SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| | SILVERCREST MINES INC. |

| | |

| | /s/ J. Scott Drever |

| Date: March 28, 2013 | J. Scott Drever |

| | Chairman and President |

UPDATED RESOURCE ESTIMATE FOR THE LA JOYA

PROPERTY

DURANGO, MEXICO

NI 43-101 TECHNICAL REPORT

PREPARED FOR SILVERCREST MINES INC.

RELEASED: MARCH 27, 2013

EFFECTIVE DATE: DECEMBER 16, 2012

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| TABLE OF CONTENTS | |

| |

| 1.0 | EXECUTIVE SUMMARY | 1 |

| | 1.1 | Property Description and Ownership | 3 |

| | 1.2 | Geology and Mineralization | 3 |

| | 1.3 | Drilling and Exploration | 5 |

| | 1.4 | Mineral Processing and Metallurgical Testing | 5 |

| | 1.5 | Mineral Resource Estimation | 7 |

| | 1.6 | Recommendations | 8 |

| | | | |

| 2.0 | INTRODUCTION AND TERMS OF REFERENCE | 10 |

| | 2.1 | Report Authors and EBA Quality Control | 10 |

| | 2.2 | Site visits | 10 |

| | | | |

| 3.0 | RELIANCE ON OTHER EXPERTS | 10 |

| | | |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 11 |

| | 4.1 | Location | 11 |

| | 4.2 | Concessions | 11 |

| | 4.3 | Property Agreements | 12 |

| | 4.4 | Mexican Mine Permitting and Regulations | 16 |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND |

| | PHYSIOGRAPHY | 17 |

| | 5.1 | Accessibility | 17 |

| | 5.2 | Climate | | 17 |

| | 5.3 | Local Resources | 17 |

| | 5.4 | Infrastructure | 19 |

| | 5.5 | Physiography | 19 |

| 6.0 | HISTORY | | 20 |

| | 6.1 | Discovery | 20 |

| | 6.2 | Pre-1977 | 20 |

| | 6.3 | 1977 to 2006, Luismin | 21 |

| | | 6.3.1 1997 to 2001, Luismin-Boliden Joint Venture | 21 |

| | 6.4 | 2001 to 2010 | 22 |

| | 6.5 | Historical Resource Estimations | 23 |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 25 |

| | 7.1 | Regional Geology | 25 |

| | 7.2 | Local Geology | 25 |

| | | 7.2.1 | Sedimentary Units | 28 |

| | | 7.2.2 | Igneous Units | 28 |

| | | 7.2.3 | Structural Events | 29 |

i

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| |

| | 7.3 | Mineralization | | 30 |

| | | 7.3.1 | La Joya and Santo Nino | 30 |

| | | 7.3.2 | Coloradito | | 32 |

| 8.0 | DEPOSIT TYPE | | 32 |

| | | | |

| 9.0 | EXPLORATION | | 34 |

| | | | |

| | 9.1 | Surface Sampling and Mapping | 34 |

| | 9.2 | Exploration History Compilation and Database Development | 34 |

| | | 9.2.1 | Rock Coding in Database | 35 |

| | | | | |

| 10.0 | DRILLING | | | 36 |

| | 10.1 | Phase 1 Drilling, Oct 2010 to July 2011 | 36 |

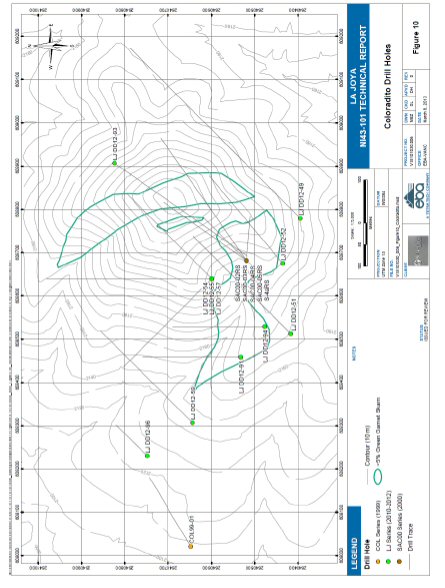

| | 10.2 | Phase II Drilling, Nov 2011 to Dec 2012 | 36 |

| | | | |

| 11.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 45 |

| | | |

| | 11.1 | Historic Sample Preparation | 45 |

| | 11.2 | SilverCrest Sample Preparation and Analysis, 2010-2013 | 45 |

| | | 11.2.1 | Laboratory Selection | 47 |

| | | 11.2.2 | Methods | | 47 |

| | | 11.2.3 | Sample Storage and Security | 47 |

| | 11.3 | QP Statement | | 48 |

| | | | | |

| 12.0 | DATA VERIFICATION | 48 |

| | | |

| | 12.1 | Site Visit IV: October 2012 | 48 |

| | 12.2 | Phase II Sampling QA/QC | 51 |

| | | 12.2.1 | SilverCrest Certified Reference Material Insertions | 51 |

| | | 12.2.2 | SilverCrest Blank Material Insertions | 55 |

| | 12.3 | QP Statement | | 57 |

| | | | | |

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 58 |

| | | |

| | 13.1 | Initial Test Work at Instituto Tecnológico de Saltillo - 2011 | 58 |

| | 13.2 | Test Work at ALS - 2012 to 2013 | 61 |

| | | 13.2.1 | Sample Selection | 61 |

| | | 13.2.2 | Test Program Scope | 61 |

| | | 13.2.3 | Sample Preparation | 62 |

| | | 13.2.4 | Sample Characterization | 62 |

| | | | 13.2.4.1 | Head Assay and Specific Gravity | 62 |

| | | | 13.2.4.2 | JKTech SMC Tests | 63 |

| | | | 13.2.4.3 | Bond Ball Mill Grindability Tests | 63 |

| | | | 13.2.4.4 | Abrasion Tests | 64 |

| | | 13.2.5 | Mineralogy Analysis | 64 |

| | | 13.2.6 | Gravity Concentration | 65 |

| | | 13.2.7 | Batch Rougher Flotation Tests | 66 |

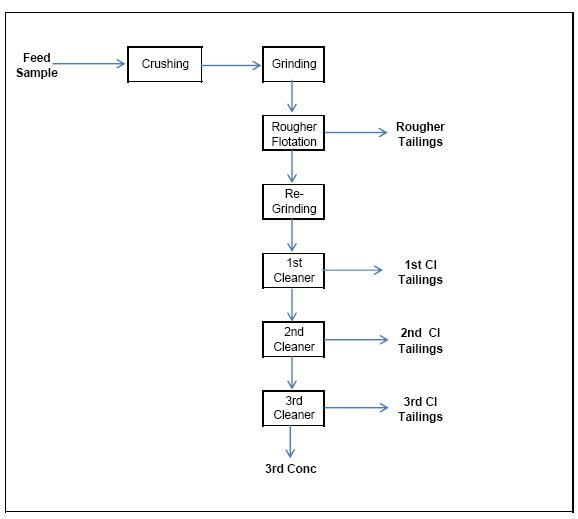

| | | 13.2.8 | Batch Cleaner Flotation Tests | 68 |

ii

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| | | 13.2.9 Optimization Tests to Control Penalty Elements | 69 |

| | | | 13.2.9.1 | Arsenic Control Test Work | 70 |

| | | | 13.2.9.2 | Antimony and Bismuth Control Test Work | 71 |

| | 13.3 | Recommendations | | 71 |

| | | | | |

| 14.0 | MINERAL RESOURCE ESTIMATE | 72 |

| | | |

| | 14.1 Previous NI 43-101 Resource Estimate (Phase 1, Jan 5, 2012) | 72 |

| | 14.2 Current NI 43-101 Resource Estimation (Phase II) | 73 |

| | | 14.2.1 | Basis of Current Estimate | 73 |

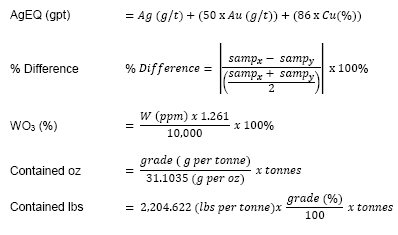

| | | 14.2.2 Metal Price Analysis and Silver Equivalent Calculation | 74 |

| | | 14.2.3 Specific Gravity Used in Resource Estimation | 77 |

| | 14.3 Geological Model Used in the Interpretation | 80 |

| | | 14.3.1 Lithocoding used in the GEMS block model | 86 |

| | | 14.3.2 Main Mineralized Trend (MMT) Geostatistics | 87 |

| | | | 14.3.2.1 | MMT High Grade Capping | 97 |

| | | 14.3.3 | Santo Nino Geostatistics | 101 |

| | | | 14.3.3.1 | Santo Nino High Grade Capping | 112 |

| | | 14.3.4 | Coloradito Geostatistics | 115 |

| | | | 14.3.4.1 | Coloradito High Grade Capping | 122 |

| | | 14.3.5 | Interpolation and Modelling Parameters | 125 |

| | | | 14.3.5.1 | Main Mineralized Trend | 125 |

| | | | 14.3.5.2 | Santo Nino | 127 |

| | | | 14.3.5.3 | Coloradito | 128 |

| | 14.4 | Resource Estimate | 128 |

| | | 14.4.1 | Mineral Resource Classification | 131 |

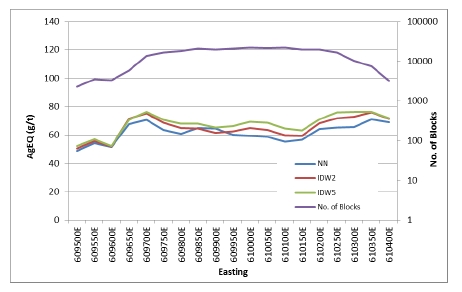

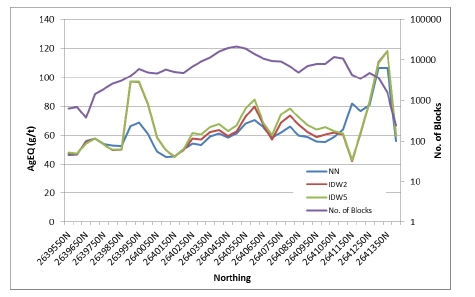

| | 14.5 | Resource Validation | 131 |

| | | | |

| 15.0 | MINERAL RESERVE ESTIMATES | 133 |

| | | |

| 16.0 | MINING METHODS | | 133 |

| | | | |

| 17.0 | RECOVERY METHODS | 133 |

| | | |

| 18.0 | PROJECT INFRASTRUCTURE | 133 |

| | | |

| 19.0 | MARKET STUDIES AND CONTRACTS | 133 |

| | | |

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT133 |

| | |

| 21.0 | CAPITAL AND OPERATING COSTS | 134 |

| | | |

| 22.0 | ECONOMIC ANALYSIS | 134 |

| | | |

| 23.0 | ADJACENT PROPERTIES | 134 |

| | | |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 134 |

iii

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 134 |

| | | |

| 26.0 | RECOMMENDATIONS | 135 |

| | | |

| REFERENCES | 138 |

Table 1: Inferred Ag-Cu-Au-W-Mo Resource Estimation for the MMT and Santo Nino Deposits, Effective Date December 16, 2012 | 2 |

Table 2: Inferred W-Mo Resource Estimation for the MMT, Santo Nino and Coloradito Deposits, Effective Date December 16, 2012 | 2 |

| Table 3: Batch Cleaner Flotation Test Results- Baseline | 6 |

| Table 4: Batch Cleaner Flotation Test Results- with Cyanide | 6 |

| Table 5: 5-Year Metal Price Trends and AgEQ Calculation for Silver, Copper and Gold | 8 |

| Table 6: Recommended Phase III Work and Estimated Costs for the La Joya Property | 9 |

| Table 7: SilverCrest Mineral Concessions for the La Joya Property | 14 |

| Table 8: Summary of Historical Drilling on the La Joya Property | 23 |

| Table 9: Historical Luismin Estimates (non-NI 43-101 Compliant) | 24 |

| Table 10: Major Deformation Events (Patterson, 2001) | 30 |

| Table 11: Rockcoding Used in Phase I and II SilverCrest Drill Logs and in GEMS Drill Hole Database | 35 |

| Table 12: Summary of SilverCrest Drilling on the La Joya Property | 40 |

| Table 13: Significant Drill Hole Intercepts > 5 M Length from Phase II Drilling | 40 |

| Table 14: Recent Significant Tungsten Drill Intersections | 44 |

| Table 15: Drill Core Samples and Duplicates Collected by EBA, October 2012 | 49 |

| Table 16: Certified Reference Material CDN-ME-16 Comparison - October 2012 | 50 |

| Table 17: Certified Reference Material CDN-W-4 Comparison - October 2012 | 50 |

| Table 18: Certified Reference Material Reporting Values Used in Phase II by SilverCrest | 51 |

| Table 19: Element Analysis - Samples CZ, ST and MA | 59 |

| Table 20: Mineral Species - Sample CZ. Samples | 59 |

| Table 21: Mineral Species - Sample ST | 60 |

| Table 22: Mineral Species - Sample MA | 60 |

| Table 23: Composite Samples of Manto, Structure and Contact, 2012 Memo of La Joya Metallurgical Sample Selection | 61 |

| Table 24: Sample Composites Summary | 62 |

| Table 25: Chemical Element Analysis | 63 |

| Table 26: JK Tech SMC Data | 63 |

| Table 27: Bond Ball Grindability Test and Abrasion Test Results | 64 |

| Table 28: Abrasion Test Results | 64 |

| Table 29: Mineral Compositions | 64 |

| Table 30: Copper Minerals Deportment | 65 |

| Table 31: Gravity Test Results On Contact Composite Samples | 66 |

| Table 32: Summary of Batch Cleaner Test Results -Baseline | 69 |

| Table 33: Penalty Element Concentration in 3rd Cleaner Concentrate | 69 |

| Table 34: As Concentration in 3rd Cleaner Concentrate after Treatment | 70 |

| Table 35: Summary of Batch Cleaner Test Results - with Cyanide | 70 |

| Table 36: Depressant Screening Tests Summary | 71 |

| Table 37: Phase I Inferred Ag-Cu-Au Resource Estimation for the La Joya Deposit, Effective Date January. 5, 2012 | 72 |

| Table 38: Phase I Inferred Zn-Pb Resource Estimation for the La Joya Deposit, Effective Date January 5, 2012 | 73 |

| Table 39: Phase I Inferred W Resource Estimation for the La Joya Deposit, Effective Date January 5, 2012 | 73 |

iv

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| Table 40: GEMS Block Model Bounds, Dimensions and Rotation Used for the LJ_2012, LJ2012COL and LJ_2012_SN Database | 74 |

| Table 41: 5-Year Metal Price Trends and AgEQ Calculation for Silver, Copper and Gold | 77 |

| Table 42 : GEMS Solid SG Distribution Summary | 80 |

| Table 43: Rockcodes Applied to MMT and Santo Nino Block Model | 86 |

| Table 44: Rockcodes Applied to Coloradito Block Model | 86 |

| Table 45: Main Mineralized Trend - Manto Raw Non-Composited Descriptive Metal Data | 87 |

| Table 46: Main Mineralized Trend - Manto 2 metre Composited Descriptive Metal Data | 88 |

| Table 47: Main Mineralized Trend - Manto 2 metre Composited >15 AgEQ Descriptive Metal Data | 88 |

| Table 48: Main Mineralized Trend - Manto 2 metre Composited >30 AgEQ Descriptive Metal Data | 89 |

| Table 49: Main Mineralized Trend - Manto 2 metre Composited >60 AgEQ Descriptive Metal Data | 89 |

| Table 50: Main Mineralized Trend - Raw Non-Composited Structure Descriptive Metal Data | 90 |

| Table 51: Main Mineralized Trend -Structure Descriptive Statistics for 2 metre Composited, Metal Data | 90 |

| Table 52: Main Mineralized Trend -2 metre Composited Structure>15 AgEQ Descriptive Metal Data | 91 |

| Table 53: Main Mineralized Trend Structure Descriptive Statistics for 2 metre Composited >30 AgEQ Metal Data | 91 |

| Table 54: Main Mineralized Trend Structure Descriptive Statistics for 2 metre Composited >60 AgEQ Metal Data | 92 |

| Table 55: Main Mineralized Trend Contact Skarn Descriptive Statistics for Raw, Non-Composited Descriptive Metal Data | 92 |

| Table 56: Main Mineralized Trend Contact Skarn Descriptive Statistics for 2 metre-Composited Descriptive Metal Data | 93 |

| Table 57: Main Mineralized Trend Contact Skarn Descriptive Statistics for 2 metre Composited >15 AgEQ Metal Data | 93 |

| Table 58: Main Mineralized Trend Contact Skarn Descriptive Statistics for 2 metre Composited >30 AgEQ Metal Data | 94 |

| Table 59: Main Mineralized Trend Contact Skarn Descriptive Statistics for 2 metre Composited >60 AgEQ Metal Data | 94 |

| Table 60: Santo Nino - Manto Descriptive Statistics for Raw, Non-Composited, Metal Data | 101 |

| Table 61: Santo Nino - Manto 2 metre Composited Descriptive Metal Data | 102 |

| Table 62: Santo Nino - Manto 2 metre Composited >15 AgEQ Descriptive Metal Data | 102 |

| Table 63: Santo Nino - Manto 2 metre Composited >30 AgEQ Descriptive Metal Data | 103 |

| Table 64: Santo Nino - Manto 2 metre Composited >60 AgEQ Descriptive Metal Data | 103 |

| Table 65: Santo Nino Structure Descriptive Statistics for Raw, Non-Composited, Metal Data | 104 |

| Table 66: Santo Nino Structure Descriptive Statistics for 2 metre Composited, Metal Data | 104 |

| Table 67: Santo Nino Structure Descriptive Statistics for 2 metre Composited >15 AgEQ Descriptive Metal Data | 105 |

| Table 68: Santo Nino Structure Descriptive Statistics for 2 metre Composited >30 AgEQ Descriptive Metal Data | 105 |

| Table 69: Santo Nino Structure Descriptive Statistics for 2 metre Composited >60 AgEQ Descriptive Metal Data | 106 |

| Table 70: Santo Nino Contact Skarn Descriptive Statistics for Raw, Non-Composited Descriptive Metal Data | 106 |

| Table 71: Santo Nino Contact Skarn Descriptive Statistics for 2 metre Composited Descriptive Metal Data | 107 |

