Updated Technical Report on the Long Canyon Project

Elko County, Nevada, USA

Prepared by:

FRONTEER GOLD, INC.

Suite 1650, 1055 West Hastings Street

Vancouver, BC, Canada V6E 2E9

Telephone: 604-632-4677

Report Date: February 25th, 2011

Effective Date:December 15, 2010

Moira Smith, Ph.D., P.Geo.

James Gray, P.Geo.

Christopher Lee, M.Sc., P.Geo.

Gary Simmons

This page left intentionally blank

TABLE OF CONTENTS

| February 25, 2011 | Page iii |

This page left intentionally blank

FIGURES

| February 25, 2011 | Page vii |

| February 25, 2011 | Page viii |

TABLES

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 1 | SUMMARY |

| | |

| Fronteer Gold, Inc . has prepared this technical report on the Long Canyon gold project, Nevada, USA, to provide an update to the technical report entitled “Updated Technical Report on the Long Canyon Project Elko County, Nevada, USA” (Gustin,et al, 2010). This updated technical report includes an interim update of the project mineral resources, as well as updates with respect to metallurgy, permitting, and drilling. This resource was produced for the purpose of supplying updated information for strategic planning and engineering studies, and does not include the results of 31 step out holes drilled late in the season. This report was written in compliance with disclosure and reporting requirements set forth in the Canadian Securities Administrators’ National Instrument 43-101, Companion Policy 43-101CP, and Form 43-101F1. The Long Canyon project has been previously described in a 2006 technical report (Griffith, 2006) prepared for NewWest Gold Corporation, a 2008 technical report issued by AuEx Ventures (Moran, 2008), and technical reports prepared for Fronteer Development Group and AuEx Ventures in 2009 and 2010 (Gustin and Smith, 2009, Gustinet al, 2009 and Gustinet al,2010). |

| | |

| Fronteer Gold, Inc . holds its interest in Long Canyon through its wholly owned subsidiary Fronteer Development (USA) Inc. Fronteer Development (USA) Inc.’s interests in the Long Canyon project are derived from the acquisition of NewWest Gold Corporation by Fronteer Gold in September 2007, and acquisition of AuEx Ventures, Inc. on November 2, 2010. Fronteer Gold, Fronteer Development (USA) Inc., and NewWest Gold Corporation are collectively referred to herein as “Fronteer”. |

| | |

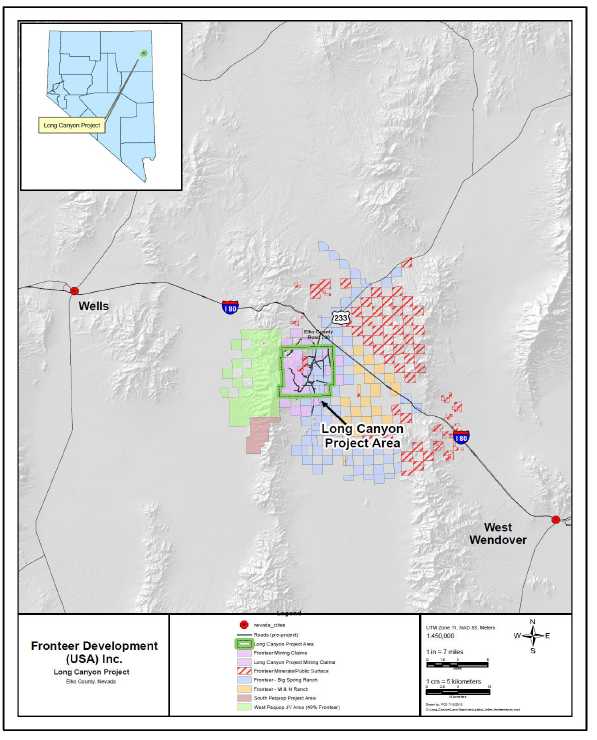

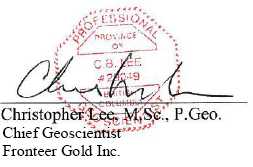

| Long Canyon, an advanced-stage exploration project, is located in Elko County in northeastern Nevada, on the east flank of the Pequop Mountains, approximately 37 kilometres southeast of the town of Wells. The project is controlled 100% by Fronteer. |

| | |

| The main portion of the property consists of approximately 49 square kilometres of unpatented federal lode mining claims and private mineral lands; additional surface and water rights are also held by Fronteer. The mineral resources reported herein are subject to the State of Nevada Net Proceeds of Mine Tax, which is limited to 5% of the production net proceeds (similar to a 5% net profits tax) . This tax is levied by the State of Nevada on all mine production in the state. |

| | |

| The Effective Date of this report is December 15, 2010 unless otherwise noted. |

| | |

| 1.1 | Geology and Mineralization |

| | |

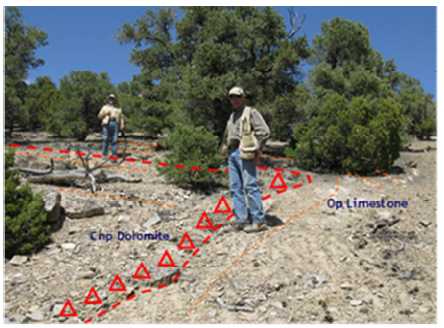

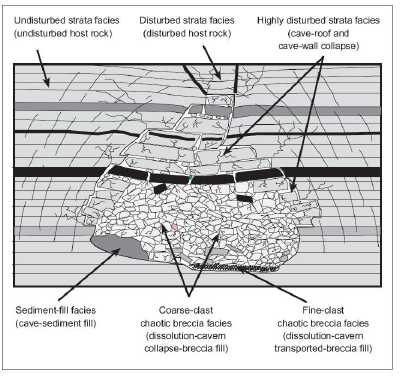

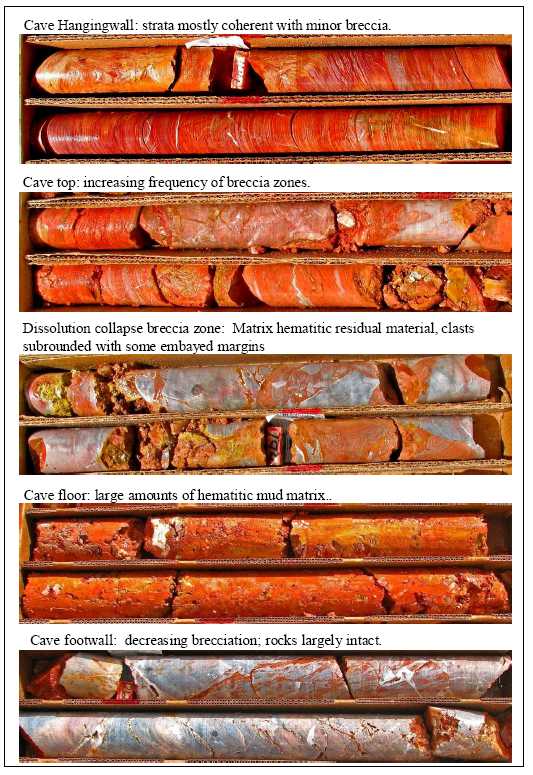

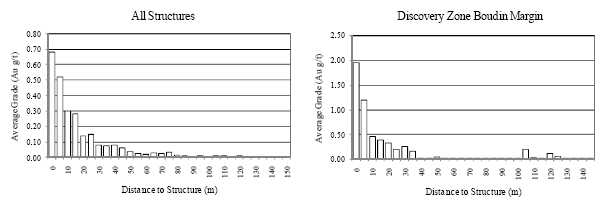

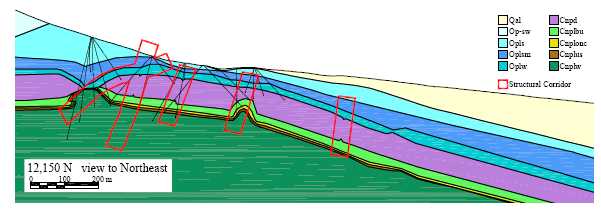

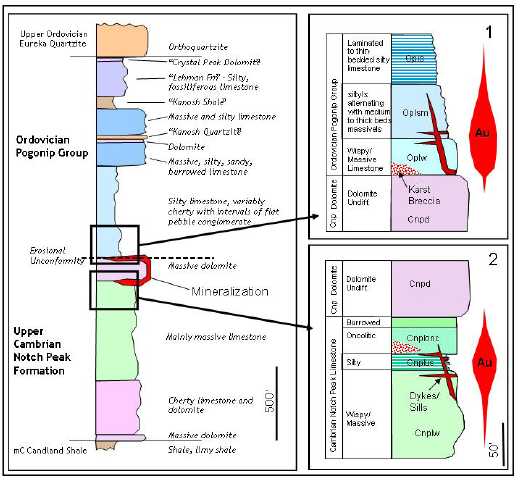

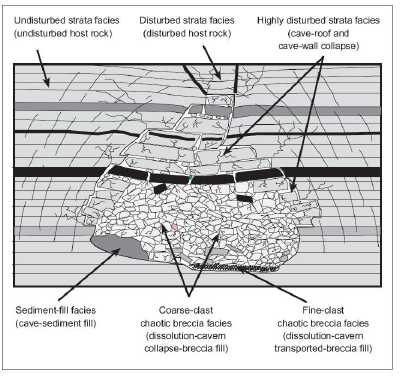

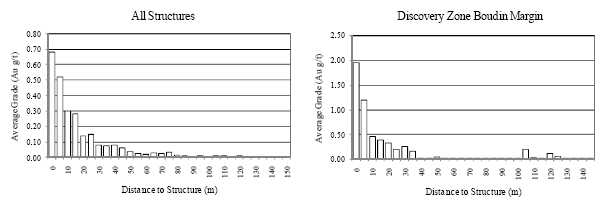

| The Pequop Mountains comprise an uplifted block of regionally east -dipping Paleozoic carbonate and siliciclastic rocks. Rocks of particular interest to the project include limestone and dolomite of the Cambrian Notch Peak Formation and limestone of the overlying Ordovician Pogonip Group. At Long Canyon, the dolomite horizon at the top of the Notch Peak Formation has been dismembered into a series of northeast- elongated “megaboudins” that strongly control the distribution of gold at the project . Gold mineralization at Long Canyon occurs mainly within limestones along dolomite boudin margins and in boudin neck areas. Significant karsting, likely of both meteoric and |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

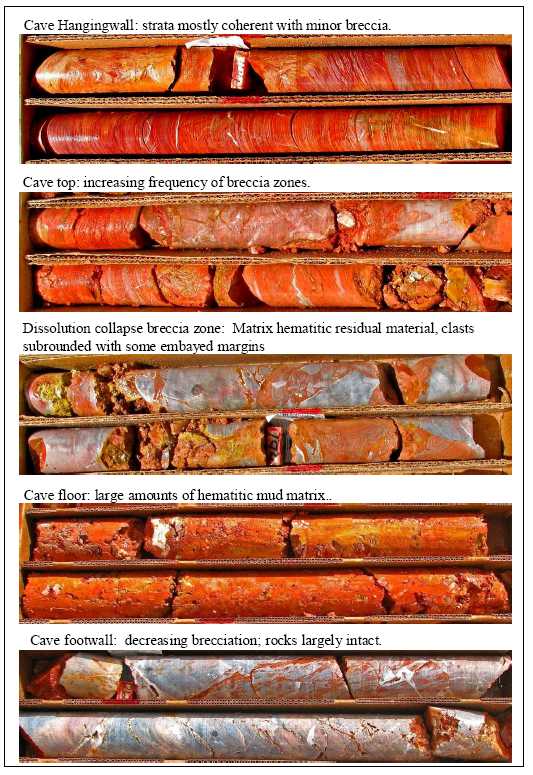

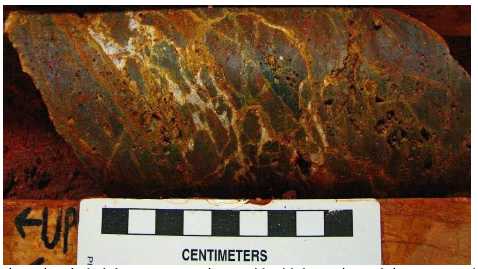

hydrothermal origin, is localized along the boudin margins and boudin necks, resulting in large, solution-collapse cavities. Much of the higher-grade mineralization at Long Canyon is hosted within the hematitic matrix of these collapse breccias, as well as in adjacent zones of stratabound mineralization characterized by strong decalcification.

The alteration, mineralization, and geochemistry of the Long Canyon deposit are similar in nature to Carlin-type sediment-hosted gold deposits. The mineralization discovered to date is almost entirely oxidized.

| 1.2 | Exploration and Mining History |

| | |

| Historic mining activities at Long Canyon appear to be limited to several small prospect pits. |

| | |

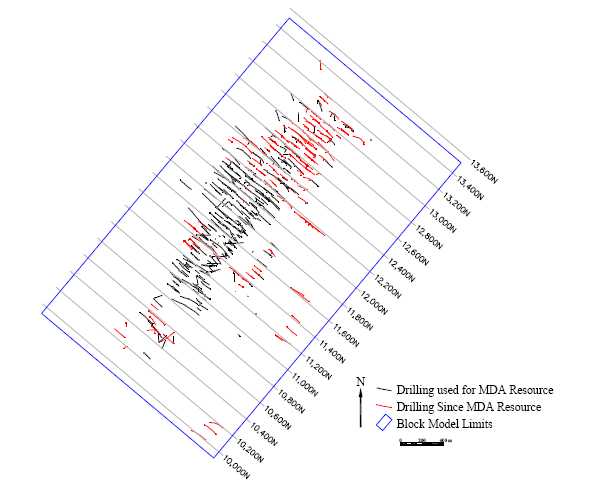

| Gold-bearing jasperoids were discovered at Long Canyon in 1999 by Pittston Nevada Gold Company (“Pittston”) as a result of follow-up work on stream-sediment anomalies defined by Pittston earlier in the year. Pittston staked claims in the area and outlined a 1400 by 300 metres gold-in-soil anomaly, which led to the drilling of seven reverse - circulation (“RC”) holes in 2000; one of these holes returned a significant gold intercept. AuEx acquired the project in 2005 and drilled seven additional RC holes, six of which intersected significant mineralization. The Fronteer-AuEx Joint Venture was formed later in 2006 when it was discovered that some of the AuEx claims were actually located over private mineral rights held by Fronteer and therefore were invalid. The Joint Venture subsequently completed 756 drill holes from 2006 through November 2, 2010. Fronteer completed an additional 31 holes through the effective date of this report, which were not included in the resource estimate. |

| | |

| 1.3 | Drilling and Sampling |

| | |

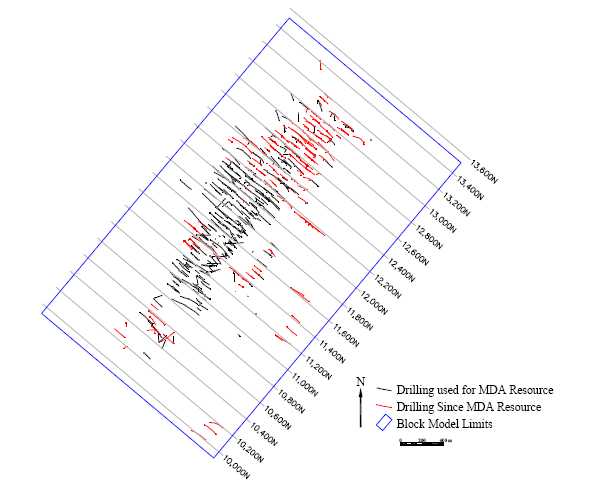

| A total of 343 drill holes (76,797 metres), including 132 RC holes and 211 diamond- core holes, were completed at the Long Canyon Project area in 2010, for exploration, metallurgical or hydrological purposes; the results from 296 of these holes were used in the resource estimation discussed in this report. Assays from 31 step-out holes drilled late in the season were not available before the effective date. Down- hole drill depths range from 18 to 429 metres, with an average depth of approximately 231 metres. The drilling was completed on a nominal 50- metre spaced grid, with the drill sections oriented northwest -southeast. Seventeen holes were drilled for hydrological purposes. Six holes lay within the drill grid or were located within a short distance of it. These holes penetrated bedrock and were assayed; they are included in the database for resource estimation. An additional 11 were not assayed and are not included in the database as they penetrated only surface alluvium. A total of 801 holes have been drilled on the Project since its inception in 2000. |

