Exhibit 99.1

Update to sANTA eLENA Pre-Feasibility Study

Sonora, Mexico

SilverCrest Mines Inc.

EFFECTIVE DATE: DECEMBER 31, 2014

fILING date: mARCH 31, 2015

Contributors:

| § | N. Eric Fier, C.P.G., P. Eng., Chief Operating Officer - SilverCrest Mines Inc. |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

table of contents

| 1.0 | Executive Summary | 1 |

| | 1.1 | Introduction | 1 |

| | 1.2 | Santa Elena Update to Mineral Resources and Mineral Reserves | 1 |

| | | 1.2.1 | Reserve Criteria | 4 |

| | 1.3 | Mining Methods | 5 |

| | 1.4 | Mining Schedule | 5 |

| | | 1.4.1 | Underground Production | 6 |

| | 1.5 | Recovery Methods | 6 |

| | 1.6 | Project Infrastructure | 7 |

| | 1.7 | Capital and Operating Costs | 8 |

| | 1.8 | Economic Analyses | 8 |

| | 1.9 | Update to Pre-Feasibility Recommendations | 10 |

| | | |

| 2.0 | Introduction | 11 |

| | 2.1 | Report Author and Qualified Person | 11 |

| | | |

| 3.0 | Reliance on other Experts | 11 |

| | | |

| 4.0 | Property Description and Location | 12 |

| | 4.1 | Mining Titles and Agreements | 14 |

| | 4.2 | Royalties | 17 |

| | 4.3 | Sandstorm Gold Stream | 17 |

| | 4.4 | Environmental Liabilities and Permitting | 17 |

| | | | |

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 19 |

| | 5.1 | Accessibility | 19 |

| | 5.2 | Climate | 19 |

| | 5.3 | Local Resources | 19 |

| | | 5.3.1 | Water Supply | 19 |

| | | 5.3.2 | Power | 20 |

| | | 5.3.3 | Community Services | 20 |

| | 5.4 | Existing Infrastructure | 20 |

| | 5.5 | Physiography | 21 |

| | | |

| 6.0 | History | 21 |

| | | |

| 7.0 | Geological Setting and Mineralization | 22 |

| | 7.1 | Regional Geological Setting | 23 |

| | 7.2 | Local and Property Geology | 23 |

| | | 7.2.1 | Santa Elena | 23 |

| | | | 7.2.1.1 Structural Geology at Santa Elena | 25 |

| | | 7.2.2 | Ermitaño | 26 |

| | | 7.2.3 | Cumobabi | 29 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| 8.0 | Deposit Types | 30 |

| | 8.1 | Mineralization | 30 |

| | | |

| 9.0 | Exploration | 31 |

| | | |

| 10.0 | Drilling | 31 |

| | 10.1 | Santa Elena | 31 |

| | 10.2 | Ermitaño | 38 |

| | | | |

| 11.0 | Sample Preparation, Analyses and Security | 39 |

| | 11.1 | Historical Sample collection methods | 39 |

| | 11.2 | Previous SilverCrest sample collection methods | 39 |

| | 11.3 | 2012 -2013 Sample Collection Methods | 39 |

| | 11.4 | 2013 -2014 Sample Collection Methods | 40 |

| | 11.5 | 2014 -2015 UG Sample Collection Methods | 41 |

| | 11.6 | 2012-2013 Laboratory Analytical Methods | 43 |

| | 11.7 | 2013-2014 Laboratory Analytical Methods | 43 |

| | | 11.7.1 | Nusantara Lab Preparation and Analyses (2012-2014) | 43 |

| | | 11.7.2 | ALS-Chemex Lab preparation and Analyses (2012-2014) | 44 |

| | 11.8 | Inspectorate Lab preparation and Analyses (2013-2014) | 44 |

| | 11.9 | Heap Leach Sampling, preparation and Analyses (2012-2013) | 45 |

| | 11.10 | QP Statement | 46 |

| | | |

| 12.0 | Data Verification | 47 |

| | 12.1 | Historical Data Verification | 47 |

| | 12.2 | 2006-2008 SilverCrest Data verification | 47 |

| | 12.3 | 2012-2013 Independent Data verification | 47 |

| | | 12.3.1 | SilverCrest Certified Reference Material Insertion | 49 |

| | 12.4 | SilverCrest Blank Material Insertions | 54 |

| | 12.5 | QP Statement on Data Verification | 55 |

| | | |

| 13.0 | Mineral Processing and Metallurgical Testing | 55 |

| | 13.1 | Previous Mineral Processing and Metallurgical test work | 55 |

| | | 13.1.1 | Previous Metallurgical Test Work Summary For Santa Elena | 55 |

| | 13.2 | Recent Mineral Processing and Metallurgical test work | 55 |

| | | 13.2.1 | Leaching Cyanidation of Samples from Santa Elena Deposit | 56 |

| | | 13.2.2 | Filtering and Thickening Test work | 65 |

| | 13.3 | Metallurgical Operational Results Up To December 31, 2014 | 66 |

| | | |

| 14.0 | Mineral Resource Estimates | 67 |

| | 14.1 | Previous Mineral Resource Estimates | 67 |

| | | 14.1.1 | Previous Underground Resource Estimate | 67 |

| | | 14.1.2 | Previous Spent Ore on Leach Pad Resource Estimate | 69 |

| | | 14.1.3 | Previous Open Pit Resource Estimate | 70 |

| | 14.2 | Current Underground Mineral Resource Estimate | 70 |

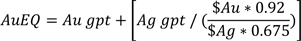

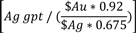

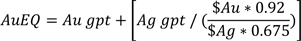

| | | 14.2.1 | Gold Equivalent (AuEq) Calculations and Assumptions | 70 |

| | | 14.2.2 | Specific Gravity used in the Resource Estimation | 71 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

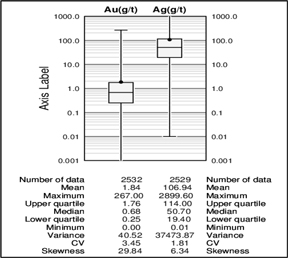

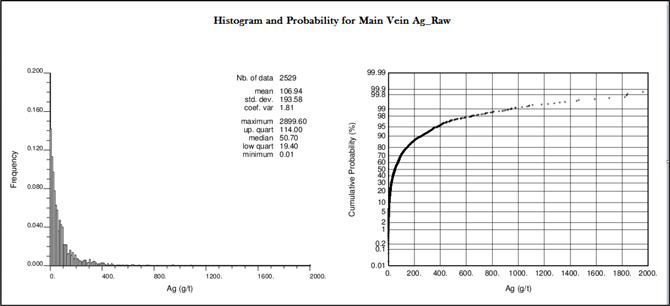

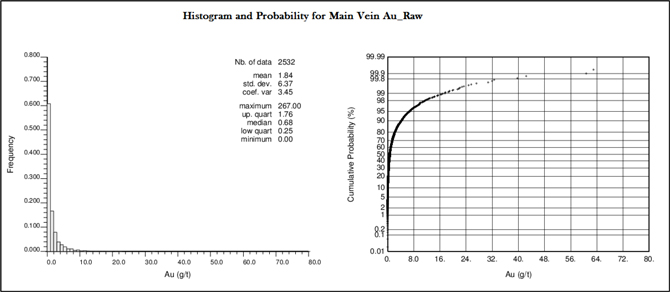

| | | 14.2.3 | MMZ Geostatistics | 71 |

| | | | 14.2.3.1 High Grade Capping | 75 |

| | | | 14.2.3.2 Compositing | 77 |

| | | 14.2.4 El Cholugo Geostatistics | 79 |

| | | 14.2.5 Tortuga Geostatistics | 80 |

| | | 14.2.6 Basis of Current Underground Mineral Resource Estimation | 81 |

| | | 14.2.7 | Drill Holes Used in Underground Mineral Resource | 82 |

| | | 14.2.8 | Lithological Interpretation Used in the Model | 83 |

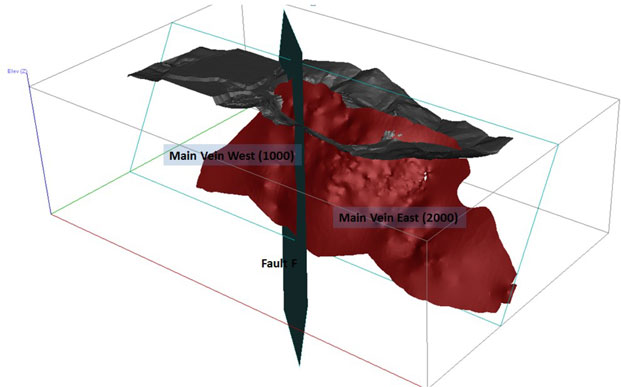

| | | 14.2.9 | Interpolation Method and Variography | 86 |

| | | 14.2.10 | Block Classification | 88 |

| | | 14.2.11 | Underground Mineral Resource Estimate | 88 |

| | | 14.2.12 | Underground Validation | 92 |

| | 14.3 | Current Heap Leach Mineral Resource Estimate | 94 |

| | | 14.3.1 | Heap Leach Resource Validation | 95 |

| | | 14.3.2 | Heap Leach Mineral Resource Statement | 95 |

| | | |

| 15.0 | Mineral Reserve Estimates | 96 |

| | 15.1 | Introduction | 96 |

| | 15.2 | Previous Reserve Estimates | 96 |

| | 15.3 | Current Reserve Estimate Parameters | 97 |

| | 15.4 | Basis for Underground Mineral Reserve | 98 |

| | | 15.4.1 | Underground Mining Method Consideration for Underground Reserves | 100 |

| | 15.5 | Open Pit Reserve | 100 |

| | 15.6 | Heap Leach Reserve | 100 |

| | 15.7 | Current Santa Elena Reserve Statement | 100 |

| | | |

| 16.0 | Mining Methods | 102 |

| | 16.1 | Introduction | 102 |

| | 16.2 | Geotechnical Analyses for Underground Mining | 102 |

| | | 16.2.1 | General | 102 |

| | | 16.2.2 | Geotechnical Data Collection | 103 |

| | | | 16.2.2.1 Drill Program | 103 |

| | | 16.2.3 Rock Mass Characteristics | 103 |

| | | 16.2.4 Design Parameters | 103 |

| | | | 16.2.4.1 Rock Mass parameters | 103 |

| | | | 16.2.4.2 Rock Strength | 104 |

| | | 16.2.5 Design Approach | 104 |

| | | | 16.2.5.1 General | 104 |

| | | | 16.2.5.2 Design Assumptions | 104 |

| | | | 16.2.5.3 Tabulation of Results | 105 |

| | | | 16.2.5.4 Methodology of Stability Graph for Stope Design | 105 |

| | | 16.2.6 Span Length Design – Longitudinal | 106 |

| | | 16.2.7 Stope Back Width Design | 106 |

| | | 16.2.8 Cut and Fill | 107 |

| | | | 16.2.8.1 Crown Pillar Design | 107 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| | 16.3 | Proposed Underground Mining Methods | 107 |

