Exhibit 99.2

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico |

| |

Report Prepared for Excellon Resources Inc.

|

Report Prepared by

SRK Consulting (Canada) Inc. 3CE016.008 October 30, 2020 |  |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page i |

Independent Technical Report

for the Evolución Polymetallic Project,

Miguel Auza, Zacatecas, Mexico

Excellon Resources Inc.

10 King Street East, Suite 200

Toronto, Ontario, Canada

M5C 1C3

E-mail: info@excellonresources.com

Website: www.excellonresources.com

Tel: +1 416 364 1130

Fax: +1 416 364 6745

SRK Consulting (Canada) Inc.

Suite 1500, 155 University Avenue

Toronto, Ontario, Canada

M5H 3B7

E-mail: toronto@srk.com

Website: www.srk.com

Tel: +1 416 601 1445

Fax: +1 416 601 9046

SRK Project Number 3CE016.008

Effective date: August 31, 2020

Signature date: October 30, 2020

Authored by:

| [Original signed] | | [Original signed] |

Joycelyn Smith, PGeo Consultant (Resource Geology) | | Aleksandr Mitrofanov, PGeo Senior Consultant (Resource Geology) |

| | | |

| [Original signed] | | |

Alfonso Soto, CPG Geologist | | |

Peer Reviewed by:

| [Original signed] |

Glen Cole, PGeo Principal Consultant (Resource Geology) |

Cover: Evolución Project site looking southeast towards the town of Miguel Auza.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page ii |

IMPORTANT NOTICE

This report was prepared as a National Instrument 43-101 Standards of Disclosure for Mineral Projects Technical Report for Excellon Resources Inc. (Excellon) by SRK Consulting (Canada) Inc. (SRK). The quality of information, conclusions, and estimates contained herein are consistent with the quality of effort involved in SRK’s services. The information, conclusions, and estimates contained herein are based on: i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Excellon subject to the terms and conditions of its contract with SRK and relevant securities legislation. The contract permits Excellon to file this report as a Technical Report with Canadian securities regulatory authorities pursuant to National Instrument 43-101. Except for the purposes legislated under provincial securities law, any other uses of this report by any third party is at that party’s sole risk. The responsibility for this disclosure remains with Excellon. The user of this document should ensure that this is the most recent Technical Report for the property as it is not valid if a new Technical Report has been issued.

© 2020 SRK Consulting (Canada) Inc.

This document, as a collective work of content and the coordination, arrangement and any enhancement of said content, is protected by copyright vested in SRK Consulting (Canada) Inc. (SRK).

Outside the purposes legislated under provincial securities laws and stipulated in SRK’s client contract, this document shall not be reproduced in full or in any edited, abridged or otherwise amended form unless expressly agreed in writing by SRK.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page iii |

Executive Summary

Introduction

The Evolución Project is an intermediate stage polymetallic silver-zinc-lead-gold exploration project near Miguel Auza on the border of Durango and Zacatecas States, Mexico. Excellon Resources Inc. (Excellon) owns 100% of the Evolución Project through its wholly owned Mexican subsidiaries, San Pedro Resources, S.A. de C.V. (San Pedro), Minera Excellon de Mexico, S.A. de C.V. (MEM), and Excellon New Mining Projects (ENMP).

This technical report documents a Mineral Resource Statement for the Evolución Project prepared by SRK Consulting (Canada) Inc. (SRK). It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1. The Mineral Resource Statement reported herein was prepared in conformity with generally accepted CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines (November, 2019).

In accordance with National Instrument 43-101 guidelines, Ms. Anna Fonseca, PGeo (APGO# 2194) visited the property from February 25 to 28, 2018, followed by Mr. Alfonso Soto, CPG (AIPG#11938) on July 22 and July 23, 2020 accompanied by Mr. Jorge Ortega, Geo (OGQ#626), Excellon’s Exploration Manager.

Property Description and Ownership

The Evolución Project covers approximately 45,433 hectares, comprising 22 mineral concessions (Table 1). Excellon holds, through its wholly owned Mexican subsidiaries, San Pedro, ENPM, and MEM, a 100% interest in these concessions

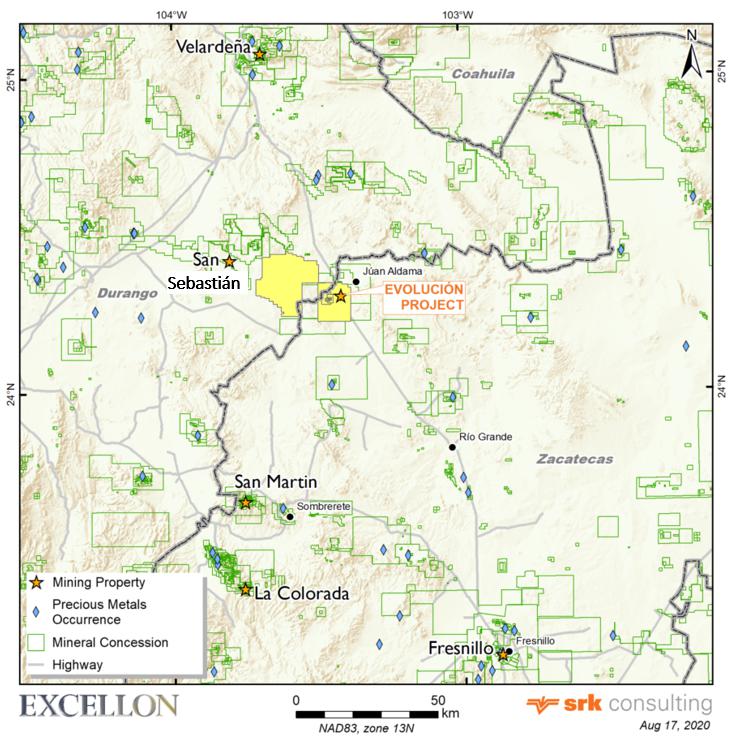

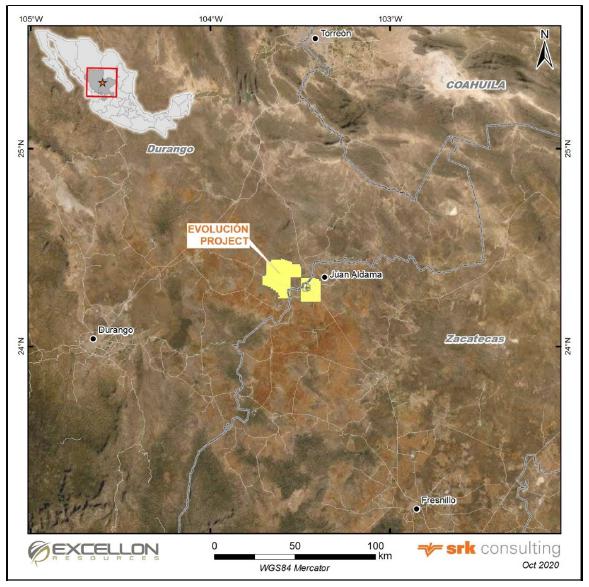

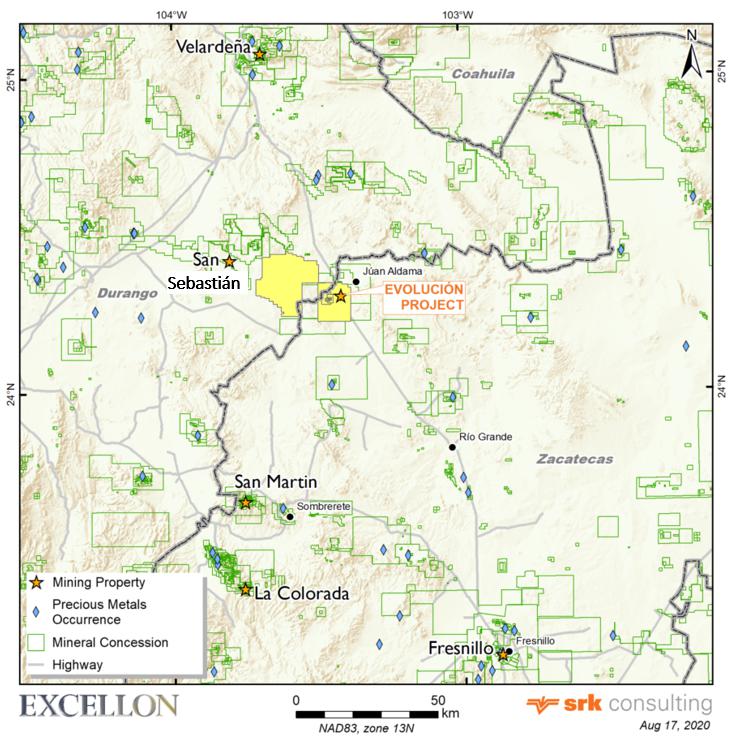

The Evolución Project is located in northern Zacatecas State on the high plateau of central Mexico, and surrounds and extends northwest of the town of Miguel Auza. The closest international airport is located in Torreón, Coahuila. The Project is approximately 200 kilometres by road south of Torreón. It can be reached via the highway system for a total travel time of approximately 2.5 hours. Toll Highway 40 south connects Cuencamé to Torreón, then paved Highway 49 is taken south- southeast to Miguel Auza.

Geology and Mineralization

The Evolución Project occurs on the Mesa Central physiographic province of central Mexico along the boundary between the Parral and Oaxaquia terranes of Gondwanic affinity, previously interpreted as the Sierra Madre Terrane.

The property is underlain by the upper Cretaceous Caracol Formation, which locally consists of a thick sequence of interbedded mudstone, siltstone, and lesser sandstones. Several small intrusive bodies of unknown age are present on the property, including a monzonite porphyry stock in the Miguel Auza area, and a smaller monzonitic stock that has been identified between the villages of Miguel Auza and Juan Aldama. Additional rhyolitic intrusions have been characterized to the east of Juan Aldama. Andesite and lamprophyre dykes occur proximal to areas of past historical production.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page iv |

Polymetallic epithermal mineralization occurs within veins that consist of massive to disseminated sulfide minerals with associated calcite, ankerite and quartz. Sulphide minerals include argentiferous galena, argentite with other silver sulphosalts, sphalerite, pyrite and arsenopyrite. Sulfide mineral content within the veins generally ranges between 15% to 25%. Oxidation processes produce alteration products of cerussite, smithsonite and various iron oxides.

Exploration Status

Since becoming the operator of the property, Excellon has conducted geological mapping, rock and soil geochemical sampling, ground geophysical surveys, fluid inclusion studies, and diamond drilling documented by detailed core logging.

Between 2005 and 2019, a total of 298 core drillholes (91,527 metres) were drilled throughout the Evolución Project by SEM and Excellon. The mineral resource evaluation discussed herein considers drilling information completed by SEM and Excellon. Drilling conducted by SEM focused on delineating the Calvario zone. Between 2010 and 2019, Excellon completed 58 core drillholes (24,555 metres) on the Evolución Project, of which 41 drillholes (17,244 metres) were drilled within the resource area, the majority of which focused on delineating the Lechuzas zone.

SRK is of the opinion that the drilling and sampling procedures adopted by Excellon are consistent with generally recognized industry best practices. The resultant drilling pattern is sufficiently dense to confidently interpret the geometry and the boundaries of the polymetallic mineralization.

Sample Preparation, Analyses, Security, and Data Verification

The exploration work conducted by Excellon was carried out using a quality assurance and quality control program meeting industry best practices. Standardized procedures were used in all aspects of the exploration data acquisition and management including mapping, surveying, drilling sampling sample security, assaying and database management.

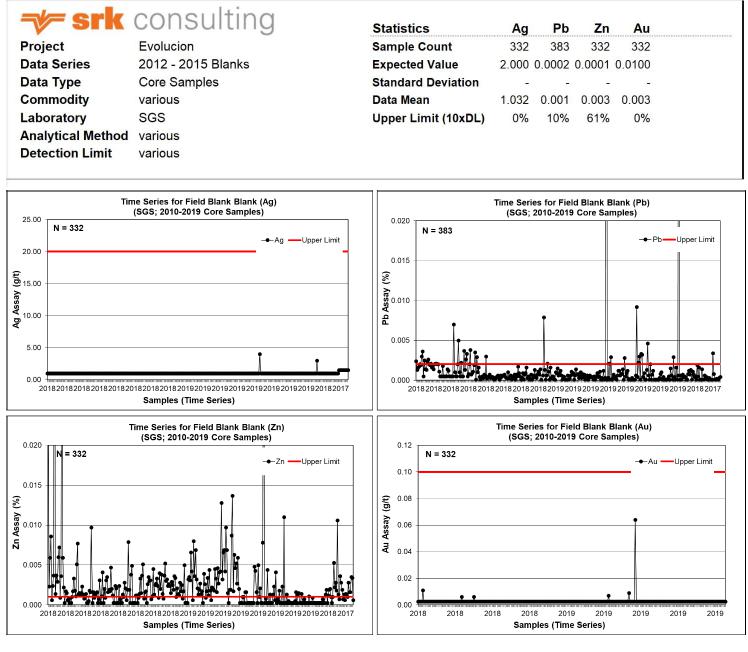

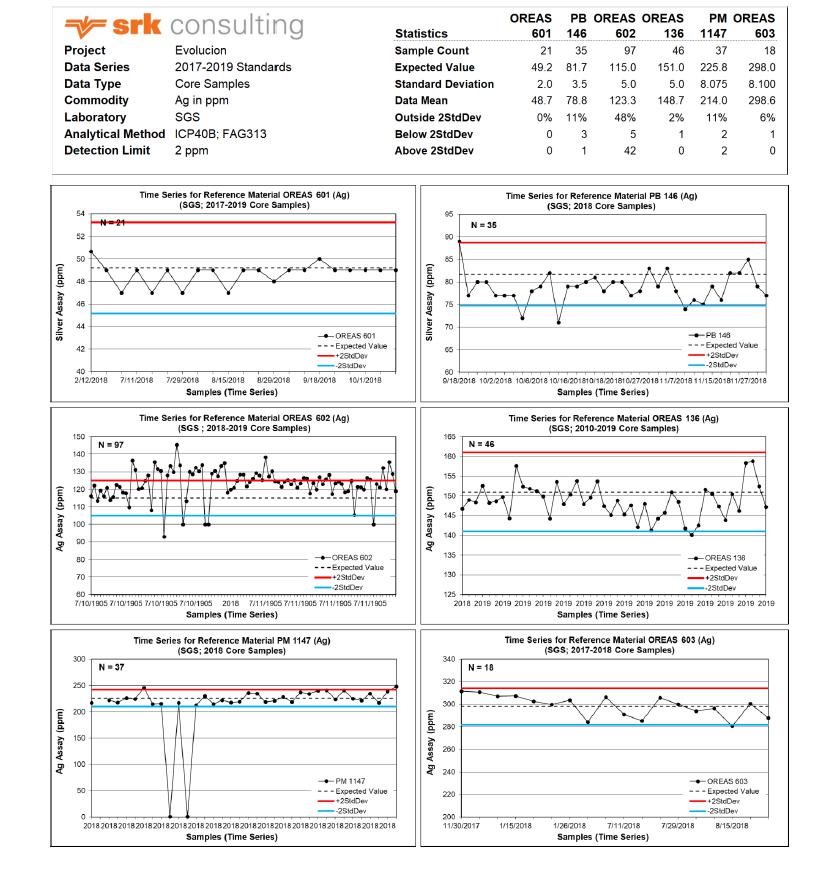

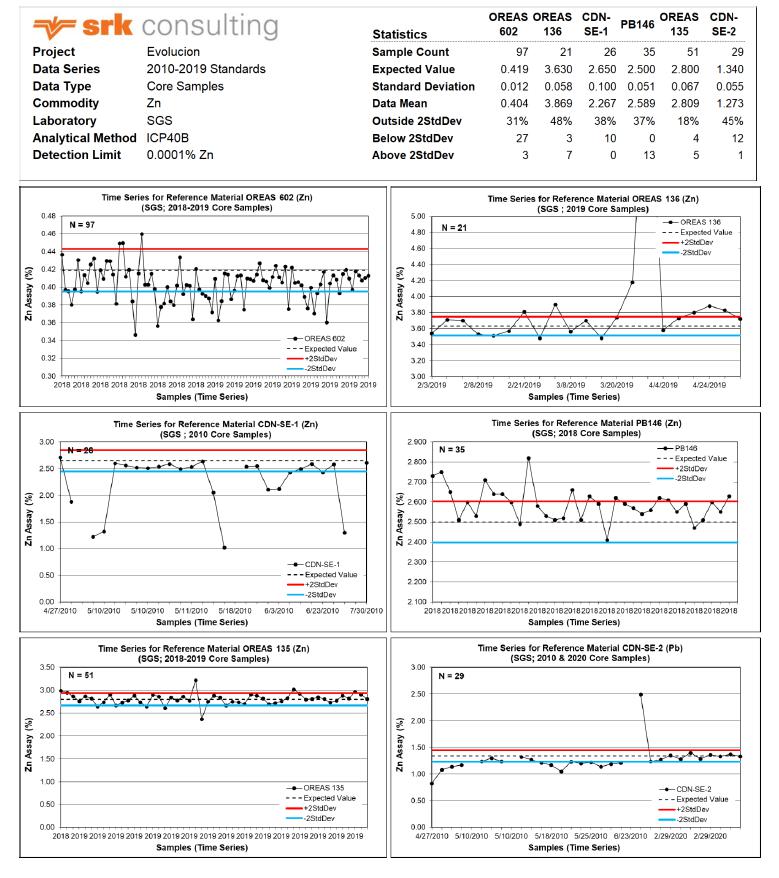

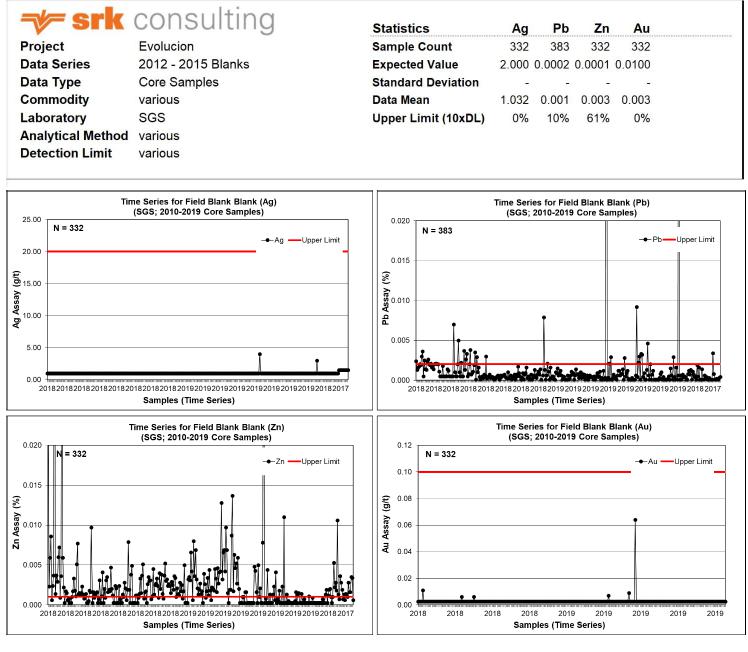

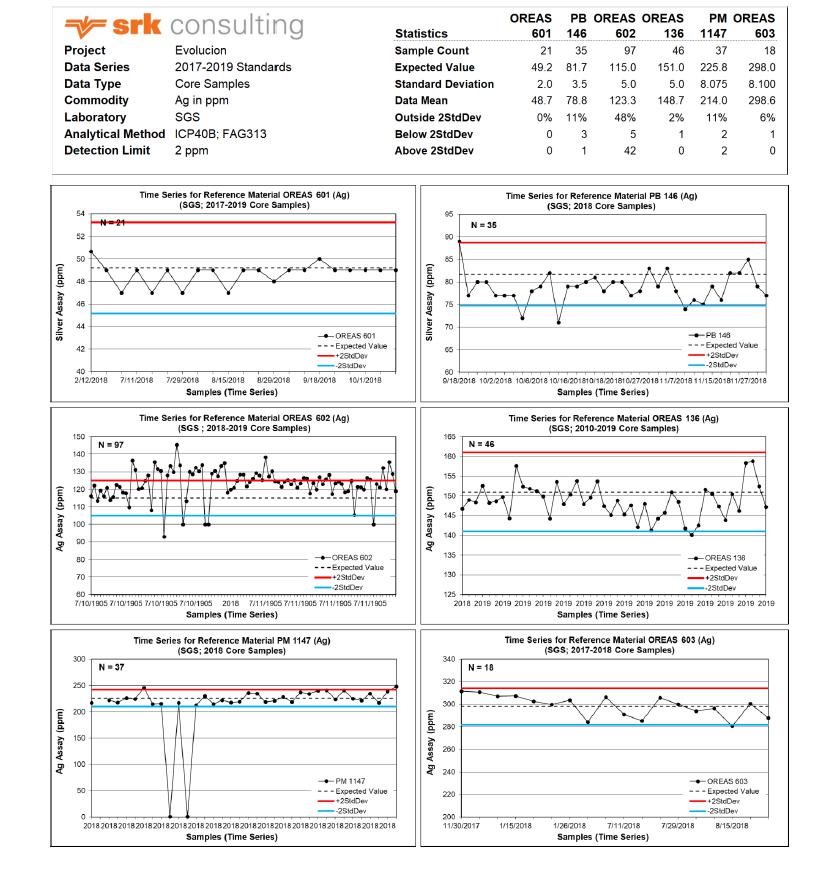

Excellon employed analytical quality control measures as part of the routine standard core sampling procedures since starting drilling on the Evolución Project in 2010. Analytical quality control measures for the 2010, 2018 and 2019 drilling programs, and the 2017 and 2019 resampling programs involved the regular insertion of blank and certified reference materials.