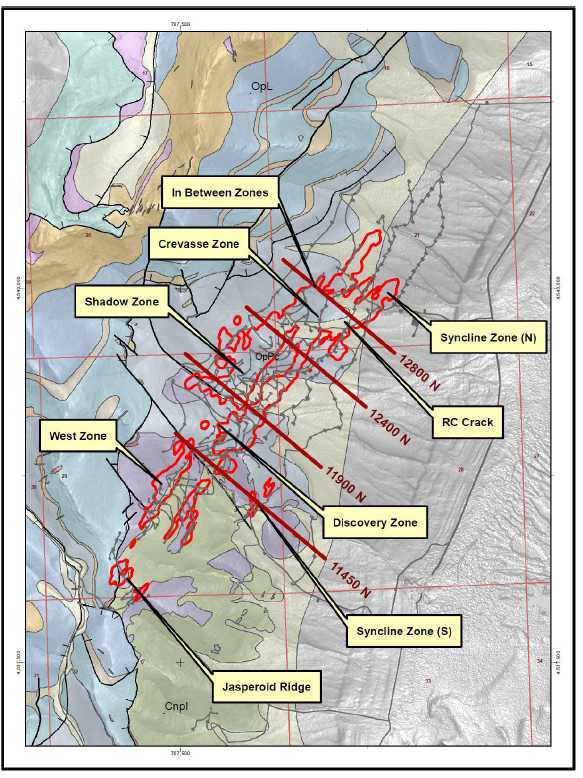

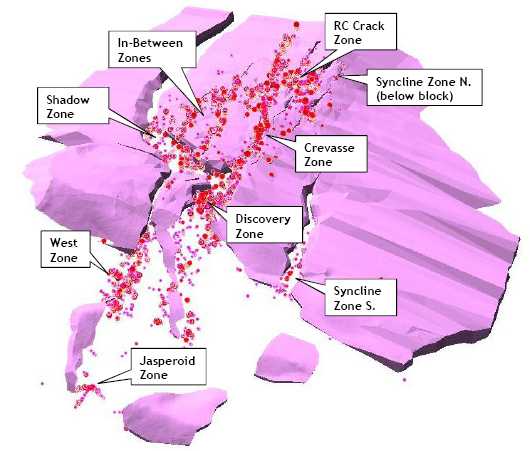

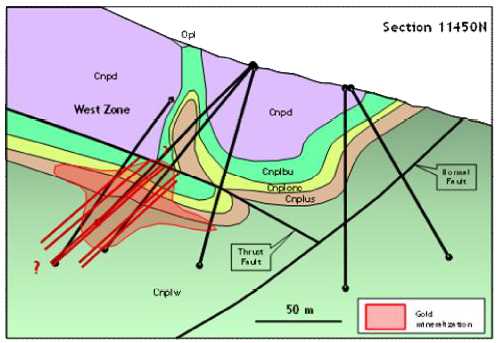

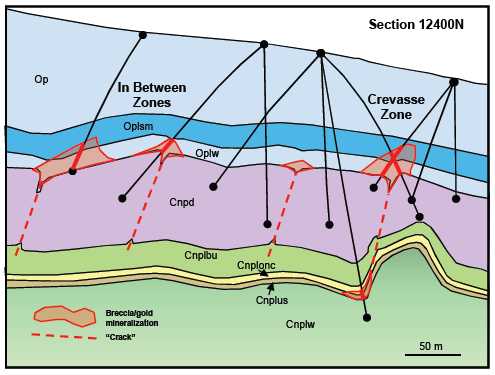

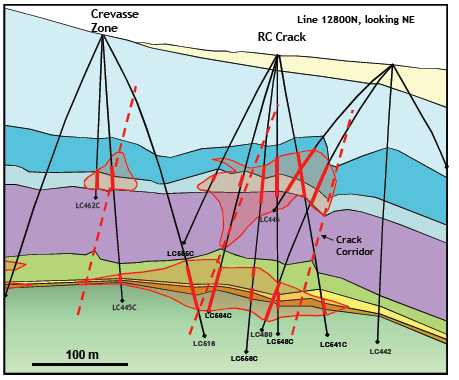

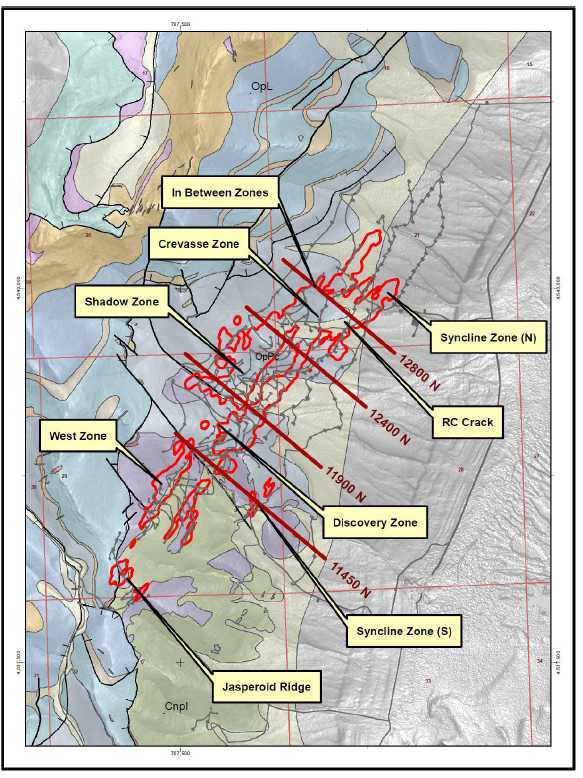

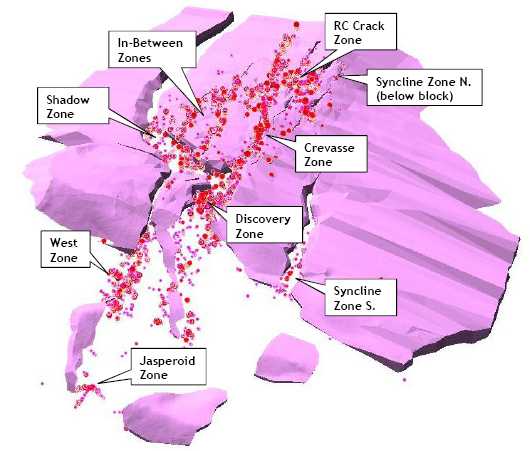

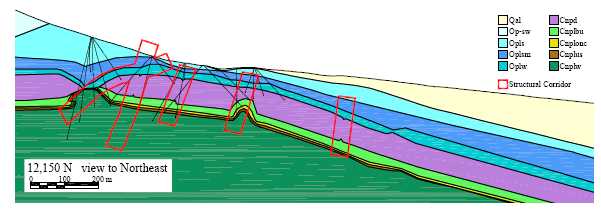

Drilling at Long Canyon has been successful in defining potentially economic gold mineralization within at least nine sub-parallel zones along a strike extent of approximately 3,000 metres. The mineralized zones at Long Canyon coalesce in various locations to form a continuous body of mineralization that plunges about ten degrees to the northeast. The mineralization has an apparent dip of five to ten degrees to

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

the southeast in sections cut across the plunge direction, reflecting the control exerted by the upper and lower contacts of the dolomite horizon. Internal to these deposit-scale geometries, boudin noses, joints, and normal faults form sub-vertical to moderately dipping controls to the mineralization that dip to the northwest or southeast. In addition, stratigraphic intervals immediately above and below the dolomite slab exert significant control on mineralization.

