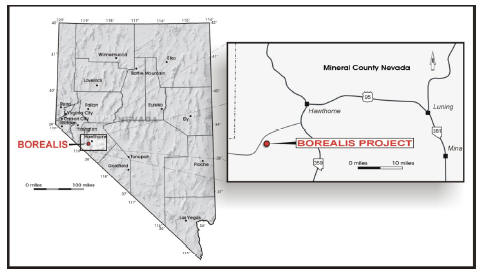

| Figure 1.1 – Location Map of the Borealis Project | 3 |

| Figure 1.2 – Local Geology of the Borealis District and Project Area | 7 |

| Figure 1.3 – 1989 Borealis District Aeromagnetic Survey Map | 9 |

| Figure 1.4 – Selected Resistivity Anomaly Trends of the Borealis District | 9 |

| Figure 1.5 – Project Sensitivity | 19 |

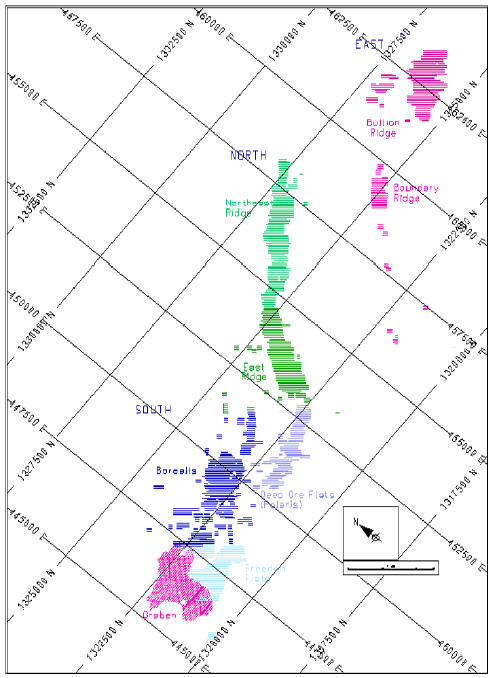

| Figure 2.1 – Mineral Deposits and Prospects of the Borealis Property | 22 |

| Figure 4.1 – Location Map of the Borealis Project | 31 |

| Figure 5.1 – Photograph of a Portion of the Borealis District, circa 1991 | 36 |

| Figure 7.1 – Walker Lane Gold and Silver Deposits | 48 |

| Figure 7.2 – Geologic Map of the Borealis Project Area | 50 |

| Figure 7.3 – Volcanostratigraphic Section in the Borealis District | 52 |

viii

| Figure 9.1 – Typical Alteration Patterns of the Borealis District Gold Deposits | 62 |

| Figure 10.1 – 1989 Borealis District Aeromagnetic Survey Map | 68 |

| Figure 10.2 – Selected Resistivity Anomaly Trends of a Portion of the Borealis District | 69 |

| Figure 11.1 – Representative Original Mylar Map of Blast Hole Data | 75 |

| Figure 11.2 – Digitized Data from an Original Mylar Map of Blast Hole Data | 75 |

| Figure 15.1 – Location of Borealis Property and Other Important Nearby Gold Mining Properties in the Walker Lane and Aurora-Borealis Cross Trend | 91 |

| Figure 16.1 – Gold Leach Rate Profiles | 98 |

| Figure 17.1 – Scanned Production Drill Hole Map | 113 |

| Figure 17.2 – Digitized Production Drill Hole Map | 114 |

| Figure 17.3 – Drill Hole Collar Locations in the South Area Model | 116 |

| Figure 17.4 – Drill Hole Collar Locations in the North Area Model | 117 |

| Figure 17.5 – Drill Hole Collar Locations in the East Area Model | 118 |

| Figure 17.6 – Drill Hole Collar Locations in the West Area Model | 119 |

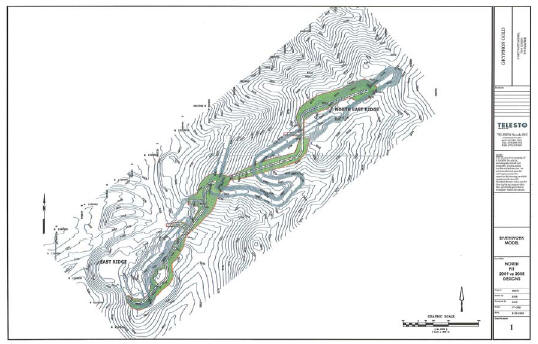

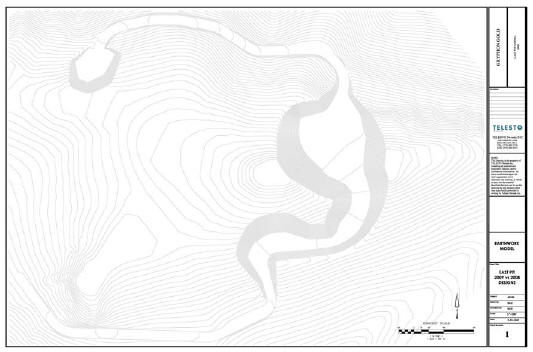

| Figure 17.7 – 2009 North Pit Design | 121 |

| Figure 17.8 – Plan View of all Sectional Grade Zones for the South, North, and East Model Areas | 126 |

| Figure 17.9 – Example of Grade Zones on Cross Sections of the Graben and Freedom Flats Deposits – Section 0+1250 (Sections at 140oazimuth – looking N. 50oE.) | 127 |

| Figure 17.10 – Example of Grade Zones on Cross Sections of the Graben and Freedom Flats Deposits – Section 0+1500 (Sections at 140oazimuth – looking N. 50oE.) | 127 |

| Figure 17.11 – Example of Grade Zones on Cross Sections of the Graben and Freedom Flats Deposits – Section 0+1750 (Sections at 140oazimuth – looking N. 50oE.) | 128 |

| Figure 17.12 – Au Composites’ Histogram and Cumulative Frequency Plot Within the Graben- High Grade Deposit Grade Zones | 129 |

| Figure 17.13 – Au Composites’ Histogram and Cumulative Frequency Plot Within the Freedom Flats Deposit Grade Zones | 130 |

| Figure 17.14 – Gold View Variograms for Bearing N 45 E | 132 |

| Figure 17.15 – Gold View Variograms for Bearing East | 133 |

| Figure 17.16 – Gold View Variograms for Bearing S 45 E | 133 |

| Figure 17.17 – Gold View Variograms for Vertical | 134 |

| Figure 17.18 – Freedom Flats Variograms for North | 134 |

| Figure 17.19 – Freedom Flats Variograms for N 45 E | 135 |

| Figure 17.20 – Freedom Flats Variograms for East | 135 |

| Figure 17.21 – Freedom Flats Variograms for S 45 E | 136 |

| Figure 17.22 – Example of the Relationship Between Drill Hole Spacing / Density and Resource Classifications (Graben-Freedom Flats - 6500 Bench) | 141 |

| Figure 17.23 – Example of the Relationship Between Drill Hole Spacing / Density and Resource Classifications (Graben-Freedom Flats - 6400 Bench) | 142 |

ix

| Figure 17.24 – Example of the Relationship between Drill Hole Spacing / Density and Resource Classifications (Graben-Freedom Flats – 6300 Bench) | 143 |

| Figure 17.25 – Extent of the Silicification Envelopes in the North Modeled Area | 144 |

| Figure 17.26 – Silicification and Argillic Envelopes in the North Modeled Area | 145 |