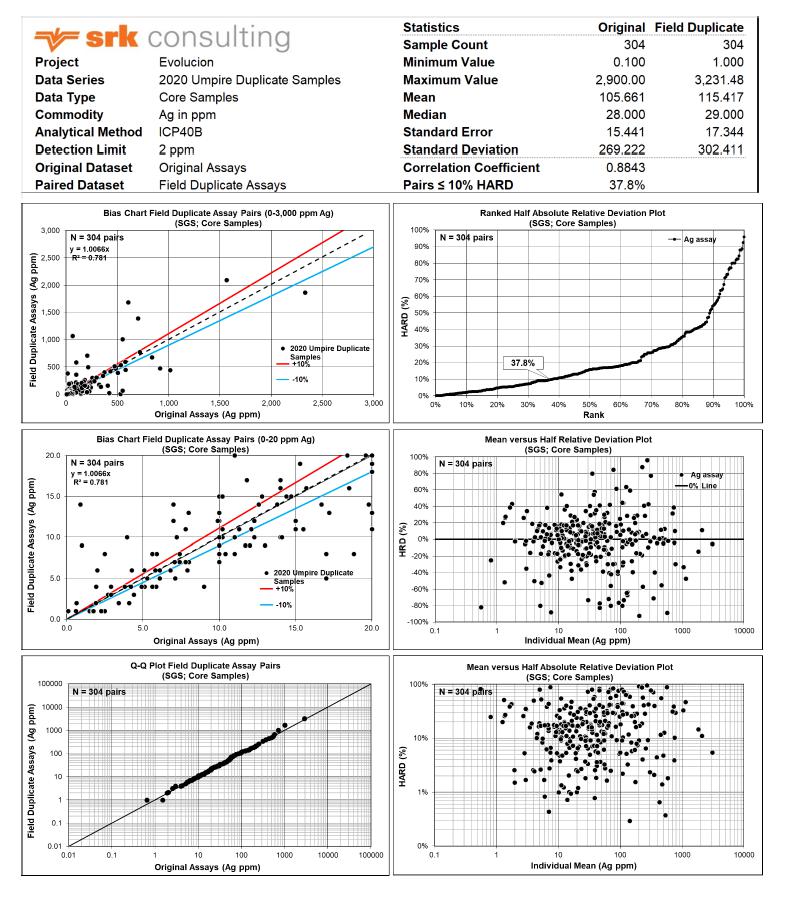

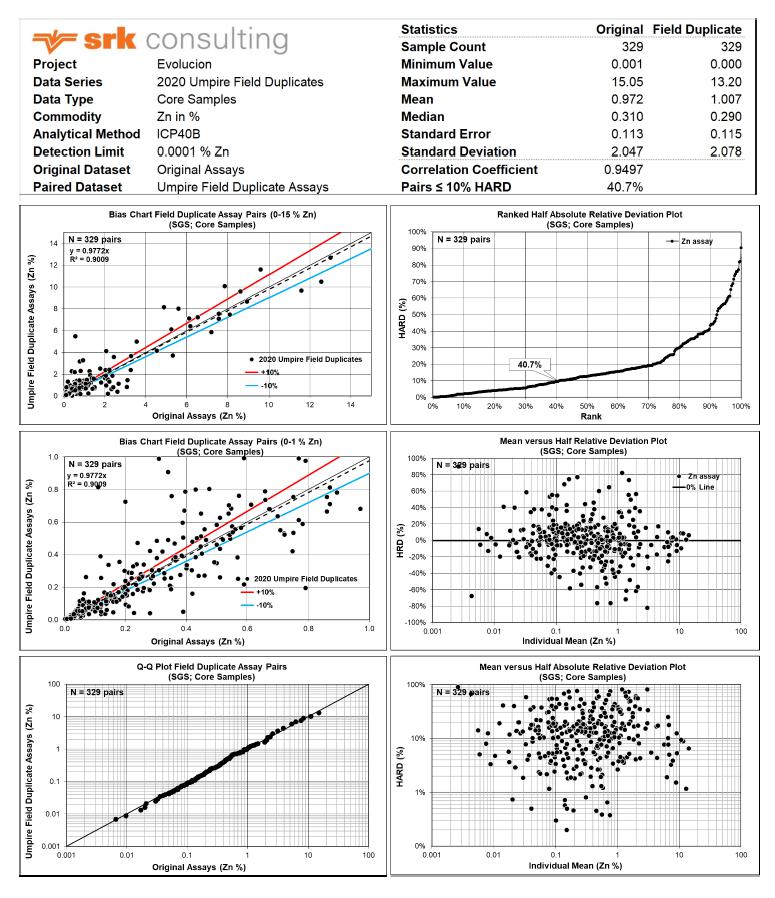

In October 2019, intervals within the Evolución Project evaluation domains were selected for field duplicate analysis across a variety of silver assay grades. Excellon quartered core from this selection for repeat analyses of silver, lead, zinc and gold at an umpire laboratory. The data validation program was undertaken to verify historical exploration data, including re-assaying archived core, where available, and where the mineral resources are informed by historical data. The ultimate objective of the work was to increase the confidence of the historical assay data used to calculate the mineral resource estimate presented in this report.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page v |

SRK reviewed the field procedures and analytical quality control measures used by Excellon and historical operators, where possible. The analysis of the analytical quality control data is presented in Section 11 below. In the opinion of SRK, Excellon personnel used care in the collection and management of the field and assaying exploration data. Based on historical reports and data, SRK is confident in the reliability of exploration and drilling information provided by previous operators.

In the opinion of SRK, the sampling preparation, security and analytical procedures used by Excellon are consistent with industry best practices and are, therefore, adequate for the purpose of informing mineral resources.

Mineral Resource and Mineral Reserve Estimates

The mineral resources have been estimated in conformity with CIM Estimation of Mineral Resource and Mineral Reserves Best Practices Guidelines and are reported in accordance with the Canadian Securities Administrators’ National Instrument 43-101.

Dr. Antoine Cate of SRK initiated geological wireframing in September 2019. The resource wireframing, geostatistical analysis, grade estimation and classification was completed by Ms. Joycelyn Smith, PGeo (APGO#2963) under the supervision of Dr. Aleksandr Mitrofanov, PGeo (APGO#2824) with geostatistical support from Dr. Oy Leuangthong, PEng (PEO#90563867). Additional contributions including quality control analyses and technical report compilation were provided by Ms. Smith.

The database used to evaluate the mineral resources of the Evolución Project includes 273 diamond drillholes (82,871 metres). The final header, down-hole survey, lithology intervals, and assay results were received by SRK on March 2, 2020.

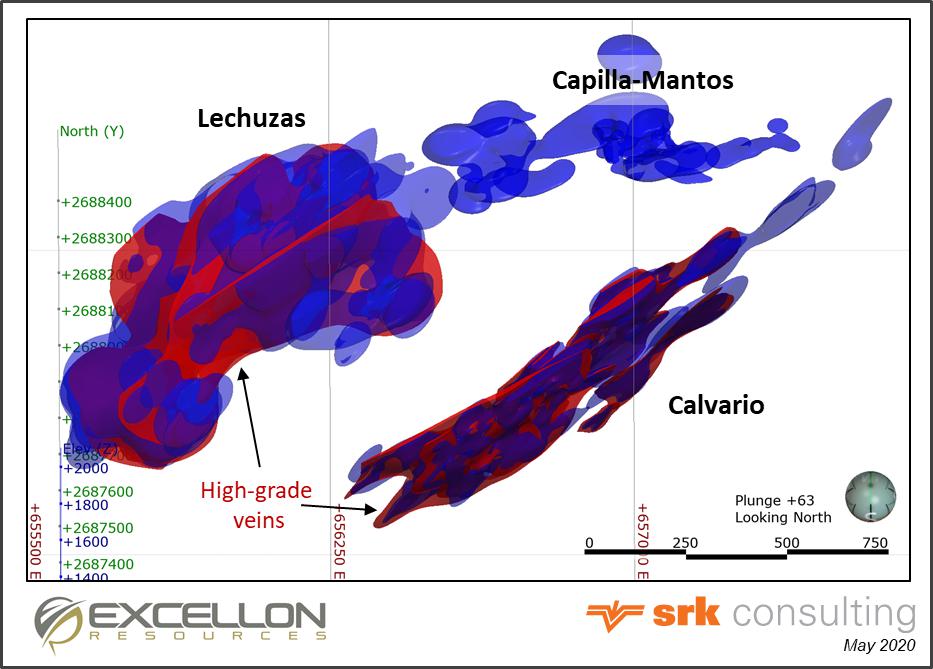

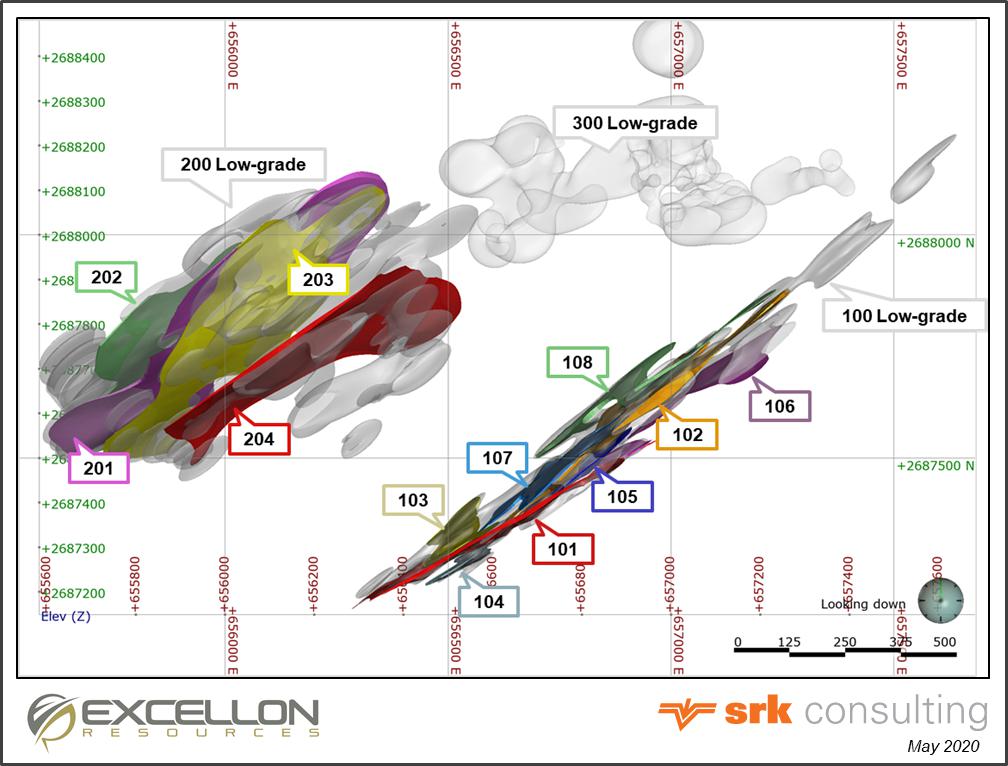

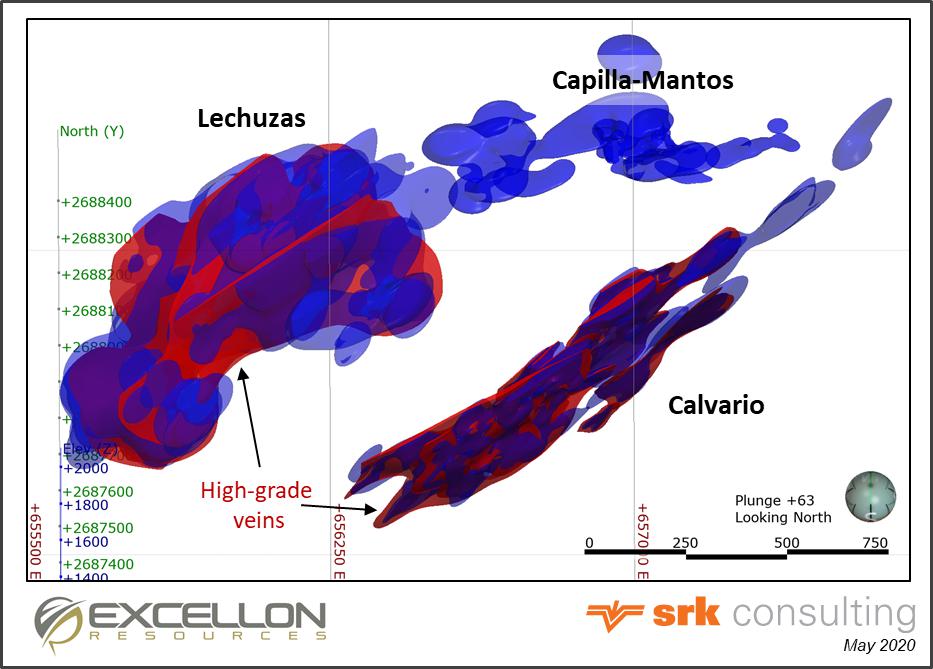

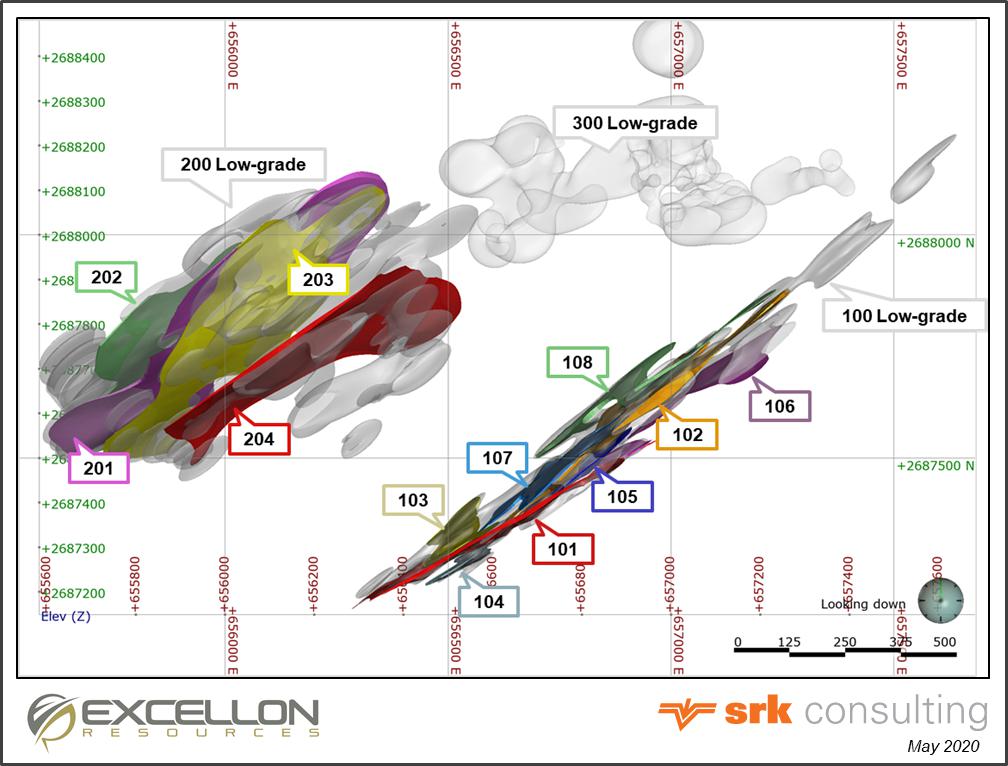

The mineral resource domains of the Evolución Project include the geology, structural and grade distribution criteria. The model comprises twelve high-grade veins (8 at Calvario and 4 at Lechuzas) constructed in Leapfrog modelling software.

