Exhibit 99.1

43-101 TECHNICAL REPORT,

UPDATED MINERAL RESERVE ESTIMATE FOR TIMMINS WEST MINE,

TIMMINS, ONTARIO, CANADA

NTS: 42-A-05,

Longitude: 81.55° West, Latitude: 48.32° North

UTM (NAD 83, Zone17): 458,915m East, 5,359,043 North

PREPARED FOR:

LAKE SHORE GOLD CORP.

181 University Ave, Suite 2000

Toronto, Ontario, Canada, M5H 3M7

Prepared by: Eric Kallio, P. Geo.

Natasha Vaz, P. Eng.

Date: March 31, 2014

Effective Date: February 21, 2014

TABLE OF CONTENTS | |

| |

| CAUTIONARY NOTE | x |

| | |

1.0 | SUMMARY | 1 |

| | |

2.0 | INTRODUCTION | 8 |

| 2.1 | LIST OF QUALIFIED PERSONS | 8 |

| 2.2 | UNITS AND CURRENCY | 8 |

| 2.3 | LIST OF ABBREVIATIONS | 9 |

| 2.4 | DEFINITIONS | 12 |

| | 2.4.1 | Mineral Resource | 12 |

| | 2.4.2 | Inferred Mineral Resource | 12 |

| | 2.4.3 | Indicated Mineral Resource | 12 |

| | 2.4.4 | Measured Mineral Resource | 12 |

| | 2.4.5 | Mineral Reserve | 13 |

| | 2.4.6 | Probable Mineral Reserve | 13 |

| | 2.4.7 | Proven Mineral Reserve | 13 |

| 2.5 | GLOSSARY | 13 |

| | 2.5.1 | General Glossary | 13 |

| | 2.5.2 | Lake Shore Gold Terminology | 15 |

| | | | |

3.0 | RELIANCE ON OTHER EXPERTS | 16 |

| | |

4.0 | PROPERTY DESCRIPTION AND LOCATION | 19 |

| 4.1 | PROPERTY DESCRIPTION | 19 |

| 4.2 | LOCATION | 23 |

| 4.3 | RECENT OWNERSHIP HISTORY AND UNDERLYING AGREEMENTS | 25 |

| 4.4 | PAST MINING ACTIVITY, ENVIRONMENTAL LIABILITIES AND PERMITTING | 26 |

| | | |

5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 28 |

| 5.1 | ACCESSIBILITY | 28 |

| 5.2 | CLIMATE | 28 |

| 5.3 | LOCAL RESOURCES AND INFRASTRUCTURE | 28 |

| 5.4 | PHYSIOGRAPHY | 29 |

| | | |

6.0 | HISTORY | 31 |

| 6.1 | PRIOR OWNERSHIP | 31 |

| 6.2 | GENERAL HISTORY | 31 |

| 6.3 | HISTORICAL RESOURCE ESTIMATES | 35 |

| | 6.3.1 | Historically Significant Resource Estimates | 35 |

| | 6.3.2 | Resource Estimates Reported in Accordance with NI 43-101 and Estimated by a QP | 35 |

| 6.4 | HISTORIC PRODUCTION | 38 |

| | | | |

7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 39 |

| 7.1 | REGIONAL GEOLOGY AND STRUCTURE | 39 |

| 7.2 | PROPERTY GEOLOGY | 43 |

| | 7.2.1 | Timmins Mine Portion of the Timmins West Mine | 43 |

| | 7.2.2 | Thunder Creek Portion of the Timmins West Mine | 44 |

| 7.3 | STRUCTURAL GEOLOGY | 47 |

| 7.4 | MINERALIZATION | 48 |

ii

TABLE OF CONTENTS

8.0 | DEPOSIT TYPES | 61 |

| | |

9.0 | EXPLORATION | 63 |

| 9.1 | GENERAL OVERVIEW | 63 |

| | 9.1.1 | Timmins Deposit | 64 |

| | 9.1.2 | Thunder Creek Deposit | 66 |

| | | | |

10.0 | DRILLING | 69 |

| 10.1 | HISTORICAL DRILLING ON THE TIMMINS WEST MINE PROPERTY | 69 |

| 10.2 | DRILLING ON THE TIMMINS DEPOSIT PROPERTY COMPLETED BY LSG | 71 |

| 10.3 | DRILLING ON THE THUNDER CREEK PROPERTY BY LSG | 71 |

| | | |

11.0 | SAMPLING PREPARATION, ANALYSIS AND SECURITY | 74 |

| 11.1 | SURFACE DIAMOND DRILL PROGRAMS | 74 |

| | 11.1.1 | General Statement | 74 |

| | 11.1.2 | Core Handling and Logging Protocols | 74 |

| | 11.1.3 | Property Grids, Hole Collar and Downhole Attitude Surveys | 74 |

| | 11.1.4 | Security | 75 |

| | 11.1.5 | Drill Core Sampling Method and Approach, Sample Preparation, Analysis and Analytical Procedures | 75 |

| 11.2 | UNDERGROUND DIAMOND DRILL PROGRAM | 78 |

| | 11.2.1 | General Statement | 78 |

| | 11.2.2 | Core Handling and Logging Protocols | 78 |

| | 11.2.3 | Property Grids, Hole Collar and Downhole Attitude Surveys | 79 |

| | 11.2.4 | Security | 80 |

| | 11.2.5 | Underground Diamond Drill Core Sampling Protocols | 80 |

| | 11.2.6 | Underground Diamond Drill Core Sample Preparations and Analytical Procedures | 82 |

| 11.3 | UNDERGROUND FACE CHIP CHANNEL AND MUCK SAMPLES | 84 |

| | 11.3.1 | Procedure for Taking Face Chip Channel Samples | 84 |

| | 11.3.2 | Procedure for Taking Muck Samples | 84 |

| | 11.3.3 | Security | 85 |

| | 11.3.4 | Data Management for Chips and Muck Samples | 85 |

| 11.4 | DATA MANAGEMENT FOR SURFACE AND UNDERGROUND DIAMOND DRILL PROGRAMS | 85 |

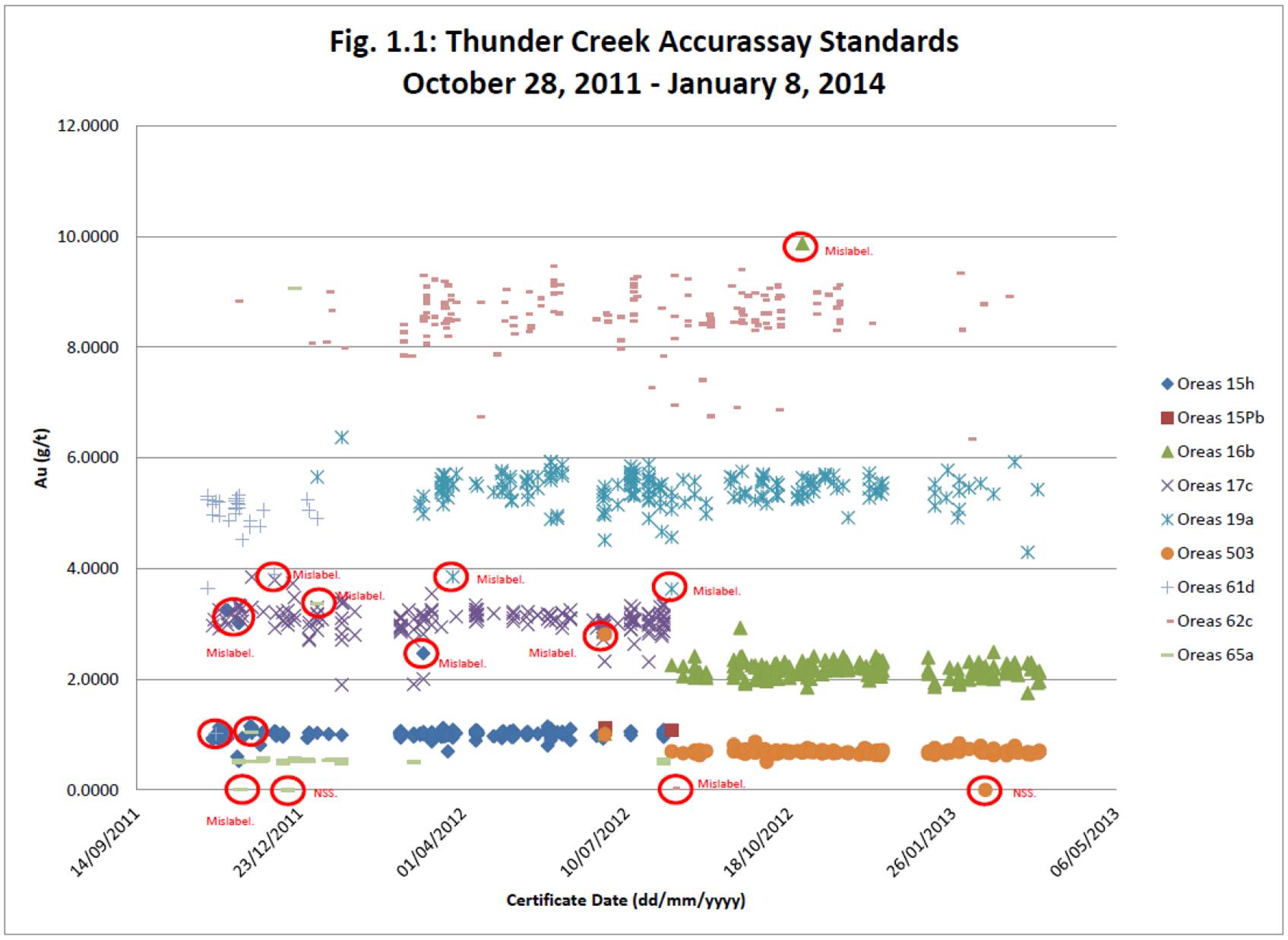

| | 11.4.1 | Accuracy Analysis - Standards and Blanks | 85 |

| | 11.4.2 | Precision Analysis — Duplicates | 86 |

| | 11.4.3 | Reporting and Plotting | 86 |

| 11.5 | CHECK ASSAY PROGRAM | 87 |

| | 11.5.1 | General Statement | 87 |

| | 11.5.2 | Procedures | 87 |

| 11.6 | DISCUSSION | 87 |

| | | |

12.0 | DATA VERIFICATION | 89 |

| 12.1 | Database Validation | 89 |

| | | |

13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 91 |

| 13.1 | HISTORICAL TEST WORK | 91 |

| 13.2 | RECENT TEST WORK | 91 |

iii

TABLE OF CONTENTS

14.0 | MINERAL RESOURCE ESTIMATES | 93 |

| 14.1 | SUMMARY | 93 |

| 14.2 | ESTIMATION METHOD | 94 |

| | 14.2.1 | Procedures Summary | 94 |

| | 14.2.2 | Database | 95 |

| | 14.2.3 | Mineralized Domains | 96 |

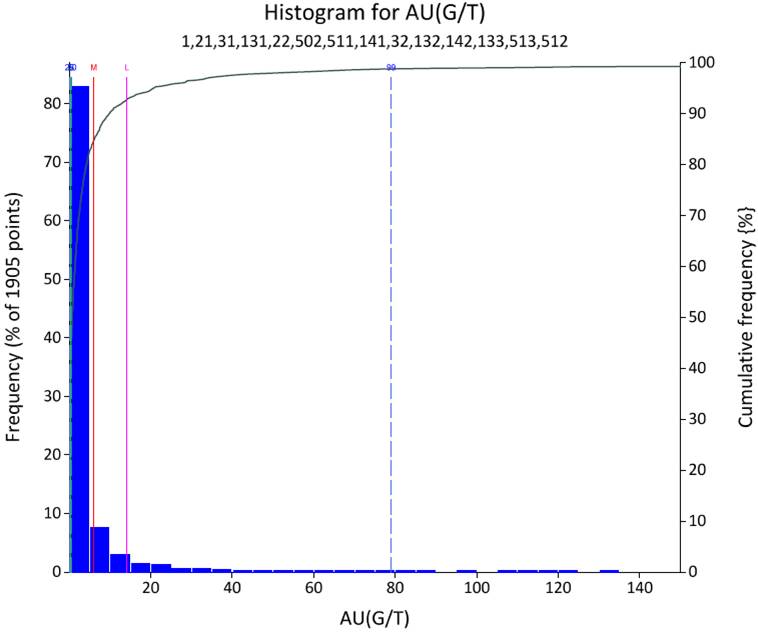

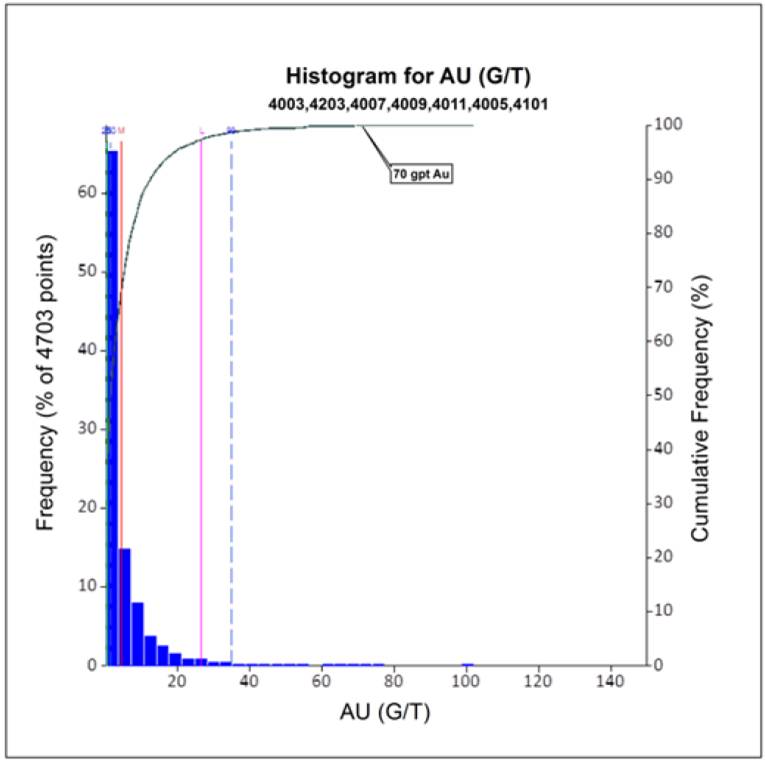

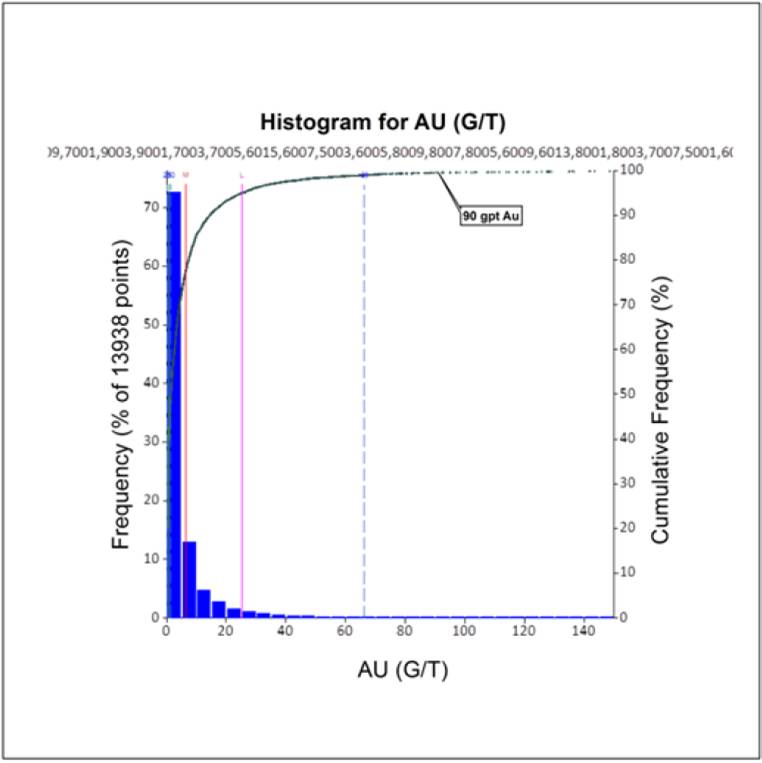

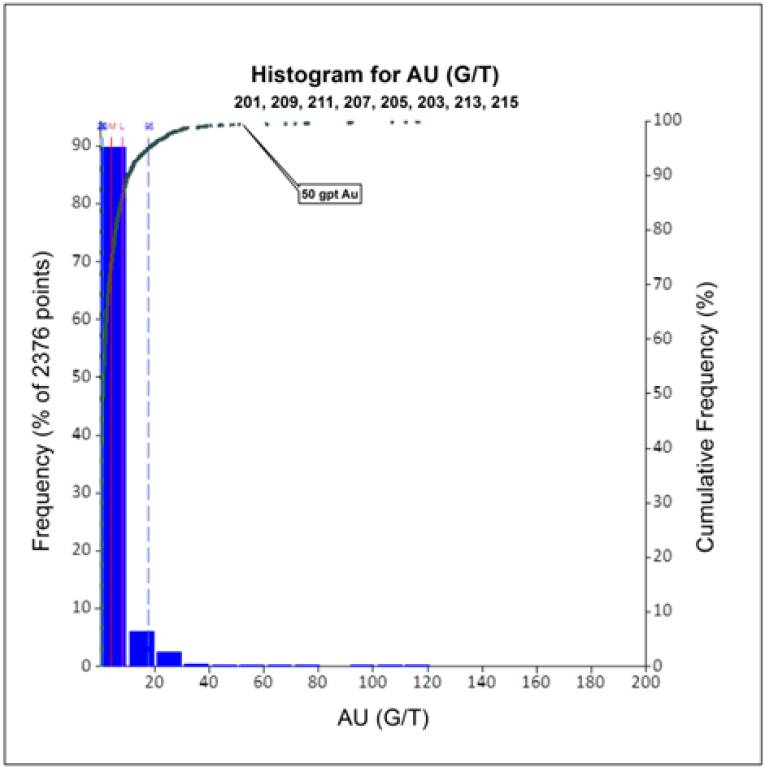

| | 14.2.4 | Grade Capping | 99 |

| | 14.2.5 | Assay Compositing | 104 |

| 14.3 | SPECIFIC GRAVITY | 105 |

| 14.4 | VARIOGRAPHY | 106 |

| 14.5 | BLOCK MODEL MINERAL RESOURCE MODELING | 109 |

| | 14.5.1 | General | 109 |

| | 14.5.2 | Block Model Parameters | 109 |

| | 14.5.3 | Grade Interpolation | 109 |

| 14.6 | BLOCK MODEL VALIDATION | 111 |

| 14.7 | MINERAL RESOURCES AND CLASSIFICATION | 117 |

| | 14.7.1 | General | 117 |

| | 14.7.2 | Mineral Resources | 117 |

| 14.8 | RECONCILIATION TO PREVIOUS RESOURCE TIMMINS DEPOSIT | 122 |

| 14.9 | ADDITIONAL DRILL HOLE INFORMATION | 126 |

| | | |

15.0 | MINERAL RESERVE ESTIMATES | 128 |

| 15.1 | CUT-OFF GRADE | 128 |

| 15.2 | TIMMINS DEPOSIT RESERVE ESTIMATE | 129 |

| 15.3 | THUNDER CREEK DEPOSIT RESERVE ESTIMATE | 130 |

| 15.4 | TIMMINS WEST MINE COMBINED RESERVES | 131 |

| | | |

16.0 | MINING METHODS | 132 |

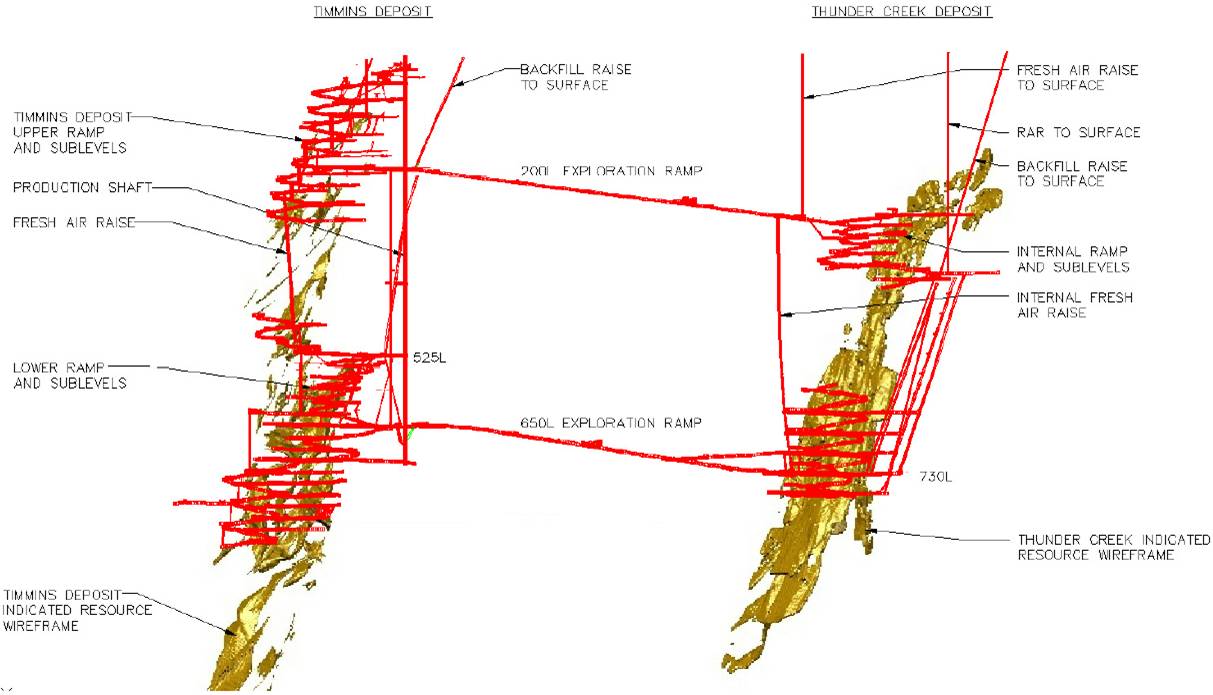

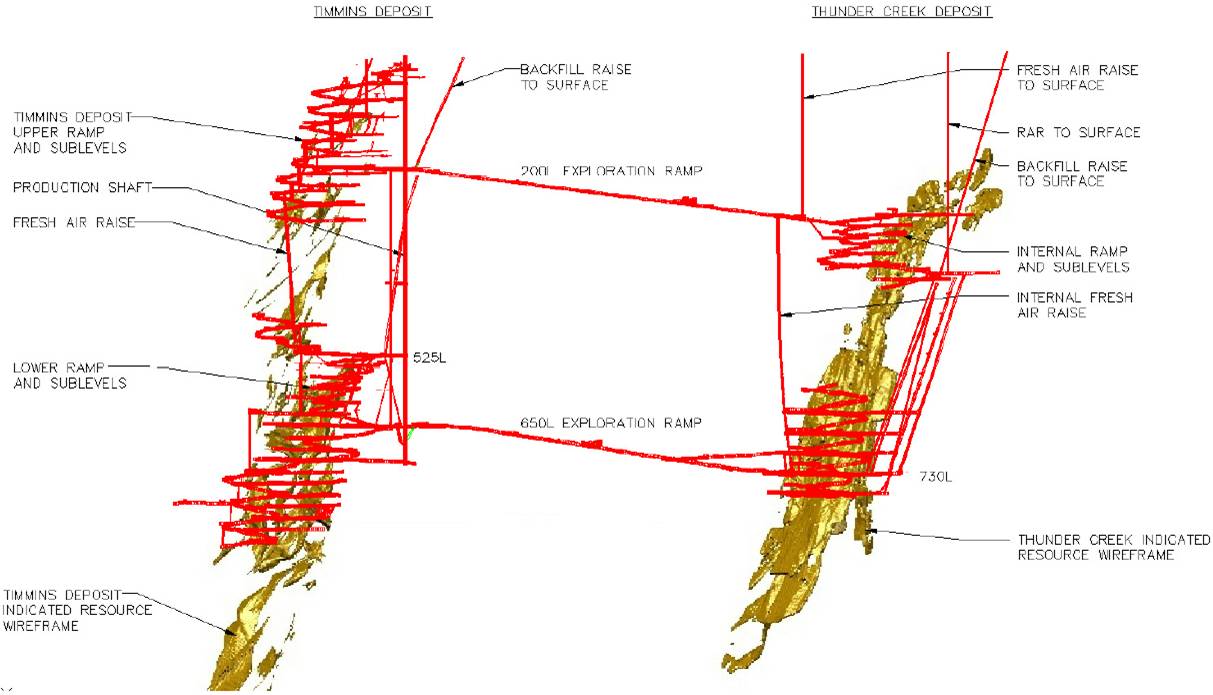

| 16.1 | UNDERGROUND ACCESS | 136 |

| | 16.1.1 | Primary / Secondary Access | 136 |

| 16.2 | SHAFT AND HOISTING FACILITIES | 136 |

| | 16.2.1 | Hoisting Plant | 136 |

| | 16.2.2 | Shaft Services | 137 |

| | 16.2.3 | Ore / Waste Handling System and Loading Pocket | 137 |

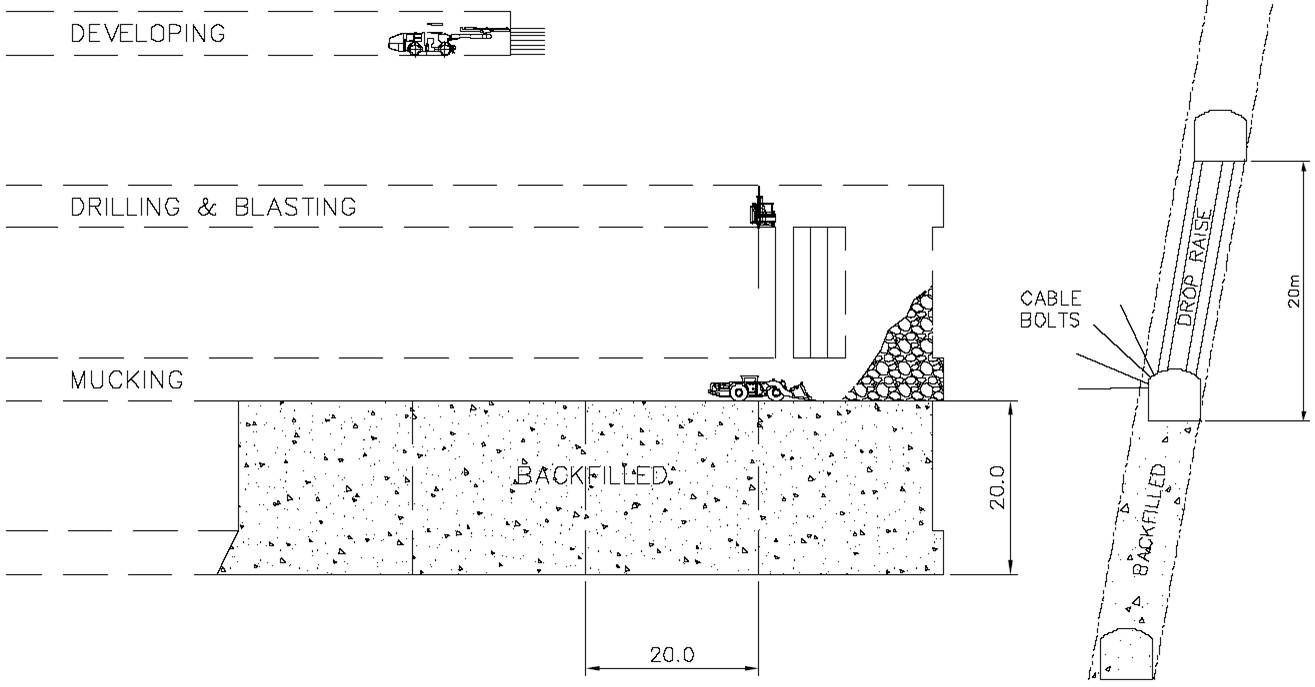

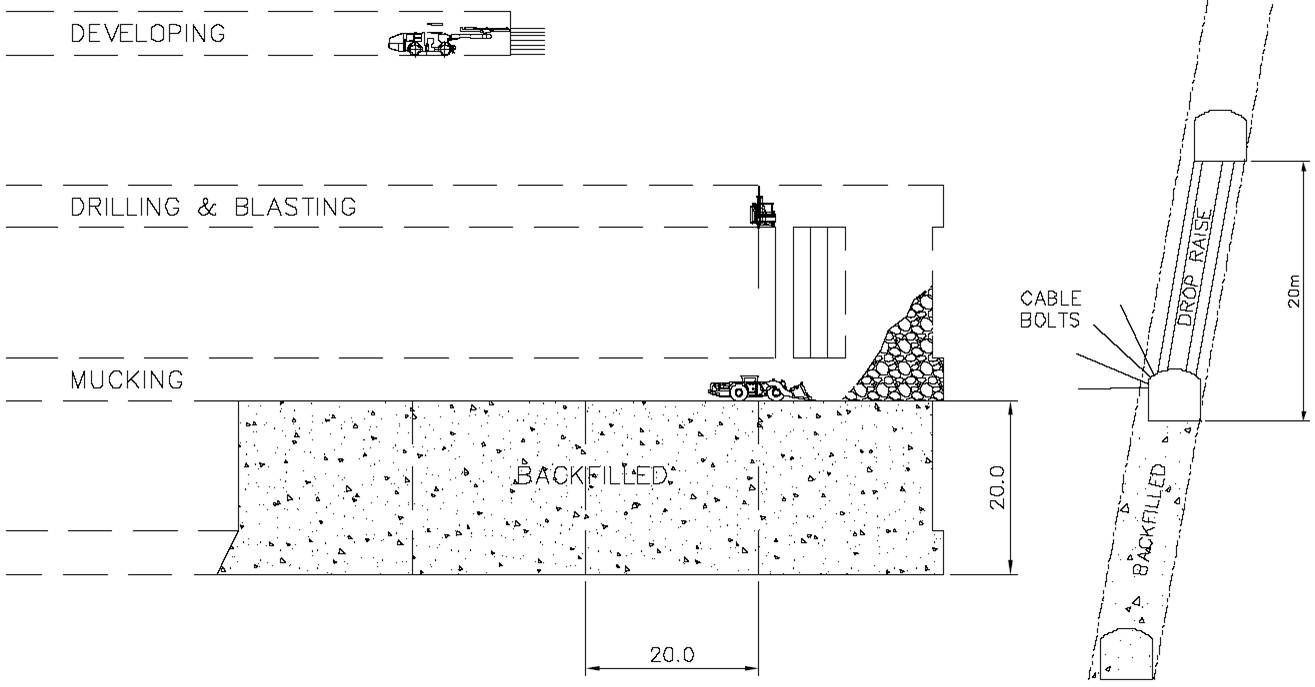

| 16.3 | STOPING METHODS | 137 |

| | 16.3.1 | Timmins Deposit | 137 |

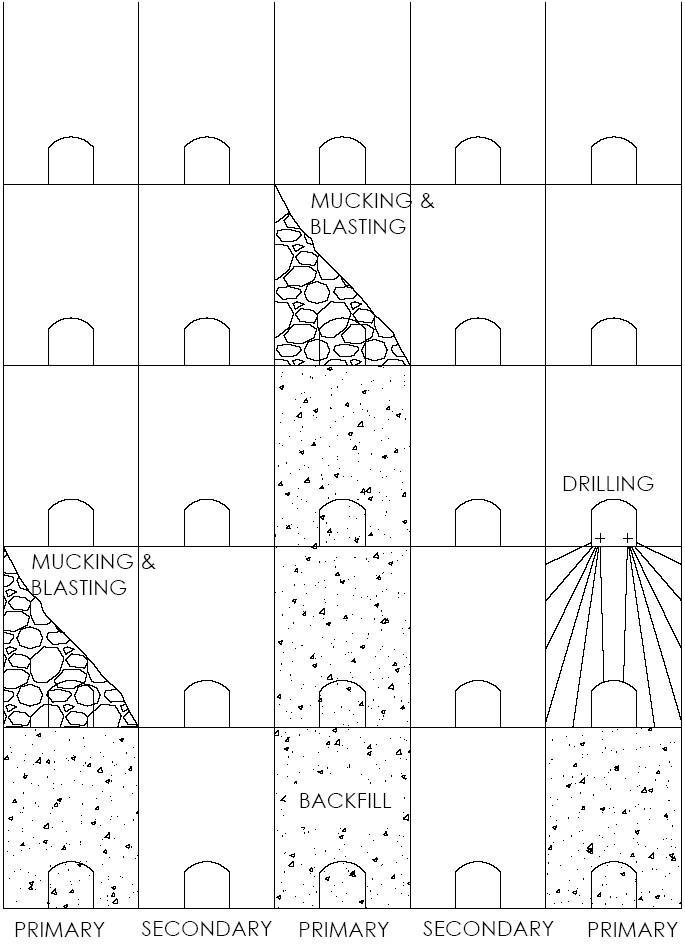

| | 16.3.2 | Thunder Creek Deposit | 139 |

| 16.4 | RESOURCE ANALYSIS (DILUTION AND RECOVERY) | 141 |

| | 16.4.1 | Mining Dilution and Recovery | 141 |

| | 16.4.2 | Stope Cut-Off Grade | 142 |

| | 16.4.3 | Timmins Deposit Reserve Estimate | 142 |

| | 16.4.4 | Thunder Creek Deposit Reserve Estimate | 144 |

| | 16.4.5 | Timmins West Mine Combined Reserves | 145 |

| 16.5 | HAULAGE | 145 |

| | 16.5.1 | Timmins Deposit Underground Truck Haulage | 146 |

| | 16.5.2 | Thunder Creek Deposit Underground Truck Haulage | 146 |

| 16.6 | DEVELOPMENT | 146 |

| | 16.6.1 | Timmins Deposit | 148 |

| | 16.6.2 | Thunder Creek Deposit | 150 |

iv

TABLE OF CONTENTS

| | 16.6.3 | Ground Support | 151 |

| 16.7 | DEVELOPMENT SCHEDULES | 151 |

| 16.8 | BACKFILL | 152 |

| 16.9 | PRODUCTION | 152 |

| | 16.9.1 | Timmins Deposit Production | 152 |

| | 16.9.2 | Thunder Creek Deposit Production | 152 |

| | 16.9.3 | Timmins West Mine Production | 153 |

| 16.10 | PRODUCTION EQUIPMENT | 154 |

| 16.11 | VENTILATION | 154 |

| | 16.11.1 | Timmins Deposit Ventilation | 154 |

| | 16.11.2 | Thunder Creek Ventilation | 155 |

| | 16.11.3 | Mine Air Heating and Cooling | 156 |

| 16.12 | PERSONNEL | 156 |

| 16.13 | UNDERGROUND MINE SERVICES | 158 |

| | 16.13.1 | Electrical Distribution and Communications | 158 |

| | 16.13.2 | Compressed Air | 158 |

| | 16.13.3 | Service Water | 159 |

| | 16.13.4 | Mine Dewatering | 159 |

| | 16.13.5 | Roadbed Material | 159 |

| 16.14 | MATERIALS SUPPLY | 159 |

| 16.15 | MAINTENANCE | 160 |

| 16.16 | SAFETY | 160 |

| 16.17 | GEOTECHNICAL | 160 |

| 16.18 | BELL CREEK TAILINGS FACILITY | 162 |

| | | |

17.0 | RECOVERY METHODS | 165 |

| 17.1 | HISTORY | 165 |

| 17.2 | BELL CREEK MILL PROCESS DESCRIPTION | 165 |

| 17.3 | METALLURGICAL BALANCE | 166 |

| | | |

18.0 | PROJECT INFRASTRUCTURE | 168 |

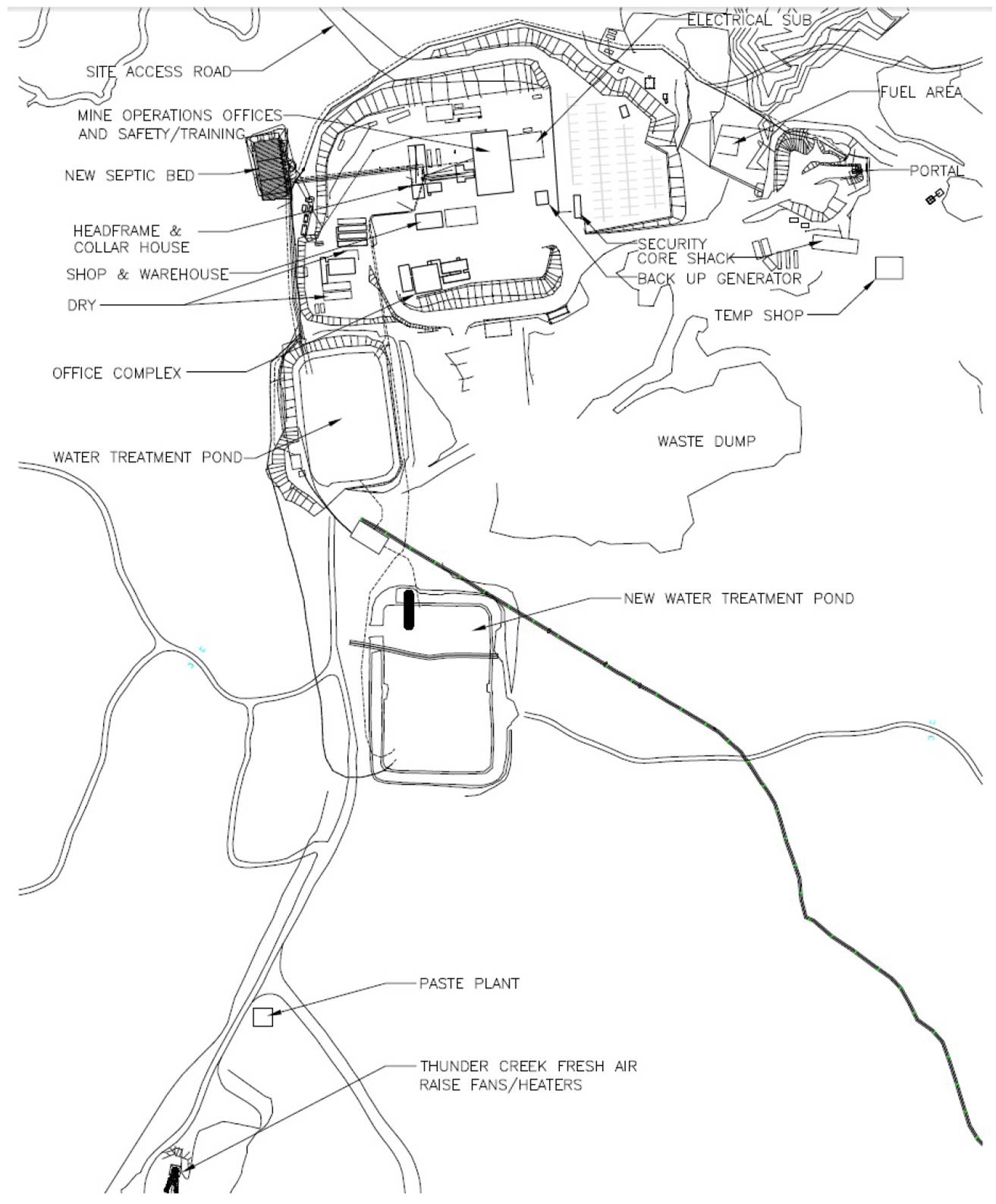

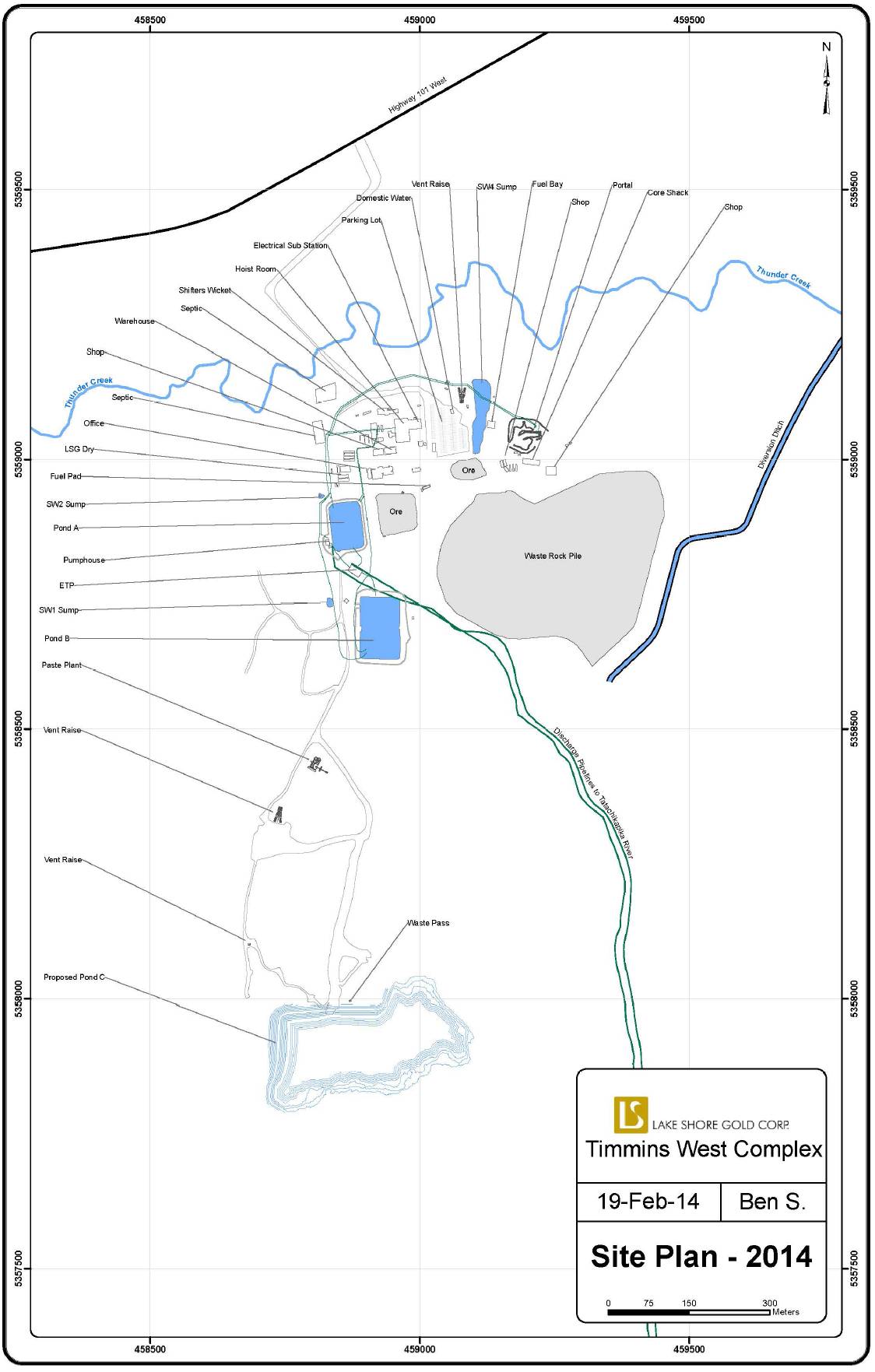

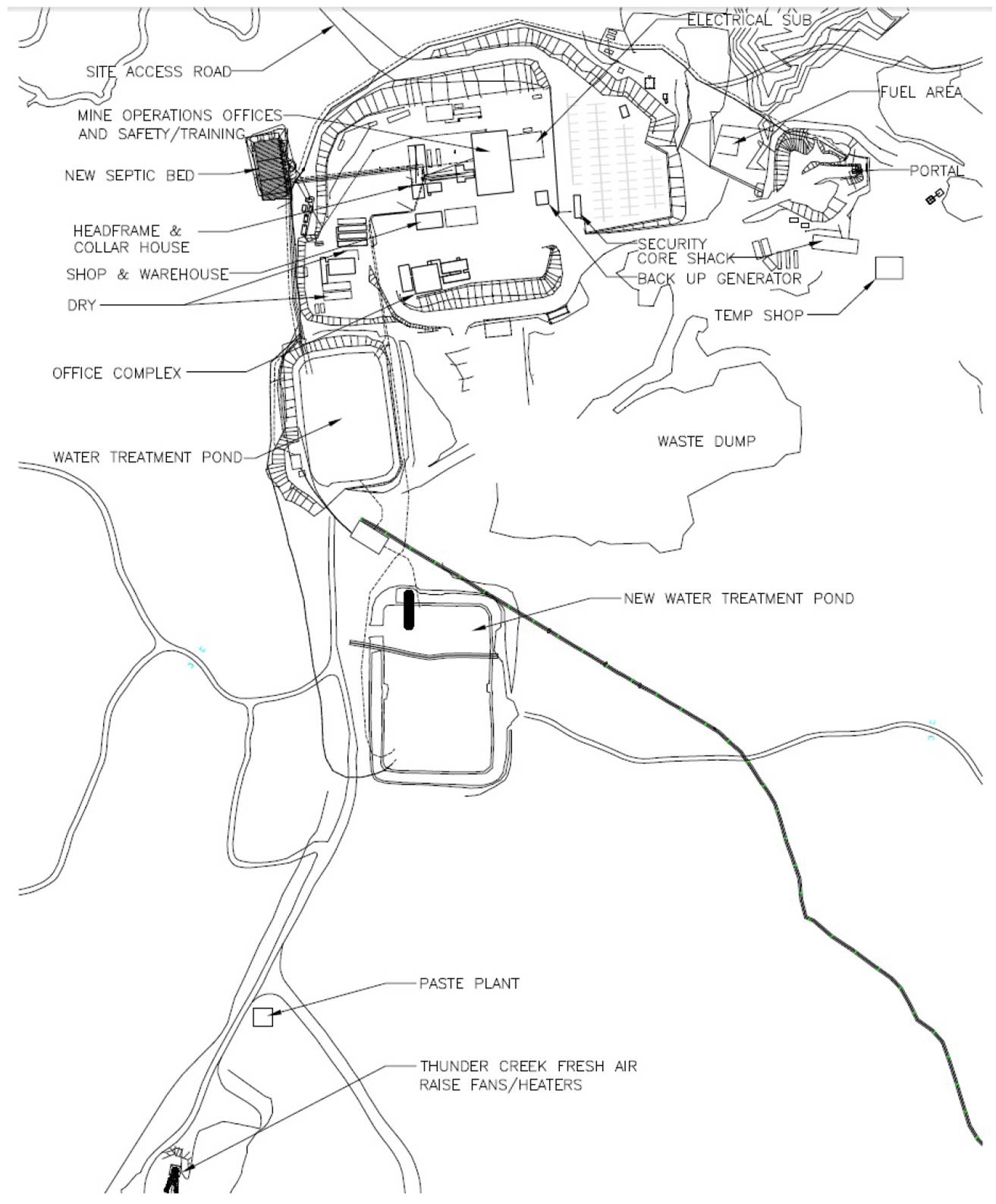

| 18.1 | TIMMINS WEST MINE SITE | 168 |

| 18.2 | BELL CREEK MILL SITE | 168 |

| | | |

19.0 | MARKET STUDIES AND CONTRACTS | 169 |

| | |

20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | 170 |

| 20.1 | REGULATORY AND FRAMEWORK | 170 |

| | 20.1.1 | Provincial Environmental Assessments | 170 |

| | 20.1.2 | Federal Environmental Assessments | 170 |

| | 20.1.3 | Provincial Permits | 170 |

| | 20.1.4 | Federal Permits | 171 |

| 20.2 | ENVIRONMENTAL IMPACTS | 172 |

| 20.3 | ENVIRONMENTAL MONITORING PROGRAM | 173 |

| 20.4 | HAZARDOUS MATERIALS HANDLING | 175 |

| 20.5 | SPILL AND EMERGENCY RESPONSE PLAN | 175 |

| 20.6 | CLOSURE PLANNING | 175 |

| 20.7 | CONSULTATION | 176 |

| | | |

21.0 | CAPITAL AND OPERATING COSTS | 177 |

| 21.1 | CAPITAL COSTS | 177 |

v

TABLE OF CONTENTS

| 21.2 | OPERATING COSTS | 179 |

| | | |

22.0 | ECONOMIC ANALYSIS | 182 |

| | |

23.0 | ADJACENT PROPERTIES | 183 |

| 23.1 | GENERAL STATEMENT ABOUT ADJACENT PROPERTIES | 183 |

| 23.2 | PELANGIO EXPLORATION INC. — POIRIER OPTION — BRISTOL TOWNSHIP | 183 |

| 23.3 | NEWCASTLE MINERALS LIMITED — WEST TIMMINS GOLD PROJECT — CARSCALLEN TOWNSHIP | 183 |

| 23.4 | RICHMONT MINES INC. — CRIPPLE CREEK PROPERTY — DENTON TOWNSHIP | 184 |

| 23.5 | EXPLOR RESOURCES INC. — TIMMINS PORCUPINE WEST (ONTARIO) PROPERTY — BRISTOL AND OGDEN TOWNSHIPS | 184 |

| | | |

24.0 | OTHER RELEVANT DATA AND INFORMATION | 187 |

| | |

25.0 | INTERPRETATION AND CONCLUSIONS | 188 |

| 25.1 | RISKS | 191 |

| | | |

26.0 | RECOMMENDATIONS | 192 |

| | |

27.0 | REFERENCES | 194 |

| 27.1 | REPORTS AND SCHEDULES | 194 |

| 27.2 | ASSESSMENT RESEARCH IMAGING FILES (AFRI) | 201 |

| 27.3 | PRESS RELEASES | 206 |

| | | |

28.0 | DATE AND SIGNATURE PAGE | 219 |

| | |

29.0 | CERTIFICATES OF QUALIFIED PERSONS | 220 |

| | |

LIST OF FIGURES | |

| | |

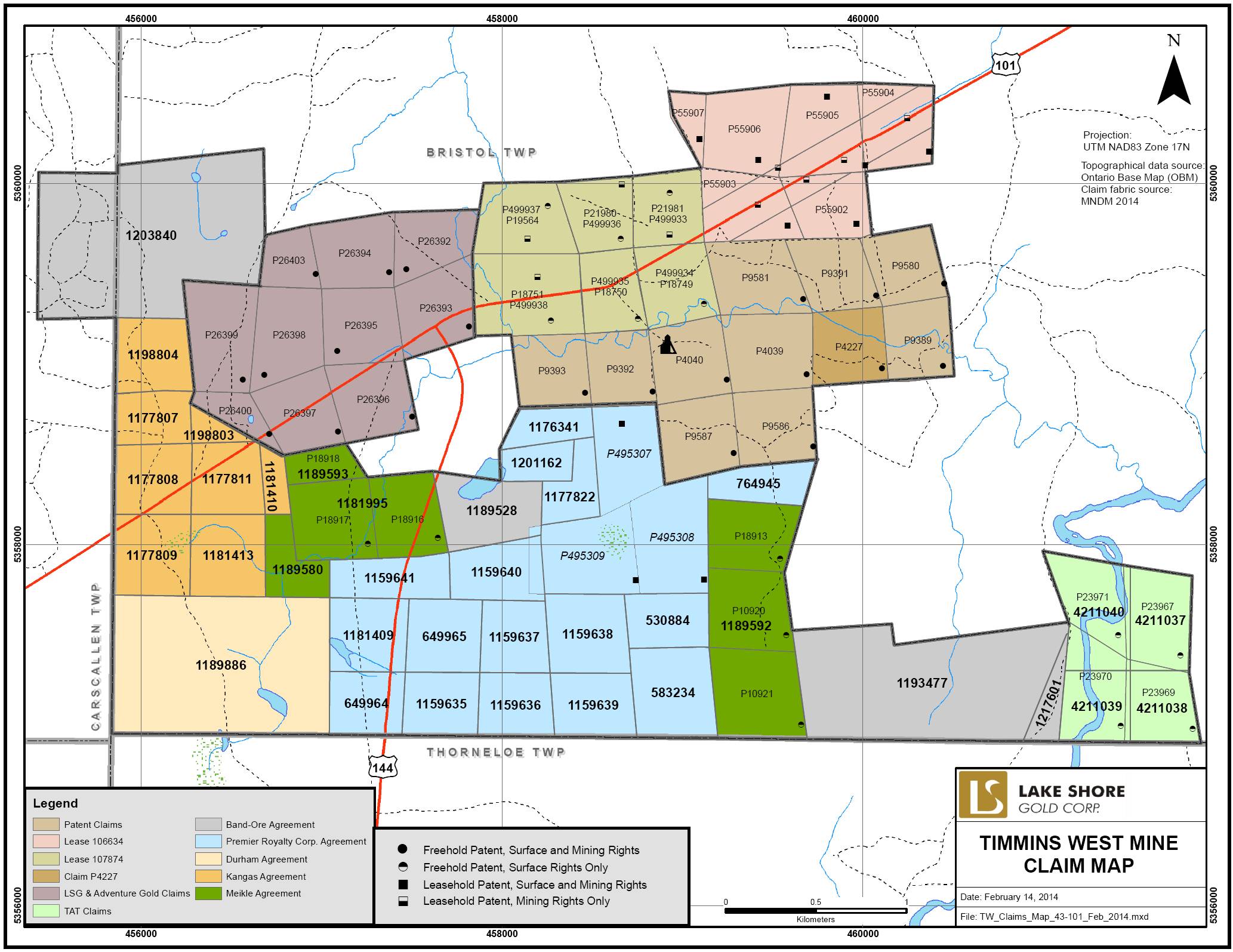

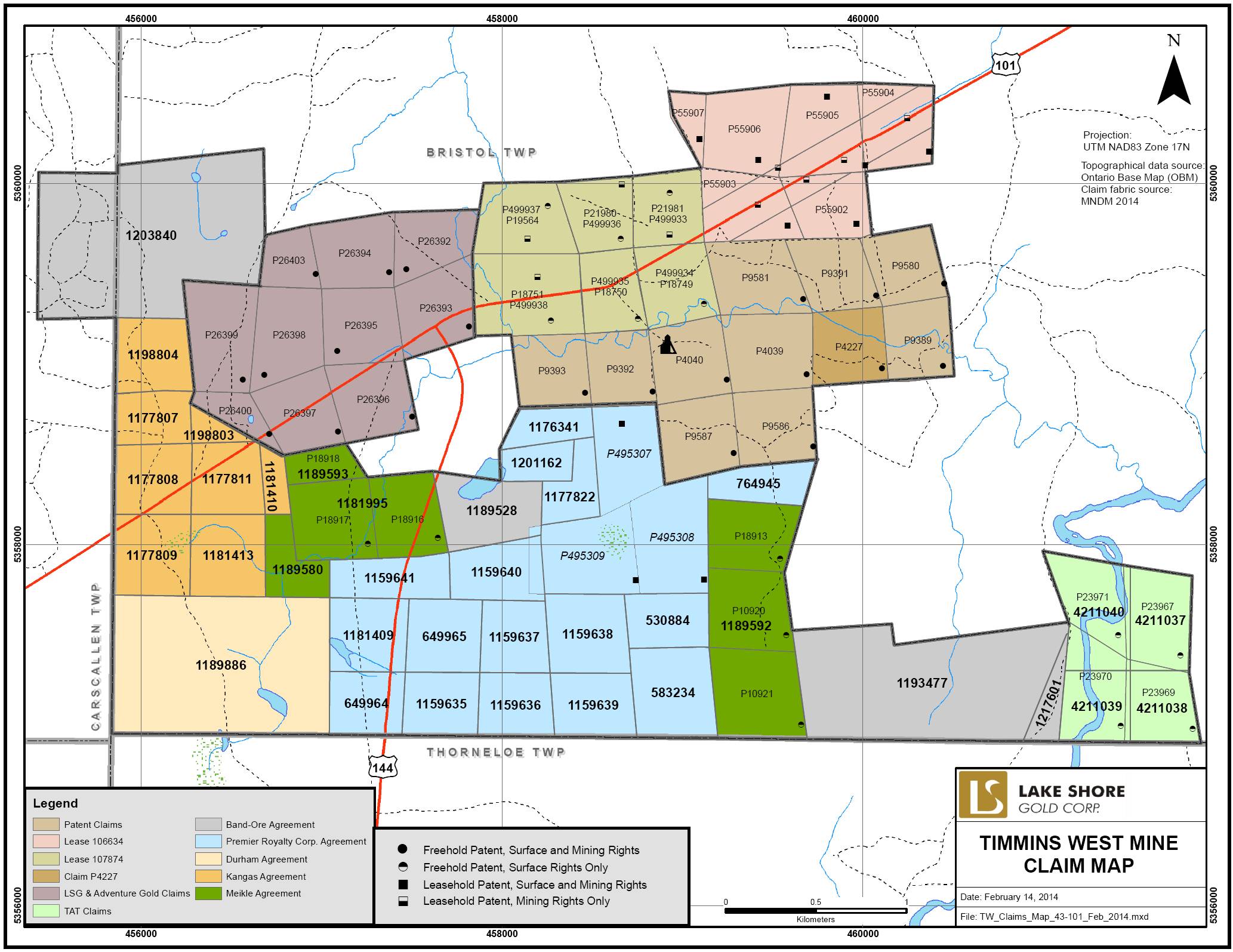

Figure 4.1: | TIMMINS WEST MINE PROPERTY | 20 |

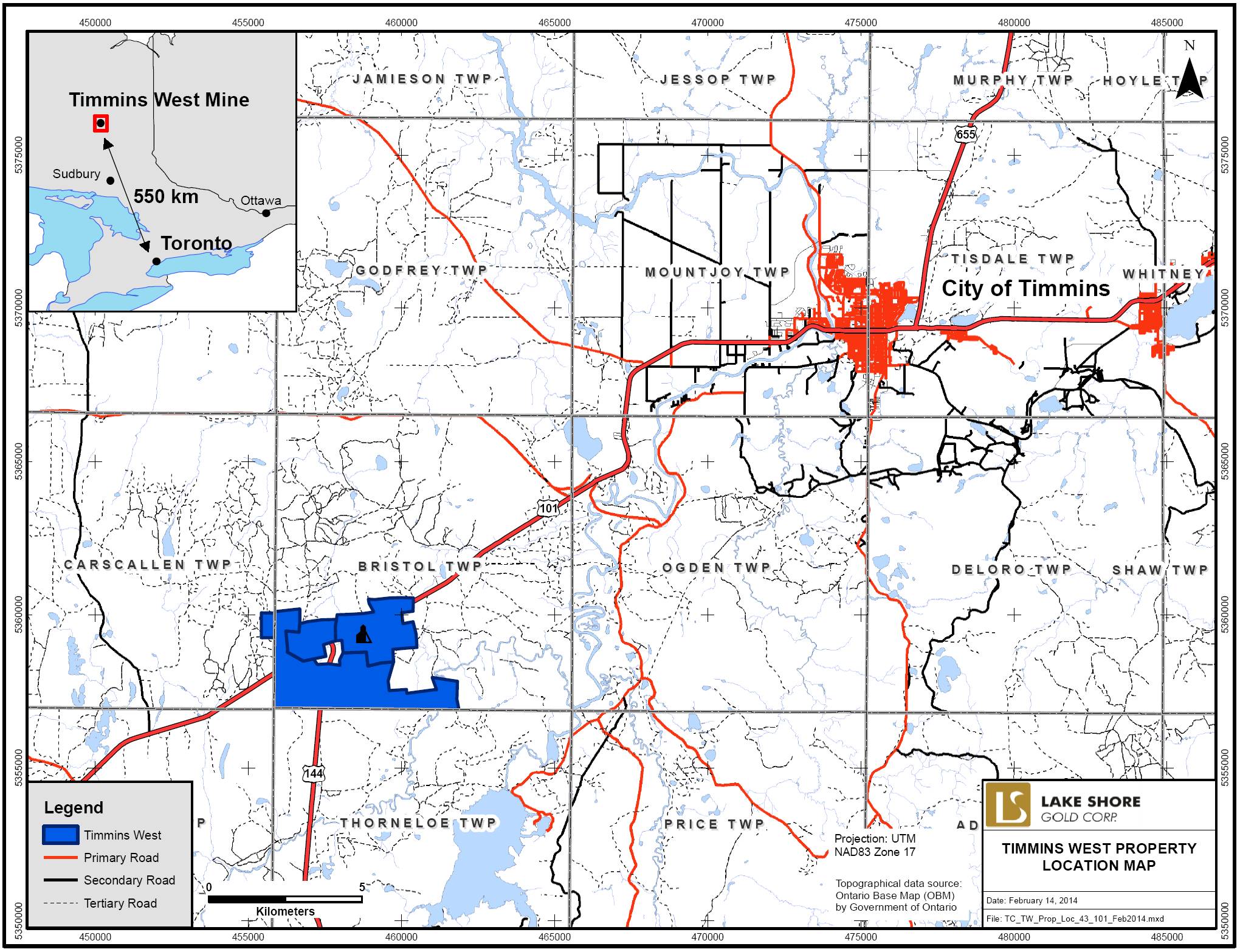

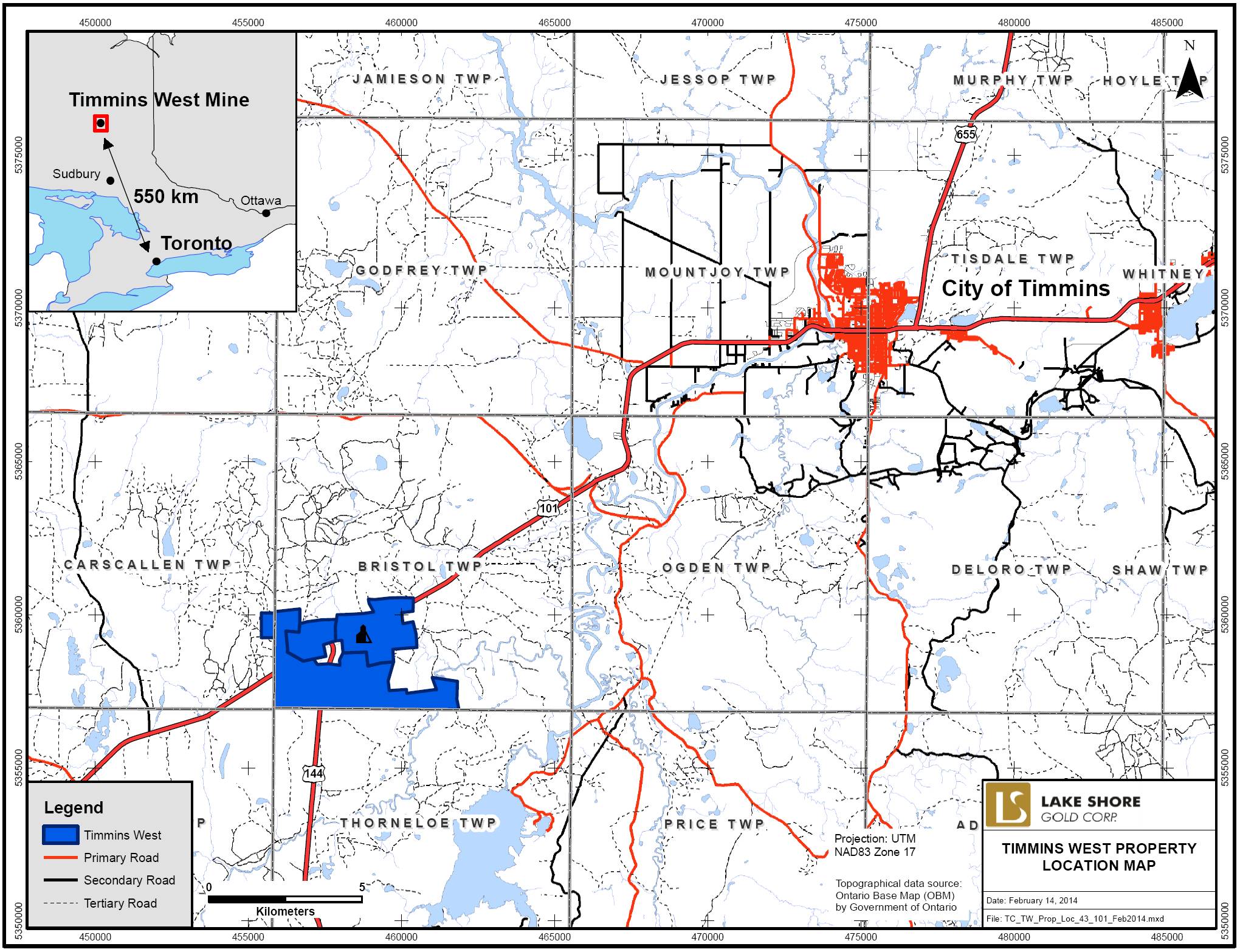

Figure 4.2: | LOCATION MAP | 24 |

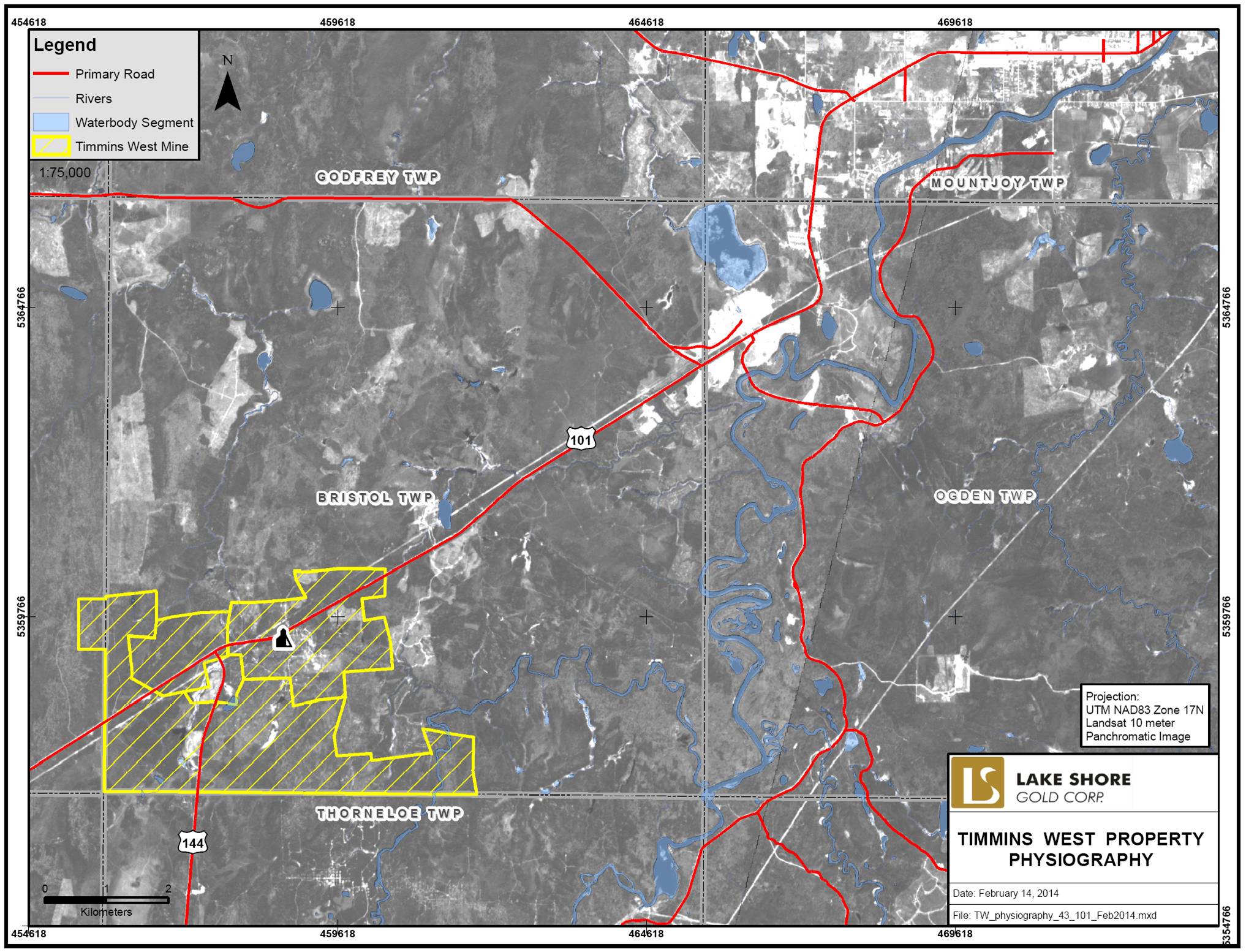

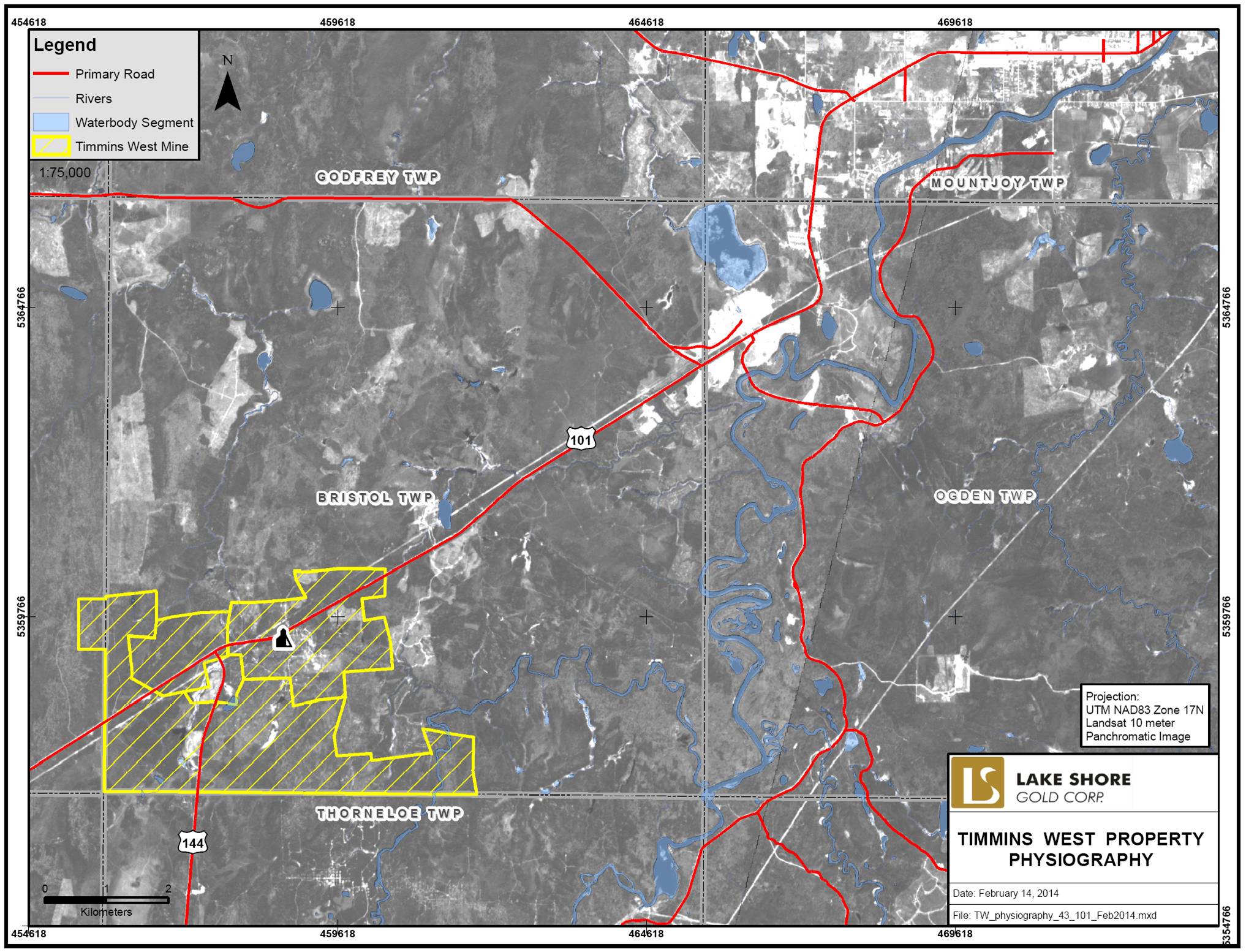

Figure 5.1: | PHYSIOGRAPHY | 30 |

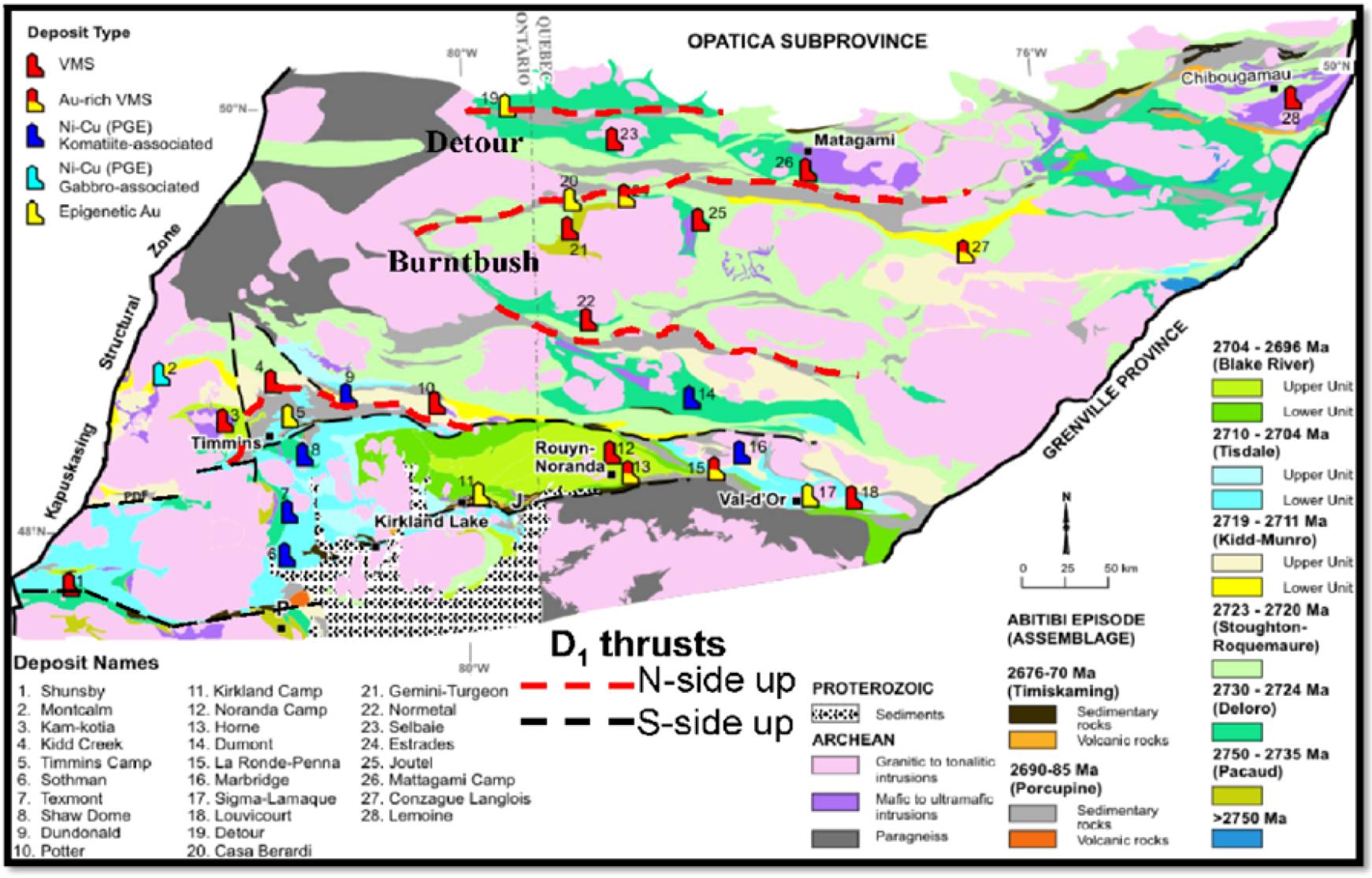

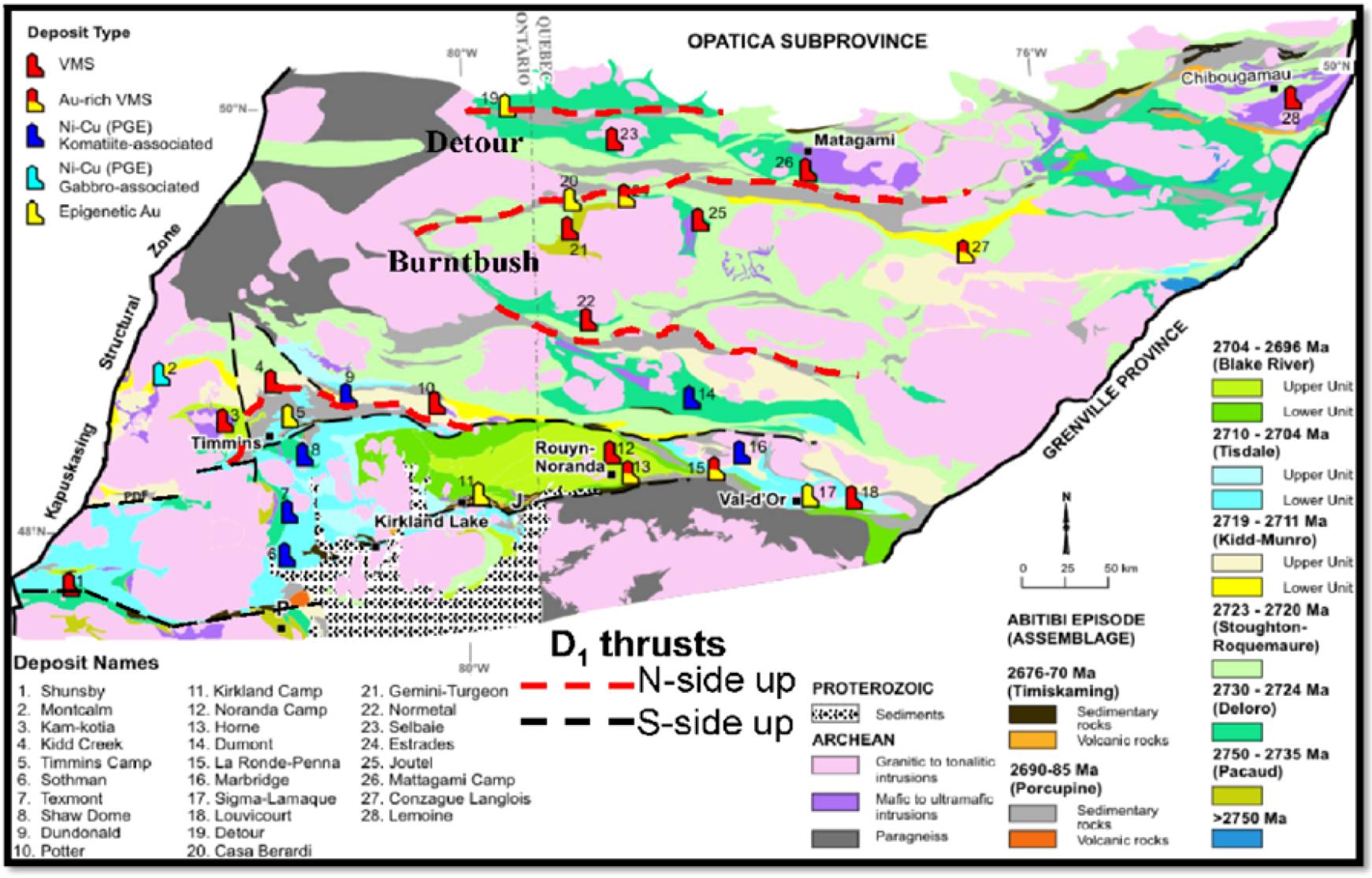

Figure 7.1: | TECTONIC ASSEMBLAGES OF THE ABITIBI SUBPROVINCE EAST OF THE KAPUSKASING STRUCTURAL ZONE (AFTER AYER, J.A., DUBÉ, B., TROWELL, N.F.; NE ONTARIO MINES AND MINERALS SYMPOSIUM, APRIL 16, 2009) | 40 |