| Figure 17.27 – Overall Site Plan | 154 |

| Figure 23A.1 – General Site Map Showing North and South Model Areas | 190 |

| Figure 23A.2 – East Model Area | 191 |

| Figure 23A.3 – West Model Area | 191 |

| Figure 23B.1 – Overall Flow Diagram | 197 |

| Figure 23B.2 – Site Plan | 198 |

| Figure 23G2.1 – Projected Income Statements | 237 |

| Figure 23G2.2 – Projected Balance Sheets | 238 |

| Figure 23G2.3 – Projected Statements of Cash Flow | 239 |

| Figure 23H.1 – Project Sensitivity | 251 |

Table of Tables

| Table 1.1 – Estimated Gold Recovery | 13 |

| Table 1.2 – Borealis Minable Gold Reserve Estimate – May 2009 | 15 |

| Table 1.3 – Borealis Minable Silver Reserve Estimate – May 2009 | 15 |

| Table 1.4 – Borealis Mineral Resource Estimate – September 2008 | 16 |

| Table 1.5 – Mineable Reserves by Ore Type at $800 per ounce Gold | 18 |

| Table 6.1 – Reported Past Borealis Production, 1981-1990 | 41 |

| Table 6.2 – Comparison of Historical Post-Mining Resource Estimates | 45 |

| Table 13.1 – Analytical Results of Bulk Sample from Road Cut Midway Between Top and Bottom of Heap 2 | 84 |

| Table 13.2 – Summary of Analytical Results from Bulk Standard Used in Quality Control Program, Accepted Value 0.019 opt Au | 84 |

| Table 13.3 – Summary of Assay Analyses for the Same Sample by American Assay Laboratories and ALS Chemex | 84 |

| Table 13.4 – Comparison of Heap 1 Assay Results with Previous Sampling Program | 85 |

| Table 14.1 – Results of Selective Check Sampling at Borealis | 90 |

| Table 16.1 – Summary Metallurgical Results, Scoping Bottle Roll Tests | 95 |

| Table 16.2 – Bottle Roll Gold and Silver Recoveries | 99 |

| Table 16.3 – Alteration and Grade for Bulk Density Samples | 101 |

| Table 16.4 - Bulk Densities for Resource Estimation | 102 |

| Table 17.1 – Mine Cutoff Grade (“COG”) Parameters | 106 |

| Table 17.2 – Existing Heaps, ROM COG | 107 |

| Table 17.3 – Mineable Reserves by Ore Type at $800 per ounce Gold | 107 |

x

| Table 17.4 – Pit Design Parameters | 108 |

| Table 17.5 – Block Model Dimensions and Location Parameters | 110 |

| Table 17.6 – Digitized Production Maps | 112 |

| Table 17.7 – Modeled Blast Holes | 112 |

| Table 17.8 – Geologic Formation Model | 123 |

| Table 17.9 – Geologic Oxidation State Model | 124 |

| Table 17.10 – Summary of Basic Gold Grade Composite Statistics by Deposit (Inside Grade Zones) | 125 |

| Table 17.11 – Gold Grade Variogram Summary | 131 |

| Table 17.12 – First Pass (Measured) Search and Weighting Parameters for Inverse Distance Estimation | 138 |

| Table 17.13 – Second Pass (Indicated) Search and Weighting Parameters for Inverse Distance Estimation | 139 |

| Table 17.14 – Third Pass (Inferred) Search and Weighting Parameters for Inverse Distance Estimation | 140 |

| Table 17.15 – Summary Statistics of Argillic and Silicic Rock Codes | 144 |

| Table 17.16 – South Model Variogram Structure | 146 |

| Table 17.17 – South Model Variogram Structure | 146 |

| Table 17.18 – Comparison of Mined-Out Portions of Resource Model to Reported Production | 147 |

| Table 17.19 – Measured and Indicated Sulfide Resource at 0.040 opt | 148 |

| Table 17.20 – Measured and Indicated Sulfide Resource at 0.049 opt | 149 |

| Table 17.21 – Measured and Indicated Sulfide Resource at 0.060 opt | 149 |

| Table 17.22 – Insitu Oxide and Sulfide Resources | 149 |

| Table 17.23 – Borealis Minable Measured and Indicated Gold Reserves | 150 |

| Table 17.24 – Borealis Minable Measured and Indicated Silver Reserves | 150 |

| Table 17.25 – Heap Name Correlation Chart | 151 |

| Table 17.26 – Production Volumes Versus Measured Heap Volumes | 152 |

| Table 17.27 – Reconciliation Waste Volumes Versus Measured Dump Volumes | 153 |

| Table 17.28 – Borealis Project March 2006 Mineral Resource Estimate | 153 |

| Summary of Indicated Resource in Heaps | 153 |

| Table 17.29 – Borealis Project March 2006 Mineral Resource Estimate | 154 |

| Summary of Inferred Resource in Heaps and Dumps | 154 |

| Table 18.1 – Other Minor Permits and Authorizations | 164 |

| Table 23A.1 – Borealis Mine Schedule | 188 |

| Table 23B.1 – Heap Leach Pad Design Criteria (By Knight Piésold) | 203 |

| Table 23B.2 – Recycle and Storm Water Pond Design Criteria (By Knight Piésold) | 205 |

| Table 23B.3 – Heap Leach Pad Water Balance Input Parameters (By Knight Piésold) | 206 |

| Table 23G1.1 – Capital Cost Summary | 228 |

xi

| Table 23G2.1 – Anticipated Contract Mining Equipment | 232 |

| Table 23G2.2 – Labor Requirements, Mining | 233 |

| Table 23G2.3 – Labor Requirements, Heap Leach and ADR Plant | 234 |

| Table 23G2.4 – Process Reagents, Heap Leach and ADR Plant | 235 |

| Table 23G2.5 – Processing Summary, Heap Leach and ADR Plant | 235 |

| Table 23G2.6 – Annual G & A Cost Summary | 236 |

| Table 23H.1 – Project Financial Summary | 250 |

xii

| 1.0 Executive Summary |

1.1 Introduction

This report presents the results of a pre-feasibility study that has been prepared for filing pursuant to National Instrument 43-101 (“NI 43-101”), Standards of Disclosure for Mineral Projects of the Canadian Securities Administrators in connection with the potential to develop a gold and silver resource at the Borealis property in Mineral County, Nevada. The report was prepared at the request of Gryphon Gold Corporation.

This pre-feasibility study is based on open pit mining and heap leaching of oxide and mixed oxide ores that occur in and around previously mined open pits and re-leaching of ores that were mined and leached during prior operations. For purposes of performing economic models of the proposed operations, a combination of measured and indicated oxide and mixed oxide material were included. Inferred mineralization was not included in the resource models. Although a large sulfide resource has been located on the Borealis property, the potential for recovery of precious metals from these ores are not included in the economics for the current project.

The purpose of this study is to provide a capital and operating cost model for mine development for the Borealis project. The resource estimates used in this analysis have been updated to May 2009 and include assays from 29,834 historical production blast holes to support the new resource classifications of measured, indicated and inferred. Prior resource estimates were reported in Technical Report on the Mineral Resources of the Borealis Gold Project Located in Mineral County, Nevada, USA, April 28, 2008. The effective date of this pre-feasibility study is July 20, 2009.

1.1.1 Terms of Reference

Borealis Mining Company (“BMC”), the wholly owned Nevada operating subsidiary of Gryphon Gold Corporation, is considering a resumption of mining and ore processing activities at the Borealis Mine Site. This pre-feasibility study was completed in an attempt to guide the exploration, expansion and development of the property in a manner that includes what is believed to be reasonably achievable resources. The principal operating permits for the south modeled area have been granted for the proposed mining operation.

Gold bearing material will be mined from existing and new pit areas and reclaimed from piles of previously processed ore and dump material. The material will be excavated by conventional open pit mining equipment. Ore will be crushed, agglomerated with lime, and stacked on a lined pad where it will be leached to recover contained gold and silver.

The Borealis Mine will produce 247,000 ounces of gold and 741,000 ounces of silver over five primary production years followed by one year of additional leaching.

1

There are no known environmental liabilities on the project site. Reclamation of new surface disturbances will be completed contemporaneously with mining operations as described in the Plan of Operations (“POO”) approved by the U.S. Forest Service (“USFS”) and the Reclamation permit from Nevada Division of Environmental Protection (“NDEP”). A reclamation bond in the approximate amount of $3,000,000 will be posted with the USFS to insure performance under the approved reclamation plan.