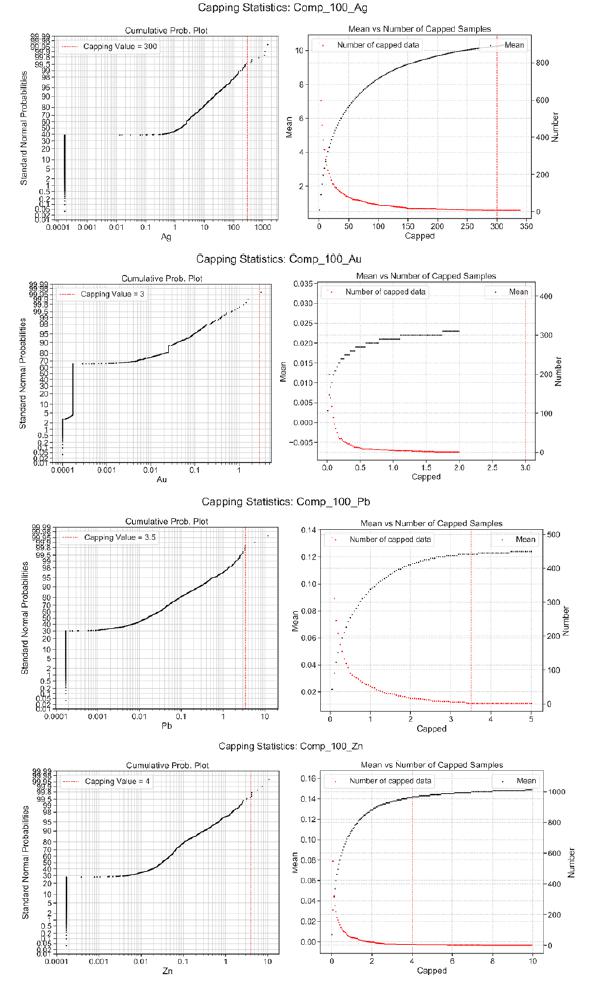

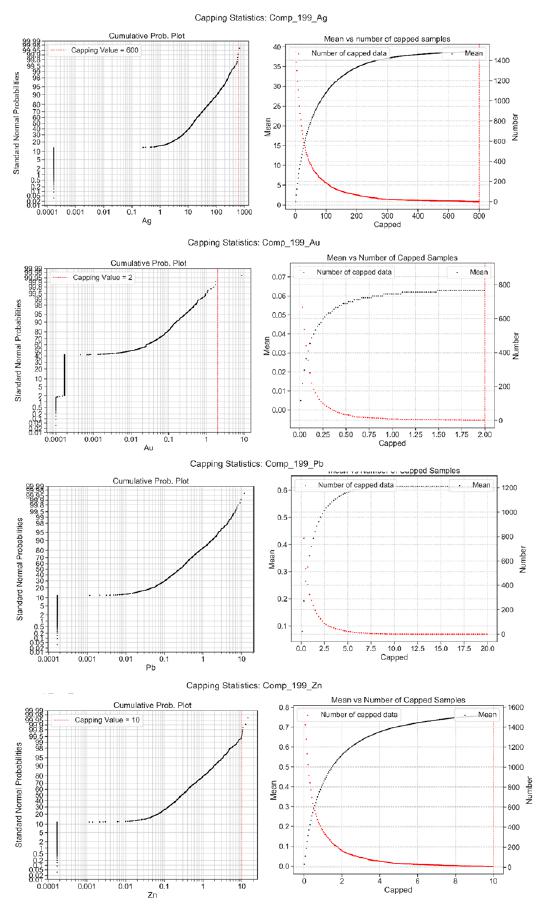

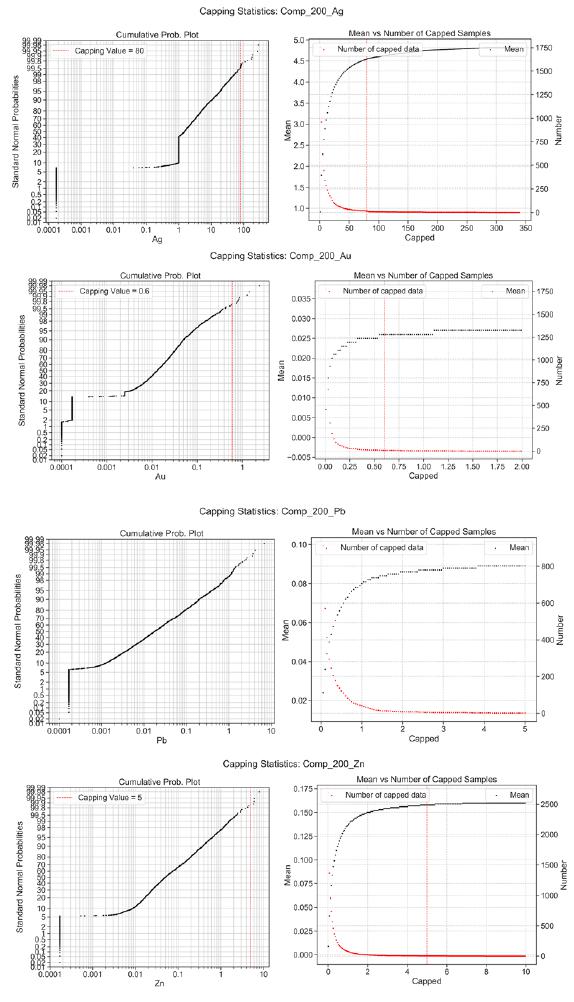

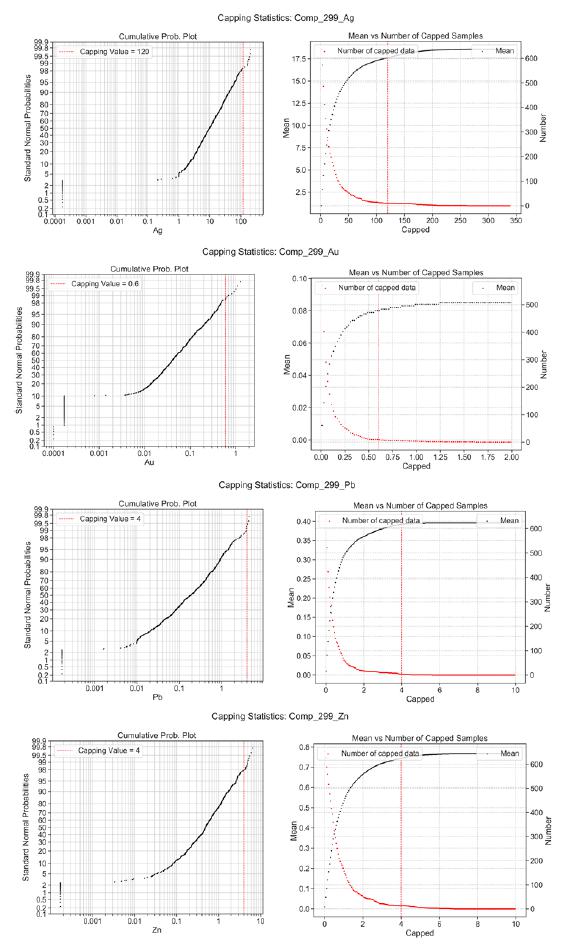

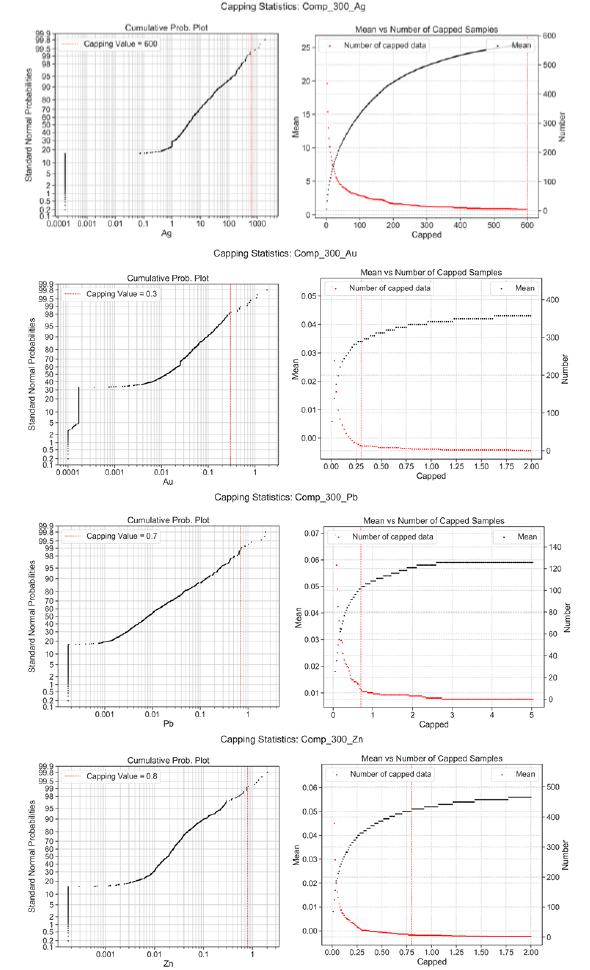

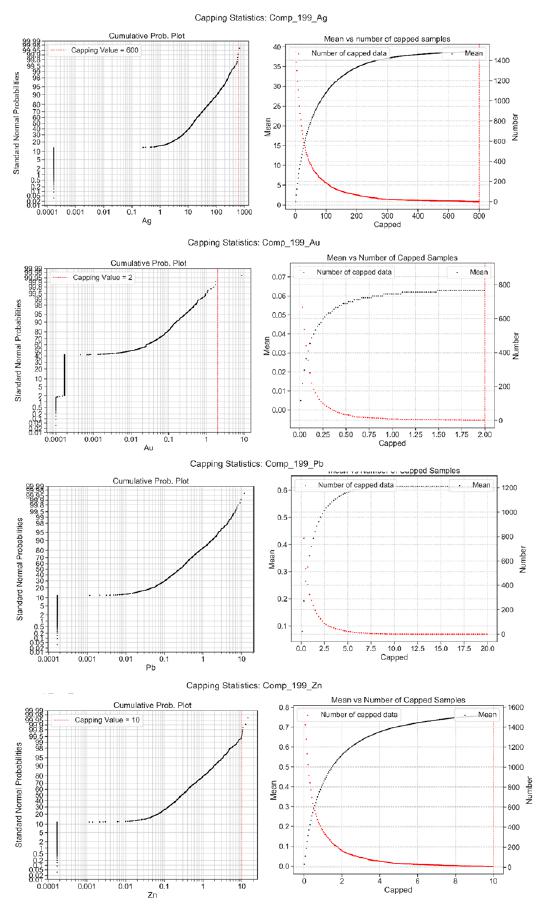

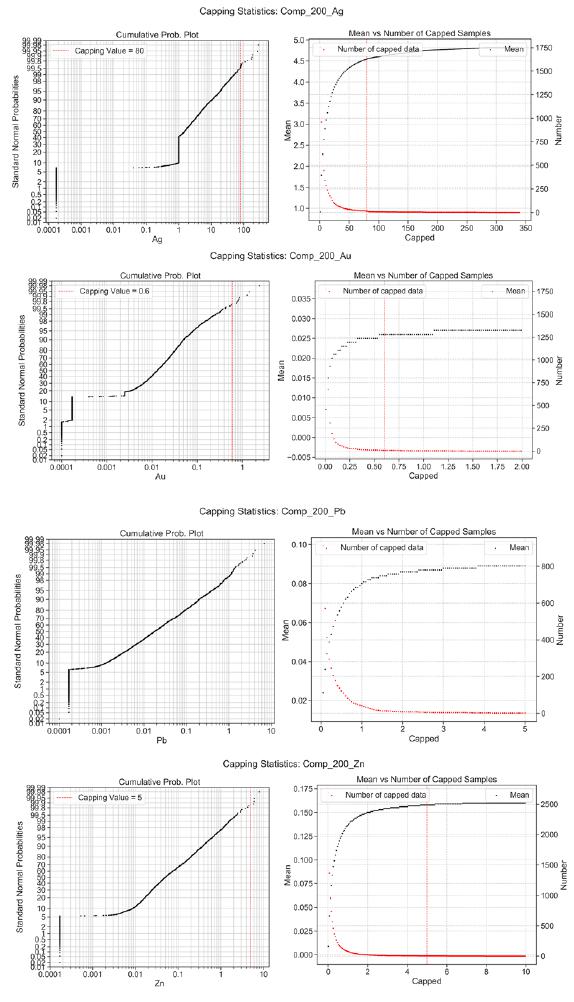

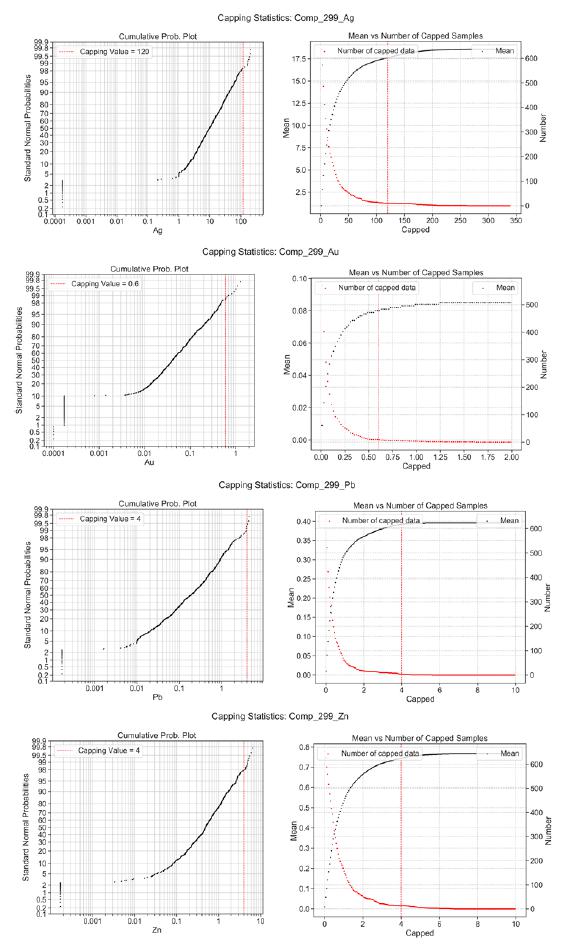

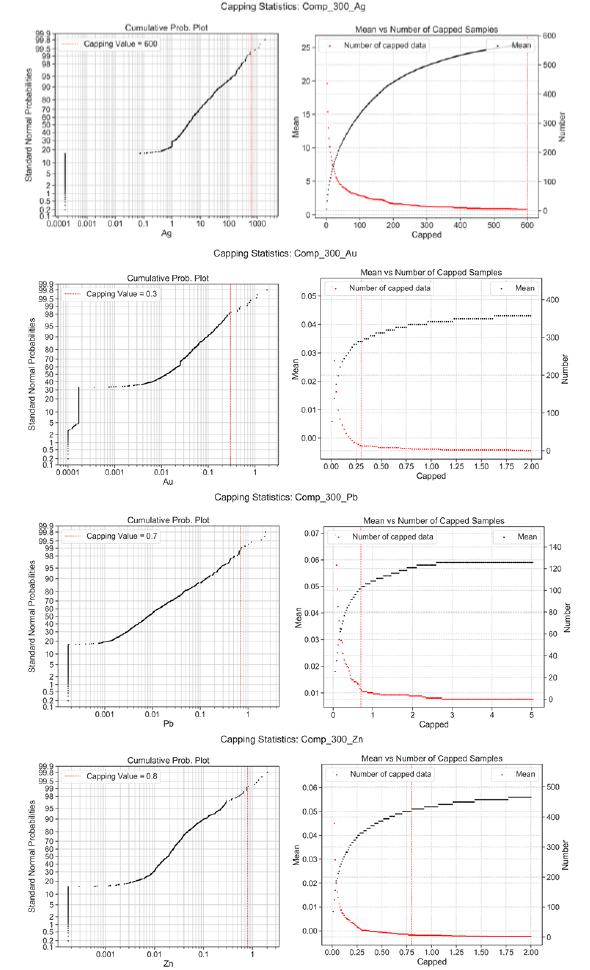

SRK chose to composite the assays to 2 metres to avoid splitting the assay intervals. To further limit the influence of high-grade outliers during grade estimation, SRK chose to cap composites. Capping was performed for the grouped mineralized subdomains for each zone.

A block size of 10 metres by 10 metres by 5 metres was selected for parent cells, with subcells of 2 metres by 2 metres by 1 metres resolution in the X, Y and Z axes, respectively, to honour the geometry of the modelled mineralization. The block model was rotated 315 degrees to better reflect the dip direction of the mineralized zones.

The block model was populated with values using ordinary kriging in the mineralized domains, informed by capped composite data for each variable (silver, gold, lead and zinc) separately, and three estimation passes with progressively larger search ellipsoids and data requirements. Specific gravity within the Lechuzas veins, low-grade and weathered zones were estimated using inverse distance weighting with a power of 2. Silver equivalent values were subsequently calculated for each block using the estimated values for gold, silver, lead and zinc.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page vi |

The block classification strategy considers drillhole spacing, geologic confidence and continuity of category. SRK considers that there are no blocks estimated in the Measured Resource category within the Evolución Project. An Indicated Resource category was assigned to blocks within the Calvario and Lechuzas zones informed within a 50-metre and 40-metre search radius for vein and low-grade domains, respectively, using a minimum of three drillholes. An Inferred category was assigned to all blocks not classified as Indicated, and within the Calvario and Lechuzas zones. Blocks within the Capilla-Mantos zone were left unclassified.

SRK considers that the Evolución Project is primarily amenable to underground extraction by longhole stoping method. Through discussions with Excellon, SRK considers that it is reasonable to report Evolución as an underground mineral resource above a cut-off grade of 90 grams per tonne (g/t) silver equivalent for both the Calvario and Lechuzas zones.

SRK is satisfied that the mineral resources were estimated in conformity with the widely accepted CIM Estimation of Mineral Resource and Mineral Reserve Best Practices Guidelines (November 2019). The mineral resources may be affected by further infill and exploration drilling that may result in increases or decreases in subsequent mineral resource estimates. The mineral resources may also be affected by subsequent assessments of mining, environmental, processing, permitting, taxation, socio-economic, and other factors. The Mineral Resource Statement for the Evolución Project is presented in Table i.

The effective date of the Mineral Resource Statement is August 31, 2020.

Table i: Mineral Resource Statement*, Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico, SRK Consulting (Canada) Inc., August 31, 2020

| | | | | | | | | Grade | | | Metal | |

| Category | | Zone | | | Quantity (000’ t) | | | Silver (g/t) | | | Gold (g/t) | | | Lead (%) | | | Zinc (%) | | | AgEq (g/t) | | | Silver (000’ oz) | | | Gold (000’ oz) | | | Lead (000’ lb) | | | Zinc (000’ lb) | | | AgEq (000’ oz) | |

| Indicated | | | Calvario | | | | 6,407 | | | | 64 | | | | 0.09 | | | | 1.00 | | | | 1.14 | | | | 170 | | | | 13,154 | | | | 19 | | | | 140,741 | | | | 161,548 | | | | 35,091 | |

| Total Indicated | | | | 6,407 | | | | 64 | | | | 0.09 | | | | 1.00 | | | | 1.14 | | | | 170 | | | | 13,154 | | | | 19 | | | | 140,741 | | | | 161,548 | | | | 35,091 | |

| Inferred | | | Calvario | | | | 5,626 | | | | 53 | | | | 0.09 | | | | 0.82 | | | | 1.08 | | | | 149 | | | | 9,570 | | | | 16 | | | | 102,223 | | | | 134,447 | | | | 26,902 | |

| | | | Lechuzas | | | | 9,335 | | | | 30 | | | | 0.11 | | | | 0.71 | | | | 1.18 | | | | 126 | | | | 8,953 | | | | 33 | | | | 145,235 | | | | 243,300 | | | | 37,911 | |

| Total Inferred | | | | 14,960 | | | | 39 | | | | 0.10 | | | | 0.75 | | | | 1.15 | | | | 135 | | | | 18,524 | | | | 49 | | | | 247,459 | | | | 377,747 | | | | 64,813 | |

| * | Mineral resources are not mineral reserves and have not demonstrated economic viability. All figures are rounded to reflect the relative accuracy of the estimate. Composites have been capped where appropriate. Mineral Resources are reported at a cut-off grade of 90 g/t silver equivalent. Cut-off grades are based on a silver price of US$17.00 per troy ounce and a silver recovery of 76%; a gold price of US$1,550 per troy ounce and a gold recovery of 20%; a lead price of US$0.90 per pound and a lead recovery of 90%; and a zinc price of US$1.15 per pound and a zinc recovery of 88%. |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page vii |

Conclusion and Recommendations

A total of 273 diamond drillholes (82,871 m) completed by previous operators and Excellon between 2005 and 2019 have been included in the geological and mineral resource modeling of the Evolución Project.

SRK is of the opinion that the drilling and sampling procedures adopted by Excellon are consistent with generally recognized industry best practices. The resultant drilling pattern is sufficiently dense to interpret the geometry and the boundaries of the polymetallic mineralization with confidence.

SRK constructed a block model using a conventional geostatistical block modeling approach constrained by high- and low-grade domains. The block model was populated with silver, lead, zinc and gold values estimated by ordinary kriging information from capped composited data and estimation parameters derived from variography. After verification and validation, block estimates were classified considering the confidence in the quality and quantity of informing data, the confidence in the geological continuity and the confidence in the quality of the estimates

SRK recommends multi-disciplinary technical studies and exploration drilling aimed at expansion, de-risking and further conceptual characterization of the project to evaluate the conceptual economic viability of the Evolución Project.

SRK supports Excellon’s proposed core drilling program, which includes approximately 25,000 metres of drilling with the following objectives:

| | ● | Delineate the southwest extension of the Lechuzas zone mineralization, as indicated by recent drilling. |

| | ● | Expand Indicated mineral resources at the Calvario zone and upgrade the mineral resources from Inferred to Indicated at the Lechuzas zone. |

| | ● | Delineate the mineralization in the Capilla-Mantos zone to gain a better understanding of the orientation of mineralizing structures, with the potential of upgrading material in this zone to Inferred. |

The total cost of the recommended work program is estimated at C$4,500,000

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page viii |

Table of Contents

| IMPORTANT NOTICE | ii |

| Executive Summary | iii |

| | Introduction | iii |

| | Property Description and Ownership | iii |

| | Geology and Mineralization | iii |

| | Exploration Status | iv |

| | Sample Preparation, Analyses, Security, and Data Verification | iv |

| | Mineral Resource and Mineral Reserve Estimates | v |

| | Conclusion and Recommendations | vi |

| Table of Contents | viii |

| List of Tables | xi |

| List of Figures | xiii |

| 1 | Introduction and Terms of Reference | 1 |

| | 1.1 | Scope of Work | 1 |

| | 1.2 | Work Program | 1 |

| | 1.3 | Basis of Technical Report | 2 |

| | 1.4 | Qualifications of SRK and SRK Team | 2 |

| | 1.5 | Site Visit | 3 |

| | 1.6 | Acknowledgement | 3 |

| | 1.7 | Declaration | 3 |

| 2 | Reliance on Other Experts | 5 |

| 3 | Property Description and Location | 6 |

| | 3.1 | Mineral Tenure | 7 |

| | 3.2 | Underlying Agreements | 8 |

| | 3.3 | Permits and Authorization | 8 |

| | 3.4 | Environmental and Social Considerations | 9 |

| | 3.5 | Mining Rights in Mexico | 9 |

| 4 | Accessibility, Climate, Local Resources, Infrastructure, and Physiography | 11 |

| | 4.1 | Accessibility | 11 |

| | 4.2 | Local Resources and Infrastructure | 11 |

| | 4.3 | Climate | 13 |

| | 4.4 | Physiography | 13 |

| 5 | History | 15 |

| | 5.1 | Historical Exploration Work and Ownership | 15 |

| | 5.2 | Previous Mineral Resource Estimates | 17 |

| 6 | Geological Setting and Mineralization | 18 |

| | 6.1 | Regional Geology | 18 |

| | 6.2 | Property Geology | 21 |

| | | 6.2.1 | Structure and Veining | 24 |

| | | 6.2.2 | Mineralization and Veining | 26 |

| 7 | Deposit Types | 28 |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page ix |

| 8 | Exploration | 29 |

| | 8.1 | Exploration by Excellon | 29 |

| | | 8.1.1 | Geological Mapping | 31 |

| | | 8.1.2 | Geochemical Soil Sampling | 31 |

| | | 8.1.3 | Geophysical Surveys | 31 |

| 9 | Drilling | 33 |

| | 9.1 | Drilling by Silver Eagle Mines Ltd. (2005-2009) | 35 |

| | 9.2 | Drilling by Excellon (2010-2019) | 35 |

| | 9.3 | Surveying | 36 |

| | 9.4 | Drill Pattern and Density | 36 |

| | 9.5 | SRK Comments | 36 |

| 10 | Sample Preparation, Analyses, and Security | 37 |

| | 10.1 | Sample Preparation and Analyses | 37 |

| | | 10.1.1 | Silver Eagle Mines (2005-2008) | 37 |

| | | 10.1.2 | Excellon (2010-2020) | 38 |

| | 10.2 | Specific Gravity Data | 40 |

| | 10.3 | Sample Security | 40 |

| | 10.4 | Quality Assurance and Quality Control Programs | 41 |

| | | 10.4.1 | Silver Eagle Mines (2005-2008) | 41 |

| | | 10.4.2 | Excellon (2010-2020) | 41 |

| | 10.5 | SRK Comments | 42 |

| 11 | Data Verification | 43 |

| | 11.1 | Verifications by Excellon | 43 |

| | | 11.1.1 | Historical Drilling Verification Program | 43 |

| | 11.2 | Verifications by SRK | 43 |

| | | 11.2.1 | Site Visit | 44 |

| | | 11.2.2 | Verifications of Analytical Quality Control Data | 46 |

| 12 | Mineral Processing and Metallurgical Testing | 48 |

| | 12.1 | Metallurgical Testing | 48 |

| | | 12.1.1 | Composite Sampling (2005) | 48 |

| | | 12.1.2 | Oxide Sample Test work (2006-2007) | 48 |

| | | 12.1.3 | Sulphide Composite Test work (2007) | 48 |

| | | 12.1.4 | Mineralogy | 49 |

| | | 12.1.5 | Reagents | 50 |

| | | 12.1.6 | Concentrate Analysis | 51 |

| | 12.2 | Mineral Processing | 51 |

| 13 | Mineral Resource Estimates | 52 |

| | 13.1 | Introduction | 52 |

| | 13.2 | Resource Estimation Procedures | 52 |

| | 13.3 | Resource Database | 53 |

| | 13.4 | Geological Interpretation and Modelling | 53 |

| | 13.5 | Assays, Compositing and Capping | 56 |

| | | 13.5.1 | Evaluation of Outliers | 58 |

| | 13.6 | Specific Gravity | 59 |

| | 13.7 | Statistical Analysis and Variography | 60 |

| | 13.8 | Block Model Parameters | 62 |

| | 13.9 | Estimation | 62 |

| | 13.10 | Model Validation and Sensitivity | 63 |

| | 13.11 | Mineral Resource Classification | 66 |

| | 13.12 | Mineral Resource Statement | 67 |

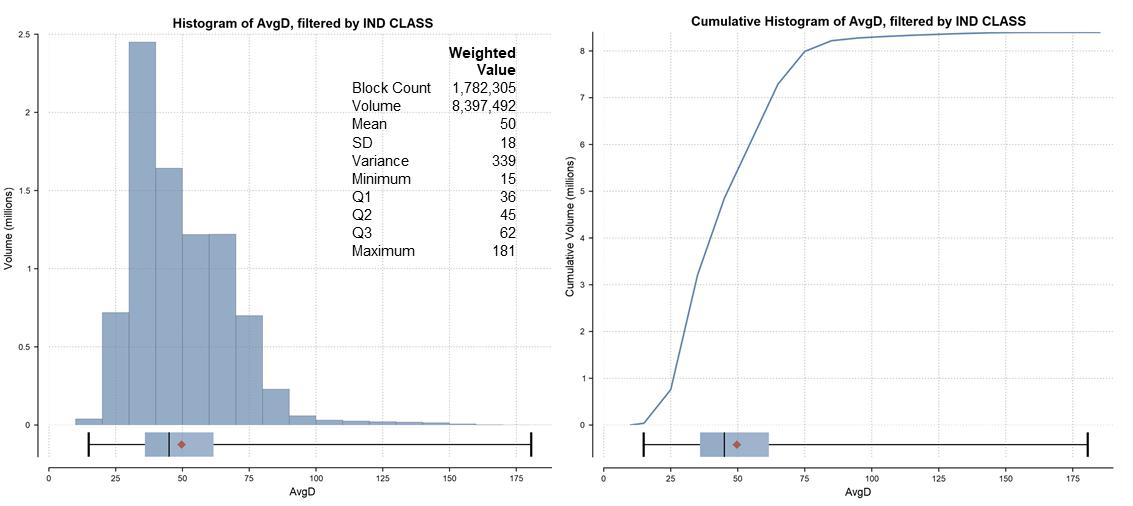

| | 13.13 | Grade Sensitivity Analysis | 68 |

| | 13.14 | Reconciliation with 2008 Mineral Resource Statement | 70 |

| 14 | Adjacent Properties | 71 |

| | 14.1 | Fresnillo | 72 |

| | 14.2 | Velardeña | 72 |

| | 14.3 | San Sebastián | 72 |

| | 14.4 | La Colorada | 73 |

| | 14.5 | Avino | 73 |

| 15 | Other Relevant Data and Information | 74 |

| 16 | Interpretation and Conclusions | 75 |

| 17 | Recommendations | 76 |

| 18 | References | 78 |

| APPENDIX A | 79 |

| APPENDIX B | 86 |

| APPENDIX C | 93 |

| APPENDIX D | 101 |

| APPENDIX E | 105 |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page x |

List of Tables

| Table i: | Mineral Resource Statement*, Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico, SRK Consulting (Canada) Inc., August 31, 2020 | vi |

| Table 1: | Mineral Tenure Information | 7 |

| Table 2: | Ownership History of the Evolución Project | 16 |

| Table 3: | Historical Mapping Areas by Operator | 17 |

| Table 4: | Exploration History of the Evolución Project | 17 |

| Table 5: | Historical Mineral Resource Estimates Completed by RPA Between 2006 and 2008 | 18 |

| Table 6: | Vein Descriptions of the Regional Madera System | 28 |

| Table 7: | Geological Mapping Programs Conducted by Excellon at the Evolución Project | 33 |

| Table 8: | Conventional Rock Samples Collected by Excellon Between 2017-2018 | 33 |

| Table 9: | Summary of Drilling Completed on the Evolución Project Between 2005 and 2019 | 36 |

| Table 10: | Summary of SGS Preparation and Assay Methods Used for the Evolución Project (2010–2019) | 41 |

| Table 11: | Summary of Upper and Lower Limits for SGS’s Four-Acid ICP Method (2010-2019) | 41 |

| Table 12: | Specifications of Control Samples Used Between 2010 and December 2019 | 44 |

| Table 13: | Summary of Duplicate Samples Collected by Excellon for Historical Drillholes Drilled Between 2005 and 2008 for the Evolución Project | 44 |

| Table 14: | Drillhole Collar Location Verification | 48 |

| Table 15: | Summary of Analytical Quality Control Data Produced by Excellon on the Evolución Project (2010-2019) | 50 |

| Table 16: | Results from the Metallurgical Composite Samples Collected by SEM (2007) | 52 |

| Table 19: | Reagent Usage | 53 |

| Table 20: | Concentrate Analysis | 54 |

| Table 21: | Summary of Drilling* on the Evolución Project, Miguel Auza, Mexico | 56 |

| Table 22: | Mineral Resource Domains with Rock Codes | 58 |

| Table 23: | Assay Statistics* for Core Samples in Evolución Project | 60 |

| Table 24: | Capping Values for the Evolución Project, Miguel Auza, Mexico | 61 |

| Table 25: | Uncapped and Capped Silver Equivalent Composite Statistics* | 62 |

| Table 26: | Uncapped and Capped Core Statistics* for Specific Gravity | 62 |

| Table 27: | Variogram Parameters for the Evolución Project, by Domain Group | 65 |

| Table 28: | Evolución Block Model* Specification | 67 |

| Table 29: | Summary of Estimation Search Parameters | 68 |

| Table 30: | Specifications for Silver Equivalent Calculation | 68 |

| Table 31: | Global Comparison of Estimators | 71 |

| Table 32: | Mineral Resource Statement*, Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico, SRK Consulting (Canada) Inc., August 31, 2020 | 73 |

| Table 33: | Global Block Model Quantities and Grade Estimates* at Various Cut-Off Grades | 74 |

| Table 34: | Mineral Resource Statement*, Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico, Roscoe Postle Associates Inc., June 2008 | 75 |

| Table 35: | Estimated Cost for the Exploration Program Proposed for the Evolución Project | 83 |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page xi |