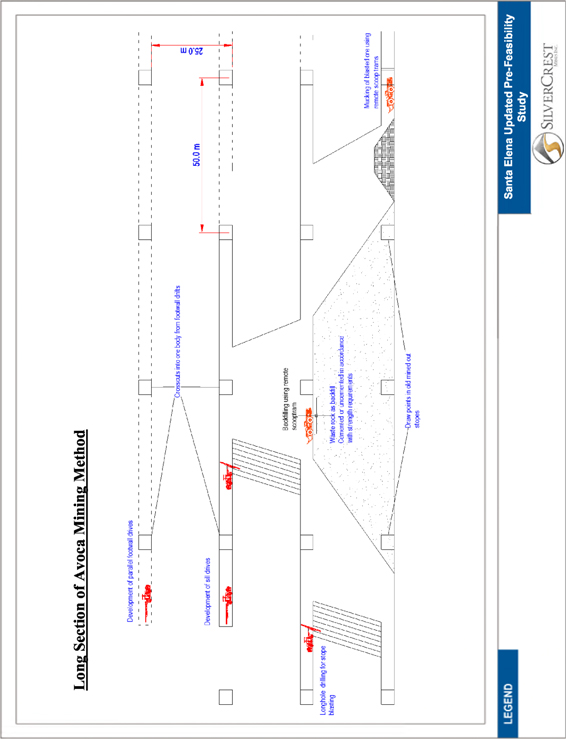

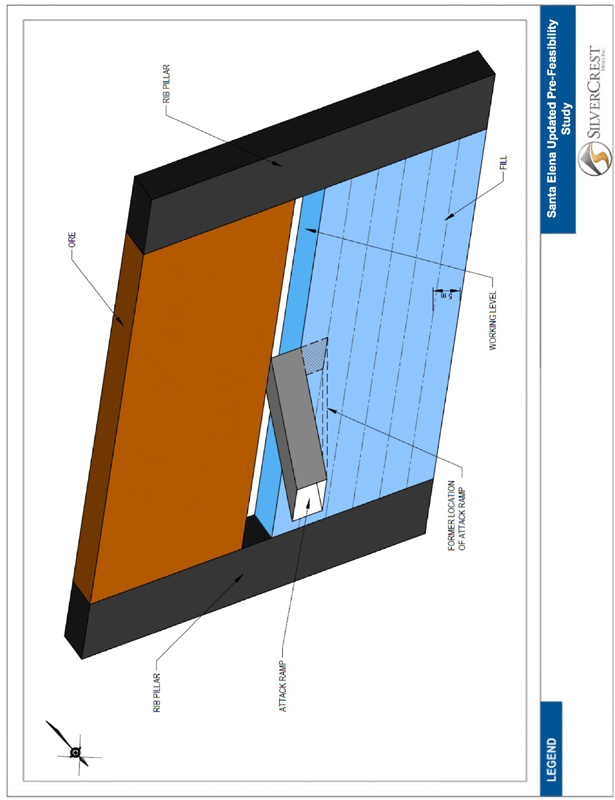

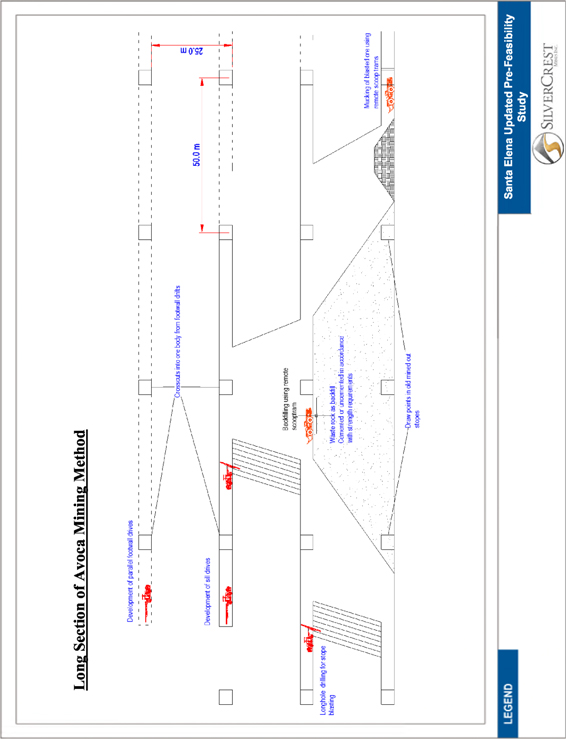

| | | 16.3.1 | Avoca Long Hole Stoping | 108 |

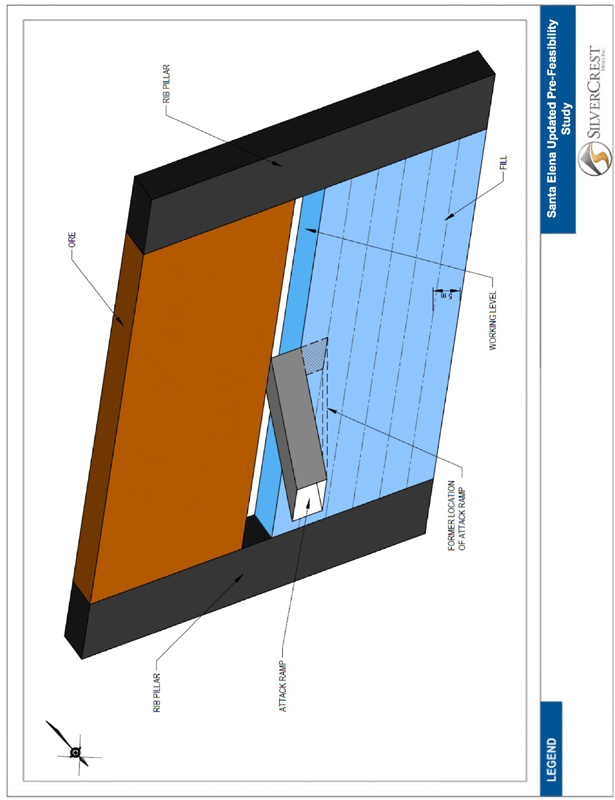

| | | 16.3.2 | Mechanized Cut and Fill | 111 |

| | | 16.3.3 | Mining Equipment | 113 |

| | 16.4 | Mine Design | 113 |

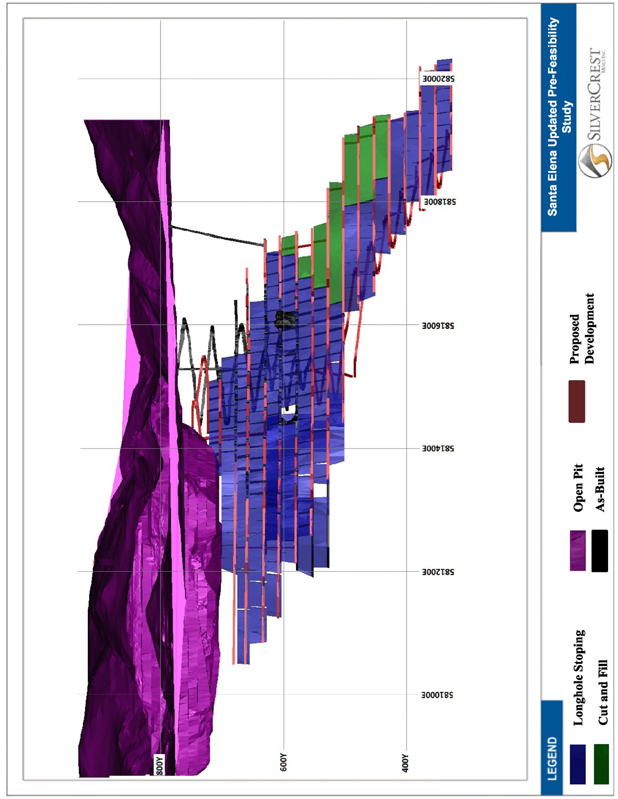

| | | 16.4.1 | Stope Layout | 113 |

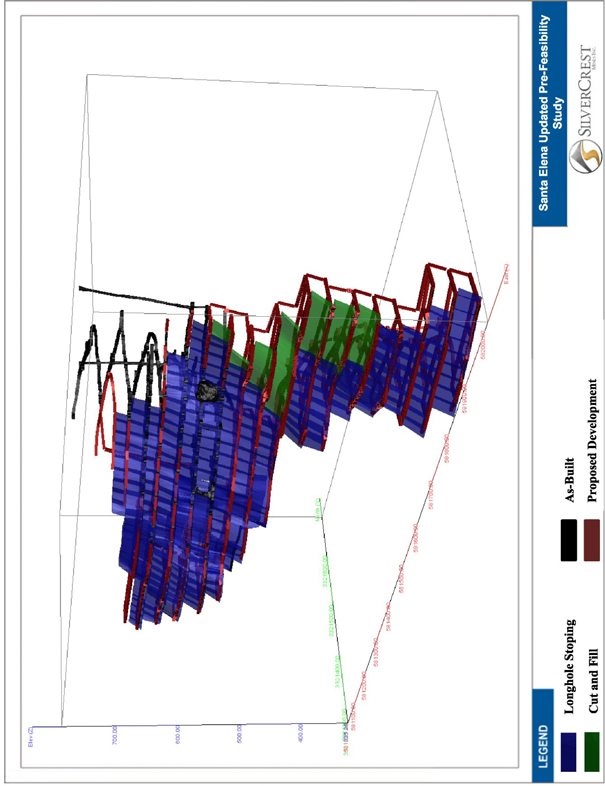

| | | 16.4.2 | Development Layout | 118 |

| | 16.5 | Backfill | 121 |

| | | 16.5.1 | Backfilling Cut and Fill Stopes | 121 |

| | | 16.5.2 | Backfilling Long Hole Stopes (Avoca Technique) | 121 |

| | 16.6 | Overall Mining Schedule | 121 |

| | | 16.6.1 | Underground Mine Production Schedule | 122 |

| | | 16.6.2 | Open Pit Mining Schedule | 124 |

| | | 16.6.3 | Heap Leach Mining Schedule | 124 |

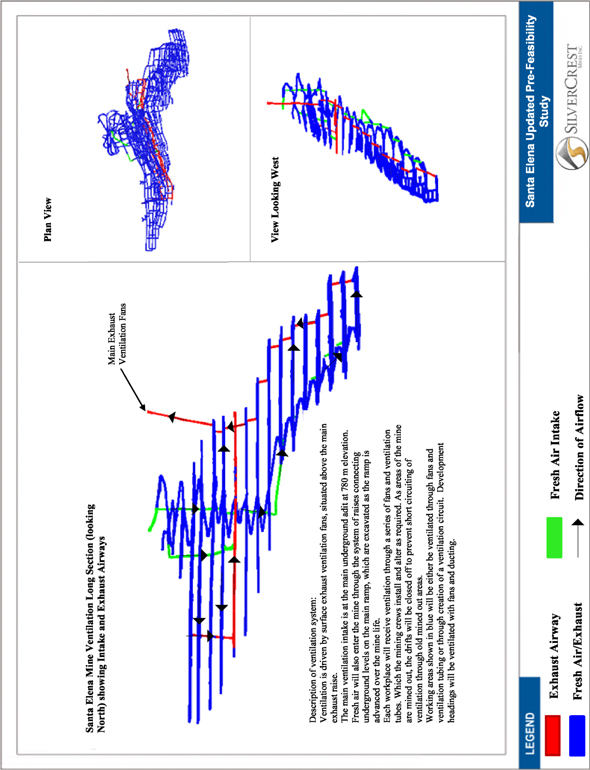

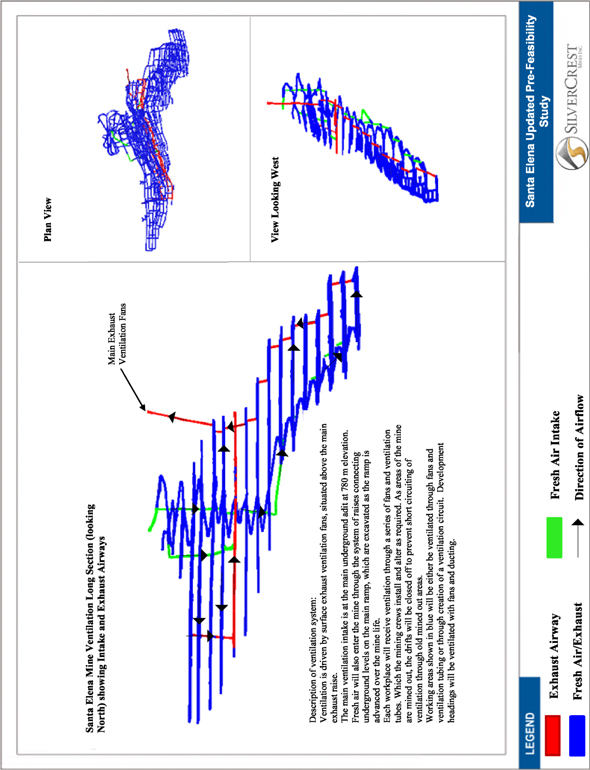

| | 16.7 | Ventilation | 124 |

| | | 16.7.1 | Ventilation Requirements | 124 |

| | | 16.7.2 | Ventilation Model | 125 |

| | | | 16.7.2.1 Conceptual ventilation design | 125 |

| | | | 16.7.2.2 Intake airway / Escape way Raise | 125 |

| | | | 16.7.2.3 Fresh Air Raise Head Without separate man way | 126 |

| | | | 16.7.2.4 Raised Bore for main exhaust ventilation airway | 126 |

| | | | 16.7.2.5 Vent Tubing Head For Tunnels and Ore drifts | 127 |

| | | | 16.7.2.6 Setup of Ventilation Model | 128 |

| | | 16.7.3 | Interpretation of Ventilation Conceptual Design | 131 |

| | 16.8 | Open Pit Mining Method | 131 |

| | 16.9 | Spent Ore (Pad Ore) Mining And Re-handling Methods | 132 |

| | 16.10 | Tailings Disposal | 132 |

| | | |

| 17.0 | Recovery Methods | 133 |

| | | |

| 18.0 | Project Infrastructure | 139 |

| | 18.1 | Surface Infrastructure for the Expansion Plan | 142 |

| | | 18.1.1 | Access Roads | 142 |

| | | 18.1.2 | Offices, Cafeteria, Warehouse and Change Houses | 142 |

| | | 18.1.3 | Fuel Storage Facility | 142 |

| | | 18.1.4 | Water storage facility | 142 |

| | | 18.1.5 | Electrical Distribution | 142 |

| | | 18.1.6 | Explosive Magazine | 142 |

| | | 18.1.7 | Maintenance Shop | 142 |

| | | 18.1.8 | On-site Laboratory | 142 |

| | 18.2 | Underground Infrastructure | 143 |

| | | 18.2.1 | Underground Maintenance Shop/Warehouse | 143 |

| | | 18.2.2 | Refuge Station | 143 |

| | | 18.2.3 | Dewatering | 143 |

| | | 18.2.4 | Underground Electrical Installations | 143 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| | | 18.2.5 | Water Services | 144 |

| | | 18.2.6 | Powder Storage | 144 |

| | | 18.2.7 | Compressed Air | 144 |

| | 18.3 | Processing Plant Infrastructure | 144 |

| | 18.4 | Waste Rock and Tailings Storage Facilities | 145 |

| | | |

| 19.0 | Market Studies and Contracts | 146 |

| | 19.1 | Metal Pricing | 146 |

| | 19.2 | Sales of gold and silver doré | 146 |

| | | |

| 20.0 | Environmental Studies, Permitting and Social or Community Impact | 146 |

| | 20.1 | Land Use Change Permit | 146 |

| | | 20.1.1 | Summary of ARD/ML Work for Santa Elena | 147 |

| | 20.2 | Closure Planning | 148 |

| | | |

| 21.0 | Capital and Operating Costs | 148 |

| | 21.1 | Capital Costs | 149 |

| | | 21.1.1 | Site infrastructure | 150 |

| | | 21.1.2 | Processing Capital Costs | 150 |

| | | 21.1.3 | Underground Development | 150 |

| | | 21.1.4 | Underground Equipment and Infrastructure | 150 |

| | | 21.1.5 | Sunk Costs | 151 |

| | 21.2 | Operating Costs | 151 |

| | | 21.2.1 | Underground Mining Cost Estimate | 153 |

| | | 21.2.2 | Costs for Loading and Transporting Existing Heap Leach Material to the Mill for Reprocessing | 155 |

| | | 21.2.3 | Processing Plant Operating Costs | 156 |

| | 21.3 | Tailings Handling Costs | 157 |

| | 21.4 | General and Administrative Operating Costs | 157 |

| | | |

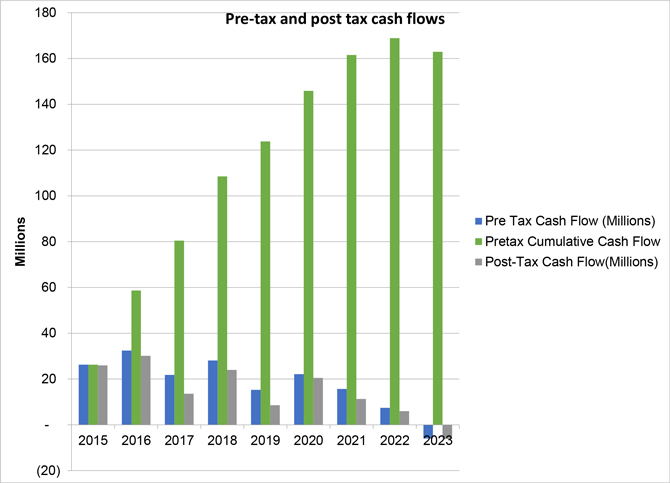

| 22.0 | Economic Analyses | 158 |

| | 22.1 | Introduction | 158 |

| | 22.2 | Technical Assumptions | 158 |

| | 22.3 | Summary of Economic Results | 159 |

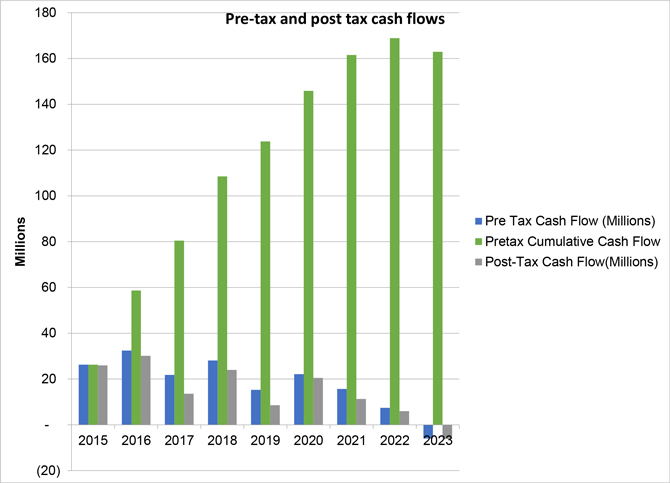

| | 22.4 | Cash flows | 160 |

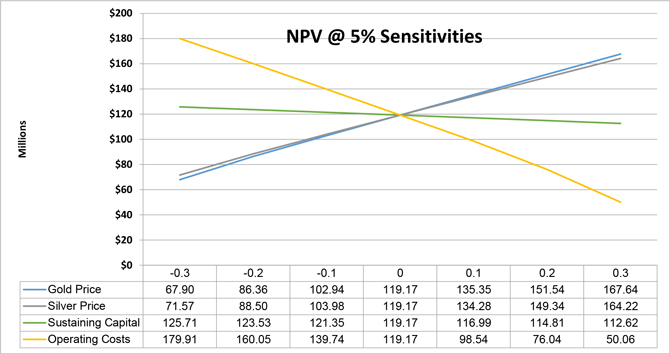

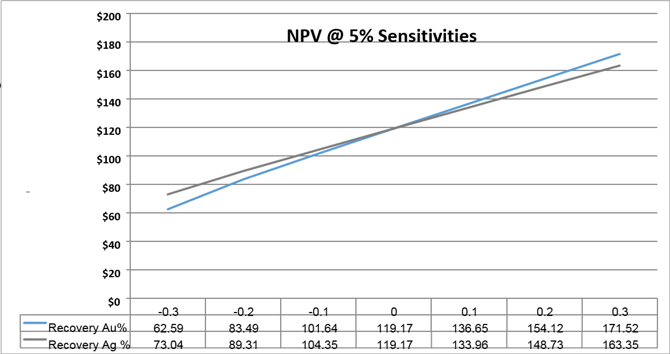

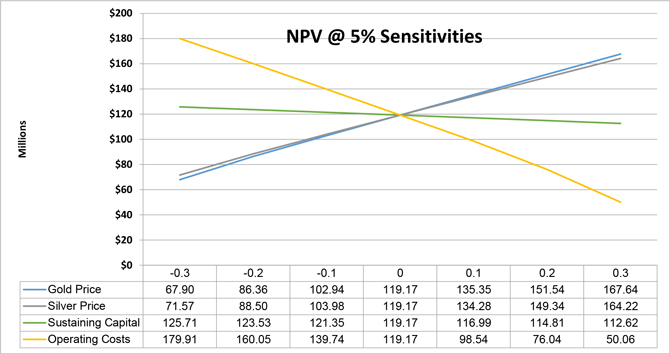

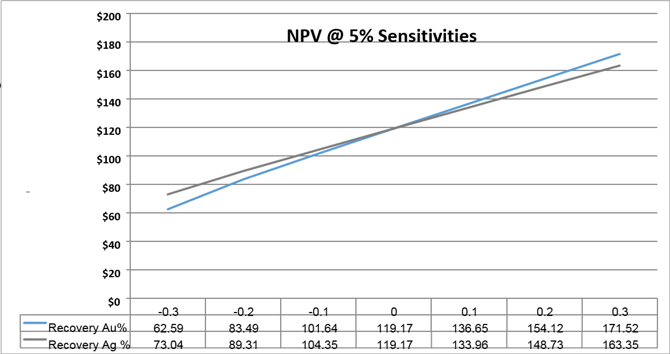

| | 22.5 | Post - tax Results and Sensitivity Analyses | 161 |

| | 22.6 | Purchase Agreement | 165 |

| | 22.7 | Smelter Terms | 165 |

| | | |

| 23.0 | Adjacent Properties | 166 |

| | | |

| 24.0 | Other Relevant Data and Information | 166 |

| | | |

| 25.0 | Interpretation and Conclusions | 166 |

| | 25.1 | Geology and Underground Resource Estimate | 166 |

| | 25.2 | Underground Reserves and Mining Methods | 166 |

| | 25.3 | Costs and Project Economic | 166 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| 26.0 | RECOMMENDATIONS | 166 |

| | 26.1 | Geology and Underground Resource Estimate | 166 |

| | | 26.1.1 | Risks and Opportunities | 166 |

| | 26.2 | Geotechnical Recommendation | 167 |

| | | 26.2.1 | Stope Size and Pillar Dimensioning | 167 |

| | | | 26.2.1.1 Hanging wall and orebody NGI-Q values | 167 |

| | | | 26.2.1.2 Joint set orientation | 167 |

| | | | 26.2.1.3 In-situ stress regime | 167 |

| | | 26.2.2 | Geotechnical Considerations in Overall Mine Design | 167 |

| | 26.3 | Metallurgical Testing | 168 |

| | 26.4 | Breakdown of costs for future work | 168 |

| | 168 |

| references | 169 |

List of Tables in Text

| Table 4.1: List of Mining Titles for Santa Elena and Surrounding Properties | 14 |

| Table 4.2: Permits for Santa Elena | 18 |

| Table 4.3: Permits for Ermitaño | 18 |

| Table 10.1: Significant Drill hole Intersections from 2014 Surface Drilling at Santa Elena | 32 |

| Table 10.2: Table Summary of Drill Holes | 34 |

| Table 10.3: Trench and Bulk Composite Samples | 37 |

| Table 10.4: SilverCrest Drilling Results at Ermitaño –Durazno Target | 38 |

| Table 11.1: RC Cutting Sample Length (From ‘SERC’- series drill holes) and frequency from the hanging wall | 39 |

| Table 11.2: Number and preparation method of samples sent to ALS-Chemex from Santa Elena mine (2012-2013) | 44 |

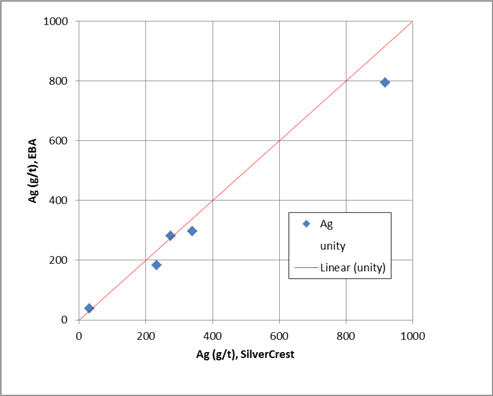

| Table 12.1:Drill core grade verification sampling (Oct 2012) | 48 |

| Table 12.2: Certified Reference Material Reporting Values used in the Santa Elena 2013-2014 Drilling by SilverCrest | 49 |

| Table 13.1: Baseline Cyanidation Performance | 56 |

| Table 13.2: Leach Optimization Test Summary | 59 |

| Table 13.3: Confirmatory Test Comp. 4 +/- 0 Nivel | 61 |

| Table 13.4: Average Recovery Rates for Underground Bulk Samples | 63 |

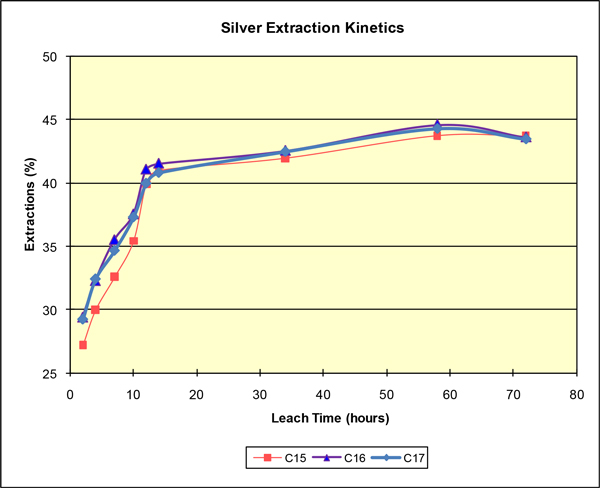

| Table 13.5: Results of Additional Testing on Samples 4, 6 and 8. | 63 |

| Table 13.6: Bulk Leach Summary | 65 |

| Table 14.1: Previous Underground Mineral Resource Estimate Including Reserves for Santa Elena (EBA, April 30th, 2013) | 68 |

| Table 14.2: Previous Underground Mineral Resource Estimate and Sensitivity, Excluding Reserves for Santa Elena (EBA April 30th, 2013) | 69 |

| Table 14.3: Previous Leach Pad Material Mineral Resource Estimate (April 30th, 2013) | 70 |

| Table 14.4: Specific Gravity | 71 |

| Table 14.5: Block Model Origin and Demission of the Santa Elena Model | 82 |

| Table 14.6: Drill Holes Used in Estimating MMZ | 82 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| Table 14.7: Drill Holes Used in Estimating El Cholugo | 82 |

| Table 14.8: Drill Holes Used in Estimating Tortuga | 82 |

| Table 14.9: Block Model Codes | 84 |

| Table 14.10: Variography by Domain | 87 |

| Table 14.11: Ellipse Parameters Summary | 87 |

| Table 14.12: Underground Mineral Resource Estimate Excluding Reserves for Santa Elena (SilverCrest, Dec 31, 2014) | 89 |

| Table 14.13: Validation of Heap Leach Resource Estimate (April 30th, 2013) | 95 |

| Table 14.14: Leach Pad Material Mineral Resource Estimate (Effective December 31st, 2014) | 95 |

| Table 15.1: Previous Santa Elena Open Pit Reserves (January, 2011) | 96 |

| Table 15.2: Previous Reserves disclosed in 2013 Technical Report (April, 2013) | 97 |

| Table 15.3: Santa Elena Mineral Reserve Estimate, diluted and recoverable (Effective Date: December 31, 2014) | 101 |

| Table 16.1: RMR’ and NGI-Q’ Values for Design – at 50% | 104 |

| Table 16.2: NGI-Q' Values for Stope Design | 106 |

| Table 16.3: Mining Method Selection Criteria | 107 |

| Table 16.4: Mining Equipment List | 113 |

| Table 16.5: Linear Meters of development remaining for life of mine | 118 |

| Table 16.6: Summary of Overall Production Schedule | 121 |

| Table 16.7: Scheduling Parameters | 122 |

| Table 16.8: Equipment Power and Utilization | 124 |

| Table 16.9: Design Parameters for Escape Way Raise | 125 |

| Table 16.10: Design Parameters for Fresh Air Raise | 126 |

| Table 16.11: Design Parameters for Exhaust Raise | 127 |

| Table 16.12: Design Parameters for Vent Tubing | 128 |

| Table 16.13: Dimensions and Friction Factors for Underground Workings | 129 |

| Table 18.1: Major Equipment Components as part of the Processing Plant | 144 |

| Table 21.1: Sustaining Capital Cost Summary | 149 |

| Table 21.2: Underground waste development for remaining life of mine | 150 |

| Table 21.3: Operating Costs | 152 |

| Table 21.4: Long Hole Mining Cost Summary (based on 2014 budget and actuals) | 153 |

| Table 22.1: Technical-Economic Modeling Assumptions | 158 |

| Table 22.2: Base Case Economic Analyses Results | 159 |

| Table 22.3: Comparison of Base Case Post Tax Results used in the PFS with Spot Price Post Tax Results at mid-December 2014 | 160 |

| Table 22.4: Discounted Post Tax Cash Flow Model | 163 |

| Table 26.1: Breakdown of future costs related to recommendations | 168 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