1.1.2 Basis of Study

The scope of work for this pre-feasibility study includes capital and operating cost models for the proposed project, using measured and indicated resources. The resources used have been updated by Telesto from previously published reports by incorporating assays from approximately 29,834 production blast holes from prior mining operations to improve the classification of measured, indicated and inferred resources. Earlier resource estimates generated by Steve Wolff and supervised by Dr. Roger Steininger were reported in April 28, 2008 in,Gryphon Gold Corporation Borealis Mining Company Canadian NI 43-101 Technical Report on the Mineral Resources of the Borealis Gold Project Located in Mineral County, Nevada, USA.

Results from the 2005-07 metallurgical test program (completed by McClelland Metallurgical Laboratories in Reno, Nevada) using material collected from development drilling and surface sampling have been utilized to support assumptions based on approximate production reports of 10 years of historical heap leaching activities at the mine in the 1980s.

The scope of work in this study includes sufficient engineering and planning to provide for an estimate of capital and operating costs in the accuracy range of +/- 15 percent.

The major units used in this report are those commonly used in the United States: dry short tons of 2,000 pounds (“tons”), troy ounces per short ton (“opt”), miles, feet, etc. Where metric units are used, such is noted.

1.2 Project Description and Location

The Borealis Gold Project is located in western Nevada, approximately 16 road miles southwest of the town of Hawthorne in the Walker Lane Mineral Belt and 12 miles northeast of the California border; see Figure 1.1 below. Hawthorne is 133 highway miles southeast of Reno and 314 highway miles northwest of Las Vegas.

2

(Source: Gryphon Gold, 2005)

Figure 1.1 – Location Map of the Borealis Project

This study includes oxide and mixed oxide ores suitable for heap leach processing. Precious metal-bearing material will be excavated by conventional open pit mining equipment, crushed, agglomerated with cement and lime, and stacked on a lined pad where it will be leached with a weak cyanide solution to recover contained gold and silver.

This pre-feasibility does not contemplate mining of any sulfide gold mineralization on the property. Sulfide material mined during normal operations will be treated as designated waste and stored appropriately to minimize the effects on the site environment.

The principal operating permits have been granted for the proposed mine for a heap leach operation for the central Borealis site. Acquisition of minor approvals, such as the artificial pond permit from the Nevada Department of Wildlife (“NDOW”), must be accomplished prior to project development and operation. These approvals are believed to be straightforward to obtain. The status of all approved permits is current and can be maintained with the appropriate fees being updated on an annual basis.

1.2.1 Land Status and Ownership

As of July 2009, the Borealis property is comprised of 751 unpatented mining claims of approximately 20 acres each totaling about 15,020 acres and one unpatented mill site claim of about 5 acres. Of the 751 unpatented mining claims, 128 claims are owned by others but leased to BMC, and 623 of the claims were staked by Golden Phoenix Minerals, Inc. (“Golden Phoenix”) or Gryphon Gold and transferred to BMC. All of the claims are shown on the US Bureau of Land Management (“BLM”) records as being in good standing. Claim fees for 2010 are scheduled to be made with the BLM in August 2009.

3

Mineral rights, through BMC as the owner or lessee of the claims, allow BMC to explore, develop, and mine the Borealis property subject to the prior procurement of required operating permits and approvals, compliance with the terms and conditions of the mining lease, and compliance with applicable federal, state, and local laws, regulations, and ordinances.

The term of the mining lease may be continued indefinitely as long as any mining, development, or processing is being conducted on the leased property on a continuous basis.

1.2.2 Royalty

Pursuant to the BMC Lease, a portion of the Borealis property including the 128 original core claims is subject to a floating rate net smelter return (“NSR”) royalty. Gryphon has the option to fix the floating rate at 5% for a fee. The initial mining operations will probably be located on the 128 claims in the core group.

The option to amend the royalty agreement was reported by Gryphon on August 22, 2008.

As described in the terms of the BMC Lease, the Borealis property is currently subject to advance royalty payments of approximately $9,590.00 per month. These advance royalty payments are subject to adjustments in the Consumer Price Index.

1.3 Access, Climate, Local Resources, and Infrastructure

Access to the Borealis property is gained from the Lucky Boy Pass gravel road located about 2 miles south of Hawthorne from Nevada State Highway 359.

The nearest available services for both mineral exploration and mine development and operations are in the small town of Hawthorne, located about 16 road miles to the northeast of the project area via a wide, well-maintained gravel road. Hawthorne has substantial housing, adequate fuel supplies, and a sufficient infrastructure available to take care of basic needs. For other goods and services, sources in Reno and elsewhere could supply any material required for the development project and mine operations.

The Borealis project area had been reclaimed to early 1990s standards. No buildings or power lines remain on the surface although a major electrical trunk line crosses the property and lies about 2 miles from the former mine site. The pits and the project boundary are fenced for public safety. Currently, access to the pits and heap leaching areas is gained through locked gates. All currently existing roads in the project area are two-track roads with most located on reclaimed haul roads. Water for the historical mining operations was supplied from a well field in a topographically isolated basin located approximately 3 miles south of the planned mine site. This well field will be redeveloped for the new project.

4

The elevation on the property ranges from 7,200 feet to 8,200 feet above sea level. Topography ranges from moderate and hilly terrain with rocky knolls and peaks to steep and mountainous terrain in the higher elevations. This relatively high elevation produces moderate summers with high temperatures in the 90°F range. Winters can be cold and windy with temperatures dropping to 0°F. Average annual precipitation is approximately 10 inches, part of which occurs as up to 60 inches of snowfall. Historically in the 1980s, the mine operated throughout the year with only limited weather related interruptions.

Predominate vegetation species include pinion pine, Utah juniper, greasewood, a variety of sagebrush species, crested wheat grass and fourwing saltbush from previous reclamation activities (JBR Environmental Consultants, 2004).

1.4 Property History

In 1978, the Borealis gold deposit was discovered by S.W. Ivosevic (1979), a Houston International Minerals Company geologist (a subsidiary of Houston Oil and Minerals Corporation). The property was acquired through a lease agreement with the Whitney Partnership, which later became the Borealis Partnership, following Houston’s examination of the submitted property. Initial discovery of ore-grade gold mineralization in the Borealis district and subsequent rapid development resulted in production beginning in October 1981 as an open-pit mining and heap leaching operation. Tenneco Minerals, Inc. (“Tenneco”) acquired the assets of Houston International Minerals in late 1981 and continued production from the Borealis open-pit mine. Subsequently, several other gold deposits were discovered along the generally northeast-striking Borealis trend and mined by open-pit methods. Also, several small deposits were discovered further to the west in the outlying area known as Orion’s Belt (encompassing the Cerro Duro, Jaimes Ridge, and Purdy Peak deposits). Tenneco’s exploration in early 1986 discovered the Freedom Flats deposit and then in October 1986, Echo Bay Mines (“Echo Bay”) acquired the Nevada assets of Tenneco Minerals.

With the completion of mining of the readily available oxide ore in the Freedom Flats deposit and other deposits in the district, active mining was terminated in January 1990, and leaching operations ended in late 1990. All eight open-pit operations are reported to have produced 10.7 million tons of ore averaging 0.059 opt Au (Golden Phoenix Minerals, 2000). Gold recovered from the material placed on heaps was approximately 500,000 ounces plus an estimated 1.5 million ounces of silver. Reclamation of the closed mine began immediately and continued for several years.