List of Figures

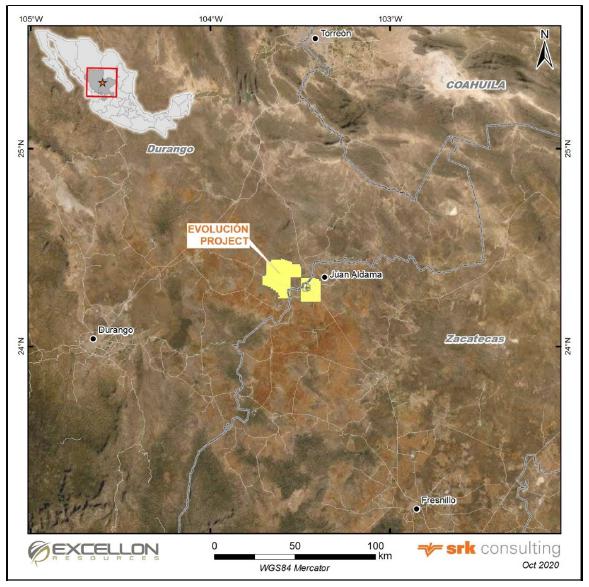

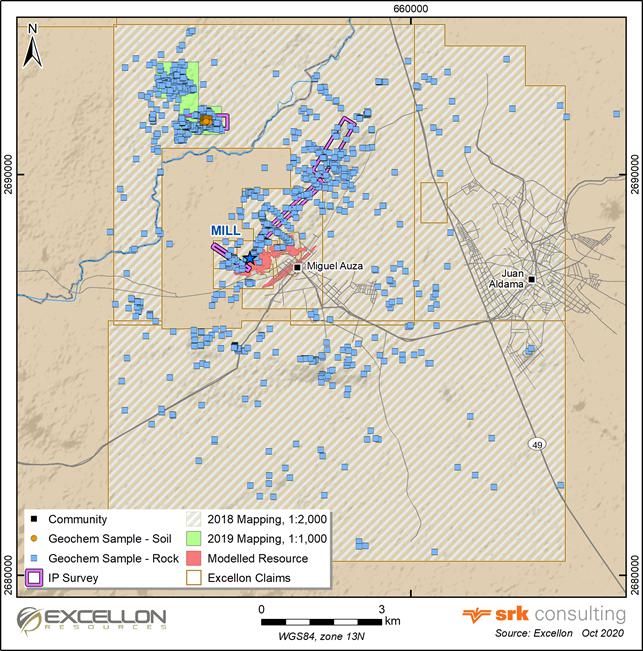

| Figure 1: | Location Map | 6 |

| Figure 2: | Land Tenure Map | 8 |

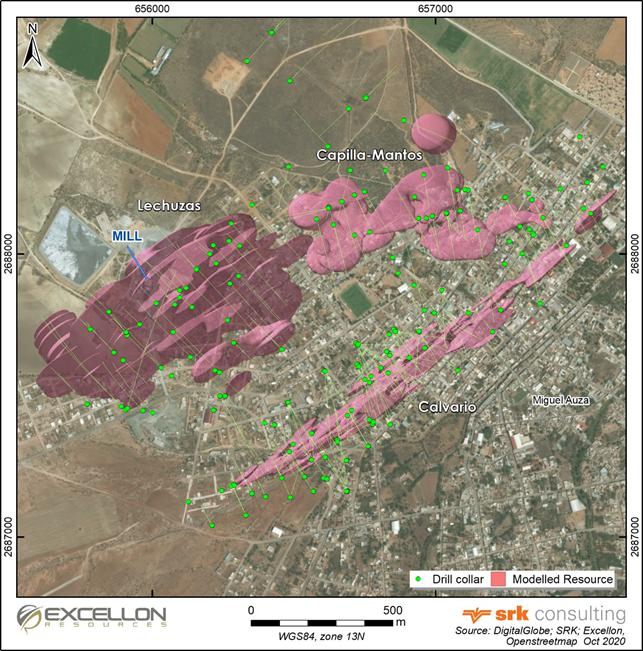

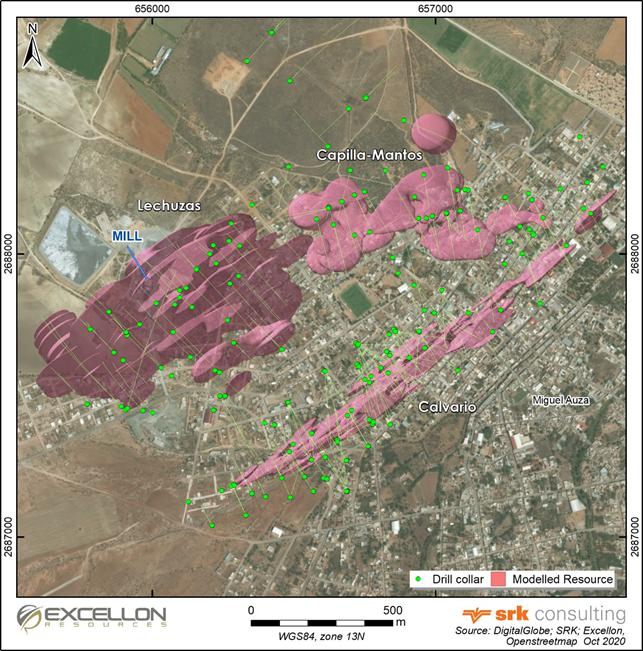

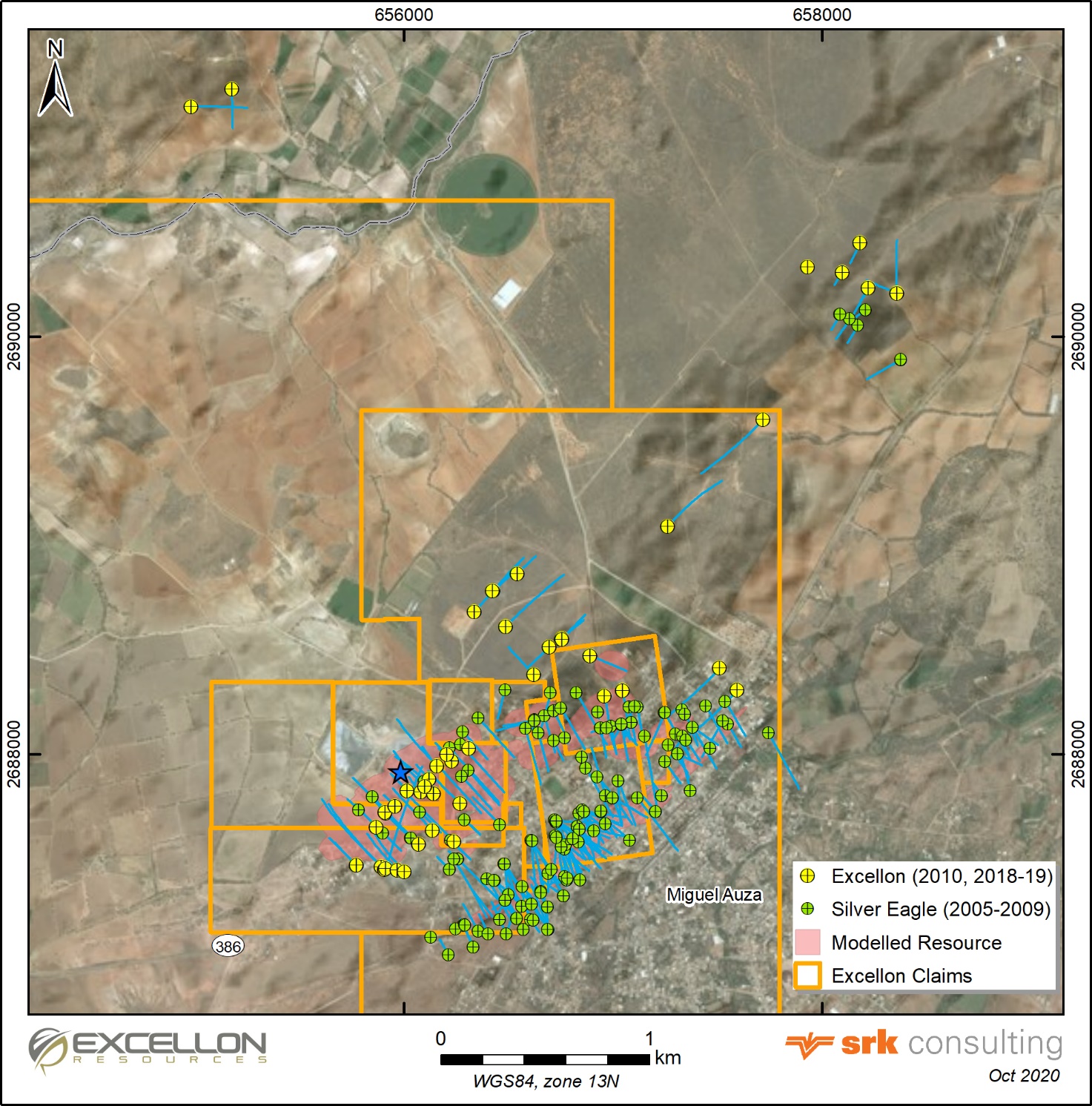

| Figure 3: | Satellite Imagery of the Town of Miguel Auza with the Mineralization Domains Projected to Surface | 13 |

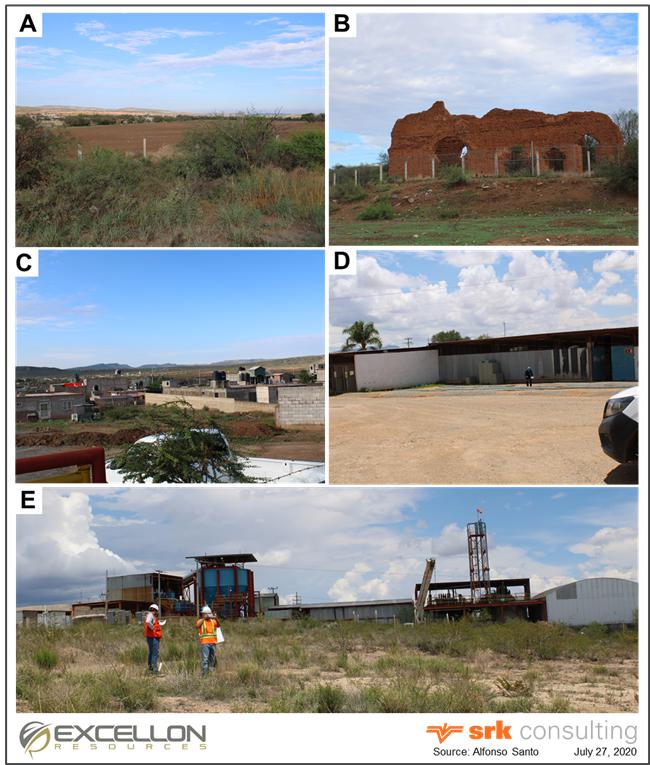

| Figure 4: | Typical Landscape and Infrastructure in the Project Area | 15 |

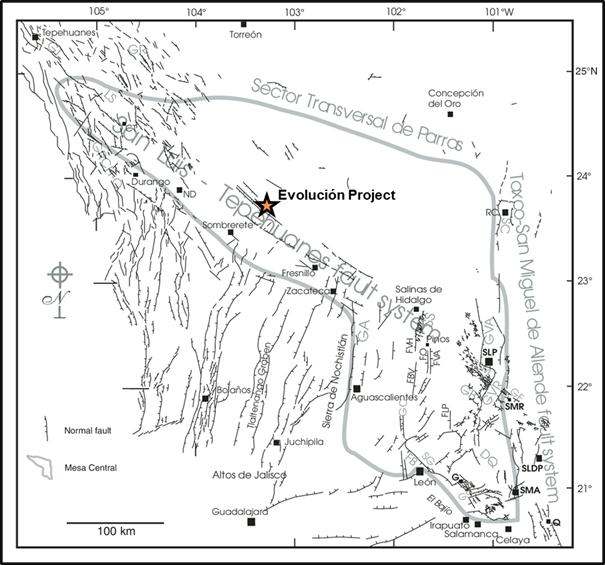

| Figure 5: | Mesa Central Physiographic Province | 19 |

| Figure 6: | Regional Geology Setting | 21 |

| Figure 7: | Local Geological Setting of the Evolución Project. | 23 |

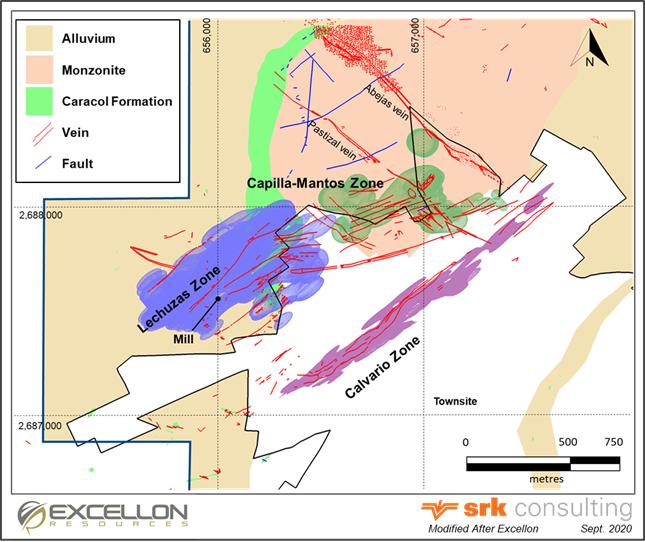

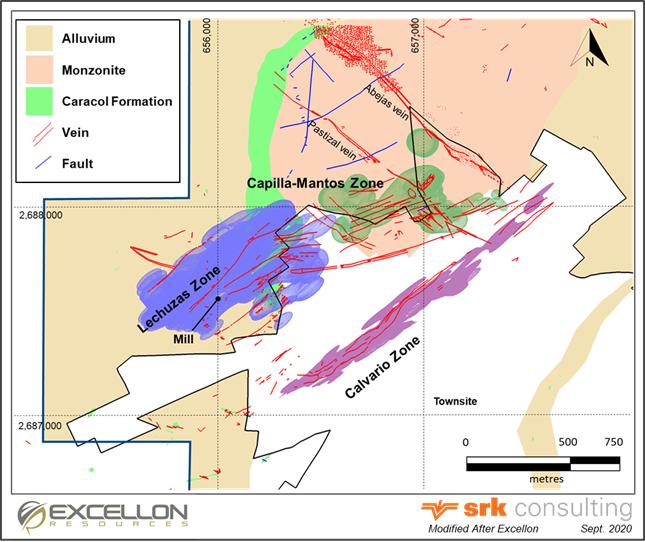

| Figure 8: | Geological Map of the Calvario Vein System Area Showing the Calvario, Lechuzas and Capilla-Mantos Mineralized Zones. | 24 |

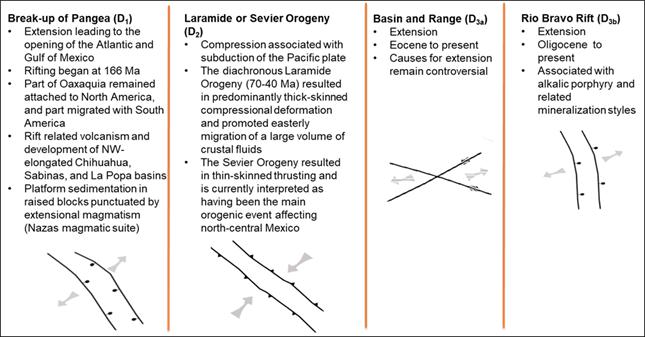

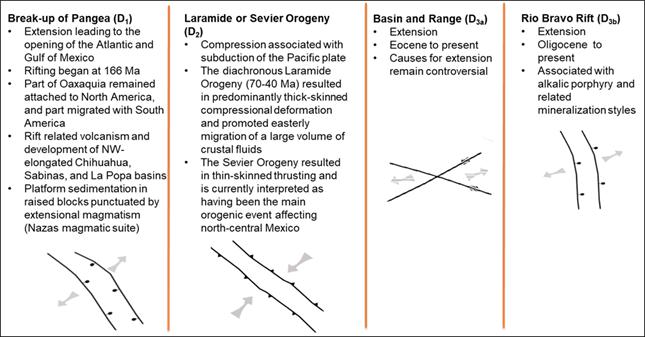

| Figure 9: | Structural Events Affecting the Evolución Project Area. | 25 |

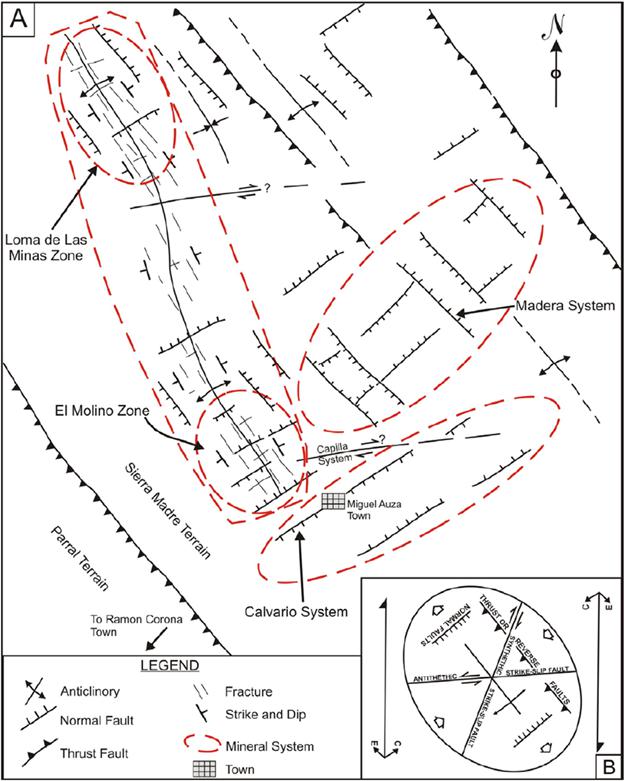

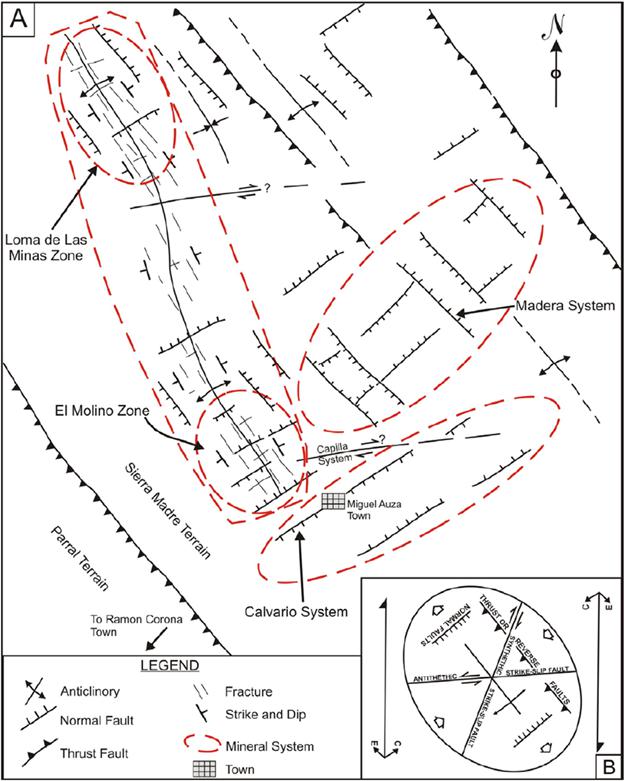

| Figure 10: | Structural Model of the Evolución Project Area | 26 |

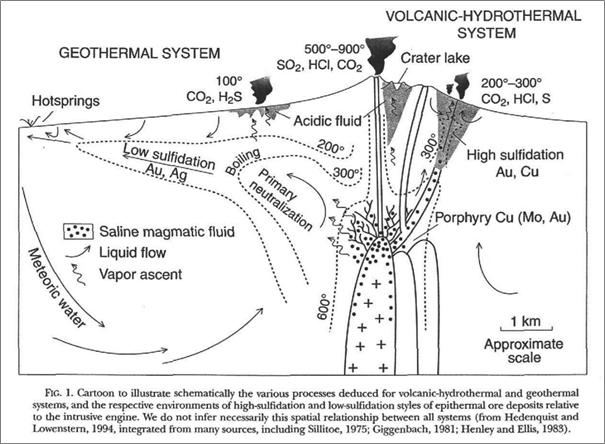

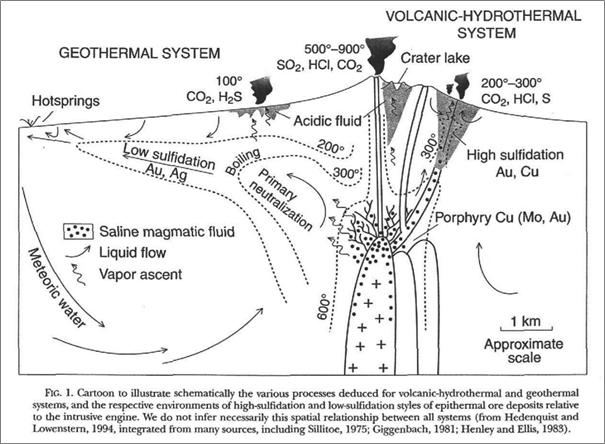

| Figure 11: | Genetic Model for Epithermal Deposit Types. | 29 |

| Figure 12: | Compilation of Exploration Work Completed by Excellon | 32 |

| Figure 13: | Drilling Completed on the Evolución Project | 35 |

| Figure 14: | Excellon’s Sample Storage Facility for the Evolución Project | 42 |

| Figure 15: | Drill Collar for Core Drillhole EX18MAZ-255 on the Evolución Project | 48 |

| Figure 16: | View of the Geological Model Looking North-Northeast | 57 |

| Figure 17: | Plan Map of the Evolución Project Evaluation Domains | 58 |

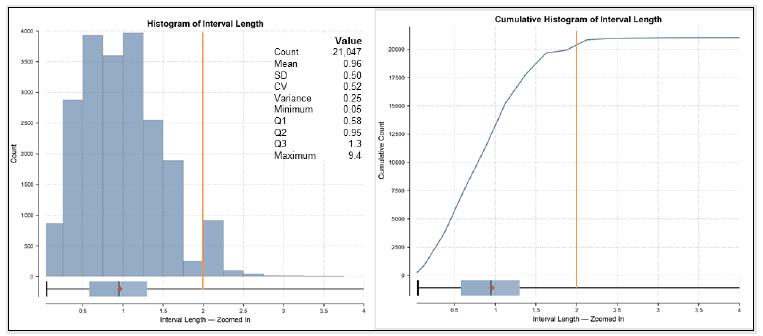

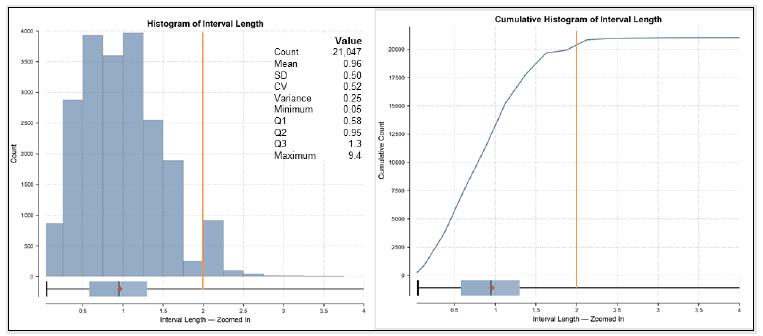

| Figure 18: | Length Statistics for Core Sample Intervals | 61 |

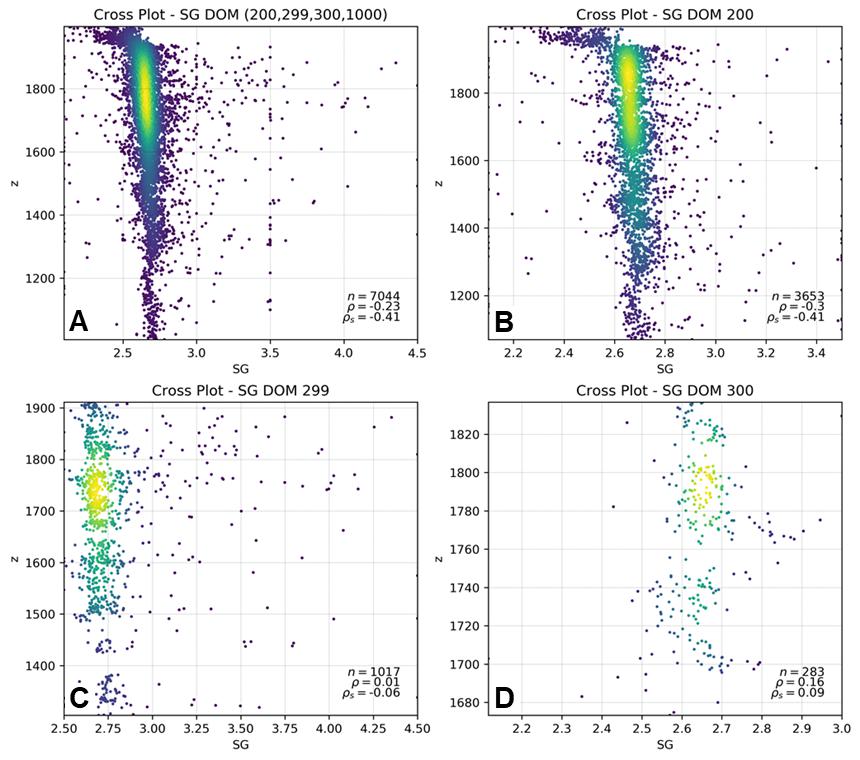

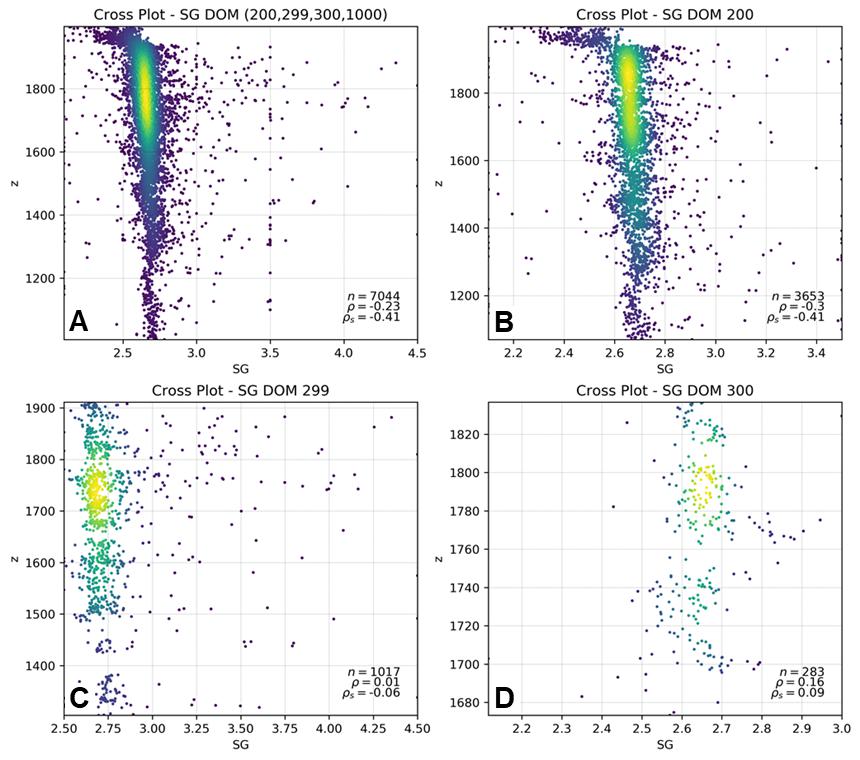

| Figure 19: | Cross Plots* Comparing Specific Gravity Values on Depth Profiles | 63 |