| Table 72: Santo Nino Contact Skarn Descriptive Statistics for 2 metre Composited >15 AgEQ Metal Data | 107 |

| Table 73: Santo Nino Contact Skarn Descriptive Statistics for 2 metre Composited >30 AgEQ Metal Data | 108 |

| Table 74: Santo Nino Contact Skarn Descriptive Statistics for 2 metre Composited >60 AgEQ Metal Data | 108 |

| Table 75: Coloradito Contact Skarn - Descriptive Statistics for Raw, Non-Composited, Metal Data | 116 |

| Table 76: Coloradito Contact Skarn - 2 metre Composited Descriptive Metal Data | 116 |

| Table 77: Coloradito Contact Skarn - Composited >15 AgEQ Descriptive Metal Data | 117 |

| Table 78: Coloradito Contact Skarn - >30 AgEQ Descriptive Metal Data | 117 |

| Table 79: Coloradito Contact Skarn - >60 AgEQ Descriptive Metal Data | 118 |

| Table 80: Coloradito Contact Skarn - >200 ppm W Descriptive Metal Data | 118 |

| Table 81: Coloradito Contact Skarn - >200 ppm W Descriptive Metal Data | 119 |

| Table 82: Model Search Parametres | 126 |

| Table 83: Average Reporting Composite Data for Block Model by Mineralized Solid Type for the MMT | 127 |

| Table 84: Main Mineralized Trend - Manto 2 metre Composited >30 AgEQ Descriptive Metal Data | 128 |

| Table 85: Average Reporting Composite Data for Block Model by Mineralized Solid Type for Coloradito | 128 |

| Table 86: Inferred Ag-Cu-Au- Resource Estimation for MMT and, Santo Nino Deposits, Effective Date Dec. 16, 2012 | 129 |

v

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Table 87: Inferred W-Mo- Resource Estimation for MMT, Santo Nino and Coloradito Deposits, Effective Date Dec. 16, 2012 | 129 |

| Table 88: Recommended Phase III Work and Estimated Costs for the La Joya Property | 137 |

| |

| |

| FIGURES | |

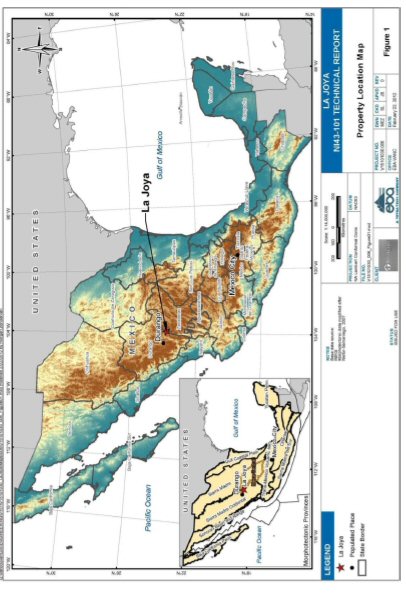

| Figure 1: Property scale location map | 13 |

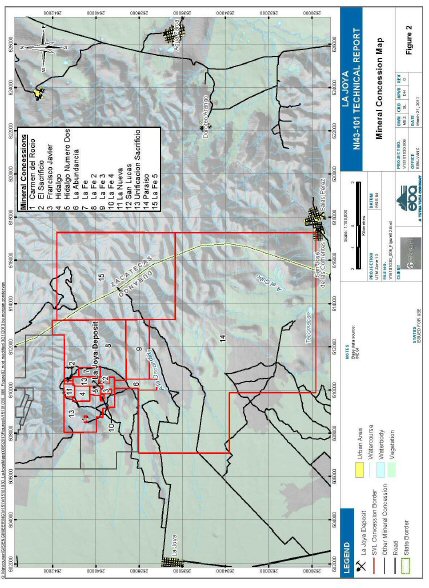

| Figure 2: Mineral concession map | 15 |

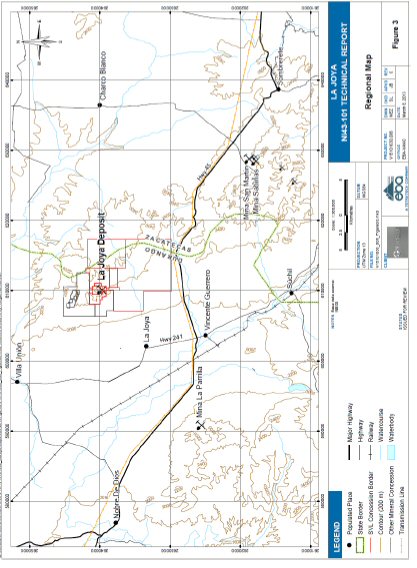

| Figure 3: Regional map showing mineral concession, local infrastructure, and proximal mines | 18 |

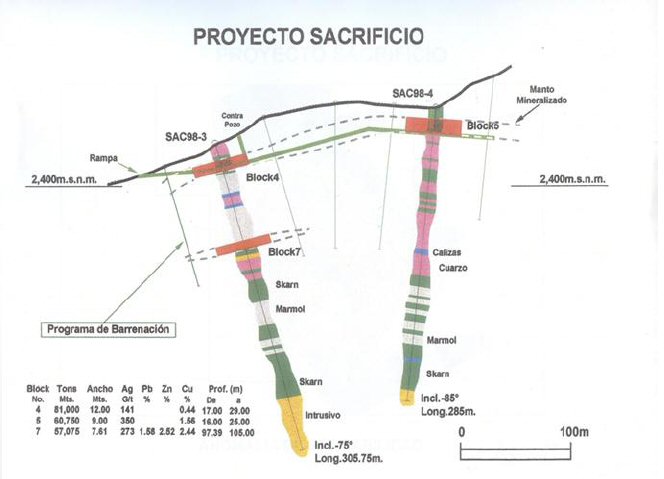

| Figure 4: Historical non-NI 43-101 compliant resource of Luismin and Boliden | 24 |

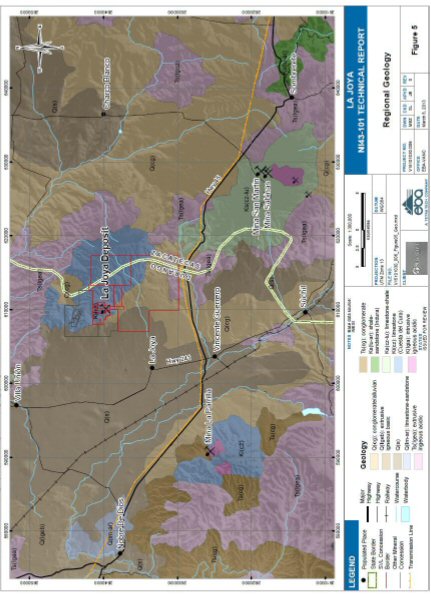

| Figure 5: Regional geology map | 26 |

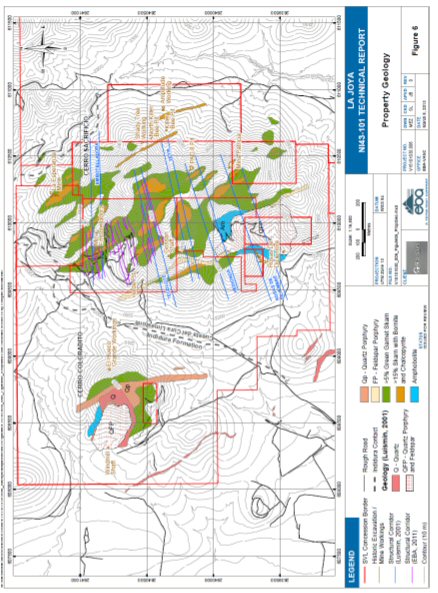

| Figure 6: Local property geology | 27 |

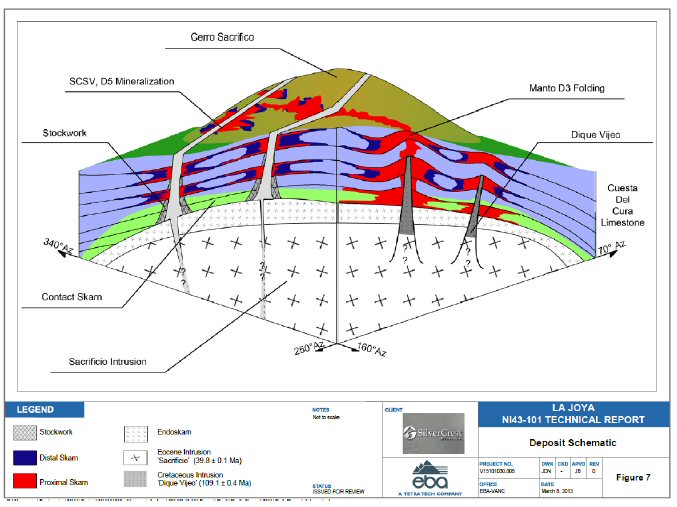

| Figure 7: La Joya deposit model schematic | 33 |

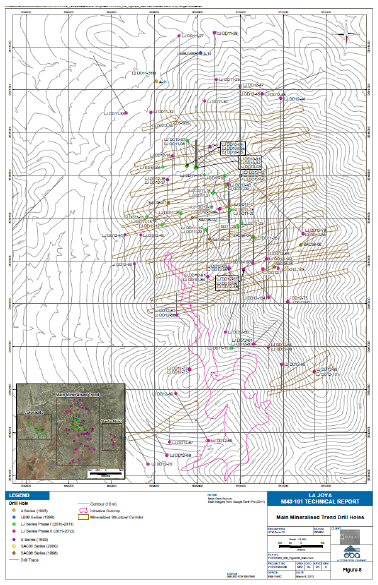

| Figure 8: Phase I and II drill hole location map of the MMT | 37 |

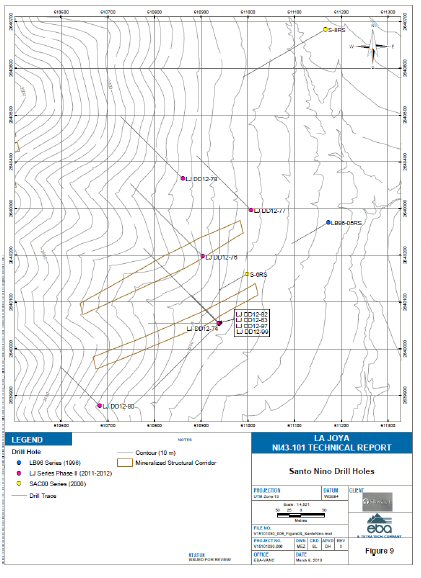

| Figure 9: Phase II drill hole map of Santo Nino | 38 |

| Figure 10: Phase II drill hole map of Coloradito | 39 |

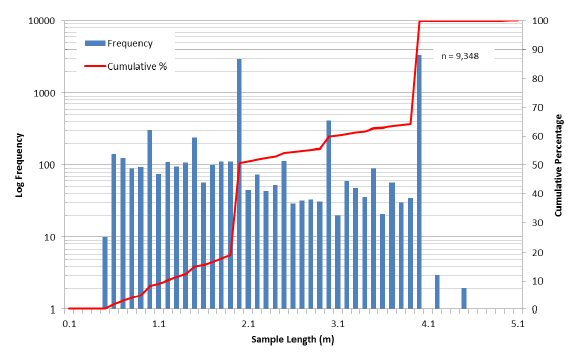

| Figure 11: Log histogram distribution of sample lengths from Phase II | 46 |

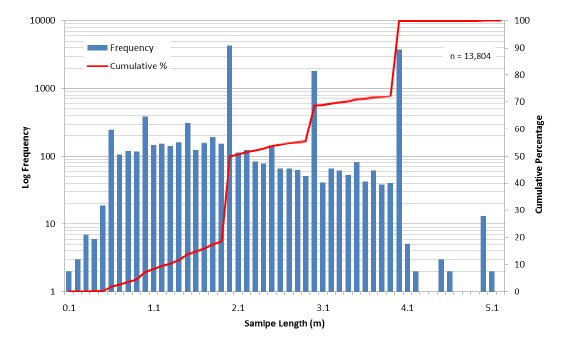

| Figure 12: Log histogram distribution of sample lengths from Historic, Phase I and II drilling | 46 |