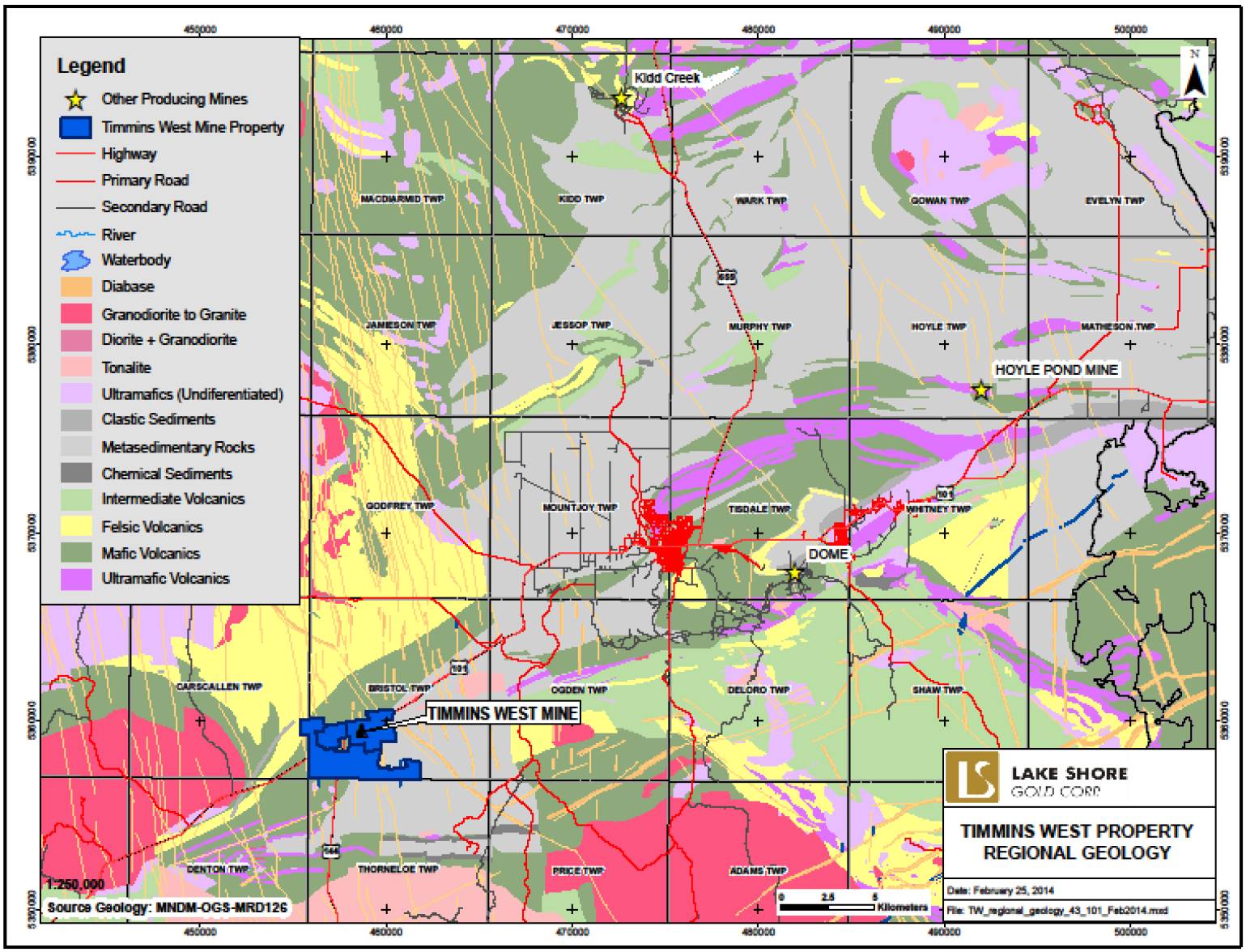

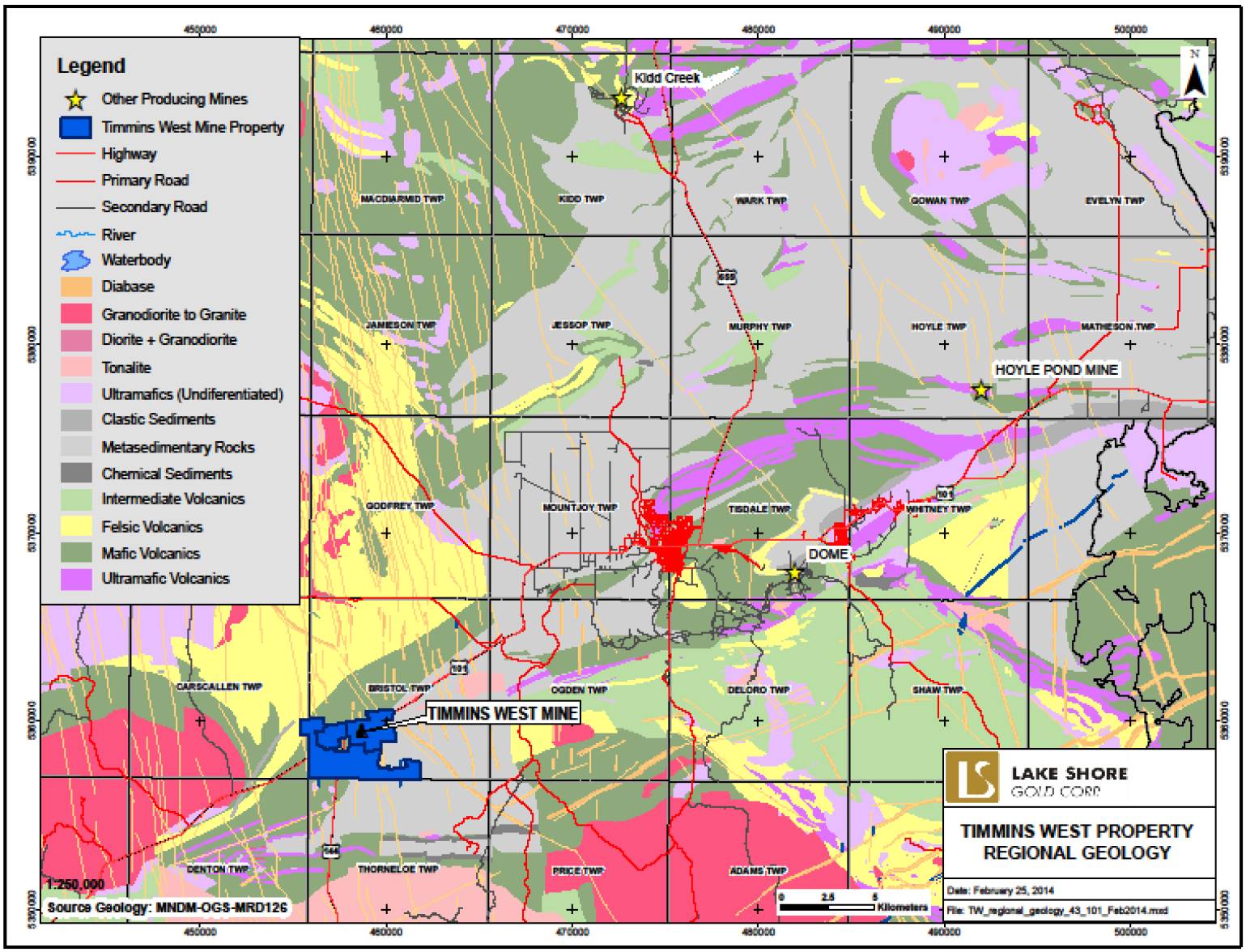

Figure 7.2: | REGIONAL GEOLOGY | 42 |

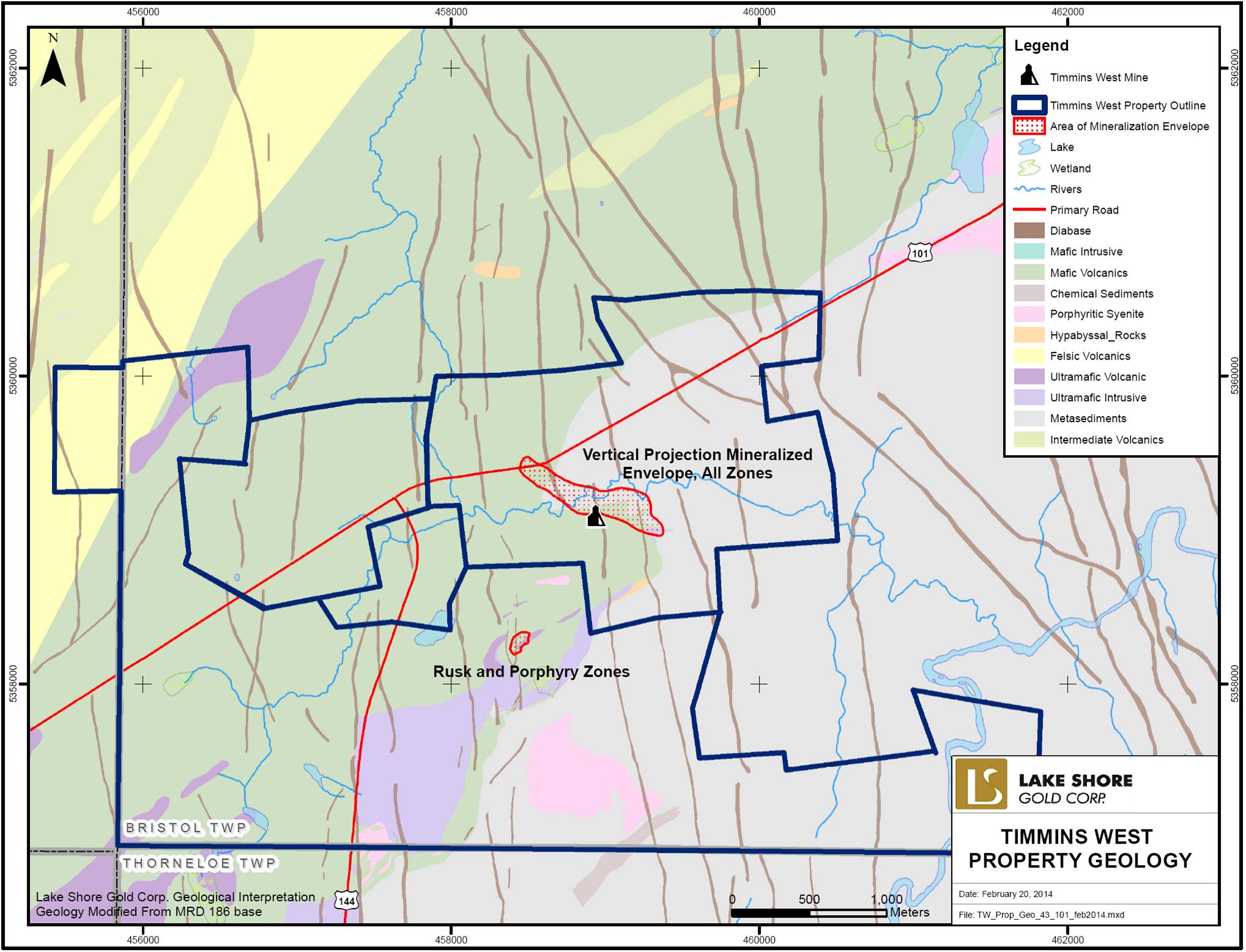

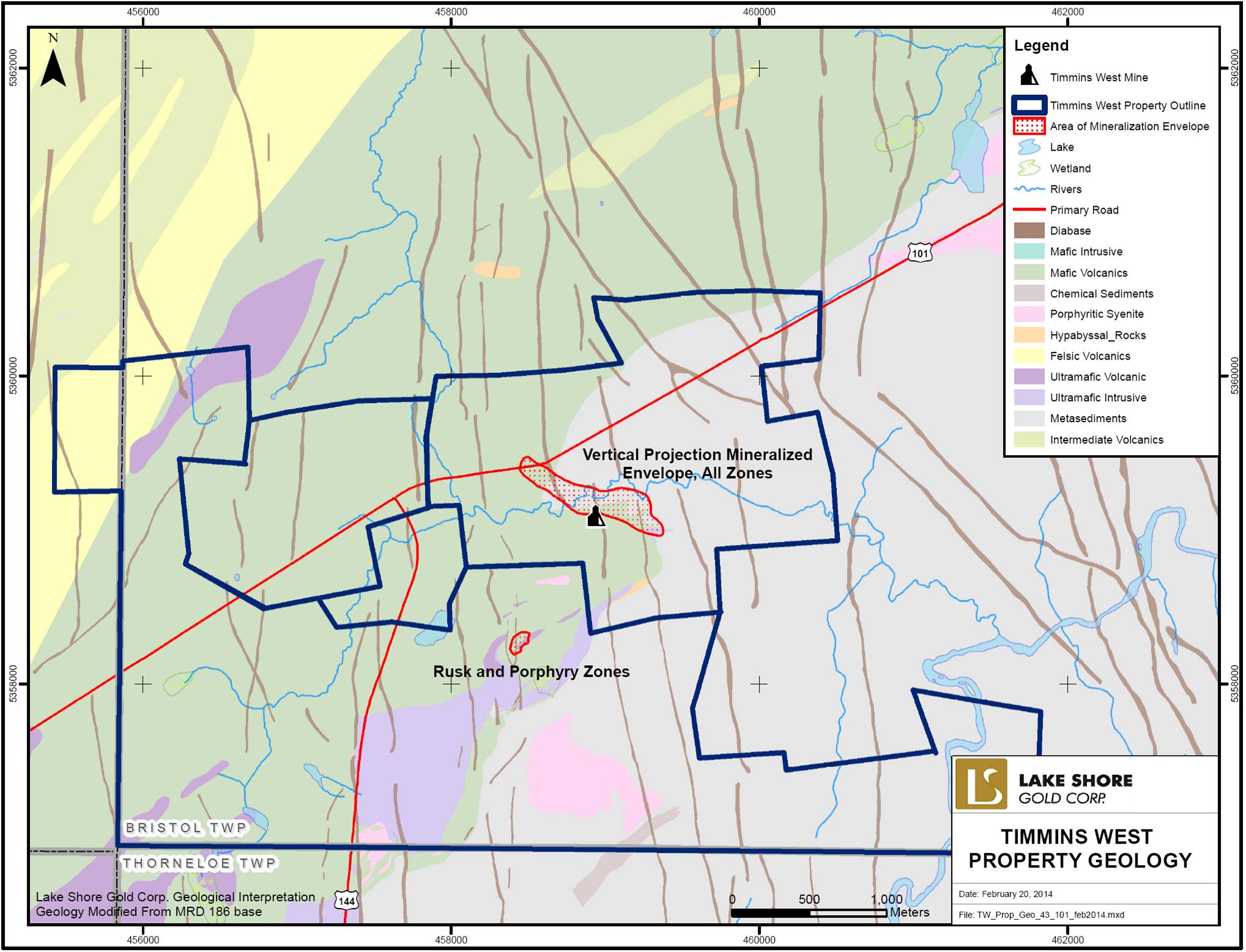

Figure 7.3: | PROPERTY GEOLOGY | 53 |

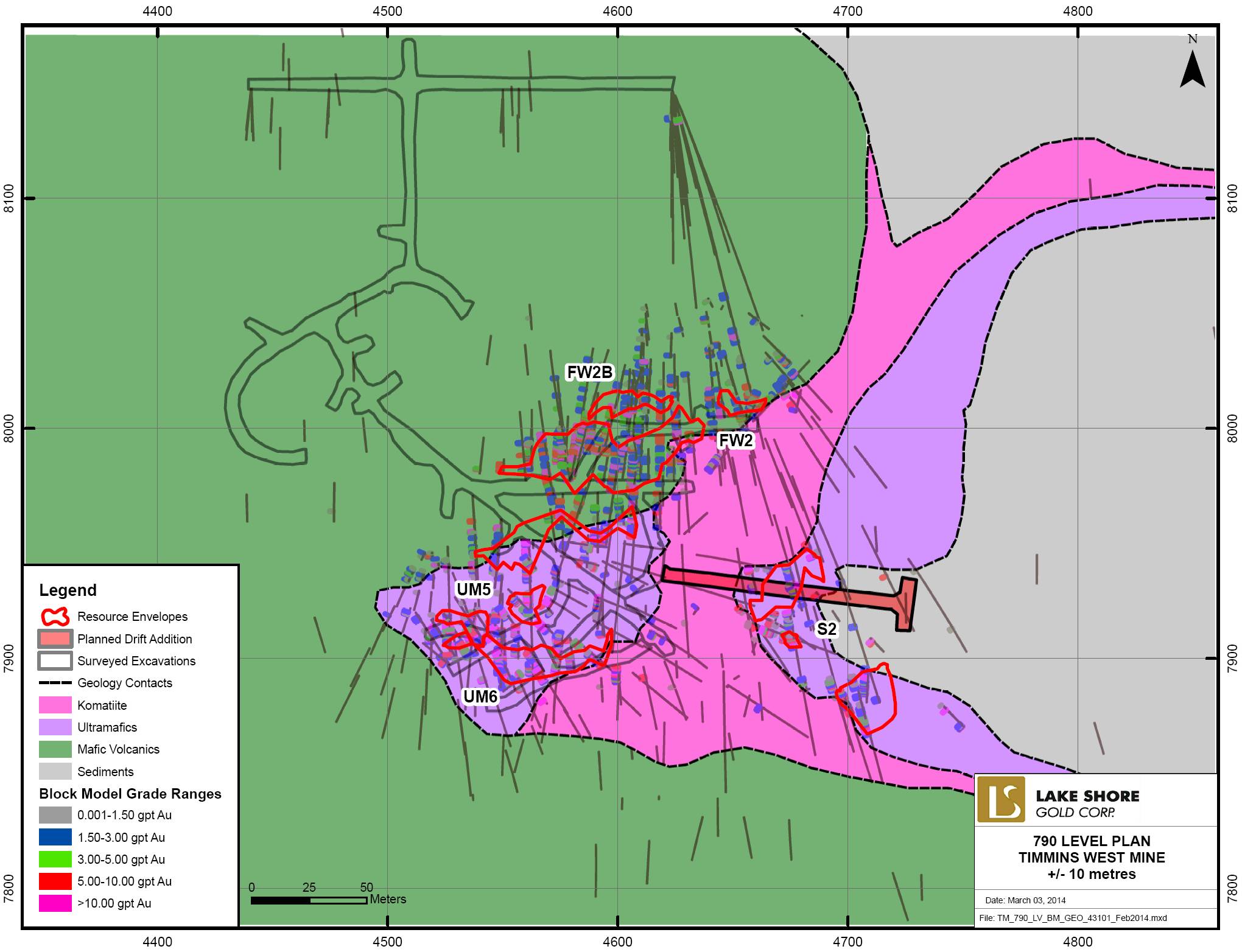

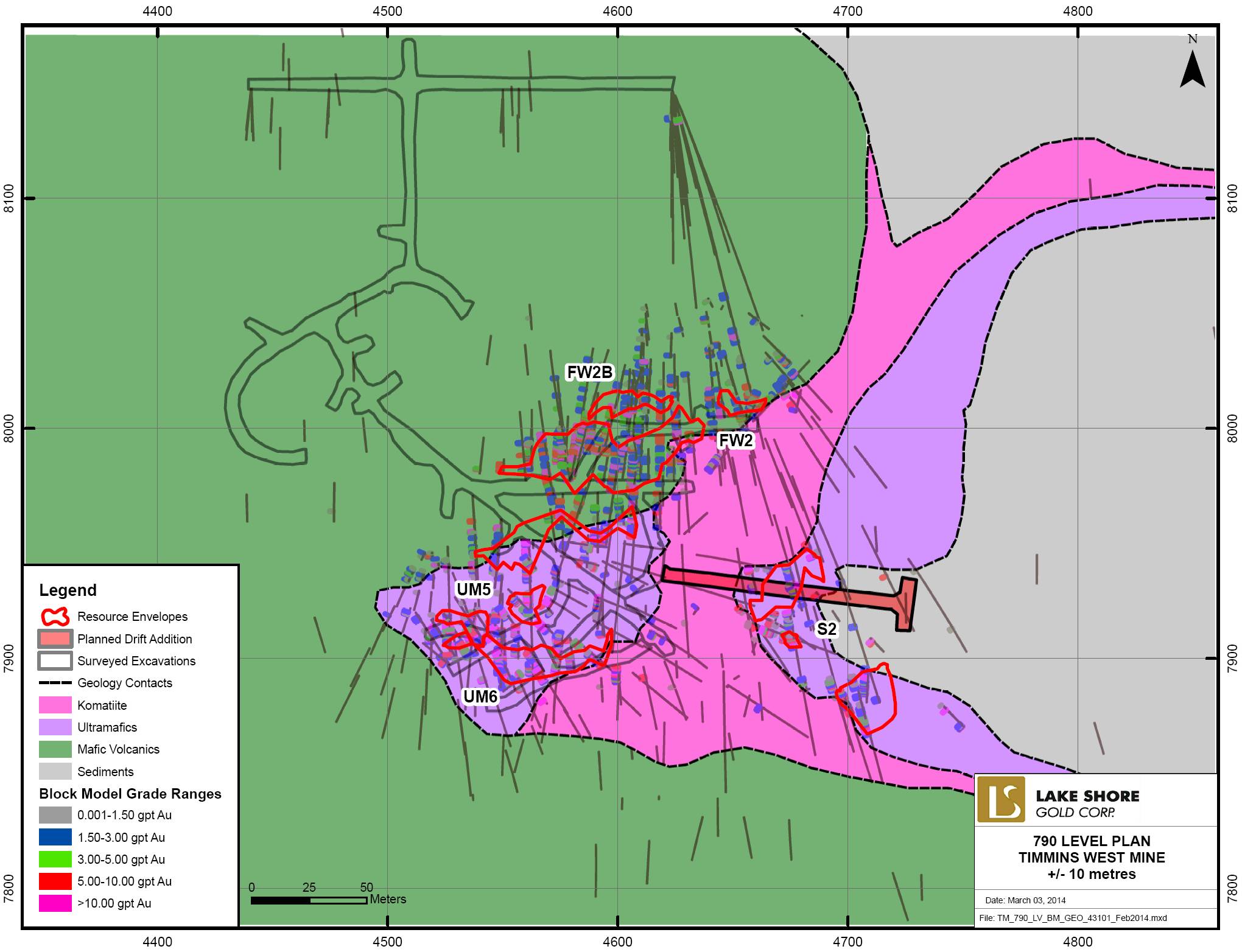

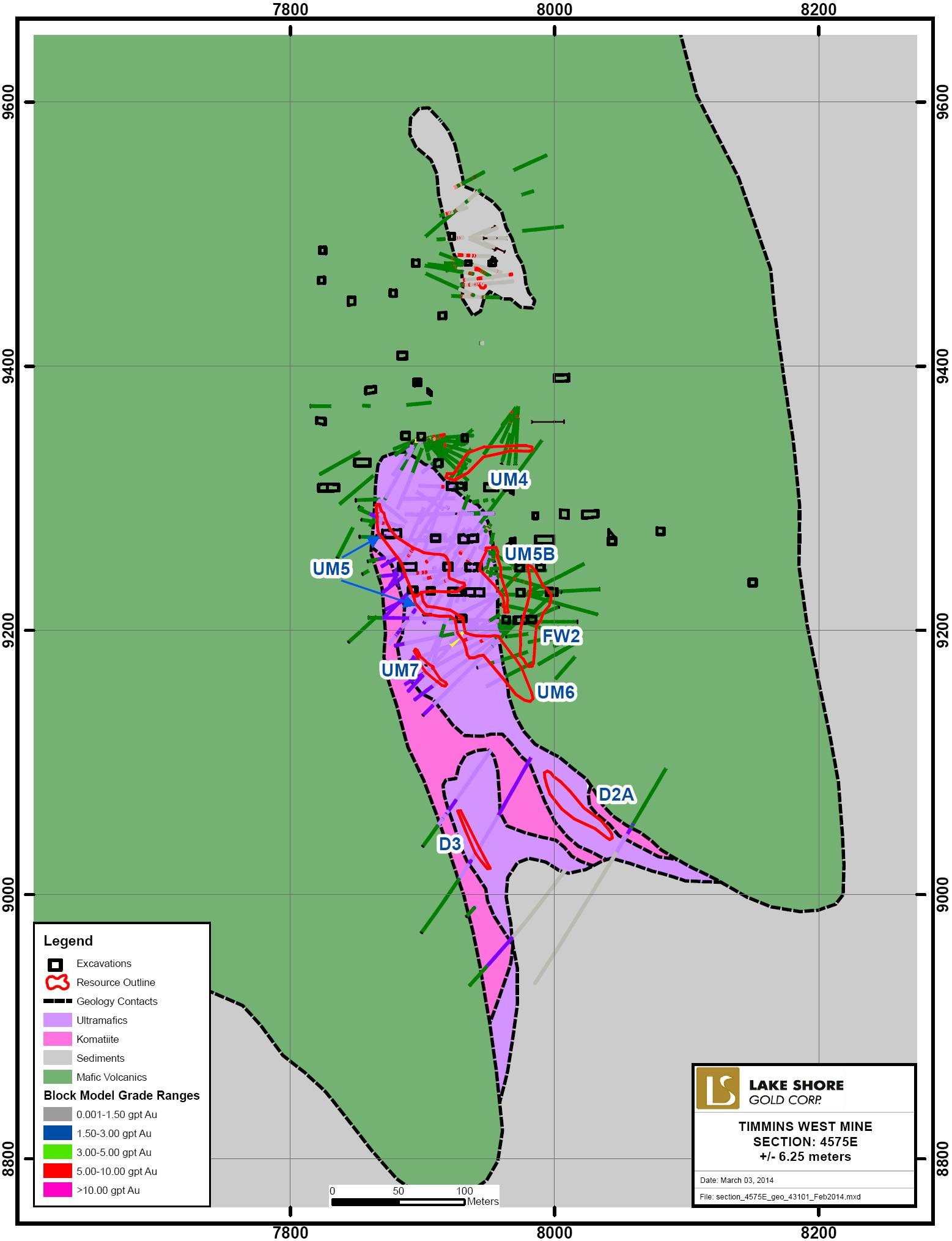

Figure 7.4: | TIMMINS DEPOSIT UNDERGROUND GEOLOGY 790 M LEVEL (UPPER LEVEL) | 54 |

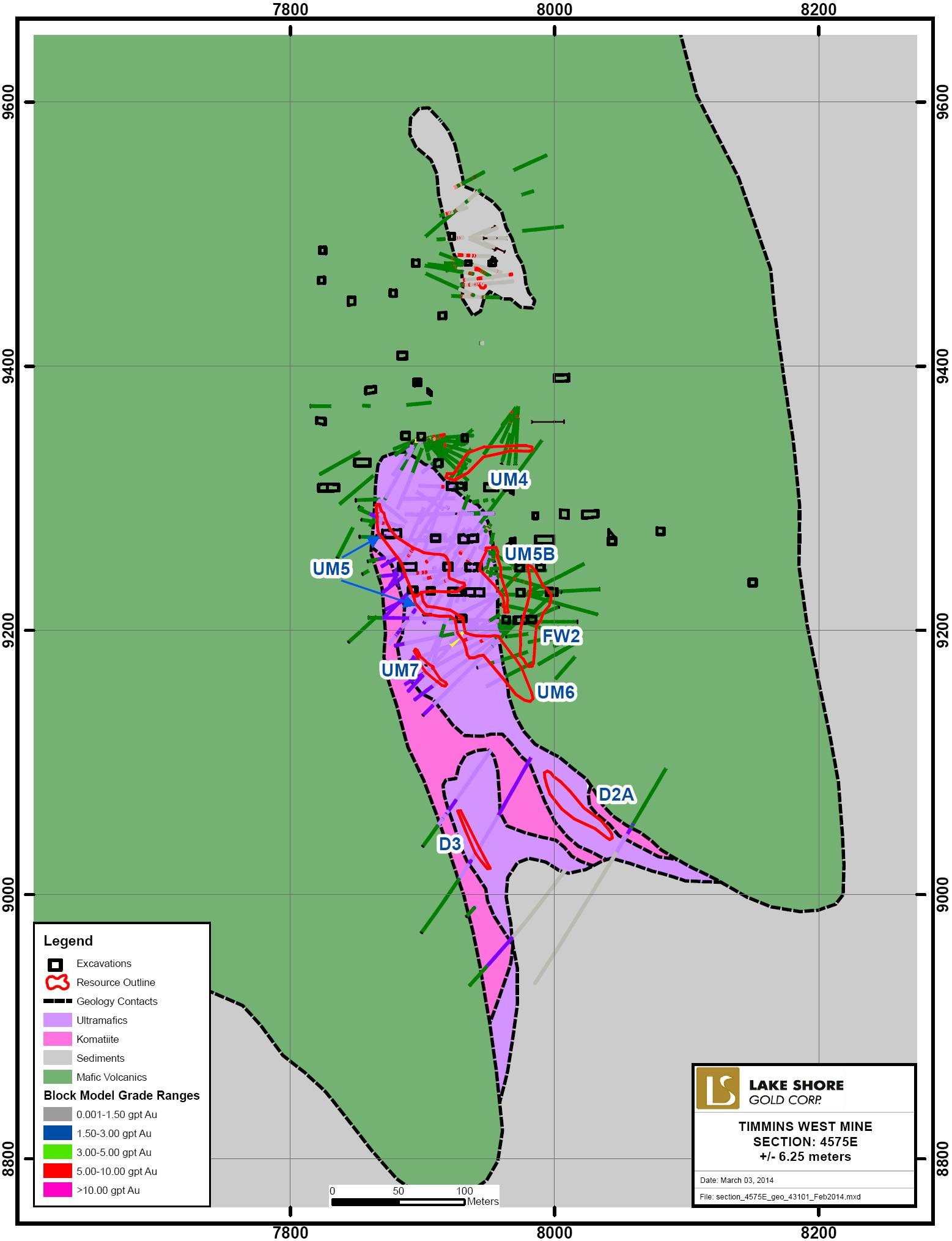

Figure 7.5: | TIMMINS DEPOSIT GENERALIZED CROSS-SECTION 4575E (TIMMINS WEST MINE GRID) | 55 |

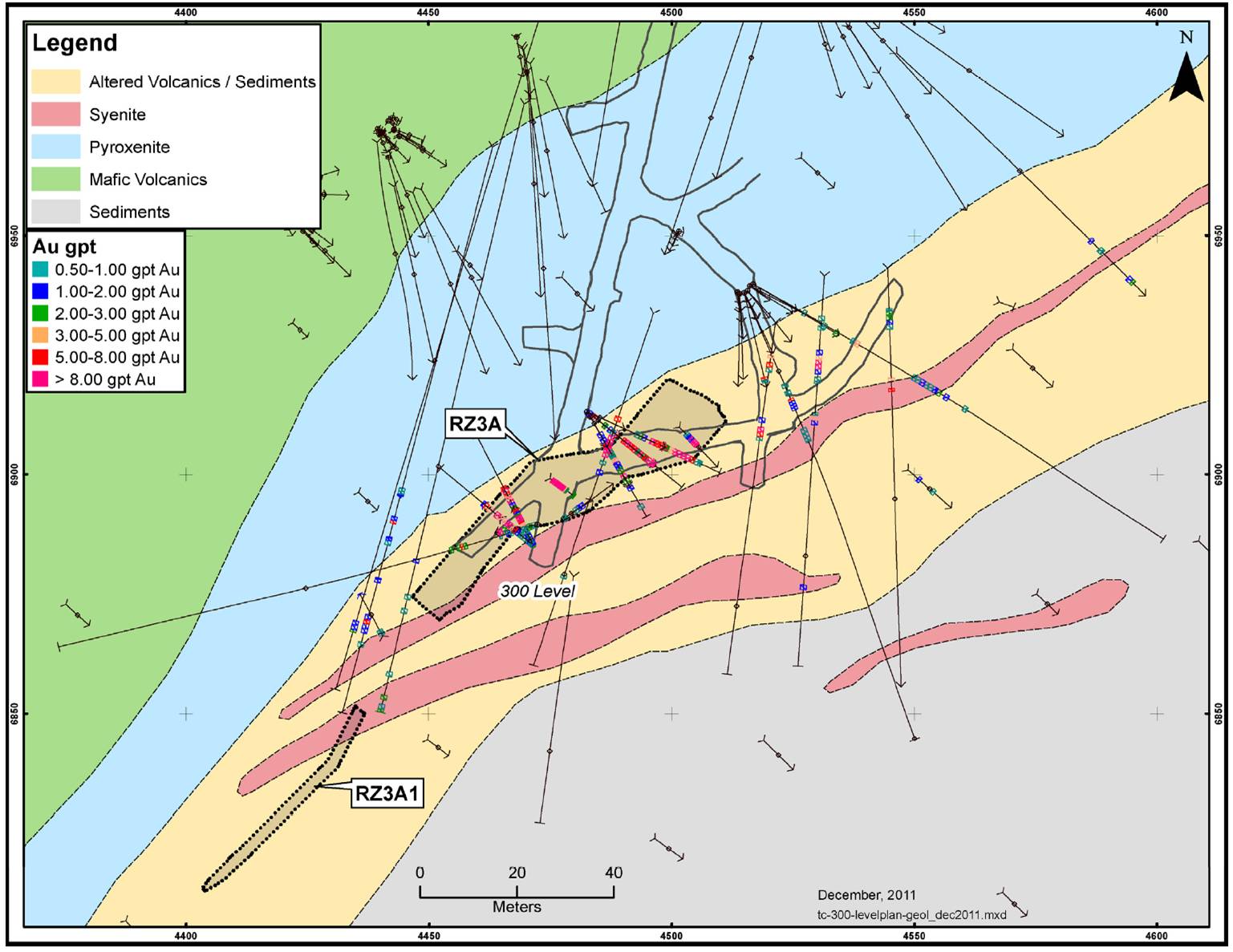

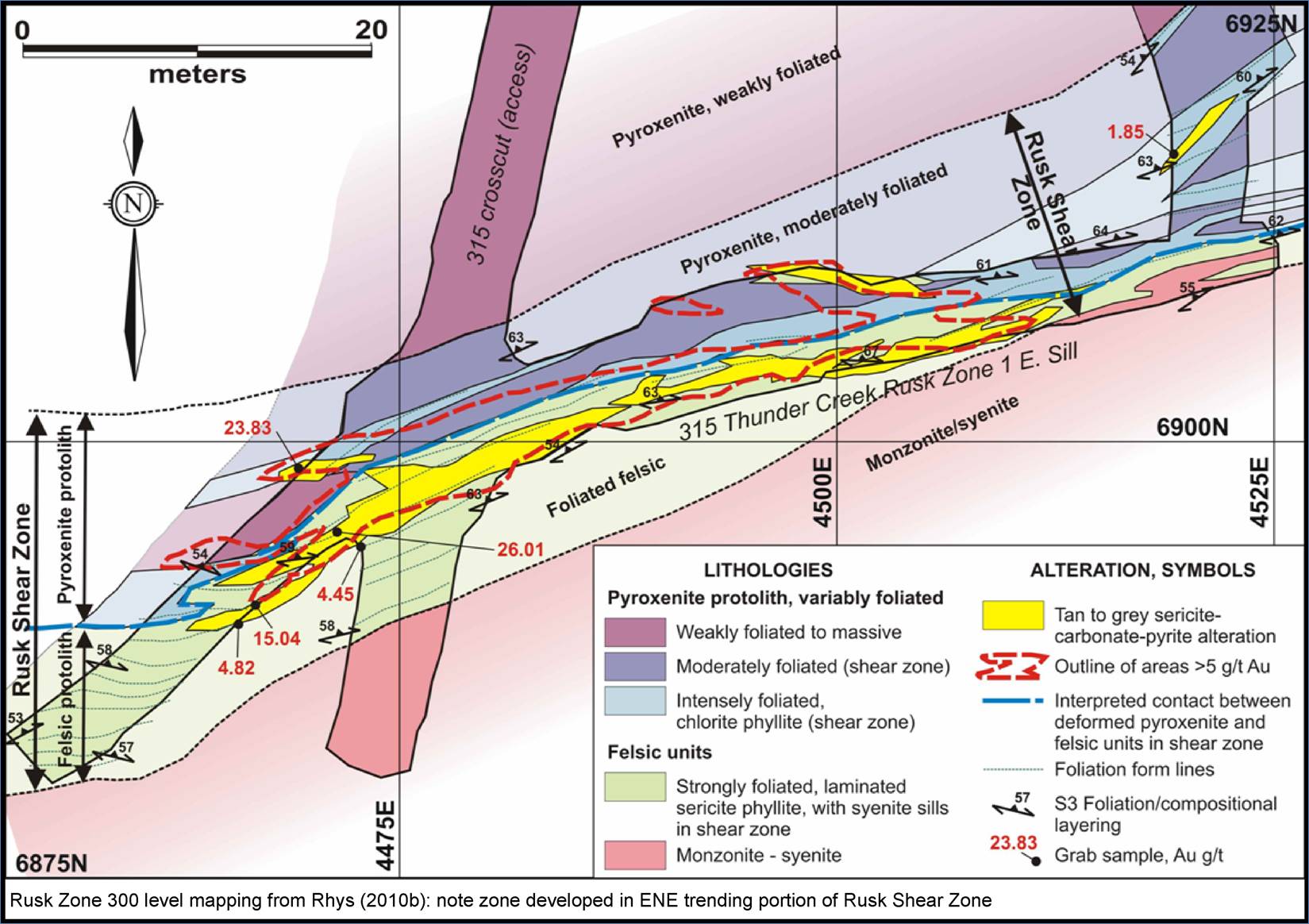

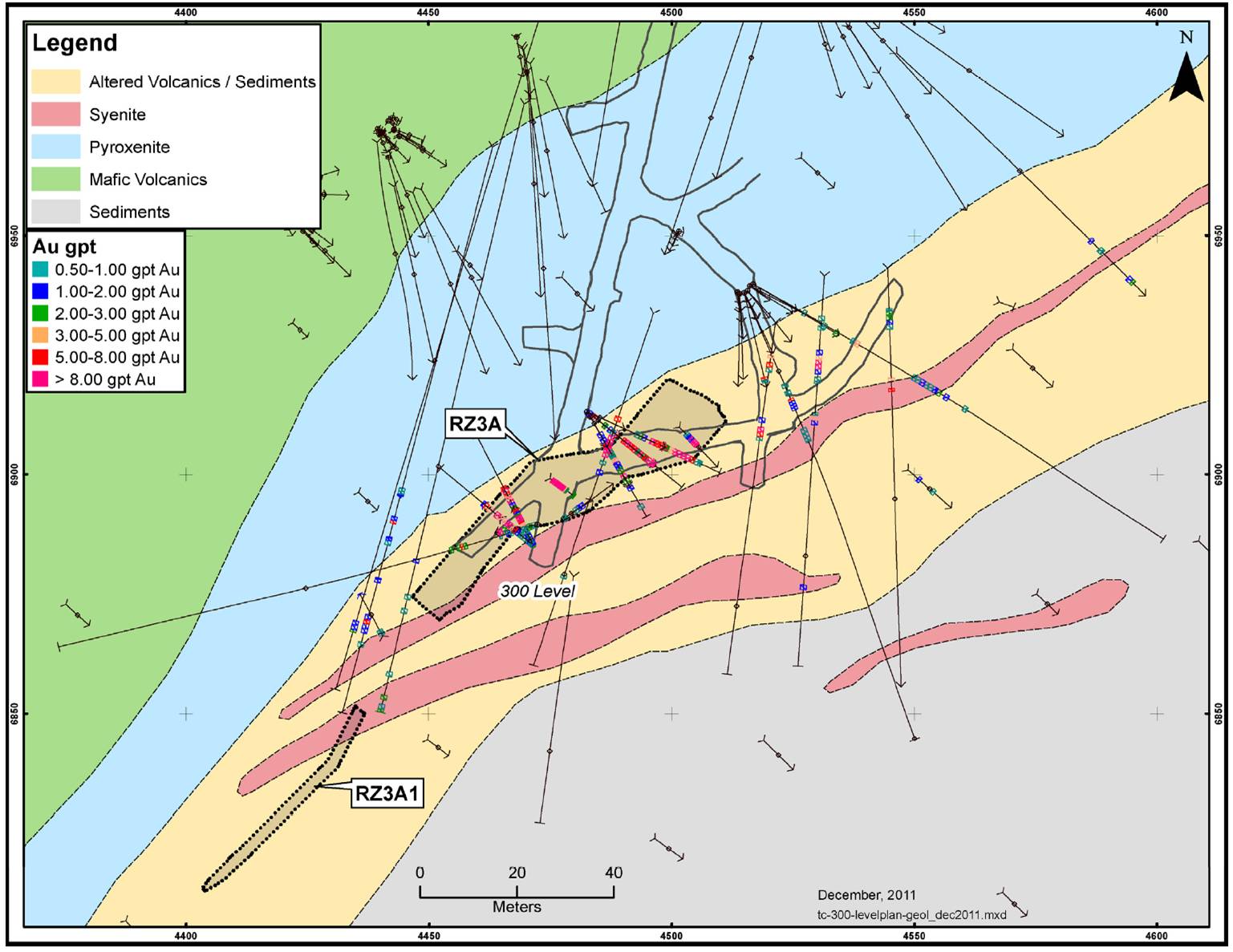

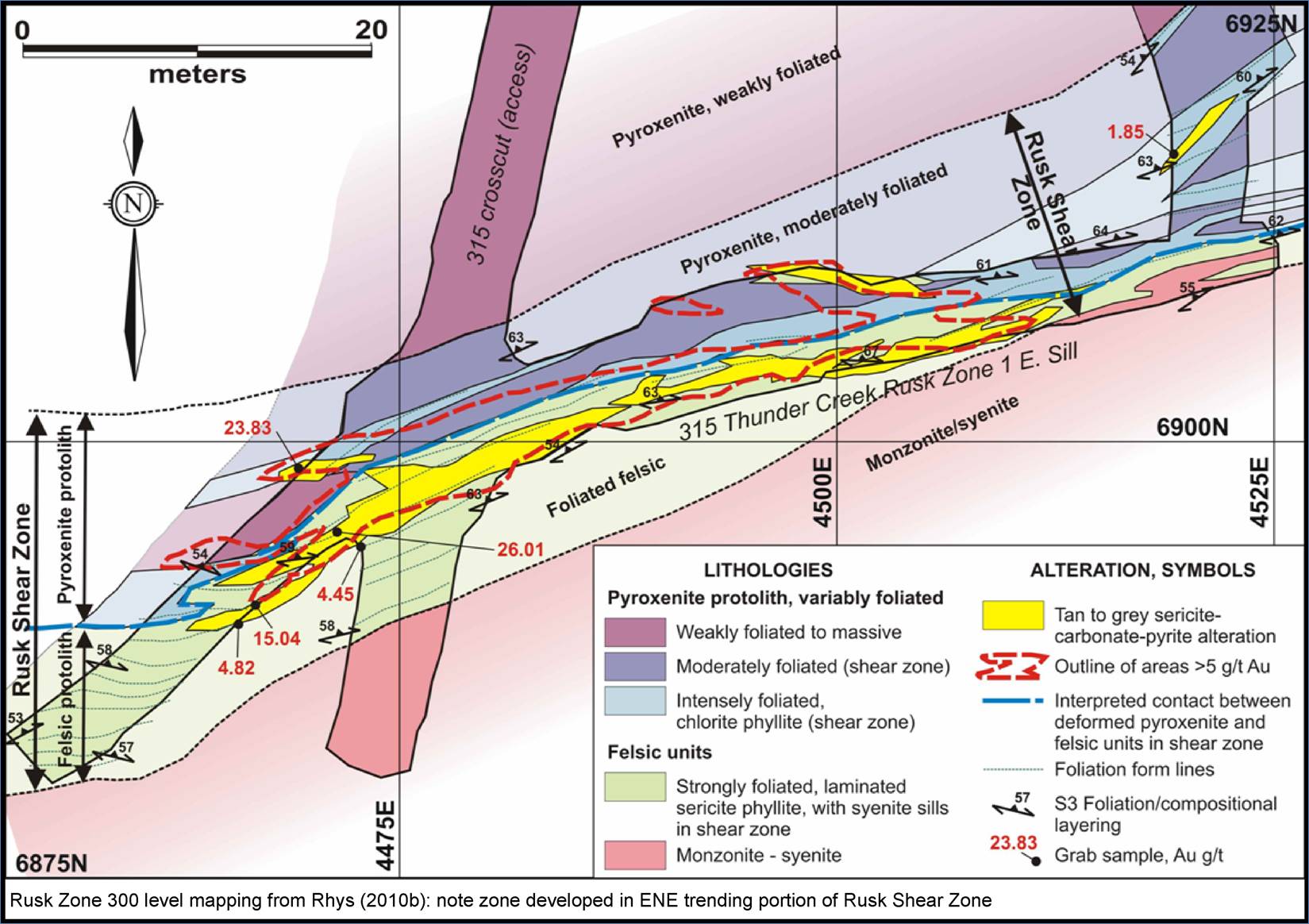

Figure 7.6: | THUNDER CREEK UNDERGROUND GEOLOGY 300 M LEVEL (UPPER MINE) | 56 |

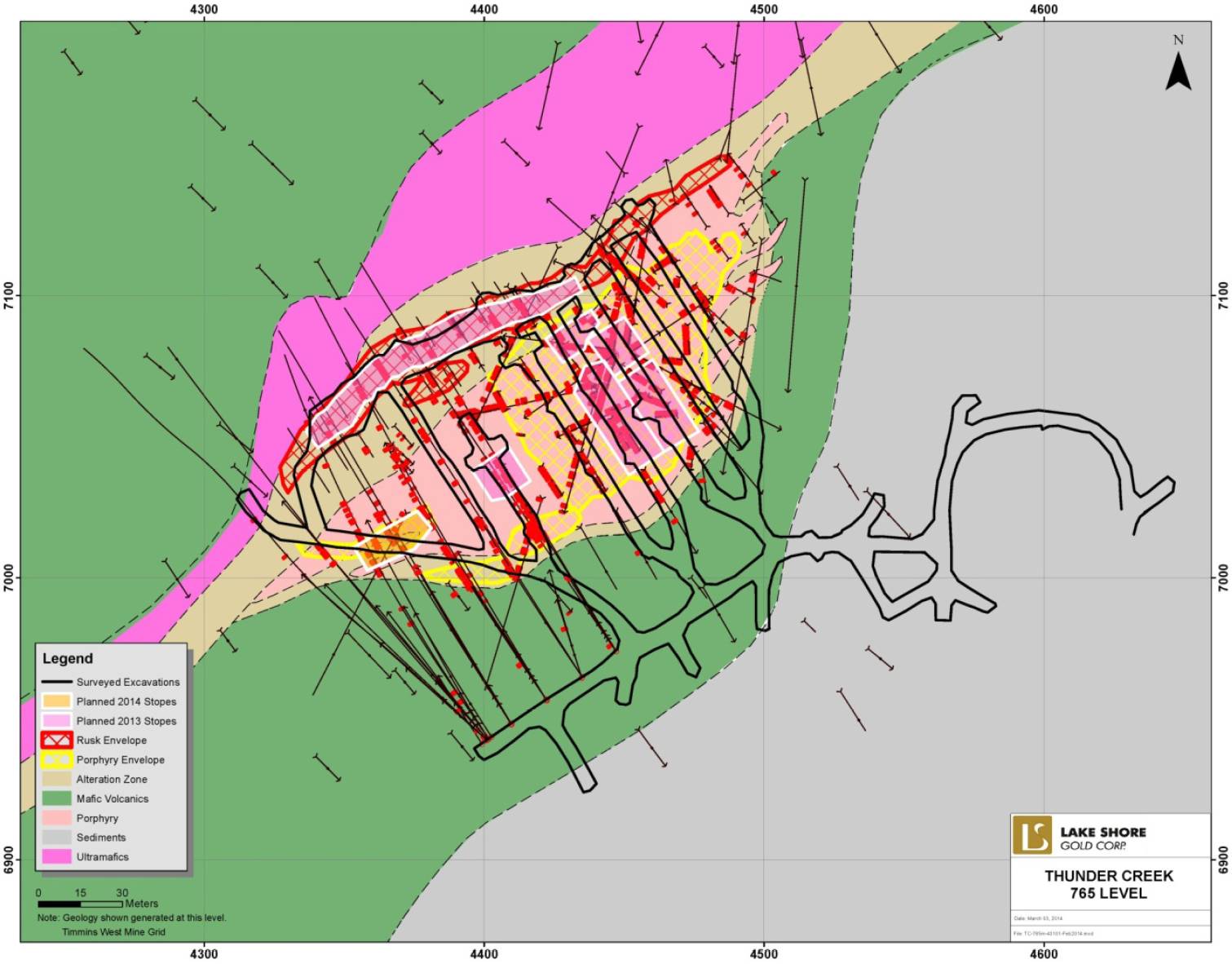

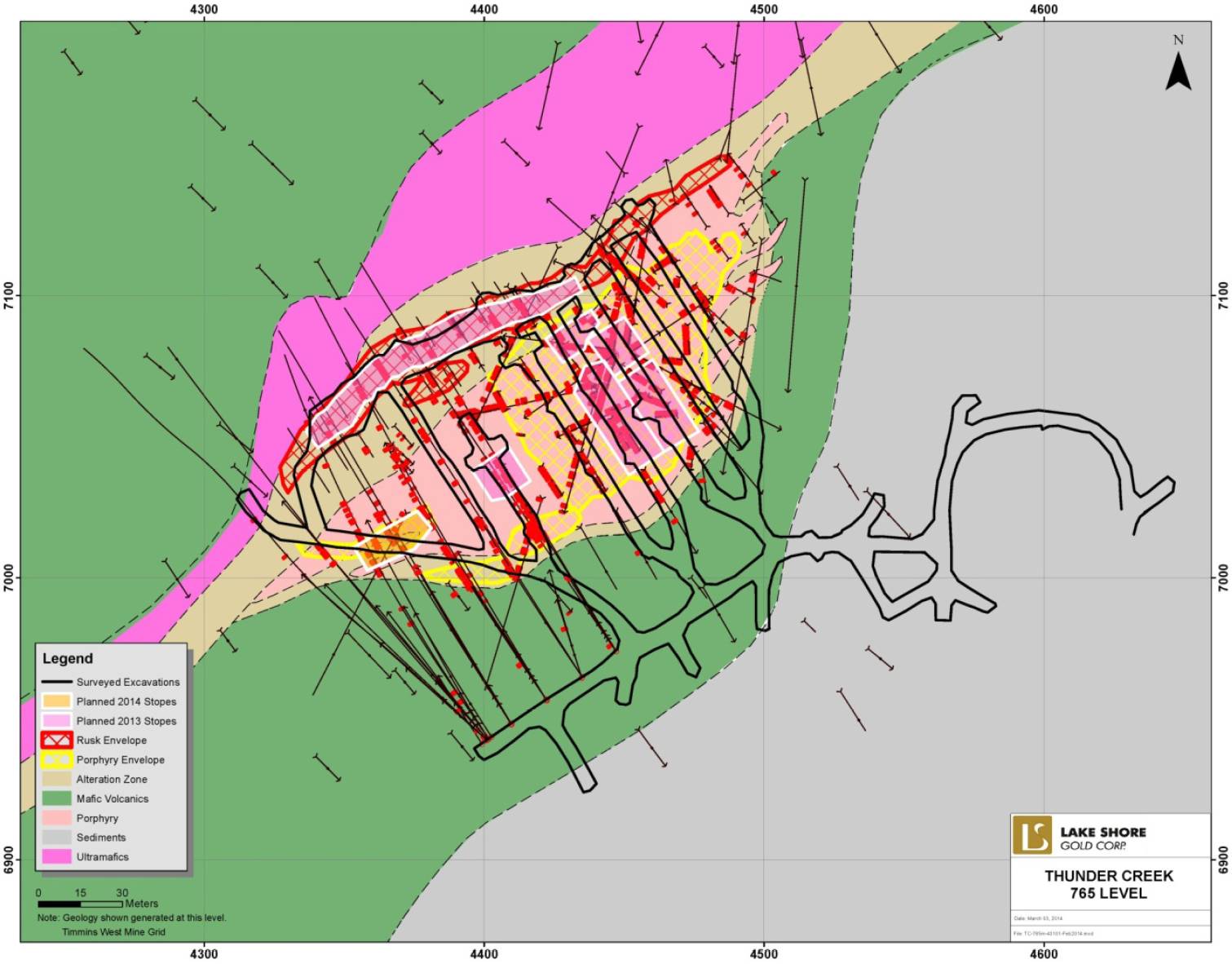

Figure 7.7: | THUNDER CREEK UNDERGROUND GEOLOGY 765 M LEVEL | 57 |

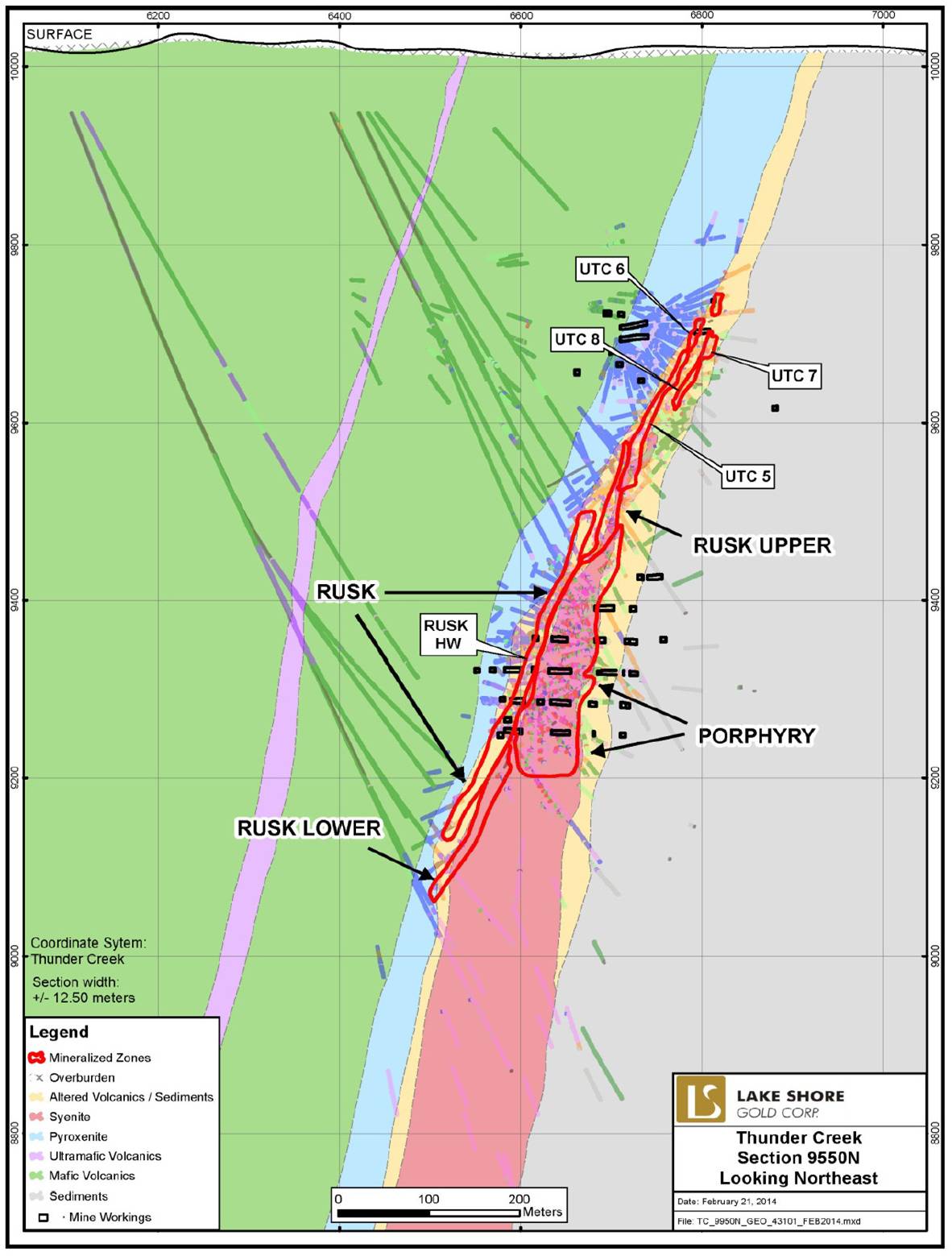

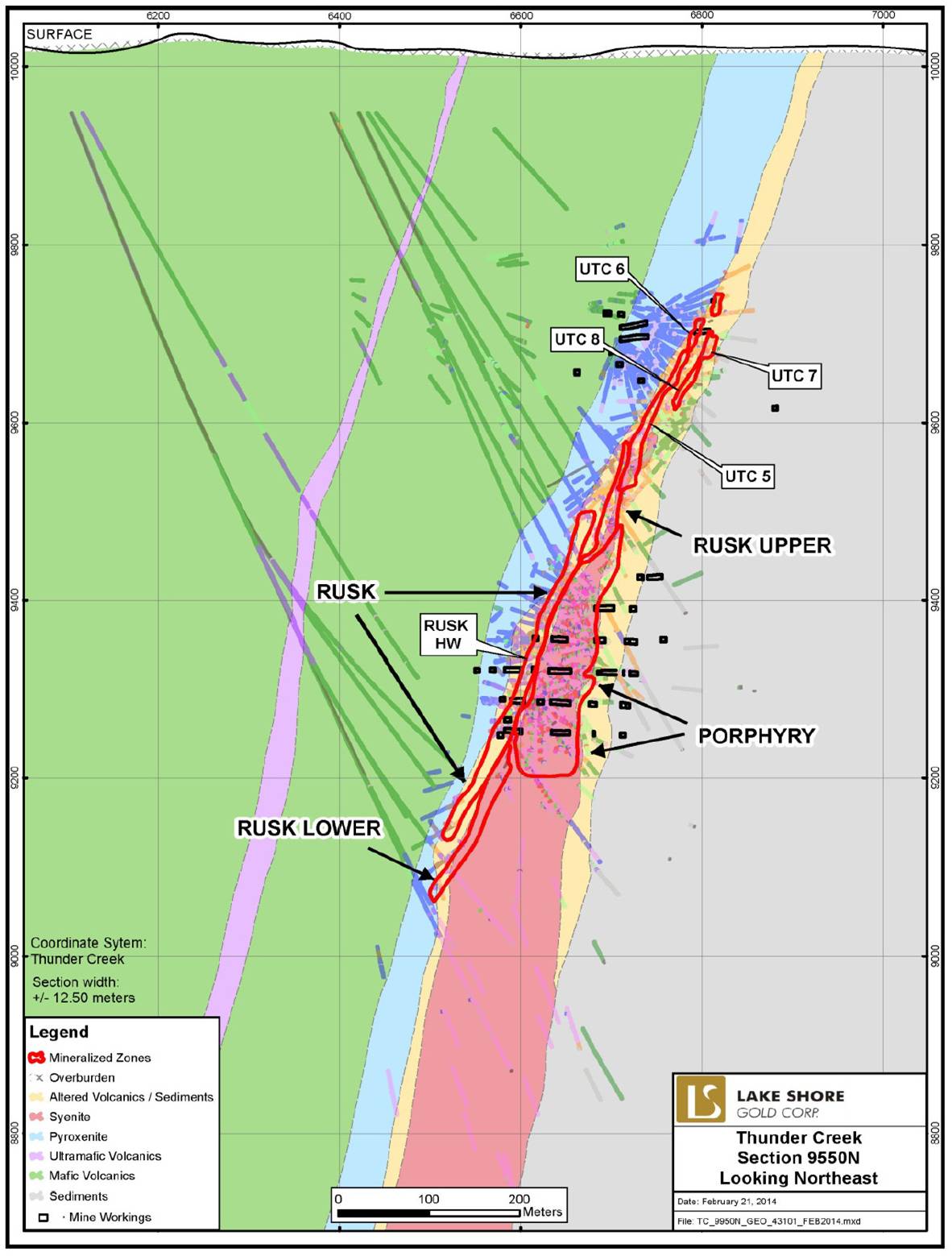

Figure 7.8: | THUNDER CREEK GENERALIZED CROSS-SECTION, 9550N (THUNDER CREEK SURFACE GRID) | 58 |

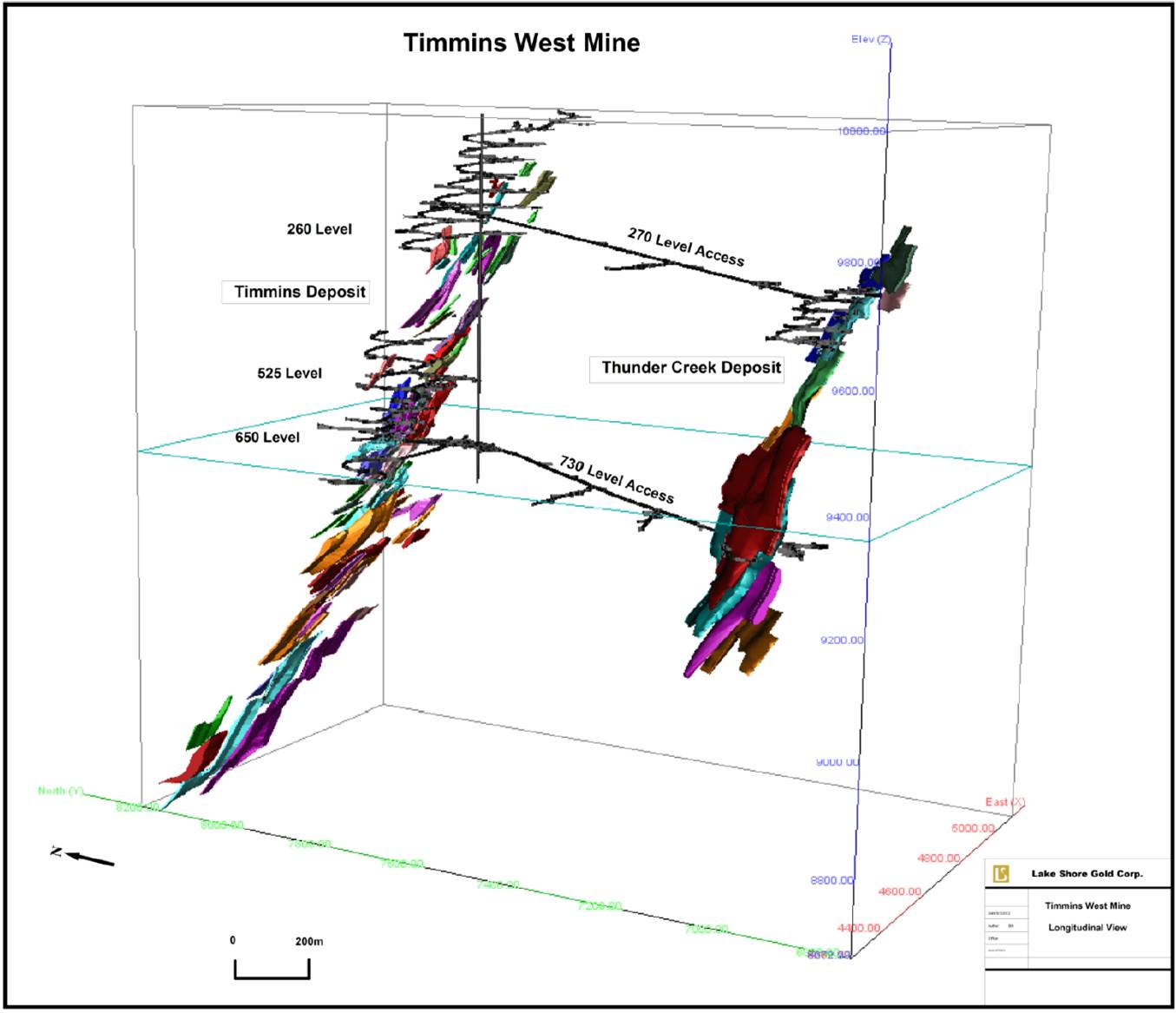

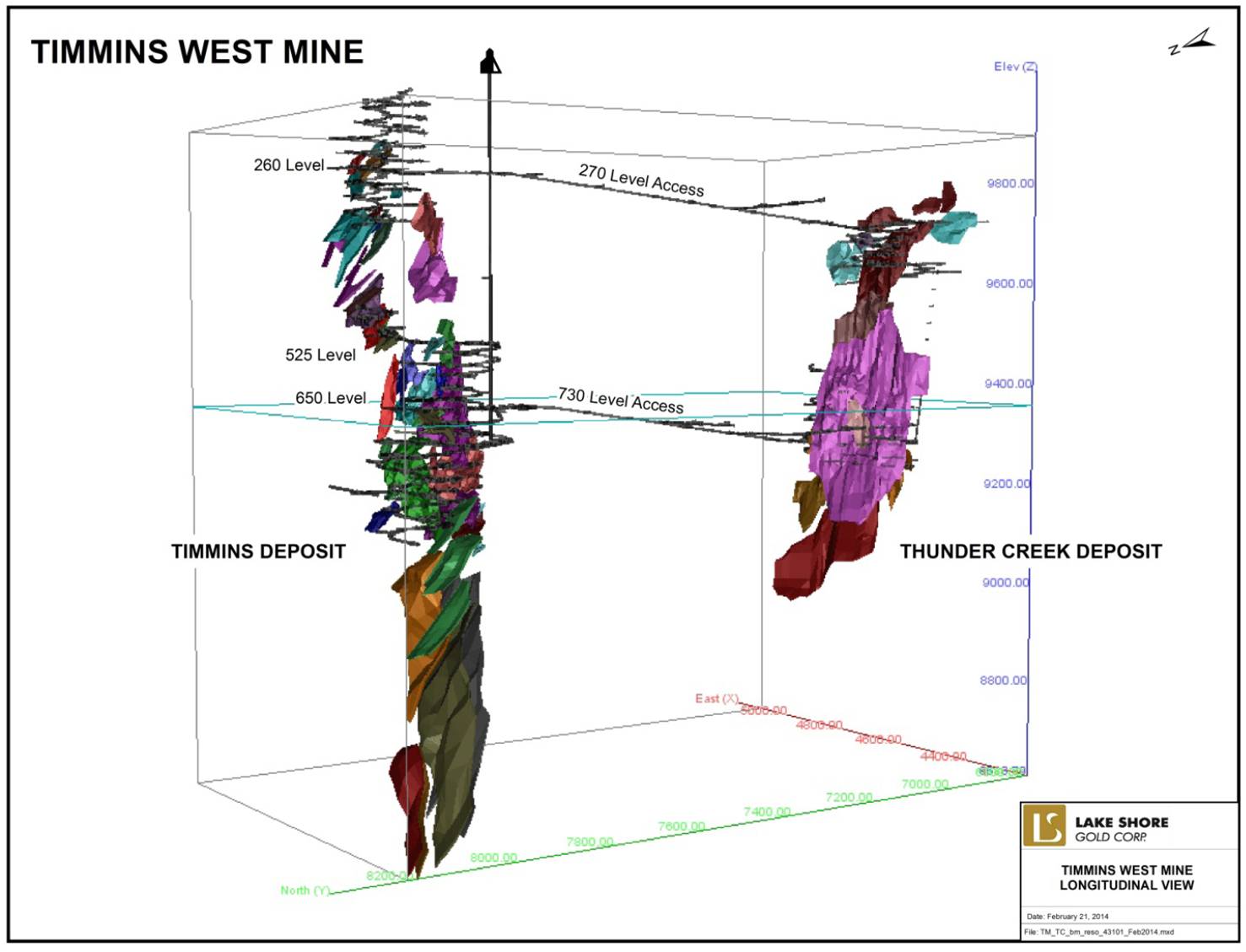

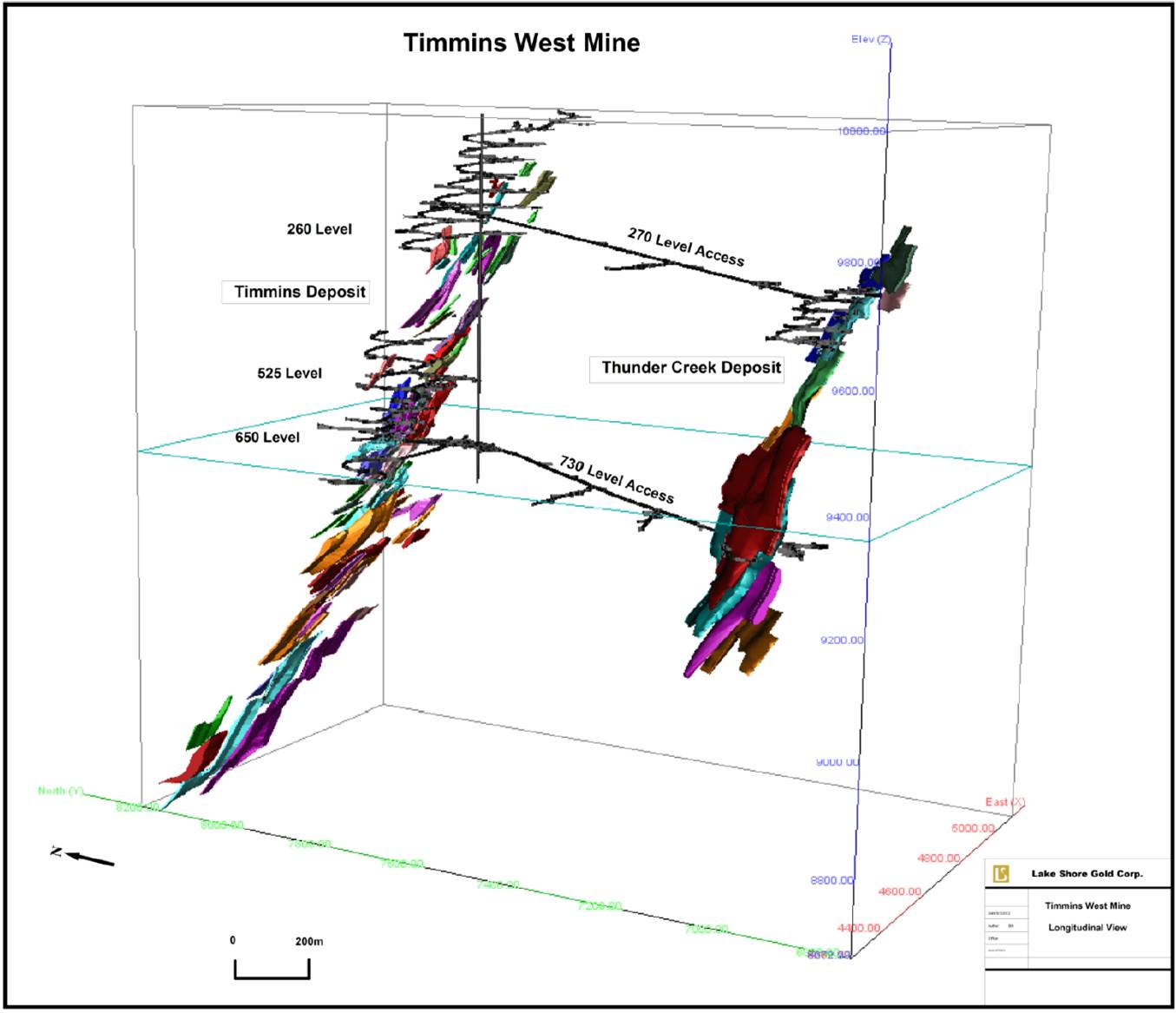

Figure 7.9: | 3-D VIEW LOOKING EAST, ILLUSTRATING TIMMINS WEST MINE SHAFT, RAMPS, LEVELS, AND RESOURCE ENVELOPES | 59 |

Figure 7.10: | STRUCTURAL PLAN, 300 LEVEL (RHYS, 2010) | 60 |

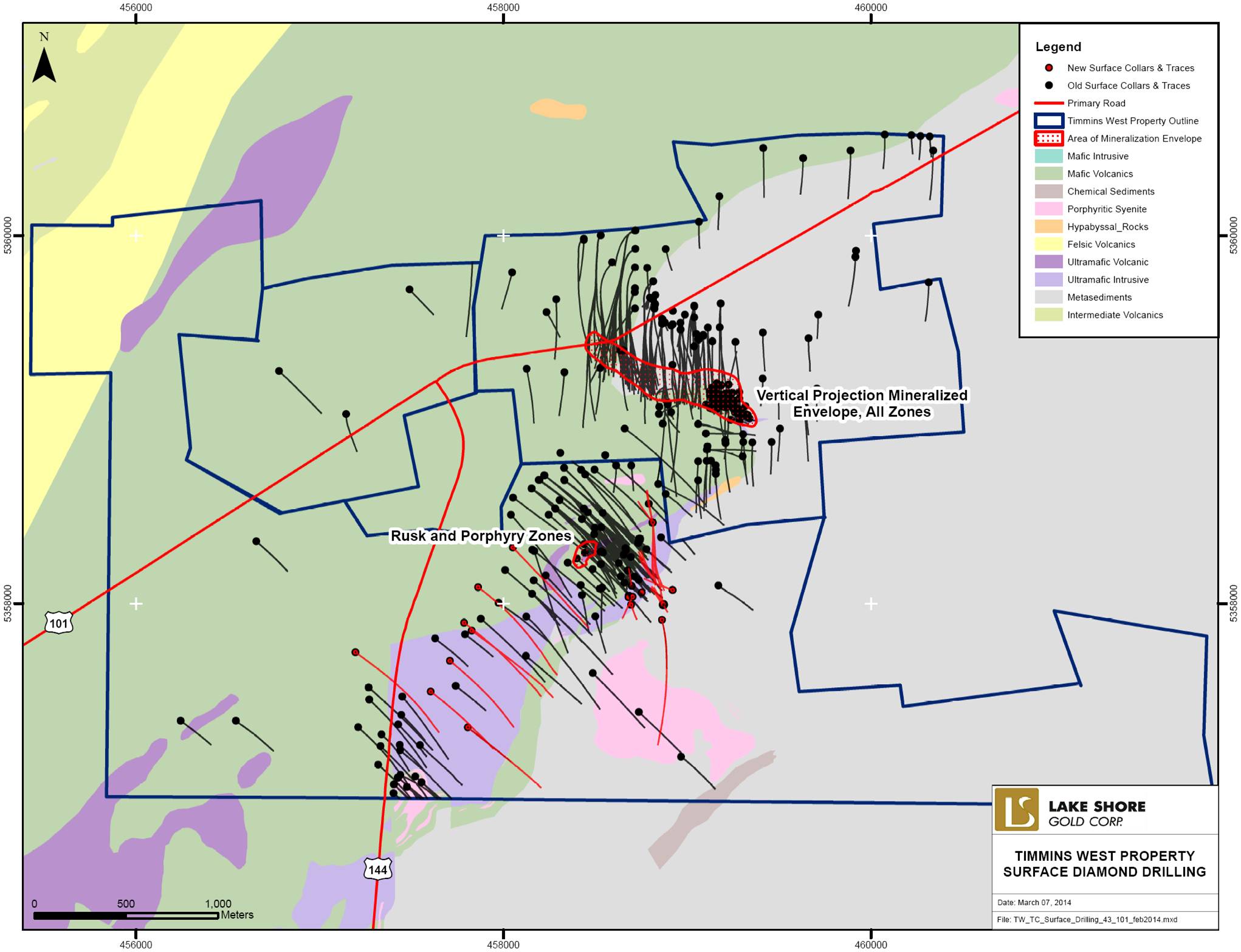

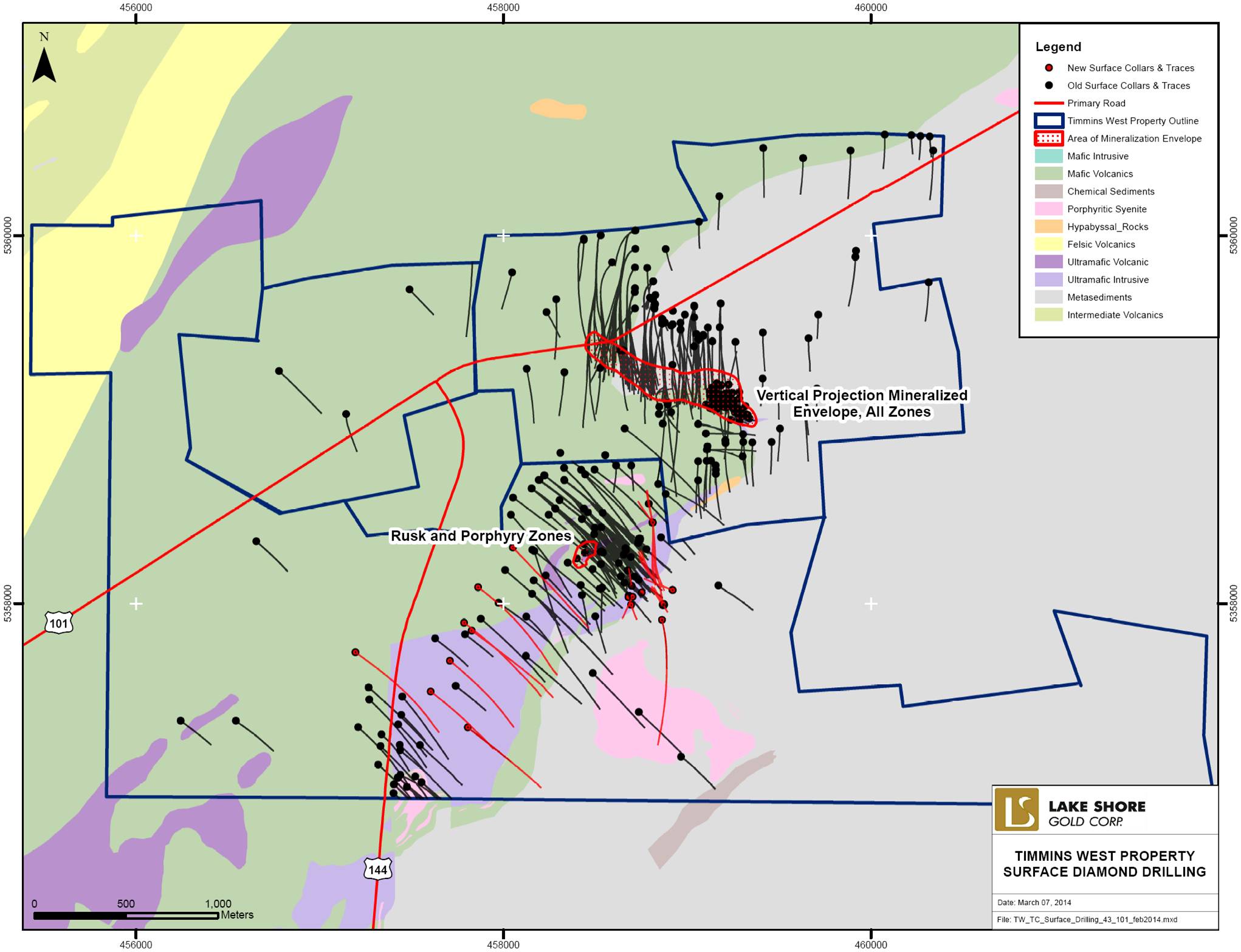

Figure 10.1: | SURFACE DIAMOND DRILL HOLE COLLAR LOCATIONS AND TRACES AND VERTICAL PROJECTION TO SURFACE OF THE OUTER PERIMETER OF THE RESOURCE | 70 |