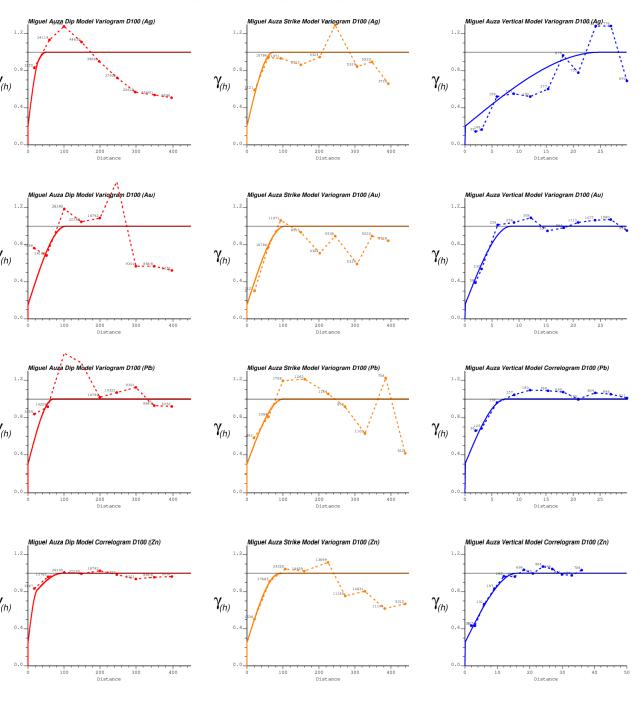

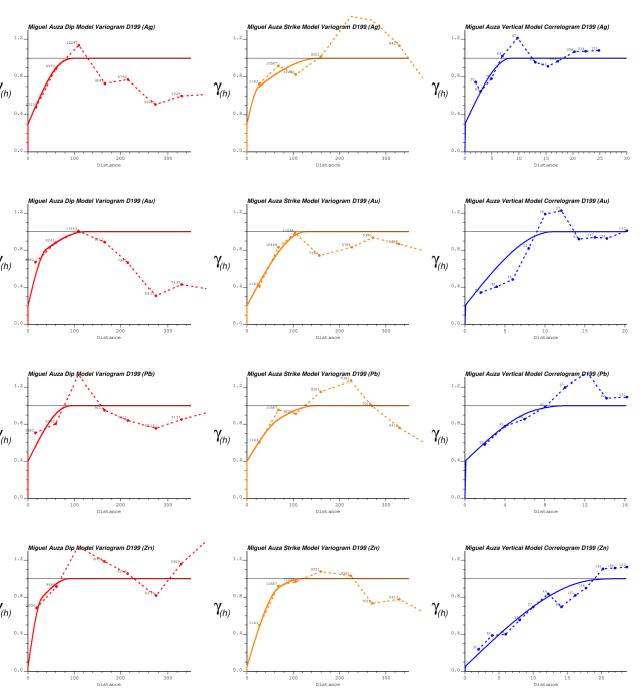

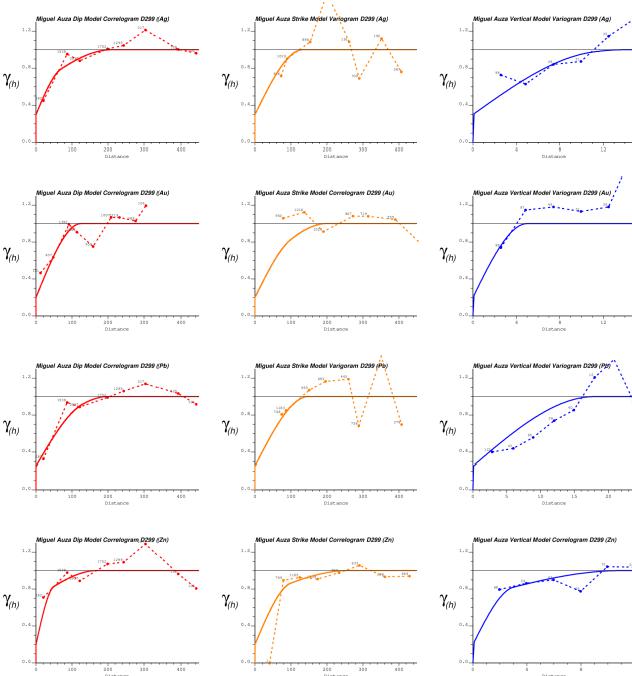

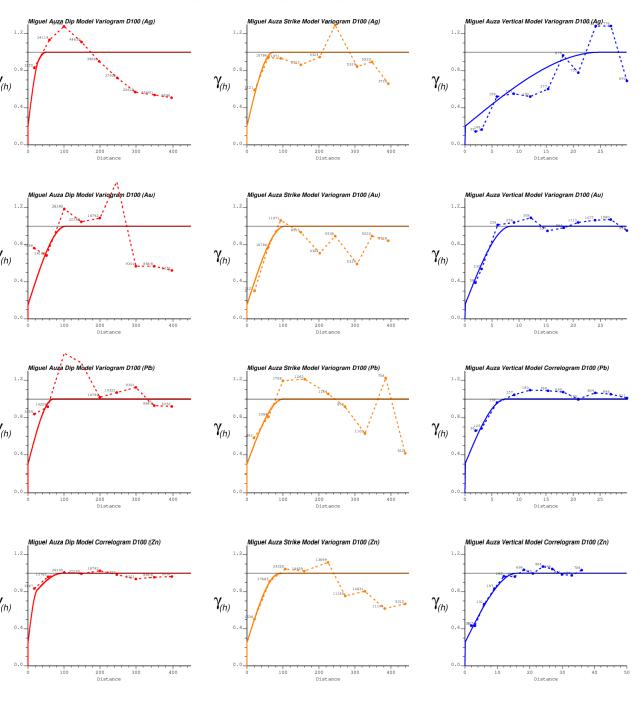

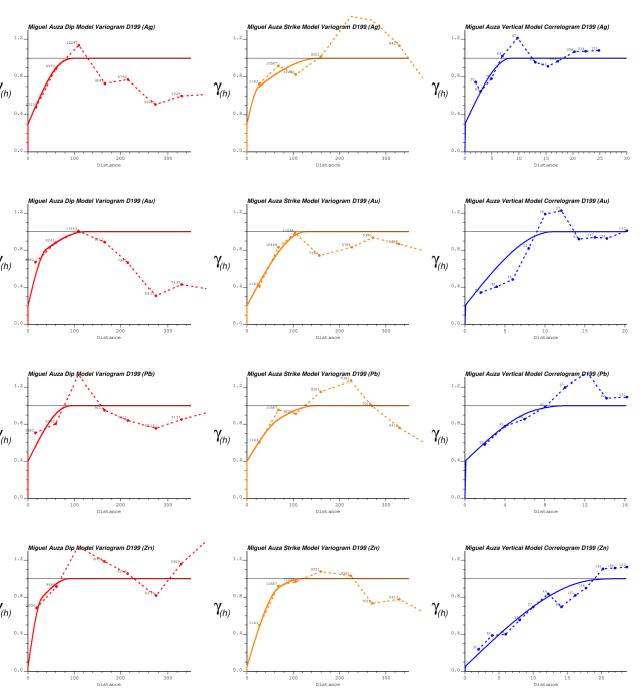

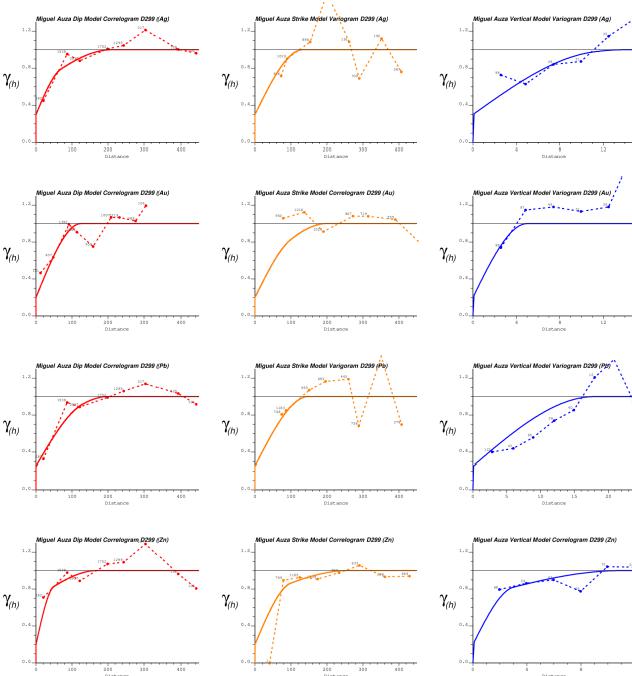

| Figure 20: | Variogram Models for Silver, Gold, Lead and Zinc for the Lechuzas Low-Grade Zone (200) for the Intermediate (Red), Maximum (Yellow) and Minor (Blue) Directions | 66 |

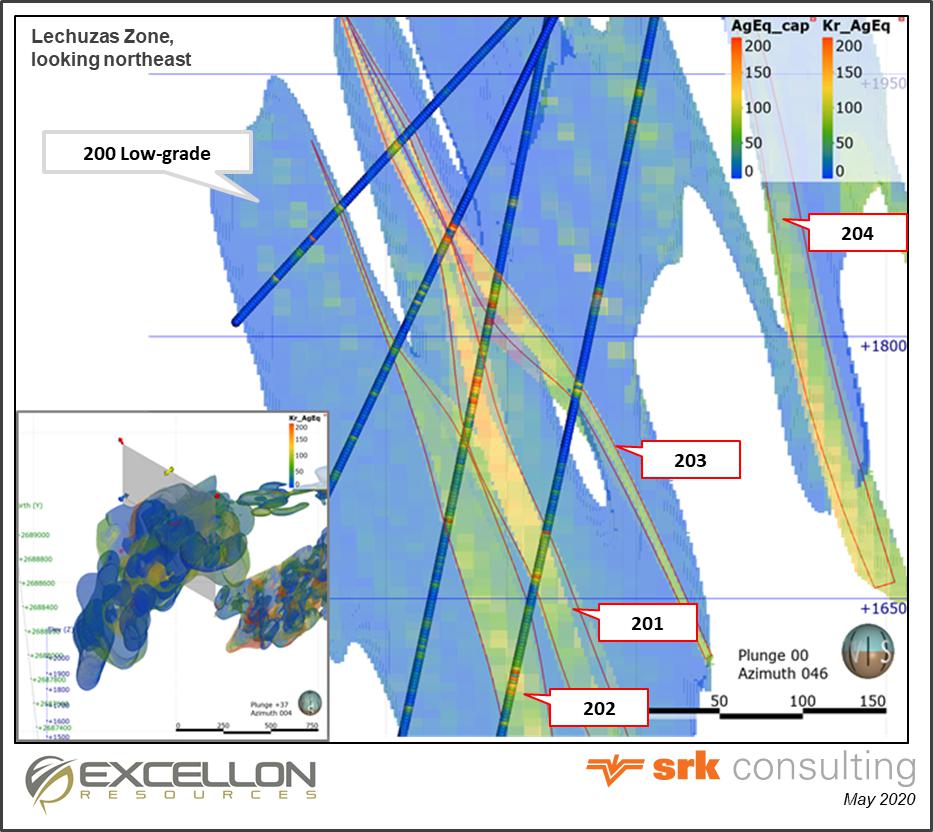

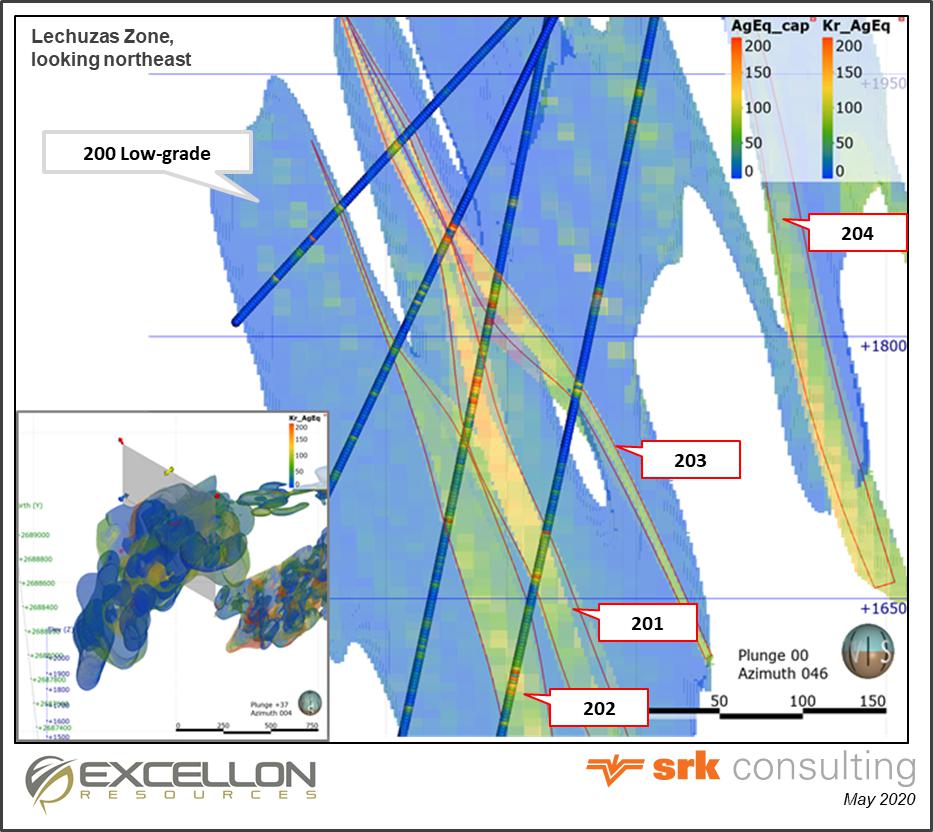

| Figure 21: | Cross Section for Lechuzas Zone (looking northeast): Comparison of Block Estimates and Informing Composites | 69 |