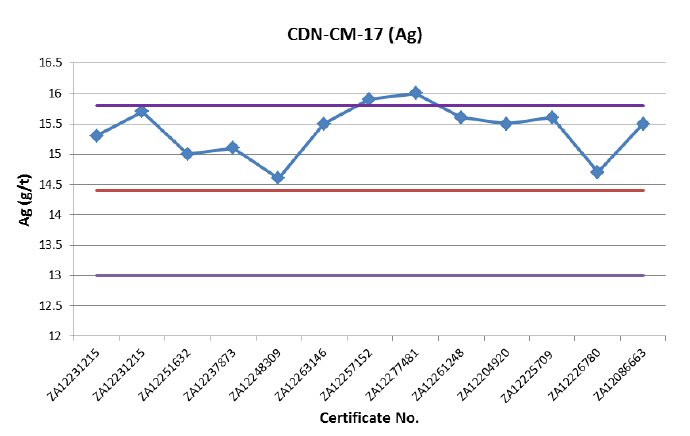

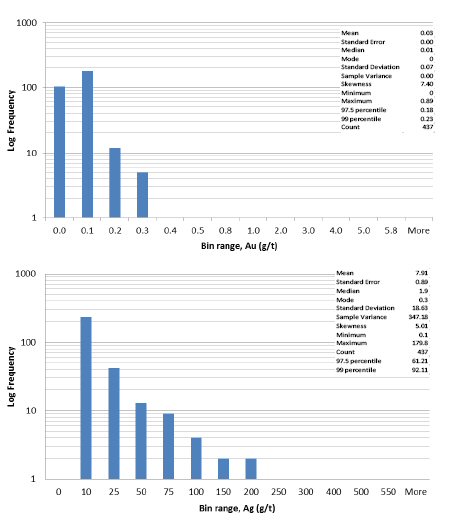

| Figure 13: CRM CDN-CM-17 (Ag) | 51 |

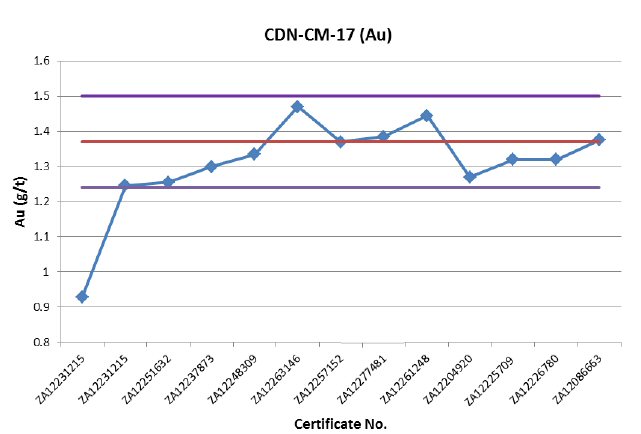

| Figure 14: CRM CDN-CM-17 (Au) | 52 |

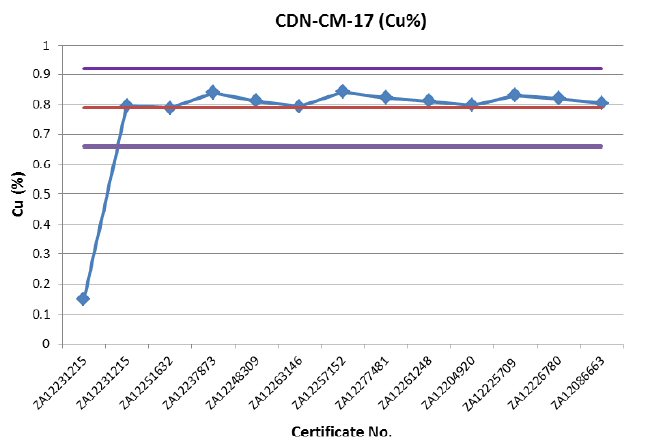

| Figure 15: CRM CDN-CM-17 (Cu%) | 52 |

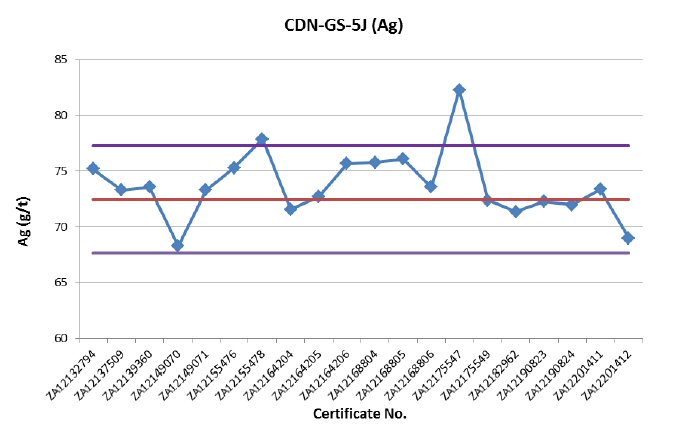

| Figure 16: CRM CDN-GS-5J (Ag) | 53 |

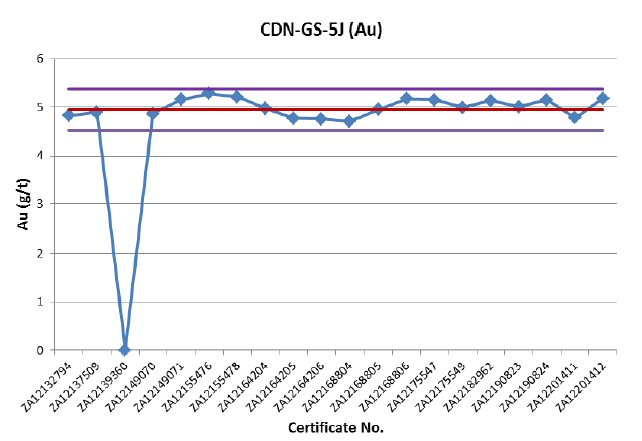

| Figure 17: CRM CDN-GS-5J (Au) | 53 |

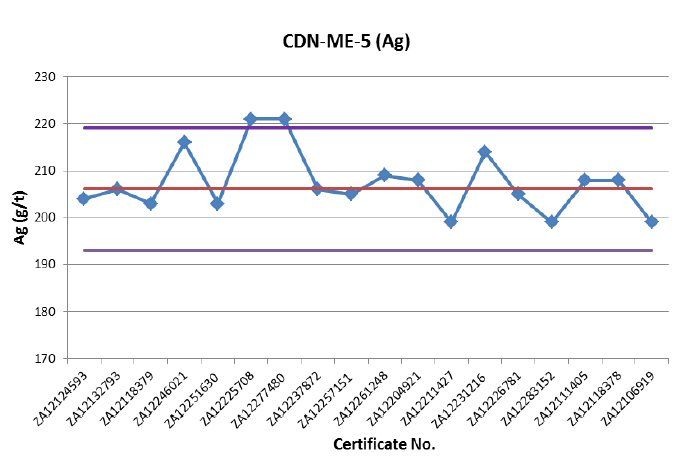

| Figure 18: CRM CDN-ME-5 (Ag) | 54 |

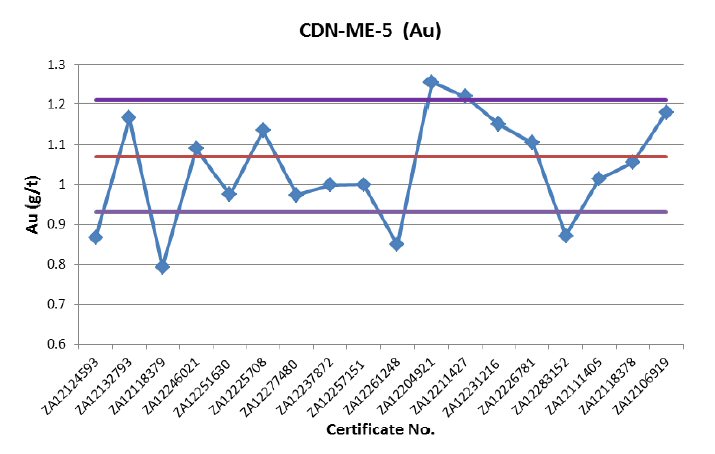

| Figure 19: CRM CDN-ME-5 (Au) | 54 |

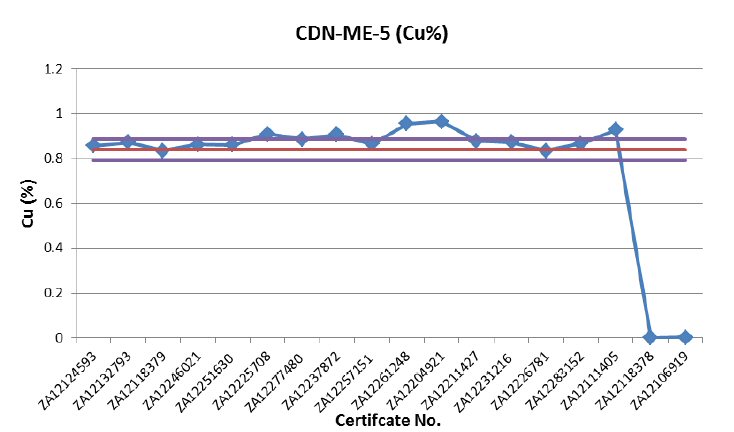

| Figure 20: CRM CDN-ME-5 (Cu) | 55 |

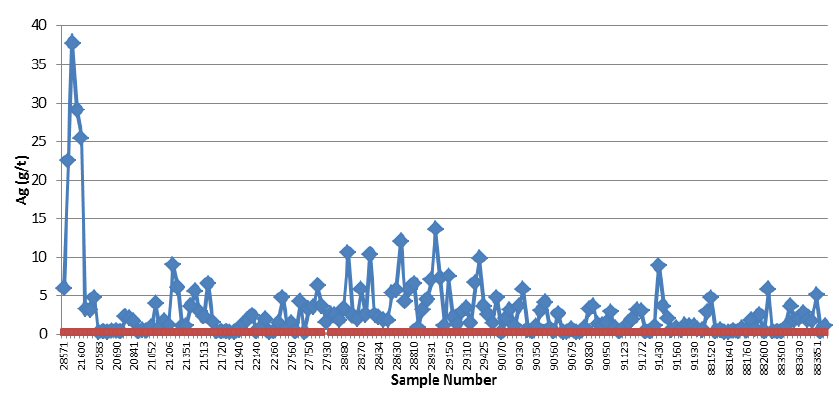

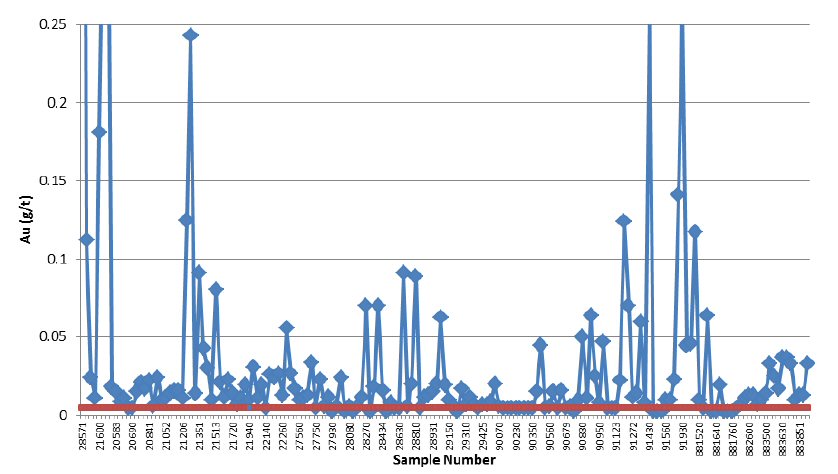

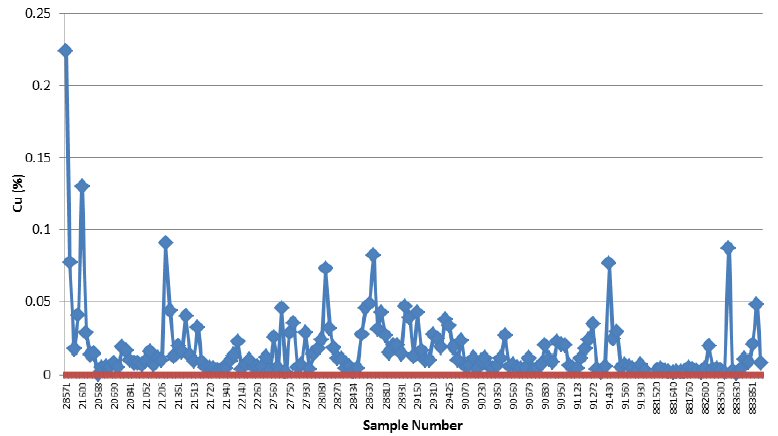

| Figure 21: SilverCrest Phase II mineralized blank material Ag (gpt) | 56 |

| Figure 22: SilverCrest Phase II mineralized blank material Au (gpt) | 56 |

| Figure 23: SilverCrest Phase II mineralized blank material Cu (%) | 57 |

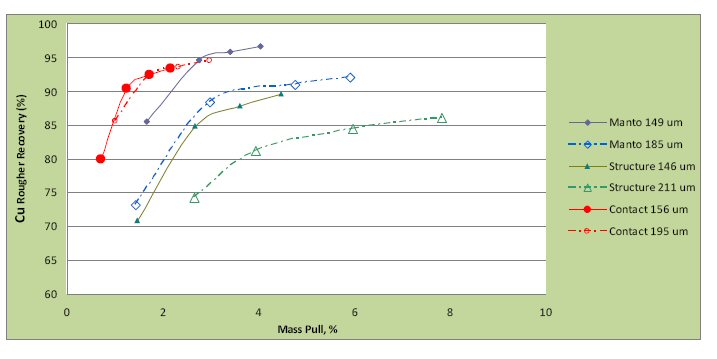

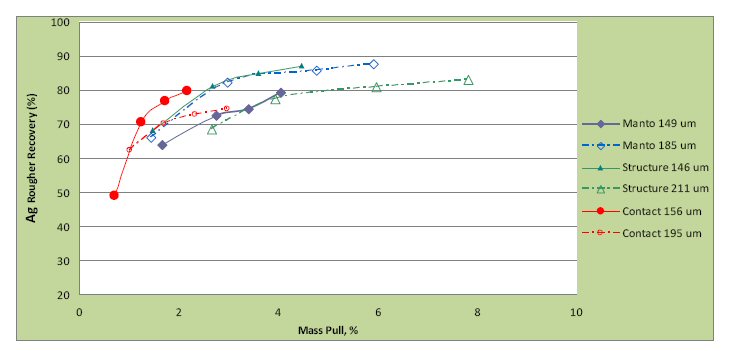

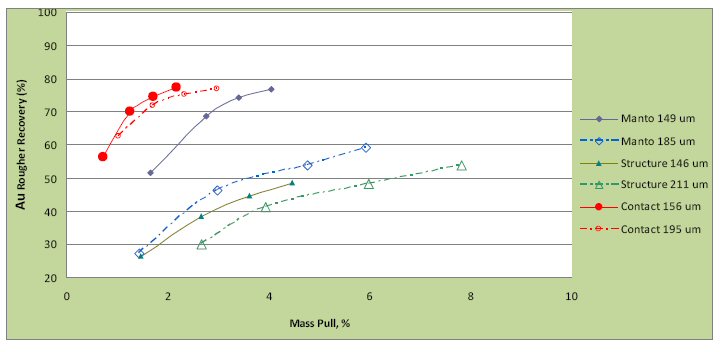

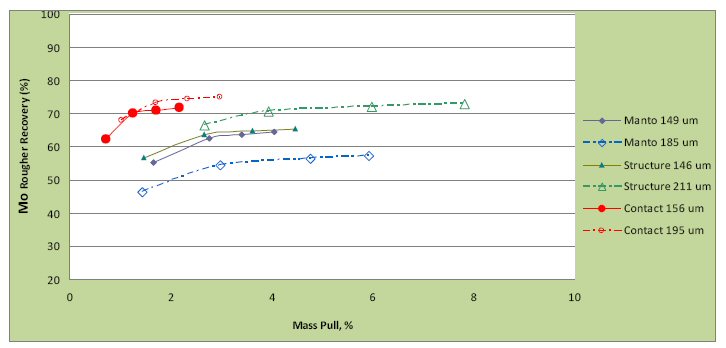

| Figure 24: Copper Recovery vs. Rougher Concentrate Mass Pull | 66 |

| Figure 25: Silver Recovery vs. Rougher Concentrate Mass Pull | 67 |

| Figure 26: Gold Recovery vs. Rougher Concentrate Mass Pull | 67 |

| Figure 27: Molybdenum Recovery vs. Rougher Concentrate Mass Pull | 67 |

| Figure 28: La Joya Batch Cleaner Flotation Test Diagram | 68 |

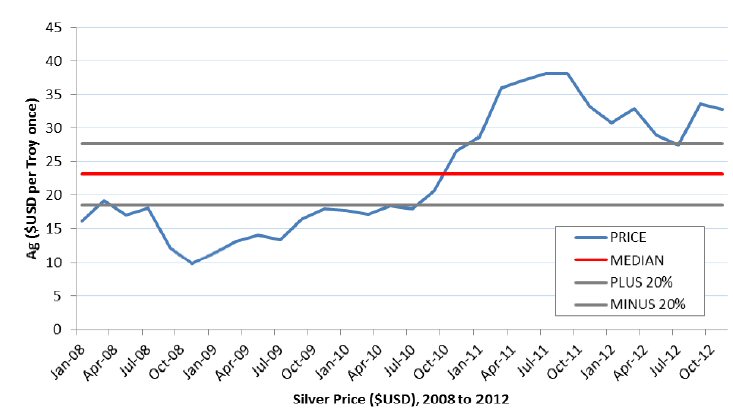

| Figure 29: 5-year silver metal price trend | 76 |

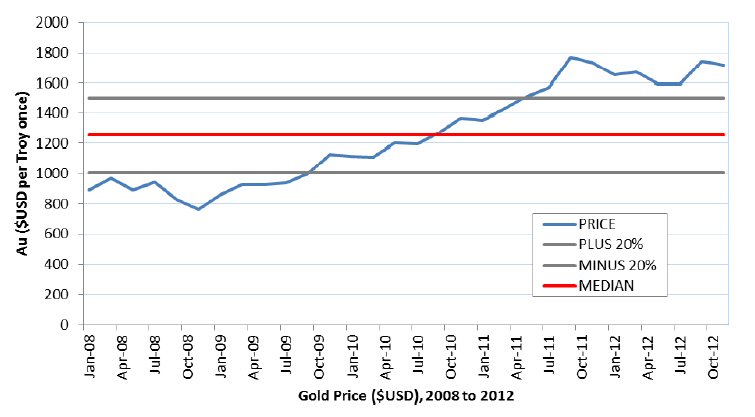

| Figure 30: 5-year gold price trend | 76 |

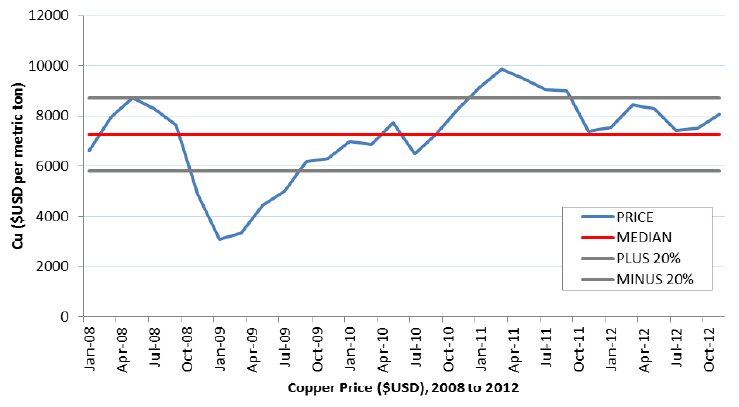

| Figure 31: 5 year copper price trend | 77 |

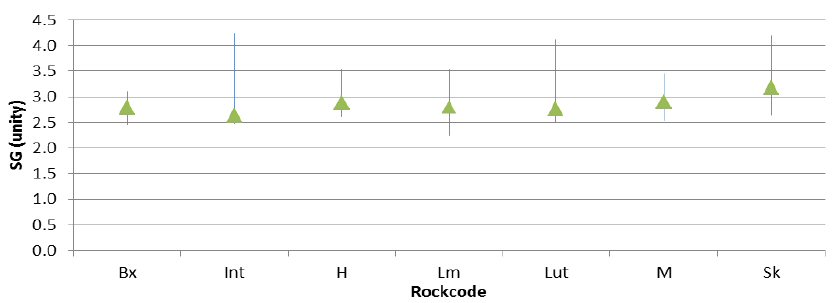

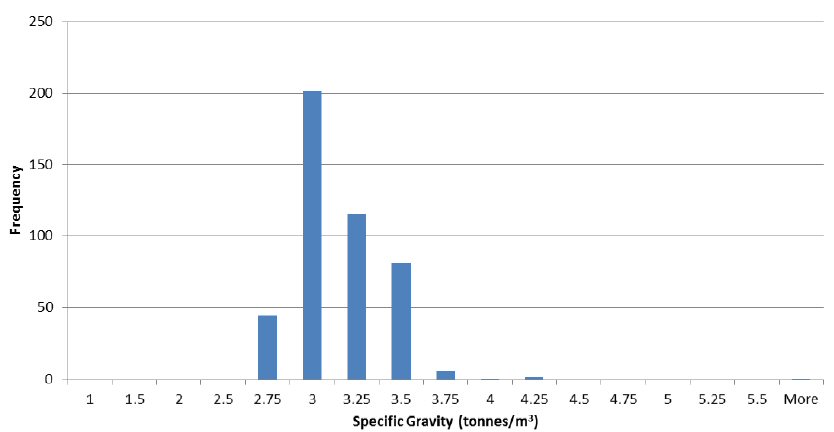

| Figure 32: Distribution of specific gravity by rockcode. (n=1279) | 78 |

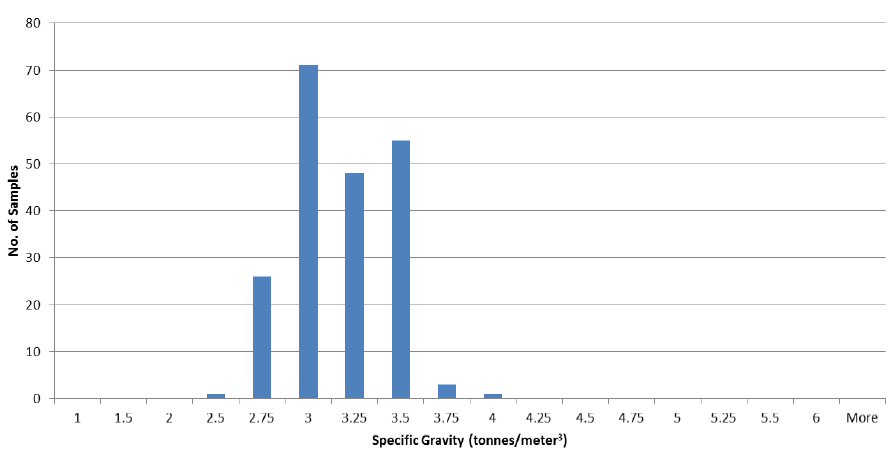

| Figure 33: Specific gravity distribution by solid; Manto | 78 |

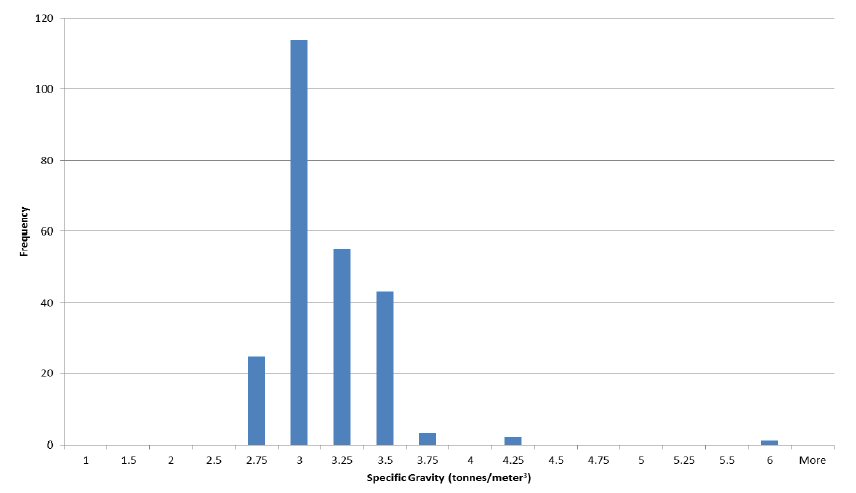

| Figure 34: Specific gravity distribution by solid: Contact Skarn | 79 |

| Figure 35: Specific gravity distribution by solid: Structure | 79 |

| Figure 36: 3D screen shot of GEMS MMT geological model | 82 |

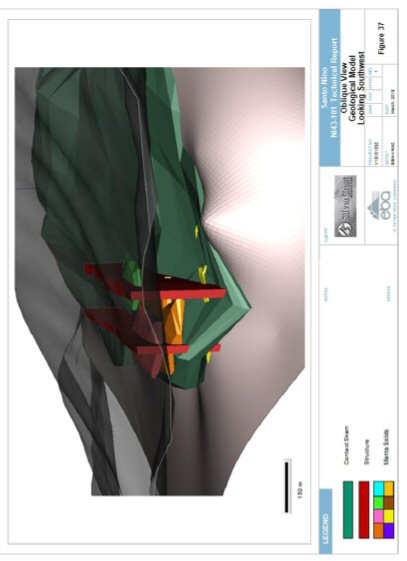

| Figure 37: 3D screen shot of GEMS Santo Nino geological model | 83 |

| Figure 38: 3D screen shot of GEMS Coloradito geological model | 84 |

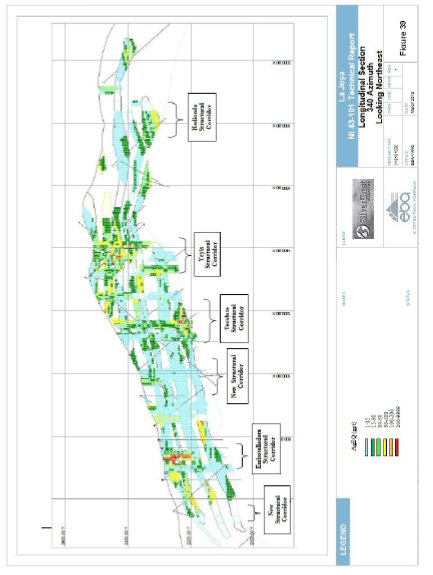

| Figure 39: Vertical cross section view of La Joya block model and mineralized solids | 85 |