Echo Bay decided not to continue with its own exploration, and the property was farmed out as a joint venture in 1990-91 to Billiton Minerals, which drilled 28 reverse circulation (“RC”) exploration drill holes totaling 8,120 feet on outlying targets. Billiton dropped the property with no retained interest. Santa Fe Pacific Mining, Inc. (“Santa Fe Pacific”) then entered into a joint venture with Echo Bay in 1992-93 (Kortemeier, 1993), compiled data, constructed a digital drill hole database, and drilled 32 deep RC and core holes, including a number of holes into the Graben deposit. Santa Fe Pacific had success in identifying new sulfide-zone gold mineralization but terminated the joint venture because of reduced exploration budgets. Echo Bay completed all reclamation requirements in 1994, and then terminated its lease agreement with the Borealis Partnership in 1996.

5

In late 1996, J.D. Welsh & Associates, Inc. (“Welsh”) negotiated an option-to-lease agreement for the Borealis property from the Borealis Partnership and immediately joint-ventured the project with Cambior Exploration U.S.A., Inc. (“Cambior”). During 1996, Welsh drilled 11 auger holes (totaling 760 feet) into Heap 1 to determine if there was sufficient remaining gold to consider reprocessing the heap. During 1997, Cambior performed a major data compilation program and several gradient Induced Polarization (“IP”) surveys. In 1998, Cambior drilled ten holes, which succeeded in extending the Graben deposit and in identifying new zones of gold mineralization near Sunset Wash. Cambior terminated the joint venture in late 1998 because of severe budget constraints.

During the Cambior joint-venture period in late 1997, Golden Phoenix entered into an agreement to purchase a portion of the Welsh interest in the property. Welsh sold its remaining interest in the property to a third party, who in turn sold it to Golden Phoenix; therefore, in 2000 the company controlled 100 percent interest in the lease (Golden Phoenix Minerals, 2000). Golden Phoenix maintained the property during the years of low gold prices, compiled a database, validated the drill hole data, and developed new mineral resource estimates for the entire property.

In July 2003, the Borealis property was joint-ventured by Golden Phoenix with BMC, which is a wholly owned subsidiary of Gryphon Gold Corporation. BMC, the operator of the joint venture, originally controlled the property through an option agreement with Golden Phoenix whereby BMC could earn a 70 percent joint-venture interest in the property. BMC had the right to acquire its interest in the Borealis property with a combination of qualified expenditures on work programs, and/or making payments to Golden Phoenix, and/or delivering a feasibility study over a period of 5½ years beginning July 2003. In January 2005, BMC purchased 100 percent interest in the lease agreement, and Golden Phoenix surrendered its interest in the property. During 2004 and 2005-07, Gryphon Gold conducted two drilling programs.

1.5 Geology and Mineralization

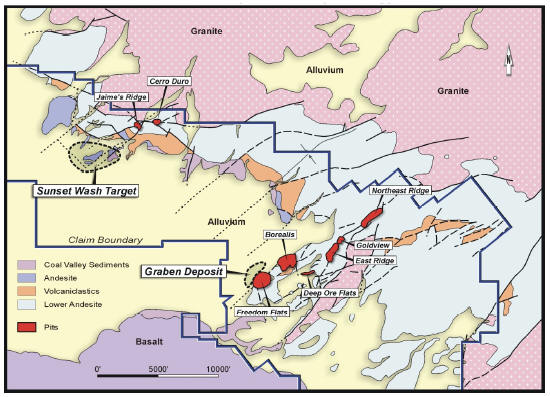

Epithermal gold and silver mineralization at Borealis is hosted by Miocene pyroclastic rocks/ tuffs, andesite flows, dacite flows, and laharic breccias. These volcanic units together exceed 1,200 feet in thickness, strike northeasterly, and dip shallowly to the northwest. Pediment gravels cover the volcanic rocks at lower elevations along the mountain front where drilling has identified large areas of hydrothermal alteration. Structures are dominantly northeast-striking faults with steep dips and generally west-northwest-striking faults with steep southerly dips. Both of these fault systems lie on regional trends of known mineralized systems; thus, Borealis appears to be at a major intersection of structural and mineralized trends. Another strong control for alteration/ mineralization within the district is a series of north to north-northeast-trending structures that host the Graben deposit and other exploration targets. A number of these pre-mineral faults in the district may have been feeders for high-sulfidation hydrothermal systems. Figure 1.2 illustrates the local geology of the Borealis district and project area.

6

(Source: Echo Bay Mines, circa 1989, modified to reflect new property boundaries controlled by Gryphon Gold in July 2009)

Figure 1.2 – Local Geology of the Borealis District and Project Area

Gold mineralization is often associated with hydrothermal breccias, pervasive silica, and sulfides, principally pyrite. It is likely that the higher-grade deposits may have been localized along the intersections of small second-order faults with the major feeder structures. Many of the oxide deposits at the project site, such as the Borealis deposit, have a flat-lying tabular shape and appear to have formed within gently dipping volcanic units. The pyroclastic/tuff unit is the most favorable host for gold mineralization. Alteration and mineralization closely associated with ore-grade material are fine-grained vuggy to massive silica and pyrite often with and enveloped by advanced-argillic alteration including alunite and dickite. Outward from the central silica zone is a zone that may contain kaolinite, quartz, pyrite, dickite, and diaspore, and is surrounded by montmorillonite and pyrite, and finally an outermost broad propylitic halo with minor pyrite. Large bodies of opaline and microcrystalline silica occur peripheral to some mineralized zones. During its emplacement, finely-disseminated gold found in the Borealis mineralizing system was enclosed in pyrite, and through natural weathering and oxidation, this gold was released and made available to extraction by cyanidation. Gold still bound in pyrite or pyrite-silica is not recovered easily by a simple cyanide heap leach operation. Widely-spaced drilling indicates that pediment gravels cover the majority of the altered and mineralized volcanic rocks over a 7-mile-long zone in the southern and southwestern parts of the district. Much of this area has received only minor testing with systematic multidisciplinary exploration. Pediment gravels overlie many of the best exploration targets in the district.

7

1.6 History of Exploration Activities

Since the late 1970s, exploration has been completed at the Borealis property with the primary objective of finding near-surface oxidized gold deposits. Exploration work has consisted of field mapping, surface sampling, geochemical surveys, geophysical surveys, and shallow exploration drilling.

Resistivity surveys were successfully used in the early exploration of the district to track favorable trends of strong silica alteration that is commonly associated with gold deposits. Chargeability anomalies were found later with the use of IP surveys that penetrated deeper to the sulfide zones and were found to reflect strong sulfide systems, for example, the Graben. Aeromagnetic data provide useful tools to identify potential hydrothermal alteration systems as magnetic lows, many of which are shown in medium to dark blue on Figure 1.3. An example of an interpretation of resistivity data is shown on Figure 1.4.

8

(Source: Echo Bay Mines, circa 1989)

Figure 1.3 – 1989 Borealis District Aeromagnetic Survey Map

(Source: J. Anzman and Gryphon Gold, 2005)

Figure 1.4 – Selected Resistivity Anomaly Trends of the Borealis District

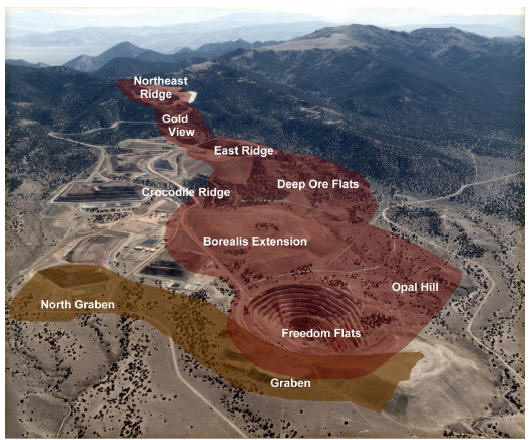

Areas with known occurrences of gold mineralization which are defined by historical exploration drilling and had historical mine production include Northeast Ridge, Gold View, East Ridge, Deep Ore Flats (also known as Polaris), Borealis, Freedom Flats, Cerro Duro and Jaimes Ridge. All of these deposits still contain gold mineralization remaining in place, contiguous with the portions of each individual deposit that were mined.