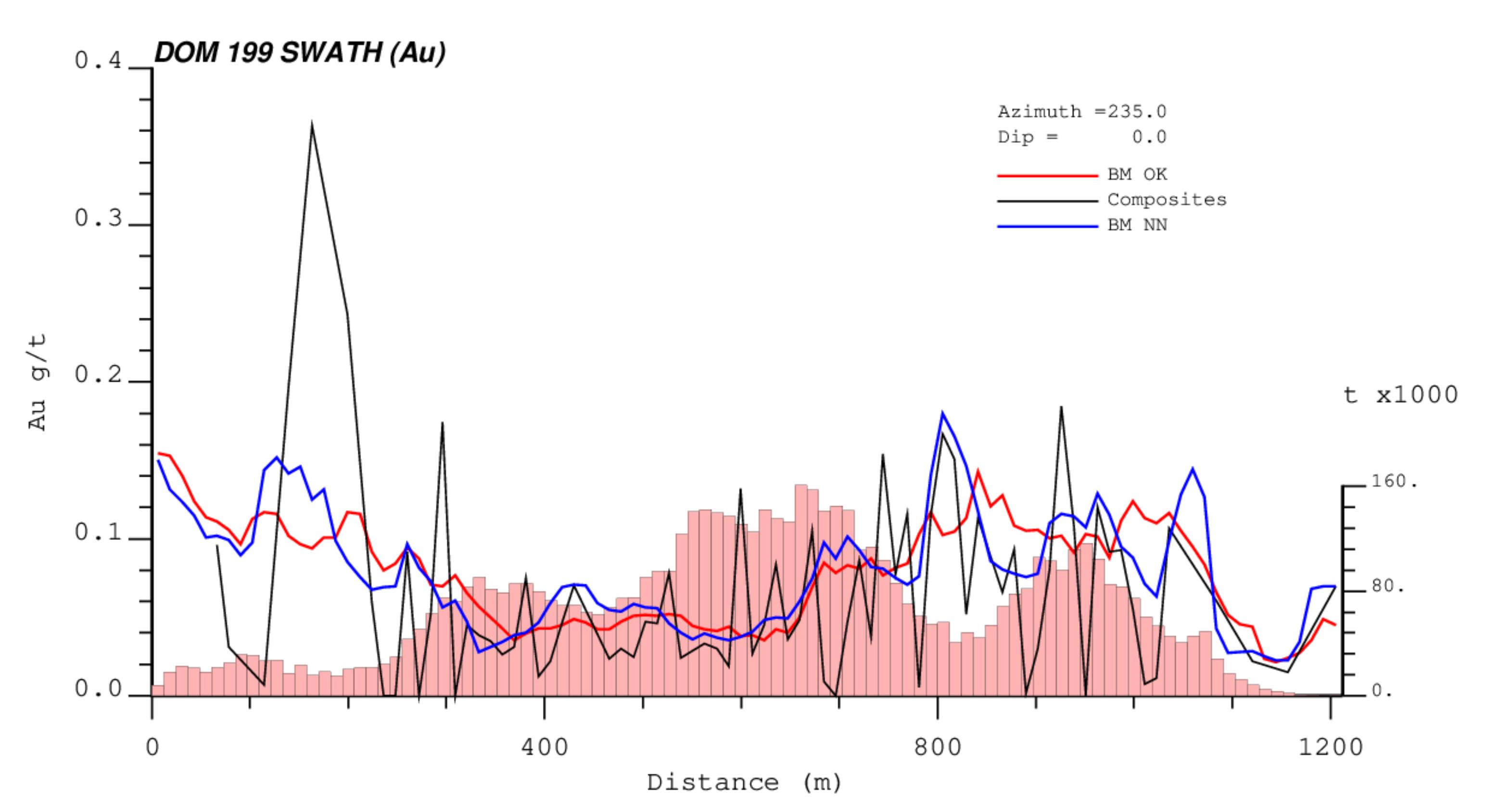

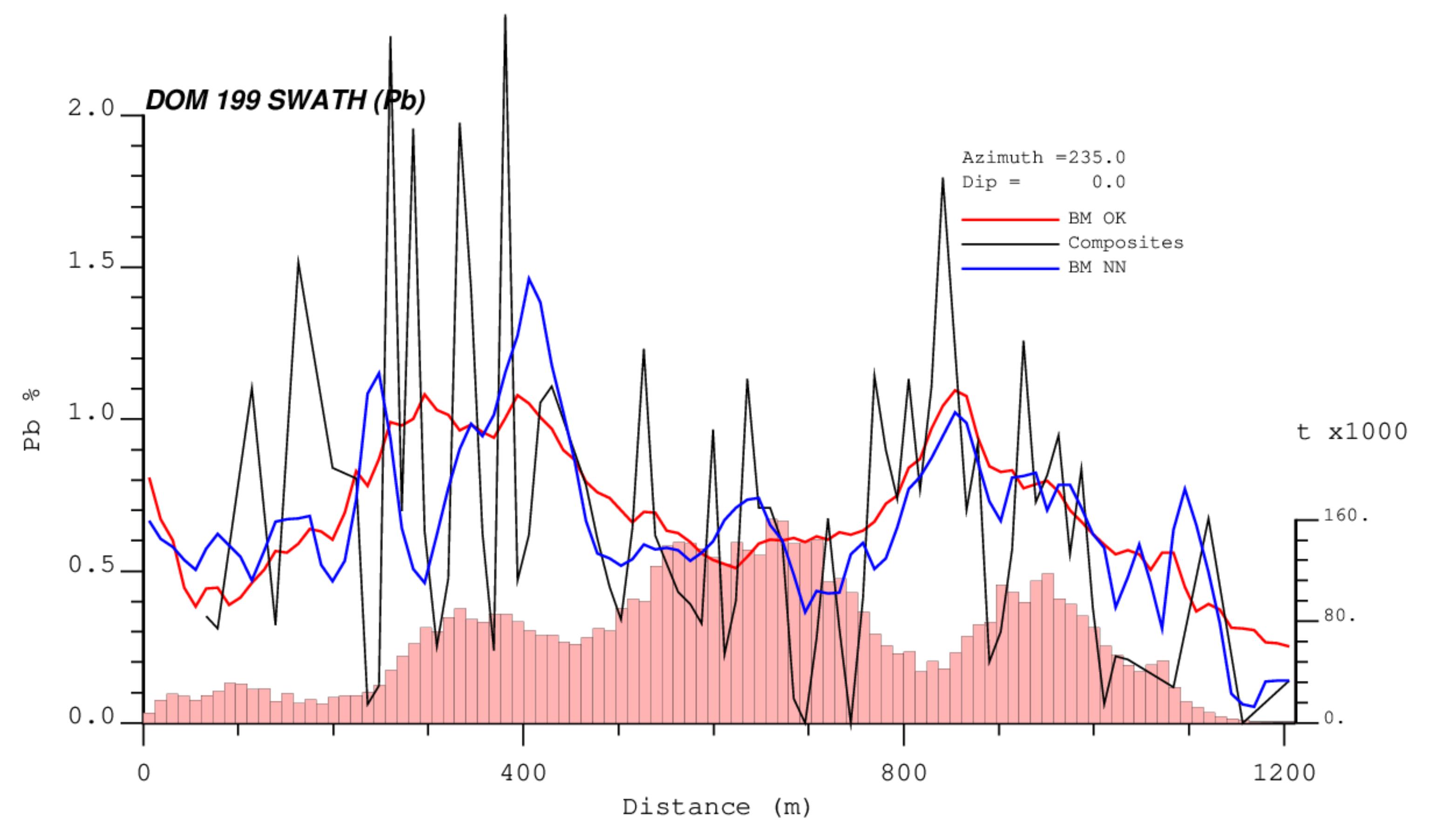

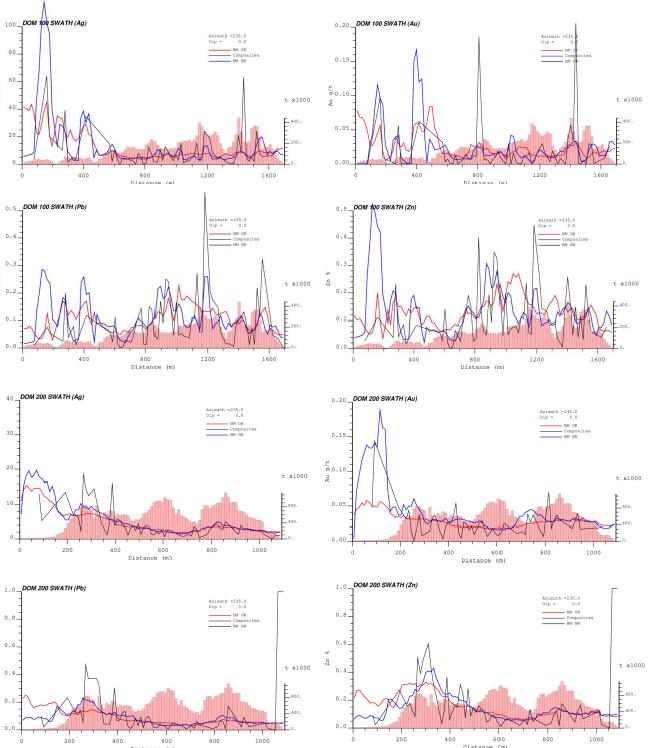

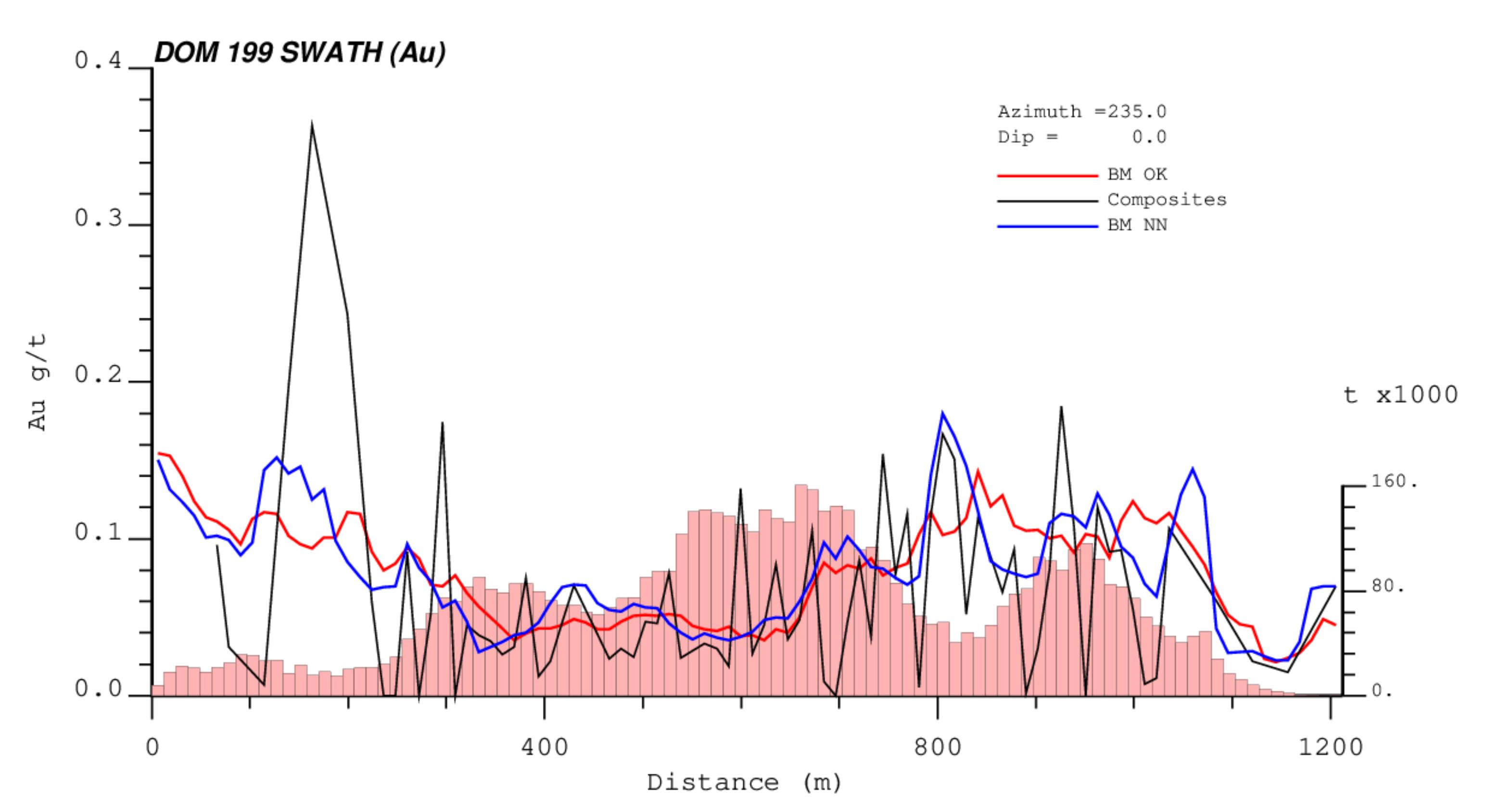

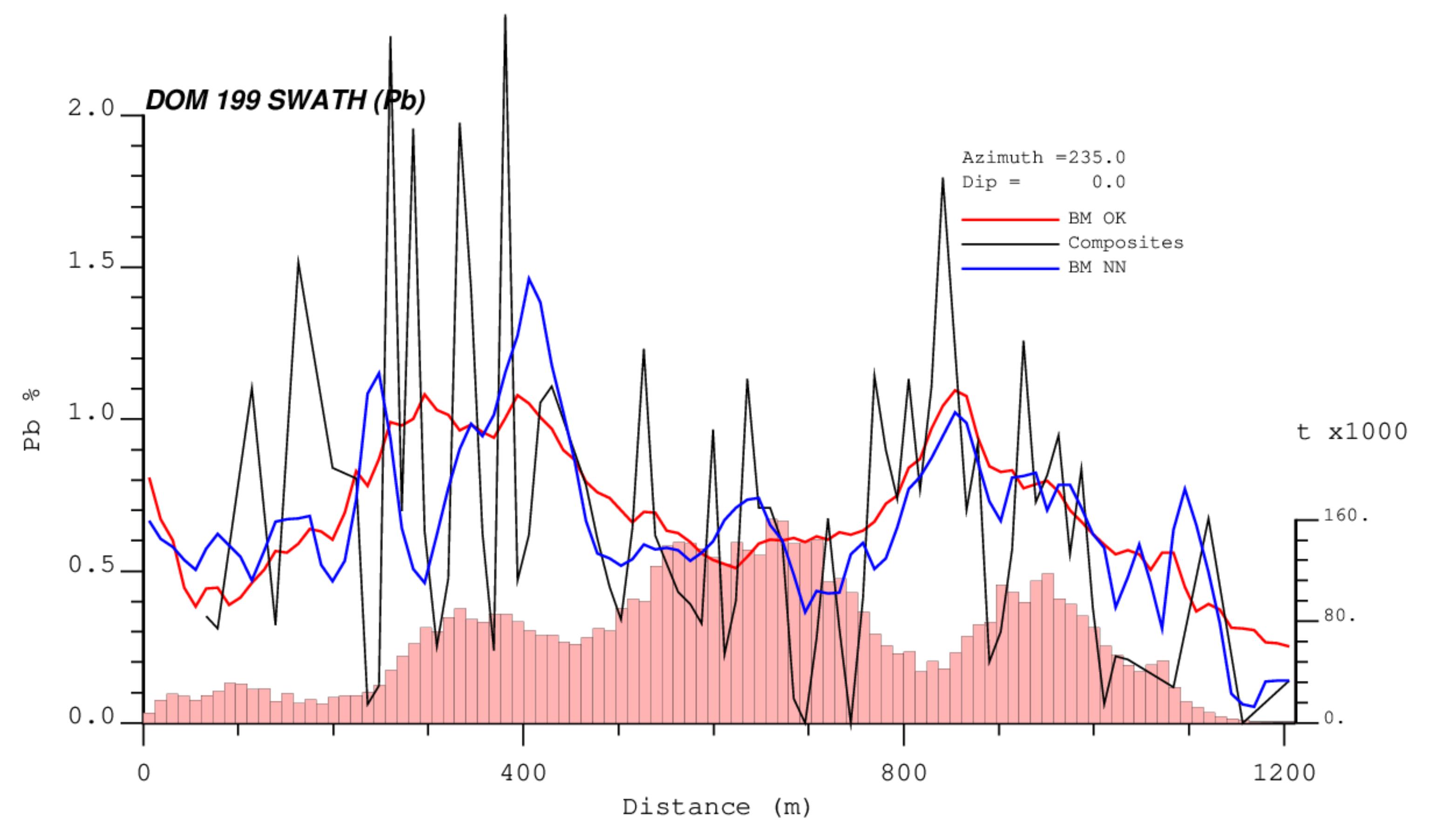

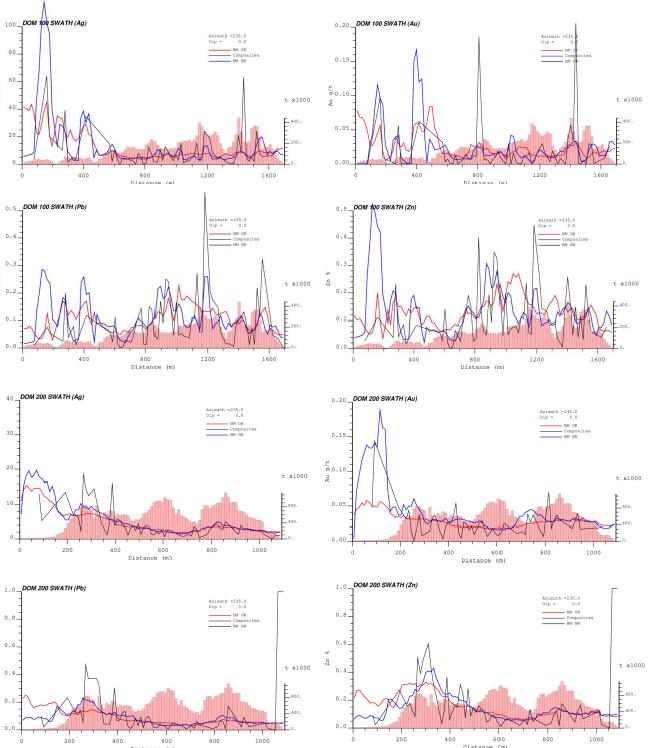

| Figure 22: | Swath Plot Grade Comparison of Block Estimates with Composites and Nearest Neighbour Estimator for Calvario Veins | 70 |

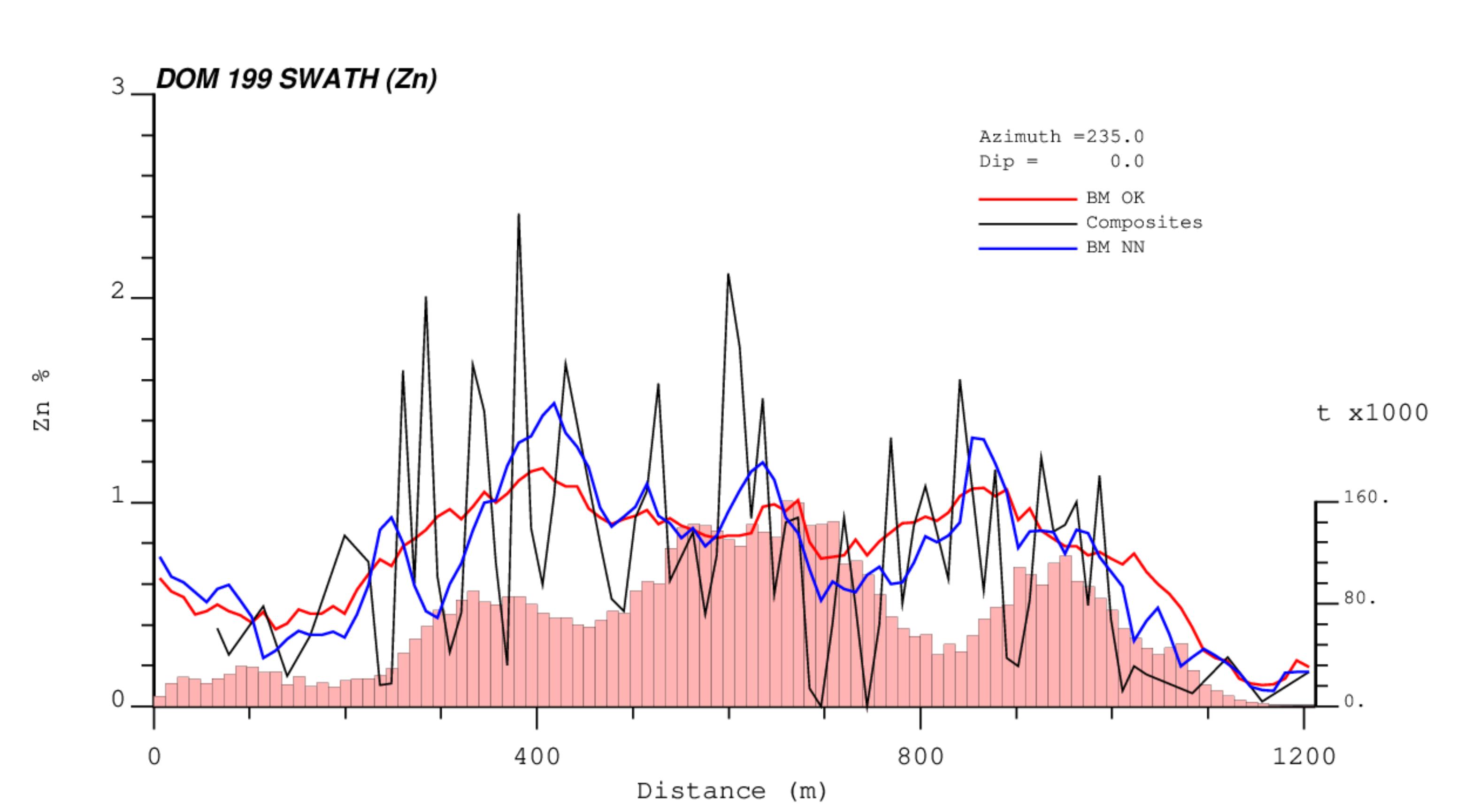

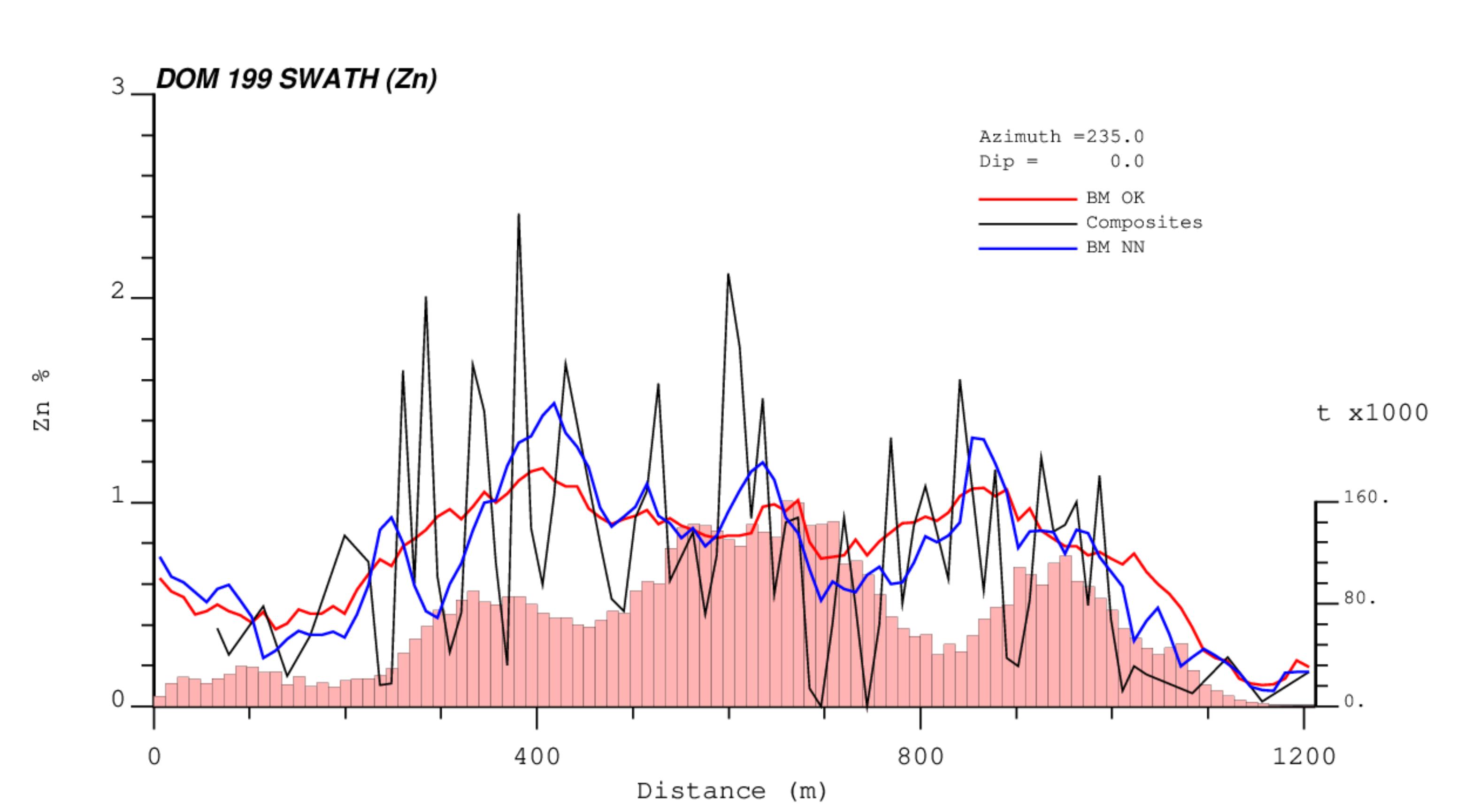

| Figure 23: | Distribution and Cumulative Distribution of Average Distance of Informing Composites for Indicated Blocks | 72 |

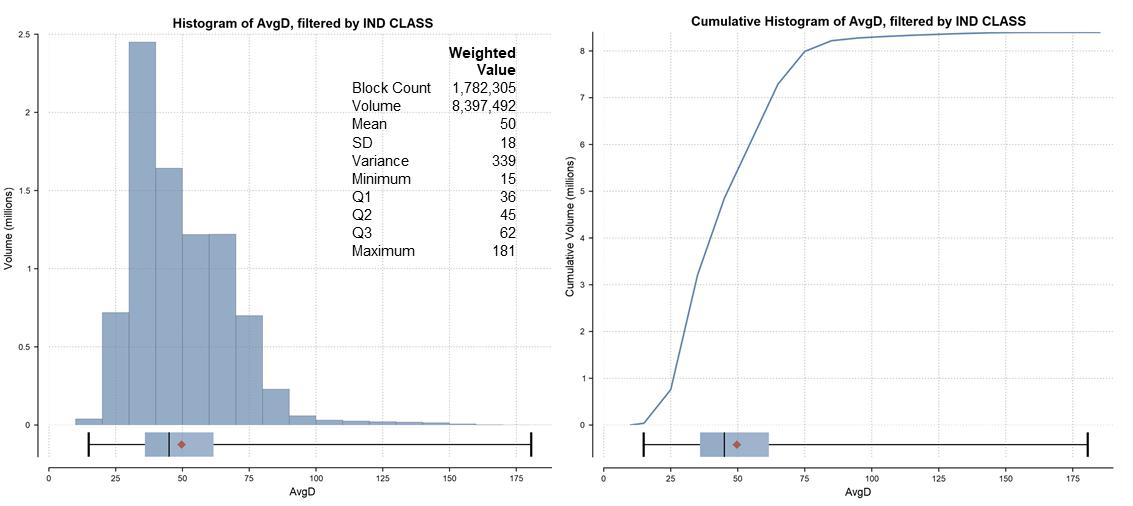

| Figure 24: | Grade-Tonnage Sensitivity to Cut-Off Grade for Mineralized Domains (Veins and Halos) and Veins | 74 |

| Figure 25: | Adjacent Properties to the Evolución Project | 77 |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 1 |

| 1 | Introduction and Terms of Reference |

The Evolución Project (the Project) is a polymetallic silver-zinc-lead-gold exploration project, located in Zacatecas, Mexico. It is located nearby and within the boundaries of the town of Miguel Auza, on the border of Durango and Zacatecas States, Mexico. Excellon Resources Inc. (Excellon) owns 100% of the Evolución Project through its wholly owned Mexican subsidiaries, San Pedro Resources, S.A. de C.V. (San Pedro) and Minera Excellon de Mexico, S.A. de C.V. (MEM).

In February 2020, Excellon commissioned SRK Consulting (Canada) Inc. (SRK) to visit the property and prepare a geological and mineral resource model for the Evolución Project. The services were rendered between March and May 2020, leading to the preparation of the mineral resource statement reported herein that was disclosed publicly by Excellon in a news release on September 17, 2020. The last technical report for this property was documented in a historical Preliminary Feasibility Study for the previous operator Silver Eagle Mines Inc. (SEM) and was prepared by Valliant et al (2008).

The current technical report documents a mineral resource statement for the Evolución Project prepared by SRK. It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1. The mineral resource statement reported herein was prepared in conformity with generally accepted CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines.

The scope of work, as defined in a letter of engagement executed on February 4, 2020 between Excellon and SRK, includes the preparation of a mineral resource model for the polymetallic mineralization delineated by drilling on the Evolución Project and the preparation of an independent technical report in compliance with National Instrument 43-101 and Form 43-101F1 guidelines. This work typically involves the assessment of the following aspects of this project:

| | ● | Topography, landscape, access |

| | ● | Regional and local geology |

| | ● | Exploration history |

| | ● | Audit of exploration work carried out on the project |

| | ● | Geological modelling |

| | ● | Mineral resource estimation and validation |

| | ● | Preparation of a Mineral Resource Statement |

| | ● | Recommendations for additional work |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 2 |

The mineral resource statement reported herein is a collaborative effort between Excellon and SRK personnel. The exploration database was compiled and maintained by Excellon and was audited by SRK. The geological model and outlines for the polymetallic mineralization were constructed by SRK from drilling data, geological maps and mine plans provided by Excellon. In the opinion of SRK, the geological model is a reasonable representation of the distribution of the targeted mineralization at the current level of sampling. The geostatistical analysis, variography and grade models were completed by SRK during March and May 2020. The mineral resource statement reported herein was presented to Excellon in a memorandum report on August 31, 2020 and disclosed publicly by Excellon in a news release dated September 17, 2020.

The technical report was assembled in Toronto during July and August 2020.

| 1.3 | Basis of Technical Report |

This report is based on information collected by SRK provided by Excellon throughout the course of SRK’s investigations and during a site visit performed between July 22 and July 23, 2020. SRK has no reason to doubt the reliability of the information provided by Excellon. Other information was obtained from the public domain. This technical report is based on the following sources of information:

| | ● | Discussions with Excellon personnel. |

| | ● | Inspection of the Evolución Project area, including drill core. |

| | ● | Review of exploration data collected by Excellon. |

| | ● | Additional information from public domain sources. |

| 1.4 | Qualifications of SRK and SRK Team |

The SRK Group comprises more than 1,400 professionals, offering expertise in a wide range of resource engineering disciplines. The independence of the SRK Group is supported by the fact that it holds no equity in any project it investigates and that its ownership rests solely with its staff. These facts permit SRK to provide its clients with conflict-free and objective recommendations. SRK has a proven track record in undertaking independent assessments of mineral resources and mineral reserves, project evaluations and audits, technical reports and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies, and financial institutions worldwide. Through its work with a large number of major international mining companies, the SRK Group has established a reputation for providing valuable consultancy services to the global mining industry.

The data verifications and site visit were performed by Mr. Alfonso Soto, CPG (AIPG#11938), an independent geological consultant. Dr. Antoine Cate of SRK constructed preliminary geological domains in September 2019. The resource wireframing, geostatistical analysis, grade estimation and classification was completed by Ms. Joycelyn Smith, PGeo (APGO#2963) under the supervision of Dr. Aleksandr Mitrofanov, PGeo (APGO#2824) with geostatistical support from Dr. Oy Leuangthong, PEng (PEO#90563867). Additional contributions including quality control analyses and technical report compilation were provided by Ms. Smith. By virtue of their education, membership to a recognized professional association and relevant work experience, Mr. Soto, Ms. Smith and Dr. Mitrofanov are independent Qualified Persons as this term is defined by National Instrument 43-101. In this report, the authors and qualified persons (QPs) of this report are collectively referred to as SRK.

Mr. Glen Cole, PGeo (APGO#1416), a Principal Consultant with SRK, reviewed drafts of this technical report prior to their delivery to Excellon as per SRK internal quality management procedures. Mr. Cole did not visit the Project.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 3 |

Two site visits to the Project were completed by SRK personnel, in accordance with National Instrument 43-101 guidelines, since Excellon became the operator of the Project in 2010.

The initial site visit was completed from February 25 to 28, 2018, by Ms. Anna Fonseca, PGeo (PGO# 2194) of SRK. The site visit involved a structural review of Excellon’s Evolución property, with focus on the Madera vein system.