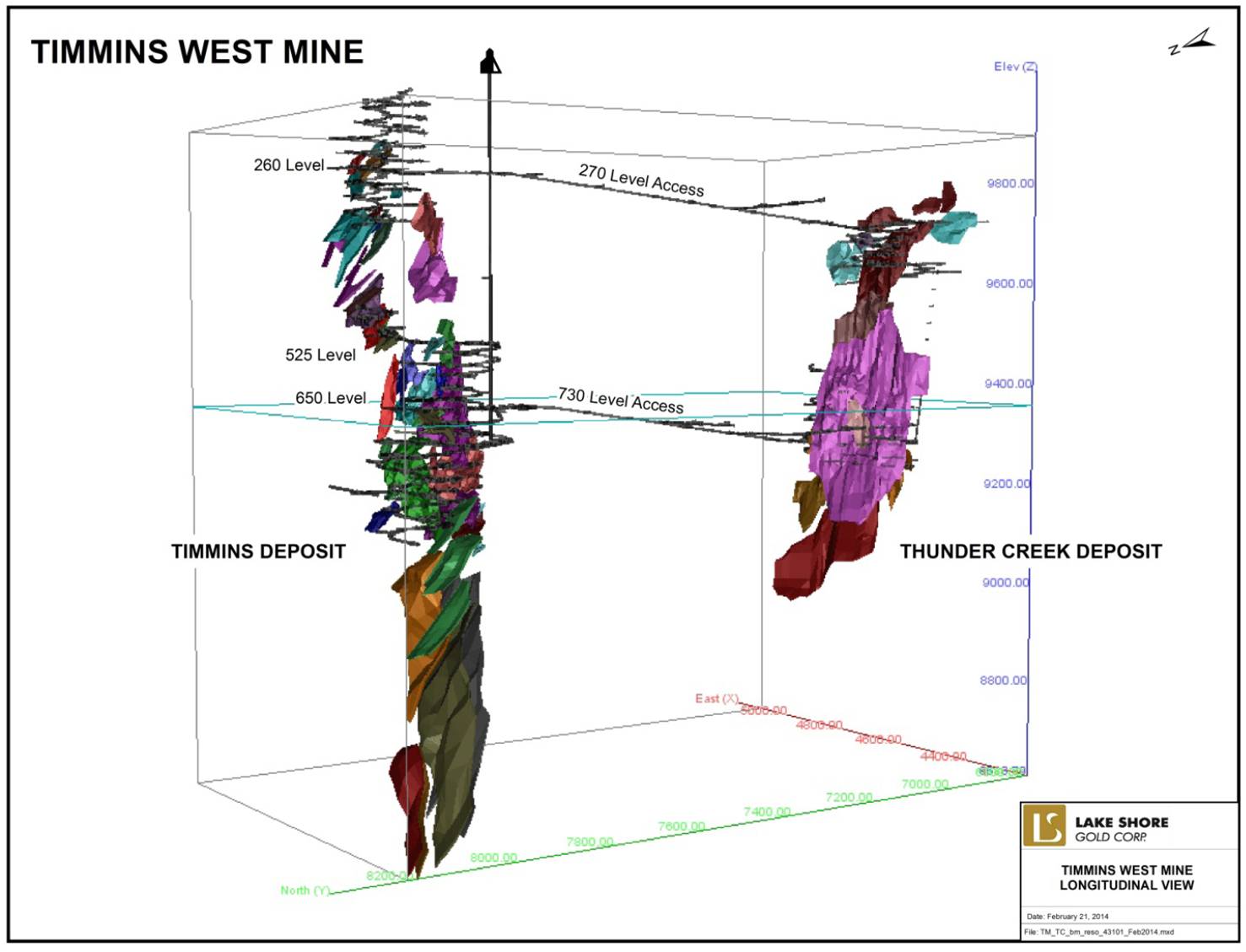

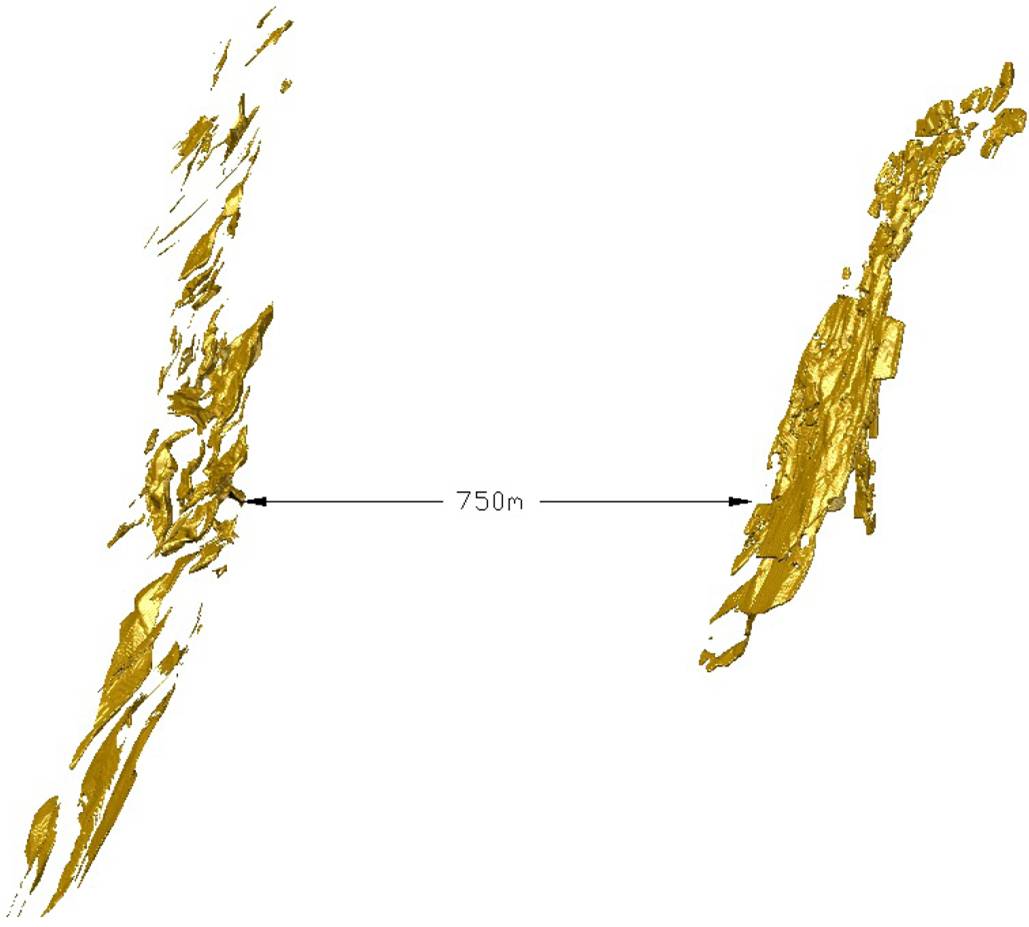

Figure 14.1: | 3D VIEW OF RESOURCE SOLIDS, LOOKING NORTHEAST | 99 |

| | | | |

vi

TABLE OF CONTENTS

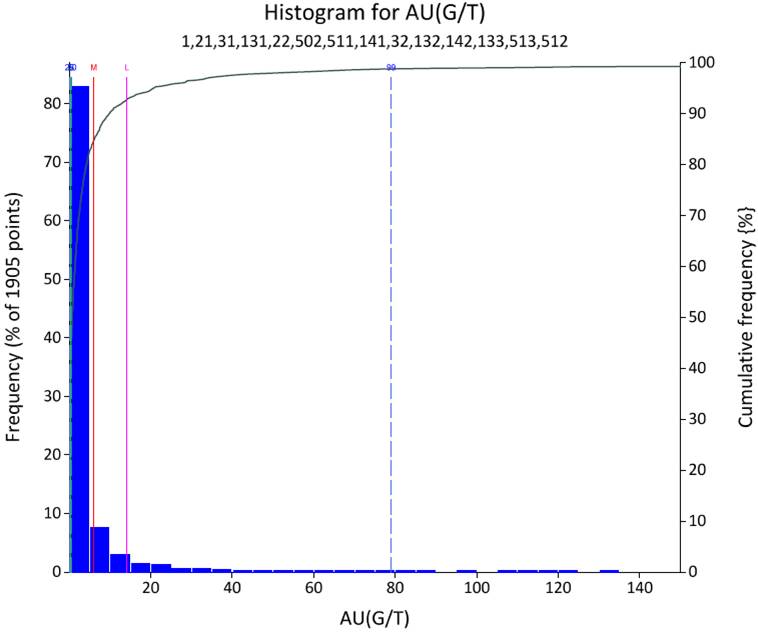

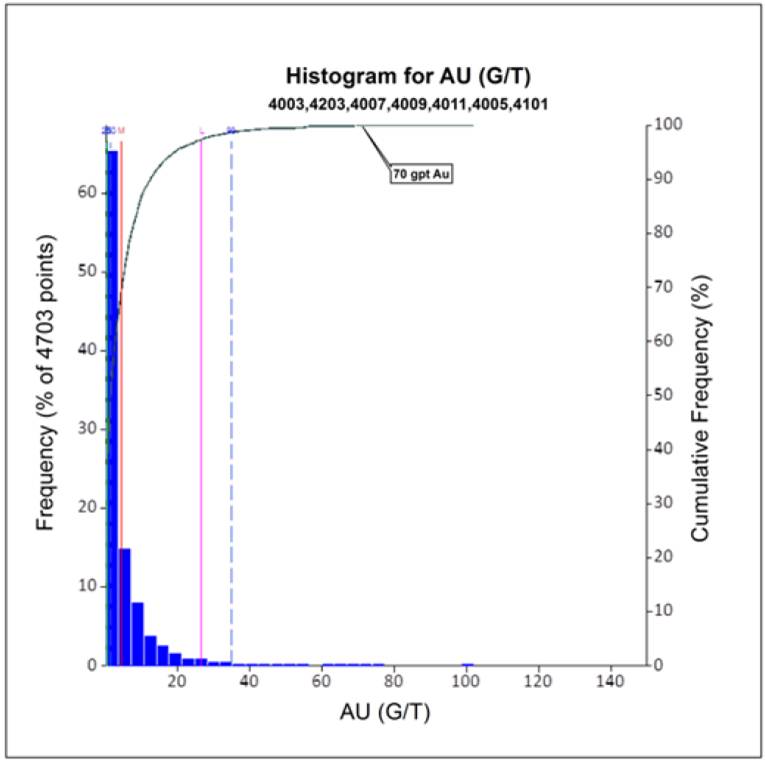

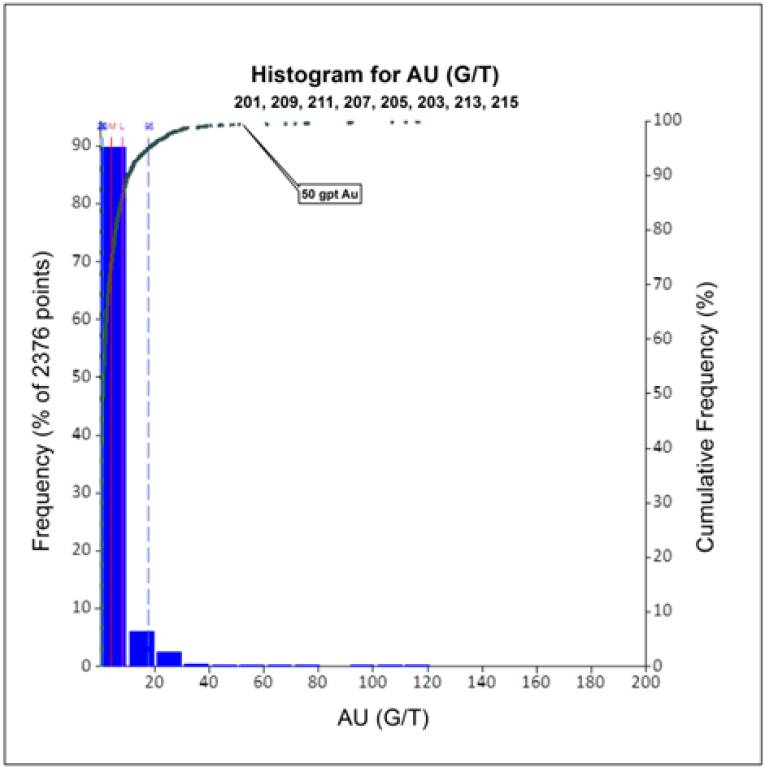

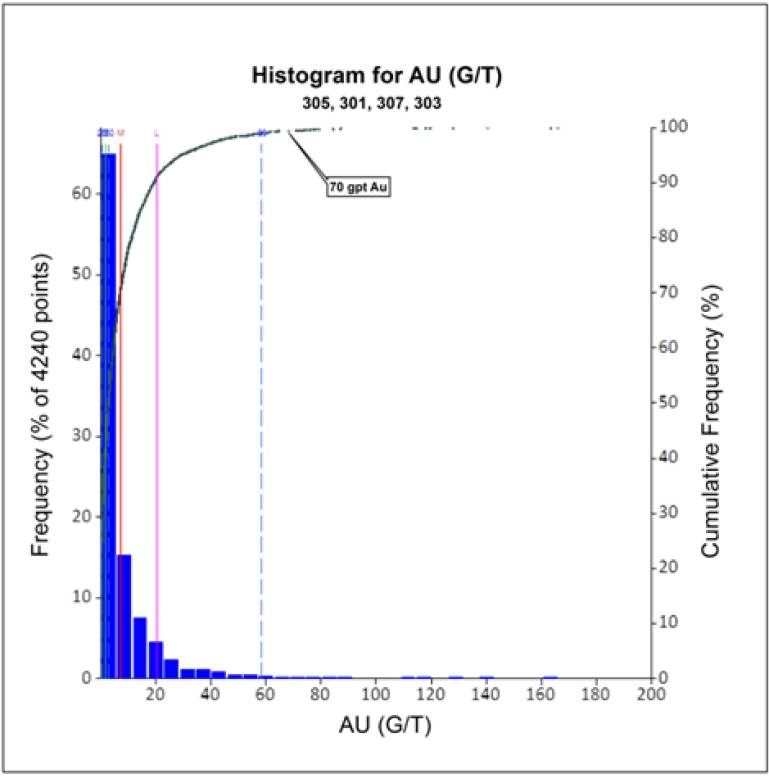

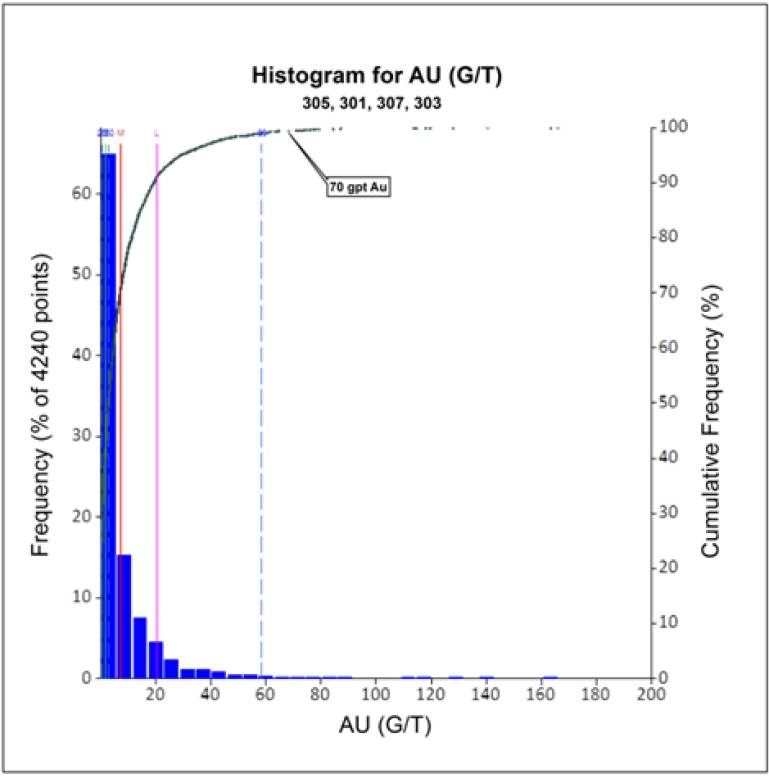

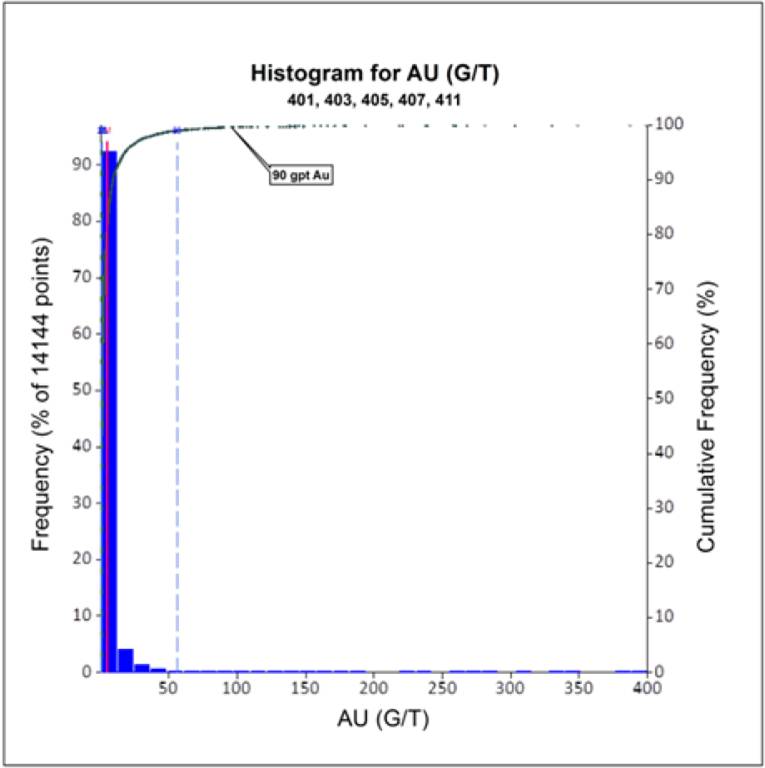

Figure 14.2: | TIMMINS DEPOSIT CUMULATIVE HISTOGRAMS | 101 |

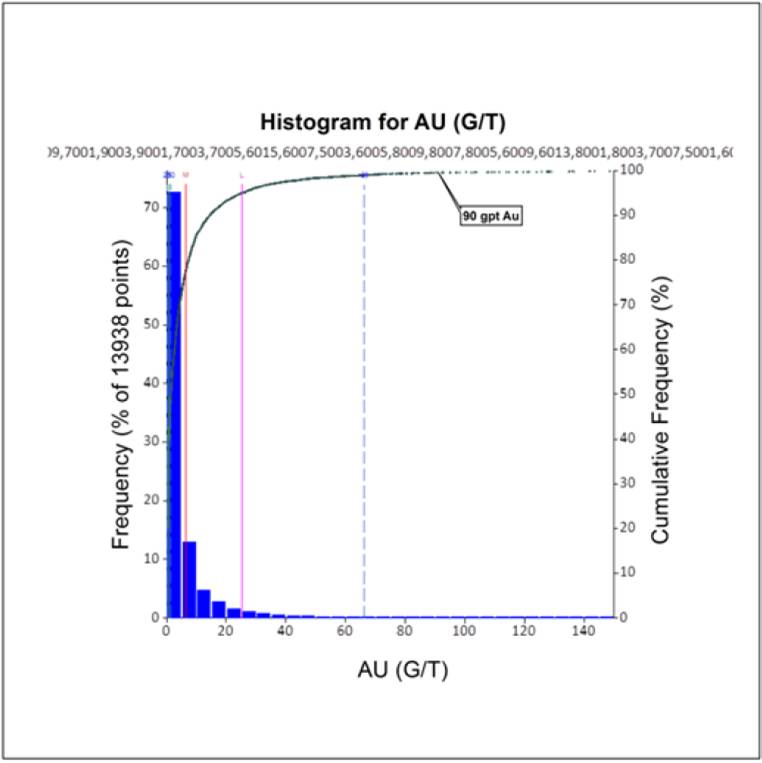

Figure 14.3: | THUNDER CREEK CUMULATIVE HISTOGRAMS | 102 |

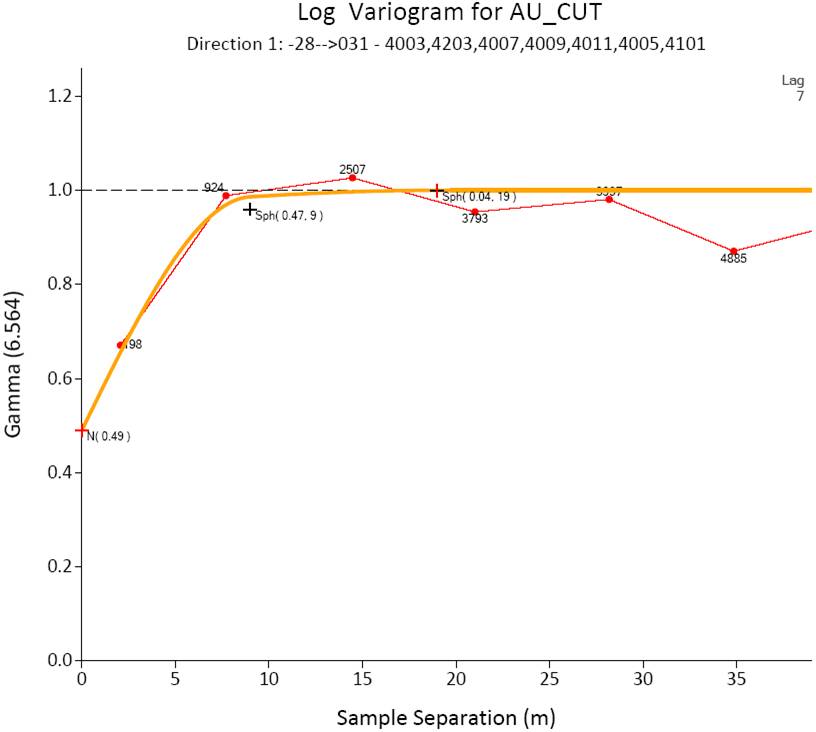

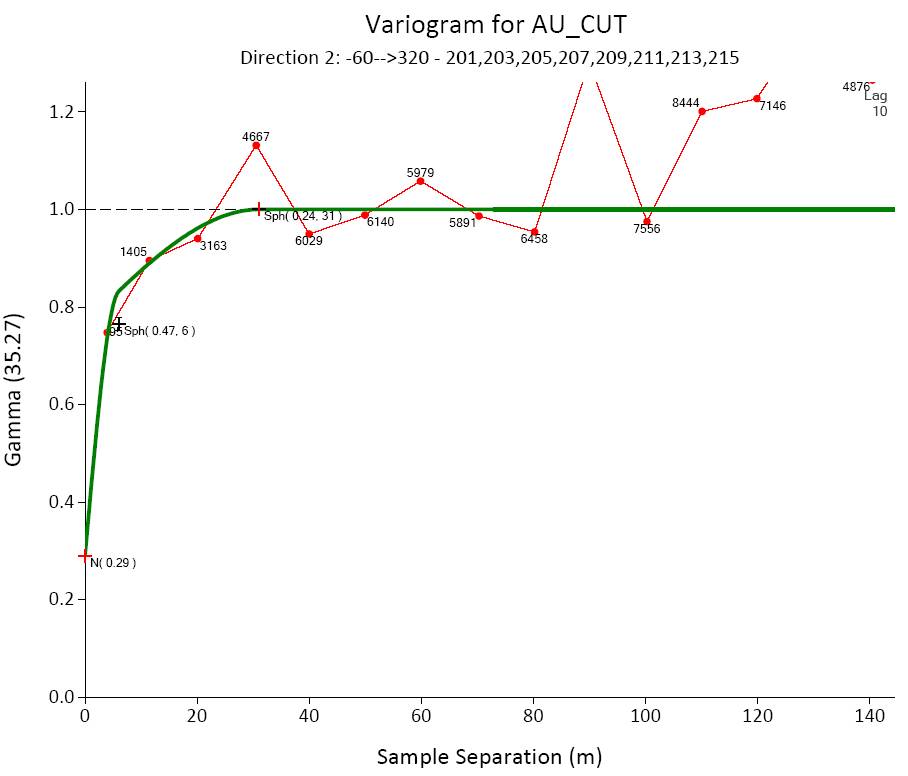

Figure 14.4: | VARIOGRAMS — TIMMINS DEPOSIT — FW ZONE, UM BELOW 650ML | 106 |

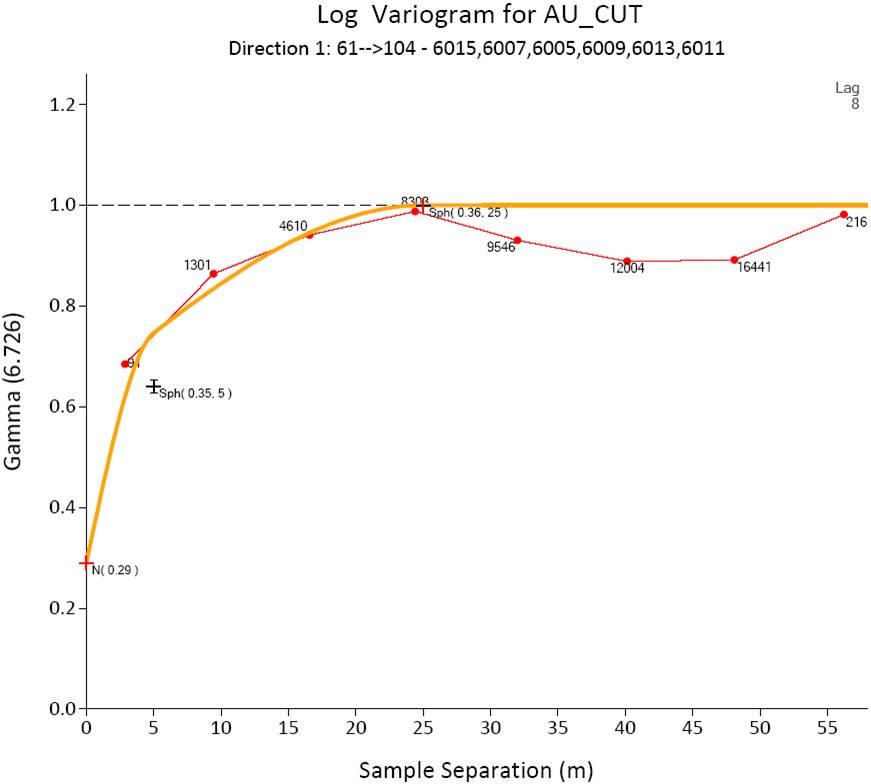

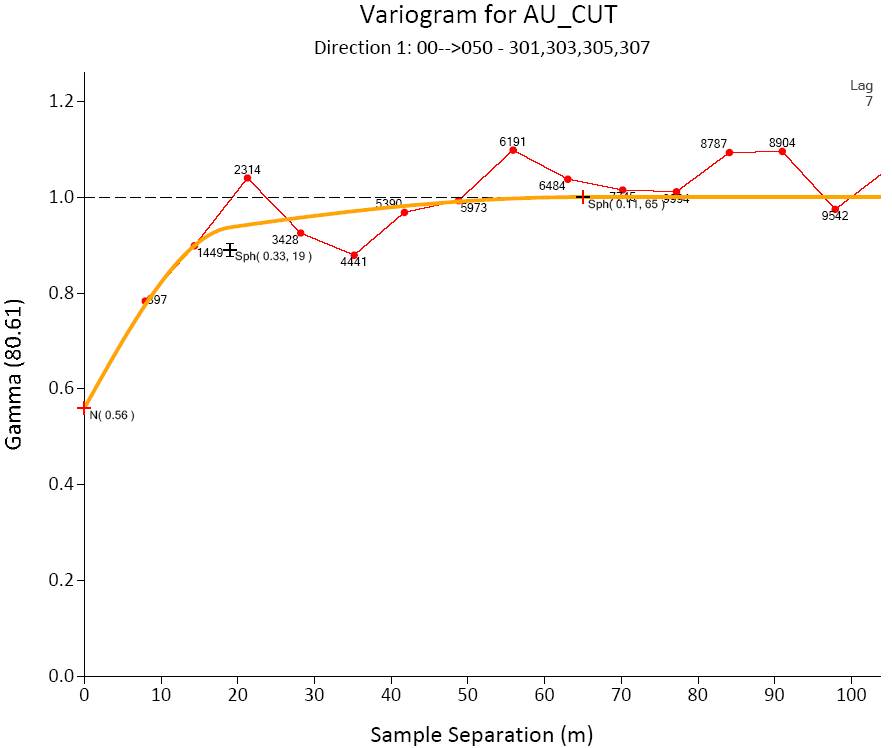

Figure 14.5: | VARIOGRAMS FOR THUNDER CREEK DEPOSIT — UTC, RUSK ZONES | 108 |

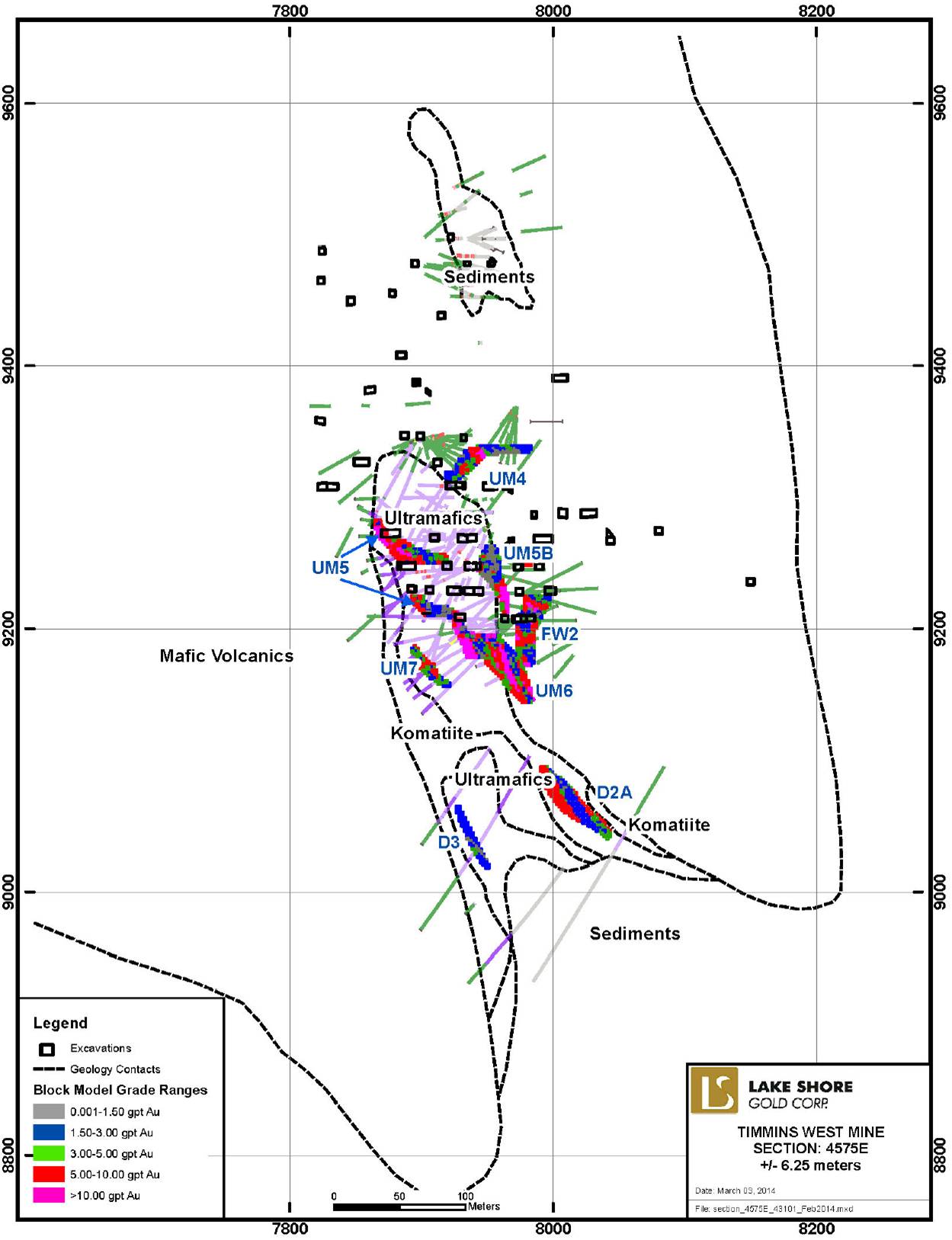

Figure 14.6: | TIMMINS MINE SECTION 4575 EAST — BLOCK MODEL AND DRILL HOLES | 112 |

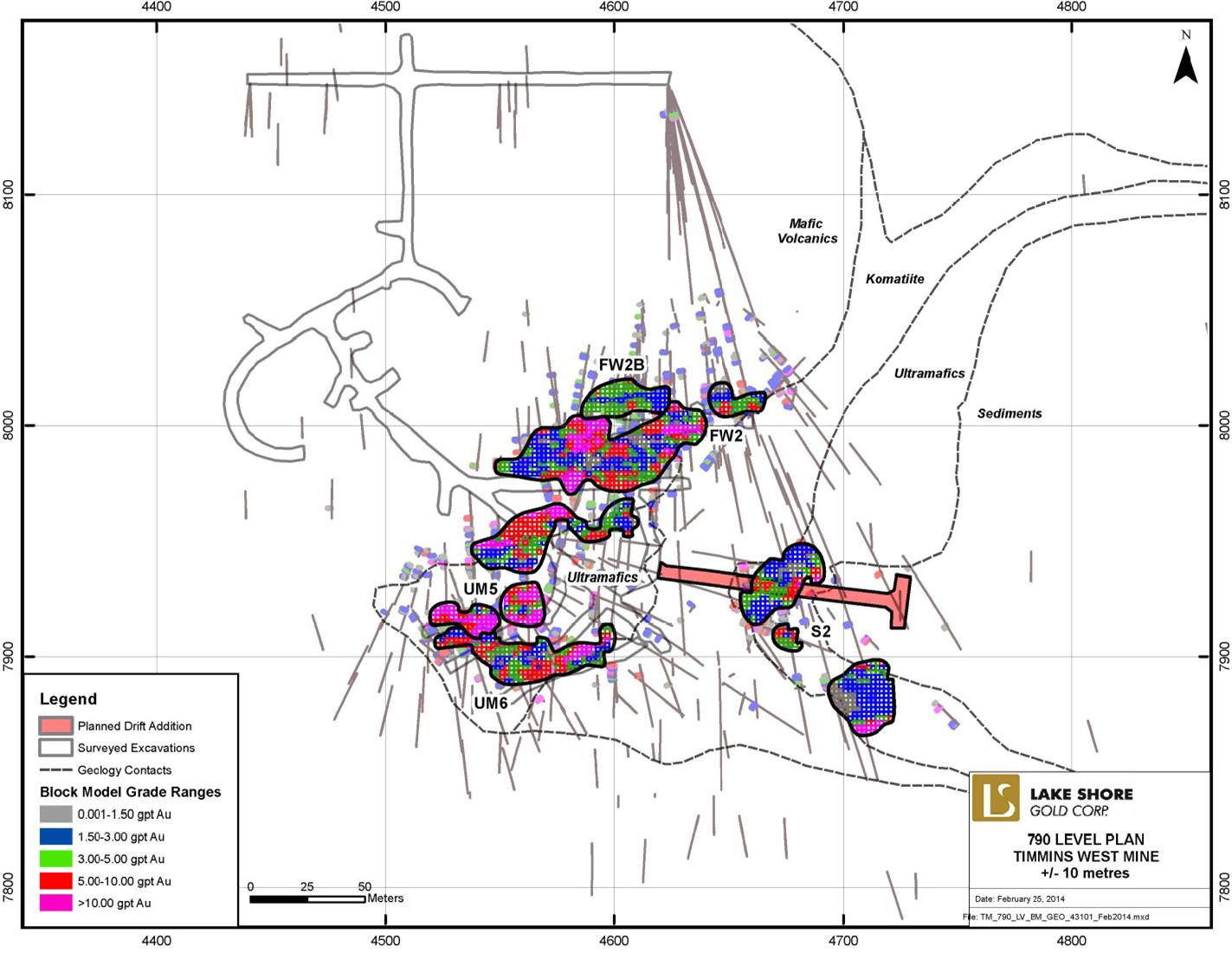

Figure 14.7: | TIMMINS MINE PLAN FOR 790 LEVEL — BLOCK MODEL AND DRILL HOLES | 113 |

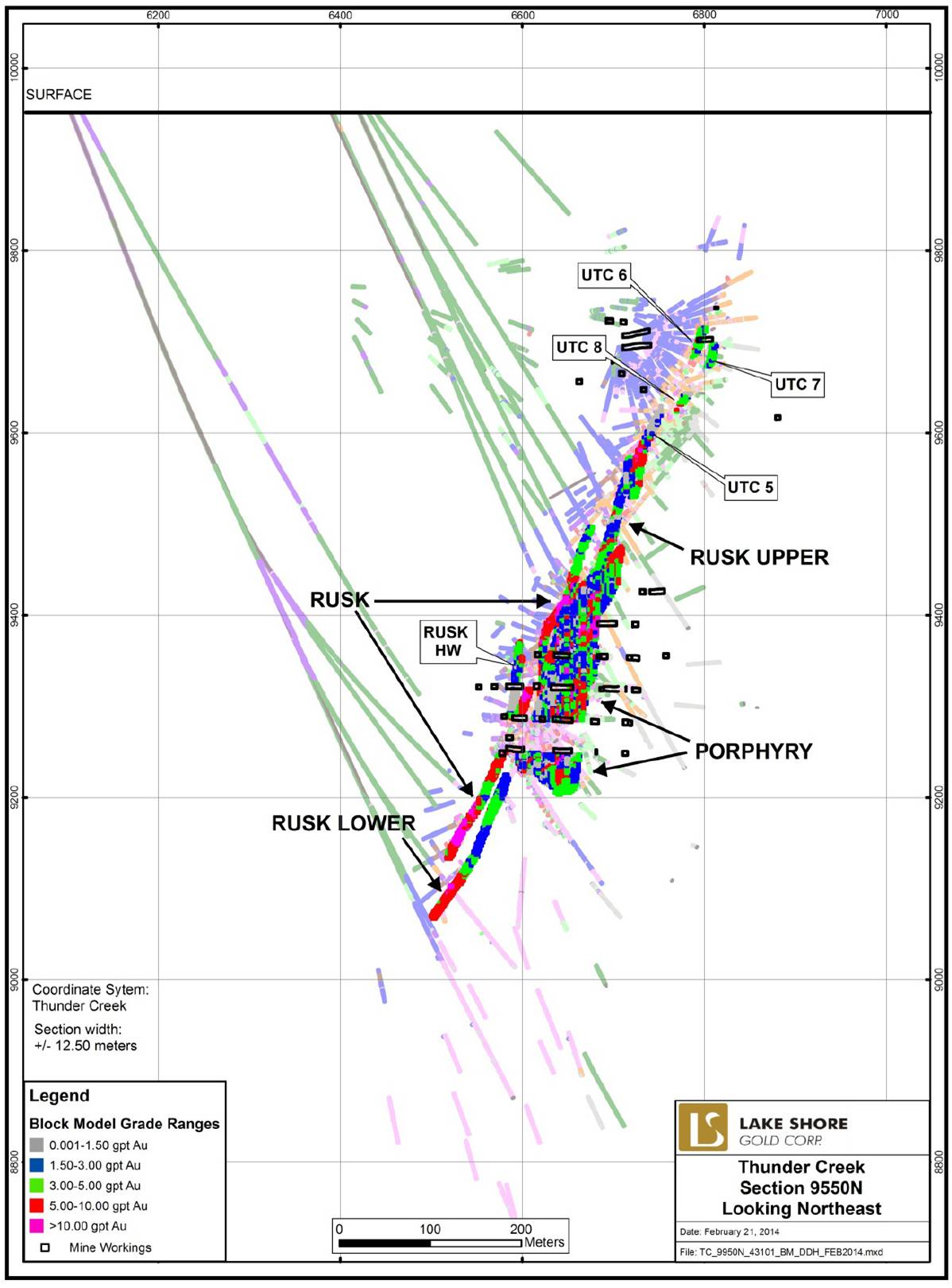

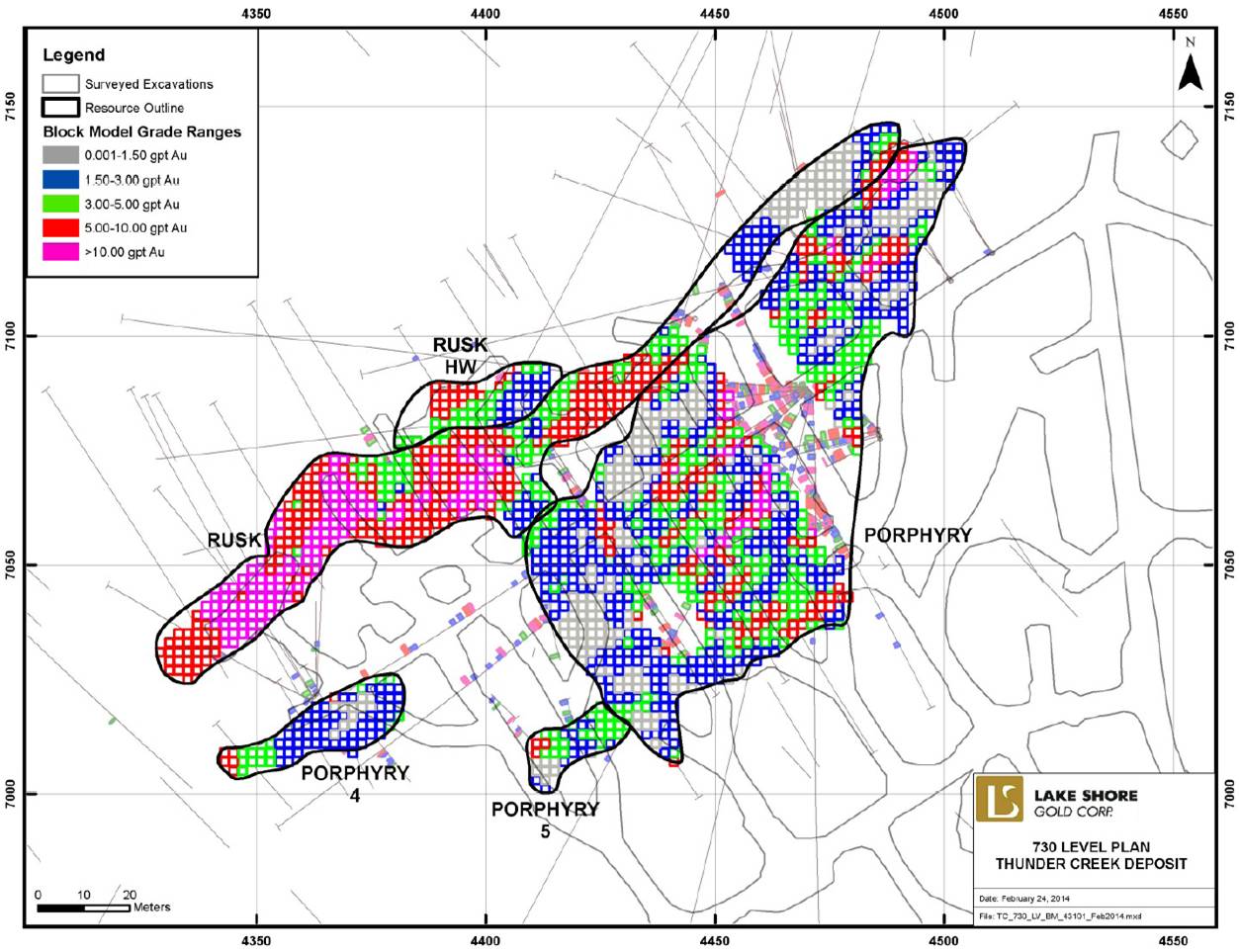

Figure 14.8: | THUNDER CREEK DEPOSIT — SECTION 9550N — BLOCK MODEL AND DIAMOND DRILL HOLES | 114 |

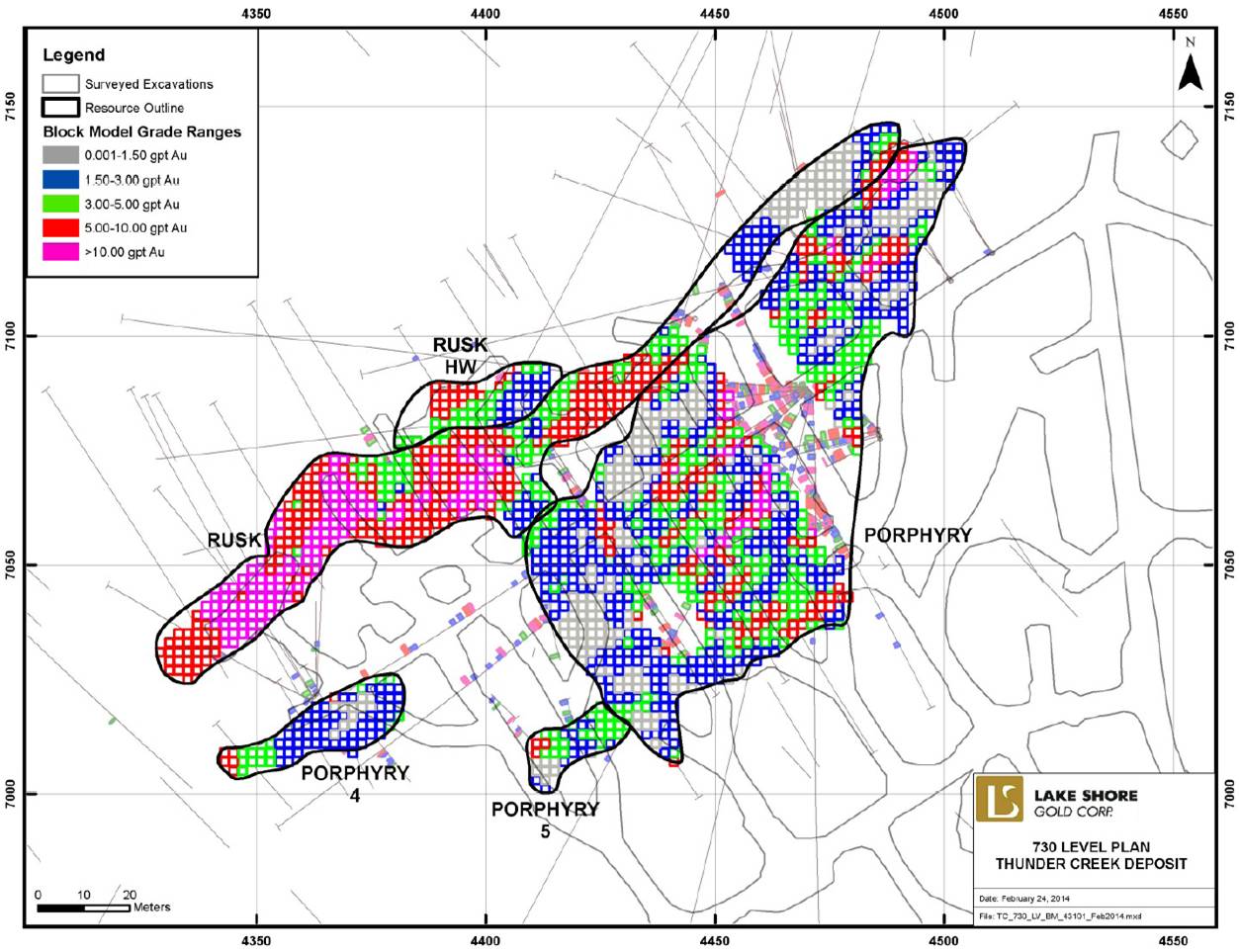

Figure 14.9: | THUNDER CREEK DEPOSIT— PLAN VIEW AT 730 LEVEL-BLOCK MODEL AND DIAMOND DRILL HOLES | 115 |

Figure 14.10: | MILL CORRECTION FOR GRADES FROM MINE PRODUCTION SAMPLING | 116 |

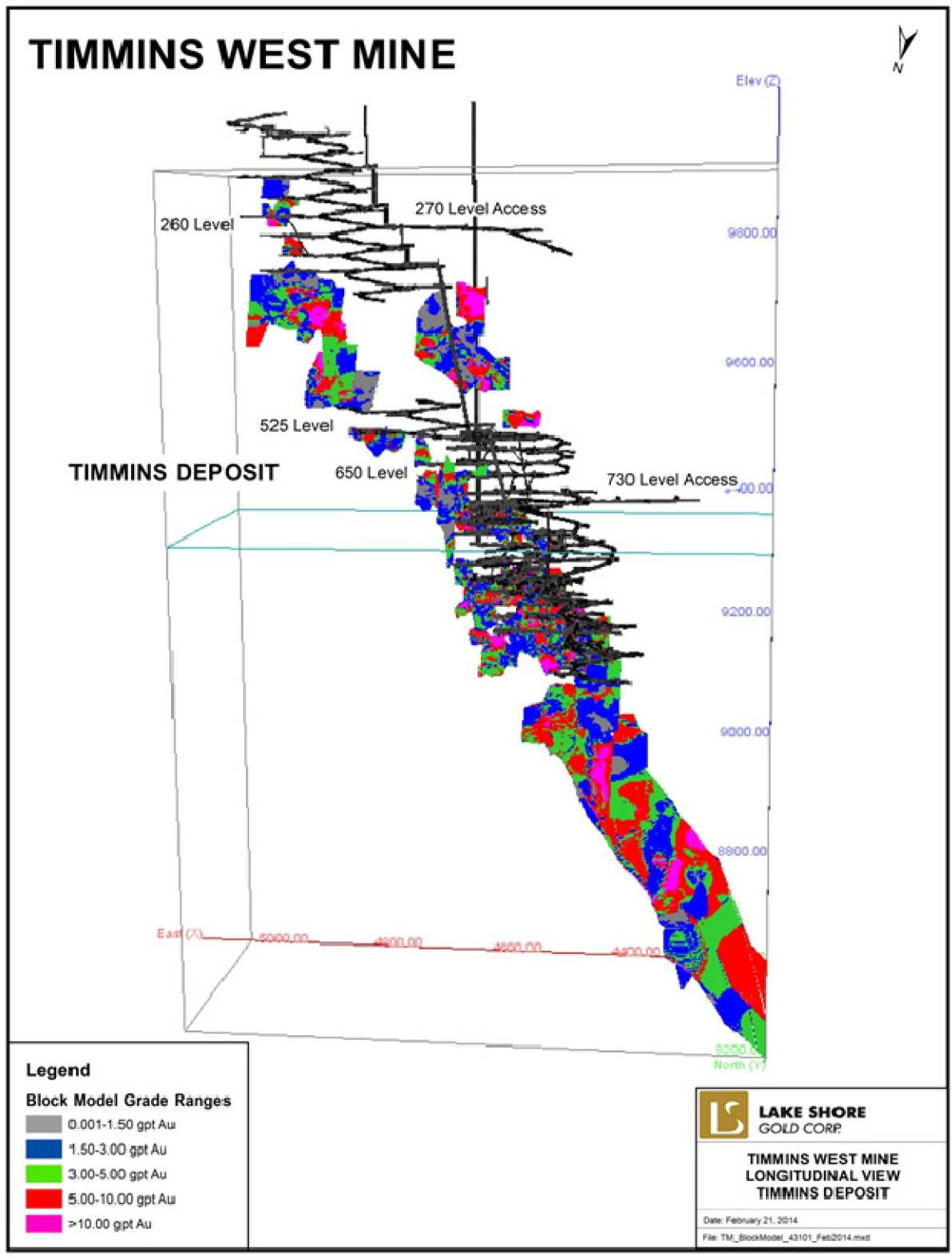

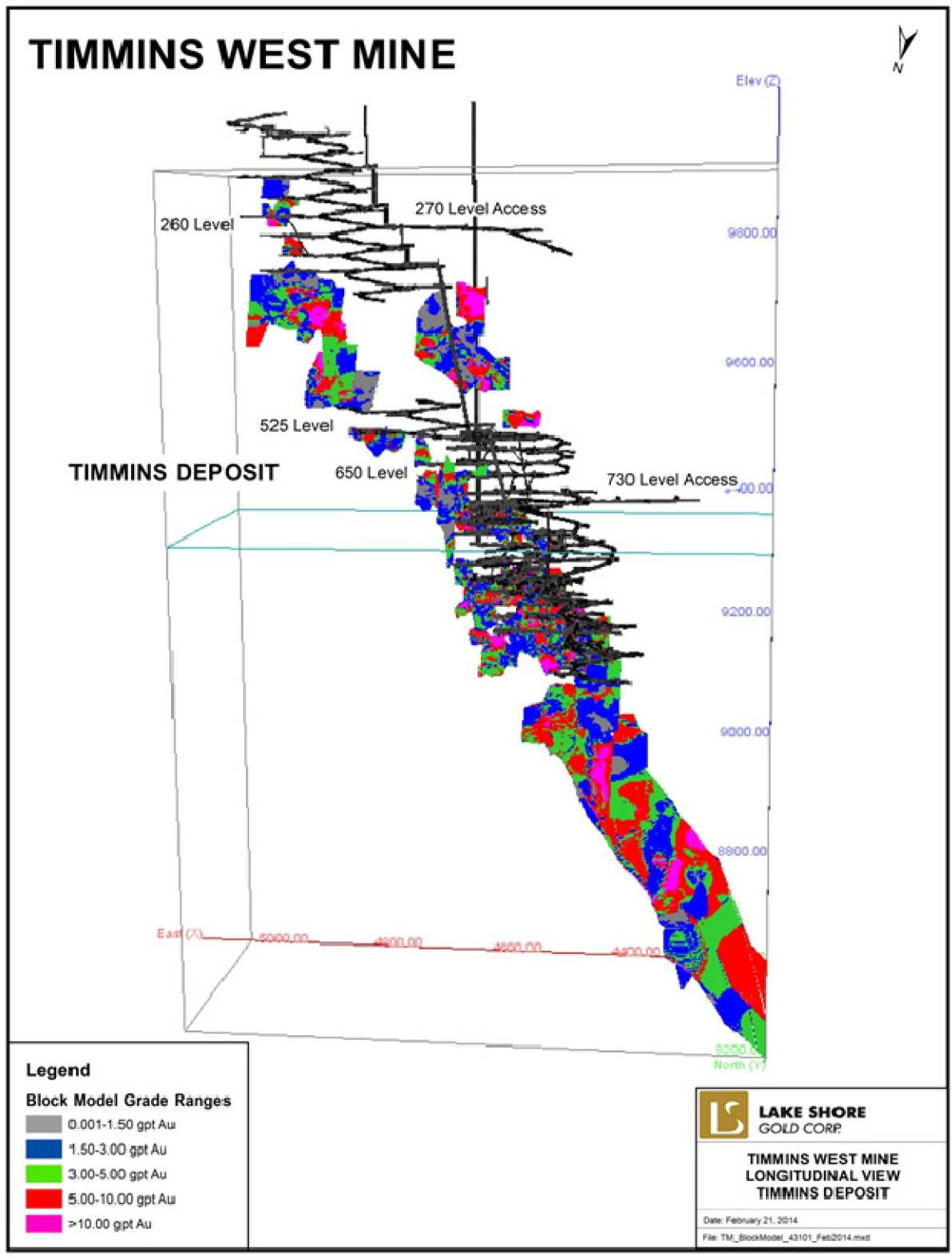

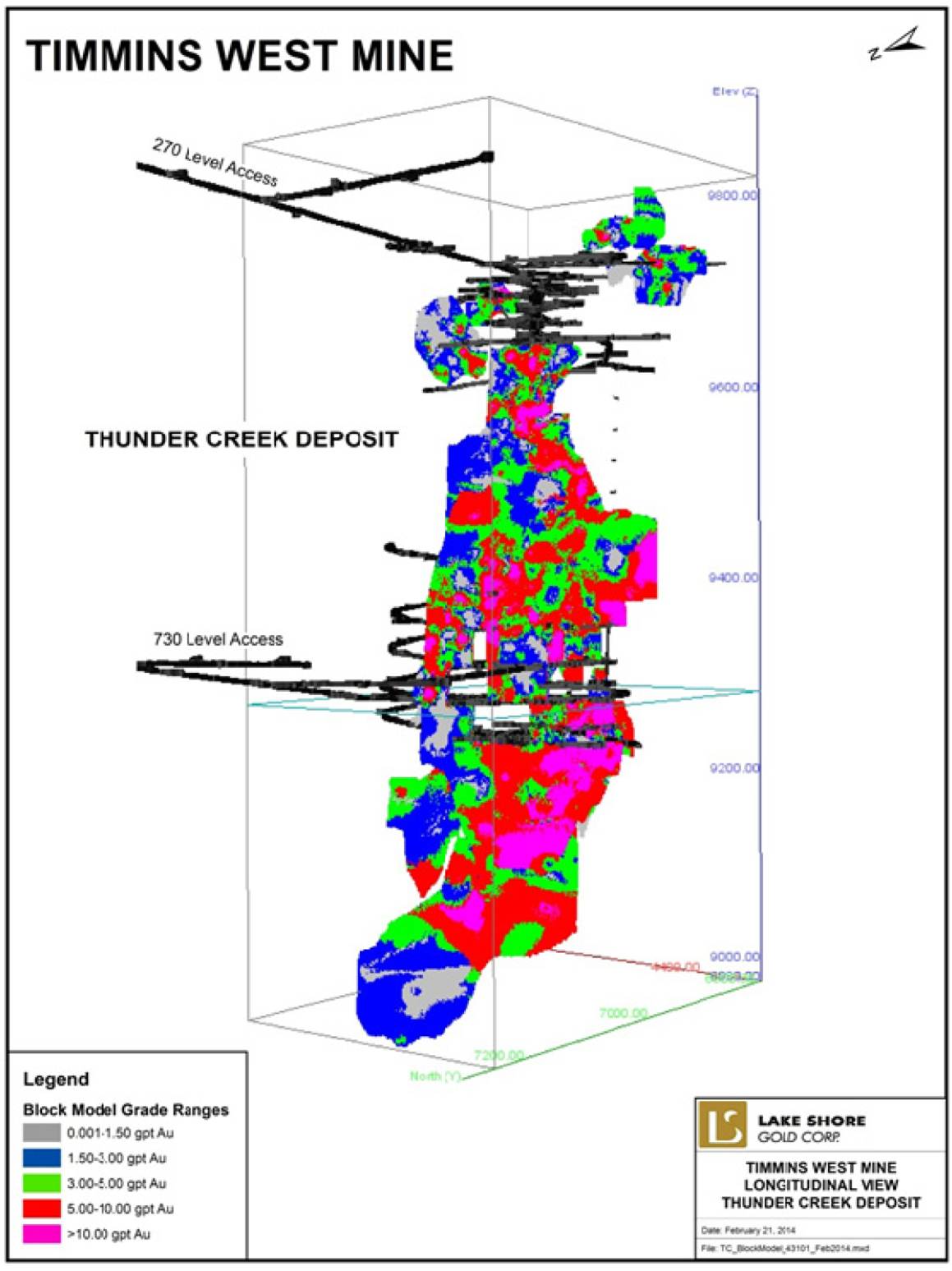

Figure 14.11: | 3D VIEW OF NEW GRADE BLOCK MODEL FOR THE TIMMINS DEPOSIT, LOOKING NORTHWEST | 119 |

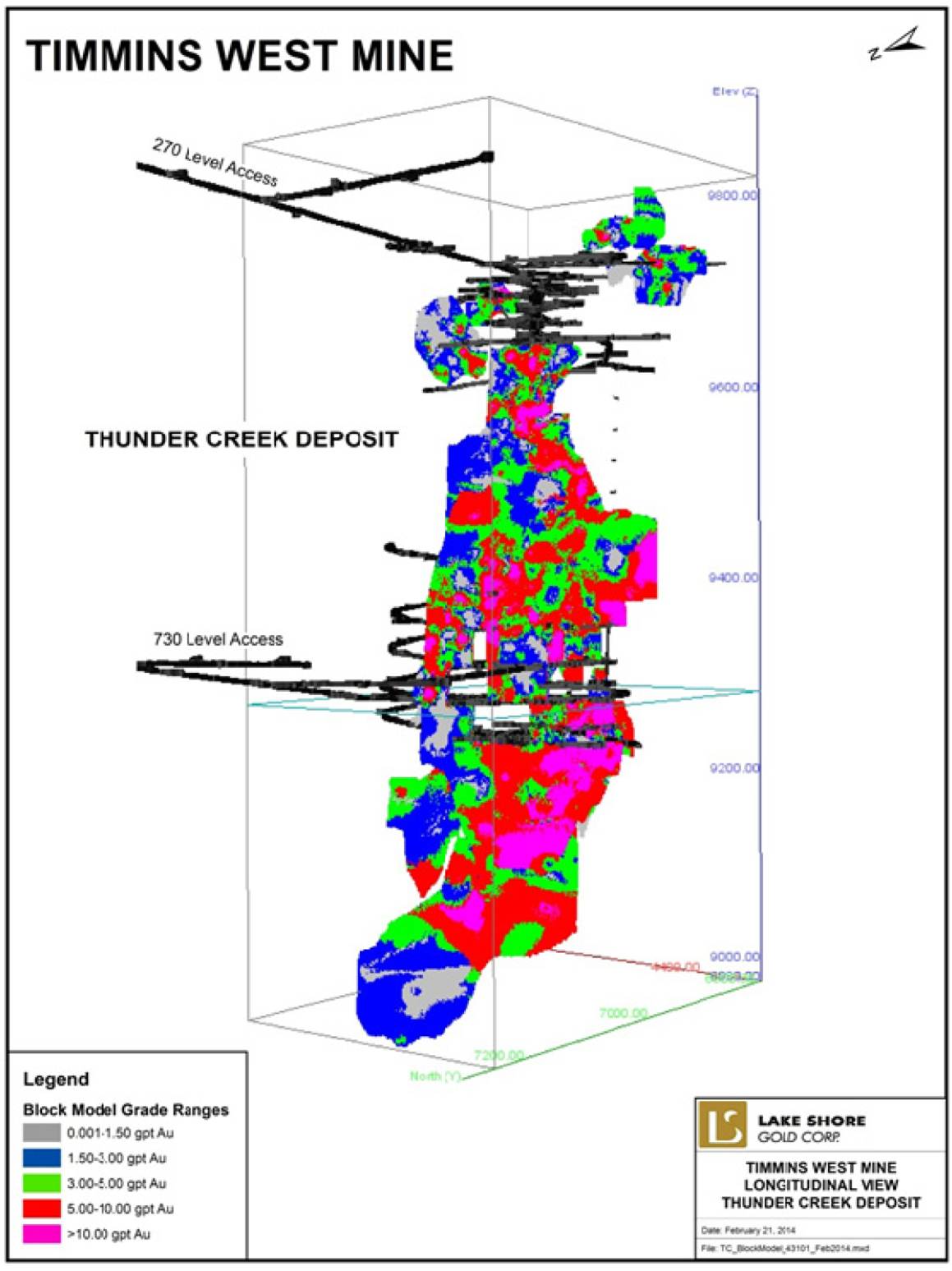

Figure 14.12: | 3D VIEW OF NEW GRADE BLOCK MODEL FOR THE THUNDER CREEK DEPOSIT LOOKING NORTHWEST | 120 |

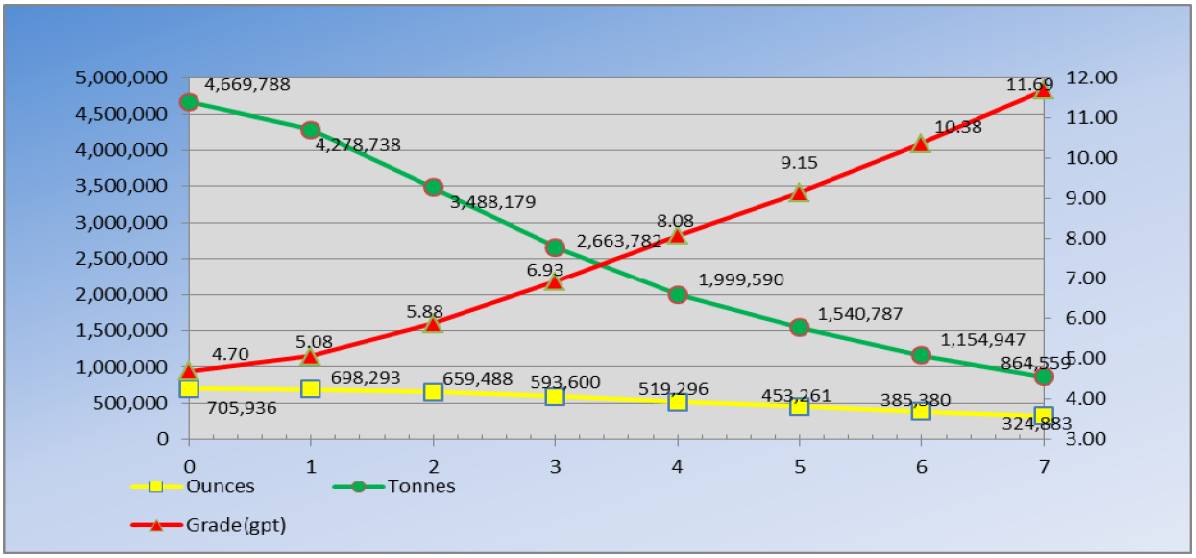

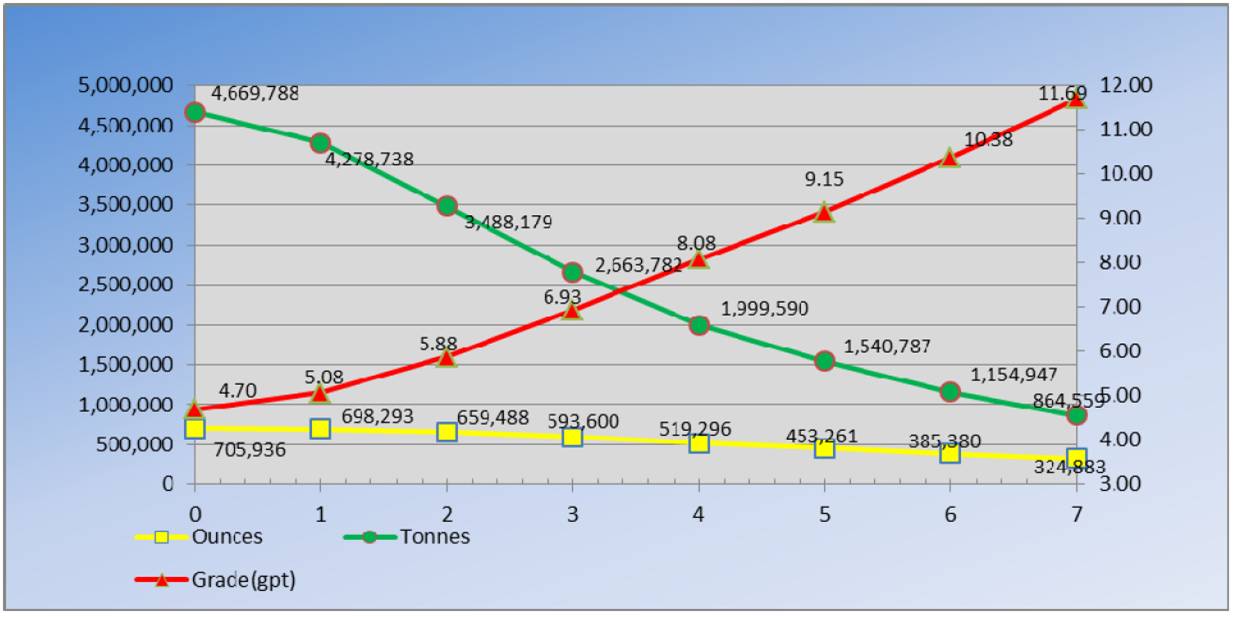

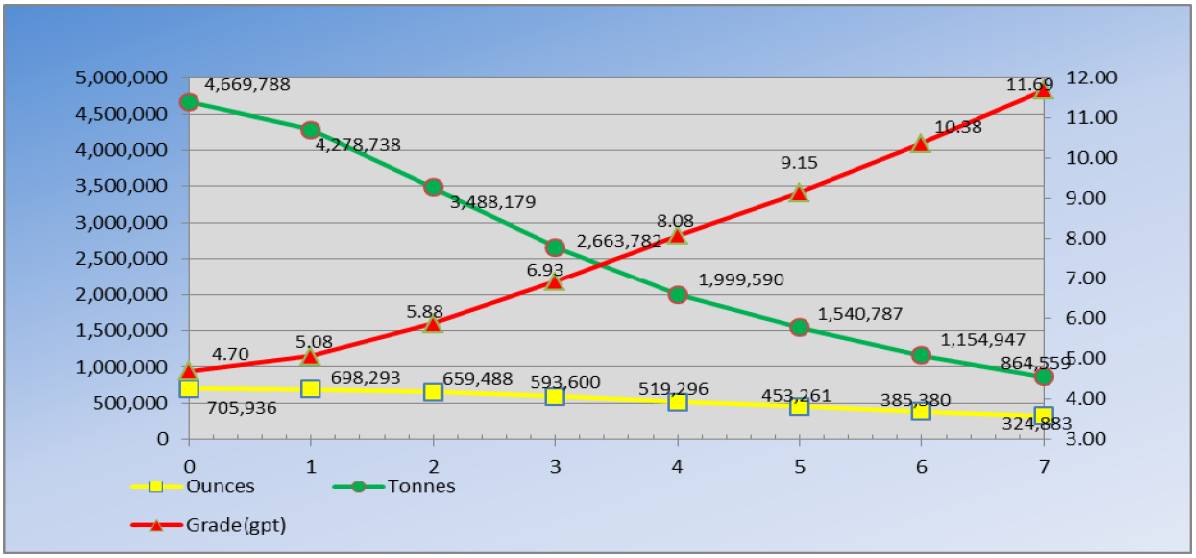

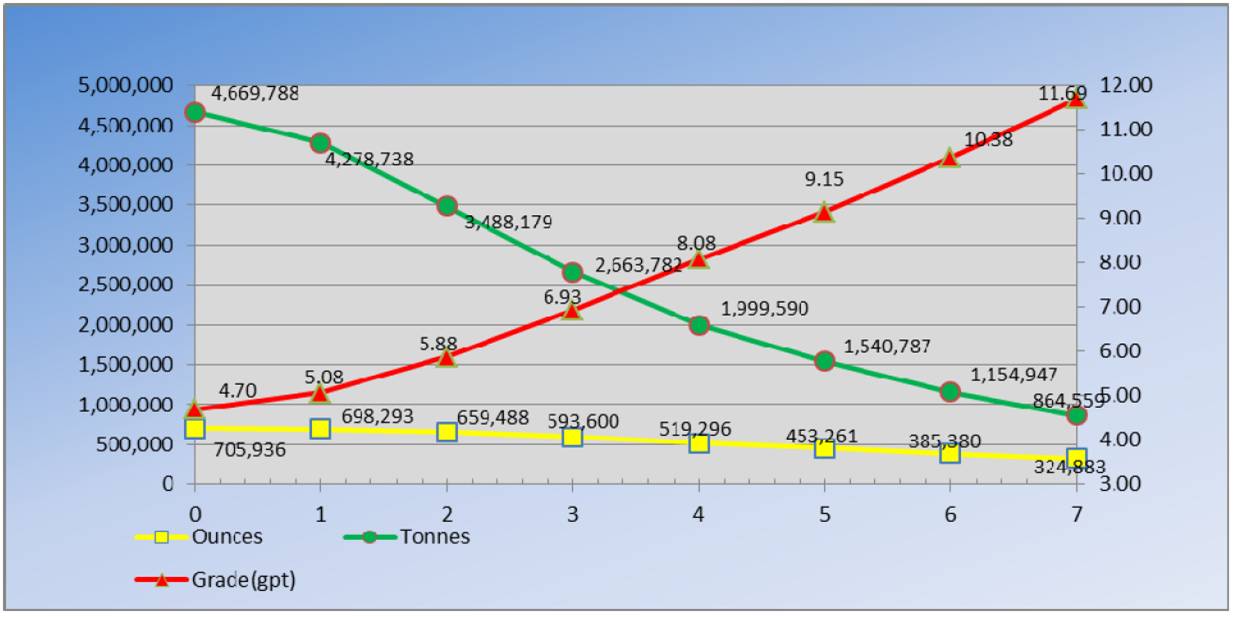

Figure 14.13: | TIMMINS DEPOSIT — GRADE TONNAGE CURVE | 121 |

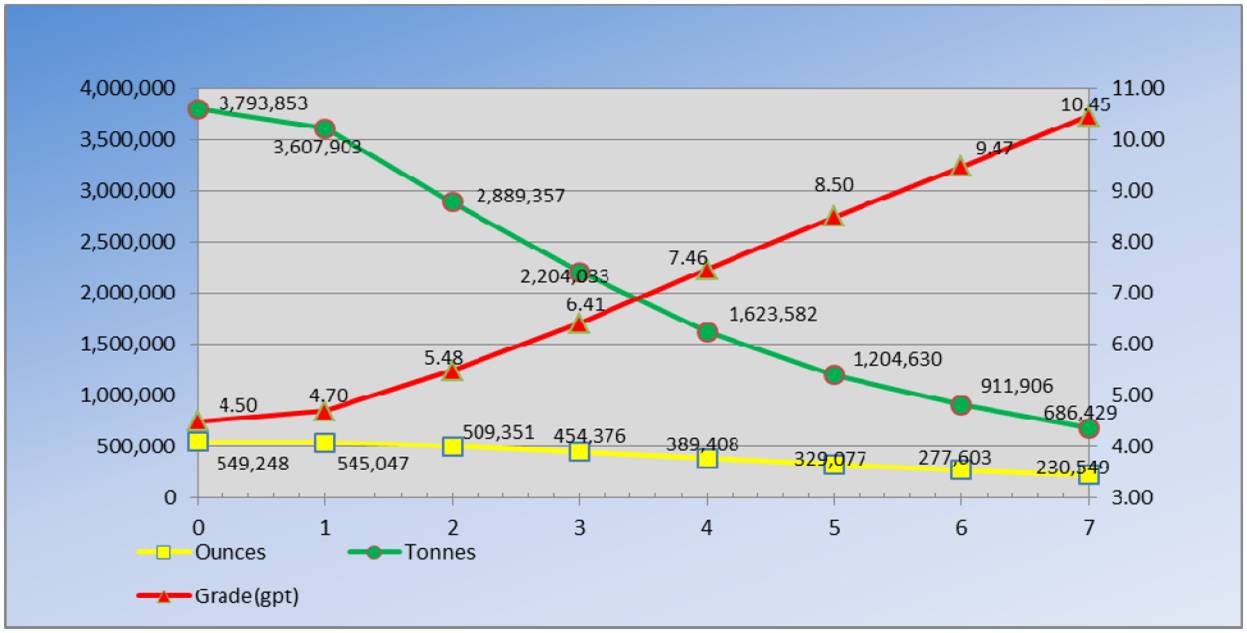

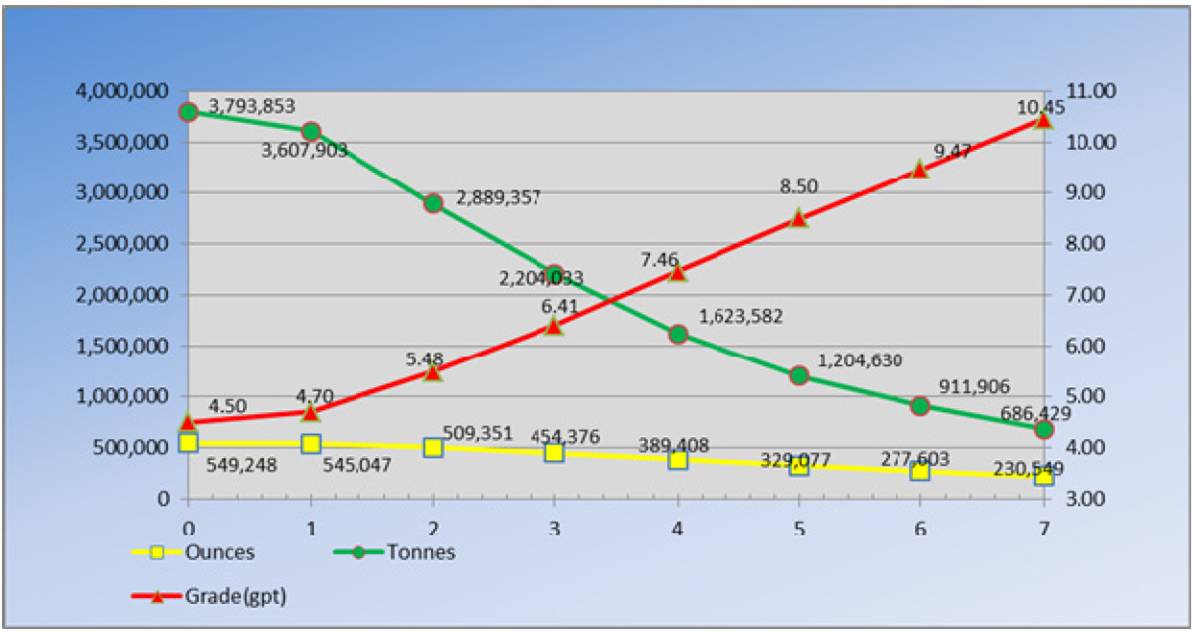

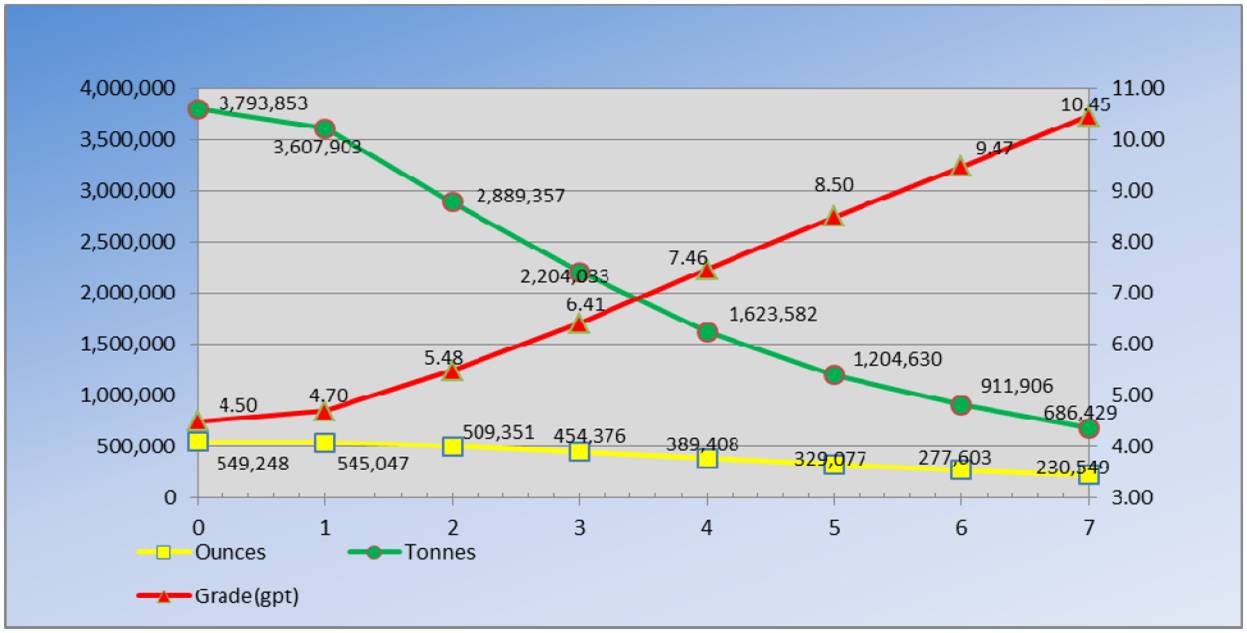

Figure 14.14: | THUNDER CREEK — GRADE TONNAGE CURVE | 121 |

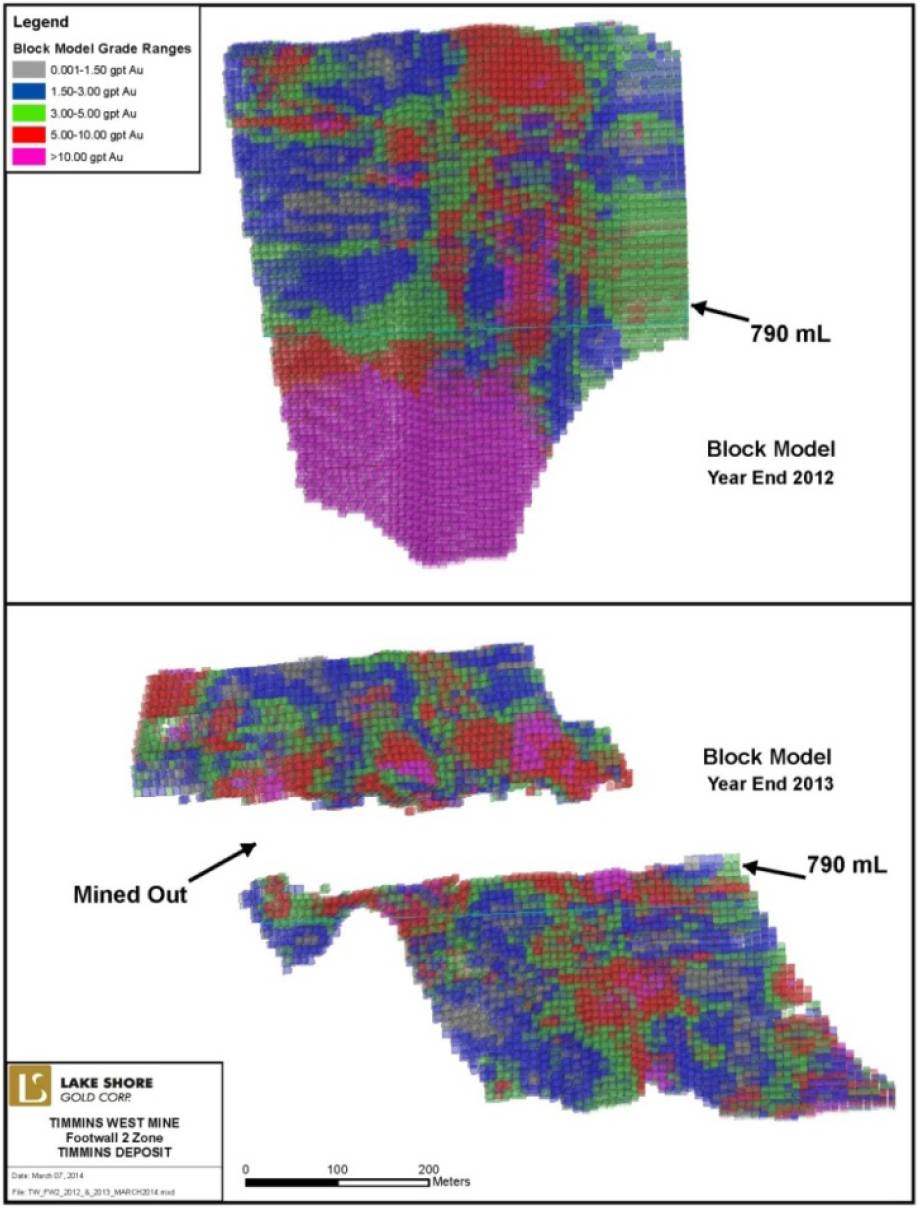

Figure 14.15: | LONG SECTION VIEW LOOKING NORTHWARDS COMPARING 2012 AND 2013 BLOCK MODELS FOR THE 790 FOOTWALL ZONE AT THE TIMMINS DEPOSIT | 123 |