List of Figures in Text

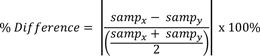

| Figure 1.1: Summary of annual tonnes and grade for the life of mine | 6 |

| Figure 4.1: Santa Elena Property Location | 13 |

| Figure 4.2: Santa Elena and Surrounding Area Property Map; | 16 |

| Figure 7.1: Santa Elena Property Geology Map | 24 |

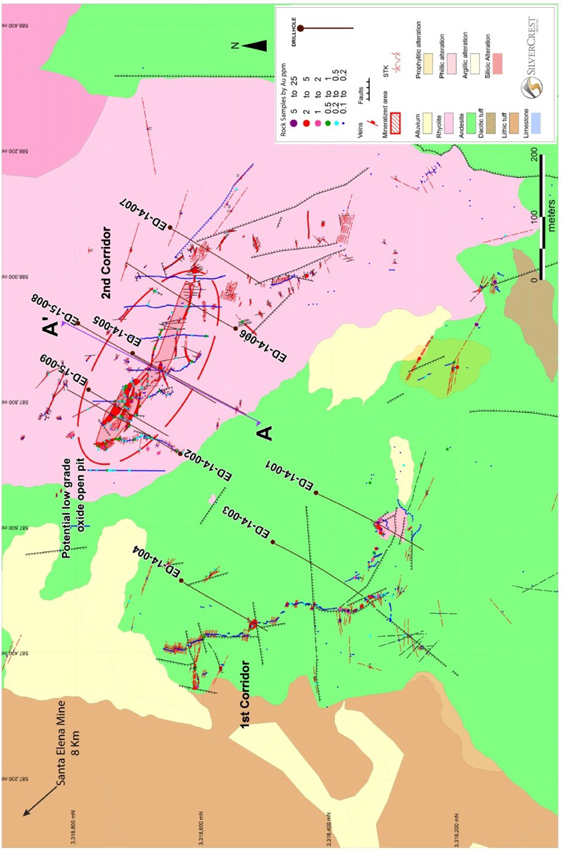

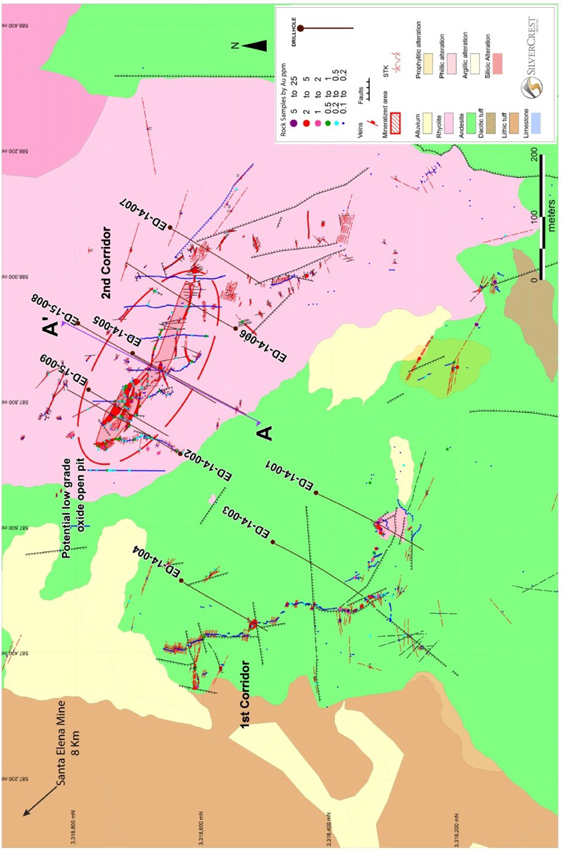

| Figure 7.2: El Durazno property Geology | 27 |

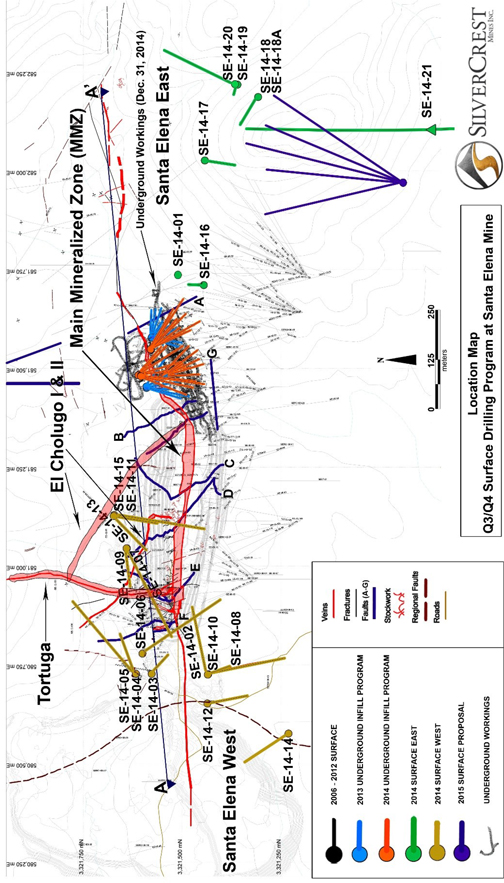

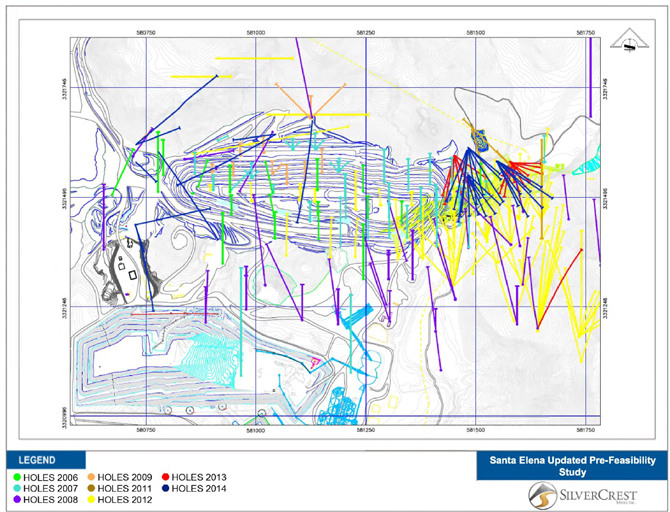

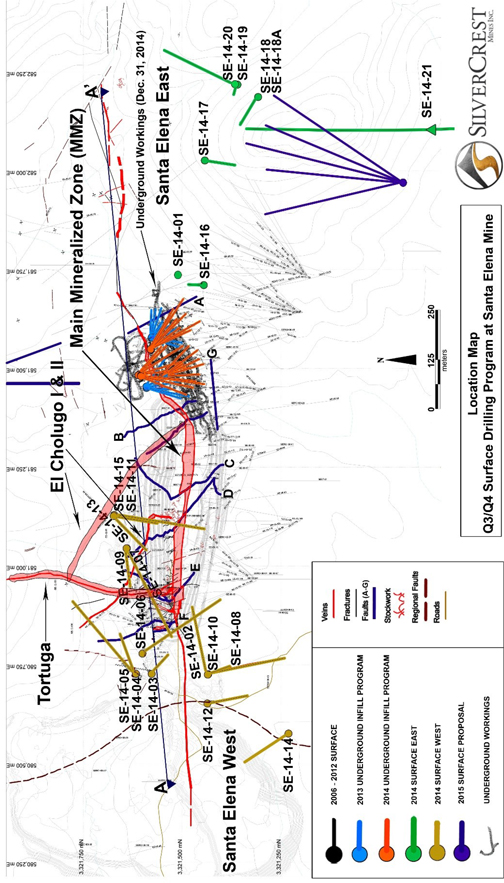

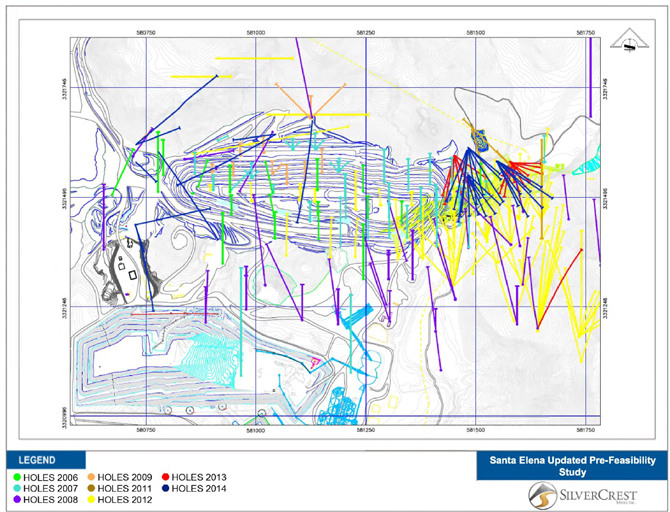

| Figure 10.1: Map Showing Drilling at Santa Elena, 2014 Drilling is Highlighted | 35 |

| Figure 10.2: Drill Program in Santa Elena MMZ by Year, Longitudinal Section | 36 |

| Figure 11.1: Santa Elena Sample Length Frequency used in 2013 Resource Estimate | 40 |