More recently, Mr. Alfonso Soto, CPG (AIPG#11938) visited the Evolución Project on July 22 and July 23, 2020 accompanied by Mr. Jorge Ortega, Geo (OGQ#626) Excellon’s Exploration Manager. The purpose of the site visit was to review the digitalization of the exploration database and validation procedures, review exploration procedures and geological modelling procedures, examine drill core, interview project personnel, and collect all relevant information for the preparation of a revised mineral resource model and the compilation of a technical report. During the visit, particular attention was given to the validation of drilling data.

The recent site visit also aimed at investigating the geological and structural controls on the distribution of the gold mineralization to confirm the accuracy of drill logs in relation to the three-dimensional polymetallic mineralization domains.

The QP was given full access to relevant data and conducted interviews with Excellon personnel to obtain information on past exploration work, to understand procedures used to collect, record, store and analyze historical and current exploration data.

SRK acknowledges the support and collaboration provided by Excellon personnel for this assignment. Their collaboration was greatly appreciated and instrumental to the success of this project.

SRK’s opinion contained herein and effective August 31, 2020 is based on information collected by SRK throughout the course of SRK’s investigations. The information in turn reflects various technical and economic conditions at the time of writing this report. Given the nature of the mining business, these conditions can change significantly over relatively short periods of time. Consequently, actual results may be significantly more or less favourable.

This report may include technical information that requires subsequent calculations to derive subtotals, totals, and weighted averages. Such calculations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, SRK does not consider them to be material.

SRK is not an insider, associate or an affiliate of Excellon, and neither SRK nor any affiliate has acted as advisor to Excellon, its subsidiaries or its affiliates in connection with this project. The results of the technical review by SRK are not dependent on any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 4 |

| 2 | Reliance on Other Experts |

SRK has not performed an independent verification of land title and tenure information as summarized in Section 3 of this report. SRK did not verify the legality of any underlying agreement(s) that may exist concerning the permits or other agreement(s) between third parties but has relied on a legal opinion provided by Excellon’s legal representative Jose Enrique Rodriguez del Bosque on August 27, 2019. A copy of the title opinion is provided in Appendix A. The reliance applies solely to the legal status of the rights disclosed in Sections 3.1 and 3.2.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 5 |

| 3 | Property Description and Location |

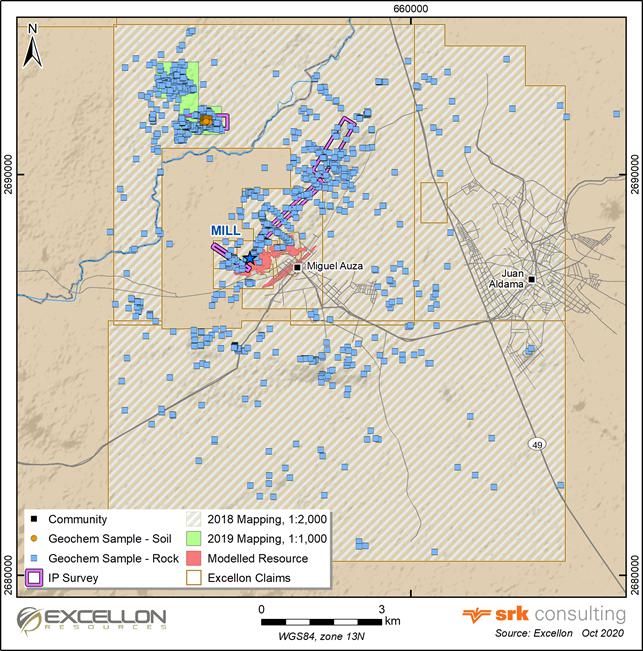

The Evolución Project is located nearby and within the boundaries of the town of Miguel Auza in northern Zacatecas State, central Mexico (Figure 1). The Project area extends several kilometres in all directions from the town center, and lies adjacent to main paved Highway 49, 200 kilometres south of the city of Torreón, Coahuila. The centre of the property is located at approximately 103o27’ W longitude and 24o18’ N latitude. The UTM WGS84 Zone 13N coordinates are 656,954.89 east and 2,688,199.89 north. An operational flotation processing and toll milling facility, owned by Excellon, is located on the property. This plant currently processes ore from Excellon’s Platosa operation, located about 200 kilometres away.

Figure 1: Location Map

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 6 |

Excellon’s Evolución Project covers approximately 45,280 hectares, comprising 22 mineral concessions (Table 1). Excellon holds, through its wholly owned Mexican subsidiaries, San Pedro, Excellon New Mining Projects (ENMP), and MEM, a 100% interest in these concessions, subject to royalties described below. Aventura, Evolución and Evolución F-1 are held by ENMP.

Excellon reports all applicable concession payments of mining duties and work commitments are in good standing in terms of the Mexican mining law. The mineral resources discussed herein are located within concessions Ampl. Thelma Fraccion 2, Antigua, El Calvario, El Rayo, La Zacatecana, Mariana Fracc. A, Negrillas Fracc. A, Nergrillas Fracc. B, Olivia, Santa Maria, and Thelma.

The property limits are illustrated in Figure 2. Details of the mineral concessions are summarized in Table 1.

Table 1: Mineral Tenure Information

| Licensee | | Title Name | | Title Number | | | Area

(ha) | | | Effective Date

(d/m/y) | | Date of Expiry

(d/m/y) |

| San Pedro | | Ampl. Thelma | | | 220891 | | | | 3,975 | | | 10/24/2003 | | 10/23/2053 |

| San Pedro | | Ampl. Thelma Fracción 1 | | | 220892 | | | | 1 | | | 10/24/2003 | | 10/23/2053 |

| San Pedro | | Ampl. Thelma Fracción 2* | | | 220893 | | | | 0 | | | 10/24/2003 | | 10/23/2053 |

| Javier Martinez Lomas† | | Antigua* | | | 195443 | | | | 73 | | | 9/14/1992 | | 9/13/2042 |

| San Pedro | | Aventura | | | 246164 | | | | 153 | | | 3/2/2018 | | 3/1/2068 |

| San Pedro | | El Calvario* | | | 151840 | | | | 3 | | | 9/23/1969 | | 9/22/2069 |

| MEM | | El Pipila | | | 238293 | | | | 70 | | | 8/26/2011 | | 8/25/2061 |

| San Pedro | | El Rayo* | | | 186878 | | | | 25 | | | 5/16/1990 | | 5/15/2040 |

| ENMP | | Evolución | | | 246481 | | | | 30,827 | | | 8/3/2018 | | 8/2/2068 |

| ENMP | | Evolución F 1 | | | 246578 | | | | 453 | | | 9/18/2018 | | 9/17/2068 |

| San Pedro | | La Zacatecana* | | | 152166 | | | | 9 | | | 12/15/1969 | | 12/14/2069 |

| San Pedro | | Mariana Fracc. A* | | | 224078 | | | | 47 | | | 3/30/2005 | | 3/29/2055 |

| San Pedro | | Mariana Fracc. B | | | 224077 | | | | 1 | | | 3/30/2005 | | 3/29/2055 |

| San Pedro | | Mariana Fracc. C | | | 224076 | | | | 1 | | | 3/30/2005 | | 3/29/2055 |

| San Pedro | | Negrillas Fracc. A* | | | 222856 | | | | 28 | | | 9/9/2004 | | 9/8/2054 |

| San Pedro | | Negrillas Fracc. B* | | | 222857 | | | | 13 | | | 9/9/2004 | | 9/8/2054 |

| San Pedro | | Olivia* | | | 151839 | | | | 11 | | | 9/23/1969 | | 9/22/2069 |

| San Pedro | | Reducción Don Pedro | | | 244224 | | | | 6,854 | | | 6/30/2015 | | 11/7/2056 |

| San Pedro | | Reducción El Siete | | | 244238 | | | | 2,427 | | | 7/14/2015 | | 5/17/2056 |

| San Pedro | | Santa Fe | | | 151825 | | | | 3 | | | 9/18/1969 | | 9/17/2069 |

| San Pedro | | Santa Maria* | | | 144880 | | | | 28 | | | 2/2/1969 | | 2/1/2066 |

| Productos Canadienses S.A. de C.V. (PROCAN) † | | Thelma* | | | 219629 | | | | 433 | | | 3/26/2003 | | 3/25/2053 |

| | | Total | | | | | | | 45,280 | | | | | |

| * | Location of Mineral Resources |

| † | See section 3.2, Underlying Agreements |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 7 |

Figure 2: Land Tenure Map

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 8 |

Excellon acquired a 100% interest of Silver Eagle Mines Inc. (SEM) and its Mexican Subsidiary, San Pedro in 2009. The following royalties, back-in rights, payments, or other agreements and encumbrances were inherited from SEM:

| | 1. | The Thelma concession exploration and exploitation rights were acquired from Michael Francis Florence Neumann on September 17, 2003 and contained a 1% net smelter return (NSR) royalty. On November 27, 2006, a renegotiated agreement was concluded with Michael Francis Florence Neumann and Javier Aguirre Sanchez, as co-owners of the claim, containing a 3% NSR royalty with a minimum payment requirement of US$20,000 per month, and the option to acquire the claim and NSR for US$2,000,000. On January 28, 2010 the agreement was renegotiated with Productos Canadienses S.A. de C.V. the current NSR holder, containing the minimum monthly NSR payment of US$5,000. |

| | | |

| | 2. | Exploration and exploitation rights for the La Antigua concession were acquired from Javier Martinez Lomas on December 2, 2003 and contained a 3% NSR royalty with a current minimum payment requirement of US$2,500 per month, and the option to acquire the claim and NSR for US$500,000. |

| 3.3 | Permits and Authorization |

Excellon’s Evolución Project operates under exploration licenses issued by the Government of Mexico. Surface rights in Mexico are commonly owned either by communal agricultural groups (ejidos) or by private owners.

The surface rights overlying the Evolución mineral concessions are owned by a combination of private owners and ejidos. Federal or state laws allow permission to access federal or state lands without other requirements through access easement rights, as mining concessions in Mexico are federal grants. However, in many cases it is necessary to negotiate access to the land with individual owners or communities. Excellon has agreements with various local farmers, landowners, and ejidos to access their ground for exploration purposes.

The Mexican mining law includes provisions to facilitate purchasing land required for mining activities, installations, and development. Excellon owns surface rights totalling 133 hectares, which include all processing facilities, office buildings and area surrounding the access to the historical El Rey Mine at the Calvario deposit. No other formal agreements for surface rights are currently in place.

Excellon’s Miguel Auza concentrator and associated facilities located within the Evolución Project area are operated under permits issued by the Government of Mexico. Excellon has obtained all necessary permits to allow for exploration activities and the operation of these facilities.

The La Antigua concession is the subject of an ongoing litigation between a subsidiary of Excellon and a plaintiff (the concession holder). Approximately 12% of the tonnage within the MRE (26% of the indicated tonnage and 6% of the inferred tonnage) is located within the La Antigua concession. The initial decision in respect of this litigation does not affect Excellon’s contractual rights to this concession.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 9 |

SRK was informed by Excellon that there are no other known litigation actions potentially affecting the Evolución Project. Since the legal opinion was completed, concessions El Calvario, La Zacatecana, Olivia and Sante Fe (title numbers 151840, 152166, 151839 and 151825, respectively) have been successfully approved for extension and are in good standing.

| 3.4 | Environmental and Social Considerations |

San Pedro carries a current Environmental Impact Statement (MIA) regarding older buildings in poor condition made of rustically crafted solid mud bricks called adobes, located within the property. These are the remnants of old mining facilities, including an old shaft, headframe and ramp. Some of the buildings were rehabilitated and purposed for operation. It is assumed that sites do not represent a threat to future development.

According to Excellon’s community agreements with agricultural landowners, no traces of drilling (including cement collar monuments) may be left upon completion of drilling activities on these properties. The town of Miguel Auza is located above a portion of the resource, which presents a potential challenge for future development of the Project. Underground mining operations could result in subsidence and vibrations from mining activity may have an affect on the buildings, residences and could generate concern from local residents.

The facilities at Miguel Auza town owned by Excellon have a relatively small footprint and therefore environmental impacts are few and of modest significance. Mine waste and associated water management and discharge, emissions to air, handling, storage and disposal of solid and hazardous waste, and storage and handling of chemicals are among the main environmental aspects associated with Excellon’s current concentrator operations. Tailings from the Miguel Auza concentrator are discharged by gravity pipeline to tailings management facility (TMF) #2, with water recycled back to the concentrator.

The primary liabilities currently associated with Excellon’s concentrator relate to the presence of buildings and other facilities used to support metal concentrate production, the former Miguel Auza ramp and associated waste storage area, and TMF #1 and TMF #2. TMF #1 has been closed, covered and re-vegetated. TMF #2 is currently active and being expanded to accommodate future production.

| 3.5 | Mining Rights in Mexico |

Mining and exploration rights in Mexico are controlled by the Federal Government. Prior to 2006, exploration and mining rights were assigned to private Mexican individuals and companies incorporated under Mexican laws, including those companies fully financed by foreign investment, by the granting of “exploration” and “exploitation” concessions, each with differing validity periods and tax and assessment obligations.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 10 |

The mining law reform of April 2005 simplified the concession regime, and all new concessions are now “mining concessions”, which are valid for a 50-year period and are renewable for an additional 50-year period. Upon enactment of the mining law reform, all previously issued “exploration” and “exploitation” concessions were automatically converted to “mining concessions” without changing the effective date of the title.

Mining concessions are administered by the Dirección General de Minas (DGM), a subsecretariat of the Subsecretaría de Minería under the cabinet-level Secretaria de Economia. To maintain concessions in good legal standing, concession holders are obligated to pay semi-annual duties and to file annual documentation of exploration or development work (a minimum investment as provided in applicable Mexican mining legislation) on the concession. Concession holders are also obligated to file production reports for statistical purposes. Both the semi-annual duties and the minimum investment increase each year in accordance with rates published by the Mexican Government in the official gazette: the older the mining concession, the higher the duties payable and the amount to be invested. When the concessions are in their 7th year of issuance or greater, the amount to be invested reaches the maximum rate applicable; when the concessions are in their 11th year of issuance or greater, the amount of payable taxes reaches the maximum rate applicable.

In addition, as part of the obligations derived from titles of mining concessions, concessionaires have the obligation to file after the sixth year of the term of the concession: (i) production reports on mineral obtained from the concessions; and, (ii) technical reports on works carried out by the concessionaires, this last obligation must be fulfilled only once after the sixth year of the term of the mining concession.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 11 |

| 4 | Accessibility, Climate, Local Resources, Infrastructure, and Physiography |

| | |

| 4.1 | Accessibility |

The Evolución Project is located in northern Zacatecas State, on the high plateau of central Mexico. The Project is within the boundaries of and surrounding the town of Miguel Auza, extending to the northwest. The closest international airport is located in Torreón, Coahuila, approximately 200 kilometres by road north of the Project.

The Project can be reached via the highway system for a total travel time of approximately 2.5 hours. Toll Highway 40 south connects Cuencamé to Torreón, then paved Highway 49 is taken south- southeast to Miguel Auza.

| 4.2 | Local Resources and Infrastructure |

Excellon’s exploration facilities are located in the town of Miguel Auza. According to the 2015 Census, the population of Miguel Auza is reported to be 23,827. Paved highways and secondary municipal roads serve local access to the town. Most services required to support exploration and operations are available in Miguel Auza and the nearby town of Juan Aldama, Durango.

Agriculture and livestock are the main economic activities in the region, with grains, corn and beans as the principal crops. Within the Excellon mining concessions and near to Miguel Auza, much of the surface land is used for farming and raising livestock, called Parcelas or Milpas, respectively. After completing any exploration activity on the agricultural lands, all evidence of the activity must be removed. For collar pictures, a portable cement monument is placed and later removed.

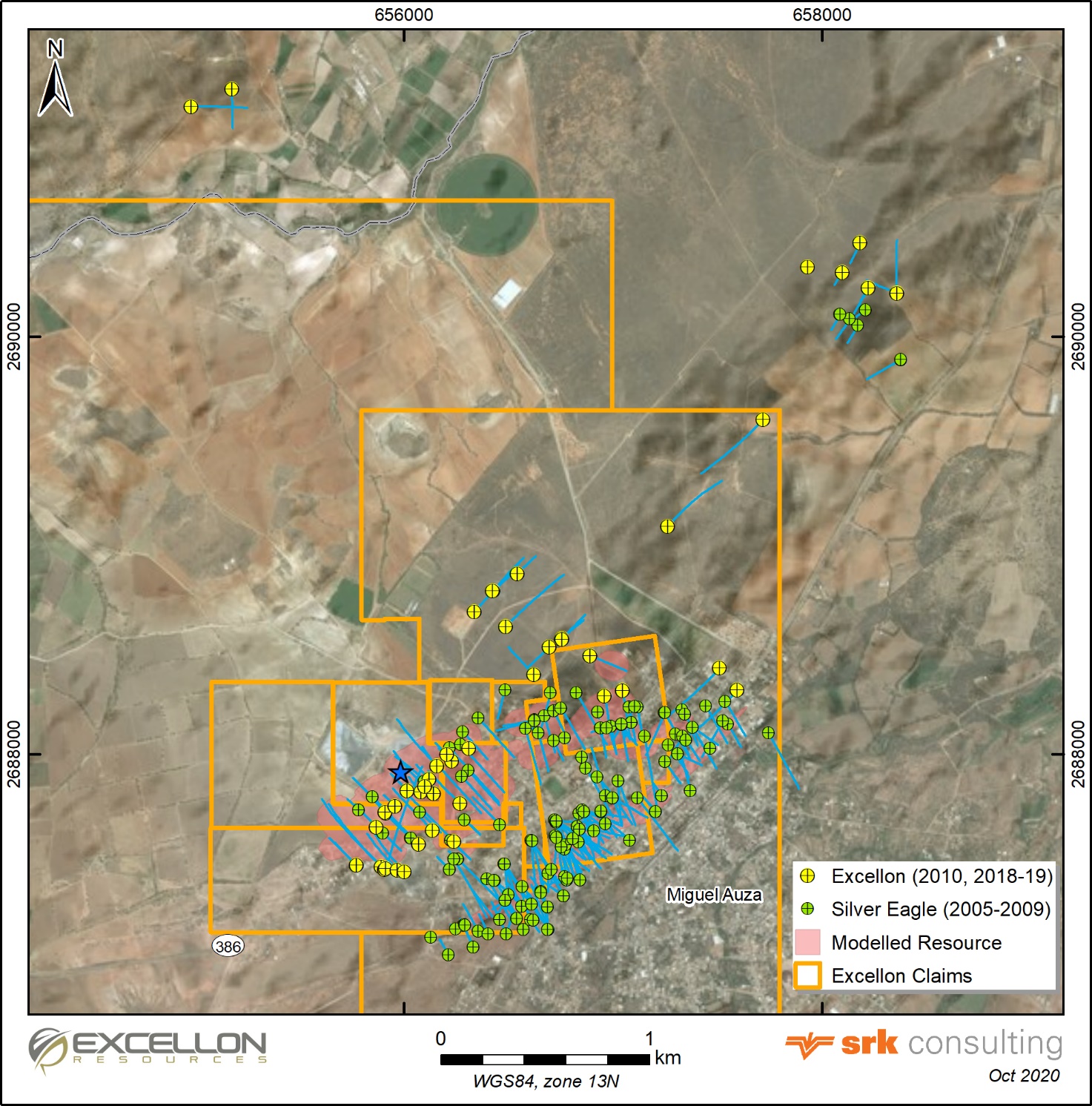

The Calvario mineralized system is located under the town of Miguel Auza (Figure 3). According to Excellon personnel, the Evolución property does not conflict with any National Institute of Anthropology and History (INAH) records of anthropological historical sites, natural areas protected by the Mexican government, or indigenous group interests.

The closest major city is Torreón, Coahuila (population 608,836 in 2010) which acts as a major supply centre to Miguel Auza. Other major cities include Torreón’s twin city Gomez Palacio, Durango (population 257,352 in 2010), located approximately 200 kilometres north by highway, and the city of Fresnillo (population 213,199 in 2010), located 130 kilometres south-southeast by highway. The state capital, Zacatecas (population 138,176 in 2010), is 65 kilometres further south of Fresnillo.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 12 |

Figure 3: Satellite Imagery of the Town of Miguel Auza with the Mineralization Domains Projected to Surface

For centuries, the State of Zacatecas has been, and still is, one of the world’s leading silver-producing districts. In the Miguel Auza district, however, underground mining has ceased with the exception of the San Sebastien mine located 40 kilometres west northwest of Excellon’s processing facilities and approximately 11 kilometres west from the Evolución Project perimeter.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 13 |

The Excellon Mill facility is operated by Excellon’s subsidiary, San Pedro, and is one of the largest employers in town of Miguel Auza. Mineralized material from Excellon’s Platosa mine, located approximately 220 kilometres by road north of Miguel Auza, is transported by truck and processed at this facility.

Excellon’s facilities, including the processing plant, tailings dam, and several heavy pieces of equipment, are located on private property on the northwestern outskirts of the town of Miguel Auza. The facilities, storage warehouses and offices are fenced and protected. Security protocols exist to allow access to the property.

Buildings inside this fenced area are in poor condition; they are remnants of old mining facilities. San Pedro has an in-force MIA (Manifestación de Impacto Ambiental or Declaration of Environmental Impact) because it is assumed that sites do not represent a threat to future development. Some of the buildings were rehabilitated and purposed for operation.

Electrical power to the Project is provided by a dedicated transmission line from the local electrical grid. A high-tension 13.2 kilovolt (kV) line has been connected to the processing plant with additional trunk lines to the main ramp, tailings dam, and the Martinez Shaft. These additional transmission lines acted as the main feed for the limited underground operations that took place during the 2000’s; these workings are currently inactive.

The climate is hot and arid, with mean daily temperatures ranging from 12 degrees Celsius (ºC) in January to 27ºC in June. The maximum temperature ranges from 21ºC in December to 31ºC in June. The minimum temperature ranges from 5ºC in January to 20ºC from June to August. Temperatures rarely reach below zero, although occasional snowfall occurs.

The rainy season typically occurs from May through to September. The annual average rain is approximately between 400 millimetres to 500 millimetres. The average recorded annual precipitation was 420 millimetres between 2003 and 2016. The rainy season occurs in the late summer and autumn period, and is the most important for agricultural activities, as this is the only source of water for irrigation of crops. The average annual humidity is around 50%.

Windstorms are common between February to the end of April. the prevailing winds come from the northwest in spring and summer and from the north in autumn and winter.

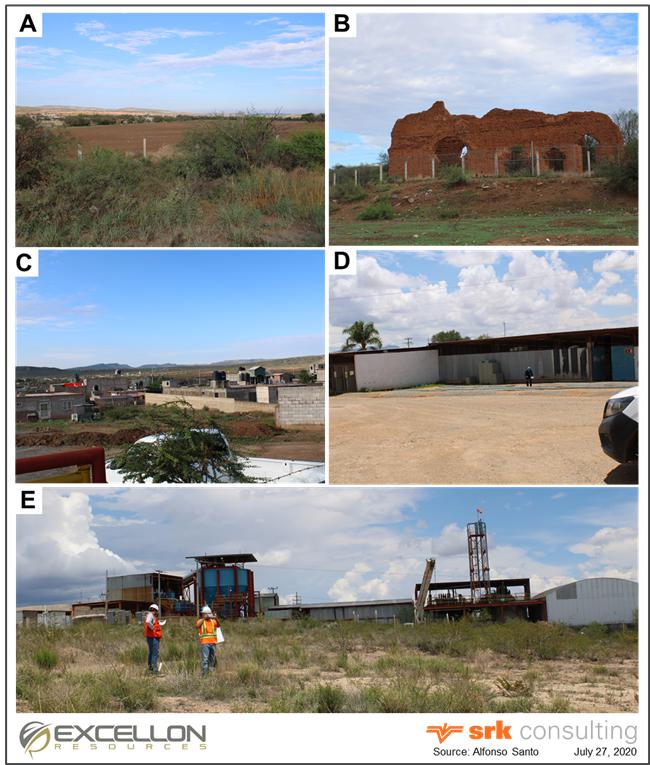

The surface property of Evolución Project is generally flat with some sparse small hills on the property (Figure 4). The project is located within the Sierras and Llanuras Potosino-Zacatecanas subprovince of the Mesa Central physiographic province. The surface elevation ranges on the property between 1,950 to 2,000 metres above sea level.