9

1.7 Drill Hole Database

The historical exploration and development drill hole database used for the Borealis project resource models contains 2,417 drill holes with a total drilled length of 671,595 feet. These holes were drilled by several different operators on the property. Drill hole types include diamond core holes, RC holes and rotary holes. Drill hole sampling lengths are generally 5 feet for the RC holes but vary for the core holes based on geologic intervals. Gold assays in parts per billion (“ppb”) and opt are provided for most of the drill hole sample intervals. Silver assays in parts per million (“ppm”) and opt are also provided for many of the sample intervals.

Mineralized zones covered by these drill holes include Northeast Ridge, Gold View, East Ridge, Deep Ore Flats, Borealis, Freedom Flats, and Graben. Except for Graben, all have been partially mined by previous operators of the project; the Borealis and Deep Ore Flats Pits are backfilled with waste from the Freedom Flats Pit. The drill holes in the west model area are mostly in the Cerro Duro, Jaimes Ridge, and Purdy Peak areas, at approximately 3 miles northwest of the main Borealis Mine site. Cerro Duro and Jaimes Ridge areas were also partially mined. Drill holes in the East Model area are mostly in the Boundary Ridge and Bullion Ridge areas, about 1 mile northeast of the main Borealis Mine site.

Also included in the drill hole data are the auger holes drilled in the heaps by J.D. Welsh, and the sonic drilling of the five Borealis heaps and parts of the Freedom Flats and Borealis Mine dumps that were completed by Gryphon Gold in May 2004. The J.D. Welsh program consisted of 11 holes totaling 760 feet. The Gryphon Gold program consisted of 32 holes totaling 2,475.5 feet. Drilling by Gryphon Gold during late 2006 through November 2007 was added to the drill hole database and reported in Technical Report on the Mineral Resources of the Borealis Gold Project, April 28, 2008. The total Company exploration and development drilling in the database currently includes 252 drill holes and 153,000.5 feet of drilling. The total number of Company drill holes used in the resource models is 214 holes and 143,516 feet of drilling.

Added to the exploration and development drill data in March 2009 was blast hole assay data digitized from the original mine planning maps. This data included 29,834 blast holes, each with one gold assay value.

1.8 Sample Preparation, Analysis, and Security

1.8.1 Historical

The Borealis Mine site operated from 1981 through 1990 producing 10.7 million tons of ore averaging 0.059 opt Au from eight open pits. The mined ore contained about 635,000 ounces Au (Eng, 1991) of which approximately 500,000 ounces of gold was recovered through a heap leach operation. This historic production can be considered a bulk sample of the deposits validating the database that was used for feasibility studies and construction decisions through the 1980s. With over 2,400 drill holes that were compiled over a 30-year period by major companies, the amount of information on the project is extensive. It is primarily these data that have been used as the foundation of the current mineral resource estimate. The bulk of the data were collected beginning in 1978, the year of discovery of the initial ore-grade mineralization, and were continuously collected through the final year of full production. Subsequent explorers starting in the 1990s added to the database.

10

Little is known of the sample security arrangements made by the previous operators, but since the pits each produced the amounts of gold predicted or higher, it has been assumed that the security was adequate and it is unlikely that sample security was a problem. The same assumption is true for most of the subsequent explorers of the property – Billiton, Santa Fe Pacific, and Cambior – which were all substantial companies and probably used sound procedures.

1.8.2 Recent Programs

A sonic drilling program was undertaken in spring 2004 to confirm the amount and grade of gold-bearing rock that exists in heaps and dumps. The drilling provided samples for metallurgical test work to define the geotechnical conditions and to obtain sufficient samples to demonstrate the geotechnical characteristics for design purposes in the waste characterization database. A separate drilling program was undertaken to install baseline groundwater monitoring systems.

As part of this program, a sonic drill rig was used to drill exploratory holes on the five previously leached heaps, as well as the Freedom Flats and Borealis Pits waste dumps. A total of 32 holes for a total of 2,475.5 feet were drilled with samples collected and composited for each hole.

Sample intervals were originally designed to be every 10 feet but were contingent upon drilling conditions. Samples were taken to American Assay Laboratories, Inc. (“AAL”) of Sparks, Nevada for analysis. An industry standard quality control procedure was used for the sampling and assaying under the supervision of Dr. Roger Steininger and is considered to be NI 43-101 compliant.

1.9 Data Limitations

Much of the data from historical records of drilling, sampling, sample security, and assay procedures is not documented to NI 43-101 standards; however the drill hole database was verified by Mr. Steven Craig, a Qualified Person for the purpose of Canadian NI 43-101 for Golden Phoenix, during an 8-month intensive effort by reviewing every one of the 2,417 historical drill holes and over 125,000 assays on original sheets and comparing them line by line with the database, ensuring that only accurate information was in the database. Where several valid assays were found for a single interval, they were averaged to determine the grade used in the database. Drill hole collar location surveys on original sheets were also compared to the database information and improved where necessary. Down-hole survey information on original sheets for the deeper holes were also reviewed and compared with the database to ensure its accuracy.

11

Original mine planning maps were retrieved from Gryphon’s project files and the hole location, elevation and gold assay value were digitized. The elevation and survey grid used in this data is consistent with current coordinates.

Information presented above describes the limitations imposed by the lack of certain historical records on verification of the data. Based on operating results and historical descriptions, it appears that the sampling, sample preparation, assaying, and security of samples were conducted in an industry acceptable manner for the time period in which the samples were collected and processed, and it is the geological Qualified Person’s opinion that the assays are suitable for mineral resource estimation.

1.10 Mineral Processing and Metallurgical Testing

Eight open pit mines were developed at the Borealis Mine site during its operating years from 1981 to 1990. They include the Northeast Ridge, Gold View, East Ridge, Deep Ore Flats, Borealis, Freedom Flats, Jaimes Ridge, and Cerro Duro mines. Each pit has associated waste-rock disposal areas proximal to their mine areas. Two of the pits, Borealis and Deep Ore Flats, were backfilled with mine waste produced from proximate pits. Processing of the ore was by conventional cyanide-agglomerated heap leaching using both permanent and reusable pads. Precious metals were recovered using a Merrill-Crowe process.

Historical heap leach operations throughout the 1980s typically produced gold recoveries in the upper 70 to mid-80 percent range. These ores were primarily oxide and mixed oxide-sulfide and required cement agglomeration in order to achieve suitable solution percolation, pH control, and precious metal dissolution. Previous heap leach operations also processed run-of-mine (“ROM”) ores (uncrushed), which were typically low-grade material that was stacked on the upper lifts of the heap leach pad (“HLP”). Historical gold recoveries for ROM ore ranged from 20 to 50 percent.

In 2004, the first phase of metallurgical test work was developed for the exploration drill samples. This work focused on determining the amenability of gold to cyanidation and the effect of particle size on gold recovery. The BMC geological staff collected 249 samples from historical leach pad areas and waste dumps for this program.

Subsequent metallurgical testing was developed in 2005 for a Phase 2 program that utilized samples collected from current exploration drilling in fresh gold mineralized zones. A total of 77 bottle roll tests were completed from these data. In addition, four bulk samples were collected from near-surface trenches for column leach tests. There has been no current test work performed on ROM-sized samples.