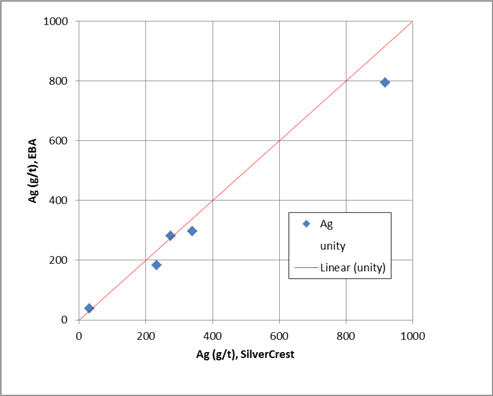

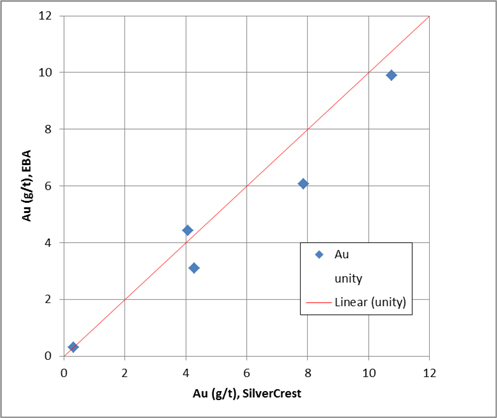

| Figure 12.1: Grade Verification Sampling, Silver | 48 |

| Figure 12.2: Grade Verification Sampling, Gold | 49 |

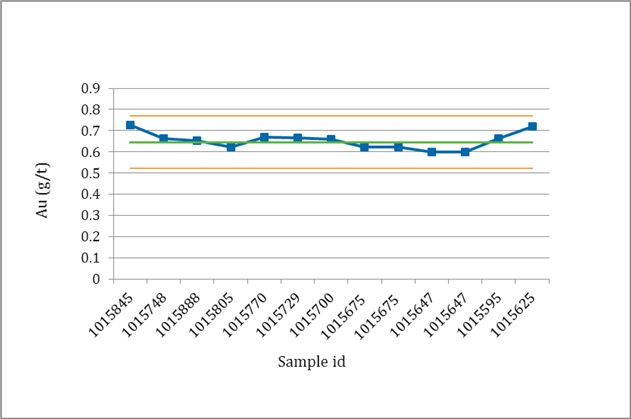

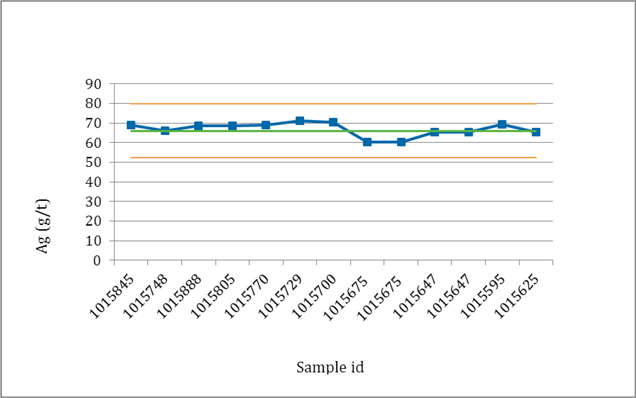

| Figure 12.3: CRM: CDN-GS-P5D – Gold | 50 |

| Figure 12.4: CRM: CDN-GS-P5D – Silver | 50 |

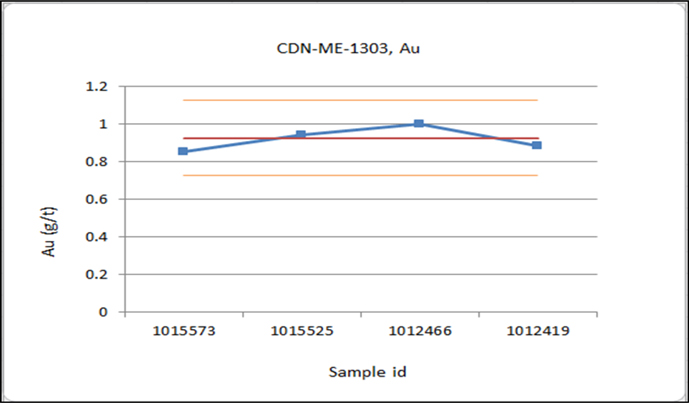

| Figure 12.5: CRM: CDN-ME-1303 – Gold | 51 |

| Figure 12.6: CRM: CDN-ME-1303 – Silver | 51 |

| Figure 12.7: CRM: CDN-ME-16 – Gold | 52 |

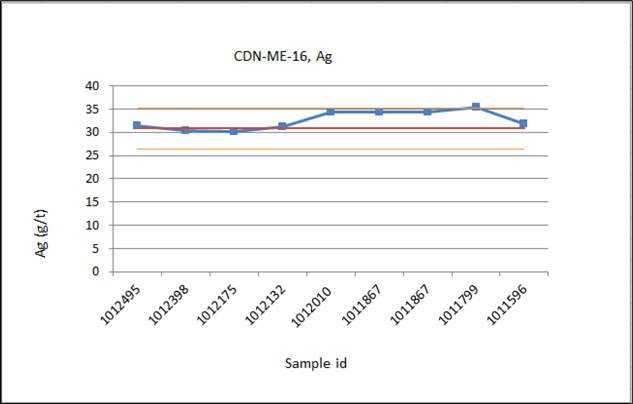

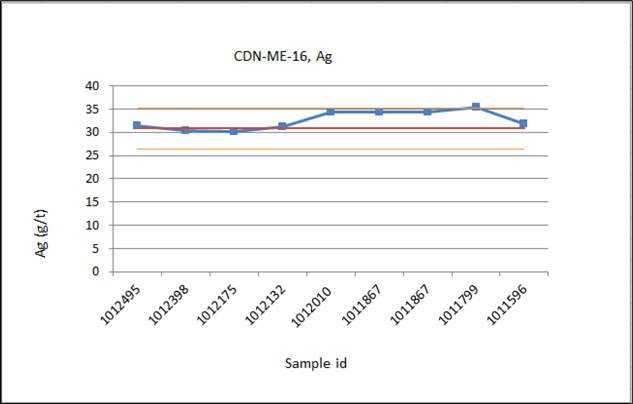

| Figure 12.8: CRM: CDN-ME-16 – Silver | 52 |

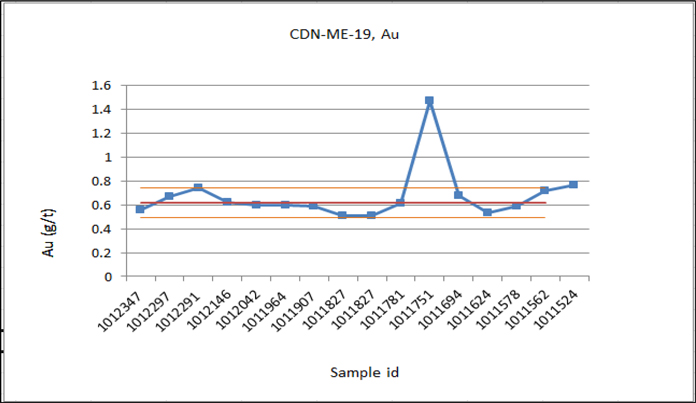

| Figure 12.9: CRM: CDN-ME-19 – Gold | 53 |

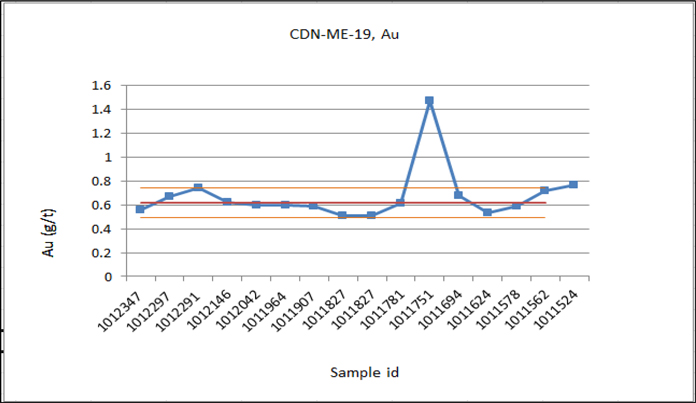

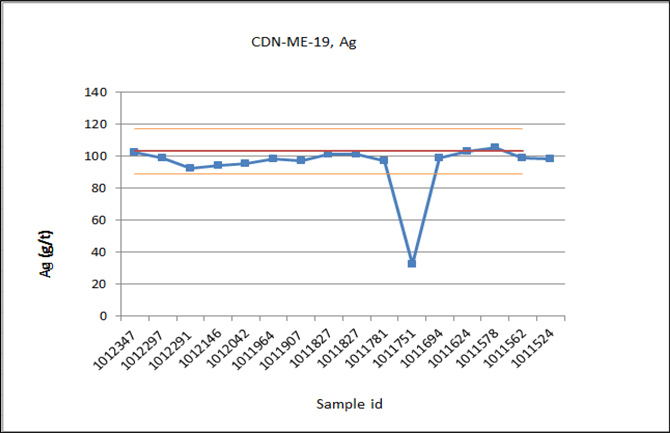

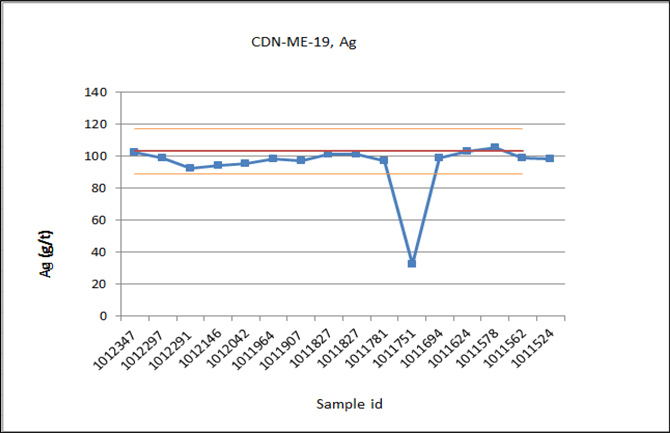

| Figure 12.10: CRM: CDN-ME-19 – Silver | 53 |

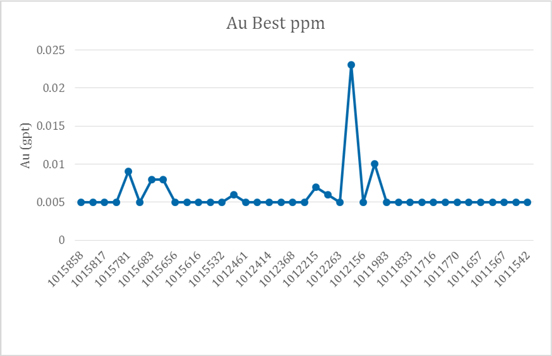

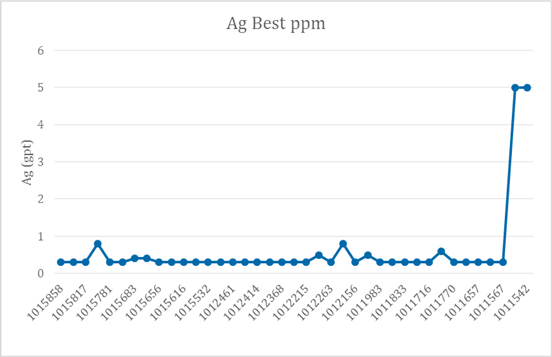

| Figure 12.11: SilverCrest 2013-2014 Reported Blank Material Au (gpt) | 54 |

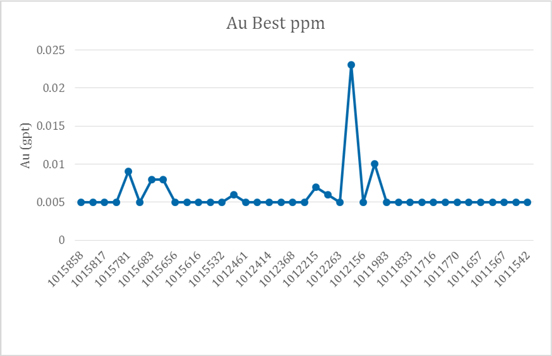

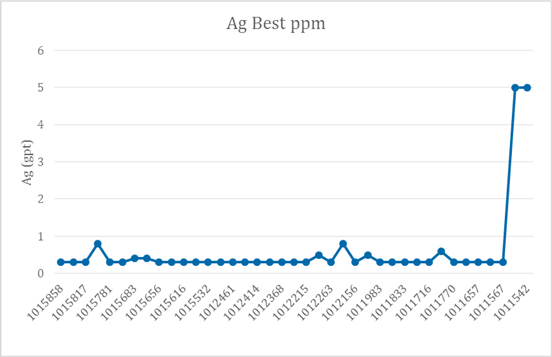

| Figure 12.12: SilverCrest 2013-2014 Reported Blank Material Ag (gpt) | 54 |

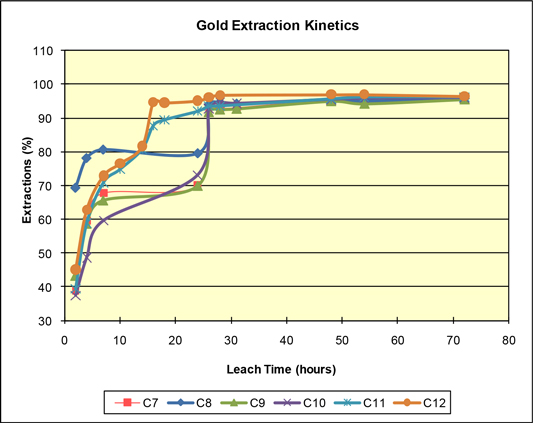

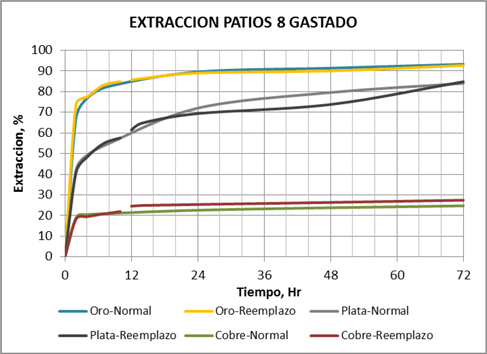

| Figure 13.1: Gold Leach Kinetics on Milled NIVEL 4 Comp | 57 |

| Figure 13.2: Silver Leach Kinetics on Milled NIVEL 4 Comp | 58 |

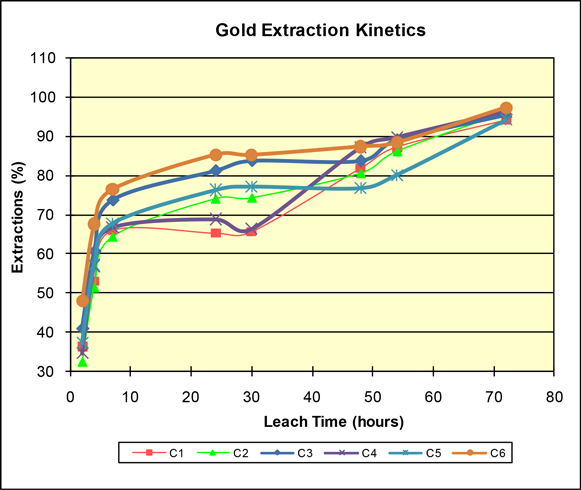

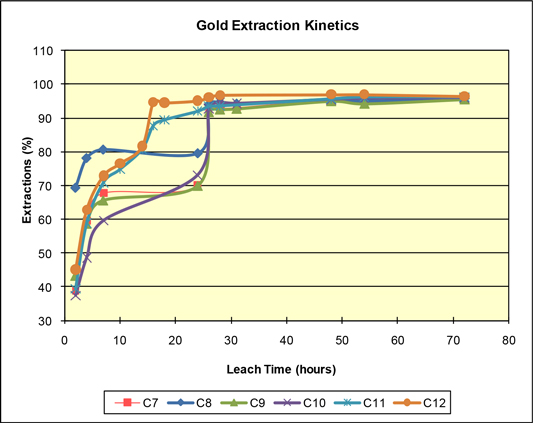

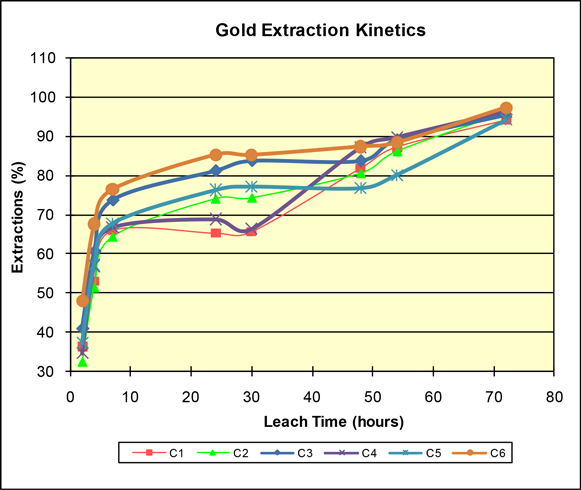

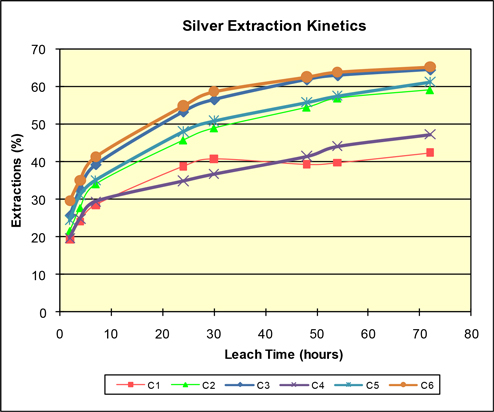

| Figure 13.3: Optimization Gold Extraction Kinetics | 59 |

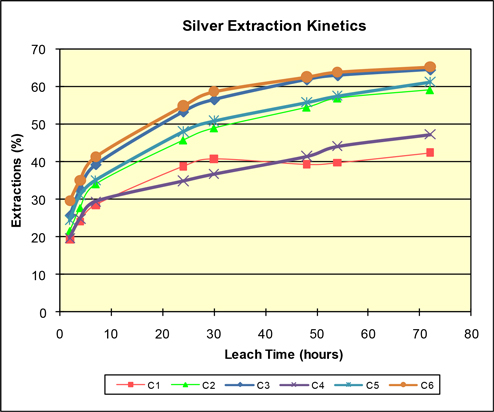

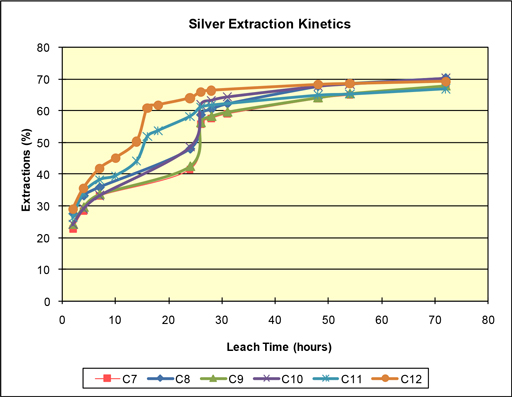

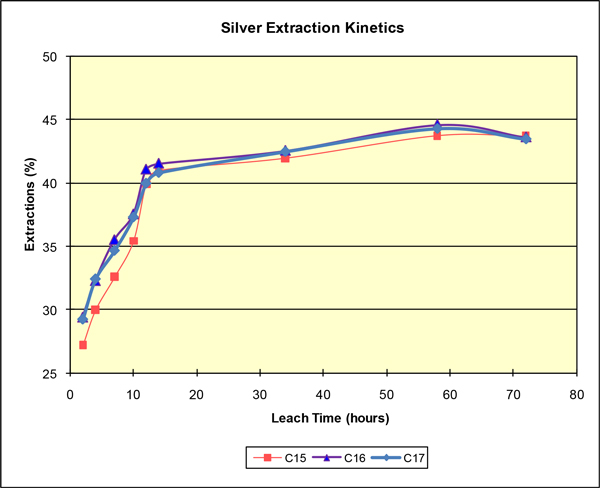

| Figure 13.4: Optimization Silver Extraction Kinetics | 60 |

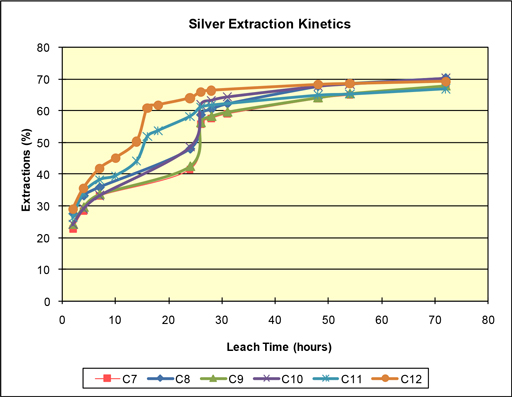

| Figure 13.5: Confirmatory Extraction Kinetics | 61 |

| Figure 13.6: Confirmatory Silver Extraction Kinetics | 62 |

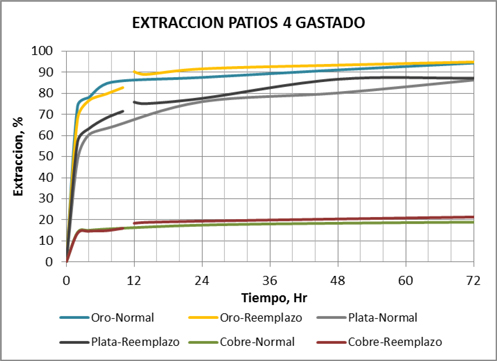

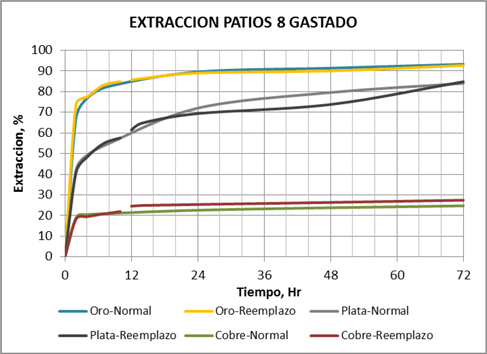

| Figure 13.7: Additional Testing of Composite Sample #4. | 64 |

| Figure 13.8: Additional Testing of Composite Sample #6. | 64 |

| Figure 13.9: Additional Testing of Composite Sample #8. | 65 |

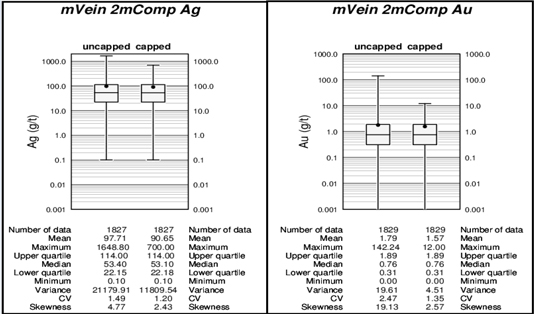

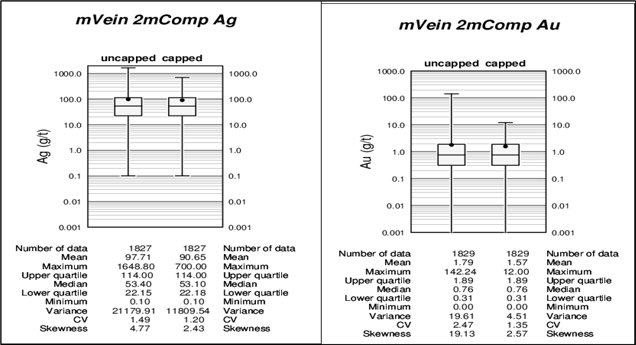

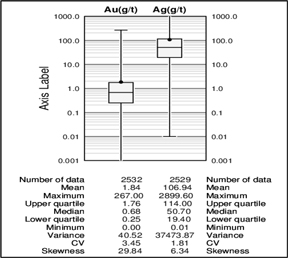

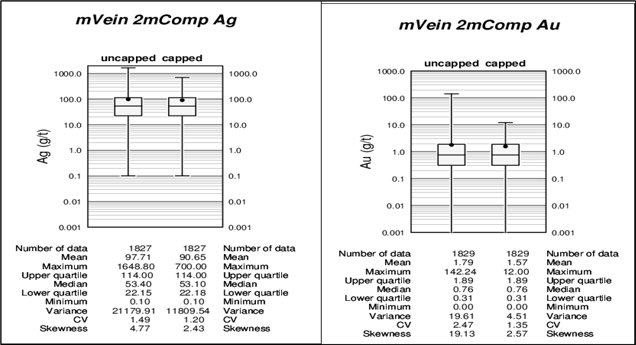

| Figure 14.1: Boxplot for Raw Gold and Silver within MMZ | 71 |

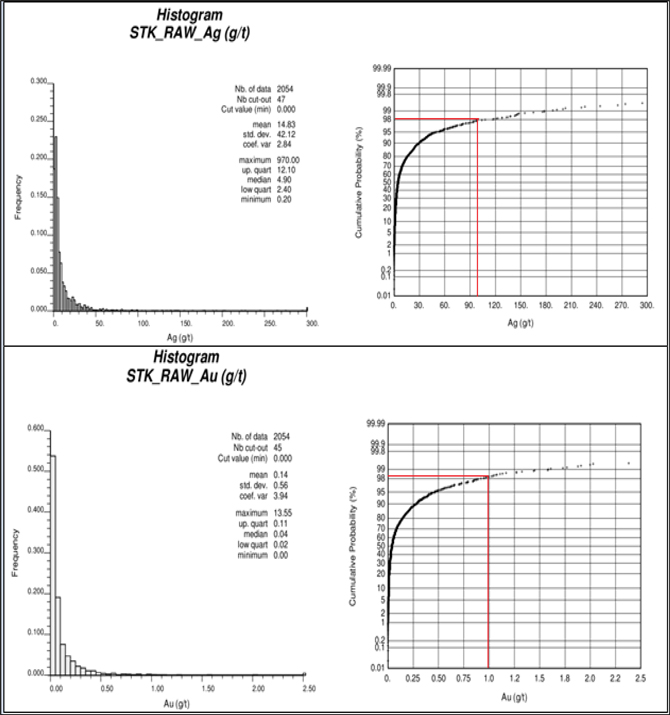

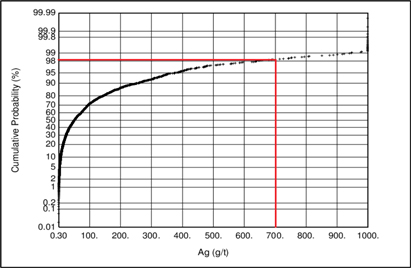

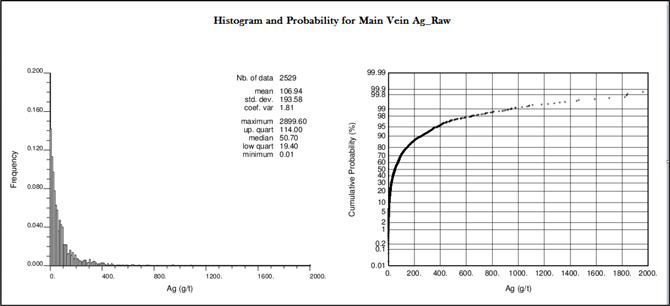

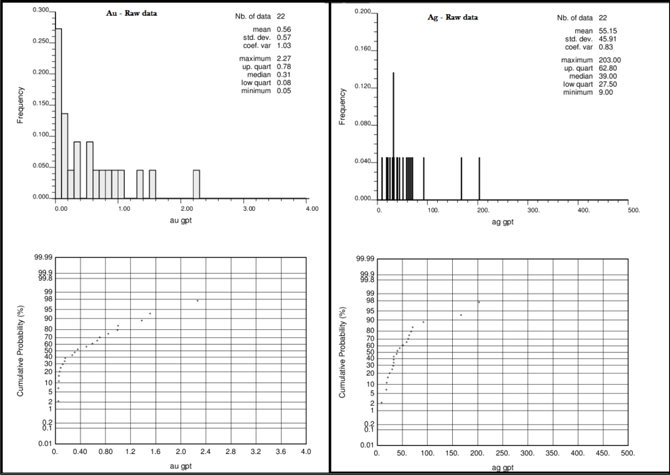

| Figure 14.2: Histogram and Probability Curve for Raw Silver within MMZ | 72 |

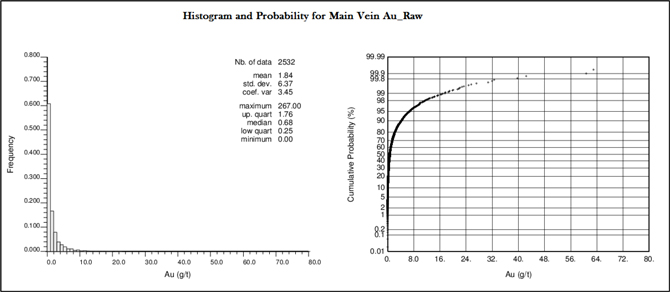

| Figure 14.3: Histogram and Probability Curve for Raw Gold within MMZ | 72 |

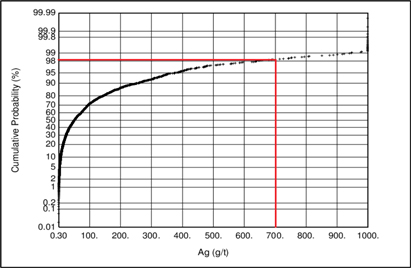

| Figure 14.4: Boxplot for Composited Gold and Silver within MMZ | 73 |

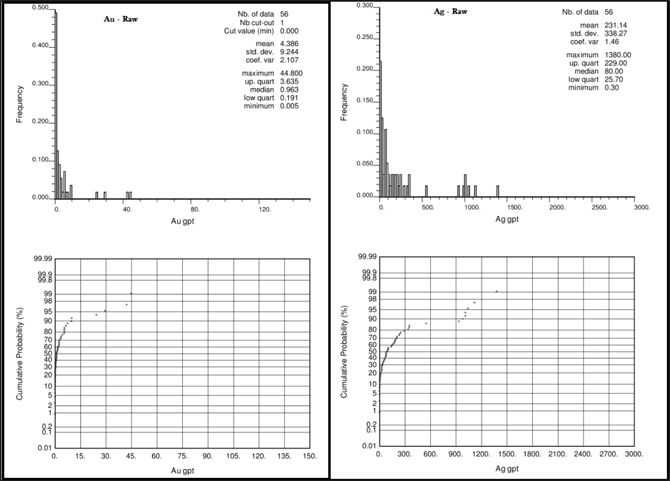

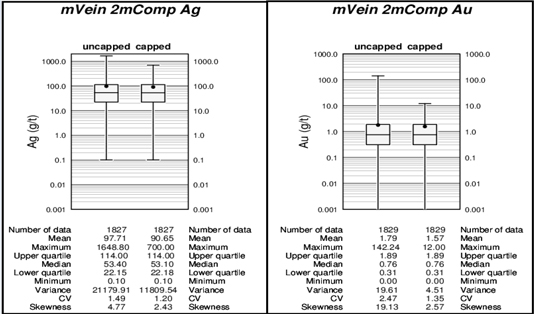

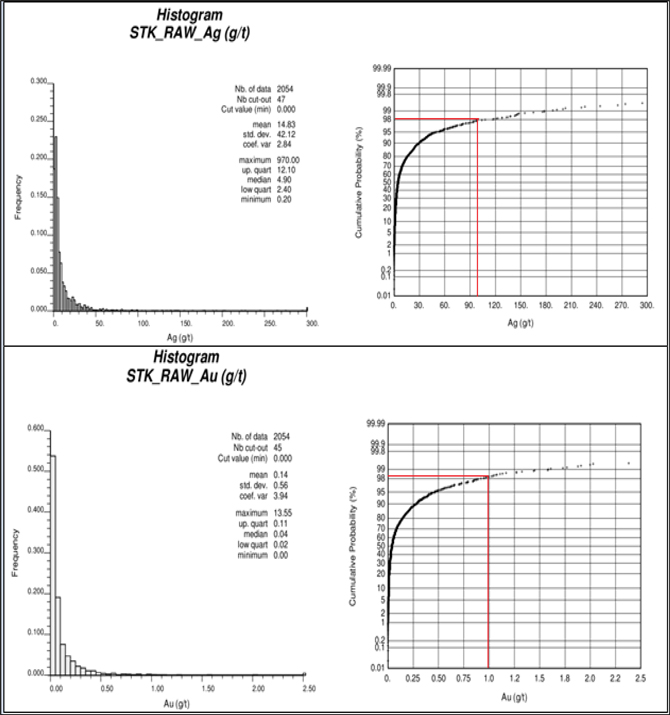

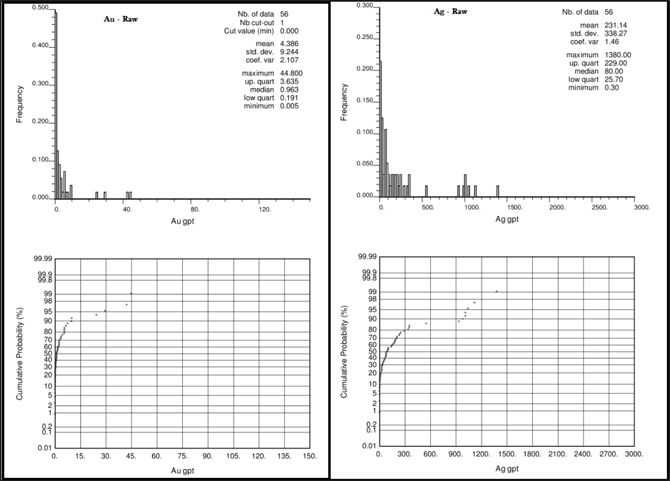

| Figure 14.5: Statistical Analyses for Stockwork | 74 |

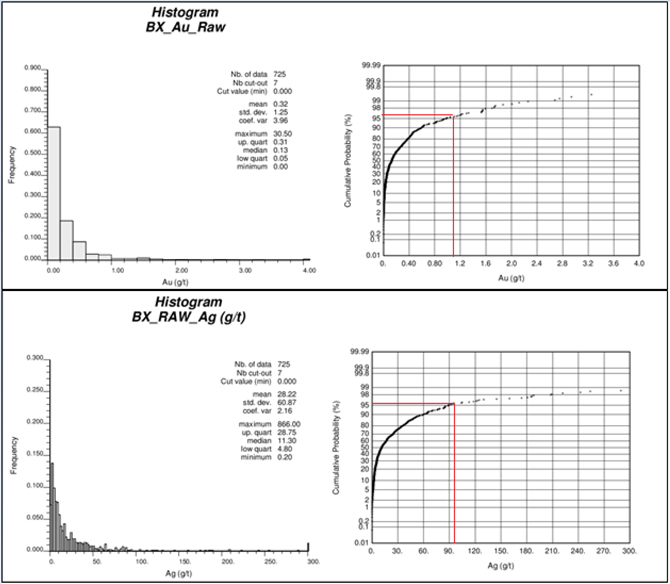

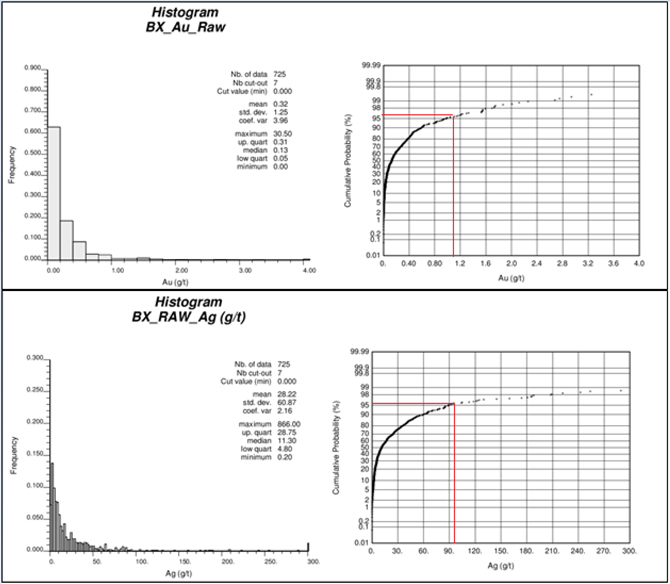

| Figure 14.6: Statistical Analyses for Breccia | 75 |

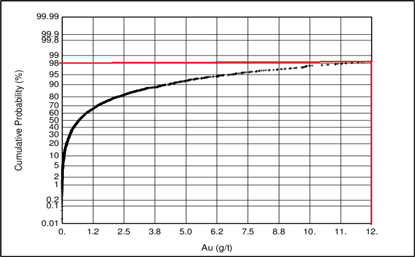

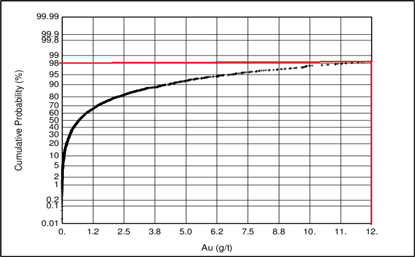

| Figure 14.7: Cumulative Log-Probability Graph for Raw Gold Grades | 76 |

| Figure 14.8: Cumulative Log-Probability Curve for Raw Silver Grades | 76 |

| Figure 14.9: Histogram and Probability Plot of Raw Length Values within the MMZ | 77 |

| Figure 14.10: Box Plots with Capped and Uncapped Samples within MMZ | 78 |

| Figure 14.11: Box Plots with Capped and Uncapped Samples within the Stockwork | 78 |

| Figure 14.12: Box Plots with Capped and Uncapped Samples within the Breccia | 79 |