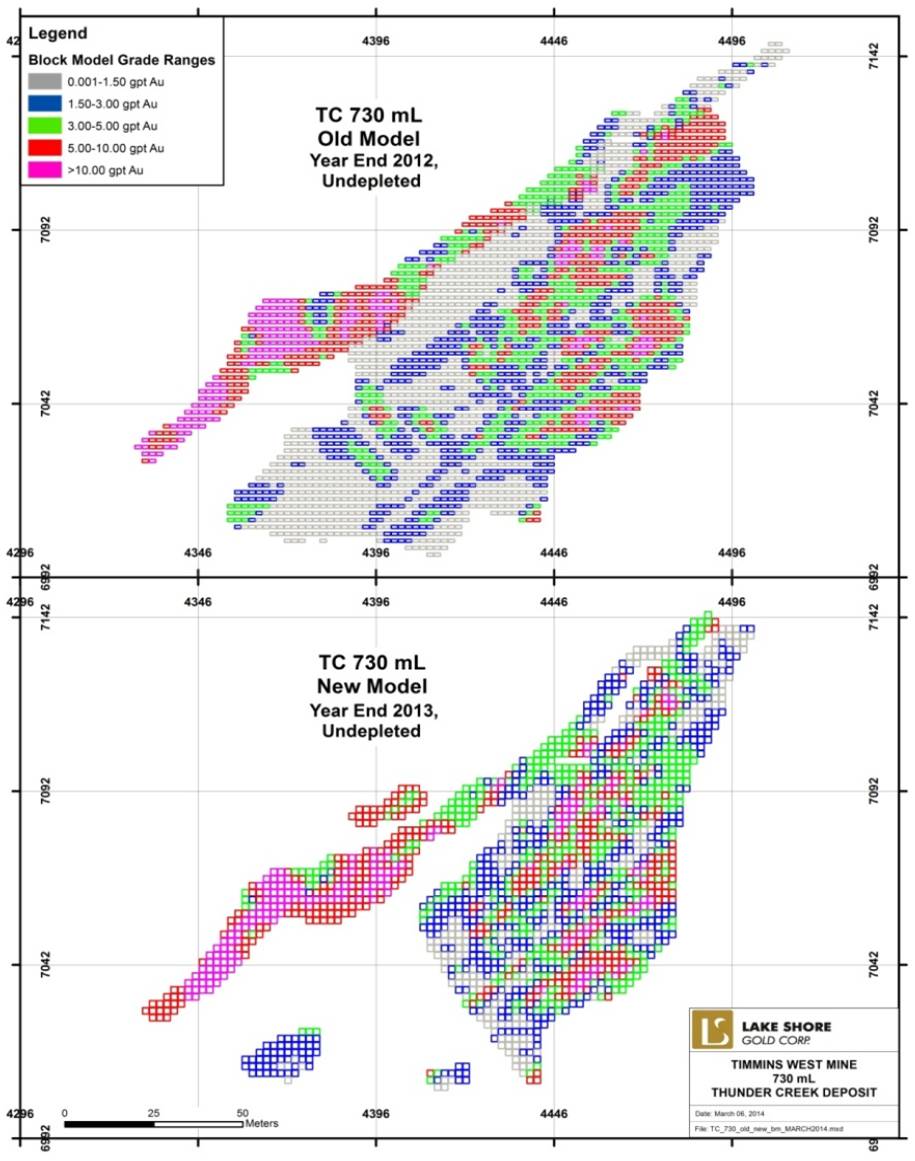

Figure 14.16: | COMPARISON OF 2012 AND 2013 BLOCK MODELS FOR THE THUNDER CREEK DEPOSIT ON 730 LEVEL | 124 |

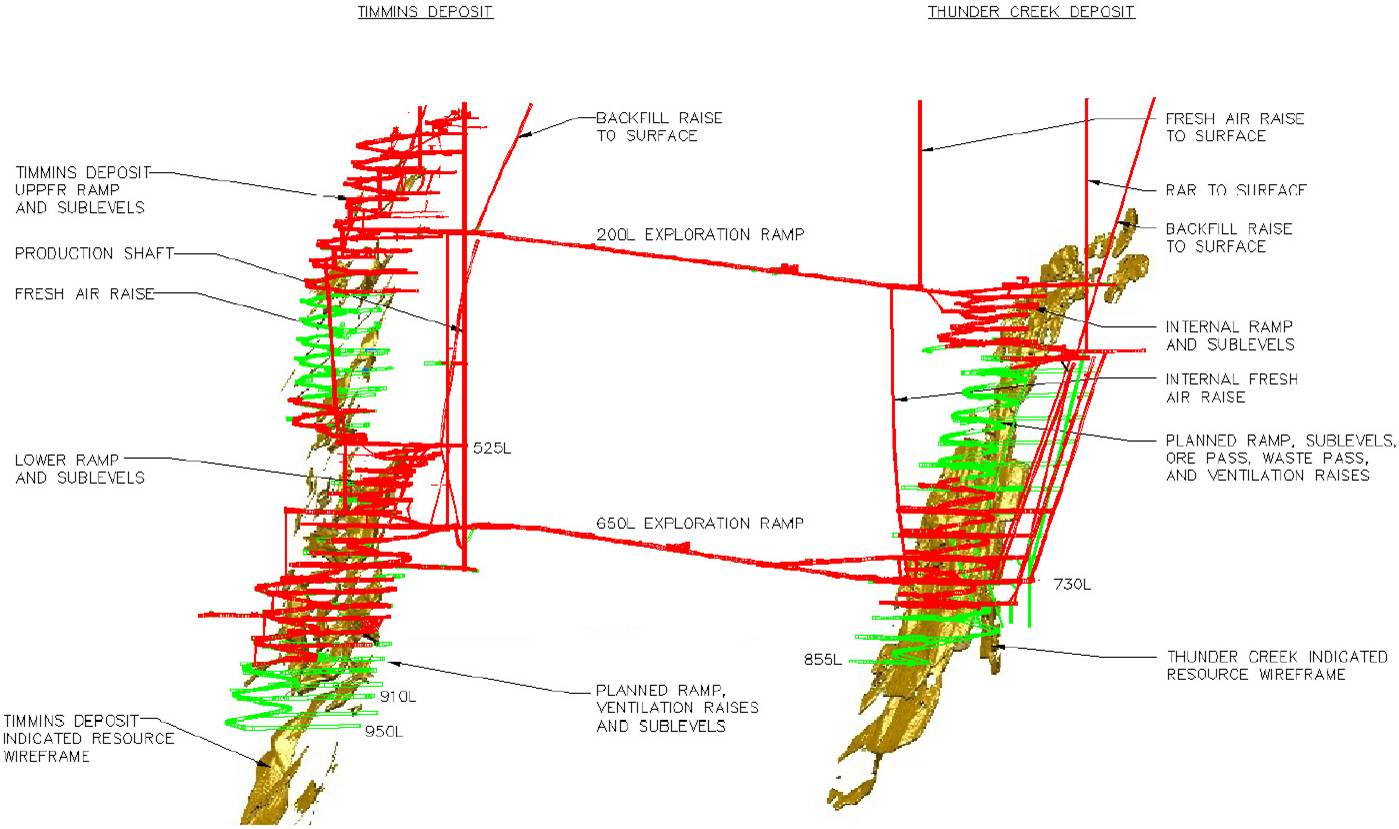

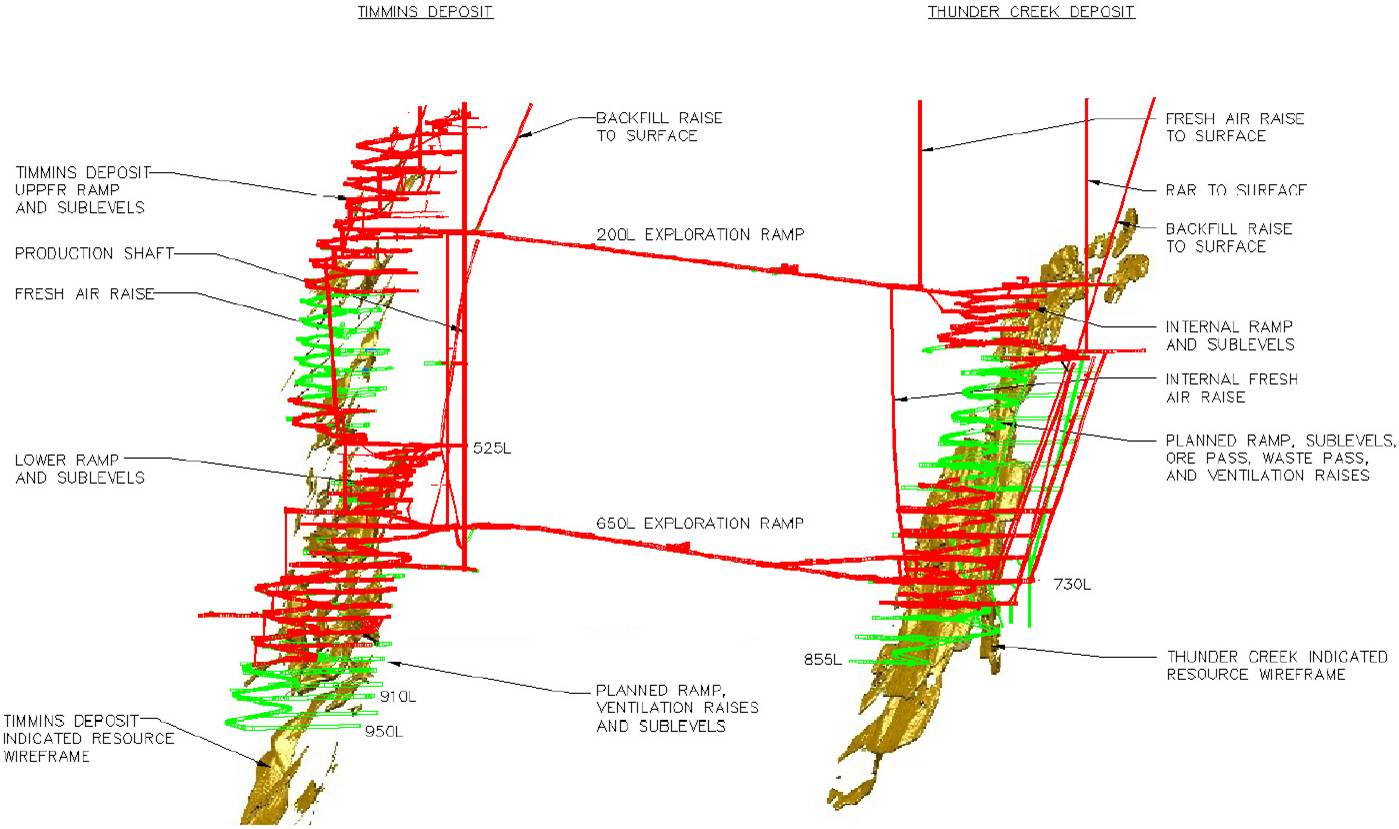

Figure 16.1: | TIMMINS DEPOSIT AND THUNDER CREEK DEPOSIT, LOOKING EAST | 132 |

Figure 16.2: | TIMMINS WEST MINE SURFACE INFRASTRUCTURE | 134 |

Figure 16.3: | TIMMINS WEST MINE EXISTING UNDERGROUND INFRASTRUCTURE | 135 |

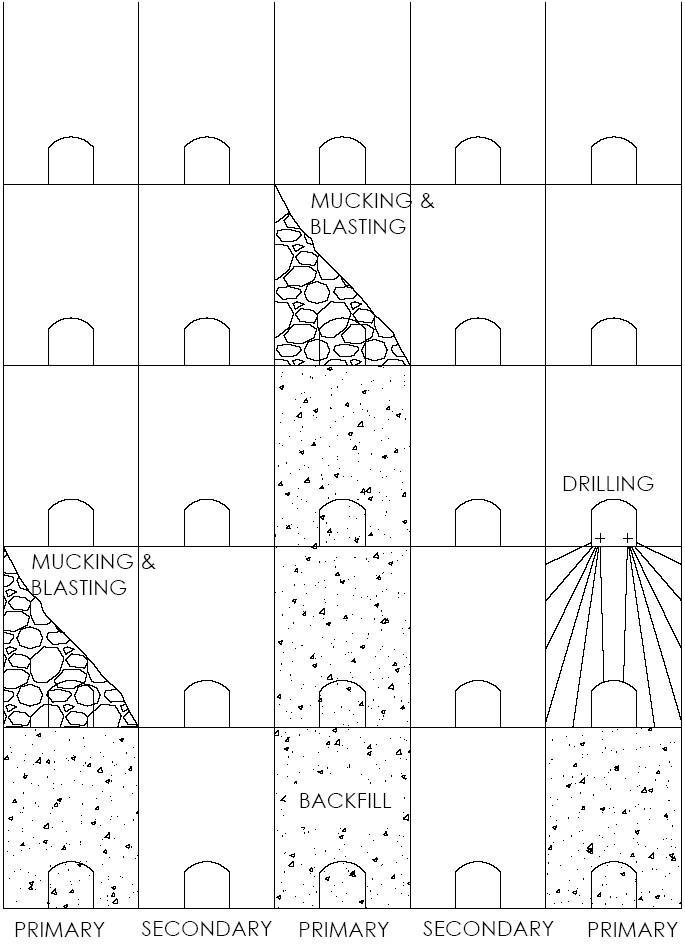

Figure 16.4: | LONGITUDINAL LONGHOLE MINING METHOD | 138 |

Figure 16.5: | TRANSVERSE LONGHOLE MINING METHOD | 140 |

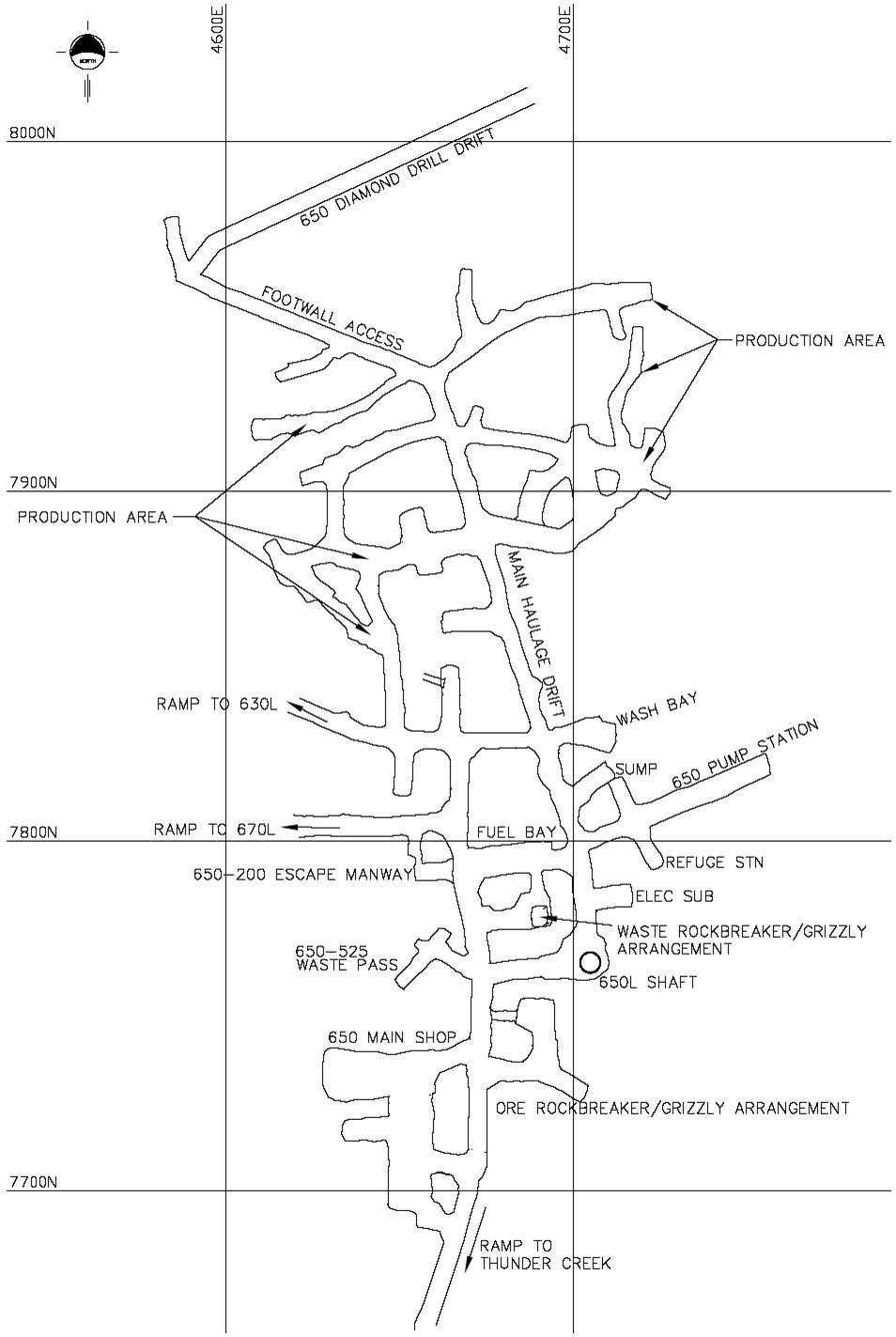

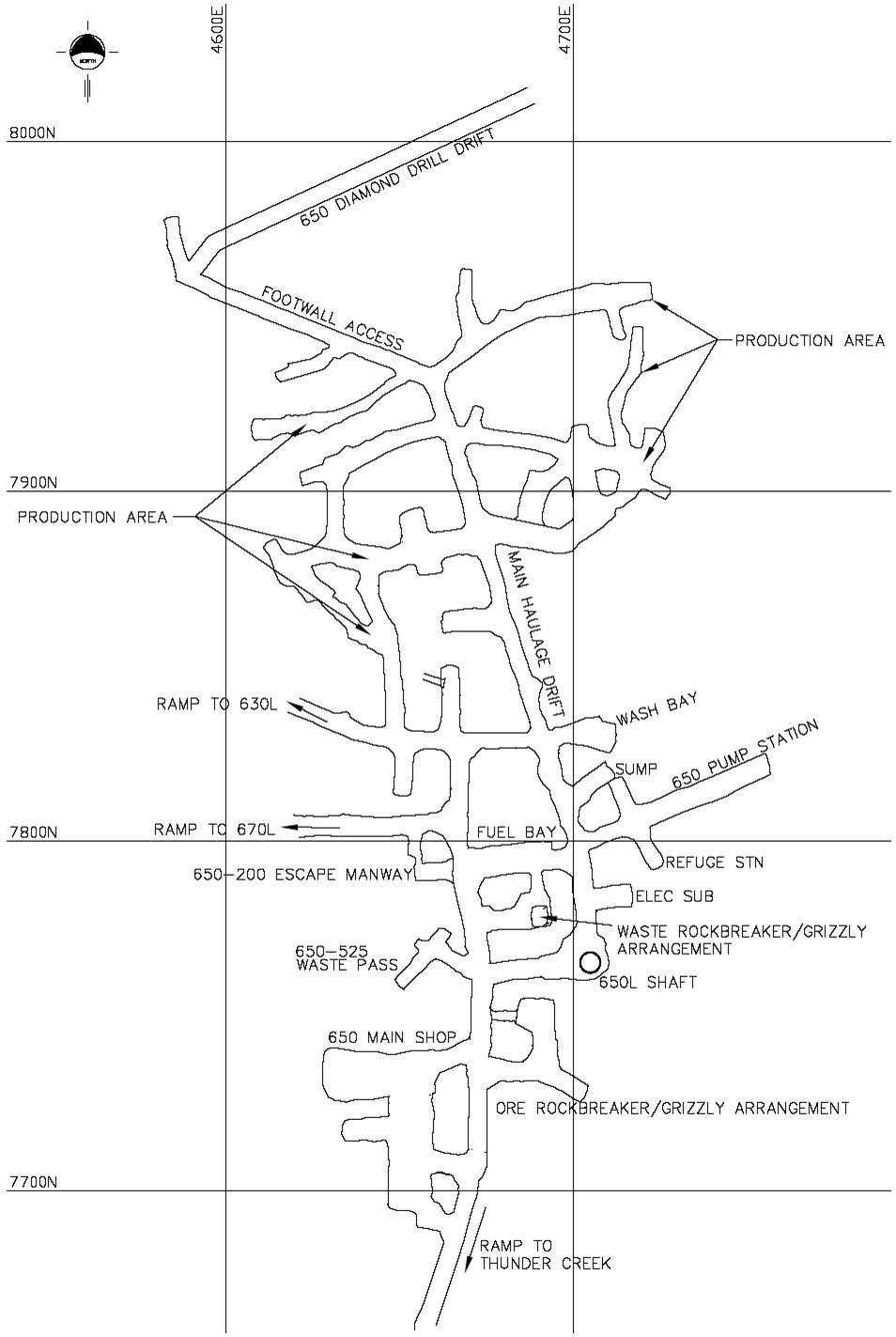

Figure 16.6: | PLANNED MINE INFRASTRUCTURE | 148 |

Figure 16.7: | EXISTING 650L INFRASTRUCTURE | 149 |

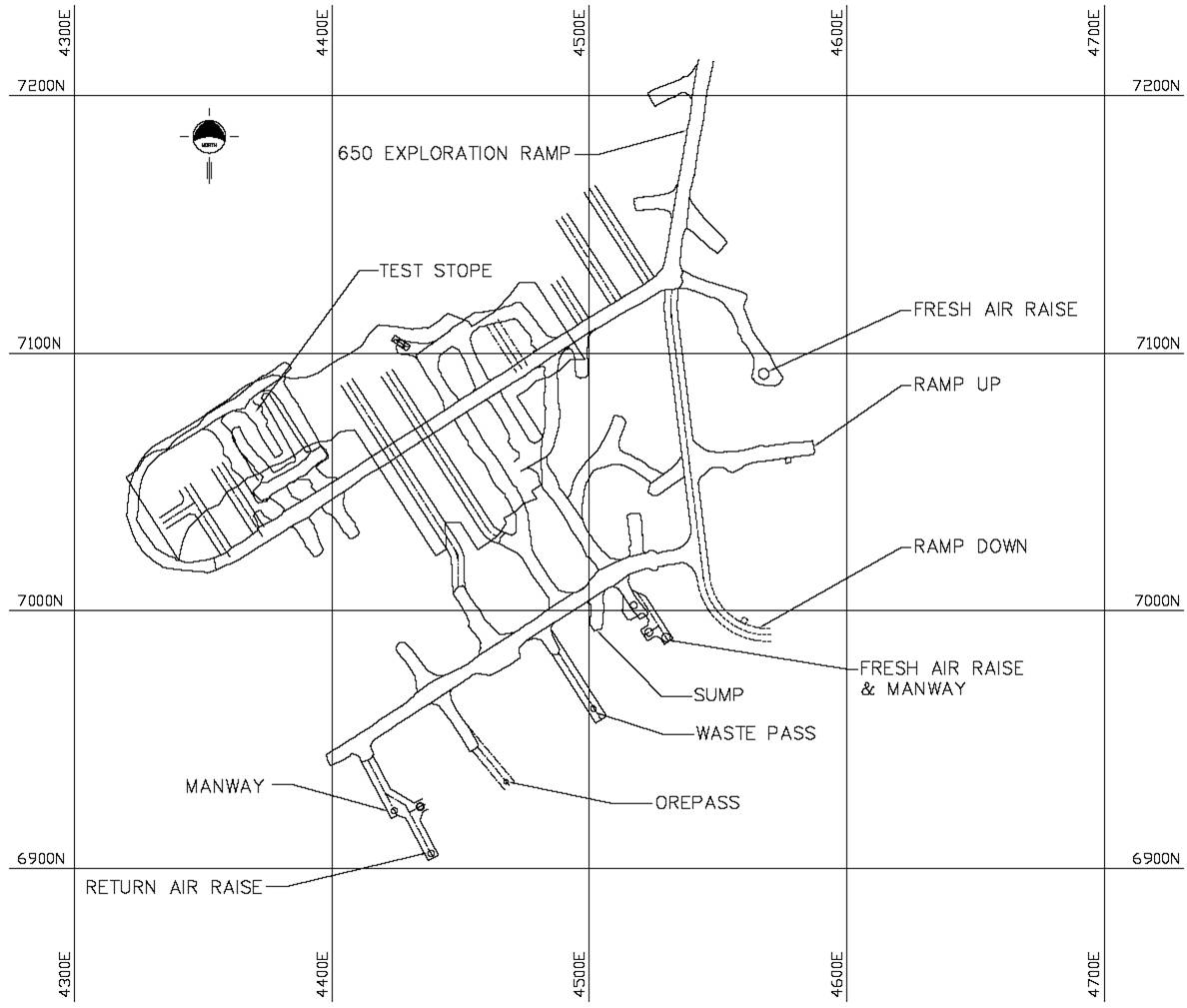

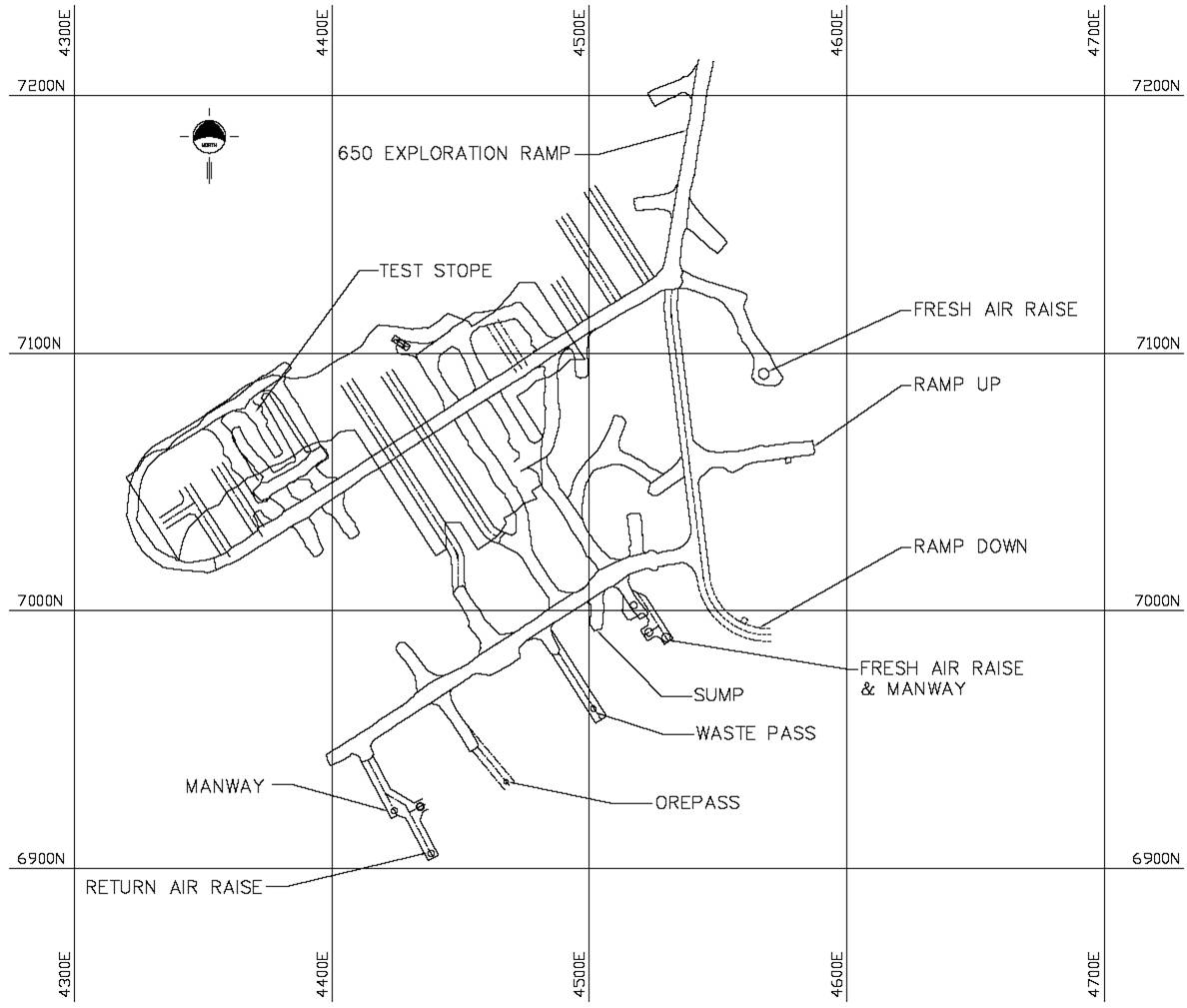

Figure 16.8: | EXISTING 730L INFRASTRUCTURE | 151 |

Figure 16.9: | LOM OUNCE PRODUCTION | 153 |

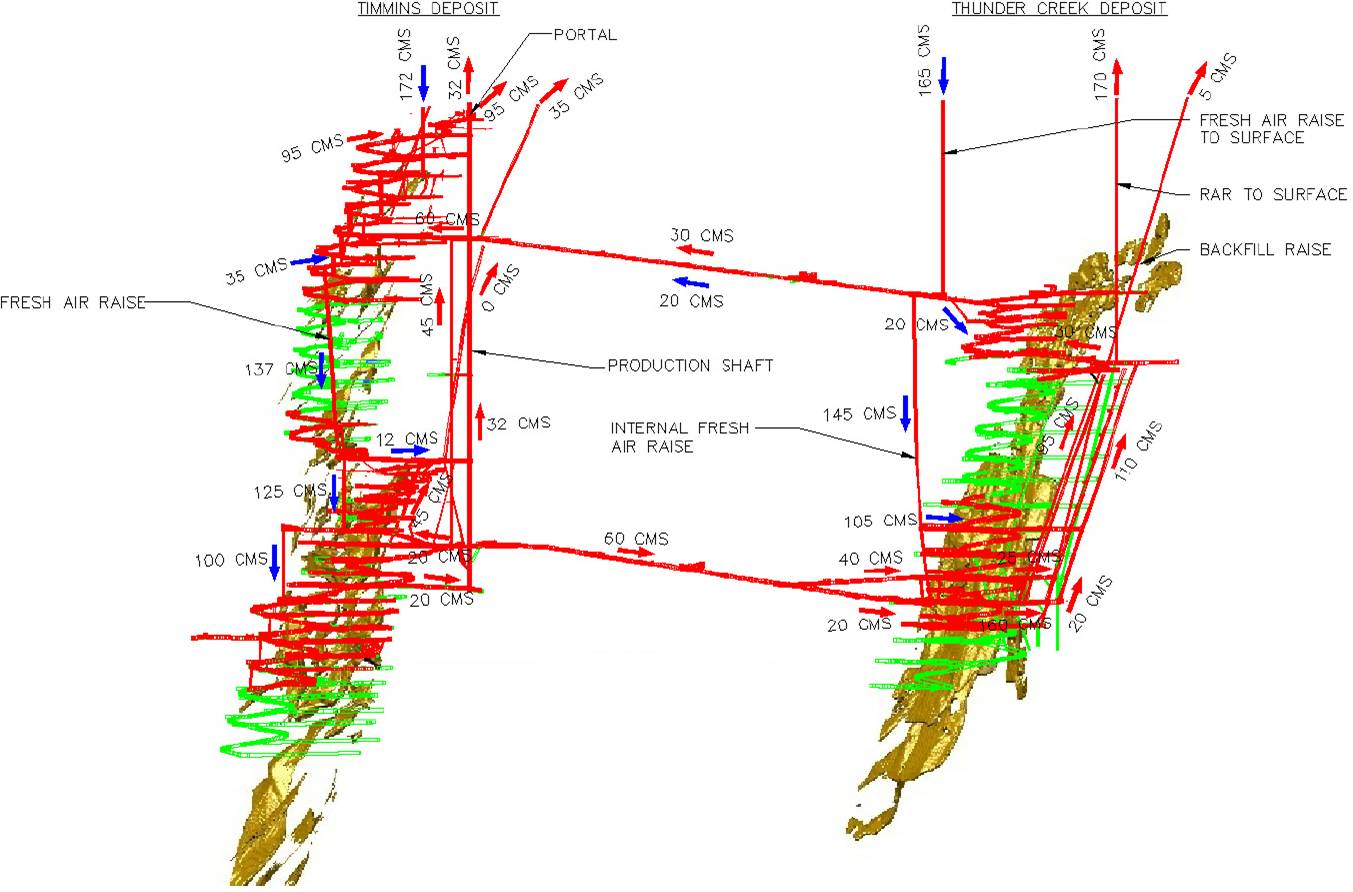

Figure 16.10: | TIMMINS WEST MINE VENTILATION SYSTEM | 155 |

Figure 16.11: | BELL CREEK TAILINGS FACILITY | 164 |

Figure 17.1: | SIMPLIFIED MILLING PROCESS AND SAMPLING POINTS | 167 |

Figure 20.1: | TIMMINS WEST MINE WATER MANAGEMENT PLAN | 173 |

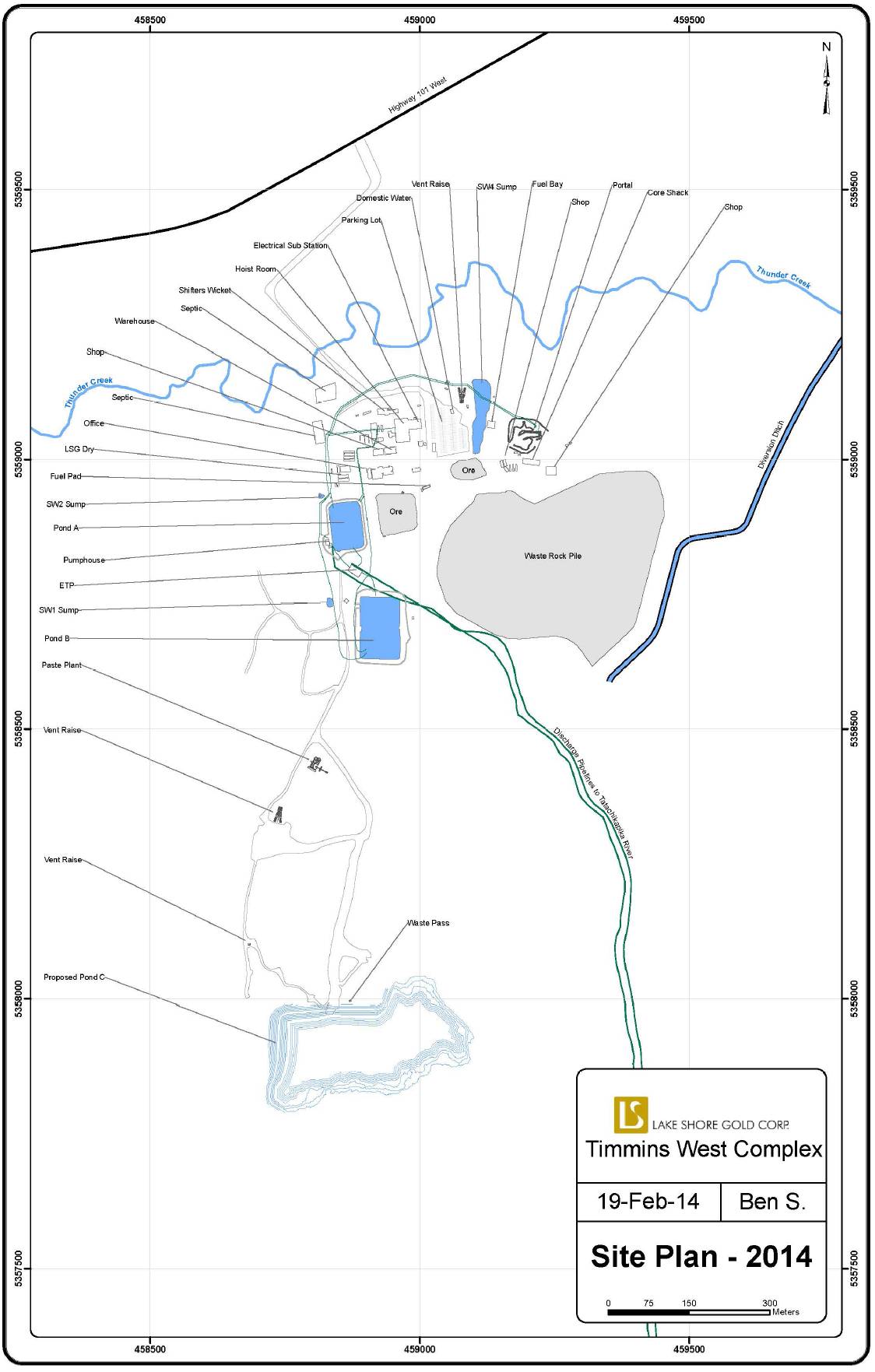

Figure 20.2: | SITE PLAN | 174 |

Figure 25.1: | GRADE-TONNAGE GRAPH AS A FUNCTION OF CUT-OFF GRADE (TIMMINS DEPOSIT) | 189 |

Figure 25.2: | GRADE-TONNAGE GRAPH AS A FUNCTION OF CUT-OFF GRADE (THUNDER CREEK) | 189 |

vii

TABLE OF CONTENTS

LIST OF TABLES

Table 1.1: | TWM RESOURCE ESTIMATE AT 1.5 G/T IN-SITU COG | 3 |

Table 1.2: | TWM RESOURCE ESTIMATES AT 3.0 G/T IN-SITU COG | 4 |

Table 1.3: | TWM ESTIMATED RESERVES | 6 |

Table 1.4: | ESTIMATED LOM PRODUCTION PROFILE | 6 |

Table 1.5: | ESTIMATED LOM CAPITAL AND OPERATING COSTS | 7 |

Table 2.1: | LIST OF ABBREVIATIONS | 9 |

Table 2.2: | GLOSSARY | 13 |

Table 3.1: | QUALIFIED PERSONs FOR TIMMINS WEST MINE | 16 |

Table 4.1: | TIMMINS WEST MINE STAKED CLAIMS | 21 |

Table 4.2: | LEASED LANDS | 22 |

Table 4.3: | PATENTED LANDS | 22 |

Table 4.4: | SPECIES AT RISK | 27 |

Table 5.1: | AVERAGE TEMPERATURES, PRECIPITATION AND SNOW FALL DEPTHS FOR THE TIMMINS AREA (1971 TO 2000) | 28 |

Table 6.1: | CHRONOLOGY OF EVENTS FOR THE TIMMINS WEST MINE AREA | 31 |

Table 6.2: | WGM MINERAL RESOURCE ESTIMATE, OCTOBER 31, 2006 | 36 |

Table 6.3: | LSG UPDATED MINERAL RESOURCE OF SRK POLYGONAL RESOURCE AND STANTEC MINERAL RESERVE, AUGUST 2009 (DARLING ET AL., 2009) | 36 |

Table 6.4: | LSG INITIAL MINERAL RESOURCE ESTIMATE FOR THE THUNDER CREEK DEPOSIT (CRICK ET AL., 2011) | 36 |

Table 6.5: | LSG UPDATED MINERAL RESOURCE ESTIMATE FOR TIMMINS WEST MINE (CRICK ET AL., 2012A) | 37 |

Table 6.6: | LSG MINERAL RESERVE AND INDICATED RESOURCE ESTIMATE FOR TIMMINS WEST MINE (CRICK ET AL., 2012B) | 37 |

Table 6.7: | LSG MINERAL RESERVE AND RESOURCE ESTIMATE FOR TIMMINS WEST MINE, AT YEAR-END 2012 (AIF 2012; PRESS RELEASE DATED MARCH 18, 2013) | 38 |

Table 6.8: | TIMMINS DEPOSIT ANNUAL PRODUCTION FIGURES | 38 |

Table 6.9: | THUNDER CREEK ANNUAL PRODUCTION FIGURES | 38 |

Table 7.1: | TECTONIC ASSEMBLAGES | 41 |

Table 7.2: | LITHOLOGICAL UNITS | 46 |

Table 8.1: | OPERATIONS WITH GREATER THAN 100,000 OUNCES OF GOLD PRODUCTION IN THE PORCUPINE GOLD CAMP | 62 |

Table 9.1: | SUMMARY OF SIGNIFICANT EXPLORATION ACTIVITY BY LSG AT THE TIMMINS WEST MINE — 2003 TO PRESENT (EXCLUDES DRILLING) | 63 |

Table 10.1: | DIAMOND DRILLING BY PREVIOUS OPERATORS (1984 — 2002) | 69 |

Table 10.2: | STATISTICS ON DIAMOND DRILLING BY LSG FOR TIMMINS WEST MINE AREA (2003 TO FEBRUARY 2014) | 72 |

Table 10.3: | DRILLING AND SAMPLING STATISTICS TO CUT-OFF DATES FROM DATABASE | 73 |

Table 11.1: | OREAS STANDARDS USED BY LAKE SHORE GOLD CORP. | 81 |

Table 11.2: | SUMMARY OF SAMPLE DISTRIBUTION BY ANALYTICAL LABORATORIES | 82 |

Table 11.3: | TIMMINS WEST MINE DIAMOND DRILL CORE QA/QC SAMPLE SUMMARY | 88 |

Table 14.1: | TIMMINS WEST MINE RESOURCE ESTIMATE | 94 |

Table 14.2: | SUMMARY OF GEMS SQL DRILL HOLE DATABASE | 96 |

Table 14.3: | MINERALIZED DOMAINS | 97 |

Table 14.4: | BASIC STATISTICS OF RAW AU ASSAYS BY RESOURCE SOLID | 100 |

Table 14.5: | CAPPED AND UNCAPPED GOLD GRADES | 104 |

viii

TABLE OF CONTENTS

Table 14.6: | BASIC STATISTICS OF 1 METRE COMPOSITES | 105 |

Table 14.7: | SPECIFIC GRAVITY BY ZONE | 105 |

Table 14.8: | BLOCK MODEL GRID PARAMETERS | 109 |

Table 14.9: | TIMMINS DEPOSIT SEARCH ELLIPSE PARAMETERS | 110 |

Table 14.10: | THUNDER CREEK SEARCH ELLIPSE PARAMETERS | 111 |

Table 14.11: | COMPARISON OF ID2 AND NEAREST NEIGHBOUR INTERPOLATION | 115 |

Table 14.12: | TIMMINS WEST MINE RESOURCE ESTIMATES | 118 |

Table 14.13: | COMPARISON OF 2012 AND 2013 RESOURCE ESTIMATES | 122 |

Table 14.14: | THUNDER CREEK RESOURCES FROM 2012 AND 2013, LISTED BY ZONE | 125 |

Table 14.15: | TIMMINS MINE RESOURCES FROM 2012 AND 2013, LISTED BY ZONE | 125 |

Table 14.16: | THUNDER CREEK RESOURCES FROM 2012 AND 2013, LISTED BY LEVEL | 125 |

Table 14.17: | TIMMINS MINE RESOURCES FROM 2012 AND 2013, LISTED BY LEVEL | 126 |

Table 15.1: | TIMMINS WEST MINE IN-SITU INDICATED RESOURCE AT 3.0 G/T CUT-OFF GRADE | 128 |

Table 15.2: | TWM COG ASSUMPTIONS | 128 |

Table 15.3: | TIMMINS DEPOSIT ESTIMATED RESERVES | 129 |

Table 15.4: | THUNDER CREEK DEPOSIT ESTIMATED RESERVES | 131 |

Table 15.5: | TIMMINS WEST MINE COMBINED RESERVES | 131 |

Table 16.1: | TIMMINS WEST MINE IN-SITU INDICATED RESOURCE AT 3.0 G/T CUT-OFF GRADE | 135 |

Table 16.2: | TWM COG ASSUMPTIONS | 142 |

Table 16.3: | TIMMINS DEPOSIT ESTIMATED RESERVES | 143 |

Table 16.4: | THUNDER CREEK UNPLANNED DILUTION PARAMETERS | 144 |

Table 16.5: | THUNDER CREEK UNPLANNED BACKFILL DILUTION PARAMETERS | 144 |

Table 16.6: | THUNDER CREEK DEPOSIT ESTIMATED PROBABLE RESERVES | 145 |

Table 16.7: | TIMMINS WEST MINE COMBINED RESERVES | 145 |

Table 16.8: | TIMMINS DEPOSIT ESTIMATED LOM DEVELOPMENT QUANTITIES | 146 |

Table 16.9: | THUNDER CREEK DEPOSIT ESTIMATED LOM DEVELOPMENT QUANTITIES | 147 |

Table 16.10: | WASTE ROCK GENERATED FROM DEVELOPMENT | 147 |

Table 16.11: | TWM ANNUAL PRODUCTION TONNES | 153 |

Table 16.12: | TWM ANNUAL OUNCES MINED TO SURFACE | 153 |

Table 16.13: | UNDERGROUND MOBILE EQUIPMENT FLEET | 154 |

Table 16.14: | PERSONNEL ON PAYROLL | 156 |

Table 16.15: | SUMMARY OF GROUND SUPPORT MINIMUM REQUIREMENTS — LATERAL DEVELOPMENT | 162 |

Table 16.16: | SUMMARY OF GROUND SUPPORT MINIMUM REQUIREMENTS — RAISES | 162 |

Table 21.1: | TIMMINS WEST MINE ESTIMATED LOM CAPITAL COSTS | 177 |

Table 21.2: | OPERATING COST SUMMARY | 179 |

Table 23.1: | DISTANCE FROM THE TIMMINS WEST MINE HEADFRAME TO SIGNIFICANT TIMMINS AREA MINING LANDMARKS | 183 |

Table 23.2: | SUMMARY OF WORK COMPLETED BY NEWCASTLE MINERALS LIMITED | 184 |

| | |

APPENDICES | |

| |

1 | MEMOS REGARDING STATISTICAL ANALYSIS OF QA/QC ASSAY DATA FOR THUNDER CREEK AND TIMMINS WEST DEPOSITS | |

2 | SGS CANADA MEMO REGARDING REVIEW OF THE TIMMINS WEST MINE RESOURCES | |

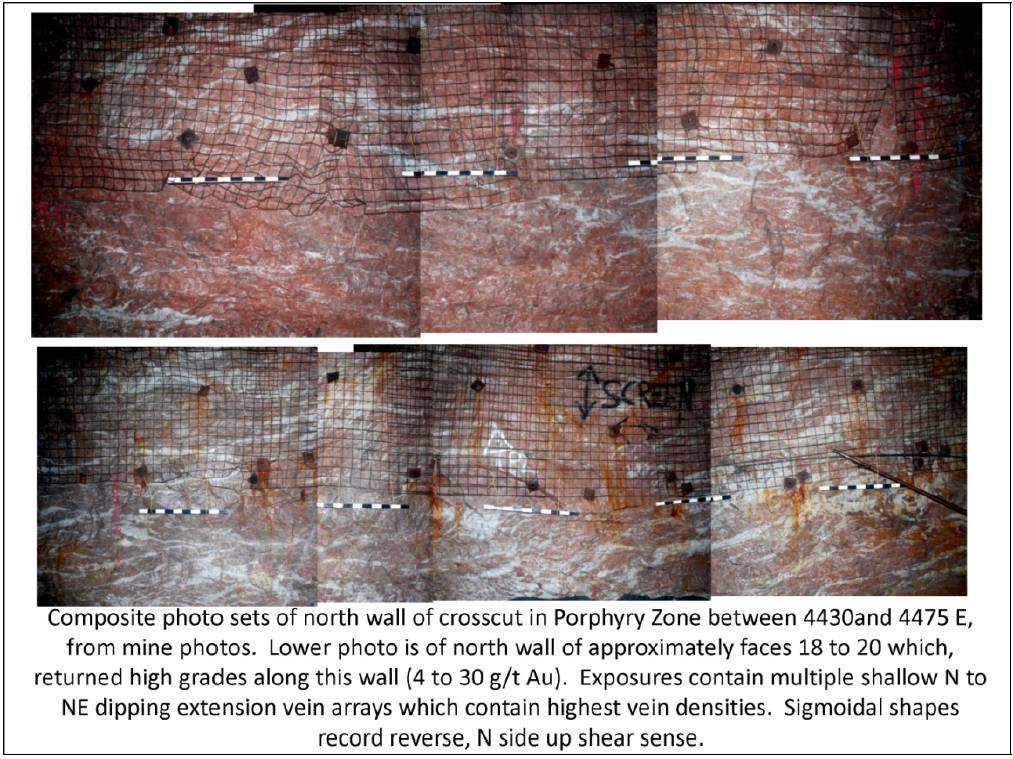

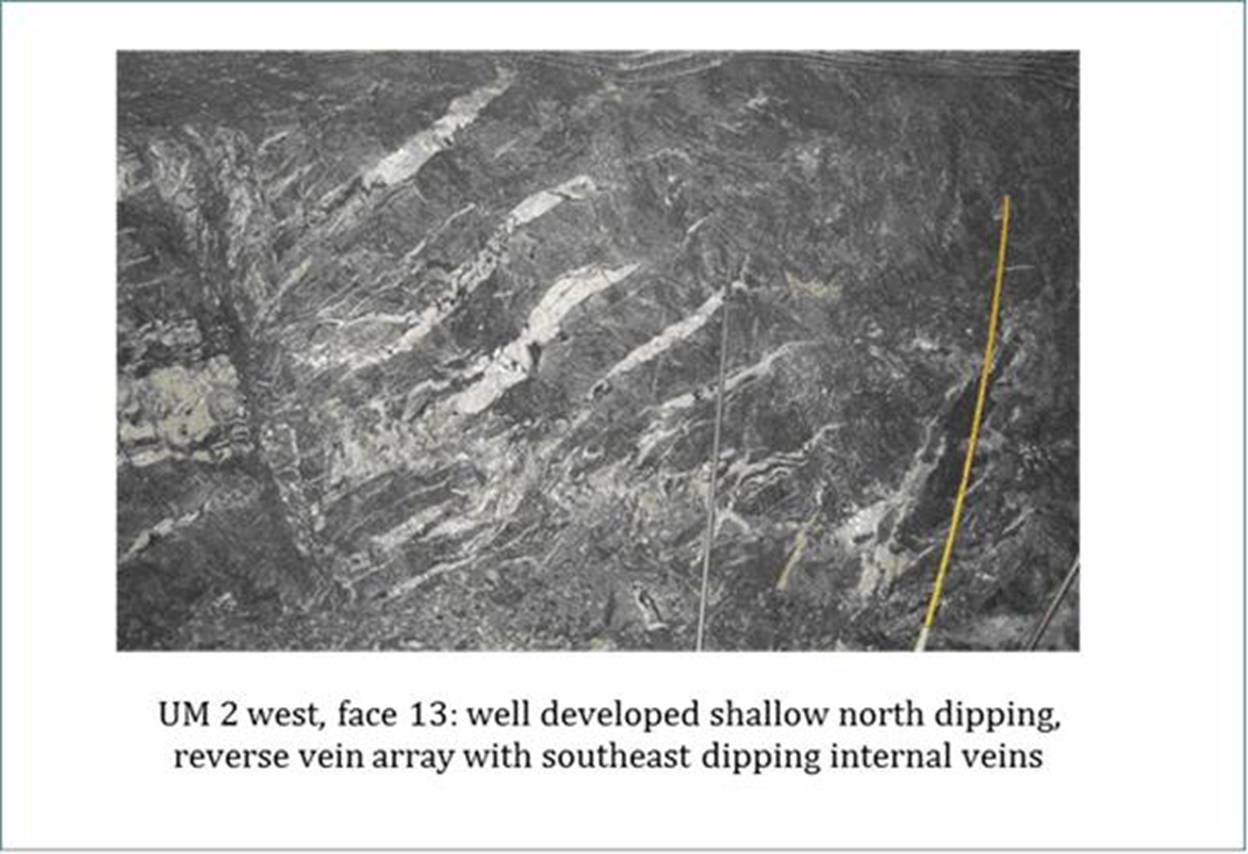

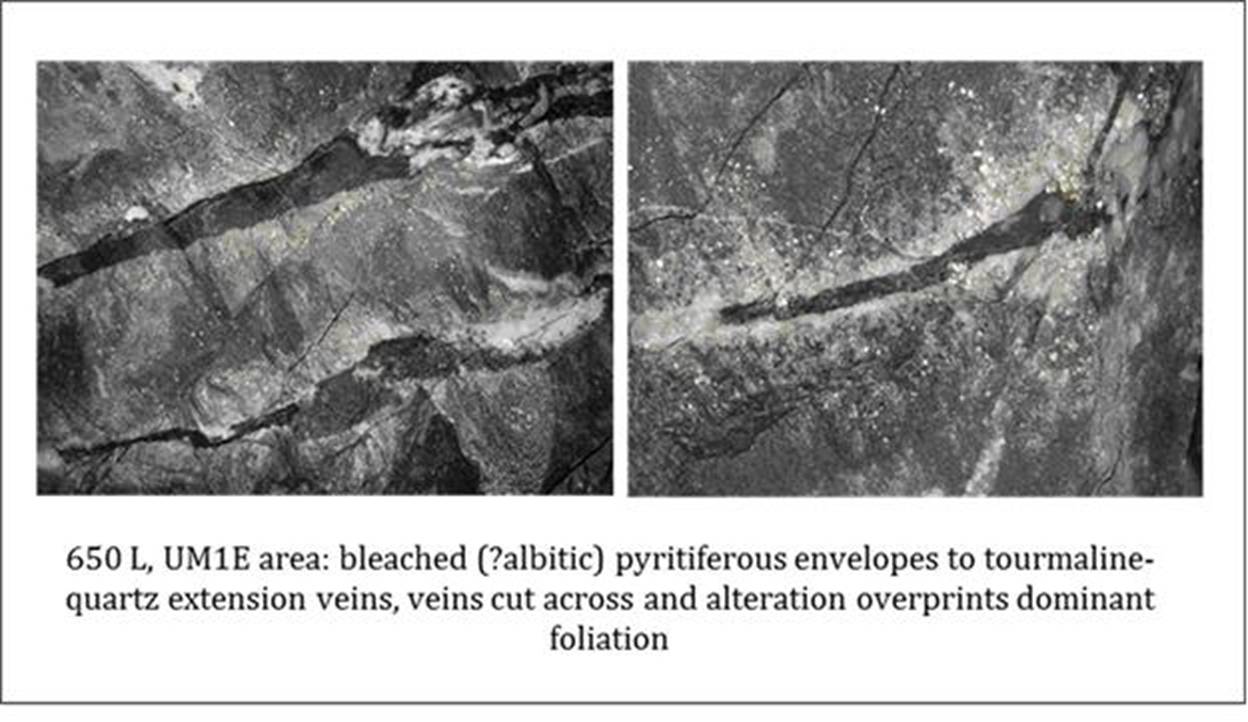

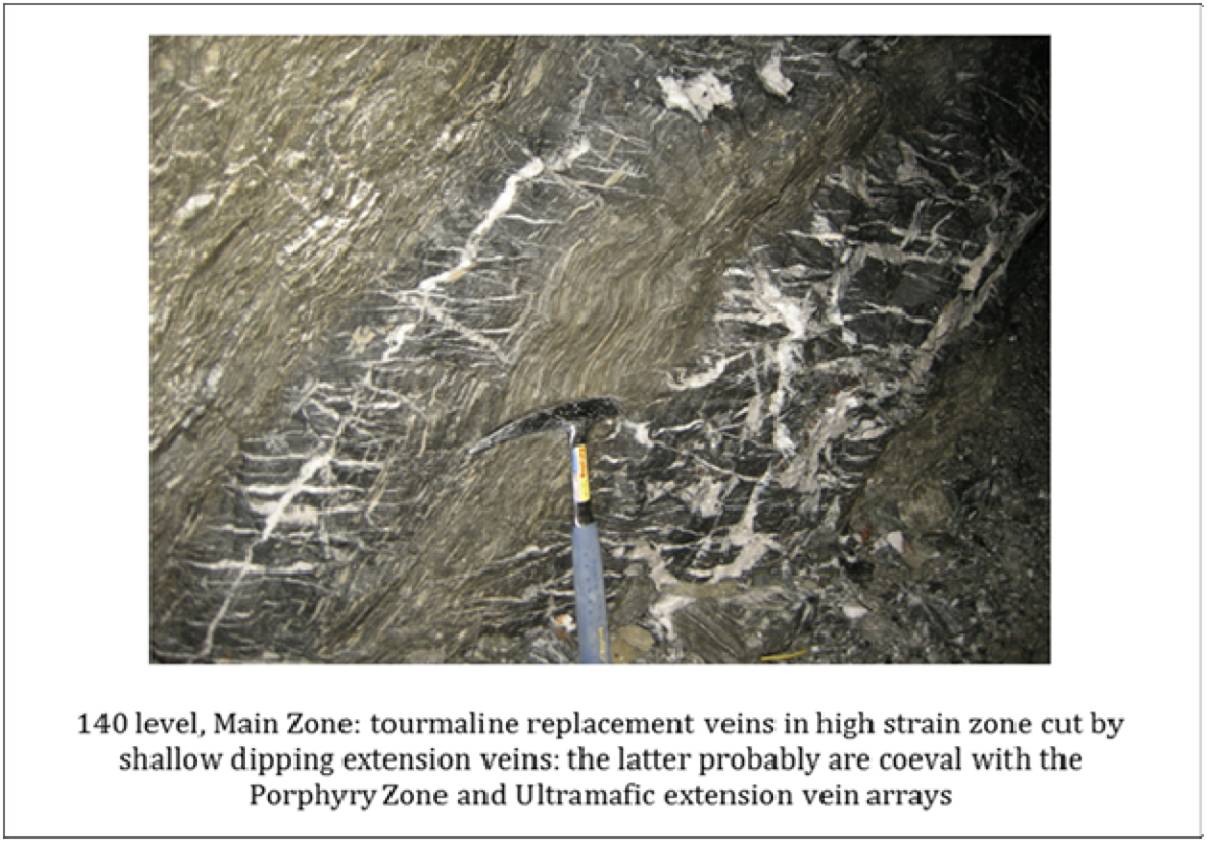

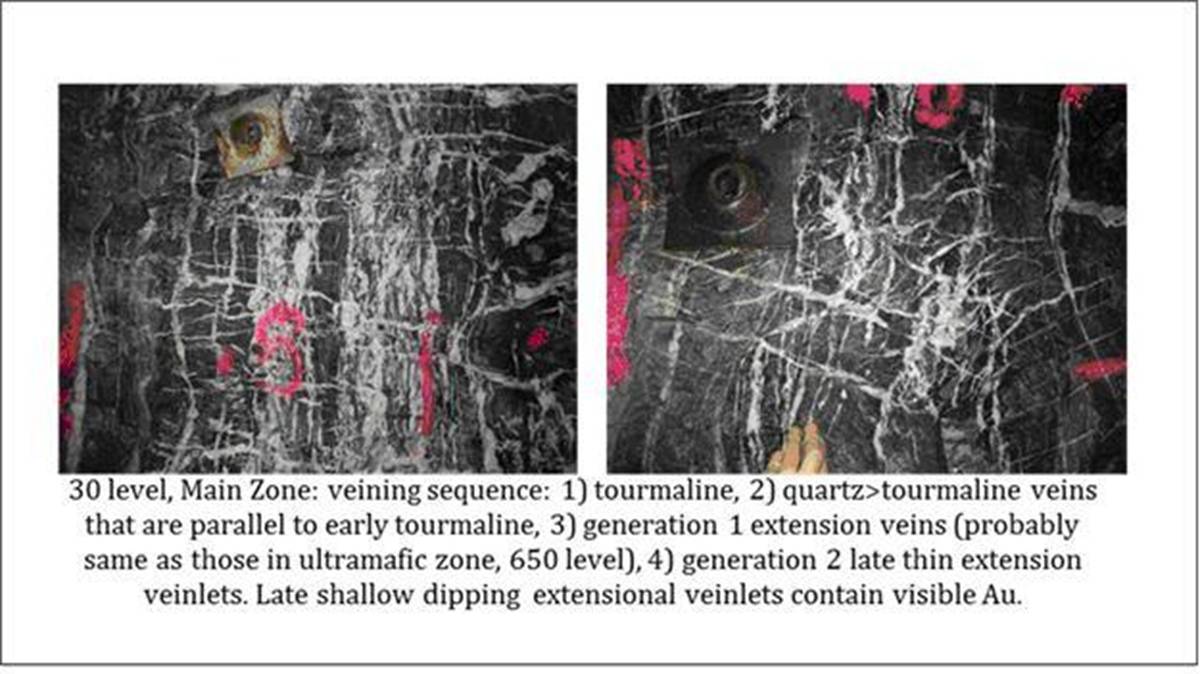

3 | UNDERGROUND PHOTOS OF THE TIMMINS WEST MINE MINERALIZATION AT THUNDER CREEK AND TIMMINS DEPOSITS | |

| | | |

ix

CAUTIONARY NOTE WITH RESPECT TO FORWARD LOOKING INFORMATION

Certain information and statements contained in this report are “forward looking” in nature. All information and statements in this report, other than statements of historical fact, that address events, results, outcomes, or developments that Lake Shore Gold and/or the Qualified Persons who authored this report expect to occur are “forward-looking statements”. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the use of forward-looking terminology such as “plans”, “expects”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates”, “projects”, “potential”, “believes” or variations of such words and phrases or statements that certain actions, events or results “may”, “could”, “would”, “should”, “might” or “will be taken”, “occur” or “be achieved” or the negative connotation of such terms. Forward-looking statements include, but are not limited to, statements with respect to anticipated production rates; grades; projected metallurgical recovery rates; infrastructure, capital, operating and sustaining costs; the projected life-of-mine; proposed development and potential impact on cash flow; estimates of Mineral Reserves and Resources; the future price of gold; government regulations; the maintenance or renewal of any permits or mineral tenures; estimates of reclamation obligations that may be assumed; requirements for additional capital; environmental risks; and general business and economic conditions.

All forward-looking statements in this report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted.

Material assumptions regarding forward-looking statements are discussed in this report, where applicable. In addition to, and subject to, such specific assumptions discussed in more detail elsewhere in this report, the forward-looking statements in this report are subject to the following assumptions: (1) there being no signification disruptions affecting the operation of the mine; (2)��the availability of certain consumables and services, and the prices for diesel, propane, cyanide, electricity and other key supplies being approximately consistent with current levels; (3) labour and materials costs increasing on a basis consistent with current expectations; (4) that all environmental approvals, required permits, licenses and authorizations will continue to be held on the same or similar terms and obtained from the relevant governments and other relevant stakeholders within the expected timelines; (5) no significant changes will be made to tax rates and no new taxes, royalties or other fees will be levied by applicable governments; (6) the timelines for exploration activities will proceed in accordance with estimates; (7) assumptions made in Mineral Resource and Reserve estimates, including geological interpretation, grade, recovery rates, gold prices, foreign exchange rates, and operational and capital costs, will hold true; and (8) general business and economic conditions will remain substantially the same.

Forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements to be materially different from any of the future results, performance or achievements expressed or implied by forward-looking statements. These risks, uncertainties and other factors include, but are not limited to: a decrease in future gold prices; costs of labour, supplies, fuel and equipment rising; adverse changes in anticipated production, including discrepancies between actual and estimated production, Reserves, Resources and recoveries; exchange rate fluctuations; title risks; regulatory risks, and political or economic developments in Canada; changes to tax rates; risks and uncertainties with respect to obtaining necessary permits, land use rights and other tenure from the Crown and private landowners or delays in obtaining same; risks associated with maintaining and renewing permits and complying with permitting requirements, and

x

other risks involved in the gold exploration, development and mining industry; as well as those risk factors discussed elsewhere in this report, in Lake Shore Gold’s latest Annual Information Form, Management’s Discussion and Analysis and its other SEDAR filings from time to time. All forward-looking statements herein are qualified by this cautionary statement.

Accordingly, readers should not place undue reliance on forward-looking statements. Lake Shore Gold and the Qualified Persons who authored this report undertake no obligation to update publicly or otherwise revise any forward-looking statements whether as a result of new information or future events or otherwise, except as may be required by law.

CAUTIONARY NOTE TO U.S. READERS CONCERNING ESTIMATES OF MEASURED, INDICATED, AND INFERRED MINERAL RESOURCES

Information concerning the Timmins West Mine has been prepared in accordance with Canadian standards under applicable Canadian securities laws, and may not be comparable to similar information for United States companies. The terms “Mineral Resource”, “Measured Mineral Resource”, “Indicated Mineral Resource” and “Inferred Mineral Resource” used in this report are Canadian mining terms as defined in accordance with National Instrument 43-101 (NI 43-101) under guidelines set out in the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Standards on Mineral Resources and Mineral Reserves adopted by the CIM Council on November 27, 2010. While the terms “Mineral Resource”, “Measured Mineral Resource”, “Indicated Mineral Resource” and “Inferred Mineral Resource” are recognized and required by Canadian securities regulations, they are not defined terms under the rules and regulations of the United States Securities and Exchange Commission applicable to mining companies. As such, certain information contained in this report concerning descriptions of mineralization and resources under Canadian standards is not comparable to similar information made public by United States companies subject to the reporting and disclosure requirements of the United States Securities and Exchange Commission. An “Inferred Mineral Resource” has a great amount of uncertainty as to its existence and as to its feasibility. It cannot be assumed that all or any part of an “Inferred Mineral Resource” will ever be upgraded to a higher category. Readers are cautioned not to assume that all or any part of an “Inferred Mineral Resource” exists, or is mineable.

xi

1.0 SUMMARY

This Technical Report has been prepared under the direct supervision of Eric Kallio (P. Geo.) and Natasha Vaz (P. Eng.) on behalf of Lake Shore Gold Corp. (LSG) for the Timmins West Mine. Timmins West Mine (TWM) consists of mineralized zones from the Timmins Deposit and Thunder Creek Deposit. The Timmins Deposit has been in commercial production since January 2011, prior to the establishment of TWM. The resource and reserves statements included in this report have an effective date of February 21, 2014.

The purpose of this report is to provide a summary of the total resource pool, current mine infrastructure, the life-of-mine (LOM) plan, and estimated mine capital and operating costs to substantiate an updated Mineral Reserve estimate for TWM. The work completed to support the updated reserves has been conducted on the indicated mineral resource only, with mining, milling, and cost estimating based on actual operating experience at TWM and the Bell Creek Mill.

This revised mineral resource and reserve statement uses data collected by LSG from underground and surface diamond drilling, and underground mapping and sampling from mineralization exposed in mine openings.

Commercial production at the Timmins Deposit was announced in January 2011 and at Thunder Creek in January 2012. As such (and meeting gross revenue criteria), LSG considers this technical report as being issued by a “Producing Issuer” under the definitions of NI 43-101.

The headframe of the Timmins West Mine is located approximately 1.1 kilometres southeast of the intersection of Provincial Highways 101 and 144, approximately 19 kilometres west of the city of Timmins. The highways and a short site access road provide year round road access to the property.

The TWM area includes the Timmins Deposit property and the Thunder Creek Deposit property for a total area of approximately 12.9 square kilometres situated in Bristol and Carscallen Townships. The Timmins Deposit portion consists of a block of 23 contiguous claims (395 hectares) of which there are 21 individual patented claims and 12 leased claims that are further divided into two 21 year leases. The Thunder Creek portion of the property consists of 57 staked claim units and three leasehold single unit patent claims totaling approximately 960 hectares. LSG owns 100% interest in the property subject to underlying royalties. The claims and leases are all in good standing.

The TWM area lies along the northeast trending contact zone between southeast facing mafic metavolcanic rocks of the Tisdale Assemblage (to the northwest) and unconformably overlaying, dominantly southeasterly facing metasedimentary rocks of the Porcupine Assemblage (to the southeast). The contact dips steeply to the northwest, and is modified and locally deflected by folds and shear zones that are associated with gold mineralization.

Gold mineralization occurs in steep north-northwest plunging mineralized zones which plunge parallel to the local orientations of the L4 lineation features. Mineralization occurs within, or in favourable lithostructural settings within 100 metres of the Holmer and Rusk Shear Zones. Mineralization comprises multiple generations of quartz-carbonate-tourmaline ±albite veins, associated with disseminated pyrite alteration envelopes. Textural evidence suggests that veining formed progressively through D3 and D4 deformation. All phases of gold-bearing veins cut and post-date alkali intrusive complex and syenitic to monzonitic intrusions (Rhys, 2010).

1

The TWM is accessed by a production shaft and portal/ramp from surface. Both facilities are located near the Timmins Deposit. Mining at the Timmins Deposit was initiated in the second half of 2009 via the main ramp from surface that had been developed to a depth of 200 vertical metres (while the production shaft was being constructed). Mining started within the Vein Zones, Footwall (FW) Zone, and the Main Zone (MZ). In the upper levels, mining results were largely as anticipated, short strike length, narrow quartz-tourmaline veins that returned low grade and small tonnes with poor continuity of mineralization.

In 2010, mining continued in the MZ and Vein Zones from the ramp between the 140 metre level and the 270 metre level. Mining in the upper part of the Timmins Deposit has been mainly idle since mid-2013. Drilling of the Main and Vein Zones below the 290 Level is limited but shows potential for new zones similar to levels above.

The first stope in the UM1 complex from the 650 metre level (accessed via the production shaft) was mined in the fourth quarter of 2010 and was highly successful. Mining a number of the smaller, structural hangingwall lenses comprising the UM complex (including the UM2 and UM1a) has also proven successful despite smaller size, moderately lower grade, and complex geometry. The positive mining results in the UM mineralization to date is a promising indicator for continued mining at depth.

From 2009 through 2013, 1.25 million tonnes at an average grade of 4.4 grams per tonne Au (176,644 ounces) have been milled from the Timmins Deposit.

Access to the Thunder Creek Deposit was gained by developing ramps from the Timmins Deposit 200 metre level (accessing Thunder Creek Rusk Zone at the 300 metre level) and 650 metre level (accessing Thunder Creek Porphyry Zone at the 730 metre level). The Rusk horizon was intersected in July of 2010 and the Porphyry Zone in November 2010.

From 2010 through 2013, 0.86 million tonnes at an average grade of 4.1 grams per tonne (g/t) Au (114,928 ounces) have been milled from the Thunder Creek Deposit.

LSG has prepared an updated Resource Estimate for the TWM which includes mineralized zones from the Timmins and Thunder Creek Deposits. The report updates the TWM Resources as reported by LSG in March 2013. The estimate for the TWM is based on historical diamond drilling dating back to March 1984 and drilling completed by LSG between July 2003 and the date of databases being closed for the current estimate. The database for the Timmins Deposit was closed November 26, 2013 and the database was for Thunder Creek was closed January 8, 2014. A total of 1,158 drill holes (totaling 215,997 metres) were used to estimate resources for the Timmins Deposit, with 670 holes (120,053 metres) used in the Thunder Creek Estimate.

The Timmins West Mine Resource totals 4.36 Mt at 5.09 g/t Au, amounting to 714,633 ounces of gold in the Indicated category and 2.94 Mt at 5.46 g/t Au amounting to 516,339ounces of gold in the Inferred category. Subdivision of the resource into the Timmins Deposit and the Thunder Creek Deposit is shown in Table 1.1.

Resources are centered on 9700E (4425E mine grid) section and extend from 9900 to 8670 elevation (115 to 1,345 metres below surface) for the Timmins Deposit and are centered on 9550N (4675E mine grid) section extending from 9820 to 8980 elevation (190 to 1,040 metres below surface) for the Thunder Creek Deposit. The Mineral Resource for the Timmins Deposit has been modeled into 51

2

sub-zones which refine the broader mineralized Ultramafic, Footwall, and Vein Zones. The Thunder Creek Deposit has been modeled into 18 sub-zones which refine the broader Rusk and Porphyry Zones.

Resources were estimated using Inverse Distance Squared (ID2) grade interpolation with an anisotropic search. All gold assays were capped with capping limits varying between 50 and 90 g/t by zone. A minimum mining width of 2 metres was assumed and only samples within a mineralized zone were used for estimation of the zone. A weighted average gold price of $1,150 per ounce was assumed which compares to the weighted average gold price of $1,500 per ounce used in the March 2013 resource and reserve update.

The mineralized zones defined and used for estimation of resources are focused on material grading 3.0 g/t with lower grade material included for internal continuity. For the purposes of this report, a base case using a cut-off grade of 1.5 g/t Au is reported in order to maintain continuity within each zone.

The in-situ TWM resource using 1.5 g/t and 3.0 g/t in-situ Cut-Off Grades (COG) are summarized in Table 1.1 and Table 1.2.

TABLE 1.1: TWM RESOURCE ESTIMATE AT 1.5 G/T IN-SITU COG

Deposit | | Resource

Classification | | Tonnes | | Capped Grade

(g/t Au) | | Contained Gold

(ounces) | |

Timmins Deposit | | Indicated | | 1,893,497 | | 5.2 | | 314,153 | |

| | Inferred | | 2,075,079 | | 5.7 | | 378,516 | |

| | Subtotal | | 3,968,576 | | 5.4 | | 692,669 | |

| | | | | | | | | |

Thunder Creek Deposit | | Indicated | | 2,470,674 | | 5.0 | | 400,480 | |

| | Inferred | | 863,633 | | 5.0 | | 137,823 | |

| | Subtotal | | 3,334,307 | | 5.0 | | 538,303 | |

| | | | | | | | | |

Total TWM | | Indicated | | 4,364,171 | | 5.1 | | 714,633 | |

| | Inferred | | 2,938,712 | | 5.5 | | 516,339 | |

| | Total | | 7,302,883 | | 5.2 | | 1,230,972 | |

Notes:

1. Sums may not add due to rounding.

2. CIM definitions were followed for classification of Mineral Resources.

3. Capped gold grades are used in estimating the Mineral Resource average grade.

4. A minimum mining width of 2 metres was used.

5. The estimate includes low grade material which is not in the current mine plan.

6. Mineral Resources are reported at a cut-off grade of 1.5 g/t and include internal dilution to maintain zone continuity.

7. Weighted average gold price was assumed at $1,150 per ounce (approximately US$1,100).

8. Metallurgical recoveries are assumed to average 96.5 percent.

3

TABLE 1.2: TWM RESOURCE ESTIMATES AT 3.0 G/T IN-SITU COG

Deposit | | Resource

Classification | | Tonnes | | Capped Grade

(g/t Au) | | Contained Gold

(ounces) | |

Timmins Deposit | | Indicated | | 1,242,932 | | 6.7 | | 267,417 | |

| | Inferred | | 1,475,976 | | 7.1 | | 335,427 | |

| | Subtotal | | 2,718,908 | | 6.9 | | 602,844 | |

| | | | | | | | | |

Thunder Creek Deposit | | Indicated | | 1,641,057 | | 6.5 | | 341,326 | |

| | Inferred | | 597,382 | | 6.2 | | 118,967 | |

| | Subtotal | | 2,238,439 | | 6.4 | | 460,293 | |

| | | | | | | | | |

Total TWM | | Indicated | | 2,883,989 | | 6.6 | | 608,743 | |

| | Inferred | | 2,073,358 | | 6.8 | | 454,394 | |

| | Total | | 4,957,347 | | 6.7 | | 1,063,137 | |

Notes:

1. Sums may not add due to rounding.

2. �� CIM definitions were followed for classification of Mineral Resources.

3. Capped gold grades are used in estimating the Mineral Resource average grade.

4. A minimum mining width of 2 metres was used.

5. The estimate includes low grade material which is not in the current mine plan.

6. Weighted average gold price was assumed at $1,150 per ounce (approximately US$1,100).

7. Metallurgical recoveries are assumed to average 96.5 percent.

The drilling, development and mining completed since the last resource/reserve update in March 2013, indicates a significant decrease in resource and reserve ounces. The decrease results from a number of factors including mining depletion, a lack of new exploration drilling over the past two years, and a reduction in the assumed average weighted gold price ($1,150 per ounce versus $1,500 per ounce in the March 2013 update). The decrease also reflects the results of extensive definition drilling which have indicated lower grades and changes in the interpretation in the geology in some areas. The effect of the lower grades is changes to resource shapes and the removal of certain low grade sections of the new models. The estimate also reflects the removal of zones from the resource model which are considered unmineable or uneconomic as well as the use of more conservative projection of grades, especially near zone boundaries.

Subsequent to the closing of the Timmins Mine and Thunder Creek databases, additional drilling was completed. This drilling is not likely to have a significant effect on the overall resource reported.

A review of the QA/QC samples routinely introduced into the drill hole sample stream, has concluded that the quality of the assaying introduced into the block model is satisfactory demonstrating no significant bias and adequate precision and reproducibility.

Several steps were taken in order to review and validate the current block model and reported results which included: comparison of solid model and block model volumes, comparison of the block model against diamond drill results, checking with nearest neighbor estimates, and comparison with recent production data.

4

Volumes of the individual solids were compared to volumes from the block model for the same domain to ensure proper coding of the model. No significant variances were encountered. Plans and sections were cut through the block model and Resource solids to view overall trends and patterns as well as compare block grades and grade distribution to the drill-hole data. Results of the review indicate a pattern for block grades which is consistent with drill hole assays but more patchy than was evident in previous block models which were based on wider spaced drilling.

A review of the resource model was also carried out by SGS Canada and no issues were identified with the resource estimation.

Sensitivities to cut-off were run at 0.50 g/t increments of gold grade from 0.00 g/t to 7.00 g/t and are summarized for unclassified resources. At the higher cut-offs, the zones become patchy and less continuous, which implies a bulk mining method could be the best approach for ore extraction. The base case resource stated at a cut-off grade of 1.5 g/t attempts to introduce some level of selectivity to the mining of the resource, yet maintains continuity of the zone. Recent work indicates that the sensitivity to cut-off grade varies between zones.

All ore mined from TWM has been, and will continue to be processed at LSG’s Bell Creek Mill. The Bell Creek Mill is located approximately 6.5 kilometres north of Highway 101 in South Porcupine, Ontario. TWM ore is loaded into surface haul trucks at TWM and hauled to the mill (approximately 56 kilometres one-way). The Bell Creek Mill is a conventional gold processing plant utilizing cyanidation with gravity and CIP recovery. Mill throughput is over 3,000 tonnes per day and recovery is approximately 96% for TWM ore.

Previous technical reports issued for the TWM (combined Timmins Deposit and Thunder Creek Deposit) include a preliminary economic assessment (PEA) completed in March 2012, “43-101 Technical Report, Preliminary Economic Assessment and Updated Mineral Resource Estimate for Timmins West Mine Timmins, Ontario, Canada, prepared by Dean Crick, (P. Geo.), Ralph Kock (P. Geo.), Robert Kusins (P. Geo.), Brian Buss (P. Eng.) and David Powers (P. Geo.) on behalf of Lake Shore Gold Corp., March 29, 2012”, and a pre-feasibility study (PFS) completed in May 2012, “43-101 Technical Report, Pre-feasibility Study and Mineral Reserve Estimate for Timmins West Mine, Timmins, Ontario, Canada, prepared by Dean Crick (P. Geo.), Ralph Koch (P. Geo.), Robert Kusins (P. Geo.), David Powers (P. Geo.), Brian Buss (P. Eng.) May 14, 2012”. The mine design used for the updated reserve estimate has been based on concepts presented in the PFS, existing surface and underground infrastructure, and operating experience gained since commercial production commenced in 2011. The majority of the main mine infrastructure (surface and underground) is in place, most equipment has been purchased, and the Bell Creek Mill expansion project has been completed to meet current production requirements. TWM successfully uses the longhole mining method which is commonly used worldwide for deposits with similar geometry and conditions. The operation also uses common, proven mining equipment and has experienced management and mine operations personnel. The Timmins area has a significant, well-established mining service/supply industry to support the operation.

Through three years of operating experience, TWM has implemented the systems and programs (i.e. health and safety, environment, training, maintenance, operating procedures, etc.) necessary to sustain production. This experience has also provided a solid basis for estimating the capital and operating costs used in preparation of the LOM plan.

5

To estimate the reserves, the following steps (summarized at a high level) were used by mine planning personnel. The indicated resources were isolated (from Inferred material) from the resource models and assessments were made of the geometry and continuity of each of the mineralized zones. Geotechnical evaluations completed over the last three years were taken into account in the assessment and assignment of appropriate mining methods and stope sizes. Individual stope designs (wireframes) were then created in three dimensions. These stope wireframes were queried against the block models to determine the in-situ resource. This allowed for fair inclusion of internal dilution from both low grade and barren material. Additional factors were assigned for external dilution (with or without grade) dependent on the specific mining method and geometry of each stoping unit being evaluated. Finally, a recovery factor was assigned to the overall reserves to allow for in-stope and mining process losses. Stope cut-off grades were estimated to determine which stopes to include in the reserves. Detailed mine development layouts and construction activities were assigned to provide access to each of the stoping units. A detailed LOM development and production schedule was prepared to estimate the annual tonnes, average grade, and ounces mined to surface. Development, construction, and production costs were estimated to allow an economic assessment to be made comparing the capital and operating expenses required for each area to the expected revenue stream to ensure economic viability.

It should be noted that all capital costs required for all surface and underground facilities at TWM and the Bell Creek Mill facility have been included in the LOM plan. It should also be noted that no contributions from the Bell Creek mining operations (positive or negative) have been considered.

The estimated reserves (diluted and recovered) are summarized in Table 1.3.

TABLE 1.3: TWM ESTIMATED RESERVES

Deposit | | Tonnes | | Grade

(g/t) | | Ounces | |

Timmins Deposit | | 1,540,344 | | 4.6 | | 227,707 | |

Thunder creek Deposit | | 1,791,821 | | 4.6 | | 264,539 | |

TWM Total Reserves Mined to Surface | | 3,332,164 | | 4.6 | | 492,246 | |

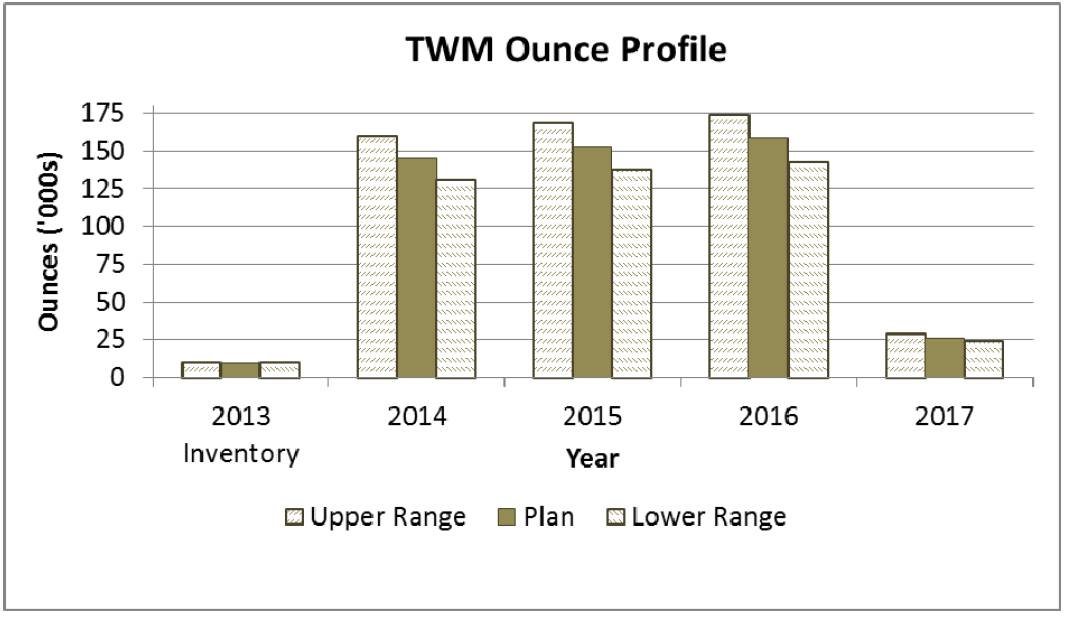

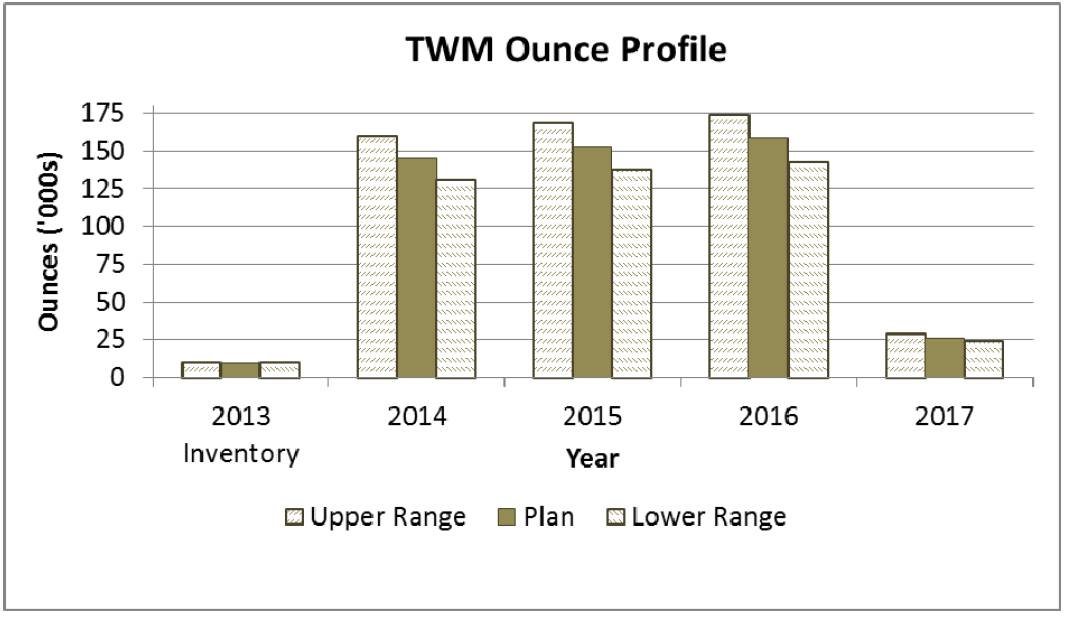

Production will average 2,800 tonnes per day from 2014 through 2016 before ramping down and ending in Q3 2017. The production profile is summarized in Table 1.4.

TABLE 1.4: ESTIMATED LOM PRODUCTION PROFILE

Item | | 2013

Year-End

Inventory | | 2014 | | 2015 | | 2016 | | 2017

(Q3) | | Total | |

Tonnes | | 59,853 | | 955,774 | | 1,056,244 | | 1,053,338 | | 206,955 | | 3,332,164 | |

Average TPD | | | | 2,618 | | 2,894 | | 2,886 | | | | | |

Average Grade | | 5.0 | | 4.7 | | 4.5 | | 4.7 | | 4.0 | | 4.6 | |

Ounces — Upper Range | | | | 159,500 | | 168,400 | | 174,000 | | 29,100 | | | |

Ounces — LOM Plan | | 9,603 | | 144,993 | | 153,087 | | 158,123 | | 26,440 | | 492,246 | |

Ounces — Lower Range | | | | 130,500 | | 137,800 | | 142,400 | | 23,800 | | | |

Annual ounce production is presented as a range (Upper and Lower). The range is based on ±10% variance from the LOM plan to reflect potential differences in the combination of stopes that may be mined during each year.

6

The estimated capital and operating costs have been based on operating experience at TWM and the Bell Creek Mill. The costs for 2014 have been developed through the TWM 2014 annual budget exercise and the costs from 2015 through 2017 comprise the remaining LOM plan. The estimated LOM capital and operating costs are summarized in Table 1.5.

TABLE 1.5: ESTIMATED LOM CAPITAL AND OPERATING COSTS

Cost Item | | Total Costs

(millions) | | Cost per Tonne | |

Capital Cost | | $ | 93.8 | | $ | 28.1/tonne | |

Operating Cost | | $ | 330.1 | | $ | 99.1/tonne | |

The costs and productivities used as the basis for estimating the reserves have been based on actual performance metrics of the operation in 2011 through 2013. These factors are considered low risk to the reserve estimate. In addition, social, political, and environmental factors are all considered to be low risk factors for the continued operation of TWM and to the reserves estimate.

Successful mining will be highly dependent on the timely completion of drilling to support both delineation and exploration. A list of some of the key targets to be tested as well as a reasonable cost estimate to complete is provided below:

Timmins Deposit (Total Cost Estimates $9.4 million, Total 74,300 metres of Drilling)

1. Delineation between 810 metre and 900 metre levels -39,300 metres, $4,205,100 (@$107/metre)

2. Exploration below 900 metre level — 5,000 metres, $535,000 (@$107/metre)

3. Exploration from 790 S2 fold nose Exploration Drift - 12,000 metres, $1,080,000 (@$90/metre)

4. Exploration from 830 metre level drill drift to test favorable Ultramafic/Mafic and Sediment contact between Timmins Mine and Thunder Creek -8,000 metres, $720,000 (@$90/metre)

5. Exploration surface drilling to test the deep extension of the Timmins Mine resource below the 1,340 metre level — 5,000 metres, $2,250,000 (@$450/metre).

6. Exploration surface drilling to the northeast of the Timmins Mine Deposit — 5,000 metres, $625,000 (@$125/metre).

Thunder Creek (Total Cost Estimate $4.2 million, Total 38,000 metres of Drilling)

1. Delineation drilling Rusk and Porphyry Zones between 660 and 520 metre level — 11,000 metres, $1,177,000 (@$107/metre).

2. Delineation drilling Rusk and Porphyry Zones above 520 metre level —4,000 metres, $428,000 (@$107/metre).

3. Delineation drilling Rusk and Porphyry Zones between 765 and 1,030 metre level — 10,000 metres, $1,070,000 (@$107/metre).

4. Exploration drilling west Thunder Creek Deposit from 710 metre level Exploration Drift — 3,000 metres, $321,000 (@$107/metre).

5. Exploration drilling west Thunder Creek Deposit from Surface — 10,000 metres, $1,250,000 (@$125/metre).

In addition to the above, closer spaced definition drilling for mining design will be locally required as mining is progressing.

7

2.0 INTRODUCTION

This Timmins West Mine Technical Report has been prepared under the supervision of Eric Kallio (P. Geo.) and Natasha Vaz (P. Eng.) on behalf of Lake Shore Gold Corp. and conforms to NI 43-101 Standards of Disclosure for Mineral Projects. These individuals are considered Qualified Persons under 43-101 definitions.

Lake Shore Gold Corp. (LSG) is a publicly traded company listed on the Toronto Stock Exchange and trading under the symbol LSG. LSG has a head office at 181 University Avenue, Suite 2000, Toronto, Ontario, Canada M5H 3M7. LSG was founded in 2002 to explore for precious and base metals hosted within the portions of the Canadian Shield situated in Quebec and Ontario.

The authors have prepared this report using a combination of publicly available and confidential information. This report is sourced from an amalgamation of several reports listed in Item 27.

The purpose of this report is to provide a summary of the total resource pool, current mine infrastructure, the life-of-mine (LOM) plan, and estimated mine capital and operating costs to substantiate an updated Mineral Reserve estimate for TWM. The work completed to support the updated reserves has been conducted on the indicated mineral resource only, with mining, milling, and cost estimating based on actual operating experience at TWM and the Bell Creek Mill.

Historical work in the TWM area was reviewed by referencing assessment reports filed at the Ministry of Northern Development and Mines’ office at the Ontario Government Complex, Highway 101 East, Timmins (Porcupine), Ontario; and the online Assessment File Research Imaging. Option and legal agreements were reviewed at the LSG Exploration Office.

2.1 LIST OF QUALIFIED PERSONS

Natasha Vaz (P. Eng.), VP of Technical Services for LSG is responsible for Items 1, 2, 3, 4, 13, 15, 16, 17, 18, 19, 20, 21, 22, 24, 25, 26, 27, 28, and 29.

Eric Kallio (P. Geo.), VP of Exploration for LSG is responsible for Items: 5, 6, 7, 8, 9, 10, 11, 12, 14, and 23, and parts of Items 1, 2, 3, 4, 24, 25, 26, and 27.

The Qualified Persons listed above are full time employees of LSG. These individuals are intimately aware of the work going on at the Timmins West Mine and have visited the site on numerous occasions.

2.2 UNITS AND CURRENCY

Metric and Imperial units are used throughout this report. Canadian dollars is the currency used unless otherwise noted.

Common conversions used included converting one ounce of gold to grams gold with a factor of 31.104 grams/troy ounce; and one ounce gold per ton with a conversion factor of 34.29 grams gold per tonne.

8

2.3 LIST OF ABBREVIATIONS

Table 2.1 lists the common abbreviations that may be used in the report.

TABLE 2.1: LIST OF ABBREVIATIONS

Unit or Term | | Abbreviation or Symbol |

Above mean sea level | | amsl |

Advanced Exploration Project | | AEP |

Atomic Absorption | | AA |

Arsenic | | As |

Arsenopyrite | | aspy |

Azimuth | | AZ |

Billion years ago | | Ga |

British thermal unit | | Btu |

Carbon in leach | | CIL |

Carbon in pulp | | CIP |

Centimetre | | cm |

Copper | | Cu |

Cubic centimetre | | cm³ |

Cubic feet per second | | ft³/s, cfs |

Cubic foot | | ft³ |

Cubic inch | | in3 |

Cubic metre | | m³ |

Cubic yard | | yd³ |

Day | | d |

Days per week | | d/wk |

Days per year (annum) | | d/a |

Dead weight tonnes | | DWT |

Degree | | ° |

Degree Celsius | | °C |

Degrees Fahrenheit | | °F |

Diamond bore hole | | dbh, DBH |

Diamond drill hole | | ddh, DDH |

Dollars Canadian | | $C |

Dry metric ton | | dmt |

Foot | | ft |

Gallon | | gal |

Gallon per minute | | gpm |

Gold | | Au |

Gold equivalent grade | | AuEq |

Gram | | g |

Gram metres | | m.g/t |

Grams per litre | | g/l |

9

Unit or Term | | Abbreviation or Symbol |

Grams per tonne | | g/t, gpt |

Greater than | | > |

Hectare (10,000m²) | | ha |

Hour | | h (not hr) |

Inch | | in, “ |

Kilo (1,000) | | k |

Kilogram | | kg |

Kilograms per cubic metre | | kg/m³ |

Kilograms per hour | | kg/h |

Kilograms per square metre | | kg/m² |

Kilometre | | km |

Kilometres per hour | | km/h |

Less than | | < |

Lead | | Pb |

Life-of-mine | | LoM |

Litre | | L |

Litres per minute | | L/m |

Metre | | M |

Metres above sea level | | masl |

Metres per minute | | m/min |

Metres per second | | m/s |

Metric ton (tonne) (2,000 kg) (2,204.6 pounds) | | t |

Micrometre (micron) | | µm |

Miles per hour | | mph |

Milligram | | mg |

Milligrams per litre | | mg/L |

Milliliter | | mL |

Millimetre | | mm |

Million | | M |

Million grams | | M g |

Million tonnes | | Mt |

Million Troy ounces | | M oz |

Million Years | | Ma |

Minute (plane angle) | | min, ‘ |

Minute (time) | | min |

Month | | mo |

National Instrument 43-101 (Canadian) | | NI 43-101 |

No Personal Liability | | N.P.L. |

Ounces | | oz |

Page | | p, pg |

Parts per billion | | ppb |

Parts per million | | ppm |

10

Unit or Term | | Abbreviation or Symbol |

Percent | | % |

Percent moisture (relative humidity) | | % RH |

Potassium | | K |

Pound(s) | | lb |

Pounds per square inch | | psi |

Preliminary Economic Assessment | | PEA |

Pyrite | | py |

Pyrrhotite | | po |

Quality Assurance/Quality Control | | QA/QC |

Quart | | qt |

Revolutions per minute | | rpm |

Rock Quality Description | | RQD |

Second (plane angle) | | sec, “ |

Second (time) | | s |

Short ton (2,000 lb) | | st |

Short ton (US) | | t (US) |

Short tons per day (US) | | tpd (US) |

Short tons per hour (US) | | tph (US) |

Short tons per year (US) | | tpy (US) |

Silver | | Ag |

Sodium | | Na |

Specific gravity | | SG |

Square centimetre | | cm² |

Square foot | | ft² |

Square inch | | in² |

Square kilometre | | km² |

Square metre | | m² |

Thousand tonnes | | kt |

Tonne (1,000 kg) | | t |

Tonnes per day | | t/d, tpd |

Tonnes per hour | | t/h |

Tonnes per year | | t/a |

Volt | | V |

Week | | wk |

Weight/weight | | w/w |

Wet metric ton | | wmt |

Yard | | yd |

Year (annum) | | a |

Year (US) | | yr |

11

2.4 DEFINITIONS

The following definitions of Mineral Resources and Mineral Reserves have been prepared by the CIM Standing Committee on Reserve Definitions and Adopted by the CIM Council on November 27, 2010.

2.4.1 Mineral Resource

Mineral Resources are sub-divided, in order of increasing geological confidence, into Inferred, Indicated and Measured categories. An Inferred Mineral Resource has a lower level of confidence than that applied to an Indicated Mineral Resource which has a lower level of confidence than a Measured Mineral Resource.

A “Mineral Resource” is a concentration or occurrence of diamonds, natural solid inorganic material, or natural solid fossilized organic material including base and precious metals, coal, and industrial minerals in or on the Earth’s crust in such form and quantity and of such a grade or quality that it has a reasonable prospect for economic extraction. The location, quantity, grade, geological characteristics, and continuity of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge.

2.4.2 Inferred Mineral Resource

An “Inferred Mineral Resource” is that part of a Mineral Resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified geological and grade continuity. The estimate is based on limited information and sampling gathering through appropriate techniques from locations such as outcrops, trenches, pits, workings, and drill holes.

2.4.3 Indicated Mineral Resource

An “Indicated Mineral Resource” is the part of the Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings, and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed.

2.4.4 Measured Mineral Resource

A “Measured Mineral Resource” is the part of the Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate applications of technical and economic parameters, to support production planning and evaluation for the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits workings and drill holes that are spaced closely enough to confirm both geological and grade continuity.