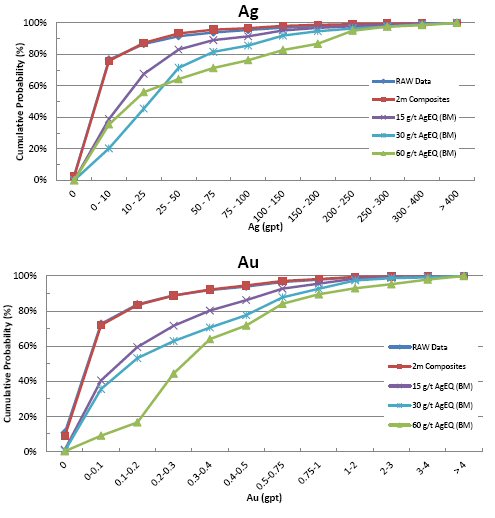

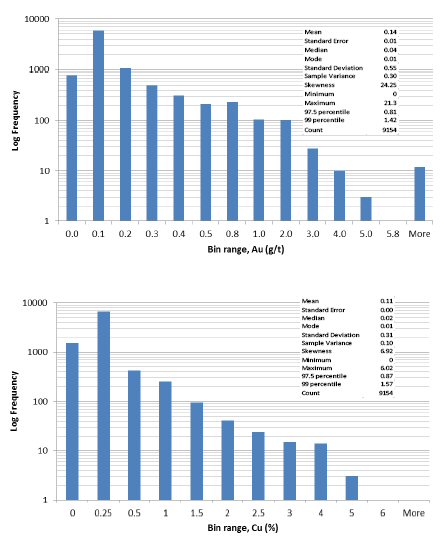

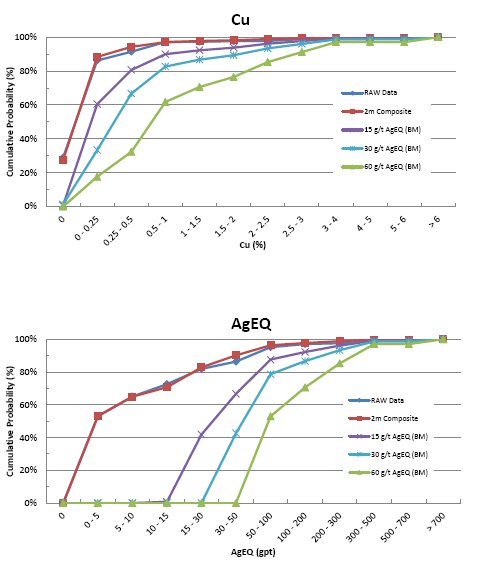

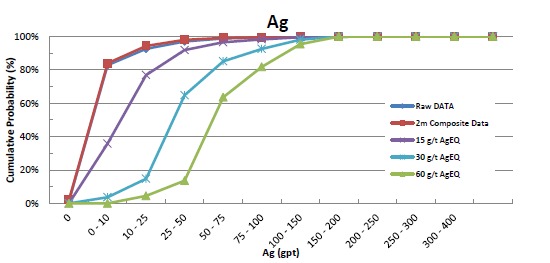

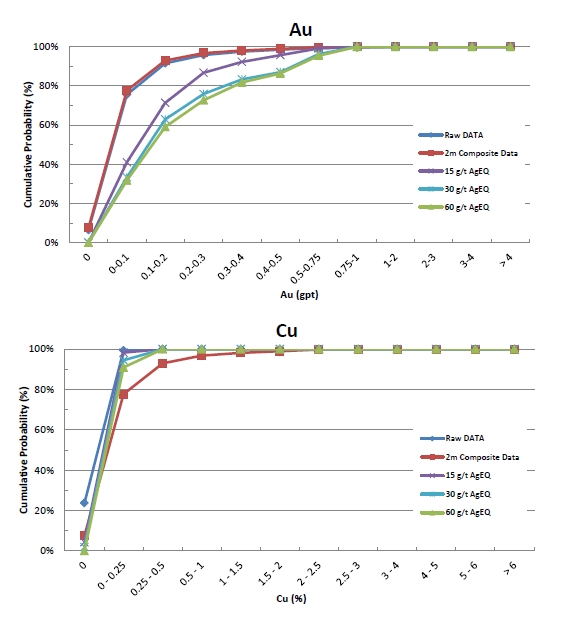

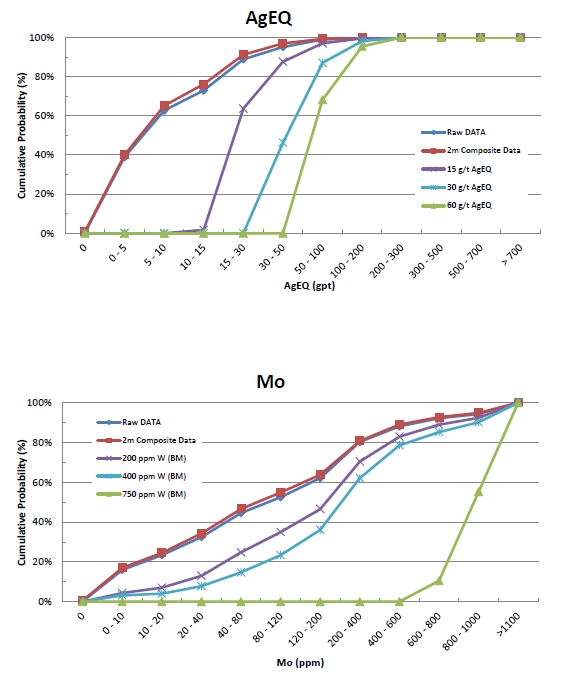

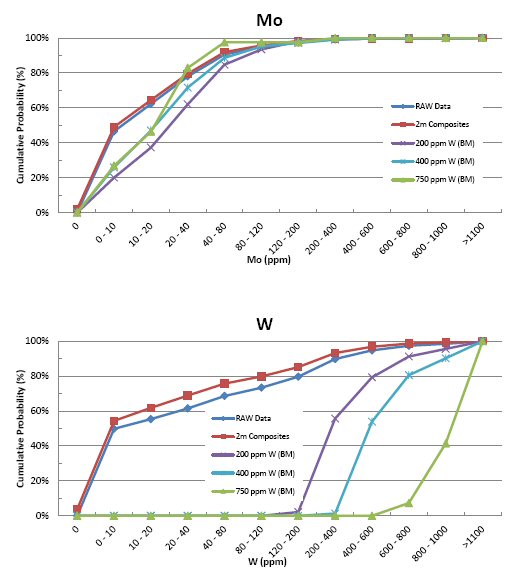

| Figure 40: MMT cumulative probability plots for silver, gold, copper, AgEQ, molybdenum and tungsten | 95 |

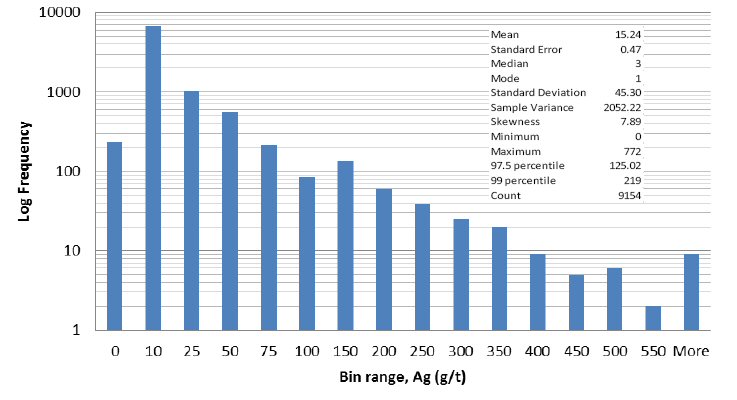

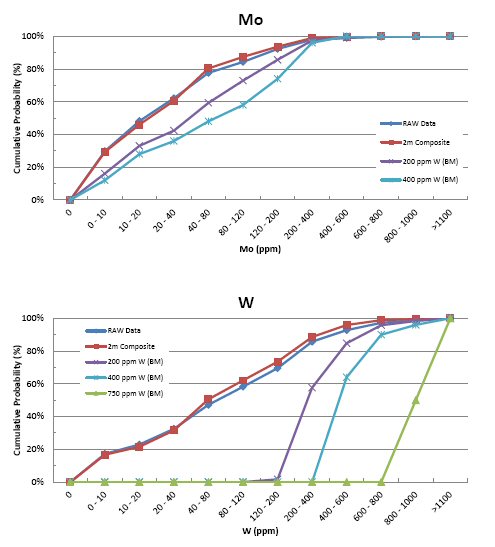

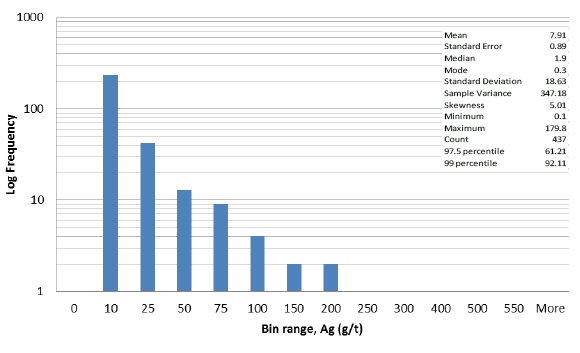

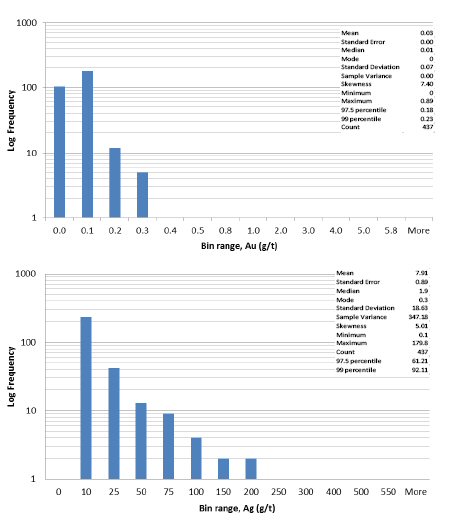

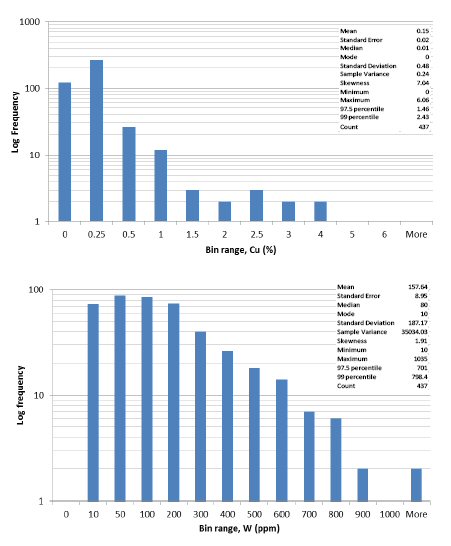

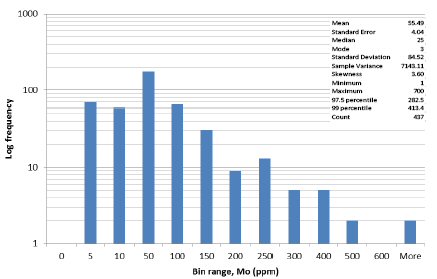

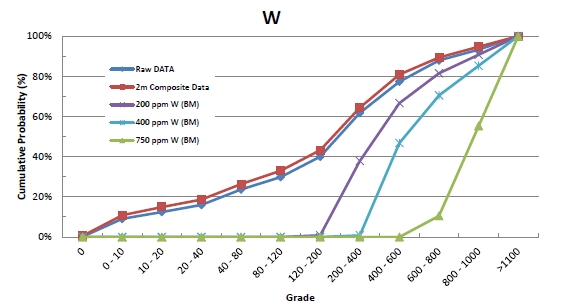

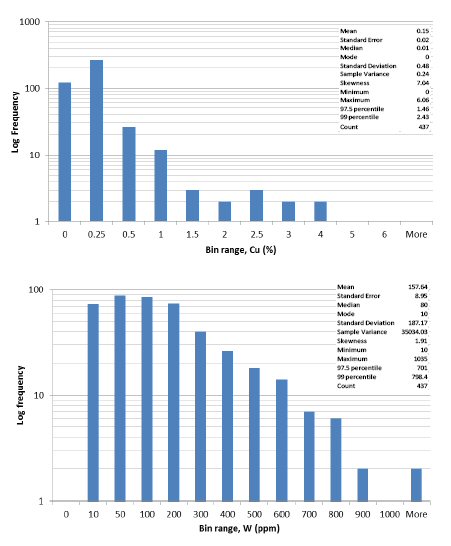

| Figure 41: MMT histogram distributions of 2 metre composite data | 98 |

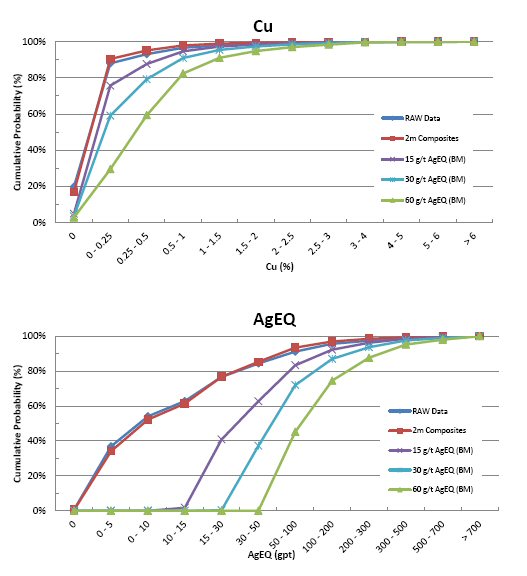

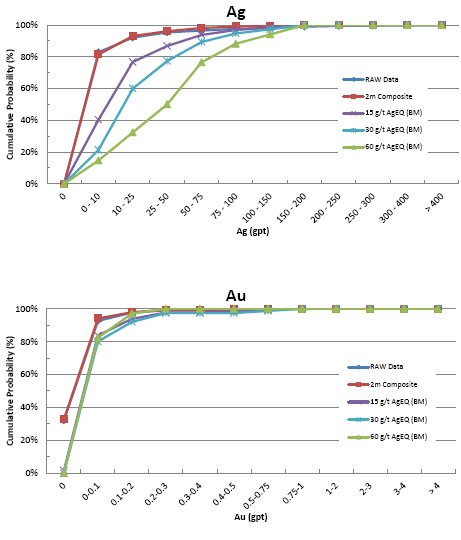

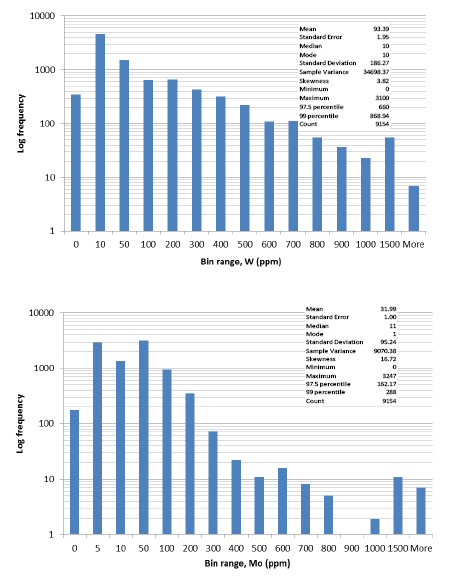

| Figure 42: Santo Nino cumulative probability plots for silver, gold, copper, AgEQ, molybdenum and tungsten | 109 |

vi

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

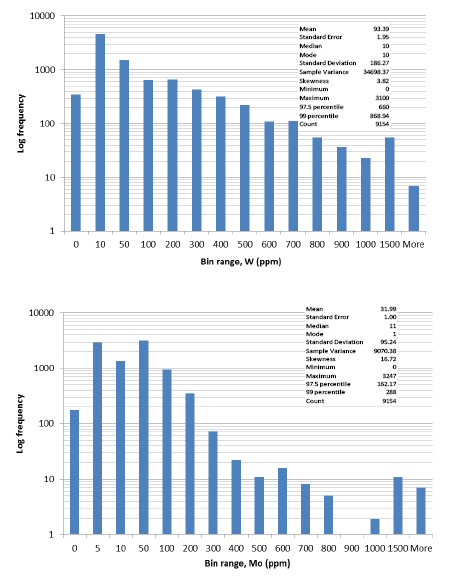

| Figure 43: Santo Nino histogram for distributions of 2 metre composite data | 112 |