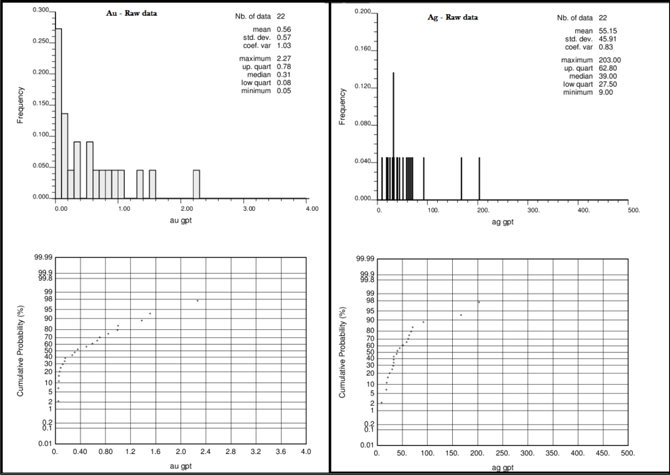

| Figure 14.13: El Cholugo Vein Statistical Analyses | 80 |

| Figure 14.14: Histogram and Probability Curve for Raw Gold and Silver within Tortuga Vein | 81 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| Figure 14.15: Location of Drill Holes used in 2015 Mineral and Solid Resource Update | 83 |

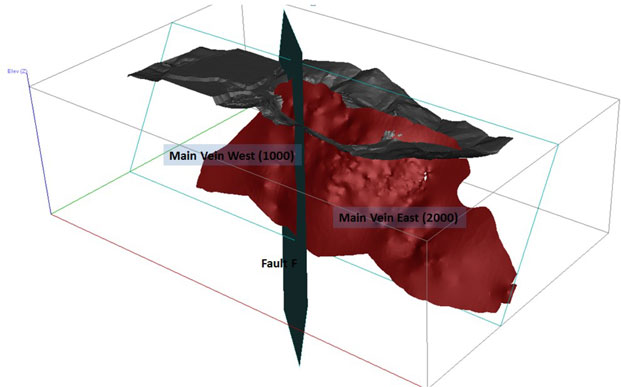

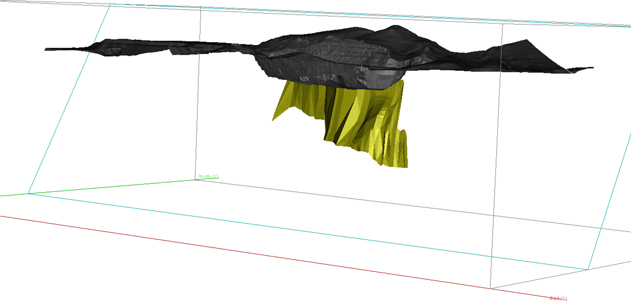

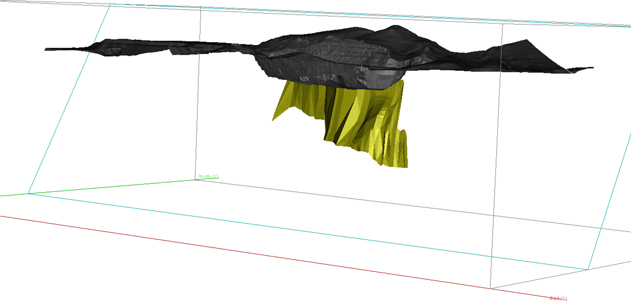

| Figure 14.16: Geological Model Showing Vein Domains, Looking Northwest | 85 |

| Figure 14.17: Geological Model Showing Lithology Units: Main Mineralized Zone (red), Breccia(grey) and Stockwork (green), Looking Northwest | 85 |

| Figure 14.18: Geological Model Showing El Cholugo, Looking Northwest | 86 |

| Figure 14.19: Oblique View of MMZ Block Model Showing Indicated AuEq Blocks, Looking Northeast | 90 |

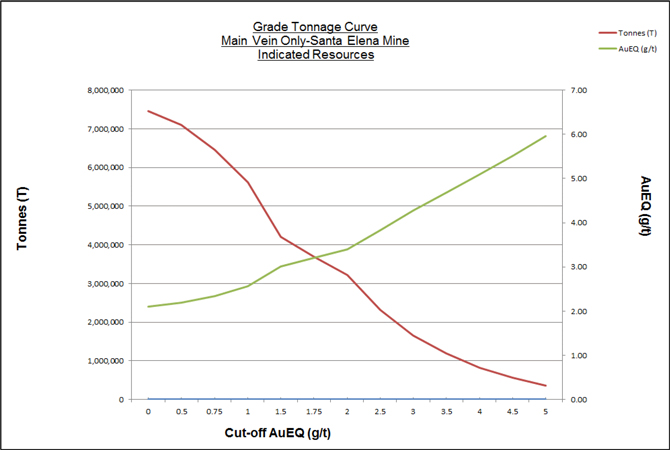

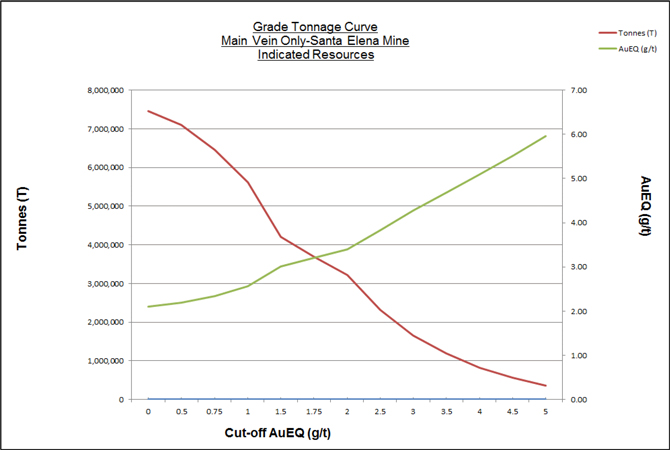

| Figure 14.20: Grade Tonnage Curve for Indicated Mineral Resources | 91 |

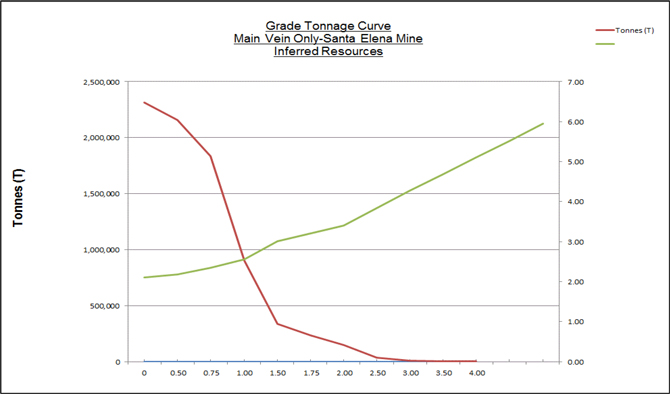

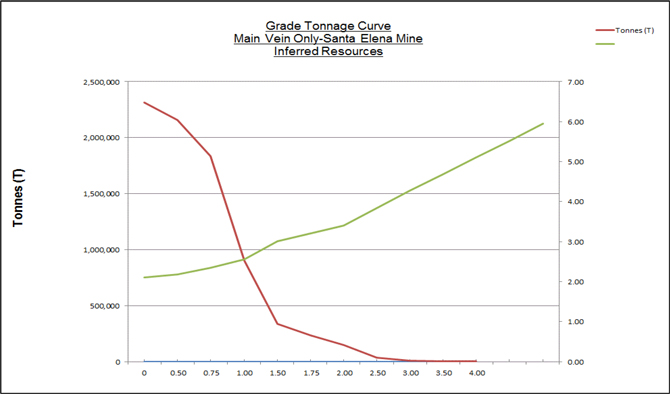

| Figure 14.21: Grade Tonnage Curve for Inferred Mineral Resources | 92 |

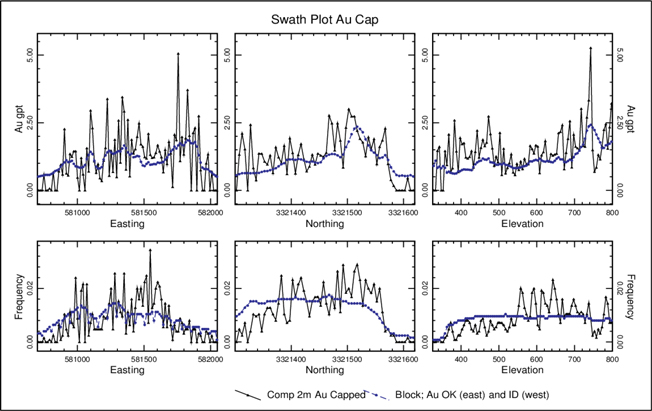

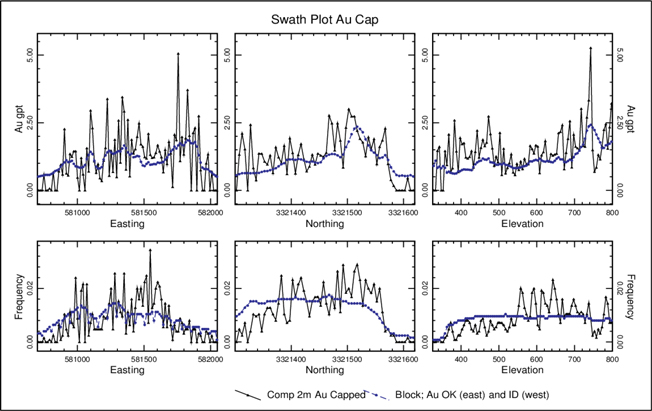

| Figure 14.22: Gold Swath Plot | 93 |

| Figure 14.23: Silver Swath Plot: | 94 |

| Figure 15.1: Stope Shapes defined for use in Reserve Definition | 99 |

| Figure 16.1: General Sublevel Stoping Operation | 110 |

| Figure 16.2: General Mechanized Cut and Fill Stoping Method | 112 |

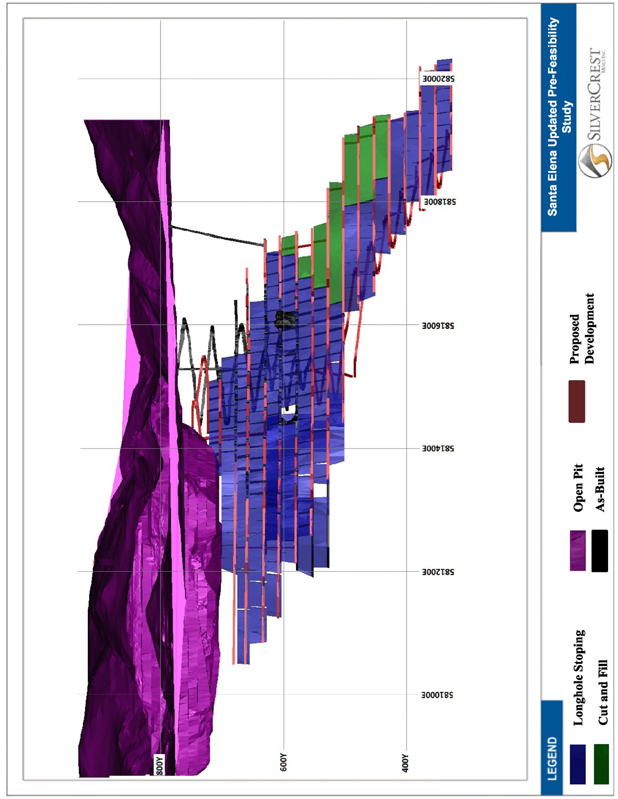

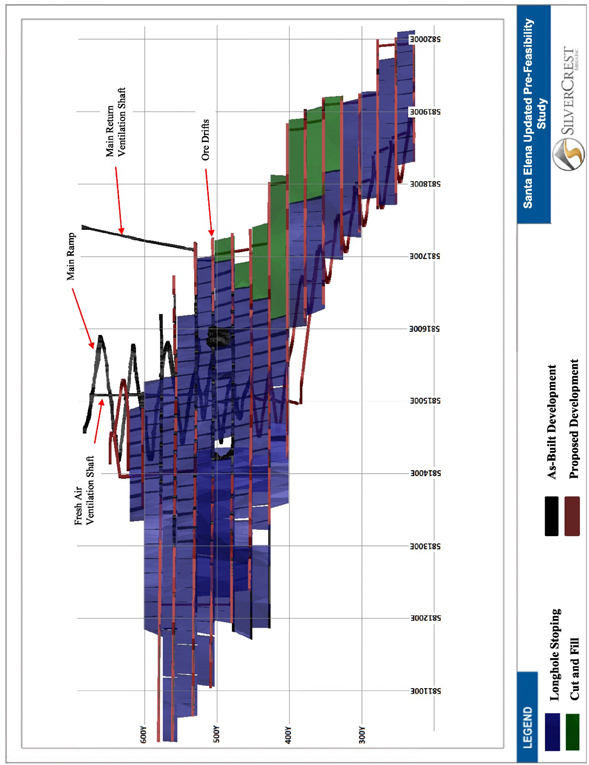

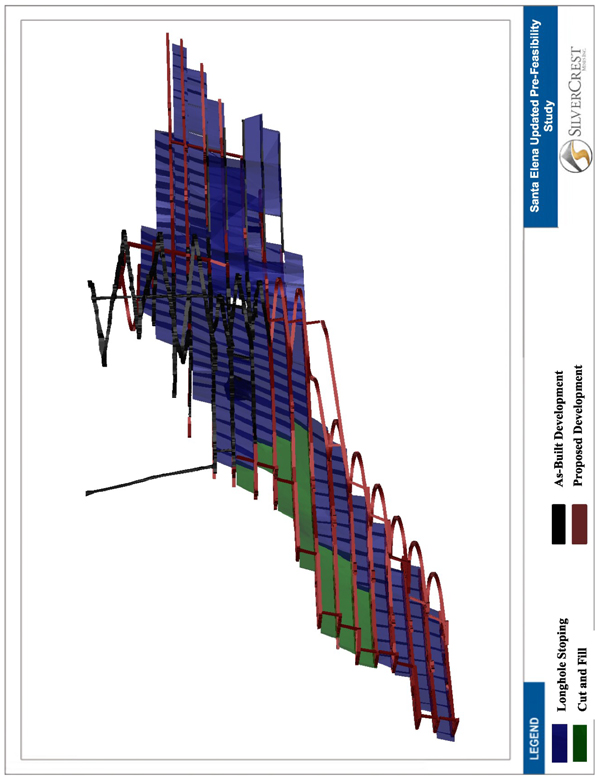

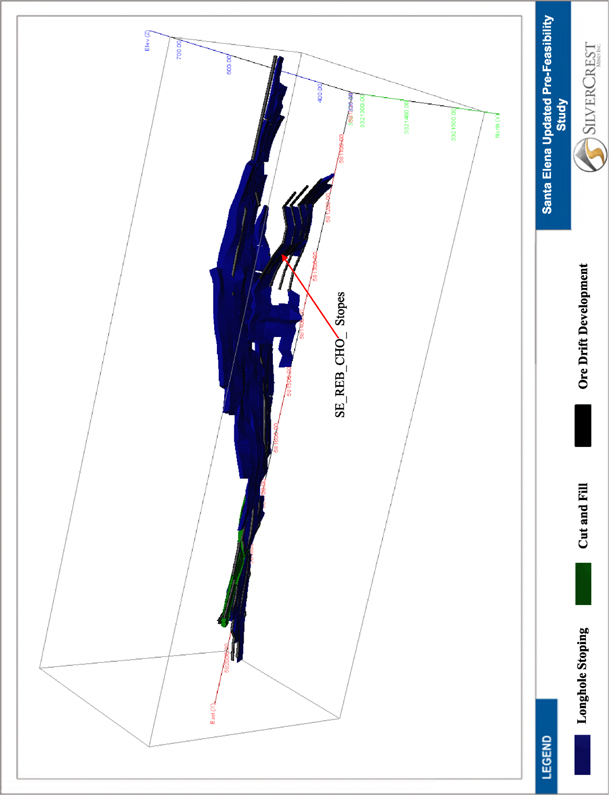

| Figure 16.3: Longitudinal View of Stopes, Looking North | 115 |

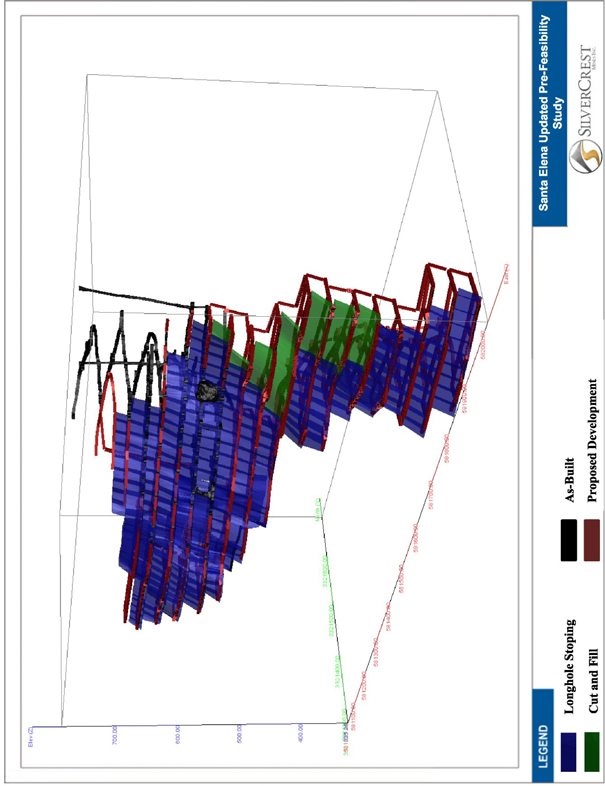

| Figure 16.4: 3D View of Stope Layout, Looking Northwest | 116 |

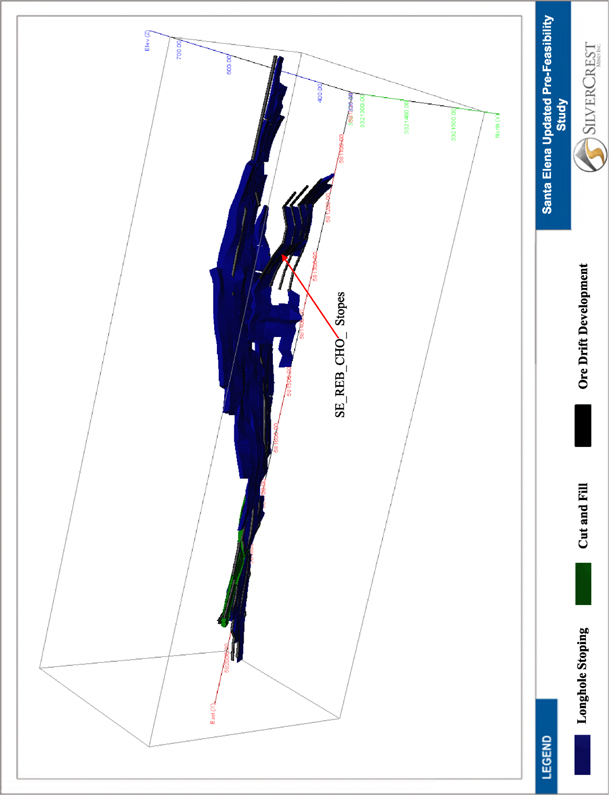

| Figure 16.5: 3D View of Stope Layout Showing El Cholugo and MMZ, Looking Down and to South | 117 |