12

2.4.5 Mineral Reserve

Mineral Reserves are sub-divided in order of increasing confidence into Probable Mineral Reserves and Proven Mineral Reserves. A Probable Mineral Reserve has a lower level of confidence than a Proven Mineral Reserve.

A Mineral Reserve is the economically mineable part of the Measured or Indicated Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A Mineral Reserve includes diluting minerals and allowances for losses that may occur when the material is mined.

2.4.6 Probable Mineral Reserve

A “Probable Mineral Reserve” is the economically mineable part of an Indicated and, in some circumstances, a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing metallurgical, economic and other relevant factors that demonstrate, at the time of reporting that economic extraction can be justified.

2.4.7 Proven Mineral Reserve

A “Proven Mineral Reserve” is the economically mineable part of a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, the economic extraction is justified.

2.5 GLOSSARY

2.5.1 General Glossary

Table 2.2 is a summary table of common technical words accompanied by a simple explanation of the term or word as the term pertains to this report.

TABLE 2.2: GLOSSARY

Term | | Explanation |

Assay | | The chemical analysis of mineral samples to determine the metal content. |

Capital Expenditure | | All other expenditures not classified as operating costs. |

Composite | | Combining more than one sample result to give an average result over a larger distance. |

Concentrate | | A metal-rich product resulting from a mineral enrichment process such as gravity concentration or floatation, in which most of the desired mineral has been separated from waste material in the ore. |

Crushing | | Initial process of reducing ore particle size to render it more amenable for further processing. |

Cut-off Grade (CoG) | | The grade of mineralized rock, which determines whether or not it is economic to recover its gold content by further concentration. |

Dilution | | Unwanted waste, which is mined with ore. |

Dip | | Angle of inclination of a geological feature / rock from the horizontal. |

Fault | | The surface of a fracture along which movement has occurred. |

13

Term | | Explanation |

Footwall | | The underlying side of an orebody or stope. |

Gangue | | Non-valuable components of the ore. |

Grade | | The measure of concentration of “gold” within mineralized rock. |

Hangingwall | | The overlying side of an orebody or stope. |

Haulage | | A horizontal underground excavation which is used to transport mined material. |

Igneous | | Primary crystalline rock formed by the solidification of magma. |

Level | | Horizontal tunnel with the primary purpose to transport personnel and materials. |

Lithological | | Geological description pertaining to different rock types. |

LoM Plans | | Life-of-mine plans. |

Material Properties | | Mining properties. |

Metamorphism | | Process by which consolidated rock is altered in composition, texture, or internal structure by conditions and forces of heat and pressure. |

Milling | | A general term used to describe the process in which the ore is crushed, ground and subjected to physical or chemical treatment to extract the valuable metals to a concentrate or finished product. |

Mineral/Mining Lease | | A lease area for which mineral rights are held. |

Mining Asset | | Material Properties and Significant Exploration Properties. |

Ongoing Capital | | Capital estimates of a routine nature, which is necessary for sustaining operations. |

Ore Reserve | | See Mineral Reserve |

RoM | | Run of Mine |

Sedimentary | | Pertaining to rocks formed by the accumulation of sediments, formed by the erosion of other rocks. |

Shaft | | An opening cut downwards from the surface for transporting personnel, equipment, supplies, ore and waste. |

Smelting | | A high temperature pyrometallurgical operation conducted in a furnace, in which the valuable metal is collected to a molten matte or doré phase and separated from gangue components that accumulate in a less dense molten slag phase. |

Stope | | Underground void created by mining. |

Stratigraphy | | The study of stratified rocks in terms of time and space. |

Strike | | Direction of line formed by the intersection of strata surfaces with the horizontal plane, always perpendicular to the dip direction. |

Sulphide | | A sulphur bearing mineral. |

Tailings | | Finely ground waste rock from which valuable minerals or metals have been extracted. |

Thickening | | The process of concentrating solid particles in suspension. |

Total Expenditure | | All expenditures including those of an operation and capital nature. |

14

2.5.2 Lake Shore Gold Terminology

Timmins West Complex: | | The Company’s entire land package on the west side of the city, Extending through Bristol, Thorneloe, Carscallen, Denton townships. |

| | |

Timmins West Mine: | | The combined areas that are currently being mined using the shared Infrastructure, namely the Timmins Deposit and the Thunder Creek Deposit. |

| | |

Timmins Deposit: | | The deposit formerly known as the Timmins Mine (now one of two deposits comprising the Timmins West Mine). |

| | |

Thunder Creek Deposit: | | The second deposit being mined in the Timmins West Mine. |

15

3.0 RELIANCE ON OTHER EXPERTS

The authors have sourced the information for this technical report from an amalgamation of several reports listed in Item 27. These references include government geological reports, press releases, company annual reports, assessment reports filed with the Ministry of Northern Development and Mines, previously filed NI 43-101 Technical Reports (SEDAR), and reports both public and confidential provided by LSG.

Exploration at the Timmins West Mine has continuously been overseen, and planned by professional geologists and qualified persons (QPs). Table 3.1 summarizes the names of the QPs and the dates that they supervised the exploration and advanced exploration activities.

TABLE 3.1: QUALIFIED PERSONS FOR TIMMINS WEST MINE

Location | | Period | | Qualified Person |

Timmins Deposit | | 2003 — 2004 | | Jacques Samson, P. Geo. |

| | 2005 — 2006 | | Dr. M.J. Byron, P. Geo. |

| | 2006 — 2009 | | Jacques Samson, P. Geo. |

| | 2009 | | Heather Miree, P. Geo. |

| | 2009 | | Stephen Conquer, P. Geo. |

| | August 2010 - May 2013 | | Dean Crick, P. Geo. |

| | May 2013 - present | | Eric Kallio, P. Geo. |

Thunder Creek Deposit | | 2003 — 2009 | | Jacques Samson, P. Geo. |

| | 2005 — 2006 | | Dr. M.J. Byron, P. Geo. |

| | 2006 — 2009 | | Jacques Samson, P. Geo. |

| | 2009 — March 2010 | | Pat Pope, P. Geo. |

| | 2009 — August 2010 | | Stephen Conquer, P. Geo. |

| | August 2010 — May 2013 | | Dean Crick, P. Geo. |

| | May 2013 - present | | Eric Kallio, P. Geo. |

From 2003 to the present, contributions to geology by outside consultants include petrography, ore microscopy and scanning electron microscope investigations by Dr. Miller of Miller and Associates of Ottawa, mineralization and structural studies comparing Thunder Creek and the Timmins Mine by Mr. David Rhys, of Panterra Geoservices Inc., petrology studies of the Timmins Mine and Thunder Creek area by Katherina Ross, Panterra Geoservices, and geological mapping of a 5 square kilometre area surrounding the Rusk surface showing by Mr. John Camier, P. Geo. Mr. Camier’s report includes petrographic analysis thin sections examined by Mr. Camier and Dr. Bob Springer, Professor Emeritus at Brandon University, Manitoba.

Several reports have been submitted to SEDAR describing in detail and outlining the exploration history of the Timmins Mine Complex (formerly known as the Timmins West Gold Project and the Holmer Mine Property) as well as the Thunder Creek Property. The reader is invited to review the detailed summaries and source material outlined in the following documents:

2002: Holmer Gold Mines Limited, Annual Information Form.

2003: Holmer Gold Mines Limited, Annual Information Form.

16

2004: A Technical Review of Holmer Gold Property, In Bristol Township, Timmins Area, Ontario, Canada for Lake Shore Gold Corp. prepared by E. Neczkar, M.W. Kociumbas, J.R. Sullivan September 07, 2004, Watts, Griffis and McQuat Limited.

2004: National Instrument 43-101 Technical Report, Timmins Gold Project, Timmins, Ontario, Lake Shore Gold Corp., L.D.S. Winter September 24, 2004.

2004: National Instrument 43-101 Technical Report, Timmins Gold Project, Timmins, Ontario, Lake Shore Gold Corp., L.D.S. Winter November 26, 2004.

2006: National Instrument 43-101 Technical Report, Timmins West Gold Project, Timmins, Ontario, Lake Shore Gold Corp., L.D.S. Winter January 25, 2006.

2007: A Technical Review of the Timmins West Gold Project In Bristol Township, Timmins Area, Ontario, for Lake Shore Gold Corp., J.R. Sullivan, J.G. Lavigne, M.W. Kociumbas, January 03, 2007, Watts, Griffis and McQuat Limited.

2007: National Instrument 43-101 Technical Report, Lake Shore Gold Corp. Timmins West Project, Timmins, Ontario, G. Darling et al. SRK Consulting, October 12, 2007.

2008: Technical Report of the Thunder Creek Gold Property, Bristol township, Timmins, Ontario, Canada, D. Wagner, June 27, 2008.

2009: Updated NI 43-101 Technical Report on the Timmins Mine Property, Ontario, Canada, prepared for Lake Shore Gold Corp., G. Darling et al. October 01, 2009.

2009: Amended Technical Review and Report of the “Thunder Creek Property” Bristol And Carscallen Townships, Porcupine Mining Division, Ontario, Canada prepared for Lake Shore Gold Corp. and West Timmins Mining Inc. July 29, 2009.

2011: Technical Report on the Initial Mineral Resource Estimate for the Thunder Creek Property Bristol Township, West of Timmins, Ontario, Canada, Prepared for Lake Shore Gold Corp. and West Timmins Mining Inc., D. Crick, R. Kusins, D. Powers, December 23, 2011.

2012: 43-101 Technical Report, Preliminary Economic Assessment and Updated Mineral Resource Estimate for Timmins West Mine Timmins, Ontario, Canada, prepared by Dean Crick, (P. Geo.), Ralph Kock (P. Geo.), Robert Kusins (P. Geo.), Brian Buss (P. Eng.) and David Powers (P. Geo.) on behalf of Lake Shore Gold Corp., March 29, 2012.

2012: 43-101 Technical Report, Pre-feasibility Study and Mineral Reserve Estimate for Timmins West Mine, Timmins, Ontario, Canada, prepared by Dean Crick (P. Geo.), Ralph Koch (P. Geo.), Robert Kusins (P. Geo.), David Powers (P. Geo.), Brian Buss (P. Eng.). May 14, 2012.

The authors rely on the professional integrity of the designated project QPs to maintain and provide true and accurate reporting of the facts throughout the project history. Where possible, the internal documents have been checked against public record filed for assessment purposes.

The authors have also relied on internal experts within the organization for input to certain sections of this report. The authors have reviewed and endorsed the contributions of these experts.

Marcel Cardinal, Manager of Environmental Affairs, Lake Shore Gold Corp. contributed to Items 4 and 20.

Dave Felsher, Chief Mineral Processing Engineer, Lake Shore Gold Corp. contributed to Items 13 and 17.

Keith Green, P. Geo., an employee of Lake Shore Gold Corp., contributed to Items 4, 5, 7, 8, 23, 25, and 26 and to Appendix 1.

17

Jacques Samson, P. Geo., an employee of Lake Shore Gold Corp., contributed to Items 6, 9, 10, 11, and 12.

Ralp Koch, P. Geo., an employee of Lake Shore Gold Corp., contributed to Item 14.

The authors have also relied on external experts for input to certain sections of this report. The authors have reviewed and endorsed the contributions of these experts.

Kathy Kalenchuk, Ph.D. of Mine Design Engineering (Sr. Geomechanics Consultant) contributed to Item 16.

Guy Desharnais, PhD, P. Geo., Technical Manager of Geological Services SGS Canada, contributed to Item 14.

18

4.0 PROPERTY DESCRIPTION AND LOCATION

4.1 PROPERTY DESCRIPTION

The Timmins West Mine (TWM) area includes the Timmins Deposit property and the Thunder Creek property for a total area of approximately 14.5 square kilometres, or approximately 1,536 hectares. The majority of the property is situated within Bristol Township, with approximately 36 hectares located in Carscallen Township. The Mining Land Tenure Map reference for the TWM is Bristol Township; Plan G-3998; Porcupine Mining Division, Land Titles/Registry Division of Cochrane; and Timmins, Ministry of Natural Resources District, Ontario, Canada.

The Timmins Deposit of the TWM consists of a block of 23 contiguous claims (395 hectares) of which there are 21 individual patented claims and 12 leased claims that are further divided into two 21 year Crown mining leases. The Thunder Creek Deposit portion of the property consists of 57 staked claim units and three Crown leasehold single unit patent claims totaling approximately 960 hectares. Lake Shore Gold Corp. (LSG) owns a 100% interest in most of the property, subject to underlying royalties. The only exception is the Meunier 144 property with LSG holding a 50% interest in these ten patent claims. The claims and leases are all in good standing. Figure 4.1 illustrates the TWM property relative to local topographic and cultural features. Table 4.1 contains the details of staked claims, numbers, ownership, size, and expiry date for the TWM property; Table 4.2 contains leased lands information; and Table 4.3 contains patent lands information.

19

FIGURE 4.1: TIMMINS WEST MINE PROPERTY

20

TABLE 4.1: TIMMINS WEST MINE STAKED CLAIMS

STAKED CLAIMS

Claim No. | | Township | | Owner | | No. of

Units | | Recording Date | | Assessment

Due Date | | Assessment Due

($) | | Banked Credits | | Royalty To | |

P1159635 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 5,387 | | Premier;FNV | |

P1159636 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 29,423 | | Premier;FNV | |

P1159637 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 97,374 | | Premier;FNV | |

P1159638 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 48,241 | | Premier;FNV | |

P1159639 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 6,400 | | Premier;FNV | |

P1159640 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 135,326 | | Premier;FNV | |

P1159641 | | Bristol | | LSG | | 1 | | 1990-Dec-18 | | 2017-Dec-18 | | 400 | | 805 | | Premier;FNV | |

P1176341 | | Bristol | | LSG | | 1 | | 1991-Feb-18 | | 2017-Feb-18 | | 400 | | 6,010 | | Premier;FNV | |

P1177807 | | Bristol | | LSG | | 1 | | 1991-May-13 | | 2017-May-13 | | 400 | | 0 | | Kangas;FNV | |

P1177808 | | Bristol | | LSG | | 1 | | 1991-May-13 | | 2017-May-13 | | 400 | | 312 | | Kangas;FNV | |

P1177809 | | Bristol | | LSG | | 1 | | 1991-May-13 | | 2017-May-13 | | 400 | | 1,637 | | Kangas;FNV | |

P1177811 | | Bristol | | LSG | | 1 | | 1991-May-13 | | 2017-May-13 | | 400 | | 1,403 | | Kangas;FNV | |

P1177822 | | Bristol | | LSG | | 1 | | 1991-Oct-04 | | 2017-Oct-04 | | 400 | | 185,760 | | Premier;FNV | |

P1181409 | | Bristol | | LSG | | 1 | | 1994-Feb-14 | | 2017-Feb-14 | | 400 | | 4,997 | | Premier;FNV | |

P1181410 | | Bristol | | LSG | | 1 | | 1994-Feb-14 | | 2017-Feb-14 | | 400 | | 17,851 | | Kangas;FNV | |

P1181413 | | Bristol | | LSG | | 1 | | 1994-Feb-14 | | 2017-Feb-14 | | 400 | | 1,793 | | Kangas;FNV | |

P1181995 | | Bristol | | LSG | | 2 | | 1992-Jun-22 | | 2017-Jun-22 | | 800 | | 4,054 | | Durham; Meikle;FNV | |

P1189528 | | Bristol | | LSG | | 1 | | 1993-Jun-18 | | 2017-Jun-18 | | 400 | | 90,032 | | FNV | |

P1189580 | | Bristol | | LSG | | 1 | | 1993-Jan-08 | | 2017-Jan-08 | | 400 | | 1,013 | | Durham; Meikle;FNV | |

P1189592 | | Bristol | | LSG | | 3 | | 1992-Jun-19 | | 2017-Jun-19 | | 1,200 | | 36,009 | | Durham; Meikle;FNV | |

P1189593 | | Bristol | | LSG | | 1 | | 1992-Jun-22 | | 2017-Jun-22 | | 400 | | 624 | | Durham; Meikle;FNV | |

P1189886 | | Bristol | | LSG | | 6 | | 1992-May-07 | | 2017-May-07 | | 2,400 | | 58,675 | | Hutteri;FNV | |

P1193477 | | Bristol | | LSG | | 6 | | 1994-May-04 | | 2017-May-04 | | 2,400 | | 1,793 | | FNV | |

P1198803 | | Bristol | | LSG | | 1 | | 1994-Feb-14 | | 2017-Feb-14 | | 400 | | 0 | | Kangas;FNV | |

P1198804 | | Bristol | | LSG | | 1 | | 1994-Feb-14 | | 2017-Feb-14 | | 400 | | 0 | | Kangas’FNV | |

P1201162 | | Bristol | | LSG | | 1 | | 1994-Jul-04 | | 2017-Jul-04 | | 400 | | 5,621 | | Premier;FNV | |

P1203840 | | Bristol | | LSG | | 6 | | 1995-Jul-21 | | 2016-Jul-21 | | 2,400 | | 0 | | FNV | |

P1217601 | | Bristol | | LSG | | 1 | | 1996-Nov-26 | | 2016-Nov-26 | | 400 | | 0 | | FNV | |

P530884 | | Bristol | | LSG | | 1 | | 1980-Oct-10 | | 2017-Oct-10 | | 400 | | 7,227 | | Premier;FNV | |

P583234 | | Bristol | | LSG | | 1 | | 1980-Oct-10 | | 2017-Oct-10 | | 400 | | 29,844 | | Premier;FNV | |

P649964 | | Bristol | | LSG | | 1 | | 1983-Mar-25 | | 2017-Mar-25 | | 400 | | 5,069 | | Premier;FNV | |

P649965 | | Bristol | | LSG | | 1 | | 1983-Mar-25 | | 2017-Mar-25 | | 400 | | 34,582 | | Premier;FNV | |

P764945 | | Bristol | | LSG | | 1 | | 1984-Apr-19 | | 2017-Apr-19 | | 400 | | 1,092 | | Premier;FNV | |

P4211037 | | Bristol | | LSG | | 2 | | 2-Jun-2006 | | 2016-Jun-2 | | 800 | | 0 | | FNV | |

P4211038 | | Bristol | | LSG | | 1 | | 2-Jun-2006 | | 2016-Jun-2 | | 400 | | 0 | | FNV | |

P4211039 | | Bristol | | LSG | | 1 | | 2-Jun-2006 | | 2016-Jun-2 | | 400 | | 0 | | FNV | |

P4211040 | | Bristol | | LSG | | 2 | | 2-Jun-2006 | | 2016-Jun-2 | | 800 | | 0 | | FNV | |

21

TABLE 4.2: LEASED LANDS

LEASED LANDS

Claim No. | | Township | | Owner | | Rights | | Lease No. | | Area

(ha) | | PIN | | Lease Due Date | | Banked

Credits | | Royalty To | |

P499933 | | Bristol | | LSG | | MRO | | 107874 | | 108.792 | | 65440-0118 | | July 31 2027 | | | | FNV | |

P499934 | | Bristol | | LSG | | MRO | | | | FNV | |

P499935 | | Bristol | | LSG | | MRO | | | | FNV | |

P499936 | | Bristol | | LSG | | MRO | | | | FNV | |

P499937 | | Bristol | | LSG | | MRO | | | | FNV | |

P499938 | | Bristol | | LSG | | MRO | | | | FNV | |

P55902 | | Bristol | | LSG | | MR & SR | | 106634 | | 99.779 | | 65440-0052 | | July 31, 2013 (Lease Renewal