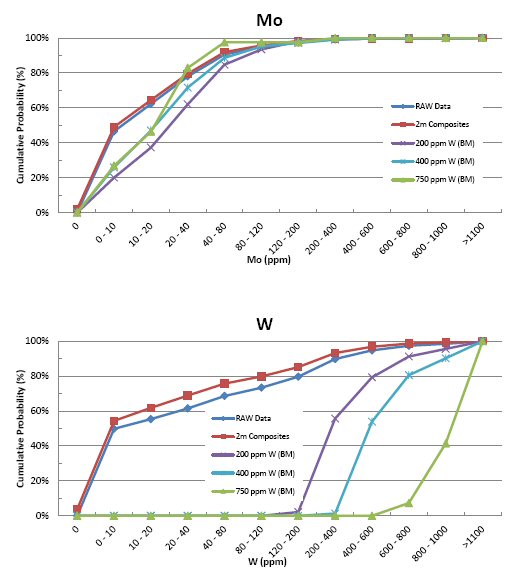

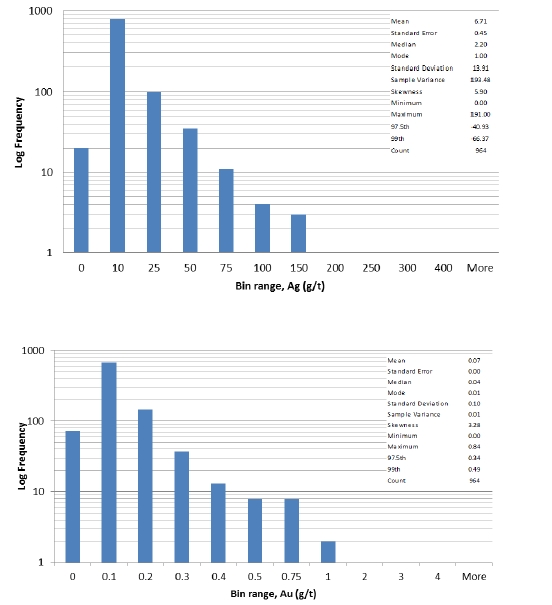

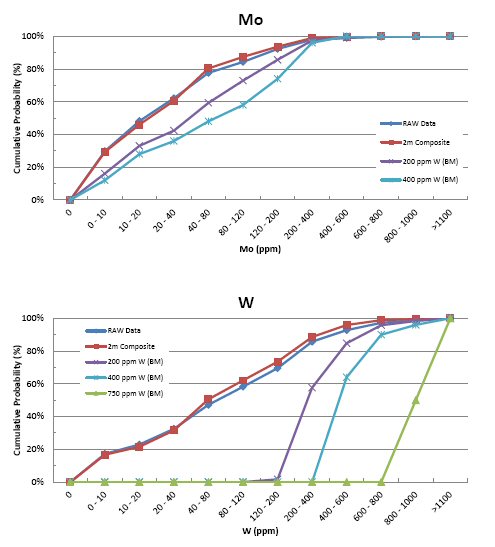

| Figure 44: Coloradito cumulative probability plots for silver, gold, copper, AgEQ, Molybdenum and Tungsten | 119 |

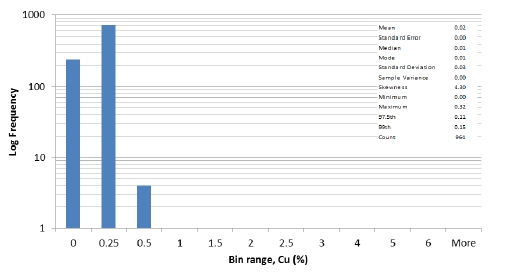

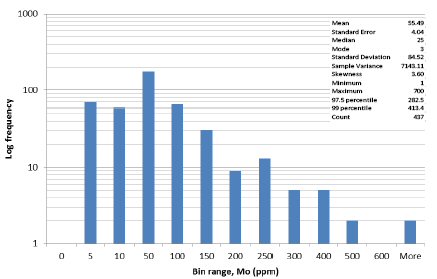

| Figure 45: Coloradito histogram distributions of 2 metre composite data | 123 |

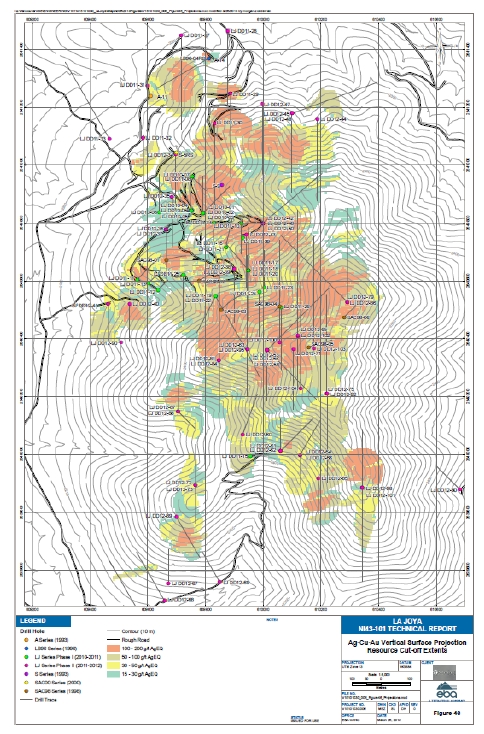

| Figure 46: Resource contours of 15, 30, 50, 100 and 200 gpt AgEQ cut-offs for MMT | 130 |

| Figure 47: Comparison of >30 gpt AgEQ from NN, IDW2 and IDW5methods of easting corridor through the La Joya MMT model | 132 |

| Figure 48: Comparison of >30 gpt AgEQ from NN, IDW2 and IDW5 methods of northing corridors through the La Joya MMT model | 132 |

| |

| PHOTOGRAPHS | |

| | |

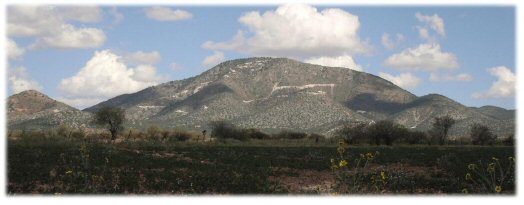

| Photo 1: | Physiography of La Joya region | 19 |

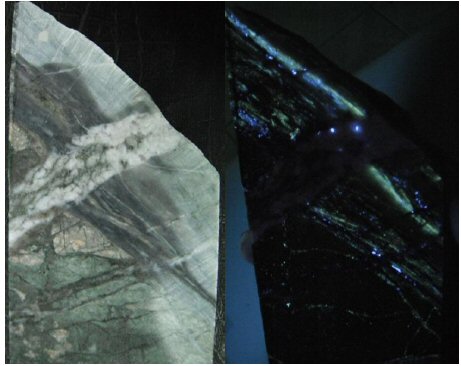

| Photo 2: | Close-up of Scheelite mineraliization in contact skarn in natural and UV light | 44 |

| Photo 3: | Verification sample of SilverCrest drill core, LJ DD12-74 # 90037 | 48 |

Appendix A Qualified Person Certificates of Qualifications

Appendix B Certified Reference Standard Data Sheets

Appendix C Metallurgical Investigation, Summary Reports

vii

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| AAS | Atomic absorption spectrometry |

| Ag | Silver |

| AgEQ | Silver Equivalent |

| Au | Gold |

| BC | British Columbia |

| CIM | Canadian Institute for Mining, Metallurgy and Petroleum |

| CRM | Certified reference material |

| DDH | Diamond Drill Hole |

| DTM | Digital terrain model |

| EBA | EBA Engineering Consultants Ltd. operating as EBA, A Tetra Tech Company |

| EM | Electromagnetic |

| FA | Fire Assay |

ID2 | Inverse Distance Squared |

| INEGI | Instituto Nacional de Geografía y Estadística de México |

| IP | Induced Polarization |

| JV | Joint Venture |

| Luismin | Minas SanLuis |

| Mo | Molybdenum |

| MMT | Main Mineralized Trend |

| NI43-101 | National Instrument 43-101 Standards of Disclosure for Mineral Projects |

| NSR | Net Smelter Returns |

| Olvera | Señior Sergio Gabriel Olvera Alevedo and Family |

| P.Eng | Professional Engineer |

| P.Geo | Professional Geologist |

| Pb | Lead |

| PEA | Preliminary economic assessment |

| pop. | Population |

| QA/QC | Quality Assurance and Quality Control |

| QP | Qualified Person |

| RC | Reverse Circulation |

| REE | Rare Earth Elements |

| RQD | Rock Quality Designation |

| S.A. de C.V. | Sociedad Anónima de Capital Variable |

| SCdM | SilverCrest de Mexico S.A. de C.V. |

| SCSV | Structurally controlled stockwork and veins |

| SEM | Scanning Electron Microscopy |

| SEMARNAT | Secretaria de Medio Ambiente y Recursos Naturales |

| SilverCrest | SilverCrest Mines Inc. |

| STFZ | San Luis-Tepehuanes Fault System |

| TDL | Total Drilled Length |

| UTM | Universal Transverse Mercator |

viii

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| Vargas | Señior Pedro Vargas | |

| W | Tungsten | |

WO3 | Tungsten trioxide | |

| WEI | Wardrop, A Tetra Tech Company |

| XRD | X-ray diffraction analysis | |

| Zn | Zinc | |

| | | |

| UNITS OF MEASUREMENT AND CONVERSION |

| |

| $USD | United States Dollar | |

| % | Percent | |

| °C | Degree Celcius | |

| gpt | Grams per tonne | |

| ha | Hectare (10,000 square meters) | |

| km | Kilometer | |

| M | Million | |

| m | Metre | |

| Ma | Million Years | |

| mm | Millimetre | |

| MxnPeso$ | Mexican Pesos | |

| oz | Ounce (troy) | |

| ppb | Part per billion | |

| ppm | Parts per million | |

| sec | Second | |

|

ix

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

EBA Engineering Consultants Ltd. operating as EBA, A Tetra Tech Company (EBA), has prepared this Technical Report for SilverCrest Mines Inc. (SilverCrest) of Vancouver for the La Joya property, located in south-eastern portion of the state of Durango, Mexico, bordering with the state of Zacatecas. SilverCrest de Mexico S.A. de C.V. a 100% owned Mexican subsidiary of SilverCrest (SilverCrest for the purposes of this report) is the holder of the rights to the La Joya property and a legal operating entity of SilverCrest.

This report has been prepared by EBA and is co-authored by James Barr, P.Geo, consultant with EBA, a Tetra Tech Company and Ting Lu, P.Eng, consultant of Tetra Tech (Wardrop Engineering, WEI). Information contained in this report has been derived from work carried out by SilverCrest, historic documentation on the property, field observations and discussions with SilverCrest personnel.

The purpose of this report is to document the current La Joya property holdings, update the mineral resource estimate for the Main Mineralized Trend (MMT), and to support an initial estimate of Mineral Resources for Santo Nino and Coloradito based on information available to EBA from the Phase I and II exploration campaigns. This Technical Report conforms to National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) and incorporates the Canadian Institute for Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves (CIM Definition Standards).

Inferred2 silver, copper and gold Mineral Resources are reported at a 30 gpt AgEQ1 cut-off for the Manto and Structure within MMT and Santo Nino deposits in Table 1, below. Block model sensitivities using 15 gpt AgEQ1and 60 gpt AgEQ1 are included. Inferred4 tungsten and molybdenum Mineral Resources are reported at a 0.05% WO3 cut-off for the Contact Zone within the MMT, Santo Nino and Coloradito deposits in Table 2, below. Block model sensitivities using 0.025% WO3 and 0.095% WO3 are included. All reported tonnages for Manto and Structure mineralization are exclusive of tonnages reported for Contact Zone mineralization.

1

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

| | |

| | |

| Table 1: Inferred Ag-Cu-Au-W-Mo Resource Estimation for the MMT and Santo Nino Deposits, Effective Date December 16, 2012 | |

| | |

| | |

| | | | AgEQ Cut | | | Rounded | | | | | | Ag | | | Au | | | Cu | | | Contained | | | Contained | | | Contained | | | Contained | |

| Zone | Category2 | | off (gpt) 1 | | | Tonnes | | | SG | | | (gpt) | | | (gpt) | | | (%) | | | Ag (oz) | | | Au (oz) | | | Cu (lbs) | | | AgEQ (oz) 1 | |

| | |

| | | | | 15 | | | | 120,570,000 | | | | 3.00 | | | | 23.7 | | | | 0.18 | | | | 0.18 | | | | 91,855,000 | | | | 708,000 | | | | 466,474,000 | | | | 185,757,000 | |

MMT 3 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| (Ag, Au, | Inferred | | | 30 | | | | 67,618,000 | | | | 3.00 | | | | 34.6 | | | | 0.24 | | | | 0.25 | | | | 75,367,000 | | | | 519,000 | | | | 377,392,000 | | | | 148,671,000 | |

| Cu) | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | 60 | | | | 26,109,000 | | | | 3.00 | | | | 58.5 | | | | 0.3 | | | | 0.42 | | | | 49,129,000 | | | | 256,000 | | | | 240,114,000 | | | | 92,035,000 | |

| Santo | | | | 15 | | | | 6,169,000 | | | | 3.00 | | | | 20.3 | | | | 0.04 | | | | 0.49 | | | | 4,039,000 | | | | 8,000 | | | | 66,775,000 | | | | 12,826,000 | |

Nino 3 | Inferred | | | 30 | | | | 3,586,000 | | | | 3.00 | | | | 29.1 | | | | 0.05 | | | | 0.75 | | | | 3,363,000 | | | | 5,000 | | | | 59,384,000 | | | | 11,079,000 | |

| (Ag, Au, | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Cu) | | | | 60 | | | | 1,818,000 | | | | 3.00 | | | | 43.0 | | | | 0.05 | | | | 1.2 | | | | 2,517,000 | | | | 3,000 | | | | 48,269,000 | | | | 872,000 | |

| | |

| | | | | 15 | | | | 126,739,000 | | | | | | | | 23.5 | | | | 0.17 | | | | 0.20 | | | | 95,894,000 | | | | 716,000 | | | | 533,249,000 | | | | 198,583,000 | |

| TOTAL | Inferred | | | 30 | | | | 71,204,000 | | | | | | | | 34.4 | | | | 0.23 | | | | 0.28 | | | | 78,730,000 | | | | 524,000 | | | | 436,776,000 | | | | 159,750,000 | |

| | | | | 60 | | | | 27,927,000 | | | | | | | | 57.5 | | | | 0.28 | | | | 0.47 | | | | 51,646,000 | | | | 259,000 | | | | 288,383,000 | | | | 92,907,000 | |

| 1. | Silver equivalency includes silver, gold and copper and excludes lead, zinc, molybdenum and tungsten values. Ag:Au is 50:1, Ag:Cu is 86:1, based on 5 year historic metal price trends of US$24/oz silver, US$1200/oz gold, US$3/lb copper. 100% metallurgical recovery is assumed. |

| 2. | Classified by EBA, A Tetra Tech Company and conforms to NI 43-101 and CIM definitions for resources. All numbers are rounded. Inferred Resources have been estimated from geological evidence and limited sampling and must be treated with a lower level of confidence than Measured and Indicated Resources. The reported Mineral Resource for each zone is based on the 30 gpt AgEQ cut-off and is highlighted in light blue. |

| 3. | Mineralization boundaries used in the interpretation of the geological model and resource estimate are based on a cut-off of 15 gpt AgEQ using the metal price ratios described above. Manto and Structure Resource blocks, and their associated volumes, are exclusive of Contact Zone blocks. |

Table 2: Inferred W-Mo Resource Estimation for the MMT, Santo Nino and Coloradito Deposits, Effective Date December 16, 2012

| Zone | Category 4 | | W03cut- | | | Rounded | | | SG | | | Mo (%) | | | WO3 (%) | | | Contained | | | Contained | |

| | | | off (%) | | | Tonnes | | | | | | | | | | | | W03(lbs) | | | Mo (lbs) | |

| | |

| | | | | 0.025 | | | | 60,508,000 | | | | 3.00 | | | | 0.0035 | | | | 0.053 | | | | 70,526,000 | | | | 4,232,000 | |

MMT 5 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Contact Zone | Inferred | | | 0.05 | | | | 25,136,000 | | | | 3.00 | | | | 0.0039 | | | | 0.075 | | | | 41,438,000 | | | | 1,942,000 | |

| (W, Mo, Ag, Au, | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Cu) | | | | 0.095 | | | | 4,395,000 | | | | 3.00 | | | | 0.0023 | | | | 0.109 | | | | 10,587,000 | | | | 205,000 | |

| Santo Nino | | | | 0.025 | | | | 5,220,000 | | | | 3.00 | | | | 0.0077 | | | | 0.040 | | | | 4,591,000 | | | | 806,000 | |

Contact Zone 5 | Inferred | | | 0.050 | | | | 950,000 | | | | 3.00 | | | | 0.0132 | | | | 0.070 | | | | 1,456,000 | | | | 250,000 | |

| (W, Mo, Ag, Au, | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Cu) | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | 0.095 | | | | 750 | | | | 3.00 | | | | 0.0115 | | | | 0.101 | | | | 2,000 | | | | 172 | |

| Coloradito | | | | 0.025 | | | | 31,907,000 | | | | 3.00 | | | | 0.0283 | | | | 0.062 | | | | 43,302,000 | | | | 18,045,000 | |

Contact Zone 5 | Inferred | | | 0.050 | | | | 18,486,000 | | | | 3.00 | | | | 0.0322 | | | | 0.079 | | | | 32,252,000 | | | | 11,921,000 | |

| (W, Mo, Ag, Au, | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Cu) | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | 0.095 | | | | 4,159,000 | | | | 3.00 | | | | 0.0335 | | | | 0.112 | | | | 10,282,000 | | | | 2,784,000 | |

| | |

| | | | | 0.025 | | | | 97,635,000 | | | | | | | | 0.0118 | | | | 0.055 | | | | 118,419,000 | | | | 23,083,000 | |

| TOTAL | Inferred | | | 0.050 | | | | 44,573,000 | | | | | | | | 0.0158 | | | | 0.076 | | | | 75,147,000 | | | | 14,113,000 | |

| | | | | 0.095 | | | | 4,159,184 | | | | | | | | 0.0175 | | | | 0.111 | | | | 20,871,000 | | | | 2,989,000 | |

| 4. | Classified by EBA and conforms to NI 43-101 and CIM definitions for resources. All numbers are rounded. Inferred Resources have been estimated from geological evidence and limited sampling and must be treated with a lower level of confidence than Measured and Indicated Resources. The reported Mineral Resource for each zone is based on the 0.05% WO3cut-off and is highlighted in light blue. |

| 5. | Mineralization boundaries used in the interpretation of the geological model and resource estimate are based on a cut-off grade of 0.05% WO3. Contact Zone Resource blocks and associated volumes are exclusive of Manto and Structure blocks. |

2

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

The La Joya property is approximately 75 km directly southeast of the state capital city of Durango, in the State of Durango, Mexico and approximately 9 km east of the community of La Joya. The property can be accessed year round by road, commencing by a paved highway going south east from city of Durango to the city of Vincente Guerrero, a distance of approximately 80 km, then north along a paved secondary road to the community of La Joya a distance of approximately 10 km, and then by a network of farming and agricultural access dirt roads that span approximately 10 km east of the community of La Joya. There is currently no maintained infrastructure on the La Joya property. Rail and power are both located in close proximity to the property.