12

Table 1.1 below summarizes the expected metal recovery from the respective mineralized material locations.

| Table 1.1 – Estimated Gold Recovery | ||

| Range of Au Recovery (%) | Estimated Au Recovery (%) |

| Borealis Upper | 62 – 86 | 78.0 |

| Borealis Main | 62 – 86 | 78.0 |

| Deep Ore Flats | 59 – 85 | 74.1 |

| Freedom Flats | 20 – 80 | 75.0 |

| Gold View/East Ridge | 40 – 92 | 63.4 |

| Northeast Ridge | 37 – 85 | 70.0 |

| Middle Ridge | 46 – 92 | 76.3 |

| Orion’s Belt | 55 – 94 | 75.3 |

| Old Leach Pads | – | 43.3 |

| ROM Leach Pads | – | 50.9 |

| Dump Material | 62 – 86 | 71.3 |

1.10.1 Processing

Surface mined ore will either be processed by crushing to a size of 80 percent less than 1 inch or will be placed as ROM on the HLP, depending on the grade of the ore. After crushing, ore will be agglomerated with lime and cement and conveyor stacked onto the HLP. Barren cyanide solution from the Adsorption, Desorption and Refining (“ADR”) plant will be pumped through a pipe network to distribute the solution over the ore using drip tubes. After gold and silver is dissolved, the resulting pregnant leach solution will be collected and pumped to the ADR plant where the gold and silver will be removed from the solution using a carbon circuit followed by pressure stripping. Concentrated pregnant solution from the strip circuit will be pumped through electro-winning cells where the precious metals will be recovered as a metallic sludge. The sludge will be placed in a mercury retort for removal of residual mercury and drying. Finally, after mixing with fluxes, gold and silver doré will be produced in a melting furnace. The doré product will be shipped offsite for further refining.

1.11 Mineral Resource Estimates

The mineral resource estimate for the Borealis Gold Project was prepared by Mr. Kim Drossulis of Telesto Nevada, Inc. based on a revised block model that included the use of variograms from historic blast hole assay data. This current model revises one prepared by Mr. Steve Wolff, mining engineer and consultant (not a Qualified Person for the purpose of Canadian NI 43-101). The study area encompasses the core of the BMC holdings and the principal gold deposits with known mineral resources.

13

1.11.1 Mineral Resource Model

Four three-dimensional block models, known as North, South, East, and West, were used to estimate the gold resource on the property. Each of these models used 20 by 20 by 20-foot blocks and three of the four were rotated so that model north was N 50° E. The North and South models overlap slightly to more easily maintain continuity across model boundaries. The West Area model also used 20- by 20- by 20-foot blocks but was not rotated.

Drill Hole Data: There are 2,669 exploration and development drill holes in the database of which 1,643 intersect zones of mineralization that are included in the resource estimate. Average grades inside the mineralized zones range from 0.007 opt Au to 0.084 opt Au. Variability of assays is moderate to high with coefficients of variation ranging from 1.02 to 3.33 within zones.

Additionally, there are gold assays from 29,834 blast holes that have been added to the data used to calculate the range of the variogram that establishes the new measured, indicated and inferred limits of the new resource model.

Mineral Resource Classification: Resource classifications were based on the drill hole grid spacing believed necessary to establish the continuity of mineralization (for indicated resources) and to provide reliable estimates for production planning (for measured resources). Internal cut-off grades used in the resource calculations varied from 0.006 opt for orebodies close to the heap, to 0.013 for legacy heap material, to 0.01 opt for new ore in the East and West orebodies (further from the heap). Inferred resource material is considered waste rock in this study.

Model Results: The minable reserve estimate for the pit areas for oxide and mixed oxide measured and indicated ore only is summarized in Table 1.2 for gold and in Table 1.3 for silver. In all cases, the quantities shown are for the remaining resource, below the mined-out topography.

The financial models prepared for this study use measured and indicated oxide and mixed oxide resources. Inferred mineral resources do not have demonstrated economic viability and were not considered in the economic model.

14

Table 1.2 – Borealis Minable Gold Reserve Estimate – May 2009

Summary of Measured and Indicated Reserves by Modeled Area

| Measured | Indicated | M&I | ||||||||

| Model | Cut-offGrade(opt) | Tons | Avg.AuGrade(opt) | ContainedOuncesGold | Tons | Avg.AuGrade(opt) | ContainedOuncesGold | Tons | Avg.AuGrade(opt) | ContainedOuncesGold |

South | 0.006 | 3,541,500 | 0.033 | 115,150 | 1,180,500 | 0.033 | 38,383 | 4,722,000 | 0.033 | 153,533 |

North | 0.006 | 3,639,000 | 0.014 | 50,600 | 1,213,000 | 0.014 | 16,867 | 4,852,000 | 0.014 | 67,467 |

East | 0.010 | 2,578,500 | 0.019 | 47,980 | 859,500 | 0.019 | 15,993 | 3,438,000 | 0.019 | 63,973 |

West | 0.010 | 961,500 | 0.032 | 30,437 | 320,500 | 0.032 | 10,146 | 1,282,000 | 0.032 | 40,583 |

Legacy Heaps | 0.013 | 1,767,000 | 0.022 | 38,850 | 589,000 | 0.022 | 12,950 | 2,356,000 | 0.022 | 51,800 |

Total | 12,487,500 | 0.023 | 283,017 | 4,162,500 | 0.023 | 94,339 | 16,650,000 | 0.023 | 377,356 | |

Table 1.3 – Borealis Minable Silver Reserve Estimate – May 2009

Summary of Measured and Indicated Reserves by Modeled Area

| Measured | Indicated | M&I | |||||||

| Model | Tons | Avg.AgGrade(opt) | ContainedOuncesSilver | Tons | Avg.AgGrade(opt) | ContainedOuncesSilver | Tons | Avg.AgGrade(opt) | ContainedOuncesSilver |

South | 3,541,500 | 0.45 | 1,610,949 | 1,180,500 | 0.45 | 536,984 | 4,722,000 | 0.45 | 2,147,932 |

North | 3,639,000 | 0.08 | 304,070 | 1,213,000 | 0.08 | 101,357 | 4,852,000 | 0.08 | 405,427 |

East | 2,578,500 | 0.01 | 20,806 | 859,500 | 0.01 | 6,935 | 3,438,000 | 0.01 | 27,741 |

West | 961,500 | 0.26 | 254,490 | 320,500 | 0.26 | 84,830 | 1,282,000 | 0.26 | 339,320 |

Legacy Heaps | 1,767,000 | 0.13 | 229,710 | 589,000 | 0.13 | 76,570 | 2,356,000 | 0.13 | 306,280 |

Total | 12,487,500 | 0.19 | 2,420,025 | 4,162,500 | 0.19 | 806,676 | 16,650,000 | 0.19 | 3,226,700 |

The inferred mineral resource estimate for the modeled areas is summarized in Table 1.4. The heap and dump estimate was completed in April 2005, based on Gryphon Gold/Welsh drilling. The mineral resource Qualified Person has reviewed this estimate and determined that it is reasonable and complies with the NI 43-101 definitions and current resource estimating criteria.

Dump and heap resource estimates are classified as indicated and inferred based on drill hole spacing of approximately 200 feet and projections of less than 200 feet beyond drill holes.

15

Table 1.4 – Borealis Mineral Resource Estimate – September 2008

Summary of Inferred Mineralization – Combined Oxide and Mixed Material

| MaterialClass | Deposit | Au Cutoff(opt) | Tons(1,000s) | Au Grade(opt) | Ag Grade(opt) | Containedoz Gold | Containedoz Silver |