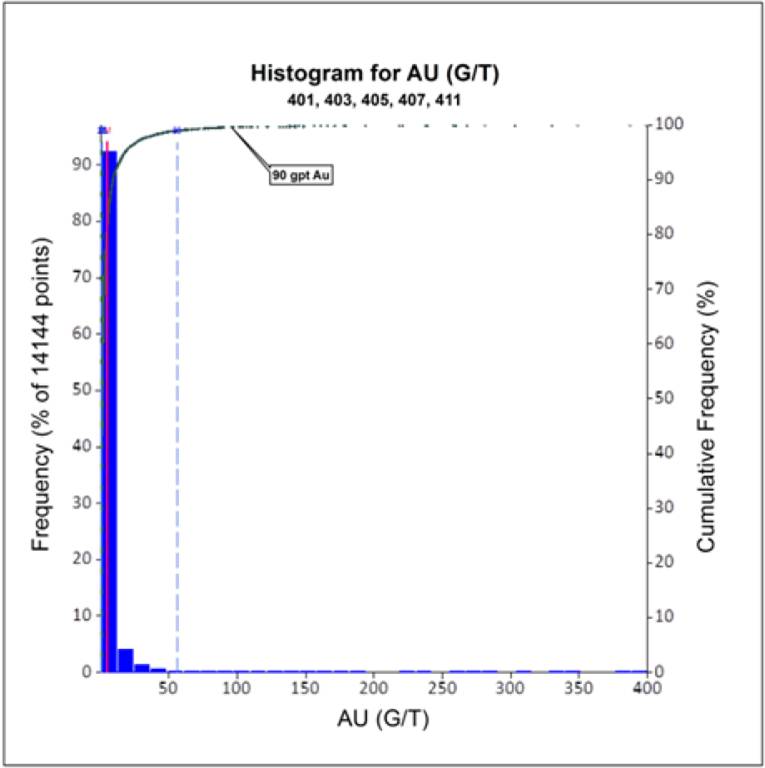

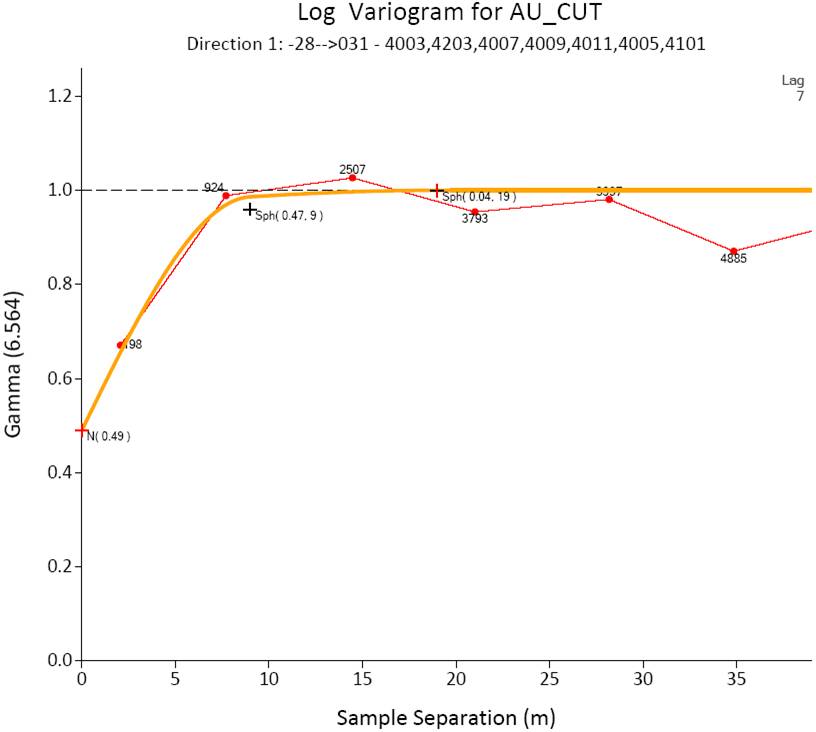

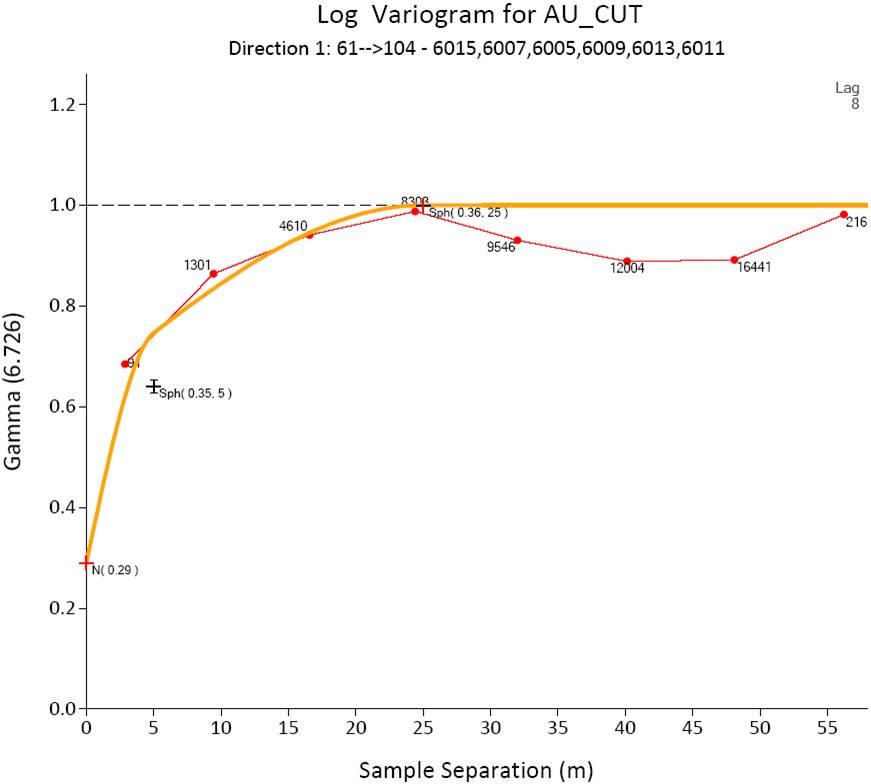

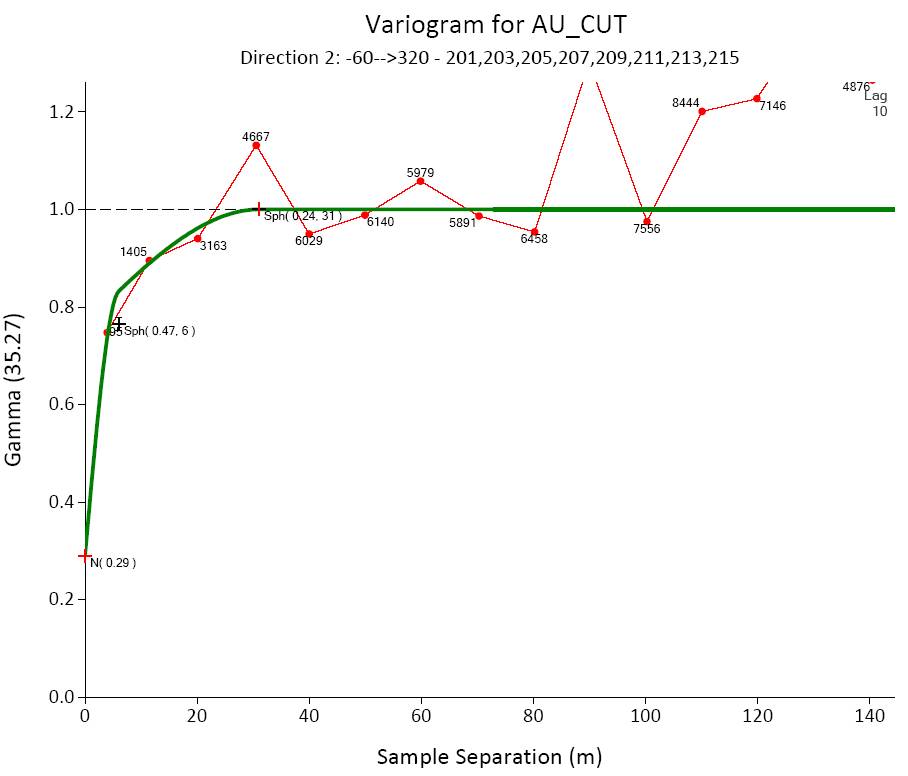

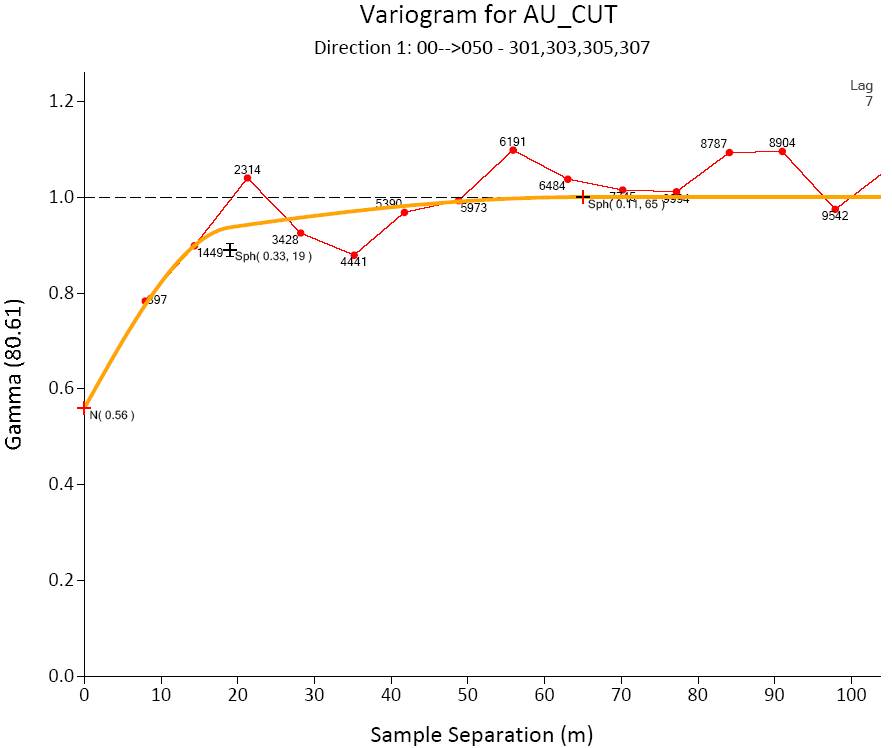

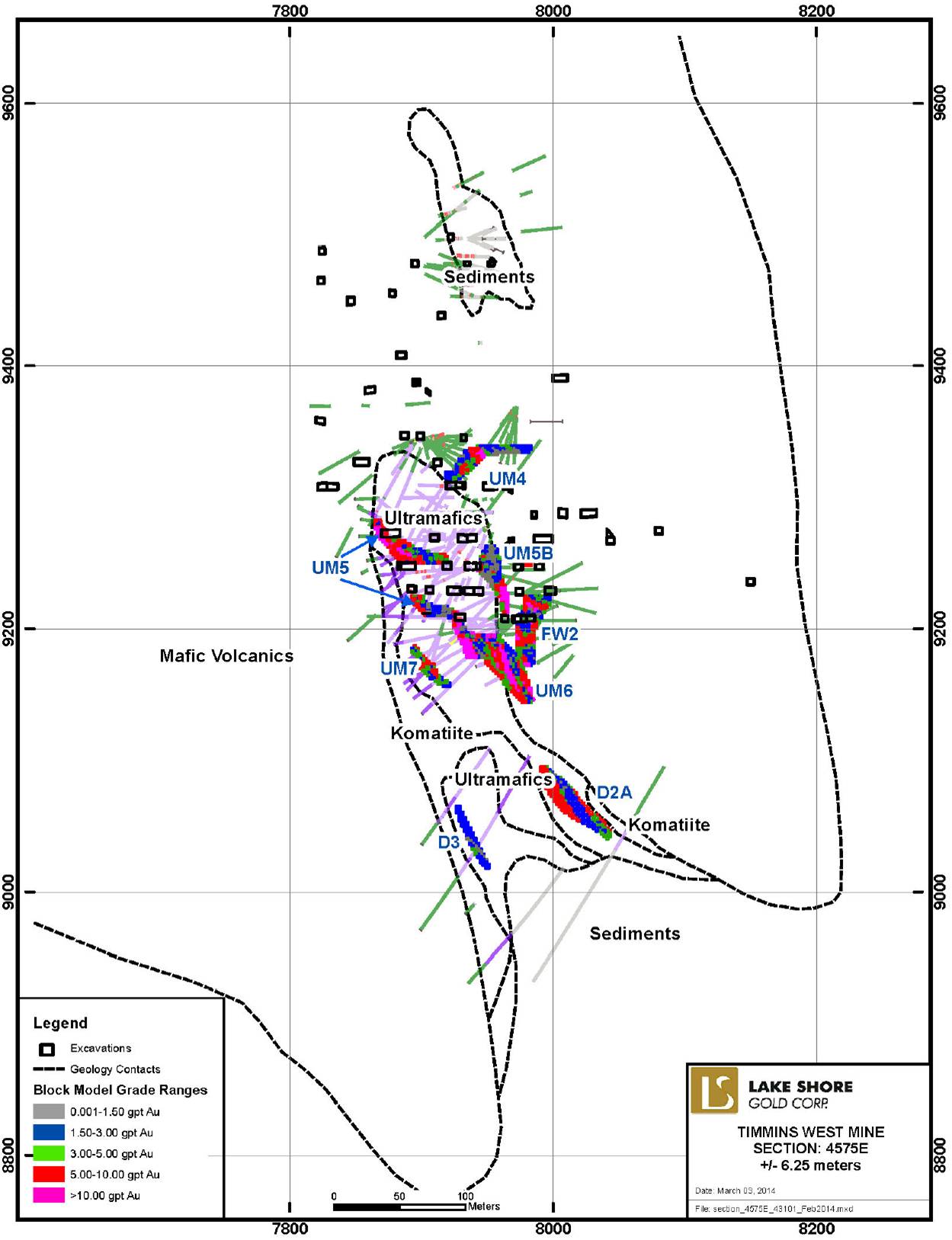

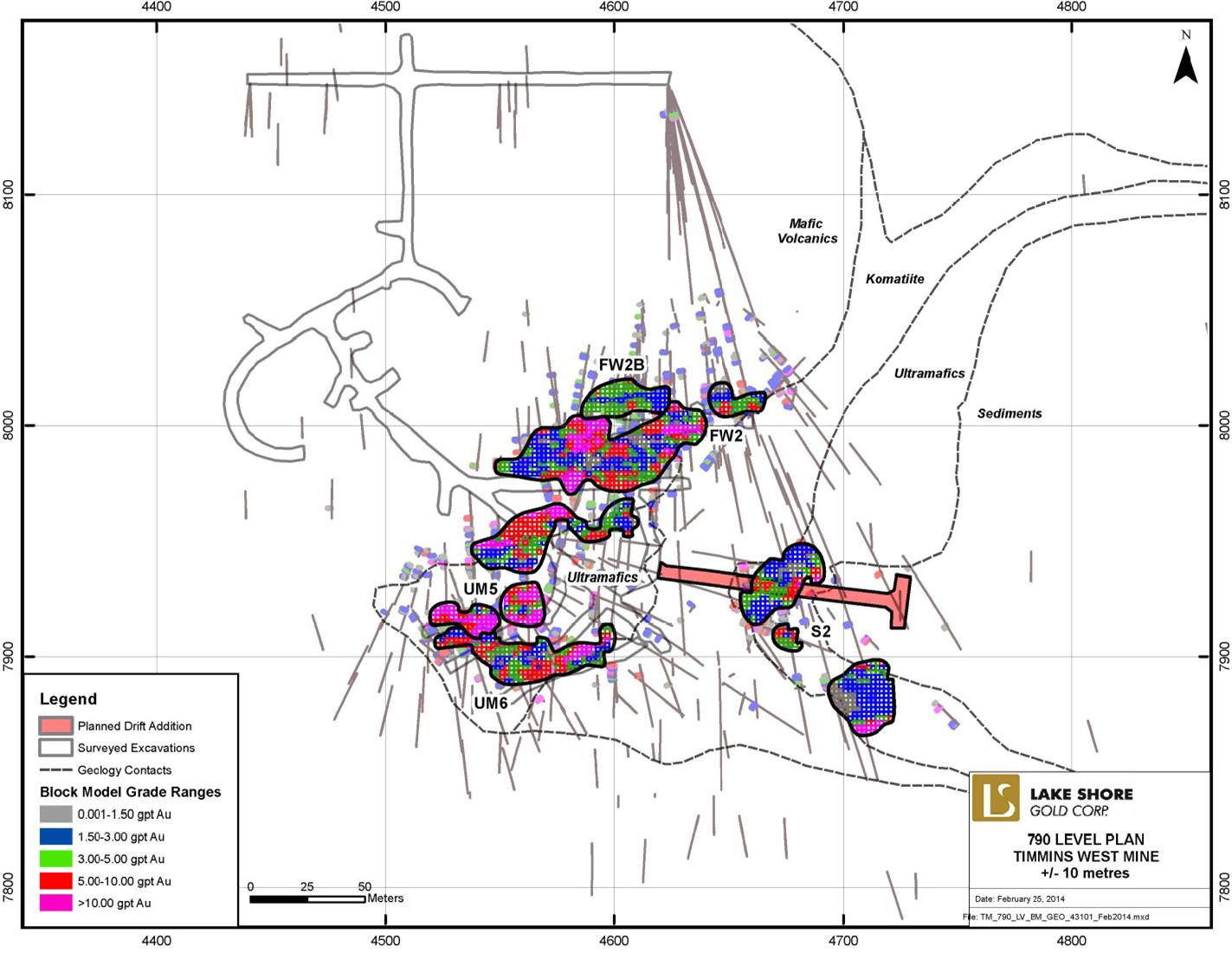

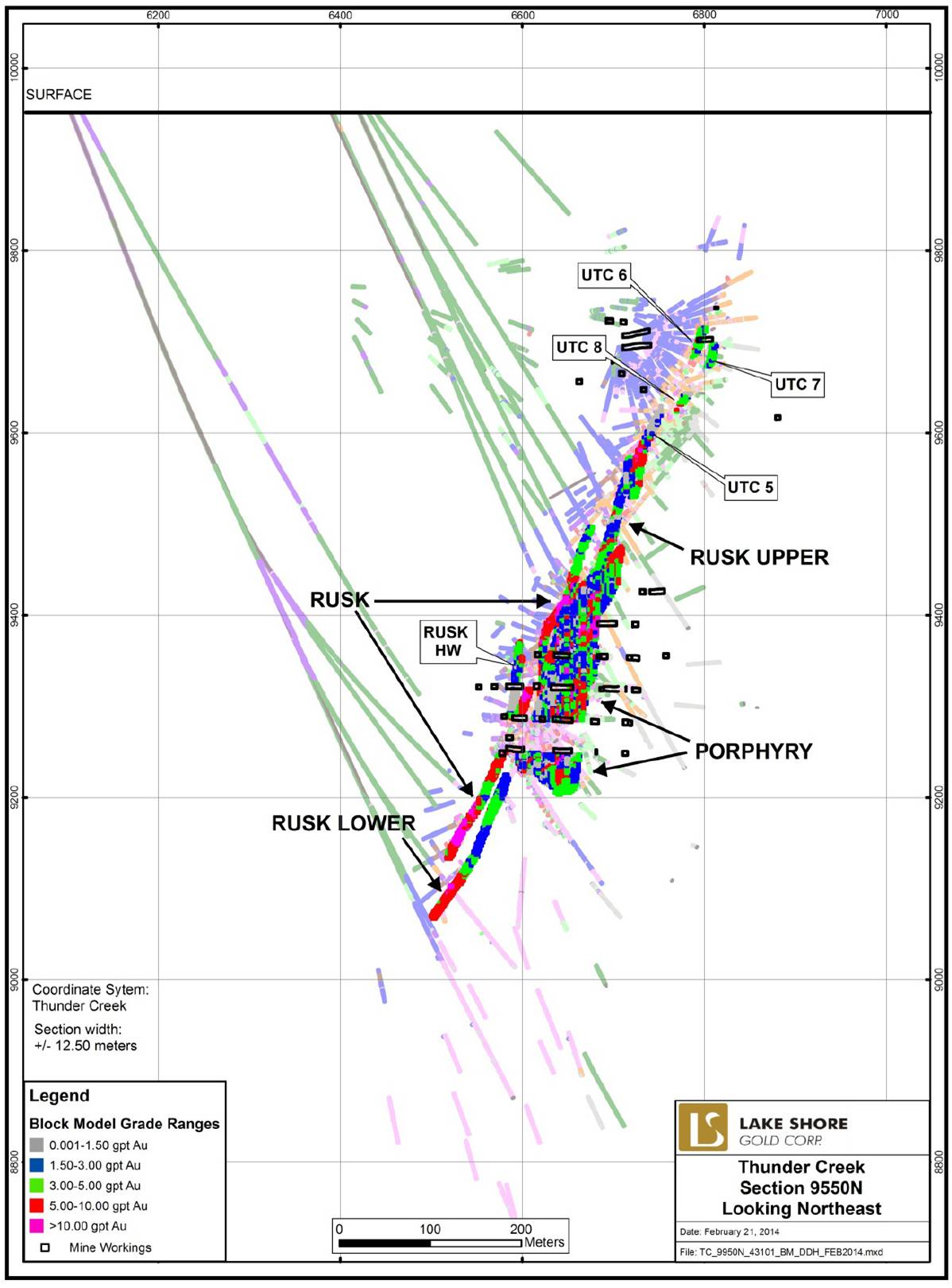

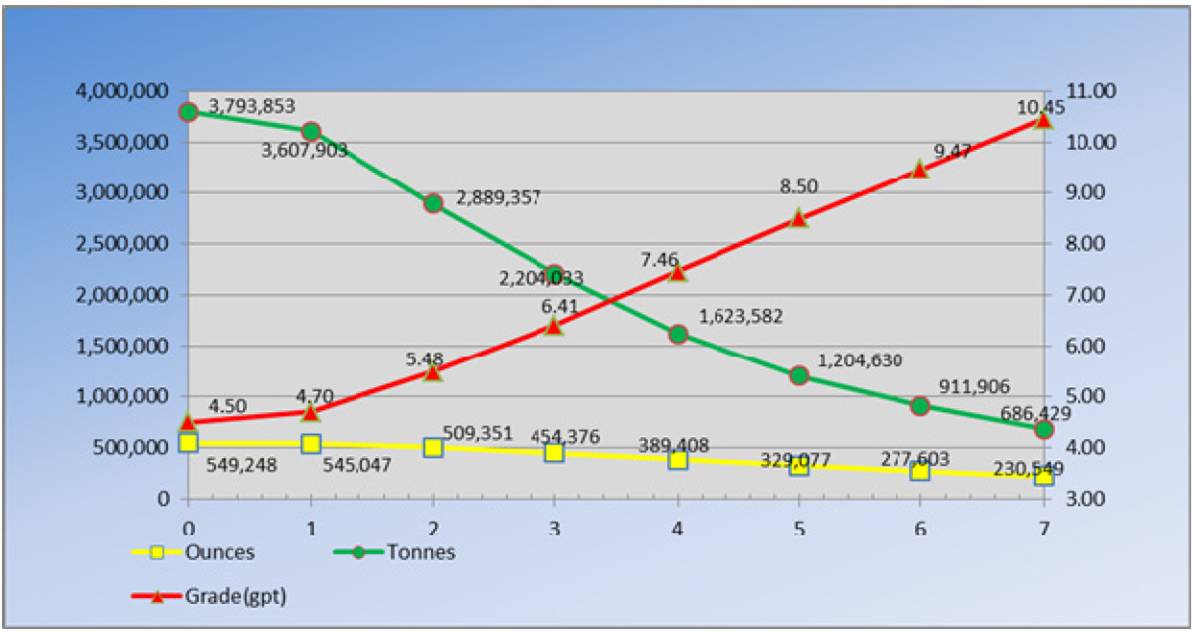

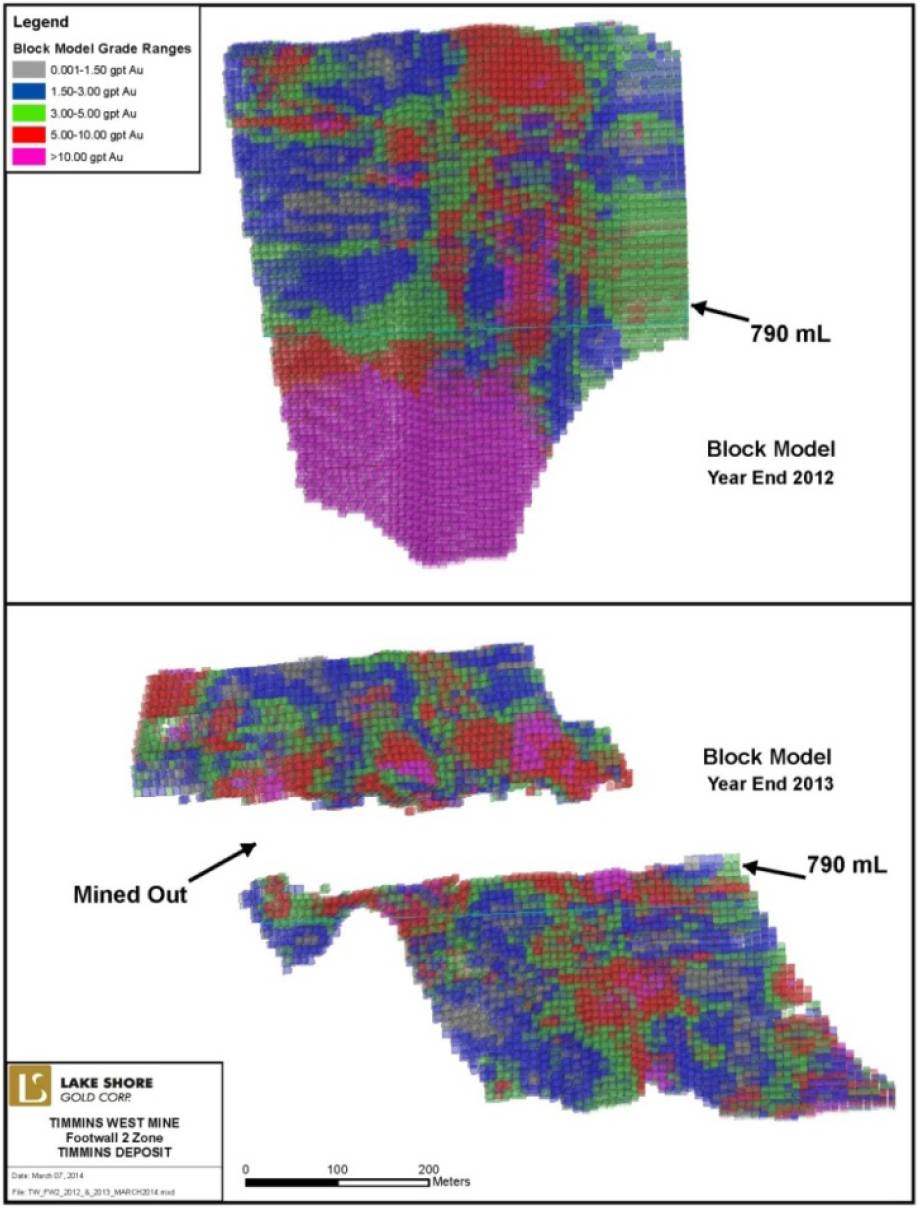

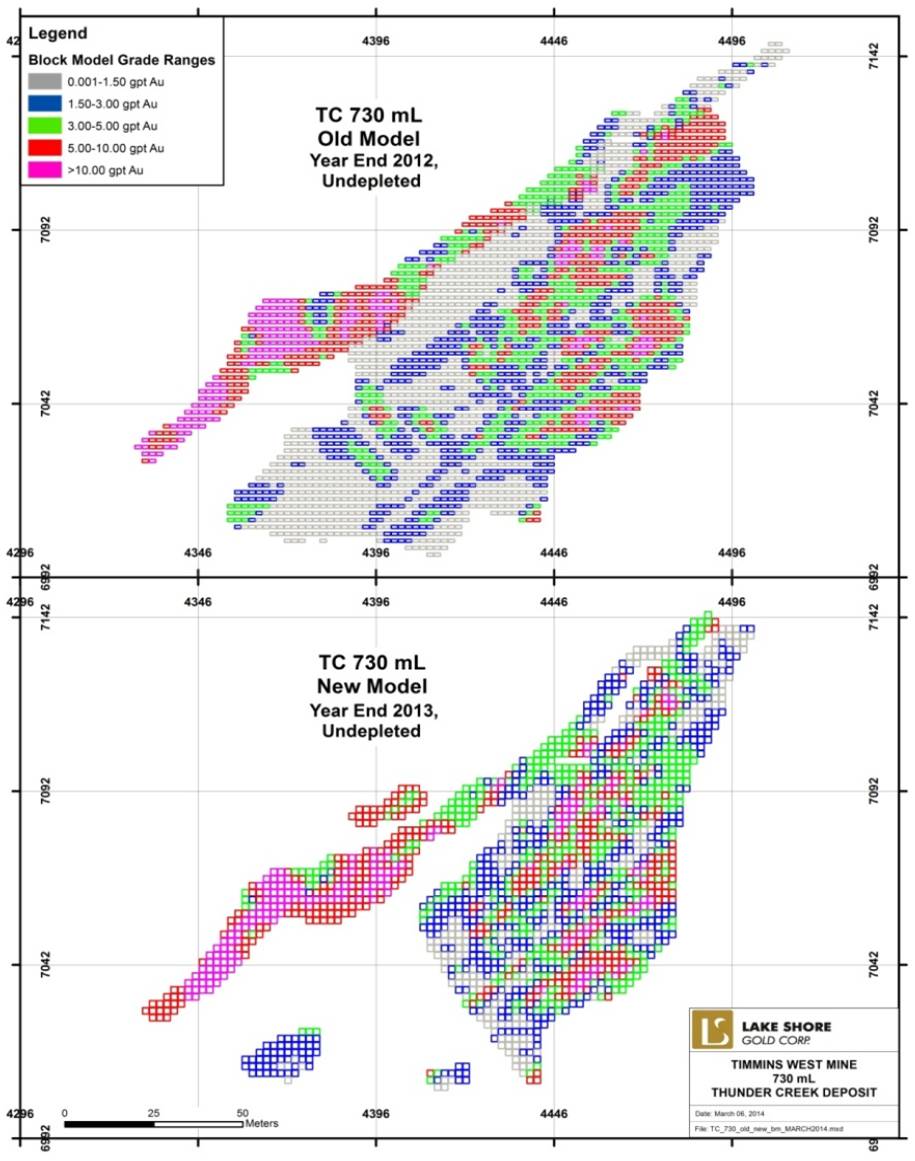

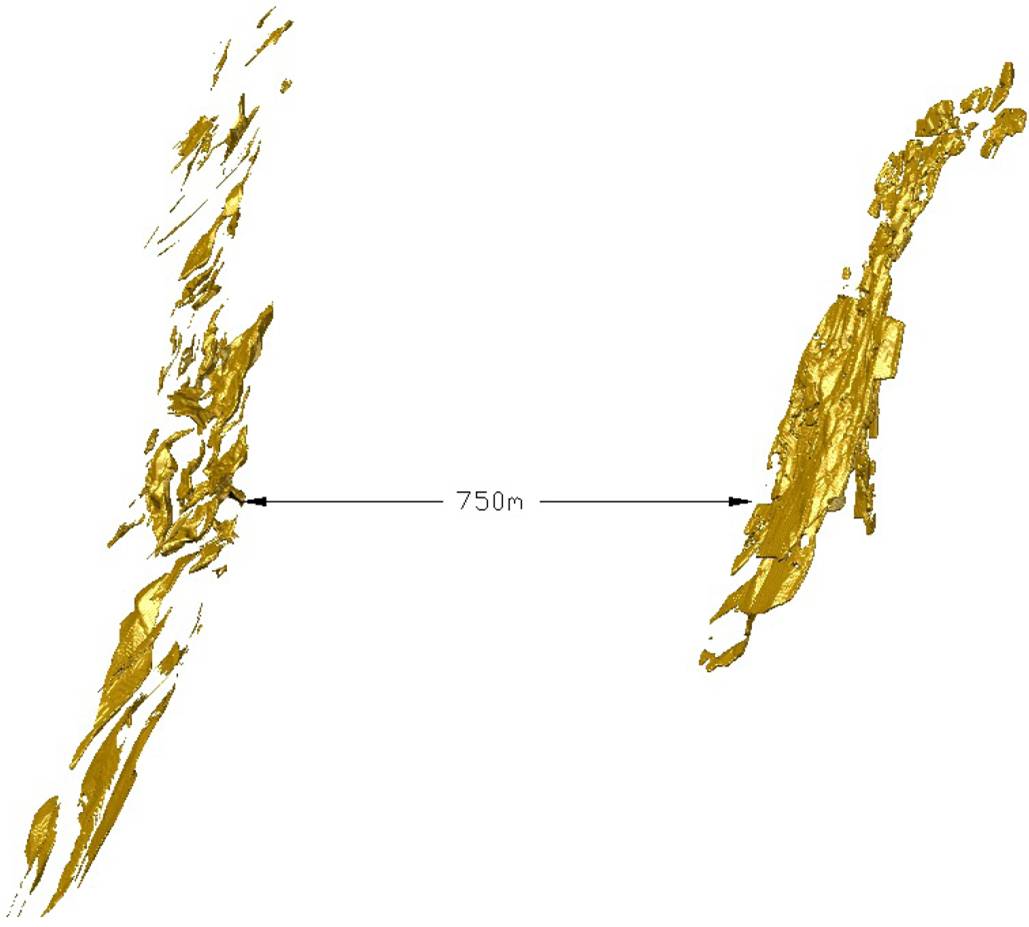

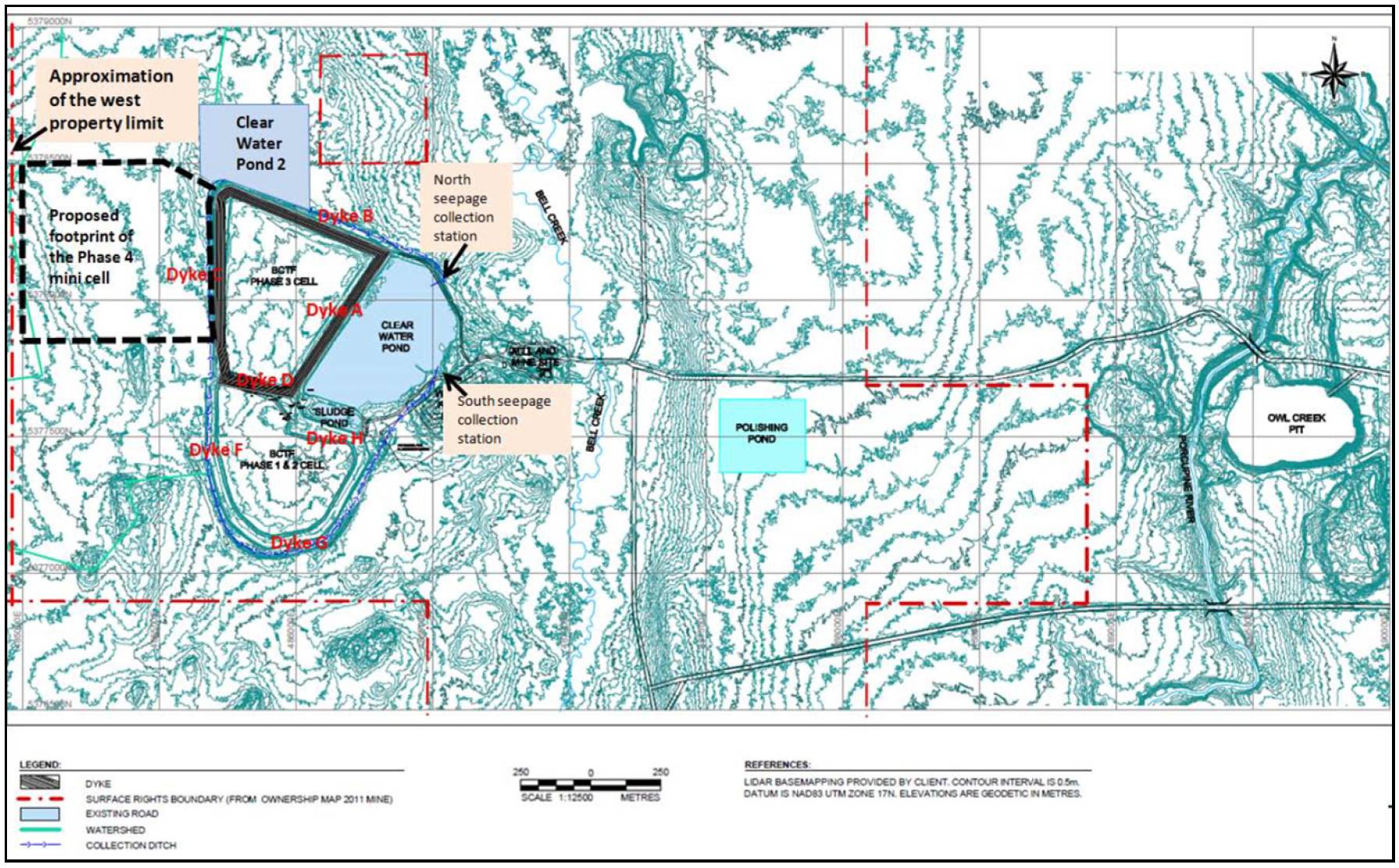

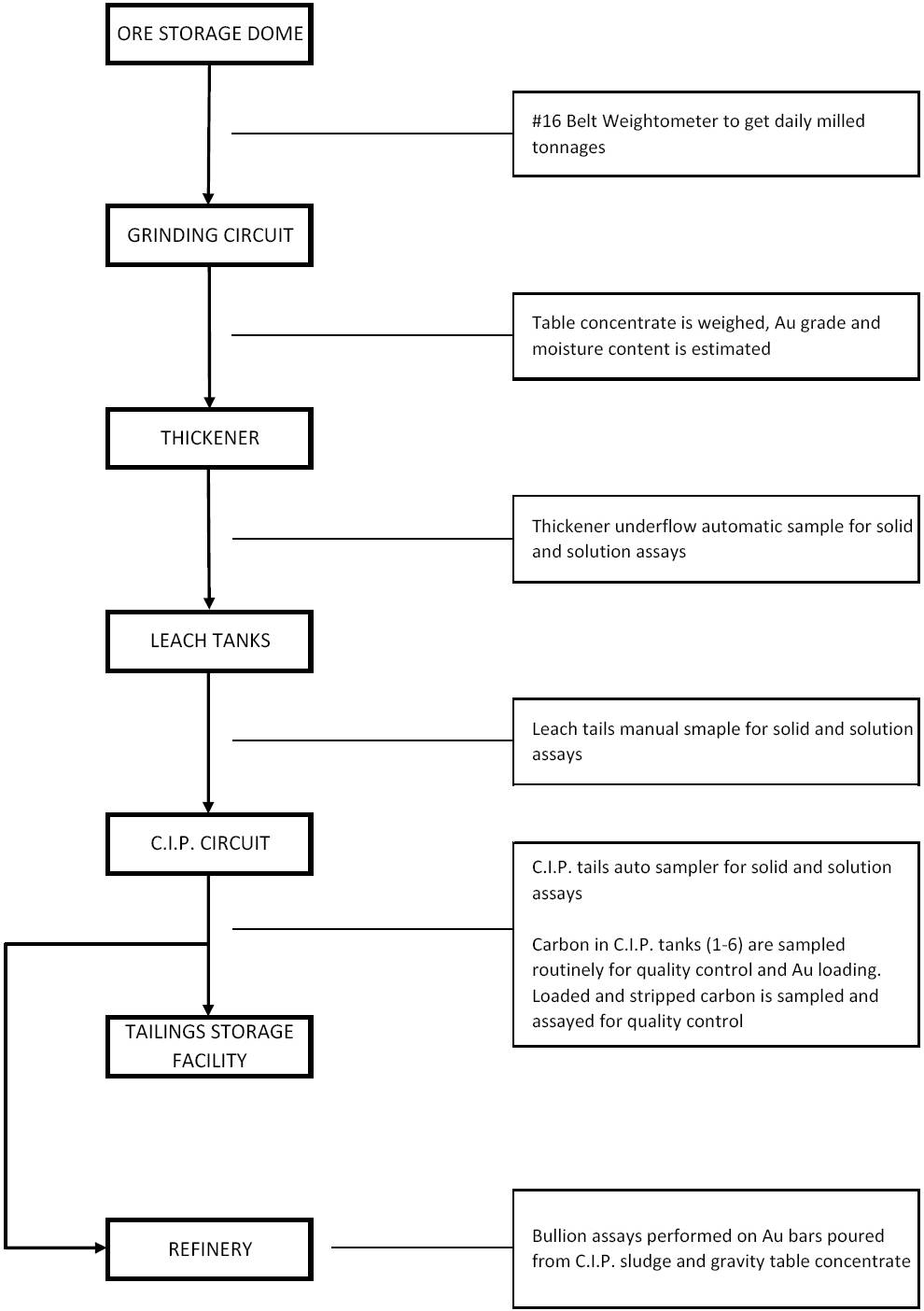

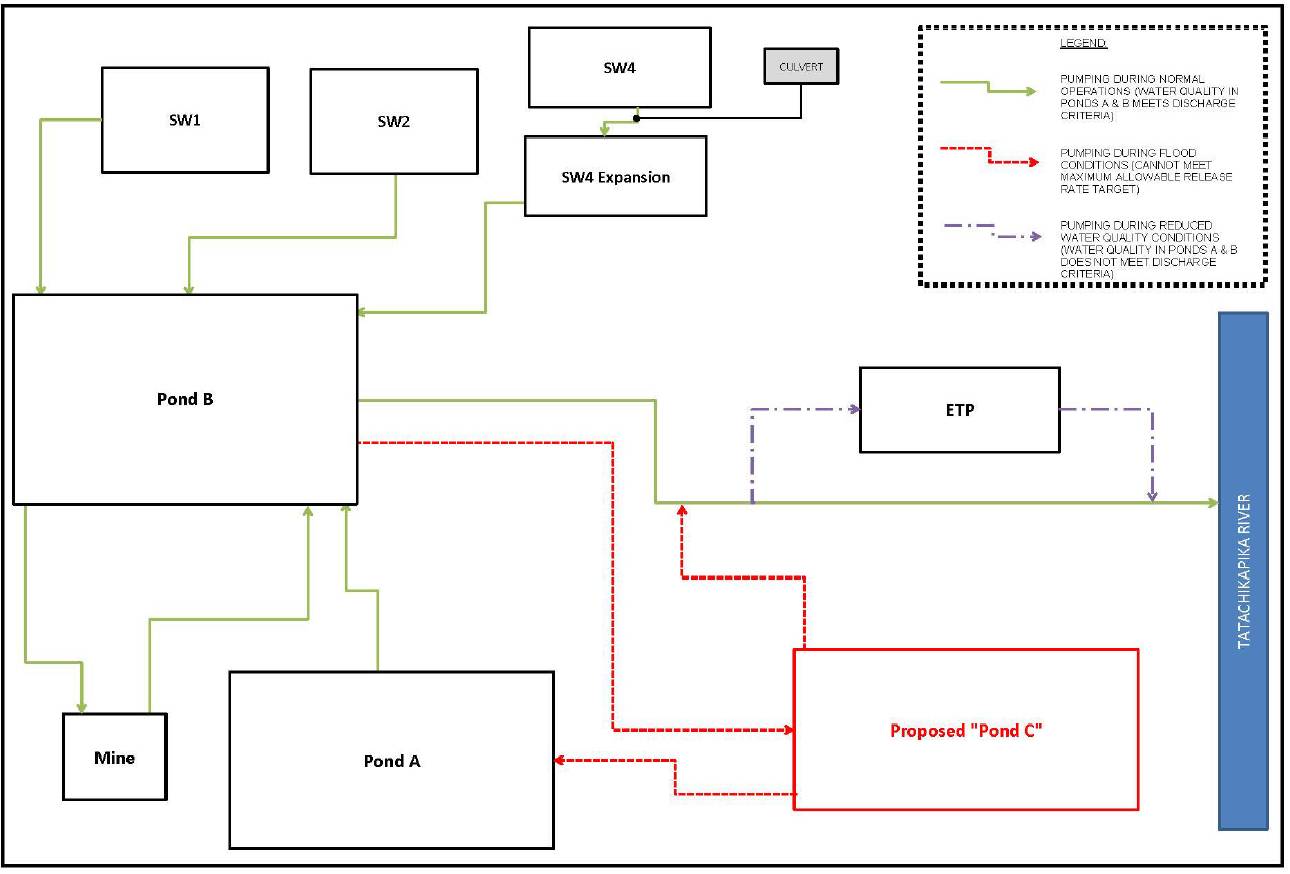

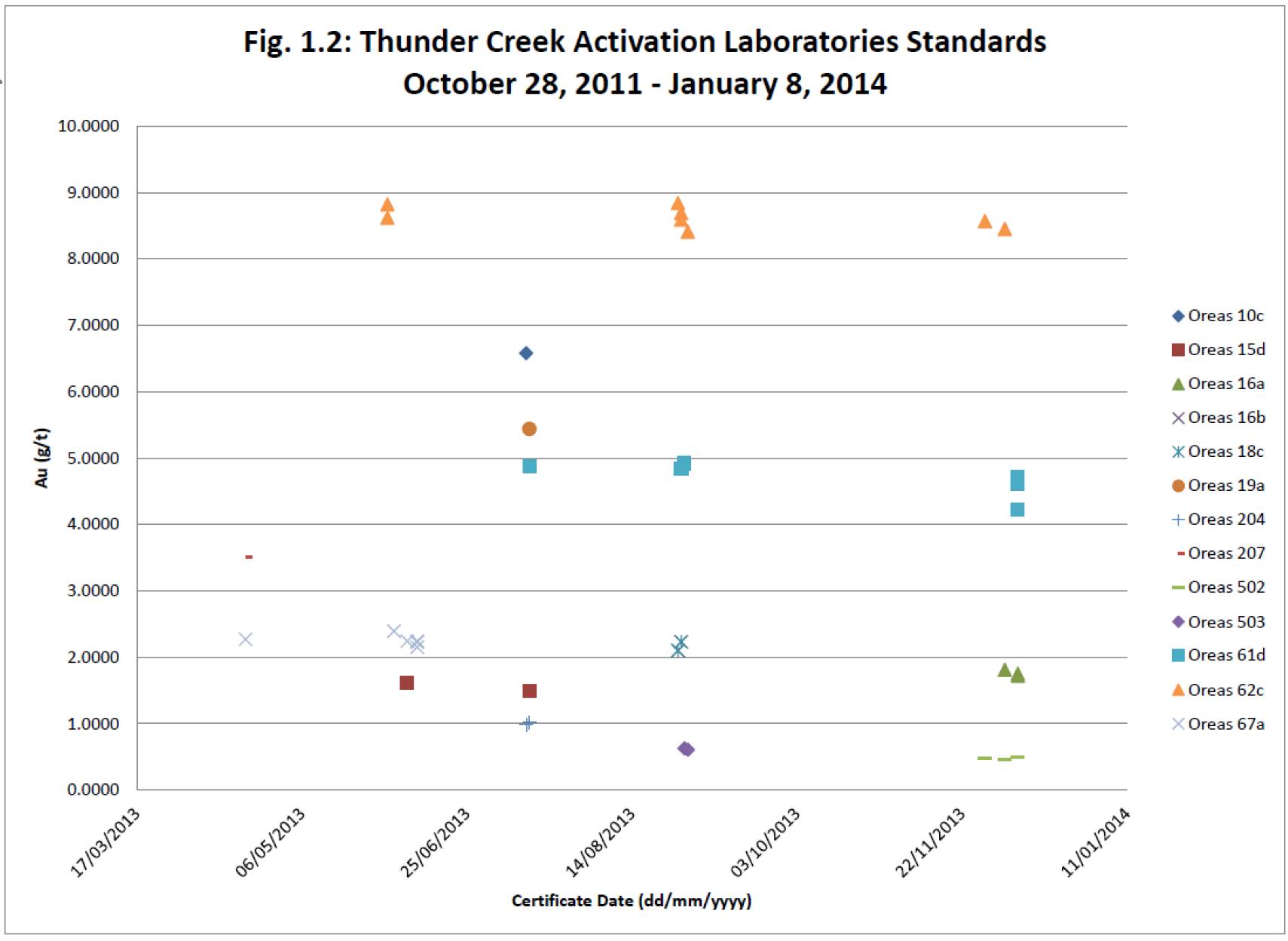

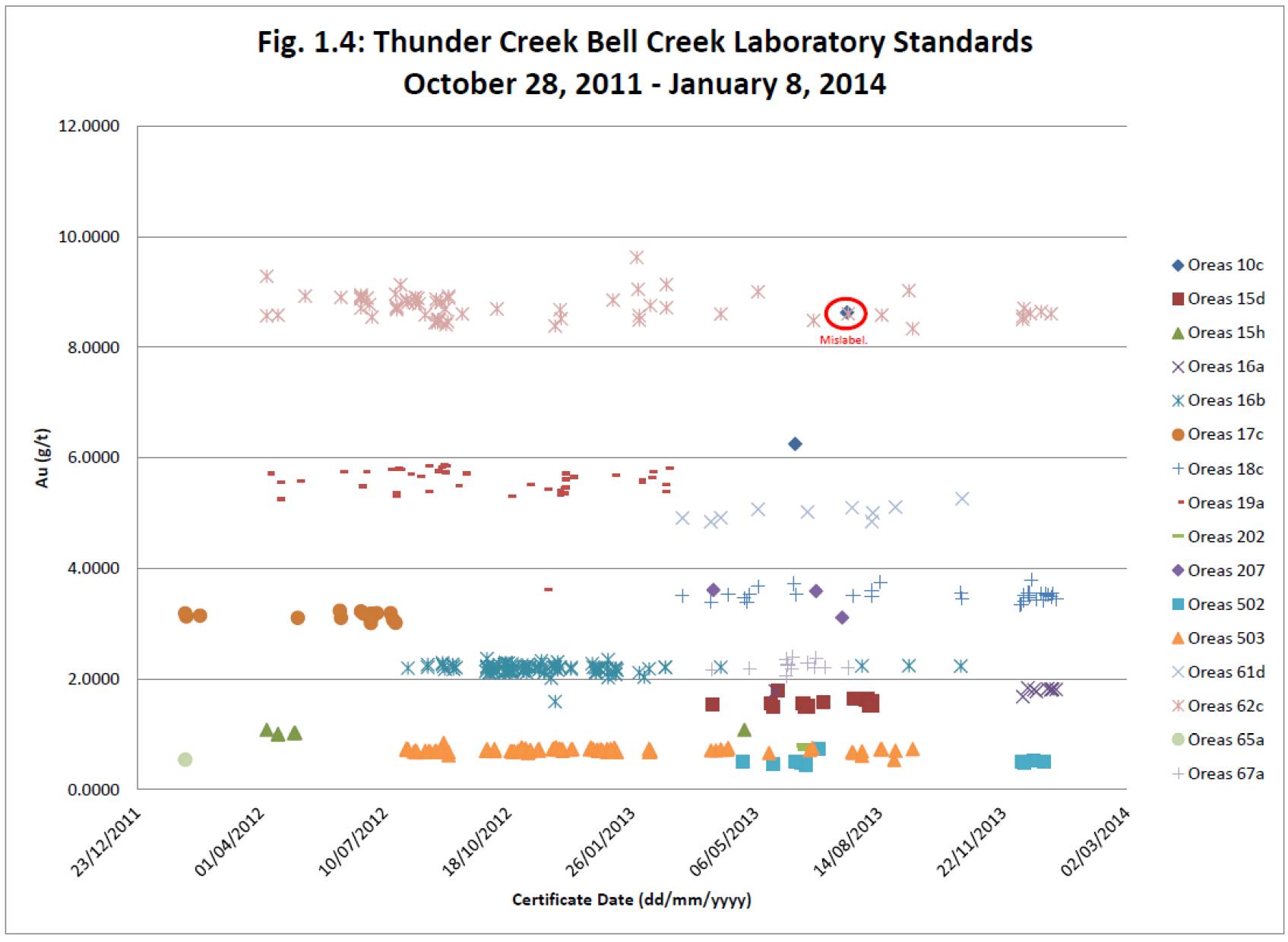

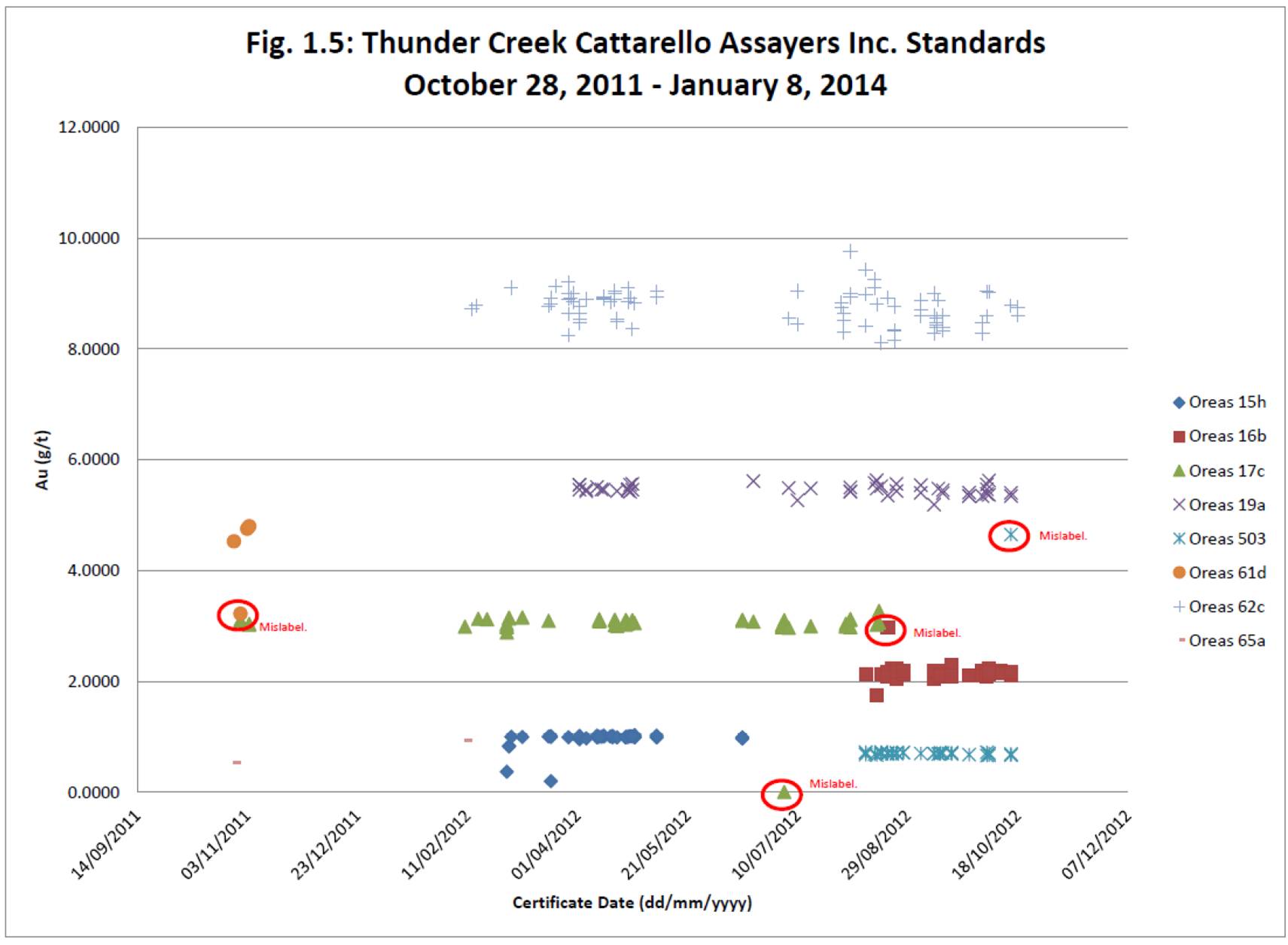

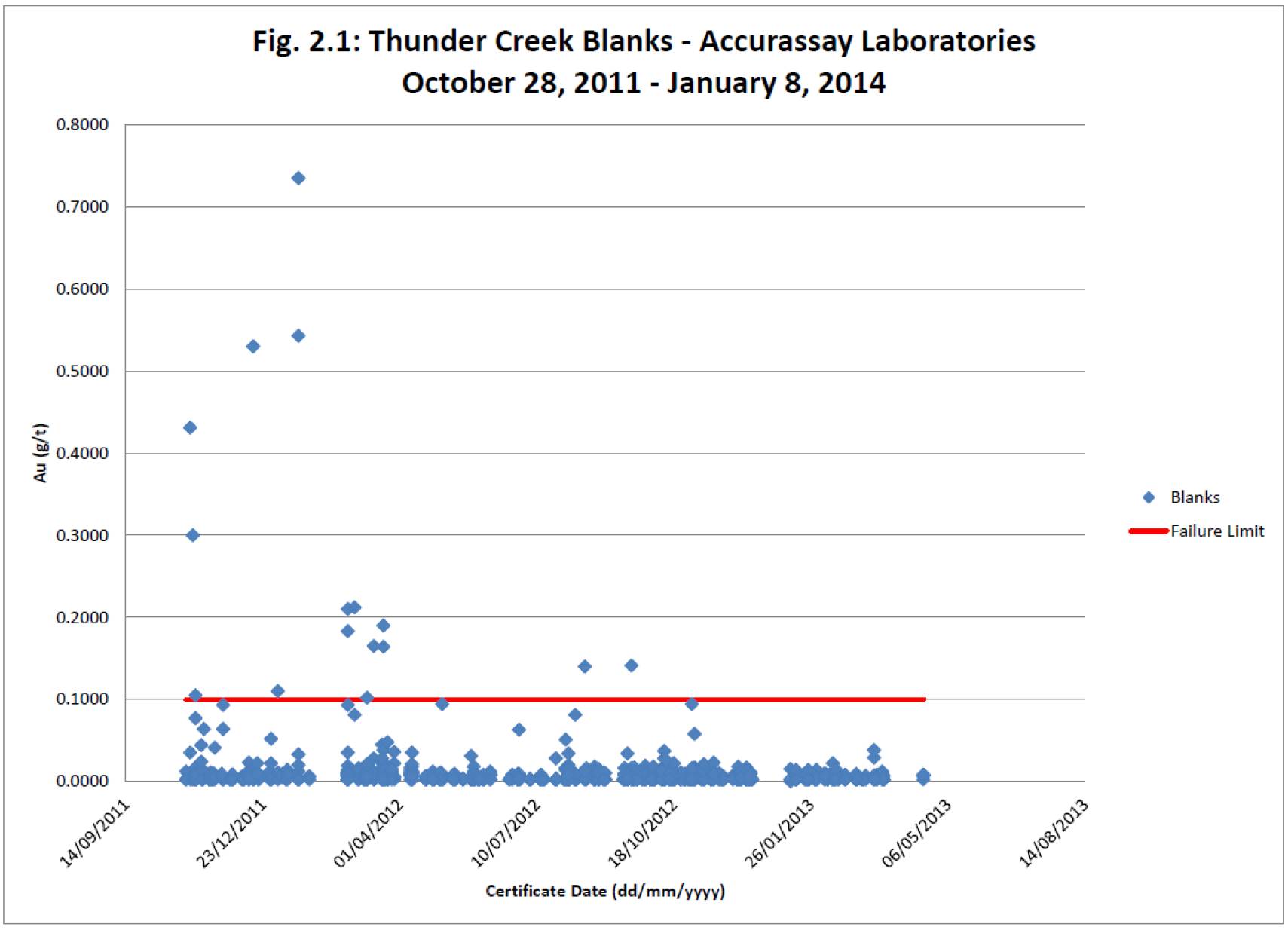

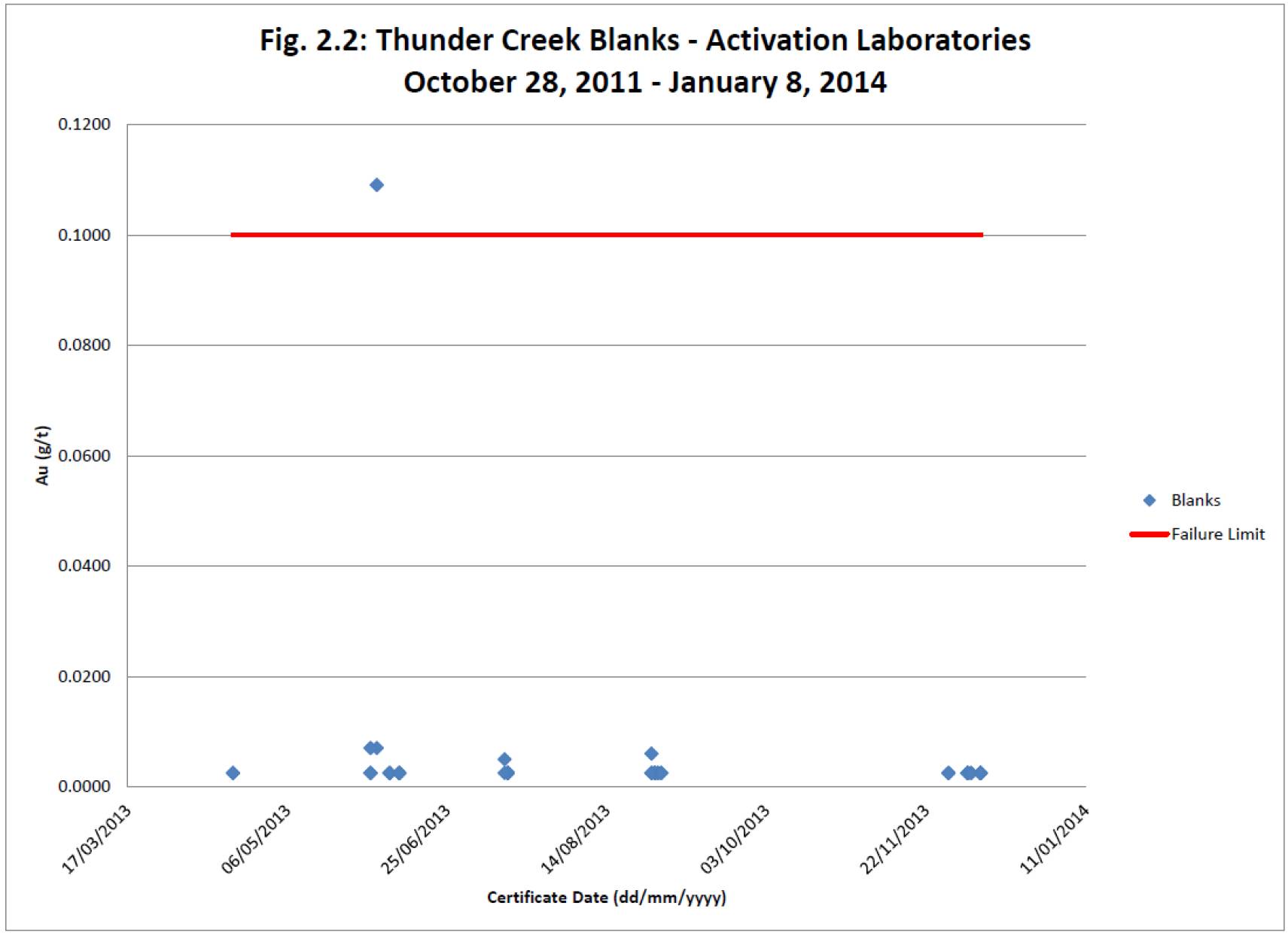

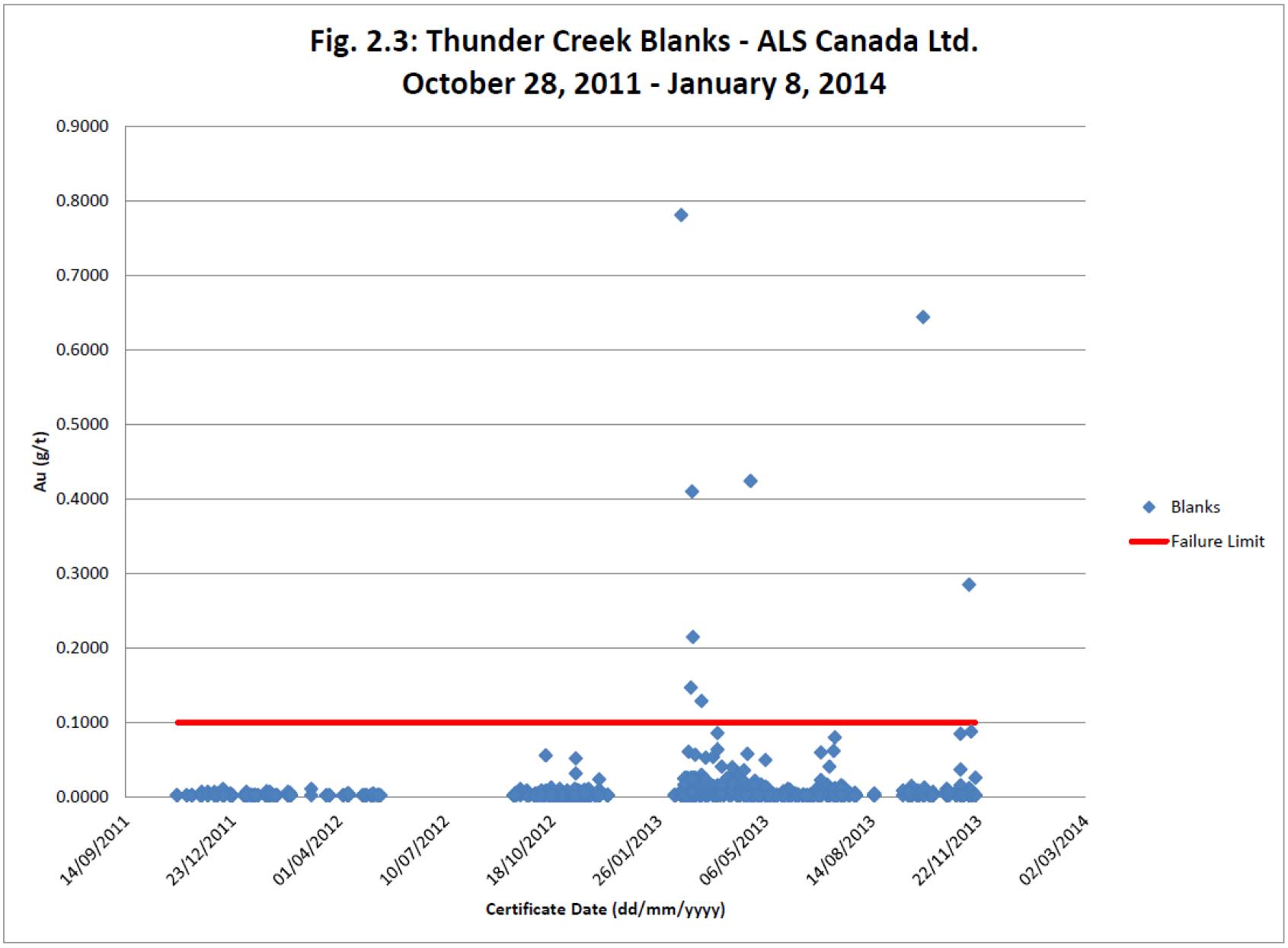

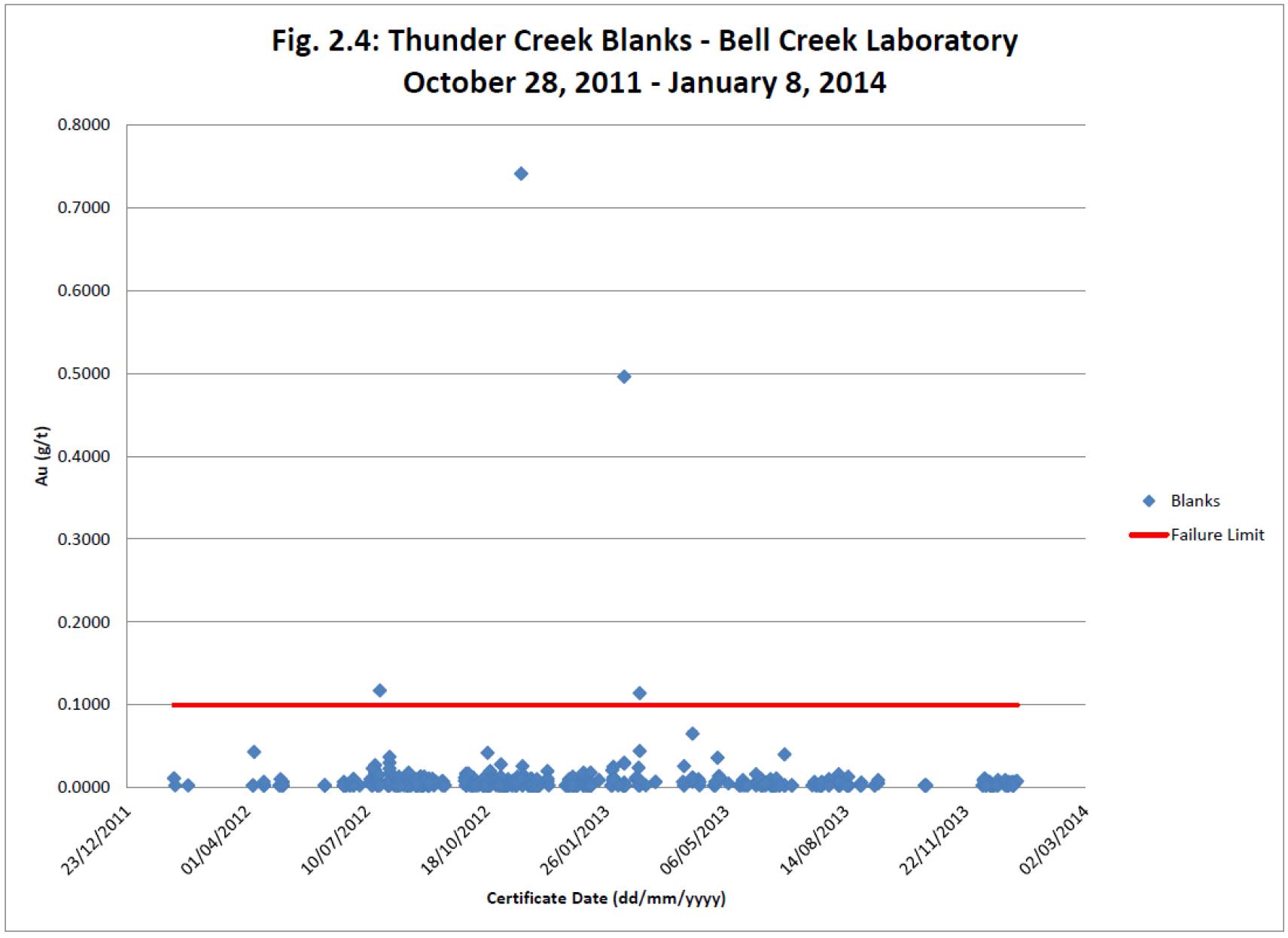

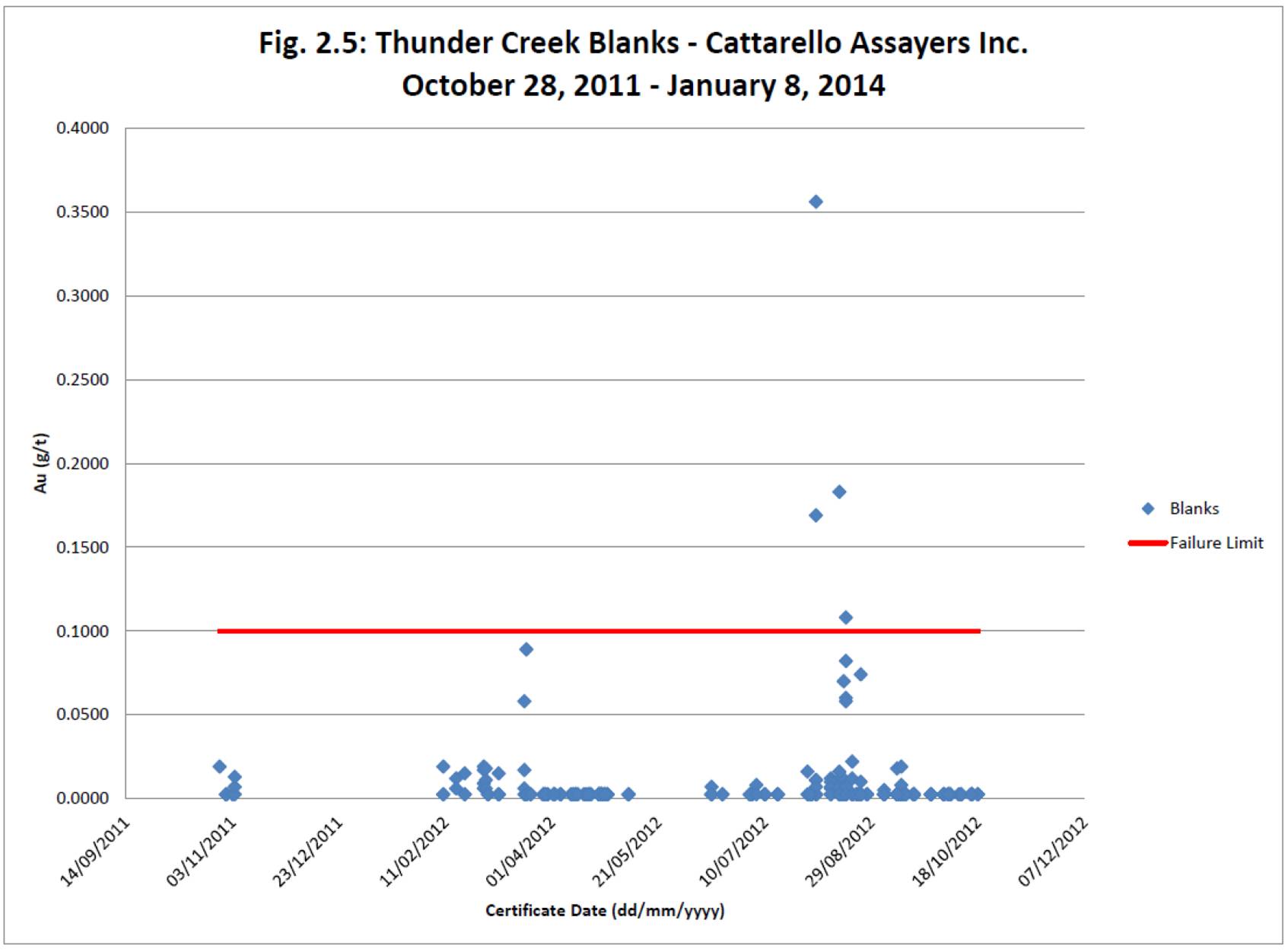

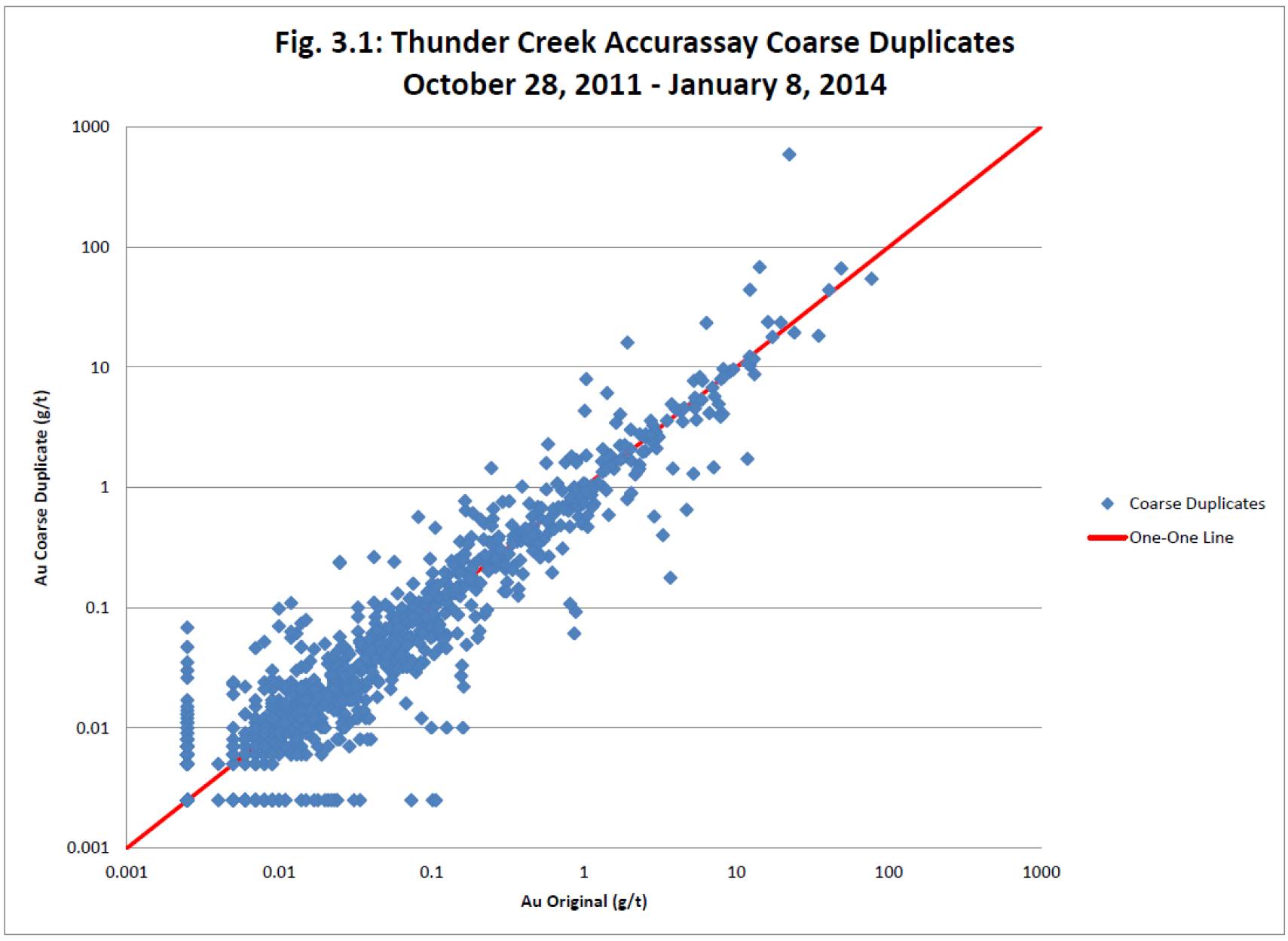

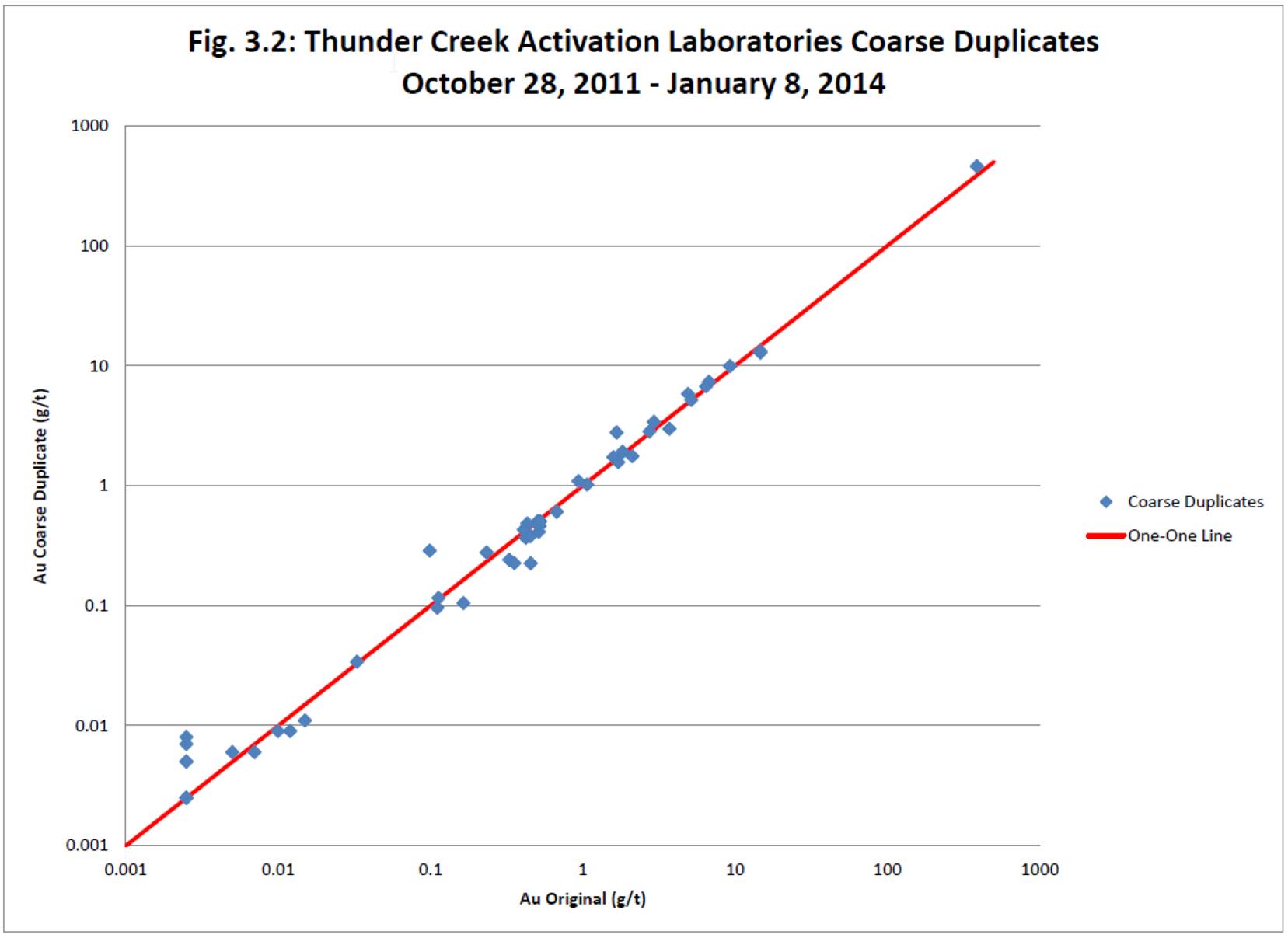

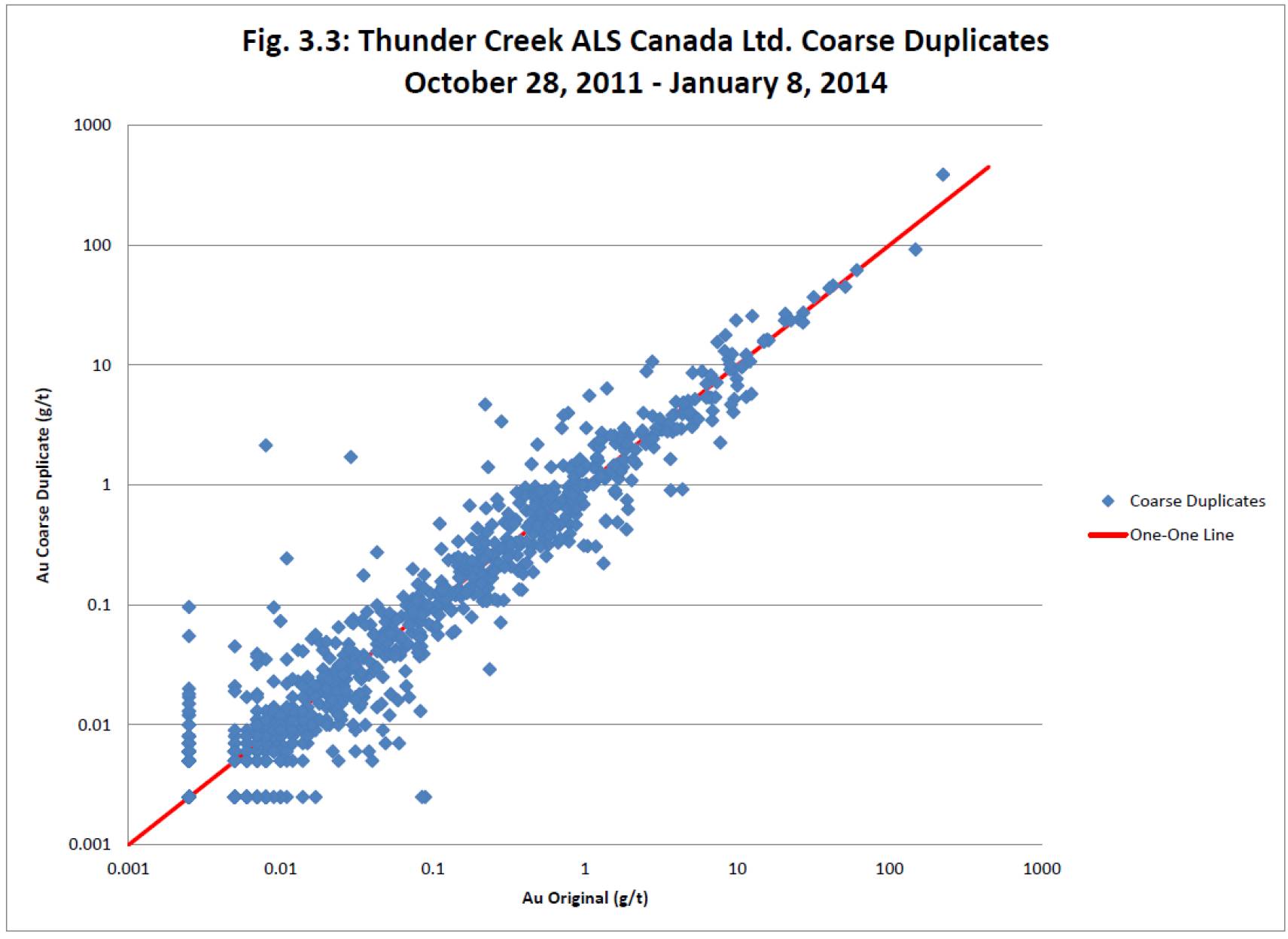

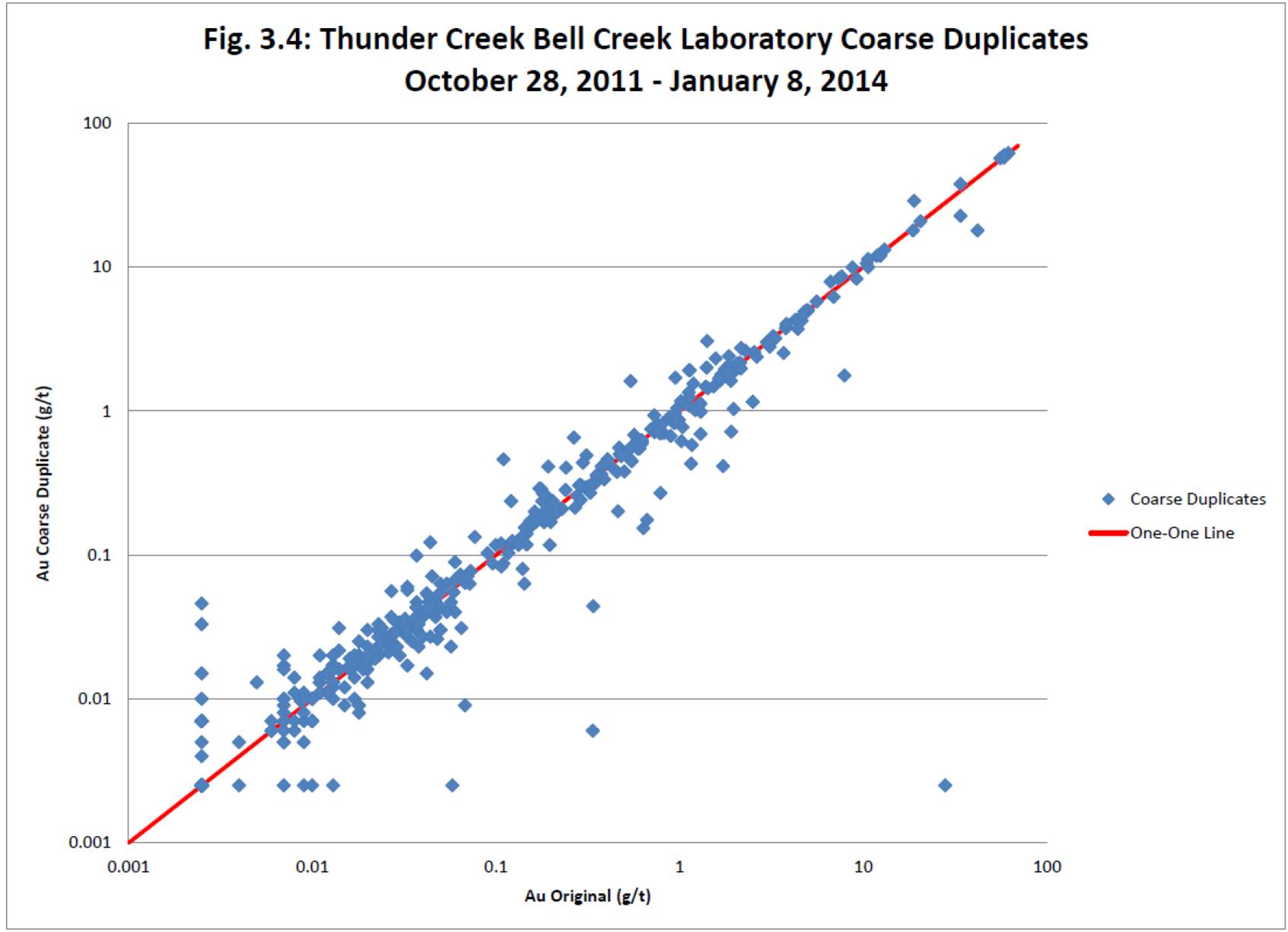

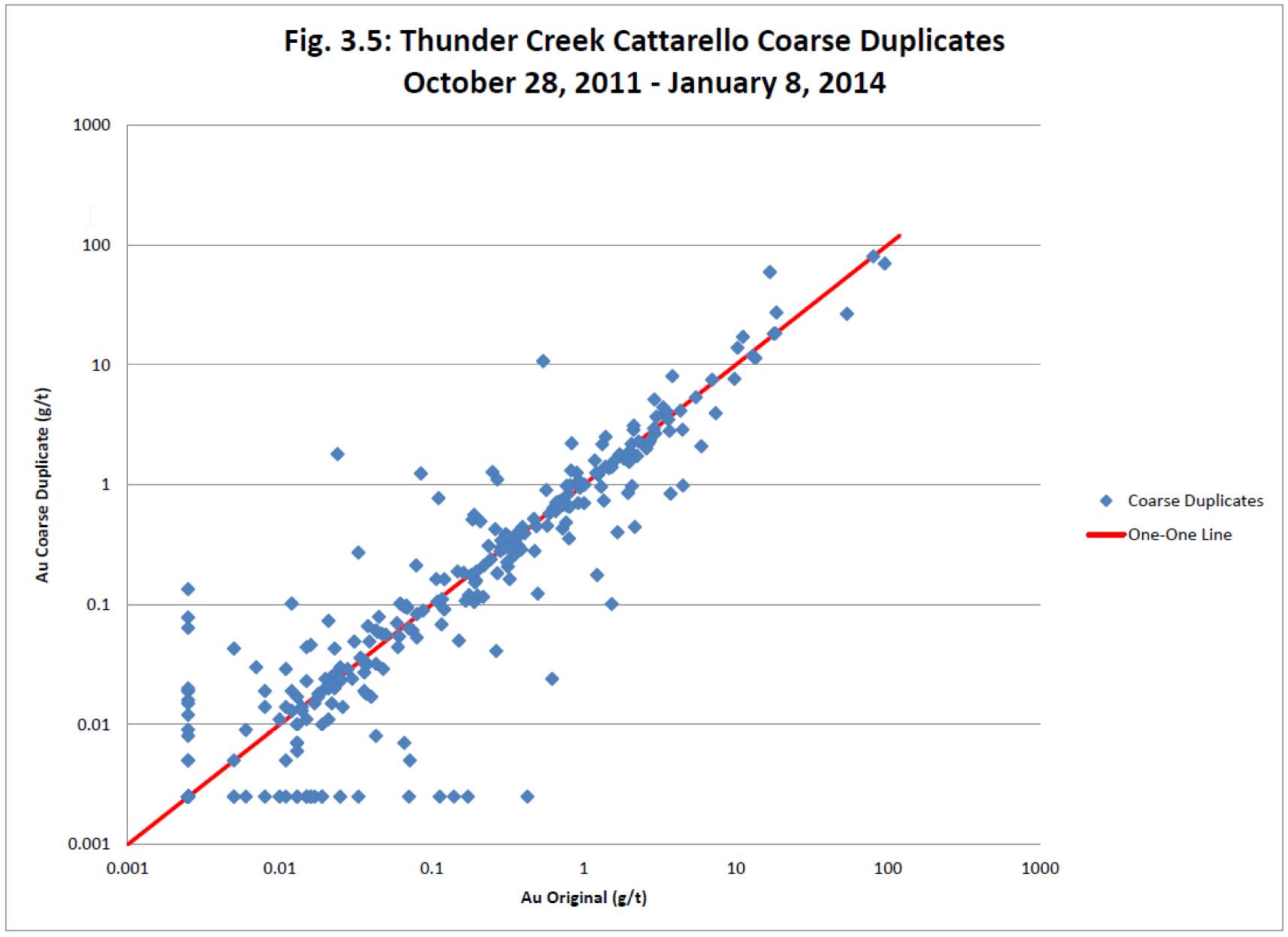

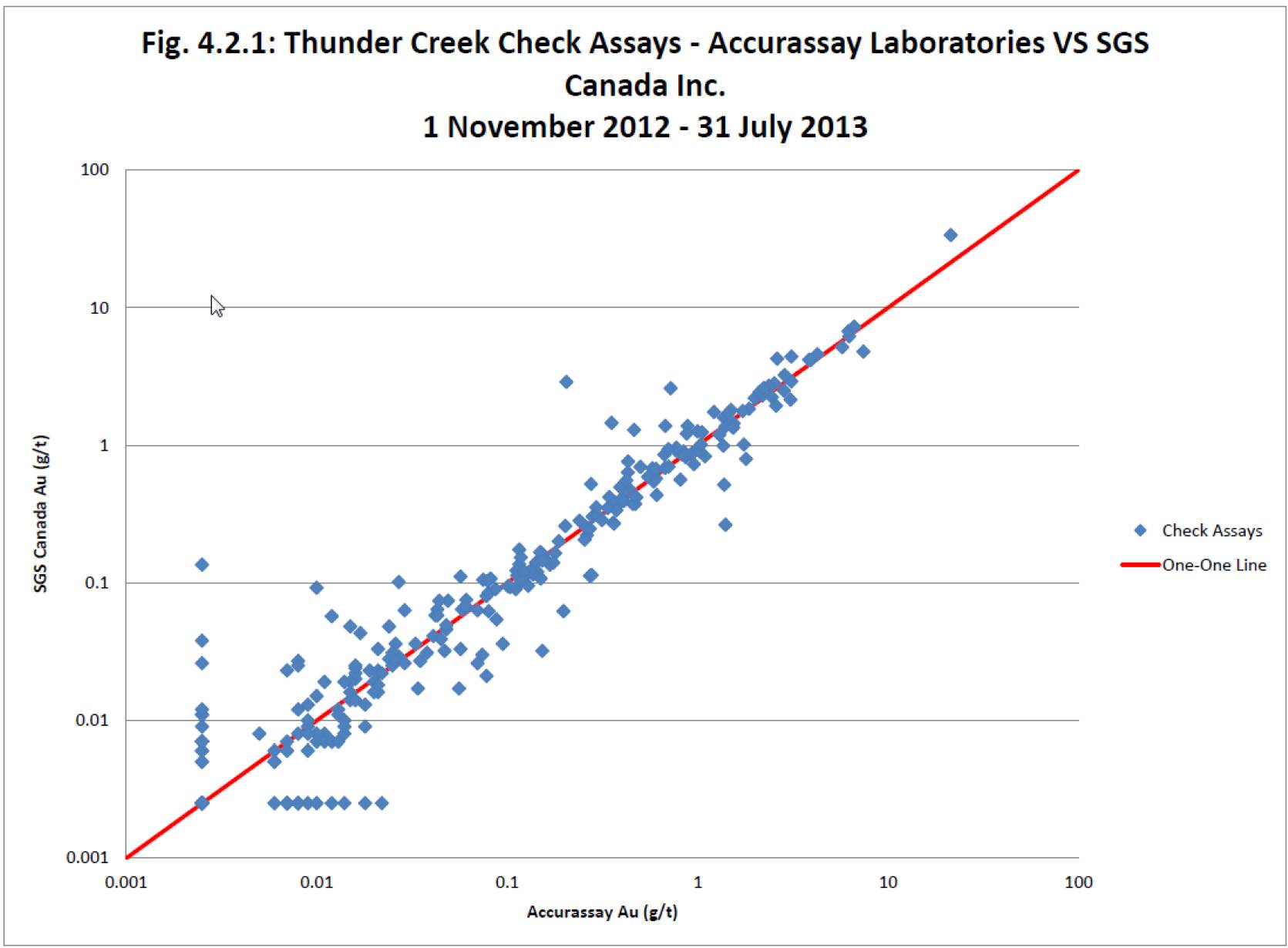

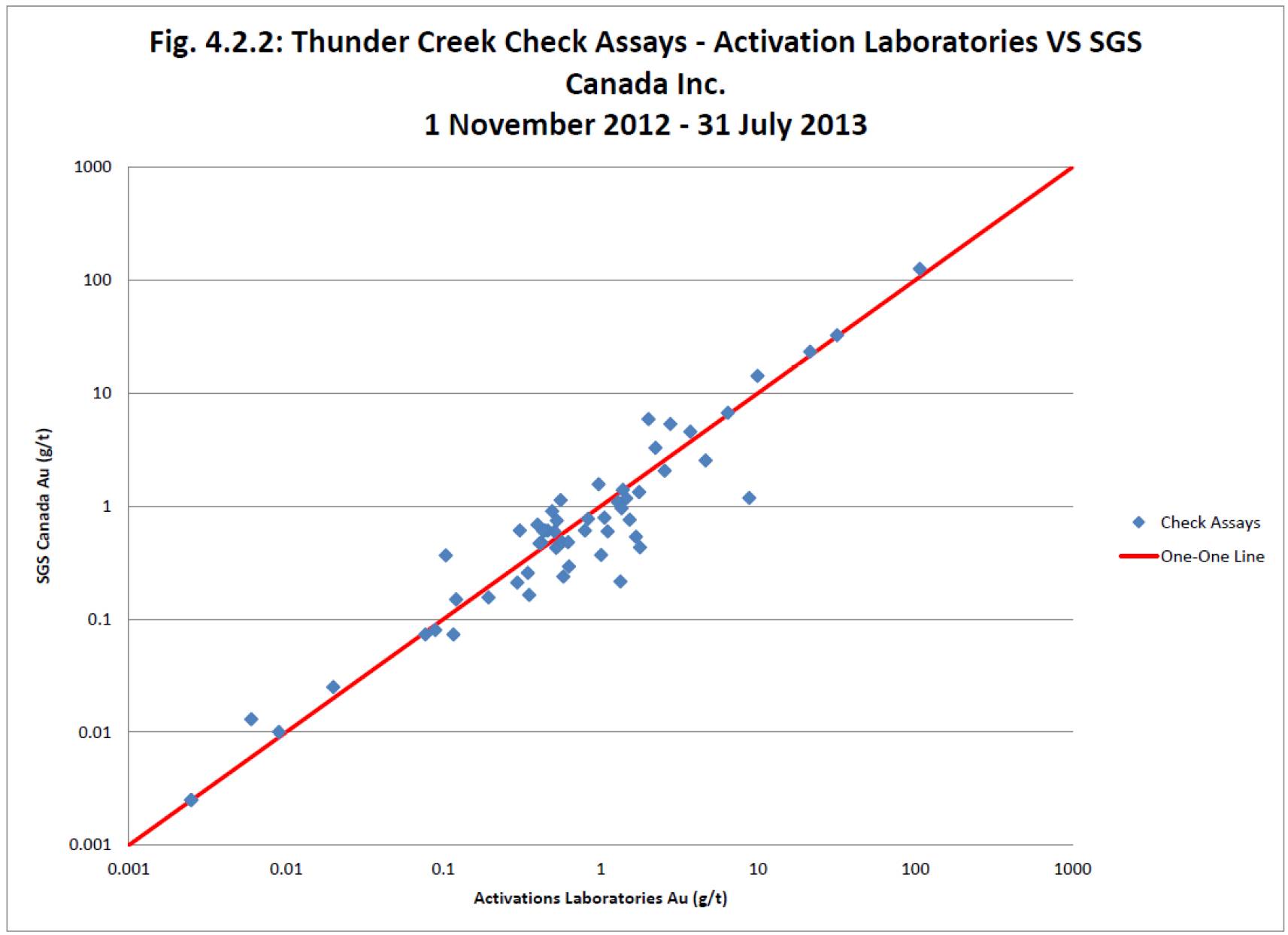

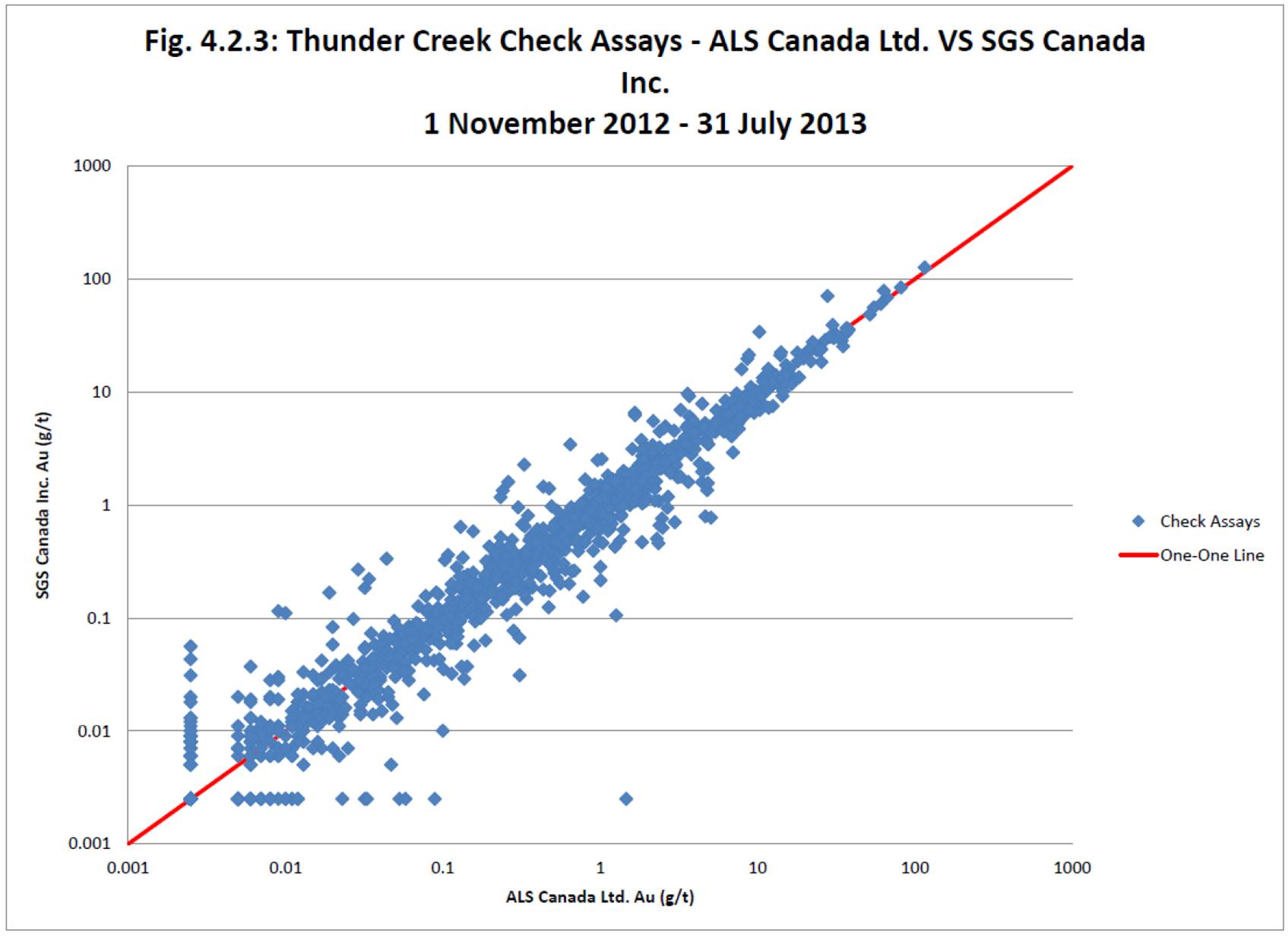