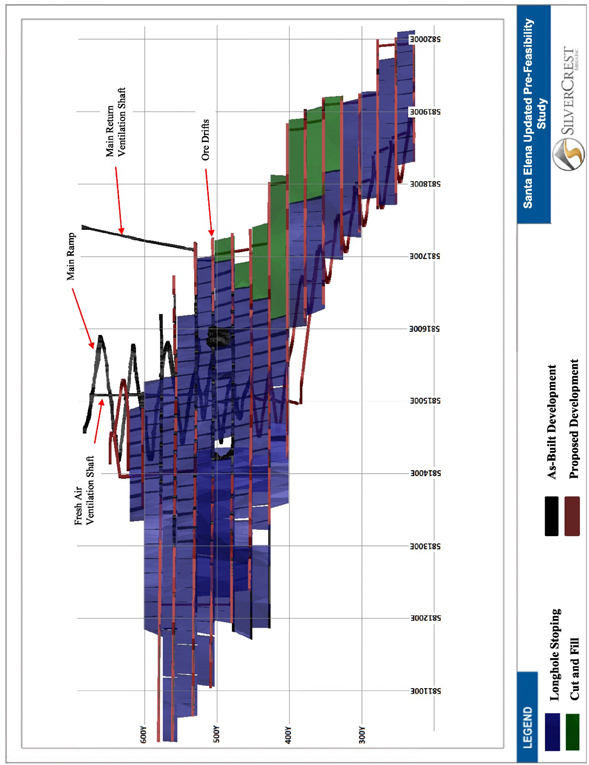

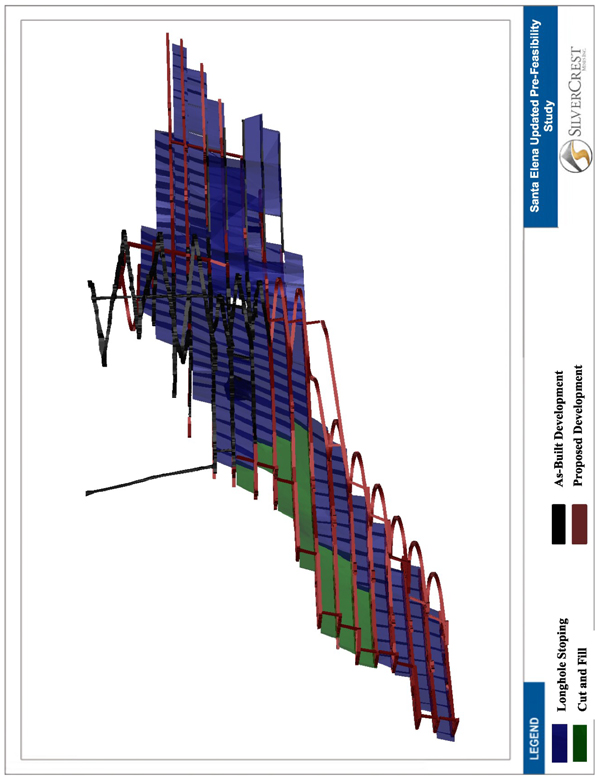

| Figure 16.6: Development and Stope Layout, Looking North | 119 |

| Figure 16.7: 3D View of Stope and Development Layout, Looking South (Footwall Side) | 120 |

| Figure 16.8: Summary of Annual Tonnes by Underground Mining Methods and Grade for the Life of Mine | 123 |

| Figure 16.9: Phase 1 Ventilation Air Flow Diagram | 130 |

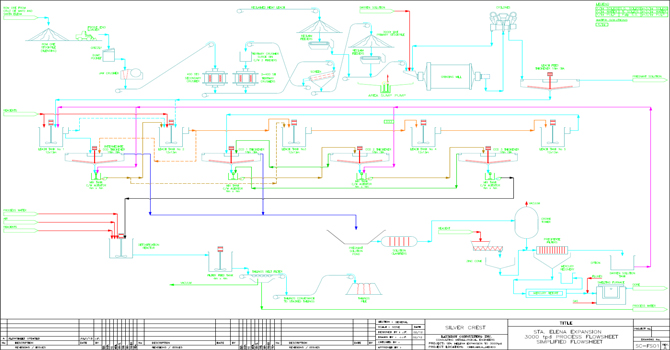

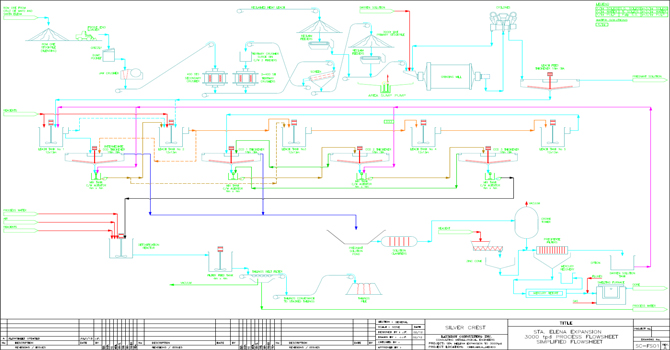

| Figure 17.1: Santa Elena Expansion 3000 tpd Process Flowsheet | 137 |

| Figure 17.2: Santa Elena Expansion Plan Plant Mechanical General Arrangement | 138 |

| Figure 18.1: Site General Arrangement Plan | 141 |

| Figure 22.1: Pre-tax and Post-tax Cash Flows | 161 |

| Figure 22.2: NPV Sensitivity Analyses | 164 |

| Figure 22.3: Gold and Silver Recoveries NPV Sensitivity Analyses | 165 |

List of PHOTOGRAPHS in Text

| Photo 7.1: View of Vein Outcrop at Ermitaño West | 28 |

| Photo 7.2: Showing Veta Valentia Epithermal Vein Outcrop | 29 |

| Photo 11.1: Heap Leach Sampling | 46 |

| Photo 16.1: View of Stope 2 (Long hole stoping with Hangingwall Cable Bolting) | 109 |

| Photo 16.2: Showing Pad Ore on Leach Pad and Recovery Conveyor System | 132 |

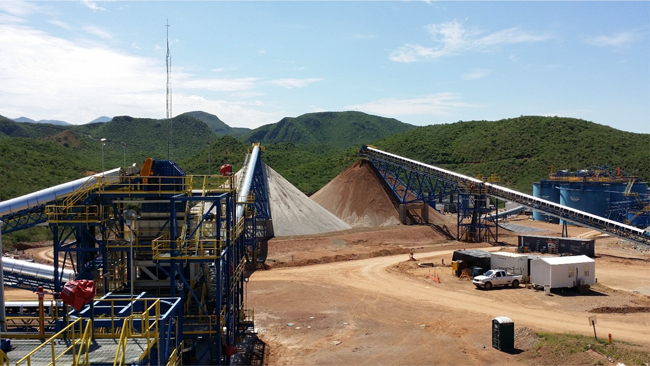

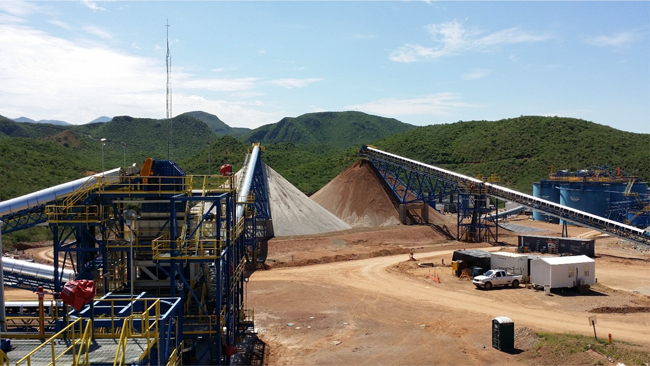

| Photo 17.1: Showing Pad Ore Recovery Conveyor and Stockpile with CCD Tanks in Background | 134 |

| Photo 17.2: Showing Two Stockpiles for Underground (White) and Pad Ore (Brown) | 135 |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Acronyms & Abbreviations

| AA | Atomic Absorption |

| Au | Gold |

| AuEq | Gold equivalent |

| BC | British Columbia |

| CIM | Canadian Institute for Mining, Metallurgy and Petroleum |

| CNCF | Cumulative Net Cash Flow |

| CONAGUA | Comision Nacional Del Agua |

| CRM | Certified Reference Material |

| DCF | Discounted Cash Flow |

| DDH | Diamond Drill Hole |

| DGGFS | Dirección General de Gestión Forestal y de Suelos |

| DTM | Digital terrain model |

| EBA | Tetra Tech EBA Inc. |

| Evrim | Evrim Resources Corp. |

| FA | Fire Assay |

| GRA | Gravimetric Determination |

| ICP-AES | Inductively coupled plasma-atomic emission spectrometry |

| IDW | Inverse Distance Weighted |

| INAH | Nation Institute of Archaeology and History |

| INEGI | Instituto Nacional de Geografía y Estadística de México |

| LOM | Life of Mine |

| LOMP | Life of Mine Plan |

| NCF | Net Cash Flow |

| NI 43-101 | National Instrument 43-101 Standards of Disclosure for Mineral Projects |

| NGI | Norwegian Geotechnical Institute |

| NN | Nearest Neighbor |

| NSR | Net Smelter Returns |

| NPV | Net present Value |

| OK | Ordinary Kriging |

| PFS | Pre-Feasibility Study |

| P.Eng | Professional Engineer |

| P.Geo | Professional Geologist |

| QA-QC | Quality Assurance and Quality Control |

| QP | Qualified Person |

| RC | Reverse Circulation |

| RMR | Rock Mass Rating |

| RQD | Rock Quality Designation |

| S.A. de C.V. | Sociedad Anónima de Capital Variable |

| SCdM | SilverCrest de Mexico S.A. de C.V. |

| SD | Standard Deviation |

| SEDENA | Mexican Secretariat of National Defense |

| SEMARNAT | Secretaría de Medio Ambiente y Recursos Naturales |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| SWRPA | Scott Wilson Roscoe Postle Associates |

| UBC | University of British Columbia |

| UG | Underground |

| UTM | Universal Transverse Mercator |

| WGS | World Geodetic System |

| XRD | X-ray diffraction analyses |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Units of Measurement and Conversions

| $USD | United States Dollar |

| % | Percent |

| °C | Degree Celsius |

| Bhp | Brake Horse Power |

| cu.m/s | Cubic Metre per Second |

| deg | Degrees |

| gal | Gallon |

| gpt | Grams per tonne |

| ha | Hectare (10,000 square meters) |

| HP | Horsepower |

| hrs | Hours |

| kg | Kilogram |

| km | Kilometre |

| kV | Kilovolt |

| kW | Kilowatt |

| kWhr | Kilowatt Hour |

| Lps | Litres per second |

| M | Million |

| M | Metre |

| m/s | Metre per second |

| m3/s | Metre cubed per second |

| Ma | Million Years |

| mm | Millimetre |

| MxnPeso$ | Mexican Pesos |

| MW | MegaWattPascal |

| Pa | Pascal |

| oz | Ounce (troy) |

| ppb | Part per billion |

| ppm | Parts per million |

| Sec | Second |

| V | Volt |

| AuEq (gpt) |  |

| % Difference |  |

| Contained oz |  |

| Contained lbs |  |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

SilverCrest Mines Inc. (SilverCrest, SVL) of Vancouver, British Columbia, Canada has prepared this Update to Pre-Feasibility Study for the Santa Elena Mine, located in central Sonora, Mexico. The Technical Report prepared is in compliance with National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) titled, “Update to Santa Elena Pre-Feasibility Study, Sonora Mexico” (the “UPFS”), for its operating Santa Elena mine. The UPFS updates the Santa Elena Pre-Feasibility Study and Open Pit Resource Update dated effective April 30, 2013, as amended March 4, 2014 (the “2013 PFS”). Summaries of the revised Reserves and Resources, Life of Mine Plan (“LOMP or LOM”), operating costs, sustaining capital costs and project economics are presented in tables below. All dollar amounts are expressed in U.S. dollars unless otherwise specified. The effective date of this Technical Report is December 31, 2014. Refer to the “Santa Elena Expansion Pre-Feasibility Study and Open Pit Reserve Update” with effective date of April 30, 2013, and amended date of March 4, 2014 for further information being referenced in this report.

Nusantara de Mexico S.A. de C.V., a 100% owned Mexican subsidiary and a legal operating entity of SilverCrest, holds the rights to the Santa Elena Mine and associated exploration concessions.

The Santa Elena Mine is currently producing gold and silver from a 3,000 tonne per day open pit, underground and reprocessing of heap leaching material using a new fully commissioned Merrill Crowe/CCD processing facility. The Santa Elena Project involves combined processing of ore from the remaining reserves in the open pit, updated reserves from underground development and reprocessing of spent ore from the existing heap leach pad. Commercial production for the 3,000 tonne per day mill and plant facility was declared on August 1, 2014. Underground development has been ongoing since January 2013 with commercial production declared on October 1, 2014. As of December 2014, the decline had been developed to approximately the 575 metre elevation with development drifts on the 700, 675, 650, 625, 600, and 575 metre levels (elevations above sea level). Underground stope production in late 2014 consisting of long hole stoping of Stope #1 which is located between the 575 to 600 metre levels and preparation and of stope #2 and #3.

The purpose of this report is to document an update to the 2013 Pre-Feasibility Study completed for the Santa Elena Project supported by updated Mineral Resource, Mineral Reserve Estimates, mine design, Life of Mine Plan, sustaining capital and operating costs and economic analyses.

This report conforms to National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101 and Form 43-101F1), and incorporates the Canadian Institute for Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves (CIM Definition Standards).

| 1.2 | Santa Elena Update to Mineral Resources and Mineral Reserves |

Update to the Mineral Reserves and Resources (open pit, underground and leach pad) are shown in the table below. Only Indicated Resources were used to define Mineral Reserves in the UPFS mine plan, schedule and economic analyses. To summarize, Total Reserves are 7.45 million tonnes grading 1.23 gpt Au and 78.4 gpt Ag, containing 295 thousand ounces of gold and 18.76 million ounces of silver. This represents a 10% decrease in contained gold and 5% decrease in contained silver over previous Probable Reserves stated in the 2013 PFS Technical Report. Updated Indicated Resources (exclusive of Probable Reserves) are estimated at 1.1 million tonnes grading 1.39 gpt Au and 89.7 gpt Ag, containing 50 thousand ounces of gold and 3.2 million ounces of silver. This represents a 57% decrease in contained gold ounces and 59% decrease in contained silver ounces over previous Indicated Resources. Updated Inferred Resources are estimated at 0.56 million tonnes grading 1.69 gpt Au and 106.5 gpt Ag, containing 31 thousand ounces of gold and 1.9 million ounces of silver. This represents a 57% decrease in contained gold ounces and 74% decrease in contained silver ounces. The percentage differences in gold and silver from PFS (April 30, 2013) are based on:

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| § | A minimal of decrease of overall reserves from mining depletion even with base case metal price used for cut off analyses changed from $1,450 per ounce of gold to $1300 and $28 per ounce of silver to $19.50. |

| § | A decrease in open pit reserves due to mining depletion due to mining from April 30, 2013 to April 1, 2014. |

| § | An increase in leach pad reserves with continuation of open pit mining in 2013 and 2014 and partial leaching (300 day leach cycle) of ore. |

| § | Overall, increase in mine life after mining depletion. |

| § | Resources have been impacted by conversion to reserves, lower base case metal prices, update geological model incorporating infill drilling, changes in estimation supported by additional drilling completed in 2013 and 2014 and production data generated during the life of mine at the open pit operations. |

Table 1.1: Update to Mineral Reserve and Resource Estimates (December 31, 2014)

| SANTA ELENA RESERVES (DECEMBER 31, 2014) |

| Classification | Tonnes | Au gpt | Ag gpt | Contained Au oz | Contained ag

oz |

| Santa Elena Underground Diluted And Recoverable Reserves* |

| Probable | 3,981,557 | 1.67 | 115.0 | 214,000 | 14,724,000 |

| Santa Elena Open Pit Reserves** |

| Probable | 121,706 | 2.75 | 117.0 | 11,000 | 458,000 |

| Santa Elena Leach Pad Reserves*** |

| Probable | 3,344,652 | 0.65 | 33.3 | 70,000 | 3,582,000 |

| Total Santa Elena Reserves |

| Probable | 7,447,915 | 1.23 | 78.4 | 295,000 | 18,764,000 |

| Santa Elena Resources (December 31, 2014) **** |

| Indicated | 1,117,032 | 1.39 | 89.7 | 50,000 | 3,220,000 |

| Inferred | 564,073 | 1.69 | 106.5 | 31,000 | 1,932,000 |

Note: All numbers are rounded. Underground and Leach Pad Reserves and Resources are based on LOMP metal price trends of $1,300/oz gold and $19.50/oz silver, and metallurgical recoveries of 92% Au and 67.5% Ag. All Mineral Resources and Reserves conform to NI 43-101 and CIM definitions for Resources and Reserves. Inferred Resources have been estimated from geological evidence and limited sampling and must be treated with a lower level of confidence than Indicated Resources.

*Underground Probable Reserve is based on a cut-off grade of 2.49 gpt AuEq with an average est. 10% dilution and 90% mine recovery. Average true thickness of the designed stopes is 10 metres.

** Open Pit Reserve is based on a cut-off grade of 0.20 gpt AuEq in a constrained pit shell with applied capping of 8 gpt Au and 300 gpt Ag.

*** Leach Pad Reserve based on production and drill hole data for volumetrics and grade model using a cut-off grade of 0.5 gpt AuEq. No capping was applied.

****Mineral Resources exclude Mineral Reserves and are based on a 1.5 gpt AuEq cut-off grade using assumptions for prices and recoveries as stated in note above. Capping was applied at 12 gpt Au and 700 gpt Ag.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Table 1.2: Previous Reserve and Resource Estimates (2013 PFS) for comparative purposes

| Classification1 | Tonnes | Au Gpt | Ag Gpt | Au Oz | Ag Oz |

| Santa Elena Underground Diluted and Recoverable Reserves2 |

| Probable | 3,920,510 | 1.57 | 108.1 | 198,170 | 13,624,640 |

| Santa Elena Open Pit Reserves3 |

| Probable | 1,426,710 | 1.52 | 66.8 | 69,830 | 3,062,200 |

| Santa Elena Leach Pad Reserves4 |

| Probable | 2,844,530 | 0.65 | 33.3 | 59,420 | 3,048,200 |

| Total Reserves | 8,191,760 | 1.24 | 74.9 | 327,430 | 19,735,050 |

| Santa Elena Underground Resources5 |

| Indicated | 2,142,820 | 1.69 | 114.9 | 116,000 | 7,919,000 |

| Inferred | 1,489,750 | 1.50 | 155.6 | 72,000 | 7,453,000 |

Note:

All numbers are rounded. Underground and Leach Pad Reserves and Resources are based on 3 year historic metal price trends of US$28/oz silver, US$1450/oz gold and metallurgical recoveries of 92% Au and 67.5% Ag with a metal ratio of Ag:Au at 70:1 used for grade cut-off determination . All Mineral Resources and Reserves conform to NI 43-101 and CIM definitions for Resources and Reserves. Inferred Resources have been estimated from geological evidence and limited sampling and must be treated with a lower level of confidence than Indicated Resources.

1Open Pit and Leach Pad Probable Reserves were classified by SilverCrest. Underground Reserves and Resources were classified by EBA, a Tetra Tech Company.

2Underground Probable Reserve is based on a cut-off grade of 1.47 gpt AuEq with an average 10% dilution and 90% mine recovery. Average true thickness of the designed stopes is 13.4 metres.

3Open Pit Reserve is based on a cut-off grade of 0.20 gpt AuEq in a constrained pit shell with applied capping of 8 gpt Au and 300 gpt Ag.

4Leach Pad Reserve based on production and drill hole data for volumetrics and grade model using a cut-off grade of 0.5 gpt AuEq. No capping was applied.

5Underground Resources are exclusive of Probable Reserves and based on 1 gpt AuEq grade shell, a cut-off grade of 1.4 gpt AuEq, and applied capping of 12 gpt Au and 600 gpt Ag.

The update to underground Reserves and Resources have been estimated by SilverCrest utilizing 2013 and 2014 drilling and production results along with previous independently-validated data (see 2013 PFS and previous NI 43-101 compliant Technical Reports on SEDAR at www.sedar.com). Drilling in 2013 and 2014 was focused on underground and surface infill drilling, conversion and expansion of underground Resources to Reserves with an average drill hole spacing of approximately 35 to 45 metres.

The update to open pit Reserves have been estimated by SilverCrest utilizing extensive production data (blastholes), exploration drilling data drilling data and a 3D computer modelling. All Indicated Resources in the currently operating open pit have been converted to Reserves.

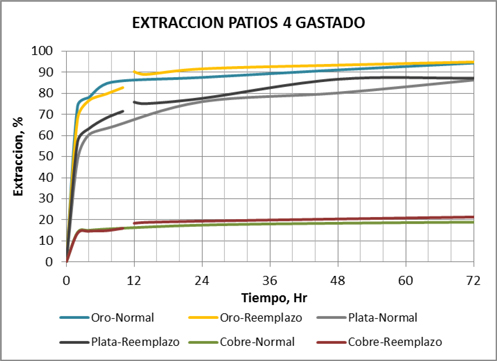

The Leach Pad Reserves (spent ore) have been estimated by SilverCrest utilizing production data, crusher composite samples, drill data from verification holes on the pad, bottle roll tests to process design specifications and SilverCrest production leach curves. Spent ore material on the leach pad is currently being reprocessed through the new processing facility. No further leach pad material is anticipated to be loaded on the pad.

Drilling data used for Resource estimation from discovery of the deposit (2006) to December 2014 included 366 holes (88,881 metres). A total of 1,983 two metre composite samples were used as the basis for the block model, with 1,871 within the Main Mineralized Zones, 88 for El Cholugo, and 24 for Tortuga.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

As of April 2011 before commencement of initial production at Santa Elena, the Reserve was stated as 5.1 million tonnes grading 1.72 gpt Au and 73.4 gpt Ag (refer to 2013 PFS). As of April 2103, the Santa Elena open pit had a Reserve of 1.43 million tonnes grading 1.52 gpt Au and 66.8 gpt Ag (refer to Technical Report dated April 30, 2013). In December 2014, the open pit Reserve was depleted by approximately 3.75 year of production and optimized with the remaining 4.79 million tonnes grading 1.81 gpt Au and 75.9 gpt Ag (reported in Technical Report dated April 1, 2011). By January 2012, the open pit was depleted from 2011 production and re-optimized with a resultant Reserve of 3.45 million tonnes grading 1.96 gpt Au and 87.3 gpt Ag showing lesser tonnes and higher grade. Re-optimization of the open pit between April 2011 and December 2014 has reclassified approximately 1.4 million tonnes of open pit Reserve to underground Resources which was converted mostly to the new underground Reserves. The main purpose for re-optimization was to avoid a higher open pit strip ratio at higher cost in future years in the mine life but still be able to mine the displaced Reserves from underground.

Extensive metallurgical test work including ongoing operations data show that all declared Reserves are amenable to conventional leaching by standard CCD milling with a Merrill Crowe recovery system for doré bar production. Estimated recovery grades are stated in Table 1.3 below, and in Section 1.5.

The updated Santa Elena Mineral Reserves as stated above were completed using GEMS resource models for defining open pit, underground and leach pad Reserves along with criteria as presented in the following table.

Table 1.3: Santa Elena Reserve Estimation Criteria

| Base Case Metal Prices1 | All US$ | | | |

| Gold | $1,300.00 | | | |

| Silver | $19.50 | | | |

| Mining Method | Open Pit | U/G Long Hole | U/G Cut & Fill | Leach Pad |

| Process Method | CCD Mill | CCD Mill | CCD Mill | CCD Mill |

| Mining Cost/T ore | $9.9 | $28.72 | $50.02 | $0.03 |

| Processing Cost/T3 | $24.5 | $24.5 | $24.5 | $24.5 |

| General & Administration4 | $5.3 | $5.3 | $5.3 | $5.3 |

| Overall Metal Recoveries (Life of Pad)5 | | | | |

| Gold | 92% | 92% | 92% | 92% |

| Silver | 67.5% | 67.5% | 67.5% | 67.5% |

| Ramp Width (metres) | 10 to 15 | 4.5 | 4.5 | NA |

| Average Dilution | 5% | 10%2 | 10%2 | NA |

| Ave. Mining Recovery | 95% | 90%2 | 90%2 | 100% |

1Based on LOMP metal price trends

2 Underground mining costs, dilution and mine recovery are based on stope type, either long hole (89% of design stopes) or cut and fill (11% of designed stopes) mining method.

3 Processing includes leach pad costs, crushing, milling, site refining and dry stack tailings disposal.

4 Estimated based on current operations and may vary on an annual basis.

5 Recoveries for leach pad material are based on recent Company production leach cycles of 300 days for life of pad to assess together with data the available reserves. During the period from 2010 through 2014, an average recovery of 60% Au and 30% Ag was achieved. Recoveries reflect partial 300 day leach cycle with pad leaching discontinued prematurely in Q2 2014. Leach pad CCD mill recoveries are based on in-situ remaining ounces on the pad.