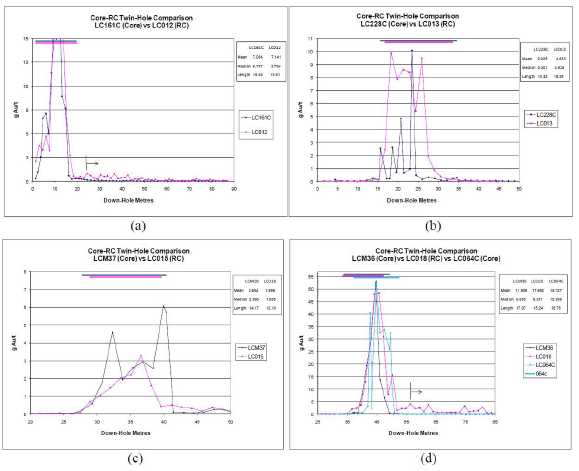

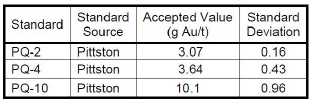

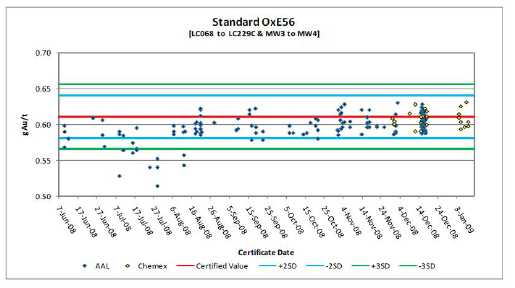

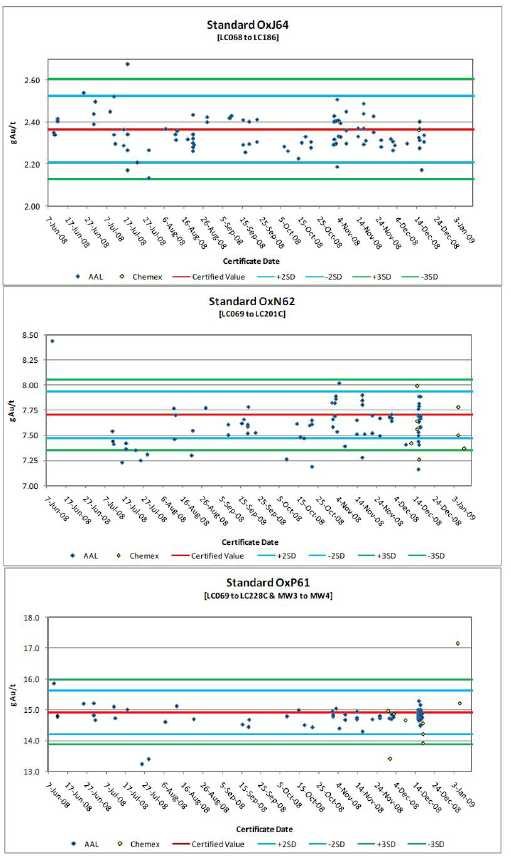

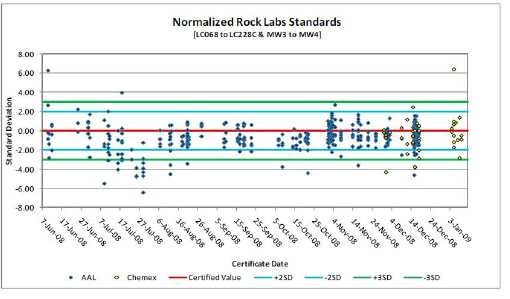

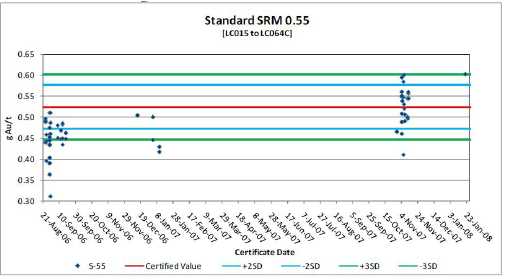

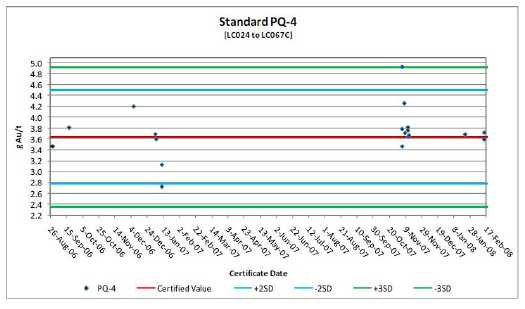

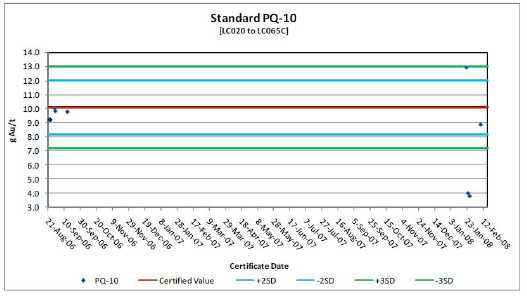

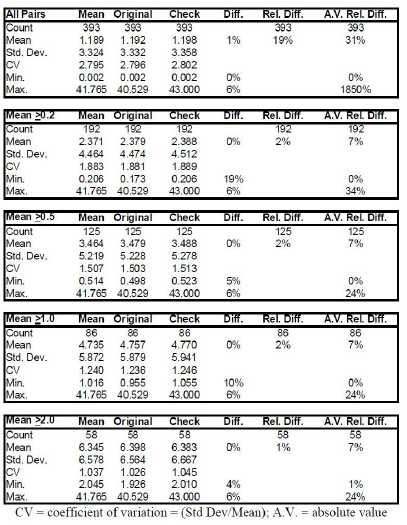

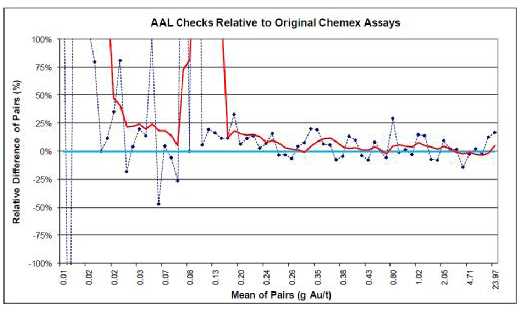

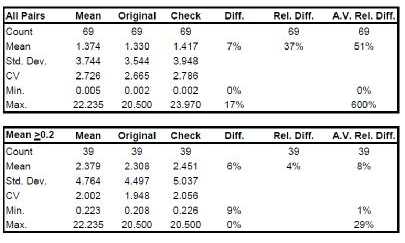

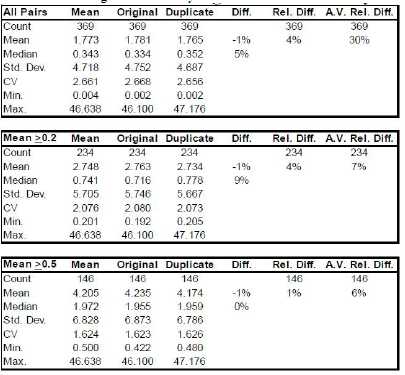

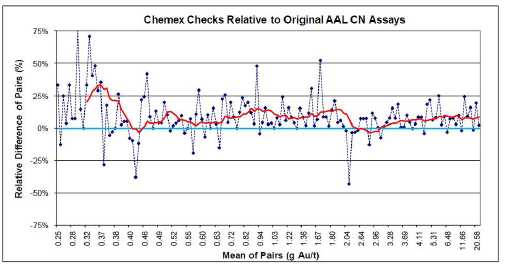

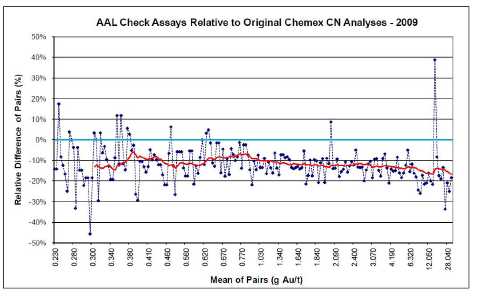

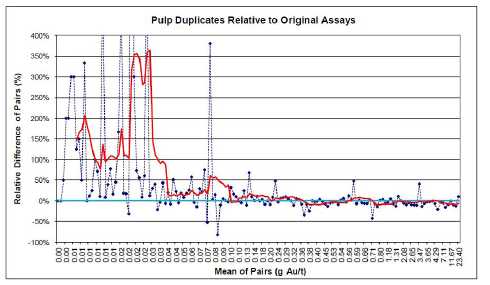

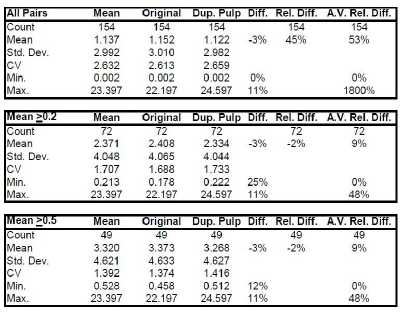

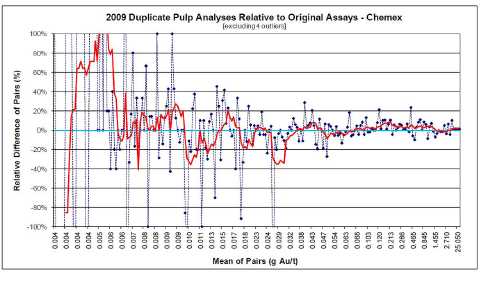

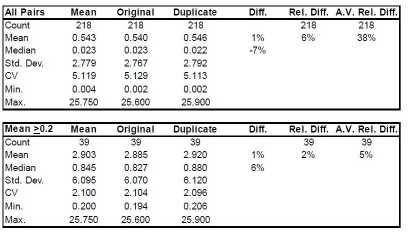

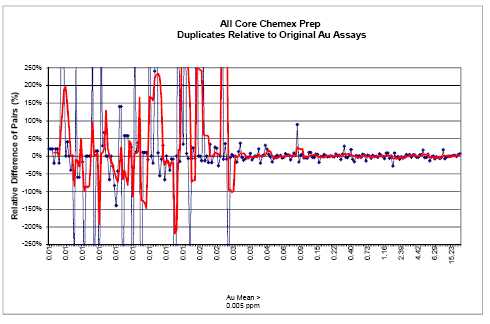

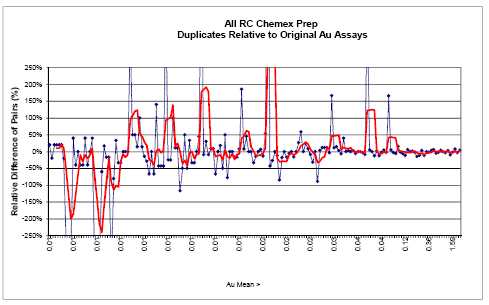

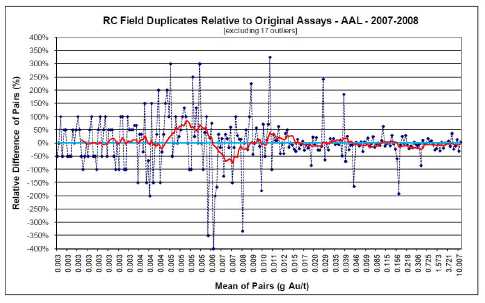

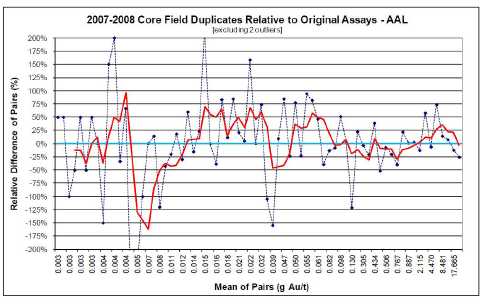

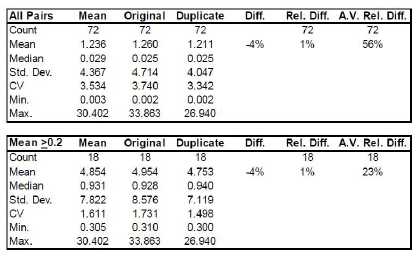

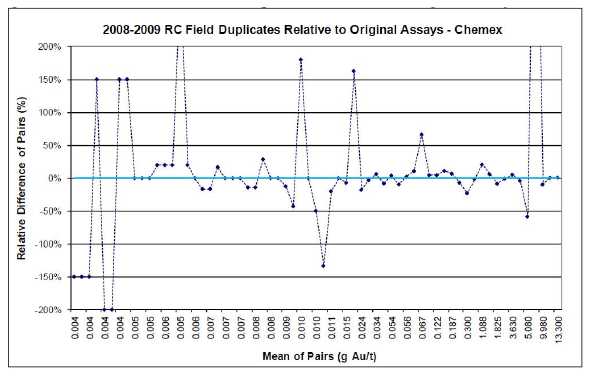

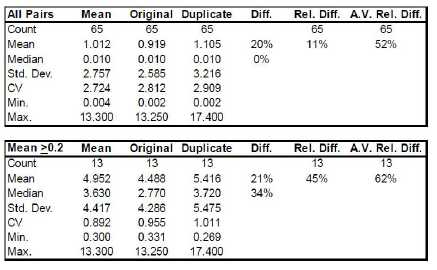

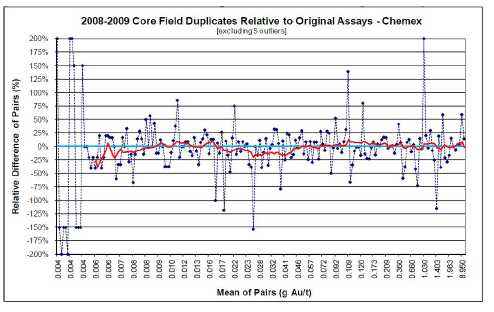

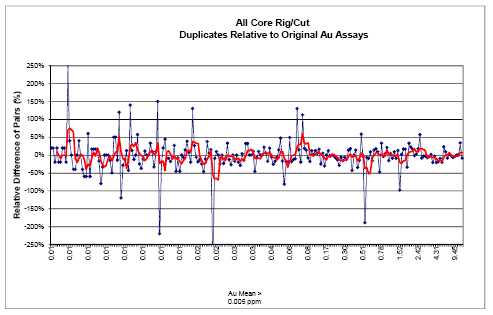

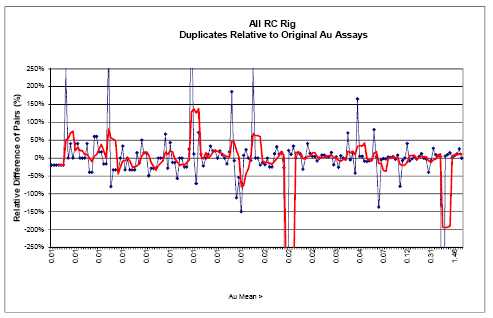

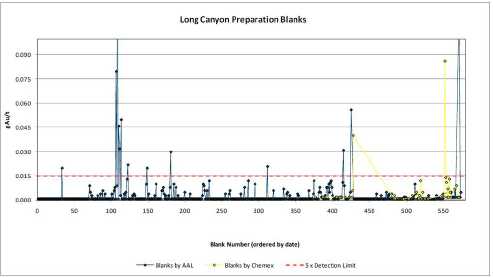

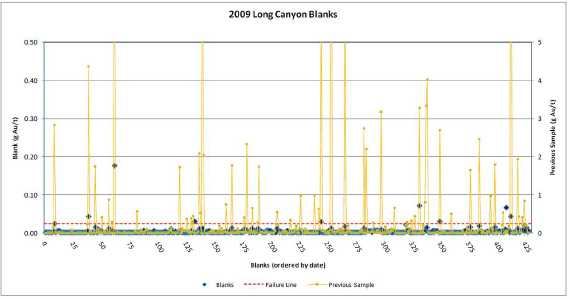

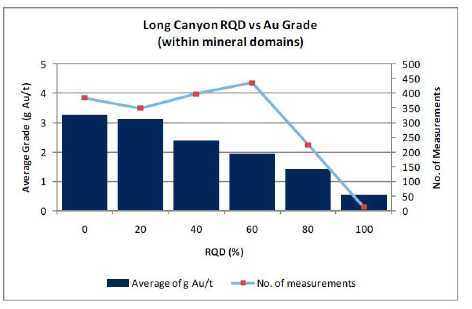

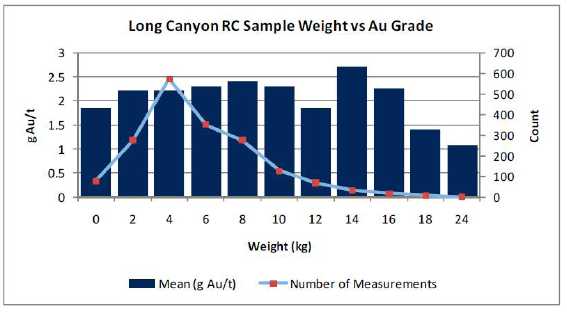

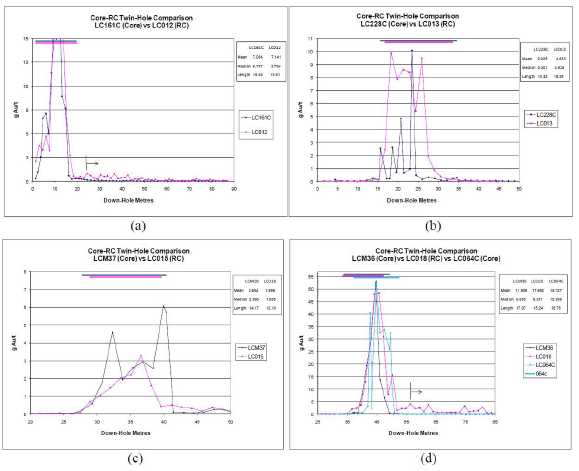

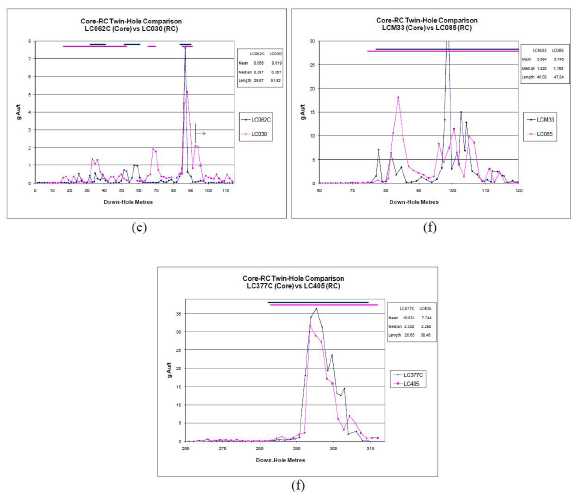

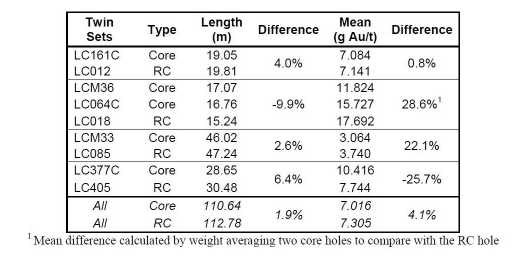

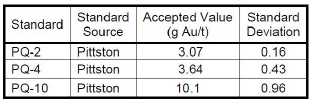

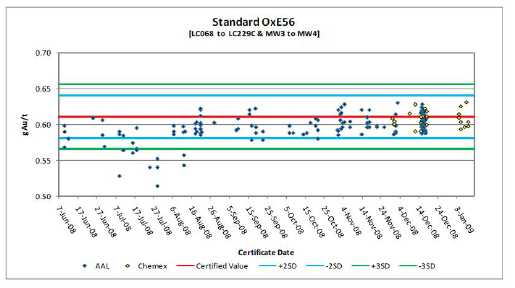

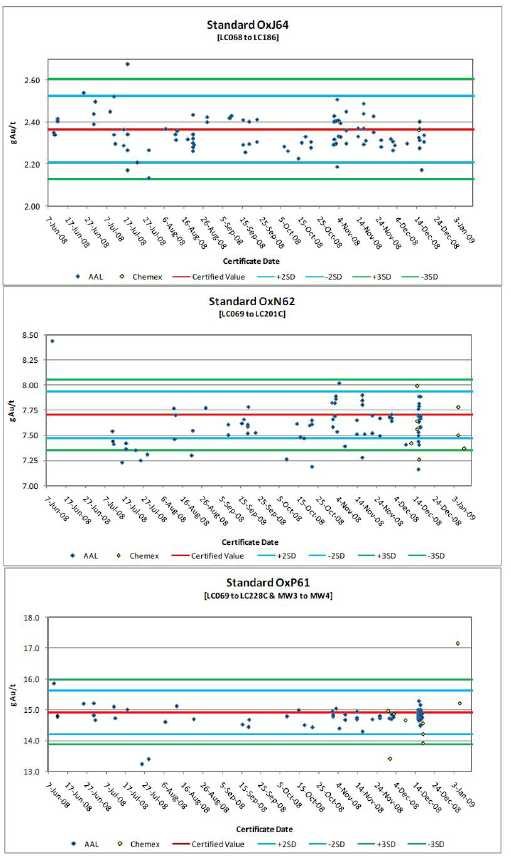

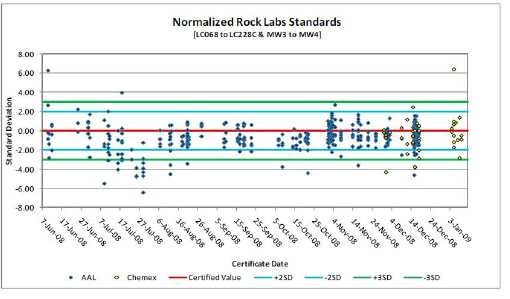

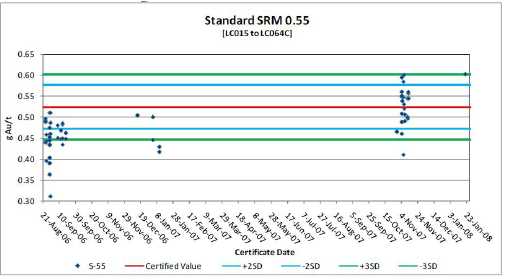

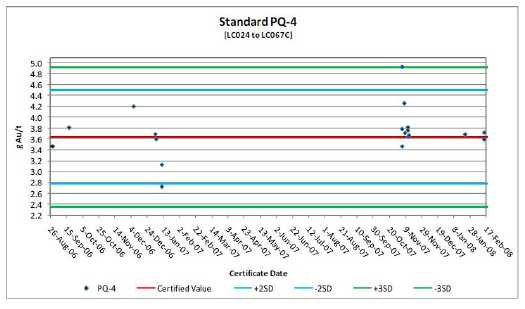

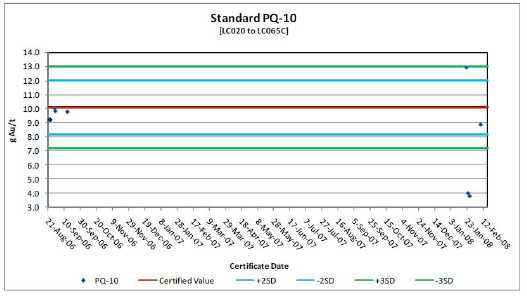

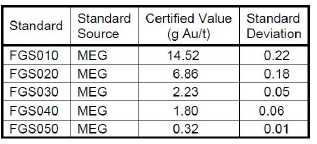

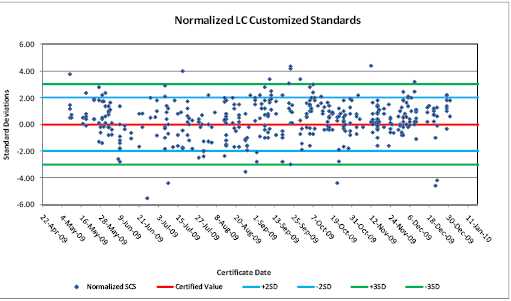

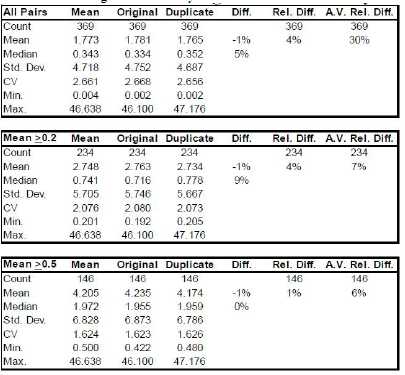

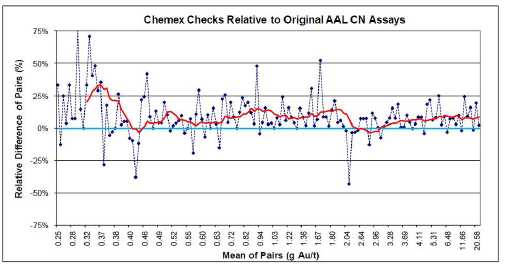

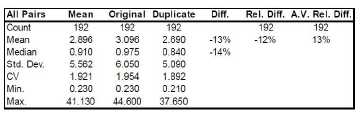

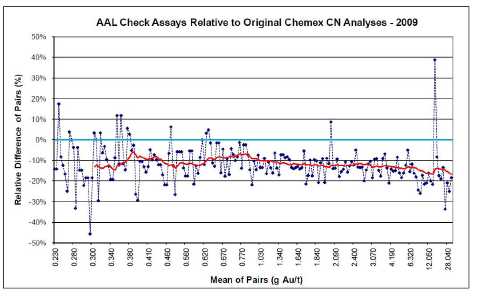

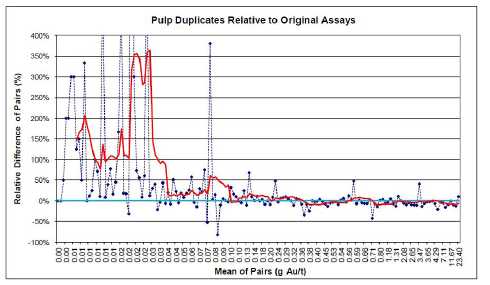

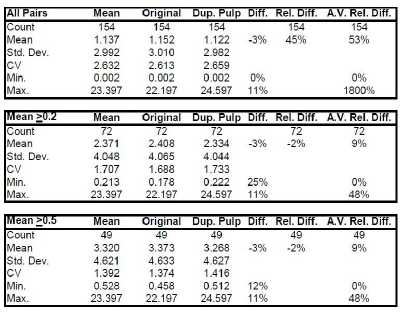

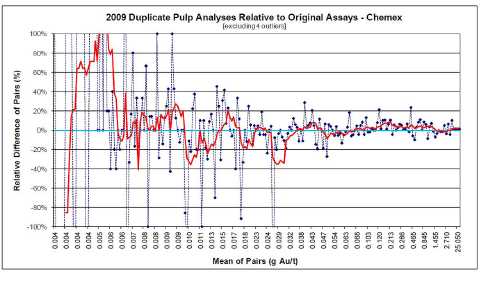

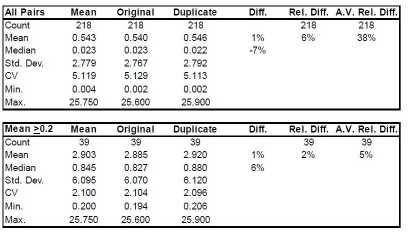

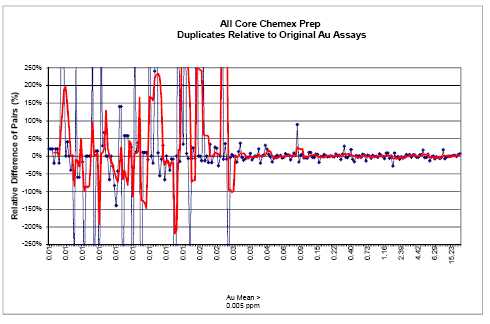

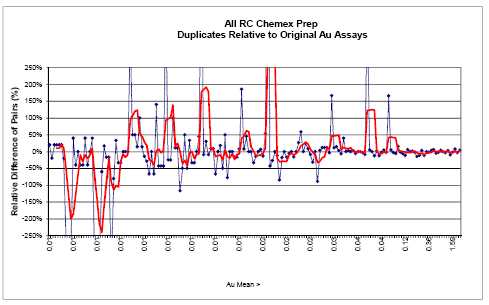

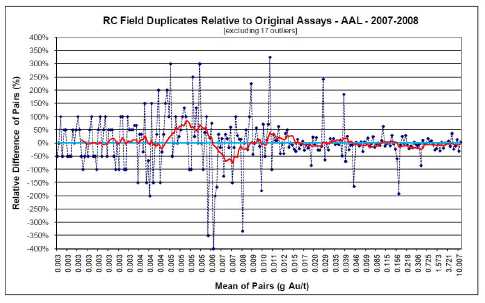

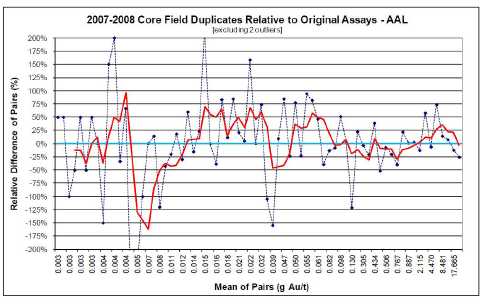

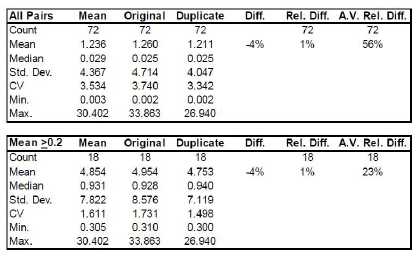

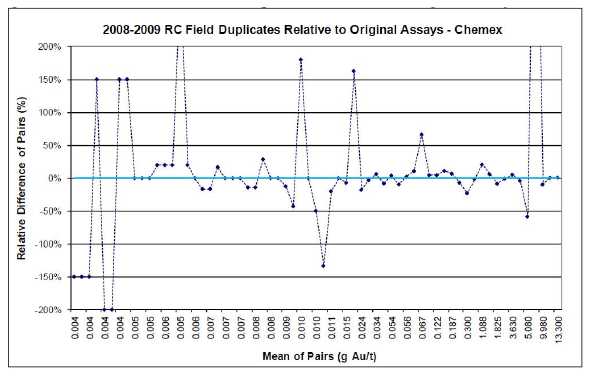

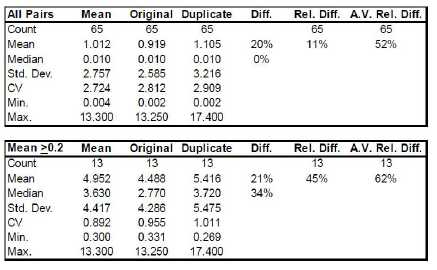

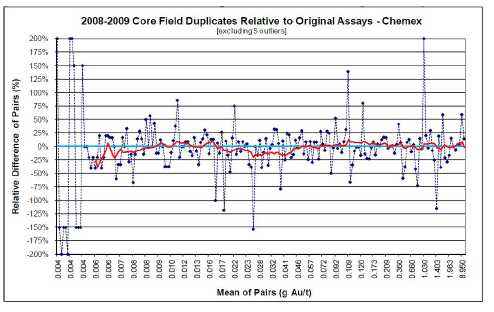

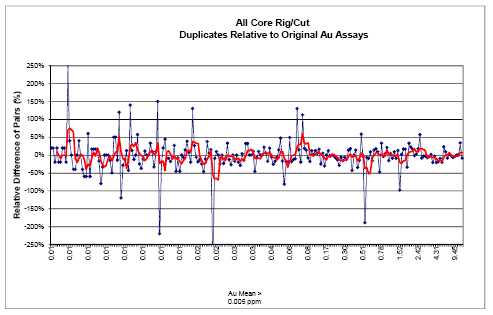

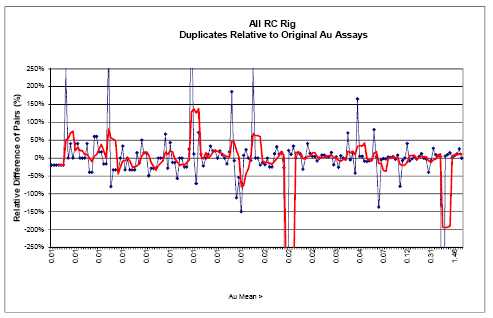

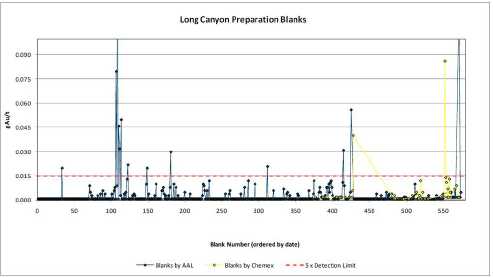

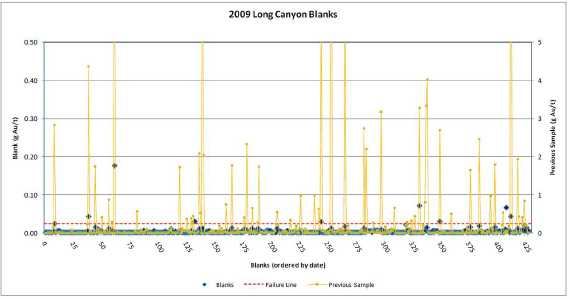

An analysis of the Quality Control/Quality Assurance data collected during the AuEx, Joint Venture and Fronteer drilling programs did not identify any serious issues with the sample preparation and analyses of the drill samples. The drill data do indicate the presence of down-hole contamination in some portion of the pre-2009 RC sample database, as well as a few 2010 drill holes. This issue was mitigated to a large extent by removing suspect intervals from the resource modeling, but some uncertainty in the remaining RC data persists. Measures to mitigate down-hole contamination at the drilling stage were implemented in 2009 and 2010.