Oxide | Freedom Flats | 0.010 | 313 | 0.035 | 0.052 | 10,995 | 16,276 |

| Borealis | 0.010 | 374 | 0.023 | 0.195 | 8,602 | 72,930 | |

| Deep Ore Flats | 0.010 | 1,353 | 0.020 | 0.325 | 27,060 | 439,725 | |

| East Ridge | 0.010 | 880 | 0.017 | 0.078 | 14,960 | 68,640 | |

| Northeast Ridge | 0.010 | 1,023 | 0.016 | 0.062 | 16,368 | 63,426 | |

| Boundary Ridge | 0.010 | 330 | 0.018 | 0.056 | 5,940 | 18,480 | |

| Bullion Ridge | 0.010 | 4,928 | 0.017 | 0.011 | 83,776 | 54,208 | |

| Cerro Duro | 0.010 | 67 | 0.026 | 0.452 | 1,742 | 30,284 | |

| Jaimes Ridge | 0.010 | 159 | 0.018 | 0.040 | 2,862 | 6,360 | |

| Purdy Peak | 0.010 | 65 | 0.015 | 0.104 | 975 | 6,760 | |

| Alluvium / Tcv | 0.010 | 247 | 0.017 | 0.074 | 4,199 | 18,278 | |

| Total Oxide | 9,739 | 0.018 | 0.082 | 177,439 | 795,367 | ||

Mixed Material | Freedom Flats | 0.010 | 3 | 0.013 | 0.366 | 39 | 1,098 |

| Borealis | 0.010 | 63 | 0.016 | 0.084 | 1,008 | 5,292 | |

| Deep Ore Flats | 0.010 | 488 | 0.021 | 0.403 | 10,248 | 196,664 | |

| East Ridge | 0.010 | 1,800 | 0.016 | 0.086 | 28,800 | 154,800 | |

| Northeast Ridge | 0.010 | 1,594 | 0.021 | 0.105 | 33,474 | 167,370 | |

| Boundary Ridge | 0.010 | 0 | 0.000 | 0.000 | 0 | 0 | |

| Bullion Ridge | 0.010 | 0 | 0.000 | 0.000 | 0 | 0 | |

| Cerro Duro | 0.010 | 0 | 0.000 | 0.000 | 0 | 0 | |

| Jaimes Ridge | 0.010 | 6 | 0.016 | 0.097 | 96 | 582 | |

| Purdy Peak | 0.010 | 13 | 0.016 | 0.073 | 208 | 949 | |

| Alluvium / Tcv | 0.010 | 0 | 0.000 | 0.000 | 0 | 0 | |

| Total Mixed Material | 3,967 | 0.019 | 0.133 | 73,873 | 526,755 | ||

| Total Inferred Oxide + Mixed Material | 13,706 | 0.018 | 0.096 | 251,312 | 1,322,122 | ||

Inferred resources were not included in the economic model due to lack of sufficient verification by drilling and other uncertainties. Additional drilling, assaying, and metallurgical testing may result in reclassification of a portion of the inferred resources to either waste or to a measured and indicated resource category.

16

1.12 Other Important Considerations

The Borealis property is located on public lands partly within the Humboldt-Toiyabe National Forest, Bridgeport Ranger District, and BLM-administered lands. Because most activity to date has been within the USFS-administered lands, the POO for this activity is subject to USFS approval and environmental analysis under the National Environmental Policy Act (“NEPA”). A project of this magnitude typically requires the preparation and approval of either an Environmental Assessment (“EA”) or an Environmental Impact Statement (“EIS”) with the EIS process generally being longer and more comprehensive. Since the Borealis project area has been extensively affected by previous mining operations, the USFS determined that resuming mining operations at the Borealis property would have no significant impact to public lands and that an EA would satisfy the NEPA requirements for this project. The Cerro Duro, Jaimes Ridge, and Purdy Peak resources and the exploration targets in the Central and West Pediment areas are within the BLM jurisdiction and require BLM approval for exploring or mining.

1.12.1 Permitting

The principal operating permits required for construction, operation, and closure of the Borealis mine have been acquired from Nevada state and Federal regulatory agencies as of the date of this report. The approvals received cover a 10 million-ton project within the central operating area and include an exploration program within that operating area that recognizes the potential to expand the resource base with successful exploration results. Expansion of the project plans beyond 10 million tons will require routine modification of the operating permits. There are no known issues that would preclude the approval of such routine modifications by the applicable regulatory agencies.

The operating permits cover only the central operating area and exclude some of the Middle Ridge area and Orion’s Belt. The deposits in Orion’s Belt have been subject to recent mining operations and have been successfully reclaimed. No fatal flaws or material concerns which would preclude the permitting and development of mining operations in this area have been identified, although the timing of such permitting processes is uncertain.

1.13 Financial Model Results

A cash flow model for the project was prepared using measured and indicated resources. Capital and operating costs were estimated based on recent contractor quotations and Telesto estimates. Gold and silver recovery was estimated based on historical results and recent testing. Mine production schedules were generated using open pit planning software.

The Borealis project will mine a total of 9.0 million tons of oxide ore, 1.3 million tons of mixed ore, 4.0 million tons of ROM ore, 2.4 million tons of historical heaps, 0.5 million tons of sulfide material and 19.2 million tons of waste rock. The ore plus ROM strip ratio is 1.38 to 1. These amounts are shown below in Table 1.5 (Mineable Reserves by Ore Type at $800 per ounce Gold.)

17

Table 1.5 – Mineable Reserves by Ore Type at $800 per ounce Gold

| Material | Ore k-tons | Au (opt) | Au oz | Wastek-tons |

| Oxide | 8,926 | 0.028 | 245,690 | |

| Mixed Oxide | 1,320 | 0.032 | 42,402 | |

| ROM | 4,048 | 0.009 | 37,464 | |

| Previously Processed Heaps | 2,356 | 0.022 | 51,800 | |

| Sulfide1 | 478 | 0.046 | 21,974 | |

| Total | 16,650 | 0.023 | 377,356 | 19,204 |

1Sulfides listed here are reported as Designated Waste and do not add to ounces in this table.

The results of the financial model at an $800 gold price are:

| » | Initial Capital Cost | $22.6 million | |

| » | Cash Operating Cost | $476/ounce of gold equivalent | |

| » | Net Present Value @ 5% Discount Rate | $12.5 million | |

| » | Payback Period | 2.25 years |

Life of Mine (“LOM”) Capital Costs are summarized as follows:

| » | Mine | $11.9 million (assumes contract mining and owner crushing) | |

| » | Leach/Process/Infrastructure | $ 9.0 million | |

| » | Owners (including closure) | $ 9.0 million | |

| » | Contingency | $ 1.0 million | |

| » | Total Capital | $30.9 million |

Life of Mine Operating Costs

| » | Mining and leaching | $111.3 million | |

| » | Processing | 14.5 million | |

| » | General and Administrative (“G & A”) | 10.2 million | |

| » | Total Operating Cost | $136.0 million | |

| » | Operating Margin | $59.9 million |

1.14 Sensitivity

Sensitivities to gold price and recovery, construction capital, operating costs, and silver price and recovery, were completed and the after-tax Internal Rate of Return (“IRR”) was measured. The base case IRR for the project was calculated at an after-tax rate of 27%. Figure 1.5 shows the projected change in IRR (expressed as a percent) for each percentage change in the underlying assumption.

18

Figure 1.5 – Project Sensitivity

Gold Price and Recovery: The base gold price for the economics was US$800 per ounce. For each 1% change in the gold price, the IRR of the project changes by approximately 2%. The sensitivity is the same for gold recovery, for each 1% change in the base assumption for gold recovery, the IRR of the project changes by approximately 2%. The project IRR is most sensitive to changes in gold price and gold recovery.

Operating Costs: The base case operating costs were increased and decreased to determine the project sensitivity to changes. For each 1% change in operating costs, the project IRR changes by approximately 1.5%. The project sensitivity to changes in operating costs is exceeded only by its sensitivity to gold price.

Capital Costs: Construction capital was varied to determine its sensitivity. For each 1% change in the cost of construction, the IRR changes by approximately 0.4%.

Silver Price and Recovery: Sensitivity was computed for changes in silver price and recovery. For each 1% change in silver price or recovery, the IRR changed by 0.1%. The project is least sensitive to changes in silver price.

Fuel Cost Sensitivity: A separate sensitivity was computed for the price of diesel fuel. The majority of diesel fuel will be consumed by the mining fleet operated by the contract miner. The financial model assumes that the fuel is directly purchased by Gryphon Gold and supplied to the contract miner. The base case financial model utilized off-road diesel fuel costs of US$2.25 per gallon. For each US$0.50 change in the price of fuel, the project pre-tax cash flow changes by US$1.45 million over the life of the project.

19

1.15 Conclusions and Recommendations

Telesto Nevada, Inc. and the authors of this document recommend that the Borealis project be put into production.