* For economic analyses, the gold prices range is defined as $1250 (2015), $1275(2016) and $1300 for remaining years for LOMP. For silver prices, the range is defined as $18 (2015), $19(2016), $20 (2017) and $21 for remaining years for LOMP.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Ore development costs are estimated at $36/t and represent approximately 6% of total underground ore planned to be mined during LOMP.

The Santa Elena ore body varies in dip and thickness along strike and at depth. As a result, two well established underground mining methods have been selected for ore extraction. These mining methods are categorized in Table 1.4 below:

Table 1.4: Mining Method Selection Criteria

| Orebody Geometry | Mining Method |

| Dip > 55 degrees, Thickness > 5m | Longitudinal Long hole Stoping (including Avoca) |

| Dip < 55 Degrees, > 5m | Mechanized Cut and Fill |

In general, conventional mechanized mining methods have been selected. The basis of the development of the mining methods and consequent equipment selection has been that SilverCrest will undertake production drilling, blasting and loading using a contractor for the waste rock and ore haulage to surface. Initially a contractor will be retained to carry out mine development, with jumbo drill rigs purchased later in the mining life, after which development will be done in house. Approximately 81% of stoping will be by long hole method and 11% by cut and fill methods. Most long hole stopes are produced early in the mine schedule. Average stope width is 10.0 metres.

Conventional open pit mining will continue using a contractor until the second quarter of 2015 when open pit reserves are depleted. Mining of the heap leach spent ore (“pad ore”) will be completed by loader and conveyor to transport material to the plant until 2021.

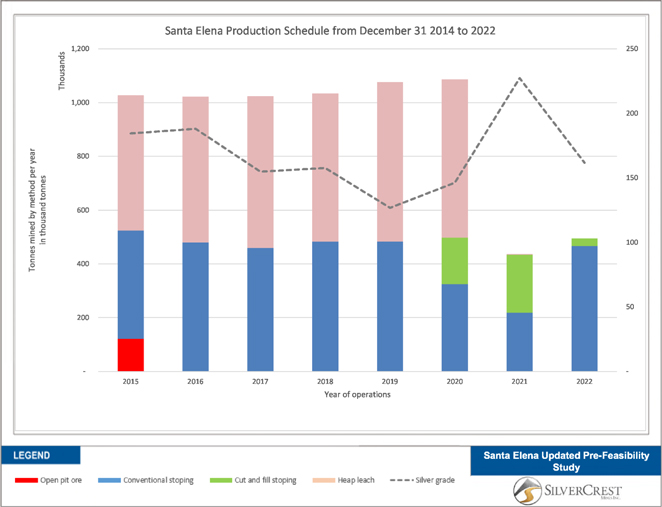

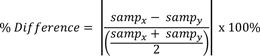

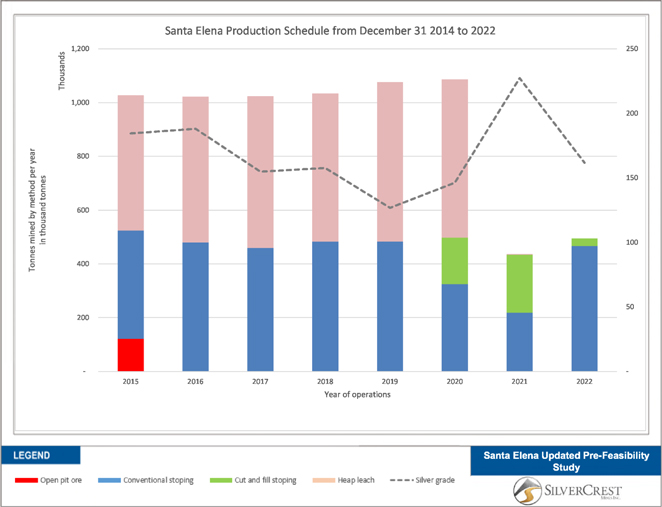

The mining schedule estimates the tonnages to be mined from the underground, open pit and the existing heap leach facility to feed the process plant at a nominal rate of 3,000 tpd. Table 1.5 shows the combined schedule for the Santa Elena Project. The schedule is based on optimizing higher grade long hole stopes first, with more costly cut and fill mining left for later in the mine life.

Table 1.5: Summary of Mining Schedule

| Aspect of operations | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | Total

Life of

Mine |

| Total Tonnes Underground | 462,200 | 543,000 | 521,100 | 535,400 | 493,700 | 497,600 | 434,300 | 494,300 | 3,981,600 |

| Total Tonnes Leach Pad | 502,300 | 543,200 | 565,100 | 550,800 | 592,500 | 588,600 | 2,200 | - | 3,344,700 |

| Total Tonnes Open pit | 121,700 | - | - | - | - | - | - | - | 121,700 |

| Total Tonnes Processed | 1,086,200 | 1,086,200 | 1,086,200 | 1,086,200 | 1,086,200 | 1,086,200 | 436,500 | 494,300 | 7,448,000 |

| Total Gold Ounces Sold | 45,000 | 45,500 | 37,200 | 35,800 | 29,400 | 38,300 | 23,500 | 16,100 | 270,700 |

| Total Silver Ounces Sold | 2,048,400 | 2,111,400 | 1,750,000 | 1,888,800 | 1,487,200 | 1,492,100 | 953,500 | 914,800 | 12,646,200 |

Note: all numbers rounded

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| 1.4.1 | Underground Production |

For the purpose of this UPFS, an underground mining schedule has been developed for the stopes in the reserve model and for development required to access the stopes throughout the life of mine. The mining schedule results in grade and tonnage performance as shown in Figure 1.1. Peak production is reached in year 6. A 50/50% mix (underground to pad ore) is assumed for the first 6 years in the schedule.

Figure 1.1: Summary of annual tonnes and grade for the life of mine

The ore from both underground and open pit resources will be processed by conventional milling and cyanide leaching technology. In addition partially leached material from the existing heap leach operations will be blended with open pit and underground ore at a variable rate and reprocessed through the same plant.

Santa Elena ore (Open Pit, Underground and Leach Pad) contains an estimated grade of 1.23 g/t Au and 78.4 g/t Ag and after crushing and grinding can be leached in cyanide to yield approximately 92% Au recovery and 67.5% Ag recovery. Because of the relatively high level of silver in the ore (and hence solutions) there are advantages and benefits to using traditional CCD and Merrill-Crowe for metal recovery rather than CIL/CIP. The partially leached heap ore yielded recoveries of approximately 60% Au and 30% Ag when crushed to 10 mm and processed on the heap leach (partial leach cycle to Q2 2014). On re-leaching after grinding in the new plant, the balance of the metals are recovered to the level expected from new ore from open pit and underground indicates as 92% for gold and 67.5% for Ag.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

The process plant has been designed to treat a nominal 3000 tonne per day (tpd) of ore, a mixture of freshly mined material and partially leached heap leach residue. The plant has been designed to treat any proportion of these two types of feed.

| 1.6 | Project Infrastructure |

Initially, the Santa Elena open pit heap leach mine was constructed in late 2009 and 2010, and was operational from 2010 to 2014. During 2013 and 2014 the open pit heap leach was transitioned into an underground, milling, and CCD/Merrill Crowe 3,000 tpd processing facility. As of December 31, 2014, all transition projects have been fully constructed, commissioned and commercial production announced. There are a number of facilities currently in use at the Santa Elena site.

Much of the same infrastructure facilities utilized for the open pit mine continue to be used for the new operations, including, but not limited to, access roads, waste dumps, explosive magazines, office buildings, fuel storage facilities, power generation, primary crushing equipment, heap leach pads and solution collection ponds. The material on the existing heap leach facility will be removed, adding additional space on the facility for rehandling of the tailings prior to transport by truck to the waste dump as dry stack tailings. With the removal of pad ore, areas will be open for additional pad loading in the future. The additional commissioned facilities as part of the UPFS include:

| 1. | A new CCD – MC processing facility. |

| 2. | Upgrade of surface power generation facility. |

| 3. | Construction of the underground decline and development (ongoing). |

| 4. | A ventilation shaft with ventilation fans (shaft completed from 625m level to surface, fans installed in H1 2015). |

| 5. | A fresh air raise which will act as an escape way. |

| 6. | Underground water recirculation facilities. |

| 7. | Underground electrical distribution system. |

| 8. | Underground maintenance facilities (ongoing). |

| 9. | Dry stack tailings disposal facility (incorporated onto existing waste rock dump -. |

| 10. | Additional surface facilities such as mine dry and maintenance shops for the underground mine. |

| 11. | New warehouse for storage and inventory. |

| 12. | Expansion of on-site laboratory (ongoing). |

| 13. | Upgrade to electronic security system including CCTV. |

| 14. | Expansion of exploration core storage facility (ongoing). |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

The Santa Elena Mine is located in the foothills of a north-south trending mountain range. Foothills area provides ample space to all required facilities and potential for future expansion.

| 1.7 | Capital and Operating Costs |

SilverCrest has estimated total sustaining capital costs during the LOM of $31 million dollars including contingency, which includes $4.8 million budgeted for surface and underground drilling. SilverCrest has estimated total operating costs ranging between $43 and $69 per tonne of ore processed, depending on mining method. The majority of the revised Reserve in this UPFS has assumed an approximate 50% underground ore to 50% pad ore blend. An average operating cost based on this assumption is $46.85 per tonne of ore including sustaining capital.

Table 1.6: Capital Cost Summary

| Sustaining capital cost table including exploration drilling expense |

| Site infrastructure | $2,066,200 |

| Mill sustaining capital | $1,785,000 |

| Underground waste development expenses | $16,086,600 |

| Underground equipment and infrastructure | $6,236,300 |

| Underground and 2015 surface drilling | $4,783,300 |

| Total capital costs | $30,957,400 |

Operating costs for the Santa Elena Project have been estimated for the underground mining, processing costs and general and administrative costs as summarized in Table 1.7. SilverCrest has estimated the LOMP operating costs at an average of $46.85 per tonne of ore processed.

Table 1.7: Operating Costs

| Mining Method | Open Pit | Underground Long Hole Average | Underground Cut & Fill Average | Leach Pad Reprocess |

| Process Method | CCD Mill | CCD Mill | CCD Mill | CCD Mill |

| Mining Cost/T ore1 | $ 9.90 | $28.71 | $50.00 | $0.002 |

| Processing Cost/T3 | $24.49 | $24.49 | $24.49 | $24.49 |

| General & Administration/T4 | $ 5.41 | $ 5.41 | $ 5.41 | $ 5.41 |

1Long hole stopes are 89% of designed stopes by volume and cut & fill stopes are 11% of designed stopes by reserve volume. Excludes ore development costs. It includes adjustment for exchange ratio impact in the mining costs.

2Mining cost of spent ore on leach pad is covered under processing costs.

3Processing includes crushing, milling, site refining and dry stack tailings disposal.

4Estimated based on current operations and may vary on an annual basis. A 4% annual inflation rate has been applied to general and administrative costs.

SilverCrest prepared an economic evaluation of the Santa Elena Project based on a pre-tax economic model and a post-tax model. For the economic analyses long-term consensus metal prices and exchange rate (as of December 31, 2014) used in the base case were as follows:

| § | Price of gold – range defined as $1,250 (2015), $1,275 (2016) and $1,300 for remaining years for LOMP; |

| § | Price of silver - range defined as $18 (2015), $19 (2016), $20 (2017) and $21 for remaining years for LOMP; |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| § | Closure costs of $6 million; and |

| § | Sandstorm receives 54,133 ounces of gold and pays SilverCrest an average price of $412/oz. |

The pre-tax economic model was established on a 100% equity basis, excluding debt financing and loan interest charges. The economic results of the base case and the two alternative cases are presented in Table 1.8.

Table 1.8: Base Case Economic Analyses Results

| Aspects of Santa Elena UPFS Economic Analyses (Base Case) |

| Production |

| Gold Ounces Sold - post refiner credit1 | 270,700 |

| Silver Ounces Sold - post refiner credit | 12,646,200 |

| Revenue | $(000) |

| Gross Sales2 | $554,530 |

| Operating Expenses3 |

| Total Operating Costs4 | $348,900 |

| Freight & Refining | $5,750 |

| Closure Costs | $6,000 |

| Sustaining Capital Expenses |

| Underground & Surface Drilling 5 | $4,780 |

| Sustaining Capital Costs6 | $26,170 |

| Pre-Tax Undiscounted Cash Flow |

| Total Cash Flow | $162,930 |

| Pre-Tax Economic Results |

| Pre-Tax NPV, DCF @ 5% | $143,840 |

| Post-Tax Economic Results |

| Post-Tax NPV, DCF @ 5% | $119,170 |

Note: All numbers rounded.

1Sandstorm to be delivered an estimated 54,000 ounce of gold over remaining LOMP.

2The financial model adopted a range of realized spot prices from 2015 to 2022. Gold prices ranged from $1,250 to $1,300 per ounce and silver prices ranged from $18 to $21 per ounce.

3Excludes 0.5% governmental environmental fee of an estimated $3 million.

4Approximate operating cost per AgEq ounce sold varies between $9 and $16 over the life of mine

5All LOMP underground drilling costs and only 2015 surface program costs included.

6Excludes sunk costs, up to December 31, 2014.

Metal price sensitivities were completed including spot price as $1,193/oz Au and $16.16/oz Ag (representing spot price at the middle of December, 2014) which showed a pre-tax NPV (DCF @ 5%) of $84.3 million.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Table 1.9: Comparison between the Base Case and the Spot Price for the Pre-Tax Economic Results

| Item | Base Case | Spot Price |

| Gold Price (US$/oz.) | Range of Prices/yr | $ 1,193 |

| Silver price (US$/oz.) | Range of Prices /yr | $ 16.16 |

| | | |

| Pre Tax DCF NPV @ 5.0% in millions | $144 | $84 |

| Post Tax DCF NPV @ 5.0% in millions* | $119 | $76 |

* Post tax results have been included in section 22 for a 30% tax rate, Mexico Mining royalty and Environmental fee

The economic analyses considers SilverCrest delivering 54,133 ounces of gold to Sandstorm Gold Ltd. (“Sandstorm”) at an average price of $412 per ounce ($350 to $450 per ounce with annual 1% inflationary increases) under the Sandstorm Purchase Agreement executed on May 14, 2009. The Purchase Agreement includes an option for Sandstorm to participate in the Santa Elena underground mine, which Sandstorm had elected to exercise in February 2014. The Purchase Agreement only applies to the original Santa Elena concessions and excludes recent regional acquisitions.

| 1.9 | Update to Pre-Feasibility Recommendations |

Further optimization of the mine schedule is warranted to investigate continued grade optimization versus stoping costs (long hole or cut and fill), potential to expand and accelerate increased underground production with a second ramp and expand resources with subsequent reserves. Further underground geotechnical studies are required to better optimize development and stoping and to ensure a safe working environment. Mineralization at Santa Elena is open in most directions with excellent potential to further increase resources and reserves for increased production and mine life. Further infill and expansion drilling is recommended. The El Cholugo zone is located immediately adjacent to the Main Mineralized Zone or MMZ and is a priority target in 2015 for potential resource and reserve expansion. Silver recoveries in the new plant facility need further metallurgical work to potentially increase recovery rates. Recommended budget for further work is estimated at $5 million to be spent over several years.

SilverCrest has estimated the costs for completion of the above recommended studies as summarized in the Table 1.10 below:

Table 1.10: Breakdown of future costs related to recommendations

| Recommendation | Future work | Estimated cost |

| Geology and Underground Resources | An infill drilling program consisting of roughly 20,000m of drilling | $4.70 million |

| Geotechnical Recommendations | Geotechnical design study for underground | $ 200,000 |

| Metallurgical Test work | Grinding, CN rates, oxidation, PbNO3, retention timing for better silver recoveries | $ 100,000 |

| Total future costs related to recommendations | $ 5 million |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

This Technical Report has been completed by SilverCrest Mines Inc. (SilverCrest) as an update to the Pre-Feasibility Report (“UPFS”) completed in April 2014, and to support a revised Mineral Reserve Estimate and Life of Mine Plan. The effective date of the report is December 31, 2014. This date acts as a cut-off to all data used for the calculation of Mineral Resources, Mineral Reserves and the Economic Analyses. Discussion on recent exploration and acquisition following the effective is included within the report.

Nusantara de Mexico S.A. de C.V., a 100% owned Mexican subsidiary of SilverCrest (SilverCrest for the purposes of this report), holds the rights to the Santa Elena Mine and is a legal operating entity of SilverCrest.

This report conforms to National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101 and Form 43-101F1) and incorporates the Canadian Institute for Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves (CIM Definition Standards).

| 2.1 | Report Author and Qualified Person |

SilverCrest is a Producing Issuer, as defined by National Instrument 43-101, and as such are entitled to Qualify and disclose material and technical information relating to the Santa Elena Mine with non-independent Qualified Persons. This report has been prepared by, and under the supervision of, Mr. N. Eric Fier, C.P.G., P. Eng, Chief Operating Officer of SilverCrest Mines Inc. Mr. Fier is a Qualified Person as defined by CIM Definition Standards.

| 3.0 | Reliance on other Experts |

Several independent consultants provide Iinformation from other experts has not been used for the completion of this report. These consultants are not considered qualified persons for this Technical Report. The following assisted with providing SilverCrest with information within this report;

| A. | Bruce Davis, P.Geo. – February 2015 Santa Elena Resource Model Audit and Comment. |

| B. | Golder & Associates – March 2015 Santa Elena Mine – Life of Mine Plan Completed Work Summary. |

| C. | Larry Breckenridge, P.E., 2013 Asset Retirement Obligation Calculation, Technical Report, Global Resources Engineering, January 30, 2014. |

| D. | Larry Breckenridge, P.E., Geochemical Characterization of Tailings, Technical Memo, Global Resources Engineering, September 30, 2014. |

Other contributors to the report include:

| A. | Brent McFarlene, V.P. Operations for SilverCrest Mines Inc. |

| B. | Marcio Fonseca, P. Geo., V.P. Corporate Development for SilverCrest Mines Inc. |

| C. | Stephany Fier, Manager Technical Services for SilverCrest Mines Inc. |

| D. | Claudio Villamizar, Chief Mine Engineer for Santa Elena Mine |

| E. | Mohammad Dadmanesh, P. Eng., Mine Engineer consultant for SilverCrest Mines Inc. |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

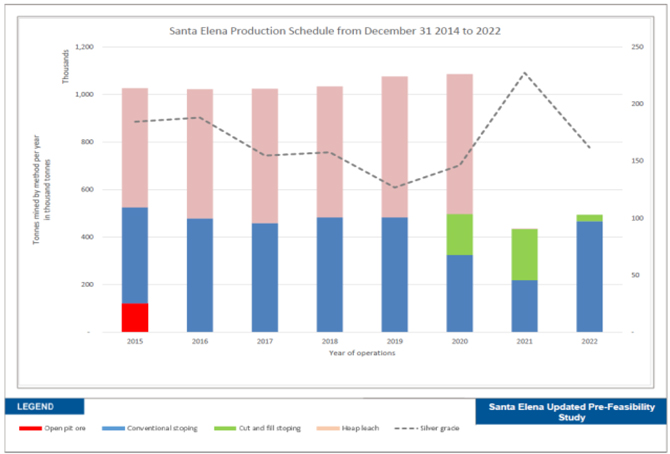

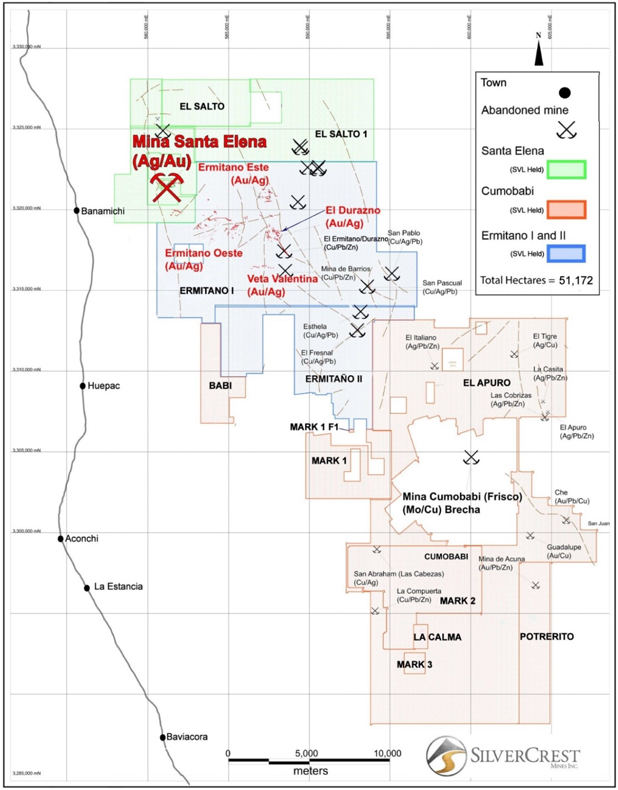

| 4.0 | Property Description and Location |

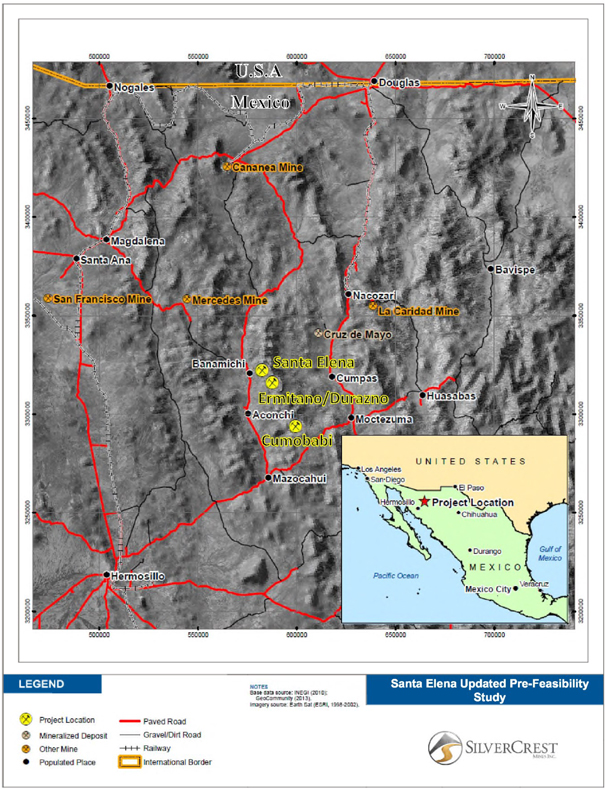

The Santa Elena mine site is approximately 150 km northeast of the state capital city of Hermosillo, Sonora, Mexico near the intersection of 30º 01' north latitude, and 110º 09' west longitude (Figure 4.1). The community of Banamichi is located 7 km west of the property. The area is covered by the INEGI “Banamichi” 1:50,000 topographic map H12-B83.