The property consists of 15 mineral concessions totalling 9,023 hectares. SilverCrest established option agreements with 2 local concession owners in 2010, which entitle SilverCrest to 100% ownership based on staged payments over a 36 month period followed by a lump sum payment and allocation of NSR entitlements. SilverCrest is registered as the primary holder of the remaining three mineral concessions staked in 2011. All concessions have been surveyed on the ground by a registered land surveyor at the time of location.

On January 20, 2011, SilverCrest signed an agreement with the civil co-operative for the community of La Joya for a three year lease on surface rights for a maximum of 3,935 ha with respect to exploration work.

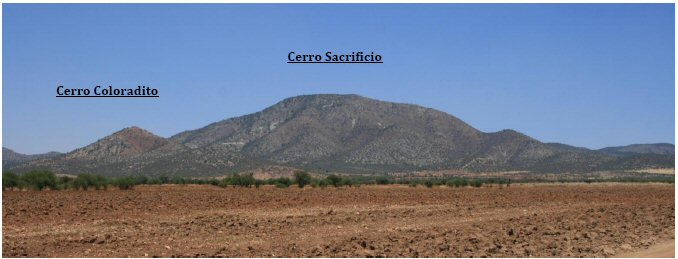

The La Joya and Santo Nino deposits lie within Cerro Sacrificio, one of two prominent topographic features on the property. The Coloradito deposit lies within Cerro Coloradito, a smaller secondary topographic feature located adjacent to the west of Cerro Sacrificio. These prominent features are the result of localized doming of sedimentary units from the emplacement of a mid-Tertiary granitic intrusion

1.2 Geology and Mineralization

The La Joya property is underlain by Cretaceous sedimentary rocks along the western margin of the Mexican Mesa Central, at the transition from the Sierra Madre Occidental, along the broadly defined San Luis-Tepehuanes fault system. The fault system is commonly referred to as the Mexican Silver Belt based on the country scale distribution of silver producing mines juxtaposed along the trend. The sedimentary package at La Joya consists of the Cuesta del Cura Limestone comprised of limestone with minor chert and siltstone, overlain by calcareous siltstone, mudstone and siliciclastic rocks of the younger Indidura Formation.

Multiple deformation events related to the Laramide orogeny during the late-Cretaceous to mid-Tertiary resulted in folding of the Cretaceous sedimentary rocks along northeast-southwest directed axes, followed by extensional basin and range style faulting generally oriented north-south throughout the mid to late Tertiary. The extension was accompanied by emplacement of intrusive stocks of various ages. These late Cretaceous and early to mid-Tertiary orogenic-related intrusions influenced both regional metamorphism as well as local metasomatic alteration within the Cretaceous sediments. The MMT of the La Joya deposit and peripheral Santo Nino is underlain by the Sacrificio quartz-feldspar phyric granite which is attributed to the mineralizing fluids responsible for skarn development and sulphide deposition within the limestone unit.

3

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

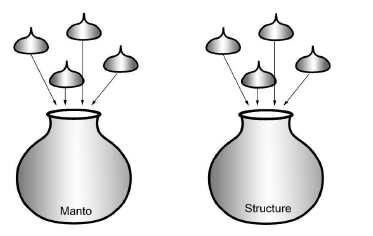

The La Joya deposits are carbonate hosted copper skarn deposits with associated silver and gold mineralization, similar in style to the Fortitude-Copper Canyon deposit in Nevada, USA, and to the adjacent Sabinas/San Martin mines in Zacatecas, Mexico. Calcsilicate skarn mineralization is found on the property as andradite garnet, pyroxene, actinolite and wollastonite and is distributed amongst three styles of mineralization recognized to exist on the property. Silver-Copper-Gold (Ag-Cu-Au) mineralization is concentrated within stratiform manto-style skarn controlled along sub-horizontal bedding. Silver-Copper- Gold, Lead-Zinc and Tungsten (Ag-Cu-Au, Pb-Zn, and W) mineralization is concentrated within structurally controlled stockwork and veining related skarn. Finally, tungsten mineralization is found within late stage retrograde skarn development along the intrusive contact. Sulphide mineralization generally transitions from chalcopyrite-dominant in proximal skarn to bornite-dominant in distal skarn. Late sub-vertical laminated quartz-calcite veins bearing freibergite and arsenopyrite cross-cut pre-existing skarn mineralization and, although related to magmatic fluids, are not considered to be related to the skarn mineralizing events. Trace amounts of oxide from meteoric weathering processes are present within the structural corridors at depth.

Bedrock is exposed on Cerro Sacrificio with few locations exhibiting minor organics as an overburden layer. Formation of caliche is a common calcium leachate overlying calcareous sediments and as an encasing matrix to alluvium fill along the lower slopes of Cerro Sacrificio outwards within the valleys. Alluvial overburden ranges in depth from 3 to 25 metre as documented in historic drilling to the north of the hill.

Cerro Coloradito occurs 1 kilometre to the west of Cerro Sacrificio and is the second prominent feature in the area. Cerro Coloradito has a surface footprint of approximately 500 x 500 metres and is centred on a Quartz Feldspar Porphyry intrusive stock with related quartz-rich breccia, possibly to the result of late stage intrusive fluids. A green garnet skarn forms a southerly located, but northerly open cuspate, mineralised zone around the intrusive. The skarn unit is hosted within the Cretaceous Indidura Formation bedded limestone and shale and most likely developed due to stock emplacement in the early to mid- Tertiary. The Coloradito deposit showing has been described as a low sulphidation style epithermal gold- silver deposit, related to mid to late Tertiary faulting, in addition to the skarn component that has anomalous tungsten +/- molybdenum. A near vertical north-south Quartz Porphyry dyke cuts the skarn and sidles the intrusive unit and is thought to be a late stage feature. Several artisanal and historic workings are located around Coloradito. It is suggested that the mineralization at Coloradito is younger than the MMT and Santo Nino.

The Santo Nino deposit is located on the eastern flank of Cerro Sacrificio. No distinct topographical features are noted for Santo Nino. The surface footprint is approximately 400 x 400 metres. A NNW-SSE near vertical lense of skarn with visible bornite and chalcopyrite mineralization was the locus of the most recent drilling program. Similarly to the MMT Silver-Copper-Gold (Ag-Cu-Au) mineralization is concentrated within stratiform manto-style skarn controlled along sub-horizontal bedding. Silver-Copper-Gold, Lead- Zinc and Tungsten (Ag-Cu-Au, Pb-Zn, and W) mineralization is concentrated within structurally controlled stockwork and veining related skarn. Finally, tungsten mineralization is found within late stage retrograde skarn development along the intrusive contact. The Contact Zone is not as thick at Santo Nino compared to the MMT. Sulphide mineralization generally transitions from chalcopyrite-dominant in proximal skarn to bornite-dominant in distal skarn. Copper mineralization is more dominant at Santo Nino compared to the MMT.

4

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

1.3 Drilling and Exploration

Evidence of historic pit and small underground mining operations within Cerro Sacrificio is seen in numerous small adits and excavations along the hillside. Today, the adits remain open and are accessible for sampling and identifying structures related to mineralization on the property. Exploitation from these small historic operations is considered to be volumetrically insignificant in respect to the current resource estimate.

Recent exploration activities began on the property in 1977 when Minas SanLuis (Luismin) entered into option agreements with local mineral concession holders and staked additional concessions. From 1977 to 1997, Luismin completed extensive drilling, mapping and geophysical surveying on the property. In total, 37 diamond and RC drill holes (9,767.34 metres) were completed across the property during this period, targeting silver-copper-gold skarn and tungsten mineralization. Between 1998 and 2001, Boliden Limited entered into a joint venture agreement with Luismin and continued to drill 15 more diamond drill holes (4,095.41 metres) targeting skarn and epithermal mineralization. Luismin did not complete the terms of the option agreement and withdrew from their interest in 2001. Mineral concessions staked by Luismin (Goldcorp) that are adjacent to the SilverCrest concessions were maintained and are now held by Goldcorp through acquisition of the Luismin assets.

In 2006, Solid Resources Ltd. completed four diamond drill holes (1,856.34 metres) to test for deep seated copper-molybdenum porphyry style mineralization in the center of the Sacrificio intrusion. Solid Resources did not consider the results to indicate significant evidence for a porphyry style deposit at that time.

SilverCrest commenced exploration on the property in June of 2010 at which time property scale mapping and chip sampling established targets for the Phase I drilling campaign. A total of 27 diamond drill holes (totalling 5,753.7 metres) were completed during the campaign between October, 2010, and July, 2011. The Phase I drill holes have been logged, sampled and analyzed a total of 2,303 core samples.

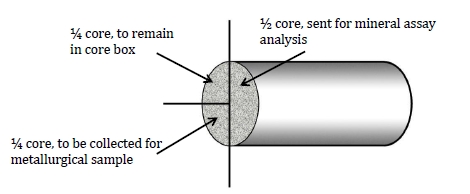

Independent validation of the SilverCrest and historic sampling was completed by EBA QP, James Barr, over 3 site visits between November 2010 and October 2011. Eight historic drill holes (2,574.35 metres) were validated in addition to the 27 SilverCrest holes (5,753.7 metres) and 177 SilverCrest surface samples, totalling 3,764 validated assay samples, for inclusion into the Phase I mineral resource estimate.