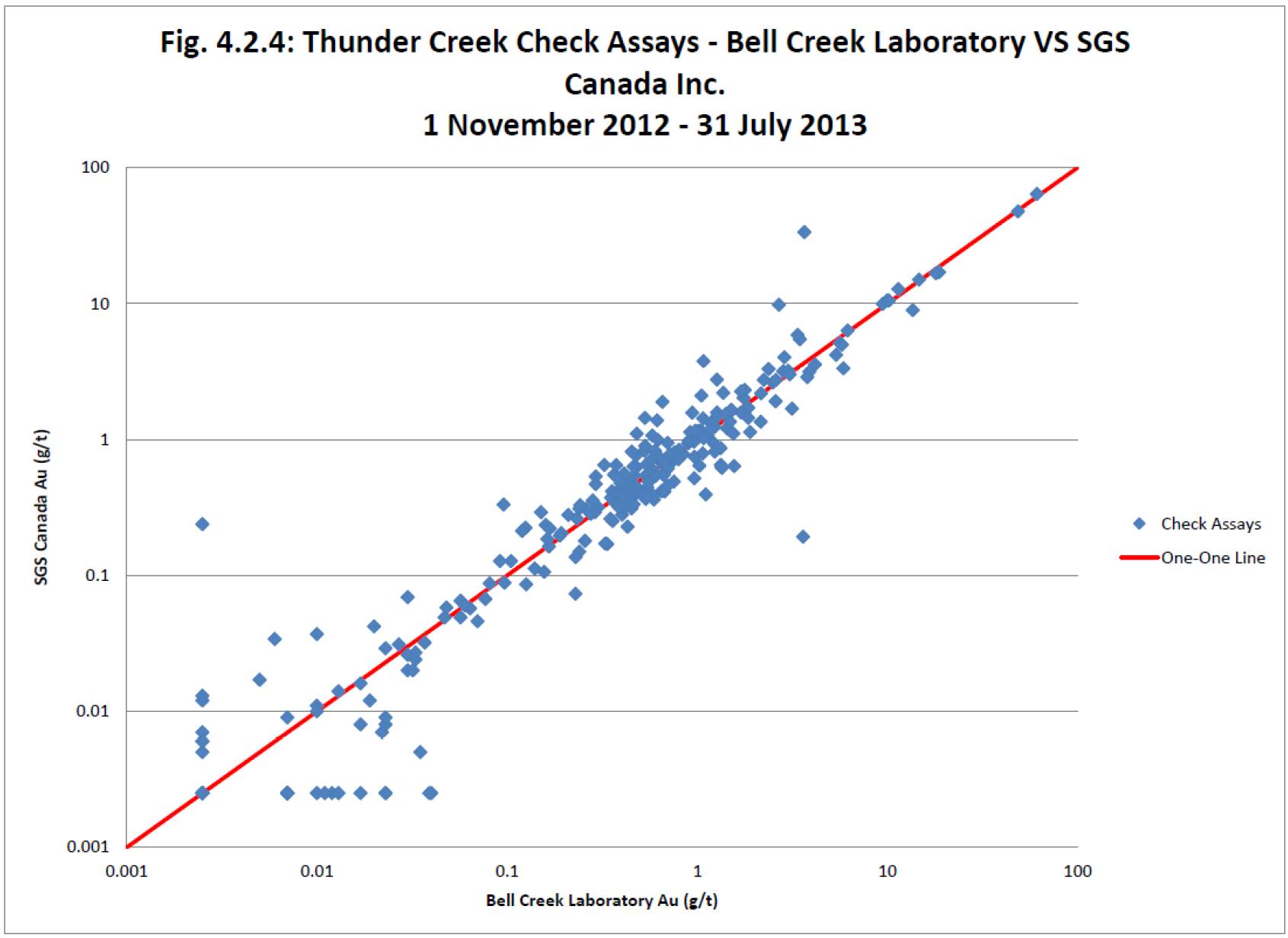

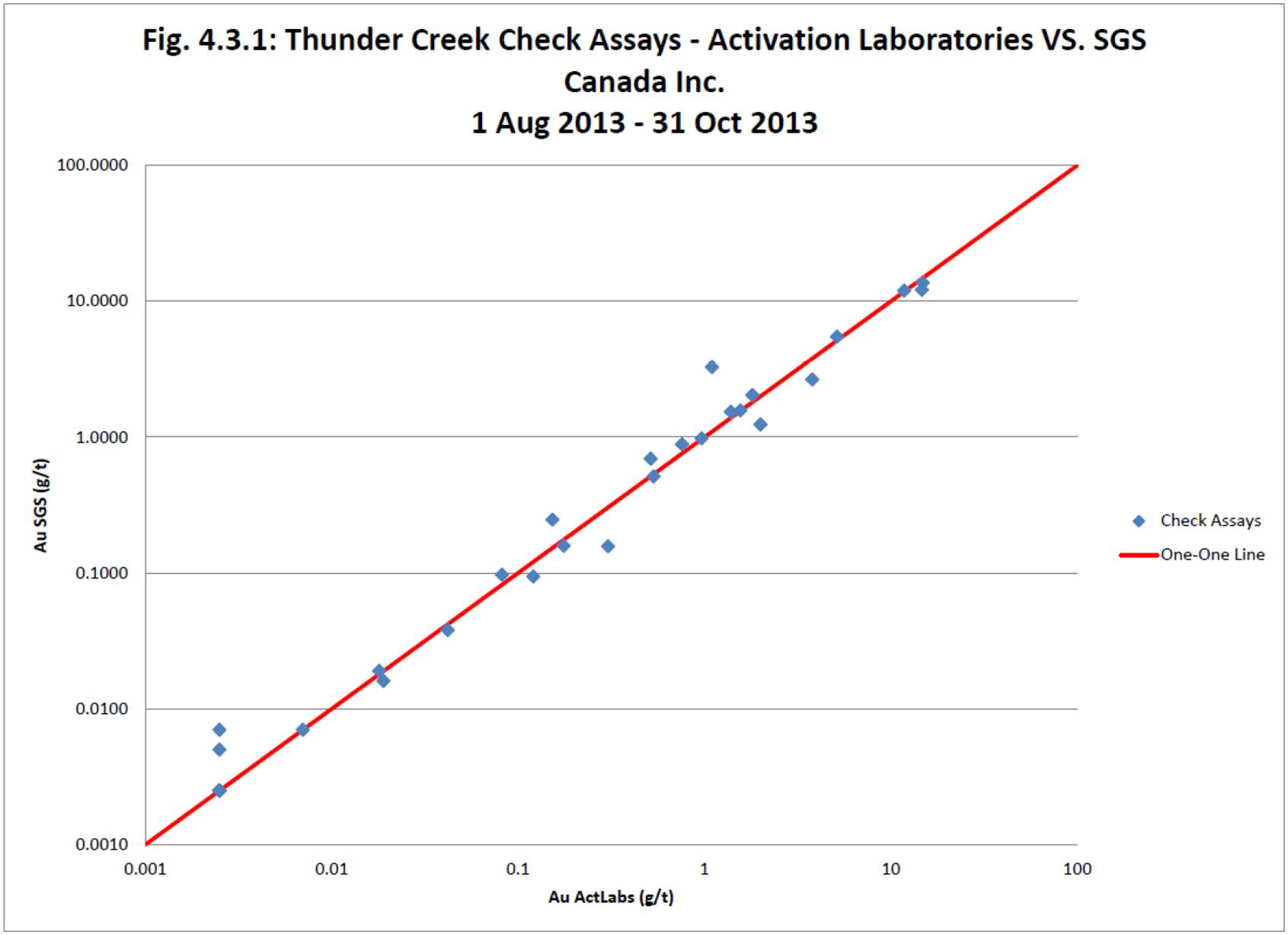

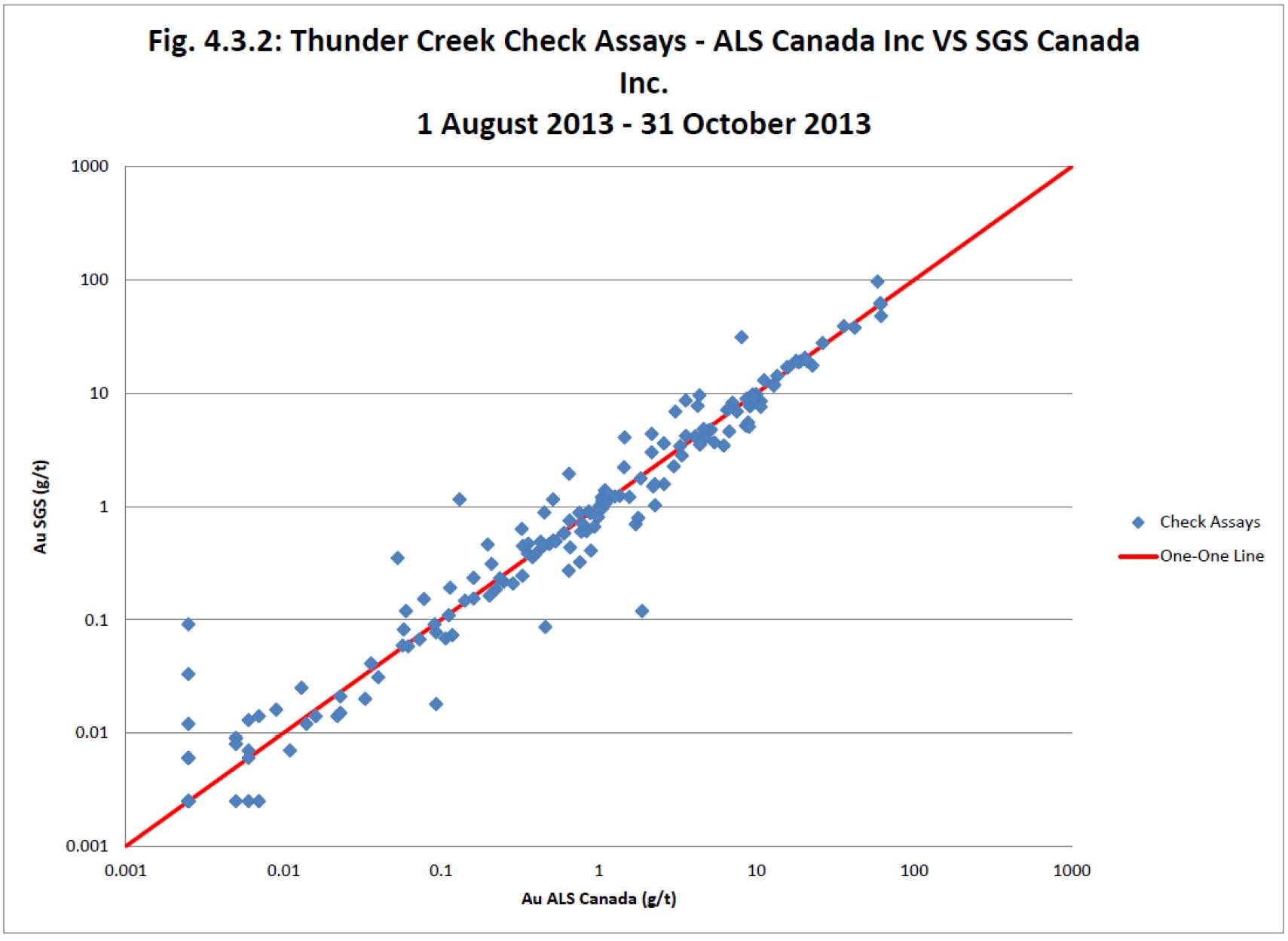

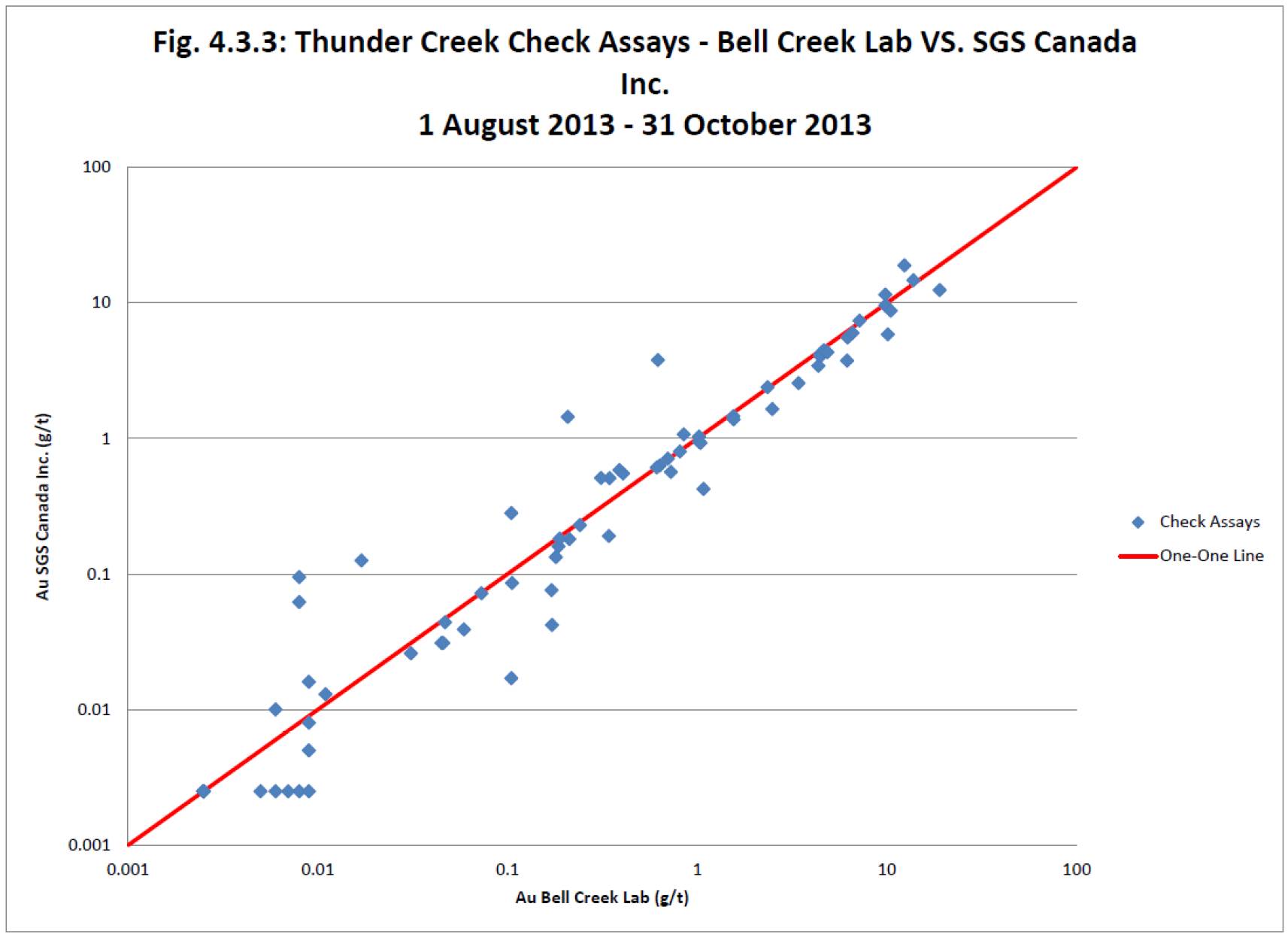

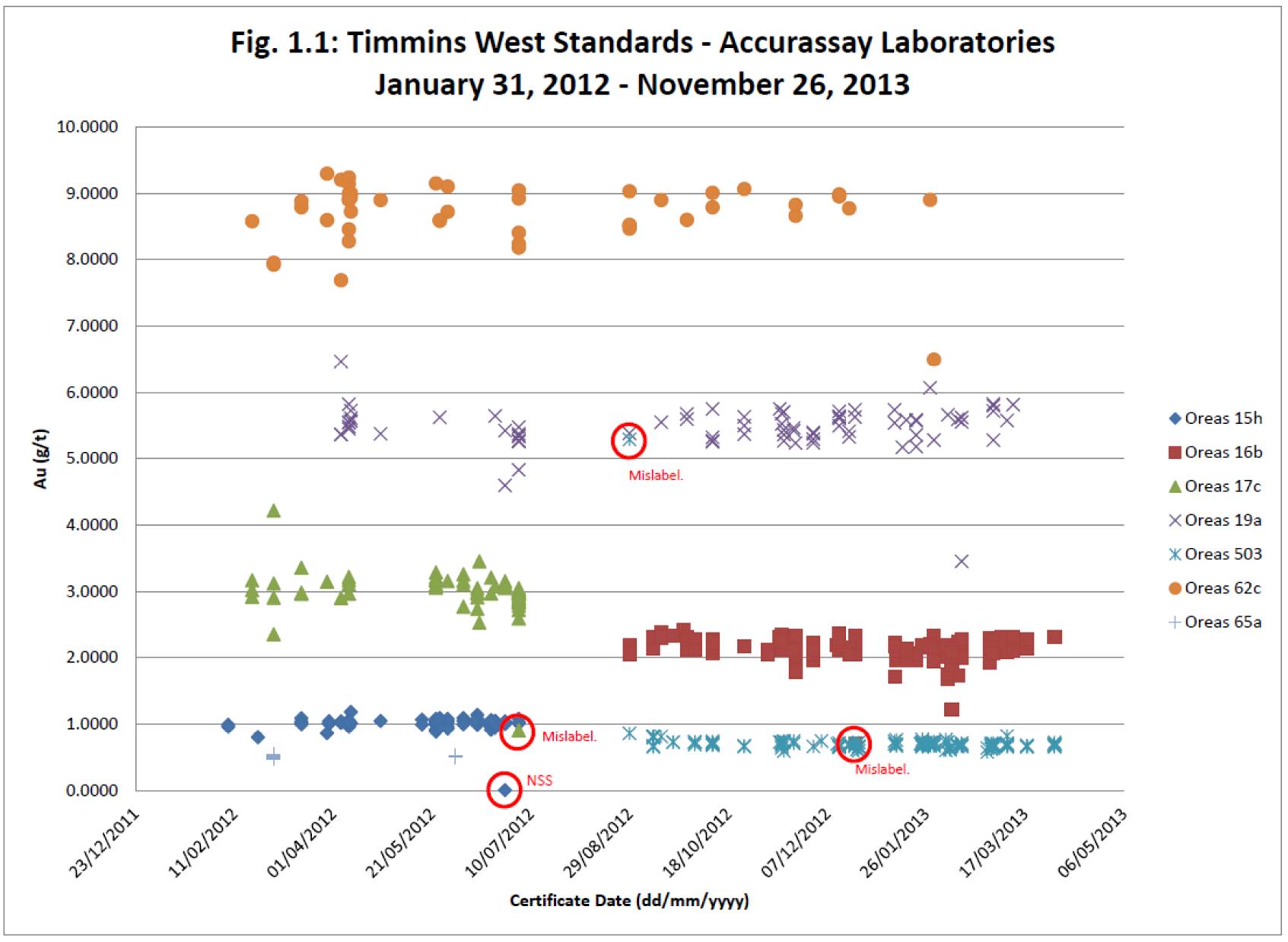

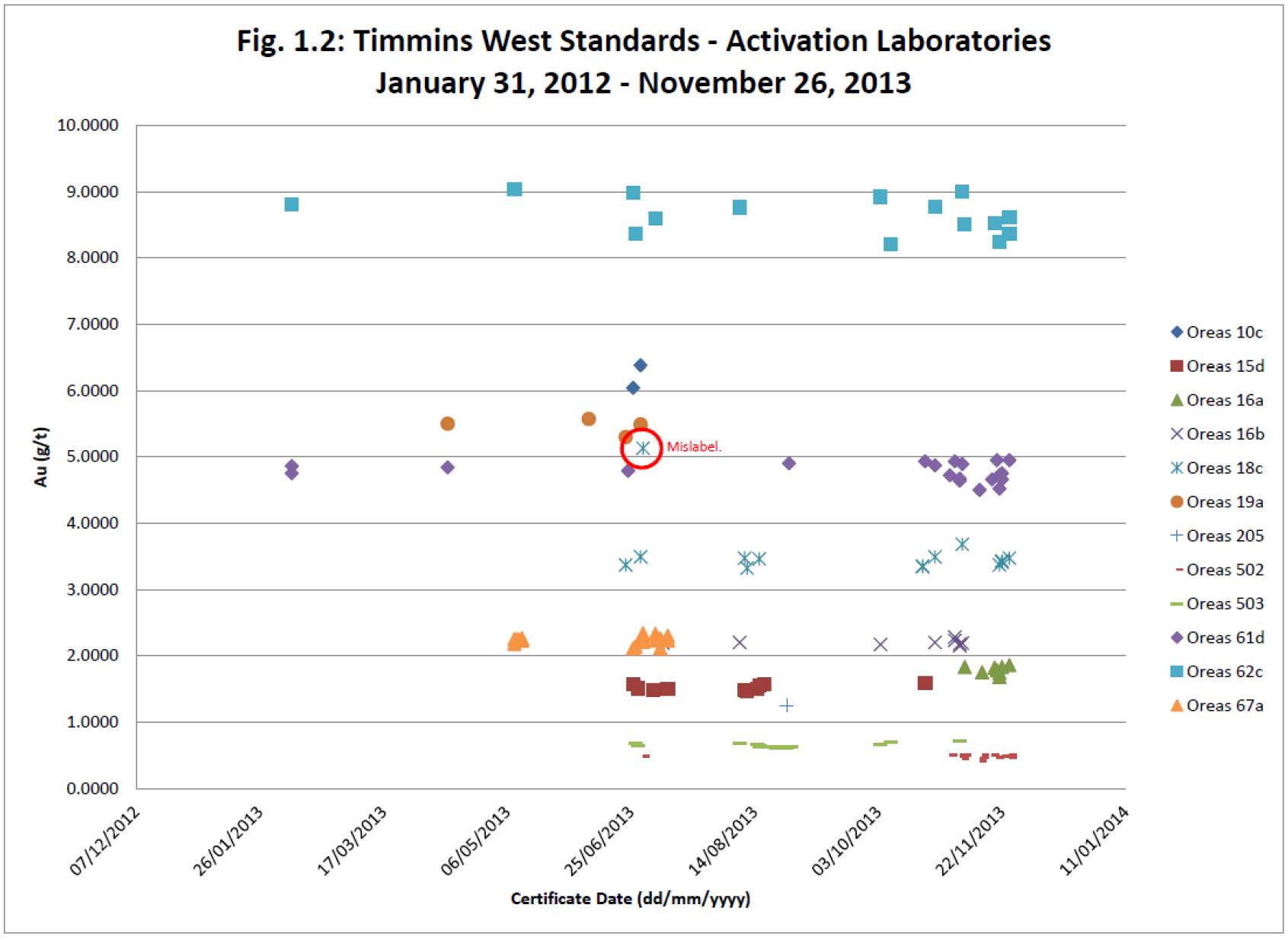

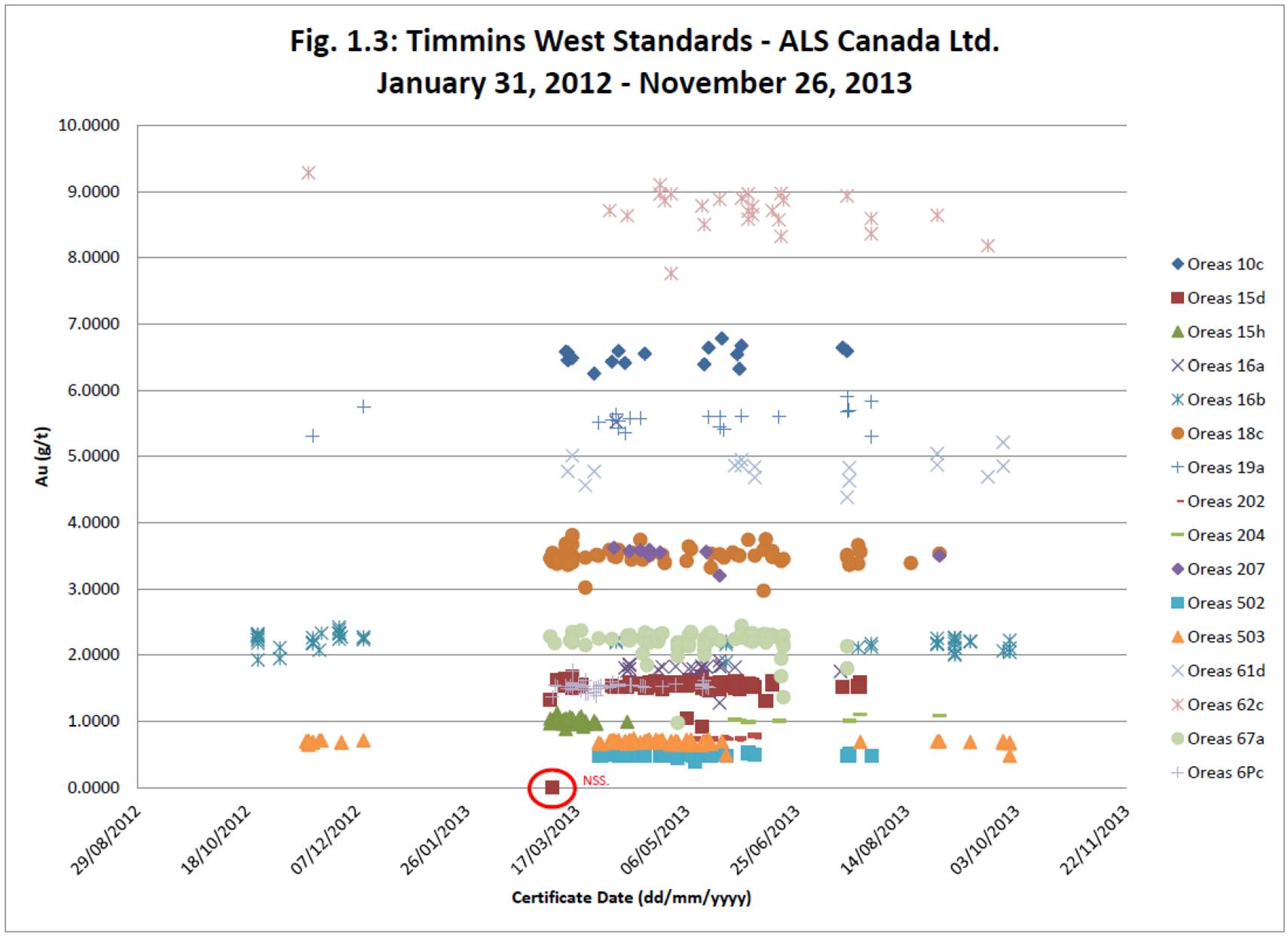

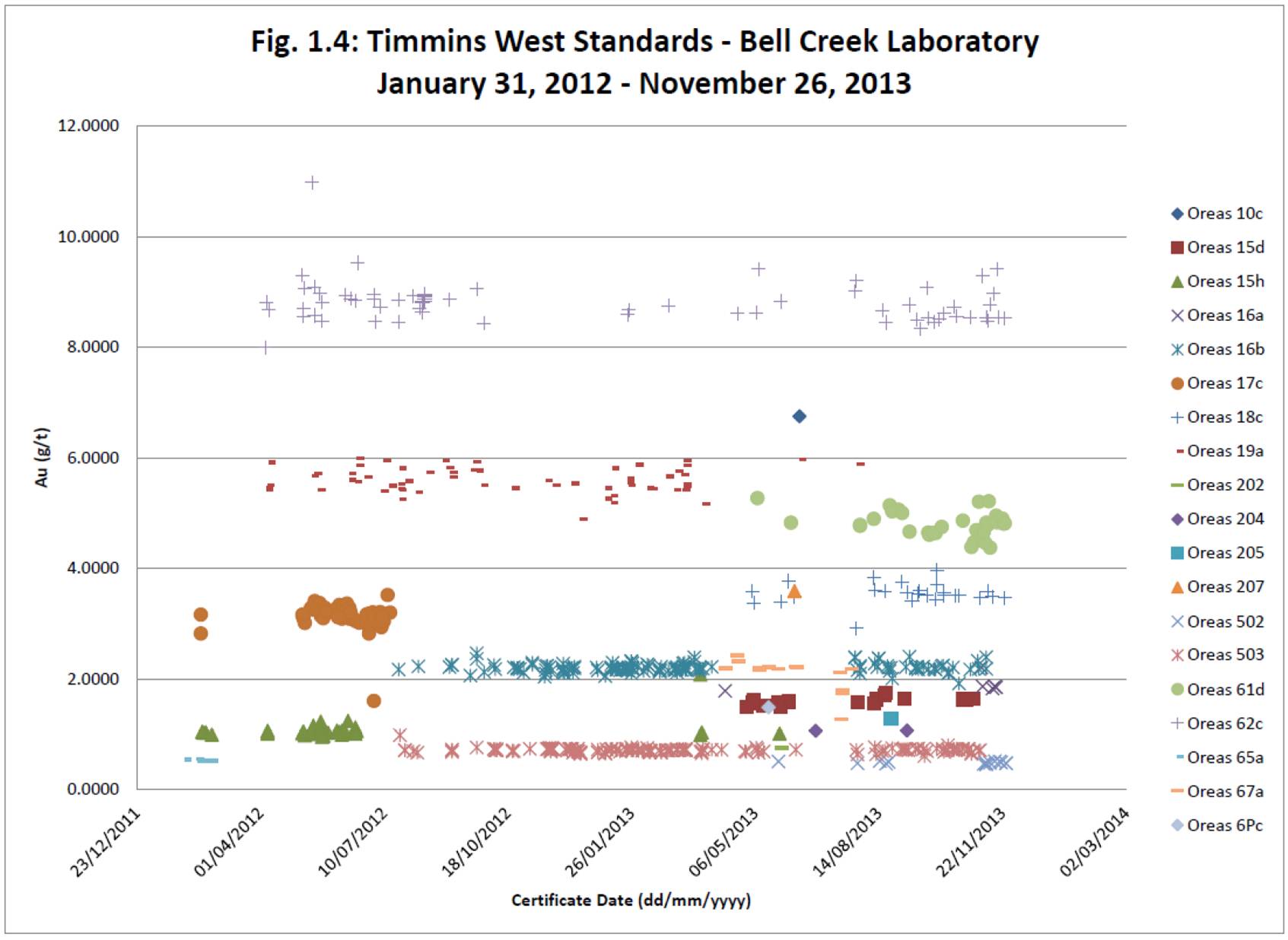

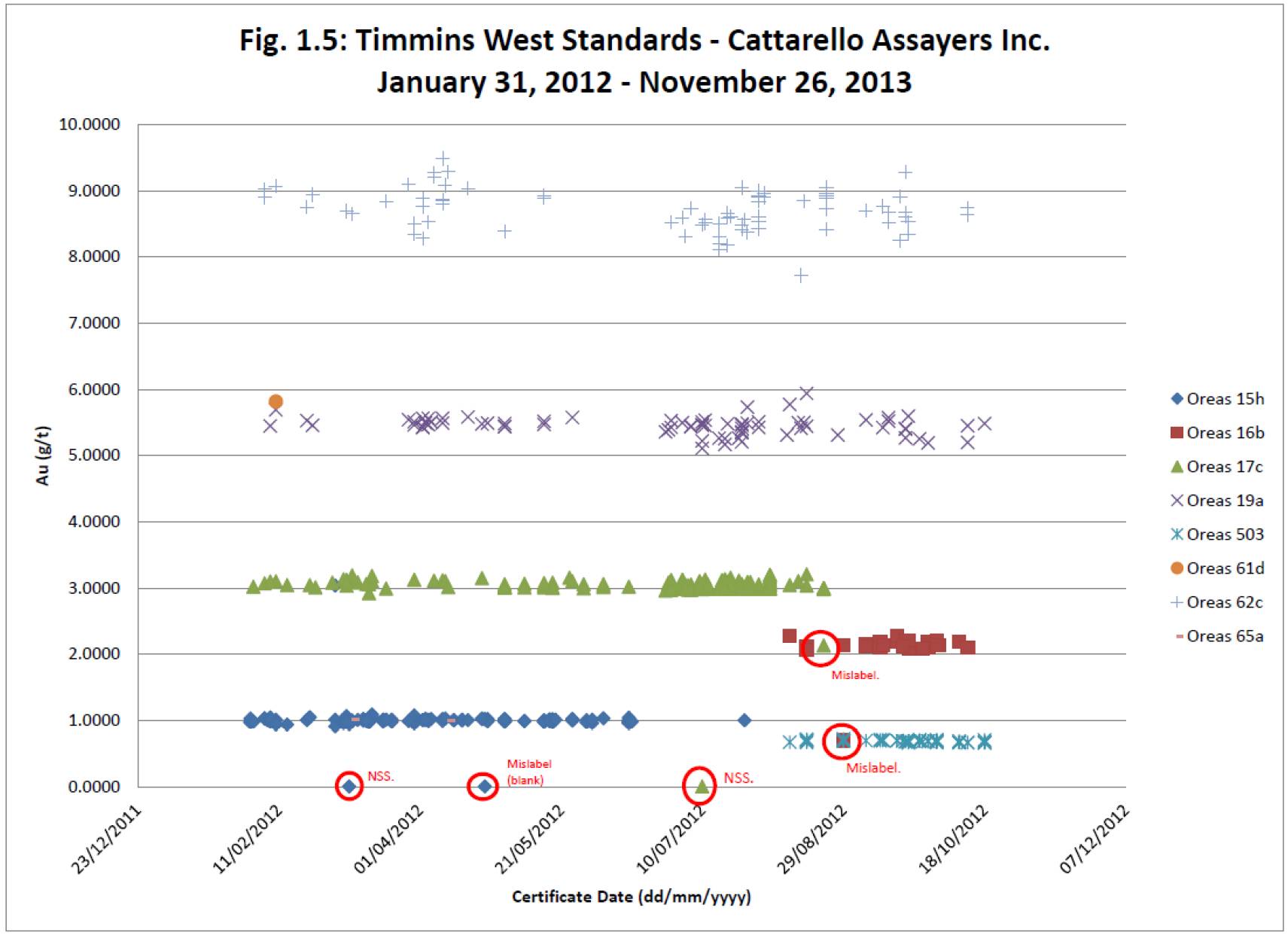

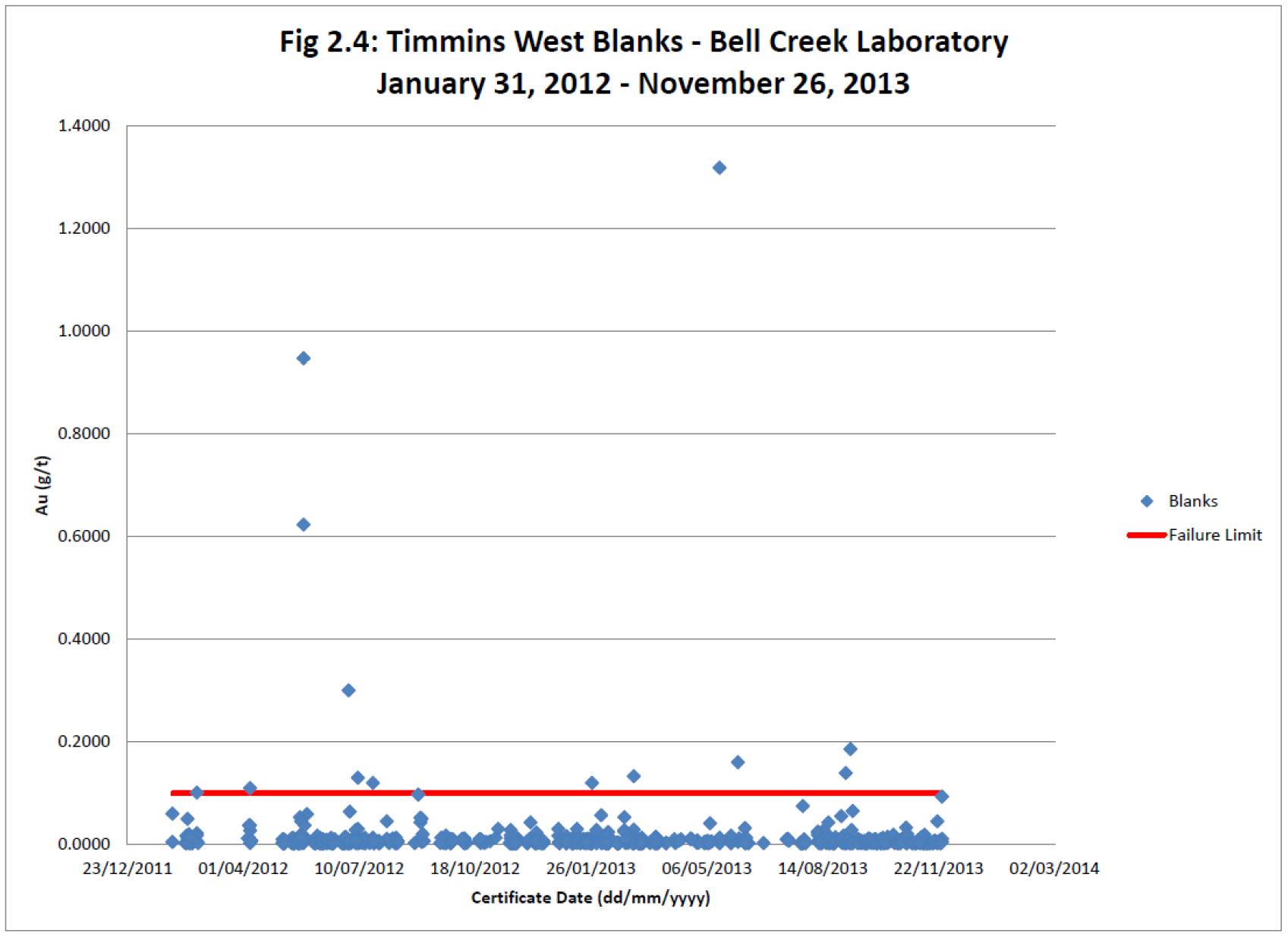

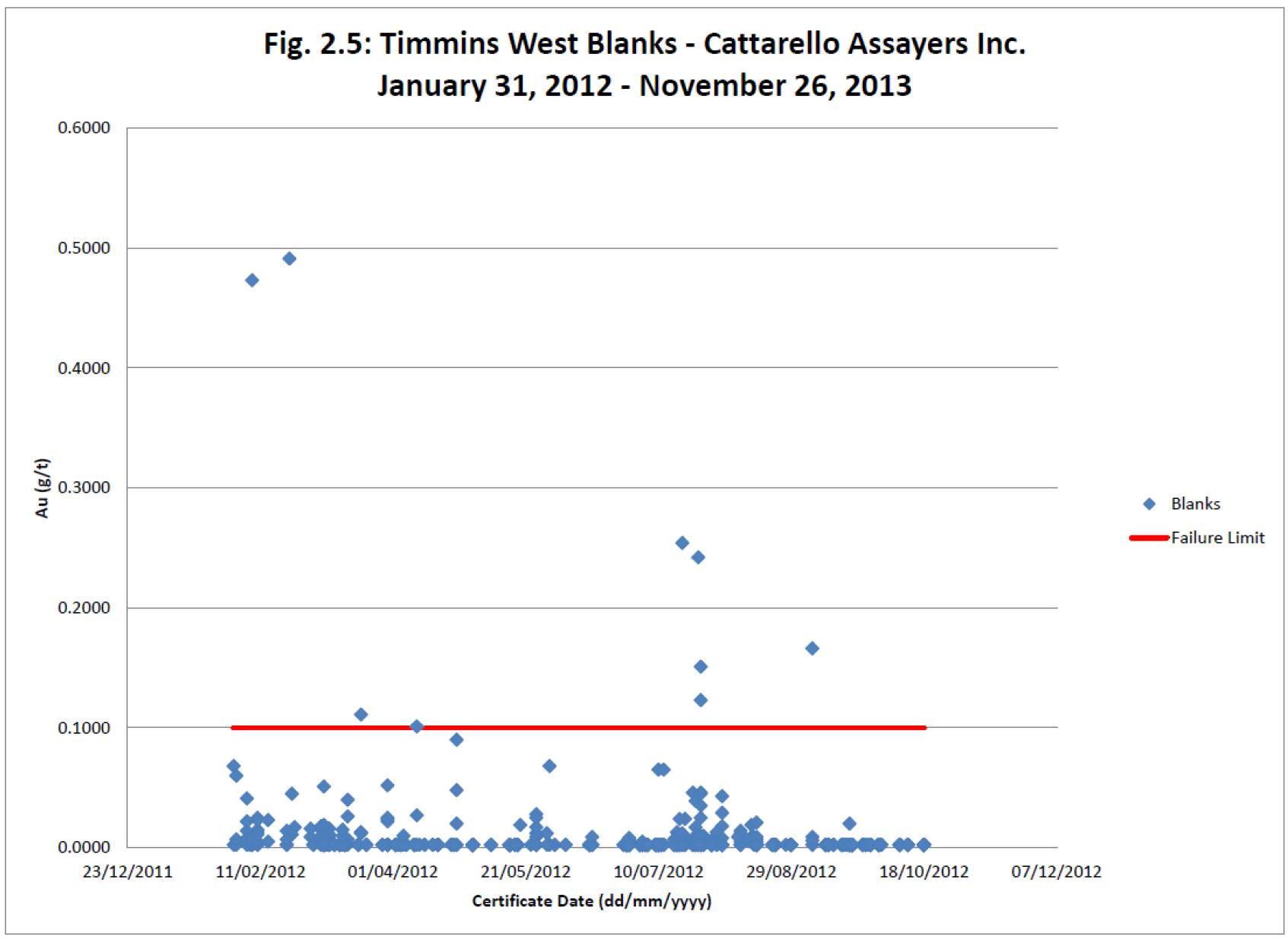

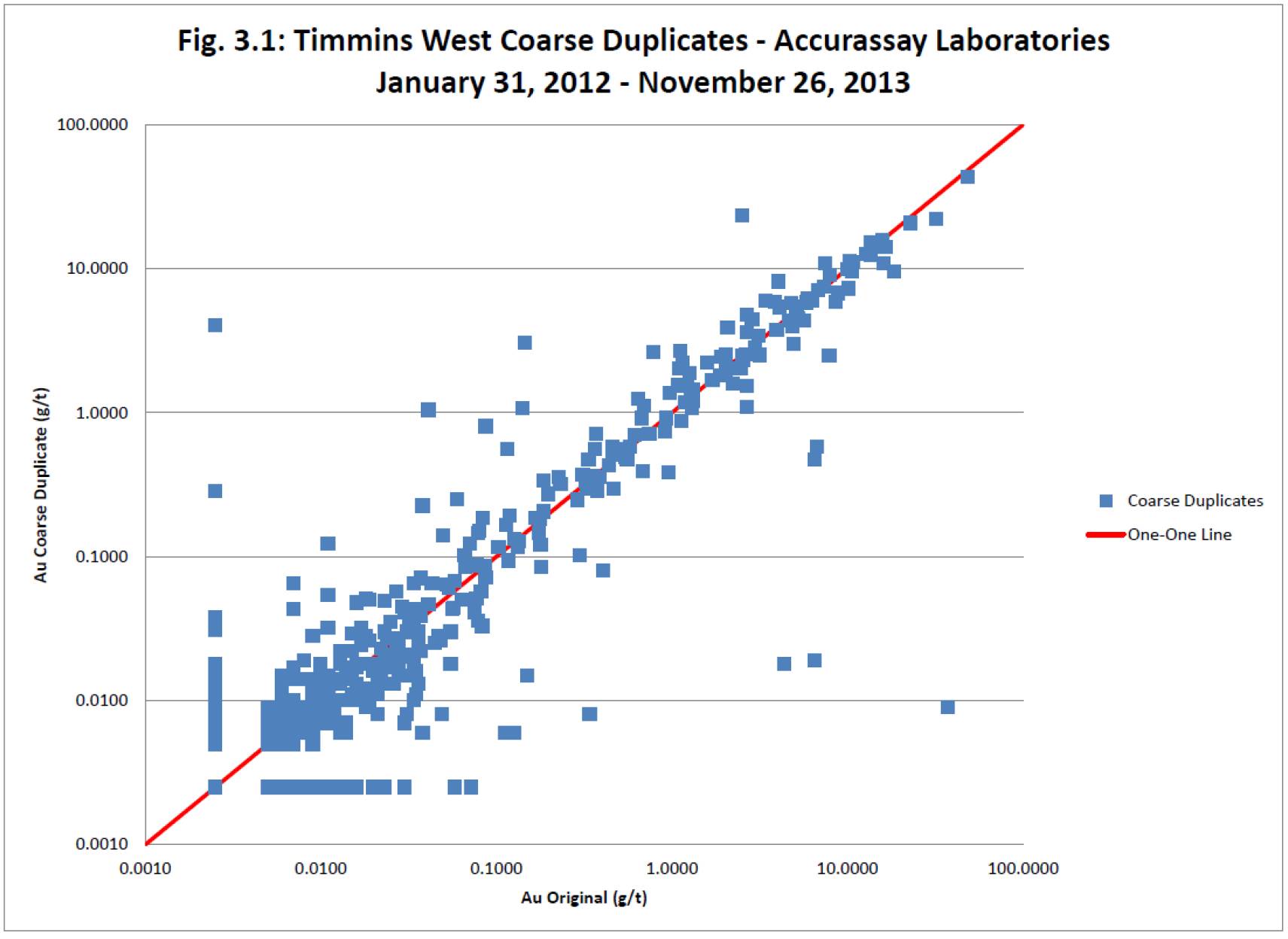

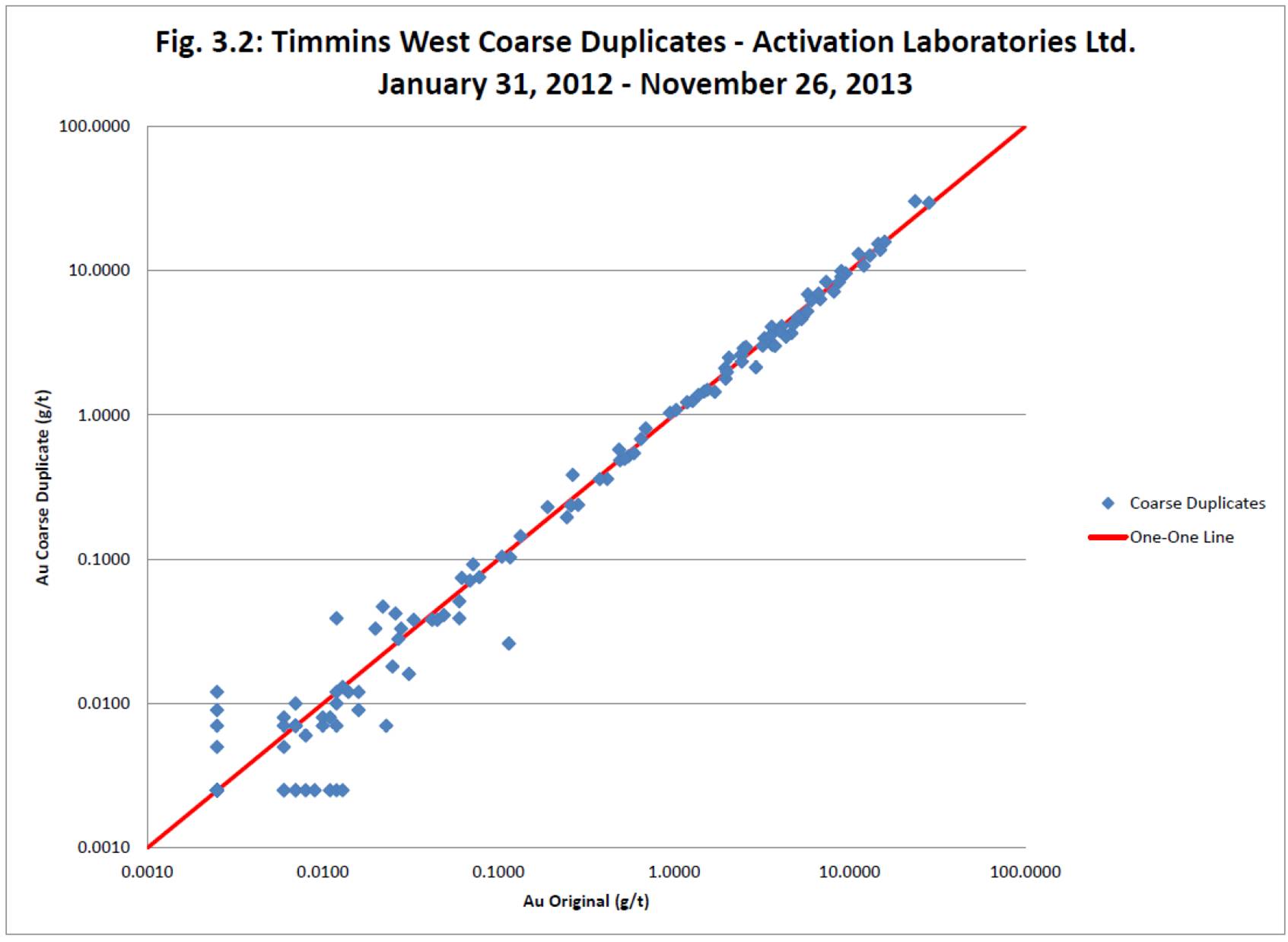

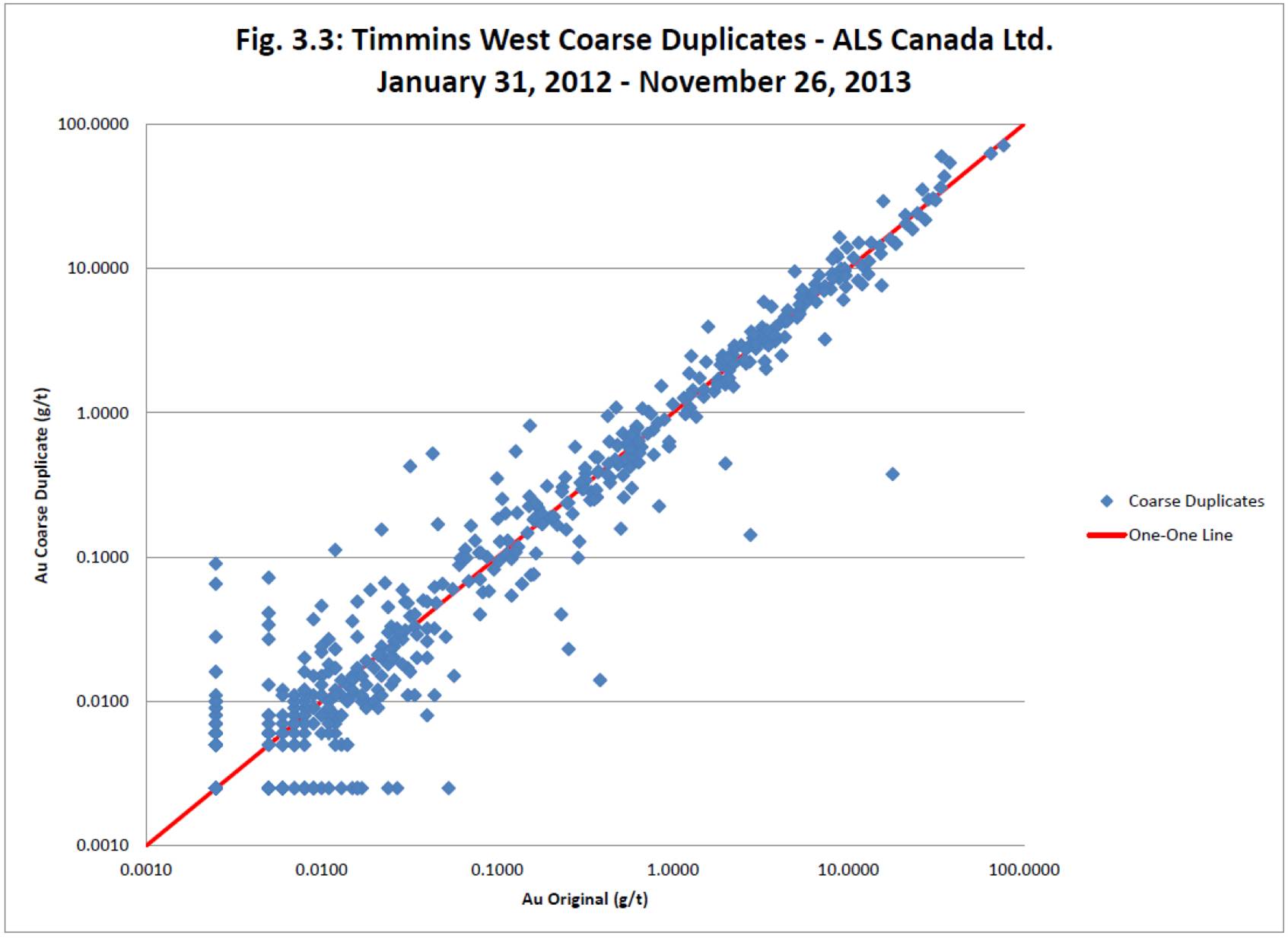

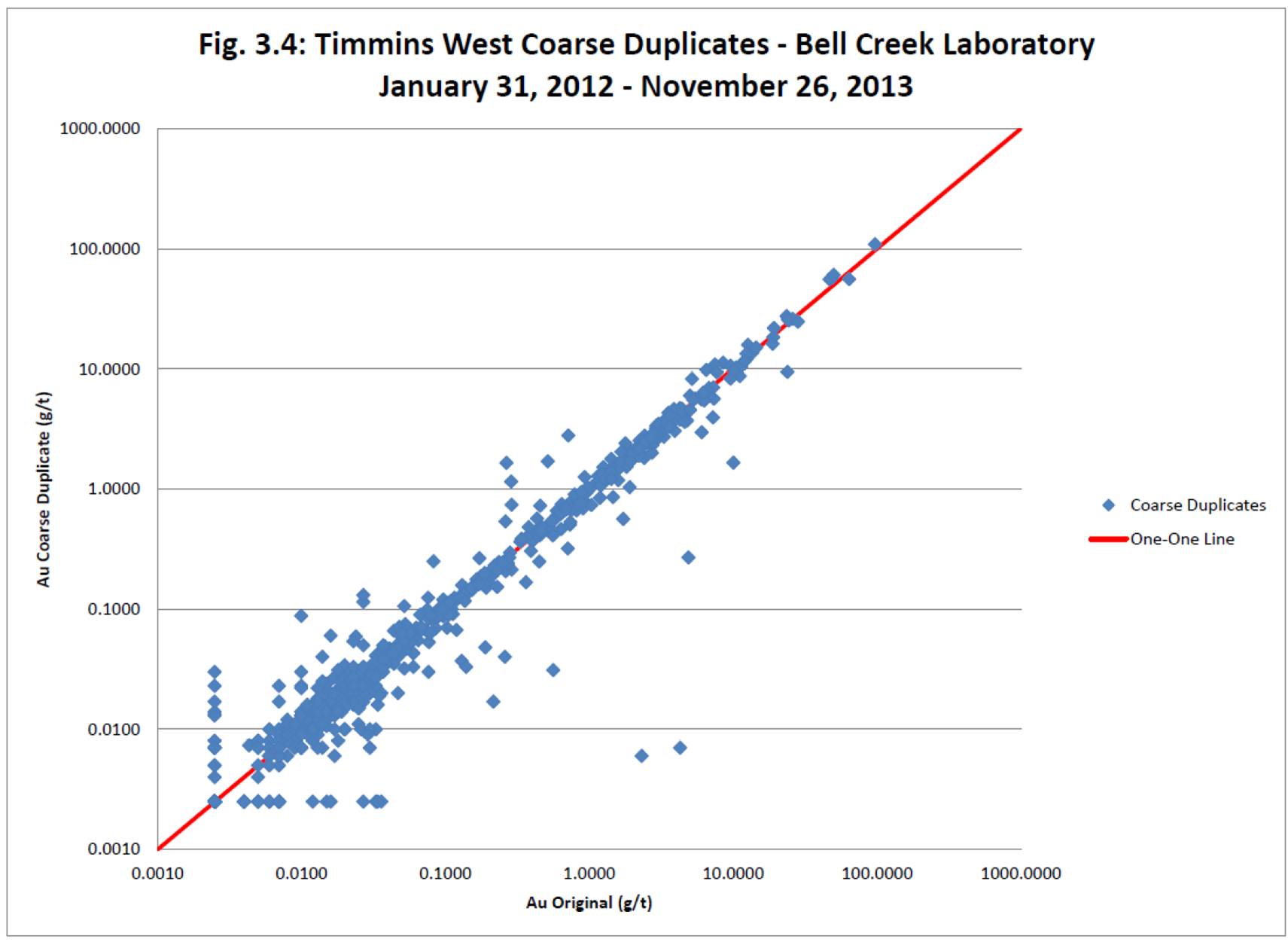

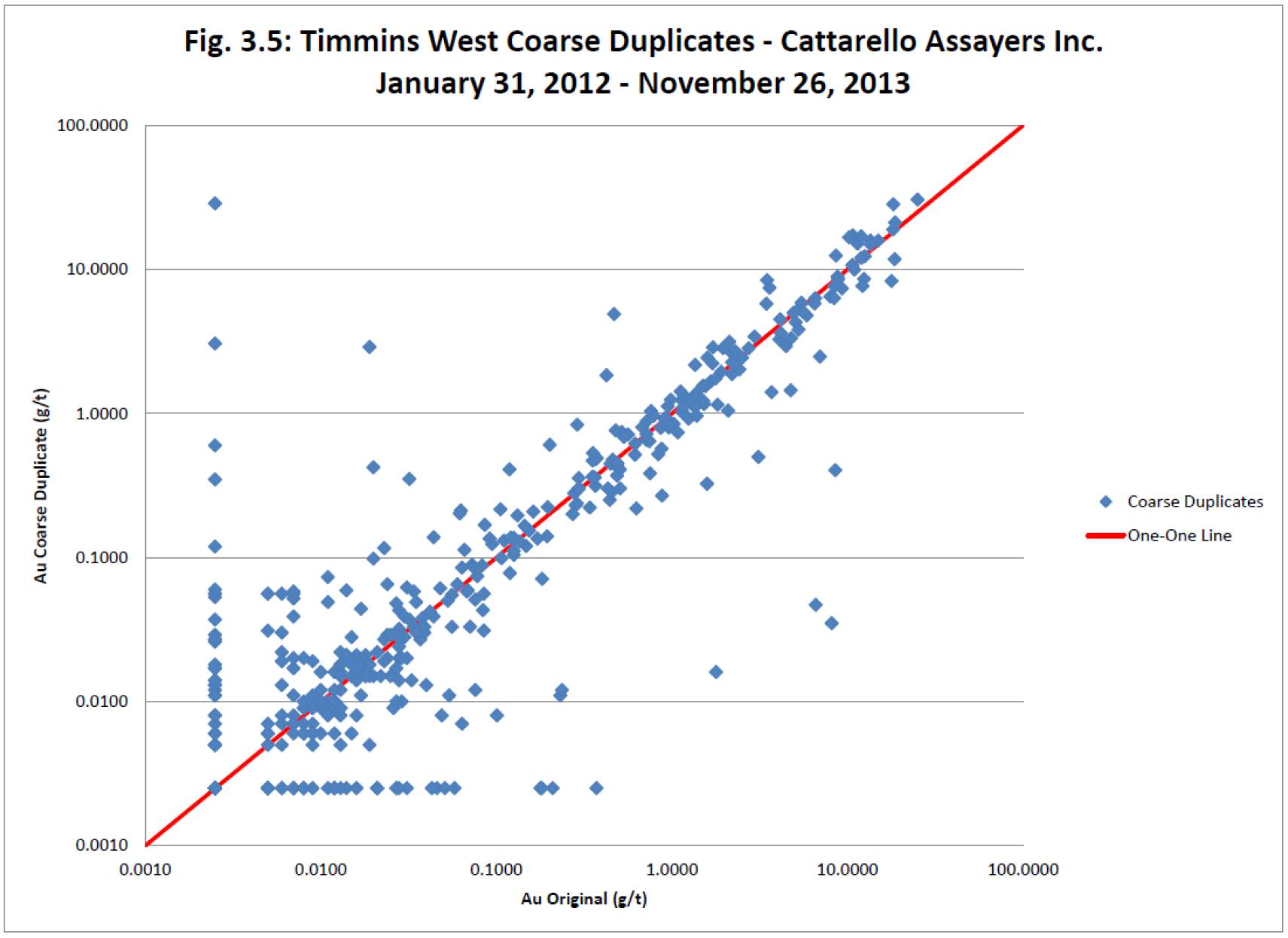

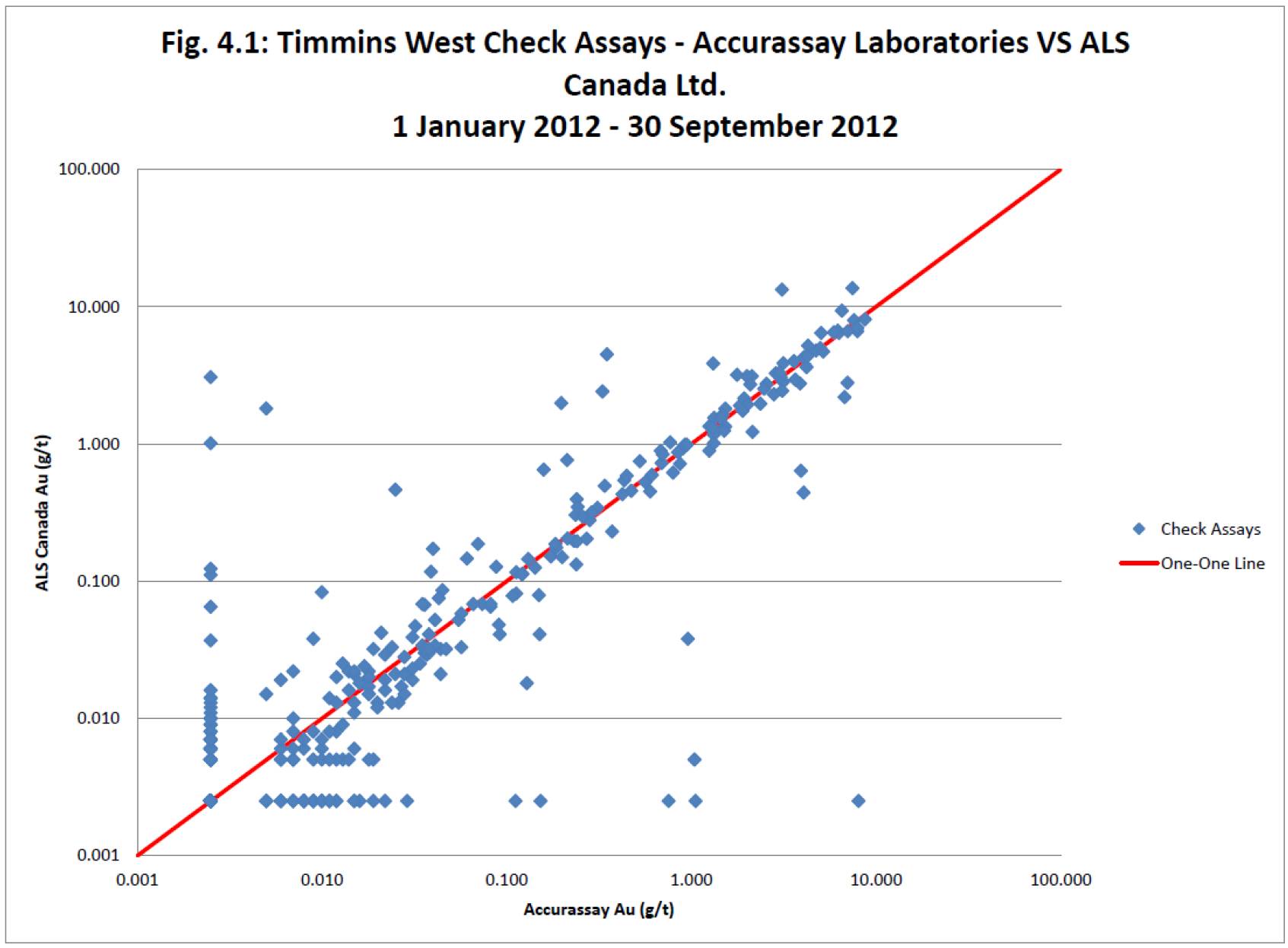

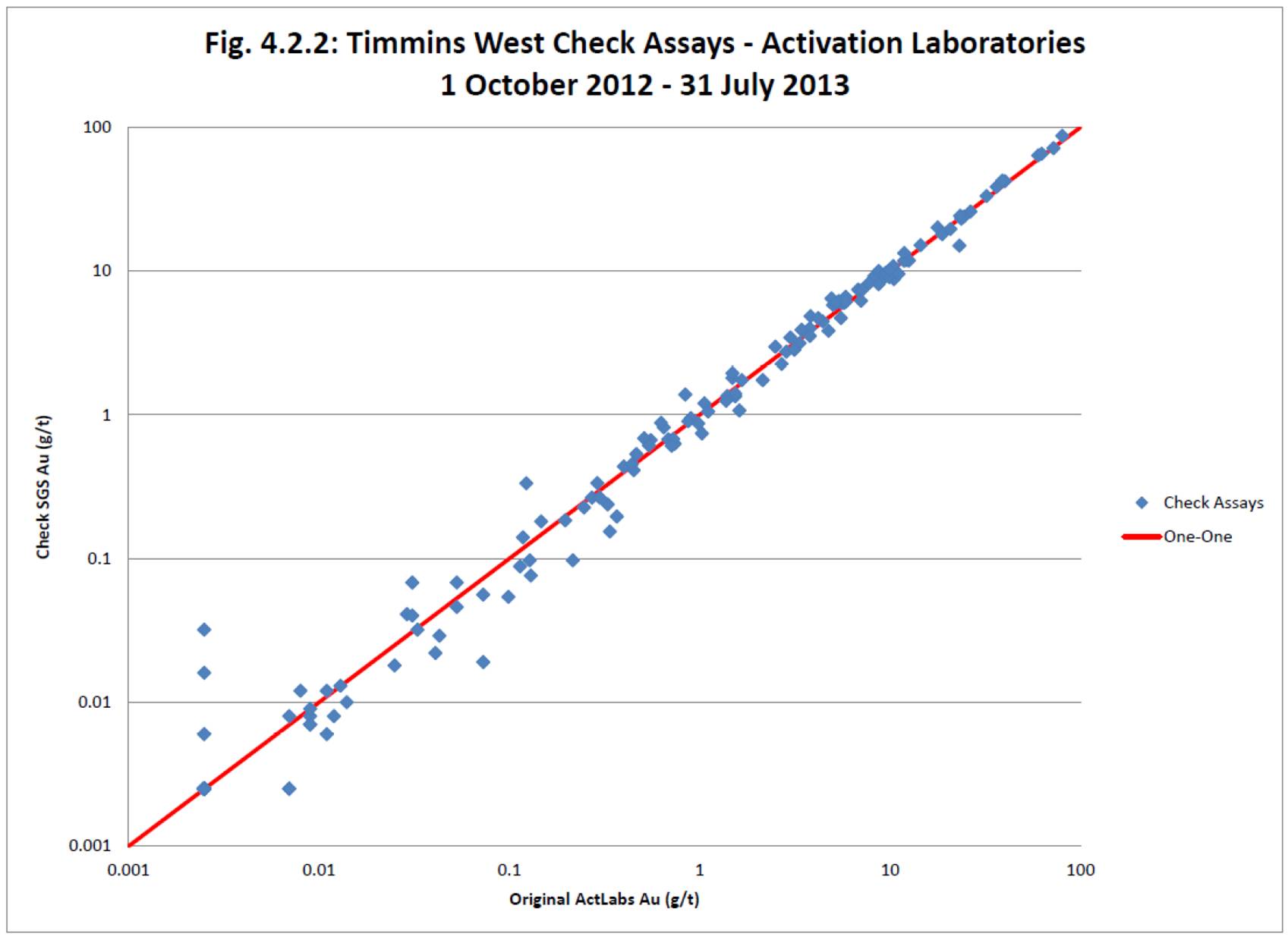

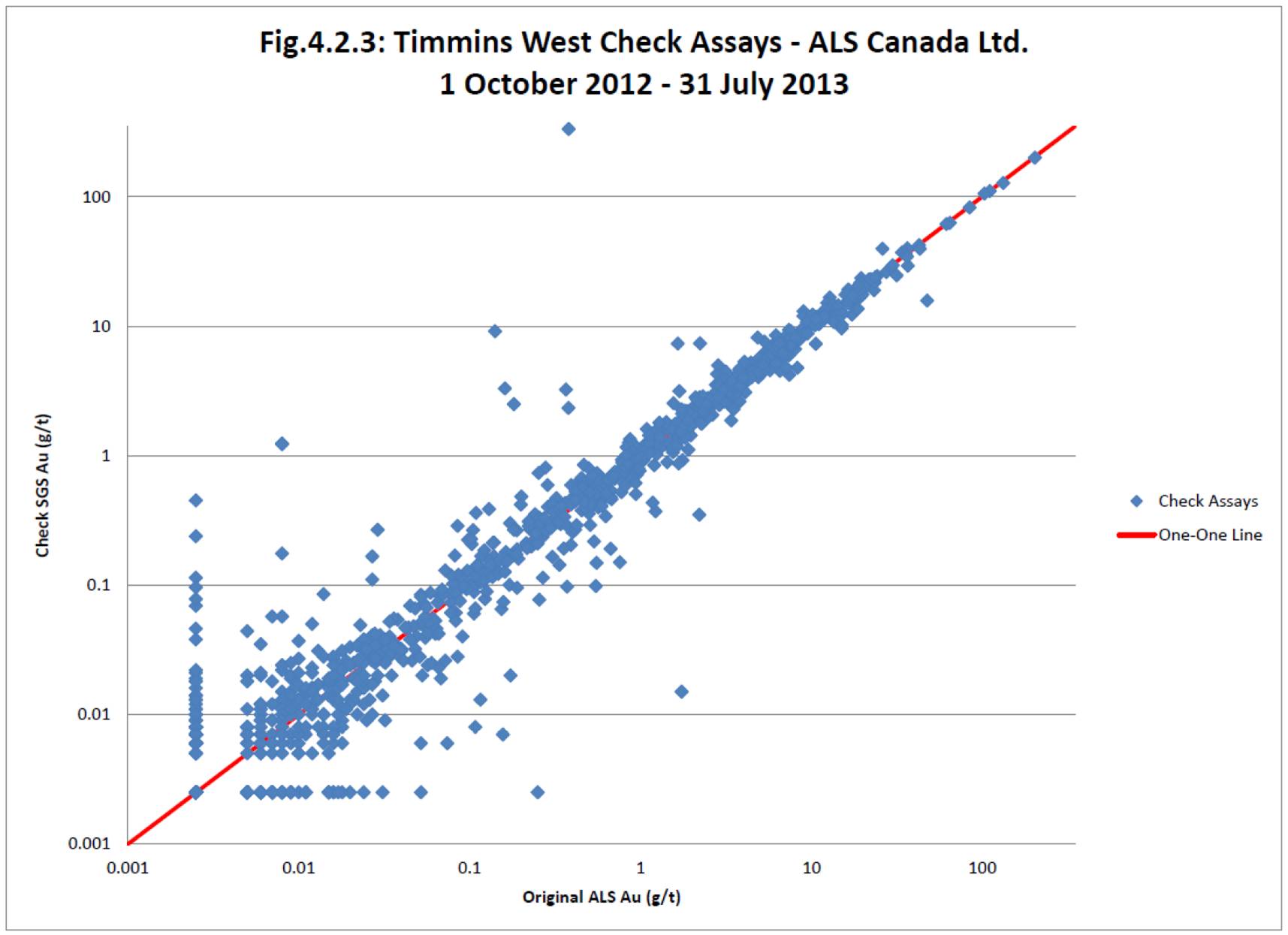

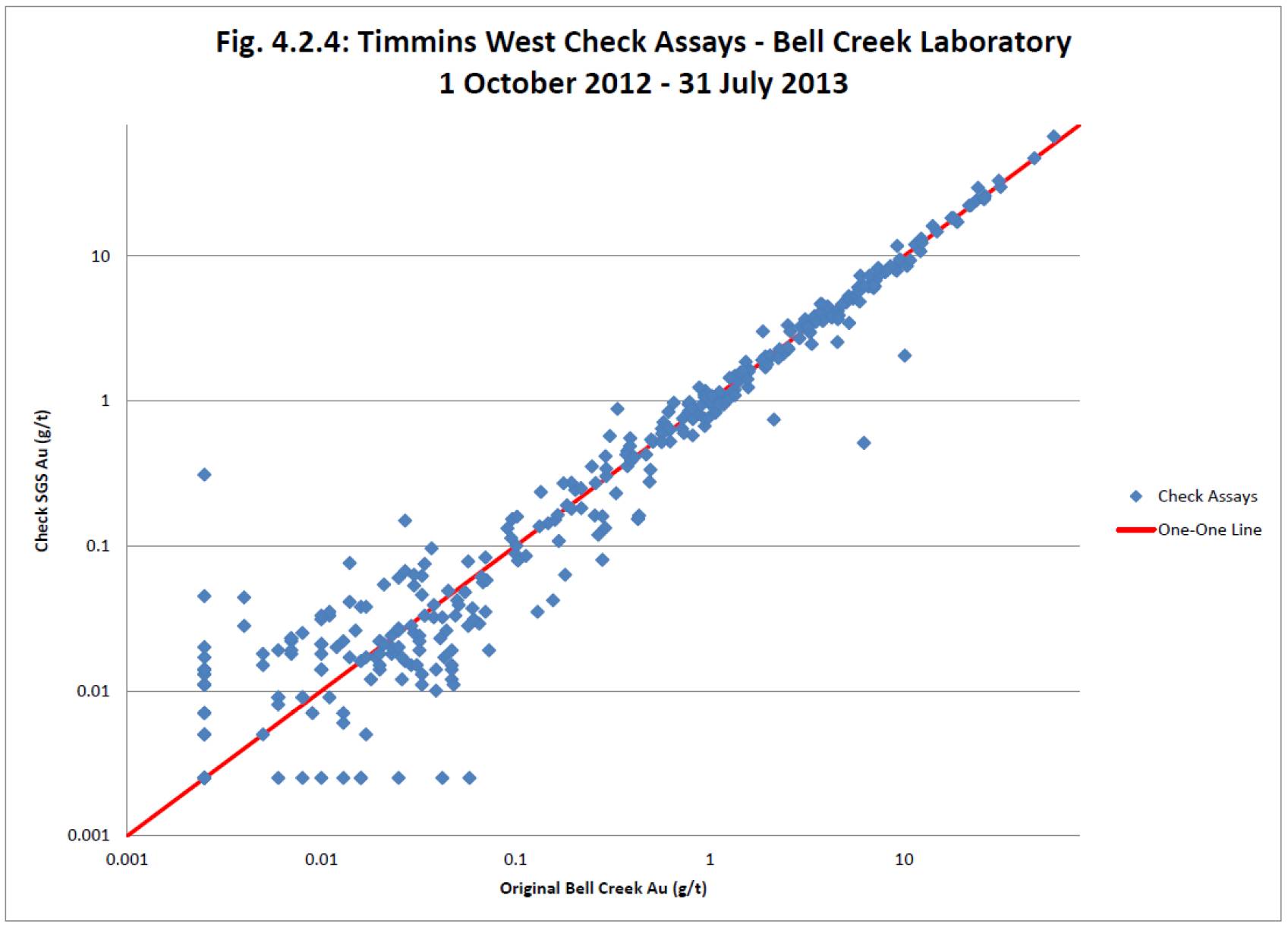

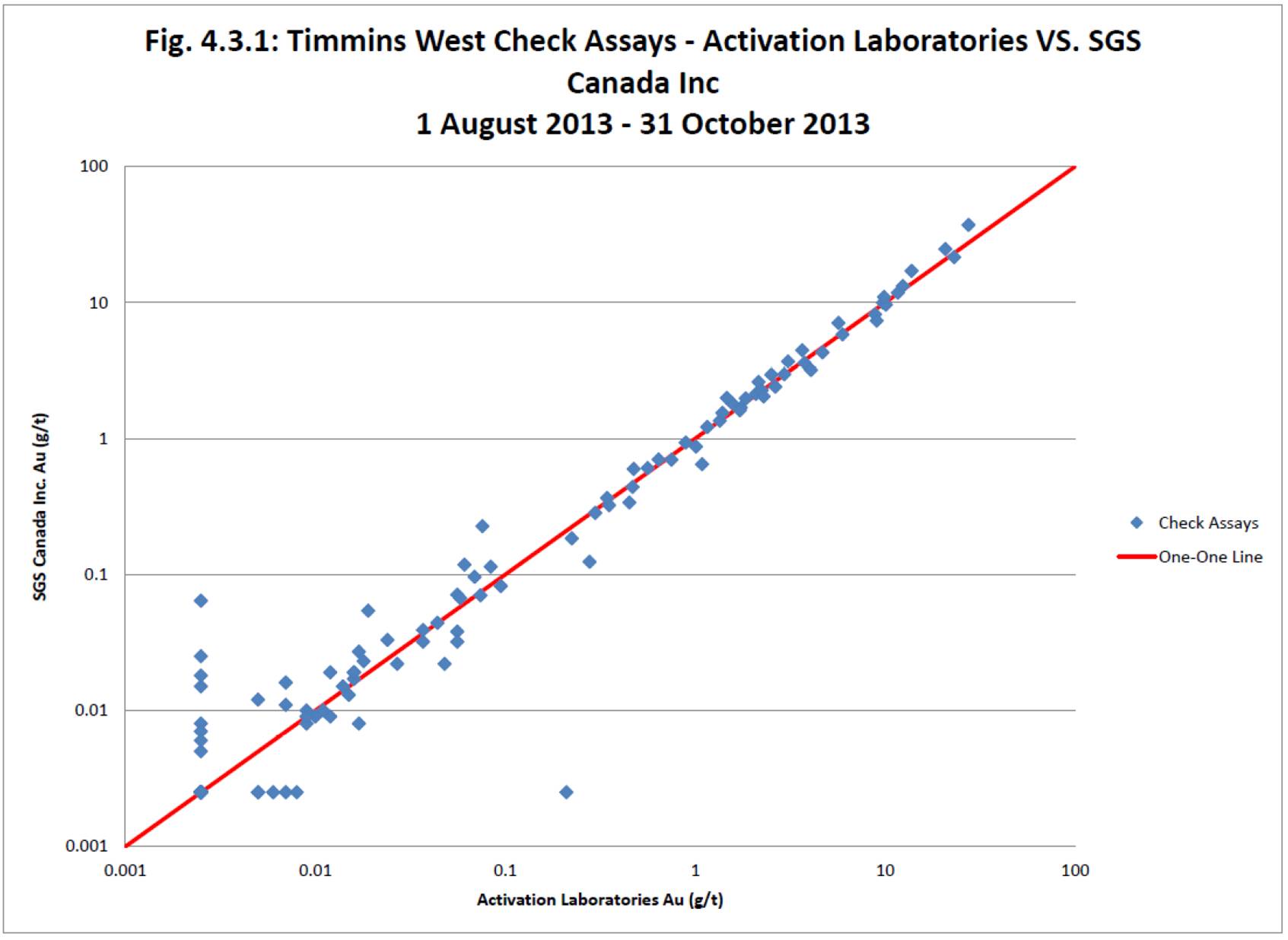

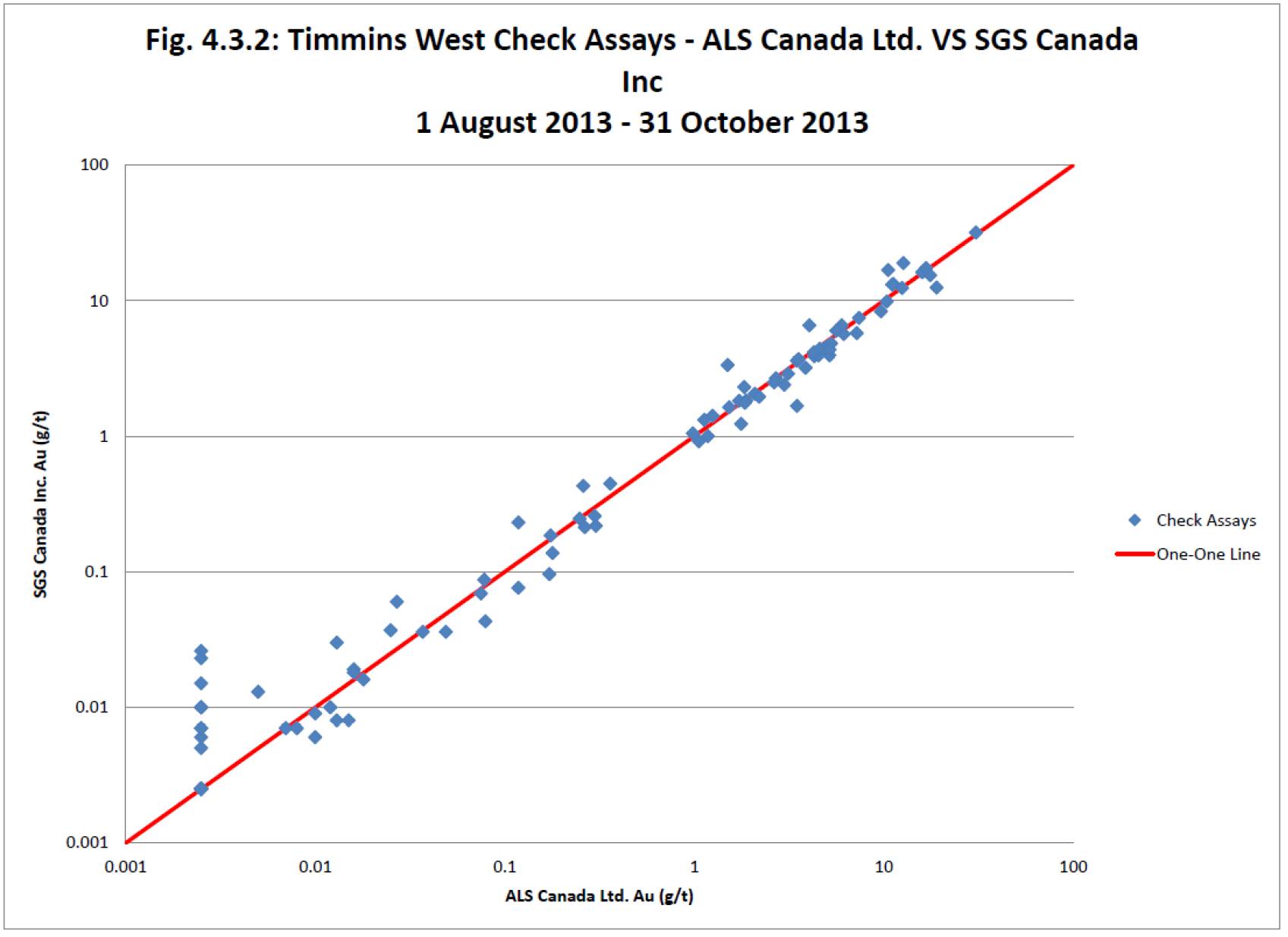

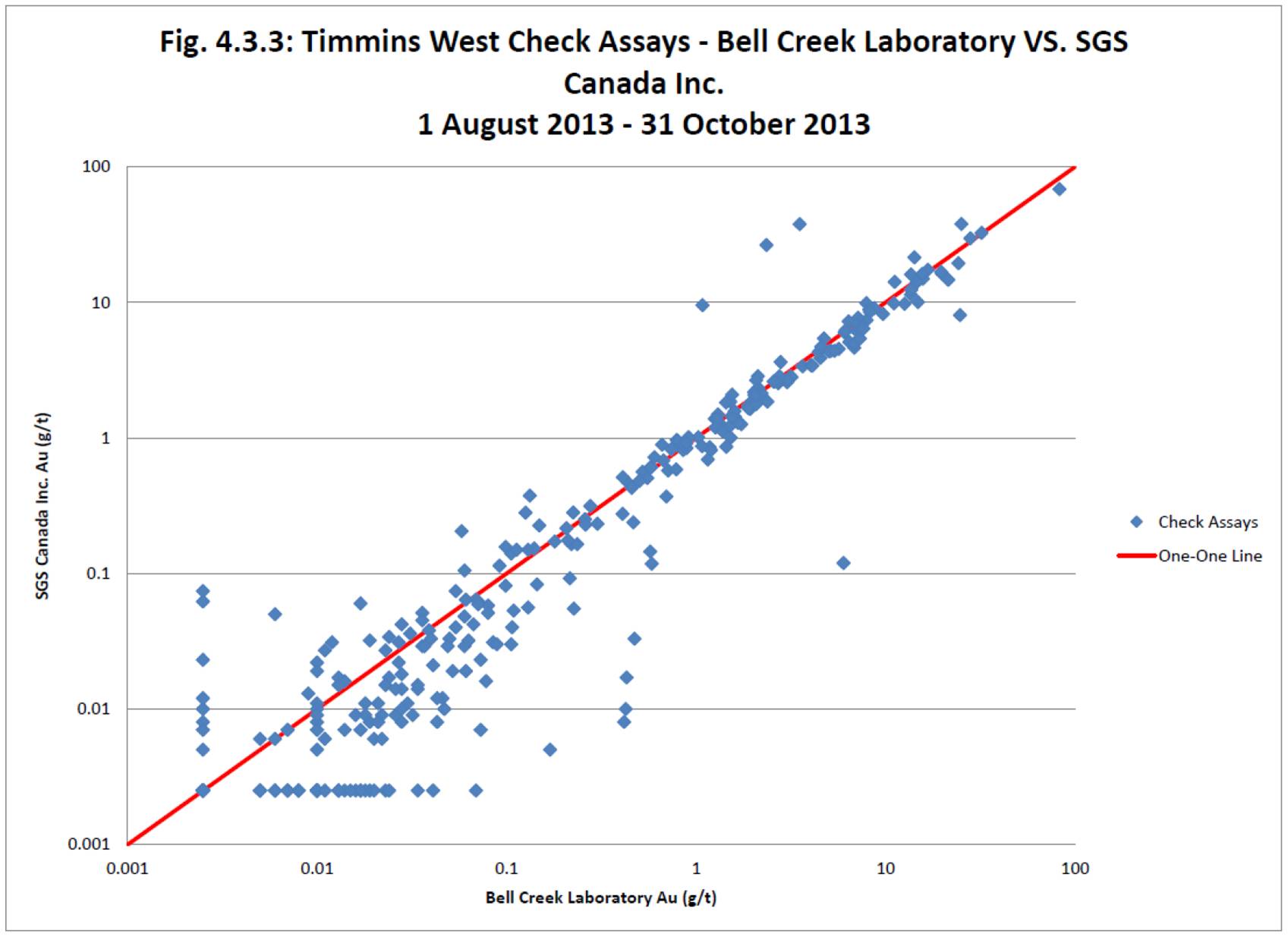

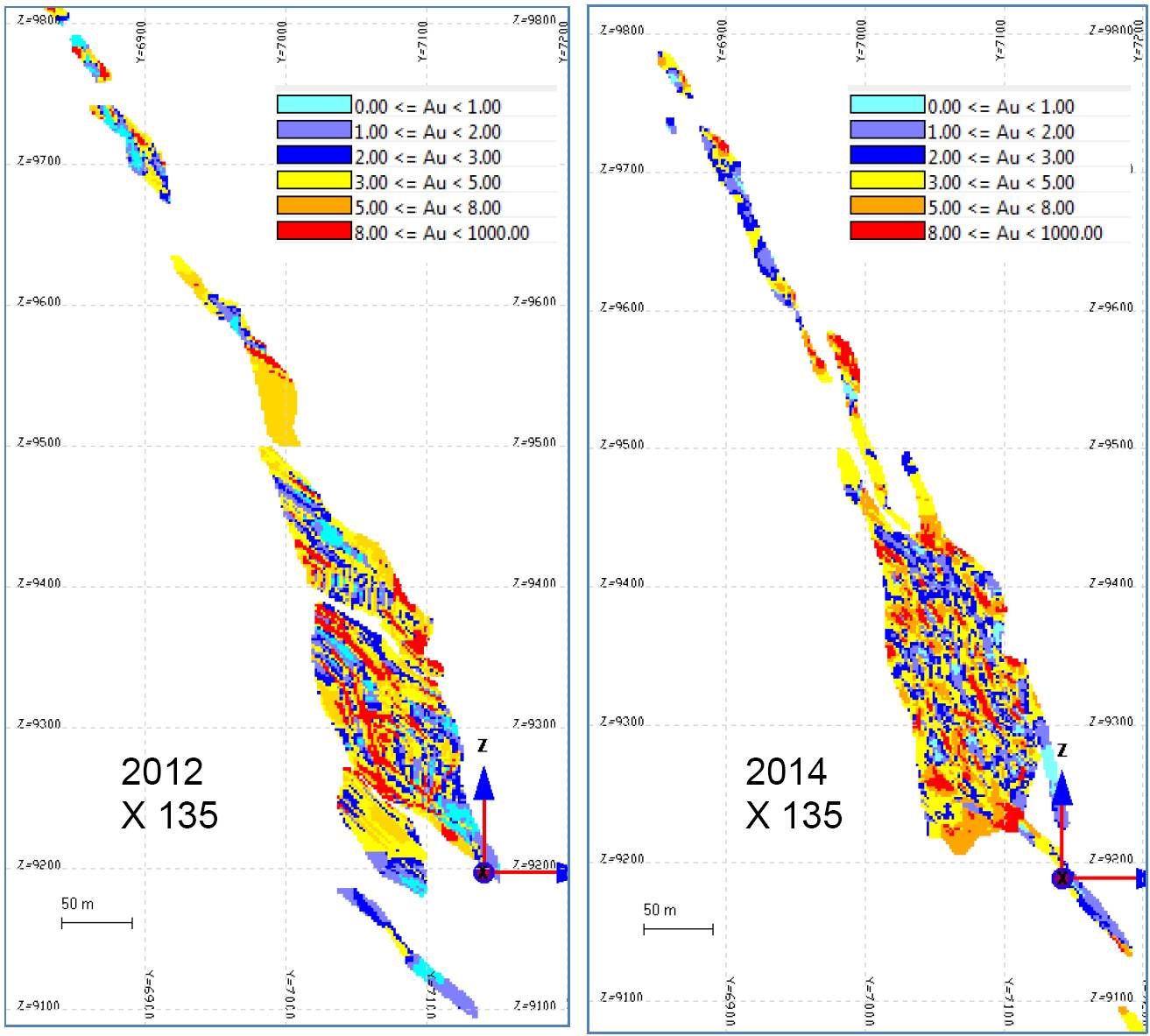

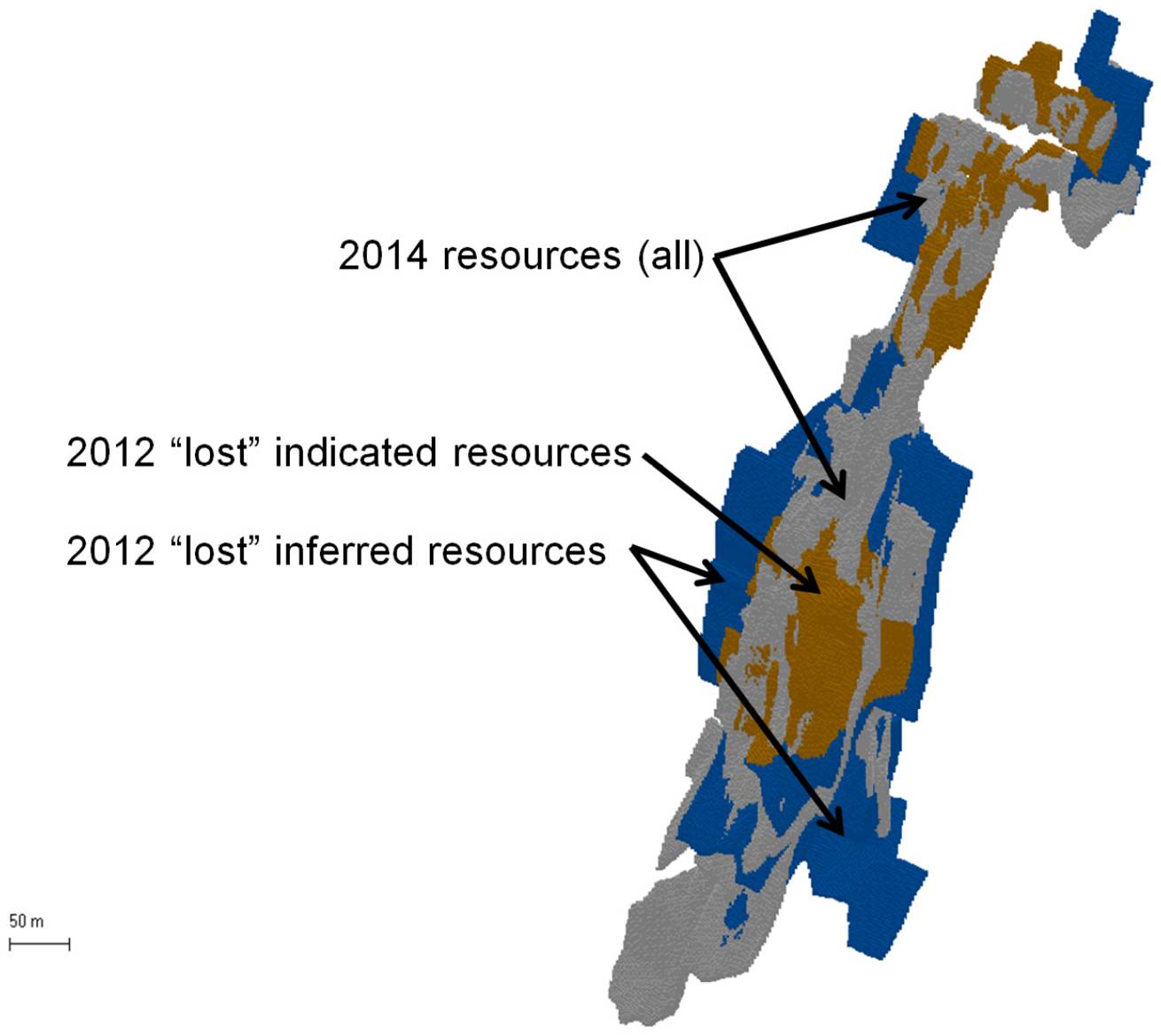

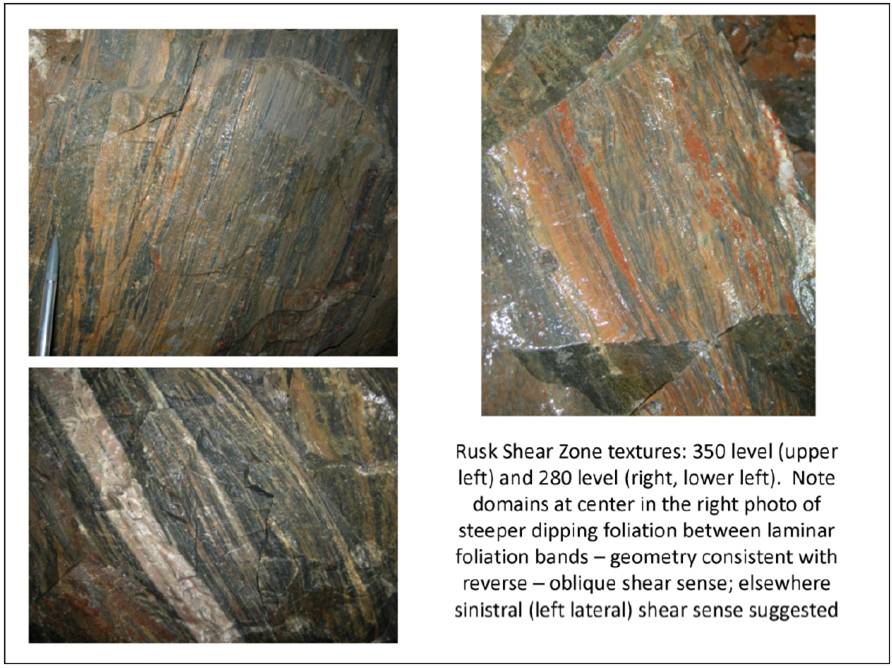

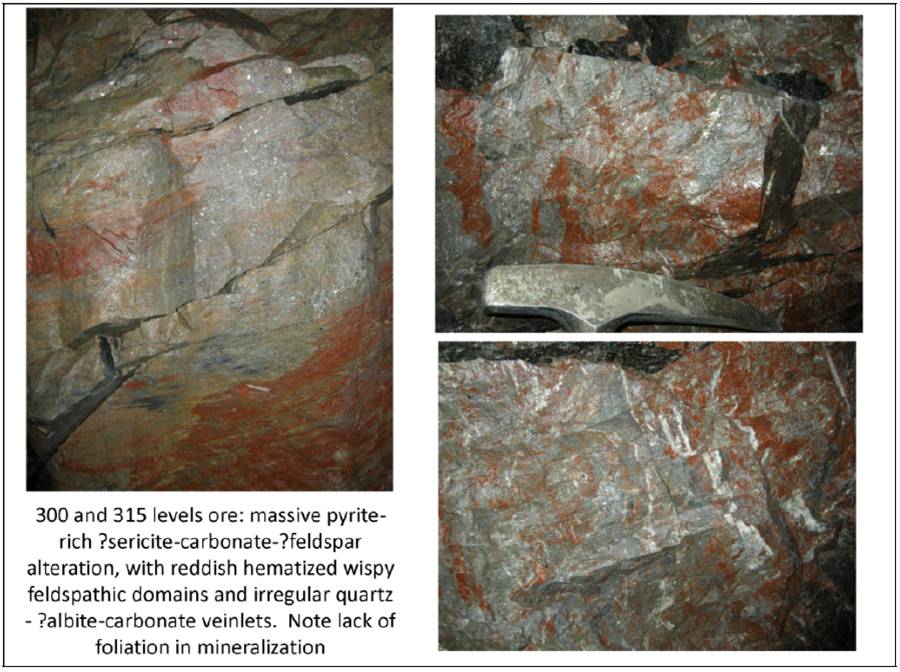

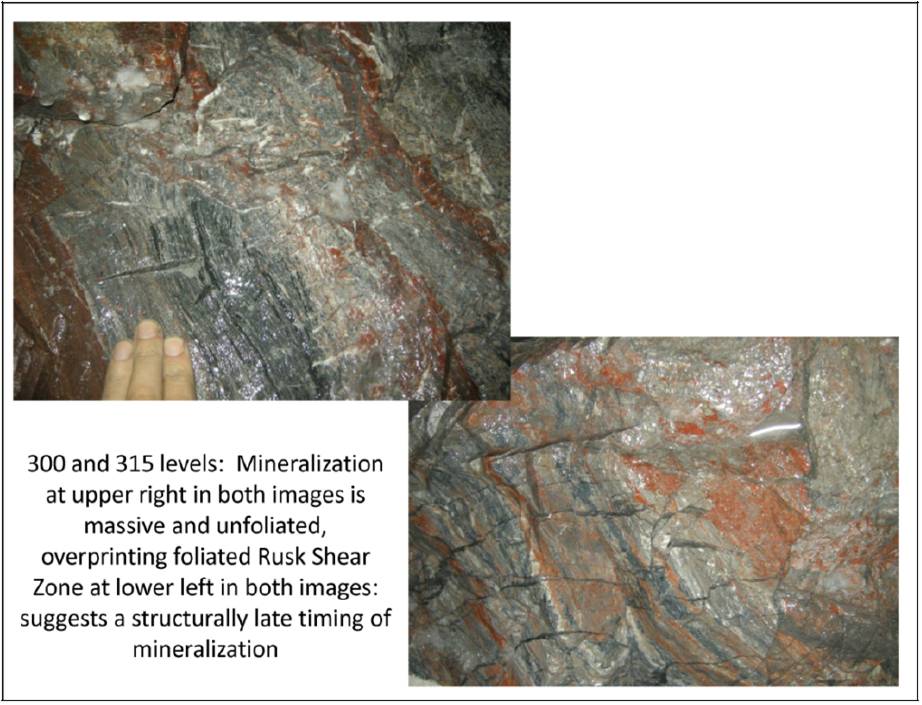

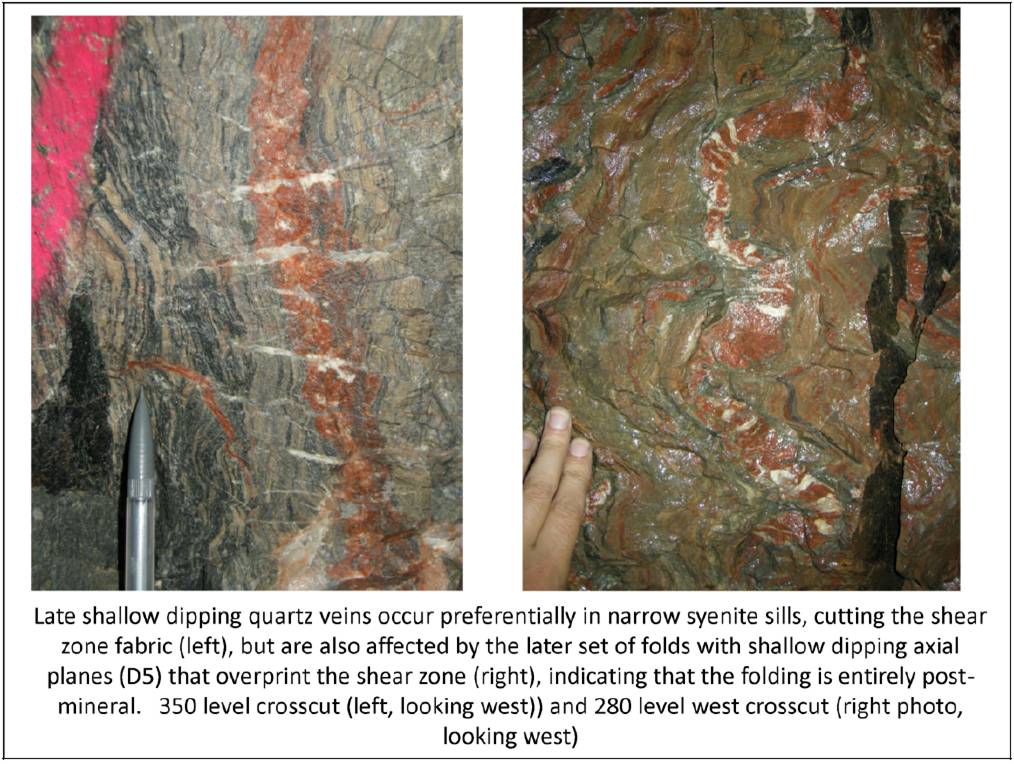

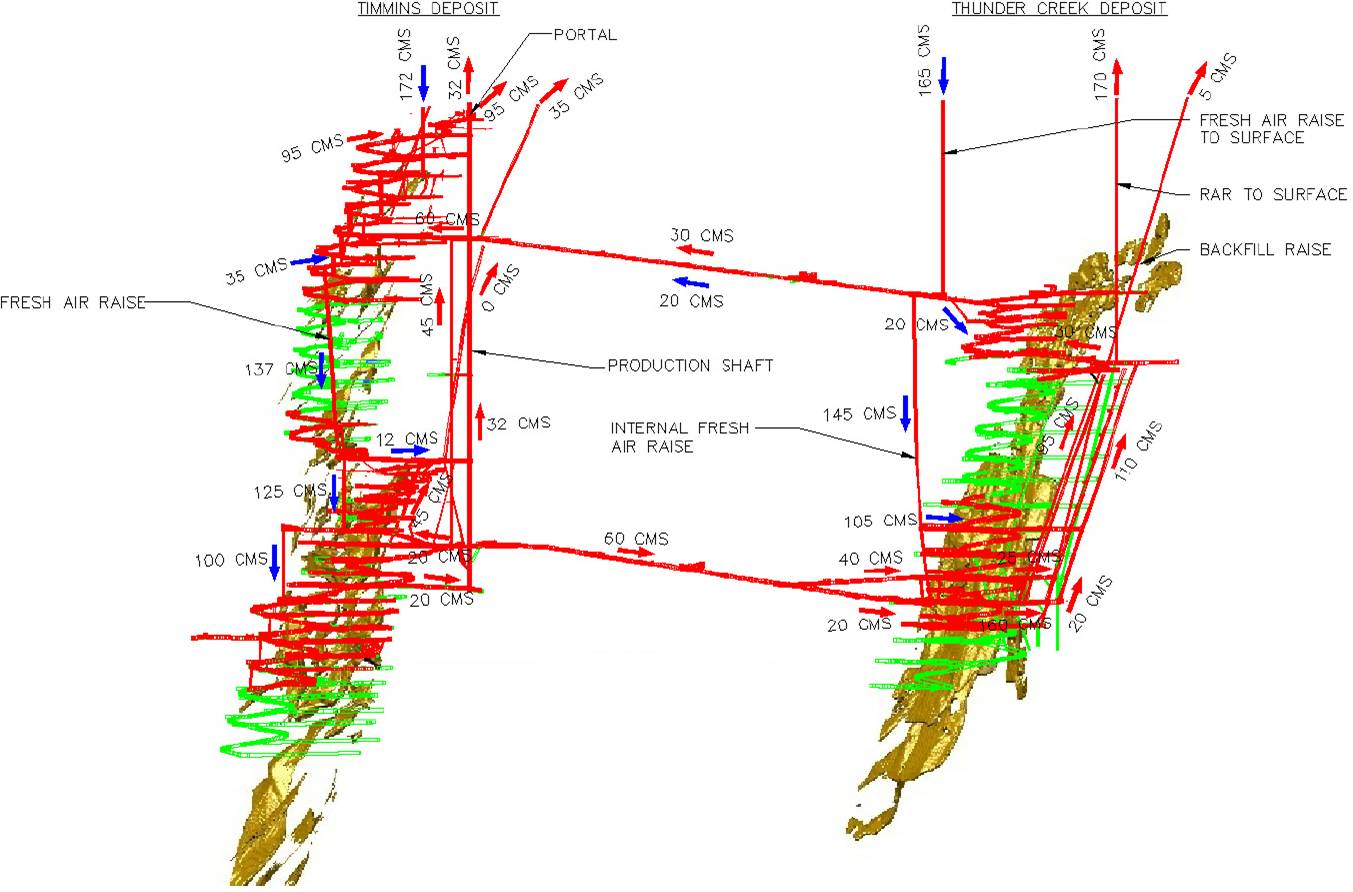

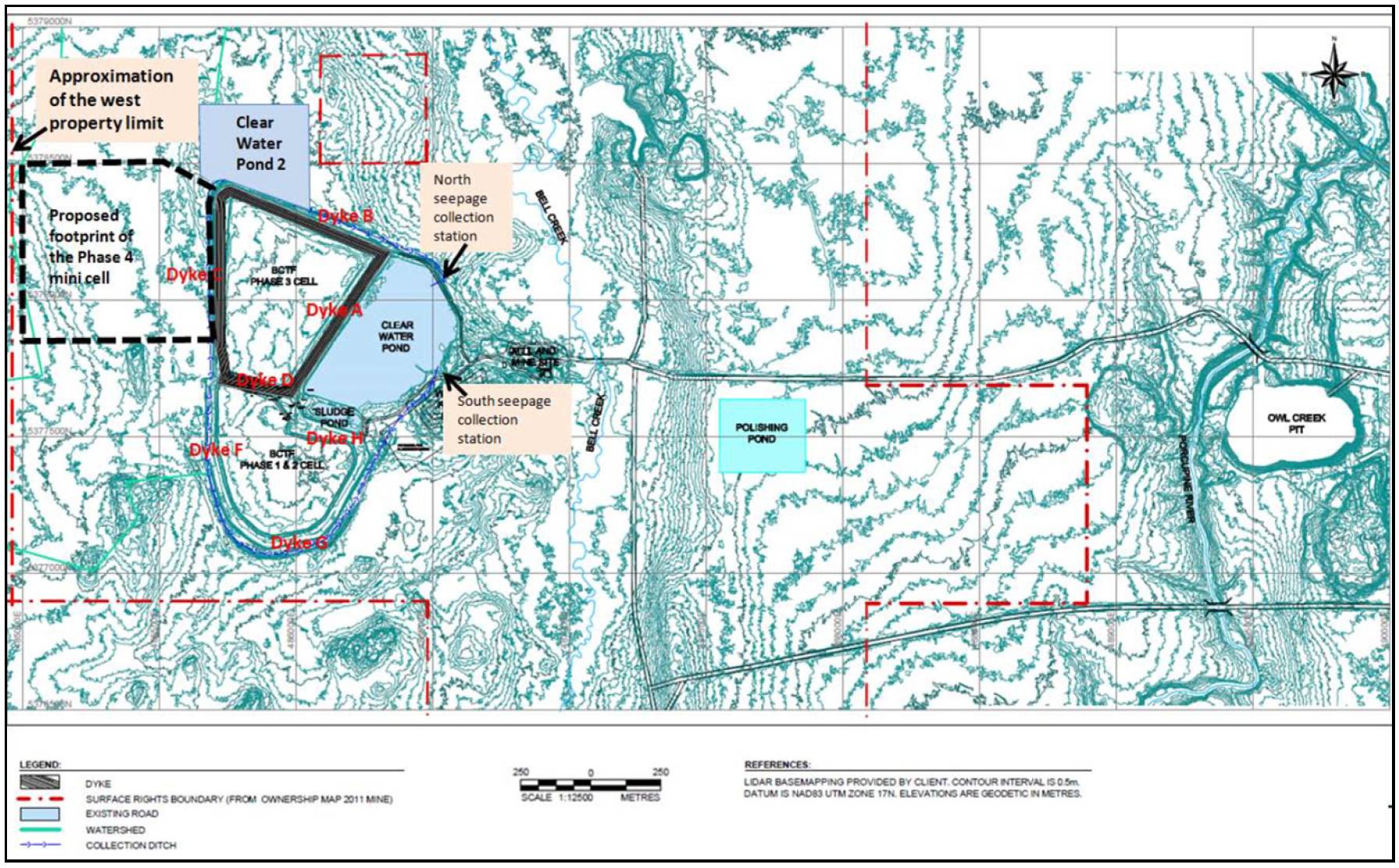