| 1.4 | Mineral Processing and Metallurgical Testing |

| | |

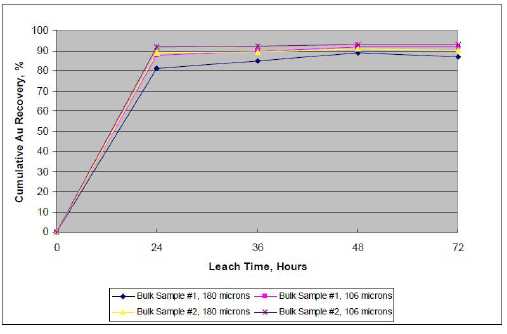

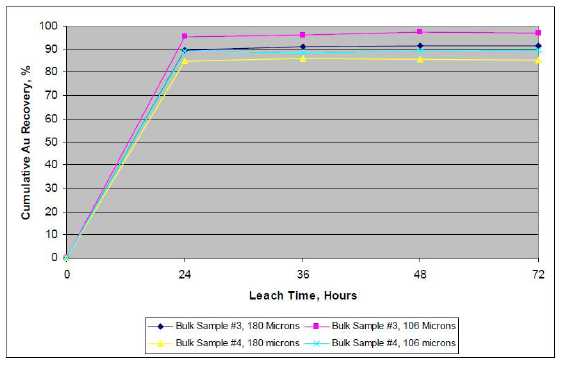

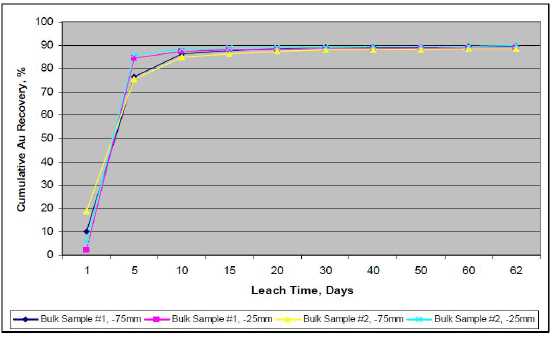

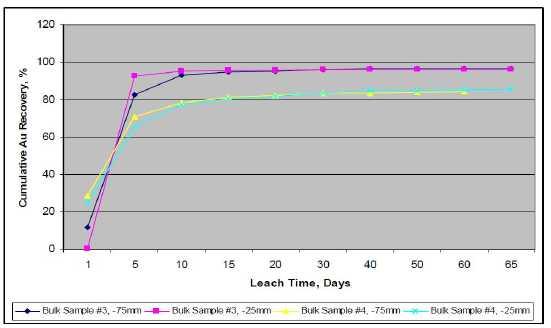

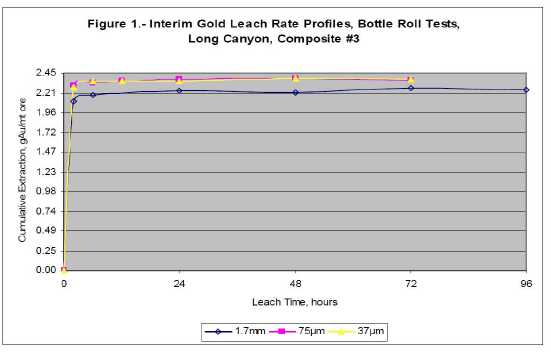

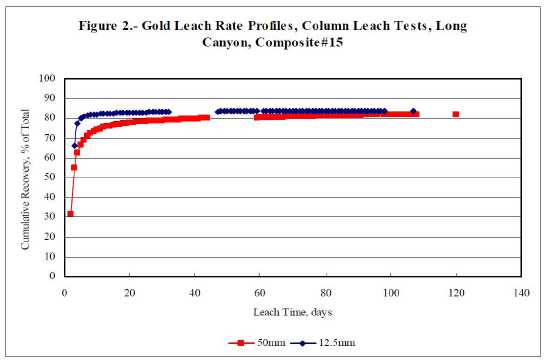

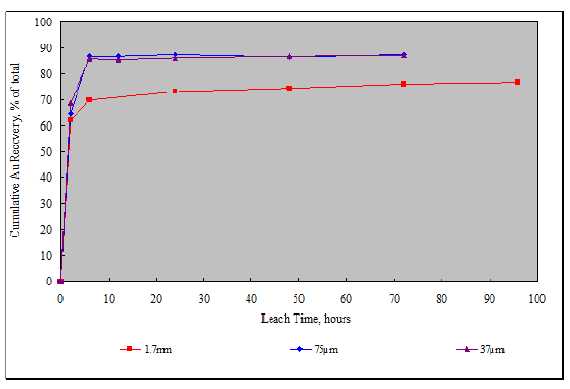

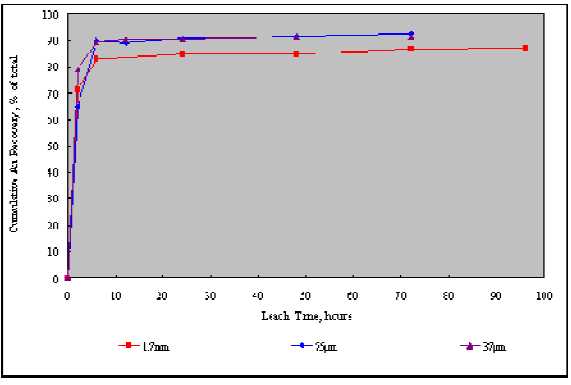

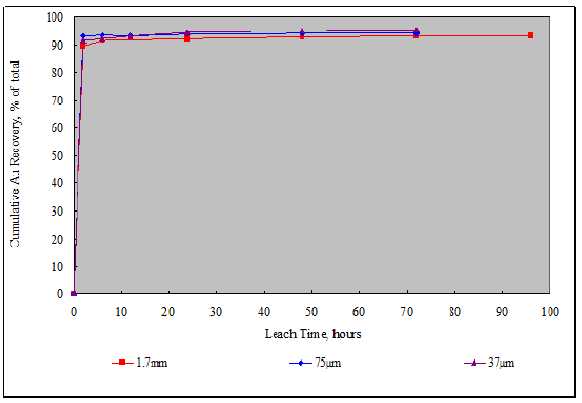

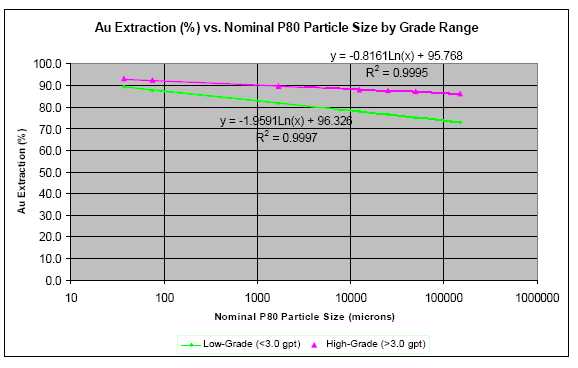

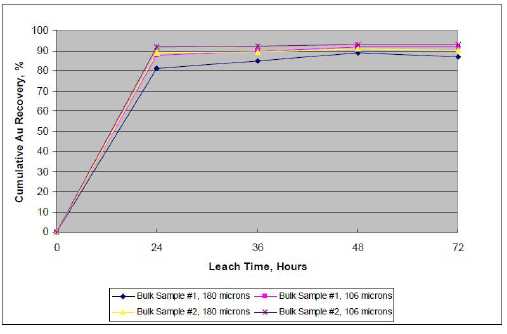

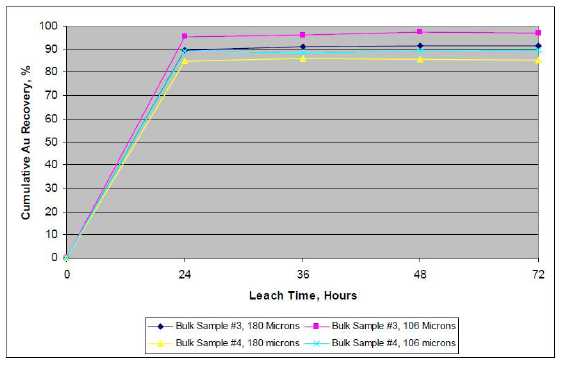

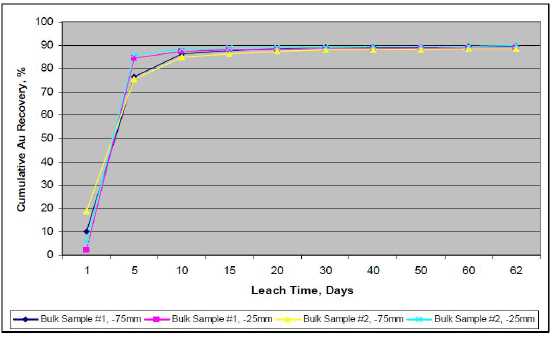

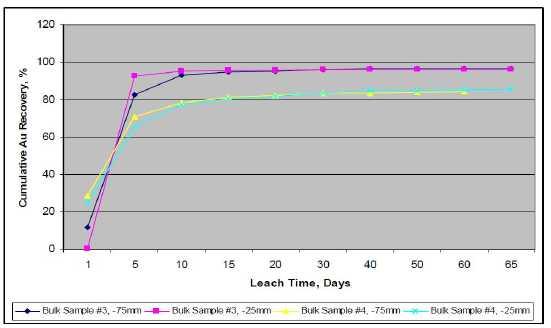

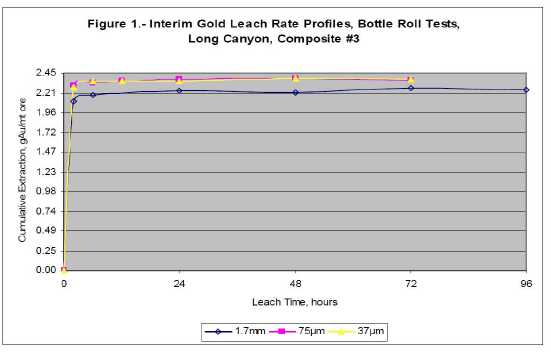

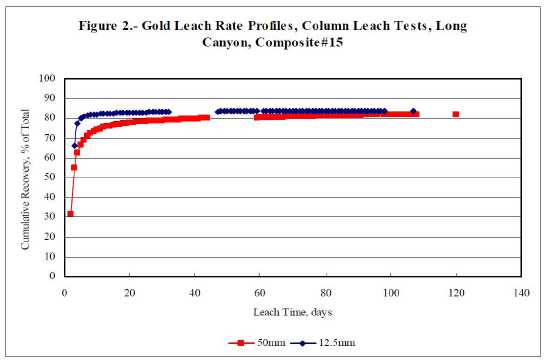

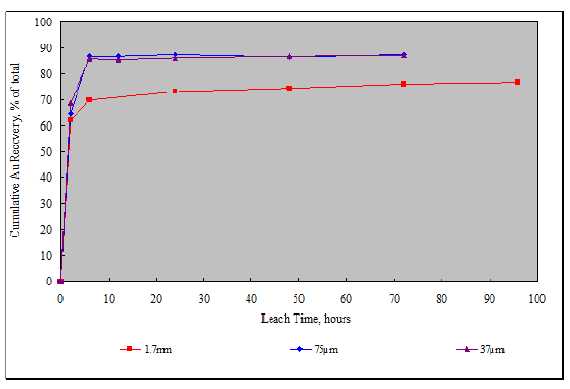

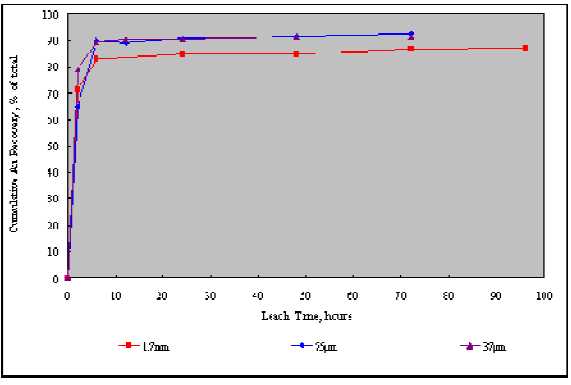

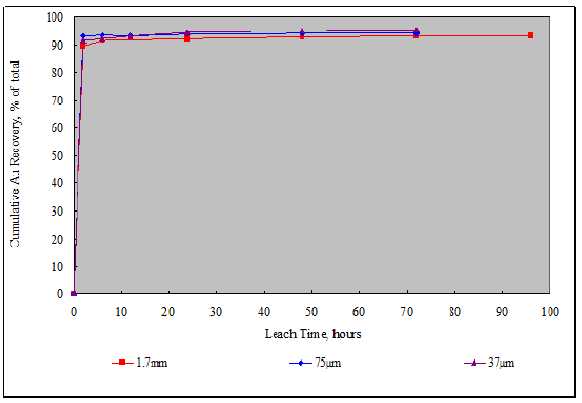

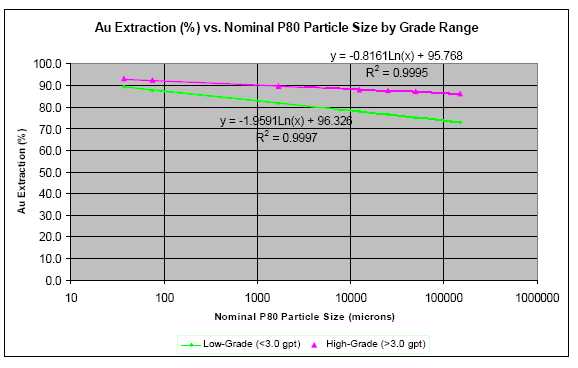

| Metallurgical testing at Long Canyon has been completed on four surface bulk samples and samples of core from approximat ely 50 drill holes. This work generally characterizes the Long Canyon mineralization as being amenable to extraction of gold by cyanidationviaoxide milling or heap leaching methods. An additional 18 composites from drill core, as well as four large surface bulk samples and one sample derived from five large-diameter core holes are currently undergoing testing. |

| | |

| 1.5 | Mineral Resource Estimate |

| | |

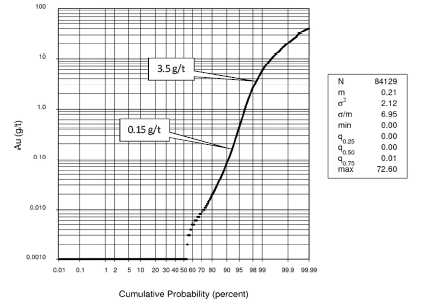

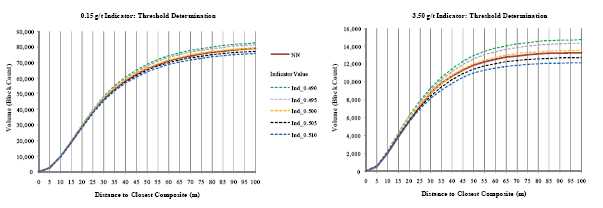

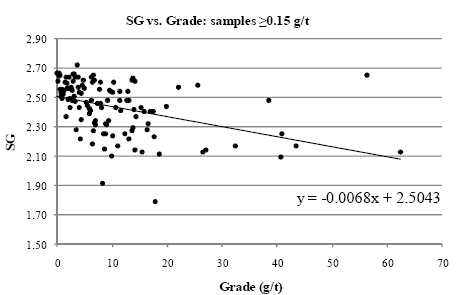

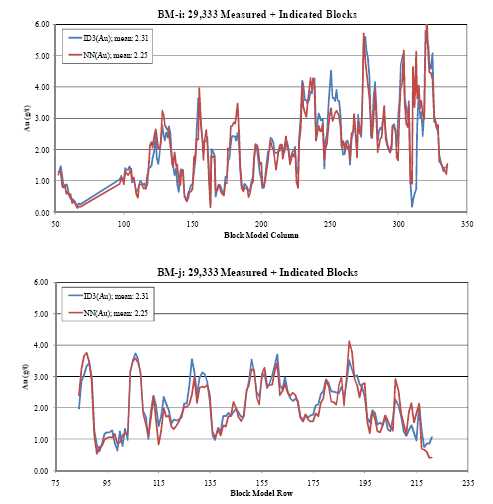

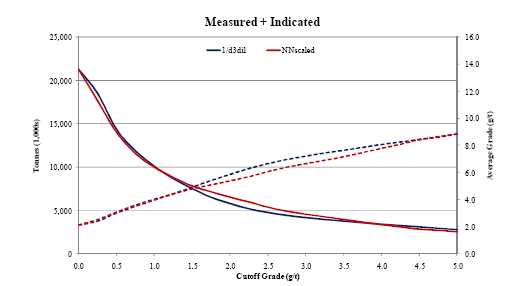

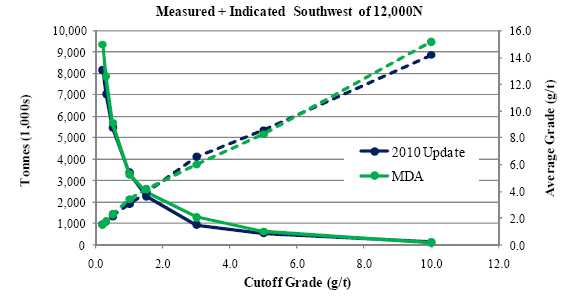

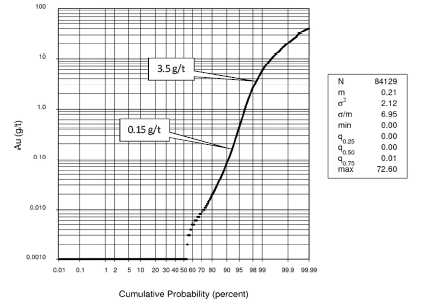

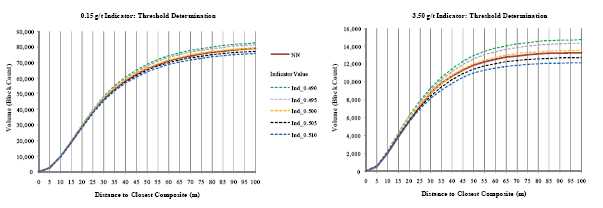

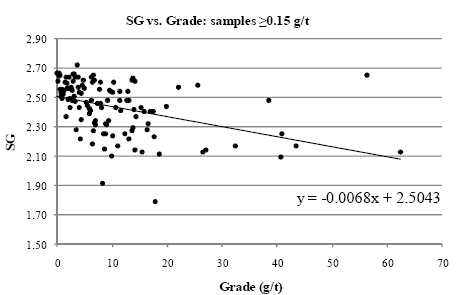

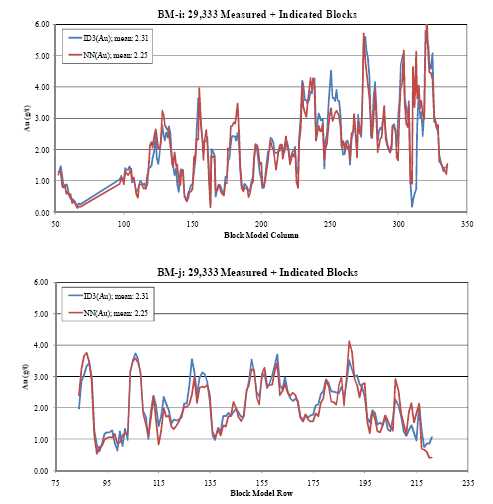

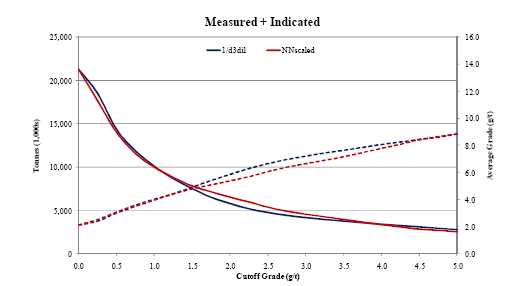

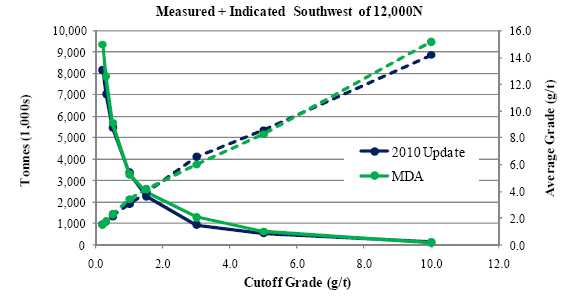

| The resource model was constructed using a new and more geostatistically-driven approach than has been used in previous Long Canyon resource estimates, and was designed to capture the combined structural and stratigraphic nature of gold mineralization. The model is based on manually- digitized 3 dimensional geological solids for 10 different lithological units and 20 different structural domains that were used to constrain the interpolation of high and low grade indicator probability shells. Gold grades were then estimated for each 5x10x5 metre block inside these probability shells by inverse-distance-cubed interpolation. Finally, each block was diluted using grades from adjacent blocks and outlying blocks were manually removed to ensure that the criteria of ‘reasonable expectations for economic extraction' have been met. Classification of the resource is based on the strength of the geological understanding of the deposit, combined with relatively conservative search parameters, such as the number of, and average distances to, nearest drill holes. This updated Mineral Resource estimate is quoted at a cutoff grade of 0.20 g/t gold to be consistent with the internal cutoff defined by Long Canyon's initial Preliminary Economic Assessment (Gustinet al2009). |