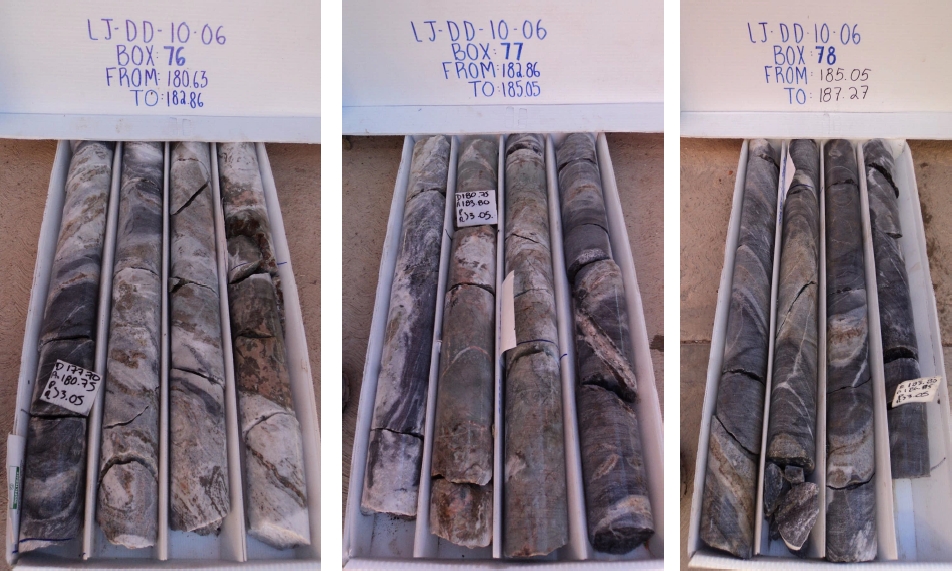

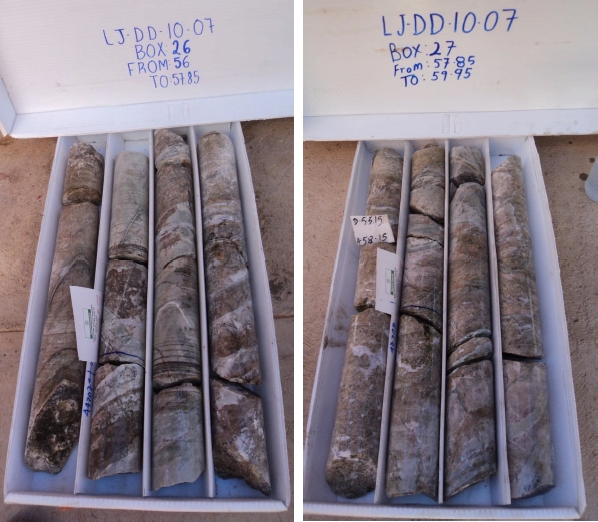

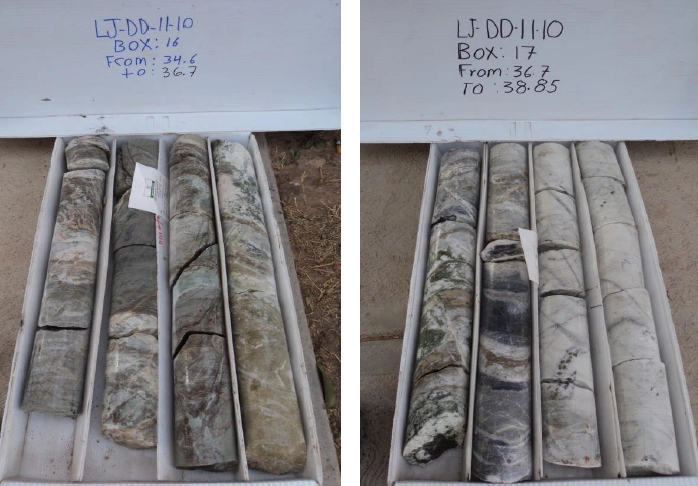

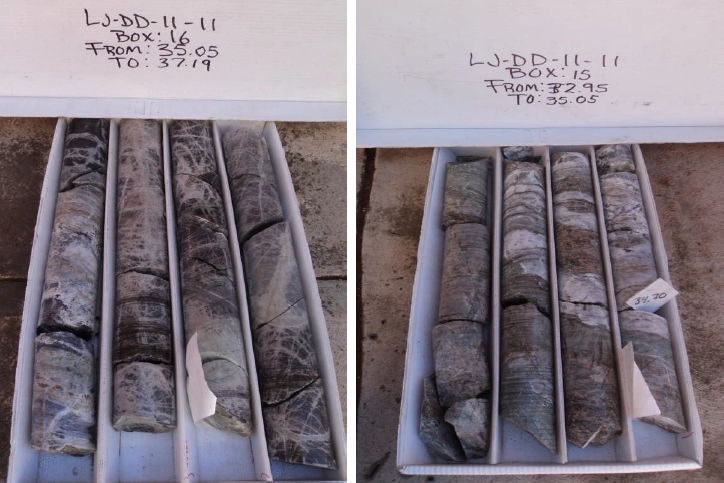

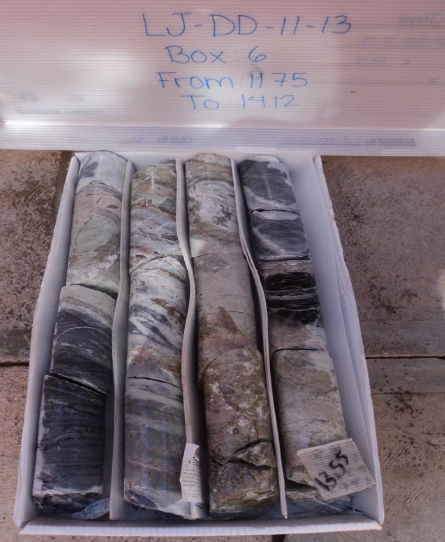

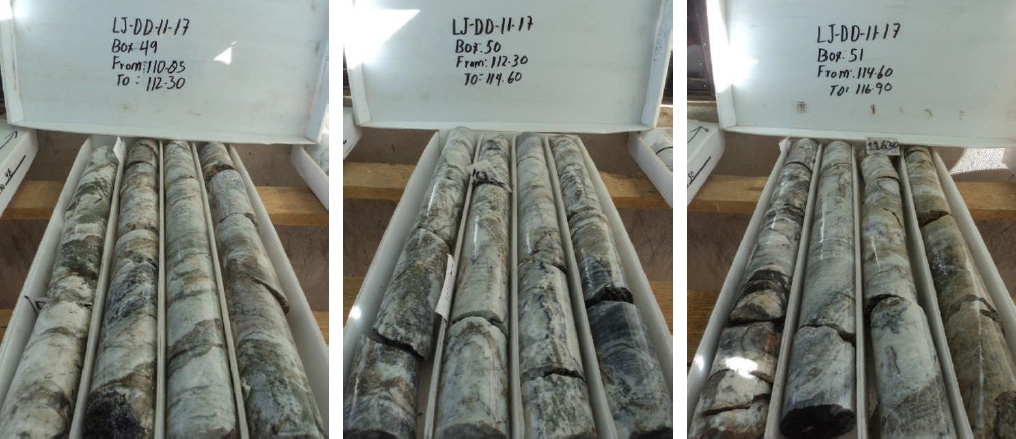

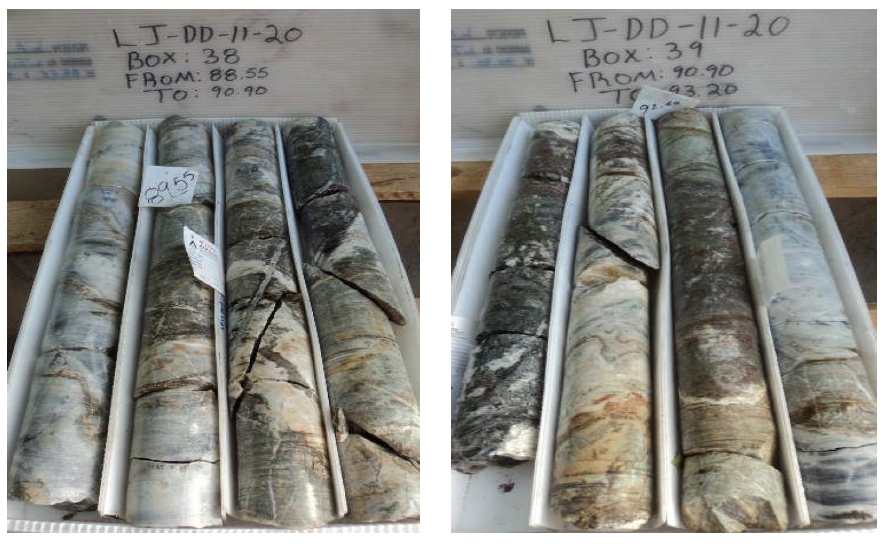

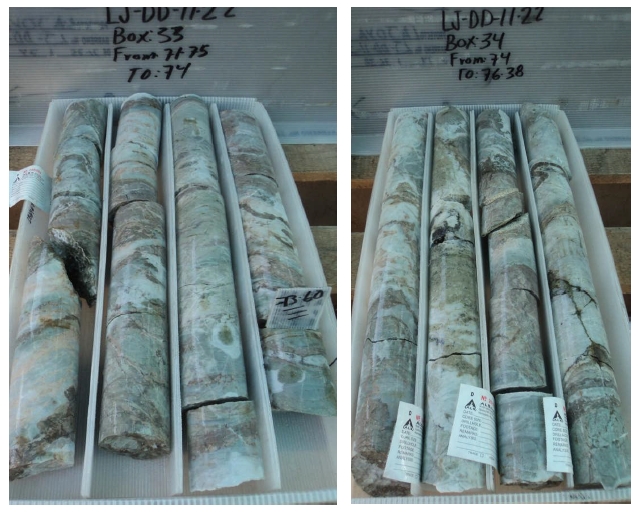

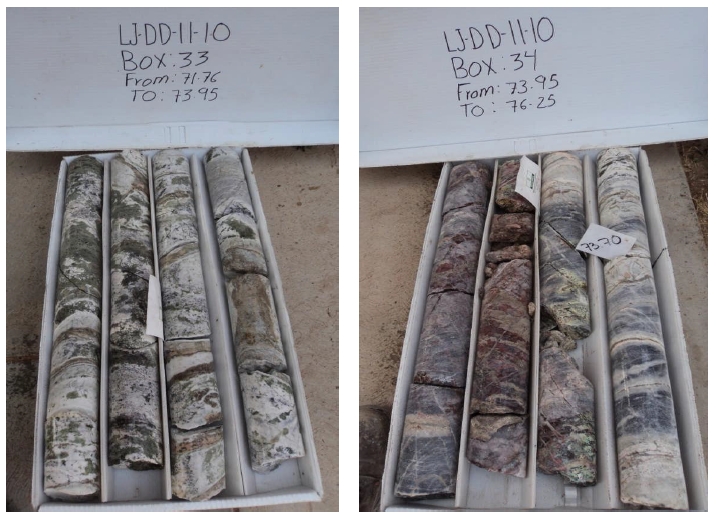

Phase II independent validation of the SilverCrest and historic sampling was completed by EBA QP, James Barr over an additional 3 site visits between November 2011 to November 2012. Phase II drilling consisted of 78 SilverCrest holes (25,812.65 metres) and 542 surface samples (not used in the resource). This program consisted of infill drilling of the Phase I resource area and drilling to extended mineralization in all directions of the MMT.

1.4 Mineral Processing and Metallurgical Testing

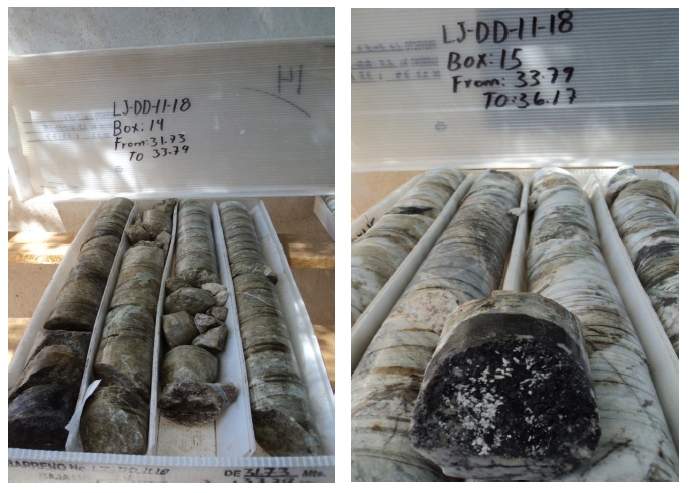

The initial metallurgical test work completed in 2011 suggested that the MMT may be amenable to conventional flotation processes with production of copper concentrates with gold and silver credits. Subsequent metallurgical test work in 2012 and 2103 at ALS Metallurgy in Kamloops, BC, Canada support the initial testwork from 2011. The ALS test work was still in progress during the preparation of this report; however the current available test results are reported herein that covers from head assay, mineralogy, harness testing, gravity, batch rougher and flotation, to batch cleaner flotation tests.

5

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Preliminary metal recoveries for near-surface (priority) Manto and Structure zones range from 81.4 to 87.7% Cu, 74.9 to 84.3% Ag, and 18.2 to 56.6% Au depending on mineralization style and testwork conditions. High copper grade bulk concentrates (the 3rd cleaner Cu/Ag/Au concentrate, >30% Cu) were obtained from batch flotation tests after adding cyanide at cleaner stages as compared with baseline test results (Table 3 and Table 4). Specifically, Manto bulk concentrate grades up to 40% Cu, 4,780 gpt Ag, and 13.1 gpt Au and Structure concentrate has approximately 38% Cu, 4,760 gpt Ag, and 9.37 gpt Au. The high grade copper results in the concentrates reflect the bornite-rich nature of the MMT mineralization. The concentrate produced from Contact Zone composite sample grades at 28.9% Cu.

Recoveries of molybdenum and tungsten from Contact zone composite were considered in the ALS test work. The molybdenum level in the 3rd cleaner concentrate ranges from 2 to 3% at a recovery from 51.4 to 65.4%. That suggests a separate molybdenum concentrate may be produced. The assessment of tungsten recoveries by gravity methods produced marginal recoveries of 7% W. Further tests on tungsten and molybdenum are recommended for next phase.

Table 3: Batch Cleaner Flotation Test Results- Baseline

| | | | | | Head | | | | | | | | | | | | | | | 3rd Cleaner Concentrate | | | | | | | | | | |

| Composite | | | | | Assay (%, gpt) | | | | | | | | | | | | Assay (%, gpt) | | | | | | | | | Recovery (%) | | | | |

| | | Cu | | | Ag | | | Au | | | AgEQ* | | | Mo | | | Cu | | | Ag | | | Au | | | AgEQ* | | | Mo | | | Cu | | | Ag | | | Au | | | Mo | |

| Manto | | | 0.34 | | | | 45 | | | | 0.15 | | | | 81.74 | | | | 0.004 | | | | 36.3 | | | | 4,700 | | | | 3.40 | | | | 7991.8 | | | | 0.27 | | | | 86.7 | | | | 84.3 | | | | 18.2 | | | | 59.6 | |

| Structure | | | 0.46 | | | | 58 | | | | 0.25 | | | | 110.06 | | | | 0.003 | | | | 34.3 | | | | 3,980 | | | | 9.45 | | | | 7402.3 | | | | 0.17 | | | | 82.7 | | | | 76.7 | | | | 42.4 | | | | 59.7 | |

| Contact** | | | 0.07 | | | | 4 | | | | 0.10 | | | | 15.02 | | | | 0.011 | | | | 16.7 | | | | 670 | | | | 17.40 | | | | 2976.2 | | | | 2.02 | | | | 83.6 | | | | 63.7 | | | | 66.4 | | | | 65.4 | |

Note: all the metal grades are based on weighted average values

| · | Silver equivalency includes silver, gold and copper and excludes lead, zinc, molybdenum and tungsten values. Ag:Au is 50:1, Ag:Cu is 86:1, based on 5 year historic metal price trends of US$24/oz silver, US$1200/oz gold, US$3/lb copper. 100% metallurgical recovery is assumed until testwork is finalized |

| · | Contact composite was collected to target tungsten and molybdenum recoveries |

Table 4: Batch Cleaner Flotation Test Results- with Cyanide

| | | Head | | | | | 3rd Cleaner Concentrate | | | |

| Composite | | Assay (%, gpt) | | | Assay (%, gpt) | | | Recovery (%) | |

| | Cu | Ag | Au | AgEQ* | Mo | Cu | Ag | Au | AgEQ* | Mo | Cu | Ag | Au | Mo |

| Manto | 0.34 | 44 | 0.17 | 81.74 | 0.004 | 40.1 | 4,780 | 13.1 | 8883.6 | 0.26 | 87.7 | 80.7 | 56.6 | 48 |

| Structure | 0.44 | 60 | 0.25 | 110.34 | 0.003 | 38.1 | 4,760 | 9.37 | 8505.1 | 0.18 | 81.4 | 74.9 | 35 | 53.1 |

| Contact** | 0.07 | 4 | 0.07 | 13.52 | 0.012 | 28.9 | 818 | 18.8 | 4243.4 | 3.05 | 81.4 | 45.9 | 57 | 51.4 |

Note: all the metal grades are based on weighted average values

| · | Silver equivalency includes silver, gold and copper and excludes lead, zinc, molybdenum and tungsten values. Ag:Au is 50:1, Ag:Cu is 86:1, based on 5 year historic metal price trends of US$24/oz silver, US$1200/oz gold, US$3/lb copper. 100% metallurgical recovery is assumed until testwork is finalized. |

| · | Contact composite was collected to target tungsten and molybdenum recoveries |

The bulk copper concentrates produced from Manto and Structure composites have indicated the presences of penalty elements such as of As, Sb and Bi. Adding cyanide at cleaner flotation stages can reduce the arsenic content to the market limits without sacrificing copper, silver and gold.. The Contact bulk flotation concentrate has much lower concentrations of As, Sb, and Bi that may be accepted by the market.

6

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Gold appears to be amenable to gravity as shown in test work on the Contact Zone with a 24% Au recovery. Further testwork is recommended for possible additional increase in gold recovery. Tungsten and tin recoveries from gravity separation appear low.

Continued metallurgical testwork should specifically investigate the nature and distribution of gold speciation and distribution. Further work should include investigation on tungsten deportment in Contact Zone samples, and to conduct gravity tests on both Manto and Structure samples to evaluate potential gold and tin recoveries. It is also recommended to conduct amenability flotation tests on the blended composites, and to carry out variability flotation tests on representative samples from the north and south areas of the MMT. Furthermore, test work on leaching of cleaner tails is recommended for possible increase in Au an Ag recoveries.

1.5 Mineral Resource Estimation

A mineral resource estimate for the La Joya deposit has been prepared by EBA in accordance with National Instrument 43-101 Standards of Disclosure and has incorporated terms as defined by the Canadian Institute of Mining, Metallurgy and Petroleum Standards on Mineral Resources and Reserves: Definitions and Guidelines.

The estimate is based on Phase I verified sampling from 27 recent SilverCrest drill holes and eight validated historic Luismin holes (totalling 8,328.05 metres), for a grand total of 3,764 assayed samples, collected between 1998 and 2011. Phase II drilling incorporated an additional 78 drill holes (25,812.65 metres) and a further 10 historic validated partial drill holes bringing the total historic drill holes to 5,907.26 metres. For Phase II, three areas were focused on for resource estimation in three geographically distinct but adjoining areas of MMT, Santo Nino, and Coloradito. The analytical data were used as the basis for geological interpretation and construction of mineralized solids created as triangulations using Gemcom GEMS software (GEMS). The analytical data was interpolated into a percent block model using the inverse distance squared (ID2) interpolation method and was constrained by mineralized solids segmented into three sets determined by mineralization style.

The MMT and Santo Nino deposits are considered to be a polymetallic Ag-Cu-Au-W-Mo deposits with metal distributions for W-Mo as part of, or immediately adjacent to, the Ag-Cu-Au resources. Ag-Cu-Au data is reported as a silver equivalent value (AgEQ) which is based on per tonne value of the metals using five-year historical price trends summarized in Table 5. AgEQ is calculated as Ag(gpt)+50*Au(gpt)+86*Cu(%). Three individual mineral resource estimates are presented below for Ag-Cu-Au concentrations, Pb-Zn concentrations and W concentrations, respectively. Molybdenum concentrations have not been considered as part of this resource estimation.

7

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Table 5: 5-Year Metal Price Trends and AgEQ Calculation for Silver, Copper and Gold

| Metal | 5-year Trend Metal Price | Price/tonne ratio to Ag |

| Ag | $24/oz (troy) | 1:1 |

| Cu | $3/lb ($6,615/t) | 86:1 |

| Au | $1,200/oz(troy) | 50:1 |

| |

| AgEQ | =Ag(gpt) + 86*Cu% + 50*Au(gpt) |

Analytical data from drill sampling on the property that was considered valid for resource estimation was composited to two metre lengths before the interpretation and construction of the mineralized wireframes. These composites were used as the explicit analytical data for the resource estimate. A value of 15 gpt AgEQ was used as an initial grade threshold for cross-sectional interpretation of mineralized wireframes defining continuous mineralization on the property. Three sets of mineralized solids were constructed using GEMS from these wireframes representing Manto, Structurally controlled stockwork and veining, or Contact Zone- skarn styles of mineralization. Twenty-nine (MMT) six (Santo Nino) and two (Coloradito) mineralized solids were used to reduce the two metre composite data set and to constrain interpolation within the block model. Block model interpolation methods were designed to control grade distribution within each mineralization style.

Anomalous high grade values from the two metre composite data set were capped at 550 gpt silver, 5.5 gpt Au and 6 % copper based on visual inspection of histogram and log-histogram population distribution.

A representative average value for specific gravity was determined to be 3.0 based on laboratory analysis of 1,279 drill core samples. This value was applied to all materials that were included in the Mineral Resource.

All mineral resource estimates in this report have been classified as Inferred based on the CIM Definition Standards for Mineral Resources and Mineral Reserves. Analytical data available from exploration on the property to date is sufficient to allow a reasonable geological interpretation and assumption of grade continuity, however, the geological understanding of the property is considered to be in early stages for the project.

The Resource Estimate for silver, copper, gold and silver equivalent concentrations has been reported based on a silver equivalent cut-off value as summarized in (Table 5). A value of 30gpt AgEQ was used as a minimum grade cut-off for reporting purposes.

Exploration potential on the La Joya property is considered excellent based on previous and current work. The defined area of alteration with subsequent potential mineralization is estimated at 2.5 km by 2.5 km. This area encompasses three defined targets, each has potential for extension and infill drilling;

| 1. | La Joya Main Mineralized Trend with Ag-Cu-Au-W- Mo +/- Pb-Zn mineralization; |

| 2. | Coloradito with Mo-W-Ag-Au-Cu mineralization; and, |

8

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

3. Santa Nino with Cu-Ag-Au-W-Mo mineralization.

The second phase of the exploration and delineation program conducted by SilverCrest for the La Joya property (including Santo Nino) has increased the Inferred Resource significantly.

The recommended Phase III program aims to further define the total extent of mineralization on the property, gain further understanding on the extent of mineralization and further define areas of higher grades to increase overall confidence in the established deposit. SilverCrest currently has ongoing metallurgical work scheduled to be completed in 2013. Estimated costs for this recommended program totals $3,030,000 and is outlined in Table 6.

Table 6: Recommended Phase III Work and Estimated Costs for the La Joya Property

| Phase III | | | | | | |

| | Description | Units | Cost/Unit ($CAN) | | Cost ($CAN) | |

| Work Type | | | | | | |

| | Regional mapping to the East of | | | | | |

| Geological | Cerro Sacrificio to Santo Nino and | 30 days | $1,000/day | | $ | 30,000 | |

| Mapping | beyond and to the south of Cerro | | | | | | |

| | Sacrificio | | | | | | |

| | Drilling within currently defined | | | | | | |

| | block model to increase confidence | | | | | | |

| Infill Drilling | | 10,000 metres | $200/metre | | $ | 2,000,000 | |

| | in mineral and grade distribution | | | | | | |

| | around areas of high grade | | | | | | |

| Expansion | Drilling beyond the limit of the | | | | | | |

| Drilling & | currently defined block model to | 5,000 metres | $200/metre | | $ | 1,000,000 | |

| Metallurgical | test for potential deposit expansion | | | | | | |

| Work | along established mineral trends | | | | | | |

| | | | TOTAL | | $ | 3,030,000 | |

9

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

2.0 INTRODUCTION AND TERMS OF REFERENCE

EBA Engineering Consultants Ltd. operating as EBA, A Tetra Tech Company (EBA) has prepared this Technical Report for SilverCrest Mines Inc. (SilverCrest) of on the La Joya property, located in south- eastern Durango, Mexico. SilverCrest de Mexico S.A. de C.V. (SilverCrest) is a legal operating entity for SilverCrest in Mexico.

The purpose of this report is to document the La Joya property holdings and to support an update estimate of Mineral Resources based on information available to EBA from the Phase II exploration campaign and the use of historical data for the property. This Technical Report conforms to National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) and incorporates the Canadian Institute for Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves (CIM Definition Standards).

2.1 Report Authors and EBA Quality Control

This report has been prepared by EBA and is co-authored by James Barr, P.Geo, independent consultant with EBA and Ting Lu, P.Eng, independent consultant of Tetra Tech WEI. EBA Peer Review process has been completed by Cameron Bartsch, P.Geo. Data compilation and verification, geological solid modelling and report preparation has been completed by Darryn Hitchcock of EBA.