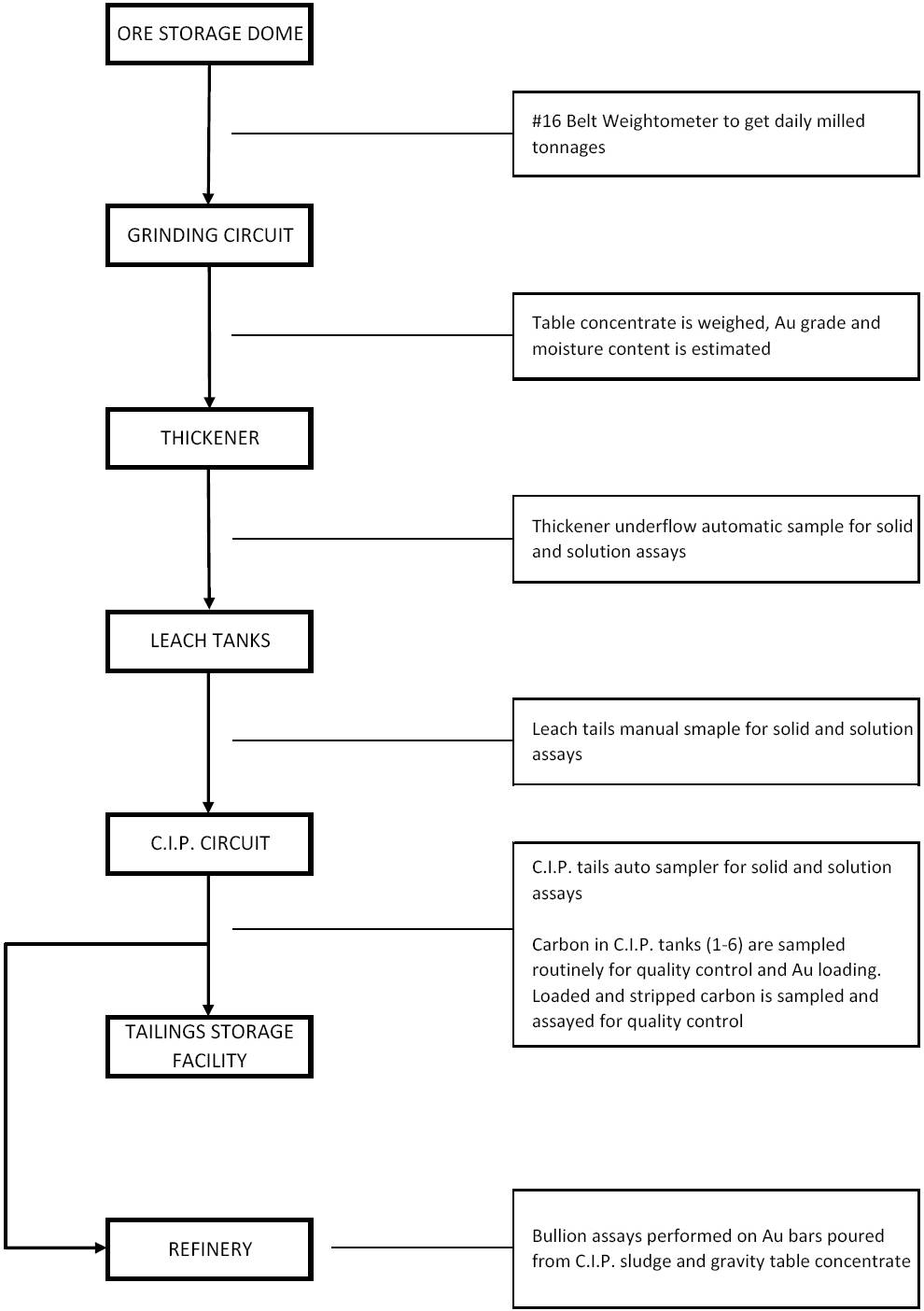

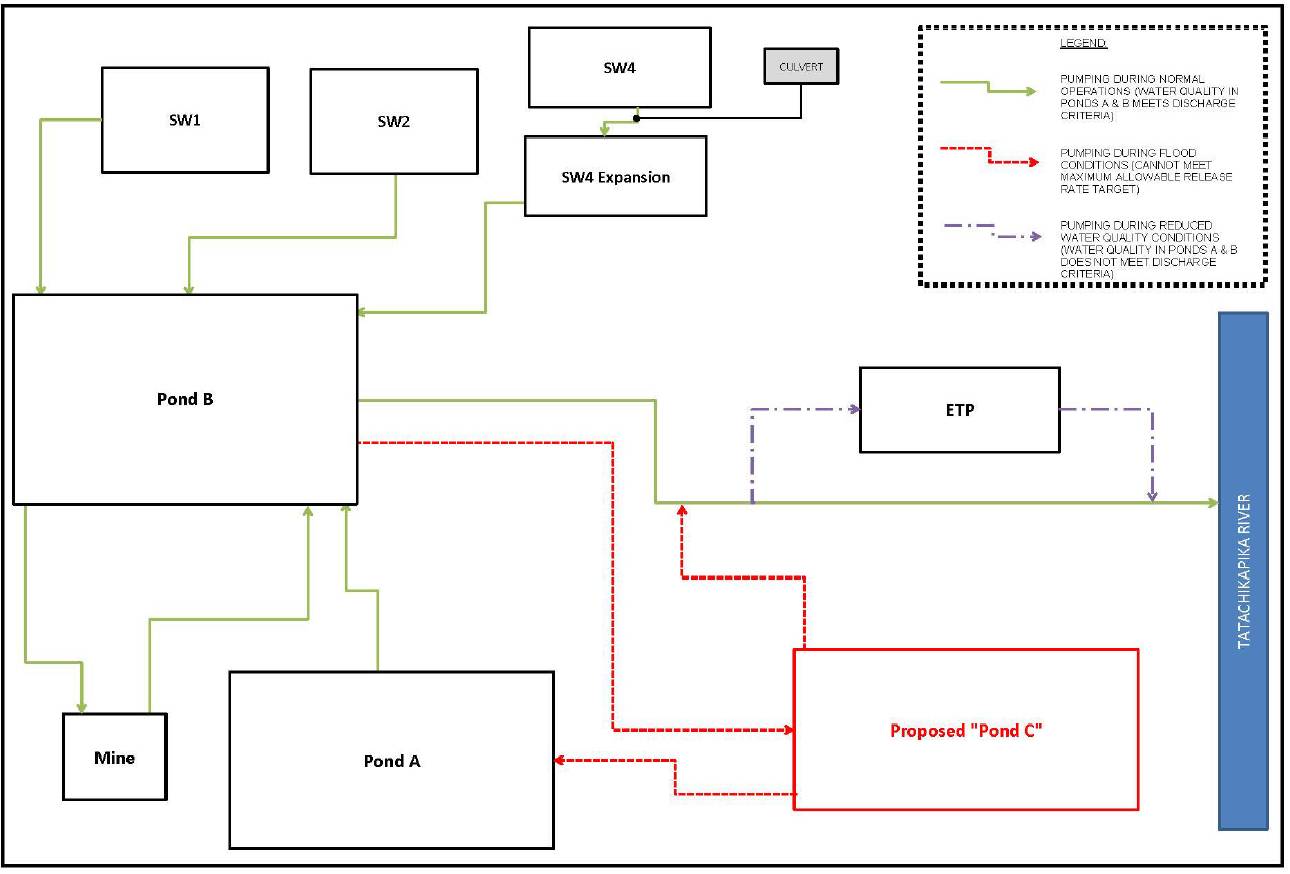

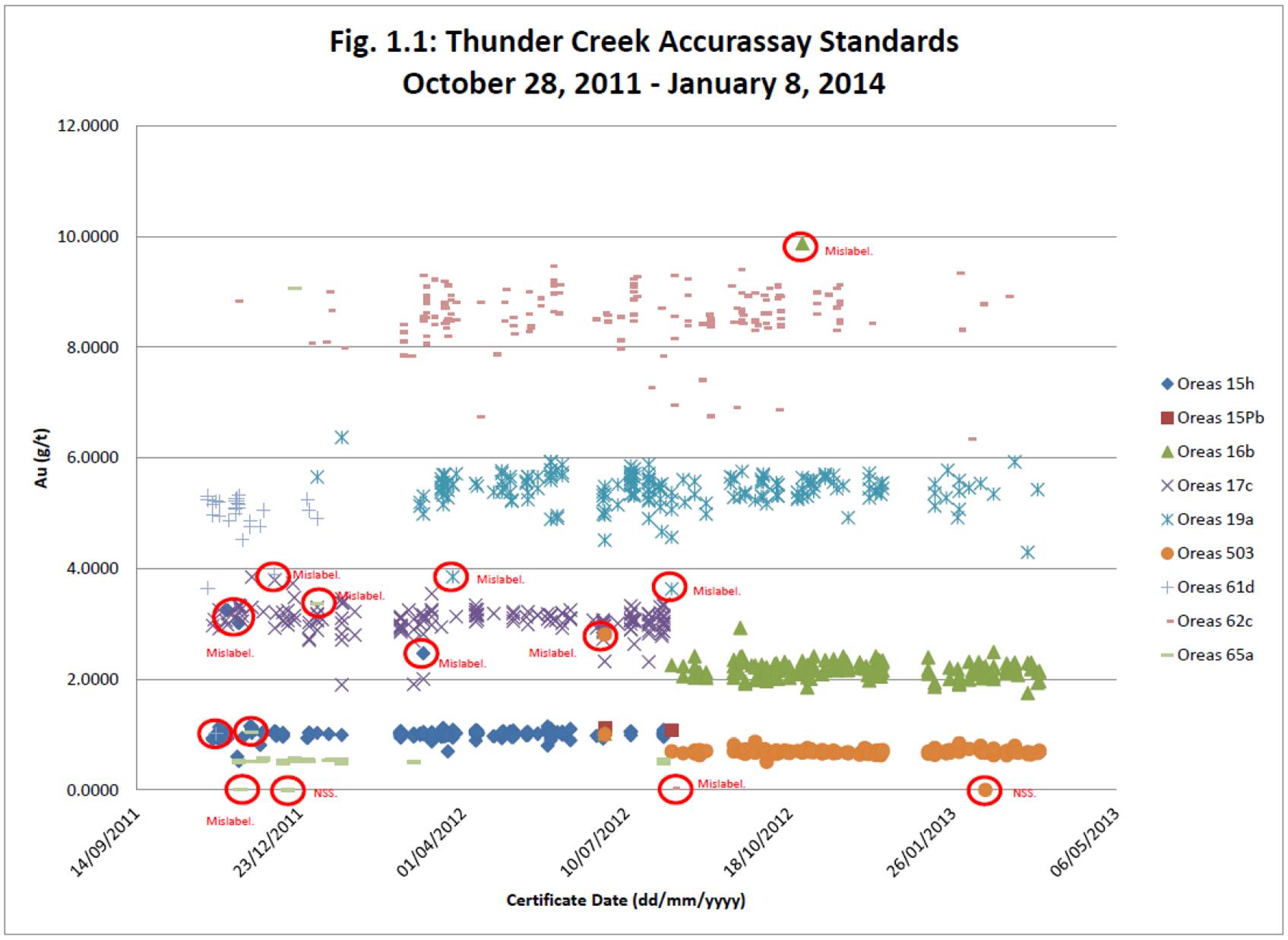

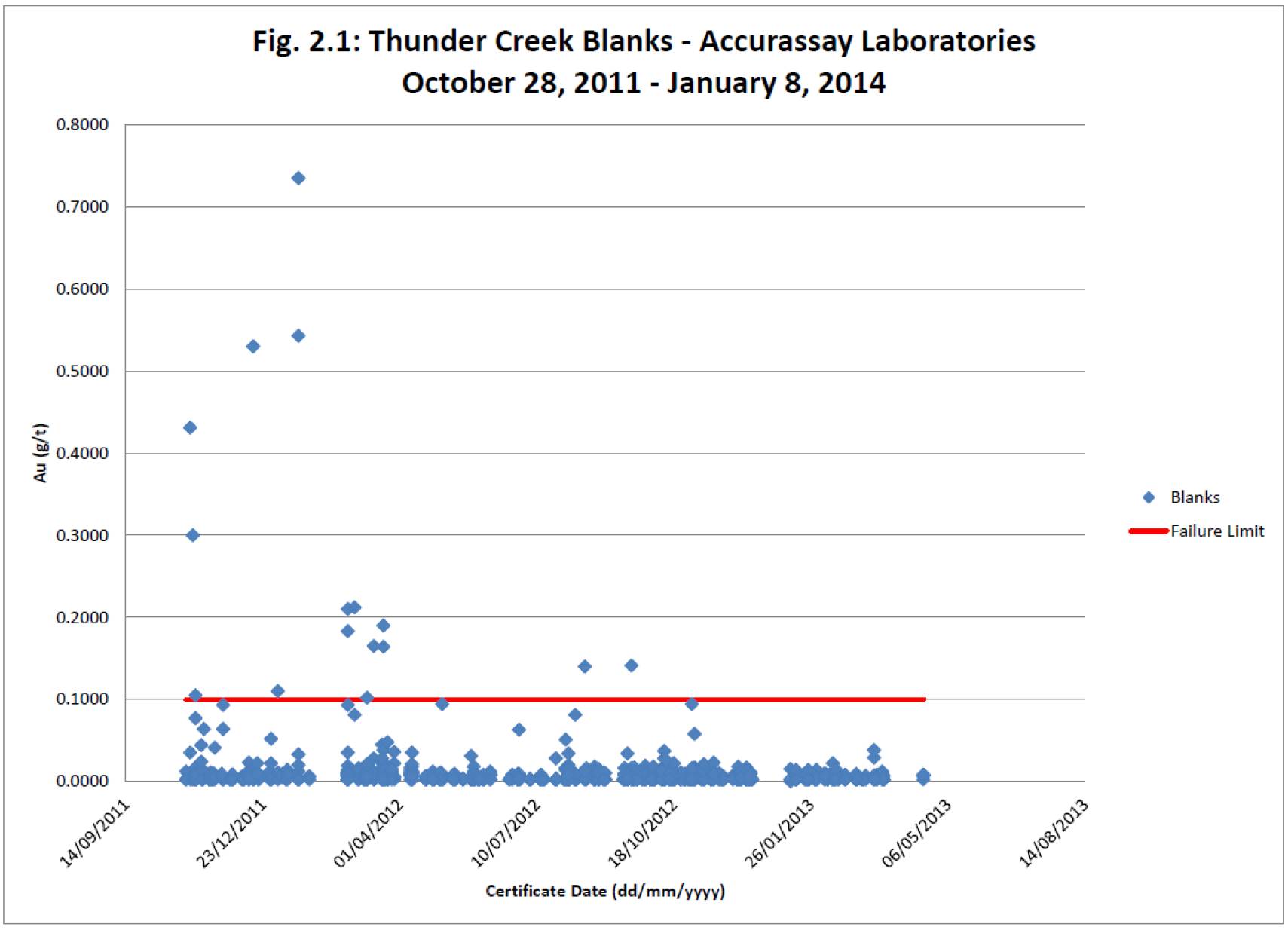

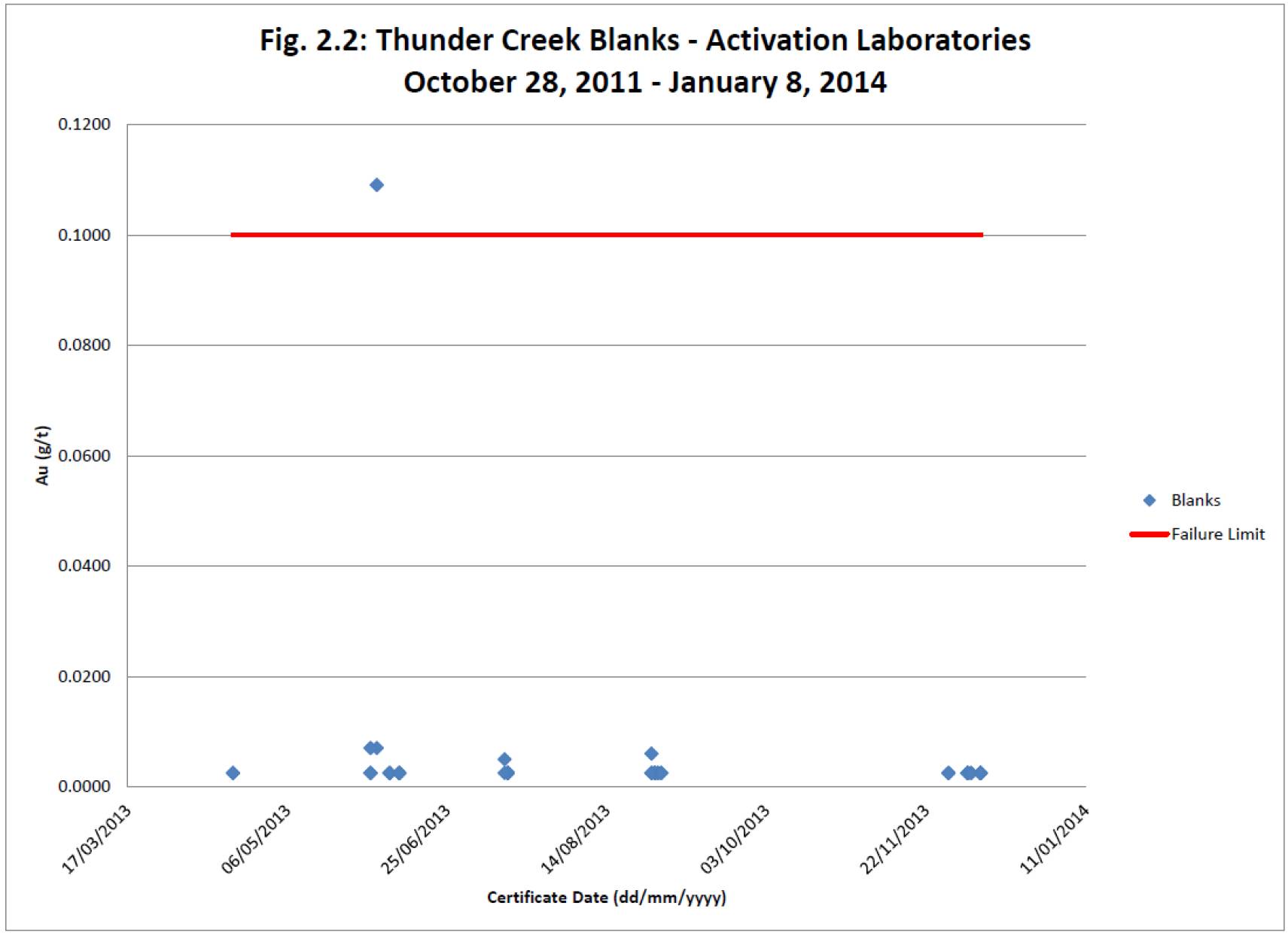

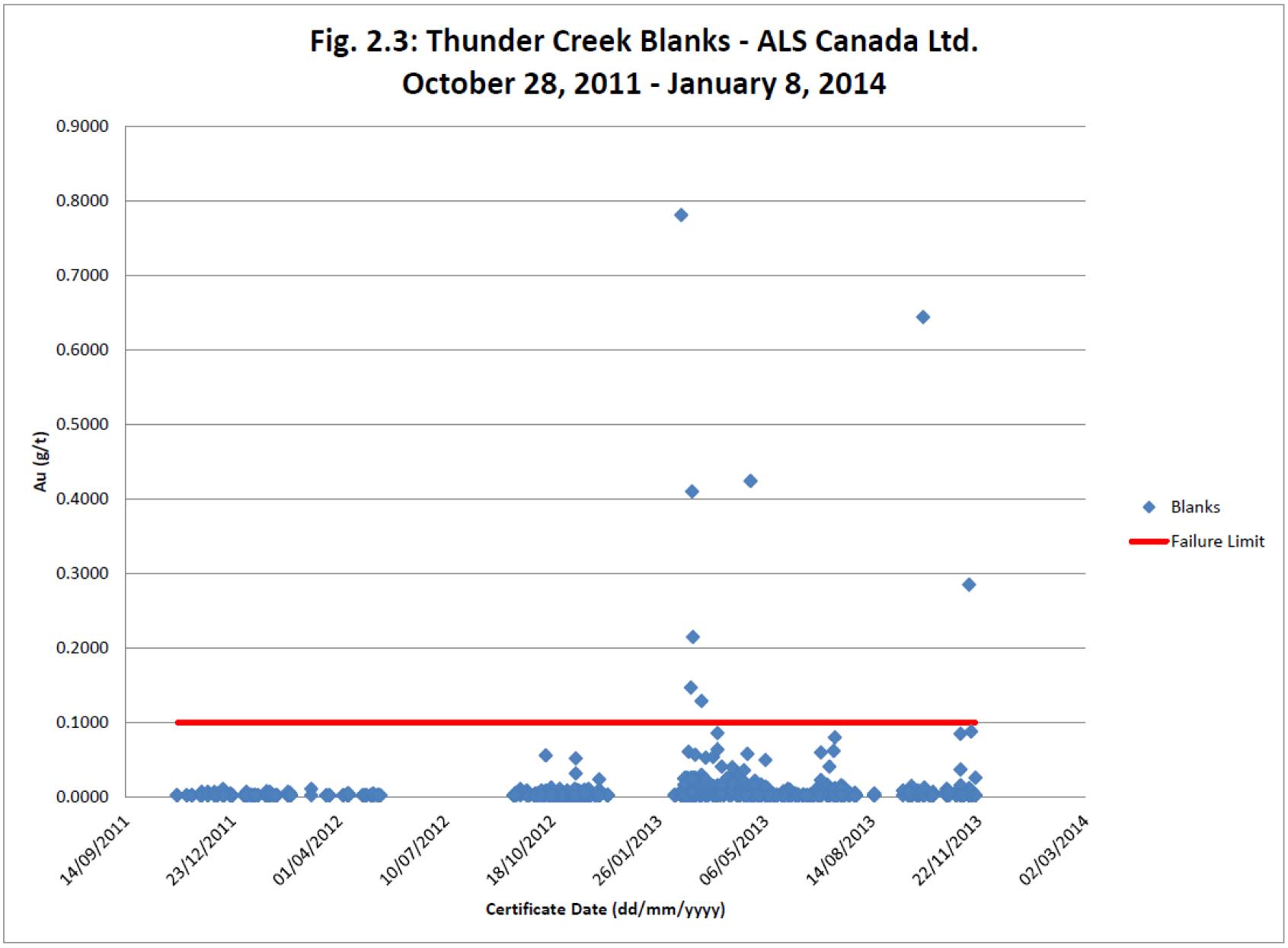

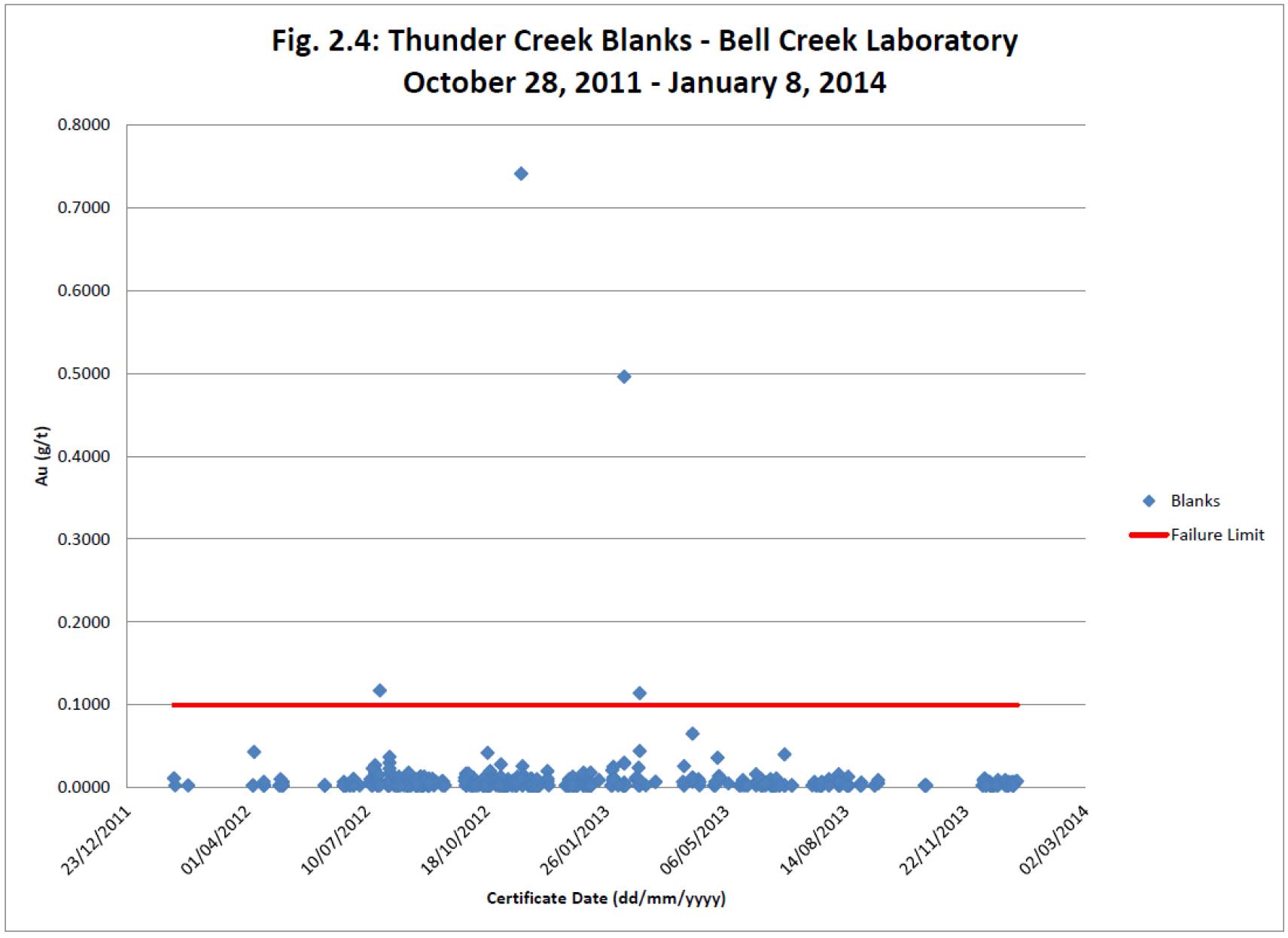

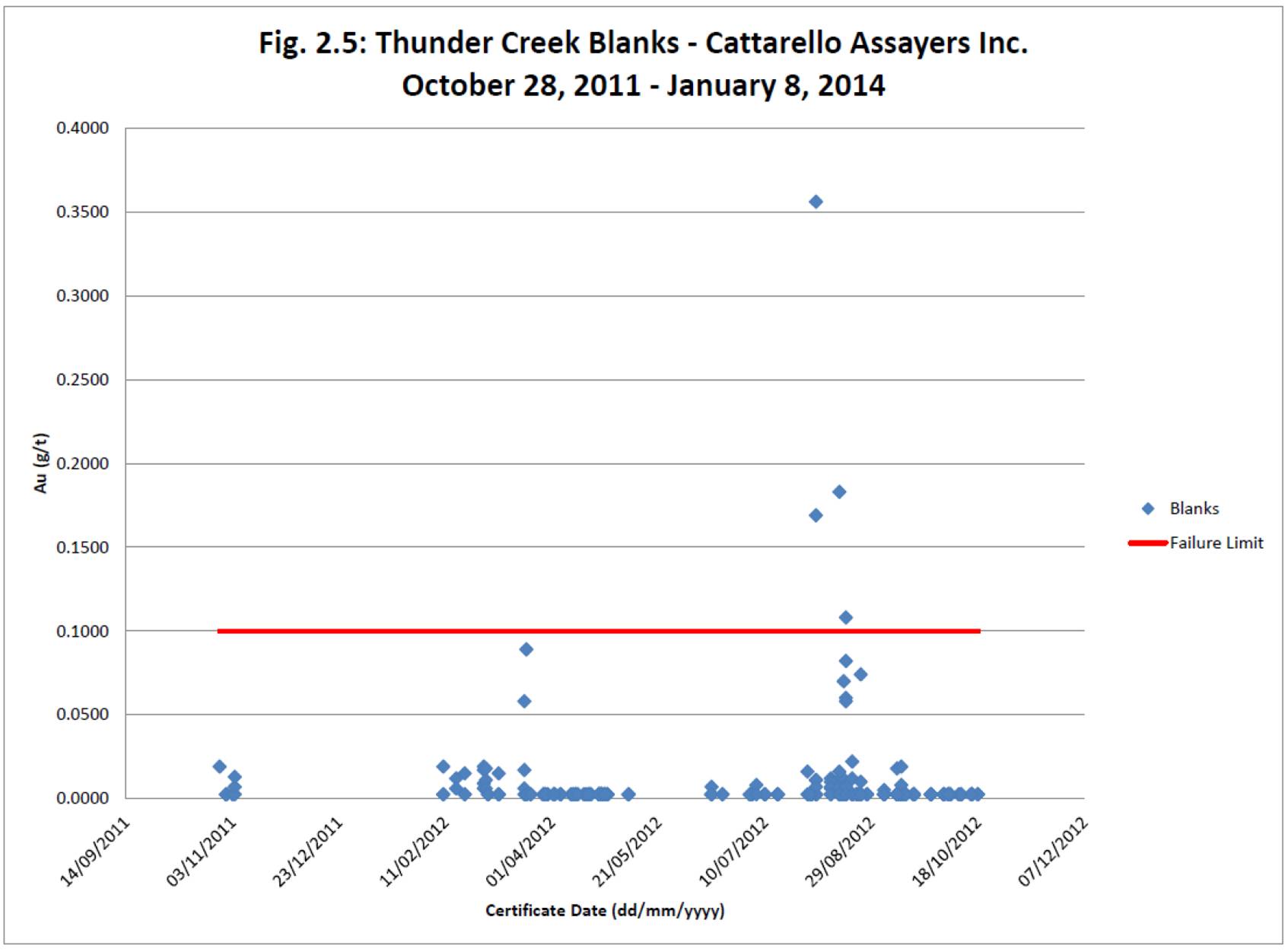

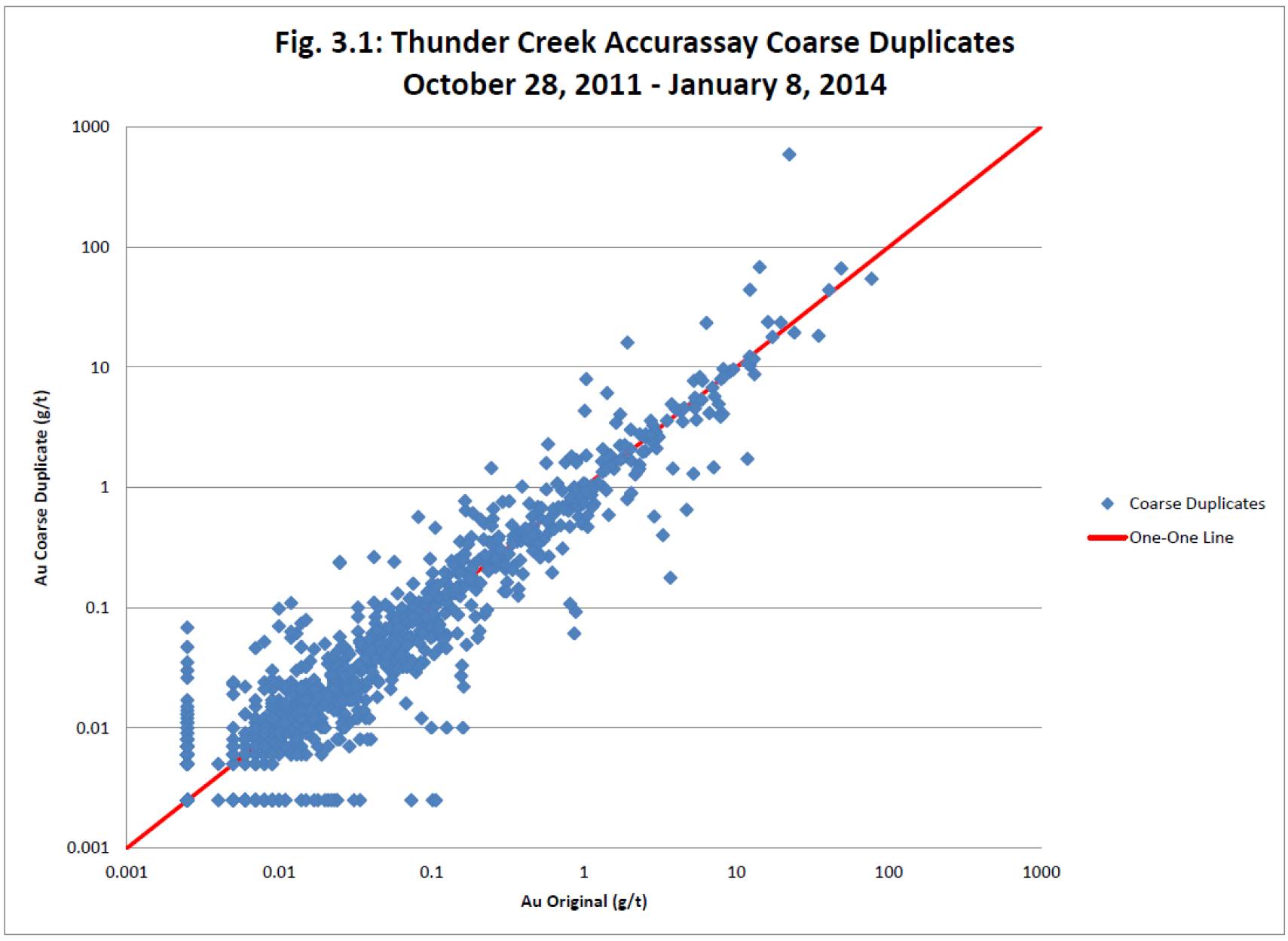

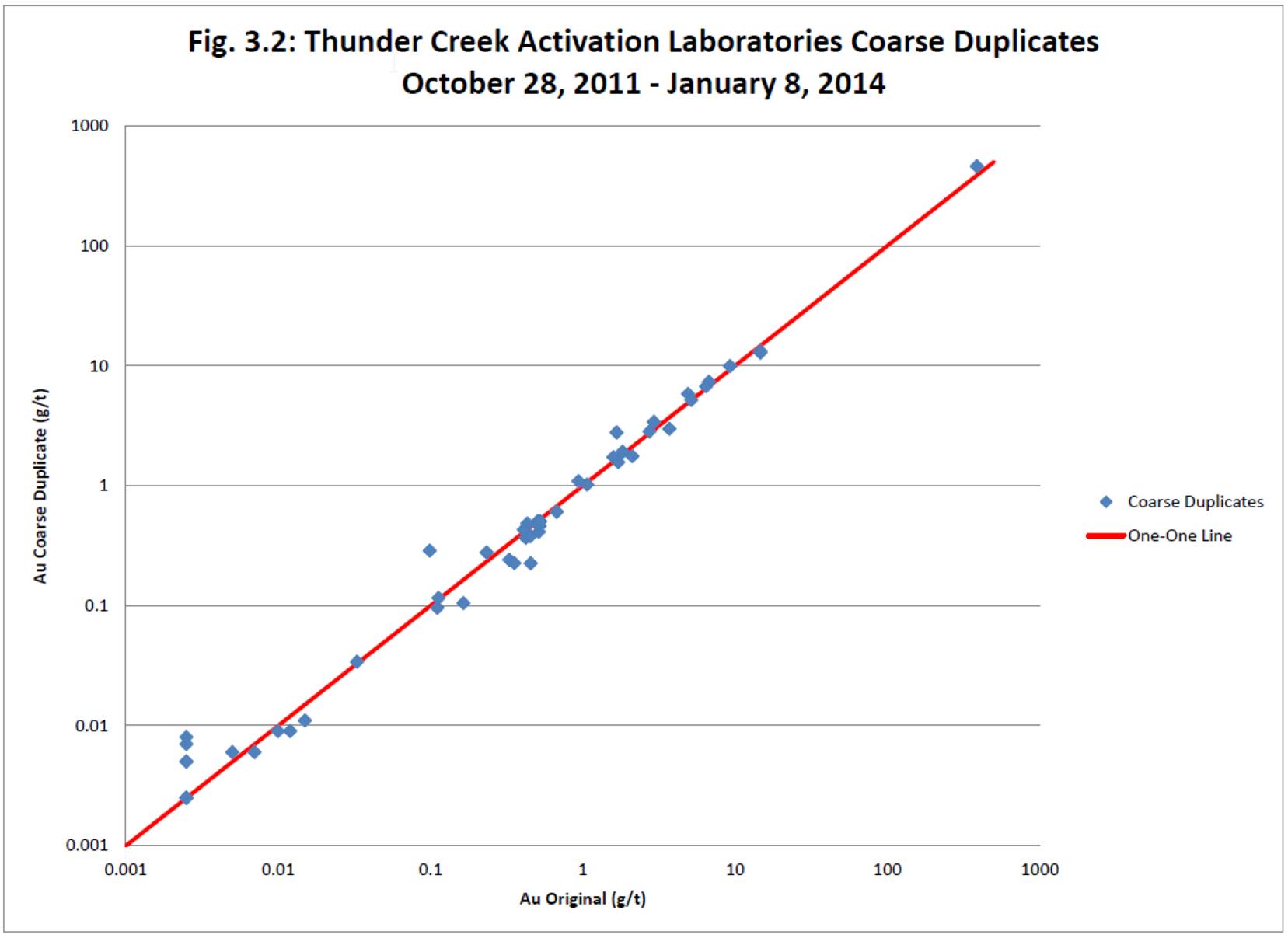

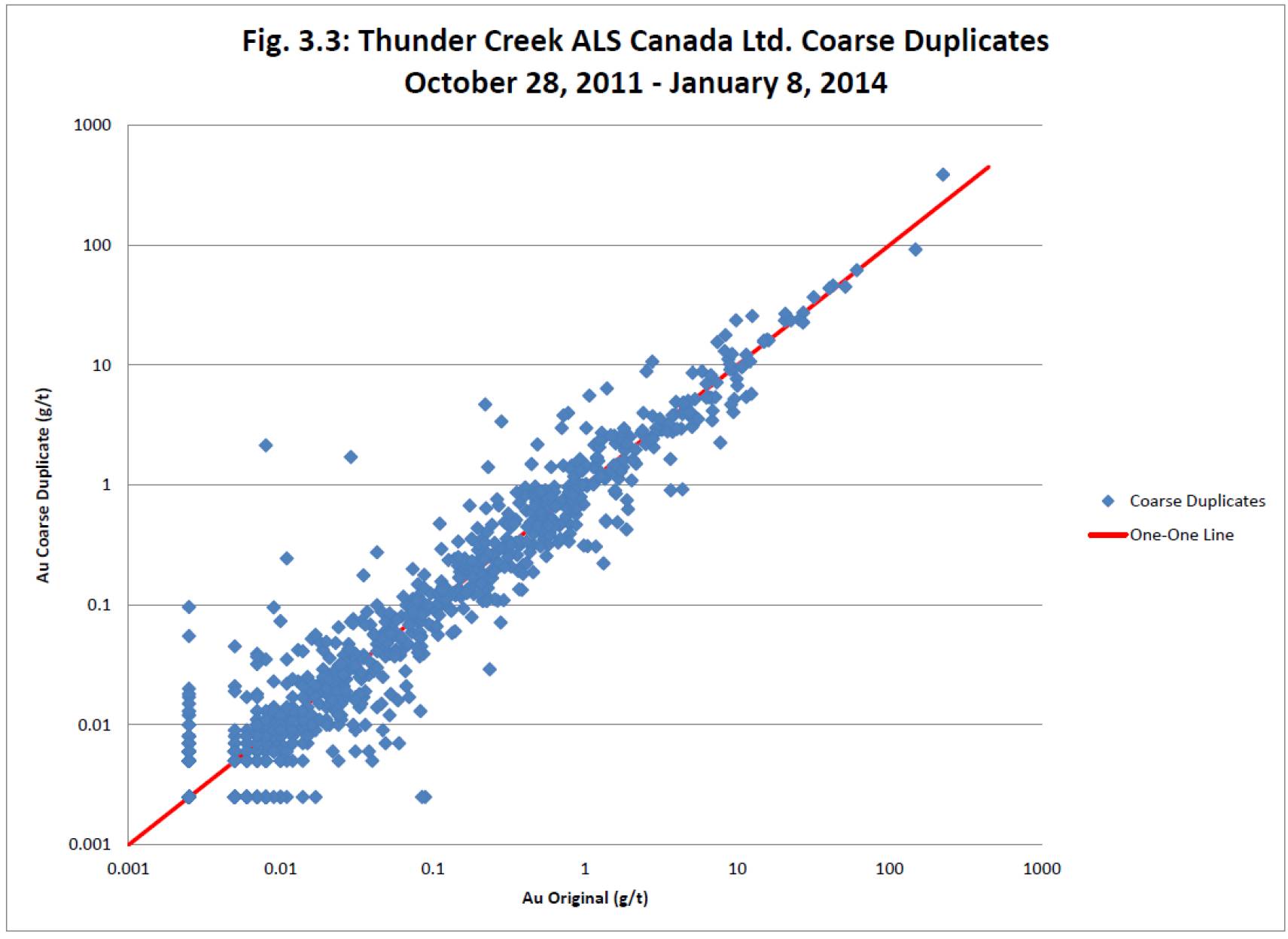

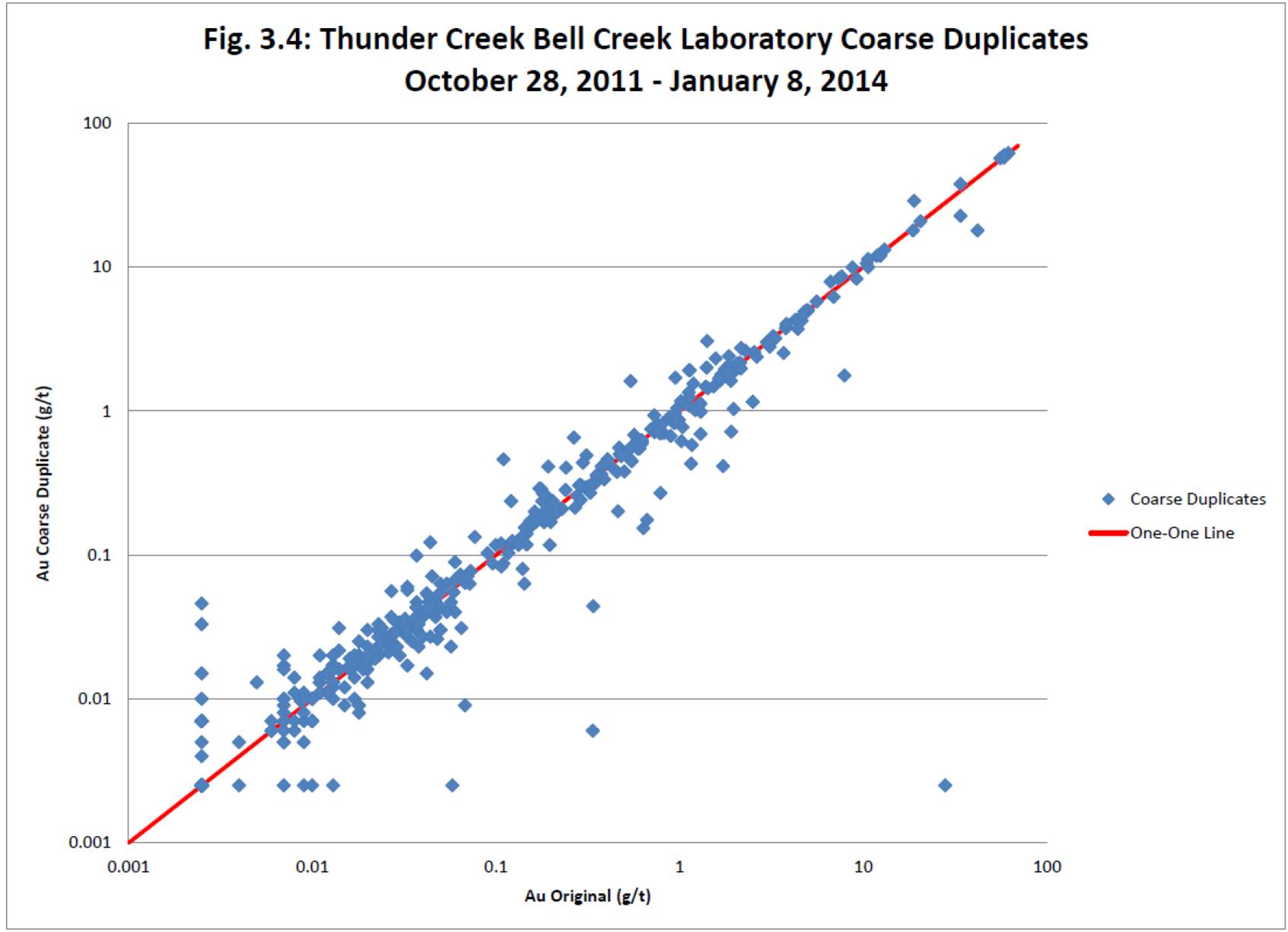

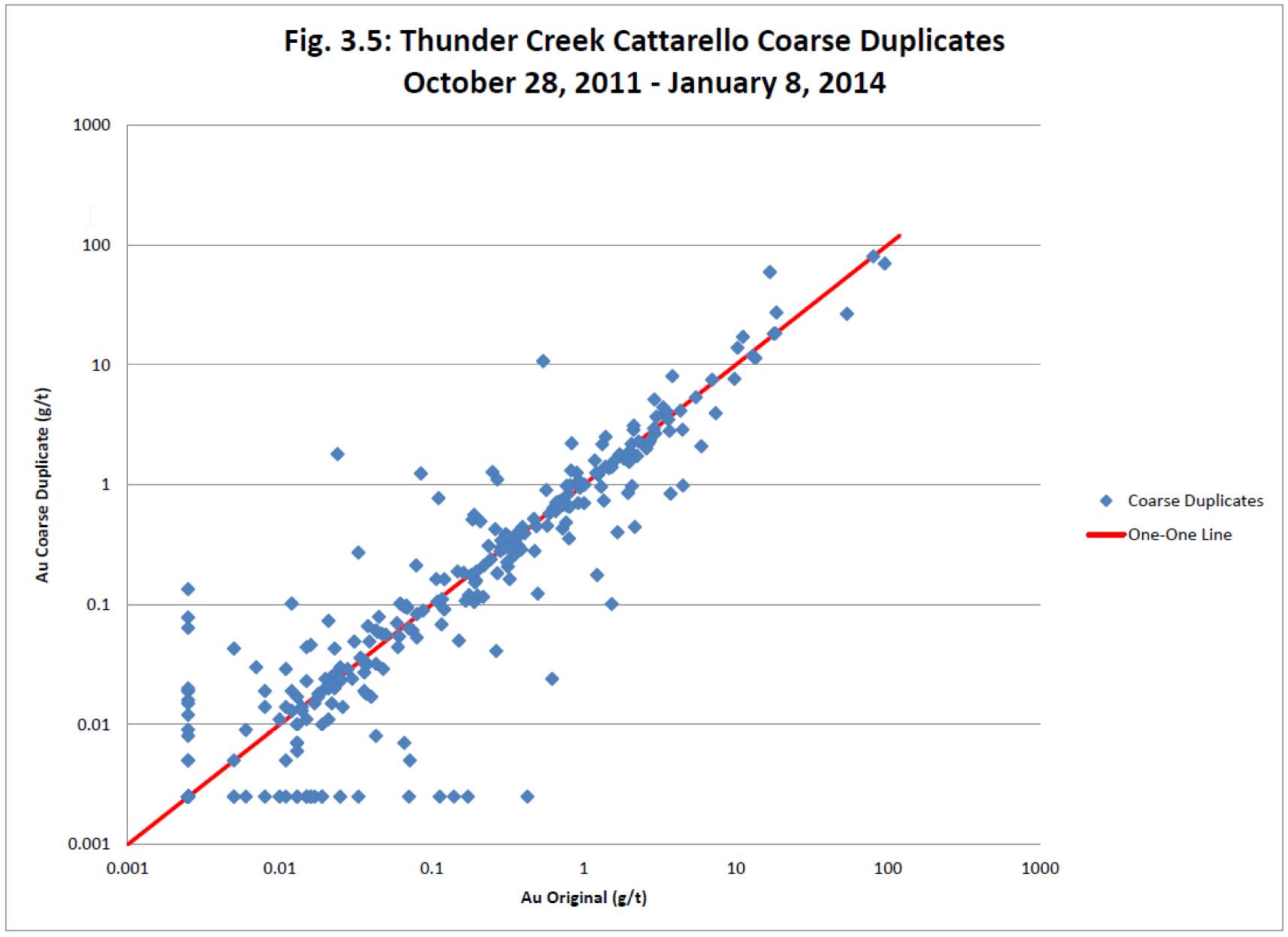

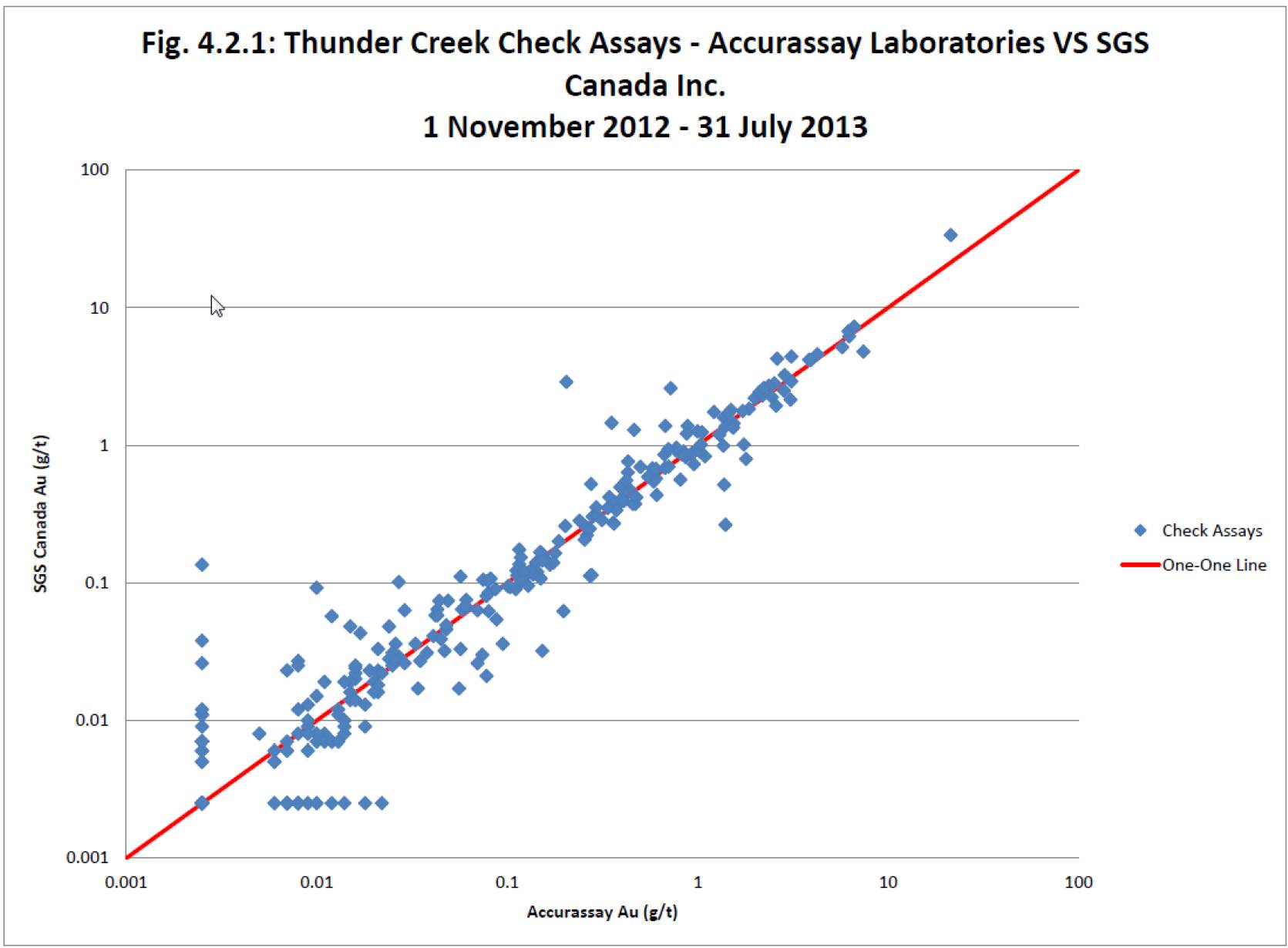

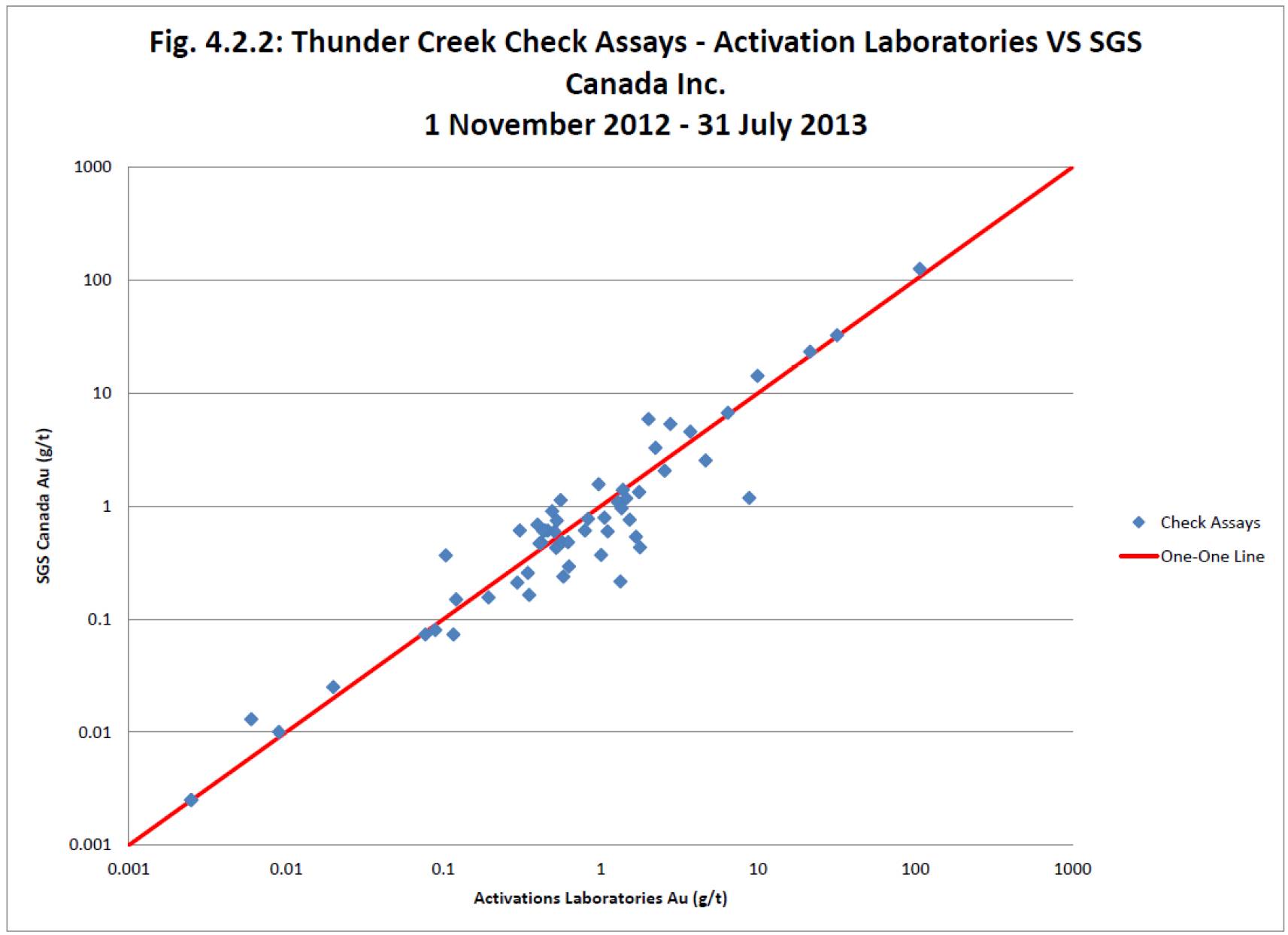

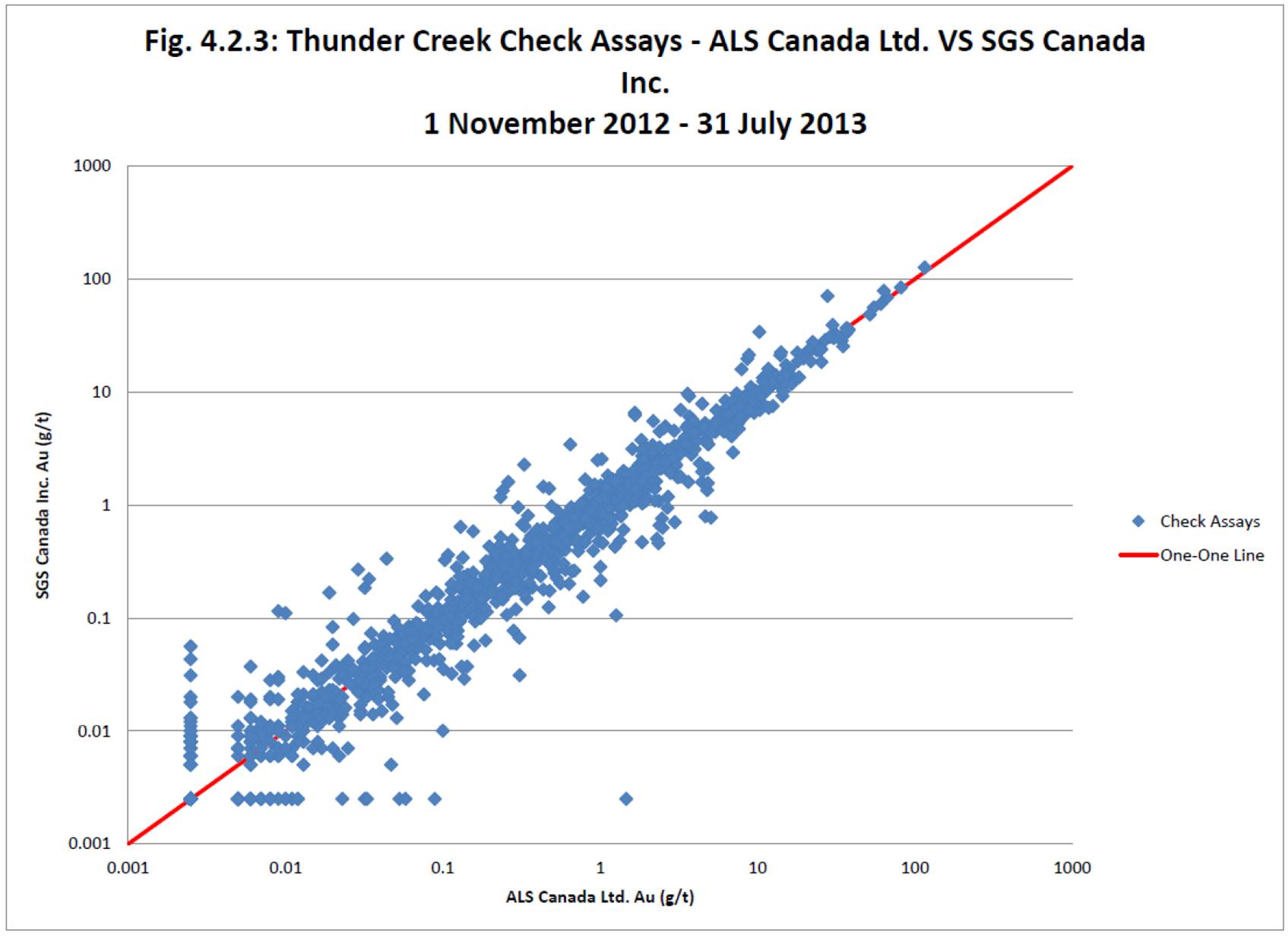

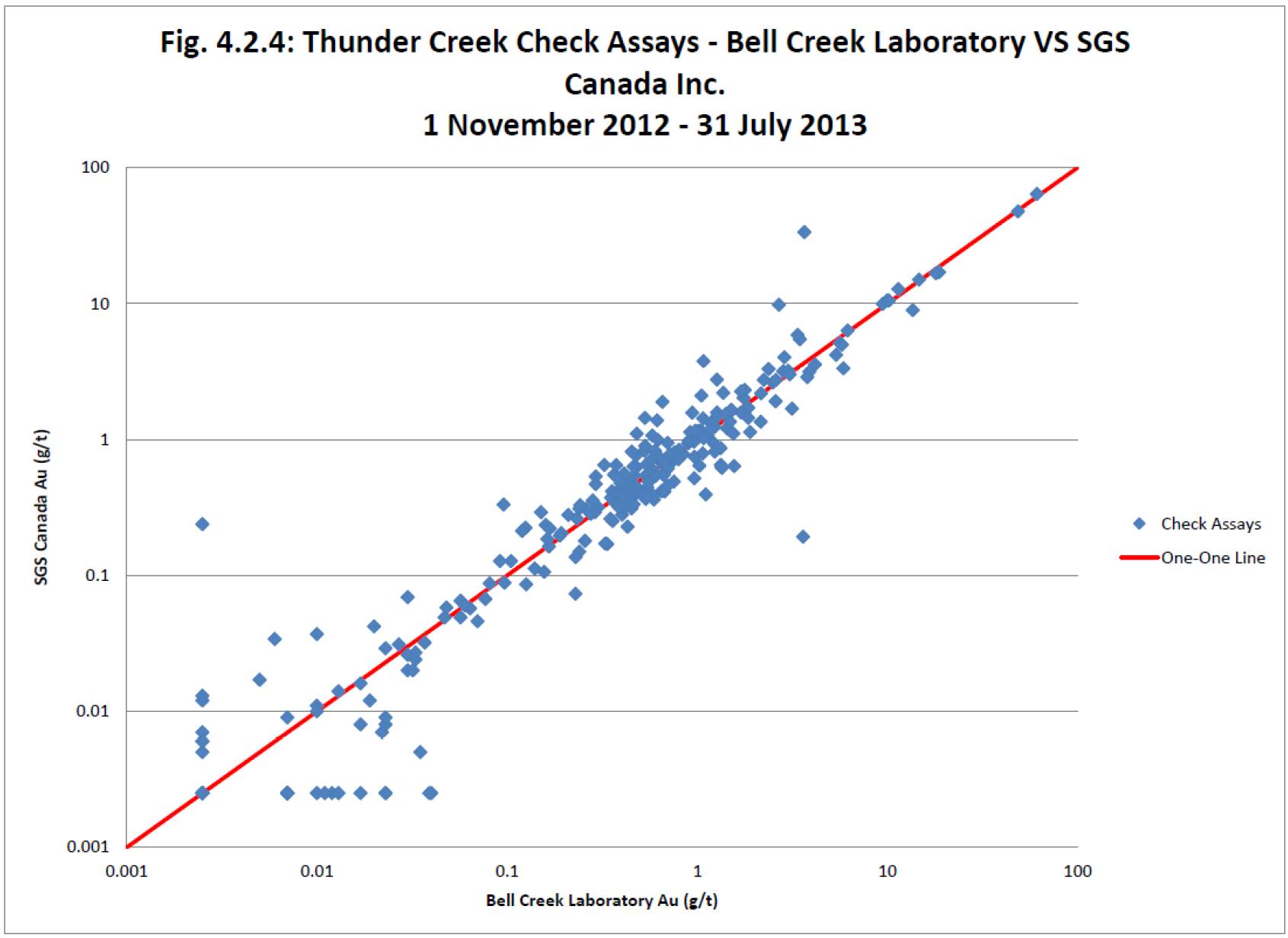

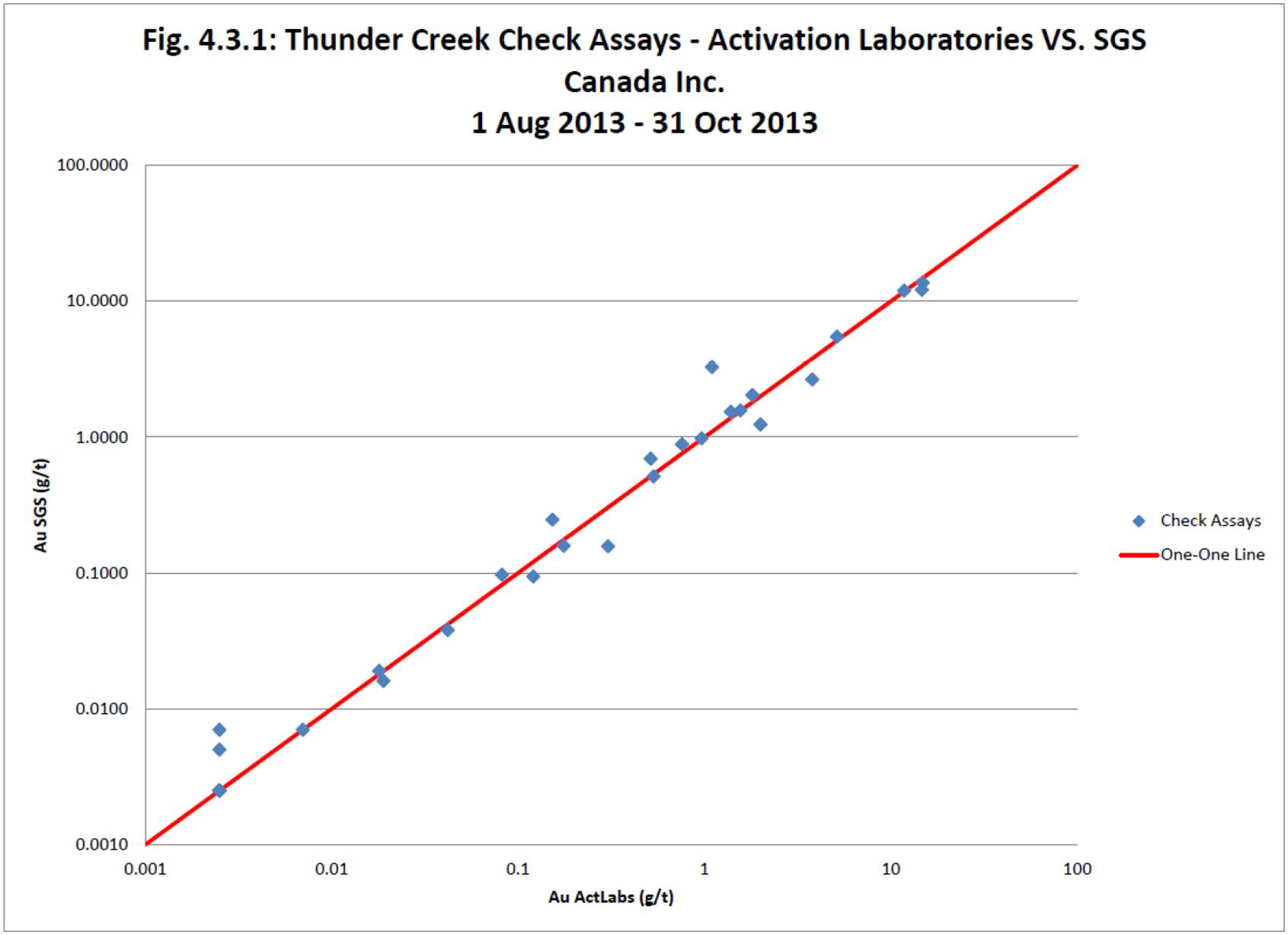

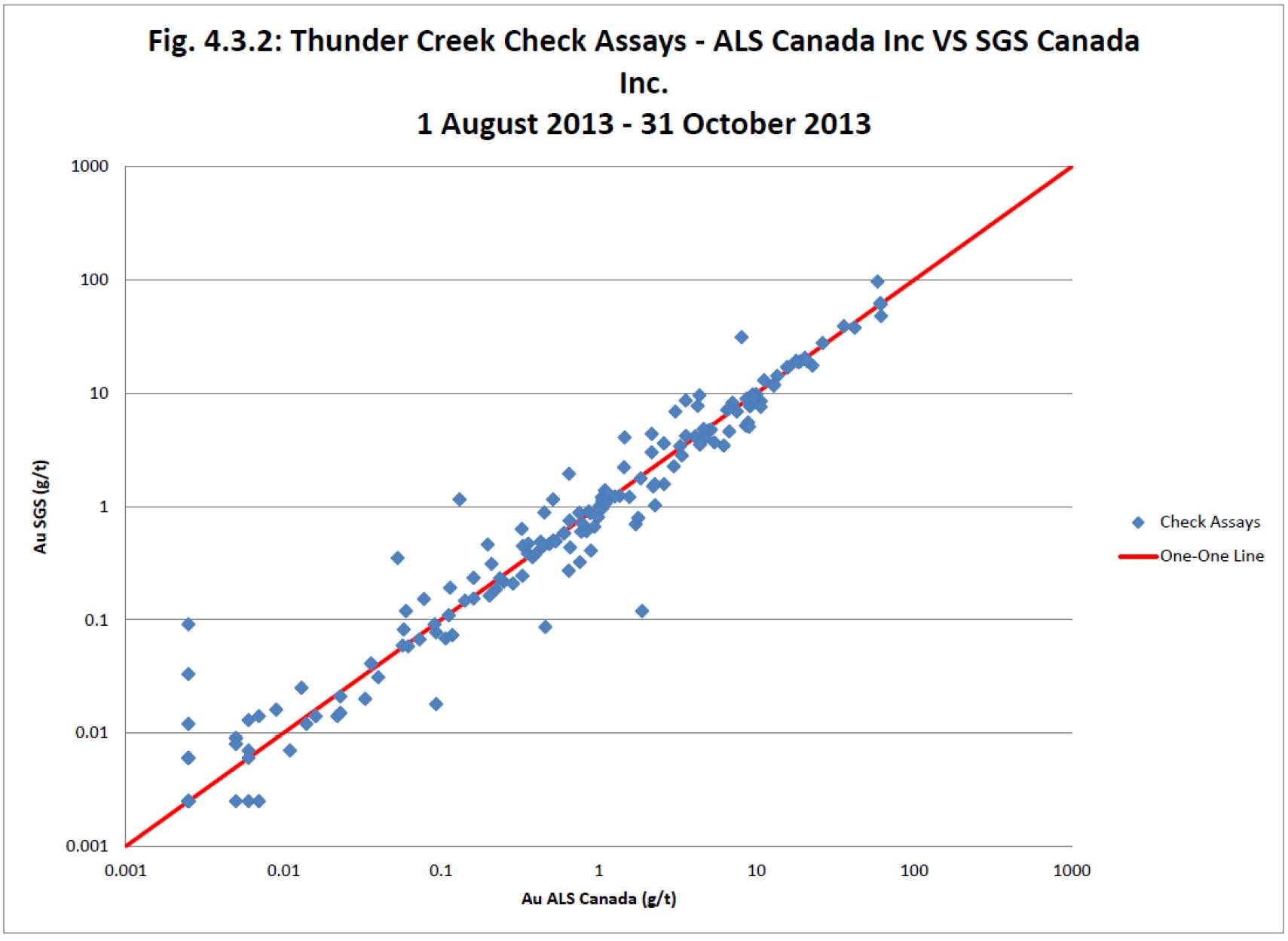

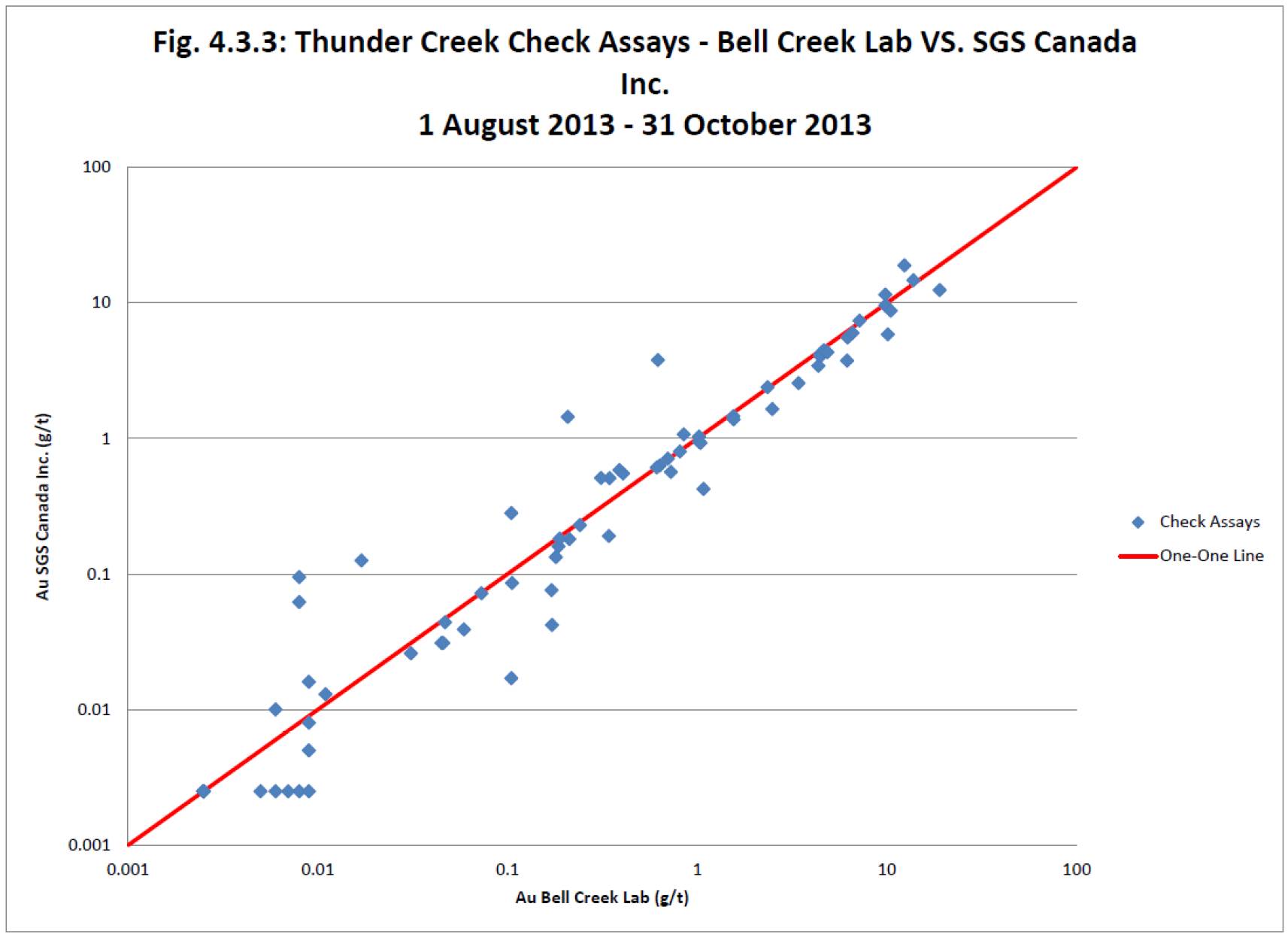

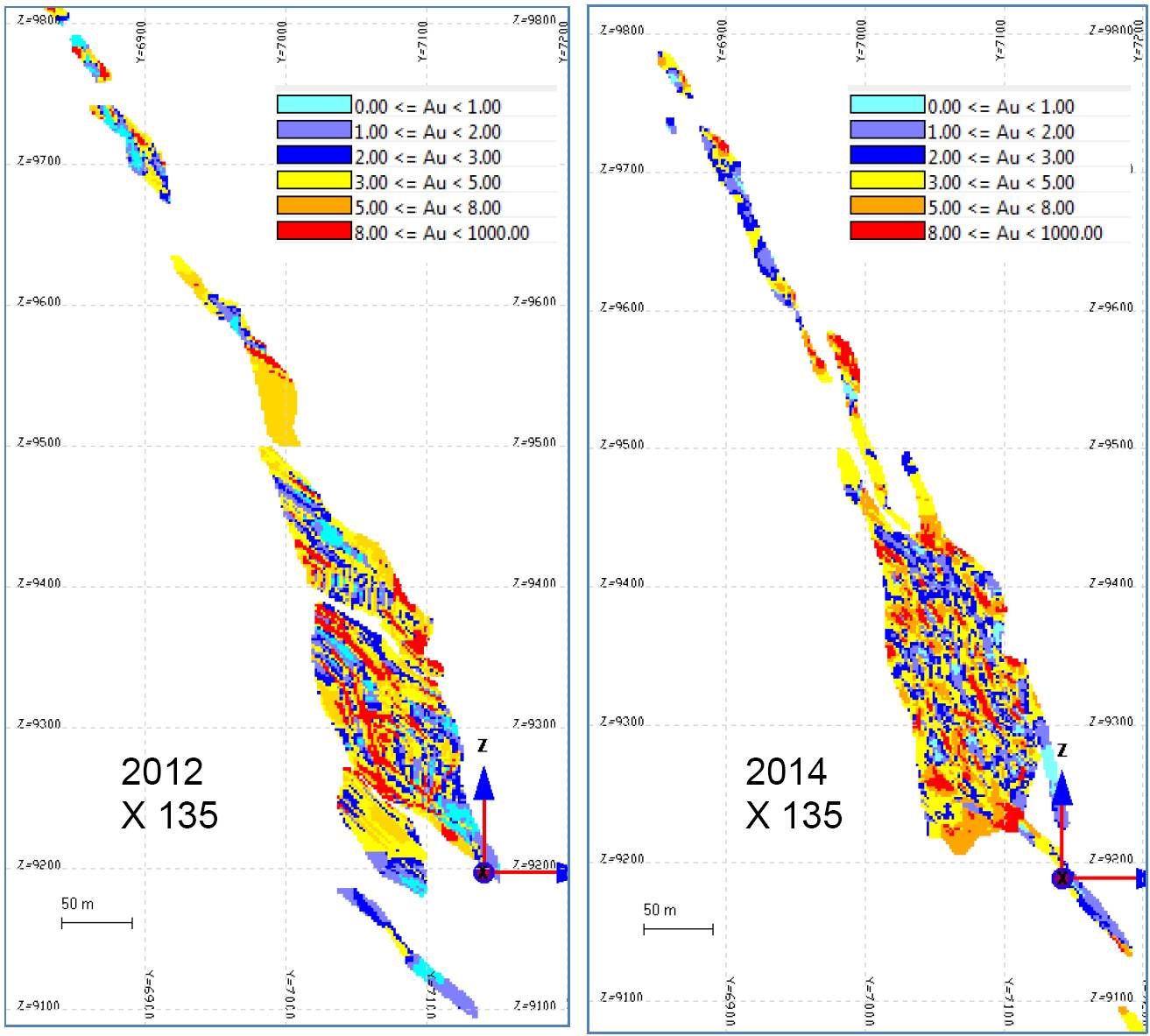

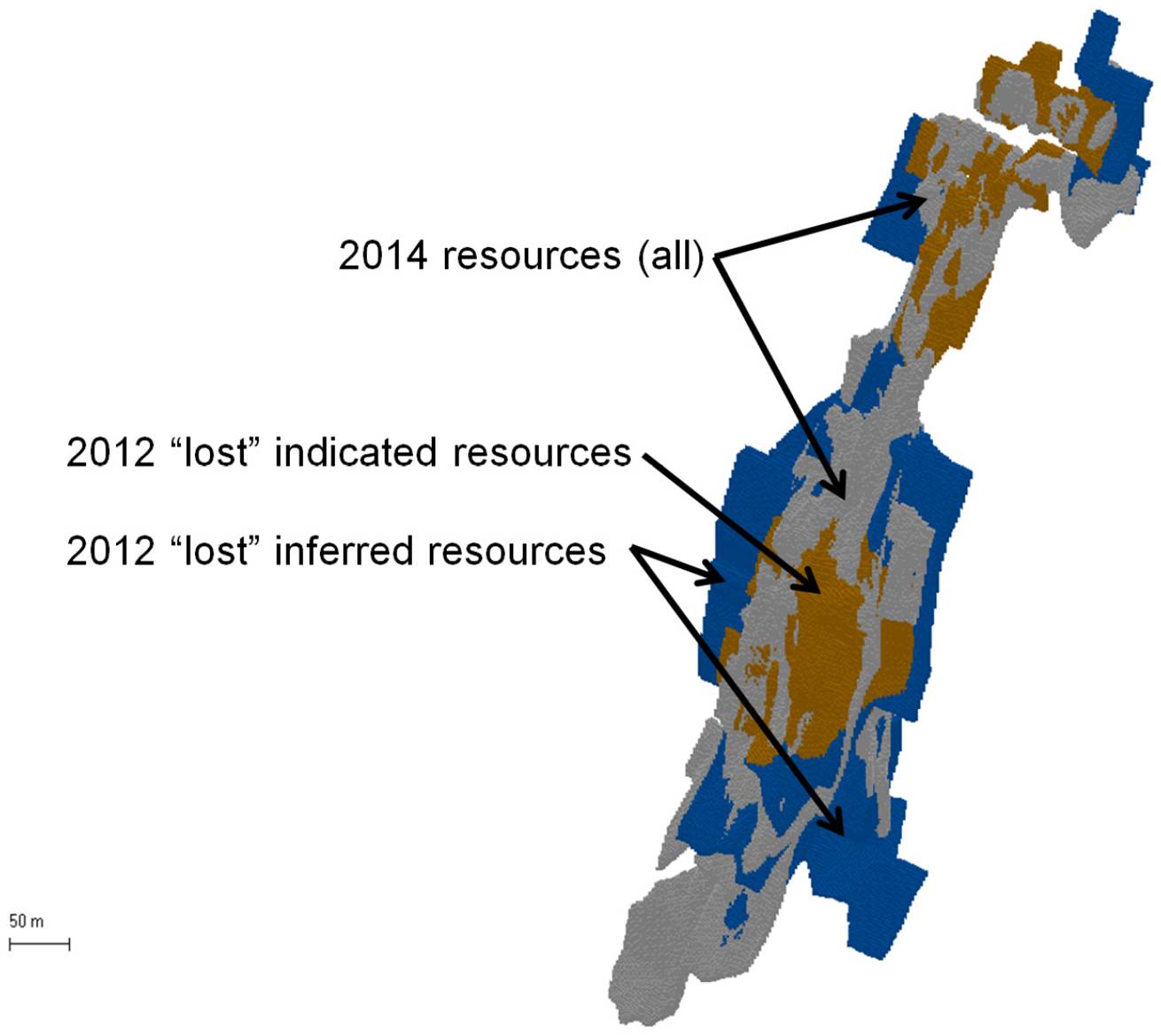

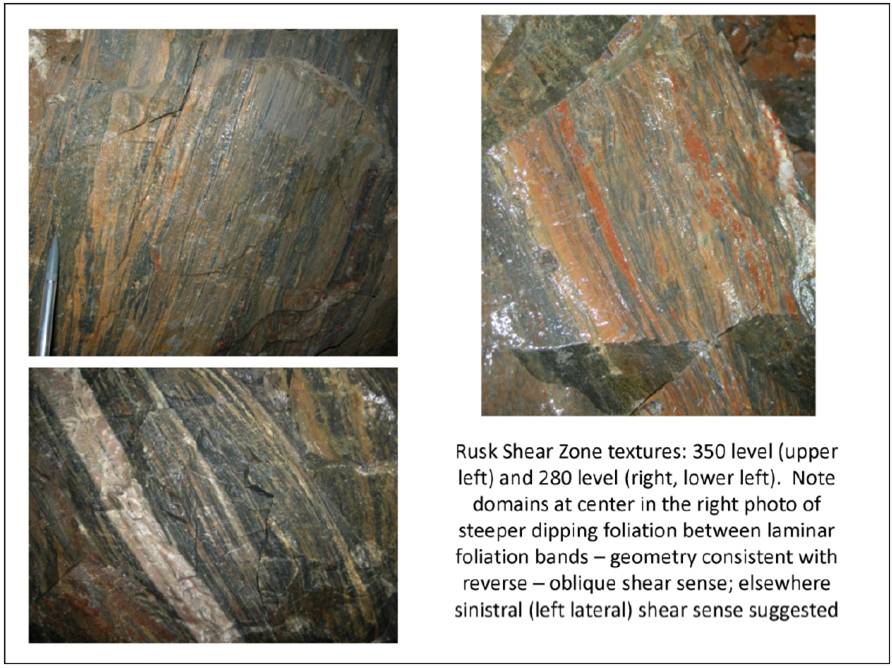

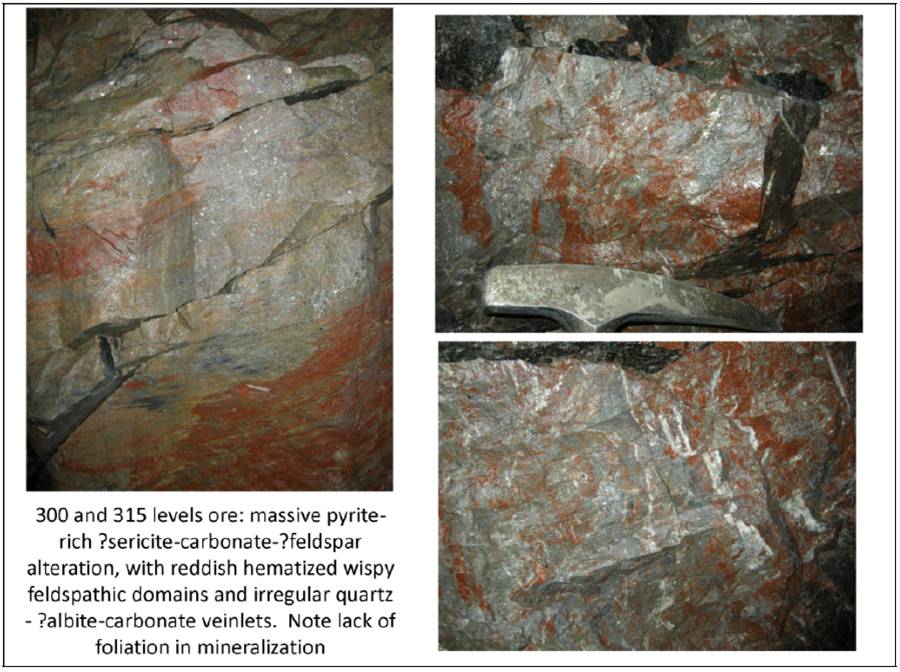

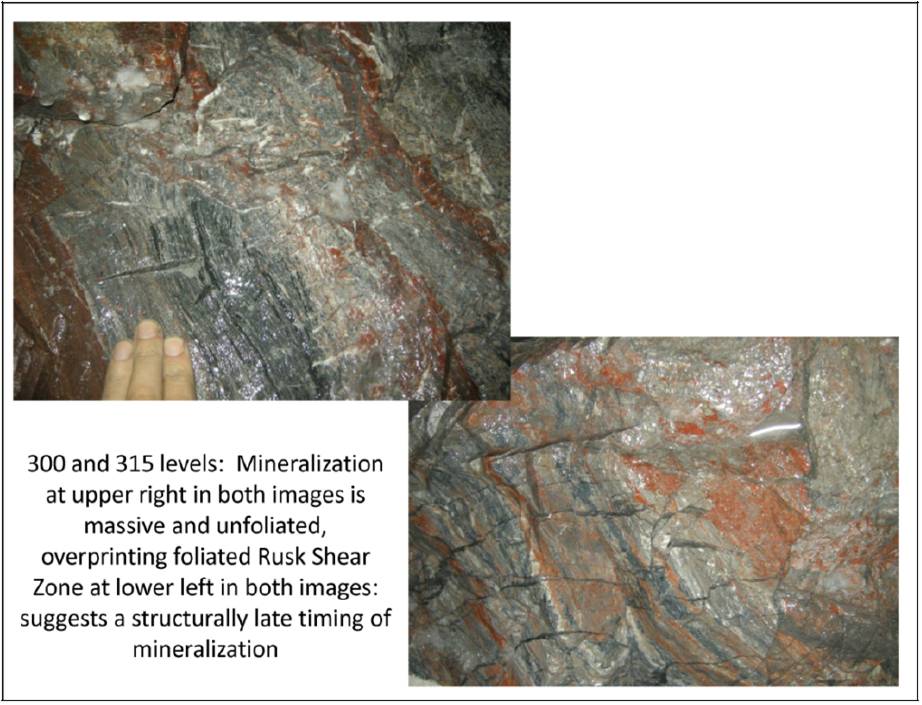

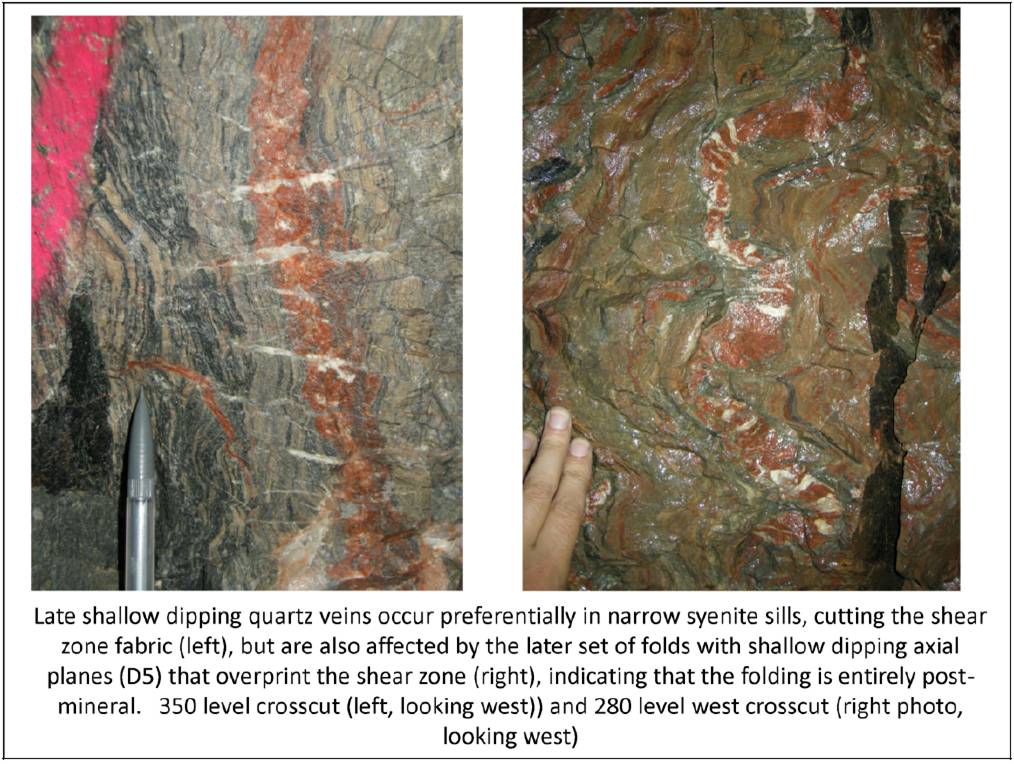

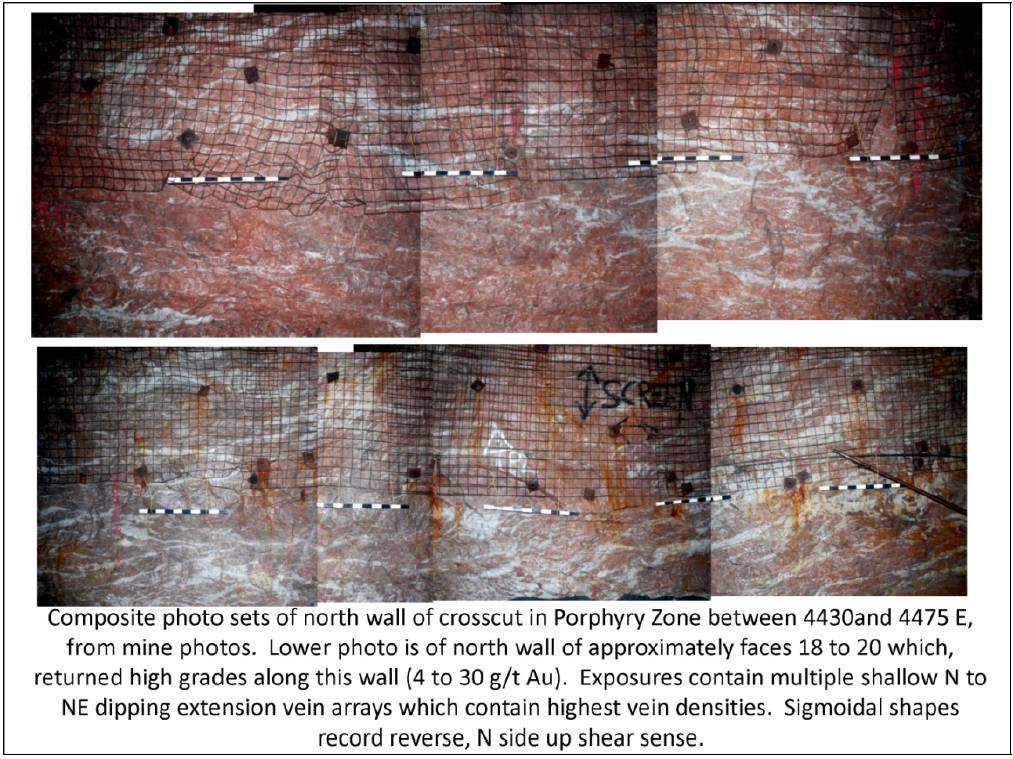

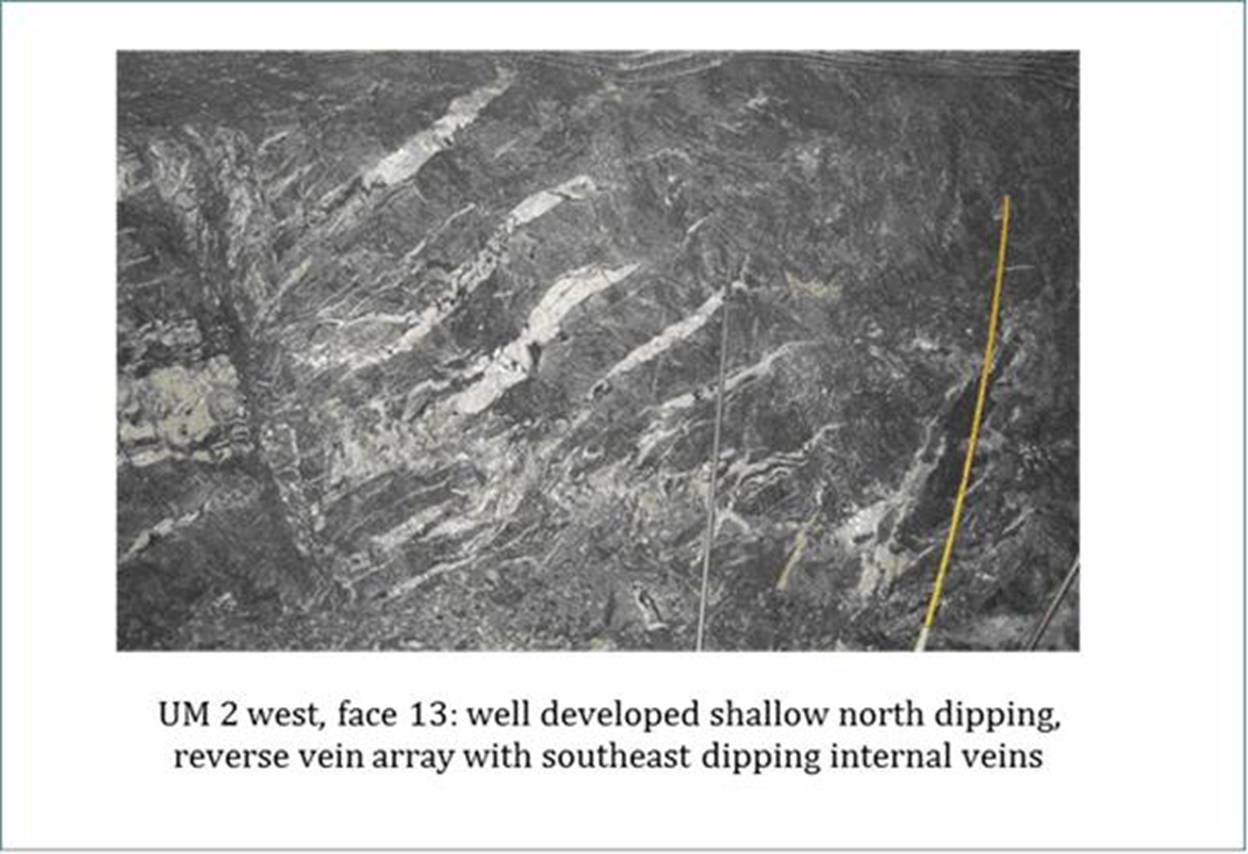

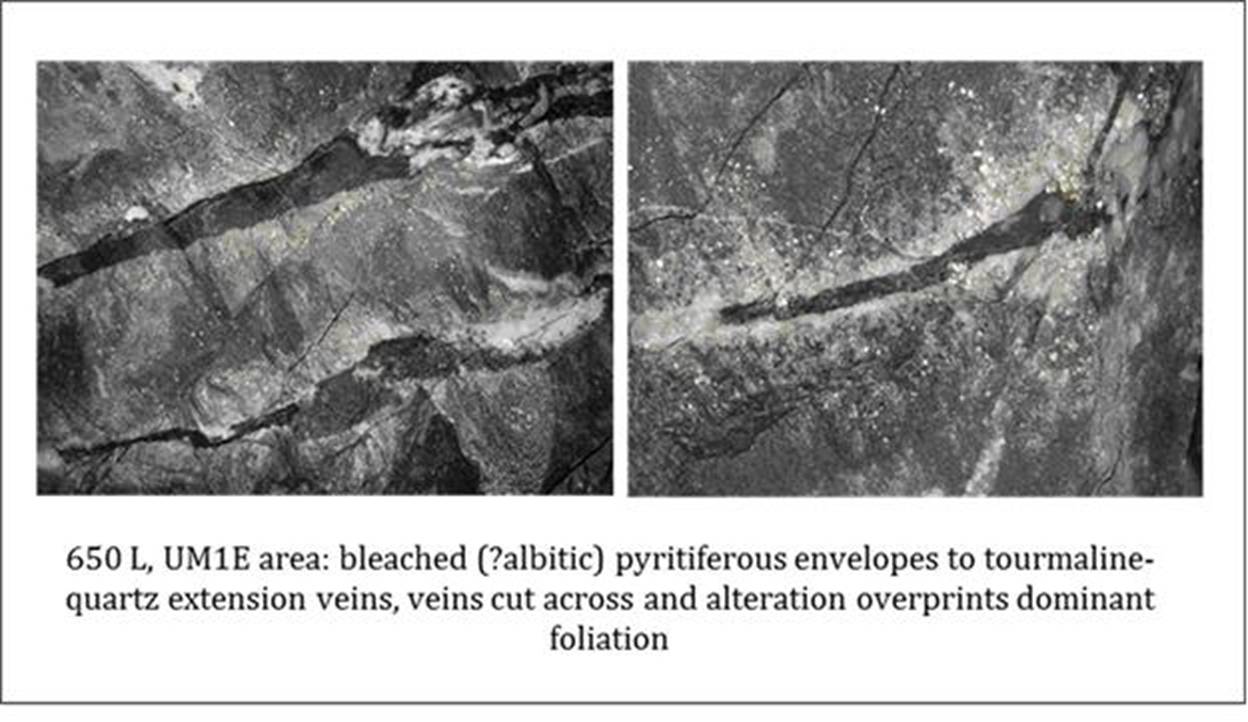

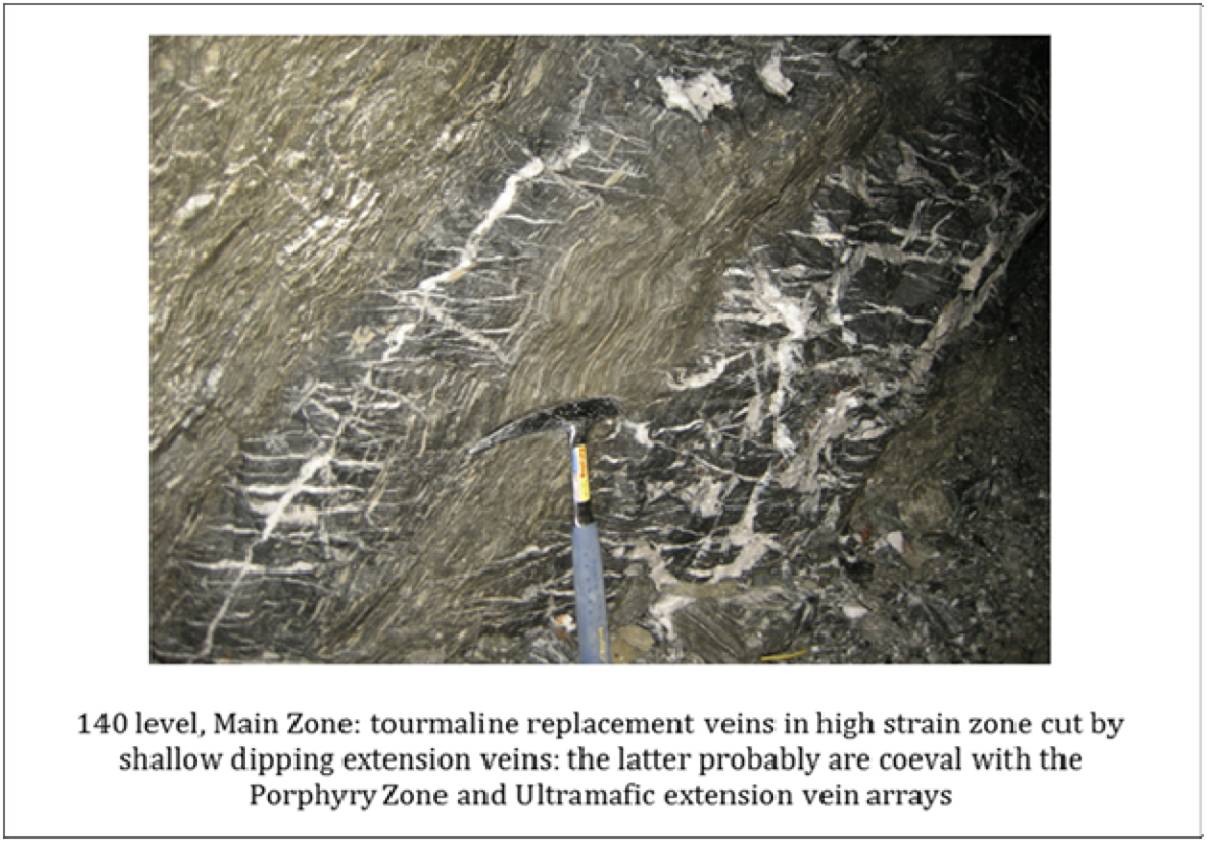

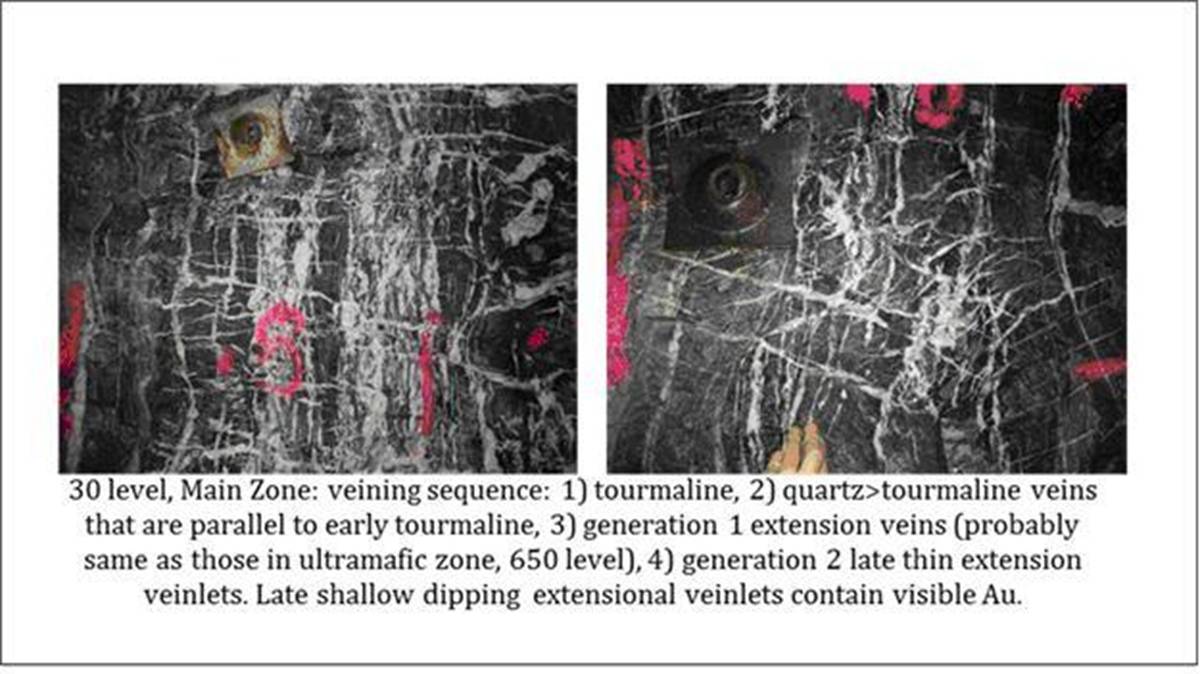

submitted