| | |

| The Long Canyon Resources are presented in Table 1-1. |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Table 1-1: Long Canyon Gold Resource Estimate

| COG | Measured | Indicated | | Measured + Indicated | | Inferred |

| (g/t) | Tonnes | Grade | Ounces | Tonnes | Grade | Ounces | | Tonnes | Grade | Ounces | | Tonnes | Grade | Ounces |

| | (1,000s) | (g Au/t) | (1,000s) | (1,000s) | (g Au/t) | (1,000s) | | (1,000s) | (g Au/t) | (1,000s) | | (1,000s) | (g Au/t) | (1,000s) |

| 0.2 | 762 | 2.91 | 71 | 17,609 | 2.34 | 1,324 | | 18,371 | 2.36 | 1,396 | | 11,170 | 2.24 | 803 |

| 0.3 | 693 | 3.18 | 71 | 15,775 | 2.58 | 1,310 | | 16,467 | 2.61 | 1,380 | | 10,209 | 2. 42 | 796 |

| 0.5 | 594 | 3.64 | 69 | 13,098 | 3.03 | 1,276 | | 13,692 | 3.06 | 1,345 | | 8,617 | 2. 80 | 776 |

| 1.0 | 458 | 4.51 | 66 | 9,286 | 3.98 | 1,187 | | 9,744 | 4.00 | 1,254 | | 5,990 | 3. 70 | 713 |

| 1.5 | 362 | 5.37 | 63 | 6,885 | 4.93 | 1,092 | | 7,247 | 4.96 | 1,155 | | 4,276 | 4. 69 | 645 |

| 3.0 | 218 | 7.53 | 53 | 3,848 | 7.21 | 892 | | 4,067 | 7.22 | 944 | | 2,250 | 7. 09 | 513 |

| 5.0 | 136 | 9.65 | 42 | 2,592 | 8.80 | 733 | | 2,728 | 8.84 | 775 | | 1,534 | 8. 56 | 422 |

| 10.0 | 42 | 15.36 | 21 | 743 | 13.28 | 317 | | 786 | 13.39 | 338 | | 423 | 12. 52 | 170 |

| A cutoff of 0.20 g Au/t was used to tabulate the gold resources. This cutoff was chosen to capture mineralization potentially available to open-pit extraction and heap- leach processing. The block-diluted resources are also tabulated at additional cutoffs in order to provide grade -distribution information, as well as to cover economic conditions other than envisioned by the 0.2 g Au/t cutoff. |

| | |

| 1.6 | Summary and Conclusions |

| | |

| The Long Canyon deposit consists primarily of high grade, oxidized gold mineralization. Gold is localized along the favourable intersections of permissive stratigraphy and low- angle to high-angle structures. The gold endowment continues to grow with each subsequent drill campaign and resource estimate . The limits of gold mineralization are not fully delineated, with potential for significant additions to the resource particularly down- plunge to the northeast. There is also excellent potential for the discovery of new, parallel, flanking zones of mineralization to the southeast and northwest. |

| | |

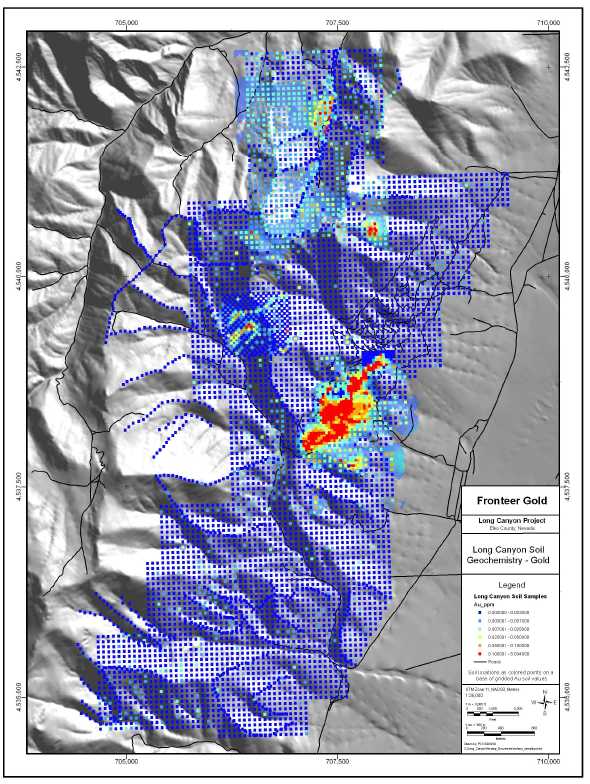

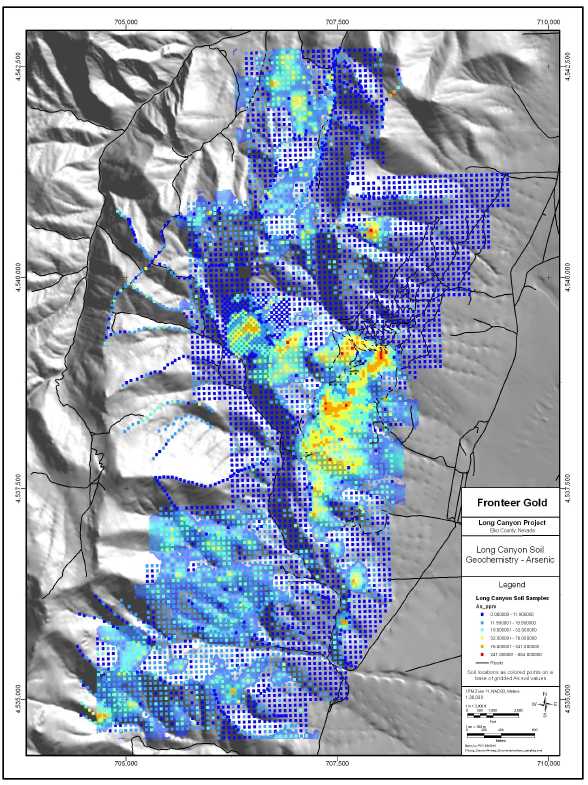

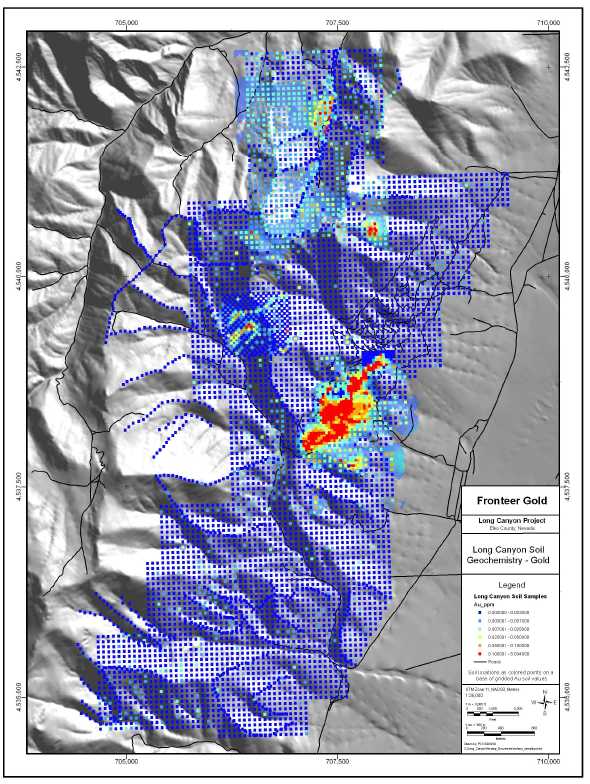

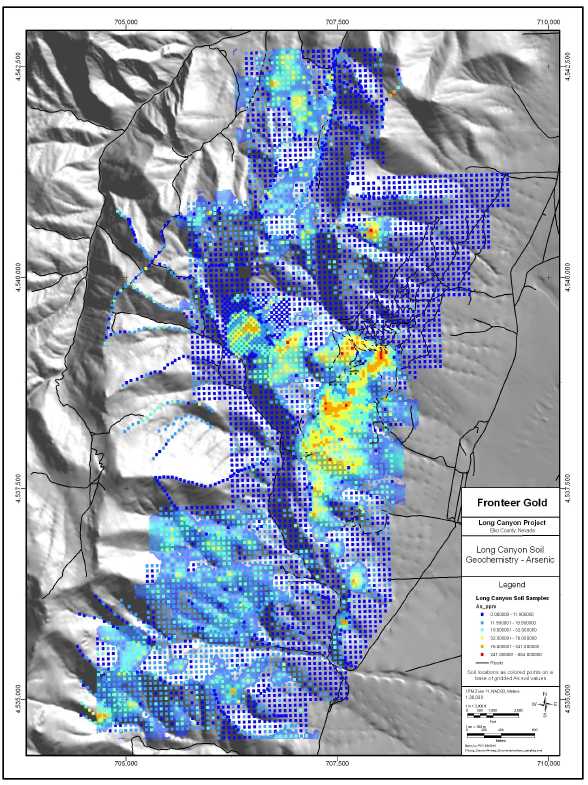

| Rock chip and soil sample results have proven to be direct guides to the definition of shallow drill targets at Long Canyon. Property-wide, several attractive geochemical anomalies within permissive geologic settings have been defined and remain to be tested. |

| | |

| The purchase of the surface and mineral rights associated with the Big Spring Ranch in 2010 increase the range of alternatives with regard to siting mine facilities on private surface. The purchase of Joint Venture partner AuEx Ventures, Inc. in 2010 consolidates ownership of the property within a single company. |

| | |

| 1.7 | Recommendations |

| | |

| Significant, relatively shallow, oxide resources have been outlined at Long Canyon that show potential to be economically viable. These resources remain open, with substantial additions likely. Beyond the extensions of known zones of mineralization, there is excellent potential for the discovery of new mineralized zones. It is clear that the Long Canyon project warrants significant additional expenditures. |

| | |

| Fronteer approved a 2011 exploration and engineering program with a budget of US $29,800,000 for Long Canyon. The budget includes up to 100,000 metres of core and RC drilling to be directed toward resource definition and expansion, as well as a |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

continuation of the ongoing geological mapping program, further rock, soil, and road cut sampling, continued efforts pursuant to refining the Long Canyon geological model and geological controls on mineralization, and the continuation of various engineering, metallurgical, and environmental investigations.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

This page left intentionally blank.

| 2 | INTRODUCTION |

| | |

| Fronteer Gold, Inc . has prepared this technical report on the Long Canyon gold project, located in the state of Nevada, for the purpose of updating the resource estimate using drill data generated in 2010 through December 15. This report was written in compliance with disclosure and reporting requirements set forth in the Canadian Securities Administrators’ National Instrument 43- 101, Companion Policy 43-101CP, and Form 43-101F1 (“NI 43- 101”). |

| | |

| Fronteer Gold, Inc ., listed on the Toronto Stock Exchange (“TSX”) and the New York Stock Exchange (NYSE Amex), holds its interest in Long Canyon through its wholly owned subsidiary Fronteer Development (USA) Inc., a Delaware corporation. |

| | |

| The Long Canyon project has been previously described in technical reports by Griffith (2006), Moran (2008), Gustin and Smith (2009), which includes the first mineral resource estimate at Long Canyon, Gustinet al.(2009), which includes a preliminary economic assessment (the “2009 PEA”), and Gustinet al. (2010), which updated the resource estimate through incorporation of 2009 drill data. Reports authored by M. Gustin were prepared through Mine Development Associates (MDA) of Reno, Nevada. This technical report relies heavily on previous information compiled in these reports by MDA, with updates where appropriate . |

| | |

| For the purposes of this report, Fronteer Gold, Fronteer Development (USA) Inc., Fronteer Development Group and NewWest Gold Corporation (“NewWest”; acquired by Fronteer Gold in September 2007) will be referred to interchangeably as “Fronteer” . |

| | |

| 2.1 | Project Scope and Terms of Reference |

| | |

| The purpose of this report is to provide an updated technical summary of the Long Canyon project, including an interim mineral resource estimate that incorporates all available drill data through December 15, 2010. This resource was produced for the purpose of supplying updated information for strategic planning and engineering studies, and does not include the results of 31 step out holes drilled late in the season. The mineral resources herein were estimated and classified by James Gray, Fronteer Director of Mineral Resources, and reviewed at a high level by Harry Parker, P.Geo., Technical Director, AMEC, and Georges Verly, P.Eng., Chief Geostatistician, AMEC (Verly and Parker, 2011). The 2009 PEA, which is only summarized herein, was completed by Thomas L. Dyer, Senior Engineer for MDA. Gary L. Simmons of GL Simmons Consulting, LLC supervised the completion of Section 16.0 (Mineral Processing and Metallurgical Testing). Mr. Dyer and Mr. Simmons are qualified persons under NI 43- 101 and have no affiliations with Fronteer except that of independent consultant/client relationships. The mineral resources reported herein for the Long Canyon project are estimated following the standards and requirements stipulated in NI 43-101. |

The scope of this report includes updates of the general setting, geology, project history, exploration activities and results, methodology, quality assurance, interpretations, drilling programs, and metallurgy, much of which remain unchanged from Gustin,et al (2010); other significant references are cited in the text and listed in

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Section 21.

Dr. Smith has worked extensively at Long Canyon and provided most of the detailed geologic descriptions, as well as the geological model, described in the report. Mr. Simmons visited the Long Canyon project site and Fronteer’s Elko office most recently on January 13, 2011 to review the metallurgical program, and made numerous visits in 2009 and 2010 to review maps, inspect metallurgical drill core, observe drilling and core handling, and inspect site conditions in general. James Gray spent significant time at the property in 2010 reviewing geology, models and drilling procedures, and worked closely with Dr. Smith during the modeling exercise. Christopher Lee has been involved in geological and resource oversight since 2007, and is responsible for Sections 12 through 14.

The Effective Date of this updated technical report is December 15, 2010, unless otherwise stated.

| 2.2 | Definitions and frequently used acronyms and abbreviations |

| | |

| Measurements are generally reported in metric units in this report . Where information was originally reported in English units, conversions have been made according to the formulas shown below; discrepancies may result in slight variations from the original data in some cases. |

| | |

| Frequently used acronyms and abbreviations AA atomic absorption spectrometry |

| | Ag | silver |

| | AOI | Fronteer – AuEx Joint Venture area of interest |

| | Au | gold |

| | As | arsenic |

| | BLM | United States Department of the Interior, Bureau of Land Management |

| | BMRR | Nevada Bureau of Mining Regulation and Reclamation |

| | °C | centigrade degrees |

| | cm | centimetre = 0.3937 inch |

| | COG | cutoff grade |

| | Gpm | gallons per minute |

| | g/t | grams per tonne = 34.2857 ppm = 0.0292 oz/ton |

| | ha | hectare = 2.471 acres |

| | Hg | mercury |

| | ICP | inductively coupled plasma |

| | K | thousand |

| | Kg | kilogram = 2.205 pounds |

| | km | kilometre = 0.6214 mile |

| | l | liter = 1.057 US quarts |

| | lpm | liters per minute |

| | Ma | million years old |

| | µm | micron = one millionth of a metre |

| | m | metre = 3.2808 feet |

| | Ma | million years |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| | NDEP | Nevada Department of Environmental Protection |

| | NSR | Net Smelter Royalty |

| | oz | troy ounce (12 oz to 1 pound) |

| | ppm | parts per million |

| | ppb | parts per billion |

| | R | range |

| | RC | reverse-circulation drilling method |

| | SEM | Scanning electron microscope |

| | Sb | antimony |

| | t, tonne | metric ton = 1.1023 short tons |

| | T | township |

| | Tl | thallium |

| | USGS | United States Geologic Survey |

CurrencyUnless otherwise indicated, all references to dollars ($) in this report refer to currency of the United States.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

This page left intentionally blank.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 3 | RELIANCE ON OTHER EXPERTS |

| | | |

| The authors are not experts in legal, tenure, environmental, permitting, geotechnical or waste rock characterization matters, and have relied on information and opinions of legal advisors and consultants with regard to the following: |

| | | |

| • | Section 4.3 pertaining to royalties on private lands was reviewed by Laura K. Granier, Esq., Attorney with Lionel Sawyer & Collins, Reno, Nevada . |

| | | |

| • | Portions of Sections 4. 2 and 4.3 pertaining to land tenure, private mineral rights and private surface rights were prepared by Mike Perry, consulting landman and member of the Nevada Landman Association. |

| | | |

| • | Sections 4.5, 4.6 and 4.7 pertaining to environmental and permitting were prepared by Dan Anderson, Fronteer employee responsible for permitting and environmental compliance. |

| | | |

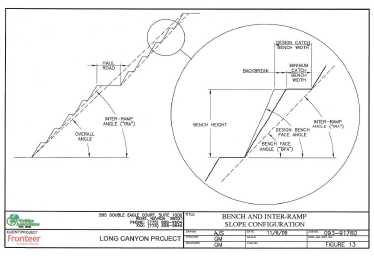

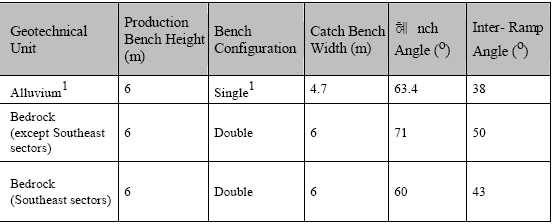

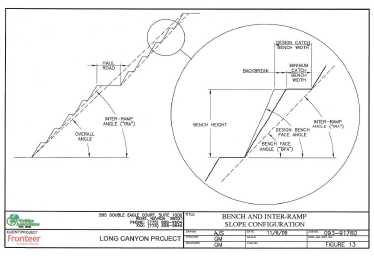

| • | Section 18.2 pertaining to geotechnical and pit slope analysis is summarized from work conducted by Golder and Associates (2010). |

| | | |

| • | Section 18.3 pertaining to waste rock characterization is summarized from work by SRK Consultants (2010). |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