The Ermitaño property consists of two concessions, Ermitaño I and Ermitaño II approximately 145 kilometres northeast of Hermosillo and contiguous with SilverCrest’s Santa Elena Mine. Ermitaño I is near intersection 29° 59´ 29.25” north latitude and 110° 05´24.95” west longitude and 12km west of Banamichi. Ermitaño II is near intersection 29°55´ 18.97” North latitude and 110° 03´58.65” west longitude and 13km west of the community of Huepec. The Ermitaño I area is covered by the INEGI “Agua Caliente” 1:50,000 topographic map H12-B84 and Ermitaño II area is covered by the INEGI maps “Aconchi” H12-D13 and “Cumpas” H12-D14, 1:50,000 topographic maps.

The Cumobabi property consists of nine concessions approximately 140 kilometres northeast of Hermosillo near intersection 29° 45´ 34.88” North latitude and 109° 58´ 21.33” west longitude (Figure 4.1) and contiguous with SilverCrest’s Santa Elena Mine. The community of Baviacora is located 19km south west of the property. This area is covered by the INEGI maps “Aconchi” H12-D13, “Cumpas” H12-D14, “Baviacor”H12-D23 and “Rodeo” H12-D24, 1:50,000 topographic maps.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Figure 4.1: Santa Elena Property Location

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| 4.1 | Mining Titles and Agreements |

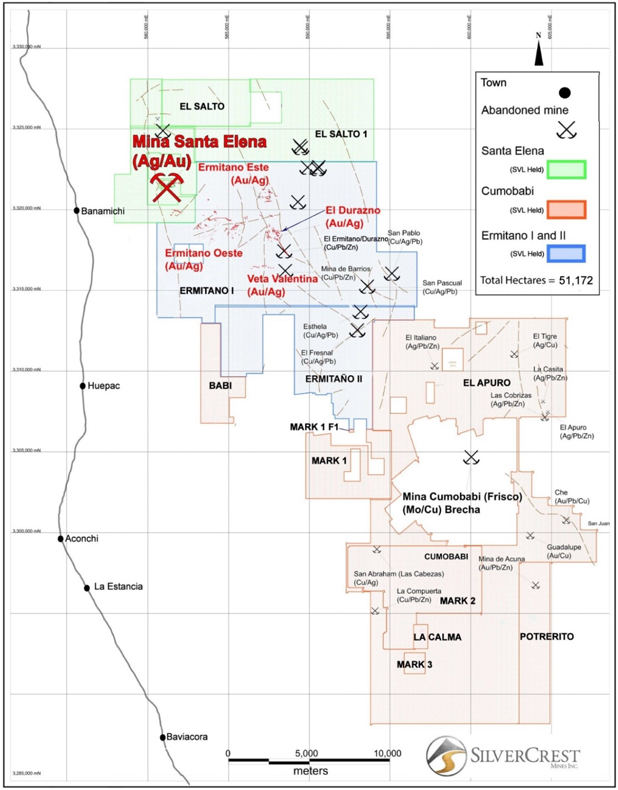

Total hectares controlled by SilverCrest in the Santa Elena area are 51,173 (Table 4.1, Figure 4.2). The Santa Elena property consists of nine contiguous concessions with a total nominal area of 9,424.54 hectares, the Ermitaño properties consist of two concessions with a total nominal area of 16,526.77 ha, the Cumobabi property consist of eight concessions with a total nominal area of 25,221.2 hectares. The Santa Elena concessions are registered with Mexico Mines Registry in Hermosillo and Mexico City in the name of Nusantara de Mexico S.A. de C.V. (Nusantara), a wholly-owned subsidiary of SilverCrest. Nusantara filed the Santa Elena 7 concession which surrounds the five other concessions. All concessions were ground surveyed by a registered land surveyor at the time of staking. Ermitaño and Cumobabi are registered with Mexico Mines Registry in Hermosillo and Mexico City in the name of Minera Evrim S.A. de C.V., a subsidiary of Evrim Resource Corporation.

Table 4.1: List of Mining Titles for Santa Elena and Surrounding Properties

| Area | Concession

Number | Date | Concession Name | Owner | Size (ha) |

| Santa Elena | 192174 | 1983 | Santa Elena | Nusantara de Mexico | 24.2 |

| Santa Elena | 178094 | 1983 | Santa Elena No 4 Fraccion SE | Nusantara de Mexico | 0.06 |

| Santa Elena | 176544 | 1983 | California Nusantara de Mexico | Nusantara de Mexico | 18.0 |

| Santa Elena | 221460 | 1995 | Elena 5 | Nusantara de Mexico | 399.9 |

| Santa Elena | 223533 | 2003 | Santa Elena 6 | Nusantara de Mexico | 416.0 |

| Santa Elena | 227239 | 2006 | Santa Elena 7 | Nusantara de Mexico | 1,868.3 |

| Santa Elena | 180494 | 1983 | Santa Elena No 3 Fraccion SW Tungsteno de | Nusantara de Mexico | 0.06 |

| Santa Elena | 82/38909 | 2014 | El SALTO | Nusantara de Mexico | 1,710.0 |

| Santa Elena | 82/38917 | 2014 | EL SALTO 1 | Nusantara de Mexico | 4,988.0 |

| EL ERMITAÑO | 230421 | 2007 | EL ERMITAÑO 1 | Minera Evrim | 12,267.6 |

| EL ERMITAÑO | 235605 | 2010 | EL ERMITAÑO 2 | Minera Evrim | 4,259.2 |

| Cumobabi | 228838 | 2004 | EL APURO | Minera Evrim | 16,721.5 |

| Cumobabi | 232857 | 2008 | MARK 1 | Minera Evrim | 1,713.6 |

| Cumobabi | 232858 | 2008 | MARK 1 Fracción 1 | Minera Evrim | 5.7 |

| Cumobabi | 232856 | 2008 | MARK 2 | Minera Evrim | 3,499.1 |

| Cumobabi | 229051 | 2007 | POTRERITO | Minera Evrim | 1,913.2 |

| Cumobabi | 221119 | 2003 | LA CALMA | Minera Evrim | 150.0 |

| Cumobabi | 232855 | 2008 | MARK 3 | Minera Evrim | 169.0 |

| Cumobabi | 236794 | 2010 | BABI | Minera Evrim | 1,049.2 |

| | Total | 51,172.5 |

*Note: The surface areas (hectares) have been updated using post-2013 PFS from revised surveys. Minera Evrim concessions are

under option to Nusantara and can be 100% acquired after meeting agreement obligations, as presented below.

Mining regulations in Mexico provides that all concessions are to be valid for a period of 50 years. Taxes are based on the surface area of each concession and are due in January and June of each year at a total annual cost of approximately $380,000. All tax payments have been paid by Nusantara to date.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

On December 8, 2005, Nusantara had the right to acquire a 100% interest in the Santa Elena property from Tungsteno de Mexico SA de C.V. On August 14, 2009, Nusantara exercised the option to acquire 100% of the Santa Elena property.

On November 12, 2007, Nusantara signed an agreement with the Community of Banamichi (Ejido) for a 20 year lease on surface rights for a maximum of 841 ha with respect to exploration and exploitation. Lease payments were dependent (at Nusantara’s discretion) on the number of hectares required for a given year. A minimum of 285 ha was required for initial exploitation. Currently 431 ha are under lease for exploitation and exploration. The annual cost per year ranged from approximately $55,000 to $160,000 dependent on the number of hectares required. Lease obligations have been met to date.

On January 30, 2014, Nusantara signed an option agreement with Evrim Resources Corp. (Evrim) whereby SilverCrest can acquire a 100% interest in Evrim’s Ermitaño Property after paying US$75,000 upon signing (paid) and US$50,000 each anniversary thereafter, complete a minimum of US$500,000 in exploration expenditures in the first year, and deliver a Production Notice within five years, specifying mine and construction plans with accompanying permits. Upon completion of this exercise, the annual payments will cease and Evrim will retain a 2% Net Smelter Royalty (NSR).

On November 7, 2014, Nusantara signed a five year option agreement with Evrim Resources Corp whereby SilverCrest can acquire 100% interest in Evrim’s Cumobabi Property after paying UG$75,000 upon signing and US$50,000 on each anniversary thereafter, completing a minimum of US$500,000 in exploration expenditures by the second anniversary and delivering a Production Notice within five years, specifying mine and construction plans with accompanying permits. Upon completion of this exercise, the annual payments will cease and Evrim will retain a 1.5% Net Smelter Royalty (NSR).

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Figure 4.2: Santa Elena and Surrounding Area Property Map;

Note: boundaries shown on concession map are approximate and not confirmed from legal survey, and surrounding land and concession title owners are omitted from the map

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

No known private or state royalties currently exist for the Santa Elena Mine. Ermitaño I and II are subject to a 2% NSR and Cumobabi is subject to a 1.5% NSR upon to Evrim Resources Corp. upon completion of the option agreements. A 3rd party underlying 2% NSR applies to all Evrim concessions.

On May 14, 2009, SilverCrest entered into a definitive Purchase Agreement with Sandstorm Gold Ltd. (Sandstorm) under which SilverCrest’s wholly-owned Mexican subsidiary, Nusantara de Mexico S.A. de C.V., agreed to sell 20% of future gold production from the Santa Elena open pit, or a total of 50,000 ounces gold, to Sandstorm in exchange for an Upfront Deposit of $12,000,000. The agreement also provides for ongoing per-ounce payments by Sandstorm equal to the lesser of $350 and the prevailing spot gold market price upon delivery of gold. In addition, Sandstorm issued $3.5 million common shares to SilverCrest. The per ounce price of $350 is subject to an increase of 1% per annum commencing on the 3rd anniversary of the date that Santa Elena Project began commercial production (i.e. July 2014).

On February 25, 2014 Sandstorm Gold Ltd. gave notice to exercise the Underground Mine Option for the Santa Elena Property. This Option allows Sandstorm to purchase 20% of the gold produced from underground operations (includes reprocessing the spent leach ore) at the Santa Elena Mine. In consideration of the exercised option, Sandstorm made an additional upfront deposit of US$10 million to SilverCrest on March 10, 2014 (paid) and will continue to make ongoing per ounce payments of US$350 until 50,000 ounces of gold have been delivered to Sandstorm, inclusive of 23,559 ounces (at December 31, 2014) already received, at which time the payments will increase to US$450 per ounce of gold (or the lesser prevailing spot gold market price), subject to an increase of 1% per annum.

| 4.4 | Environmental Liabilities and Permitting |

Currently, Nusantara has maintained all of the necessary permits for exploration and exploitation at the Santa Elena mine site. A Manifestacion de Impacto Ambiental (MIA) was submitted to Secretaría de Medio Ambiente y Recursos Naturales (SEMARNAT) in early January of 2013 for amendment of the land use licence related to the underground expansion project and was approved in May, 2013. This amendment approval allows for tailings facilities that were not previously required for the open pit and heap leach operation.

A mining concession in Mexico does not confer any ownership of surface rights. However, use of surface rights for exploration and production can be obtained under the terms of various acts and regulations if the concession is on government land. The Santa Elena concessions are located on Ejido (community or co-op) land, and as of November 12, 2007, an agreement with the surface owners has been signed which allows SilverCrest access and authorization to complete exploration and mine operations activities.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

Table 4.2: Permits for Santa Elena

| Permit | Mining Stage | Agency | Status |

| Environmental Impact Statement (MIA) | Construction/operation/abandonment | Secretary of environment and natural Resources (SEMARNAT)-State offices | in place |

| Land use change study | Construction/operation | SEMARNAT-General Department of Permitting for Forestry and soils (DGGFS)-State offices | in place |

| Land use license | Construction | Banamichi Municipality | in place |

| Explosive handling and storage permits | Construction | National Secretary of Defense (SEDENA). (Need approval from state and municipal authorities) | in place |

| Archaeological release letter | Construction | Construction Nation Institute of Archaeology and History (INAH) | in place |

| Water use concession title | Construction/operation/prior to utilization of water | National Commission of Water (CAN)-State offices | in place |

| Water discharge permit | Operation | CAN-(State offices) | in place |

| Construction permit | Construction | Municipality of Banamichi | in place |

SilverCrest has maintained all of the necessary permits for direct exploration and drilling at the Ermitaño and Cumobabi project site. Ermitaño concessions are located on private properties and an agreement with the surface owners has been signed which allows SilverCrest access and authorization to complete exploration and mine operations activities.

Table 4.3: Permits for Ermitaño

| Permit | Mining Stage | Agency | Status |

| Preventive Environmental Impact Report and Resolution | Road conditioning and Direct Exploration | Secretary of Environment and Natural Resources (SEMARNAT) – State Offices | In place |

| Surface Owners Agreement | Access, Direct Exploration and Drilling | Surface Owners | In place |

| Drilling and Direct Exploration “Ermitaño 1” | Direct Exploration | Secretary of Environment and Natural Resources (SEMARNAT) – State Offices | In Place |

| Drilling and Direct Exploration “Ermitaño 2” | Direct Exploration | Secretary of Environment and Natural Resources (SEMARNAT) – State Offices | In Place |

| Drilling and Direct Exploration “Durazno” | Direct Exploration | Secretary of Environment and Natural Resources (SEMARNAT) – State Offices | In Place |

| Drilling and Direct Exploration “Ampliación Durazno” | Direct Exploration | Secretary of Environment and Natural Resources (SEMARNAT) – State Offices | In Place |

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

The Santa Elena property can be accessed easily year round by paved highways 90 km east from Hermosillo to Ures, then 50 km north along a paved secondary road to the community of Banamichi, then by a maintained gravel road that runs east for 7 km to the mine site.

The climate is typical for the Sonoran desert, with a dry season from October to May. Average rainfall is estimated at 300 mm per annum. There are two wet seasons, one in the summer (July to September) and another in the winter (December). The summer rains are short with heavy thunderstorms whereas the winter rains are longer and lighter. Seasonal temperatures vary from 0ºC to 40ºC. Summer afternoon thunderstorms are common and can temporarily impact the local electrical service. Flash flooding is common in the area.

The main supply well currently used at the mine site, PSA-1, was installed and tested in September 2009 and a pump installed at approximately 109 metres depth. Pumping tests indicated the well was located in a confined aquifer with a potential association to geothermal sources and an estimated sustained supply of 25 L/s, sufficient to support the open pit mining operation (Breckenridge, 2010).

Well PSA-2 was constructed in the summer of 2011 as a back-up well to support Santa Elena Mine’s primary water supply, Well PSA-1 (formally MW-1). The well is 171 metres deep, and screened from a depth of 72m to the base of the well. There is a steel casing that extends from surface to a depth of 72m. The casing and screen section are eight inches in diameter. The well was started by using an air rotary drill; however, due to the unstable and unconsolidated nature of sediment in this portion of the sand and gravel aquifer the well was completed using a mud rotary drill.

The well was pumped at a rate of 10.6 litres per second (lps) over a 72 hour period, and the final measured drawdown in the well was approximately 20 metres. During the pumping test the water level dropped from its static level at 68m to a depth of 90m within a few minutes. The water level stabilized at 90 metres after two hours of pumping. The testing suggests that the well could be pumped indefinitely at a rate of 10.6 lps with no increase in drawdown (GRE, 2011a). The safe yield of the well is 12.9 lps, based on the criterion that drawdown equivalent to 25% of the aquifer thickness is allowable (GRE, 2011a).

Due to the presence of the screen and the fact that it is open to a smaller aquifer depth, it is noted that Well PSA-2, although very productive, is less productive than Well PSA-1. The screen in general reduces the ability of water to enter the well, and the vertical-slot screen used in Well PSA-2 was not optimized for maximum yield. The pumping test indicates that there is minor hydraulic interference between the two water wells, and that the cumulative safe yield of the well field, with both wells pumping at the same time is 35 lps (GRE, 2011a).

The mine site including newly completed expansion has adequate water supply for operations.

| | SANTA ELENA UPDATE TECHNICAL REPORT |

| | EFFECTIVE DATE: DECEMBER 31, 2014 |

| | |

A minor amount of electrical line power available from nearby sources currently supplies municipalities and agriculture, but is insufficient for the Santa Elena operation. Power for current operations is provided by diesel generators. Provision of grid power is possible in the future, but requires permitting and a significant capital expenditure.

The Santa Elena Mine is located near to the village of Banamichi for which accommodations and local food services are found. The mining centre of Cananea is the closest sizable urban area (pop. est. 30,000), and is located approximately 100 km north by road from the Santa Elena mine site. Most services and supplies are available in Cananea. Sonora’s capital city, Hermosillo, is located approximately 150 km southwest of the property, and is regarded as the main industrial hub for the majority of the local mining operations. Services are available for heavy machine purchase and repair, materials fabrication, and engineering services. Alternatively, Tucson Arizona is approximately a 4 hour drive north across the international Mexican USA border from the Santa Elena mine site.

Northern Mexico has significant precious and base metal mines and there is a significant workforce of trained mining and processing personnel. Many of the trades and skills learned in the region would be transferable to the new operations. The nearby Cananea and La Caridad mines are amongst the largest mines in North America.

| 5.4 | Existing Infrastructure |

The Santa Elena mine and processing facility was initially constructed between 2009 and 2010 with expansion in 2013 and 2014. The new mine infrastructure is described in further detail in Section 18.0. Generally, the following operational infrastructure is in place or under ongoing construction:

| § | A new CCD – MC processing facility; |

| § | Upgrade of surface power generation facility; |

| § | Construction of the underground decline and development (ongoing); |

| § | A ventilation shaft with ventilation fans (shaft completed from 625m level to surface, fans installed in H1 2015); |

| § | A fresh air raise which will act as an escape way; |

| § | Underground water recirculation facilities; |

| § | Underground electrical distribution system; |

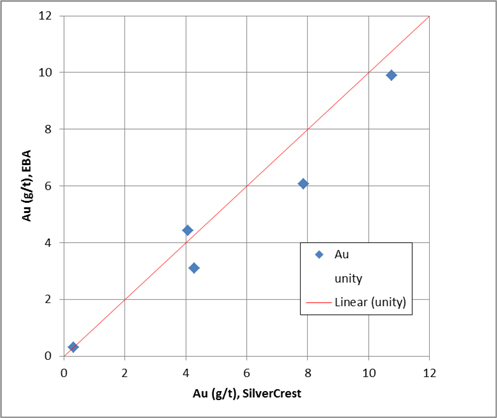

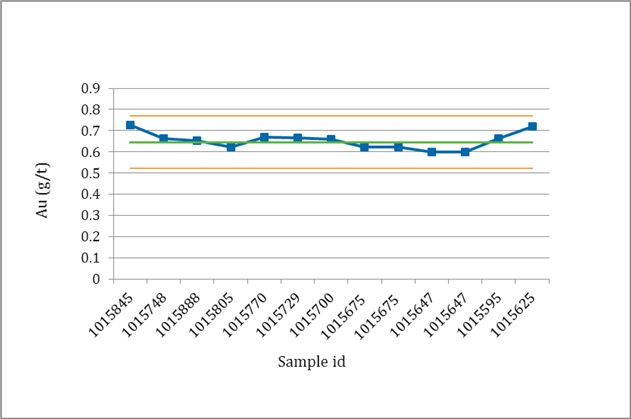

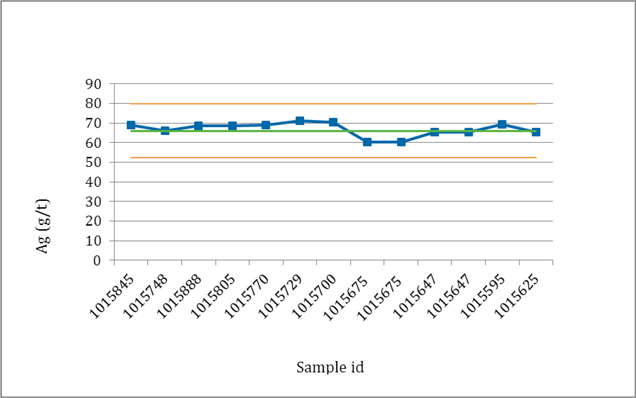

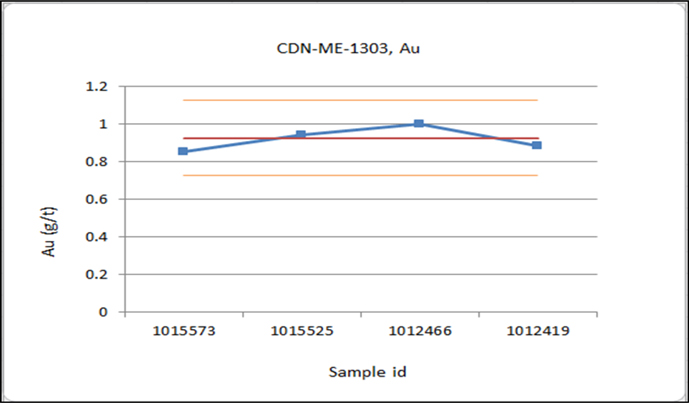

| § | Underground maintenance facilities (ongoing); |