Other goals of the Borealis Gold Project going forward are to increase current resources and discover and delineate new deposits within the greater Borealis property.

Analysis of the geologic data has identified a significant in-place mineral resource that supports an open pit, heap leach gold and silver mine. Based on historical operational data and similar deposits and projects in the area, the field-proven process technology selected (heap leach and ADR plant, using carbon adsorption) will be able to effectively produce gold and silver doré for sale.

Having successfully obtained the major permits from the USFS and the NDEP, environmental and permitting issues no longer represent a significant risk to future project development.

Further sampling of the historical heaps and dumps is recommended because of the immediate potential to move inferred resources into indicated resources that may be considered for reserves.

Exploration should be conducted along the known structural trends to move inferred resources into mineable reserves. Discovery potential in the Borealis district includes oxidized gold mineralization adjacent to existing pits and new oxide gold deposits at shallow depth. Expansion of gold mineralization adjacent to existing pits provides the best potential for rapid development of additional mineral resources. Projection of known mineralized structures and trends into covered areas provides the best potential for discovery of new deposits, including both near surface oxide and deeper sulfide systems.

In conjunction with the exploration program, metallurgical testing should be performed on representative core samples.

20

| 2.0 Introduction and Terms ofReference |

Gryphon Gold Corporation (referred to as “Gryphon Gold” or the “Company” in this report) is progressing with technical work at its 100 percent-owned Borealis Gold Project in Mineral County, Nevada, which will potentially allow the Company to produce gold and silver from the mine. The purpose of this pre-feasibility study is to provide a development model that includes enhanced geologic interpretation of additional data acquired and analyzed from 2005 through 2009 by Company geologists and engineers, upgrade certain resources, update capital and operating costs, and report on technical activities to date. The newly developed and updated resource model lies within a defined study area that falls within the area disturbed by previous mining activities. The deposits within the boundaries of the central study area have been approved for mine development by State and Federal regulatory agencies. Other known deposits containing mineral resources are located outside the limits of the central study area in outlying areas. No fatal flaws or material concerns, which would preclude mining operations in these areas, have been identified to date although the timing of such permitting processes is uncertain.

Resource models for several in-place gold deposits located within the boundaries of the central and outlying study areas were used for this study and include the following deposits: West Alluvial Deposit, Graben, Freedom Flats, Borealis, Crocodile Ridge, Deep Ore Flats (also known as Polaris), East Ridge, Gold View, Middle Ridge (located between Gold View and Northeast Ridge), Northeast Ridge, and also the Purdy Peak, Jaimes Ridge, and Cerro Duro deposits located further to the west, and Boundary Ridge and Bullion Ridge deposits located to the east. Resource estimates for deposits outside the study areas, but on claims controlled by Gryphon Gold, rely on historical drill hole data which were completed prior to the promulgation of the guidelines of Canadian NI 43-101.

21

(Based on information from Echo Bay Mines, circa 1989, modified by Gryphon Gold, 2005)

Figure 2.1 – Mineral Deposits and Prospects of the Borealis Property

Names of gold deposits and exploration targets are shown on Figure 2.1, which can be used as a reference to the geographic location and place names used in this report. Some of the most important exploration targets are reviewed in Section 10.0, Exploration.

Telesto mining engineer Mr. Kim Drossulis, working closely with Gryphon Gold and its other consultants, prepared new resource models. Additional input was provided by Knight Piésold regarding environmental, permitting, and metallurgical issues. In addition, Dr. Roger Steininger, CPG, was the Chief Consulting Geologist in regard to geology, sampling, and exploration.

The principal author of this technical report is John R. Danio, P.E., a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects. Mr. Danio visited the property for one day on March 5, 2008. Contributing to this report is Dr. Roger C. Steininger, Chief Consulting Geologist for Gryphon Gold, a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects. Dr. Steininger visited the Borealis property numerous times during 2003, 2004, 2005, 2006, 2007, 2008 and 2009. Jaye Pickarts, P.E., Principal Metallurgical Engineer, Knight Piésold, individually visited the Borealis property on several occasions during 2004, 2005, and 2006 for the duration of one day in each instance; he observed the district geologic setting and existing site conditions, and reviewed selective RC drill-sample intercepts of the mineralization for metallurgical purposes only and assisted in developing the metallurgical testing.

22

The following summarizes the technical experts and Qualified Persons who have contributed to this report under the general direction of the principal author:

● Mr. John R. Danio, P.E., a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects, is the principal author of this report. Mr. Danio is responsible for capital and operating cost estimates, mine production schedules and financial models. Mr. Danio is a graduate mining engineer with over 20 years of open pit, heap leach mine operating experience.

● Dr. Roger C. Steininger, Ph.D., CPG (AIPG), a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects, Consulting Chief Geologist for Gryphon Gold is responsible for geology, sampling, exploration and mineral resource estimates. Dr. Steininger is not independent of Gryphon Gold.

● Mr. Steven D. Craig, CPG (AIPG), a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects, Senior Consulting Geologist for Gryphon Gold assisted with for geology and permitting. Mr. Craig is not independent of Gryphon Gold.

● Mr. Kim Drossulis, not a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects. Mr. Drossulis prepared updated resource block models and conducted Learch Grossman pit optimization models based on mineral and economic parameters provided by other parties listed in this report.

● Mr. Jaye T. Pickarts, P.E., a Qualified Person for the purpose of Canadian NI 43-101, Standards of Disclosure for Mineral Projects, Principal Metallurgical Engineer, Knight Piésold and Co. Mr. Pickarts prepared the metallurgical test work evaluation and conceptual processing flow sheet.

Technical support has been provided by additional associates of these listed firms and individuals. Knight Piésold has provided support in the ongoing permit acquisition activities, geotechnical engineering, and metallurgical engineering (Knight Piésold and Co., 2003). Gryphon Gold provided staff support and assistance by drafting certain figures incorporated in the report (as credited below each illustration) and aiding in the final assembly of the report.

This study uses considerable existing information contained in Gryphon Gold’s Borealis project files. This information consists of several thousand pages of documents and data gathered during more than 20 years of exploration, development, mining, and post-mining reclamation activities at Borealis and includes exploration results, geophysical surveys, mineralogical analyses, geologic interpretations, metallurgical testing, design engineering, operating results, technical correspondence and scientific publications. Gryphon Gold converted this information to electronic format to allow for ease of search and recovery.

23

Archival information used in this study was provided by Gryphon Gold. The database has not been independently verified at this time. As the Borealis project advances, certain additional information will be gathered which will allow for further verification of historical results and confirmation of the possible technical concepts.

Drossulis and Steininger frequently undertake mineral property studies, and are familiar with the mineral resource definitions and disclosure requirements of Canadian NI 43-101. None of the principals involved in this project have any direct pecuniary or contingent interests of any kind in Gryphon Gold or its mining properties. Telesto is to receive a fee based on time expended and expenses incurred according to the Company’s standard fee schedule.

The major units used in this report are those commonly used in the United States – dry short tons of 2,000 pounds (tons), troy ounces per short ton (opt), miles, feet, etc. Where metric units are used, such is noted.

The following acronyms and abbreviations are used throughout this report:

| AAL: American Assay Laboratories |

| ADR: Adsorption, Desorption and Refining |

| Ag: Silver |

| AIPG: American Institute of Professional Geologists |

| AMC: Antecedent Moisture Condition |

| AMT: Alternative Minimum Tax |

| ASTM: American Society for Testing and Materials |

| Au: Gold |

| BA/BE: Biological Assessment and Biological Evaluation |

| BAPC: Bureau of Air Pollution Control |

| BECOG: Breakeven cutoff grade |

| BLM: U.S. Bureau of Land Management |

| BMC: Borealis Mining Company |

| BMRR: Bureau of Mining Regulation & Reclamation |

| BSDW: Bureau of Safe Drinking Water |

| BWPC: Bureau of Water Pollution Control |