This page left intentionally blank.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 4 | PROPERTY DESCRIPTION AND LOCATION |

| 4.1 | Property Location |

| | |

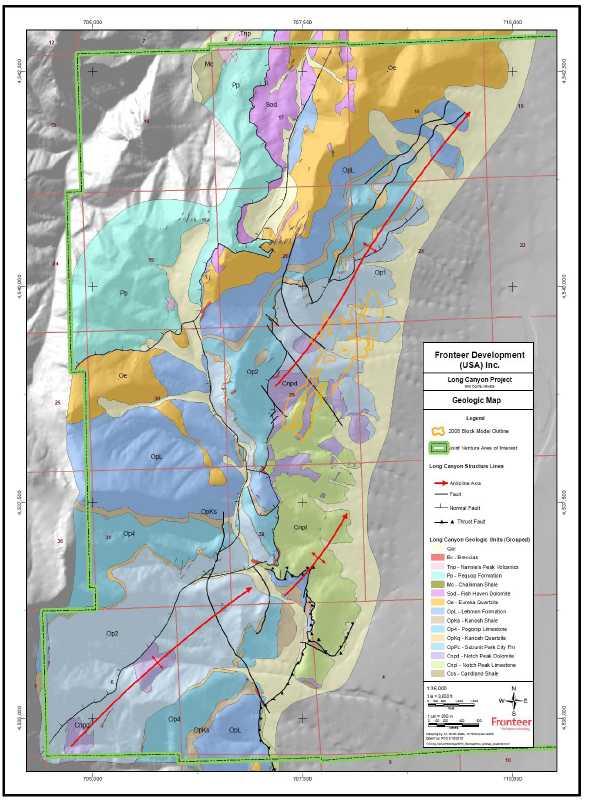

| The Long Canyon project is located in the Pequop Mountains, Elko County, northeastern Nevada, approximately 37 kilometres by road southeast from the town of Wells, Nevada, and approximately 6 kilometres south of Interstate Highway 80. The main area of the Project is defined to include approximately 49 square kilometres of land that is located on the east side of the range (Figure 4-1); additional surface and water rights are also held by Fronteer (discussed below). The approximate geographic centre of the Long Canyon project resources is 40° 58′23.70″N latitude and 114° 31′52.33″W longitude. |

| 4.2 | Land Area |

| | |

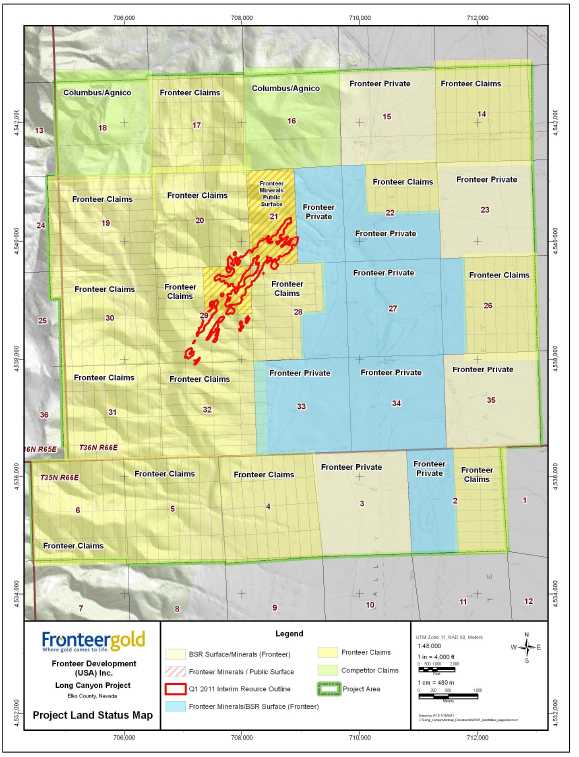

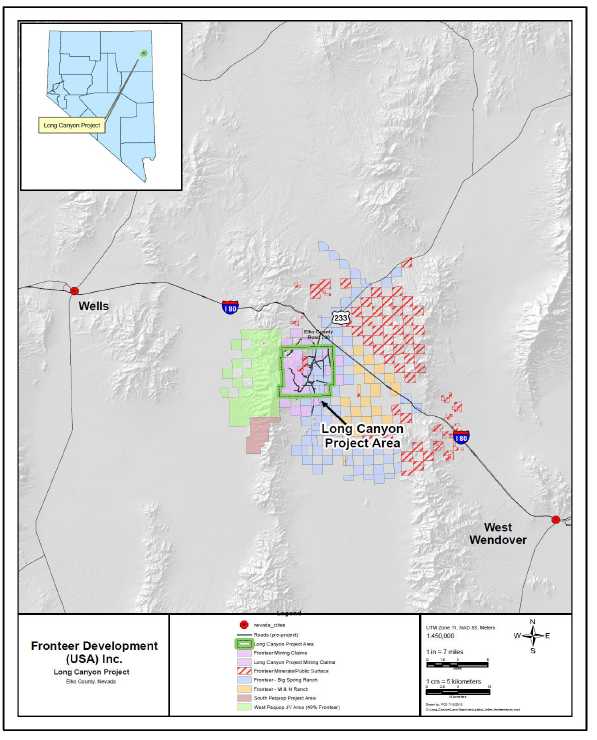

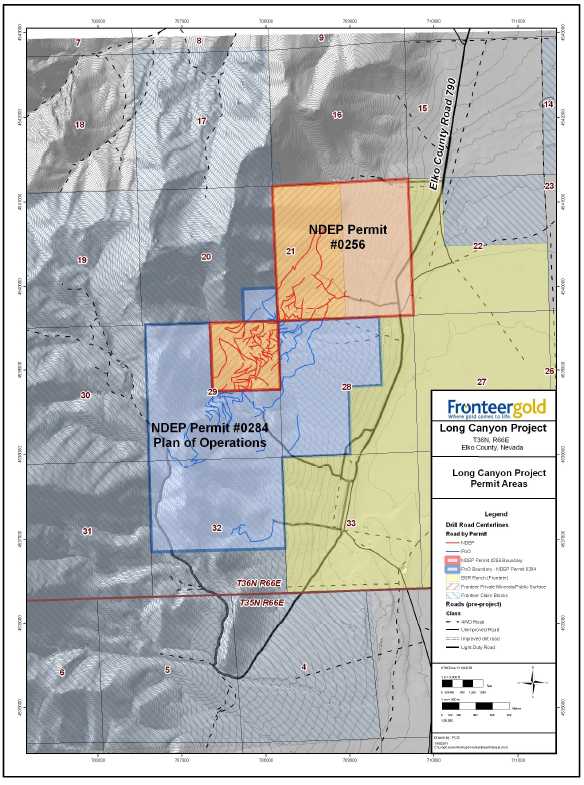

| The Long Canyon Project is controlled 100% by Fronteer. The Project area is defined for the purpose of this report as the former Joint Venture Area of Interest (AOI) boundary (Gustin and Smith, 2009) and includes 477 unpatented mining claims (approximately 3,322 ha) and approximately 1,578 hectares of private mineral rights held by Fronteer or its wholly-owned subsidiary Pittston Nevada Gold Company that lie in portions or all of Sections 14, 17, 19 through 22, and 26 through 34, T36N, R66E and Sections 2, 4, 5 and 6, T35N, R66E, Mount Diablo Baseline and Meridian (Figure 4-2). These claims and mineral rights form a contiguous block of ground. The Project area also includes a few contiguous blocks of third-party claims not controlled by Fronteer (identified as “Columbus” on Figure 4-2), as well as surface and mineral rights owned by Fronteer known as the Big Spring Ranch. |

| | |

| Prior to October 29, 2010, the Project was controlled by a 51%-49% Joint Venture between Fronteer Gold, Inc . and AuEx Ventures, Inc. On October 29, 2010, Fronteer Gold, Inc. acquired AuEx Ventures, Inc. Under the agreement, AuEx shareholders received 0.645 of a Fronteer common share, CDN $0.66 in cash and 0.5 of a Renaissance Gold, Inc. share. Renaissance Gold, Inc . received all properties owned by AuEx outside of the northern Pequop Mountains and CDN$5 million in cash. The fully diluted equity value of the transaction was valued at CDN$280.8 million. After the transaction, former AuEx shareholders held 18.6% of outstanding shares of Fronteer, while Fronteer held 9.9% of Renaissance Gold Shares. The agreement gave Fronteer 100% ownership of the Long Canyon Property, a 49% carried interest (in Joint Venture with Agnico Eagle Mines) of the West Pequop Property, located to the west of Long Canyon, 100% interest in the Pequop South Property located to the southwest of Long Canyon, subject to a 70% earn- in agreement with Golden Dory, Inc. and title to two square miles of unpatented claims located immediately south of the Long Canyon Project area. |

| | |

| Unpatented Claims. The numbers of claims reported in this section are current as of December 15, 2010 and are listed in Appendix A. |

| | |

| The unpatented claims within the project are located in the field with wooden posts that meet Nevada regulations. The validity and location of unpatented mining claims staked |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

prior to 2006 have not been independently verified in the field. A review is currently underway involving field examination and surveying of section corners and selected claims. Claims staked subsequent to 2006 were located using a differential GPS system accurate to within 10 centimetres. Fronteer represents that the list of unpatented claims in Appendix A is complete and accurate as of December 15, 2010 and that all claims are valid through August 31, 2011.

Ownership of unpatented mining claims is in the name of the holder (locator), subject to the paramount title of the United States of America, under the administration of the U.S. Bureau of Land Management (“BLM”). Under the Mining Law of 1872, which governs the location of unpatented mining claims on Federal lands, the locator has the right to explore, develop, and mine minerals on unpatented mining claims without payments of production royalties to the U.S. government, subject to the surface management regulation of the BLM. It should also be noted that in recent years there have been efforts in the U.S. Congress to change the 1872 Mining Law to include, among other items, a provision of production royalties to the U.S. government. Currently, annual claim maintenance fees are the only federal payments related to unpatented mining claims. Nevada BLM records of mining claims can be searched on-line atwww.nv.blm.gov/lr2000/. The holding costs of the unpatented mining claims in 2011 are estimated at about $127,081.50 (Table 4-1).

Table 4-1: Unpatented Mining Claims: 2011 Filing and Holding Costs

| BLM Maintenance Fee Payment | $66,780.00 |

| Elko County Annual Filing | $5,016.50 |

| Nevada new fee as per legislature1 | $55,285.00 |

| Total Filing and Holding Cost | $127,081.50 |

1The Nevada legislature recently enacted a one-time fee of $195.00 per claim for companies holding more than 1,299 claims.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 4-1: Long Canyon Project Location Map

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 4-2: Long Canyon Project Property Map

(resource outline shown in red)

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Private Mineral Rights. Fronteer owns the right to metalliferous minerals in the private mineral estate beneath the Big Spring Ranch surface lands, including Sections 21, 28, and 33, T36N R66E within the defined Long Canyon Project area, as well as areas to the east of the Project area. Fronteer enjoys a broad right to use the surface of the land for exploration and mineral development purposes as successor in interest to the mineral estate reserved pursuant to the mineral reservation in the officially recorded Grant, Bargain, and Sale Deed to Joint Tenants dated October 18, 1946. This mineral reservation reserves to the owner of the mineral estate, (i.e., Fronteer) “...all right, title and interest, to coal, oil, gas and other minerals of every kind and within said lands, including the right to the use of so much of the surface thereof as may be required in prospecting for, in locating, developing, producing and transporting said coal, oil, gas or minerals and any of their byproducts thereof.”

Fronteer acquired these private mineral rights through a series of transactions. Western States Minerals Corporation acquired from its affiliate, Stampede Investments Inc., the private mineral interests of the Bernard H. Grube estate underlying a large part of northeastern Nevada, which Stampede acquired on May 3, 1994. This includes a 75% interest in the mineral rights underlying a portion of the Big Springs Ranch. The additional 25% was acquired from Mobil Exploration and Producing North America Inc. NewWest acquired the metalliferous mineral rights of Western States Minerals Corporation in August 2006 and contributed these mineral rights to the Joint Venture when it was formed in 2006. Fronteer acquired NewWest in 2007. Fronteer acquired the mineral rights underlying the remainder of the Big Spring Ranch when the ranch was purchased on August 19, 2010.

Private Surface Rights.Except for the NE ¼ of Section 29 and the W ½ of Section 21, T36N, R66E, Fronteer owns the surface rights overlying Fronteer’s private minerals throughout the Big Spring Ranch area. The surface estate in the NE ¼ of Section 29 and the W1/2 of Section 21, T36N, R66E is public land managed by BLM. This land, which was formerly part of the Big Spring Ranch, is now BLM-administered public land by virtue of a land exchange with the Big Spring Ranch that closed on May 20, 1999 and was recorded on May 26, 1999.

On July 15, 2009, Fronteer completed the purchase of 47.8 square kilometres of surface rights known as the M&N Ranch, located five to ten kilometres east of the Long Canyon Project area. This acquisition includes 1,657 acre feet of water rights zoned quasi-municipal. Fronteer owns the mineral rights under all of these acquired surface rights. This land was amalgamated into the Big Spring Ranch property.

The surface estate on a small parcel of private land, totaling 4.5 acres, was purchased from the Beaumont Trust in February 2010 by the Joint Venture. Fronteer already owned the mineral rights to this parcel. This parcel was conveyed 100% to Fronteer as part of the acquisition of AuEx, and was amalgamated into the Big Spring Ranch.

On August 19, 2010, Fronteer completed arrangements to purchase the adjacent Big Spring Ranch, including surface rights totaling 37,540 acres , all mineral rights not previously held and some water rights.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 4.3 | Agreements and Encumbrances |

| | |

| The Long Canyon Project was formerly subject to a May 23, 2006 Joint Venture agreement between Fronteer and AuEx, whereby Fronteer contributed its private mineral and surface rights and AuEx contributed its federal lode claims. The agreement required Fronteer to earn- in to 51% of the project by spending 5 million dollars (requirement met in September, 2008), after which both companies contributed toward exploration expenses on a 51%/49% basis, with Fronteer as operator of the Joint Venture. Both companies retained a 3% net smelter return (NSR) royalty on their respective lands contributed to the Joint Venture. The Joint Venture, as well as all obligations associated with it, was dissolved on November 2, 2010, when Fronteer purchased AuEx. |

| | |

| Gold production from Long Canyon is subject to the State of Nevada Net Proceeds of Mine Tax, which is limited to 5% of the production net proceeds (similar to a 5% net profits tax). This tax is levied by the State of Nevada on all mine production in the state. |

| | |

| Mobil Exploration and Producing North America Inc . reserved and retained a production royalty of 0.625 percent NSR on certain lands hosting a portion of the Long Canyon Deposit. There is an advance payment of royalty identified in the deed as $350,000 at that time. There appear of record six oil and gas royalties on the production of oil and gas and arguably certain other minerals that purport to burden some of the land. |

| | |

| 4.4 | Location of Mineralization |

| | |

| The gold mineralization identified and drilled thus far on the Long Canyon project is located on both the private land holdings of Fronteer and on public lands, as shown in Figure 4-3. |

| | |

| 4.5 | Environmental Permits and Licenses |

| | |

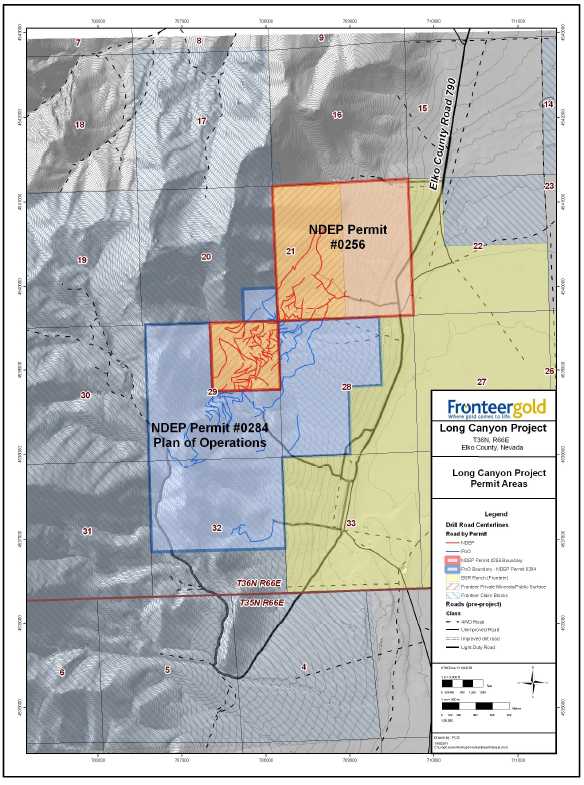

| Fronteer has acquired all of the state and federal regulatory approvals and permits required for the 2011 exploration program. Three permits currently govern exploration activity at Long Canyon: NDEP/BMRR Reclamation Permit No. 0256, NDEP/BMRR Reclamation Permit No. 0284, and BLM Plan of Operations NVN-82445 (Table 4-2). |

| | |

| In March 2010, a Plan Amendment was submitted in accordance with the BLM’s 43 CFR 3809 regulations and the Bureau of Mining Regulation and Reclamation’s (BMRR) Nevada Administrative Code (NAC) 519A regulations. The 2010 Plan Amendment proposal will authorize 69.43 acres of additional disturbance for a total of 114.36 acres of permitted surface disturbance on public lands open to location over a period of ten years. |

| | |

| An Environmental Assessment (EA) was prepared by a third party contractor as required by the National Environmental Policy Act (NEPA) to analyze potential environmental resource impacts associated with the proposed action. The Administrative Draft EA was issued September 2010. A Record of Decision is expected in the 2ndquarter of 2011. |

A Minor Modification application to Reclamation Permit #0256 was prepared and submitted to NDEP-BMRR in December 2010. The permit modification requests

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

approval to increase the total permitted surface disturbance covered under this permit by 13.7 acres, from 54.93 acres to 68.63 acres.

Table 4-2: Permits Covering Operations at Long Canyon

| Permit | Land Status | Land Areas | Approval Date | BondAmount | AuthorizedDisturbance | CurrentDisturbance | NewDisturbanceProposed in2010 | Comment |

| NDEP/BMRR Reclamation Permit No. 0256 (amended) | Public and Private Surface & Private Mineral Lands | NE1/4 Section 29, Section 21, T36N, R66E | 19-Mar-09 | $228,200 | 54.93 acres (22.22 ha) | 53.84 acres (21.79 ha) | 13.7 acres 5.54 ha) | Original Permit No. 0256 granted in 2006; amended to authorize additional disturbance in 2009 |

| NDEP/BMRR Reclamation Permit No. 0284/BLM Plan of Operations NVN-82445 (amended) | Public Surface - Mining claims over Public Minerals | Sections 28,29, and 32, SE1/4, SE1/4 Section 20, T36N, R66E, | Permit 0284:

8/28/08 Plan

of Ops:

9/15/2008 | $169,644; secured with $500,000 statewide bond | 44.93 acres (18.18 ha) | 32.31 acres (13.07 ha) | 69.43 acres (28.09 ha) | 44.88 acres (18 .00 ha) of disturbance currently bonded |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 4-3: Fronteer Claims and Private Mineral Rights Within Drill Area

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Disturbance on Unpatented Mining Claims on Public Lands. BLM Plan of Operations NVN-82445 and the corresponding Nevada Division of Environmental Protection/Bureau of Mining Regulation and Reclamation (“NDEP/BMRR”) Reclamation Permit No. 0284 (the "Plan of Operations") authorizes 44.93 acres (18.18 ha) of surface disturbance in Sections 28, 29, and 32, T36N, R66E, which together form the eastern and central portion of the unpatented mining claims on Federal lands. This disturbance is associated with exploration work that will be conducted in two or more phases over a period of five years. Phase 1 authorized 19.60 acres (7.93 ha) of new surface disturbance, which required a bond of $131,964. Fronteer provided the BLM with a $500,000 Statewide bond to satisfy the $131,964 reclamation bond requirement. Fronteer applied for permission to commence Phase 2 disturbance on a total of 44.88 of the 44.93 acres authorized under the Plan of Operations in July 2009 and received permission on July 10, 2009. Prior to commencing Phase 2, Fronteer provided the BLM with additional financial assurance from the Statewide bond to secure the increased bonding obligation ($169,644). In June 2009, Fronteer filed for an amendment to expand the project boundary of the Plan of Operations to include 40 acres in the extreme southeast corner of Section 20. The BLM approved this amendment in July 2009. No additional bonding was needed, as the total amount of permitted disturbance remained unchanged at 40 acres. A total of 32.31 acres (13.07 ha) had been disturbed under Permit No. 0284 as of December 15, 2010.

Fronteer received new permits to govern the installation of seventeen monitoring wells within the Project Area. These holes, along with the existing six monitoring wells, are designed to test and characterize the aquifer as to water depth, quality, and gradients. Additionally, these holes will give other information with respect to the structural and rock-permeability controls of the aquifer. These holes will also assist in the geotechnical engineering, site characterization, facilities layout, and future permitting activities for the project.

Disturbance on Private Mineral Lands. The Nevada Division of Environmental Protection/Bureau of Mining Regulation and Reclamation (“NDEP/BMRR”) approved an amendment to Reclamation Permit No. 0256 on March 19, 2009, which increases the authorized surface disturbance for exploration activities on private mineral lands to 54.93 acres (22.22 ha). Reclamation Permit No. 0256 governs the exploration activities on the private mineral lands in the NE ¼ of Section 29 and all of Section 21, T36N, R66E, which together form the northwestern part of the area of private mineral rights owned by Fronteer (Figure 4-2). Fronteer provided a reclamation bond in the amount of $228,200 to NDEP/BMRR on April 16, 2009. With this permit in hand, Fronteer extended the road network and drilling effort to the northeast to allow for testing of extensions of the presently identified mineralized zones. As of De ce mb er 15 , 2010, a total of 53. 84 acres (21.79 ha) had been disturbed on private mineral lands subject to NDEP/BMRR Permit No. 0256.