Vegetation in the area is sparse, with desert thorn bushes and some hardy trees growing only on shaded slopes and in areas where the water table is close to the surface. Shrubs and small bushes are the most common type of vegetation in the area, and prickly pear cactus, huisache, and mesquite are the most abundant species in the region.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 14 |

Figure 4: Typical Landscape and Infrastructure in the Project Area

A: Agricultural Lands on the Evolución Project

B: Private Land for Historical Benefit Plant with historic abode buildings

C: Buildings near the Mill in the Lechuzas Zone

D: Core Storage Facility

E: Mill

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 15 |

| 5 | History |

| | |

| 5.1 | Historical Exploration Work and Ownership |

A variety of owners and operators have explored and mined the Miguel Auza area since the 1500’s (Table 2). Mining activity was first recorded in the 1560s by colonial miners during the Spanish Conquest. Multiple mines were established in the area to exploit silver-, lead- and zinc-bearing hydrothermal quartz veins. The thriving mining activity at the time led to the establishment of the town of Miguel Auza. According to historical records, at least twelve vertical shafts were constructed in the late 1800s to access polymetallic veins, ranging in depth from 49 metres to 114 metres (Foster 1921). The mines used horse-powered winders to facilitate the hoisting of ore. Remnants of these mines and associated surface infrastructure are still visible in the region.

Table 2: Ownership History of the Evolución Project

| Year | | Owner |

| 1560’s to 1910 | | Private Ownership Spaniard Colony to Mexican Revolution |

| 1966 to 1970 | | Alejandro Gaitan |

| 1984 to 1987 | | Javier Martinez Lomas |

| 2003 to 2005 | | A.J. Resources Inc. |

| 2005 to 2009 | | Silver Eagle Mines Inc. |

| 2009 to present | | Excellon Resources Inc. |

Five major vein systems were exploited historically in the Evolución Project area, including the San Ramon, Escondida, Esperanza, Union, and Calvario veins, as well as numerous minor vein systems. Mining of these systems ceased around 1900 due to a limited ability to manage the high volumes of water, as well as metallurgical problems related to sulphide-associated mineralization. The workings were allowed to flood subsequent to the withdrawal of mining activities.

From 1966 to 1970, Alejandro Gaitan reopened the Calvario Shaft and produced approximately 16,000 tonnes of material grading 0.8 grams of gold per tonne (g/t gold), 583 g/t silver, 9% lead, and 9% zinc from the main Calvario vein system. Hand-sorted ore was shipped to the Asarco and Peñoles smelters in Chihuahua and Torreón, respectively, for processing.

From 1984 to 1987, Javier Martinez Lomas mined several thousand tonnes of high-grade mineralization from the Antigua Vein via the Martinez Shaft. The production comprised hand-cobbed mineralization, as well as some concentrate. Martinez constructed a processing plant in the 1980s, which included a ball mill, coarse and fine ore bins, and one set of flotation cells. The processing plant was designed with a capacity of 50 tonnes to 100 tonnes per day, however the plant did not operate as efficiently as expected.

In 1987, Consejo de Recursos Minerales (CRM), now Mexican Geological Survey, conducted a small sampling program consisting of 33 underground chip samples of the Ramal and Antigua vein systems.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 16 |

AJ Resources Inc. (AJ Resources), through its 80% ownership of San Pedro, acquired the property in December 2003. AJ Resources conducted exploration programs consisting mainly of surface geological mapping (Table 3), trenching, mine rehabilitation, ramping, and diamond drilling. The surface diamond drilling program in 2005 consisted of 9,768 metres of drilling in 48 holes.

Table 3: Historical Mapping Areas by Operator

| Area | | Company | | Year | | Scale | | Description |

| Mine area | | AJR | | 2003 | | N/A | | Mapping and prospecting |

| Las Lechuzas | | SEM | | 2005 | | N/A | | Mapping and prospecting |

| Calvario | | SEM | | 2005 | | N/A | | Mapping and prospecting |

| Miguel Auza concessions | | SEM | | 2007 | | 1:10,000 | | Mapping and prospecting |

In 2003, AJ Resources commissioned Charles Lammle, PEng, to complete an independent mineral resource estimate and technical report on the Project. AJ Resources officially changed their name to Silver Eagle Mines Inc. (SEM) in December 2005.

After an extensive drilling program involving 38,000 metres, SEM commissioned Scott Wilson Roscoe Postle Associates Inc. (RPA) to complete an estimate of mineral resources in June of 2008, supported by a Technical Report.

The historical exploration activities completed in the area of the Evolución Project are summarized in Table 4.

Table 4: Exploration History of the Evolución Project

| Company | | Year | | Exploration Work |

| Colonial Miners | | 1560s to 1910 | | 12 shafts and U/G mining of San Ramon, Escondida, Esperanza, Union and Calvario. |

| | | 1900 | | Mines closed and flooded. |

| Alejandro Gaitan | | 1966 to 1970 | | Reopening of Calvario Shaft and production of approx.16,000 tonnes of material. |

| Javier Martinez Lomas | | 1984 to 1987 | | Mining of Antigua Vein by Martinez Shaft and production of approx. 867 tonnes of material. Construction of processing plant. |

| CRM | | 1982 | | Limited U/G sampling. |

| | | 1987 | | 33 underground chip samples. |

| AJ Resources Inc. | | 2003 | | Surface mapping of the mine area, trenching, mine rehabilitation, ramping and diamond drilling. Non-compliant, independent Mineral Resource Estimate completed by Charles Lammle, PEng. |

| | | 2004 | | Reopening of Negrillas, San Jose, Martinez and Compromiso Shafts |

| Silver Eagle Mines Ltd. | | 2005 | | Mapping and prospecting of the Calvario and Lechuzas areas. Diamond drilling (9,768 m). |

| | | 2006 | | NI 43-101 Mineral Resource Estimate and technical report completed by Wayne Valliant, PGeo |

| | | 2006 to 2007 | | Diamond drilling (38,000 m) Construction of a 1.2 kilometres ramp 1.66 kilometres of lateral U/G development Construction of a 150 tpd mill |

| | | 2007 | | Mapping of Miguel Auza concessions at a 1:10,000 scale. |

| | | 2008 | | Two NI 43-101 Mineral Resource Estimates and technical report completed by RPA in January and July. |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 17 |

| 5.2 | Previous Mineral Resource Estimates |

Historical mineral resource estimates presented in this section are superseded by the mineral resource estimate discussed herein. The QP has not done sufficient work to classify the historical estimate as a mineral resource or mineral reserve. Excellon is not treating the historical estimate as current mineral resources or mineral reserves. The information presented in this section is relevant to provide context but should not be relied upon.

In 2003, SEM (then AJ Resources) commissioned Charles Lammle, PEng, to complete a Mineral Resource Estimation supported by an independent technical report. The estimation was generated considering the underground sampling results conducted by CRM, and the smelter returns of Gaitan and Martinez. Lammle (2003) estimated an Inferred resource of 269,000 tonnes grading 0.5 g/t gold, 680 g/t silver, 6.0% lead and 5.5% zinc based on this information.

Wayne Valliant, PGeo, of Scott Wilson Roscoe Postle Associates Inc. (RPA) prepared a mineral resource estimate for the Calvario Zone in January 2006 for SEM that was accompanied by a technical report compiled in compliance with NI 43-101 guidelines (Valliant et al., 2008) to support a public offering.

RPA updated the mineral resource estimate of the Calvario Zone in both December 2007 and January 2008 (Valliant et al 2008). Both the 2007 and 2008 estimates were completed in accordance with CIM’s Best Practice Guidelines for the Estimation of Mineral Resources and Mineral Reserves and were supported by National Instrument 43-101 Technical Reports.

The results of the 2007 and 2008 estimates are summarized in Table 5. The supporting technical reports are filed and available on SEDAR.

Table 5: Historical Mineral Resource Estimates Completed by RPA Between 2006 and 2008

| Effective Date | | Category | | Tonnage (‘000) | | | Au (g/t) | | | Ag (g/t) | | | Pb (%) | | | Zn (%) | |

| February 28, 2006 | | Total Indicated | | | 186 | | | | 0.31 | | | | 243 | | | | 2.53 | | | | 2.86 | |

| | | Total Inferred | | | 740 | | | | 0.18 | | | | 150 | | | | 2.43 | | | | 2.34 | |

| December 31, 2007 | | Total Indicated | | | 2,031 | | | | 0.18 | | | | 142 | | | | 2.06 | | | | 2.25 | |

| | | Total Inferred | | | 768 | | | | 0.24 | | | | 252 | | | | 1.27 | | | | 1.12 | |

| June, 2008 | | Total Indicated | | | 2,058 | | | | 0.19 | | | | 152 | | | | 2.30 | | | | 2.41 | |

| | | Total Inferred | | | 858 | | | | 0.23 | | | | 242 | | | | 1.55 | | | | 2.42 | |

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 18 |

| 6 | Geological Setting and Mineralization |

| | |

| 6.1 | Regional Geology |

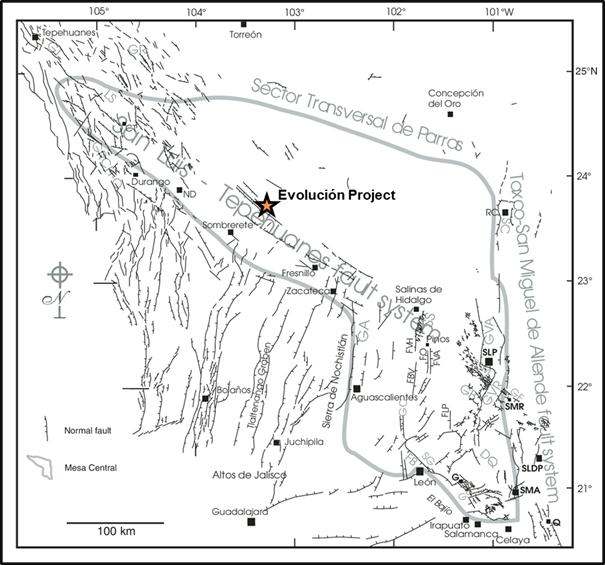

The Project is located in the Mesa Central physiographic province of central Mexico (Figure 5), along the boundary between the Parral and Oaxaquia terranes of Gondwanic affinity, previously interpreted as the Sierra Madre Terrane. The Parral terrane is the least studied and least understood of all Mexican terranes. It has a basement of Paleozoic schist overlain by Triassic to Cretaceous supracrustal sedimentary rocks. The Mesozoic sedimentary rocks deposited along a series of northwesterly elongated troughs and highs formed during the Triassic breakup of Pangea, opening of the Atlantic Ocean, and opening of the Gulf of Mexico.

Figure 5: Mesa Central Physiographic Province

Source: Modified after Nieto-Samaniego (2007)

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 19 |

The Parral terrane and the Evolución Project have a key location in the Mexican terranes. They are located where large volumes of easterly migrating crustal fluids, generated by the Cretaceous to Eocene Laramide compression, met supracrustal rocks undergoing crustal extension. This extension occurred at the eastern front of the Basin and Range physiographic province and was compounded by the overlapping Rio Grande Rift deformation.

The Mesa Central physiographic province is an elevated plateau which extends 400 kilometers south-southeast. It is bound to the north and east by the Sierra Madre Oriental, to the west by the Sierra Madre Occidental, and to the south by the Trans-Mexican volcanic belt (Nieto-Samaniego et al., 2007). The northwest-trending San Luís-Tepehuanes fault system, which extends 1,600 kilometres, divides the Mesa Central into two regions.

The northern region is characterized by lower elevations (typically below 2,000 metres above mean sea level) exposing Mesozoic supracrustal rocks. The Mesozoic Basin dominates the northern part of the Mesa Central and is comprised of an ancient sedimentary ocean basin filled with alluvial and lake sediments, overlying a thick sequence of calcareous siltstones and sandstone. Basin rocks are overlain by sandstones that contain volcanic rock fragments.

The southern region is characterized by minimal erosion where rugged Cenozoic volcanic rocks are abundant, with elevations typically over 2,000 metres above sea level. The region is cut by the Aguascalientes valley.

The Mesa Central consists of a Paleocene to Pliocene sequence of dacite-rhyolite, andesite, and basalt, and related intrusive bodies and intercalated local basin fill deposits of coarse sandstones and conglomerates (Figure 6; Nieto Samaniego et al., 2005).

The dominant intrusive rocks of the region range from late Cretaceous and mid-Tertiary in age. The Cretaceous intrusions formed during a tectonic regime of east-west compression resulting in folding of limestones. The mid-Tertiary intrusive rock were emplaced during a reversal in tectonic regime to extension, resulting in a Basin and Range geomorphological feature.

Erosion and volcanism occurred in the interval between the two intrusive events, creating continental conglomerates and rhyolite flow, breccias, and ash deposits. Erosion continued after the mid-Tertiary intrusive events, forming additional conglomerate layers. Lastly, during the late Tertiary, mafic volcanic rocks were extruded locally onto pre-existing strata. Much of the area is covered now by rocky Quaternary soils and caliche.

Like the intrusions, mineralization is classified into two stages. The first stage is associated with the late Cretaceous intrusive event and is base-metal-dominant. The second stage is associated with mid-Tertiary intrusions and is polymetallic, with silver, lead, zinc and, in locally, gold-bearing minerals. A large number of ore deposits of the Central Altiplano are located along the San Luís-Tepehuanes fault system.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 20 |

Figure 6: Regional Geology Setting

Source: Nieto Samaniego et al., 2005

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 21 |

The property is underlain by the upper Cretaceous Caracol Formation (Figure 7), which locally consists of a thick sequence of interbedded mudstone, siltstone, and lesser sandstones. The Caracol Formation rocks are gently folded along northwest-southeast trending fold axes. Caracol strata strike north-easterly with gentle to moderate dips to the west.

Tertiary rhyolites form distinctive ridges south of the village of Miguel Auza. These in turn are capped by extensive conglomerate beds, also of Tertiary age.

Several small intrusive bodies of unknown age are present on the property, including a monzonite porphyry stock in the Miguel Auza area, and a smaller monzonitic stock that has been identified between the villages of Miguel Auza and Juan Aldama. Additional rhyolitic intrusions have been characterized to the east of Juan Aldama. Andesite and lamprophyre dykes occur in proximity to areas of historic metal production.

This suite of intrusive rocks is closely associated with polymetallic veins at the Evolución Project. The large mesocratic medium-grained central intrusion is oval in shape, approximately five square kilometres in extent, and elongated northeast southwest. This unit is expressed as a laccolith and dips gently to the northeast. The extension at depth and laterally to the northeast is unknown. The known vertical depth varies from 0 metres to 125 metres where it has been intersected by drilling. The contact between the monzonite and the underlying Caracol Formation dips shallowly to the northeast and is expressed by a brittle fault zone.

Exposed intermediate to low sulphidation epithermal mineralization includes the approximately northeast-trending iron-oxide-carbonate-quartz veins and stockworks of the Lechuzas and Calvario zones, as well as the northwest-southeast-trending quartz +/-carbonate veins of the Madera vein system. The Capilla-Mantos zone dips shallowly northeast and underlies the monzonitic intrusion contact with the Caracol Formation. The various zones at the Evolución Project are displayed in Figure 8.

| JCS / ah – vp - mml | Excellon_Evolucion_TR_3CE016_008_SRK_Team_20201030 | October 30, 2020 |

3CE016.008 – Excellon Resources Inc.

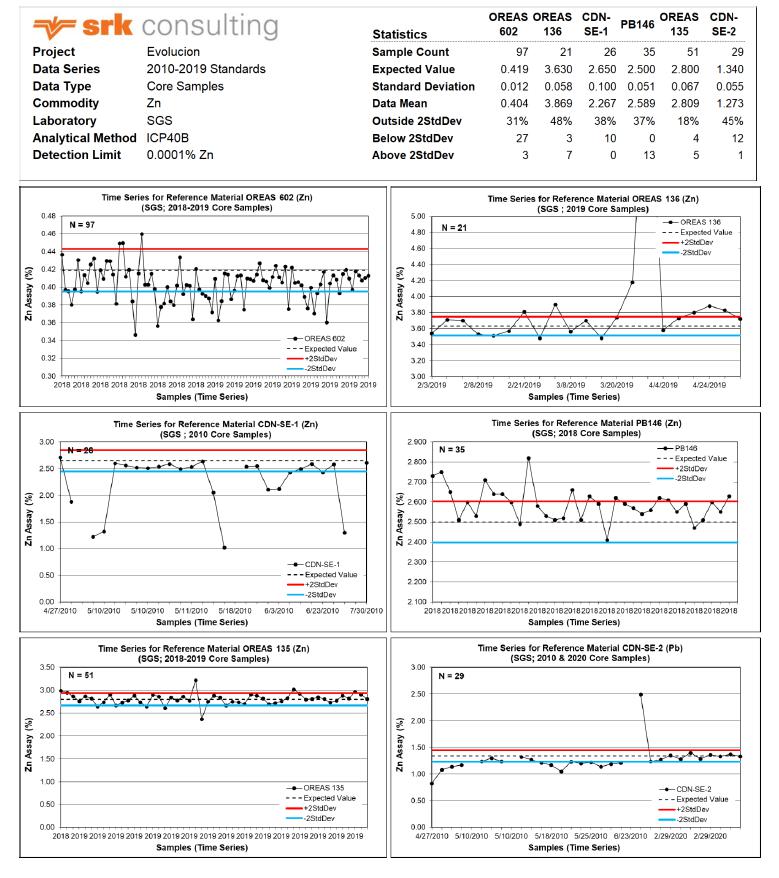

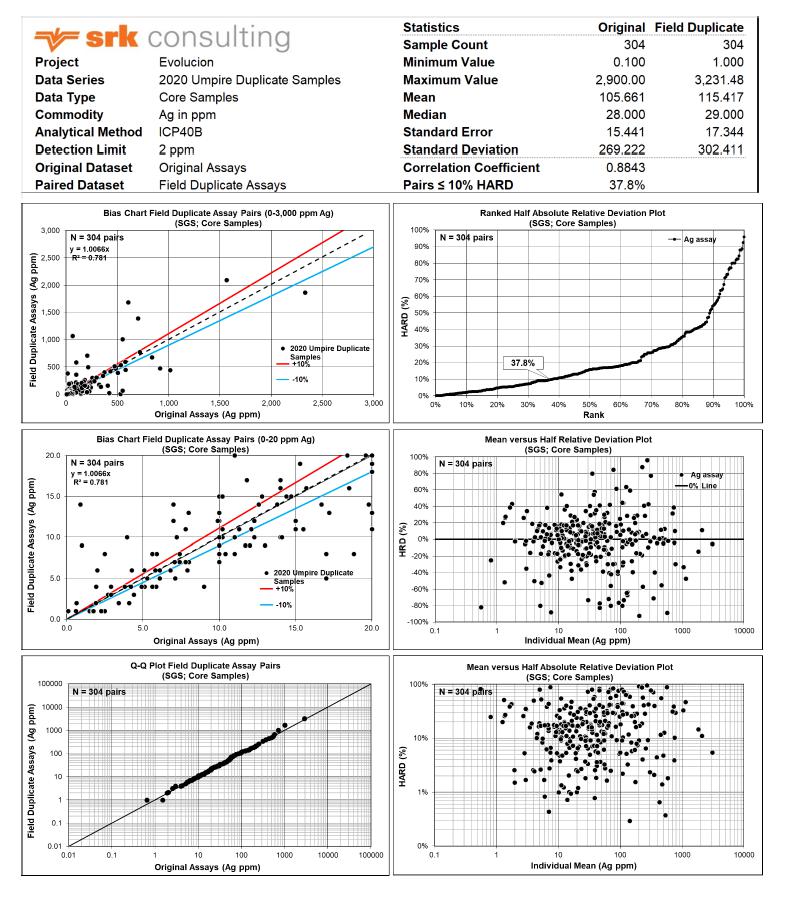

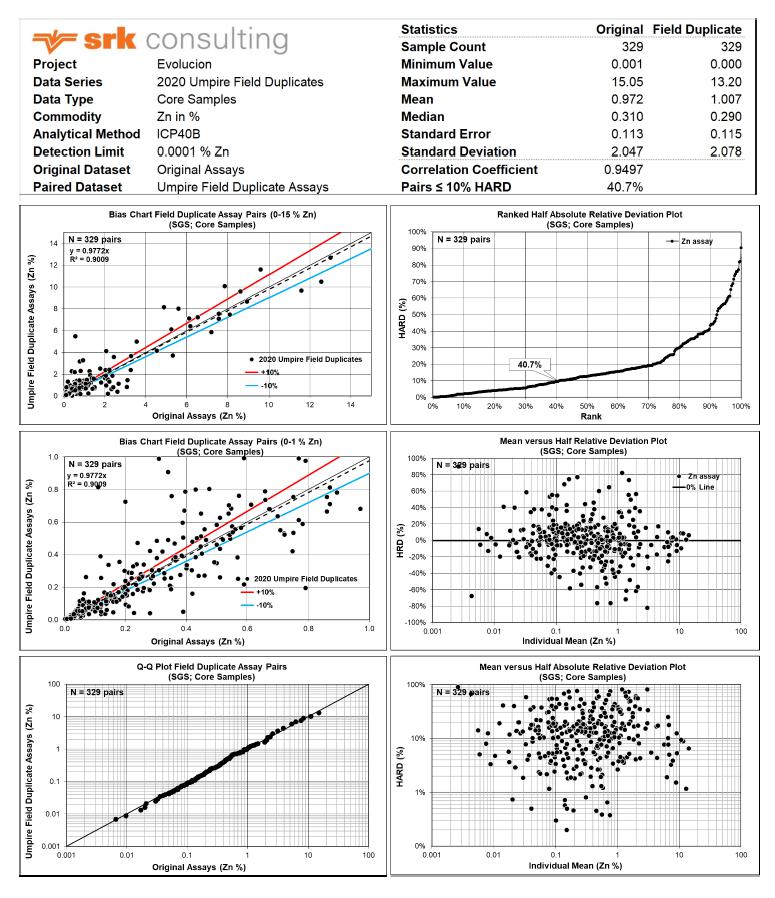

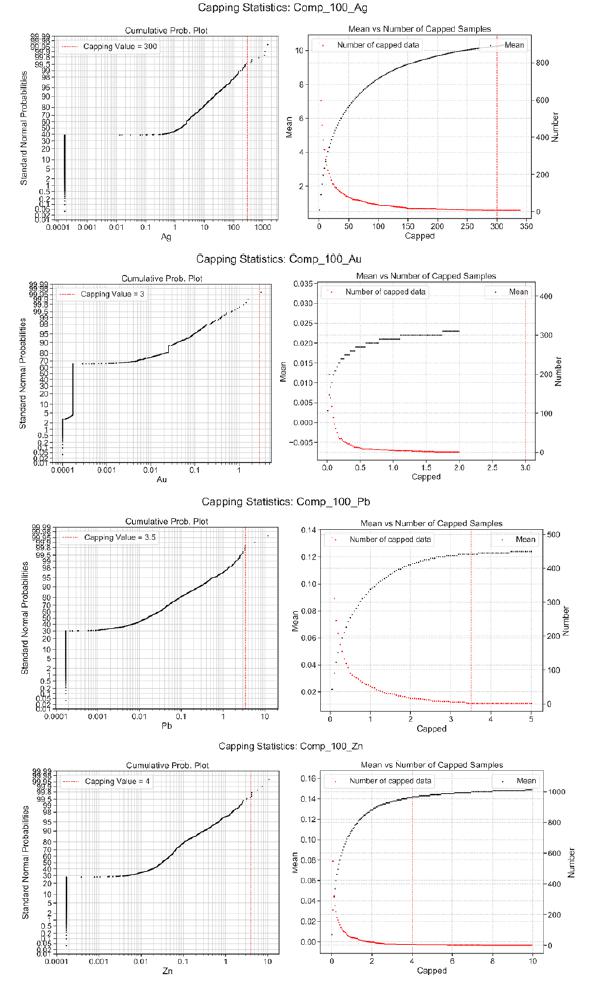

Independent Technical Report for the Evolución Polymetallic Project, Miguel Auza, Zacatecas, Mexico | Page 22 |