The information, conclusions, opinions, and estimates contained herein are based on:

| · | Information available to the authors at the time of preparation of this report; |

| · | Assumptions, conditions, and qualifications as set forth in this report; and |

| · | Data, reports, and other information supplied by SilverCrest and other third party sources. |

Several site visits have been completed by James Barr to the La Joya property: November 23rd-26th, 2010, Feb 4th-6th, 2011, May 6th-7th & 13th-17th, 2011, June 19th-20th, 2011, Sept 25th-Oct 4th, 2011, May 8th, 2012, and Oct 18th, 2012. The purpose the site visits was to conduct QA/QC of drilling practices, review and conduct re-logging of drill core; and the collection of verification samples.

Ting Lu visited the site from May 14th to 17th, 2012, at which time she reviewed geological material, site layout and regional infrastructure.

3.0 RELIANCE ON OTHER EXPERTS

Ownership information has been provided by SilverCrest. SilverCrest has obtained a Title Opinion completed by Urias Romero Y Asociados, S.C. of Mazatlan, Sinaloa, Mexico that confirms no outstanding agreements or liens exist on the property and that SilverCrest holds legal rights to the claimed areas. EBA has not independently confirmed the legality of this information and relies on the Title Opinion completed in 2012 to confirm these legal rights.

10

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

4.0 PROPERTY DESCRIPTION AND LOCATION

4.1 Location

The La Joya property is approximately 75 km southeast of the state capital city of Durango, state of Durango, Mexico near the intersection of 23º 52' north latitude, and 103º 55' west longitude or 609,700E and 2,640,100 N (UTM WGS 84, zone 13Q) (Figure 1). The property elevation ranges from 2,000 to 2,600 metres above sea level. The community of La Joya has a population of approximately 1,000 people and is located 9 km southwest of the La Joya property. Topographic information for the area is covered by the

Instituto Nacional de Geografía y Estadística de México (INEGI) "La Joya" map; sheet F13B14, at a scale of 1:50,000.

The property consists of 15 concessions with a total nominal area of 8,473.6 hectares (Table 7). The La Joya concessions are contiguous within the area and are registered with the Mexico Mines Registry in the city of Durango and Mexico City in the name of Señior Sergio Gabriel Olvera Alevedo and Family (9 concessions), Señior Pedro Vargas (3 concessions), and SilverCrest de Mexico S.A de C.V. (3 concessions). SilverCrest has option agreements to acquire the concessions held by Sr. Olvera and Sr. Vargas as described below. Subsequent to negotiating these option agreements, SilverCrest staked and filed for ownership of the La Abundancia and Parasio concessions at the southern extent of the existing 12 concessions. All concessions were surveyed on the ground by a registered land surveyor at the time of location (Figure 2). Mineral concessions contiguous to the west and north of the La Joya property are currently owned by Goldcorp through acquisition of Luismin assets.

11

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Under the terms of an agreement dated June 21, 2010, SilverCrest has the right to acquire a 100% interest in the La Joya mineral concessions (La Joya West) owned by Sr. Sergio Gabriel Olvera Alevedo and Family (Olvera) by making staged payments (all amounts in $USD) of $2,680,000 over a period of three years, beginning with a payment of $20,000 on signing (completed), followed by $20,000 four months after signing (completed), $60,000 six months after the second payment (completed), and $80,000 twelve months after the second payment (completed). Thirty six months after the first payment (June 2013) a single payment of $2,500,000 is to be paid to receive 100% ownership of the Olvera concessions. SilverCrest has the option to pay 50% or less of the final payment in company shares at the market price and approval of the BC Securities Commission and Toronto Stock Exchange. At any point during the term of this agreement SilverCrest has the option to purchase the concessions for the full price of the option agreement. A 2% NSR from commercial production would be payable to Olvera upon fulfillment of this agreement.

12

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Figure 1: Property scale location map

13

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Table 7: SilverCrest Mineral Concessions for the La Joya Property

| | | | | | | Original | | | | | | | | | | | | |

| Map | | | Concession | | | | | | Recent | | | Expiry | | Concession | | | | |

| | | | | | | Staking | | | | | | | | | Owner | | Size (ha) | |

| Index | | | number | | | | | | Renewal | | | Date | | name | | | | |

| | | | | | | Date | | | | | | | | | | | | |

| | | | | | | | | | | | | | | CARMEN DEL | SERGIO GABRIEL OLVERA | | | |

| | 1 | | | | 126712 | | | | 1954 | | | Nov 2010 | | | | 2060 | | | | | | 3.03 | |

| | | | | | | | | | | | | | | | | | | ROCÍO | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | SERGIO GABRIEL OLVERA | | | | |

| | 2 | | | | 25/37726 | | | | 2011 | | | | n/a | | | | 2061 | | EL SACRIFICIO | | | | 5.92 | |

| | | | | | | | | | | | | | | | | | | | | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | FRANCISCO | SERGIO GABRIEL OLVERA | | | | |

| | 3 | | | | 121114 | | | | 1954 | | | Nov 2010 | | | | 2060 | | | | | | 10 | |

| | | | | | | | | | | | | | | | | | | | JAVIER | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | | SERGIO GABRIEL OLVERA | | | | |

| | 4 | | | | 163510 | | | | 1954 | | | Nov 2010 | | | | 2060 | | HIDALGO | | | | 51 | |

| | | | | | | | | | | | | | | | | | | | | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | HIDALGO | SERGIO GABRIEL OLVERA | | | | |

| | 5 | | | | 122149 | | | | 1954 | | | Nov 2010 | | | | 2060 | | | | | | 42 | |

| | | | | | | | | | | | | | | | | | | | NÚMERO DOS | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | | SILVERCREST DE MEXICO | | | | |

| | 6 | | | | 25/37722 | | | | 2011 | | | | n/a | | | | 2061 | | LA ABUNDANCIA | | | | 86.57 | |

| | | | | | | | | | | | | | | | | | | | | S.A. DE C.V. | | | | |

| | 7 | | | | 231202 | | | | 2008 | | | | n/a | | | | 2058 | | LA FE | PEDRO VARGAS AGUIRRE | | | 42.87 | |

| | 8 | | | | 232199 | | | | 2008 | | | | n/a | | | | 2058 | | LA FE 2 | PEDRO VARGAS AGUIRRE | | | 760.79 | |

| | 9 | | | | 237706 | | | | 2011 | | | | n/a | | | | 2061 | | LA FE 3 | PEDRO VARGAS AGUIRRE | | | 308 | |

| | | | | | | | | | | | | | | | | | | | | SERGIO GABRIEL OLVERA | | | | |

| | 10 | | | | 25/37304 | | | | 2011 | | | | n/a | | | | 2061 | | LA FE 4 | | | | 2.79 | |

| | | | | | | | | | | | | | | | | | | | | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | | SERGIO GABRIEL OLVERA | | | | |

| | 11 | | | | 119602 | | | | 1953 | | | Nov 2010 | | | | 2060 | | LA NUEVA | | | | 29.48 | |

| | | | | | | | | | | | | | | | | | | | | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | | SERGIO GABRIEL OLVERA | | | | |

| | 12 | | | | 130550 | | | | 1957 | | | Nov 2010 | | | | 2060 | | SAN LUCAS | | | | 15.17 | |

| | | | | | | | | | | | | | | | | | | | | ACEVEDO | | | | |

| | | | | | | | | | | | | | | | | | | | UNIFICACIÓN | SERGIO GABRIEL OLVERA | | | | |

| | 13 | | | | 183039 | | | | 1988 | | | Nov 2010 | | | | 2060 | | | | | | 370.97 | |

| | | | | | | | | | | | | | | | | | | | SACRIFICIO | ACEVEDO | | | | |

| | 14 | | | | 25/37740 | | | | 2011 | | | | n/a | | | | 2061 | | PARAISO | SILVERCREST DE MEXICO | | | 6,745 | |

| | | | | | | | | | | | | | | | | | | | | S.A. DE C.V. | | | | |

| | | | | | | | | | | | | | | | | | | | | SILVERCREST DE MEXICO | | | | |

| SN 15 | | | | 025/38116 | | | | 2012 | | | | n/a | | | | 2062 | | LA FE 5 | | | | 594.4 | |

| | | | | | | | | | | | | | | | | | | | | S.A. DE C.V. | | | | |

| | | | | | | | | | | | | | | | | | | | | TOTAL | | | 9023 | |

14

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Figure 2: Mineral concession map

15

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Under the terms of an agreement dated Dec 7, 2010, SilverCrest has the right to acquire a 100% interest in the La Joya mineral concessions (La Joya East) owned by Sr. Pedro Vargas by making staged payments (all amounts in $USD) of $1,500,000 over a period of three years, beginning with a payment of $25,000, 45 days after signing (completed), followed by payments of $20,000 six months after the first payment (completed), $50,000 due twelve months after the first payment (completed), $60,000 to be paid eighteen months after the first payment (completed), $70,000 to be paid twenty four months after the first payment (paid), and $100,000 to be paid thirty months after the first payment. No later than thirty six months after the first payment a lump sum of $1,175,000 is to be paid in cash or up to 50% in shares at the discretion of SilverCrest. At any point during the term of this agreement SilverCrest has the option to purchase the concessions for the full price of the option agreement. A 2% NSR from commercial production would be payable to the to the property owners upon fulfillment of the agreement.

On January 20, 2011, SilverCrest signed an agreement with the civil co-operative for the community of La Joya for a three-year lease on surface rights for a maximum of 3,935 ha with respect to exploration work. Lease payments are dependent (at SilverCrest's discretion) on the number of hectares required for a given year. The annual cost per year will be approximately MxnPesos $1,000 to $10,000, payable to the community, dependent on the number of hectares required. A payment of approximately MxnPesos $1,000 has been made to initiate the agreement and cover the first year of the lease. The second payment is due Q2, 2103.

4.4 Mexican Mine Permitting and Regulations

Mining Law (enacted by congress on June 26, 1992) is jurisdiction of the Federal body as declared in Article 27 of the Mexican Constitution, adopted in 1917. The Mining Law deems essentially all minerals to be owned by the Mexican nation.

The right to explore for or exploit minerals is given to private parties, through mining concessions issued by the Federal executive branch. Amendments to the Mining Law in April 2005, and put into effect in January 2006, provide for all mining concessions to be valid for a period of 50 years and may be extended for an equal period given notification 5 years prior to expiration and no other cause for cancellation of the concession is evident. A concession in Mexico does not confer any ownership of surface rights. However, use of surface rights for exploration and production can be obtained under the terms of various acts and regulations if the concession is on government land.

Concession taxes payable to the Secretaria de Economia, division the Mexican Government, based on the surface area of the concession, are due in January and July of each year at an annual cost of approximately USD$11,000 for the current La Joya property configuration. All tax payments have been paid by SilverCrest to date.

Work permits required for the exploration work have been obtained for Phase I and II which are now complete. Phase III drilling permit is under review and awaits issuance. The Mexican government issued an environmental permit (Environmental Assessment) for all proposed exploration work in December, 2010. Phase I inspection of the site was conducted in May 2011.

No water permits are required for exploration work since the water is purchased locally from private active wells.

16

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

5.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

5.1 Accessibility

The La Joya property can be accessed year round by road, commencing by a paved highway going southeast from city of Durango to the city of Vicente Guerrero, a distance of approximately 80 km, then north along a paved secondary road to the community of La Joya, a distance of approximately 10 km, and then by a network of farming and agricultural access dirt roads that span approximately 10 km east of the community of La Joya. The city of Durango has an international airport with multiple daily flights between Mexico and the USA.

Regional climate is warm and semi-arid with rain generally occurring between July and September. The average rainfall is estimated at 590 mm. The average temperature is approximately 22°C, with the lowest monthly average of 19.7°C occurring in February, and highest monthly average of 30.5° C occurring in May. Due to the high elevation of the region, freezing temperatures in the region have been recorded. Periods of freezing can last from 1 to 20 days, typically during the month of February (regional information extracted from INEGI, Instituto Nacional de Geografía y Estadística de México).

Water for drilling is currently being transported to the property and stored in a lined sump from two active wells, the first located at 608333 E, 2639173 N elev. 1,948 metres which is reported by local ranchers to yield approximately 20 litres/sec, and the second located at 604531 E, 2634627 N which is reported to yield approximately 15 litres/sec. Water for a production facility could come from a local groundwater source or a pre-constructed reservoir. The characteristics of the well, water supply and water quality have not been verified by EBA.

Electrical power is readily available from nearby sources that currently supply municipalities and agriculture. Regional reliable grid power could be considered if a mining operation is justifiable. The main high voltage electrical transmission lines are located approximately 15 km from the property.

Sufficient area is available for a processing plant, waste dumps and tailings disposal on the property. Surface rights are held by a local civil co-operative and need to be obtained if mining facilities are required as described in Section 4.3. No permanent structures occupy the property.

The town of Vicente Guerrero is the closest urban area of any size (pop. est. 15,000), and is about 20 km southwest of the La Joya property by paved and unpaved road from the property. Many services and supplies are available in Vicente Guerrero, but it may be necessary to go to Durango for heavier machine shop, fabrication, and engineering services. While Vicente Guerrero is more of an agricultural community, Durango is considered to be an exploration and mining centre within a prolific mining state.

Northern Central Mexico has significant precious and base metal mines and there are a significant number of people with experience in mining and processing of those commodities. Many of the trades and skills learned there would be transferable to a new operation. The San Martin, Sabinas and La Parrilla mines are the major mines operating within 20 kilometres of the La Joya property (Figure 3).

17

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Figure 3: Regional map showing mineral concession, local infrastructure, and proximal mines

18

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

5.4 Infrastructure

Currently, infrastructure on the La Joya property is limited to access roads, historical open cut and underground workings and an abandoned low-voltage power transmission line which crosses the property between Cerro Sacrificio and Cerro Coloradito.

Several drifts to accommodate underground mining were excavated during the early 20th century along with several small hillside excavations (<100m3 each). There is very little information that has been recorded from these exploitation activities, however, the underground workings do not appear to be extensive. They are all accessible with very few signs of rock failure or collapse.

Local ranchers have installed small water catchments and pipe diversions to supply livestock and agriculture with water from local run-off. On the west side of the property, a well exists that supplies water for local agriculture irrigation. The well is reported to be artesian with temperatures in excess of 30°C. The characteristics of the well, water supply and water quality are not known to EBA at this time.

SilverCrest rents and maintains a house, core processing facility and separate core storage facility within the town of La Joya. The house accommodates SilverCrest personnel and sub-contractors and is used as the company's exploration office for the area. Samples collected from surface sampling are securely stored within this building. Drill core is delivered to the core storage facility adjacent to the house where all logging and sampling of the core is completed. Samples collected from drill core are securely stored within the fenced and locked facility. EBA considers both facilities to be secure.

An active railway is located west of the community of La Joya, which connects the area to cities and ports in central and southern Mexico (Figure 3).

The landscape surrounding the La Joya property is controlled predominantly by large scale north-south directed horst and graben geological features. The grabens have been filled with alluvium eroded from the horst blocks to form relatively flat-lying valleys. The community of La Joya is situated within a valley that is roughly 20 km wide and that is typically cultivated for agriculture or livestock.

Two prominent topographic features exist on the northern portion of the La Joya property, located on the uplifted horst block along with numerous rolling hills of exposed and incised bedrock features. Cerro Coloradito is the smaller of the two with and approximate vertical rise of 400 metres and is located to the west of and Cerro Sacrificio. Cerro Sacrificio has approximately 600 metres of vertical rise and is the host to the La Joya deposit Photo 1.

19

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

Photo 1: Physiography of La Joya region (photo taken Nov 2010)

Bedrock is exposed on Cerro Sacrificio with few locations exhibiting minor organics as an overburden layer. Formation of caliche is a common calcium leachate overlying calcareous sediments, and encasing alluvium fill along the lower slopes of Cerro Sacrificio outwards within the valleys. Alluvium overburden ranges in depth from 3 to 25 metres as documented in historic drilling to the north of the cerro. No significant overburden was documented in recent SilverCrest drilling.

Water drainage from the elevated horst features flows towards the valley, where locally, the water gradient is to the north in the Arroyo Suchil and ultimately south-west through the Sierra Madre Occidental towards the Pacific coast.

Early records exist of exploration and mining by Spanish explorers in the nearby Real de San Martin district starting from 1548. Continued development is seen in the region at other mines from this era, such as Fresnillo and La Colorada. By inference, it can be expected that similar historical exploration efforts were directed towards the area surrounding Cerro Sacrificio on the La Joya property as part of regional initiatives. No detailed records of the discovery or early Spanish exploitation of the property were available to EBA.

Evidence of historic pit and small underground mining operations within Cerro Sacrificio is seen by numerous small adits and excavations along the hillside. Today, the adits remain open and are accessible for sampling and identifying structures related to mineralization on the property. At least two periods of small scale artesian mining are thought to have occurred on the La Joya property dating back to the early 20th century prior to recent exploration initiatives. The first period occurred for roughly 50 years prior to the 1960's (Burkhardt, 2006). Historic records on the specific nature of the land ownership, the parties responsible for the exploitation or production figures have not been recovered to date.

20

| | LA JOYA, NI 43-101 TECHNICAL REPORT |

| | RELEASED: MARCH 27, 2013 |

The second period occurred through the 1960'S to the mid-1970s, and based on property ownership at the time it is expected that the operations would have been carried out by the Olvera family. An estimated 40,000 tonnes of ore were mined over a fifteen year period (from Patterson ref. Albinson and Sanchez, 1977), much of which was extracted from the Embotelladora mine, the Rosas de Diciembre mine and Mina Patricia. Patterson (2001) describes in brief the exploitation at the Embotelladora mine during this time and references Albinson and Sanchez (1977), who described the ore as skarn-related sulphide mineralization with grades of 50 gpt Ag, 0.5% Cu, 0.05% Pb, and 0.05% Zn. The context of these grades is not clear to EBA and they are considered only in historical context.

6.3 1977 to 2006, Luismin

The first records of recent activity on the property arises in 1977 when Minas Sanluis S.A de C.V, an operating subsidiary of Mexican industrial group Sanluis Corp.'s mining division Luismin (Luismin, now Goldcorp) began their exploration activities on the property. The exact details of the land ownership and exploration agreements for this period are not known, however, the property has been held by the Olvera family since the 1950's and agreements during this period are assumed.