Hydrologic Investigations. In 2009, in order to satisfy a permit condition in the Plan of Operations, Fronteer drilled a supplemental water production well for the cities of Wendover, Utah and West Wendover, Nevada (Cit ies) to address the cities’ concerns about potential impacts from exploration drilling to the nearby Johnson Springs, one of the Cities’ water sources. The well (known as Shafter # 6), wa s completed and tested

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

at 530 gallons per minute (33.5 liters per second) continual pumping for 48 hours. The water quality meets all drinking water standards. A well house, pumping and piping facilities, and supplemental power were completed and commissioned in April 2010.

Following completion and testing of the Shafter # 6 well, the Cities and BLM approved a request by Fronteer to allow exploration drilling below the level of the of the Johnson Springs water table (an elevation of 1,731 metres).

In addition to working together on the supplemental well, Fronteer and the Cities have entered into a conceptual Memorandum of Understanding (“MOU”) establishing a mutually beneficial public-sector, private-sector working relationship to characterize and develop groundwater resources that will support future municipal growth and mineral development. Recognizing the importance of these key stakeholders, Fronteer is continuing to work closely with the Cities to enhance all stakeholders’ understanding of the hydrology of the area.

Hydrologic investigations were ongoing in 2010 with the planning, development, and implementation of a large scale aquifer test program. Fronteer worked closely with the Cities to develop a testing program that would provide data and information on the local and regional groundwater aquifer to further advance Fronteer’s mine planning and design. The program includes stressing the aquifer by pumping 2,000 gpm for up to 72 hours continuously, from a large diameter production well while measuring the effects of this pumping on monitoring wells throughout an area of influence.

One test was conducted in 2010 on an existing irrigation well (BSR #1) located south of the project area and east of the range front fault. This test was designed to measure the effects on the Goshute Valley alluvial aquifer. Three monitoring wells were installed near the BSR test well and fitted with continuously recording transducers to record static water levels during the test. Three additional monitoring wells were installed for the test, also fitted with transducers, which will serve as long term environmental monitoring points.

A second test was designed to measure the deep bedrock aquifer in the near vicinity of the ore body. Preparations for this test were not yet completed as of December 15 but included a 1,500 foot, 19-inch diameter production well and three 1500 foot, dual-completion monitoring wells. Other monitoring wells were installed to measure potential effects over a larger area up gradient in the ore zone.

Groundwater discharged from these tests was directed to Fronteer’s BSR Ranch irrigation pastures under a permit issued by NDEP-Bureau of Water Pollution Control (BWPC).

The flow and turbidity measurements at Big Springs and the Johnson Springs complex were a key monitoring parameter of both tests. The Cities and Fronteer developed a target monitoring and termination protocol should the test cause an impact to the base flow of Big Springs. The BSR test had no effect on Big Springs.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 4.6 | Environmental Considerations |

| | |

| Environmental liabilities at the Long Canyon Project are limited to the reclamation of disturbed areas resulting from exploration work conducted by Pittston, AuEx, and Fronteer since 2000. Evidence of previous mineral exploration activity consists of several small, widely spaced, shallow prospect pits of unknown origin and age. Class III cultural resource surveys, providing sufficient detail to satisfy the regulatory agencies, were conducted in 2000, 2006, 2007, 2008, and 2009, primarily by ASM Affiliates of Reno, Nevada . These studies recorded some prehistoric and historic artifact sites within the project area. In accordance with applicable permits, exploration activities will avoid or mitigate cultural resources. Mitigation of some cultural sites in the Long Canyon deposit area will be carried out in 2011. |

| | |

| 4.7 | Meteorological and Air Monitor Stations |

| | |

| IML Air Science, a division of Inter- Mountain Laboratories, Inc., (IML) completed the procurement, integration and installation of a solar-powered meteorological monitoring system and third-party monitoring of meteorological data for the project . The system measures wind speed, wind direction, standard deviation of horizontal wind direction, precipitation, relative humidity temperature at two and ten metres, solar radiation, and evaporation. |

| | |

| Fronteer has purchased an air quality monitoring station capable of monitoring both PM2.5 and PM10. Air Sciences Inc . has been retained to procure approvals for the siting and installation of the station and the preparation, submission, and approval of a Quality Assurance Project Plan. |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

This page left intentionally blank.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 5 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

| | |

| 5.1 | Access to Property |

| | |

| Access to the Long Canyon Project is via Interstate Highway 80 to exit 378 (the Oasis exit), 42 kilometres east of Wells, Nevada, then proceeding 6.4 kilometres south on Elko County Road 790, which is an all-weather gravel road to the Big Spring Ranch. |

| | |

| In April 2009, Fronteer entered into a five- year road maintenance agreement with Elko County. Under the terms of this agreement, Elko County and Fronteer now share the responsibility to maintain County Road 790. Although this road proceeds through the Big Spring Ranch and provides public access to points south of the Ranch, exploration traffic uses a dirt by-pass road that AuEx constructed and improved in 2005. The bypass road circumnavigates the Ranch headquarters on the uphill side. From the by-pass road, several short, unimproved dirt roads access the drill grid area. The drill grid area is located approximately 1.6 kilometres west of the Big Spring Ranch (Figure 5-1) . |

| | |

| 5.2 | Climate |

| | |

| Climate is typical for the high-desert regions of northeastern Nevada with hot, dry summers and cold, snowy winters. Summer high temperatures range from 30°to 38°C, with winter low temperatures typically -20°to -10°C and winter high temperatures of 0°to 5°C. Most of the precipitation in the region falls as snow in the winter months, with lesser precipitation as rain in the spring and thunderstorms during the late summer. Winter storms can deposit several metres of snow, with elevations above 2100 metres being continually snow covered from November through April. |

| | |

| In the absence of all-weather road access to drill sites, a typical exploration-operating season for the Long Canyon project is from mid- May through early November. Improved road access and road maintenance/snow removal equipment could extend the exploration operating season through the winter months if necessary, although winter operations must comply with winter mule deer habitat protection requirements. |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 5-1: Long Canyon Project Access

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 5.3 | Physiography |

| | |

| The Long Canyon project lies in the Basin and Range physiographic province of Nevada and western Utah. The project site is located on the eastern side of the Pequop Mountains in northeastern Nevada, which has elevations ranging from 1675 metres in valley bottoms to over 2750 metres on the ridge tops. Elevations for Long Canyon exploration drill-hole collars range from 1900 to 2050 metres. |

| | |

| The lower slopes of the project area are covered by sagebrush, progressing up-slope to piñon and juniper woodlands typical of high-desert mountain vegetation in northeast Nevada. Locally scattered subalpine fir, limber pine, and mountain mahogany are present at higher slope elevations, giving way to sagebrush and grasses on ridge tops. The majority of the Long Canyon exploration activities to date have been in tree-covered (piñon and juniper) areas on the lowermost, eastern slopes of the range. The resource area lies on moderate to steep slopes that require road construction to develop drill sites and access. |

| | |

| 5.4 | Local Resources and Infrastructure |

| | |

| Reverse circulation (“RC”) and diamond core drilling (“core”) contractors, heavy equipment contractors, and field technical personnel to support continued exploration activities are all available from service companies and contractors in Elko, Nevada. Should an economic gold deposit be delineated on the Long Canyon project, experienced mining personnel and equipment suppliers are available in Elko as well as elsewhere in Nevada. |

| | |

| Electric power for domestic use extends to the Big Spring Ranch. The nearest major power grid is near an east-west rail line located approximately 15 kilometres north of the Long Canyon project, north of Interstate 80. |

| | |

| Water for drilling at Long Canyon is available from a well at the Oasis Truck Stop located 6.4 kilometres north of the project. Fronteer has a five-year lease with the owner of the truck stop to use water from the well to support the exploration activities. Fronteer has also obtained a temporary waiver from the Nevada Division of Water Resources authorizing the use of water from the Oasis well for mineral exploration drilling and dust control at the Long Canyon project . The agreement with Oasis also allows Fronteer to lease land for the purpose of establishing a field headquarters to support the Long Canyon project. Infrastructure at this location consists of a fenced yard with three trailers utilized for project activities, as well as access to water, power, electricity, phone, and high-speed internet. |

| | |

| Accommodations for field personnel are available in Wells, Nevada, the nearest town to provide food and lodging (Figure 4-1). The town of Wendover, located approximately 48 kilometres to the east on Interstate 80, is another alternative used by drilling contractors. There is no campsite or other housing facilities on the project . |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

��

This page left intentionally blank.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 6 | HISTORY |

| | |

| This section describes work conducted prior to formation of the Fronteer-AuEx Joint Venture in 2006, and briefly summarizes work conducted by the Joint Venture through 2009. Some specifics of the Pittston exploration program were provided by S. Green and S. Mason, former Pittston employees. |

| | |

| Aside from a few, small, historical lead-zinc prospect pits within the Long Canyon Project area, there is no evidence of any historical mining production. |

Pittston conducted the first known modern gold exploration within the Pequop Mountains in 1994 when it conducted a regional Bulk Leach Extractable Gold (“BLEG”) sampling program. This program returned anomalous gold from dry washes draining the western flanks of the Pequop Mountains. Pittston expanded this program to include the Long Canyon project area on the east side of the range in 1999. A number of BLEG samples in the Long Canyon region yielded anomalous gold (Figure 6-1).

Figure 6-1: Pittston BLEG Anomalies, 2000 Soil Anomalies, and Drill-Hole Collars

The detailed BLEG sampling was followed by prospecting up drainage and the discovery of gold- bearing jasperoids. Ridge-and-spur soil sampling followed, as well as soil sampling on a 61 metres x 61 metres grid up drainage from anomalous BLEG

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| samples and over areas that yielded gold-bearing jasperoids. Pittston staked the first claims of record at Long Canyon in 2000. The soil sampling yielded a >25ppb soil anomaly over 1.5-kilometre long, elongate in a northeast direction (Figure 6-1). In addition to gold, multi-element ICP geochemical analyses showed anomalous arsenic, antimony, and mercury to be present in areas of anomalous gold. Rock chip sampling and road cut sampling were also done in advance of drilling. |

| | |

| Later in 2000, Pittston drilled seven RC holes, for a total of 1148 metres, to test the far northeastern portion of the soil anomaly. Five holes encountered weak gold mineralization, but the discovery hole, LC-03, encountered 21 metres averaging 2.7 g Au/t, including 3 metres averaging 5 g Au/t . |

| | |

| Pittston terminated exploration activities in the U.S. in December 2000. AuEx acquired Pittston in August 2004 and renewed exploration at Long Canyon in 2005, including mapping, surface sampling, road- cut sampling, and drilling. The drill program consisted of seven RC holes for a total of 768 metres. Significant gold mineralization was encountered in six of the seven holes. |

| | |

| In November 2005, NewWest Gold recognized that some of the claims controlled by AuEx at Long Canyon covered public surface lands but were underlain by private mineral rights owned by NewWest Gold and therefore were not open to mineral entry and staking. As a result, a Joint Venture agreement for the Long Canyon project was drafted between NewWest Gold and AuEx, with NewWest contributing private mineral lands and AuEx contributing federal lode claims. |

| | |

| NewWest operated the Joint Venture and conducted all exploration at Long Canyon property between May 23, 2006 and September, 2007, at which point Fronteer purchased NewWest Gold and assumed its interest and earn- in commitment in the Long Canyon project. In September, 2008, Fronteer completed its earn-in to a 51% interest in the Project . A total of 132 holes (20,400 m) were drilled between 2006 and September of 2008. Subsequently, the Project was operated as a Joint Venture with Fronteer as operator through November 2, 2010. On that date, Fronteer assumed a 100% interest in the Project through a buy-out of AuEx Ventures. Fronteer completed 624 holes between the earn-in date and the effective date of this report, and completed resource estimates in March, 2009 and May, 2010. Work completed by Fronteer for the Joint Venture is described in subsequent sections of this report. |

| | |

| 6.1 | Historic Mineral Resource and Reserve Estimates/Production |

| | |

| There is no known historical mineral production from, or resource or reserve estimate for, the project or immediately adjacent properties. |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| 7 | GEOLOGIC SETTING |

| | |

| 7.1 | Regional Geology |

| | |

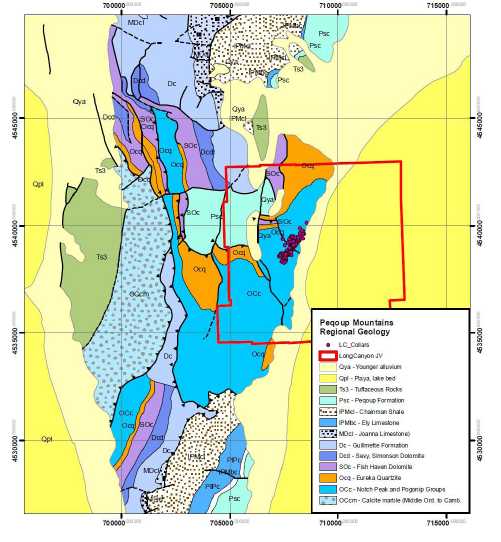

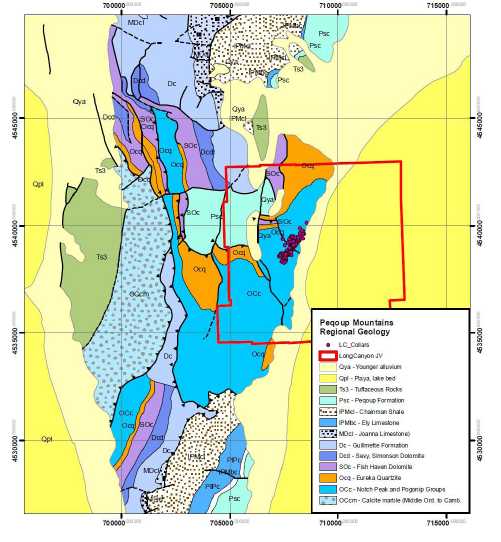

| Most of northeast Nevada is underlain by carbonate and siliciclastic rocks that record a passive margin setting throughout most of the Lower Paleozoic, transitioning to a more active continental margin from the mid-Paleozoic onward. A major east -trending, crustal- scale fault known as the Wells Fault of unknown (post mid-Paleozoic) age, separates primarily platform and platform margin rocks on the south side of the fault (including most of the Pequop Mountains, shown in Figure 7-1) from platform margin and slope facies to the north. This separation suggests considerable (tens of kilometres) right-lateral offset across the fault (Thormanet al., 1992). In the Long Canyon project area, Cambrian and Ordovician rocks record many cycles of sea level rise and fall, with periods of low sea level marked by dolomite horizons and sheets of cross -bedded orthoquartzite . |

| | |

| To the north of the Wells Fault, the Paleozoic section records the mid-Paleozoic Antler Orogeny in the form of the Roberts Mountains thrust fault and emplacement of deeper- water siliciclastic rocks of the Roberts Mountains allochthon over platform and slope facies rocks. To the south of the Wells Fault, the Antler Orogeny is manifested by thick accumulations of foreland-basin sediments of Early Mississippian age that were shed eastward off the Roberts Mountains allochthon. |

| | |

| In Jurassic time, rocks throughout northeastern Nevada and easternmost Utah were affected by the Elko Orogeny (Thormanet al.,1992). The Elko Orogeny resulted in metamorphism and plastic deformation of primarily Lower Paleozoic strata over a large area. Manifestations include weak to strong, near- bedding-parallel foliation, northeast -trending folds, east -southeast-trending stretching lineations, and older-over- younger and younger- over-older layer-parallel faults (attenuation faults). Metamorphic effects are strong in the Wood Hills to the west of the Pequop Mountains, weaker in the western Pequop Mountains, and weaker still in the Long Canyon project area. The Elko Orogeny is presumed to be approximately coeval with Jurassic plutonism in eastern Nevada. |

| | |

| The Tertiary Period includes a number of episodes of extension in the Great Basin, including Eocene volcanism and normal faulting and mid-Tertiary low-angle listric normal faulting. The latter includes periods of “hyperextension” from approximately 33 to 20 Ma, including the formation and unroofing of the Ruby Mountains Core Complex, located approximately 80 kilometres to the west . Rocks as young as 10 Ma in the eastern Great Basin are tilted up to 50°to the east, suggesting that low-angle normal faulting continued until fairly recently. High-angle basin and range faulting, resulting in the familiar pattern of mountain ranges and valleys, continues to the present . Most ranges, including the Pequop Mountains, are bounded by steep faults on one or both sides. |

Gold occurrences in the eastern Great Basin are widely spaced and generally small, but most appear to be of the sediment-hosted type that is more prolific and well

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

documented in the Carlin and Cortez Trends in the central Great Basin. Mineralization of this type was emplaced approximately 38 - 40 million years ago throughout the region, more or less coeval with two phases of felsic to intermediate volcanism in the region. Some examples are present in the vicinity of the Pequop Mountains, including the Tug and KB deposits, located to the northeast. Gold is also associated with mid-Jurassic intrusions in the region, including some or all of the mineralization at Bald Mountain, located to the southwest of Long Canyon.

The following discussion of property geology is based primarily on the mapping and interpretation of Smith (2009), which built upon earlier efforts by AuEx and Pittston. The reader is referred to unpublished company reports by consulting stratigrapher Jon Thorson (2007, 2008) for more details on the stratigraphy of the Notch Peak Formation and Pogonip Group. Previous mapping in the Long Canyon area was carried out by Thorman (1970), Camillari (1994), Coolbaugh (2006), and Pittston geologists, who provided a framework for subsequent work. Thompson (2009) mapped portions of the Long Canyon project area in 2009.

Figure 7-1: Regional Geologic Map of Long Canyon Area

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

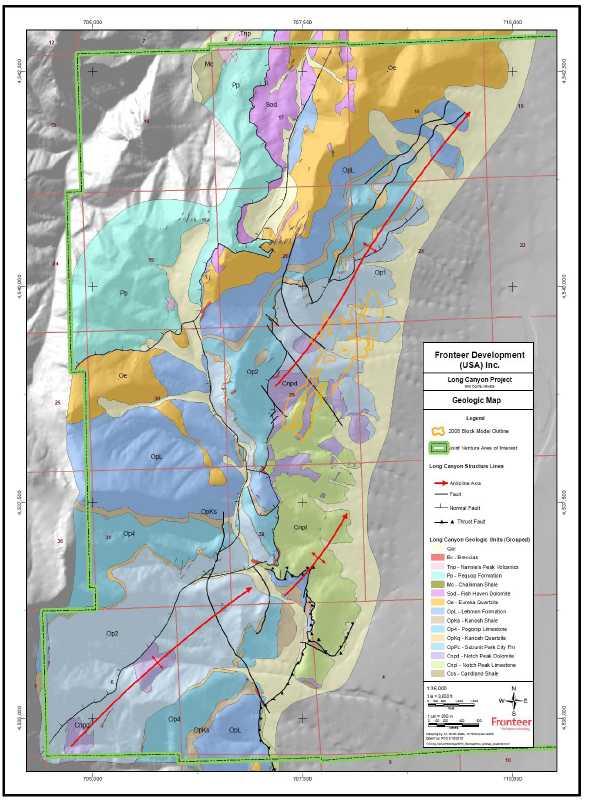

| 7.2.1 | Project-Scale Lithology |

| | |

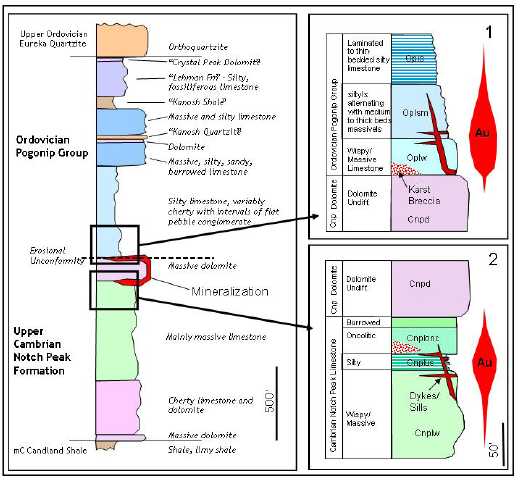

| The Pequop Mountains are underlain primarily by Paleozoic carbonate rocks and lesser siliciclastic rocks representing a transition from slope through platform facies over time (Figure 7-2). The Long Canyon project is underlain primarily by the Notch Peak Formation and the Ordovician Pogonip Group and Eureka Quartzite, with younger rocks (Fish Haven Dolomite, Chainman Shale, and Pequop Formation) mapped on the northern boundary of the project area. On a property- wide scale, stratigraphic units presented in this report (Figure 7-3) reflect mappable subdivisions defined by Smith (2009) for regional mapping efforts. Additional stratigraphic detail at the top of the Notch Peak Formation and the base of the Pogonip Group is also described below, as these units appear to significantly influence the distribution of gold mineralization at Long Canyon. |

Cambrian Candland Shale. Thinly bedded calcareous siltstone and silty limestone are exposed at the extreme south end of Long Canyon ridge. The strata, as well as the contact with the overlying Notch Peak Formation, are highly strained, but the contact appears to be depositional. These strata are tentatively assigned to the Candland Shale (Ccs) mapped elsewhere in the region based on discussions with Jon Thorson (pers. comm., 2008.)

Cambrian Notch Peak Formation. Cambrian carbonate rocks are widely distributed in the region, but are mostly referred to as “undifferentiated”. The name “Notch Peak Formation” is used to describe mainly massive limestone and/or dolomite in adjacent ranges to the east, and has been adopted here.

The lowest mappable unit in the Notch Peak (Cnp1) consists of a massive dolomite horizon approximately 20 to 30-metres thick exposed in the extreme south end of Long Canyon ridge. Overlying the massive dolomite unit in the southern part of the project area is a unit of unknown thickness (probably up to a few hundred metres thick) of fairly massive dolomite and limestone with 3 to 5-centimetres thick chert ribbons and nodules (Cnp2). Dolomite is suspected to be a secondary feature (late diagenetic, metamorphic, or possibly hydrothermal).

The Cnp2 unit grades upward into mainly limestone (Cnp3). This unit consists of an amalgamation of at least four shallowing-upward depositional cycles. Overall, however, the unit can be characterized by the predominance of fairly massive, medium- to thick-bedded, medium to pale grey, sparsely fossiliferous, finely crystalline limestone with areas of thinner, silty interbeds. Small-scale depositional features, including fossil hash, oolitic and oncolitic horizons, and rarely mudcracks, are noted locally. Several small dolomite lenses have also been mapped within the Cnp3 unit. Some appear to be derived from primary dolomitic deposits, while others appear to be related to alteration along fault zones or fold hinges.

The highest unit in the Notch Peak Formation consists of a thick (approximately 75 metres) sequence of massive dolomite (Cnp4). This unit ranges from light to dark grey in

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

colour, from coarse to (rarely) fine grained, and from massive to (rarely) well bedded, probably reflecting varying degrees of secondary recrystallization.

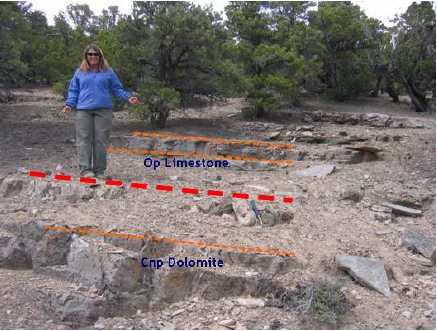

Ordovician Pogonip Group. Following the deposition of the Notch Peak Formation, there was likely an emergent period (global sea level low-stand) spanning up to several million years, represented by an erosional unconformity and local areas where a paleosol and/or breccias are present between the top of the Notch Peak Formation and the base of the Pogonip Group.

The Pogonip Group in the map area is suspected to be up to 600 metres thick, and on the scale of the mapping for this report, is comprised of six main units and several sub-units. Nomenclature varies considerably throughout the region, likely a result of facies changes and the formation’s broad regional extents (from eastern California to western Utah). Thorman (1970), following Hintze (1951), divided the Pogonip Group in the Wood Hills and Pequop Range into four formations, which include (from lowest to highest) the Wahwah and Juab Limestone, Kanosh Shale, Lehman Formation and Crystal Peak Dolomite. The Wahwah and Juab Formations are also known as the Garden City Formation in the Toano Range. In the Toano Range, a quartzite referred to as the Swan Peak Quartzite occurs between the Lehman Formation and the Crystal Peak Dolomite. Smith (2009) used a numbering system based on units felt to be consistently and reliably applicable in the field at the scale of mapping (approximately 1:2400).

The basal unit of the Pogonip Group in the Long Canyon area (Op1) is the host for much of the mineralization in the Long Canyon deposit, and consists of recessive, thin-bedded, silty limestone (Figure 7-4) with thicker (up to one metre thick) interbeds and areas of more massive limestone. Limestone ranges from medium grey to buff and typically weathers in a platy, rounded habit. Chert (probably diagenetic) comprises approximately 5% of the lower part of this unit. Thicker beds are often conglomeratic, with tabular limestone clasts in a sandy (grainstone) matrix. Near the top of the section in the north, Op1 is very recessive and poorly exposed, covered by an apron of talus from the overlying, cliff forming unit Op2.

Unit Op2 is a massive, cliff-forming unit exposed mainly in the northern part of the map area. The unit consists of massive beds of heavily burrowed limestone. Burrow fill consists of tan-weathering, partly dolomitic, silty, buff-coloured, partially silicified limestone, giving the rock a “net-textured” or nodular appearance.

Unit Op3 consists of approximately 15 metres of white, cross-bedded quartz arenite. In the Wood Hills, this quartzite is named the “Kanosh Quartzite” by Thorman (1970). This unit is flanked by dolomitic sandy limestone in some areas.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 7-2: Long Canyon Project Geologic Map (after Smith,2009).

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 7-3: Stratigraphic column of the lower Pogonip Group and upper Notch Peak Formation

(after Smith, 2009; Thorson, 2007, 2008)

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 7-4: Silty, Thin-bedded to Laminated Limestone of Lower Pogonip Group (Op1)

Unit Op4 is similar in nature to unit Op2, consisting of fairly massive, burrowed, “net textured” to nodular, silty limestone, as well as massively bedded limestone with minor wispy silt laminae, cherty limestone, and grainstone.

Unit Op5 consists of a very recessive weathering shale horizon, known regionally as the “Kanosh Shale”. The Kanosh Shale is rarely exposed, and is usually defined by a zone of grey- to olive- weathering shale and thin-bedded silty limestone float with very minor outcrop of thin-bedded, silty limestone. Shale typically displays a slaty cleavage at low angles to bedding.

Unit Op6 consists mainly of massive grey limestone with 20% to 70% buff to red silt “wisps”. Silt wisps were likely continuous silty beds, which have been deformed into a series of rootless isoclinal folds on a centimetre scale. In some areas, this unit is overlain by the Crystal Peak Dolomite, a thin, highly fossiliferous stratigraphic unit.

Ordovician Eureka Quartzite.The Ordovician Eureka Quartzite caps the higher ridges above and to the north and west of the Long Canyon deposit. The Eureka quartzite consists of white to pale grey, hard, massive, variably cross-bedded orthoquartzite, and exceeds 100 metres in thickness in this area. The contact with the underlying Pogonip Group is usually covered by thick talus. Where exposed, quartzite near the base of the unit is often brecciated and re-healed with silica, suggesting the bottom contact may be modified by low-angle, layer-parallel faulting.

Units present in the Long Canyon project area above the Eureka Quartzite include the Late Ordovician to Silurian Fish Haven Dolomite, Mississippian Chainman Shale, and the Permian Pequop Formation.

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

| Lamprophyre Sills and Dikes. Thin lamprophyric sills and dikes are present throughout the map area, usually as rubble trains. Most of the sills and dikes are less than one- metre thick. The rock is fine to medium grained and variably porphyritic. Whole-rock data from variably altered samples shows silica content as low as 38% and elevated Ni, Cr, Co, K, V, Ba, and P. They are invariably altered, with alteration ranging from propylitic (chlorite- muscovite -phlogopite) to argillic and/or phyllic altered in mineralized zones. Secondary biotite is suspected in some areas. Sills range from nearly undeformed to strongly foliated. Examination of dikes and sills in road cuts suggests that they crosscut second-phase folds and are thus post -metamorphic. The foliation is largely internal to the dikes, which suggests that it is formed by squeezing the phyllosilicate-rich rocks between rigid buttresses of limestone. Lamprophyre dikes and sills may be found throughout the deposit, but appear to concentrate in linear, northeast -trending swarms that closely (but not exactly) parallel boudin margins. |

| | |

| Nannie’s Peak Volcanic Rocks. Felsic volcanic and/or shallow intrusive rocks are noted in two locations on the property, one at the bottom of Long Canyon and a second near the northern property boundary. The rock most often is massive and crowded with quartz, feldspar, and biotite phenocrysts. The Nannie’s Peak volcanic rocks have been dated as approximately 41 Ma. |

| | |

| Quaternary/Holocene Unconsolidated Deposits. Lower elevations of the map area are covered by alluvium, characterized by the presence of relatively rounded boulders (up to several metres in diameter) of Eureka Quartzite, as well as a diverse range of other lithologies. IP resistivity data suggest that the alluvial deposits thicken gradually basinward, and then thicken abruptly on the east side of a high- angle Basin and Range fault . |

| | |

| 7.2.2 | Deposit Scale Lithology |

| | |

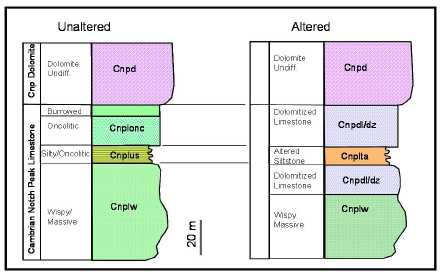

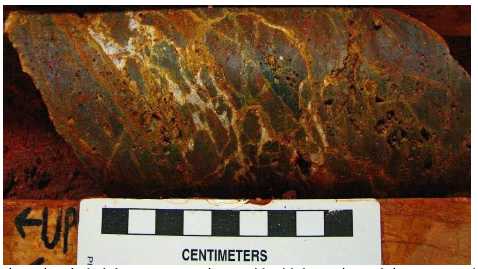

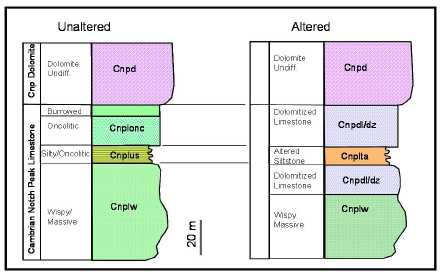

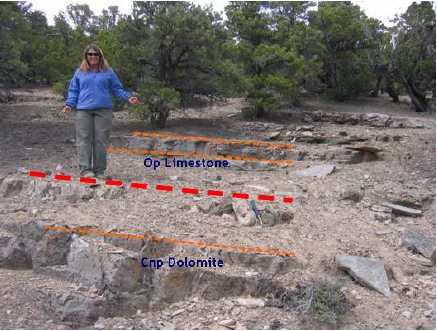

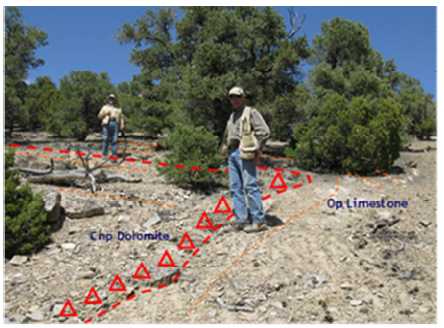

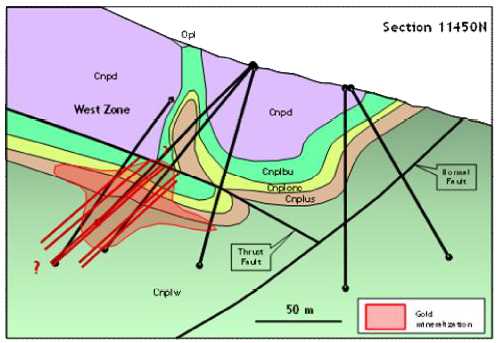

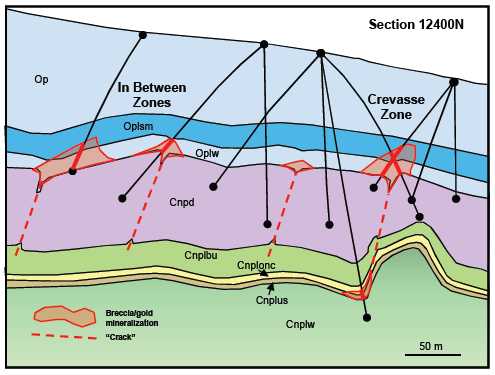

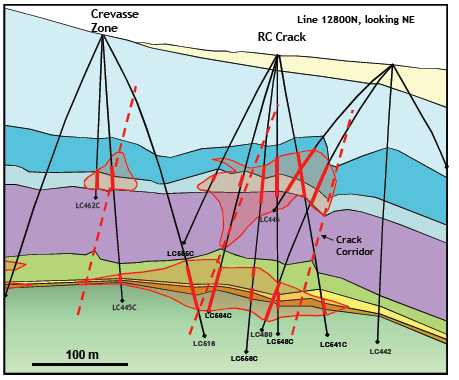

| Additional core drilling in 2009 made it possible to break out distinct lithologic units above and below the Notch Peak Dolomite (Figure 7-5 and Figure 7-6). These units appear to control the distribution of mineralization to a degree not recognized in previous drilling. From approximately 100 metres below the top of the Cnp3 unit, progressing up section, the following units were broken out: |

| | |

| Cnplw: “Wispy Massive Limestone”A unit of variable thickness comprised of laminated to thin beds of limestone and silty limestone to siltstone or shale. This unit is variably bioturbated, with coarser, cleaner limestone filling burrows. This activity, as well as ductile strain, parsed the silty laminations into discontinuous small lenses or “wisps”. In some areas, thin to medium beds of sand-sized bioclastic material is also present. This unit grades down into bioclastic to oolitic limestone, and up into Cnplus. |

| | |

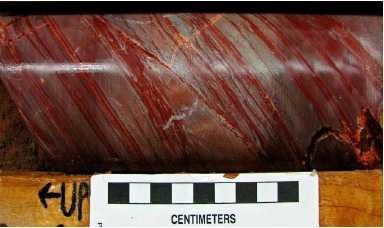

| Cnplus: “Upper Siltstone”The upper siltstone unit is made up of alternating 1 to 2 metre thick intervals of thin-bedded to laminated silty limestone, siltstone, and shaly limestone with 1 to 3 metre- thick intervals of massive oncolitic limestone (Figure 7-7). Silty intervals are dark grey fresh, but are very prone to alteration/oxidation and typically appear tan, orange, or red where mineralized (Figure 7-7 and Figure 7-8). |

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Oncolitic horizons are typically medium grey. Oncolites often contain grainy brown dolomite rhombs. The unit as a whole ranges from a few metres to approximately 12 metres thick depending on degree of strain (which is quite variably close to the Notch Peak Dolomite), layer parallel attenuation faulting, and other factors.

Cnplonc: “Oncolitic Limestone”The upper siltstone is bounded on the top by a thick horizon of massive oncolitic limestone, which was originally identified in 2008 field mapping. It is identical to the oncolitic limestone interlayered with siltstone in the Cnplus unit, but lacks the siltstone horizons. It is of variable thickness, but typically 10 to 12-metres thick. It is notably thinned in areas of high ductile strain, such as near or within boudin neck areas. The Cnplonc unit is gradational upward into unit Cnplbu.

Figure 7-5: Stratigraphy Immediately Above and Below the Notch Peak Dolomite

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 7-6: Altered Stratigraphic Equivalents Immediately Below the Notch Peak Dolomite

Figure 7-7: Relatively Unaltered Cnplus “Upper Siltstone” Unit

(Massive oncolitic limestone (pale grey) interlayered with intervals of silty limestone

(dark grey)).

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Figure 7-8: Dolomite-Altered Equivalent of the Cnplus “Upper Siltstone” Unit

(Tan areas (Cnplt) are after the silty limestone, grey areas are dolomitized oncolitic

limestone (protolith textures are preserved).

Cnplbu: “Burrowed Limestone”A massive unit consisting of bioturbated/burrowed limestone lies above the Cnplonc. Overall, the unit is very massive, and has a distinctive mottled, light to medium grey appearance. Some oncolites may be present near the base of this unit. The unit is probably over 20-metres thick, but is only rarely seen in its entirety due to variable degrees of dolomitization at the base of the Notch Peak Dolomite.

Together, these newly-defined units form a distinctive package that has proved useful in defining the structural setting and alteration in and around the base of the Notch Peak Dolomite. For example, the oncolitic limestone unit proves to be very robust in terms of recognizing protolith types despite profound dolomitization. The Cnplus unit is also a useful marker in dolomitized areas (see below). Finally, the Cnplus unit is the most important unit at the top of the Notch Peak Formation from an economic standpoint, as it appears to be the best conduit and host for gold mineralization.

The lowermost portion of the Pogonip Group (unit Op1 of Smith, 2009) was also examined in some detail during core logging. While not as precisely defined as the upper portion of the Notch Peak Limestone, there is still a crude stratigraphy that can be discerned in it.

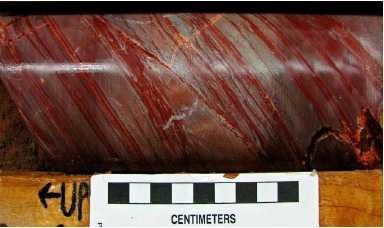

Oplw: “Wispy Massive Limestone”This unit is very similar in nature to unit Cnplw, consisting of massive, pale to medium grey limestone with silt wisps defined by silt/shale laminations, dismembered by burrowing activity and ductile strain (Figure 7-9). This unit averages approximately 10 to 12 metres thick, and directly overlies the Notch

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Peak Dolomite on a sharp contact. This unit is where most of the solution breccia-hosted gold mineralization in the Pogonip Group is hosted (Figure 7-5, Figure 7-10).

Figure 7-9: Relatively Unaltered “Wispy Massive” Limestone (Oplw)

Figure 7-10: Mineralized Equivalent of the Oplw Unit

| Fronteer Gold Inc. |

| Long Canyon Project, Elko County, Nevada |

| Updated Technical Report and Interim Resource Estimate |

Opsm: “Silty/Massive Limestone”Above unit Oplw, there is a zone of alternating, approximately one metre thick beds of massive limestone, alternating with approximately one metre thick intervals of laminated to thin-bedded silty limestone, limy siltstone and shaly limestone (Figure 7-11). This unit is of variable thickness but probably averages approximately 10 to 20 metres thick. It bears a superficial resemblance to unit Cnplus, the upper siltstone unit in the Notch Peak Limestone, but lacks oncolites in the massive beds. This unit is gradational into gradually thinner, thick to medium beds of massive limestone alternating with intervals of laminated to thin bedded silty limestone, eventually giving way upwards into predominantly laminated to thin bedded silty limestone, limy siltstone, and shaly limestone.

Figure 7-11: Opsm Unit

Alternating Massive (grey) and Weakly-Altered Laminated/Thinly Bedded Limestone

(orange)

| 7.2.3 | Structure |

| | |

| The structural history of the Long Canyon area was elucidated primarily through geological mapping, examination of drill core, and research. |

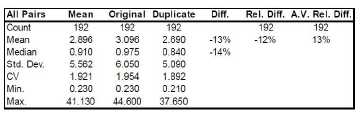

| | |